Page 1

Intel® 41110 Serial to Parallel PCI Bridge

Design Guide

March 2006

Order Number: 310335-001

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL® PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED, BY

ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS PROVIDED IN

INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUM ES NO LIABILITY WHATSOEVER, AND INTEL DISCLAIMS

ANY EXPRESS OR IMPLIED WARRANTY, RELATING TO SALE AND/OR USE OF INTEL PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING T O FITNESS FOR A PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRI GHT OR OTHER

INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving, life sustaining applications.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an ordering number and are referenced in this document, or other Intel literature may be obtained by calling

1-800-548-4725 or by visiting Intel's website at http://www.intel.com.

Intel is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

*Other names and brands may be cla imed as the property of others.

Copyright © Intel Corporation, 2006

ii Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 3

Contents

Contents

1 About This Document ...................................................................................................................7

1.1 Terminology and Definitions .................................................................................................7

2 Introduction....................................................................................................................................9

2.1 PCI Express Interface Features............................................................................................9

2.2 PCI-X Interface Features......................................................................................................9

2.3 Power Management............................................................................................................10

2.4 SMBus Interface .................................................................................................................10

2.5 JTAG...................................................................................................................................12

2.6 Related Documents ............................................................................................................12

2.7 Intel® 41110 Serial to Parallel PCI Bridge Applications .....................................................13

3 Package Information ...................................................................................................................15

3.1 Package Specification ........................................................................................................15

4 Power Plane Layout ....................................................................................................................17

4.1 41110 Decoupling Guidelines......................... ...... ...... ....... ...... ....... ...... ....... .......................1 7

4.2 Split Voltage Planes............................................................................................................19

5 41110 Reset and Power Timing Considerations.......................................................................21

5.1 A_RST# and PERST# Timing Requirements.....................................................................21

5.2 VCC15 and VCC33 Voltage Requirements........................................................................21

6 General Routing Guidelines .......................................................................................................23

6.1 General Routing Guidelines................................................................................................23

6.2 Crosstalk.............................................................................................................................23

6.3 EMI Considerations ............................................................................................................24

6.4 Power Distribution and Decoupling.....................................................................................25

6.5 Trace Impedance................................................................................................................25

7 Board Layout Guidelines............................................................................................................27

7.1 Adapter Card Topology.. ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ....................................27

8 PCI-X Layout Guidelines.............................................................................................................29

8.1 Interrupts.............................................................................................................................29

8.2 PCI Arbitration ....................................................................................................................30

8.3 PCI General Layout Guidelines ..........................................................................................31

8.4 PCI Clock Layout Guidelines ..............................................................................................32

8.5 PCI-X Topology Layout Guidelines.....................................................................................35

8.6 41110 Layout Analysis............................. ....... ...... ...... ....... ....................................... ...... ....35

9 PCI Express Layout.....................................................................................................................41

9.1 General recommendations .................................................................................................41

9.2 PCI-Express Layout Guidelines..........................................................................................42

9.3 Adapter Card Layout Guidelines.........................................................................................42

10 Circuit Implementations..............................................................................................................45

10.1 41110 Analog Voltage Filters.......................... ...... ...... ....................................... ....... ...... ....45

Intel® 41110 Serial to Parallel PCI Bridge Design Guide iii

Page 4

Contents

10.2 41110 Reference and Compensation Pins.........................................................................48

11 41110 Customer Reference Boards...........................................................................................51

11.1 Board Stack-up..................................... ...................................... ....... ...... ....... ...... ....... .......51

11.2 Material...............................................................................................................................52

11.3 Impedance..........................................................................................................................52

11.4 Board Outline.................... ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... .................................53

12 Design Guide Checklist ..............................................................................................................55

Figures

1 Microcontroller Block Diagram....................................................................................................11

2 41110 Microcontroller Connections............................................................................................12

3 41110 Block Diagram .................................................................................................................13

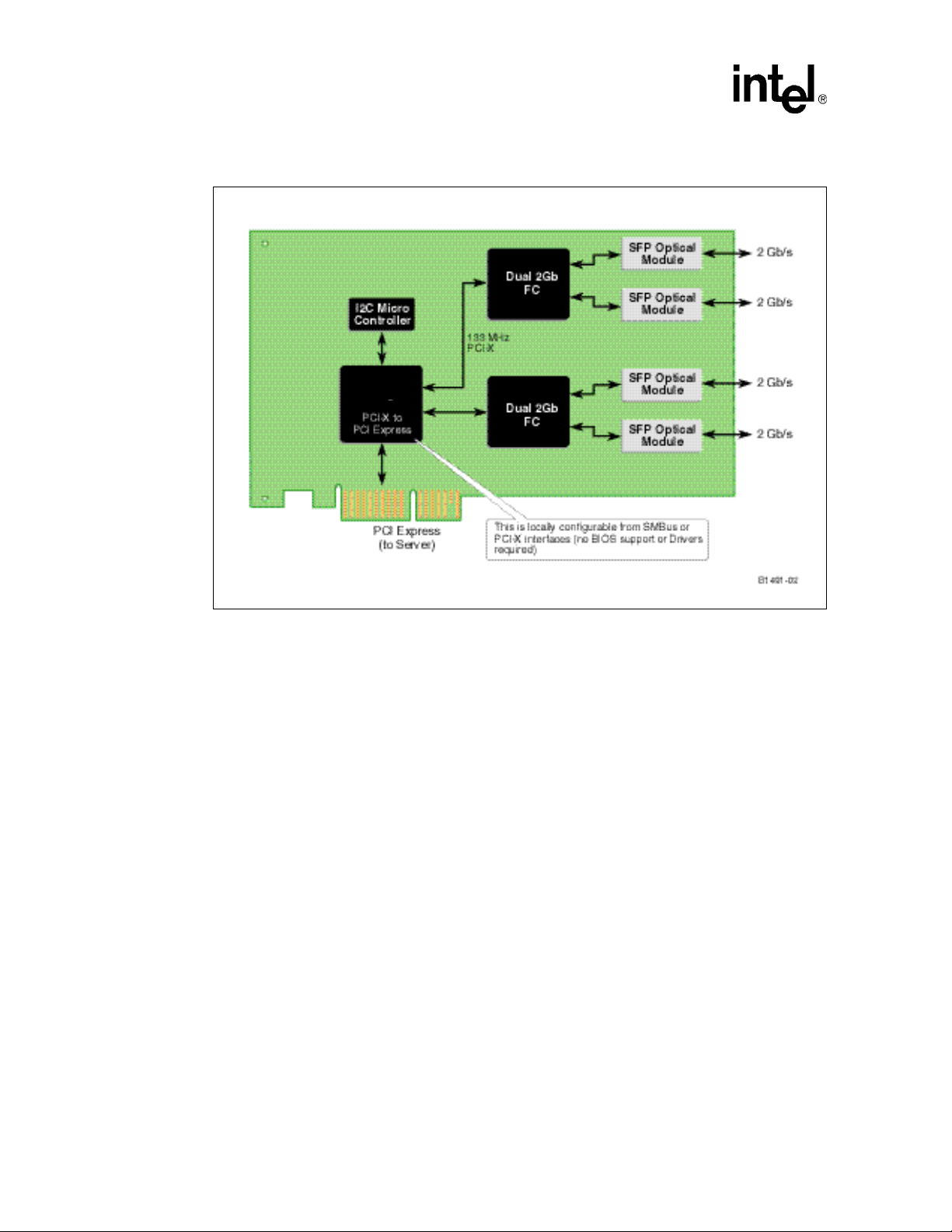

4 41110 Adapter Card Block Diagram...........................................................................................14

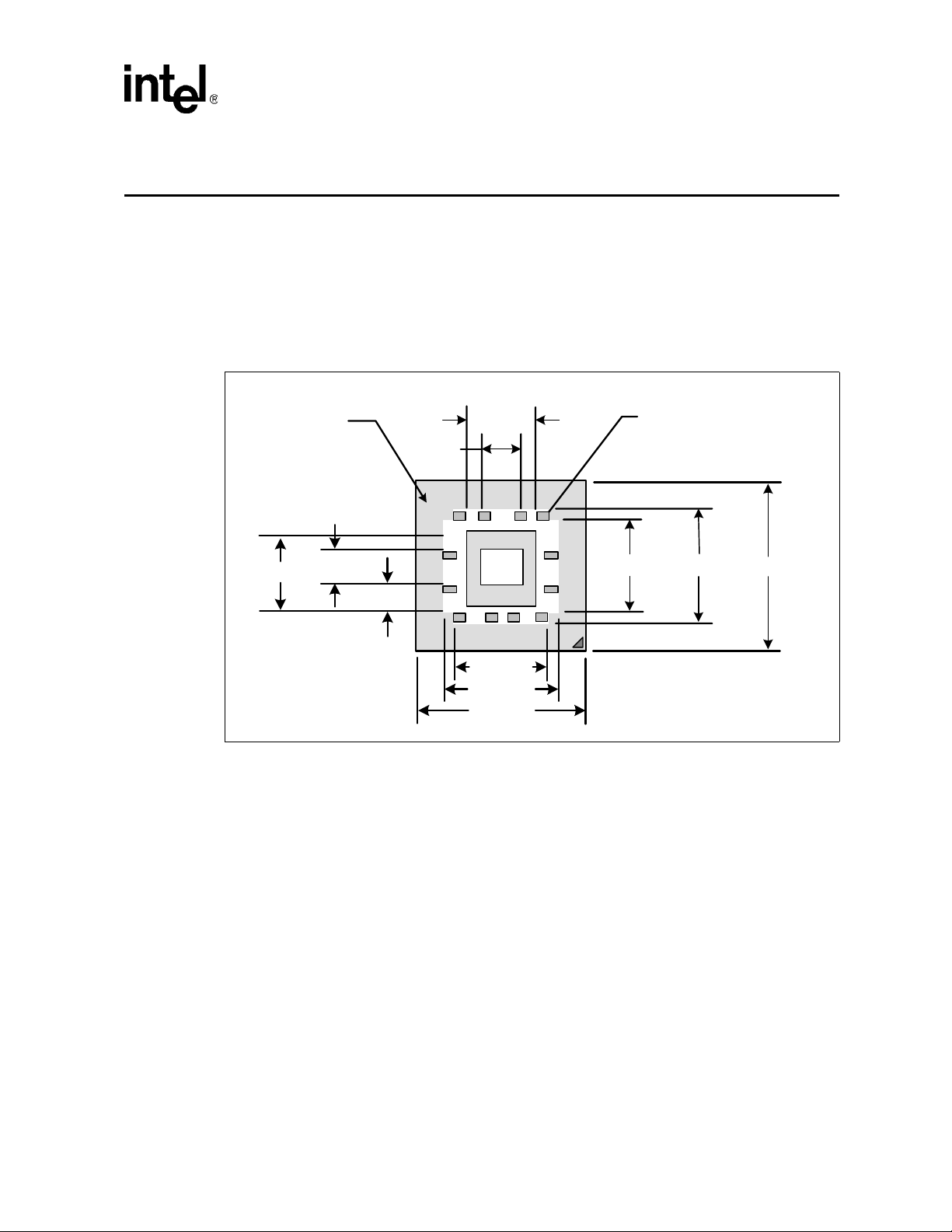

5 41110 Bridge Package Dimensions (Top View) .........................................................................15

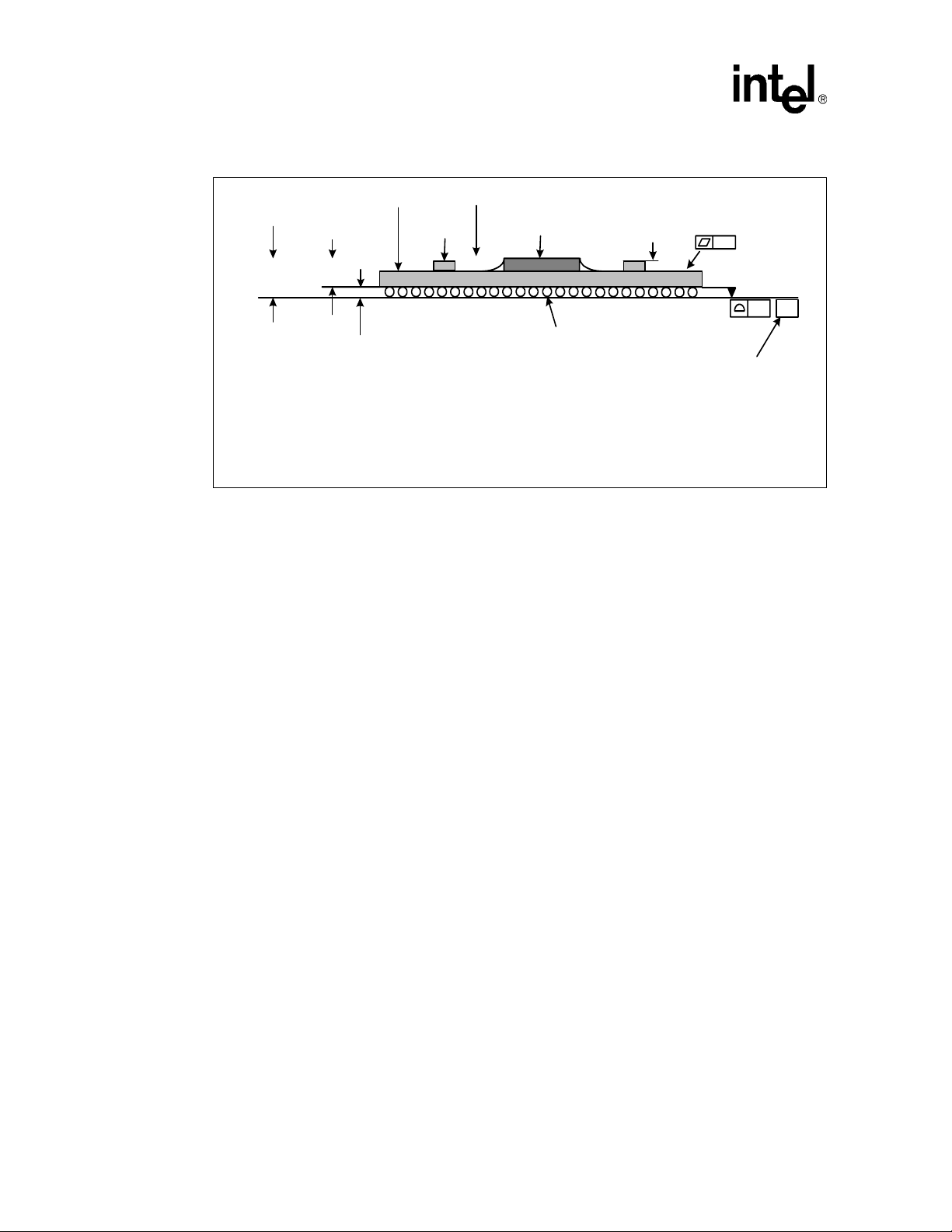

6 41110 Bridge Package Dimensions (Side View)........................................................................16

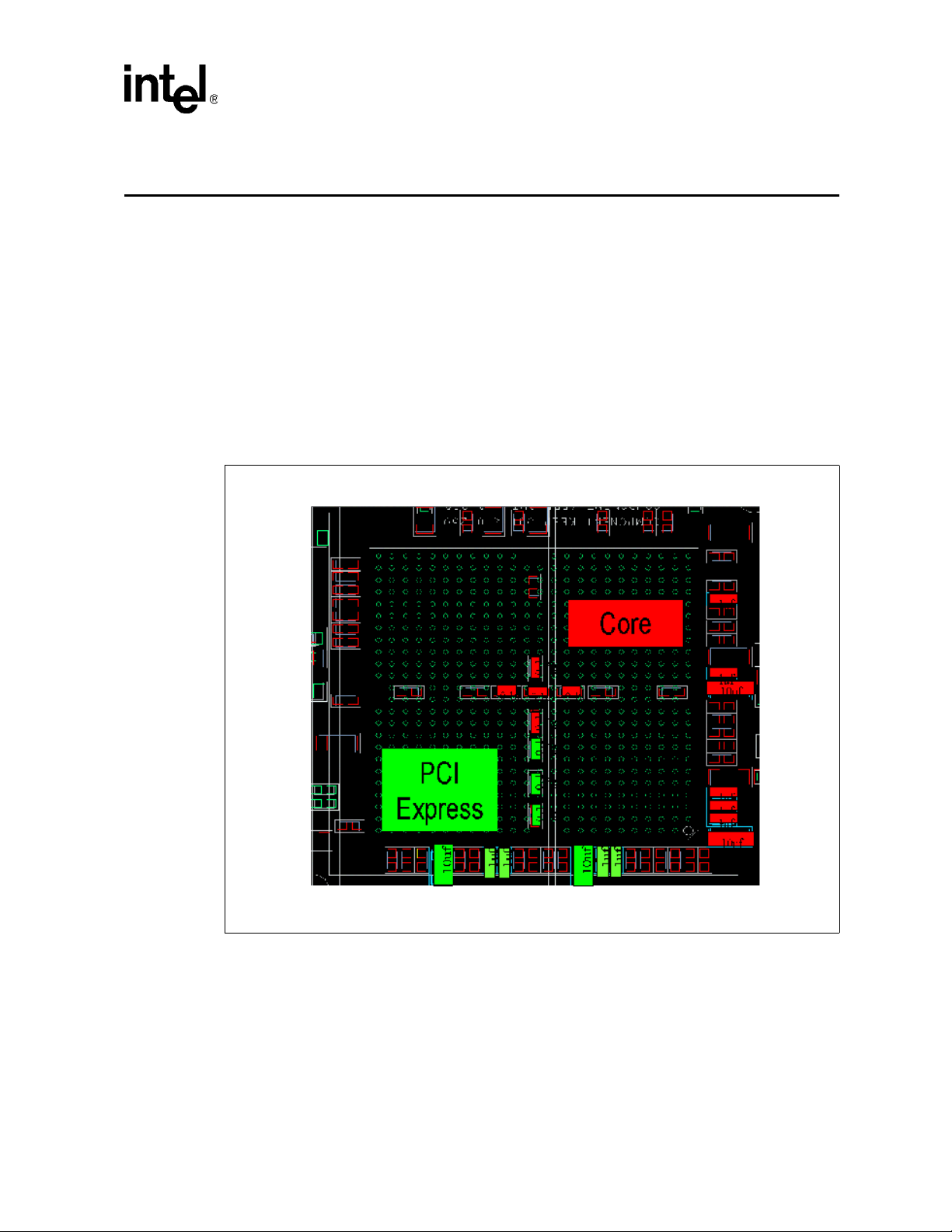

7 Decoupling Placement for Core and PCI Express Voltage Planes ............................................17

8 Decoupling Placement for PCI/PCI-X 1.5V and 3.3V Voltage Planes........................................18

9 41110 Bridge Single-Layer Split Voltage Plane..........................................................................20

10 Crosstalk Effects on Trace Distance and Height........................................................................24

11 PCB Ground Layout Around Connectors ...................................................................................24

12 Cross Section of Differential Trace.............................................................................................26

13 Two-by-two Differential Impedance Matrix .................................................................................26

14 Adapter Card Stackup .............. ....... ...... ....... ...... ....... ...... ...... ....... ...... ....... ...... ...........................28

15 PCI RCOMP ...............................................................................................................................31

16 PCI Clock Distribution and Matching Requirements...................................................................33

17 Embedded PCI-X 133 MHz Topology ........................................................................................36

18 Embedded PCI-X 100 MHz Topology ........................................................................................37

19 PCI-X 66 MHz Embedded Routing Topology.............................................................................38

20 PCI 66 MHz Embedded Topology..............................................................................................39

21 PCI 33 MHz Embedded Mode Routing Topology.......................................................................40

22 PCI Analog Voltage Filter Circuit................................................................................................46

23 PCI Express Analog Voltage Filter Circuit..................................................................................47

24 Bandgap Analog Voltage Filter Circuit........................................................................................48

25 Reference and Compensation Circuit Implementations .............................................................49

26 Mechanical Outline of the 41110................................................................................................53

Tables

1 Terminology and Definitions .........................................................................................................7

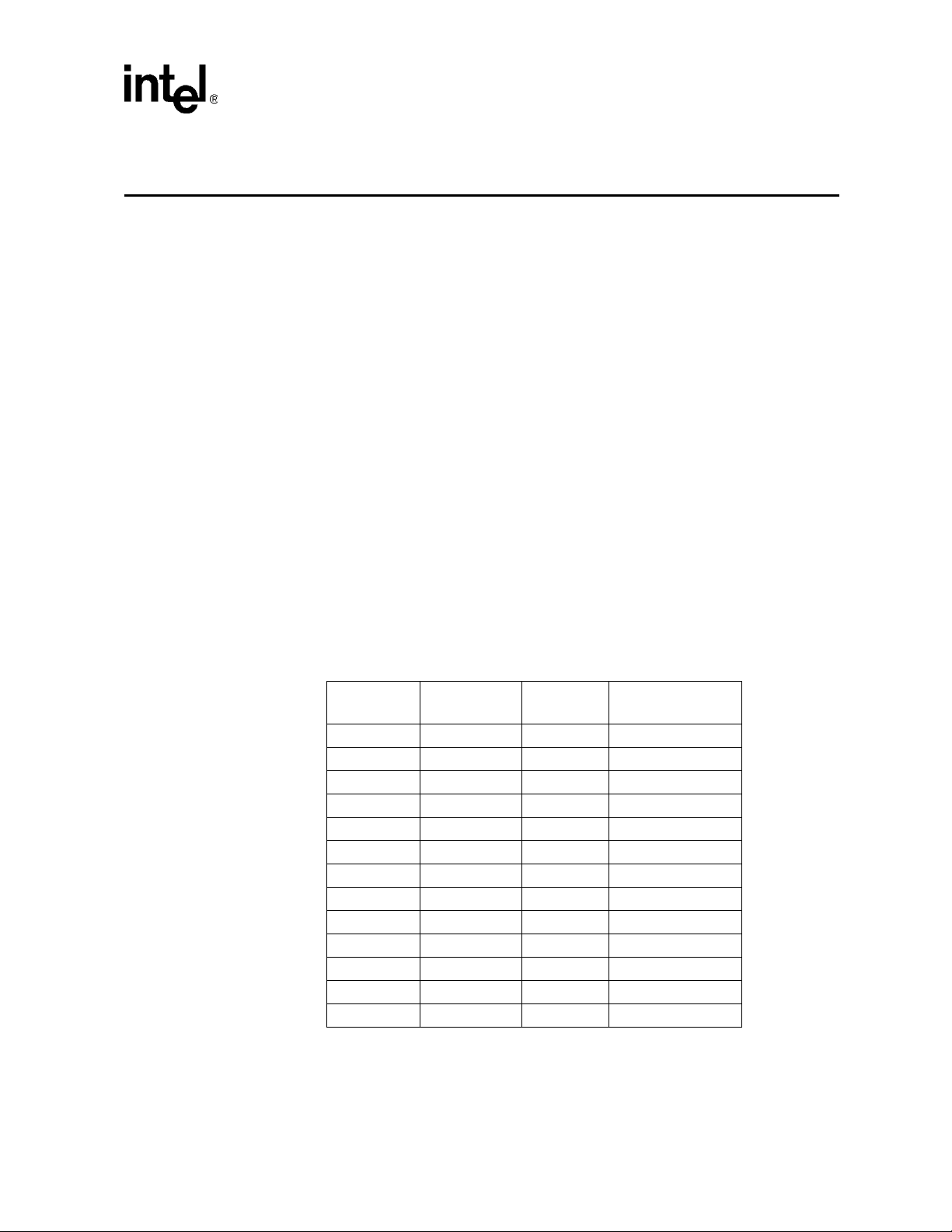

2 41110 Decoupling Guidelines.....................................................................................................19

3 Adapter Card Stack Up, Microstrip and Stripline ........................................................................27

4 INTx Routing Table.....................................................................................................................29

5 Interrupt Binding for Devices Behind a Bridge...........................................................................30

6 PCI-X Signals .............................................................................................................................32

7 PCI/PCI-X Frequency/Mode Straps............................................................................................32

8 PCI-X Clock Layout Requirements Summary ............................................................................34

9 PCI-X Slot Guidelines.................................................................................................................35

iv Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 5

Contents

10 Embedded PCI-X 133 MHz Routing Recommendations............................................................36

11 Embedded PCI-X 100 MHz Routing Recommendations............................................................37

12 PCI-X 66 MHz Embedded Routing Recommendations..............................................................38

13 PCI 66 MHz Embedded Table....................................................................................................39

14 PCI 33 MHz Embedded Routing Recommendations..................................................................40

15 Adapter Card Routing Recommendations..................................................................................42

16 Recommended R, L and C Values for 41110 Analog Filter Circuits...........................................45

17 SMBUs Address Configuration...................................................................................................49

18 CRB Board Stackup....................................................................................................................51

19 PCI Express Interface Signals....................................................................................................55

20 PCI/PCI-X Interface Signals .......................................................................................................56

21 Miscellaneous Signals ................................................................................................................57

22 SMBus Interface Signals ............................................................................................................58

23 Reset Pins ..................................................................................................................................59

24 Power and Ground Signals.........................................................................................................60

25 JTAG Signals......................... ....... ...... ....... ...... ....................................... ...... ....... ...... .................61

Intel® 41110 Serial to Parallel PCI Bridge Design Guide v

Page 6

Contents

Revision History

Date Revision Description

March 2006 001 Initial release.

vi Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 7

About This Document 1

This document provides layout i nformation and guide lines for designing p latform or add-in board

applications with the Intel® 41110 Serial to Parallel PCI Bridge (also called the 411 10 Bridge). It is

recommended that this document be used as a guideline. Intel recommends employing best-known

design practices with board level simulation, signal integrity testing and validation for a robust

design.

Designers should note that this guide focuses upon specific design considerations for the 41110

Bridge and is not intended to be an all-inclusive list of all good design practices. Use this guide as

a starting point and use empirical data to optimize your particular design.

1.1 Terminology and Definitions

Table 1 provides a list of terms and definitions that may be useful when working with the 41110

Bridge product.

Table 1. Terminology and Definitions (Sheet 1 of 2)

Term Definition

Stripline in a PCB is composed of the

conductor inserted in a dielectric with GND

planes to the top and bottom.

Stripline

NOTE: An easy way to distinguish stripline

from microstrip is that you need to

strip away layers of the board to view

the trace on stripline.

Microstrip

Prepreg

Core

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 7

Material used for the lamination process of manufacturing PCBs. It consists of a layer of

epoxy material that is placed between two cores. This layer melts into epoxy when heated and

forms around adjacent traces.

Material used for the lamination process of manufacturing PCBs. This material is two sided

laminate with copper on each side. The core is an internal layer that is etched.

Microstrip in a PCB is composed of the

conductor on the top layer above the dielectric

with a ground plane below

Page 8

About This Document

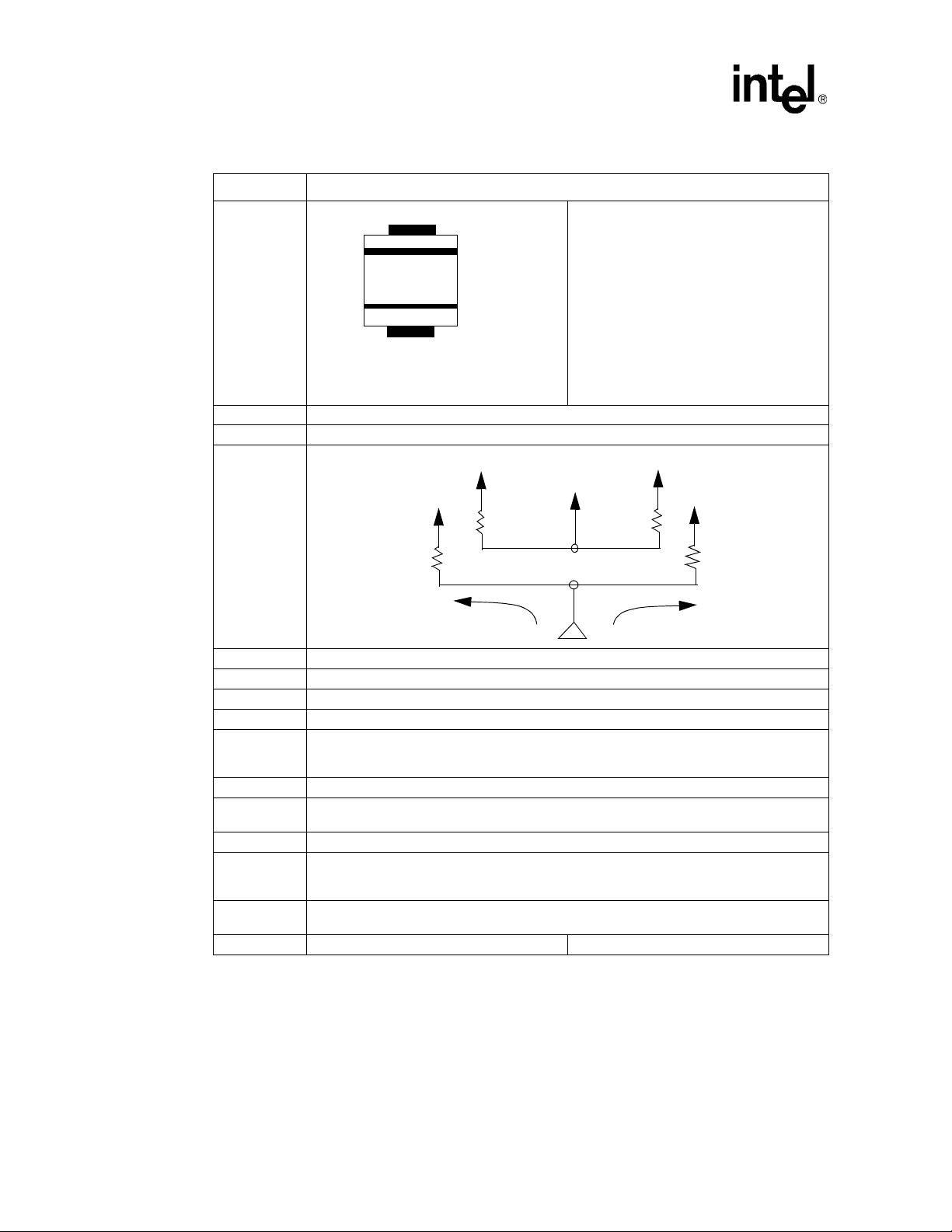

Table 1. Terminology and Definitions (Sheet 2 of 2)

Term Definition

Layer 1: copper

Prepreg

Layer 2: GND

Core

PCB

Example of a Four-Layer Stack

SSTL_2 Series Stub Terminated Logic for 2.5 V

JEDEC Provides standards for the semiconductor industry.

A network that transmits a coupled signal to another network is aggressor network.

Aggressor

Victim A network that receives a coupled cross-talk signal from another network is a victim network.

Network The trace of a PCB that completes an electrical connection between two or more components.

Stub Branch from a trunk terminating at the pad of an agent.

CRB Customer Reference Board

Downstream

Upstream

Local memory

DWORD 32-bit data word.

Flip Chip

Mode

Conversion

PCI-E PCI-Express

Downstream refers either to the relative position of an interconnect/system element (Link/

device) as something that is farther from the Root Complex, or to a direction of information

flow, i.e., when information is flowing away from the Root Complex.

Memory subsystem on the Intel XScale

busses.

FC-BGA (flip chip-ball grid array) chip packages are designed with processor core flipped up

on the back of the chip, facing away from the PCB. This allows more efficient cooling of the

package.

Mode Conversions are due to imperfections on the interconnect which transform differential

mode voltage to common mode voltage and common mode voltage to differential voltage.

Zo

Layer 3: VCC15

Prepreg

Layer 4: copper

Zo

Victim Network

Aggressor Network

Printed circuit board.

Example manufacturing process consists of

the following steps:

• Consists of alternating layers of core and

prepreg stacked

• The finished PCB is heated and cured.

• The via holes are drilled

• Plating covers holes and outer surfaces

• Etching removes unwanted copper

• Board is ti nned, coated with solder mask

and silk screened

Zo

Zo

®

processor DDR SDRAM or Peripheral Bus Interface

8 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 9

Introduction 2

The Intel® 411 1 0 Serial to Parallel PCI Bridge integrates a PCI Express-to-PCI bridge. The bridge

follows the PCI-to-PCI Bridge programming model. The PCI Express port is compliant to the PCI

Express Specification, Revision1.0. The PCI bus interface is fully compliant to the PCI Lo cal Bus

Specification, Revision 2.3.

2.1 PCI Express Interface Features

• PCI Express Specification, Revision 1.0b compliant.

• Support for single x8, single x4 or single x1 PCI Express operation.

• 64-bit addressing support.

• 32-bit CRC (cyclic redundancy checking) covering all transmitted data packets.

• 16-bit CRC on all link message information.

• Raw bit-rate on the data pins of 2.5 Gbit/s, resulting in a raw bandwidth per pin of 250 MB/s.

• Maximum realized bandwidth on PCI Express interface is 2 GB/s (in x8 mode) in each

direction simultaneously, for an aggregate of 4 GB/s.

2.2 PCI-X Interface Features

• PCI Local Bus Specification, Revision 2.3 compliant.

• PCI-to-PCI Bridge Specification, Revision 1.1 compliant.

• PCI-X Addendum to the PCI Local Bus Specification, Revision 1.0a compliant.

• 64-bit 66 MHz, 3.3 V, NOT 5 V tolerant.

• On Die Termi nati on (ODT) with 8.2KΩ pull-up to 3.3V for PCI signals.

• Six external REQ/GNT Pairs for internal arbiter on the PCIX bus segment respectively.

• Programmable bus parking on either the last agent or always on Int el® 41 1 10 S erial to Parallel

PCI Bridge.

• 2-level programmable round-robin internal arbiter with Multi-Transaction Timer (MTT)

• External PCI clock-feed support for asynchronous primary and secondary domain operation.

• 64-bit addressing for upstream and downstream transactions

• Downstream LOCK# support.

• No upstream LOCK# support.

• PCI fast Back-to-Back capable as target.

• Up to four active and four pending upstream memory read transactions

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 9

Page 10

Introduction

• Up to two downstream delayed (memory read, I/O read/write and configuration read/write)

transaction.

• Tunable inbound read prefetch algorithm for PCI MRM/MRL commands

• Local initialization via SMBus

• Secondary side initialization via Type 0 configuration cycles.

2.3 Power Management

• Support for PCI Express Active State Power Management (ASPM) L0s link state

• Support for PCI PM 1.1 compatible D0, D3hot and D3cold device power states

• Support for PME# event propagation on behalf of PCI devices

2.4 SMBus Interface

• Compatible with System Management Bus Specification, Revision 2.0

• Slave mode operation only.

• Full read/write access to all configuration registers

2.4.1 SMBus for configuration register initialization

• Support for local initialization of the configuration registers can be implemented using a

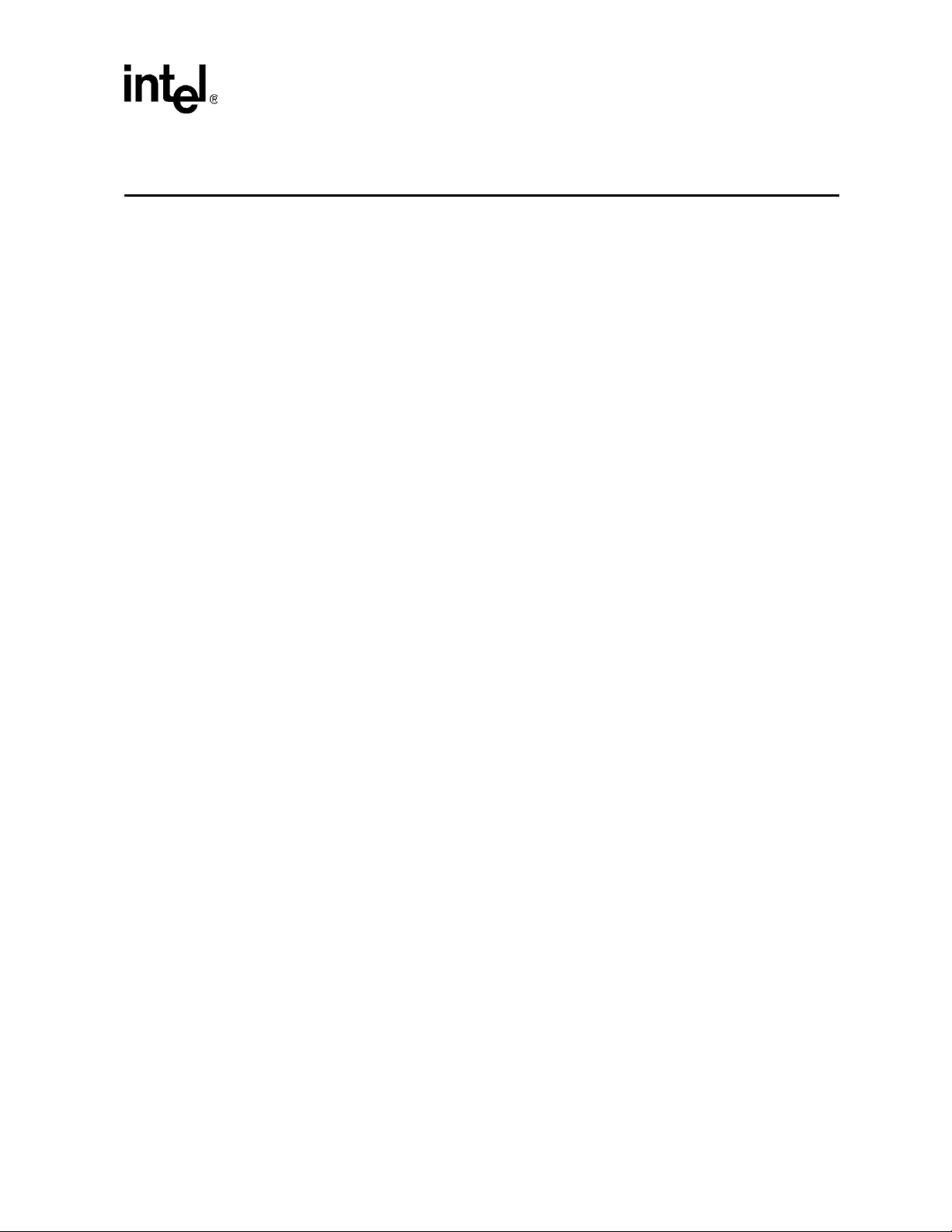

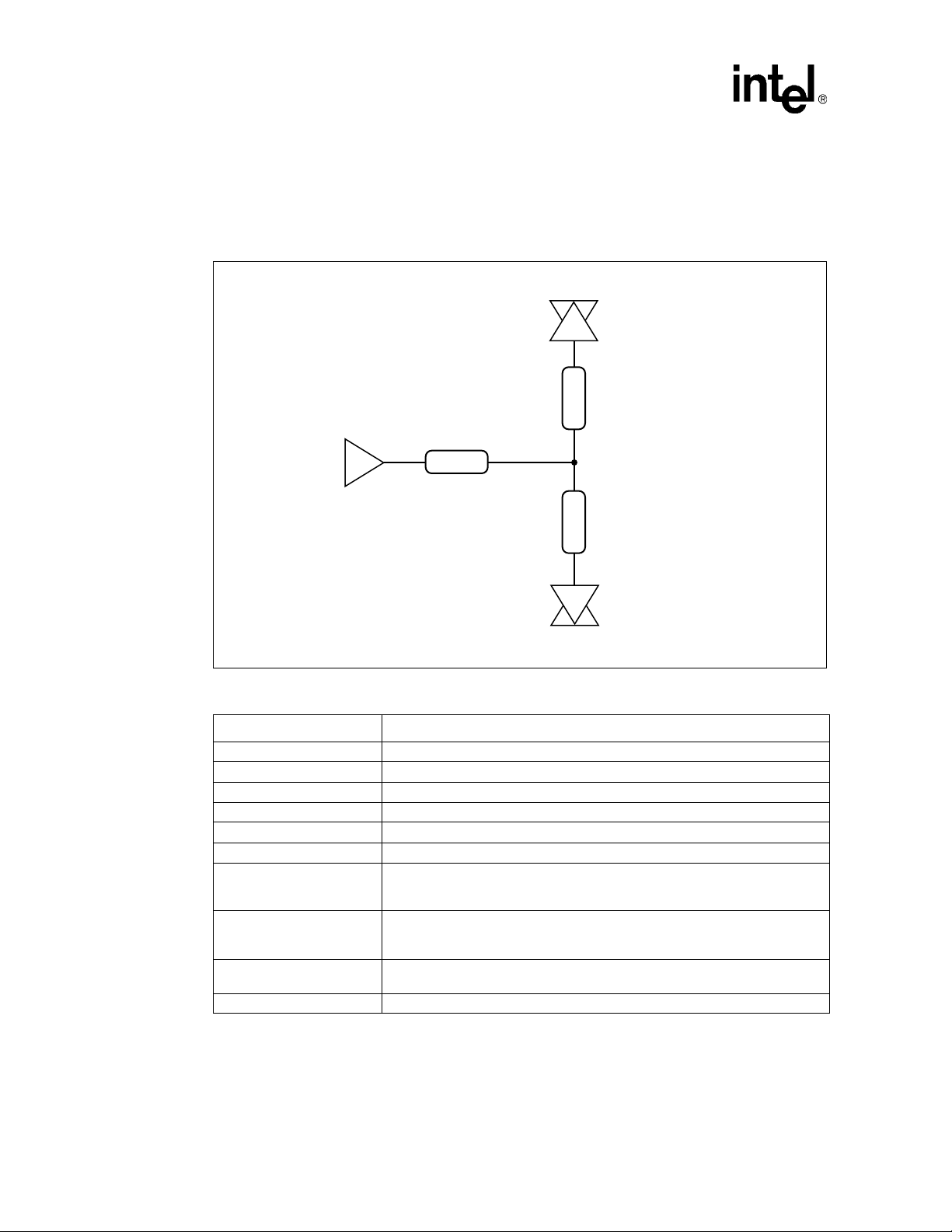

microcontroller via SMB. Figure 1shows this SMBus and the data transfer that occurs between

the 41110 and the microcontroller.

• Configuration Register information is stored internally in a microcontroller and the

information is transferred to the product via System Managed Bus (SMBus) protocols when

the device receives power or reset.

• The requirements of the microcontroller are as follows:

— Supports I

— Has at least 256 Byte of internal EEprom space

— To facilitate this programming on the Customer Reference Board a Microchip part

PIC16F876A was used.

— Code space: estimated code size is ~2K words of program s pace and 32 words of RAM

2

C and SMBus Prot ocols

10 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 11

Figure 1. Micro c ontro l ler Block Diag ra m

Introduction

Se rial to P ar a lle l

PCI Bridge

2.4.2 Microcontroller Connections to the 41110

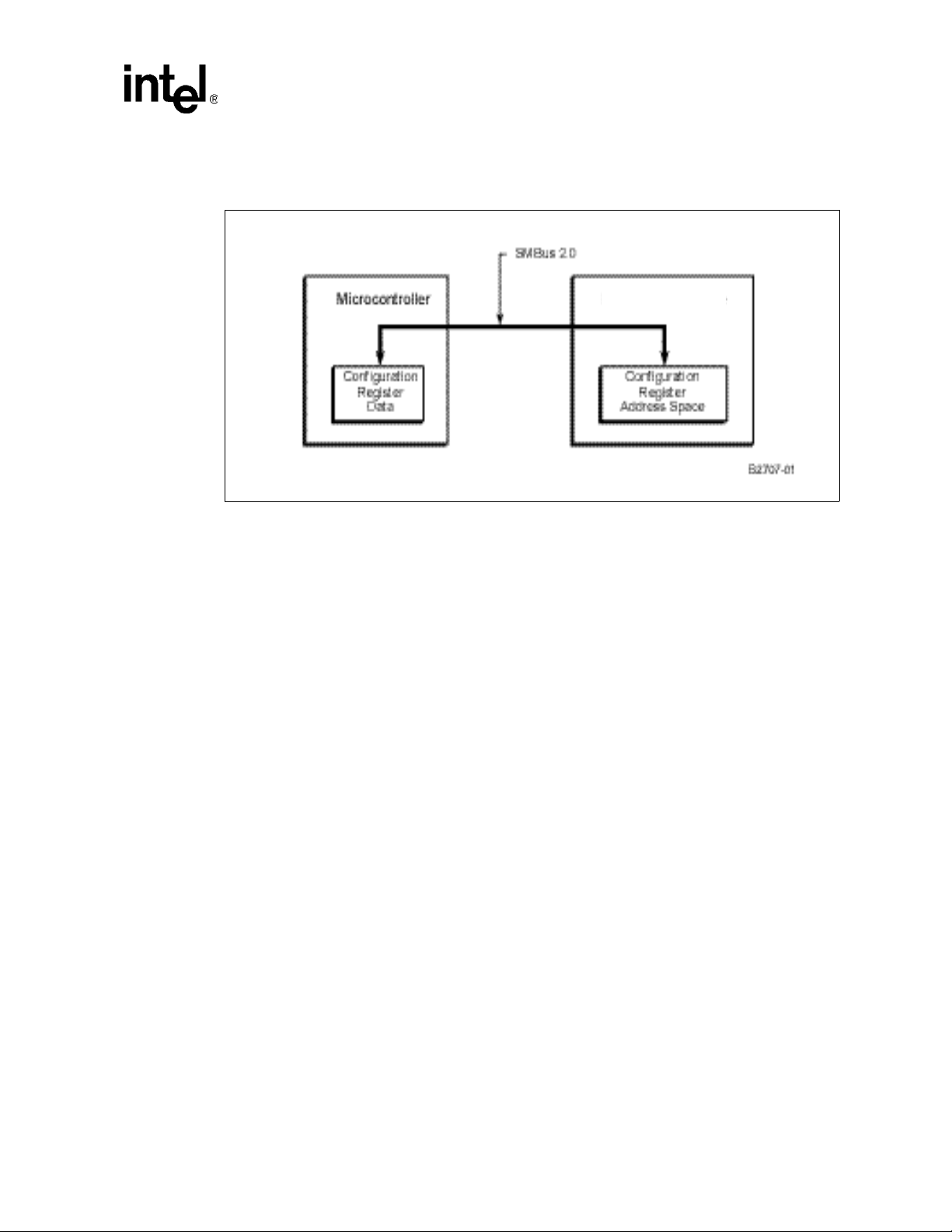

Figure 2 shows the SMB interface from the 41110 to the microcontroller.

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 11

Page 12

Introduction

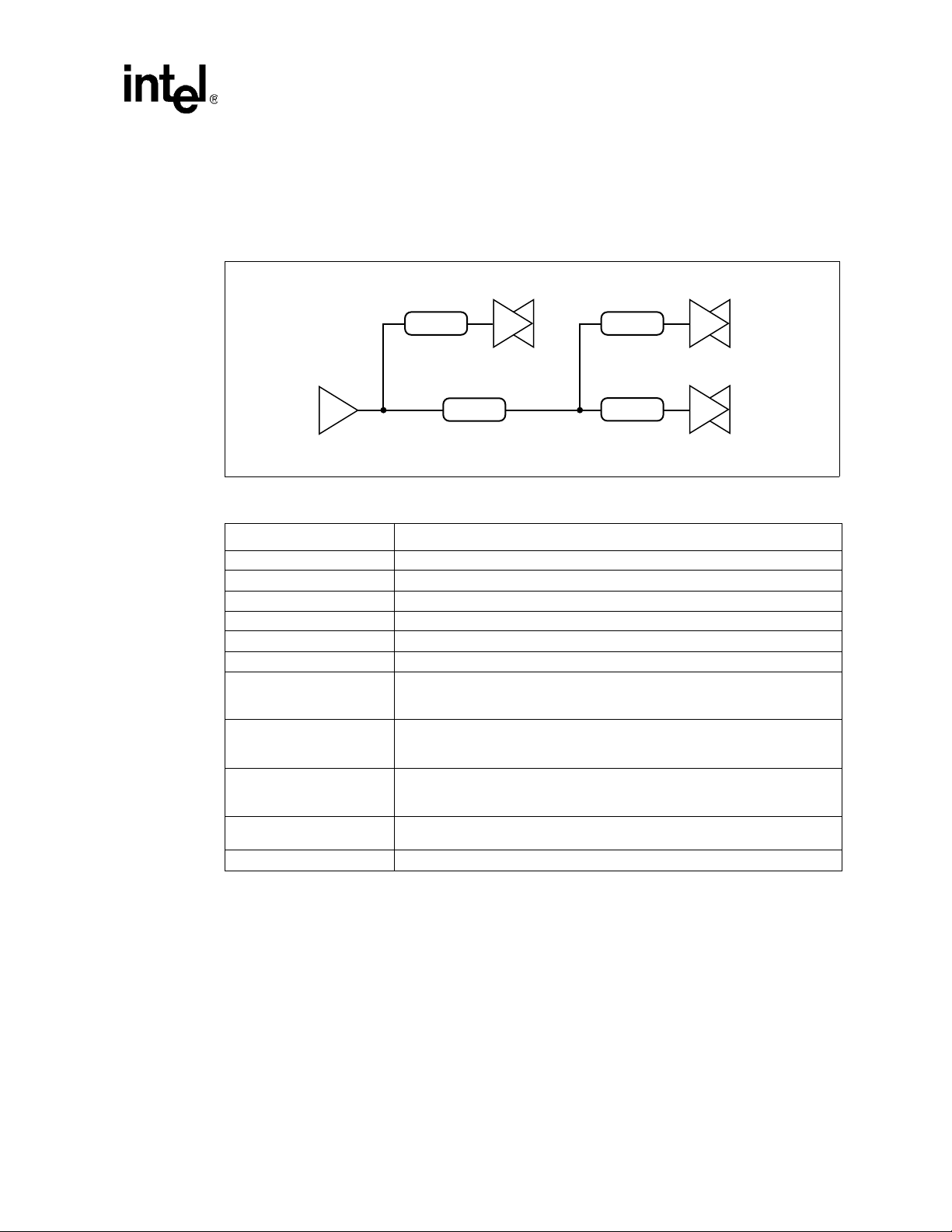

Figure 2. 41110 Microcontroller Connections

Serial to

Parallel PCI

Bridge

2.5 JTAG

• Compliant with IEEE Standard Test Access Port and Boundary Scan Architecture 1149.1a

2.6 Related Documents

• .

• PCI Express Specification, Revision 1.0, from www.pci-s ig.com.

• PCI Express Design Guide, Revision 0.5

• PCI Local Bus Specification, Revision 2.3, from www.pci-sig.com.

• PCI-X Addendum to the PCI Local Bus Specification, Revision 1.0a, from www.pci-sig.com.

• IEEE Standard Test Access Port and Boundary Scan Architecture 1149.1a

• System Management Bus Specification, Revision 2.0

12 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 13

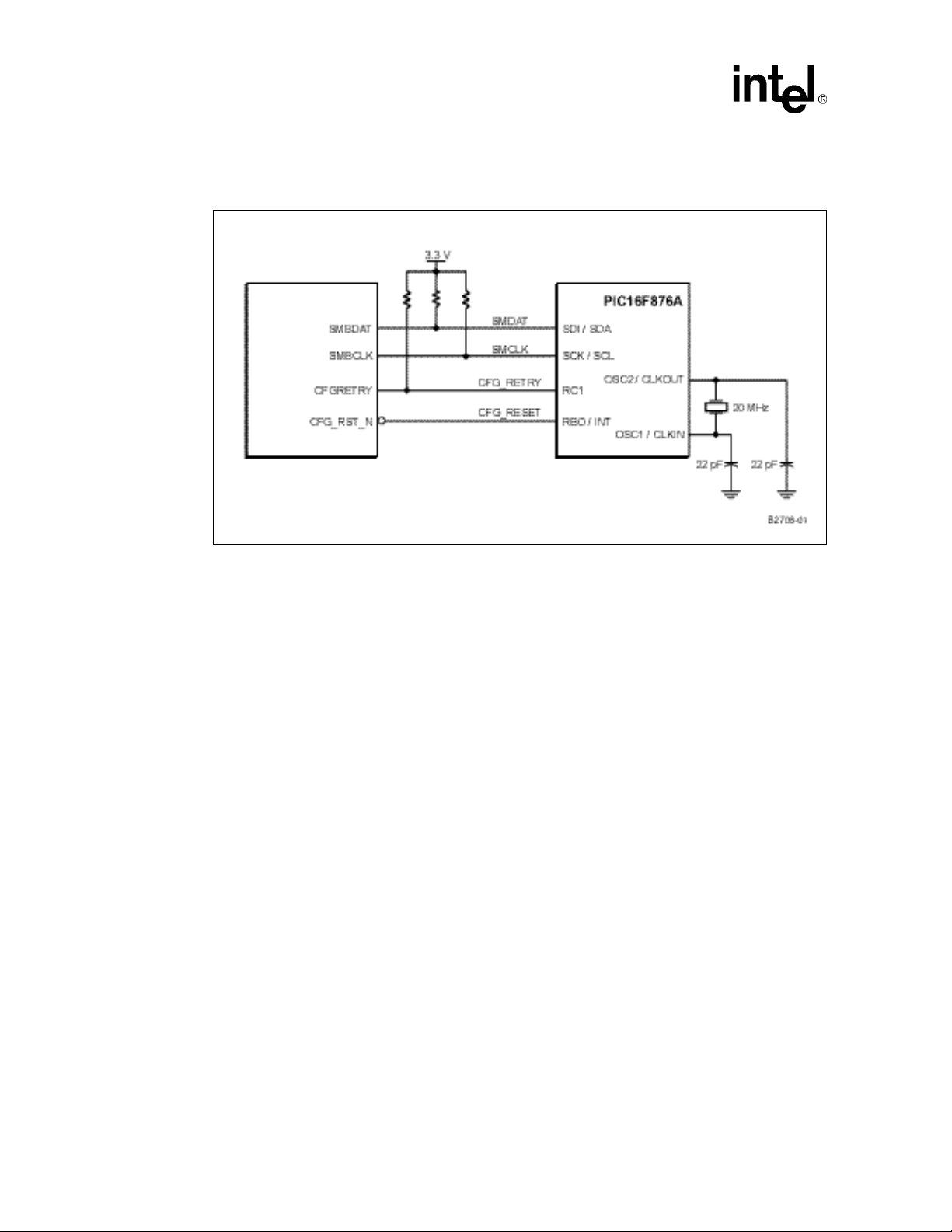

Figure 3. 41110 Block Diagram

Introduction

Serial to Parallel

PCI Bridge

2.7 Intel® 41110 Serial to Parallel PCI Bridge Applications

This section provides a block diagram for a typical the 41110 application. This application shows a

PCI-E adapter card with two Dual 2Gb Fibre Channel controllers. Each of the PCI-X bus segmen ts

is connected to the Dual 2Gb Fibre Channel chip running at 133MHz. The two Dual FC chips

provides the four 2Gb/s outputs.

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 13

Page 14

Introduction

Figure 4. 41110 Adapter Card Block Diagram

Serial to Pa rallel

PCI Bridge

14 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 15

Package Information 3

3.1 Package Specification

The 41110 Bridge is in a 567-ball FCBGA package, 31mm X 31mm in size, with a 1.27mm ball

pitch (see Figure 5 and Figure 6).

Figure 5. 41110 Bridge Package Dimensions (T o p View)

Handling

Exclusion

0. 547 in.

Area

0. 247 in.

0. 200 in.

0. 291 in.

0. 491 in.

17. 00 mm

21. 00 mm

31. 00 mm

Die

Keepout

Area

17. 00 mm 21 . 00 mm 31 . 00 mm

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 15

Page 16

Package Information

Figure 6. 41110 Bridge Package Dimensions (Side View)

Substrate

2.445±0.102 mm

2.010±0.099 mm

0.435±0.025 mm

Se e Note 3

Notes:

1. Primary datum -C- and seating plan are defined by the spherical crowns of the solder balls (shown before motherboard attach).

2. All dimensions and tolerances conform to ANSI Y14.5M-1994

3. BGA has a pre-SMT height of 0.5 mm and post-SMT height of 0.41-0.46 mm

4. Shown before motherboard attach; FCBGA has a convex (dom e shape) orientation before reflow and is expected to have a slightly

concave (bowl shaped) orientation after reflow.

0.84±0.05 mm

Decoup

Cap

Die

Seating Plane

0.7 mm Max

0.20

See Note 4.

0.20

Se e Note 1

Note: Primary datum -C- and seating plane are defined by the spherical crowns of the solder balls.

Note: All dimensions and tolerance s conform t o ANSI Y14.5M -1982

-C-

16 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 17

Power Plane Layout 4

This chapter provides details on the decoupling and voltage planes needed to bias the 41110

package.

4.1 41110 Decoupling Guidelines

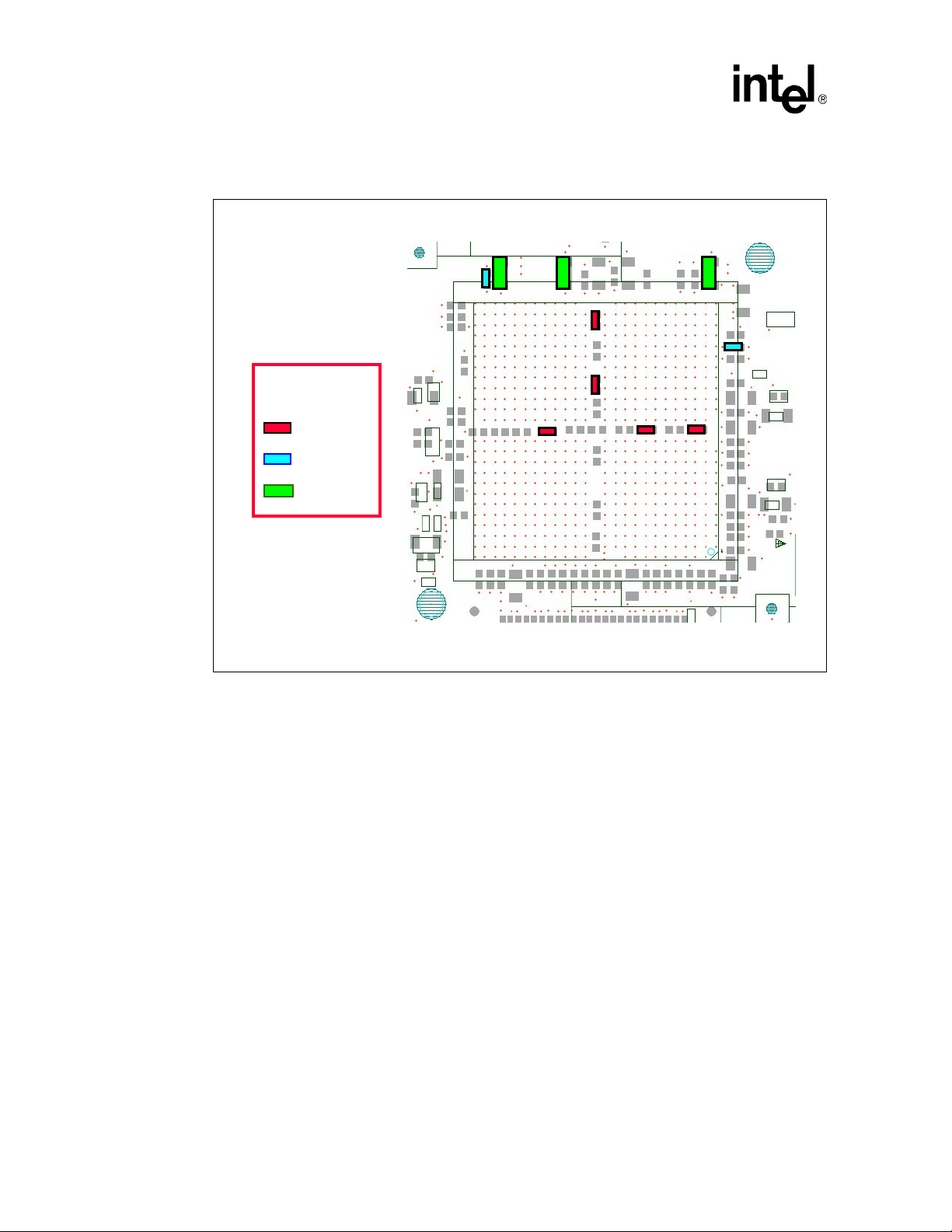

Table 2 lists the decoupling guidelines for the 41110. Figure 7 and Figure 8 provide the decoupling

capacitors around the 41110 ball grid pins.

Figure 7. Decoupling Placement for Core and PCI Express Voltage Planes

B2713-01

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 17

Page 18

Power Plane Layout

Figure 8. Decoupling Placement for PCI/PCI-X 1.5V and 3.3V Volt age Planes

Capacitor Legend

0603-0.1 F

0603-1 F

1206-10 F

B2714-01

18 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 19

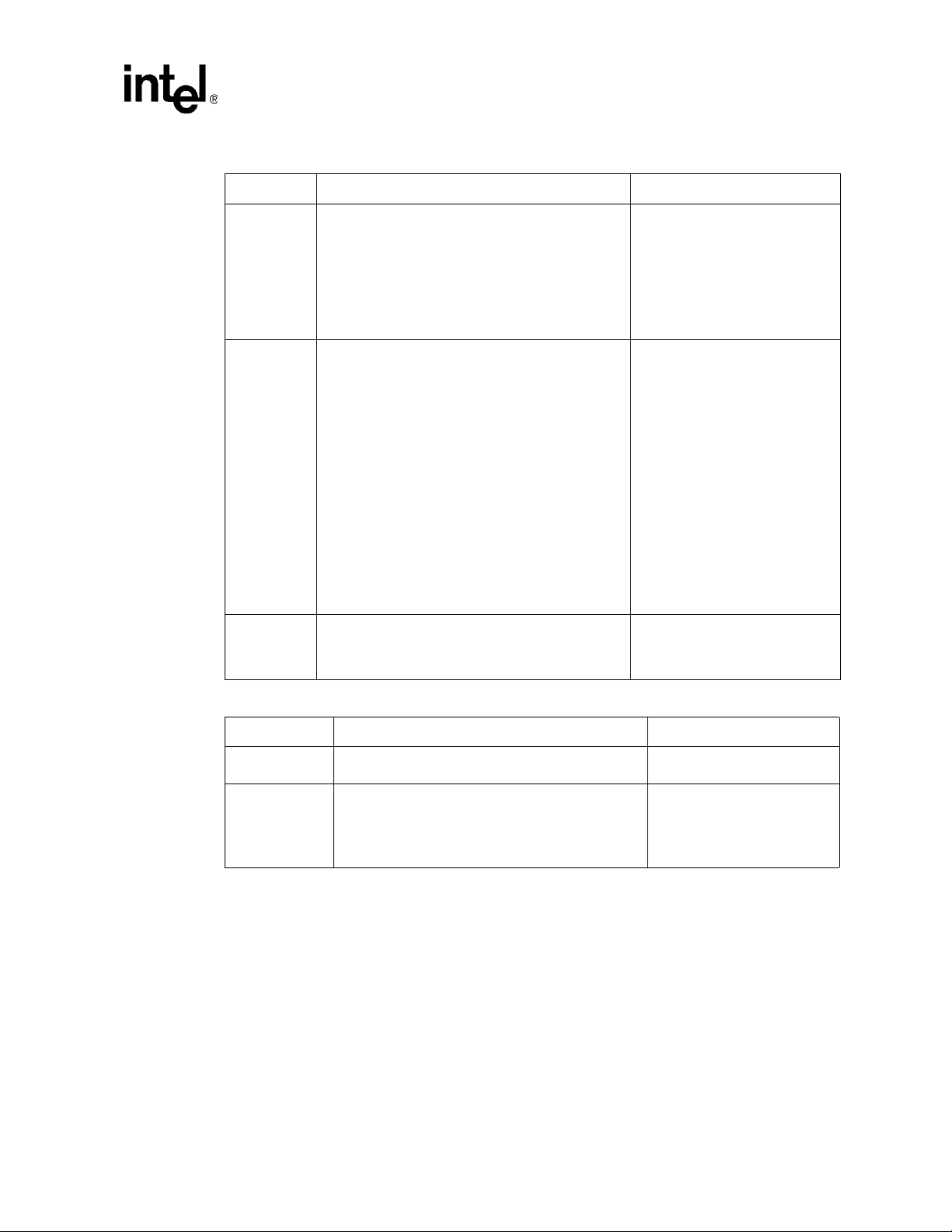

T a ble 2. 41110 Decoupling Guidelines

Power Plane Layout

Vol tage Plane Voltage

PCI/PCI-X

Voltage

PCI/PCI-X

Voltage

PCI/PCI-X

Voltage

Core Voltage 1.5V VCC15 0.1 0603 200 2.0 5

Core Voltage 1.5V VCC15 1.0 0805 200 2.3 5

Core Voltage 1.5V VCC15 10 1206 200 1.9 2

PCI Express

Voltage

PCI Express

Voltage

PCI Express

Voltage

3.3V VCC33 0.1 0603

3.3V VCC33 1.0 0603

3.3V VCC33 10 1206

1.5V VCCPE 0.1 0603 200 2.0 3

1.5V VCCPE 1 0805 200 2.3 4

1.5V VCCPE 10 1206 200 1.9 2

41110

Bridge

Pins

C

(uF)

Package

ESR

(mΩ)

50-

300

50-

300

50-

300

ESL

(nH)

1.0-

3.0

1.0-

3.0

1.0-

3.0

Caps

# of

5

As close as design

2

41110 Bridge BGA

As close as design

3

41110 Bridge BGA

As close as design

41110 BridgeBGA

As close as design

41110 Bridge BGA

As close as design

41110 Bridge BGA

As close as design

41110 Bridge BGA

Location

Beneath 41110

Bridge BGA

rules will allow to

rules will allow to

Beneath 41110

Bridge BGA

rules will allow to

rules will allow to

Beneath41110

Bridge BGA

rules will allow to

rules will allow to

4.2 Split Voltage Planes

There are two 1.5V voltage planes that supply power to the 4111 0:

• VCC15:1.5V ±5% (1.5V core voltage)

• VCCPE:1.5V ±3% (1.5V PCI Express voltage)

The 41110 Bridge core (VCC15), PCI-Express (VCCPE) voltages should be supplied by t wo

separate voltage regulators or a single regulator. If VCC15 and VCCPE is supplied by a single

voltage regulator the power planes should be split as shown in Figure 9.

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 19

Page 20

Power Plane Layout

Note: Linear voltage regulators are recommended when using 1.5 Volt power supplies.

Figure 9. 41110 Bridge Single-Layer Split Voltage Plane

re

Core

PCI

Express

B2715-01

20 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 21

41110 Reset and Power Timing

Considerations 5

This chapter describes the 41110 reset timing considerations.

5.1 A_RST# and PERST# Timing Requirements

The PCI-X Specification requires that there is a 100ms delay from valid power (PERST#) to reset

deassertion (A_RST#). 41110 will keep A_RST# asserted for a minimum of 320ms after PERST#

is deasserted.

5.2 VCC15 and VCC33 Voltage Requirements

The following steps are the power sequencing requirements th at must be followed with the

41110:

1. The 41110 requires that the VCC33 voltage rail be no less than 0.5V below VCC15 (absolute

voltage value) at all times during 41110 operation, including during system power up and

power down. In other words, the f ollowing mu st always be t rue:

VCC33 >= (VCC15 – 0.5V)

This can be accomplished by placing a diode (with a voltage drop <0.5V) between VCC15 and

VCC33. A node will be connected to VCC15 and cathode will be connected to VCC33.

If VCC15 (1.5V PCI-X I/O voltage) and VCC15 (1.5V core voltage) are tied together on the

platform, then both voltages must meet the above rule.

Note: Linear voltage regulators are recommended when using 1.5 Volt power supplies.

2. If a voltage regulator solution is used which shunts VCC15 to ground while VCC33 is

powered, the maximum all owa ble t ime that VCC15 can be shunted to ground w hil e V C C33 is

fully powered is 20ms.

3. The maximum allowed time between VCC33 and VCC15 ramping is 525ms .

Note: There is no minimum sequencing time requirement other thanrequirements in Steps 2 and 3.

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 21

Page 22

41110 Reset and Power Timing Considera tions

This page intentionally left blank.

22 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 23

General Routing Guidelines 6

This chapter provides some basic ro uting guidel ines for layout and design of a printed circuit board

using the 41110. The high-speed clocking required when designin g with the 41110 requires special

attention to signal integrity. In fact, it is highly recommended that the board design be simulated to

determine optimum layout for signal integrity. The information in this chapter provides guidelines

to aid the designer with board layout. Several factors influence the signal integrity of a 41110

design. These factors include:

• power distribution

• minimizing crosstalk

• decoupling

• layout considerations when routing the PCI Express bus and PCI-X bus interfaces

6.1 General Routing Guidelines

This section details general routing guidelines for designing with the 41110. The order in which

signals are routed varies from designer to designer. Some designers prefer to route all clock signals

first, while others pre fer to route al l high -speed b us sig nals fi rst. Ei ther ord er can be u sed, pr ovide d

the guidelines listed here are followed.

6.2 Crosstalk

Crosstalk is caused by capacitive and inductive coupling between signals. Crosstalk is composed of

both backward and forward cr osstalk comp onents. Back ward crosstalk cre ates an induced signal on

victim network that propagates in the opposite direction of the aggressor signal. Forward crosstalk

creates a signal that propagates in the same direction as the aggressor signal.

Circuit board analysis software is used to analyze your board layout for crosstalk problems.

Examples of 2D analysis tools include Parasitic Parameters from ANSOFT

*

Design

software is not available, the layout should be designed to maintain at least the minimum

recommended spacing for bus interfaces.

. Crosstalk problems occur when circuit etch lines run in parallel. When board analysis

• A general guideline to use is, that space distance between adjacent signals be a least 3.3 times

the distance from signal trace to the nearest return plane. The coupled noise between adjacent

traces decreases by the square of the distance between the adjacent traces.

• It is also recommended to specify the height of the above reference plane when laying out

traces and provide this parameter to the PCB manufacturer. By moving traces closer to the

nearest reference plane, the coupled noise decreases by the square of the distance to the

reference plane.

*

and XFS from Quad

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 23

Page 24

General Routing Guidelines

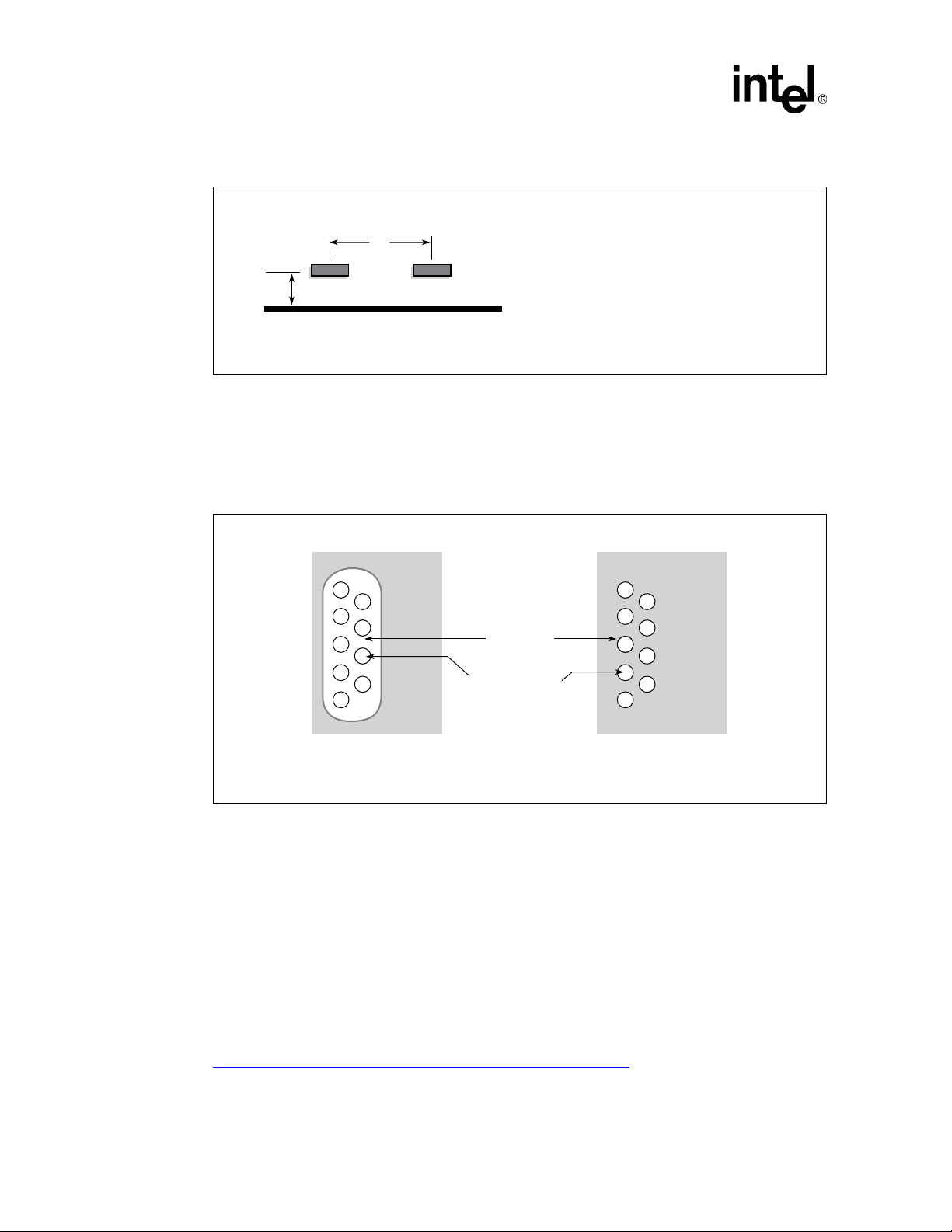

Figure 10. Crosstalk Effects on Trace Distance and Height

P

H

aggressor victim

• Avoid slots in the ground plane. Slots increases mutual inductance thus increasing crosstalk.

• Make sure that ground plane surrounding connector pin fields are not completely cleared out.

When this area is completely cleared out, around the connector pins, all the return current must

flow together around the pin field increasing crosstalk. The preferred method of laying out a

connector in the GND layer is shown in Figure 11.

Figure 11. PCB Ground Layout Around Connectors

Connector

Connector Pins

Reference Plane

Reduce Crosstalk:

- Maximize P

- Minimize H

A9259-01

GND PCB Layer

A. Incorrect method B. Correct method

A9260-01

6.3 EMI Considerations

It is highl y recommen ded that good EMI design practice s be followed when designing with th e

41110.

• To minimize EMI on your PCB a useful technique is to not extend the power planes to the

edge of the board.

• Another technique is to surround the perimeter of your PC B layers with a GND trace. This

helps to shield the PCB with grounds minimizing radiation.

The below link can provide some useful general EMI guidelines considerations:

http://developer.intel.com/design/auto/mcs96/applnots/272673.htm

24 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 25

6.4 Power Distribution and Decoupling

Have ample decoupling to ground, for the power planes, to minimize the effects of the switching

currents. Three types of decoupling are: the bulk, the high-frequency ceramic, and the inter-plane

capacitors.

• Bulk capacitance consist of electrolytic or tantalum capacitors. These capacitors supply large

reservoirs of charge, bu t they are useful only at lower frequencies due to lead inductance

effects. The bulk capacitors can be located anywhere on the board.

• For fast switching currents, high-frequency low-inductance capacitors are most effective.

Place these capacitors as close to the device being decoupled as possible. This minimizes the

parasitic resistance and inductance associated with board traces and vias.

• Use an inter-plane capacitor between power and ground planes to reduce the effective plane

impedance at high frequencies. The general guideline for placing capacitors is to place highfrequency ceramic capacitors as close as possi ble to the module.

6.4.1 Decoupling

Inadequate high-frequency decoupling results in intermittent and unreliable behavior.

General Routing Guidelines

A general guideline recommends that you use the largest easily available capacitor in the lowest

inductance package. For specific decoupling requirements for a 41110 appli cation please refer to

Chapter 4.

6.5 Trace Impedance

All signal layers require contr olled impeda nce 60 Ω +/- 15%, microstrip or stripline for add-in card

applications. Selecting the appropriate board stack-up to minimi ze impedan ce variation s is very

important. When calculating flight times, it is important to consider the minimum and maximum

trace impedance based on the switching neighboring traces. Use wider s paces between traces, since

this can minimize trace-to-trace coupling, and reduce cros s talk.

When a different stack up is used the trace widths must be adjusted appropriately. When wider

traces are used, the trace spacing must be adjusted accordingly (linearly).

It is highly recommended that a 2D Field Solver be used to design the high-speed traces. The

following Impedance Calculator URL provide approximations for the trace impedance of various

topologies. They may be used to generate the starting point for a full 2D Field solver.

http://emclab.umr.edu/pcbtlc/

The following website link provides a useful basic guideline for calculating trace parameters:

http://www.ultracad.com/calc.htm

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 25

Page 26

General Routing Guidelines

Note: Using stripline transmission lines may give better results than m icrost rip. This is due to th e

difficulty of precisely controlling the dielectric constant of the solder mask, and the difficulty in

limiting the plated thickness of microstrip conductors, which can substantially increase cross-talk.

6.5.1 Differential Impedance

The PCI Express standard defines a 100 Ω differential impedance. This sect ion provides some basi c

background information on the differential impedance calculations. In the cross section of

Figure 12 shows the cross section of two traces of a differential pair.

Figure 12. Cross Section of Different ial Trace

Ground reference plane

B2716 -01

To calculate the coupled impedance requires a 2x2 matrix. The diagonal values in the matrix

represent the impedance of the traces to ground and the off-diagonal values provide a measure of

how tightly the traces are coupled. The “differential impedance is the value of the line-to-line

resistor terminator that optimally terminates pure differential signals.” The two by two matrix is

shown below as:

Figure 13. Two-by-two Differential Impedance Matrix

Z11 Z12

=

Z

o

Z21 Z22

For a symmetric trace Z11 = Z22, the differential impedance can be calculated from this equation:

Z

differential

For two traces to be symmetric, they must have the same width, thickness and height above the

ground plane.

= 2(Z11-Z12)

1

With the traces terminated with the appropriate differential, impedance ringing is

minimized.

B2717 -01

1. “Terminating Differential Signals on PCBs”, Steve Kaufer and Kelee Crisafulli, Printed Circuit Design, March 1999

26 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 27

Board Layout Guidelines 7

This chapter provides details on adapter card stackup suggestions. It is highly recommend ed that

signal integrity simulations be run to verify each 41110 PCB layout especially if it deviates from

the recommendations listed in these design guidelines.

7.1 Adapter Card Topology

The 41110 will be implemented on PCI-E adapter cards with an eight layer stackup PCB. The

specified impedance range for all adapter card implementations will be 60

will be made for interfaces specified at other impedances. Table 3 defines the typical layer

geometries for eight layer boards.

T a ble 3. Adapter Card Stack Up, Microstrip and Stripline

Ω +/-15%. Adjustments

Variable Type

Solder Mask Thickness (mil) N/A 0.8 0.6 1.0

Solder Mask E

Core Thickness (mil) N/A 2.8 3.0 3.2

Core E

Plane Thickness (mil)

Trace Height

Trace Thickness (mil)

Trace Width (mil) Microstrip 4.0 2.5 5.5

Total Thickness (mil) FR4 62.0 56.0 68.0

(mil)

Preg E

N/A 3.65 3.65 3.65

r

N/A 4.3 3.75 4.85 2113 material

r

Power 2.7 2.5 2.9

Ground 1.35 1.15 1.55

13.53.33.7

23.53.33.7

3 10.5 9.9 11.1

Microstrip 4.30 3.75 4.85 2113 material

Stripline1 4.30 3.75 4.85 2113 material

r

Stripline2 4.3 3.75 4.85

Microstrip 1.75 1.2 2.3

Stripline 1.4 1.2 1.6

Stripline 4.0 2.5 5.5

Nominal

(mils)

Minimum

(mils)

Maximum

(mils)

Notes

The trace height will be determined to

achieve a nominal 60 Ω.

7628 material. Trace height 3 is composed

of one piece of 2113 and one piece of

7628.

Trace Spacing (using

microstrip E2E/C2C)

Trace Spacing (using

stripline E2E/C2C)

Trace Impedance

[12]/[16]

[12]/[16]

Microstrip 60 51 69

Stripline 60 51 69

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 27

Page 28

Board Layout Guidelines

Note: Each interface will set the trace spacing based on its signal integrity of differential impedance

requirements. For the purposes of the building the transmission line models, it is assumed the

artwork is very accurate and therefore a constant. All the variability in the trace spacing is the result

of the tolerances of the trace width.

Figure 14. Adapter Card Stackup

L8

Stripline

Trace

Spacing

Microstrip

Trace

Width

L1

L3

Stripline

Trace

Width

Microstrip Trace Thickness

Solder Mask Thickness

Trace Height 1

Trace Height 2

Stripline Trace Thickness

Trace Height 3

Core Thickness

Plane Thickness

L4

B1436-01

Microstrip

Trace

Spacing

L1

L2 (GND)

L3

L4 (VCC)

Total Thicken ss

L5 (VCC)

L4

L7 (GND)

28 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 29

PCI-X Layout Guidelines 8

This chapter describes several factors to be considered with a 41110 PCI/PCI-X design. These

include the PCI IDSEL, PCI RCOMP, PCI Interrupts and PCI arbitration.

8.1 Interrupts

PCI Express provides interrupt messages that emulate the legacy wired mechanism. This allows IO

devices to signal PCI-style interrupts using a pair of ASSERT and DEASSERT messages This

message pairing preserves the level-sensitive semantics of the PCI interrupts on PCI Express.

The 41110 uses four interrupts - A_INTA:A_INTD on bus A segment corresponding to the four

interrupts defined in the PCI specification. The 41110 routes its PCI interrupt pins and the internal

interrupts to PCI Express INTx interrupts according to Table 4.

Table 4. INTx Routing Table

A_INT# Interrupt Pins PCI Express INTx Message

A_INTA INTA

A_INTB INTB

A_INTC INTC

A_INTD INTD

The 411 10 wi ll use its primary bu s number and dev ice number in the Requ ester ID field fo r the PCI

Express INTx messages. As stated in the PCI Express specification, the function number is

reserved for interrupt messages and wil l always be 0.

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 29

Page 30

PCI-X Layout Guidelines

Note: PCI Express Assert_INTx/Deassert_INTx messages are not inhibited by the BME bit.

8.1.1 Interrupt Routing for Devices Behind a Bridge

Given the legacy interrupt sharing scheme shown in Table 5, to get the best legacy interrupt

performance (by reducing interrupt sharing), adapter boards have to select the appropriate

A_INTX# (where X is A, B, C or D) inpu t pin to us e on the P CI bus segm ent. The ch osen inte rrupt

input also imposes a PCI device number requirement for the interrupt source as specified in the

PCI-to-PCI Bridge specification and reproduced in Table 5

Table 5. Interrupt Binding for Devices Behind a Bridge

.

Device Number on

Secondary Bus

a

. 4, 8b, 12, 16, 20, 24, 28

-

b

1, 5, 9

, 13, 17, 21, 25, 29

b

2, 6, 10

3, 7, 11

a. Device number 0 is reserved for the Bridge and should not be assigned to secondary devices.

b. AD[27:24] which correspond to devices 11:8 should not be used for IDSEL# connections as these signals are used

, 14, 18, 22, 26, 30

b

, 15, 19, 23, 27, 31

when accessing the extended configuration space in the bridge from the secondary bus.

Interrupt Pin on Device Interrupt on 41110 Bridge

INTA# INTA#

INTB# INTB#

INTC# INTC#

INTD# INTD#

INTA# INTB#

INTB# INTC#

INTC# INTD#

INTD# INTA#

INTA# INTC#

INTB# INTD#

INTC# INTA#

INTD# INTB#

INTA# INTD#

INTB# INTA#

INTC# INTB#

INTD# INTC#

8.2 PCI Arbitration

The 41110 supports a high-performance internal PCI arbiter that supports up to seven masters on

each PCI segment A and B PCI Buses. The request inputs into the internal arbiter include: six

external request inputs and 1 internal request input. All request inputs to the internal arbiter are

split into two groups, a high priority group and a low priority group. Any master, including the

internal master, c an be p rog rammed to be i n eit her of the t wo g rou ps . Thi s could al so m ean that all

the request inputs into the arbiter could be in one single group. Within a group, priority is roundrobin. The entire low-priorit y group represents one slot in the high priority group. The 41110

provides a 16-bit arbiter control register to control two aspects of the internal arbiter behavior:

• Priority group for a master (i.e., whether a master is in low priority group or high priority

group).

30 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 31

• Bus parking on last PCI agent or the bridge.

By default, the arbiter parks the bus on the bridge and drives the A/D, C/BE# and PAR lines to a

known value while the bus is idle.

8.2.1 PCI Resistor Compensation

Figure 15 provides the recommended resistor compensation pin termination for the PCI A bus.

Figure 15. PCI RCOMP

RCOMP

100

PCI-X Layout Guidelines

Ω

– 1%

8.3 PCI General Layout Guidelines

For acceptable signal integrity with bus speeds up to 133MHz it is important to PCB design layout

to have controlled impedance.

• Signal traces should have an unloaded impedance of 60 +/- 10% Ω.

• Signal trace velocity should be roughly 150 – 190ps/inch

There are a couple of general guidelines which s hould be used when routing your PCI bus signals:

• Avoid routing signals > 8”.

• The following signals have no length restrictions: A_INTA#, A_INTB#, A_INTC#,

A_INTD#, and TCK, TDI, TDO, TMS and TRST#. Most PCI-X signals are timing critical.

These signals have length restrictions for propagation, setup, and hold requirements. Table 6

shows the PCI-X signals.

B2718 -01

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 31

Page 32

PCI-X Layout Guidelines

Table 6. PCI-X Signals

A PCI Bus Segment:

Timing Critical Signals

Reset Signals

Non Timing Critica l

Signals

A_ACK64#, A_AD[63:0], A_C BE _ [7: 0] # , A_DEVSEL#, A_FRAME#,

A_GNT_[5:0]#, A_IRDY#, A_LOCK#, A_PAR64, A_REQ64#, A_REQ_[5:0]#,

A_STOP#, A_TRDY#, A_CLKO [6: 0 ], A_C LKI

A PCI Bus Segment:

A_RST#, A_PME#

A PCI Bus Segment:

A_133EN, A_IRQ[15:0]#, A_M 66EN, A_PCIXCAP, A_PERR#, A_SERR#

Table 7. PCI/PCI-X Frequency/Mode Straps

A_PCIXCAP A_M66EN A_133EN(on

00XPCI 33

01XPCI 66

PCI-X 66MHz cards connect this

signal to ground through a 10KΩ

±5% resistor in parallel with a

0.01uF ±10% capacitor.

PCI-X 133 MHz cards connect

PCIXCAP to ground through a

0.01uF ±10% capacitor.

PCI-X 133 MHz cards connect

PCIXCAP to ground through a

0.01uF ±10% capacitor.

XXPCI-X 66

X0PCI-X 100

X1PCI-X 133

board)

Note: All signals sampled on the rising edge of PERST#.

8.3.1 PCI Pullup Resistors Not Required

PCI control signal s on the 41110 do NOT require pullup resi stor s on the adapt er card to ens ure that

they contain stable values when no agent is actively driving the bus. These include:

A_ACK64#, A_AD[63:32], A_CBE#[7:4], A_DEVSEL#, A_FRAME#, A_INTA#, A_INTB#,

A_INTC#, A_INTD#, A_IRDY#, A_PERR#, A_PAR, A_GNT#[5:0], A_REQ#[5:0], A_LOCK#,

A_PAR64, A_REQ64#, A_SERR #, A_STOP#, and A_TRDY#

Bus

Mode/

Freq

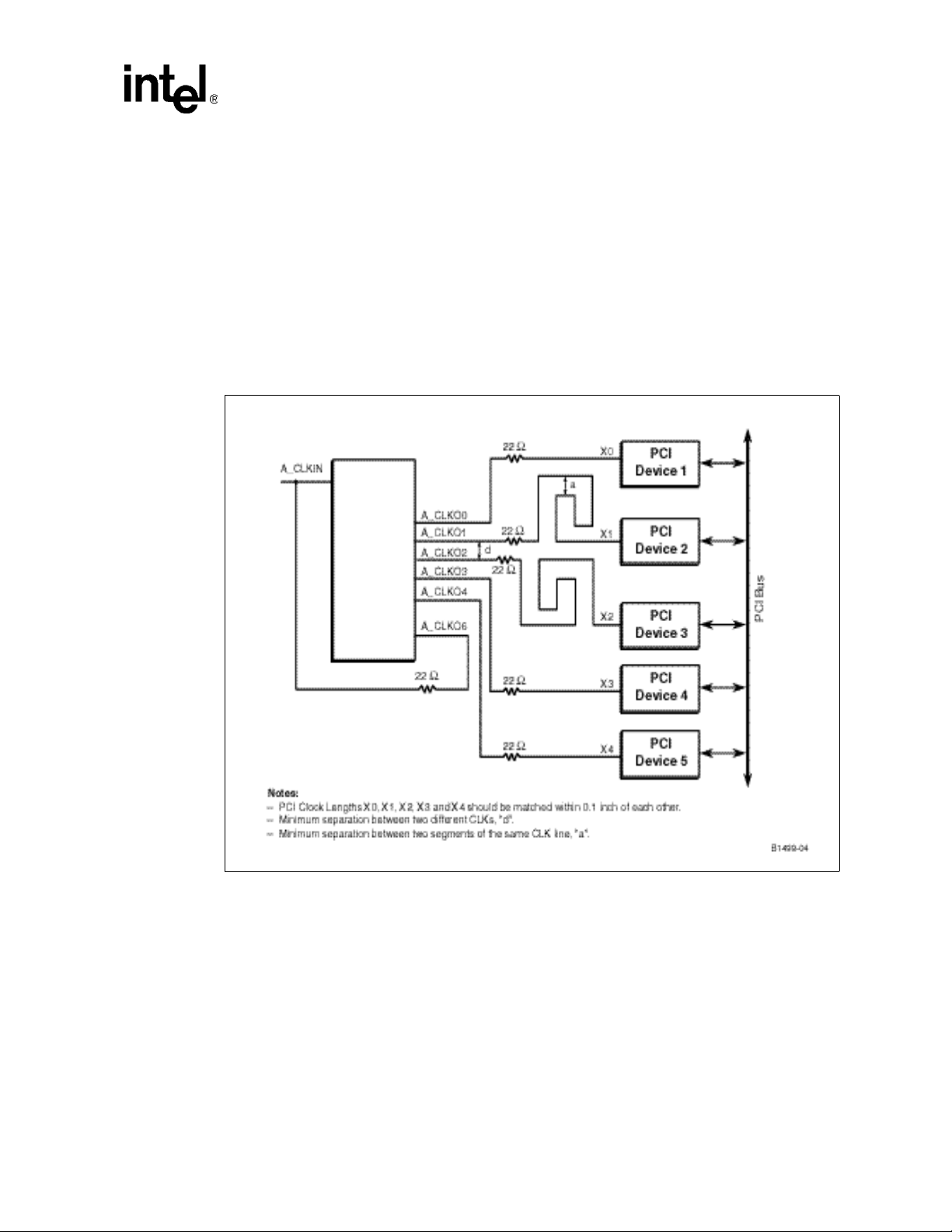

8.4 PCI Clock Layout Guidelines

The PCI-X Addendum to the PCI Local Bus Specification, Revision 1.0a compliant, allows a

maximum of 0.5 ns clock skew timing for each of the PCI-X frequencies: 66 MHz, 100 MHz and

133 MHz. A typical PCI-X application may require separate clock point-to-point connections

32 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 33

distributed to each PCI device. The 411 10 provides seven bu f fered cl ocks o n th e PCI b us to conn ect

to multiple PCI-X devices. The Figure 16 shows the use of four PCI “A” clock outputs and length

matching requirements. . The recommended clock buffer layout are specified as follows:

• Match each of the used the 41 1 1 0 outpu t clock len gths A_CLK[6:0 ] to within 0.1”to h elp keep

the timing within the 0.5 ns maximum budget.

• Keep the distance between the clock lines and other signals “d” at least 25 mils from each other.

• Keep the distance between the clock line and itself “a” at a minimum of 25mils apart (for

serpentine clock layout).

• A_CLKIN gets connected to A_CLKO6 through a 22Ω +/- 1% resistor The 22 +/- 1% Ω

resistor is within 500 mils of A_CLKO.

Figure 16. PCI Clock Distribution and Matching Requirements

Serial to

Parallel PCI

Bridge

PCI-X Layout Guidelines

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 33

Page 34

PCI-X Layout Guidelines

Table 8. PCI-X Clock Layout Requirements Summary

Parameter Routing Guidelines

Signal Group PCI Clocks A_CLK[6:0]

Reference Plane Route over unbroken ground or power plane

Stripline Tr ace Width 4 mils

Stripline Trace Spacing: Separation between two

different clock lines, “d” clock lines

Stripline Trace Spacing: Separation between two

segments of the same clock line (on serpentine

layout), “a” dimension

Stripline T race Sp acing: Separation between clocks

and other lines

Length Matching Requirements

Total Length of the 41110 PCI CLKs on the adapter

card

A_CLKIN Series Termination

A_CLK[6:0] Series Termination

Routing Guideline 1

Routing Guideline 2 Minimize number of vias

25 mils center to center from any other signal

25 mils center to center from any other signal

50 mils center to center from any other signal

All 41110 Output Clocks A_CLK[6:0] connected to

devices must be length matched to 0.1 inch of each

other.

The clock feedback line lengths from A_CLKOUT to

A_CLKIN should be length matched to all other clock

lines within 0.1”.

10” -14”

Connect A_CLKIN to one end of a 22Ω +/- 1% resistor

and the other end connected to A_CLKOUT

Each of the clock outputs A_CLKO[6:0] should have

series 22Ω resistor located within 500 mils of the

41110 clock output.

Point to point signal routing should be used to keep

the reflections low.

34 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 35

8.5 PCI-X Topology Layout Guidelines

The PCI-X Addendum to the PCI Local Bus Specification, Revision 1.0a compliant, recommends

the following guide lines f or th e number of loads for your PC I-X d esigns. Any deviati on fro m these

maximum values requires close attention to layout with regard to loading and trace lengths.

Table 9. PCI-X Slot Guidelines

Frequency Maximum Loads Maximum Number of Slots

66 MHz 8 4

100 MHz 4 2

133 MHz 2 1

8.6 41110 Layout Analysis

The following sections describes layout recommendations based on the signal integrity analysis.

This analysis was conducted using the following parameters:

• Card stack up: 60 Ω +/- 15% single-ended impedance

• Driver Model 41110 IBIS

• Receiver Model: generic models for PCI-X and PCI

PCI-X Layout Guidelines

• Driver Package Model: 41110 Model

• Cross talk and ISI impact on timing were not modeled

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 35

Page 36

PCI-X Layout Guidelines

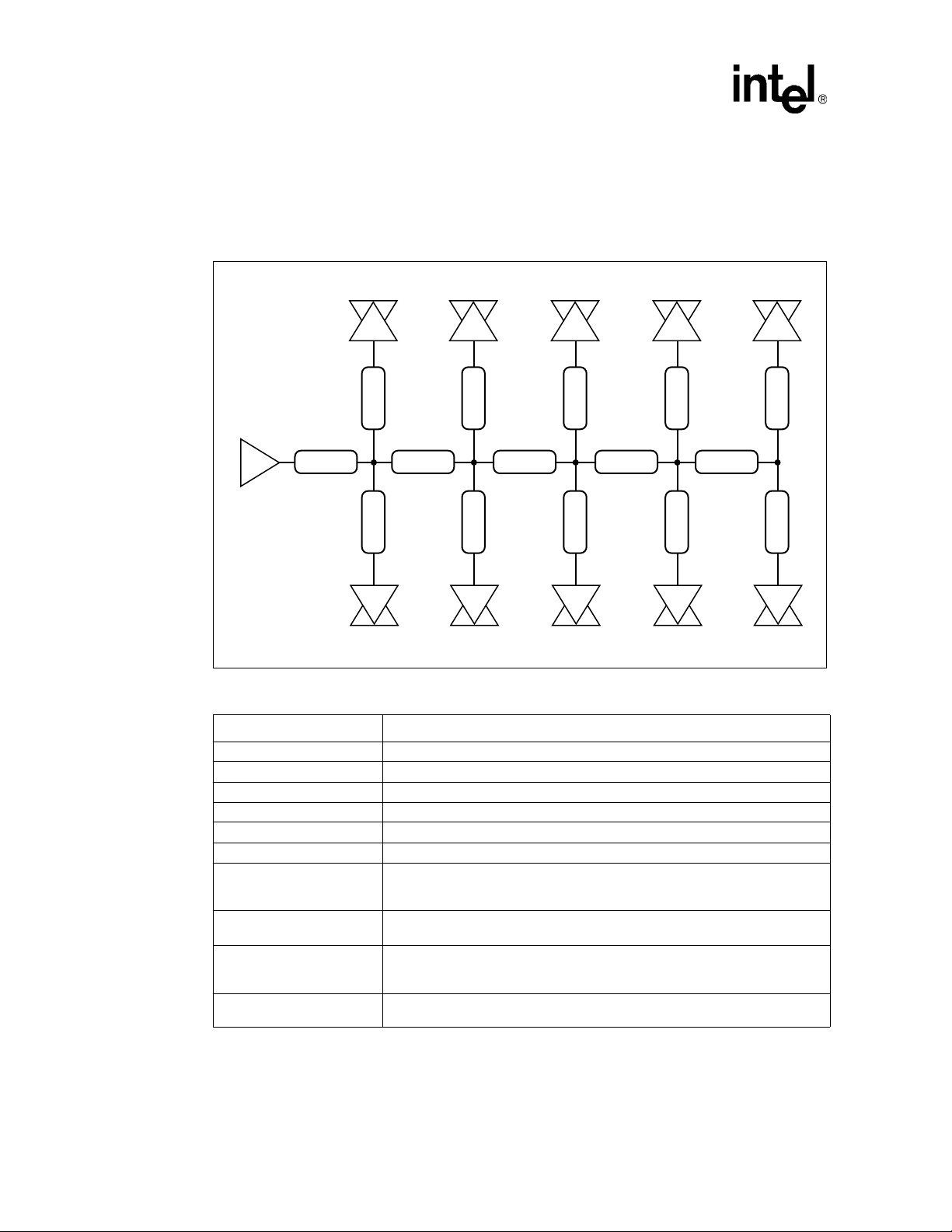

8.6.1 Embedded PCI-X 133 MHz

This section lists the routing recommendations for PCI-X 133 MHz without a slot. Figure 17 shows

the block diagram of this topology and Table 10 describes the routing recommendations.

Figure 17. Embedded PCI-X 133 MHz Topology

TL1

EM1

TL_EM2 TL_EM1

EM2

Table 10. Embedded PCI-X 133 MHz Routing Recommendations

Parameter Routing Guideline for Lower AD Bus

Reference Plane Route over an unbroken ground plane

Board Impedance 60 Ω +/- 15%

Stripline Trace Spacing 12 mils from edge to edge

Microstrip Trace Spacing 18 mils, from edge to edge

Break Out 5 mils on 5 mils spacing. Maximum length of breakout region can be 500 mils

Group Spacing Spacing from other groups: 25 mils min, edge to edge

Trace Length 1 (TL1): From

41110 signa l Bal l to fi rs t

junction

Trace Length 3 junction of

TL_EM1 and TL_EM2 to the

embedded device

Length Matching

Requirements:

Number of vias 3 vias max per path

1.75” min - 4.0” max

1.25” min - 3.25” max

Clocks coming form the clock driver must be on the same layer and length

matched to within 25 mils.

B2719 -01

36 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 37

8.6.2 Embedded PCI-X 100 MHz

This section lists the embedded routing recommendations for PCI-X 100 MHz. Figure 18 shows

the block di agram of this topology and Table 11 describes the routing recommendations.

Figure 18. Embedded PCI-X 100 MHz Topology

PCI-X Layout Guidelines

TL_EM1

EM1

TL1

Table 11. Embedded PCI-X 100 MHz Routing Recommendations

Parameter Routing Guideline for Lower AD Bus

Reference Plane Route over an unbroken ground plane

Board Impedance 60 Ω +/- 15%

Stripline Trace Spacing 12 mils from edge to edge

Microstrip Trace Spacing 18 mils, from edge to edge

Break Out 5 mils on 5 mils spacing. Maximum length of breakout region can be 500 mils

Group Spacing Spacing from other groups: 25 mils min, edge to edge

Trace Length 1 (TL1): From

41110 signal Ball to first

junction

Trace Length: TL_EM1: from

41110 signal ball to the first

embedded device

Trace Length TL_EM2 TL_EM3: from junction to the

embedded device

Length Matching

Requirements:

Number of vias 4 vias max per path

0.5” min - 3.0” max

2.5” min - 3.5” max

1.5” min - 3.5” max

Clocks coming form the clock driver must be on the same layer and length

matched to within 25 mils.

TL_EM3

TL_EM2

EM3

EM2

B2720 -01

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 37

Page 38

PCI-X Layout Guidelines

8.6.3 PCI-X 66 MHz Embedded Topology

Figure 19 and Table 12 provide routing details for a topology with an embedded PCI-X 66 MHz

application.

Figure 19. PCI-X 66 MHz Embedded Routing Topology

TL1

EM1

TL2

TL_EM2 TL_EM1

EM2

EM3

TL3

TL_EM4 TL_EM3

EM4

Table 12. PCI-X 66 MHz Embedded Routing Recommendations

Parameter Routing Guideline for Lower AD Bus

Reference Plane Route over an unbroken ground plane

Board Impedance 60 Ω +/- 15%

Stripline Trace Spacing 12 mils edge to edge

Microstrip Trace Spacing 18 mils, edge to edge

Break Out 5 mils on 5 mils. Maximum length of breakout region can be 500 mils

Group Spacing Spacing from other groups: 25 mils min, edge to edge

Trace Length 1 (TL1): From

41110 signa l Bal l to fi rs t

junction

Trace Length TL2 to TL4 between junctions

Trace Length TL_EM1 to

TL_EM8 from junction

connector to the embedded

device

Length Matching

Requirements:

Number of vias 4 vias max.

1.0” - 5.0” max

1.0” min - 2.5” max

2.0” min - 3.0” max

Clocks coming form the clock driver must be length matched to within 25 mils

and routed identical in layers.

EM5

TL_EM6 TL_EM5

EM6

EM7

TL4

TL_EM8 TL_EM7

EM8

B2721 -01

38 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 39

8.6.4 PCI 66 MHz Embedded Topology

Figure 20 and Table 13 provide routing details for a topology with an embedded PCI 66 MHz

design.

Figure 20. PCI 66 MHz Embedded Topology

PCI-X Layout Guidelines

Table 13. PCI 66 MHz Embedded Table

Parameter Routing Guideline for Lower AD Bus

Reference Plane Route over an unbroken ground plane

Board Impedance 60 Ω +/- 15%

Microstrip Trace Spacing 18 mils center to center

Stripline Trace Spacing 12 mils center to center

Group Spacing Spacing from other groups: 25 mils min, edge to edge

Breakout

Trace Length 1 TL1: From 41110 signal Ball to first

junction

Trace Length TL2 between junctions 0. 5” min - 3.5” max

Trace Length TL_EM1 to TL_EM4 from junction to

embedded devices

Length Matching Requirements

Number of vias 4 vias max.

P

TL1

EM1

TL2

TL_EM2 TL_EM1

EM2

5 mils on 5 mils spacing. Maximum length of breakout

region can be 500 mils.

5.0” max

2.0” min - 3.0” max

Clocks coming from the clock driver must be length

matched to within 25 mils.

EM3

TL_EM4 TL_EM3

EM4

B2722 -01

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 39

Page 40

PCI-X Layout Guidelines

8.6.5 PCI 33 MHz Embedded Mode Topology

Figure 21 and Table 14 provide routing details for a topology with an embedded PCI 33 MHz

design.

Figure 21. PCI 33 MHz Embedded Mode Routing Topology

TL1

EM1

TL2

TL_EM2 TL_EM1

EM2

EM3

EM4

EM5

TL3

TL_EM4 TL_EM3

EM6

Table 14. PCI 33 MHz Embedded Routing Recommendations

Parameter Routing Guideline for Lower AD Bus

Reference Plane Route over an unbroken ground plane

Board Impedance 60 Ω +/- 15%

Stripline Trace Spacing 12 mils, edge to edge

Microstrip Trace Spacing 18 mils edge to edge

Group Spacing Spacing from other groups: 25 mils min, edge to edge

Breakout 5 mils on 5 mils spacing. Maximum length of breakout region can be 500 mils.

Trace Length 1 TL1: From

41110 signa l Bal l to fi rs t

junction

Trace Length TL2 to TL5 between junctions

Trace Length TL_EM1 to

TL_EM10 from junction to

embedded devices

Length Matching

Requirements

5.0” max

0.5” min - 3.5” max

2.0” min - 3.0” max

Clocks coming from the clock driver must be length matched to within 25 mils.

TL_EM6 TL_EM5

TL4

EM7

TL_EM8 TL_EM7

EM8

EM9

TL5

TL_EM10 TL_EM9

EM10

B2723 -01

40 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 41

PCI Express Layout 9

This section provides an overview of the PCI-Exp ress stackup recommended based on Intel

presimulation results. For additional information, refer to the Intel® 41110 Serial to Parallel PCI

Bridge Developer’s Manual or the PCI Express Specification, Revision 1.0 from the

www.pcisig.com

9.1 General recommendations

PCI Express is a serial differential low-voltage point-to-point interconnect. The PCI Express was

designed to support 20 inches between components with standard F R4. The 41 110 supports x8 lanes.

PCI-Express requires special considerations be made for intercon nect loss es, ji tter, crosstalk and

mode conversions. The below list provides some general guidelines f or t he layo ut of a PCI-Express

trace:

1. Jitter: Trace lengths of a PCB trace can introduce around 1 to 5 ps of jitter and 0.35 to 0.5 dB

of loss per inch of differential pai r. An add-in card the trace length from edge-finger pad to

device is limited to 3 inches.

2. Matching within pair: Trace lengths of matching differential pairs are required to be matched

within +/-5 mil delta. Each net within a differential pair should be length matched on a

segment-by-segment basis at point of discontinuity such as an breakout area, routes between

vias, routes between AC coupling capacitors and conn ector pins.

website.

3. Trac e Sym met ry: T race Symmetry is required between two traces of the same differential pair.

4. Vias: Vias contribute 0.5 to 1.0 dB/via toward the loss budget. Vias on an add-in card should

be limited to one near the breakout section of the pads and one near the edge finger.

5. Bends: Trace bends should be kept to a minimum. If bends are used they should be at a 45-

degree angle or smaller. The number of left and right bends should be matched as closely as

possible to even out the overall lengths of each segment of the differential pair.

6. AC Coupling capacitors: AC coupling capacitor with a value of 75nF to 200nF should line

up at the same location from one trace to the other within t he pair. The 0402 size capacitor

with a small pad size is highly recommended. The breakout from the capacitor should be

symmetrical for both signal traces in the differential pair.

7. Connector pins: Length compensation for the connector pins of the differential pair being

offset from each other the PCB trace should be considered.

8. Ground Plane Refer encing: Ground plan e referencing is require d along the entire route of the

differential pair. Traces routed near the edge should maintain a 40 mil air gap to the edge.

Layer switching should also maintain the ground plane. Grounds between pl anes should be

connected with stitching vias (with one to three recommended per differential pair).

9. Breakout Areas: Breakout areas near a device package should be limited to 500 mils in lengths.

The necking down to a smaller trace width should be symmetrical on the differential pair.

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 41

Page 42

PCI Express Layout

9.2 PCI-Express Layout Guidelines

The layout guidelines for PCI-Express were developed for an adapter card topologies. The models and

assumptions used in development of these guidelines were as follows:

• Add-In Card Stackup: 60 Ω single-ended impedance

• Target Differential Impedance: 100 Ω +/- 20%.

• Driver Model: 41110 PCI-E IBIS

• Receiver Model: 41110 PCI-E IBIS. Specification model did not meet specifications

• Driver Package Model: Preliminary 41110 model.

• No receiver package model used since specification eye is at package pin.

• Assumed that traces in a lane could be routed totally on microstrip, totally on stripline, or a

mixture of microstrip and stripline.

• AC coupling capacitors were modeled as a parasitic resistor and inductor in series.

• Add-in card was modeled as micro-strip routes only.

• No vias were modeled at this time.

• Only the receiver eye was evaluated. The next revision will evaluate the eye at the transmitter

and connector as well as the receiver.

9.3 Adapter Card Layout Gu idelines

Table 15. Adapter Card Routing Recommendations (Sheet 1 of 2)

Parameter Routing Guidelines

Reference Plane Route over an unbroken ground plane

Target Single Ended

Impedance

Target Differential

Impedance

Microstrip and Stripline Trace

Width

Microstrip Trace Spacing

Group Spacing Spacing from other groups: 25 mils minimum, center to center

Transmit Trace Length

(41110 signal pin to AC

coupling capacitor.)

Transmit Trace Length (AC

coupling capacitor to card

edge finger.)

60 Ω nominal

100 Ω +/- 20% Differential Impedance

4 mils

Intrapair: 10 mils center-to-center

Interpair: 30 mils center-to-center

22 mils. center to center (pair to pair).

Transmit and Receive pairs should be interleaved. If no interleaving, then inter

pair spacing should be increased to 50 mils (c2c). Center to center of inter pair is

defined as center of Positive of one pair to Center of Negative of the next or vice

versa

0.25”- 5.0” max

1.00”- 4.5” max

42 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 43

Table 15. Adapter Card Routing Recommendations (Sheet 2 of 2)

Receive Trace Length (Card

edge finger to 411 10 receiver

pin

Length Matching

Requirements:

Number of vias 4 max

1.0” min - 6.0” max

Total allowable intra-pair length mis-match must not exceed 25 mils. Each

routing segment should be matched as close as possible. Total skew across all

lanes must be less than 20 ns. See the PCI-Express Desktop Design Guidelines

for additional routing requirements

PCI Express Layout

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 43

Page 44

PCI Express Layout

This page intentionally left blank.

44 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 45

Circuit Implementations

Circuit Implementations 10

This chapter describes 41110 circuit implementations.

10.1 41110 Analog Voltage Filters

The 4111 0 requires several external analog voltage filter circuits to be placed on the system board,

three for the PCI interface, one for the PCI Express interface, and one fo r the bandgap voltage. The

411 10 lists the recommended filter values for these filter circuits -- any one of the filter circuits can

use any one of the four R, L and C combinations shown in Table 16, except that configuration

number 4 cannot be used for the PCI Express analog voltage filter.

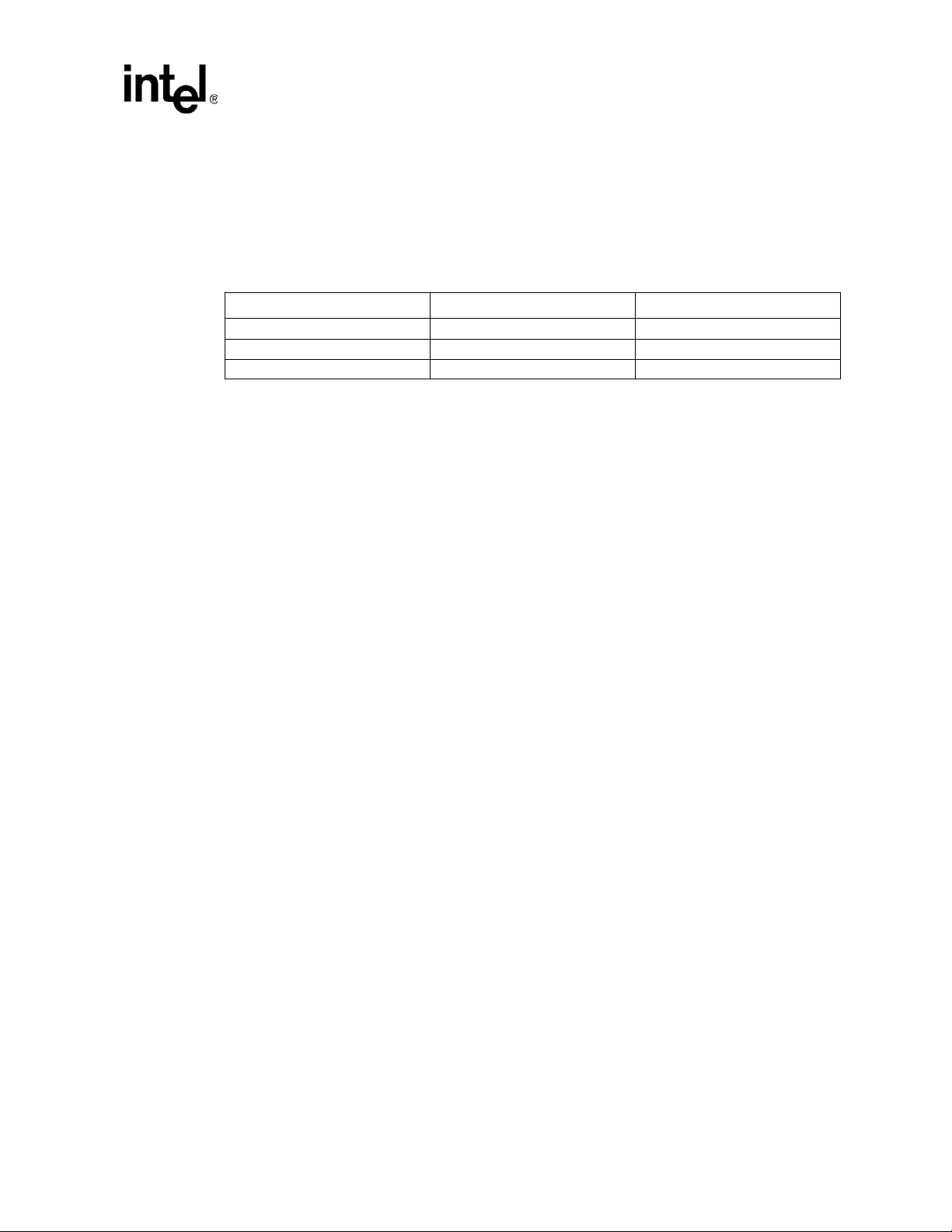

T able 16. Recommended R, L and C Values for 41110 Analog Filter Circuits

Config R L C

1

2

3

a

4

a. Configuration number 4 cannot be used for the PCI Express analog voltage filter.

0.5Ω ±1%

1/16W

0.5Ω ±1%

1/16W

0.5Ω ±1%

1/16W

1.0Ω ±1%

1/16W

4.7uH ±25%

PCI, PCI-E: 45mA

Bandgap: 30mA

4.7uH ±20

PCI, PCI-E: 45mA

Bandgap: 30mA%

4.7uH ±20%

PCI, PCI-E: 45mA

Bandgap: 30mA

4.7uH ±20%

PCI: 45mA

Bandgap: 30mA

Additional Notes:

• L (Inductor)

— L must be magnetically shielded

—ESR: max < 0.4

Ω

— rated at 45mA (or 30mA for bandgap circuit only)

• C (Capacitor)

—ESR: max < 0.5

Ω

33uF ±20%

6.3V

22uF ±20%

6.3V

2x10uF ±20%

6.3V

10uF ±20%

6.3V

— ESL < 3.0nH

• R (Resistor)

—1/16W

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 45

Page 46

Circuit Implementations

10.1.1 PCI Analog Voltage Filters

The following filter circuit is recommended for the PCI interface. Three separate, identical

versions of this circuit should be placed on the system board, one for each VCCAPCI[2:0] pin on

the 41110.

Figure 22. PCI Analog Voltage Filter Circuit

Serial to

Paralle l P C I

Bridge

Note: Three of these PCI filter circuits must be placed on the system board, one for each of the

VCCAPCI[2:0] pins on the 41110.

• Place C as close as possible to package pin.

• R must be placed between VCC15 and L.

• Route VCCPCI[x] and VSS as differential traces.

• VCCPCI[x] and VSS traces must be ground referenced (No VCC15 references).

• Max total board trace length = 1.2”.

• Min trace space to other nets = 30 mils.

10.1.2 PCI Express Analog Voltage Filter

Figure 23 shows the PCI Express Analog Voltage Circuit.

46 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 47

Figure 23. PCI Express Analog Voltage Filter Circuit

Additional Notes:

• Place C as close as possible to package pin.

• R must be placed between VCC15 and L.

Circuit Implementations

Serial to

Paralle l P CI

Bridge

• Route VCCAPE and VSSAPE as differential traces.

• VCCAPE and VSSAPE traces must be ground referenced (No VCC15 references).

• Max total board trace length = 1.2”.

• Min trace space to other nets = 30 mils.

10.1.3 Bandgap Analog Voltage Filter

Figure 24 shows the Bandgap Analog Voltage Filter Circuit.

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 47

Page 48

Circuit Implementations

Figure 24. Bandgap Analog Voltage Filter Circuit

Additional Notes:

• Place C as close as possible to package pin.

• R must be placed between the 2.5V supply and L.

Serial to

Parallel PCI

Bridge

• Route VCCBGPE and VSSBGPE as differential traces.

• VCCBGPE and VSSBGPE traces must be ground referenced (No 2.5V references).

• VSSBGPE should be grounded at the capacitor.

• Max total board trace length = 1.2”.

• Min trace space to other nets = 30 mils.

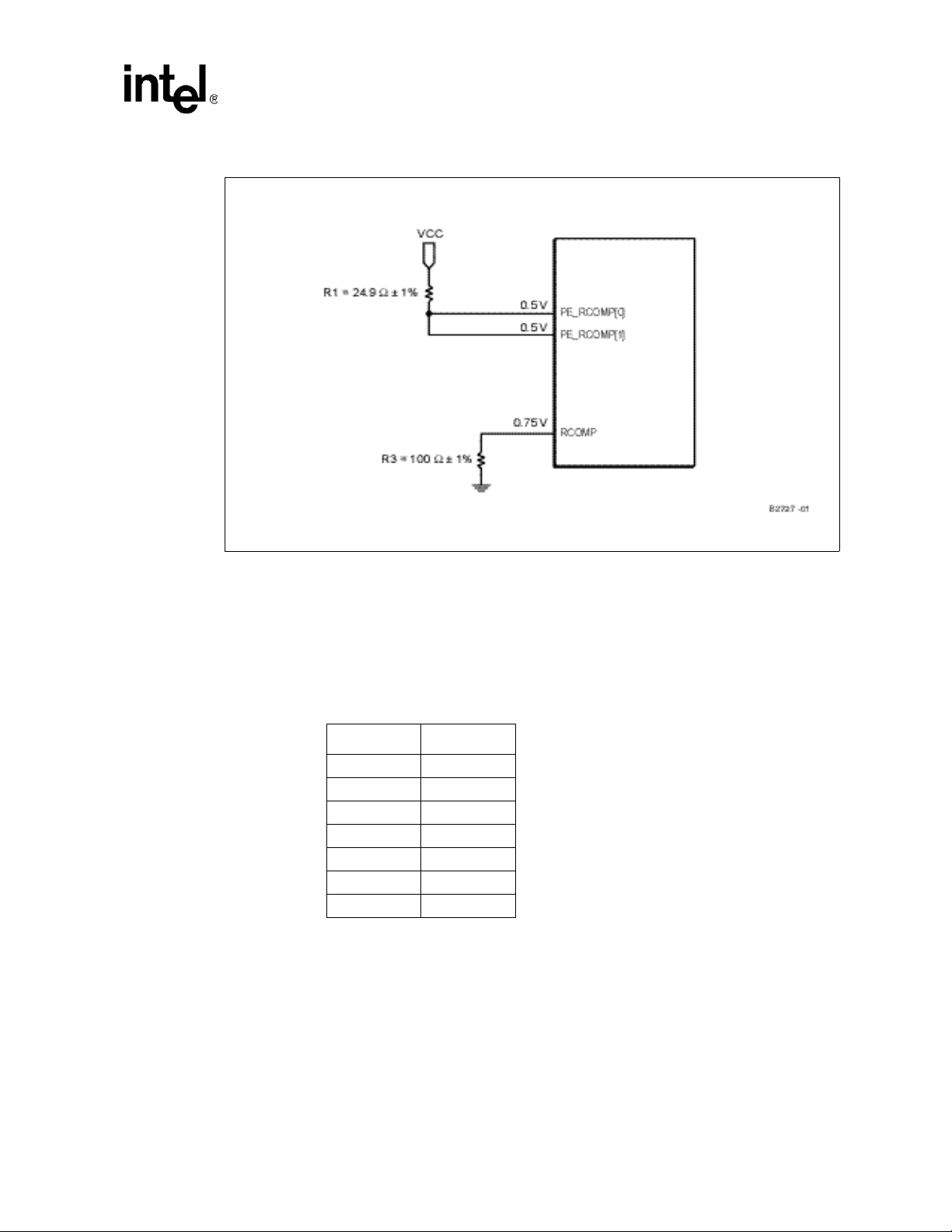

10.2 41110 Reference and Compensation Pins

There are three compensation pins on 41110.

PE_RCOMP[1:0] are two separate pins that provide voltage compensation for the PCI Express

interface on the 41110. The nominal compensation voltage is 0.5V. An external 24.9

resistor should be used to connect to VCC15. A single pullup resistor can be used to for both of

these signals.

RCOMP is an analog PCI interf ace compens ation pin, providin g 0.75V to th e 41110. A 100

pulldown resistor should be used to connect the RCOMP pin to ground.

These implementations are shown in Figure 25.

Ω ±1% pullup

Ω ±1%

48 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 49

Figure 25. Reference and Compensation Circuit Implementations

Serial to

Paralle l P C I

Bridge

Circuit Implementations

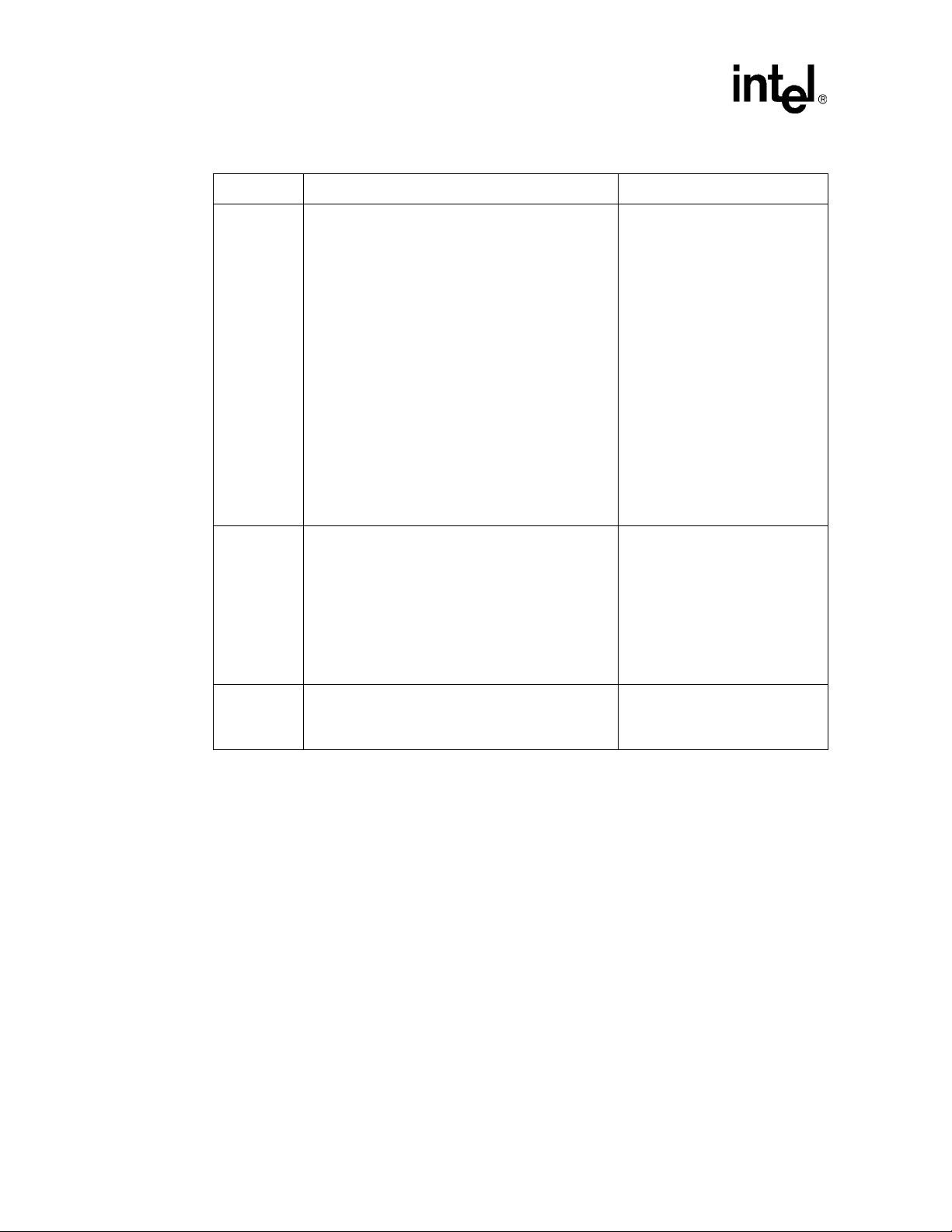

10.2.1 SM Bus

The SMBus interface does not have configuration registers. The SMBus addr ess is set by the states

of pins SMBUS[5] and SMBUS [3: 1] when PERST# is asserted as described in Table 17.

T a ble 17. SMBUs Address Configuration

Refer to Section 2.4 for details on how to use the SMBus to initialize 41110 registers with a

microcontroller.

Bit Value

71

61

5SMBUS[5]

40

3SMBUS[3]

2SMBUS[2]

1SMBUS[1]

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 49

Page 50

Circuit Implementations

This page intentionally left blank.

50 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 51

41110 Customer Reference Boards 11

This chapter describes the 41110 Customer Reference Board (CRB).

11.1 Board Stack-up

The proposed layout of the PCB is eight layers with the following stackup:

• Signal #1 (Top/Component Side)

• Ground Plane: GND

• Signal #2

• Power Plane

• Power Plane

• Signal #3

• Ground Plane

• Signal #4 (Bo t t om)

The permittivity constant Er = 4.5

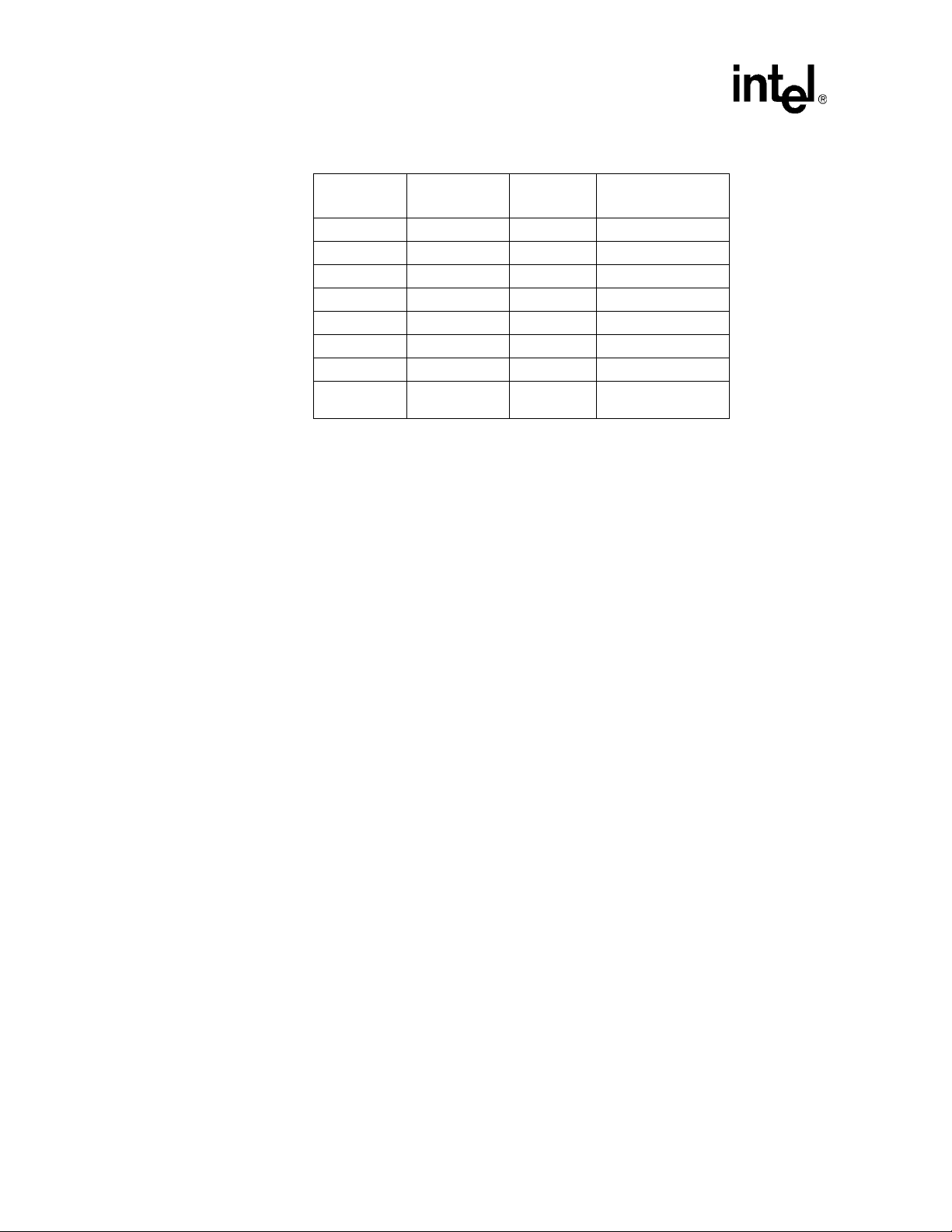

Table 18. CRB Board Stackup (Sheet 1 of 2)

Layer Type

1 Signal 2.00 1/2 + plating

Prepreg 4.50

2 Plane: GND 1.20 1

Core 4.80

3 Signal 1.20 1

Prepreg 14.00

4 Plane: PWR 1.20 1

Core 3.8

5 Plane: PWR 1.20 1

Prepreg 14.00

6 Signal 1.20 1

Core 4.80

7 Plane: Power 1.20 1

Thickness

(mils)

Copper Weight

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 51

Page 52

41110 Customer Reference Boards

T able 18. CRB Board Stackup (Sheet 2 of 2)

Thickness

11.2 Material

The following materials are used with the 41110 CRB:

• FR-4, 0.062 in. +/- .007, 1.0 oz Copper Power/GND.

• Full length PCI Raw Card (3.3V Universal) 6.2” high x 7.00” long max with ½ inch cut away.

11.3 Impedance

Layer Type

1 Signal 2.00 1/2 + plating

Prepreg 4.50

2 Plane: GND 1.20 1

Core 4.80

3 Signal 1.20 1

Prepreg 4.50

8 Signal 2.00 1/2 + plating

Est. Total

Thickness

(mils)

62 +/- 7

Copper Weight

Most signal layers require controlled Impedance of 60 Ω +/- 5% microstrip or stripline where

appropriate.

Differential signals for the PCI-E interface require matched 100

as matched 50

Ω resistances referenced to ground.

Ω differential termination realized

52 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 53

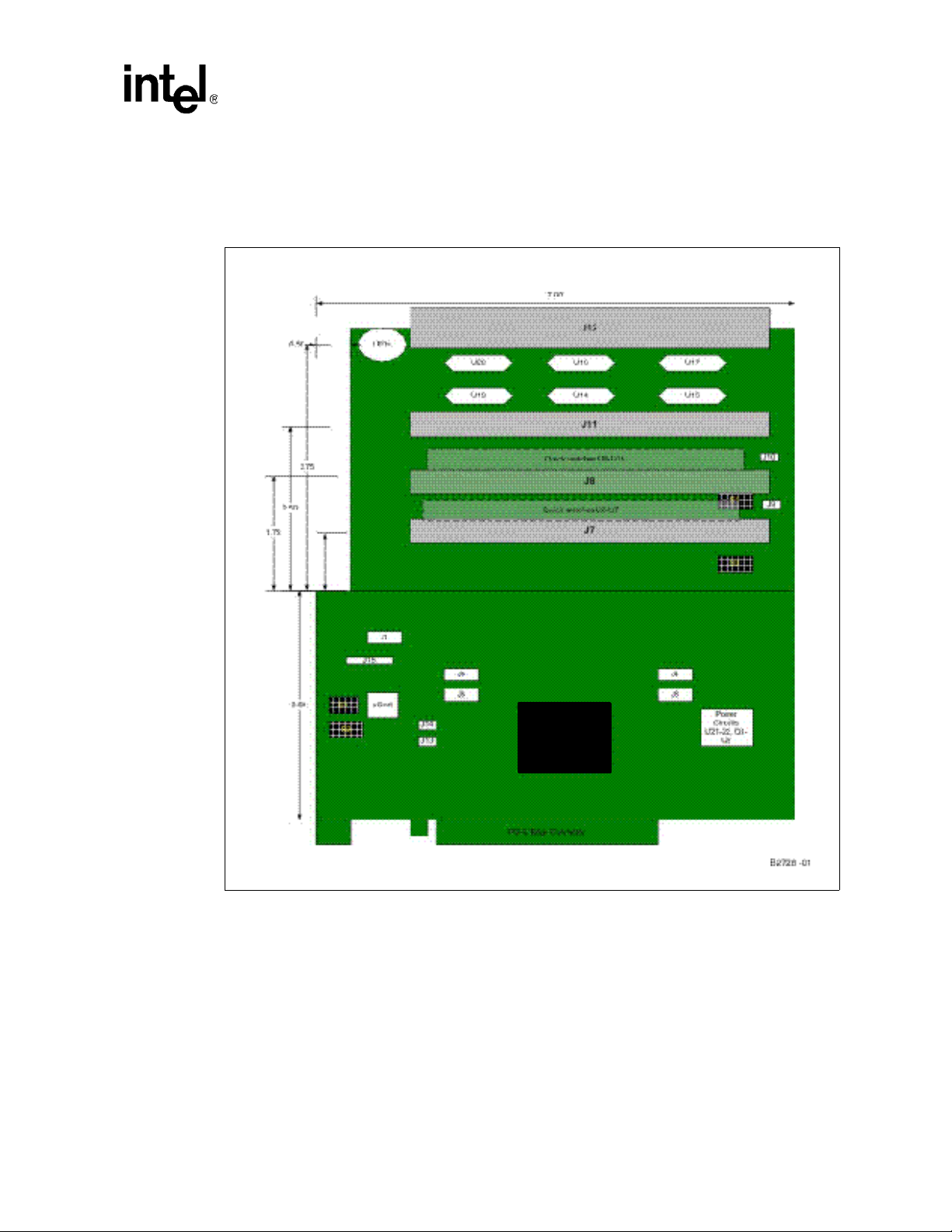

11.4 Board Outline

Figure 26 provides the mechanical outline of the 41110 CRB.

Figure 26. Mechanical Outline of the 41110

41110 Customer Reference Boards

U1

Serial to

Parallel PCI

Bridge

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 53

Page 54

41110 Customer Reference Boards

This page intentionally left blank.

54 Intel® 41110 Serial to Parallel PCI Bridge Design Guide

Page 55

Design Guide Checklist 12

This checklist highlights design considerations that should be reviewed prio r to manufacturing an

adapter card that implements the 41110 product. The items contained within this checklist attempt

to address important connections to these devices and any critical supporting circuitry . This is not a

complete list and does not guarantee that a design will function properly.

T able 19. PCI Express Interface Signals

Signals Recommendations Reason/Impact

REFCLKn,

REFCLKp

PE_RCOMP[1:0]

PERP[7:0]

PERN[7:0]

PETP[7:0]

PETN[7:0]

Must be connected to clock from a PCI Express

connector for add-in card designs or to a 100MHz

oscillator for an embedded design.

24.9Ω ±1% pullup resistor to 1.5V . A single resistor can

be used for both signals. Place resistor as close as

possible to REFCLKn, REFCLKp pins.

For X1 mode, only signals PERp[0] and PERn[0] or

PERp[7] and PERn[7] are used.

For X4 mode, only signals PERp[3:0] and PERn[3:0]

are used.

For X8 mode, all of these signals, PERp[7:0] and

PERn[7:0], are used.

For X1 mode, only signals PETp[0] and PETn[0] or

PETp[7] and PETn[7] are used.

For X4 mode, only signals PETP[3:0] and PETN[3:0]

are used.

For X8 mode, all of these signals, PETP[7:0] and

PETN[7:0], are used.

PCI Express compensation pin.

0.5V nominal.

PCI Express data serial inputs

(differential data receive

signals).

PCI Express data serial inputs

(differential data transmit

signals).

Intel® 41110 Serial to Parallel PCI Bridge Design Guide 55

Page 56

Design Guide Checklist

Table 20. PCI/PCI-X Interface Signals (Sheet 1 of 2)

Signals Recommendations Reason/Impact

A_AD[63:32]

A_CBE[7:4]#

A_DEVSEL#

A_FRAME#

A_IRDY#

A_TRDY#

A_STOP#

A_PERR#

A_SERR#

A_REQ[5:0]#

A_GNT[5:0]#

A_LOCK#

A_PAR

A_PAR64

A_ACK64#

A_REQ64#

A_133EN

No external pullup resistors required on system board.

Only relevant when running in PCI-X Mode

(X_PCIXCAP = 1).

Determines the max PCI-X Mode 1 frequency for a

particular segment (100 MHz or 133 MHz):

0 = 100 MHz PCI-X max frequency

1 = 133 MHz PCI-X max frequency

41110 has internal pullup resistors

on these signals.

X_AD[31:0] and X_CBE#[3:0]

signals do not require pullups

according to the PCI Specification.

Sampled on the rising edge of

PERST#.

A_INTA#

A_INTB#

A_INTC#

A_INTD#

Use an 8.2KΩ pullup resistor to VCC33. This resistor is

located on the system board.

No pullup resistors required on these signals.