Ingersoll-Rand 23644-400 User Manual

OPERAT

OPERATION,

INST

ALLA

OR’S MANUAL

TION & MAINTENANCE

23644-400

ARO STOP

PUMP SAVER CONTROL VALVE - 1/2” PIPE SIZE

R

23644Ć400

RELEASED: 1-30-81

REVISED: 6-23-00

(REV.

B)

READ THIS MANUAL CAREFULL

OPERA

It

is the responsibility of the employer to place this information in the hands of the operator

GENERAL

This device is to terminate operation of a 4" to 7" reciprocating type air

motor in the event of aruptured outlet hose or the pump runsout of meĆ

dia. For compressed air use only.

Operating Pressure Range 20 Ć 175 p.s.i. (1.4 Ć 12 bar)...

Temperature Range 0_ to 180_F(Ć18_ to 82_C).........

DESCRIPTION

TING OR SER

OPERATION

The AROĆSTOP control valve senses an increased volume of air to the

pump, beyond the preadjusted setting, and shuts off the air supply to

the pump. The runaway" condition may be caused by any of the followĆ

ing: 1.) depleted pumping material, 2.) a ruptured line on the outlet of

the pump, 3.) excessive cavitation in the material supply.

INSTALLATION

The AROĆSTOP valve should be installed in a filtered and regulated air

line as close to the inlet of the pump as possible. Equipment other than

a lubricator should not be installed between the AROĆSTOP valve and

the inlet of the pump. Upstream plumbing from the AROĆSTOP valve

should be 1/2" minimum. A swivelor 1/2" connector & coupler shouldbe

installed before the AROĆSTOP valve to facilitate easy adjustment.

Use one AROĆSTOP valve for each pump. See typical installation phoĆ

to.

Y BEFORE INST

ALLING,

VICING THIS EQUIPMENT

. Keep for future reference.

B

A

.

C

ADJUSTMENT

THE AROĆSTOP VALVE MUST BE PROPERLY ADJUSTED AND

TESTED. THE INSTALLATION SHOULD BE TESTED REGULARLY

AND ADJUSTED WHEN A CHANGE IN OPERATING CONDITIONS

OCCURS.

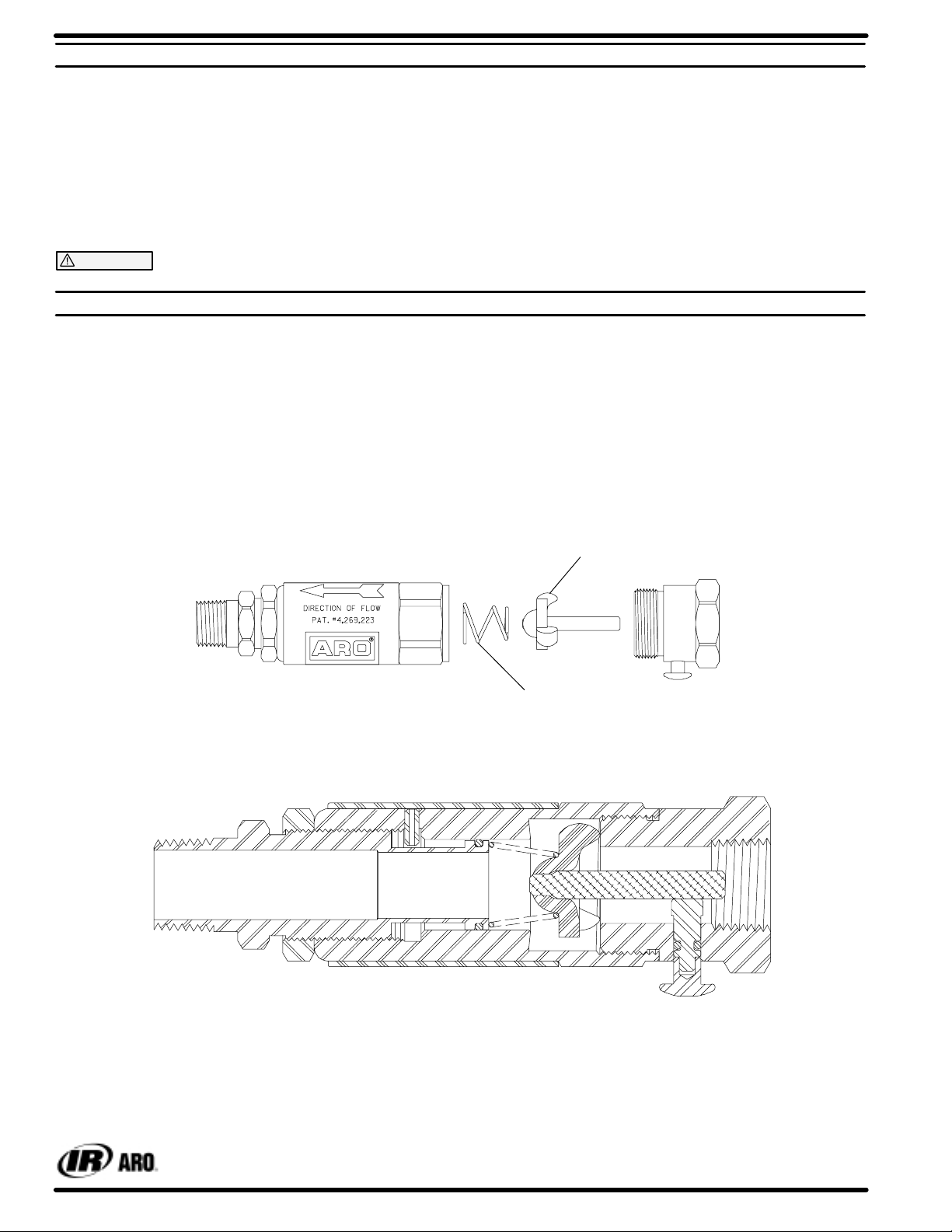

1. Turn A" sleeve clockwise to the maximum inward position. See arĆ

row on sleeve of AROĆSTOP valve.

2. Supply AROĆSTOP valve with desired inlet operating pressure.

3. Depress C" reset button on the AROĆSTOP valve to start the

pump. Open the pump outlet to the desired flow condition.

4. Turn A" sleeve counterclockwise slowly until the pump stops.

5. Turn A" sleeve clockwise one turn and tighten B" locking nut

against body.

6. To restart pump, depress the C" reset button and hold it in for

approx. 3 seconds or until pump primes. If the pump does not reset

AROĆSTOPR is a registered trademark of The Aro Corporation.

INGERSOLL-RAND COMPANY

P.O. BOX 151 D ONE ARO CENTER D BRYAN, OHIO 43506Ć0151

&

(419) 636-4242 D F

AX (419) 633-1674

E2000 D PRINTED IN U.S.A.

and run, repeat step (5). If pump operates, continue on th TestSecĆ

tion.

TEST:

7. To test installation, with the pump operating, remove the pump (or

siphon tube) from the material supply. If the pump shuts off, the unit

is set properly.

8. If the pump continues to turn, resubmerge the pump (or siphon

tube) in the material supply.Loosen the B" locking nut and turn the

A" sleeve counterclockwise approx. one half turn, tighten B" lockĆ

ing nut, and repeat step (7).

RESTART:

9. To restart: Remedy the cause of the shutdown. If the air supply is

shutĆoff, turn the air back on.

10. Depress the C" reset button and hold it in approx. 3 seconds.

TROUBLE SHOOTING

AROĆSTOP valve does not close when it should.

• Improper adjustment. Readjust and test.

• Change has occurred in operating conditions (i.e. decrease in supĆ

ply pressure). Readjust and test.

AROĆSTOP valve closes for no apparent reason.

• Change has occurred in operating conditions (i.e. increase in supĆ

ply pressure). Readjust and test.

• Material supply has been interrupted. Insureconstant materialsupĆ

ply.

WARNING Always disconnect and relieve air pressure from the AROĆSTOP valve before removing it from the system for servicing.

• Air supply turned on too quickly. Depress reset button.

Pump continues to cycle after AROĆSTOP valve closes.

• Foreign matter on sealing surface of AROĆSTOP valve. DisasĆ

semble and clean valve as described in Service Section.

NOTE: Very slow cycling may occur even after AROĆSTOP valve

closes. This is normal.

AROĆSTOP valve does not start when reset button is depressed.

• Improper adjustment. Readjust and test.

SERVICE INSTRUCTIONS

DISASSEMBLY:

1. Unscrew therear adapter assembly from the sleeve assembly. This

allows accessibility to the 22836 valve assembly and the 22207

spring.

2. Clean all parts and inspect for damage or wear. Replace the 22836

valve assembly or 22207 spring if necessary.

ASSEMBLY:

1. Reassemble the 22836 valve assembly and the 22207 spring as

shown in the view.

2. Apply thread locking compound to the threads of the rear adapter

assembly and tighten to the sleeve assembly using 30 Ć 40 ft lb

(40.7 Ć 54.2 Nm) torque.

NOTE: Parts other than 22836 valve assembly and 22207 spring,

are not accessible for service and should not be disassembled.

22207

22836

PAGE2OF2

PN 103994

23644Ć400

Loading...

Loading...