A

NetworX NX-548E Receiver Installation

Instructions

Content

Introduction ..................................................................... 1

Internal mounting ............................................................ 1

External mounting........................................................... 2

Wiring ........................................................................... 3

DIP switch settings ......................................................... 3

Power up......................................................................... 3

Programming .................................................................. 4

Testing and troubleshooting ........................................... 7

Programming settings table............................................ 7

Supported devices........................................................ 11

Specifications................................................................ 12

Regulatory information ................................................. 12

Contact information....................................................... 12

Introduction

The NX-548E Receiver adds wireless capabilities to the

NetworX line of control panels. Adding a receiver makes these

control panels compatible with NX wireless transmitters.

Only three wire connections are required for power and

communication to the control panel.

Internal mounting

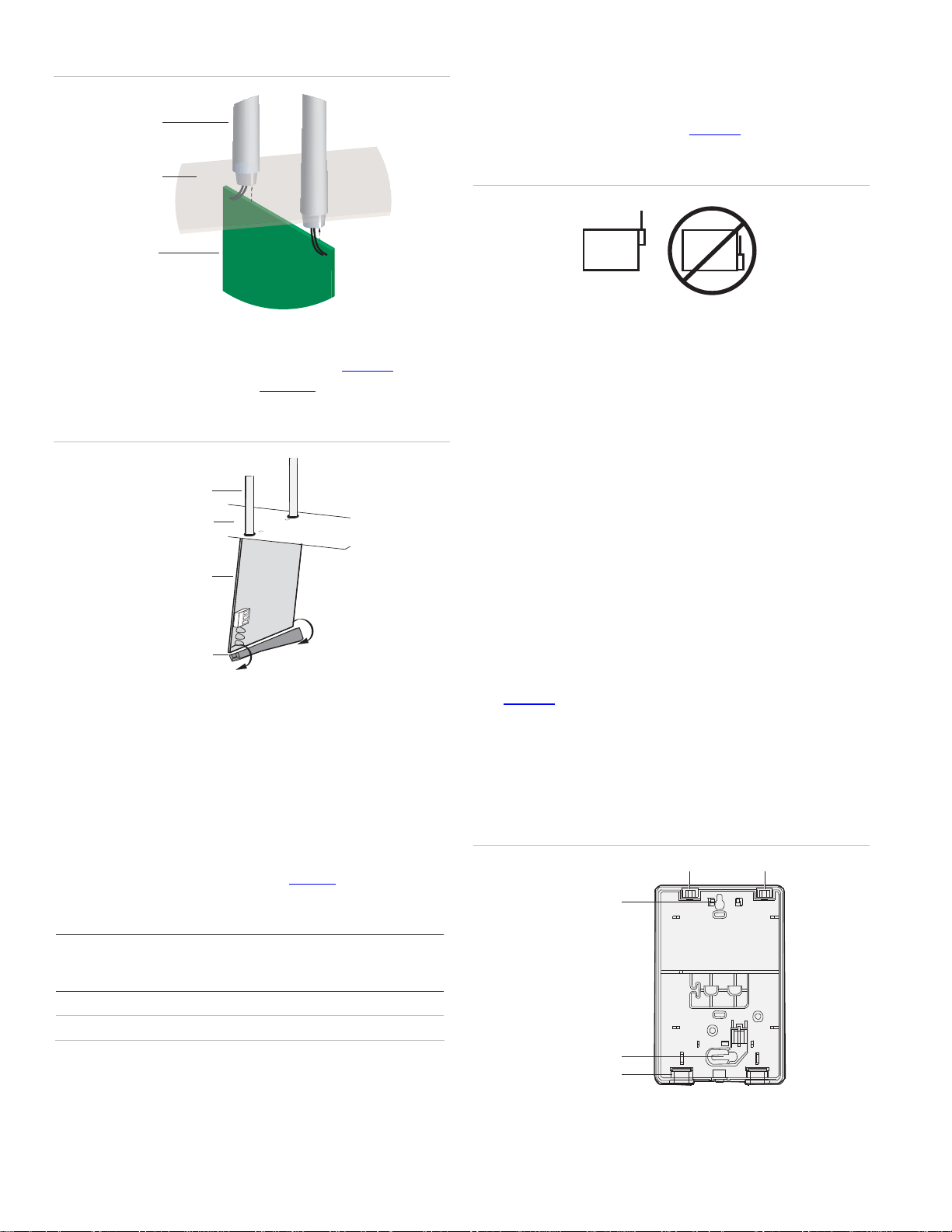

3. Insert the shrouds into the knockout holes (Figure 1

Figure 1. Installing the antenna shrouds

ntenna shroud

Enclosure top

O-ring

Knockout hole

4. Use the mounting screw provided to loosely install the

edge guide standoff in the lower mounting hole in the

appropriate space to the left of the control panel (Figure

2). Do not tighten the mounting screw down at this time.

Figure 2. Installing the edge guide standoffs

).

For internal mounting, mount the receiver inside the control

panel enclosure. Use the following installation guidelines:

• Leave at least 10 in. (25 cm) above the control panel for

the receiver’s antennas.

• Avoid areas that expose the receiver to moisture.

• Avoid areas with excessive metal or electrical wiring,

including furnaces and utility rooms.

To mount the receiver, do the following:

1. Remove the appropriate knockouts on the top of the

control panel enclosure for the antenna shrouds.

2. Assemble the antenna shrouds and fit the black O-rings to

the bottom of each shroud.

P/N 466-2225 • REV C • January 2011 1

Caution: You must be free of static electricity before handling

circuit boards. Touch a bare metal surface or wear a grounding

strap to discharge yourself.

5 Slide the printed circuit board into the antennae shroud

slots, after inserting wires into antennae shrouds (Figure

3).

Mounting screw

Edge guide standoff

Figure 3. A

ntenna shrouds

Antennae

shrouds

• Avoid areas with excessive metal or electrical wiring

including furnace and utility rooms. If unavoidable, mount

on or near metal with the antenna extending above the

metallic surfaces as shown in Figure 5

.

Enclosure

Circuit

board

6. Align the bottom of the circuit board in the edge guide

standoff and twist the standoff into place (Figure 4

Tighten the mounting screw (Figure 2

Figure 4. Installing the circuit board

Antenna shroud

Enclosure

Circuit board

).

).

Figure 5. Mounting on or near metal

METAL

METAL

Tools and supplies needed

To complete the installation, you will need the following tools

and supplies:

• Screwdrivers;

• Drill with bits;

• Mounting screws and anchors (included); and

• 3-conductor, 22-gauge (0.65 mm) or larger, stranded wire.

Mounting

The module can be mounted on any interior wall (protected

from the elements). To mount the module, do the following:

Edge guide standoff

External mounting

This installation uses enclosure model NX-569 (600-1029-03).

The module comes as a kit that is assembled in the field. Use

the following installation guidelines:

• Allow at least 10 in. (25 cm) of clearance above the

enclosure for the antennas.

• Use the wire length guidelines in Table 1

Table 1. Wire lengths

Wire gauge

(shielded or

unshielded)

22 AWG (0.65 mm) 250 feet (76 m)

18 AWG (1.02 mm) 500 feet (152 m)

Maximum wire length between module

and panel

• Install the module in its own plastic enclosure. It should

not be installed inside the panel’s enclosure.

.

1. Remove the module back plate from the packaging.

2. Hold the base against the mounting surface and mark the

two mounting holes and the wire access hole as shown in

Figure 6

. Remember to leave at least 10 in. (25 cm) above

the back plate for the antennas.

Note: The wire access hole is molded into the plastic so

that you can access the wire, yet keep it hidden from the

back plate.

Figure 6. Back plate

Antenna shroud locations

Mounting hole

Mounting hole

Wire access

• Avoid mounting locations that expose the module to

moisture.

2 NetworX NX-548-E Receiver Installation Instructions

3. Drill holes and insert the appropriate anchors (included).

4 Run a 3-conductor, 22 or 18 gauge (0.65 or 1.02 mm)

ON EC

E

1 2 3 4

stranded wire cable from the module wire access hole

location to the panel (Figure 6

).

Figure 8. Receiver wiring connections and LEDs

5. Secure the back plate to the wall with the pan head

screws provided.

6. To assemble the antenna shrouds, attach the proper

number of sections together, then attach the top cap.

7. Install each antenna shroud on top of the back plate.

8. Remove the transceiver circuit board from the antistatic bag

Caution: You must be free of static electricity before handling

circuit boards. Touch a bare metal surface or wear a grounding

strap to discharge yourself.

9. To install the circuit board onto the back plate (Figure 7),

insert the antennas into the antenna shrouds, then gently

slide the top of the circuit board under the two top latches,

and snap the circuit board in at the bottom latch to secure

it in place.

Figure 7. Circuit board and back plate

Antenna shrouds

+ 12 (to panel POS)

GND (to panel COM)

DATA (to panel DATA)

Green (power) LED

Red (data) LED

Red (not used) LED

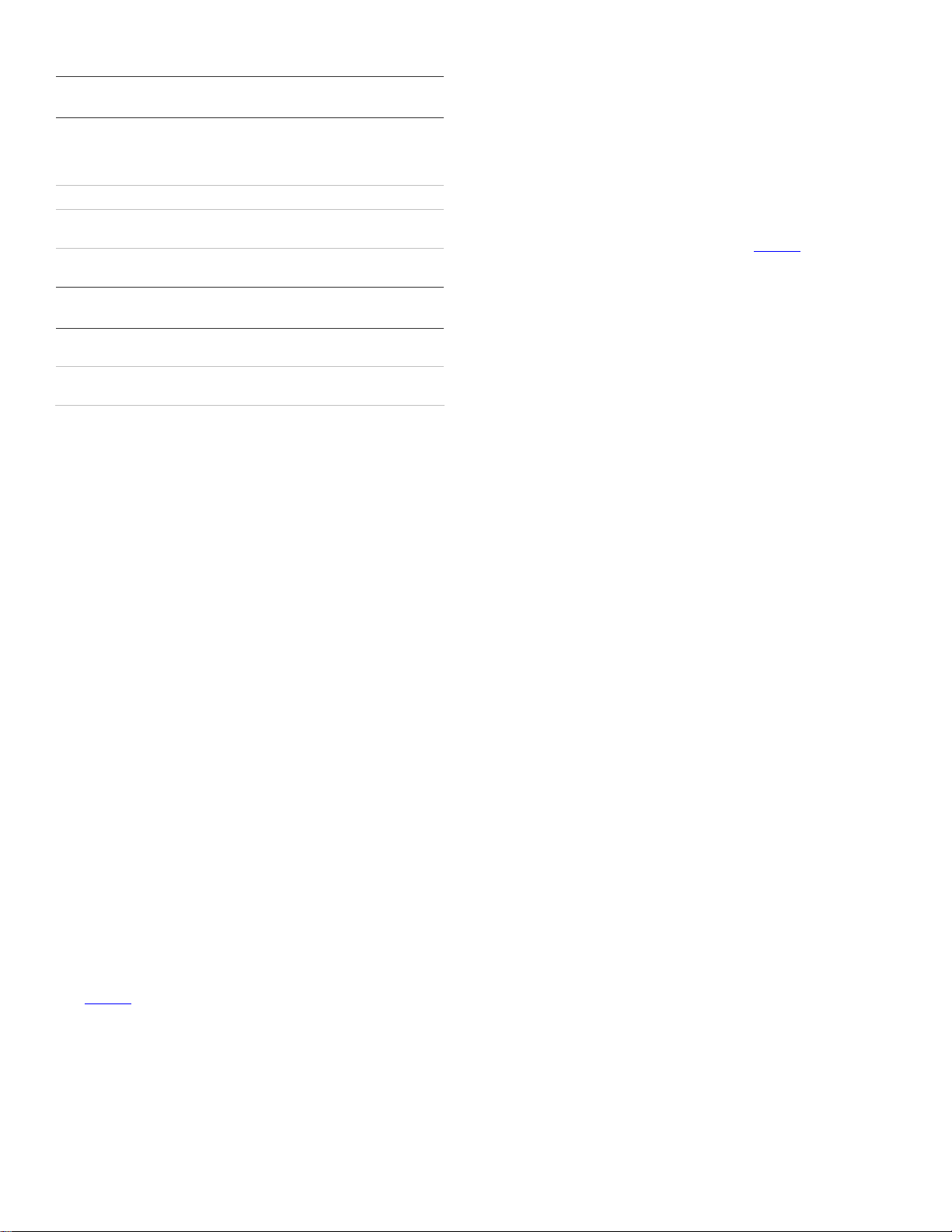

DIP switch settings

The DIP switches (Figure 7) on the circuit board are used to

set the receiver module number. Use Table 2

switches to the desired module number.

Table 2. DIP switch settings

Module number 32

ON

12

EDG

43

Module number 33

to set the DIP

ON

EDG

43

12

Top latches

Circuit board

Back plate

DIP switches

Wiring terminals

LEDs

Bottom latch

ON ECE

1 2 3 4

Wiring

To wire the receiver, do the following:

1. Remove power (if applied) from the control panel. Use 22-

gauge, or larger, stranded wire to connect the +12, GND,

and DATA terminals on the receiver (Figure 8

power, common, and data terminals on the control panel.

) to the

Module number 34

ON

12

Module number 36

ON

1 2

Module number 38

ON

1 2

EDG

EDG

EDG

43

43

43

Module number 35

ON

1 2

Module number 37

ON

1 2

Module number 39

ON

12

EDG

EDG

EDG

43

43

43

Power up

When you apply power to the control panel, the green (power)

LED on the receiver (Figure 8

seconds. Table 3 describes the receiver status based on LED

conditions. The lower red LED at the bottom of the receiver

(Figure 8

) may emit a dim glow, but is not used as an indicator

) blinks for approximately 10

NetworX NX-548-E Receiver Installation Instructions 3

Table 3. LED i

Green (data) LED

status

Power-up blinks

Off No packets from sensors being received.

Short blink on Receiver received a valid packet from an

Long blink on Receiver received a valid packet from an

Red (data) LED

status

Off No data communication with the control

Short blink on Normal data communication with the control

ndications

Meaning

LED blinks represent Product Version

Number (PVN). Long blink on is 1, short

blink on is 0. PVN is in binary, from most

significant to least significant bit.

unknown sensor.

enrolled sensor.

Meaning

panel. Check wiring and power source.

panel.

Programming

Hardwire expander

P

Panel

This gives you all the programming information in one place to

facilitate the programming process.

Zone locations 1 to 192

Zone locations 1 to 192 are not numbered in Table 5

since

these locations vary depending on location 194, Receiver zone

bank setting.

The default settings shown for segments 1 and 2 in the first

zone location apply to all zone locations.

Add transmitters

LCD touchpads will display instructions when accomplishing

tasks.

To add transmitters, do the following:

This section describes how to program the units.

Programming guidelines

Use the following programming guidelines:

• NX-4 and NX-6 control panels can have receivers added

with zones that overlap those contained in the control

panel. No hardware expanders can be used.

• NX-8 control panels can have expansion zones (hardwire

or wireless) set the same as those contained in the control

panel. To do this you must disable the onboard control

panel zones in panel location 37. All zone expansion

modules must not overlap any blocks of 8 zones.

• All other control panels can have wireless zones added to

any zone. If a hardwire input (on either the control panel or

hardwire expander) is also present on the same zone as

an enabled wireless zone, the wireless transmitter takes

priority.

Transmitter programming

When programming wireless transmitters into the receiver, you

can set various options and partitions for each transmitter.

These settings appear in segments of each programming

location.

Use Table 5

to circle where each zone resides:

RM

Receiver module

HE

to record zone assignments and settings. Be sure

1. Enter * 8 at the keypad. On LED touchpads, the five

function lights start flashing.

2. Enter the program code (factory default is 9 7 1 3). On

LED touchpads, the service light flashes and the five

function lights change from flashing to on steady.

3. Enter the DIP switch setting module number and press #.

On LED touchpads, the Armed LED turns on, indicating

the control panel is waiting for a programming location

entry.

4. For new installations, enter 9 1 0 # to load factory defaults

and clear any unwanted information in memory.

5. For new installations, set the receiver zone bank setting in

location 194 to determine the starting zone number for the

specific receiver. This applies only to NX-8E. This must be

set before learning sensors. For example, if location 194 is

set to 3, the first available location is 25. The total number

of available locations depends on the zone limits for both

the panel and receiver.

6. Enter 0 # to enter the sensor learning location. On LED

touchpads, the Ready LED turns on and the Armed LED

turns off.

7. Enter the zone number (1 through 192) and press *. Three

beeps from the keypad indicate an entry error. This occurs

if you enter a transmitter number that is not within the

receiver’s zone block or if the location already has a

sensor learned into it.

Note: If you change your mind about your entry, terminate

programming by entering 0 # 0 * and start over at step 6.

4 NetworX NX-548-E Receiver Installation Instructions

Loading...

Loading...