Page 1

Model 4520

Conductivity/TDS Meter

Operating Manual

452 050/REV A/03-03

Page 2

Safety

Please read this information carefully prior to installing or using this equipment.

1. The unit described in this manual is designed to be operated only by trained personnel. Any

adjustments, maintenance and repair must be carried out as defined in this manual, by a person

qualified to be aware of the hazards involved.

2. It is essential that both operating and service personnel employ a safe system of work, in addition to

the detailed instructions specified in this manual.

3. References should always be made to the Health and Safety data supplied with any chemicals

used. Generally accepted laboratory procedures for safe handling of chemicals should be employed.

4. If it is suspected that safety protection has been impaired in any way, the unit must be made

inoperative and secured against any intended operation. The fault condition should immediately be

reported to the appropriate servicing authority.

452 050/REV A/03-03

Page 3

Conductivity/TDS Meter

Operating Manual

Contents

Section 1 Introduction

Instrument Description 1.1

Instrument Specification 1.2

Section 2 Installation

Unpacking 2.1

Installation 2.2

Displays 2.3

Controls 2.4

Inputs/Outputs 2.5

Section 3 Operation

Good Practice Guidelines 3.1

Set Up Parameters 3.2

Preparation of Conductivity Standards 3.3

Calibration with Known Cell Constant 3.4

Calibration with Standard Solution 3.5

Sample Measurement 3.6

Model 4520

Section 4 Maintenance

General 4.1

Section 5 Optional Accessories

Optional Accessories 5.1

Section 6 Interfacing

Analogue 6.1

RS232 6.2

Keypad Emulation 6.3

Printing 6.4

Alarm Outputs 6.5

Section 7 Troubleshooting

Troubleshooting 7.1

EC Declaration of Conformity

452 050/REV A/03-03

Page 4

Section 1

Introduction

1.1 Instrument Description

A fully specified laboratory Conductivity/Resistivity/TDS/Salinity/Temperature meter that includes full

support for good laboratory practices (GLP). The meter supports 1, 2 or 3 point conductivity

calibration. Powerful data logging capabilities are included with the ability to store up to 500

readings either manually, at timed intervals or alarmed events.

1.2 Instrument Specifications

Conductivity

Ranges 0 to 19.99µS / 0 to 199.9µS / 0 to 1999µS /

0 to 19.99mS / 0 to 199.9mS / 0 to 1999mS / 0 to 19.99S*

Resolution 0.01µS / 0.1µS / 1µS / 0.01mS / 0.1mS / 1mS / 0.01S*

*only with cell constant >5

Accuracy ±0.5%±2 digits

TDS

Ranges 0 to 19.99mg/l / 0 to 199.9mg/l / 0 to 1999mg/l /

0 to 19.99g/l / 0 to 199.9g/l / 0 to 1999g/l

Resolution 0.01mg/l / 0.1mg/l / 1mg/l / 0.01g/l / 0.1g/l / 1g/l*

*only with cell constant >5

Accuracy ±0.5%±2 digits

Temperature

Range -10 to +105°C (14 to 221°F)

Resolution 0.1°C (1°F)

Accuracy ±0.5°C (±1°F)

ATC Range 0 to 100°C (32 to 212°F)

Manual Temp. Comp. Range 0 to 100°C (32 to 212°F)

Outputs Analogue 1mV per 0.01pH

RS232 serial and IrDA printer interface

Alarm - open collector

Clock 24 hours, hrs/min/sec or day of month/month/year, leap year

corrected (European and American formats)

GLP Calibration reminder interval (1-999 hours)

Alarm outputs (open collector and audible)

Security code protected user data

Display Back lit 1/8 VGA monochrome LCD

Languages English, French, German, Italian, Spanish, Portuguese

Display 3½ digit LCD

Power 9V power supply

Size 210x250x55mm

Weight 850g

1

452 050/REV A/03-03

Page 5

Section 2

Installation

2.1 Unpacking

Remove the Model 4520 from the packaging and ensure the following items are included:

1. Model 4520 Conductivity/TDSMeter

2. Glass bodied conductivity cell with ATC K=1 (027 013)

3. Electrode holder

4. Power Supply (as specified at time of ordering the product)

5. Condensed operating instructions (452 051)

6. Operating Manual (452 050)

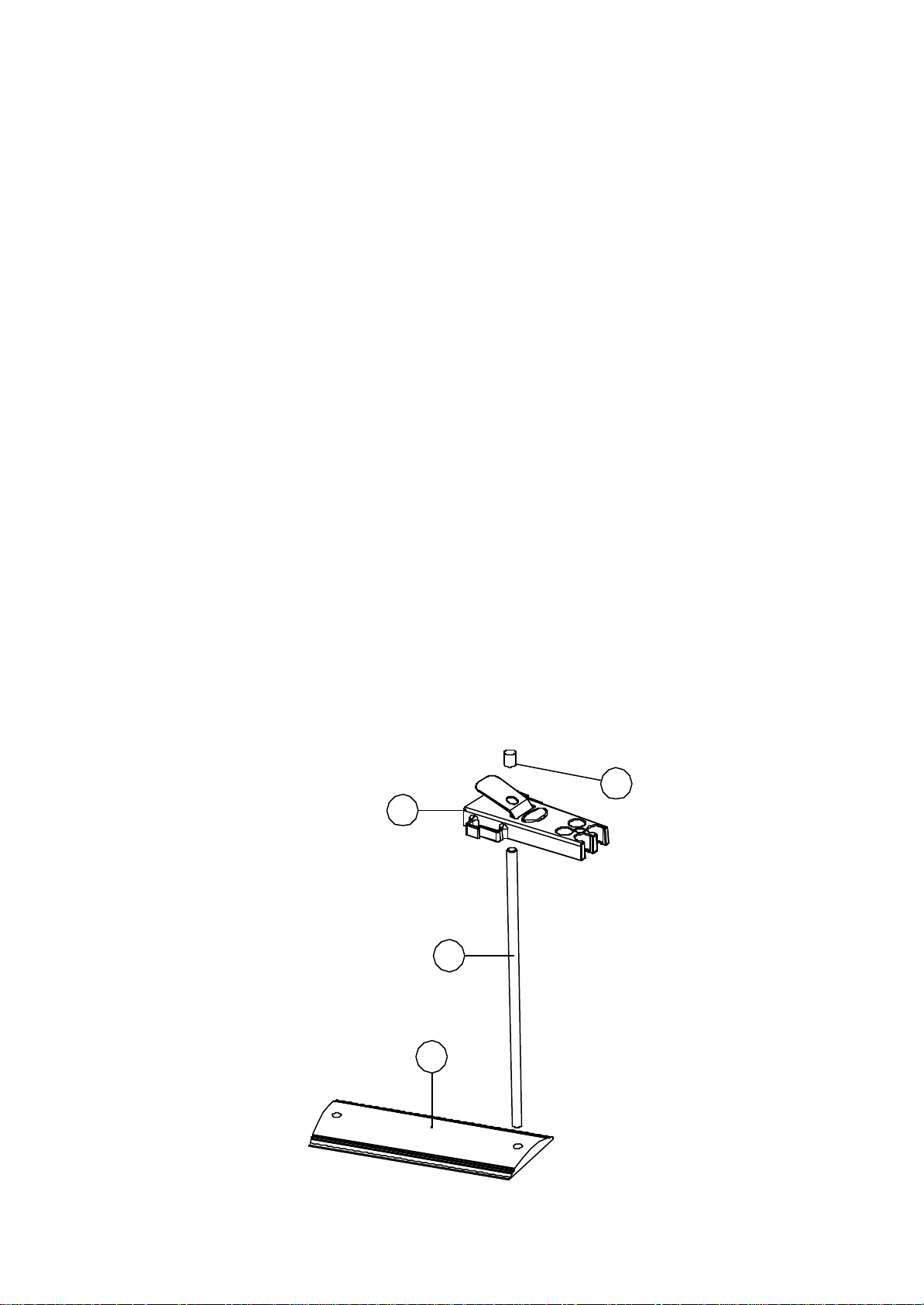

The electrode stand requires minimal assembly (refer to the diagram below).

Any shortages or damage should be reported immediately to the manufacturer or your local

distributor.

2.2 Installation

The Model 4520 is supplied ready to use. Connect the conductivity cell to the rear panel DIN socket.

The electrode stand requires minimal assembly (refer to the diagram below).

Fig. 2.2.1 Electrode Holder Assembly

4

1

2

3

2

452 050/REV A/03-03

Page 6

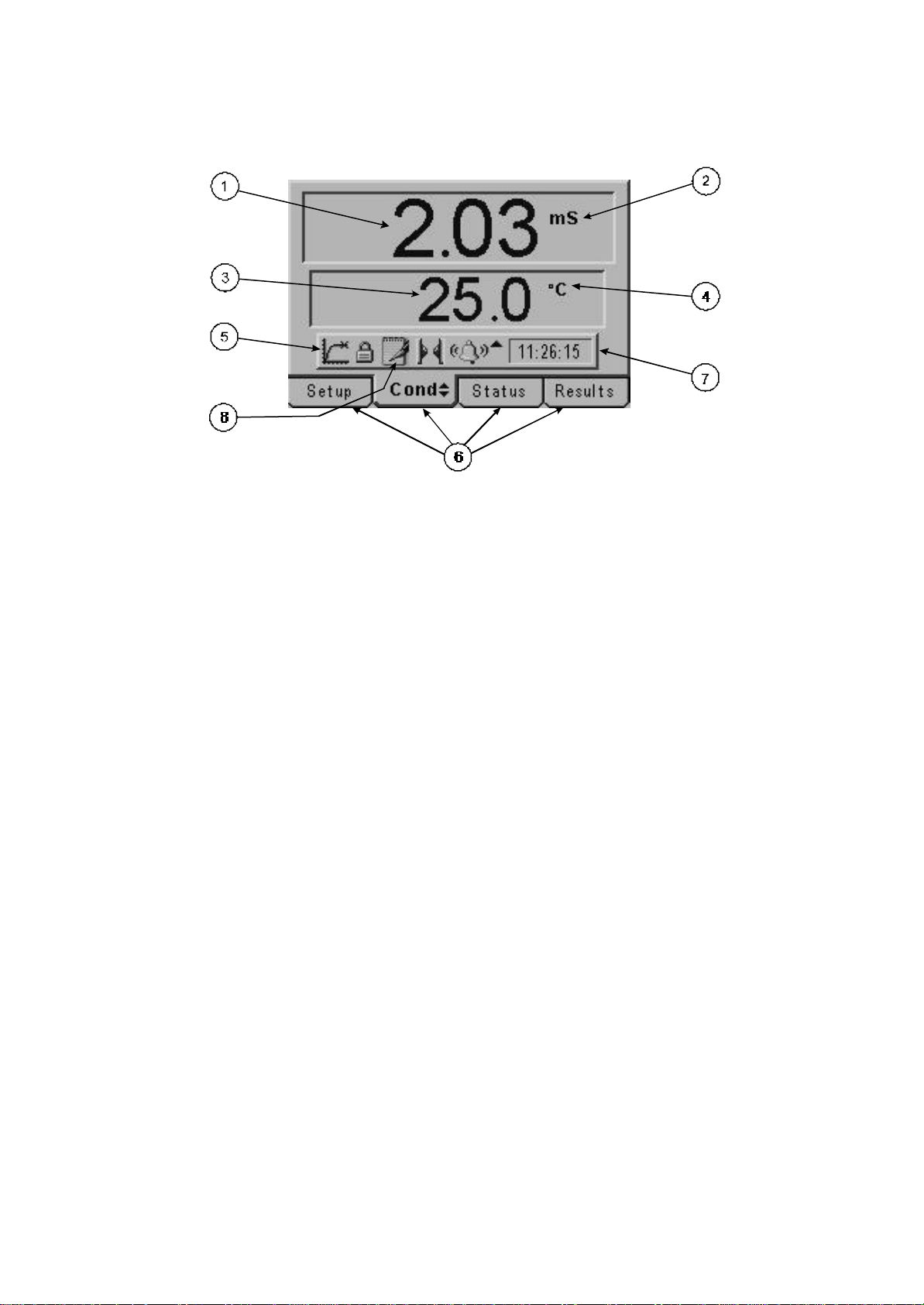

2.3 Displays

1. Primary display – 4½ digit. Provides direct readout in Conductivity and TDS of samples and

standards.

2. Mode annunciators – shows selected measurement mode; Conductivity or TDS.

3. Secondary display – 3½ digit display. Provides direct readout of automatic or manual

temperature.

4. Mode annunciators – indicates temperature in °C or °F and whether the measurements are

manually temperature compensated (MAN symbol).

5. Endpoint symbol – this symbol is displayed when an endpoint has been detected.

6. Mode tags – Each mode tag is highlighted when selected; SETUP, MODE,

STATUS or RESULTS. If a double headed arrow symbol is present this indicates that the

mode can be changed to an alternative option (pH/mV).

7. Real time clock - will display either date or time.

8. The following symbols will appear along the display:

Padlock - Set up parameters security locked

Notepad symbol - data logging to internal memory

IrDA status

Alarm indication - an Up arrow refers to Hi alarm / a Down arrow refers to Low alarm

3

452 050/REV A/03-03

Page 7

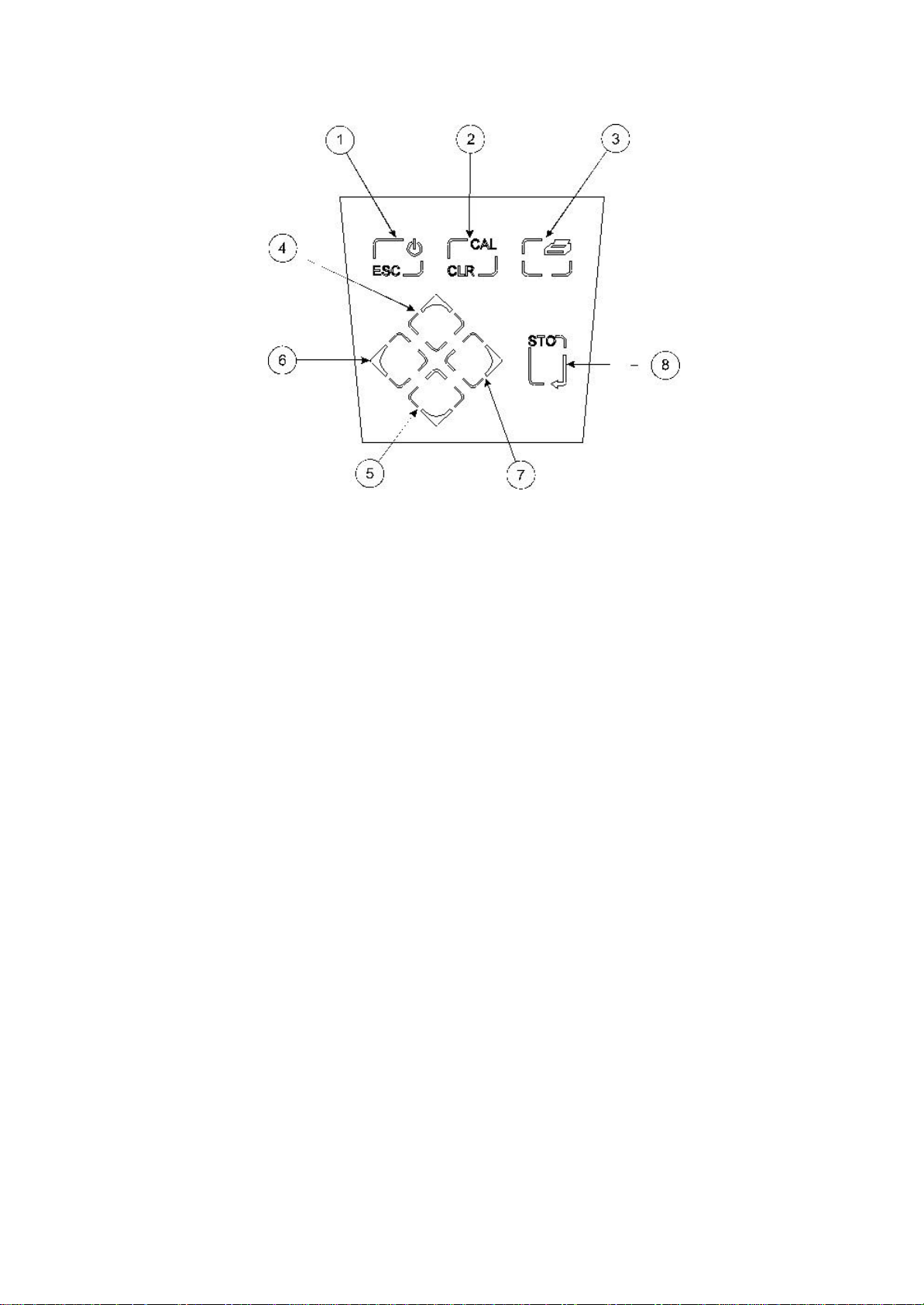

2.4 Keypad

1. ESC used to switch the instrument on and to place into standby mode (only if power

supply lead remains connected to the instrument). Also used to escape/exit a

mode.

2. CAL / CLR used to select and perform a calibration sequence. This key is also used to clear

readings from Memory.

3. Print key used to initiate a print.

4. Up Arrow used for adjustment during set up, to scroll results and to toggle between

Conductivity (µS or mS) and TDS (mg/l or g/l) modes.

5. Down Arrow used for adjustment during set up, to scroll results and to toggle between

Conductivity µS or mS) and TDS (mg/l or g/l) modes.

6. Left Arrow used for adjustment during set up and to move between mode tags.

7. Right Arrow used for adjustment during set up and to move between mode tags.

8. STO used to accept an entered value in set-up mode and to instigate a stored reading.

This key can also be used as a CAL key during calibration.

4

452 050/REV A/03-03

Page 8

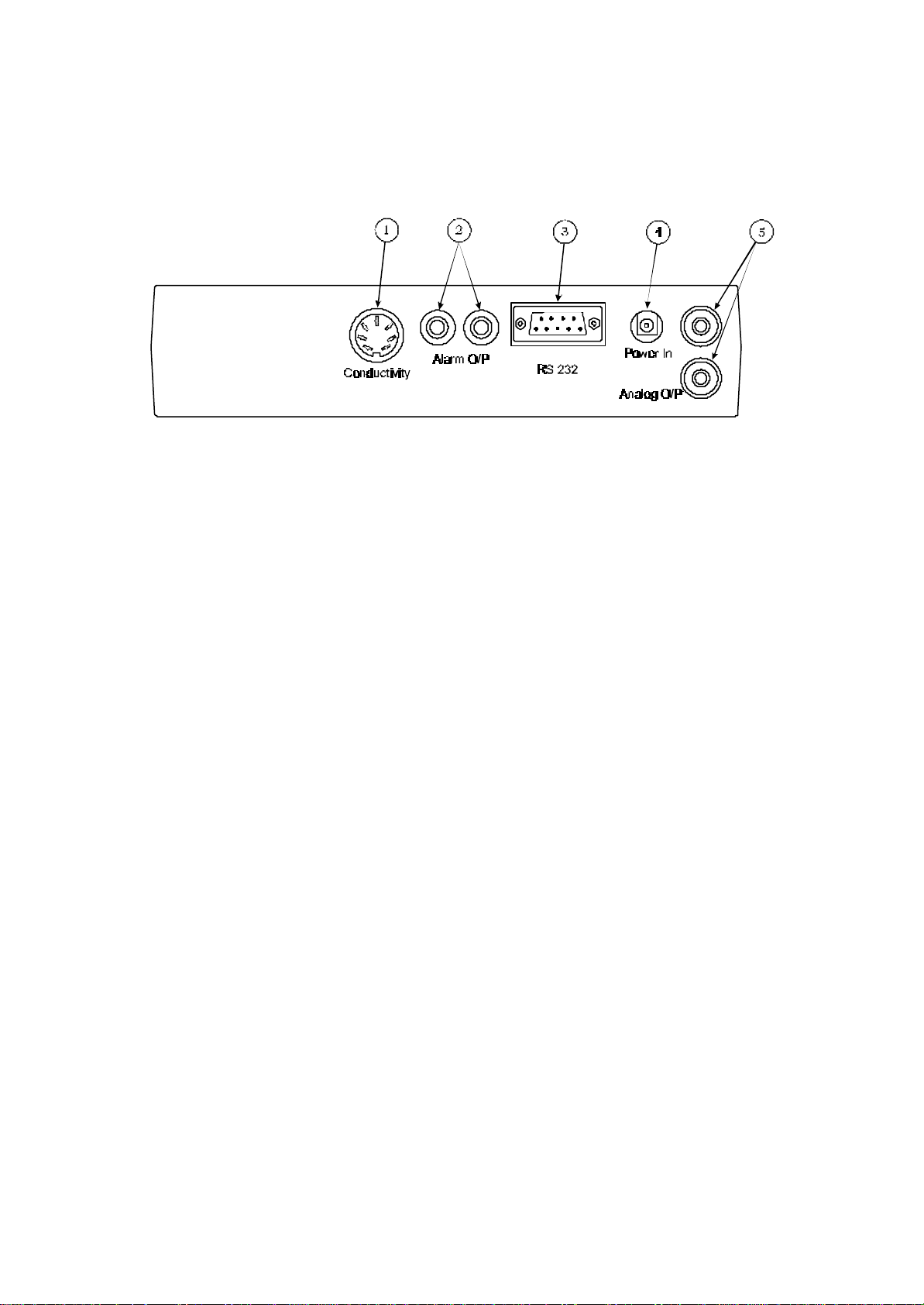

2.5 Inputs/Outputs

2.5.1 Rear panel layout

1. Conductivity Socket 7 pin DIN socket which allows the conductivity cell to be connected.

2. Alarm Out 2 x 4mm sockets. Open collector alarm output.

3. Output Socket 9 way connection for RS232.

4. Power In AC 9V I/P socket. 2.1 x 5.5mm socket allowing the power supply to be

connected to the instrument.

5. Analog Out 2 x 4mm sockets. Analogue output (buffered electrode potential).

5

452 050/REV A/03-03

Page 9

Section 3

Operation

3.1 Good Practice Guidelines

1. For greatest accuracy ensure no particulate matter is suspended in the solution under test. If

necessary, filter or allow the particles to settle prior to use. Do not allow the cell to come into

contact with any sediment which may be present.

2. Ensure no air bubbles are trapped in the cell area between the plates.

3. Ensure the cell plates are completely immersed in the solution under test.

4. Thoroughly rinse the cell plates in deionised water after use, and for short term storage

immerse the cell in deionised water. Although it is not essential to store the conductivity cell

with the plates in a wetted condition, if they are allowed to dry out completely, initial stability on

re-use may be impaired until the cell plates become re-wetted.

5. Do not attempt to clean the cell plates as this will remove the black platinization and alter the

calibration and accuracy of the probe. If the cell plates become worn or damaged the plates

should be re-platinised and the cell constant recalculated.

6. Ensure no salt deposits or particulate matter are allowed to build up around the cell plates or

on the probe body as this may produce a conductivity path lower than that through the

solution. It is recommended that such deposits be removed by soaking the cell in deionised

water. No attempt should be made to wipe off these deposits as this may cause damage to

the cell plates.

7. Ensure the correct reference temperature is selected for the operating procedures being

used.

6

452 050/REV A/03-03

Page 10

3.2 Set Up Parameters

The following section details the set-up modes available to the user on the main menu screen:

3.2.1 Instrument Setup

This option will allow the following parameters to be set:

Exit allows the user to exit this menu.

Language enables the selection of the appropriate language – English, French,

German, Italian, Spanish or Portuguese. Use the Up/Down keys to scroll

through thelanguage options.

LCD Brightness (%) enter the value using the keypad. Press the STO key to accept the value.

7

452 050/REV A/03-03

Page 11

3.2.2 Temperature Setup...

Select the Temperature Setup sub menu by highlighting the option and pressing the STO key. The

following menu will be shown:

Temp units allows selection of the preferred unit of measurement (either °C or °F) using

the Up/Down keys which toggle between the two units.

Manual temperature allows the manual temperature value to be set. Press the STO key to

accept the value.

3.2.3 Calibration Set up …

This option allows the following parameters to be set:

Exit enables the user to exit the Setup menu and return to the main set up

screen.

Cell Constant (K) allows setting of the cell constant by using the Up/Down keys. The

Left/Right arrow keys allow forward and backward movement along the

row of digits. Press the STO key to accept the value.

EC Ratio allows setting of the TDS EC ratio between the values of 0.50 and 0.80

(default value of 0.60) by using the Up/Down keys. The Left/Right arrow

keys allow forward and backward movement along the row of digits. Press

the STO key to accept the value.

Temp Coefficient (%) allows set of the temperature coefficient between the values of 0.00% to

4.00% (default 1.91%) using the Up/Down keys. TheLeft/Right arrow keys

allow forward and backward movement along the row of digits. Press the

STO key to accept the value

8

452 050/REV A/03-03

Page 12

Reference Temp allows the reference temperature to be set to 18, 20 or 25°C (default 25°C)

using the Up/Down keys which toggle between the values.

Ultra-Pure Temp this option can be enabled or disabled by using the Up/Down keys which

Correction toggle between the two options.

3.2.4 Calibration Buffer Setup...

Select the Calibration Buffer Setup sub menu by highlighting the option and pressing the STO key.

The following menu will be shown:

Exit enables the user to exit the Setup menu and return to the main set up

screen.

Cal Buffers Used allows selection of 1, 2 or 3 point calibration.

Cal Buffer Set allows selection of Auto Recognition or Manual Entry of buffers. Selection of

the preferred option can be made using the Up/Down keys which toggle

between the two options.

Cal 1 Buffer (mS) allows Cal 1 manual buffer value to be set using the Up/Down keys. The

Left/Right arrow keys allow forward and backward movement along the

row of digits. Press the STO key to accept the value.

Cal 2 Buffer (mS) allows Cal 2 manual buffer value to be set using the Up/Down keys. The

Left/Right arrow keys allow forward and backward movement along the

row of digits. Press the STO key to accept the value.

Cal 3 Buffer (mS) allows Cal 3 manual buffer value to be set using the Up/Down keys. The

Left/Right arrow keys allow forward and backward movement along the

row of digits. Press the STO key to accept the value.

9

452 050/REV A/03-03

Page 13

3.2.4 Alarms Setup...

Exit enables the user to exit the Setup menu and return to the set up

screen.

Alarm Outputs can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

Audible Alarm Warning can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

3.2.5 Alarm Point Settings....

Select the Calibration Buffer Setup sub menu by highlighting the option and pressing the STO key.

The following menu will be shown:

Exit enables the user to exit the Setup menu and return to the main

set up screen.

Cond Alarm High (mS) allows the user to set the high alarm limit up to 1999.999

Cond Alarm Low (mS) allows the user to set the high alarm limit up to 000.000.

TDS Alarm High (g/l) allows the user to set the high alarm limit up to 1999.999

TDS Alarm Low (g/l) allows the user to set the low alarm limit down to 000.000

Resistivity Alarm High allows the user to set the high alarm limit up to 20.00

Resistivity Alarm Low allows the user to set the low alarm limit 00.01

452 050/REV A/03-0310

Page 14

3.2.6 G.L.P Setup …

Exit enables the user to exit the Setup menu and return to the main

set up screen.

Cal Reminder can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

Cal Reminder Interval can be set within the limits of 001 to 999 hours by using the Up/Down

keys.The Left/Right arrow keys allow forward and backward

movement along the row of digits. Press the STO key to accept the

value.

Cal Reminder Audible Alarm can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

User ID up to a 4 digit code can be set using the Up/Down keys. The Left/

Right arrow keys allow forward and backward movement along the

row of digits. Press the STO key to accept the value.

Batch ID up to a 3 digit code can be set by using the Up/Down keys.The Left/

Right arrow keys allow forward and backward movement along the

row of digits. Press the STO key to accept the value.

3.2.7 Security Setup …

Select the Security Setup sub menu buy highlighting the option and pressing the STO key. The

following menu will be shown:

Exit enables the user to exit the Set Up menu and return to the previous

menu .

Data Entry Security can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

Security Code up to a 3 digit code can be set by using the Up/Down keys.The Left/

Right arrow keys allow forward and backward movement along the

row of digits. Press the STO key to accept the value.

452 050/REV A/03-0311

Page 15

3.2.8 Data Logging Set up …

Exit enables the user to exit the Set Up menu and return to the main

set up screen.

Data Log Event can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

Data Log To allows the data to be sent to Memory or to the external Printer.

Selection is made via the Up/Down keys which toggle between the

two settings.

Data Log Interval can be set between 00:00:01 and 23:59:59.

Memory Full gives the user to select the Stop (cease storing results and not to

overwrite existing stored information) or Overwrite (overwrite existing

results) options when the memory is full. Selection is made via the

Up/Down keys which toggle between thetwo settings.

Prompt Before Deleting can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

Clr Key toggles between Deletes Results Before, Deletes All Results and

Deletes Results Since. Selection is made via the Up/Down keys

which toggle between the two settings.

3.2.9 Printer Setup …

Select the Printer Setup sub menu buy highlighting the option and pressing the STO key. The

following menu will be shown:

Exit enables the user to exit the Setup menu and return to the main

instrument display.

Printer Interface toggles between Infrared and Serial. Selection of the preferred option

can be made using the Up/Down keys which toggle between the two

settings.

Serial Printer Baudrate toggles between 9600 and 1200. Selection of the preferred option

can be made using the Up/Down keys which toggle between the two

settings.

12

452 050/REV A/03-03

Page 16

3.2.10 Endpoint Detection Set up …

Exit enables the user to exit the Set Up menu and return to the main

instrument display.

Endpoint detection can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

Endpoint Audible Alarm can be enabled or disabled by using the Up/Down keys which toggle

between the two settings.

Endpoint Stability (Sec) can be set within the limits of 001 TO 999 SECONDS.

3.2.11 Clock Set up …

Select the Clock Setup sub menu buy highlighting the option and pressing the STO key. The

following screens will be shown:

Exit enables the user to exit the Setup menu and return to the main

instrument display.

Display toggles between Time and Date. Selection of the preferred option

can be made using theUp/Down keys which toggle between the two

settings.

Date Format toggles between European (DD/MM/YY) and American (MM/DD/YY)

formats. Selection of the preferred option can be made using the Up/

Down keys which toggle between the two settings.

Time allows time to be set (hrs/min/sec) using the Up/Down

keys. The Left/Right arrow keys allow forward and backward

movement along the row of digits. Press the STO key to accept the

setting.

Date allows date to be set (in previously selected format – European or

American) using the Up/Down keys. The Left/Right arrow keys allow

forward and backward movement along the row of digits. Press the

STO key to accept the setting.

13

452 050/REV A/03-03

Page 17

3.3 Preparation of Conductivity Standards

Suitable conductivity standards are available commercially or these can be made up as required from

A.R. grade reagents with reference to relevant physical tables.

Method for general purpose Conductivity Standard

Accurately weigh out 0.746 grammes of dried A.R. grade Potassium Chloride (KCl) and dissolve in 1

litre of good quality water. This produces a 0.01N solution with a conductivity of 1413µS at 25°C.

Storage

This solution must be stored in a plastic container and the air space above the solution should be kept

to an absolute minimum. The shelf life of 1 week can be increased by storing below 4°C, but where

any doubt exists about the viability of stored solution a fresh batch should be prepared.

3.4 Calibration with Known Cell Constant

1. Connect a standard pre-calibrated cell to the unit.

2. Select SETUP mode on the display using the Left arrow key.

3. Set the cell constant value as indicated on the body of the conductivity cell (refer Section 3.2.1)

The standard X1.0 cell has a cell constant range from 0.8 to 1.20 and is generally calibrated to

2 decimal places. The display should be set to indicate this figure exactly.

The X10 cell has a cell constant range from 8.0 to 12.0 and is generally calibrated to 2 decimal

places. The display should be set to indicate this figure.

4. Set the Temperature Coefficient value (refer Section3.2.2).

5. Select the required reference temperature (refer Section 3.2.3).

3.5 Calibration with Standard Solution

Calibration of the unit and cell with standard solutions will only be necessary if:

1) The cell constant is unknown.

2) The cell constant has changed due to replatinising, wear or damage to the plates.

3) An ATC slope other than 2%/°C is required (refer Special Calibration).

General Calibration

1) Immerse the conductivity cell into the prepared standard.

2) Select the MODE menu using the keypad.

3) Press the CAL/CLR key. The unit will calibrate to the nearest standard.

14

452 050/REV A/03-03

Page 18

3.6 Sample Measurement

General

Conductivity is a temperature dependent measurement. All substances have a conductivity

coefficient which varies from 1% per °C to 3% per °C for most commonly occurring substances.

The automatic temperature compensation on the 4520 defaults to 1.91% per °C, this being

adequate for most routine determinations.

Conductivity readings varying with temperature may be due to the substances under test having a

coefficient other than the typical value of 1.91% per °C. To eliminate this variation it is necessary to

maintain all samples at the reference temperature by use of a thermostatic water bath or

equivalent.

Adjustment may be made by entering the SETUP menu and selecting COEFF (refer Section 3.2.2).

The reading can then be adjusted to the required value (0.00 to 4.00) by using the keypad.

Sample Measurement

After calibration the measurement of samples is carried out by immersing the cell in the samples,

allowing the readout to stabilise, and recording the result. The cell should be rinsed in deionised

water between each sample to avoid contamination, shaken to remove internal droplets, and the

outside wiped prior to immersion in the next sample.

On completion of sample measurement the cell should be thoroughly rinsed in deionised water.

Storage

Short Term the cell should be immersed in deionised water to keep the plates wetted.

Long Term the cell should be thoroughly rinsed in deionised water, the exterior body

wiped and then stored dry.

NOTE: When preparing the cell for storage the plate area MUST NOT be wiped dry.

When using a dry cell initial stability on re-use may be impaired until the cell

plates become re-wetted.

To obtain optimum performance refer to Section 3.1 - Good Practice Guidelines.

15

452 050/REV A/03-03

Page 19

3.7 Status Page

The Status page displays the current calibration information.

If no valid calibration data is stored (e.g. after a reset or a failed calibration) the warning screen:

will be shown.

The status page will show the calibration data in the order it was carried out. Date, time,

temperature and Conductivity/TDS readings will be displayed for each standard.

16

452 050/REV A/03-03

Page 20

3.8 Results storage and display

The Model 4520 has a variety of options relating to the storage of data.

To initiate data logging the Data Log Event setting should be ENABLED.

By default this option is MANUAL.

The settings available are: Manual, Timed Interval, Endpoint Detection, Timed After Endpoint, Alarm

Set, Alarm Clear, Alarm Set & Clear and Disabled. Press the Up/Down arrows to cycle through

them.

Manual - logs results on pressing the STO key.

Timed Interval - logs on time and interval set by Data Log Interval in Hr:Min:Sec.

Endpoint Detection - logs data when the endpoint is detected.

Timed After Endpoint - logs at the Data Log Interval after the endpoint.

Alarm Set - data logs when the alarm set point is reached.

Alarm Clear - data logs when the alarm is cleared.

Alarm Set & Clear - data logs at the alarm set point and when the alarm condition clears.

Disabled - no data logging is possible when this option is selected.

The 4520 can log to either the memory or the printer. The memory can hold 500 data points which

can be accessed via the Results screen.

When the memory is full there are two options available regarding any additional logging. The

default is STOP.

Stop - when the memory is full no further data logging can occur until some

locations are deleted.

Overwrite overwrites data from the earlier storage point.

To prevent the accidental erasure of data the "Prompt Before Deleting" option can be either Enabled

or Disabled.

The function of the CLR key can also be set in this menu. The options define the use of the delete

key.

17

452 050/REV A/03-03

Page 21

Disabled - no manual deleting of results is possible.

Deletes Results Before - deletes all results before the selected data point.

Delete Results Since - deletes all results since the selected data points.

Deletes All Results - deletes all stored results.

3.8.1 Accessing Stored Results

To access results which have been stored use the Right arrow key to select results.

The most recently stored results will be displayed on the screen. If more results are stored than

can fit on a single screen then a series of data screens are available. The current screen and total

number of screens are shown in the bottom right hand corner of the screen.

The CLR key will delete data according to the set mode.

If the PROMPT BEFORE DELETING warning is set then a second CLR is required to delete

results.

The PRINT key will print all stored data.

Other screens of data can be accessed using the Up/Down arrow keys.

18

452 050/REV A/03-03

Page 22

3.9 GLP Functions

A variety of GLP functions are available via the GLP Setup menu.

A reminder that calibration is due can be set via the Cal Reminder option. Once this option is set a

valid calibration is required to use the 4520 after the time limit has elapsed. This option is

DISABLED by default.

The interval time is set in hours on this menu.

NOTE: A calibration should be performed immediately after the setting of this value to

reset the clock. This should be done as soon as set up is complete.

The on screen reminder can be accompanied by an audible alarm this is set using the audible

alarm setting on this menu.

NOTE: The use of the Calibration Reminder feature will prevent the user from

performing measurements with the 4520 until a valid calibration is carried out.

The user and batch ID can be used to identify sets of samples and a specific user. This information

is printed when data is output to the printer. The batch number is also stored in the results memory.

3.13.1 Security

To control access to set up options and data manipulation functions a security code can be set

using this menu. When enabled a password is required to make any changes to the set up menus.

When the code is ENABLED a user can measure a sample, log data and calibrate the unit, but

cannot change settings within the set up screens until a valid password is entered.

19

452 050/REV A/03-03

Page 23

Section 4

Maintenance

4.1 General

The Model 4520 is designed to give optimum performance with minimum maintenance. It is only

necessary to keep the external surfaces clean and free from dust. To give added protection when

the unit is not in use the unit should be disconnected from the mains supply and covered with the

optional dust cover (060 406). For longer term storage or re-shipment it is recommended that the

unit be returned to the original packing case.

All conductivity cells should be thoroughly rinsed after use and stored in deionised water. Do not

attempt to clean the surface of the plates as this could result in damage to the black platinised

surface.

Section 5

Optional Accessories

5.1 Optional Accessories

060 406 Dust cover

037 701 IrDA printer supplied with roll of thermal paper, serial connection lead, power

supply, power connection lead (UK) and pouch

037 801 Interface cable kit

050 002 Serial communication software (3½” disk)

Conductivity Cells

027 013 Conductivity Cell K=1

027 113 Conductivity Cell K=0.1

027 114 Conductivity Cell K=1 (plastic covered)

NOTE: The cells listed below are glass free and epoxy bodied.

027 211 Conductivity Cell with ATC K=0.1

027 212 Conductivity Cell with ATC K=1

027 213 Conductivity Cell with ATC K=10

Calibration Standards

025 138 1413µS Standard (500ml)

025 156 12.88mS Standard (500ml)

025 164 84µS Standard (500ml)

025 139 10µS Standard (500ml)

025 165 1382ppm TDS Standard (500ml)

037 702 Paper roll, thermal

021 030 UK 230V power supply

021 031 European 230V power supply

021 032 US 115V power supply

021 033 230V leaded power supply

20

452 050/REV A/03-03

Page 24

Section 6

Interfacing

6.1 Analogue

All units are provided with 2 x 4mm sockets, marked as ANALOG OUT, on the rear panel. An analogue

output voltage of 1mV per least significant digit is available from these sockets.

6.2 RS232

The Bi-directional RS232 interface is available on the rear panel 9 way D type connector.

The connections are as follows:

DCD 1 - LINKED TO DTR AND DSR

RXD 2 - INPUT TO 4520

TXD 3 - OUTPUT FROM 4520

DTR 4 - LINKED TO DCD AND DSR

GND 5

DSR 6 - LINKED TO DCD AND DTR

RTS 7 - OUTPUT FROM 4520

CTS 8 - INPUT TO 4520

Suggested interconnections are detailed below:

4520 IBM PC XT (25 way “D”)

1 DCD DCD 8

2 RXD RXD 3

3 TXD TXD 2

4 DTR DTR 20

5 GND GND 7

6 DSR DSR 6

7 RTS RTS 4

8 CTS CTS 5

9

4520 IBM PC XT (9 way “D”)

1 DCD 1 DCD

2 RXD 2 RXD

3 TXD 3 TXD

4 DTR 4 DTR

5 GND 5 GND

6 DSR 6 DSR

7 RTS 7 RTS

8 CTS 8 CTS

9 9

NOTE: Inerface Cable (Order Code: 013 203) is required.

21

452 050/REV A/03-03

Page 25

Interfacing (continued)

The RS232 communications parameters on the computer or printer need to be set to match those of

the Model 4510, as detailed below:

1200 Baud 9600 Baud

7 Data Bits 8 data bits

Odd Parity OR No parity

1 Stop Bit 1 stop bit

Setting of these options is detailed in Section 3.6.6.

The Model 4520 supports both hardware (CTS/RTS) flow control and software XON/XOFF flow con-

trol.

Pressing the PRINT key outputs from the RS232 interface.

Sending an ASCII “D” to the 4520 causes a printout of the current displayed reading plus sample

number.

Sending an ASCII “C” causes a printout of the last calibration parameters.

Sending an ASCII "P" causes a printout of the stored readings.

6.3 Keypad Emulation

Keypad remote control using RS232 interface:

7 - Instrument On / Standby / Escape

1 - Calibrate / Memory Clear

9 - Print

8 - Up Arrow

2 - Down Arrow

4 - Left Arrow

6 - Right Arrow

3 or 5 - Enter / Store

22

452 050/REV A/03-03

Page 26

6.4 Printing

A 32 column serial printer (037 701) is available for use with the Model 4520.

There are two methods of connecting the serial printer to the Model 4520:

a) IrDA - the IrDA interface is a line of sight, wireless communication protocol. The IrDA sensor

(located on the front left hand corner of the printer) should be in line with the Ir window on the side of

the 3520. The Ir icon on the symbol display indicates whether the units are attempting to connect

(single icon flashing) or connected (two icons).

b) Connect serial cable supplied with the printer to the 9 way socket located on the rear panel of the

instrument.

To intiate a print out of data press the print key.

When the first print is performed a header section will be printed showing:

Instrument name

Time and Date

Spacing for entry of Operator & User ID

Most recent calibration information (Cell constant)

Reference temperature

Temperature coefficient

TDS EC Ratio

This will be followed by results data in either Conductivity or TDS dependent on mode selected.

Details will also be given on temperature. Time and date of the stored readings will be displayed.

An asterisk (*) indicates that manual temperature compensation is being used.

Each reading will be identified by a batch number.

A calibration will reset the printout and the header information will be re-printed.

To obtain a print out of stored readings, enter the RESULTS MODE and press the print key. A print

out of all filled memory locations will then be generated.

6.5 Alarm Outputs

The 4520 provides two alarm outputs. These can be accessed using the two 4mm connectors on

the rear of the 4520. They are open collector outputs. To set the alarm limts at which these are

activated, please refer to section 3.2.4.

To use the alarm outputs, they should be ENABLED in the Alarms Setup screen see section 3.2.4

They will operate in both pH measurement and absolute millivolts. The alarm outputs will remain

active until the alarm condition is no longer evident or the alarm limits are reset in the Alarm Set up

menu.

For the Hi alarm output please use the Red 4mm phone connector.

For the Low alarm output please use the Black 4mm Phono connector.

For further information please contact your local distributor or the manufacturer.

452 050/REV A/03-0323

Page 27

Section 7

Troubleshooting

7.1Troubleshooting

Fault Possible Cause Action

No display Check power supply Check that correct 9V ac power supply

is connected and switched on.

Erratic display Check power supply Unit must be used with supplied 9V

acpower supply. Usage of other units will

cause the 4520 not to operate.

Unstable display Conductivity cell defective Replace conductivity cell.

Display permanently Intermittent or no connection Check cell connection to 4510.

under or over range Conductivity cell defective Replace conductivity cell

Contaminated solutions Replace solutions

Intermittent display Conductivity cell not fitted Check connections.

correctly

Reading drifts Conductivity cell stored dry Allow to soak for 2 hours

CO2 absorbtion by sample Noticeable for low conductivity - do not

allow sample to stand in unstoppered

bottles.

Non linear readings Conductivity cell not zeroed Zero conductivity cell.

Poor reproducibility Carryover between solutions Rinse cell in distilled water between

measurements.

Will not print IrDA connection broken Line up units or alternatively use

supplied RS232 connector.

Paper out The feed light on the printer will flash if

the unit requires paper.

Battery flat Connect ac power supply.

If the above does not answer your query try the FAQ section on the www.Jenway.com Website.

452 050/REV A/03-0324

Page 28

EC Declaration of Conformity

JENWAY Model 4520 Conductivity/TDS Meter complies with the following European Standards:

EN 50081-1:1992 Electromagnetic compatibility - Generic emission standard

EN 50082-1:1992 Electromagnetic compatibility - Generic immunity standard (Performance crite-

rion B)

EN 61010-1:2001 Safety requirements for electrical equipment for measurement, control and

laboratory use

Following the provision of:

EMC Directive - 89/336/EEC and Low Voltage Directive - 73/23/EEC

Martyn J. Fall

Managing Director, Jenway

Gransmore Green, Felsted, Dunmow,

Essex, CM6 3LB, England

25 452 050/REV A/03-03

Loading...

Loading...