User’s Guide

EasyCoder PF4i

Compact Industrial Printer

(Fingerprint Version)

Intermec Technologies Corporation

Corporate Headquarters

6001 36th Ave. W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is proprietary and is provided solely

for the purpose of allowing customers to operate and service Intermecmanufactured equipment and is not to be released, reproduced, or used

for any other purpose without written permission of Intermec.

Information and specifi cations contained in this document are subject to

change without prior notice and do not represent a commitment on the

part of Intermec Technologies Corporation.

© 2004 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, CrossBar,

Data Collection Browser, dcBrowser, Duratherm, EasyCoder, EasyLAN,

Enterprise Wireless LAN, EZBuilder, Fingerprint, i-gistics, INCA (under

license), InterDriver, Intermec Printer Network Manager, IRL, JANUS,

LabelShop, Mobile Framework, MobileLAN, Nor*Ware, Pen*Key,

Precision Print, PrintSet, RoutePower, TE 2000, Trakker Antares, UAP,

Universal Access Point, and Virtual Wedge are either trademarks or registered trademarks of Intermec Technologies Corporation.

Throughout this manual, trademarked names may be used. Rather than

put a trademark (™ or ®) symbol in every occurrence of a trademarked

name, we state that we are using the names only in an editorial fashion,

and to the benefi t of the trademark owner, with no intention of infringement.

There are U.S. and foreign patents pending.

The name Centronics is wholly owned by GENICOM Corporation.

Kimdura is a registered trademark of Kimberly Clark.

Microsoft is a registered trademark of Microsoft Corporation.

Torx is a registered trademark of Camcar Division of Textron Inc.

TrueDoc is a registered trademark of Bitstream, Inc.

TrueType is a trademark of Apple Computer Inc.

Unicode is a trademark of Unicode Inc.

Valeron is a registered trademark of Valéron Strength Films, an ITW

Company.

Windows is a trademark of Microsoft Corporation.

Document Change Record

This page records changes to this document. The document was originally released as version -00.

Version Date Description of Change

-00 May 2003 Supports original Fingerprint version (v8.00).

-01 Oct. 2003 Revised to support Fingerprint v8.10. Information about

EasyLAN Wireless interface added.

-02 Feb. 2004 Revised to support Fingerprint v8.20 and Intermec Shell

v8.1. Information on Intermec Readiness Indicator added.

New method for returning to factory default added. New

setup node for LSS test added. More bar codes supported.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) iii

FCC Notice (United States of America)

WARNING

This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instructions manual,

may cause interference to radio communications. It has been tested and

found to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area

is likely to cause interference in which case the user at his own expense

will be required to take whatever measures may be required to correct the

interference.

DOC Notice (Canada)

Canadian Dept. of Communication

REGULATIONS COMPLIANCE (DOC-A)

This digital apparatus does not exceed the class A limits for radio noise

emissions from a digital apparatus as set out in the radio interference

regulations of the Canadian Department of Communication.

Ministère des Communications du Canada

CONFORMITE DE REGLEMENTS (DOC-A)

Le présent appareil numérique n’émet pas de bruits radio-électriques

dépassant les limites applicables aux appareils numériques de classe A

prescrites dans le règlement sur brouillage radioélectrique édicté par le

Ministère des Communications du Canada.

GS Notice (Germany)

ALLGEMEINE VORSCHRIFT

Reparaturen oder sonstige Eingriffe, die sich nicht auf normale Bedienung der Maschine beziehen, dürfen ausschließlich nur von einem

ausgebildeten, zuständigen Fachmann vorgenommen werden.

EU Standard EN 55022 (The European Union)

WARNING

This is a Class A ITE product. In a domestic environment this product

may cause radio interference in which case the user may be required to

take adequate measures.

iv Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Declaration of Conformity (CE)

We,

Intermec Printer AB

Box 123

S-431 22 Mölndal

Sweden

1

declare under our sole responsibility

EasyCoder PF4i Compact Industrial

to which this declaration relates is in conformity

with the following standards

EMC:

EN 61000-6-4:2001

EN 61000-6-2:2001

Electrical Safety:

EN 60 950

following the provisions of Directives

89/336/EEC and 73/23/EEC

Mölndal 2003-03-12

that the product

...................................................................

Per-Ove Jacobsson

1

/. Intermec assumes no responsibility regarding the CE Directive if the

printer is handled, modifi ed, or installed in other manners than those

described in Intermec’s manuals.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) v

vi Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Contents

Before You Begin ........................................................................... xi

Global Services and Support .......................................................xiii

Introduction

1

2

Description of EasyCoder PF4i Compact Industrial ....................... 2

Safety Summary ............................................................................. 3

Product Identifi cation ....................................................................3

Installation

Unpacking the Printer .................................................................... 6

Front View .....................................................................................7

Rear View ......................................................................................8

Media Compartment .....................................................................9

Print Mechanism ..........................................................................12

Connections .................................................................................13

Controls and Indicators ...............................................................14

Contents

Safety Summary ..............................................................xi

Safety Icons ...................................................................xii

Warranty Information ...................................................xiii

Web Support ................................................................xiii

Telephone Support ....................................................... xiii

Related Documents ...................................................... xiii

Description ...................................................................... 9

Media Supply Roll Post .................................................10

Media Supply Positions .................................................. 11

Power ............................................................................ 13

Computer ...................................................................... 13

Indicator Lamps ............................................................14

Display ..........................................................................15

Keyboard ....................................................................... 15

Beeper ...........................................................................16

Starting Up

3

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) vii

Startup Files .................................................................................18

Memory Card ..............................................................................19

Switching On the Printer ............................................................. 20

Contents

4

5

6

Media Load

Tear-Off (Straight-through) .........................................................22

Tear-Off (Straight-through) with Quick-Load ..............................26

Cut-Off ........................................................................................ 29

Peel-Off (Self-strip) ......................................................................33

External Supply (Fanfold) ............................................................38

Thermal Transfer Printing

Ribbon Load ................................................................................40

Setting Up the Printer

Description. ................................................................................. 46

Default Setup ...............................................................................47

Reading the Current Setup ........................................................... 48

Setup Parameters .......................................................................... 49

Serial Communication ...................................................49

Baud Rate .......................................................49

Character Length ............................................50

Parity ...............................................................50

Stop Bits ..........................................................50

Flow Control ................................................... 50

New Line ........................................................ 51

Receive Buffer .................................................51

Transmit Buffer ...............................................51

Feed Adjust .................................................................... 52

Start Adjust .....................................................52

Stop Adjust .....................................................52

Recommended Feed Adjustments ....................53

Media ............................................................................54

Media Size ....................................................... 54

Media Type ..................................................... 56

Paper Type .......................................................57

Contrast .......................................................... 59

Testfeed ........................................................... 59

Print Defi nes .................................................................59

Head Resistance ..............................................59

Testprint .......................................................... 59

Print Speed ...................................................... 61

LSS (Label Stop Sensor) ..................................61

viii Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

7

8

9

Contents

LTS (Label Taken Sensor) ................................61

Returning to Factory Default Setup .............................................62

Setup Mode

Entering the Setup Mode at Installation ....................................... 64

Navigating in Setup Mode ...........................................................65

Setup Mode Overviews ................................................................67

Intermec Shell Startup Program

Introduction ................................................................................76

Starting with Intermec Shell .........................................................78

Intermec Shell Overview .............................................................. 82

Line Analyzer ............................................................................... 83

Options

Introduction ................................................................................86

Side Doors and Megatop .............................................................. 87

Paper Cutter .................................................................................87

Integral Liner Takeup Unit ...........................................................87

Media Supply Hub .......................................................................87

3-inch Adapter ............................................................................. 87

Label Taken Sensor ......................................................................88

Real Time Clock ..........................................................................88

CompactFlash Protection Plate ....................................................88

Special Printheads ........................................................................88

Interface Boards ...........................................................................89

Troubleshooting

10

Intermec Readiness Indicator .......................................................92

Troubleshooting List ....................................................................95

Maintenance

11

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) ix

Printhead Cleaning ......................................................................98

External Cleaning ......................................................................101

Cleaning the Media Guides ........................................................ 102

Printhead Replacement ..............................................................103

Media Jams ................................................................................ 106

Contents

12

A

B

C

Adjustments

Narrow Media ............................................................................108

Label Stop Sensor ....................................................................... 109

Printhead Pressure ...................................................................... 112

Ribbon Break Shaft ....................................................................113

Label Taken Sensoe ....................................................................114

Technical Data

Technical Data ..........................................................................116

Media Specifi cations

Media Roll Size ..........................................................................120

Media ........................................................................................122

Non-Adhesive Strip .....................................................122

Self-Adhesive Strip ....................................................... 123

Self-Adhesive Labels ..................................................... 124

Tickets with Gap ......................................................... 126

Tickets with Black Mark .............................................. 128

Interfaces

RS-232 Interface ........................................................................ 132

USB Interface ............................................................................133

Bar Code Wand Interface ........................................................... 134

Optional Interfaces ....................................................................135

Intermec Supplies

D

x Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Direct Thermal Media ...............................................................138

Thermal Transfer Media ............................................................. 139

Transfer Ribbons ........................................................................140

Bar Code Directions ..................................................................141

Recommended Paper Type Settings (Europe) ............................. 142

Recommended Paper Type Settings (North America) .................144

Before You Begin

Before You Begin

This section provides you with safety information, technical support

information, and sources for additional product information.

Safety Summary

Your safety is extremely important. Read and follow all warnings and

cautions in this document before handling and operating Intermec

equipment. You can be seriously injured, and equipment and data can be

damaged if you do not follow the safety warnings and cautions.

Do not repair or adjust alone

Do not repair or adjust energized equipment alone under any circumstances. Someone capable of providing fi rst aid must always be present

for your safety.

First aid

Always obtain fi rst aid or medical attention immediately after an injury.

Never neglect an injury, no matter how slight it seems.

Resuscitation

Begin resuscitation immediately if someone is injured and stops breathing. Any delay could result in death. To work on or near high voltage,

you should be familiar with approved industrial fi rst aid methods.

Energized equipment

Never work on energized equipment unless authorized by a responsible

authority. Energized electrical equipment is dangerous. Electrical shock

from energized equipment can cause death. If you must perform authorized emergency work on energized equipment, be sure that you comply

strictly with approved safety regulations.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) xi

Before You Begin

Safety Icons

This section explains how to identify and understand dangers, warnings,

cautions, and notes that are in this document. You may also see icons

that tell you when to follow ESD procedures.

A warning alerts you of an operating procedure, practice,

condition, or statement that must be strictly observed to

avoid death or serious injury to the persons working on the

equipment.

A caution alerts you to an operating procedure, practice,

condition, or statement that must be strictly observed to

prevent equipment damage or destruction, or corruption or

loss of data.

This icon appears at the beginning of any procedure in this

manual that could cause you to touch components (such as

printed circuit boards) that are susceptible to damage from

electrostatic discharge (ESD). When you see this icon, you

must follow standard ESD guidelines to avoid damaging

the equipment you are servicing.

Note: Notes either provide extra information about a topic or

contain special instructions for handling a particular condition

or set of circumstances.

xii Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Before You Begin

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the

Intermec web site at http://www.intermec.com and click Service &

Support. The Intermec Global Sales & Service page appears. From the

Service & Support menu, move your pointer over Support, and then

click Warranty.

Web Support

Visit the Intermec web site at http://www.intermec.com to download

our current documents in PDF format. To order printed versions of the

Intermec manuals, contact your local Intermec representative or distributor.

Visit the Intermec technical knowledge base (Knowledge Central) at

http://intermec.custhelp.com to review technical information or to

request technical support for your Intermec product.

Telephone Support

Contact your local Intermec representative. To search for your local representative, from the Intermec web site, click Contact.

Related Documents

The Intermec web site at http://www.intermec.com contains our current

documents that you can download in PDF format. To order printed versions of the Intermec manuals, contact your local Intermec representative

or distributor.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) xiii

Before You Begin

xiv Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Introduction

1

This chapter introduces the EasyCoder PF4i Compact

Industrial printer. The chapter covers the following

topics:

• Description of EasyCoder PF4i Compact Industrial

• Safety summary

• Product identifi cation

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 1

Chapter 1—Introduction

Description of EasyCoder PF4i Compact Industrial

The EasyCoder PF4i Compact Industrial is a sturdy industrial thermal transfer printer with a printhead resolution of 8 dots/mm = 203.2

dot/inch (standard) or 11.81 dots/mm = 300 dpts/inch (option) and a

maximum print width of 104 mm (4.095 inches) or 105.7 mm (4.161

inches) respectively. It offers a large number of useful features, such as:

• Flash memory SIMMs for fi rmware, fonts, bar codes, and application

programs

• Built-in CompactFlash memory card adapter

• Built-in RS-232 and USB interfaces

• Provision for extra interface boards including wired and wireless

EasyLAN connections

• Keyboard and display with backlight for improved user interface.

A large number of factory-installed or fi eld-installable options are available, so the printer can be confi gured for a wide range of applications.

See Chapter 9 and Appendix A for more information.

The EasyCoder PF4i Compact Industrial supports the unique and fl exible Intermec Fingerprint v8.20 programming language, which allows the

user or third-party developer to create custom-made application programs and label formats in a BASIC-like environment.

The printer is also designed to work with the Intermec Direct Protocol programming language, the Intermec InterDriver and Intermec

Labelshop. The InterDriver allows you to print labels from standard MS

Windows applications, for example Microsoft Offi ce.

The EasyCoder PF4i Compact Industrial supports 15 scaleable Unicode TrueType and TrueDoc fonts as standard. Additional fonts can be

downloaded into the printer’s Flash memory, or be plugged in using a

CompactFlash card. The Unicode standard allows the use of special characters for various languages including non-Latin fonts, such as Arabic,

Cyrillic, Chinese, Japanese, Korean, Hebrew, and similar.

A version of EasyCoder PF4i Compact Industrial, that supports the

Intermec Programming Language (IPL), is described in a special User’s

Guide.

2 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 1—Introduction

Safety Summary

Intermec assumes no responsibility regarding the CE Directive if the

printer is handled, modifi ed, or installed in any way other than that

described in Intermec’s manuals.

• Read this manual carefully before connecting the printer.

• Moving parts are exposed when the doors are open, so ensure that the

doors are closed before you operate the printer.

• Do not open the front/left-hand cover. Dangerous voltage!

• Do not remove the bottom plate. Dangerous voltage!

• Do not put your fi ngers inside the print mechanism when the power is

on.

• Place the printer on an even surface which can support its weight of

approximately 7 to 8 kg (15.5 to 17.7 pounds) plus supplies.

• Do not spray the printer with water. If you are using a hose to clean

the premises in an industrial environment, remove the printer or protect it carefully from spray and moisture.

• Carefully read the warning text on the envelope before using a cleaning card.

Product Identifi cation

The machine label is attached to the printer’s rear plate and contains

information on type, model, and serial number as well as AC voltage. It

also contains various signs of approval.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 3

Chapter 1—Introduction

4 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Installation

2

This chapter explains how to unpack and install the

EasyCoder PF4i Compact Industrial printer and also

describes the printer’s various parts in detail. It covers

the following topics:

• Unpacking the printer

• Parts on the printer’s front

• Parts on the printer’s rear plate

• Parts in the media compartment

• Parts in the print mechanism

• Connecting the printer

• Using the controls and understanding the indicators

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 5

Chapter 2—Installation

Unpacking the Printer

Before you install the printer, examine the package for possible damage

or missing parts:

• Open the box and lift the printer out.

• Check that the printer has not been visibly damaged during transportation. Keep the packing materials in case you need to move or reship

the printer.

• Check the label on the printer’s rear plate, which gives the voltage, the

part number, and the serial number.

• Check that any options you ordered are included.

• Check that all the accessories are included. As standard, the box contains:

- Intermec EasyCoder PF4i Compact Industrial printer

- Two sets of Quick-Load Guides (wide and narrow)

- Power cord

- Quality check card

- Cleaning card

- Short strip of labels

- Starter pack of thermal transfer ribbon

- This User’s Guide

- Supporting software and product information on CD.

• Check that the type of power cord is appropriate for the local standard. The printer works within 90 to 265 VAC, 50 to 60 Hz.

If the printer has been damaged in any way during transportation, complain to the carrier immediately.

If the delivery is incorrect or any parts are missing, report it immediately

to the distributor.

6 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

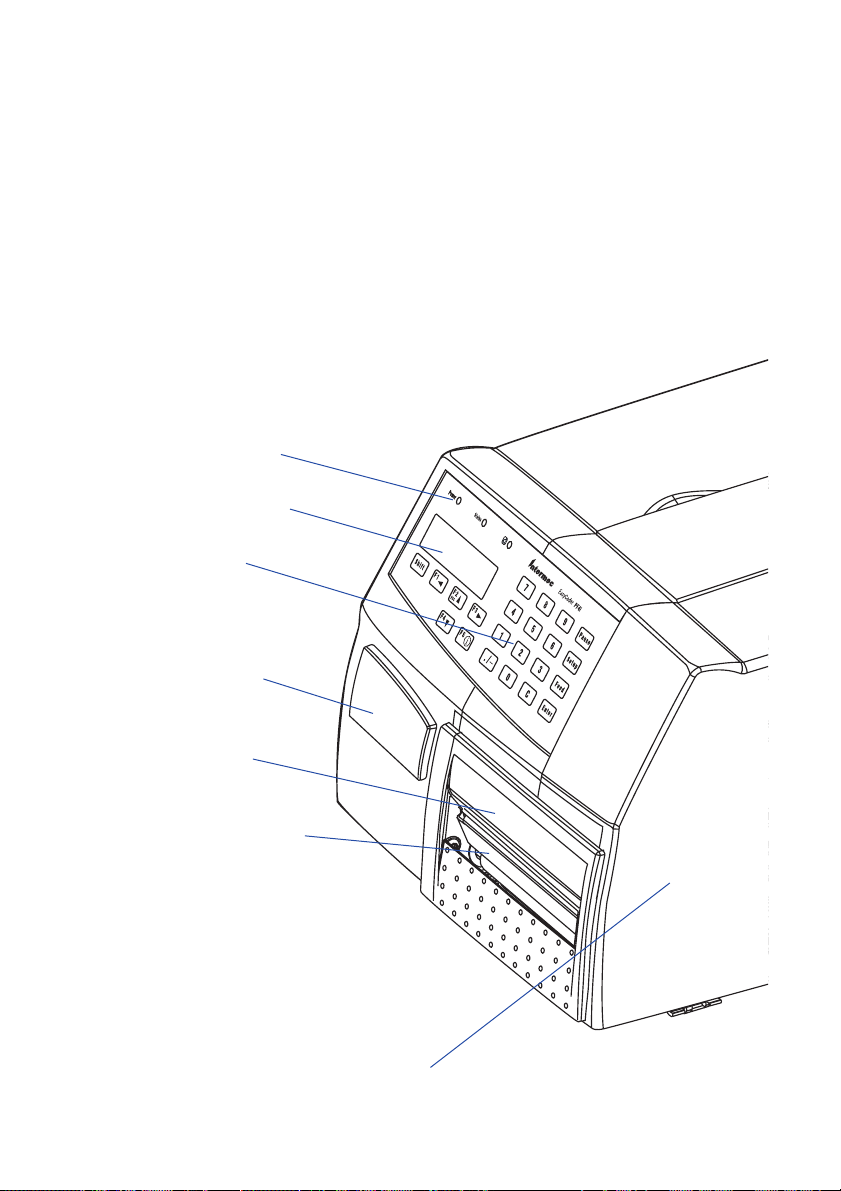

Front View

At the front of the printer are the display window, the indicator lamps,

and the keyboard. These features allow the operator to control and set up

the printer manually.

The printed labels, tickets, or tags are presented at the front of the print

mechanism.

Indicator lamps

Display window

Keyboard

Print button

Front door

Print mechanism

Side door

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 7

Chapter 2—Installation

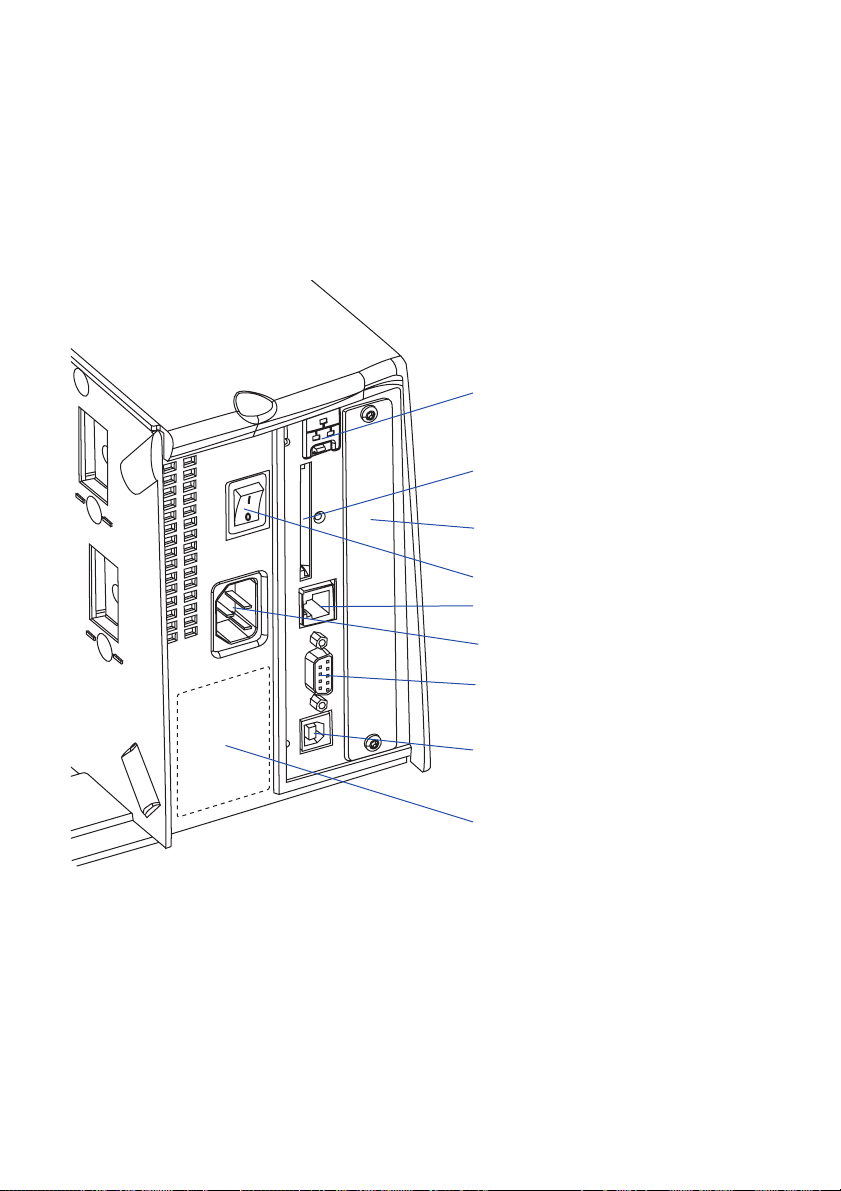

Rear View

The rear plate contains the On/Off switch, the AC power cord socket,

and various interface connectors and slots.

Provision for EasyLAN

Ethernet connection

(option)

Memory card slot

Provision for one optional

interface board

On/Off Switch

Bar code wand socket

AC Power cord socket

RS-232 serial interface

("uart1:")

USB Interface

("usb1:")

Machine label

8 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

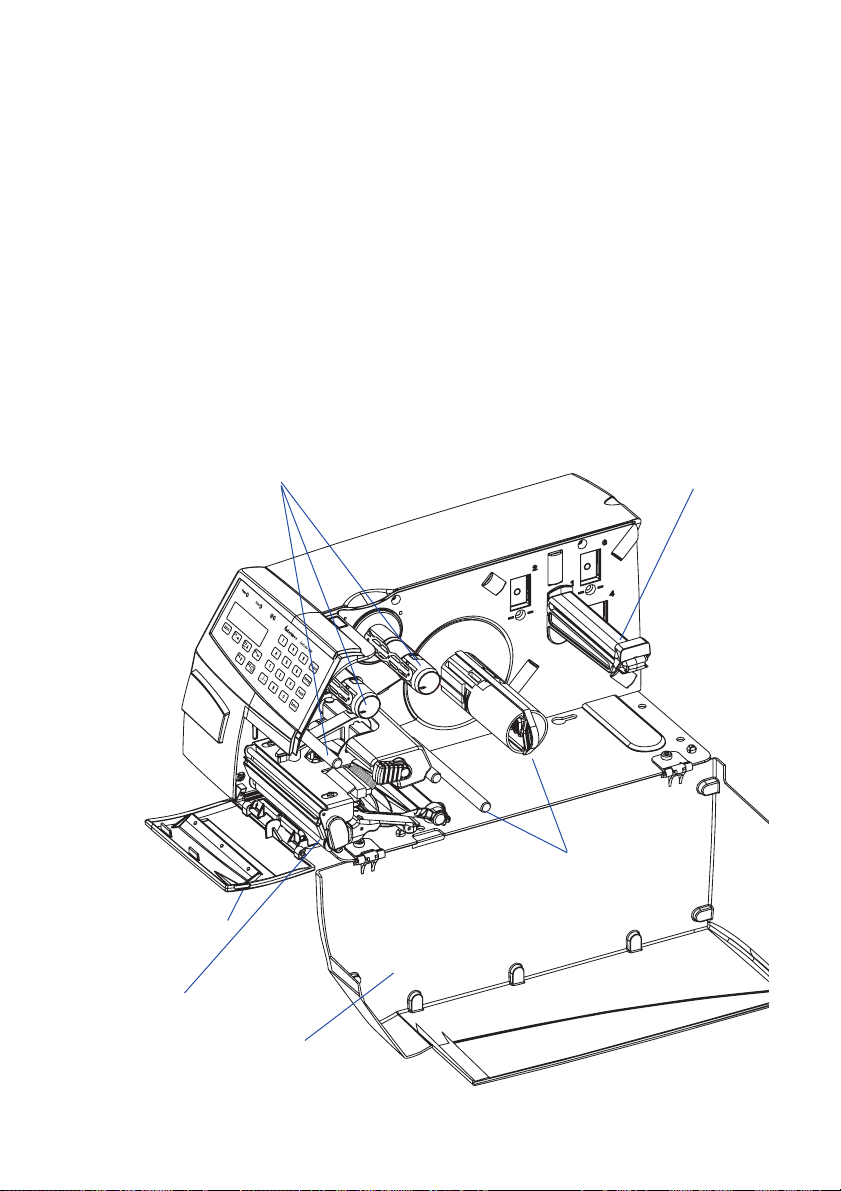

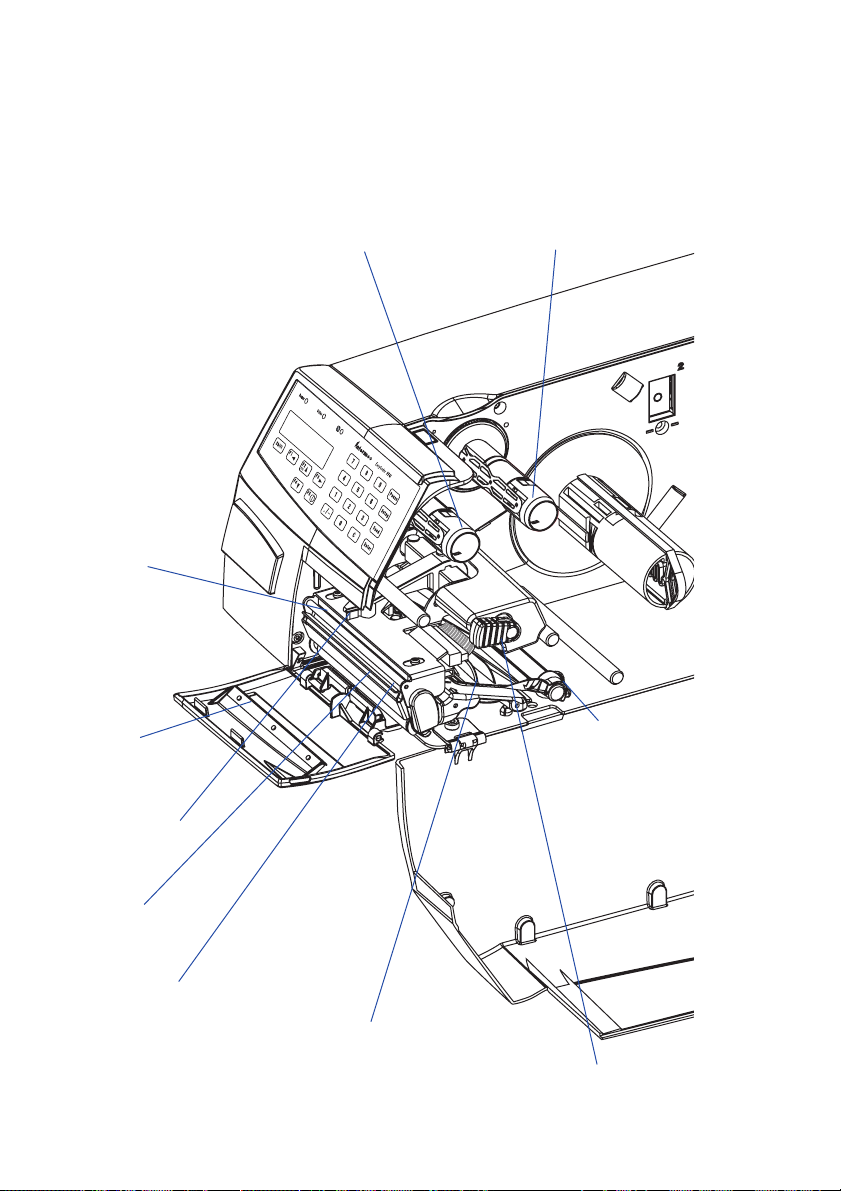

Media Compartment

Description

The media compartment is as standard covered by a long side door that

completely encloses the print mechanism and media compartment.

(Optionally, the printer can be fi tted with a two part “Megatop” that

allows a larger media roll to be used.) The door is held by a magnetic

lock. It can be opened 180° to provide full access to the media compartment.

The media supply can be from a supply post, or from an external supply

of fan folds behind the printer. There is also an optional rotating media

supply hub. Also see Chapter 9, “Options.”

Thermal transfer

mechanism

Media supply

roll post with

edge guide

Optional integral

liner takeup with

guide shaft

Front door

Print

mechanism

Long side door

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 9

Chapter 2—Installation

The EasyCoder PF4i Compact Industrial uses a media supply roll post

that can be fi tted in three different positions inside the media compartment. The position depends on the type of side door and whether the

printer is fi tted with an integral liner takeup or not. Alternatively, an

external media supply (for example a box of fan-folded tickets) behind

the printer can be used. A rotating media supply hub is also available as

an option, see Chapter 9, “Options.”

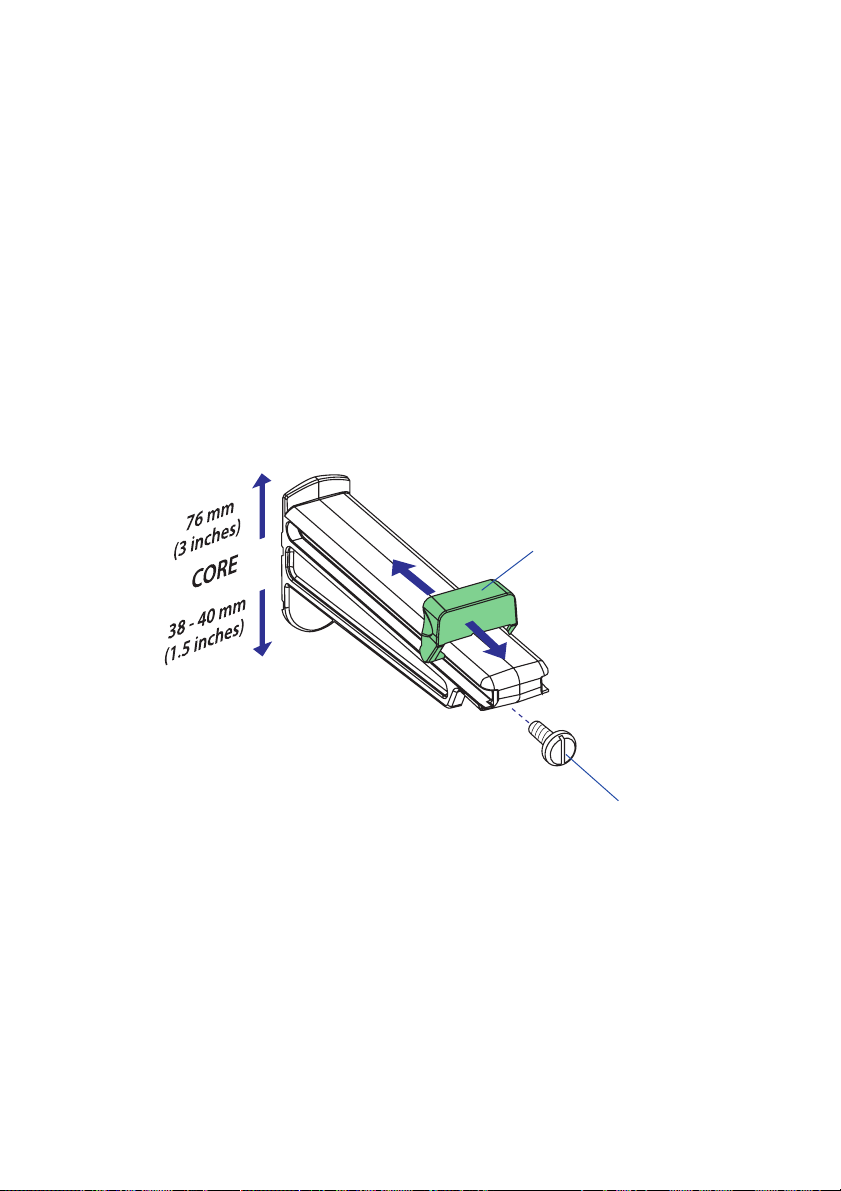

Media Supply Roll Post

The media supply roll post fi ts both 38-40 mm (1.5 inches) and 76 mm

(3.0 inches) cores since it can be moved vertically in the slot in the center

section. The bottom position is intended for small cores and the top

position is for large cores. The post is locked by a straight-slot screw and

has a moveable edge guide to fi t various media widths.

Edge guide

Screw

To move the post to a different slot; remove the screw, twist the post a

quarter of a turn, and pull it out.

To fi t the post; rotate it a quarter of a turn, insert it into the appropriate slot in the center section (see next page), and twist back so the lips

engage the cutouts in the sides of the slot. Move it up (large core) or

down (small core) as far as it goes and secure it with the screw.

10 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

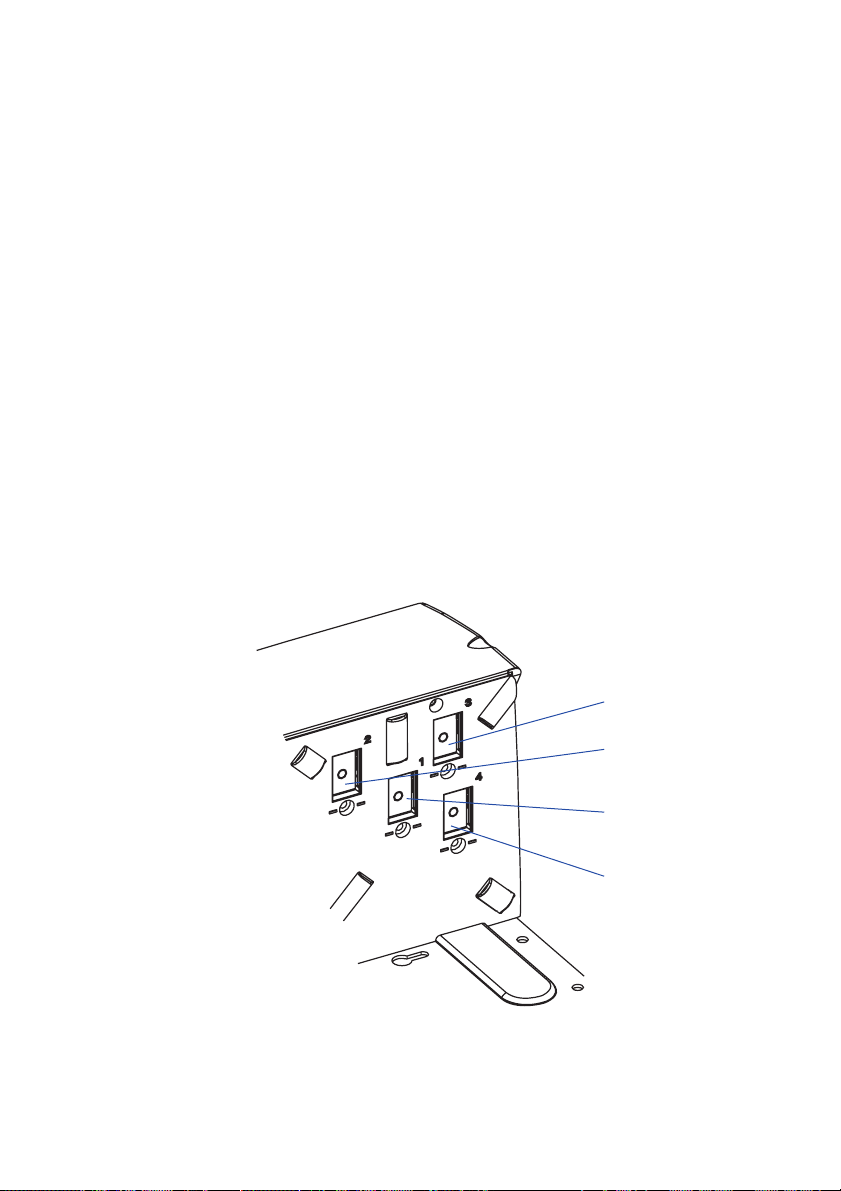

Media Supply Positions

There are four sets of slots and threaded holes in the printer’s center section for the media supply roll post or rotating hub (optional). These slots

allow the largest possible roll size to fi t, given the limitations of any liner

takeup unit and/or the full enclosure provided by the long side door or

Megatop. The positions are indicated by numbers engraved in the center

section.

• Position 1 is used when the media compartment is fully enclosed by a

long side door, regardless of the existence of any integral liner takeup

unit. Maximum roll size is 152 mm (6 inches).

• Position 2 is not used.

• Position 3 is used when the printer has an integral liner takeup unit

and a long side door. This position is also used with the 8-inch

Megatop. Maximum roll size is 213 mm (8.38 inches).

• Position 4 is not used.

The printer can also use an external media supply located behind the

printer, except when it has an 8-inch Megatop.

Position 3

Position 2

(not used)

Position 1

Position 4

(not used)

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 11

Chapter 2—Installation

Print Mechanism

The print mechanism features a high-performance thermal printhead

with quick-mount fi ttings to facilitate replacement.

Thermal

printhead

Tear bar

(tear upwards)

Ribbon rewind hub

Ribbon supply hub

Edge guide

Pressure arm

Tear bar

(tear downwards

and peel-off))

Platen roller

Label stop sensor

position adjustment

(bottom sensor hidden)

12 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Printhead lift lever

Chapter 2—Installation

Connections

Power

1 Place the printer on a level surface, near an AC outlet. You should be

able to access the printer to load supplies and to remove the printout.

2 Check that the printer is switched off.

3 Connect the power cord from the socket on the rear plate to an elec-

trical outlet (90 to 265 VAC).

Computer

The Easycoder PF4i Compact Industrial is fi tted with one 9-pin D-style

subminiature (DB9) socket for the RS-232 serial interface port and one

class B connector for the USB interface port (see Appendix C).

RS-232 Serial Interface ("uart1:")

Use the serial interface with Intermec LabelShop or the Intermec InterDriver. Also use it with the Intermec Direct Protocol or the Intermec

Fingerprint programming language because you can receive error messages from your printer. Before you can use the serial interface, you may

need to set up the communication parameters, such as baud rate, parity,

etc. as described in Chapter 6, “Setting Up the Printer.”

USB Interface ("usb1:")

Use the USB interface with an USB-compatible version of the Intermec

InterDriver for printing. The USB interface is not suitable for programming because the host cannot receive error messages from your printer.

Optional Interface and Network Boards

("uart2:", "uart3:", "centronics:", or "net1:")

Several types are available (see Chapter 9, “Options”). Refer to Chapter

6, Chapter 7, and Appendix C for connection and setup instructions.

The printer can be set to scan all communication ports. When it detects

incoming data on a port, the printer automatically switches to use that

port for both input and output. This facility ("auto") can be selected in

Intermec Shell (see Chapter 8) or using the Intermec Fingerprint instruction SETSTDIO, see Intermec Fingerprint v8.xx, Programmer’s Reference

Manual. Use the <F5/i> key to get information on the active communication channels.

Switch off both PC and printer before connecting them together.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 13

Chapter 2—Installation

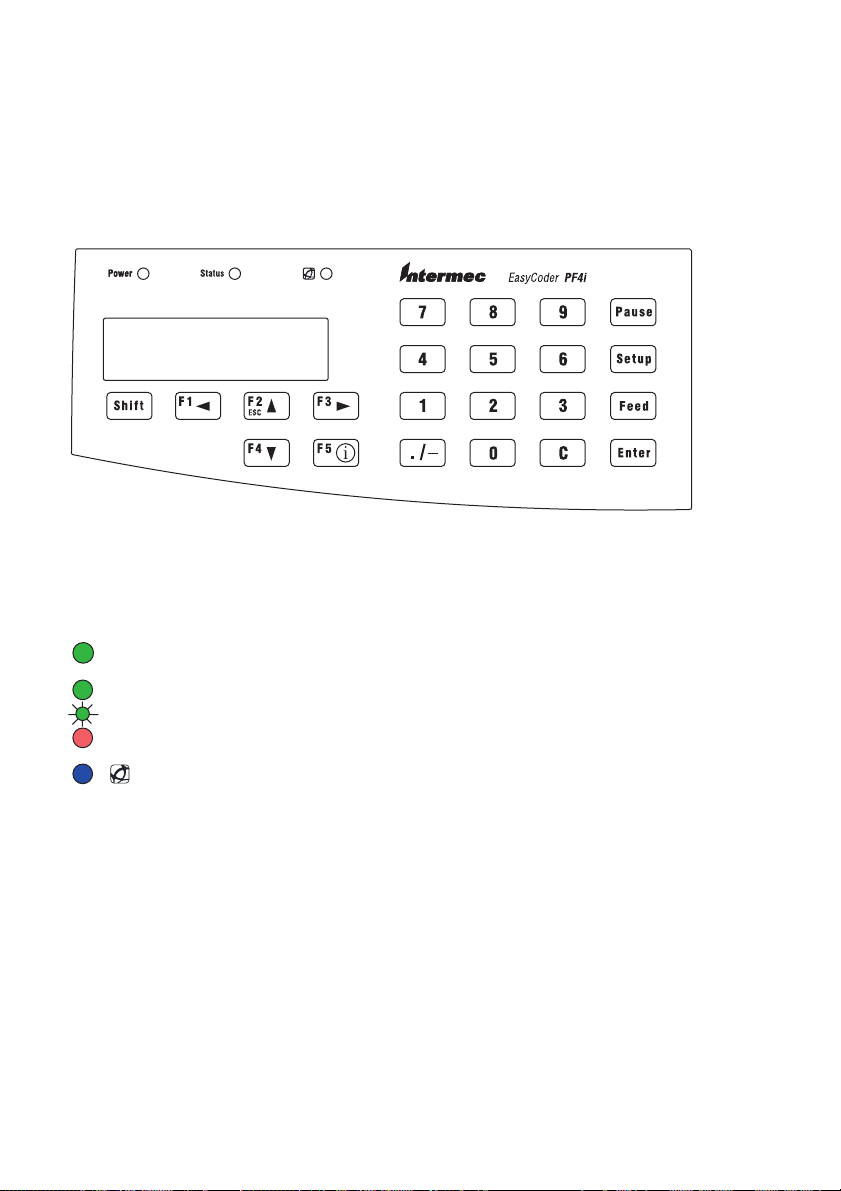

Controls and Indicators

The EasyCoder PF4i Compact Industrial has several ways of communicating directly with its operator: three colored indicator lamps, a display

window, a membrane-switch keyboard with 22 programmable keys, a big

programmable “Print” button on the printer’s front, and a beeper.

Indicator Lamps

The indicators are colored LEDs (Light Emitting Diodes) and are used

for the following purposes:

Power (solid green) indicates that the power is on.

Status (solid green) indicates that the printer is ready for use.

Status (fl ashing green) indicates that the printer is communicating.

Status (solid red) indicates an error condition (see Chapter 10).

Intermec Readiness Indicator (blue; on, blink, or off).

Represented by a blue light on Intermec handheld computers, access

points, and printers, the Intermec Readiness Indicator is part of an

exclusive monitoring system from Intermec. The Intermec Readiness

Indicator helps users quickly determine the readiness of the Intermec

device individually and as part of a solution. The Intermec Readiness

Indicator has three different states: On, Blinking, and Off. When the

Indicator is off, the device is not ready to operate individually or as

part of a solution. When the Indicator is blinking, the device may be

initializing, waiting for external resources, or in need of user attention. And when the Indicator is On, the device is ready for use as

part of a solution. Also see Chapter 10.

14 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 2—Installation

Display

The display window contains an LCD (Liquid Crystal Display) with

background illumination and two lines of text, each with 16 characters.

It guides the operator through the setup and indicates possible errors

during printing.

The Intermec Fingerprint programming language and the Intermec

Direct Protocol allow custom-made messages to be composed and displayed according to the requirements of the application.

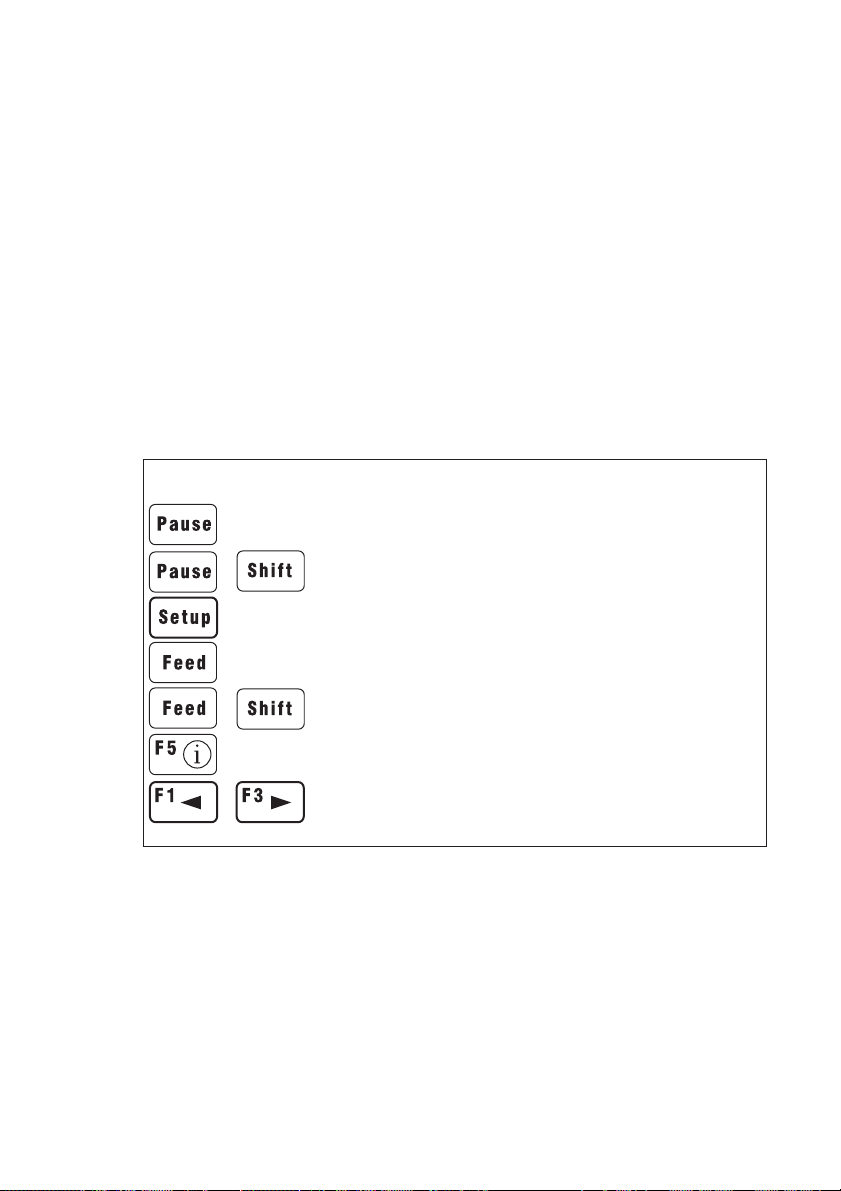

Keyboard

The keyboard is of the membrane-switch type and has 22 keys. The keyboard is supplemented by a large “Print” button on the printer’s front.

Some keys have hard-coded functions in the startup and setup modes.

Print button

Feed/Pause a print job. Repeat last printed label.

Toggle between pause and printing when executing a print job.

+

+

Interrupt a running Fingerprint program.

Enter the Setup Mode (see Chapter 7).

Feed out a blank label or the equivalent.

Perform a Testfeed (feed a blank label, adjust the media feed).

Display error messages, IRI status, and communication channel

information.

Scroll between various types of information after pressing the

<F5/i> key. Possible error messages and information on active

communication channels are shown in a loop.

Keyboard Color Code

Yellow Operation of the printer (operator level)

Green Setup or service (site or service technician level)

White Data input to printer (operator or technician level)

In application programs created using the Intermec Fingerprint programming language, the keys can be assigned to various functions or

be disabled individually. Since one key is assigned as shift key, up to 44

different key combinations are possible. An audible signal, which can be

turned off if so desired, acknowledges that a key has been pressed.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 15

Chapter 2—Installation

Beeper

The beeper notifi es the operator when an error has occurred and

acknowledges that a key has been pressed. The Intermec Fingerprint programming language allows the key acknowledge signal to be turned off.

The frequency and duration of signals can be specifi ed. Thus, it is possible to create different signals for different conditions or even to make

the printer play simple melodies!

16 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Starting Up

3

This chapter explains how to start up the printer after

installation or after having been switched off. It covers

the following topics:

• Startup fi les

• Memory cards

• Switching on the printer

• Display messages at startup

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 17

Chapter 3—Starting Up

Startup Files

When the printer is switched on, its behavior depends on the existence of

a startup fi le (autoexec.bat) in its memory. There are two cases:

A The printer is only fi tted with the Intermec Shell fi le-managing

program, which allows the operator to choose between a variety of

applications and functions.

B In addition to Intermec Shell, the printer is also fi tted with a custom-

made application program that is design to perform a specifi c task, for

example to print tickets, baggage tags, or product labels for a certain

company. Such a program may be initiated by a startup fi le (autoexec.

bat) stored in the printer’s permanent memory or in a memory card.

There can be one startup fi le stored in each of three different parts of the

printer’s memory. If there are startup fi les stored in more than one part,

only one will be used with the following priority:

1. An autoexec.bat fi le stored in a memory card, provided the card was

inserted in the printer before the power was switched on.

2. An autoexec.bat fi le stored in the read/write part of the printer’s permanent memory (device "/c").

3. The pup.bat fi le (Intermec Shell) in the read-only part of the printer’s

permanent memory (device "/rom").

Note: If you insert a CompactFlash memory card that contains

a startup fi le before you switch on the printer, this startup fi le

will be used instead of Intermec Shell.

18 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 3—Starting Up

Memory Card

If you want to use a memory card, you must insert it into the slot in the

printer’s rear plate before you switch on the power. The memory card

must be a CompactFlash card (8MB-1GB). CompactFlash cards marked

“CF+” will not work. You can use the CompactFlash card to expand the

printer’s storage memory ("card1:"). There are also three types of preprogrammed CompactFlash cards:

• Font Cards provide additional fonts that can be used as long as the

card remains inserted in the printer.

• Font Install Cards permanently install additional fonts in the printer,

which can be used even after the card has been removed.

• Firmware Cards automatically replace the printer’s fi rmware, usually

with an updated version.

CompactFlash cards are widely used for consumer’s computer products

like digital cameras. You can get a certain protection from theft by installing an optional plate that covers an inserted CompactFlash card.

CompactFlash

memory card

Protection plate

with screw

(option)

Note: Always switch off the power before inserting or removing

a memory card! The card will only fi t in one way. A memory

card is only detected if it is inserted before the printer is

started.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 19

Chapter 3—Starting Up

Switching On the Printer

Before switching on the printer, make the necessary connections, insert

any memory card you want to use, and check that the printhead is

engaged.

Switch on the power using the On/Off switch on the rear plate. The

“Power” control lamp on the front panel lights up when the power is on.

Wait for a few moments, while the printer loads the program and runs

some self-diagnostic tests:

Starting

After a short time, the printer is initialized. The progress of the initialization is indicated by an increasing number of colons on the lower line in

the display:

Initializing

:::

The type of startup fi le running in the printer is indicated by the message

shown in the display window immediately after initialization.

A. Intermec Shell Startup Program

ENTER=SHELL

5 sec. v.8.1

4 sec. v.8.1

3 sec. v.8.1

2 sec. v.8.1

1 sec. v.8.1

Refer to Chapter 8 for more information on Intermec Shell. The digits

in the lower right corner of the display indicate the version of Intermec

Shell.

B. Custom-Made Application Program

Any other display messages than those illustrated above indicates that the

printer is running some custom-made, non-standard application program, or that some error has occurred.

20 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Media Load

4

This chapter explains how to load the printer with

media, that is labels, tickets, tag, or strips, for the following modes of operation:

• Tear-Off (straight-through)

• Tear-Off with Quick-Load (straight-through)

• Cut-Off

• Peel-Off (self-strip)

• External supply (fan-folds)

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 21

Chapter 4—Media Load

Tear-Off (Straight-through)

The EasyCoder PF4i Compact Industrial can print on labels, tickets,

tags, and continuous stock in various forms. This section describes the

case when the media is torn off manually against the printer’s tear bar.

This method is also known as “straight-through printing.”

Use the <Feed> key (see fi gure #10) when loading the same type of

media. When switching to a new type of media, or if the printer does not

feed out the media properly, simultaneously press the <Shift> and <Feed>

keys to perform a “testfeed.”

Tear-off can be used for:

• Non-adhesive continuous stock

• Self-adhesive continuous stock with liner

• Self-adhesive labels with liner

• Tickets with gaps, with or without perforations

• Tickets with black marks, with or without perforations

An optional label taken sensor can hold the printing of the next copy

in the batch until the present copy has been removed, see Chapter 9,

“Options.”

22 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Tear-Off , cont.

Chapter 4—Media Load

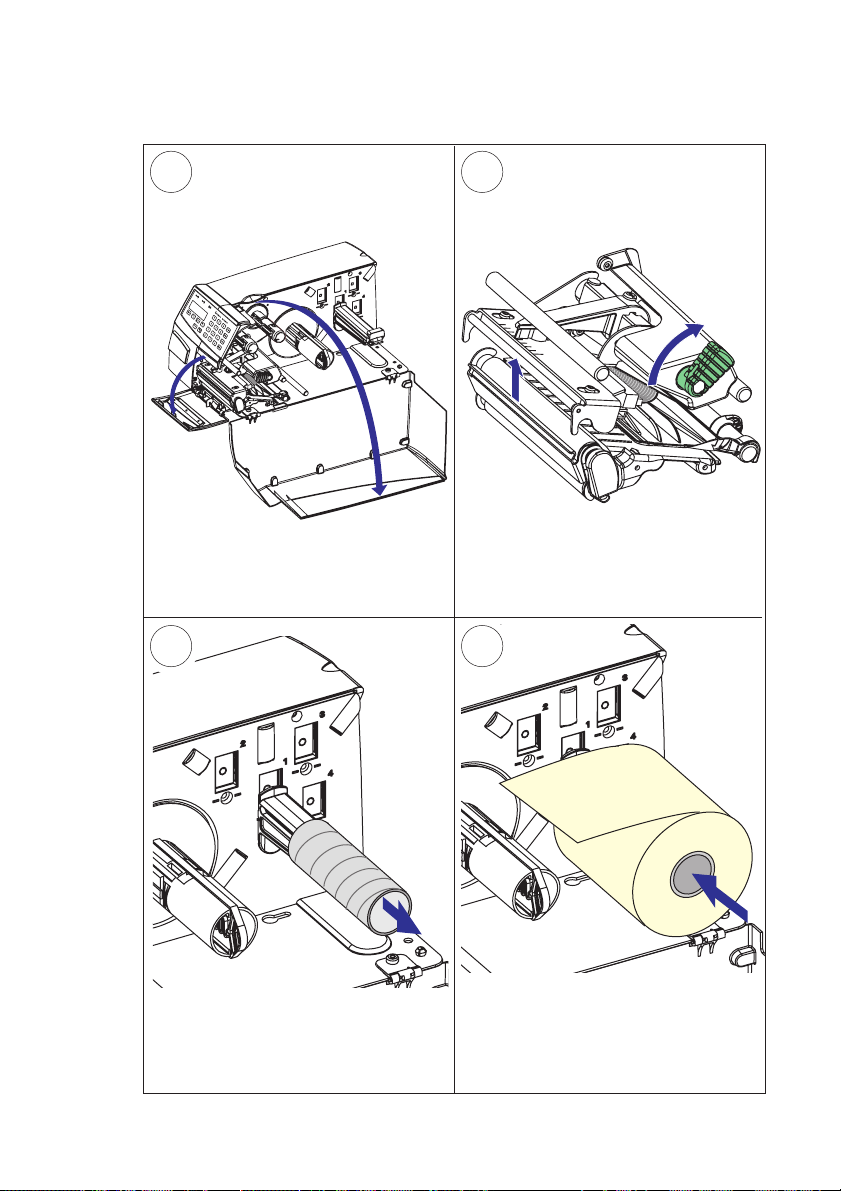

1

Open the front and side doors.

3

2

Turn the printhead lift lever clockwise to

raise the printhead.

4

If necessary, fold down the edge guide.

Remove any empty core from the media

supply roll post.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 23

Fit a new roll of media on the supply

post and adjust the edge guide so

the roll becomes fl ush with the center

section.

Chapter 4—Media Load

Tear-Off , cont.

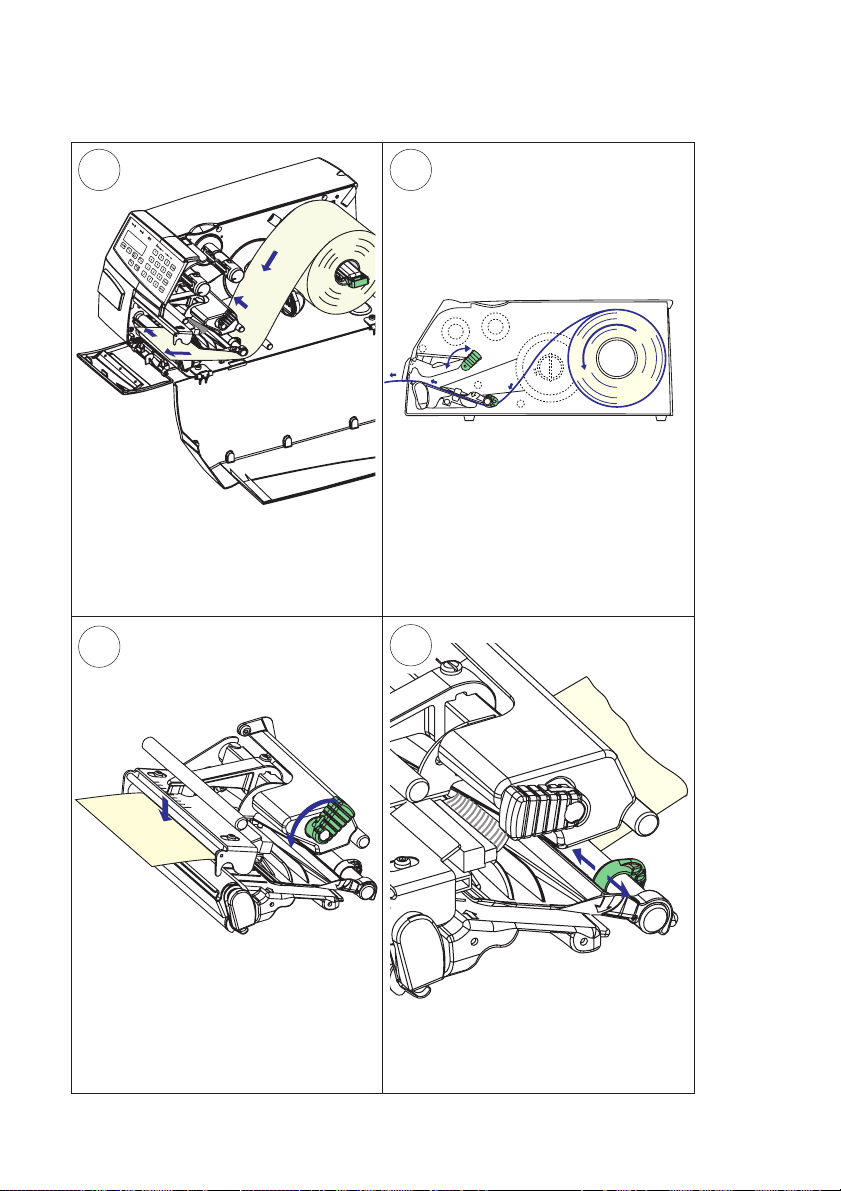

5 6

Route the media through the print

mechanism. Then push it inwards as far

as it will go. Close the edge guide on the

media supply post.

This diagram shows the media path.

7

Turn the printhead lift lever counterclockwise to engage the printhead.

24 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

8

Adjust the position of the green edge

guide so the media is guided with a

minimum of play.

Tear-Off , cont.

Chapter 4—Media Load

9

Close the front and side door, making

sure that the media runs through the

slot in the front door.

10

Press the Feed key to advance the media

and adjust the media feed. Tear off the

media by pulling it either upwards or

downwards.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 25

Chapter 4—Media Load

Tear-Off with Quick-Load (Straight-through)

In addition to the media load procedure for tear-off (straight-through)

operation described earlier in this chapter, the EasyCoder PF4i Compact

Industrial can optionally be fi tted with a set of Quick-Load guides that

makes media load much easier and quicker.

The printer is normally delivered with two different sets of Quick-Load

guides: wide and narrow. The wide type generally guides the media

better, but the media must be at least 80 mm (3.15 inches) wide. The

narrow type allows a media width as narrow as 40 mm (1.57 inches), but

it may be less suited for wide and thin media.

Quick-Load cannot be combined with peel-off (self-strip) operation.

An optional label taken sensor can hold the printing of the next copy

in the batch until the present copy has been removed, see Chapter 9,

“Options.”

Use the <Feed> key (see fi gure #5) when loading the same type of media.

When switching to a new type of media, or if the printer does not feed

out the media properly, simultaneously press the <Shift> and <Feed>

keys to perform a “testfeed.” Fully automatic loading, without the operator having to press any key, requires a special set of Intermec Fingerprint

instructions in the application program.

26 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Tear-Off with Quick-Load, cont.

Chapter 4—Media Load

1

Lift up the upper media guide and pull

out the green edge guide (save it for

later use).

2

Narrow Guides

Rail

Notch

Wide Guides

Press the wide or narrow Quick-Load

guides onto the shaft as illustrated,

making sure that the notches fi t the rail

at the rear of the lower media guide.

43

Insert the media between the guides

and feed it forward until the media

If necessary, adjust the outer QuickLoad guide to fi t the width of the media.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 27

reaches the platen roller and cannot be

inserted any further.

Chapter 4—Media Load

Tear-Off with Quick-Load, cont.

5 6

Close the front and side doors, making

Keep pushing the media forward while

pressing the Feed key.

sure that the media runs through the

slot in the front door.

28 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 4—Media Load

Cut-Off

The EasyCoder PF4i Compact Industrial can print on labels, tickets,

tags, and continuous stock in various forms. This section describes

the case when the media is to be cut off by an automatic paper cutter

(option).

Use the <Feed> key (see fi gure #12) when loading the same type of

media. When switching to a new type of media or if the printer does not

feed out the media properly, simultaneously press the <Shift> and <Feed>

keys to perform a “testfeed.”

Cut-off can be used for:

• Non-adhesive continuous stock

• Self-adhesive labels with liner (cut only liner between labels)

The cutter is designed to cut through paper-based media with a thickness

between 60 and 175 µm, whick roughly corresponds to a paper weight

of 60 to 175 grams/m

not be used to cut through labels, because the adhesive will stick to the

shears, which can damage the cutter.

The cutter is held by a snap-lock and can be tilted forward to facilitate

media load. A switch prevents the cutter from operating when in open

position.

2

(basis weight 40 to 120 lb). The cutter should

The optional label taken sensor cannot be used with the cutter.

The paper cutter can be used with both a standard edge guide and

Quick-Load guides and with any type of side door. In this chapter, a

printer with a standard edge guide and a long side door is illustrated.

There is no front door when a cutter is installed.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 29

Chapter 4—Media Load

Cut-Off , cont.

1

Open the cutter and the side door.

3

2

Turn the printhead lift lever clockwise to

raise the printhead.

4

Fit a new roll of media on the supply

If necessary, fold down the edge guide.

Remove any empty core from the media

supply roll post.

30 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

post and adjust the edge guide so

the roll becomes fl ush with the center

section.

Chapter 4—Media Load

Cut-Off , cont.

5 6

Route the media through the print

mechanism and cutter. Then push it

towards the center section as far as it

will go. This diagram shows the media path.

7

Turn the printhead lift lever counterclockwise to engage the printhead.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 31

8

Adjust the position of the green edge

guide so the media is guided with a

minimum of play.

Chapter 4—Media Load

Cut-Off , cont.

9 10

Close the side door.

Close the cutter while pulling at the

media.

11

An optional tray can be attached to the

cutter to collect the cut off labels, tickets,

or tags.

32 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

12

Press the Feed key to advance the media

and adjust the media feed.

Chapter 4—Media Load

Peel-Off (Self-strip)

The EasyCoder PF4i Compact Industrial can print on labels, tickets,

tags, and continuous stock in various forms. This section describes the

case when self-adhesive labels are separated from the liner immediately

after printing. The liner is then wound up on an integral liner takeup

hub. This is also known as “Self-strip” operation.

Peel-off operation cannot be performed when Quick-Load guides are

fi tted.

Use the <Feed> key (see fi gure #13) when loading the same type of

media. When switching to a new type of media, or if the printer does not

feed out the media properly, simultaneously press the <Shift> and <Feed>

keys to perform a “testfeeed.”

Peel-off can only be used for:

• Self-adhesive labels with liner

An optional label-taken sensor can hold the printing of the next label

in a batch until the present label has been removed, see Chapter 9,

“Options.”

Note: Peel-off operation sets high demands on the media in

regard of label stiffness, release characteristics of the adhesive

and liner, resistance against electrostatic charging etc., so the

labels will be dispensed properly. Consult your media supplier

or test the media to ascertain that it is suitable for your application.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 33

Chapter 4—Media Load

Peel-Off , cont.

1

Open the front and side doors.

3

2

Turn the printhead lift lever clockwise to

raise the printhead.

4

If necessary, fold down the edge guide.

Pull out the handle to collapse the

takeup hub, then remove any liner.

34 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Remove any empty core from the media

supply roll post.

Peel-Off , cont.

5 6

Fit a new roll of labels on the supply

post.

Chapter 4—Media Load

Remove labels from the fi rst 50 cm

(20 inches) of the liner. Route the liner

through the print mechanism, push it

inwards, and adjust the edge guides so

the label path becomes fl ush with the

center section.

7

Close the edge guide on the supply post.

Route the liner around the tear bar and

the liner drive roller and back under the

print mechanism and guide shaft.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 35

8

Insert the start of the liner under the lip

of the takeup hub, then rotate the hub

counterclockwise a few turns to wind up

some of the liner.

Chapter 4—Media Load

Peel-Off , cont.

9 10

This diagram shows the media and liner

paths.

11

Adjust the position of the green edge

guide so the media is guided with a

minimum of play.

36 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Turn the printhead lift lever counter-

clockwise to engage the printhead.

12

Close the front and side doors.

Peel-Off , cont.

13

Press the Feed key to advance the media

and adjust the media feed.

Chapter 4—Media Load

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 37

Chapter 4—Media Load

External Supply (Fan-fold)

The EasyCoder PF4i Compact Industrial can print on labels, tickets,

tags, and continuous stock in various forms. This section describes the

case when the media supply is placed behind the printer, usually in the

form of fan-folded tickets or tags. External supply can be used with tearoff (straight-through) printing—preferably with Quick-Load.

External supply can only be used with a long side door, not the megatop.

There is no need to remove the media supply roll post.

When using an external media supply, take care to protect the media

from dust, dirt or other foreign particles, that can impair the printout

quality or cause unnecessary wear to the printhead.

Depending on brand and quality, all direct thermal media are more or

less sensitive to heat, direct sunlight, moisture, oil, plasticizers, fat, and

other substances. You should protect them accordingly.

This diagram shows the media path from an external supply. In case of the standard

edge guide (as opposed to Quick-Load guides), turn it to vertical position.

38 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Thermal Transfer

5

Printing

This chapter explains how to load the printer with

ribbon for thermal transfer printing.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 39

Chapter 5—Thermal Transfer Printing

Ribbon Load

The EasyCoder PF4i Compact Industrial can print on labels, tickets,

tags, and continuous stock using either direct thermal printing on special

heat-sensitive media or thermal transfer printing using a special inkcoated ribbon.

Thermal transfer printing makes it possible to use a wide range of receiving face materials and gives a durable printout less vulnerable to fat,

chemicals, heat, sunlight etc. than direct thermal printing. Make sure to

select a type of ribbon that matches the type of receiving face material

and to set up the printer accordingly.

The EasyCoder PF4i Compact Industrial can use transfer ribbon rolls

wound with the ink-coated side facing either outward or inward. Illustrations in this manual show the ink-coated side facing inward.

Even if ribbon usually is loaded in connection with media replenishment,

no loaded media are shown in the illustrations in this chapter in order to

give a clearer view of the ribbon path. Refer to Chapter 4 for media load

instructions.

Most transfer ribbons do not smear at room temperature.

40 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Ribbon Load, cont.

Chapter 5—Thermal Transfer Printing

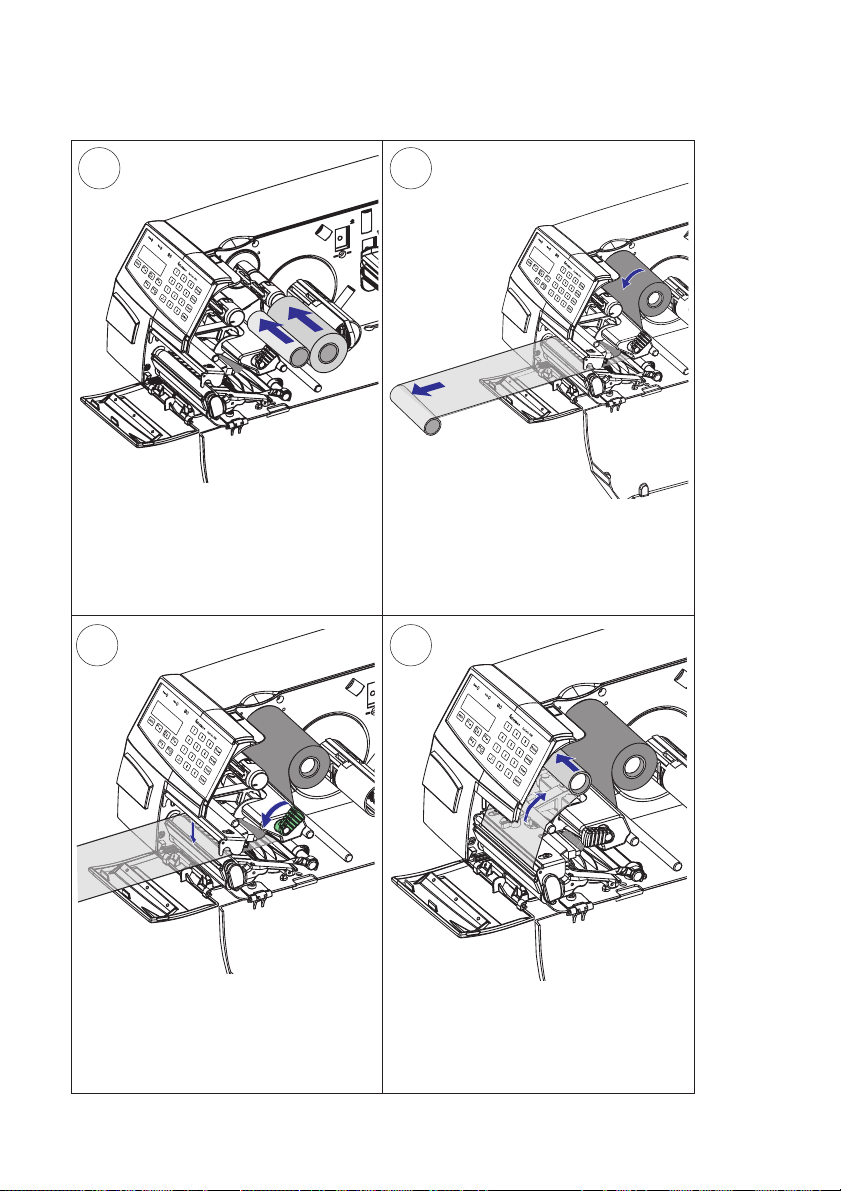

1

Open the front and side doors.

2

Turn the printhead lift lever clockwise to

raise the printhead.

43

In case of ribbon reload, remove any

used ribbon and empty ribbon core.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 41

Unpack a roll of original Intermec

thermal transfer ribbon.

Chapter 5—Thermal Transfer Printing

Ribbon Load, cont.

5

Slide the ribbon roll onto the supply hub

so the ink-coated side faces down when

the ribbon is routed through the print

mechanism.

7

6

20 cm (8 in.)

Route the ribbon through the print

mechanism and pull out approximately

20 cm (8 inches) of ribbon.

8

Without releasing the ribbon, turn the

printhead lift lever counterclockwise

to engage the printhead and lock the

ribbon.

42 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Slide the empty cardboard core onto

the ribbon rewind hub so the ribbon

is wound up when the hub rotates

counterclockwise.

Ribbon Load, cont.

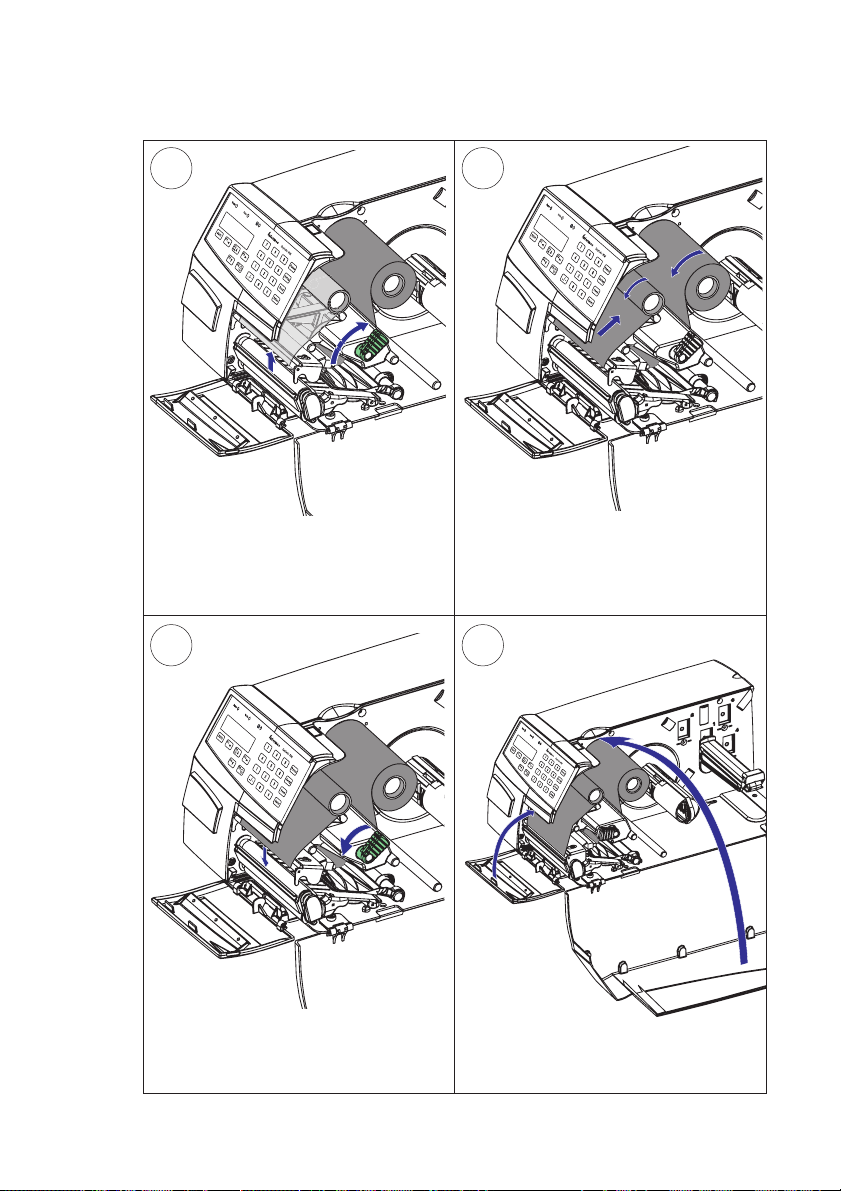

9 10

Turn the printhead lift lever clockwise

to raise the printhead and release the

ribbon.

Chapter 5—Thermal Transfer Printing

Manually advance the ribbon until all

of the transparent leader has passed

the printhead and the ribbon becomes

tight.

11

Turn the printhead lift knob counterclockwise to engage the printhead. Close the front and side doors.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 43

12

Chapter 5—Thermal Transfer Printing

44 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Setting Up the Printer

6

This chapter describes the various parameters that are

used in the Setup Mode (see Chapter 7) or in the various application programs to confi gure the printer for

the user’s specifi c requirements. It covers the following

topics:

• Description

• Default setup

• Setup Parameters in regard of communication, feed

adjust, media, and print defi nes.

When measures are specifi ed as “dots”, the actual

length in millimeters or inches depends on the

printhead density. Convert as follows:

8 dots/mm (203.2 dots/inch) printhead:

1 dots = 0.125 mm = 0.0049 inches (4.9 mils)

11.81 dots/mm (300 dots/inch) printhead:

1 dot = 0.085 mm = 0.0033 inches (3.3 mils)

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 45

Chapter 6—Setting Up the Printer

Description

The setup controls the printer in regard of serial communication, media

feed, and print speed, and specifi es which type of media and (optionally)

ribbon is loaded in the printer.

Check the list of the printer’s default setup parameters on the next page

to see if they match your requirements. If not, you will have to change

the setup using one of the methods described below. The setup may also

be changed by Intermec PrintSet, InterDriver, and LabelShop, or thirdparty application programs.

Setup Mode

• Press the <Setup> key on the printer’s built-in keyboard to enter the

Setup Mode, or

• select the Setup option in Intermec Shell to enter the Setup Mode, or

• execute the Intermec Fingerprint

Setup Mode, or

• access the Setup Mode via the printer’s home (requires an optional

EasyLAN interface board).

See Chapter 7, “Setup Mode” in this manual and the EasyLAN docu-

mentation.

SETUP instruction to enter the

Intermec Fingerprint

• Use setup strings to change individual setup parameters remotely

from the host, or

• use setup fi les to create sets of setup parameters remotely from the

host.

See the Intermec Fingerprint v8.xx manuals.

Intermec Direct Protocol

• Use setup strings to change individual setup parameters remotely

from the host.

See the Intermec Direct Protocol v8.xx manuals.

46 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Default Setup

The printer’s default setup is listed below (assuming no options installed):

Ser-Com "uart1:"

Baud rate 9600 bps

Character length 8 bits

Parity None

Stop bits 1 bit

RTS/CTS Disable

ENQ/ACK Disable

XON/XOFF, data to host Disable

XON/XOFF, data from host Disable

New line CR/LF

Receive buffer 1024 bytes

Transmit buffer 1024 bytes

Feedadjust:

Startadjust 0

Stopadjust 0

Media:

X-start (8 dots/mm = 203.2 dpi) 24

X-start (11.81 dots/mm = 300 dpi) 36 (option)

Width (8 dots/mm = 203.2 dpi) 832

Width (11.81 dots/mm = 300 dpi) 1248 (option)

Length (8 dots/mm = 203.2 dpi) 1200

Length (11.81 dots/mm = 300 dpi) 1800 (option)

Media type Label (w Gaps)

Paper type Thermal transfer

Ribbon constant 90

Ribbon factor 25

Label offset 0

Low diameter 0

Contrast ±0%

Print Defi nes:

Print speed 100 mm/sec.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 47

Chapter 6—Setting Up the Printer

Reading the Current Setup

The printer’s current setup values can be read from the printer’s display

window by browsing through the Setup Mode.

You can list the printer’s current setup values by printing test label “Setup

Info” in the Setup Mode or by using Intermec Shell.

The current setup values can be sent to the host via the standard serial

communication channel using a SETUP WRITE "uart1:" statement (see Intermec Fingerprint v8.xx, Programmer’s Reference Manual).

48 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Setup Parameters

Serial Communication

The serial communication parameters control the communication

between the printer and the connected computer or other devices on the

standard serial port "uart1:" and the optional serial ports "uart2:" and

"uart3:". The optional ports require an optional interface board. The

printer’s fi rmware detects if an interface board is installed in the printer

and presents additional sets of communication setup menus depending

on type of communication (refer to diagrams 3-5 in Chapter 7, “Setup

Mode”).

Note: The serial communication parameters have no effect on

parallel or EasyLAN communications, or on the IN and OUT

ports on the optional Industrial Interface Board.

For the serial communication channel "uart1:", the following parameters

can be set. Make sure they match the setup of the connected device or

vice versa. If the setup of the printer and the setup of the host do not

match, the response from the printer to host will be garbled.

Baud Rate

The baud rate is the transmission speed in bits per second. There are 10

options:

• 300

• 600

• 1200

• 2400

• 4800

• 9600 (default)

• 19200

• 38400

• 57600

• 115200

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 49

Chapter 6—Setting Up the Printer

Character Length

The character length specifi es the number of bits that will defi ne a

character. Eight bits are recommended, because that option allows more

special characters and characters specifi c for foreign languages to be used.

Refer to the Intermec Fingerprint v8.xx, Programmer’s Reference Manual

for more information.

• 7 Characters ASCII 000 to 127 decimal

• 8 Characters ASCII 000 to 255 decimal (default)

Parity

The parity decides how the fi rmware will check for transmission errors.

There are fi ve options:

• None (default)

• Even

• Odd

• Mark

• Space

Stop Bits

The number of stop bits specifi es how many bits will defi ne the end of a

character. There are two options:

• 1 (default)

• 2

Flow Control

RTS/CTS is a protocol where the communication is controlled by currents through separate lines in the cable being set either to high or low.

By default, this option is disabled.

RTS high indicates that the transmitting unit is able to receive characters.

RTS low indicates that the receive buffer is fi lled to 75% (see XON/

XOFF).

CTS high indicates that the unit transmitting the CTS signal is ready to

receive data. CTS low indicates that the receive buffer is full (see XON/

XOFF). In some computer programs, for example MS Windows Terminal, RTS/CTS is designated “Hardware.”

ENQ/ACK is a protocol where the communication is controlled by

the control characters ENQ (ASCII 05 dec.) and ACK (ASCII 06 dec.)

being transmitted on the same line as the data. The sending unit transmits ENQ at regular intervals. If the response ACK is not received, the

50 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

transmission is held up awaiting an ACK character from the receiving

unit. By default, ENQ/ACK is disabled.

XON/XOFF is a protocol where the communication is controlled by

the control characters XON (ASCII 17 dec.) and XOFF (ASCII 19 dec.)

being transmitted on the same line as the data. XON/XOFF can be

enabled/disabled separately for data received from the host by the printer

(printer sends XON/XOFF) and for data transmitted to the host from

the printer (host sends XON/XOFF).

XOFF is sent from the printer when its receive buffer is fi lled to 75%,

and the transmission from the host is held, waiting for an XON character. When enough data have been processed so the receive buffer is fi lled

only to 50%, the printer sends an XON character and the host resumes

transmitting data. The same principles apply to XON/XOFF sent by the

host, even if the percentage fi gure may differ. By default, XON/XOFF is

disabled for data in both directions.

New Line

Selects the character(s) transmitted from the printer to specify the switching to a new line. There are three options:

• CR/LF ASCII 13 + 10 dec. (default)

• LF ASCII 10 dec.

• CR ASCII 13 dec.

Receive Buff er

The receive buffer stores the input data before processing. Default size is

1024 bytes.

Transmit Buff er

The transmit buffer stores the output data to be transmitted before transmission. Default size is 1024 bytes.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 51

Chapter 6—Setting Up the Printer

Feedadjust

The Feedadjust part of the Setup Mode controls how much of the media

is fed out or pulled back before and/or after the actual printing. These

settings are global and will be effected regardless of which program is

run.

Note: The fi rmware uses the front edges of labels w. gaps, the

ends of detection slots, and the forward edges of black marks

for detection, all seen in relation to the feed direction.

Start Adjust

The Start Adjust value is given as a positive or negative number of dots.

Default value is 0, which places the origin a certain distance back from

the forward edge of the copy.

• A positive start adjustment means that the specifi ed length of media

will be fed out before the printing starts. Thus, the origin is moved

further back from the forward edge of the copy.

• A negative start adjustment means that the specifi ed length of media

will be pulled back before the printing starts. Thus, the origin is

moved towards the forward edge of the copy.

Stop Adjust

The Stop Adjust value is given as a positive or negative number of dots.

Default value is 0, which stops the media feed in a position suitable for

tear off operation.

• A positive stop adjustment means that the normal media feed after

the printing is completed will be increased by the specifi ed value.

• A negative stop adjustment means that the normal media feed after

the printing is completed will be decreased by the specifi ed value.

52 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Recommended Feed Adjustments

The following settings allow printing from the top of the label. Minor

deviations from the recommended values may be required due to various

combinations of media types, roll size, type of media supply device, and

individual differences between printers.

Adjustment 8 dots/mm 11.81 dots/mm Distance Distance

type 203.2 dpi (std) 300 dpi (option) in mm in inches

Tear-Off (Straight-through)

Start adjust: -100 dots -148 dots 12.5 0.49

Stop adjust: 0 dots 0 dots 0 0

Peel-Off (Self-strip)

Start adjust: -56 dots -83 dots 7 0.28

Stop adjust: -44 dots -65 dots 5.5 0.22

Cut between labels

Start adjust: 0 dots 0 dots 0 0

Stop adjust: +160 dots +236 dots 20.0 0.78

Cut between labels and print from leading edge of next label

Start adjust: -250 dots -369 dots 31.25 1.23

Stop adjust: +160 dots +236 dots 20.0 0.78

Cut variable length strip (No liner allowed!)

Start adjust: -250 dots -369 dots 31.25 1.23

Stop adjust: +275 dots +406 dots 34.38 1.35

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 53

Chapter 6—Setting Up the Printer

Media

The media parameters tell the fi rmware the characteristics of the media

that will be used, so the printout will be positioned correctly and get the

best quality possible.

Media Size

The size of the printable area is defi ned by three parameters; X-Start,

Width, and Length.

X-Start

Specifi es the position of the origin along the dots on the printhead.

The default X-start value prevents printing outside labels when the liner

is slightly wider than the labels. If you want to maximize the print width,

reset the X-start value to 0.

By increasing the value for the X-start parameter, the origin will be

moved outwards, away from the inner edge of the media path. In other

words, the larger X-start value, the wider inner margin and the less available print width.

Width

Specifi es the width of the printable area in number of dots from the

origin. Thus, the sum of the X-start and width values gives the outer

margin of the printable area. The width should be set to prevent printing

outside the media, which may harm the printhead.

Length

Specifi es the length of the printable area in number of dots from the

origin along the Y-coordinate and allocates memory space for two identical image buffers in the printer’s temporary memory.

The size of each buffer can be calculated using this formula:

Buffer size (bits) = [Print length in dots] x [Printhead width in dots]

Note: The temporary memory has other functions that also

require some memory space. To obtain a longer print area, the

memory can be increased by fi tting a larger SDRAM SIMM on

the printer’s CPU board as described in the Service Manual.

• The length setup also decides the amount of media feed when using

“fi x length strip.”

54 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

PRINT

WINDOW

Chapter 6—Setting Up the Printer

• The length setup creates an emergency stop, which works when the

printer is set up for “Label (w gaps)”, “Ticket (w mark)”, or “Ticket

(w gaps).” If the label stop sensor (LSS) has not detected a gap or

mark within 150% of the set length, the media feed is automatically

stopped to avoid feeding out a whole roll of media, because of an LSS

malfunction.

By setting up the X-start, the Width, and the Length, you will create a

print window inside which the printing can be performed. Any object or

fi eld extending outside the print window in any direction will either be

clipped or cause an error condition (Error 1003 “Field out of label”), see

Intermec Fingerprint v8.xx, Programmer’s Reference Manual.

Print Window (8 dots/mm standard printhead)

10.3 mm (0.41 in)

max. 104.0 mm (4.095 in)

PRINT

PRINT

WINDOW

WINDOW

FEED

DIRECTION

Dot #831

Dot-line

on printhead

Dot #0

Length

Origin

X-start Width (1-832)

25-114.3 mm (1-4.5 in)

Intermec offers a number of non-standard thermal printheads, see Chapter 8.

Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint) 55

Chapter 6—Setting Up the Printer

Media Type

The Media Type parameters control how the label stop sensor (LSS) and

the media feed work. There are fi ve media type options:

• Label (w gaps) is used for adhesive labels mounted on liner.

• Ticket (w mark) is used for labels, tickets, or continuous stock provided with black marks at the back.

• Ticket (w gaps) is used for tickets and tags with detection slits.

• Fix length strip is used for continuous stock where the length of the print

window decides the length of media to be fed out.

• Var length strip is used for continuous stock. The size of the print

image decides the length of each copy.

It is important to select the correct media type, so the printer can indicate the following errors.

• Error 1005 “Out of paper” indicates that the last ordered copy could

not be printed because of an empty media stock.

• Error 1031 “Next label not found” indicates that the last ordered label

or ticket was successfully printed, but no more labels/tickets can be

printed because of an empty media stock.

56 Intermec EasyCoder PF4i Compact Industrial—User’s Guide (Fingerprint)

Chapter 6—Setting Up the Printer

Paper Type

The Paper Type parameters control the heat emitted from the printhead

to the direct thermal media or, optionally, the transfer ribbon in order to

produce the dots that make up the printout image.

Labels, tickets, tags, strip, and ribbons for various types of application

are available from Intermec. For the best printout quality and maximum

life of the printhead, use Intermec supplies. Setup recommendations

for Intermec supplies offered in Europe and North America are listed in

Appendix D.

As a general rule, high energy and/or high print speed will shorten the

life of the printhead. Never use higher paper type and print speed settings than necessary for obtaining an acceptable printout quality and

throughput speed.

If the ambient temperature is lower than +15°C (+59°F), decrease the

print speed by 50 mm/sec.

Start by choosing between two alternatives:

• Direct Thermal printing (option)

• Thermal Transfer printing (default)

Your choice will decide which parameters to enter next:

Direct Thermal Printing

• Label Constant (range 50 to 115)

• Label Factor (range 10 to 50)

When adjusting the image darkness for non-Intermec direct thermal

media, set the Label Factor to the recommended value for the type of

direct thermal media. Set the Label Constant to the value listed below

and decrease or increase it for lighter or darker images respectively until

you are satisfi ed with the printout quality.

General Paper Type Settings Guide (Direct Thermal)

Sensitivity1 Label Label Max Print Speed