Page 1

Translation of the original operating instructions

LDS3000, LDS3000 AQ

Mass spectrometer module

560-300, 560-600

From software version:

MS-Modul 2.71

jiqa54en1-07-(1803)

Page 2

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

Page 3

INFICON Table of Contents

Table of Contents

1 About these instructions ...................................................................................................................................7

1.1 Other associated documents ....................................................................................................................7

1.2 Target groups ...........................................................................................................................................7

1.3 Warnings...................................................................................................................................................7

1.4 Definition of terms.....................................................................................................................................8

2 Safety .............................................................................................................................................................11

2.1 Intended use ...........................................................................................................................................11

2.2 Owner requirements ...............................................................................................................................11

2.3 Duties of the operator .............................................................................................................................12

2.4 Dangers ..................................................................................................................................................12

3 Shipment, Transport, Storage ........................................................................................................................14

4 Description......................................................................................................................................................15

4.1 Function ..................................................................................................................................................15

4.2 Device setup ...........................................................................................................................................16

4.2.1 Entire device (LDS3000)............................................................................................................. 16

4.2.2 Entire device (LDS3000 AQ)....................................................................................................... 16

4.2.3 Connection block ........................................................................................................................ 20

4.2.4 MSB box ..................................................................................................................................... 20

4.2.5 Nameplate................................................................................................................................... 23

4.3 Technical data ........................................................................................................................................24

4.4 Factory settings ......................................................................................................................................25

5 Mounting LDS3000.........................................................................................................................................28

5.1 Adjust the position of the connections to the installation dimensions .....................................................28

5.2 Installing the mass spectrometer module on the test system .................................................................29

5.3 Select connection ULTRA, FINE, or GROSS .........................................................................................30

5.4 Establish component connection ............................................................................................................31

5.5 Establish electrical connections..............................................................................................................32

6 Mounting LDS3000 AQ (Accumulation)..........................................................................................................33

6.1 Adjust the position of the connections to the installation dimensions .....................................................33

6.2 Installing the mass spectrometer module on the test system .................................................................34

6.3 Select components and connect.............................................................................................................36

6.4 Establish electrical connections..............................................................................................................38

7 Operation LDS3000........................................................................................................................................39

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) iii

Page 4

Table of Contents INFICON

7.1 Switching the device on ..........................................................................................................................39

7.2 Default settings .......................................................................................................................................40

7.3 Selecting a unit for the leak rate .............................................................................................................42

7.4 Select device for pressure ......................................................................................................................43

7.5 Select Compatibility Mode ......................................................................................................................43

7.6 Select operation mode............................................................................................................................45

7.7 Select gas type (mass) ...........................................................................................................................46

7.8 Calibrating the device .............................................................................................................................47

7.8.1 Time and general preferences ....................................................................................................47

7.8.2 Internal Calibration Configuration and Start................................................................................ 49

7.8.3 External Calibration Configuration and Start............................................................................... 50

7.8.4 Start external dynamic calibration............................................................................................... 52

7.8.5 External calibration with sniffer line SL3000XL........................................................................... 54

7.8.6 Check the calibration .................................................................................................................. 55

7.8.6.1 Calibration using the internal calibration leak test..............................................................55

7.8.6.2 Calibration using the external calibration leak test.............................................................55

7.8.7 Entering the calibration factor .....................................................................................................56

7.8.7.1 Calibration factor sniffing....................................................................................................56

7.8.7.2 Calibration factor vacuum ..................................................................................................56

7.8.8 Setting machine and sniff factor.................................................................................................. 57

7.8.8.1 Setting machine and sniff factor manually .........................................................................57

7.8.8.2 Setting machine and sniff factor using machine calibration ...............................................58

7.9 Starting and stopping the measurement.................................................................................................58

7.10 Loading and saving parameters .............................................................................................................59

7.11 Copying measurement data, deleting measurement data ......................................................................60

7.12 Suppressing gas backgrounds with "ZERO" functions ...........................................................................60

7.13 Measurement result display with signal filters ........................................................................................61

7.14 Control of the Gas Ballast Valve of the Backing Pump...........................................................................62

7.15 Selecting display limits............................................................................................................................63

7.16 Setting trigger values ..............................................................................................................................63

7.17 Setting capillary surveillance ..................................................................................................................63

7.18 Set the rotation speed of the turbo molecular pump...............................................................................64

7.19 Cathode Selection ..................................................................................................................................65

7.20 Settings for the XL sniffer adapter ..........................................................................................................65

7.21 Resetting the settings .............................................................................................................................68

8 Operation LDS3000 AQ (Accumulation).........................................................................................................69

8.1 Switching the device on ..........................................................................................................................69

iv LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 5

INFICON Table of Contents

8.2 Default settings .......................................................................................................................................69

8.3 Selecting a unit for the leak rate .............................................................................................................70

8.4 Select device for pressure ......................................................................................................................71

8.5 Select Compatibility Mode ......................................................................................................................71

8.6 Making basic settings via the wizard ......................................................................................................73

8.7 Determine peak ......................................................................................................................................74

8.8 Store leak rate of calibration leaks..........................................................................................................75

8.9 Calibrating the device .............................................................................................................................76

8.9.1 Time and general preferences ....................................................................................................76

8.9.2 Entering the calibration factor .....................................................................................................77

8.9.3 Calibration factor vacuum ...........................................................................................................77

8.9.4 Calibrating................................................................................................................................... 78

8.10 Perform ZERO ........................................................................................................................................80

8.11 Setting machine and sniff factor .............................................................................................................81

8.11.1 Setting machine and sniff factor manually ..................................................................................81

8.12 Carrying out a measurement ..................................................................................................................82

8.13 Loading and saving parameters .............................................................................................................83

8.14 Copying measurement data, deleting measurement data ......................................................................83

8.15 Adjust ”Zero time factor AQ” ...................................................................................................................84

8.16 Selecting display limits............................................................................................................................84

8.17 Set the rotation speed of the turbo molecular pump...............................................................................84

8.18 Cathode Selection ..................................................................................................................................85

8.19 Resetting the settings .............................................................................................................................85

9 Using the expansion module (LDS3000, LDS3000 AQ).................................................................................87

9.1 Selecting the type of expansion module .................................................................................................87

9.2 Settings for I/O module IO1000 ..............................................................................................................87

9.2.1 General interface settings ...........................................................................................................87

9.2.2 Assigning inputs and outputs ......................................................................................................87

9.2.2.1 Assigning the digital inputs of the I/O module ....................................................................95

9.2.2.2 Assigning the digital outputs of the I/O module..................................................................98

9.3 Settings for bus module BM1000..........................................................................................................100

10 Warning and error messages (LDS3000, LDS3000 AQ).............................................................................. 101

10.1 Illustration of error codes with the help of the status LEDs...................................................................109

11 Operating CU1000 (optional)........................................................................................................................ 110

11.1 Touchscreen elements .........................................................................................................................110

11.1.1 Measurement display elements ................................................................................................110

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) v

Page 6

Table of Contents INFICON

11.2 Elements of the error and warning display ...........................................................................................113

11.3 Settings and functions ..........................................................................................................................113

11.3.1 Touch screen settings ............................................................................................................... 113

11.3.2 Operator types and authorizations ............................................................................................ 117

11.3.2.1 Logging out the operator ..................................................................................................118

11.3.3 Functions .................................................................................................................................. 118

11.3.3.1 Resetting the settings.......................................................................................................118

11.3.3.2 Recording data.................................................................................................................119

11.3.3.3 Calling up information ......................................................................................................120

11.3.4 Updating the software ............................................................................................................... 123

11.3.4.1 Updating the software of the control unit..........................................................................123

11.3.4.2 Checking and updating the software version of the MSB box..........................................123

11.3.4.3 Updating the software of the I/O module..........................................................................124

12 Maintenance .................................................................................................................................................126

12.1 Maintenance at INFICON .....................................................................................................................126

12.2 General maintenance information.........................................................................................................126

12.3 Maintenance plan .................................................................................................................................127

12.4 Maintenance work.................................................................................................................................128

12.4.1 Change operating fluid reservoir of turbo molecular pump ....................................................... 128

13 Decommissioning the measuring instrument................................................................................................ 133

13.1 Shutting down the leak detector ...........................................................................................................133

13.2 Disposing of the mass spectrometer module........................................................................................133

13.3 Returning the mass spectrometer module............................................................................................133

14 Appendix....................................................................................................................................................... 134

14.1 CE Declaration of Conformity ...............................................................................................................134

14.2 Declaration of Incorporation..................................................................................................................135

14.3 Declaration of Contamination ...............................................................................................................136

vi LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 7

INFICON About these instructions | 1

1 About these instructions

This document applies to the software version stated on the title page.

Product names may occur in the document, which are added for identification pur-

poses only and belong to the respective owner of the rights.

This operating manual describes the installation and operation of the LDS3000 mass

spectrometer module. It is available in two variants:

• LDS3000

• LDS3000 AQ (accumulation), switchable to all other operating modes.

1.1 Other associated documents

Operating Manual Control Unit CU1000 jina54

Operating instructions bus module jiqb10

Operating instructions I/O module jiqc10

Operating instructions XL sniffer adapter jinxa54

Interface protocols jira54

1.2 Target groups

These operating instructions are intended for the owner and for technically qualified

personnel with experience in leak detection technology and integration of leak detec-

tion devices in leak detection systems. In addition, the installation and use of the de-

vice require knowledge of electronic interfaces.

1.3 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 7 / 138

Page 8

1 | About these instructions INFICON

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

1.4 Definition of terms

Mention of helium in the manual

The device is a helium leak detector. If you want to use a forming gas instead of he-

lium to detect the hydrogen contained therein, the information for helium also applies

to hydrogen.

Accumulation

In connection with leak testing, it is about the enrichment of tracer gas over a defin-

able period of time. This allows the detection of small leak rates without the use of a

vacuum chamber. Helium or forming gas can be used.

When you talk about "AQ” in this manual, it's about accumulation mode. It is only

available for devices in the AQ version.

Automatic tuning / mass setting

This function adjusts the mass spectrometer so that a maximum leak rate indicator is

achieved. In order to detect a maximum ion current with the ion detector, the control

computer adjusts the voltage for accelerating the ions within the selected mass range

accordingly.

During each calibration, there is an automatic adjusted.

Operation mode

The leak detector distinguishes between the operation modes "vacuum" and "sniffing".

With the operation mode "vacuum", generally the tracer gas flows into the test object.

The pressure in the test object is less than the ambient pressure.

In the operation mode "sniffing" the tracer gas flows out from the test object and is ex-

tracted with a sniffer probe. The pressure in the test object is greater than the ambient

pressure.

8 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 9

INFICON About these instructions | 1

FINE

FINE denotes the connection to the turbo molecular pump for inlet pressures up to 0.4

mbar. This is also used for the "sniffing" operation mode.

Forming gas

Forming gas is a collective term for gas mixtures of nitrogen and hydrogen.

GROSS

GROSS donates the connection to the turbo molecular pump with the lowest sensitiv-

ity. This allows high inlet pressures (up to 15 mbar).

Internal helium background

The measurement system of the leak detector also contains a residual amount of he-

lium. This creates an internal measurement signal component (background signal),

which overlaps the display of the leak right from the beginning and thus disturbs the

search for leaks.

So that this background signal can be suppressed, an internal "background suppres-

sion" can be activated with the factory settings.

Minimum detectable leak rate

The minimum detectable leak rate which can be detected by the leak detector under

ideal conditions (< 5 x 10

-12

mbar l/s).

ULTRA

ULTRA denotes the connection to the turbo molecular pump for the measurement

range with the highest sensitivity at inlet pressures below 0.4 mbar (adjustable).

Background signal

Helium or hydrogen (as part of water) are natural components of air.

Operation mode "Vacuum": Before any leak detection, a certain amount of the ad-

justed tracer gas is already in the volume on the surfaces of the test chamber, supply

lines, and even in the leak detector itself. This certain amount of tracer gas generates

a measurement signal which is called the "Background signal". The ongoing evacua-

tion of the test chamber continuously reduces this background signal.

Operation mode "Sniffing": Ambient air is continuously fed into the leak detector via

the sniffer line. The amount of helium or hydrogen occurring naturally in air creates a

constant background signal.

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 9 / 138

Page 10

1 | About these instructions INFICON

Foreline pressure

Pressure of the backing pressure between the turbo molecular pump and the backing

pump.

ZERO

There is helium that is weakly bound to the surfaces of a specimen as a natural part of

the ambient air and is pumped bit by bit into the measurement system of the leak de-

tector. It produces a slowly decreasing measurement signal.

If you want to hide this background signal or the display of existing leaks, then use the

function ZERO.

10 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 11

INFICON Safety | 2

2 Safety

2.1 Intended use

The device is a modular leak detector for installation in industrial leak testing unit sys-

tems. The tracer gases that can be measured with the device are helium and hydro-

gen (forming gas).

The LDS3000 is suitable for overpressure and negative pressure testing, whereby in

addition to the test in vacuum, a local test with a sniffer line is also possible.

The LDS3000 AQ is intended for the measurement of test gases when enriched in an

external measuring chamber, but can also be rebuilt for all other purposes.

► You must install, operate and service the device only in compliance with these oper-

ating instructions.

► Comply with application limits, see "Technical Data".

Improper use

Avoid the following, non-intended uses:

• Use in radioactive areas

• Pumping down of explosive, aggressive, corrosive, flammable, toxic or reactive

substances

• Pumping down of condensable fluids and vapors.

• Aspiration of liquids into the device

• Operation with excessive gas loads

• Operation with excessive foreline pressure

• Operation in incorrect gas mode

• Operation at too high ambient temperature

• Flushing with excessive flushing rate

• Usage of the pumps in plants where sudden loads and vibrations or periodic

forces act upon the pump

2.2 Owner requirements

The following notes are for companies or any person who is responsible for the safety

and effective use of the product by the user, employee or third party.

Safety conscious oper-

ation

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 11 / 138

• Operate the device only if it is in perfect technical condition and has no damage.

• Only operate the device in accordance with this instruction manual, in a safety and

risk conscious manner.

• Adhere to the following regulations and observe their compliance:

– Intended use

Page 12

2 | Safety INFICON

– General applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional device-related provisions and regulations

• Only use original parts or parts approved by the manufacturer.

• Keep this instruction manual available on site.

Personnel qualifica-

tions

• Only instructed personnel should be permitted to work with and on the device. The

instructed personnel must have received training on the device.

• Make sure that authorized personnel have read and understood the operating in-

structions and all other applicable documents.

2.3 Duties of the operator

• Read, observe, and follow the information in this manual and in the work instruc-

tions provided by the owner. This concerns in particular the safety instructions and

warnings.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, please contact Customer Service.

2.4 Dangers

The measuring instrument was built according to the state-of-the-art and the recog-

nized safety regulations. Nevertheless, improper use may result in risk to life and limb

on the part of the user or third parties, or damage to the measuring instrument or other

property may occur.

Hazards due to liquids

and chemicals

Permanent magnets

Dangers from electric

power

12 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Liquids and chemical substances can damage the instrument.

• Comply with application limits, see "Technical Data".

• Do not suck up liquids with the instrument.

• Keep the hydrogen concentration below 5% to prevent ignition.

Permanent magnets in the device pose a hazard to health. Cardiac pacemaker may

be affected in their function.

• Keep a sufficient distance from the device.

• Always comply with the distances recommended by the pacemaker manufacturer

without fail.

The device is operated with electrical voltages of up to 24 V. Inside the device there

are voltages that are considerably higher. There is a danger to life from the contact of

conductive parts inside the device.

Page 13

INFICON Safety | 2

• Disconnect the device from the power supply prior to any installation and mainte-

nance work. Make sure that the electric power supply cannot reconnected without

authorization.

• Before starting the leak test, disconnect electrically operated test objects from the

power supply.

The device contains electric components that can be damaged from high electric volt-

age.

• Make sure before connecting to the power supply that the supply voltage is 24 V

+/- 5 %.

Kinetic energy

Injury from bursting ob-

jects

Danger due to implod-

ing measuring chamber

If the rotating parts in the turbo molecular pump are blocked because of some dam-

age, high centrifugal forces must be absorbed. If this is not successful, the mass spec-

trometer module will breakaway and possibly cause damage to property or personal

injury.

• Make sure the mount of the mass spectrometer module is able to absorb a braking

torque of 820 Nm.

There is risk of injury from bursting objects causes by a test object notwithstanding the

vacuum pressure when a test object is connected.

• Take appropriate precautions.

An external measuring chamber connected to an LDS3000 AQ is pumped off at ap-

proximately 60 sccm. Within normal measurement times (2 - 30 seconds) no danger-

ous negative pressure is generated.

If the measuring chamber is leak-proof, but not vacuum resistant, and continues to

pump, it may implode. This can occur, for example, in a 1-liter measuring chamber af-

ter about 10 minutes.

• Do not continue pumping a measuring chamber after the measuring time has ex-

pired.

• Consider suitable protective measures!

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 13 / 138

Page 14

3 | Shipment, Transport, Storage INFICON

3 Shipment, Transport, Storage

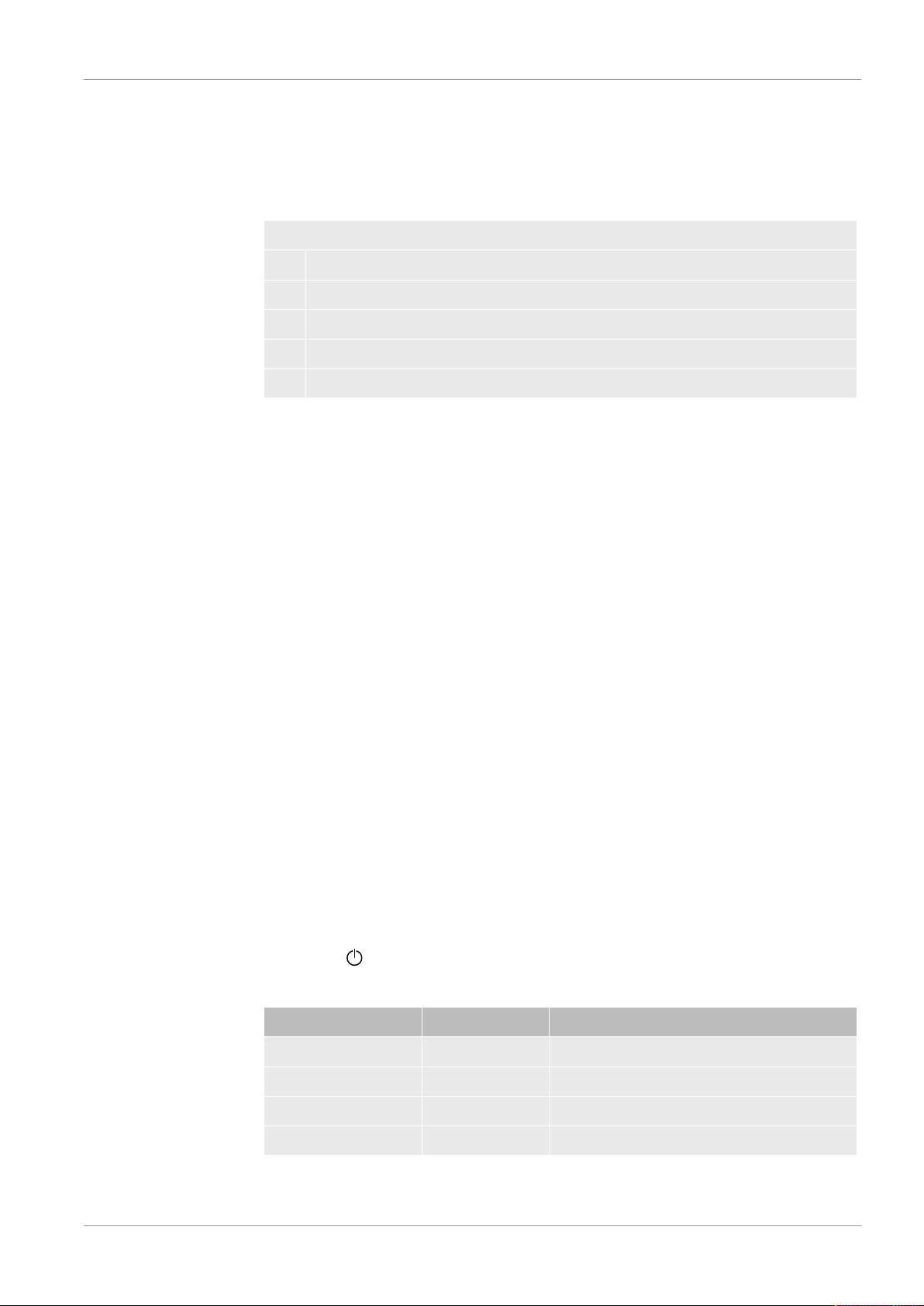

Scope of delivery

Transport

Item Quantity

Mass spectrometer module

Plug for 24V connection 1

Pressure sensor PSG500 1

Self-locking nuts 4

Plug for Output 1

Plug for Gauges Exit 1

Inlet module (LDS3000 AQ version only) 1

Adapter DN16 with throttle2) (LDS3000 AQ version only) 1

Operating instructions 1

USB flash drive with instructions, 3D drawings and videos 1

1.) Includes either 560-300 LDS3000 or 560-600 LDS3000 AQ (accumulation).

2.) See "Select components and connect [}36]".

► Please check the delivery for completeness after receiving the device.

1)

1

Storage

NOTICE

Damage due to unsuitable packaging material

Transport in unsuitable packaging material can damage the device.

► Transport the device only in the original packaging material.

► Keep original packaging material.

NOTICE

Damage to property due to missing attachment of the vibration damper

► Secure the vibration damper with the transport screws to prevent damage due to vi-

bration.

► Always store the device in compliance with the technical data, see "Technical Data".

14 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 15

INFICON Description | 4

4 Description

4.1 Function

Objective

Mode AQ (Accumula-

tion)

Device Interfaces

Other accessories

The mass spectrometer module is a detection device for the test gases helium and hy-

drogen. Integrated in test systems, the device is used to detect gas being emitted from

a test object in order to indicate leaks.

The device can be used both as a vacuum leak detector and a sniffer leak detector.

Sniffer lines with different lengths are available for the sniffer mode.

In order to be able to detect small leak rates without the use of a vacuum chamber,

devices for the AQ mode are connected to an external measuring chamber. In the ex-

ternal measuring chamber, the tracer gas is enriched (accumulation).

The test object filled with helium or forming gas under pressure is brought into the

measuring chamber or pressurized in the measuring chamber. If there is a leak in the

test object, the concentration of helium or forming gas in the measuring chamber will

increase. This increase is measured and output as a leak rate.

The mass spectrometer module is part of the leak detection system LDS3000 and

LDS3000 AQ. Es can be operated in a test system together with a bus module or I/O

module and a data cable without additional INFICON accessories.

The MSB box outputs data on digital interfaces to the control unit CU1000, I/O module

IO1000 or bus module BM1000.

With the available accessories XL sniffer adapter and sniffer line SL3000XL, it is pos-

sible to capture leaks at a larger distance from the expected leak if the detection limit

is deteriorated (operation in "high flow" mode).

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 15 / 138

Page 16

4 | Description INFICON

4.2 Device setup

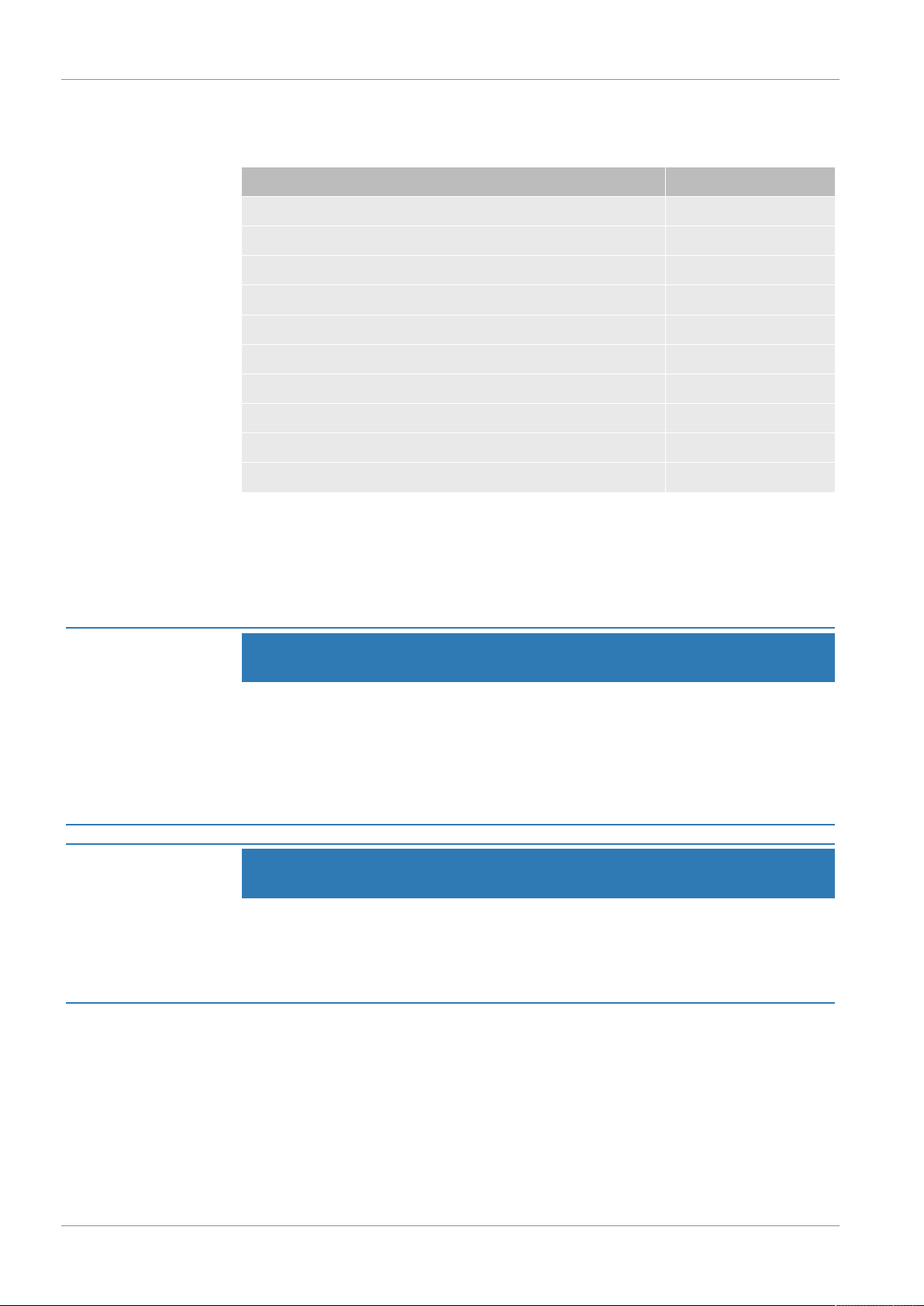

4.2.1 Entire device (LDS3000)

Fig.1:

Mass spectrometer module LDS3000

1 Connection block. Connections for test system, backing pump, pressure sen-

sor PSG500, internal calibration leak and sniffer line, see also "Connection

block [}20]".

2 Pressure sensor PSG500 for measuring the pressure of the backing pump

3 Preamplifier of the mass spectrometer module

4 Turbo molecular pump with cooling unit

5 MSB box. Interfaces to the mass spectrometer module (see "MSB box

[}20]")

6 Inverter for turbo-molecular pump

7 Fasteners for installing the mass spectrometer module in a test system

8 Rating plate containing mass spectrometer module specifications

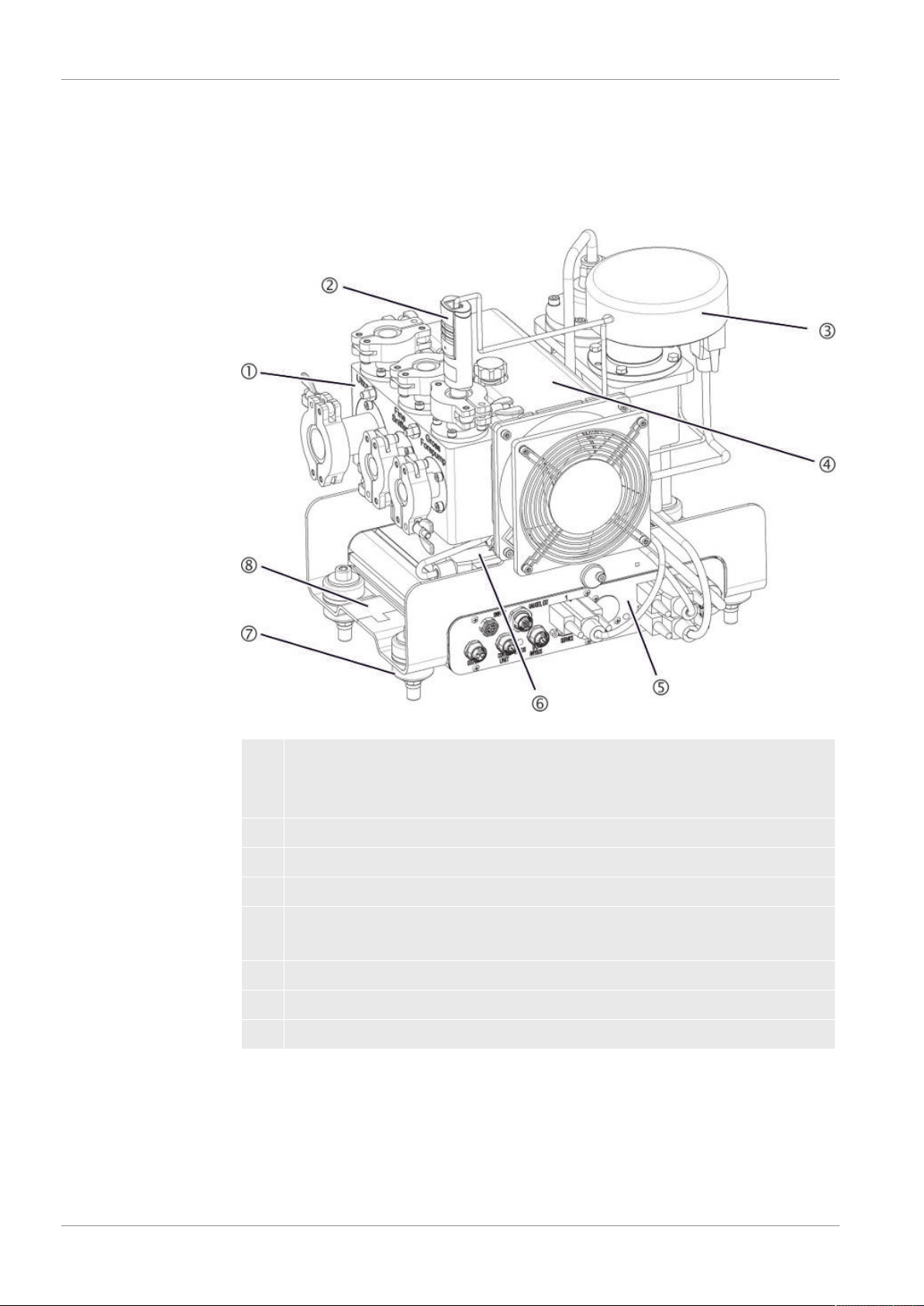

4.2.2 Entire device (LDS3000 AQ)

In the accumulation version, the mass spectrometer module is integrated into a spe-

cial measurement setup by hardware and software.

16 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 17

INFICON Description | 4

3

1

2

6

7

1

4

5

48

49

4

11

4

10

Fig.2:

Accumulation: Overview of the structure

1 Measuring chamber with fan 7 Power supply 24 V

2 ISO-KF DN16 8 Dry backing pump with separate

power supply)

3 Inlet module 9 Hose ID 10

4 Corrugated tube 10 Straight connector 8 to 10 mm

5 Blank flange 11 Adapter to DN16

6 Mass spectrometer module

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 17 / 138

Page 18

4 | Description INFICON

2

1

3

34

Fig.3:

Mass spectrometer module (execution accumulation)

1 Pressure sensor PSG500 for mea-

2 Connecting hose to backing pump

suring the inlet pressure

3 Corrugated hose to the measuring

4 Flanged ULTRA connections

chamber

Fig.4:

Inlet module. It does not require an electrical connection for connection to a measuring

chamber.

When using a two-chamber system, the inlet module valve can be switched by applying 24V.

1 For connection to the measuring chamber

Accessories of the cus-

tomer

To complete the measurement setup, missing parts can be provided by the customer.

If you want to use your own backing pump, make sure it is a dry backing pump with a

gas flow greater than 60 sccm and a base pressure of less than 5 mbar. It should

have its own power supply.

18 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 19

INFICON Description | 4

Connection for hose ID 10 mm

Connection for silencer (optional)

Connection Plus (24 V)

Connection minus

If you want to use your own control unit, please note that the wizard for performing the

measurement settings, calibrating and setting the ZERO function is only located on

the INFICON CU1000 control unit.

See also “Select components and connect [}36]“.

Optional accessories

from INFICON

With the exception of the measuring chamber, the required parts are also offered by

INFICON.

• Control unit CU1000 (including wizard for carrying out important settings)

• I/O1000 (The I/O module is a device interface between a leak detector and an ex-

ternal controller)

• BM1000 (The bus module is a device interface between e.g. the MSB box of the

mass spectrometer module LDS3000 and an external controller.)

• Dry backing pump from INFICON (catalog number 560-630)

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 19 / 138

Fig.5:

INFICON backing pump

See also

2 Entire device (LDS3000) [}16]

Page 20

4 | Description INFICON

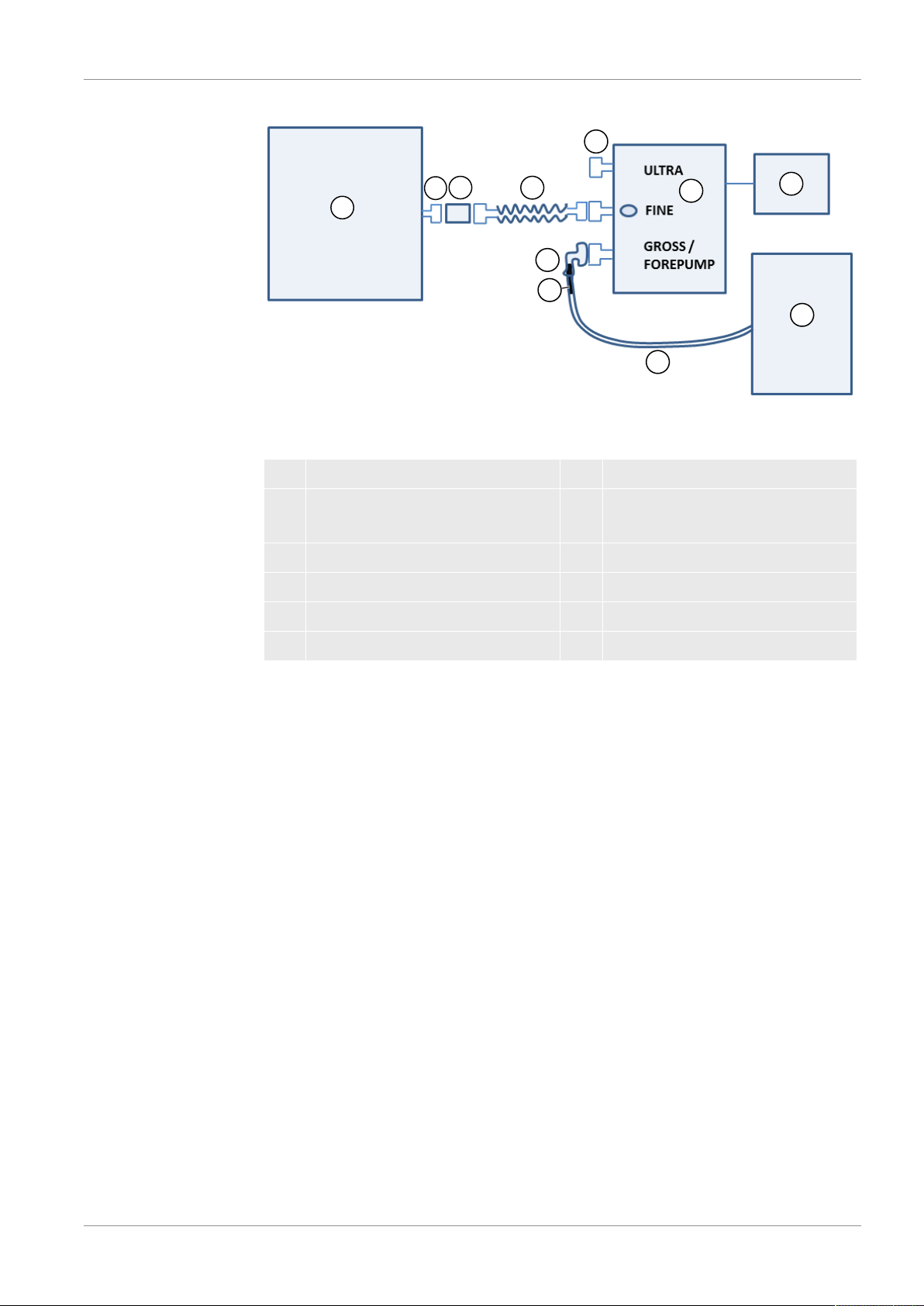

4.2.3 Connection block

Fig.7:

MSB box connections

Fig.6:

Connection block

1 Connection ULTRA 3 Connection GROSS/FOREPUMP

2 Connection FINE/SNIFFER

4.2.4 MSB box

OUTPUT

Connection for gas ballast and three valves

Connection plug arrangement

1 Valve 2 (gas ballast), 24 V, max.1 A

2 Valve 3 (not used, reserve)

3 Valve 4 (not used, reserve)

4 Valve 6 (not used, reserve)

5 GND

SNIFFER

Electrical connection for the sniffer line

20 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 21

INFICON Description | 4

GAUGES, EXT

Connection for optional external service gauges (0 - 10 V / 0 - 20 mA) for INFICON

service

Connection plug arrangement

1 +24-V-Output, max.200 mA

2 Input for P3 service gauge, 0 - 10 V

3 GND

4 Reference to input for P3 service gauge

5 20 mA input for P3 service gauge

1

(See also Figure MSB box)

Connection for pressure sensor PSG500, calibration leak and suppressor on the

preamplifier (premounted, three-core cable)

24VDC

Connection for 24 V power supply pack used to supply mass spectrometer module,

control unit, I/O module and bus module.

2

(See also Figure MSB box)

Connection for inverter turbo molecular pump and fan turbo molecular pump (pre-

mounted, two-core cable)

ON SOURCE

I

Connection for ion source

3

(See also Figure MSB box)

Connection for preamplifier

Power LED

/ Status LED

The Power LED and Status LED indicate the status of the device.

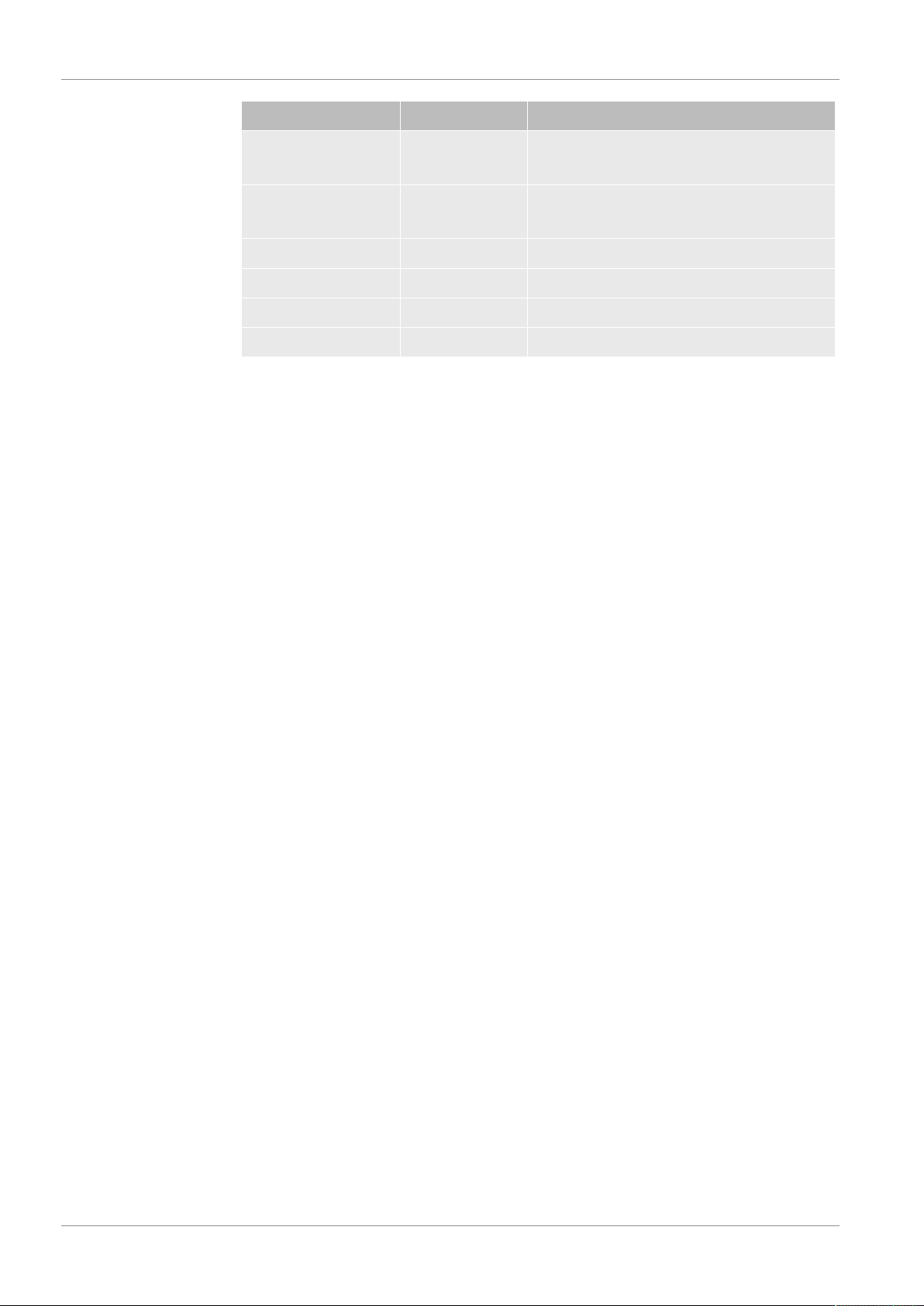

Power LED Status LED Meaning

Off Red Device not ready for operation

Green Blue Turbo molecular pump is starting

Green Orange Emission is switched on

Green Green Emission is stable

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 21 / 138

Page 22

4 | Description INFICON

Power LED Status LED Meaning

Green Violet Rotation speed of the turbo molecular

pump is not within the normal range

Green Error codes of

Different activities of the unit

the status LED

Green, flashes slowly Supply voltage < 21.6 V

Green, flashes fast Supply voltage > 26.4 V

Green, flashes Off Software is being updated

Green Green, flashes Software is being updated

SERVICE

RS232 connection for INFICON Service

I/O / ANYBUS

CONTROL UNIT

Connection for I/O or bus module or control unit

The connections "I/O Anybus" and "Control Unit" have the same functions. You have

the choice of connecting:

– Control unit CU1000 + I/O module IO1000

– Control unit CU1000 + bus module BM1000

STATUS

Status LED

The Power LED and Status LED indicate the status of the unit.

22 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 23

INFICON Description | 4

4.2.5 Nameplate

A nameplate is located on the device. The symbols on the nameplate have the follow-

ing meaning:

Label for the returns to the recycling circuit.

Instrument cannot be scrapped with the normal domestic waste.

Information given on the nameplate are:

• Manufacturer's address

• Device name

• Year of production

• Catalog number

• Serial number

• Operating temperature

• Disposal instructions

• Detectable gases

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 23 / 138

Page 24

4 | Description INFICON

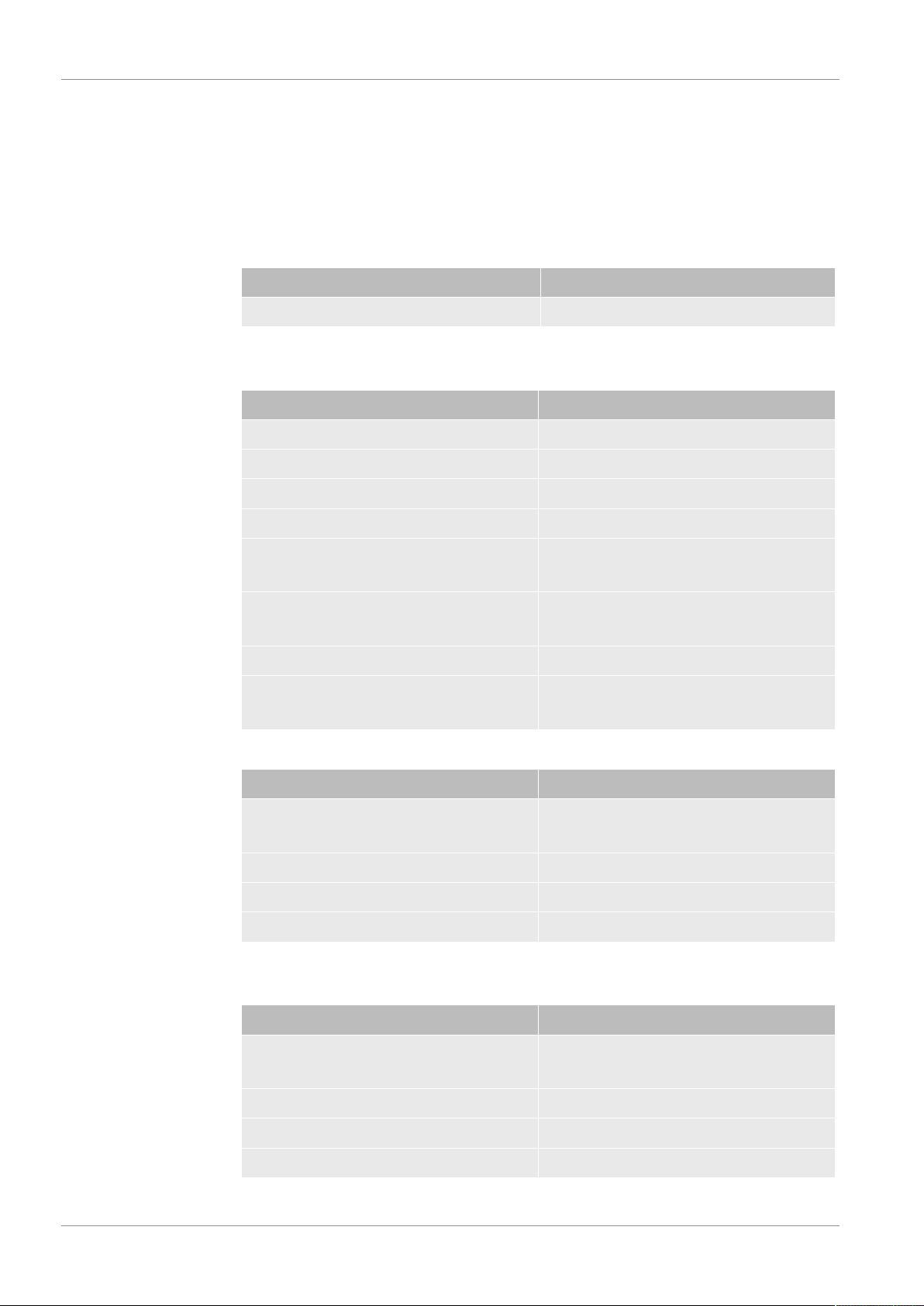

4.3 Technical data

Mechanical data

Electrical data

560-300, 560-600

Power input max. 10 A

Physical data

560-300, 560-600

Response time in Sniffer mode Gross: < 5 s, Fine/Ultra: < 1 s

Maximum inlet pressure 0,2 mbar - 18 mbar

Run-up time 150 s

Detectable gases Helium, hydrogen

Minimum detectable leak rate vacuum

mode

Minimum detectable leak rate sniffer

mode

Detectable masses 4He, H2, mass 3 (e.g. H-D, 3He or H3)

Ion source 2 longlife Iridium filaments, Yttrium-oxide

Minimum detectable leak rate forming

gas or helium

Measurement range 6 decades

Pressure in test chamber 1 atm

Time constant of the leak rate signal < 1 s

5E-12 mbar l/s

1E-7 mbar l/s

coated

560-600 (AQ mode)

1 x 10-7 mbar l/s

Ambient conditions

560-300, 560-600

Permissible ambient temperature (during

operation)

Max. altitude above sea level 2000 m

Permissible magnetic field max. 7 mT

Max. relative humidity above 40 °C 50%

24 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

10 °C ... 45 °C

Page 25

INFICON Description | 4

560-300, 560-600

Max. relative humidity from 31 °C to 40°C80% ... 50% (decreasing linearly)

Max. relative humidity to 40 °C 80%

Storage temperature -20 °C ... 60 °C

Pollution degree II

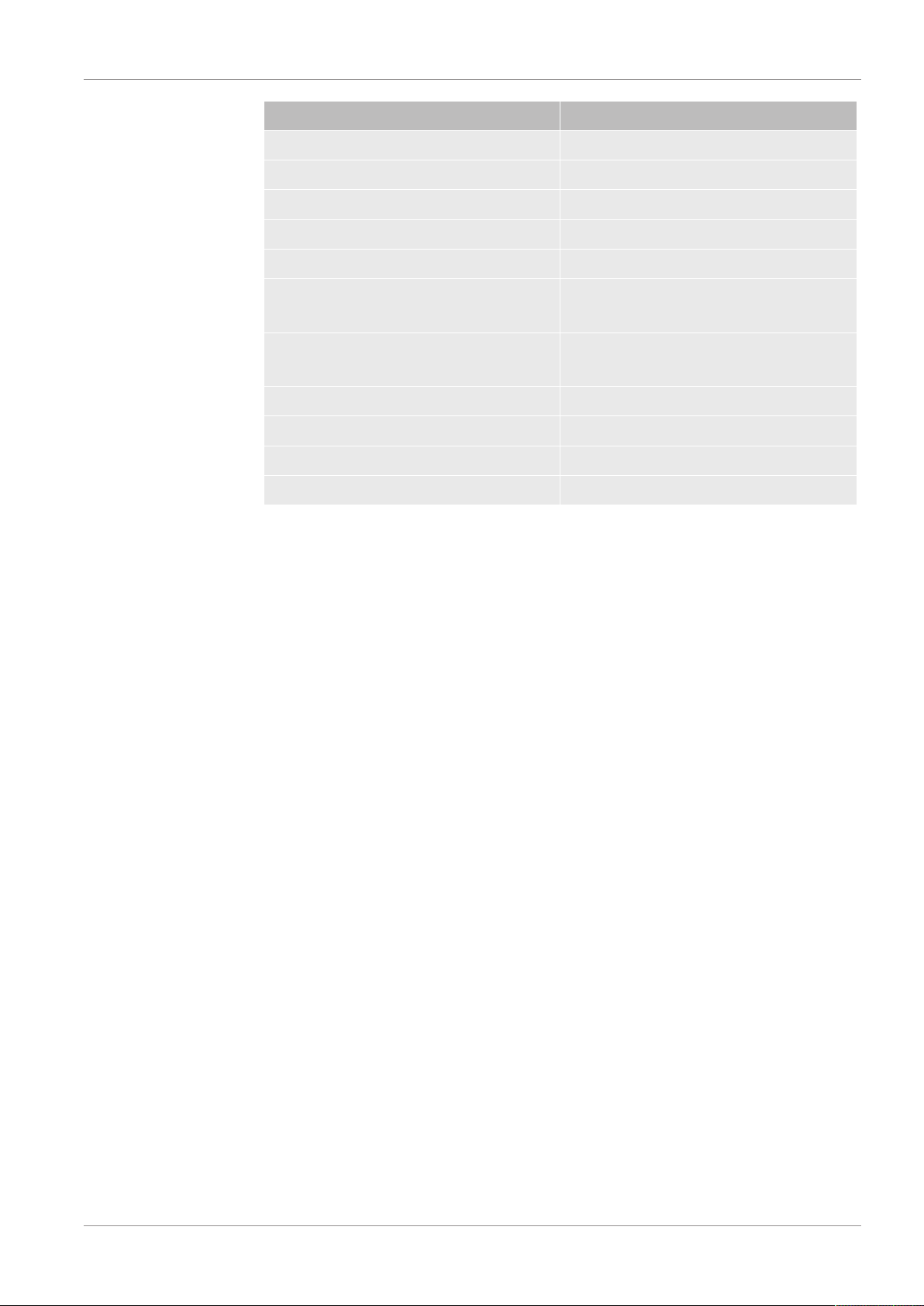

4.4 Factory settings

Parameter Factory setting

AO upper limit exp. 1 x 10

-5

Operation mode Vacuum

1)

AQ

AQ chamber volume 1 l

AQ measurement time 10 s

Zero time factor AQ 4

1)

1)

1)

Bus module address 126

Clogged pressure capillary monitoring

- with XL Sniffer Adapter (low flow)

Broken pressure capillary monitoring

- with XL Sniffer Adapter (low flow)

0.4 mbar

0.2 mbar

2 mbar

0.6 mbar

Clogged pressure capillary monitoring

- with XL Sniffer Adapter (high flow) 150 mbar

Broken pressure capillary monitoring

- with XL Sniffer Adapter (high flow) 400 mbar

Pressure unit (interface) mbar

Emission On

Filter leak rate threshold 1 x 10

-10

Filter ZERO time 5 s

Filter mode I•CAL

Gas percentage in H2 (M3, He) 100 %

5 % H2 (-, 100 % He)

1)

Gas ballast Off

I/O module protocol ASCII

Calibration request On

Calibration factor VAC/SNIF Mx

1.0

(for vacuum, sniffing and all masses)

Cathode selection Auto Cat1

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 25 / 138

Page 26

4 | Description INFICON

Parameter Factory setting

Compatibility mode LDS3000

1)

AQ

Config. Analog output 1 Leak rate mantissa

Config. Analog output 2 Leak rate exponent

Config. Analog output scale 0.5 V / decade

Configuration of digital outputs Pin 1: Trigger 1, inverted

Pin 2: Trigger 2, inverted

Pin 3: Trigger 3, inverted

Pin 4: Trigger 4, inverted

Pin 5: Ready

Pin 6: Error, inverted

Pin 7: CAL request, inverted

Pin 8: Open, inverted

Configuration of digital Inputs Pin 1: Select dyn. / normal CAL

Pin 2: Sniff

Pin 3: Start/Stop, inverted

Pin 4: ZERO

Pin 5: External CAL

Pin 6: Internal CAL

Pin 7: Clear

Pin 8: ZERO update

Pin 9: –

Pin 10: –

Leak rate unit SNIF, (display and inter-

mbar l/s

face)

Leak rate unit VAC, (display and inter-

mbar l/s

face)

Leak rate upper limit VAC (interface) 1.0 x 10

Leak rate lower limit VAC (interface) 1.0 x 10

Leak rate upper limit SNIF (interface) 1.0 x 10

Leak rate lower limit SNIF (interface) 1.0 x 10

4

-12

4

-8

Fan mode Fan always on

Machine factor in standby Off

Machine factor / Sniff factor 1.0 (for all masses)

Mass 4

Module on the I/O connection IO1000

Nominal state TMP On

calibration leak external SNIF 9.9 x 10

calibration leak external VAC 9.9 x 10

-2

-2

26 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 27

INFICON Description | 4

Parameter Factory setting

calibration leak internal 9.9 x 10

-2

Open calibration leak internal Off

Sniffer line detection On

Sniffer key ZERO On

Language English

TMP rotation speed 1500

1)

1000

Trigger level 1 (2, 3, 4) 1 x 10-5 mbar l/s

5 x 10-5 (1 x 10-5) mbar l/s

Preamplifier test at CAL On

Maintenance warning Off

ZERO with start Off

ZERO mode Suppress everything

1) in AQ mode

1)

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 27 / 138

Page 28

5 | Mounting LDS3000 INFICON

5 Mounting LDS3000

5.1 Adjust the position of the connections to the

installation dimensions

Select location

Select the most helium-free environment possible for the measurement setup. For reli-

able measurements with the device, the helium content in the air must be less than 10

ppm.

By nature, air contains 5 ppm (0.0005%) helium.

Mount MSB box

In order to ideally match the installation position space, the MSB box can be turned

and rotated.

The MSB box is seated in two guide rails and can be pushed into the housing from the

left or from the right. It can also be rotated, if necessary, so that the labels are upside

down.

The locking washer must be released to pull out the MSB box.

If the MSB box is to be pushed into housing from the other side, the locking washer

must also be tightened on the other side of the housing. An appropriate threaded hole

is available.

Fig.8:

Lock

28 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 29

INFICON Mounting LDS3000 | 5

5.2 Installing the mass spectrometer module on the

test system

The mass spectrometer module can be mounted in any position.

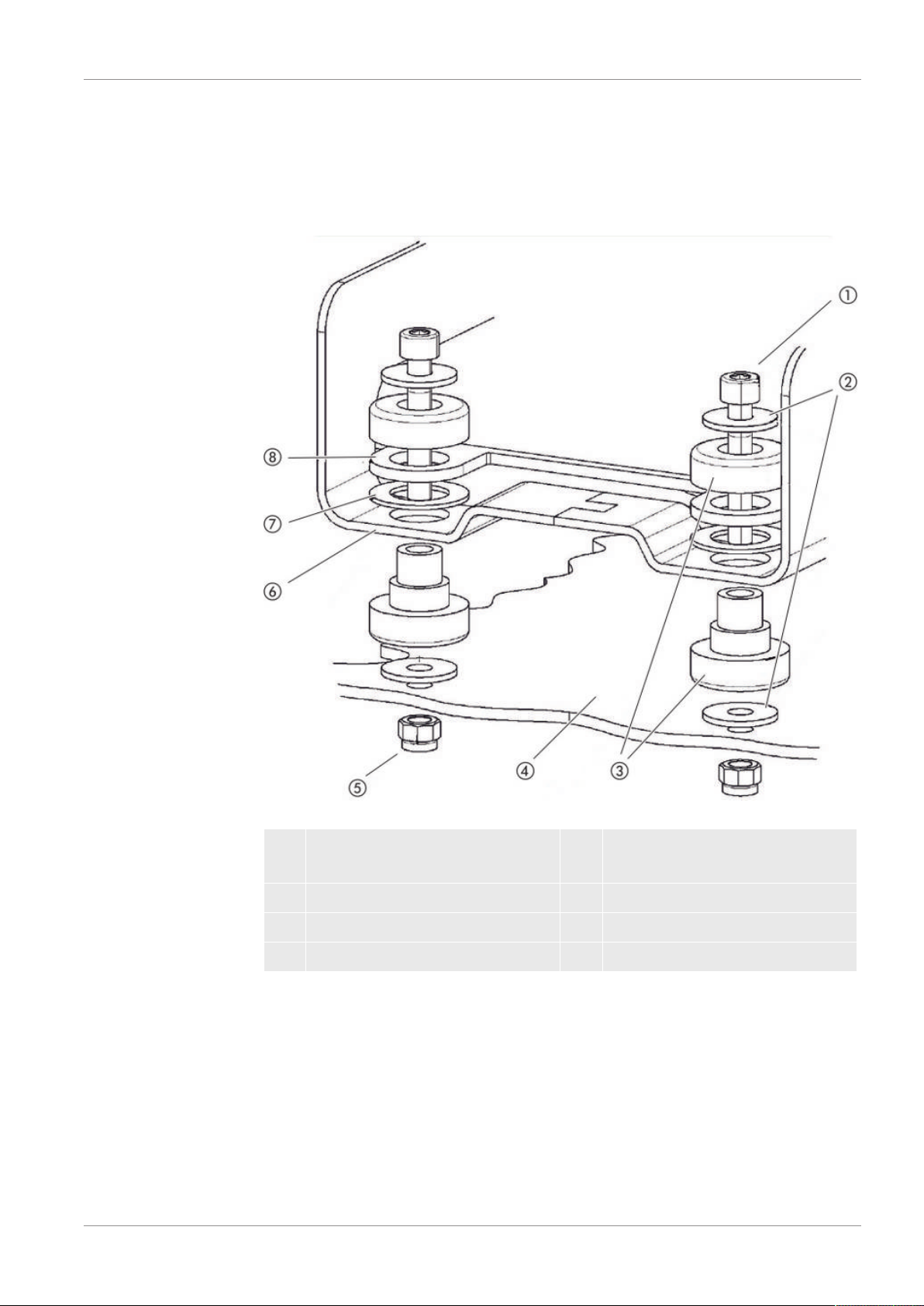

Fig.9:

Components of a fastener

1 Hexagon socket head screw

M8x50

2 Washer 6 Base frame

3 MO bearing 7 Spring rubber

4 Test system 8 MSB box guide

You will need:

- Self-locking nuts M8

- Open-end wrench, SW13

- Allen wrench SW6

- Holes for installation inside the test system

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 29 / 138

5 Nut M8 (self-locking)

Page 30

5 | Mounting LDS3000 INFICON

In delivery condition, the bearings are attached to the base frame with the hexagon

socket screws and transport nuts. Use the supplied self-locking nuts for the installation

of the mass spectrometer module – not the transport nuts.

The background must be stable.

WARNING

Severe injuries due to mass spectrometer module breaking out

If not screwed down properly, the mass spectrometer module can be caused to break

out if the rotor of the turbo molecular pump suddenly locks up. This can result in in-

juries of the most severe kind.

► Make sure the mount of the mass spectrometer module is able to absorb a braking

torque of 820 Nm.

1

Drill through-holes:

– X distance: 283 mm

– Y-distance: 121,5 mm

– Through hole in sheet: Ø 9 mm

– Fixing screws: M8 x 50

2

Remove transport nuts.

3

Place the mass spectrometer module on top of the through-holes and screw it

down using the fasteners as shown in the upper figure .

5.3 Select connection ULTRA, FINE, or GROSS

The operation mode of the vacuum connection and the rotation speed of the turbo

molecular pump define:

• Minimum detectable leak rate (MDLR)

• Constantly permissible inlet pressure (p

• Pumping speed (S)

The following information applies to the use of helium as a tracer gas.

To reach the MDLR, the following conditions must be met:

• The LDS3000 must be in operation for at least 20 minutes.

• Ambient conditions must be steady (temperature, no vibrations/shocks, clean envi-

ronment)

30 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

max

)

Page 31

INFICON Mounting LDS3000 | 5

• The specimen must be operated with switched-off ZERO until to the background is

stable. The ZERO function may be switched on only after that.

Connection Turbo molecular pump rotation speed

1000 Hz 1500 Hz

ULTRA MDLR: 5 x 10

p

: 0.2 mbar 0.2 mbar

max

p

short-term (< 3 s): 0.2 mbar 0.4 mbar

max

-12

mbar l/s 1 x 10

-11

mbar l/s

S: 5 l/s 6 l/s

FINE MDLR: 1 x 10

p

: 0.9 mbar 0.4 mbar

max

p

short-term (< 3 s): 0.9 mbar 0.7 mbar

max

-11

mbar l/s 5 x 10

-11

mbar l/s

S: 1.8 l/s 2.5 l/s

GROSS MDLR: 1 x 10-9 mbar l/s 2 x 10-8 mbar l/s

p

: 18 mbar 15 mbar

max

S: depends on the backing pump

Exceedance of the constantly permissible inlet pressure generates the warning "TMP

overheating".

NOTICE

Material damage due to pressure surges

Pressure surges exceeding the maximum inlet pressure will damage the mass spec-

trometer module.

- Do not exceed the maximum inlet pressure.

1

Set the operation mode vacuum connection and the rotation speed turbo molec-

ular pump in accordance with the physical vacuum conditions found in the test

system.

2

Connect the mass spectrometer module to the "ULTRA", "FINE" or "GROSS"

connections on the vacuum system of the test system.

3

Set the rotation speed of the turbo molecular pump.

5.4 Establish component connection

1

Connect pressure sensor PSG500 to one of the GROSS/FOREPUMP connec-

tions.

2

Connect the backing pump to the second GROSS/FOREPUMP connection.

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 31 / 138

Page 32

5 | Mounting LDS3000 INFICON

3

For sniffer mode, connect the sniffer line to one of the FINE-/SNIFFER connec-

tions.

4

If available, connect internal calibration leak 560-323 to the second free flange

(FINE or ULTRA) of the vacuum connection.

When using a sniffer valve: For the device to operate correctly upon opening of the

sniffer valve, no additional line can be connected between the connection block and

the sniffer valve or between the sniffer valve and the sniffer line.

5.5 Establish electrical connections

All electrical connections run from and to the MSB box.

NOTICE

Material damage if power supply pack has the wrong specifications or is con-

nected improperly

A power supply pack that has the wrong specifications or is connected improperly can

destroy the unit.

► Use a suitable power supply pack: Use a power supply pack that supplies an output

voltage with electrically protective separation, output voltage: 24 V +/- 5%, current ca-

pacity: min. 8 A

► If the short-circuit current of the power supply pack is > 10 A, connect a fuse be-

tween power supply pack and mass spectrometer module.

► Use a power cable with a large enough cross section.

1

Connect the 24 V power cable to the included plug (connections: +24 V on 1+

and GND on 1-).

2

Connect the power cable to the socket "24VDC".

3

Connect the control unit to the socket "Control Unit".

4

Connect the I/O or bus module to the Socket "I/O" .

5

Connect pressure sensor PSG500 and, if used, calibration leak 560-323 on the

cable of socket "1". For socket 1 see “MSB box [}20]“.

6

Connect the sniffer line to the socket "Sniffer" .

7

Connect gas ballast valve to the socket "Output".

32 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 33

INFICON Mounting LDS3000 AQ (Accumulation) | 6

6 Mounting LDS3000 AQ (Accumulation)

6.1 Adjust the position of the connections to the

installation dimensions

Select location

Select the most helium-free environment possible for the measurement setup. For reli-

able measurements with the device, the helium content in the air must be less than 10

ppm.

By nature, air contains 5 ppm (0.0005%) helium.

Mount MSB box

In order to ideally match the installation position space, the MSB box can be turned

and rotated.

The MSB box is seated in two guide rails and can be pushed into the housing from the

left or from the right. It can also be rotated, if necessary, so that the labels are upside

down.

The locking washer must be released to pull out the MSB box.

If the MSB box is to be pushed into housing from the other side, the locking washer

must also be tightened on the other side of the housing. An appropriate threaded hole

is available.

Fig.10:

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 33 / 138

Lock

Page 34

6 | Mounting LDS3000 AQ (Accumulation) INFICON

6.2 Installing the mass spectrometer module on the

test system

The mass spectrometer module can be mounted in any position.

Fig.11:

You will need:

- Self-locking nuts M8

- Open-end wrench, SW13

- Allen wrench SW6

- Holes for installation inside the test system

34 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Components of a fastener

1 Hexagon socket head screw

M8x50

2 Washer 6 Base frame

3 MO bearing 7 Spring rubber

4 Test system 8 MSB box guide

5 Nut M8 (self-locking)

Page 35

INFICON Mounting LDS3000 AQ (Accumulation) | 6

In delivery condition, the bearings are attached to the base frame with the hexagon

socket screws and transport nuts. Use the supplied self-locking nuts for the installation

of the mass spectrometer module – not the transport nuts.

The background must be stable.

WARNING

Severe injuries due to mass spectrometer module breaking out

If not screwed down properly, the mass spectrometer module can be caused to break

out if the rotor of the turbo molecular pump suddenly locks up. This can result in in-

juries of the most severe kind.

► Make sure the mount of the mass spectrometer module is able to absorb a braking

torque of 820 Nm.

1

Drill through-holes:

– X distance: 283 mm

– Y-distance: 121,5 mm

– Through hole in sheet: Ø 9 mm

– Fixing screws: M8 x 50

2

Remove transport nuts.

3

Place the mass spectrometer module on top of the through-holes and screw it

down using the fasteners as shown in the upper figure .

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 35 / 138

Page 36

6 | Mounting LDS3000 AQ (Accumulation) INFICON

3

1

2

6

7

1

4

5

48

49

4

11

4

10

6.3 Select components and connect

Fig.12:

Accumulation: Overview of the structure

1 Measuring chamber with fan 7 Power supply 24 V

2 ISO-KF DN16 8 Dry backing pump with separate

power supply

3 Inlet module 9 Hose ID 10

4 Corrugated tube 10 Straight connector 8 to 10 mm

5 Blank flange 11 Adapter to DN16

6 Mass spectrometer module

ü You have the INFICON mass spectrometer module (accumulation), a corrugated

tube and the connections shown.

ü You have a dry backing pump with its own power supply.

All dry vacuum pumps can be used with a gas flow of more than 60 sccm at a basic

pressure of under 5 mbar. This manual describes how to use the dry INFICON

backing pump (catalog number 560-630).

ü You have a suitable measuring chamber.

The measurement chamber must be leak-proof. The net volume, i.e. the measure-

ment chamber volume minus the volume of the test object, must be between 0.1

and 10,000 liters. The measurement chamber should not be bigger than necessary,

but the test object may not touch the walls.

The measurement chamber must have a fan that blows air at the test object. The

helium or forming gas escaping from the leak is distributed equally in the measure-

ment chamber by the fan.

It is therefore irrelevant from the point of view of the measurement result whether

the leak is close to the measuring line. The flow of gas from the fan should be equal

to at least 1 volume of the measurement chamber per second. For measurement

36 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 37

INFICON Mounting LDS3000 AQ (Accumulation) | 6

-

+

times under 15 seconds, the flow of gas from the fan should be equal to at least 2

volumes of the measurement chamber per second. A suitable measuring time is

calculated by the device.

Note that a measuring chamber that is leak-proof but not vacuum-resistant can im-

plode if it is pumped further out than usual measuring times. See also “Carrying out

a measurement [}82]“.

1

Connect the pressure sensor PSG500 to the FINE connector.

2

Connect a corrugated tube to the FINE port on the mass spectrometer module.

3

Connect the open end of the corrugated tube to the measuring chamber via the

inlet module.

4

Fit an adapter to DN16 with throttle on the connection GROSS / FOREPUMP of

the mass spectrometer module.

5

Insert the 8 mm pin of the straight connector supplied with the INFICON backing

pump (catalog number 560-630) into the adapter.

Fig.13:

Fig.14:

Straight connector, 8 to 10 mm

6

Connect the 10 mm connector of the straight connector via a ID 10 mm hose to

the dry backing pump.

7

Establish the electrical connection of the backing pump.

When using the INFICON backing pump (catalog number 560-630), proceed as

follows:

ð Determine if the plus and minus terminals on the terminal block are already

connected to cables by the manufacturer.

Connection strip on the dry backing pump of INFICON

ð If so, connect plus and minus cables to a DC power source, 24 V +/- 10%, 5

A.

ð If not, insert the positive and negative cables with ferrules 8 mm AWG 18 with

red insulation into the corresponding terminals and then connect the cables to

a DC power source, 24 V +/- 10 %, 5 A.

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 37 / 138

Page 38

6 | Mounting LDS3000 AQ (Accumulation) INFICON

The backing pump exhaust air opening should be as far as possible from the test

chamber.

See also

2 Entire device (LDS3000 AQ) [}16]

6.4 Establish electrical connections

All electrical connections run from and to the MSB box.

NOTICE

Material damage if power supply pack has the wrong specifications or is con-

nected improperly

A power supply pack that has the wrong specifications or is connected improperly can

destroy the unit.

► Use a suitable power supply pack: Use a power supply pack that supplies an output

voltage with electrically protective separation, output voltage: 24 V +/- 5%, current ca-

pacity: min. 8 A

► If the short-circuit current of the power supply pack is > 10 A, connect a fuse be-

tween power supply pack and mass spectrometer module.

► Use a power cable with a large enough cross section.

1

Mount the 24 V power supply cable to the enclosed plug (connections: +24 V on

1+ and GND on 1-).

2

Connect the power supply cable to the "24VDC" socket.

3

Connect the operating unit to the "Control Unit" socket.

4

Connect the I/O or bus module to the "I/O" socket.

5

Connect the pressure sensor PSG500 to the cable of socket 1. For socket 1 see

“MSB box [}20]“.

38 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 39

INFICON Operation LDS3000 | 7

7 Operation LDS3000

You can use the following accessories in combination with the mass spectrometer

module:

• Control unit CU1000

• Bus module BM1000

• I/O module IO1000

With the available accessories XL sniffer adapter and sniffer line SL3000XL, it is pos-

sible to capture leaks at a larger distance from the expected leak if the detection limit

is deteriorated (operation in "high flow" mode).

LDS3000 AQ devices can also be used if they are not operated in AQ mode.

Additional information on the control unit, the modules and the XL sniffer adapter is in-

cluded in the documents:

• Operating Manual Control Unit CU1000

• Operating instructions I/O module IO1000

• Operating instructions bus module BM1000

• Operating instructions XL sniffer adapter

• Interface protocols LDS3000

The paths listed in the following sections refer to the operation of the mass spectrome-

ter module with the control unit CU1000. If the bus module or the I/O module is used,

the actions must be implemented within the scope of the protocol that is used.

The path information for the control unit always starts in the main menu.

WARNING

Danger to life and material damage due to unsuitable operating conditions

There is danger to life due to unsuitable operating conditions. The device can become

damaged.

► Avoid changing the position of the device in an abrupt manner.

► Avoid extreme external vibrations and impact.

7.1 Switching the device on

1

Switch on the backing pump.

2

Establish the power supply to the mass spectrometer module.

ð System starts up automatically.

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 39 / 138

Page 40

7 | Operation LDS3000 INFICON

ð If an XL Sniffer Adapter and the CU1000 are connected, your will be asked after

run-up, whether the "XL Sniffer Adapter" operation mode should be set. This

does not apply to devices in AQ mode.

Longer run-up time for devices in AQ mode

To counteract falsification of the measurement results by an increased background

value, the warm-up time after switching on is about 10 minutes.

Wait at least 60 minutes before determining the peak or before calibrating.

See also “Carrying out a measurement [}82]“.

7.2 Default settings

Language selection

Setting date and time

Select the display language. The factory setting is English. (The display on the han-

dle of the SL3000XL sniffer line shows messages in English instead of in Russian

and Chinese.)

German

English

French

Italian

Spanish

Portuguese

Russian

Chinese

Japanese

Control unit Settings > Set up > Control unit > Language

LD protocol Command 398

ASCII protocol *CONFig:LANG

Setting the date

Format: DD.MM.YY

Control unit Settings > Date/Time > Date

LD protocol Command 450

ASCII protocol *HOUR:DATE

Setting the time

Format: hh: mm

Control unit Settings > Date/Time > Time

40 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 41

INFICON Operation LDS3000 | 7

LD protocol Command 450

ASCII protocol *HOUR:TIME

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 41 / 138

Page 42

7 | Operation LDS3000 INFICON

7.3 Selecting a unit for the leak rate

Leak rate unit display

Selecting the leak rate unit in the display for vacuum or sniff

0 mbar l/s (factory setting)

1 Pa m3/s

2 atm cc/s

3 Torr l/s

4 ppm (not VAC, not AQ)

5 g/a (not VAC, not AQ)

6 oz/yr (not VAC, not AQ)

7 sccm (AQ only)

Control unit Display > Units (display) > Leak rate device VAC (SNIF)

LD protocol Command 396 (vacuum)

Command 396 (sniffing)

ASCII protocol Command *CONFig:UNIT:VACDisplay

Command *CONFig:UNIT:SNDisplay

Leak rate unit interface

Selecting the leak rate unit of the interfaces for vacuum or sniff

0 mbar l/s (factory setting)

1 Pa m3/s

2 atm cc/s

3 Torr l/s

4 ppm (not VAC)

5 g/a (not VAC)

6 oz/yr (not VAC)

7 sccm (AQ only)

Control unit Settings > Set up > Interfaces > Units (interface) > Leak rate de-

vice VAC (SNIF)

LD protocol Command 431 (vacuum)

Command 432 (sniffing)

ASCII protocol Command *CONFig:UNIT:LRVac

Command *CONFig:UNIT:LRSnif

42 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 43

INFICON Operation LDS3000 | 7

7.4 Select device for pressure

Pressure device inter-

face

7.5 Select Compatibility Mode

Selecting the pressure device of the interfaces

0 mbar (factory setting)

1 Pa

2 atm

3 Torr

Control unit Settings > Set up > Interfaces > Units (interface) > Pressure unit

LD protocol Command 430 (Vacuum/Sniff)

ASCII protocol Command *CONFig:UNIT:Pressure

To retrofit an existing leak detection system LDS1000 / LDS2010 with a LDS3000, ac-

tivate the appropriate compatibility mode:

• Compatibility mode for LDS1000 or

• Compatibility mode for LDS2010

When changing to a compatibility mode all parameters are to be reset to factory set-

tings and the device is to be restarted. The language is displayed according to the

factory setting. To change the language, see “Default settings [}40]“.

If you want to use the LDS3000 later in normal operation mode, make sure to save

your parameters on a USB flash drive, see "Loading and saving parameters [}59]".

You can load the saved parameters again after you have switched to normal opera-

tion.

Compatibility mode for LDS1000

Compatibility mode for LDS2010

Mode LDS3000

Mode XL Sniffer Adapter

Mode AQ (This mode is only available for AQ devices. It is preset for AQ devices.

Switching to other modes is possible.)

Control unit Settings > Set up > Compatibility > Compatibility mode

LD protocol Command 2594 (dec)

ASCII protocol Command *CONFig:COMP

The following table shows the functional differences between and common features of

LDS2010 and LDS3000:

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 43 / 138

Page 44

7 | Operation LDS3000 INFICON

LDS2010 LDS3000

Trigger outputs without joint reference with joint reference

other outputs with joint reference with joint reference

Trigger 1 (sniffer LED, relay exit,

audio signal)

Limit Low / High (serial interfaces,

display, analogue output)

Gas ballast (3 settings)

Control of sniffer LED, PWM audio

outputs an the control unit for active

speakers

Limit Low affects all outputs, Limit

High only the display

OFF:

Switches the gas ballast valve

of the pump module off.

ON:

Switches the gas ballast valve

of the pump module on until the

next mains-off.

If "CAL fashion" is unequal to 3

(menu item 26), the gas ballast

valve can be controlled with digital

input DynCAL.

F-ON:

Fixed on enables switching

the gas ballast valve on perma-

nently (power failure-proof and in-

dependent of the digital inputs).

Control of sniffer LED, audio out-

puts an the control unit for active

speakers

separately adjustable for interface

protocols, display and analog out-

puts

0 = Off

1 = on, but controllable via digital in-

put on IO1000

2 = on, but not controllable via digi-

tal input on IO1000

Control mode LOCAL, RS232, RS485 None, control is also possible from

all control locations.

LDS1000 compatibility mode 9.2 other functions Default values and error messages

(default values are output via inter-

face, the touchscreen shows the

original message - -> reason: new

hardware can cause errors that did

not exist with previous models)

Correcting the leak rate in Standby

adjustable (yes/no) adjustable (yes/no)

(machine factor)

ZERO with start starting with V1.02 like LDS2010

Opening the sniffer valve in SNIF after start in SNIF after start

Rotation speed of turbo molecular

pump

only 2 rotation speeds adjustable Adjustable via serial interface from

750Hz to 1500Hz, via operator unit

1000Hz and 1500Hz

Address RS485 Yes, because bus capable No, because not bus capable

Sniffer key on/off selectable selectable

Default value for int. calibration

1E-15 mbar l/s 9.9E2 mbar l/s

leak

44 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 45

INFICON Operation LDS3000 | 7

LDS2010 LDS3000

Default value ext. calibration leak

VAC/SNIF mode

Setting range for int. calibration

leak

Machine factor adjustment manually manually/automatically

Machine / sniff factor value range Machine factor: 1E-3...9.9E+3

Pressure: Capillary surveillance 20 available, pressure adjustable

Analog output fixed characteristics freely configurable

Calibration request Preamplifier temperature change

Pressure / leak rates units (VAC/

SNIF) for all interfaces

User permissions 3 levels over PIN on the control unit

Key-operated switch permanently installed can, if required, be connected exter-

1E-7 mbar l/s 9.9E2 mbar l/s

10E-7 1E-9 ... 9.9E-1 mbar l/s

Machine factor: 1E-4...1E+5

Sniffer factor: 1E-3...9.9E+3

5K or 30min

yes Control unit and rest separated

or key switch

Sniffer factor: 1E-4...1E+4

Preamplifier temperature change

5K or 30min. or TMP rotation

speed changed

4 levels through control unit or op-

tional key switch

nally, see "Assigning the digital in-

puts of the I/O module [}95]" (Key

switch)

7.6 Select operation mode

The device has the following operation modes:

• Vacuum mode

• Sniffer mode

• XL Sniffer Adapter (sniffing mode with a high flow rate, XL Sniffer Adapter re-

quired).

The device automatically switches over to the "XL Sniffer Adapter" if you connect

an XL Sniffer Adapter.

The LDS3000 AQ is preset to "AQ".

► If necessary, you can reset "AQ" under "Compatibility Mode".

Select operation mode

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 45 / 138

Page 46

7 | Operation LDS3000 INFICON

0

1

2

VAC (vacuum)

SNIF (sniffing)

Operation mode XL Sniffer Adapter

Control unit Operation mode vacuum operation or sniffing mode:

Main menu > Features > VAC / SNIF

Operation mode XL Sniffer Adapter:

Settings > Set up > Accessories > XL Sniffer Adapter

LD protocol Command 401

ASCII protocol Command *CONFig:MODE

7.7 Select gas type (mass)

The machine, calibration and sniff factor are dependent on the configured mass and

are saved in the mass spectrometer module.

2

3

4

H2 (Hydrogen, forming gas)

3

He or deuterated hydrogen (HD), not in AQ mode

4

He (Helium) (factory setting)

Control unit Settings > Mass

LD protocol Command 506 with value 2 (3, 4)

ASCII protocol Command *CONFig:MASS 2 (3, 4)

For devices with AQ mode: The easiest way to change the gas type is via the wizard.

46 / 138 LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803)

Page 47

INFICON Operation LDS3000 | 7

7.8 Calibrating the device

7.8.1 Time and general preferences

NOTICE

Incorrect calibration because of operating temperature that is too low

Calibrating the device in the cold state can deliver incorrect measurement results.

► For optimum accuracy the device should have been turned on at least 20 minutes

previously.

It is recommended to calibrate the device once per shift in the desired operating

modes and for the desired gases. Thereafter you can switch between the operation

modes and gases without re-calibrating.

Switching off the

preamplifier test

Additionally applicable for operation with the XL Sniffer Adapter:

The device should be calibrated once per shift in LOW FLOW and in HIGH FLOW.

Thereafter you can switch between the different flows without re-calibrating.

Calibration is also required after the following actions:

• Sniffer line replacement

• Filter replacement

• Prompt for calibration by the system

The device tests the installed preamplifier during calibration. You can switch off of

the amplifier test. This increases the speed of the calibration, but reliability drops off.

0 OFF

1 ON

Control unit Settings > Set-up> MS-module > Preamplifier > Test >

Preamplifier test with CAL

LD protocol Command 370

ASCII protocol Command *CONFig:AMPTest (ON,OFF)

Enabling calibration re-

quest

LDS3000-MSM-Operating-instructions-jiqa54en1-07-(1803) 47 / 138

If Calibration request is enabled, the device will prompt the operator to perform a cal-

ibration 30 minutes after it has been switched on and in case of temperature

changes greater than 5°C.

0 OFF

1 ON

Page 48

7 | Operation LDS3000 INFICON

Control unit Functions > CAL > Settings > CAL request. > Calibration re-

quest

or

Settings > Set-up> CAL request. > Calibration request

LD protocol Command 419

ASCII protocol *CONFig:CALREQ (ON,OFF)

Calibration warning

Wrn650

Calibration Features

The warning message Wrn650 "Calibration within the first 20 minutes is not recom-

mended" can be allowed or suppressed.

0 OFF (suppressed)

1 ON (allowed)

Control unit Functions > CAL > Settings > CAL request. > Calibration

warning W650

or

Settings > Set-up> CAL request. > Calibration warning

W650

LD protocol Command 429

ASCII protocol *CONFig:CALWarn ON (OFF)

The device can be calibrated in all its operation modes. A distinction is made between

internal and external calibration.

Internal calibration can be performed using the optional built-in test leak. A separate

calibration leak is needed for external calibration.