Page 1

®

VT 275 V6 ENGINE

model year 2005

Page 2

FORWARD

This publication is intended to provide technicians and service personnel with an overview of technical features of the

International

service literature. Consult the latest SERVICE and DIAGNOSTIC manuals before conducting any service or repairs.

®

VT 275 Diesel Engine. The information contained in this publication will supplement information contained in available

Safety Information

s

BBaatttteerriiees

This manual provides general and specific service procedures

and repair methods essential for reliable engine operation and

your safety. Since many variations in procedures, tools, and

service parts are involved, advice for all possible safety

conditions and hazards cannot be stated.

Departure from instructions in this manual or disregard of

warnings and cautions can lead to injury, death, or both, and

damage to the engine or vehicle.

Read safety instructions below before doing service and test

procedures in this manual for the engine or vehicle. See related

application manuals for more information.

Safety Instructions

e

VVeehhiicclle

• Make sure the vehicle is in neutral, the parking brake is set,

and the wheels are bloc

diagnostic procedures on the engine or vehicle.

ked before doing any work or

• Batteries produce highly flammable gas during and after

c

harging.

• Always disconnect the main negative battery cable first.

• Always connect the main negative battery cable last.

• Avoid leaning over batteries.

• Protect your eyes.

• Do not expose batteries to open flames or sparks.

• Do not smoke in workplace.

CCoommpprreesssseedd AAiir

• Limit shop air pressure for blow gun to 207 kPa (30psi).

• Use approved equipment.

• Do not direct air at b

r

ody or clothing.

WWoorrkk AArreea

• Keep area clean, dry and organized.

• K

• Make sure the work area is ventilated and well lit.

• Make sure a First Aid Kit is available.

SSaaffeettyy EEqquuiippmmeennt

• Use correct lifting devices.

• Use saf

PPrrootteeccttiivvee MMeeaassuurrees

• Wear protective glasses and saf

bare feet, sandals, or sneakers).

• Wear appropriate hearing protection.

• Wear correct clothing.

• Do not wear rings, watches, or other jewelry.

• Restrain long hair.

FFiirree pprreevveennttiioon

• Make sure charged fire extinguishers are in the work area.

NNOOTTEE:

ensure that the following fire types can be extinguished.

a

eep tools and parts off the floor.

t

ety blocks and stands.

s

ety shoes (do not work in

n

:

Check the classification of eac

1. Type A - Wood, paper, textiles, and rubbish

2. Type B - Flammable liquids

3. Type C - Electrical equipment

h fire extinguisher to

• Wear safety glasses or goggles.

• Wear hearing protection.

• Use shielding to protect others in the work area.

s

TToooolls

• Make sure all tools are in good condition.

• Make sure all standard electrical tools are grounded.

• Check for frayed power cords before using power tools.

FFlluuiiddss UUnnddeerr PPrreessssuurre

• Use extreme caution when working on systems

under pressure.

• F

ollow approved procedures only.

l

FFuueel

• Do not over fill fuel tank. Over fill creates a fire hazard.

• Do not smoke in the work area.

• Do not refuel the tank when the engine is running.

RReemmoovvaall ooff TToooollss,, PPaarrttss,, aanndd EEqquuiippmmeennt

• Reinstall all safety guards, shields and covers after servicing

the engine.

• Make sure all tools, parts, and service equipment are

removed from the engine and vehicle after all work is done.

e

t

2

International®VT 275 V6 Engine

Page 3

TABLE OF CONTENTS

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

COMPONENT LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

DESIGN FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

ELECTRONIC CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

AIR MANAGEMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

FUEL SUPPLY SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

FUEL MANAGEMENT SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

INJECTOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

UNIQUE REPAIR PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

DIAGNOSTIC PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

DIAGNOSTIC TROUBLE CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

ENGINE & CHASSIS SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

POWER DISTRIBUTION CENTER FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . .104

GLOSSARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

International®VT 275 V6 Engine

3

Page 4

4

Page 5

DIRECT INJECTION TURBOCHARGED DIESEL ENGINE

VT 275 FEATURES

• 90° V6

• Offset Crankpins

• Rear Gear Train

• Primary Balancer

• Regulated Two-Stage Turbocharging System

• Four Valves per Cylinder

• Cooled Exhaust Gas Recirculation

• Electro-Hydraulic Generation 2 Fuel Injection System

• Top Mounted Oil and Fuel Filters

International®VT 275 V6 Engine

5

Page 6

VT 275 OVERVIEW

0

50

100

150

200

250

300

350

400

450

500

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

0

25

50

75

100

125

150

175

200

225

250

Torque (ft-lb)

Power (HP)

Engine Speed (RPM)

Load (ft-lb)

Power (HP)

Power & Torque Curve

VT 275 ENGINE SPECIFICATIONS

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-stroke, direct injection diesel

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . V6, pushrod operated four valves / cylinder

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275 cu. in. (4.5 liters)

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.74 in. (95 mm)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.134 in. (105 mm)

Compression Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.0:1

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Twin turbocharged and charge air cooled

Rated Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 hp @ 2700 rpm

Peak Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440 lb-ft @ 1800 rpm

Engine Rotation, Facing the Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Counterclockwise

Injection System . . . . . . . . . . . . . . . . . . . . . . . . . Electro-hydraulic generation 2 fuel injection

Cooling System Capacity (Engine Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 quarts

Lube System Capacity (Engine Only) . . . . . . 13 quarts with oil filter (14 quarts at overhaul)

Slide Title Goes Here

Horsepower and Torque

• The VT 275 engine is offered with only one

horsepower and torque rating for the 2005

model year. The engine creates 200

horsepower at 2700 rpm and 440 lb-ft of

torque at 1800 rpm. The engine has a

high idle speed of 2775 rpm with

automatic transmission. The engine idle

speed is set at 700 rpm and is not adjustable.

6

International®VT 275 V6 Engine

Page 7

Engine Serial Number

2

4

6

5

3

1

Front

L

R

• The Engine Serial Number (ESN) for the

VT 275 is located on a machined surface

at the left rear corner of the crankcase just

below the cylinder head.

• The ESN identifies the engine family, the

build location, and the sequential

build number.

• Engine Serial Number Example

4.5HM2Y0135617

4.5 = Engine displacement

H = Diesel, T

M2 = Motor Truck

Y = Huntsville

0135617 = Build Sequence

urbocharged

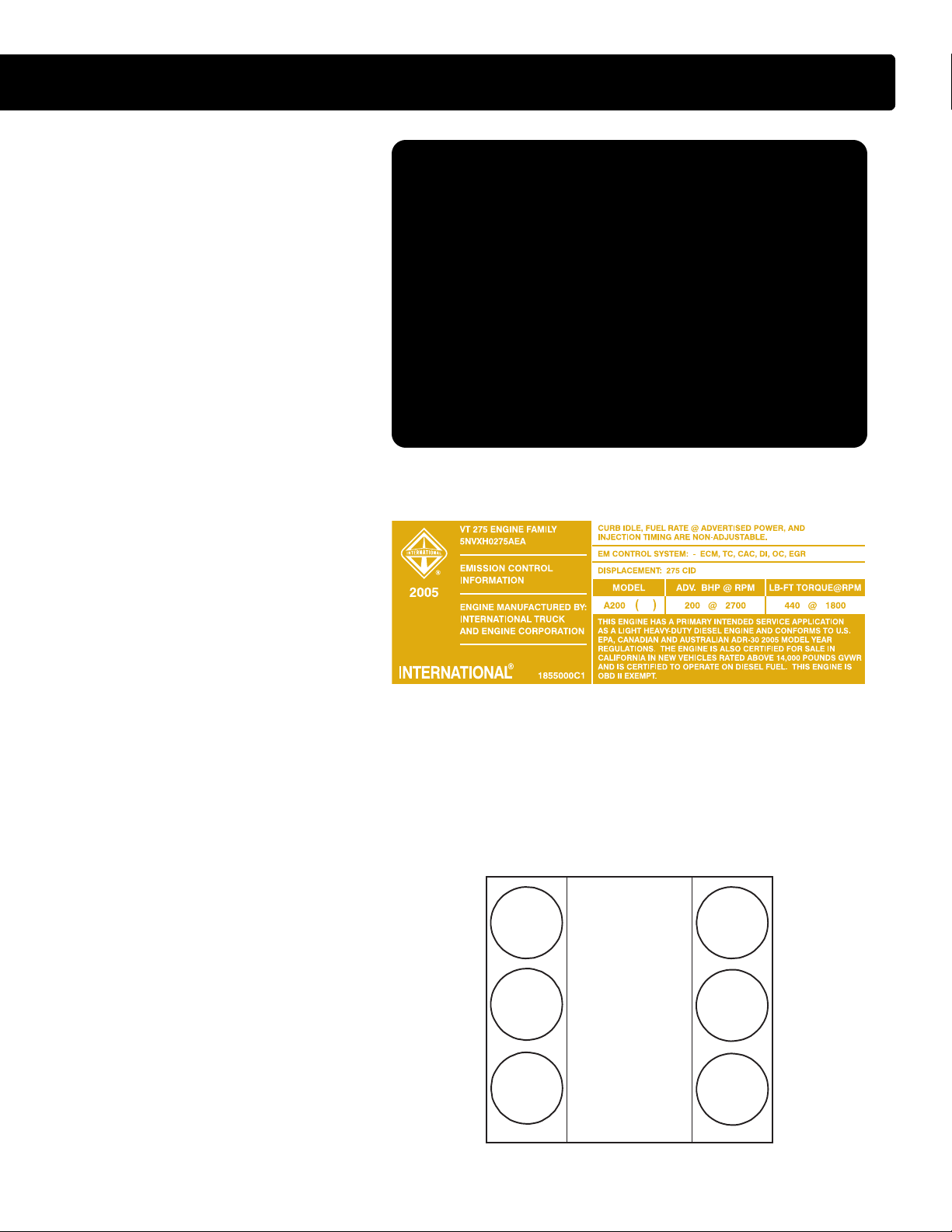

Emissions Label

• The Environmental Protection Agency

(EPA) emissions label is on top of the

breather, toward the front, on the left valve

cover. The label includes the following:

VT 275 OVERVIEW

-Advertised horsepower rating

-Engine model code

-Service application

-Emission family and control system

-Year the engine was certified to meet EPA

emission standards.

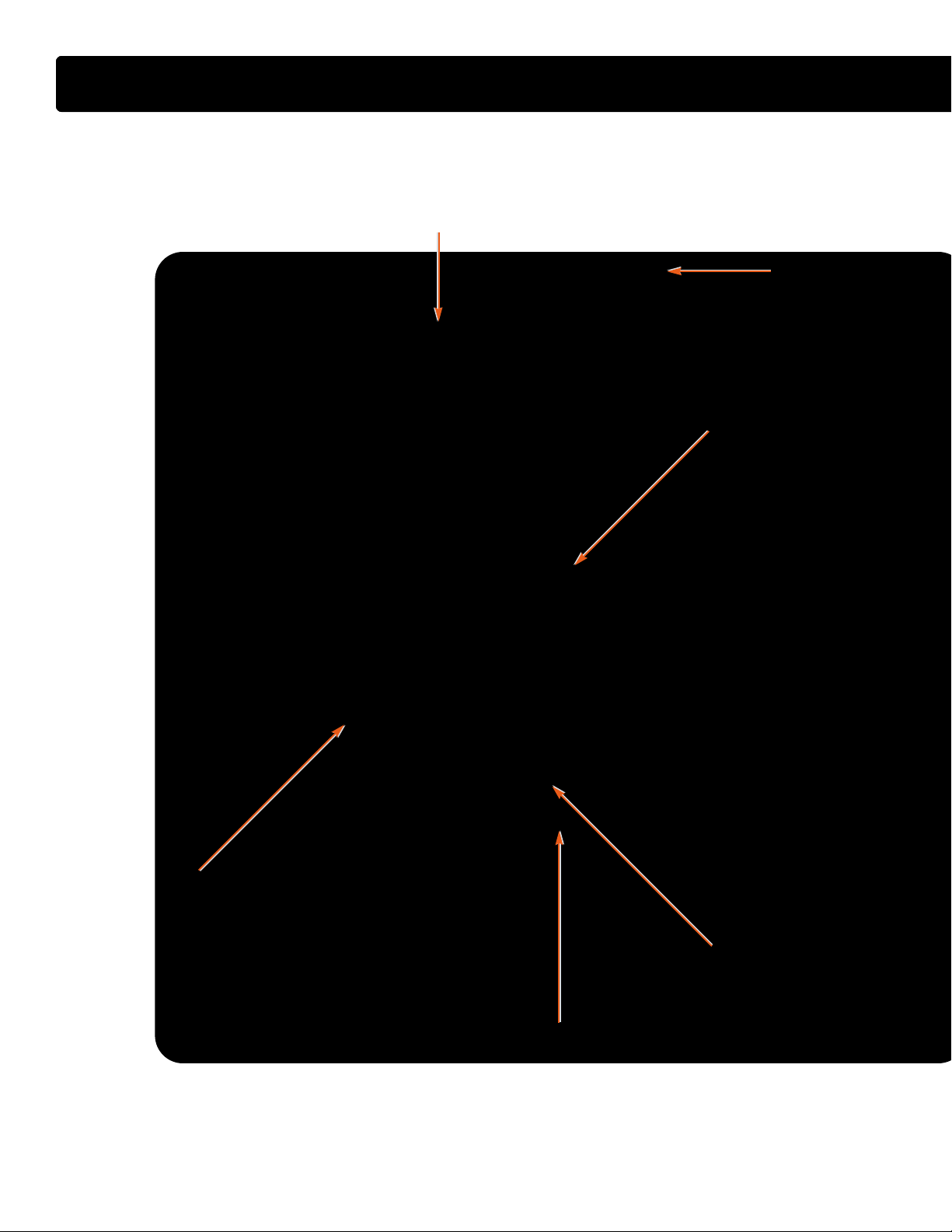

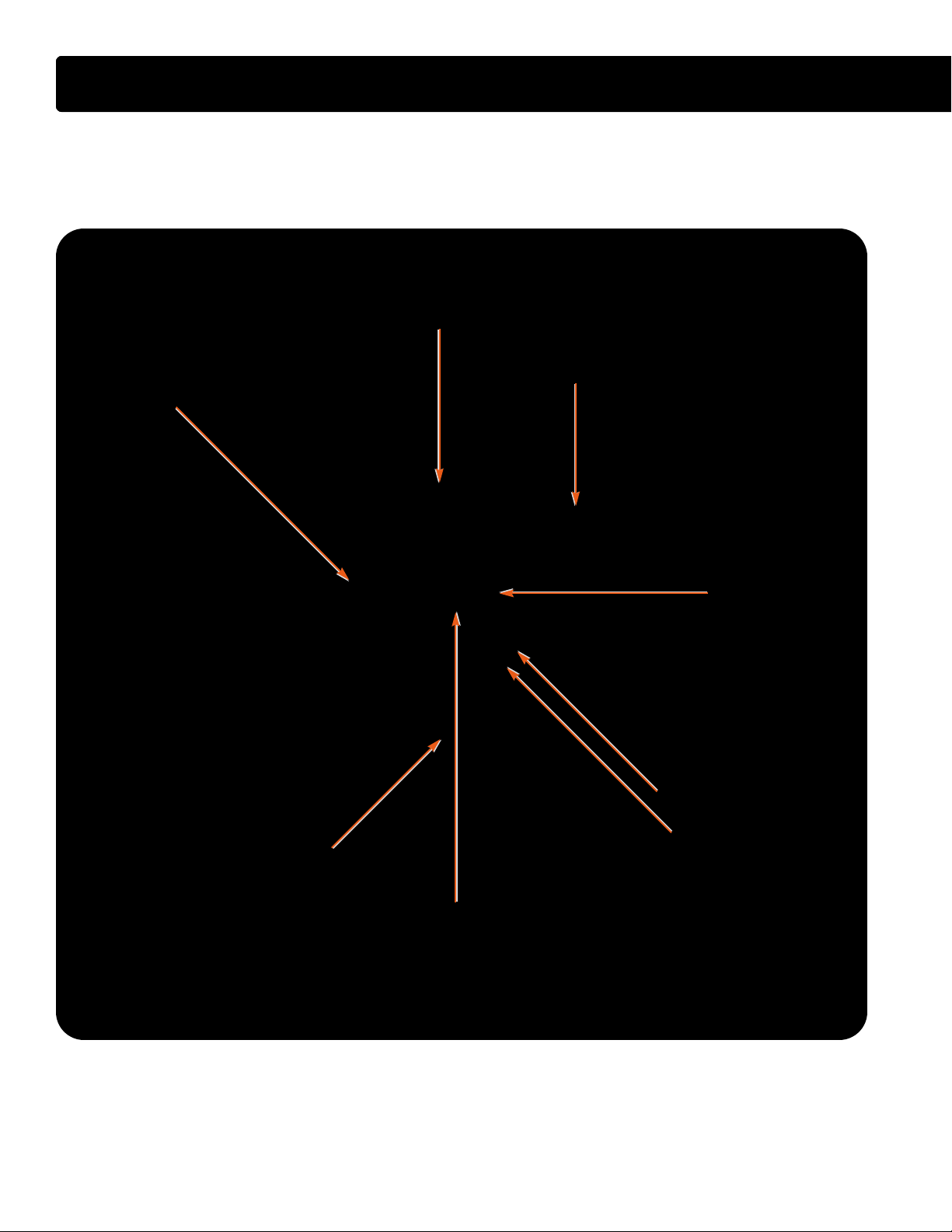

Cylinder Numbering

• The cylinders on the VT 275 are numbered

from the front of the right bank 1, 3, 5 and

from the front of the left bank 2, 4 and 6.

• The engine firing order is 1-2-5-6-3-4

International®VT 275 V6 Engine

7

Page 8

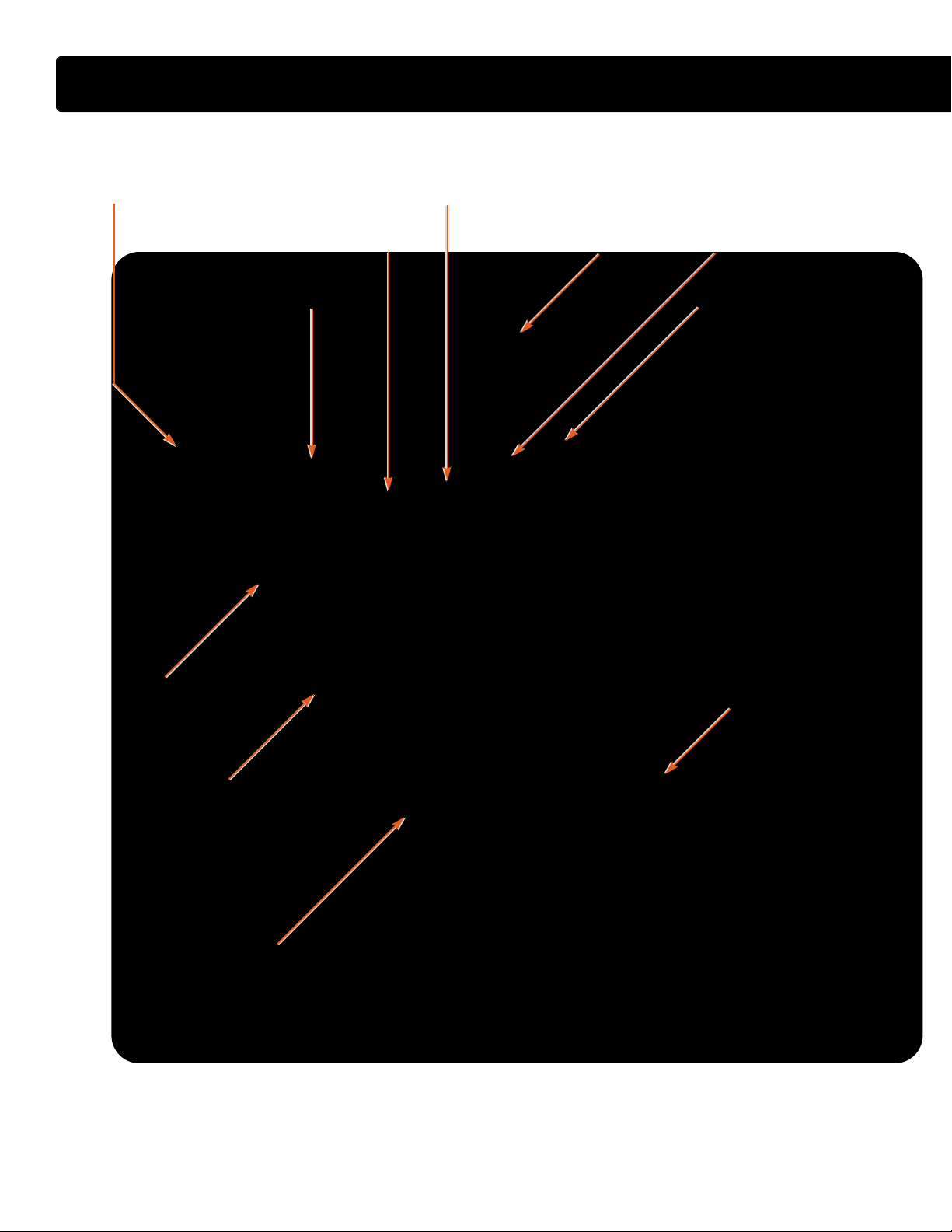

COMPONENT LOCATIONS - FRONT OF ENGINE

AAIIRR IINNLLEETT HHEEAATTEERR

HHEEAATTEERR SSUUPPPPLLYY TTUUBBEE

HHEEAATTEERR SSUUPPPPLLYY TTUUBBEE

SSMMOOOOTTHH IIDDLLEERR PPUULLLLEEYY

SSMMOOOOTTHH IIDDLLEERR PPUULLLLEEYY

AAIIRR IINNLLEETT HHEEAATTEERR

AAIIRR IINNLLEETT

AAIIRR IINNLLEETT

IINNTTAAKKEE MMAANNIIFFOOLLDD

IINNTTAAKKEE MMAANNIIFFOOLLDD

BBAANNJJOO BBOOLLTT WWIITTHH

BBAANNJJOO BBOOLLTT WWIITTHH

CCHHEECCKK VVAALLVVEE

CCHHEECCKK VVAALLVVEE

FFUUEELL TTUUBBEE TTOO RRIIGGHHTT BBAANNKK

FFUUEELL TTUUBBEE TTOO RRIIGGHHTT BBAANNKK

MMAATT SSEENNSSOORR

MMAATT SSEENNSSOORR

PPOOWWEERR SSTTEEEERRIINNGG

PPOOWWEERR SSTTEEEERRIINNGG

PPUUMMPP BBRRAACCKKEETT

PPUUMMPP BBRRAACCKKEETT

BBEELLTT TTEENNSSIIOONNEERR

BBEELLTT TTEENNSSIIOONNEERR

OOIILL PPUUMMPP CCOOVVEERR

OOIILL PPUUMMPP CCOOVVEERR

8

International®VT 275 V6 Engine

Page 9

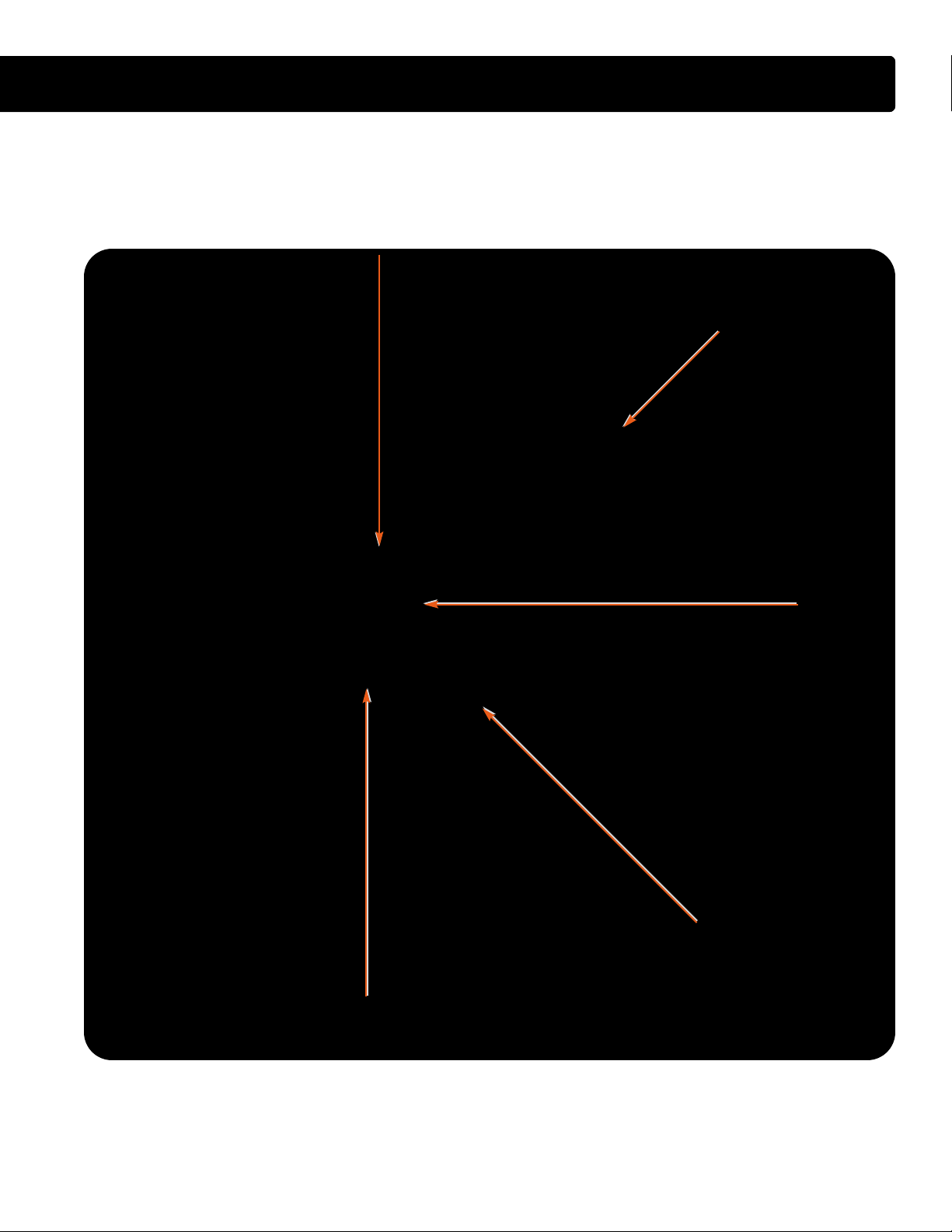

COMPONENT LOCATIONS - LEFT FRONT OF ENGINE

GGRROOOOVVEEDD IIDDLLEERR PPUULLLLEEYY

GGRROOOOVVEEDD IIDDLLEERR PPUULLLLEEYY

BBRREEAATTHHEERR

BBRREEAATTHHEERR

SSMMOOOOTTHH IIDDLLEERR PPUULLLLEEYY

SSMMOOOOTTHH IIDDLLEERR PPUULLLLEEYY

RREETTUURRNN TTUUBBEE

RREETTUURRNN TTUUBBEE

CCOOOOLLAANNTT OOUUTTLLEETT

CCOOOOLLAANNTT OOUUTTLLEETT

HHEEAATTEERR

HHEEAATTEERR

International®VT 275 V6 Engine

9

Page 10

COMPONENT LOCATIONS - LEFT SIDE OF ENGINE

AAIIRR IINNLLEETT DDUUCCTT

AAIIRR IINNLLEETT DDUUCCTT

OOIILL LLEEVVEELL

OOIILL LLEEVVEELL

LLEEFFTT BBAANNKK

LLEEFFTT BBAANNKK

GGLLOOWW PPLLUUGGSS

GGLLOOWW PPLLUUGGSS

GGAAUUGGEE

GGAAUUGGEE

10

CCMMPP SSEENNSSOORR

CCMMPP SSEENNSSOORR

FFUUEELL RREETTUURRNN TTOO TTAANNKK

FFUUEELL RREETTUURRNN TTOO TTAANNKK

International®VT 275 V6 Engine

SSUUPPPPLLYY FFRROOMM FFUUEELL PPUUMMPP

SSUUPPPPLLYY FFRROOMM FFUUEELL PPUUMMPP

AANNDD PPRRIIMMAARRYY FFIILLTTEERR

AANNDD PPRRIIMMAARRYY FFIILLTTEERR

Page 11

IIPPRR AANNDD

IIPPRR AANNDD

HHEEAATT SSHHIIEELLDD

HHEEAATT SSHHIIEELLDD

COMPONENT LOCATIONS - LEFT REAR OF ENGINE

LLIIFFTTIINNGG EEYYEESS

LLIIFFTTIINNGG EEYYEESS

LLEEFFTT BBAANNKK

LLEEFFTT BBAANNKK

EEXXHHAAUUSSTT MMAANNIIFFOOLLDD

EEXXHHAAUUSSTT MMAANNIIFFOOLLDD

RREEAARR CCOOVVEERR

RREEAARR CCOOVVEERR

International®VT 275 V6 Engine

11

Page 12

COMPONENT LOCATIONS - REAR OF ENGINE

OOIILL FFIILLTTEERR HHOOUUSSIINNGG

OOIILL FFIILLTTEERR HHOOUUSSIINNGG

FFUUEELL FFIILLTTEERR HHOOUUSSIINNGG

FFUUEELL FFIILLTTEERR HHOOUUSSIINNGG

TTUURRBBIINNEE OOUUTTLLEETT

TTUURRBBIINNEE OOUUTTLLEETT

EEXXHHAAUUSSTT TTUUBBEE AASSSSEEMMBBLLYY

EEXXHHAAUUSSTT TTUUBBEE AASSSSEEMMBBLLYY

HHIIGGHH PPRREESSSSUURREE PPUUMMPP CCOOVVEERR

HHIIGGHH PPRREESSSSUURREE PPUUMMPP CCOOVVEERR

12

International®VT 275 V6 Engine

Page 13

COMPONENT LOCATIONS - RIGHT REAR OF ENGINE

HHIIGGHH PPRREESSSSUURREE CCOOMMPPRREESSSSOORR HHOOUUSSIINNGG

HHIIGGHH PPRREESSSSUURREE CCOOMMPPRREESSSSOORR HHOOUUSSIINNGG

CCOOOOLLAANNTT

CCOOOOLLAANNTT

HHEEAATTEERR

HHEEAATTEERR

UUPPPPEERR OOIILL PPAANN

UUPPPPEERR OOIILL PPAANN

LLOOWWEERR OOIILL PPAANN

LLOOWWEERR OOIILL PPAANN

International®VT 275 V6 Engine

13

Page 14

COMPONENT LOCATIONS - RIGHT SIDE OF ENGINE

OOUUTTLLEETT TTOO CCHHAARRGGEE AAIIRR CCOOOOLLEERR

OOUUTTLLEETT TTOO CCHHAARRGGEE AAIIRR CCOOOOLLEERR

TTUURRBBOOCCHHAARRGGEERR CCRROOSSSSOOVVEERR TTUUBBEE

TTUURRBBOOCCHHAARRGGEERR CCRROOSSSSOOVVEERR TTUUBBEE

IICCPP

IICCPP

SSEENNSSOORR

SSEENNSSOORR

RRIIGGHHTT BBAANNKK

RRIIGGHHTT BBAANNKK

GGLLOOWW PPLLUUGGSS

GGLLOOWW PPLLUUGGSS

CCRRAANNKKCCAASSEE

CCRRAANNKKCCAASSEE

LLOOWWEERR

LLOOWWEERR

CCRRAANNKKCCAASSEE

CCRRAANNKKCCAASSEE

CCKKPP SSEENNSSOORR

CCKKPP SSEENNSSOORR

14

International®VT 275 V6 Engine

Page 15

COMPONENT LOCATIONS - RIGHT FRONT OF ENGINE

PPNNEEUUMMAATTIICC AACCTTUUAATTOORR

PPNNEEUUMMAATTIICC AACCTTUUAATTOORR

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

MMAAPP

MMAAPP

SSEENNSSOORR

SSEENNSSOORR

EECCTT

EECCTT

SSEENNSSOORR

SSEENNSSOORR

WWAATTEERR PPUUMMPP

WWAATTEERR PPUUMMPP

PPUULLLLEEYY

PPUULLLLEEYY

AANNDD FFAANN DDRRIIVVEE

AANNDD FFAANN DDRRIIVVEE

International®VT 275 V6 Engine

15

Page 16

COMPONENT LOCATIONS - TOP OF ENGINE WITHOUT HARNESS

HHIIGGHH PPRREESSSSUURREE PPUUMMPP

HHIIGGHH PPRREESSSSUURREE PPUUMMPP

IINNJJEECCTTOORR CCOONNNNEECCTTOORRSS

IINNJJEECCTTOORR CCOONNNNEECCTTOORRSS

HHIIGGHH PPRREESSSSUURREE TTUURRBBIINNEE HHOOUUSSIINNGG

HHIIGGHH PPRREESSSSUURREE TTUURRBBIINNEE HHOOUUSSIINNGG

EEGGRR VVAALLVVEE

EEGGRR VVAALLVVEE

LLOOWW PPRREESSSSUURREE TTUURRBBOO CCOOMMPPRREESSSSOORR HHOOUUSSIINNGG

LLOOWW PPRREESSSSUURREE TTUURRBBOO CCOOMMPPRREESSSSOORR HHOOUUSSIINNGG

TTUURRBBOOCCHHAARRGGEERR

TTUURRBBOOCCHHAARRGGEERR

OOIILL SSUUPPPPLLYY LLIINNEE

OOIILL SSUUPPPPLLYY LLIINNEE

EEOOPP SSWWIITTCCHH

EEOOPP SSWWIITTCCHH

EEOOTT SSEENNSSOORR

EEOOTT SSEENNSSOORR

16

International®VT 275 V6 Engine

Page 17

COMPONENT LOCATIONS - TOP OF ENGINE WITH HARNESS

MMAAFF SSEENNSSOORR CCOONNNNEECCTTOORR

MMAAFF SSEENNSSOORR CCOONNNNEECCTTOORR

((SSEENNSSOORR NNOOTT SSHHOOWWNN))

((SSEENNSSOORR NNOOTT SSHHOOWWNN))

IINNJJEECCTTOORR HHAARRNNEESSSS CCOONNNNEECCTTOORR

IINNJJEECCTTOORR HHAARRNNEESSSS CCOONNNNEECCTTOORR

HHAARRNNEESSSS TTOO

HHAARRNNEESSSS TTOO

CCHHAASSSSIISS MMOOUUNNTTEEDD

CCHHAASSSSIISS MMOOUUNNTTEEDD

EECCMM//IIDDMM

EECCMM//IIDDMM

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

AALLTTEERRNNAATTOORR FFUUSSIIBBLLEE LLIINNKKSS

AALLTTEERRNNAATTOORR FFUUSSIIBBLLEE LLIINNKKSS

((AALLTTEERRNNAATTOORR NNOOTT SSHHOOWWNN))

((AALLTTEERRNNAATTOORR NNOOTT SSHHOOWWNN))

International®VT 275 V6 Engine

17

Page 18

VT 275 DESIGN FEATURES

RROOCCKKEERR AARRMM CCAARRRRIIEERR

RROOCCKKEERR AARRMM CCAARRRRIIEERR

RROOCCKKEERR AARRMM

RROOCCKKEERR AARRMM

RROOCCKKEERR AARRMM FFUULLCCRRUUMM

RROOCCKKEERR AARRMM FFUULLCCRRUUMM

Cylinder Head Assembly

• The VT 275 has an aluminum rocker arm

carrier for each cylinder head. The carrier

holds the fulcrum plates and the attached

rocker arms and can be removed as an

assembly from the cylinder head without

removing the rocker arms.

• Each rocker arm pivots on a steel ball

located by detents in the fulcrum plate.

Four head bolts on each cylinder head

pass through the two single and two dual

fulcrum plates serving to clamp the plates

to the carrier.

• The cylinder head is sealed to the

crankcase deck surface with a shim type

gasket that must be replaced if any of the

head bolts are removed. The 14mm head

bolts are torque to yield and cannot

be reused.

• The carrier is sealed to the cylinder head

with a push-in-place gasket. The cylinder

head and carrier are clamped to the

crankcase with eight 14mm bolts. Six

additional 8mm bolts around the perimeter

clamp the carrier to the cylinder head and

four additional 8mm bolts serve to clamp

the top of the head to the crankcase. Two

hollow dowels in the cylinder head are

used to align the rocker arm carrier to the

cylinder head.

IINNJJEECCTTOORR

PPAASSSS--

TTHHRROOUUGGHH

DDUUAALL FFUULLCCRRUUMM PPLLAATTEE

HHEEAADD BBOOLLTTSS

SSIINNGGLLEE

FFUULLCCRRUUMM

PPLLAATTEE

18

88mmmm FFUULLCCRRUUMM BBOOLLTT

GGLLOOWW PPLLUUGG

CCOONNNNEECCTTOORR OOPPEENNIINNGG

International®VT 275 V6 Engine

Rocker Arm Carrier

• The rocker arm carrier serves as an

attachment point for the fulcrum plates and

the rocker arms. In addition to the head

bolts, single fulcrum plates are attached to

the rocker arm carrier with one 8mm bolt.

The dual fulcrum plates are attached with

two 8mm bolts. The fulcrum plates are

marked with E and I as assembly aids to

show the valves they support. The E and I

must be visible after assembly to the head.

In addition, the carrier provides a passage

for each snap-in-place injector passthrough and the push-in-place glow

plug connectors.

Page 19

VT 275 DESIGN FEATURES

Crankcase Assembly

• The VT 275 has four main bearings but

replaces the traditional individual main

bearing caps with a one-piece lower

crankcase assembly. The lower crankcase

is made of cast iron and is stronger than

the individual caps. The lower crankcase is

attached to the crankcase with sixteen

14mm main bearing bolts of two lengths

with the shorter bolts to the outside. Three

additional 8mm bolts are used on each

side at the perimeter. The lower crankcase

is sealed to the crankcase with two pushin-place seals.

Crankcase and Oil Pan

• The upper oil pan bolts to the lower

crankcase and is sealed with a full

perimeter push-in-place gasket. The lower

sheet metal oil pan is sealed to the upper

cast aluminum oil pan with a full perimeter

push-in-place gasket. The upper oil pan is

wider than the crankcase and allows for

greater oil pan capacity without

increased depth.

1144mmmm MMAAIINN BBEEAARRIINNGG BBOOLLTTSS

1144mmmm MMAAIINN BBEEAARRIINNGG BBOOLLTTSS

LLOOWWEERR OOIILL PPAANN

LLOOWWEERR OOIILL PPAANN

OOIILL PPIICCKK--UUPP TTUUBBEE

OOIILL PPIICCKK--UUPP TTUUBBEE

LLOOWWEERR CCRRAANNKKCCAASSEE

LLOOWWEERR CCRRAANNKKCCAASSEE

88mmmm BBOOLLTTSS

UUPPPPEERR OOIILL PPAANN

UUPPPPEERR OOIILL PPAANN

• The oil pickup is sealed to the upper oil

pan with an O-ring and attached with two

6mm bolts. Oil pulled through the oil

pickup tube passes through a passage

cast in the upper oil pan to the lower

crankcase. The lower crankcase has a

machined passage that takes oil to a front

cover passage that leads to the oil pump.

Openings in the upper oil pan allow oil to

return to the pan during engine operation

but also serve to keep oil in the pan away

from the rotating crankshaft.

CCRRAANNKKSSHHAAFFTT

CCRRAANNKKSSHHAAFFTT

UUPPPPEERR

UUPPPPEERR

CCRRAANNKKCCAASSEE

CCRRAANNKKCCAASSEE

LLOOWWEERR

LLOOWWEERR

CCRRAANNKKCCAASSEE

CCRRAANNKKCCAASSEE

International®VT 275 V6 Engine

19

Page 20

VT 275 DESIGN FEATURES

CCAAMMSSHHAAFFTT

GGEEAARR

BBAALLAANNCCEERR SSHHAAFFTT

GGEEAARR

CCRRAANNKKSSHHAAFFTT FFLLAANNGGEE

AANNDD GGEEAARR

HHIIGGHH PPRREESSSSUURREE OOIILL

HHIIGGHH PPRREESSSSUURREE OOIILL

PPUUMMPP GGEEAARR

PPUUMMPP GGEEAARR

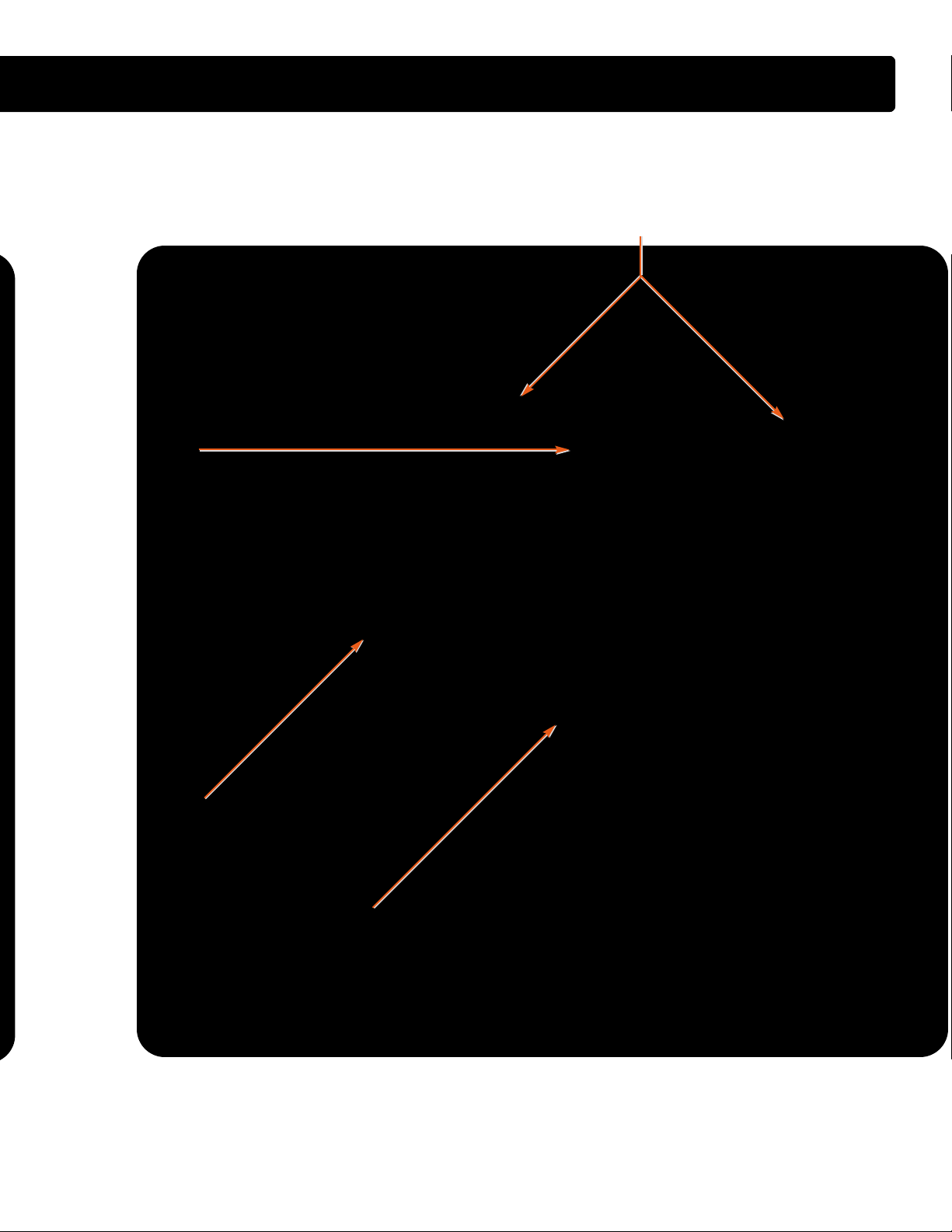

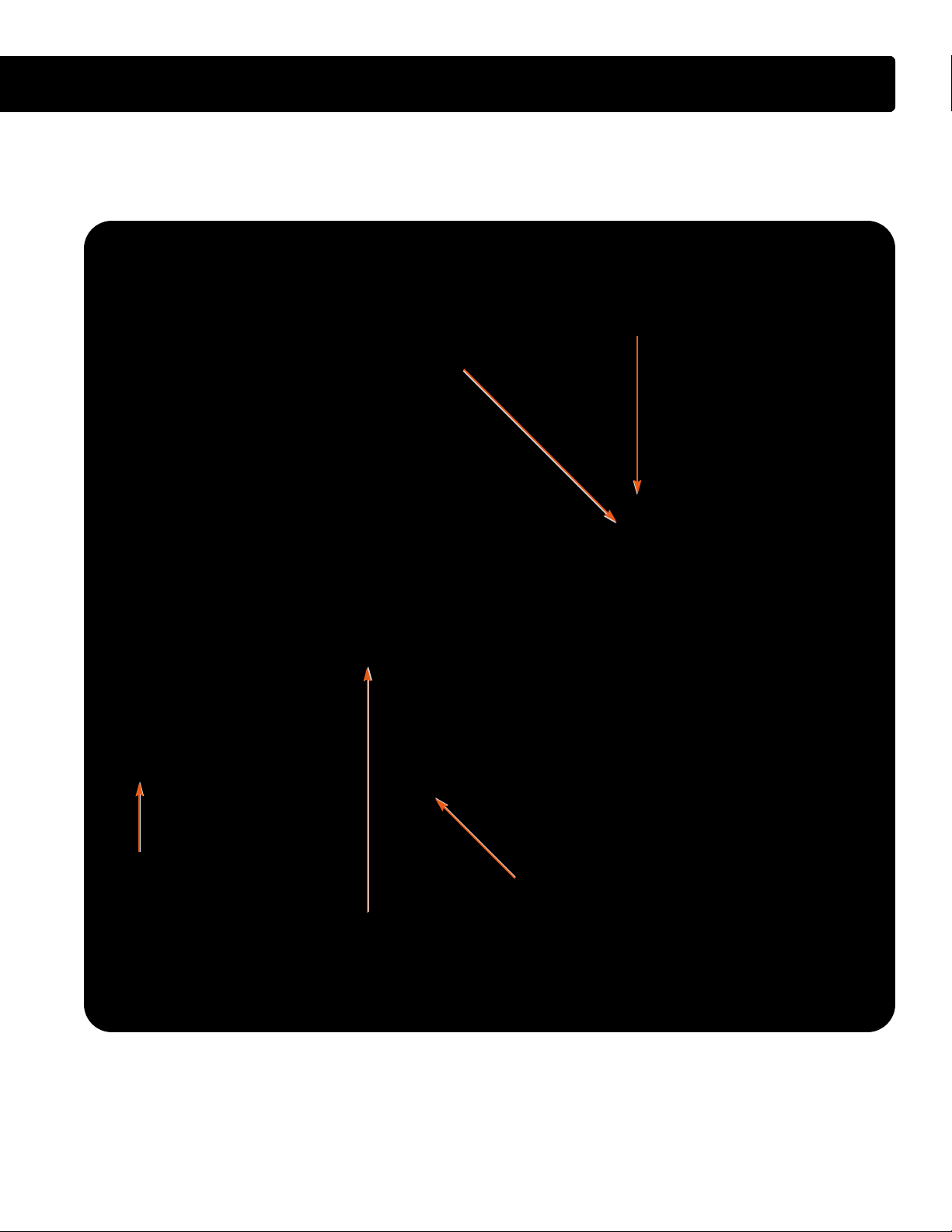

Rear Gear Train

• The VT 275 gear train is located at the rear

of the engine. The crankshaft gear is a

press fit on the crankshaft and drives the

camshaft gear directly. The crankshaft

flange with integral gear is pressed on the

end of the crankshaft then clamped with

six 12mm bolts. The camshaft gear must

be timed to the crankshaft gear during

assembly to maintain the correct relationship.

• The rear flange gear drives the primary

balance shaft gear at a one-to-one ratio.

The balance shaft runs through the hollow

camshaft to the front of the crankcase and

has the balance shaft counterweight

bolted to the front of the shaft. The flange

gear and balance shaft gear must be timed

to maintain the correct relationship

between the balance shaft counterweight

and the crankshaft.

• The high-pressure oil pump is located in

the Vee of the engine and is driven directly

off the camshaft gear. The oil pump gear

does not require timing.

CCRRAANNKKSSHHAAFFTT

FFLLAANNGGEE && GGEEAARR

TTIIMMIINNGG PPIINN HHOOLLEE

CCAAMMSSHHAAFFTT

BBAALLAANNCCEERR

SSHHAAFFTT GGEEAARR

TTIIMMIINNGG GGEEAARR

DDOOTTSS

GGEEAARR

• Note: The crankshaft gear that drives the

camshaft is located behind the flange gear

Gear Timing

• The camshaft and balance shaft must be

timed to the crankshaft for proper engine

operation. During reassembly a timing pin

that aligns the camshaft gear and the

balance shaft gear is placed through the

gears and into a hole machined in the

crankcase, then the crankshaft is installed

while aligning the balance shaft and flange

gear dots. If only the balance shaft is out of

the engine, the shaft can be installed while

aligning the balance shaft gear and flange

gear dots.

.

20

International®VT 275 V6 Engine

Page 21

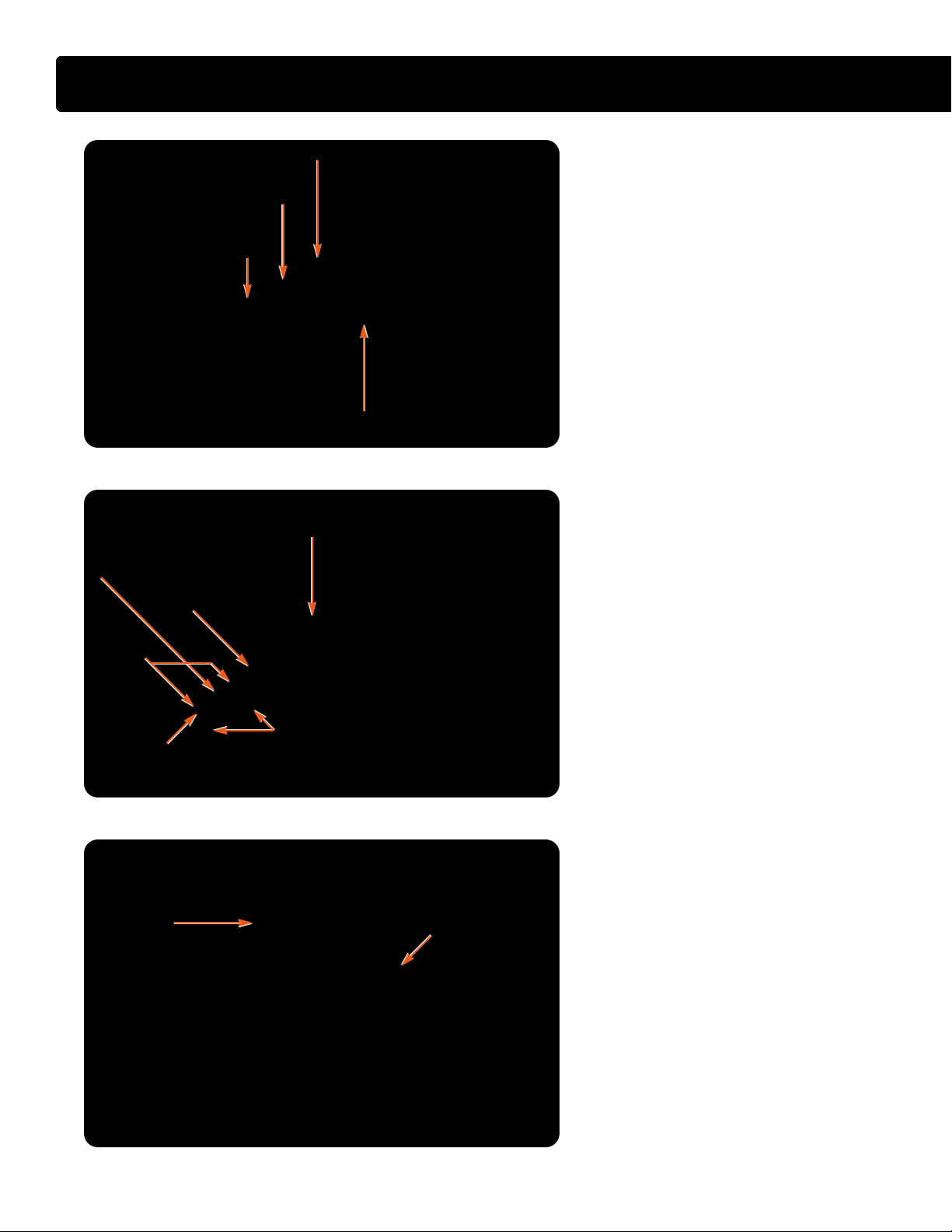

Offset Crankpins

• The 4-stroke engine requires 720° of

crankshaft rotation to complete all four

strokes of the cycle. In a multi-cylinder

engine dividing the 720 degrees by the

number of cylinders will equal the ideal

crankshaft rotation between combustion

events in the firing order. The VT 275

achieves equal spacing of the combustion

events by splitting the crankpins and

staggering the individual journals 30º.

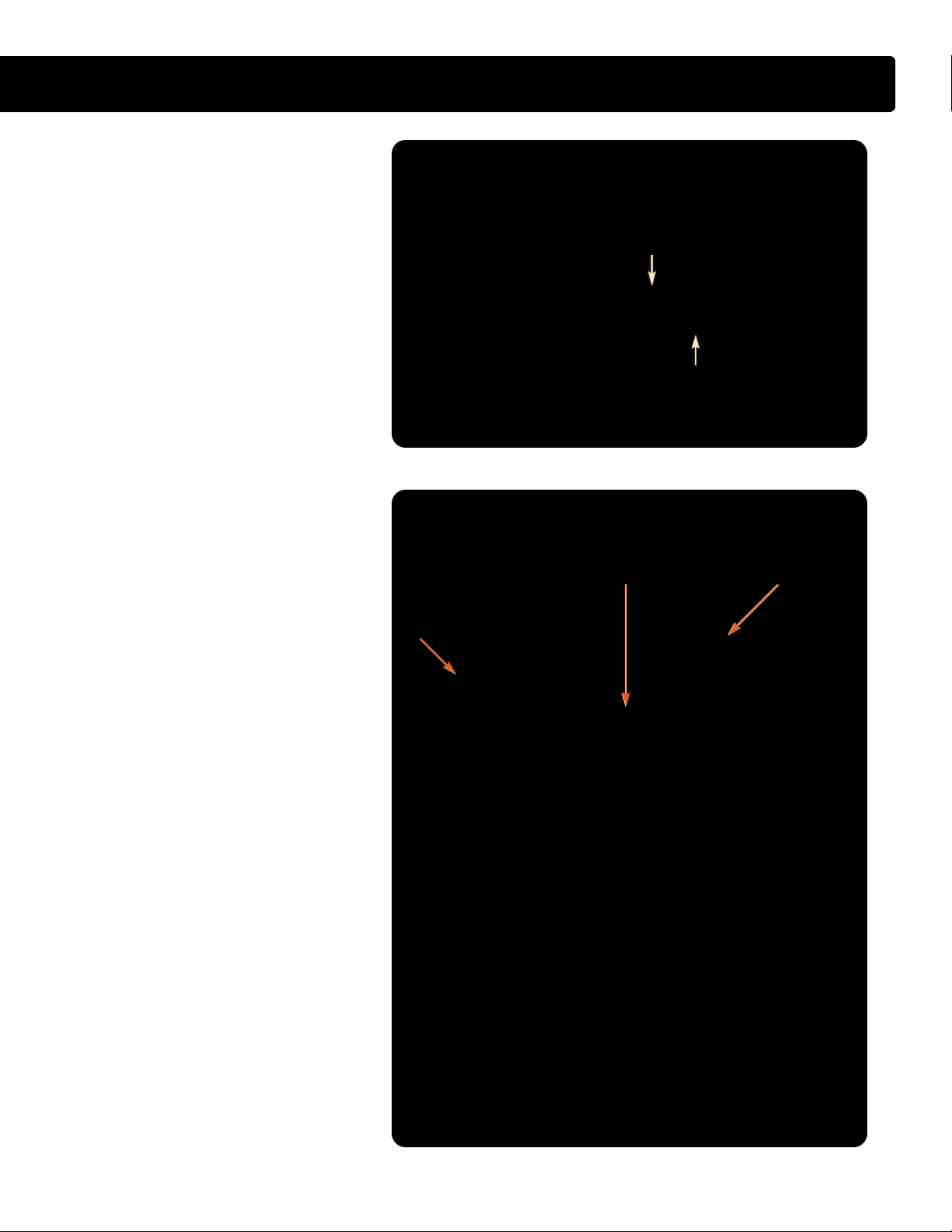

Balance Shaft Timing

• The crankshaft counterweight, flywheel,

and damper are used to offset the rotating

and reciprocating forces developed in the

90° V6 engine, but these components

alone will not offset the couple imbalance.

Couple imbalance is created when two or

more forces act on the crankshaft at

different points along its length. Couple

imbalance, if not offset, results in pitch and

yaw forces on the engine that are felt by

the vehicle occupants as a vibration.

CCOOUUNNTTEERR WWEEIIGGHHTTEEDD

CCOOUUNNTTEERR WWEEIIGGHHTTEEDD

BBAALLAANNCCEERR SSHHAAFFTT GGEEAARR

BBAALLAANNCCEERR SSHHAAFFTT GGEEAARR

VT 275 DESIGN FEATURES

##44 CCRRAANNKKPPIINN

##33 CCRRAANNKKPPIINN

BBAALLAANNCCEERR SSHHAAFFTT

BBAALLAANNCCEERR SSHHAAFFTT

CCOOUUNNTTEERR WWEEIIGGHHTT

CCOOUUNNTTEERR WWEEIIGGHHTT

• Couple imbalance forces in the engine are

offset by the balance shaft forces as it

rotates at crankshaft speed but in the

opposite direction.

International®VT 275 V6 Engine

21

Page 22

ECT

ECM

CKP

IDM

BAP

EOP

MAPICPIPR

EGR DRIVE

MODULE

BCS MAF / IAT

EOTMAT APS / IVS

CMP

®

ELECTRONIC CONTROL

SYSTEM

• ECM and IDM control system

• Dual magnetic pick-up timing sensors

• Electric motor driven EGR valve

• ECM boost control

System Features

• The VT 275 engine uses the Diamond

Logic™ II Control System. The electronic

control system features an Engine

Control Module (ECM) and an Injector

Drive Module (IDM).

• The Exhaust Gas Recirculation (EGR)

valve is positioned by an ECM controlled

electric stepper motor. The system uses

an EGR drive module to communicate

commands from the ECM to the

EGR valve.

• VT 275 engines use two magnetic pickup sensors to determine crankshaft

speed and position and camshaft

position. Magnetic pick-up sensors

feature high reliability and accuracy.

22

• The VT 275 engine uses a twin

turbocharger with ECM boost control.

International®VT 275 V6 Engine

Page 23

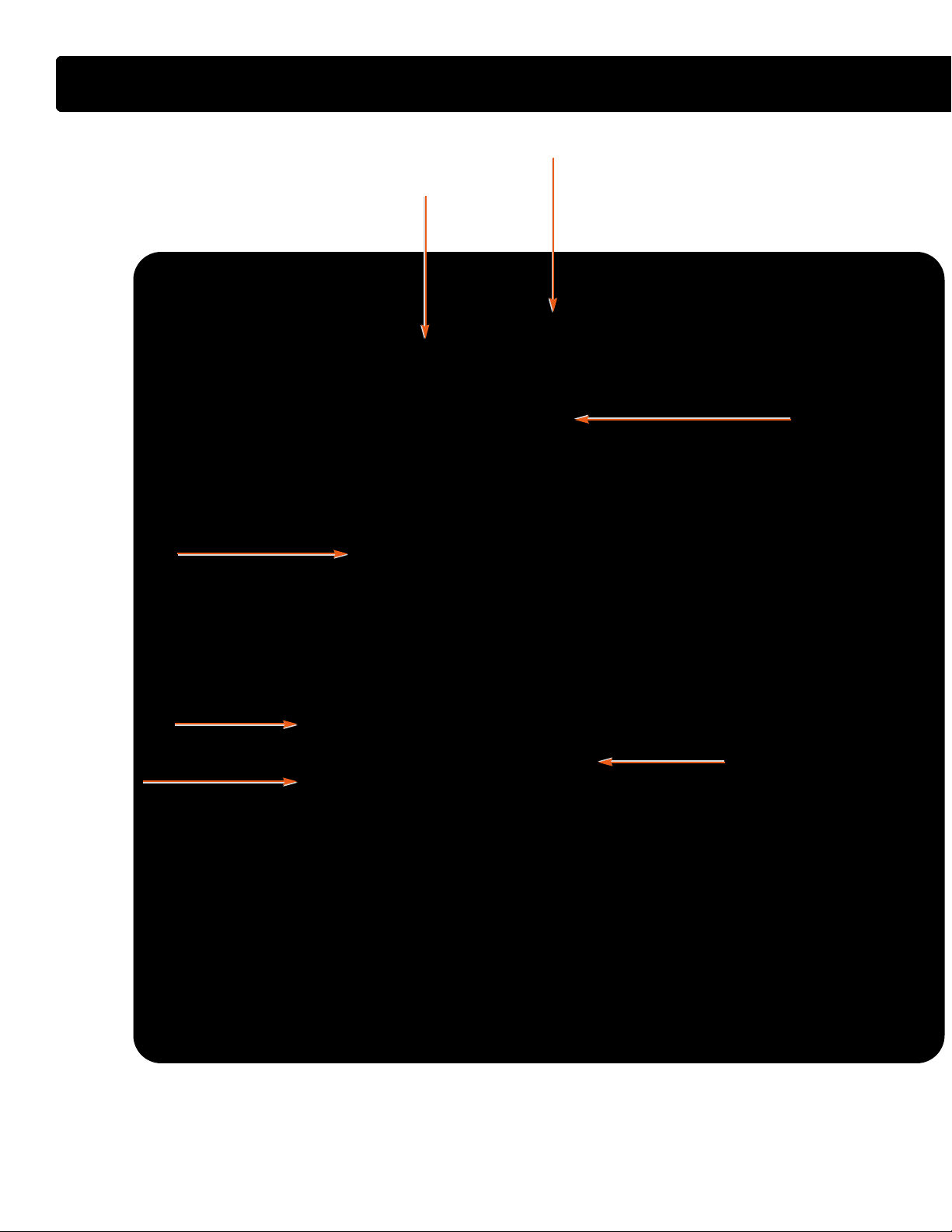

ELECTRONIC CONTROL SYSTEM

ECM

• The ECM uses sensor inputs to control the

Injection Pressure Regulator (IPR), the

EGR valve, the boost control solenoid, the

glow plug relay and the inlet air heater

relay. The ECM also shares sensor data

with the IDM over communication links

between the two modules.

• The IDM is mounted on brackets cast into

the ECM. The ECM and IDM are then

mounted with vibration isolator grommets

to the control module assembly bracket.

The bracket is bolted to the truck's frame

directly behind the passenger side of the

cab and serves as the mounting point for

the inlet air heater relay, the glow plug relay,

and the Power Distribution Center (PDC).

IINNLLEETT AAIIRR

IINNLLEETT AAIIRR

HHEEAATTEERR RREELLAAYY

HHEEAATTEERR RREELLAAYY

CCOONNTTRROOLL MMOODDUULLEE

CCOONNTTRROOLL MMOODDUULLEE

AASSSSEEMMBBLLYY BBRRAACCKKEETT

AASSSSEEMMBBLLYY BBRRAACCKKEETT

EECCMM

EECCMM

GGLLOOWW PPLLUUGG RREELLAAYY

GGLLOOWW PPLLUUGG RREELLAAYY

IDM

• The Injector Drive Module (IDM) receives

sensor information from the ECM over

three communication links: the CAN 2 link,

the CMPO circuit, and the CKPO circuit.

The IDM uses this information to calculate

injection timing and duration. The IDM

controls injector operation through 48-volt

signals to the twin injector coils.

• The ECM has four connectors. The

connectors are called X1 through X4 with

ECM X1 being the top ECM connector as

mounted on the truck. The IDM has three

connectors with IDM X1 being the top

connector as mounted on the truck. The

ECM X1 and X2 connectors are for engine

sensor inputs and X3 and X4 are for

chassis inputs. The IDM X1 and X2

connectors are for injector operation and

X3 is for chassis inputs and

communication between the ECM and IDM.

IIDDMM XX11

IIDDMM XX11

IIDDMM XX22

IIDDMM XX22

IIDDMM XX33

IIDDMM XX33

IIDDMM

IIDDMM

EECCMM XX11

EECCMM XX11

EECCMM XX22

EECCMM XX22

EECCMM XX33

EECCMM XX33

EECCMM XX44

EECCMM XX44

International®VT 275 V6 Engine

23

Page 24

ELECTRONIC CONTROL SYSTEM

EGR Drive Module

• The EGR Drive Module is mounted below

the de-aeration tank. The module receives

the desired EGR valve position from the

ECM over the engine CAN 2 link. The

module then sends a series of voltage and

ground signals to the Motor U, V, and W

terminals of the EGR valve. The voltage

signals are Pulse Width Modulated (PWM)

to control current flow to the motor field coils.

• The module receives battery voltage and

ground through the 12-way engine-tochassis connector. The module supplies a

reference voltage to three position sensors

within the EGR valve. The drive module

uses the sensor signals to determine the

percent of valve opening.

EEGGRR DDRRIIVVEE MMOODDUULLEE

IINNLLEETT AAIIRR HHEEAATTEERR

IINNTTAAKKEE MMAANNIIFFOOLLDD

Inlet Air Heater Element

• The Inlet Air Heater element is located in

the lower side of the intake manifold and

projects through the manifold and into the

inlet air stream.

• The element warms the incoming air to aid

cold start and reduce emissions during

warm-up. The ECM turns the inlet air

heater on for a predetermined amount of

time, based on engine oil temperature,

intake air temperature, and barometric air

pressure. The inlet air heater can remain on

while the engine is running to reduce white

smoke during engine warm-up.

24

International®VT 275 V6 Engine

Page 25

Inlet Air Heater Relay

• The Inlet Air Heater (IAH) element is used

to improve cold start operation, reduce

emissions and white smoke, and improve

engine warm-up. The relay is mounted next

to the Power Distribution Center and is the

taller of the two relays. The IAH relay

receives battery power from the starter

power-feed terminal and the normally open

terminal connects to the element through

the harness. One end of the relay coil is

grounded through the engine 12-way

connector. The relay closes when the coil

receives voltage from the ECM.

AAIIRR HHEEAATTEERR RREELLAAYY

AAIIRR HHEEAATTEERR RREELLAAYY

ELECTRONIC CONTROL SYSTEM

Glow Plug Relay

• Glow plugs are used to improve cold

engine starting. Glow plug operation is

controlled by the ECM through the glow

plug relay. The glow plug relay is mounted

next to the Power Distribution Center and

is the shorter of the two relays. The relay

common terminal is connected by jumper

to the common terminal of the Inlet Air

Heater relay. The normally open terminal

connects to the glow plug harness. One

end of the relay coil is grounded through

the engine 12-way connector. The relay is

closed when the other end of the coil

receives voltage from the ECM.

Injection Pressure Regulator (IPR) Valve

• The IPR mounts to the high-pressure pump

and controls the amount of oil allowed to

drain from the high-pressure system.

When the ECM increases the IPR signal

duty cycle, the valve blocks the oil’s path to

drain and pressure rises. When the ECM

reduces the duty cycle, a larger volume of

oil is allowed to drain from the system and

pressure is reduced. The valve contains a

pressure relief valve for the system that

opens if system pressure reaches 4500

psi. The IPR is protected by a heat shield

that must be reinstalled after servicing.

GGLLOOWW PPLLUUGG RREELLAAYY

GGLLOOWW PPLLUUGG RREELLAAYY

IIPPRR

IIPPRR

SSWWIIVVEELL CCOONNNNEECCTTOORR

SSWWIIVVEELL CCOONNNNEECCTTOORR

International®VT 275 V6 Engine

25

Page 26

ELECTRONIC CONTROL SYSTEM

NNOOTT UUSSEEDD

NNOOTT UUSSEEDD

GGRREEEENN HHOOSSEE TTOO

GGRREEEENN HHOOSSEE TTOO

AAIIRR IINNLLEETT DDUUCCTT

AAIIRR IINNLLEETT DDUUCCTT

BBLLAACCKK HHOOSSEE TTOO IINNTTAAKKEE

BBLLAACCKK HHOOSSEE TTOO IINNTTAAKKEE

MMAANNIIFFOOLLDD EELLBBOOWW

MMAANNIIFFOOLLDD EELLBBOOWW

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

EEGGRR VVAALLVVEE

EEGGRR VVAALLVVEE

EEXXHHAAUUSSTT IINNLLEETT

EEXXHHAAUUSSTT IINNLLEETT

EEXXHHAAUUSSTT OOUUTTLLEETT

EEXXHHAAUUSSTT OOUUTTLLEETT

PPOOPPPPEETTSS

PPOOPPPPEETTSS

OO--RRIINNGGSS

EEXXHHAAUUSSTT

EEXXHHAAUUSSTT

OOUUTTLLEETT

OOUUTTLLEETT

OO--RRIINNGGSS

Boost Control Solenoid

• The turbocharger boost control solenoid

valve is controlled by the ECM. When

the ECM signal to the Boost Control

solenoid is high, the valve opens,

allowing pressure in the pneumatic

actuator to vent into the turbo inlet duct.

When the ECM signal is low, the valve

closes, and pressure to the actuator

equals boost pressure in the intake manifold.

Exhaust Gas Recirculation (EGR) Valve

• The EGR valve is used to control the

percent of exhaust gas in the intake

charge. The EGR valve consists of circuit

board mounted position sensors, field

coils surrounding an armature, and the

valve group. The valve group has two

poppet valves mounted to a common

stem. When the drive module provides

voltage and ground to the field coils in the

proper sequence, stepped armature

rotation occurs. A threaded rod engaged

in the center of the rotating armature

pushes or pulls against the spring

loaded valve stem to force the valve to

open or close.

26

MMAAFF // IIAATT

MMAAFF // IIAATT

55--PPIINN

55--PPIINN

CCOONNNNEECCTTOORR

CCOONNNNEECCTTOORR

MMAAFF

MMAAFF

International®VT 275 V6 Engine

Mass Air Flow (MAF) Sensor

• The Mass Air Flow (MAF) sensor is

mounted with ductwork between the

turbocharger inlet and the air filter element.

The sensor applies voltage to a low

resistance thermistor exposed to the fresh

air portion of the intake charge. The MAF

sensor circuitry measures the increase in

voltage required to offset the cooling

effect of the air flow over the thermistor.

This voltage is then converted into a

variable frequency that is sent to the ECM.

The MAF value can be read with

MasterDiagnostics

®

software in lb./min.

Page 27

ELECTRONIC CONTROL SYSTEM

ECM

BATT ERY

200 A F4

F-46

TO IDM RELAY

TO

ENGINE

INLINE

12-WAY

F41

F-12

R

PDC

1

STAR TER

MOTOR

RELAY

KEY SWITCH

PDC#

F4

F12

F41

F46

R

Device

30A...IDM/ECM

20A...RUN/ACC

10A...ECM PWR

5A...ECM KEY PWR

ECM RELAY - POSITION 5 0

X1

X2

X3

X4

X1

X2

X3

X4

X3-3 V

IGN

X3-5 ECM M PR

X4-1 ECM PWR

X4-2 ECM PWR

1

5

2

3

1

ECM Relay Circuit Operation

• The ECM controls its own power up

and power down process. When

the key is OFF, the ECM stays

powered up for a brief period. The

ECM then powers down after

internal housekeeping functions

have been completed.

Key Power

• The Run/Accessory position of the

key switc

h receives battery voltage

from the Power Distribution Center

(PDC) fuse F-12. When the key is

ON, the switch supplies battery

voltage through fuse F46 to ECM

pin X3-3. Battery voltage is

available at all times through fuses

F4 and F41 to ECM relay pins 1

and 3. The two fuses are in series,

with F4 feeding both the IDM and

ECM relays, and F41 dedicated to

protecting the ECM circuit alone.

Pin 1 supplies voltage to the

relay coil.

• Pin 2 connects the coil to pin X3-5

of the ECM.

• When the key is ON, voltage

supplied to pin X3-3 signals the

ECM that the operator is going to

start the engine. The ECM then

supplies a ground circuit to pin X3-5.

When this occurs, current flows

through the ECM relay coil and

creates a magnetic field causing

the relay to latch. When latched, the

relay connects pin 3 to pin 5 and

supplies current to the ECM

through pin X4-1 and X4-2.

International®VT 275 V6 Engine

Shut Down

• When the key is OFF and volt

removed from ECM pin X3-3, the

ECM shuts down the engine but

keeps the ECM powered up briefly

until the internal house keeping is

completed.

age is

27

Page 28

ECM

BATT ER

Y

200 A F4

F-46

TO IDM RELAY

F-12

R

PDC

F40

2

IDM

STAR TER

MOTOR

RELAY

KEY SWITCH

PDC#

F4

F12

F40

F46

R

Device

30A...IDM/ECM

20A...RUN/ACC

10A...IDM LOGIC

5A...ECM KEY PWR

IDM RELAY - POSITION 55

X1

X2

X3

X1

X2

X3

X3-8 IDM LOGIC POWER

X3-24 IDM M AIN POWER

X3-25 IDM MAIN POWER

X3-4 IDM M AIN POWER

X3-23 IDM M AIN POWER

X3-27 IDM M PR

X3-7 V

IGN

12

6

8

9

ENGINE IN-LINE

12-WAY

30 87

85 86

2

X1

X2

X3

X4

X1

X2

X3

X4

ELECTRONIC CONTROL SYSTEM

IDM Relay Circuit Operation

• The IDM controls its own power up

and power down process. When

the key is OFF, the IDM stays

powered up for a brief period. The

IDM then powers down after

internal housekeeping functions

have been completed.

IDM Power Up

• The key switch receives battery

age from the Power Distribution

volt

Center (PDC) F-12 fuse. When the

key is ON, the switch supplies

battery voltage through F-46 fuse

and pin 9 of the engine 12-way

connector to pin X3-7 of the IDM.

• Battery voltage is available through

the PDC F-4 fuse to IDM relay pin

30 and 85 at all times. Pin 85

supplies voltage to the relay coil.

Pin 86 takes that voltage through

pin 8 of the engine 12-way

connector to pin X3-27 of the IDM.

When the key is ON, voltage

supplied to pin X3-7 signals the

IDM to provide a ground circuit to

pin X3-27. When this occurs,

current flowing through the IDM

relay coil builds a magnetic field

that causes the relay to latch. When

latched, the relay connects pin 30

to pin 87 and supplies current

through pin 12 of the engine in-line

12-way connector to pin X3-4, X323, X3-24, and X3-25 of the IDM.

Four pins receive voltage to spread

the current draw over multiple pins.

IDM Logic

• The IDM also requires volt

age for

the internal logic circuit. When the

IDM relay latches, pin 87 of the relay

supplies voltage to the IDM logic

circuit through the F-40 fuse in the

PDC. The F-40 fuse feeds through

pin 6 of the engine in-line 12-way

connector to the IDM pin X3-8.

28

International®VT 275 V6 Engine

Page 29

ELECTRONIC CONTROL SYSTEM

ECM

VOLTAGE

RR

SENSOR

IDM

ECM

X1

X2

X3

X4

E DC BA

IAT

X1-7 IAT

X1-6 GRD

X1-8 ECT

X2-1 EOT

X2-14 MAT

MAF / IAT

EGR

DRIVE

MODULE

IAH RELAY

GLOW PLUG

RELAY

BCS

IPR

EGR

VALVE

ECT

EOT

MAT

RIGHT BANK INJECTORS

LEFT BANK I NJECTORS

REFERENCE

VOLTAGE

MICROPROCESSOR

R

R

1

1

2

2

X1

X2

X3

X1

X2

X3

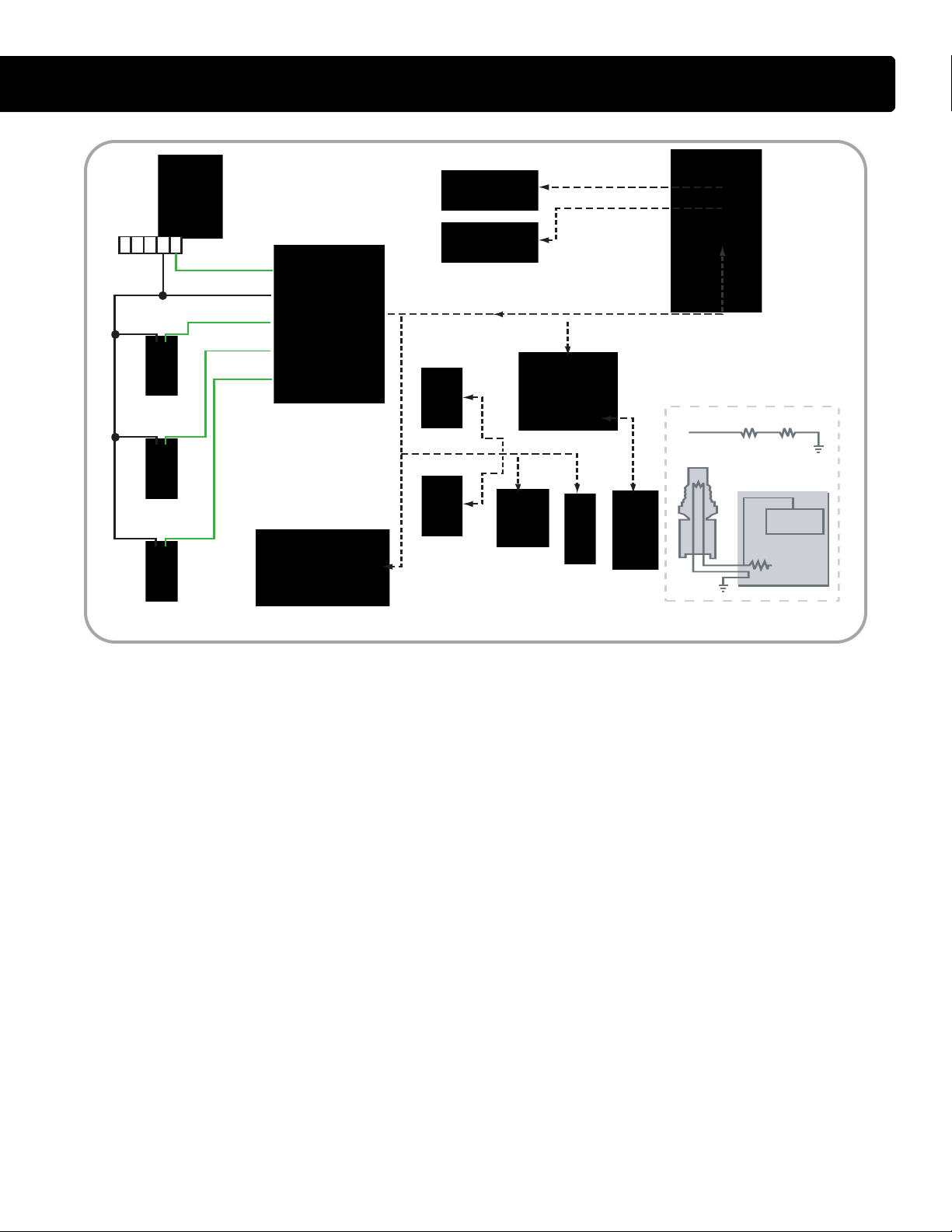

Temperature Sensor Operation

• There are four, two-wire temperature sensors on the VT 275

engine. Each sensor contains a

resistor whose value varies depending on temperature. The ECM

supplies a separate reference

voltage to each temperature sensor.

Then, the sensor conditions its

voltage to produce the sensor signal.

Sensor Circuit

• A temperature variable resistor is a

thermistor

connected to a current-limiting

resistor of fixed value within the

. Each thermistor is

ECM. The thermistor and the

resistor make a series circuit with a

reference voltage applied at one

end and a ground at the other. The

voltage in the circuit between the

two resistors changes as the

thermistor's resistance changes.

When the temperature is low, the

sensor's resistance is high and the

signal voltage is high. When the

temperature is high, the resistance

is low and the signal voltage is low.

Engine Coolant Temperature

(E

CT) Sensor

• The ECT sensor is mounted in the

front cover. The body of the sensor

is exposed to coolant as it returns

from the cylinder heads. The ECT

signal is input into the optional

engine warning protection system,

coolant compensation, glow plug

operation and the instrument

cluster temperature gauge.

Engine Oil Temperature

OT) Sensor

(E

• The EO

oil filter adapter. The EOT signal

allows the ECM to compensate for

viscosity changes in the oil due to

temperature. The EOT signal is

input into calculations that

determine the fuel quantity and timing.

T sensor is mounted in the

International®VT 275 V6 Engine

Manifold Air Temperature

(MAT) Sensor

• The MAT sensor is mounted

towards the front of the left bank leg

of the intake manifold. T

sensor measures the temperature

of the air in the intake manifold. The

ECM uses this information in

calculations that control the EGR

valve operation.

Intake Air Temperature

T) Sensor

(IA

• The IAT sensor is contained within

the Mass Air Flow (MAF) sensor

housing. The MAF sensor is

mounted to the inlet duct leading to

the turbocharger. The ECM uses

the IAT information to control

injection timing and fuel rate when

starting cold.

he MAT

29

Page 30

ECM

IDM

ECM

X1

X2

X3

X4

EGR

DRIVE

MODULE

BCS

IPR

EGR

VALVE

EOPS

ICP

MAP

RIGHT BANK INJECTORS

LEFT BANK I NJECTORS

REFERENCE

VOLTAGE

MICROPROCESSOR

SWITCH

Functional Equivelant

X1-6 GRD

X1-13 EOPS

X1-14 V

REF

X1-20 ICP

X2-3 MAP

X1

X2

X3

X1

X2

X3

VREF

SENSOR

ELECTRONIC CONTROL SYSTEM

Pressure Sensor Operation

• The Manifold Absolute Pressure

(MAP) sensor, the Injection Control

Pressure (ICP) sensor and the

Engine Oil Pressure Switch

(EOPS) are used to send pressure

information to the ECM.

• The MAP and ICP are three-wire

pressure sensors. Three-wire

pressure sensors receive a

reference voltage and a ground

from the ECM. The sensor returns a

portion of the reference voltage,

proportional to the pressure, back

to the ECM as a signal.

Injection Control Pressure

(ICP) Sensor

• The ICP sensor is a Micro Strain

Gauge (M

MSG type sensor has a small strain

gauge that senses changes in

pressure. Sensor mounted

electronic circuitry converts the

30

SG) style sensor. The

• T

change into a signal voltage

proportional to the pressure being

measured. The ICP sensor is used

to make corrections to the IPR

signal and to continually check the

performance of the Injection

Control Pressure system.

Manifold Absolute Pressure

(MAP) sensor

he MAP sensor is a variable

capacitance style sensor. In a

variable capacitance sensor, the

pressure being measured deflects a

ceramic disk towards a metal disk.

The two materials make up a

variable capacitor. Sensor mounted

circuitry converts the capacitance

into a signal voltage proportional to

the measured pressure. The MAP

sensor measures turbocharger

boost in the intake manifold. The

MAP signal is input into calculations

that determine fueling quantities

and the desired EGR valve position.

International®VT 275 V6 Engine

Engine Oil Pressure Switch

(EOPS)

• The EOPS is used to detect oil

pressure and is an input to the dash

cluster and the engine warning

protection system. T

he switch is

normally open with the engine off

but closes when oil pressure

reaches 5 to 7 psi. The ECM sends

5 volts through a current limiting

resistor to the EOPS and reads the

voltage between the resistor and

the switch. When oil pressure is

low, the switch is open and the

ECM reads 5 volts.

When the oil pressure is greater

than 5 to 7 psi, the switch is closed,

the circuit is shorted to ground, and

the ECM reads a low voltage.

When the ECM detects oil pressure, MasterDiagnostics

®

will display

40 psi. When the oil pressure is

below 5 psi, MasterDiagnostics

will display 0 psi.

®

Page 31

ELECTRONIC CONTROL SYSTEM

IDM

CAMSHAFT

POSITION

SENSOR

ECM

X1

X2

X3

X4

X1

X2

X3

X4

RIGHT BANK INJECTORS

CKPO X3-5

CMPO X3-10

CKP (+) X1-1

CKP (-) X1-2

CMP (+) X1-9

CMP (-) X1-10

CKPO X1-19

CMPO X1-24

LEFT BANK INJECTORS

CRANKSHAFT

POSITION

SENSOR

1

2

1

2

+

-

+

-

X1

X2

X3

X1

X2

X3

Magnetic Pick-Up Sensors

• The Camshaft Position (CMP)

sensor and Crankshaft Position

(CKP) sensor are both magnetic

pick-up type sensors. Each sensor

contains a permanent magnet core

surrounded by a coil of wire. The

sensor generates a signal through

the collapse of a magnetic field

created by a moving metal trigger.

Movement of the trigger induces an

Alternating Current (AC) voltage in

the sensor coil.

Camshaft Position

(CMP) Sensor

• The CMP sensor is mounted on the

left front of the crankcase. T

CMP sensor reacts to a single peg

pressed into the camshaft. The peg

passes the sensor once per

camshaft revolution producing an

AC signal in the coil.

he

• The ECM uses the AC signal to

determine the position of the

camshaft. The ECM converts the

AC signal to a square wave output.

The output signal, Camshaft

Position Output (CMPO), is sent to

the IDM for fueling calculations.

The ECM conditions the CMP

signal and sends it out as the TACH

signal for body builder use.

Crankshaft Position

(CKP) Sensor

• The CKP sensor is mounted on the

right front of the lower crankcase.

The CKP sensor reacts to a sixtyminus-two tooth trigger wheel

affixed to the front of the crankshaft.

The sensor produces pulses for

eac

h of the 58 teeth as they pass

the magnet. The two tooth gap

allows the ECM to calculate the

position of the crankshaft.

• The ECM uses the CKP signal to

determine the position and speed

of the crankshaft. The ECM

converts the AC signal to a square

wave output, Crankshaft Position

Output (CKPO), and sends it to the

IDM for fueling calculations.

• The ECM needs both the CKP and

CMP signals to calculate engine

speed and crankshaft position.

From the CKP signal the ECM can

determine the speed of the

crankshaft and the position of each

piston relative to Top Dead Center.

From the CMP sensor the ECM can

determine the current stroke of

each (i.e., compression or exhaust).

International®VT 275 V6 Engine

31

Page 32

ECM

BATT ERY

200 A

IAH

RELAY

GLOW PLUG

RELAY

GPC

GPD

GLOW PLUGS

ECT

STAR TER IAH

BAP

X1-17 GPC

X1-21 GPD

246

135

4

12-WAY

ENGINE TO CHASSIS

CONNECTOR

N.O. TERMINAL

X1

X2

X3

X4

X1

X2

X3

X4

ELECTRONIC CONTROL SYSTEM

Glow Plug System

• The VT 275 uses glow plugs to aid

cold starts. The ECM turns on the

glow plugs prior to engine cranking

to increase the temperature of the

cylinders. Glow plug operation is

controlled by the ECM through the

glow plug relay. The glow plugs

have full voltage if battery voltage is

normal, or pulse width modulated to

control the current if battery voltage

is above normal.

The ECM calculates glow plug ontime based on coolant temperature

and barometric pressure. The

required time to warm up the

cylinders decreases as engine

coolant temperature increases.

Warm up time decreases as

barometric air pressure increases.

The glow plugs may continue to be

energized after start-up to

reduce emissions.

Relay Operation

• The glow plug relay receives battery

voltage to its common terminal from

the starter power-feed terminal. The

normally open terminal connects to

the individual glow plugs through

the glow plug harness. One end of

the relay coil is always grounded

through pin 4 of the engine 12-way

connector. The ECM supplies 12

volts to the other end of the coil

through ECM pin X1-17 in order to

close the relay contacts.

Glow Plug Lamp

• The glow plug lamp is used as a

wait-to-st

art indicator. The ECM

lights the glow plug lamp at glow

plug activation to signal the

operator to wait for the cylinders to

warm up.

• Both lamp operation and the glow

plug operation are based on BAP

and ECT values but are independent of each other.

• The glow plug operation may

continue after the lamp is off.

Glow Plug Diagnostics

• Glow plug diagnostics are used to

determine if the relay is operating

correctly when commanded on. An

additional wire on the relay's

normally open terminal connects to

E

CM pin X1-21. This circuit, GPD,

allows the ECM to monitor the

relay operation.

• The glow plugs can be turned on

using the KOEO Glow Plug/Inlet

Air Heater Test. The test can only

be activated twice per key cycle.

32

International®VT 275 V6 Engine

Page 33

ELECTRONIC CONTROL SYSTEM

ECM

BATT ERY

200 A

IAHC

IAHD

MAF / IAT

IAH

RELAY

EOT

STAR TER IAH

BAP

X1-18 IAHC

X2-11 IAHD

N.O. TERMINAL

4

12-WAY

ENGINE TO CHASSIS

CONNECTOR

X1

X2

X3

X4

X1

X2

X3

X4

Inlet Air Heater Operation

• The VT 275 has an Inlet Air Heater

(IAH) element mounted in the front

of the intake manifold. The IAH is

used to improve cold start

operation, reduce emissions and

white smoke, and improve engine

warm-up. When the key is ON, the

ECM determines if the element

should be activated and for how

long, based on barometric pressure

and engine oil temperature. On time

is limited to prevent heater element

damage and to prevent damage to

the intake manifold.

The heater relay delivers full voltage

to the element if battery voltage is

normal, or the relay is pulsed by the

ECM to control the current if battery

voltage is above normal. If the

battery voltage is so low that the

starter motor operation may be

Inlet Air Heater Diagnostics

• An additional wire on the normally

open terminal connects to E

CM pin

X2-11. This diagnostic circuit

allows the ECM to determine if the

IAH relay is on when commanded

on by the ECM.

affected, the inlet air heater is disabled.

• The Inlet Air Heater can be turned

Relay Operation

he IAH relay receives battery

• T

power from the starter power feed

terminal. The normally open terminal

connects to the element through

the harness. One end of the relay

on using the KOEO Glow

Plug/Inlet Air Heater Test. The test

can only be activated twice per key

cycle. The ECM will delay the Inlet

Air Heater operation for three

seconds after the test is activated.

coil is always grounded through pin

4 of the engine 12-way connector.

The other end of the coil receives

12 volts from ECM pin X1-18 to

close the relay contacts.

International®VT 275 V6 Engine

33

Page 34

IDM

ECM

X1

X2

X3

X4

EDCBA

MAF / IAT

EGR

DRIVE

MODULE

BCS

IPR

EGR

VALVE

RIGHT BANK INJECTORS

X1-7 IAT

X1-6 IAT SIG G RD

X2-2 MAF

LEFT BANK I NJECTORS

FIXED

RESISTOR

HEATED

ELEMENT

FIXED

RESISTOR

THERMISTOR

MAF

ECM

VREF

SIG

GRD

MICROPROCESSOR

4

9

ENGINE

IN-LINE 12-WAY

CONNECTOR

ACT GRD

KEY PWR

MAF SIGNAL

KEY POWER

ACTUATOR GRD

SIGNAL GRD

IAT

B+

B+

SIGNAL

CONTROL

X1

X2

X3

X1

X2

X3

ELECTRONIC CONTROL SYSTEM

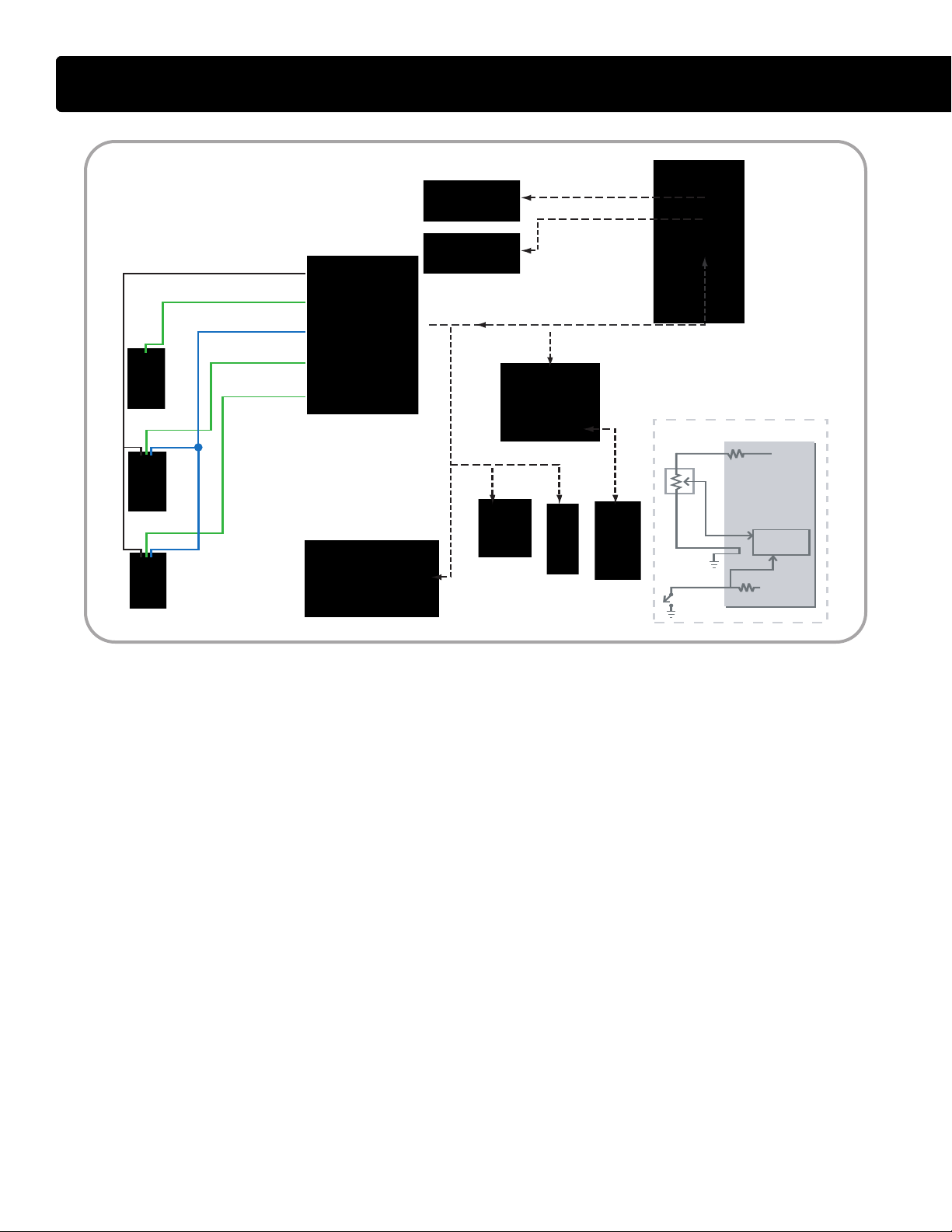

Mass Air Flow (MAF) Sensor

• The MAF sensor is used to measure

the mass of the fresh air portion of

the intake air charge. To reduce

Oxides of Nitrogen (NOx), a portion

of the fresh air charge is displaced

with cooled exhaust gases.

The ECM calculates the total

engine gas flow based on MAT,

MAP and RPM. The ECM then

determines the required EGR

percent based on the current

engine operating conditions. At this

point, the ECM commands the

exhaust portion of the total charge

through the EGR valve while

monitoring the fresh air portion

through the MAF sensor.

Sensor Construction

• The sensor housing contains two

sensors, the MAF sensor and the

Intake Air Temperature (IAT) sensor.

The MAF sensor contains a heated

element placed in the air stream.

The amount of electrical power

needed to maintain the element at

the proper temperature depends

directly on the mass of air moving

over the element.

Sensor Operation

• The MAF sensor is made up of two

age divider circuits. A thermistor

volt

and a fixed resistor make up one

voltage divider circuit, and the

heated element and a fixed resistor

make up the other voltage divider

circuit. The two voltage divider

circuits are combined into a bridge

circuit with a common power supply

and a common ground.

• During operation, when voltage is

applied to the bridge, the

temperature of the heated element

increases and the resistance

decreases. This affects the output

of the divider circuit.

The thermistor side is affected only

by ambient air temperature. The

divider voltages are compared and

the input voltage to the bridge is

increased or decreased until both

divider voltages are equal.

An increase or decrease in airflow

will change the ratio between the

divider voltages, which results in a

change to the supply voltage.

The signal controller circuit

measures the voltage to the bridge

and, based on that value, sends a

frequency signal to the ECM. The

correct key-on, engine-off

frequency is 400+

100 Hz.

34

International®VT 275 V6 Engine

Page 35

ELECTRONIC CONTROL SYSTEM

ECM

BATT ERY

200 A

F11

F19

HFCM

PDC

FUEL

PUMP

RELAY

FUEL HEATER RELAY

TO KEY SWITCH

TO

RUN / ACC

RELAY

X3-9 FPC

X4-15 FPM

X3-1 WIF

GRD

PUMP

HEATER

TO

IGNITION

POWER

1

2

2

1

2

1

3

1

25

3

1

25

X1

X2

X3

X4

X1

X2

X3

X4

PDC#

F11

F19

Device

20A...FUEL PUMP

20A...FUEL HEATER

Pump Operation

• The VT 275 has an ECM controlled

chassis mounted electric fuel pump.

At key-on, the ECM will operate the

fuel pump for up to 60 seconds to

prime the system. Priming allows

the pump to pressurize the system

and to allow air in the system to

bleed out through an orifice

between the filter housing and the

fuel return circuit.

When the engine is in run mode, the

pump will operate continuously. If

the engine dies or is shut down, or

if it is not started within 60 seconds, the ECM will stop the pump.

Circuit Operation

• To operate the pump, the ECM

provides a ground at ECM pin X3-9

to latch the fuel pump relay. The

relay takes power from fuse F11

and provides it to pin 1 of the pump

connector. The ECM monitors the

relay's operation through ECM pin

X4-15. Battery voltage should be

present at X4-15 when the relay is

commanded on. If the ECM does

not detect the voltage, a DTC will

be logged.

Fuel Heater

• The Horizontal Fuel Conditioning

Module (H

heater. When the key is ON, the fuel

heater relay latches and provides

power to pin 1 of the heater

connector. The heater element

contains a thermostat that

controls the heater operation.

FCM) contains a fuel

Water-In-Fuel Sensor

• The pump module contains a

Water-In-Fuel (W

IF) sensor. The

WIF sensor receives voltage from

the key switch. If the filter detects

water, the sensor sends the voltage

to ECM pin X3-1. The ECM then

activates the dash WIF lamp.

International®VT 275 V6 Engine

35

Page 36

ECM

APS / IVS

IN CAB CRUISE SWITCH ES

TO KEY SWITCH

F46

BAP

IDM

EGR

DRIVE

MODULE

BCS

IPR

EGR

VALVE

RIGHT BANK INJECTORS

LEFT BANK I NJECTORS

A

B

C

E

D

F

PDC

X4-6 COO

X3-14 RAS

X3-21 SCS

X3-24 BAP

X4-18 APS

X4-24 GRD

X4-4 V

REF

B

X4-12 IVS

X1

X2

X3

X1

X2

X3

X1

X2

X3

X4

X1

X2

X3

X4

PDC#

F46

Device

5A...ECM KEY PWR

ELECTRONIC CONTROL SYSTEM

Accelerator Pedal Position

Sensor / Idle Validation Switch

(APS/IVS)

• The APS/IVS sensor has two

components built into one housing:

the Accelerator Pedal Position

Sensor (APS) and the Idle

Validation Switch (IVS).

• The APS is a potentiometer type

sensor. The ECM supplies a

reference voltage (Vref) and ground

to the potentiometer and the sensor

sends a voltage signal back to the

ECM indicating the pedal position.

The idle validation switch receives

12 volts from the chassis harness

and signals the ECM when the

pedal is in the idle position. If the

ECM detects an APS signal out of

range high or low, the ECM will

ignore the APS signal and operate

at low idle.

• If a disagreement in the state of IVS

and APS is detected by the ECM,

and the ECM determines that the

IVS is at fault, the ECM will allow a

maximum of 50% of APS. If the

ECM cannot determine that the IVS

is at fault, the engine will be

restricted to low idle only.

Barometric Absolute Pressure

(BAP) sensor

• The BAP sensor is mounted in the

cab. The BAP sensor provides

altitude information to the E

fuel quantity and timing, glow plug

on time, intake heater on time, and

the operation of the Boost Control

CM, so

Solenoid can be adjusted to

compensate for air density

changes.

Cruise Control

• Cruise control operation is

controlled through the E

CM. Two

switches in the cab are used to

signal the operator's intention for

speed control. The switches receive

battery voltage through fuse 46 in

the Power Distribution Center

(PDC). The Cruise On/Off (COO)

switch sends a voltage signal to

ECM pin X4-6. With the COO

switch on, the operator can use the

Set (SCS) and resume (RES)

switch to control the vehicle speed.

36

International®VT 275 V6 Engine

Page 37

ELECTRONIC CONTROL SYSTEM

IDM

ECM

EGR DRIVE

MODULE

X1

X2

X3

X4

X1

X2

X3

X1

X2

X3

X4

X1

X2

X3

5

2

3

4

1

6

7

8

16

X2-13 X3-31

X2-6

X2-12 SHD

X3-30

WV U

SENSOR GRD

POSITION SENSOR W

POSITION SENSOR V

POSITION SENSOR U

SENSOR 5V SUPPLY

SHIELD DRAIN

MOTOR W

MOTOR V

MOTOR U

CAN2CAN2+

GRD

ACT PWR

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

EGR

VALVE

10

4

ENGINE IN-LINE

RELAY

TO ECM RELAY

‘NORMALLY OPEN’

TERMINAL

TO FRAME

GROUND

EGR DRIVE MODULE

EGR VALVE

POWER

GRD

POWER

GRD

S

S

S

S

S

SNN

N

N

N

N

EGR System

• The motor-actuated EGR valve is

controlled and monitored by the

EGR Drive Module. The module is

connected to the engine CAN 2 link

allowing bi-directional communication with the ECM.

EGR Valve

• The EGR Valve poppet stem is

positioned by a three-phase motor

The armature of the motor has

twelve permanent magnet

segments alternating as north or

south poles of a magnet. The

armature is surrounded by nine field

coils divided into three sets or

phases. Each phase has three coils

wired in parallel and spaced 120°

apart around the motor armature.

One lead of each coil set is

connected to the respective motor

circuit on the drive module. The

other leads from all of the nine coils

are joined together.

Two coil sets are powered together

to reposition the motor, with one set

connected to power and the other

to ground. Each powered coil set

creates either a north or a south

magnetic field depending on the

direction of current flow through

the coils.

Drive Module Operation

• The direction of current flow

.

through the coil sets is controlled

by the EGR Drive Module. When

the integrated circuit in the module

connects one coil set to ground,

and one of the other two coil sets to

a Pulse Width Modulated (PWM)

power source, the magnetic fields

created by the coils oppose the

armature magnetic fields and a

controlled rotation of the

armature occurs.

International®VT 275 V6 Engine

The drive module constantly

switches the coil sets (identified as

Motor W, V, and U) from power and

ground to continually produce

rotation. Pulse width modulation is

used to control the current.

Communication

• Three Hall-Effect sensors are

located on a circuit board at the top

of the valve housing. The sensors

are supplied power and ground

through the drive module and

produce a series of signals so the

module can track the rotation of the

motor and the opening position of

the valve.

37

Page 38

IDM

EGR DRIVE

MODULE

ECM

X1

X2

X3

X4

4

3

2

3

ENGINE IN-LINE

12-WAY CO NNECTOR

9-WAY DIAGNOSTIC

CONNECTOR

F

G

D

C

EGR

DRIVE MODULE

CONNECTOR

X1-19 CKPO X3-5

X3-28

X3-29

X1-24 CMPO X3-10

X2-6 CAN 2 (+) X3-30

X2-13 C AN 2 (-)

X3-12 C AN 1 (+)

X3-13 C AN 1 (-)

X4-20 ATA (+)

X4-21 ATA (-)

X3-31

X1

X2

X3

X1

X2

X3

X1

X2

X3

X4

TO TRANS

CONTROLLER

ELECTRONIC CONTROL SYSTEM

ECM/IDM Communications

• The ECM and IDM communicate

over three independent communication links. The three links are

CMPO, CKPO, and CAN 2. In

addition to communications with

the IDM, the ECM also sends

engine information over the CAN 1

link to the vehicle's instrument

cluster and the 9-pin

Diagnostic connector.

CAN 2

• The engine CAN 2 link is a twowire, bi-directional communication

circuit between the ECM and IDM

and the E

Module. The ECM and IDM use the

link to share operating strategies,

sensor information, diagnostic

demands, and Diagnostic Trouble

Codes (DTC). The ECM also shares

desired EGR valve position with the

EGR drive module over the CAN 2

link. The EGR Drive Module

38

CM and the EGR Drive

translates those messages and

then commands the EGR valve

motor. The EGR drive module

monitors the valve action and

communicates any faults back to

the ECM over the CAN 2 link.

Cam Position Output (CMPO)

• The CMPO signal is a 0-12V digital

signal used to communicate the

camshaft position to the IDM. The

CMPO signal is a square wave

signal derived from the information

contained in the camshaft position

sensor's AC voltage signal. The

ECM generates the CMPO signal

by pulling down (switching to

ground) a single wire 12V circuit

that originates in the IDM. The IDM

reads the signal and uses it for

injector timing calculations.

Crank Position Output (CKPO)

• The CKPO signal is a 0-12V digital

signal used to communicate the

International®VT 275 V6 Engine

crankshaft position and speed to

the IDM. The CK

PO signal is a

square wave signal derived from the

information contained in the

crankshaft position sensor's AC

voltage signal. The ECM generates

the CKPO signal by pulling down

(switching to ground) a single wire

12V circuit that originates in the

IDM. CKPO is used by the IDM for

injector timing and fuel quantity

calculations.

American Trucking Association

(A

TA)

• The ATA link is a 0-5V signal that

enables communications between

the E

CM and the MasterDiagnostics software. The data

communication link also allows for

programming of the ECM and IDM.

Page 39

ELECTRONIC CONTROL SYSTEM

ECM

F34

F12

PDC

FUNCTION SELECTOR

SWITCH

HPSW LPSW T-STAT SW

ECT

TO

TRANS

CONTROLLER

X3-10 AC DEMAND

CAN1+

CAN 1(+)

CAN1-

CAN 1(-)

X3-22 AC CONTR OL

TO IGN

SW

IGNITION

SWITCH

200A

MEGA

FUSE

TO BATTERY

POSITIVE

h

X1

X2

X3

X4

X1

X2

X3

X4

7

5

1

CA

2

CMP

APS

BATTERY

GRD

A/C

CLUTCH

A/C CLUTCH

DIODE

A/C CLUTCH

RELAY

3

5

1

2

A/C Clutch Control

• The VT 275 ECM controls the A/C

clutch. The ECM receives an A/C

demand signal from the chassis,

and engages the A/C clutch if

engine conditions are correct. If

conditions are not right, clutch

action may be delayed. When the

ECM receives the A/C demand

signal, it considers engine run time

(to avoid stalling at start up) and

engine coolant temperature (to

avoid compressor operation when

liquid refrigerant may be present in

the compressor). In addition, the

ECM looks at transmission shift

action (to avoid clutch action during

a transmission shift), engine RPM

(to avoid clutch overspeed), and

APS percent (to avoid engagement

during full throttle acceleration).

A/C Demand

• The A/C demand signal originates

at the E

CM as a reference voltage

on X3-10. The ECM supplies 5

volts to pin 10 and considers clutch

engagement when the voltage is

pulled low (shorted to ground) by

the A/C on/off switch in the dashlocated A/C Control Head.

The low-pressure switch (LPSW),

high-pressure switch (HPSW), and

the thermostat switch (T-STAT SW)

are in series in the A/C demand

circuit. If the compressor head

pressure rises above 350 psi, the

high-pressure switch opens and the

demand signal will be 5V. If

pressure on the low side of the

compressor goes below 7 psi, the

low-pressure switch will open and

the demand signal will be 5V.

The last switch is the thermostat

control in the A/C Control Head. If

the thermostat is positioned so that

in-cab temperature demands are

satisfied, the thermostat will open

and the demand signal will be 5V.

International®VT 275 V6 Engine

A/C Control

• If the A/C demand signal is pulled

low and the E

CM determines that

the clutch can be engaged, the

ECM pulls the AC Control circuit

low at pin X3-22. When pin 22 is

low, a ground is provided for the

A/C Clutch Relay. The relay latches

and battery voltage is provided to

the A/C clutch through pin 5 of the

engine 12-way connector.

Switches

• The thermostatic switch (T-STAT

W) monitors evaporator core

S

temperature to prevent freezing and

to regulate cab temperatures.

• The low pressure switch (LPSW)

prevents compressor damage in the

event of a refrigerant leak.

• The high pressure cutoff Switch

(HPSW) interrupts compressor

operation in the event of high

system pressures.

39

Page 40

Inlet air

Compressed air

Exhaust gas

Crankcase vapors

Charge Air Cooler

(CAC)

Air filter

MAF/IAT

sensor

Dual stage

turbocharger

Normal exhaust

flow bypass

shut

Exhaust flow

bypass open

Right

exhaust in

Left

exhaust in

IAH

MAP

Right cylinder

head

Right exhaust

manifold

Exhaust system

Left cylinder

head

Left exhaust

manifold

MAT

EGR

valve

Intake

manifold

EGR

cooler

Exhaust tube assembly

Exhaust to dual stage

turbocharger

Left Right

Air Management

System

• Regulated two-stage turbocharger

• Cooled exhaust gas recirculation

• Intake air heater

®

System Features

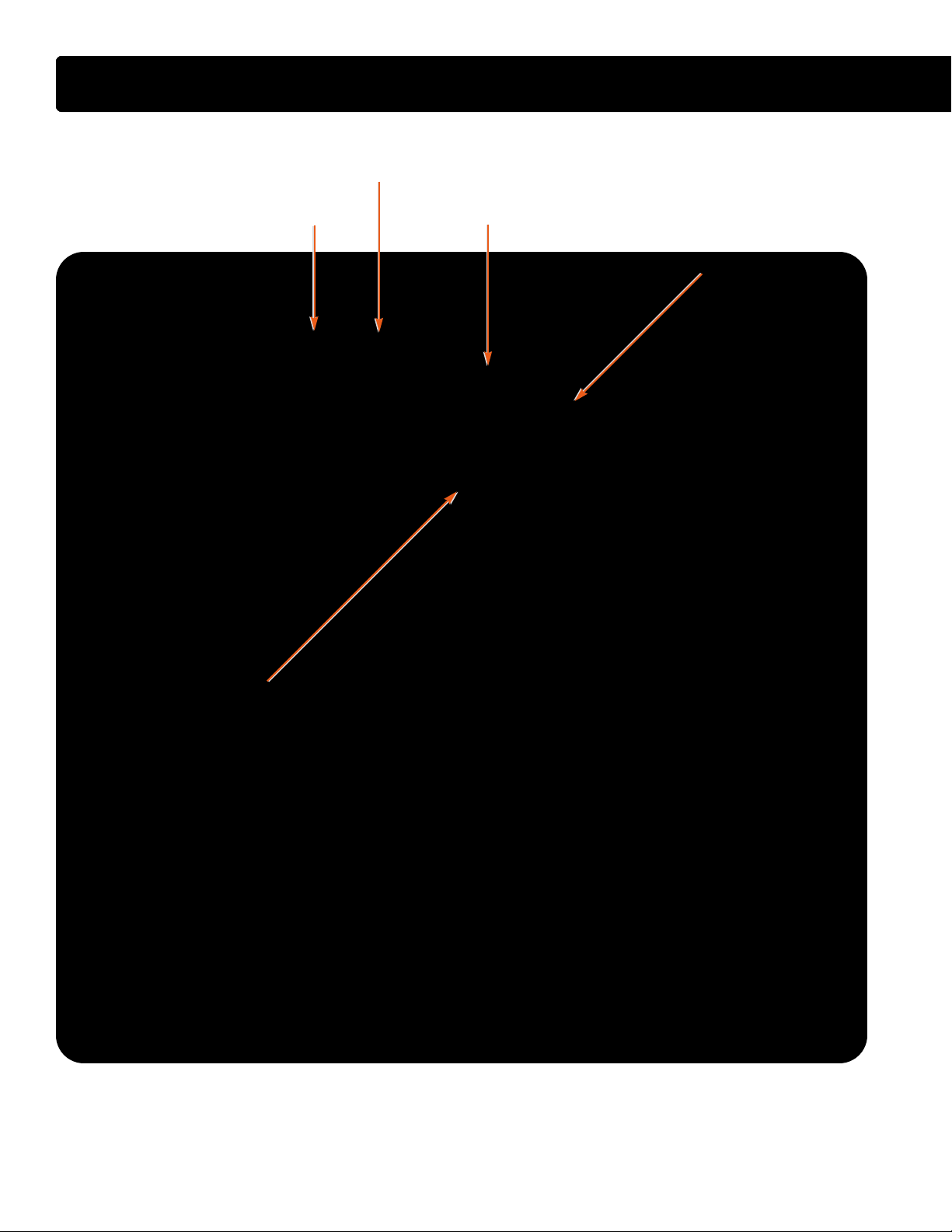

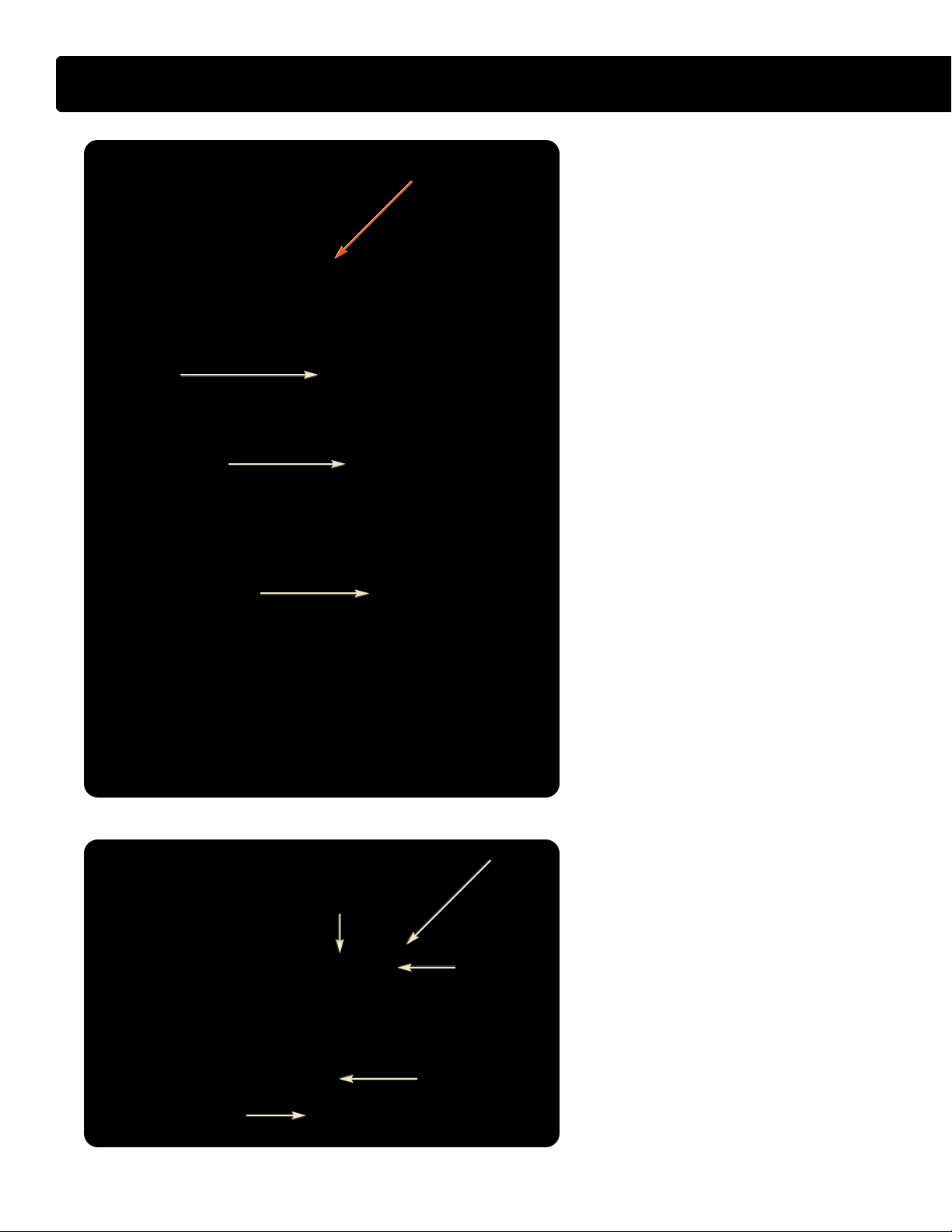

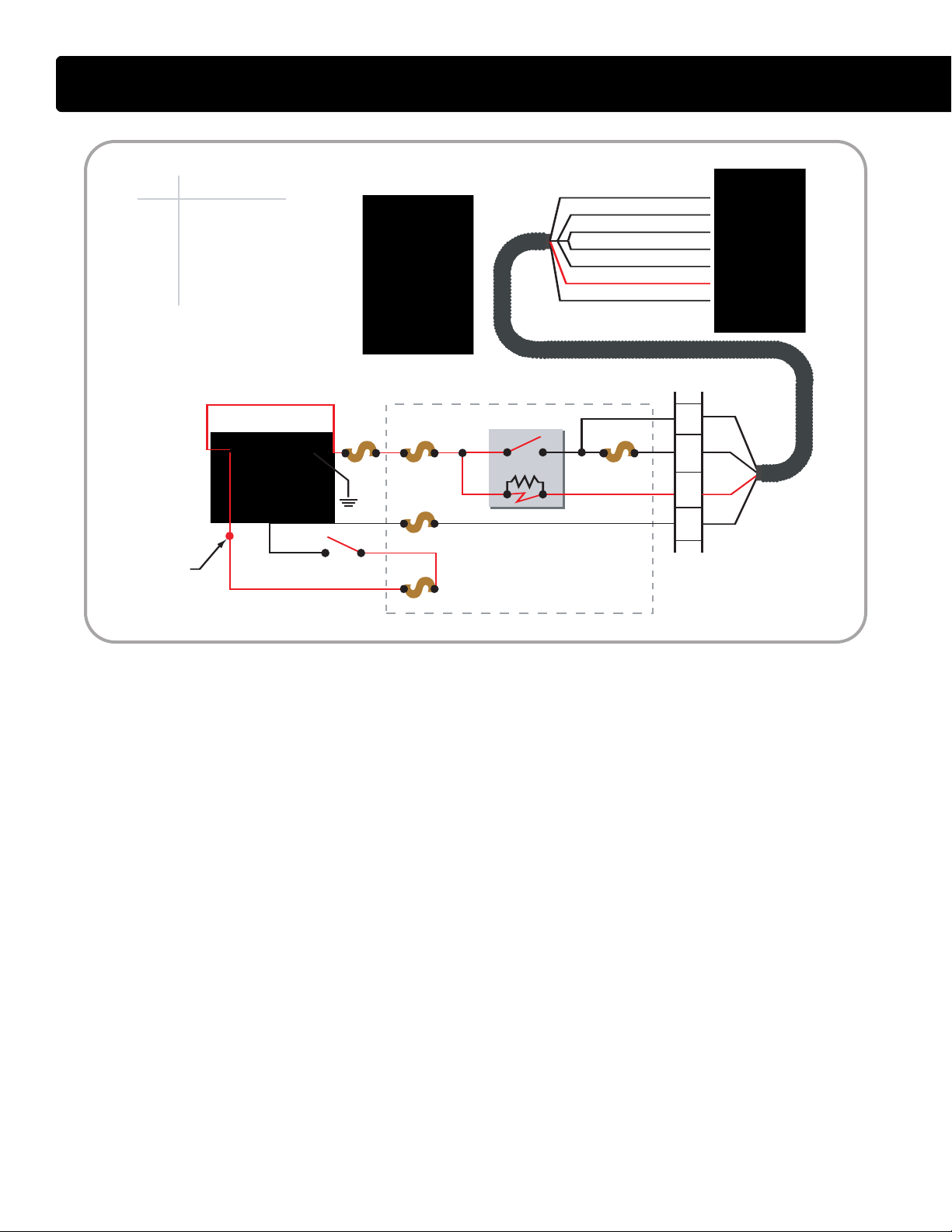

• The Air Management System consists of

the air filter, two-stage turbocharger,

charge air cooler, intake manifold,

Exhaust Gas Recirculation (EGR) cooler

and EGR valve. The mass air flow

sensor, the intake air temperature

sensor, the manifold air temperature

sensor, the manifold absolute pressure

sensor, and the EGR valve position

sensors within the EGR valve are all

inputs from the system to the ECM. The

ECM controls the system through the

EGR valve, and the turbocharger boost

control solenoid.

40

International®VT 275 V6 Engine

Page 41

LLOOWW PPRREESSSSUURREE

LLOOWW PPRREESSSSUURREE

CCOOMMPPRREESSSSOORR IINNLLEETT

CCOOMMPPRREESSSSOORR IINNLLEETT

IINNTTAAKKEE MMAANNIIFFOOLLDD

IINNTTAAKKEE MMAANNIIFFOOLLDD

AIR MANAGEMENT SYSTEM

FFRROOMM CCHHAARRGGEE AAIIRR CCOOOOLLEERR ((CCAACC))

FFRROOMM CCHHAARRGGEE AAIIRR CCOOOOLLEERR ((CCAACC))

EEGGRR VVAALLVVEE

EEGGRR VVAALLVVEE

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

BBOOOOSSTT CCOONNTTRROOLL SSOOLLEENNOOIIDD

PPNNEEUUMMAATTIICC AACCTTUUAATTOORR

PPNNEEUUMMAATTIICC AACCTTUUAATTOORR

CCOOMMPPRREESSSSOORR OOUUTTLLEETT TTOO

CCOOMMPPRREESSSSOORR OOUUTTLLEETT TTOO

CCHHAARRGGEE AAIIRR CCOOOOLLEERR ((CCAACC))

CCHHAARRGGEE AAIIRR CCOOOOLLEERR ((CCAACC))

LLOOWW PPRREESSSSUURREE

LLOOWW PPRREESSSSUURREE

TTUURRBBIINNEE OOUUTTLLEETT

TTUURRBBIINNEE OOUUTTLLEETT

System Operation

• The VT 275 uses a regulated twostage turbocharger to boost the

volume of air flowing into the

cylinders. The system consists of

two turbochargers with exhaust

flow through the units controlled by

the turbocharger boost control

solenoid. The smaller of the two

turbochargers is identified as the

high-pressure turbocharger and is

sized to provide boost for low to

medium speeds. The larger

turbocharger is the low-pressure

turbo and is sized to work in tandem

with the high-pressure unit to

provide the boost and air flow

needed for high-speed, high-load

engine conditions.

• Air passes through the air filter

element and the mass air flow

sensor to enter the compressor of

the low-pressure turbocharger. Air

that leaves the low-pressure

EEXXHHAAUUSSTT TTUUBBEE AASSSSEEMMBBLLYY

EEXXHHAAUUSSTT TTUUBBEE AASSSSEEMMBBLLYY

compressor flows through the

crossover tube to the compressor

inlet of the high-pressure turbocharger. Air from the compressor

goes to the Charge Air Cooler (CAC).

• The CAC is mounted in front of the

radiator. The cooler is an air-to-air

heat exchanger that uses airflow to

remove heat energy from the

pressurized intake charge. Reducing the temperature of the air

increases the charge density, which

results in a more efficient engine

with quicker engine response and

reduced emissions.

• After the CAC, the air flows through

piping to the intake manifold where

it is distributed to the cylinders.

• Exhaust flow from the cylinders

exits the exhaust manifolds and

spools up the high-pressure turbine.

The exhaust passes through the

high-pressure turbine and enters

the low-pressure turbine. The

exhaust gases then exit the turbine

and flow out the exhaust system.

• A bypass valve controls the exhaust

flow through a passage that allows

a portion of the exhaust to bypass

the high-pressure turbine and go

directly to the low-pressure turbine.

Part of the exhaust gas that leaves

the left bank exhaust manifold is

diverted to the EGR cooler. Heat

energy is removed from the exhaust

while in the cooler and transferred

to the engine's coolant. The cooled

exhaust gases then flow through a

short internal passage in the intake