Page 1

Operation, Safety, Maintenance

and service Manual

Original Instructions - Keep this manual with the machine at all times.

Boom Lift Models

X23J

X23JR062

January, 2013

Page 2

Page 3

JLG LIFT

FOREWORD

For:

• Accident Reporting

• Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Safety

• Standards and Regulations Compliance Information

• Questions Regarding Special Product Applications

• Questions Regarding Product Modifications

Contact:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

or Your Local JLG Office

(See addresses on manual cover)

In USA:

Toll Free: 877‑JLG‑SAFE (877‑554‑7233)

Outside USA:

Phone: 240‑420‑2661

Fax: 301‑745‑3713

E‑mail: ProductSafety@JLG.com

X23JR062

Page 4

X23JR062

REVISION LOG

Rev. Manual code Date

Original Issue X23JR002 January, 2011

01 X23JR012 February, 2011

02 X23JR022 February, 2011

03 X23JR032 March, 2011

04 X23JR042 March, 2012

05 X23JR052 December, 2012

06 X23JR062 January, 2013

JLG LIFT

FOREWORD

Page 5

BOOM LIFT MODELS X23J

JLG

INDEX

CHAPTER 1 PRESENTATION ....................................................................................Page 08

CHAPTER 2 OPERATOR MANUAL .........................................................................Page 09

2.1 Description of the machine ...................................................................Page 09

2.1.1 Control position ......................................................................................Page 09

2.1.2 Machine identification plate .................................................................Page 12

2.1.3 Machine clearance ..................................................................................Page 13

2.1.4 Technical data..........................................................................................Page 14

2.1.4.1 Petrol engine technical data ..................................................................Page 15

2.1.4.2 Diesel engine technical data..................................................................Page 15

2.1.4.3 Hydraulic system technical data ..........................................................Page 15

2.1.4.4 Electric plant technical data ..................................................................Page 16

2.1.4.5 Electrical system technical specifications lithium..............................Page 16

2.1.5 Terminology ............................................................................................Page 17

2.1.6 Transport and stabilisation position (standard version)...................Page 21

2.2 General safety standards .......................................................................Page 22

2.3 Safety warnings.......................................................................................Page 26

2.3.1 Generalities..............................................................................................Page 26

2.3.2 Noise and vibrations ..............................................................................Page 26

2.3.3 Pictograms positioned on the machinea .............................................Page 27

CHAPTER 3 SAFETY DEVICES..................................................................................Page 40

3.1 Battery cut‑off..........................................................................................Page 41

3.2 Distributors over‑pressure valves ........................................................Page 41

3.3 Cylinder cut‑off valves...........................................................................Page 42

3.4 Alignment photocell of the aerial part of the structure and machine base ..Page 42

3.5 Outriggers position micro switches .....................................................Page 43

3.6 Jib position micro switch .......................................................................Page 45

3.7 Ropes integrity micro switch ................................................................Page 45

3.8 Basket load sensor ..................................................................................Page 45

3.9 Control protections.................................................................................Page 46

3.10 Spirit level ................................................................................................Page 46

3.11 Screws and nuts locking pins................................................................Page 47

3.12 Safety device control circuit board.......................................................Page 49

3.13 Outrigger joint lock pins........................................................................Page 50

3.14 Arms position sensors............................................................................Page 50

CHAPTER 4 INSTRUMENTS AND CONTROLS.....................................................Page 51

4.1 Remote control ........................................................................................Page 51

4.1.1 Display .....................................................................................................Page 52

4.1.1.1 Display main screen .................................................................................Page 52

4.1.2 Joystick .....................................................................................................Page 57

4.1.3 Buttons ......................................................................................................Page 59

4.2 Footswitch.................................................................................................Page 63

4.3 Control positions ......................................................................................Page 63

CHAPTER 5 EMERGENCY DEVICES .......................................................................Page 64

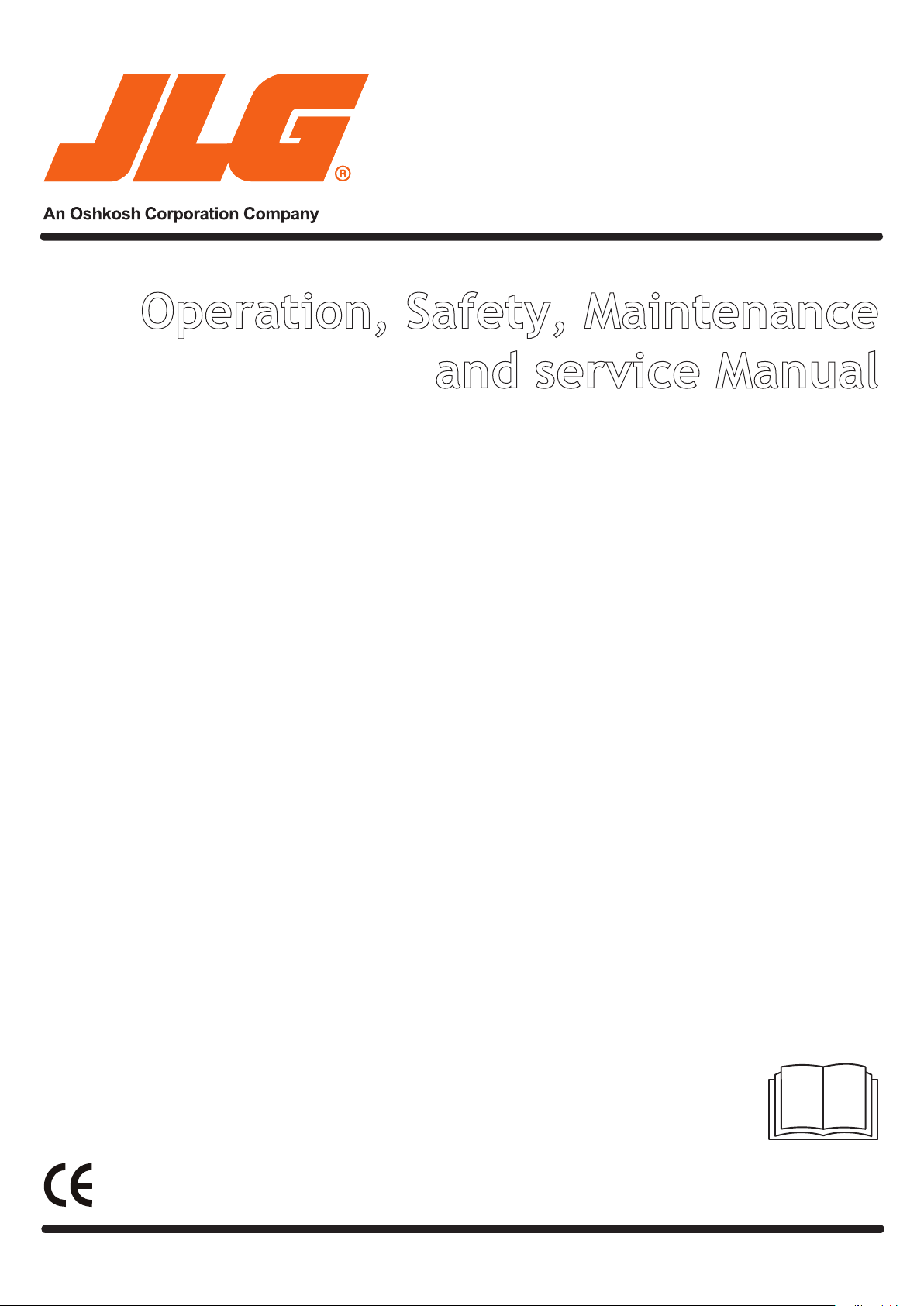

5.1 Emergency stop button..........................................................................Page 64

5.2 Hand pump .............................................................................................Page 65

5.3 Solenoid valves for emergency descent...............................................Page 65

5.4 Safety devices by‑pass key ....................................................................Page 65

5.5 Emergency position control ..................................................................Page 66

CHAPTER 6 MACHINE USE ......................................................................................Page 72

6.1 Safety standards to adopt before using the platform ................................Page 72

6.1.1 Electrocution hazard ..............................................................................Page 72

6.1.2 Danger due to atmospheric conditions ...............................................Page 72

6.1.3 Danger due to the work area ................................................................Page 73

6.2 Procedures for correct use.....................................................................Page 73

6.2.1 Summary table of the safety standards for the operator ................Page 73

1

X23JR0620113

Page 6

6.3 Working area...........................................................................................Page 75

6.4 Use of the elevating work platform (MEWP).....................................Page 76

6.4.1 Preliminary checks before starting work ............................................Page 77

6.4.2 Starting the petrol and diesel engine ..................................................Page 78

6.4.3 Starting the electric engine ....................................................................Page 79

6.4.4 Engine turning‑of....................................................................................Page 81

6.4.5 Stopping the motor lithium version.....................................................Page 81

6.4.6 Operative load automatic selection......................................................Page 82

6.4.7 Passage from transport configuration to stabilisation

configuration Standard version............................................................Page 82

6.4.8 Traversing ................................................................................................Page 86

6.4.9 Jib arm movement for traversing .........................................................Page 88

6.4.10 Parking the machine on slopes or on uneven ground.......................Page 90

6.4.11 Stabilising and levelling the machine..................................................Page 90

6.4.12 Automatic stabilization and destabilization.......................................Page 94

6.4.13 Track widening........................................................................................Page 96

6.4.14 Basket movement....................................................................................Page 96

6.4.15 Manual levelling of the cage .................................................................Page 102

6.5 Aerial part emergency manoeuvres.....................................................Page 104

6.5.1 Activation of emergency descent from the basket.............................Page 104

6.5.2 Manoeuvre of the machine from the emergency position on the

ground in the case of sudden indisposition of the operator ............Page 105

6.5.3 Activation of the emergency descent in the case of accidental

destabilisation of the machine ..............................................................Page 106

6.5.4 Activation of the emergency descent from the ground in case of operator

indisposition, engine functioning and electric plant broken down.......Page 108

6.5.5 Activation of the emergency descent from the ground with manual

pump if all energy systems should break down ...............................Page 110

6.5.6 Track part emergency manoeuvre: movement of the platform

outriggers with manual pump to allow machine tran sport............Page 112

6.5.7 The manoeuvre illustrated successively must only be performed

with the machine closed ........................................................................Page 113

6.6 Electrical disconnection of the remote control ...................................Page 116

6.7 Recharging the battery...........................................................................Page 117

6.8 Main declared uses of the platform .....................................................Page 121

6.8.1 Plant engineering....................................................................................Page 121

6.8.2 Closed rooms...........................................................................................Page 121

6.8.3 Use for pruning.......................................................................................Page 121

6.8.4 Use for repair and maintenance of roofs and gutters........................Page 122

6.8.5 Use for painting, sanding and plastering............................................Page 122

6.8.6 Use in marine environment...................................................................Page 122

CHAPTER 7 MAINTENANCE....................................................................................Page 123

7.1 Greasing and lubrication specifications ..............................................Page 123

7.2 Table of recommended lubricants ........................................................Page 123

7.3 Greasing points .......................................................................................Page 125

7.4 Greasing the telescopic extension arm ................................................Page 125

7.5 Maintenance safety regulations............................................................Page 126

7.6 Manoeuvre of the machine from the second emergency position from the ground through

the optional second remote control in case of maintenance operations ......Page 127

7.7 Periodic maintenance limits..................................................................Page 128

7.8 Electric motor ..........................................................................................Page 131

7.8.1 Electric motor maintenance...................................................................Page 131

7.9 Inspection and maintenance .................................................................Page 132

7.10 General periodic control ........................................................................Page 134

7.11 Rubber track maintenance.....................................................................Page 135

7.11.1 Checking track tension...........................................................................Page 135

7.11.2 Operations for loosening/tightening the track ...................................Page 135

7.11.3 Checking the rubber tracks ...................................................................Page 136

7.11.4 Replacing the rubber tracks ..................................................................Page 138

2

X23JR0620113

BOOM LIFT MODELS X23J

JLG

Page 7

3

7.12 Checking tightness of nuts and bolts...................................................Page 139

7.13 Checking hydraulic oil level .................................................................Page 144

7.13.1 Hydraulic oil............................................................................................Page 144

7.14 Checking leakage from the hydraulic system ....................................Page 144

7.15 Checking the status of the filtering cartridge .....................................Page 144

7.16 Checking the presence and integrity of the machine plates ............Page 145

7.17 Checking the working pressures of the hydraulic system ...............Page 145

7.18 Checking tightness of the screw fasteners of the pin retainers

and the locknuts......................................................................................Page 146

7.19 Replacing/checking extension ropes and pulleys ..............................Page 146

7.19.1 Checking wear and deformation of ropes and pulleys.....................Page 147

7.20 Three‑monthly inspection .....................................................................Page 148

7.21 Five‑year inspection ...............................................................................Page 150

7.22 Checking wear of the telescopic arm slide blocks .............................Page 150

7.23 Checking extension pulley wear ..........................................................Page 151

7.24 Checking tightness of the coupling element screws..........................Page 151

7.25 Battery: checks and maintenance thermic version.............................Page 151

7.25.1 Checking the electrolyte thermic version............................................Page 151

7.25.2 Re‑charging the battery thermic version.............................................Page 152

7.25.3 Replacing the battery thermic version.................................................Page 153

7.25.4 Disposal of the battery ...........................................................................Page 153

7.26 Battery pack operating specifications..................................................Page 153

7.26.1 Components and diagrams ...................................................................Page 154

7.26.2 Personal protective equipment.............................................................Page 156

7.26.3 Handling in dangerous conditions ......................................................Page 156

7.26.3.1 Procedure for handling hot cells ..........................................................Page 156

7.26.3.2 Procedure for handling vented cells....................................................Page 157

7.26.3.3 Procedure for exploded cells.................................................................Page 159

7.26.3.4 Lithium battery fire ................................................................................Page 160

7.27 Engine maintenance thermic version ..................................................Page 162

CHAPTER 8 SAFETY STANDARDS REGARDING TRANSPORT .......................Page 162

8.1 Removing the basket..............................................................................Page 162

8.2 Safety standards regarding transport..................................................Page 163

8.3 Lifting the machine.................................................................................Page 164

8.3.1 How and where to attach the platform ...............................................Page 165

8.3.2 What to use to attach the platform.......................................................Page 165

8.4 Transporting the machine......................................................................Page 166

CHAPTER 9 REMOTE CONTROL SERVICE MENU ..............................................Page 168

9.1 Menu' input .............................................................................................Page 168

9.2 Errors menu.............................................................................................Page 170

9.3 Working hours menu .............................................................................Page 170

9.4 Set‑up menu ............................................................................................Page 170

9.5 Joystick menu ..........................................................................................Page 170

CHAPTER 10 TROUBLESHOOTING...........................................................................Page 171

CHAPTER 11 CHECKS TO MAKE ON THE MACHINE AFTER REPAIRS..........Page 178

11.1 Checking the correct functioning of controls .....................................Page 178

11.2 Checking functioning of the safety devices ........................................Page 178

CHAPTER 12 HYDRAULIC SYSTEM..........................................................................Page 179

12.1 Hydraulic system diagram thermic version.......................................Page 179

12.2 Key to the hydraulic system diagram thermic version.....................Page 181

12.3 Hydraulic system diagram lithium version........................................Page 182

12.4 Key to the hydraulic system diagram lithium version........................Page 184

CHAPTER 13 ELECTRIC PLANT.................................................................................Page 185

13.1 Electric plant thermic version ...............................................................Page 185

13.2 Electric plant lithium version................................................................Page 187

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Page 8

PREFACE

The scope of this manual is to supply the user with the necessary instructions and indispen‑

sable operational procedures in order to favour the correct and safe use of the machine for

the objectives to which it is destined and to prevent serious injury to the operator and others.

IMPORTANT

ALL INFORMATION PRESENTED IN THIS MANUAL IS UNQUESTIONABLE AND IT

MUST BE READ CAREFULLY AND UNDERSTOOD BEFORE MAKING ANY MANOEU‑

VRES WITH THE MACHINE.

As this manual is the most important work instrument, it must always be kept in the machi‑

ne, in the relevant compartment, in order to always be available at any time for clarifications.

As it is impossible for the manufacturer to check the status of the machine and the opera‑

tions it performs THE USER IS RESPONSIBLE for compliance with the safety procedures

described in this manual.

Every machine is adjusted and inspected scrupulously before delivery so that the operator

does not have to perform adjustments.

Every alteration and/or modification of the features of the original machine design without

previous written authorisation from the Constructor are PROHIBITED and THE RESPONSI‑

BILITY FOR THESE ACTIONS FALLS ON THE OPERATOR.

THE EMPLOYER MUST CHECK THAT THE OPERATOR HAS THE VOCATIONAL

REQUISITES NECESSARY FOR RUNNING THE MACHINE CORRECTLY AND THAT

HE HAS CAREFULLY EXAMINED AND UNDERSTOOD THAT STATED IN THIS USE

AND MAINTENANCE MANUAL, RECEIVING SUITABLE TRAINING REGARDING

USE OF THE MACHINE IN STANDARD AND EMERGENCY CONDITIONS.

THE EMPLOYER MUST ALSO TRAIN THE OPERATORS REGARDING ANY NATIO‑

NAL STANDARDS THAT COMMEWSTE THAT CONTAINED IN THIS DOCUMENT.

If the manual is damaged or lost, a copy must be requested directly from JLG.

Note: All of the photos and drawings inserted in this manual have been added to ease

comprehension by the reader. The machine you own may differ from some parts of the

photos and drawings given.

BOOM LIFT MODELS X23J

JLG

4

X23JR0620113

Page 9

5

NORMATIVE REFERENCES

The machine has been designed, built and inspected according to that prescribed in the EN280

prA2:2009 harmonised standard, which supplies the presumption of conformity with the Essen‑

tial Safety Requisites of the 2006/42/CE Machinery Directive even if a type C Voluntary Technical

Standard.

According to that stated in EN280 prA2, the JLG platform is classified in GROUP B, as the

vertical projection of the centre of gravity of the load can be outside of the tilting lines and in

TYPE 1 as traversing is only allowed with the platform at rest.

The stability tests of the machine have been made in accordance with what described in

paragraph 6.1.4.2 of the EN280 with load test calculated in conformity with 5.2.4 and have

been successful.

In addition what prescribed in this manual it is necessary to apply the technical requirements of

the following national/international safety standards:

‑ UNI ISO 18893

‑ ISO 16368

‑ ISO 18878

With the exception of stricter local or national regulations in the working area of the MEWP.

WARRANTY

On purchasing a JLG platform, a warranty and inspection certificate is issued that clearly

indicates the warranty terms and where any interventions on the machine must be reported.

LIABILITY

The Constructor is exonerated from any liability and obligation for any injury/damage cau‑

sed to persons/objects due to any of the reasons listed below:

• Failure to comply with the instructions indicated in this USE AND MAINTENANCE

MANUAL regarding running, use and maintenance of the machine;

• Violent or sudden actions or incorrect manoeuvres when using or servicing the machine;

• Modifications made to the structure or machine components without previous authori‑

sation from the Constructor and/or without the use of suitable equipment;

• Strange events with respect to normal and correct use of the machine, described in this

USE AND MAINTENANCE MANUAL.

• Use of non‑original spare parts not authorised by the manufacturer.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Page 10

EC DECLARATION OF CONFORMITY

BOOM LIFT MODELS X23J

JLG

6

X23JR0620113

EC DECLARATION OF

CONFORMITY

Manufacturer

Address

Technical File:

Authorised contact

Machine Type:

Model Type: ...

Serial Number:

Notified Body:

EC Number:

Address

JLG Industries Inc

1 JLG Drive

McConnellsburg

PA17233

USA

JLG Industries Inc

JLG Technology & Development Centre

Bruntingthorpe Aerodrome & Proving Ground

Lutterworth, Leicestershire

LE17 5QS

United Kingdom.

Alan S. McInt

Mobile Elevating Work Platform

...

ECO Certificazioni S.p.A

0714

Via Mengollna

33 - 48108

Faenza

Italy

yre

Position:

Manager, Engineering

Support - Europe

Certificate Number:

Reference Standards:

JLG Industries hereby declare that the above mentioned machine conforms

with the requirements of:

2006/42/EC Machiner

2004/108/EC EMC Directive

2000/14/EC Outdoor Noise

Signed:

Name: Alan S. McIntyre Position: Manager,Engineering Support-

Remark:

An

y modification to the above described machine violates the validity of this declaration.

This declaration conforms with the requirements of annex II-A of the council directive

2006/42/EC

Machine manufactured for JLG Industries Inc. by HINOWA S.p.a via Fontana 37054

NOGARA VR Ital

y

To Be Advised

EN12100-1 & 2:2003 + A1:2009

EN280:2001 + A2:2009

y

Date: ...

Europe

Place: Bruntingthorpe, UK

Page 11

7

BOOM LIFT MODELS X23J

JLG

X23JR0620113

y

y

EC DECLARATION OF

CONFORMITY

Manufacturer

Address

Machine Type:

Model Type:

Serial Number:

Document Control:

Measured

Lwa

Guaranteed

Lwa ...dB(A)

Engine Power:

...kW

Lwa = (Sound Power Level)

JLG Industries Inc

1 JLG Drive

McConnellsburg

PA17233

USA

Mobile Elevating Work Platform

...

...

HINOWA S.p.A

Via Fontana - 37054

Nogara

Italy

...dB(A)

Technical File:

JLG Industries Inc

JLG Technology &

Development Centre

Bruntingthorpe

Aerodrome & Proving

Ground

Lutterworth,

Leicestershire

LE17 5QS

United Kingdom.

Applicable Procedure:

Applicable Directive:

EN ISO 3744:1995

2000/14/EC Annex V Internal Control of Production.

We hereby declare that the above mentioned machine

conforms with the requirements of the "Noise Emission in

the Environment by Equipment for Use Outdoors"

Directive 2000/14/EC & 2005/88/EC

Remark:

This declaration conforms with the requirements of Annex II of the council directive

2000/14/EC

An

modification to the above described machine violates the validity of this declaration.

Machine manufactured for JLG Industries Inc. by HINOWA S.p.a via Fontana 37054

NOGARA VR Ital

Page 12

1. PRESENTATION

This manual presents the warning signs used to bring the reader’s attention to several parti‑

cularly important warnings.

The safety warnings are divided into two main types, which are identified and described

below.

DANGER

This symbol accompanied by the word DANGER indicates that the situation

described, if not prevented, can lead to serious injury or death of the persons

involved (operator, ground staff, staff present in proximity of the platform, main‑

tenance technicians etc.).

ATTENTION

This symbol accompanied by the word ATTENTION indicates that the situation

described represents a potential risk for the structure of the machine. Dangerous

situations could be determined from this condition (also injury or death) for the

persons involved.

BOOM LIFT MODELS X23J

JLG

8

X23JR0620113

Page 13

9

2. OPERATOR MANUAL

2.1. DESCRIPTION OF THE MACHINE

The JLG machine is a self‑propelled hydraulic lifting device, equipped with a rotating work

basket positioned at the top of an extendable articulated structure, which also rotates. The

JLG lifting device is destined for the POSITIONING OF PERSONS AND THEIR EQUIP‑

MENT AND MATERIALS IN HIGH POSITIONS WITH RESPECT TO GROUND LEVEL.

2.1.1 CONTROL POSITION

‑ CONTROL POSITION IN THE CAGE

The JLG overhead platform has been designed to be controlled by the operator in the basket

using a remote control, where all of the machine functional controls are gathered, positioned

in the relevant support inside the basket (see photo). A pedal button is also present in the

basket to allow movement of the aerial part (photo).From this control position it is possible

to control the extendible structure and machine stabilisation. When the machine is manoeu‑

vred from the control position in the basket, the remote control must be positioned in the

appropriate seat, and the footswitch must be pushed (the footswitch must be release and

pressed again if no movements are made for more of 7 second). The remote control is con‑

nected to the machine using a flexible cable that allows to shift it if the basket is to be remo‑

ved or the ground control unit is to be used.

Stabilisation of the machine must be preferably controlled from the basket drive position.

Machine traversing must be carried out from the control position on the ground.

After having reached or left the control position in the basket, ALWAYS remember to close

the ladder to avoid any damages during the use of the machine. After having left the con‑

trol position in the basket always remember to close the remote control protection cover.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

ATTENTION

ATTENZIONE

Page 14

CONTROL POSITION ON THE GROUND:

There is a second control position for the track part. This position is not fixed but is located

on the ground within a radius equal to 2.5m from the basket attachment. To control the

machine, use the same remote control present in the basket, which is withdrawn from its seat

and moved away from the basket using the free cable length available.

This control position IS NOT enabled to control the aerial part of the

machine, but only the trailers, outriggers and track widening.

ATTENTION: when controlling the machine from the ground position keep

at a distance of at least 1m from the tracks.

ATTENTION: when the machine is controlled from the ground position

always check there is complete visibility of the component that is

to be moved and its trajectory for the entire duration of the movement.

‑ EMERGENCY CONTROL POSITION

There is a control position that will be identified as the emergency control position. It is on

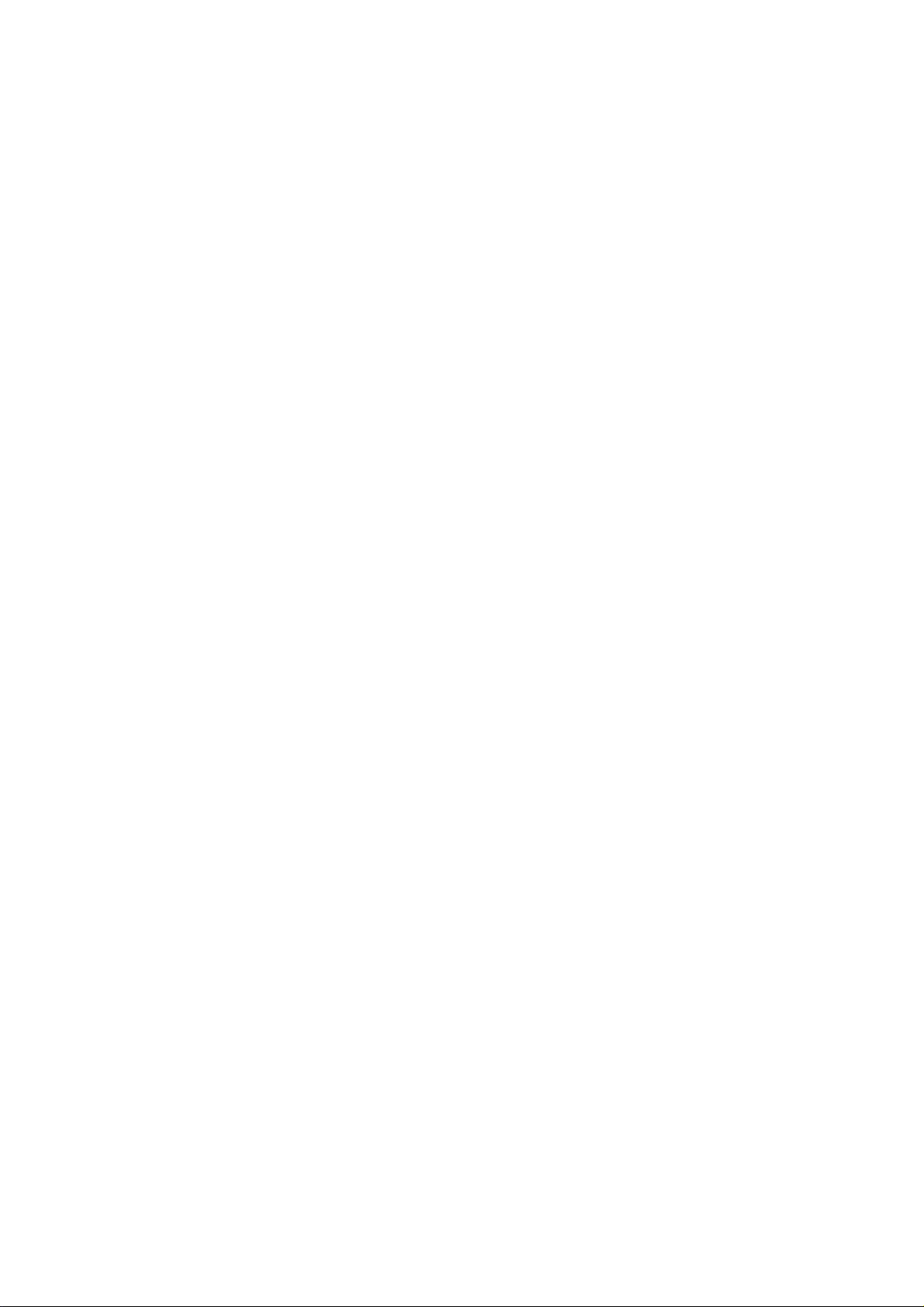

the part of the machine on the ground in correspondence with the aerial part distributor. To

enable, act on the relevant selector switch at the base of the turret (see photo) until the green

indicator switches on. This indicates movement enabling of the aerial part.

From here it is possible to make machine movements by acting directly on the levers present

on the various hydraulic distributor elements, aerial (see photo 1) and proportional areas

(aerial part see photo 2).

The emergency control position has been designed, to operate on the extendible structure

only for emergency manoeuvres by rescue staff on the ground, which must be trained and

have know‑how regarding the functioning of the machine and its safety devices, for main‑

tenance interventions and to perform checks before starting work.

It is prohibited to move the structure from the ground position, if someone is present in

the basket, unless it is an emergency situation (sudden indisposition of the operator, tech‑

BOOM LIFT MODELS X23J

JLG

10

X23JR0620113

ATTENTION

THERMIC MOTOR

LITHIUM MOTOR

ATTENZIONE

Page 15

11

nical breakdown).

There is a control position usable only for operations of ordinary and extraordinary mainte‑

nance operations, position placed next the machine near the electic components box.

At the back of the protection box of the circuit board an auxiliary connector is placed for the

connection of the optional second remote control (see picture).

To enable this position it is necessary to operate on the key selector placed on the base of the

turret and connect the optional second remote control to the machine.

Before proceeding with the connection read carefully paragraph regarding the use of the

optional second remote control.

This control position is usable only to carry out controls and maintenance on the machine.

Do not use this position to control the machine during normal working operations.

Note: it is absolutely forbidden to move the machine from this position if one ore more

operators are in the basket.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

PHOTO 1

PHOTO 2

POSITION OF THE OPTIONAL SECOND

REMOTE CONTROL CONNECTOR

OPTIONAL SECOND REMOTE

CONTROL CONNECTOR

ATTENTION

ATTENZIONE

Page 16

2.1.2 MACHINE IDENTIFICATION PLATE

The manufacturer’s plate is located in the front of the machine, on the electric engine protec‑

tion sump.

The image is shown below.

BOOM LIFT MODELS X23J

JLG

12

X23JR0620113

Manufactured by

HINOWA S.p.A.

Via Fontana

200

37054 NOGARA (VR)

ITALY

kg

2x80

JLG Industries. Inc - McConnellsburg. PA - USA

Model

Serial number

Date of manufacture

G.V.W. (Dry)

MAXIMUM ALLOWABLE OPERATING INCLINATION

MAX

12.5

M/S

=+

MAX

12.5

M/S

120

1x80

kg

kg

1°

kg

kg

kg

40

40

kg

07041700

200

N400

N

Page 17

13

2.1.3 MACHINE CLEARANCE

Maximum length in running order with basket installed ................................6003 mm

Track width ..............................................................................................................990/1290 mm

Maximum height in running order ......................................................................1990 mm

Approach angle ......................................................................................................22°

Maximum stabilisation angle on individual axle ..............................................13°

Outriggers max. base side......................................................................................3983 mm

Note: standard version with double manned basket.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Page 18

2.1.4 TECHNICAL DATA

NB: The lateral reach is measured from the coupling attachment centre to the external edge

of the cage.

BOOM LIFT MODELS X23J

JLG

14

X23JR0620113

PLATFORM CAPACITY 200 kg 120 kg

PLATFORM HEIGHT (walkway surface) 19,70 m 21,10 m

MAX WORKING HEIGHT 21,80 m 23,20 m

STANDARD BASKET DIMENSIONS 1335 x 690 x H1100 mm

HORIZONTAL REACH (basket not rotated) 9,75 m 11,13 m

MAX. HORIZONTAL WORK REACH (basket not rotated) 10,25 m 11,63 m

ROTATION (non-continuous) 360° 360°

BASKET ROTATION 124° (+/- 62°)

MAX GROUND REACTION FORCE FOR EACH STABILISER 2100 daN

MAX GROUND PRESSURE FOR EACH STABILISER 3 daN/cm

2

NO. OF OPERATORS 2 1

JIB - TYPE OF ARTICULATED JOINT 85° (-1°/-86°)

MAX WORKING GRADIENT 1°/1,75%

MAX STABILISATION SLOPE 13°

TOTAL EMPTY MACHINE WEIGHT (Petrol vers.) 2990 kg

TOTAL EMPTY MACHINE WEIGHT (Diesel vers.) 3100 kg

ENGINE

HONDA iGX440-12,7CV-3600 rpm

PERKINS 402.05 -14CV-3600 rpm

ELECTRIC MOTOR

2.2 kw/230V/50Hz single phase 1500 rpm

2.2 kw/240V/50Hz single phase 1500 rpm

2.2 kw/110V/50Hz single phase 1500 rpm

ELECTRICAL SYSTEM VOLTAGE 12 V

PUMPS 2x4.27cc

MAX. TRAVERSING SPEED Autotwospeed 1,0 / 1,7 km/h (thermic motor)

MAX. TRAVERSING SPEED Autotwospeed 0,7 / 1,2 km/h (lithium motor)

TRAVEL/STAB. SYSTEM PRESSURE 160 bar

AERIAL PART SYSTEM PRESSURE 200 bar

MAX SLOPE ALLOWED IN TRAVEL DIRECTION 15°

MAX WIND SPEED 12,5 m/s

MAX MANUAL FORCE ALLOWED 400 N

Page 19

15

2.1.4.1 PETROL ENGINE TEHNICAL DATA

Mark/Model........................................................................HONDA iGX440

Fuel/Cooling ......................................................................PETROL/AIR

Power SAEJ1349 ................................................................9,5 kW (12,7 CV) / 3600 rpm

Maximum adjusted output rpm......................................3600 rpm

Maximum torque ..............................................................29,8 Nm/2500 rpm (80/1269/EC)

Number of cylinders..................................................................1

Displacement......................................................................440 cm

3

Cooling................................................................................air

Sound pressure level at operator’s ear ..........................88 dB

Measured sound power level ..........................................102 dB

Guaranteed sound power level ......................................104 dB

2.1.4.2 DIESEL ENGINE TECHNICAL DATA

Mark/Model........................................................................PERKINS 402.05

Fuel/Cooling ......................................................................DIESEL/LIQUID

Power SAEJ1349 ................................................................10,2 kW (14 CV) / 3600 rpm

Adjusted maximum speed rpm ......................................3500 rpm

Maximum torque ..............................................................29,7 Nm/2400 rpm (80/1269/EC)

Number of cylinders..................................................................2

Displacement......................................................................510 cm

3

Cooling................................................................................liquid

Sound pressure level at operator’s ear ..........................90 dB

Measured sound power level ..........................................102 dB

Guaranteed sound power level ......................................104 dB

2.1.4.3 HYDRAULIC SYSTEM TECHNICAL DATA

Hydraulic oil tank capacity..............................................48 liters

Engine pump......................................................................double 2x4,27cm

3

Hydraulic system max. pressure ....................................200 bar

For further information, refer to the hydraulic layout attached to the manual and the para‑

graph relative to maintenance of these components.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Page 20

2.1.4.4 ELECTRICAL SYSTEM TECHNICAL SPECIFICATIONS THERMIC

Battery ................................................................................55 Ah ‑ 417 A ‑ 12V

Alternator petrol engine ..................................................20 A (3600 rpm)

Alternator diesel engine ..................................................15 A (3600 rpm)

Electric engine: ‑ nominal voltage ..................................230V (110 V, 240 V optional)

‑ frequency............................................50 Hz (60 Hz optional)

‑ nominal power ..................................2,2 kW

For further information, refer to the wiring diagram attached to the manual and the para‑

graph relative to maintenance of these components.

2.1.4.5 ELECTRICAL SYSTEM TECHNICAL SPECIFICATIONS LITHIUM

Battery ................................................................................90 Ah ‑ 70V

Electric motor: ‑ rated voltage ..................................80 V

‑ rated power....................................3500 W

Sound pressure level at operator’s ear ..........................70 dB

Measured sound power level ..........................................86 dB

Guaranteed sound power level ......................................88 dB

Onboard battery charger .................................................. 220V±10V 50÷60Hz

Battery charger (option).................................................... 110V±10V 50÷60Hz

Max power absorbed by the battery charger during recharge phase: 3000W

For further information, see wiring diagram enclosed with the manual and the paragraph on

maintenance of electrical components.

BOOM LIFT MODELS X23J

JLG

16

X23JR0620113

Page 21

17

2.1.5 TERMINOLOGY

To make the content of this manual easier to understand, a layout is put at the reader’s

disposal that gives the exact terms with which the parts of the platform will be identified.

KEY

1 Tracked undercarriage

2 Emergency controls

3 Overhead part distributors

4 Swivelling turret

5 Coupling attachment + rotation motor

6 Diesel tank (only in diesel version)

7 Base

8 Track part distributors compartment

9 Oil tank

10 Outrigger joint

11 Geared double pump

12 Petrol/diesel engine

13 Jib return

14 Outrigger cylinder

15 Outrigger

16 First arm

17 First arm tie‑rod

18 First‑second arm cylinder

19 First‑second arm return

20 Jib arm

21 Jib return

BOOM LIFT MODELS X23J

JLG

X23JR0620113

THERMIC MOTOR

Page 22

22 Basket on basket levelling cylinder

23 Rotary actuator for basket rotation

24 Basket support

25 Basket access ladder

26 Basket

27 Use and maintenance manual compartment

28 Movement control remote control

29 Jib tie‑rod

30 Jib cylinder

31 Telescopic arm 2

32 Telescopic arm1

33 Third arm

34 Outrigger plate

35 Second ‑ third arm return

36 Basket levelling cylinder on connection

37 Third arm cylinder

38 Second arm

39 Second arm tie‑rod

40 Double pump with gears

41 Proportional valves compartment and hand pump

42 Electric components compartment

BOOM LIFT MODELS X23J

JLG

18

X23JR0620113

Page 23

19

KEY

1 Tracked undercarriage

2 Emergency controls

3 Overhead part distributors

4 Battery charge

5 Coupling attachment + rotation motor

6 Swiveling turret

7 Base

8 Track part distributors compartment

9 Oil tank

10 Outrigger joint

11 Geared double pump

12 Battery pack + inverter + battery charger (

LITHIUM MOTOR)

13 Electric motor

14 Outrigger cylinder

15 Outrigger

16 First arm

17 First arm tie‑rod

18 First‑second arm cylinder

19 First‑second arm return

20 Jib arm

21 Jib return

22 Basket on basket levelling cylinder

23 Rotary actuator for basket rotation

24 Basket support

25 Basket access ladder

BOOM LIFT MODELS X23J

JLG

X23JR0620113

LITHIUM MOTOR

Page 24

26 Basket

27 Use and maintenance manual compartment

28 Movement control remote control

29 Jib tie‑rod

30 Jib cylinder

31 Telescopic arm 2

32 Telescopic arm1

33 Third arm

34 Outrigger plate

35 Second ‑ third arm return

36 Basket levelling cylinder on connection

37 Third arm cylinder

38 Second arm

39 Second arm tie‑rod

40 Ignition key

41 Proportional valves compartment and hand pump

42 Electric components compartment + buffer battery

BOOM LIFT MODELS X23J

JLG

20

X23JR0620113

Page 25

21

2.1.6 TRANSPORT AND STABILISATION POSITION (STANDARD VERSION)

The overhead platform has rotating outriggers on a joint connecting the frame and outrigger

itself.

Regarding the outriggers, two positions are defined:

• TRANSPORT POSITION

• STABILISATION POSITION

The transport position is defined as the completely closed configuration and aligned with the

completely lifted and turned outriggers in a way to be parallel to the machine axle.

This configuration is the most compact possible for the machine and is that recommended for

all traversing operations on flat surfaces.

In the transport configuration, the vicinity of the outrig‑

ger plates to the basket handrail creates a potential

shearing hazard, it is appropriately indicated with

stickers.

Do not place the hands in this area during traversing

phases.

The stabilisation position is defined as that with the

outriggers raised from the ground, but turned by

about 45° with respect to the machine axis in a way

to almost create a square with the outrigger plates

positioned on the ends.

A lock pin with spring positioning blocks the outrig‑

gers in one or other position.

For the stabilization positions of the version with variable stabilization area please read

paragraph 6.4.6 Passage from transport configuration to stabilisation configuration Stan‑

dard version.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

IMPORTANT

IMPORTANTE

Page 26

2.2 GENERAL SAFETY STANDARDS

The functioning of the MEWP must be in compliance with international standards of referen‑

ce (see paragraph “NORMATIVE REFERENCES” in the first pages of the manual) and natio‑

nal or regional standards if stricter.

The operator must read, understand and follow all the instructions and warnings, contained

in this manual and on the machine, regarding the safe use of the MEWP.

FAILURE TO COMPLY WITH THE SAFETY PRECAUTIONS LISTED IN THIS SECTION

AND STATED ON THE MACHINE CAN CAUSE INJURY OR DEATH OF THE STAFF AND

DAMAGE TO THE MACHINE AND CONSTITUTES A SERIOUS INFRACTION OF THE

SAFETY STANDARDS.

This section of the USE AND MAINTENANCE MANUAL describes those procedures or

dangerous situations that can cause damage/injury to objects/persons and what the operator

must do to prevent them.

• The operator must always act as a professional, complying with safety standards, paying

attention not to under‑estimate his responsibility to himself and all objects and persons that

surround him.

• Before starting work it is indispensable that the operator has been completely and

clearly trained regarding the use of the machine in standard and emergency conditions.

That he has examined, understood and taken in all that stated in this user manual. That he

is sure that the safety devices are in perfect working order, that the necessary checks on

the machine are performed and that he becomes familiar with the conditions of the

ground on which he must manoeuvre and stabilise.

• The presence of at least one specialised person is necessary on the ground during working.

This person must know how to use the machine and be aware of the content of the USE AND

MAINTENANCE MANUAL and can intervene if necessary.

• It is prohibited to make modifications to the machine that could jeopardise functioning and

safety, without previous written authorisation from The Constructor which is not liable for

any injury or damage caused by this behaviour.

Protection devices and garments

Do not wear loose clothing, rings, watches or anything else

that may become entangled in moving parts.

When using the machine or performing maintenance wear a

hard helmet, goggles and accident‑prevention shoes, gloves

and hearing protection after having checked their integrity

along with any other IPD that the safety manager deems

necessary according to the risk analysis he has performed.

BOOM LIFT MODELS X23J

JLG

22

X23JR0620113

ATTENZIONE

WARNING

Page 27

23

ALWAYS WEAR TYPE‑APPROVED AND CERTIFIED THE SLINGING. WHEN WORKING AT A HEIGHT MAKE

SURE YOU ARE WEARING THE SAFETY BELTS CORRECTLY AND THEY HAVE BEEN APPROPRIATELY ATTA

‑

CHED TO THE RELEVANT ANCHORAGE POINTS ON THE BASKET.

T

HE USE OF THE SLINGINGS IS COMPULSORY IN CONNECTION WITH THE LOCAL REGULATINS OF

EVERY SINGLE

STAT E. IN THOSE STATES WHERE THE LAW DOES NOT REQUIRE THE USE OF HOLDING

SYSTEMS

, THE CHOICE IS OF THE EMPLOYER OR/AND USER

Safety valves and safety components of the electric system

It is prohibited to modify and/or tamper with the safety and control valves of the main

hydraulic system and the adjustments of the electric plant. The Constructor is not liable

for injury to persons and damage to objects or to the machine if the standard calibration

of any hydraulic and electric/electronic component is tampered with.

Fire prevention

Keep the area around the engine clean, removing fragments of

wood, paper and other inflammable products; clean any fuel

leaks as they can be a potential cause of fire.

Petrol is extremely inflammable and explosive in particular

conditions. Re‑fuel in a well‑aired place with the engine at a

standstill.

Do not smoke or make sparks in the re‑fuel area or fuel stora‑

ge area.

After having re‑fuelled, make sure the cap is closed securely.

Do not touch the exhaust when hot during machine functioning or immediately after the

engine is switched off.

Prevention of damage caused by washing the machine

Do not aim high pressure jets onto electric components when

washing the machine. Do not use chemical detergents or

petrol that could cause serious damage to plastic components

and the paintwork.

A

LWAYS REMEMBER TO REMOVE THE REMOTE CONTROL AND COR‑

RECTLY CLOSE THE REMOTE CONTROL CONNECTION SOCKETS AND

EQUIPMENT POSITIONED ON THE MACHINE

, BEFORE WASHING.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

IMPORTANT

IMPORTANTE

Page 28

• Cleaning the machine

Always park the machine as shown in the figure in point 2.1.6.

When washing the machine, the ignition block must be disengaged, the key removed and the

emergency stop button pressed.

• Washing the outside of the machine

Never use flammable liquids. Adopt the above safety measures to

prevent sparks due to short‑circuits.

If washing the track with water cleaners, carefully protect all the

important parts and above all the electrical components. Follow the

instructions provided by the manufacturer of the detergent.

Clean the machine using water‑soluble detergents.

The more the elevating platform is cleaned, the more it will need to be greased (see par.

Grease points).

Do not wet the electric motors and the other electrical components directly. Do not aim the

spray directly onto adhesive labels and rating plates.

• Cleaning the electrical system

Never clean the inverter or the electric motor with water, as this may

cause damage to the electrical system.

BOOM LIFT MODELS X23J

JLG

24

X23JR0620113

ATTENZIONE

ATTENZIONE

ATTENTION

ATTENTION

ATTENTION

ATTENTION

ATTENZIONE

ATTENZIONE

Page 29

25

Only use dry detergents, in accordance with the manufacturer’s instructions. Never remove

covers, guards and the like.

‑ Clean the electrical system using a dry, non‑metallic brush and low pressure air.

• After cleaning

Dry the machine carefully before starting it again (for example using compressed air).

If, despite all the precautions, moisture has penetrated into the electric motor or other parts

of the electric system, these must be dried using compressed air to avoid the risk of short‑cir‑

cuits.

Prevention of damage caused by the working machine

When the machine is stabilised and work started, do not enter its radius of action.

Systematically manoeuvre the controls slowly and regularly, do not reverse movements

abruptly.

During work operations outside of the basket, ALWAYS remain at a MINIMUM DISTANCE

OF 1 METER from the machine.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

IMPORTANTE

IMPORTANT

ATTENTION

ATTENZIONE

Page 30

2.3 SAFETY WARNINGS

2.3.1 GENERALITIES

To prevent accidents, before starting work or carrying out any

maintenance, read, understand and follow all precautions and

warnings contained in this manual. The user / operator of the

machine must refuse all operating responsibility until this

manual has been read and he has learned to manoeuvre the

machine completely under the surveillance of a skilled and qua‑

lified operator.

Carefully read all safety messages in this manual along with the safety signs on your machi‑

ne.

Keep the safety signs in a good state and replace them if they are damaged.

Make sure that any new machine components have the correct safety signs.

2.3.2 NOISE AND VIBRATIONS

The JLG platforms with engine have been tested according to the parameters of the 2000/14

CE European Standard, having a guaranteed sound power level detected, stated in the

machines EC Declaration of Conformity.

During the use of machines for aerial operations this value is further reduced due to the

moving away of the basket from the main source of noise.

The values of the vibrations transmitted to the operator via the controls and directly from the

surface of the basket resulted less than the maximum accepted limits.

BOOM LIFT MODELS X23J

JLG

26

X23JR0620113

Page 31

27

2.3.3 PICTOGRAMS POSITIONED ON THE MACHINE

Here we report the positions of the various boards with pictograms on the machine.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

26

57

63

73

17

27

83

72

19

75

73

28

47 75

18

28

26 8 10

27

32

59

82

58

33

20

54

28 76 80 28

25

19

30

18

75

77

48

26

83

81

44

79

49

11

11

Ed. 06/12/2012 Tav 01

Cod. 17062700

ADHESIEKIT - X23J

28 39 47 41 1 28 39 47 41 39

47

39

28

11

18

10

25

20

4

25 31 14

70

18

30 19 53

50

51

24

60

64

11

12

67

23

KIT ADESIVI - X23J AUFKLEBERSATZ - X23J

SET OF DECALS - X23J KIT ADHESIVOS - X23J

KIT COLLANTS - X23J

Page 32

BOOM LIFT MODELS X23J

JLG

28

X23JR0620113

47 39 28

18

21

73

75

v

v

84

10

28

11

v

v

74

v

v

25

20

v

v

v

v

30 18 19 55 73

29

v

Ed. 06/12/2012 Tav 02

v

v

35

v

v

70

v

Cod. 17062700

47

28 47 39 1 41 39

41

18

28 28 47 39

66

75

8

75

26

10

4 25 31 14

56 19 30 18

20

25

27

37

v

v

40

v

12

24

45

v

v

38

23

60

v

v

v

v

v

v

11

64

KIT ADESIVI - X23J AUFKLEBERSATZ - X23J

SET OF DECALS - X23J KIT ADHESIVOS - X23J

ADHESIEKIT - X23J

KIT COLLANTS - X23J

Page 33

29

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Pos. Code qty

01 07060700 02

02

03

04 07060500 02

05

06

07

08 07061300 02

09

10 1646410008 04

11 06040300 06

12 1704277 02

13

14 1646410007 02

15

16

17

18 06039900 12

19 06039700 09

20 06039600 04

21 06527700 01

22

23

24

25 06041200 06

26

27 06040900 03

28 06041300 12

29 06056300 01

30 06044000 08

31 06040500 02

32 1702155 01

33 1701542 01

33 1701505 01

34

35 06598400 01

36

37 1701504 01

38 06165000 01

39 1703814 08

40 07034200 01

41 07056700 04

42

43

44 1646410010 01

45

46

Pos. Code qty

47 1701499 08

48 06086000 01

49 06085900 01

50 1646410013 01

51 1646410012 01

52

53 06555500 01

54 06555600 01

55 06555700 01

56 06555800 01

57 06560500 01

58 06232100 01

59 06060000 01

60 06040000 02

61

62

63 06600000 01

64 06086700 02

65

66

67 06706500 01

68

69

70 07056800 02

71

72 07060000 01

73 07060400 04

74 1646410006 01

75 1001125483 06

76 06924300 01

77 06919400 01

78

79 1706898 01

80 1706493 01

81 1705828 01

82 1706098 01

83 07050700 02

84 07071000 01

Page 34

LANGUAGE STICKERS

BOOM LIFT MODELS X23J

JLG

30

X23JR0620113

Pos. Code qty

170627IT

17 06555300 01

23 06448100 02

24 06448200 02

26 06561200 04

45 07203200 01

66 07070200 01

170627GB

17 06562600 01

23 06462100 02

24 06462700 02

26 06561200 04

26 06042400 04

45 07206200 01

66 07042300 01

170627FR

17 06562700 01

23 06462200 02

24 06462800 02

26 06561200 04

45 07206300 01

66 07070300 01

170627DE

17 06562800 01

23 06462300 02

24 06462900 02

26 06561200 04

45 07206400 01

66 07070400 01

170627ES

17 06562900 01

23 06462400 02

24 06463000 02

26 06561200 04

45 07206500 01

66 07070500 01

Pos. Code qty

170627NL

17 06563000 01

23 06462500 02

24 06463100 02

26 06561200 04

45 07206600 01

66 07070600 01

170627PT

17 06563100 01

23 06462600 02

24 06463200 02

26 06561200 04

45 07206700 01

66 07070700 01

170627DA

17 07138100 01

23 07137900 02

24 07138000 02

26 06561200 04

45 07206800 01

66 07138200 01

170627SW

17 07137300 01

23 07137400 02

24 07137500 02

26 06561200 04

45 07206900 01

66 07148800 01

170627NO

17 07162000 01

23 07161900 02

24 07161800 02

26 06561200 04

45 07207000 01

66 07162100 01

Page 35

31

BOOM LIFT MODELS X23J

JLG

X23JR0620113

9

Ed. 31/10/2012 Tav 01

cod. 17187700

4

5

13

KIT ADESIVI - X23J AUFKLEBERSATZ - X23J

SET OF DECALS - X23J KIT ADHESIVOS - X23J

ADHESIEKIT - X23J

KIT COLLANTS - X23J

Page 36

BOOM LIFT MODELS X23J

JLG

32

X23JR0620113

4

18

Sotto il carter / Under the hood

18

16

Ed. 31/10/2012 Tav 02

cod. 17187700

9

4

ADHESIEKIT - X23J

1

KIT ADESIVI - X23J AUFKLEBERSATZ - X23J

SET OF DECALS - X23J K IT ADHESIVOS - X23J

KIT COLLANTS - X23J

Page 37

33

LANGUAGE STICKERS

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Pos Code

qty

1

2

3

4 1001125483 3

5 06506400 1

9 06520600 2

18 07264800 2

Pos Code

qty

171877IT

1 07188700 1

7

10

11

12

13 07188100 1

14

16 1693870003 1

16 1705720001 1

Pos Code

qty

171877GB

1 07201700 1

7

10

11

12

13 07202100 1

14

16 1693870004 1

16 1705720002 1

Pos Code

qty

171788FR

1 07201800 1

7

10

11

12

13 07202200 1

14

16 1693870005 1

16 1705720003 1

Pos Code

qty

171877DE

1 07188800 1

7

10

11

12

13 07188200 1

14

16 1693870006 1

16 1705720004 1

Page 38

BOOM LIFT MODELS X23J

JLG

34

X23JR0620113

Pos Code

qty

171877ES

1 07201900 1

7

10

11

12

13 07202300 1

14

16 1693870007 1

16 1705720005 1

Pos Code

qty

171877NL

1 07188900 1

7

10

11

12

13 07188300 1

14

16 1693870008 1

16 1705720006 1

Pos Code

qty

171877PT

1 07202000 1

7

10

11

12

13 07202400 1

14

16 1693870009 1

16 1705720007 1

Pos Code

qty

171877SW

1 07189000 1

7

10

11

12

13 07188400 1

14

16 1693870010 1

16 1705720010 1

Pos Code

qty

171877DA

1 07189100 1

7

10

11

12

13 07188500 1

14

16 1693870011 1

16 1705720011 1

Pos Code

qty

171877NO

1 07189200 1

7

10

11

12

13 07188600 1

14

16 1693870012 1

16 1705720012 1

Page 39

35

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Code Name Description Identikit

06040300

WARNING KEEP

SAFE DISTANCE

06040500

SENSE OF MOVING

UNDERCARRIAGE

DEFINED AS THE

DIRECTION FORWARD

06040800

CRUSHING HAZARD

PERSON

06040900

OBLIGATION TO

READ THE MANUAL

BEFORE USE OF

MACHINE

1703814

FIXING POINT FOR

TRANSPORT

INDICATES CORRECT

FIXING POINT FOR

TRANSPORT OF THE

MACHINE

06041200

CRUSHING HAZARD

FEET

INDICATES AREAS

WHERE THERE IS A

DANGER OF CRU‑

SHING LOWER LIMBS

FOR THE OPERATOR

06041300

CRUSHING HAZARD

PERSON

INDICATES AREAS

WHERE THERE IS A

DANGER OF CRU‑

SHING UPPER LIMBS

FOR THE OPERATOR

06040300

06040500

06040800

06040900

1703814A

06041200

06041300

Page 40

BOOM LIFT MODELS X23J

JLG

36

X23JR0620113

Code Name Description Identikit

06044000 LIFTING POINT

INDICATES CORRECT

LIFTING POINTS FOR

LIFT THE MACHINE

06056300

DANGER HIGHT

TEMPERATURE

06060000 ENGINE OIL LEVEL

06085900

EMERGENCY DEVI‑

CE FOR AERIAL

PART

DEVICE THAT ALLOWS

TO EXCLUDE THE

SAFETY OF THE

AEREAL PART IN CASE

OF EMERGENCY OPE‑

RATIONS

06086000

EMERGENCY DEVI‑

CE FOR UNDERCAR‑

RIAGE

DEVICE THAT ALLOWS

TO EXCLUDE THE

SAFETY OF THE

UNDERCARRIAGE IN

CASE OF EMERGENCY

OPERATIONS

06086600

WARNING KEEP

SAFE DISTANCE

AND CRUSHING

HAZARD PERSON

0

6

0

4

4

0

0

0

06056300

0

0

0

0

6

0

6

0

06085900

06086000

06086600

Page 41

37

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Code Name Description Identikit

06165000

HYDRAULIC OIL

LEVEL

1701499

FORBIDDEN LIFTING

POINT

1001125483

DO NOT WASH WITH

WATER

06560500 GROUNDING

06598400

HAND PUMP

LEGEND

QUICK INSTRUCTIONS

FOR USING THE EMER‑

GENCY HAND PUMP

06924300

BE CAREFULL AT

WORK

USING SAFETY HAR‑

NESSES, USE PROTECTI‑

VE EQUIPMENT (HEL‑

MET), PROHIBITION OF

WELD ON THE MACHI‑

NE, PROHIBITION OF

USE SYSTEMS TO

INCREASE THE AREA

OF WORK INSIDE THE

BASKET , PROHIBITION

OF WORKING IN THE

VICINITY OF VOLTAGE

ELECTRIC, PROHIBI‑

TION OF USE OF THE

PLATFORM FOR RAI‑

SING LOADS

1701499

1001125483

06560500

0

0

0

5

6

1

6

0

06598400

0692430006924300

Page 42

REPLACE STICKERS AND PLATES AS SOON AS THEY DETERIORATE.

THE FAILURE TO COMPLY WITH ANY PRESCRIPTION DUE TO DETERIORA‑

TION, LOSS, OR NON‑CONSULTATION OF A SAFETY STICKER, CAN BE THE

CAUSE OF SERIOUS ACCIDENTS.

BOOM LIFT MODELS X23J

JLG

38

X23JR0620113

Code Name Description Identikit

07107200

BATTERY PACK

WARNINGS

CORROSIVE LIQUID

Presence of highly corro‑

sive liquid, dangerous to

the body and eyes.

HIGH VOLTAGE

Presence of high voltage

with danger of electric

shock.

DANGER OF EXPLO‑

SION

Formation of potentially

explosive mixture inside

the battery.

NO NAKED FLAMES

Do not smoke or use

naked flames when

recharging and near the

vehicle. Risk of explo‑

sion.

RECYCLING

It is highly recommended

to comply with legislati‑

ve and environmental

standards as regards the

demolition, reuse, recy‑

cling and recovery of

materials.

Page 43

39

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Page 44

3 SAFETY DEVICES

The notions stated below concerning the safety devices are made available to the user in

order to understand machine behaviour and possible work sequences; moreover, in this way

it is possible to identify any breakdowns with greater certainty in order to supply more

detailed information to the after‑sales service for quicker, less expensive interventions.

The machine is equipped with safety devices used to prevent dangerous situations for the

operator from occurring. It is important that before starting any operation, the operator

checks the perfect working order of these devices.

The non‑functioning of a safety device, whether caused by a fault or tampering, can cause

serious damage to the machine and consequently put the operator’s life at risk. The Con‑

structor has designed the machine and safety devices in order to guarantee the maximum to

its customers, however the devices must be checked periodically according to that described

in this manual and they must never be tampered with.

The service function on the remote control can be used as an aid for checking electric safety

devices.

Never intervene on the safety devices. If they are tampered with the manufacturer declines

all liability regarding any accidents that can be blamed on these interventions.

It is prohibited to tamper with the lead sealing or calibration of the maximum pressure val‑

ves and the adjustments of the electric components. If they are tampered with the manufac‑

turer declines liability for any accidents that can be blamed on these interventions.

The Constructor is not liable for any damage/injury caused by the machine to objects and/or

persons due to failure to comply of that stated above.

BOOM LIFT MODELS X23J

JLG

40

X23JR0620113

Page 45

41

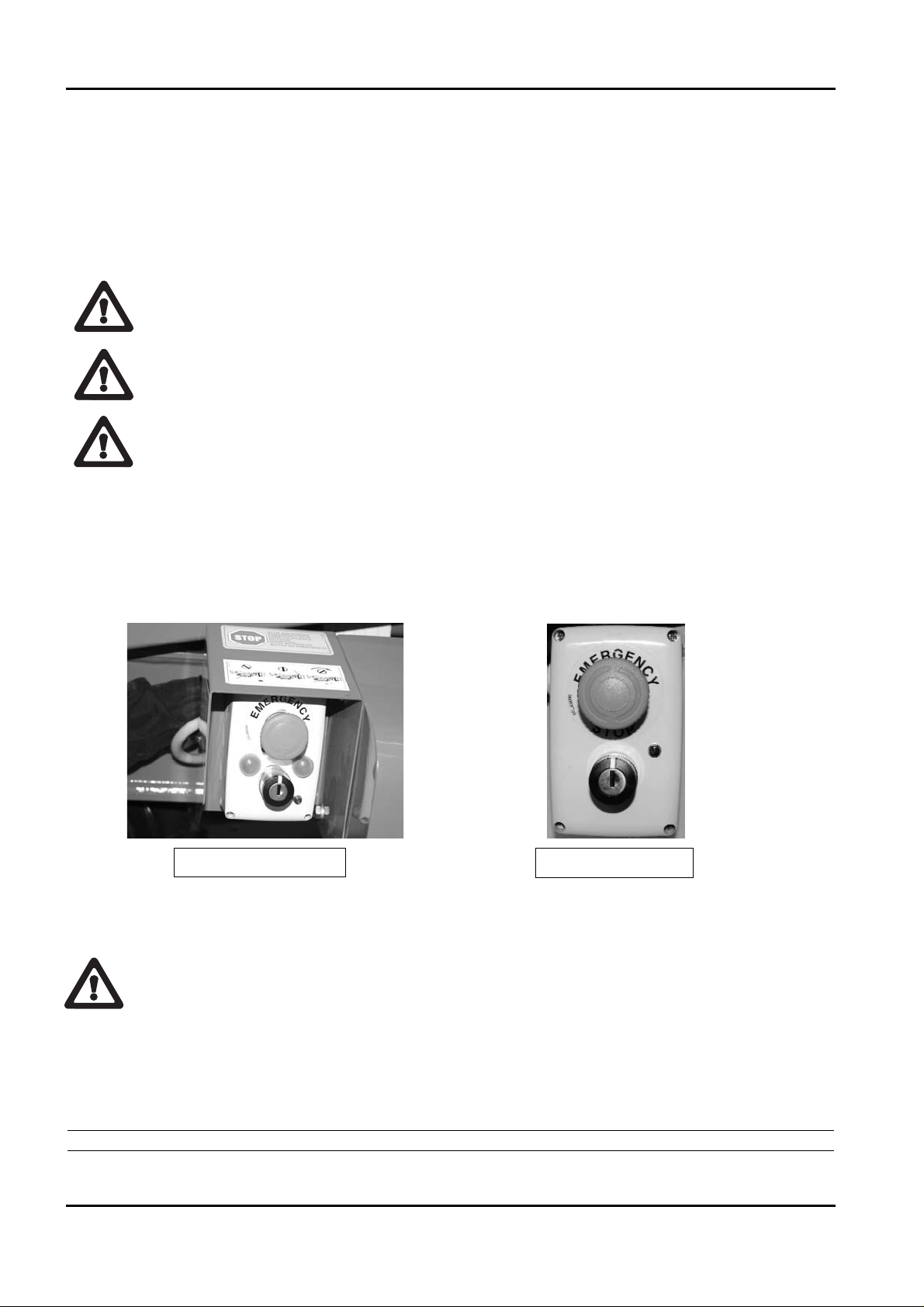

3.1 BATTERY CUT‑OUT

This device, positioned on the left side of the electric components box allows to cut‑off the machine

electric circuit, blocking any movement. It is well‑visible and easily accessed without the use of

tools. It has to be activated only in case of prolonged machine down time or maintenance

assistance.

By turning the key in a clockwise direction the machine’s electric circuit is closed, while tur‑

ning it in an anti‑clockwise direction the machine’s electric circuit is cut‑off and the key can

be removed.

B

EFORE DISCONNECTING THE BATTERY THROUGH THIS DEVICE, MAKE SURE THAT THE ENGINE KEY IS

IN

OFF POSITION, AND THE REMOTE CONTROL AND ELECTRIC BOARD ARE COMPLETELY TURNED OFF.

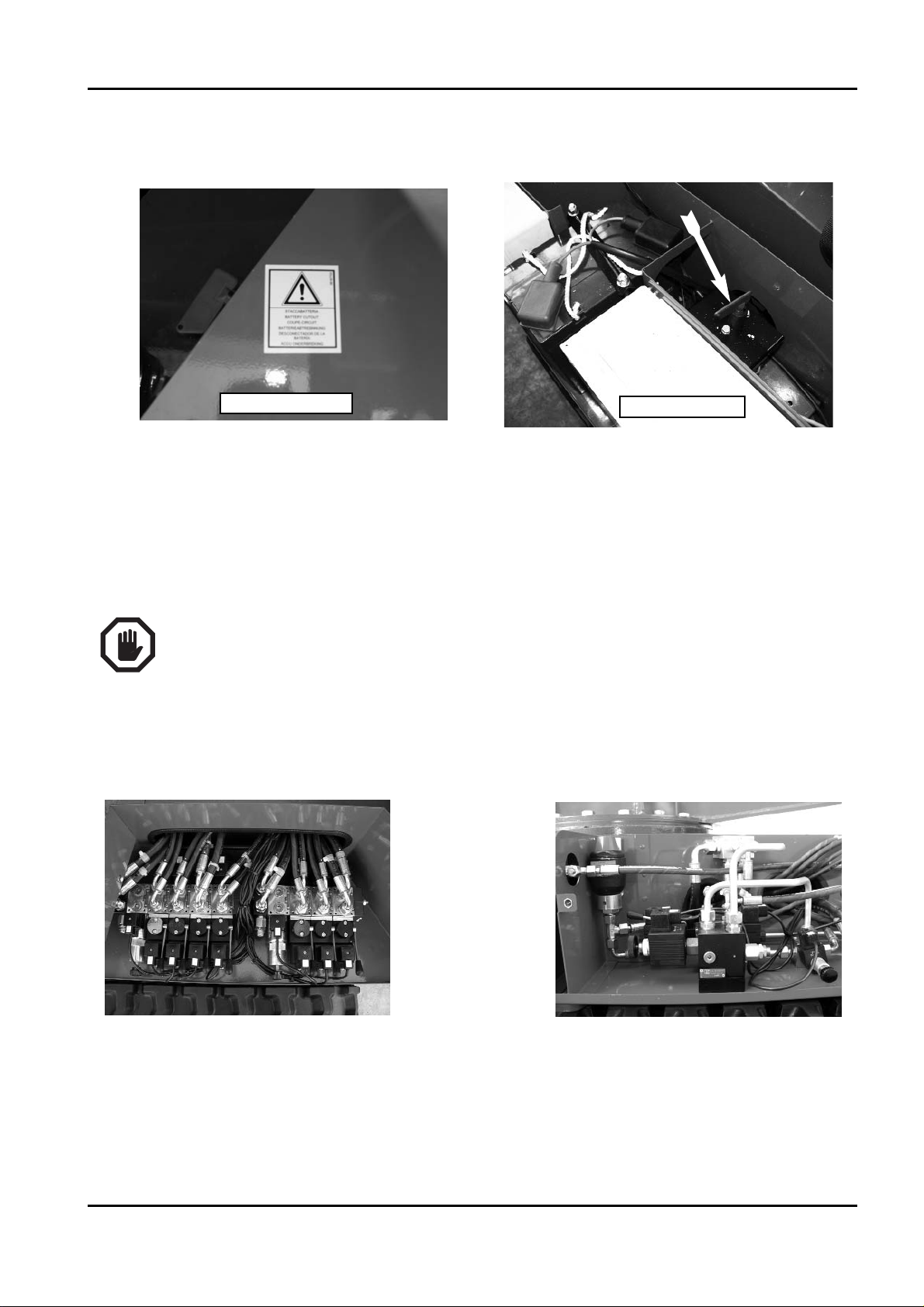

3.2 D

ISTRIBUTORS OVER‑PRESSURE VALVES

All platform distributors have an over‑pressure valve that limits the pressure that can be rea‑

ched inside the calibration pressure plant of the valve itself.

These valves are calibrated in the platform inspection phase by qualified staff working and

must not be tampered with for any reason.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

IMPORTANT

THERMIC MOTOR

LITHIUM MOTOR

IMPORTANTE

Page 46

3.3 CYLINDER CUT‑OFF VALVES

The outrigger cylinders have a double cut‑off valve, which in case of plant breakdown or

pipe breakage, cut‑off the cylinder preventing dangerous platform instability situations. All

cylinders that move the aerial part of the platform structure are equipped with a cut‑off

valve, which in case of plant breakdown or pipe breakage cut‑off the cylinder preventing the

basket falling due to gravity.

These valves are calibrated in the platform inspection phase by qualified staff working

and must not be tampered with for any reason.

3.4 A

ERIAL PART ALIGNMENT PHOTOCELLS OF THE STRUCTURE AND MACHINE BASE

The platform has two reflection safety photocells that check that the aerial part of the machi‑

ne structure is completely lowered and aligned with the base and that the telescopic arm is

completely retracted.

When these conditions do not occur, a signal is given that disables outrigger movement.

BOOM LIFT MODELS X23J

JLG

42

X23JR0620113

Page 47

43

3.5 OUTRIGGERS POSITION MICRO SWITCHES STANDARD VERSION

The position of the outriggers and their contact with the ground is detected by 4 pairs of

micro switches positioned in proximity of the outriggers orientation joints and the outrigger

cylinder rod fixing pin.

SEE PHOTO

The micro switches positioned on the joints must be released when the outrigger is in the sta‑

bilisation position (about 58° with respect to machine axis)and pressed when the outrigger is

in the remaining positions until it reaches the transport position parallel to the machine axis.

The micro switches fixed onto the outrigger must be released when the outrigger rests on the

ground. Control the correct functioning of the micro‑switches daily.

VERSION WITH VARIABLE STABILIZATION AREA

The machines with variable sabilization area, in addition to the

above described, are equippeed with four microswitches which con‑

trol the position of the outriggers, total or reduced area, and based

on this allow or limit the rotation of the aerial part of the machine.

They are also equipped with a sensor which controls the angular

position of the aerial part compared to the the undercarriage part of

the machine.

The checking of the correct functioning of the four microswitches

is compulsory before every stabilization of the machine, in order

to do this operation position one outrigger in reduced stabilization

area and the other three in total area and check that on the remote

control appears the reduced area icon, repeat this operation for

every outrigger.

Check the correct positioning of the microswitches at every use, as indicated on the decal

positioned on the machine.

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Page 48

BOOM LIFT MODELS X23J

JLG

44

X23JR0620113

POSM

POS

POSM

POS

PRIMA DI OGNI UTILIZZO VERIFICARE IL CORRETTO

FUNZIONAMENTO E FISSAGGIO DEI MICROINTERRUTTORI

BEFORE EVERY USE CHECK THE CORRECT FUNCTIONING AND

FASTENING OF THE MICROSWITCHES

AVANT DE CHAQUE EMPLOI, VERIFIER LE CORRECT

FONCTIONNEMENT ET FIXAGE DES MICROINTERRUPTEURS

VOR JEDER INBETRIEBNAHME DAS KORREKTE FUNKTIONIEREN UND

DIE BEFESTIGUNG DER MIKROSCHALTER ÜBERPRÜFEN

ANTES DE CADA

FUNCIONAMIENTO Y FIJACION DE LOS MICROINTERRUPTORES

VOOR GEBRUIK DIENT U HET FUNCTIONEREN EN DE SNELHEID VAN

DE MICROSCHAKELAARS TE CONTROLEREN

ANTES DE

FUNCIONAMENTO E FIXAÇÃO DOS MICRO-INTERRUPTORES

STABILIZZATORE IN AREA TOTALE SPIA ACCESA

OUTRIGGER IN TOTAL AREA WARNING LIGHT ON

STABILISATEUR DANS SUFACE TOTALE VOYANT ALLUMÉ

STABILISATOR AUF GESAMTER FLÄCHE WARNLICHT AN

ESTABILIZADORES EN AREA TOTAL LUZ PERMANENTE

BIJ MAXIMALE UITSTEMPELING BRANDT HET

WAARSCHUWINGSLICHT

ESTABILIZADOR EM ÁREA TOTAL LUZ INDICADORA ACENDIDA

STABILIZZATORE IN AREA RIDOTTA SPIA INTERMITTENTE

OUTRIGGER IN REDUCED AREA INTERMITTENT WARNING LIGHT

STABILISATEUR DANS SUR

STABILISATOR AUF BEGRENZTER FLÄCHE WARNLICHT BLINKEND

ESTABILIZADORES EN AREA REDUCIDA LUZ INTERMITENTE

BIJ GEDEELTELIJKE UITSTEMPELING KNIPPERT HET

WAARSCHUWINGSLICHT

ESTABILIZADOR EM ÁREA REDUZIDA LUZ INDICADORA INTERMITENTE

UTILIZACION VERIFICAR EL CORRECTO

CADA UMA UTILIZAÇÃO VERIFICAR O CORRECTO

FACE REDUITE VOYANT INTERMITTENT

07060400A

POSM

POS

STABILIZZATORE CHIUSO

CLOSED OUTRIGGER

STABILISATEUR FERMÉ

GESCHLOSSENER STABILISATOR

ESTABILIZADOR CERRADO

ONTROLEER HET FUNCTIONEREN VAN DE MICROSCHAKELAARS

ESTABILIZADOR FECHADO

Page 49

45

3.6 JIB POSITION MICRO SWITCH

The position of the Jib is detected by a micro switch fixed

onto the jib arm itself and it works in a slot made in the

JIB transmission.

The micro switch must be released when the Jib arm is

closed.

Control daily the status and correct functioning of the MICRO JIB.

3.7 R

OPES INTEGRITY MICRO SWITCH

The integrity of the ropes system that moves the telescopic arm is verified by a micro switch

that detects the position of the rope pull balancing system.

When both ropes are integral, the balancing system is parallel to the machine axle and the

micro switch must be released.

If the micro switch is not released due to an anomaly on one of the two ropes, a warning

message appears on the remote control display.

3.8 B

ASKET LOAD SENSOR

The load sensor present on the basket is made up from a

basket support with two shafts that only allow vertical

basket movement. The basket support is supplied by the

load cell itself. Two strain gauges are positioned inside the

sensor positioned under the basket, which change over

the relative weight inside the basket to an electric signal.

The electric signal is then sent to the circuit board that ela‑

borates it and identifies any dangerous conditions.

The max load depends on the working mode, if the

BOOM LIFT MODELS X23J

JLG

X23JR0620113

Page 50

machine works with jib open this load is 120 kg. If working with jib closed, the maximum

accepted load is 200 kg.

The indication of the max load based on the working mode is always displayed on the remo‑

te control.

When the maximum accepted load is reached, an icon appears on the remote control display

along with an acoustic signal and all platform movements are prevented. To restore platform

functioning the excess weight must be removed in order to drop below the maximum weight

accepted. (see paragraph regarding the display visualizations ).

The Constructor recommends that maximum attention is paid to

the state of all safety components and in particular to the system

that makes up the basket load sensor; always check correct func‑

tioning whenever objects are struck with the basket or if jobs are

being carried out that can damage the system (e.g. pruning,

painting etc.).

Before ascending, always make sure that the two lids of the vertical pins are COMPLE‑

TELY fastened into their seat.

3.9 C

ONTROL PROTECTIONS

The remote control is protected against the accidental fall

of objects from above and involuntary activation by the

operator by a protection structure.

Always check integrity before using the machine.

3.10 S

PIRIT LEVEL

The spirit level is positioned on the turret where it can be well

seen from the basket and from the ground. The spirit level must

be used to check that during the platform levelling phase the

maximum accepted inclination limit of 1° is respected. For this

to take place, the air bubble must never go out of the green area.

A second electronic spirit level, contained in the control board,

checks that this condition is effectively satisfied and checks the power supply of the controls

relative to the aerial part.

BOOM LIFT MODELS X23J

JLG

46

X23JR0620113

ATTENTION

DANGER

LID

ATTENZIONE

PERICOLO

Page 51

47

Control always the correct levelling of the machine after every self‑levelling operation.