Page 1

g

GE Security

NetworXTM Series

NX-507E/508E Output Expander

Installation manual

Page 2

GE Security

g

CONTENTS

CONTENTS.........................................................................................................................................................................2

GENERAL INFORMATION.............................................................................................................................................3

ORDERING INFORMATION...........................................................................................................................................3

INSTALLING THE NX-507E AND NX-508E..................................................................................................................4

ENROLLING THE NX-507E AND NX-508E EXPANDER ...........................................................................................4

PROGRAMMING THE NX-507E AND NX-508E MODULE........................................................................................5

PROGRAMMING THE NX-507E AND NX-508E VIA THE LED KEYPAD ...............................................................................5

ENTERING THE PROGRAM MODE ...........................................................................................................................5

SELECTING THE MODULE TO PROGRAM...............................................................................................................5

PROGRAMMING A LOCATION...................................................................................................................................5

EXITING A LOCATION................................................................................................................................................5

EXITING THE PROGRAM MODE...............................................................................................................................6

PROGRAMMING THE NX-507E AND NX-508E VIA THE LCD KEYPAD...............................................................................6

PROGRAMMING DATA.........................................................................................................................................................7

PROGRAMMING THE LOCATIONS.............................................................................................................................8

NX-507E/508 PROGRAMMING WORKSHEETS........................................................................................................17

PROGRAMMING EXAMPLES......................................................................................................................................28

NX-507E TERMINAL DESCRIPTIONS AND LAYOUT............................................................................................30

NX-508E TERMINAL DESCRIPTIONS AND LAYOUT............................................................................................31

ENCLOSURE DIAGRAM ...............................................................................................................................................32

TECHNICAL SPECIFICATIONS..................................................................................................................................33

CE DECLARATION.........................................................................................................................................................34

NX-507E/NX-508E Installation manual Page 2 09/05/04

Page 3

GE Security

g

GENERAL INFORMATION

The NX-507E and NX-508E are microprocessor controlled output modules that may be

added to new or existing NetworX control panels. Up to eight NX-507E or NX-508E

modules can be added to the NetworX control panels for a total output count of 64. Each

NX-507E and NX-508E have an optional tamper switch and a 12 Volt auxiliary power

terminal (see terminal descriptions) making it ideal for use in a remote location.

NX-507E SEVEN RELAY EXPANDER

Microprocessor controlled 7-relay module

Designed with 7 separate normally open and normally closed relay contacts for a variety

of applications, including access control, home control/automation, wireless interfaces,

and security functions.

Includes 1 low current open collector output (output 8)

Up to 8 modules can be connected to the NetworX control panel

Can be programmed to activate for an event in any or all partitions

Each relay can be programmed to follow up to 8 different schedules to either activate the

relay during the on-time, or used in conjunction with another programming option to

create time zones

NX508-E EIGHT OUTPUT EXPANDER

Microprocessor controlled 8-output module

Equipped with 8 low current open collector outputs (see terminal drawing)

Up to 8 modules can be added for a total output count of 64

Each output can be programmed to follow up to 8 different schedules to either activate

the output during the on-time, or used in conjunction with another programming option to

create time zones

Has a built-in parallel interface for local printouts of all communicator activity

ORDERING INFORMATION

For detailed ordering information and part numbers, please refer to the SLC Distribution

price list of the Caddx product range.

NX-507E/NX-508E Installation manual Page 3 09/05/04

Page 4

GE Security

g

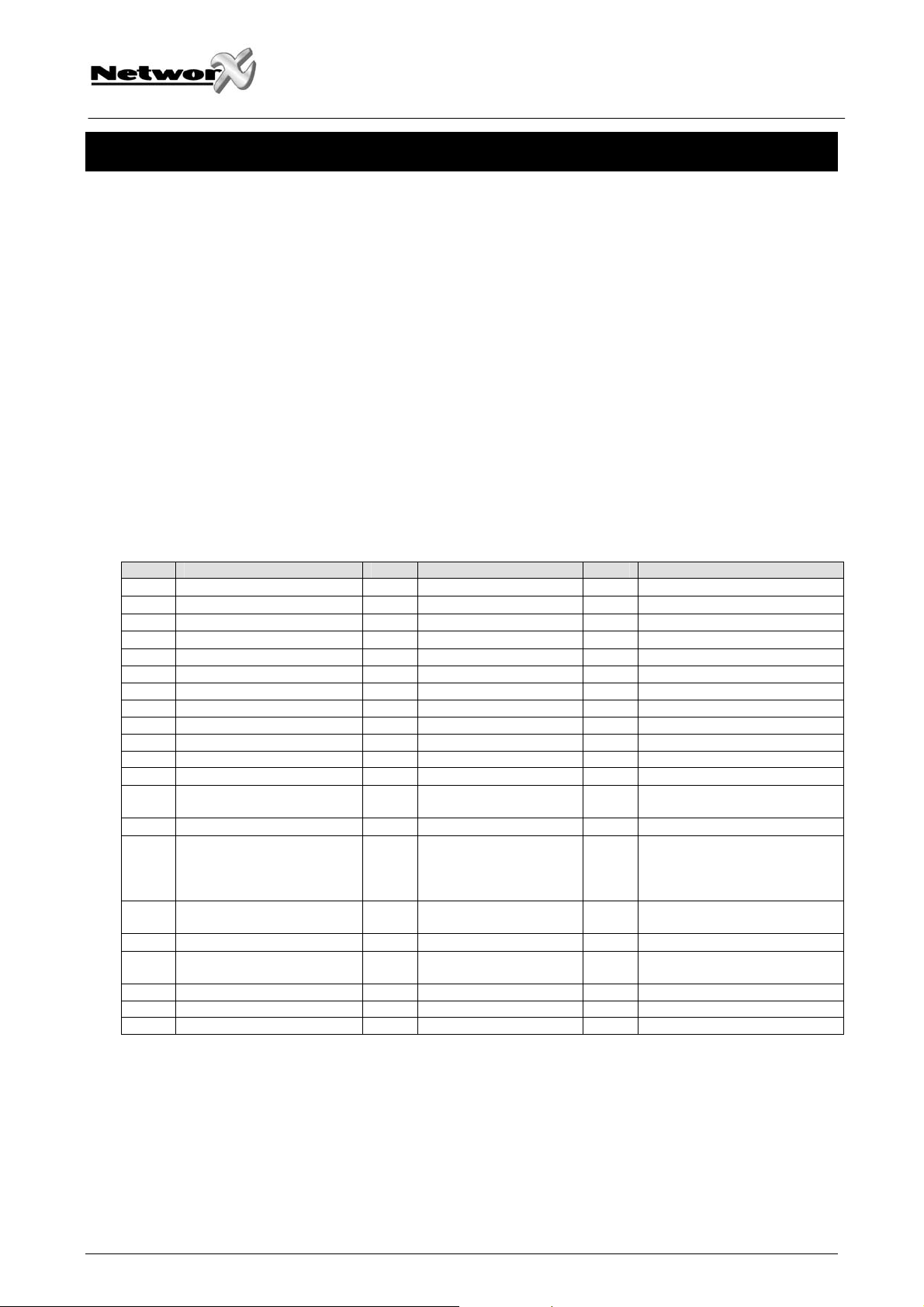

INSTALLING THE NX-507E AND NX-508E

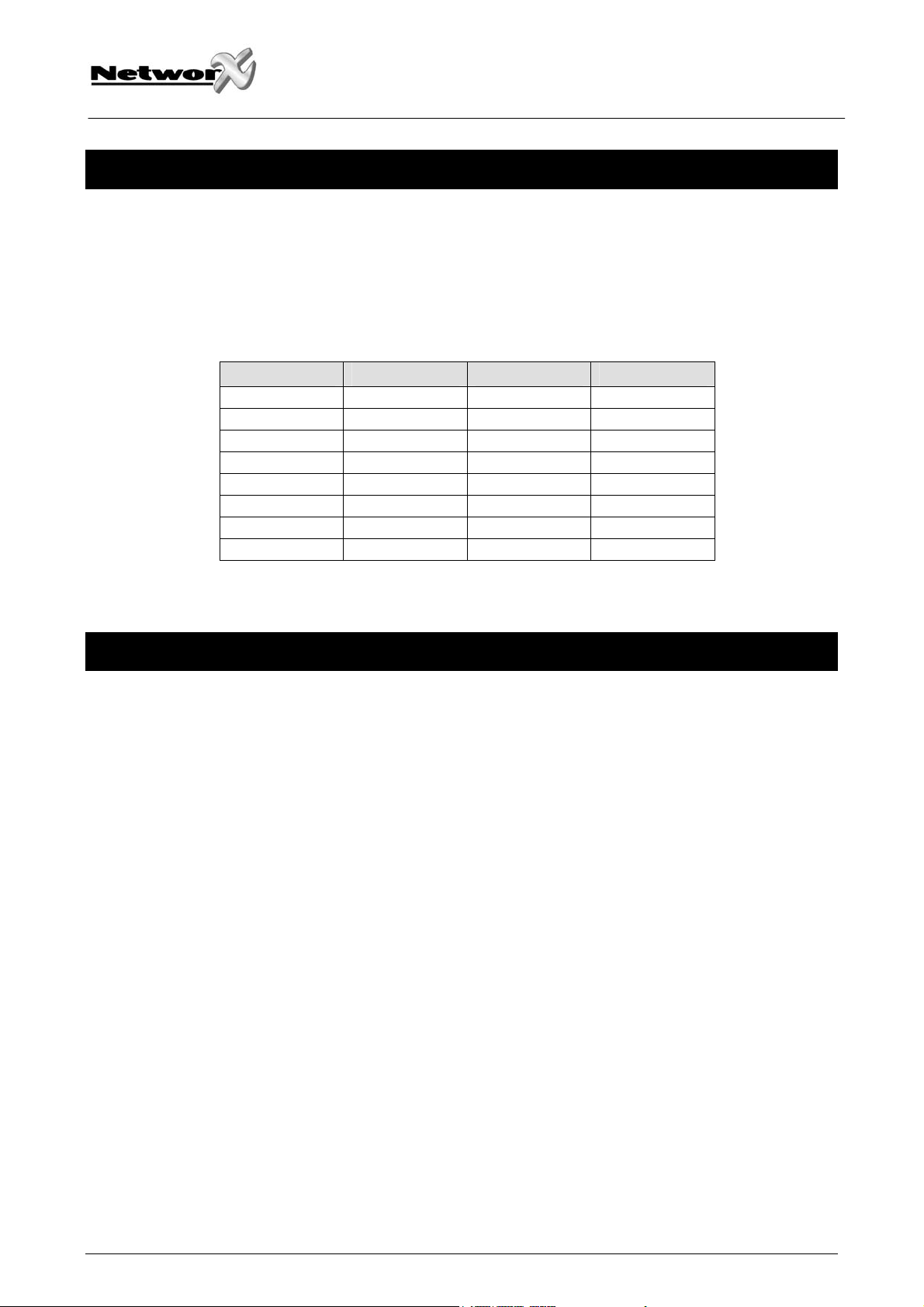

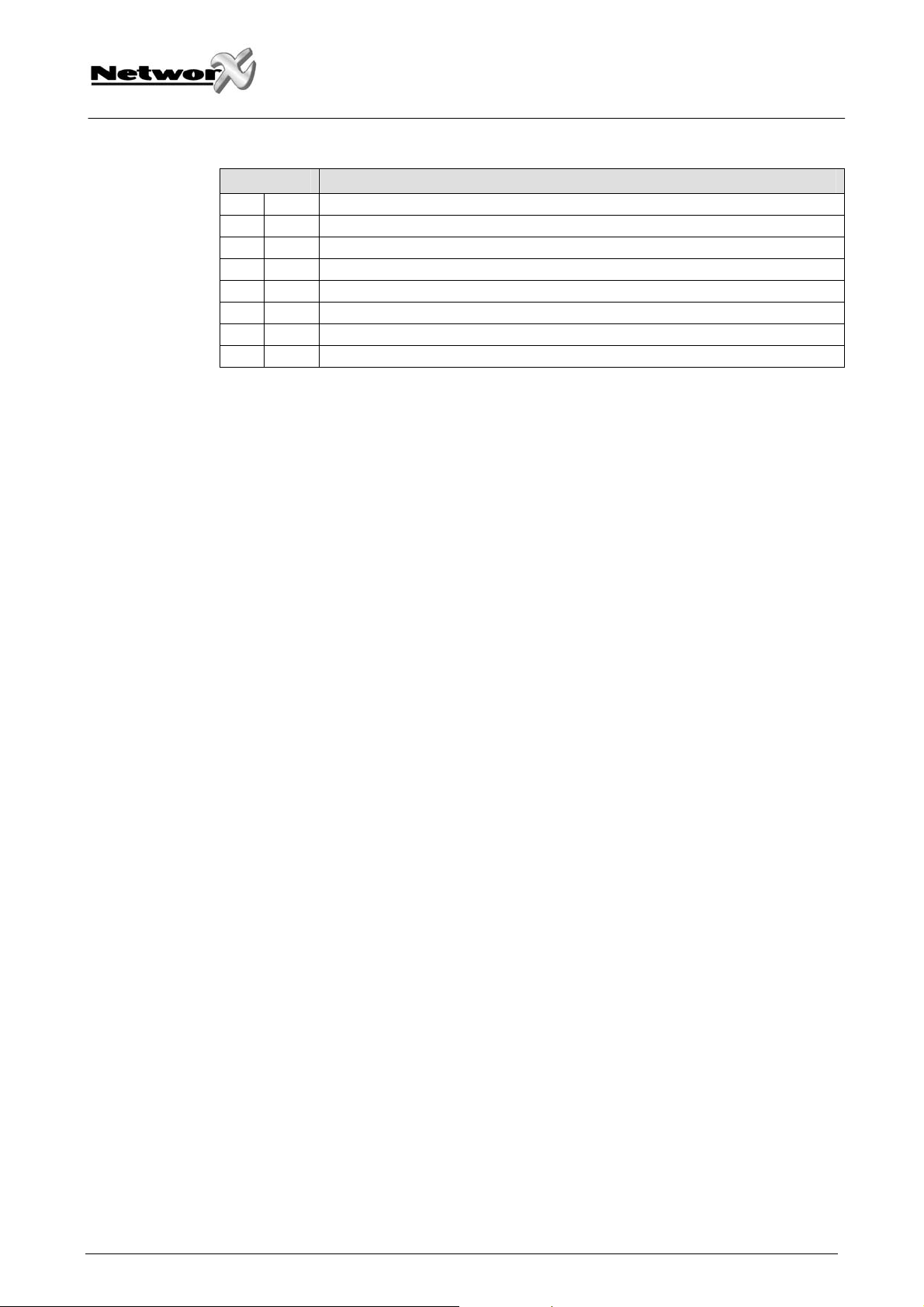

The first thing that must be decided is the address of this particular output module. This is

the address that will be selected when programming the NX-507E and NX-508E. To set

the addresses use the table below.

DIP switch 4 is used to disable the tamper feature of the NX-508E (“On” = enabled /

“Off” = disabled).

Location Dip switch 1 Dip switch 2 Dip switch 3

24 ON ON OFF

25 OFF OFF ON

26 ON OFF ON

27 OFF ON ON

28 ON ON ON

29 OFF OFF OFF

30 ON OFF OFF

31 OFF ON OFF

ENROLLING THE NX-507E AND NX-508E EXPANDER

For supervision purposes, the presence of all keypads, zone expanders, wireless

receivers, and any other modules connected to the data terminal can automatically be

found and stored in the NetworX’s memory. This allows the control panel to supervise

these modules. To enroll the modules, enter the program mode for the NetworX control

panel as described in the NetworX installation manual. If necessary, go on to program the

rest of the control panel and the devices. When you exit from program mode, the control

panel will automatically enroll the devices. The enrolling process takes about 12 seconds,

during which time the “Service” LED will light up. If a module has been enrolled but it is

not detected by the control, the “Service” LED will light up.

NX-507E/NX-508E Installation manual Page 4 09/05/04

Page 5

g

PROGRAMMING THE NX-507E AND NX-508E

MODULE

Programming the NX-507E and NX-508E via the LED keypad

ENTERING THE PROGRAM MODE

To enter the program mode, press [*]-[8]. At this time, the five functions LED’s (Stay,

Chime, Exit, Bypass and Cancel) will begin to flash. Next, enter the “Go To Program

Code” (factory default is [9]-[7]-[1]-[3]). If the “Go To Program Code” is valid, the “Service”

LED will flash and the five function LED’s will illuminate steady. You are now in the

program mode and ready to select the module to program.

Note: it is impossible to enter program mode if any partition or the system is armed.

GE Security

SELECTING THE MODULE TO PROGRAM

Since all modules connected to the NetworX are programmed through the keypad, the

module you are programming should be the first entry. To program the NX-507E and NX508E module, enter the address of the module, followed by [#]. See DIP switch chart on

page 4.

PROGRAMMING A LOCATION

Once the number of the module to be programmed has been entered, the “Armed” LED

will illuminate, indicating it is waiting for a programming location to be entered. Any

location can be accessed by directly entering the desired programming location followed

by the pound [#] key. If the location entered is a valid location, the “Armed” LED will

extinguish, the “Ready” LED will illuminate, and the zone LED’s will show the binary data

for the first segment of this location. While entering new data, the “Ready” LED will begin

flashing to indicate a data change in process. The flashing will continue until the new data

is stored by pressing the [*] key. Upon pressing the [*] key, the keypad will advance to the

next segment and display its data. This procedure is repeated until the last segment is

reached. Pressing the [#] key will exit from this location and the “Armed” LED will

illuminate again waiting for a new programming location to be entered. If the desired

location is the next sequential location, press the [Police] key. If the previous location is

desired press the [Fire] key. If the same location is desired press the [Medic] key. To

review the data in a location, repeat the above procedure, pressing the [*] key without any

numeric data entry. Each time the [*] key is pressed, the programming data of the next

segment will be displayed for review.

EXITING A LOCATION

After the last segment of a location is programmed, pressing the [*] key will exit that

location, turn the “Ready” LED off and the “Armed” LED on. As before, you are now ready

to enter another programming location. If an attempt is made to program an invalid entry

for a particular segment, the keypad sounder will emit a triple error beep (beep, beep,

beep) and remain in that segment awaiting a valid entry.

NX-507E/NX-508E Installation manual Page 5 09/05/04

Page 6

g

EXITING THE PROGRAM MODE

When all the desired changes in programming have been made, it is time to exit the

program mode. Pressing the [Exit] key will exit this programming level, and then return to

the “Select a Module to Program” level. If no additional modules are to be programmed,

pressing the [Exit] key again will exit the program mode. If there is a module to be

programmed, it may be selected by entering its address followed by the [#] key (See

“Selecting the Module To Program” above). The procedure for programming these

devices is the same as for the control panel, except the locations will be for the module

selected.

Note: the timeout for the program mode is 15 minutes.

Programming the NX-507E and NX-508E via the LCD keypad

All steps required for programming are the same as the aforementioned LED keypad. Th e

LCD keypad display will prompt you for the data required. While in the programming

mode, and not in a location, the number in parenthesis is the location you were previously

changing.

GE Security

For example: if the display reads “Enter location, then # (5)”, it is reminding you that

location 5 was the last location you programmed. Refer also to “Programming Data”

which follows.

NX-507E/NX-508E Installation manual Page 6 09/05/04

Page 7

Programming data

Programming data is always one of two types. One type of data is numerical, which can

have values from 0-15 or 0-255 depending on the segment size. The other type of data,

feature selection data, is used to turn features on or off. Use the following procedures

with these two data types:

NUMERICAL DATA: Numerical data is programmed by using the numeric keys of the

system keypad to enter a number from 0-255. To view the data in a location, a binary

process is used. With this process, the LED’s for zones 1 through 8 are utilized, and the

numeric equivalents of their illuminated LED’s are added together to determine the data

in a programming location. The numeric equivalents of these LED’s are as follows:

Zone 1 LED = 1 Zone 2 LED = 2 Zone 3 LED = 4 Zone 4 LED = 8

Zone 5 LED = 16 Zone 6 LED = 32 Zone 7 LED = 64 Zone 8 LED = 128

Example:

GE Security

g

If the numerical data to be programmed in a location is “66”, press [6] - [6] on the keypad.

The LED’s for zone 2 and zone 7 will become illuminated indicating 66 is in that location

(2 + 64 = 66).

Once the data is programmed, press the [*] key to enter the data and advance to the next

segment of that location. After the last segment of a location is programmed, pressing the

[*] key will exit that location, turn the “Ready” LED off and the “Armed” LED on. As before,

you are now ready to enter another programming location. If an attempt is made to

program a number too large for a particular segment, the keypad sounder will emit a triple

beep, indicating an error, and remain in that segment awaiting a valid entry.

Remark: on the LCD keypad, the number in the location will be displayed. For locations

with a maximum of 15, the hexadecimal equivalent will be displayed in parenthesis.

Example: 11 (B) or 14 (E).

FEATURE SELECTION DATA: Feature selection data will display the current condition

(on or off) of eight features associated with the programming location and segment

selected. Pressing a button on the keypad (1 through 8) that corresponds to the “feature

number” within a segment will toggle (on/off) that feature. Pressing any numeric key

between [1] and [8] for selection of a feature will make the corresponding LED illuminate

(feature ON). Press the number again, and the LED will extinguish (feature OFF). You will

see that numerous features can be selected from within one segment. For instance, if all

eight features of a segment are desired, pressing [1] - [2] - [3] - [4] - [5] - [6] - [7] - [8] will

turn on LED’s 1 through 8 as you press the keys, indicating that those features are

enabled.

LCD keypad users note: the numbers of the enabled features will be displayed. However,

the features not enabled will display a hyphen (-).

After the desired setting of features is selected for this segment, press the [*] key. This

will enter the data and automatically advance to the next segment of the location. When

you are in the last segment of a location and press the [*] to enter the data, you will exit

that location. This will now turn the “Ready” LED off and the “Armed” LED on. As before,

you are now ready to enter another programming location.

NX-507E/NX-508E Installation manual Page 7 09/05/04

Page 8

GE Security

g

PROGRAMMING THE LOCATIONS

LOCATION 0 - PROGRAMMING THE EVENT, USER/ZONE AND TIME FOR OUTPUT 1 (3 segments,

numerical data)

Segment 1 - Event

Selects the event that will trigger the output. See chart below for the specific events that

can be selected.

Segment 2 - Zone/user

Selects the zone or user number necessary to trigger an output. If this location is

programmed as a zero (“0”), any zone or user will activate the output (see also location

68).

Segment 3 - Time

Selects the amount of time an output will remain activated when an output triggers. If this

location is programmed as a zero, the output will follow the particular event.

Nr. Event Nr. Event Nr. Event

Burglary alarm

0√

Fire alarm

1√

24 hour alarm

2√

Zone trouble (fire/day)

3√

Zone tamper

4√

5

Burglary siren

6

Fire siren

7

Any siren

8

Zone bypass

9

AC failure

10

System low battery

11√

12√

13√

14√

16√

Duress

Manual fire

Manual medical alarm

Keypad panic

15

Keypad tamper (wrong

codes)

Automatic test

17

Alarm memory

18

Entry

19

Exit

20

Entry or exit

v See locations 52 and 53 in installation manual of NetworX control panel

21

22

23

24

25

26

27

28√

29

30v

31v

32

33

34

35

36

37

38

39

40

41

Armed

Not armed

Ready

Not ready

Fire

Fire trouble

Chime

Expander trouble

Dynamic battery test

Open schedule

Closed schedule

Listen in

Line seizure

Failed to communicate

Telephone line fault

Program mode

Download

Follow zone status in

alarm

Over current (12 Vdc)

Box tamper

Siren tamper

42

43√

44

45√

46♦

47♦

48♠

49♠

50♠

51

52

53

54

55

56

57

58

59

60

61

62

Any zone faulted

Any alarm

Keypad beeping

Code entry

Key FOB function 1

Key FOB function 2

Auto arm control

Auto disarm control

Auto arm & disarm control

Follow schedule of NX-508E

Flash X-10 for alarm memory

Flash X-10 for siren

Armed in ‘Exit’ mode, after

exit time

End listen-in

Compare X-10 commands

with X-10 addresses (activate

exit by means of DTMF

commands

Disarmed : state of zone

Armed : latch

Service required

Armed in “STAY” mode

Sensor low battery

Sensor missing (lost)

B-alarm

√ If set to follow condition, these events will be 1 second

♦ Events 46 and 47 require wireless receivers to operate

♠ Events 48, 49 and 50 will arm or disarm the NetworX control panel at the open (disarm)

or close (arm) time for the appropriate schedule (see example 3 on page 29)

NX-507E/NX-508E Installation manual Page 8 09/05/04

Page 9

GE Security

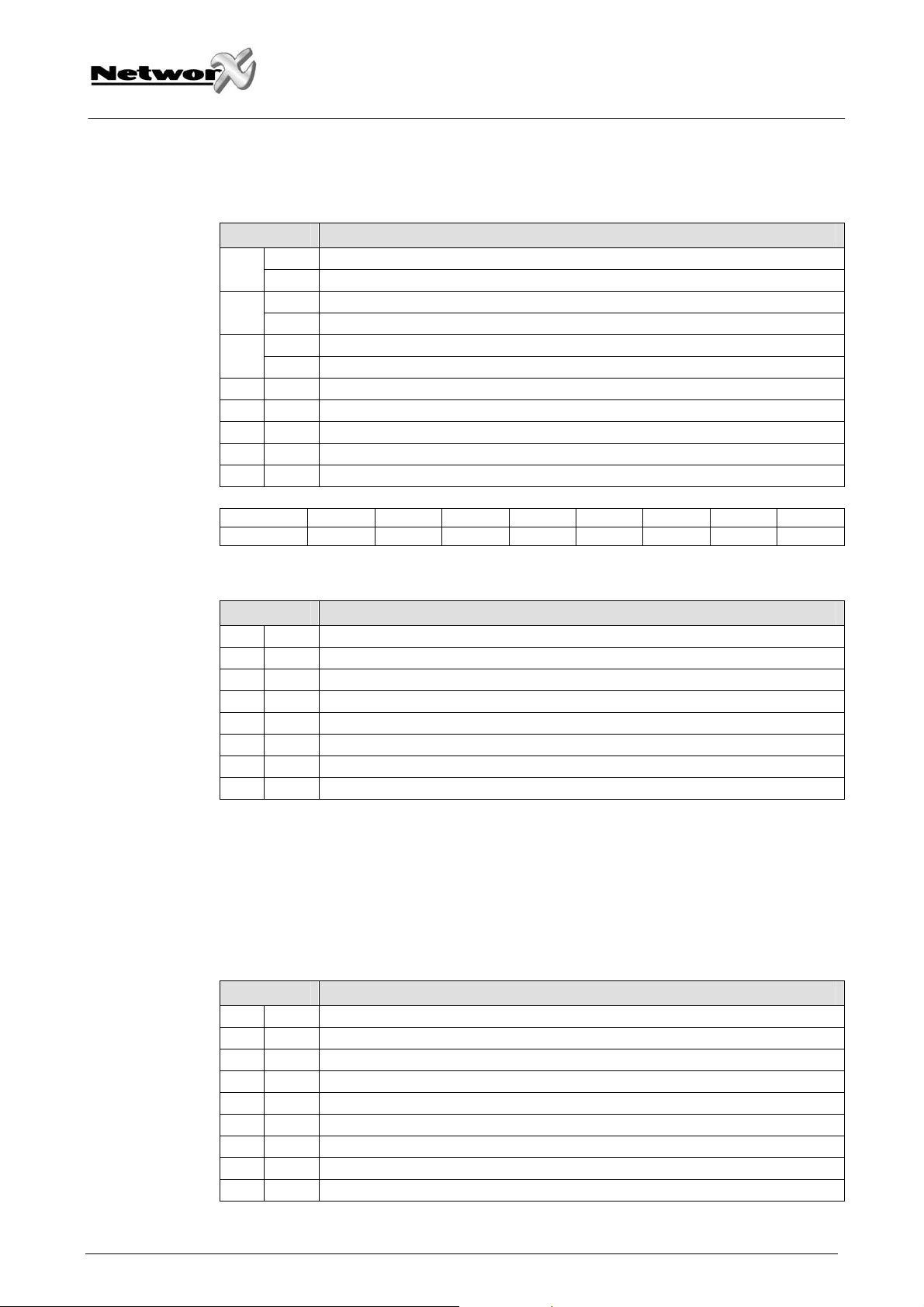

LOCATION 1 - PROGRAMMING SPECIAL FUNCTIONS AND PARTITIONS FOR OUTPUT 1 (2

segments, feature selection data)

Segment 1 - selects the following special conditions

Option Function

ON If output should time in minutes 1

OFF If output times in seconds

ON Output “Latch”: should latch until a code is entered 2

OFF Output is timed

ON Timed or output should be reset if a code is entered while it is being timed 3

OFF Stays timed (not reset) after code is entered

4 ON If output should only trigger during a closed schedule

5 ON If output should only trigger during an open schedule

6 ON If the output should be inverted (from 0 Volt to 12 Volt when activated)

7 ON If a trigger should be logged in the event buffer (see chart)

8 Reserved

Address

Output

Segment 2 - selects the following partitions

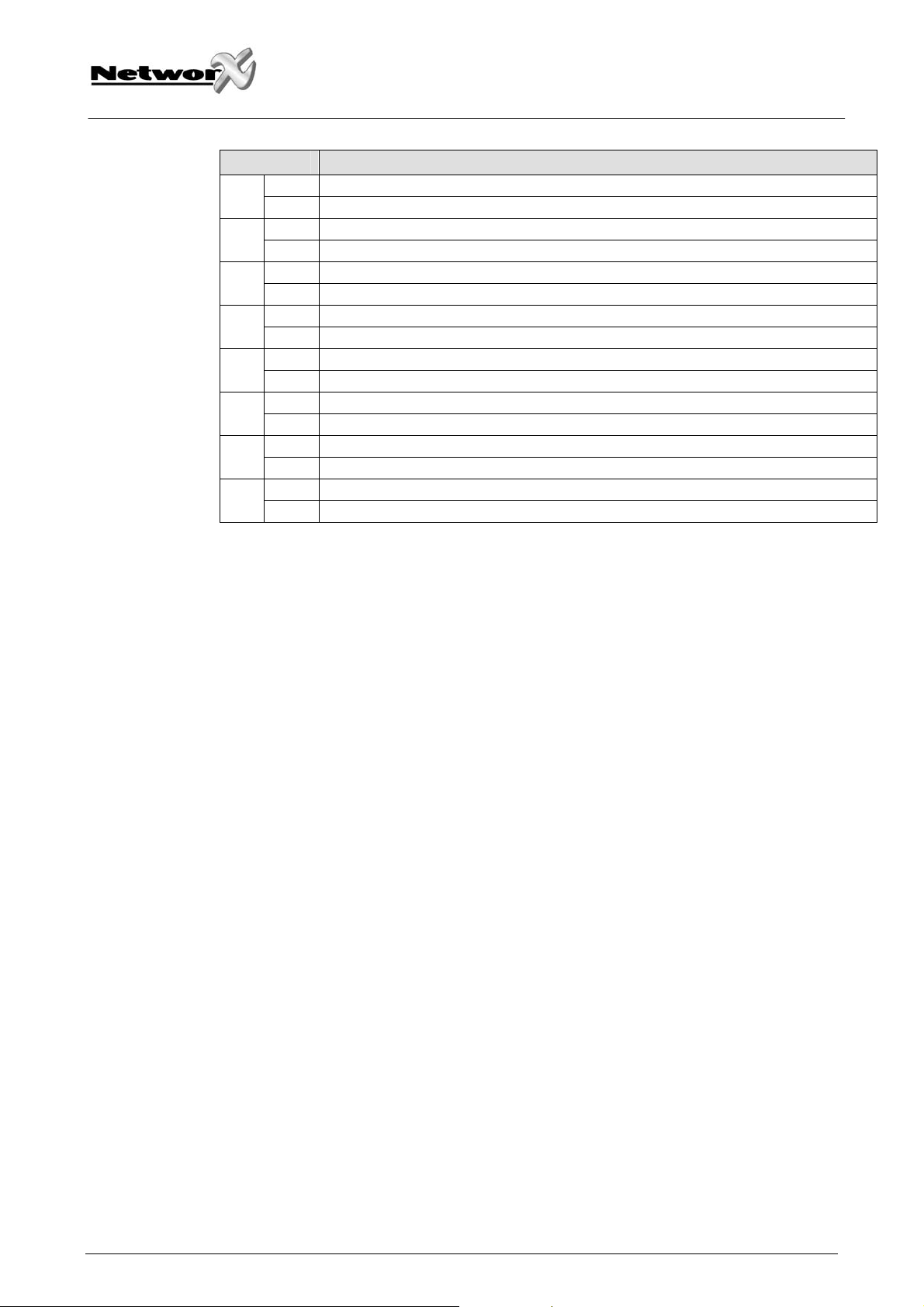

24 25 26 27 28 29 30 31

1-8 9-16 17-24 25-32 33-40 41-48 49-56 57-64

g

Option Function

1 ON If the event should activate when it occurs in partition 1

2 ON If the event should activate when it occurs in partition 2

3 ON If the event should activate when it occurs in partition 3

4 ON If the event should activate when it occurs in partition 4

5 ON If the event should activate when it occurs in partition 5

6 ON If the event should activate when it occurs in partition 6

7 ON If the event should activate when it occurs in partition 7

8 ON If the event should activate when it occurs in partition 8

LOCATION 2 - ENABLING THE SCHEDULES FOR OUTPUT 1 (1 segment, feature selection data)

Location 2 is used to enable any or all of the eight (8) schedules. LED 1 corresponds to

schedule 1 (see locations 32-34) and LED 8 corresponds to schedule 8 (see lo cations 53-

55). This location can be used in conjunction with the special function location to create

an output that will only activate during certain times and/or certain days.

Option Function

1 ON If the event should follow schedule 1

2 ON If the event should follow schedule 2

3 ON If the event should follow schedule 3

4 ON If the event should follow schedule 4

5 ON If the event should follow schedule 5

6 ON If the event should follow schedule 6

7 ON If the event should follow schedule 7

8 ON If the event should follow schedule 8

NX-507E/NX-508E Installation manual Page 9 09/05/04

Page 10

GE Security

LOCATION 3 - PROGRAMMING THE X-10 LOCATION FOR OUTPUT 1 (2 segments, numerical data)

Segment 1 - Module number

Program a number from 0-15 to represent the corresponding X-10 module number from

the following table.

g

Module

Segm 1

Segment 2 - House code

Program a number from 0-15 to represent the corresponding house code from the

following table.

X-10 Location code (house code)

0=A 4=E 8=I 12=M

1=B 5=F 9=J 13=N

2=C 6=G 10=K 14=O

3=D 7=H 11=L 15=P

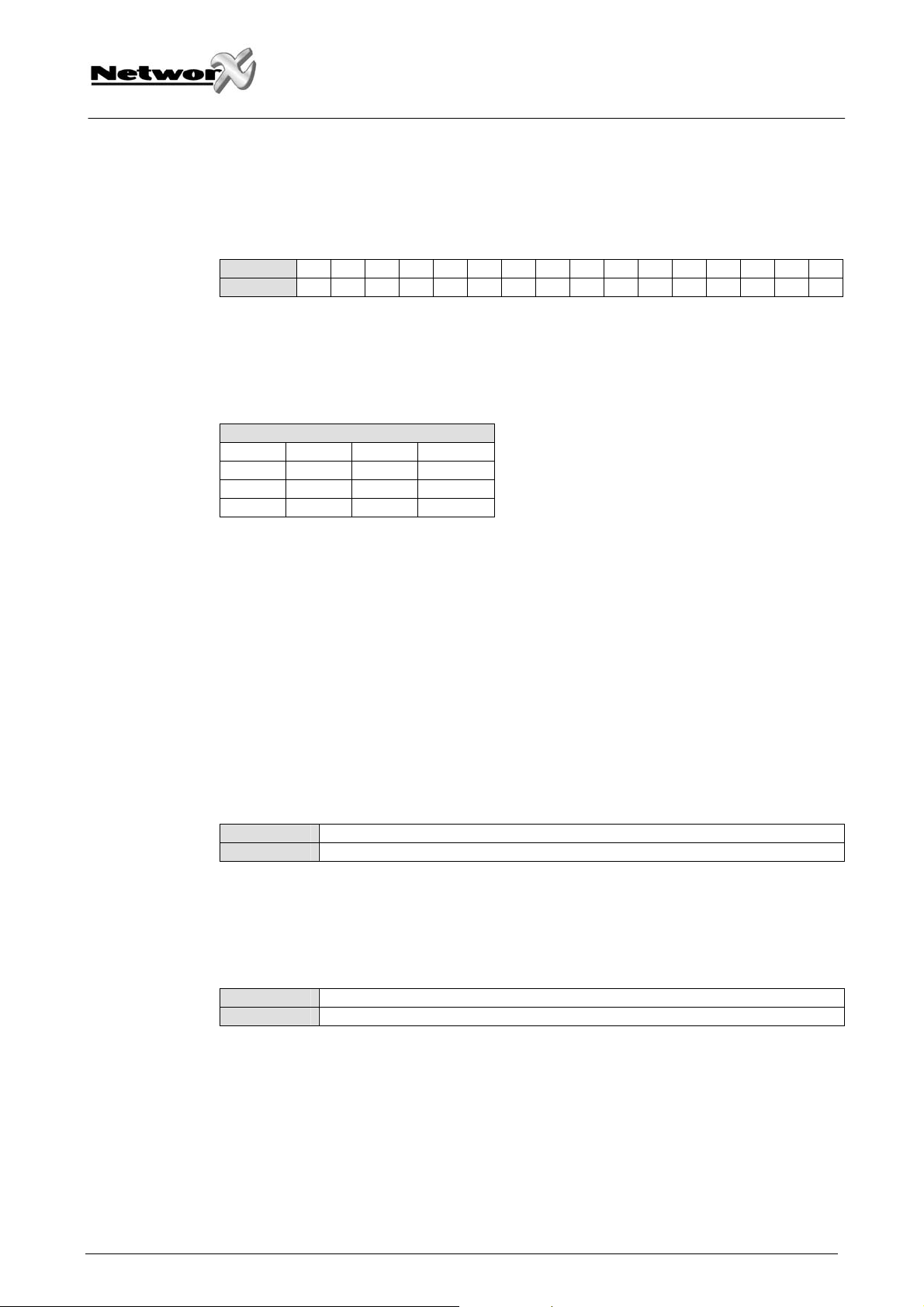

LOCATIONS 4-31 - PROGRAMMING FOR OUTPUTS 2 - 8

Locations 4 - 31 are used to program the events, zones/users and times, as well as the

special functions, partitions, schedules and X-10 addresses for outputs 2 - 8. Each output

has four locations, which are programmed with the same steps, as output 1 described

previously. Refer to output 1 for specific instructions (locations 0 - 3). Also refer to the

programming worksheets.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

LOCATION 32 - PROGRAMMING THE OPENING TIME FOR SCHEDULE 1 (2 segments, numerical

data)

Segment 1

Segment 2

LOCATION 33 - PROGRAMMING THE CLOSING TIME FOR SCHEDULE 1 (2 segments, numerical data)

Segment 1

Segment 2

Program the hour of the opening time in 24 hour format (1:00 PM = 13)

Program the minutes after the hour of the opening time for schedule 1

Program the hour of the closing time in 24 hour format (1:00 PM = 13)

Program the minutes after the hour of the closing time for schedule 1

NX-507E/NX-508E Installation manual Page 10 09/05/04

Page 11

GE Security

LOCATION 34 - PROGRAMMING THE DAYS FOR SCHEDULE 1 (1 segment, feature selection data)

Option Function

1 ON If the schedule is active on Sunday

2 ON If the schedule is active on Monday

3 ON If the schedule is active on Tuesday

4 ON If the schedule is active on Wednesday

5 ON If the schedule is active on Thursday

6 ON If the schedule is active on Friday

7 ON If the schedule is active on Saturday

8 ON If the schedule is disabled on Holidays

LOCATIONS 35-55 - PROGRAMMING FOR SCHEDULES 2 - 8

Locations 35 - 55 are used to program the opening times, closing times, and days for

schedules 2 - 8. Each schedule has three locations, which are programmed with the

same steps, as schedule 1 described previously. Refer to schedule 1 for specific

instructions (locations 32 - 34). Also refer to the programming worksheets.

g

LOCATION 56 - PROGRAMMING THE DATE OF HOLIDAYS IN JANUARY (8 segments, numerical data)

Program the day of the month in January that the opening time in a schedule is

suppressed. For example, if the opening should not occur on January 1, program a “1” in

segment 1. This feature can be repeated up to a maximum of 8 holidays per location

(month).

LOCATIONS 57-67 - PROGRAMMING THE DATE OF HOLIDAYS FROM FEBRUARY TO DECEMBER (8

segments, numerical data)

Locations 57 - 67 are used to program the day of each month, from February to

December, in which the opening time in a schedule is suppressed. Each location will

accommodate up to a maximum of 8 holidays, and programmed with the same steps as

location 56 described previously. Refer also to the programming to worksheets.

LOCATION 68 - AUTHORIZING USERS 1 - 10 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code (event 45), location 68 can be used to restrict

certain codes from activating certain outputs. Location 68 contains 10 segments.

Segment 1 corresponds to user 1, segment 10 corresponds to user 10. The LED’s

correspond to outputs 1 - 8.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

NX-507E/NX-508E Installation manual Page 11 09/05/04

Page 12

GE Security

Option Function

ON Code will activate Output 1 1

OFF Code will NOT activate output 1

ON Code will activate Output 2 2

OFF Code will NOT activate output 2

ON Code will activate Output 3 3

OFF Code will NOT activate output 3

ON Code will activate Output 4 4

OFF Code will NOT activate output 4

ON Code will activate Output 5 5

OFF Code will NOT activate output 5

ON Code will activate Output 6 6

OFF Code will NOT activate output 6

ON Code will activate Output 7 7

OFF Code will NOT activate output 7

ON Code will activate Output 8 8

OFF Code will NOT activate output 8

LOCATION 69 - AUTHORIZING USERS 11 - 20 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

g

When activating outputs with a user code, location 69 can be used to restrict certain

codes from activating certain outputs. Location 69 contains 10 segments. Segment 1

corresponds to user 11, segment 10 corresponds to user 20. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 70 - AUTHORIZING USERS 21 - 30 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 70 can be used to restrict certain

codes from activating certain outputs. Location 70 contains 10 segments. Segment 1

corresponds to user 21, segment 10 corresponds to user 30. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 71 - AUTHORIZING USERS 31 - 40 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 71 can be used to restrict certain

codes from activating certain outputs. Location 71 contains 10 segments. Segment 1

corresponds to user 31, segment 10 corresponds to user 40. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

NX-507E/NX-508E Installation manual Page 12 09/05/04

Page 13

GE Security

LOCATION 72 - AUTHORIZING USERS 41 - 50 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 72 can be used to restrict certain

codes from activating certain outputs. Location 72 contains 10 segments. Segment 1

corresponds to user 41, segment 10 corresponds to user 50. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 73 - AUTHORIZING USERS 51 - 60 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 73 can be used to restrict certain

codes from activating certain outputs. Location 73 contains 10 segments. Segment 1

corresponds to user 51, segment 10 corresponds to user 60. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

g

LOCATION 74 - AUTHORIZING USERS 61-70 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 74 can be used to restrict certain

codes from activating certain outputs. Location 74 contains 10 segments. Segment 1

corresponds to user 61, segment 10 corresponds to user 70. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 75 - AUTHORIZING USERS 71 - 80 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 75 can be used to restrict certain

codes from activating certain outputs. Location 75 contains 10 segments. Segment 1

corresponds to user 71, segment 10 corresponds to user 80. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 76 - AUTHORIZING USERS 81 - 90 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 76 can be used to restrict certain

codes from activating certain outputs. Location 76 contains 10 segments. Segment 1

corresponds to user 81, segment 10 corresponds to user 90. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

NX-507E/NX-508E Installation manual Page 13 09/05/04

Page 14

GE Security

LOCATION 77 - AUTHORIZING USERS 91 - 100 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 77 can be used to restrict certain

codes from activating certain outputs. Location 77 contains 10 segments. Segment 1

corresponds to user 91, segment 10 corresponds to user 100. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 78 - AUTHORIZING USERS 101 - 110 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 78 can be used to restrict certain

codes from activating certain outputs. Location 78 contains 10 segments. Segment 1

corresponds to user 101, segment 10 corresponds to user 110. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

g

LOCATION 79 - AUTHORIZING USERS 111 - 120 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 79 can be used to restrict certain

codes from activating certain outputs. Location 79 contains 10 segments. Segment 1

corresponds to user 111 segment 10 corresponds to user 120. The LED’s corre spond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 80 - AUTHORIZING USERS 121 - 130 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 80 can be used to restrict certain

codes from activating certain outputs. Location 80 contains 10 segments. Segment 1

corresponds to user 121, segment 10 corresponds to user 130. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 81 - AUTHORIZING USERS 131 - 140 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 81 can be used to restrict certain

codes from activating certain outputs. Location 81 contains 10 segments. Segment 1

corresponds to user 131, segment 10 corresponds to user 140. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

NX-507E/NX-508E Installation manual Page 14 09/05/04

Page 15

GE Security

LOCATION 82 - AUTHORIZING USERS 141 - 150 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 82 can be used to restrict certain

codes from activating certain outputs. Location 82 contains 10 segments. Segment 1

corresponds to user 141, segment 10 corresponds to user 150. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 83 - AUTHORIZING USERS 151 - 160 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 83 can be used to restrict certain

codes from activating certain outputs. Location 83 contains 10 segments. Segment 1

corresponds to user 151, segment 10 corresponds to user 160. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

g

LOCATION 84 - AUTHORIZING USERS 161 - 170 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 84 can be used to restrict certain

codes from activating certain outputs. Location 84 contains 10 segments. Segment 1

corresponds to user 161, segment 10 corresponds to user 170. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 85 - AUTHORIZING USERS 171 - 180 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 85 can be used to restrict certain

codes from activating certain outputs. Location 85 contains 10 segments. Segment 1

corresponds to user 171, segment 10 corresponds to user 180. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 86 - AUTHORIZING USERS 181 - 190 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 86 can be used to restrict certain

codes from activating certain outputs. Location 86 contains 10 segments. Segment 1

corresponds to user 181, segment 10 corresponds to user 190. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

NX-507E/NX-508E Installation manual Page 15 09/05/04

Page 16

GE Security

LOCATION 87 - AUTHORIZING USERS 191 - 200 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 87 can be used to restrict certain

codes from activating certain outputs. Location 87 contains 10 segments. Segment 1

corresponds to user 191, segment 10 corresponds to user 200. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 88 - AUTHORIZING USERS 201 - 210 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 88 can be used to restrict certain

codes from activating certain outputs. Location 88 contains 10 segments. Segment 1

corresponds to user 201, segment 10 corresponds to user 210. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

g

LOCATION 89 - AUTHORIZING USERS 211 - 220 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 89 can be used to restrict certain

codes from activating certain outputs. Location 89 contains 10 segments. Segment 1

corresponds to user 211, segment 10 corresponds to user 220. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 90 - AUTHORIZING USERS 221 - 230 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 90 can be used to restrict certain

codes from activating certain outputs. Location 90 contains 10 segments. Segment 1

corresponds to user 221, segment 10 corresponds to user 230. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

LOCATION 91 - AUTHORIZING USERS 231 - 240 TO TRIGGER OUTPUTS 1 - 8 (10 segments, feature

selection data)

When activating outputs with a user code, location 91 can be used to restrict certain

codes from activating certain outputs. Location 91 contains 10 segments. Segment 1

corresponds to user 231, segment 10 corresponds to user 240. The LED’s correspond to

outputs 1 - 8. Refer to location 68 chart.

NOTE: the zone/user for the corresponding output must be “0” to use this location.

NX-507E/NX-508E Installation manual Page 16 09/05/04

Page 17

GE Security

g

NX-507E/508 PROGRAMMING WORKSHEETS

(Defaults are printed in bold italic text)

LOC PG DESCRIPTION DEFAULT PROGRAMMING DATA

0 8 OUTPUT 1: EVENT, ZONE, TIME 43 1 10

1 9

2 9

3 10

4 10 OUTPUT 2: EVENT, ZONE, TIME 43 2 10

5 10

6 10

7 10

OUTPUT 1: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 1: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 1: X-10 ADDRESS

1 Module number 0

2 House code 0

OUTPUT 2: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 2: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 2: X-10 ADDRESS

1 Module number 0

2 House code 0

NX-507E/NX-508E Installation manual Page 17 09/05/04

Page 18

GE Security

LOC PG DESCRIPTION DEFAULT PROGRAMMING DATA

8 10 OUTPUT 3: EVENT, ZONE, TIME 43 3 10

9 10

10 10

11 10

OUTPUT 3: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 3: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 3: X-10 ADDRESS

1 Module number 0

2 House code 0

12 10 OUTPUT 4: EVENT, ZONE, TIME 43 4 10

13 10

14 10

15 10

OUTPUT 4: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 4: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 4: X-10 ADDRESS

1 Module number 0

2 House code 0

g

NX-507E/NX-508E Installation manual Page 18 09/05/04

Page 19

GE Security

LOC PG DESCRIPTION DEFAULT PROGRAMMING DATA

16 10 OUTPUT 5: EVENT, ZONE, TIME 43 5 10

17 10

18 10

19 10

OUTPUT 5: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 5: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 5: X-10 ADDRESS

1 Module number 0

2 House code 0

20 10 OUTPUT 6: EVENT, ZONE, TIME 43 6 10

21 10

22 10

23 10

OUTPUT 6: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 6: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 6: X-10 ADDRESS

1 Module number 0

2 House code 0

g

NX-507E/NX-508E Installation manual Page 19 09/05/04

Page 20

GE Security

LOC PG DESCRIPTION DEFAULT PROGRAMMING DATA

24 10 OUTPUT 7: EVENT, ZONE, TIME 43 7 10

25 10

26 10

27 10

OUTPUT 7: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 7: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 7: X-10 ADDRESS

1 Module number 0

2 House code 0

28 10 OUTPUT 8: EVENT, ZONE, TIME 43 8 10

29 10

30 10

31 10

OUTPUT 8: SPECIAL FEATURES & PARTITIONS

Segment 1 (Circle Numbers To Program)

1 ON: if timed in minutes. OFF: if timed is seconds

2 ON: If latched until code is entered. OFF: for timed

3 ON: If output should stop timing when a code is entered. OFF: timed

4 ON: If output should only trigger during a closed schedule

5 ON: If output should only trigger during an open schedule

6 ON: If the output should be inverted

7 ON: If a trigger should be logged in the event buffer

8 Reserved

Segment 2 (Circle Numbers To Program)

1 Partition 1 5 Partition 5

2 Partition 2 6 Partition 6

3 Partition 3 7 Partition 7

4 Partition 4 8 Partition 8

OUTPUT 8: SCHEDULE

1 Schedule 1 5 Schedule 5

2 Schedule 2 6 Schedule 6

3 Schedule 3 7 Schedule 7

4 Schedule 4 8 Schedule 8

OUTPUT 8: X-10 ADDRESS

1 Module number 0

2 House code 0

g

NX-507E/NX-508E Installation manual Page 20 09/05/04

Page 21

GE Security

LOC PG DESCRIPTION DEFAULT PROGRAMMING DATA

32 10 SCHEDULE 1 OPENING TIME 8 0

33 10 SCHEDULE 1 CLOSING TIME 20 0

34 11

SCHEDULE 1 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

4 Wednesday 8 Disabled on holidays

35 11 SCHEDULE 2 OPENING TIME 8 0

36 11 SCHEDULE 2 CLOSING TIME 20 0

37 11

SCHEDULE 2 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

4 Wednesday 8 Disabled on holidays

38 11 SCHEDULE 3 OPENING TIME 8 0

39 11 SCHEDULE 3 CLOSING TIME 20 0

40 11

SCHEDULE 3 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

4 Wednesday 8 Disabled on holidays

41 11 SCHEDULE 4 OPENING TIME 8 0

42 11 SCHEDULE 4 CLOSING TIME 20 0

43 11

SCHEDULE 4 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

4 Wednesday 8 Disabled on holidays

44 11 SCHEDULE 5 OPENING TIME 8 0

45 11 SCHEDULE 5 CLOSING TIME 20 0

46 11

SCHEDULE 5 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

4 Wednesday 8 Disabled on holidays

47 11 SCHEDULE 6 OPENING TIME 8 0

48 11 SCHEDULE 6 CLOSING TIME 20 0

49 11

SCHEDULE 6 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

4 Wednesday 8 Disabled on holidays

g

NX-507E/NX-508E Installation manual Page 21 09/05/04

Page 22

GE Security

LOC PG DESCRIPTION DEFAULT PROGRAMMING DATA

50 11 SCHEDULE 7 OPENING TIME 8 0

51 11 SCHEDULE 7 CLOSING TIME 20 0

52 11

SCHEDULE 7 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

Disabled on holidays 4 Wednesday 8

53 11 SCHEDULE 8 OPENING TIME 8 0

54 11 SCHEDULE 8 CLOSING TIME 20 0

55 11

SCHEDULE 8 DAYS (Circle the numbers to program)

1 Sunday 5 Thursday

2 Monday 6 Friday

3 Tuesday 7 Saturday

4 Wednesday 8 Disabled on holidays

56 11 JANUARY HOLIDAYS 0-0-0-0-0-0-0-0

57 11 FEBRUAY HOLIDAYS 0-0-0-0-0-0-0-0

58 11 MARCH HOLIDAYS 0-0-0-0-0-0-0-0

59 11 APRIL HOLIDAYS 0-0-0-0-0-0-0-0

60 11 MAY HOLIDAYS 0-0-0-0-0-0-0-0

61 11 JUNE HOLIDAYS 0-0-0-0-0-0-0-0

62 11 JULY HOLIDAYS 0-0-0-0-0-0-0-0

63 11 AUGUST HOLIDAYS 0-0-0-0-0-0-0-0

64 11 SEPTEMBER HOLIDAYS 0-0-0-0-0-0-0-0

65 11 OCTOBER HOLIDAYS 0-0-0-0-0-0-0-0

66 11 NOVEMBER HOLIDAYS 0-0-0-0-0-0-0-0

67 11 DECEMBER HOLIDAYS 0-0-0-0-0-0-0-0

68 11

CODES 1-10 OUTPUT SELECTION (Circle numbers to program)

User 1 2 3 4 5 6 7 8 9 10

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

69 12

CODES 11-20 OUTPUT SELECTION (Circle numbers to program)

User 11 12 13 14 15 16 17 18 19 20

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

g

NX-507E/NX-508E Installation manual Page 22 09/05/04

Page 23

70 12

71 12

72 13

73 13

74 13

GE Security

CODES 21-30 OUTPUT SELECTION (Circle numbers to program)

User 21 22 23 24 25 26 27 28 29 30

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 31-40 OUTPUT SELECTION (Circle numbers to program)

User 31 32 33 34 35 36 37 38 39 40

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 41-50 OUTPUT SELECTION (Circle numbers to program)

User 41 42 43 44 45 46 47 48 49 50

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 51-60 OUTPUT SELECTION (Circle numbers to program)

User 51 52 53 54 55 56 57 58 59 60

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 61-70 OUTPUT SELECTION (Circle numbers to program)

User 61 62 63 64 65 66 67 68 69 70

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

g

NX-507E/NX-508E Installation manual Page 23 09/05/04

Page 24

75 13

76 13

77 14

78 14

79 14

GE Security

CODES 71-80 OUTPUT SELECTION (Circle numbers to program)

User 71 72 73 74 75 76 77 78 79 80

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 81-90 OUTPUT SELECTION (Circle numbers to program)

User 81 82 83 84 85 86 87 88 89 90

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 91-100 OUTPUT SELECTION (Circle numbers to program)

User 91 92 93 94 95 96 97 98 99 100

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 101-110 OUTPUT SELECTION (Circle numbers to program)

User 101 102 103 104 105 106 107 108 109 110

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 111-120 OUTPUT SELECTION (Circle numbers to program)

User 111 112 113 114 115 116 117 118 119 120

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

g

NX-507E/NX-508E Installation manual Page 24 09/05/04

Page 25

80 14

81 14

82 15

83 15

84 15

GE Security

CODES 121-130 OUTPUT SELECTION (Circle numbers to program)

User 121 122 123 124 125 126 127 128 129 130

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 131-140 OUTPUT SELECTION (Circle numbers to program)

User 131 132 133 134 135 136 137 138 139 140

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 141-150 OUTPUT SELECTION (Circle numbers to program)

User 141 142 143 144 145 146 147 148 149 150

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 151-160 OUTPUT SELECTION (Circle numbers to program)

User 151 152 153 154 155 156 157 158 159 160

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 161-170 OUTPUT SELECTION (Circle numbers to program)

User 161 162 163 164 165 166 167 168 169 170

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

g

NX-507E/NX-508E Installation manual Page 25 09/05/04

Page 26

85 15

86 15

87 16

88 16

89 16

GE Security

CODES 171-180 OUTPUT SELECTION (Circle numbers to program)

User 171 172 173 174 175 176 177 178 179 180

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 181-190 OUTPUT SELECTION (Circle numbers to program)

User 181 182 183 184 185 186 187 188 189 190

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 191-200 OUTPUT SELECTION (Circle numbers to program)

User 191 192 193 194 195 196 197 198 199 200

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 201-210 OUTPUT SELECTION (Circle numbers to program)

User 201 202 203 204 205 206 207 208 209 210

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 211-220 OUTPUT SELECTION (Circle numbers to program)

User 211 212 213 214 215 216 217 218 219 220

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

g

NX-507E/NX-508E Installation manual Page 26 09/05/04

Page 27

90 16

91 16

GE Security

CODES 221-230 OUTPUT SELECTION (Circle numbers to program)

User 221 222 223 224 225 226 227 228 229 230

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

CODES 231-240 OUTPUT SELECTION (Circle numbers to program)

User 231 232 233 234 235 236 237 238 239 240

Output 1 1 1 1 1 1 1 1 1 1 1

Output 2 2 2 2 2 2 2 2 2 2 2

Output 3 3 3 3 3 3 3 3 3 3 3

Output 4 4 4 4 4 4 4 4 4 4 4

Output 5 5 5 5 5 5 5 5 5 5 5

Output 6 6 6 6 6 6 6 6 6 6 6

Output 7 7 7 7 7 7 7 7 7 7 7

Output 8 8 8 8 8 8 8 8 8 8 8

g

NX-507E/NX-508E Installation manual Page 27 09/05/04

Page 28

GE Security

g

PROGRAMMING EXAMPLES

Possible application for outputs:

Example 1

Example 2

Example 3

NOTE to example 3: The opening time is defaulted to 08.00h for all schedules. With this

example, the NX-507E/508 will try to auto-arm after every 45 minutes of inactivity on the

ready LED, from closing time to opening time.

Feature selections to be programmed are shown in bold italic text.

Example 1: To have output 1 trip and activate an X-10 module with house code C and

unit code 4 for 6 minutes when zone 1 is faulted only from 5:00 p.m. to 9:00 a.m.,

program the following:

0

1

2

Turn on entryway light upon entry only during nighttime.

Turn a device on or off during business hours.

Arm the system.

Segment Segment Location

1 2 3

42 1 3

1

2 33

3

4

5

6

7

8

1

2

3

4

5

6

7

8

32

Location

3

34

1 2 3

3 2

9 0

17 0

1

2

3

4

5

6

7

8

NX-507E/NX-508E Installation manual Page 28 09/05/04

Page 29

GE Security

Example 2: To have output 5 trip and activate an X-10 module with a house code of P

and a unit code of 8 from 9:00 a.m. to 5:00 p.m. Monday to Friday, but not all on Saturday

of Sunday, program the following:

g

Segment Segment Location

1 2 3

16

17

33

Example 3: To have output 3 auto arm partitions 1 and 2 at 7:00 p.m. Monday thru

Friday, 9:00 p.m. Saturday, but not at all on Sunday, program the following:

8

9

10

6

7

8

51 0 0

1 2

2 3

3 4

4 5

5

6 7

7

8 19

1 2 3

48 3 10

1

2

3

4

5 2

6 3

7 4

8 5

6

32

Segment Segment Location

1

2

3 2

4 3

5 4

6 5

7 6

8

36

1

38

39

Location

33

18

Location

37

40

1 2 3

1

8

7 14

9 0

17 0

1 2 3

19 0

21 0

7

8

0 0

23 59

1

NX-507E/NX-508E Installation manual Page 29 09/05/04

Page 30

GE Security

g

NX-507E TERMINAL DESCRIPTIONS AND LAYOUT

Terminal Description

DATA

COM

POS Connect to control panel AUX POWER + terminal. This terminal supplies power to the NX-507E board.

TAM

COM Connect to the tamper terminal through a normally closed contact.

AUX This terminal can supply up to 100 mA fused separate from the power in the control panel.

Rel7

Relays 1-6 Same as relay 7 shown above.

OUT 8 Open collector outputs that switch to ground when activated, max. 100 mA.

COM Common dry contact rated 1 Amp at 30 Volts.

Connect to the control panel Data terminal. This terminal is the data-signalling terminal to all the

devices on the bus.

Connect to the control panel COMMON terminal. This terminal supplies the common side of he power

to the NX-507E board.

This is an option tamper terminal. To use this feature, connect the normally closed tamper switch

between this terminal and COM. If this feature is not used, a jumper must be connected between this

terminal and common (or put DIP 4 to ON).

NOTE: Any power drain from this terminal should be included in total current draw from the

NetworX control panel or NX-320 power supply as applicable.

This allows an isolation of the power between the main control and remote devices. If a short is created

past the AUX terminal, those devices will cease to function, but the other devices, including the NX507E, will continue to operate. The NX-507E will report this problem to the control for display on the

keypad as an expander power trouble.

NC Normally closed dry contact rated 1 Amp at 30 Volts.

NO Normally open dry contact rated 1 Amp at 30 Volts.

NOTE: If device is connected to outputs, it must see the transition from 13V to GND. The enclosed

resistors must be used. Connect the resistor between AUX and the output being used.

NX-507E/NX-508E Installation manual Page 30 09/05/04

Page 31

GE Security

g

NX-508E TERMINAL DESCRIPTIONS AND LAYOUT

Terminal Description

DATA

COM

POS Connect to control panel AUX POWER + terminal. This terminal supplies power to the NX-508E board

TAM

COM Connect to the tamper terminal through a normally closed contact.

AUX This terminal can supply up to 100 mA fused separate from the power in the control panel.

OUT 1- 8 Open collector outputs that s witch to ground when activated, max. 100 mA.

Connect to the control panel Data terminal. This terminal is the data-signalling terminal to all the

devices on the bus.

Connect to the control panel COMMON terminal. This terminal supplies the common side of the power

to the NX-508E board.

This is an option tamper terminal. To use this feature, connect the normally closed tamper switch

between this terminal and COM. If this feature is not used, a jumper must be connected between this

terminal and common (or put DIP 4 to ON).

NOTE: Any power drain from this terminal should be included in total current draw from the

NetworX control panel or NX-320 power supply as applicable.

This allows an isolation of the power between the main control and remote devices. If a short is created

past the AUX terminal, those devices will cease to function, but the other devices, including the NX508E, will continue to operate. The NX-508E will report this problem to the control for display on the

keypad as an expander power trouble.

NOTE: If device is connected to outputs, it must see the transition from 13V to GND. The enclosed

resistors must be used. Connect the resistor between AUX and the output being used.

NX-507E/NX-508E Installation manual Page 31 09/05/04

Page 32

GE Security

g

ENCLOSURE DIAGRAM

Inside the can, several 2-holed insertion points have been constructed. This allows for

either vertical or horizontal placement of the modules.

Notice that the insertion points have two sizes of holes: a larger hole and a smaller hole.

Diagram 1: The black plastic PCB guides are grooved on one ed ge

where the PC board will be seated. The end with the half-moon

protrusion fits into the larger hole. The smaller hole is for the screw.

Diagram 2: Place the first black plastic PCB guide in the top insertion

point, grooved edge downward. The half-moon protrusion will be in the

large hole. It does not require force. Insert one of the provided screws

into the smaller hole (from inside the can) to secure it in place. A

screwdriver should reach through the notch that runs the length of the

guide to tighten the screw. The second PCB guide should be positioned

opposite of the first (grooved edge up) and placed in the lower insertion

point, using the same procedures described above. Once mounted,

screw it in securely.

Diagram 3: The PC board should slide freely in the grooves of both

guides.

NX-507E/NX-508E Installation manual Page 32 09/05/04

Page 33

GE Security

g

TECHNICAL SPECIFICATIONS

Power supply (supplied from NetworX control panel or NX-320 power supply)

• nominal:

• minimum/maximum:

12 Vdc Auxiliary power output (supplied from NetworX control panel or NX-320 power supply)

• max. current consumption

Current consumption:

• nominal:

• Maximum (NX-507E):

• Maximum (NX-508E):

• Remark: + current consumption of any device attached to NX-507E or NX-508E

Operating temperature:

Dimensions (PCB): 154 x 69 x 20 mm

Weight (PCB):

• NX-507E:

• NX-508E:

12 Vdc

9 Vdc - 14 Vdc

100 mA restricted by NX-507E and NX-508E

10 mA (no outputs active)

311 mA (all relays active)

25 mA (all outputs active)

0 - 50° C

110 g

86 g

NX-507E/NX-508E Installation manual Page 33 09/05/04

Page 34

GE Security

g

CE DECLARATION

NX-507E/NX-508E Installation manual Page 34 09/05/04

Page 35

GE Security

GE Security

g

g

NX-507E/NX-508E Installation manual Page 35 09/05/04

NX-507E/NX-508E Installation manual Page 35 09/05/04

Page 36

GE Security

GE Security

g

g

NX-507E/NX-508E Installation manual Page 36 09/05/04

NX-507E/NX-508E Installation manual Page 36 09/05/04

Page 37

GE Security

g

NX-507E/NX-508E Installation manual Page 37 09/05/04

Page 38

www.ge-interlogix.com

SLC Distribution is a division of GE Security EMEA bvba

COPYRIGHT ©2004

© GE Security EMEA bvba. All rights reserved. GE Security EMEA bvba grants the right to reprint this

manual for internal use only. GE Security EMEA bvba reserves the right to change information without

notice.

Loading...

Loading...