Page 1

R

Intel® 820E Chipset

Design Guide

May 2001

Document Number: 298187-003

Page 2

Intel® 820E Chipset

A

y

R

Information in this document is provided in connection with Intel® products. No license, express or implied, by estoppel or otherwise, to any intellectual

property rights is granted by this document. Except as provided in Intel’s Terms and Conditions of Sale for such products, Intel assumes no liability

whatsoever, and Intel disclaims any express or implied warranty, relating to sale and/or use of Intel products including liability or warranties relating to fitness

for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property right. Intel products are not intended for use in

medical, life saving, or life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.

Designers must not rely on the absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for future

definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

®

The Intel

Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

I

Implementations of the I

Corporation.

Copies of documents that have an ordering number and are referenced in this document, or other Intel literature, may be obtained from:

www.intel.com

or call 1-800-548-4725

Intel, Pentium III, Pentium II, PentiumPro, Celeron, and MMX are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United

States and other countries.

*Other names and brands ma

820E Chipset may contain design defects or errors known as errata which may cause the product to deviate from published specifications.

2

C is a two-wire communications bus/protocol developed by Philips. SMBus is a subset of the I2C bus/protocol and was developed by Intel.

lert on LAN is a result of the Intel-IBM Advanced Manageability Alliance and a trademark of IBM

Intel Corporation

2

C bus/protocol may require licenses from various entities, including Philips Electronics N.V. and North American Philips

be claimed as the property of others.

2 Design Guide

Page 3

Intel® 820E Chipset

R

Contents

Introduction ................................................................................................................................ 13

1.

1.1. About This Design Guide .............................................................................................. 13

1.2. Reference Documents................................................................................................... 14

1.3. System Overview........................................................................................................... 15

1.3.1. Chipset Components................................................................................... 16

1.3.2. Bandwidth Summary ................................................................................... 17

1.3.3. System Configuration .................................................................................. 18

1.4. Platform Initiatives ......................................................................................................... 20

1.4.1. Direct Rambus RAM (RDRAM*) ................................................................. 20

1.4.2. Streaming SIMD Extensions ....................................................................... 20

1.4.3. AGP 2.0....................................................................................................... 20

1.4.4. Hub Interface............................................................................................... 20

1.4.5. Integrated LAN Controller............................................................................ 21

1.4.6. Ultra ATA/100 Support ................................................................................ 21

1.4.7. Expanded USB Support .............................................................................. 21

1.4.8. Manageability .............................................................................................. 21

1.4.9. AC’97 ........................................................................................................ 23

1.4.10. Low-Pin-Count (LPC) Interface ................................................................... 25

2. Layout/Routing Guidelines ......................................................................................................... 27

2.1. General Recommendations........................................................................................... 27

2.2. Component Quadrant Layout ........................................................................................ 27

2.3. Intel® 820E Chipset Component Placement.................................................................. 29

2.4. Core Chipset Routing Recommendations ..................................................................... 30

2.5. Source-Synchronous Strobing....................................................................................... 32

2.6. Differential Clocking/Strobing ........................................................................................ 33

2.7. Direct RDRAM* Interface .............................................................................................. 33

2.7.1. Stack-Up...................................................................................................... 34

2.7.2. Direct RDRAM* Layout Guidelines.............................................................. 34

2.7.2.1. RSL Routing ................................................................................... 35

2.7.2.2. RSL Termination............................................................................. 38

2.7.2.3. Direct RDRAM* Ground Plane Reference...................................... 39

2.7.2.4. Direct RDRAM* Connector Compensation..................................... 41

2.7.2.4.1. Direct RDRAM* Channel Connector Compensation

Enhancement Recommendation .................................. 47

2.7.2.5. RSL Signal Layer Alternation.......................................................... 49

2.7.2.6. Length Matching Methods .............................................................. 50

2.7.2.7. Via Compensation .......................................................................... 52

2.7.2.8. Length Matching and Via Compensation Example......................... 52

2.7.3. Direct RDRAM* Reference Voltage............................................................. 54

2.7.4. High-Speed CMOS Routing ........................................................................ 54

2.7.4.1. SIO Routing .................................................................................... 55

2.7.4.2. Suspend-to-RAM Shunt Transistor................................................. 56

2.7.5. Direct RDRAM* Clock Routing .................................................................... 57

2.7.6. Direct RDRAM* Design Checklist ............................................................... 57

2.8. AGP 2.0 .........................................................................................................................60

2.8.1. AGP Interface Signal Groups ...................................................................... 60

2.8.2. 1× Timing Domain Routing Guidelines........................................................ 62

Design Guide 3

Page 4

Intel® 820E Chipset

R

2.8.3.

2×/4× Timing Domain Routing Guidelines ...................................................62

2.8.4. AGP 2.0 Routing Summary .........................................................................64

2.8.5. AGP Clock Routing ...................................................................................... 65

2.8.6. General AGP Routing Guidelines ................................................................65

2.8.6.1. Recommendations ..........................................................................65

2.8.7. V

2.8.8. V

Generation and TYPEDET# ................................................................ 66

DDQ

Generation for AGP 2.0 (2× and 4×).................................................... 68

REF

2.8.9. Compensation.............................................................................................. 70

2.8.10. AGP Pull-Ups...............................................................................................70

2.8.10.1. AGP Signal Voltage Tolerance List ................................................. 71

2.8.11. Motherboard / Add-in Card Interoperability..................................................71

2.8.12. AGP Universal Retention Mechanism (RM) ................................................ 72

2.9. Hub Interface .................................................................................................................74

2.9.1. 8-Bit Hub Interface Routing Guidelines .......................................................75

2.9.1.1. 8-Bit Hub Interface Data Signals..................................................... 75

2.9.1.2. 8-Bit Hub Interface Strobe Signals.................................................. 75

2.9.1.3. 8-Bit Hub Interface HUBREF Generation/Distribution..................... 75

2.9.1.4. 8-Bit Hub Interface Compensation ..................................................77

2.9.1.5. 8-Bit Hub Interface Decoupling Guidelines .....................................77

2.10. System Bus Design – Pentium® III Processor for the Intel® PGA370 Socket Layout

Guidelines ......................................................................................................................77

2.10.1. System Bus Ground Plane Reference ......................................................... 78

2.11. Additional Host Bus Guidelines...................................................................................... 78

2.12. IDE Interface ..................................................................................................................79

2.12.1. Cable Detection for Ultra ATA/66 and Ultra ATA/100..................................80

2.12.2. Combination Host-Side/Device-Side Cable Detection ................................. 80

2.12.3. Device-Side Cable Detection ....................................................................... 82

2.12.4. Primary IDE Connector Requirements ........................................................83

2.12.5. Secondary IDE Connector Requirements....................................................84

2.13. AC’97 .............................................................................................................................85

2.13.1. AC’97 Audio Codec Detect Circuit and Configuration Options ....................86

2.13.2. Communication and Networking Riser (CNR) .............................................90

2.13.3. AC’97 Routing..............................................................................................91

2.13.4. Motherboard Implementation ....................................................................... 92

2.14. USB................................................................................................................................92

2.14.1. Using Native USB Interface .........................................................................92

2.14.3. Disabling the Native USB Interface of ICH2 ................................................93

2.15. ISA Support....................................................................................................................93

2.16. I/O APIC Design Recommendation ...............................................................................94

2.17. SMBus/SMLink Interface ...............................................................................................94

2.18. PCI .................................................................................................................................96

2.19. RTC................................................................................................................................96

2.19.1. RTC Crystal .................................................................................................97

2.19.2. External Capacitors .....................................................................................97

2.19.3. RTC Layout Considerations......................................................................... 98

2.19.4. RTC External Battery Connection................................................................98

2.19.5. RTC External RTCRST Circuit ....................................................................99

2.19.6. RTC Routing Guidelines ............................................................................100

2.19.7. VBIAS DC Voltage and Noise Measurements ...........................................100

2.19.8. RTC-Well Input Strap Requirements .........................................................100

2.20. SPKR Pin Consideration ..............................................................................................100

2.21. ICH2 PIRQ Routing......................................................................................................101

4 Design Guide

Page 5

Intel® 820E Chipset

R

2.22.

LAN Layout Guidelines ................................................................................................ 102

2.22.1. ICH2 – LAN Interconnect Guidelines ........................................................ 103

2.22.1.1. Bus Topologies ............................................................................. 104

2.22.1.2. Point-to-Point Interconnect ........................................................... 104

2.22.1.3. LOM/CNR Interconnect ................................................................ 104

2.22.1.4. Signal Routing and Layout............................................................ 105

2.22.1.5. Crosstalk Consideration ............................................................... 106

2.22.1.6. Impedances .................................................................................. 106

2.22.1.7. Line Termination ........................................................................... 106

2.22.2. General LAN Routing Guidelines and Considerations .............................. 107

2.22.2.1. General Trace Routing Considerations ........................................ 107

2.22.2.1.1. Trace Geometry and Length....................................... 108

2.22.2.1.2. Signal Isolation ........................................................... 108

2.22.2.2. Power and Ground Connections .................................................. 108

2.22.2.2.1. General Power and Ground Plane Considerations .... 108

2.22.2.3. 4-Layer Board Design................................................................... 110

2.22.3. Intel® 82562EH Home/PNA* Guidelines ................................................... 112

2.22.3.1. Power and Ground Connections .................................................. 112

2.22.3.2. Guidelines for Intel® 82562EH Component Placement ................ 112

2.22.3.3. Crystals and Oscillators ................................................................ 112

2.22.3.4. Phoneline HPNA Termination....................................................... 113

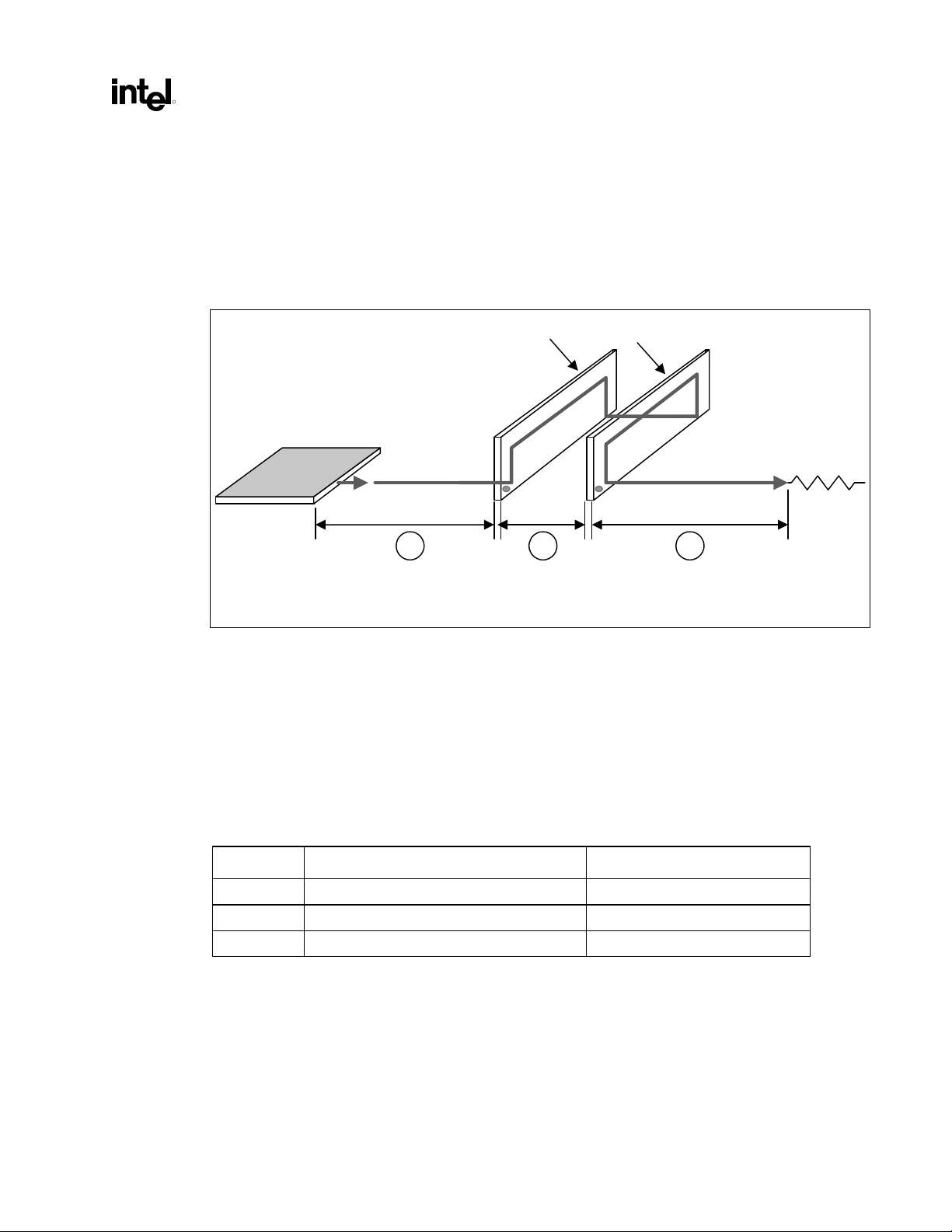

2.22.3.5. Critical Dimensions ....................................................................... 114

2.22.3.5.1. Distance from Magnetics Module to Line RJ11.......... 114

2.22.3.5.2. Distance from Intel® 82562EH Component to

Magnetics Module ...................................................... 114

2.22.3.5.3. Distance from LPF to Phone RJ11 ............................. 115

2.22.4. Intel® 82562ET / Intel® 82562EM Component Guidelines......................... 115

2.22.4.1. Guidelines for Intel® 82562ET / Intel® 82562EM Component

Placement .................................................................................... 115

2.22.4.2. Crystals and Oscillators ................................................................ 116

2.22.4.3. Intel® 82562ET / Intel® 82562EM Component Termination

Resistors .................................................................................... 116

2.22.4.4. Critical Dimensions ....................................................................... 116

2.22.4.4.1. Distance from Magnetics Module to RJ45.................. 117

2.22.4.4.2. Distance from the Intel® 82562ET Component to the

Magnetics Module ...................................................... 118

2.22.4.5. Reducing Circuit Inductance......................................................... 118

2.22.4.6. Terminating Unused Connections ................................................ 118

2.22.4.6.1. Termination Plane Capacitance ................................. 118

2.22.5. Intel® 82562ET/EM Disable Guidelines ....................................................... 119

2.22.6. Intel® 82562ET and Intel® 82562EH Components’ Dual-Footprint

Guidelines.................................................................................................... 120

2.22.7. ICH2 Decoupling Recommendations ........................................................ 122

2.23. FWH Flash BIOS Guidelines....................................................................................... 124

2.23.1. In-Circuit FWH Flash BIOS Programming ................................................ 124

2.23.2. FWH Flash BIOS VPP Design Guidelines ................................................ 124

2.24. ICH2 Design Checklist ................................................................................................ 125

2.25. ICH2 Layout Checklist ................................................................................................. 134

3. Advanced System Bus Design................................................................................................. 139

3.1. Terminology and Definitions ........................................................................................ 139

3.2. AGTL+ Design Guidelines........................................................................................... 141

3.2.1. Initial Timing Analysis................................................................................ 142

3.2.2. Determine the Desired General Topology, Layout, and Routing............... 145

Design Guide 5

Page 6

Intel® 820E Chipset

R

3.2.3.

Pre-Layout Simulation................................................................................145

3.2.3.1. Methodology.................................................................................. 145

3.2.3.2. Sensitivity Analysis........................................................................145

3.2.3.3. Monte Carlo Analysis ....................................................................146

3.2.3.4. Simulation Criteria......................................................................... 146

3.2.4. Place and Route Board..............................................................................147

3.2.4.1. Estimate Component-to-Component Spacing for AGTL+ Signals 147

3.2.4.2. Layout and Route Board ...............................................................147

3.2.4.3. Host Clock Routing .......................................................................148

3.2.4.4. APIC Data Bus Routing................................................................. 148

3.2.5. Post-Layout Simulation .............................................................................. 149

3.2.5.1. Intersymbol Interference ...............................................................149

3.2.5.2. Crosstalk Analysis......................................................................... 150

3.2.5.3. Monte Carlo Analysis ....................................................................150

3.2.6. Validation ...................................................................................................150

3.2.6.1. Measurements ..............................................................................150

3.2.6.2. Flight Time Simulation................................................................... 150

3.2.6.3. Flight Time Hardware Validation ...................................................151

3.3. Theory..........................................................................................................................152

3.3.1. AGTL+ ......................................................................................................152

3.3.2. Timing Requirements................................................................................. 152

3.3.3. Crosstalk Theory........................................................................................ 153

3.3.3.1. Potential Termination Crosstalk Problems....................................154

3.4. More Details and Insight ..............................................................................................155

3.4.1. Textbook Timing Equations .......................................................................155

3.4.2. Effective Impedance and Tolerance/Variation ...........................................156

3.4.3. Power/Reference Planes, PCB Stack-Up, and High-Frequency

Decoupling .................................................................................................156

3.4.3.1. Power Distribution .........................................................................156

3.4.3.2. Reference Planes and PCB Stack-Up ..........................................157

3.4.3.3. High-Frequency Decoupling.......................................................... 159

3.4.4. Clock Routing ............................................................................................160

3.5. Definitions of Flight Time Measurements/Corrections and Signal Quality...................160

3.5.1. V

Guard Band .......................................................................................161

REF

3.5.2. Ringback Levels ........................................................................................161

3.5.3. Overdrive Region....................................................................................... 161

3.5.4. Flight Time Definition and Measurement ................................................... 162

3.6. Conclusion ...................................................................................................................162

4. Clocking .................................................................................................................................... 163

4.1. Clock Generation .........................................................................................................163

4.2. Component Placement and Interconnection Layout Requirements ............................168

4.2.1. 14.318 MHz Crystal to CK133 ...................................................................168

4.2.2. CK133 to DRCG ........................................................................................168

4.2.3. MCH to DRCG ...........................................................................................169

4.2.4. DRCG-to-RDRAM Channel .......................................................................170

4.2.5. Trace Length.............................................................................................. 170

4.3. DRCG Impedance Matching Circuit.............................................................................172

4.3.1. DRCG Layout Example..............................................................................173

4.4. AGP Clock Routing Guidelines ....................................................................................173

4.5. Clock Routing Guidelines for Intel® PGA370 Designs..................................................173

4.6. Series Termination Resistors for CK133 Clock Outputs.............................................. 173

4.7. Unused Outputs ...........................................................................................................174

6 Design Guide

Page 7

Intel® 820E Chipset

R

4.8.

Decoupling Recommendation for CK133 and DRCG ................................................. 174

4.9. DRCG Frequency Selection and the DRCG+ ............................................................. 175

4.9.1. DRCG Frequency Selection Table and Jitter Specification....................... 175

4.9.2. DRCG+ Frequency Selection Schematic .................................................. 176

5. System Manufacturing ............................................................................................................. 177

5.1. Stack-Up Requirement ................................................................................................ 177

5.1.1. PCB Materials ........................................................................................... 177

5.1.2. Design Process ......................................................................................... 178

5.1.3. Test Coupon Design Guidelines................................................................ 178

5.1.4. Recommended Stack-Up .......................................................................... 179

5.1.5. Inner-Layer Routing................................................................................... 179

5.1.6. Impedance Calculation Tools .................................................................... 180

5.1.7. Testing Board Impedance ......................................................................... 181

5.1.8. Board Impedance/Stack-up Summary ...................................................... 181

6. System Design Considerations ................................................................................................ 183

6.1. Power Delivery............................................................................................................. 183

6.1.1. Terminology and Definitions...................................................................... 183

6.1.2. Power Delivery of Intel® 820E Chipset Customer Reference Board ......... 184

6.1.3. ICH2 1.8 V / 3.3 V Power Sequencing ...................................................... 188

6.1.5. Excessive Power Consumption by 64/72-Mbit RDRAM............................ 190

6.1.5.1. Option 1: Reduce the Clock Frequency During Initialization ........ 190

6.1.5.2. Option 2: Increase the Current Capability of the 2.5 V Voltage

Regulator ...................................................................................... 191

6.2. ICH2 Power Plane Split ............................................................................................... 192

6.3. Thermal Design Power ................................................................................................ 193

6.4. Glue Chip 3 (Intel® 820E Chipset Glue Chip) .............................................................. 193

Appendix A: Reference Design Schematics (Uniprocessor) ........................................................................... 195

Design Guide 7

Page 8

Intel® 820E Chipset

R

Figures

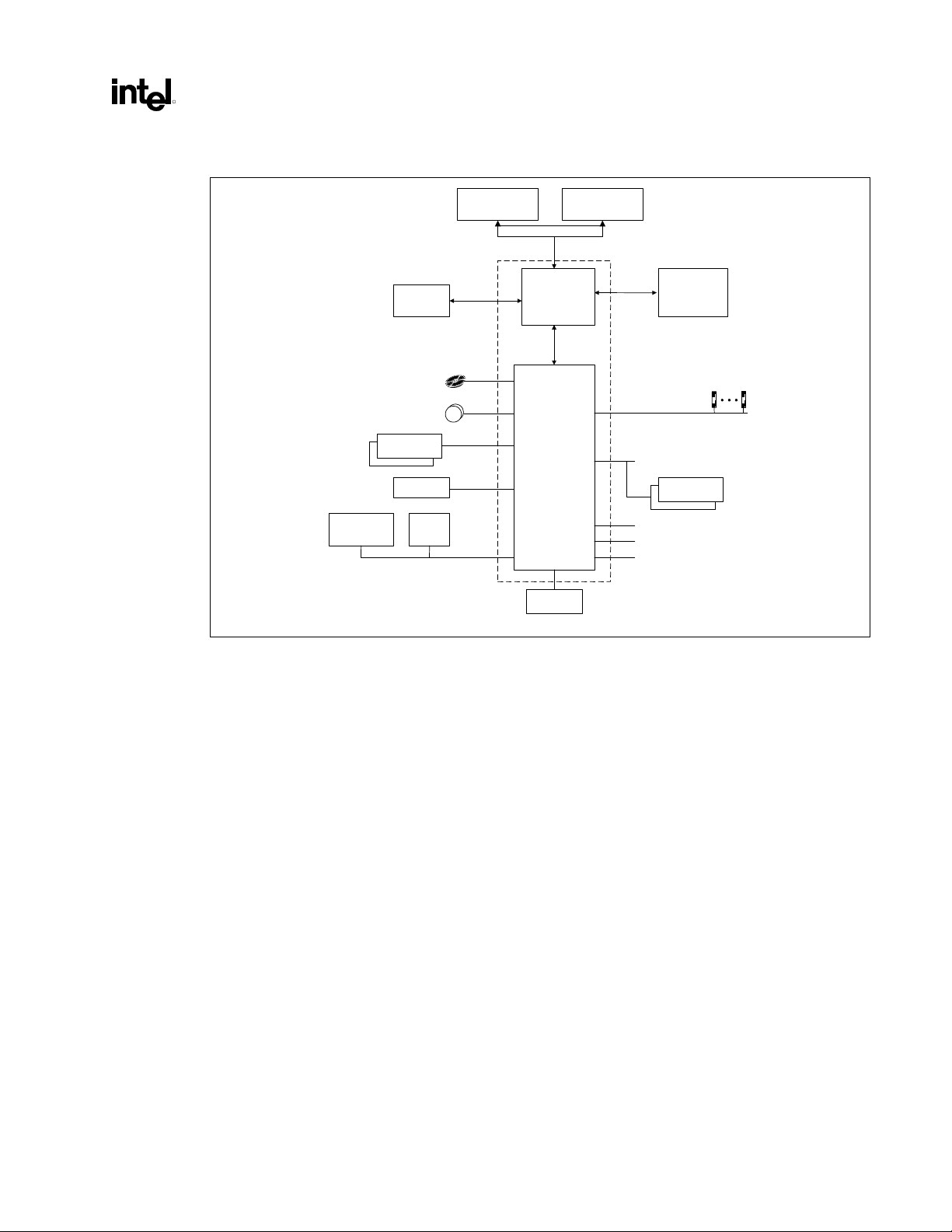

Figure 1. Intel® 820E Chipset Platform Performance Desktop Block Diagram ........................18

Figure 2. Intel® 820E Chipset Platform Performance Desktop Block Diagram

(with ISA Bridge)........................................................................................................18

Figure 3. Intel® 820E Chipset Platform Dual-Processor Performance Desktop Block

Diagram.....................................................................................................................19

Figure 4. (A-C) AC’97 Connections ..........................................................................................24

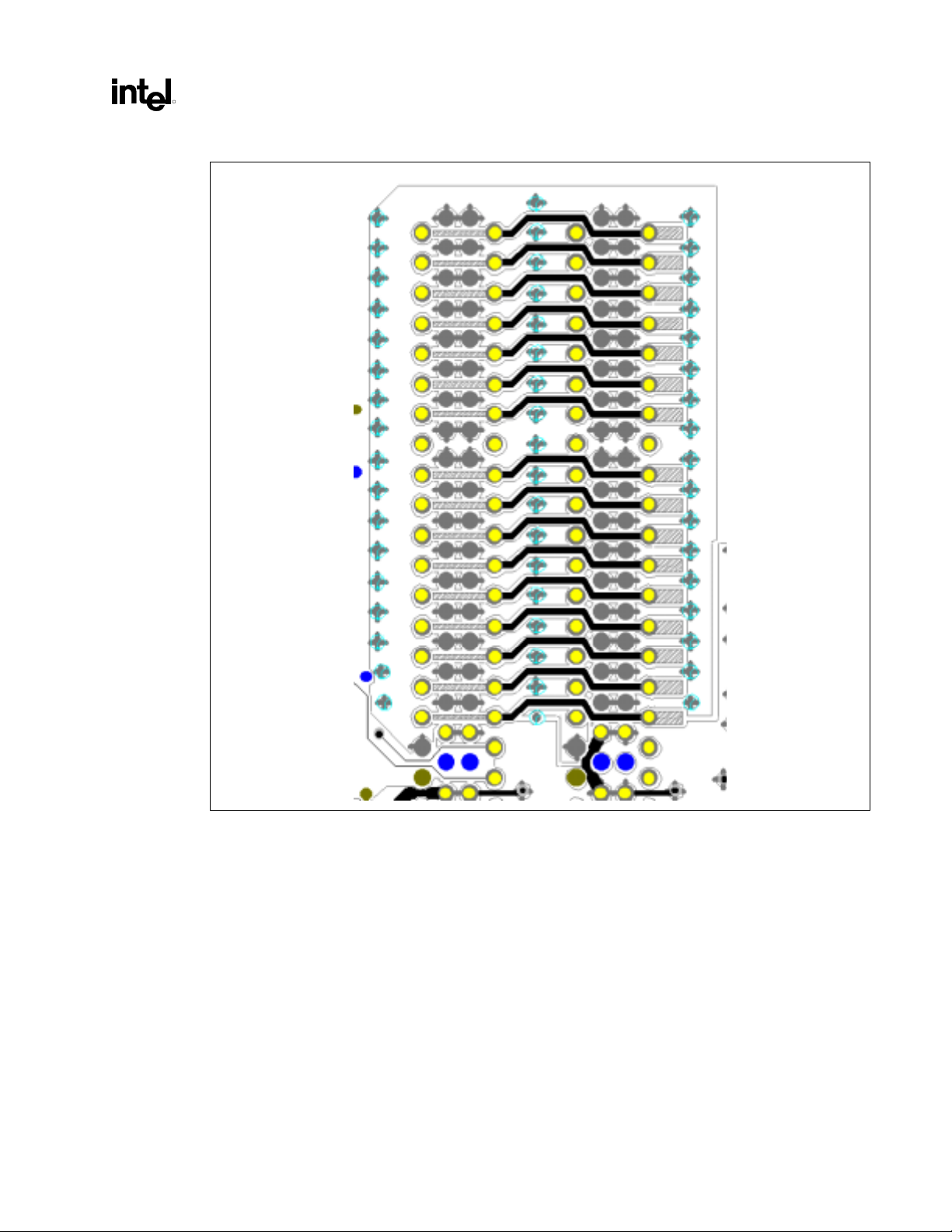

Figure 5. MCH 324-Ball µBGA* CSP Quadrant Layout (Top View) .........................................28

Figure 6. ICH2 360-Ball EBGA Quadrant Layout (Top View) ...................................................28

Figure 7. Sample ATX and NLX MCH/ICH2 Component Placement .......................................29

Figure 8. Primary-Side MCH Core Routing Example (ATX).....................................................30

Figure 9. Secondary-Side MCH Core Routing Example (ATX) ................................................31

Figure 10. Data Strobing Example ...........................................................................................32

Figure 11. Effect of Crosstalk on Strobe Signal .......................................................................32

Figure 12. RIMM Diagram ........................................................................................................33

Figure 13. RSL Routing Dimensions ........................................................................................35

Figure 14. RSL Routing Diagram .............................................................................................36

Figure 15. Primary-Side RSL Breakout Example .....................................................................36

Figure 16. Secondary-Side RSL Breakout Example ................................................................37

Figure 17. Direct RDRAM Termination.....................................................................................38

Figure 18. Direct RDRAM* Termination Example ....................................................................39

Figure 19. Incorrect Direct RDRAM* Ground Plane Referencing.............................................40

Figure 20. Direct RDRAM* Ground Plane Reference...............................................................40

Figure 21. Connector Compensation Example ........................................................................43

Figure 22. Section A (See Note), Top Layer.............................................................................44

Figure 23. Section A (See Note), Bottom Layer .......................................................................45

Figure 24. Section B (See Note), Top Layer.............................................................................46

Figure 25. Section B (See Note), Bottom Layer .......................................................................47

Figure 26. Top-Layer CTAB with RSL Signal Routed on the Same Layer (C

= 0.8 pF) ......48

EFF

Figure 27. Bottom-Layer CTAB with RSL Signal Routed on the Same Layer

(C

= 1.35 pF).......................................................................................................48

EFF

Figure 28. Bottom-Layer CTABs Split across the Top and Bottom Layer to Achieve an

Effect C

~1.35 pF...............................................................................................49

EFF

Figure 29. RSL Signal Layer Alternation ..................................................................................50

Figure 30. Example of RDRAM Trace Length Matching ..........................................................51

Figure 31. “Dummy” Via vs. “Real” Via.....................................................................................52

Figure 32. RAMREF Generation Example Circuit ....................................................................54

Figure 33. High-Speed CMOS Termination..............................................................................55

Figure 34. SIO Routing Example ..............................................................................................55

Figure 35. RDRAM CMOS Shunt Transistor ............................................................................56

Figure 36. AGP 2×/4× Routing Example for Interfaces < 6 Inches ..........................................63

Figure 37. Top Signal Layer .....................................................................................................66

Figure 38. AGP V

Figure 39. AGP 2.0 V

Generation Example Circuit ...................................................................68

DDQ

Generation and Distribution ..............................................................69

REF

Figure 40. AGP Left-Handed Retention Mechanism ................................................................72

Figure 41. AGP Left-Handed RM Keep-Out Information..........................................................73

Figure 42. Hub Interface Signal Routing Example ...................................................................74

Figure 43. 8-Bit Hub Interface with a Shared Reference Divider Circuit

(Normal/Single Mode) .............................................................................................76

Figure 44. 8-Bit Hub Interface with Locally Generated Reference Divider Circuits

(Normal/Local Mode) ...............................................................................................76

Figure 45. Ground Plane Reference (4-Layer Motherboard)....................................................78

Figure 46. Combination Host-Side/Device-Side IDE Cable Detection .....................................81

8 Design Guide

Page 9

Intel® 820E Chipset

R

Figure 47. Device-Side IDE Cable Detection ........................................................................... 82

Figure 48. Connection Requirements for Primary IDE Connector ........................................... 83

Figure 49. Connection Requirements for Secondary IDE Connector ...................................... 84

Figure 50. ICH2 AC’97– Codec Connection ............................................................................ 85

Figure 51. CDC_DN_ENAB# Support Circuitry for a Single Codec on Motherboard ............... 87

Figure 52. CDC_DN_ENAB# Support Circuitry for Multi-Channel Audio Upgrade .................. 88

Figure 53. CDC_DN_ENAB# Support Circuitry for Two-Codecs on Motherboard /

One-Codec on CNR................................................................................................ 88

Figure 54. CDC_DN_ENAB# Support Circuitry for Two-Codecs on Motherboard /

Two-Codecs on CNR.............................................................................................. 89

Figure 55. CNR Interface ......................................................................................................... 90

Figure 56. USB Data Signals ................................................................................................... 93

Figure 57. SMBUS/SMLink Interface ....................................................................................... 95

Figure 58. PCI Bus Layout Example ........................................................................................ 96

Figure 59. External Circuitry for the ICH RTC2........................................................................ 97

Figure 60. Diode Circuit Connecting RTC External Battery .....................................................98

Figure 61. RTCRST External Circuit for ICH2 RTC................................................................. 99

Figure 62. SPKR Circuit ......................................................................................................... 101

Figure 63. Example PCI IRQ Routing .................................................................................... 102

Figure 64. ICH2 / LAN Connect Section ................................................................................ 103

Figure 65. Single-Solution Interconnect ................................................................................. 104

Figure 66. LOM/CNR Interconnect ........................................................................................ 105

Figure 67. LAN_CLK Routing Example.................................................................................. 106

Figure 68. Trace Routing ....................................................................................................... 107

Figure 69. Ground Plane Separation ..................................................................................... 109

Figure 70. Intel® 82562EH Component Termination.............................................................. 113

Figure 71. Critical Dimensions for Component Placement .................................................... 114

Figure 72. Intel® 82562ET/82562EM Component Termination.............................................. 116

Figure 73. Critical Dimensions for Component Placement .................................................... 117

Figure 74. Termination Plane................................................................................................. 119

Figure 75. Intel® 82562ET/EM Disable Circuit ....................................................................... 119

Figure 76. Dual-Footprint LAN Connect Interface.................................................................. 120

Figure 77. Dual-Footprint Analog Interface ............................................................................ 121

Figure 78. Decoupling Capacitor Layout................................................................................ 123

Figure 79. One Signal Layer and One Reference Plane........................................................ 157

Figure 80. Layer Switch with One Reference Plane .............................................................. 157

Figure 81. Layer Switch with Multiple Reference Planes (Same Type) ................................. 158

Figure 82. Layer Switch with Multiple Reference Planes ....................................................... 158

Figure 83. One Layer with Multiple Reference Planes........................................................... 159

Figure 84. Overdrive Region and V

Guard Band............................................................... 161

REF

Figure 85. Rising-Edge Flight Time Measurement ................................................................ 162

Figure 86. Intel® 820E Chipset Platform Clock Distribution.................................................... 164

Figure 87. Intel® 820E Chipset Clock Routing Guidelines

1,2

.................................................. 166

Figure 88. CK133-to-DRCG Routing Diagram....................................................................... 168

Figure 89. MCH-to-DRCG Routing Diagram.......................................................................... 169

Figure 90. Direct RDRAM* Clock Routing Dimensions.......................................................... 169

Figure 91. Differential Clock Routing Diagram (Sections A, C & D) ...................................... 171

Figure 92. Non-Differential Clock Routing Diagram (Section B) ............................................ 171

Figure 93. Termination for Direct RDRAM* Clocking Signals CFM/CFM# ............................ 171

Figure 94. DRCG Impedance Matching Network................................................................... 172

Figure 95. DRCG Layout Example......................................................................................... 173

Figure 96. DRCG+ Frequency Selection................................................................................ 176

Figure 97. 28 Ω Trace Geometry ........................................................................................... 177

Figure 98. Microstrip (a) and Stripline (b) Cross Section for 28 Ω Trace............................... 180

Figure 99. 7 mil Stack-Up (Not Routable) .............................................................................. 181

Design Guide 9

Page 10

Intel® 820E Chipset

R

Tables

Figure 100. 4.5 mil Stack-Up ..................................................................................................181

Figure 101. Intel® 820E Chipset Power Delivery Example......................................................184

Figure 102. 1.8 V and 2.5 V Power Sequencing (Schottky Diode) .........................................187

Figure 103. Example 1.8V/3.3V Power Sequencing Circuit ...................................................189

Figure 104. Example 3.3V/5V REF Sequencing Circuitry ......................................................190

Figure 105. Use a GPO to Reduce DRCG Frequency ...........................................................191

Figure 106. Example of ICH2 Power Plane Split ....................................................................192

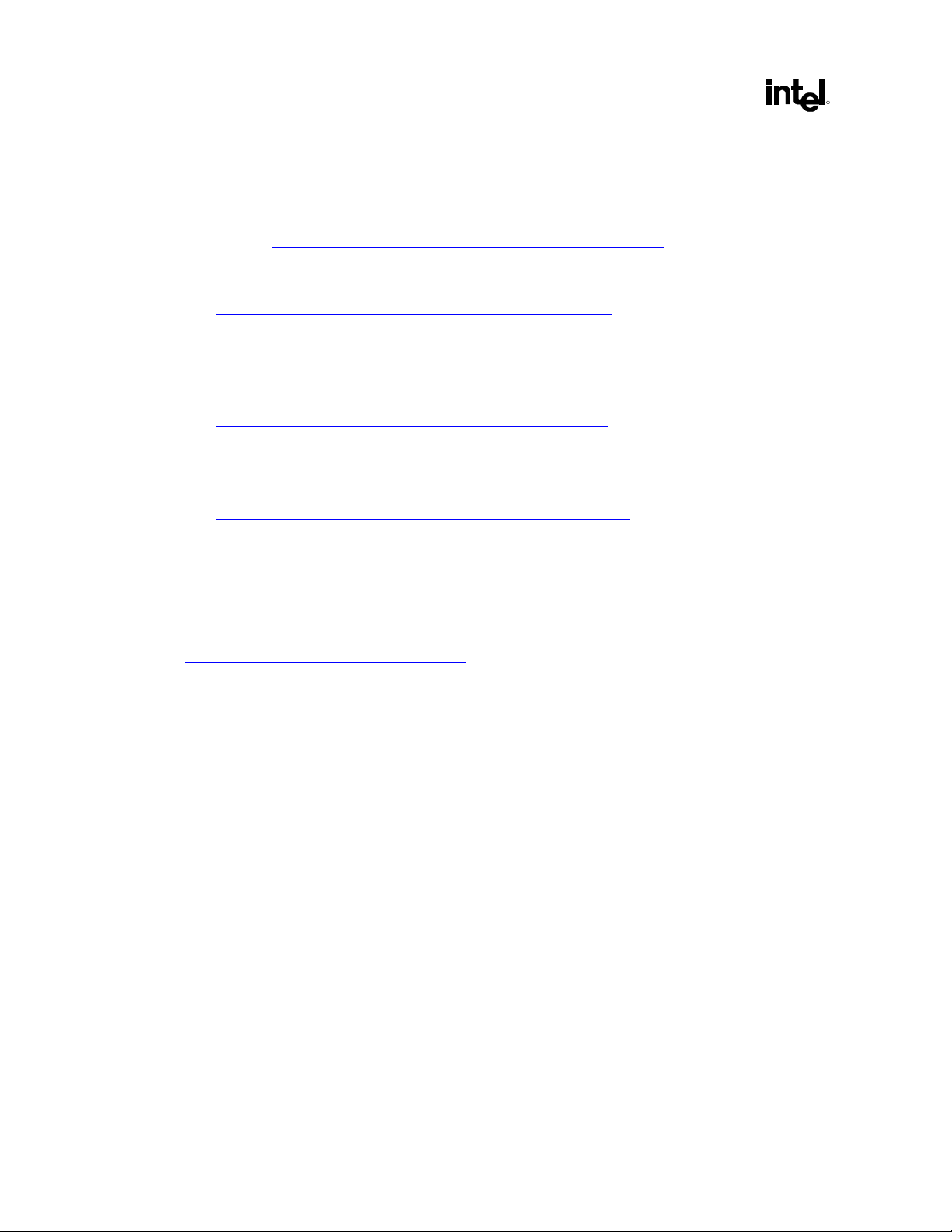

Table 1. Intel® 820E Chipset Platform Bandwidth Summary ....................................................17

Table 2. AGP 2× Data/Strobe Association ...............................................................................33

Table 3. Placement Guidelines for Motherboard Routing Lengths...........................................35

Table 4. Copper Tab Area Calculation .....................................................................................42

Table 5. RSL and Clocking Signal RIMM Connector Capacitance Recommendations ...........47

Table 6. Copper Tab Area Calculation .....................................................................................48

Table 7. RSL Routing Layer Requirements ..............................................................................50

Table 8. Line Matching and Via Compensation Example.........................................................53

Table 9. Signal List ...................................................................................................................57

Table 10. AGP 2.0 Data/Strobe Associations...........................................................................62

Table 11. AGP 2.0 Routing Summary ......................................................................................64

Table 12. TYPDET#/V

Relationship ....................................................................................67

DDQ

Table 13. Connector / Add-in Card Interoperability ..................................................................71

Table 14. Voltage / Data Rate Interoperability..........................................................................71

Table 15. 8-Bit Hub Interface Buffer Configuration Setting ......................................................75

Table 16. 8-Bit Hub Interface HUBREF Generation Circuit Specifications ..............................76

Table 17. 8-Bit Hub Interface RCOMP Resistor Values ...........................................................77

Table 18. Signal Descriptions...................................................................................................89

Table 19. Codec Configurations ...............................................................................................90

Table 20. Pull-Up Requirements for SMBus and SMLink Signals............................................95

Table 21. Usage of I/O APIC Interrupt Inputs 16 through 23..................................................101

Table 22. LAN Design Guide Section Reference ...................................................................103

Table 23. Length Requirements for Figure 66........................................................................105

Table 24. Related Documents ................................................................................................112

Table 25. Decoupling Capacitor Recommendation ................................................................122

Table 26. PCI Interface...........................................................................................................125

Table 27. Hub Interface ..........................................................................................................126

Table 28. LAN Interface..........................................................................................................126

Table 29. EEPROM Interface .................................................................................................126

Table 30. FWH Flash BIOS Interface.....................................................................................126

Table 31. Interrupt Interface ...................................................................................................127

Table 32. GPIO.......................................................................................................................128

Table 33. USB Interface .........................................................................................................128

Table 34. Power Management ...............................................................................................129

Table 35. Processor Signals...................................................................................................129

Table 36. System Management..............................................................................................130

Table 37. RTC ........................................................................................................................130

Table 38. AC’97 ......................................................................................................................130

Table 39. Miscellaneous Signals ............................................................................................131

Table 40. Power......................................................................................................................131

Table 41. IDE Checklist ..........................................................................................................132

Table 42. ISA Bridge Checklist ...............................................................................................133

Table 43. 8-Bit Hub Interface..................................................................................................134

Table 44. IDE Interface...........................................................................................................134

10 Design Guide

Page 11

Intel® 820E Chipset

R

Table 45. USB........................................................................................................................ 134

Table 46. LAN Connect I/F..................................................................................................... 135

Table 47. AC’97 ..................................................................................................................... 136

Table 48. ICH2 Decoupling .................................................................................................... 136

Table 49. CK-SKS Clocking ................................................................................................... 137

Table 50. RTC........................................................................................................................ 137

Table 51. AGTL+ Parameters for Example Calculations

Table 52. Example T

Table 53. Example T

Calculations for 133 MHz Bus1.................................................. 144

FLT_MAX

Calculations1 (Frequency Independent)..................................... 145

FLT_MIN

1,2

.................................................... 143

Table 54. Trace Width Space Guidelines .............................................................................. 148

Table 55. Intel® 820E Chipset Platform System Clocks......................................................... 163

Table 56. Intel® 820E Chipset Platform Clock Skews ............................................................ 165

Table 57. Intel® 820E Chipset Platform System Clock Cross-Reference .............................. 167

Table 58. Placement Guidelines for Motherboard Routing Lengths (Direct RDRAM*

Clock Routing Length Guidelines) .......................................................................... 170

Table 59. External DRCG Component Values....................................................................... 172

Table 60. Unused Output Termination................................................................................... 174

Table 61. 28 Ω Stack-Up Examples....................................................................................... 179

Table 62. 3D Field Solver vs. ZCALC .................................................................................... 180

Table 63. Intel® 820E Chipset Component Thermal Design Power....................................... 193

Table 64. Glue Chip Vendors................................................................................................. 194

Design Guide 11

Page 12

Intel® 820E Chipset

R

Revision History

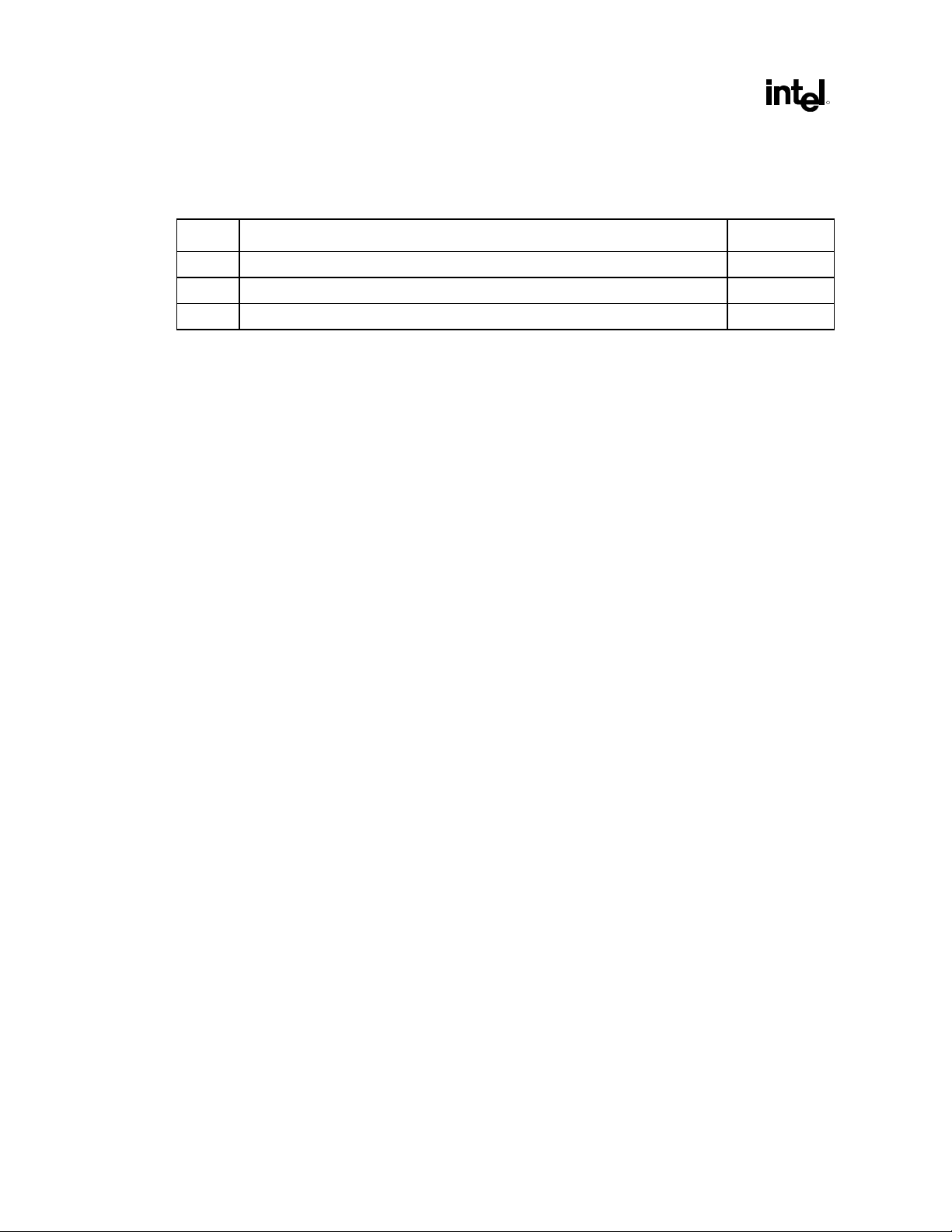

Rev. Description Date

-001 • Initial Release June 2000

-002 • Minor edits for clarity July 2000

-003 • Revised ICH2 sections May 2001

12 Design Guide

Page 13

Intel® 820E Chipset

R

1. Introduction

The Intel® 820E Chipset Design Guide provides design recommendations for systems using the Intel

820E chipset. This includes motherboard layout, routing guidelines, system design issues, system

requirements, debug recommendations, and board schematics. In addition to providing motherboard

design recommendations (e.g., layout and routing guidelines), this document also addresses system

design issues such as thermal requirements for Intel 820E chipset-based systems. The design

recommendations should be used during system design. The guidelines have been developed to provide

maximum flexibility to board designers while reducing the risk of board-related issues.

The Intel board schematics in Appendix A: Reference Design Schematics (Uniprocessor) implement

®

Intel

PGA370 architecture and are intended for use as references by board designers. While the

schematics included cover specific designs, the core schematics for each chipset component remain the

same for most Intel 820E chipset platforms. The appendix provides a set of reference schematics for each

chipset component, in addition to common motherboard options. Additional flexibility is possible via

other permutations of these options and components.

1.1. About This Design Guide

This design guide is intended for hardware designers who are experienced with PC architectures and

board design. This design guide assumes that the designer has a working knowledge of the vocabulary

and practices of PC hardware design.

• Chapter 1, Introduction — This chapter introduces the designer to the purpose and organization of

this design guide, and provides a list of references of related documents. This chapter also provides

an overview of the Intel 820E chipset.

®

• Chapter 2, Layout/Routing Guidelines — This chapter provides a detailed set of motherboard

layout and routing guidelines for designing an Intel 820E chipset-based platform. The

motherboard’s functional units are discussed (e.g., chipset component placement, system bus

routing, system memory layout, display cache interface, hub interface, IDE, AC’97, USB, interrupts,

SMBUS, PCD, LPC/FWH Flash BIOS, and RTC).

• Chapter 4, Advanced System Bus Design — This chapter discusses the AGTL+ guidelines and

theory of operation. It also provides more details about the methodologies used to develop these

guidelines.

• Chapter 4, Clocking — This chapter provides the motherboard clocking guidelines (e.g., clock

architecture, routing, capacitor sites, clock power decoupling, and clock skew).

• Chapter 5, System Manufacturing — This chapter includes the board stack-up requirements.

• Chapter 6, System Design Considerations— This chapter includes the guidelines for power

delivery, decoupling, thermal, and power sequencing.

• Appendix A, Reference Design Schematics (Uniprocessor) — This appendix provides a set of

schematics for uniprocessor designs. It also provides a feature list for board design.

Design Guide 13

Page 14

Intel® 820E Chipset

R

1.2. Reference Documents

• Intel® 820 Chipset Family: 82820 Memory Controller Hub (MCH) Datasheet (document number:

290630) http://developer.intel.com/design/chipsets/datashts/290630.htm

• Intel® 820 Chipset Design Guide Addendum for the Intel® Pentium® III Processor for the

PGA370 Socket (document number 298718)

http://developer.intel.com/design/chipsets/designex/298178.htm

• Intel® 82802AB/82802AC Firmware Hub (FWH) Datasheet (document number: 290658)

http://developer.intel.com/design/chipsets/datashts/290658.htm

• Intel® 82801BA I/O Controller Hub 2 (ICH2) and Intel® 82801BAM I/O Controller Hub 2 Mobile

(ICH2-M) Datasheet (document number: 290687)

http://developer.intel.com/design/chipsets/datashts/290687.htm

• CK97 Clock Synthesizer Design Guidelines (document number: 243867)

http://developer.intel.com/design/PentiumII/applnots/243867.htm

• VRM 8.4 DC-DC Converter Design Guidelines (document number 245335)

http://developer.intel.com/design/PentiumIII/designgd/245335.htm

• PCI Local Bus Specification, Revision 2.2

• Universal Serial Bus Specification, Revision 1.0

Further information regarding the Pentium III processor can be found at

http://developer.intel.com/design/PentiumIII/

.

14 Design Guide

Page 15

Intel® 820E Chipset

R

1.3. System Overview

The Intel 820E chipset is designed for Intel

®

Pentium

®

III microprocessors and is the first chipset to

support the integrated LAN capability and expanded USB capability. It supports the 4× capability of the

AGP 2.0 Interface Specification and it supports the 400 MHz Direct RDRAM* interface. The 400 MHz,

16-bit, double-clocked Direct RDRAM interface provides 1.6-GB/s access to main memory. To provide

more efficient communication between chipset components, the hub interface component interconnect is

designed into the Intel 820E chipset.

Support of AGP 4×, 400 MHz Direct RDRAM and the hub interface provides a balanced system

architecture for the Pentium III processor, minimizing bottlenecks and increasing system performance. By

increasing memory bandwidth to 1.6 GB/s by means of 400 MHz Direct RDRAM and by increasing the

graphics bandwidth to 1 GB/s by means of AGP 4×, the Intel 820E chipset delivers the data throughput

necessary to take advantage of the high performance provided by the powerful Pentium III processors.

In addition, the Intel 820E chipset architecture enables security and manageability infrastructures through

the Firmware Hub (FWH)component.

The ACPI-compliant Intel 820E chipset platform can support the Full-On, Stop Grant, Suspend to RAM,

Suspend to Disk, and Soft-Off power management states. Through the use of the integrated LAN

functions, the Intel 820E chipset also supports Wake on LAN* for remote administration and

troubleshooting.

The Intel 820E chipset architecture eliminates the need for the ISA expansion bus traditionally integrated

into the I/O subsystem of Intel chipsets. This eliminates many conflicts experienced when installing

hardware and drivers into legacy ISA systems. The elimination of ISA provides true plug and play for the

Intel 820E chipset platform. Traditionally, the ISA interface was used for audio and modem devices. The

addition of AC’97 allows the OEM to use software-configurable AC’97 audio and modem

encoders/decoders (codecs), instead of traditional ISA devices. The 82801BA ICH2 component expands

the support of AC’97 to include up to 6-channel audio. The ISA bus can be implemented with a PCI-toISA bridge from an external component supplier.

The Intel 820E chipset contains two core components: the Memory Controller Hub (MCH) and the I/O

Controller Hub 2 (ICH2). The MCH integrates the 133 MHz processor system bus controller, an AGP

2.0 controller, a 400 MHz Direct RDRAM controller, and a high-speed hub interface for communication

with the ICH2. The ICH2 integrates an Ultra ATA/100 controller, two USB host controllers, an LPC

interface controller, an FWH Flash BIOS interface controller, a PCI interface controller, an AC’97

digital controller, an integrated LAN controller, and a hub interface for communication with the MCH.

The Intel 820E chipset provides the data buffering and interface arbitration required to ensure that the

system interfaces operate efficiently and provide the system bandwidth necessary to obtain peak

performance with the Pentium III processor.

Design Guide 15

Page 16

Intel® 820E Chipset

R

1.3.1. Chipset Components

The Intel 820E chipset consists of the Intel

®

Intel

82801BA I/O Controller Hub (ICH2). Additional functionality can be provided through the use of

®

82820 Memory Controller Hub (MCH) and the

a PCI-to-ISA bridge.

Memory Controller Hub (MCH)

The MCH provides the interconnect between the Direct RDRAM and the system logic. It integrates the

following functions:

• Support for single or dual Intel PGA370 processors with a 100 MHz or 133 MHz system bus

• 256 MHz, 300 MHz, 356 MHz or 400 MHz Direct RDRAM interface supporting 1 GB of Direct

RDRAM

• 4×, 1.5 V AGP interface (3.3 V 1×, 2×, and 1.5 V 1×, 2× devices also supported)

• Downstream hub interface for access to the ICH2

In addition, the MCH provides arbitration, buffering, and coherency management for each of these

interfaces. Refer to Chapter 2 Layout/Routing Guidelines for more information regarding these

interfaces.

I/O Controller Hub 2 (ICH2)

The ICH2 provides the I/O subsystem with access to the rest of the system. Additionally, it integrates

many I/O functions. The ICH2 integrates:

• Upstream hub interface for access to the MCH

• Two-channel Ultra ATA/100 bus master IDE controller

• Two USB controllers (expanded capabilities for 4 ports)

• I/O APIC

• SMBus controller

• FWH interface (FWH Flash BIOS)

• LPC interface

• AC’97 2.1 interface

• PCI 2.2 interface

• Integrated system management controller

• Alert on LAN*

• Integrated LAN controller

The ICH2 also contains the arbitration and buffering necessary to ensure efficient utilization of these

interfaces. Refer to Section 2 for more information on these interfaces.

16 Design Guide

Page 17

Intel® 820E Chipset

R

FWH Flash BIOS

The FWH Flash BIOS component is a key element in providing a new security and manageability

infrastructure for the PC platform. The device operates under the FWH Flash BIOS interface and

protocol. The hardware features of this device include a unique Random Number Generator (RNG),

register-based locking, and hardware-based locking.

ISA Bridge

For legacy needs, ISA support is an optional feature of the Intel 820E chipset. Implementations that

require ISA support can benefit from the enhancements of the Intel 820E chipset, while “ISA-less”

designs are not burdened with the complexity and cost of the ISA subsystem.

The Intel 820E chipset platform with optional ISA support takes advantage of an external component

supplier’s ISA bridge, which is a PCI-to-ISA bridge that resides on the PCI bus of the ICH2.

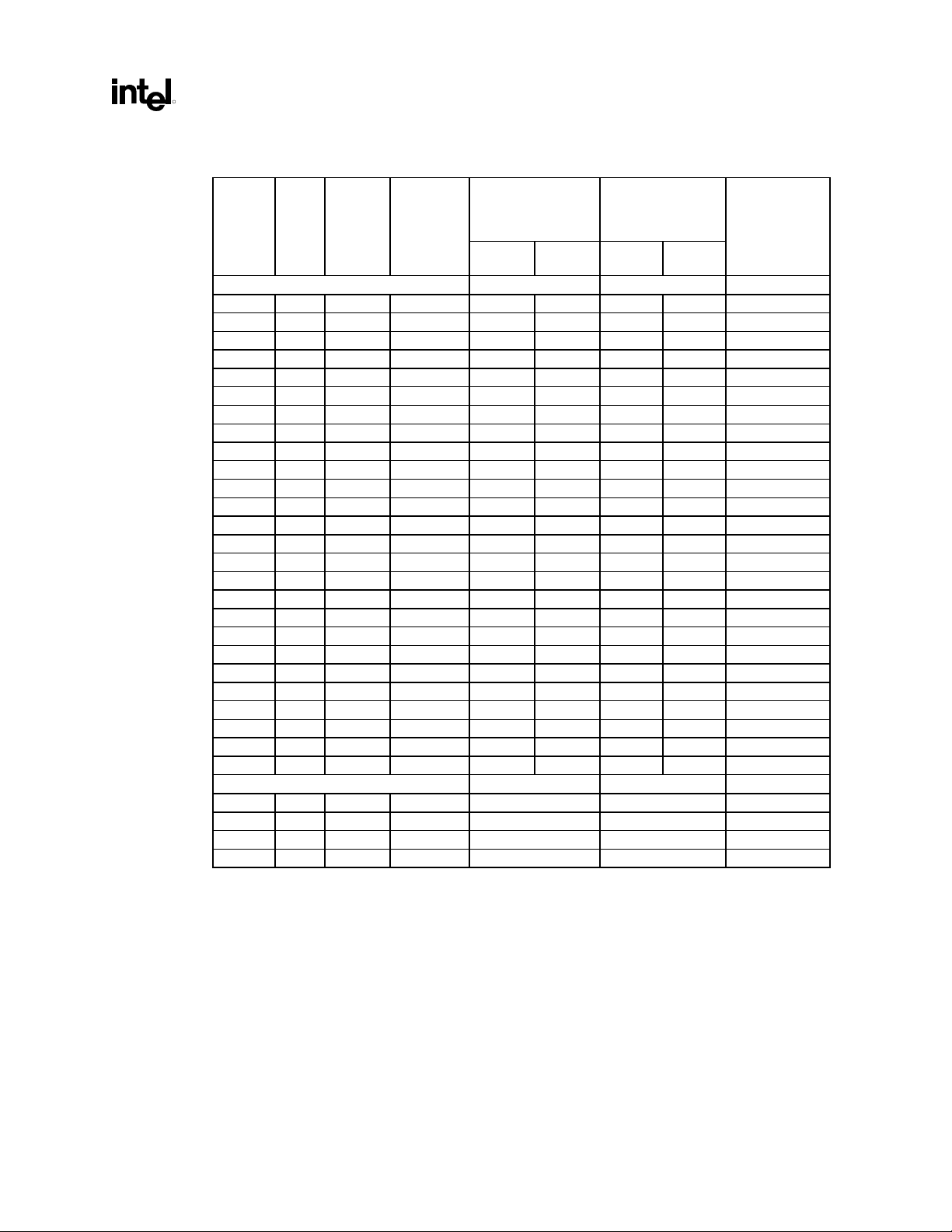

1.3.2. Bandwidth Summary

The following table provides a summary of the bandwidth requirements for the Intel 820E chipset.

Table 1. Intel

Processor bus 100/133 1 100/133 8 800/1066

RDRAM 266/300/356/400 2 533/600/711/800 2 1066/1200/1422/1600

AGP 2.0 66 4 266 4 1066

Hub interface 66 4 266 1 266

PCI 2.2 33 1 33 4 133

®

820E Chipset Platform Bandwidth Summary

Interface Clock Speed

(MHz)

Samples

Per Clock

Data Rate

(megasamples/s)

Data Width

(Bytes)

Bandwidth

(MB/s)

Design Guide 17

Page 18

Intel® 820E Chipset

®

R

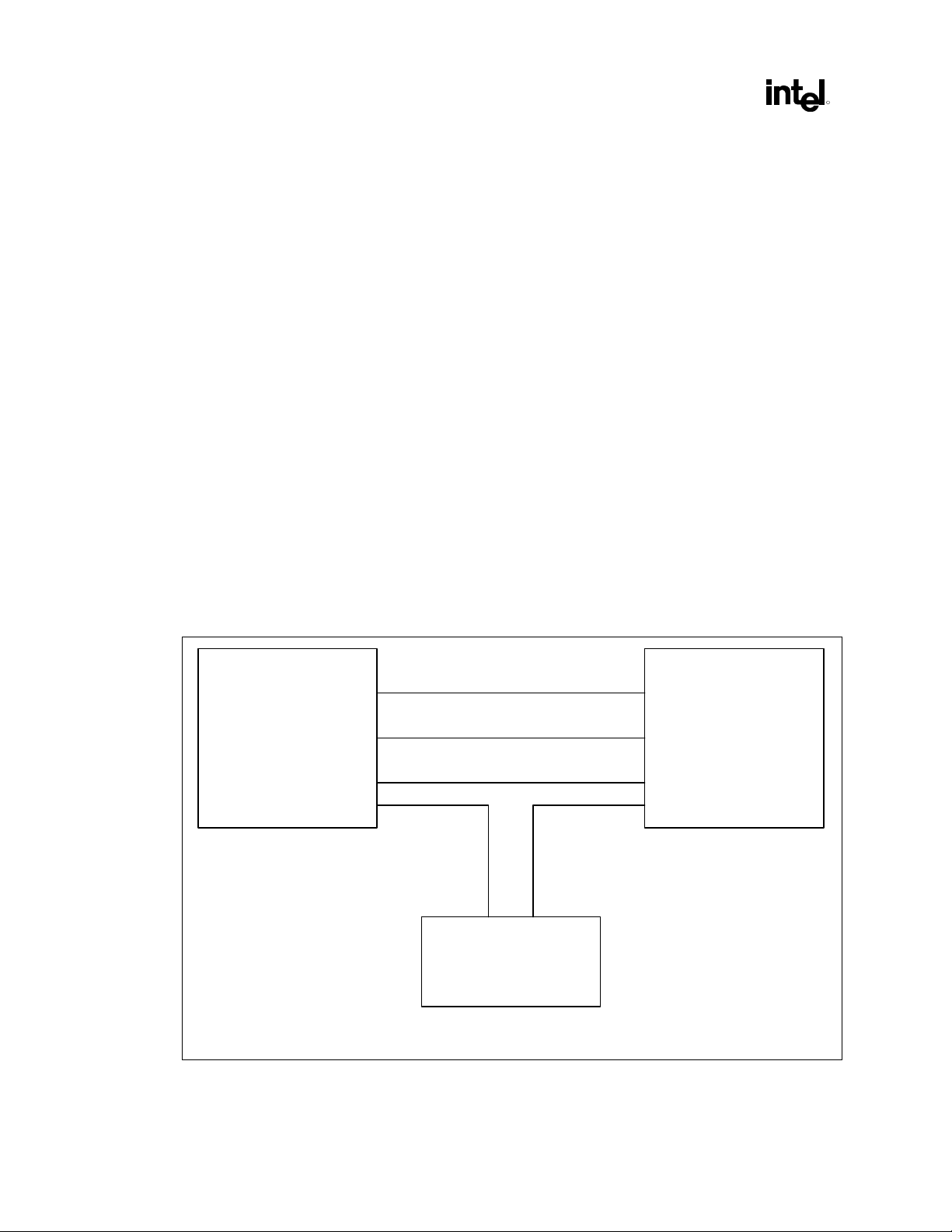

1.3.3. System Configuration

The following figures show typical platform configurations using the Intel 820E chipset:

Figure 1. Intel

®

820E Chipset Platform Performance Desktop Block Diagram

®

Intel® Pentium

Other ASICs

(optional)

4x AGP

Graphics

Controller

4 IDE Drives

UltraATA/100/66/33

4 USB Ports; 2 HC

AC'97 Codec(s)

(optional)

LAN Connect

Super I/O

AGP 2.0

AC'97 2.1

LPC I/F

III

Processor

Intel® 820E Chipset

Intel® 82820

Controller Hub

(MCH)

Hub

Interface

I/O Controller Hub

Intel® 82801BA

(ICH2)

FWH Flash

BIOS

Main

Memory

(Direct RDRAM*)

PCI Bus

Power Management

Clock Generators

System Management (T CO)

2

SMBus/I

C

GPIO

PCI

Slots

sys_blk_820E

Figure 2. Intel® 820E Chipset Platform Performance Desktop Block Diagram (with ISA Bridge)

®

Intel ® Pentium

Other ASICs

(optional)

4x AGP

Graphics

Controller

4 IDE Drives

UltraATA/100/ 66/33

4 USB Ports; 2 HC

AC'97 Codec(s)

(optional)

LAN Connect

Super I/O

AGP 2.0

AC'97 2.1

LPC I/F

Proc essor

Intel ® 820E Chips et

Intel

82820 Memory

Controller Hub

(MCH)

Hub

Interface

I/O Controller Hub

Intel® 82801BA

(ICH2)

FWH F lash

BIOS

III

Main

Memory

(Direct RDRAM*)

PCI Bus

ISA Bridge

(optional)

Power Management

Clock Generators

System Management (TCO)

SMBus/I 2 C

GPIO

PCI

Slots

ISA

Slots

sys_blk_isa_820E

18 Design Guide

Page 19

Intel® 820E Chipset

R

®

Figure 3. Intel

820E Chipset Platform Dual-Processor Performance Desktop Block Diagram

Other ASICs

(optional)

4x AGP

Graphics

Controller

4 IDE Drives

UltraATA/100/66/33

4 USB Ports; 2 HC

AC'97 Codec(s)

(optional)

LAN Connect

Super I/O

Intel ® Pentium

Processor

AGP 2.0

AC'97 2.1

LPC I/F

®

III

Intel®

22 Mmr

Controller Hub

(MCH)

I/O Controller Hub

Intel® 82801BA

(ICH2)

FWH Flash

BIOS

®

Pentium

Processor

®

Intel

Intel ® 820E Chipset

Hub

Interface

III

Main

Memory

(Direct RDRAM*)

PCI Bus

Power Management

Clock Generators

System Management (T CO)

SMBus/I 2 C

GPIO

PCI

Slots

sys_blk_2P_820E

Design Guide 19

Page 20

Intel® 820E Chipset

R

1.4. Platform Initiatives

1.4.1. Direct Rambus RAM (RDRAM*)

The Direct Rambus RAM (RDRAM) initiative provides the memory bandwidth necessary to obtain

optimal performance from the Pentium III processor as well as a high-performance AGP graphics

controller. The MCH RDRAM interface supports 266 MHz, 300 MHz, 356 MHz, and 400 MHz

operation. The latter delivers 1.6 GB/s of theoretical memory bandwidth, which is twice the memory

bandwidth of 100 MHz SDRAM systems. Coupled with the greater bandwidth, the heavily pipelined

RDRAM protocol provides substantially more efficient data transfer. The RDRAM memory interface can

utilize more than 95% of the 1.6-GB/s theoretical maximum bandwidth.

In addition to the RDRAM’s performance features, the new memory architecture provides enhanced

power management capabilities. The powerdown mode of operation allows Intel 820E chipset-based

systems to provide cost-effective support of Suspend to RAM.

1.4.2. Streaming SIMD Extensions

The Pentium III processor provides 70 new streaming SIMD (single-instruction, multiple-data)

extensions. The Pentium III processor’s new extensions are floating-point SIMD extensions. Intel

MMX™ technology provides integer SIMD extensions. The Pentium III processor’s new extensions

complement the Intel MMX technology SIMD extensions and provide a performance boost to floatingpoint-intensive 3D applications.

1.4.3. AGP 2.0.

In combination with Direct RDRAM memory technology, the AGP 2.0 interface allows graphics

controllers to access main memory at over 1 GB/s, which is twice the AGP bandwidth of previous AGP

platforms. AGP 2.0 provides the infrastructure necessary for photorealistic 3D. In conjunction with

Direct RDRAM and the Pentium III processor’s new streaming SIMD extensions, AGP 2.0 delivers the

next level of 3D graphics performance.

1.4.4. Hub Interface

As the I/O speed has increased, the demand placed on the PCI bus by the I/O bridge has become

significant. With the addition of AC’97 and ATA/100, coupled with the existing USB, I/O requirements

will begin to affect PCI bus performance. The Intel 820E chipset’s hub interface architecture ensures that

the I/O subsystemboth PCI and the integrated I/O features (IDE, AC’97, USB, etc.)will receive

adequate bandwidth. By placing the I/O bridge on the hub interface instead of the PCI, the hub

architecture ensures that both the I/O functions integrated into the ICH2 and the PCI peripherals will

obtain the bandwidth necessary for peak performance. In addition, the hub interface’s lower pin count

allows a smaller package for the MCH and ICH2.

®

20 Design Guide

Page 21

Intel® 820E Chipset

R

1.4.5. Integrated LAN Controller

The ICH2 component incorporates an integrated LAN Controller. Its bus master capabilities enable the

component to process high-level commands and perform multiple operations, which lowers processor

utilization by off-loading communication tasks from the processor.

The ICH2 functions with several options of LAN connect components, allowing the targeting of the

desired market segment. The Intel

The Intel

®

82562ET component provides a basic Ethernet* 10/100 connection. The Intel® 82562EM

®

82562EH component provides a HomePNA 1-Mbit/sec connection.

component provides an Ethernet 10/100 connection with the added flexibility of Alert on LAN. More

advanced LAN solutions can be implemented with the Intel

1.4.6. Ultra ATA/100 Support

The ICH2 (82801BA) component supports the IDE controller with two sets of interface signals (primary

and secondary) that can be enabled independently, tri-stated or driven low. The component supports

UltraATA/100, Ultra ATA/66, UltraATA/33, and multiword p modes for transfers of up to

100 Mbytes/sec.

1.4.7. Expanded USB Support

The ICH2 component contains two USB host controllers. Each host controller includes a root hub with

two separate USB ports each, for a total of four USB ports. The addition of a USB host controller

expands the functionality of the platform.

1.4.8. Manageability

The Intel 820E chipset platform integrates several functions designed to manage the system and lower

the system’s total cost of ownership (TCO). These system management functions are designed to report

errors, diagnose the system, and recover from system lock-ups, without the aid of an external

microcontroller.

®

82550 or other PCI-based product offerings.

TCO Timer

The ICH2 integrates a programmable TCO timer, which is used to detect system locks. The first

expiration of the timer generates an SMI#, which the system can use to recover from a software lock. The

second expiration of the timer causes a system reset, to recover from a hardware lock.

Processor Present Indicator

The ICH2 looks for the processor to fetch the first instruction after reset. If the processor does not fetch

the first instruction, the ICH2 will reboot the system at the safe-mode frequency multiplier.

ECC Error Reporting

After detecting an ECC error, the MCH can send one of several messages to the ICH2. The MCH can

instruct the ICH2 to generate either an SMI#, NMI#, SERR# or TCO interrupt.

Design Guide 21

Page 22

Intel® 820E Chipset

R

Function Disable

The ICH2 provides the ability to disable the following functions: AC’97 Modem, AC’97 Audio, IDE,

USB or SMBus. Once disabled, these functions no longer decode I/O, memory or PCI configuration

space. Also, no interrupts or power management events are generated by the disabled functions.

Intruder Detect

The ICH2 provides an input signal (INTRUDER#) that can be attached to a switch that is activated when

the system case is opened. The ICH2 can be programmed to generate an SMI# or TCO interrupt resulting

from an active INTRUDER# signal.

SMBus

The ICH2 integrates an SMBus controller. The SMBus provides an interface to manage peripherals such

as serial presence detection (SPD) on RIMMs and thermal sensors. The slave interface allows an external

microcontroller to access system resources.

The Intel 820E chipset platform integrates several functions designed to expand the capability of

interfacing several components to the system.

Interrupt Controller

The interrupt capabilities of the Intel 820E chipset platform expands support for up to eight PCI interrupt

pins and PCI 2.2 message-based interrupts. In addition, the ICH2 supports system bus interrupt delivery.

FWH Flash BIOS

The Intel 820E chipset-based system platform supports firmware hub BIOS memory sizes up to 8 MB,

for increased system flexibility.

Alert on LAN*

The ICH2 supports Alert on LAN. In response to a TCO event (intruder detect, thermal event, processor

not booting), the ICH2 sends a message over ALERTCLK and ALERTDATA to alert the network

manager.

22 Design Guide

Page 23

Intel® 820E Chipset

R

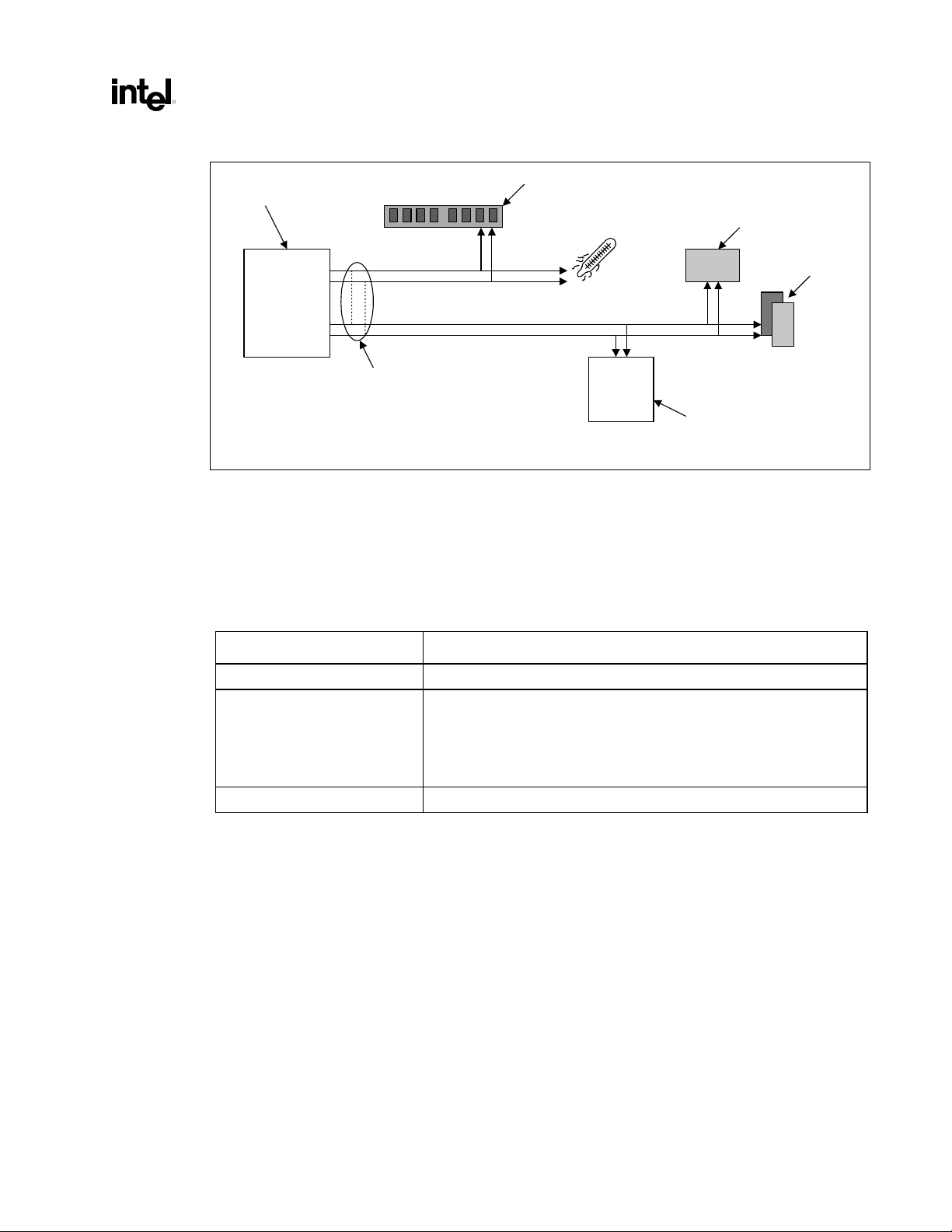

1.4.9. AC’97

The Audio Codec ’97 (AC’97) specification defines a digital interface that can be used to attach an audio

codec (AC), a modem codec (MC), an audio/modem codec (AMC) or both an AC and an MC. The

AC’97 specification defines the interface between the system logic and the audio or modem codec,

known as the AC’97 Digital Link.

The Intel 820E chipset platform’s AC’97 (with the appropriate codecs) not only replaces ISA audio and

modem functionality, but also improves overall platform integration by incorporating the AC’97 digital

link. The use of the ICH2-integrated AC’97 digital link reduces cost and eases migration from ISA.

By using an audio codec, the AC’97 digital link allows for cost-effective, high-quality, integrated audio

on an Intel 820E chipset-based platform. In addition, an AC’97 soft modem can be implemented with the

use of a modem codec. Several system options exist when implementing AC’97. The ICH2-integrated

digital link allows several external codecs to be connected to the ICH2. The system designer can provide

audio with an audio codec, a modem with a modem codec, or an integrated audio/modem codec (Figure

4C). The digital link is expanded to support two audio codecs or a combination of an audio and modem

codec (Figures 4A and 4B).

The modem implementations for different countries must be taken into consideration, because telephone

systems may vary. By using a split design, the audio codec can be on-board and the modem codec can be

placed on a riser. Intel is developing an AC’97 digital link connector. With a single integrated codec, or

AMC, both audio and modem can be routed to a connector near the rear panel, where the external ports

can be located.

The digital link in the ICH2 is compliant with Revision 2.1 of the AC’97 specification, so it supports two

codecs with independent PCI functions for audio and modem. Microphone input and left and right audio

channels are supported for a high quality, two-speaker audio solution. Wake on Ring from Suspend also

is supported with the appropriate modem codec.

The ICH2 expands the audio capability with support for up to six channels of PCM audio output (full

AC3 decode). Six-channel audio consists of Front Left, Front Right, Back Left, Back Right, Center, and

Woofer, for a complete surround-sound effect. ICH2 has expanded support for two audio codecs on the

AC’97 digital link.

Design Guide 23

Page 24

Intel® 820E Chipset

R

Figure 4. (A-C) AC’97 Connections

4A. AC'97 with Audio Codecs (4-Channel Secondary)

AC’97

Audio

Codec

Audio Port

AC’97

Audio

Codec

Audio Port

ICH2 360

EBGA

AC’97 Digital

Link

4B. AC'97 with Modem and Audio Codecs

AC’97 Digital

ICH2 360

EBGA

4C. AC'97 with Audio/Modem Codec

ICH2 360

EBGA

Link

AC’97 Digital

Link

Modem Port

AC’97

Modem

Codec

AC’97

Audio/

Codec

Audio Port

Modem Port

AC’97

Audio/

Modem

Codec

Audio Port

AC97_conn

24 Design Guide

Page 25

Intel® 820E Chipset

R

1.4.10. Low-Pin-Count (LPC) Interface

In the Intel 820E chipset platform, the super I/O component has migrated to the Low-Pin-Count (LPC)

interface. Migration to the LPC interface enables lower-cost super I/O designs. The LPC super I/O

component requires the same feature set as traditional super I/O components. It should include a

keyboard and mouse controller, floppy disk controller, and serial and parallel ports. In addition to the

super I/O features, an integrated game port is recommended because the AC’97 interface does not

provide support for a game port. In systems with ISA audio, the game port typically existed on the audio

card. The fifteen-pin game port connector provides for two joysticks and a two-wire MPU-401 MIDI

interface. Consult your super I/O vendor for a comprehensive list of devices offered and features

supported.

In addition, depending on system requirements, a device bay controller and USB hub could be integrated

into the LPC super I/O component. For systems requiring ISA support, an ISA-IRQ to serial-IRQ

converter is required. This converter could be integrated into the super I/O.

Design Guide 25

Page 26

Intel® 820E Chipset

R

This page is intentionally left blank.

26 Design Guide

Page 27

Intel® 820E Chipset

R

2. Layout/Routing Guidelines

This chapter documents the motherboard layout and routing guidelines for Intel 820E chipset-based

systems. This chapter does not discuss the functional aspects of any bus or the layout guidelines for an

add-in device.

Caution: If the guidelines in this document are not followed, it is very important to complete thorough signal

integrity and timing simulations for each design. Even if the guidelines are followed, critical signals still

should be simulated to ensure proper signal integrity and flight time. As bus speeds increase, it is

imperative that the guidelines documented be followed precisely. Any deviation from these guidelines

must be simulated!

2.1. General Recommendations

The trace impedance typically noted (i.e., 60 Ω ± 10%) is the “nominal” trace impedance. That is, it is

the impedance of a trace when not subjected to the fields created by changing the current in neighboring

traces. When calculating flight times, it is important to consider the minimum and maximum impedance

of a trace based on the switching of neighboring traces. This trace-to-trace coupling can be minimized by

using wider spaces between the traces. In addition, these wider spaces reduce crosstalk and settling time.

Coupling between two traces is a function of the coupled length, the distance separating the traces, the

signal edge rate, and the degree of mutual capacitance and inductance. To minimize the effects of traceto-trace coupling, the routing guidelines documented in this chapter should be followed. In addition, the