Page 1

User’s Guide

EasyCoder® PD42

Printer

Page 2

Intermec Technologies Corporation

Worldwide Headquarters

6001 36th Ave.W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is provided solely for the purpose of allowing customers to

operate and service Intermec-manufactured equipment and is not to be released, reproduced, or

used for any other purpose without written permission of Intermec Technologies Corporation.

Information and specifications contained in this document are subject to change without prior

notice and do not represent a commitment on the part of Intermec Technologies Corporation.

© 2007 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, Beverage Routebook, CrossBar,

dcBrowser, Duratherm, EasyADC, EasyCoder, EasySet, Fingerprint, INCA (under license), igistics, Intellitag, Intellitag Gen2, JANUS, LabelShop, MobileLAN, Picolink, Ready-to-Work,

RoutePower, Sabre, ScanPlus, ShopScan, Smart Mobile Computing, SmartSystems, TE 2000,

Trakker Antares, and Vista Powered are either trademarks or registered trademarks of Intermec

Technologies Corporation.

There are U.S. and foreign patents as well as U.S. and foreign patents pending.

ii EasyCoder PD42 Printer User’s Guide

Page 3

Contents

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Global Services and Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Web Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Telephone Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Who Should Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Using the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1

Introducing the EasyCoder PD42 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Front View of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Back View of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Media Compartment and Print Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . 4

Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Working With the Print Button and LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 6

Working With the Display and the Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2

Connecting the Printer to Your System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting the Printer Through the USB Interface . . . . . . . . . . . . . . . . . .10

Connecting the Printer Through the Serial Port . . . . . . . . . . . . . . . . . . . . . 11

Connecting the Printer Through the Parallel Port. . . . . . . . . . . . . . . . . . . . 11

Connecting the Printer to a Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Connecting Peripherals Through USB Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting a Mass Storage Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connecting a Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting a Bar Code Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting a USB Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Loading Media for Tear-Off (Straight-Through) Operation . . . . . . . . . . . . 14

Loading Media for Peel-Off (Self-Strip) Operation. . . . . . . . . . . . . . . . . . . 17

EasyCoder PD42 Printer User’s Guide iii

Page 4

Loading Thermal Transfer Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Plugging in the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Printing Test Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Creating and Printing a Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Configuring the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3

Understanding Printer States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Understanding the Printer Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Changing Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Changing Configuration Settings From the Display . . . . . . . . . . . . . . . . . 31

Changing Configuration Settings With PrintSet 4. . . . . . . . . . . . . . . . . . . 33

Changing Configuration Settings From the Printer Home Page . . . . . . . . 33

Changing Configuration Settings Using the Command Line. . . . . . . . . . . 33

Running Testmode and Extended Testmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Running Testmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Running Extended Testmode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Upgrading the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting and Maintaining the Printer . . . . . . . . . . . 39

4

Printer Operation Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Troubleshooting Communication Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Using the Line Analyzer (Fingerprint) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Using Dumpmode (IPL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Contacting Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Adjusting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Preventing Ribbon Wrinkling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Clearing Media Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Adjusting the Printhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Adjusting Printhead Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Adjusting Printhead Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

iv EasyCoder PD42 Printer User’s Guide

Page 5

Adjusting Printhead Dot Line . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Adjusting the Label Gap Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Maintaining the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Cleaning the Printhead. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleaning the Media Compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cleaning the Exterior of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Specification, Interfaces, and Options. . . . . . . . . . . . . . . . . . . . . 59

A

Printer Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

RS-232 Serial Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Interface Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

USB Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

USB Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

EasyLAN Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Parallel IEEE 1284 Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Interface Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

EasyLAN Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Parallel IEEE 1284 Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cutter Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Internal Rewinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Printhead Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Real Time Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Media Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

B

Media Roll Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Internal Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Ribbon Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Paper Types and Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Non-Adhesive Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Self-Adhesive Strip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Self-Adhesive Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Tickets With Gaps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Tickets With Black Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

EasyCoder PD42 Printer User’s Guide v

Page 6

Setup Parameters (Fingerprint) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

C

Setup Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Navigating the Setup Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Serial Communication Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Com Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Emulation Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Feed Adjust Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Media Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Print Defs Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Network Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Setup Parameters (IPL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

D

Setup Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Printing Test Labels With IPL Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Navigating the Setup Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Serial Communication Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Com Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Test/Service Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Media Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Configuration Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Network Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Returning to Factory Default Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

vi EasyCoder PD42 Printer User’s Guide

Page 7

Before You Begin

This section provides you with safety information, technical

support information, and sources for additional product

information.

Safety Information

Your safety is extremely important. Read and follow all warnings

and cautions in this document before handling and operating

Intermec equipment. You can be seriously injured, and

equipment and data can be damaged if you do not follow the

safety warnings and cautions.

This section explains how to identify and understand warnings,

cautions, and notes that are in this document.

A warning alerts you of an operating procedure,

practice, condition, or statement that must be

strictly observed to avoid death or serious injury to

the persons working on the equipment.

A caution alerts you to an operating procedure,

practice, condition, or statement that must be

strictly observed to prevent equipment damage or

destruction, or corruption or loss of data.

Before You Begin

Note: Notes either provide extra information about a

topic or contain special instructions for handling a

particular condition or set of circumstances.

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the

Intermec web site at www.intermec.com and click Service &

Support > Warranty.

EasyCoder PD42 Printer User’s Guide vii

Page 8

Before You Begin

Disclaimer of warranties: The sample code included in this

document is presented for reference only. The code does not

necessarily represent complete, tested programs. The code is

provided “as is with all faults.” All warranties are expressly

disclaimed, including the implied warranties of merchantability

and fitness for a particular purpose.

Web Support

Visit the Intermec web site at www.intermec.com to download

our current manuals (in PDF). To order printed versions of the

Intermec manuals, contact your local Intermec representative or

distributor.

Visit the Intermec technical knowledge base (Knowledge

Central) at intermec.custhelp.com to review technical

information or to request technical support for your Intermec

product.

Telephone Support

These services are available from Intermec.

In the USA and

Canada call 1-800755-5505 and

Services Description

Order Intermec

products

Order Intermec

media

Order spare

parts

Te c h n i ca l

Support

• Place an order.

• Ask about an existing

order.

Order printer labels and

ribbons.

Order spare parts. 1 or 2 and then

Talk to technical support

about your Intermec product.

choose this option

1 and then choose 2

1 and then choose 1

choose 4

2 and then choose 2

viii EasyCoder PD42 Printer User’s Guide

Page 9

Services Description

Before You Begin

In the USA and

Canada call 1-800755-5505 and

choose this option

Service • Get a return authorization

Service

contracts

Outside the U.S.A. and Canada, contact your local Intermec

representative. To search for your local representative, from the

Intermec web site, click Contact.

Who Should Read This Manual

This user’s guide is for the person who is responsible for

installing, using, configuring, and maintaining the PD42 printer.

This document provides you with information about the features

of the PD42, and how to install, configure, operate, maintain,

and troubleshoot it.

Related Documents

number for authorized

service center repair.

• Request an on-site repair

technician.

• Ask about an existing

contract.

•Renew a contract.

• Inquire about repair billing

or other service invoicing

questions.

2 and then choose 1

1 or 2 and then

choose 3

This table contains a list of related Intermec documents and their

part numbers.

Document Title Part Number

Intemec Fingerprint Programmer’s Reference Manual 937-005-xxx

IPL Programmer’s Reference Manual 066396-xxx

EasyLAN User’s Guide 1-960590-xx

The Intermec web site at www.intermec.com contains our

documents (as PDF files) that you can download for free.

EasyCoder PD42 Printer User’s Guide ix

Page 10

Before You Begin

To d ownloa d docume nts

1 Visit the Intermec web site at www.intermec.com.

2 Click Service & Support > Manuals.

3 In the Select a Product field, choose the product whose

documentation you want to download.

To order printed versions of the Intermec manuals, contact your

local Intermec representative or distributor.

x EasyCoder PD42 Printer User’s Guide

Page 11

1

This chapter includes the following sections:

• Introducing the EasyCoder PD42 Printer

• Features of the Printer

• Working With the Print Button and LED Indicators

• Working With the Display and the Soft Keys

Using the Printer

EasyCoder PD42 Printer User’s Guide 1

Page 12

Chapter 1 — Using the Printer

Introducing the EasyCoder PD42 Printer

The EasyCoder PD42 printer is a dependable and versatile

printer suitable for medium-duty applications in manufacturing,

transportation and warehouse environments. It has all-metal

chassis and covers, proven printing mechanics, and powerful

electronics providing sturdiness, performance, and reliability. It

features an intuitive user interface with a large graphical display

and programmable buttons.

Features of the Printer

This section describes the exterior of the printer, connectors, and

the media compartment.

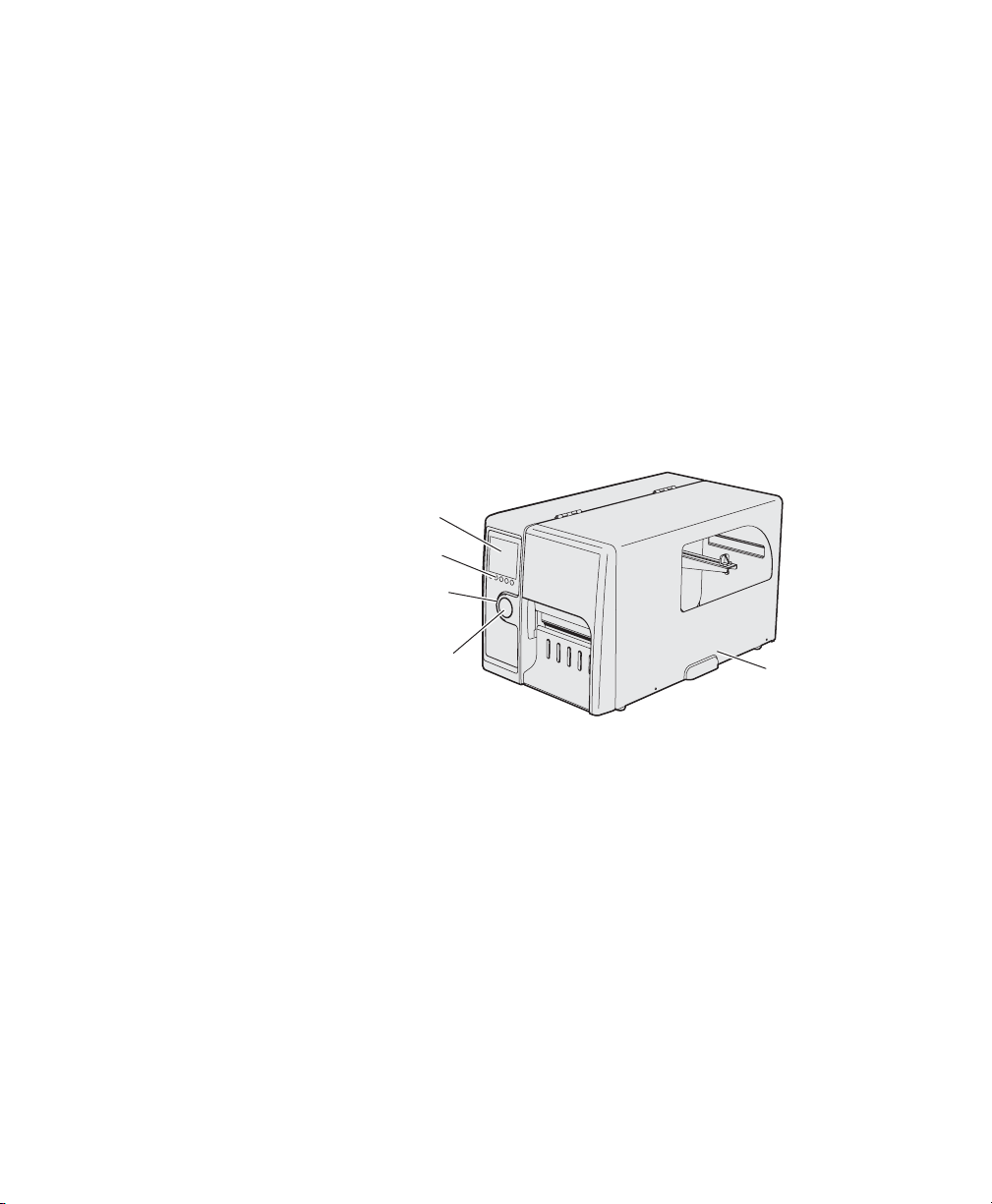

Front View of the Printer

Display

Soft keys (5)

Control LEDs (4)

Print button

Side door

Front View

2 EasyCoder PD42 Printer User’s Guide

Page 13

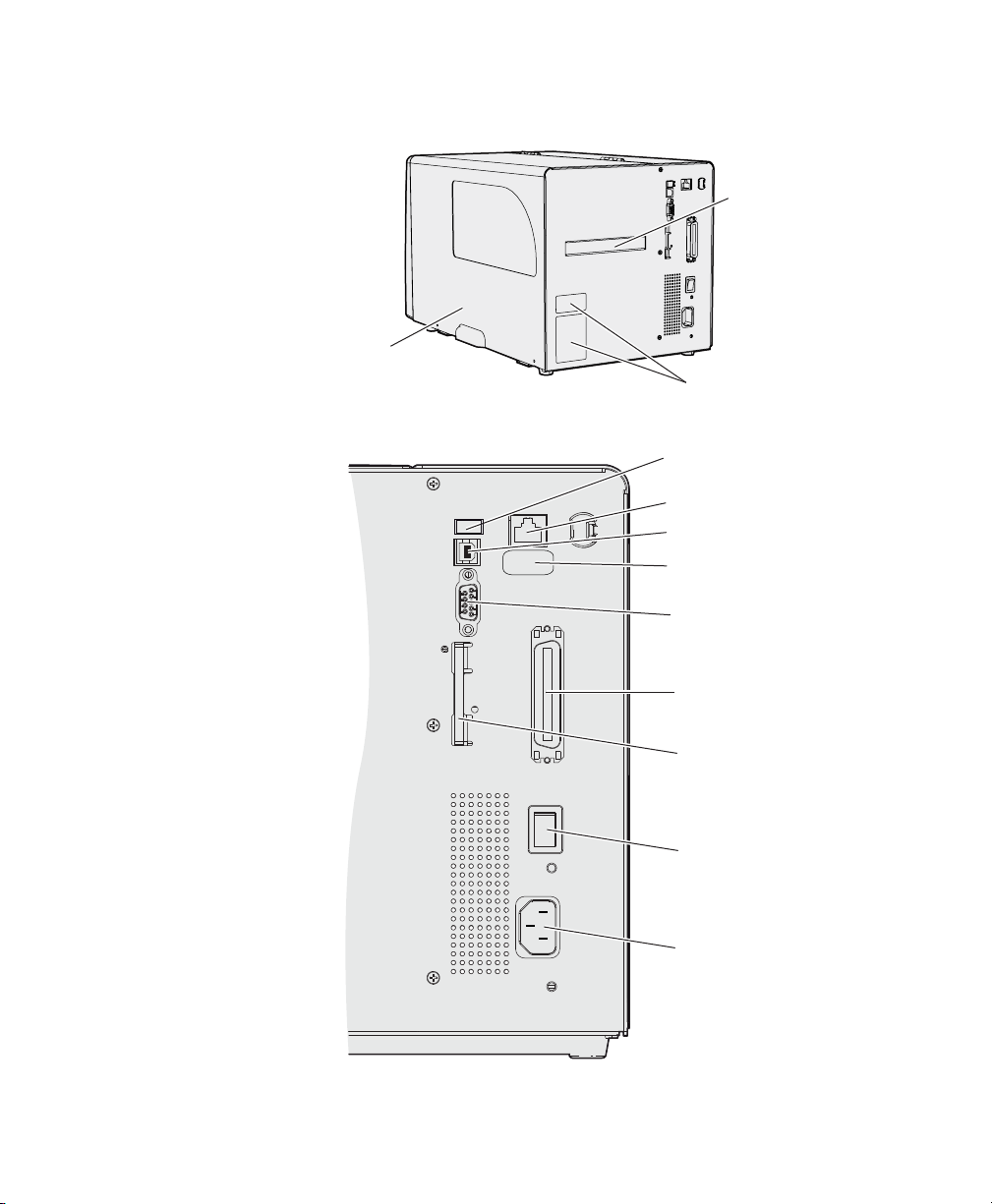

Back View of the Printer

I

O

Ethernet RJ-45 port

USB port

MAC address label

RS-232 serial port

IEEE 1284 parallel port

CompactFlash socket

Power switch

AC power cord socket

USB host port

Side door

Back View

Chapter 1 — Using the Printer

Intake for external

media supply

Machine labels

Back View: Connectors

EasyCoder PD42 Printer User’s Guide 3

Page 14

Chapter 1 — Using the Printer

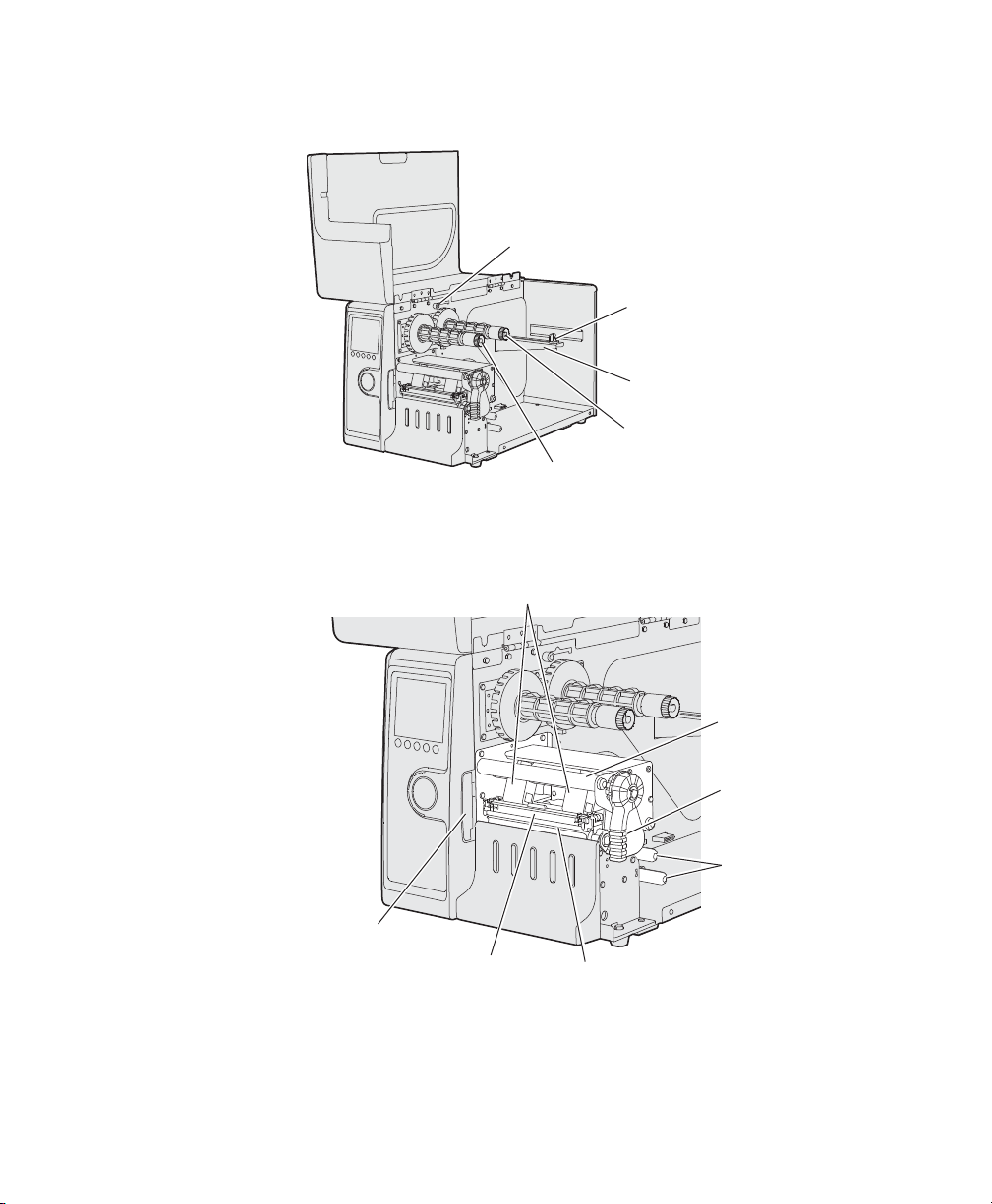

Ink position lever

Edge guide

Media supply post

Ribbon supply shaft

Ribbon rewind shaft

Media Compartment and Print Mechanism

Media Compartment

Printhead

balance boxes

Ribbon

rod

Printhead

lever

Media

feed rods

Label taken

4 EasyCoder PD42 Printer User’s Guide

sensor

Print Mechanism

Thermal

printhead

Tear bar

Page 15

Firmware

Chapter 1 — Using the Printer

Your PD42 printer comes with either Fingerprint or IPL

(Intermec Printer Language) firmware. The choice of firmware

affects the functionality of the printer and how you interact with

it. This manual contains information that applies exclusively to

the type of firmware, so it is strongly recommended that you

familiarize yourself enough with your PD42 to know whether it

runs Fingerprint or IPL.

The current firmware type and version is displayed on the

printer’s LCD, when the printer is fully operational and in “idle”

mode (awaiting print jobs).

Fingerprint

10.1.0

Test

The display window of a PD42 running Fingerprint firmware.

EasyCoder PD42 Printer User’s Guide 5

Page 16

Chapter 1 — Using the Printer

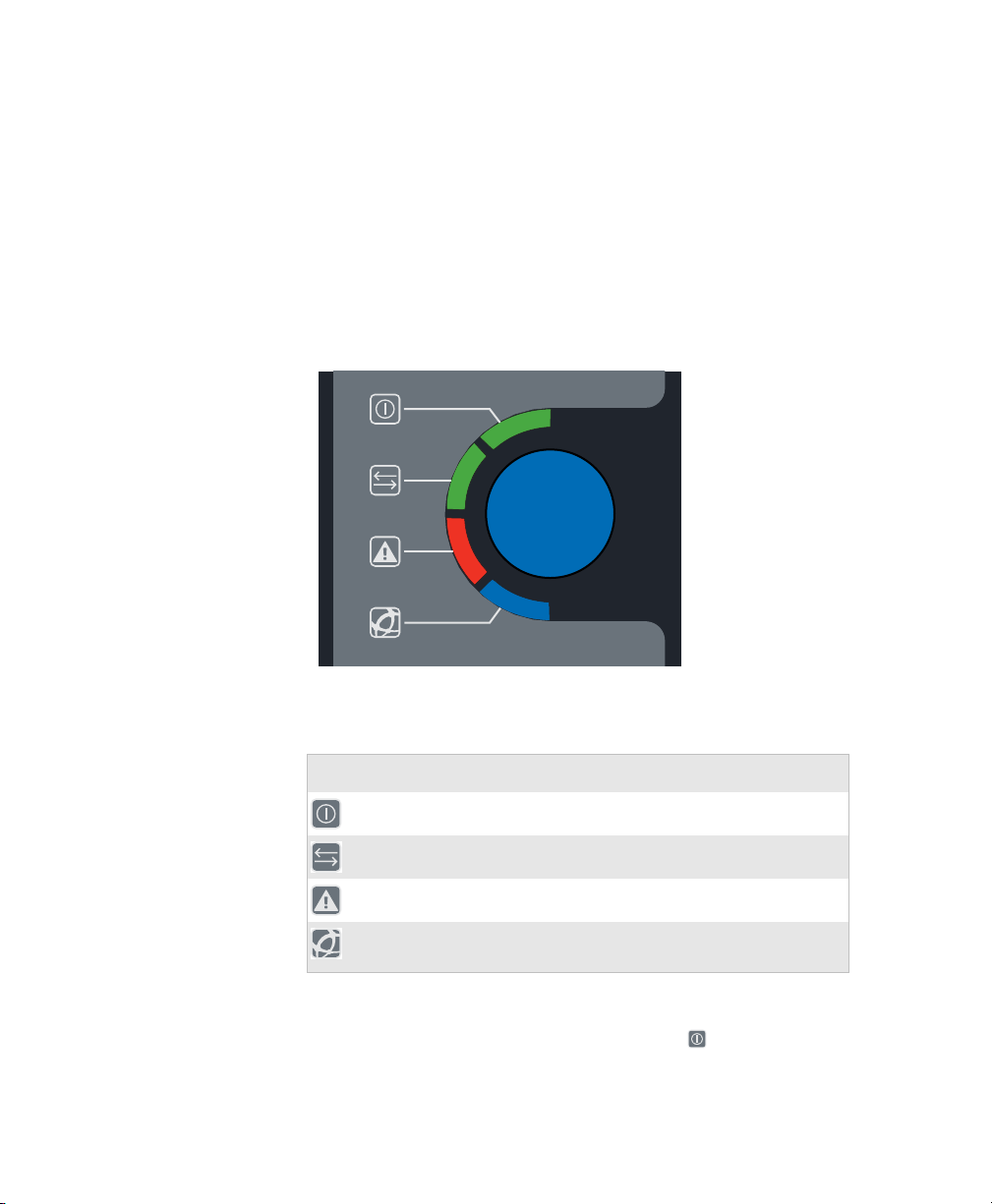

Working With the Print Button and LED Indicators

The blue button on the front panel is the Print button. The

primary function of the Print button is to feed media and pause

print jobs. However, the functionality varies depending on which

state the printer is in, and which firmware it is running. All this is

explained in detail in “Understanding Printer States” on

page 26.

There are four LEDs (Light Emitting Diodes) surrounding the

Print button.

LEDs and the Print Button

Control LEDs

Symbol LED Color Function

Power Green Power indicator

Ready/Data Green Printer ready

Error Red Error indicator

Ready-to-Work™ Blue Intermec Ready-to-Work™

indicator

The four LED indicators are on, off, or flashing depending on

which state the printer is in. The Power LED ( ) is always on for

all states except Power Off.

6 EasyCoder PD42 Printer User’s Guide

Page 17

Chapter 1 — Using the Printer

The blue Ready-to-Work LED ( )shows the operational status

of the printer. In simple terms, it is turned on when the printer is

operational. The indicator is set to flash when the printer is

receiving data or under certain “mild” error conditions, for

example when the printer is awaiting an IP address from the

network, when the printhead is lifted, or when media is loaded

incorrectly. It also flashes when the printer is in Setup mode,

Testmode, and Extended Testmode (see Chapter 3, “Configuring

the Printer.”).

When more serious errors occur, the indicator turns off

completely, and the red Error LED ( ) turns on or flashes. There

are a number of conditions that can cause this behavior; for help,

see Chapter 4, “Troubleshooting and Maintenance.”

The green Ready/Data LED ( ) turns on, off, or flashes

depending on the current state of the printer. A more thorough

description of this behavior can be found in “Understanding

Printer States” on page 26.

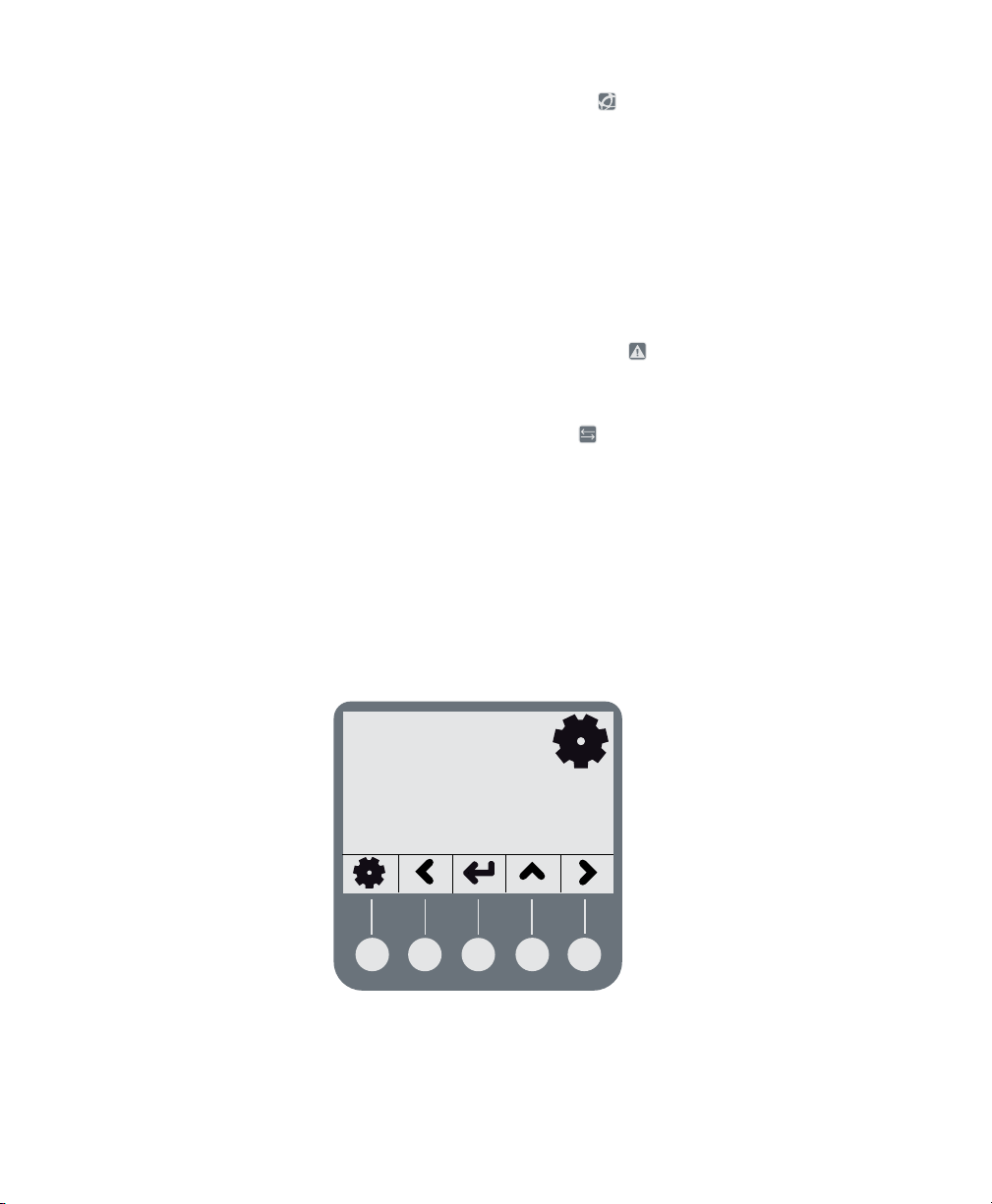

Working With the Display and the Soft Keys

The display communicates detailed information about the

current state of the printer. Using the display, the printer tells you

if a specific error has occurred or if it is waiting for input from

you.

Current state

(Setup)

Text or error

messages

Active soft keys

The different areas of the display and the soft keys.

EasyCoder PD42 Printer User’s Guide 7

Page 18

Chapter 1 — Using the Printer

Test

Below the display are five buttons that act as “soft keys,” which

means that the function of each button depends on the state of

the printer. The function is indicated with a small icon in the

display just above the key itself.

You can use the buttons for things like pausing a print job,

running a testfeed or changing setup parameters.

Note: If the printer is running a Fingerprint application, access to

Setup mode is controlled by the application.

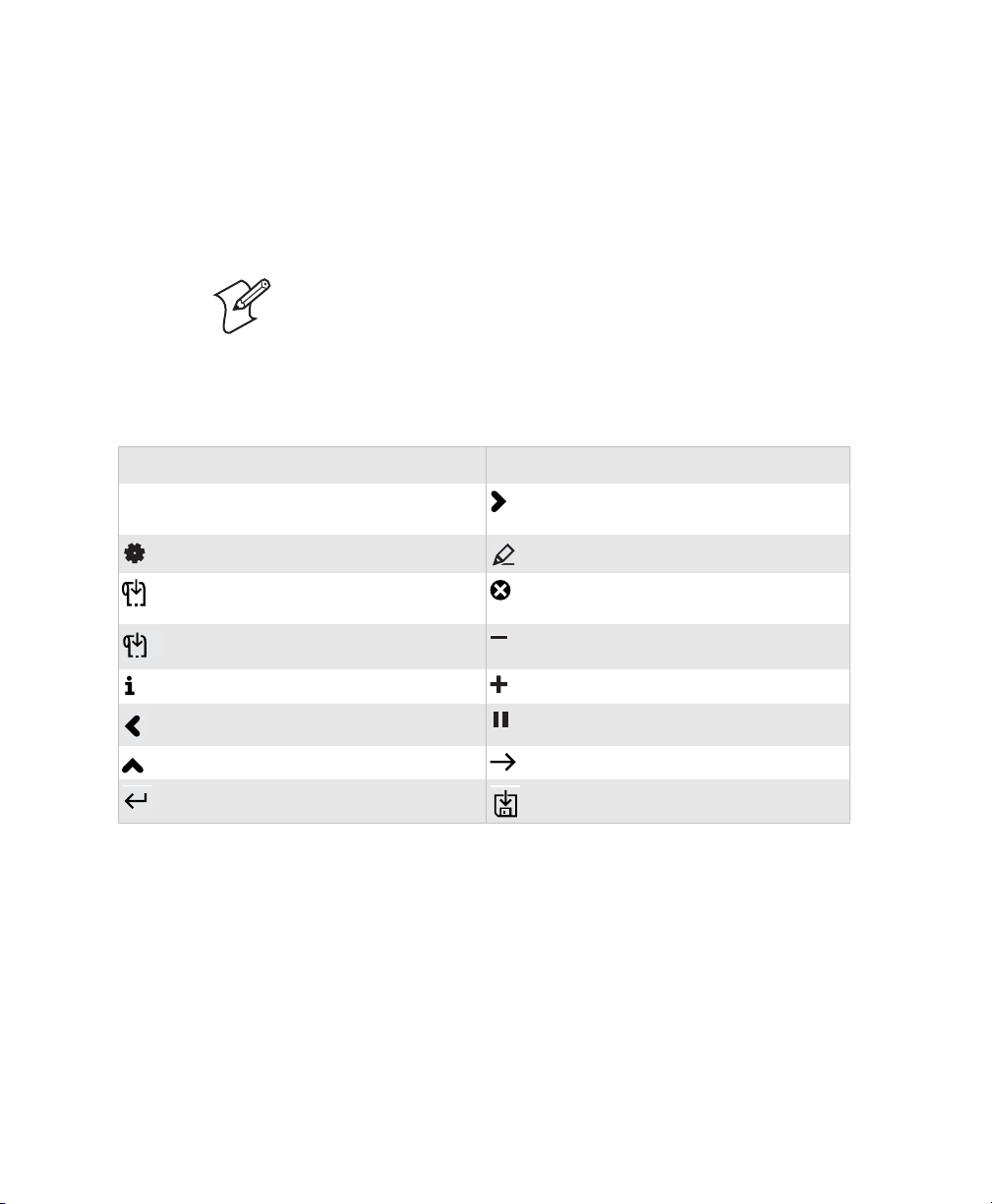

The function of each soft key is described below.

Soft Key Functions

Soft Key Function Soft Key Function

F1 to F5 Defined by Fingerprint

application

Enter/Exit setup Edit value

Feed Exit editing/cancel/exit test

Testfeed Decrease selected digit

Right/next state

mode/exit dumpmode

Enter/Exit i-mode Increase selected digit

Left/previous state Pause

Up Continue

apply/acknowledge/select Save to file

8 EasyCoder PD42 Printer User’s Guide

Page 19

2

This chapter contains the following sections:

• Connecting the Printer to Your System

• Connecting Peripherals Through USB Host

• Loading Media

• Loading Thermal Transfer Ribbon

• Plugging in the Printer

•Printing Test Labels

• Creating and Printing a Label

Installing the Printer

EasyCoder PD42 Printer User’s Guide 9

Page 20

Chapter 2 — Installing the Printer

Connecting the Printer to Your System

There are a number of ways you can connect the PD42 to your

system. As a standard, the printer is equipped with:

• one USB Type B connector for the USB interface port.

• one USB Type A connector for the USB host interface port.

• one 9-pin D-style subminiature (DB9) socket for the RS-232

serial interface port.

Optional interfaces include:

• one 36-pin socket for the parallel (IEEE 1284) port.

• one RJ-45 socket for the Ethernet network connection.

Information on the socket and connector types can be found in

Appendix A, “Specification, Interfaces, and Options.”

Note: USB and Parallel IEEE 1284 cannot be used at the same

time. Select the active interface in Setup (see “Changing

Configuration Settings” on page 31).

There are advantages and disadvantages associated with each of

these interfaces, which are described in the following sections.

Your current system setup will most likely tell you what

connection method is most suitable.

Connecting the Printer Through the USB Interface

To use the USB connection, you need to install the Intermec

InterDriver software on your computer. To ensure you get the

latest version, check the Intermec web site first. This software can

also be found on the PrinterCompanion CD along with

instructions on how to install it. The USB interface is not

suitable for terminal connections and thus not for programming.

10 EasyCoder PD42 Printer User’s Guide

Page 21

Chapter 2 — Installing the Printer

Connecting the Printer Through the Serial Port

You can use the serial connection with either LabelShop or the

Intermec InterDriver. You can also use it to send commands

directly to the printer through a terminal connection, for

instance with Telnet. The printer’s default serial communication

settings are: baud rate 9600, 8 data bits, no parity, 1 stop bit and

no flow control. Appendixes C and D contain information about

serial communication setup parameters for IPL and Fingerprint,

respectively.

Connecting the Printer Through the Parallel Port

You can use the parallel connection with LabelShop or the

Intermec InterDriver. The parallel port supports Windows plugn-play and additional status reporting through IEEE 1284 nibble

ID mode. Cable is not included with the kit.

Connecting the Printer to a Network

With an optional EasyLAN Ethernet card installed in your

PD42, you can set it up as a network printer. The printer is set to

automatically retreive an IP number from the network (DHCP)

once it is turned on. You can use the network connection either

with LabelShop or the Intermec InterDriver. You can also use it

to directly send commands to the printer through a terminal

connection (Telnet), or you can send instructions via FTP. For

terminal connections, it utilizes the Raw TCP protocol through

port 9100.

To connect the PD42 to your network

1 Plug a connected Ethernet cable into the Ethernet port in the

rear of the printer.

2 Turn the printer on. Wait for the blue Ready-to-Work LED to

stop blinking, and for the message “IP configuration error” to

disappear from the screen.

3 Enter i-mode by pressing ( ).

i-mode cycles through the interfaces installed on the printer

in five-second intervals and displays them on the screen. The

IP address is displayed under net1: in Fingerprint and net in

IPL.

EasyCoder PD42 Printer User’s Guide 11

Page 22

Chapter 2 — Installing the Printer

4 Enter the printer’s IP address in the address field of your web

browser (for example http://255.255.255.001). This brings

up the printer’s home page, where it is possible to check and

modify various printer settings. Modifying settings requires a

login name and a password: by default, these are set to

“admin” and “pass” respectively.

Please refer to the EasyLAN User’s Guide (P/N 1-960590-xx) for

more information on how to set up and operate the PD42 in

your network environment.

If your network does not assign IP numbers automatically, or the

Ready-to-Work indicator is flashing to indicate a network error,

you can use PrintSet 4 (available on the PrinterCompanion CD)

to correct the network settings. Alternatively, set up a terminal

connection through the serial interface and use the Fingerprint

Setup command. See “Changing Configuration Settings” on

page 31, or refer to the Intermec Fingerprint Programmer’s

Reference Manual (P/N 937-005-xxx).

Connecting Peripherals Through USB Host

The USB host interface supports the following external devices:

• Mass storage device

•Keyboard

• Bar code scanner

•USB hub

Connecting a Mass Storage Device

You can use a USB mass storage device (the “thumbdrive” or

“dongle” type) to store additional fonts and images. You can also

use the device to upgrade your firmware (see “Upgrading the

Firmware” on page 38).

Connecting a Keyboard

You can use an external USB keyboard to:

• input data in Fingerprint applications. Some applications may

require more complex input from users than the simple push

of a button.

12 EasyCoder PD42 Printer User’s Guide

Page 23

Chapter 2 — Installing the Printer

• manage setup in Fingerprint/Direct Protocol and IPL. In the

installed keyboard layouts, the arrow keys on the keyboard are

mapped to the up/down/right/left functions in the Setup

menu. The five function keys F1-F5 correspond to the five

soft keys on the front panel, starting from the left. The Enter

key will have the same apply/acknowledge function.

The printer comes with four keyboard layouts installed (US,

Swedish, French, and German).

To change keyboard layout

1 Plug your USB-keyboard into the USB connector in the back

of the printer.

2 Turn the printer on.

3 Press Setup ().

4 Navigate to COM > USB KEYBOARD.

5 Choose a keyboard layout.

6 Exit Setup by pressing ( ).

Fingerprint users can create their own custom keyboard layouts.

For help, see the Fingerprint Programmer’s Reference Manual (P/N

937-005-xxx).

Connecting a Bar Code Scanner

Note: Only printers running Fingerprint firmware can use a bar

code scanner.

You can connect a bar code scanner of HID (Human Interface

Device) type to the printer. The scanner will send data to the

“console:” device in the same way as a USB keyboard. This data

can then be used in a Fingerprint application.

The keyboard map chosen in setup (see above) applies for

connected scanners as well.

EasyCoder PD42 Printer User’s Guide 13

Page 24

Chapter 2 — Installing the Printer

Connecting a USB Hub

A USB hub makes it possible to connect several USB devices to

the printer at the same time.

Note: Only one of the devices connected to the USB hub can be a

mass storage device, and only one device can be a Human

Interface Device (keyboard or bar code scanner).

Loading Media

The EasyCoder PD42 can print on labels, tickets, tags, and

continuous stock in various formats. Refer to Appendix B,

“Media Specifications” for more detailed information about

media types, media dimensions and other media specifications.

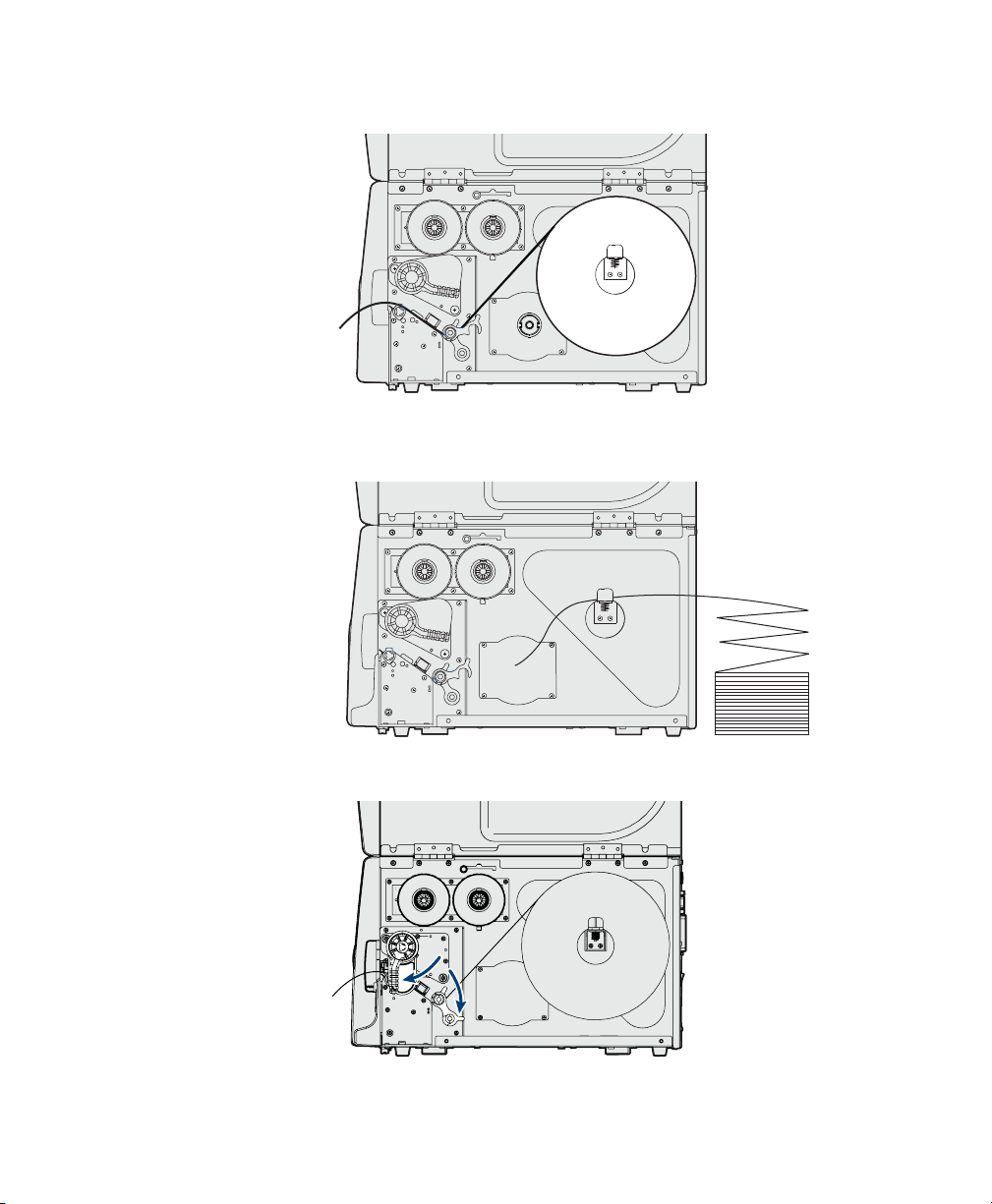

Loading Media for Tear-Off (Straight-Through) Operation

This section describes the case when media is torn off manually

against the printer’s tear bar. This method is also known as

“straight-through” printing. You can use different types of media

in Tear-Off operation:

• Non-adhesive continuous stock

• Self-adhesive continuous stock with liner

• Self-adhesive labels with liner

• Tickets with gaps, with or without perforations

• Tickets with black marks, with or without perforations

To load media for tear-off operation

1 Open the printer’s side door.

14 EasyCoder PD42 Printer User’s Guide

Page 25

Chapter 2 — Installing the Printer

Label feed guide

Printhead lever

2 Pull out the printhead lever and turn it counterclockwise. Lift

the label feed guide.

3 Load a media roll onto the media supply hub. Be sure to push

it all the way in.

EasyCoder PD42 Printer User’s Guide 15

Page 26

Chapter 2 — Installing the Printer

4 Route the media through the print mechanism.

5 If you are using fan-fold media, load it through the rear intake

and route the it the same way as you would a media roll.

6 Reset the label feed guide and the printhead lever.

7 Close the side door.

16 EasyCoder PD42 Printer User’s Guide

Page 27

Chapter 2 — Installing the Printer

8 Press the Print button to advance the media (“Feed”). If you

are switching to a new type of media, for instance going from

tickets with gaps to ticket with black marks, you must run a

“Testfeed” ( ) to calibrate the printer’s sensors.

Loading Media for Peel-Off (Self-Strip) Operation

This section describes the case when self-adhesive labels are

separated from the liner immediately after printing. This method

is also known as self-strip operation. The label-taken sensor can

hold the printing of the next label in a batch until the present

label has been removed. You can only use self-adhesive labels with

liner in peel-off operation. Use the same procedure when

installing media for Batch Takeup, with the difference that both

label and liner is rewound, and the label-taken sensor is not used.

Note: These modes of operation require an internal rewinder

unit, for more information see Appendix A, “Specification,

Interfaces, and Options.”

To load media for peel-off operation

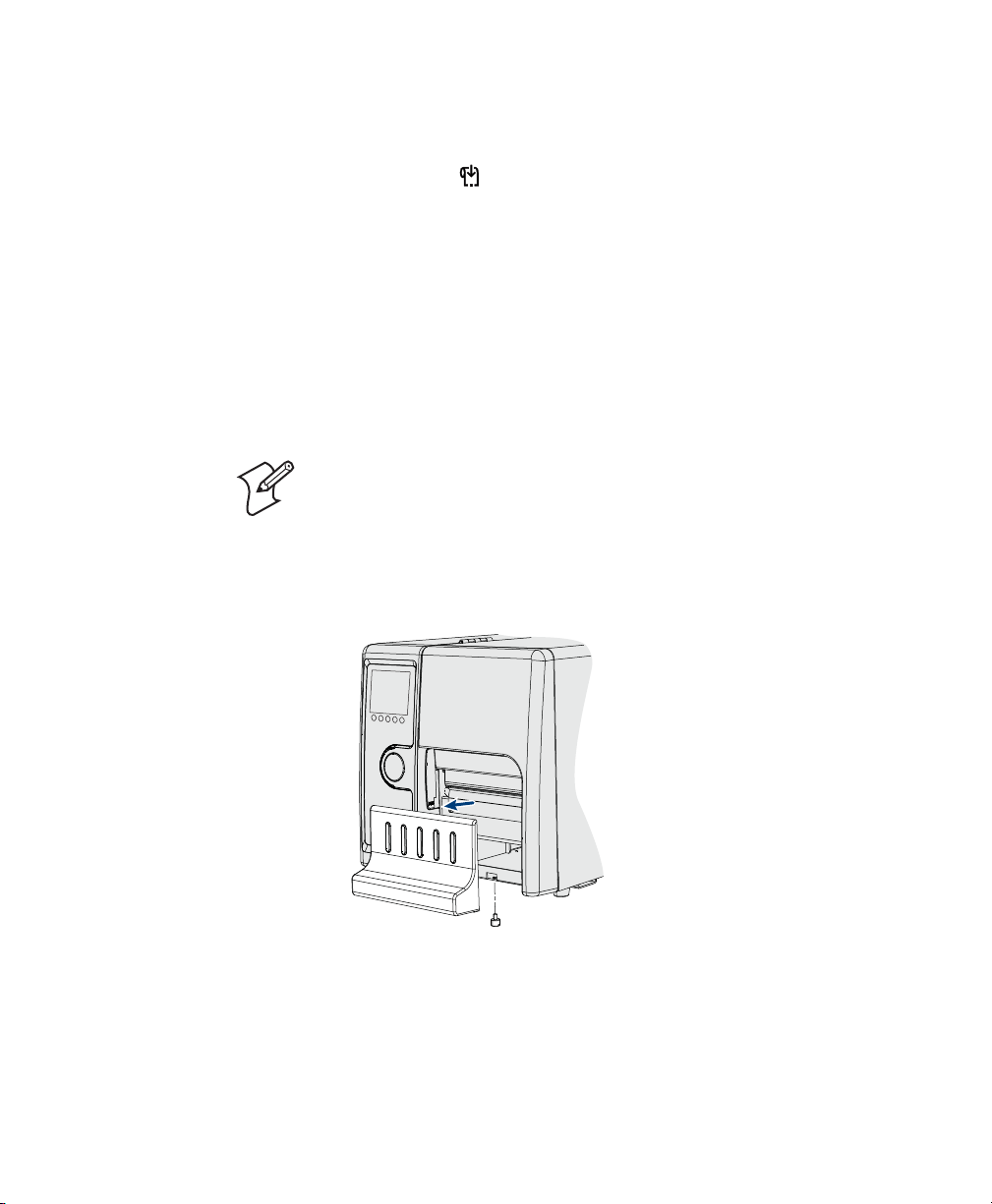

1 Remove the thumbscrew to remove the front cover.

2 Open the side door, mount the media roll, and route the

media through the media feed rods (refer to Steps 1-4 in “To

load media for tear-off operation” on page 14).

EasyCoder PD42 Printer User’s Guide 17

Page 28

Chapter 2 — Installing the Printer

3 Route the label liner through the print mechanism and back

into the media compartment.

4 Wrap the liner around the takeup roll and lock it in place.

5 Reset the label feed guide and the printhead lever.

18 EasyCoder PD42 Printer User’s Guide

Page 29

Chapter 2 — Installing the Printer

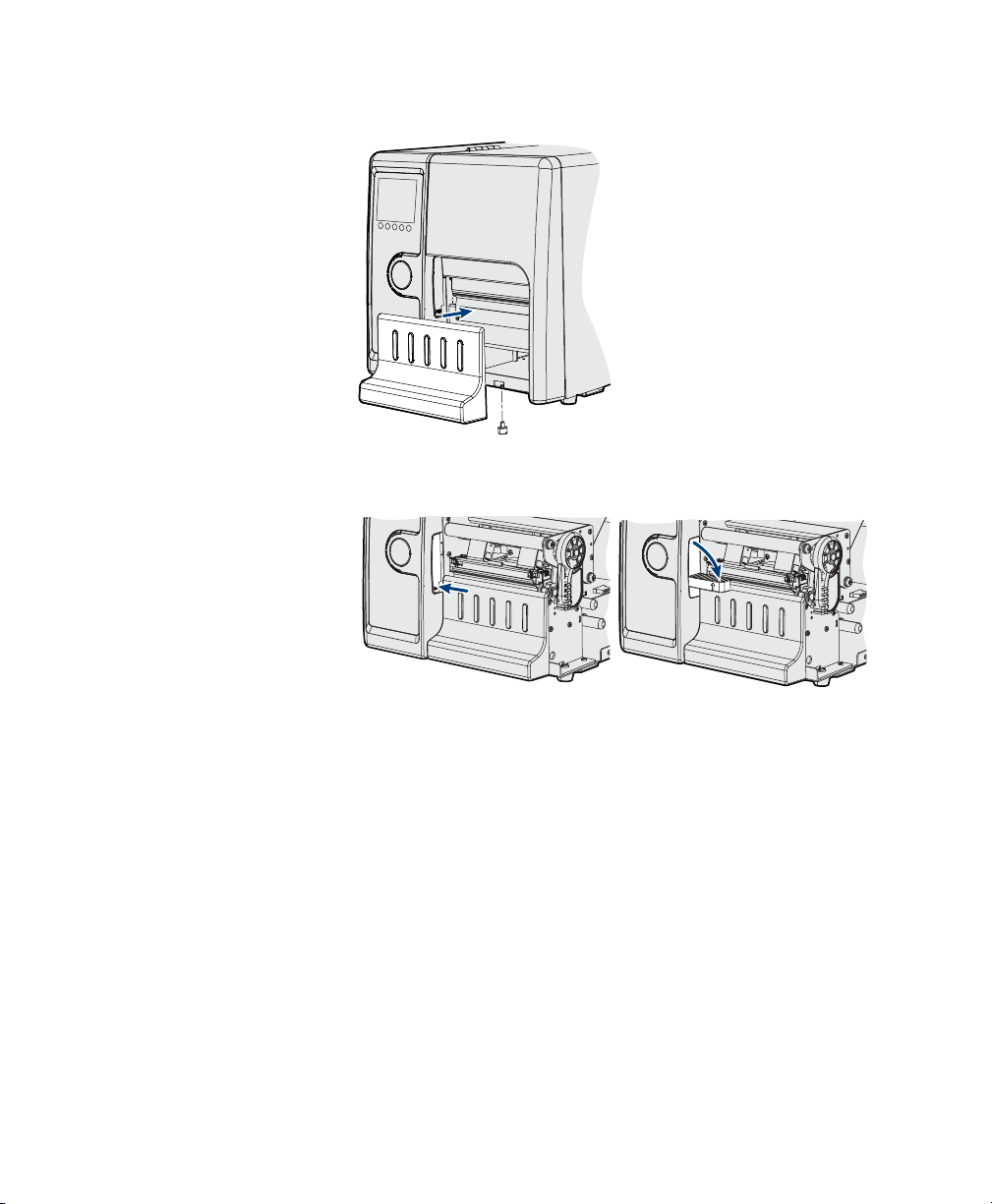

6 Reattach the front cover.

7 Push in on the lower part of the label-taken sensor and bring

it out to a fully horizontal position.

8 Close the side door.

9 Press the Print button to advance the media.

Loading Thermal Transfer Ribbon

Thermal transfer printing makes it possible to use a wide range of

receiving face materials and gives a durable printout that is less

vulnerable to fat, chemicals, heat, sunlight and so on than direct

thermal printing. Make sure to select a ribbon type that matches

the type of receiving material and set up the printer accordingly.

The ribbon is normally loaded at the same time as a new media

roll. For clarity, the following illustrations do not show the media

roll. See the previous sections for information on how to load

media for your type of operation.

EasyCoder PD42 Printer User’s Guide 19

Page 30

Chapter 2 — Installing the Printer

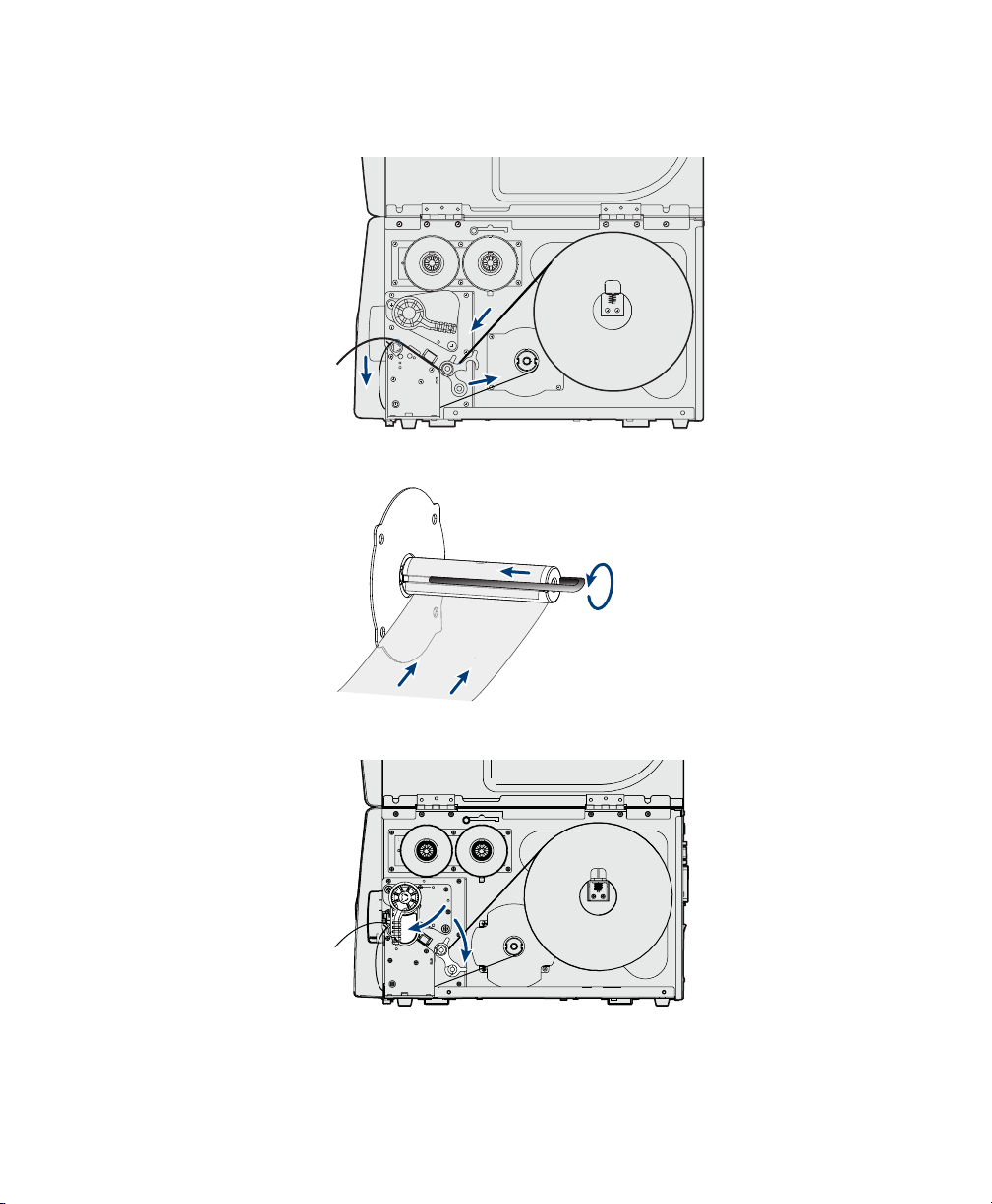

The EasyCoder PD42 can use transfer ribbon rolls wound with

the ink-coated side facing either outward or inward. To

determine which type of ribbon you have, use a pen or another

sharp object to scratch through the ribbon against a piece of

paper. If it leaves a mark, your ribbon is wound ink in or ink out

according to the following model.

Test to determine whether your transfer ribbon is wound ink-in or ink-out.

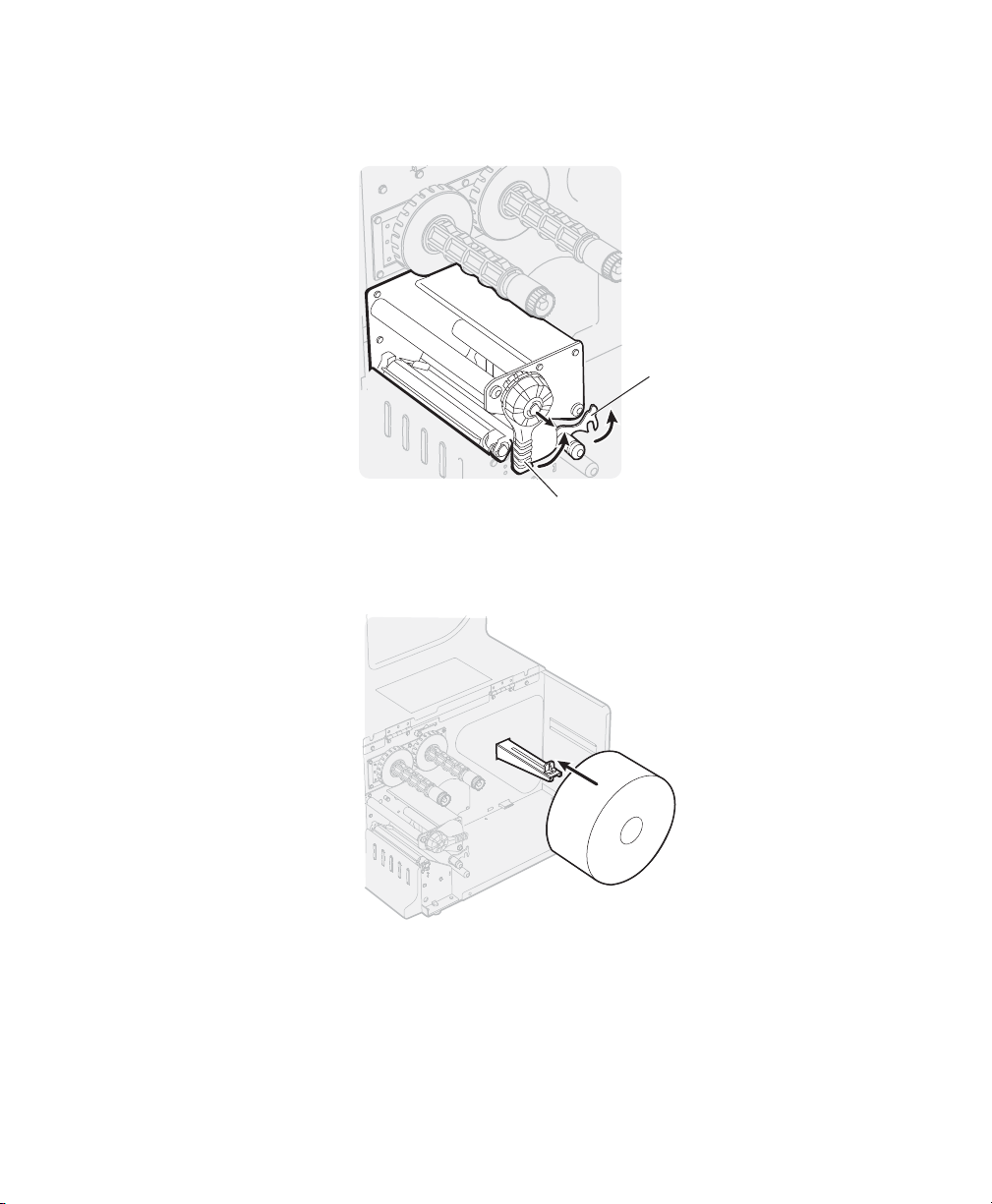

To load thermal transfer ribbon

= Ink in

= Ink out

1 Open the side door of the printer.

2 Pull out the printhead lever (1) and turn it counterclockwise

(2) to raise the printhead.

1

2

20 EasyCoder PD42 Printer User’s Guide

Page 31

Chapter 2 — Installing the Printer

3 Slide the ribbon roll onto the right ribbon hub, and the

empty ribbon core on the left hub.

4 “Ink out” ribbon only: route the ribbon and set the ink

position lever as indicated below.

EasyCoder PD42 Printer User’s Guide 21

Page 32

Chapter 2 — Installing the Printer

5 “Ink in” ribbon only: route the ribbon and set the ink

position lever as indicated below.

6 Load media in the printer, if you have not already done so.

7 Restart the printer and print test labels (See “Printing Test

Labels” on page 23).

Plugging in the Printer

1 Make sure the Power switch is turned off.

2 Connect the power cable to the printer.

3 Plug the power cable into your electrical outlet.

22 EasyCoder PD42 Printer User’s Guide

Page 33

Printing Test Labels

In order to verify that the printer is fully functional and to obtain

its current configuration, you can print test labels for the various

printer functions (for instance ,hardware and software

configuration).

To print a set of test labels from startup

1 Make sure the printer is turned off.

2 Load media as described in “Loading Media” on page 14.

3 Press and hold the blue Print button.

4 Keep the Print button pressed down, and turn on the power

switch. After approximately ten seconds the printer enters

Testmode and three of the front LEDs start flashing one at a

time.

The display window lights up, and the printer runs a media

setup routine.

5 Continue to press the Print button until the printer starts

cycling through the selectable media types (Gap/Mark/

Continuous). For help, see Appendix B, “Media

Specifications.”

Chapter 2 — Installing the Printer

6 Select your media type by releasing the Print button at the

appropriate time.

SELECT MEDIA

MARK

SELECT MEDIA

GAP

SELECT MEDIA

CONTINUOUS

The printer will print several test labels containing the

printer’s setup parameters. It will then enter Dumpmode.

EasyCoder PD42 Printer User’s Guide 23

Page 34

Chapter 2 — Installing the Printer

7 Press the Print button once, or press Cancel () to exit

Dumpmode.

Creating and Printing a Label

There are many different ways you can create a label and send it

to your printer. You can design labels in Fingerprint or IPL, use

dedicated label design tools (such as LabelShop and XMLLabel),

or use word processing software like Microsoft Word. Your choice

of design tool will likely be influenced by your system setup and

communication interface (Ethernet, USB, serial or parallel).

Please refer to the manual of each respective tool for information

on how to create and print labels.

24 EasyCoder PD42 Printer User’s Guide

Page 35

3

This chapter contains the following sections:

• Understanding Printer States

•The Printer Startup Sequence

• Changing Configuration Settings

• Running Testmode and Extended Testmode

• Upgrading the Firmware

Configuring the Printer

EasyCoder PD42 Printer User’s Guide 25

Page 36

Chapter 3 — Configuring the Printer

Understanding Printer States

The PD42 printer can enter a number of different states, which

in turn indicate its current mode of operation. Information about

the state of the printer is provided via the LEDs and the display.

PD42 Printer States

State Explanation

Power Off

Upgrading Firmware is being upgraded.

TestMode See page 34.

Extended TestMode See page 36.

Setup Mode Setup mode is accessed from the display

i-mode i-mode is accessed from the display when

PUP Power-UP (starting up)

Idle The printer is operational and is waiting for

Application running The printer is running a (Fingerprint)

Printing

Printing (wait for LTS) Waiting for Label Taken Sensor to indicate

Paused Paused during print job

Error Error state

Dumpmode In Dumpmode, the printer listens on all

(this may require a password if the printer

is running a Fingerprint application). In

Setup mode, you can change various

printer settings.

the printer is idle. In i-mode the printer

will cycle through the various interfaces

with 5 second intervals.

print jobs.

application

that label has been taken.

communication ports and prints incoming

characters.

26 EasyCoder PD42 Printer User’s Guide

Page 37

Chapter 3 — Configuring the Printer

The Print button has different functionality depending on the

state of the printer. Different actions can be carried out by

pressing the button less than and more than one second

respectively. An empty field means no action is performed.

Print Button Function

Button pressed

State

Power Off

Upgrading

Testmode See “Running

Extended

Te s t m o de

Setup mode

Idle (FP) Formfeed/

Idle (IPL) Formfeed Continuous feed

Application

running

Printing Pause print job

Paused (FP) Continue print job Cancel print job

Paused (IPL) Continue print job Continue print job

Error See Chapter 4, “Troubleshooting and

< 1 s

Tes t m od e a nd

Extended

Tes t m od e” o n

page 34

See “Running

Tes t m od e a nd

Extended

Tes t m od e” o n

page 34

Printfeed

Defined by

application

Maintaining the Printer.”

Button pressed

> 1 s

See “Running

Testmode and

Extended

Tes tm od e” o n

page 34

See “Running

Testmode and

Extended

Tes tm od e” o n

page 34

Testfeed

while button is

pressed

Defined by

application

“Doubleclick”

Enter Pause

mode

Defined by

application

EasyCoder PD42 Printer User’s Guide 27

Page 38

Chapter 3 — Configuring the Printer

The behavior of the green Data/Ready LED and red Error LED

in various states is shown in the table below.

Ready/Data and Error LED Behavior

State Ready/Data LED Error LED

Power Off Off Off

Upgrading LEDs turned on one after the other.

Testmode See Chapter 5 for description.

Extended Testmode See Chapter 5 for description.

PUP On Off

Idle On/Flash

Application running On Off

Printing On/Flash

Printing (wait for LTS) Quick flashes

Paused Flash

Error Off On / Flash

Footnotes:

1 Flashing with 50% duty cycle, 0.8 second period when receiving

data, synchronized with Ready-to-Work LED.

2 Two fast flashes, 1.6 second period.

3 Flashing with 50% duty cycle, 0.8 second period, not synchronized

with Ready-to-Work LED.

4 Error LED will be lit for these conditions: Out of Paper, Out of

Ribbon, Head Lifted, Cutter Error, and Testfeed not Done. Will

flash as (2), when thermal printhead is too hot. Will flash as (3) for

other error conditions caught by the Direct Protocol error handler.

1

1

2

3

Off

Off

Off

Off

4

28 EasyCoder PD42 Printer User’s Guide

Page 39

Chapter 3 — Configuring the Printer

The state of the printer also determines what functions/icons are

active in the display window:

Fingerprint

10.2.0

F1 F2 F3 F4 F5

Test

Idle

Running application

Paused

Testmode

TEST

Setup, navigation

Setup, edit value

Extended Testmode

TEST

Dumpmode

i-mode

Printing

Upgrading

Active soft keys in different printer states.

EasyCoder PD42 Printer User’s Guide 29

Page 40

Chapter 3 — Configuring the Printer

Understanding the Printer Startup Sequence

When you switch on the printer, it will go through a sequence of

steps in which it determines what settings should be set and what

application (if any) should be started. Users that run Fingerprint

firmware on their PD42 are given more options and more control

over the printer’s startup behavior.

Printer Startup Sequence (Fingerprint)

1 Check for firmware binary file on CompactFlash card. If

found, upgrade.

2 Check for firmware binary file on USB mass storage device. If

found, upgrade.

Note: The printer will install the firmware stored on the

CompactFlash card even if it is older than the version

currently loaded on the printer.

3 Check if printhead is lifted and button is pressed. If so, go to

Extended Testmode, otherwise continue startup with step 3.

4 Check for the presence of a startup file (AUTOEXEC.BAT),

first on CompactFlash, then on “c/”. If found, run the startup

file.

5 Check to see if button is pressed. If so, go to Testmode.

6 Continue power-up. Check APPLICATION file in “c/:” for

program file name. If found, run. If empty, go to idle state.

This means you can control the printer’s behavior after startup in

a variety of ways: you can create an autoexec.bat file and save it

on a memory card or in the printer’s permanent memory (device

“c/”), you can write an application and store the link to it in the

APPLICATION file, or you can choose to enter Testmode.

It is recommended to start custom applications by writing the

name of the desired program (“ProgramName.PRG”) in the

APPLICATION file in “c/”.

30 EasyCoder PD42 Printer User’s Guide

Page 41

Chapter 3 — Configuring the Printer

Starting a custom application can also be done by creating a

startup file (autoexec.bat) which will execute on startup. This file

must contain Fingerprint commands that are interpreted

immediately. Normal commands are LOAD and RUN. See the

Intermec Fingerprint Programmer’s Reference Manual (P/N 937005-xxx) to learn how to create and save such a file to the printer.

Printer Startup Sequence (IPL)

1 Check for firmware binary on CompactFlash card. If found,

upgrade.

2 Check for firmware binary on USB mass storage device. If

found, upgrade.

Note: The printer will install the firmware stored on the

CompactFlash card or USB mass storage device even if it is

older than the version currently loaded on the printer.

3 Check if printhead is lifted and button is pressed. If so, go to

Extended Testmode, otherwise continue startup with step 3.

4 Check to see if button is pressed. If so, go to Testmode.

5 Continue power-up. Run a testfeed.

The process of entering and using Testmode and Extended

Testmode is described later in this chapter.

Changing Configuration Settings

There are several different ways you can change the configuration

settings of the printer. You can do it directly from the display, or

remotely from the host PC using a USB, serial or ethernet

connection.

Refer to Appendixes C and D for a detailed view of the Setup tree

in Fingerprint and IPL, and for more extensive information

about the various setup parameters.

Changing Configuration Settings From the Display

In order to change configuration settings, you need to enter

Setup mode. Access Setup mode from the display by pressing

Setup ().

EasyCoder PD42 Printer User’s Guide 31

Page 42

Chapter 3 — Configuring the Printer

While in Setup mode, use the soft keys to navigate through the

various options in the setup tree.

Navigating in Setup Mode

Soft Key Function

The main nodes of the setup tree are organized in a loop, as

shown below (detailed overviews are provided in Appendix C

(Fingerprint) and Appendix D (IPL)). Each main node branches

out to a number of sub-nodes. At startup, the firmware

determines if optional equipment such as a cutter or an interface

board is installed in the printer, and these are added to the Setup

tree.

Move one menu item to the left on the same level.

Move one menu item to the right on the same level.

Move up one level.

Acknowledge/Move down one level.

Edit value

Increase value

Decrease value

Exit Setup mode.

Starting point

SETUP:

NET-COM, NET1

SETUP:

EMULATION

SETUP:

COM

SETUP:

NETWORK

Option

SETUP:

PRINT DEFS

SETUP:

MEDIA

SETUP:

FEEDADJ

SETUP:

SER-COM, UART1

The main nodes of the Setup tree (Fingerprint).

32 EasyCoder PD42 Printer User’s Guide

Page 43

Starting point

Chapter 3 — Configuring the Printer

SETUP:

SER-COM

SETUP:

CONFIGURATION

SETUP:

MEDIA

The main nodes of the Setup tree (IPL).

SETUP:

TEST/SERVICE

SETUP:

COM

SETUP:

NETWORK

Option

Changing Configuration Settings With PrintSet 4

PrintSet 4 is a printer configuration tool which is available on the

PrinterCompanion CD, and for download from the Intermec

website. PrintSet 4 can communicate with your printer either via

a serial cable or a network connection, and works on all PCs

running Windows 98 (or later). The program allows you to easily

change all of the setup parameters. It also includes setup wizards,

which guide you through common configuration tasks.

Changing Configuration Settings From the Printer Home Page

If you have an optional EasyLAN network card and the printer is

connected to your network, you can use your web browser to

browse to the printer home page and make any desired setup

changes there. Follow the instructions provided in “Connecting

the Printer to a Network” on page 11.

Once on the home page, click Configuration on the left side of

the screen to access the setup parameters of the printer.

Changing Configuration Settings Using the Command Line

You can change setup parameters by sending commands directly

to the printer using your terminal program (either through serial

or network connection). The Fingerprint command to use is

SETUP, followed by the node, subnode and parameter setting.

For example, to set your media settings to labels with gaps, send

the following instruction:

SETUP “MEDIA,MEDIA TYPE,LABEL (w GAPS)”

EasyCoder PD42 Printer User’s Guide 33

Page 44

Chapter 3 — Configuring the Printer

The corresponding instruction in IPL is:

<STX><SI>T1<ETX>

Note: IPL users should first verify that they have the

correct HyperTerminal settings. See the screen capture

below.

Hyperterminal settings (IPL only)

For more information on how to change setup parameters, see

the Fingerprint Programmer’s Reference Manual (P/N 937-005-

xxx), or the IPL Programmer’s Reference Manual (P/N 066396-

xxx).

Running Testmode and Extended Testmode

Use Testmode and Extended testmode when you want to verify

printer settings, print test labels, restore factory default settings,

or enter Dumpmode for troubleshooting purposes. Two

testmodes are available, Testmode and Extended Testmode.

Testmode is a simple linear sequence which requires little input,

while Extended Testmode gives the user more options.

Running Testmode

Testmode performs the following sequence:

1 Select media type (gaps/mark/continuous).

34 EasyCoder PD42 Printer User’s Guide

Page 45

Chapter 3 — Configuring the Printer

2 Perform a sensor calibration (Testfeed).

3 Print test labels.

4 Enter Dumpmode.

To run testmode

1 Make sure the printer is turned off, loaded with media and

that the printhead is lowered.

2 Press and hold the blue Print button.

3 Keep the Print button pressed down, and turn on the power

switch. After approximately ten seconds the printer enters

Testmode and three of the front LEDs start flashing one at a

time. The display window lights up, and the printer runs a

media setup routine.

As long as you keep the Print button pressed, the printer

cycles through the selectable media types (Gap/Mark/

Continuous).

SELECT MEDIA

MARK

SELECT MEDIA

GAP

SELECT MEDIA

CONTINUOUS

4 Select your media type by releasing the Print button at the

appropriate time.

The printer automatically performs a sensor calibration

(Testfeed) based on your selection, and selects thermal

transfer printing if ribbon is installed, otherwise direct

thermal is selected as default.

The printer prints several test labels containing the printer’s

setup parameters. To skip test labels, tap the Print button.

EasyCoder PD42 Printer User’s Guide 35

Page 46

Chapter 3 — Configuring the Printer

The printer is now in Dumpmode and scans the

communication ports. Any characters received on the

communication ports will be printed on a label when

Dumpmode is exited.

5 Press the Print button once to exit Dumpmode.

You also have the option to save the dump by pressing Save

()

For more information about Dumpmode, see

“Troubleshooting Communication Problems” on page 45

The printer will start as on rebooted status. Once operational,

the Data/Ready and Ready-to-Work LEDs light up.

Running Extended Testmode

Extended Testmode can be used to run additional tests. This

includes the option to print test labels, running a testfeed in slow

mode, entering Dumpmode, and resetting to factory defaults.

To run Extended Testmode

1 Make sure the printer is turned off, loaded with media, and

that the printhead is lifted.

2 Press and hold the blue Print button.

3 Keep the Print button pressed down, and turn on the power

switch. After approximately ten seconds the printer enters

Extended Testmode.

All three LEDs flash rapidly four times to signal that

Extended testmode is activated.

4 Release the Print button.

5 Lower the printhead.

6 You are now in Extended Testmode. Press Right ( ) to cycle

through the different options.

To select a test function, press Acknowledge ().

To exit Extended Testmode, press Cancel ().

36 EasyCoder PD42 Printer User’s Guide

Page 47

Chapter 3 — Configuring the Printer

SELECT MEDIA

TEST

Functions in Extended Testmode

Function Description

Select Media This is the same media setup function as in

Test mode, with the important difference

that the printer performs a slow sensor

calibration (slow testfeed). Performing a

Slow testfeed can be a way to resolve gap/

mark detection problems.

Tes t L ab el s Se tu p In fo Print configuration labels, one at a time.

Press Acknowledge ( ) to print the next

label. The display indicates which test label

is next.

Dumpmode Enter Dumpmode. For more information

about running Dumpmode, see

“Troubleshooting Communication

Problems” on page 45.

Factory Default Restore factory default settings. Select the

option, and follow instructions in the

display.

Setup and Exit Exit Extended Testmode, enter Setup

mode.

Exit Exit Extended Testmode.

EasyCoder PD42 Printer User’s Guide 37

Page 48

Chapter 3 — Configuring the Printer

Upgrading the Firmware

The latest firmware and software is always available for download

from the Intermec web site at www.intermec.com.

To download firmware updates

1 Visit the Intermec web site at www.intermec.com.

2 Click Service & Support > Downloads.

3 In the Select a Product field, choose the EasyCoder PD42

and you will be presented with the latest software available.

4 Download the latest firmware version to your computer.

5 Extract the zip file to a folder on your computer. Normally,

three versions of the firmware are included with the following

differences and naming conventions:

• No suffix: Normal firmware upgrade.

• FD suffix: Firmware upgrade resetting Factory Default.

Only applicable when upgrading through a CompactFlash

card.

• NU suffix: Boots with new firmware, yet printer returns to

previous firmware version on reboot (No Upgrade). Only

applicable when upgrading through a Compact Flash card.

To upgrade your printer with new firmware

• Use PrintSet 4 and follow the firmware upgrade procedure.

• If you have a network connection, browse to the printer’s

home page (see “Connecting the Printer to a Network” on

page 11), and select Maintenance. Upload the firmware file.

• Copy the firmware binary file to a CompactFlash card. Turn

the printer off, insert the card into the printer’s CompactFlash

socket and switch on the printer. The printer will be upgraded

automatically.

• Copy the firmware binary file to a USB mass storage device.

Put the firmware binary file in a directory named /d/upgrade,

and the printer will use that file to upgrade unless the printer

is already running that firmware. The printer will look for a

file named FIRMWARE.BIN first. If there is no such file, it

will look for any firmware file.

38 EasyCoder PD42 Printer User’s Guide

Page 49

4

Troubleshooting and Maintaining the Printer

This chapter covers the following topics:

• Printer Operation Problems

•Print Quality Problems

• Troubleshooting Communication Problems

• Contacting Product Support

• Adjusting the Printer

• Maintaining the Printer

EasyCoder PD42 Printer User’s Guide 39

Page 50

Chapter 4 — Troubleshooting and Maintaining the Printer

Test

Printer Operation Problems

The following tables list problems that affect the ability of the

printer to operate.

Note: Fingerprint users can obtain an error diagnosis with the

command

through a terminal connection to receive the printer’s Ready-toWork st at us .

Display Error Messages (Blue Ready-to-Work LED Blinks)

Error Symbol Error Message Solution

SYSHEALTH$. Enter the line PRINT SYSHEALTH$

Printhead lifted. Lower printhead.

Maintenance. The printer is upgrading its

IP link error. Check if the network cable has

firmware. Wait for it to

complete the task.

been unplugged

Press feed not done. Press Feed( ) or Testfeed( )

40 EasyCoder PD42 Printer User’s Guide

Page 51

Chapter 4 — Troubleshooting and Maintaining the Printer

Display Error Messages (Blue Ready-to-Work LED Blinks)

Error Symbol Error Message Solution

Label not taken. Printing has been halted because

a label is obstructing the LTS

sensor.Remove label to resume

printing.

LSS too high, LSS

too low.

IP Configuration

Error.

These errors can occur when

you run a testfeed without any

media installed, or if you have

incorrect media settings.

Load the printer with media

(see “Loading Media” on

page 14). Restart the printer in

Test mode (see “Running

Testmode” on page 34) and

select the appropriate media

type.

The printer is trying to acquire

an IP address from the network.

Wait for it to complete the task.

Display Error Messages (Error LED Blinks)

Error Symbol Error Message Solution

Field out of label. You are attempting to print in

an area that extends beyond the

“print window.” See appendices

C (Fingerprint) and D (IPL)

information on how to set the

media parameters.

Out of media. Load media in printer. See

“Loading Media” on page 14.

EasyCoder PD42 Printer User’s Guide 41

Page 52

Chapter 4 — Troubleshooting and Maintaining the Printer

Test

Display Error Messages (Error LED Blinks) (continued)

Error Symbol Error Message Solution

Ribbon empty. Load transfer ribbon. See

Label not found. The printer does not find a label

Printhead hot. The printhead is overheated and

Testfeed not done. Press Testfeed ( ).

“Loading Thermal Transfer

Ribbon” on page 19. This error

could also occur if you have just

switched to direct thermal

media, and the printer is

expecting ribbon to be loaded. If

this is the case, change Paper

Typ e in Se tu p .

gap or black mark.

• Go into Setup mode and

verify that the label length

parameter is correct (see

“Media Setup” on page 91

for Fingerprint and page 109

for IPL).

• Verify that the Media type

settings are correct. This

error can occur if you are, for

instance, using continuous

media but your media

settings are set to labels with

gaps.

needs to cool down.Wait for

printing to be resumed

automatically.

Cutter not found. A cut-command has been sent

but the printer cannot find the

cutter. Check that the cutter is

installed properly.

Cutter not

responding.

Check that the cutter is installed

properly.

42 EasyCoder PD42 Printer User’s Guide

Page 53

Chapter 4 — Troubleshooting and Maintaining the Printer

Test

Other Printing Operation Problems

Problem Solution / Reason

The Power control LED is

not lit when power is

switched on.

Error LED is turned on

after printing.

Label is jammed after

printing.

When printing, labels are

skipped.

When using cutter, label is

not cut straight.

When using cutter, label

cannot feed or abnormal

cutting occurs.

When using internal

rewinder, abnormal

function occurs.

Printer keeps printing or

feeding when it should

stop.

Printing is slow. Check application.

Check that the power cable is correctly

connected to the printer and electrical

outlet.

• Check if printer is out of media or

ribbon.

• Check if media is jammed or tangled.

• Check that the print mechanism is

locked and closed correctly.

• Check the cutter.

• Check application.

Clear the media jam (see “Clearing Media

Jams” on page 49). If the label is stuck on

the thermal printhead, clean the printhead

(see “Cleaning the Printhead” on

page 57).

• Run a new testfeed (press ( )).

• Check if label gap sensor is disturbed

by dust or foreign particles (see

“Adjusting the Label Gap Sensor” on

page 53).

• Check whether the media thickness

exceeds 0.25mm (9.8 mils).

• Check that the media is loaded

correctly. Check that the media runs as

close to the center section of the printer

as possible, and that the paper path is

straight.

• Check that the cutter is installed

properly.

• Check if paper feed rods are sticky.

Clean if needed (see “Cleaning the

Media Compartment” on page 58).

Check that media is loaded correctly.

• Check media settings.

• Check label gap sensor position.

• Clean if sensors need cleaning.

EasyCoder PD42 Printer User’s Guide 43

Page 54

Chapter 4 — Troubleshooting and Maintaining the Printer

Print Quality Problems

Print Quality Problems

Problem Solution / Reason

Printout is faded or weak. • Fingerprint users: Adjust the media

settings: Constant, Factor and

Contrast.

• IPL users: Adjust the Sensitivity

setting.

• Check if printhead needs cleaning, see

“Cleaning the Printhead” on page 57.

• Check printhead pressure, see

“Adjusting Printhead Pressure” on

page 51.

• Check printhead dotline position, see

“Adjusting Printhead Dot Line” on

page 51.

Printer is working but

nothing is printed.

Only partial labels are

printed.

Part of the images is not

printed along the feed

direction.

• Printing on Direct Thermal media:

check that media is loaded with the

heat-sensitive side facing the printhead.

• Printing with Thermal Transfer ribbon:

Check that the ink-side of the ribbon

faces the media. See “Loading Thermal

Transfer Ribbon” on page 19.

• Select the correct media type (labels

with gaps, black mark or continuous),

and the correct paper type (direct

thermal or thermal transfer).

• Check that the printhead is correctly

connected to the print mechanism.

Check printhead balance, see “Ad j us ti ng

Printhead Balance” on page 50.

• Check if printhead needs cleaning, see

“Cleaning the Printhead” on page 57

• Check that the ribbon does not

wrinkle, see “Preventing Ribbon

Wrinkling” on page 47.

44 EasyCoder PD42 Printer User’s Guide

Page 55

Chapter 4 — Troubleshooting and Maintaining the Printer

Print Quality Problems (continued)

Problem Solution / Reason

Printout darkness is

uneven across media path.

Printout is not in desired

position.

• Check printhead balance, see

“Adjusting Printhead Balance” on

page 50.

• Check printhead pressure, see

“Adjusting Printhead Pressure” on

page 51.

• Check for errors in software

application.

• Check if label gap sensor is disturbed

by media, dust or ribbon.

• Check the lateral position of label gap

sensor.

• Check the edge guide and media guide.

• Check the media (insufficient

transparency, interfering preprint lines

in black mark operation, and so on).

• Check if platen roller needs cleaning or

replacement.

Troubleshooting Communication Problems

Use Dumpmode to verify that the printer is receiving data from

the host correctly.

Using the Line Analyzer (Fingerprint)

In Dumpmode, the printer runs a Fingerprint program called

Line Analyzer. As the name implies, the Line Analyzer captures

incoming characters on the communication ports and prints

them on one or more labels. Line Analyzer uses “autohunt” which

means the program scans all applicable ports for data.

The easiest way to enter Dumpmode is through Testmode or

Extended Testmode (see “Running Testmode and Extended

Testmode” on page 34)

When Dumpmode has been entered, the Printer will tell you this

by printing “DumpMode entered” on a label. The display shows

the Dumpmode icon, and the printer is ready to receive data.

EasyCoder PD42 Printer User’s Guide 45

Page 56

Chapter 4 — Troubleshooting and Maintaining the Printer

While the printer is receiving data, the Ready/Data LED blinks.

There is a half-second timeout which means that if no more

characters have been received after 0.5 seconds, the program

considers the transmission terminated and prints out a label.

Printable characters are printed in black-on-white, whereas

control characters and space characters (ASCII 000–032 dec) are

printed in white-on-black.

As long as a continuous string of characters is being received, the

program wraps the lines until the label is full and then starts to

print another label. After each character transmission, the

following information is printed:

• Page number

• Number of characters printed on the label

• Total number of characters received so far

Before you exit Dumpmode, you can choose to save the dump in

the printer’s internal memory. The printer prints a label with the

location of the saved file (the maximum size of the saved file is

128 kB).

When you exit Dumpmode, a final label with the text “Exit from

Dump Mode” is printed.

Using Dumpmode (IPL)

When Dumpmode is activated, the printer captures incoming

characters on the communication ports and prints them on one

or more labels.

Users that run IPL firmware on their printer can access

Dumpmode in two different ways, which produce slightly

different results:

• Access Dumpmode through Testmode or Extended Testmode

and you will receive printouts that look exactly as those

produced with the Line Analyzer program on Fingerprintoperated machines. See “Using the Line Analyzer

(Fingerprint)” on page 45 for information on how to

interpret the labels.

• Access Dumpmode from Setup, and characters will be printed

on a continuous line, along with corresponding hexadecimal

numbers.

46 EasyCoder PD42 Printer User’s Guide

Page 57

Chapter 4 — Troubleshooting and Maintaining the Printer

To enter Dumpmode from Setup

1 Enter Setup by pressing ( ).

2 Navigate to Te s t / S e r v i c e > Data Dump.

3 Select Ye s.

4 To exit Dumpmode, reboot the printer.

Contacting Product Support

If you cannot find the answer to your problem in the

“Troubleshooting and Maintaining the Printer” section, you can

visit the Intermec technical knowledge base (Knowledge Central)

at intermec.custhelp.com to review technical information or to

request technical support. If you still need help after visiting

Knowledge Central, you may need to call Product Support. To

talk to an Intermec Product Support representative in the U.S.A.

or Canada, call:

1-800-755-5505

Outside the U.S.A. and Canada, contact your local Intermec

representative.

Before you call Intermec Product Support, make sure you have

information about your printer model ready.

The machine and serial number labels are attached to the

printer’s rear plate, and contain information on type, model and

serial number as well as AC voltage and frequency.

Adjusting the Printer

This section describes some of the adjustments you can perform

to solve problems related to printout quality.

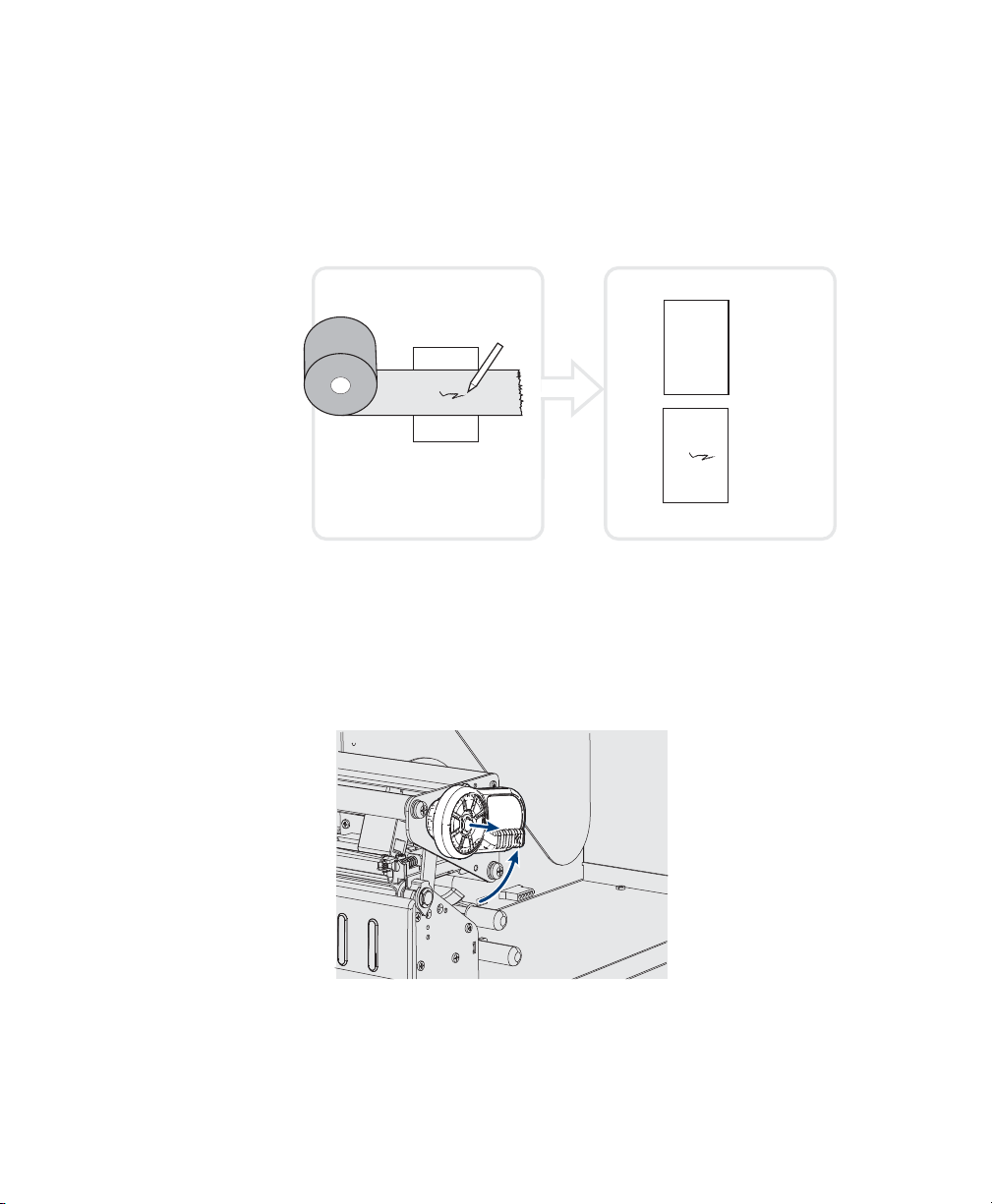

Preventing Ribbon Wrinkling

If you have problems with transfer ribbon getting wrinkled, you

can attempt to adjust ribbon tension or ribbon shield.

To adjust ribbon tension

1 Push the knob on the ribbon supply hub.

2 Rotate it clockwise to increase breaking force or

counterclockwise to decrease breaking force.

EasyCoder PD42 Printer User’s Guide 47

Page 58

Chapter 4 — Troubleshooting and Maintaining the Printer

If your labels look as depicted below, you may want to try

adjusting the ribbon shield.

Test Label A

1234567890

Printouts of low quality caused by ribbon wrinkling.

The ribbon shield mechanism is located on the thermal

printhead. It has two adjustable screws, A and B, as shown below.

A

Ribbon shield adjustment screws

To adjust ribbon shield

Test Label B

1234567890

B

1 If the label printout matches Test label A, turn screw A

clockwise. If the printout matches Test label B, turn screw B

clockwise.

48 EasyCoder PD42 Printer User’s Guide

Page 59

Clearing Media Jams

Chapter 4 — Troubleshooting and Maintaining the Printer

2 Twist the screw half a turn and perform a new test print.

3 Continue until you achieve a smooth printout quality.

Screw adjustment must not exceed two full turns or paper

may not feed smoothly. In such a case, turn the screws

counterclockwise completely and start over.

To clear media jam in print mechanism

1 Switch off the power to the printer.

2 Pull the printhead lever out and turn it counterclockwise to

lift the printhead.

3 Pull out the media from the print mechanism.

If the media has been wound up or is stuck on the platen

roller, carefully remove it by hand without using any sharp

tools that can damage the platen roller or the printhead.

Avoid rotating the platen roller.

Take care to avoid causing the platen roller to rotate. The

electronic components may be damaged permanently.

4 Cut off any damaged or wrinkled part of the media.

5 Check to see if there adhesive is sticking to parts of the print

mechanism. If so, clean as described in “Maintaining the

Printer” on page 56.

6 Reload the media as described in “Loading Media” on

page 14.

7 Switch on the power.

8 Press the Print button to readjust the media feed.

Adjusting the Printhead

Keeping the printhead properly balanced is crucial for obtaining

printouts of high quality.

EasyCoder PD42 Printer User’s Guide 49

Page 60

Chapter 4 — Troubleshooting and Maintaining the Printer

Adjusting Printhead Balance

The printer is factory-adjusted for full-size media width. If you

are using media with less than full media width, Intermec

recommends that you adjust the position of the printhead

balance boxes so that the printhead is appropriately pressured

against the media. If your printouts are weaker on one side than

on the other, this is most likely due to an unbalanced printhead.

To adjust the printhead balance

1 Open the side door.

2 If transfer ribbon has been installed, remove it.

3 Lift the printhead by pulling the printhead lever out and

turning it a quarter of a turn counterclockwise.

4 Move the balance box on the right side (outer) to the right

(outward) for wider media, and inwards (to the left) for

narrower media.

Balance

box

5 Engage the printhead and load the ribbon.

6 Test and readjust if necessary. (Tip: Use direct thermal media

to avoid loading and unloading of ribbon multiple times.)

50 EasyCoder PD42 Printer User’s Guide

Page 61

Chapter 4 — Troubleshooting and Maintaining the Printer

Adjusting Printhead Pressure

The pressure of the thermal printhead against the platen roller is

factory-adjusted. However, if the printing is weaker on one side

of the media, or if the thermal transfer ribbon starts to crease

(indicated by unprinted white streaks along the media feed

direction), it may be necessary to readjust the printhead pressure.

Note: Before readjusting the printhead pressure, try to move the

outer balance box as described in the previous Adjusting

Printhead Balance procedure.

To adjust printhead pressure

1 Open the side door.

2 Remove the ribbon.

3 Lift the printhead by pulling the printhead lever out and