Page 1

Model 3540

Combined pH & Conductivity Meter

Operating Manual

Safety

This is important information; please read carefully before installing or using this instrument.

1. The Model 3540 pH/Conductivity meter is only for operation by

aware of the principles and applications involved in making electrochemical measurements. For

further help and advice please contact your local distributor, e-mail sales@jenway.com

www.jenway.com

2. The Model 3540 pH/Conductivity meter is a sensitive electronic measuring instrument designed

for use in a laboratory environment. Careful adherence to the installation instructions must be

observed. If in doubt contact a relevant and competent authority for advice before proceeding.

3. In addition to observing the instructions detailed in the Operating Manual and Service Manual for

this instrument all installation, operating and service personnel must be aware of, and employ, a

safe system of work.

4. Voltage levels hazardous to life are present in this instrument, for personal safety only trained

engineers aware of the risk and avoidance of electric shock should remove protective covers from

the instrument.

5. This instrument is designed for minimal maintenance, which must be carried out carefully following

the

procedures detailed in this manual

those defined locally for the area or environment where the work is being carried out must be

observed.

6. Other than for those items defined in the maintenance procedures herein there are no user

serviceable items in this instrument. Removal of covers and attempted adjustment or service by

unqualified personnel will invalidate any warranty and incur additional charges for repair.

7. Reference should always be made to the

used. All available information, advice and warnings on the handling, storage, use and disposal of

such must be carefully observed. When not available this data must be requested from the

supplier before proceeding in any way.

8. It is important that good laboratory practice is observed when handling samples, chemicals,

reagents and ancillary equipment in order to carry out measurement and analysis with this

instrument. Suitable safety and personal protective equipment must be used at all times.

9. If it is suspected that safety protection has been impaired in any way, the instrument must be

made inoperative and secured against any intended operation. The fault condition must be

reported to the appropriate servicing authority. In all such reports the model number and serial

number of the instrument must be quoted.

. All safety instructions in these procedures as well as

Health and Safety Data

personnel who are trained

for any chemicals or reagents

and

or visit

Page 2

Contents:

Section 1 Introduction

Instrument description 1.1

Display & controls 1.2

Outputs 1.3

Electrode Selection 1.4

Good practice guidelines - pH 1.5

Good Practice Guidelines – Conductivity 1.6

Section 2 Getting Started

Unpacking 2.1

Installation 2.2

Section 3 Set Up - General

Instrument Set Up 3.1

GLP Set Up 3.2

Data Logging Set Up 3.3

Time/Date Set Up 3.4

Section 4 Conductivity Set Up

Conductivity Calibration Set Up 4.1

Conductivity Alarms Set Up 4.2

Conductivity End Point Set Up 4.3

Conductivity ATC/MTC Set Up 4.4

Section 5 pH Set Up

pH resolution 5.1

mV Resolution 5.2

pH Calibration Set Up 5.3

pH Alarms Set Up 5.4

pH End Point Set Up 5.5

pH ATC/MTC Set Up 5.6

Section 6 Calibration

pH Calibration 6.1

Conductivity Calibration 6.2

Section 7 Measurement

pH/Conductivity Measurement 7.1

mV Measurement 7.2

TDS Measurement 7.4

Resistivity Measurement 7.5

Salinity Measurement 7.6

Section 8 Maintenance & Troubleshooting

General and routine maintenance 8.1

Cleaning/Re-conditioning of Glass Electrodes 8.2

Error codes and troubleshooting - pH 8.3

Error codes and troubleshooting – Conductivity 8.4

Functional Check – pH 8.5

Functional Check – Conductivity 8.6

Functional Check – Temperature 8.7

Functional Reset 8.8

Page 3

Section 9 Accessories and Spares

Optional accessories 9.1

Spares 9.2

Section 10 Specification & Data

Technical specification 10.1

Analogue output 10.2

RS232 serial interface 10.3

Keypad emulation 10.4

Printing 10.5

Alarm Outputs 10.6

Addendum Buffer/Standard Vs Temperature Tables

Jenway Ad.1

NIST Ad.2

DIN Ad.3

JIS Ad.4

Conductivity Ad.5

Page 4

Section 1

Introduction

1.1 Instrument Description

The model 3540 pH/conductivity meter is a dual channel, dual readout instrument that

displays both pH and conductivity values simultaneously. The model 3540 is designed to

show both readings in real time and eliminates cross channel interference, as well as the

need to either switch manually or automatically between measurements. The design also

enables both dual channel and independent single channel operation. Predictive Selection

simplifies operation by taking you directly to the screen relevant to your current task.

The unit enables pH measurements to be made with a 1, 2 or 3 decimal place resolution

against a 1, 2 or 3 point calibration. Automatic calibration can be carried out against standard

NIST, DIN, JIS or Jenway buffers. Alternative values can be entered and stored for semiautomatic operation. The pH channel can also display Absolute and Relative mV values to

0.1mV resolution, enabling Redox/ORP and simple ISE measurement to be made.

The conductivity channel is auto ranging from 0.01µS up to 19.99S (with x10 probe). This

eliminates the need for manual range selection across this wide measuring range. Reference

temperatures of 18, 20 and 25°C are offered, along with a temperature coefficient that can be

varied from 0% (off) up to 4% per degree Celsius. Three calibration methods can be

employed: automatic recognition of common conductivity calibration standards, semiautomatic calibration against manually entered values within the measuring range or, a

simple calibration against the quoted cell constant (K factor) for the probe being used. The

conductivity channel can also be set to readout in Resistivity, Salinity or TDS values.

Configuring the instrument to your ideal options is easily achieved using the clear and simple

set up menus. Once entered, these options can be locked against inadvertent change by

entering a Supervisor Security Code.

Access to Set Up menus blocked by incorrect security code entry

GLP functions include user and sample batch identity, calibration reminder, security set up

and date/time stamping of results.

Data logging and alarm functions are also included. Results can be stored to the internal

memory (250 pH and 250 conductivity readings) or output via the RS232 serial port to a

printer or computer. This storage or output function can be triggered manually by pressing

the Store key, or be set on a timed basis. It can also be triggered when a sample reading

reaches stability, or on the activation and reset of any alarm level.

The model 3540 has a high specification and a comprehensive range of features and

functions. Please read through this manual before installation. Refer to it frequently to ensure

you are making full use of all the functions.

Page 5

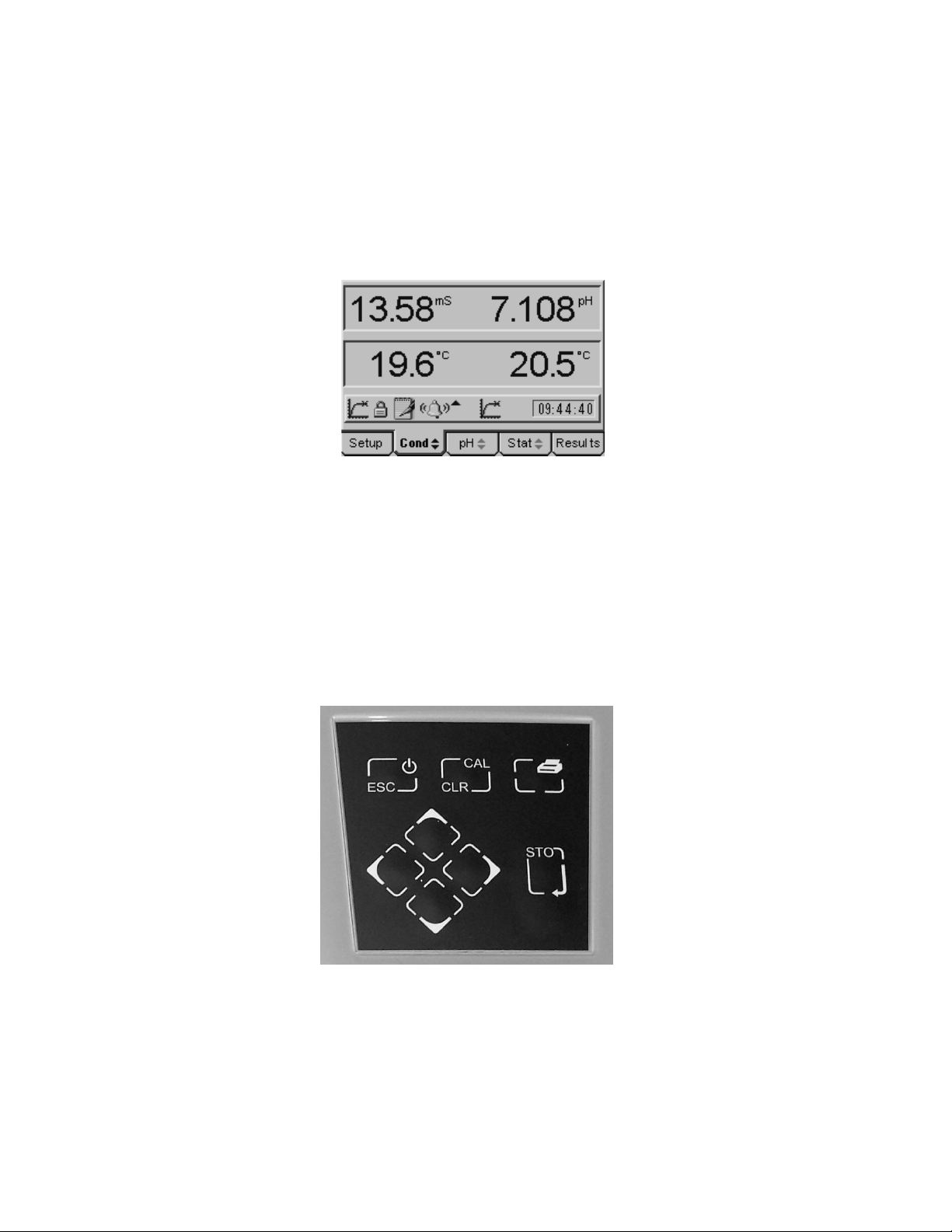

1.2 Display and Controls

The model 3540 has a back lit 1/8 VGA dot matrix LCD. In normal measurement mode the

left-hand side displays the conductivity value and the right hand side the pH value. Both

channels have their own temperature/ATC input displayed below the measured value,

making them fully independent. The display includes a number of icons and prompts used to

inform and indicate to the user the instrument status and measurement conditions. The

operating system is based around five separate screens, each of which can be displayed by

moving the cursor along the tabbed menu bar at the bottom of the display.

Typical display showing independent temperature/ATC

measurement and a range of prompting icons

The simple keypad controls all the functions of the instrument. The ON/OFF key operates as

an escape [ESC] key at sub-menu levels, each press returning to the next highest level until

the main measurement screen is reached, where a further press will switch the instrument

off.

Pressing the CAL key initiates the calibration sequence for the channel highlighted on the

tabbed menu bar. The calibration sequence will be based on the options selected in the

relevant calibration set up menu. When recalling results, with the Results tab highlighted, the

CAL key functions as a Clear [CLR] key, returning the function defined for the Clear key in

the data logging set up menu.

Simple keypad enables easy operation

The Print key outputs the currently displayed measurement, stored results or statistics

screen to the RS232 serial port, where it can be printed on the optional serial printer. An

option to print the measurement displayed on one or both channels can be selected in the

Printer Set Up menu.

Page 6

The Enter key confirms selections as they are made in the set up menus. With the

measurement screen displayed it acts as the Store [STO] key and stores the current

readings in the internal memory. Up to 250 pH and conductivity readings can be stored. The

action taken when the memory is full can be selected in the data logging set up menu.

The four Cursor keys enable easy navigation through the set up menus, as well as selection

of the required screen on the tabbed menu bar. The Up or Down Cursor keys are also used

to select alternative measuring modes from the highlighted channel on the main

measurement screen.

1.3 Outputs

The Model 3540 has RS232 serial, analogue and alarm outputs.

The serial output includes data for both channels as displayed on the measurement screens.

The analogue output can be switched between the pH and conductivity measurement by

highlighting the required channel on the tabbed menu bar. The alarm function can be set

independently for each channel with high and low options for every mode of operation. The

‘open collector’ output can be used directly for low current switching, or via relays for other

control functions.

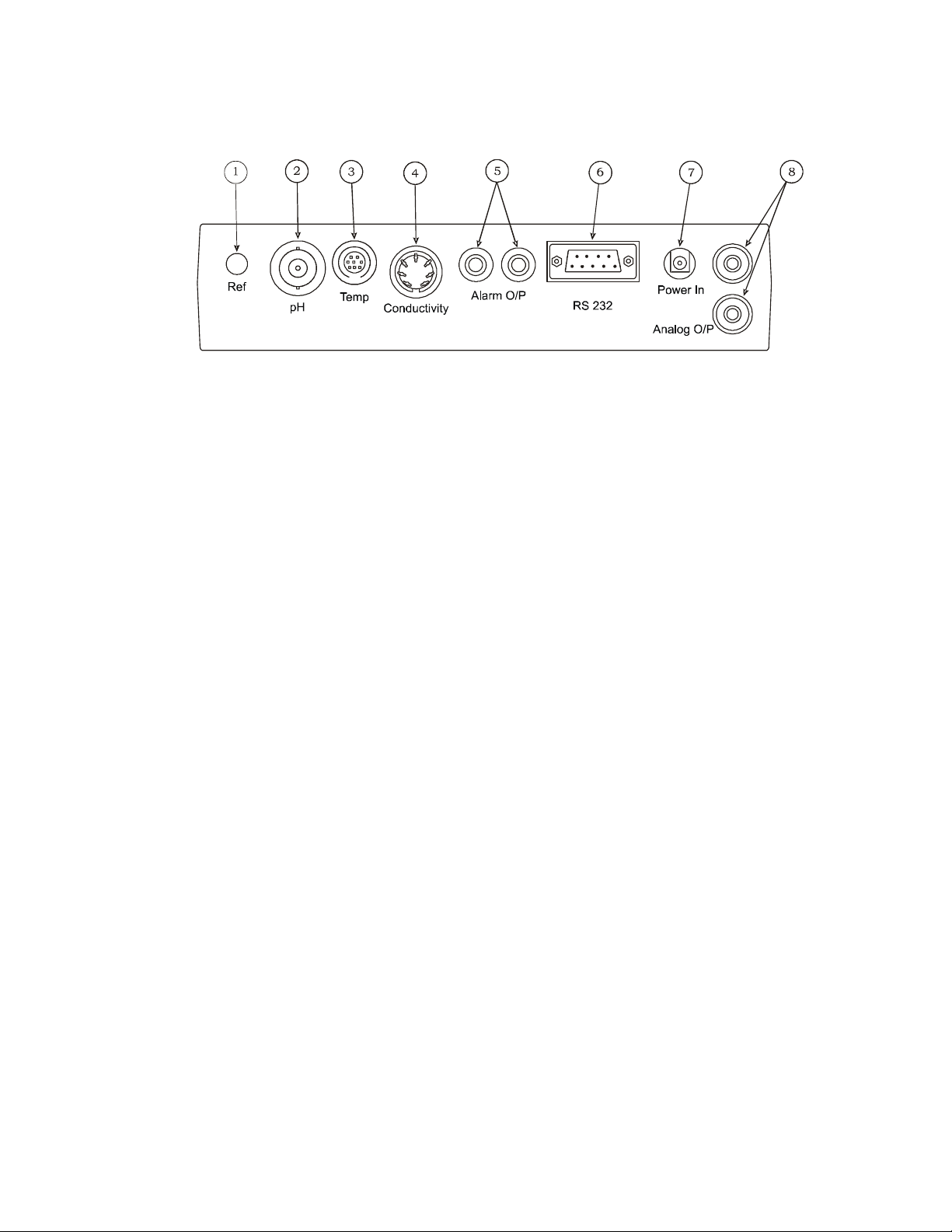

Rear Panel showing output connectors

1.4 Electrode Selection

The performance of any electrochemistry measurement system is highly dependent on the

selection of appropriate sensing electrodes suitable for the sample being measured. Jenway

offer a comprehensive range of pH and conductivity electrodes with versions suitable for

most applications and sample types. For help or advice on choosing the best electrodes for

your application contact

sales@jenway.com or visit www.jenway.com.

Page 7

1.5 Good Practice Guidelines – pH

1. Selection of the correct electrode for your application is the most important factor in

achieving good performance and extended electrode life. The use of

Specific electrodes is recommended for all but the simplest sample matrix and

measurement conditions. Please contact Jenway if you require further help or advice

on electrode suitability and application support.

2. For best results follow Good Laboratory Practice (GLP) at all times. Ensure regular

calibration using buffer solutions with values that bracket the expected sample pH

levels. Always record the sample/buffer temperature with its corresponding pH value.

3. Always ensure that all buffer solutions and reagents used are within their expiry

dates. Never return unused solutions to the bottle, nor insert the electrode directly

into the bottle. Always replace caps on their respective bottles immediately after use.

4. Ensure that the correct buffer set is selected (e.g. NIST, DIN, JIS, etc), or that the

temperature corrected value of the buffer is used for calibration, NOT the nominal

value.

5. Recording the electrode Offset and Slope values after each calibration will enable

electrode condition to be monitored and the most effective calibration and

maintenance procedures to be implemented.

6. Ensure

confirming calibration. Where sample and/or buffer temperature vary, or are

significantly different from ambient, greater accuracy and faster analysis can be

achieved by keeping buffers, samples, rinse solution, electrode and ATC probe in a

water bath or other temperature controlled environment.

7. Ensure the electrode is rinsed with deionised water between each sample and

calibration buffer.

DO NOT touch the sensitive pH glass membrane or reference junction. Excess liquid

may be removed by gentle blotting with a soft tissue.

DO NOT rub the electrode as this may cause an electrostatic charge.

8. For Refillable Electrodes:

Ensure that the electrode’s outer chamber is at least two thirds full. Always use the

correct fill solution for the electrode. Use of the wrong solution WILL cause

irreversible damage. Always open the fill port during use.

9.

10. Always use electrodes within their specified temperature range. Degradation of

11. Always use and store the electrode in an upright vertical position. Ensure no air

12. Regular electrode cleaning and maintenance will improve performance and extend

DO NOT

those designated as submersible).

electrodes used above their operating temperature is rapid and irreversible.

bubbles are trapped in the internal solutions. Air bubbles may be removed by gently

shaking the electrode in a downward direction.

working life. Use only cleaning solutions and procedures detailed in the instructions

supplied with the electrode. Others may damage the electrode and degrade

performance.

BOTH

pH and temperature values are stable before recording results or

immerse any electrode below the level of the internal fill solution (except for

Application

Page 8

13. Storage conditions can have a greater impact on electrode performance and

operational life than sample type. Store only as directed in the instructions supplied

with the electrode.

For general guidance:

Refillable Electrodes

After Use

Overnight Rinse thoroughly with deionised water. Leave the fill port open and

Short Term Clean according to instructions and rinse thoroughly with deionised

Long Term Clean according to instructions and rinse thoroughly with deionised

Sealed Non Fillable Electrodes

After Use/ Rinse thoroughly with deionised water and immerse in a small

Overnight beaker containing electrode storage solution. Ensure both glass bulb

Short Term Clean according to instructions and rinse thoroughly with deionised

Long Term Clean according to instructions and rinse thoroughly with deionised

Rinse thoroughly with deionised water. Leave the fill port open and

immerse in a beaker of 4 pH buffer solution. Ensure both glass bulb

and reference junction are covered.

immerse in a small beaker containing electrode storage solution.

Ensure both glass bulb and reference junction are covered.

water. Close the fill port and re-fit the soaking bottle or wetting cap

filled with storage solution.

water. Top up the fill solution and close the fill port. Re-fit the soaking

bottle or wetting cap filled with storage solution. Return to the original

packaging and store away from direct sunlight in a vertical position and

within the electrodes specified temperature range.

and reference junction are covered.

water. Re-fit the soaking bottle or wetting cap filled with electrode

storage solution.

water. Re-fit the soaking bottle or wetting cap filled with electrode

storage solution. Return to the original packaging and store away from

direct sunlight in a vertical position within the electrodes specified

temperature range.

Page 9

1.6 Good Practice Guidelines – Conductivity

1. After using the conductivity probe ensure it is rinsed thoroughly, or cleaned then

rinsed if used in adhering samples. Between samples and for short-term storage the

probe should be stored with the measuring plates immersed in a beaker of deionised

water. This should be replaced regularly to ensure no contamination or growth

occurs.

For longer-term storage conductivity probes may be stored dry, but will need soaking

in deionised water for at least 1 hour before re-use.

2. Conductivity measurements are temperature dependent, for greater accuracy and for

measurement comparisons sample temperature must be recorded, along with the

reference temperature and temperature coefficient used.

3. Calibration against quoted cell constants (K factors) should only be carried out where

these are known and are reliable. If in doubt, good quality calibration standards

should be used for calibration and/or re-calculating the cell constant (K factor).

4. For greatest accuracy in laboratory measurements, and to conform to USP

standards, temperature compensation should be switched off (set temperature

coefficient to zero). In addition, all samples and calibration standards should be kept

at the reference temperature by use of a water bath or other temperature controlled

environment.

5. When measuring samples at a temperature that differs significantly from ambient,

sufficient time must be allowed for the internal temperature sensor to respond to this

change.

6. The presence of particulate matter in the sample can lead to unstable and nonreproducible results. If necessary filter, or allow the particles to settle prior to

measurement.

7. Ensure no air bubbles are trapped in the measuring cell. Gentle agitation of the cell

should ensure that bubbles are purged.

8. The entire plate area must be immersed in the solution under test. The slots in the

side of the sensor should be below the surface. Ensure the probe is rinsed with

deionised water between each test. A further ‘sample rinse’ may be necessary for low

conductivity measurements.

9. The measurement of low conductivity samples must be performed with great care to

avoid contamination. At the lowest levels the leeching of substances from the sample

container or absorption of gasses from the atmosphere may affect readings.

10. It is advisable to clean the sensor if contamination is evident. This should be

approached in a progressive manner, beginning with deionised water and

progressing to other solvents or a soft airbrush if the deposits persist. The plates can

be damaged and should not come into contact with anything that is likely to abrade

their surface.

Page 10

11. The temperature coefficient is very dependent on the solution being measured and its

concentration level. The effect of temperature change on conductivity can be very

significant, and if the temperature coefficient is not know it is wise to measure all

samples at the reference temperature.

12. The TDS mode displays results that have been calculated from the conductivity

measurement and assumes some knowledge of the electrolyte balance of the

sample. The EC ratio allows selection of a factor suitable for the solution under test.

Most instruments that do not offer this option use a default value of 0.6.

Page 11

Section 2

2.1 Unpacking

Remove the 3540 from the packaging and ensure the following items are included:

1. Model 3540 pH/Conductivity Meter

2. Glass bodied combination pH electrode (924 005)

3. Epoxy bodied Conductivity Cell K=1 (027 013)

4. ATC probe (027 500)

5. Electrode Holder

6. 4, 7 & 10 pH buffer sachets

7. BNC shorting plug (009 146)

8. Power supply (as specified at the time of ordering)

9. Condensed operating instructions (354 051)

10. Operating Manual (354 050)

Any shortages or damage must be reported to your local distributor or the

manufacturer as soon as possible.

Keep all packing materials in case the unit has to be re-shipped at a later date. It is

important that when re-packing the instrument it is first placed in a sealed polythene

bag.

2.2 Installation

2.21 Location

The Model 3540 must be positioned within 1.5 meters of an electric supply socket.

In ideal circumstances the installation environment will be clean, dry and dust free.

Where conditions are less than ideal, maintenance and cleaning must be carried out

regularly and additional protection offered, where possible. The optional dust cover

should always be fitted when the unit is not being used or is stored for short periods.

Getting Started

Typical Items supplied

Page 12

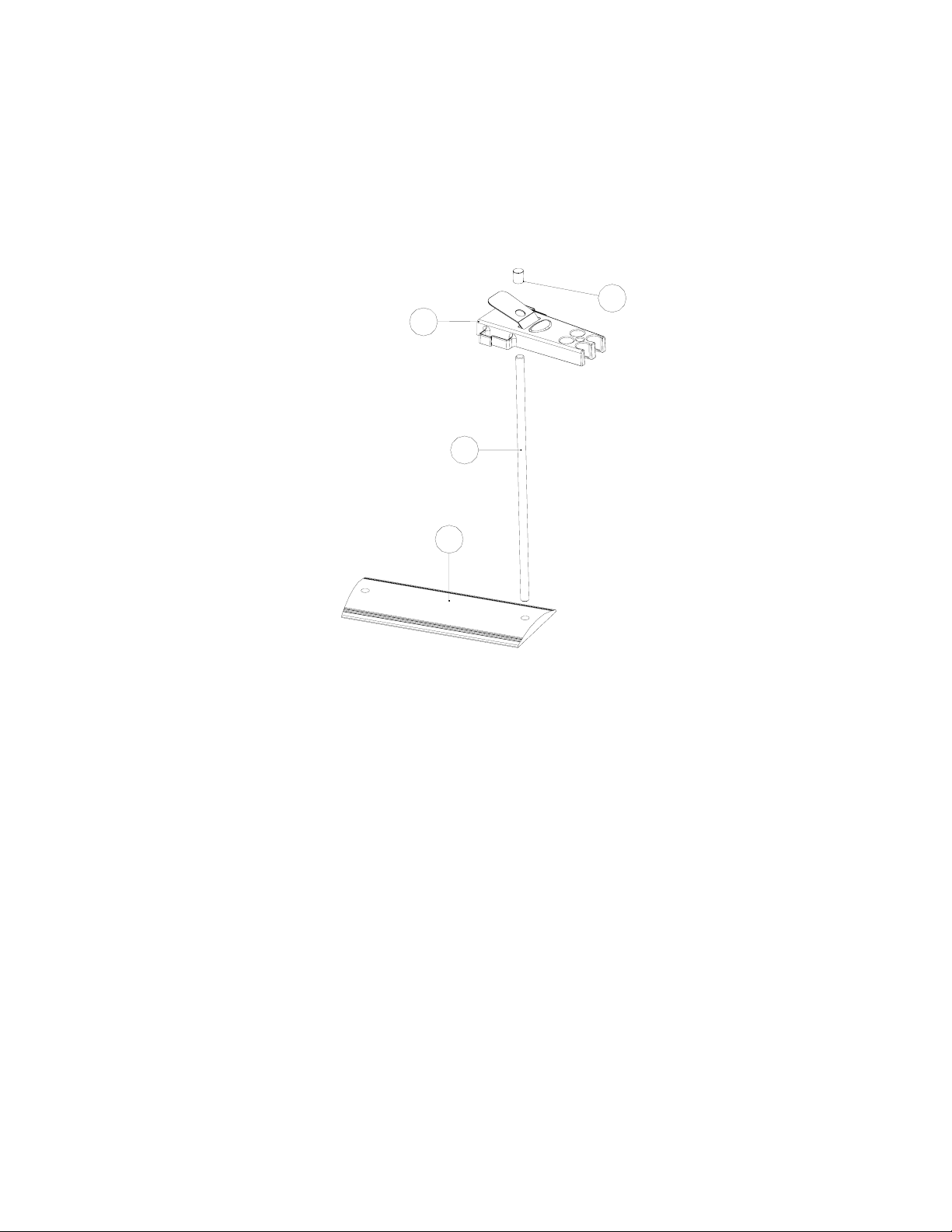

2.22 Electrode Holder Assembly

The electrode holder requires minimal assembly (refer to the diagram below).

4

1

2

3

Decide on which side of the instrument you require the electrode stand to be

positioned. Align the base plate with the shorter edge to the front of the instrument, so

that the tapered sides match the taper on the instrument.

Screw the rod into the base on the side required. If gripping the rod is difficult an Allen

key or small screwdriver inserted in the 4mm hole at the bottom of the rod enables it

to be tightened further.

Remove the rubber top cap and slide the electrode down the rod while squeezing the

sprung retainer. Replace the rubber top cap.

Fit the electrodes and ATC probe into the holder, use the side clips to keep the

cables tidy.

Adjust the height and rotation of the electrode holder to suit your work station and

sample containers as necessary.

Page 13

2.2.3 Power Supply, probes and accessory connection

Rear Panel showing Input and Output Connectors

1. Ref Socket 2mm-pin type socket. Connection socket for separate reference

electrode. When performing measurements with some pH and

ion selective electrodes a separate reference electrode is

needed.

2. pH Socket BNC type socket which allows combination pH or redox

electrodes to be used.

3. Temp Socket 8-pin mini-DIN socket. This allows the supplied Automatic

Temperature Compensation (ATC) probe to be connected.

4. Conductivity Socket 7-pin DIN socket. This allows the conductivity cell to be

connected.

5. Alarm Output 2x4mm sockets. Open collector alarm outputs.

Red for High / Black for Low.

6. Printer Socket 9-way socket for RS232 serial communication, for serial printer,

PC connection or other data communication.

7. Power In AC 9V I/P socket. 2.1 x 5.5mm socket allowing the power

supply to be connected to the instrument.

8. Analog O/P Two 4mm sockets. Analogue output for selected channel.

Page 14

Section 2.24 Installation Verification

1. Connect the power supply, conductivity cell and ATC probe to the rear panel, as

described in the previous section. (Do not immerse the probes in solution at this

stage).

2. Connect the BNC shorting plug (009 146) to the pH input in place of the pH electrode.

3. Switch on the power at the mains supply socket, if necessary, then press the power

on/off key on the instrument.

4. The 3540 start up screen is shown for a few seconds…

Start Up screen shown during internal self checking

…followed by the main measurement

screen with either the pH or conductivity tab

highlighted (depending on which was active when power was switched off).

Main measurement screen with pH tab highlighted

5. The pH reading should be close to 7.00(0). The actual value will depend on the last

calibration and the resolution that was selected in the pH set up menu.

6. The conductivity reading should be a low µS value. This will also depend on the last

calibration.

7. With the ATC and conductivity probes in the same environment, the temperature

readings should equilibrate to within ±0.5°C of the ambient temperature.

8. Remove the BNC shorting plug from the pH input and reconnect the pH electrode.

Remove the wetting cap or soaking bottle from the sensing end of the pH electrode.

9. Soak the pH electrode in 4 pH buffer solution and the conductivity probe in deionised

water for at least 30 minutes before carrying out calibration and sample

measurement.

10. This procedure should be followed if the instrument is re-installed at a new location,

or when put back into use after a period of storage. For routine power-on and

operation see Section 4.

Page 15

Section 3

Set Up - General

3.00 General Set Up

The general set up options include instrument wide functions that are relevant for

both pH and conductivity channels. Functions that can be set in these menus are

language, display brightness, GLP options, data logging options, clock, security and

printer set up. Adjustments made to these settings are stored in non-volatile memory

so will not need to be re-entered unless further changes are required. They will also

be retained regardless of the power connection to the instrument.

3.01 Connect the power supply as described in section 2.2.3. It is not necessary to

connect the probes for the set-up procedures.

3.02 Switch on the power at the supply socket; then press the power on/off key on the

instrument.

3.03 The 3540 start up screen is shown for a few seconds followed by the main

measurement

screen with either the pH or conductivity tab highlighted (depending on

which was active when power was switched off).

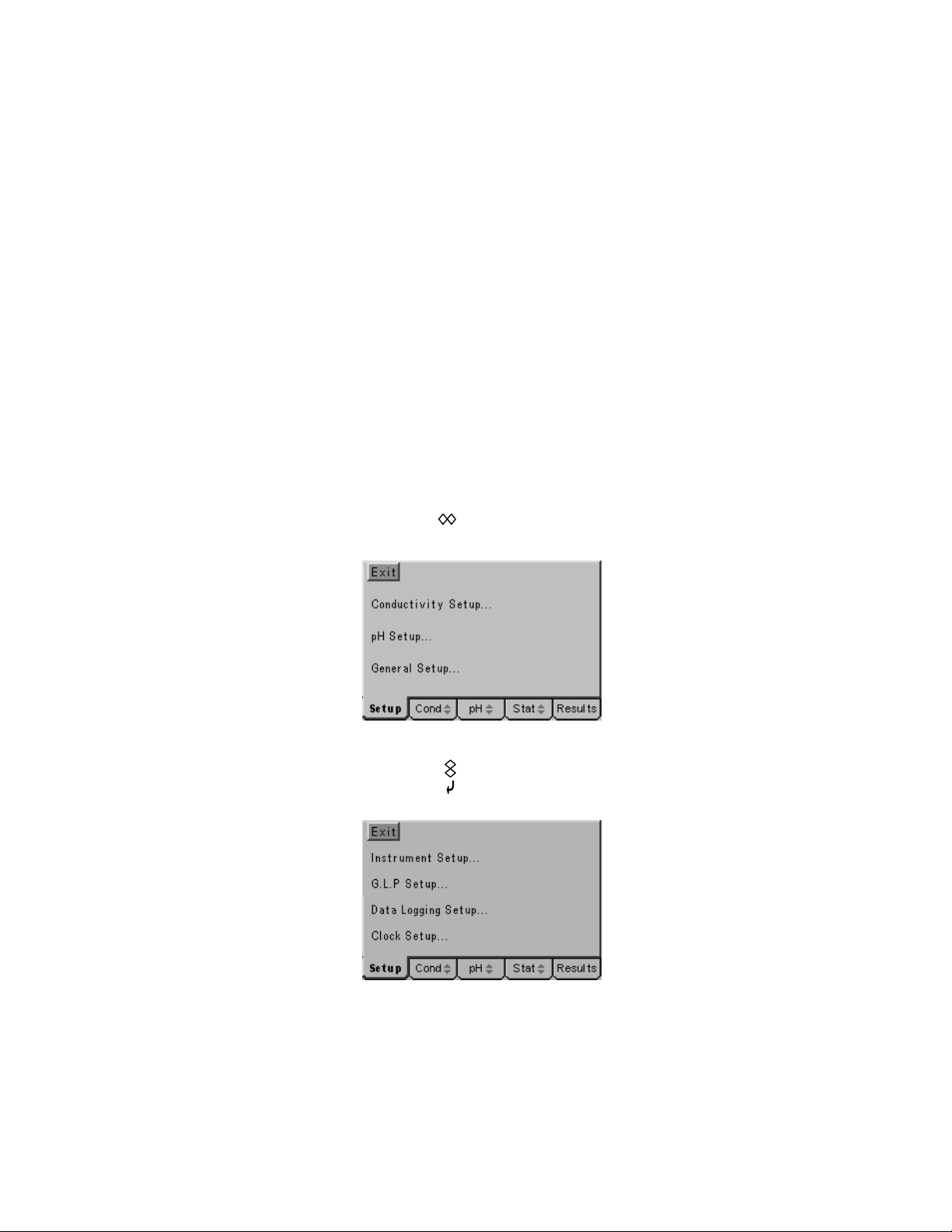

3.04 Press the right or left arrow keys [ ] to highlight the

Set Up

tab on the menu bar at

the bottom of the screen. This will open the main Set Up page.

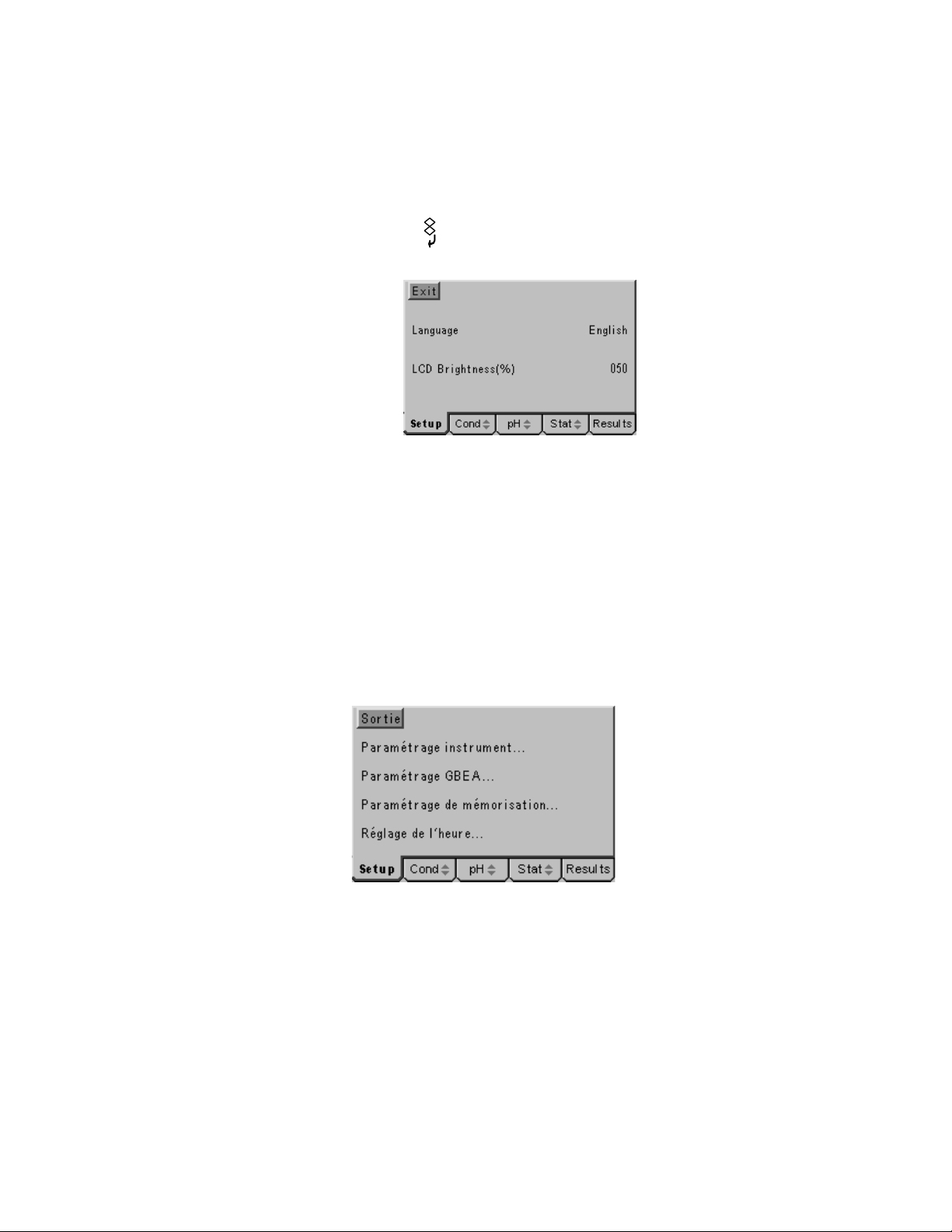

Main Set Up screen

3.05 Press the up or down arrow keys [ ] to move the highlight over the General Set

Up… option. Press the enter key [ ] to open the General Set Up page.

General Set Up Screen

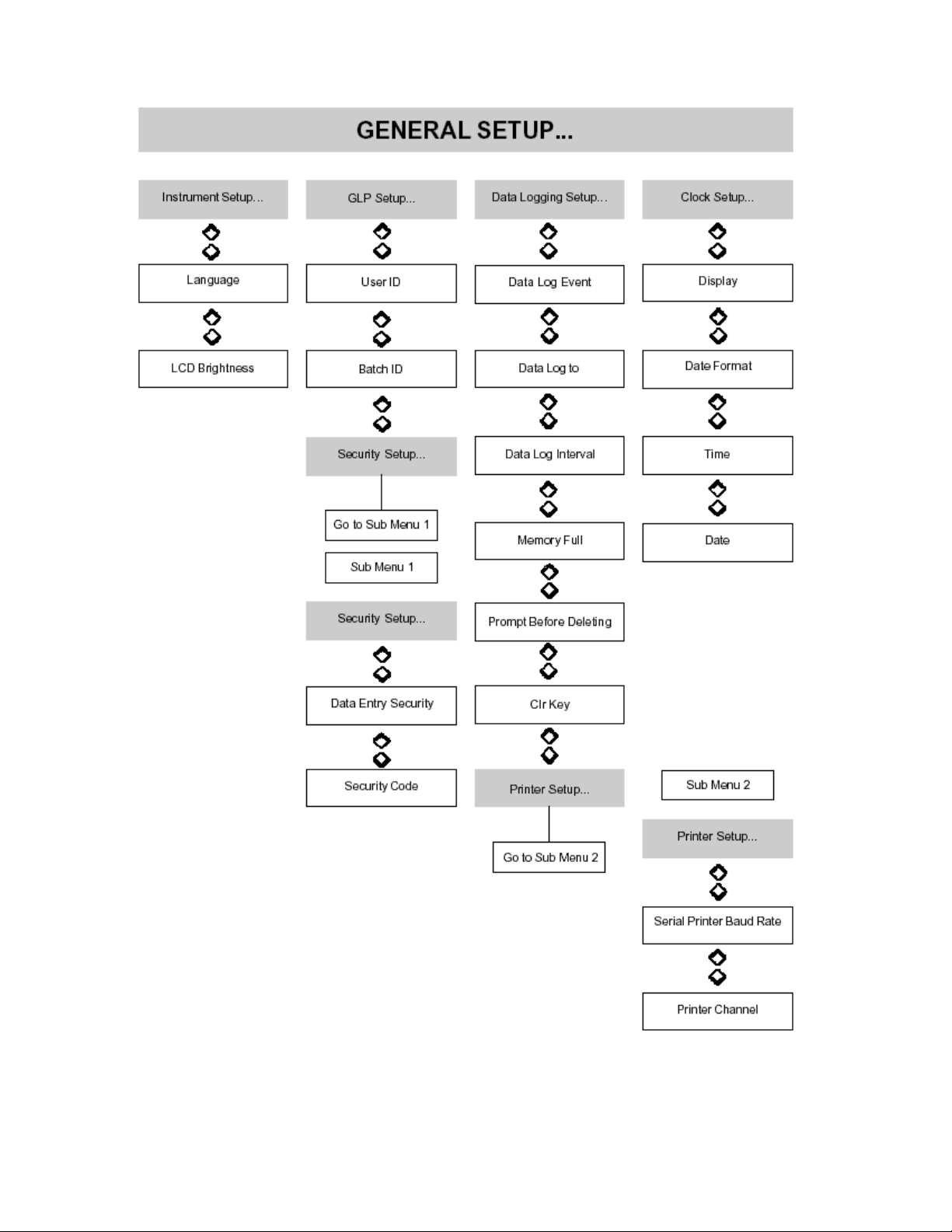

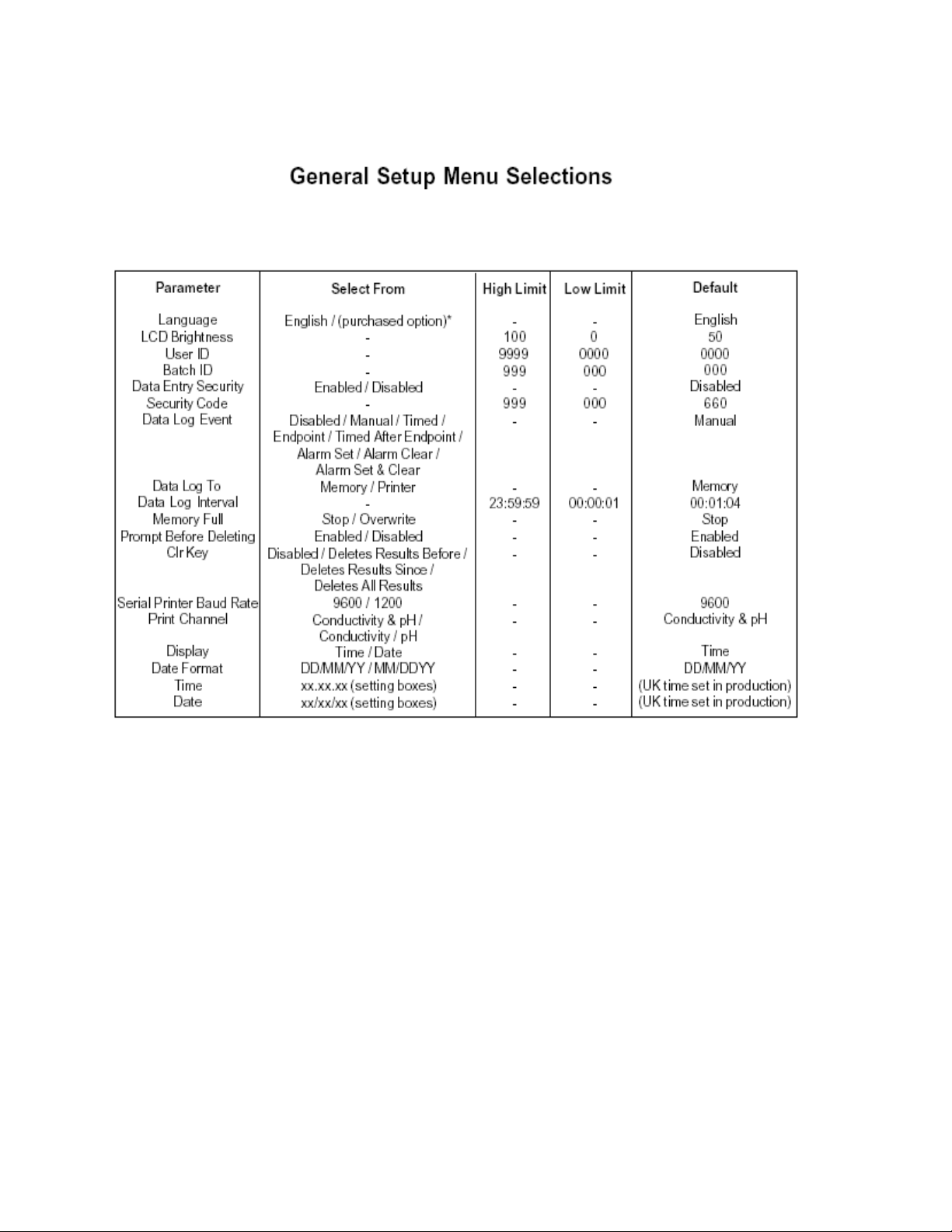

Use the General Set Up flow diagram and General Set Up menu selections on the

following pages to identify the settings that you wish to adjust from their default

values. Then refer to the following paragraphs for further guidance on making these

adjustments.

Page 16

Page 17

Page 18

3.10 Instrument Set Up

The Instrument Set Up menu contains options for selecting the operating language

and adjusting the brightness of the display to compensate for adverse lighting

situations.

Access the Instrument Set Up menu by carrying out paragraphs 3.01 to 3.05, then

use the up or down arrow keys [ ] to move the highlight over the Instrument Set Up

option then press the Enter key [ ]. The Instrument Set Up screen below will be

displayed…

3.11 Language Options

The model 3540 is supplied with two operating languages as standard. English is the

default language with the alternative being selected at the time of purchase from

French, German, Italian or Spanish.

To change the language on the display press the down arrow to highlight the

Language option in the Instrument Set Up screen, then press the Enter key. The

highlight will move across to the default language of ‘English’ or the alternative if this

has been previously changed. Use the up or down arrow keys to toggle between the

two language options and press the Enter key to accept your preferred alternative

and return the highlight to the left-hand side of the menu. Use the Escape key to

return to other menu levels or continue with setting the LCD brightness as below.

3.12 LCD Brightness %

The display brightness is optimised for a wide range of lighting conditions, should

installation in an area with unusual lighting requirements be necessary the display

brightness can be adjusted to ensure clarity is maintained. The value displayed for

the brightness is a percentage of the maximum, with 100% being the brightest and

0% being the darkest. At both extremes the contrast is such that the display can still

be read. The default value of 50% should give optimum brightness in normal

conditions.

Instrument Set Up screen

General Set Up screen displayed in French

Page 19

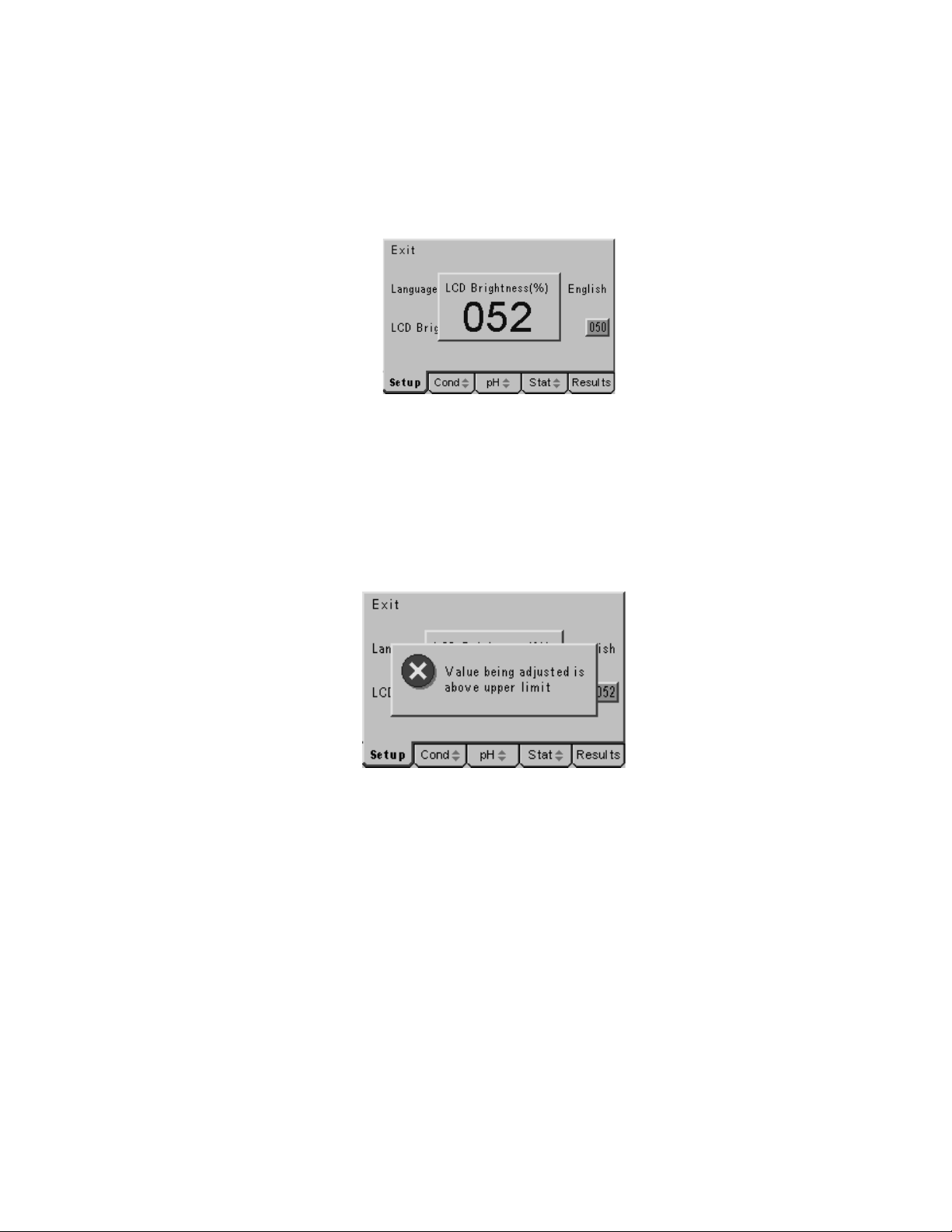

To change the brightness of the display press the down arrow to highlight the LCD

Brightness (%) option in the Instrument Set Up screen, then press the Enter key. The

highlight will move across to the percentage previously set (or the default value of

050). A data entry box will appear in the centre of the screen. The box around the

least significant digit will be flashing to indicate that this digit can be changed by

pressing the up or down arrow keys.

When this is set to the desired value the right or left arrow keys can be used to move

the flashing highlight to the other digits which in turn can be adjusted to the desired

levels with the up or down arrow keys. When all digits are set to the desired levels

press the Enter key to confirm the setting and return the highlight to the left-hand side

of the menu. Use the Escape key to return to other menu levels or continue with

setting the Language as above.

Should a value above the maximum (100%) be selected, then when the Enter key is

pressed a warning message is displayed and the setting automatically corrected to

the maximum level permitted.

Data entry box for adjusting display brightness

Warning that value entered is outside limits

Page 20

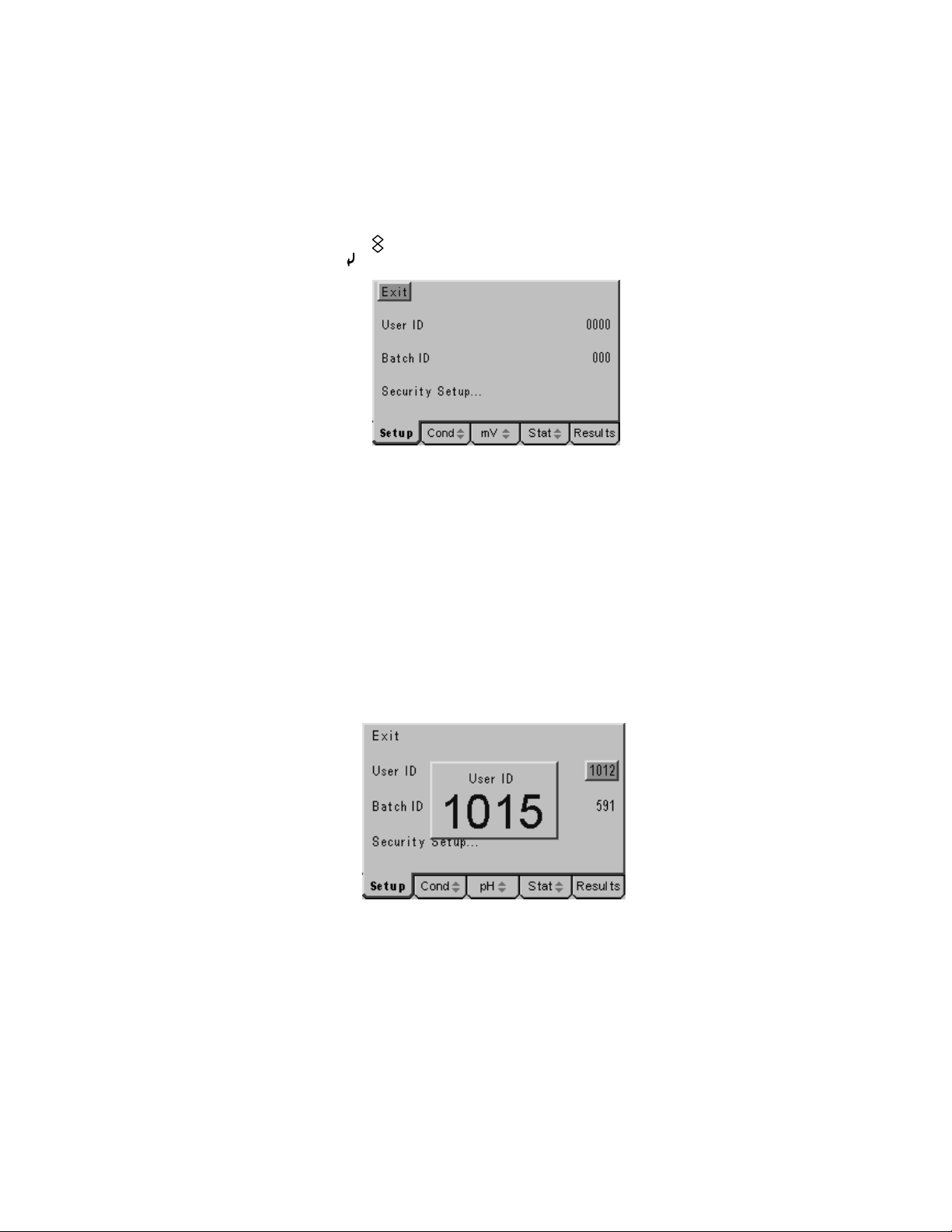

3.20 GLP Set Up

The GLP Set Up menu contains options for entering a User ID (4-digit code), a Batch

ID (3-digit code) and the Security Code options. GLP functions relating to Calibration

periods and calibration performance data are included in the Calibration Set Up

menus for each channel individually.

Access the GLP Set Up menu by carrying out paragraphs 3.01 to 3.05, then use the

up or down arrow keys [ ] to move the highlight over the GLP Set Up option then

press the Enter key [ ]. The GLP Set Up screen below will be displayed…

3.21 User ID

A four digit numeric code can be entered to identify individual users of the instrument.

This code is printed in the header of any print out generated and included with data

transmitted to a PC.

To change or set a User ID, press the down arrow to highlight the User ID option in

the GLP Set Up screen, then press the Enter key. The highlight will move across to

the User ID previously set (or the default value of 0000). A data entry box will appear

in the centre of the screen. The box around the least significant digit will be flashing to

indicate that this digit can be changed by pressing the up or down arrow keys. When

this is set to the desired value the right or left arrow keys can be used to move the

flashing highlight to the other digits which in turn can be adjusted to the desired levels

with the up or down arrow keys. When all digits are set to the desired levels press the

GLP Set Up screen

Enter key to confirm the setting and return the highlight to the left-hand side of the

menu. Use the Escape key to return to other menu levels or continue with setting the

Batch ID or Security Set Up as below.

3.22 Batch ID

A four digit numeric code can be entered to identify specific sample batches. This

code is stored with the results in internal memory, printed with all results and included

with data transmitted to a PC.

Data entry box for setting User ID

Page 21

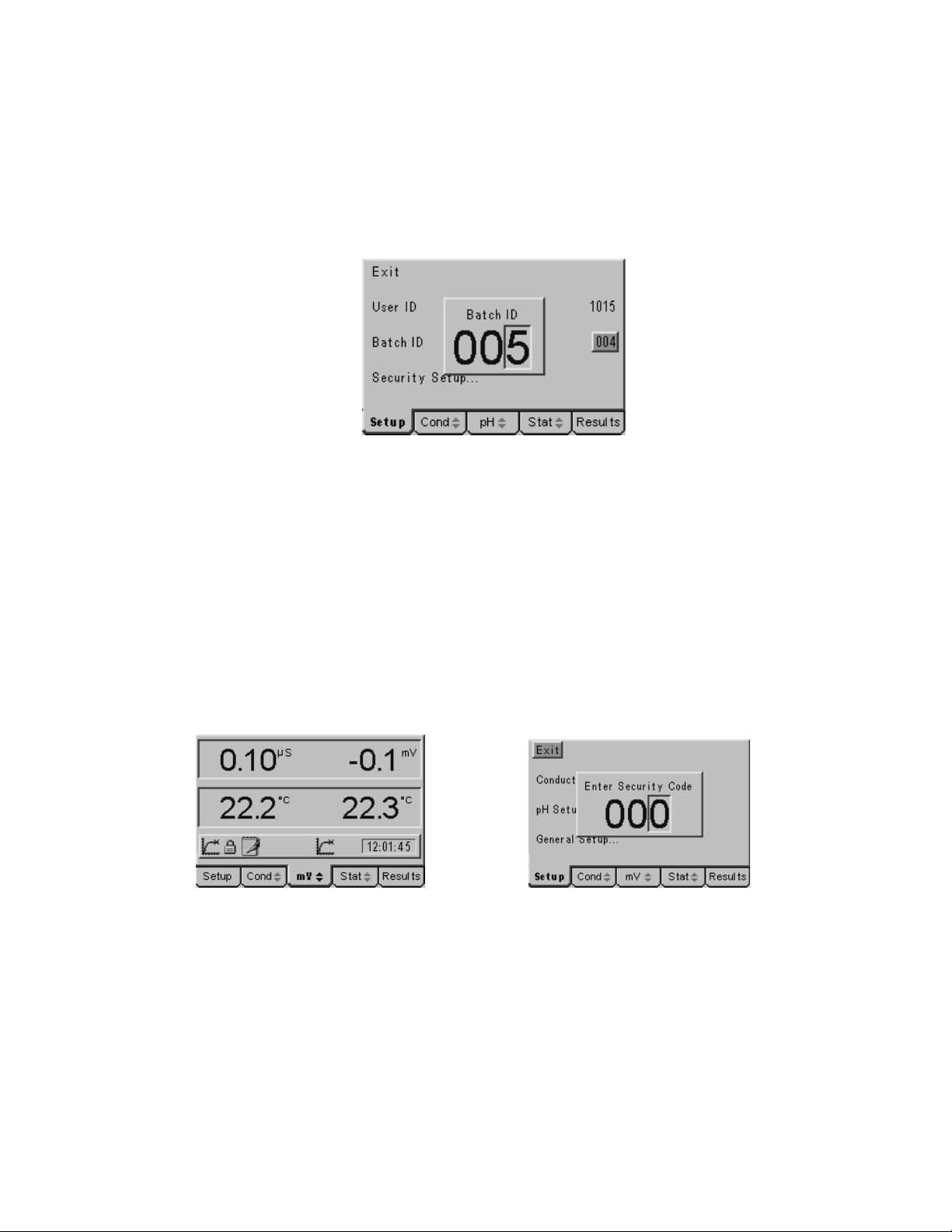

To change or set a Batch ID, press the down arrow to highlight the Batch ID option in

the GLP Set Up screen, then press the Enter key. The highlight will move across to

the Batch ID previously set (or the default value of 000). A data entry box will appear

in the centre of the screen. The box around the least significant digit will be flashing to

indicate that this digit can be changed by pressing the up or down arrow keys. When

this is set to the desired value the right or left arrow keys can be used to move the

flashing highlight to the other digits which in turn can be adjusted to the desired levels

with the up or down arrow keys.

When all digits are set to the desired levels press the Enter key to confirm the setting

and return the highlight to the left-hand side of the menu. Use the Escape key to

return to other menu levels or continue with setting the Security Set Up as follows.

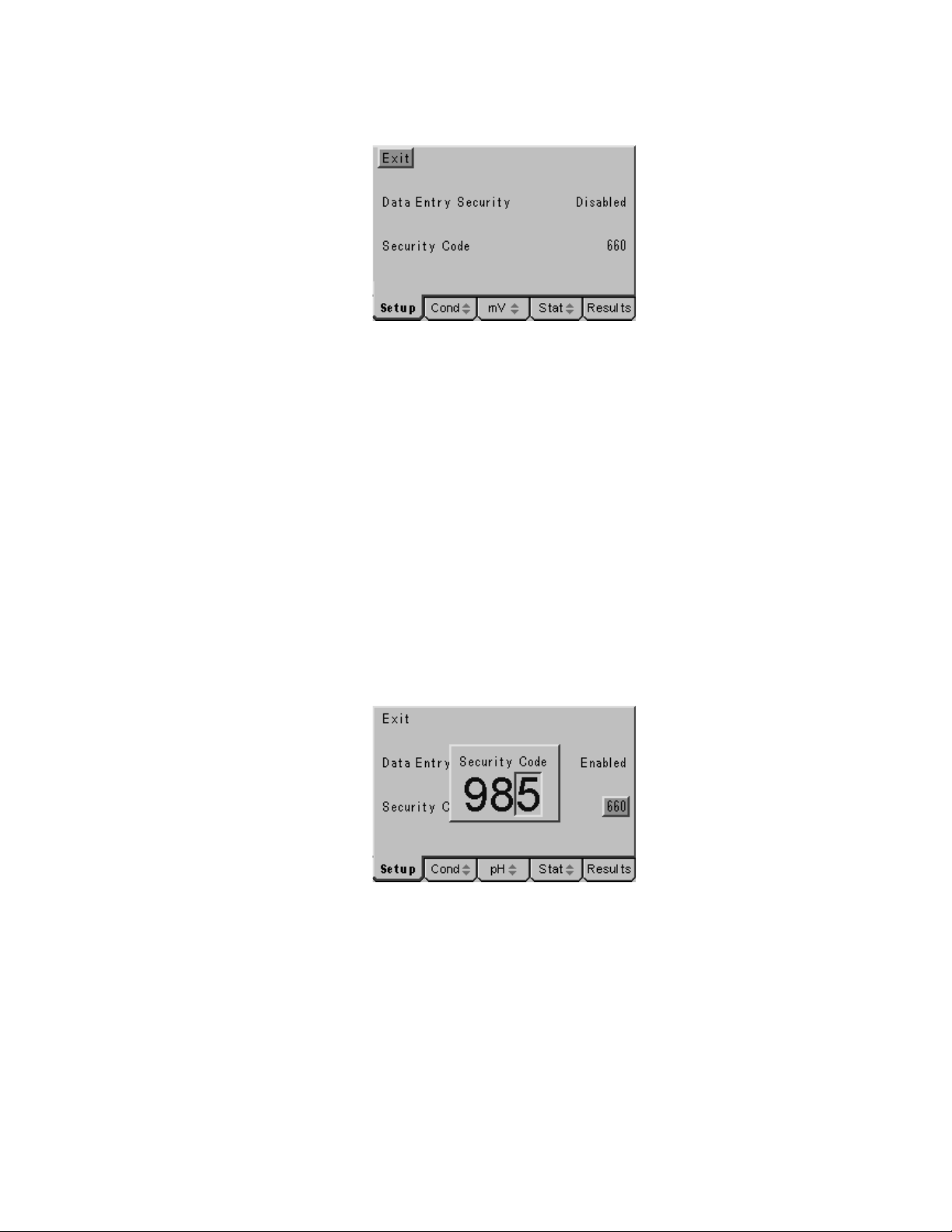

3.23 Security Set Up

The Security Set Up has a sub-menu with options to enable or disable the security

code. With it disabled there is free access to all the set up menus, with it enabled no

set up menus can be accessed without the entry of the security code. When the

security code is enabled a padlock icon appears in the status bar on the display and

when the Set Up tab is highlighted a data entry box is displayed for entry of the

security code before any further access is allowed. The sub-menu also enables the

security code to be changed by a supervisor as necessary.

Data entry box for setting Batch ID

Padlock icon indicates set up is secure Security code required to access Set Up menus

To enter the Security Set Up sub-menu, press the down arrow to highlight Security

Set Up… in the GLP Set Up screen, then press the Enter key.

Page 22

The following sub-menu is displayed.

3.23 Data Entry Security

To enable or disable data entry security (as described above) press the down arrow

key in the Security Set Up sub-menu to highlight the Data Entry Security option in the

menu. Then press the Enter key to move the highlight to the current selection. Press

the up or down key to toggle between the Disabled and Enabled options. Press the

Enter key to confirm your choice when it is highlighted and return to the left-hand side

of the menu. Use the Escape key to return to other menu levels or continue with

setting the Security Code as below.

3.24 Security Code

To change the security code from the default value or to set a new security code

press the down arrow to highlight Security Code in the Security Set Up sub-menu.

Press the Enter key to move the highlight to the current selection. A data entry box

will appear in the centre of the screen. The box around the least significant digit will

be flashing to indicate that this digit can be changed by pressing the up or down

arrow keys. When this is set to the desired value the right or left arrow keys can be

used to move the flashing highlight to the other digits, which in turn can be adjusted

to the desired levels with the up or down arrow keys.

Security Set Up sub-menu

When all digits are set to the desired levels press the Enter key to confirm the setting

and return the highlight to the left-hand side of the menu. Use the Escape key to

return to other menu levels or the main measurement screen.

Data entry box for setting a new security code

Page 23

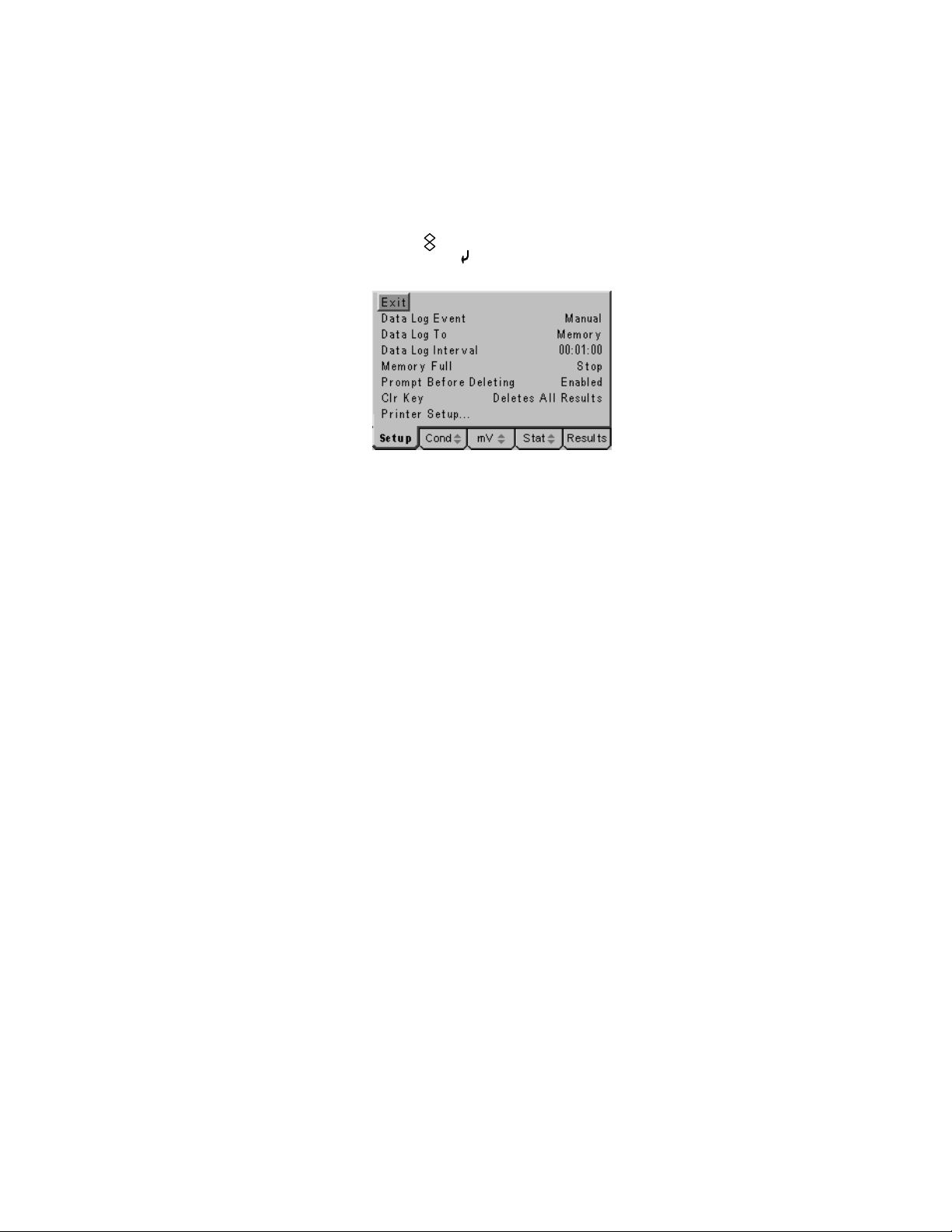

3.30 Data Logging Set Up

The data logging set up menu enables all the functions of the data logger to be set,

including the event trigger, logging period and data destination. The function of the

Clear [CLR] key on stored data can also be set, there is also a sub-menu for the

Printer options.

Access the Data Logging Set Up menu by carrying out paragraphs 3.01 to 3.05, then

use the up or down arrow keys [ ] to move the highlight over the Data Logging Set

Up option, then press the Enter key [ ]. The Data Logging Set Up screen below will

be displayed…

3.31 Data Log Event

The data log event is the occurrence that triggers data to be sent to either internal

memory or the printer/computer via the serial port. There are eight options, making

this a useful and comprehensive function.

Disabled: Effectively switches data logging functions off.

Manual:

Data logging is triggered from a press of the Store [STO] key only.

Timed Interval: Data logging is triggered on a period set by the Data Log interval.

Endpoint Detection:

reaches stability – this can be used to enhance productivity when measuring batches

of samples by having the results automatically printed or stored without the operator

having to even press a button.

Timed after Endpoint:

only after the endpoint detection – this enables data from reactions or slowly

changing sample streams to be logged with more control.

Alarm Set: Data logging is triggered when one of the alarm conditions is reached.

This is useful for tracking time/date of problems occurring.

Alarm Clear: Data logging is triggered when one of the alarm conditions is cleared.

This is useful for tracking time and date when problems are cleared.

Alarm Set & Clear: Data logging is triggered when one of the alarm conditions is set

and also when they are cleared. This gives useful data for analysing problems or

control functions.

Data Logging Set U p screen

Data logging is triggered when the sample measurement

Data logging is triggered at the entered data log interval but

Page 24

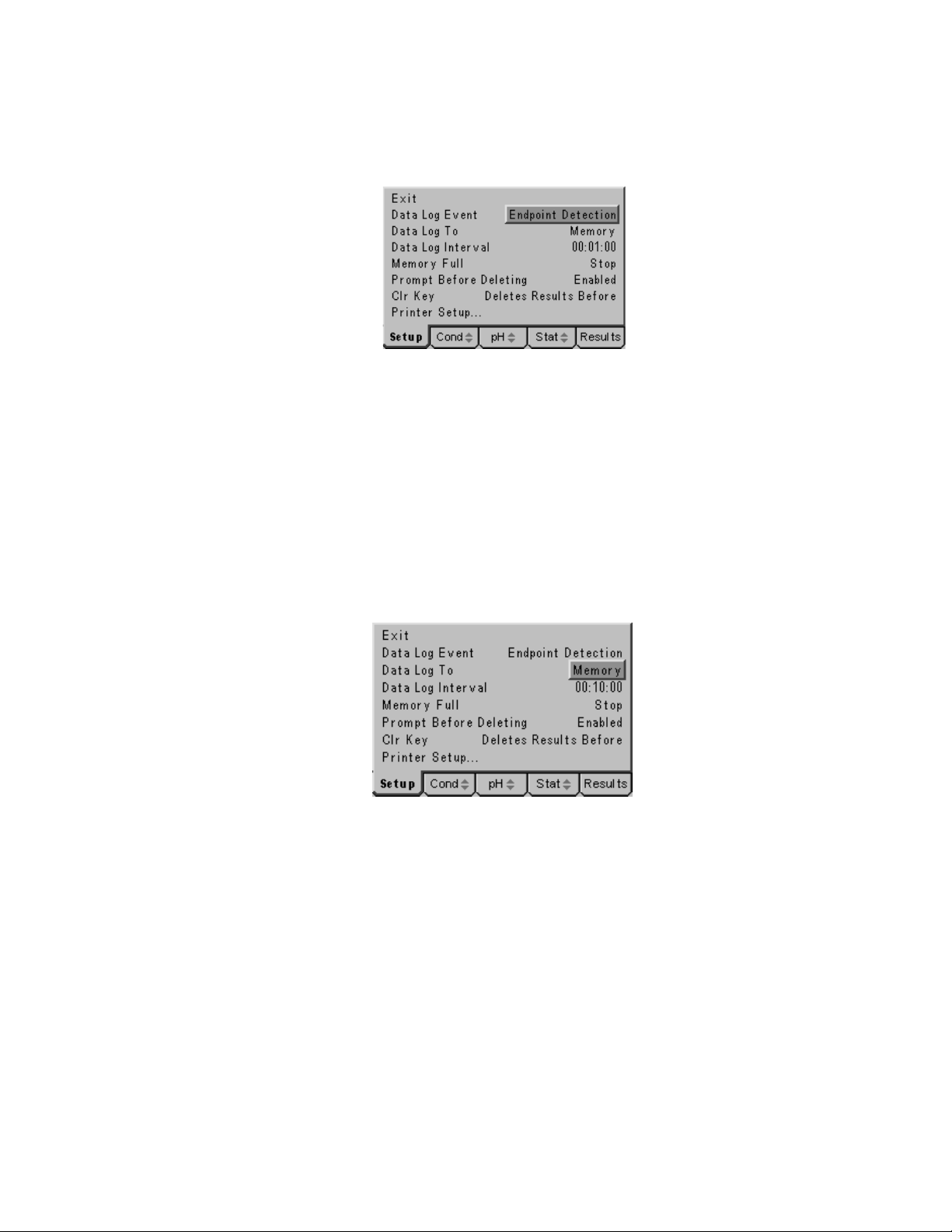

To change the data logging trigger press the down arrow to highlight Data Log Event

in the Data Logging Set Up screen, then press the Enter key. The highlight will move

across to the default setting of ‘Manual’ or an alternative from the above if this has

previously been changed. Use the up or down arrow keys to review the options and

press the Enter key to accept your preferred setting when this is highlighted on the

display. Use the Escape key to return to other menu levels or continue with setting

the other data logging options as follows.

3.32 Data Log To

Data logged on the event selected from the above can either be stored in internal

memory or sent via the serial port to a printer or PC. The Data Log To option allows

selection of either the internal memory or printer for this function.

To change the destination for logged data press the down arrow to highlight Data Log

To in the Data Logging Set Up screen, then press the Enter key. The highlight will

move across to the default setting of ‘Memory’ or ‘Printer’ if this has previously been

changed.

Use the up or down arrow keys to toggle between the options and press the Enter

key to accept your preferred setting when this is highlighted on the display. Use the

Escape key to return to other menu levels or continue with setting the other data

logging options as below.

3.33 Data Log Interval

The data log interval is effective when timed data logging is selected and also sets

the time delay after the endpoint if this option is selected. Time periods from 1 second

to 24 hours (1 result stored per day) can be set.

Use the up or down keys to select required Data Log Event

Select destination for logged data

Page 25

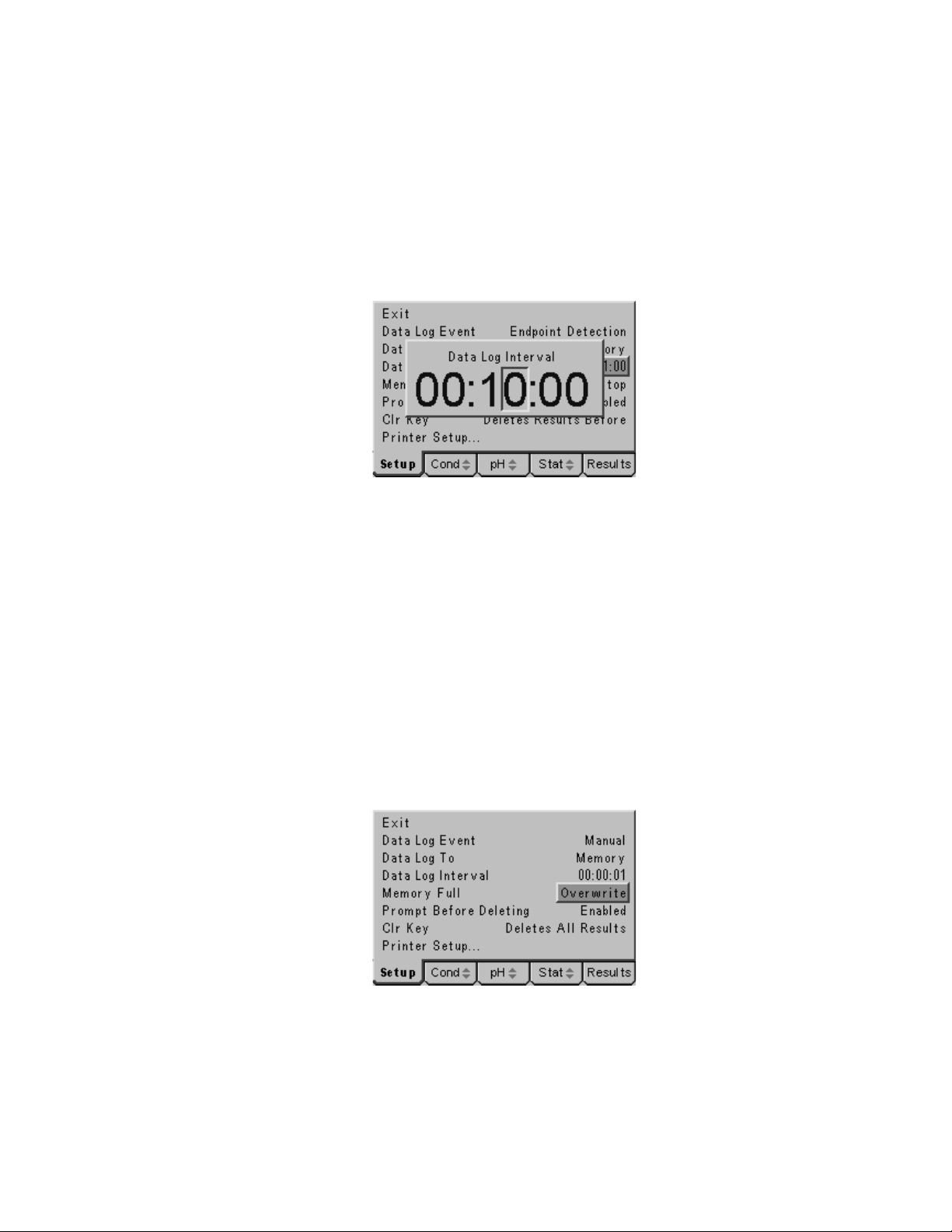

To change the data log interval from the default value or to set a new interval press

the down arrow to highlight Data Log Interval in the Data Logging Set Up screen.

Press the Enter key to move the highlight to the current selection. A data entry box

will appear in the centre of the screen. The box consists of three pairs of digits

separated by colons, from the left these represent hours, minutes and seconds. The

box around the least significant of the seconds’ digits will be flashing to indicate that

this digit can be changed by pressing the up or down arrow keys. When this is set to

the desired value the right or left arrow keys can be used to move the flashing

highlight to the other digits, which in turn can be adjusted to the desired levels with

the up or down arrow keys.

When all digits are set to give the desired time period press the Enter key to confirm

the setting and return the highlight to the left-hand side of the menu. Use the Escape

key to return to other menu levels or continue with setting the other data logging

options as follows.

3.34 Memory Full

The internal memory can store up to 250 pH and conductivity readings. The ‘Memory

Full’ option offers two alternative actions when this limit is reached; Stop, which stops

further logging and switches off the data pad icon on the display, or Overwrite, which

starts overwriting the oldest records with the newly stored data.

To change the action when the memory is full press the down arrow to highlight

Memory Full in the Data Logging Set Up screen, then press the Enter key. The

highlight will move across to the default setting of ‘Stop’ or ‘Overwrite’ if this has

previously been changed. Use the up or down arrow keys to toggle between the

Set Data Log Interval by adjusting each digit in turn

Select the required action if the memory is full

options and press the Enter key to accept your preferred setting when this is

highlighted on the display. Use the Escape key to return to other menu levels or

continue with setting the other data logging options as below.

Page 26

3.35 Prompt Before Deleting

Data stored in memory can be deleted by use of the clear [CLR] key on the keypad. If

this option is enabled it allows the operator to be prompted by a message to confirm

the deletion, or if disabled the result is deleted on the first press of the clear [CLR]

key. The function of the clear [CLR] key can also be set in the Data Logging Set Up

screen.

To enable or disable the ‘Prompt Before Deleting’ function press the down arrow to

highlight Prompt Before Deleting in the Data Logging Set Up screen, then press the

Enter key. The highlight will move across to the default setting of ‘Enabled’ or

‘Disabled’ if this has previously been changed. Use the up or down arrow keys to

toggle between the options and press the Enter key to accept your preferred setting

when this is highlighted on the display.

Use the Escape key to return to other menu levels or continue with setting the other

data logging options as below.

3.36 Clear Key Function

The clear [CLR] key is only active when the Results screen has been selected on the

tabbed menu bar. The clear [CLR] key is used to delete records from the internal

memory. To make manipulation of stored data more efficient the clear [CLR] key can

be given a range of functions:

Disabled: With this setting the clear key has no effect at all on stored results.

Deletes All Results:

from the internal memory – it is recommended that this is always used with the

Prompt Before Deleting option enabled.

Deletes Results Since..: With this setting a press of the clear key will display a

message box indicating this function is active. A highlight then appears on the

displayed page of results; this can be moved up or down the page with the up or

down arrow keys. When at the required point on the page a further press of the clear

key will delete all results stored since that time and date.

Deletes Results Before..: With this setting a press of the clear key will display a

message box indicating this function is active. A highlight then appears on the

displayed page of results; this can be moved up or down the page with the up or

down arrow keys. When at the required point on the page a further press of the clear

key will delete all results stored before that time and date.

Warning on first press of Clear key

With this setting a press of the clear key will delete all results

Page 27

To change the clear key function, press the down arrow to highlight ‘Clr Key’ in the

Data Logging Set Up screen, then press the Enter key. The highlight will move across

to the default setting of ‘Disabled’ or an alternative from the above if this has

previously been changed.

With Clear key function set as ‘Deletes results Before’ a further key press will delete all results before the highlight

Use the up or down arrow keys to review the options and press the Enter key to

accept your preferred setting when this is highlighted on the display.

Use the Escape key to return to other menu levels or continue with setting the other

data logging options as below.

3.37 Printer Set up…

The printer set up has a separate sub-menu that can be accessed by pressing the up

or down arrow keys to highlight Printer set up… in the Data Logging Set Up screen,

then pressing the Enter key. The Printer Set Up screen has options for setting the

Baud rate of the transmission as well as the channel(s) printed.

3.38 Baud Rate

To set the Serial Printer Baudrate press the down arrow key to highlight the Serial

Printer Baudrate option on the Printer Set Up screen, then press the Enter key. The

highlight will move across to the default setting of ‘9600’ or ‘1200’ if this has

previously been changed. Use the up or down arrow keys to toggle between the

options and press the Enter key to accept your preferred setting when this is

highlighted on the display. Use the Escape key to return to other menu levels or

continue with setting the other printer set up options as below.

Printer Set Up screen

Page 28

3.38 Print Channel

This enables the print data to be configured so that just conductivity, just pH or

conductivity and pH results are printed, reducing the print out of unnecessary data.

To select which channel(s) are printed press the down arrow to highlight Print

Channel on the Printer Set Up screen, then press the Enter key. The highlight will

move across to the default setting of ‘Conductivity & pH’ or one of the above options if

this has previously been changed. Use the up or down arrow keys to view the options

and press the Enter key to accept your preferred setting when this is highlighted on

the display. Use the Escape key to return to other menu levels or the measurement

screen.

3.40 Time/Date Set Up

The Clock Set up menu enables the time and date to be set and enables either the

time or date to be selected for display on the main measurement screen.

Access the Clock Set Up menu by carrying out paragraphs 3.01 to 3.05, then use the

up or down arrow keys [ ] to move the highlight over the Clock Set Up option, then

press the Enter key [ ]. The Clock Set Up screens below will be displayed, the initial

warning that data will be lost from memory if the clock is adjusted is to protect, for

GLP conformance, the integrity of the date/time stamp on stored results. For this

reason clock/time settings should always be made before any data is stored or if

changes are made all data should be copied to an external source first. Corrections

for daylight saving are permitted with no effect on stored data.

Changing date will invalidate stored data Clock Set Up screen

3.41 Display

To select between the display of the Time or Date on the main measuring screen

press the down arrow key in the Clock set Up menu to highlight the Display option,

then press the Enter key. The highlight will move across to the default setting of

‘Time’ or ‘Date’ if this has previously been changed. Use the up or down arrow keys

to toggle between the options and press the Enter key to accept your preferred

setting when this is highlighted on the display. Use the Escape key to return to other

menu levels or continue with setting the other Clock Set Up options as below.

3.42 Date Format

The date can be displayed in either European format (with the day first, DD/MM/YY)

or in American format (with the month first, MM/DD/YY). To select between the two

formats press the down arrow key in the Clock set Up menu to highlight the Date

Format option, then press the Enter key. The highlight will move across to the default

setting of ‘DD/MM/YY’ or ‘MM/DD/YY’ if this has previously been changed. Use the

up or down arrow keys to toggle between the options and press the Enter key to

accept your preferred setting when this is highlighted on the display. Use the Escape

key to return to other menu levels or continue with setting the other Clock Set Up

options as below.

Page 29

3.43 Time Setting

To adjust the time (see warning in paragraph 3.40) Press the down arrow to highlight

the Time option in the Clock Set Up screen. Then press the Enter key to move the

highlight to the current time setting. A data entry box will appear in the centre of the

screen. The box consists of three pairs of digits separated by colons, from the left

these represent hours, minutes and seconds.

The box around the least significant of the seconds’ digits will be flashing, press the

right or left arrow keys to move this to the hours digits and adjust each digit in turn

with the up or down arrow keys to display the current hour of the day. Then press the

right or left arrow key to set the minutes to the current time with the up or down arrow

keys. Finally repeat the process with the seconds digits allowing time to press the

Enter key to confirm the setting. Use the Escape key to return to other menu levels or

continue with setting the other Clock Set Up options as below.

3.44 Date Setting

To adjust the date (see warning in paragraph 3.40) Press the down arrow to highlight

the Date option in the Clock Set Up screen. Then press the Enter key to move the

highlight to the current Date setting. A data entry box will appear in the centre of the

screen. The box consists of three pairs of digits separated by /, these represent the

date in the format selected. The box around the least significant of the years’ digits

will be flashing, adjust each digit in turn with the up or down arrow keys to display the

current year.

Data entry box for adjusting the time setting

Data entry box for adjusting the date setting

Then press the right or left arrow key to set the month (or day depending on format

selected) to the correct value with the up or down arrow keys. Finally repeat the

process with the day (or month depending on format selected) then press the Enter

key to confirm the setting. Use the Escape key to return to other menu levels or the

main measurement screen.

Page 30

Section 4

Conductivity Set Up

4.00 General Set Up

The conductivity set up options include settings for all the functions that are relevant

for the conductivity channel only. Functions that can be set in these menus are

calibration settings, alarm settings, endpoint stability and ATC/temperature settings.

Adjustments made to these are stored in non-volatile memory so will not need to be

re-entered unless further changes are required. They will also be retained regardless

of the power connection to the instrument.

4.01 Connect the power supply as described in section 2.2.3. It is not necessary to

connect the probes for the set-up procedures.

4.02 Switch on the power at the supply socket; then press the power on/off key on the

instrument.

4.03 The 3540 start up screen is shown for a few seconds followed by the main

measurement

screen with either the pH or conductivity tab highlighted (depending on

which was active when power was switched off).

4.04

Press the right or left arrow keys [ ] to highlight the Set Up tab on the menu bar at

the bottom of the screen. This will open the main Set Up page.

Main Set Up screen

4.05 Press the up or down arrow keys [ ] to move the highlight over the Conductivity

Set Up… option. Press the enter key [ ] to open the Conductivity Set Up page.

Conductivity Set Up screen

Use the Conductivity Set Up flow diagram and Conductivity Set Up menu selections

on the following pages to identify the settings that you wish to adjust from their default

values. Then refer to the following paragraphs for further guidance on making these

adjustments.

Page 31

Page 32

Page 33

4.10 Conductivity Calibration Set Up

The conductivity calibration set up menu contains options for setting the Cell

Constant (K factor), the EC ratio for TDS measurement, the Reference temperature

and co-efficient as well as the ultra-pure water compensation algorithm. There are

also sub-menus for entering Calibration standard values and for the calibration

reminder. Access the Conductivity Calibration Set Up menu by carrying out

paragraphs 4.01 to 4.05, then use the up or down arrow keys to move the highlight

over the Calibration Set Up option then press the Enter key. The Calibration Set Up

screen below will be displayed…

4.11 Cell Constant (K)

Most conductivity probes are supplied with a cell constant (K factor) that has been

calculated during manufacture. This offers a quick and basic method for calibration

without the need for standard solutions. It should be noted that this cell constant is

dependent on the condition of the plates in the probe; wear and the quality of routine

maintenance will affect these. This method of calibration should be used with care.

The cell constant that is shown in this menu is up-dated whenever a calibration is

carried out with standard solutions so can be used to re-calculate this value.

To set the cell constant to that indicated on the conductivity probe in use, press the

down arrow to highlight Cell Constant (K) in the Conductivity Calibration set Up

screen then press the Enter key to move the highlight to the current selection. A data

entry box will appear in the centre of the screen (as shown below). The box around

the least significant digit will be flashing to indicate that this digit can be changed by

pressing the up or down arrow keys. When this is set to the desired value the right or

left arrow keys can be used to move the flashing highlight to the other digits, which in

turn can be adjusted to the desired levels with the up or down arrow keys.

Conductivity calibration Set Up screen

Data entry box for setting the Cell Constant (K)

When all digits are set to the desired levels press the Enter key to confirm the setting

and return the highlight to the left-hand side of the menu. Use the Escape [ESC] key

to return to other menu levels or continue with the conductivity calibration set up as

follows.

Page 34

4.12 EC Ratio Setting

The EC ratio is the factor that calculates the TDS value from the conductivity

measurement. There are a number of different international and trade standards that

specify this value. The model 3540 offers adjustment over the range of 0.5 to 0.8, this

covers all potential requirements for this value. The most common standard requires

a value of 0.60 that is the default setting. Should you require to set an alternative

value press the down arrow to highlight EC Ratio in the Conductivity Calibration set

Up screen, then press the Enter key to move the highlight to the current selection. A

data entry box will appear in the centre of the screen (as shown below). The box

around the least significant digit will be flashing to indicate that this digit can be

changed by pressing the up or down arrow keys. When this is set to the desired value

the right or left arrow keys can be used to move the flashing highlight to the other

digits, which in turn can be adjusted to the desired levels with the up or down arrow

keys. When all digits are set to the desired levels press the Enter key to confirm the

setting and return the highlight to the left-hand side of the menu. Use the Escape

[ESC] key to return to other menu levels or continue with the conductivity calibration

set up as follows.

Data entry box for setting the EC ratio for TDS measuremnts

4.13 Temperature Co-efficient Setting

Conductivity varies with temperature; this variation is dependent on the different ions

in solution and their total and respective concentrations. The temperature co-efficient

is the percentage change in conductivity per degree Celsius. Where just one ionic

species is present in solution relevant data is available and an accurate temperature

co-efficient can be entered. Where a more complex mixture of ions exists in solution

the co-efficient will need to be estimated or calculated by experiment. The default

value of 1.91 is regarded as an effective average where the temperature co-efficient

is unknown. Alternatively (and in conformance with USP standards) the temperature

co-efficient can be set to zero (where the temperature compensation is switched off)

and all calibration and sample measurement carried out at the Reference

Temperature.

Page 35

Should you require to change the temperature co-efficient press the down arrow key

to highlight Temperature Co-efficient (%) in the Conductivity Calibration set Up

screen, then press the Enter key to move the highlight to the current selection. A data

entry box will appear in the centre of the screen.

Data entry box for setting the Temperature Co-efficient

The box around the least significant digit will be flashing to indicate that this digit can

be changed by pressing the up or down arrow keys. When this is set to the desired

value the right or left arrow keys can be used to move the flashing highlight to the

other digits, which in turn can be adjusted to the desired levels with the up or down

arrow keys. When all digits are set to the desired levels press the Enter key to

confirm the setting and return the highlight to the left-hand side of the menu. Use the

Escape [ESC] key to return to other menu levels or continue with the conductivity

calibration set up as follows.

4.14 Reference Temperature Setting

The conductivity value displayed is the value as it would be at a reference

temperature based on the temperature co-efficient as described above. The most

common reference temperature is 25 degrees Celsius, but other standards have

quoted both 20 and 18 degrees Celsius.

To select an alternative reference temperature from those above, press the down

arrow to highlight Reference Temperature on the Conductivity Calibration Set Up

screen, then press the Enter key. The highlight will move across to the default setting

o

of ‘25

C’ or one of the above options if this has previously been changed. Use the up

or down arrow keys to view the options and press the Enter key to accept your

preferred setting when this is highlighted on the display. Use the Escape key to return

to other menu levels or continue setting up the Conductivity calibration as follows.

4.15 Ultra-Pure Water Temperature Correction

The measurement of ultra-pure water is a major conductivity application, for this

purpose the 3540 has a non-linear temperature compensation algorithm that can be

used to report results conforming to BS/EN 2788, DIN 3840 sec 2.35 and BS6068.

This option must only be enabled for the above application and must be disabled for

all other applications.

To enable the ultra-pure water temperature compensation, press the down arrow to

highlight Ultra-Pure Temp Correction on the Conductivity Calibration Set Up screen,

then press the Enter key. The highlight will move across to the default setting of

‘Disabled’. Use the up or down arrow keys to select ‘Enabled’ and press the Enter key

to accept this setting when it is highlighted on the display. Use the Escape key to

return to other menu levels or continue setting up the Conductivity calibration as

follows.

Page 36

4.16 Calibration Standard Set up

A sub-menu for the selection of calibration standards, including the manual or

automatic recognition of from one to three values is available. To select the sub-menu

press the down arrow key to highlight Calibration Buffer Set up… in the Conductivity

Calibration Set Up screen, press the Enter key to display the screen below…

Calibration Standards for conductivity calibration

Cal Buffers Used

This option enables the number of standards used for calibration to be selected. Up

to three points can be selected as well as a probe zero setting (see section 6.2).

To set the number of calibration points required press the down arrow key in the

Conductivity Calibration Set Up sub menu to highlight the Cal Buffers Used option.

Press the Enter key to move the highlight to the default value of One (this may be

Two or Three if previously adjusted). Use the up or down arrow keys to view the

options and press the Enter key to accept the desired value when it is highlighted on

the display. Use the Escape [ESC] key to move to other menu levels or continue with

the Conductivity calibration settings as follows.

Cal Buffer Set

Three values for standard solutions can be entered into memory. If these are from the

four values automatically recognised, then they can be measured in any order at any

time with the Auto Recognition setting. These values are 12.88mS, 1413µS, 84µS

and 10µS at 25 degrees Celsius. If other values that are not automatically recognised

are required they must be measured in the order they are entered with the Manual

setting.

To select Manual standard entry press the down arrow key in the Conductivity

Calibration Set Up sub menu to highlight the Cal Buffers Set option. Press the Enter

key to move the highlight to the default value of Auto Recognition. Use the up or

down arrow keys to toggle between the options and press the Enter key to accept the

desired setting when it is highlighted on the display. Use the Escape [ESC] key to

move to other menu levels or continue with the Conductivity calibration settings as

follows.

Cal 1 to 3 Buffer (mS)

The three values for the standard solutions to be used should be entered in the last

three lines of this menu. The setting procedure is identical so will be described once

for all three options. Values for the automatically recognised standards should be

entered with the Auto Recognition setting as described above other values must be

measured in the order they are entered. To limit carry over the lowest conductivity

standard should be measured (therefore entered) first. All values entered here should

reflect the conductivity of the standard at the reference temperature selected.

Page 37

Press the down arrow in the Conductivity Calibration Set Up sub menu to highlight

the Cal 1 (2 or 3) Buffer(mS) option. Press the Enter key to move the highlight to the

current value. Use the Escape [ESC] key to move to other menu levels or continue

with the Conductivity calibration settings as follows. A data entry box will appear in

the centre of the screen. This has 7 digits and represents the calibration standard in

value in mS, with three decimal places the least significant digit represents 1

µS. The

box around the least significant digit will be flashing to indicate that this digit can be

changed by pressing the up or down arrow keys. When this is set to the desired value

the right or left arrow keys can be used to move the flashing highlight to the other

digits, which in turn can be adjusted to the desired levels with the up or down arrow

keys.

Adjusting one of the three conductivity calibration values

When all digits are set to the desired levels press the Enter key to confirm the setting

and return the highlight to the left-hand side of the menu. Use the Escape [ESC] key

to return to other menu levels or the main measurement screen.

Calibration Reminder Set Up…

To ensure correct calibration at routine intervals a calibration reminder can be set for

the conductivity channel (and independently for the pH channel, see section 5.17).

The settings enable a variable time interval from 1 to 999 hours to be set. A visible

warning replaces the displayed reading when this time period has elapsed; it is also

possible to enable an audible warning if required.

Warning replaces conductivity reading when calibration id due

Page 38

To select the sub-menu for setting the Calibration Reminder options press the up or

down arrow key to highlight Calibration Reminder Set up… in the Conductivity

Calibration Set Up screen, press the Enter key to display the screen below…

Calibration Reminder Set Up screen

Cal Reminder

The calibration reminder function can be enabled or disabled. The default condition is

disabled, to enable the calibration reminder press the down arrow key in the

Calibration Reminder sub-menu to highlight the Cal Reminder option; then press the

Enter key. The highlight will move across to the current setting, use the up or down

keys to toggle between the enabled and disabled options, press the Enter key to

select the desired option when it is highlighted on the display. Use the Escape [ESC]

key to return to other menu levels or continue with setting the Calibration Reminder

options as follows.

Cal Reminder Interval (Hr)

With the calibration reminder function enabled the Cal reminder interval becomes

effective as the period from the last calibration when the warning is displayed. The

calibration reminder interval can be set from 1 hour to 999 hours and can only be

cleared by carrying out a new calibration. To set the calibration reminder interval

press the down arrow key in the Calibration Reminder sub-menu to highlight the Cal

Reminder Interval (Hr); then press the Enter key. A data entry box will appear in the

centre of the screen. The box around the least significant digit will be flashing to

indicate that this digit can be changed by pressing the up or down arrow keys. When

this is set to the desired value the right or left arrow keys can be used to move the

flashing highlight to the other digits, which in turn can be adjusted to the desired

levels with the up or down arrow keys. When all digits are set to the desired levels

press the Enter key to confirm the setting and return the highlight to the left-hand side

Data box for setting the Cal reminder Interval in Hours

of the menu. Use the Escape [ESC] key to return to other menu levels or continue

with setting the Calibration Reminder options as follows.

Page 39

Cal Reminder Audible Alarm

When the cal reminder interval has elapsed a visual warning is displayed in place of

the relevant reading, to enhance this warning an audible alarm that bleeps every 5

seconds can also be enabled. This audible warning is active whenever the

conductivity tab on the menu bar is selected. To enable the audible alarm, press the

down arrow to highlight the Cal Reminder Audible Alarm option on the Cal Reminder

sub-menu, then press the Enter key. The current selection is highlighted and the up

or down arrow keys can be used to toggle between the enabled and disabled options.

Press the Enter key to accept the desired setting when it is highlighted on the display.

Use the Escape [ESC] key to move to other menu levels or return to the main

measurement screen.

4.20 Conductivity Alarms Set Up

Two alarm levels are available for each mode of operation. One is a HIGH level with

the alarm being tripped when the measured value goes ABOVE the high level

entered. The other is a LOW level with the alarm being tripped when the measured

value goes BELOW the low level entered.

With the alarm function enabled a visible indication is given, when the alarms are

tripped, via the alarm bell icon on the display with an upward pointing arrow when the

Conductivity High Al arm indicated by alarm bell icon and upward arrow

high alarm is tripped and downward pointing arrow when the low alarm is tripped. It is

also possible to enable an internal audible alarm to complement the alarm bell icon.

An output from the rear panel sockets is also available to switch external audio/visual

alarms or for simple control/telemetry functions via external relays. Details of the

relevant connections for these outputs are contained in Section 10.6.

Page 40

To enable the alarms and set the relevant high and low alarm levels press the down

arrow key in the Conductivity Set Up menu to highlight Alarms Set Up…

Conductivity Set Up menu – Alarms Set Up highlighted

Press the Enter key to display the Alarms Set Up menu as below…

4.21 Alarm Outputs

This option enables or disables all of the alarm functions and overrides the audible

alarm warning that can be separately disabled/enabled only when this function is

enabled.

To change the Alarm Outputs setting press the down arrow key to highlight Alarm

Outputs in the Alarms Set up menu then press the Enter key. The highlight will move

to the current setting. Use the up or down arrow keys to toggle between Disabled (the

default setting) and Enabled, press the Enter key to select your preferred setting

when it is highlighted on the display. Then use the ESC key to return to other menu

levels, the main measurement screen or continue with the alarms settings as follows.

4.22 Audible Alarm Warning

With the Alarm Outputs enabled the internal audible alarm can be separately enabled

or disabled so as not to be intrusive when not required or to complement the visual

alarm bell icon when necessary.

To change the Audible Alarm Warning setting press the down arrow key to highlight

Audible Alarm Warning in the Alarms Set up menu then press the Enter key. The

highlight will move to the current setting. Use the up or down arrow keys to toggle

between Disabled (the default setting) and Enabled, press the Enter key to select

your preferred setting when it is highlighted on the display. Then use the ESC key to

return to other menu levels, the main measurement screen or continue with the

alarms settings as follows.

Alarms Set Up Menu

Page 41

4.23 Alarm Point Settings…

A sub-menu for setting the high and low alarm points for each mode can be accessed

by pressing the down arrow in the Alarms Set Up menu to highlight Alarm Point

Settings… then press the Enter key for the following display…

High and Low alarm settings

High and Low alarm levels are available for Conductivity, TDS and Resistivity, these

are effective when the relevant mode is selected (use the up or down arrow when the

Cond tab is highlighted in the main measurement screen). Alarm levels for Salinity

measurements should be based on the equivalent conductivity value, this is displayed

with the Salinity reading. The adjustment of the High and Low alarm levels is similar

for each level and each mode so will be described once for the Conductivity Alarm

High level only.

Press the down arrow to highlight Cond Alarm High (mS) (or any other relevant alarm

level in the menu). Press the Enter key to display a data entry box, the box around

the least significant digit will be flashing. Use the up or down arrow keys to adjust this

digit to the required figure if necessary, or use the right or left arrow keys to select

other digits for adjustment with the up or down arrow keys. When all the digits are set

to display the required alarm level press the Enter key to accept this value. Use the

up or down arrow key to adjust other alarm settings as required or press the ESC key

to escape to other menu levels or return to the main measurement screen.

High alarm level se t to 150mS

4.30 Conductivity Endpoint Set Up

All measurements made with electrochemical sensors are subject to a response time

for the sensor to equilibrate to the sample conditions and while the temperature

sensor compensates for temperature differences between samples and ambient

conditions. This response time will vary dependant on the sample, sensor(s) and

measurement conditions, a special algorithm can automatically determine when the

reading has reached a stable condition and the endpoint is reached. The Endpoint

Page 42

icon will then be displayed and an optional audible alarm can be enabled. The period

over which the instrument looks for stability can be adjusted for special applications

where slow changes, reaction rates and special probe types are used.

Measurement display showing two endpoint icons

To adjust the Endpoint Detection settings select Endpoint Detection Set Up… in the

Conductivity Set Up menu and press the Enter key to display the menu as follows…

4.31 Endpoint Detection

The automatic endpoint detection can be enabled (default) or disabled. In the later

case results can be recorded by observation of the reading or on a timed basis using

the data logging functions.

To change the Endpoint Detection setting press the down arrow key to highlight

Endpoint Detection in the End Point Detection Set up menu then press the Enter key.

The highlight will move to the current setting. Use the up or down arrow keys to

toggle between Enabled (the default setting) and Disabled, press the Enter key to

select your preferred setting when it is highlighted on the display. Then use the ESC

key to return to other menu levels, the main measurement screen or continue with the

other endpoint settings as follows.

4.32 Endpoint Audible Alarm

To complement and re-enforce the display of the endpoint icon an audible alarm can

be enabled to indicate a reading reaching stability.

To change the Endpoint Audible Alarm setting press the down arrow key to highlight

Endpoint Audible Alarm in the Endpoint Detection Set up menu then press the Enter

key. The highlight will move to the current setting. Use the up or down arrow keys to

toggle between Disabled (the default setting) and Enabled, press the Enter key to

select your preferred setting when it is highlighted on the display. Then use the ESC

key to return to other menu levels, the main measurement screen or continue with the

endpoint settings as follows.

Endpoint Detection Set Up menu

Page 43

4.33 Endpoint Stability (Sec)

The endpoint algorithm looks for a reading that is stable, within a certain window of

variation, over a set period of time. The default is 5 seconds and this is ideal for all

normal measurement applications, giving the fastest result with maximum confidence

in stability. Should a specific application require this time period to be increased or

decreased it can be adjusted as follows.

Press the up or down arrow key in the Endpoint detection Set Up menu to highlight

the Endpoint Stability (Sec) option then press the Enter key. A data entry box will

appear on the display with the box around the least significant digit flashing to

indicate it can be adjusted with the up or down arrow keys. When set to the desired

value use the right or left arrow keys to move the flashing box to the other digits for

adjustment with the up or down arrow keys. When all the digits are set to the desired

value press the Enter key to confirm the setting. Use the Escape [ESC] key to return

to other menu levels or the main measurement screen.

Setting the endpoi nt stability monitoring period

4.40 Conductivity ATC/MTC Set Up

Temperature measurement and compensation processes are carried out

automatically during measurement procedures. However adjustments can be made to

display temperature values in the Celsius or Fahrenheit scales and where automatic

compensation is not required, or possible, then a manual compensation value may be

entered. To change these settings select the Temperature Set Up option from the

Conductivity Set Up menu and press the Enter key to display the following screen…

4.41 Temp Units

The displayed temperature can be in degrees Celsius or Fahrenheit to change this

setting press the down arrow key in the Temperature Set Up menu to highlight Temp

Units then press the Enter key. The current setting will be highlighted and the up or

down arrow keys can be used to toggle between

confirm the desired units when that option is highlighted on the display. Use the

Temperature Set Up menu

o