Page 1

Intel® 3210 and 3200 Chipset

Thermal/Mechanical Design Guide

November 2007

Reference Number: 318465 Revision: 001

Page 2

INFORMATION IN THIS DOCUMENT IS PROVIDED IN CONNECTION WITH INTEL

BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS DOCUMENT. EXCEPT AS

PROVIDED IN INTEL'S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, INTEL ASSUMES NO LIABILITY WHATSOEVER,

AND INTEL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY, RELATING T O SALE AND/OR USE OF INTEL PRODUCT S INCLUDING

LIABILITY OR WARRANTIES RELA TING T O FITNES S FOR A PARTICULAR PURPOSE, MERCHANT ABILITY, OR INFRINGEMENT OF ANY

PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. Intel products are not intended for use in medical, life saving,

®

PRODUCTS. NO LICENSE, EXPRESS OR IMPLIED,

life sustaining applications.

Intel may make changes to specifications and product descriptions at any time, without notice.Designers must not rely on the

absence or characteristics of any features or instructions marked "reserved" or "undefined." Intel reserves these for future

definition and shall have no responsibility whatsoever for conflicts or incompatibilities arising from future changes to them.

The Intel 3210 and 3200 Chipset, Dual Core Intel Xeon processor 3000 Sequence, and Intel Xeon processor 3200 Sequence may

contain design defects or errors known as errata which may cause the product to deviate from published specifications. Current

characterized errata are available on request.

Contact your local Intel sales office or your distributor to obtain the latest specifications and before placing your product order.

Copies of documents which have an order number and are referenced in this document, or other Intel literature, may be obtained

by calling 1-800-548-4725, or by visiting http://www.intel.com

Intel, Xeon, Intel I/O Controller, and the Intel logo are trademarks of Intel Corporation in the U.S. and other countries.

Copyright © 2007, Intel Corporation. All rights reserved.

* Other brands and names may be claimed as the property of others.

2 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 3

Contents

1Introduction..............................................................................................................7

1.1 Design Flow........................................................................................................8

1.2 Definition of Terms..............................................................................................8

1.3 Reference Documents......................... ......................... .. .......................... .. ..........9

2 Packaging Technology.............................................................................................11

2.1 Non-Critical to Function Solder Joints...................................................................13

2.2 Package Mechanical Requirements................................................ .......................13

3 Thermal Specifications ............................................................................................15

3.1 Thermal Design Power (TDP) ..............................................................................15

3.2 Thermal Specification.........................................................................................15

4 Thermal Simulation .................................................................................................17

5 Thermal Metrology ..................................................................................................19

5.1 MCH Case Measurement.....................................................................................19

5.1.1 Supporting Test Equipment......................................................................19

5.1.2 Thermal Calibration and Controls..............................................................20

5.1.3 IHS Groove ...........................................................................................20

5.1.4 Thermocouple Attach Procedure...............................................................22

6 Reference Thermal Solution.....................................................................................35

6.1 Operating Environment.......................................... .. .. .. ......................................35

6.2 Heatsink Performance........................................................................................35

6.3 Mechanical Design Envelope ...............................................................................36

6.4 Thermal Solution Assembly.................................................................................36

6.4.1 Extruded Heatsink Profiles.......................................................................37

6.4.2 Retention Mechanism Responding in Shock and Vibration.............................38

6.4.3 Thermal Interface Material.......................................................................38

6.4.4 Reference Thermal Solution Assembly Process........ ....................................39

6.5 Reliability Guidelines.......................................................................................... 40

A Thermal Solution Component Suppliers ...................................................................43

A.1 Heatsink Thermal Solution..................................................................................43

B Mechanical Drawings...............................................................................................45

Figures

1-1 Thermal Design Process .......................................................................................8

2-1 MCH Package Dimensions (Top View)................................................ ...................11

2-2 MCH Package Height..........................................................................................11

2-3 MCH Package Dimensions (Bottom View)..............................................................12

2-4 Non-Critical to Function Solder Joints...................................................................13

2-5 Package Height.......................... .. .................................................. .. ... .. ............14

5-1 Omega Thermocouple........................................................................................20

5-2 FCBGA7 Chipset Package Reference Groove Drawing..............................................21

5-3 IHS Groove on the FCBGA7 Chipset Package on the Live Board................................21

5-4 The Live Board on the Fixture Plate......................................................................22

5-5 Inspection of Insulation on Thermocouple.............................................................23

5-6 Bending the Tip of the Thermocouple...................................................................23

5-7 Extending Slightly the Exposed Wire over the End of Groove ................................... 24

5-8 Securing Thermocouple Wire with Kapton* Tape Prior to Attach............................. ..24

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 3

Page 4

5-9 Detailed Thermocouple Bead Placement................................................................25

5-10 Tapes Installation ..............................................................................................25

5-11 Placing Thermocouple Bead into the Bottom of the Groove......................................26

5-12 Second Tape Installation.....................................................................................26

5-13 Measuring Resistance between Thermocouple and IHS............................................27

5-14 Adding a Small Amount of Past Flux to the Bead for Soldering .................................27

5-15 Cutting Solder...................................................................................................28

5-16 Positioning Solder on IHS....................................................................................28

5-17 Solder Block Setup.............................. .. .. ................................................... .. .. ....29

5-18 Observing the Solder Melting...............................................................................30

5-19 Pushing Solder Back into the End of Groove ..........................................................30

5-20 Remove Excess Solder....................... .. .. ........................... ..................................31

5-21 Thermocouple Placed into Groove ........................................................................32

5-22 Remove Excess Solder....................... .. .. ........................... ..................................32

5-23 Fill Groove with Adhesive....................................................................................33

5-24 Finished Thermocouple Installation.......................................................................34

6-1 Reference Heatsink Measured Thermal Performance vs. Approach Velocity ................36

6-2 Design Concept for Reference Thermal Solution.....................................................37

6-3 Heatsink Extrusion Profiles..................................................................................37

6-4 Reference Thermal Solution Assembly Process - Heatsink Sub-Assembly (Step 1).......39

6-5 Reference Thermal Solution Assembly Process - Heatsink Assembly (Step 2) .............40

B-1 Intel® 3210 and 3200 Chipset Package Drawing........................................... .........46

B-2 Intel® 3210 and 3200 Chipset Motherboard Component

Top-Side Keep-Out Restrictions ...........................................................................47

B-3 Intel® 3210 and 3200 Chipset Motherboard Component

Back-Side Keep-Out Restrictions..........................................................................48

B-4 Intel® 3210 and 3200 Chipset Reference Thermal Solution Assembly.......................49

B-5 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Heatsink Drawing..........50

B-6 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Spring Preload Clip........51

B-7 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Fastener Nut................52

B-8 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Bracket (1 of 2)............53

B-9 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Bracket (2 of 2)............54

B-10 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Backplate Assembly ......55

B-11 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Backplate.....................56

B-12 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Insulator......................57

B-13 Intel® 3210 and 3200 Chipset Reference Thermal Solution - Flush Mount Stud ..........58

Tables

3-1 Intel® 3210 Chipset Thermal Specifications ....................... ...................................15

3-2 Intel® 3200 Chipset Thermal Specifications ....................... ...................................15

5-1 Thermocouple Attach Support Equipment..............................................................19

6-1 Honeywell PCM45F* TIM Performance as a Function of Attach Pressure.....................38

6-2 Reference Thermal Solution Environmental Reliability Guidelines..............................41

4 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 5

Revision History

Document

Number

318465 001 • Initial release of the document. November 2007

Revision

Number

Description Date

§

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 5

Page 6

6 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 7

Introduction

1 Introduction

As the complexity of computer systems increases, so do the power dissipation

requirements. Care must be taken to ensure that the additional power is properly

dissipated. Typical methods to improve heat dissipation include selective use of

ducting, and/or passive heatsinks.

The goals of this document are to:

• Outline the thermal and mechanical operating limits and specifications for

• Describe a reference thermal solution that meets the specification of

Properly designed thermal solutions provide adequate cooling to maintain Intel® 3210

and 3200 Chipsets die temperatures at or below thermal specifications. This is

accomplished by providing a low local-ambient temperature, ensuring adequate local

airflow, and minimizing the die to local-ambient thermal resistance. By maintaining

Intel

system designer can ensure the proper functionality, performance, and reliability of the

chipset. Operation outside the functional limits can degrade system performance and

may cause permanent changes in the operating characteristics of the component.

®

Intel

Intel® 3210 and 3200 Chipsets.

3210 and 3200 Chipsets.

®

3210 and 3200 Chipsets die temperature at or below the specified limits, a

The simplest and most cost-effective method to improve the inherent system cooling

characteristics is through careful chassis design and placement of fans, vents, and

ducts. When additional cooling is required, component thermal solutions may be

implemented in conjunction with system thermal solutions. The size of the fan or

heatsink can be varied to balance size and space constraints with acoustic noise.

This document addresses thermal design and specifications for Intel

Chipsets components only. For thermal design information on other chipset

components, refer to the respective component datasheet. F or the Intel® ICH9, refer to

the Intel

Note: Unless otherwise specified, the term “MCH” refers to the Intel

Chipsets.

®

I/O Controller Hub9 (ICH9) Thermal Design Guidelines.

®

3210 and 3200

®

3210 and 3200

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 7

Page 8

1.1 Design Flow

Figure 1-1. Thermal Design Process

Step 1: Thermal

Simulation

y Thermal Model

y Thermal Model User's Guide

1.2 Definition of Terms

FC-BGA Flip Chip Ball Grid Array. A package type defined by a plastic

substrate where a die is mounted using an underfill C4

(Controlled Collapse Chip Connection) attach style. The primary

electrical interface is an array of solder balls attached to the

substrate opposite the die. Note that the device arrives at the

customer with solder balls attached.

BLT Bond line thickness. Final settled thickness of the thermal

interface material after installation of heatsink.

MCH Memory controller hub. The chipset component contains the

processor interface, the memory interface, the PCI Express*

interface and the DMI interface.

ICH I/O controller hub. The chipset component contains the MCH

interface, the SATA interface, the USB interface, the IDE

interface, the LPC interface, and so forth.

IHS Integrated Heat Spreader. A thermally conductive lid integrated

into the package to improve heat transfer to a thermal solution

through heat spreading.

T

case_max

T

case_min

TDP Thermal design power. Thermal solutions should be designed to

TIM Thermal Interface Material. Thermally conductive material

T

LA

Maximum die or IHS temperature allowed. This temperature is

measured at the geometric center of the top of the package die

or IHS.

Minimum die or IHS temperature allowed. This temperature is

measured at the geometric center of the top of the package die

or IHS.

dissipate this target power level. TDP is not the maximum power

that the chipset can dissipate.

installed between two surfaces to improve heat transfer and

reduce interface contact resistance.

The local ambient air temperature at the component of interest.

The local ambient temperature should be measured just

Introduction

Step 2: Heatsink Selection

y Thermal Reference

y Mechanical Reference

Step 3: Thermal Validation

y Thermal Testing Software

y Software User's Guide

001239

8 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 9

Introduction

upstream of airflow for a passive heatsink or at the fan inlet for

an active heatsink.

Ψ

Case-to-ambient thermal solution characterization parameter

CA

(Psi). A measure of thermal solution performance using total

package power. Defined as (T

source size should always be specified for Ψ measurements.

1.3 Reference Documents

The reader of this specification should also be familiar with material and concepts

presented in the following documents:

Document Title Document Number / Location

®

Intel

I/O Controller Hub9 (ICH9) Thermal Design Guidelines Contact your Intel Field Sales

®

Intel

3210 and 3200 Chipset Datasheet www.developer.intel.com

®

Intel

3210 and 3200 Chipset Specification Update www.developer.intel.com

Dual-Core Intel

Quad-Core Intel

BGA/OLGA Assembly Development Guide Contact your Intel Field Sales

Various system thermal design suggestions http://www.formfactors.org

®

Xeon® Processor 3000 Series Datasheet www.developer.intel.com

®

Xeon® Processor 3200 Series Datasheet www.developer.intel.com

- TLA)/T otal Package Power. Heat

C

Representative

Representative

Note: Contact your Intel field sales representative for the latest revision and order number of this document.

§

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 9

Page 10

Introduction

10 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 11

Packaging Technology

2 Packaging Technology

The Intel® 3210 and 3200 Chipset consists of two individual components: the Memory

Controller Hub (MCH) and the Intel® I/O Controller (Intel® ICH9). The Intel® 3210 and

3200 Chipset MCH component uses a 40 mm [1.57 in] x 40 mm [1.57 in] Flip Chip Ball

Grid Array (FC-BGA) package with an integrated heat spreader (IHS) and 1300 solder

balls. A mechanical drawing of the package is shown in Figure 2-1. For information on

the Intel

Design Guidelines.

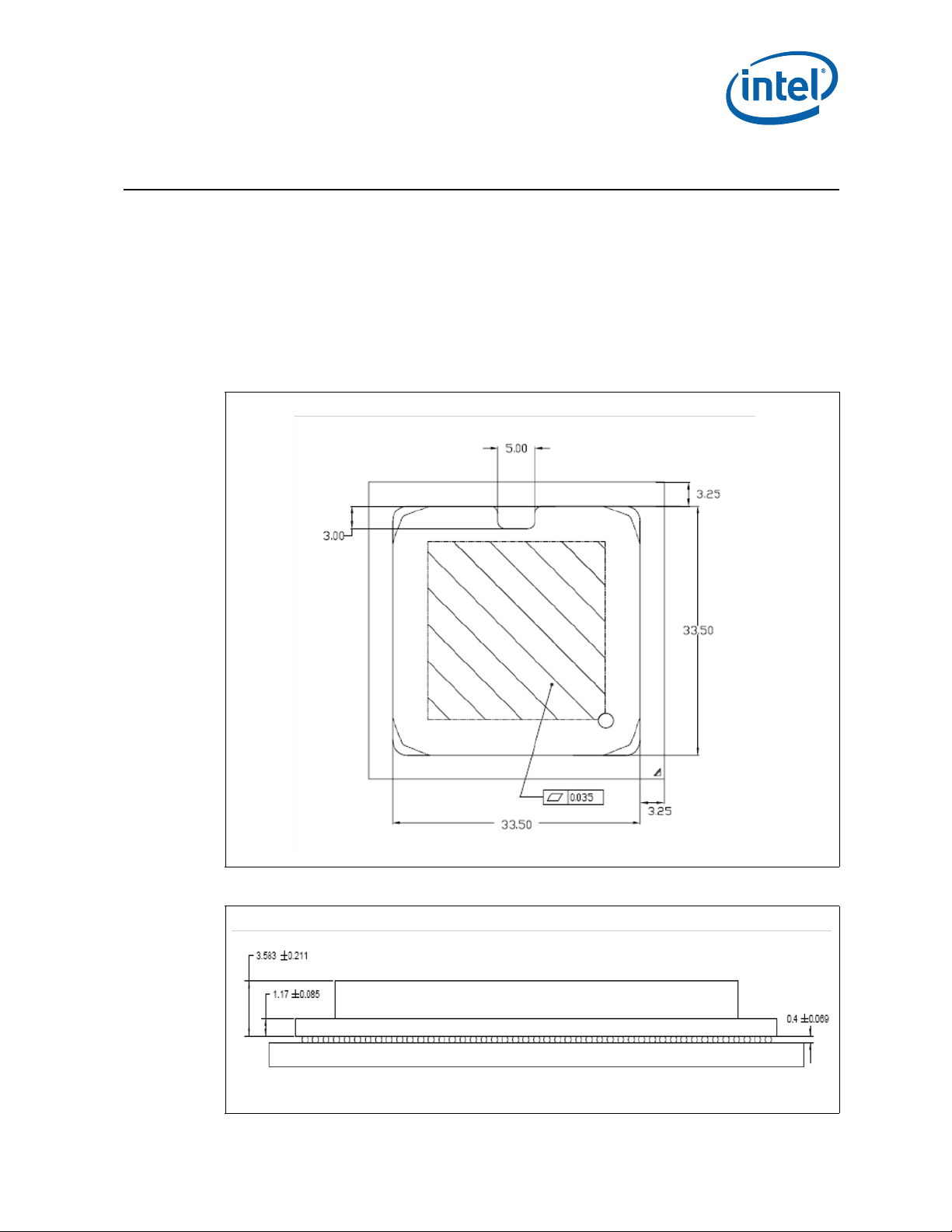

Figure 2-1. MCH Package Dimensions (Top View)

®

ICH9 package, refer to the Intel® I/O Controller Hub9 (ICH9) Thermal

Figure 2-2. MCH Package Height

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 11

Page 12

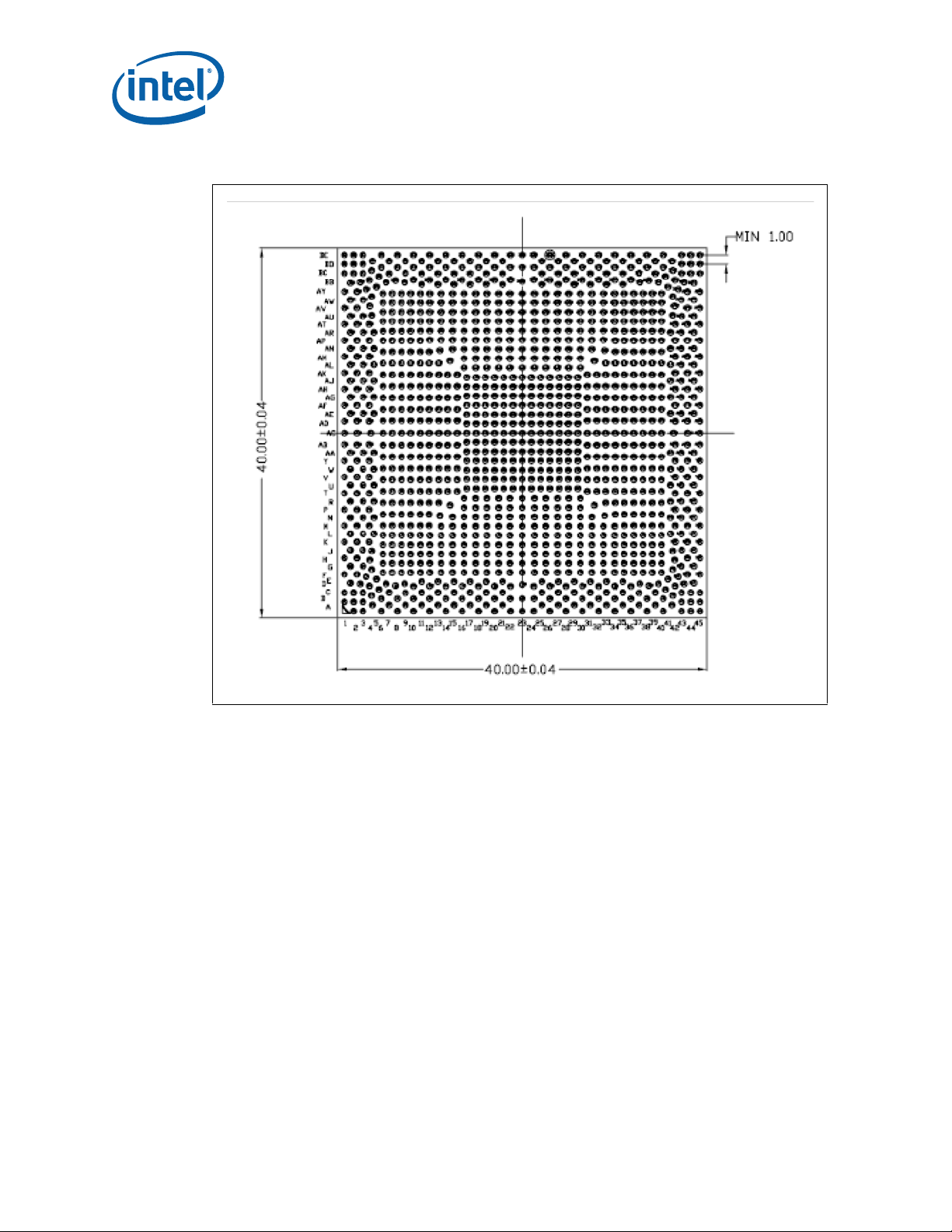

Figure 2-3. MCH Package Dimensions (Bottom View)

Packaging Technology

Notes:

1. All dimensions are in millimeters.

2. All dimensions and tolerances conform to ANSI Y14.5 - 1994.

12 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 13

Packaging Technology

2.1 Non-Critical to Function Solder Joints

Figure 2-4. Non-Critical to Function Solder Joints

Intel has defined selected solder joints of the MCH as non-critical to function (NCTF)

when evaluating package solder joints post environmental testing. The MCH signals at

NCTF locations are typically redundant ground or no-critical reserved, so the loss of the

solder joint continuity at end of life conditions will not affect the overall product

functionality. Figure 2-4 identifies the NCTF solder joints of the MCH package.

2.2 Package Mechanical Requirements

The Intel® 3210 and 3200 Chipset package has an Integrated Heat Spreader (IHS)

which is capable of sustaining a maximum static normal load of 15-lbf. This mechanical

maximum load limit should not be exceeded during heatsink assembly, shipping

conditions, or standard use conditions. Also, any mechanical system or component

testing should not exceed the maximum limit. The package substrate should not be

used as a mechanical reference or load-bearing surface for the thermal and mechanical

solution.

Notes:

1. These specifications apply to uniform compressive loading in a direction normal to

the package.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 13

Page 14

2. This is the maximum force that can be applied by a heatsink retention clip. The clip

must also provide the minimum specified load of 7.6 lbf on the package to ensure

TIM performance assuming even distribution of the load.

3. These specifications are based on limited testing for design characterization.

Loading limits are for the package only.

To ensure that the package static load limit is not exceeded, the designer should

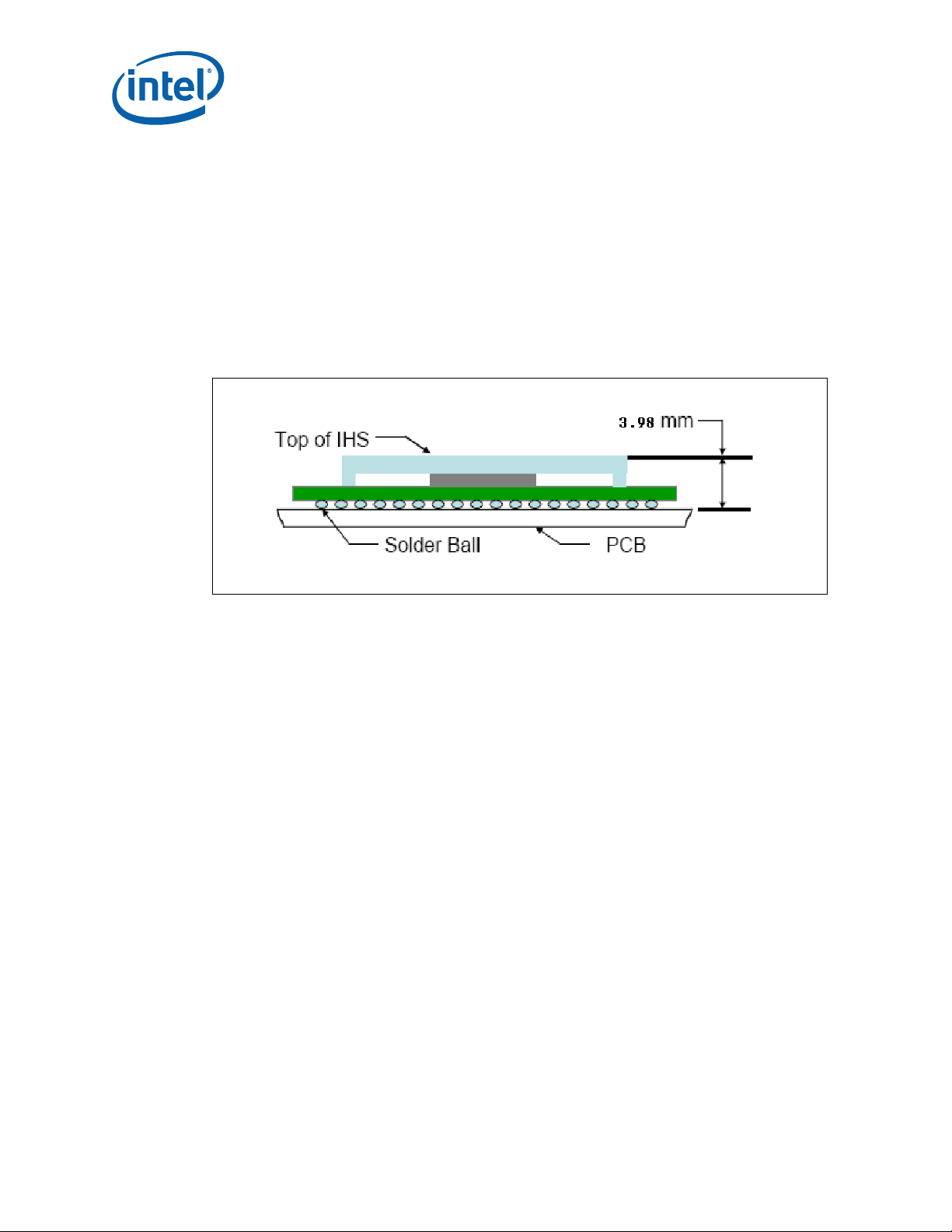

understand the post reflow package height shown in Figure 2-5. The following figure

shows the nominal post-reflow package height assumed for calculation of a heatsink

clip preload of the reference design. Please refer to the package drawing in Figure 2-1

to perform a detailed analysis.

Figure 2-5. Package Height

Packaging Technology

§

14 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 15

Thermal Specifications

3 Thermal Specifications

3.1 Thermal Design Power (TDP)

Analysis indicates that real applications are unlikely to cause the MCH component to

consume maximum power dissipation for sustained time periods. Therefore, in order to

arrive at a more realistic power level for thermal design purposes, Intel characterizes

power consumption based on known platform benchmark applications. The resulting

power consumption is referred to as the Thermal Design Power (TDP). TDP is the target

power level that the thermal solutions should be designed to. TDP is not the maximum

power that the chipset can dissipate.

®

For TDP specifications, see Table 3-1 for Intel

3200. FC-BGA packages have poor heat transfer capability into the board and have

minimal thermal capability without a thermal solution. Intel recommends that system

designers plan for a heatsink when using the Intel

3.2 Thermal Specification

3210 Chipset and Table 3-2 for Intel®

®

3210 and 3200 Chipset.

To ensure proper operation and reliability of the Intel® 3210 and 3200 Chipset, the

case temperatures must be at or between the maximum/minimum operating

temperature ranges as specified in Table 3-1 and Table 3-2. System and/or component

level thermal solutions are required to maintain these temperature specifications. Refer

to Chapter 5 for guidelines on accurately measuring package die temperatures.

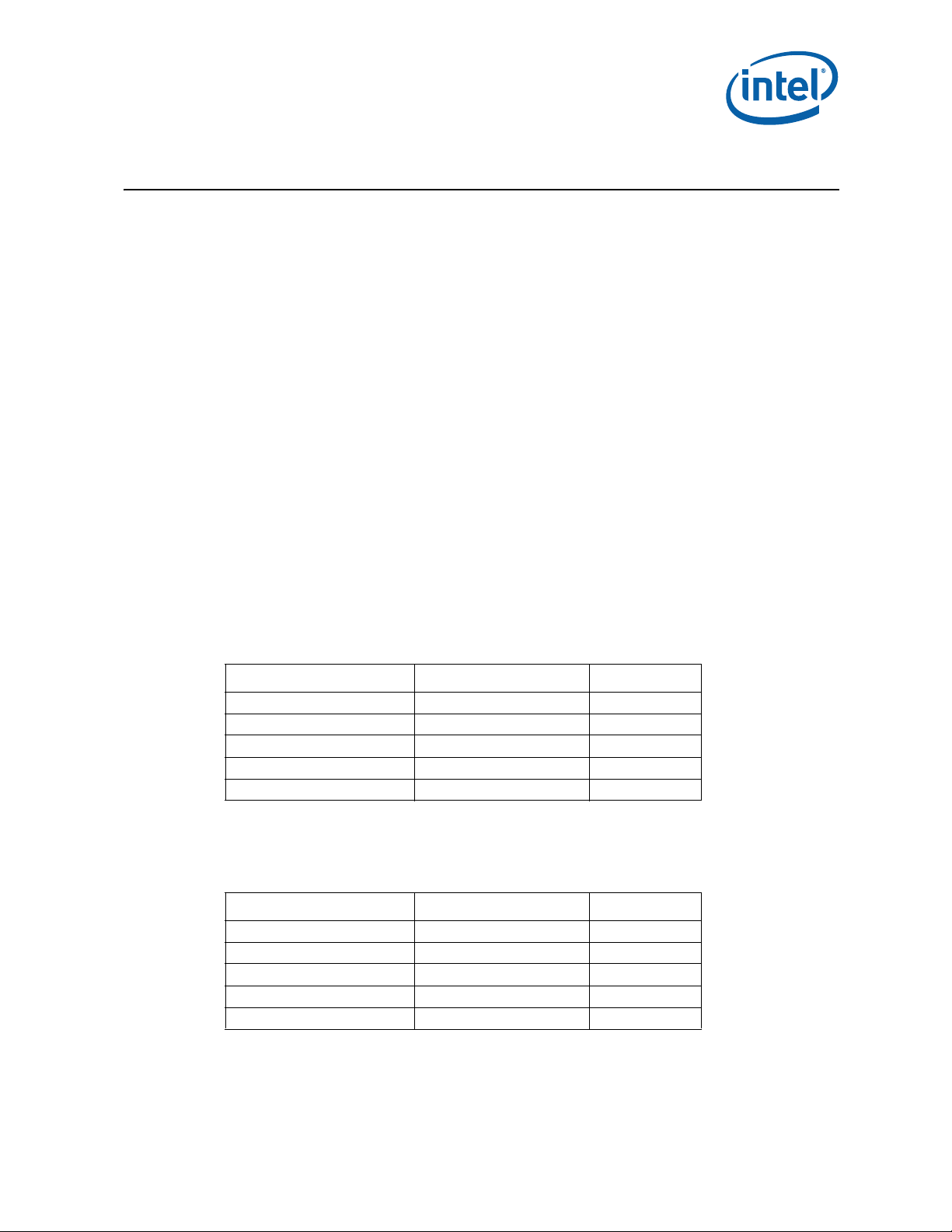

Table 3-1. Intel® 3210 Chipset Thermal Specifications

Parameter Value Notes

T

case_max

T

case_min

TDP

dual channel

TDP

dual channel

P

Idle_max

Notes:

1. The above specifications are based on post-si analysis.

2. The maximum idle power is the worst-case idle power with L1 ASPM state.

96 °C

5 °C

20.2 W DDR2-667

21.3 W DDR2-800

11.3 W

Table 3-2. Intel® 3200 Chipset Thermal Specifications

Parameter Value Notes

T

case_max

T

case_min

TDP

dual channel

TDP

dual channel

P

Idle_max

97 °C

5 °C

18.9 W DDR2-667

20.0 W DDR2-800

11.3 W

Notes:

1. The above specifications are based on post-silicon analysis.

2. The maximum idle power is the worst case idle power with L1 ASPM state.

§

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 15

Page 16

Thermal Specifications

16 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 17

Thermal Simulation

4 Thermal Simulation

Intel provides thermal simulation models of the Intel® 3210 and 3200 Chipset and

associated user's guides to aid system designers in simulating, analyzing, and

optimizing their thermal solutions in an integrated, system-level environment. The

models are for use with the commercially available Computational Fluid Dynamics

(CFD)-based thermal analysis tool FLOTHERM* (version 5.1 or higher) by Flomerics,

Inc. Contact your Intel field sales representative for the information of the thermal

models and user's guides.

§

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 17

Page 18

Thermal Simulation

18 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 19

Thermal Metrology

5 Thermal Metrology

The system designer must make temperature measurements to accurately determine

the thermal performance of the system. Intel has established guidelines for proper

techniques to measure the MCH IHS temperatures. Section 5.1 provides guidelines on

how to accurately measure the MCH case temperature.

5.1 MCH Case Measurement

Intel® 3210 and 3200 Chipset cooling performance is determined by measuring the

case temperature using a thermocouple. For case temperature measurements, the

attached method outlined in this section is recommended for mounting a

thermocouple.

Special case is required when measuring case temperature (Tc) to ensure an accurate

temperature measurement. Thermocouples are often used to measure Tc. When

measuring the temperature of a surface that is at a different temperature from the

surrounding local ambient air, errors may be introduced in the measurements. The

measurement errors can be caused by poor thermal contact between the thermocouple

junction and the surface of the integrated heat spreader, heat loss by radiation,

convection, by conduction through thermocouple leads, or by contact between the

thermocouple cement and the heatsink base. To minimize these measurement errors,

the approach outlined in the next section is recommended.

5.1.1 Supporting Test Equipment

T o apply the reference thermocouple attach procedure, it is recommended that you use

the equipment (or equivalent) given in Table 5-1.

Table 5-1. Thermocouple Attach Support Equipment (Sheet 1 of 2)

Item Description Part Number

Measurement and Output

Microscope Olympus* Light microscope or equivalent SZ-40

DMM Digital Multi Meter for resistance

Thermal Meter Hand held thermocouple meter Multiple Vendors

Special Modified Tip Solder

Block Fixture

Solder Indium Corp. of America

Flux Indium Corp. of America 5RMA

Loctite* 498 Adhesive Super glue w/ thermal characteristics 49850

Adhesive Accelerator Loctite 7452 for fast glue curing 18490

Kapton* Tape for holding thermocouple in place

Thermocouple Omega*, 36 gauge, T type

measurement

Test Fixtures (see notes for ordering information)

40 W 120 V~60 Hz modified soldering

iron

Miscellaneous Hardware (see notes for ordering information)

Alloy 57BI/42SN/1AG 0.010 Diameter

(see note 2 for ordering information)

Fluke 79 Series

Weller SP40L solder tool

52124

OSK2K1280/5SR TC-TT-T-36-72

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 19

Page 20

Table 5-1. Thermocouple Attach Support Equipment (Sheet 2 of 2)

Item Description Part Number

Calibration and Control

Ice Point Cell Omega, stable 0°C temperature source

Hot Point Celll Omega, temperature source to control

Notes:

1. The Special Modified Tip Solder Block Fixture is available from Test Equipment Depot 800-517-8431.

2. The Alloy 57BI/42SN/1AG 0.010 Diameter solder and the solder flux are available from Indium Corp. of

America 315-853-4900.

3. The Loctite* 498 Adhesive and Adhesive Accelerator are available from R.S. Hughes 916-737-7484.

4. This part number is a custom part with the specified insulation trimming and packaging requirements

necessary for quality thermocouple attachment, See Figure 16. Order from Omega Eng +1-800-826-6342.

for calibration and offset

and understand meter slope gain

TRCIII

CL950-A-110

Figure 5-1. Omega Thermocouple

Thermal Metrology

5.1.2 Thermal Calibration and Controls

It is recommended that full and routine calibration of temperature measurement

equipment be performed before attempting to perform case temperature

measurements. Intel recommends checking the meter probe set against know

standard. This should be done at 0 °C (using ice bath or other stable temperature

source) and at an elevated temperature, around 80 °C (using an appropriate

temperature source).

Wire gauge and length should also be considered, as some less expensive

measurement systems are heavily impacted by impedance. There are numerous

resources available throughout the industry to assist with implementation of proper

controls for thermal measurements.

Note: 1. It is recommended to follow company-standard procedures and wear safety items

like glasses for cutting the IHS and gloves for chemical handling.

2. Please ask your Intel field sales representative if you need assistance to groove

and/or install a thermocouple according to the reference process.

5.1.3 IHS Groove

Cut a groove in the package IHS according to the drawing given in Figure 5-2.

20 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 21

Thermal Metrology

Figure 5-2. FCBGA7 Chipset Package Reference Groove Drawing

The orientation of the groove relative to the package pin 1 indicator (gold triangle in

one corner of the package) is shown in Figure 5-3 for the FCBGA7 chipset package IHS.

Figure 5-3. IHS Groove on the FCBGA7 Chipset Package on the Live Board

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 21

Page 22

Select a machine shop that is capable of holding drawing-specified tolerances. IHS

groove geometry is critical for repeatable placement of the thermocouple bead,

ensuring precise thermal measurements. A fixture plate should be used to machine the

IHS groove on the FCBGA7 Chipset Package on the Live Board. Refer to Figure 5-4.

Figure 5-4. The Live Board on the Fixture Plate

Thermal Metrology

5.1.4 Thermocouple Attach Procedure

In order to accomplish the thermocouple attach procedure, the following steps are

required:

1. Thermocouple conditioning and preparation

2. Thermocouple attach to the IHS

3. Soldering process

4. Cleaning and completion of the thermocouple installation

5.1.4.1 Thermocouple Conditioning and Preparation

1. Use a calibrated thermocouple, as specified in Section 5.1.3.

2. Under a microscope verify the thermocouple insulation meets the quality

requirements. The insulation should be about 1/16 inch (0.062 ± 0.030) from the

end of the bead. Refer to Figure 5-5.

22 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 23

Thermal Metrology

Figure 5-5. Inspection of Insulation on Thermocouple

3. Measure the thermocouple resistance by holding both contacts on the connector on

one probe and the tip of thermocouple to the other probe of the DMM

(measurement should be about ~3.0 ohms for 36-gauge type T thermocouple).

4. Straighten the wire for about 38 mm [1.5 inch] from the bead.

5. Using the microscope and tweezers, bend the tip of the thermocouple at

approximately 10 degree angle by about 0.8 mm [.030 inch] from the tip. Refer to

Figure 5-6.

Figure 5-6. Bending the Tip of the Thermocouple

5.1.4.2 Thermocouple attach to the IHS

6. Clean groove and IHS with Isopropyl Alcohol (IPA) and a lint free cloth removing all

residues prior to thermocouple attachment.

7. Place the Thermocouple wire inside the groove and let the exposed wire extend

slightly over the end of groove. Refer to Figure 5-7.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 23

Page 24

Figure 5-7. Extending Slightly the Exposed Wire over the End of Groove

8. Bend the wire at the edge of the IHS groove and secure it in place using Kapton*

tape. Refer to Figure 5-8.

Thermal Metrology

Figure 5-8. Securing Thermocouple Wire with Kapton* Tape Prior to Attach

9. Verify under the microscope that the Thermocouple bead is still slightly bent, if not,

use a fine point tweezers to put a slight bend on the tip. The purpose of this step is

to ensure that the Thermocouple tip is in contact with the bottom of groove. Refer

to Figure 5-9.

24 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 25

Thermal Metrology

Figure 5-9. Detailed Thermocouple Bead Placement

10.Place the device under the microscope to continue with the process.

11.Using tweezers or a finger, slightly press the wire down inside the groove for about

5 mm from tip and place small piece of Kapton* tape to hold the wire inside the

groove. Refer to Figure 5-10.

Figure 5-10. Tapes Installation

12.Thermocouple bead is placed into the bottom of the groove (Refer to Figure 5-11)

and a small piece of tape is installed to secure it under the microscope to perform

this task.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 25

Page 26

Figure 5-11. Placing Thermocouple Bead into the Bottom of the Groove

13.Place a second small piece of Kapton* tape on top of the IHS where it narrows at

the tip. This tape will create a solder dam and keep solder from flowing down the

IHS groove during the melting process. Refer to Figure 5-12.

Thermal Metrology

Figure 5-12. Second Tape Installation

14.Measure resistance from the Thermocouple connector (hold both wires to a DMM

probe) to the IHS surface, this should display the same value as read during

Thermocouple conditioning Section 5.1.4.1 step 3. This step insures the bead is still

making good contact to the IHS. Refer to Figure 5-13.

26 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 27

Thermal Metrology

Figure 5-13. Measuring Resistance between Thermocouple and IHS

15.Using a fine-point device such as a toothpick, place a small amount of Indium paste

flux on the Thermocouple bead. Refer to Figure 5-14.

Figure 5-14. Adding a Small Amount of Past Flux to the Bead for Solder ing

Note: Make sure you are careful to keep solder flux from spreading on the IHS surface or down the groove. It

should be contained to the bead area and only the tip (narro w section of the g roov e). This will k ee p the

solder from flowing onto the top of the device or down the groove to the insulation area.

16.Cut two small pieces of solder 1/16 inch (0.065 inch/ 1.5 mm) from the roll using

tweezers to hold the solder while cutting with a fine blade. Refer to Figure 5-15.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 27

Page 28

Figure 5-15. Cutting Solder

17.Place the two pieces of solder in parallel, directly over the thermocouple bead.

Refer to Figure 5-16.

Thermal Metrology

Figure 5-16. Positioning Solder on IHS

18.Measure the resistance from the thermocouple end wires again using the DMM

(Refer to Section 5.1.4.1 step 3) to ensure that the bead is still properly contacting

the IHS.

5.1.4.3 Solder Process

19.Turn on the Solder Block station and heat it up to 170 °C±5 °C.

Note: The heater block temperature must be set at a greater temperature to ensure that the

solder on the IHS can reach 150 °C - 155 °C. Make sure to monitor the Thermocouple

meter when waiting for solder to flow. Damage to the package may occur if a

temperature of 155 °C is exceeded on the IHS.

28 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 29

Thermal Metrology

20.Attach the tip of the thermocouple to the solder block (perform this before turning

on the solder station switch) and connect to a Thermocouple meter to monitor the

temperature of the block. Refer to Figure 5-17.

21.Connect (Thermocouple being installed) to a second thermocouple meter to

monitor the IHS temperature and make sure this doesn’t exceed 155 °C at any

time during the process. Refer to Figure 5-17.

Figure 5-17. Solder Block Setup

Note: Device in place; Two temper ature monitoring meters; Heater block fixtu re. The heate r block is cu rrently

reading 157 °C and the Thermocouple inside IHS is reading 23 °C.

22.Place the solder fixture on the IHS device. Refer to Figure 5-18.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 29

Page 30

Figure 5-18. Observing the Solder Melting

Thermal Metrology

Note: Do not touch the copper block at any time as it is hot.

23.Move a magnified lens light close to the device to get a better view when the solder

starts melting. Manually assist this if necessary as the solder sometimes tends to

move away from the end of the groove. Use fine tip tweezers to push solder into

the end of groove until a solder ball is built up. Refer to Figure 5-19.

Figure 5-19. Pushing Solder Back into the End of Groove

30 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 31

Thermal Metrology

Note: The target IHS temperature during reflow is 150°C ±3°C. At no time should the IHS temperature

exceed 155 °C during the solder process as damage to the device may occur.

24.Lift the solder block and magnified lens, quickly rotate the device 90 degrees

clockwise and use the back side of the tweezers to press down on the solder. This

will force out excess solder. Refer to Figure 5-20.

Figure 5-20. Remove Excess Solder

25.Allow the device to cool down. Blowing compressed air on the device can accelerate

the cooling time. Monitor the device IHS temperature with a handheld meter until it

drops below 70 °C before moving it to the microscope for the final steps.

5.1.4.4 Cleaning and Completion of Thermocouple Installation

26.Remove the Kapton* tape with tweezers (avoid damaging the wire insulation) and

straighten the wire to insert the remaining portion in the groove for the final gluing

process.

Note: The wire needs to be straighten in order to keep it at or below the IHS surface. Refer to

Figure 5-21.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 31

Page 32

Figure 5-21. Thermocouple Placed into Groove

Thermal Metrology

27.Using a blade, carefully shave the excess solder above the IHS surface. Only shave

in one direction until solder is flush with the groove surface. Refer to Figure 5-22.

Figure 5-22. Remove Excess Solder

Notes:

1. Always insure tools are very sharp and free from any burrs that may scratch the IHS surface. It is a good

practice to minimize any surface scratching or other damage during this process.

2. Shaving excess solder to insure the IHS surface is flat and will mate properly with the heatsink surface.

Scratches and protrusions may impact the thermal transfer from IHS.

28.Clean the surface of the IHS with Alcohol and wipes, use compressed air to remove

any remaining contaminants.

29.Fill the test of the groove with Loctite* 498 Adhesive. Verify under the microscope

that the Thermocouple wire is below the surface along the entire IHS groove. Refer

to Figure 5-23.

32 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 33

Thermal Metrology

Figure 5-23. Fill Groove with Adhesive

30.T o speed up the curing process apply Loctite* Accelerator on top of the Adhesive

and let it set for a couple of minutes.

31.Using a blade carefully shave any Loctite* left above the IHS surface; take into

consideration instructions from step 27.

Note: The adhesive shaving process should be performed when the glue is partially cured but

still soft (about 1 hour after applying). This will keep the adhesive surface flat and

smooth with no pits or voids. If you have void areas in the groove, refill them and

shave the surface a second time.

32.Clean the IHS surface with Alcohol and keep the Thermocouple wire properly

managed to avoid insulation damage kinks and tangling.

33.Once again, measure resistance from the Thermocouple connector (hold both wires

to a DMM probe) to the IHS surface, this should display the same value as read

during Thermocouple conditioning Section xxx. This step insures the bead is still

making good contact to the IHS after attachment is complete.

34.Wind the thermocouple wire into loops and now it’s ready to be used for thermal

testing use. Refer to Figure 5-24.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 33

Page 34

Figure 5-24. Finished Thermocouple Installation

Thermal Metrology

§

34 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 35

Reference Thermal Solution

6 Reference Thermal Solution

The design strategy of the reference thermal solution for the Intel® 3210 and 3200

Chipset uses backing plate stiffness/design to show significant improvement in MB

strain and BGA forces. The thermal interface material and extrusion design

requirements are being evaluated for changes necessary to meet the Intel

3200 Chipset thermal requirements. The Keep Out Zone (KOZ) will have the

requirements of heatsink mounting hole with Intel® 3210 and 3200 Chipset. Refer to

Figure B-2 and Figure B-3 for details. Other chipset components may or may not need

attached thermal solutions, depending on the specific system local-ambient operating

conditions. For information on the Intel

®

I/O Controller Hub9 (ICH9) Thermal Design Guidelines.

Intel

6.1 Operating Environment

The reference thermal solution will be designed assuming a maximum local-ambient

temperature of 55 °C. The minimum recommended airflow velocity through the crosssection of the heatsink fins is 350 linear feet per minute (lfm) for 1U system and 450

linear feet per minute (lfm) for 2U+ system. The approaching airflow temperature is

assumed to be equal to the local-ambient temperature. The thermal designer must

carefully select the location to measure airflow to obtain an accurate estimate. These

local-ambient conditions are based on a 35 °C external-ambient temperature at sea

level. (External-ambient refers to the environment external to the system.)

®

ICH9, refer to thermal specification in the

®

3210 and

6.2 Heatsink Performance

Figure 6-1 depicts the measured thermal performance of the reference thermal solution

versus approach air velocity. Since this data was measured at sea level, a correction

factor would be required to estimate thermal performance at other altitudes.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 35

Page 36

Reference Thermal Solution

Figure 6-1. Reference Heatsink Measured Thermal Performance vs. Approach Velocity

6.3 Mechanical Design Envelope

While each design may have unique mechanical volume and height restrictions or

implementation requirements, the height, width, and depth constrains typically placed

on the Intel® 3210 and 3200 Chipset thermal solution are shown in Appendix B.

The location of hole patens and keepout zones for the reference thermal solution are

shown in Figure B-2 and Figure B-3.

6.4 Thermal Solution Assembly

The reference thermal solution for the Intel® 3210 and 3200 Chipset is a passive

extruded heatsink with thermal interface. Figure 6-2 shows the reference thermal

solution assembly and associated components.

Full mechanical drawings of the thermal solution assembly and the heatsink are

provided in Appendix B.

36 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 37

Reference Thermal Solution

Figure 6-2. Design Concept for Reference The rmal Solution

6.4.1 Extruded Heatsink Profiles

The reference thermal solution uses an extruded heatsink for cooling the chipset MCH.

Figure 6-3 shows the heatsink profile. Other heatsinks with similar dimensions and

increased thermal performance may be available. A full mechanical drawing of this

heatsink is provided in Appendix B.

Figure 6-3. Heatsink Extrusion Profiles

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 37

Page 38

Reference Thermal Solution

6.4.2 Retention Mechanism Responding in Shock and Vibration

The lead-free process, large package and Integrated Heat Spreader (IHS) application

on the Intel® 3210 and 3200 Chipset changed the mechanical responses during shock

and vibration comparing with the legacy generation MCH chipset.

The Intel reference thermal solution uses a back plate design that adequately protects

®

the Solder Ball Joint Reliability (SBJR) of the Intel

3210 and 3200 Chipset. Analysis

data indicates that the back plate design provides measurable improvement in SBJR of

®

the Intel

3210 and 3200 Chipset in ATX form factors (1U ATX-like system is included)

where processor heatsink is attached to the motherboard. Hence, Intel recommends

using the back plate design on chipset heatsink in such a circumstance to protect the

SBJR.

For customized form factors where the processor heatsink is Direct Chassis Attach

(DCA), customers are recommended to do shock and vibration analysis and test to

determine whether a back plate design is needed or not, which probably will benefit the

customer in controlling the heatsink cost.

6.4.3 Thermal Interface Material

A Thermal Interface Material (TIM) provides improved conductivity between the IHS

and heatsink. The reference thermal solution uses Honeywell PCM45 F*, 0.25mm

(0.010 in.) thick, 20mm x 20mm (0.79 in. x 0.79 in.) square.

Note: Unflowed or “dry“ Honeywell PCM45F has a material thickness of 0.010 inch. The

flowed or “wet“ Honeywell PCM45F has a material thickness of ~0.003 inch after it

reaches its phase change temperature.

6.4.3.1 Effect of Pressure on TIM Performance

As mechanical pressure increases on the TIM, the thermal resistance of the TIM

decreases. This phenomenon is due to the decrease of the bond line thickness (BLT).

BLT is the final settled thickness of the thermal interface material after installation of

heatsink. The effect of pressure on the thermal resistance of the Honeywell PCM45F

TIM is shown in Table 6.1.

Intel provides both End of Line and End of Life TIM thermal resistance values of

Honeywell PCM45F. End of Line and End of Life TIM thermal resistance values are

®

obtained through measurement on a Test Vehicle similar to Intel

3210 and 3200

Chipset’s physical attributes using an extruded aluminum heatsink. The End of line

value represents the TIM performance post heatsink assembly while the End of Life

value is the predicted TIM performance when the product and TIM reaches the end of

its life. The heatsink clip provides enough pressure for the TIM to achieve End of Line

2

thermal resistance of 0.345 °C inch

2

/W.

inch

/W and End of Life thermal resistance of 0.459 °C

Table 6-1. Honeywell PCM45F* TIM Performance as a Function of Attach Pressure

2

Pressure on Psi

Thermal Resistance (°C x in

End of Line End of Life

2.18 0.391 0.551

4.35 0.345 0.459

38 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

)/W

Page 39

Reference Thermal Solution

6.4.4 Reference Thermal Solution Assembly Process

1. Snap the preload clip spring onto the bracket. Assemble the bracket with heatsink,

as shown in Figure 6-4.

Figure 6-4. Reference Thermal Solut ion Assembly Process - Heatsink Sub-Assembly

(Step 1)

2. Populate the backplate to the motherboard and align the nuts with the studs on the

backplate, as shown in Figure 6-5.

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 39

Page 40

Reference Thermal Solution

Figure 6-5. Reference Thermal Solution Assembly Process - Heatsink Assembly (Step 2)

3. To assemble the heatsink with the backplate, screw in the nuts with 8 in-lb.

6.5 Reliability Guidelines

The environmental reliability requirements for the reference thermal solution are

shown in Table 6-2. These should be considered as general guidelines. Each

motherboard, heatsink and attach combination may vary the mechanical loading of the

component. Based on the end-user environment, the user should define the

appropriate reliability test criteria and carefully evaluate the completed assembly prior

to use in high volume.

The testing will be performed with the sample board mounted on a test fixture. The test

profiles are unpacked board level.

40 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 41

Reference Thermal Solution

Table 6-2. Reference Thermal Solution Environmental Reliability Guidelines

(1)

Test

Mechanical Shock 3 drops for + and – directions in each of 3

Random Vibration Duration: 10 min/axis, 3 axes

Temperature Life 85 °C, 2000 hours total, checkpoints at 168, 500,

Thermal Cycling -40 °C to +70 °C, 50 cycles Visual Check

Notes:

1. It is recommended that the above tests be performed on a sample size of at least twelve assemblies from

three lots of material.

2. Additional pass/fail criteria may be added at the discretion of the user.

perpendicular axes

Profile: 50 G, Trapezoidal waveform, 4.3 m/s [170

in/s] minimum velocity change

Frequency Range: 5 Hz to 500 Hz

Power Spectral Density (PSD) Profile: 3.13 g RMS

1000, and 2000 hours

Requirement Pass/Fail Criteria

Visual Check and Electrical

Functional Test

Visual Check and Electrical

Functional Test

Visual Check

§

(2)

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 41

Page 42

Reference Thermal Solution

42 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 43

Thermal Solution Component Suppliers

A Thermal Solution Component

Suppliers

A.1 Heatsink Thermal Solution

Part

Heatsink Assembly D96730-001 Monika Chih

Heatsink D96729-001 1

Retainer D92698-001 1

Nuts-Inserts D92621-001 4

Bracket E 11663-001 1

Stiffener-backplate D94244-001 1

Intel Part

Number

Quantity Contact Information

monika_chih@ccic.com.tw

886-2-29952666-1131

§

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 43

Page 44

Thermal Solution Component Suppliers

44 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 45

Mechanical Drawings

B Mechanical Drawings

The following table lists the mechanical drawings available in this document.

Drawing Name Page Number

Intel® 3210 and 3200 Chipset Package Drawing page 46

Intel® 3210 and 3200 Chipset Motherboard Component Top-Side Keep-Out Restrictions page 47

Intel® 3210 and 3200 Chipset Motherboard Component Back-Side Keep-Out Restrictions page 48

Intel® 3210 and 3200 Chipset Reference Thermal Solution Assembly page 49

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Heatsink Drawing page 50

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Spring Preload Clip page 51

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Fastener Nut page 52

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Bracket (1 of 2) page 53

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Bracket (2 of 2) page 54

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Backplate Assembly page 55

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Backplate page 56

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Insulator page 57

Intel® 3210 and 3200 Chipset Reference Thermal Solution - Flush Mount Stud page 58

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 45

Page 46

Figure B-1. Intel® 3210 and 3200 Chipset Package Drawing

Mechanical Drawings

46 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 47

Mechanical Drawings

Figure B-2. Intel® 3210 and 3200 Chipset Motherboard Component Top-Side Keep-Ou t

Restrictions

B

1 HOLE PLACEMENT FABRICATION

NOTES:

TOLERANCE PER INTEL 454979, CLASS 1,2,3

2. HEATSINK COMPONENT HEIGHT NOT TO EXCEED

38.1MM ABOVE MOTHERBOARD SURFACE.

DETAIL A

SCALE 8

2200 MISSION COLLEGE BLVD.

R

DESCRIPTIONPART NUMBERITEM NO

DEPARTMENT

PARTS LIST

DATEDESIGNED BY

DRAWING,KO,MCH,BEARLAKEC,BONE TRAILD94910TOP

-001-002-003

QTY PER ASSY

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

A

REVDRAWING NUMBERCAGE CODESIZE

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

CORP.

HEAT SINK KEEP OUT

ATX BEARLAKE MCH

PST

TITLE

03/15/07K.CEURTER

DATEAPPROVED BY

DATECHECKED BY

DATECHECKED BY

THIRD ANGLE PROJECTION

IN ACCORDANCE WITH ASME Y14.5M-1994

DIMENSIONS ARE IN MILLIMETERS

TOLERANCES:

LINEAR 0.1MM

1

D94910D

FINISH:NAMATERIAL:

COMPONENT CENTER

MAX 25 [1.000]

COMPONENT HEIGHT

13

REVISION HISTORY

D94910 1 1

DWG. NO SHT. REV

ZONE REV DESCRIPTION DATE APPROVED

4

PRELIMINARY RELEASE 03/15/07

***

D

C

.4134[]

NO COMPONENTS THIS AREA

4X 10.5

4X 5.06 TRACE KEEPOUT

AROUND HOLES

1

.1591[]

4X THROUGH HOLE4.04

EAST

2.9134[]

74

SHEET 1 OF 2DO NOT SCALE DRAWINGSCALE: NONE

NA

123

4

.1575[]

135

4

MAX 1.27 [.050]

COMPONENT HEIGHT

(NON-MCH COMPONENTS)

5678

5678

DETAIL A

2.386[]

1.890[]

60.6

48

1.055[]

26.79

NORTH

PRIMARY SIDE KEEPOUTS

1.803[]

45.79

2.638[]

67

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

D

3.189[]

81

C

B

A

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 47

Page 48

Mechanical Drawings

Figure B-3. Intel® 3210 and 3200 Chipset Motherboard Component Back-Side Keep-O ut

Restrictions

D

C

13

D94910 2 1

DWG. NO SHT. REV

4

COMPONENT CENTER

B

3.1890[]

81

1.4980[]

38.05

A

1D94910XD

REVDRAWING NUMBERCAGE CODESIZEDEPARTMENT

SHEET 2 OF 2DO NOT SCALE DRAWINGSCALE: 1

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

CORP.

R

TMD

123

4

5678

.7500[]

2.3858[]

19.05

60.6

5678

SECONDARY SIDE KEEPOUTS

NO COMPONENTS THIS AREA

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

D

C

B

A

48 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 49

Mechanical Drawings

Figure B-4. Intel® 3210 and 3200 Chipset Reference Thermal Solution Assembly

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 49

Page 50

Mechanical Drawings

Figure B-5. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Heatsink Drawing

50 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 51

Mechanical Drawings

Figure B-6. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Spring Preload

Clip

D92698 1 1

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

1 PRODUCTION RELEASE 06/20/07 KJC

- A INITIAL DV RELEASE 03/09/07 KJC

G

F

E

53.8 0.1

D

A

4.2 0.25

C

B

2200 MISSION COLLEGE BLVD.

R

DEPARTMENT

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

A

1

OF

1

SHEET

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

DO NOT SCALE DRAWING

PST

DATEDRAWN BY

03/09/07K.CEURTER

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

4

BONE TRAIL,SPRING CLIP,PRELOAD

SIZE DRAWING NUMBER REV

A1 D92698 1

TITLE

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

03/09/07P.BORNEMANN

DATEAPPROVED BY

03/09/07R.AOKI

03/09/07A.VALPIANI

DATECHECKED BY

03/09/07K.CEURTER

ANGLES ±1

DIMENSIONS ±0.3

ALL UNTOLERANCED LINEAR

THIRD ANGLE PROJECTION

DIMENSIONS ARE IN MILLIMETERS

5 . CRITICAL TO FUNCTION DIMENSION/FEATURE

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS

2. BREAK ALL SHARP EDGES AND CORNERS, GRIND PUNCH MARKS FLAT, NO BURS FROM PUNCH

3. MATERIAL: AISI TYPE 301 1/2 HARD FOR MIN YIELD STRENGTH OF 760 MPa OR INTEL APPROVED EQUIVALENT

CRITICAL MATERIAL PROPERTIES: MIN YIELD STRENGTH = 760 MPa

4. FINISH: ZINC OR ELECTROLYTIC NICKEL PLATING PLUS CLEAR CHROMATE COLORLESS PER ASTM B 633

8 7 6 5 4 3 2

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

IF NON STAINLESS STEEL ALTERNATE CHOSEN

H

8

C

1.9

51.2 0.05

G

F

E

9.651

A

5

Cpk TARGET = 1.0

ACCEPTABLE

0.451 0.15

B543.7 0.25

8 7 6 5 4 3 2 1

D

C

B

A

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 51

Page 52

Mechanical Drawings

Figure B-7. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Fastener Nut

D92621 1 1

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

1 PRODUCTION RELEASE 06/20/07 KJC

- A INITIAL DV RELEASE 03/09/07 KJC

B3 B CHANGED COLLAR HT FROM 2 TO 4 05/09/07 KJC

G

B

F

A A

E

B

D

C

5 0.1

B

A

4 0.1

A

A

1

OF

1

SHEET

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

DO NOT SCALE DRAWING

BONE TRAIL, FASTNER, NUT

SIZE DRAWING NUMBER REV

TITLE

03/09/07P.BORNEMANN

DATEAPPROVED BY

03/09/07R.AOKI

03/09/07A.VALPIANI

DATECHECKED BY

03/09/07K.CEURTER

ANGLES ±0.5

DIMENSIONS ±0.1

ALL UNTOLERANCED LINEAR

THIRD ANGLE PROJECTION

15

A1 D92621 1

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

PST

DEPARTMENT

DATEDRAWN BY

03/09/07K.CEURTER

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN MILLIMETERS

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

SECTION B-B

A

0.13 A B

8 7 6 5 4 3 2

NOTES:

1. USE PEM PART NUMBER = OR INTEL APPROVED ALTERNATE

2. DIMENSIONS ARE IN MILLIMETERS

3. MATERIAL:

- LOW CARBON STEEL

4. FINISH:

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

- ZINC PLUS CLEAR CHROMATE PER ASTM B633 COLORLESS

H

6 0.25

()62

RECESS FOR #2 PHILLIPS DRIVER

6-32 UNC - 2B TAP 5

5 . CRITICAL TO FUNCTION

6. REFERENCE AND NON-DIMENSIONED FEATURES MAY BE MODIFIED PER INTEL APPROVAL

G

F

E

D

#36 DRILL ( 2.71 ) THRU -( 1 ) HOLE

C

2.71

0.13 A B

SECTION A-A

B 57 0.01

8 7 6 5 4 3 2 1

B

A

52 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 53

Mechanical Drawings

Figure B-8. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Bracket (1 of 2)

H

03/23/07 KJC

05/16/07 KJC

E11663 1 1

DWG. NO SHT. REV

REVISION HISTORY

REMOVED ROUNDS

NUT LATCH SIZE IN SEC II

PART NUMBER CHANGED FROM D92625-001;

REMOVED Z-STOP FROM SEC III; INCREASED

CHANGED DRAFT ANGLE FROM 0.5 TO 1 DEG

B

1

- A INITIAL DV RELEASE 03/09/07 KJC

ZONE REV DESCRIPTION DATE APPROVED

S1-C3

S2-B7

4X 10

G

C

5

A

F

66.4 0.018

63

60

2X 4

E

D

4X 1.84

TYP 2

REV B

REMOVED ROUNDS

C

B

REV B

4X REM ROUNDS

A

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

DO NOT SCALE DRAWING

BONE TRAIL,FRAME,TOP

PST

SIZE DRAWING NUMBER REV

DEPARTMENT

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

A1 E11663 1

TITLE

FINISHMATERIAL

03/12/07K.KOEPSELL

DATEAPPROVED BY

03/12/07R.AOKI

03/12/07A.VALPIANI

DATECHECKED BY

03/09/07K.CEURTER

DATEDRAWN BY

03/09/07K.CEURTER

ANGLES ±0.5

DIMENSIONS ±0.1

ALL UNTOLERANCED LINEAR

THIRD ANGLE PROJECTION

DIMENSIONS ARE IN MILLIMETERS

IN ACCORDANCE WITH ASME Y14.5M-1994

2

OF

1

SHEET

3

SCALE:

SEE NOTESSEE NOTES

63.7 0.1

0.15 A H

4X

44

0.1

0.1 A H C

38

IV

8 7 6 5 4 3 2

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

H

610.2 0.12

0.15 A H

4X

IV

I

I

4X 7.438 0.12

G

66

33

H

1.5

C

23.5

2X 3

47

III

III

47.6 0.1

II

II

22.2

5 MARK PART WITH INTEL P/N, REVISION, CAVITY NUMBER AND DATE CODE APPROX WHERE SHOWN PER INTEL MARKING STANDARD 164997

NOTES:

1. THIS DRAWING TO BE USED IN CONJUNCTION WITH SUPPLIED 3D DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS DRAWING TAKE

PRECEDENCE OVER SUPPLIED FILE AND ARE APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS INDICATED OTHERWISE.

2. TOLERANCES ON DIMENSIONED AND UNDIMENSIONED FEATURES UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS.

FOR FEATURE SIZES < 10MM: LINEAR .07

FOR FEATURE SIZES BETWEEN 10 AND 25 MM: LINEAR .08

FOR FEATURE SIZES BETWEEN 25 AND 50 MM: LINEAR .10

FOR FEATURE SIZES > 50MM: LINEAR .18

ANGLES: 0.5

3. MATERIAL:

A) TYPE: ENVIRONMENTALLY COMPLIANT THERMOPLASTIC OR

EQUIVALENT UPON INTEL APPROVAL (REF. GE LEXAN 500ECR-739)

B) CRITICAL MECHANICAL MATERIAL PROPERTIES

FOR EQUIVALENT MATERIAL SELECTION:

TENSILE YIELD STRENGTH (ASTM D638) > 57 MPa

F

E

D

C

6 CRITICAL TO FUNCTION DIMENSION

FLEXURAL YIELD STREGTH (ASTM D638) > 99 MPa

TENSILE ELONGATION AT BREAK (ASTM D638) >= 46%

FLEXURAL MODULUS (ASTM D638) 3116 MPa 10%

SOFTENING TEMP (VICAT, RATE B): 154 C

C) COLOR: APPROXIMATING BLACK, (REF GE 739)

D) REGRIND: 25% PERMISSIBLE.

7. ALL DIMENSIONS SHOWN SHALL BE MEASURED FOR FAI

8. DEGATE: FLUSH TO 0.35 BELOW STRUCTURAL THICKNESS (GATE WELL OR GATE RECESS ACCEPTABLE)

9. FLASH: 0.15 MAX.

10. SINK: 0.25 MAX.

11. EJECTOR MARKS: FLUSH TO -0.25

12. PARTING LINE MISMATCH NOT TO EXCEED 0.25.

B

8 7 6 5 4 3 2 1

13. EJECTION PIN BOSSES, GATING, AND TOOLING INSERTS REQUIRE INTEL'S APPROVAL PRIOR TO TOOL CONSTRUCTION.

ALL EJECTION PIN BOSSES AND GATE FEATURES SHOWN ARE FOR REFERENCE ONLY.

14. EDGES SHOWN AS SHARP R 0.1 MAX.

15. TOOLING REQUIRED TO MAKE THIS PART SHALL BE THE PROPERTY OF INTEL, AND SHALL BE PERMANENTLY MARKED

WITH INTEL'S NAME AND APPROPRIATE PART NUMBER.

16. ALL SECONDARY UNIT DIMENSIONS ARE FOR REFERENCE ONLY.

A

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 53

Page 54

Mechanical Drawings

Figure B-9. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Bracket (2 of 2)

H

E11663 2 1

DWG. NO SHT. REV

G

2.55

F

A

E

2

SECTION II-II

SCALE 10

D

1.5

C

A

SECTION IV-IV

4

B

SCALE 10

A

2

OF

2

SHEET

DO NOT SCALE DRAWING

3

SIZE DRAWING NUMBER REV

A1 E11663 1

SCALE:

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

PST

DEPARTMENT

8 7 6 5 4 3 2

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

H

A

7.5

TYP 2.8

SECTION III-III

SCALE 10

2X 4.5 0.07

G

F

E

D

C

A

8

2

REV B

TYP ( )

SECTION I-I

SCALE 10

8 7 6 5 4 3 2 1

B

A

54 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 55

Mechanical Drawings

Figure B-10. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Backplate

Assembly

D94244 1 1

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

1 PRODUCTION RELEASE 06/20/07 KJC

- A INITIAL DV RELEASE 03/09/07 KJC

G

F

E

D

1

3

C

B

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

DESCRIPTIONPART NUMBERITEM NOQTY

PST

DEPARTMENT

TITLE

PARTS LIST

03/09/07K.CEURTER

DATEDRAWN BY

03/09/07K.CEURTER

DATEDESIGNED BY

BONE TRAIL,INSULATOR,BACK PLATED92624-00131

BONE TRAIL,STUD,SELF-CLINCHING, DOG POINTD92622-00124

ASSY,STIFFENER,BD,BONE TRAILD94244-001TOP

BONE TRAIL, MCH, STIFFENER, PLATED92620-00111

ALL UNTOLERANCED LINEAR

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN MILLIMETERS

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

A

1

OF

1

SHEET

DO NOT SCALE DRAWING

2

BONE TRAIL,MCH,STIFFENER,PLATE

SIZE DRAWING NUMBER REV

A1 D94244 1

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

03/12/07K.KOEPSELL

DATEAPPROVED BY

03/12/07R.AOKI

03/12/07A.VALPIANI

DATECHECKED BY

ANGLES ±1

DIMENSIONS ±0.1

THIRD ANGLE PROJECTION

()2.127

0.13

4

2

PLATE PUNCH/BURR DIRECTION

3

4

D

C

B

8 7 6 5 4 3 2 1

A

8 7 6 5 4 3 2

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

3 INSTALL STUDS FLUSH TO THIS SURFACE +0.1 / -0.25 MM

4 INSULATOR WILL OVERHANG EDGE UPON PLACEMENT AND IS ACCEPTABLE

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS

2. REMOVE OILS-GREASE FROM PLATE PRIOR TO INSULATOR (3) INSTALLATION.

H

1

1

G

F

E

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 55

Page 56

Mechanical Drawings

Figure B-11. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Back plate

D92620 1 A

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

- A INITIAL DV RELEASE 03/09/07 KJC

+0.08

G

53.48

0

0.25 A B C

0.125 A B

4X

F

B

A

39.75

E

D

79.5 0.25

40

C

C

B

52 0.05

A

1

OF

1

SHEET

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

DO NOT SCALE DRAWING

PST

DEPARTMENT

DATEDRAWN BY

03/09/07K.CEURTER

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN MILLIMETERS

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

3

BONE TRAIL, MCH, STIFFENER, PLATE

SIZE DRAWING NUMBER REV

A1 D92620 A

TITLE

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

03/09/07P.BORNEMANN

DATEAPPROVED BY

03/09/07R.AOKI

03/09/07A.VALPIANI

DATECHECKED BY

03/09/07K.CEURTER

ANGLES ±1

DIMENSIONS ±0.3

ALL UNTOLERANCED LINEAR

THIRD ANGLE PROJECTION

B

29.5

47

21

TYP R2

8 7 6 5 4 3 2 1

C

B

A

8 7 6 5 4 3 2

5 . CRITICAL TO FUNCTION DIMENSION/FEATURE

NOTES:

1. DIMENSIONS ARE IN MILLIMETERS

2. BREAK ALL SHARP EDGES AND CORNERS, GRIND PUNCH MARKS FLAT, NO BURRS FROM PUNCH

3. MATERIAL: AISI 1020 COLD ROLLED STEEL OR INTEL APPROVED EQUIVALENT

CRITICAL MATERIAL PROPERTIES: MIN YEILD STRENGTH = 250 MPa

4. FINISH: ZINC OR ELECTROLYTIC NICKEL PLATING PLUS CLEAR CHROMATE

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

PER ASTM B 633 COLORLESS

H

59 0.25

TYP R1

G

F

66

E

D

56 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Page 57

Mechanical Drawings

Figure B-12. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Insulator

D92624 1 1

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

1 PRODUCTION RELEASE 06/20/07 KJC

- A INITIAL DV RELEASE 03/09/07 KJC

G

F

A

44.2 0.2

E

THICK0.127

D

C

B

2200 MISSION COLLEGE BLVD.

R

DEPARTMENT

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

A

1

OF

1

SHEET

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

DO NOT SCALE DRAWING

PST

DATEDRAWN BY

03/09/07K.CEURTER

DIMENSIONS ARE IN MILLIMETERS

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

3

SIZE DRAWING NUMBER REV

A1 D92624 1

BONE TRAIL,INSULATOR,BACK PLATE

TITLE

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

03/09/07P.BORNEMANN

DATEAPPROVED BY

03/09/07R.AOKI

03/09/07A.VALPIANI

DATECHECKED BY

03/09/07K.CEURTER

ANGLES ±1

DIMENSIONS ±0.3

ALL UNTOLERANCED LINEAR

THIRD ANGLE PROJECTION

8 7 6 5 4 3 2

4 . CRITICAL TO FUNCTION FEATURE.

NOTES:

1. DIMENSIONS ARE IN MILLIMETER

2. MATERIAL: POLYPROPYLENE SHEET( ITW FORMEX GK-5BK) .127MM NOMINAL THICKNESS

ONE SIDE PRESSURE SENSITIVE ADHESIVE APPLIED; TOTAL THICKNESS= .178MM.

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

3: FLAMMABILITY: UL 94-V0 OR VTM-0 RATING

H

0.2 A C B

4X

B

TYP R2

C459.5 0.25

TYP R1

480.5

0.25

40

47

21

66

8 7 6 5 4 3 2 1

G

F

E

D

C

B

A

Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide 57

Page 58

Mechanical Drawings

T

Figure B-13. Intel® 3210 and 3200 Chipset Reference Thermal Solution - Flush Mount Stud

D92622 1 1

DWG. NO SHT. REV

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPROVED

H

1 PRODUCTION RELEASE 06/20/07 KJC

- A INITIAL DV RELEASE 03/09/07 KJC

G

F

E

D

C

B

2200 MISSION COLLEGE BLVD.

R

DEPARTMENT

DATEDESIGNED BY

UNLESS OTHERWISE SPECIFIED

A

1

OF

1

SHEET

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

DO NOT SCALE DRAWING

PST

DATEDRAWN BY

03/09/07K.CEURTER

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

20

SIZE DRAWING NUMBER REV

A1 D92622 1

BONE TRAIL,STUD,SELF-CLINCHING, DOG POIN

TITLE

SCALE:

SEE NOTESSEE NOTES

FINISHMATERIAL

03/09/07P.BORNEMANN

DATEAPPROVED BY

03/09/07R.AOKI

03/09/07A.VALPIANI

DATECHECKED BY

03/09/07K.CEURTER

ANGLES ±1

DIMENSIONS ±0.3

ALL UNTOLERANCED LINEAR

THIRD ANGLE PROJECTION

DIMENSIONS ARE IN MILLIMETERS

8.525 0.35

AREA

3.78

()

REFERENCE FOR

LOWEST THREADED

6

()4

2.2

1.58

()

()

NOMINAL BACK PLATE

+ INSULATOR THICKNESS

NOMINAL DT PCB THICKNESS

B

( )5.8

0.05 A B

3.51 0.08

A

8 7 6 5 4 3 2 1

A

8 7 6 5 4 3 2

NOTES:

1. USE PEM PART NUMBER (TBD) OR INTEL APPROVED ALTERNATE

2. DIMENSIONS ARE IN MILLIMETERS

3. MATERIAL:

- LOW CARBON STEEL

4. FINISH:

THIS DRAWING CONTAINS INTEL CORPORAT ION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONT ENTS

MAY NOT BE DISCLOSED, REPRODUCED, DI SPLAYED OR MODIFIED, WITHOUT THE PRI OR WRITTEN CONSENT OF INTEL CORPORATION.

- ZINC PLUS CLEAR CHROMATE PER ASTM B633 COLORLESS

H

B2.2

5 . CRITICAL TO FUNCTION

6 . FEATURE DETAIL PER VENDOR SPECIFICATION

- FLUSH MOUNT HEAD

- PUSHOUT FORCE > 250LBS

- TORQUE OUT FORCE > 18 IN-LBS

- SHEET METAL HOLE SIZE = 4 +0.08 -0MM

- SHEET METAL THICKNESS = 2.2 0.05MM

7. REFERENCE AND NON-DIMENSIONED FEATURES MAY BE MODIFIED

PER INTEL APPROVAL

G

F

E

1 0.25

"DOG POINT" TO

ASSIST BLING ASSEMBLY

4.745

()

UNC #6-32

THREADED SECTIONS

(THREADS SHOWN FOR REFERENCE ONLY)

D

C

§

58 Intel® 3210 and 3200 Chipset Thermal/Mechanical Design Guide

Loading...

Loading...