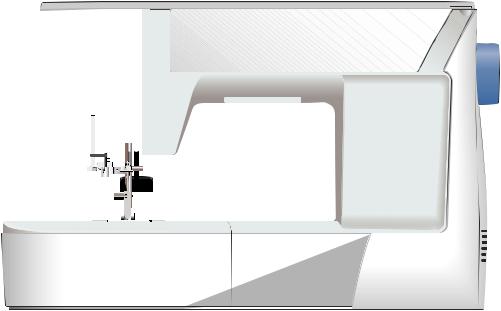

Janome Skyline S5 Instruction Manual

Instruction Book

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

This sewing machine is designed and manufactured for household use only.

Read all instructions before using this sewing machine.

DANGER— To reduce the risk of electric shock:

1.An appliance should never be left unattended when plugged in. Always unplug this sewing machine from the electric outlet immediately after using and before cleaning.

WARNING— To reduce the risk of burns, re, electric shock, or injury to persons:

1.Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near children.

2.Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3.Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

4.Never operate the appliance with any air opening blocked. Keep ventilation openings of this sewing machine and foot controller free from accumulation of lint, dust and loose cloth.

5.Never drop or insert any object into any opening.

6.Do not use outdoors.

7.Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8.To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9.Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10.Keep ngers away from all moving parts. Special care is required around the sewing machine needle and/or cutting blade.

11.Always use the proper needle plate. The wrong plate can cause the needle to break.

12.Do not use bent needles.

13.Do not pull or push fabric while stitching. It may de ect the needle causing it to break.

14.Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as threading the needle, changing the needle, threading the bobbin or changing the presser foot, and the like.

15.Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or when making any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

For Europe only:

This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning use of the appliance in a safe way and understand the hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children without supervision.

For outside Europe (except U.S.A and Canada):

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Please note that on disposal, this product must be safely recycled in accordance with relevant National legislation relating to electrical/electronic products. If in doubt please contact your retailer for guidance. (European Union only)

1

TABLE OF CONTENTS

ESSENTIAL PARTS |

|

Names of Parts............................................................... |

3 |

Standard Accessories .................................................... |

4 |

Accessory Storage ......................................................... |

5 |

Extension Table.............................................................. |

5 |

Free-arm sewing ............................................................ |

5 |

GETTING READY TO SEW |

|

Connecting the Power Supply ........................................ |

6 |

Operating Instructions: ................................................... |

6 |

Machine Operating Buttons............................................ |

7 |

Controlling Sewing Speed.............................................. |

8 |

Foot Control.................................................................... |

8 |

Function Keys................................................................. |

9 |

Raising and Lowering the Presser Foot ....................... |

10 |

Knee Lifter .................................................................... |

10 |

Adjusting the Foot Pressure .......................................... |

11 |

Dropping the Feed Dog ................................................. |

11 |

Balancing Thread Tension............................................ |

12 |

Lockout Key.................................................................. |

13 |

Changing the Presser Foot .......................................... |

13 |

Removing and Attaching the Foot Holder .................... |

14 |

Replacing the Needle Plate.......................................... |

15 |

Changing Needles........................................................ |

16 |

Fabric and Needle Chart .............................................. |

16 |

Winding the Bobbin ...................................................... |

17 |

Threading the Machine................................................. |

20 |

Built-in Needle Threader .............................................. |

21 |

Drawing up the Bobbin Thread..................................... |

22 |

Selecting the Patterns .................................................. |

23 |

Customizing Machine Settings..................................... |

24 |

BASIC SEWING |

|

Straight Stitch ............................................................... |

27 |

Securing Seams ........................................................... |

27 |

Sewing from the Edge of Thick Fabric ......................... |

27 |

Changing Sewing Direction.......................................... |

27 |

Cutting Threads............................................................ |

28 |

Needle Plate Guides .................................................... |

28 |

Cornering Guide ........................................................... |

28 |

Adjusting the Needle Drop Position ............................. |

29 |

Adjusting the Stitch Length .......................................... |

29 |

Needle Plate for Straight Stitch .................................... |

30 |

Lock-a-Matic Stitch....................................................... |

30 |

Locking Stitch............................................................... |

30 |

Straight Stitch with Left Needle Position ...................... |

31 |

Triple Stretch Stitch ...................................................... |

31 |

Knit Stitch ..................................................................... |

31 |

Sewing with Even Feed Foot (Walking foot) ................ |

32 |

Zipper Sewing .............................................................. |

33 |

Rolled Hem................................................................... |

36 |

Gathering...................................................................... |

37 |

Pintucking..................................................................... |

37 |

Zigzag Stitch................................................................. |

38 |

Multiple Zigzag Stitch (Tricot stitch) ............................. |

39 |

Overcasting Stitch ........................................................ |

39 |

Knit Stitch ..................................................................... |

40 |

Double Overcasting Stitch............................................ |

40 |

Blind Hemming ............................................................. |

41 |

Shell Tuck ..................................................................... |

43 |

Buttonholes .................................................................. |

43 |

Square Buttonhole........................................................ |

44 |

Using the Stabilizer Plate ............................................. |

48 |

Round End and Fine Fabric Buttonholes ..................... |

49 |

Keyhole Buttonholes .................................................... |

49 |

Stretch Buttonholes...................................................... |

49 |

Corded Buttonhole ....................................................... |

50 |

Welted Buttonhole ........................................................ |

51 |

Button Sewing .............................................................. |

53 |

Darning......................................................................... |

54 |

Tacking ......................................................................... |

56 |

Eyelet............................................................................ |

57 |

DECORATIVE STITCHING |

|

Applique ....................................................................... |

58 |

Fringing......................................................................... |

59 |

Drawn Work.................................................................. |

59 |

Smocking...................................................................... |

60 |

Fagoting........................................................................ |

61 |

Scallop.......................................................................... |

61 |

French Knots ................................................................ |

61 |

Patchwork Piecing........................................................ |

62 |

Patchwork..................................................................... |

62 |

Quilting ......................................................................... |

63 |

Stippling........................................................................ |

64 |

Clasp Stitches .............................................................. |

64 |

Free Motion Quilting ..................................................... |

64 |

Hand-look Quilt Stitches............................................... |

65 |

Satin Stitches ............................................................... |

65 |

Elongation ratio ............................................................ |

65 |

Twin Needle Sewing..................................................... |

66 |

PROGRAMMING A PATTERN COMBINATION |

|

Pattern Combination..................................................... |

68 |

Programming Auto-lock Stitch...................................... |

69 |

Programming Automatic Thread Cutting...................... |

70 |

Pattern Combination with a Mirror Image..................... |

71 |

Resuming a Pattern from the Beginning ...................... |

72 |

Resuming a Pattern Combination from the Beginning . 72 |

|

Bridge Stitches ............................................................. |

73 |

Monogramming ............................................................ |

75 |

Editing a Pattern Combination...................................... |

77 |

Deleting and Inserting a Pattern................................... |

78 |

Duplicating a Pattern .................................................... |

78 |

Uniform Stitch Adjustment............................................ |

79 |

Uni ed Needle Drop Position ....................................... |

79 |

Individual Stitch Adjustment ......................................... |

80 |

Correcting Distorted Stitch Patterns............................. |

81 |

CARE AND MAINTENANCE |

|

Cleaning the Hook Area ............................................... |

82 |

Cleaning the Inside of the Thread Guide...................... |

83 |

Problems and Warning Signals .................................... |

84 |

Troubleshooting............................................................ |

86 |

2

r |

t |

y u i |

e |

|

|

w |

|

|

q |

|

|

!3 |

!2!1 !0o |

|

@7

!4

@6

@6

!5

!6 |

!7 |

@3@4@5 |

|

@8 |

@2 |

#7 |

@9 |

@1 |

|

||

#6 |

#0 |

@0 |

#5 |

#1 |

!9 |

#4 |

|

!8 |

|

#2 |

|

|

#3 |

|

|

#8 |

|

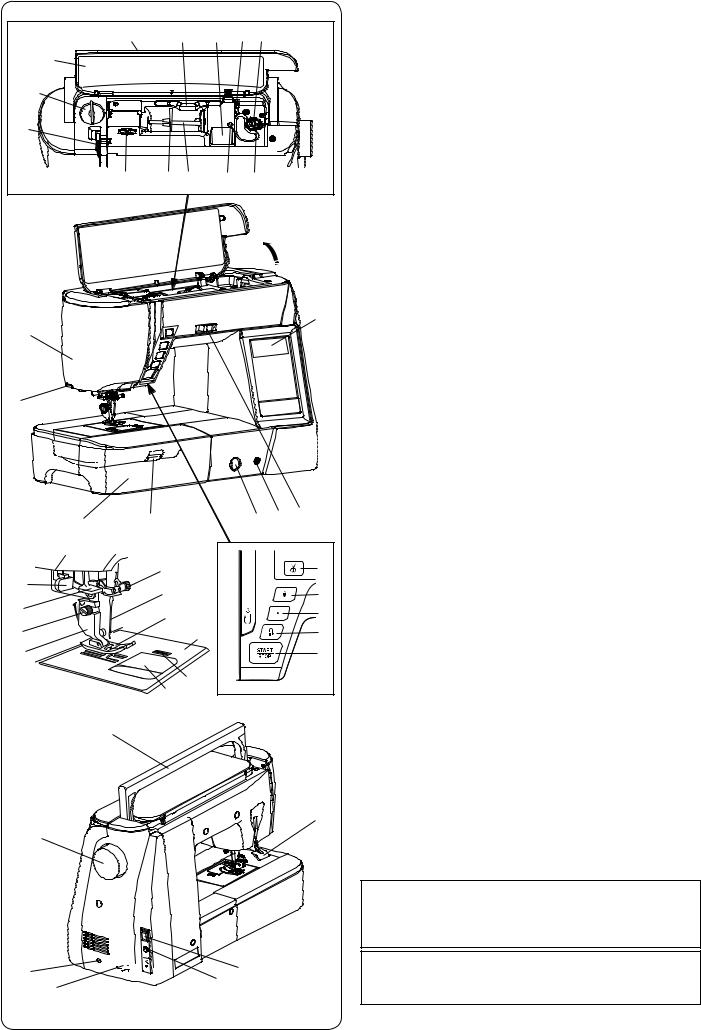

ESSENTIAL PARTS

Names of Parts

q Thread take-up lever w Foot pressure dial e Reference chart

r Top cover

t Touch panel stylus holder y Foot storage compartment u Bobbin thread cutter B

i Bobbin winder spindle o Bobbin thread cutter A !0Hole for extra spool pin !1Spool pin

!2Spool holder (large) !3Thread tension dial !4Face cover !5Thread cutter

!6Extension table (accessory storage) !7Needle plate release lever !8Start/stop button

!9Reverse button @0Auto-lock button @1Needle up/down button @2Thread cutter button @3Feed balancing dial @4Knee lifter socket @5Speed control slider

@6Touch panel (Function keys) @7LCD screen

@8Needle clamp screw @9Needle

#0Zigzag foot A #1Needle plate

#2Hook cover release button #3Hook cover plate

#4Foot holder #5Setscrew #6Needle threader #7Buttonhole lever #8Carrying handle #9Handwheel

$0Thread cutter switch jack* $1Drop feed lever $2Machine socket

$3Foot control jack $4Power switch $5Presser foot lifter

#9

$0$1

$2$3$4

$2$3$4

$5

NOTE:

To carry the sewing machine, hold the carrying handle with your hand, and support the sewing machine with the other hand.

NOTE:

Sewing machine design and speci cations are subject to change without prior notice.

* Thread cutter switch is an optional item.

3

qw

yu

!0

!3

!6

@0 @1

@4

@7

#0

e

i

!1

!4

!7 !8

@2

@5

@8

#1

r t

o

!2

!5

!9

@3

@6

@9

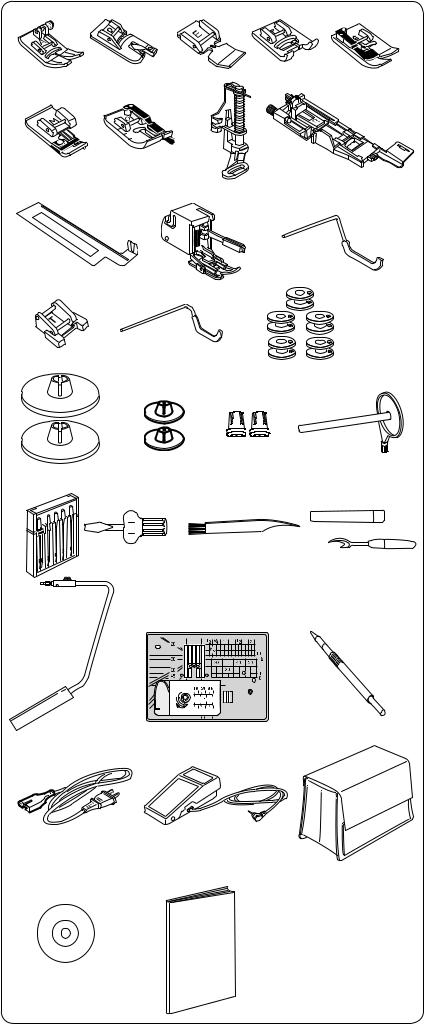

Standard Accessories

q Zigzag foot A (set on the machine) w Rolled hem foot D

e Zipper foot E

r Satin stitch foot F

t Blind hemming foot G y Overcast foot M

u 1/4 seam foot O i Darning foot PD-H

oAutomatic buttonhole foot R (in the accessory storage)

!0Buttonhole stabilizer plate (in the accessory storage)

!1Even feed foot

!2Quilting guide bar (for even feed foot) !3Button sewing foot T

!4Quilting guide bar

!5Bobbin (5 pcs.) (1 set on the machine) !6Spool holder (large, 1 set on the machine) !7Spool holder (small)

!8Spool holder (special) !9Extra spool pin @0Needle set @1Screwdriver

@2Lint brush

@3Seam ripper (Buttonhole opener) @4Knee lifter

@5Needle plate for straight stitch @6Touch panel stylus

@7Power cable @8Foot control

@9Semi-hard fabric cover #0Instructional video DVD #1Instruction book

4

q

r

t q

w

e |

y

w

q

w

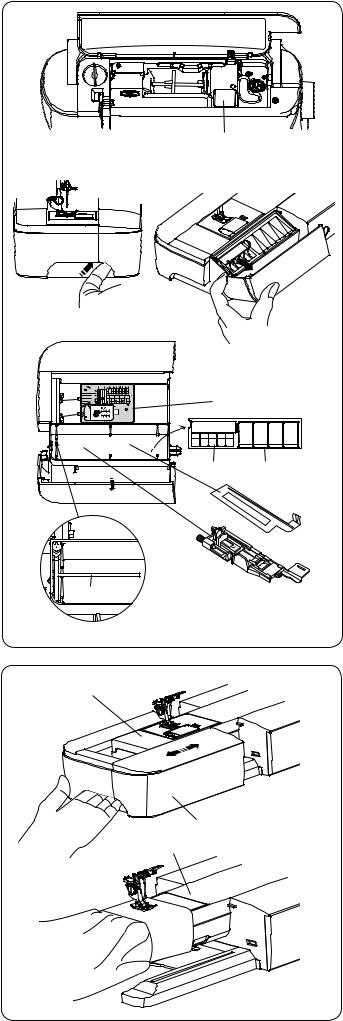

Accessory Storage

The accessories can be conveniently stored in the compartment of the extension table and the compartment under the top cover.

To store the accessories in the compartment of the extension table, push up the cover towards you to open the accessory storage.

q Presser foot

w Buttonhole stabilizer plate e Automatic buttonhole foot R

r Needle plate for straight stitch

t Bobbin

y Extra spool pin

Other accessories can be also stored in the compartment in the extension table.

Extension Table

The extension table provides an extended sewing area and can be removed for free-arm sewing.

q Extension table w Free-arm

To detach:

Draw the table out to the left.

To attach:

Slide the table on the base and push the table to the right.

Free-arm sewing

Free-arm sewing is used for stitching sleeves, waistbands, pant legs or any other tubular garments. It is also useful for darning socks or mending knees or elbows.

w Free-arm

5

GETTING READY TO SEW

Connecting the Power Supply

z First make sure the power switch q is off.

zx Insert the machine plug w of the power supply cord

|

|

into the machine socket e. |

q |

|

c Insert the power supply plug r into the wall outlet t, |

c |

and turn the power switch q on. |

|

|

qPower switch |

|

|

|

|

|

|

wMachine plug |

|

|

eMachine socket |

e |

|

rPower supply plug |

|

tWall outlet |

|

|

|

|

w |

|

NOTE: |

|

|

Make sure to use the power supply cable that came |

|

|

with the machine. |

|

|

If you turn off the power switch, wait for 5 seconds |

|

|

before turning it on again. |

|

|

t |

r |

|

WARNING: |

|

While in operation, always keep your eyes on the |

|

|

|

sewing area, and do not touch any moving parts such |

|

|

as the thread take-up lever, handwheel or needle. |

|

|

Always turn off the power switch and unplug the |

|

|

machine from the power supply: |

-when leaving the machine unattended.

-when attaching or removing parts.

-when cleaning the machine.

|

|

|

|

|

Do not place anything on the foot control. |

|

|

|

|

|

If you wish to use the foot control, insert the pin connector |

|

|

|

z |

|

into the jack on the machine. |

|

|

|

|

z First make sure the power switch q is off. |

|

|

|

|

|

|

|

|

|

|

|

|

x Insert the pin connector w into the jack e on the |

|

|

|

v |

|

machine. |

q |

|

|

|

c Insert the machine plug r of the power supply cord |

|

|

|

|

|

||

|

|

|

|

|

into the machine socket t. |

|

|

|

|

|

v Insert the power supply plug y into the wall outlet u, |

e |

|

|

|

|

and turn the power switch on. |

|

|

w |

|

|

The foot control sign i will be displayed when the foot |

|

|

|

|

control is connected to the machine. |

|

|

|

|

|

|

|

|

r |

|

|

|

qPower switch |

|

|

|

|

wPin connector |

|

|

|

|

|

|

|

|

|

|

|

|

eJack |

t |

|

|

|

|

rMachine plug |

|

|

|

|

tMachine socket |

|

|

|

|

|

|

|

|

|

|

|

u |

yPower supply plug |

|

|

|

|

uWall outlet |

|

|

|

|

|

|

|

|

|

|

y |

|

iFoot control sign |

|

|

|

|

NOTE: |

|

|

|

|

|

|

|

|

|

|

|

|

The start/stop button does not work when the foot |

|

|

|

|

|

control is connected. |

Operating Instructions:

The symbol “O” on a switch indicates the “off” position of

the switch.

i

i

For the U.S.A. and Canada only

Polarized plug (one blade wider than the other):

To reduce the risk of electric shock, this plug is intended to t in a polarized outlet only one way. If it does not t fully in the outlet, reverse the plug. If it still does not t, contact a quali ed electrician to install the proper outlet. Do not modify the plug in any way.

6

|

|

|

|

|

|

|

|

|

|

|

|

|

|

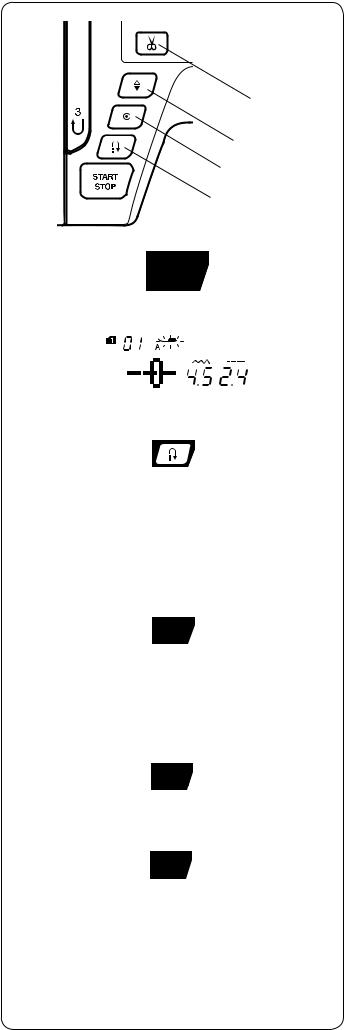

Machine Operating Buttons |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

q Start/stop button |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press this button to start or stop the machine. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The machine starts running slowly for the rst few |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

stitches, it then runs at the speed set by the speed control |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

t |

slider. The machine runs slowly as long as this button is |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

pressed. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The button will turn red when the machine is running, and |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

r |

green when it has been stopped. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

e |

Pressing and holding this button while sewing will slow |

|||||||

q |

|

|

|

|

|

|

|

|

|

|

|

down the sewing speed and the machine will stop when |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

w |

the button is released. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• The start/stop button cannot be used when the foot |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

control is connected to the machine. |

|||||

|

|

|

|

|

|

q |

|

|

|

|

|

|

• The machine will not run and the presser foot mark |

|||||||

|

|

|

|

|

|

|

|

|

|

y will blink if you start the presser foot in the up |

||||||||||

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

position. Lower the presser foot and press the start/ |

|||||

|

|

|

|

|

|

|

|

|

y |

|

stop button. |

|||||||||

|

|

|

|

|

|

|

|

|

|

• You can select the desired start-up speed from |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

slow, medium or high (refer to page 25). |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

w Reverse button |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When |

sewing stitch pattern 01, 04-07, 11-13, 01S, |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

04S-07S, (mode 1) or 37-38 (mode 2), the machine will |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

sew in reverse as long as the reverse button is pressed. |

||||||

|

|

|

|

|

|

w |

If stitch |

pattern 01, 04-07, 11-13, 01S, 04S-07S, (mode 1) |

||||||||||||

|

|

|

|

|

|

or 37-38 |

(mode 2) has been selected and the foot control |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

is not |

connected, the machine will start sewing in reverse |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

as long |

as the reverse button is pressed. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If you press the reverse button when sewing any other |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

patterns, the machine will immediately sew locking |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

stitches and automatically stop. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e Auto-lock button |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When sewing stitch pattern 01, 04-07, 11-13, 01S, |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

04S-07S, (mode 1) or 37-38 (mode 2) the machine will |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

immediately sew locking stitches and automatically stop |

||||||

|

|

|

|

|

|

e |

|

|

when the auto-lock button is pressed. |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When sewing all other patterns, the machine will sew to |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the end of the current pattern, sew locking stitches and |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

stop automatically. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The machine will trim the threads automatically after |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

locking the stitch when the auto thread cutting is turned |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

on (refer to page 70). |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

r Needle up/down button |

||||||

|

|

|

|

|

|

r |

|

Press this button to bring the needle bar up or down. |

||||||||||||

|

|

|

|

|

|

The machine will stop with the needle in down position. |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

However, you can change the needle stop position in the |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

machine setting mode (refer to page 25). |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

t Thread cutter button |

||||||

|

|

|

|

|

|

t |

After nish sewing, press this button to trim the threads. |

|||||||||||||

|

|

|

|

|

|

The needle bar automatically rises after trimming the |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

threads (refer to page 28). |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Use the thread cutter on the face cover if the thread is |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

#30 or thicker (refer to page 28). |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

Controlling Sewing Speed

Speed control slider

You can limit the maximum sewing speed with the speed control slider according to your sewing needs.

To increase the sewing speed, move the slider to the right.

To decrease the sewing speed, move the slider to the left.

Foot Control

Pressing on the foot control can vary sewing speed. The harder you press the foot control, the faster the machine runs.

NOTE:

The machine runs at the maximum speed set by the speed control slider when the foot control is fully depressed.

Operating Instructions:

Foot control model YC-485EC is for use with this sewing machine.

8

r |

t |

|

e |

|

|

q |

|

|

w |

y |

u |

i o |

!0 |

!1 |

!2 |

|

|

|

|

!6 |

|

|

!7 |

!3 |

|

!8 |

|

|

|

|

|

!9 |

|

|

@0 |

!4 |

|

@1 |

|

@2 |

|

|

|

|

!5 |

|

|

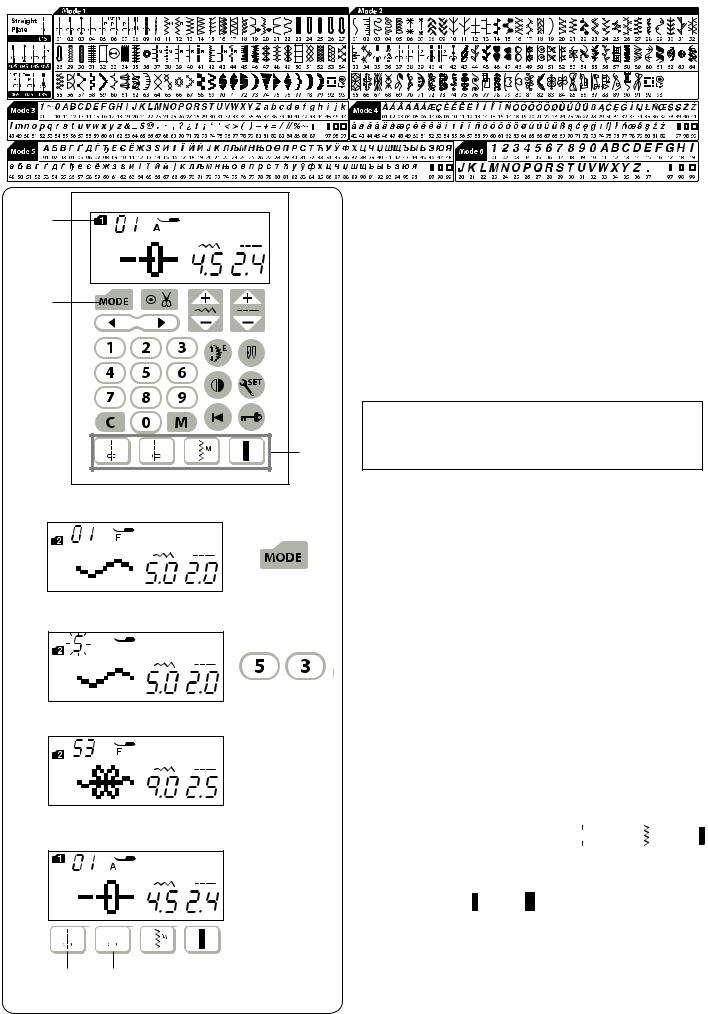

Function Keys

q LCD screen

The LCD screen shows the following information when the machine is turned on:

w Stitch pattern e Mode

r Stitch pattern number

t Recommended type of presser foot y Stitch width

uStitch length

i Cursor key (refer to page 77)

Press “ ” or “ ” to move the cursor to check or edit the pattern combination.

o Auto thread cutting key (refer to page 70)

Press this key if you wish to cut the threads automatically after nish sewing with a locking stitch.

When programming a pattern combination, press this key to cut the threads automatically after nish sewing.

!0Stitch width adjusting key (refer to pages 29, 38, 47) Press this key to alter the stitch width.

!1Stitch length adjusting key (refer to pages 29, 38, 47) Press this key to alter the stitch length.

!2Mode key (refer to pages 23, 24) Press the mode key to select the mode.

When the power is turned on, the pattern selection mode 1 is set automatically.

!3Number keys (refer to page 23)

Enter a 2-digit pattern number to select the desired stitch pattern in modes 1 to 6.

!4Clear key (refer to pages 25, 78)

Press the clear key to clear the memorized stitch pattern. Press and hold this key until the buzzer sounds to delete the whole pattern combination.

!5Direct pattern selection keys (refer to page 23)

You can select the stitch patterns 01 , 04

, 04 , 11

, 11 and 23

and 23 in mode 1 directly.

in mode 1 directly.

When the needle plate for straight stitch is being attached, you can select the stitch patterns 01S  or 04S

or 04S  only.

only.

!6Elongation key (refer to page 65)

Press this key to elongate satin stitch patterns.

!7Twin needle key (refer to page 66)

Press this key when sewing with a twin needle.

!8Mirror image key (refer to page 71)

Press this key to sew a mirror image of the selected pattern.

!9Set key (refer to page 24-26)

Press this key to enter the machine setting mode for customizing the machine settings.

@0Startover key (refer to page 72)

Press this key to sew a pattern combination from the beginning.

@1Lockout key (refer to page 13)

Press this key to lockout the machine when threading the machine, replacing the accessories etc.

To reduce the risk of injury, all the buttons and keys are deactivated.

To unlock the machine, press this key again.

@2Memory key (refer to page 68)

Press this key to register programmed pattern combinations.

Up to 50 stitch patterns combination can be memorized.

9

Raising and Lowering the Presser Foot

The presser foot lifter raises and lowers the presser foot.

|

w |

q Presser foot lifter |

|

You can raise the presser foot higher than the normal up |

|

|

|

|

q |

|

position. This allows for changing the needle plate, and |

|

also helps you to place thick layers of fabrics under the |

|

|

|

|

|

|

foot. |

|

|

w Extra lifted position |

|

|

NOTE: |

|

|

Do not turn the hand wheel of press the up/down |

|

|

needle button when the presser foot is in the extra |

|

|

lifted position. |

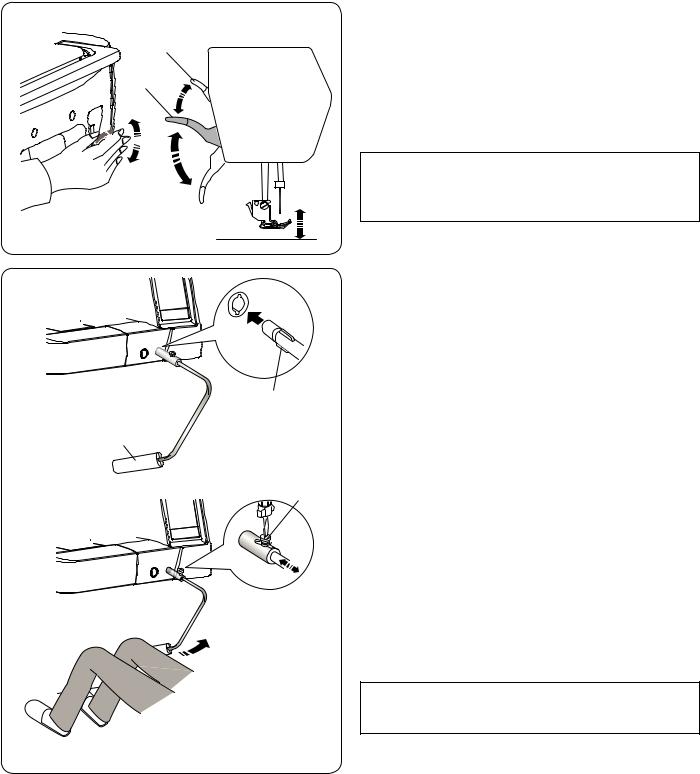

Knee Lifter

The knee lifter is extremely helpful when sewing

e patchwork, quilting etc, since it allows you to handle the fabric while your knee controls the presser foot.

e patchwork, quilting etc, since it allows you to handle the fabric while your knee controls the presser foot.

|

|

Attaching the knee lifter |

|

|

Match the ribs on the knee lifter with the notches in the |

|

w |

knee lifter socket and insert the knee lifter. |

|

q Knee lifter |

|

|

|

|

|

|

w Rib |

q |

|

e Knee lifter socket |

|

|

|

|

|

Adjusting the knee lifter |

|

|

The angle of the knee lifter can be adjusted to t you. |

rLoosen the setscrew and slide the angle bar in or out to adjust the angle of the knee lifter.

Tighten the setscrew to secure the angle bar.

r Setscrew t Angle bar

Using the knee lifter

Push the knee lifter with your knee to easily move the

t presser foot up and down.

t presser foot up and down.

You can control how high the foot rises by the amount of knee pressure you exert.

NOTE:

Do not touch the knee lifter while stitching, otherwise the fabric will not be fed smoothly.

10

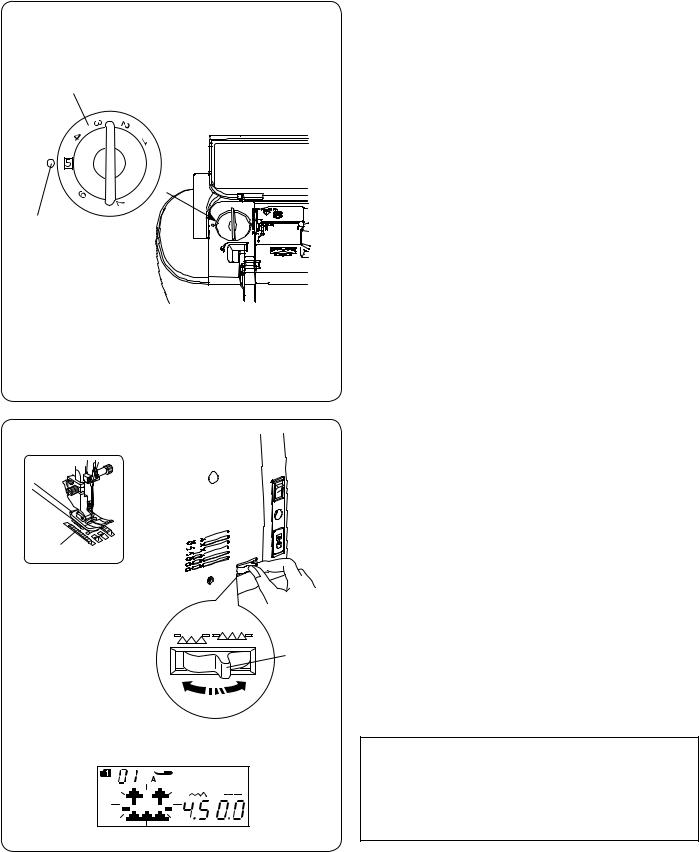

Adjusting the Foot Pressure

The foot pressure can be adjusted with the foot pressure dial located under the top cover.

The dial has 7 setting positions from 1 to 7. q For ordinary sewing, set 5 at the setting mark.

q Foot pressure dial w Setting mark

Reduce the pressure when sewing ne synthetics and stretch fabrics.

To reduce the pressure, set the dial at a lower number.

|

Increase the pressure when sewing heavy weight fabrics. |

w |

To increase the pressure, set the dial at a higher number. |

Dropping the Feed Dog

The feed dog can be lowered for sewing on buttons, free motion quilting etc.

Shift the drop feed lever toward you to lower the feed dog.

q Drop feed lever

w Feed dog w

w Feed dog w

Shift the drop feed lever away from you to raise the feed dog, it will return to the up position when you start the machine.

q

NOTE:

If you start the machine with the feed dog lowered, a message will appear on the LCD screen.

The machine will not run with the feed dog lowered when selected following pattern numbers; 23 to 32, 34 to 36 in mode 1, stitch patterns in mode 3 to 6.

11

Balancing Thread Tension

Auto-thread tension

For general sewing, set the thread tension dial at AUTO, which covers a wide range of sewing conditions.

|

|

|

|

|

|

q Thread tension dial |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

q |

|

|

|||

|

|

|

|

|

|

Balanced thread tension |

|

|

|

|

|

|

|

|

w |

q |

For straight stitch sewing, both needle and bobbin |

|||

|

threads will join at the middle of the fabrics. |

|||||

|

|

|

|

|

|

|

|

e |

|

|

|||

r |

|

For zigzag stitch sewing, the needle thread will appear |

|

|

|

slightly on the wrong side of the fabric. |

|

w |

q |

q Wrong side of fabric |

|

w Right side of fabric |

|||

|

|

||

e |

|

e Needle thread |

|

|

r Bobbin thread |

||

|

|

r

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manual thread tension adjustment |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

You may need to adjust tension manually depending |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

on the sewing conditions such as the type of fabric and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

number of layers. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If the needle thread is too tight, the bobbin thread |

w |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

appears on the right side of the fabric. |

q |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

q Wrong side of fabric |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

e |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

w Right side of fabric |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e Needle thread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

r Bobbin thread |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Turn the thread tension dial to a lower number to |

r |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

decrease the thread tension. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

w |

If the needle thread is too loose, the needle thread loops |

|

on the underside of the fabric. |

||

q |

||

e |

q Wrong side of fabric |

|

w Right side of fabric |

||

|

||

|

e Needle thread |

|

|

r Bobbin thread |

|

r |

Turn the thread tension dial to a higher number to |

|

|

increase the thread tension. |

|

|

NOTE: |

|

|

Manual thread tension adjustment may be required |

|

|

when the stitch width is set more than “7.0”. |

12

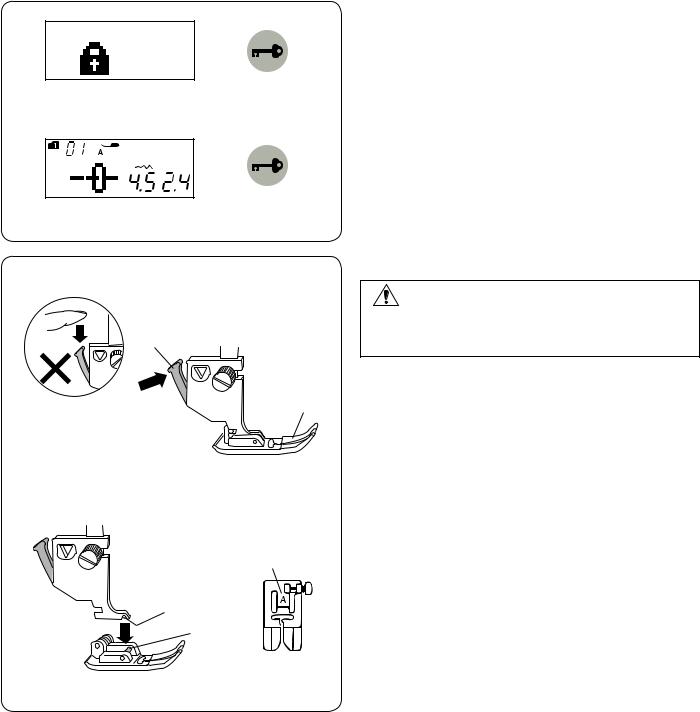

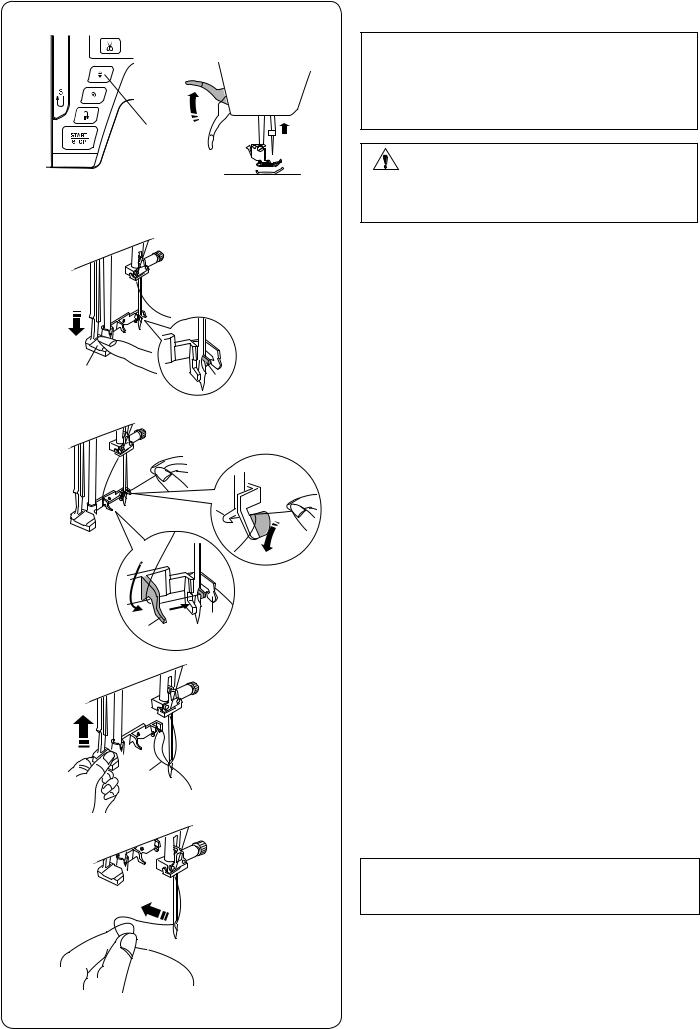

Lockout Key

Press this key to lockout the machine when threading the machine, replacing the accessories etc.

To reduce the risk of injury, all the buttons and keys are deactivated.

To unlock the machine, press this key again.

|

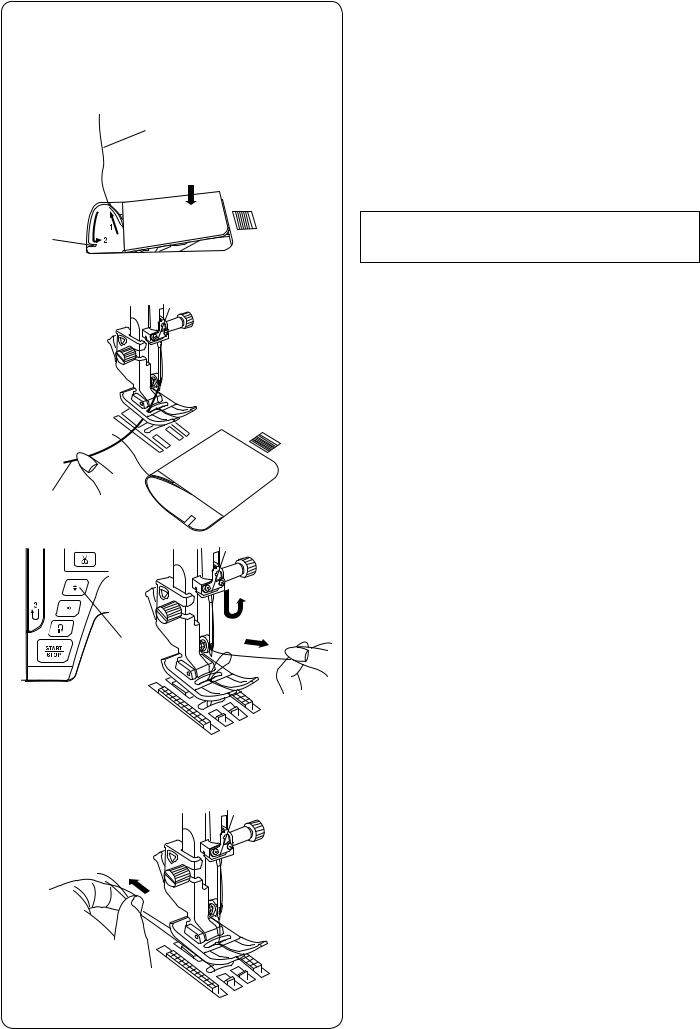

Changing the Presser Foot |

|

CAUTION: |

|

Always make sure to press the lockout key to lockout |

q |

the machine or turn the power switch off before |

replacing the presser foot. |

|

|

Raise the needle to its highest position and raise the |

|

presser foot lifter. |

wPress the black lever on the back of the foot holder. The presser foot will drop off.

q Lever

w Presser foot

|

Attaching the presser foot |

|

Place the presser foot so that the pin on the foot lies just |

t |

under the groove of the foot holder. |

|

Lower the presser bar to lock the foot in place. |

e |

Each foot is marked with an identi cation letter. |

e Groove |

|

r |

r Pin |

|

t Identi cation letter |

13

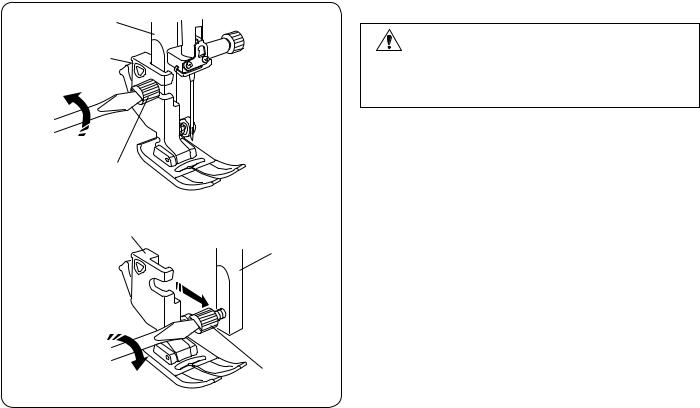

Removing and Attaching the Foot Holder

q

w |

|

CAUTION: |

|

Always make sure to press the lockout key to lockout |

|

|

|

the machine or turn the power switch off before |

|

|

replacing the presser foot. |

|

|

Removing the foot holder |

|

|

Raise the presser foot and loosen the setscrew. |

e |

|

Remove the foot holder. |

|

q Presser bar |

|

|

|

w Foot holder |

|

|

e Setscrew |

|

w |

Attaching the foot holder |

|

|

qAttach the foot holder to the presser bar from the rear.

Tighten the thumbscrew securely with the screwdriver.

e

14

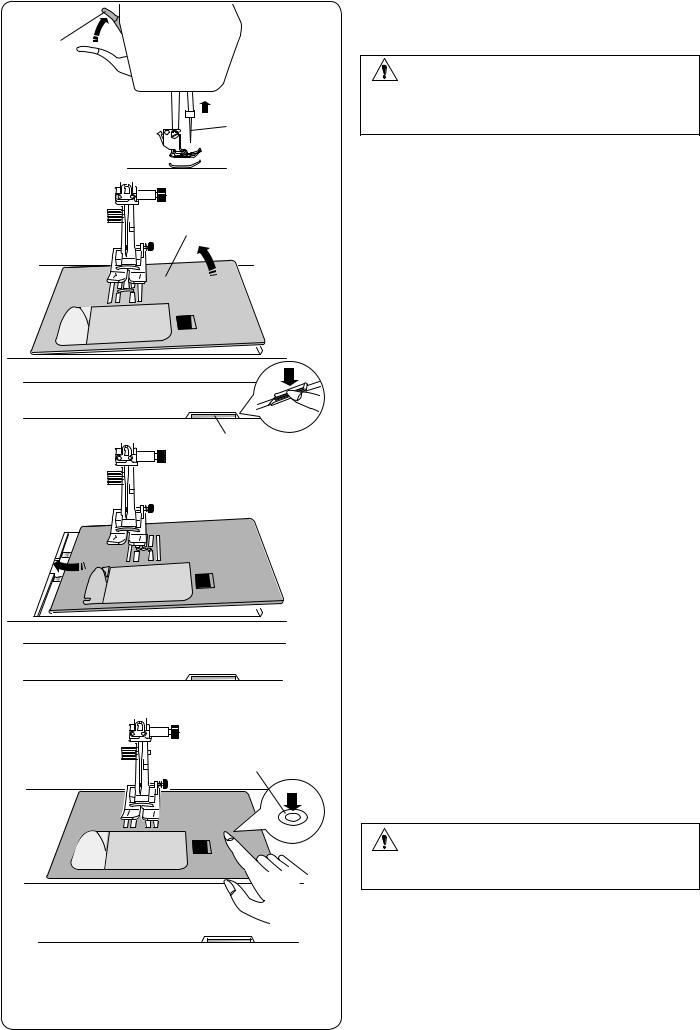

|

Replacing the Needle Plate |

z |

Use the straight stitch needle plate when sewing ne |

q |

fabrics or sewing with straight stitches. |

|

CAUTION: |

|

|

Always make sure to press the lockout key to lockout |

|

|

the machine or turn the power switch off before |

|

w |

replacing the needle plate. |

|

|

z Slide the extension table to the left to remove it. |

|

x |

Turn the handwheel and raise the needle to the |

|

highest position. |

||

|

Raise and hold the presser foot lifter to the extra lifted |

|

r |

position. |

|

qPresser foot lifter |

||

|

||

|

wNeedle |

|

|

x Push down the needle plate release lever and the |

|

|

needle plate will snap off. |

|

|

eNeedle plate release lever |

|

|

rNeedle plate |

e

c

c Place the straight stitch needle plate on the machine. Set the left edge of the needle plate into the opening.

v |

|

v Push down on the needle plate mark until the needle |

|

|

|

|

|

plate locks in place. |

|

|

Turn the power switch on or press the lockout key to |

|

t |

unlock. |

|

Turn the handwheel slowly and make sure that the |

|

|

|

|

|

|

needle does not hit the needle plate. |

|

|

t Needle plate mark |

CAUTION:

Never press the needle plate release lever while running the machine.

15

Changing Needles

CAUTION:

CAUTION:

Always make sure to press the lockout key to lockout the machine or turn the power switch off before changing the needle.

q

Raise the needle by pressing the needle up/down button

|

and lower the presser foot. |

|

Press the lockout key to lockout the machine or turn the |

|

power switch off. |

e |

Loosen the needle clamp screw and remove the needle |

|

from the clamp. |

|

q Needle clamp screw |

w |

Insert a new needle into the needle clamp with the at |

|

side of the needle to the rear. |

|

When inserting the needle into the needle clamp, push it |

|

up against the stopper pin and tighten the needle clamp |

|

screw rmly with a screwdriver. |

|

w Flat side |

|

e Stopper pin |

|

To check needle straightness, place the at side of the |

r |

needle onto something at (a needle plate, glass etc.) |

The gap between the needle and the at surface should |

|

|

be consistent. |

|

Never use a blunt needle. |

|

r Gap |

Fabric |

Thread |

Needle |

||

|

Lawn |

|

|

|

|

Georgette |

Silk #80-100 |

Blue tip needle |

|

Fine |

Tricot |

Cotton #80-100 |

Universal needle |

|

|

Organza |

Synthetic #80-100 |

#9/65-11/75 |

|

|

Crepe |

|

|

|

|

Sheeting |

Silk #50 |

Red tip needle |

|

|

Jersey |

Purple tip needle |

||

Medium |

Cotton #50-80 |

|||

Broadcloth |

Universal needle |

|||

|

Fleece |

Synthetic #50-80 |

#11/75-14/90 |

|

|

Denim |

Silk #30-50 |

Red tip needle |

|

Heavy |

Tweed |

Purple tip needle |

||

Cotton #40-50 |

||||

weight |

Coating |

Universal needle |

||

Synthetic #40-50 |

||||

|

Quilting |

#14/90-16/100 |

||

NOTE:

1 x twin needle, 2 x blue tip needle (#11/75), 1 x red tip needle (#14/90) and 1 x purple tip needle (#14/90) are included in the needle case (Part No. 859856005).

Fabric and Needle Chart

•For general sewing, use red needle.

•Fine threads and needles should be used for sewing

ne fabrics.

•In general, use the same thread for both needle and bobbin.

•Use a blue tip needle for sewing fine fabrics, stretch fabrics, tricot and buttonholes to prevent skipped stitches.

•Use a purple tip needle for sewing knits, free quilting and across the hem to prevent skipped stitches.

•Use a stabilizer or interface to stretch or fine fabrics to prevent seam puckering.

•Always test the thread and needle size on a small piece of the same fabric you will use for actual sewing.

16

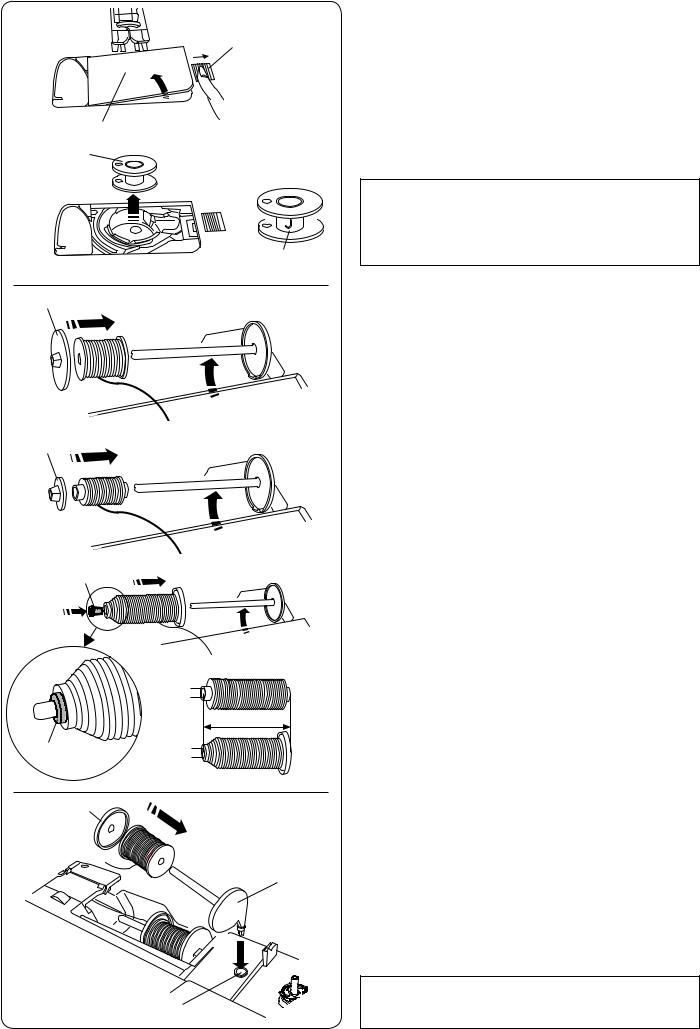

|

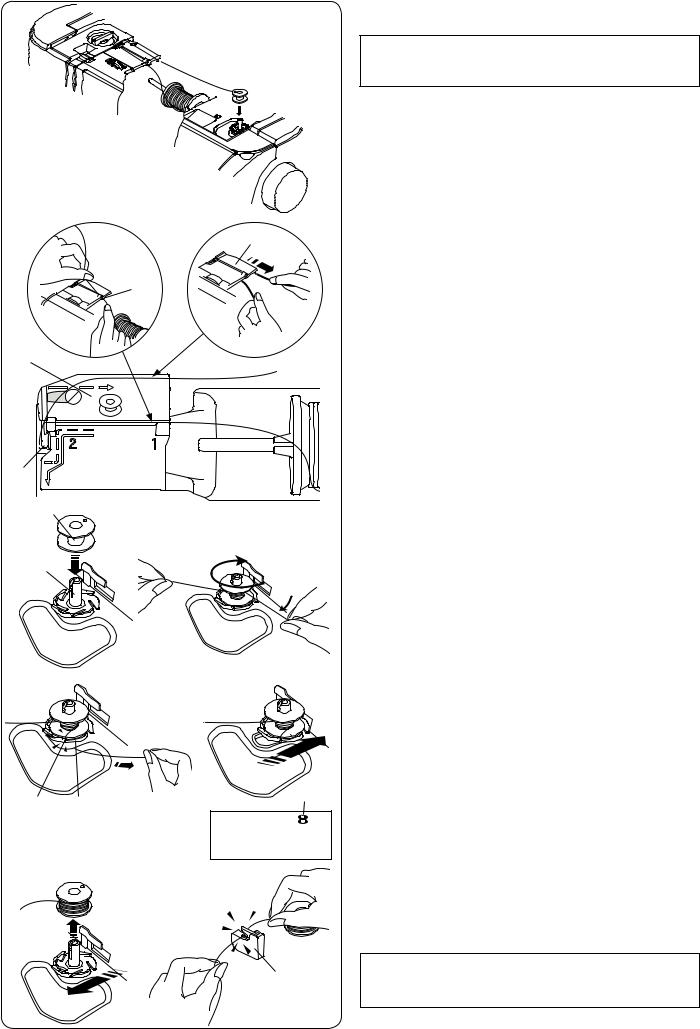

Winding the Bobbin |

|

|

Removing the Bobbin |

|

q |

Slide the hook cover release button to the right, and |

|

|

remove the hook cover plate. |

|

|

q Hook cover release button |

|

|

w Hook cover plate |

|

w |

Lift out the bobbin from the bobbin holder. |

|

e Bobbin |

||

|

||

e |

|

|

|

NOTE: |

|

|

Use the “J” plastic bobbins for horizontal hook(marked |

|

|

with “J”r). Using other bobbins, such as pre-wound |

|

|

paper bobbins, may cause stitching problems and/ or |

|

r |

damage to the bobbin holder. |

|

q |

Setting the spool of thread |

|

|

Lift up the spool pin. Place the spool of thread on the |

|

|

spool pin. |

|

|

Attach the large spool holder, and press it rmly against |

|

|

the spool of thread. |

|

|

q Large spool holder |

w |

Use the small spool holder to hold narrow or small spools |

|

of thread. |

|

w Small spool holder |

e

Use the spool holder (special) to hold the speci c size of the spool of threads as shown.

The sizes of the spools of thread are as follows;

The hole diameter of the spool has a range of 3/8 to 7/16 (9.5 to 10.5 mm)), and the spool length has a range of 2 3/4 to 3 (70 to 75 mm).

r |

e Spool holder (special) |

|

r Hole diameter (3/8 to 7/16 ) |

tt Spool length (2 3/4 to 3 )

e |

r |

Firmly insert the spool holder (special) into the hole and |

|

hold the spool as illustrated. |

|||

|

|||

|

|

e |

Extra spool pin |

|

Use the extra spool pin when you need to wind a bobbin |

|

without unthreading the machine while working on a |

|

sewing project. |

qInsert the extra spool pin into the hole as shown.

Place a spool of thread on the extra spool pin and x the spool with the spool holder.

q Extra spool pin

w Hole for extra spool pin e Large spool holder

|

NOTE: |

|

w |

The extra spool pin is also used for twin needle |

|

sewing. |

||

|

17

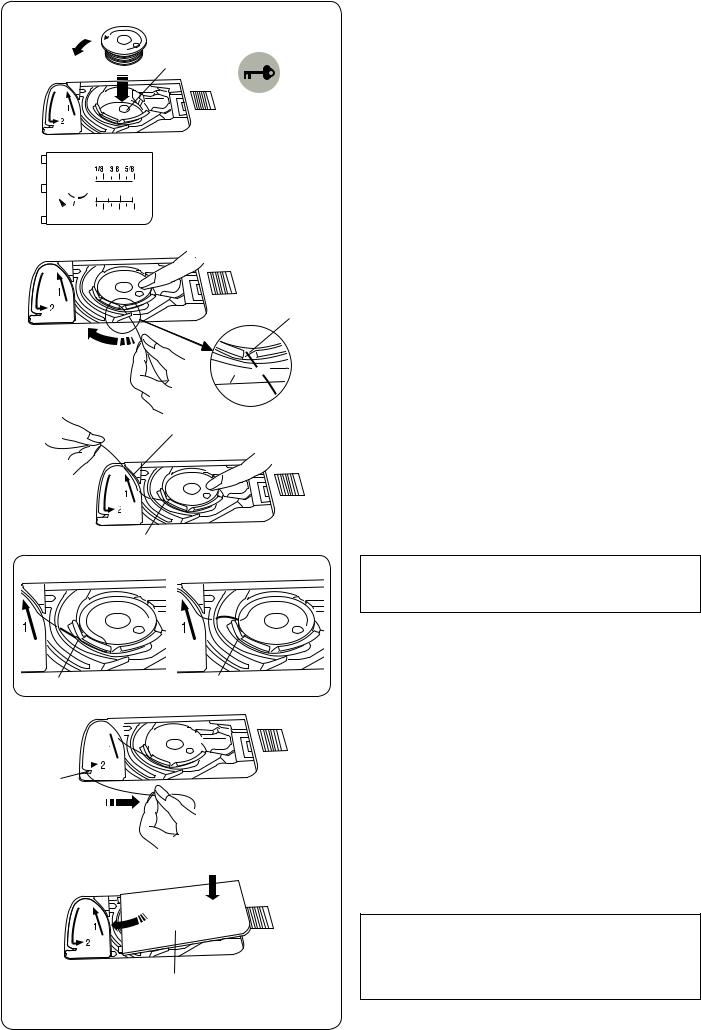

Winding the bobbin

NOTE:

Set the speed control slider at the fastest position (refer to page 8).

|

|

z Pull the thread from the spool. |

z |

x |

Hold the thread with both hands and pass the thread |

|

e |

into the guide slot q. |

|

|

q Guide slot |

|

q |

x Draw the thread to the left and forward around the |

|

|

thread guide w. |

|

|

Draw the thread to the rear and to the right around |

|

|

and under the guide plate e. |

e |

|

Firmly pull the thread to the right while holding it with |

|

both hands. |

|

|

|

|

|

|

w Thread guide |

|

|

e Guide plate |

w |

|

|

|

|

c |

r |

v |

|

c Put the bobbin on the bobbin winder spindle. |

|

|

|

|

rBobbin |

|

|

|

|

tBobbin winder spindle |

|

t |

|

|

v Pass the thread to the bobbin. |

|

|

|

|

|

|

|

|

|

Hold the thread with both hands and wind it around |

|

|

|

|

the bobbin clockwise several times. |

|

|

|

|

b Insert the thread into one of the slits u of the ange |

b |

|

n |

|

plate y and pull the thread to cut. |

|

|

yFlange plate |

||

|

|

|

|

|

|

|

|

|

uSlit |

|

|

|

|

n Push the bobbin to the right. The bobbin mark |

|

|

|

|

appears on the LCD screen. |

|

|

|

|

iBobbin mark |

|

u |

y |

i |

m Start the machine. |

|

|

|||

|

|

|

|

Stop the machine when the bobbin is fully wound and |

|

|

|

|

stops spinning. |

|

|

|

|

Return the bobbin winder spindle to its original |

m , |

|

|

position. |

|

|

|

|

||

|

|

|

|

, Remove the bobbin. Cut the thread with bobbin thread |

|

|

|

|

cutter B o. |

|

|

|

|

oBobbin thread cutter B |

|

|

o |

|

NOTE: |

|

|

|

For safety purposes, the machine will automatically |

|

|

|

|

|

stop 1.5 minutes after starting bobbin winding. |

18

z

w

e

e

q

r

x

t

y

y

c u

i

Correct |

Wrong |

ii

v o

!0

b

r

Inserting the bobbin

zPress the lockout key.

Place a bobbin in the bobbin holder with the thread running off counterclockwise as shown on the hook cover plate.

qLockout key wEnd of thread eBobbin holder rHook cover plate

xHold the bobbin with your ngertip so it does not rotate.

Guide the thread into the front notch of the bobbin holder.

Pull the thread to the left to pass it under the guide. tFront notch

yGuide

cDraw the thread to the left to pass it into the guide path marked “1”.

Make sure that the thread comes out from the side notch of the bobbin holder.

uGuide path 1 iSide notch

NOTE:

If the thread does not come out from the side notch, rethread from step z.

vContinue to draw the thread along the guide path marked “2” and pull the thread to the right through the slit. The thread will be cut to a proper length and held in place.

oGuide path 2 !0Slit (Thread cutter)

bSet the left edge of the hook cover plate into opening. Push down the hook cover plate to t in place.

NOTE:

Unless otherwise noted, you can start sewing without drawing up the bobbin thread.

Refer to page 22 for how to draw up the bobbin thread.

19

v x z

b c

c

n

m

m

z

q

q

w

x

e

e

c |

v |

y

t

r

r

b n m

u

i

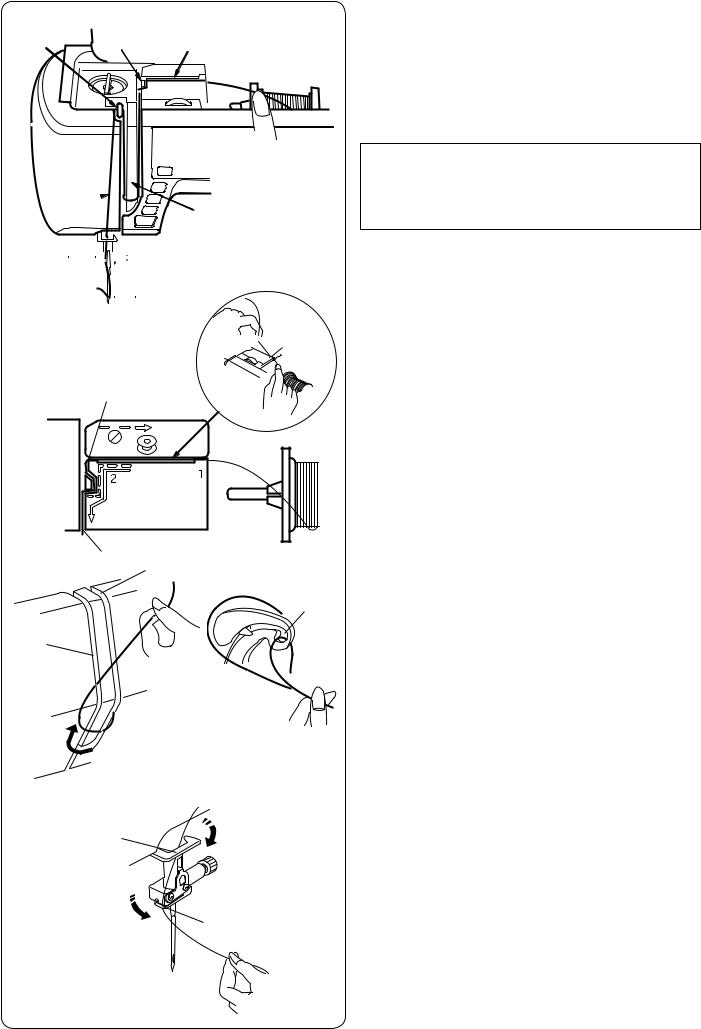

Threading the Machine

Raise the presser foot lifter to raise the presser foot. Turn the power switch on.

Press the needle up/down button to raise the take-up lever to the highest position.

Press the lockout key or turn the power switch off. Pass the thread in the order from z to m.

CAUTION:

CAUTION:

Always make sure to press the lockout key to lockout the machine or turn the power switch off before threading the machine.

zHold the thread with both hands and pass the thread into the guide slot.

q Guide slot

xHold the thread with both hands and draw the thread around the corner of the guide.

Firmly pull the thread toward you along the right channel until the thread snaps.

w Corner of the guide e Right channel

cDraw the thread down along the right channel and around the bottom of the thread guide plate. Pull the thread up along the left channel.

e Right channel

r Thread guide plate t Left channel

vWhile holding the thread at the spool, rmly draw the thread up and to the back of the take-up lever. Draw the thread forward to slip it into the eye of the take-up lever.

y Eye of the take-up lever

bThen pull the thread down along the left channel and through the lower thread guide.

u Lower thread guide

nSlide the thread behind the needle bar thread guide on the left.

i Needle bar thread guide

mThread the needle with the needle threader (refer to the next page).

20

Built-in Needle Threader

z

|

NOTE: |

|

• The needle threader can be used with a #11 to #16 |

|

needle. |

|

Thread size 50 to 90 is recommended. |

|

• The needle threader cannot be used with the twin |

q |

needle. |

|

|

|

CAUTION: |

|

|

Always make sure to press the lockout key to lockout |

|

|

the machine or turn the power switch off before using |

|

|

the built-in needle threader. |

|

|

z Turn the power switch ON. |

|

|

Press the needle up/down button to raise the needle. |

|

|

Press the lockout key to lock the machine. |

|

|

Pull down the needle threader knob as far as it will go. |

|

|

The threader hook comes out through the needle eye |

|

|

from behind. |

|

|

q Needle up/down button |

w |

|

w Threader knob |

e |

e Threader hook |

|

|

|

|

x |

|

x Draw the thread from left to right, under the left guide, |

|

|

threader hook and right guide. |

|

|

Draw the thread around the right guide toward you. |

|

|

r Left guide |

|

|

t Right guide |

|

t |

|

r |

c |

c Raise the threader slowly so a loop of the thread is |

|

pulled up through the needle eye. |

|

y Threader loop |

|

y |

v |

v Remove the thread end through the needle eye to the |

|

rear. |

|

NOTE: |

|

The needle threader cannot be used with the twin |

|

needle. |

21

Drawing up the Bobbin Thread

|

After using auto thread cutting or threading the bobbin |

|

holder, you can start sewing without drawing up the |

|

bobbin thread. |

|

However, you need to draw up the bobbin thread when |

z |

sewing gathering stitches etc. |

|

|

q |

z Remove the bobbin. Insert the bobbin into the bobbin |

|

holder again and rethread the bobbin holder according |

|

to the instructions on page 19, but leave a 10 cm (4 ) |

|

tail of bobbin thread as shown. |

|

qBobbin thread |

|

NOTE: |

w |

Do not cut the bobbin thread with the thread cutter. |

|

w Thread cutter |

x |

x Raise the presser foot. Hold the needle thread lightly |

|

with your left hand. |

|

eNeedle thread |

e

c

c Press the needle up/down button twice to lower and raise the needle and pick up the bobbin thread.

rNeedle up/down button

r

|

v Pull both threads 10 cm (4 ) under and behind the |

v |

presser foot. |

|

22

Selecting the Patterns

w |

q |

e |

z |

x |

c |

Mode 1–6

To select stitch patterns in modes 1–6, rst press the mode key q to select your desired mode. Each time you press the mode key, the mode number w indicated on the left side of the screen will change, and the mode changes as follows,

Mode 1: Utility and decorative stitch pattern selection Mode 2: Decorative stitch pattern selection

Mode 3: Number and letter selection

Mode 4: European accented letter selection Mode 5: Cyrillic letter selection

Mode 6: 9 mm monogram selection

NOTE:

When the straight stitch needle plate is attached to the machine, the patterns not suitable for the straight stitch needle plate cannot be selected.

Example: To select stitch pattern 53 in mode 2

zTurn the power switch on.

When the power switch is turned on, the utility and decorative stitch pattern selection (mode 1) is set automatically.

Press the mode key once to select mode 2.

xPress the number keys on the touch panel. First press key 5 and then press key 3.

c Now pattern 53 in mode 2 is selected.

rt

Direct pattern selection

You can select the stitch patterns 01 04

04 11

11  and 23 directly by pressing the corresponding direct pattern selection keys e.

and 23 directly by pressing the corresponding direct pattern selection keys e.

Stitch pattern 01S  or 04S

or 04S

can be also selected when the needle plate for straight stitch is attached to the machine (refer to page 15).

can be also selected when the needle plate for straight stitch is attached to the machine (refer to page 15).

Press the direct pattern selection key r to select the stitch pattern 01S.

Press the direct pattern selection key t to select the stitch pattern 04S.

23

|

|

|

|

|

|

|

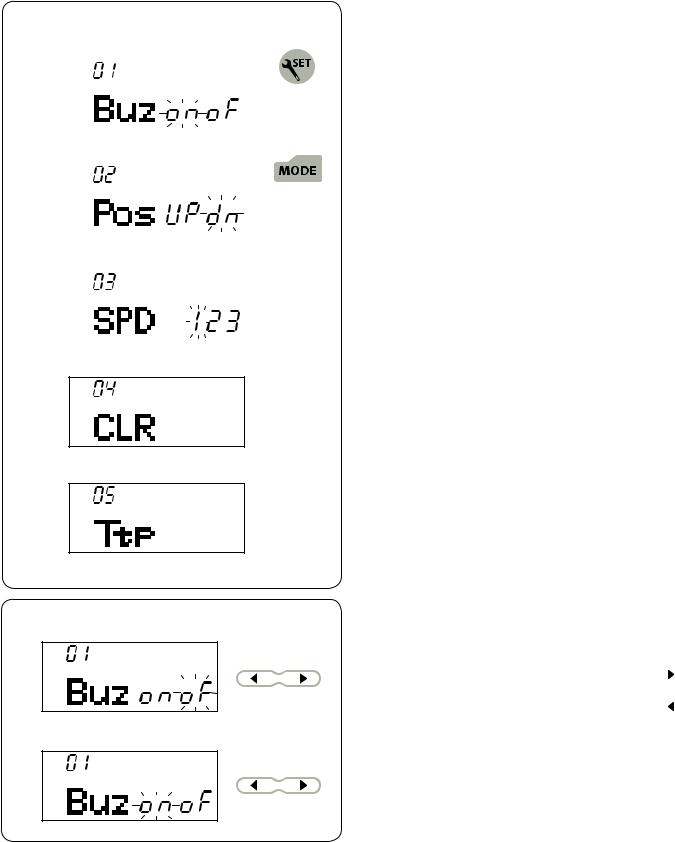

Customizing Machine Settings |

|

|

|

|

|

q |

You can customize the machine settings to your |

|

|

|

e |

preference. |

||||

|

|

|

|

||||

r |

|

|

|

|

|

|

Press the set key q and LCD screen will show the |

|

|

|

|

|

|

machine setting mode. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press the mode key w to select the desired setting. |

|

|

|

|

|

|

|

Each time you press the mode key, the mode number e |

|

|

|

|

|

w |

changes, and you can set the following machine functions |

|

|

|

|

|

|

as follows: |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e Mode number |

t |

|

|

|

|

|

|

r Buzzer sound setting |

|

|

|

|

|

|

|

t Needle stop position setting |

|

|

|

|

|

|

|

y Start up speed setting |

|

|

|

|

|

|

|

u Resetting all to default |

|

|

|

|

|

|

|

i Key position calibration |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

To exit the machine setting mode, press the set key q. |

|

|

|

|

|

|

|

|

y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

u

i

Buzzer sound setting

The buzzer sound can be turned on or off. The default buzzer sound setting is “ON”.

Enter the machine setting mode.

To turn off the buzzer sound, press the cursor key “ ” and the “oF” mark will blink.

To turn on the buzzer sound, press the cursor key “ ” and the “on” mark will blink.

Press the set key to exit the machine setting mode.

24

Needle stop position setting

The machine always stops with the needle in the down position except when sewing buttonholes, specialty stitches such as darning or eyelet, monograms, etc. However you can select the needle stop position up or down.

Enter the machine setting mode. Press the mode key to enter the needle stop position setting.

The default needle stop position setting is down position “dn”.

To change the needle stop position, press the cursor key “ ” and the “UP” mark will blink.

Press the set key to exit the machine setting mode.

|

|

Start-up speed setting |

q |

|

The machine will start running slowly and the sewing |

|

||

|

speed will gradually increase to maximum when pressing |

|

|

|

|

|

|

the start/stop button. |

|

|

You can select the desired start-up speed from 1 (slow) q, |

|

|

2 (medium) w or 3 (high) e. |

|

|

Enter the machine setting mode. Press the mode key |

w |

|

twice to enter the start-up speed setting. |

|

||

|

|

The default start-up speed setting is “1” (slow). To change |

|

|

the start-up speed, press the cursor key “ ” or “ ”, and |

|

|

the selected speed number will blink. |

e |

|

Press the set key to exit the machine setting mode. |

|

||

|

|

|

|

|

|

|

|

|

|

|

Resetting all to default |

|

|

The following customized settings can be reset to the |

|

|

default settings (factory settings). |

|

|

• Buzzer sound |

q |

• Needle stop position |

|

|

|

• Start up speed setting |

|

|

Enter the machine setting mode. Press the mode key 3 |

|

|

times to enter the Resetting all to default mode. |

|

|

Press and hold the clear key q until the machine beeps |

|

|

to reset the machine to the factory default setting. |

|

|

Press the set key to exit the machine setting mode. |

25

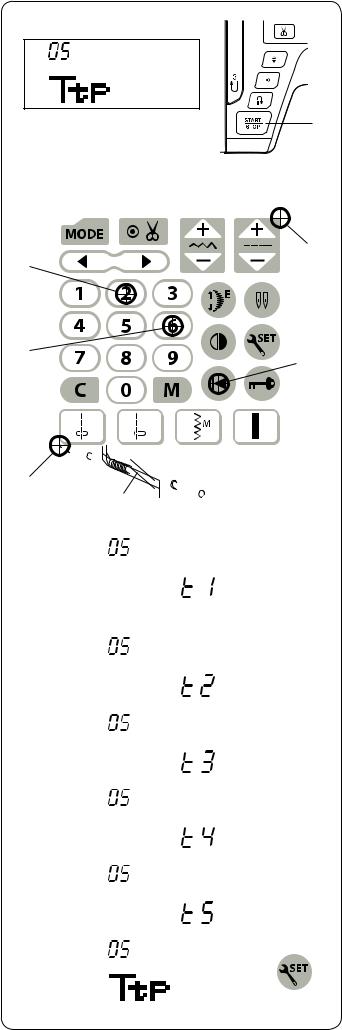

Key position calibration

z x

If the function keys seem out of alignment, calibrate the key position as follows.

z Enter the machine setting mode. Press the mode key 4 times to enter the key position calibration.

q |

x Press the start/stop button q. |

|

t(t3)

u

(t5)

r |

y(t4) |

|

(t2) |

||

|

e(t1)

|

w |

|

c |

|

c The key position adjustment screen appears and |

|

||

|

|

“t1” is shown on the right side of the screen. With the |

|

|

touch panel stylus w, press e on the touch panel of |

|

|

your machine. |

v |

|

v “t2” will be shown on the LCD screen. Press r on the |

|

||

|

||

|

|

touch panel. |

b |

|

b “t3” will be shown on the LCD screen. Press t on the |

|

||

|

||

|

|

touch panel. |

n |

|

n “t4” will be shown on the LCD screen. Press y on the |

|

||

|

||

|

|

touch panel. |

m |

|

m “t5” will be shown on the LCD screen. Press u on the |

|

||

|

||

|

|

touch panel. |

, |

|

, The screen will be back to the key position adjustment |

|

||

|

||

|

|

screen. Press the set key to exit the machine setting |

|

|

mode. |

|

|

|

26

Loading...

Loading...