Page 1

Model 7300 and 7305

Spectrophotometer

Operating Manual

730 005 REV E/12-14

Page 2

2

Page 3

3

Safety

Please read this information carefully prior to installing or using this equipment.

1. The unit described in this manual is designed be operated only by trained personnel. Any

adjustments, maintenance and repair must be carried out as defined in this manual, by a

person qualified to be aware of the hazards involved.

2. It is essential that both operating and service personnel employ a safe system of work, in

addition to the detailed instructions specified in this manual.

3. Other than for those items defined in the maintenance procedures herein there are no

user serviceable items in this instrument. Removal of covers and attempted adjustment or

service by unqualified personnel will invalidate the warranty and may incur additional

charges for repair.

4. References should always be made to the Health and Safety data supplied with any

chemicals used. Generally accepted laboratory procedures for safe handling of chemicals

should be employed.

5. If it is suspected that safety protection has been impaired in any way, the unit must be

made inoperative and secured against any intended operation. The fault condition should

immediately be reported to the appropriate servicing authority.

Merci de lire attentivement ces informations avant d'installer ou d'utiliser cet appareil.

1. L'appareil décrit dans ce manuel est conçu pour être utilisé uniquement par des

personnes formées. Tout réglage, maintenance ou réparation doit être effectué comme

décrit dans ce manuel, par une personne qualifiée consciente des risques encourus.

2. Il est essentiel que les personnes utilisant et intervenant sur cet appareil respectent les

règles de sécurité de travail, en plus des instructions détaillées précisées dans ce

manuel.

3. En-dehors des éléments décrits dans les procédures de maintenance ci-incluses, cet

appareil ne contient aucun élément réparable par l'utilisateur. L'enlèvement des capots et

les tentatives de réglage ou de réparation par des personnes non qualifiées invalide toute

garantie et entraîne un risque de frais de réparation supplémentaires.

4. Toujours se référer aux fiches techniques de santé et de sécurité accompagnant tout

produit chimique utilisé. Respecter les procédures de laboratoire généralement

acceptées pour la manipulation en toute sécurité des produits chimiques.

5. Si l'utilisateur suspecte qu'un problème quelconque puisse mettre en cause la sécurité,

l’appareil doit être rendu inopérant en empêchant son utilisation. Communiquer la

défaillance constatée au service de maintenance compétent.

Page 4

4

Bitte lesen Sie diese Hinweise vor Installation oder Gebrauch dieser Ausrüstung sorgfältig

durch.

1. Das in diesem Handbuch beschriebene Gerät darf nur von geschultem Personal bedient

werden. Alle Anpassungen, Wartungsarbeiten und Reparaturen müssen entsprechend

der Vorgaben in diesem Handbuch und von einer kompetenten Person, die mit den damit

verbundenen Gefahren vertraut ist, durchgeführt werden.

2. Es ist wichtig, dass sowohl das Bedienungs- als auch das Service-Personal zusätzlich zu

den detaillierten Anweisungen in diesem Handbuch ein sicheres Arbeitssystem

einsetzen.

3. Mit Ausnahme der Teile, deren Wartungsverfahren in diesem Handbuch beschrieben

sind, enthält dieses Gerät keine weiteren Teile, die vom Benutzer gewartet werden

können. Das Entfernen von Abdeckungen und Versuche von hierfür unqualifiziertem

Personal, Anpassungen oder Wartungsarbeiten durchzuführen, haben zur Folge, dass

die Garantie verfällt und können zusätzliche Reparaturkosten auslösen.

4. Es ist jederzeit auf die sicherheitsrelevanten Daten sämtlicher verwendeter Chemikalien

Bezug zu nehmen. Allgemein anerkannte Labormethoden zum sicheren Umgang mit

Chemikalien sollten eingesetzt werden.

5. Besteht der Verdacht, dass die Sicherheitsvorrichtungen in irgendeiner Weise beschädigt

wurden, muss das Gerät außer Betrieb genommen und gegen weiteren Gebrauch

gesichert werden. Die Störung sollte der zuständigen Serviceeinrichtung unverzüglich

gemeldet werden.

Leggere attentamente queste istruzioni prima di installare o utilizzare il dispositivo.

1. L'unità descritta nel presente manuale è stata realizzata per essere utilizzata solo da

personale che ha ricevuto l'apposita formazione. Qualsiasi operazione di regolazione,

manutenzione e riparazione deve essere effettuata sulla base di quanto indicato nel

presente manuale da personale qualificato consapevole dei rischi connessi.

2. È fondamentale che il personale operativo e il personale addetto alla manutenzione

utilizzino un sistema di lavoro sicuro, oltre a seguire le istruzioni specificate nel presente

manuale.

3. Oltre a quelli indicati nelle procedure di manutenzione, all'interno di questo dispositivo

non sono presenti altri elementi sui quali è possibile effettuare interventi. La rimozione

delle protezioni e qualsiasi tentativo di regolazione o di manutenzione posto in essere da

personale non qualificato invaliderà la garanzia. In questi casi, sarà necessario pagare un

importo per le riparazioni effettuate.

4. È sempre necessario fare riferimento ai dati sulla salute e sulla sicurezza forniti con le

sostanze chimiche utilizzate. Adottare le procedure di laboratorio generalmente accettate

per la gestione delle sostanze chimiche.

Page 5

5

5. Nel caso in cui si sospetti che la salute possa essere pregiudicata in qualsiasi modo,

disattivare l'unità per renderla inutilizzabile. Qualsiasi condizione di errore deve essere

immediatamente segnalata al responsabile per la manutenzione.

Lea esta información atentamente antes de instalar o utilizar este equipo.

1. La unidad descrita en este manual está diseñada para que solamente la utilice personal

con formación. Cualquier operación de ajuste, mantenimiento y reparación debe llevarse

a cabo del modo indicado en este manual y debe realizarla una persona cualificada que

sea consciente de los peligros que implica.

2. Es fundamental que tanto los operarios como el personal de servicio utilicen un sistema

de trabajo seguro, así como las instrucciones detalladas que se especifican en este

manual.

3. Cualquier elemento que no se encuentre entre los definidos en los procedimientos de

mantenimiento aquí descritos no podrá utilizarse en este instrumento. La extracción de

las tapas y los intentos de ajuste o reparación por parte de personal no cualificado

invalidarán la garantía y pueden incurrir en cargos adicionales por reparación.

4. Siempre deberían consultarse los datos sobre Salud y Seguridad que se suministran con

cualquier producto químico que se utilice. Es necesario llevar a cabo los procedimientos

de laboratorio de aceptación generalizada para la manipulación segura de productos

químicos.

5. Si existe la sospecha de que las medidas protectoras de seguridad han quedado

dañadas en cualquier modo, la unidad debe inutilizarse y protegerse contra toda

operación que se intente llevar a cabo. El estado de fallo debe comunicarse

inmediatamente a la autoridad de servicio de mantenimiento y reparación pertinente.

Page 6

6

Contents

Safety ......................................................................................................................... 3

Contents ..................................................................................................................... 6

SECTION 1 - Introduction .......................................................................................... 8

1.1 INSTRUMENT DESCRIPTION............................................................................................. 8

1.2 INSTRUMENT SPECIFICATION.......................................................................................... 8

SECTION 2 – Installation ........................................................................................... 9

2.1 UNPACKING......................................................................................................................... 9

2.2 INSTALLATION .................................................................................................................... 9

2.3 DISPLAY ............................................................................................................................. 10

2.4 CONTROLS ........................................................................................................................ 11

2.5 REAR PANEL ..................................................................................................................... 12

2.6 FRONT PANEL ................................................................................................................... 12

SECTION 3 – Theory and Practice of Spectroscopy Measurements ....................... 13

3.1 THEORY OF SPECTROSCOPY MEASUREMENT .......................................................... 13

3.2 SPECTROSCOPY MEASUREMENT ................................................................................. 14

3.3 GOOD PRACTICE GUIDELINES ....................................................................................... 15

SECTION 4 – Instrument Setup ............................................................................... 17

4.1 NAVIGATING AND SCREEN SETUP ................................................................................ 17

4.2 TIME AND DATE ................................................................................................................ 18

4.3 INSTRUMENT SETTINGS MENU...................................................................................... 18

4.4 SCREEN CONTRAST ........................................................................................................ 19

4.5 LAMP SAVE........................................................................................................................ 19

SECTION 5 – PHOTOMETRICS ............................................................................. 21

5.1 MODE SPECIFIC PARAMETERS ..................................................................................... 21

5.2 METHOD SET UP .............................................................................................................. 21

5.2.1 Selecting a Wavelength ...................................................................................................... 21

5.3 CALIBRATION .................................................................................................................... 22

5.4 SAMPLE MEASURMENT ................................................................................................... 22

SECTION 6 – CONCENTRATION ........................................................................... 23

6.1 MODE SPECIFIC PARAMETERS ..................................................................................... 23

6.2 METHOD SETUP ............................................................................................................... 23

6.2.1 Selecting a Wavelength ...................................................................................................... 23

6.2.2 Settings ............................................................................................................................... 24

6.2.2.1 Selecting Concentration Units ............................................................................................ 24

6.2.2.2 Changing the Resolution .................................................................................................... 25

6.2.2.3 Using a Standard ................................................................................................................ 25

6.2.2.4 Using a Factor .................................................................................................................... 25

6.3 CALIBRATION .................................................................................................................... 26

6.3.1 Calibrating to a Standard .................................................................................................... 26

6.3.2 Calibrating to a Factor ........................................................................................................ 27

6.4 SAMPLE MEASUREMENT ................................................................................................ 27

6.4.1 Measuring a Sample After Calibrating to a Standard ......................................................... 27

6.4.2 Measuring a Sample After Calibrating to a Factor ............................................................. 27

6.5 POST MEASUREMENT OPTIONS .................................................................................... 27

6.5.1 Changing Concentration Units ............................................................................................ 28

6.5.2 Changing the Concentration Factor .................................................................................... 29

Page 7

7

6.5.3 Changing the Calibration Standard Value .......................................................................... 29

SECTION 7 – PRINTING AND AUTOLOGGING ..................................................... 30

7.1 PRINTING ........................................................................................................................... 30

7.1.1 Print Setup .......................................................................................................................... 30

7.1.2 Printing Results ................................................................................................................... 31

7.2 AUTOLOGGING ................................................................................................................. 31

7.2.1 Setting the Number of Sample Repetitions ........................................................................ 31

7.2.2 Selecting Result’s Destination ............................................................................................ 32

7.3 CONNECTING TO A PC .................................................................................................... 33

SECTION 8 – Accessories and Spare Parts ............................................................ 34

8.1 OPTIONAL ACCESSORIES............................................................................................... 34

8.2 CONNECTING THE ACCESSORIES ................................................................................ 34

8.2.1 Internal Printer .................................................................................................................... 34

8.2.2 Passive Accessories ........................................................................................................... 35

8.2.2.1 Water-heated cuvette holder .............................................................................................. 35

8.2.3 Active Accessories .............................................................................................................. 38

8.2.3.1 Automatic 8 cell turret ......................................................................................................... 38

8.2.3.2 Peltier .................................................................................................................................. 39

8.2.3.3 Sipper pump ....................................................................................................................... 40

8.2.3.4 Combined sipper Peltier pump ........................................................................................... 42

8.3 USING THE ACCESSORIES ............................................................................................. 43

8.3.1 Automatic 8 cell turret ......................................................................................................... 43

8.3.2 Peltier .................................................................................................................................. 43

8.3.3 Sipper pump ....................................................................................................................... 44

8.3.3.1 Manual Sipper Pump Settings ............................................................................................. 45

8.3.3.2 Timed Sipper Pump Settings ............................................................................................... 46

8.3.4 Combined sipper Peltier pump ........................................................................................... 49

8.4 SPARES ............................................................................................................................. 49

SECTION 9 – Maintenance and Service .................................................................. 50

9.1 ROUTINE MAINTENANCE ................................................................................................ 50

9.2 LAMP REPLACEMENT ...................................................................................................... 50

9.2.1 Tungsten Halogen Lamp Replacement .............................................................................. 50

9.2.2 Xenon Lamp Module Replacement .................................................................................... 51

9.3 SERVICE ............................................................................................................................ 51

SECTION 10 – Troubleshooting ............................................................................... 52

10.1 ERROR CODES ................................................................................................................. 52

10.2 TROUBLESHOOTING GUIDE ........................................................................................... 54

10.3 TECHNICAL SUPPORT ..................................................................................................... 54

SECTION 11 – Declaration of Conformity ................................................................ 55

Page 8

8

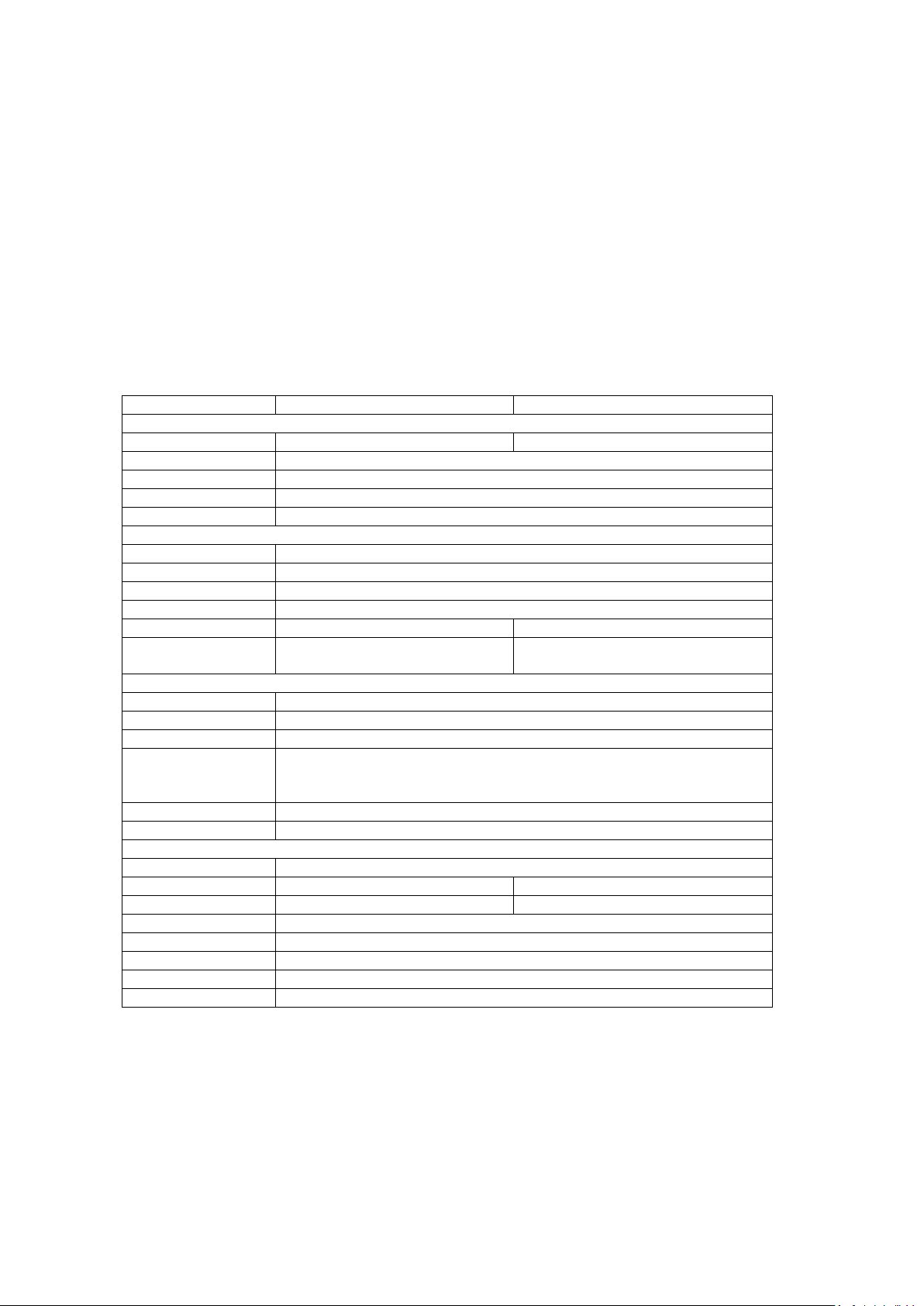

SECTION 1 - Introduction

7300

7305

Wavelength

Range

320 to 1000nm

198 to 1000nm

Resolution

1nm

Accuracy

± 2nm

Repeatability

± 0.5nm

Spectral bandwidth

5nm

Photometrics

Transmittance

0 to 199.9%

Absorbance

-0.300 to 2.500A

Accuracy

±1%T, ±0.01Abs at 1.000 Absorbance

Resolution

0.1%T, 0.001A

Stray light

<0.5% at 340nm

<0.5% at 340nm and 220nm

Stability

<0.002Abs/hr after 30 minute

warm up

<0.001Abs/hr without warm up

Concentration

Range

-300 to 9999

Resolution

Selectable 1/0.1/0.01/0.001

Calibration

Blank with a single standard or factor

Units

no units, %, ppm, EBC, SRM, mEq/l, mEq, M, mM, µM, nM, U, U/l,

U/ml, g/l, mg/l, µg/l, ng/l, g/dl, mg/dl, µg/dl, mg/ml, µg/ml, ng/ml, µg/µl,

ng/µl, mol/l, mmol/l

Factor

0.001 to 10000

Standard

0.001 to 1000

Other

Beam height

15mm

Light source

Tungsten halogen lamp

Xenon lamp

Lamp save

Yes

Not applicable

GLP

Current time and date

Outputs

Analogue, RS232, Internal printer

Power

24V

Size (w x d x h)

275 x 400 x 220mm

Weight

6kg

1.1 INSTRUMENT DESCRIPTION

The 7300 and 7305 spectrophotometers are suited to a wide range of applications in education,

quality control, environmental and clinical analysis. The 7300 is a visible spectrophotometer

covering a wavelength range from 320nm to 1000nm. The 7305 is a UV/Visible

spectrophotometer with a wavelength range from 198nm to 1000nm. Both models feature

measurement modes for absorbance, % transmittance and concentration. These instruments use

icon driven software and have an improved navigation system for easy and intuitive usability.

1.2 INSTRUMENT SPECIFICATION

Page 9

9

SECTION 2 – Installation

2.1 UNPACKING

Remove the 7300 or 7305 from the packaging and ensure the following items are included:

1. Model 7300 spectrophotometer (730 001), or Model 7305 spectrophotometer (730 501)

2. 24V 65W power supply unit (021 060)

3. 7300 - Pack of 100 disposable plastic visible wavelength cuvettes (060 084),

7305 - Pack of 100 disposable UV plastic cuvettes (060 230)

4. Jenway 73 series PC software (735 100) and interface cable (013 203)

5. Instruction manual (730 005)

6. Jenway Foreign Manual CD (JENMANCD)

7. Optional accessories (as ordered)

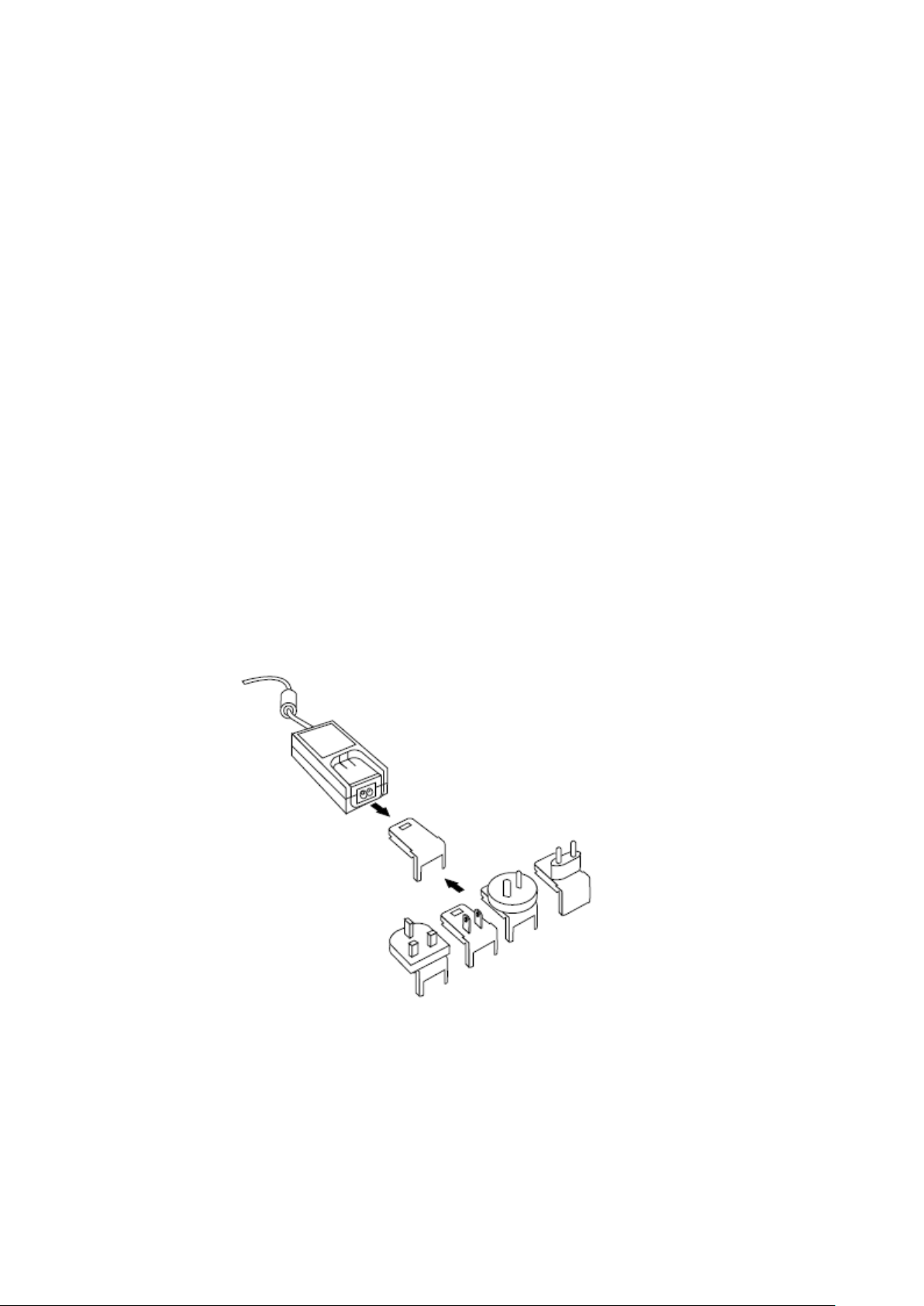

2.2 INSTALLATION

Models 7300 and 7305 are supplied ready to use.

The unit should be placed on a clean flat surface which is free from drafts and vibrations. The

units are designed for operation on 90V to 264V AC input at 47 to 63Hz. Select the correct plug

attachment and attach to the power supply unit as shown below:

Fig 2.2.1 – Power supply unit with various plugs

Connect the power supply unit to the power inlet socket on the rear panel of the instrument and

connect to the mains socket. Turn the power on at the mains and switch the instrument on using

the power switch on the rear of the instrument.

The instrument will perform several power on tests before displaying the main menu:

Page 10

10

1. Instrument check – ensures the validity of the saved parameters

2. Dark test

3. Checks for the accessory fitted. If an active accessory is found the instrument verifies

communication and response

4. Self-calibration of wavelengths

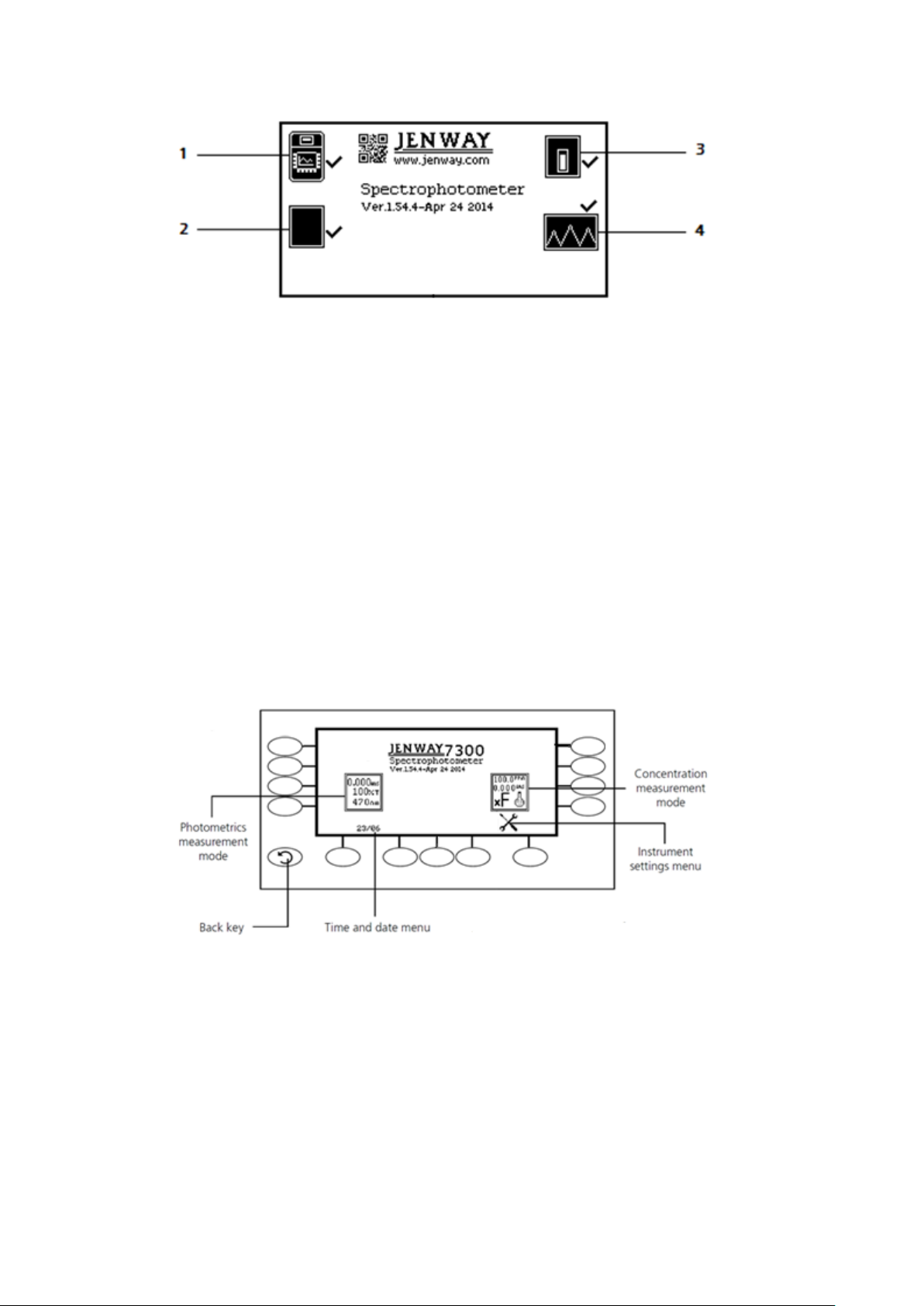

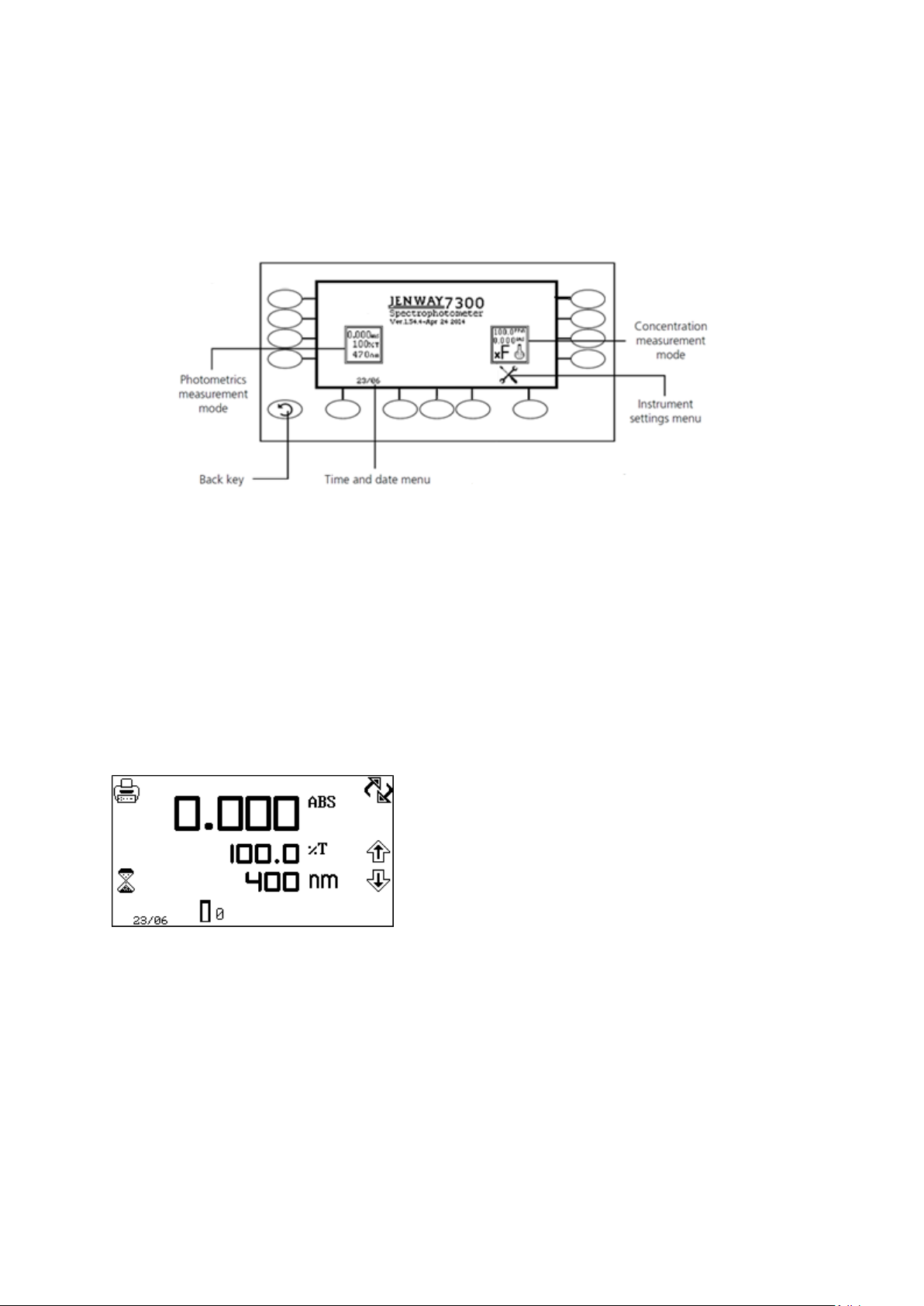

2.3 DISPLAY

These spectrophotometers have a dot matrix display which enables icons to be displayed

clearly. Following successful completion of the power on tests the main menu screen will

be displayed:

Fig 2.2.2 – All Power On Tests Complete

Fig. 2.3 – Display

Page 11

11

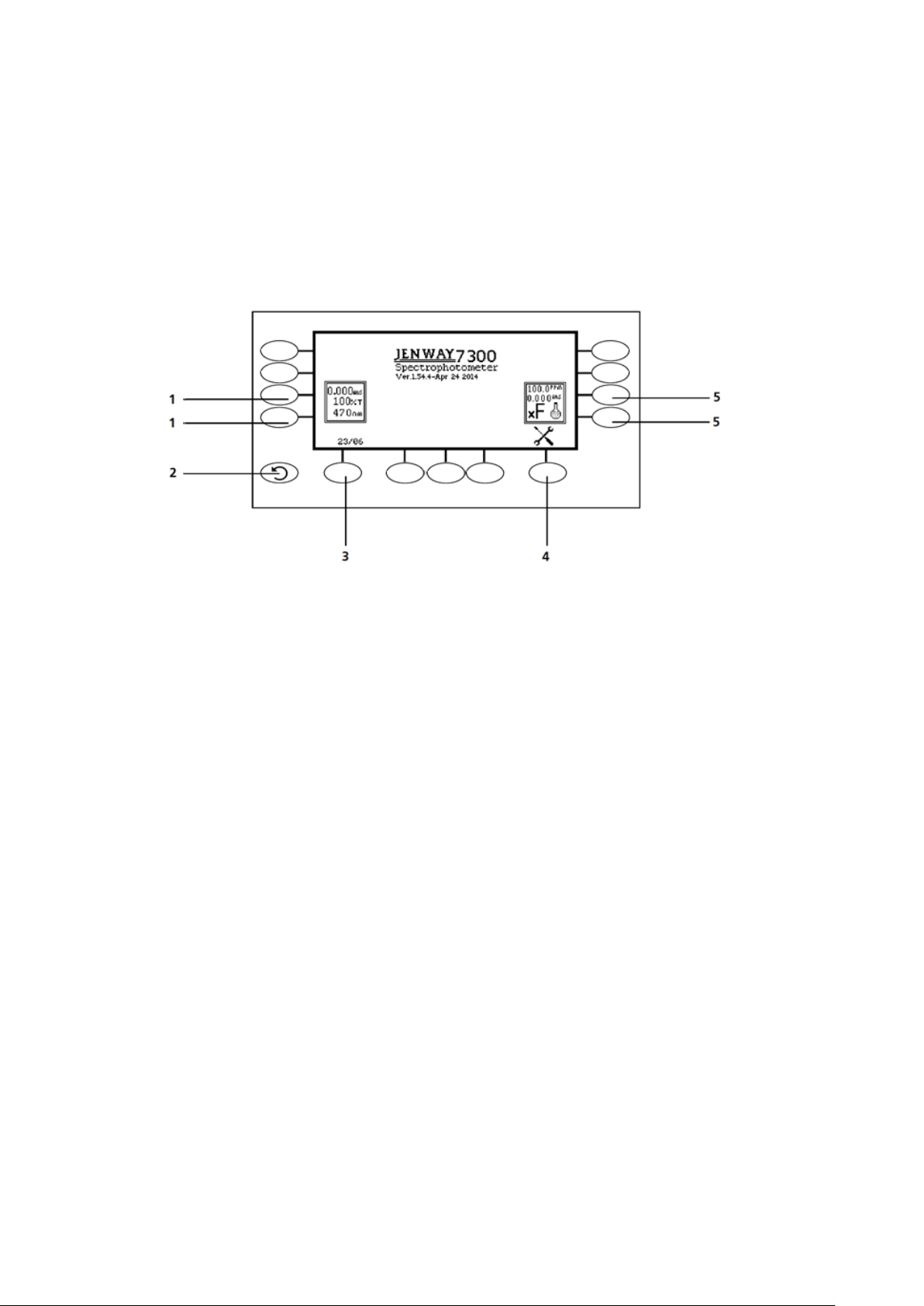

2.4 CONTROLS

The keypad used for these models enables an easy and effective way of navigating the

different measurement modes, entering numbers, saving and analysing results. The soft

keys are active when an icon is displayed above or adjacent to the key. The only

exception to this is the back key which is always active.

The main menu screen and surrounding keypad is displayed below.

1. Photometrics measurement mode

2. Back key

3. Time and date menu

4. Instrument settings menu

5. Concentration measurement mode

Fig. 2.4 – Display

Page 12

12

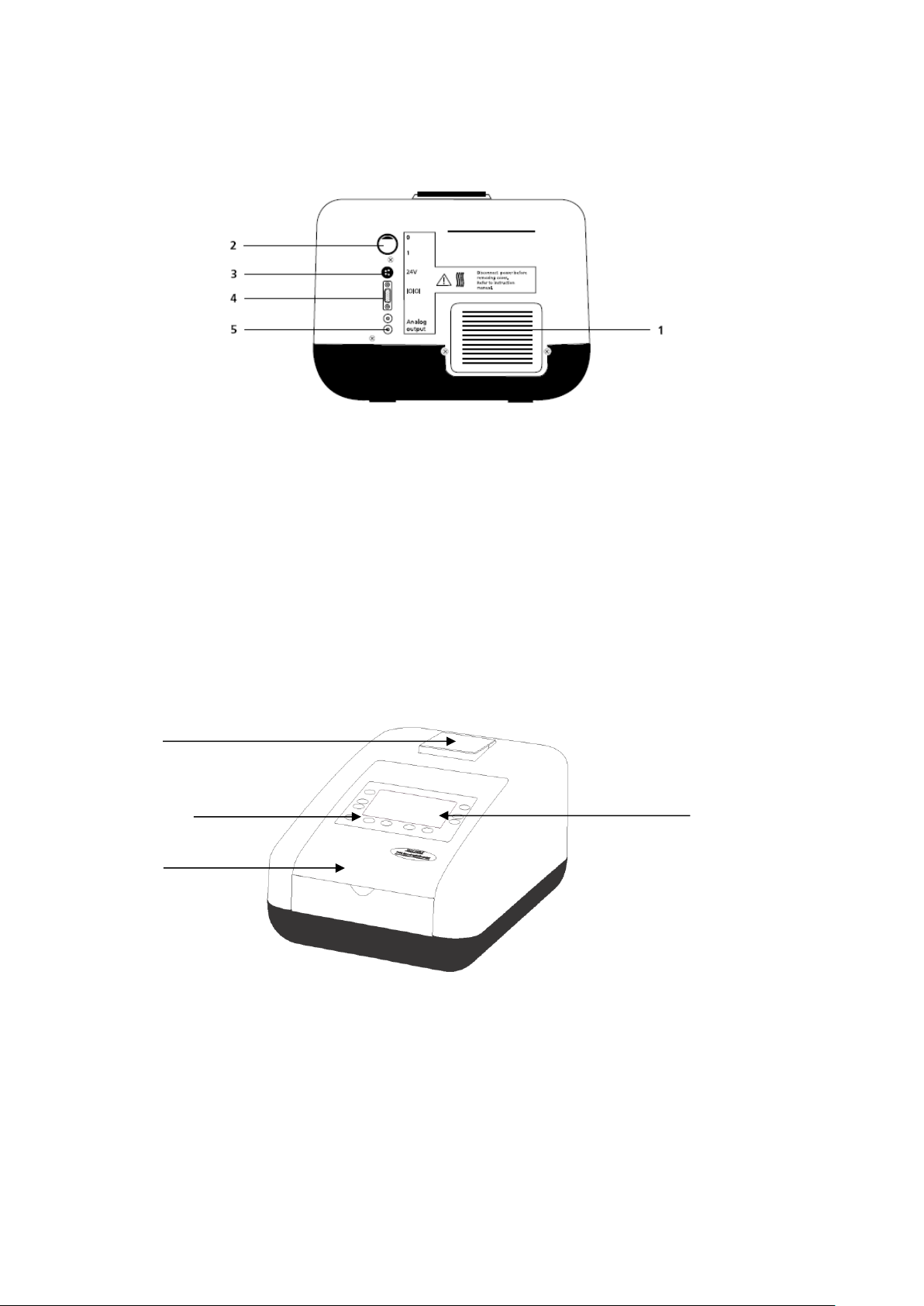

2.5 REAR PANEL

1 2 4

3

The image below shows the rear panel on the instrument:

Fig. 2.5.1 – Rear Panel

1. Lamp access panel Allows access to lamp when replacement is necessary

2. Power switch On/off switch for the unit

3. Power in socket Connection socket for power supply unit

4. RS232 serial port Connection to a PC or external serial printer

5. Output sockets Analogue output

2.6 FRONT PANEL

The image below shows the front panel of the instrument:

Fig. 2.6.1 – Front Panel

1. Integral printer (optional accessory)

2. Keypad

3. Instrument lid

4. Display

Page 13

13

SECTION 3 – Theory and Practice of Spectroscopy Measurements

I

0

I

t

Where:

Io is the incident light

It is the transmitted light

l is the path length

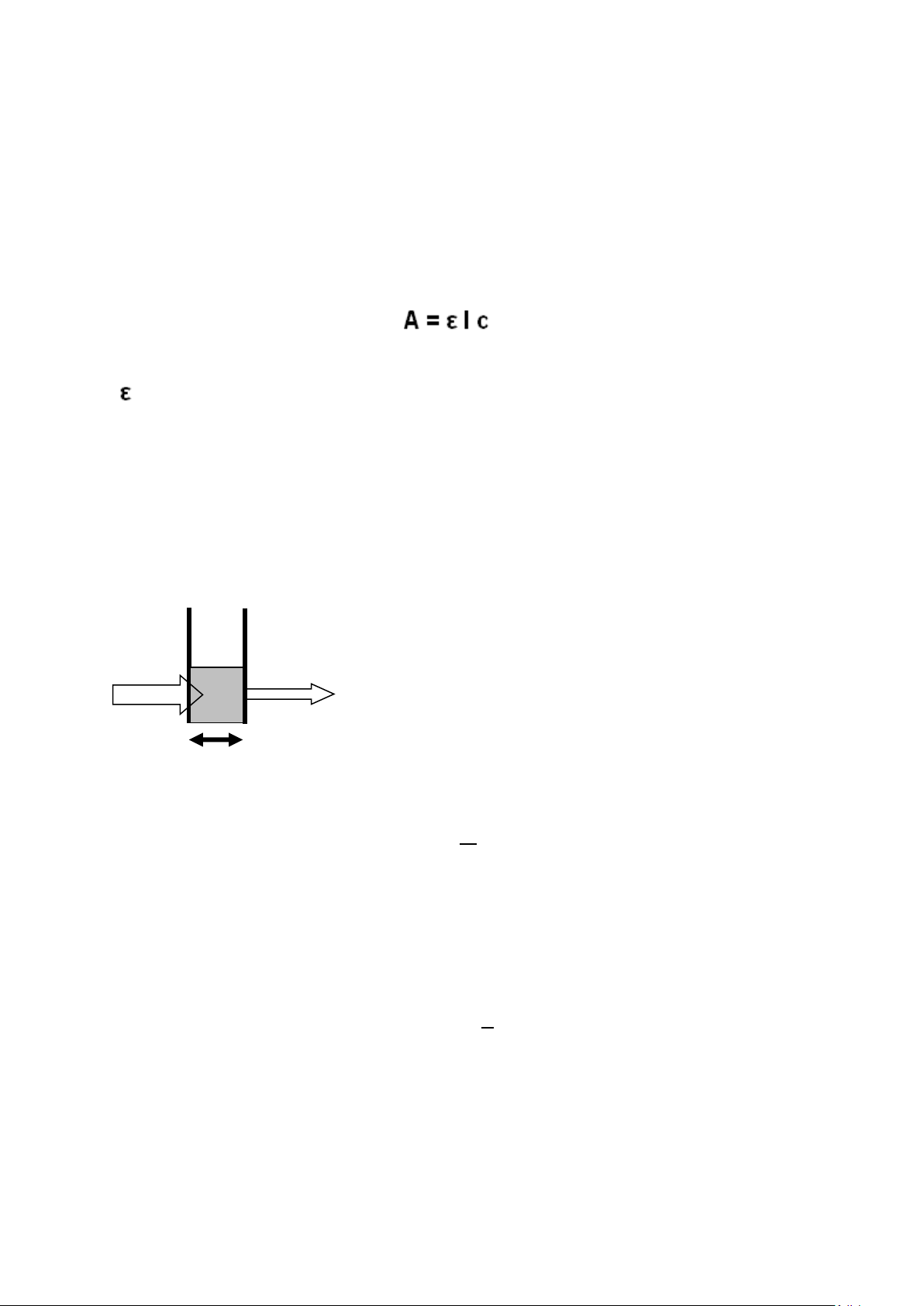

3.1 THEORY OF SPECTROSCOPY MEASUREMENT

UV-visible spectroscopy is the measurement of the absorbance of light at a specific wavelength in

a sample. This is used to identify the presence and concentration of molecular entities within the

sample. The Beer-Lambert law is used to relate the absorption of light to the properties of the

sample through which the light is travelling through. The Beer-Lambert law states that:

A is the absorbance

is the molar absorption coefficient (l mol-1cm-1)

c is the concentration (mol l-1)

l is the path length (cm)

This law shows that absorbance is linear to concentration but this is only true for low

concentrations. For absorbance levels above 3 the concentration starts to move away from the

linear relationship.

Transmittance is the proportion of the light which passes through the sample:

Therefore:

I

T =

Absorbance is inversely related to transmittance:

t

I

𝟎

1

A = Log

T

Page 14

14

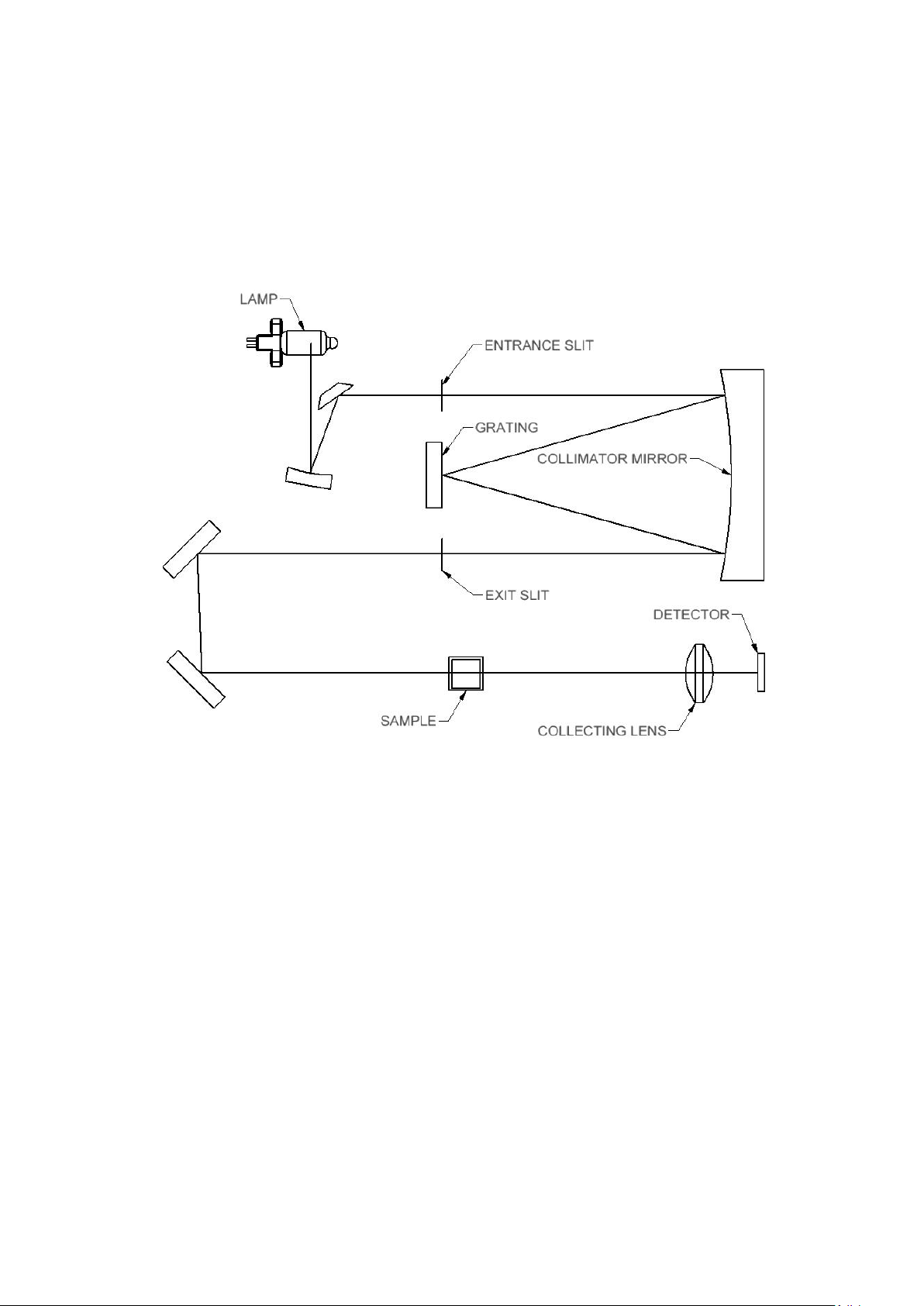

3.2 SPECTROSCOPY MEASUREMENT

There are four main components of a spectrophotometer. These are a light source to emit a high

and constant amount of energy over the full wavelength range; a method for separating the light

into discreet wavelengths; a sample holder and a light detector.

The optical layout of the 7300 and 7305 spectrophotometers is shown below:

Figure 3.2.1 – Diagram of light path

The light from the pre-focused tungsten halogen (7300) or pre-aligned xenon (7305) lamp is

focused onto the grating, with 1200 lines per millimeter, which separates the light into discreet

wavelengths. The diffracted spectrum of light then passes through a further slit and lens

arrangement before passing through the sample in the sample chamber from left to right. The

light which is not absorbed by the sample is transmitted through a collecting lens and onto the

signal detector. The photo-diode detector used is mounted directly onto the detector PCB and is

used to calculate the % transmittance. The result is displayed either as % transmittance or

absorbance on the instrument display.

Page 15

15

3.3 GOOD PRACTICE GUIDELINES

1. For optimum performance all spectrophotometers should be sited in a clean, dry, dust

free atmosphere. When in use ambient temperature and light levels should remain as

constant as possible.

2. If required adherence to Standard Operating Procedures (SOP) and Good Laboratory

Practice (GLP) should be monitored with regular calibration checks and a suitable

Quality Control (QC) programme.

3. The sample chamber lid must be fully closed during measurement and before any

readings are recorded or printed.

4. The correct selection of sample containers is imperative for accurate and

reproducible results:

a) Check that the material of the sample container is compatible with the

wavelengths to be used for measurement. In general glass can only be used

down to 360nm or 320nm depending on quality. Standard plastic cuvettes can be

used down to 320nm. Special UV versions can be used down to 260nm. Below

this level quartz cuvettes must be used.

b) Plastic disposable cuvettes should only be used ONCE.

c) Glass cuvettes should be thoroughly cleaned after use. Discard when scratches

become evident on optical surfaces.

d) Care should be taken when selecting semi-micro or micro cuvettes. The cuvette

window on the inner chamber (the area filled with sample) must be wider than the

aperture in the sample holder or light will reach the detector without passing

through the sample. In this case, semi-micro or micro cuvettes with self-screening

black surrounds must be used or, alternative holders for these cuvettes should be

used.

e) Glass test tubes and other sample tubes should be used with care. Where

possible, matched tubes should be used and any index mark set to the correct

position before measurements are made.

f) Ensure any sample containers used are compatible with the constituents of both

the samples and standards they are to hold. Plastic cuvettes are not compatible

with organic solvents.

g) All sample containers must be handled with care; by the top, bottom and non-

optical surfaces only. Any finger marks evident must be removed by a suitable

cleaning process.

h) Flow-through cuvettes must be selected with care and consideration for the

sample type, sample volume, pumping system, rinse, sample and waste handling

to be used.

Page 16

16

5. Samples and standards should not be stored in open cuvettes or sample containers

as evaporation will change the value and lead to staining of the walls which may be

irreversible. If stored in stoppered and sealed cuvettes, they should be filled with little

or no air space and the values regularly checked against a reference standard or

quality control material.

6. Samples should be allowed to equilibrate to ambient temperature before

measurement (unless a suitable temperature controlled sample holder is in use).

Temperature change during measurement may cause air bubbles to form on the

walls of the sample holder. This is a common cause of drift during measurement.

7. In the preparation of samples and standards high grade borosilicate glass and AR

grade chemicals and reagents must be used. Good quality deionised water or other

suitable solvents must be used for dissolving or diluting samples, chemicals and

reagents.

8. All measurements require calibration to a blank, for maximum accuracy this should be

prepared with care using the same deionised water or solvent used for dissolving or

diluting the sample. Where reagents are added to the sample to produce a colour

proportional to its concentration a ‘sample based’ blank should be used. In this case

the blank should consist of all reagents or chemicals to be used, except the sample

which will produce the colour to be measured.

9. Deviations from the Beer-Lambert Law may occur at high and low concentrations

giving non-linear response during sample concentration measurements. For all new

methods a linear range should be defined by the preparation of a calibration curve.

10. Cuvettes and sample holders must be filled to a minimum level which covers the light

path. All Jenway spectrophotometers have a beam height of 15mm.

11. The instrument must be calibrated to zero absorbance/100% transmittance prior to

taking readings.

Page 17

17

SECTION 4 – Instrument Setup

To navigate around the spectrophotometer screen press the soft keys adjacent to icons displayed

on the screen. In the main menu either of the two soft keys adjacent to the measurement mode

icon can be pressed to access the mode. There is a back key which returns to the previous menu

without saving any changes.

The main menu screen provides access to the measurement modes, the time and date menu and

the instrument settings menu. The measurement modes are photometrics and concentration. The

instrument settings menu enables access to the screen contrast and lamp save menus.

Operating Menu

(Photometrics measurement mode)

When a measurement mode is selected the

operating menu is opened. This menu enables

changes to be made to the measurement

parameters and method settings. The measurement

settings can be accessed through the utility toolbar

displayed on the left hand side of the operating

menu. This toolbar provides the same functions in

all of the measurement modes. The utility toolbar

enables access to printing, print setup

options and autologging options. For more details on the different functions of the utility toolbar

refer to section 7.

4.1 NAVIGATING AND SCREEN SETUP

The main menu screen is displayed below.

Fig 4.1 – Home Screen

Page 18

18

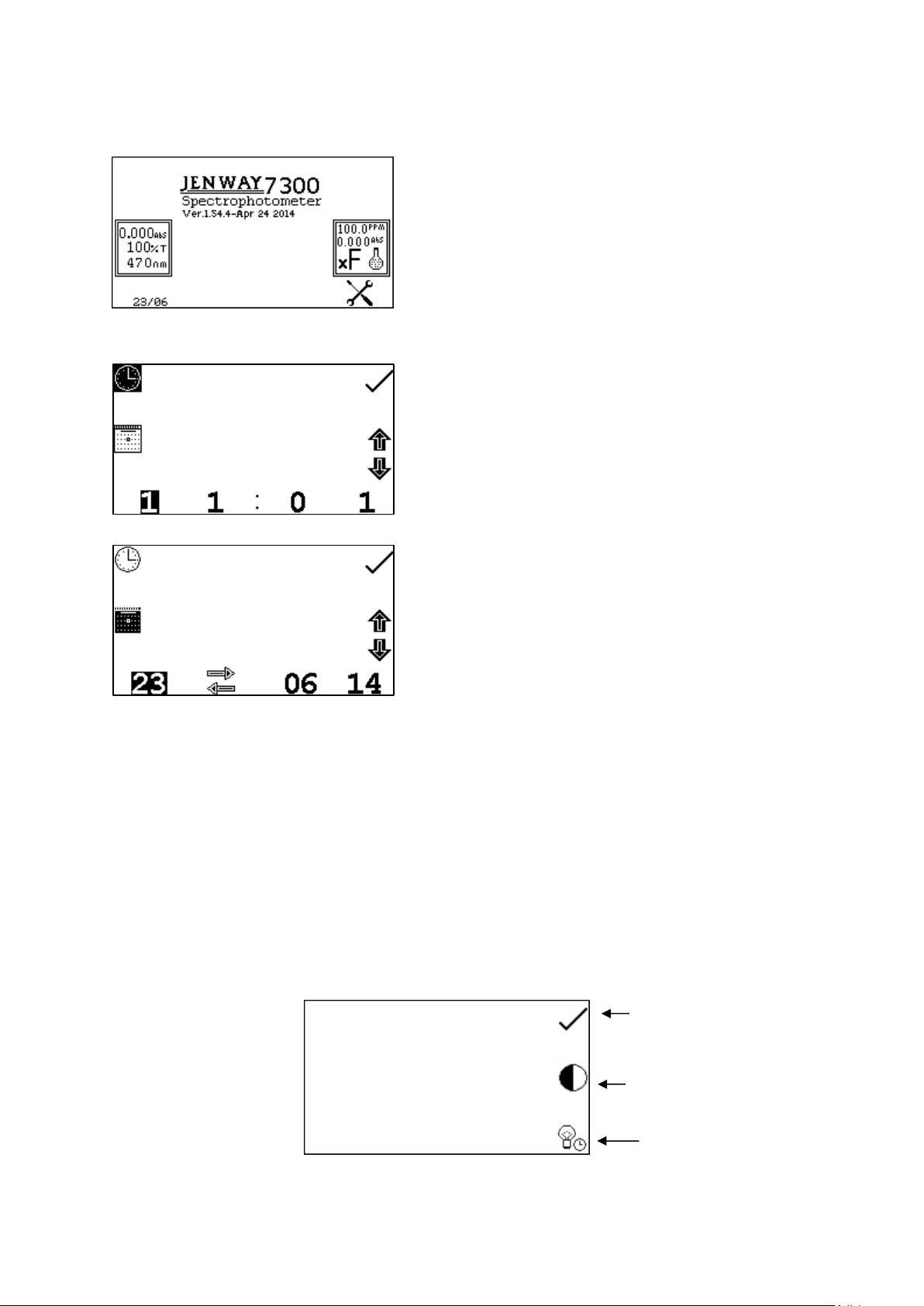

4.2 TIME AND DATE

The time and date menu enables the current time

and date to be set. This information will be saved on

all results and displayed on printouts. The time and

date menu can be accessed from the main menu by

holding the key below the time and date icon for 2

seconds. Pressing the key once cycles the display

between time and date.

In the time and date menu to set the time press the

key adjacent to the clock icon. Select the digit to be

changed using the keys at the bottom of the screen.

Use the keys adjacent to the arrow icons to

increase or decrease the number. The clock

function uses a 24 hour format.

In the time and date menu to set the date press the

key adjacent to the calendar icon. Select the digit to

be changed using the keys at the bottom of the

screen. Use the keys adjacent to the arrow icons to

increase or decrease the number. The date format

can be displayed as either European dd/mm/yy or

American

mm/dd/yy. To change between the two formats press the key below the toggle icon. Once the

current time and date have been set press the key adjacent to the tick icon to save the changes.

To exit this menu without saving any changes press the back key and the screen will return to the

main menu.

The instrument settings menu is accessed by pressing the key below the instrument settings icon

in the main menu. This menu enables access to screen contrast and lamp save menus. The tick

icon saves any changes made and returns to the main menu.

Lamp save

Screen contrast

Tick

4.3 INSTRUMENT SETTINGS MENU

Fig 4.3 - Settings Menu

Page 19

19

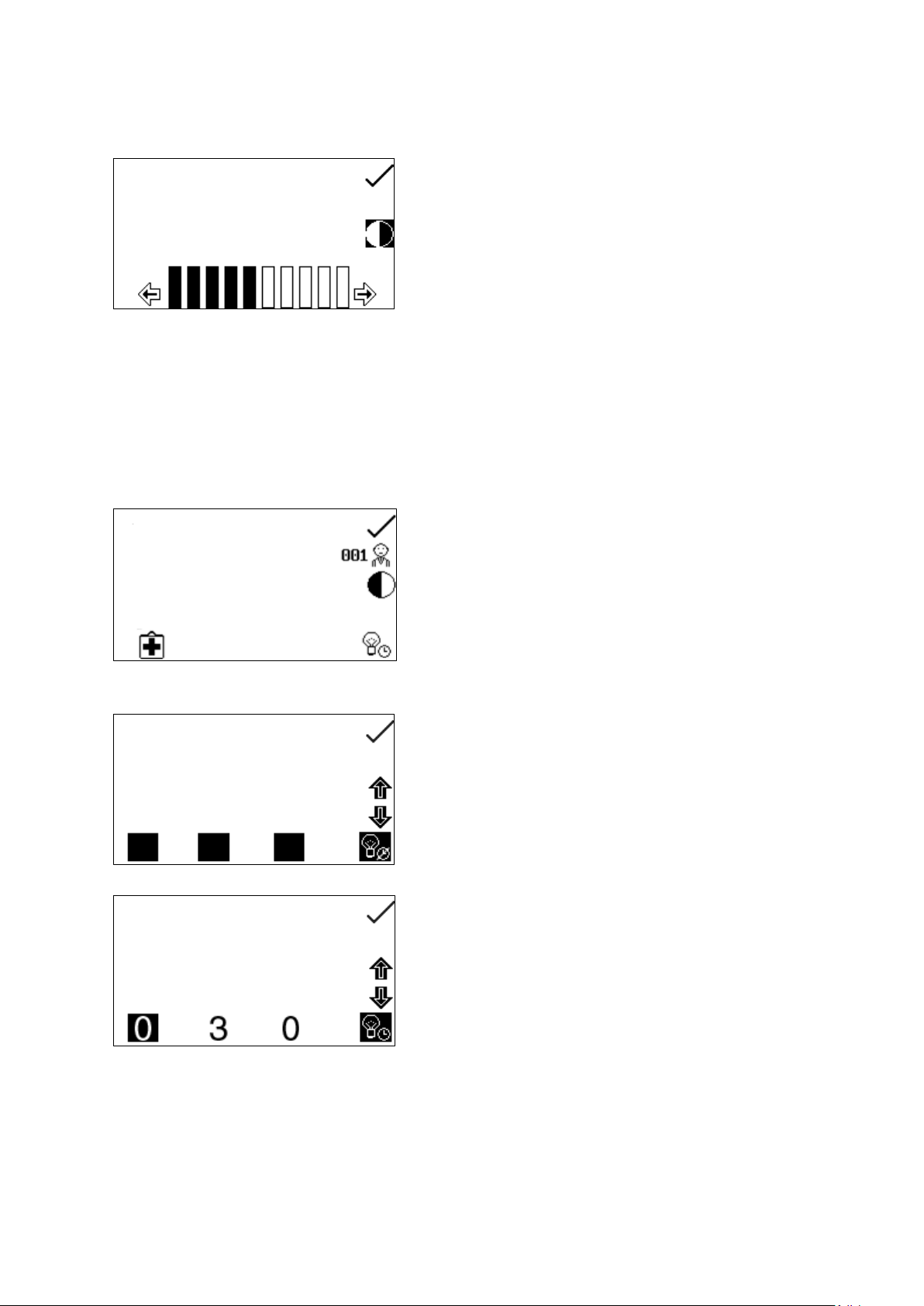

4.4 SCREEN CONTRAST

The screen contrast function enables the brightness

of the screen to be set. In the instrument settings

menu press the key adjacent to the screen contrast

icon. Use the keys below the arrow icons to

increase or decrease the screen contrast. Once the

required brightness level has been reached press

the key adjacent to the tick icon to save and return

to the instrument settings menu.

This function is only available on the 7300 visible spectrophotometer which uses a tungsten

halogen lamp.

The lamp save function enables the time in

minutes to be set after which the lamp will be

turned off following a period of no lamp activity,

i.e. no readings have been performed. This

function is accessed through the instrument

settings menu by pressing the key adjacent to the

lamp save icon.

When this menu is first accessed the lamp save is

turned off. To activate the lamp save function

press the key below the lamp save icon. To

deactivate the lamp save function press the key

below the lamp save icon.

The default minimum time is set to 30 minutes.

Select the digit to be changed using the keys at

the bottom of the screen. Use the keys adjacent

to the arrow icons to increase or decrease the

number. Once the required time in minutes has

been set press the key adjacent to the tick icon to

save and return to the instrument settings menu.

4.5 LAMP SAVE

Page 20

20

The time set will begin to count down when there

is no lamp activity. When the count down is

complete the lamp and the fan will be turned off

and the lamp save icon is shown in all the

measurement modes. To bring the instrument out

of the lamp save in order to perform a

measurement press the key below the lamp save

icon. The lamp and fan will be turned back on and

the lamp will begin to warm up.

The lamp cold icon is displayed adjacent to the

calibrate to zero icon in the measurement mode.

The time needed for the lamp to warm up is five

minutes.

Calibration and measurements can be performed

whilst the lamp is warming up but these results

may not be accurate.

Once the warm up time of five minutes is

complete the lamp cold icon disappears.

Page 21

21

SECTION 5 – PHOTOMETRICS

The photometrics operating menu enables measurement parameters to be changed. The utility

toolbar on the left hand side of the screen enables access to printing, print setup options and

autologging options. For more details on the different functions of the utility toolbar refer to section

7.

This measurement mode is very simple and the

only parameters which can be adjusted are the

wavelength and the display format.

The toggle icon enables the large primary display to be set to show the absorbance or %

transmittance. To change the primary and secondary displays press the key adjacent to the

toggle icon. Repeat presses will cycle the displays between absorbance or % transmittance.

Autolog menu

Calibrate to zero

Decrease wavelength

Toggle

Print/print settings

Increase wavelength

Measure sample

The photometrics measurement mode enables simple measurements of absorbance and %

transmittance to be performed. The sample is measured at one wavelength and at one point in

time. There are no post measurement calculations available in this measurement mode.

5.1 MODE SPECIFIC PARAMETERS

5.2 METHOD SET UP

Fig 5.1 - Operating Menu

5.2.1 Selecting a Wavelength

The wavelength can be adjusted in the operating menu by using the keys adjacent to the arrow

icons to increase or decrease the wavelength. Once the required wavelength has been selected a

calibration can be performed.

Page 22

22

5.3 CALIBRATION

The calibration must be performed at the same

wavelength at which the sample will be measured.

Insert a cuvette containing the blank solution into

the sample chamber and close the instrument lid.

Press the key below the calibrate to zero

absorbance icon. This sets the instrument to zero

absorbance and 100% transmittance.

Once the calibration is complete the measure sample icon appears and the sample can be

measured. If the wavelength is adjusted before a sample is measured the measure sample icon

will disappear and the instrument must be calibrated again at the new wavelength.

It is not possible to measure a sample before the

instrument has been calibrated at the selected

wavelength. Once the calibration has been

performed the measure sample icon is displayed

and a sample can be measured. Remove the

cuvette containing the blank solution and place a

cuvette containing the

sample to be measured in the sample holder. Close the instrument lid and press the key below

the measure sample icon. Once the measurement is complete the photometric result will be

shown on the screen.

Subsequent samples can be measured in the same way. If the wavelength is adjusted between

sample measurements then the instrument must be calibrated again before more samples can be

measured.

5.4 SAMPLE MEASURMENT

Page 23

23

SECTION 6 – CONCENTRATION

The concentration operating menu enables measurement parameters to be changed. The utility

toolbar on the left hand side of the screen enables access to printing, print setup options and

autologging options. For more details on the different functions of the utility toolbar refer to section

7. The settings icon enables the wavelength, units, resolution, standard or factor to be set.

The wavelength can be adjusted in the operating

menu or in the settings menu. To adjust the

wavelength in the operating menu use the keys

adjacent to the arrow icons to increase or decrease

the wavelength.

The settings menu is accessed through the

operating menu by pressing the key adjacent to the

settings icon. In the settings menu press the key

below the wavelength icon.

Autolog menu

Calibrate to zero

Decrease wavelength

Settings

Print/print settings

Increase wavelength

Measure sample

The concentration measurement mode enables simple measurements of absorbance and

concentration to be performed. In this measurement mode it is possible to calibrate against a

standard of a known concentration or use a known factor. The sample is measured at one

wavelength at one point in time. There are no post measurement calculations available in this

measurement mode.

6.1 MODE SPECIFIC PARAMETERS

6.2 METHOD SETUP

6.2.1 Selecting a Wavelength

Fig 6.1 - Operating Menu

Page 24

24

This will open a number entry screen. Use the keys

at the bottom of the screen to select the digit to be

adjusted. Use the keys adjacent to the arrow icons

to increase or decrease the wavelength to the

required number. Press the key adjacent to the tick

icon to save the changes and return to the settings

menu.

6.2.2 Settings

The settings menu enables the wavelength, units, resolution, standard or factor to be set and is

accessed from the operating menu by pressing the key adjacent to the settings icon. Once all of

the required settings have been entered press the key adjacent to the tick icon to save and return

to the operating menu.

Fig 6.2.2 – Settings Menu

When setting the method parameters either the standard or the factor should be selected. The

standard should be used if the factor is not known as selecting this option will calculate the factor.

If the factor is known it is not necessary to measure a known standard’s concentration. When the

standard or factor is not selected the value should be set to 1.00.

The units of concentration can be selected from a number of options: no units, %, ppm, EBC,

SRM, mEq/l, mEq, M, mM, µM, nM, U, U/l, U/ml, g/l, mg/l, µg/l, ng/l, g/dl, mg/dl, µg/dl, mg/ml,

µg/ml, ng/ml, µg/µl, ng/µl, mol/l, mmol/l.

In the settings menu press the key below the units

icon. This opens the unit selection screen which

displays all the different units. Use the keys

adjacent to the arrow icons to navigate around the

screen to select the required units. Once the

required units have been highlighted press the key

adjacent to the tick icon to

Selecting

concentration

units

Selecting a wavelength

Standard menu

Factor menu

Tick icon

Selecting resolution

6.2.2.1 Selecting Concentration Units

Page 25

25

save and return to the settings menu. The selected unit will be displayed in the minimal and

operating menu along with absorbance and selected wavelength.

6.2.2.2 Changing the Resolution

The standard menu enables the value of a standard

to be entered. This function is accessed by pressing

the key adjacent to the standard icon. This opens

the extended number entry screen. Use the keys at

the bottom of the screen to select the digit to be

changed. The key below the digit must be pressed

twice to select

the adjacent digit. For example 00 the first press of the key alters 10, the second press alters 01.

Use the keys adjacent to the arrow icons to increase or decrease the selected number. Standard

values from 0.001 to 1000 can be entered. The standard value can be reset to one by pressing

the key adjacent to the 001 icon. Once the standard value has been entered press the key

adjacent to the tick icon to save and return to the settings menu. The entered value is displayed in

the settings menu adjacent to the standard icon.

A standard value should only be entered if the factor is not known. If the factor is known the

standard value should be set to 1.000.

The factor menu enables a factor to be entered.

This function is accessed by pressing the key

adjacent to the factor icon. This opens the extended

number entry screen. Use the keys at the bottom of

the screen to select the digit to be changed. The

key below the digit must be pressed twice to select

the adjacent digit.

For example 00 the first press of the key alters 10, the second press alters 01. Use the keys

adjacent to the arrow icons to increase or decrease the selected number. Factor values of 0.001

to 10,000 can be entered. The factor value can be reset to one by pressing the key adjacent to

the 001 icon. Once the factor has been entered press the key adjacent to the tick icon to save and

return to the settings menu. The entered value is displayed in the settings menu adjacent to the

factor icon.

The resolution that the concentration is displayed as can be selected from 1, 0.1, 0.01 or 0.001 by

repeat presses of the key below the resolution icon in the settings menu.

6.2.2.3 Using a Standard

6.2.2.4 Using a Factor

Page 26

26

If the factor is not known a standard should be measured in order to calculate the factor. If a

standard is used the factor value should be set to 1.000.

6.3 CALIBRATION

In the concentration measurement mode

calibrations against a standard or a factor can be

performed following a zero calibration. If the factor

is not known calibration against a known standard is

performed in order to calculate the factor. However

if the factor is known there is no need to calibrate

using a standard.

The calibration must be performed at the same wavelength at which the sample will be measured.

Insert a cuvette containing the blank solution into the sample chamber and close the instrument

lid. Press the key below the calibrate to zero absorbance icon. The instrument will calibrate to

zero absorbance. Insert a cuvette containing the standard concentration sample solution into the

sample chamber and close the instrument lid.

Press the key below the calibrate to zero

absorbance or standard icon, this will open another

menu with the option to re-calibrate to zero

absorbance or to calibrate to the previously entered

standard value. Press the key adjacent to the

calibrate to standard icon.

If the standard selected requires a factor beyond the range of the instrument the check standard

icon will be displayed.

The instrument will take a reading and calibrate to

the standard concentration. Once the calibration is

complete the sample can be measured using the

measure to standard icon.

6.3.1 Calibrating to a Standard

Page 27

27

6.3.2 Calibrating to a Factor

Insert a cuvette containing the blank solution into

the sample chamber and close the instrument lid.

Press the key below the calibrate to zero

absorbance icon. The instrument will calibrate to

zero absorbance. Once the calibration is complete

the sample can be measured using the measure to

factor icon.

Remove the cuvette containing the standard sample

and place a cuvette containing the sample to be

measured in the sample chamber. Close the

instrument lid and press the key below the measure

to standard icon. Once the measurement is

complete the concentration and absorbance values

are displayed.

Remove the cuvette containing the blank solution

and place a cuvette containing the sample to be

measured in the sample chamber. Close the

instrument lid and press the key below the measure

to factor icon. Once the measurement is complete

the concentration and absorbance values are

displayed.

In order to measure a sample based on a known factor the value for the factor must be entered in

the settings menu before commencing measurement of the sample.

6.4 SAMPLE MEASUREMENT

It is not possible to perform sample measurements before the instrument has been calibrated at

the selected wavelength. In this operating mode the type of sample measurement performed

depends on the calibration which has been carried out.

6.4.1 Measuring a Sample After Calibrating to a Standard

6.4.2 Measuring a Sample After Calibrating to a Factor

6.5 POST MEASUREMENT OPTIONS

Post measurement changes to the selected concentration units, the concentration factor and the

calibration standard values are restricted.

Page 28

28

6.5.1 Changing Concentration Units

Users can adjust the displayed concentration unit after a measurement. If the measurements

concentration unit is updated, the instrument will adjust the displayed concentration value to

reflect the new selection. This functionality is limited to ensure that the user can only update the

measurement unit to one that is a direct conversion from the original measurement unit. These

restrictions are summarized in Table 6.5.1, where the selectable measurement units are grouped

according to those which are interchangeable after a measurement.

Interchangeable Measurement Units

1 2 3 4 5 6 7 8 9 % EBC

mEq/l

mEq M U

U/l

g/l

mol/l

ppm

SRM

mM

U/ml

mg/l

mmol/l

uM

ug/l

nM

ng/l

g/dl

mg/dl

ug/dl

mg/ml

ug/ml

ng/ml

ug/ul

ng/ul

Table 6.5.1 – Post Measurement Unit Change Restrictions

Once a measurement is complete, press the key

adjacent to the settings icon, then press the key

below the units icon. This will either cycle through

the available unit options or open the units selection

page.

In the units selection page, select the updated

measurement unit from the available options and

press the key adjacent to the tick icon to confirm.

In the concentration settings menu, the calibration

standard and concentration factor values are

updated.

Page 29

29

The updated concentration value and unit are

shown in the main display.

6.5.2 Changing the Concentration Factor

Users cannot adjust the concentration factor once a blank measurement is performed. If the

concentration factor needs to be changed, the user must exit and re-enter the concentration

measurement mode.

6.5.3 Changing the Calibration Standard Value

Users cannot adjust the calibration standard value once a blank measurement is performed. If the

calibration standard value needs to be changed, the user must exit and re-enter the concentration

measurement mode.

Page 30

30

SECTION 7 – PRINTING AND AUTOLOGGING

The utility toolbar in the operating menu provides access to printing, print setup options, and

autologging options.

Fig 7.1 - Operating Menu

To open the print setup menu hold the key adjacent

to the printer icon for 2 seconds in the operating

menu.

To select the language for the printouts press the

key adjacent to English icon. Repeat pressing of the

key cycles the language between English, Français,

Deutsche, Espânôl and Italiano.

The destination of the printouts can be the internal printer or an external serial printer. The results

can only be sent to an external serial printer if there is a serial printer connected to the instrument

via the RS232 serial port. Press the key adjacent to the computer icon to select the external

Operating Menu

The utility toolbar in the operating menu enables

results to be printed and print setup options to be

set. The print setup menu enables the destination of

the printouts and language of the printouts to be

set.

Print/print settings

Autolog menu

7.1 PRINTING

7.1.1 Print Setup

Page 31

31

printer. The results can only be sent to the internal printer if there is an internal printer connected.

To select the internal printer for the printout destination press the key adjacent to the printer icon.

Once the required printout destination and language has been selected press the key adjacent to

the tick icon to save and return to the operating menu.

7.1.2 Printing Results

Results displayed in the operating menu can be

printed by pressing the key adjacent to the printer

icon. Depending on the printout destination

previously selected the result will be sent to the

internal printer or the external printer. If the printer

icon is pressed when there is not a result on the

screen the

no result to printer or no result to RS232 icon (depending on results destination) will flash up on

the screen.

Operating Menu

The autolog function enables repeat measurements

of the same sample to be performed with a set time

period between each measurement. This produces

a batch of results for the same sample. The autolog

function also enables the results to be autologged

to different destinations. The autolog menu is

accessed from the utility toolbar in the operating

menu by pressing the key adjacent to the autolog

icon.

To set the number of repeat measurements of the

same sample press the key below the sample icon

and use the keys adjacent to the arrow icons to

increase or decrease the number of repetitions

required. To reset the number to zero press and

hold the key below the sample icon for 2 seconds.

7.2 AUTOLOGGING

7.2.1 Setting the Number of Sample Repetitions

Page 32

32

To set the time period between each measurement

press the key below the timer icon and use the keys

adjacent to the arrow icons to increase or decrease

the time in 1 second intervals. To reset the time to

one second press and hold the key below the timer

icon for 2 seconds.

Once the required number of repetitions and time interval have been selected press the key

adjacent to the tick icon to save the changes and return to the operating menu.

The number of repetitions and time period will be

displayed below the autolog icon. To commence

autologging press the key below the measure

sample icon. Once the first measurement has been

performed the time period starts counting down until

it reaches zero and then the next measurement will

be taken.

This will reduce the repetition number by one. When the number of repetitions reaches zero,

autologging is complete. Autologging can be stopped before all the measurements have been

completed by pressing the key adjacent to the autolog icon. Confirmation will be needed to stop

autologging. Press the key adjacent to the tick icon to confirm stopping autologging or press the

key adjacent to the cross icon to continue autologging.

7.2.2 Selecting Result’s Destination

The autolog menu enables the result’s destination

to be set. To select the internal printer press the key

adjacent to the printer icon. This option is only

available if an internal printer is connected. To send

the results to an external instrument such as a PC

or a serial printer press the key adjacent to the

computer icon.

Page 33

33

7.3 CONNECTING TO A PC

Connect the interface cable to the RS232 serial port on the rear of the instrument and connect to

the serial port on the rear of the PC. Turn the PC on and load the PC software by inserting the PC

software disc into the CD drive. If the PC software does not auto run open My Computer and

double click on the Jenway 73 series software icon. Follow the instructions to install the PC

software to the required location. Refer to the PC software manual for further instructions. Once

the software is installed, turn the mains power on to the instrument.

The PC software is pre-configured to run using the following settings:

9600 baud

8 data bits

No parity

1 stop bit

Page 34

34

SECTION 8 – Accessories and Spare Parts

Part Code

Description of Accessory

660 101

Internal printer

735 401

Automatic 8 cell turret

735 201

Sipper pump

735 301

Peltier

735 701

Combined sipper Peltier pump

735 801

10x10mm path length cuvette holder

735 901

16/24mm test tube holder

736 001

10x100mm path length cuvette holder

736 101

10x10mm path length micro-cuvette holder

736 201

Water heated 10x10 single cell holder

035 088

Visible calibration set

035 091

UV/Visible calibration set

060 422

Moulded cuvette rack for 16 10x10mm cuvettes

735 001

Dust cover

019 146

4GB USB memory sticks for external memory

037 551

RS232 to USB converter for use with computer without a serial port

Use a small screw driver to lift the blanking panel on the top of

the instrument. Squeeze the two clips in order to remove the

blanking panel. Disconnect the printer wires which are

secured to the underside of the blanking plate.

Unpack the printer from the packaging. Turn the printer upside

down and connect the printer wires by clipping into the

connector on the printer.

Squeeze the grey plastic clips together so that the printer top

opens. Slot the printer into the top of the instrument and push

down until it fits flush to all four sides.

Clips

8.1 OPTIONAL ACCESSORIES

8.2 CONNECTING THE ACCESSORIES

There are two types of accessories which can be fitted in the sample chamber – passive or active

accessories. The range of passive accessories includes 10 x 10mm single cuvette holders, single

water heated cuvette holders, adjustable path length (10 to 100 mm) cuvette holders, test tube

holders, boiling tube holders and micro-cuvette holders. The range of active accessories includes

an automated 8 cell changer, sipper pump, Peltier and combined sipper Peltier pump. The

instrument must be turned off before any accessories are fitted.

8.2.1 Internal Printer

Page 35

35

Insert the paper roll into the printer – ensuring that there is

some paper sticking out of the printer before clicking the grey

plastic back into place. Switch the instrument on. The power

and error lights on the printer will flash. Once the instrument

power on tests are complete press the feed button to check

that the paper is fed correctly.

8.2.2 Passive Accessories

Unscrew the thumb screw to undo the passive

accessory. Lift out the passive accessory. To

fit a different passive accessory simply place

the accessory in the correct orientation, align

the thumb screw and tighten to fix in place.

To replace the passive accessory with an

active accessory refer to section 8.2.3.

The water heated cuvette holder is supplied with an additional front panel which also needs to be

fitted.

The water heated cuvette holder is already fitted to a

base plate so the base plate in the instrument must be

removed before installation. Unscrew screws 1 to 4

and lift out the metal base plate.

Thumb

screw

2

4

3

1

8.2.2.1 Water-heated cuvette holder

Page 36

36

For this accessory as well as removing the passive

accessory base plate, the front panel of the

instrument must also be removed. Loosen screws 5

and 6 until the front panel can be lifted out in the

forwards direction.

Once the base plate and front panel have

been removed insert the water-heated

cuvette holder into the chamber, ensuring

the base plate rests flat in the unit. Replace

the screws 1 to 4, securing the accessory in

place.

5

6

Page 37

37

Fit the custom front panel to the unit

ensuring the metal pipes on the accessory

are aligned and fed through the two holes

in the front panel. The metal pipes should

protrude from the outer casing. Secure the

custom accessory front plate to the unit

with screws 5 and 6.

From the rubber tubing supplied, cut two

shorter lengths of tubing and use these to

connect the internal metal pipes of the cell

block (7) to the internal metal pipes on the

outer casing (8).

Using two separate pieces of rubber tubing

connect the two external metal tubes (9) to

an external water bath and pump. Ensure

the water is pumped in through the left and

out through the right hand side of the cell

block.

All tubing must be kept as short as possible

and the tubing must not be allowed to

obstruct the ligth path.

IN

OUT

Page 38

38

8.2.3 Active Accessories

Unscrew the thumb screw to undo the passive

accessory. Lift out the passive accessory. To

fit an active accessory unscrew screws 1 to 4

and lift out the metal base plate.

This will expose the bottom of the sample

chamber with the power supply connection

needed to operate the active accessories.

Take the 8 cell turret base plate. Connect the

power supply in the bottom of the sample

chamber to the connector on the underside of

the base plate. Place the base plate in the

sample chamber. Replace screws 1 to 4.

Take the 8 cell carousel and place on top of

the motor, taking care to align the three ball

bearings with the grooves on the motor shaft.

Gently push the carousel down onto the motor

shaft until it is located into place. Gently rotate

the carousel until there is some resistance.

The carousel is now in the correct position.

If the fitting is too tight use a small screw driver

to loosen the ball bearings before pushing the

carousel down onto the shaft.

8.2.3.1 Automatic 8 cell turret

Page 39

39

8.2.3.2 Peltier

For this accessory as well as removing the

passive accessory base plate, the front panel

of the instrument must also be removed.

Loosen screws 5 and 6 until the front panel

can be lifted out in the forwards direction.

Take the Peltier base plate. Connect the

power supply in the bottom of the sample

chamber to the connector on the underside of

the base plate. Place the base plate in the

sample chamber. Replace screws 1 to 4. Take

the Peltier front panel and slot into place

before retightening screws 5 and 6.

When the accessory is fitted the instrument

will look like this.

5

6

Page 40

40

8.2.3.3 Sipper pump

For this accessory as well as removing the

passive accessory base plate, the front panel

of the instrument must also be removed.

Loosen screws 5 and 6 until the front panel can

be lifted out in the forwards direction.

Take the sipper base plate. Connect the power

supply in the bottom of the sample chamber to

the connector on the underside of the base

plate. Place the base plate in the sample

chamber. Replace screws 1 to 4. Take the

sipper Peltier front panel and slot into place

before retightening screws 5 and 6.

The tubing should be connected depending on

the function that the sipper pump is going to

perform. All tubing must be kept as short as

possible and the tubing must not be allowed to

obstruct the ligth path.

5

6

Bi directional flow A

(sipping)

Bi directional flow B

(pumping)

Continuous flow

Page 41

41

For sipping:

1. Connect the sipper pump tubing to the outlet

port on the flow-through cuvette.

2. Secure the tubing using the clip on the

righthand side of the pump head.

3. Ease the tubing round the rollers by carefully

rotating them clockwise, by hand. Clamp the

tubing into the clip on the left hand side of the

motor.

4. Once secured, ensure the tubing is routed into the two retaining clips located on the base plate at

the side of the pump head.

5. Cut the tubing at the point where it fits comfortably onto the left hand tube located on the inside of

the front bulk head.

6. Connect a suitable length of this tubing to the external waste pipe.

7. Cut a small length of the sipper pump tube and push this over one end of the capillary tube.

Connect this to the inlet port of the flow-through cuvette.

8. Route the tube into the two retaining clips located on the base plate at the side of the pump head.

9. Fit the sipper probe and secure using the thumbscrew. Feed the capillary tubing through the tube

and up through the sipper probe, allowing sufficient length for it to pass into a suitable receptacle.

For pumping:

1. Cut two pieces of sipper pump tubing

approximately 300mm in length. Take one

length of tubing and fit this to the pump head,

as shown, securing the tubing using the clip on

the right hand side of the pump head.

2. Ease the tubing round the rollers carefully

rotating them clockwise, by hand. Clamp the

tubing into the clip on the left hand side of the

motor.

3. Fit the other end onto the inlet port on the

flow-through cuvette.

4. Fit the second 300mm length of tubing to the outlet port of the flow-through cuvette. Once

secured, ensure the tubing is routed into the two retaining clips located on the base plate at the side

of the pump head.

Page 42

42

5. Fit the other end of the tubing onto the outlet port, located on the inside of the front bulkhead.

6. Connect a suitable length of sipper pump tubing to the external outlet port.

7. Insert one end of the capillary tube into the sipper pump tubing, as shown.

8. Feed the other end through the inlet port located on the inside of the bulkhead.

9. Fit the sipper probe and secure using the thumbscrew.

10. Carefully feed the tubing through the sipper probe, allowing sufficient length for it to pass into a

suitable receptacle.

When the sipper accessory has been fitted and

the tubing has been connected the instrument

will look like this.

Refer to section 8.2.3.3 for more details.

8.2.3.4 Combined sipper Peltier pump

Page 43

43

8.3 USING THE ACCESSORIES

When the automatic 8 cell turret is in use the 8 cell

turret icon is displayed in the bottom right hand

corner of the screen. The current cell position is

displayed adjacent to the 8 cell turret icon. The 0

position should always be used for the zero

calibration blank sample.

To perform measurements using the automatic 8 cell turret, insert the cuvettes containing the

samples into turret positions 1 to 7. Insert the cuvette containing the blank solution into turret

position 0. Enter the required measurement mode and set up the required measurement

parameters. Press the key below the calibrate to zero icon. The instrument will automatically

move the turret around to position zero to perform the measurement. Once the calibration is

complete the measure sample icon will appear and the turret will return to its original starting

position.

Press the key below the 8 cell turret icon to highlight

the icon and the two arrow icons above. Press the

keys adjacent to the arrow icons to increase or

decrease the current cell position of the turret, until

the required sample position has been selected.

Press the key below the measure sample icon. The

instrument will

perform a reading and display the result on the screen. To measure the next sample select the

next turret position and press the key below the measure sample icon. Repeat this process until

all the samples have been measured. To adjust the wavelength press the key below the 8 cell

turret icon and use the arrow icons to adjust the wavelength.

When the Peltier is in use the Peltier icon is

displayed in the bottom right hand corner of the

screen. The current temperature is displayed above

the set point temperature adjacent to the Peltier

icon. An arrow icon is displayed above or below the

Peltier icon depending on if the current temperature

is above or below the set temperature.

To adjust the set point temperature hold the key below the Peltier icon for 2 seconds.

8.3.1 Automatic 8 cell turret

8.3.2 Peltier

Page 44

44

This opens the Peltier settings screen. Use the keys

at the bottom of the screen to select the digit to be

changed and use the arrow icons to increase or

decrease the number. The temperature can be set

in °C or °F by pressing the key adjacent to the °C

icon.

Repeat presses will cycle between °C and °F. Once

the required temperature has been selected press

the key adjacent to the tick icon to save and return

to the operating menu. The Peltier will begin to heat

or cool depending on the current temperature.

8.3.3 Sipper pump

When the sipper is in use the sipper pump icon is

displayed in the bottom right hand corner of the

screen. The sipper pump can operate in manual or

timed mode, depending on the option selected in

sipper pump settings. If the manual mode is

selected an arrow icon indicating pump direction will

be displayed below the sipper pump icon.

If the time mode is selected a clock icon will be

displayed adjacent to the sipper pump icon.

To open the sipper pump settings hold the key

below the sipper pump icon for 2 seconds.

Page 45

45

8.3.3.1 Manual Sipper Pump Settings

To operate the sipper pump in manual mode press

the key adjacent to the manual sipper icon. Select

the preferred pump direction by pressing the key

below the forwards or backwards arrow. Press the

key adjacent to the tick icon to save and return to

the operating menu.

To perform a measurement place the sipper tubing

into the sample and press the key below the sipper

pump icon.

Confirmation will be needed to start the sipper

pump. Press the key adjacent to the tick icon to

confirm and start the sipper pump. Press the key

adjacent to the cross icon to cancel and return to

the operating menu.

To stop the sipper pump press the key adjacent to

the stop icon. Ensure that the flow through cuvette

contains enough sample before pressing the key

below the measure sample icon.

Page 46

46

8.3.3.2 Timed Sipper Pump Settings

To operate the sipper pump in timed mode press

the key adjacent to the timed sipper pump icon.

Press the key below the calibrate timed sipper icon.

Select the required pump direction by pressing the

key below the forwards or backwards arrow. Press

the key adjacent to the tick icon to continue to the

next stage of the calibration sequence.

Insert the inlet tubing into the sample container and

press the key adjacent to the single greater than

icon. The sipper pump will start and the sample will

be pumped through the tubing to the flow through

cuvette. It is possible to skip this setup stage by

pressing the key adjacent to the double greater than

icon.

Once the cuvette is full press the key adjacent to

the stop icon to stop the sipper pump. The time

taken for sample uptake is recorded.

To fine tune the amount of sample uptake press the

keys below the plus or minus icons to increase or

decrease the amount of sample taken up. The

recorded time will be adjusted accordingly. Once

the fine tuning is complete, or if none is required,

press the key adjacent to the tick icon to move to

the next stage of the calibration sequence.

Page 47

47

This stage allows an air gap to be added to the

calibration sequence. If an air gap is not required

press the key below the 001 icon to set the air gap

to one. If a previously programmed air gap is to be

used press the key adjacent to the double greater

than icon to skip this stage and retain the current air

gap time.

To program an air gap remove the inlet tubing from the sample container and press the key

adjacent to the single greater than icon. The sipper pump will start and air will be pumped through

the tubing to the flow through cell.

Once the required amount of air has been taken up

press the key adjacent to the stop icon. The time

taken for air uptake is recorded.

To fine tune the amount of air uptake press the keys

below the plus or minus icons to increase or

decrease the amount of air taken in. The recorded

time will be adjusted accordingly. Once the fine

tuning is complete, or if none is required press the

key adjacent to the tick icon to move to the next

stage of the calibration sequence.

Once the sample uptake and air gap have been

programmed the preferred disposal of the sample

can be set. There are two options, the sample can

either be sent back to the sample container or it can

be sent to the waste pipe. Press the key below the

forward or backward arrows to select what happens

to the sample

after measurement. If the original pump direction selected was forwards, selecting the forwards

direction at this stage will send the sample to waste and selecting the backwards direction will

send the sample back to the sample container. Once the required direction has been selected

press the key adjacent to the tick icon to save the calibration sequence and return to the

operating menu. To exit the sipper calibration sequence without saving any changes press the

back key at any point during the calibration sequence.

Page 48

48

To perform a measurement place the sipper tubing

into the sample and press the key below the sipper

pump icon.

Confirmation will be needed to start the sipper

pump. Press the key adjacent to the cross icon to

cancel and return to the operating menu. Press the

key adjacent to the tick icon to confirm and start the

sipper pump. The pump will run for the previously

recorded sample take up time. Ensure that the flow

through

cuvette contains enough sample before pressing the key below the measure sample icon.

Once the measurement has been performed remove the tubing from the sample and press the

key below the sipper pump icon to perform the next stage of the calibration sequence.

Confirmation will be needed to start the sipper

pump. Press the key adjacent to the cross icon to

cancel and return to the operating menu. Press the

key adjacent to the tick icon to confirm and start the

sipper pump. The pump will run for the previously

recorded air gap take up time.

If an air gap of zero was previously selected this screen will not appear and the calibration

sequence will continue to sample disposal.

Once this stage of the calibration sequence is

complete press the key below the sipper pump icon

to dispose of the sample. Confirmation will be

needed to start the sipper pump. Press the key

adjacent to the cross icon to cancel and return to

the operating menu. Press the key adjacent to the

tick icon to confirm and

start the sipper pump. Depending on the disposal route previously selected the sample will either

go to drain or back to the sample container.

Page 49

49

8.3.4 Combined sipper Peltier pump

When the combined sipper Peltier is in use the

sipper Peltier icon is displayed in the bottom right

hand corner of the screen. The current temperature

is displayed above the set point temperature

adjacent to the sipper Peltier icon. Adjacent to the

current temperature is an arrow to indicate if it is

below or above the set

temperature. The pump direction is displayed by an arrow icon below the sipper Peltier icon. The

combined sipper Peltier pump combines the functionality of the Peltier and sipper pump. To open

the sipper Peltier settings hold the key below the sipper Peltier icon for 2 seconds.

The settings menu is the same as the sipper pump

settings except for the Peltier icon in the top left

hand corner. Pressing the key adjacent to the

Peltier icon will open the Peltier settings enabling

the temperature to be set. Refer to section 8.3.2 for

more details. The sipper pump can operate in a

manual or timed mode. Refer to section 8.3 for

more details.

Part Code

Description of Spare Part

012 075

Tungsten halogen lamp

730 545

Xenon lamp module

735 801

10x10mm path length cuvette holder

060 084

Pack of 100 disposable plastic visible wavelength 10x10 cuvettes

060 230

Pack of 100 disposable plastic UV wavelength 10x10 cuvettes

037 702

Paper roll for printer

021 060

24V 65W power supply unit with various plug attachments

8.4 SPARES

Page 50

50

SECTION 9 – Maintenance and Service

9.1 ROUTINE MAINTENANCE