Page 1

FOR SERVICE TRAINING

-Engine Mechanical Features-

4HK1-TC ENGINE

-Engine Control System & Diagnosis-

Applicable Model

Model Year Vehicle Model Main Market

2005 NPR & NQR

General Export (Euro 3 Regulation)

Europe, Australia, Thailand, South Afric a & etc .

ISUZU MOTORS LIMITED

Page 2

f

r

f

Y

N*R 4HK1-TC Engine-1

INTRODUCTION & ENGINE MECHANICAL FEATURES

The 2005 model year NPR/NQR truck, the 4HK1-TC

inline 4 cylinder engine replaces the 4HE1-TC engine

for advanced exhaust emission c ount ries. The 4HK 1-TC

engine has been newly developed on the basis o

previous 4HE1-TC engine, with additional features

including the employment of four valve mechanism pe

a cylinder that are operated via a single camshaft,

common rail fuel injection system, water-cooled exhaus t

gas re-circulation (EGR) system, and the change o

combustion chamber form. The larger engine

displacement and the common rail fuel injection system

have resulted in an increase both in maximum output

and torque, and met Euro 3 emission regulation

standard. Most conspicuous items are listed below.

Multi fuel injection type high-pressure common rail

system and is made with Denso.

Single overhead camshaft (OHC) w ith 4 valves per a

cylinder.

Electrical control EGR valve, water-cooled EGR

cooler.

Turbocharger with intercooler.

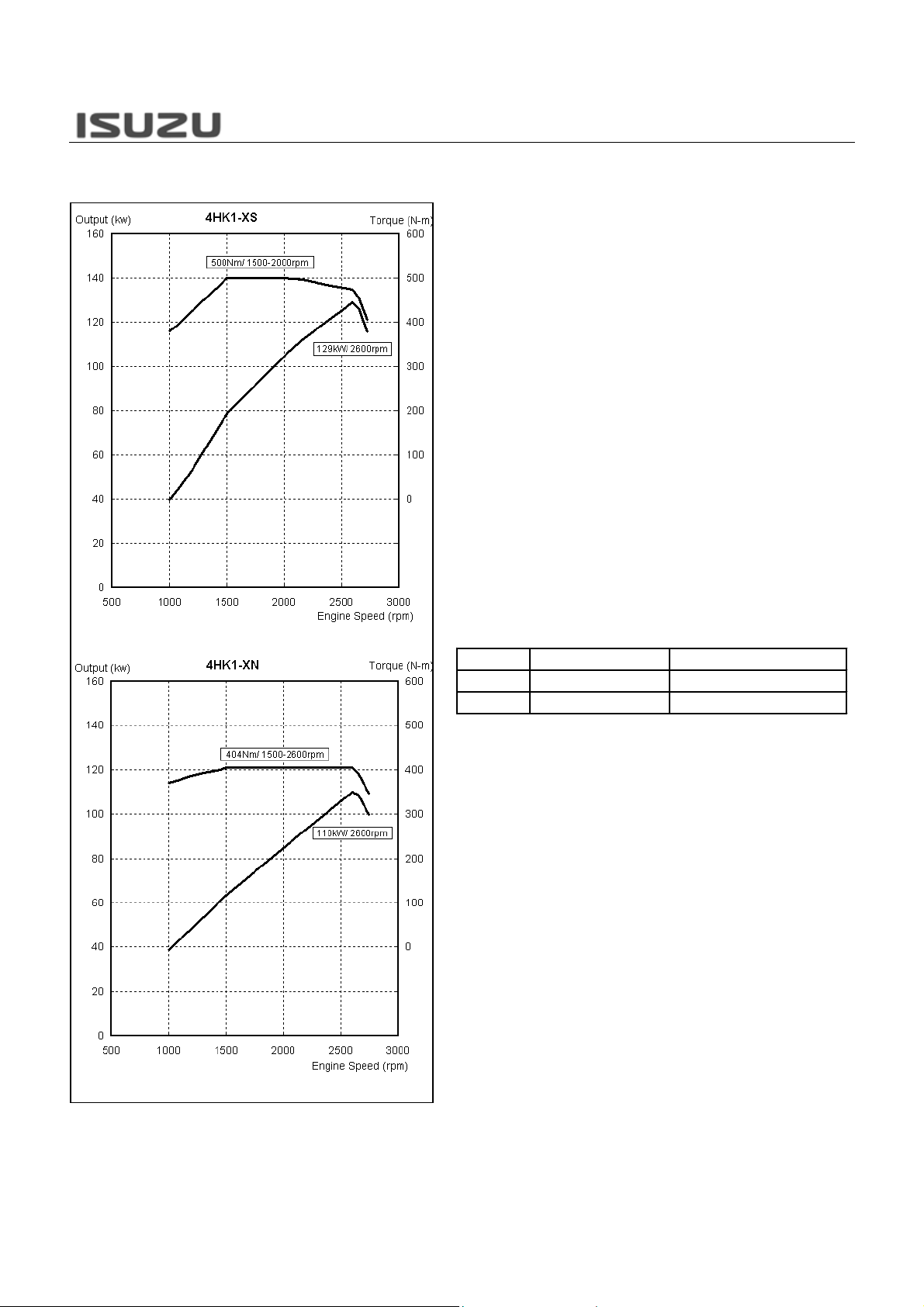

Engine Type Maximum Output Maximum Toruque

4HK1-TCS 129kw (175ps)/2600RPM 500Nm (51kgm)/1500-2000RPM

4HK1-TCN 110kw (150ps)/2600RPM 404Nm (41kgm)/1500-2600RPM

The base transmission is MYY for 4HK1-TCN low

output engine, MZZ for 4HK1-TCS high output engine.

The Smoother system is available for only MY

transmission.

Page 3

N*R 4HK1-TC Engine-2

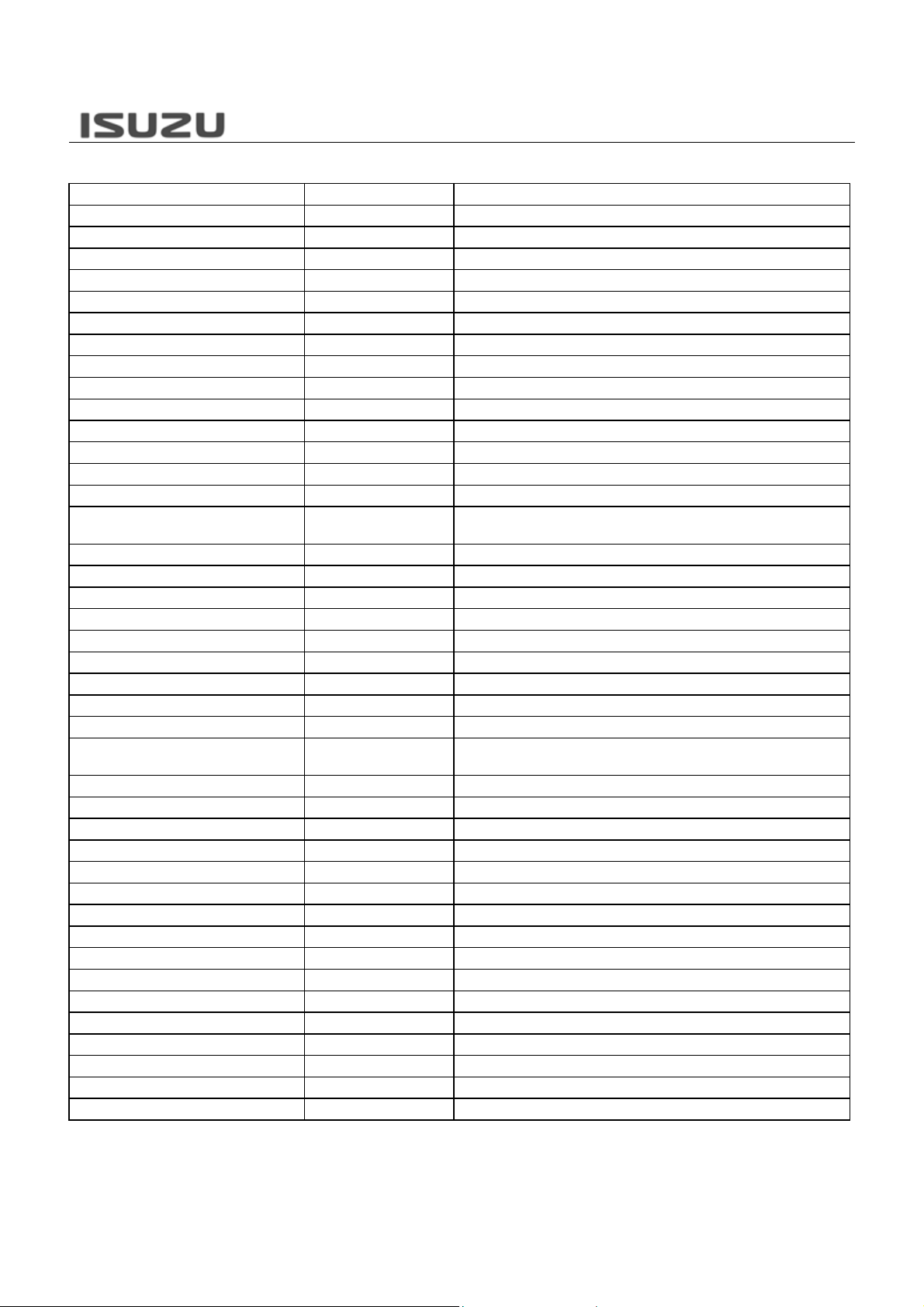

Part Status Description or Reason in Comparison with 4HE1-TC Engine

Cylinder Block Change Bore size is upped (110mm to 115mm / 4.33in to 4.53in)

Crankshaft Carry-over Cylinder Head Change Four valve type with camshaft position sensor hole

Cylinder Head Gasket Change Cylinder head is changed

Camshaft Change Four valve type is employed

Camshaft Gear Change Scissors gear type is employed

Inlet Valve Change Four valve type is employed

Exhaust Valve Change Four valve type is employed

Valve Spring Change Four valve type is employed

Rocker Arm Cha nge Four valve type is employed

Cylinder Head Cover Change Four valve type is employed

Timing Gear T rain Change Fuel system is changed

Flywheel Change Crankshaft position sensor is ring added

Flex Plate Carry-over -

Flywheel Housing Change

Engine Hanger Change Cylinder head and EGR layout is changed

Piston Change Bore size is upped

Piston Ring Change Bore size is upped

Connecting Rod Carry-over Oil Pan Change Oil level switch is added

Oil Pump Carry-over Oil Cooler Change Engine size is changed

Front Cover Carry-over Water Pump Carry-over -

Cooling Fan

EGR Cooler New Newly adopted

EGR Pipe Change EGR layout is changed

EGR Valve Change Electrical control type

PCV System Carry-over Fuel Pump Change Common rail system is employed (supply pump)

Injection Nozzle Change Common rail system is employed

Injection Pipe Change Common rail system is employed

Fuel Pipe Change Common rail system is employed

Intake Duct Change Layout is changed & boost pressure sensor are added

Intake Manifold Change Layout is changed

Intercooler Change Size is upped

Exhaust Manifold Carry-over Turbocharger Change Wastegate valve actuator setting is changed

ACG Change

Starter Carry-over Engine Harness Change Common rail system is employed

Change (4HK1-TCS)

Carry-over (4HK1-TCN)

Major mechanical changed items are listed below.

Common rail system is employed & crankshaft position sensor

hole

4HK1-TCS: Size is changed to improve performance

Page 4

N*R 4HK1-TC Engine-3

ENGINE MAIN DATA & SPECIFICATIONS

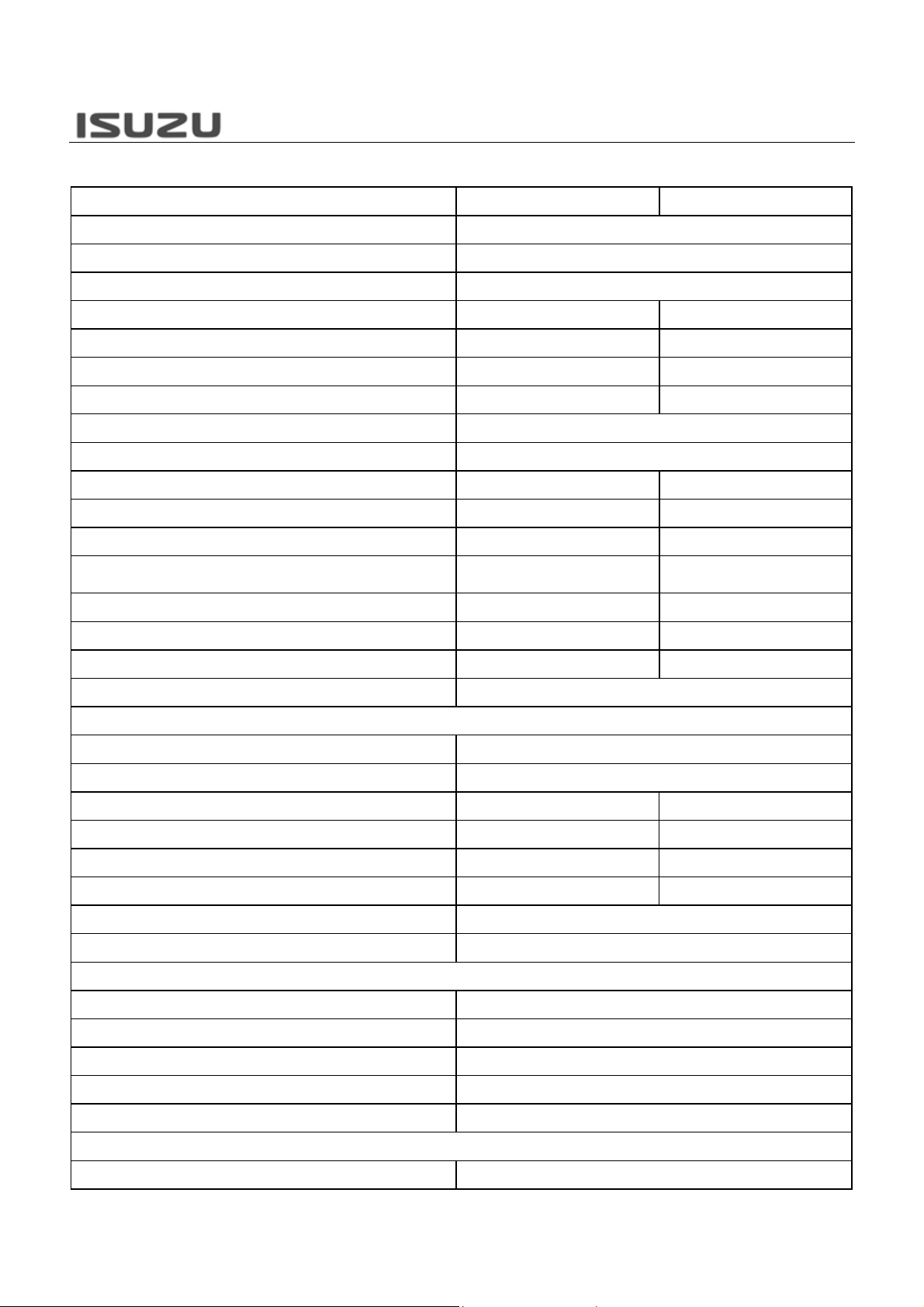

Engine Model 4HE1-TC 4HK1-TC

Engine Type Diesel, Four Cycle

Cylinder Layout - Number of Cylinders Inline-Four Cylinders

Fuel Injection Order 1-3-4-2

Bore x Stroke (mm/in) 110.0 x 125.0 / 4.33 x 4.92 115.0 x 125.0 / 4.53 x 4.92

Total Displacement (cc) 4751 5193

Compression Ratio 18.0 18.5

Compression Pressure at 200 rpm (MPa / psi) 3.0 / 441 3.3 / 478

Combustion Camber Type Direct Injection

Cylinder Liner Dry Type

Idle Speed (rpm) 800±25 650±25

Fuel System Mechanical Type Governor Common Rail System

Injection Pump Type BOSCH In-line Type (MITICS) DENSO (HP3) Supply Pump

Injection Nozzle Type Hole Nozzle (Mechanical Type)

Number of Injection Hole 6 7

Electrical Controlled Injector

(G2)

Diameter of Injection Hole (mm) 0.21 0.16

Injection Nozzle Operating Pressure (MPa) 17.65 Electrically Controlled

Fuel Filter Type Cartridge Paper Element & Water Separator

Valve System

Valve Layout Overhead Valve

Drive Type Gear Drive

Intake Valve Open At BTDC (deg) 14.0 19.0

Intake Valve Close At ABDC (deg) 51.0 53.0

Exhaust Valve Open At BBDC (deg) 49.0 48.0

Exhaust Valve Close At ATDC (deg) 16.0 14.0

Intake Valve Clearance At Cold (mm) 0.4

Exhaust Valve Clearance At Cold (mm) 0.4

Cooling System

Cooling Method Water Cooled

Water Capacity (litter/gal) 14 (3.7)

Water Pump Type Centrifugal Impeller Type

Thermostat Type Wax Pellet

Thermostat Opening Temperature (deg. C / deg. F) 82 & 85 / 180 & 185

Lubricating System

Lubricating Method Full Flow Pressure Circulation

Page 5

Oil Pump Type Gear

Oil Capacity (litter/gal) 13 (3.4)

Oil Filter Type Cartridge Paper Element

Air Cleaner Type Dry Paper Element

N*R 4HK1-TC Engine-4

EGR System

PCV System Open Type

Preheating System Glow Plug

Starting System

Starter Motor Output (V-kW) 24 - 3.0

Charge System

Alternator Output (V-A) 24 – 50, 60 or 80

Regulator Type IC

Battery Size 115E41R x 2

W/O Cooler & Vacuum Control

EGR Valve

W/Cooler & Electrical Control

EGR Valve

Page 6

f

N*R 4HK1-TC Engine-5

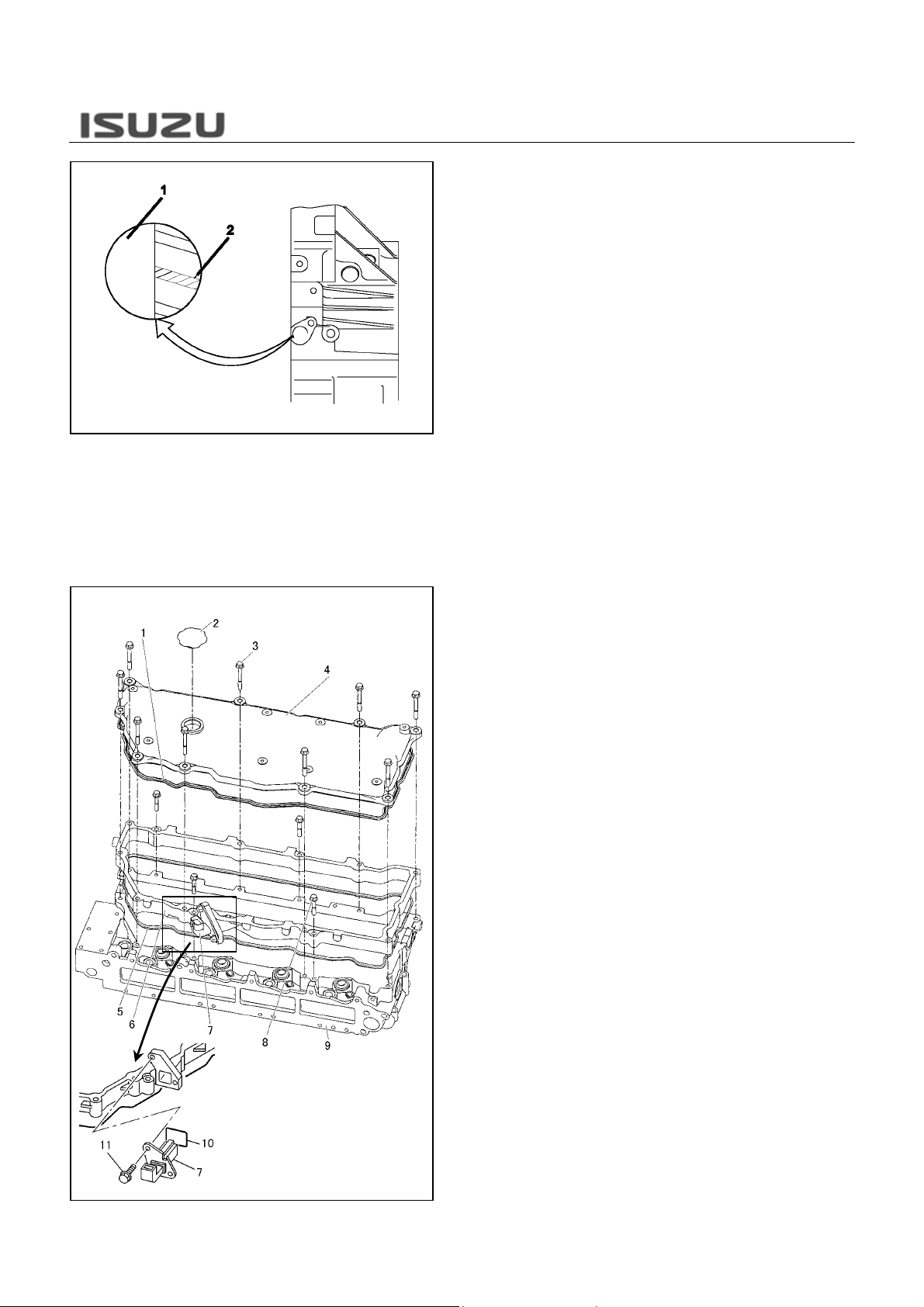

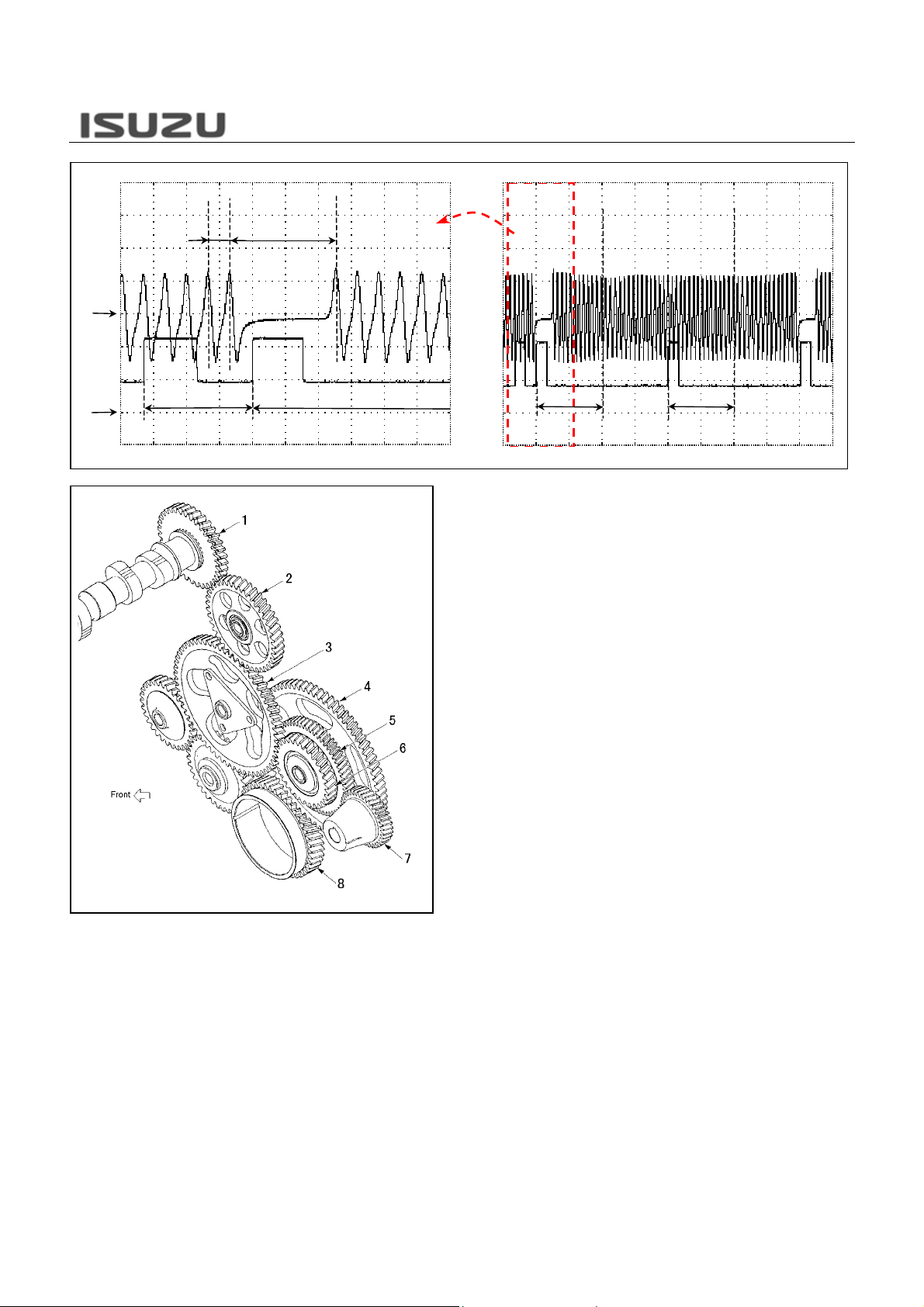

GEAR TRAIN

Valve Train

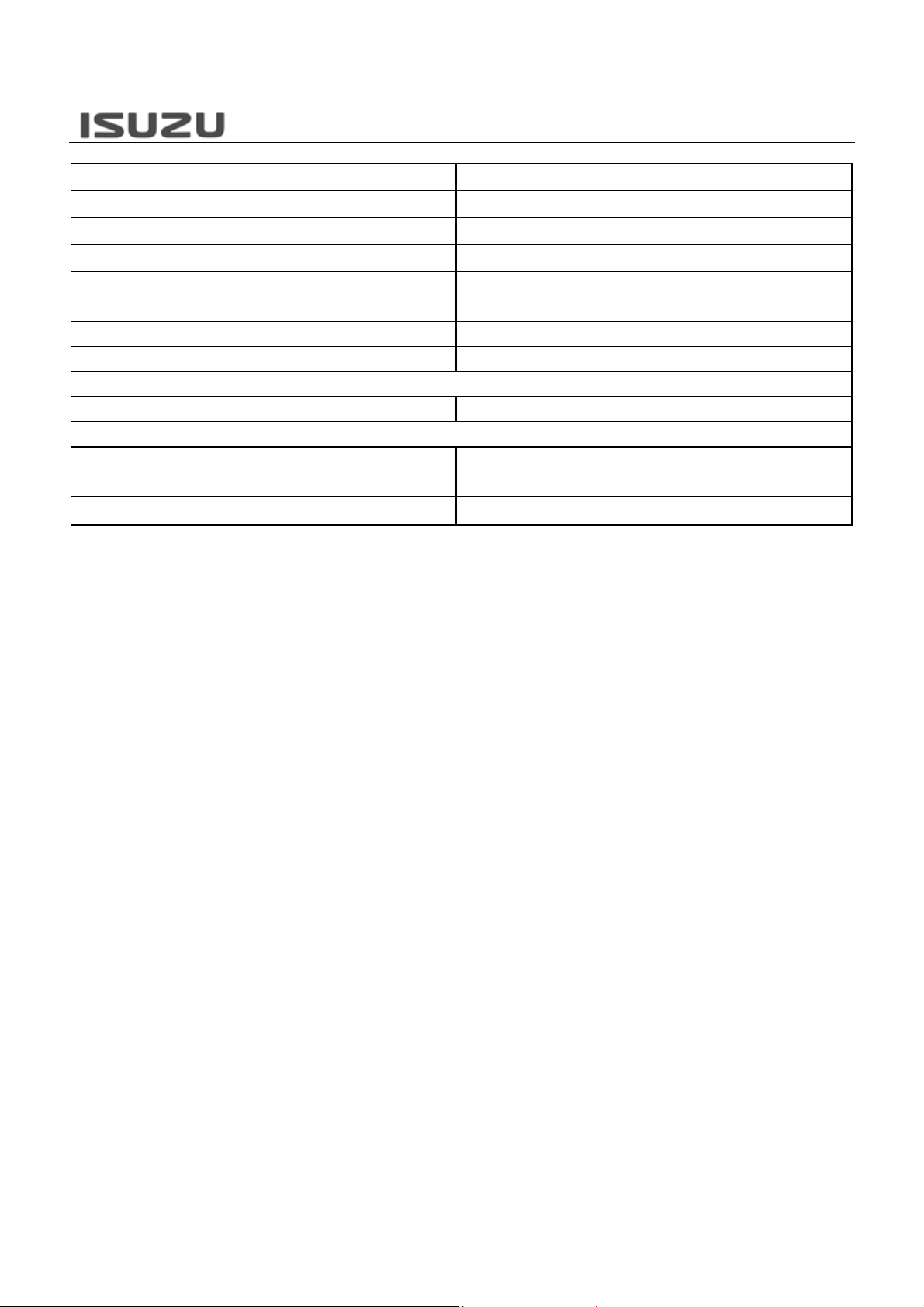

To rotate the fuel supply pump wit h engine speed, idle

gear has changed with three steps. The crankshaft

gear (42 teeth) correspon ds with the large diameter o

idle gear A (72 teeth). The fuel s upply pump gear (35

teeth) corresponds with the middle diameter of idle

gear A (60 teeth). The idle gear B (61 teeth)

corresponds with the small diamet er of idle gear A (30

teeth).

1. Camshaft Gear (Z=35)

2. Idle Gear C (Z=41)

3. Idle Gear B (Z=61)

4. Idle Gear A (Large) (Z=72)

5. Idle Gear A (Middle) (Z=60)

6. Idle Gear A (Small) (Z=30)

7. Fuel Supply Pump Gear (Z=35)

8. Crankshaft Gear (Z=42)

To improve exhaust emission and engine output

performance, four valve mechanism is newly adopted

for 4HK1-TC engine. Note that the adjustm ent method

of valve clearance has been changed from 4HK1-TC

engine as following steps.

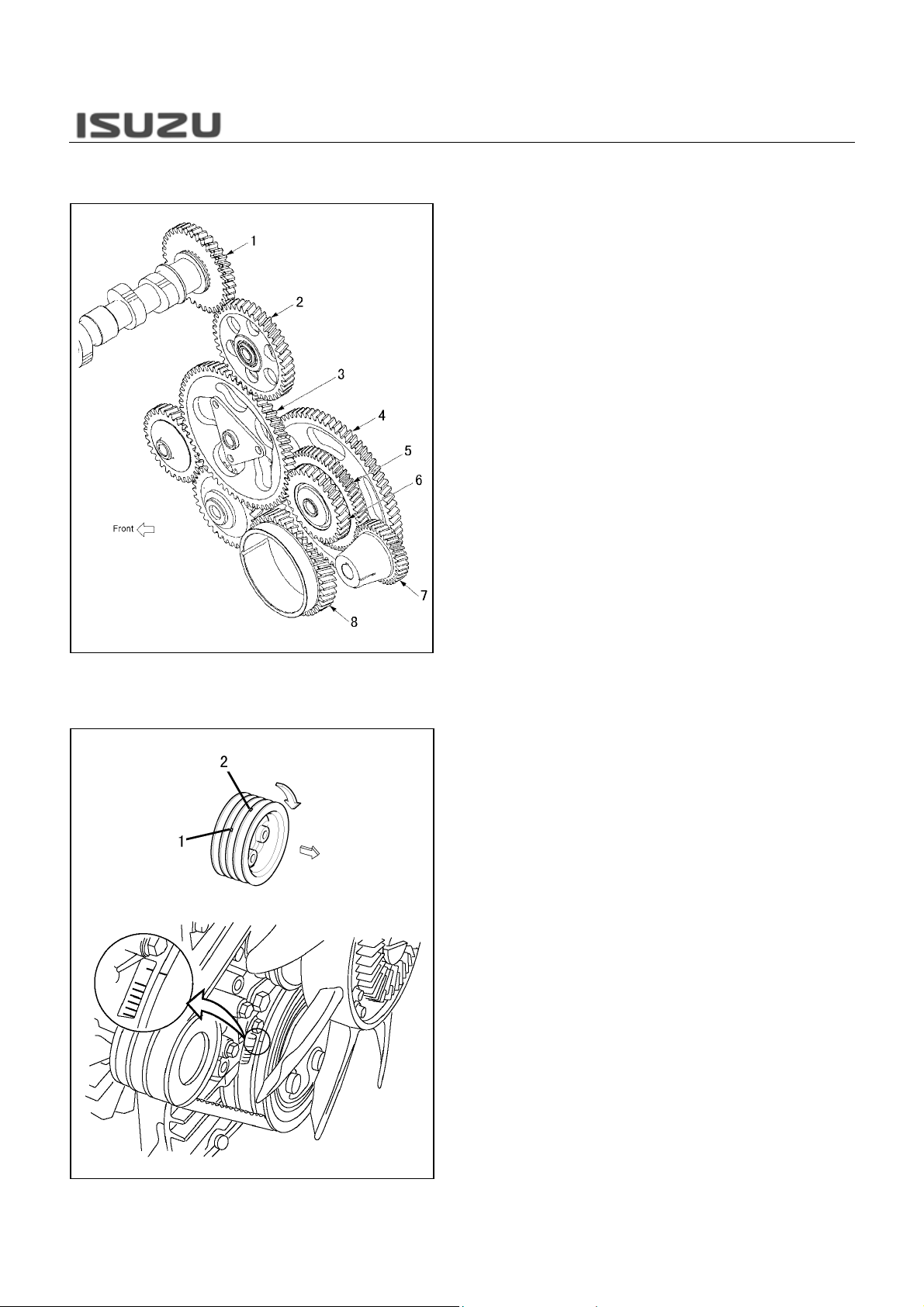

1. Rotate the crankshaft to make the No.1 cylinder meet

the compression top dead center (TDC). There are 2

marks stamped on the crank pulley. The mark (1) is

used to bring the engine No.1 or No. 4 cylinder to TDC .

The mark (2) is irrelevant. Do not use the mark (2).

Page 7

r

r

Cylinder No.1234

Valve INEXINEXINEXINEX

No.1 Cylinder

Compression

TDC

No.4 Cylinder

Compression

TDC

OOO O

XX XX

N*R 4HK1-TC Engine-6

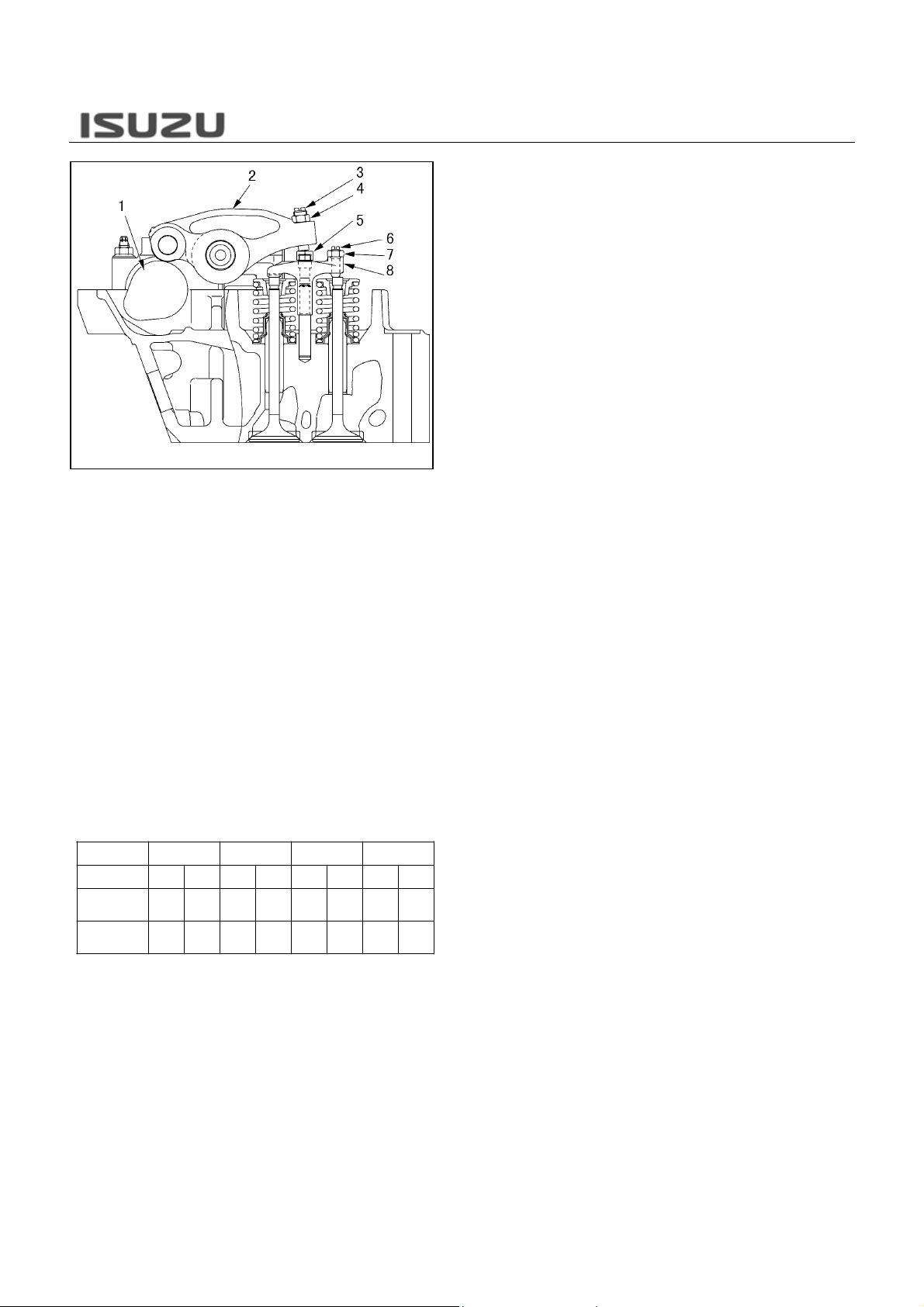

2. Loosen fully each adjusting screw (8) & (2) of the bridge

and the rocker arm.

3. Insert a 0.4mm (0.016in) thickness gauge between the

tip of the rocker arm and bridge cap (5), and adjust the

clearance with the adjusting screw (3) on the rocke

arm, and then fix it with a lock nut (4).

4. With a thickness gauge kept inserted, check that the

adjusting screw (6) contacts the valve shaft end and the

movement of the thickness gauge has become tight

when the adjusting screw (6) on the bridge is tightened

lightly.

5. Check the valve shaft end on the opposite side floats o

it contacts obliquely. In case of a floating or oblique

contact, loosen a little the adjusting screw (6) on the

bridge side and adjust so that the valve shaft ends on

both sides get in contact properly. Bridge (8) & valve

shaft end clearance less than 0.1 mm (0.004in).

6. After the adjustment so that the end of the valves on

both sides touch properly, tighten up the lock nut (7) on

the bridge (8).

Note that unless the bridge is kept hor izontal, t he bridge

is pressed obliquely, thus cau sing the bridge a nd bridge

guide to be seized or damaged. Therefore, exact

adjustment is required.

Valve clearance: 0.4mm (0.016in) intake & exhaust

side at cold

Adjusting screw lock nut tightening torque: 22Nm

(16lb ft)

At the No.1 cylinder compression top dead center, the

valves with “O” mark in the following table, or at the

No.4 cylinder compression top dead center, the valve

with “X“ mark can be adjusted.

Page 8

r

Fuel Supply Pump Installation

N*R 4HK1-TC Engine-7

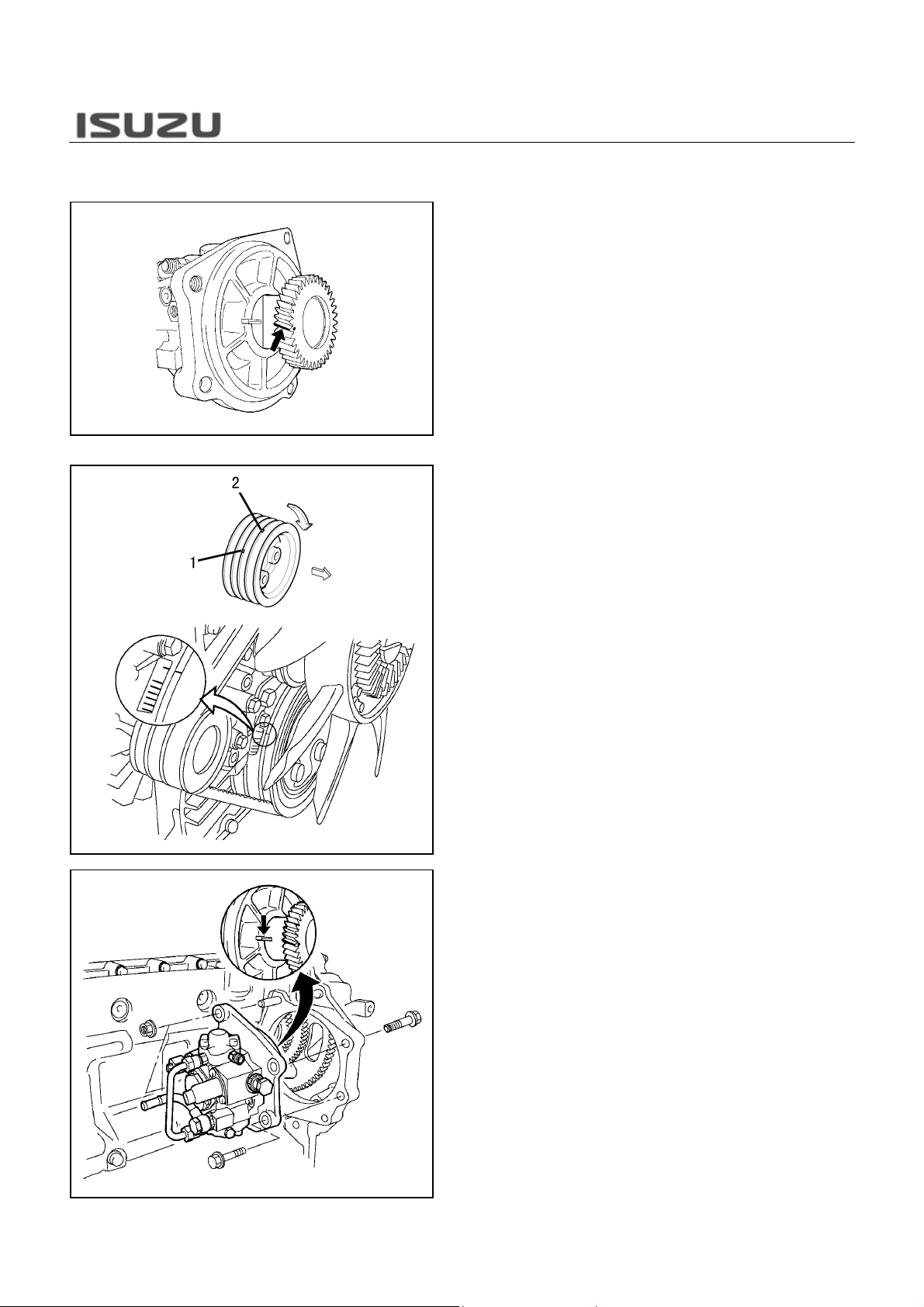

1. Apply white paint to the top of the fuel supply pump gear

tooth directly above the stamped “O” mark.

2. Rotate the crankshaft to the compression top dead

center (TDC). There are 2 marks stamped on th e crank

pulley. The mark (1) is used to b ring th e engin e No.1 o

No. 4 cylinder to TDC. The mark (2) is irrelevant. Do not

use the mark (2).

3. Install the O-ring to the fuel supply pump.

4. Align a slit of the fuel supply pump bracket with a white

paint on the gear and install the fuel supply pump in the

gear case using the stud bolts as a guide.

Page 9

A

r

CYLINDER HEAD COVER & HEAD COVER

CASE

N*R 4HK1-TC Engine-8

5. Check through the hole (1) that a white paint (2) on the

gear is in the position shown on the left.

Fixing nut tightening torque: 50Nm (37lb ft)

Fixing bolt tightening torque: 76Nm (56lb ft)

long with the employment of a common rail type f uel

injection system, the head cover is split and housed in a

newly introduced head cover case attached with an

intermediate connector for th e injector. The head cove

case is so designed that it is secured indi vidually to the

cylinder head with four bolts, and further it is tightened

together with the head cover with nine bolts.

Accordingly, the head cover is removable individually

regardless of the injector harness, thus enabling easy

inspection and service including the valve clearance

adjustment.

1. Gasket

2. Oil Filler Cap

3. Head Cover Bolt

4. Head Cover

5. Gasket

6. Head Cover Case

7. Intermediate Harness Connector

8. Cylinder Head Cover Case Bolt

9. Cylinder Head

10. Gasket

11. Connector Fixing Bolt

Page 10

f

r

r

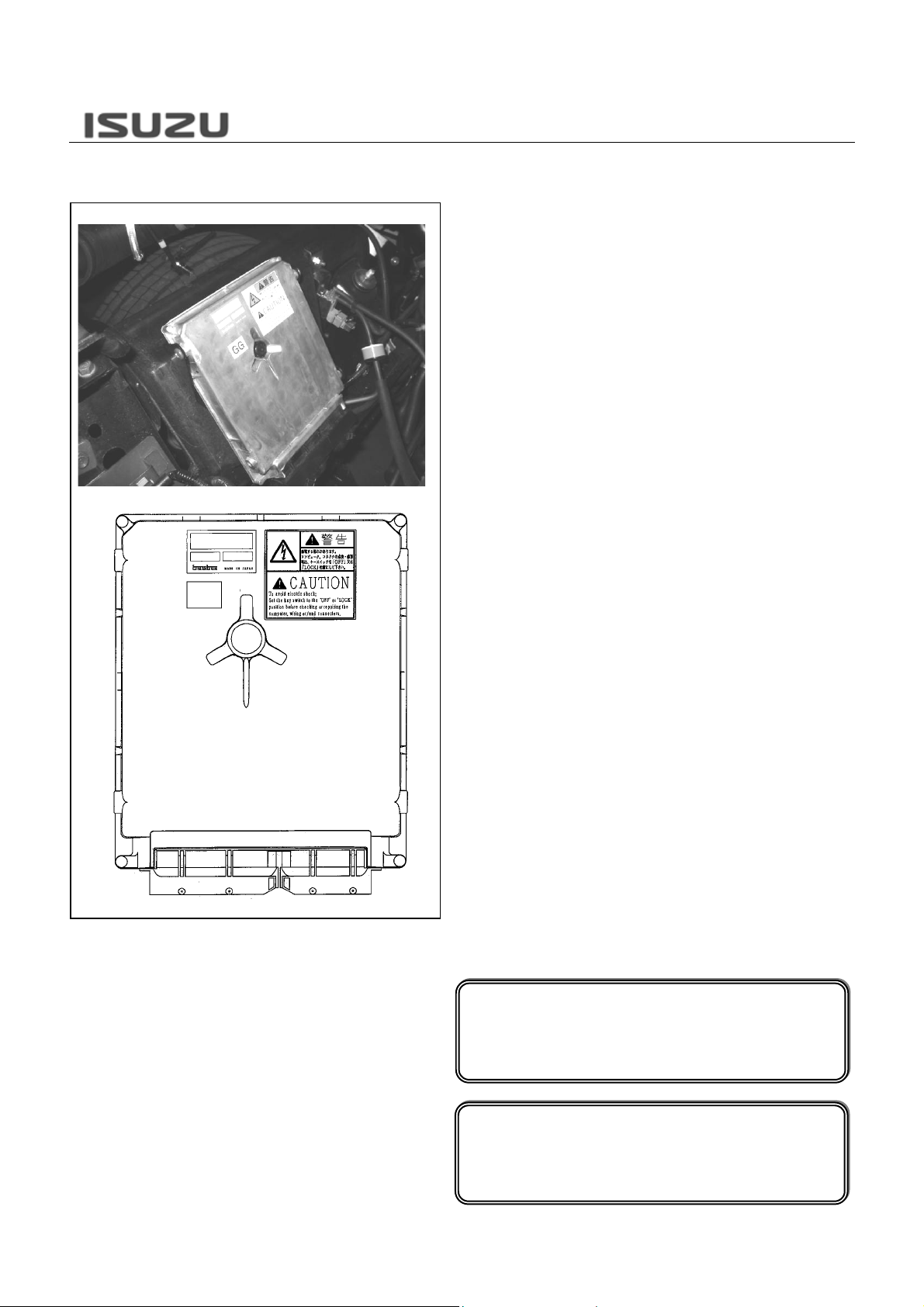

ENGINE CONTROL MODULE (ECM)

N*R 4HK1-TC Engine-9

The engine control module (ECM) is located at inside o

engine-side cover on the left via mounting bracket and

is beside the engine. The ECM is made by Transtron.

The ECM mainly controls the following.

Fuel injection control

Fuel timing control

Exhaust gas recirculation (EGR) system control

Preheating system control

Exhaust brake control

Power take off (PTO) control

On-board diagnostics for engine control

The ECM constantly observes the information from

various sensors. The ECM controls the systems that

affect vehicle performance. The ECM performs the

diagnostic function of the system. The ECM can

recognize operational problems, alert the driver through

the malfunction indicator lamp (MIL), and store

diagnostic trouble code (DTC). DTC identify the syst em

faults to aid the technician in making repair.

This diagnostic applies to internal microprocesso

integrity conditions within the ECM. The electronically

erasable programmable read only memory (EEPROM)

memorize learning data and injector ID code data fo

engine control and communication with other control

module.

Symbol “!” warns you of an electric shock haza rd. To avoid

shock and possible serious injury, DO NOT touch the

terminals. When disconnecting the harness connector,

always turn OFF the ignition switch or disconnect the

battery cable.

Parts number of each ECM mainly differs with following

contents.

Engine specification (output or torque)

Transmission specification (MYY, MZZ or Smoother)

Speed limiter application

Notice!

If the ECM is to be replaced the fuel injector ID

Code Data (24, 0-9 or A-F characters for each fuel

injector) MUST be programmed into the new ECM.

Notice!

This ECM does not have ability of re-flash function

by Service Programming System (SPS) via Tech 2

scan tool.

Page 11

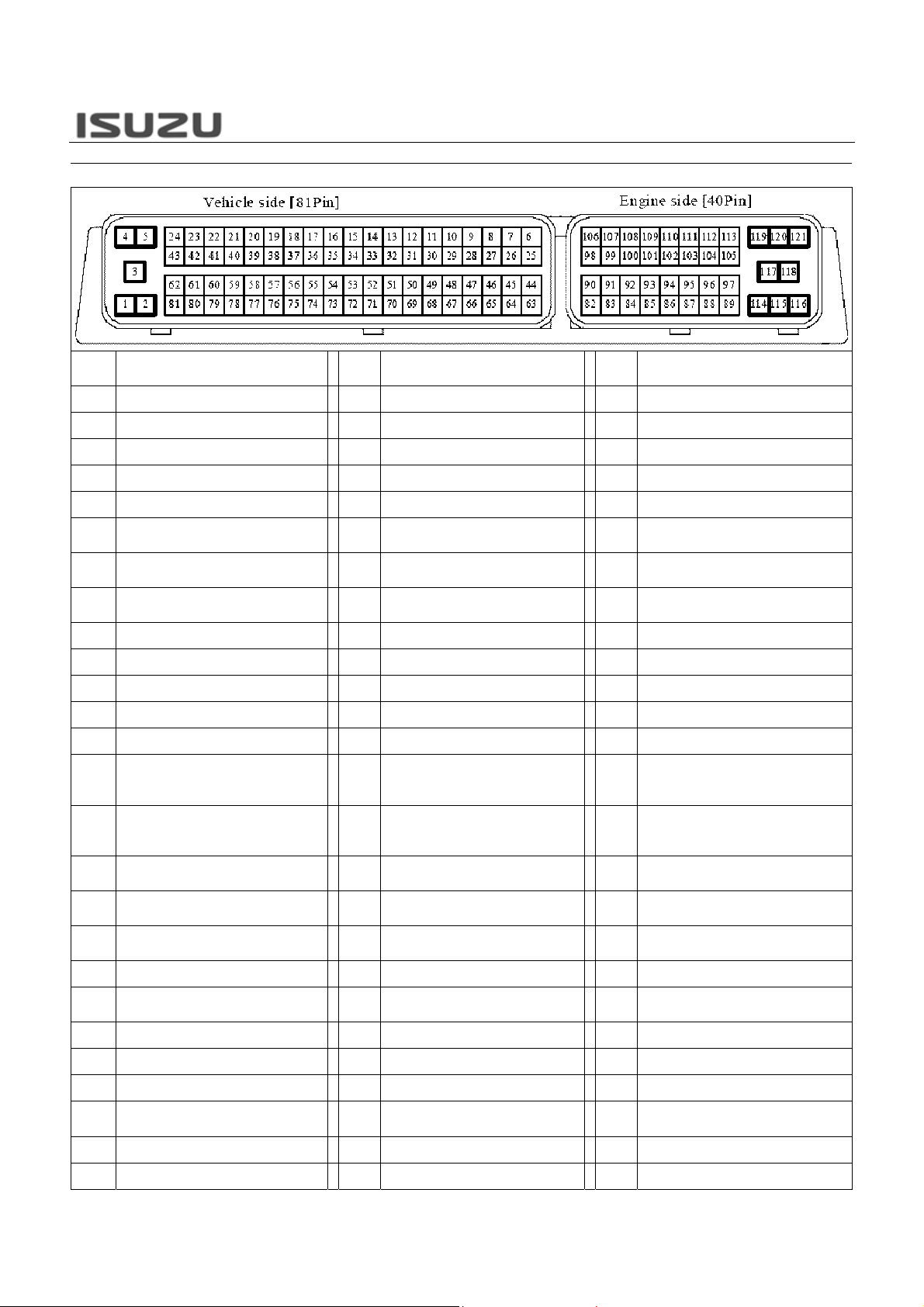

N*R 4HK1-TC Engine-10

Page 12

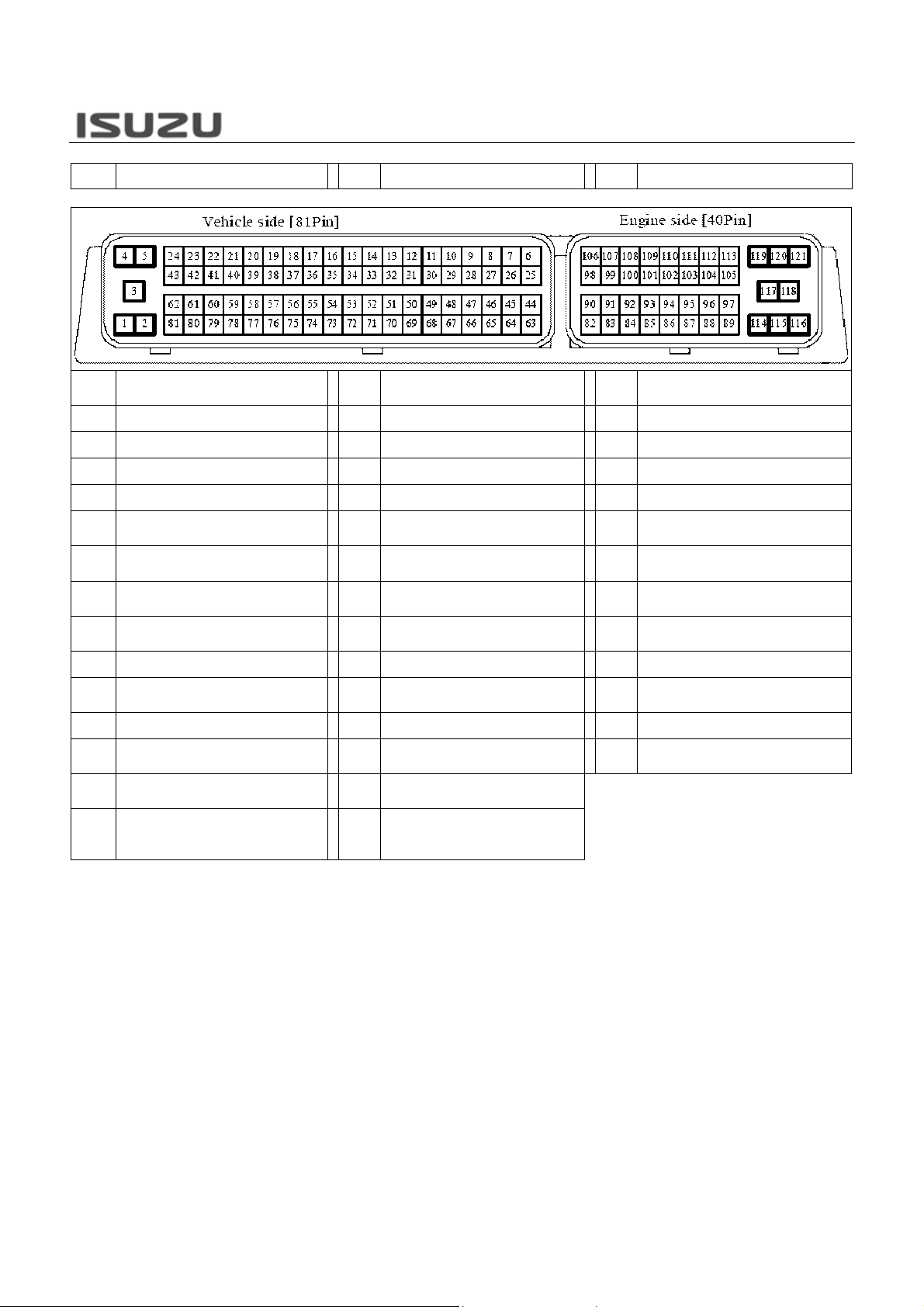

ECM Connector Pin Assignment

N*R 4HK1-TC Engine-11

Pin No. Pin Function

1 ECM Power Ground 28 Not Used 55 Not Used

2 Main Relay Voltage 29 Not Used 56 Not Used

3 ECM Power Ground 30 Not Used 57 Not Used

4 ECM Power Ground 31 Not Used 58 Not Used

5 Main Relay Voltage 32 Not Used 59 Not Used

Malfunction Indicator Lamp (MIL)

6

Control

7 Exhaust Brake Lamp Control 34 A/C Switch Input Signal 61

Engine Speed Signal Output to

8

IPC

9 Not Used 36 Not Used 63 APP Sensor 1 Input Signal

10 Glow Plug Relay Control 37 CAN Low Signal 64 APP Sensor 2 Input Signal

11 Glow Indicator Lamp Control 38 Keyword 2000 Serial Data 65 Not Used

12 Not Used 39 APP Sensor 2 Shield 66 Idle Up Sensor Input Signal

13 Not Used 40 Main Relay Power Supply 67 Not Used

14 Starter Cut Relay Control 41

15 Exhaust Brake Solenoid Control 42

16 Not Used 43 ECM Signal Ground 70

17 Not Used 44

18 CAN High Signal 45

19 VSS Input Signal 46 Start Position Input Signal 73 Not Used

20 APP Sensor 1 Shield 47

21 Main Relay Power Supply 48 Park Brake Switch Input Signal 75 Not Used

22 Not Used 49 Not Used 76 Not Used

23 Not Used 50 Neutral Switch Input Signal 77 Not Used

24 Ignition ON Switch Input Signal 51

25 Not Used 52 Diag Switch 79 Not Used

26 Not Used 53 Not Used 80 Not Used

Pin

No.

33 Refrigerator Switch Input Signal 60

35 Not Used 62 ECM Signal Ground

APP Sensor 1, Idle Up Sensor,

Remote PTO Accelerator

Sensor Low Reference

APP Sensor 1, Idle Up Sensor,

Remote PTO Accelerator

Sensor 5V Reference

PTO Operation Switch Input

Signal

Exhaust Brake Switch Input

Signal

Clutch Switch Input Signal (M/T

Only)

Engine Warm Up Switch Input

Signal

Pin Function

Pin

No.

APP Sensor 2, BARO Sensor, IAT

Sensor Low Reference

APP Sensor 2, BARO Sensor, IAT

Sensor 5V Reference

68 Not Used

69 Not Used

Remote PTO Accelerator Sensor

Input Signal

71 BARO Sensor Input Signal

72 IAT Sensor Input Signal

74 Not Used

78 Not Used

Pin Function

Page 13

27 Not Used 54 Not Used 81 ECM Case Ground

N*R 4HK1-TC Engine-12

Pin No. Pin Function

82 FRP Sensor Input Signal 96 Not Used 110 Not Used

83 FT Sensor Input Signal 97 SCV Low Control 111 EGR Valve DC Motor Control

84 ECT Sensor Input Signal 98 CMP Sensor 12V Reference 112 Not Used

85 Not Used 99 CMP Sensor Input Signal 113 SCV High Control

EGR Valve Position Sensor Input

86

Signal

FRP Sensor, EGR Valve Position

87

Sensor Input Signal

88 Not Used 102

89 SCV Low Control 103

90 FRP Sensor Input Signal 104 Not Used 118 Cylinder #2 Injector Control

Boost Pressure Sensor Input

91

Signal

92 Not Used 106 CKP Sensor Low Signal Input 120 Cylinder #3 Injector Control

93 Not Used 107 CKP Sensor High Signal Input 121

94 Not Used 108

Boost Pressure Sensor 5V

95

Reference

Pin

No.

100

101

105 SCV High Control 119 Cylinder #1 Injector Control

109

FRP Sensor, CMP Sensor

Shield

FRP Sensor, EGR Valve

Position Sensor Low Reference

Intake Throttle Solenoid Valve

Control

EGR Valve DC Motor Power

Supply

Boost Pressure Sensor, CKP

Sensor Shield

Boost Pressure Sensor, ECT

Sensor, FT Sensor Low

Reference

Pin Function

Pin

No.

114 Not Used

115 Not Used

Cylinder #2, #3 Injector Power

116

Supply

117 Cylinder #4 Injector Control

Cylinder #1, #4 Injector Power

Supply

Pin Function

Page 14

A

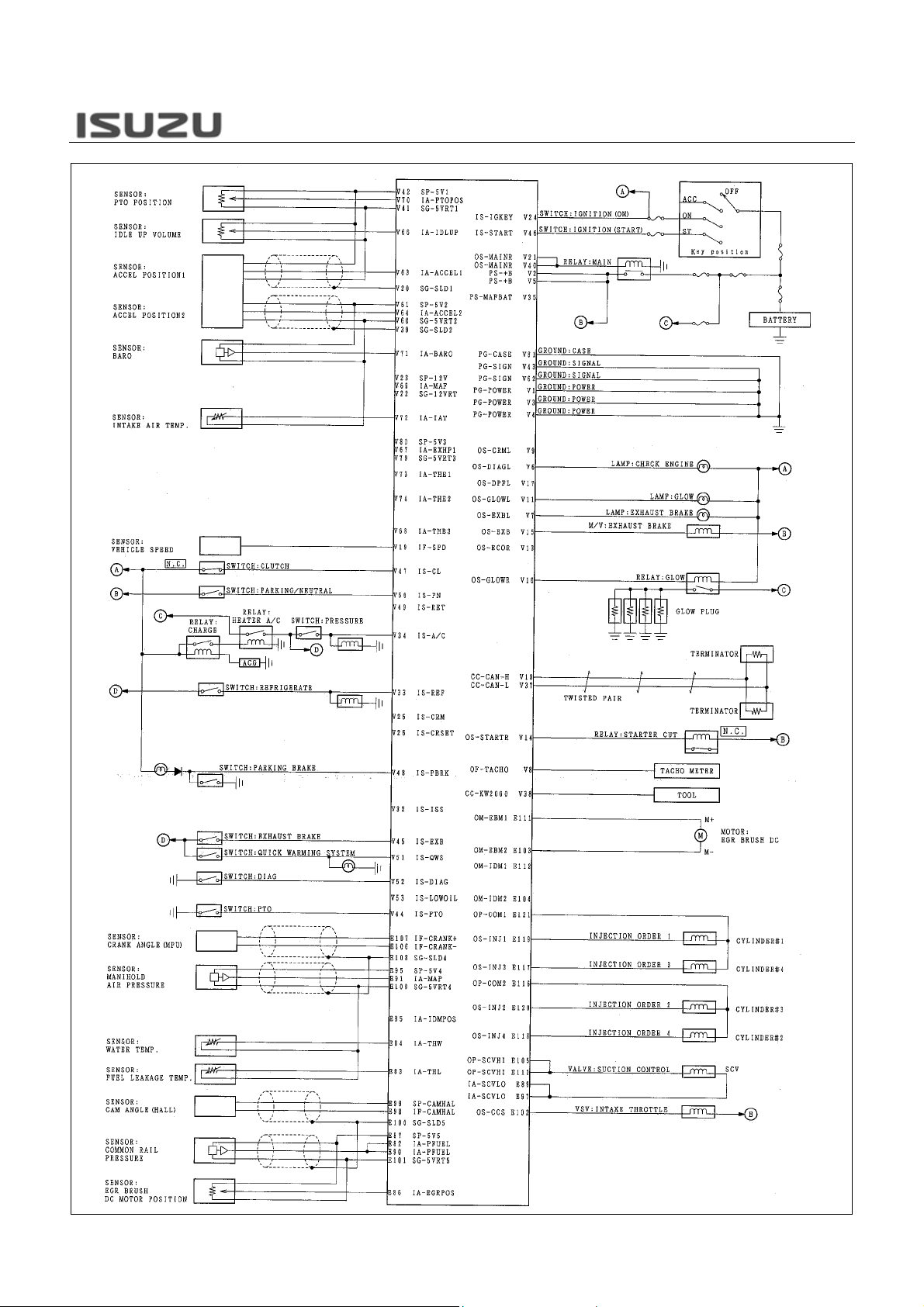

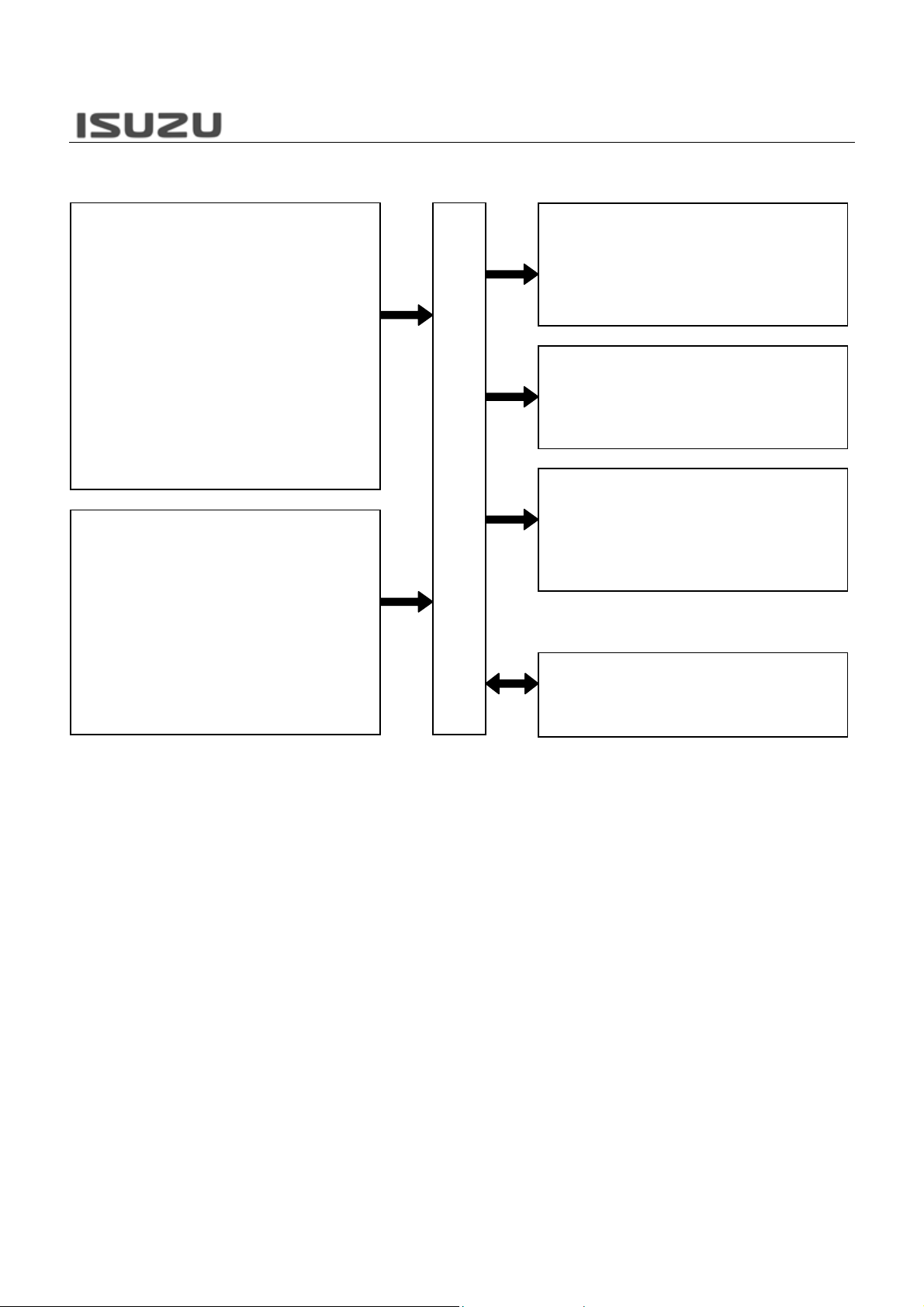

ECM Inputs & Outputs

Sensor Input

Crankshaft position (CKP) sensor

•

• Camshaft position (CMP) sensor

Intake air temperature (IAT) sensor

•

• Engine coolant temperature (ECT) sensor

Fuel temperature (FT) sensor

•

• Fuel rail pressure (FRP) sensor

Barometric pressure (BARO) sensor

•

• Boost pressure sensor

Accelerator pedal position (APP) sensor

•

• Vehicle speed sensor (VSS)

EGR valve position sensor

•

• Idle up control sensor

Remote PTO accelerator sensor

•

Switch Input

• Ignition switch (ON/start position)

Clutch switch (M/T)

•

• Park brake switch

Park/Neutral switch

•

• Exhaust brake switch

Engine warm up switch

•

• A/C switch

PTO switch

•

• Refrigerator switch

Diag request switch

•

EC

M

N*R 4HK1-TC Engine-13

Fuel Injection Control Output

• Suction control valve (SCV)

Fuel injector #1

•

• Fuel injector #2

Fuel injector #3

•

• Fuel injector #4

ctuator Control Output

• Intake throttle solenoid valve

Exhaust brake solenoid valve

•

• EGR valve motor

Relay & Lamp Control Output

Glow relay

•

• Starter cut relay

Malfunction indicator lamp (MIL)

•

• Glow indicator lamp

Exhaust brake indicator lamp

•

Communication

Tech 2 (Keyword 2000)

•

• Controller area network (CAN)

Page 15

N*R 4HK1-TC Engine-14

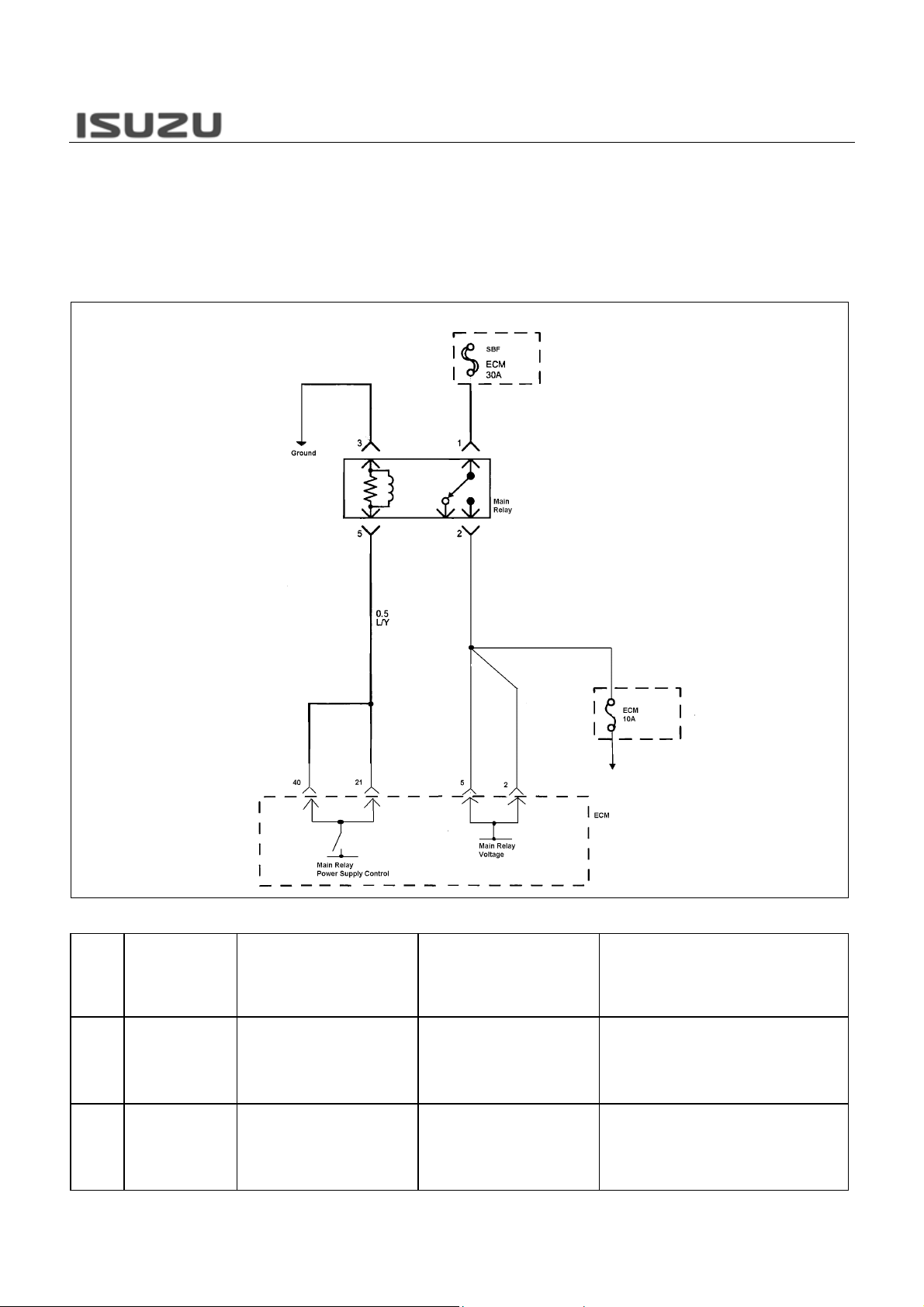

The ECM monitors the battery voltage through the ECM

main relay load supply voltage terminals “2” and “5”,

and the ignition voltage on the ignition voltage feed

terminal “24” to make sure that t he voltage stays within

the proper range. When the char ging system detects a

malfunction, the charge indicator will light.

Related DTC

DTC

DTC Name On Scan

P1625 ECM Main Relay

P1625 ECM Main Relay

Tool

Circuit

Circuit

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTC P1603 is not set.

The ignition switch is ON.

The ignition switch ON time is

longer than 3 seconds.

The ignition switch is OFF.

The ECM detects that a low

voltage condition on the ECM

main relay voltage feed circuit for

longer than 3 seconds when the

ECM main relay is commanded

ON.

The ECM detects that a high

voltage condition on the ECM

main relay voltage feed circuit for

longer than 5 seconds when the

ECM main relay is commanded

OFF.

ECM main relay coil side power supply circuit is

open circuit or high resistance.

ECM main relay voltage feed circuit is open

circuit or high resistance.

Faulty ECM main relay.

ECM main relay coil side power supply circuit is

short to battery voltage circuit.

ECM main relay voltage feed circuit is short to

battery voltage circuit.

Faulty ECM main relay.

Page 16

N*R 4HK1-TC Engine-15

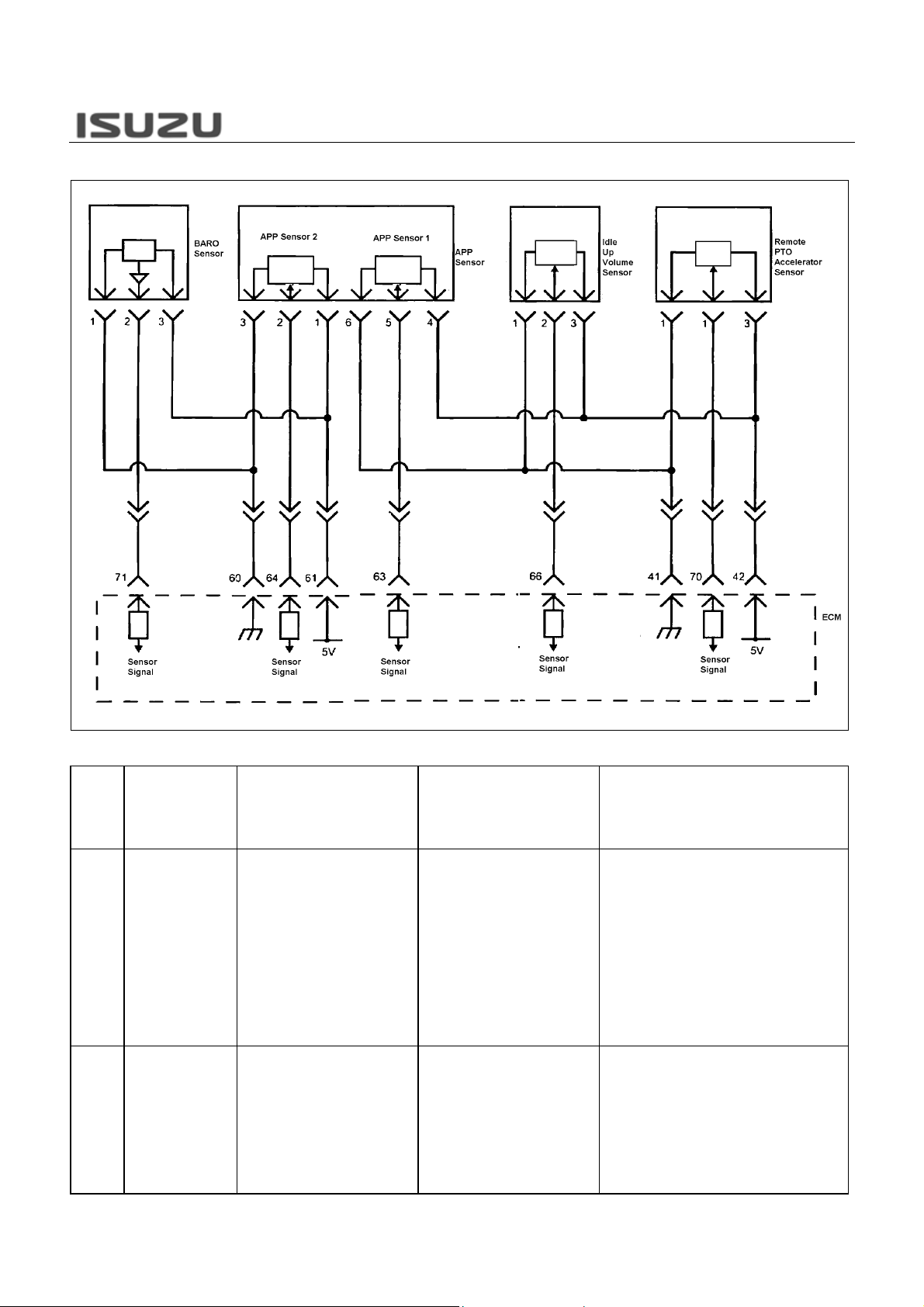

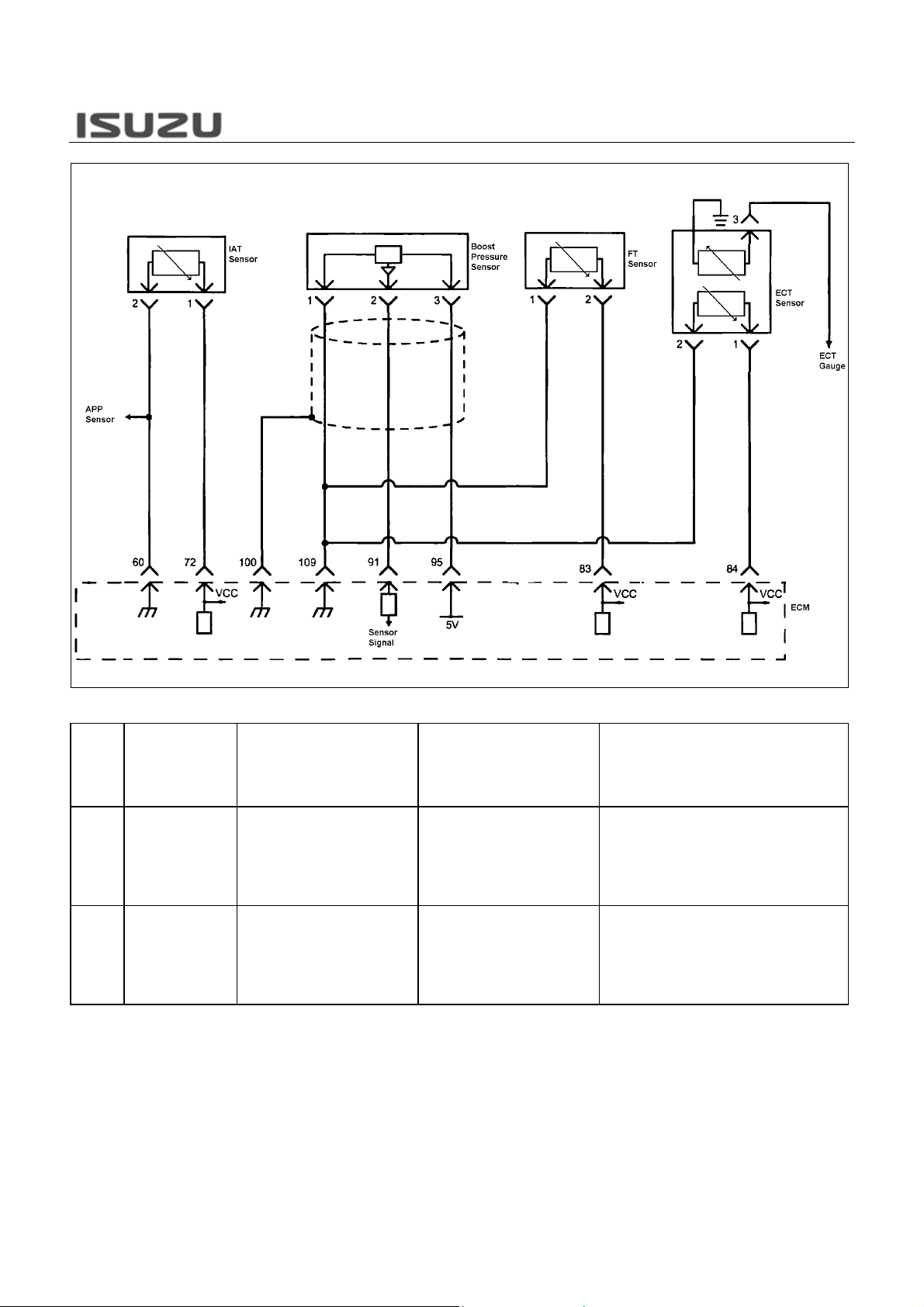

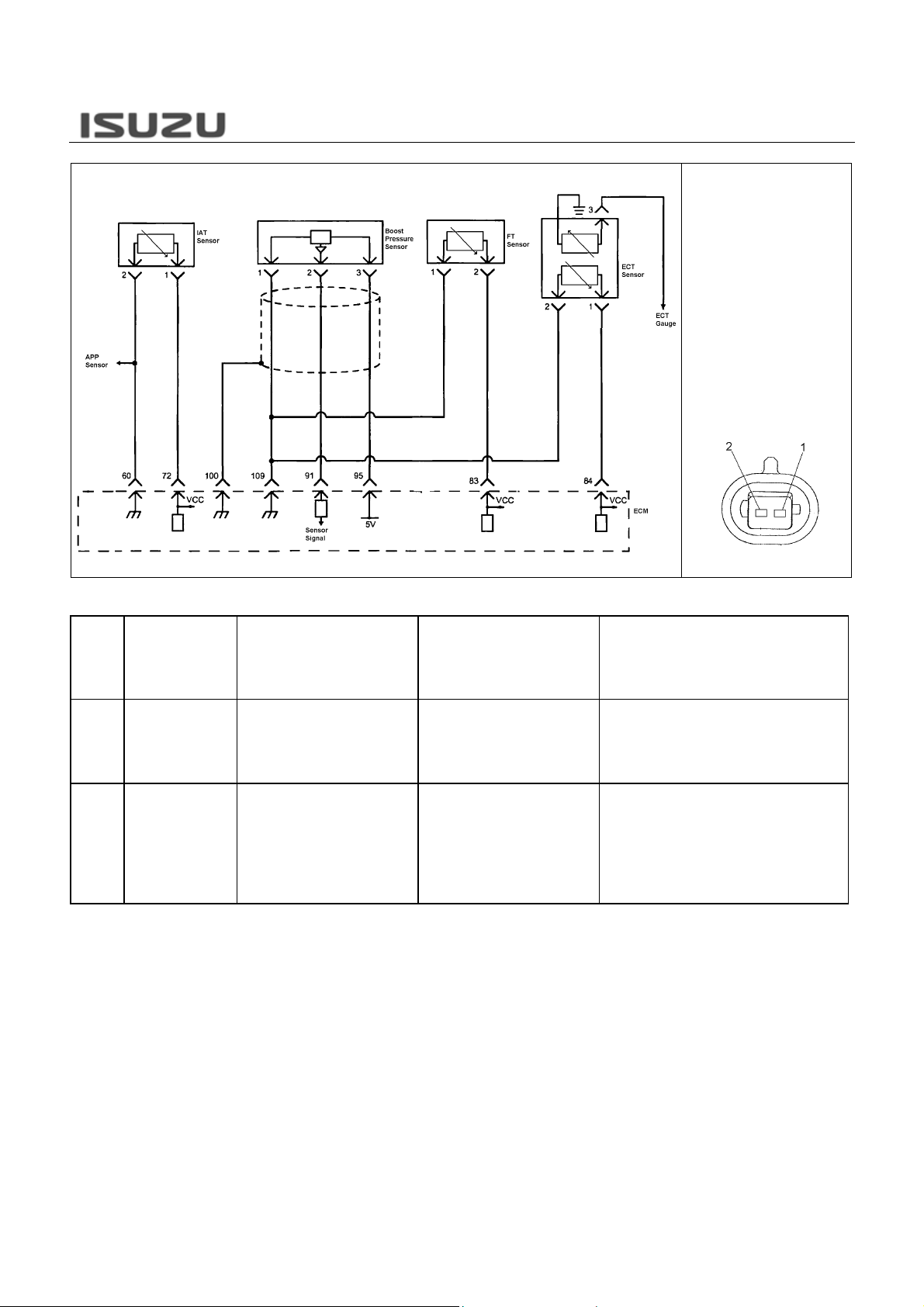

The engine control module (ECM) provides 5volts

reference voltage through the refer ence circuit 1, 2, 3, 4

and 5 to the following sensors.

5volts reference circuit 1

Accelerator pedal position (APP) sensor 1

Idle up volume sensor

Remote PTO accelerator sensor

5volts reference circuit 2

APP sensor 2

Barometric pressure (BARO) sensor

5volts reference circuit 3 (Not Used)

5volts reference circuit 4

Boost pressure sensor

5volts reference circuit 5

Fuel rail pressure (FRP) sensor

EGR valve position sensor

Page 17

N*R 4HK1-TC Engine-16

Related DTC

DTC

DTC Name On Scan

P1631 5 Volt Reference

P1632 5 Volt Reference

Tool

Circuit 1

Circuit 2

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTC P1630 is not set.

The battery voltage is between 16

– 32 volts.

The ignition switch is ON.

DTC P1630 is not set.

The battery voltage is between 16

– 32 volts.

The ignition switch is ON.

The ECM detects that the 5 volts

reference circuit 1 voltage is less

than 4.5 volts.

OR

The ECM detects that the 5 volts

reference circuit 1 voltage is more

than 5.5 volts.

The ECM detects that the 5 volts

reference circuit 2 voltage is less

than 4.5 volts.

OR

The ECM detects that the 5 volts

reference circuit 2 voltage is more

than 5.5 volts.

APP sensor 1 5V reference circuit is short to

ground, short to any 12V reference circuit, short

to battery or ignition voltage circuit.

Idle up sensor 5V reference circuit is short to

ground, short to any 12V reference circuit, short

to battery or ignition voltage circuit.

PTO accelerator sensor 5V reference circuit is

short to ground, short to any 12V reference

circuit, short to battery or ignition voltage circuit.

Faulty APP sensor 1.

Faulty Idle up sensor.

Faulty PTO accelerator sensor.

Faulty ECM.

Notice: APP sensor 1 is internal to APP sensor

assembly.

APP sensor 2 5V reference circuit is short to

ground, short to any 12V reference circuit, short

to battery or ignition voltage circuit.

BARO sensor 5V reference circuit is short to

ground, short to any 12V reference circuit, short

to battery or ignition voltage circuit.

Faulty APP sensor 2.

Faulty BARO sensor.

Faulty ECM.

Notice: APP sensor 2 is internal to APP sensor

assembly.

Page 18

N*R 4HK1-TC Engine-17

Related DTC

DTC

DTC Name On Scan

P1633 5 Volt Reference

P1634 5 Volt Reference

Tool

Circuit 3

Circuit 4

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTC P1630 is not set.

The battery voltage is between 16

– 32 volts.

The ignition switch is ON.

DTC P1630 is not set.

The battery voltage is between 16

– 32 volts.

The ignition switch is ON.

The ECM detects that the 5 volts

reference circuit 3 voltage is less

than 4.5 volts.

OR

The ECM detects that the 5 volts

reference circuit 3 voltage is more

than 5.5 volts.

The ECM detects that the 5 volts

reference circuit 4 voltage is less

than 4.5 volts.

OR

The ECM detects that the 5 volts

reference circuit 4 voltage is more

than 5.5 volts.

Boost pressure sensor 5V reference circuit is

short to ground, short to any 12V reference

circuit, short to battery or ignition voltage circuit.

Faulty boost pressure sensor.

Faulty ECM.

-

Page 19

N*R 4HK1-TC Engine-18

Related DTC

DTC

DTC Name On Scan

P1635 5 Volt Reference

Tool

Circuit 5

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTC P1630 is not set.

The battery voltage is between 16

– 32 volts.

The ignition switch is ON.

The ECM detects that the 5 volts

reference circuit 5 voltage is less

than 4.5 volts.

OR

The ECM detects that the 5 volts

reference circuit 5 voltage is more

than 5.5 volts.

FRP sensor 5V reference circuit is short to

ground, short to any 12V reference circuit, short

to battery or ignition voltage circuit.

EGR valve position sensor 5V reference circuit is

short to ground, short to any 12V reference

circuit, short to battery or ignition voltage circuit.

Faulty FRP sensor.

Faulty EGR valve position sensor.

Faulty ECM.

Notice: EGR valve position sensor is internal to

EGR valve assembly.

Page 20

N*R 4HK1-TC Engine-19

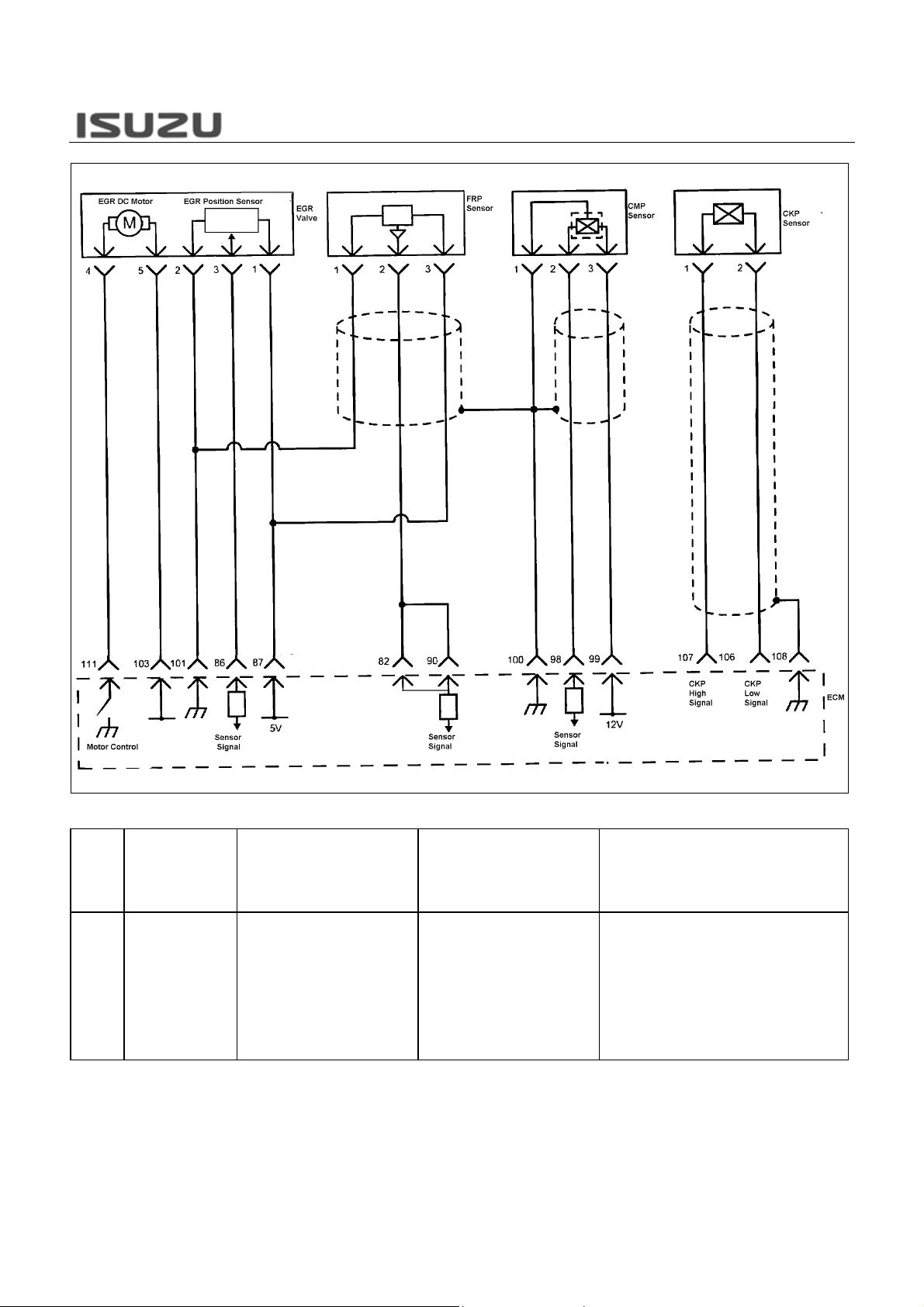

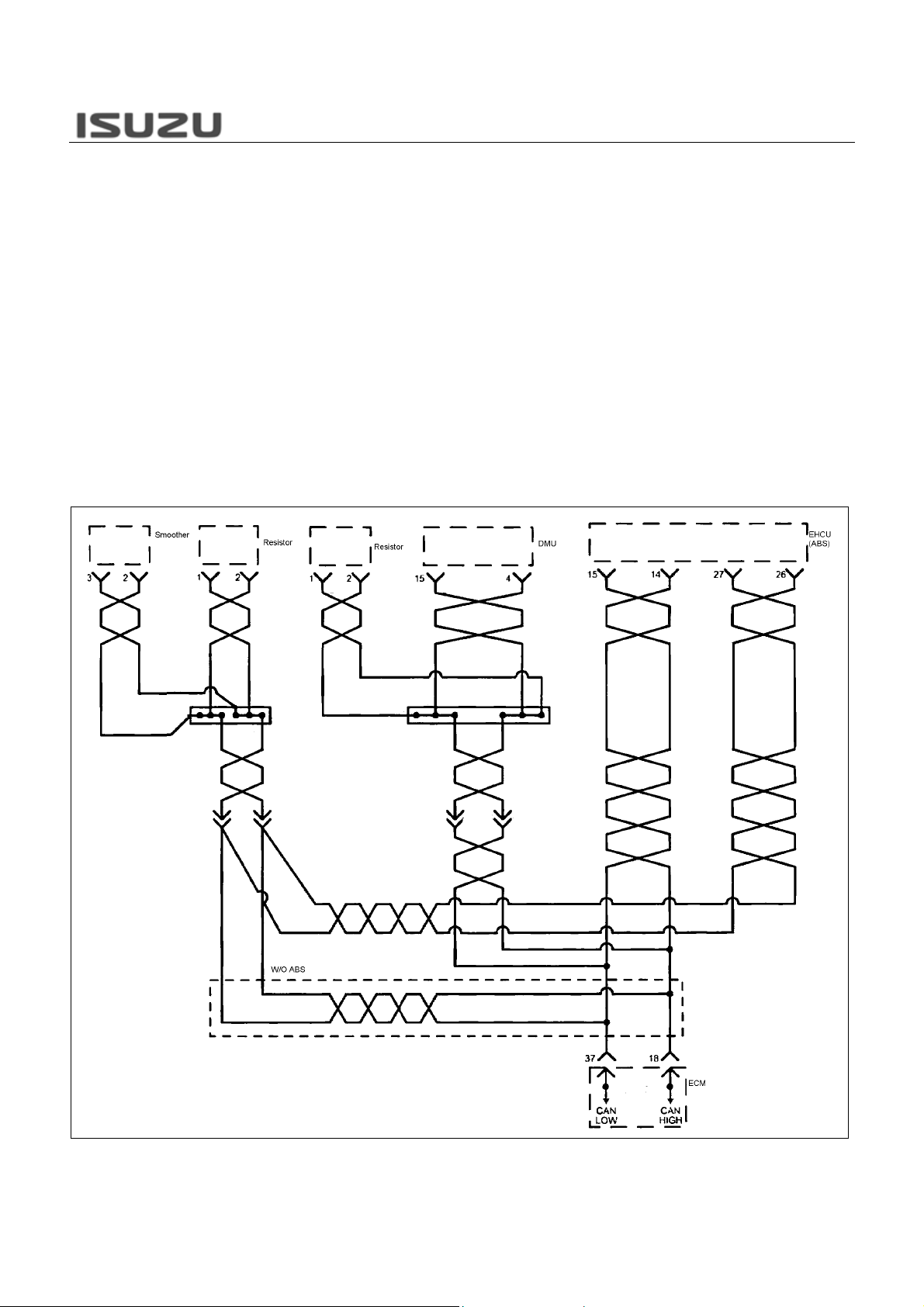

The engine control module (ECM), the smoother control

module, ABS control module (EHCU) and the DMU,

interchange of data among each contr oller per formed via a

controller area network (CAN) communication bus.

Following signals are communicated via a CAN bus.

• Accelerator pedal position signal

Engine output torque

•

• PTO control signal

Exhaust brake cut signal

•

• Engine speed signal

Injection volume reduction signal

•

The ECM monitors CAN operational status by expecting a

constant flow of messages from each module. If the ECM

fails to receive an expected message from each module,

DTC U2104, U2106 or U2108 will set depending on what

communication is lost.

Page 21

Related DTC

DTC

DTC Name On Scan

Tool

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

N*R 4HK1-TC Engine-20

U2104 CAN Bus Reset

Counter Overrun

U2106 Lost CAN

Communications With

Transmission Control

System

U2108 Lost Communications

With ABS/TCS Control

System

The ignition switch is ON.

The ignition switch is ON.

The ignition switch is ON.

The ECM detects that the CAN

Bus OFF is detected.

The ECM detects that the CAN

Bus messages from the TCM are

not being received.

The ECM detects that the CAN

Bus messages from the EHCU

(ABS control unit) are not being

received.

CAN high circuit is short to ground, short to

battery or ignition voltage.

CAN low circuit is short to ground, short to

battery or ignition voltage.

Electrical interference.

Faulty ECM.

Faulty TCM.

Faulty EHCU.

CAN high circuit is short to ground, short to

battery or ignition voltage.

CAN low circuit is short to ground, short to

battery or ignition voltage.

Electrical interference.

Faulty ECM.

Faulty TCM.

CAN high circuit is short to ground, short to

battery or ignition voltage.

CAN low circuit is short to ground, short to

battery or ignition voltage.

Electrical interference.

Faulty ECM.

Faulty EHCU.

Page 22

r

r

r

ELECTRICAL COMPONENTS

N*R 4HK1-TC Engine-21

INTAKE AIR TEMPERATURE (IAT)

SENSOR

Resistance (Ohms)

-20-100 102030405060708090

IAT Sensor Characteristic -Reference30000

27500

25000

22500

20000

17500

15000

12500

10000

7500

5000

2500

0

Temperature (C)

°C °F Ohms Volts

90 194 240 0.2

80 176 320 0.3

70 158 450 0.4

60 140 660 0.6

50 122 960 0.8

40 104 1440 1.1

30 86 2300 1.6

20 68 3430 2.1

10 50 5410 2.7

03297703.3

-10 14 16410 3.8

-20 -4 28560 4.2

Ohms

Volts

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

The intake air temperature (IAT) sensor is fitted

between the air cleaner and turbocharger. The IAT

sensor is a variable resistor. The IAT se nsor measures

the temperature of the air entering the engine. The

engine control module (ECM) supplies 5 volts to the I AT

sensor signal circuit and a ground for the IAT senso

low reference circuit. When the IAT sensor is cold, the

sensor resistance is high. When the air temperature

increases, the sensor resistance decreases. With high

sensor resistance, the ECM detects a high voltage on

the IAT sensor signal circuit. With lower senso

resistance, the ECM detects a lower volt age on the IAT

sensor signal circuit. The ECM uses to this value to

calculate a fuel injection quantity, injection timing and

EGR control.

The characteristic of the IAT sen sor is displayed in the

graph and table. Calculated intak e air temperature can

be found on the Tech 2 by unit “°C” or “°F”. The output

voltage also can be found on the Tech 2.

Notice!

In data display “°C” or “°F” will be fixed to a default

value when DTC is set relating to the I AT senso

open or short circuit. To diagnose this DTC,

observe the “Volts” in the data display.

Output (Volts)

Page 23

N*R 4HK1-TC Engine-22

Related DTC

IAT Sensor

Connector Face

DTC Name On Scan

DTC

P0112 Intake Air Temperature

P0113 Intake Air Temperature

Tool

(IAT) Sensor Circuit

Low Voltage

(IAT) Sensor Circuit

High Voltage

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P1630 and P1632 are not

set.

The ignition switch is ON.

The ignition voltage is more than 18

volts.

DTCs P1630 and P1632 are not

set.

The ignition switch is ON.

The ignition voltage is more than 18

volts.

The engine run time is longer than

3 minutes.

The ECM detects that the IAT

sensor signal voltage is less than

0.1 volts for 5 seconds.

The ECM detects that the IAT

sensor signal voltage is more than

4.8 volts for 5 seconds.

Sensor signal circuit is short to ground or short to

the low reference circuit.

Faulty IAT sensor.

Faulty ECM.

Sensor signal circuit is open circuit, high

resistance, short to any 5V or 12V reference

circuit, short to battery or ignition voltage circuit.

Sensor low reference circuit is open circuit or

high resistance.

Poor harness connector connection.

Faulty IAT Sensor.

Faulty ECM.

Page 24

r

r

r

N*R 4HK1-TC Engine-23

ENGINE COOLTANT TEMPERATURE

(ECT) SENSOR

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

0

Ohms

Volts

Output (Volts)

ECT Sensor Characteristic -Reference28000

26000

24000

22000

20000

18000

16000

14000

12000

10000

Resistance (Ohms)

8000

6000

4000

2000

0

-30-20-100 10203040506070809010011

Temperature (C)

°C °F Ohms Volts

110 230 160 0.2

100 212 200 0.3

90 194 260 0.4

80 176 350 0.5

70 158 470 0.6

60 140 640 0.8

50 122 880 1.1

40 104 1250 1.5

30 86 1800 1.9

20 68 2650 2.3

10 50 4000 2.8

0 32 6180 3.3

-10 14 9810 3.8

-20 -4 16000 4.2

-30 -22 27000 4.5

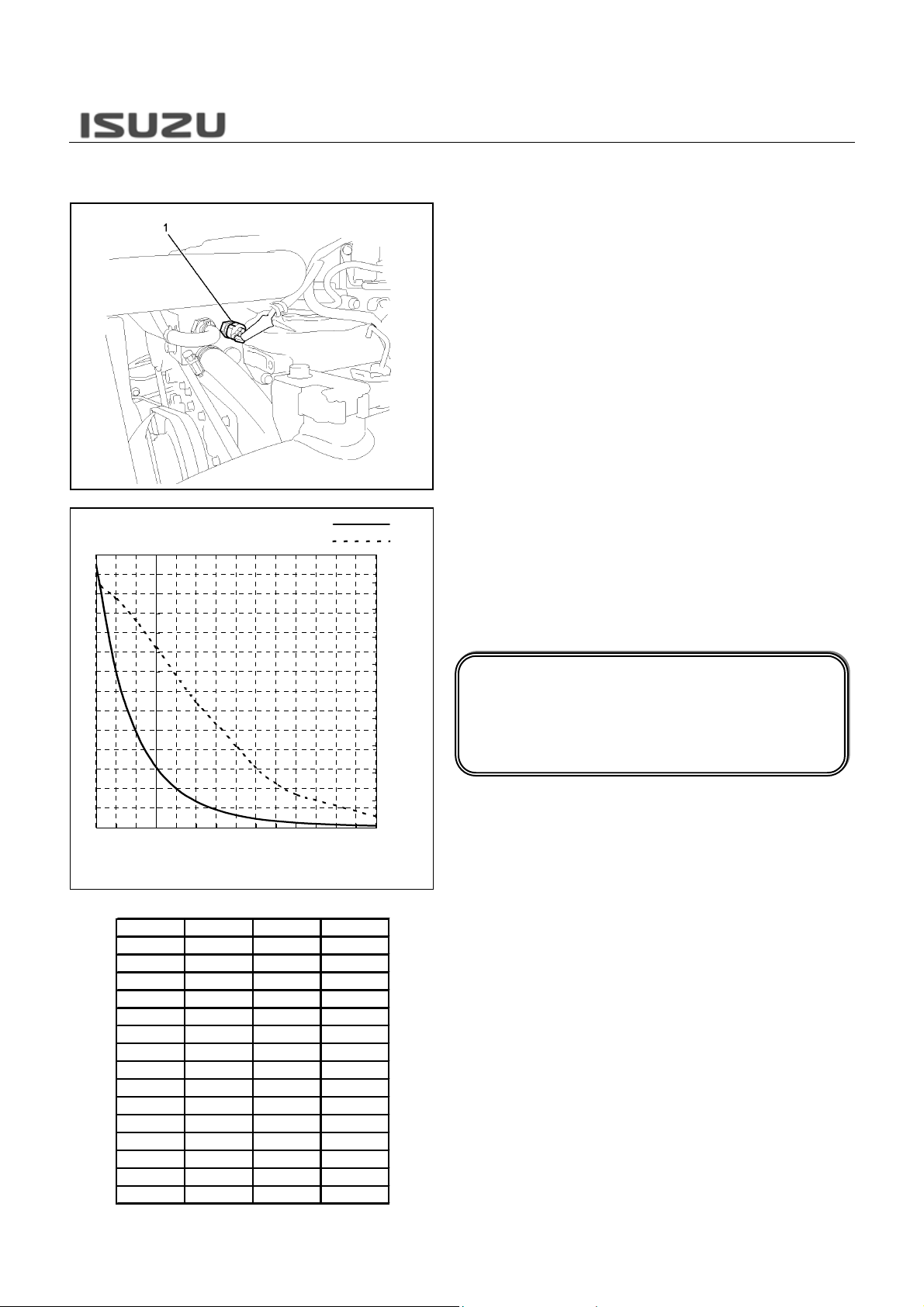

The engine coolant temperature (ECT) sensor is

installed to the coolant stream on the thermostat

housing. It is a variable resistor. The ECT senso

measures the temperature of the engine coolant. The

engine control module (ECM) supplies 5 volts to the

ECT sensor signal circuit and a ground for the ECT

sensor low reference circuit. When the ECT sensor is

cold, the sensor resistance is high. When the ai

temperature increases, the sensor resistance

decreases. With high sensor resistance, the ECM

detects a high voltage on the ECT sensor signal circuit .

With lower sensor resistance, the ECM detec ts a lowe

voltage on the ECT sensor signal circuit. The ECM uses

to this value to calculate a fuel injection quantity,

injection timing and EGR control and pr ehe ating control.

1.Engine Coolant Temperature (ECT) Sensor

The characteristic of the ECT sensor is di splayed in the

graph and table. Calculated coolant temper ature can be

found on the Tech 2 by unit “°C” or “°F“. The output

voltage also can be found on the Tech 2.

Notice!

In data display “°C” or “°F” will be fixed to a default

value when DTC is set relating to the ECT sensor.

To diagnose this DTC, observe the “Volts” in the

data display.

Page 25

N*R 4HK1-TC Engine-24

Related DTC

ECT Sensor

Connector Face

DTC Name On Scan

DTC

P0117 Engine Coolant

P0118 Engine Coolant

Tool

Temperature (ECT)

Sensor Circuit Low

Voltage

Temperature (ECT)

Sensor Circuit High

Voltage

P1173 Engine Overheat

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P1630 and P1634 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

DTCs P1630 and P1634 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The engine run time is longer than

3 minutes.

DTCs P0117, P0118, P1630 and

P1634 are not set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The engine is running.

The ECM detects that the ECT

sensor signal voltage is less than

0.1 volts for 5 seconds.

The ECM detects that the ECT

sensor signal voltage is more than

4.8 volts for 5 seconds.

The ECM detects that the ECT is

more than 110°C (230°F) for 5

seconds.

Sensor signal circuit is short to ground or short to

the low reference circuit.

Faulty ECT sensor.

Faulty ECM.

Sensor signal circuit is open circuit, high

resistance, short to any 5V or 12V reference

circuit, short to battery or ignition voltage circuit.

Sensor low reference circuit is open circuit or

high resistance.

Poor harness connector connection.

Faulty ECT Sensor.

Faulty ECM.

Engine overheat.

Faulty engine cooling system

Faulty ECT sensor.

Page 26

r

r

r

N*R 4HK1-TC Engine-25

FUEL TEMPERATURE (FT) SENSOR

FT Sensor Characteristic -Reference26000

24000

22000

20000

18000

16000

14000

12000

10000

8000

Resistance (Ohms)

6000

4000

2000

0

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110

°C °F Ohm s V o lts

110 230 140 0.2

100 212 180 0.3

90 194 240 0.4

80 176 310 0.5

70 158 420 0.6

60 140 580 0.9

50 122 810 1.1

40 104 1150 1.5

30 86 1660 1.8

20 68 2450 2.3

10 50 3700 2.8

0 32 5740 3.3

-10 14 9160 3.8

-20 -4 15000 4.2

-30 -22 25400 4.5

Temperature (C)

Ohms

Volts

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

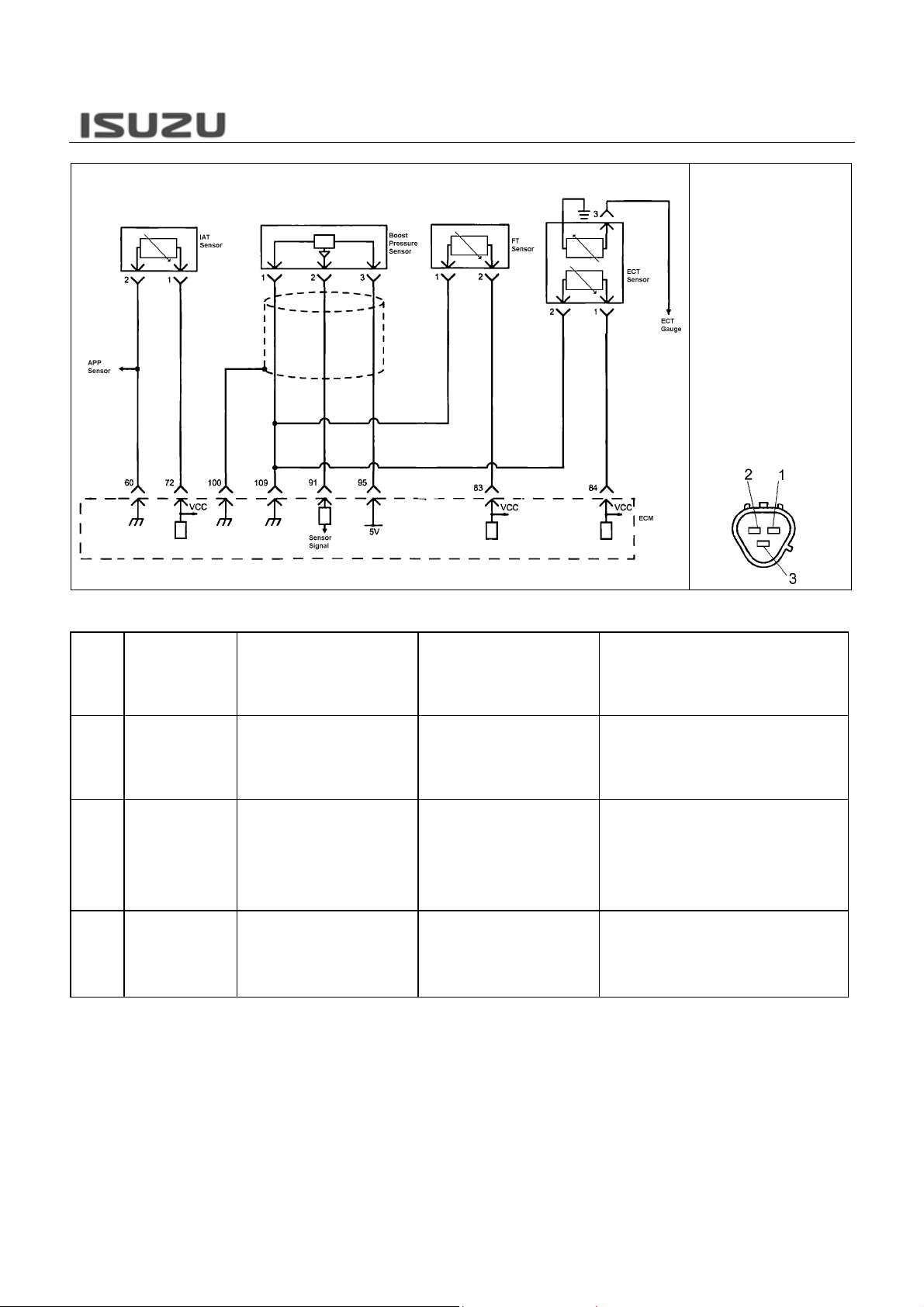

The fuel temperature (FT) sensor is installed to the

supply pump. It is a variable resistor. The FT senso

measures the temperature of the fuel. The engine

control module (ECM) supplies 5volts to the FT senso

signal circuit and a ground for the FT sensor low

reference circuit. When the FT sensor is cold, the

sensor resistance is high. When the air temperature

increases, the sensor resistance decreases. With high

sensor resistance, the ECM detects a high voltage on

the FT sensor signal circuit. With lower senso

resistance, the ECM det ects a lower voltage on the FT

sensor signal circuit. The ECM uses to this value to

calculate a fuel injection volume, injection timing and

EGR control.

1.

Fuel Temperature (FT) Sensor

2. Suction Control Valve (SCV)

The characteristic of the FT sensor is displayed in the

graph and table. Calculated coolant temper ature can be

found on the Tech 2 by unit “°C” or “°F “. The output

voltage also can be found on the Tech 2.

Notice!

In data display “°C” or “°F” will be fixed to a default

value when DTC is set relating to the FT sensor.

To diagnose this DTC, observe the “Volts” in the

Output (Volts)

data display.

Page 27

N*R 4HK1-TC Engine-26

Related DTC

FT Sensor

Connector Face

DTC Name On Scan

DTC

P0182 Fuel Temperature

P0183 Fuel Temperature

Tool

Sensor Circuit Low

Voltage

Sensor Circuit High

Voltage

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P1630 and P1634 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

DTCs P1630 and P1634 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The engine run time is longer than

3 minutes.

The ECM detects that the FT

sensor signal voltage is less than

0.1 volts for 5 seconds.

The ECM detects that the FT

sensor signal voltage is more than

4.8 votls for 5 seconds.

Sensor signal circuit is short to ground or short to

the low reference circuit.

Faulty FT sensor.

Faulty ECM.

Sensor signal circuit is open circuit, high

resistance, short to any 5V or 12V reference

circuit, short to battery or ignition voltage circuit.

Sensor low reference circuit is open circuit or

high resistance.

Poor harness connector connection.

Faulty FT Sensor.

Faulty ECM.

Page 28

r

N*R 4HK1-TC Engine-27

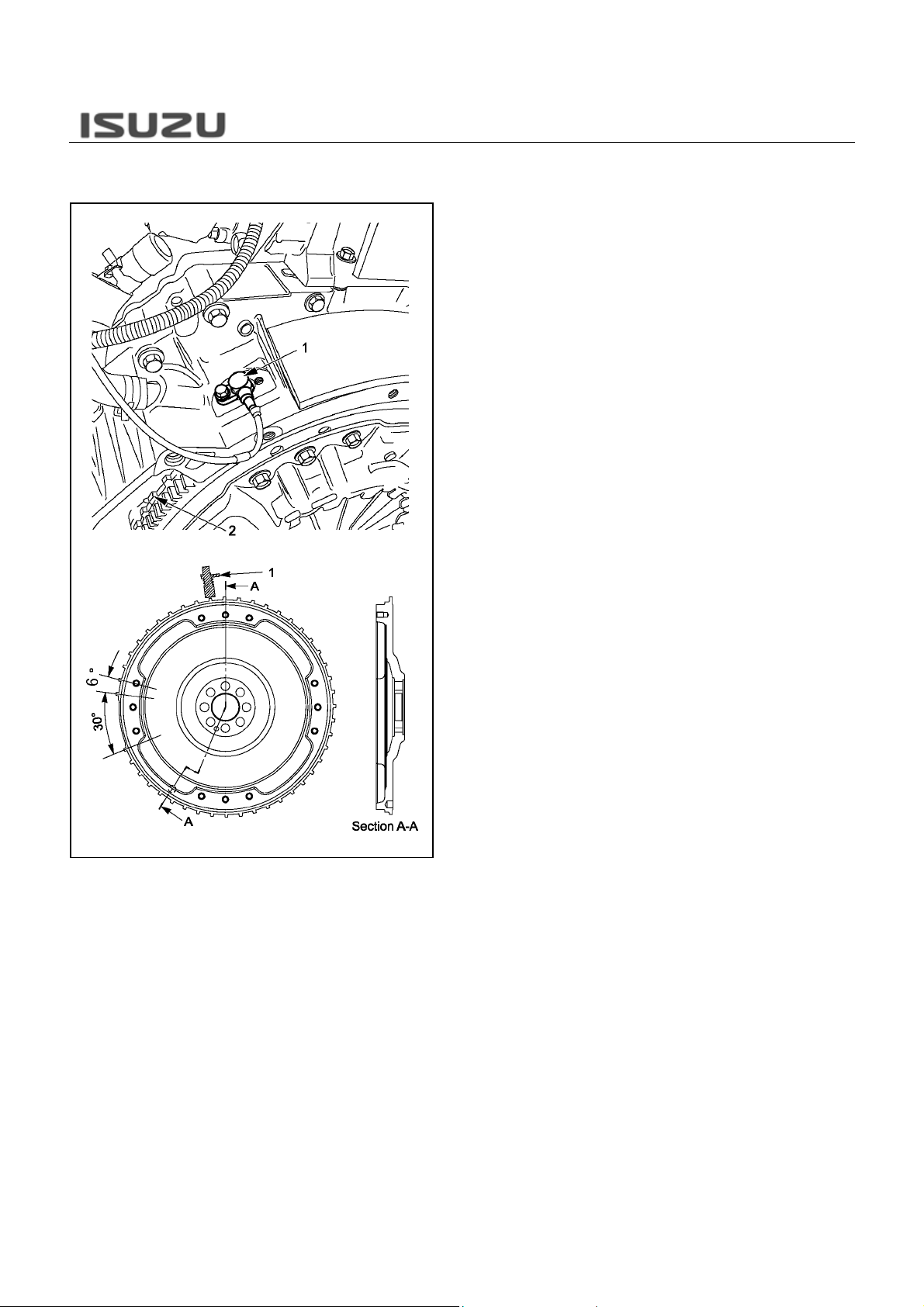

CRANKSHAFT POSITION (CKP) SENSOR

& CAMSHAFT POSITION (CMP) SENSOR

The crankshaft position (CKP) sensor is located on top

of the flywheel housing. There are 56 notches spaced

6deg. apart and a 30deg. section that is uncut. This

uncut portion allows for the detecti on of top dead cente

(TDC). The CKP sensor is a magnet coil type sensor,

which generates an AC signal voltage based on the

crankshaft rotational speed. If th e CKP sensor fails, the

camshaft position (CMP) sensor signals will substitute

for the CKP sensor signal backup.

1. Crankshaft Position (CKP) Sensor

2. Sensor Wheel

Page 29

r

r

N*R 4HK1-TC Engine-28

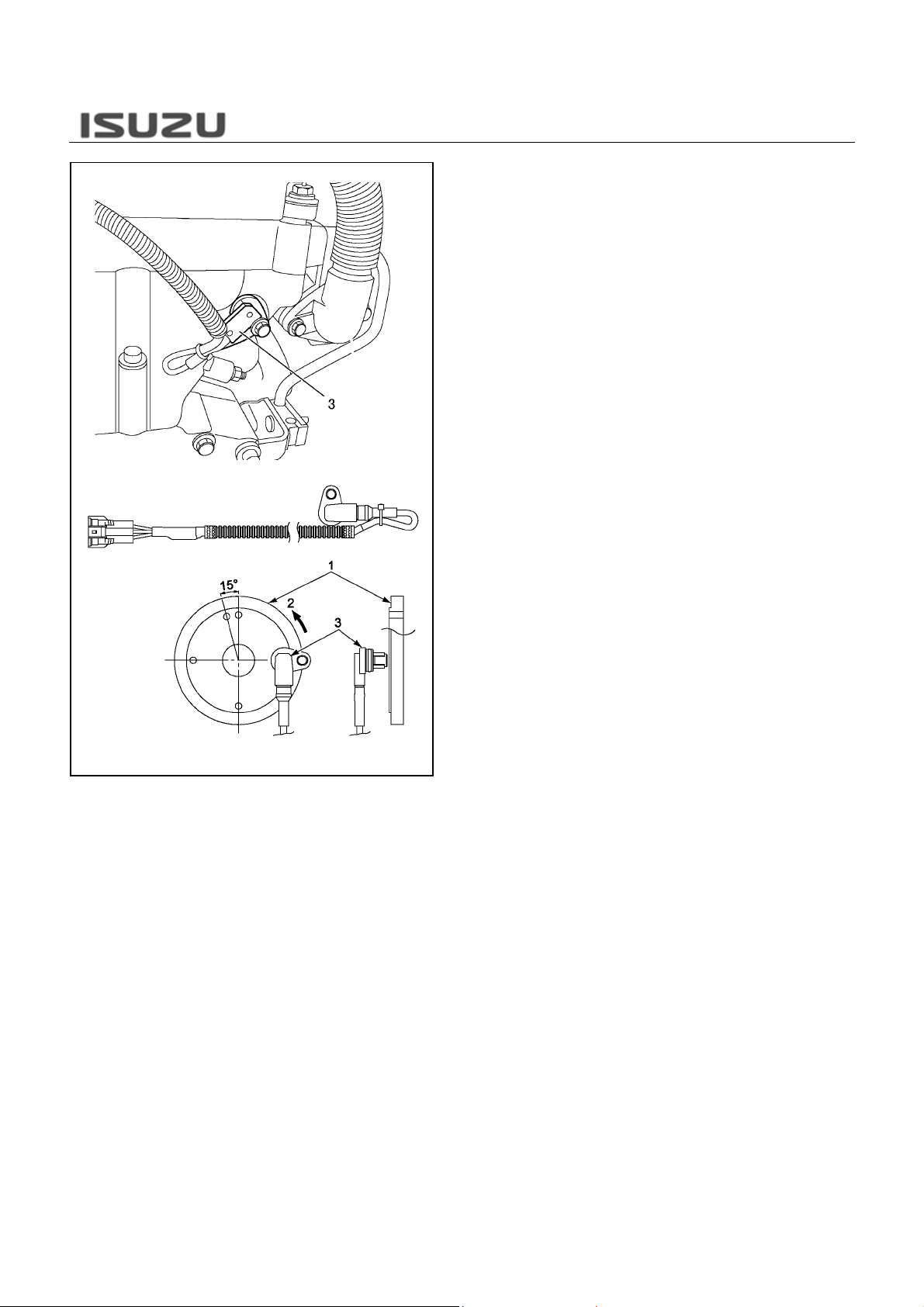

The camshaft position (CMP) s ensor is installed on the

cylinder head at the rear of the camshaft. The CMP

sensor detects a total five through holes, four reference

holes arranged equally every 90deg. space and one

reference hole on the camshaft gea r flan ge surf ac e, and

sends signals to the engine control module (ECM).

Receiving these signals, the ECM determines cylinde

#1 compression top dead center (TDC). If the CMP

sensor fails, the crankshaft position (CKP) senso

signals will NOT substitute for the CMP sensor signal

backup. Engine cranks but does not start.

1. Camshaft Gear

2. Gear Rotating Direction

3. Camshaft Position (CMP) Sensor

Page 30

r

6deg.CA

CH1

0V

CH2

0V

No.1 TDC No.3 TDC

30deg.CA

90deg.CA No.1 TDC 30deg.CA

90deg.CA

The relationship of CKP sensor and CMP sensor is

displayed on the above picture. The ECM detects 112

CKP sensor pulses (56 x 2) and 5 CMP se nsor pulses

per 2 crankshaft rotations (720 deg.CA). Both senso

wheels are mechanically bit with each other. Theref ore,

the relationship of each pulse is always constant. The

injection timing suitable for the vehicle conditions is

controlled based on the inputs from respecti ve se nso rs.

N*R 4HK1-TC Engine-29

90deg.CA

Page 31

N*R 4HK1-TC Engine-30

CKP Sensor

Connector Face

CMP Sensor

Connector Face

Related DTC

DTC Name On Scan

DTC

Tool

P0219 Engine Overspeed -

P0335 Crankshaft Position

(CKP) Sensor No

Pulse

P0336 Crankshaft Position

(CKP) Sensor Extra or

Missing

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P0336, P0340, P0341 and

P1345 are not set.

The ignition switch is ON.

The CMP sensor signal pulse is

detected.

DTCs P0335, P0340, P0341 and

P1345 are not set.

The ignition switch is ON.

The CMP sensor signal pulse is

detected.

Engine speed is higher than 4300

RPM for 1 second.

The ECM detects that the CKP

sensor pulses are not generated.

The ECM detects extra or missing

CKP sensor pulses

Engine over-running.

Faulty CKP sensor.

Faulty ECM.

Electrical interference.

Magnetic interference.

Sensor high circuit is open circuit, short to

ground or short to battery, short to ignition

voltage or short to any 5V reference.

Sensor low circuit is open circuit, or short to

battery, short to ignition voltage or short to any

5V reference.

Sensor shield wire open circuit, short to battery,

short to ignition voltage or short to any 5V

reference.

Sensor harness connector is poor connection.

Faulty CKP sensor.

Electrical interference.

Magnetic interference.

Faulty ECM.

Sensor installation is poor condition.

Faulty sensor wheel.

Sensor high circuit is intermittently open circuit or

poor connection.

Sensor low circuit is intermittently open circuit or

poor connection.

Faulty CKP sensor.

Electrical interference.

Magnetic interference.

Sensor installation is poor condition.

Faulty sensor wheel.

Page 32

N*R 4HK1-TC Engine-31

P0340 Camshaft Position

(CMP) Sensor No

Pulse

P0341 Camshaft Position

(CMP) Sensor Pulse

Faulty or Invalid

P1345 Crankshaft Position &

Camshaft Position

Signal Off Phase

DTCs P0335, P0336, P0341 and

P1345 are not set.

The ignition switch is ON.

The CKP sensor signal pulse is

detected.

DTCs P0335, P0336, P0340 and

P1345 are not set.

The ignition switch is ON.

The CKP sensor signal pulse is

detected.

DTCs P0335, P0336, P0340 and

P0341 are not set.

The ignition switch is ON.

The CKP sensor signal pulse is

detected.

The CMP sensor signal pulse is

detected.

The ECM detects that the CMP

sensor pulses are not generated.

The ECM detects extra or missing

CMP sensor pulses

The ECM detects that the CKP

sensor signals and CMP sensor

signals are out of synchronization

Sensor 12V reference circuit is open circuit, short

to ground circuit.

Sensor signal circuit is open circuit, short to

battery, short to ignition voltage or short to any

5V reference.

Sensor shield wire open circuit or short to battery

or ignition voltage

Sensor harness connector is poor connection.

Faulty CMP sensor.

Electrical interference.

Magnetic interference.

Faulty ECM.

Sensor installation is poor condition.

Faulty sensor wheel.

Sensor 12V feed circuit is intermittently open

circuit or poor connection.

Sensor signal circuit is intermittently open circuit

or poor connection.

Sensor shield wire is intermittently open circuit or

poor connection.

Faulty CMP sensor.

Electrical interference.

Magnetic interference.

Sensor installation is poor condition.

Faulty sensor wheel.

Incorrect engine mechanical timing.

Page 33

N*R 4HK1-TC Engine-32

VEHICLE SPEED SENSOR (VSS)

0V

The vehicle speed sensor (VSS) is a magnet rotated by

the transmission output shaft. The VS sensor uses a

hall effect element. It interacts with the magnetic field

created by the rotating magnet and outputs square

wave pulse signal. The 24 volts operating supply form

the “Meter” (15A) fuse. The engine control module

(ECM) calculates the vehicle spee d by the V S sensor.

Calculated signal can be found on the Tech 2 as vehicle

speed unit “km/h” or “MPH”. The reference waveform of

the VS sensor is displayed on the left.

Page 34

N*R 4HK1-TC Engine-33

Related DTC

VS Sensor

Connector Face

DTC Name On Scan

DTC

P0500 Vehicle Speed Sensor

P0501 Vehicle Speed Sensor

Tool

(VSS) Circuit No Pulse

(VSS) Performance

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The engine speed is more than

2000 RPM.

The commanded fuel supply is

OFF.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The ECM detects that the VSS

signals are not generated for 5

seconds.

The ECM detects that the VSS

signals are changed larger than a

predetermined speed.

Sensor +12V circuit is open circuit.

Sensor signal circuit is open circuit, short to

ground or short to battery or ignition voltage.

Sensor low reference circuit is open circuit.

Sensor harness connector is poor connection.

Sensor internal circuit is open circuit or short

circuit.

Electrical interference.

ECM malfunction.

Sensor +12V circuit is open circuit.

Sensor signal circuit is open circuit, short to

ground or short to battery or ignition voltage.

Sensor low reference circuit is open circuit.

Sensor harness connector is poor connection.

Sensor internal circuit is open circuit or short

circuit.

Electrical interference.

ECM malfunction.

Page 35

r

BAROMETRIC PRESSURE (BARO)

SENSOR

The barometric pressure (BARO) sensor is located

under the instrument panel cluster near the clutch p edal

bracket. But, it is not installed into the manifold. Just

placed on via a bracket. The BARO sensor is a

transducer that varies voltage according to changes

surrounding barometric pressure. The BARO senso

provides a signal to the engine control module (ECM)

on the BARO sensor signal circuit, which is relative to

the pressure changes. The sens or should detect a low

signal voltage at low barometric pr essure, such as high

altitude area. The ECM should detect high signal

voltage at high barometric pressure, s uch as sea level

area. The ECM uses this voltage signa l to calibrate the

fuel injection volume and injection timing for altitude

compensation.

3.0

BARO Sensor Characteristic -Reference-

The characteristic of the BARO sensor is displayed in

the graph and table. Calculated barometric pressure

can be found on the Tech 2 by unit “kpa”. The output

2.5

voltage also can be found on the Tech 2.

2.0

1.5

1.0

Output (Volts)

0.5

0.0

50 60 70 80 90 100 110

Barometric Pres s u re (k pa )

kpa psi Volts

50 7.3 1.0

60 8.7 1.3

70 10.2 1.6

80 11.6 1.8

90 13.1 2.1

100 14.5 2.3

110 16.0 2.6

N*R 4HK1-TC Engine-34

Notice!

In data display “kpa” will be fixed to the default

value when DTC is set relating to the BARO

sensor. To diagnose this DTC, observe the “Volts”

in the data display.

Page 36

N*R 4HK1-TC Engine-35

Related DTC

BARO Sensor

Connector Face

DTC Name On Scan

DTC

P0107 Barometric Pressure

P0108 Barometric Pressure

Tool

(BARO) Sensor Circuit

Low Voltage

(BARO) Sensor Circuit

High Voltage

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P1630 and P1635 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

DTCs P1630 and P1635 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The ECM detects that the BARO

sensor signal voltage is less than

0.5 volts for 5 seconds.

The ECM detects that the BARO

sensor signal voltage is more than

4.9 volts for 5 seconds.

Sensor 5V reference circuit is open circuit, high

resistance.

Sensor 5V reference circuit is short to ground or

short to the low reference circuit. (P1632 may

also set.)

Sensor signal circuit is open circuit, high

resistance, short to ground or short to the low

reference circuit.

Poor harness connector connection.

Faulty BARO sensor.

Faulty ECM.

Sensor 5V reference circuit is short to battery,

ignition voltage circuit or short to any 12V

reference circuit. (P1632 may also set.)

Sensor signal circuit is short to any 5V or 12V

reference circuit, short to battery or ignition

voltage circuit.

Sensor low reference circuit is open circuit or

high resistance.

Poor harness connector connection.

Faulty BARO sensor.

Faulty ECM.

Page 37

r

N*R 4HK1-TC Engine-36

BOOST PRESSURE SENSOR

Boost Pressure Sensor Characteristic -Reference-

5.0

4.5

4.0

3.5

3.0

2.5

2.0

Output (Volts)

1.5

1.0

0.5

0.0

60 80 100 120 140 160 180 200 220 240

kpa psi Volts

60 8.7 0.4

80 11.6 0.7

100 14.5 1.0

110 16.0 1.2

150 21.8 1.8

200 29.0 2.5

250 36.3 3.3

Boost Pressure (kpa)

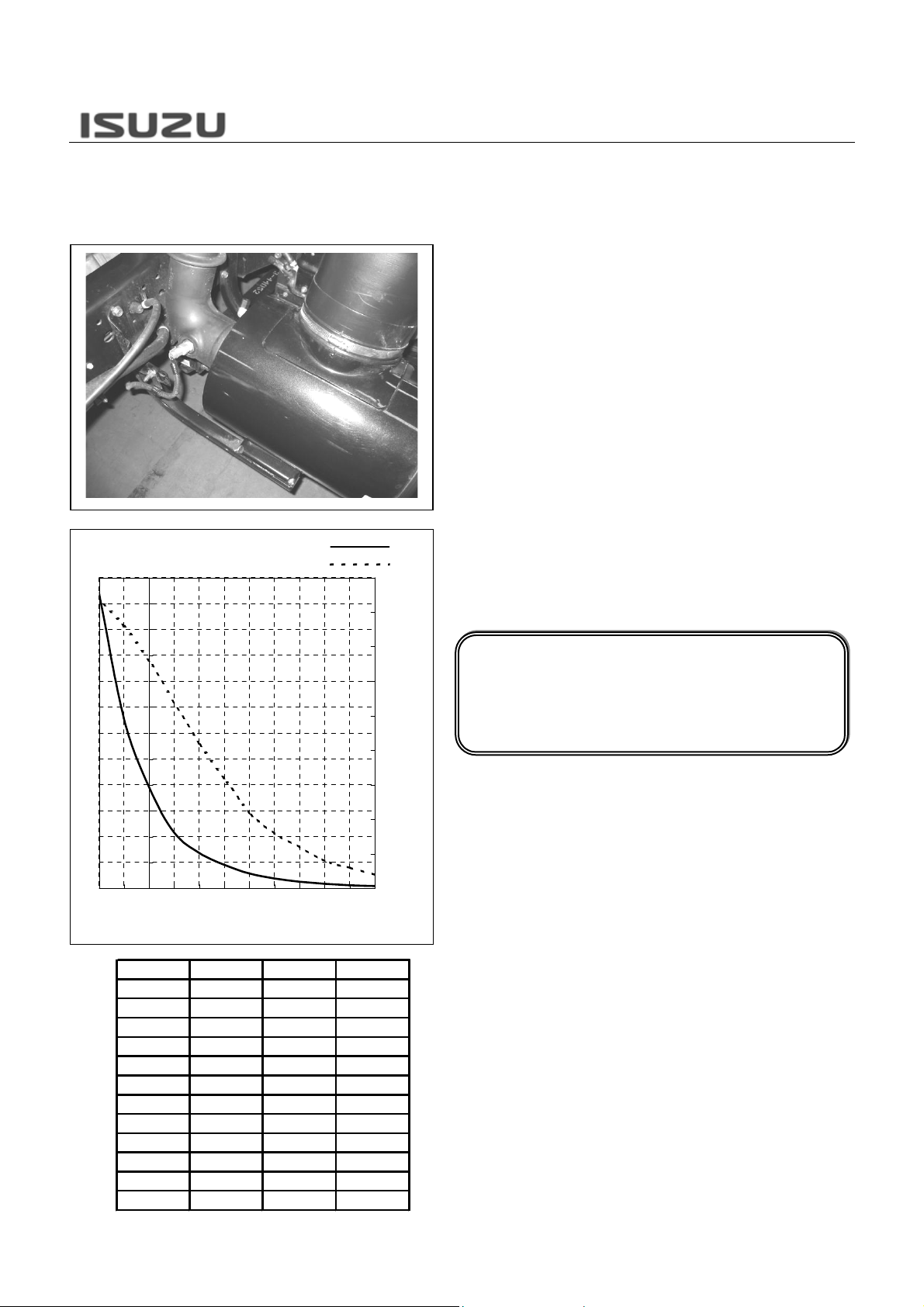

The boost pressure sensor is locate d in the air indu ction

tubing. The boost pressure sensor is a t ransducer that

varies voltage according to changes in the air pressure

inside the air tubing. The boost pressure senso

provides a signal to the engine control module (ECM)

on the boost pressure sensor signal circuit, which is

relative to the pressure changes in the manifold. The

sensor should detect a low signal voltage at low b oost

pressure, such as low engine load. The ECM should

detect high signal voltage at a high boost pressure,

such as high engine load. The ECM uses to this value

to calculate a fuel injection volume.

1. Boost Pressure Sensor

2. Retaining Plate

3. Fixing Bolt

4. Intake Pipe

The characteristic of the boost pressure sensor is

displayed in the graph and table. Calculated boost

pressure can be found on t he Tech 2 by unit “kpa” . The

output voltage also can be found on th e Tech 2.

Notice!

In data display “kpa” will be fixed to a default value

when DTC is set relating to the boost pressure

sensor. To diagnose this DTC, observe the “Volts”

in the data display.

Page 38

N*R 4HK1-TC Engine-37

Related DTC

Boost Pressure Sensor

Connector Face

DTC Name On Scan

DTC

P0234 Turbocharger Engine

P0236 Turbocharger Engine

Tool

Overboost

Underboost

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P0237, P0238, P1630 and

P1634 are not set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The engine is running.

The fuel injection quantity is more

than a calculated value.

DTCs P0107, P0108, P0237,

P0238, P1630, P1634 and P1635

are not set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The engine is running.

The fuel injection quantity is more

than a calculated value.

The ECM detects that the boost

pressure is more than 228 kPa (33

psi) for 3 seconds.

The ECM detects that the boost

pressure is less than 78 kPa (11

psi) for 20 seconds when the

engine speed is less than 900

RPM.

OR

The ECM detects that the boost

pressure is less than 82 to 151

kPa (12 to 22 psi) for 20 seconds

when the engine speed is

between 1200 and 3000 RPM.

When the barometric pressure

(BARO) is lower than 100 kPa, the

BARO is subtracted from 100 kPa

(100 kPa – BARO) is added to the

thresholds.

Boost pressure sensor low reference circuit is

intermittently open circuit or high resistance.

Faulty boost pressure sensor.

Faulty turbocharger waste gate valve.

Restricted intake or collapsed hose between the

intake throttle and sensor.

Intake throttle plate sticking in the closed

position.

Faulty BARO sensor.

Faulty ECM.

Boost pressure sensor 5V reference circuit is

intermittently open circuit or high resistance.

Boost pressure sensor signal circuit is

intermittently open circuit or high resistance.

Faulty boost pressure sensor.

Air leakage.

Intake duct is disconnected.

Intake system is obstructed.

Faulty turbocharger waste gate valve.

Faulty turbocharger. (Shaft stick)

Faulty BARO sensor.

Faulty ECM.

Page 39

N*R 4HK1-TC Engine-38

P0237 Turbocharger Boost

Sensor Circuit Low

Voltage

P0238 Turbocharger Boost

Sensor Circuit High

Voltage

DTCs P1630 and P1634 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

DTCs P1630 and P1634 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The ECM detects that the boost

pressure sensor signal voltage is

less than 0.1 volts for 3 seconds.

The ECM detects that the boost

pressure sensor signal voltage is

more than 4.9 volts for 3 seconds.

Sensor 5V reference circuit is open circuit, high

resistance.

Sensor 5V reference circuit is short to ground or

short to the low reference circuit. (P1634 may

also set.)

Sensor signal circuit is open circuit, high

resistance, short to ground or short to the low

reference circuit.

Poor harness connector connection.

Faulty boost pressure sensor.

Faulty ECM.

Sensor 5V reference circuit is short to battery,

ignition voltage circuit or short to any 12V

reference circuit. (P1634 may also set.)

Sensor signal circuit is short to any 5V or 12V

reference circuit, short to battery or ignition

voltage circuit.

Sensor low reference circuit is open circuit or

high resistance.

Poor harness connector connection.

Faulty boost pressure sensor.

Faulty ECM.

Page 40

r

f

N*R 4HK1-TC Engine-39

ACCELERATOR PEDAL POSITION (APP)

SENSOR

LHD

RHD

4.5

4

3.5

3

2.5

2

Output (Volts)

1.5

1

APP Sensor Characteristic -Reference-

APP2

APP1

The accelerator pedal position (AP P) s ensor is mo unted

on the accelerator pedal assemb ly. The sensor is made

up of two individual sensors within one housing. The

engine control module (ECM) uses the APP sensors to

determine the amount of acceleration or deceleration

desired by the person driving the vehicle via the fuel

injection control.

The characteristic of the APP sensor 1 and 2 is

displayed in the graph and table. Calculated accelerato

pedal angle can be found on the Tech 2 by unit “%”.

Also, output voltage can be f oun d on the Tech 2.

The ECM monitors both sensor signals. If out o

correlation between two sensors such as skewed

sensor, P1271 will set.

Notice!

If one of the APP sensor is failed (DTC set), the

ECM will use the remaining another APP sensors

to calculate pedal angle. Indicated APP angle will

being 0 –100%.

0.5

0

0 102030405060708090100

Accelerator Pedal Position (%)

Page 41

N*R 4HK1-TC Engine-40

Related DTC

APP Sensor

Connector Face

DTC Name On Scan

DTC

P1271 Accelerator Pedal

P1277 Accelerator Pedal

Tool

Position (APP) Sensor

1-2 Correlation

Position (APP) Sensor

1 Circuit Low Voltage

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P1630, P1631 and P1632

are not set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

DTCs P1630 and P1631 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The ECM detects that the APP

sensor 1 and 2 are more than

45% out of range of each other.

The ECM detects that the APP

sensor 1 signal voltage is less

than 0.2 volts.

APP sensor 1 5V reference circuit is high

resistance.

APP sensor 1 signal circuit is high resistance.

APP sensor 1 low reference circuit is high

resistance.

APP sensor 2 5V reference circuit is high

resistance.

APP sensor 2 signal circuit is high resistance.

APP sensor 2 low reference circuit is high

resistance.

Poor harness connector connection.

Electrical interference.

Faulty APP sensor 1 or 2.

Faulty ECM.

Notice: APP sensor 1 or 2 is internal to APP sensor

assembly.

Sensor 5V reference circuit is open circuit, hig h

resistance.

Sensor 5V reference circuit is short to ground or

short to the low reference circuit. (P1631 may

also set.)

Sensor signal circuit is open circuit, high res ist ance,

short to ground or short to the low reference

circuit.

Poor harness connector connection.

Faulty APP sensor 1.

Faulty ECM.

Notice: APP sensor 1 is internal to APP sensor

assembly.

Page 42

N*R 4HK1-TC Engine-41

P1278 Accelerator Pedal

Position (APP) Sensor

1 Circuit High Voltage

P1282 Accelerator Pedal

Position (APP) Sensor

2 Circuit Low Voltage

P1283 Accelerator Pedal

Position (APP) Sensor

2 Circuit High Voltage

DTCs P1630 and P1631 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

DTCs P1630 and P1632 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

DTCs P1630 and P1632 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The ECM detects that the APP

sensor 1 signal voltage is more

than 4.9 volts.

The ECM detects that the APP

sensor 2 signal voltage is less

than 0.2 volts.

The ECM detects that the APP

sensor 2 signal voltage is more

than 4.9 volts.

Sensor 5V reference circuit is short to battery,

ignition voltage circuit or short to any 12V

reference circuit. (P1631 may also set.)

Sensor signal circuit is short to any 5V or 12V

reference circuit, short to battery or ignition

voltage circuit.

Sensor low reference circuit is open circuit or

high resistance.

Poor harness connector connection.

Faulty APP sensor 1.

Faulty ECM.

Notice: APP sensor 1 is internal to APP sensor

assembly.

Sensor 5V reference circuit is open circuit or high

resistance.

Sensor 5V reference circuit is short to ground or

short to the low reference circuit. (P1632 may

also set.)

Sensor signal circuit is short to ground or short to

the low reference circuit.

Poor harness connector connection.

Faulty APP sensor 2.

Faulty ECM.

Notice: APP sensor 2 is internal to APP sensor

assembly.

Sensor 5V reference circuit is short to battery,

ignition voltage circuit or short to any 12V

reference circuit. (P1635 may also set.)

Sensor signal circuit is open circuit, high

resistance, short to any 5V or 12V reference

circuit, short to battery or ignition voltage circuit.

Sensor low reference circuit is open circuit or

high resistance.

Poor harness connector connection.

Faulty APP sensor 2.

Faulty ECM.

Notice: APP sensor 2 is internal to APP sensor

assembly.

Page 43

e

N*R 4HK1-TC Engine-42

ENGINE IDLE UP CONTROL VOLUME

Characteristic of Idle Up Control Volume -Reference-

5

4.5

4

3.5

3

Output Voltage (V)

2.5

2

1.5

1

0.5

0

Full Counterclockwise

Rotatin g A n g le

Full C lockw is

The idle up volume controls the idle speed during warmup and it is installed in the driver’s side instrument

panel. This volume is active only when the gear position

is neutral position. When the shift lever is moved to

another position, the volume is canceled. The engine

control module (ECM) receives the idle up volume

signal form the idle up volume and controls the fuel

injection volume.

1. Idle Up Volume

The characteristic of the idle up volum e is displayed in

the graph.

Page 44

N*R 4HK1-TC Engine-43

Related DTC

Idle Up Sensor

Connector Face

DTC Name On Scan

DTC

P1225 Engine Idle Speed

Tool

Selector Sensor

Circuit

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P1630 and P1631 are not

set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The ECM detects that the idle up

control sensor signal voltage is

less than 0.1 volts for 3 seconds.

OR

The ECM detects that the idle up

control sensor signal voltage is

more than 4.9 volts for 3 seconds.

Sensor 5V reference circuit is open circuit, high

resistance.

Sensor 5V reference circuit is short to ground or

short to the low reference circuit. (P1635 may

also set.)

Sensor 5V reference circuit is short to battery,

ignition voltage circuit or short to any 12V

reference circuit. (P1631 may also set.)

Sensor signal circuit is open circuit, high

resistance, short to ground or short to the low

reference circuit.

Sensor signal circuit is short to any 5V or 12V

reference circuit, short to battery or ignition

voltage circuit.

Poor harness connector connection.

Faulty idle up control sensor.

Faulty ECM.

Page 45

FUEL SYSTEM

N*R 4HK1-TC Engine-44

FEATURE OF THE COMMON RAIL SYSTEM

1. Fuel Tank

2. Fuel Filter

3. Fuel Supply Pump

4. Fuel Rail

5. Pressure Limiter

6. Flow Damper

7. Fuel Rail Pressure Sensor

8. Injector

9. Engine Control Module (ECM)

10. Other Control Module

11. Camshaft Position (CKP)

Sensor

12. Crankshaft Position (CKP)

Sensor

13. Various Sensor Inputs

The common rail system uses a type of accumulator

chamber called the fuel rail to store pressurized fuel,

and injectors that contain electronically controlled

solenoid valves to spray the pressurized fuel in the

combustion chambers. The injection system (injection

pressure, injection rate, and injection timing) is

controlled by the engine control module (ECM), and

therefore the common rail system can be controlled

independently, free from the influence of engine speed

and load. This ensures a stable injection press ure at all

time, particularly in the low engine speed range, so that

black smoke specific to diesel e ngines generat ed during

vehicle starting or acceleration can be reduced

dramatically. As a result, exhaust gas emissions are

clear and reduced, and higher output is achieved.

1. High Pressure Control

Enables high pressure injection from low engine

speed range.

Optimizes control to minimize particulate matter and

NOx emissions.

2. Injection Timing Control

Enables finely tuned optimized control in accordance

with running conditions.

3. Injection Rate Control

Pilot injection control that performs a small amount of

injection before main injection.

Page 46

A

N*R 4HK1-TC Engine-45

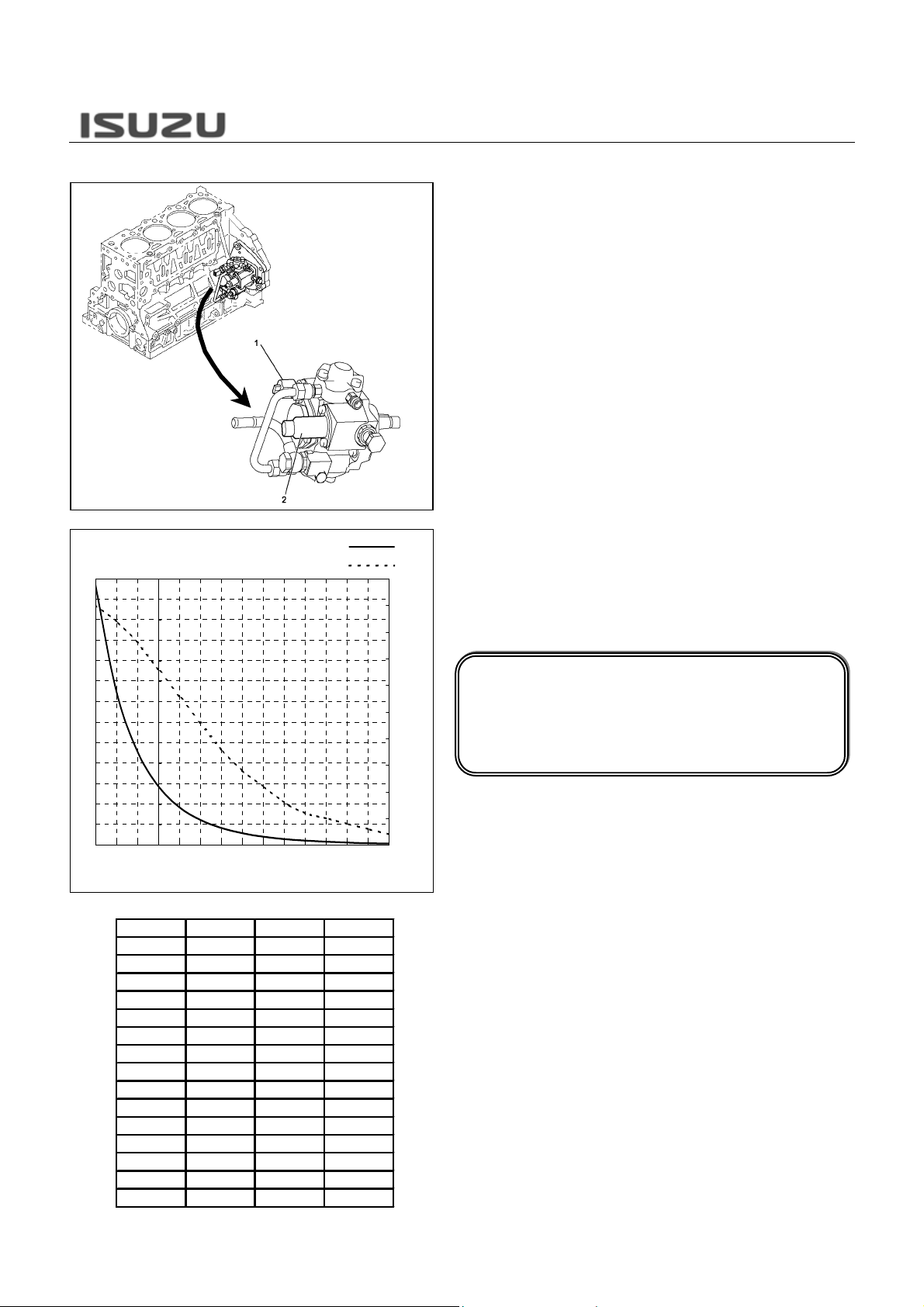

FUEL SUPPLY PUMP

Along with the employment of the common rail type

electronic control fuel injection system, the injection

pump was disused and a plunger type supply pump is

provided to supply high pressure fuel to the fuel rail. The

supply pump is installed at the position where

conventionally the injection pump was installed, and it is

driven 1:1 to the engine. The feed pump (trochoid typ e)

is built in the supply pump to feed fuel from t he fuel tank

to the plunger chamber.

lso, the supply pump is

attached with a suction control valve (SCV) to control

high pressure fuel supply to the fuel rail and a fuel

temperature (FT) sensor to detec t fuel temperature.

1. Fuel Temperature (FT) Sensor

2. Suction Control Valve (SCV)

3. Fuel Supply Pump

4. Fuel Rail

Notice!

In order to make the fuel supply pump

characteristic r elearn into the ECM, let the engine

idle until warm-up after ECM or supply pump

replacement.

Type HP3

Gear Ratio to Crankshaft 1:1

Rotational Direction

Feed Pump Trochoid type

Plunger Diameter x Number 8.5mm x 2

Plunger Lift 5.6mm

SCV Type Normally Open

Counterclockwise as

viewed from drive side

1. Driveshaft

2. Ring Cam

3. Pump Body

4. Plunger

5. Filter

6. Regulating Valve

7. Feed Pump

8. Suction Control Valve (SCV)

9. Fuel Temperature (FT) Sensor

Page 47

r

r

N*R 4HK1-TC Engine-46

The fuel is fed under pressure to th e plunger chambe

by the feed pump built in the supply pump, and furth er it

1. Fuel Tank

2. Fuel Filter

3. Suction

4. Fuel Inlet

5. Feed Pump

6. Regulating Valve

7. Suction Control Valve (SCV)

8. Return Spring

9. Plunger

10. Suction Valve

11. Delivery Valve

12. Fuel Overflow

13. Return

14. Fuel Rail

15. Injector

16. Driveshaft

17. Suction Pressure

18. Feed Pressure

19. High Pressure

Return Pressure

20.

is fed under high pressure to the fuel rail by two

plungers driven by the camshaft t herein. Operating the

SCV based on the signals from the engine control

module (ECM) controls the quantity and timing of fuel

supply to the fuel rail. Since this type of pump adjusts

the fuel amount at low pressure side, and it c an delive

required high pressure and is efficient .

Page 48

l

l

N*R 4HK1-TC Engine-47

Operation of the Fuel Feed Pump

1. From Fuel Tank

2. Intake Port

3. To Pump Chamber

4. Discharge Port

5. Inner Rotor

6. Outer Rotor

7. Fuel Quantity Decrease

8. Fuel Quantity Increase

9. Fuel Quantity Decrease (Fue

Discharge)

10. Fuel Quantity Increase (Fue

Intake)

The trochoid type feed pump, which is integrated in the

fuel supply pump, draws fuel from the fuel tank and

feeds it to the two plungers via the filt er and SCV. The

feed pump is driven by the drive shaft. With the rotation

of the inner rotor, the feed pump draws fuel from its

suction port and pumps it out through the discharge

port. This is done in accordance with the space that

increases and decreases with the movement of the

outer and inner rotors.

1. Ring Cam

2. Plunger A

3. Plunger B

4. Feed Pump

Page 49

f

r

N*R 4HK1-TC Engine-48

Operation of the Fuel Supply Pump

1. Suction Control Valve (SCV)

2. Suction Valve

3. Delivery Valve

4. Eccentric Cam

5. Ring Cam

6. Plunger A Top Dead Center

(TDC) at Compression Stroke

7. Plunger B Bottom Dead

Center (BDC) at Intake Stroke

8. Plunger A Beginning of

Compression Stroke

9. Plunger B Beginning of

Compression Stroke

10. Plunger A Bottom Dead

Center (BDC) at Intake Stroke

11. Plunger B Top Dead Center

(TDC) at Compression Stroke

12. Plunger A Beginning of

Compression Stroke

13. Plunger B Beginning of Intake

Stroke

The ring cam pushes the plunger “A” in upward direction

as the eccentric cam rotates as shown above picture.

The plunger “B” is pulled in the opposite direction o

plunger “A” by a spring force. As a result, the plunge

“B” sucks fuel while the plunger “A” feeds fuel under

pressure to the fuel rail.

Page 50

A

N*R 4HK1-TC Engine-49

Operation of Suction Control Valve (SCV)

2

1

A

linear solenoid type valve has been adopted. The

ECM controls the 250Hz duty ratio (the length of time

that the current is applied to the SCV), in order to

control the quantity of fuel that is su pplied to the highpressure plunger. Because only t he quantity of fuel tha t

is required for achieving the target rail press ure is drawn

in, the drive load of the supply pumps decreases

When current flows to the SCV, variable electromotive

force is created in accordance with the duty ratio,

moving the armature to the left side. The armature

moves the cylinder to the left side, changing the

opening of the fuel passage and thus re gulating the fue l

quantity. With the SCV OFF, the return spring c ontrac ts,

completely opening the fuel passage and supplying fuel

to the plungers. (Full quantity intake and full quantity

discharge) When the SCV is ON, the force of the return

spring moves the cylinder to the right, closing the fuel

passage (normally opened).

SCV control feedback current ca n be found on the Te ch

2 data display by unit “mA”. SCV On duty ratio also can

be found on the Tech 2 data display by “%”.

1. Valve

2. Coil

A. Small Duty Ratio (Large Suction Quantity)

B. Large Duty Ratio (Small Suction Quantity)

Notice!

DO NOT attempt engine cranking or s tarting with

the SCV harness connector or ECM harness

connector disconnect. The pressure limiter valve

will be opened since the SCV is normal open and

full amount of fuel is supplied to the fuel rail.

Therefore, unless a diagnostic procedure instructs

B

you, DO NOT disconnect.

Notice!

If the SCV control low circuit between the ECM

and SCV are short to ground, DTC may not

stored. This condition will case engine stall, hard

start or engine cranks but may not start. But SCV

feedback current will be dropped approximately

300 - 500mA.

Page 51

N*R 4HK1-TC Engine-50

1. Feed Pump

2. Suction Control Valve (SCV)

3. Cylinder

4. Large Valve Opening (Maximum Intake Quantity)

5. Small Valve Opening (Minimum Intake Quantity)

Page 52

N*R 4HK1-TC Engine-51

Related DTC

Suction Control Valve (SCV)

Connector Face

DTC Name On Scan

DTC

P0090 Fuel Pressure

Regulator Solenoid

Control Circuit Invalid

(Suction Control Valve

Solenoid Circuit

Invalid)

Tool

Condition for Running the DTC Condition for Setting the DTC Suspected Cause

DTCs P1630 is not set.

The ignition switch is ON.

The ignition voltage is more than

18 volts.

The SCV commanded duty cycle

is between 10 – 90 %.

The ECM detects that the SCV

feedback current is less than 50

mA.

OR

The ECM detects that the SCV

feedback current is more than

2400 mA

OR

The ECM detects that the

difference of SCV desired current

and feedback current is more than

1000 mA .

SCV control high circuit is open circuit or high

resistance.

SCV control high circuit is high resistance, short to

ground, short to battery or ignition voltage.

SCV control low circuit is open circuit, high

resistance or short to ground.

SCV control low circuit is short to battery or ignition

voltage.

Faulty SCV.

Faulty ECM.

Notice: SCV is internal to fuel supply pump assembly.

Page 53

A

A

r

N*R 4HK1-TC Engine-52

FUEL RAIL (COMMON RAIL)

Operation of the Pressure Limiter Valve

long with the employment of a common rail type

electronic control fuel injection system, the fuel rail is

provided to store high pressure fuel between supply

pump and injectors.

pressure sensor and a pressure

limiter are installed on the fuel rail. The pressure senso

detects the fuel pressur e inside the fuel rail and sends

its signal to the ECM. Based on this signal, the ECM

controls the fuel pressure inside the fuel rail via the

suction control valve of the supply pump. The pres sure

limiter opens the valve mechanically to relieve the

pressure when the fuel pressure inside the fuel rail

increases extremely.

1. Fuel Rail Bracket

2. Fuel Rail

3. Flow Damper

4. Pressure Limiter

5. Fuel Rail Pressure Sensor

6. High Pressure Fuel Inlet

7. To Fuel Tank

8. To Injectors

The pressure limiter valve relieves pressur e by opening

the valve (2) if abnormally high pressure is generated.

The valve (2) opens when pressure in rail reaches

approximately 200MPa (29000psi), and close when

pressure falls to approximately 50MPa (7250psi). Fuel

leaked by the pressure limiter valve re-turns to the fuel

tank through the return line.

1. From Fuel Rail

2. Valve

3. Valve Body

4. Valve Guide

5. Spring

6. Housing

7. To Fuel Return Pipe

Notice!

If the pressure limiter valve is operated many

times, opening pressure has fallen and it may

cause fuel system DTCs set.

Page 54

r

r

N*R 4HK1-TC Engine-53

Operation of the Flow Damper

The flow dampers are installed at the outle t of fuel rail to

damp a pulsation of fuel pressure inside the fuel rail o

to cut off the fuel supply when the fuel leaks in the

downstream of flow damper. The fuel is supplied to the

injectors through an orifice of the piston. Th e pressure

pulsation occurring in the fuel rail is damped by a

resistive force of the return spring (5) and a passing

resistance of the orifice (2), wherein the pist on (4) a cts

as a damper. Also, the leading end of pist on (4) closes

an fuel supply port to cut off the fuel supply, if the fuel

leak occurs in the injection p ipe or injectors, and the fuel

pressure on the downstream side of flow dampe

supplied through an orifice (2) + resistive f orce of return

spring (5) do not balance with the fuel pressure applied

on the piston (4) surface prior to the orifice (2). The

piston (4) will return when the fuel pressure inside the

common rail less than 1.0MPa (145psi).

1. From Fuel Rail

2. Orifice

3. Slit

4. Piston

5. Return Spring

6. Housing

7. To Injector

Page 55

r

r

N*R 4HK1-TC Engine-54

FUEL RAIL PRESSURE (FRP) SENSOR

5.0

4.5

4.0

3.5

3.0

2.5

Output (Volts)

2.0

1.5

1.0

0.5

0.0

0 20 40 60 80 100 120 140 160 180 200 220

FRP Sensor Characteristic -Reference-

Fuel Rail Pressure (Mpa)

Mpa psi Volts

001.0

20 2900 1.3

40 5800 1.6

60 8700 2.0

80 11600 2.3

100 14500 2.6

120 17400 2.9

140 20310 3.2

160 23210 3.6

180 26110 3.9

200 29010 4.2

220 31910 4.5

The fuel rail pressure (FRP) sensor is installed to the

fuel rail and it detects the fuel pressure in the fuel rail,

converts the pressure into a voltage signal, and sends