Page 1

Intel® Celeron® Processor 200Δ

Sequence

Thermal and Mechanical Design Guidelines

— Supporting the Intel® Celeron® processor 220 Δ

October 2007

318548-001

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR

IMPLIED, BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT

AS PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY

WHATSOEVER, AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL

PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY,

OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS OTHERWISE AGREED IN WRITING BY INTEL, THE INTEL PRODUCTS ARE NOT DESIGNED NOR INTENDED FOR ANY

APPLICATION IN WHICH THE FAILURE OF THE INTEL PRODUCT COULD CREATE A SITUATION WHERE PERSONAL INJURY OR

DEATH MAY OCCUR.

Intel may make changes to specifications and product descriptions at any time, without notice. Designers must not rely on the

absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for future

definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them. The

information here is subject to change without notice. Do not finalize a design with this information.

The Intel Celeron processor 200 sequence may contain design defects or errors known as errata which may cause the product to

deviate from published specifications. Current characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

This document contains information on products in the design phase of development.

All products, platforms, dates, and figures specified are preliminary based on current expectations, and are subject to change

without notice. All dates specified are target dates, are provided for planning purposes only and are subject to change.

This document contains information on products in the design phase of development. Do not finalize a design with this

information. Revised information will be published when the product is available. Verify with your local sales office that you have

the latest datasheet before finalizing a design.

Intel processor numbers are not a measure of performance. Processor numbers differentiate features within each processor

family, not across different processor families. See www.intel.com/products/processor_number for details.

Shelton Conroe, Woodcrest and other code names featured are used internally within Intel to identify products that are in

development and not yet publicly announced for release. Customers, licensees and other third parties are not authorized by

Intel to use code names in advertising, promotion or marketing of any product or services and any such use of Intel's internal

code names is at the sole risk of the user.

Intel, Celeron and the Intel logo are trademarks of Intel Corporation in the U.S. and other countries.

*Other names and brands may be claimed as the property of others.

Copyright © 2007, Intel Corporation. All rights reserved.

2 Thermal and Mechanical Design Guidelines

Page 3

Contents

1 Introduction .....................................................................................................7

1.1 Document Goals and Scope .....................................................................7

1.1.1 Importance of Thermal Management............................................7

1.1.2 Document Goals........................................................................7

1.1.3 Document Scope .......................................................................8

1.2 Reference Documents .............................................................................9

1.3 Definition of Terms .................................................................................9

2 Processor Thermal/Mechanical Information .........................................................11

2.1 Mechanical Requirements ......................................................................11

2.1.1 Processor Package................................................................... 11

2.1.2 Heatsink Attach ......................................................................16

2.2 Thermal Requirements .......................................................................... 18

2.2.1 Processor Junction Temperature ................................................19

2.3 Heatsink Design Considerations.............................................................. 19

2.3.1 Heatsink Size..........................................................................20

2.3.2 Heatsink Mass ........................................................................21

2.3.3 Thermal Interface Material........................................................21

2.4 System Thermal Solution Considerations ................................................. 22

2.4.1 Chassis Thermal Design Capabilities...........................................22

2.4.2 Improving Chassis Thermal Performance .................................... 22

2.4.3 Summary...............................................................................25

3 Thermal Metrology ..........................................................................................27

3.1 Characterizing Cooling Performance Requirements ....................................27

3.1.1 Example ................................................................................29

3.2 Local Ambient Temperature Measurement Guidelines.................................30

3.3 Processor Power Measurement Metrology Recommendation ........................ 32

3.3.1 Sample Preparation .................................................................33

4 System Thermal/Mechanical Design Information..................................................37

4.1 Overview of the Reference Design...........................................................37

4.1.1 Altitude..................................................................................37

4.1.2 Heatsink Thermal Validation .....................................................37

4.2 Environmental Reliability Testing ............................................................ 38

4.2.1 Structural Reliability Testing ..................................................... 38

4.2.2 Power Cycling ......................................................................... 40

4.2.3 Recommended BIOS/CPU/Memory Test Procedures ...................... 40

4.3 Material and Recycling Requirements ...................................................... 40

4.4 Safety Requirements ............................................................................41

4.5 Reference Attach Mechanism..................................................................41

4.5.1 Structural Design Strategy .......................................................41

4.5.2 Mechanical Interface to the Reference Attach Mechanism ..............41

Thermal and Mechanical Design Guidelines 3

Page 4

Appendix A Heatsink Clip Load Metrology............................................................................ 43

A.1 Overview ............................................................................................43

A.2 Test Preparation...................................................................................43

A.2.1 Heatsink Preparation ...............................................................43

A.2.2 Typical Test Equipment ............................................................43

A.3 Test Procedure Examples.......................................................................45

Appendix B Intel® Enabled Boxed Processor Thermal Solution Information............................... 47

Appendix C Mechanical Drawings .......................................................................................49

Figures

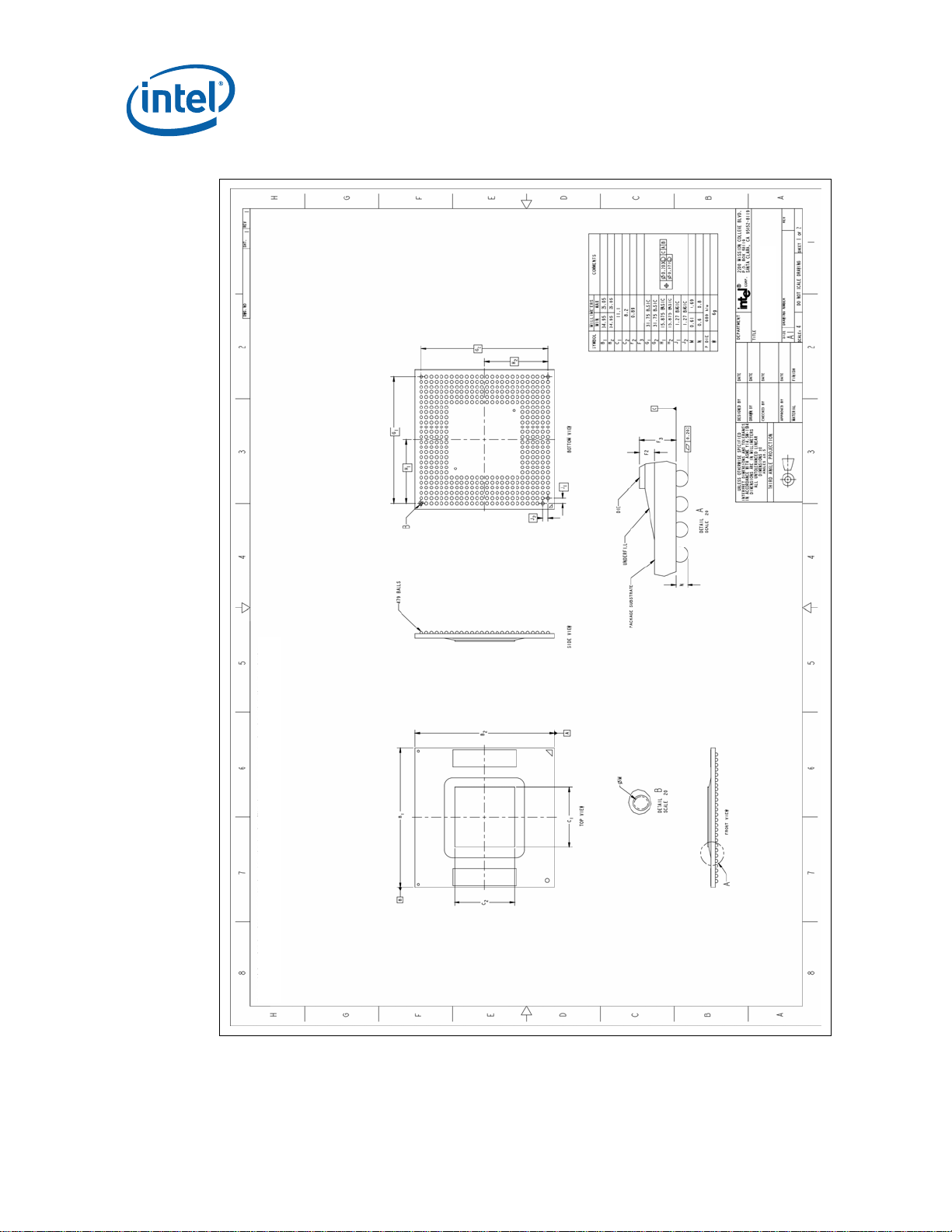

Figure 1. Micro-FCBGA Processor Package Drawing – Isometric View .....................13

Figure 2. Micro-FCBGA Processor Package Drawing (Sheet 1 of 2)......................... 14

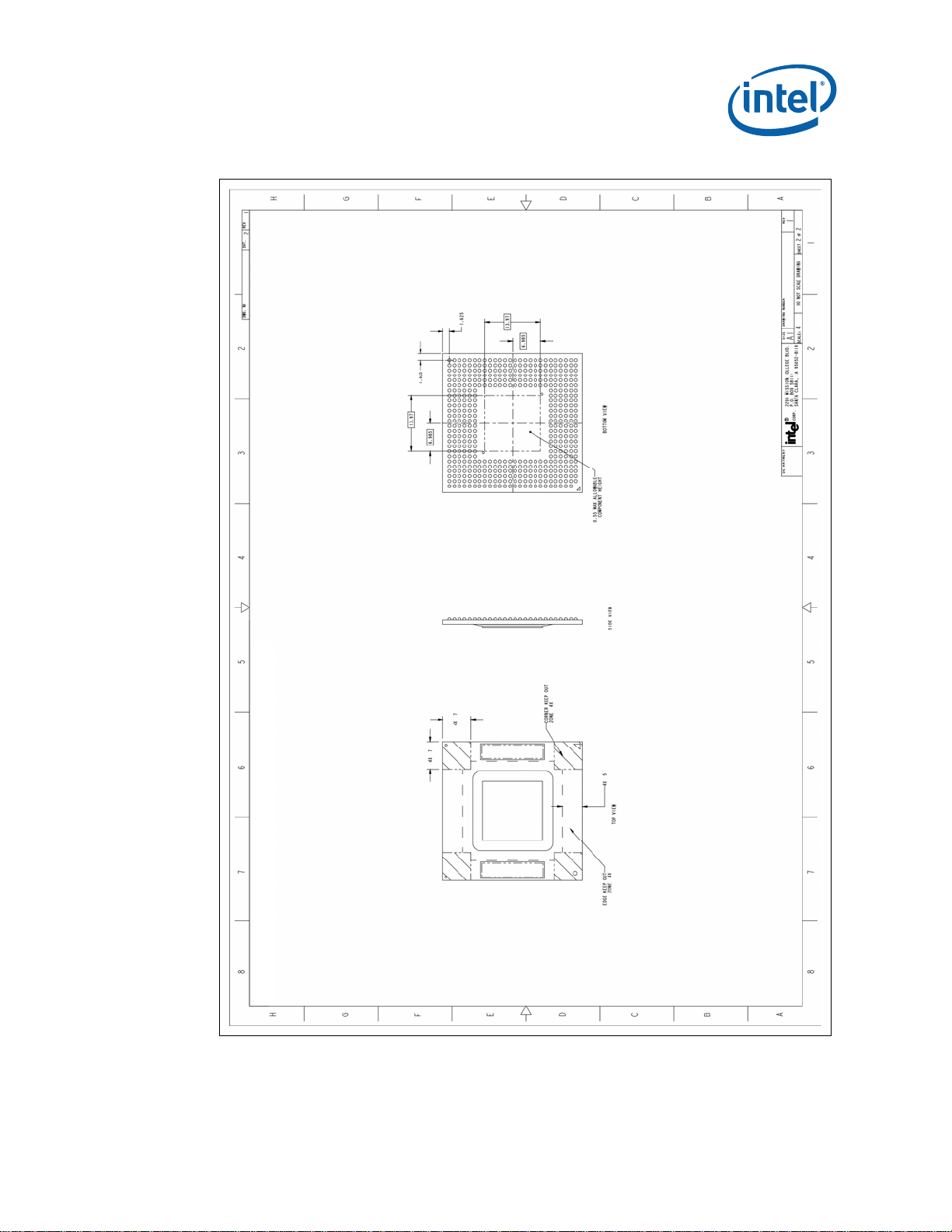

Figure 3. Micro-FCBGA Processor Package Drawing (Sheet 2 of 2)......................... 15

Figure 4. Vertical Lock-Down Alignment Feature................................................. 18

Figure 5. Various Types of Solder Crack ...........................................................18

Figure 6. Case Study #1: Top view — Poor μATX Chassis Layout Design for

Intel® Celeron® Processor 200 Sequence on Intel® Desktop Board

D201GLY2 (chassis cover removed for illustration)................................

Figure 7. Case Study #2: Relocate System Fan to CAG Venting for Airflow

Improvement ..................................................................................

Figure 8. Case Study#3: An μATX Chassis Equipped with Two Exhaust Fans ...........24

Figure 9. Case Study #4: A “Top Mount Fan” PSU is located next to Processor

in μATX Chassis for System Thermal Performance Improvement .............

Figure 10. Processor Thermal Characterization Parameter Relationships................. 29

Figure 11. Locations for Measuring Local Ambient Temperature, Active Heatsink .....31

Figure 12. Locations for Measuring Local Ambient Temperature, Passive Heatsink ... 32

Figure 13. Precision Resistor Connected in-series with Processor Circuitry for

Power Measurement .........................................................................

Figure 14. Installation of Isotek Resistor on Intel® Desktop Board D201GLY2 to

Setup Connection for Power Measurement ..........................................

Figure 15. Probing Resistance of the Soldered Walsin Resistor (R =19.6 KΩ)

on Intel

®

Desktop Board D201GLY2 to Ensure Proper Attachment ..........35

Figure 16. Precision Resistor Soldered on on Intel® Desktop Board D201GLY2,

and Connected to netDAQ for Voltage Measurement .............................

Figure 17. Random Vibration PSD..................................................................... 38

Figure 18. Shock Acceleration Curve................................................................. 39

Figure 19. Top Plate and Package Simulator Fasten onto Clip Force Measurement

Machine.........................................................................................

Figure 20. Anchors Installed and Glued Down the BTX Base Plate – for reference only46

Figure 21. Motherboard Keep-out Footprint Definition and Height Restrictions for

Enabling Components ......................................................................

Figure 22. Reference Clip E21952-001 ..............................................................51

Figure 23. Reference Heatsink D96271-001 ....................................................... 52

Figure 24. Intel

®

Boxed Processor Thermal Solution E21953-001 ..........................53

23

24

25

34

34

35

45

50

4 Thermal and Mechanical Design Guidelines

Page 5

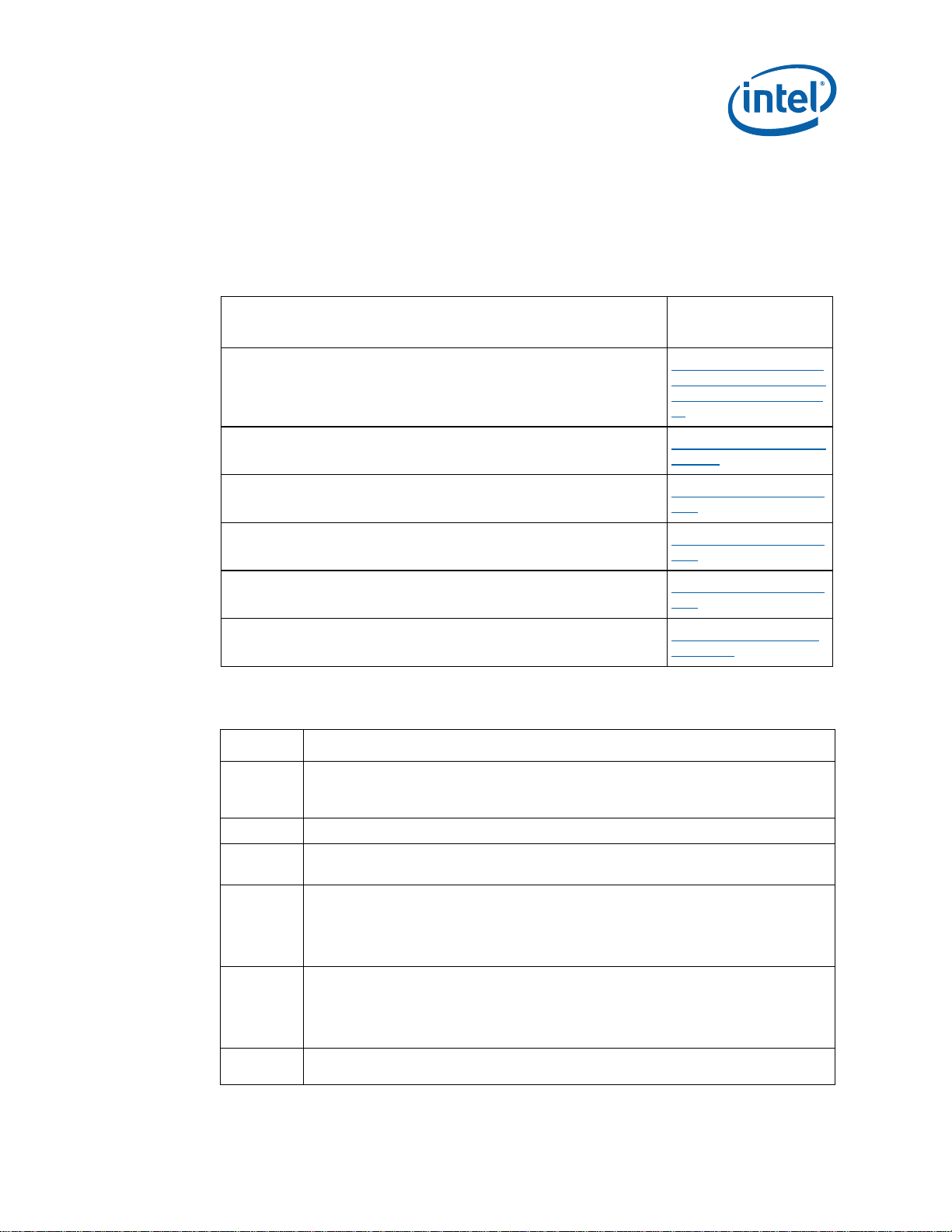

Tables

Table 1. Micro-FCBGA Package Mechanical Specifications..................................... 12

Table 2. Thermal Specifications for Intel® Celeron

®

Processor 200 Sequence .......... 19

Table 3. System Thermal Solution Design Requirement .......................................22

Table 4. Test Accessories ................................................................................33

Table 5. Typical Test Equipment....................................................................... 44

Table 6. Intel

®

Boxed Processor Thermal Solution Providers................................. 47

Thermal and Mechanical Design Guidelines 5

Page 6

Revision History

Revision

Number

-001 • Initial Release October 2007

Description Revision Date

§

6 Thermal and Mechanical Design Guidelines

Page 7

Introduction

1 Introduction

1.1 Document Goals and Scope

1.1.1 Importance of Thermal Management

The objective of thermal management is to ensure that the temperatures of all

components in a system are maintained within their functional temperature range.

Within this temperature range, a component is expected to meet its specified

performance. Operation outside the functional temperature range can degrade

system performance, cause logic errors or cause component and/or system damage.

Temperatures exceeding the maximum operating limit of a component may result in

irreversible changes in the operating characteristics of this component.

In a system environment, the processor temperature is a function of both system and

component thermal characteristics. The system level thermal constraints consist of

the local ambient air temperature and airflow over the processor as well as the

physical constraints at and above the processor. The processor temperature depends

in particular on the component power dissipation, the processor package thermal

characteristics, and the processor thermal solution.

All of these parameters are affected by the continued push of technology to increase

processor performance levels and packaging density (more transistors). As operating

frequencies increase and packaging size decreases, the power density increases while

the thermal solution space and airflow typically become more constrained or remains

the same within the system. The result is an increased importance on system design

to ensure that thermal design requirements are met for each component, including

the processor, in the system.

1.1.2 Document Goals

Depending on the type of system and the chassis characteristics, new system and

component designs may be required to provide adequate cooling for the processor.

The goal of this document is to provide an understanding of these thermal

characteristics and discuss guidelines for meeting the thermal requirements imposed

on single processor systems using the Intel

The concepts given in this document are applicable to any system form factor.

Specific examples used will be the Intel enabled reference solution for a system.

®

Celeron® processor 200 sequence.

Thermal and Mechanical Design Guidelines 7

Page 8

1.1.3 Document Scope

This design guide supports the following processors:

®

• Intel

In this document the Intel Celeron Processor 200 sequence will be referred to as “the

processor”.

In this document when a reference is made to “the processor” it is intended that this

includes all the processors supported by this document. If needed for clarity, the

specific processor will be listed.

Celeron® Processor 200 sequence applies to the Intel® Celeron® processor

220.

Introduction

In this document, when a reference is made to “datasheet”, the reader should refer to

the Intel

®

Celeron® Processor 200 Sequence Datasheet. If needed for clarity, the

specific processor datasheet will be referenced.

In this document, when a reference is made to the “the reference design” it is

intended that this includes all reference designs (D16869-001 and D96271-001)

supported by this document. If needed for clarify, the specific reference design will be

listed.

Chapter

2 of this document discusses package thermal mechanical requirements to

design a thermal solution for the Intel Celeron processor 200 sequence in the context

of personal computer applications. Chapter

3 discusses the thermal solution

considerations and metrology recommendations to validate a processor thermal

solution. Chapter

4 gives information on the Intel reference thermal solution for the

processor in a system application.

The physical dimensions and thermal specifications of the processor that are used in

this document are for illustration only. Refer to the Datasheet for the product

dimensions, thermal power dissipation, and maximum junction temperature. In case

of conflict, the data in the datasheet supersedes any data in this document.

8 Thermal and Mechanical Design Guidelines

Page 9

Introduction

1.2 Reference Documents

Material and concepts available in the following documents may be beneficial when

reading this document.

Document Document

Intel® Celeron® Processor 200 Sequence Datasheet http://developer.intel

Power Supply Design Guide for Desktop Platform Form Factors (Rev

1.1)

ATX Thermal Design Suggestions http://www.formfactors.

microATX Thermal Design Suggestions http://www.formfactors.

Balanced Technology Extended (BTX) System Design Guide http://www.formfactors.

Thermally Advantaged Chassis version 1.1 http://www.intel.com/g

1.3 Definition of Terms

Term Description

No./Location

.com/design/processo

r/datashts/318546.ht

m

http://www.formfacto

rs.org/

org/

org/

org/

o/chassis/

The measured ambient temperature locally surrounding the processor. The

TA

TJ Processor junction temperature.

T

S-TOP

ΨJA

ΨJS

ΨSA

Thermal and Mechanical Design Guidelines 9

ambient temperature should be measured just upstream of a passive heatsink or

at the fan inlet for an active heatsink.

Heatsink temperature measured at vicinity to center on the top surface of

heatsink base.

Junction-to-ambient thermal characterization parameter (psi). A measure of

thermal solution performance using total package power. Defined as

– TA) / Total Package Power.

(T

J

Note: Heat source must be specified for Ψ measurements.

Junction-to-sink thermal characterization parameter. A measure of thermal

interface material performance using total package power. Defined as

– TS) / Total Package Power.

(T

J

Note: Heat source must be specified for Ψ measurements.

Sink-to-ambient thermal characterization parameter. A measure of heatsink

thermal performance using total package power. Defined as

Page 10

Introduction

Term Description

(TS – TA) / Total Package Power.

Note: Heat source must be specified for Ψ measurements.

Thermal Interface Material: The thermally conductive compound between the

TIM

heatsink and the processor die surface. This material fills the air gaps and voids,

and enhances the transfer of the heat from the processor die surface to the

heatsink.

PD

Processor total power dissipation (assuming all power dissipates through the

processor die).

Thermal Design Power: a power dissipation target based on worst-case

TDP

applications. Thermal solutions should be designed to dissipate the thermal

design power.

P

USAGE

Maximum usage power of processor when running SysMark utility.

§

10 Thermal and Mechanical Design Guidelines

Page 11

Processor Thermal/Mechanical Information

2 Processor Thermal/Mechanical

Information

2.1 Mechanical Requirements

2.1.1 Processor Package

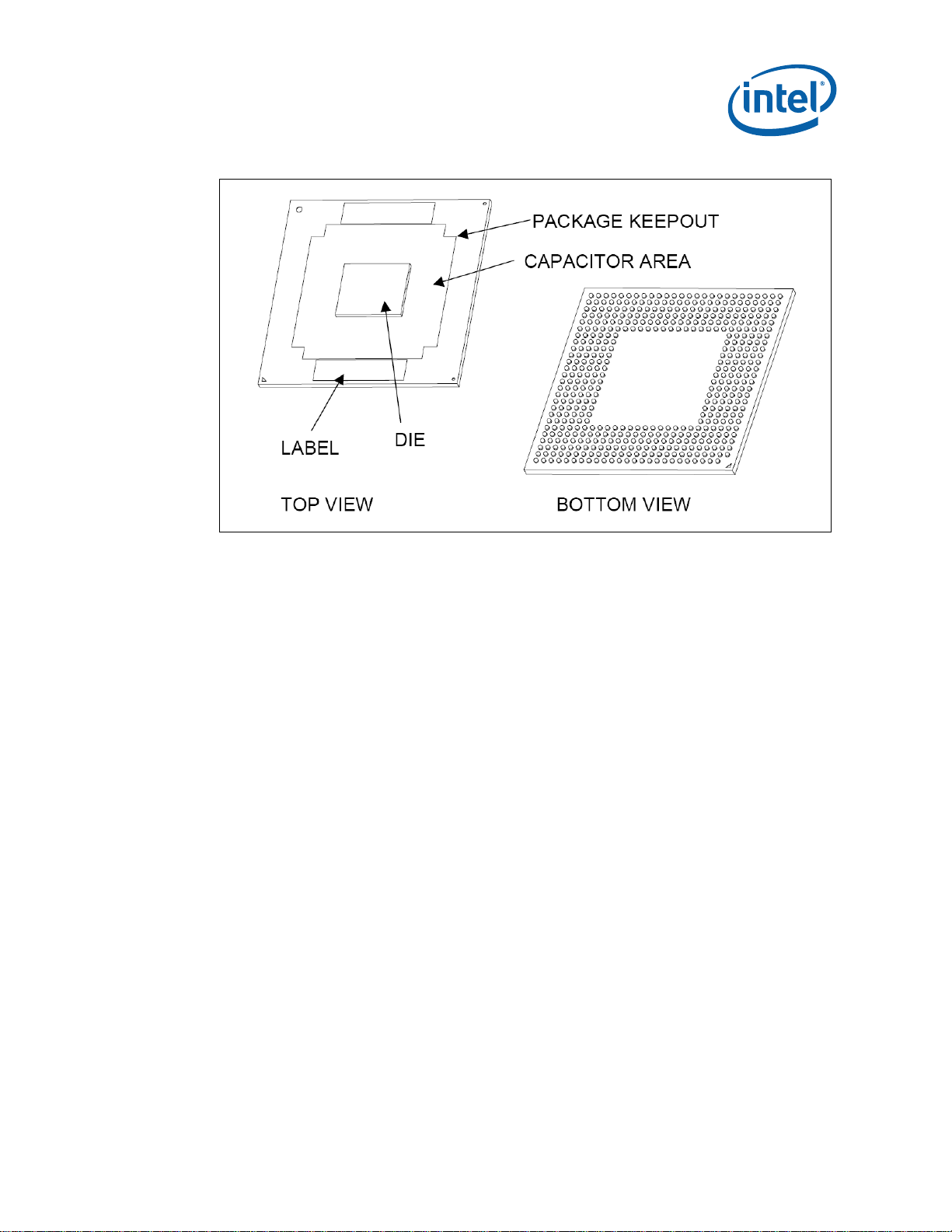

The Intel Celeron processor 200 sequence is available in a 479-pin Micro-FCBGA

package, as shown in

Array (FC-BGA6) package technology that directly solder down to a 479-pin footprint

on PCB surface.

Figure 1 to Figure 3. The processor uses a Flip-Chip Ball Grid

Mechanical specifications of the package are listed in

for detailed mechanical specifications. In case of conflict, the package dimensions in

the datasheet supersedes dimensions provided in this document.

The processor package has mechanical load limits that are specified in the processor

datasheet. The specified maximum static and dynamic load limits should not be

exceeded during their respective stress conditions. These include heatsink

installation, removal, mechanical stress testing, and standard shipping conditions.

• When a compressive static load is necessary to ensure thermal performance of the

thermal interface material between the heatsink base and the processor die, it

should not exceed the corresponding specification given in the processor

datasheet.

• When a compressive static load is necessary to ensure mechanical performance, it

should remain in the minimum/maximum range specified in the processor

datasheet.

No portion of the substrate should be used as a mechanical reference or load-bearing

surface for the thermal or mechanical solution.

The processor datasheet provides package handling guidelines in terms of maximum

recommended shear, tensile and torque loads for the processor substrate. These

recommendations should be followed in particular for heatsink removal operations.

Table 1. Refer to the datasheet

Thermal and Mechanical Design Guidelines 11

Page 12

Processor Thermal/Mechanical Information

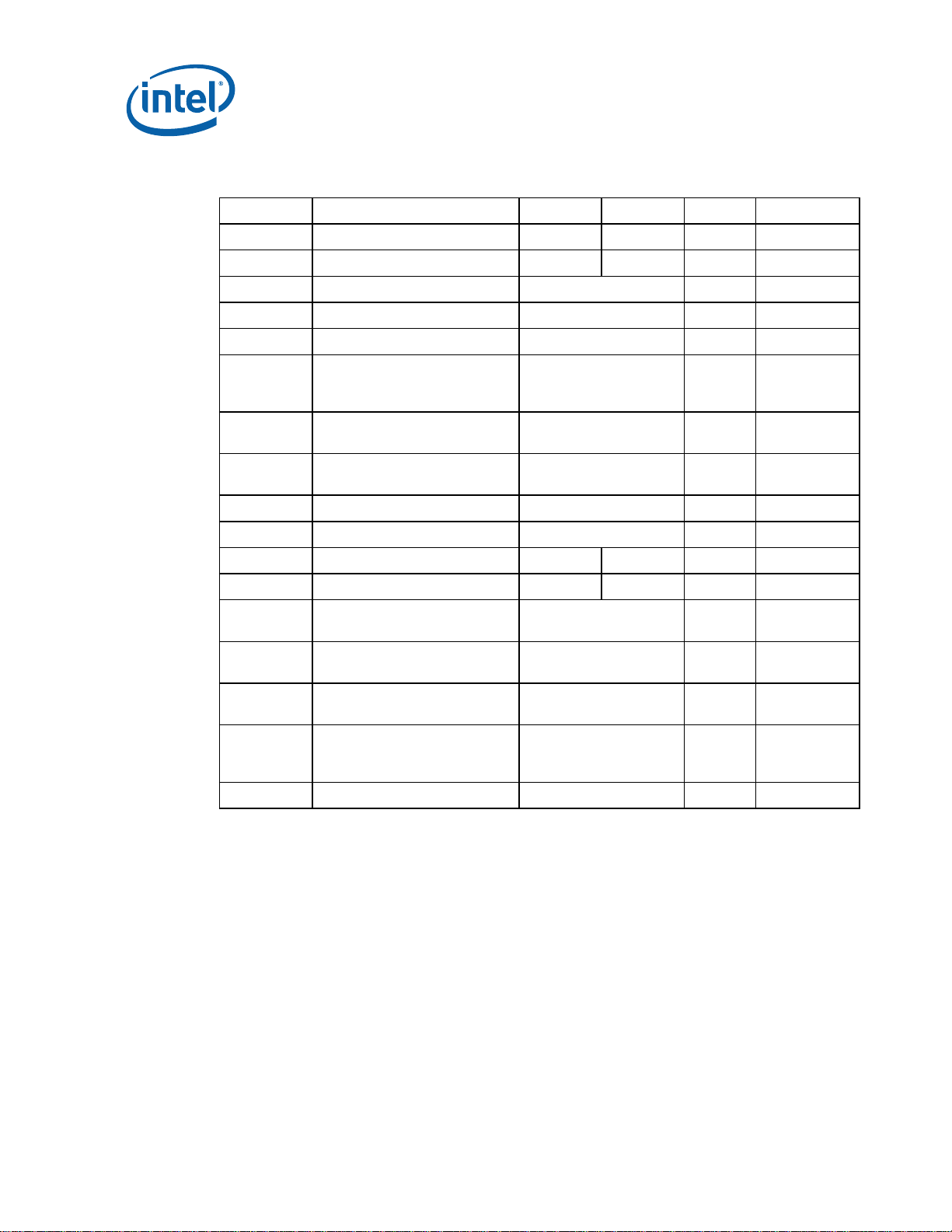

Table 1. Micro-FCBGA Package Mechanical Specifications

Symbol Parameter Min Max Unit Figure

B1 Package substrate width 34.95 35.05 mm Figure 2

B2 Package substrate length 34.95 35.05 mm Figure 2

C1 Die width 11.1 mm Figure 2

C2 Die length 8.2 mm Figure 2

F2 Die height (with underfill)

F3 Package overall height

(package substrate to

die)

G1 Width (first ball center to

last ball center)

G2 Length (first ball center

to last ball center)

J1 Ball pitch (horizontal) 1.27 Basic mm Figure 2

J2 Ball pitch (vertical) 1.27 Basic mm Figure 2

M Solder Resist Opening 0.61 0.69 mm Figure 2

N Ball height 0.6 0.8 mm Figure 2

-- Corner Keep-out zone at

corner (4X)

-- Keep-out from edge of

package (4X)

-- Package edge to first ball

center

P

Allowable pressure on

die

the die for thermal

solution

W Package weight 6 g

0.89 mm Figure 2

2.022 Max mm

31.75 Basic mm Figure 2

31.75 Basic mm Figure 2

7 × 7 mm Figure 3

5 mm Figure 3

1.625 mm Figure 3

689 kPa

Figure 2

NOTE:

1. All dimensions are subject to change.

2. Overall height as delivered. Values were based on design specifications and tolerances.

Final height after surface mount depends on OEM motherboard design and SMT

process.

12 Thermal and Mechanical Design Guidelines

Page 13

Processor Thermal/Mechanical Information

Figure 1. Micro-FCBGA Processor Package Drawing – Isometric View

Thermal and Mechanical Design Guidelines 13

Page 14

Processor Thermal/Mechanical Information

Figure 2. Micro-FCBGA Processor Package Drawing (Sheet 1 of 2)

NOTE: All dimensions in millimeters. Values shown are for reference only. See Table 1 for

14 Thermal and Mechanical Design Guidelines

specific details.

Page 15

Processor Thermal/Mechanical Information

Figure 3. Micro-FCBGA Processor Package Drawing (Sheet 2 of 2)

NOTE: All dimensions in millimeters. Values shown are for reference only. See Table 1 for

Thermal and Mechanical Design Guidelines 15

specific details.

Page 16

2.1.2 Heatsink Attach

2.1.2.1 General Guidelines

The micro-FCBGA package may have capacitors placed in the area surrounding the

processor die. The die-side capacitors, which are only slightly shorter than the die

height, are electrically conductive and contact with electrically conductive materials

should be avoided. The use of an insulating material between the capacitors and any

thermal and mechanical solution should be considered to prevent capacitors shorting.

A thermal and mechanical solution design must not intrude into the required keep-out

zones as specified in the datasheet.

There are no features on the 479-pins micro-FCBGA package for direct heatsink

attachment: a mechanism must be designed to attach the heatsink directly to the

motherboard. In addition to holding the heatsink in place on top of the processor die,

this mechanism plays a significant role in the robustness of the system in which it is

implemented, in particular:

• Ensuring thermal performance of the thermal interface material (TIM) applied

between the processor die and the heatsink. TIMs based on phase change

materials are very sensitive to applied pressure: the higher the pressure, the

better the initial performance. Designs should incorporate a possible decrease in

applied pressure over time due to potential structural relaxation in retention

components (creep effect causing clip to lose its preload and causing anchor pullout). It is not recommended to use TIMs such as thermal greases onto small bare

die package, due to the TIM “pump-out” concern after heatsink is assembled.

• Ensuring system electrical, thermal, and structural integrity under shock and

vibration events. The mechanical requirements of the heatsink attach mechanism

depend on the mass of the heatsink and the level of shock and vibration that the

system must support. The overall structural design of the motherboard and the

system should be considered in designing the heatsink attach mechanism. The

design should provide a means for protecting the solder joints.

Processor Thermal/Mechanical Information

2.1.2.2 Heatsink Clip Load Requirement

The attach mechanism for the heatsink developed to support the processor creates a

nominal static compressive preload on the package of 9.9 lbf ± 1.2 lbf throughout the

life of the product for designs compliant with the Intel reference design assumptions:

• Using TIM Honeywell PCM45F (pad version).

• 55.88 mm (2.2”) x 54.88 mm (2.16”) attach pattern. Refer to

heatsink keep-out zone.

• And no board stiffening device (backing plate, chassis attach, etc.).

The minimum load is required to thermal performance while protecting solder joint

against fatigue failure in temperature cycling.

Notes the load range above is required to ensure a minimum load of 8.7lbf at end-oflife. The tolerance and nominal load is based on reference design and will slightly

differ on alternate thermal solution provided by third party.

It is important to take into account potential load degradation from creep over time

when designing the clip or fastener to the required minimum load. This means that,

16 Thermal and Mechanical Design Guidelines

Figure 21 for

Page 17

Processor Thermal/Mechanical Information

depending on clip stiffness, the initial preload at beginning of life of the product may

be significantly higher than the minimum preload that must be met throughout the life

of the product.

Refer to

Appendix A for clip load metrology guidelines.

2.1.2.3 Heatsink Attach Mechanism Design Considerations

In addition to the general guidelines given above, the heatsink attach mechanism for

the processor should be designed to the following guidelines:

• Solder joint reliability compliant with INTEL quality specification before & after

reliability test such as shock & vibration. The Critical-To-Function (CTF) corner

solder joints of processor package for Intel

high stress concentration during shock and vibration test, therefore the “vertical

lock-down” alignment feature is integrated into z-clip design to prevent solder

joints failures. Please refer to the datasheet for CTF and NCTF locations.

• Vertical Lock-Down Alignment Feature. Generic z-clip solution should include this

feature to improve structural performance during shock and vibration test. The

vertical lock-down feature is basically an additional feature (bends etc.) that is

incorporated into the z-clip to better constraint the heatsink. The reference

thermal solution adds a vertical bend that contacts the heatsink after preload

application. This in turn provides a 4 contact constraint as opposed to the 2

contact constraint as shown in

Figure 4 (thru z-clip center indentation). Note that

the vertical lock feature sizing must be determined thru FOC (First Order

Calculation) or FEA (Finite Element Analysis) to ensure it touches the heatsink

base just enough to provide the required restraint without causing the center

indent feature losing contact. Refer to

• Figure 5 illustrates solder crack types.

• Heatsink should be held in place under mechanical shock and vibration events and

applies force to the heatsink base to maintain desired pressure on the thermal

interface material. Note that the load applied by the heatsink attach mechanism

must comply with the package specifications described in the processor datasheet.

One of the key design parameters is the height of the top surface of the processor

die above the motherboard, is expected in the range of 2.73 mm ± 0.125 mm.

This data is provided for information only, and should be derived from:

⎯ The height of the package, from the package seating plane to the top of the

die, and accounting for its nominal variation and tolerances that are given in

the corresponding processor datasheet.

• Engages easily, and if possible, without the use of special tools. In general, the

heatsink is assumed to be installed after the motherboard has been installed into

the chassis. Ergo force requirement states that assembly force shall not exceed

15lbf (target is 10lbf).

• Minimizes contact with the motherboard surface during installation and actuation

to avoid scratching/damaging the motherboard.

®

Desktop Board D201GLY2 experience

Figure 4 for further illustration.

Thermal and Mechanical Design Guidelines 17

Page 18

Figure 4. Vertical Lock-Down Alignment Feature

Figure 5. Various Types of Solder Crack

Processor Thermal/Mechanical Information

2.2 Thermal Requirements

The processor requires a thermal solution to maintain temperatures within operating

limits. Refer to the datasheet for the processor thermal specifications.

To allow for the optimal operation and long-term reliability of Intel processor-based

systems, the system/processor thermal solution should remain within the minimum

and maximum junction temperature specifications at corresponding thermal design

power (TDP) as listed in datasheet.

The thermal limits for the processor are the junction temperature (T

the maximum junction temperature as a function of power being dissipated.

Designing to this specification allows optimization of thermal designs for processor

performance.

18 Thermal and Mechanical Design Guidelines

). The TJ defines

J

Page 19

Processor Thermal/Mechanical Information

2.2.1 Processor Junction Temperature

Table 2. Thermal Specifications for Intel® Celeron® Processor 200 Sequence

Symbol

TDP 220 1.20 GHz 512 KB 19 1, 4, 5

Symbol Parameter Min Max Notes

TJ (°C) Junction Temperature 0 °C 100 °C 3, 4

NOTE:

1. The TDP is not the maximum theoretical power the processor can generate.

2. Not 100% tested. These power specifications are determined by characterization of the

3. As measured by the activation of the on-die Intel

4. The Intel Thermal Monitor automatic mode must be enabled for the processor to

5. At T

Processor

Number

processor currents at higher temperatures and extrapolating the values for the

temperature indicated.

Monitor’s automatic mode is used to indicate that the maximum T

Refer to datasheet for more details.

operate within specifications, please refer to datasheet for more details.

of 100 °C.

J

Core

Frequency

and

Voltage

Cache

Thermal Design

®

Thermal Monitor. The Intel Thermal

2.3 Heatsink Design Considerations

To remove the heat from the processor, three basic parameters should be considered:

• The area of the surface on which the heat transfer takes place. Without

any enhancements, this is the surface of the processor die. One method used to

improve thermal performance is by attaching a heatsink to the die. A heatsink

can increase the effective heat transfer surface area by conducting heat out of the

die and into the surrounding air through fins attached to the heatsink base.

• The conduction path from the heat source to the heatsink fins. Providing a

direct conduction path from the heat source to the heatsink fins and selecting

materials with higher thermal conductivity typically improves heatsink

performance. The length, thickness, and conductivity of the conduction path from

the heat source to the fins directly impact the thermal performance of the

heatsink. In particular, the quality of the contact between the package die and

the heatsink base has a higher impact on the overall thermal solution performance

as processor cooling requirements become stricter. Thermal interface material

(TIM) is used to fill in the gap between the die and the bottom surface of the

heatsink, and thereby improve the overall performance of the stack-up (die-TIMHeatsink). With extremely poor heatsink interface flatness or roughness, TIM may

not adequately fill the gap. The TIM thermal performance depends on its thermal

conductivity as well as the pressure applied to it. Refer to Section

further information.

• The heat transfer conditions on the surface on which heat transfer takes

place. Convective heat transfer occurs between the airflow and the surface

exposed to the flow. It is characterized by the local ambient temperature of the

Power

(W)

Notes

has been reached.

J

2.3.3 for

Thermal and Mechanical Design Guidelines 19

Page 20

air, TA, and the local air velocity over the surface. The higher the air velocity over

the surface, and the cooler the air, the more efficient is the resulting cooling. The

nature of the airflow can also enhance heat transfer via convection. Turbulent

flow can provide improvement over laminar flow. In the case of a heatsink, the

surface exposed to the flow includes in particular the fin faces and the heatsink

base.

Active heatsinks typically incorporate a fan that helps manage the airflow through

the heatsink.

Passive heatsink solutions require in-depth knowledge of the airflow in the chassis.

Typically, passive heatsinks see lower air speed. These heatsinks are therefore

typically larger (and heavier) than active heatsinks due to the increase in fin surface

required to meet a required performance. As the heatsink fin density (the number of

fins in a given cross-section) increases, the resistance to the airflow increases: it is

more likely that the air travels around the heatsink instead of through it, unless air

bypass is carefully managed. Using air-ducting techniques to manage bypass area

can be an effective method for controlling airflow through the heatsink.

2.3.1 Heatsink Size

Processor Thermal/Mechanical Information

The size of the heatsink is dictated by height restrictions for installation in a system

and by the real estate available on the motherboard and other considerations for

component height and placement in the area potentially impacted by the processor

heatsink. The height of the heatsink must comply with the requirements and

recommendations published for the motherboard form factor of interest. Designing a

heatsink to the recommendations may preclude using it in system adhering strictly to

the form factor requirements, while still in compliance with the form factor

documentation.

For the ATX/microATX form factor, it is recommended to use:

• The ATX motherboard keep-out footprint definition and height restrictions for

enabling components, defined for the platforms designed with the micro-FCBGA of

this design guide.

• The motherboard primary side height constraints defined in the ATX Specification

V2.2 and the microATX Motherboard Interface Specification V1.2 found at

http://www.formfactors.org/.

The resulting space available above the motherboard is generally not entirely available

for the heatsink. The target height of the heatsink must take into account airflow

considerations (for fan performance for example) as well as other design

considerations (air duct, etc.).

20 Thermal and Mechanical Design Guidelines

Page 21

Processor Thermal/Mechanical Information

2.3.2 Heatsink Mass

With the need to push air cooling to better performance, heatsink solutions tend to

grow larger (increase in fin surface) resulting in increased mass. The insertion of

highly thermally conductive materials like copper to increase heatsink thermal

conduction performance results in even heavier solutions. As mentioned in

Section

the heatsink attach mechanical capabilities, and the mechanical shock and vibration

profile targets. Beyond a certain heatsink mass, the cost of developing and

implementing a heatsink attach mechanism that can ensure the system integrity

under the mechanical shock and vibration profile targets may become prohibitive.

The recommended maximum heatsink mass for the Intel Celeron processor 200

sequence reference thermal solution is 62 g. This mass includes the fan and the

heatsink only. The attach mechanism (clip, fasteners, etc.) are not included.

Note: The 62 g mass limit for current solution is based on the capabilities of reference

design components that retain the heatsink to the board and apply the necessary

preload. Any reuse of the clip and fastener in alternate or derivative designs should

not exceed 62 g. Designs that have a mass of greater than 62 g should analyze the

preload and retention limits of the fastener.

2.1.2, the heatsink mass must take into consideration the package load limits,

Note: The chipset components on the board are affected by processor heatsink mass.

Exceeding these limits may require the evaluation of the chipset for shock and

vibration.

2.3.3 Thermal Interface Material

Thermal interface material application between the processor die and the heatsink

base is generally required to improve thermal conduction from the die to the heatsink.

Many thermal interface materials can be pre-applied to the heatsink base prior to

shipment from the heatsink supplier and allow direct heatsink attach, without the

need for a separate thermal interface material dispense or attach process in the final

assembly factory.

All thermal interface materials should be sized and positioned on the heatsink base in

a way that ensures the entire processor die area is covered. It is important to

compensate for heatsink-to-processor attach positional alignment when selecting the

proper thermal interface material size.

When pre-applied material is used, it is recommended to have a protective film

applied. This film must be removed prior to heatsink installation.

The recommended TIM for the Intel Celeron processor 200 sequence reference

thermal solution is Honeywell PCM45F (pad version). It is not recommended to use

TIMs such as thermal greases onto small bare die package as specified in

Section

2.1.2.1.

Thermal and Mechanical Design Guidelines 21

Page 22

Processor Thermal/Mechanical Information

2.4 System Thermal Solution Considerations

2.4.1 Chassis Thermal Design Capabilities

The reference thermal solution for the Intel Celeron processor 200 sequence on the

Intel Desktop Board D201GLY2 is a passive heatsink design, which requires chassis to

deliver sufficient airflow cooling to ensure stability and reliability of processor. The

maximum allowable heatsink temperature (T

S-TOP-MAX

processor to ensure the capability of a chassis in providing sufficient airflow for

processor cooling. T

to T

CASE-MAX

for lidded processors.

S-TOP-MAX

is the maximum limit value for heatsink which is similar

) is set to 91 °C for

The “usage power consumption” (P

CPU-USAGE

) of the Intel Celeron processor 200

sequence was quantified at maximum of 16 W based on measurement done on Intel

Desktop Board D201GLY2 when tested with SYSMark04. The reference thermal

solution for processor is designed at P

considerations. Do not mistaken P

CPU-USAGE

CPU-USAGE

for performance & cost optimal

with processor’s TDP as documented in

datasheet.

Table 3. System Thermal Solution Design Requirement

1. System Thermal Solution Design Requirement Note

3. T

S-TOP-MAX

NOTE:

1. Based on processor maximum Usage Power Consumption (P

®

Intel

Desktop Board D201GLY2 when tested with SYSMark04.

≤ 91°C 4. 1

To evaluate the system thermal capability of a given chassis, the system designer is

recommended to conduct in-chassis system thermal test. The data to be collected are

both processor power consumption (P

) and heatsink temperature (T

CPU

above mentioned processor load at 35 °C external ambient condition. The T

can be estimated using

can be met if T

Equation 1 T

S-SYSTEM

S-SYSTEM

Equation 1. The thermal pass requirement for a given chassis

≤ T

S-TOP-MAX

= TA + (T

.

− TA) × 16/P

S-TOP

CPU

≤ T

S-TOP-MAX

) of 16 W measured on

USAGE

) with the

S-TOP

S-SYSTEM

= 91°C

®

2.4.2 Improving Chassis Thermal Performance

The heat generated by components within the chassis must be removed to provide an

adequate operating environment for the processor and all other components in the

system. Moving airflow through the chassis brings in fresh cool air from the external

ambient environment and transports the heat generated by the processor and other

system components out of the system. Therefore, the number, size and relative

position of fans and vents determine the chassis thermal performance, and the

resulting ambient temperature around the processor.

It is particularly important to choose a thermally advantaged chassis for the reference

thermal solution for Intel Celeron processor 200 sequence on the Intel Desktop Board

D201GLY2, which is a passive heatsink design.

22 Thermal and Mechanical Design Guidelines

Page 23

Processor Thermal/Mechanical Information

By analyzing airflow condition in an μATX chassis, a case study in Figure 6 shows that

a chassis layout is critical to components cooling in the system. The alignment of

system fan (80×80mm

2

) with power supply fan results in pass-through airflow which

bypasses the motherboard region. The cooling airflow from external environment is

not able to reach motherboard region to cool critical components on the motherboard.

Vents located at chassis top and side causes thermal gradient that induces natural

convection flow (blue arrow) for processor and MCH. Majority of regions are

dominated by natural convection or low flow eddies (yellow lines).

For a Chassis Air Guide Design Guide (Rev 1.1) compliant μATX chassis, such as in

Case Study #1, it is recommended to relocate system fan to CAG (Chassis Air Guide)

venting to provide impingement airflow to processor and MCH on motherboard as well

as improving overall airflow within chassis.

relocating system fan to CAG venting location for airflow improvement.

System exhaust fan located at rear side of chassis (at motherboard input/output back

panel) will effectively improve chassis thermal by exhausting hot air heated by

components on board, and regulating cool air from environment into chassis via

chassis venting.

Figure 8 shows Case Study #3 of an μATX chassis with two exhaust

fan installed for system cooling.

Additionally, mounting position and type of power supply unit with fan could assist to

improve system thermal performance.

supply located next to processor is able to direct airflow to heatsink for cooling. Refer

to Power Supply Design Guide (Rev 1.1) for power supply selection.

Figure 7 shows a Case Study #2 by

Figure 9 shows that a “top mount fan” power

Figure 6. Case Study #1: Top view — Poor μATX Chassis Layout Design for Intel

Celeron® Processor 200 Sequence on Intel® Desktop Board D201GLY2

(chassis cover removed for illustration)

®

Thermal and Mechanical Design Guidelines 23

Page 24

Processor Thermal/Mechanical Information

Figure 7. Case Study #2: Relocate System Fan to CAG Venting for Airflow

Improvement

Figure 8. Case Study#3: An μATX Chassis Equipped with Two Exhaust Fans

24 Thermal and Mechanical Design Guidelines

Page 25

Processor Thermal/Mechanical Information

Figure 9. Case Study #4: A “Top Mount Fan” PSU is located next to Processor in μATX

Chassis for System Thermal Performance Improvement

2.4.3 Summary

In summary, heatsink design considerations for the Intel Celeron processor 200

sequence on the Intel Desktop Board D201GLY2 include:

• The heatsink temperature

performance must be compliant in order to ensure processor reliability.

• Heatsink interface to die surface characteristics, including flatness and roughness.

• The performance of the thermal interface material used between the heatsink and

the die.

• The required heatsink clip static load, 9.9 lbf ± 1.2 lbf, throughout the life of the

product (refer to Section

• Surface area of the heatsink.

• Heatsink material and technology.

• Volume of airflow over the heatsink surface area.

• Development of airflow entering and within the heatsink area.

• Physical volumetric constraints placed by the system.

TS-TOP-MAX

which is a function of system thermal

2.1.2.2 for further information).

§

Thermal and Mechanical Design Guidelines 25

Page 26

Processor Thermal/Mechanical Information

26 Thermal and Mechanical Design Guidelines

Page 27

Thermal Metrology

3 Thermal Metrology

This section discusses guidelines for testing thermal solutions, including measuring

processor temperatures. In all cases, the thermal engineer must measure power

dissipation and temperature to validate a thermal solution. To define the performance

of a thermal solution the “thermal characterization parameter”, Ψ (“psi”) will be used.

3.1 Characterizing Cooling Performance Requirements

The idea of a “thermal characterization parameter”, Ψ (“psi”), is a convenient way to

characterize the performance needed for the thermal solution and to compare thermal

solutions in identical situations (same heat source and local ambient conditions). The

thermal characterization parameter is calculated using total package power.

Note: Heat transfer is a three-dimensional phenomenon that can rarely be accurately and

easily modeled by a single resistance parameter like Ψ.

The junction-to-local ambient thermal characterization parameter value (Ψ

as a measure of the thermal performance of the overall thermal solution that is

attached to the processor package. It is defined by the following equation, and

measured in units of °C/W:

) is used

JA

Equation 2 ΨJA = (TJ – TA) / PD

Where:

= Junction-to-local ambient thermal characterization parameter (°C/W)

Ψ

JA

= Processor junction temperature (°C)

T

J

T

= Local ambient temperature in chassis at processor (°C)

A

P

= Processor total power dissipation (W) (assumes all power dissipates

D

through the processor die)

Thermal and Mechanical Design Guidelines 27

Page 28

Thermal Metrology

For reference thermal solution of Intel Celeron processor 200 sequence on Intel

Desktop Board D201GLY2, the junction-to-local ambient thermal characterization

parameter of the processor, ΨJA, is comprised of ΨJS, the thermal interface material

thermal characterization parameter, Ψ

the thermal characterization parameter

HS_BASE

of the heatsink base from bottom center of heatsink base to top center of heatsink

base surface, and of Ψ

, the sink-to-local ambient thermal characterization

S-TOP-A

parameter:

Equation 3 Ψ

= ΨJS + Ψ

JA

HS_BASE

+ Ψ

S-TOP-A

Where:

= Thermal characterization parameter of the thermal interface material

Ψ

JS

(°C/W)

Ψ

HS_BASE

Ψ

S-TOP-A

= Thermal characterization parameter of the heatsink base (°C/W)

= Thermal characterization parameter from heatsink top to local

ambient (°C/W)

is strongly dependent on the thermal conductivity, thickness and performance

Ψ

JS

degradation across time of the TIM between the heatsink and processor die.

Ψ

is a measure of the thermal characterization parameter of the heatsink base.

HS_BASE

It is dependent on the heatsink base material, thermal conductivity, thickness and

geometry.

Ψ

point of the heatsink base to the local ambient air. Ψ

is a measure of the thermal characterization parameter from the top center

S-TOP-A

is dependent on the

S-TOP-A

heatsink material, thermal conductivity, and geometry. It is also strongly dependent

on the air flow through the fins of the heatsink.

Ψ

Equation 4 (Ψ

JA

−

JS

−

Ψ

HS_BASE

) × PD + T

= T

A

S-TOP-MAX

With a given processor junction-to-local ambient requirement (ΨJA) and TIM

performance (Ψ

requirement (T

28 Thermal and Mechanical Design Guidelines

) and processor power consumption (PD), the processor’s heatsink

JS

S-TOP-MAX)

could be defined by Equation 4.

Page 29

Thermal Metrology

Figure 10 illustrates the combination of the different thermal characterization

parameters.

Figure 10. Processor Thermal Characterization Parameter Relationships

Ψ

Ψ

-

-

Ψ

3.1.1 Example

The cooling performance, Ψ

characterization parameter described above:

• The junction temperature

processor datasheet.

• Define the allowable heatsink temperature for processor, T

T

is then defined using the principle of thermal

JA,

and thermal design power TDP given in the

TJ-MAX

S-TOP-MAX

S-TOP

.

T

A

TIM

T

J

The following provides an illustration of how one might determine the appropriate not

related to any specific Intel processor thermal specifications, and are for illustrative

purposes only.

Assume the TDP, as listed in the datasheet, is 20 W and the maximum junction

temperature 20 W is 90 °C. Assume as well that the system airflow has been

designed such that the local ambient temperature is 42 °C, and Ψ

Then the following could be calculated using

Ψ

= (TJ – TA) / TDP = (90 – 55) / 20 = 1.75 °C/W

JA

Thermal and Mechanical Design Guidelines 29

Equation 2:

HS_BASE

= 0.3 °C/W.

Page 30

Thermal Metrology

To determine the required heatsink performance, a heatsink solution provider would

need to determine Ψ

performance for the selected TIM and mechanical load

JS

configuration. If the heatsink solution were designed to work with a TIM material

performing at Ψ

≤ 0.50 °C/W, solving for Equation 3 from above, the performance of

JS

the heatsink would be:

Ψ

= ΨJA − ΨJS = 1.75 − 0.50 = 1.25 °C/W

SA

The heatsink temperature requirement can be obtained from Equation 4.

T

S-TOP-MAX

= (Ψ

− Ψ

jS

− Ψ

jA

) × PD + TA = (1.25 – 0.30) × 20 + 55 = 74 °C

HS_BASE

3.2 Local Ambient Temperature Measurement Guidelines

The local ambient temperature TA is the temperature of the ambient air surrounding

the processor. For a passive heatsink, T

temperature; for an actively cooled heatsink, it is the temperature of inlet air to the

active cooling fan.

It is worthwhile to determine the local ambient temperature in the chassis around the

processor to understand the effect it may have on the die temperature.

is best measured by averaging temperature measurements at multiple locations in

T

A

the heatsink inlet airflow. This method helps reduce error and eliminate minor spatial

variations in temperature. The following guidelines are meant to enable accurate

determination of the localized air temperature around the processor during system

thermal testing.

For active heatsinks, it is important to avoid taking measurement in the dead flow

zone that usually develops above the fan hub and hub spokes. Measurements should

be taken at four different locations uniformly placed at the center of the annulus

formed by the fan hub and the fan housing to evaluate the uniformity of the air

temperature at the fan inlet. The thermocouples should be placed approximately

3 mm to 8 mm [0.1 to 0.3 in] above the fan hub vertically and halfway between the

fan hub and the fan housing horizontally as shown in

spokes). Using an open bench to characterize an active heatsink can be useful, and

usually ensures more uniform temperatures at the fan inlet. However, additional tests

that include a solid barrier above the test motherboard surface can help evaluate the

potential impact of the chassis. This barrier is typically clear Plexiglas*, extending at

least 100 mm [4 in] in all directions beyond the edge of the thermal solution. Typical

distance from the motherboard to the barrier is 81 mm [3.2 in]. For even more

realistic airflow, the motherboard should be populated with significant elements like

memory cards, graphic card, and chipset heatsink. If a barrier is used, the

thermocouple can be taped directly to the barrier with a clear tape at the horizontal

location as previously described, half way between the fan hub and the fan housing.

If a variable speed fan is used, it may be useful to add a thermocouple taped to the

barrier above the location of the temperature sensor used by the fan to check its

speed setting against air temperature. When measuring T

motherboard, add-in cards, and other system components, it is likely that the T

is defined as the heatsink approach air

A

Figure 11 (avoiding the hub

in a chassis with a live

A

A

30 Thermal and Mechanical Design Guidelines

Page 31

Thermal Metrology

measurements will reveal a highly non-uniform temperature distribution across the

inlet fan section.

For passive heatsinks, thermocouples should be placed approximately 3 mm away

from the heatsink as shown in

Figure 12.

Note: Testing an active heatsink with a variable speed fan can be done in a thermal

chamber to capture the worst-case thermal environment scenarios. Otherwise, when

doing a bench top test at room temperature, the fan regulation prevents the heatsink

from operating at its maximum capability. To characterize the heatsink capability in

the worst-case environment in these conditions, it is then necessary to disable the fan

regulation and power the fan directly, based on guidance from the fan supplier.

Figure 11. Locations for Measuring Local Ambient Temperature, Active Heatsink

NOTE: Drawing Not to Scale

Thermal and Mechanical Design Guidelines 31

Page 32

Thermal Metrology

Figure 12. Locations for Measuring Local Ambient Temperature, Passive Heatsink

3MM AWAY FR OM HE ATSIN K SIDES

3MM AWAY FR OM HE ATSIN K SIDES

HALF OF HEATSINK FIN HEIGHT

HALF OF HEATSINK FIN HEIGHT

SIDE VIEW

SIDE VIEW

POTISTION THERMOCOUPLES (X4)

POTISTION THERMOCOUPLES (X4)

AT LOCATIONS AS IND ICATED

AT LOCATIONS AS IND ICATED

TO MEASURE T

TO MEASURE T

NOTE: Drawing Not to Scale

.

.

A

A

TC1

TC1

TC2

TC2

TC4

TC4

TC3

TC3

TOP VIEW

TOP VIEW

It is recommended that full and routine calibration of temperature measurement

equipment be performed before attempting to perform temperature measurement.

Intel recommends checking the meter probe set against known standards. This

should be done at 0 ºC (using ice bath or other stable temperature source) and at an

elevated temperature, around 80 ºC (using an appropriate temperature source).

Wire gauge and length also should be considered as some less expensive

measurement systems are heavily impacted by impedance. There are numerous

resources available throughout the industry to assist with implementation of proper

controls for thermal measurements.

3.3 Processor Power Measurement Metrology Recommendation

This section recommends a metrology to measure power consumption of the Intel

Celeron processor 200 sequence on the Intel Desktop Board D201GLY2. Should there

be any modification of motherboard layout or design, contact Intel field sales

representative or product marketing staff for clarification of this metrology.

32 Thermal and Mechanical Design Guidelines

Page 33

Thermal Metrology

3.3.1 Sample Preparation

In order to accurately measure the processor power consumption, it is required to

attach sense resistor and replace one of the motherboard resistors. Schematic

diagram in

processor circuitry. The processor power consumption can be estimated by

Equation 5.

Figure 13 illustrates the precision resistor (R

) attached in series with

SENSE

Equation 5 PD = VCC × (Vi / R

Where:

P

= Processor total power dissipation (W) (assumes all power dissipates

D

V

= Processor core voltage.

CC

V

= Voltage measured across precision sense resistor.

i

R

SENSE

The Isotek 4 terminal (Kelvin) precision resistor (with resistance of 1 mΩ and

Tol=0.1%) is recommended to be used for processor power measurement. Locate the

inductor L1VR inductor (near processor) on motherboard and attach the Isotek

precision resistor in-series with inductor as illustrated in

Figure 14 board layout schematic diagram. Additionally, it is required to replace

R27VR chip resistor (near processor) with a 19.6 KΩ rated chip resistor as illustrated

in

Figure 15. The Walsin chip resistor (WR06X1962FTL) is one of the recommended

chip resistors for the rework.

Table 4. Test Accessories

5. Description Q

9. Isotek 4 terminal

13. Walsin chip

through the processor die)

= Given resistance value of precision resistor.

(Kelvin) precision

resistor

resistor

SENSE)

Figure 13 schematic and

uantity

10. 1 11. P/N A-N-R001-F1-K2-0.1.

14. 1 15. WR06X1962FTL. R= 19.6 KΩ,

7. Part Number N

R=1 mΩ, Tol=0.1%, P=2W,

TCR<10 ppm/°C

Tol =1%, P=0.1W, TCR<200

ppm/°C.

otes

12.

1

16.

2

NOTE:

1.

http://www.isotekcorp.com/productDisplay.asp?CatID=1&SubCatID

2.

http://www.passivecomponent.com/lh3/search.asp

Thermal and Mechanical Design Guidelines 33

Page 34

Thermal Metrology

Figure 13. Precision Resistor Connected in-series with Processor Circuitry for Power

Measurement

Figure 14. Installation of Isotek Resistor on Intel® Desktop Board D201GLY2 to Setup

Connection for Power Measurement

Measuring V

Measuring V

1

1

Measuring V

Measuring V

2

2

i

i

CC

CC

Isotek

Isotek

Resistor

Resistor

2

1

1

2

34 Thermal and Mechanical Design Guidelines

Page 35

Thermal Metrology

Figure 15. Probing Resistance of the Soldered Walsin Resistor (R =19.6 KΩ) on Intel®

Desktop Board D201GLY2 to Ensure Proper Attachment

Figure 16. Precision Resistor Soldered on on Intel® Desktop Board D201GLY2, and

Connected to netDAQ for Voltage Measurement

§

Thermal and Mechanical Design Guidelines 35

Page 36

Thermal Metrology

36 Thermal and Mechanical Design Guidelines

Page 37

System Thermal/Mechanical Design Information

4 System Thermal/Mechanical

Design Information

4.1 Overview of the Reference Design

This chapter will document the requirements for designing a passive heatsink that

meets the maximum usage power consumption that mentioned in Section

®

Boxed Processor thermal solution E21953-001 satisfies the specified thermal

Intel

requirements.

Note: The part number E21953-001 provided in this document is for reference only. The

revision number -001 may be subject to change without notice. OEMs and System

Integrators are responsible for thermal, mechanical and environmental validation of

this solution (refer to Sections 4.1.2 and 4.2).

2.4. The

The Intel

savings. The thermal solution supports the unique and smaller desktop PCs including

small and ultra small form factors, down to a 5L system size.

The motherboard keep-out and height recommendations shown in Section

the same for a thermal solution for the Intel Celeron processor 200 sequence in the

micro-FCBGA package.

®

Boxed Processor thermal solution E21953-001 takes advantage of cost

4.1.1 Altitude

Many companies design products that must function reliably at high altitude, typically

1,500 m [5,000 ft] or more. Air-cooled temperature calculations and measurements

at the test site elevation must be adjusted to take into account altitude effects like

variation in air density and overall heat capacity. This often leads to some

degradation in thermal solution performance compared to what is obtained at sea

level, with lower fan performance and higher surface temperatures. The system

designer needs to account for altitude effects in the overall system thermal design to

make sure that the T

altitude.

requirement for the processor is met at the targeted

S-TOP-MAX

4.1.2 Heatsink Thermal Validation

Intel recommends evaluation of the heatsink within the specific boundary conditions

based on the methodology described in Chapter

2.1 remain

3.

Testing is done on bench top test boards at ambient laboratory temperature.

The test results, for a number of samples, are reported in terms of a worst-case mean

+ 3σ value for thermal characterization parameter using real processors.

Thermal and Mechanical Design Guidelines 37

Page 38

System Thermal/Mechanical Design Information

4.2 Environmental Reliability Testing

4.2.1 Structural Reliability Testing

Structural reliability tests consist of unpackaged, board-level vibration and shock tests

of a given thermal solution in the assembled state. The thermal solution should meet

the specified thermal performance targets after these tests are conducted; however,

the test conditions outlined here may differ from your own system requirements.

4.2.1.1 Random Vibration Test Procedure

Duration: 10 min/axis, 3 axes

Frequency Range: 5 Hz to 500 Hz

Power Spectral Density (PSD) Profile: 3.13 G RMS

Figure 17. Random Vibration PSD

0.1

0.01

PSD (g^2/Hz)

0.001

(5, 0.01)

5 Hz

1

4.2.1.2 Shock Test Procedure

Recommended performance requirement for a motherboard:

• Quantity: 3 drops for + and - directions in each of 3 perpendicular axes (i.e.,

total 18 drops).

• Profile: 50 G trapezoidal waveform, 170 in/sec minimum velocity change.

• Setup: Mount sample board on test fixture.

3.13GRMS (10 minutes per axis)

(20, 0.02)

10 100 1000

Frequency (Hz)

(500, 0.02)

500 Hz

38 Thermal and Mechanical Design Guidelines

Page 39

2

8

)

System Thermal/Mechanical Design Information

Figure 18. Shock Acceleration Curve

A

c

c

60

50

e

40

l

e

30

r

a

t

20

i

o

10

n

(g)

0

0

4.2.1.2.1 Recommended Test Sequence

Each test sequence should start with components (i.e. motherboard, heatsink

assembly, etc.) that have never been previously submitted to any reliability testing.

The test sequence should always start with a visual inspection after assembly, and

BIOS/CPU/Memory test (refer to Section

Prior to the mechanical shock & vibration test, the units under test should be

preconditioned for 72 hours at 45 ºC. The purpose is to account for load relaxation

during burn-in stage.

4 6

Time (milliseconds

4.2.1.2.2).

10 12

The stress test should be followed by a visual inspection and then BIOS/CPU/Memory

test.

4.2.1.2.2 Post-Test Pass Criteria

The post-test pass criteria are:

1. No significant physical damage to the heatsink attach mechanism (including such

items as clip and motherboard fasteners).

2. Heatsink must remain attached to the motherboard.

3. Heatsink remains seated and its bottom remains mated flatly against die surface.

No visible gap between the heatsink base and processor die. No visible tilt of the

heatsink with respect to its attach mechanism.

4. No signs of physical damage on motherboard surface due to impact of heatsink or

heatsink attach mechanism.

5. No visible physical damage to the processor package.

6. Successful BIOS/Processor/memory test of post-test samples.

7. Thermal compliance testing to demonstrate that the case temperature

specification can be met.

Thermal and Mechanical Design Guidelines 39

Page 40

System Thermal/Mechanical Design Information

4.2.2 Power Cycling

Thermal performance degradation due to TIM degradation is evaluated using power

cycling testing. The test is defined by 7500 cycles for the heatsink temperature from

room temperature (~23 ºC) to T

S-TOP-MAX

at usage power consumption.

4.2.3 Recommended BIOS/CPU/Memory Test Procedures

This test is to ensure proper operation of the product before and after environmental

stresses, with the thermal mechanical enabling components assembled. The test shall

be conducted on a fully operational motherboard that has not been exposed to any

battery of tests prior to the test being considered.

Testing setup should include the following components, properly assembled and/or

connected:

• Appropriate system motherboard

• Processor

• All enabling components, including socket and thermal solution parts

• Power supply

• Disk drive

• Video card

• DIMM

• Keyboard

• Monitor

The pass criterion is that the system under test shall successfully complete the

checking of BIOS, basic processor functions and memory, without any errors.

4.3 Material and Recycling Requirements

Material shall be resistant to fungal growth. Examples of non-resistant materials

include cellulose materials, animal and vegetable based adhesives, grease, oils, and

many hydrocarbons. Synthetic materials such as PVC formulations, certain

polyurethane compositions (e.g., polyester and some polyethers), plastics which

contain organic fillers of laminating materials, paints, and varnishes also are

susceptible to fungal growth. If materials are not fungal growth resistant, then MILSTD-810E, Method 508.4 must be performed to determine material performance.

Material used shall not have deformation or degradation in a temperature life test.

Any plastic component exceeding 25 grams must be recyclable per the European Blue

Angel recycling standards.

40 Thermal and Mechanical Design Guidelines

Page 41

System Thermal/Mechanical Design Information

4.4 Safety Requirements

Heatsink and attachment assemblies shall be consistent with the manufacture of units

that meet the safety standards:

• UL Recognition-approved for flammability at the system level. All mechanical and

thermal enabling components must be a minimum UL94V-2 approved.

• CSA Certification. All mechanical and thermal enabling components must have

CSA certification.

• All components (in particular the heatsink fins) must meet the test requirements

of UL1439 for sharp edges.

• If the International Accessibility Probe specified in IEC 950 can access the moving

parts of the fan, consider adding safety feature so that there is no risk of personal

injury.

4.5 Reference Attach Mechanism

4.5.1 Structural Design Strategy

Structural design strategy for the Intel reference thermal solution is to minimize

upward board deflection during shock.

The design uses a high clip stiffness that resists local board curvature under the

heatsink, and minimizes, in particular, upward board deflection.

4.5.2 Mechanical Interface to the Reference Attach Mechanism

The attach mechanism component (E21952-001) from the Intel Boxed Processor

thermal solution can be used by other 3

mechanism consists of:

• A metal clip that interfaces with the heatsink, see

drawings.

• Heatsink/fan mass ≤ 62 g

rd

party cooling solutions. The attach

Figure 22 for the component

§

Thermal and Mechanical Design Guidelines 41

Page 42

System Thermal/Mechanical Design Information

42 Thermal and Mechanical Design Guidelines

Page 43

Heatsink Clip Load Metrology

Appendix A Heatsink Clip Load

Metrology

A.1 Overview

The primary objective of the preload measurement is to ensure the preload designed

into the retention mechanism is able to meet minimum of 8.7lbf at end-of-line and

does not violate the maximum specifications of the package.

A.2 Test Preparation

A.2.1 Heatsink Preparation

The following components are required to validate a generic z-clip solution:

1. Thermal solution heatsink (for example, PN: D96271-001 for the Intel Celeron

processor 200 sequence on Intel

2. Z-clip (for example, PN: D96271-001 for the Intel Celeron processor 200

sequence on Intel

3. 2X Anchors (IPN: A13494-008 if using Intel’s part)

4. Customized top plate to allow anchor attachment and package simulator

®

Desktop Board D201GLY2)

®

Desktop Board D201GLY2)

A.2.2 Typical Test Equipment

For the heatsink clip load measurement, use equivalent test equipment to the one

Table 5.

listed

Thermal and Mechanical Design Guidelines 43

Page 44

Table 5. Typical Test Equipment

Heatsink Clip Load Metrology

7. Item 18. Description

20. Load

cell

21. Notes:

1, 5

26. Data

Logger

(or

scanner

)

27. Notes:

2, 3, 4

30. Clip

Force

Measure

ment

machine

31. Notes:

644

NOTES:

1. Select load range depending on expected load level. It is usually better, whenever

possible, to operate in the high end of the load cell capability. Check with your load cell

vendor for further information.

2. Since the load cells are calibrated in terms of mV/V, a data logger or scanner is

required to supply 5 volts DC excitation and read the mV response. An

automated model will take the sensitivity calibration of the load cells and convert the

mV output into pounds.

3. With the test equipment listed above, it is possible to automate data recording and

control with a 6101-PCI card (GPIB) added to the scanner, allowing it to be connected

to a PC running LabVIEW* or Vishay's StrainSmart* software.

4. IMPORTANT: In addition to just a zeroing of the force reading at no applied load, it is

important to calibrate the load cells against known loads. Load cells tend to drift.

Contact your load cell vendor for calibration tools and procedure information.

5. When measuring loads under thermal stress (bake for example), load cell thermal

capability must be checked, and the test setup must integrate any hardware used along

with the load cell. For example, the Model 13 load cells are temperature compensated

up to 71°C, as long as the compensation package (spliced into the load cell's wiring) is

also placed in the temperature chamber. The load cells can handle up to 121 °C

(operating), but their uncertainty increases according to 0.02% rdg/°F.

6. Clip force measurement machine is recommended to be calibrated before usage.

Standard weights should be used to check for preload cell accuracy and consistency.

22. Honeywell*-Sensotec* Model 13

subminiature load cells, compression

only

23. Select a load range depending on load

level being tested.

www.sensotec.com

24.

28. Vishay* Measurements Group Model

6100 scanner with a 6010A strain card

(one card required per channel).

32. Customized machine that houses load

cell for force measurement. Top side

plate can be modified to accommodate

various attach pattern

. Part Number

(Model)

25. AL322BL

29. Model 6100

33. CFM-001 (Cool

Star

Technology)

44 Thermal and Mechanical Design Guidelines

Page 45

Heatsink Clip Load Metrology

A.3 Test Procedure Examples

The following procedure is for a generic z-clip solution using the clip force time0

measurement machine at room temperature:

1. Install anchors onto top plate. Anchor can be secured using epoxy or glue.

2. Fasten top plate onto the clip force measurement machine. Place package

simulator on top of the preload cell as well.

3. Place the heatsink (remove any TIM material) on top of the package simulator.

Power on the clip force measurement machine.

4. Install the z-clip and record down the measured preload. Make sure measurement

is taken after the reading stabilized. Remove the z-clip and repeat 2 times (in

total 3 times) to ensure consistency.

5. Repeat step4 for remaining clip samples. Recommended minimum samples are

10 z-clip samples.

Figure 19. Top Plate and Package Simulator Fasten onto Clip Force Measurement

Machine

Thermal and Mechanical Design Guidelines 45

Page 46

Heatsink Clip Load Metrology

Figure 20. Anchors Installed and Glued Down the BTX Base Plate – for reference only

§

46 Thermal and Mechanical Design Guidelines

Page 47

Intel® Enabled Boxed Processor Thermal Solution Information

Appendix B Intel® Enabled Boxed

Processor Thermal

Solution Information

This appendix includes supplier information for Intel enabled vendors.

Table 6 lists suppliers that produce Intel® Boxed Processor thermal solution E21953001 components. The part numbers listed below identifies these reference

components. End-users are responsible for the verification of the Intel enabled

component offerings with the supplier. OEMs and System Integrators are responsible

for thermal, mechanical, and environmental validation of these solutions.

®

Table 6. Intel

Boxed Processor Thermal Solution Providers

. S

upplier

40. C

These vendors and devices are listed by Intel as a convenience to Intel's general

customer base, but Intel does not make any representations or warranties whatsoever

regarding quality, reliability, functionality, or compatibility of these devices. This list

and/or these devices may be subject to change without notice.

. Part

Description

41. CPU

C

I

Heats

ink

Asse

mbly

. Par

t Number

42. E21

953001

. Con

tact

43. Moni

ca