Page 1

OPERATION and SERVICE MANUAL

MDC-260

Film Deposition Controller

IPN 622800 Rev. E

Page 2

Page 3

OPERATION and SERVICE MANUAL

MDC-260

Film Deposition Controller

IPN 622800 Rev. E

®

www.inficon.com reachus@inficon.com

Due to our continuing program of product improvements, specifications are subject to change without notice.

©2007 INFICON

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

INFICON® is a trademark of INFICON Inc.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Disclosure

The disclosure of this information is to assist owners of INFICON equipment to properly operate and maintain

their equipment, and does not constitute the release of rights thereof. Reproduction of this information and

equipment described herein is prohibited without prior written consent from INFICON, Two Technology Place,

East Syracuse, NY 13057-9714. Phone 315.434.1100. See www.inficon.com.

Copyright

©2005 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

First Edition Revision A January 2005

Revision B August 2005

Revision C October 2005

Revision D July 2007

Revision E October 2007

General Safety Warning

WARNING

All standard safety procedures associated with the safe

handling of electrical equipment must be observed. Always

disconnect power when working inside the controller. Only

properly trained personnel should attempt to service the

instrument.

Page 5

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly. It

has been constructed in accordance with good engineering practice in safety matters in force in the

Community and does not endanger the safety of persons, domestic animals or property when properly

installed and maintained and used in applications for which it was made.

Equipment Description: MDC-260 Thin Film Deposition Controller, including the

SO-100 Oscillator Package.

Applicable Directives: 73/23/EEC as amended by 93/68/EEC (LVD)

89/336/EEC as amended by 93/68/EEC (EMC)

2002/95/EC (RoHS)

Applicable Standards: EN 61010-1:2001 (Safety)

EN 61326-1:1997/A1:1998/A2:2001, Class A: Emissions per Table 3

Immunity per Table A.1

Due to the classification of this product it is currently

exempt from the RoHS directive.

CE Implementation Date: October 1, 2007

Authorized Representative: Duane H. Wright

Quality Assurance Manager, ISS

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED,

IN WRITING, TO THE QUALITY ASSURANCE DEPARTMENT AT THE ABOVE ADDRESS.

10/01/07

Page 6

Page 7

Warranty

INFICON warrants the product to be free of functional defects in material and

workmanship and that it will perform in accordance with its published specification

for a period of (twenty-four) 24 months.

The foregoing warranty is subject to the condition that the product be properly

operated in accordance with instructions provided by INFICON or has not been

subjected to improper installation or abuse, misuse, negligence, accident,

corrosion, or damage during shipment.

Purchaser's sole and exclusive remedy under the above warranty is limited to, at

INFICON's option, repair or replacement of defective equipment or return to

purchaser of the original purchase price. Transportation charges must be prepaid

and upon examination by INFICON the equipment must be found not to comply

with the above warranty. In the event that INFICON elects to refund the purchase

price, the equipment shall be the property of INFICON.

This warranty is in lieu of all other warranties, expressed or implied and

constitutes fulfillment of all of INFICON's liabilities to the purchaser. INFICON

does not warrant that the product can be used for any particular purpose other

than that covered by the applicable specifications. INFICON assumes no liability in

any event, for consequential damages, for anticipated or lost profits, incidental

damage of loss of time or other losses incurred by the purchaser or third party in

connection with products covered by this warranty or otherwise.

www.inficon.com reachus@inficon.com

Page 8

Page 9

SAFETY PRECAUTION AND PREPARATION FOR USE

Input Power Requirements

The MDC-260 Thin Film Controller can be set to operate one of the following

line voltages: 100, 120, 200, or 240 VAC at line frequency of 50 or 60 Hz.

Maximum power consumption is 25 watts. See Section 8.3.3 for instruction on

selecting line voltage.

Power Entry Module

The AC (alternating current) power entry module, located in the rear panel of the

MDC-260, provides connection to the power source and a protective ground. It

also holds the fuses and the voltage selection wheel.

Power Cord

WARNING: To avoid electrical shock, always connect the power cord to an

AC outlet which has a proper protective ground.

The MDC-260 comes with a detachable, three-wire power cord for connection to

a power source with protective ground.

The MDC-260 chassis is connected to the power ground to protect against

electrical shock. Always connect to an AC outlet which has a properly connected

protective ground. If necessary, or when in doubt, consult a certified electrician.

Grounding

A grounding lug is located on the rear panel, near the power entry module. Use

heavy ground wire, wire braid, or copper strap of #12 AWG or larger to connect

this grounding lug directly to a facility protective earth ground to provide

additional protection against electrical shock.

Line Fuses

There are two 5 x 20 mm fuses mounted inside the power entry module. They are

accessible via the snap-in cover. Replace with the correct fuse rating: IEC T Type

(Slow), 4/10 A, 250 VAC. Refer to Section 8.3.3 for instruction to replace the

fuse.

Power Switch

WARNING: Do NOT use the power switch as a disconnecting device;

disconnect the power cord from the power entry module to fully remove

hazardous voltage from inside the MDC-260.

The power switch is located on the front lower left of the MDC-260. Pressing the

switch will toggle the controller on or off. The MDC-260 is off when the LCD

and all of the LEDs behind the operating keys are off. However, turning the

power switch off does not fully remove the AC power from inside the unit.

Always disconnect the power cord from the power entry module to fully remove

AC power from inside the unit.

iv

Page 10

SAFETY TERMS AND SYMBOLS

Terms Used in This Manual

WARNING. Warning statements identify conditions or practices that could

result in personnel injuries or loss of life.

CAUTION. Caution statements identify conditions or practices that could

result in damage to the MDC-260 or other property.

NOTE. Note statements identify a sensitive or irreversible procedure. Proceed

with caution.

Terms Used on the MDC-260

DANGER indicates and injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to the MDC-260 or other property.

Symbols Used on the Product and in the Manual

DANGER

Hazardous Voltage

FUSE

Refer to Manual for

Instruction

ATTENTION

Refer to Manual

AC

Alternating Current

Protective Ground

POWER

On/Off Switch

v

Page 11

Table of Contents

SAFETY PRECAUTION AND PREPARATION FOR USE...................................................IV

SAFETY TERMS AND SYMBOLS.............................................................................................V

1. GENERAL DESCRIPTION.............................................................................................1-1

1.1 PURPOSE....................................................................................................................... 1-1

1.2 FEATURES ....................................................................................................................1-1

1.2.1 AMPLE PROGRAM STORAGE................................................................................. 1-1

1.2.2 DYNAMIC MEASUREMENT UPDATE RATE .......................................................... 1-1

1.2.3 SUPERIOR COLOR GRAPHICS DISPLAY .............................................................. 1-1

1.2.4 PROGRAM SECURITY.............................................................................................. 1-1

1.2.5 DESIGNED FOR UNATTENDED OPERATION ...................................................... 1-1

1.2.6 FAIL SAFE ABORTS.................................................................................................. 1-2

1.2.7 ABORT STATUS RETENTION .................................................................................. 1-2

1.2.8 RUN COMPLETION ON CRYSTAL FAILURE ......................................................... 1-2

1.2.9 POWERFUL SYSTEM INTERFACE.......................................................................... 1-2

1.2.10 POWER SUPPLY NOISE TOLERANCE............................................................... 1-2

1.2.11 INTERNATIONAL STANDARD POWER CONNECTOR ..................................... 1-2

1.3 SPECIFICATIONS......................................................................................................... 1-3

1.3.1 MEASUREMENT .......................................................................................................1-3

1.3.2 DISPLAY ....................................................................................................................1-3

1.3.3 COMMUNICATION................................................................................................... 1-3

1.3.4 PROGRAM STORAGE CAPACITY ........................................................................... 1-3

1.3.5 PROCESS PARAMETERS ......................................................................................... 1-3

1.3.6 MATERIAL PARAMETERS ....................................................................................... 1-4

1.3.7 INPUT/OUTPUT CAPABILITY ................................................................................. 1-5

1.3.8 SENSOR PARAMETERS............................................................................................ 1-5

1.3.9 SOURCE PARAMETERS ........................................................................................... 1-6

1.3.10 UTILITY SETUP PARAMETER ............................................................................ 1-6

1.3.11 OTHERS ................................................................................................................ 1-6

1.4 ACCESSORIES..............................................................................................................1-7

vi

2. FRONT PANEL DISPLAYS AND CONTROLS........................................................... 2-1

2.1 GRAPHIC LCD DISPLAY................................................................................................ 2-1

2.1.1 PROGRAMMING SCREENS (MENUS) .................................................................... 2-1

2.1.2 RUN-TIME GRAPHS ................................................................................................. 2-1

2.1.3 STATUS SCREENS .................................................................................................... 2-1

2.1.3.1 MAIN RUN SCREEN....................................................................................................2-1

2.1.3.2 SOURCE/SENSOR STATUS SCREEN........................................................................ 2-1

2.1.3.3 INPUT/OUTPUT STATUS SCREEN........................................................................... 2-1

2.1.3.4 ACTIVE LAYER PARAMETER UPDATE SCREEN ................................................. 2-2

2.1.3.5 POSITION CONTROL SCREEN.................................................................................. 2-2

2.2 OPERATING CONTROLS............................................................................................ 2-2

2.2.1 STATUS KEY.............................................................................................................. 2-2

2.2.2 GRAPH KEY .............................................................................................................. 2-2

2.2.3 PROGRAM KEY......................................................................................................... 2-2

2.2.4 MANUAL KEY ........................................................................................................... 2-2

2.2.5 START KEY ................................................................................................................ 2-3

2.2.6 ABORT KEY ............................................................................................................... 2-3

2.2.7 RESET KEY ................................................................................................................ 2-3

2.2.8 ZERO KEY ................................................................................................................. 2-3

2.2.9 SHUTTER KEY .......................................................................................................... 2-3

2.2.10 ARROW KEYS .......................................................................................................2-4

Page 12

ALPHANUMERIC KEYPAD................................................................................. 2-4

2.2.11

3. BENCH CHECKOUT & INSPECTION......................................................................... 3-1

3.1 INSPECTION................................................................................................................. 3-1

3.2 COLD POWER UP ......................................................................................................... 3-1

3.3 WARM POWER UP....................................................................................................... 3-1

3.4 SAMPLE PROGRAM.................................................................................................... 3-1

3.4.1 MATERIAL #1 PARAMETERS .................................................................................. 3-2

3.4.2 MATERIAL #2 PARAMETERS .................................................................................. 3-3

3.4.3 PROCESS PARAMETERS ......................................................................................... 3-4

3.5 SIMULATE OPERATION............................................................................................. 3-4

3.6 MANUAL OPERATION ............................................................................................... 3-4

4. PROGRAMMING AND CONTROLLER SETUP........................................................ 4-1

4.1 GENERAL...................................................................................................................... 4-1

4.1.1 NAVIGATING THE MENU STRUCTURE ................................................................ 4-1

4.1.2 ENTERING ALPHA CHARACTERS.......................................................................... 4-1

4.1.3 ENTERING TIME PARAMETERS............................................................................. 4-2

4.1.4 COPYING AND DELETING ..................................................................................... 4-2

4.1.5 PASSWORD PROTECTION ...................................................................................... 4-2

4.1.5.1 VIEW/RUN PROCESS PASSWORD ...........................................................................4-2

4.1.5.2 EDIT PROCESS PASSWORD ......................................................................................4-3

4.1.5.3 EDIT MATERIAL PASSWORD................................................................................... 4-3

4.1.6 ADJUSTING LCD DISPLAY CONTRAST................................................................. 4-3

4.1.7 SPECIAL FUNCTION KEY ....................................................................................... 4-3

4.2 GETTING STARTED.................................................................................................... 4-3

4.2.1 UTILITY SETUP ........................................................................................................ 4-4

4.2.2 SOURCE SETUP ....................................................................................................... 4-4

4.2.3 SENSOR SETUP ........................................................................................................ 4-7

4.2.3.1 EXAMPLE USING THE RSH-600 SIX CRYSTAL SENSOR HEAD ........................4-9

4.2.4 INPUT, OUTPUT AND ACTION SETUP.................................................................. 4-9

4.2.5 DISPLAY SETUP ......................................................................................................4-10

4.2.6 MATERIAL SETUP...................................................................................................4-11

4.2.6.1 POWER RAMPS..........................................................................................................4-11

4.2.6.2 AUTOMATIC CRYSTAL SWITCHING.................................................................... 4-12

4.2.6.3 RATE ESTABLISH..................................................................................................... 4-12

4.2.6.4 RATE RAMPS.............................................................................................................4-12

4.2.6.5 RATE SAMPLE MODE.............................................................................................. 4-12

4.2.6.6 RATE DEVIATION ACTIONS...................................................................................4-13

4.2.7 PROCESS SETUP.....................................................................................................4-13

4.2.8 STARTING A NEW PROCESS..................................................................................4-13

4.2.9 RESUMING A PROCESS FROM ABORT OR HALT...............................................4-13

4.3 DETAILED PROGRAMMING ....................................................................................4-14

4.3.1 VIEW/EDIT PROCESS .............................................................................................4-14

4.3.1.1 DEFINE A PROCESS..................................................................................................4-14

4.3.2 VIEW/EDIT MATERIAL ...........................................................................................4-16

4.3.2.1 DEFINE A MATERIAL...............................................................................................4-16

4.3.3 SYSTEM SETUP .......................................................................................................4-24

4.3.3.1 EDIT DISPLAY SETUP .............................................................................................. 4-24

4.3.3.2 PROGRAM INPUTS...................................................................................................4-26

4.3.3.3 PROGRAM OUTPUTS................................................................................................4-27

4.3.3.4 PROGRAM ACTIONS................................................................................................4-32

4.3.3.5 EDIT SENSOR SETUP................................................................................................4-34

4.3.3.6 EDIT SOURCE SETUP...............................................................................................4-37

4.3.3.7 EDIT UTILITY SETUP...............................................................................................4-40

5. OPERATING THE MDC-260.......................................................................................... 5-1

5.1 SIGN-ON SCREEN........................................................................................................ 5-1

5.2 STARTING A NEW PROCESS..................................................................................... 5-1

5.3 STARTING A NEW LAYER......................................................................................... 5-2

vii

Page 13

5.4

RESUMING AN ABORTED OR HALTED PROCESS................................................. 5-2

5.5 GRAPH DISPLAYS........................................................................................................ 5-2

5.6 STATUS DISPLAYS......................................................................................................5-3

5.6.1 MAIN RUN SCREEN ................................................................................................. 5-4

5.6.2 SOURCE-SENSOR STATUS SCREEN....................................................................... 5-4

5.6.3 I/O STATUS SCREEN ................................................................................................ 5-5

5.6.4 ACTIVE LAYER PARAMETER UPDATE SCREEN .................................................. 5-5

5.6.5 POSITION CONTROL SCREEN................................................................................ 5-5

5.7 MODES ..........................................................................................................................5-6

5.7.1 PROCESS READY...................................................................................................... 5-6

5.7.2 ABORT ....................................................................................................................... 5-6

5.7.3 HALT (SOFT ABORT) ............................................................................................... 5-6

5.7.4 IN PROCESS .............................................................................................................. 5-6

5.7.5 NOT SAMPLING........................................................................................................ 5-7

5.7.6 PROCESS COMPLETE ............................................................................................. 5-7

5.7.7 MANUAL.................................................................................................................... 5-7

5.7.8 SIMULATE................................................................................................................. 5-7

5.8 STATES..........................................................................................................................5-7

5.9 TROUBLE, ERROR AND WARNING MESSAGES.................................................... 5-7

5.9.1 DESCRIPTION .......................................................................................................... 5-8

5.9.1.1 MIN RATE&MAX POWER..........................................................................................5-8

5.9.1.2 MAX RATE&MIN POWER..........................................................................................5-9

5.9.1.3 SYSTEM SETUP MEMORY CORRUPTED................................................................ 5-9

5.9.1.4 PROCESS MEMORY CORRUPTED........................................................................... 5-9

5.9.1.5 MATERIAL MEMORY CORRUPTED........................................................................ 5-9

5.9.1.6 RATE EST. ERROR...................................................................................................... 5-9

5.9.1.7 CRYSTAL FAILURE.................................................................................................... 5-9

5.9.1.8 SOURCE FAULT.......................................................................................................... 5-9

5.9.1.9 SENSOR FAULT........................................................................................................... 5-9

5.9.1.10 NO SENSORS ENABLED.......................................................................................... 5-10

5.9.1.11 TIME POWER............................................................................................................. 5-10

5.9.1.12 RATE DEV. ALARM.................................................................................................. 5-10

5.9.1.13 ALARM ACTION ....................................................................................................... 5-10

5.9.1.14 CRYSTAL MARGINAL ............................................................................................. 5-10

5.9.1.15 RATE DEV. ALERT ................................................................................................... 5-10

5.9.1.16 MAX POWER ALERT................................................................................................ 5-10

5.9.1.17 MIN POWER ALERT ................................................................................................. 5-10

5.9.1.18 ALERT ACTION......................................................................................................... 5-10

5.9.1.19 XTAL FAIL SWITCH................................................................................................. 5-10

5.9.1.20 XTAL MRGN SWITCH.............................................................................................. 5-11

5.9.1.21 RATE DEV. ATTEN ................................................................................................... 5-11

5.9.1.22 MAXIMUM POWER .................................................................................................. 5-11

5.9.1.23 MINIMUM POWER.................................................................................................... 5-11

5.9.1.24 CHANGE POCKET..................................................................................................... 5-11

5.9.1.25 CHANGE CRYSTAL... ............................................................................................... 5-11

5.9.1.26 ATTENTION ACTION ............................................................................................... 5-11

5.9.1.27 PRESS START TO RESUME PROCESS................................................................... 5-11

viii

6. TUNING THE MDC-260 CONTROL LOOP................................................................. 6-1

6.1 CONTROL LOOP BASICS............................................................................................6-1

6.2 CONTROL LOOPS APPLIED TO VACUUM DEPOSITION....................................................... 6-2

6.3 ESTABLISHING MDC-260 CONTROL LOOP PARAMETERS ................................................ 6-3

7. INPUT/OUTPUT CHARACTERISTICS........................................................................7-1

7.1 SOURCE CONTROL VOLTAGE OUTPUT................................................................. 7-1

7.2 SENSOR INPUT............................................................................................................. 7-1

7.3 DISCRETE OUTPUTS................................................................................................... 7-1

7.4 DISCRETE INPUTS....................................................................................................... 7-1

8. CONTROLLER INSTALLATION .................................................................................8-1

Page 14

MOUNTING .................................................................................................................. 8-1

8.1

8.2 PROPER GROUNDING................................................................................................ 8-1

8.3 EXTERNAL CONNECTIONS ...................................................................................... 8-1

8.3.1 POWER ENTRY MODULE ....................................................................................... 8-1

8.3.2 POWER CORD .......................................................................................................... 8-2

8.3.3 LINE VOLTAGE SELECTION AND FUSE REPLACEMENT .................................. 8-2

8.3.4 GROUND LUG.......................................................................................................... 8-3

8.3.5 REMOTE POWER HANDSET................................................................................... 8-3

8.3.6 SENSOR INTERFACE ............................................................................................... 8-3

8.3.7 SOURCE INTERFACE .............................................................................................. 8-3

8.3.8 USB COMMUNICATION .......................................................................................... 8-3

8.3.9 DISCRETE INPUT/OUTPUT .................................................................................... 8-3

8.3.9.1 CONFIGURING INPUT TYPE .....................................................................................8-4

8.4 POWER SWITCH ............................................................................................................... 8-4

8.5 CONTROLLER COVER REMOVAL........................................................................... 8-5

9. SYSTEM INSTALLATION............................................................................................. 9-1

9.1 SENSOR HEAD DESCRIPTION .................................................................................. 9-1

9.2 SENSOR HEAD INSTALLATION............................................................................... 9-1

9.3 SENSOR OSCILLATORS.............................................................................................. 9-2

9.3.1 SO-100 OSCILLATOR ............................................................................................... 9-2

9.3.2 VPLO-6 OSCILLATOR.............................................................................................. 9-2

9.3.3 INSTALLATION......................................................................................................... 9-2

9.4 INSTRUMENTATION FEEDTHROUGH.................................................................... 9-2

9.5 SENSOR CRYSTAL REPLACEMENT........................................................................ 9-3

9.5.1 CRYSTAL CARE AND HANDLING........................................................................... 9-3

9.5.2 CRYSTAL REPLACEMENT PROCEDURE .............................................................. 9-3

9.6 TYPICAL SYSTEM INSTALLATION......................................................................... 9-6

10. THEORY OF OPERATION......................................................................................10-1

10.1 BASIC MEASUREMENT ............................................................................................10-1

10.2 FILM THICKNESS CALCULATION..........................................................................10-1

10.3 SENSOR CRYSTAL.....................................................................................................10-3

10.3.1 CRYSTAL HEALTH .............................................................................................10-3

10.3.2 CRYSTAL STABILITY..........................................................................................10-4

10.3.3 TEMPERATURE COEFFICIENT OF THE CRYSTAL........................................10-4

10.3.4 CRYSTAL LIFE EXPECTANCY...........................................................................10-5

10.3.5 CRYSTAL ELECTRODE TYPE RECOMMENDATION ......................................10-6

10.4 RATE CALCULATION................................................................................................10-6

10.5 EMPIRICAL CALIBRATION......................................................................................10-6

10.5.1 FILM DENSITY....................................................................................................10-7

10.5.2 TOOLING FACTOR.............................................................................................10-7

10.5.3 ACOUSTIC IMPEDANCE...................................................................................10-8

11. COMPUTER INTERFACE........................................................................................11-1

11.1 GENERAL.....................................................................................................................11-1

11.2 HOST API FUNCTIONS....................................................................................................11-2

SI_GetNumDevices..................................................................................................................11-2

SI_GetProductString...............................................................................................................11-3

SI_Open...................................................................................................................................11-3

SI_Close ..................................................................................................................................11-4

SI_Read ...................................................................................................................................11-4

SI_Write...................................................................................................................................11-5

SI_SetTimeouts........................................................................................................................11-5

SI_GetTimeouts.......................................................................................................................11-6

SI_SetBaudRate.......................................................................................................................11-6

11.3 PROTOCOL..................................................................................................................11-7

11.4 DATA TYPES...............................................................................................................11-7

ix

Page 15

11.5

TRANSMISSION RECEIPT........................................................................................ 11-8

11.6 TRANSMITTING AND RECEIVEING MESSAGES................................................. 11-8

11.7 INSTRUCTION SUMMARY..................................................................................... 11-10

11.8 INSTRUCTION DESCRIPTIONS............................................................................. 11-11

Code #00: Remote Keypress Activation of Controller.......................................................... 11-11

Code #01: Send System Information..................................................................................... 11-12

Code #02: Send Utility Parameters ...................................................................................... 11-13

Code #03: Receive Utility Parameters ................................................................................. 11-14

Code #04: Not Supported ..................................................................................................... 11-14

Code #05: Not Supported ..................................................................................................... 11-14

Code #06: Send a Material................................................................................................... 11-15

Code #07: Receive a Material.............................................................................................. 11-17

Code #09: Send Number of Undefined Layers ..................................................................... 11-18

Code #10: Send Process....................................................................................................... 11-19

Code #11: Receive Process .................................................................................................. 11-20

Code #12: Delete Process .................................................................................................... 11-21

Code #13: Send Process Layer............................................................................................. 11-21

Code #14: Insert Process Layer ........................................................................................... 11-22

Code #15: Replace Process Layer........................................................................................ 11-23

Code #16: Delete Process Layer .......................................................................................... 11-24

Code #17: Send Process List................................................................................................ 11-24

Code #18: Send Source Setup............................................................................................... 11-25

Code #19: Receive Source Setup.......................................................................................... 11-26

Code #20: Send Sensor Setup............................................................................................... 11-27

Code #21: Receive Sensor Setup .......................................................................................... 11-28

Code #22: Send Input Setup ................................................................................................. 11-29

Code #23: Receive Input Setup............................................................................................. 11-30

Code #24: Send Output Setup............................................................................................... 11-30

Code #25: Receive Output Setup .......................................................................................... 11-33

Code #26: Send Action Setup ............................................................................................... 11-33

Code #27: Receive Action Setup........................................................................................... 11-35

Code #28: Send Controller Status ........................................................................................ 11-36

Code #29: Start Process....................................................................................................... 11-39

Code #30: Send Run-Time Values ........................................................................................ 11-39

Code #31: Initiate Automatic Data Logging ........................................................................ 11-43

Code #32: Internal Command ..............................................................................................11-45

Code #33: Set Active Source Power ..................................................................................... 11-45

Code #34: Internal Command ..............................................................................................11-45

Code #35: Internal Command ..............................................................................................11-46

Code #36: Not Supported ..................................................................................................... 11-46

Code #37: Not Supported ..................................................................................................... 11-46

Code #38: Remote Activation of Controller ......................................................................... 11-46

Code #39: Send a Run-Time Value....................................................................................... 11-47

Code #40: Enable/Disable the Front Panel Keyboard......................................................... 11-48

12. REPAIR AND MAINTENANCE.............................................................................. 12-1

12.1 HANDLING PRECAUTIONS ..................................................................................... 12-1

12.2 MAINTENANCE PHILOSOPHY................................................................................12-1

12.3 TROUBLE SHOOTING AIDS.....................................................................................12-1

12.4 RETURNING THE MDC-260 TO THE FACTORY.................................................... 12-3

13. APPENDIX A – MATING CABLE COLOR CODES ............................................ 13-1

14. APPENDIX B – PARAMETER TEMPLATES....................................................... 14-1

14.1 MATERIAL..................................................................................................................14-2

14.2 PROCESS..................................................................................................................... 14-4

14.3 DISPLAY SETUP......................................................................................................... 14-5

x

Page 16

INPUTS.........................................................................................................................14-6

14.4

14.5 OUTPUTS.....................................................................................................................14-7

14.6 ACTIONS......................................................................................................................14-8

14.7 SENSOR SETUP...........................................................................................................14-9

14.8 SOURCE SETUP...........................................................................................................14-9

14.9 UTILITY SETUP.........................................................................................................14-10

15. INDEX.............................................................................................................................11

16. MENU MAPS...............................................................................................................16-1

xi

Page 17

Table of Figures

FIGURE 2-1 ARROW KEYS.......................................................................................................2-4

FIGURE 2-2 ALPHANUMERIC KEYPAD ................................................................................ 2-4

FIGURE 3-1 REMOTE POWER HANDSET ............................................................................. 3-5

FIGURE 4-1 THE MAIN MENU................................................................................................ 4-1

FIGURE 4-2 SELECT PROCESS SCREEN............................................................................. 4-14

FIGURE 4-3 DEFINE PROCESS SCREEN..............................................................................4-14

FIGURE 4-4 SELECT LAYER MATERIAL SCREEN.............................................................4-16

FIGURE 4-5 SELECT MATERIAL SCREEN........................................................................... 4-16

FIGURE 4-6 DEFINE MATERIAL SCREEN...........................................................................4-16

FIGURE 4-7 SYSTEM SETUP MENU SCREEN .................................................................... 4-24

FIGURE 4-8 DISPLAY SETUP SCREEN................................................................................4-24

FIGURE 4-9 PROGRAM INPUT SCREEN...............................................................................4-27

FIGURE 4-10 SELECT OUTPUT SCREEN............................................................................. 4-28

FIGURE 4-11 PROGRAM OUTPUT SCREEN........................................................................ 4-28

FIGURE 4-12 OUTPUT CONDITIONS SELECTION SCREEN............................................. 4-29

FIGURE 4-13 OUTPUT CONDITIONS SELECTION - SUB MENU...................................... 4-29

FIGURE 4-14 ACTION SELECTION SCREEN.......................................................................4-32

FIGURE 4-15 PROGRAM ACTION SCREEN......................................................................... 4-33

FIGURE 4-16 SELECT DEFINED ACTION SCREEN ............................................................ 4-33

FIGURE 4-17 SENSOR SETUP SCREEN................................................................................4-35

FIGURE 4-18 SOURCE SETUP SCREEN............................................................................... 4-37

FIGURE 4-19 UTILITY SETUP SCREEN............................................................................... 4-40

FIGURE 5-1 SIGN-ON SCREEN................................................................................................5-1

FIGURE 5-2 RUN PROCESS SELECTION SCREEN............................................................... 5-1

FIGURE 5-3 RATE VS. TIME GRAPH......................................................................................5-2

FIGURE 5-4 RATE DEVIATION VS. TIME GRAPH............................................................... 5-3

FIGURE 5-5 THICKNESS VS. TIME GRAPH..........................................................................5-3

FIGURE 5-6 POWER VS. TIME GRAPH..................................................................................5-3

FIGURE 5-7 MAIN RUN SCREEN.............................................................................................5-4

FIGURE 5-8 SOURCE-SENSOR STATUS SCREEN.................................................................5-4

FIGURE 5-9 I/O STATUS SCREEN............................................................................................5-5

FIGURE 5-10 ACTIVE LAYER PARAMETER UPDATE SCREEN ........................................ 5-5

FIGURE 5-11 POSITION CONTROL SCREEN.........................................................................5-5

FIGURE 5-12 TYPICAL PROCESS PROFILE........................................................................ 5-12

FIGURE 7-1 PASSIVE INPUT BUFFER CIRCUIT .................................................................. 7-3

FIGURE 7-2 ACTIVE INPUT BUFFER CIRCUIT.....................................................................7-4

FIGURE 7-3 SENSOR INPUT BUFFER CIRCUIT.................................................................. 7-5

FIGURE 7-4 SOURCE OUTPUT DRIVER CIRCUIT ............................................................... 7-6

FIGURE 8-1 POWER ENTRY MODULE...................................................................................8-2

FIGURE 8-2 INPUT TYPE SELECTION SWITCHES...............................................................8-4

FIGURE 8-3 MDC-260 FRONT PANEL....................................................................................8-6

FIGURE 8-4 MDC-260 REAR PANEL ...................................................................................... 8-7

FIGURE 8-5 SOURCE SOCKET CONNECTOR PIN OUT...................................................... 8-8

FIGURE 8-6 USB “B” TYPE SOCKET FRONT AND REAR PANEL CONNECTOR............. 8-8

FIGURE 8-7 D37P DISCRETE I/O PLUG CONNECTOR......................................................... 8-9

FIGURE 8-8 FRONT PANEL MANUAL POWER CONNECTOR.........................................8-10

FIGURE 8-9 MDC-260 TOP VIEW (COVER REMOVED)..................................................... 8-11

FIGURE 8-10 RECOMMENDED GROUNDING METHOD...................................................8-12

FIGURE 9-1 REMOVING THE CRYSTAL RETAINER........................................................... 9-5

FIGURE 9-2 INSTALLING THE SENSOR CRYSTAL ............................................................. 9-5

FIGURE 9-3 SO-100 SENSOR OSCILLATOR OUTLINE........................................................ 9-7

FIGURE 9-4 VPLO-6 SENSOR OSCILLATOR OUTLINE....................................................... 9-8

FIGURE 9-5 IF-111 INSTRUMENTATION FEEDTHROUGH OUTLINE..............................9-9

FIGURE 9-6 SH-102 SENSOR HEAD OUTLINE...................................................................9-10

FIGURE 9-7 TYPICAL SYSTEM INSTALLATION............................................................... 9-11

xii

Page 18

FIGURE 13-1 PLUG PIN OUT - SOURCE CABLE CONNECTOR.........................................13-1

FIGURE 16-1 MAP OF STATUS AND GRAPH SCREENS.....................................................16-1

FIGURE 16-2 MAP OF PROGRAMMING MENU SCREENS.................................................16-2

List of Tables

TABLE 4-1 TABLE OF INPUT STATES FOR BCD FEEDBACK TYPE...............................4-37

TABLE 4-2 TABLE OF INPUT STATES FOR BCD FEEDBACK TYPE................................4-39

TABLE 5-1 TROUBLE CONDITIONS AND WARNINGS...................................................... 5-8

TABLE 6-1 DEFAULT AND RANGE FOR PID PARAMETERS............................................. 6-3

TABLE 6-2 SUGGESTED PID STARTING VALUES FOR DIFFERENT SOURCES............. 6-3

TABLE 8-1 SOURCE CONTROL SYSTEM INTERFACE CONNECTOR PIN

ASSIGNMENTS................................................................................................................. 8-8

TABLE 8-2 DISCRETE I/O SYSTEM INTERFACE CONNECTOR PIN ASSIGNMENTS... 8-9

TABLE 8-3 FRONT PANEL MANUAL POWER CONNECTOR PIN ASSIGNMENTS.......8-10

TABLE 10-1 MATERIAL DENSITY AND ACOUSTIC IMPEDANCE VALUE....................10-9

xiii

Page 19

MDC-260 DEPOSITION CONTROLLER

1. GENERAL DESCRIPTION

1.1 PURPOSE

The MDC-260 is a full-featured deposition controller which can provide

automatic control of single or multi-layer film deposition in either a production or

development environment. The MDC-260 will improve predictability and

repeatability of deposited film characteristics through dependable digital control.

The MDC-260 makes programming and operation easy with an easy to use menudriven user interface and a large graphic LCD for displaying important run-time

information and graphs. The plain-English programming interface offers

unmatched simplicity and control of all processes, materials, inputs, outputs and

actions.

1.2 FEATURES

The MDC-260 incorporates numerous features which are economically justifiable

as a result of rapid advances in semiconductor technology and the advent of low

cost microprocessors.

1.2.1 AMPLE PROGRAM STORAGE

The MDC-260 is capable of storing up to 10 processes, 250 layer definitions and

8 complete material definitions. Once a program is entered it will be maintained

in internal Flash Memory indefinitely (for a minimum of 100 years) without

external power.

1.2.2 DYNAMIC MEASUREMENT UPDATE RATE

Measurement is dynamically adjusted from 0.5 to 10 Hz for optimum resolution

and control.

1.2.3 SUPERIOR COLOR GRAPHICS DISPLAY

The MDC-260 features a 240x64 pixel color LCD graphics display allowing realtime graphing of important process information such as rate, rate deviation,

thickness and power.

1.2.4 PROGRAM SECURITY

To assure the integrity of stored programs, the MDC-260 incorporates view/edit

passwords to guard against unauthorized program changes.

1.2.5 DESIGNED FOR UNATTENDED OPERATION

The MDC-260 has been designed for truly automatic operation and toward this

end incorporates extensive internal monitoring and overriding abort circuitry to

minimize the possibility of damage in the event of a failure or other problem in

the total deposition system. In addition there are attention, alert and alarm signals

with adjustable volume for trouble and routine operator call.

GENERAL DESCRIPTION 1-1

Page 20

MDC-260 DEPOSITION CONTROLLER

1.2.6 FAIL SAFE ABORTS

In the event of an MDC-260 failure, as evidenced by unsatisfactory internal

checks, the MDC-260 will abort the process and shut off all outputs. In addition

to the internal checks, the MDC-260 also provides user enabled aborts on

excessive rate control error or crystal failure.

1.2.7 ABORT STATUS RETENTION

In the event that the MDC-260 does abort during the deposition process, pertinent

information is stored at the time of abort. More importantly, the process can be

easily resumed once the problem is corrected without re-programming.

1.2.8 RUN COMPLETION ON CRYSTAL FAILURE

The extensive monitoring and abort functions are designed to protect the system

and/or process from serious and hopefully infrequent malfunctions of the

deposition system. A condition which need not cause an abort is the condition of

crystal failure. The MDC-260 can be set to abort upon crystal failure or run to

completion using a backup crystal or time/power method.

1.2.9 POWERFUL SYSTEM INTERFACE

Fully programmable discrete inputs and outputs permit the MDC-260 to be easily

interfaced into deposition systems controlling the most complex processes. Also,

source control outputs are fully isolated avoiding ground loop problems. The

MDC-260 also supports input from an optical monitor for optical termination of

film thickness.

1.2.10 POWER SUPPLY NOISE TOLERANCE

Integral RFI filter and large energy storage capacitors will tolerate high levels of

power supply noise and power interruptions of 700 ms or less without effect.

1.2.11 INTERNATIONAL STANDARD POWER CONNECTOR

The power connector is internationally approved and meets IEC (International

Electrotechnical Commission) standards. It allows selection of input power

voltages ranging from 100 to 240 volts at a frequency of 50 or 60 Hz and includes

an integral RFI filter.

GENERAL DESCRIPTION 1-2

Page 21

MDC-260 DEPOSITION CONTROLLER

1.3 SPECIFICATIONS

1.3.1 MEASUREMENT

Frequency Resolution 0.03 Hz @ 6.0 MHz

Mass Resolution 0.375 ng/cm2

Thickness Accuracy 0.5% + 1 count

Measurement Update Rate Dynamically adjusted, 0.5 to 10 Hz

Display Update Rate 10 Hz

Sensor Crystal Frequency 2.5, 3, 5, 6, 9, 10 MHz

1.3.2 DISPLAY

Thickness Display Autoranging: 0.000 to 999.9 KÅ

Rate Display Autoranging: 0.0 to 999 Å/sec

Power Display 0.0 to 99.9%

Time Display 0 to 9:59:59 H:MM:SS

Crystal Health 0-99 %

Layer Number 1 to 250

Graphics Display 240X64 Color LCD with CCFL

backlighting

Color Schemes 4 built-in color presets

1.3.3 COMMUNICATION

Protocol USB 1.1

Driver Microsoft Windows driver included

1.3.4 PROGRAM STORAGE CAPACITY

Process 10 (user definable)

Layer 250 (user definable)

Material 8 (user definable)

1.3.5 PROCESS PARAMETERS

Process Name 12 character string

View/Run Password 4 character string

Edit Password 4 character string

Layer# 1 to 250 Thickness, material name

GENERAL DESCRIPTION 1-3

Page 22

MDC-260 DEPOSITION CONTROLLER

1.3.6 MATERIAL PARAMETERS

Material Name 10 character string

Sensor # 1 to 2

Crystal # 1 to 16

Source # 1 to 2

Pocket # 1 to 16

Density 0.80 to 99.9 gm/cm3

Acoustic Impedance 0.50 to 59.9 gm/cm2 sec

Tooling Factor 10.0 to 499.9%

Proportional Gain 0.00 to 9999

Integral Time Constant 0 to 99.9 sec

Derivative Time Constant 0 to 99.9 sec

Rise to Soak Time 0 to 9:59:59 H:MM:SS

Soak Power 0 to 99%

Soak Time 0 to 9:59:59

Rise to Predeposit Time 0 to 9:59:59

Predeposit Power 0 to 99.9%

Predeposit Time 0 to 9:59:59

Rate Establish Time 0 to 60 sec

Rate Establish Error * 0 to 99.9%

Deposition Rate (#1, #2*, #3*) 00.0 to 999.9 Å/sec

Ramp (#1, #2*) Start Thickness 0 to 100% [100% = Ramp Disabled]

Ramp (#1*, #2*) Stop Thickness 0 to 100%

Time Setpoint 0 to 9:59:59

Ramp to Feed Time 0 to 9:59:59

Feed Power 0 to 99.9%

Feed Time 0 to 9:59:59

Ramp to Idle Time 0 to 9:59:59

Idle Power 0 to 99.9%

Maximum Power 0 to 99.9%

Power Alarm Delay 0 to 99 sec

Minimum Power 0 to 99.9%

Rate Deviation Attention 0 to 99.9%

Rate Deviation Alarm 0 to 99.9%

Rate Deviation Abort 0 to 99.9%

Sample Dwell % 0 to 100%

Sample Period * 0:01:00 to 9:59:59

Crystal Fail Switch, Time Power, Halt, Abort

Backup Sensor # 1 to 2

Backup Crystal # 1 to 16

Backup Tooling Factor 10.0 to 499.9%

Material Password 4 character string

* These options are made available based on the settings of surrounding

parameters, and will not appear if their value is not needed.

GENERAL DESCRIPTION 1-4

Page 23

MDC-260 DEPOSITION CONTROLLER

The MDC-260 also has a built in material library that contains many common

material names along with their density and acoustic impedance values.

1.3.7 INPUT/OUTPUT CAPABILITY

Sensor Inputs 2 BNC inputs

Source Outputs 2 fully isolated, 2.5, 5, 10 volts @ 20

ma. 0.002% resolution

Discrete Inputs 8 fully programmable inputs, user

selectable ground true (Passive) or 12

to 120 volt AC/DC (Active).

Discrete Outputs 8 fully programmable outputs, SPST

relay, 120VA, 2A max.

Abort Output 1 SPST Relay, 120VA, 2A max.

Remote Power Handset Front panel, RJH jack

USB 1.1 Communication USB “B” connectors on both front

and rear panel

1.3.8 SENSOR PARAMETERS

Number of Crystals 1 to 16

Shutter Relay Type Normally open, normally closed, dual,

or none

Position Control Manual, direct, BCD, or individual

Position Drive Up, down, Fast, inline, single step, or

double step

Feedback Type Individual, BCD, single home, in

position, or no feedback

Rotator Delay 0 to 99 sec

GENERAL DESCRIPTION 1-5

Page 24

MDC-260 DEPOSITION CONTROLLER

1.3.9 SOURCE PARAMETERS

Number of Pockets 1 to 16

Shutter Relay Type Normally open, normally closed, or

none.

Shutter Delay 0.0 to 9.9 sec

Position Control Manual, direct, BCD, or individual

Position Drive Up, down, Fast, inline, single step, or

double step

Feedback Type Individual, BCD, single home, in

position, or no feedback

Rotator Delay 0 to 99 sec

Source Voltage Range 2.5, 5, 10 volts

1.3.10 UTILITY SETUP PARAMETER

Crystal Frequency 2.5, 3, 5, 6, 9, 10 MHz

Simulate Mode On/Off

USB Interface Address 1 to 32

Attention Volume 0 to 10

Alert Volume 0 to 10

Alarm Volume 0 to 10

1.3.11 OTHERS

Input Power Requirements 100, 120, 200, 240 VAC; 50/60 Hz;

25 watts

Fuse Rating IEC T-Type (Slow), 4/10 A, 250 V

Operating Temperature Range

0 to 50°C

Physical Size Rack-mount configuration (with ears)

10.4” wide x 3.5” high x 9.7” deep

Desktop configuration (with feet)

8.5” wide x 4.2” high x 9.7” deep

GENERAL DESCRIPTION 1-6

Page 25

MDC-260 DEPOSITION CONTROLLER

1.4 ACCESSORIES

The table below lists the most commonly used accessories. Refer to the Price

List for more accessories and other products.

Part Number Description

611200 DCM-250 V2.0

179220 Remote Power Handset

123200-5 SH-102 Sensor Head, cables, and

carousel of 10 each 6MHz Gold SC-101

sensor crystals

123213 BSH-150 Single Bakeable Sensor Head

with 2-3/4 innch Conflat® Flange.

150212 ASF-140 Adjustable Single Sensor with

1 inch Feedthrough Combo.

124201-4 SO-100 Oscillator with 6" and 10' BNC

Cables.

621201 VPLO-6 Vacuum Phase-Lock

Oscillator with 6" and 10' BNC Cables.

130200-2 IF-111 Instrument Feedthrough, 1" O-

Ring with 1 electrical connector and

dual 3/16" water tubes.

130204-2 IF-276 Instrumentation Feedthrough, 2

3/4" Conflat® Flange seal with 1

electrical connector and dual 3/16"

water tubes.

150902 SF-120 Combination Sensor Head,

Feedthrough, Cables, Crystals and

Oscillator.

123204-1 Internal Coax Cable 30".

123204-2 Internal Coax Cable 60".

124202-1 BNC Cable Assembly 10'.

124202-2 BNC Cable Assembly 20'

124204 BNC Cable Assembly 6".

103220 SC-101 Carousel of 10 each 6MHz gold

sensor crystals.

103221 SC-102 Carousel of 10 each 6MHz

silver sensor crystals.

GENERAL DESCRIPTION 1-7

Page 26

Page 27

MDC-260 DEPOSITION CONTROLLER

2. FRONT PANEL DISPLAYS AND CONTROLS

Using the front panel is the most direct method of accessing the MDC-260. Both

the programmer and the operator will find it beneficial to become familiar with it.

2.1 GRAPHIC LCD DISPLAY

All programming and status information is shown through the central color LCD.

This section lists the available screens. These screens are grouped in three

distinctive areas: Programming screens, Graph screen, and Status screens. For

detailed descriptions of the different programming and status screens, refer to

Section 4 and 5.

2.1.1 PROGRAMMING SCREENS (MENUS)

Pressing the Program key at any time will cause the MDC-260 to return to the

main programming mode. In this mode, the user has the ability to make changes

to any parameter settings. Upon power up, the LCD display automatically reverts

to the last viewed status screen.

2.1.2 RUN-TIME GRAPHS

There are four graphs that may be displayed to show the progress of a deposition

process. Pressing the Graph key scrolls through the four available graphs: Rate,

Power, Thickness and Rate Deviation. The graphs automatically adjust the time

axis as the deposition proceeds.

2.1.3 STATUS SCREENS

Pressing the Status key scrolls through the four available screens of run-time data

(Status Screens). Each shows a different aspect of the current process. All of the

parameters are updated ten times per second unless the controller is in the Abort

mode.

2.1.3.1 MAIN RUN SCREEN

The Main Run Screen is a useful data screen which displays the most pertinent

run-time information in large, easy-to-read numbers. The data shown specifically

applies to the active Source/Sensor combination and the active process.

2.1.3.2 SOURCE/SENSOR STATUS SCREEN

The Source/Sensor Status Screen presents run-time data concerning both sources

and sensors. Also, from this view, the Pocket #, Sensor # or Crystal # may be

changed.

2.1.3.3 INPUT/OUTPUT STATUS SCREEN

The Input/Output Status Screen shows the state of all of the external inputs and

output.

FRONT PANEL DISPLAYS AND CONTROLS

2-1

Page 28

MDC-260 DEPOSITION CONTROLLER

2.1.3.4 ACTIVE LAYER PARAMETER UPDATE SCREEN

The Active Layer Parameter Update screen displays a set of parameters of the

current active. It allows the user to quickly change these values, if needed, to

fine-tune the run, without having to go into the Edit Material Definition screen.

This screen is only available during a process.

2.1.3.5 POSITION CONTROL SCREEN

This screen allows the user to easily switch to a desired pocket or crystal in order

to replace the material or crystal. The Position Control Screen is only available

when the controller is in idle (not in process or abort state).

2.2 OPERATING CONTROLS

Normal operation of the MDC-260 is controlled by three viewing-mode keys

(Status, Graph, and Program) and six action keys (Manual, Start, Abort, Reset,

Zero and Shutter). Except for Zero, each of the action keys is equipped with an

LED to indicate the controller’s status.

2.2.1 STATUS KEY

Pressing the Status key will bring up one of the four run-time status screens.

Repeatedly pressing the key will cycle through the different status screens.

Refer to Section 5 for a detailed description of the viewing modes.

2.2.2 GRAPH KEY

Pressing the Graph key will bring up one of the four run-time graph screens.

Repeatedly pressing the key will cycle through the different graph screens.

Refer to Section 5 for a detailed description of the viewing modes.

2.2.3 PROGRAM KEY

Pressing the Program key return the controller into Programming Mode, which

allows the operator to adjust settings and enter program parameters. The last

viewed programming screen will appear immediately (If a programming screen

is already shown, this key has no effect.) This key is also used in conjunction

with the Up and Down Arrow keys to adjust the contrast of the LCD . If the

screen background is too bright, press and hold the Program and the down

arrow keys until the text is easy to read. If the screen background is too dark

and the text cannot be seen, press and hold the Program and the up arrow keys.

Refer to Section 5 for a detailed description of the viewing modes.

2.2.4 MANUAL KEY

This key is used to toggle Manual Mode on and off. A red light behind this key

indicates the controller is in manual power control mode. This mode may be

selected at any time providing that the controller is not in Abort mode. The

Manual mode indicates that the source control voltage output for the active

source is being controlled through the Remote Power Handset. (The active

source is set by the active material's Source parameter).

FRONT PANEL DISPLAYS AND CONTROLS 2-2

Page 29

MDC-260 DEPOSITION CONTROLLER

In the Manual mode the control voltage remains constant unless incremented up

or down by means of the Remote Power Handset. At entry into the Manual

mode, the power is left at the last value prior to entry and is thereafter modified

only through the Remote Power Handset. Exit from the manual mode is

accomplished by means of the Manual or Reset key.

The MDC-260 can also be aborted through the Remote Power Handset. This

abort feature is active whether or not MDC-260 is in the manual mode.

2.2.5 START KEY

The Start key starts a process, starts a layer, or resumes an aborted process. A

green light behind this key indicates the controller is in process. When this key is

pressed the first time a list of stored processes is displayed in the LCD window.

You simply scroll the cursor on to the desired process and press Start again to

start the process.

2.2.6 ABORT KEY

The Abort key drives the MDC-260 into the Abort mode. All source powers are

set to zero and discrete outputs are set to inactive state. A red light behind this

key indicates the controller is in the abort mode.

2.2.7 RESET KEY

The Reset key is used to clear the controller from Abort mode and put it into the

Ready mode. A yellow light behind this key indicates a Ready mode. The Reset

key is inactive during the In Process mode so that a premature exit from the In

Process mode requires an abort.

CAUTION: Once a process is reset, it cannot be resumed. Consequently, don't

reset an aborted process if you want to resume it once the problem is cleared.

2.2.8 ZERO KEY

Pressing the Zero key causes the thickness display to go to zero. This key is

active at all times and if pressed during the deposit state will result in a film

thicker than that desired by an amount equal to the thickness displayed at the time

the display was zeroed.

2.2.9 SHUTTER KEY

This key is used to manually open and close all source shutters. The red light is

illuminated when the active source shutter relay is closed. This key is only active

when the controller is in the Process Ready mode.

FRONT PANEL DISPLAYS AND CONTROLS

2-3

Page 30

MDC-260 DEPOSITION CONTROLLER

2.2.10 ARROW KEYS

The arrow keys are used to navigate through the programming and setup menu structure.

These keys will auto-repeat if they are held down for more than half a second.

Figure 2-1 Arrow Keys

2.2.11 ALPHANUMERIC KEYPAD

The alphanumeric keyboard is used to edit

controller parameters. Refer to Section 4 for

details on enter new parameter values

Figure 2-2 Alphanumeric Keypad

.

FRONT PANEL DISPLAYS AND CONTROLS 2-4

Page 31

MDC-260 DEPOSITION CONTROLLER

3. BENCH CHECKOUT & INSPECTION

3.1 INSPECTION

Your MDC-260 was released to the carrier in good condition and properly

packed. It is essential to all concerned that the contents of the shipment be

carefully examined when unpacked to assure that no damage occurred in transit.

Check the material received against the packing list to be certain that all elements

are accounted for. Items included with your controller are:

1 MDC-260 Deposition Controller

1 Operation and Service Manual

1 Power cord

1 Source cable (4 pin mini DIN connector)

1 Discrete I/O connector kit (37P D shell)

In addition, you may have ordered one or more of the accessories listed in Section

1.4. If there is evidence of loss or damage:

a) Notify the carrier or the carrier agent to request inspection of the loss

or damage claimed.

b) Keep the shipping containers until it is determined whether or not they

are needed to return the equipment to INFICON.

3.2 COLD POWER UP

When external power is initially supplied (a “cold” power up), the unit will run a

series of tests and initialize all program data. The LCD will show the controller

Sign-on screen with its configuration information. See Figure 5-1. The unit will

stay in this state until a key is pressed, at which time the LCD display will return

to the last viewed screen prior to loss of power.

3.3 WARM POWER UP

Pressing the front-panel “Power” key does not completely remove power from the

system, but rather puts the MDC-260 into a power-saving “Stand-by Mode”.

Pressing the key again wakes up the MDC-260 (a “warm” power up) and resumes

whatever operation was in process when the unit was disabled.

3.4 SAMPLE PROGRAM

The sample program listed below is included in the MDC-260 memory at the time

of shipment. It can be used to evaluate the controller by running it in Simulate

Mode. Follow instructions in Section 4 to navigate through the menu structure.

Check the controller parameter values against the sample program for discrepancy

and change if necessary. Note also, if the source or sensor configuration has been

changed during familiarization with the controller programming, appropriate

source and sensor parameter values also need to be retained for the sample

program to run correctly.

BENCH CHECKOUT & INSPECTION

3-1

Page 32

MDC-260 DEPOSITION CONTROLLER

3.4.1 MATERIAL #1 PARAMETERS

Material Name Cr

Sensor # 1

Crystal # 1

Source # 1

Pocket # 1

Density 07.20 gm/cm3

Acoustic Impedance 28.95 gm/cm2 sec

Tooling Factor 100%

Proportional gain 2400

Integral Time constant 99.9 seconds

Derivative Time constant 0.00 seconds

Rise to Soak Time 0:00:10

Soak Power 5 %

Soak Time 0:00:10

Rise to Predeposit Time 0:00:10

Predeposit Power 9.5 %

Predeposit Time 0:00:05

Rate Establish Time 0 seconds

Deposition Rate #1 10.0 Å/second

Ramp #1 Start Thickness 100 % (No Rate Ramps)

Time Setpoint 0:00:00

Ramp to Feed Time 0:00:05

Feed Power 7 %

Feed Time 0:00:10

Ramp to Idle Time 0

Idle Power 0

Maximum Power 20 %

Power Alarm Delay 5 seconds

Minimum Power 0 %

Rate Deviation Attention 0 %

Rate Deviation Alarm 0 %

Rate Deviation Abort 0 %

Sample Dwell % 100 % (Continuous Sampling)

Crystal Fail TimePwr

Backup Sensor # 1

Backup Crystal # 1

Backup Tooling Factor 100 %

Material Password 0000

BENCH CHECKOUT & INSPECTION 3-2

Page 33

MDC-260 DEPOSITION CONTROLLER

3.4.2 MATERIAL #2 PARAMETERS

Material Name Au

Sensor # 1

Crystal # 1

Source # 1

Pocket # 2

Density 19.30 gm/cm3

Acoustic Impedance 23.18 gm/cm2 sec

Tooling Factor 100 %

Proportional gain 5000

Integral Time constant 99.9 seconds

Derivative Time constant 0.00 seconds

Rise to Soak Time 0:00:05

Soak Power 25 %

Soak Time 0:00:05

Rise to Predeposit Time 0:00:05

Predeposit Power 37.5 %

Predeposit Time 0:00:10

Rate Establish Time 0 sec

Deposition Rate #1 20.0 Å/sec

Ramp #1 Start Thickness 100% (No Rate Ramps)

Time Setpoint 0:00:00

Ramp to Feed Time 0:00:05

Feed Power 10 %

Feed Time 0:00:10

Ramp to Idle Time 0

Idle Power 0

Maximum Power 50 %

Power Alarm Delay 5 seconds

Minimum Power 0 %

Rate Deviation Attention 0 %

Rate Deviation Alert 0 %

Rate Deviation Alarm 0 %

Sample Dwell % 100 % (Continuous Sampling)

Crystal Fail TimePwr

Backup Sensor # 1

Backup Crystal # 1

Backup Tooling Factor 100 %

Material Password 0000

BENCH CHECKOUT & INSPECTION

3-3

Page 34

MDC-260 DEPOSITION CONTROLLER

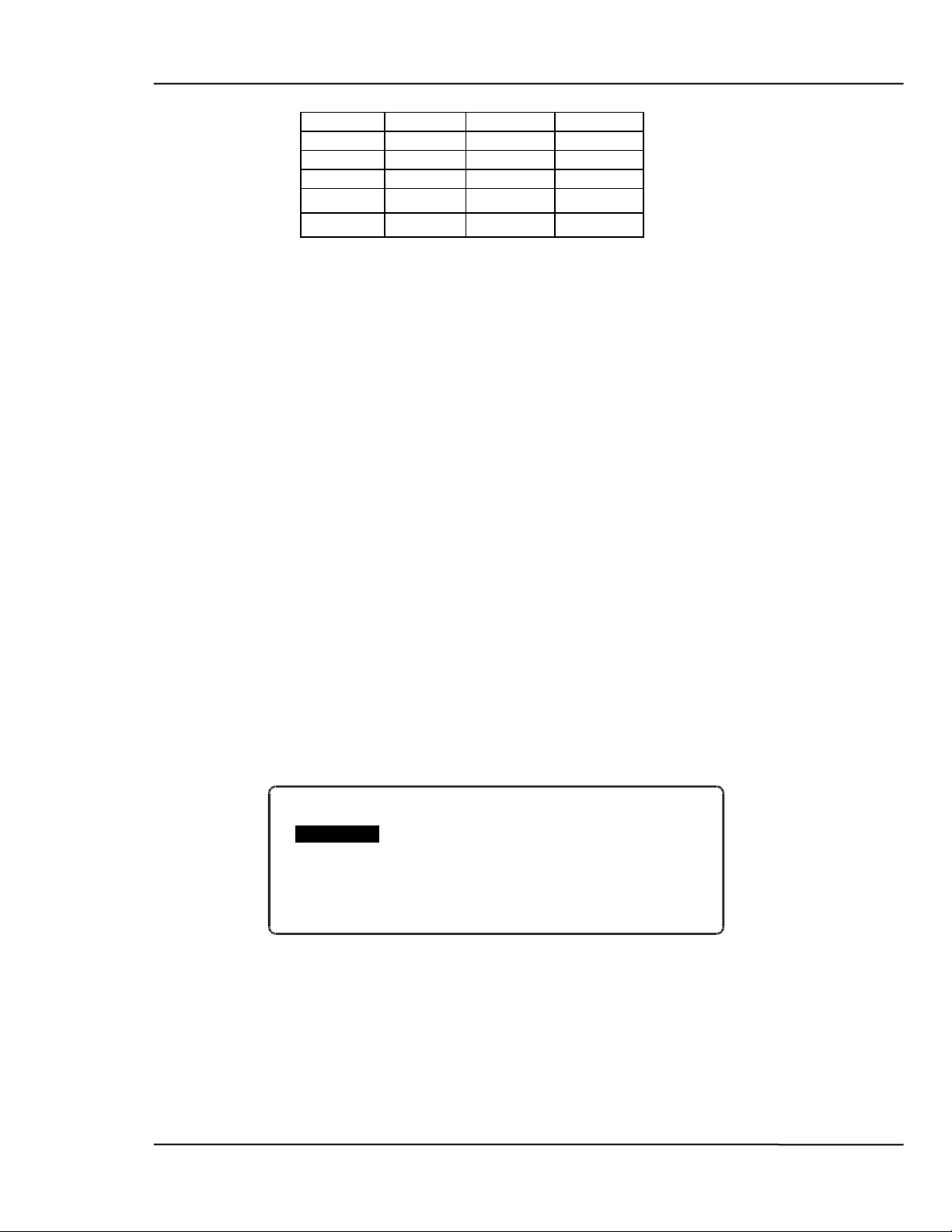

3.4.3 PROCESS PARAMETERS

Process Name Layer No. Thickness Material

Sample 1 0.400 KÅ Cr

2 1.050 KÅ Au

3.5 SIMULATE OPERATION

Testing the MDC-260 is best accomplished by checking its operation in the

Simulate Mode. This mode can be selected by entering the following

programming sequence: (Main Menu, Edit System Setup, Edit Utility Setup,

Simulate Mode ON). After enabling Simulate Mode, you may run a process in

Simulate Mode by pressing the Start key and selecting the process that you want

to run.

Simulate Mode is identical to the Normal Mode except that the sensor inputs are

simulated. For this reason, entry to the Simulate Mode will switch off the Crystal

Failure message if it is flashing. No other difference between the Simulate Mode

and the Normal Mode occurs until entry to the Deposit State.

3.6 MANUAL OPERATION

Manual Mode is selected by depressing the Manual key. The LED behind the key

will light up indicating the controller is in Manual Mode.

The Manual Mode is identical to the Normal Mode in all respects except that

source power for the active source is controlled only through the Remote Power

Handset.

The Remote Power Handset has three push buttons (see Figure 3-1). Without any

of the buttons depressed, the output power is maintained at its last value.

Depressing the “POWER (+)” button will increase the power, depressing the

“POWER (-)” button will decrease the power and depressing the “ABORT”

button will put the controller into the Abort Mode.

The “ABORT” button on the handset is active whether or not the MDC-260 is in

Manual Mode and therefore can be used as a remote “panic button”.

The minimum increment by which the power is increased or decreased is 0.1%.

BENCH CHECKOUT & INSPECTION 3-4

Page 35

MDC-260 DEPOSITION CONTROLLER

Figure 3-1 Remote Power Handset

TO MDC-260 FRONT PANEL

BENCH CHECKOUT & INSPECTION

3-5

Page 36

Page 37

MDC-260 DEPOSITION CONTROLLER

4. PROGRAMMING AND CONTROLLER SETUP

4.1 GENERAL

4.1.1 NAVIGATING THE MENU STRUCTURE

Before attempting to navigate the menu structure of the MDC-260 controller,

please refer to Section 2 which provides a brief summary of the front-panel

displays and key functions. A graphical menu structure is shown in Figure 16-2.

Note that following a power-on (“cold” or “warm”), the LCD will begin at the last

screen the unit was displaying when it was turned off.

This may be confusing until the full scope of the controller’s capabilities are

understood. However, as their names suggest, the Status, Graph and Program

keys select the display of status screens, graph screens and programming screens,

respectively. Also note that the last viewed screen for each type is remembered

and will be displayed the next time that display type is selected.

Main Menu

View/Edit Process..

View/Edit Material

Edit System Setup

Figure 4-1 The Main Menu