KNOW YOUR MACHINE................................................................................................2-4

Name of Parts ....................................................................................................................2

Standard Accessories ........................................................................................................ 3

Detachable Extension Table .............................................................................................. 4

GETTING READY TO SEW ......................................................................................... 5-18

Connecting the Power Supply............................................................................................ 5

Start/Stop Button................................................................................................................ 5

Winding the Bobbin .........................................................................................................6-8

Removing the bobbin .................................................................................................. 6

Setting the spool of thread .......................................................................................... 6

Additional spool pin..................................................................................................... 6

Winding the bobbin ..................................................................................................... 7

Inserting the bobbin .................................................................................................... 8

Raising the Presser Foot.................................................................................................... 9

Threading the Machine .................................................................................................9-11

Needle Threader ..............................................................................................................11

Drawing up the Bobbin Thread ........................................................................................ 12

Adjusting the Thread Tension .......................................................................................... 13

Changing Needles............................................................................................................14

Embroidery Hoops ........................................................................................................... 15

Templates ........................................................................................................................ 15

Stabilizer .......................................................................................................................... 16

Types of stabilizer ..................................................................................................... 16

Usage........................................................................................................................ 16

Setting the Fabric in an Embroidery Hoop ....................................................................... 17

Attaching the Embroidery Hoop to the Machine............................................................... 18

KEY OPERATIONS ....................................................................................................19-25

Pattern Selection Window ................................................................................................ 19

Opening a Saved File....................................................................................................... 20

Mode Setting ...............................................................................................................21-23

Language Selection ......................................................................................................... 24

On-screen Help ................................................................................................................ 25

Selecting Patterns .......................................................................................................26-28

EMBROIDERY SEWING ............................................................................................29-45

Starting to Sew Embroidery ............................................................................................. 29

Monogram Selection Window ..................................................................................... 30-31

Monogram Embroidery................................................................................................32-33

2-Letters Monogram......................................................................................................... 34

Correcting the Monogram ................................................................................................ 35

PC Card Designs ............................................................................................................. 41

Editing Mode ............................................................................................................... 37-42

Saving a File .................................................................................................................... 36

Combining a Built-in Design and Monogramming....................................................... 43-44

CARE AND MAINTENANCE......................................................................................45-46

Cleaning the Hook Race and Feed Dog .......................................................................... 45

Replacing the Light Bulb ..................................................................................................46

Troubleshooting ............................................................................................................... 47

1

10

13

14

8

9

11

12

5

6

7

4

15

3

16

2

1

17

KNOW YOUR MACHINE

Name of Parts

1. Visual Touch Screen

2. Bobbin Winder Spindle

3. Bobbin Thread Cutter

4. Spool Holder (Large)

5. Spool Pin

6. Bobbin Winding Thread Guide

7. Thread Guide Plate

8. Thread Take-Up Lever

9. Thread Tension Dial

10. Face Plate

11. Thread Cutter & Thread Holder

12. Needle Threader

13. Needle Plate

14. Hook Cover Plate

15. Extension Table (Accessory Box)

16. Hook Cover Plate Release Button

17. Start/Stop Button

18. Needle Clamp Screw

19. Needle

20. Embroidery Foot

26

27

25

24

23

19

20

22

18

21

31

30

21. Carrying Handle

22. Hole for Additional Spool Pin

23. Bobbin Winder Stopper

24. Handwheel

25. PC Card Slot

26. PC Card (Optional Item)

27. Card Eject Button

28. Power Switch

29. Machine Socket

30. Carriage (For Embroidery)

31. Presser Foot Lifter

28

29

2

1

2

3

4

5

6

7

8

Standard Accessories

1. Bobbins

2. Lint Brush

3. Additional Spool Pin

4. Spool Pin Felt

5. Spool Stand

6. Spool Holder (Large)

7. Spool Holder (Small)

8. Scissors

9. Screwdriver

10. Screwdriver

11. Set of Needles

12. Standard Hoop (A) (with Template)

13. Large Hoop (B) (with Template)

14. Power Supply Cord

15. Instruction Book

16. Template Sheets (for Built-in Designs)

9

10

12

13

11

14

15

16

3

Detachable Extension Table

1

2

To remove, lift out the extension table toward you as

illustrated.

To attach, position the tabs on the base tab holes and

push down gently.

1 Extension table

2 Tabs

3 Base tab holes

3

1

Sewing accessories are stored in the extension table.

4

GETTING READY TO SEW

Connecting the Power Supply

The Memory Craft 300E is equipped with an auto

1

5

2

3

4

voltage system, which automatically adjusts the

equipment to accept any local power supply voltage

between 100 and 240V, 50/60 Hz.

Turn off the power switch and insert the machine

plug into the machine.

Insert the power supply plug into the wall outlet and

turn the power switch on.

1 Power switch

2 Machine plug

3 Machine socket

4 Power supply plug

5 Wall outlet

NOTE:

After turning on the power, it takes approximately six

seconds for the pattern selection window to be

displayed on the visual touch screen.

(This is the required boot up time and is not a defect)

For Y our Safety:

While in operation, always keep your eyes on the

sewing area, and do not touch any moving parts

such as the thread take-up lever, handwheel or

needle.

Always turn off the power switch and unplug the

power supply:

START

STOP

- when leaving the machine unattended.

- when attaching or removing parts.

- when cleaning the machine.

Operating Instructions:

“The symbol "O" of a switch indicates the "off"

position of a switch.”

“For appliances with a polarized plug (one blade

wider than the other). To reduce the risk of electric

shock, this plug is intended to fit in a polarized outlet

only one way. If it does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not

modify the plug in any way.”

Start/Stop Button

Press this button to start or to stop the machine. The

color of the button changes each time you press it—

red when the machine is running, and green when it

is stopped.

NOTE:

The Memory Craft 300E is equipped with an

automatic shutdown safety feature to prevent

overheating when the machine is running

overloaded. Follow safety instructions that appear on

the visual touch screen if it happens.

5

Winding the Bobbin

1

1

2

2

3

Removing the bobbin

Slide the hook cover plate release button to the right,

and remove the hook cover plate. Lift out the bobbin

from the bobbin holder.

1 Hook cover plate release button

2 Hook cover plate

3 Bobbin

Setting the spool of thread

1

Place the spool of thread on the spool pin with the

thread coming off the spool as shown. Attach the large

spool holder, and press it firmly against the spool of

thread.

NOTE:

Use the small spool holder to hold narrow or small

2

4

1

2

3

spools of thread.

1 Large spool holder

2 Small spool holder

Additional spool pin

Use the additional spool pin when you need to wind the

bobbin without unthreading the machine while working

on a sewing project.

Insert the additional spool pin into the spool stand then

into the hole besides the horizontal spool pin.

Place the felt on the spool pin and place a spool of

thread on it as shown.

1 Additional spool pin

2 Spool stand

3 Hole

4 Felt

6

Winding the bobbin

2

1

1

1

2

2

3

1 Guide the thread around the bobbin winder thread

guide while holding the thread at the spool.

1 Bobbin winder thread guide

2 Thread through the hole in the bobbin from the

inside to the outside. Put the bobbin on the bobbin

winder spindle.

2 Bobbin winder spindle

3 Push the spindle to the right. Press the Start/Stop

button while holding the end of the thread. Stop

the machine after the bobbin has made a few

turns. Cut the thread close to the hole in the

bobbin.

4

3

4 Press the Start/Stop button again. When the

bobbin is fully wound it will stop automatically.

Press the Start/Stop button to stop the machine

then return the bobbin winder spindle to the left.

Remove the bobbin and cut the thread with the

bobbin thread cutter.

3 Bobbin thread cutter

NOTES:

Do not move the bobbin winder spindle while the

machine is running.

For safety purposes, the motor will stop automatically

after running for two minutes.

7

1

1

2

Inserting the bobbin

1 Place the Bobbin in the Bobbin Holder with the

thread running off in the counterclockwise

direction.

1 Thread

2 Bobbin holder

2

3

3

4

2 Guide the thread into front notch on the front of

the bobbin holder.

Draw the thread to the left, sliding it between the

tension spring blades.

3 Front notch

3Continue to draw the thread lightly until the

thread slips into side notch.

Pull out about 10 cm (4") of thread to the rear.

4 Side notch

5

4 Refer to the threading chart shown on the hook

4

4

8

cover plate.

Reattach the hook cover plate.

4 Hook cover plate

5 Threading chart

Raising the Presser Foot

The presser foot lifter raises and lowers the presser

foot.

You can raise the presser foot about 6 mm (1/4") higher

than the normal up position by exerting more pressure

when lifting the presser foot lifter.

1

3

1

4

2

5

1

2

Threading the Machine

1 Raise the presser foot lifter. Turn the hand wheel

to bring the needle to its highest position. Draw

the thread around and under the thread guide

while holding the thread at the spool. Then draw

the thread down through the right channel of the

thread guide plate.

1Presser foot lifter

2 Thread guide

2

3

2 Firmly draw the thread around the thread guide

plate and up to the thread take-up lever.

3 Thread guide plate

9

3

5

4

3 Slip the thread through the slit and down into the

eye of the take-up lever as shown. Draw the

thread down through the left channel.

4Slit

5 Eye of the take-up lever

4 5

5

6

4 Slip the thread behind the lower thread guide

from the right.

5 Lower thread guide

5 Slip the thread in the needle bar thread guide

from the left.

6 Needle bar thread guide

Thread the needle from front to back by hand or use the

built-in needle threader.

NOTE:

Refer to page 11 for built-in needle threader

10

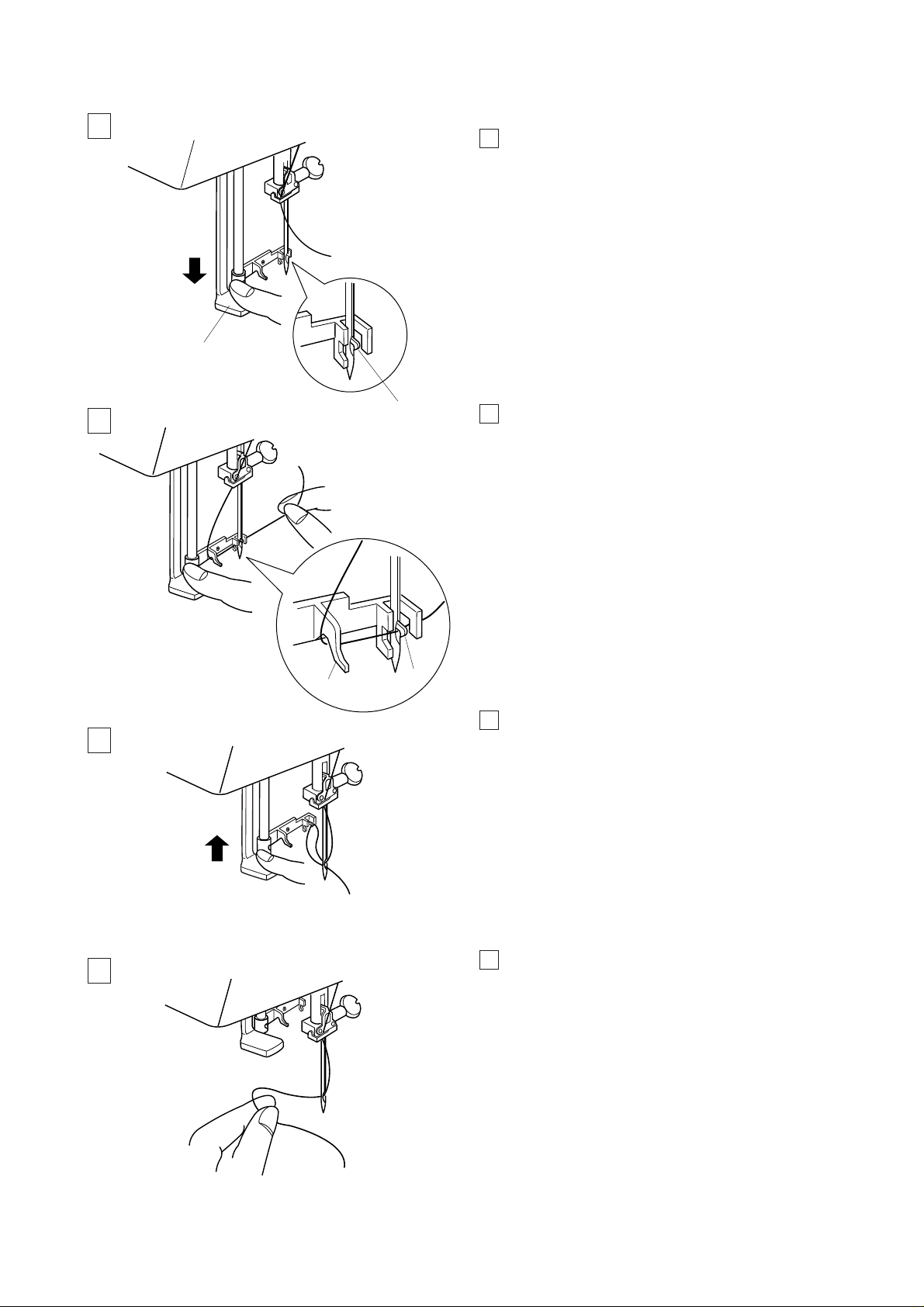

Needle Threader

1

1

1 Lower the presser foot. Depress the needle

threader knob as far as it will go. The hook

comes out through the needle eye from behind.

1 Needle threader knob

2 Hook

2

3

3

2

2

2 Draw the thread down around the threader guide

and under the hook.

3 Threader guide

3Release the threader knob slowly while holding

the thread end with your hand. A loop of the

thread is pulled up through the needle eye.

4

4 Remove the loop from the threader and pull out the

thread end from the needle eye.

NOTE:

The needle threader works well with the threads #50100 and needles #11-16, the blue tipped needle as well.

11

Drawing up the Bobbin Thread

1

1Raise the presser foot lifter. Hold the needle

thread with your finger.

1 Needle thread

2

1

2 Bobbin thread

2

1

2

3

2 Turn the handwheel one complete turn toward

you. Draw the needle thread to bring up a loop of

the bobbin thread.

1 Needle thread

2 Loop of bobbin thread

3 Pass the needle thread through the hole in the

embroidery foot and draw it up to the thread

holder leaving an inch of free thread.

3 Hole

4 Thread holder

3

4

12

Adjusting the Thread Tension

Balanced thread tension:

Small amount of the needle thread shows on the wrong

side of the fabric.

1

When the needle thread tension is too tight:

The bobbin thread shows on the right side of the fabric.

Reduce the tension by turning the tension dial to a

lower number.

1 Bobbin thread

When the needle tension is too loose:

The needle thread forms loops and the stitches look

shaggy.

Increase the tension by turning the dial to a higher

number.

13

Changing Needles

1

2

2

1

1

1 Turn off the power switch. Raise the needle by

turning the handwheel and lower the presser foot.

2Loosen the needle clamp screw by turning it

counterclockwise.

Remove the needle from the clamp.

Insert a new needle into the needle clamp with the

flat side of the needle to the rear.

1 Needle clamp screw

2 Flat side of the needle

When inserting the needle into the needle clamp, push

it up as far as it will go and tighten the needle clamp

screw firmly.

To check needle straightness, place the flat side of the

needle onto something flat (a needle plate, glass etc.)

The gap between the needle and the flat surface should

be consistent.

3

3 Gap

Never use a blunt needle.

NOTES:

Use the size 11 Blue Tipped Needles for fine fabrics.

For medium to heavy weight fabrics, use the size 14

needles.

14

Loading...

Loading...