Page 1

Powertrain DTC Summaries – OBD II

Quick Reference Diagnostic Guide

Jaguar X

Revised January, 2002:

P0706, P0731, P0732, P0733, P0734, P0735, P0740, P1780 “POSSIBLE CAUSES” Revised

P0860 Added

P1606 Revised CK ENG

Evaporative System Monitor Drive Cycle Revised

Revised April, 2002: P0831, P0832, P1517, P1601

Revised August, 2002: P0507, P1260

Refer to page 2 for important information regarding the use of “Powertrain DTC Summaries”.

-

TYPE 2.5L and 3.0L 2002 Model Year

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Page 2

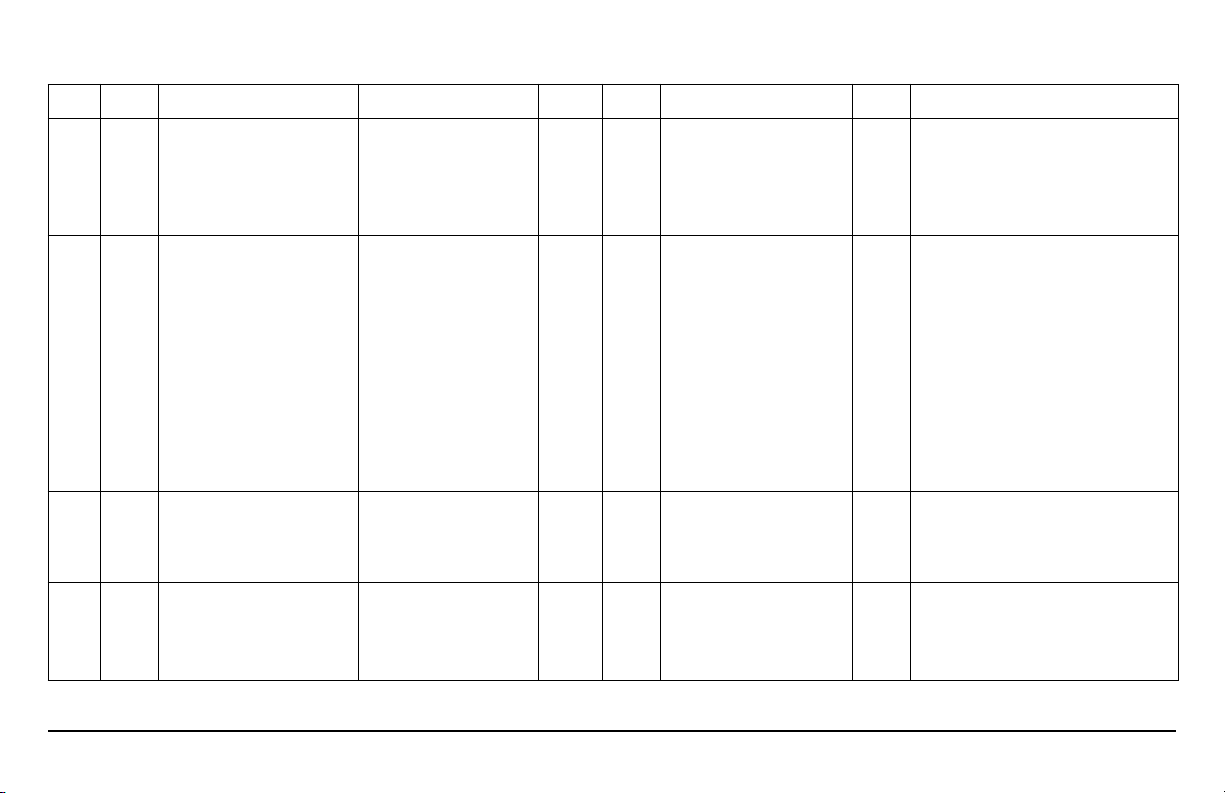

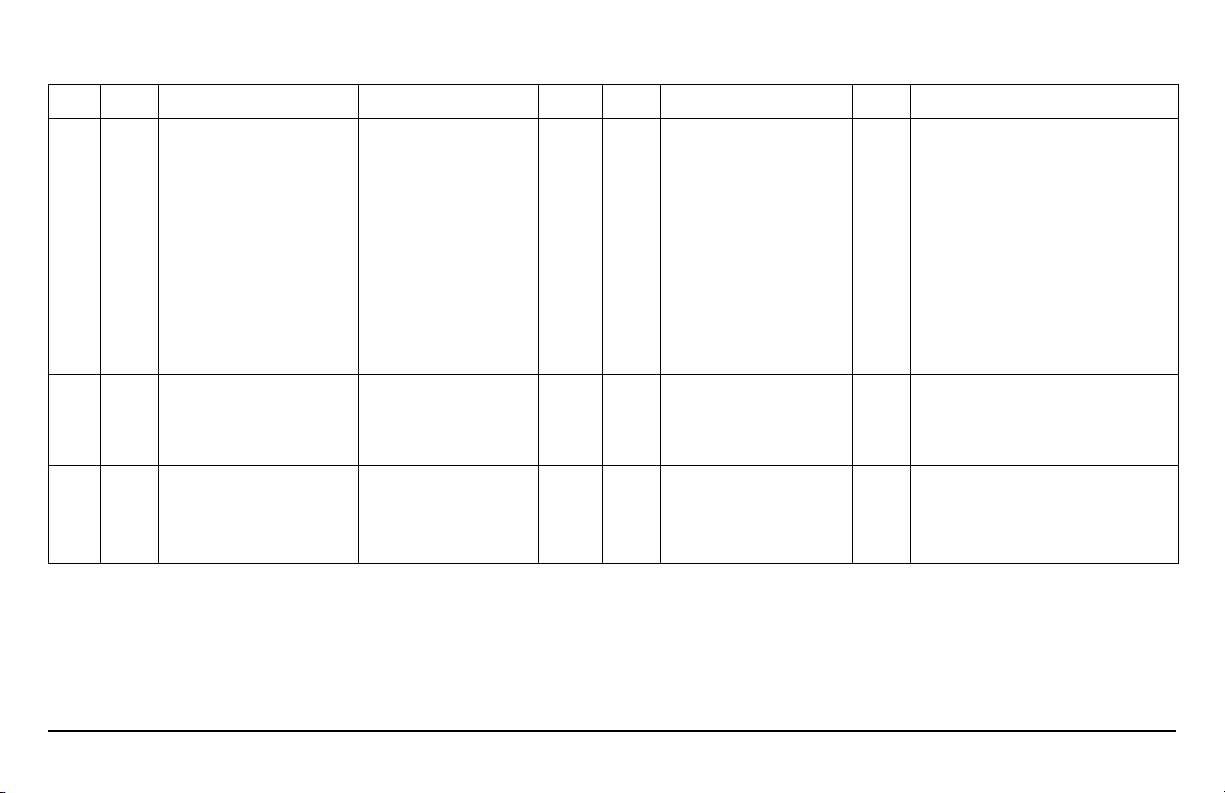

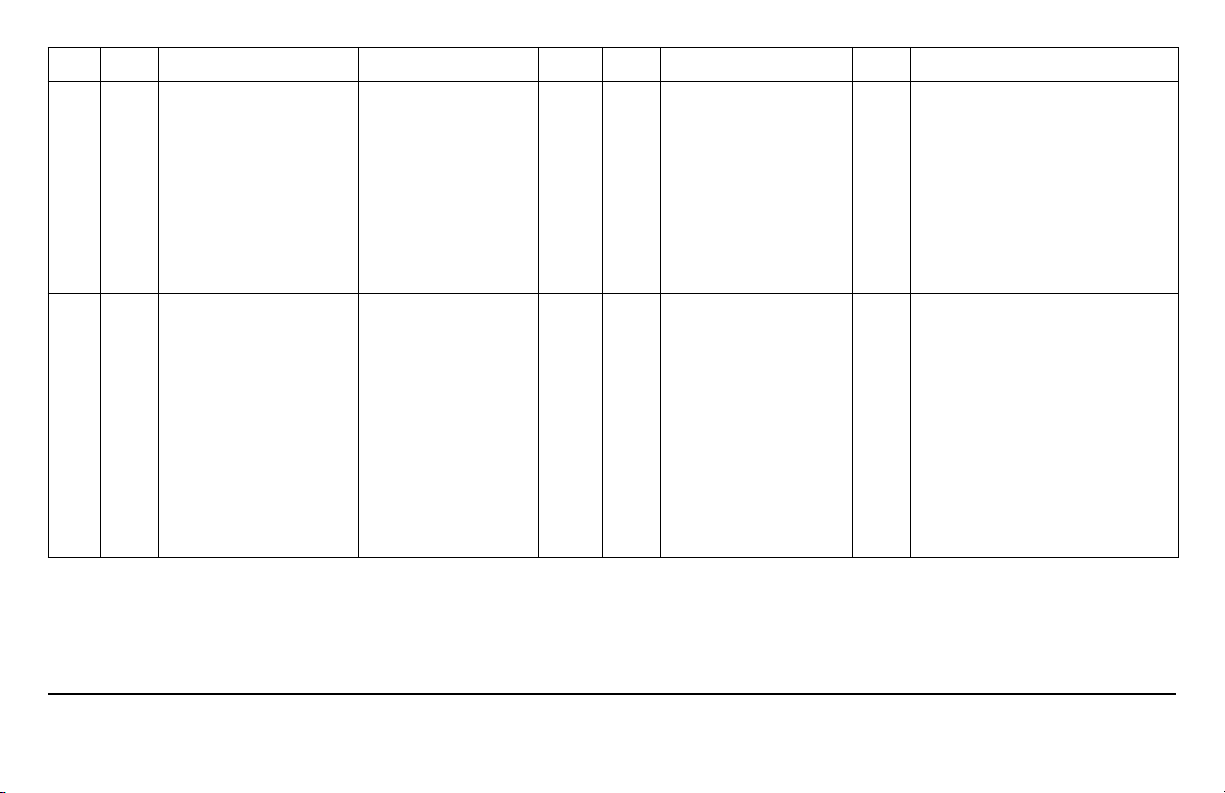

KEY TO COLUMN HEADINGS

DTC Diagnostic Trouble Code.

SYS The powertrain system with which the DTC is associated – EMS, TRANS, ABS/TC (DSC).

DTC retrieval tools:

OBD II – indicates that the DTC is an OBD II code and can be accessed via a generic scan tool or WDS.

JAG – indicates that the DTC is not an OBD II code and is accessed only via WDS.

FAULT DESCRIPTION Fault description.

MONITORING CONDITIONS “DIAGNOSTIC MONITOR DRIVE CYCLE” for the particular DTC. Operate the vehicle as described to check for a reoccurrence of

the DTC. Refer to pages 4 – 7.

Use WDS Datalogger or Scan Tool to monitor specified engine parameter(s).

CHECK ENGINE MIL 1 1 TRIP – indicates that the CHECK ENGINE MIL is activated by a fault occurring during ONE “TRIP”.

(CK ENG) 2 2 TRIPS – indicates that the CHECK ENGINE MIL is activated by a fault occurring during TWO CONSECUTIVE “TRIPS”.

N NO – indicates that the CHECK ENGINE MIL is not activated.

OTHER Driver Warnings:

N None

R RED MIL / Message or Powertrain Warning Indicator

A AMBER MIL / Message or Powertrain Warning Indicator

C Charge indicator

DEFAULT ACTION Control Module default action:

Logged – DTC stored in ECM memory buffer; Flagged – DTC stored in ECM memory / CHECK ENGINE MIL activated.

CM PIN ECM (SYS – EMS) / TCM (SYS – TRANS) Connector pin number(s)

POSSIBLE CAUSES Possible causes are listed in the order of diagnostic checking.

HIGH VOLTAGE – High voltage can be either sensor supply voltage (5 volts) or B+ voltage.

REFERENCE: It is recommended that the applicable “Electrical Guide” be referenced when using the information contained in this document.

Jaguar X-TYPE P DTC OBD II 2002 Model Year

2

Page 3

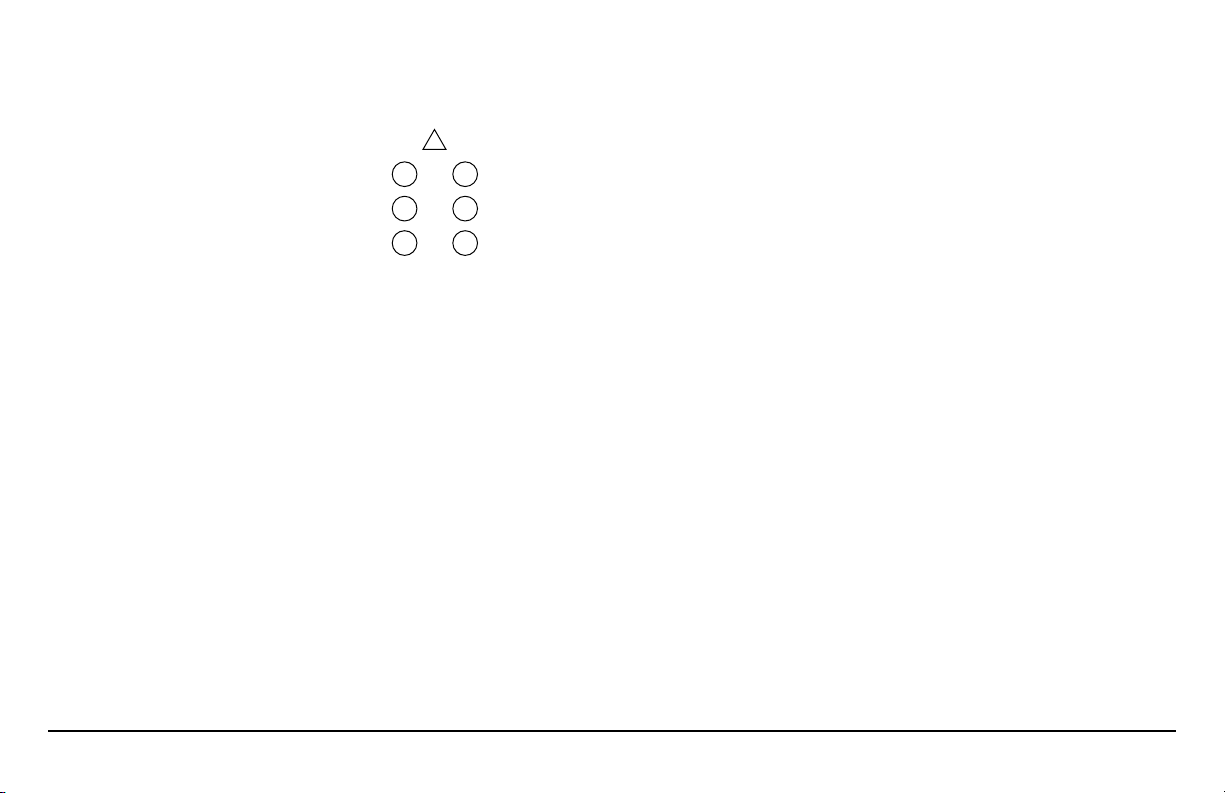

CYLINDER NUMBERING

Engine cylinder numbering is as follows:

FRONT OF ENGINE

2 1

4 3

6 5

OBD SYSTEM READINESS – ENGINE MANAGEMENT

If DTC P1000 is flagged after DTCs have been cleared, all engine management OBD diagnostic monitor drive cycles HAVE NOT BEEN COMPLETED.

If DTC P1111 is flagged after DTCs have been cleared, all engine management OBD diagnostic monitor drive cycles HAVE BEEN COMPLETED.

OBD SYSTEM READINESS – TRANSMISSION

Use WDS Datalogger “TOTAL NUMBER OF DTC SET” to determine if transmission OBD monitoring has been completed. Refer to page 7.

OBD DIAGNOSTIC MONITORS

The Engine Management and Transmission Control systems are continuously checked during vehicle operation by the Engine Control Module (ECM) and Transmission

Control Module (TCM) on-board diagnostic (OBD) facilities. Powertrain OBD incorporates six diagnostic monitors. Each monitor has an associated group of DTCs. The

diagnostic monitors will complete the diagnostic test(s) if a specified service “drive cycle” is carried out.

The six diagnostic monitors are as follows:

– Heated Oxygen Sensors Monitor

– Adaptive Fuel Monitor

– Misfire Monitor

– Catalyst Efficiency Monitor

– Evaporative System Monitor

– Comprehensive Component Monitor (Engine Management / Transmission)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

3

Page 4

DIAGNOSTIC MONITORS DRIVE CYCLES

Technicians can ensure that an OBD Monitor drive cycle is completed and that all or specific components have been checked by completing a specified drive cycle.

Use the following service drive cycles to confirm that the components and subsystems covered by the Diagnostic Monitors are operating correctly.

HEATED OXYGEN SENSORS MONITOR DRIVE CYCLE

Upstream (Universal) oxygen sensors:

1 Engine OFF; cooling fans inoperative > 20 seconds.

2 Start engine and bring to normal operating temperature > 82 °C (180 °F).

3 Drive the vehicle between 3000 – 4000 rpm at a steady speed. Lift foot completely off accelerator and coast to a stop within 30 seconds. Do not touch accelerator

pedal for 4 seconds after coming to a stop.

4 Repeat step 3.

5 Idle engine for 11 minutes.

Downstream oxygen sensors:

1 Start engine and bring to normal operating temperature > 82 °C (180 °F).

2 Drive the vehicle steadily between 48 – 97 km/h (30 – 60 mph) for 10 minutes.

3 Drive the vehicle above 3000 rpm in 4th gear at a steady speed. Lift foot completely off accelerator and coast for 30 seconds.

Oxygen sensor heaters:

1 Start engine and bring to normal operating temperature > 82 °C (180 °F).

2 Idle engine for 3 minutes.

ADAPTIVE FUEL MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature > 82 °C (180 °F).

2 Idle for a minimum of 10 minutes.

Jaguar X-TYPE P DTC OBD II 2002 Model Year

4

Page 5

MISFIRE MONITOR DRIVE CYCLE

1 Record flagged DTC (s) and accompanying WDS DTC Monitor freeze frame(s) data.

2 Fuel level > 25%.

3 Start engine and bring to normal operating temperature > 82 °C (180 °F).

4 Drive vehicle to the recorded freeze frame conditions (from step 1).

5 Repeat several times.

Note regarding misfire monitor DTCs:

If on the first trip, the misfire is severe enough to cause excess exhaust emission, the individual cylinder DTC plus DTC P1316 will be logged. The CHECK ENGINE MIL

will not be activated. If the fault reoccurs on the second trip, the individual cylinder DTC plus DTC P1316 will be flagged, and the CHECK ENGINE MIL will be activated.

If on the first trip, the misfire is severe enough to cause catalyst damage (more severe than excess exhaust emission), the CHECK ENGINE MIL will flash while the

fault is present and the individual cylinder DTC plus DTC P1313 (bank 1), DTC P1314 (bank 2) will be logged. When the fault is no longer present the MIL will be deactivated. If the fault reoccurs on the second trip, the CHECK ENGINE MIL will flash while the fault is present and the individual cylinder DTC plus DTC P1313 (bank 1),

DTC P1314 (bank 2) will be flagged. When the fault is no longer present the CHECK ENGINE MIL will be activated.

CATALYST EFFICIENCY MONITOR DRIVE CYCLE

1 Start engine and bring to normal operating temperature > 82 °C (180 °F).

2 Drive vehicle steadily between 1700 – 2500 rpm for 5 minutes.

Jaguar X-TYPE P DTC OBD II 2002 Model Year

5

Page 6

EVAPORATIVE SYSTEM MONITOR DRIVE CYCLE

1 Ensure that fuel filler cap is fully closed (minimum three clicks).

2 Fuel level > 30% and < 85%.

3 Using WDS, perform ECM DTC Clear (even if no DTCs are flagged).

4 Drive vehicle for a minimum of 2 minutes, and until engine is at normal operating temperature.

5 Using WDS, ensure that the EVAP Canister Purge Valve is operating by observing “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”. If the valve is not

active, ECM adaptions have not been learned. Conduct a “green ECM” Drive Cycle as described in Technical Service Bulletin.

6 Drive vehicle to the road where the EVAP System Drive Cycle will be conducted. Stop vehicle and switch OFF the ignition. Leave ignition OFF for 30 seconds,

then restart the engine.

7 Accelerate briskly to 80 km/h (50 mph) ensuring that the engine speed reaches a minimum of 3500 rpm for a minimum of 5 seconds.

8 (0.040 inch EVAP Test) View WDS “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”, “CANISTER CLOSE VALVE – VAPOR RECOVERY SYSTEM”, and

FUEL TANK PRESSURE – VAPOR RECOVERY SYSTEM”. Avoiding high engine loads, drive the vehicle steadily between 65 km/h (40 mph) and 100 km/h (60

mph). Avoid driving conditions that will produce excessive fuel movement. WDS should give an indication that the test is active (it may take up to 30 minutes

before the test will initialize). When the test has initialized (EVAP Canister Close Valve CLOSED), it will take approximately 90 seconds for the test to complete.

9 (0.020 inch EVAP Test) Continue driving vehicle as explained in Step 8 for an additional 10 minutes.

10 Gently coast the vehicle to a stop. Allow the engine to idle for 2 minutes and view WDS “PURGE VAPOR MANAGEMENT VALVE – DUTY CYCLE”, “CANISTER

CLOSE VALVE – VAPOR RECOVERY SYSTEM”, and FUEL TANK PRESSURE – VAPOR RECOVERY SYSTEM”. WDS should give an indication that the test is

active. When the test has initialized (EVAP Canister Close Valve CLOSED), it will take approximately 90 seconds for the test to complete.

11 If the 0.020 inch EVAP Test is not activated, the purge system vapor concentration may be too great. To reduce the vapor concentration proceed as follows:

12 Drive the vehicle for an additional 30 minutes avoiding driving conditions that will produce excessive fuel movement. Repeat Step 10. If the 0.020 inch EVAP

Test is still not activated, repeat the Drive Cycle from Step 6.

13 Using WDS, check for and clear flagged DTCs.

COMPREHENSIVE COMPONENT MONITOR ENGINE MANAGEMENT DRIVE CYCLE

To avoid unnecessary complexity, a single comprehensive engine management drive cycle has not developed for X-TYPE. Refer to the individual DTC for specific drive

cycle / monitoring conditions.

Jaguar X-TYPE P DTC OBD II 2002 Model Year

6

Page 7

COMPREHENSIVE COMPONENT MONITOR TRANSMISSION DRIVE CYCLE

The Comprehensive Component Monitor transmission drive cycle will “check” all transmission system components.

1 Engine and transmission at normal operating temperature. Ignition OFF

2 With gear selector in P and the ignition ON. Check gearshift interlock by attempting to move selector without pressing the brake pedal. Verify P state illumination.

3 Press and hold the brake pedal. Move the gear selector to R. Verify R state illumination.

4 Set the parking brake. Press and hold the brake pedal. Attempt to start the engine. The engine should not start.

5 Move the gear selector to N. Verify N state illumination. Start the engine.

6 With the hand brake set and the brake pedal pressed, move the gear selector to the remaining positions in the J Gate (D, 4, 3, 2) for five (5) seconds each. Verify

the state illumination in each position.

7 Move the gear selector back to 4. Verify 4 state illumination.

8 Move the gear selector to D. Verify D state illumination.

9 Move the gear selector to N. Verify N state illumination.

10 Select R, release the brakes and drive the vehicle in Reverse for a short distance.

11 Stop the vehicle.

12 Select 2 and drive the vehicle up to 65 km/h (40 mph). Hold 65 km/h (40 mph) for a minimum of five (5) seconds.

13 Select 3 and hold 65 km/h (40 mph) for a minimum of five (5) seconds.

14 Select 4 and hold 65 km/h (40 mph) for a minimum of five (5) seconds.

15 Select D and accelerate to a minimum speed of 80 km/h (50 mph). Hold 80 – 129 km/h (50 – 80 mph) for a minimum of 1.7 kilometers (1 mile).

16 Stop the vehicle; do not switch OFF the engine.

17 Use WDS Datalogger “TOTAL NUMBER OF DTC SET” to ensure that transmission DTC monitoring is complete.

Jaguar X-TYPE P DTC OBD II 2002 Model Year

7

Page 8

POWERTRAIN CONTROL ACRONYMS:

A/C Air conditioning

APP Sensor Accelerator Pedal Position Sensor

B+ Battery Voltage

Bank 1 RH Engine cylinder bank (cylinders 1, 3, 5) (A Bank)

Bank 2 LH Engine cylinder bank (cylinders 2, 4, 6) (B Bank)

BARO Sensor Barometric Pressure Sensor

CAN Controller Area Network

CKP Sensor Crankshaft Position Sensor

CMP Sensor 1 Camshaft Position Sensor – Bank 1

CMP Sensor 2 Camshaft Position Sensor – Bank 2

DLC Data Link Connector

ECM Engine Control Module

ECT Sensor Engine Coolant Temperature Sensor

EFT Sensor Engine Fuel Temperature Sensor

EOT Sensor Engine Oil Temperature Sensor

EVAP Canister Close Valve Evaporative Emission Canister Close Valve

EVAP Canister Purge Valve Evaporative Emission Canister Purge Valve

FTP Sensor Fuel Tank Pressure Sensor

HO2 Sensor 1 / 1 Heated Oxygen Sensor – Bank 1 / Upstream

HO2 Sensor 1 / 2 Heated Oxygen Sensor – Bank 1 / Downstream

HO2 Sensor 2 / 1 Heated Oxygen Sensor – Bank 2 / Upstream

HO2 Sensor 2 / 2 Heated Oxygen Sensor – Bank 2 / Downstream

IAT Sensor Intake Air Temperature Sensor

IMT Valve 1 Intake Manifold Tuning Valve: Bottom

IMT Valve 2 Intake Manifold Tuning Valve: Top

IP Sensor Injection Pressure Sensor

KS 1 Knock Sensor – Bank 1

KS 2 Knock Sensor – Bank 2

MAF Sensor Mass Air Flow Sensor

MAP Sensor Manifold Absolute Pressure Sensor

TCC Torque converter clutch

TCM Transmission Control Module

TFT Sensor Transmission Fluid Temperature Sensor

TP Sensor Throttle Position Sensor

VVT Valve 1 Variable Valve Timing Valve – Bank 1

VVT Valve 2 Variable Valve Timing Valve – Bank 2

Jaguar X-TYPE P DTC OBD II 2002 Model Year

8

Page 9

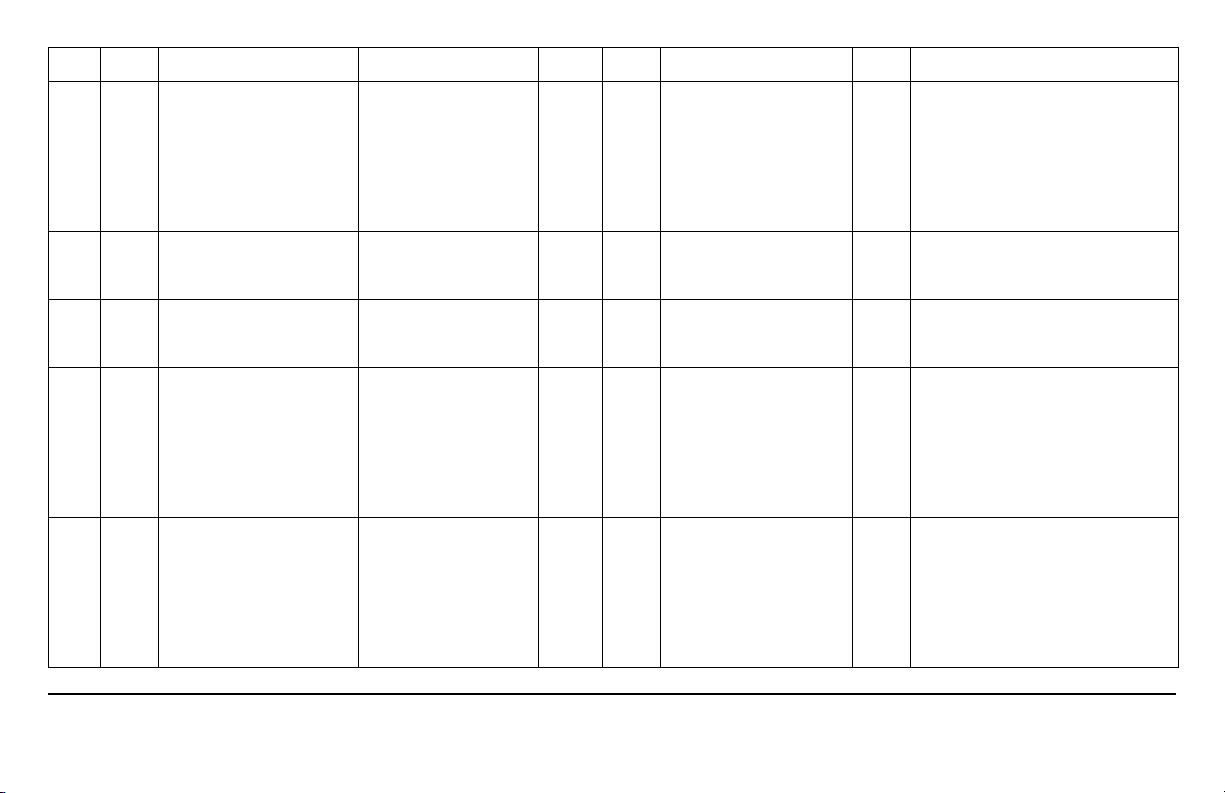

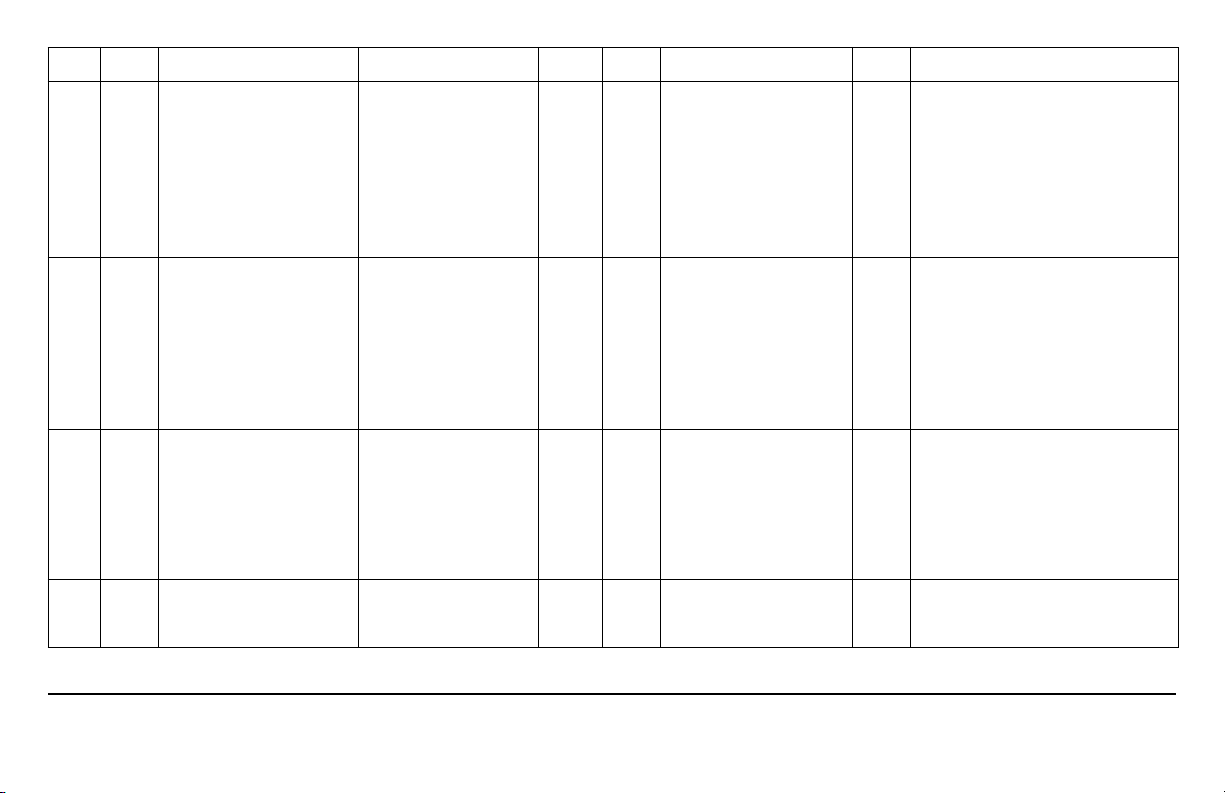

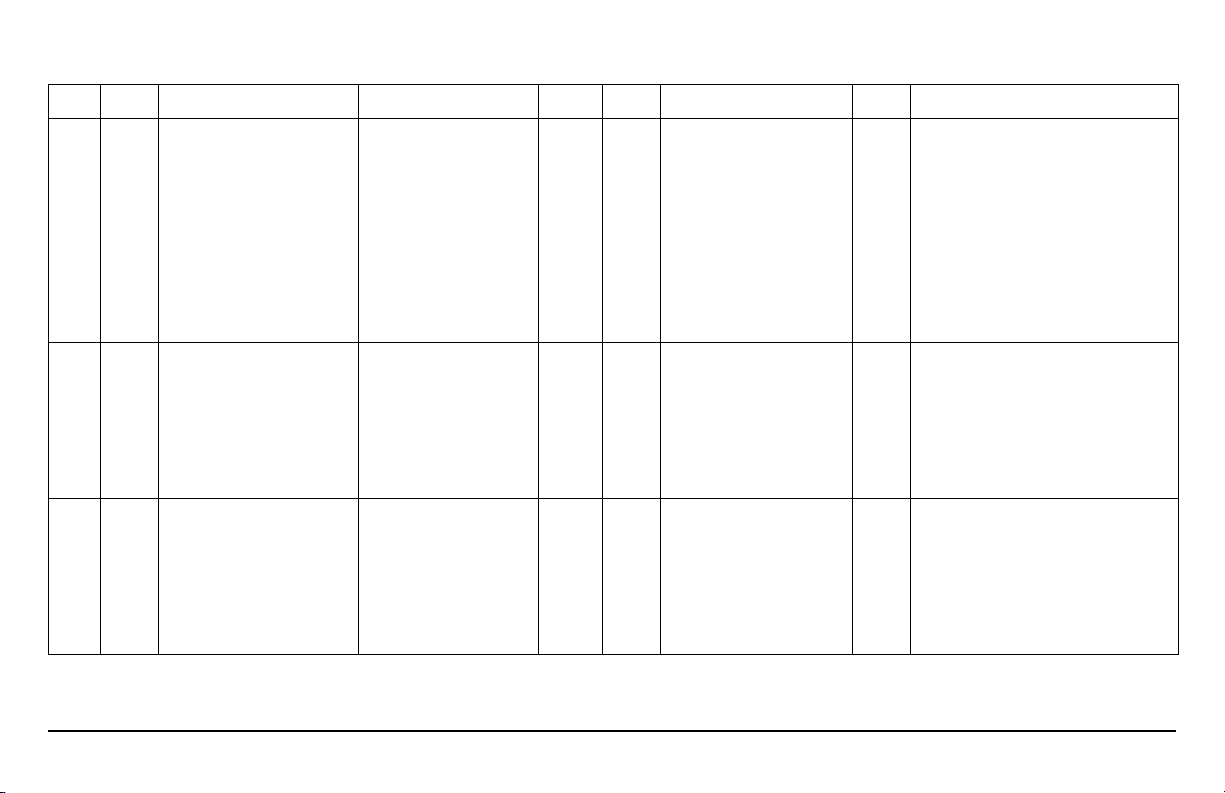

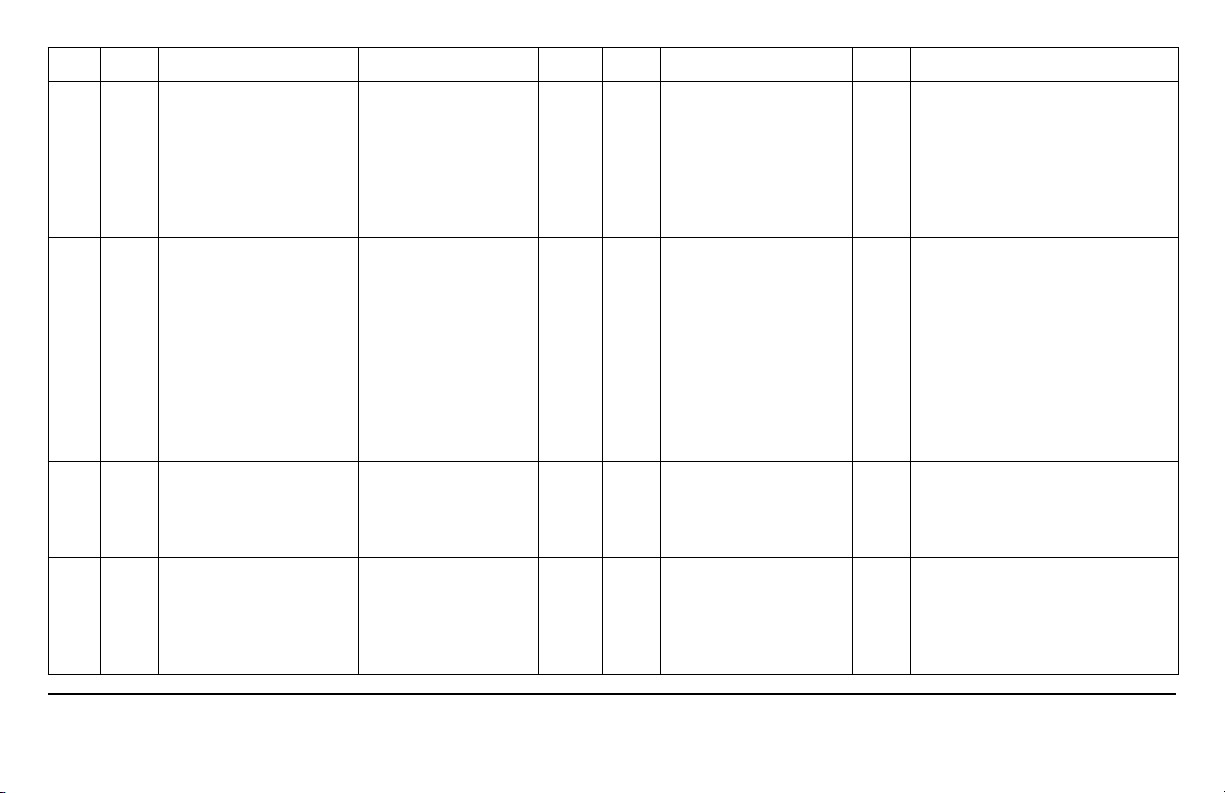

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0010 EMS

VVT circuit malfunction – bank 1 Idle engine 30 seconds

OBD II

Accelerate from stop through

complete engine rpm range

Coast to a stop

Drive the vehicle steadily

between 48 – 97 km/h (30 –

60 mph) for 5 minutes; coast

to a stop

Accelerate smoothly through

complete accelerator pedal

travel; coast to a stop

2NECM Default:

– Bank 1 VVT hold current set at

a constant value of 450 mA

EN16

VVT solenoid valve to ECM PWM drive circuit:

open circuit, short circuit, high resistance

-109

VVT solenoid failure

Idle engine 30 seconds

P0020 EMS

VVT circuit malfunction – bank 2 Idle engine 30 seconds

OBD II

P0031 EMS

HO2 Sensor heater control circuit

low current –

OBD II

bank 1, upstream (1/1)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Accelerate from stop through

complete engine rpm range;

coast to a stop

Drive the vehicle steadily

between 48 – 97 km/h (30 –

60 mph) for 5 minutes; coast

to a stop

Accelerate smoothly through

complete accelerator pedal

travel; coast to a stop

Idle engine 30 seconds

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

2NECM Default:

– Bank 2 VVT hold current set at

a constant value of 450 mA

2NECM Default:

– Bank 1 closed loop fuel

metering and adaptive fuel

metering inhibited

– Canister purge inhibited

– Bank 1 upstream HO2S

heater control circuit switched

off

EN16

VVT solenoid valve to ECM PWM drive circuit:

open circuit, short circuit, high resistance

-110

VVT solenoid failure

HO2 Sensor 1/1 heater power supply circuit:

EN16

open circuit

-001

-002

HO2 Sensor 1/1 heater control circuit:

-029

open circuit, high resistance

-030

HO2 Sensor 1/1 heater ground circuit(s) fault

(EN16-029, EN16-030)

HO2 Sensor 1/1 heater failure

9

Page 10

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0032 EMS

HO2 Sensor heater control circuit

high current –

OBD II

bank 1, upstream (1/1)

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

2NECM Default:

– Bank 1 closed loop fuel

metering and adaptive fuel

metering inhibited

– Canister purge inhibited

– Bank 1 upstream HO2S

heater control circuit switched

off

HO2 Sensor 1/1 heater control circuit:

EN16

short circuit to ground

-001

-002

HO2 Sensor 1/1 heater ground circuit(s) fault

-029

(EN16-029, EN16-030)

-030

HO2 Sensor 1/1 heater failure

P0037 EMS

P0038 EMS

P0051 EMS

P0052 EMS

HO2 Sensor heater control circuit

low resistance –

OBD II

bank 1, downstream (1/2)

HO2 Sensor heater control circuit

high resistance –

OBD II

bank 1, downstream (1/2)

HO2 Sensor heater control circuit

low current –

OBD II

bank 2, upstream (2/1)

HO2 Sensor heater control circuit

high current –

OBD II

bank 2, upstream (2/1)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

2NNone EN16

2NNone EN16

2NECM Default:

– Bank 2 closed loop fuel

metering and adaptive fuel

metering inhibited

– Canister purge inhibited

– Bank 2 upstream HO2S

heater control circuit switched

off

2NECM Default:

– Bank 2 closed loop fuel

metering and adaptive fuel

metering inhibited

– Canister purge inhibited

– Bank 2 upstream HO2S

heater control circuit switched

off

-092

-092

EN16

-055

-056

-081

-082

EN16

-055

-056

-081

-082

HO2 Sensor 1/2 heater control circuit:

short circuit to ground

HO2 Sensor 1/2 heater failure

HO2 Sensor 1/2 heater control circuit:

open circuit; high resistance

HO2 Sensor 1/2 heater failure

HO2 Sensor 2/1 heater power supply circuit:

open circuit

HO2 Sensor 2/1 heater control circuit:

open circuit, high resistance

HO2 Sensor 2/1 heater ground circuit(s) fault

(EN16-081, EN16-082)

HO2 Sensor 2/1 heater failure

HO2 Sensor 2/1 heater control circuit:

short circuit to ground

HO2 Sensor 2/1 heater ground circuit(s) fault

(EN16-081, EN16-082)

HO2 Sensor 2/1 heater failure

10

Page 11

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0057 EMS

HO2 Sensor heater control circuit

low resistance –

OBD II

bank 2, downstream (2/2)

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

2NNone EN16

-93

HO2 Sensor 2/2 heater control circuit:

short circuit to ground

HO2 Sensor 2/2 heater failure

P0058 EMS

P0101 EMS

P0102 EMS

HO2 Sensor heater control circuit

high resistance –

OBD II

bank 2, downstream (2/2)

MAF Sensor circuit range /

performance

OBD II

MAF Sensor circuit low voltage Ignition ON 10 seconds 2 A ECM Default:

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Heated oxygen sensors

monitor drive cycle – page 4

(Oxygen sensor heaters)

Fuel level > 25%.

Start engine and bring to

normal operating temperature

> 82 °C (180 °F)

Drive the vehicle steadily in

4th or 5th gear on a level road

between 1700 – 2300 rpm;

hold the engine speed

constant for 40 seconds while

maintaining a steady throttle

2NNone EN16

2AECM Default:

– Default air mass used

– Adaptive fuel metering

inhibited

– Catalyst warm up ignition

retard inhibited

-93

EN16

-044

– Canister purge inhibited

– Maximum engine speed

reduced

EN16

– Default air mass used

– Adaptive fuel metering

inhibited

– Catalyst warm up ignition

retard inhibited

-044

– Canister purge inhibited

– Maximum engine speed

reduced

HO2 Sensor 2/2 heater control circuit:

open circuit; high resistance

HO2 Sensor 2/2 heater failure

Blocked air cleaner

Air intake leak

Engine breather leak

Throttle control malfunction

MAF Sensor to ECM sensing circuit:

high resistance, intermittent short circuit

to ground

MAF Sensor supply circuit: high resistance

MAF Sensor failure

Blocked air cleaner

MAF Sensor to ECM sensing circuit:

high resistance, open circuit, intermittent

short circuit to ground

MAF Sensor supply circuit:

open circuit, short circuit to ground

MAF Sensor failure

11

Page 12

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0103 EMS

MAF Sensor circuit high voltage Ignition ON 10 seconds 2 A ECM Default:

OBD II

– Default air mass used

– Adaptive fuel metering

inhibited

– Catalyst warm up ignition

retard inhibited

EN16

MAF Sensor to ECM sensing circuit:

short circuit to B+ voltage

-044

MAF Sensor to ECM sensor ground circuit:

-045

open circuit

-046

MAF Sensor failure

– Canister purge inhibited

– Maximum engine speed

reduced

P0105 EMS

MAP Sensor circuit malfunction Fuel level > 25%

OBD II

P0106 EMS

P0107 EMS

BARO Sensor circuit range /

performance

OBD II

BARO Sensor circuit low voltage Ignition ON 10 seconds 2 N ECM Default:

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Start engine and bring to

normal operating temperature

> 82 °C (180 °F)

Drive the vehicle steadily in

4th or 5th gear on a level road

between 1700 – 2300 rpm;

hold the engine speed

constant for 40 seconds while

maintaining a steady throttle

Engine temperature cool

(cooling fans not running)

Remove ignition key for 20

seconds (cooling fans not

running)

Ignition key in, position II for 5

seconds (do not start)

Repeat cycle twice more

2NECM Default:

– Default value of 1.013 BAR

(29.92 in hg) used

2NECM Default:

– Default value of 1 BAR (29.53

in hg) used

– Default value of 1 BAR (29.53

in hg) used

EN16

MAP Sensor to ECM circuit(s) fault

-127

MAP Sensor failure

— BARO Sensor failure (internal ECM fault)

— BARO Sensor failure (internal ECM fault)

12

Page 13

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0108 EMS

BARO Sensor circuit high voltage Ignition ON 10 seconds 2 N ECM Default:

OBD II

– Default value of 1 BAR (29.53

in hg) used

— BARO Sensor failure (internal ECM fault)

P0111 EMS

P0112 EMS

P0113 EMS

IAT Sensor circuit range /

performance

OBD II

IAT Sensor circuit high voltage

(low air temperature)

OBD II

IAT Sensor circuit low voltage

(high air temperature)

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Engine OFF; coolant

temperature <35 °C (95 °F)

Start engine and hold 3000

rpm in P or N for 30 seconds

2NECM Default:

– Default value of 25 °C (77 °F)

used

Ignition ON 10 seconds 2 N ECM Default:

– Default value of 25 °C (77 °F)

used

Ignition ON 10 seconds 2 N ECM Default:

– Default value of 25 °C (77 °F)

used

EN16

Blocked air cleaner

-071

Air intake leak

Engine breather leak

IAT Sensor to ECM wiring:

open circuit or high resistance

IAT Sensor to ECM sensing circuit:

short circuit to high voltage

IAT Sensor failure

EN16

IAT Sensor to ECM wiring:

open circuit or high resistance

-071

IAT Sensor to ECM sensing circuit:

short circuit to B+ voltage

IAT Sensor failure

EN16

IAT Sensor to ECM wiring:

short circuit to ground

-071

IAT Sensor failure

13

Page 14

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0116 EMS

ECT Sensor circuit range /

performance

OBD II

Engine coolant temperature

and ambient temperature

within 10 °C (50 °F)

Drive the vehicle steadily in

4th or 5th gear above 1700

rpm for 5 minutes

Idle engine until engine

coolant temperature reaches

80 °C (176 °F)

CAUTION: Overheating is

possible if the ECT sensor is

faulty and cooling fans do not

operate

2AECM Default:

– EOT value substituted (no

greater than 95 °C (203 °F)

– Closed loop fuel metering

inhibited

– Adaptive fuel metering

inhibited

– Catalyst warm-up ignition

retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

EN16

Low coolant level

-070

Contaminated coolant

Engine thermostat failure

ECT Sensor to ECM sensing circuit:

high resistance when hot, intermittent high

resistance

ECT Sensor failure

P0117 EMS

ECT Sensor circuit high voltage

(low coolant temperature)

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Ignition ON 10 seconds 2 A ECM Default:

– EOT value substituted (no

greater than 95 °C (203 °F)

– Closed loop fuel metering

inhibited

– Adaptive fuel metering

inhibited

– Catalyst warm-up ignition

retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

EN16

ECT Sensor disconnected

-070

ECT Sensor to ECM sensing circuit:

high resistance, open circuit, short circuit

to B+ voltage

ECT Sensor failure

14

Page 15

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0118 EMS

ECT Sensor circuit low voltage

(high coolant temperature)

OBD II

Ignition ON 10 seconds 2 A ECM Default:

– EOT value substituted (no

greater than 95 °C (203 °F)

– Closed loop fuel metering

inhibited

– Adaptive fuel metering

inhibited

– Catalyst warm-up ignition

retard inhibited

EN16

Engine overheat condition

-070

ECT Sensor to ECM wiring:

short circuit to ground

ECT Sensor failure

– Canister purge inhibited

– Maximum engine speed

reduced

P0121 EMS

P0122 EMS

TP Sensor range / performance

(TP1 compared to TP2)

OBD II

TP Sensor circuit 1 low voltage Battery voltage > 10 v

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Battery voltage > 10 v

Ignition ON

Slowly press accelerator

pedal to the floor over a 5

second period

Slowly return the pedal to rest

Repeat 3 times

Ignition ON

Slowly press accelerator

pedal to the floor over a 5

second period

Slowly return the pedal to rest

Repeat 3 times

2RECM Default:

– Throttle motor and throttle

motor relay disabled

– Throttle valve opening set to

default value

– Idle speed controlled by fuel

injection intervention

– Idle speed adaption inhibited

2RECM Default:

– Throttle motor and throttle

motor relay disabled

– Throttle valve opening set to

default value

– Idle speed controlled by fuel

injection intervention

– Idle speed adaption inhibited

EN16

TP Sensor to ECM wiring:

open circuit, high resistance

-075

-076

TP Sensor to ECM sensing circuits (TP1 or

TP2): short circuit to B+ voltage

TP Sensor failure

EN16

TP Sensor to ECM sensing circuit (TP1):

open circuit, high resistance

-075

TP Sensor failure

15

Page 16

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0123 EMS

TP Sensor circuit 1 high voltage Battery voltage > 10 v

OBD II

Ignition ON

Slowly press accelerator

pedal to the floor over a 5

second period

Slowly return the pedal to rest

Repeat 3 times

2RECM Default:

– Throttle motor and throttle

motor relay disabled

– Throttle valve opening set to

default value

– Idle speed controlled by fuel

injection intervention

– Idle speed adaption inhibited

EN16

TP Sensor to ECM sensing circuit (TP1):

short circuit to high voltage

-075

TP Sensor failure

P0125 EMS

ECT Sensor response

(for closed loop fuel control)

OBD II

(Coolant thermostat monitor)

P0128 EMS

Coolant thermostat range /

performance

OBD II

P0131 EMS

HO2 Sensor sense circuit low

current – bank 1, upstream (1/1)

OBD II

(Universal oxygen sensor: lean

condition at ECM – high current at

sensor)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Engine coolant temperature

and ambient temperature

within 10 °C (50 °F)

Drive the vehicle steadily in

4th or 5th gear above 1700

rpm for 5 minutes

Idle engine until engine

coolant temperature reaches

80 °C (176 °F)

CAUTION: Overheating is

possible if the ECT sensor is

faulty and cooling fans do not

operate

Engine OFF; coolant

temperature <35 °C (95 °F)

Start engine and drive until

normal engine operating

temperature > 82 °C (180 °F)

Heated oxygen sensors

monitor drive cycle – page 4

(Upstream oxygen sensors)

2AECM Default:

– EOT value substituted (no

greater than 95 °C (203 °F)

– Closed loop fuel metering

inhibited

– Adaptive fuel metering

inhibited

– Catalyst warm-up ignition

retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

EN16

Low coolant level

-070

Contaminated coolant

Engine coolant thermostat failure

ECT Sensor to ECM sensing circuit:

high resistance, open circuit or short circuit

to high voltage

Engine cooling fan stuck on high speed

Above normal air flow through engine

compartment due to accident damage and/

or missing panels

2NNone — Contaminated coolant

Engine coolant thermostat failure

ECT Sensor failure

(ECT Sensor DTC(s) also flagged)

2NNone EN16

HO2 Sensor 1/1 disconnected

-083

HO2 Sensor 1/1 to ECM variable current

-084

circuit fault (HO2 Sensor pin 3)

ECM to HO2 Sensor 1/1 constant current

circuit fault (HO2 Sensor pin 4)

HO2 Sensor 1/1 failure

16

Page 17

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0132 EMS

OBD II

HO2 Sensor sense circuit high

current – bank 1, upstream (1/1)

(Universal oxygen sensor: rich

condition at ECM – low current at

sensor)

Heated oxygen sensors

monitor drive cycle – page 4

(Upstream oxygen sensors)

2NNone EN16

-083

-084

HO2 Sensor 1/1 disconnected

HO2 Sensor 1/1 to ECM variable current

circuit fault (HO2 Sensor pin 3)

ECM to HO2 Sensor 1/1 constant current

circuit fault (HO2 Sensor pin 4)

HO2 Sensor 1/1 failure

P0133 EMS

P0137 EMS

P0138 EMS

HO2 Sensor sense circuit

slow response –

OBD II

bank 1, upstream (1/1)

HO2 Sensor sense circuit

low voltage –

OBD II

bank 1, downstream (1/2)

HO2 Sensor sense circuit

high voltage –

OBD II

bank 1, downstream (1/2)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Heated oxygen sensors

monitor drive cycle – page 4

(Upstream oxygen sensors)

Heated oxygen sensors

monitor drive cycle – page 4

(Downstream oxygen

sensors)

Heated oxygen sensors

monitor drive cycle – page 4

(Downstream oxygen

sensors)

2NECM Default:

– Bank 1 closed loop fuel

metering inhibited

EN16

-083

-084

– Canister purge inhibited

2NNone EN16

2NNone EN16

-128

-128

Engine misfire

HO2 Sensor 1/1 disconnected

HO2 Sensor 1/1 mechanical damage

HO2 Sensor 1/1 to ECM wiring fault

HO2 Sensor 1/1 short circuit to ground

HO2 Sensor 1/1 to ECM wiring shield open

circuit

HO2 Sensor 1/1 heater circuit fault

Exhaust leak

Low exhaust temperature

Injector flow partially blocked

Catalyst efficiency decrease

HO2 Sensor 1/1 failure

HO2 Sensor 1/2 disconnected

HO2 Sensor 1/2 to ECM wiring open circuit

HO2 Sensor 1/2 short circuit to ground

HO2 Sensor 1/2 failure

HO2 Sensor 1/2 sensing circuit:

short circuit to high voltage

HO2 Sensor 1/2 ground (BRD – braided shield)

open circuit

HO2 Sensor 1/2 failure

17

Page 18

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0140 EMS

HO2 Sensor sense circuit

no activity –

OBD II

bank 1, downstream (1/2)

Heated oxygen sensors

monitor drive cycle – page 4

(Downstream oxygen

sensors)

2NNone EN16

-128

HO2 Sensor 1/2 disconnected

HO2 Sensor 1/2 mechanical damage

HO2 Sensor 1/2 to ECM wiring open circuit

HO2 Sensor 1/2 sensing circuit:

short circuit to high voltage

HO2 Sensor 1/2 short circuit to ground

HO2 Sensor 1/2 ground (BRD – braided shield)

open circuit

Exhaust leak

Low exhaust temperature

HO2 Sensor 1/2 failure

P0151 EMS

OBD II

HO2 Sensor sense circuit

low current –

bank 2, upstream (2/1)

(Universal oxygen sensor: lean

condition at ECM – high current at

sensor)

Heated oxygen sensors

monitor drive cycle – page 4

(Upstream oxygen sensors)

2NNone EN16

-107

-108

HO2 Sensor 2/1 disconnected

HO2 Sensor 2/1 to ECM variable current

circuit fault (HO2 Sensor pin 3)

ECM to HO2 Sensor 2/1 constant current

circuit fault (HO2 Sensor pin 4)

HO2 Sensor 2/1 failure

P0152 EMS

HO2 Sensor sense circuit

high current –

OBD II

bank 2, upstream (2/1)

(Universal oxygen sensor: rich

condition at ECM – low current at

sensor)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Heated oxygen sensors

monitor drive cycle – page 4

(Upstream oxygen sensors)

2NNone EN16

-107

-108

HO2 Sensor 2/1 disconnected

HO2 Sensor 2/1 to ECM variable current

circuit fault (HO2 Sensor pin 3)

ECM to HO2 Sensor 2/1 constant current

circuit fault (HO2 Sensor pin 4)

HO2 Sensor 2/1 failure

18

Page 19

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0153 EMS

HO2 Sensor sense circuit

slow response –

OBD II

bank 2, upstream (2/1)

Heated oxygen sensors

monitor drive cycle – page 4

(Upstream oxygen sensors)

2NECM Default:

– Bank 1 closed loop fuel

metering inhibited

– Canister purge inhibited

EN16

Engine misfire

-107

HO2 Sensor 2/1 disconnected

-108

HO2 Sensor 2/1 mechanical damage

HO2 Sensor 2/1 to ECM wiring fault

HO2 Sensor 2/1 short circuit to ground

HO2 Sensor 2/1 to ECM wiring shield open

circuit

HO2 Sensor 2/1 heater circuit fault

Exhaust leak

Low exhaust temperature

Injector flow partially blocked

Catalyst efficiency decrease

HO2 Sensor 2/1 failure

P0157 EMS

P0158 EMS

HO2 Sensor sense circuit

low voltage –

OBD II

bank 2, downstream (2/2)

HO2 Sensor sense circuit

high voltage –

OBD II

bank 2, downstream (2/2)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Heated oxygen sensors

monitor drive cycle – page 4

(Downstream oxygen

sensors)

Heated oxygen sensors

monitor drive cycle – page 4

(Downstream oxygen

sensors)

2NNone EN16

2NNone EN16

-129

-129

HO2 Sensor 2/2 disconnected

HO2 Sensor 2/2 to ECM wiring open circuit

HO2 Sensor 2/2 short circuit to ground

HO2 Sensor 2/2 failure

HO2 Sensor 2/2 sensing circuit:

short circuit to high voltage

HO2 Sensor 2/2 ground (BRD – braided shield)

open circuit

HO2 Sensor 2/2 failure

19

Page 20

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0160 EMS

HO2 Sensor sense circuit

no activity –

OBD II

bank 2, downstream (2/2)

Heated oxygen sensors

monitor drive cycle – page 4

(Downstream oxygen

sensors)

2NNone EN16

-129

HO2 Sensor 2/2 disconnected

HO2 Sensor 2/2 mechanical damage

HO2 Sensor 2/2 to ECM wiring open circuit

HO2 Sensor 2/2 sensing circuit short circuit to

high voltage

HO2 Sensor 2/2 short circuit to ground

HO2 Sensor 2/2 ground (BRD – braided shield)

open circuit

Exhaust leak

Low exhaust temperature

HO2 Sensor 2/2 failure

P0171 EMS

Bank 1 combustion too lean Start engine and bring to

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

normal operating temperature

> 82 °C (180 °F)

Idle for 10 minutes

2AECM Default:

– Bank 1 catalyst warm-up

ignition retard inhibited

– Bank 1 closed loop fuel

metering inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

— Engine misfire

Air intake leak between MAF Sensor and

throttle

Fuel filter / system restriction

Fuel injector restriction

Fuel pressure sensor failure (low fuel

pressure)

Low fuel pump output

HO2 Sensor(s) (1/1, 1/2)

harness wiring condition fault

Exhaust leak (before catalyst)

ECM receiving incorrect signal from one or

more of the following components:

ECT Sensor, MAF Sensor, IAT Sensor,

IP Sensor, EFT Sensor, TP Sensor

20

Page 21

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0172 EMS

Bank 1 combustion too rich Start engine and bring to

OBD II

normal operating temperature

> 82 °C (180 °F)

Idle for 10 minutes

2AECM Default:

– Bank 1 catalyst warm-up

ignition retard inhibited

– Bank 1 closed loop fuel

metering inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

— Restricted air filter

Leaking fuel injector(s)

Fuel pressure sensor failure

(high fuel pressure)

ECM receiving incorrect signal from one or

more of the following components:

ECT Sensor, MAF Sensor, IAT Sensor,

IP Sensor, EFT Sensor, TP Sensor

P0174 EMS

Bank 2 combustion too lean Start engine and bring to

OBD II

P0175 EMS

Bank 2 combustion too rich Start engine and bring to

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

normal operating temperature

> 82 °C (180 °F)

Idle for 10 minutes

normal operating temperature

> 82 °C (180 °F)

Idle for 10 minutes

2AECM Default:

– Bank 2 catalyst warm-up

ignition retard inhibited

– Bank 2 closed loop fuel

metering inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

2AECM Default:

– Bank 2 catalyst warm-up

ignition retard inhibited

– Bank 2 closed loop fuel

metering inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

— Engine misfire

Air intake leak between MAF Sensor and

throttle

Fuel filter / system restriction

Fuel injector restriction

Fuel pressure sensor failure

(low fuel pressure)

Low fuel pump output

HO2 Sensor(s) (2/1, 2/2)

harness wiring condition fault

Exhaust leak (before catalyst)

ECM receiving incorrect signal from one or

more of the following components:

ECT Sensor, MAF Sensor, IAT Sensor,

IP Sensor, EFT Sensor, TP Sensor

— Restricted air filter

Leaking fuel injector(s)

Fuel pressure sensor failure

(high fuel pressure)

ECM receiving incorrect signal from one or

more of the following components:

ECT Sensor, MAF Sensor, IAT Sensor,

IP Sensor, EFT Sensor, TP Sensor

21

Page 22

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0181 EMS

EFT Sensor range / performance Engine OFF; coolant

OBD II

temperature <35 °C (95 °F)

Start engine and drive until

normal engine operating

temperature > 82 °C (180 °F)

Drive for an additional 25

minutes

2NECM Default:

– Default value of 25 °C (77 °F)

used

EN16

EFT Sensor to ECM sensing circuit:

high resistance, open circuit, short circuit to

-050

ground short circuit to high voltage

EFT Sensor to splice sensor ground circuit:

high resistance, open circuit

EFT Sensor failure

P0182 EMS

P0183 EMS

P0191 EMS

EFT Sensor circuit low voltage

(high temperature)

OBD II

EFT Sensor circuit high voltage

(low temperature)

OBD II

IP Sensor circuit range /

performance

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Ignition ON 10 seconds 2 N ECM Default:

– Default value of 25 °C (77 °F)

used

Ignition ON 10 seconds 2 N ECM Default:

– Default value of 25 °C (77 °F)

used

Fuel level > 25%

Idle engine 30 seconds

Accelerate from stop through

complete engine rpm range;

coast to a stop

Drive the vehicle steadily

between 48 – 97 km/h (30 –

60 mph) for 5 minutes; coast

to a stop

Accelerate smoothly through

complete accelerator pedal

travel; coast to a stop

2NECM Default:

– Default value of 3.80 BAR

(55.11 psi) used

– Fuel pump feedback control

inhibited

Idle engine 30 seconds

EN16

EFT Sensor to ECM sensing circuit:

short circuit to ground

-050

EFT Sensor to splice sensor ground circuit:

short circuit

EFT Sensor failure

EN16

EFT Sensor disconnected

-050

EFT Sensor to ECM sensing circuit:

high resistance, open circuit, short circuit

to high voltage

EFT Sensor to splice sensor ground circuit:

high resistance, open circuit

EFT Sensor failure

EN16

Fuel filter / system restriction

-073

Fuel system leak

Incorrect fuel pump output

IP Sensor to ECM sensing circuit:

high resistance, open circuit, short circuit

to ground, short circuit to high voltage

IP Sensor to splice sensor supply circuit:

high resistance, open circuit

IP Sensor to splice sensor ground circuit:

high resistance, open circuit, short circuit

to ground, short circuit to high voltage

IP Sensor failure

22

Page 23

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0192 EMS

IP Sensor sensor circuit

low voltage (low pressure)

OBD II

Ignition ON 10 seconds 2 N ECM Default:

– Default value of 3.80 BAR

(55.11 psi) used

Fuel pump feedback control

inhibited

EN16

IP Sensor disconnected

-073

IP Sensor to ECM sensing circuit:

open circuit or short circuit to ground

IP Sensor to splice sensor supply circuit:

high resistance open circuit

IP Sensor failure

P0193 EMS

P0196 EMS

IP Sensor sensor circuit

high voltage (high pressure)

OBD II

EOT Sensor range / performance Engine OFF; coolant

OBD II

P0197 EMS

P0198 EMS

EOT Sensor low voltage

(high temperature)

OBD II

EOT Sensor high voltage

(low temperature)

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Ignition ON 10 seconds 2 N ECM Default:

– Default value of 3.80 BAR

(55.11 psi) used

Fuel pump feedback control

inhibited

temperature <35 °C (95 °F)

Start engine and drive until

normal engine operating

temperature > 82 °C (180 °F)

2NECM Default:

– ECT substituted

Ignition ON 10 seconds 2 N ECM Default:

– ECT substituted

Ignition ON 10 seconds 2 N ECM Default:

– ECT substituted

EN16

IP Sensor to ECM wiring (supply, sense):

short circuit to each other

-073

IP Sensor to ECM sense circuit:

short circuit to high voltage

IP Sensor to splice sensor ground circuit:

open circuit

IP Sensor failure

EN16

EOT Sensor to ECM sensing circuit;

high resistance when hot, intermittent

-078

high resistance

EOT Sensor failure

EN16

EOT Sensor to ECM sensing circuit:

short circuit to ground

-078

EOT Sensor failure

EN16

EOT Sensor disconnected

-078

EOT Sensor to ECM sensing circuit:

high resistance, open circuit, short circuit

to B+ voltage

EOT Sensor failure

23

Page 24

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0201 EMS

Fuel injector 1 circuit malfunction Start engine

OBD II

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 1 closed loop fuel

metering inhibited

– Bank 1 adaptive fuel metering

inhibited

– Bank 1 catalyst warm up

ignition retard inhibited

EN16

Injector disconnected

-115

Injector harness wiring:

open circuit, short circuit

Injector failure

– Canister purge inhibited

– Maximum engine speed

reduced

P0202 EMS

Fuel injector 2 circuit malfunction Start engine

OBD II

P0203 EMS

Fuel injector 3 circuit malfunction Start engine

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Battery voltage > 12 v

Idle for 2 minutes

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 2 closed loop fuel

metering inhibited

– Bank 2 adaptive fuel metering

inhibited

– Bank 2 catalyst warm up

ignition retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

2AECM Default:

– Bank 1 closed loop fuel

metering inhibited

– Bank 1 adaptive fuel metering

inhibited

– Bank 1 catalyst warm up

ignition retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

EN16

Injector disconnected

-120

Injector harness wiring:

open circuit, short circuit

Injector failure

EN16

Injector disconnected

-114

Injector harness wiring:

open circuit, short circuit

Injector failure

24

Page 25

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0204 EMS

Fuel injector 4 circuit malfunction Start engine

OBD II

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 2 closed loop fuel

metering inhibited

– Bank 2 adaptive fuel metering

inhibited

– Bank 2 catalyst warm up

ignition retard inhibited

EN16

Injector disconnected

-119

Injector harness wiring:

open circuit, short circuit

Injector failure

– Canister purge inhibited

– Maximum engine speed

reduced

P0205 EMS

Fuel injector 5 circuit malfunction Start engine.

OBD II

Battery voltage > 12 v

Idle for 2 minutes.

2AECM Default:

– Bank 1 closed loop fuel

metering inhibited

– Bank 1 adaptive fuel metering

inhibited

– Bank 1 catalyst warm up

ignition retard inhibited

EN16

Injector disconnected

-113

Injector harness wiring:

open circuit, short circuit

Injector failure

– Canister purge inhibited

– Maximum engine speed

reduced

P0206 EMS

Fuel injector 6 circuit malfunction Start engine.

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Battery voltage > 12 v

Idle for 2 minutes.

2AECM Default:

– Bank 2 closed loop fuel

metering inhibited

– Bank 2 adaptive fuel metering

inhibited

– Bank 2 catalyst warm up

ignition retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

EN16

Injector disconnected

-118

Injector harness wiring:

open circuit, short circuit

Injector failure

25

Page 26

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0222 EMS

TP Sensor sense circuit 2 (TP2)

low voltage

OBD II

Battery voltage > 10 v

Ignition ON

Slowly press accelerator

pedal to the floor over a 5

second period

Slowly return the pedal to rest

Repeat 3 times

2RECM Default:

– Throttle motor and throttle

motor relay disabled

– Throttle valve opening set to

default value

– Idle speed controlled by fuel

injection intervention

– Idle speed adaption inhibited

EN16

TP Sensor to ECM sensing circuit (TP2):

open circuit, high resistance

-076

TP Sensor failure

P0223 EMS

P0300 EMS

TP Sensor sense circuit 2 (TP2)

high voltage

OBD II

Random misfire detected

OBD II

*Refer to Misfire Note, page 5

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Battery voltage > 10 v

Ignition ON

Slowly press accelerator

pedal to the floor over a 5

second period

Slowly return the pedal to rest

Repeat 3 times

Misfire monitor drive cycle –

page 5

2RECM Default:

– Throttle motor and throttle

motor relay disabled

– Throttle valve opening set to

default value

– Idle speed controlled by fuel

injection intervention

EN16

TP Sensor to ECM sensing circuit (TP2):

short circuit to high voltage

-076

TP Sensor failure

– Idle speed adaption inhibited

1 or 2* N None — Cylinder compression low

Worn camshaft / broken valve spring(s)

Fuel delivery pressure (low / high)

Fuel injector(s) restricted / leaking

Fuel injector(s) continuously open

Fuel contamination

Fuel injector circuit fault(s)

(Injector DTCs also flagged)

Spark plug failure / fouled / incorrect gap

ECM to ignition coil primary circuit fault

(Cylinder misfire detected DTC also

flagged)

Ignition coil failure

26

Page 27

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0301 EMS

P0302 EMS

P0303 EMS

P0304 EMS

P0305 EMS

P0306 EMS

P0332 EMS

Misfire detected – cylinder 1

OBD II

*Refer to Misfire Note, page 5

Misfire detected – cylinder 2

OBD II

*Refer to Misfire Note, page 5

Misfire detected – cylinder 3

OBD II

*Refer to Misfire Note, page 5

Misfire detected – cylinder 4

OBD II

*Refer to Misfire Note, page 5

Misfire detected – cylinder 5

OBD II

*Refer to Misfire Note, page 5

Misfire detected – cylinder 6

OBD II

*Refer to Misfire Note, page 5

KS sense circuit out of range –

low voltage

OBD II

Misfire monitor drive cycle –

page 5

Misfire monitor drive cycle –

page 5

Misfire monitor drive cycle –

page 5

Misfire monitor drive cycle –

page 5

Misfire monitor drive cycle –

page 5

Misfire monitor drive cycle –

page 5

Start engine

Battery voltage > 12 v

Idle for 2 minutes

1 or 2* N None — Refer to P0300 Possible Causes

1 or 2* N None — Refer to P0300 Possible Causes

1 or 2* N None — Refer to P0300 Possible Causes

1 or 2* N None — Refer to P0300 Possible Causes

1 or 2* N None — Refer to P0300 Possible Causes

1 or 2* N None — Refer to P0300 Possible Causes

2AECM Default:

– Maximum ignition retard

– Maximum engine speed

reduced

EN16

Poor sensor contact with the cylinder block

-098

KS to ECM sense circuit short circuit to

ground

KS failure

P0333 EMS

KS sense circuit out of range –

high voltage

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Start engine

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Maximum ignition retard

– Maximum engine speed

reduced

EN16

Poor sensor contact with the cylinder block

-098

KS to ECM sense circuit: high resistance,

open circuit, short circuit to high voltage

KS failure

27

Page 28

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0335 EMS

OBD II

CKP Sensor circuit malfunction Start engine; momentarily

race the engine; stop engine

Repeat two additional times

Start engine; idle 30 seconds.

Accelerate from stop through

complete engine rpm range;

coast to a stop

Drive the vehicle steadily

between 48 – 97 km/h (30 –

60 mph) for 5 minutes; coast

to a stop

Accelerate smoothly through

complete accelerator pedal

travel; coast to a stop

2AECM Default:

– Maximum engine speed

reduced

EN16

CKP Sensor disconnected

-036

CKP Sensor gap incorrect / foreign matter on

-037

sensor face

CKP Sensor sensing circuit:

open circuit, short circuit to ground,

short circuit to high voltage

CKP Sensor failure

Idle engine 30 seconds

Note: If CKP Sensor fault

exists and engine will not

start, battery voltage must

drop below 10.5 V during

cranking for DTC to be

flagged. (Crank period – 30

seconds.) If CKP Sensor fault

exists, engine will start on the

second crank as the ECM will

default to CMP signals for

synchronization.

Jaguar X-TYPE P DTC OBD II 2002 Model Year

28

Page 29

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0336 EMS

CKP Sensor circuit range /

performance

OBD II

Start engine; momentarily

race the engine; stop engine

Repeat two additional times

Start engine; idle 30 seconds

Accelerate from stop through

complete engine rpm range;

coast to a stop

Drive the vehicle steadily

between 48 – 97 km/h (30 –

60 mph) for 5 minutes; coast

to a stop

Accelerate smoothly through

complete accelerator pedal

travel; coast to a stop

2AECM Default:

– Maximum engine speed

reduced

EN16

CKP Sensor reluctor: foreign matter /

damaged teeth

-036

-037

CKP Sensor sensing circuit:

intermittent open circuit, short circuit

to ground, short circuit to high voltage

CKP Sensor failure

Idle engine 30 seconds

P0340 EMS

CMP Sensor 1 circuit malfunction

– bank 1

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Start engine; momentarily

race the engine; stop engine

Repeat two additional times

Start engine idle 30 seconds

Accelerate from stop through

complete engine rpm range;

coast to a stop

Drive the vehicle steadily

between 48 – 97 km/h (30 –

60 mph) for 5 minutes; coast

to a stop

Accelerate smoothly through

complete accelerator pedal

travel; coast to a stop

Idle engine 30 seconds

2NNone EN16

-094

-095

CMP Sensor disconnected

CMP Sensor gap incorrect / foreign matter on

sensor face

CMP Sensor sensing circuit:

open circuit, short circuit to ground,

short circuit to high voltage

CMP Sensor 1 failure

29

Page 30

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0341 EMS

CMP Sensor 1 circuit range /

performance – bank 1

OBD II

Start engine; momentarily

race the engine; stop engine

Repeat two additional times

Start engine; idle 30 seconds

Accelerate from stop through

complete engine rpm range;

coast to a stop

Drive the vehicle steadily

between 48 – 97 km/h (30 –

60 mph) for 5 minutes; coast

to a stop

Accelerate smoothly through

complete accelerator pedal

travel; coast to a stop

2NNone EN16

-094

-095

CMP Sensor disconnected

CMP Sensor gap incorrect / foreign matter on

sensor face

CMP Sensor sensing circuit:

open circuit, short circuit to ground,

short circuit to high voltage

CMP Sensor 1 failure

Idle engine 30 seconds

P0351 EMS

Ignition module primary circuit

malfunction – cylinder 1

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Start engine

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 1 closed loop fuel

metering inhibited

– Bank 1 adaptive fuel metering

inhibited

– Bank 1 catalyst warm up

ignition retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

– Fuel injection cut off

(cylinder 1)

EN16

ECM to ignition module primary circuit:

open circuit, short circuit to ground,

-087

high resistance

Ignition module ground circuit:

open circuit, high resistance

Ignition module / coil failure

30

Page 31

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0352 EMS

Ignition module primary circuit

malfunction – cylinder 2

OBD II

Start engine

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 2 closed loop fuel

metering inhibited

– Bank 2 adaptive fuel metering

inhibited

– Bank 2 catalyst warm up

ignition retard inhibited

EN16

ECM to ignition module primary circuit:

open circuit, short circuit to ground,

-061

high resistance

Ignition module ground circuit:

open circuit, high resistance

Ignition module / coil failure

– Canister purge inhibited

– Maximum engine speed

reduced

– Fuel injection cut off

(cylinder 2)

P0353 EMS

Ignition module primary circuit

malfunction – cylinder 3

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Start engine

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 1 closed loop fuel

metering inhibited

– Bank 1 adaptive fuel metering

inhibited

– Bank 1 catalyst warm up

ignition retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

– Fuel injection cut off

(cylinder 3)

EN16

ECM to ignition module primary circuit:

open circuit, short circuit to ground,

-088

high resistance

Ignition module ground circuit:

open circuit, high resistance

Ignition module / coil failure

31

Page 32

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0354 EMS

Ignition module primary circuit

malfunction – cylinder 4

OBD II

Start engine

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 2 closed loop fuel

metering inhibited

– Bank 2 adaptive fuel metering

inhibited

– Bank 2 catalyst warm up

ignition retard inhibited

EN16

ECM to ignition module primary circuit:

open circuit, short circuit to ground,

-062

high resistance

Ignition module ground circuit:

open circuit, high resistance

Ignition module / coil failure

– Canister purge inhibited

– Maximum engine speed

reduced

– Fuel injection cut off

(cylinder 4)

P0355 EMS

Ignition module primary circuit

malfunction – cylinder 5

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Start engine

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 1 closed loop fuel

metering inhibited

– Bank 1 adaptive fuel metering

inhibited

– Bank 1 catalyst warm up

ignition retard inhibited

– Canister purge inhibited

– Maximum engine speed

reduced

– Fuel injection cut off

(cylinder 5)

EN16

ECM to ignition module primary circuit:

open circuit, short circuit to ground,

-089

high resistance

Ignition module ground circuit:

open circuit, high resistance

Ignition module / coil failure

32

Page 33

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0356 EMS

Ignition module primary circuit

malfunction – cylinder 6

OBD II

Start engine

Battery voltage > 12 v

Idle for 2 minutes

2AECM Default:

– Bank 2 closed loop fuel

metering inhibited

– Bank 2 adaptive fuel metering

inhibited

– Bank 2 catalyst warm up

ignition retard inhibited

EN16

ECM to ignition module primary circuit:

open circuit, short circuit to ground,

-063

high resistance

Ignition module ground circuit:

open circuit, high resistance

Ignition module / coil failure

– Canister purge inhibited

– Maximum engine speed

reduced

– Fuel injection cut off

(cylinder 6)

P0420 EMS

P0430 EMS

Catalytic converter system

efficiency below threshold –

OBD II

bank 1

Catalytic converter system

efficiency below threshold –

OBD II

bank 2

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Catalyst efficiency monitor

drive cycle – page 5

Catalyst efficiency monitor

drive cycle – page 5

2NNone — HO2 Sensor disconnected

HO2 Sensor to ECM wiring fault

HO2 Sensor heater to ECM wiring fault

HO2 Sensor heater failure

Upstream HO2 Sensor failure

Downstream HO2 Sensor failure

Catalyst failure

2NNone — HO2 Sensor disconnected

HO2 Sensor to ECM wiring fault

HO2 Sensor heater to ECM wiring fault

HO2 Sensor heater failure

Upstream HO2 Sensor failure

Downstream HO2 Sensor failure

Catalyst failure

33

Page 34

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0442 EMS

EVAP system leak detected –

small (0.040 in.)

OBD II

Evaporative system monitor

drive cycle – page 6

2NECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

— Fuel cap seal defective

EVAP system leak (canister damage,

pipework damage)

EVAP Canister purge valve to ECM drive

circuit: open circuit, short circuit, high

resistance

EVAP Canister purge valve power supply

circuit: open circuit, short circuit

EVAP Canister purge valve to engine purge

pipe: restricted, leaking, disconnected

EVAP Canister purge valve operating vacuum

hose leak / restriction

EVAP Canister purge valve failure

Fuel tank leak

P0443 EMS

P0444 EMS

P0445 EMS

EVAP canister purge valve circuit

malfunction

OBD II

EVAP canister purge valve circuit

open circuit

OBD II

EVAP canister purge valve circuit

short circuit

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Evaporative system monitor

drive cycle – page 6

Evaporative system monitor

drive cycle – page 6.

Evaporative system monitor

drive cycle – page 6.

2NECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

2NECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

2NECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

EN16

EVAP Canister purge valve to ECM drive

circuit: open circuit, short circuit, high

-066

resistance

EVAP Canister purge valve power supply

circuit: open circuit, short circuit

EVAP Canister purge valve operating vacuum

hose leak / restriction

EVAP Canister purge valve failure

EN16

EVAP Canister purge valve disconnected

-066

EVAP Canister purge valve to ECM drive

circuit: open circuit, high resistance

EVAP Canister purge valve failure

EN16

EVAP Canister purge valve to ECM drive

circuit: short circuit to ground

-066

EVAP Canister purge valve failure

34

Page 35

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0446 EMS

EVAP canister close valve circuit

malfunction

OBD II

Evaporative system monitor

drive cycle – page 6

2NECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

EN16

EVAP canister close valve power supply

circuit: open circuit, short circuit

-067

EVAP canister close valve to ECM drive

circuit: open circuit, high resistance, short

circuit to B+ voltage

EVAP canister close valve failure

P0447 EMS

P0448 EMS

P0450 EMS

EVAP canister close valve circuit

open circuit

OBD II

EVAP canister close valve circuit

short circuit

OBD II

FTP Sensor circuit malfunction Evaporative system monitor

OBD II

P0452 EMS

FTP Sensor circuit low voltage

(low pressure)

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Ignition ON 10 seconds 2 N ECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

Ignition ON 10 seconds 2 N ECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

drive cycle – page 6

2NNone EN16

Ignition ON 10 seconds 2 N None EN16

EN16

-067

EN16

-067

-104

-104

EVAP canister close valve power supply

circuit: open circuit, short circuit

EVAP canister close valve to ECM drive

circuit: open circuit, high resistance, short

circuit to B+ voltage

EVAP canister close valve failure

EVAP canister close valve to ECM drive

circuit: short to ground

EVAP canister close valve failure

FTP Sensor disconnected

FTP Sensor to ECM sense circuit:

open circuit, short circuit to ground,

short circuit to B+ voltage

FTP Sensor to splice sensor supply circuit:

open circuit, high resistance

FTP Sensor to splice ground circuit:

open circuit, high resistance

FTP Sensor failure

FTP Sensor disconnected

FTP Sensor to ECM sense circuit:

open circuit, short circuit to ground

FTP Sensor to splice sensor supply circuit:

open circuit, high resistance

FTP Sensor failure

35

Page 36

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0453 EMS

FTP Sensor circuit high voltage

(high pressure)

OBD II

Ignition ON 10 seconds 2 N None EN16

-104

FTP Sensor to splice sensor ground circuit:

open circuit, high resistance

FTP Sensor to ECM sense circuit:

short circuit to high voltage

FTP Sensor failure

P0455 EMS

EVAP system leak detected –

large

OBD II

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Evaporative system monitor

drive cycle – page 6

2NECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

— Fuel cap off

Fuel cap seal defective

EVAP system leak

(canister damage, pipework damage)

EVAP Canister purge valve to ECM drive

circuit: open circuit, short circuit, high

resistance

EVAP Canister purge valve power supply

circuit: open circuit, short circuit

EVAP Canister purge valve to engine purge

pipe: restricted, leaking, disconnected

EVAP Canister purge valve operating vacuum

hose leak / restriction

EVAP Canister purge valve failure

Fuel tank leak

36

Page 37

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0456 EMS

EVAP system leak detected –

very small (0.020 in.)

OBD II

Evaporative system monitor

drive cycle – page 6

2NECM Default:

– Canister purge inhibited

– Adaptive fuel metering

inhibited

— Fuel cap seal defective

EVAP system leak

(canister damage, pipework damage)

EVAP Canister purge valve to ECM drive

circuit: open circuit, short circuit, high

resistance

EVAP Canister purge valve power supply

circuit: open circuit, short circuit

EVAP Canister purge valve to engine purge

pipe: restricted, leaking

EVAP Canister purge valve operating vacuum

hose leak / restriction

EVAP Canister purge valve failure

Fuel tank leak

P0460 EMS

P0480 EMS

Fuel level sensor(s) circuit range /

performance

OBD II

Radiator cooling fan module drive

circuit malfunction

JAG

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Fuel tank empty

Fill in stages: 1/4, 1/2, 3/4, full

Check fuel gauge reading at

each stage

Start and run engine > 2000

rpm for 2 minutes

(Ensures voltage stays above

14 V for the required time)

2NNone — Fuel level sensor to instrument pack circuit(s):

intermittent short circuit, open circuit, high

resistance

Fuel level sensor failure

Instrument pack fault (incorrect fuel level data)

NNECM Default:

– With ignition ON, fan operates

at maximum speed

EN16

ECM to radiator cooling fan module drive

circuit: short circuit, open circuit, high

-051

resistance

Radiator cooling fan module fault

37

Page 38

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0506 EMS

Idle RPM lower than expected Start engine and drive until

OBD II

normal engine operating

temperature > 82 °C (180 °F)

Stop vehicle and idle 30

seconds

Drive vehicle for 2 minutes

Stop vehicle and idle 30

seconds

Repeat drive / idle two

additional times

2NNone — Air intake restriction

Accessory drive overload

(defective / seized component)

Throttle valve stuck closed

Throttle body failure

P0507 EMS

Idle RPM higher than expected Start engine and drive until

OBD II

P0560 EMS

Battery power supply voltage

malfunction

OBD II

Note: This DTC can be flagged

due to fuel injection pressure

sensor fault. If P0193 is also

flagged, correct first.

Jaguar X-TYPE P DTC OBD II 2002 Model Year

normal engine operating

temperature > 82 °C (180 °F)

Stop vehicle and idle 30

seconds

Drive vehicle for 2 minutes

Stop vehicle and idle 30

seconds

Repeat drive / idle two

additional times

Engine temperature cool

(cooling fans not running)

Remove ignition key for 20

seconds (cooling fans not

running)

Ignition key in, position II for 5

seconds (do not start)

Repeat cycle two additional

times

2NNone — Intake air leak between MAF sensor and

throttle

Intake air leak between throttle and engine

Engine crankcase breather leak

Throttle valve stuck open

Throttle body failure

2NNone EN16

ECM battery power supply open circuit, high

resistance

-022

38

Page 39

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0565 EMS

Cruise control ON / OFF switch

fault

JAG

Ignition ON 45 seconds N A ECM Default:

– Speed control inhibited

– Maximum engine speed

reduced

EN16

Cruise control switches internal steering

wheel circuit: short circuit to ground

-047

Steering wheel cassette reel:

short circuit to ground

Cassette reel to ECM circuit:

short circuit to ground

ON / OFF switch failure (stuck ON)

P0566 EMS

P0567 EMS

P0568 EMS

Cruise control CANCEL switch

ON fault

JAG

Cruise control RESUME switch

ON fault

JAG

Cruise control input signal low /

high resistance

JAG

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Ignition ON 45 seconds N A ECM Default:

– Speed control inhibited

– Maximum engine speed

reduced

Ignition ON 45 seconds N A ECM Default:

– Speed control inhibited

– Maximum engine speed

reduced

Ignition ON 45 seconds N A ECM Default:

– Speed control inhibited

– Maximum engine speed

reduced

EN16

Cruise control switches internal steering

wheel circuit: short circuit to ground

-047

Steering wheel cassette reel:

short circuit to ground

Cassette reel to ECM circuit:

short circuit to ground

CANCEL switch failure (stuck ON)

EN16

Cruise control switches internal steering

wheel circuit: short circuit to ground

-047

Steering wheel cassette reel:

short circuit to ground

Cassette reel to ECM circuit:

short circuit to ground

RESUME switch failure (stuck ON)

EN16

Cruise control switches internal steering

wheel circuit: open circuit; high resistance

-047

Steering wheel cassette reel open circuit, high

resistance

Cassette reel to ECM circuit:

open circuit, high resistance

39

Page 40

DTC SYS FAULT DESCRIPTION MONITORING CONDITIONS CK ENG OTHER DEFAULT ACTION CM PIN POSSIBLE CAUSES

P0569 EMS

Cruise control SET / - switch ON

fault

JAG

Ignition ON 45 seconds N A ECM Default:

– Speed control inhibited

– Maximum engine speed

reduced

EN16

Cruise control switches internal steering

wheel circuit: short circuit to ground

-047

Steering wheel cassette reel:

short circuit to ground

Cassette reel to ECM circuit:

short circuit to ground

SET / - switch failure

P0570 EMS

P0603 EMS

Cruise control SET / + switch ON

fault

JAG

ECM Keep alive memory error Engine temperature cool

OBD II

P0616 EMS

Starter relay drive circuit low

voltage / starter relay request off

OBD II

(ignition switch position III OFF)

Jaguar X-TYPE P DTC OBD II 2002 Model Year

Ignition ON 45 seconds N A ECM Default:

– Speed control inhibited

– Maximum engine speed

reduced

(cooling fans not running)

Remove ignition key for 20

seconds (cooling fans not

running)

Ignition key in, position II for 5

seconds (do not start)

Repeat cycle two additional

times.

Ignition ON

2NNone — ECM Failure

2NNone EN16

Battery voltage > 12 v

Automatic – P for 5 seconds;

manual – clutch fully pressed

for 5 seconds

Start engine

EN16

Cruise control switches internal steering

wheel circuit: short circuit to ground

-047