Page 1

772A MOTOR GRADER

ENGINE PERFORMANCE

Nm Ilb-ft

w 651 460

::J

~597 440

0

I- 542 400

I-

!!;!466 360

g/kWh

I hph

-' 274

~ 243 .40

1

LL 213 .35

Ibl

FUEL CONSUMPTION

.45

1000

ENGINE SPEED-RPM

TORQUE

POWER

1400 1600 2200

hp I kW

160 119 a:

140 104 ~

120 69 "-

100 75 z

60 60

FEATURES

150 SAE net hp (112 kW)

12-ft. (3.65 m) moldboard with 0.62 x 6 in. (16 x

152 mm) through-hardened Dura-MaX@cutting

edge; 13- and 14-ft. (3.95 and 4.25 m)

moldboards and 2-ft. (610 mm) extensions

available

Power Shift transmission;

w

0

I-

W

8 speeds forward, 4 reverse

Articulated frame steering

Differential lock-unlock

All-wheel drive, standard system to 6.7 mph

(10.8 km/h), optional system to 11.5 mph

(18.5 km/h), switch-controlled for two modes of

operation

22-ft. 6 in. (6.86 m) turning radius

All-hydraulic control of blade and machine

functions

Closed-center hydraulic system with

operational no-leak, drift-free poppet valves

Pushbutton control

Hydraulically controlled, 7-position lift arms let

you position blade for 90-degree bank cuts, left

or right, in approximately one minute, without

leaving the seat

Oscillating front axle and rear tandem

Hydraulic front-wheel lean

Rollover protective structure (ROPS) w/cab

Model shown may include options

ADD VERSATILITY WITH:

Scarifier

Rear-mounted ripper

Snow plow and wings

Bulldozer

Automatic blade control

69

Page 2

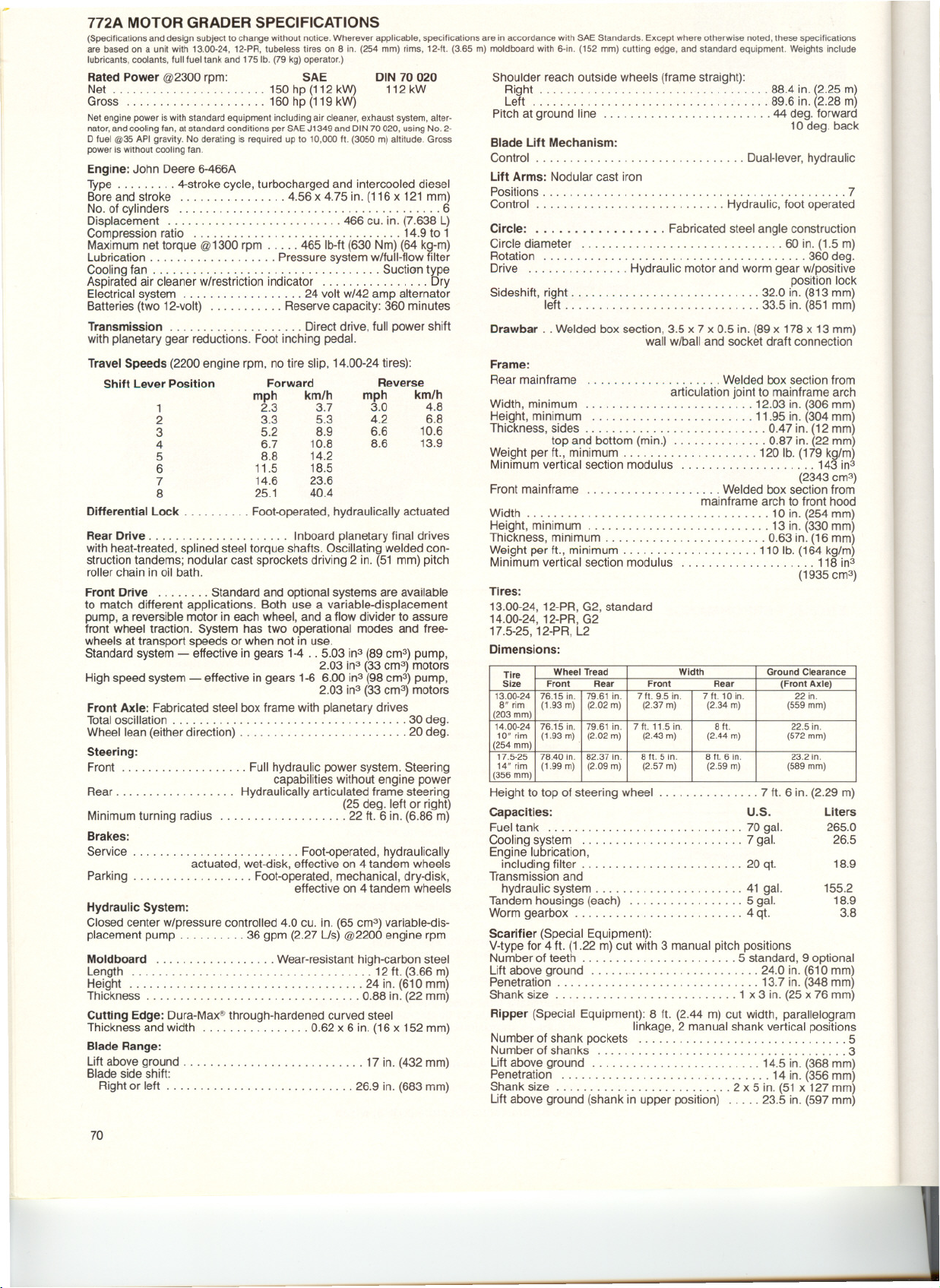

772A MOTORGRADERSPECIFICATIONS

(Specifications and design subject to change without notice. Wherever applicable, specifications are in accordance with SAE Standards. Except where otherwise noted, these specifications

are based on a unit with 13.00-24, 12-PR, tubeless tires on 8 in. (254 mm) rims, 12-ft. (3.65 m) moldboard with 6-in. (152 mm) cutting edge, and standard equipment. Weights include

lubricants, coolants, full fuel tank and 175 lb. (79 kg) operator.)

Rated Power @2300rpm: SAE

Net

Gross.. .. .. .. .. .. .. .. .. .. . 160 hp (119 kW)

Net engine power iswith standard equipment including air cleaner, exhaust system, alter-

nator,andcooling fan, at standard conditions per SAEJ1349 and DIN 70020, usingNo. 2-

D fuel @35API gravity. No derating is required upto 10,000 ft. (3050 m) altitude. Gross

power is without coolingfan.

150hp(112kW)

Engine: John Deere 6-466A

Type. . . . . . . . . 4-stroke cycle, turbocharged and intercooled diesel

Bore and stroke. . . . . . . . . . . . . . . .4.56 x 4.75 in. (116 x 121 mm)

No.ofcylinders 6

Displacement 466cu.in.(7.638L)

Compression ratio 14.9t01

Maximum net torque @1300 rpm . . . . . 4651b-ft (630 Nm) (64 kg-m)

Lubrication. . . . . . . . . . . . . . . . . . . Pressure system w/full-flow filter

Coolingfan Suctiontype

Aspiratedaircleanerw/restrictionindicator. . . . .. .. . . . . . .. .Dry

Electricalsystem. . . . . . .. . . . . . .. . . .24 volt w/42 amp alternator

Batteries(two 12-volt) Reserve capacity: 360 minutes

Transmission. .. .. .. .. . . .. . . . . . . .Direct drive, full power shift

with planetary gear reductions. Foot inching pedal.

Travel Speeds (2200engine rpm, no tire slip, 14.00-24tires):

Shift Lever Position Forward Reverse

1 2.3 3.7 3.0 4.8

2 3.3 5.3 4.2 6.8

3 5.2 8.9 6.6 10.6

4 6.7 10.8 8.6 13.9

mph km/h mph km/h

5 8.8 14.2

6 11.5 18.5

7 14.6 23.6

8 25.1 40.4

Differential Lock. . . . . . . . .. Foot-operated, hydraulically actuated

Rear Drive. . . . . . . . . . . . . . . . . . . .. Inboard planetary final drives

with heat-treated, splined steel torque shafts. Oscillating welded con-

struction tandems; nodular cast sprockets driving 2 in. (51 mm) pitch

roller chain in oil bath.

Front Drive. . . . . . . . Standard and optional systems are available

to match different applications. Both use a variable-displacement

pump, a reversible motor in each wheel, and a flow divider to assure

front wheel traction. System has two operational modes and free-

wheels at transport speeds or when not in use.

Standard system - effective in gears 1-4 . . 5.03 in3 (89 cm3) pump,

High speed system - effective in gears 1-6 6.00 in3 (98 cm3) pump,

Front Axle: Fabricated steel box frame with planetary drives

Totaloscillation 30deg.

Wheel lean (either direction) ...20deg.

Steering:

Front. . . . . . . . . . . . . . . . . . . Full hydraulic power system. Steering

Rear. . . . . . . . . . . . . . . . .. Hydraulically articulated frame steering

Minimumturningradius 22ft.6in.(6.86m)

Brakes:

Service Foot-operated,hydraulically

Parking. . . . . . . . . . . . . . . . . . Foot-operated, mechanical, dry-disk,

Hydraulic System:

Closed center w/pressure controlled 4.0 cu. in. (65 cm3) variable-dis-

placement pump. . . . . . . . . . 36 gpm (2.27 Us) @2200 engine rpm

Moldboard.

Length 12ft.(3.66m)

Height 24in.(610mm)

Thickness 0.88in.(22mm)

actuated, wet-disk, effective on 4 tandem wheels

. . . . . . . . . . . . . . . . . Wear-resistanthigh-carbon steel

2.03 in3 (33 cm3) motors

2.03 in3 (33 cm3) motors

capabilities without engine power

effective on 4 tandem wheels

Cutting Edge: Dura-MaX@through-hardenedcurved steel

Thicknessand width. . . . . . .. . . . . . .. .0.62 x 6 in. (16 x 152 mm)

Blade Range:

Liftaboveground

Bladeside shift:

Rightor left 26.9in.(683mm)

DIN 70 020

112kW

(25 deg. left or right)

.17 in. (432 mm)

Shoulder reach outside wheels (frame straight):

Right 88.4in.(2.25m)

Left 89.6in.(2.28m)

Pitch at ground line 44deg.forward

10deg. back

Blade Lift Mechanism:

Control Dual-lever,hydraulic

LiftArms: Nodular cast iron

Positions 7

Control Hydraulic,footoperated

Circle: Fabricated steel angle construction

Circle diameter 60in.(1.5m)

Rotation 360deg.

Drive. . . . . . . . . . . . . . .Hydraulic motor and worm gear w/positive

position lock

Sideshift,right 32.0in.(813mm)

Drawbar . . Welded box section, 3.5 x 7 x 0.5 in. (89 x 178 x 13 mm)

left 33.5in.(851mm)

wall wlball and socket draft connection

Frame:

Rear mainframe. . . . . . . . .. . . . . . .. . . .Welded box section from

articulation joint to mainframe arch

Width, minimum 12.03in.(306mm)

Height,minimum 11.95in.(304mm)

Thickness, sides 0.47in.(12mm)

top andbottom (min.) 0.87 in. (22 mm)

Weight per ft., minimum 120Ib.(179kg/m)

Minimum vertical section modulus. . . . . . . . . . . . . . . . . . . . 143 in3

Front mainframe. . . . . . . . . . . . . .. . . . . . Welded box sectionfrom

Width 10in.(254mm)

Height, minimum 13in.(330mm)

Thickness, minimum ... ... ...0.63in.(16mm)

Weightperft., minimum .110Ib.(164kg/m)

Minimum vertical section modulus 118in3

mainframe arch to front hood

(2343cm3)

(1935cm3)

Tires:

13.00-24, 12-PR, G2, standard

14.00-24, 12-PR, G2

17.5-25, 12-PR, L2

Dimensions:

Tire

Size Front Rear Front

13.00-24 76.15 in. 79.61 in.

8"rim

(203 mm)

14.00-24

10" rim

(254 mm)

17.5-25 78.40 in. 82.37 in.

14" rim

(356 mm)

Height to top of steering wheel. . . . . . .. . . . . . . . 7 ft. 6 in.(2.29m)

Capacities: U.S. Liters

Fueltank 70gal. 265.0

Cooling system 7gal. 26.5

Engine lubrication,

includingfilter 20qt.

Transmissionand

hydraulicsystem 41gal.

Tandem housings (each) 5 gal.

Worm gearbox 4qt.

Scarifier (Special Equipment):

V-type for 4 ft. (1.22 m)cut with 3 manual pitch positions

Number of teeth 5standard,90ptional

Lift above ground 24.0in.(610mm)

Penetration 13.7in.(348mm)

Shank size 1x3in.(25x76mm)

Wheel Tread Width Ground Clearance

(1.93m) (2.02m) (2.37m) (2.34m) (559 mm)

76.15 in. 79.61 in. 7ft. 11.5 in. 8ft.

(1.93m) (2.02m) (2.43m) (2.44 m) (572 mm)

(1.99m) (2.09 m) (2.57m) (2.59 m) (589 mm)

7ft. 9.5 in. 7ft. 10 in.

8 It. 5 in. 8ft. 6 in. 23.2 in.

Rear

(Front Axle)

22 in.

22.5 in.

18.9

155.2

18.9

Ripper (Special Equipment): 8 ft. (2.44 m) cut width, parallelogram

Numberofshankpockets 5

Number of shanks 3

Liftaboveground 14.5in.(368mm)

Penetration 14in.(356mm)

Shank size 2x5in.(51x127mm)

Lift above ground (shank in upperposition) 23.5 in. (597mm)

linkage, 2 manual shank vertical positions

3.8

70

Page 3

772A MOTOR GRADER SPECIFICATIONS

J

Additional Standard Equipment:

Gauges: Horn

Air filter indicator Hourmeter

Engine oil pressure Lights, stop andtail

Front-wheel-drivereturn filter Lights, driving

indicator Precleaner

Front-wheel-drivecharge Reversewarning alarm

pressure ROPS cab w/seat belt, front wiper

Fuel level and dome light

Hydraulic function return filter Seat, cushioned vinyl

indicator Turnsignals

Transmissionclutch pressure

Transmissionfilter indicator

Transmissionlube pressure

Transmissiontemperature

Water temperature

Optional or Special Equipment with Weights:

(Add these weights to SAE Standard Equipment operating weights

to obtain total operating weights.)

lb.

Accelerato r-dece Ierator

Air conditioner w/heavy-duty

alternator

Automatic blade control

Articulation indicator

Batteries, heavy-duty

w/620-minute reserve capacity

Blade, front bulldozer

w/float control

Bottom guard, heavy-duty

w/rear hitch

Bottom guard, regular

Cold-weather starting aid

Dura-Max through-hardened

cutting edge, 3/4x 8 in. (19 x 203 mm)

Engine disconnect, cold weather

Engine side shields

Fan, defroster

Front wheel drive in 1st through 6th gears,

11.5 mph (19 km/h),

free wheeling in 7th and 8th

gears, 6 cu in. (98 cm3)

variable displacement pump

Heater, cab, 19,000 BTU (5.6 kW)

Heater, cab, 38,000 BTU (11.1 kW)

Heater, cab, 40,000 BTU (11.7 kW)

Heater coolant

Heater, roof-mounted, 25,000 BTU

(7.3 kW) (add to air conditioner)

Hydraulic pump, pressure controlled,

variable displacement, 6.0 cu. in.

(98 cm3), 52.4 gpm (3.3 Us)

Lights, blade

Lights, work, 2 fronU2 rear floods

Mat, floor

Mirror, outside rear view, convex, outside

Mirror, outside rear view, convex,

both sides

Mirror, outside rear view, flat, one side

Mirror, outside, rear view, flat, both sides

Moldboards: .

12-ft. (3.66 m) Wf3/4x 8 in

(19 x 203 mm) through-hardened

Dura-Max cutting edge

130ft. (3.96 m) w/5/ax 6 in.

(16 x 152 mm) through-hardened

Dura-Max cutting edge

13-ft. (3.96 m) wf3/4x 8 in.

(19 x 203 mm) through-hardened

Dura-Max cutting edge

140ft. (4.27 m) wfS/ax 6 in.

(16 x 152 mm) through-hardened

Dura-Max cutting edge

140ft. (4.27 m) Wf3/4x 8 in.

(19 x 203 mm) through-hardened

Dura-Max cutting edge

7 3

187 85

350 159

6 3

101

1618

459

160 73

3 1

8.5 Ib/ft (13 kg/m)

30

60 27

4 2

34 15

16 7

31 14

31 14

1

17 8

50

4 2

12 5

9

6

12 5

6 3

12 5

106

60 27

116 53

146

155 70

kg

46

734

208

14

0.5

23

48

66

On Front

SAEOperating Weight

Standardequipment.

. . .

Wheels

9237 lb.

(4190kg)

Standard equipment

andscarifier.. .. .. .. .

Standard equipment,

scarifier and ripper. . . .

10,548lb.

(4784kg)

9780 lb.

(4436kg)

Moldboard extensions, 2-ft. (610 mm),

right or left (lesscutting edge)

Moldboard float 14 6

Overlay end bits (1 pair),6 in. (152 mm)

Overlay end bits (1 pair), 8 in. (203 mm)

Rear hitch

On Rear

Wheels

21,666 lb.

(9827kg)

21,470 lb.

(9739kg)

24,712 lb.

(11 209 kg)

Total

30,903lb.

(14017 kg)

32,018lb.

(14523 kg)

34,492lb.

(15645 kg)

lb.

220 100

62 28

77 35

61

kg

28

II

II

Rims:

10in. (254 mm) for 14.00-24tires

14 in. (356 mm)for 17.50-25tires

Ripper,rear mounted with hitch

ROPS canopy w/seat belt and

instrument panel cover

Scarifier, regularw/five teeth

1 x 3 in. (25x 76 mm)

Scarifier float 9

Seat belt, 3-in.(76 mm)

Seat, deluxe suspension, cloth

covered 111 50

Seat, deluxe suspension, vinyl

covered 58 26

Sound suppression package

(includes bottom guard)

Sound suppression package

(for use w/ripper)

Tires:

14.00-24, 12 PR,G2

17.5-25,12 PR, L2

Toolbox

Winter door cam for cab

Wiper, rear windshield

452 205

645 293

2474

1123

-447 -203

1115

506

3 1

542 246

295 134

210 95

468 213

11 5

4

4

4

2

2

4

3

71

Page 4

772A MOTOR GRADER DIMENSIONS

-r

10ft.6in.

(3.20m)

19 ft. 7 in. (5.97 m)

27 ft. 9.5 in. (8.47 m)

30 ft. 2 in. (9.20 m) .

32 It. 6 in. (9.90 m)

,ftT

(2.92m)

8 ft. 11 in.

(2.72m)

72

Loading...

Loading...