Page 1

iGuide

OPERATOR’S MANUAL

iGuide

OMPFP10808 ISSUE J0 (ENGLISH)

DCYOMPFP10808

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm.

If this product contains a gasoline engine:

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

The State of California requires the above two warnings.

Additional Proposition 65 Warnings can be found in this manual.

John Deere Ag Management Solutions

(This manual replaces OMPC21775)

Printed in U.S.A.

Page 2

Introduction

www.StellarSupport.com

NOTE: Product functionality may not be fully represented in this document due to product changes occurring after the time of printing. Read the

latest Operator’s Manual and Quick Reference Guide prior to operation. To obtain a copy, see your dealer or visit www.StellarSupport.com

OUO6050,0000FB1 1910AUG101/1

Foreword

WELCOME to the GreenStar™ system offered by John

Deere.

READ THIS MANUAL carefully to learn how to operate

and service your system correctly. Failure to do so could

result in personal injury or equipment damage. This

manual and safety signs on your machine may also be

available in other languages. (See your John Deere

dealer to order.)

THIS MANUAL SHOULD BE CONSIDERED a permanent

part of your system and should remain with the system

when you sell it.

MEASUREMENTS in this manual are given in both

metric and customary U.S. unit equivalents. Use only

correct replacement parts and fasteners. Metric and inch

fasteners may require a specific metric or inch wrench.

RIGHTHAND AND LEFTHAND sides are determined by

facing in the direction of forward travel.

RECORD PRODUCT IDENTIFICATION NUMBERS

(P.I.N.). Accurately record all the numbers to help in

GreenStar is a trademark of Deere & Company

Read The Guidance Manual

tracing the components should they be stolen. Your dealer

also needs these numbers when you order parts. File the

identification numbers in a secure place off the machine.

WARRANTY is provided as part of John Deere’s support

program for customers who operate and maintain their

equipment as described in this manual. The warranty is

explained on the warranty certificate which you should

have received from your dealer.

This warranty provides you the assurance that John

Deere will back its products where defects appear within

the warranty period. In some circumstances, John Deere

also provides field improvements, often without charge

to the customer, even if the product is out of warranty.

Should the equipment be abused, or modified to change

its performance beyond the original factory specifications,

the warranty will become void and field improvements

may be denied.

JS56696,0000218 1910DEC081/1

Before attempting to operate Parallel Tracking or

AutoTrac™, fully read the Guidance manual to understand

components and procedures required for safe and proper

operation.

AutoTrac is a trademark of Deere & Company

The Guidance manual is for both Parallel Tracking and

AutoTrac guidance systems applications.

JS56696,000039F 1923SEP091/1

102110

PN=2

Page 3

Contents

Page

Safety.......................................................... 051

Getting Started

Theory of Operation............................................ 101

Making Implement Guidance Function...............102

Accuracy............................................................. 102

iGuide Activation.................................................103

Useful Buttons and Icons....................................103

Setup

Getting Started ................................................... 151

Machine Setup....................................................152

Machine Offsets..................................................154

Implement Setup ................................................ 156

Implement Offsets .............................................. 158

Implement GPS Offsets....................................1510

Measuring in line dimension from

receiver to receiver.......................................1510

Receiver Installation ......................................... 1511

GPS Receiver Setup ........................................1512

TCM Calibration................................................1515

Guidance Setup................................................1517

Operation

Operation of iGuide ............................................201

Page

Unified Inch Bolt and Screw Torque Values........402

Integrating iGuide and iTEC Pro

Hardware and Software Requirements ..............251

Hardware and Software Requirements ..............251

Setup ..................................................................251

Operation............................................................ 252

Using Implement Receiver

forDocumentation and Coverage Map ...........253

Tuning Guide

Setting Up Vehicle Offsets..................................301

Setting Up Implement Offsets.............................302

Setting Up Implement GPS Offsets ....................302

Tuning Slope Compensation ..............................304

Tuning iGuide Sensitivity .................................... 304

Troubleshooting

Troubleshooting Tips ..........................................351

Valid Configuration .............................................352

Specifications

Metric Bolt and Screw Torque Values.................401

Original Instructions. All information, illustrations and specifications in this

manual are based on the latest information available at the time of publication.

The right is reserved to make changes at any time without notice.

COPYRIGHT © 2009

DEERE & COMPANY

Moline, Illinois

A John Deere ILLUSTRUCTION ® Manual

All rights reserved.

i

102110

PN=1

Page 4

Contents

ii

102110

PN=2

Page 5

Safety

Recognize Safety Information

This is a safetyalert symbol. When you see this symbol

on your machine or in this manual, be alert to the potential

for personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word—DANGER, WARNING, or CAUTION—is

used with the safetyalert symbol. DANGER identifies the

most serious hazards.

DANGER or WARNING safety signs are located near

specific hazards. General precautions are listed on

CAUTION safety signs. CAUTION also calls attention to

safety messages in this manual.

T81389 —UN—07DEC88

DX,ALERT 1929SEP981/1

Follow Safety Instructions

Carefully read all safety messages in this manual and on

your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from your John Deere dealer.

There can be additional safety information contained on

parts and components sourced from suppliers that is not

reproduced in this operator’s manual.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition.

Unauthorized modifications to the machine may impair the

function and/or safety and affect machine life.

TS187 —19—30SEP88

DX,SIGNAL 1903MAR931/1

TS201 —UN—23AUG88

If you do not understand any part of this manual and need

assistance, contact your John Deere dealer.

DX,READ 1916JUN091/1

051

102110

PN=5

Page 6

Safety

Park Machine Safely

Before working on the machine:

Lower all equipment to the ground.

•

Stop the engine and remove the key.

•

Disconnect the battery ground strap.

•

Hang a "DO NOT OPERATE" tag in operator station.

•

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance

service, hospital, and fire department near your telephone.

TS230 —UN—24MAY89

DX,PARK 1904JUN901/1

TS291 —UN—23AUG88

DX,FIRE2 1903MAR931/1

052

102110

PN=6

Page 7

Practice Safe Maintenance

Understand service procedure before doing work. Keep

area clean and dry.

Never lubricate, service, or adjust machine while it is

moving. Keep hands, feet , and clothing from powerdriven

parts. Disengage all power and operate controls to relieve

pressure. Lower equipment to the ground. Stop the

engine. Remove the key. Allow machine to cool.

Securely support any machine elements that must be

raised for service work.

Keep all parts in good condition and properly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease, oil, or debris.

On selfpropelled equipment, disconnect battery ground

cable () before making adjustments on electrical systems

or welding on machine.

On towed implements, disconnect wiring harnesses from

tractor before servicing electrical system components or

welding on machine.

Safety

Support Machine Properly

Always lower the attachment or implement to the ground

before you work on the machine. If the work requires

that the machine or attachment be lifted, provide secure

support for them. If left in a raised position, hydraulically

supported devices can settle or leak down.

Do not support the machine on cinder blocks, hollow tiles,

or props that may crumble under continuous load. Do not

work under a machine that is supported solely by a jack.

Follow recommended procedures in this manual.

When implements or attachments are used with a

machine, always follow safety precautions listed in the

implement or attachment operator’s manual.

TS218 —UN—23AUG88

DX,SERV 1917FEB991/1

TS229 —UN—23AUG88

DX,LOWER 1924FEB001/1

053

102110

PN=7

Page 8

Safety

Keep Riders Off Machine

Only allow the operator on the machine. Keep riders off.

Riders on machine are subject to injury such as being

struck by foreign objects and being thrown off of the

machine. Riders also obstruct the operator’s view

resulting in the machine being operated in an unsafe

manner.

Handle Electronic Components and Brackets Safely

Falling while installing or removing electronic components

mounted on equipment can cause serious injury. Use a

ladder or platform to easily reach each mounting location.

Use sturdy and secure footholds and handholds. Do not

install or remove components in wet or icy conditions.

TS290 —UN—23AUG88

DX,RIDER 1903MAR931/1

If installing or servicing a RTK base station on a tower or

other tall structure, use a certified climber.

If installing or servicing a global positioning receiver mast

used on an implement, use proper lifting techniques and

wear proper protective equipment. The mast is heavy and

can be awkward to handle. Two people are required when

mounting locations are not accessible from the ground

or from a service platform.

Operate Guidance Systems Safely

Do not use AutoTrac system on roadways.

Always turn off (Deactivate and Disable) AutoTrac

•

system before entering a roadway.

Do not attempt to turn on (Activate) AutoTrac system

•

while transporting on a roadway.

AutoTrac and iGuide are intended to aid operator in

performing field operations more efficiently. Operator is

always responsible for machine path. To prevent injury

to operator and bystanders:

DX,WW,RECEIVER 1924AUG101/1

Verify the machine, implement, and iGuide are set up

•

correctly.

Remain alert and pay attention to surrounding

•

environment.

Take control of steering wheel when necessary to

•

avoid field hazards, bystanders, equipment, or other

obstacles.

Stop operation if poor visibility conditions impair your

•

ability to operate the machine or identify people or

obstacles in machine path.

JS56696,00003A0 1922JUL081/1

TS249 —UN—23AUG88

054

102110

PN=8

Page 9

Getting Started

Theory of Operation

iGuide is a passive implement guidance system which

allows a machine to be driven in such a way as to keep

the implement on its desired track. It is able to do this

with a StarFire™ GPS receiver on both the machine and

the implement.

The following criteria are required:

Machine receiver (iTC only or SF3000)

•

Implement receiver (iTC only or SF3000)

•

iGuide requires a second receiver installed on the

implement and connected to the machine’s Implement

CAN Bus through the ISO connector. The following items

need to be included:

Hardware Needed:

Constant power harness on machine

•

Front Extension harness

•

Center Extension harness (as needed for long

•

implements)

Rear Extension harness (as needed for tow behind air

•

cart)

StarFire is a trademark of Deere & Company

GreenStar is a trademark of Deere & Company

AutoTrac is a trademark of Deere & Company

Implement Harness(s) for receiver (quantity may vary)

•

Implement GPS Bracket and receiver

•

Compatible only with GreenStar™ 2 2600 display (GS2)

•

and GreenStar™ 3 2630 (GS3)

Software and Settings:

Update StarFire receiver software.

•

NOTE: When updating the receiver software, only

one receiver may be connected to the CAN

Bus while updating the software. Software

updates for both receivers must be performed

at the vehicle receiver location.

Updated GreenStar display software

•

Machine and implement setup

•

Machine receiver TCM calibration

•

Implement receiver setup including offsets and TCM

•

calibration

Other setup including AutoTrac™, Client, Farm, Field

•

and so on

CZ76372,00001CA 1912OCT101/1

101

102110

PN=9

Page 10

Getting Started

Making Implement Guidance Function

Implement Guidance will work with pull type implements

only.

The following criteria are required:

In iGuide mode, both receivers must have the same

•

receiver level (RTK)

iGuide software installed on the GreenStar display

•

iGuide activation for the GreenStar display

•

AutoTrac SF2™ activation on display

•

AutoTrac and iGuide setup complete (incomplete setup

•

would prevent operator from activating guidance)

Updated StarFire iTC™ software on the implement

•

Implement Guidance is designed to give implement

control for the first implement.

iGuide does not support:

AutoTrac SF1™ Signal Level

•

AutoTrac SF2™ Signal Level

•

Tow Between Air Carts

•

Integral Implements (3pt)

•

Balers

•

Mowers and MowerConditioners that can swing left and

•

right behind the machine (unless using a fixed offset)

Wideswinging drawbar on 9X00T tractors

•

AutoTrac Universal Steering Kit™ (Original or 200)

•

Bedded Crops

•

Standing row crop applications

•

Bedded crop applications (see iSteer if this is needed)

•

Circle Track

•

Original GSD4 Displays

•

GreenStar 2 1800 Display

•

Original StarFire Receivers

•

NH3 Cart behind Air Cart

•

NOTE: Make sure AutoTrac is properly setup and

adjustments are completed prior to using iGuide.

NOTE: iGuide performance is contingent upon the ability

of the machine to compensate for the implement. If

the machine is not weighted properly or slippage is

excessive, iGuide performance may be degraded.

NOTE: It is recommended to always save a backup copy

of AB lines from the data card to your computer.

This best practice will ensure data will be safe in

case of Data Card or Compact Flash Card problems.

NOTE: Always verify implement dimensions are correct

when using the “out of box” dimensions from

the GreenStar display or Apex.

NOTE: iGuide does not support the use of the 7.6

cm (3 in.) extension with the 22.9 cm (9 in.)

antennas on the implement AutoTrac RTK™ radio.

iGuide will support only the 30.5 cm (12 in.) RTK

antenna or the high gain antennas to be used

on the RTK radio at the implement.

NOTE: iGuide will not support reverse mode, this

functionality is exclusive to AutoTrac.

NOTE: iGuide performance is degraded when the

machine is in a "crabbing" condition with the front

wheels parallel or near parallel to the guidance path

and the rear wheels at an angle to the line.

NOTE: Do not mount the implement receiver higher than

4.0 m (13.1 ft.) for transportation purposes.

AutoTrac SF2 is a trademark of Deere & Company

StarFire iTC is a trademark of Deere & Company

AutoTrac SF1 is a trademark of Deere & Company

AutoTrac Universal Steering Kit is a trademark of Deere & Company

AutoTrac RTK is a trademark of Deere & Company

Accuracy

A GreenStar AutoTrac RTK Assisted Steering System

with iGuide may provide up to a 60% improvement in

implement accuracy versus a GreenStar AutoTrac RTK

Assisted Steering System without iGuide.

Accuracy is measured at the implement and may be

•

affected by various factors, including ground conditions,

implement performance, tractor performance,

ballasting, and speed. The performance of the AutoTrac

CZ76372,00001C9 1906OCT101/1

RTK system with iGuide is contingent upon the tractor’s

ability to effectively locate the implement. Therefore, if

the tractor is not weighted properly or wheel slippage

is excessive, the system’s performance and accuracy

may be degraded.

Stated implement accuracy improvement is the

•

improvement in the total percentage of seed placed

within +/ 5 cm (2 in.) of its desired location, as

measured in field tests.

JS56696,000052E 1901APR091/1

102

102110

PN=10

Page 11

Getting Started

iGuide Activation

See GreenStar Display Operator Manual for activating.

To activate iGuide, please visit www.StellarSupport.com

or call our Customer Contact Center with the following

items in hand:

Useful Buttons and Icons

The MENU Softkey allows access to all display

applications. The MENU Softkey will be on every display

screen.

The HOME Softkey allows accessing the currently defined

home page.

Press the GREENSTAR Softkey to access GreenStar

applications.

iGuide Order Number

•

GreenStar display Serial Number

•

GreenStar display Challenge Code

•

PC8663 —UN—05AUG05

MENU Softkey

PC9033 —UN—17APR06

HOME Softkey

PC12685 —UN—14JUL10

CZ76372,00001CB 1912OCT101/1

CZ76372,00001CC 1912OCT101/11

CZ76372,00001CC 1912OCT102/11

Use the STARFIRE MACHINE Softkey to setup the

vehicle StarFire Receiver and start the TCM calibration

for this receiver.

NOTE: The machine receiver must be a StarFire iTC.

GREENSTAR 3 Softkey

CZ76372,00001CC 1912OCT103/11

PC9965 —UN—09FEB07

STARFIRE MACHINE Softkey

Continued on next page CZ76372,00001CC 1912OCT104/11

103

102110

PN=11

Page 12

Getting Started

Use the STARFIRE IMPLEMENT Softkey to setup the

implement Receiver and start the TCM calibration for this

receiver. The Serial Number of the receiver is shown on

this button.

NOTE: The implement receiver must be a StarFire iTC.

Press the GUIDANCE Softkey to input required

information on desired Guidance Operation.

Press the EQUIPMENT Softkey to define Machine,

Implement and Implement receiver offsets.

PC9966 —UN—09FEB07

STARFIRE IMPLEMENT Softkey

CZ76372,00001CC 1912OCT105/11

PC12947 —UN—12OCT10

Guidance Softkey

CZ76372,00001CC 1912OCT106/11

PC12948 —UN—12OCT10

Use CANCEL button to ignore the changes made to this

page.

Use ENTER button to accept the current changes and

get back to the last page.

EQUIPMENT Softkey

CZ76372,00001CC 1912OCT107/11

PC8582 —UN—01NOV05

CANCEL Button

CZ76372,00001CC 1912OCT108/11

PC8649 —UN—01NOV05

ENTER Button

Continued on next page CZ76372,00001CC 1912OCT109/11

104

102110

PN=12

Page 13

Getting Started

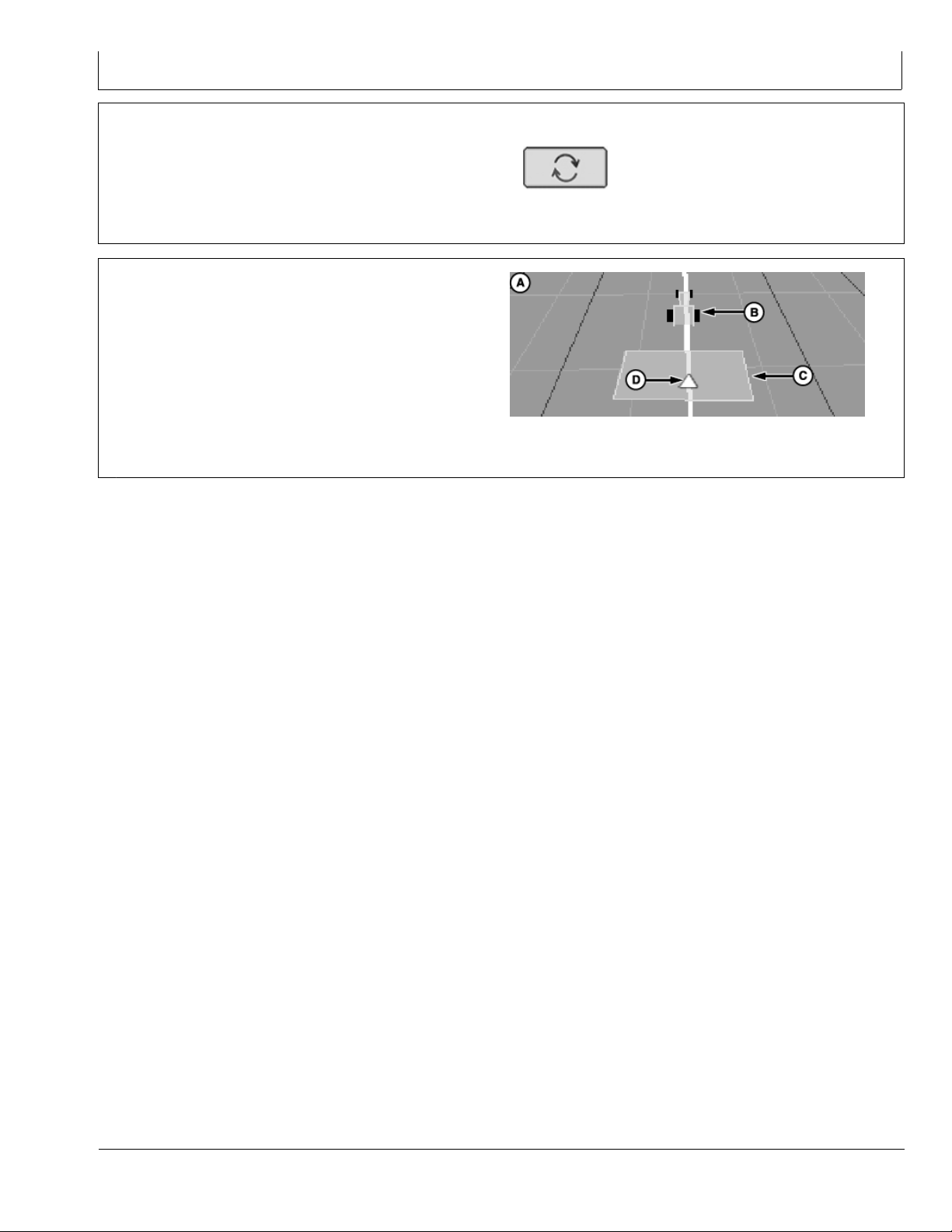

Use Offset Toggle button to toggle lateral offset from left

to right and vice versa.

Machine icon on guidance screen represents the location

of the machine.

Implement icon on guidance screen represents the

location of the implement.

Guidance reference point on guidance screen represents

the location of the guidance point for the system.

A—Guidance Screen

B—Machine Icon

C—Implement Icon

D—Guidance Reference Icon

PC10846 —UN—07DEC07

Offset Toggle Button

CZ76372,00001CC 1912OCT1010/11

PC11041 —UN—19FEB08

Guidance Screen Icons

CZ76372,00001CC 1912OCT1011/11

105

102110

PN=13

Page 14

Setup

Getting Started

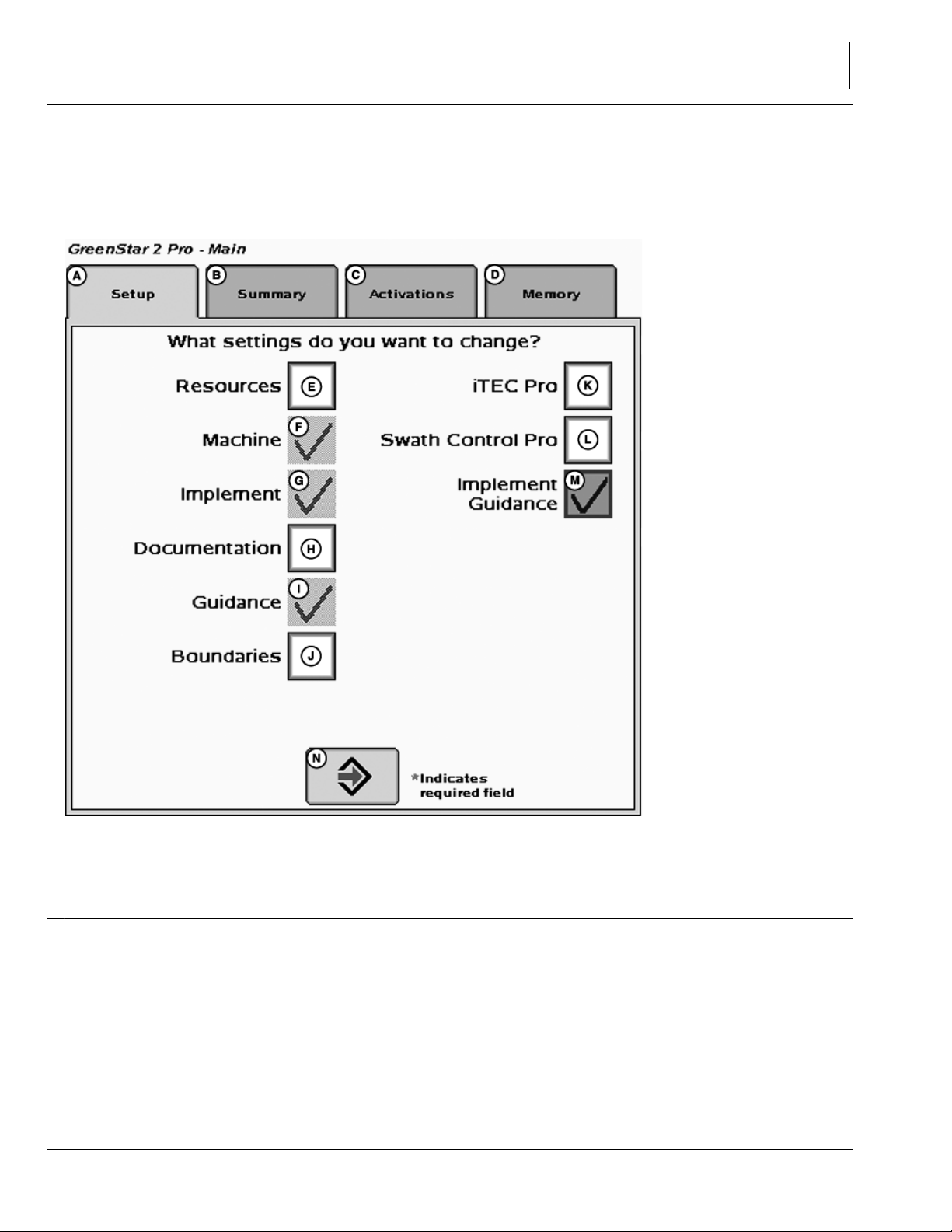

To make iGuide function, the following criteria are required

to be setup:

Machine setup and offsets

•

Implement setup and offsets

•

Machine GPS receiver settings under StarFire softkey

•

Implement GPS receiver settings under StarFire softkey

•

Guidance Setting—Tracking mode, Implement

•

Guidance Mode, and iGuide settings

These items can be set up separately or the Setup Wizard

can be used by checking the Implement Guidance option

(M). To access the Setup Wizard, select Softkey (F)

(GreenStar).

A—Setup Tab

B—Summary Tab

C—Activations Tab

D—Memory Tab

Setup Wizard

E—Resources Check Box

F— Machine Check Box

G—Implement Check Box

H—Documentation Check Box

151

I— Guidance Check Box

J— Boundaries Check Box

K—iTEC Pro Check Box

L— Swath Control Pro Check Box

PC11791 —UN—09MAR09

M—Implement Guidance Check

Box

N—Next Page

CZ76372,00001CD 1906OCT101/1

102110

PN=14

Page 15

Setup

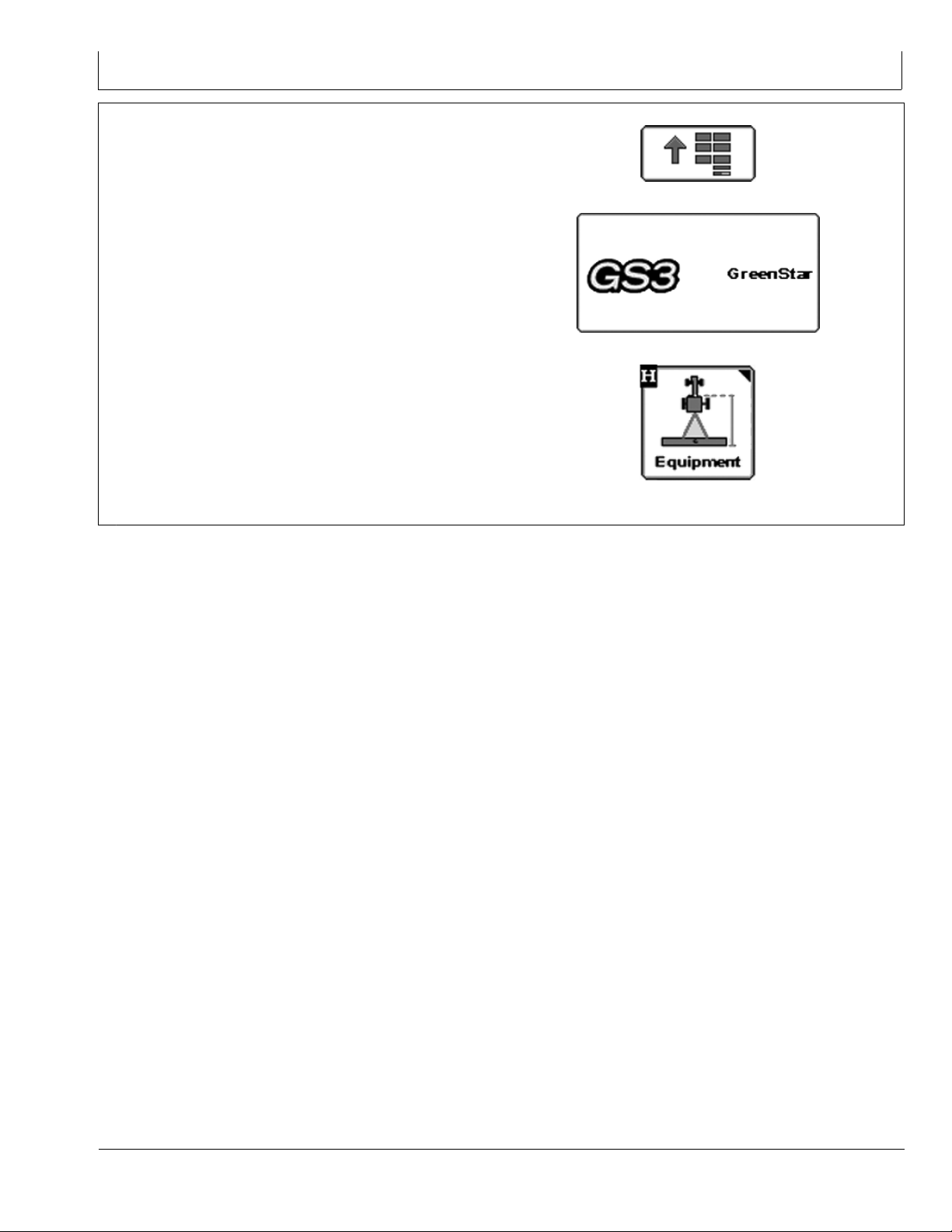

Machine Setup

MENU >> GREENSTAR >> EQUIPMENT allows access

to MACHINE and IMPLEMENT setup screens.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC12948 —UN—12OCT10

Continued on next page CZ76372,00001CE 1912OCT101/2

MENU Softkey

GREENSTAR 3 Softkey

EQUIPMENT Softkey

152

102110

PN=15

Page 16

Setup

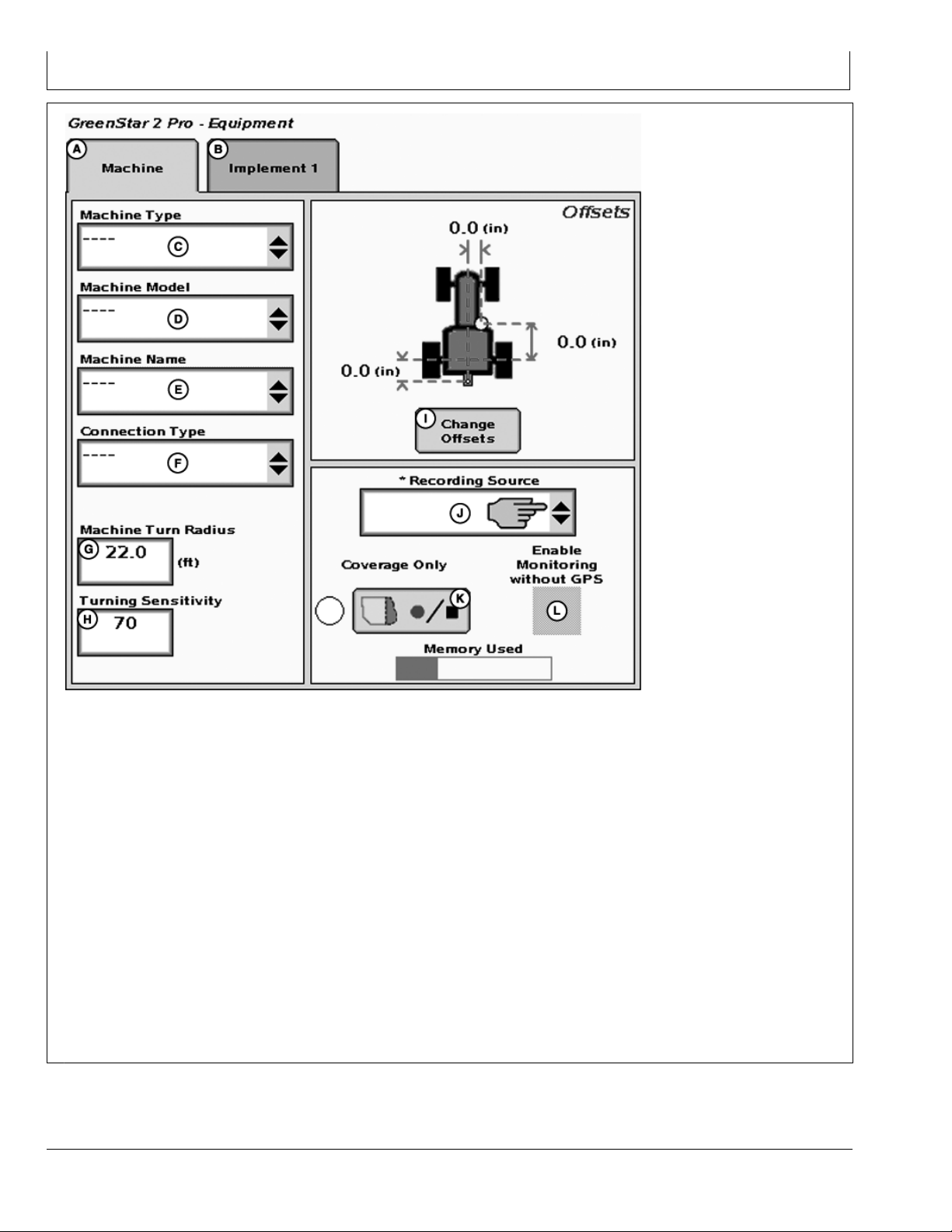

A—Machine Tab

B—Implement 1 Tab

C—Machine Type DropDown

Menu

D—Machine Model DropDown

Menu

E—Machine Name DropDown

Menu

F— Connection Point DropDown

Menu

NOTE: Machine name must be defined in order to

change offsets. All offsets will be saved under

the current machine name.

The Machine tab is required to be populated with the

following equipment information:

Machine Type—Vehicle type being used (Example:

•

Tractor).

Machine Name—Allows the operator to save

•

vehiclespecific offsets.

Connection Type—Defines how the implement is

•

attached to the machine.

Rear Rigid 3pt (not compatible with iGuide)

Rear Pivot 2pt

Machine Tab

G—Machine Turn Radius

InputBox

H—Turning Sensitivity InputBox

I— Change Offsets Button

J— Recording Source DropDown

Menu

K—Record/Pause Button

L— Enable Monitoring Without

GPS Check Box

Rear Pivot Drawbar

Rear Pivot Wagon Hitch (for European use)

Front Rigid 3pt (not compatible with iGuide)

Machine Offsets—modify by pressing Change Offsets

•

button (I).

Verify offsets correspond to the machine selected.

•

Machine Model—Model number of the vehicle being used.

For John Deere vehicles, model numbers will be available

from the dropdown list.

NOTE: Machine Model is not required for iGuide operation.

NOTE: Machine Turn Radius and Turning Sensitivity

are for use with iTEC Pro only.

CZ76372,00001CE 1912OCT102/2

PC10802 —UN—08JUL08

153

102110

PN=16

Page 17

Setup

Machine Offsets

Change Offsets

MENU >> GREENSTAR2 PRO Softkey >> EQUIPMENT

Softkey

Press CHANGE OFFSET button on Machine Setup

screen.

Enter machine offsets:

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC12948 —UN—12OCT10

PC11204 —UN—14JUL08

MENU Softkey

GREENSTAR 3 Softkey

EQUIPMENT Softkey

CHANGE OFFSETS Button

Continued on next page CZ76372,00001DC 1912OCT101/3

154

102110

PN=17

Page 18

InLine distance from nonsteering axle to GPS receiver

(B) will be

Row crop tractors—rear axle

•

Articulated tractors—front axle

•

Track tractors—rear axle

•

NOTE: Offset (B) for track tractors should be measured

from the receiver to the pivot point.

Offset Toggle button (E) toggles the receiver from the left

side of machine to the right side.

Verify that the correct connection point is selected and

measure from the center of nonsteering axle to the

center of connection point (Example: center of drawbar

pin or lower links, except in the case of a rear pivot 2pt

mount—measure to the pivot point of the implement

tongue).

NOTE: Offset (C) will change when the connection

point changes.

IMPORTANT: Offsets must be accurate because they

will be used to calculate the guidance

path for iGuide.

Setup

A—Lateral distance from

centerline of machine to

GPS receiver

B—Inline distance from

nonsteering axle to GPS

receiver

C—Inline distance from

nonsteering axle to

connection point

PC11898 —UN—01APR09

Machine Offsets

D—Vertical distance from the

GPS receiver to the ground

E—Offset Toggle Button

F— NonSteering Location

DropDown Menu

Machine Offsets—The machine and implement offsets

are important for implement guidance to function properly.

1. On Track machines, the nonsteering axle should be

selected as rear axle.

2. Offsets B and C should be measured to the turning

point or pivot point of the machine. For example: when

turning machine, it usually does not rotate on the rear

axle but somewhere in front of the rear axle.

This dimension can be measured by turning the machine

in a fairly tight turn, such as an end turn. Stop half way

through the turn. Looking at the inside track and its

relationship to the tracks on the ground, determine the

pivot point of the machine. Vehicle ballasting and drawbar

load could affect these offsets.

X—Pivot Point Y—Tractor Tracks

CZ76372,00001DC 1912OCT102/3

PC11205 —UN—14JUL08

Track Machines

CZ76372,00001DC 1912OCT103/3

155

102110

PN=18

Page 19

Setup

Implement Setup

NOTE: The implement setup should be verified

before operating iGuide.

MENU >> GREENSTAR >> EQUIPMENT >> Then press

Implement Tab

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC12948 —UN—12OCT10

Continued on next page CZ76372,00001CF 1912OCT101/2

MENU button

GREENSTAR 3 Softkey

EQUIPMENT Softkey

156

102110

PN=19

Page 20

Setup

Implement Tab

A—Machine Tab

B—Implement 1 Tab

C—Implement 2 Tab

D—Implement Type DropDown

Menu

E—Implement Model DropDown

Menu

F— Implement Name DropDown

Menu

Press Implement 1 tab to get to the implement setup page.

NOTE: All offsets including GPS offsets on the implement

will be stored to the implement name.

The name will also be the base for transferring

data to the desktop software.

G—Change Offsets Button

H—GPS Offsets Button

I— Change Widths Buttons

For the implement setup, the following information is

required to be populated:

Implement Type (D)

•

Implement Name (F)

•

CZ76372,00001CF 1912OCT102/2

PC11178 —UN—14JUL08

157

102110

PN=20

Page 21

Implement Offsets

Press CHANGE OFFSET button on Implement Setup

screen.

Implement name must be defined to save implement

offsets.

Implement Offsets—Used to define the actual implement

position relative to the machine.

Control Point—The location around which the implement

rotates.

Enter Implement Offsets:

A) Inline distance from connection point to front of

•

implement. On pulltype implements, think of this as the

tongue. This would be the distance from the connection

point to the first point of ground engagement (front

ranks of field cultivator, seed drop point on a planter).

For planters with a 2pt mount, measure from where the

planter pivots just behind the 2pt.

B) Inline distance from front to rear of implement. On

•

ground engaging tools, this is the distance from the front

rank of sweeps or points to the rear rank. On a standard

pull type sprayer, this offset would be 0 and the sprayer

has nozzles at the same point along the boom.

C) Lateral distance from connection point to control

•

point of implement. This is the lateral distance from the

center of the machine to the center of the implement,

which will be 0.0 for most common implements.

NOTE: Examples of equipment that will not be centered

include most split row planters with an even

number of 38 cm (15 in.) rows, (Examples: 1790

12/24, 16/32 CCS, 24R15 or 32R15) unless

using an adjustable hitch crossbar.

Setup

A—Inline distance from

connection point to front of

implement.

B—Inline distance from front

to rear of implement.

C—Lateral distance from

connection point to control

point of implement.

D—Inline distance from

connection point to control

point of implement.

PC11838 —UN—20MAR09

Offsets

E—Inline distance from

connection point to

connection point for

second implement. Value

only needed if second

implement is used.

F— Offset Toggle Button

G—A+B Documentation/Swath

Control location when in

use.

For the implements listed, it is required to enter an

implement offset dimension C on the implement

offset page. By entering implement offset

dimension C, iGuide will make the necessary

adjustments for the system to perform accurately.

Another example of this scenario is a planter

with a 2pt hitch offset of 19 cm (7.5 in.) to

the right. This planter must have an offset

of 19 cm (7.5 in.) entered for dimension C

on the implement offsets page.

NOTE: When using an adjustable hitch crossbar,

a lateral offset for the machine and

implement is needed.

D) Inline distance from connection point to control point

•

of implement. In many cases, this distance will be from

the connection point to the carrying wheels. For proper

turns, measure this distance with implement at the

height it typically will be at while in the lower position.

For planters with a 2pt mount, measure from where the

planter pivots just behind the 2pt.

E) Inline distance from connection point to connection

•

point for second implement. Value only needed if

second implement is used.

See MACHINE IMPLEMENT DIMENSIONS section.

Continued on next page JS56696,0000503 1902APR091/2

158

102110

PN=21

Page 22

Change Widths—Used to enter implement width and

track spacing for guidance. Change implement width and

track spacing when changing implements. Implement

width and track spacing are independent of each other.

NOTE: IMPLEMENT tab will show HEADER for

Combines, ROW UNITS for Cotton Pickers,

and BOOM for Sprayer.

NOTE: Implement width may come from certain

controllers such as SeedStar.

Defining Implement Width and Track Spacing.

Implement Width and Track Spacing can be defined

two ways: enter the working width of the implement, or

enter the number of rows and the row spacing. To toggle

between these two, press the cm (ft)/(rows) button (A).

Setup

Implement Width cm (ft)/(rows)—enter total implement

working width or the number of rows and row spacing

distance.

This value is used to calculate total area when

documenting the operation.

Track Spacing—Used in guidance for how far each pass

is from the last pass. It is entered the same way as

Implement Width. For “perfect” guess rows, this distance

will be the same as Implement Width. To ensure some

overlap for tillage or spraying, or to account for some

GPS drift, you may choose to make the Track Spacing

somewhat less than the Implement Width.

Physical Width—The actual width of the entire implement

when being used in the field when the implement is raised.

It is sometimes larger than Implement Width.

Change Widths

A—Toggle Button

B—Implement Width InputBox

C—Track Spacing InputBox

D—Physical Width InputBox

E—Row Width InputBox

F— Row Width InputBox

NOTE: Physical Width is not used for Implement Guidance.

There are certain value constraints to make Implement

Guidance work refer to APPENDIX Valid Configuration.

JS56696,0000503 1902APR092/2

PC11072 —UN—29FEB08

159

102110

PN=22

Page 23

Implement GPS Offsets

Press GPS OFFSET button on Implement Setup screen.

This button will only be active if an implement GPS

receiver is connected to the CAN Bus.

Enter Implement GPS Offsets:

IMPORTANT: Drive a vehicle forward and have

the vehicle & implement in a straight line

before measuring and calculating these

dimensions. This is very important for

accurate measurements.

IMPORTANT: Values must be accurate because

they will be used to calculate the track for

implement guidance and documentation.

NOTE: Minor adjustments to dimension B on the

Implement 1 GPS Offsets page can result in

measurable changes in offtrack error performance.

When modifying this value, minor increment

changes 1 cm (0.5 in.) is recommended.

Setup

PC11841 —UN—23MAR09

GPS Offsets

There are certain value constraints to make iGuide work

refer to APPENDIX—VALID CONFIGURATION.

Measuring in line dimension from receiver to receiver

Measure the distance between the vehicle receiver to

the implement receiver and then compare to the total

of dimensions "B" and "C" from Machine Offsets Page

(section 155), and dimension "A" from the Implement

GPS Offsets Page (section 15 10). The physical distance

between the receivers should match the distance found in

adding these three dimensions.

Example:

Distance between vehicle and implement receivers =

•

255 inches

A—Inline distance from

connection point to GPS

receiver.

B—Lateral distance from

implement center to GPS

receiver.

C—Vertical distance from GPS

receiver to ground with

implement engaged.

Dimensions "B" in Vehicle offset page = 55, "C" in

•

D—Lateral offset toggle button

E—Verify implement fore/aft

and offsets in the StarFire

setup pages.

CZ76372,00001D0 1906OCT101/1

Vehicle offset page = 65, and "A" in Implement receiver

offset page = 135 in. In total equaling, 255 inches.

NOTE: Measure from middle of vehicle receiver to

middle of implement receiver.

NOTE: For articulated tractors, the distance from

receiver to connection point is B subtracted from

C. (i.e. distance = "C" "B" + "A")

CZ76372,00001D1 1906OCT101/1

1510

102110

PN=23

Page 24

Receiver Installation

Setup

Possible Mounting Location

A—Connection Point B—Control Point

The mounting example diagram has a distance of 10 m

(32.8 ft) from the connection point (A) to the control point

(B).

The minimum distance needed between the connection

point and the GPS receiver of 2 m (6.6 ft) incorporated

1511

PC11843 —UN—23MAR09

with the maximum of 2 m (6.6 ft) to left or right from center

gives possible mounting location (dark shaded portion

in example diagram).

The ideal mounting location should be as close as

possible to the control point (B) on the implement.

JS56696,0000510 1911DEC081/1

102110

PN=24

Page 25

Setup

GPS Receiver Setup

MENU >> STARFIRE iTC Implement >> SETUP tab

allows access to StarFire iTC setup on the implement.

NOTE: The implement receiver will detect its position

automatically when it is attached to the implement

receiver application harness. If there is no

implement receiver shown on the CAN bus,

check implement harness connection.

NOTE: Original StarFire receivers cannot be used on

the implement or machine for iGuide.

NOTE: When updating the receiver software, only

one receiver may be connected to the CAN

bus while updating the software. Software

updates for both receivers must be performed

at the machine receiver location.

The number below the text on the StarFire iTC Softkey

shows the serial number of the receiver.

On the StarFire Main page the receiver definition (Machine

or Implement) is shown in the headline.

PC8663 —UN—05AUG05

PC9966 —UN—09FEB07

PC9965 —UN—09FEB07

MENU Softkey

StarFire iTC Implement Softkey

StarFire iTC Machine Softkey

JS56696,0000505 1901APR091/4

Machine iTC Receiver

PC12310 —UN—28SEP09

Implement iTC Receiver

Continued on next page JS56696,0000505 1901APR092/4

1512

PC11529 —UN—10DEC08

102110

PN=25

Page 26

Setup

StarFire iTC Implement—Main

A—Info Tab

B—Setup Tab

C—Activations Tab

D—Serial Port Tab

E—Correction Mode DropDown

Menu

F— Correction Default CheckBox

G—Mount Direction DropDown

Menu

H—Fore/Aft InputBox

Select Correction Mode to match the desired correction

mode. iGuide requires both receivers to have the same

RTK differential correction level (SF1 and SF2 are not

compatible with iGuide).

See APENDIX—VALID CONFIGURATION for more

information.

I— Height InputBox

J— Enable Optimize Shading

CheckBox

K—Enable QuickStart CheckBox

L— Hours On After Shutdown

DropDown Menu

M—TCM On/Off Toggle Button

N—TCM Calibrate Button

Select the correct mounting direction. The preferred

mounting direction for the implement is forward.

NOTE: Face receiver directly straight forward or backward.

Continued on next page JS56696,0000505 1901APR093/4

PC11844 —UN—23MAR09

1513

102110

PN=26

Page 27

Enter the correct receiver height above the ground. To

measure the receiver height, put the implement at its

working depth (if possible) and measure the height. If this

is not possible, lower the implement to the ground, and

subtract the desired working depth to get the value to

be entered.

Example: 2210 field cultivator—Lower the implement so

the sweeps are on the ground. Measure the height from

the ground to the top of the receiver. Subtract the working

depth from this number and enter as the receiver height.

If the height measured equals 180 cm (71 in.) and your

desired working depth is 10 cm (4 in.), enter 170 cm (67

in.) as the receiver Height.

NOTE: Enter 0 for the Fore/Aft offset for the

implement receiver.

Hours After Shutdown— The use of this feature is

recommended when two StarFire receivers are connected

on the CAN Bus to prevent excessive battery discharge.

Set hours after shutdown between 3 and 12 hours.

Setup

For optimized performance make the Hours On After

Shutdown the same value as on the machine receiver.

PC11208 —UN—14JUL08

Rear View Of Mast

JS56696,0000505 1901APR094/4

1514

102110

PN=27

Page 28

TCM Calibration

Setup

TCM Calibration

A—Implement with one main axle B—Implement with carrying

wheels at the front and rear

One of the most important steps in making iGuide function

at its peak performance is the TCM Calibration for both

the machine and implement. If the TCM calibration is

not performed correctly then a bias could occur in the

machine, implement or both. A bias is when the machine

AutoTracs down and back on the same path and the wheel

tracks do not line up. This can be caused by a poor TCM

calibration or the receiver is not centered on the machine.

A bias can be fixed by either recalibrating the TCM or

entering a machine or implement GPS lateral offset.

NOTE: When checking for bias, turn iGuide to “none”

and use AutoTrac to check the machine bias.

If you need to check implement bias, use

iGuide. Use Straight track only.

NOTE: When performing a TCM calibration on the

implement receiver, the wheels of the main

frame need to be in the same location after

turning implement around so that the righthand

1515

wheels are in the same place as where the

lefthand wheels were.

NOTE: A TCM calibration should be performed

each time the receiver is moved to a different

implement or vehicle.

Tips for a good TCM calibration:

Let the receiver warm up for 10—15 minutes, especially

•

if the air temperature is cold.

Calibrate on a flat surface.

•

Make sure the machine or implement are level with

•

respect to the ground by having proper tire inflation,

correct ballasting, and the same tire sizes.

Follow diagram example for proper rotation of

•

implement during the calibration process.

For more information refer to your StarFire iTC users

manual.

Continued on next page JS56696,0000506 1909DEC081/3

102110

PN=28

PC11066 —UN—29FEB08

Page 29

Adjusting Lateral Offsets

If TCM’s have been properly calibrated and machine or

implement still cannot track on same line going both

directions, a lateral offset should be entered.

NOTE: Remember, when checking bias on machine,

use AutoTrac. When checking bias on

implement, use iGuide.

1. The offset will be half the distance the two paths were

offset and in the same direction.

2. When entering lateral offset for implement, enter a

GPS offset on GPS offsets page.

3. Remember, when looking at tracks on the ground,

machine and implement must be symmetrical. Tires

must have same spacing from center of machine or

implement.

4. Another way of getting the correct lateral offset for the

implement is to measure guess rows. This method will

work with the implement in the ground and will also

achieve good guess rows.

Before measuring guess rows, make sure row units

are correctly spaced from center of implement.

Make three adjacent passes (preferably in straight

track mode with iGuide on). Make sure passes are

long enough so system has time to become stable.

Measure distance between guess rows in the middle

of pass.

Setup

A—Second Pass

PC11507 —UN—09DEC08

Lateral Offsets

B—First Pass

NOTE: Do not measure the ends of the passes.

NOTE: Wheels must be accurately spaced on vehicle

axles. This is critical for calibration accuracy .

5. Implement GPS Lateral Offset Example— Using

the Lateral Offsets 2 graphic and trying to get 762

mm (30 in.) guess rows. The guess row that is too

narrow (overlap), was measured at 64 cm (25 in.).

The wide side guess row was measured at 89 cm (35

in.). Therefore a 6.4 cm (2.5 in.) GPS offset to the left

(narrow side) should be entered in the GPS Offsets

page.

JS56696,0000506 1909DEC082/3

PC11067 —UN—29FEB08

Lateral Offsets 2

JS56696,0000506 1909DEC083/3

1516

102110

PN=29

Page 30

Setup

Guidance Setup

Guidance Setup

MENU >> GREENSTAR >> GUIDANCE softkey >>

GUIDANCE SETTINGS tab (A)

Select desired Tracking Mode first (refer to AutoTrac

Operators Manual). If Curve Track was selected, check

Curve Track settings.

Set Implement Guidance Mode (B) to iGuide.

Select iGuide Settings (C) to define Slope Compensation

and iGuide sensitivity.

For information on Turning View, Turn Predictor, Lead

Compensation, Arrow Segments, and Tracking Tones

refer to the AutoTrac Operators Manual.

A—Guidance Settings Tab

B—Implement Guidance Mode

C—iGuide Settings

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC12947 —UN—12OCT10

MENU button

GREENSTAR 3 Softkey

GUIDANCE Softkey

Guidance Settings

Continued on next page CZ76372,00001DD 1912OCT101/6

1517

PC11792 —UN—09MAR09

102110

PN=30

Page 31

Slope compensation aids in helping drive the machine up

a hill to account for implement drift. It looks at the machine

roll angle and slope compensation value to determine the

amount to move the machine up hill. On a 5 degree slope

with a value of 2.54 cm (1.0 in.)/degree this will move the

machine 12.7 cm (5 in.) up the hill to compensate for

the implement drifting down hill. If the implement drifts

more than that, increase the slope compensation value.

If the implement drifts less than that, decrease the slope

compensation value.

Recommendation for use:

Unless the field is completely flat, the slope

•

compensation value can aid in keeping the implement

on line.

02 degrees—Slope compensation may not be needed.

•

Recommended starting value 1.3 cm (0.5 in.)/degree.

25 degrees—Slope compensation provides a moderate

•

amount of machine correction and is recommended to

be turned on. Typical values of 1.3 to 3.8 cm (0.5 to

1.5 in.)/degree.

5 degrees and above—Slope compensation is

•

recommended to be on. Typical values can range from

2 to 7.6 cm (0.8 to 3.0 in.)/degree.

NOTE: Values above 7.6 cm (3 in.)/degree should be

used with caution. On a 10 degree slope with

a value of 7.6 cm (3 in.)/degree, the system will

try to move the machine 76 cm (30 in.) up hill

to compensate for implement drift.

Using the Calibration Feature:

Machine and Implement should be tracking on line with

•

iGuide activated. Do not perform the calibration during

line acquisition.

If the current slope compensation value is more than 1.3

•

cm (0.5 in.)/degree difference, it may be better to enter

the value manually with the increment and decrement

buttons. If a large change is made, it could cause some

system instability until the system has time to react to

the large changes.

Calibrations made at roll angles between 25 degrees

•

may not be ideal for larger roll angles and vice versa.

NOTE: You cannot navigate away from the iGuide

screen while calibrating slope compensation. Stop

calibration then navigate to other screens.

Adjusting the value manually:

When transiting to a hillside and implement error is

•

showing the implement needs to move down hill, slope

compensation needs to be reduced.

If the implement error is showing implement needs

•

to move up hill, slope compensation value should be

increased.

When slope compensation (A) is checked, slope

compensation will be turned on.

Calibrated slope compensation displays the last slope

compensation value created during calibration.

Setup

A—Slope Compensation

On/Off

B—Calibrated Slope

Compensation Button

C—Slope Calibration Help

Button

D—Decrease Slope

Compensation Value

E—Calibrated Slope

Compensation Value

F— Increase Slope

Compensation Value

G—Decrease iGuide Sensitivity

H—iGuide Sensitivity Input

I— Increase iGuide Sensitivity

J— Machine Roll Angle

K—iGuide Status Pie

Slope compensation (E) is an input field allowing for

manual adjustment of the slope compensation value and

shows current compensation value.

Adjusting Slope Compensation Value

Slope Compensation can be changed by three methods:

1. Calibrate slope compensation by pressing (B). Also

see GUIDANCE SETUP for detailed information.

2. Use decrement (D) and increment (F) buttons to

change slope compensation value (E).

3. Manually enter Slope Compensation value (E).

Adjustment for slope compensation using decrement (D)

and increment (F) buttons is 0.01 cm (0.01 in.)/degree.

NOTE: Average slope compensation range is 1.3 to 8.9

cm/degree (0.5 to 3.5 in./degree). If value is higher,

recalibrate. If value is still too large, turn off slope

calibration. This can typically be seen on flat ground.

NOTE: If upon calibration, slope compensation value

is above 4.00, calibrate again. Recalibration

is recommended to verify a consistent slope

compensation value. If a consistent value is not

achieved, review the slope compensation guidelines

in the GUIDANCE SETUP section.

Continued on next page CZ76372,00001DD 1912OCT102/6

PC11793 —UN—10MAR09

1518

102110

PN=31

Page 32

The slope compensation can be calibrated rather than

manually entered.

1. iGuide must be active to calibrate

2. Calibrate at operating speed and with implement at

operating depth

3. Do not calibrate when

Roll angle is less than 2 degrees

Direction of roll angle may change

On tight curves

A line acquisition is occurring

4. Slope compensation may not be required on slopes

less than 5 degrees

5. Stop calibration after calibrated slope compensation

value stabilizes

Setup

CZ76372,00001DD 1912OCT103/6

The slope compensation value has changed. Please

accept the new value or cancel the changes to keep the

previous value.

Selecting the “Accept” button may cause the vehicle to

move laterally.

Slope Range

Degree

0 2 ~ 0.5 ~ 1.3

2 5 0.5 1.5 1.3 3.8

5 >

Inches / Degree Centimeter / Degree

0.8 3.0 2 7.6

Typical Value

If the new calibrated value is significantly outside these

ranges, you may need to recalibrate.

A—Previous Calibrated Slope

Compensation

B—New Calibrated Slope

Compensation

PC11794 —UN—09MAR09

Slope Compensation

CZ76372,00001DD 1912OCT104/6

Slope Compensation

Continued on next page CZ76372,00001DD 1912OCT105/6

1519

PC11795 —UN—09MAR09

102110

PN=32

Page 33

A—Up Hill

B—Down Hill

C—25.4 cm (10 in.)

D—Tractor

Setup

10 Degree Slope Compensation

E—Implement

F— Desire Path

PC11062 —UN—29FEB08

G—Implement Drift Path

Calculating Slope Compensation Manually

If the center of the machine and center of the implement

positions are 25.4 cm (10 in.) apart on a slope with a

roll angle of 10 degrees, the slope compensation value

should be set to 2.54 cm (1 in.) per degree (25.4 cm (10

in.) of drift divided by 10 degrees of roll angle). If there is

a 25.4 cm (10 in.) difference on a slope with a 5 degree

roll angle, then the value would be 5.1 cm (2 in.)/degree.

Implement Error / Roll Angle = Slope Compensation

NOTE: Recommended adjustment in 0.2 cm (0.05 in.)/deg.

iGuide Sensitivity

iGuide Sensitivity affects how aggressively the system

responds to implement error. This function is similar to

AutoTrac steer sensitivity.

iGuide Sensitivity allows the system to respond to

•

implement errors. Higher sensitivity enables iGuide to

quickly react to implement error.

Too high of a value may cause the system to oscillate

•

around the intended path. Too low of a value may cause

the implement to react slow when trying to maintain the

implement on the guidance path.

A starting value of 15 is recommended. Adjust the

•

sensitivity in small increments until optimal tracking

performance is achieved.

NOTE: Machine steer sensitivity may need to be increased

or decreased to keep the machine on the guidance

path. iGuide is dependent on the machines ability to

track accurately on the intended guidance path.

CZ76372,00001DD 1912OCT106/6

1520

102110

PN=33

Page 34

Operation

Operation of iGuide

MEMU >> GREENSTAR >> GUIDANCE allows access to

Guidance Settings and Shift Track Settings.

PC8663 —UN—05AUG05

PC12685 —UN—14JUL10

PC12947 —UN—12OCT10

Continued on next page CZ76372,00001DE 1912OCT101/2

MENU Softkey

GREENSTAR 3 Softkey

GUIDANCE Softkey

201

102110

PN=34

Page 35

Operation

GreenStar—Guidance

A—View Tab

B—Guidance Setting Tab

C—Shift Track Settings Tab

D—iTEC Pro Tab

E—Path Accuracy Indicator

F— Shift Track Left Button

G—Shift Track Center Button

H—Shift Track Right Button

In order to operate iGuide, a valid setup must be available

(see APPENDIX—VALID CONFIGURATION). AutoTrac

can be engaged when the “steering wheel” icon is visible

in the AutoTrac enable button.

While in iGuide mode, machine and implement icons are

displayed in the perspective view. The implement will

have the guidance triangle. The error bar (D) at the top of

the page will display the error at the implement.

Blue line—recorded implement path

•

White line—implement tracking line

•

For all other settings refer to the GreenStar Display

operator’s manual.

If iGuide is not set up correctly, the AutoTrac steer on/off

button will be shown as a wrench. If the diagnostic wrench

I— Steer Sensitivity InputBox

J— Set Track 0 Button

K—iGuide Status Pie

L— Steer On/Off button

M—iTEC Pro Status Pie

N—iTEC Pro Enable Button

O—iTEC Pro Icon

P—Implement Receiver Location

Icon

is pressed, the AutoTrac diagnostic pages will appear to

indicate which items are not properly set up. Once iGuide

is properly configured, the steer on/off button will replace

the diagnostic wrench.

When the AutoTrac diagnostic wrench button is selected,

the AutoTrac diagnostic page will be displayed. If the

valid configuration is not valid, select implement guidance

from the dropdown menu on the diagnostic page to view

implement guidance diagnostics.

NOTE: For Line acquisition, the vehicle must be

within the 40% of the tracking width and

within 80 degrees of the line.

CZ76372,00001DE 1912OCT102/2

PC11899 —UN—01APR09

202

102110

PN=35

Page 36

Integrating iGuide and iTEC Pro

Hardware and Software Requirements

In order to run iTEC Pro and iGuide simultaneously, the

following hardware and software are required:

1. Both receivers must be iTC receivers

2. RTK GPS signal level on both receivers

3. Vehicle must have integrated AutoTrac components

4. GreenStar 2 2600 display must have AutoTrac SF2

activation

Hardware and Software Requirements

In order to run iTEC Pro and iGuide simultaneously, the

following hardware and software are required:

1. Both receivers must be iTC receivers

2. RTK GPS signal level on both receivers

3. Vehicle must have integrated AutoTrac components

4. GreenStar Display must have AutoTrac SF2 activation

Setup

1. Complete iTEC Pro and iGuide vehicle and implement

setup as described in their separate Operator’s

Manual.

5. GreenStar 2 2600 display must have iGuide and iTEC

Pro software activation

6. Drawn implements

NOTE: Please check the iGuide OM for a

complete list of supported and not supported

implements and applications.

JS56696,0000522 1923APR091/1

5. GreenStar Display must have iGuide and iTEC Pro

software activation

6. Drawn implements

NOTE: Please check the iGuide OM for a

complete list of supported and not supported

implements and applications.

CZ76372,00001DF 1912OCT101/1

2. Control point distance should be set for optimal iGuide

performance.

JS56696,0000523 1923MAR091/1

251

102110

PN=36

Page 37

Operation

Integrating iGuide and iTEC Pro

GreenStar—Guidance

A—View Tab

B—Guidance Setting Tab

C—Shift Track Settings Tab

D—iTEC Pro Tab

E—Path Accuracy Indicator

F— Shift Track Left Button

G—Shift Track Center Button

H—Shift Track Right Button

1. Tracking Mode—The operation of iGuide and iTEC

Pro will be available only on straight tracking mode.

2. End of Turn Performance

a. When both systems are activated, the operator will

see two paths on the screen.

b. The solid white line is the implement path and

current guidance path.

I— Steer Sensitivity InputBox

J— Set Track 0 Button

K—iGuide Status Pie

L— Steer On/Off button

M—iTEC Pro Status Pie

N—iTEC Pro Enable Button

O—iTEC Pro Icon

c. The dashed white line is the projected vehicle path

and is shown as a reference for the operator.

d. If iTEC Pro detects a collision with an impassable

boundary, both solid and dashed line paths will turn

red until the collision is passed.

CZ76372,00001E0 1912OCT101/1

PC11845 —UN—23MAR09

252

102110

PN=37

Page 38

Integrating iGuide and iTEC Pro

Using Implement Receiver for

Documentation and Coverage Map

When using iGuide guidance mode, the documentation

and coverage map will use the implement receiver

position as a reference point.

When iGuide is not in use and the implement receiver

is connected to the CAN bus, the system will use the

implement receiver position for documentation and

coverage map purposes.

NOTE: If you are not using iGuide guidance mode and do

not want to use the Implement Receiver position as

a reference point for documentation and coverage

map, unplug the implement receiver from the CAN

Bus. After unplugging the Implement Receiver from

the CAN Bus, the GreenStar Display will use the

Machine Receiver position as a reference point

for documentation and coverage map.

CZ76372,00001E1 1912OCT101/1

253

102110

PN=38

Page 39

Tuning Guide

Setting Up Vehicle Offsets

Vehicle Offsets

Offsets “A”, “B”, “C”, and “D” are critical for iGuide to

operate efficiently.

A—Lateral distance from

centerline of machine to

GPS receiver

B—Inline distance from

nonsteering axle to GPS

receiver

C—Inline distance from

nonsteering axle to

connection point

D—Vertical distance from the

GPS receiver to the ground

E—Offset Toggle Button

F— NonSteering Location

DropDown Menu

Offset “D” should match Receiver Height from Machine

Receiver softkey.

PC11898 —UN—01APR09

Machine Offsets

JS56696,00006D7 1931AUG091/2

PC9965 —UN—09FEB07

StarFire iTC Machine

JS56696,00006D7 1931AUG092/2

301

102110

PN=39

Page 40

Tuning Guide

Setting Up Implement Offsets

Implement Offsets

Offsets “A”, “B”, and “D” are critical for iGuide to operate

efficiently.

Offset “E” is not required for iGuide.

NOTE: Offset “C” is required when using a non

centered implement.

A—Inline distance from

connection point to front of

implement.

B—Inline distance from front

to rear of implement.

C—Lateral distance from

connection point to control

point of implement.

D—Inline distance from

connection point to control

point of implement.

E—Inline distance from

connection point to

connection point for

second implement. Value

only needed if second

implement is used.

F— Offset Toggle Button

G—A+B Documentation/Swath

Control location when in

use.

Setting Up Implement GPS Offsets

Implement GPS Offsets

Offsets “A”, “B”, and “C” are critical for iGuide to operate

efficiently.

A—Inline distance from

connection point to GPS

receiver.

B—Lateral distance from

implement center to GPS

receiver.

C—Vertical distance from GPS

receiver to ground with

implement engaged.

D—Lateral offset toggle button

E—Verify implement fore/aft

and offsets in the StarFire

setup pages.

PC11838 —UN—20MAR09

Offsets

JS56696,00006D8 1931AUG091/1

GPS Offsets

Continued on next page CZ76372,00001E2 1912OCT101/3

302

PC11841 —UN—23MAR09

102110

PN=40

Page 41

Tuning Guide

Offset “C” should match Receiver Height from Implement

Receiver softkey.

Check the GreenStar Display for correct inline

distance between vehicle receiver and implement

receiver.

Measuring in line dimension from receiver to receiver:

Measure the distance between the vehicle receiver to the

implement receiver and compare with the sum of offsets

“B” and “C” from Vehicle Offset page and dimension “A”

from the Implement Receiver Offset page. The distance

between and the distance found in adding these three

offsets, should match.

Example:

Distance between vehicle and implement receivers is

•

647.7 cm (255 in.).

Offsets:

•

Offset “A” is 342.9 cm (135 in.)

Offset “B” is 139.7 cm (55 in.)

Offset “C” is 165.1 cm (65 in.)

Total: 647.7 cm (255 in.)

PC9966 —UN—09FEB07

StarFire iTC Implement Softkey

CZ76372,00001E2 1912OCT102/3

PC12219 —UN—19AUG09

Receiver Offsets

NOTE: When measuring distance between vehicle and

implement receivers, measure from middle of

vehicle receiver to middle of implement receiver.

NOTE: For articulated tractors, distance from receiver

to connection point is “B” subtracted from “C”

(Example: distance = “C” – “B” + “A”).

CZ76372,00001E2 1912OCT103/3

303

102110

PN=41

Page 42

Tuning Guide

Tuning Slope Compensation

Slope Compensation works as a lookahead for the

vehicle. Slope Compensation helps aids in moving the

vehicle up the hill to keep the implement on the guidance

line.

Slope Range

Degree

0—2 1.3 0.5

2—5 1.3—3.8 0.5—1.5

Greater Than 5

0—2 degrees Slope Compensation may not be needed

•

2—5 degrees Use of Slope Compensation is

•

Cm/Degree Inches/Degree

2.0—8.9 0.8—3.5

recommended to provide moderate amount of machine

correction

Greater than 5 degrees Use of Slope Compensation is

•

recommended

NOTE: If slope compensation value is above 4.00

after calibration, calibrate again. Recalibration

is recommended to verify a consistent slope

compensation value. If a consistent value is not

achieved, review the slope compensation guidelines.

General Slope Compensation Guidelines:

1. iGuide must be active to calibrate

2. Calibrate at operating speed with implement at

operating depth

Typical Value

A—Slope Compensation

On/Off

B—Calibrated Slope

Compensation Button

C—Slope Calibration Help

Button

D—Decrease Slope

Compensation Value

E—Calibrated Slope

Compensation Value

F— Increase Slope

Compensation Value

G—iGuide Status Pie

3. Do not calibrate when:

Roll angle is less than 2 degrees

Direction of roll angle may change

On tight curves

A line acquisition is occurring

4. Slope compensation may not be required on slopes

less than 5 degrees

5. Stop calibration after calibrated slope compensation

value stabilizes

JS56696,00006D4 1926AUG091/1

PC12220 —UN—27AUG09

Tuning iGuide Sensitivity

Tuning iGuide Sensitivity properly will ensure the system

responds quickly to line and heading acquisition.

iGuide Sensitivity works in a similar way as the AutoTrac

Sensitivity and will be different according to the soil

conditions, machine, and implement models. iGuide

Sensitivity is lower when soil condition is harder and is

higher when soil condition is softer.

Adjust AutoTrac Steering sensitivity for the vehicle.

Verify Implement Guidance Mode is set to “None”

•

Refer to GreenStar Display Operator’s Manual for

•

process of tuning steering sensitivity

PC12221 —UN—27AUG09

A—Decrease iGuide Sensitivity

B—iGuide Sensitivity

InputBox

C—Increase iGuide Sensitivity

NOTE: For some platforms, such as four wheel drive

tractors, use a higher AutoTrac Sensitivity

for best performance.

CZ76372,00001D2 1912OCT101/1

304

102110

PN=42

Page 43

Troubleshooting

Troubleshooting Tips

1. Implement receiver not showing up in the GreenStar

Display

Check if Constant Power Extension harness

(PF90550 or PF90551) is installed.

Check for latest software (version 2.3.1385 or

higher) on Implement Receiver.

Check if receiver is receiving Switched, Unswitched,

CAN Low and CAN High power.

Check machine fuse panel for blown fuses

2. Implement GPS loses RTK signal more often than

machine receiver

Check antenna on GPS receiver for tight

connection.

Verify receiver has good line of sight to the base

station.

Set machine to Vehicle Repeater. Only one

Repeater or Vehicle Repeater can be used for

selected base station ID.

3. Implement Error is not reduced in a reasonable

amount of time

Incorrect machine or implement offsets.

iGuide sensitivity is set too low.

Incorrect Slope compensation value.

Engage iGuide closer to desired path.

Adjust control point.

4. Machine or implement is “S’ing” around the line

iGuide sensitivity is too high.

Steer sensitivity is too high.

5. Guess rows having a reoccurring skip/overlap pattern

Calibrate TCM on implement and machine

receivers.

Change Implement GPS offsets.

Implement row units not properly spaced.

6. Reduced Accuracy

If possible, mount the implement receiver as

close as possible to the control point. Mounting

receiver too close to rear of machine may result

in less accurate performance. Mounting receiver

too far from control point may also cause poor

performance.

Control Point— location around which the

implement rotates. This is typically the axle of the

implement.

7. Adjusting the Control Point offset (examples)

If the implement consistently tracks inside curve,

increase control point offset.

If the implement consistently tracks outside curve,

decrease control point offset.

8. Slow to line acquisition and Sing when reentering

passes at headlands

Resume switch should be activated when making

the turn.

NOTE: Do not wait until implement is aligned to

push the resume switch as this may cause

Sing at the beginning of passes.

9. After unloading data in Apex and saving setup back

to the data card, iGuide produces wide and narrow

guess rows

Make sure the offsets saved in Apex are the same

as when you measured the vehicle, implement, and

implement receiver offsets.

If the offsets are the same, create a new machine

name, machine model, implement name, and

implement model. Then enter the measured offsets.

Recalibrate both TCMs (vehicle and implement).

For best results, calibrate the TCM on a flat surface.

NOTE: If the problem still exists, format or use a

new data card. Then enter the correct offsets

for the vehicle offset page, implement offset

page, and implement receiver offset page.

NOTE: If keeping the measured offsets, create

a unique vehicle and implement name to

store them under. If unique vehicle and

implement names are not used, GSDNet

updates will overwrite offsets.

10. iGuide is oversteering on flat ground (less than 2

degrees)

Verify Slope Compensation is off.

Lower iGuide Sensitivity.

11. iGuide respond for lateral implement draft is too slow

Verify Slope Compensation is on.

Recalibrate Slope Compensation.

Increment Slope Compensation value using the

increment button until the proper value is found.

Raise iGuide Sensitivity.

12. iGuide calculates a high value after Slope

Compensation Calibration

Check if iGuide was active during the calibration.

Check if calibration was performed on ground with

less than 2 degree of roll angle.

13. iGuide does not work properly with row crop cultivation

iGuide is not designed to work on row crop

cultivation.

14. Poor performance on articulated tractors

Verify if front axle has been selected as Non Steer

Axle and remeasure vehicle offsets.

15. Points to Remember

In iGuide mode, remember error on the display is

error at the implement. Error for iGuide may be

higher on the display than machine error was when

the system was in normal AutoTrac mode.

iGuide may not perform as well in tight turns or end

turns as it does on more gradual curves; especially

on severe slopes when the implement is sliding

down hill.

iGuide is a reactive system and can only respond to

implement errors.

System performance can be affected by several

factors on the machine and implement. Examples:

ballasting, tire inflation, hitch play, amount of

weight on the implement (seed, fertilizer, chemical),

second implement (air cart, tank), ground engaging

equipment in proper working order, and offsets,

values, and sensitivities in the GreenStar Display.

Continued on next page CZ76372,00001E3 1912OCT101/2

351

102110

PN=43

Page 44

Troubleshooting

Always verify correct implement dimensions

when using the “out of box” dimensions from the

GreenStar Display or Apex.

Valid Configuration

iGuide requires certain settings to be available and certain

offsets need to be within a defined range. If one of these

constraints is not given, tracking cannot be activated.

For a new, unknown implement, all offset will be zero as

a default.

General constraints:

Will not work with 3pt implements.

•

Implement receiver installed and set up to be an

•

implement receiver.

Both receivers need to have the same differential

•

correction level (RTK).

The following settings and constraints are mandatory for

the machine:

Machine type and name selected.

•

Rear pivot connection type selected.

•

Distance between connection point and non steering

•

axle is larger than 30 cm (11.8 in.).

The following settings and constraints are mandatory for

the implement:

CZ76372,00001E3 1912OCT102/2

PC11846 —UN—24MAR09

Implement Guidance diagnostics page 1

Implement type, name, and model are selected.

•

Distance between connection point and control point

•

shall be larger than 49 cm (1.6 ft).

Location of implement receiver is defined.

•

The distance between the connection point and the

•

implement GPS receiver needs to be larger than 201

cm (79 in.).

Lateral offset from control point to implement GPS

•

receiver shall be less than 201 cm (79 in.).

The following settings and constraints are mandatory for

the implement GPS receiver:

Implement receiver height should be between 50 cm

•

(20 in.) and 508 cm (200 in.).

A—View DropDown Menu

B—Information Column

C—Current Column

D—Status Column

E—Previous Page

F— Next Page

G—Valid Range Column

PC11797 —UN—09MAR09

Implement Guidance diagnostics page 2

JS56696,000050A 1910DEC081/1

352

102110

PN=44

Page 45

Specifications

4.84.8 8.8 9.8 10.9

12.9

12.9

12.9

12.9

10.9

9.8

8.8

4.8

Metric Bolt and Screw Torque Values

TS1670 —UN—01MAY03

Bolt or Class 4.8 Class 8.8 or 9.8 Class 10.9 Class 12.9

Screw

Lubricated

a

Dry

b

Lubricated

a

Dry

b

Lubricated

a

Dry

b

Lubricated

a

Size N∙m lbin N∙m lbin N∙m lbin N∙m lbin N∙m lbin N∙m lbin N∙m lbin N∙m lbin

M6 4.7 42 6 53 8.9 79 11.3 100 13 115 16.5 146 15.5 137 19.5 172

N∙m lbft N∙m lbft N∙m lbft N∙m lbft

M8 11.5 102 14.5 128 22 194 27.5 243 32 23.5 40 29.5 37 27.5 47 35

N∙m lbft N∙m lbft N∙m lbft

M10 23 204 29 21 43 32

N∙m

lbft

M12 40 29.5 50 37

75 55

55

40 63 46 80 59

95 70 110 80 140 105 130 95 165 120

75 55

M14 63 46 80 59 120 88 150 110 175 130 220 165 205 150 260 190

M16 100 74 125 92 190 140 240 175 275 200 350 255 320 235 400 300

M18 135 100 170 125 265 195 330 245 375 275 475 350 440 325 560 410

M20 190 140 245 180 375 275 475 350 530 390 675 500 625 460 790 580

M22 265 195 330 245 510 375 650 480 725 535 920 680 850 625 1080 800

M24 330 245 425 315 650 480 820 600 920 680 1150 850 1080 800 1350 1000

M27 490 360 625 460 950 700 1200 885 1350 1000 1700 1250 1580 1160 2000 1475

M30 660 490 850 625 1290 950 1630 1200 1850 1350 2300 1700 2140 1580 2700 2000

M33 900 665 1150 850 1750 1300 2200 1625 2500 1850 3150 2325 2900 2150 3700 2730

M36 1150 850 1450 1075 2250 1650 2850 2100 3200 2350 4050 3000 3750 2770 4750 3500

Torque values listed are for general use only, based on the strength of

the bolt or screw. DO NOT use these values if a different torque value or

tightening procedure is given for a specific application. For stainless steel

fasteners or for nuts on Ubolts, see the tightening instructions for the

specific application. Tighten plastic insert or crimped steel type lock nuts

by turning the nut to the dry torque shown in the chart, unless different

instructions are given for the specific application.

Shear bolts are designed to fail under predetermined loads. Always