Page 1

SUPPLEMENT TO THE MDC-360C MANUAL

MDC-361C

Film Deposition Controller

IPN 624811 Rev. C

Page 2

Page 3

SUPPLEMENT TO THE MDC-360C MANUAL

MDC-361C

Film Deposition Controller

IPN 628411 Rev. C

®

www.inficon.com reachus@inficon.com

Due to our continuing program of product improvements, specifications are subject to change without notice.

©2007 INFICON

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

INFICON® is a trademark of INFICON Inc.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Disclosure

The disclosure of this information is to assist owners of INFICON equipment to properly operate and maintain

their equipment, and does not constitute the release of rights thereof. Reproduction of this information and

equipment described herein is prohibited without prior written consent from INFICON, Two Technology Place,

East Syracuse, NY 13057-9714. Phone 315.434.1100. See www.inficon.com.

Copyright

©2004 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

First Edition, Rev. A March 2004

Rev. B February 2006

Rev. C October 2007

General Safety Warning

WARNING

All standard safety procedures associated with the safe

handling of electrical equipment must be observed. Always

disconnect power when working inside the controller. Only

properly trained personnel should attempt to service the

instrument.

Page 5

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly. It

has been constructed in accordance with good engineering practice in safety matters in force in the

Community and does not endanger the safety of persons, domestic animals or property when properly

installed and maintained and used in applications for which it was made.

Equipment Description: MDC-361C Thin Film Deposition Controllers (Black Box), including the SO-

100 Oscillator Package.

Applicable Directives: 73/23/EEC as amended by 93/68/EEC (LVD)

89/336/EEC as amended by 93/68/EEC (EMC)

2002/95/EC (RoHS)

Applicable Standards: EN 61010-1:2001 (Safety)

EN 61326-1:1997/A1:1998/A2:2001, Class A: Emissions per Table 3

Immunity per Table A.1

Due to the classification of this product it is currently exempt from the RoHS

directive.

CE Implementation Date: November 1, 2007

Authorized Representative: Duane H. Wright

Quality Assurance Manager, ISS

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED,

IN WRITING, TO THE QUALITY ASSURANCE DEPARTMENT AT THE ABOVE ADDRESS.

10/01/07

Page 6

Page 7

Warranty

INFICON warrants the product to be free of functional defects in material and

workmanship and that it will perform in accordance with its published specification

for a period of (twenty-four) 24 months.

The foregoing warranty is subject to the condition that the product be properly

operated in accordance with instructions provided by INFICON or has not been

subjected to improper installation or abuse, misuse, negligence, accident,

corrosion, or damage during shipment.

Purchaser's sole and exclusive remedy under the above warranty is limited to, at

INFICON's option, repair or replacement of defective equipment or return to

purchaser of the original purchase price. Transportation charges must be prepaid

and upon examination by INFICON the equipment must be found not to comply

with the above warranty. In the event that INFICON elects to refund the purchase

price, the equipment shall be the property of INFICON.

This warranty is in lieu of all other warranties, expressed or implied and

constitutes fulfillment of all of INFICON's liabilities to the purchaser. INFICON

does not warrant that the product can be used for any particular purpose other

than that covered by the applicable specifications. INFICON assumes no liability in

any event, for consequential damages, for anticipated or lost profits, incidental

damage of loss of time or other losses incurred by the purchaser or third party in

connection with products covered by this warranty or otherwise.

www.inficon.com reachus@inficon.com

Page 8

iv

Page 9

Table of Contents

1. INTRODUCTION.................................................................................................................1

2. COMPUTER INTERFACES...............................................................................................1

3. DISPLAY DESCRIPTION...................................................................................................1

3.1 RS-232/RS-485 INDICATORS...............................................................................................1

3.2 IEEE-488 INDICATORS........................................................................................................2

3.3 STATUS INDICATORS............................................................................................................2

3.4 MANUAL CONTROL .............................................................................................................2

4. INITIAL POWER UP INDICATION.................................................................................3

5. OPERATION.........................................................................................................................3

6. REFERENCES:.....................................................................................................................3

v

Page 10

Page 11

1. INTRODUCTION

This supplement is to be used with the MDC-360C Manual. Its intention is to point out

the differences between the MDC-360C and the MDC-361C. Information supplied

herein is either a replacement or addition to the MDC-360C Manual.

The MDC-361C Deposition Controller was designed for users who want to interface to

the controller solely through a computer. The MDC-361C is a black box version of the

MDC-360C Controller, meaning an MDC-360C with all of the front panel displays and

keys removed. The users can either create their own computer software for a custom

interface or purchase INFICON's DCM-250 computer software to provide complete

computer control of the deposition process.

The key point to emphasize here is, since the MDC-361C is a black box, there is no user

interface on the front panel. All functions are provided through the computer interface.

2. COMPUTER INTERFACES

The MDC-361C is equipped standard with an RS-232 serial interface through a 9-pin DSub located on the rear panel. Optionally, RS-485 and IEEE-488 interfaces are available.

Refer to Section 10 of the MDC-360C Manual for details on communication protocol of

these interfaces.

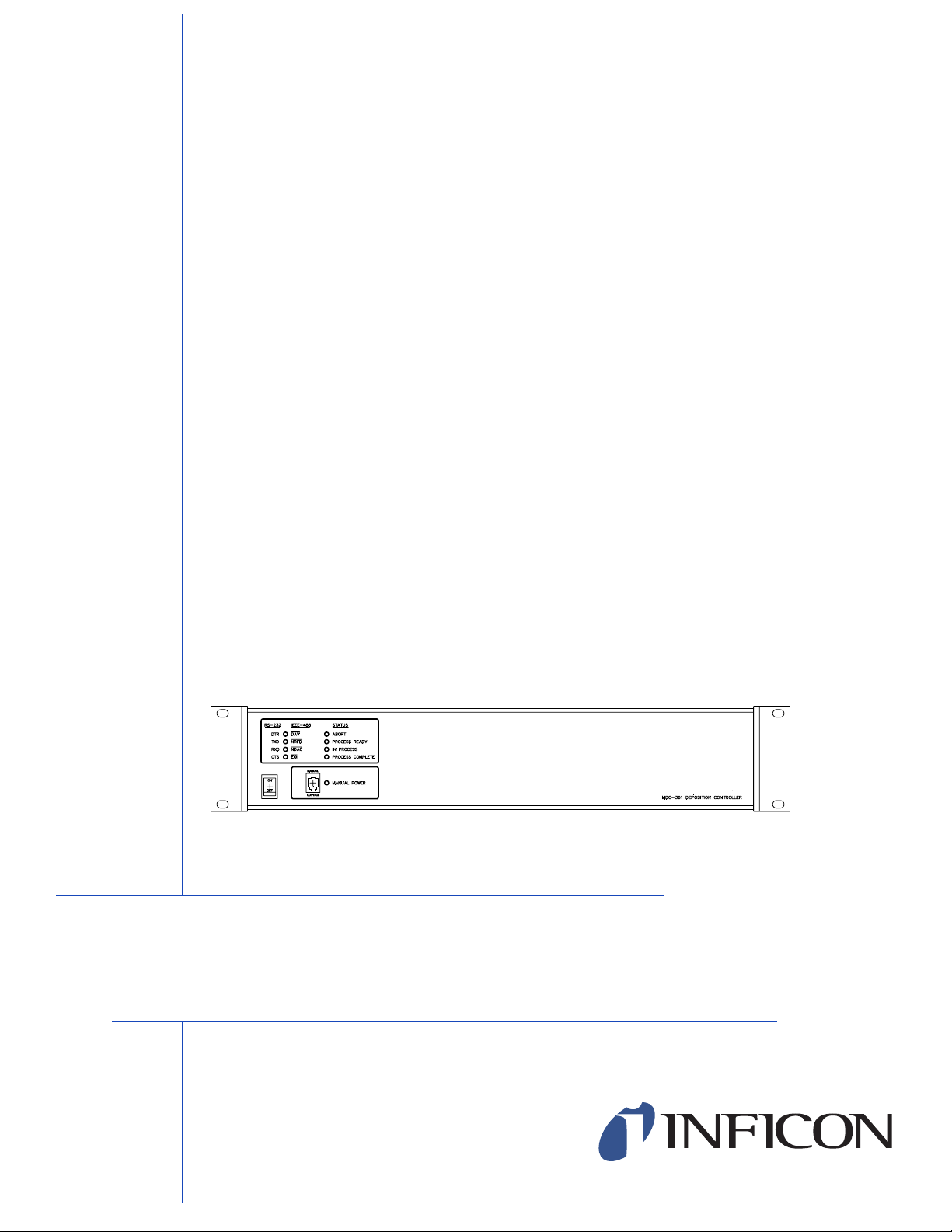

3. DISPLAY DESCRIPTION

Minimal indicators are provided on the MDC-361C front panel. There are four LED’s

displaying the data exchange status between the MDC-361C and the computer. Also,

there are four indicators displaying the MDC-361C’s status. The front panel indicators

are described below.

3.1 RS-232/RS-485 INDICATORS

RTS (Request to Send)

Indicates the host is permitting the MDC-361C to transmit data.

TxD (Transmit Data)

Indicates data being transmitted from the MDC-361C to the host. This LED will briefly

flash each time the 361C sends data to the host.

RxD (Receive Data)

1

Page 12

Indicates the MDC-361C is receiving data from the host. This LED will briefly flash each

time the 361C receives data from the host.

CTS (Clear to Send)

Indicates the MDC-36

1C is ready to receive data. This LED should always be on unless

the host is sending data too fast.

3.2 IEEE-488 INDICATORS

DAV (Data valid)

Indicates that the d

ata on the bus is valid.

NRFD (Not ready for data)

Indicates that the 361C is no

t ready to receive data. This LED should always be on

unless the host is sending data too fast.

NDAC (Not data accepted)

Indicates that the data was n

ot accepted.

EOI (End or identify)

Indicates the end of a m

ulti-byte data transfer.

3.3 STATUS INDICATORS

Abort – Indicates that the controller is

in the abort mode. In this mode, all source powers

are set to zero and discrete outputs are disable. To exit the abort mode a Reset command

has to be sent to the controller.

Process Ready – Indicates that t

he controller has been reset from an abort condition and

is in the Ready State. The controller is awaiting a Start command to run a process.

In Process – Indicates that the controller is running a process. The controller will re

main

In Process until the process has either been aborted and reset or completed.

Process Complete – Indicates that the selected process has run to completion

. The

controller will remain in this mode until it receives a reset command.

3.4 MANUAL CONTROL

In addition to the indicators, a 4 posi

tion RJ-11 connector is provided for connection to

the Remote Power Handset. The Remote Power Handset provides for manual adjustment

of the active source power level, a remote abort command and a manual crystal switch

command.

To manually

Power indicated by the Manual Power LED on the front panel. Note that Manual mode

adjust the active source power, the 361 must first be put into the Manual

has to be selected through software since there are no keys on the MDC-361C front

panel. Depress the “+” button to increase the source control power, depress the “– “

button to decrease the power. Without any of the buttons depressed, the output powe

r is

maintained at its last value.

2

Page 13

Depress the “ABORT” button to put the controller in the Abort mode. This “ABORT”

button is active at all times, regardless which mode the controller is in. Therefore it can

be used as a “panic button”.

To manually switch between the primary and backup sensor/crystal settings for the

current material, press both the “+” and "-" buttons at the same time while the 361C

in the Manual Power Mode. If the primary sensor/crystal is in use, the 361C will switch

to the backup sensor/crystal. If the backup sensor/crystal is already in use then the 361C

will switch to the next crystal for the backup sensor if one is available. If not, the 361C

will switch back to the primary sensor/crystal.

is not

4. INITIAL POWER UP INDICATION

Upon power up, all LED’s turn on for a few seconds then turn off. The Abort LED will

remain on until a reset command is sent to the MDC-361C. The CTS LED will also

remain on indicating the controller is ready to receive data.

5. OPERATION

All operating functions including programming of the MDC-361C is done through one of

the available computer interface.

If you purchased a copy of the DCM-250 software, refer to its manual on how to operate

the software to control your MDC-361C.

If you decided to write your own software to interface with the MDC-361C, please refer

to Section 10 of the MDC-360C Manual for details on communication protocol. Also

refer to the programming and operating sections of the MDC-360C manual to familiarize

yourself with the MDC-360/361C's programming and operation before you write your

interface software. Keep in mind that your software has to provide a complete user

interface for the operators including error messages, warning messages and operator

intervention messages such as layer complete and change source pocket requests. For

example, the 360/361C can be setup to prompt the operator to change the source pock of

a multi-pocket source. So, your software must recognize this request, alert the operator

and signal the 361C that it is OK to continue.

6. REFERENCES:

For other topics such as specifications, installation, maintenance, etc. please refer to the

MDC-360C Manual.

3

Page 14

Loading...

Loading...