Page 1

User’s Guide

PF8d/PF8t Printers

Page 2

Page 3

Page 4

User’s Guide

PF8d/Pf8t Printers

Page 5

Intermec Technologies Corporation

Worldwide Headquarters

6001 36th Ave.W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is provided solely for the purpose of allowing customers to

operate and service Intermec-manufactured equipment and is not to be released, reproduced, or

used for any other purpose without written permission of Intermec Technologies Corporation.

Information and specifications contained in this document are subject to change without prior

noticed and do not represent a commitment on the part of Intermec Technologies Corporation.

© 2007 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, Beverage Routebook, CrossBar,

dcBrowser, Duratherm, EasyADC, EasyCoder, EasySet, Fingerprint, i-gistics, INCA (under

license), Intellitag, Intellitag Gen2, JANUS, LabelShop, MobileLAN, Picolink, Ready-to-Work,

RoutePower, Sabre, ScanPlus, ShopScan, Smart Mobile Computing, SmartSystems, TE 2000,

Trakker Antares, and Vista Powered are either trademarks or registered trademarks of Intermec

Technologies Corporation.

There are U.S. and foreign patents as well as U.S. and foreign patents pending.

Wi-Fi is a registered certification mark of the Wi-Fi Alliance.

Microsoft, Windows, and the Windows logo are registered trademarks of Microsoft Corporation

in the United States and/or other countries.

Bluetooth is a trademark of Bluetooth SIG, Inc., U.S.A.

ii PF8d/PF8t Printer User’s Guide

Page 6

Document Change

This page records changes to this document. The document was

originally released as version 001.

Version Date Description of Change

002 8/07 Removed listing of accessories. Revised

information about installing and using a

compact flash card. Made a few minor format

corrections.

iii PF8d/PF8t Printer User’s Guide

Page 7

iv PF8d/PF8t Printer User’s Guide

Page 8

Contents

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Global Services and Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Web Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Telephone Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Who Should Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Patent Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Using the PF8 Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1

Introducing the PF8 Printers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features of the PF8 Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Media Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Other Features and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Understanding the LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contents

Installing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2

Connecting the Printer to Your Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting the Printer Through the USB Interface . . . . . . . . . . . . . . . . . .10

Connecting the Printer Through the Serial Port . . . . . . . . . . . . . . . . . . . . . 10

Connecting the Printer Through the Parallel Port. . . . . . . . . . . . . . . . . . . . 10

Installing the Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Turning On the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing the Compact Flash (PF8t Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Understanding Auto-Sensing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Creating and Printing Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Loading Media for Tear-off Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Loading Media for Peel-Off Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Loading Media for Cut-Off Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PF8d/PF8t Printers User’s Guide v

Page 9

Contents

Loading an Media from an External Supply. . . . . . . . . . . . . . . . . . . . . . . . 23

Loading Thermal Transfer Ribbon (PF8t Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting and Maintaining the Printer . . . . . . . . . . . 29

3

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Upgrading the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning the Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Adjusting the Thermal Printhead Pressure (PF8t only) . . . . . . . . . . . . . . . . . . . . . . 32

Adjusting the Printhead Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Adjusting the Label Taken Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Adjusting the Label Gap Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

A

PF8d Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

PF8t Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cutter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Stripper Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Media Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

B

Direct Thermal Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Thermal Transfer Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Transfer Ribbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Tags and Strip with Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

vi PF8d/PF8t Printers User’s Guide

Page 10

Contents

Tags and Strip with Black Marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Plain Continuous Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

PF8d/PF8t Printers User’s Guide vii

Page 11

Before You Begin

Before You Begin

This section provides you with safety information, technical

support information, and sources for additional product

information.

Safety Information

Your safety is extremely important. Read and follow all warnings

and cautions in this document before handling and operating

Intermec equipment. You can be seriously injured, and

equipment and data can be damaged if you do not follow the

safety warnings and cautions.

This section explains how to identify and understand dangers,

warnings, cautions, and notes that are in this document. You may

also see icons which tell you when to follow ESD procedures.

A warning alerts you of an operating procedure, practice,

condition, or statement that must be strictly observed to avoid

death or serious injury to the persons working on the

equipment.

A caution alerts you to an operating procedure, practice,

condition, or statement that must be strictly observed to

prevent equipment damage or destruction, or corruption or

loss of data.

This icon appears at the beginning of any procedure in this

manual that could cause you to touch components (such as

printed circuit boards) that are susceptible to damage from

electrostatic discharge (ESD). When you see this icon, you

must follow standard ESD guidelines to avoid damaging the

equipment you are using.

Note: Notes either provide extra information about a topic or

contain special instructions for handling a particular condition or

set of circumstances.

viii PF8d/PF8t Printers User’s Guide

Page 12

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the

Intermec web site at www.intermec.com and click Service &

Support > Warranty.

Web Support

Visit the Intermec web site at www.intermec.com to download

our current manuals (in PDF). To order printed versions of the

Intermec manuals, contact your local Intermec representative or

distributor.

Visit the Intermec technical knowledge base (Knowledge

Central) at intermec.custhelp.com to review technical

information or to request technical support for your Intermec

product.

Telephone Support

These services are available from Intermec.

Services Description

Order Intermec

products

Order Intermec

media

Order spare

parts

Te c h n i ca l

Support

Service • Get a return authorization

Service contracts Renew a contract, ask about

In the USA and

Canada call 1-800755-5505 and

choose this option

• Place an order.

• Ask about an existing

order.

Order printer labels and

ribbons.

Order spare parts. 1 or 2 and then

Talk to technical support

about your Intermec

product.

number for authorized

service center repair.

• Request an on-site repair

technician.

an existing contract.

1 and then choose 2

1 and then choose 1

choose 4

2 and then choose 2

2 and then choose 1

1 or 2 and then

choose 3

PF8d/PF8t Printers User’s Guide ix

Page 13

Outside the U.S.A. and Canada, contact your local Intermec

representative. To search for your local representative, from the

Intermec web site, click Contact.

Who Should Read This Manual

This user’s guide is for the person who is responsible for

installing, configuring, and maintaining the PF8d and PF8t

printers.

This user’s guide provides you with information about the

features of the PF8d and PF8t printers, and how to install,

configure, operate, maintain, and troubleshoot them.

Patent Information

This product is protected by one or more of the following United

States patents:

5,581,293; 5,613,790; 5,927,876; 6,088,049; 6,345,920

There may be U.S. and Foreign Patents Pending.

x PF8d/PF8t Printers User’s Guide

Page 14

1

Use this chapter to familiarize yourself with the PF8 printers. In

this chapter you will find these sections:

• Introducing the PF8 Printers

• Features of the PF8 Printers

• Understanding the LED Indicators

Using the PF8 Printers

PF8d/PF8t Printers User’s Guide 1

Page 15

Chapter 1 — Using the PF8 Printers

Introducing the PF8 Printers

The PF8 are lightweight, reliable, and easy-to-use printers. Both

printers are designed to print a low volume of labels per day (less

than 1000 labels per day). There are two models of the PF8

printer:

• The PF8d is a 203 dpi direct thermal printer.

• The PF8t is a direct thermal/thermal transfer printer that is

available in 203 and 300 dpi models.

Both PF8 printers are provided with parallel, serial RS-232, and

USB ports. As an option, both models can be fitted with a cutter

attachment, or label stripper module. The PF8t can also be fitted

with a compact flash card adapter.

The discharge of electrostatic energy accumulated on the

human body, clothing, or other surfaces can damage or

destroy the printhead or electronic components used in these

printers. Avoid touching the electrical connectors while

unpacking or setting up your printer.

2 PF8d/PF8t Printers User’s Guide

Page 16

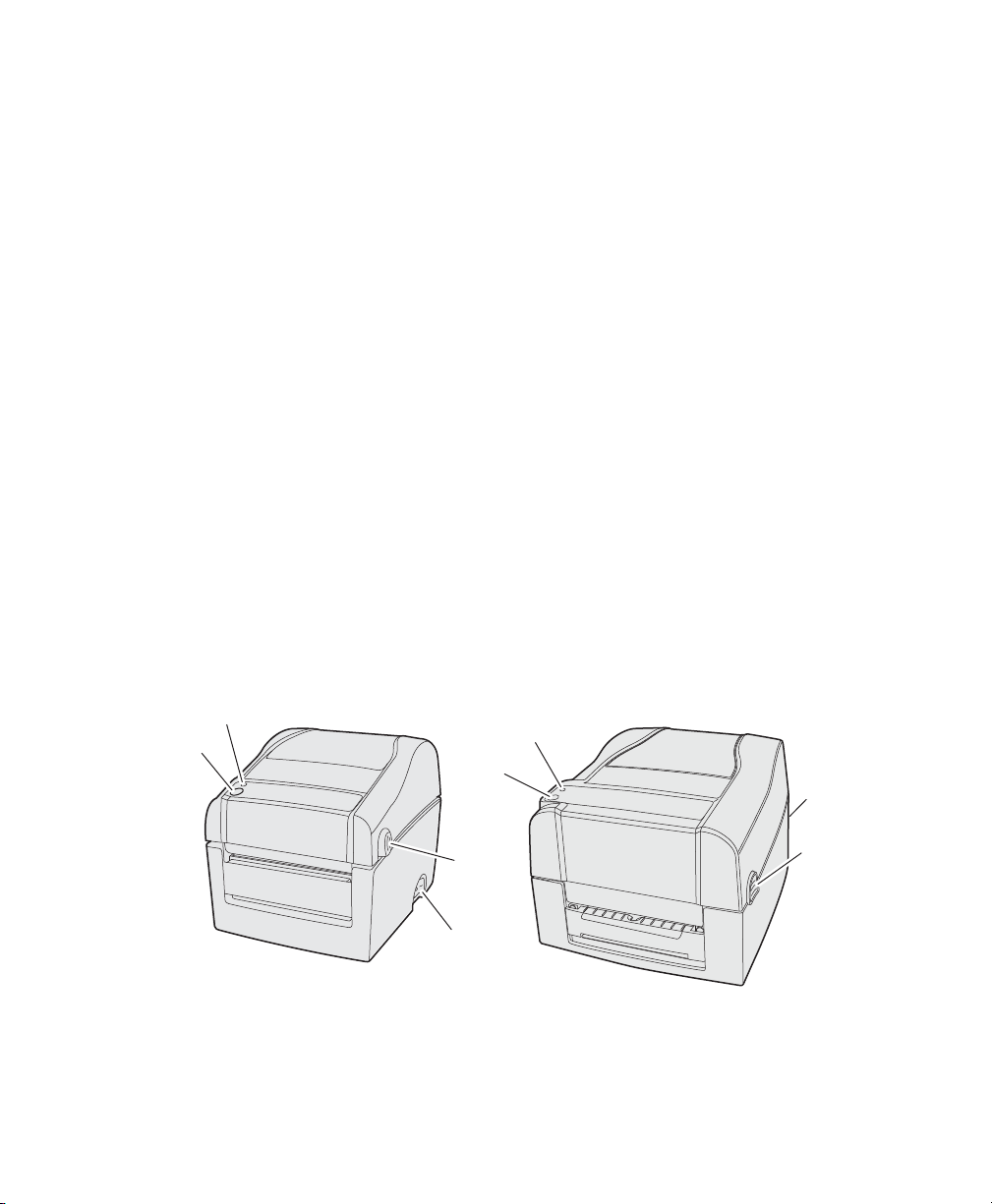

Features of the PF8 Printers

Status LED

Power

switch

Cover

open

button

Feed

button

PF8d

Status LED

Feed

button

PF8t

Cover

open

button

Power

switch

This section describes the front controls and indicators,

components of the media compartment, and connections located

on the rear of the PF8d and PF8t printers.

Front Controls and Indicators

The PF8 printers are controlled by using a Power switch, a Feed

button, and a multi-color status LED.

The Power switch is located on the side of the PF8d and on the

back of the PF8t.

You can use the Feed button in two ways:

•Tapping it

When power is turned on and the printer is loaded with

media (and possibly ribbon), tapping the Feed button causes

the media to form feed.

•Holding it down

When power is turned on, holding the Feed button down

causes the printer to enter Media Sensing mode and print the

printer configuration page when the button is released.

Chapter 1 — Using the PF8 Printers

There are also cover open buttons located on each side of the

printer which you press to access the media compartment.

PF8d and PF8t Front Controls

PF8d/PF8t Printers User’s Guide 3

Page 17

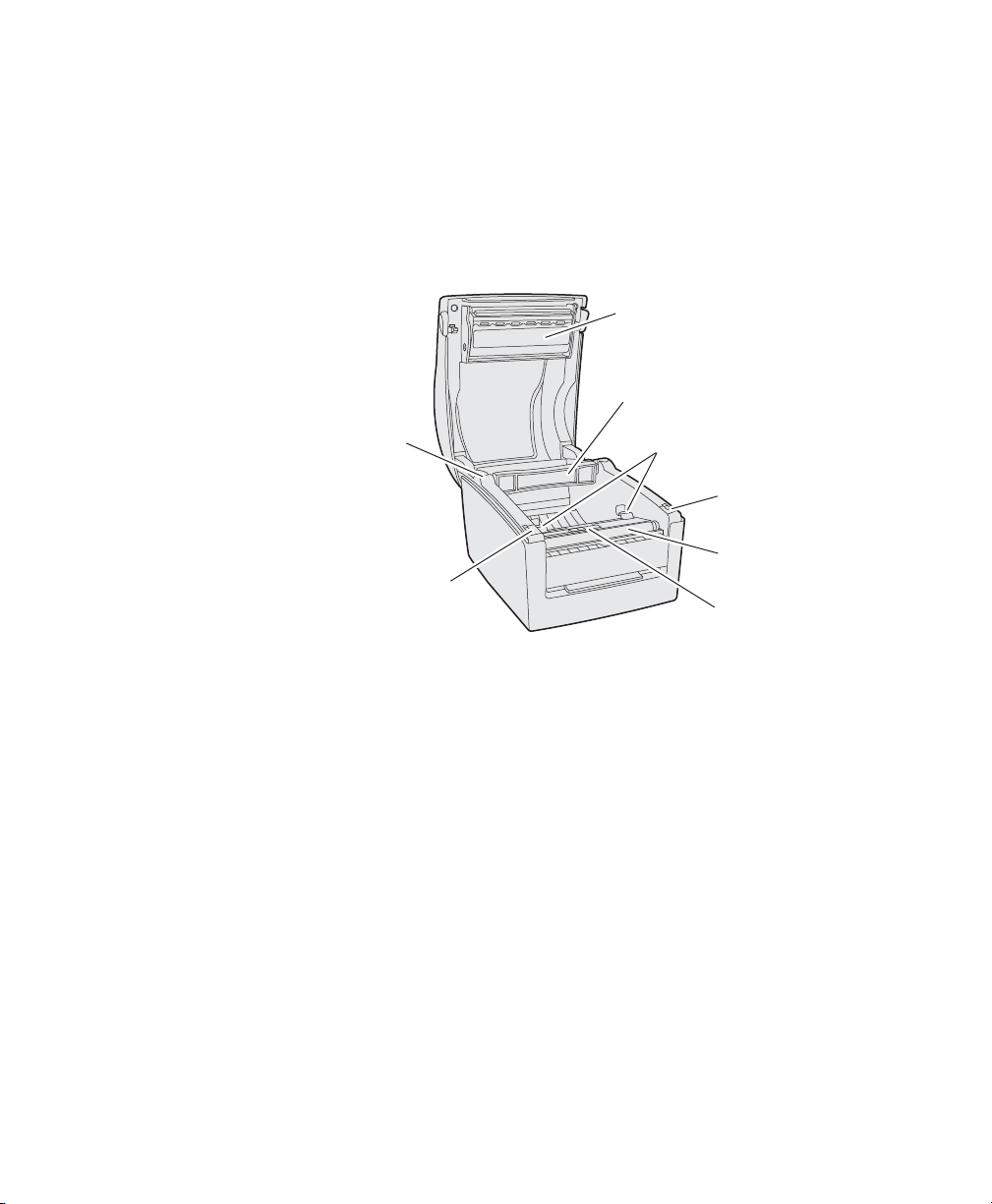

Chapter 1 — Using the PF8 Printers

Label guide

(2 places)

Print

mechanism

Label roll

holder

Black mark

sensor

Platen

roller

Platen

cover

Platen

cover

Spindle

Media Compartment

The PF8t is a thermal transfer/direct thermal capable printer.

The media compartment for thermal transfer printers

accommodates the media supply and the transfer ribbon supply.

In direct thermal printers like the PF8d, the top cover and the

print mechanism are combined into a single unit.

PF8d Media Compartment

4 PF8d/PF8t Printers User’s Guide

Page 18

Ribbon rewind

wheel

Rewind shaft

and empty

ribbon take

up core

PF8t Media Compartment

Cover open

button

Label roll

core

Print

mechanism

Locking

mechanism

(2 places)

Label guide

(2 places)

Black mark

sensor

Platen

roller

Chapter 1 — Using the PF8 Printers

Print line

adjustment

gear

Ribbon

supply

shaft

PF8d/PF8t Printers User’s Guide 5

Page 19

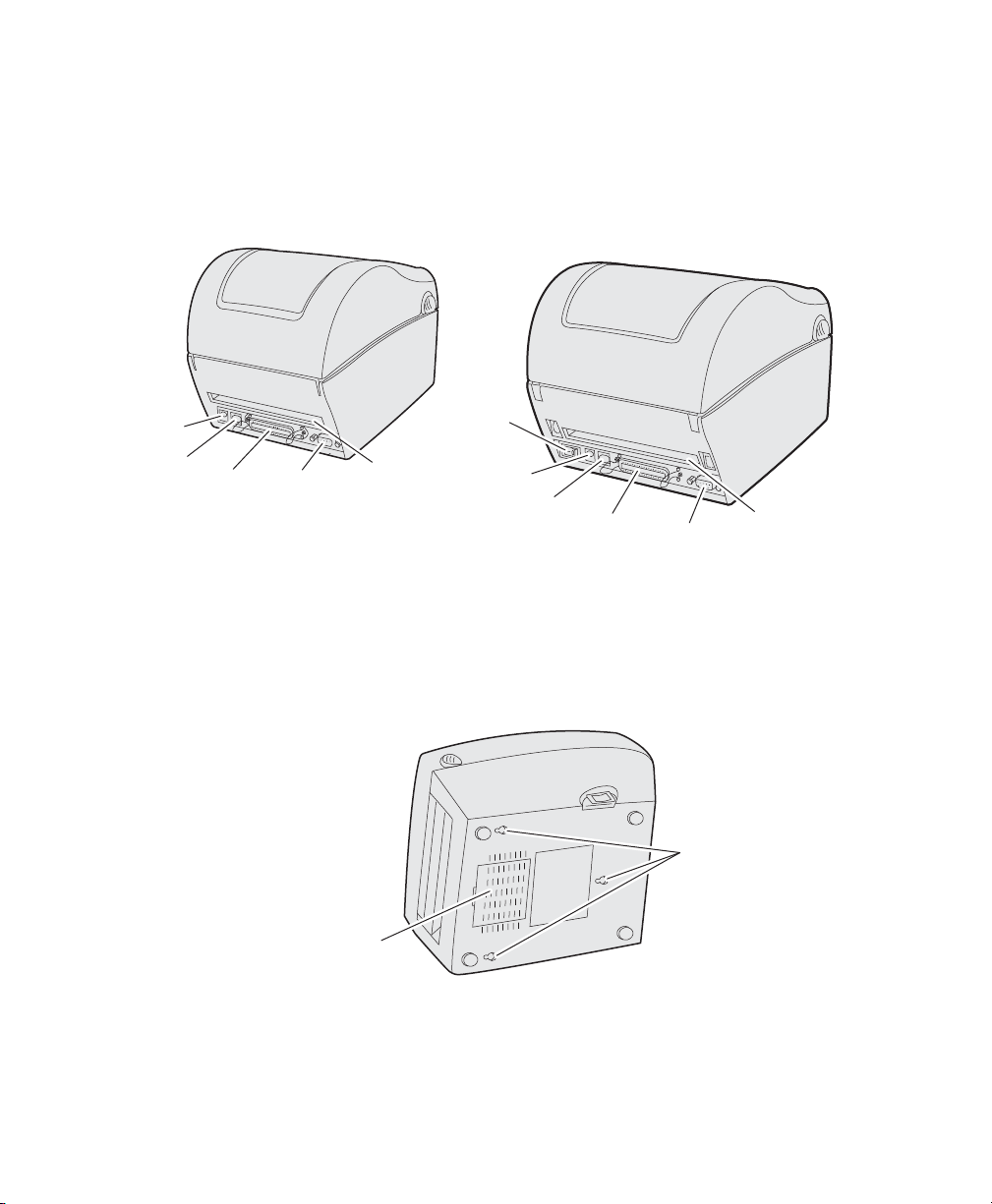

Chapter 1 — Using the PF8 Printers

Other Features and Connections

The rear and underside of the printers contain provide USB,

serial, and parallel connections and additional features.

PF8d

Power

socket

USB

Parallel

port

port

PF8d and PF8t Rear View Connections and Controls

Serial

port

(RS-232)

Fan-fold

label slot

Power

switch

Power

socket

The bottom of the PF8d also has hanger holes that allow you to

wall-mount the printer.

USB

port

Parallel

port

PF8t

Serial

port

Fan-fold

label slot

Wall-mount

holes

Bottom

case

cover

PF8d Wall-Mount Holes

6 PF8d/PF8t Printers User’s Guide

Page 20

Understanding the LED Indicators

When power to the printer to the printer is switched on, the

status LED turns green indicating that the printer is ready to

accept print commands.

If the printer runs out of media and/or ribbon during printing,

the LED glows red. Other status indicators are shown in the table

below:

LED Status Indicators

LED Meaning

Green (blinking) Autosensing mode

Green (blinking) Downloading font, form, or

Green (solid) Dump mode

Green (solid) Ready mode

Green (solid) Print mode

Orange (solid) Boot mode

Red (blinking) Media jam, overheated printhead or

Red (blinking) Downloading firmware

Red (solid) Error mode

Chapter 1 — Using the PF8 Printers

graphic

stepper motor

PF8d/PF8t Printers User’s Guide 7

Page 21

Chapter 1 — Using the PF8 Printers

8 PF8d/PF8t Printers User’s Guide

Page 22

2

Use this chapter to install your PF8d and PF8t printers. In this

chapter you will find these sections:

• Connecting the Printer to Your Network

• Turning on the Printer

• Installing the Compact Flash (PF8t Only)

• Understanding Auto-Sensing Mode

• Creating and Printing Labels

• Loading Media

Installing the Printer

• Loading Thermal Transfer Ribbon

PF8d/PF8t Printers User’s Guide 9

Page 23

Chapter 2 — Installing the Printer

Connecting the Printer to Your Network

All PF8 models are fitted with a 36-pin connector for the parallel

interface port, a 9-pin connector for the RS-232 serial interface

port, and a USB connector.

Note: The PF8 printers ship with a USB cable.

Connecting the Printer Through the USB Interface

To use the USB connection, you need to install the Intermec

InterDriver software on your computer. To ensure you get the

latest version, check the Intermec web site first. This software can

also be found on the PrinterCompanion CD. The USB interface

is not suitable for terminal connections or programming.

Connecting the Printer Through the Serial Port

You can use the serial connection with either LabelShop or the

Intermec InterDriver. You can also use it to send commands

directly through the terminal connection. A serial cable is not

included with the printer.

Connecting the Printer Through the Parallel Port

You can use the parallel connection with LabelShop or Intermec

InterDriver. The parallel port supports Windows plug and play

and additional status reporting.

Installing the Printer Driver

You must install the Intermec InterDriver print driver in order to

communicate with your PF8 printer. The InterDriver files are on

the PrinterCompanion CD that is shipped with your PF8 printer

or from the Intermec web site at http://www.intermec.com/

support/downloads/index.aspx.

To install InterDriver

1 Load the PrinterCompanion CD into your PC.

2 On the main screen, click the Software button and the

InterDriver with ActiveX Controls introduction screen

appears. Click the Installation Instructions link at the

bottom of the page.

10 PF8d/PF8t Printers User’s Guide

Page 24

Chapter 2 — Installing the Printer

3 Click the Install InterDriver link.

4 The File Download - Security Warning screen appears. Click

the Run button to run the .exe or the Save button to save it to

your PC to be run later. In this procedure, the Run button

was selected.

PF8d/PF8t Printers User’s Guide 11

Page 25

Chapter 2 — Installing the Printer

5 The Internet Explorer - Security Warning screen appears.

Click the Run button to start the InterDriver installation.

6 The Intermec End User License Agreement appears. To

continue with the installation, read the agreement and select

the radio button to accept the agreement, and then click the

Next button.

12 PF8d/PF8t Printers User’s Guide

Page 26

Chapter 2 — Installing the Printer

7 The Installation Directory screen appears. The default

installation directory is c:\Intermec\InterDriver7. Click the

Next button to use the default directory or specify a different

location to install the files.

8 Clear the Run Add Print Wizard after unpacking drivers

check box and click the Finish button.

9 On the New Hardware Wizard screen, click the Install from

a list or specific location radio button and then the Next

button to continue.

Note: For LPT connections, you must restart your PC for

Windows to detect the new hardware. For USB connections,

the New Hardware Wizard will launch automatically when

the printer is connected and turned on.

PF8d/PF8t Printers User’s Guide 13

Page 27

Chapter 2 — Installing the Printer

10 Click the Next button on the Search and Installation Options

screen.

11 Click the Continue Anyway button on the Hardware

Installation warning screen.

14 PF8d/PF8t Printers User’s Guide

Page 28

12 Click the Finish button to exit the New Hardware Wizard.

InterDriver files are now installed on your PC.

Turning On the Printer

To power the printer

Chapter 2 — Installing the Printer

1 Place the printer on a stable surface.

Danger of personal injury if the printer and power supply

are operated in an environment where they can get wet.

Only use with Intermec power supply adapter

P/N 1-092363-xx.

2 Place the power supply adapter in a suitable location between

the printer and an electrical outlet. The power supply adapter

can be use for 100 to 240 VAC, 50 to 60 Hz. The

configuration of the supplied power cord differs according to

national standards.

3 Make sure the printer’s On/Off switch is in the Off position

(O).

4 Insert the power cord’s round connector into the power

receptacle in the back of the printer.

5 Insert the power cord plug into an AC socket.

6 Turn the On/Off switch to the On position (

PF8d/PF8t Printers User’s Guide 15

⎯).

Page 29

Chapter 2 — Installing the Printer

7 The status LED will cycle from red to green indicating that

the power is turned on.

Installing the Compact Flash (PF8t Only)

The PF8t is supplied with 4MB flash memory and 8MB of

SDRAM memory. The built-in memory can be expanded by

using a compact flash card if more memory is required for your

application. You will need to purchase and install a compact flash

adapter to use a CF card.

You can select which memory source you want to use: built-in

memory or compact flash. Use Windows HyperTerminal to send

an ESim M command to the printer to select your memory

source. You can only use one memory source.

ESim memory allocation commands are:

M0 Select built-in memory

M1 Select compact flash memory

MF Format the compact flash card

For more information on ESim commands, refer to the ESim for

the PC4/PF8 Bar Code Label Printer Programmer’s Reference

Manual (P/N 1-960629-xx).

Turn the printer power off when installing or removing the

compact flash card.

To install the compact flash card

1 Turn the PF8t power off.

2 Open the top cover by pressing the cover open buttons on

either side of the top cover.

3 Remove any media and the spindle.

4 Open and remove the compact flash card slot cover from the

printer base.

16 PF8d/PF8t Printers User’s Guide

Page 30

Compact ash

card slot cover

5 Insert the compact flash card in the compact flash adapter.

Make sure that the card is oriented correctly to fit in the slot.

Push firmly to seat the card.

6 Install the compact flash card slot cover.

7 Close the top cover and turn on the printer power.

Understanding Auto-Sensing Mode

The Auto-Sensing mode can be used for the following:

Chapter 2 — Installing the Printer

• Adjusting the label gap sensor

• Printing a test label with a test pattern and list of the printer’s

current settings

•Entering Dump mode

To use Auto-Sensing mode

1 Load media in the printer.

2 Press and hold the Feed button while turning the Power

switch to the On position (

The status LED blinks green for 2 seconds, blinks red for 2

seconds, and then blinks green again.

Note: If you are using continuous stock or gap media, release

the Feed button when the status LED is blinking green. If you

are using black marked media, release the Feed button when

the LED is blinking red.

PF8d/PF8t Printers User’s Guide 17

⎯).

Page 31

Chapter 2 — Installing the Printer

3 The printer automatically adjusts the label gap sensor and

media feed according to the characteristics of the media. The

printer may feed three to four labels before the adjustment is

completed. If you are using peel-off media, remove the labels

as they are fed out.

After a short delay, a test label will print and the printer will

enter Dump mode. See the ESim for the PC4/PF8 Bar Code

Label Printer Programmer’s Reference Manual

(P/N 1-960629-xx) for additional information about Dump

mode.

4 Press the Feed button once to return to normal operation, or

press and hold the Feed button for at least 3 seconds after the

test label prints to reset the printer to the default settings. The

sttaus LED will glow red indicating that the printer was reset

to the default settings and then cycle to green.

Refer to the ESim for the PC4/PF8 Bar Code Label Printer

Programmer’s Reference Manual (P/N 1-960629-xx) for an

illustration and explanation of the test label.

Creating and Printing Labels

The PrinterCompanion CD that ships with the PF8 printers

contains software programs that you can use to configure the

printer to create a wide variety of labels. These programs include:

• LabelShop (v6.12, SP5)

• InterDriver (v7.06 M5)

• ESim Config Tool (v2.1)

Refer to the software documentation on the PrinterCompanion

CD for detailed information about using these programs.

Loading Media

Introduction

Both models of the PF8 printers can print on direct thermal

media. The PF8t also has the ability to print on thermal transfer

media such as self-adhesive labels, non-adhesive tags, or

continuous stock. When printing on thermal transfer media you

must also install a thermal transfer ribbon.

There are three ways of using media on the PF8 printers:

18 PF8d/PF8t Printers User’s Guide

Page 32

Te a r - O f f

Tear-Off (straight-through) media is fed out the front of the

printers and can be torn off by pulling it upwards against the

edge of the top cover.

Cut-Off

Cut-Off media requires an optional paper cutter fitted on the

front of the printer. The cutter is not designed to cut through

adhesive and doing so will cause the adhesive to stick to the

cutting shears and prevent the cutter from operating.

Peel-Off

Peel-Off (self-strip) media means that self-adhesive labels are

automatically separated from the label backing after printing.

Peel-Off media cannot be used with the cutter option.

Loading Media for Tear-off Operation

To load tear-off media

1 Press the cover open buttons on both sides of the case to open

the top cover. Fold the cover upwards/rearwards.

Chapter 2 — Installing the Printer

2 Pull or lift the spindle and remove the empty label roll core (if

present).

PF8d/PF8t Printers User’s Guide 19

Page 33

Chapter 2 — Installing the Printer

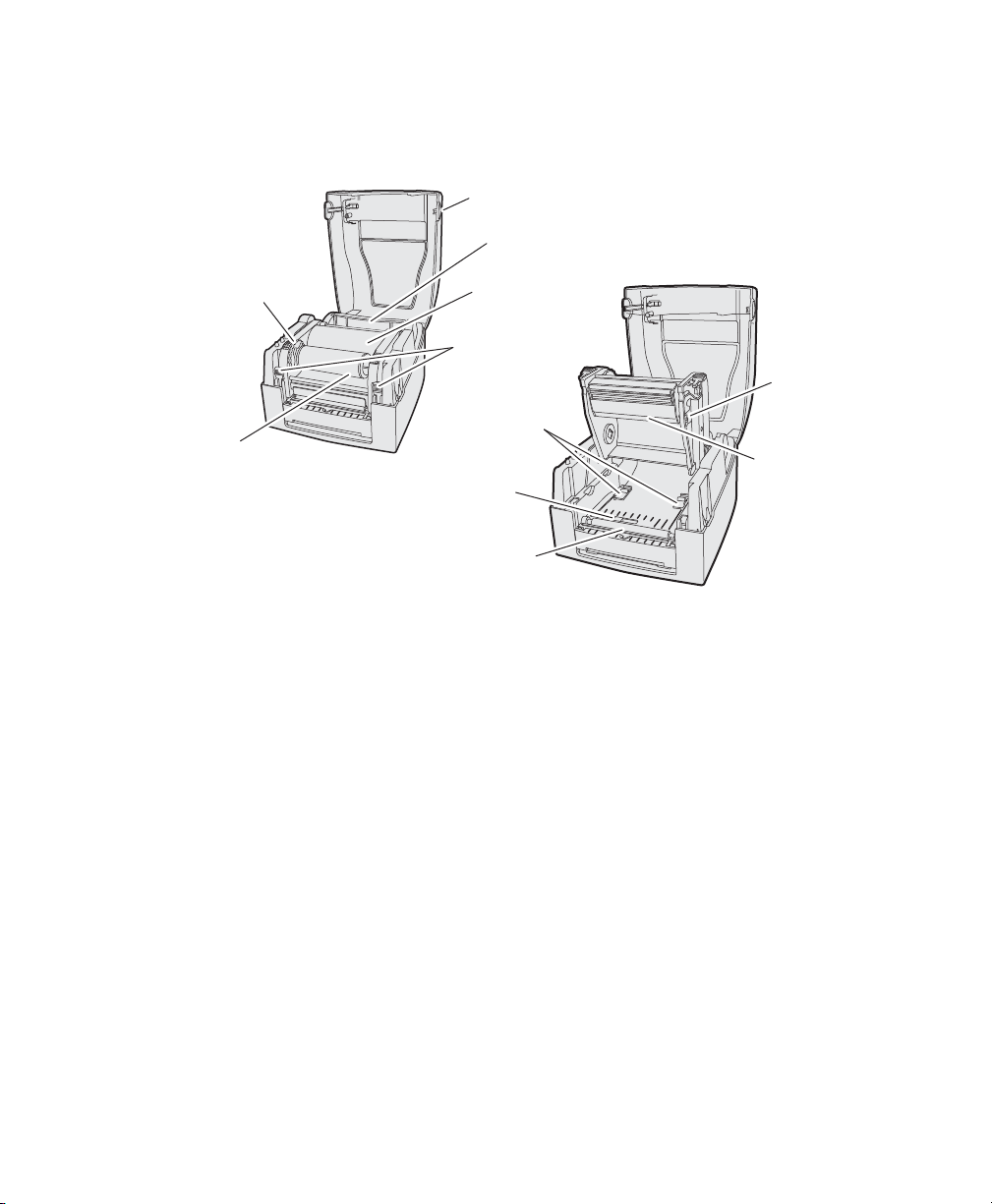

PF8d

PF8t

Note: The PF8d spindle lifts up, but remains attached to the

printer while the PF8t spindle lifts completely out of the

spindle compartment.

3 Insert the spindle into the core of a fresh media roll. Rotate

the spindle to fit the inside diameter of the core (see the core

diameter markings on the spindle).

20 PF8d/PF8t Printers User’s Guide

Page 34

Chapter 2 — Installing the Printer

PF8d

PF8t

PF8d

PF8t

4 Put the label between the label guides and pull it forward.

Note: On the PF8t you will also need to press the locking

mechanism and open the print mechanism/ribbon container

to load media and access the media adjustment tabs.

5 Adjust the label guide to fit the media you are using.

PF8d/PF8t Printers User’s Guide 21

Page 35

Chapter 2 — Installing the Printer

6 Close the top cover. On the PF8t you will first need to close

the print mechanism/ribbon container before closing the

cover.

Note: If you are loading media for the first time or changing

from another type or size of media, perform a label gap sensor

adjustment as described on page 34.

Loading Media for Peel-Off Operation

To load peel-off media

1 Press the cover open buttons on both sides of the case to open

the top cover. Fold the cover upwards/rearwards.

2 Open the peel-off mechanism on the front of the printer.

3 Pull or lift the spindle and remove the empty label roll core (if

present).

Note: The PF8d spindle lifts up, but remains attached to the

printer while the PF8t spindle lifts completely out of the

spindle compartment.

4 Insert the spindle into the core of a fresh media roll. Rotate

the spindle to fit the inside diameter of the core (see the core

diameter markings on the spindle).

5 Put the label between the label guides and pull it forward.

6 Peel away the label from the first 10 cm (4 in) of the liner.

7 Thread the liner around the peel-off bar and insert inside the

peel-off mechanism so that it protrudes from the slot below

the mechanism.

8 Hold the labels and pull on the liner until it becomes tight.

9 Close the peel-off mechanism.

10 Close the top cover.

Note: If you are loading media for the first time or changing

from another type or size of media, perform a label gap sensor

adjustment as described on page 34.

22 PF8d/PF8t Printers User’s Guide

Page 36

Loading Media for Cut-Off Operation

The cutter (optional accessory) cannot be used to cut through

labels, only through the liner between the labels. Cutting

through the labels will cause the adhesive to stick to cutting

parts and prevent the cutter from working properly. Media

rolls must be wound with the printable side facing upward to

prevent jamming the cutter.

To l oad cut- off media

1 Press the release buttons on both sides of the case to open the

top cover. Fold the cover upwards/rearwards.

2 Pull or lift the spindle and remove the empty label roll core (if

present).

Note: The PF8d spindle lifts up, but remains attached to the

printer while the PF8t spindle lifts completely out of the

spindle compartment.

3 Insert the spindle into the core of a fresh media roll. Rotate

the spindle to fit the inside diameter of the core (see the core

diameter markings on the spindle).

Chapter 2 — Installing the Printer

4 Put the label between the label guides and pull the label

forward.

5 Adjust the label guide to fit the media you are using.

6 Route the media through the slot in the optional cutter

mechanism just in front of the tear bar.

7 Close the top cover.

Note: If you are loading media for the first time or changing

from another type or size of media, perform a label gap sensor

adjustment as described on page 34.

Loading an Media from an External Supply

Insert the media through the slot in the back of the printer.

Follow the instructions for the type of media you are using. The

spindle is not used when using an external media supply.

Note: Be careful to protect an external media supply from dirt,

grit, dust, water, and direct sunlight.

PF8d/PF8t Printers User’s Guide 23

Page 37

Chapter 2 — Installing the Printer

Loading Thermal Transfer Ribbon (PF8t Only)

Thermal transfer ribbons are required when you print on thermal

transfer (non-heat sensitive) media. The type of transfer ribbon

you use should match the face materials of the media to obtain

the best durability and print quality.

To load a fresh ribbon roll

1 Press the cover open buttons on both sides of the case to open

the top cover. Fold the cover upwards/rearwards.

2 Press the green release tabs at the bottom of the top cover on

both sides of the printhead.

24 PF8d/PF8t Printers User’s Guide

Page 38

Chapter 2 — Installing the Printer

3 Lift the print carriage halfway up while keeping the top cover

fully opened. Insert a new ribbon roll onto the ribbon supply

shaft.

4 Feed the transfer ribbon from the ribbon supply shaft under

the printhead.

5 Wrap the ribbon around the ribbon shaft. Using the tape

fitted at the front of the ribbon leader, attach the leader to the

top of the rewind core. Be careful to center align the ribbon

leader with the core.

PF8d/PF8t Printers User’s Guide 25

Page 39

Chapter 2 — Installing the Printer

6 Close the print carriage by pressing firmly down on both

sides. A loud click indicates the print carriage locked into

place.

7 Firmly close the printer’s top cover.

8 Tap th e Feed button until the status LED glows green.

When you switch between direct thermal and thermal transfer

printing, or when you switch between different types of transfer

ribbon, you can remove a partially used transfer ribbon and save

it for later use.

To remove a partially used ribbon

1 Press the cover open buttons on both sides of the case to open

the top cover. Fold the cover upwards/rearwards.

2 Press the green release tabs at the bottom of the top cover on

both sides of the printhead and lift the print carriage halfway

up while keeping the top cover fully opened.

3 Using a pair of scissors, cut the transfer ribbon just below the

rewind roll.

4 Rewind the unused ribbon onto the supply spool. Remove the

roll by pushing it to the left until the right end disengages

then lift the roll up. Fasten the loose end with a piece of tape

or label to prevent the roll from unwrapping.

26 PF8d/PF8t Printers User’s Guide

Page 40

Chapter 2 — Installing the Printer

5 Remove the rewind roll by pushing it to the left until the right

end disengages, then lift out. Dispose of the used ribbon.

Note: Keep the ribbon core. You will need it the next time you

load ribbon.

PF8d/PF8t Printers User’s Guide 27

Page 41

Chapter 2 — Installing the Printer

28 PF8d/PF8t Printers User’s Guide

Page 42

3

Troubleshooting and Maintaining the Printer

Use this chapter to troubleshoot and maintain your PF8d and

PF8t printers. This chapter contains these sections:

• Troubleshooting

• Upgrading the Firmware

•Cleaning the Case

• Cleaning the Printhead

• Adjusting the Thermal Printhead Pressure

• Adjusting the Print Alignment

• Adjusting the Label Taken Sensor

• Adjusting the Label Gap Sensor

PF8d/PF8t Printers User’s Guide 29

Page 43

Chapter 3 — Troubleshooting and Maintaining the Printer

Troubleshooting

Problem Solution or Reason

LED not green when power

is on.

LED is green but printer will

not feed.

Printer seems to be working

but nothing prints.

Print quality is poor. Clean the printhead. If cleaning the printhead does not improve

Partial labels printed. • Print carriage is not completely locked.

Printer continues print or

feed when it should stop

printing.

Printing stops and indicator

LED glows orange.

Label stuck on roller. Open the peel-off mechanism and peel off the stuck label while

Label taken sensor does not

hold printing until the label/

tag has been removed.

Indicator LED flashes red

and printing is interrupted.

Make sure connections on the power supply are securely plugged

into the AC receptacle on the printer and to an AC outlet.

• Label taken sensor active, label not removed.

• Make sure correct type of interface cable is securely plugged in

to both the printer and computer.

Direct Thermal Printing

• Check that the heat sensitive side of the media faces the

printhead.

• Verify that the media is intended for direct thermal printing

by testing to see if the media is blackened by heat from a hot

object (70

Thermal Transfer Printing

• Verify that the printer is loaded with thermal transfer ribbon

and that the ink coated side faces the media surface.

print quality, adjust the printhead contact.

• Label caught on printhead. Remove label and clean

printhead.

• Label caught on the label gap sensor. Open the top cover,

remove the label and clean the printhead using the Cleaning

Card or isopropyl alcohol.

• Possible firmware problem.

• Possible problem with label gap sensor. Perform an auto

adjust in Auto-Sensing mode.

• Possible media jam.

• Possible firmware problem.

manually rotating the roller. Do not use any sharp tools to

remove the label. Clean the peel-off mechanism using the

Cleaning Card or isopropyl alcohol.

• Label/tag bend down due to excessive length and/or too thin

or soft media.

• Label or tag too short.

• Label taken sensor or cable defective.

Overheated. Wait for the printer to cool down and the indicator

LED changes to green and printing (if halted) resumes.

°C [160°F] or higher).

30 PF8d/PF8t Printers User’s Guide

Page 44

Chapter 3 — Troubleshooting and Maintaining the Printer

Upgrading the Firmware

To upgrade the printer firmware you will need the following:

• The Intermec ESim Config Tool for the PF8, which is on the

PrinterCompanion CD that ships with the printer, or can be

downloaded at www.intermec.com. You can use the Config

Tool to download a new firmware version directly to the

printer. The Config Tool also supports font downloading and

memory partitioning. It supports seven languages and comes

with comprehensive online help.

• An upgrade file (.ufz). You can also download new upgrade

files from www.intermec.com.

• A host PC running Microsoft Windows with a USB, parallel,

or serial RS-232 connection. Parallel or USB connections are

recommended.

Cleaning the Case

Keep your PF8 printer clean by periodically wiping it with a soft

cloth dampened with water. Do not use abrasive cleaners or

solvents that will scratch the surface of the case.

Cleaning the Printhead

Intermec recommends using the special Cleaning Card

(P/N 1-110501-00) and the procedure below to clean the

printhead before loading a new media roll.

To clean the printhead

1 Turn off power to the printer.

2 Open the top cover/print carriage.

3 Unload the media stock. If you are doing thermal transfer

printing, also remove the transfer ribbon.

4 Insert the cleaning card under the print carriage as when

loading media. Approximately 2 to 3 cm (1 in) of the card

should extend to the front of the printhead.

5 Fold down the print carriage to the locked position.

PF8d/PF8t Printers User’s Guide 31

Page 45

Chapter 3 — Troubleshooting and Maintaining the Printer

Adjustment

screws

(2 places)

PF8t

6 Use one hand to hold the printer and the other hand to pull

the cleaning card forward until you pull the card out of the

printer.

7 Repeat Steps 4-6 to complete a second cleaning pass.

8 Dispose of the used cleaning card and reload media and

ribbon supplies.

Adjusting the Thermal Printhead Pressure (PF8t only)

When you print with different label materials or use different

types of ribbons, print quality may affected due to differences in

the material. If this happens you will need to adjust the thermal

printhead pressure for the type of material you are using.

To adjust thermal printhead pressure

1 Turn off power to the printer.

2 Press the cover open buttons on both sides of the case to open

the top cover. Fold the cover upwards/rearwards.

3 Using a straight-slot screwdriver, turn the screws clockwise to

increase printhead pressure or counterclockwise to decrease

printhead pressure.

32 PF8d/PF8t Printers User’s Guide

Page 46

Chapter 3 — Troubleshooting and Maintaining the Printer

Adjusting the Printhead Alignment

You can improve the print quality by adjusting the alignment

between the printhead and the platen roller.

• Turn the printhead adjusting screw counterclockwise or

clockwise to adjust the contact surface (alignment) between

the printhead and the platen roller.

Adjustment

screw

PF8t

Adjusting the Label Taken Sensor

The built-in label taken sensor can be enable to stop printing

until a printed label is removed from the printer’s output slot. As

long as the label taken sensor detects a label, the printer will be

busy and unable to receive data from the host.

When you are using the ESim protocol, note the following:

• The label taken sensor must be enabled using the manual

switch next to the sensor before it can be enabled or disabled

using ESim commands.

• When switching between peel-off, tear-off, and cut-off

operation, you must adjust the media feed in ESim by using a

j command.

If you are using InterDriver you can select a mode of operation

without issuing commands. You can select the following modes:

PF8d/PF8t Printers User’s Guide 33

Page 47

Chapter 3 — Troubleshooting and Maintaining the Printer

•Tear-off

• Peel-off with label taken sensor enabled

• Peel-off with label taken sensor disabled

Adjusting the Label Gap Sensor

The PF8 printers are fitted with a label gap sensor that detects the

slots between tickets and tags or gaps between labels as media if

fed past the sensor during printing. The label gap sensor

determines the length or tag or labels and controls the media/

ribbon feed accordingly.

The label gap sensor is a center-aligned photoelectric sensor that

measures the light that passes through the media path. The

transparency of the liner of a label supply may change from batch

to batch, making it difficult for the sensor to determine the

length of the media. If this happens, the status LED will change

from green to orange, indicating you need to adjust the sensor

using the Auto-Sensing mode. For more information see

“Understanding Auto-Sensing Mode” on page 17.

34 PF8d/PF8t Printers User’s Guide

Page 48

A

This appendix provides technical specifications for the PF8d and

PF8t printers and their available features and options.

Specifications

PF8d/PF8t Printers User’s Guide 35

Page 49

Appendix A — Specifications

PF8d Specifications

Resolution

8 dot/mm (203 dpi)

Print Mode

Direct Thermal

CPU

32 bit

Memory

4MB flash, 8MB SDRAM

Print Speed

2, 3, and 4 ips

Print Length

Max. 1727 mm (68 in) Min. 12.0 mm (0.47 in)

Print Width

Max. 104 mm (4.09 in)

Sensor Type

Adjustable reflective sensor, Fixed transmissive sensor center

aligned

Sensor Detection

Label gap and black mark sensing, Label length autosensing and/

or program command setting

Media

Label roll outside diameter: Max. 127 mm (5 in)

Core diameter: 25 mm, 38 mm (1 in, 1.5 in)

Width: 25 mm to 118 mm (1 in to 4.65 in)

Thickness: 0.05 to 0.18 mm (.002 to .007 in)

Firmware

ESim (v7.x)

Software

ActiveX Controls (v1.3)

InterDriver (v7.06 M5)

ESim Config Tool (v2.1)

LabelShop Patch (v6.12 SP5)

Resident Fonts

6, 7, 10, 12, 24 points

36 PF8d/PF8t Printers User’s Guide

Page 50

Appendix A — Specifications

Fonts Download

Windows bitmap font: Can be rotated in 8 orientations and

expandable 8 times horizontally and vertically

TrueType Font: v2.xx can be rotated in 4 orientations

Image Handling

BMP, PCX, Support ICO, WMF, JPG, EMF files through

software.

Bar Codes

Code 39, Code 93, Code 128 (subset A, B, C), UCC/EAN-128,

UPC A / E (add on 2 & 5), I 2 of 5, I 2 of 5 with check digit, I 2

of 5 with human readable check digit, EAN 8 / 13 (add on 2 &

5), Codabar, Post NET, MaxiCode, PDF417, Datamatrix code,

QR code, UPC SCC, EAN?UCC composite code

Interfaces

Serial port: RS-232 (Baud rate: 1200 to 115200, XON/XOFF,

RTS/CTS)

USB port: v2.0

Parallel port: Compatible mode

Control Panel

One tri-color power LED, Feed function button.

Power

Input: ~100-240V 1,6A 50/60 Hz

Output: 24V 2,5A

Environment

Operation: 5°C to 40°C (40°F to 104°F)

Storage: -20°C to 50°C) (-4°F to 122°F)

Certification

cULus, FCC Class A, CCC, CE, cUL, BSMI

Humidity

Operation: 30% to 85%, non-condensing. Free air

Storage: 10% to 90%, non-condensing. Free air

Printer Dimensions

Length: 218 mm (8.58 in)

Height: 166 mm (6.53 in)

Width: 168 mm (6.61 in)

Weight: 2.0 Kg (4.4 lbs)

PF8d/PF8t Printers User’s Guide 37

Page 51

Appendix A — Specifications

Communication Interfaces

Serial Interface Connections

Pin Host - DB9 Socket Printer - DB9 Plug

1 +5V, max 500ma

2 RXD TXD

3TXDRXD

4 DTR N/C

5 GND GND

6 DSR RTS

7RTSCTS

8 CTS RTS

9RIN/C

Note: The total current output from the serial port cannot exceed

500 ma.

Serial Default: 9600 baud, no parity, 8 data bits, 1 stop bit,

XON/XOFF protocol

Setting: RTX/CTS

RS-232 Housing: 9-pin to 9-pin

USB Interface

Pin Function

1VBUS

2 D3D+

4 GND

Connector Type: B

38 PF8d/PF8t Printers User’s Guide

Page 52

Appendix A — Specifications

Parallel Interface

Pin Function Transmitter

1/Strobehost/printer

2-9 Data 0-7 host

10 /Acknowledge printer

11 Busy printer

12 /Paper empty printer

13 /Select printer

14 /Auto line feed host/printer

15 N/C

16 N/C

17 N/C

18 +5V, max 500ma

19-30 Signal GND host

31 /Initialize host/printer

32 /Error printer

33 Signal GND

34-35 N/C

36 /Select in host/printer

Handshake: DSTB connects to the printer, BUSY connects to

the host

Interface cable: Parallel cable compatible with PC

PF8d/PF8t Printers User’s Guide 39

Page 53

Appendix A — Specifications

Internal Interface

Pin UART1 Wafer Ethernet Module

1N.CN.C

2 TXD RXD

3RXDTXD

4 CTS RTS

5 GND GND

6 RTS CTS

7 E_MD E_MD

8 RTS CTS

9 E_RST E_RST

10 +5V +5V

11 GND GND

12 +5V +5V

PF8t Specifications

Resolution

8 dot/mm (203 dpi) or 12 dot/mm (300 dpi)

Print Mode

Direct Thermal/Thermal Transfer

CPU

32 bit

Memory

4MB flash, 8MB SDRAM

Print Speed

2, 3, and 4 ips

Print Length

203 dpi Max. 1727 mm (68.0 in) Min. 12 mm (0.47 in)

300 dpi Max. 900 mm (35.43 in) Min. 12 mm (0.47 in)

Print Width

Max. 104 mm (4.09 in)

Sensor Type

Adjustable reflective sensor, Fixed transmissive sensor center

aligned

40 PF8d/PF8t Printers User’s Guide

Page 54

Appendix A — Specifications

Sensor Detection

Label gap and black mark sensing, Label length autosensing and/

or program command setting

Media

Label roll outside diameter: Max. 127 mm (5.00 in)

Core diameter: 25 mm, 38 mm (1 in, 1.5 in)

Width: 25 mm to 118 mm (1 in to 4.65 in)

Thickness: 0.05 to 0.18 mm (.0025 to .0098 in)

Firmware

ESim (v7.x)

Software

ActiveX Controls (v1.3)

InterDriver (v7.06 M5)

ESim Config Tool (v2.1)

LabelShop Patch (v6.12 SP5)

Resident Fonts

203 dpi: 6, 7, 10, 12, 24 points

300 dpi: 4, 6, 8, 10, 21 points

Fonts Download

Windows bitmap font: can be rotated in 8 orientations and

expandable 8 times horizontally and vertically

TrueType Font: v2.xx can be rotated in 4 orientations

Image Handling

BMP, PCX, Support ICO, WMF, JPG, EMF files through

software.

Bar Codes

Code 39, Code 93, Code 128 (subset A, B, C), UCC/EAN-128,

UPC A / E (add on 2 & 5), I 2 of 5, I 2 of 5 with check digit, I 2

of 5 with human readable check digit, EAN 8 / 13 (add on 2 &

5), Codabar, Post NET, MaxiCode, PDF417, Datamatrix code,

QR code, UPC SCC, EAN?UCC composite code

Interfaces

Serial port: RS-232 (Baud rate: 4800 to 115200, XON/XOFF,

RTS/CTS)

USB port: v2.0

Parallel port: Compatible mode

Control Panel

One tri-color power LED, Feed function button

PF8d/PF8t Printers User’s Guide 41

Page 55

Appendix A — Specifications

Power

Input: ~100-240V 1,6A 50/60 Hz

Output: 24V 2,5A

Environment

Operation: 5°C to 40°C (40°F to 104°F)

Storage: -20°C to 50°C) (-4°F to 122°F)

Certification

cULus, FCC Class A, CCC, CE, cUL, BSMI

Humidity

Operation: 30% to 85%, non-condensing. Free air

Storage: 10% to 90%, non-condensing. Free air

Printer Dimensions

Length: 285 mm (11.2 in)

Height: 172 mm (6.8 in)

Width: 226 mm (8.9 in)

Weight: 2.5 Kg (5.5 lbs)

Communication Interfaces

Serial Interface Connections

Pin Host - DB9 Socket Printer - DB9 Plug

1 +5V, max 500ma

2 RXD TXD

3TXDRXD

4 DTR N/C

5 GND GND

6 DSR RTS

7RTSCTS

8 CTS RTS

9RIN/C

Note: The total current output from the serial port cannot exceed

500 ma.

Serial Default: 9600 baud, no parity, 8 data bits, 1 stop bit,

XON/XOFF protocol

Setting: RTX/CTS

42 PF8d/PF8t Printers User’s Guide

Page 56

Appendix A — Specifications

RS-232 Housing: 9-pin to 9-pin

USB Interface

Pin Function

1VBUS

2 D3D+

4 GND

Connector Type: B

Parallel Interface

Pin Function Transmitter

1/Strobehost/printer

2-9 Data 0-7 host

10 /Acknowledge printer

11 Busy printer

12 /Paper empty printer

13 /Select printer

14 /Auto line feed host/printer

15 N/C

16 N/C

17 N/C

18 +5V, max 500ma

19-30 Signal GND host

31 /Initialize host/printer

32 /Error printer

33 Signal GND

34-35 N/C

36 /Select in host/printer

Handshake: DSTB connects to the printer, BUSY connects to

the host

Interface cable: Parallel cable compatible with PC

PF8d/PF8t Printers User’s Guide 43

Page 57

Appendix A — Specifications

Internal Interface

Pin UART1 Wafer Ethernet Module

1N.CN.C

2 TXD RXD

3RXDTXD

4 CTS RTS

5 GND GND

6 RTS CTS

7 E_MD E_MD

8 RTS CTS

9 E_RST E_RST

10 +5V +5V

11 GND GND

12 +5V +5V

Pin UART2 Wafer Expansion Module

1 +5V +5V

2 CTS RTS

3TXDRXD

4 RTS CTS

5RXDTXD

6 GND GND

Accessories

You can use these accessories (sold and ordered separately) with

the PF8 printers. Installation instructions are provided in each

kit. Serial and parallel cables, media, and transfer ribbons are also

available for the PF8 printers. To order accessories, media, or

transfer ribbon, contact your local Intermec sales representative.

Cutter Kit

The cutter is designed to cut off continuous paper-based stock or

liner between labels.

44 PF8d/PF8t Printers User’s Guide

Page 58

Stripper Module

Appendix A — Specifications

The self-strip feature peels the label away from the liner (backing

paper) and presents the label to the operator for easier and faster

on-demand labeling.

PF8d/PF8t Printers User’s Guide 45

Page 59

Appendix A — Specifications

46 PF8d/PF8t Printers User’s Guide

Page 60

B

This appendix explains the different types of media that the PF8

printers can use and indicates the allowed dimensions of that

media.

Media Specifications

PF8d/PF8t Printer User’s Guide 47

Page 61

Appendix B — Media Specifications

Direct Thermal Media

Intermec offers a premium and an economy grade of direct

thermal media for the PF8 printers:

Premium Quality

Top-coated media with high demands on printout quality and

resistance against moisture, plasticizers and vegetable oils.

Examples of Premium Quality Media

Europe North America

Thermal Top Board Duratherm Ltg.

Thermal Top Duratherm IR

Thermal Top High Speed

Economy Quality

Uncoated media with less resistance to moisture, plasticizers and

vegetable oils. In all other respects, it is equal to premium quality.

Examples of Economy Quality Media

Europe North America

Thermal Eco Duratherm II

Thermal Eco Board Duratherm II Tag

Thermal Transfer Media

Intermec offers stock media for thermal transfer printing in a

wide range of quality grades.

Uncoated Papers

Used for economical high-volume printing in combinations with

GP/TMX1500 ribbons.

Examples of Uncoated Papers

Europe North America

TTR Uncoated Not Available

48 PF8d/PF8t Printer User’s Guide

Page 62

Chapter B — Media Specifications

Coated Papers

Coated papers have various coat-weight, smoothness, and gloss.

To be used with HP/TMX2200 and GP/TMX1500 ribbons.

Examples of Coated Papers

Europe North America

TTR Matte Duratran II

TTR Premium Duratran II Tag

TTR Premium Board

Polyethylene Plastics

Good resistance to water and many common chemicals. Can be

used outdoors and offers good tear resistance. Most often used in

combination with HP/TMX2200 ribbons.

Examples of Polyethylene Plastics

Europe North America

TTR Polyethylene Duratran II Kimdura

TTR Gloss Polyethylene Duratran II Synthetic Tag

Duratran II Syntran

Polyesters

The materials of choice in combination with HR/TMX3201/

TMX3202 ribbons. Gives high resistance to chemicals, heat, and

mechanical abrasion.

Examples of Polyesters

Europe North America

TTR High Gloss Polyester Duratran II Gloss Polyester

PF8d/PF8t Printer User’s Guide 49

Page 63

Appendix B — Media Specifications

Transfer Ribbons

Intermec offer three types of thermal transfer ribbons optimized

for different purposes:

General Purpose (GP/TMX1500)

General purpose transfer ribbons allow high speed printing and

give a good printout, but are somewhat sensitive to smearing.

These are best suited choice for uncoated and coated papers.

High Performance (HP/TMX2200)

High performance transfer ribbons allow high speed printing and

gives a highly readable and defined printout on most face

materials with smooth surfaces. They have good “smear

resistance” and are most suitable for intricate logotypes and

images on matte coated papers and synthetic face materials.

High Resistance (HR/TMX3201/TMX3202)

High resistance transfer ribbons give an extremely durable

printout that is resistant to most chemical agents and high

temperatures. However, such transfer ribbons set high demands

on the receiving face material, which must be very smooth, such

as polyesters.

Note: Intermec thermal transfer ribbons are engineered

specifically for the PF8 printheads.

50 PF8d/PF8t Printer User’s Guide

Page 64

Labels

a

b

c

LABELS

Chapter B — Media Specifications

Media width includes liner (a)

Maximum:116.0 mm (4.57 in)

Minimum: 25.0 mm (1 in)

Label length (b)

Minimum: 6.35 mm (0.25 in)

Label gap height (c)

Maximum: 10 mm (0.39 in)

Minimum: 2 mm (0.08 in)

Liner

Opacity: 75%

PF8d/PF8t Printer User’s Guide 51

Page 65

Appendix B — Media Specifications

a

c

TICKETS,TAGS, &

CONTINUOUS STRIP

d

b

Tags and Strip with Slots

Tag or strip width (a)

Maximum: 116.0 mm (4.57 in)

Minimum: 25.0 mm (1.00 in)

Tag length (b)

Minimum: 6.35 mm (0.25 in)

Detection slot width (c)

Minimum: 14 mm (0.55 in)

Detection slot height (d)

Maximum: 10 mm (0.39 in)

Minimum: 1 mm (0.08 in)

The label gap sensor is offset 4.5 mm (0.177 in) to the right of

the center of the media path.

52 PF8d/PF8t Printer User’s Guide

Page 66

Tags and Strip with Black Marks

Tag or strip width (a)

Maximum: 116.0 mm (4.57 in)

Minimum: 25.0 mm (1.00 in)

Tag length (b)

Minimum: 6.35 mm (0.25 in)

Detection slot/Black mark width (c)

Minimum: 28 mm (1.10 in)

Black mark height (d)

Maximum: 10 mm (0.39 in)

Minimum: 3 mm (0.12 in)

The black mark sensor is offset 10 mm (0.394 in) to the right of

the center of the media path.

Max. reflectance 5% at 940 nanometer. Carbon black.

a

Chapter B — Media Specifications

b

c

d

TICKETS,TAGS, &

CONTINUOUS STRIP

PF8d/PF8t Printer User’s Guide 53

Page 67

Appendix B — Media Specifications

Plain Continuous Stock

The PF8 printers can use continuous stock without any detection

slots or black marks. The printer must be set for continuous stock

by using the ESim Q command (see ESim Programmer’s Reference

Manual).

The length of each copy is decided by the size of the print image

and any additional media feed is decided by the Q command.

Continuous stock cannot be used in the Auto-Sensing mode.

Tag or strip width (a)

Maximum: 116.0 mm (4.57 in)

Minimum: 25.0 mm (1.00 in)

a

CONTINUOUS STRIP

54 PF8d/PF8t Printer User’s Guide

Page 68

Worldwide Headquarters

6001 36th Avenue West

Everett, Washington 98203

U.S.A.

tel 425.348.2600

fax 425.355.9551

www.intermec.com

PF8d/PF8t Printer User’s Guide

*934-011-002*

P/N 934-011-002

Loading...

Loading...