Page 1

J9

Mechanical Tiller

30-Inch

OPERATOR’S MANUAL

OMM141979 J9

North American Version

Litho in U.S.A.

Page 2

INTRODUCTION

Introduction

Thank You for Purchasing This Product

We appreciate your business and wish you many years of

safe and satisfied use of your machine.

Using Your Operator’s Manual

This manual is an important part of your machine and

should remain with the machine when you sell it.

Reading your operator’s manual will help you and others

avoid personal injury or damage to the machine.

Information given in this manual will provide the operator

with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly

will allow you to train others who may operate t his machine.

Section in your operator’s manual are placed in a s pecific

order to help you understand all the safety messages and

learn the controls so you can operate this machine safely.

You can also use this manual to answer any specific

operating or ser vicing questions. A convenient index

located at the end of this book will help you to find needed

information quickly.

The machine shown in this manual may differ slightly from

your machine, but will be similar enough to help you

understand our instructions.

RIGHT-HAND and LEFT-HAND sides are determined by

facing in the direction the machine will travel when going

forward. When you see a broken line arrow (------>), the

item referred to is hidden from view.

cCAUTION: Avoid injury! !

This symbol and text highlight potential

hazards or death to the operator or bystanders

may occur if the hazards or procedures are

ignored.

IMPORTANT: Avoiddamage!!Thistextisusedto

tell the operator of actions or conditions that might

result in damage to the machine.

NOTE: General information is given throughout the

manual that may help the operator in the operation of

the machine.

Special Messages

Your manual contains special messages to bring attention

to potential safety concerns, machine damage as well as

helpful operating and servicing information. Please read all

the highlighted information carefully to avoid injury and

machine damage.

Introduction

Page 3

PRODUCT IDENTIFICATION

ProductIdentification

Record Identification Numbers

Mechanical Tiller

30-Inch Ser ial No. (010001 - )

If you need to contact an Authorized Service Center for

information on servicing, always provide the product model

and serial number.

You will need to locate the identification number for the

machine and for the engine. Record the information in the

spaces provided below.

A

M96308

DATE OF PURCHASE:

_________________________________________

DEALER NAME:

_________________________________________

DEALER PHONE:

_________________________________________

SERIAL NUMBER (A):

__ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __

Product Identification

Page 4

TABLE OF CONTENTS

Tableof Contents

Safety ..........................................................................................1

PreparsVehicle ...................................................................................4

Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Removing........................................................................................9

Operating...................................................................................... 12

Service.........................................................................................17

Troubleshooting..................................................................................23

Storage.........................................................................................24

Assembly.......................................................................................25

Specifications....................................................................................29

Index...........................................................................................30

All information, illustrations and

specifications in this manual are based

on the latest information at the time of

publication. The right is reserved to

make changes at any time without

notice.

COPYRIGHT© 1999

Deere & Co.

John Deere Worldwide Commercial and

Consumer Equipment Division

Horicon, WI

All rights reserved

Previous Editions

COPYRIGHT©

Table of Contents

OMM141979 J9 - English

Page 5

SAFETY

Safety

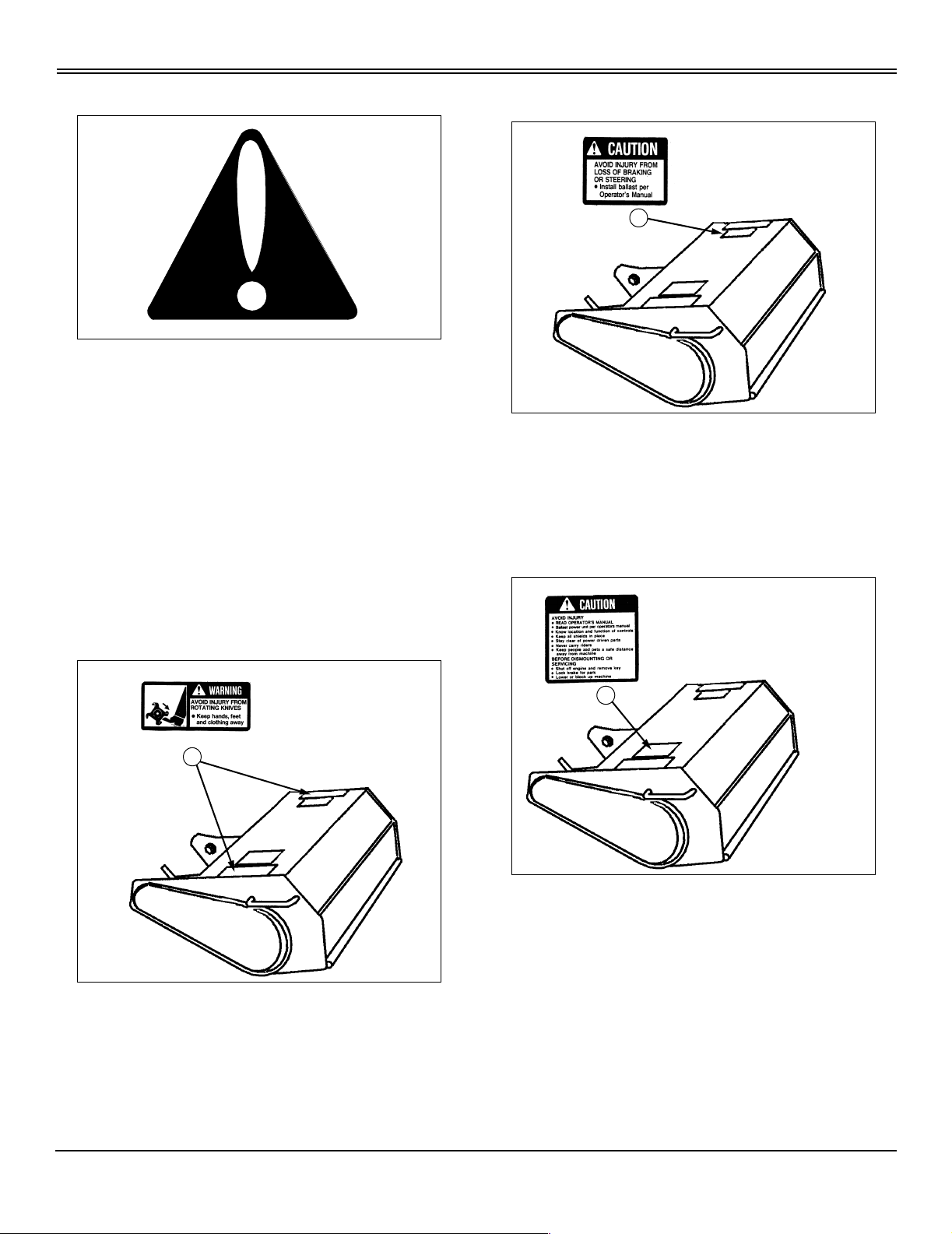

Understanding The Machine Safety Labels

The machine safety labels shown in this section are placed

in impor tant areas on your machine to draw attention to

potential safety hazards.

On your machine safety labels, the words DANGER,

WARNING, and CAUTION are used with this safety-alert

symbol, (

hazards.

The operator’s manual also explains any potential safety

hazards whenever necessary in special safety messages

that are identified with the word, CAUTION, a nd the safetyalert symbol, (

c). DANGER identifies the most serious

c).

CAUTION (B)

M74626

AVOID INJURY FROM LOSS OF BRAKING OR

STEERING

• Install ballast per Operator’sManual.

B

M74608

CAUTION (C)

M74568

WARNING (A)

M74570

A

AVOID INJURY FROM ROTATING KNIVES

• Keep hands, feet and clothing away.

M74608

C

M74608

AVOID INJURY

• READ OPERATOR’SMANUAL

• Ballast power unit per operator’smanual.

• Know location and function of controls.

• Keep all shields in place.

• Stay clear of power driven parts.

• Never carry riders.

• Keep people and pets a safe distance away from

machine.

Safety - 1

Page 6

SAFETY

BEFORE DISMOUNTING OR SERVICING

• Shut off engine and remove key.

• Lock brake for park.

• Lowerorblockupmachine.

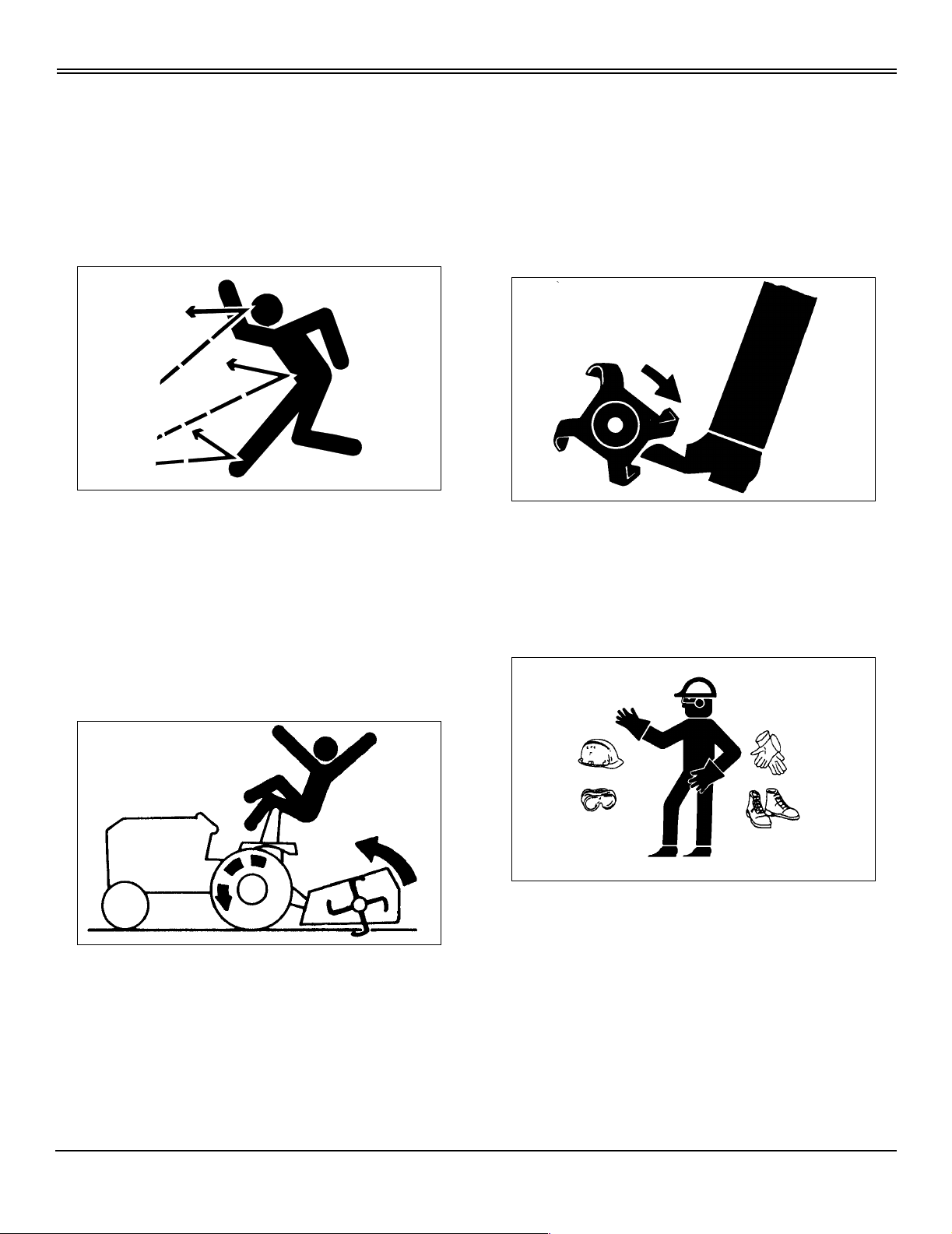

Operate Safely

• Checkvehicle brake actionbefore you operate.Adjust or

service brakes as necessary.

• Inspect machine before you operate. Be sure hardware

is tight. Repair or replace damaged, badly worn, or missing

parts. Be sure guards and shields are in good condition

and fastened properly. Make any necessary adjustments

before you operate.

• DO NOT let children or an untrained person operate

machine.

• Raise tiller as-high-as it will go before you drive between

work areas.

• DO NOT use tiller near the edge of a ditch or bank. Tiller

can push tractor.

• Slow down on slopes.

• Stop tiller when you are NOT tilling.

• Tines turn at 250 rpm and can cause serious injury.

Keep hands, feet and clothing away from tiller when tines

are turning—always keep bystanders well away.

Wear Appropriate Clothing

• Clear work area of objects that might be thrown. Keep

people and pets out of the work a rea. Stop machine if

anyone enters the area.

• If you hit an object, stop the machine and inspect it.

Make repairs before continuing operate. Keep machine

properly maintained and in good working order. Keep all

shields and guards in place and fastened properly.

• DO NOT leave machine unattended when it is running.

• Only operate during daylight or with good artificial light.

• DO NOT let anyone, ESPECIALLY CHILDREN, ride on

machine or vehicle.

• Wear close fitting clothing and safety equipment

appropriate for the job.

• Wearasuitableprotectivedevicesuchasearplugs.

Loud noise can cause impairment or loss of hearing,

• DO NOT wear radio or music headphones. Safe service

and operation requires your full attention.

Safety - 2

Page 7

SAFETY

Practice Safe Maintenance

• Understand service procedure before doing work. Keep

area clean and dry.

• Never lubricate, service, or adjust machine while it is

moving. Keep safety devices in place and in working

condition. Keep hardware tight.

• Keep all parts in good condition and proper ly installed.

Fix damage immediately. Replace worn or broken parts.

Remove any buildup of grease or debris.

• Do not modify machine. Unauthorized modifications to

the machine may impair its function and safety.

• Keep hands, feet, clothing, jewelry, and long hair away

from any moving parts, to prevent them from getting

caught.

• Lower attachments to the ground before servicing

machine. Disengage all power and stop the engine. Lock

park brake and remove the key. Let engine cool.

• Securly support any machine elements that must be

raised for service work.

• Never run engine unless park brake is locked.

Safety - 3

Page 8

PREPARE VEHICLE

PrepareVehicle

Remove Mower Deck

Tractormower deck must be removed from before installing

tiller. See your tractor operator’s manual or mower deck

manual for removal instructions.

Ballasting Requirements

All tractors require front wheel weights to be installed when

using this tiller.

Follow these recommendations to help improve traction:

• Install tire chains on turf tires or install bar tires on the

tractor.

• Install rear wheel weights.

Ballast weights can be purchased from your Authorized

Service Center. See your tractor operator’s manual for

further information.

Prepare Vehicle - 4

Page 9

INSTALLING

Installing

Park Vehicle Safely

• Stop vehicle on a level surface, not on a slope.

• Disengage PTO.

• Engage the park brake.

• STOP the engine.

• Remove the key.

• Beforeyou leavethe operator’s seat, wait for engine and

all moving parts to STOP.

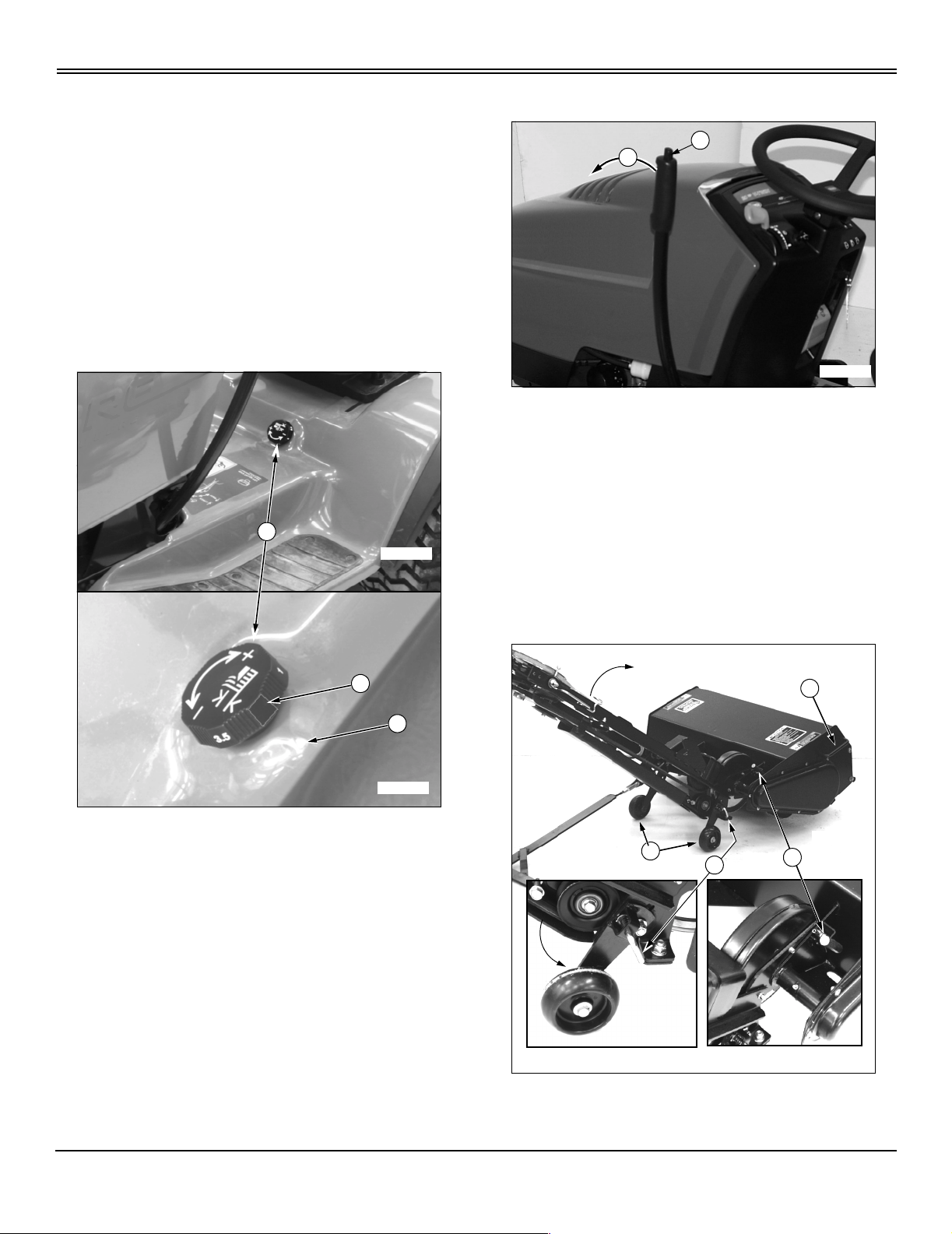

Setting Depth Control Knob

A

M96267

Move Implement Lift Lever

B

A

M97160

1. Pull implement lift lever (A) rearward slightly, then

depress and hold down button (B) to unlock lift leverlocking

mechanism.

2. Push lift lever (A) forward out of “RAISE” position,

releasebutton(B)asyoucontinuetopushliftleverall-theway forward until a loud metallic-click is heard, signalling

leveris in “LOCK-OUT” position, then release lift lever—it is

now locked into “LOWER” position.

B

C

M96268

Turn depth control knob (A) to “ZERO” setting (B), raised

indicator that is blank should be aligned with fender deck

raised indicator (C).

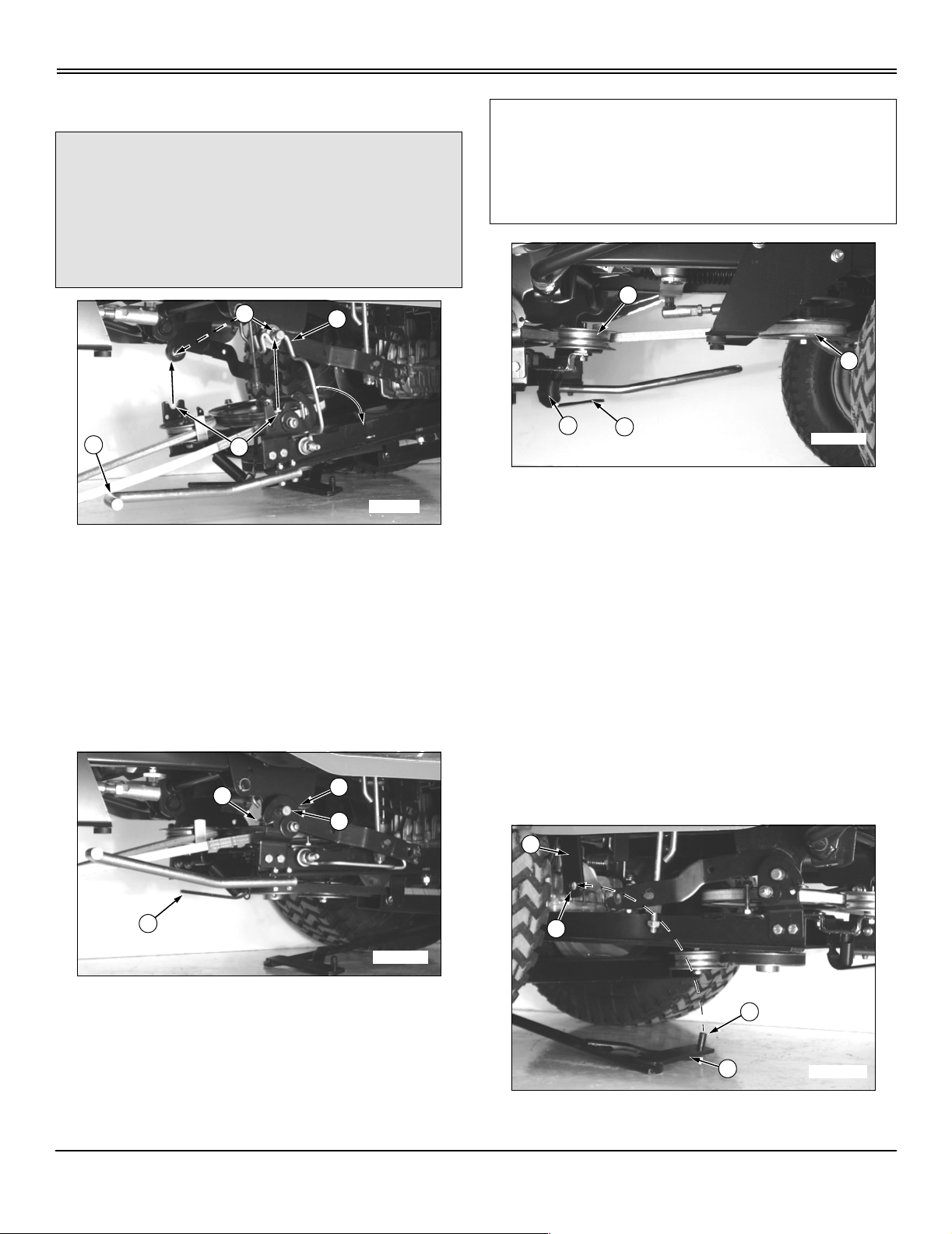

Put Tiller Frame Rails In Transport Position

B

C

D

M96275

M96259

A

M96274

1. Pull left frame rail up until locking pin (A) can be locked

into locking bracket hole. Push down on tiller housing

Installing - 5

Page 10

INSTALLING

handle (B) to rotate tiller housing while pulling left frame rail

upwards to gain clearance to lower frame wheels (C).

2. Unlock locking pin (D) and rotate frame wheel down into

engaged position and make sure locking pin locks into

locking hole. Lock right frame wheel down into engaged

position in similar fashion.

Install Tiller On Tractor Rear-Frame Mounting Hardware

1. Roll tiller under rear of tractor.

A

Engage Frame Support Rod

cCAUTION:Avoid injury! Maintain a secure grasp

of lift handle until support rod is in place. Keep

hands clear of pinch areas between tiller and

tractor frame.

D

A

B

1. Move to left side, under tractor footrest—open tiller latch

clips (A) at both sides of tiller.

2. Push and hold down lift handle (B).

C

M96279

M41781

B

M96255

2. Get a helper or use a floor jack with wheels to safely lift

and install tiller, frame hooks (A) slide over spacers (B) of

rear-frame mounting hardware.

3. Pivot left-side frame support rod (C) upward so loop in

rod is under mounting pin (D) of tractor frame.

4. Slowly release downward pressure on lift handle (B) to

engage rod loop.

Lock Frame Wheels into Storage Position

A

B

M96277

1. Move to left rear, behind tractor drive wheels—pull and

hold out wheel locking pin (A).

2. Swing left wheel assembly (B) up into “RAISED”

position. Make sure locking pin engages hole in locking

bracket. Repeat steps for right frame wheel.

Installing - 6

Page 11

Disengage Frame Support Rod

cCAUTION: Avoid injury!

Maintain a secure grasp of lift handle (B) until

tiller frame clips (A) are seated against

mounting pins (D).

Keep hands clear of pinch areas between tiller

and tractor frame.

D

INSTALLING

IMPORTANT: Avoid damage! Check that belt

tensioning idler spring (G) is installed in top detent

of belt tensioning lever (D). Damage to spring may

occur or tensioning of idler may not apply proper

tension on drive belt if spring is installed in the

lower detent.

E

C

F

B

A

M96279

1. Move to left side, under tractor footrest—hold lift handle

(B) down.

2. Pivot support rod (C) d own into storage position.

3. Slowly release downward pressure on lift handle (B)

until cups of tiller frame latches (A) are seated up against

mounting pins (D).

Fasten Frame Clip Latches And Install Belt

C

A

B

G

D

M96283

3. Move to right side, under tractor footrest—swing belt

tensioning lever (D) toward front of tractor to loosen belt

tensioning idler (E).

4. Move belt tensioning idler (E), by hand, towards right

frame to help install belt on PTO drive sheave (F). Release

idler after belt is completely seated in sheave.

5. Swing belt tensioning lever (D) toward rear of tractor to

tighten belt.

Fasten Tiller Lift Rod to Tractor Lift Link

NOTE: Lock implement lift lever into “LOWER”

position and unlock tiller housing from “TRANSPORT”

position and lower it onto ground before fastening tiller

lift rod (B)—this allows ease-of-alignment between

tractor lift link (A) and tiller lift rod pin (C).

A

D

M96280

1. Close clip of latch (A) around mounting pin (B) on each

side of tractor.

2. Install spring locking pin (C), from bag of parts, into

holes of each clip latch (A), outside-in, to preventclips from

vibrating or bouncing open.

Installing - 7

D

C

B

M96281

1. Move to right side, under tractor footrest—as you rotate

Page 12

INSTALLING

tiller lift rod (B) upright, align tractor lift link (A) so pin (C) fits

into hole (D) of lift link (A).

C

E

F

M96284

2. Install M13 x 24 x 2.5 mm washer (E), from bag of parts,

on lift rod pin (C).

3. Fasten lift rod to lift link with spring locking ring (F), from

bag of parts.

Adjust Tiller Lift Height

B

A

E

D

F

G

C

M96294

3. Move to left side of tiller housing—grasphandle(C)to

raise tiller housing to remove pressure on transport locking

pin (D) and continue to hold tiller housing stationary while

you pull transport locking pin (D) out and rotate it forward

into “LOCK-OUT” position,rolledpin(E)lockedinframe

slot (F).

4. Slowly lower tiller housing down (G) against tractor lift

linkage.

M97160

1. Push implement lift lever (A) forward slightly, then

depress and hold down button (B) to unlock lift leverlocking

mechanism.

2. Pull lift lever (A) reward out of “LOWER” position,

release button (B) and continue to pull lever all-the-way

reward until a loud metallic-click is heard, signalling lever is

in “LOCK-OUT” position, then release lift lever—it is now

locked into “RAISE” position.

C

M96289

5. Measure distance (C) between lowest tine and ground.

Distance should be 75 mm (3-in.). This will allow a

maximum 150 mm (6-in.) tilling depth and enough ground

clearance for turns on ends of tilling area. If distance is not

correct, see Adjusting Tilling Depth in the OPERATING

section.

Installing - 8

Page 13

REMOVING

Removing

Park Vehicle Safely

• Stop vehicle on a level surface, not on a slope.

• Disengage PTO.

• Engage the park brake.

• STOP the engine.

• Remove the key.

• Beforeyou leavethe operator’s seat, wait for engine and

all moving parts to STOP.

Move Implement Lift Lever

B

A

Disconnect Tiller Lift Rod From Tractor Lift Link And Unhook Right Clip Latch

NOTE: Lock implement lift lever into “LOWER”

position and unlock tiller housing from “TRANSPORT”

position and lower it onto ground before disconnecting

tiller lift rod (B)—this allows ease-of-disconnect

between tractor lift link (A) and tiller lift rod pin (C).

A

C

1. Move to right side, under tractor foot rest—remove

spring locking ring (D) and washer (E) from tiller lift rod pin

(C).

E

D

B

M96284

M97160

1. Pull implement lift lever (A) rearward slightly, then

depress and hold down button (B) to unlock lift leverlocking

mechanism.

2. Push lift lever (A) forward out of “RAISE” position,

release button (B) as you continue to push lift lever all-theway forward until a loud metallic-click is heard, signalling

leveris in “LOCK-OUT” position, then release lift lever—itis

now locked into “LOWER” position.

A

G

C

B

F

M96281

2. Pull tiller lift rod pin (C) from lift link (A) as you lower tiller

lift rod (B) inward, onto ground.

3. Store washer (E) and spring locking ring (D) on lift rod

pin (C).

4. Removespring locking pin from clip latch (F) and flip clip

of latch rearward to clear tractor mounting pin (G).

Removing - 9

Page 14

REMOVING

Disengage Belt And Unhook Left Clip Latch

B

A

M96283

1. Move to right side, under tractor footrest—move belt

tensioning idler lever (A) out of “ENGAGED” position into

“DISENGAGED” position (pointing toward front of tractor).

2. Pull and hold tensioning idler (B) towards right frame

while you remove belt from P TO drive sheave (C).

E

C

stationary while you rotate transport locking pin handle (H)

rearward until spring tension “LOCKS-OUT” pin into

“TRANSPORT” position.

5. Slowlylift housing handle (E) up-and-down to ensure pin

is “LOCKED-OUT” before letting go of handle.

Engage Frame Support Rod

cCAUTION:Avoid injury! Maintain a secure grasp

of lift handle until support rod is in place. Keep

hands clear of pinch areas between tiller and

tractor frame.

C

B

D

M96280

3. Move to left side, under tractor footrest—remove spring

locking pin from clip latch (D) and flip latch of clip reward to

clear tractor mounting pin (E). I nstall spring locking pins in

clips for storage when finished removing tiller from tractor.

G

H

H

F

E

A

M96279

1. Move to left side, under tractor footrest—push and hold

down lift handle (A) as you pivot left-side frame support rod

(B) upward so loop in rod is under mounting pin (C) of

tractor frame.

2. Slowly release downward pressure on lift handle (A) to

engage rod loop.

M96294

4. Move to left side of tiller housing—grasp handle (E) to

raise tiller housing to align transport locking pin (F) with

locking plate hole (G). Continue to hold tiller housing

Removing - 10

Page 15

REMOVING

Lock Frame Wheels Into Engage Position

A

A

M96277

1. Move to left rear, behind tractor drive wheels—pull and

hold out wheel locking pin (A).

2. Swing left wheel assembly (B) down into “ENGAGE”

position. Make sure locking pin engages hole in locking

bracket. Repeat for right frame wheel.

Remove Tiller From Tractor Rear-Frame Mounting Hardware

A

M41781

1. Get a helper or use a floor jack with wheels to safely

support and slide tiller housing as you slide frame hooks

(A) from of rear-frame mounting hardware (B).

B

Disengage Frame Support Rod

cCAUTION: Avoid injury! Maintain a secure grasp

of lift handle (A). Keep hands clear of pinch

areas between tiller and tractor frame.

B

A

M96279

1. Move to left side, under tractor footrest—push and hold

lift handle (A) down.

2. Pivot support rod (B) down into storage position.

3. Slowly release downward pressure on lift handle (A).

M96255

2. Carefully roll tiller out-from-under rear of tractor.

Removing - 11

Page 16

OPERATING

Operating

Tilling Tips

Install correct front and rear tractor weights. See I nstall

Weights and Chains in Installing the Tiller section.

IMPORTANT: Avoid damage!

DONOTbackupormakesharpturnswiththetiller

in the ground.

Till with engine at FAST throttle, control ground speed with

appropriate transmission speed range.

Check tines before you till. Replace missing, bent, or

broken tines.

When you till hard ground or sod, till at a shallow depth for

the first pass. Till deeper on each pass after that.

When you till a small area, make a pass through the

middle, then circle alongside the original pass, working to

the outside. After you finish, make a few passes around the

edge to cover ridges left by turning.

Till straight ahead when possible. This will leave fewer

ridges from turning.

For seed bed preparation, till the soil once in the fall.

Decaying vegetation will add valuable nutrients to the soil

by spring. If the terrain is hilly or uneven, wait until spring,

or leave some untilled strips, to help reduce soil erosion.

The climate and terrain will help you decide the best time to

till.

Before Tilling

Always pick up rocks, branches, and other objects that

might damage tiller.

Always check tines before tilling. Repair or replace loose,

bent, or broken tines.

Move Implement to “LOWER” Position

B

A

M97160

1. First pull implement lift lever (A) rearward slightly, t hen

depress and hold down button (B) to unlock lift leverlocking

mechanism.

2. Push lift lever (A) forward out of “RAISE” position

(shown), release button (B) as you continue to push lift

lever all-the-way forward until a loud metallic-click is heard,

signalling lever is in “LOCK-OUT” position, then release lift

lever—it is now locked into “LOWER” position (see next

figure).

“LOCK-OUT” Position: locks tiller in “LOWER” position—for

difficult conditions, such as, heavy soils, clay,or sod. When

lift lever is “LOCKED-OUT” this means the lift spring in the

lift linkage has no effect on tiller weight.

M34147

Test soil condition by squeezing it in your hand. If soil forms

a ball, it is too wet to till. If soil does not compress easily or

falls apart, it is ready to till.

DO NOT till when soil is wet. Wet soil will stick to tines and

tine shaft. Wet soil will clump-up and dry out hard, making it

difficult to work during t he growing season.

Before tilling mow tall weeds and grass to keep them from

wrapping around tines or tine shaft.

Operating - 12

Page 17

OPERATING

Move Implement to “RAISE” Position

B

A

M97160

1. First push implement lift lever (A) forward slightly,then

depress and hold down button (B) to unlock lift leverlocking

mechanism.

2. Pull lift lever reward out of “LOWER” position, release

button (B) and continue to pull lever all-the-way reward until

a loud metallic-click is heard, signalling lever is in “LOCKOUT” position, then release lift lever—it is now locked into

“RAISE” position.

“LOCK-OUT” Position: locks tiller in “RAISE” position—for

making turns at end of rows. When lift lever is “LOCKEDOUT” this means the lift spring in the lift link age has no

effect on tiller weight.

“FLOAT”Position allows implement to move with contour of

ground which causes the lift spring in the lift linkage to exert

maximum depth force on tiller weight. “FLOAT” position

performs best in light-to-medium soils: such as sandy,

loam, or soils previously tilled.

Using Depth Control Knob

Adjust depth control knob to set tilling depth. Tiller will

return to the same depth each time you lower it.

B

A

M96267

1. Use lift lever (B) to raise tiller as high as it will go.

2. Turn knob (A) clockwise to raise the tiller depth or

counter-clockwise to lower the depth, as viewed from

operator’sseat.

3. If you cannot adjust for the desired tilling depth, see

Adjusting Tilling Depth.

Move Implement to “FLOAT” Position

B

A

M97160

1. First pull implement lift lever (A) rearward slightly, then

depress and hold down button (B) to unlock lift leverlocking

mechanism.

2. Push lift lever(A) out of “RAISE” position, release button

(B) and lift lever. Lift lever is now in “FLOAT” position

(between “RAISE” and “LOWER” positions).

Adjusting Tilling Depth

1. Stop engine and set PARK brake.

A

M97160

2. “LOCK-OUT” lift lever (A) into “LOWER” position to

release spring tension in lift linkage.

Operating - 13

Page 18

OPERATING

E

C

B

A

D

M96284

3. Move to right side, below tractor footrest—remove

spring locking ring (A) and flat washer (B) form lift rod pin

(C).

4. Remove lift rod (D) form tractor lift link (E).

IMPORTANT: Avoid damage!

DO NOT expose more than 30 mm (1-1/4 in.) of

thread (G) or lift rod and clevis threads could be

damaged or lift rod could separate from clevis.

NOTE: Maximum tilling depth is 150 mm (6-in.)—

bottom of shaft to bottom edge of lowest tine.

H

M96289

• Measure distance (H) between ground and the

lowest tine. The distance should be 75 mm (3-in.).

Operating Tiller

cCAUTION: Avoid injury!

• Pick up objects from tilling area.

• Guards and shields must be in place.

• Clear the work area of people.

• DO NOT let children operate the tractor/tiller.

• DO NOT let children ride on the tractor or

tiller.

D

G

F

M96272

Picture Note: Tiller frame removed from tractor for

clarity.

5. Turn lift rod (D) clockwise into clevis (F) to increase

tilling depth and counterclockwise out of clevis (F) to

decrease tilling depth.

6. Fasten lift rod (D) to tractor lift link (E) with washer (B)

and spring locking ring (A).

7. Check tiller ground clearance:

• Use lift lever to raise tiller as high as it will go.

B

A

M96277

1. Move to rear of tractor—lock frame wheels (A) in the

RAISED position (shown). Make sure locking pins (B) are

locked into locking bracket hole.

Operating - 14

Page 19

OPERATING

E

D

F

G

2. Move to left side of tiller housing—grasp handle (C) to

raise tiller housing to remove pressure on transport locking

pin (D) and continue to hold tiller housing stationary while

you pull transport locking pin (D) out and rotate it forward

into “LOCK-OUT” position,rolledpin(E)lockedinframe

slot (F).

3. Slowly lower tiller housing down (G) against tractor lift

linkage.

4. Start engine. Put throttle lever at 1/4 position. (See your

tractor operator’s manual for throttle lever operation.)

NOTE: For those tractors with Reverse Implement

Option (RIO), the tiller will stop when the tractor is put

in reverse unless Reverse Implement Switch (RIS) is

activated before going in reverse.

5. To engage tiller, put PTO control in the ON position.

(See your tractor operator's manual for PTO operation.)

6. Push throttle lever to the FAST position.

7. UNLOCK the park brake.

8. Till ground at a safe travel speed using appropriate

transmission ground speed.

C

M96294

A

M96293

7. Move to rear of tiller—lift shield (A) to gain access to

tines and shaft.

8. Safely inspect or unplug tines and shaft area.

Parking Tiller

1. STOP tractor and turn PTO switch OFF.

2. STOP engine, LOCK park brake, and remove key.

3. Lower tiller to ground.

Transporting Tiller

Drive the tractor with the tiller in the “TRANSPORT”

position when traveling from one tilling area to the other.

Drive the tractor at a safe travel speed. Slow down on

slopes or rough ground.

Place tiller in “TRANSPORT” position as follows:

Inspecting Or Unplugging Tiller

cCAUTION: Avoid injury! Stop the engine and

wait for all moving parts to stop before leaving

tractor seat.

1. STOP the tractor.

2. Put PTO control in the OFF position.

3. Lower tiller to the ground.

4. LOCK the park brake.

5. STOP the engine.

6. Remove the key.

B

A

M97160

1. First push implement lift lever (A) forward slightly, then

depress and hold down button (B) to unlock lift leverlocking

Operating - 15

Page 20

OPERATING

mechanism.

2. Pull lift lever (A) reward out of “LOWER” position

(shown),releasebutton(B)andcontinuetopullleverallthe-way reward until a loud metallic-click is heard,

signalling lever is in “LOCK-OUT” position, then release lift

lever—it is now locked into “RAISE” position, lift lever in

close proximity to steering wheel.

F

D

E

C

G

M96294

3. Move to left side of tiller housing—grasp handle (C) to

raise tiller housing to align transport locking pin (D) and

transport bracket locking hole (E). Rotate transport locking

pin (D) reward to unlock rolled pin (F) from frame slot (G)

and release transpor t locking pin so it springs into “LOCKOUT” position in transport bracket locking hole (E).

4. Slowly lift up and push down on handle (C) before

releasing it to ensure tiller housing is “LOCKED-OUT” into

“TRANSPORT” position.

Operating - 16

Page 21

Service

Service Intervals

5 Hours Check belt tension.

SERVICE

Clean under belt shield.

10 Hours Lubricate drive sheave bearing.

Lubricate rear jackshaft.

Checking Belt Tension

A

Picture Note: Tiller removed for clarity purposes

only.

M96301

G

F

M96300

• Moveto left rear of tiller frame—loosen nut (F) on the

idler pulley.

C

H

M41784

1. Check position of belt tension rod (A):

B

A

C

D

E

M72980

• If rod end is in position (B), against the vertical frame

rail (C), the belt is too tight and must be loosened.

• If rod end is in position (D), extends beyond

horizontal frame rail (E), the belt is too loose and must

be tightened.

2. To adjust belt tension:

• To tighten belt—turn bolt (G) counter-clockwise until

a 3 mm (1/8 in.) clearance existsbetween inside edge of

rod end (H) and vertical frame rail (C).

• To loosen belt—turn bolt (G) clockwise until a 3mm

(1/8 in.) clearance exists between inside edge of rod

end (H) and vertical frame rail (C).

• Tighten nut (F) on the idler pulley after adjustment.

Service - 17

Page 22

SERVICE

Cleaning Under Belt Shield

B

A

M96299

Picture Note: Tiller removed for clarity purposes

only.

1. Move to left side of tiller housing—remove two selftapping cap screws (A) and belt shield (B).

Lubricating Drive Sheave Bearing

B

A

M96309

Picture Note: Tiller removed for clarity purposes

only.

Move to front of tiller frame—lubricate drive shaft assembly

bearing (A) at grease fitting (B) with a Multi-Purpose

Grease, or equivalent, until grease comes out of bearing

seals.

M96305

2. Clean dirt from sheave and surrounding area.

3. Install shield (B) and self-tapping cap screws (A) until

snug—DO NOT over-tightenor youmay damage threads in

shield holes.

Lubricating Rear Jackshaft

A

M96310

Picture Note: Tiller removed for clarity purposes

only.

Move to left side of tiller housing—lubricate jackshaft

grease fitting (A) with two or three shots of a Multi-Purpose

Grease, or equivalent.

Remove Primary Drive Belt

1. Remove tiller from tractor. (See the REMOVING

section.)

Service - 18

Page 23

SERVICE

B

A

D

C

C

M96301

2. Loosen flange lock nut (A) on tensioning idler. Move belt

guide (B) away from belt.

3. Loosen top jam nuts (C), one on each side, to tilt guide

bolts (D) away from drive sheave.

4. Remove belt.

Install Primary Drive Belt

1. Install belt on drive sheave with wide-edge of belt facing

guide bolts (D).

2. Tighten top jam nuts (C), one on each side, to properly

align guide bolts (D).

3. Install belt between tensioning idler and belt guide (B)

so narrow-edge of belt faces belt guide (B).

B

E

A

C

D

M96300

2. Removetwoself-tappingcapscrews(A)toremovebelt

shield (B).

3. Loosen flange nut (C) to loosen tensioning idler (D).

4. Turn bolt (E) clockwise to move tensioning idler (D) up in

the slot.

G

A

B

M97633

4. Position belt guide (B), as shown. Tighten tensioning

idler flange lock nut (A) to 40 N•m (354 lb-in.) while holding

belt guide stationary.

Remove Secondary Drive Belt

1. Remove tiller from tractor. (See the REMOVING

section.)

F

M96306

5. Move to front of tiller frame—remove secondary belt

from front idler (F) and front drive sheave (G).

I

H

J

M41764

6. Move to left rear of tiller—remove lock nut (H) on inside

of frame from idler mounting bolt (I) to remove V-idler (J)

from inside of belt.

Service - 19

Page 24

K

SERVICE

J

E

K

M96305

7. Remove secondary belt (K) from tiller drive sheave.

Install Secondary Drive Belt

B

A

M41766

1. Install new secondary drive belt with one twist (A), as

shown, to seat “V” of belt in secondary drive sheave (B).

DO NOT cross-over belt (forming an “X” pattern) when

installing or tiller drive rotation will be reversed.

C

I

F

M96300

C

H

M41784

3. Turn bolt (E) counterclockwise to move tensioning idler

(F) as far down in slot as necessary to tension belt

properly—until inside-edge of front gauge rod (G) has

3 mm (1/8 in.) clearance from vertical frame rail (H).

4. Tighten tensioning idler nut (I).

D

B

M41764

2. Move to left rear of tiller—install V-idler (B) inside belt

and fasten with mounting bolt (C), outside-in, and tighten

withlocknut(D)oninsideofframe.

5. Install shield (J) and fasten with two self tapping cap

screws (K) until snug—DO NOT over-tighten or you may

damage threads in shield holes.

Replacing Tines

cCAUTION: Avoid injury! DO NOT work under a

raised tiller unless it is safely supported. Tiller

could fall on you, causing serious injury.

1. Park machine safely.

Service - 20

Page 25

SERVICE

2. Raise tiller as high as it will go if still on tractor.

NOTE: For ease in replacing tines, you can remove

tiller from the tractor and turn it completely upside

down. Put down protective tarp or carpet to protect

paint finish.

3. Put tiller in TRANSPORT position. (See Transporting

Tiller in OPERATING section.)

NOTE: Make sure you install the new tines and

hardware EXACTLY as the old tines and hardware were

positioned. Use the pictures to help you install tines

correctly. Properly installed tines have a step-up

pattern from left-to-right.

Each cluster of tines MUST have two left tines (D) and

two right tines (E):

• Alternate left and right tines in each cluster.

• AboltwithNOSPACERisanM10x35bolt.

• A bolt with ONE SPACER is an M10 x 45 bolt.

• AboltwithTWOSPACERSisanM10x60bolt.

M96313

4. Safelyput jack stand or blocks under tiller (tiller removed

or still on tractor).

M96311

5. Replace tines:

D

B

C

E

A

M96317

• Left Set: Remove lock nuts (A), bolts (B), spacers

(C), two left tines (D), and two right tines (E). Remember

to install new bolts so heads are to left side and new

lock nuts are to right side. A total of two spacers are

used in this set.

Service - 21

Page 26

SERVICE

D

E

C

B

A

M96318

• MiddleTine Sets: Remove lock nuts (A), bolts (B),

spacers (C), two left tines (D), and two right tines (E).

Remember to install new bolts so heads are to left side

and new lock nuts are to r ight side. A total of eight

spacers are used in these middle tine sets—four in each

set.

Replacing Shaft Bolts

B

A

M96317

1. Moveto left side of tiller shaft—removelock nuts (A) and

bolts (B).

2. Align shaft holes and install new bolts (B) and lock nuts

(A). Tighten lock nuts to 75 N•m (55 lb-ft).

Grease

Use a SAE Multi-purpose grease based on the expected air

temperature range during the service interval.

D

B

A

C

E

M96304

• Right Tine Set: Remove lock nuts (A), bolts (B),

spacer (C), two left tines (D), and two right tines (E).

Remember to install new bolts so heads are to right side

and new lock nuts are to left side. A total of two spacers

areusedinthisset.

6. Tighten all lock nuts to 75 N•m(55lb-ft).

Service - 22

Page 27

TROUBLESHOOTING

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this

chart, see your authorized dealer for service.

Whenyouhavecheckedallthepossiblecauseslistedand

you are still experiencing the problem, see your authorized

dealer.

IF CHECK

Tiller is Noisy Tines need to be straightened, tightened or replaced.

Rocks and debris in tilling area.

Erratic Tiller Operation Tines need to be straightened, tightened or replaced.

Drive belts need to be tightened or replaced.

Tiller Will Not Till Drive belt needs to be tightened or replaced.

Replace shaft bolts.

Tractor and Engine Slow Down Throttle not at “FAST” position.

Tilling too deep

Decrease travelspeed.

Not Enough Tillage Depth Throttle not at “FAST” position.

Check tine placement or replace tines.

Tine Shaft Rotates But Tiller Does Not Till Clean tines.

Install tines correctly.

Till at shallower depth.

Replace shaft bolts.

Tilled Ground is Uneven Rocks and debris in tilling area.

Keep travel speed the same.

Tilling Results Are Poor Cut tall grass or weeds before you till.

Adjust transmission travel speed - slow down.

Tractor Will Not Pull Tiller Because Wheels Slip

Too Much

Tine Shaft Does Not Rotate Remove rock or trash wedged between shaft and housing.

Cut tall grass or weeds before you till.

Till at shallower depth.

Make more than one pass.

Add rear wheel weights or tire chains on turf tires, or install bar tires.

Replace shaft bolts.

Tighten or replace drive belts.

Tiller Hard To Raise Remove dirt, mud, and trash from shaft and tines.

Tiller Bounces When It Is Tilling Or Will Not

Penetrate

Tiller Pushes Tractor Add rear wheel weights, or tire chains on turf tires, or install bar tires.

Secondary drive belt installed incorrectly.

Troubleshooting - 23

Page 28

STORAGE

Storage

Storing Tiller

1. Remove tiller from tractor. (See the REMOVING

section.)

2. Clean tiller with water pressure.

3. Check belts. If necessary, get new belts from your

Authorized Service Center. DO NOT install the new belts

until you take tiller out of storage.

4. Replace or repair badly worn or damaged parts.

5. Paint scratched areas to preventrust.

6. Lubricate two grease points. (See the SERVICE

section.)

7. Store tiller on a hard, level surface in a clean, dry place.

If you must store tiller outside, cover it with a waterproof

cover.

Storage - 24

Page 29

ASSEMBLY

Assembly

Identify Parts – 30 Inch Mechanical Tiller

M96256

Bag of Parts

B

A

F

J

N

C

G

K

O

Qty. Used Part Description Size

1 Handle, Lift (A)

2 Pin, Mounting (B)

1 Sheave, Idler (C)

1 Guide, Belt (D)

2 Bolt, Flange (E) M12 x 1.75 x 50 mm

2 Bolt, Flange (F) M6 x 1.00 x 30 mm

4 Bolt, Hex (G) M8 x 1.25 x 25 mm

1 Bolt, Flange (H) M8 x 1.25 x 50 mm

2 Spacer, Rear (I)

2 Nut,Flange(J) M6x1.00mm

5 Locknut, Flange (K) M8 x 1 .25 mm

1 Washer, Flat (L) M13 x 24 x 2.5 mm

2 Locknut, Flange (M) M12 x 1.75 mm

1 Tiller Clip, Left-Hand (N)

1 Tiller Clip, Right-Hand (O)

2 Pin, Spring Locking (P)

1 Ring, Spring Locking (Q)

D

H

E

I

L

P

M

Q

M96254

Assembly - 25

Page 30

Install Tractor Rear-Frame Hardware

ASSEMBLY

C

C

A

M96276

B

M96287

1. Frombag of parts, install one spacer (A) on each M12 x

1.75 x 50 mm flange bolt (B).

2. Install spacers and bolts in BOTTOM holes at rear of

tractor frame and secure with M12 x 1.75 locknuts (C) on

inside of tractor frame. Tighten locknuts to 105 N•m (78 ftlb).

C

B

F

E

A

M96278

2. Place draft ar ms (A) back in their or iginal positions.

Make sure spacers (E) are installed properly inside draft

arms (A).

3. Install original washers (C) on tiller mounting pins (F),

from bag of parts, then install in draft arms, spacers, and

mounting brackets. Fasten with original locknuts (B) on

inside of mounting brackets. Tighten locknuts to 140 N•m

(103 lb-ft).

Install Clips On Tiller Frame Rails

D

Install Tractor Mid-Frame Mounting Pins

IMPORTANT: Avoid damage! If spacer (E) falls out of

draft arm (A) when pivot bolt (D) is removed, return

spacer to its original position inside the draft arm

hole. Damage may occur if spacer is missing or

improperly installed.

C

D

B

E

1. Locate draft arms (A) under left and right tractor foot

rests.Removelocknut(B),washer(C),andpivotbolt(D)

from each side. Discard original pivot bolts.

A

M96288

D

A

C

A

M96260

B

From bag of parts, install left and right tiller clips (A) to

outside of correct tiller frame rails, so latches (D) flip

forward. Fasten with two M8 x 1.25 x 25 mm hex bolts (B)

and M8 x 1.25 locknuts (C). Tighten locknuts to 28 N•m

(247 lb-in.).

Assembly - 26

Page 31

ASSEMBLY

Put Tiller Frame Rails In Transport Position

B

M96259

C

M96275

A

M96274

B

F

D

A

E

C

M97633

2. From bag of parts, position idler sheave (A) and belt

guide (B) onto tiller tensioning arm (C). Make sure shoulder

(D) on sheave is seated against the belt guide.

3. Install M8 x 1.25 x 50 mm flange bolt (E) from bottom

side of tensioning arm. Install M8 x 1.25 locknuton top side

of sheave finger tight only.

1. Pull left frame rail up until locking pin (A) can be locked

into locking bracket hole. Push down on tiller handle (B) to

rotate tiller housing while pulling left frame rail up to gain

clearance to lower left frame wheel.

2. Unlock locking pin (C) and rotate wheel down into

engaged position and make sure locking pin locks in

locking hole. Lock right frame wheel down into engaged

position in similar fashion.

Install Lift Handle And Idler Sheave

B

A

M96261

C

F

A

M96262

B

4. Remove shipping tape from belt and route belt between

belt guide (B) and idler sheave (A) so small V-edge (F) is

facing belt guide.

G

B

M97633

1. From bag of parts, install lift handle (A) under left frame

rail with two M6 x 1.0 x 30 mm flange bolts (B), top-down,

and fasten with two M6 x 1.0 flange nuts (C). Tighten two

flange nuts to 17 N•m (150 lb-in.).

Assembly - 27

5. Adjust the position of belt guide (B) as shown. Make

sure belt guide does not contact idler sheave at (G).

Page 32

ASSEMBLY

NOTE: Make sure belt guide does not move out of

position when tightening locknut.

6. TightenM8x1.25locknutto40N•m (354 lb-in.).

7. After tightening, make sure the idler sheave rotates

freely on the tensioning arm.

8. Pull the belt tight and make sure belt guide does not

contact idler sheave or belt.

Adjust Tiller Lift Rod

C

B

A

M96256

C

B

A

M96272

Turn threaded end (B) of tiller lift rod (A) clockwise into

clevis (C), far enough so three-to-four threads are exposed

inside clevis.

Assembly - 28

Page 33

SPECIFICATIONS

Specifications

Tiller Specifications

Tiller Specifications

Dimensions:

CuttingWidth.......................................................................762mm (30-in.)

MaximumCuttingDepth...............................................................150mm (6-in.)

MaximumLiftHeight...................................................................76mm(3-in.)

TransportHeight .....................................................................204mm(8-in.)

RotorDiameter......................................................................356mm(14-in.)

Miscellaneous:

RotorSpeed.............................................................................. 250rpm

DriveChain......................................................................No.50RollerChain

TineShaftBearings..............................................................SealedBallBearings

Recommended Lubricants

Grease....................................................................SAEMulti-PurposeGrease

(Specifications and design subject to change without notice.)

Specifications - 29

Page 34

INDEX

Index

B

Ballasting Requirements .........................................4

Before Tilling ........................................................12

Belt Shield, Cleaning Under .................................18

Belt Tension, Checking .........................................17

Belt, Disengage .....................................................10

Belt, Install ..............................................................7

C

Clips, Tiller Frame Rails - Install .........................26

D

Depth Control Knob, Setting ..................................5

Depth Control Knob, Using ..................................13

Drive Sheave Bearing, Lubricating .......................18

F

Frame Clip Latches, Fasten ....................................7

Frame Support Rod, Disengage ........................7, 11

Frame Support Rod, Engage .............................6, 10

Frame Wheels, Engage Position ...........................11

Frame Wheels, Storage Position .............................6

G

Grease ...................................................................22

H

Hooks on Spacers, Install ........................................6

I

Idler Sheave, Install ..............................................27

Implement Lift Lever, Move ...............................5, 9

Implement to "FLOAT" Position, Move ..............13

Implement to "LOWER" Position, Move .............12

Implement to "RAISE" Position, Move ................13

L

Left Clip Latch, Unhook .......................................10

Lift Handle, Install ................................................27

Lift Height, Adjust Tiller ........................................8

Lift Rod, Install .....................................................28

Lubricants, Recommended ...................................29

Lubricating Drive Sheave Bearing ........................18

Lubricating Rear Jackshaft ...................................18

M

P

Parking Tiller ........................................................15

Parts, Identify ........................................................25

Primary Drive Belt, Install ....................................19

Primary Drive Belt, Remove ................................18

R

Rear Jackshaft, Lubricating ..................................18

Right Clip Latch, Unhook .......................................9

S

Safety, Installing .....................................................5

Safety, Operating ....................................................2

Safety, Removing ....................................................9

Safety, Service Machine .........................................3

Safety-Alert Symbol; Labels, Safety ......................1

Secondary Drive Belt, Install ................................20

Secondary Drive Belt, Remove ............................19

Service Intervals ...................................................17

Shaft Bolts, Replacing ..........................................22

Specifications, Lubricants .....................................29

Specifications, Tiller .............................................29

Storage, Tiller .......................................................24

T

Tiller Frame Rails, Put In Transport Position .......27

Tiller Frame Rails, Transport Position ...................5

Tiller from Tractor Rear-Frame Mounting Hardware,

Remove .................................................................11

Tiller Lift Height, Adjust ........................................8

Tiller Lift Rod to Tractor Lift Link, Disconnect ....9

Tiller Lift Rod to Tractor Lift Link, Fasten ............7

Tiller Specifications ..............................................29

Tiller, Inspecting or Unplugging ..........................15

Tiller, Operating ....................................................14

Tiller, Parking .......................................................15

Tiller, Storage .......................................................24

Tiller, Transporting ...............................................15

Tilling Depth, Adjusting .......................................13

Tilling Tips ...........................................................12

Tines, Replacing ...................................................20

Tractor, Mid-Frame Mounting Pins, Install ..........26

Tractor, Rear-Frame Mounting Hardware - Install 26

Transporting Tiller ................................................15

Troubleshooting Chart, Using ...............................23

Mower Deck, Remove ............................................4

O

Operating Tiller .....................................................14

Index - 30

Page 35

NOTES

Notes

Notes - 31

Page 36

QUALITY STATEMENT

Quality Statement

Your product, designed and built by John Deere, is more

than just a purchase, it’s an investment in quality. That

quality goes beyond our equipment to your dealer’sparts

and service support.

That’s why John Deere has initiated a process to handle

your questions or problems, should they arise. If you have

questions or problems with your new product, please follow

the steps below.

To locate your nearest authorized servicing dealer, please

call the toll free number listed in your Tractor Operator’s

Manual.

Step 1

Refer to your operator’smanual

A. It has many illustrations and detailed information on the

safe and proper operation of your equipment.

B. It gives troubleshooting procedures, and specification

information.

C. It gives ordering information for parts catalogs, service

and technical manuals.

D. If your questions are not answered in the operator’s

manual, then go to Step 2.

Step 2

Contact your dealer

A. Your authorized servicing dealer has the responsibility,

authority, and ability to answer questions, resolve

problems, and fulfill your parts and service needs.

B. First, discuss your questions or problems with your

dealer’s trained parts and service staff.

C. If the parts and service people are unable to resolve

your problem, see the dealership manager or owner.

D. If your questions or problems are not resolved by the

dealer,thengotoStep3.

Step 3

Call the Customer Communications Center

A. Your authorized servicing dealer is the most efficient source in addressing any concern, but if you are not able to

resolve your problem after checking your operator’s manual and contacting your dealer, call the Customer

Communications Center.

B. For prompt, effective service, please have the following ready before you call:

• The name of the dealer with whom you’ve been

working.

• Your equipment model number.

• Number of hours on machine (if applicable).

C. Then refer to your Tractor Operator’sManual to locate the C ustomer Communications Center toll free number and call

our advisor who will work with your dealer to investigate your concern.

• Your 13-digit serial number which you recorded on the

inside front cover of this manual.

• If the problem is with an attachment, your attachment

identification number.

Quality Statement - 32

Loading...

Loading...