Page 1

INSTALLATION MANUAL

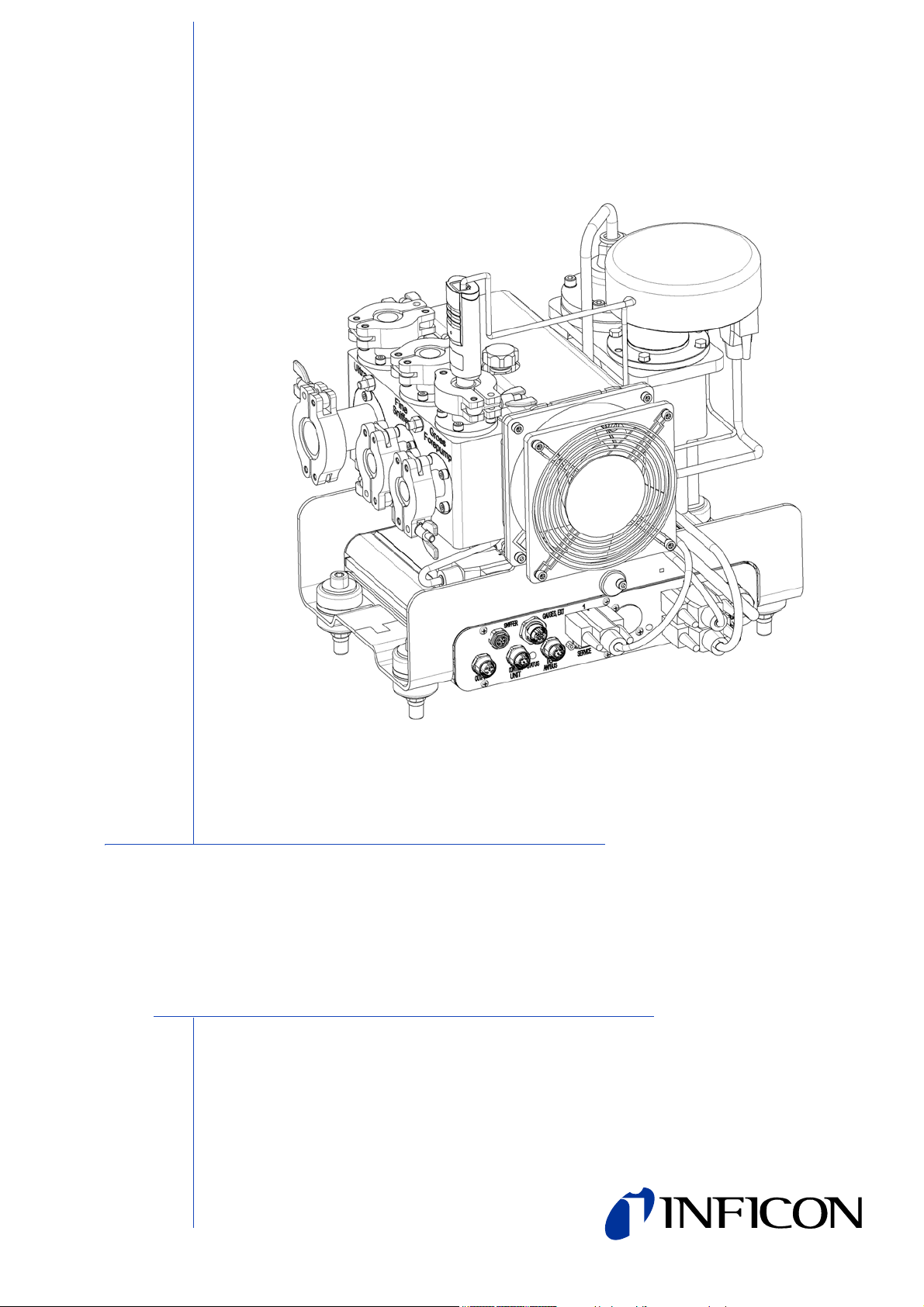

Type designation

LDS3000

Product description

Mass spectrometer module

Catalog no.

from software version

Document no.

560-300

MS Module 1.0

jiqa54en1-b (1301)

Page 2

This document applies to the software version stated on the cover page. If you need

a different version, please contact our sales staff.

Reprint, translation and duplication need to be approved in writing by

INFICON GmbH.

2

Page 3

Content

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Target groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Other applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Presentation of information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2 Text markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 User requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 User requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 General safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Shipment check, transport, storage . . . . . . . . . . . . . . . . 9

3.1 Checking shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Construction of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1.1 MSB box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.1 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.3 Physical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.4 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.5 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Rotating the MSB box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Installing the mass spectrometer module on the test system . . . . . . . 17

5.3 Connecting the mass spectrometer module to the test system . . . . . 19

5.4 Connection of the connection block . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Connecting the MSB box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Switching the unit on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Assigning the analog outputs of the I/O module . . . . . . . . . . . . . . . . . 21

6.2.1 Factory layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Content 3

Page 4

6.2.2 Possible layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.3 Output voltages in case of error . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.4 Configuration (LDS2010-compatible) . . . . . . . . . . . . . . . . . . 24

6.3 Assigning the digital inputs of the I/O module . . . . . . . . . . . . . . . . . . . 27

6.4 Assigning the digital outputs of the I/O module . . . . . . . . . . . . . . . . . . 28

6.5 Starting/stopping the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.6 Loading and storing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.7 Select operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.8 Activate/deactivate Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.9 Selecting a signal filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.10 Calibrating the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.10.1 Internal calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.10.2 External calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.10.3 Enable/disable Calibration request . . . . . . . . . . . . . . . . . . . . 34

6.10.4 Setting machine and sniff factor . . . . . . . . . . . . . . . . . . . . . . 34

6.11 Select sample gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.12 Decontaminating backing pump from test gas . . . . . . . . . . . . . . . . . . 35

6.13 Selecting units for leakage rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.14 Selecting units for pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.15 Enable/disable correction of the leakage rate in Standby . . . . . . . . . . 36

6.16 Setting the leakage rate threshold value . . . . . . . . . . . . . . . . . . . . . . . 36

6.17 Enable/disable Z

6.18 Setting capillary surveillance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.19 Compatibility with LDS1000 and LDS2010 . . . . . . . . . . . . . . . . . . . . . 36

6.20 Warning and malfunction messages . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.20.1 Error codes of the status LED . . . . . . . . . . . . . . . . . . . . . . . . 42

ERO key (Sniffer key) . . . . . . . . . . . . . . . . . . . . . . . . 36

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 Maintenance and service at INFICON . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 General maintenance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.3 Maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.4 Maintenance steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.4.1 Change operating fluid reservoir of turbo molecular pump . . 45

8 Taking out of service . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1 Shutting down the leak detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.2 Disposing of the mass spectrometer module . . . . . . . . . . . . . . . . . . . 49

8.3 Returning the mass spectrometer module . . . . . . . . . . . . . . . . . . . . . 49

9 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

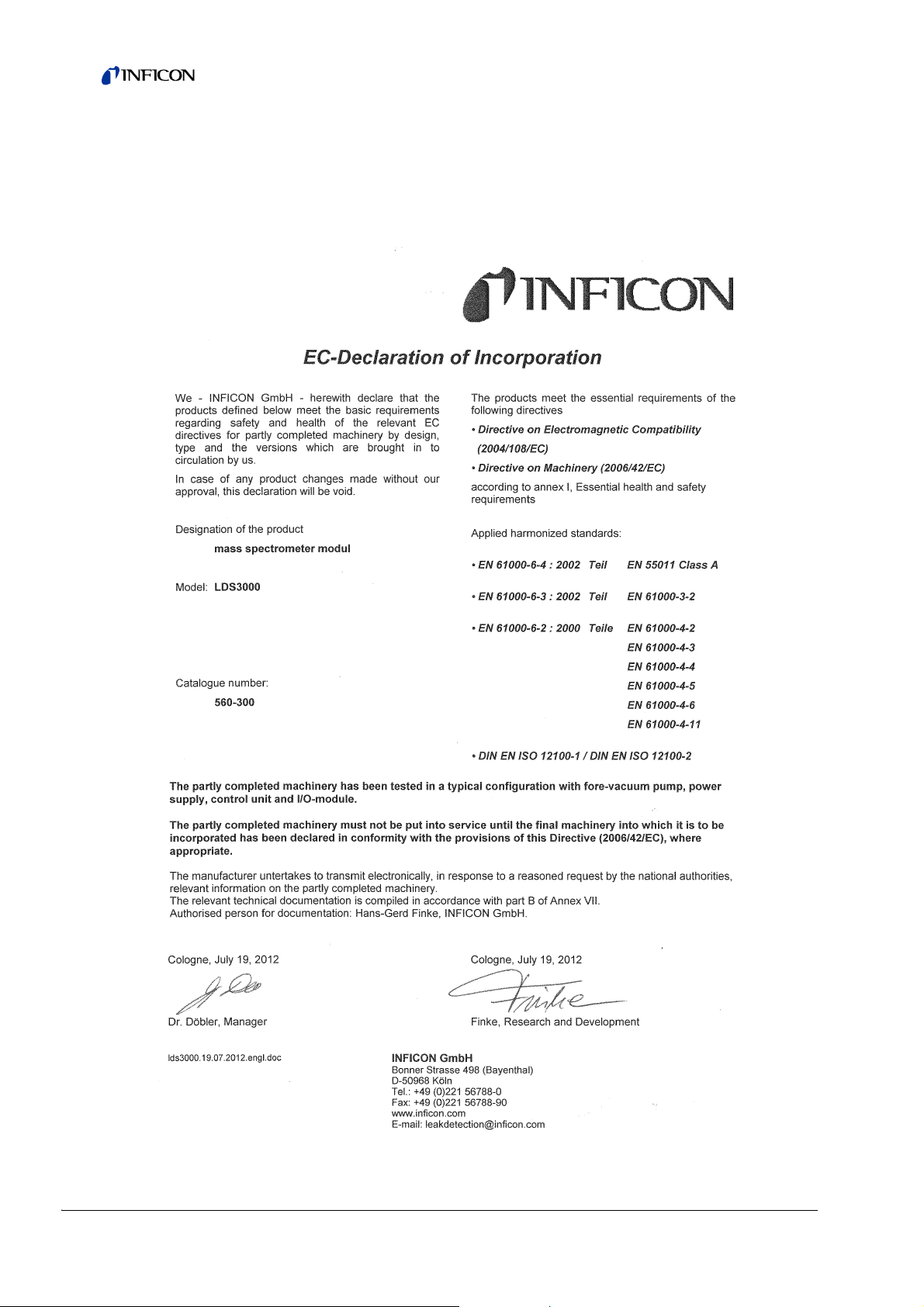

9.1 EC Declaration of Incorporation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.2 Declaration of Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4 Content

Page 5

1 About this manual

1.1 Target groups

This installation manual is intended for the operator and for technically qualified

personnel with experience in leak detection technology and integration of leak

detection devices in leak detection systems. In addition, the installation and use of

the unit require knowledge of electronic interfaces.

1.2 Other applicable documents

Control unit operating manual jina54

Bus module installation manual jiqb10

I/O module installation manual jiqc10

Interface protocols jira54

1.3 Presentation of information

1.3.1 Warnings

Imminent threat of danger resulting in death or severe injuries

Dangerous situation potentially resulting in death or severe injuries

Dangerous situation resulting in minor injuries

Dangerous situation resulting in damage to property or the environment

About this manual 5

Page 6

1.3.2 Text markings

Marking Meaning

►

1, 2, 3, ... Several instructions in a fixed order

S

MALL CAPS

Information

Requirement for execution of an action

Tool or aid for an action

Instruction

Result of an action

Designation of the unit or command/term from the menu

Useful tips and information

6 About this manual

Page 7

2 Safety

2.1 Intended use

The unit is a modular leak detector for installation in industrial leak detection

systems. The test gases that can be measured with the unit are helium and hydrogen

(forming gas).

The unit is suitable for pressure and vacuum testing. The unit is used for integral

testing in a vacuum and for local testing with a sniffer line.

► Install, operate and service the unit only in compliance with this manual.

► Comply with the limits of application (see Chapter 4.3, page 13).

2.2 User requirements

Safety conscious operation

► Operate and install the unit only if it is in perfect working order and as intended,

in a safety-conscious manner and fully aware of dangers, in compliance with this

manual.

► Fulfill and ensure compliance with the following regulations:

– Intended use

– Generally applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional provisions and regulations that are specific to the unit

► Use only original parts or parts approved by the manufacturer.

► Keep this manual available at the operating site.

Personnel qualifications

► All work must be performed only by technical specialists who have been trained

on the unit.

► Allow personnel in training to work with the unit only under the supervision of

technical specialists.

► Make sure that the authorized personnel have read and understood this manual

and all other applicable documents (see Chapter 1.2, page 5), especially the

information on safety, maintenance and repairs, before starting work.

► Define responsibilities, authorizations and supervision of personnel.

2.3 User requirements

► Read, observe and follow the information in this manual and the working

instructions created by the owner, especially the safety instructions and warnings.

► Perform all work based on the complete manual.

Safety 7

Page 8

2.4 General safety information

The unit was built according to the state of the art and the recognized safety

regulations. Nevertheless, improper use can result in danger to life and limb of the

user or other persons and damage to the unit and other property.

Electric power

The unit is operated with electric voltages up to 24 V. Inside the unit there are

voltages that are considerably higher. Touching parts where electric voltage is

present can result in death.

► Disconnect the unit from the power supply prior to any installation and

maintenance work.

Touching live parts with the sniffer probe can result in death.

► Before starting the leak test, disconnect electrically operated test objects from the

power supply.

The unit contains electric components that can be damaged from high electric

voltage.

► Before connecting the unit to the power supply, make sure that the supply voltage

is 24V +/-10%.

Liquids and chemical substances

Liquids and chemical substances can damage the unit.

► Comply with the limits of application (see Chapter 4.3, page 13).

► Do not suck up any liquids.

► Keep the hydrogen concentration low to prevent ignition.

Permanent magnets

Permanent magnets in the unit pose a hazard to health.

► Keep a sufficient distance from the unit.

Kinetic energy

A high force that is caused by sudden blocking of the turbo molecular pump can

damage the unit.

► Make sure the mount of the mass spectrometer module is able to absorb a

braking torque of 620 Nm.

8 Safety

Page 9

3 Shipment check, transport, storage

Interference with pacemakers

The magnets in the mass spectrometer module can affect the proper functioning of

pacemakers.

► Always comply with the distances recommended by the pacemaker

manufacturer.

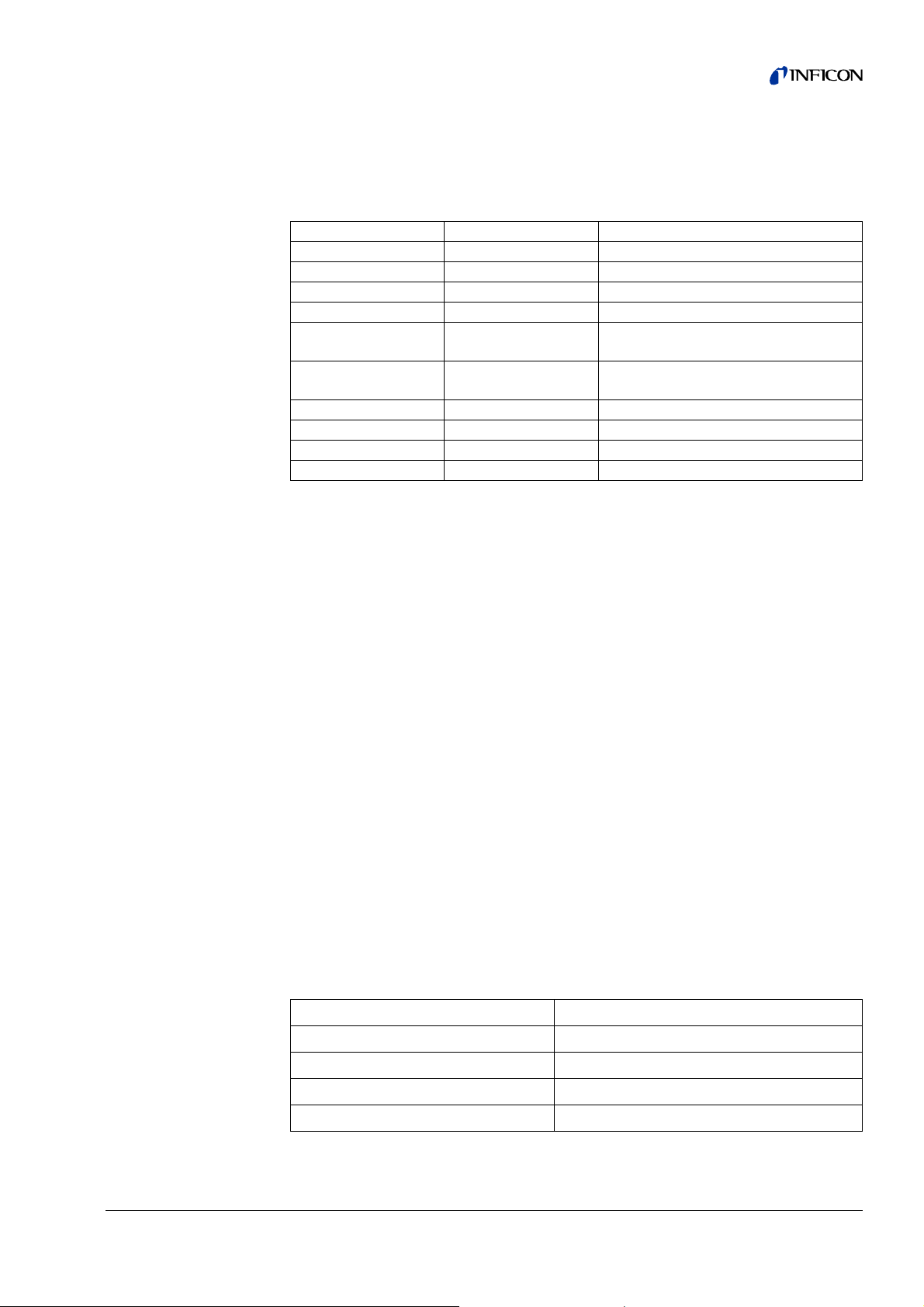

3.1 Checking shipment

Scope of delivery

Article Quantity

Mass spectrometer module 1

Plug for 24V connection 1

PIRANI gauge 1

Self-locking nuts 4

Plug for O

Plug for G

Installation manual 1

USB stick 1

► Check shipment to make sure it is complete.

UTPUT 1

AUGES EXIT 1

3.2 Transport

3.3 Storage

Damage due to unsuitable packaging material

Transport in unsuitable packaging material can damage the unit.

► Transport the unit only in the original packaging material.

► Keep original packaging material.

Damage if feet are missing

► Install the mounting screws on the feet.

► Always store the unit in compliance with the technical data, see Chapter 4.3,

page 13.

Shipment check, transport, storage 9

Page 10

4 Description

The mass spectrometer module is part of the leak detection system LDS3000. The

mass spectrometer module can be operated as part of a test system without the need

for additional equipment from INFICON.

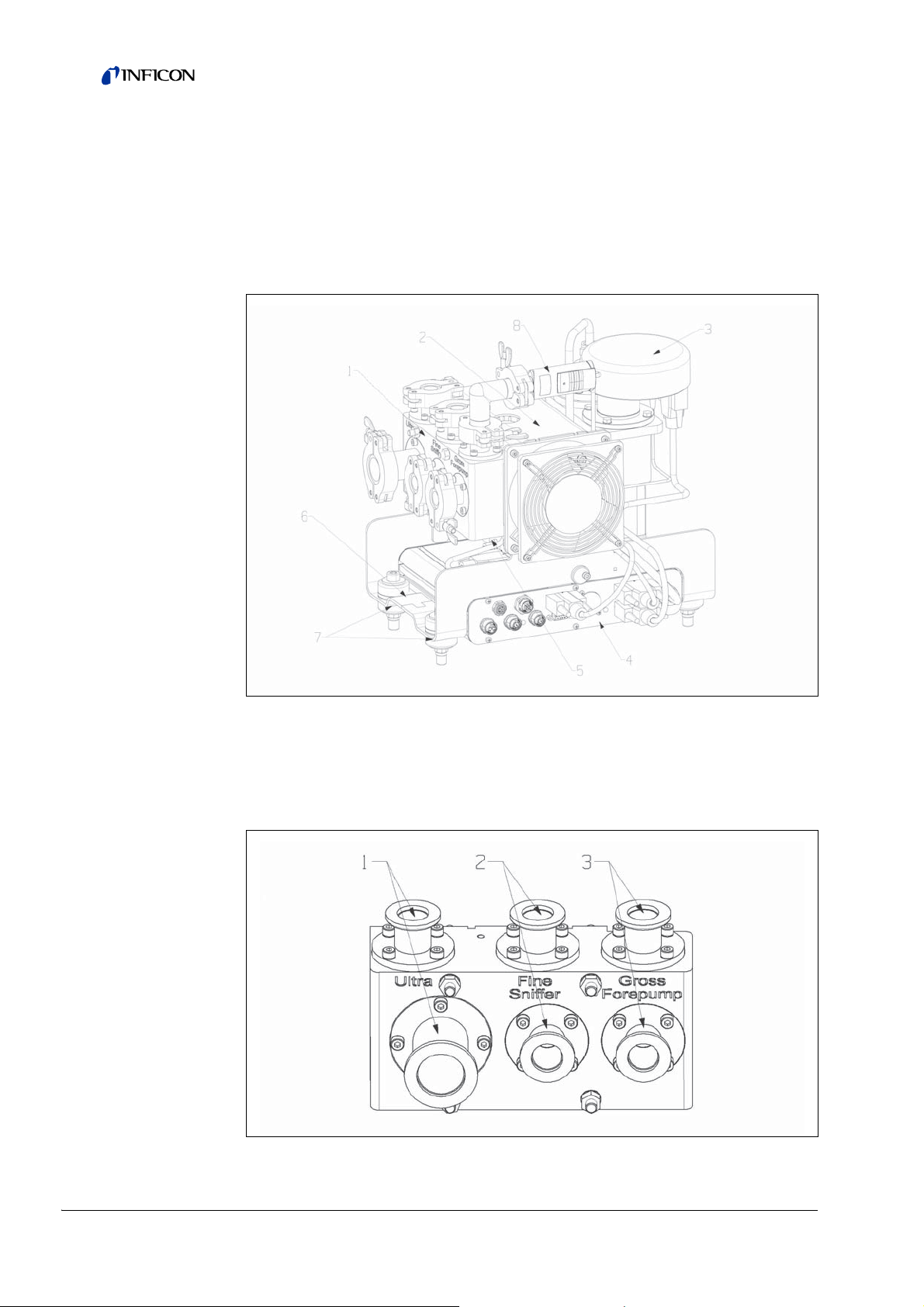

4.1 Construction of the unit

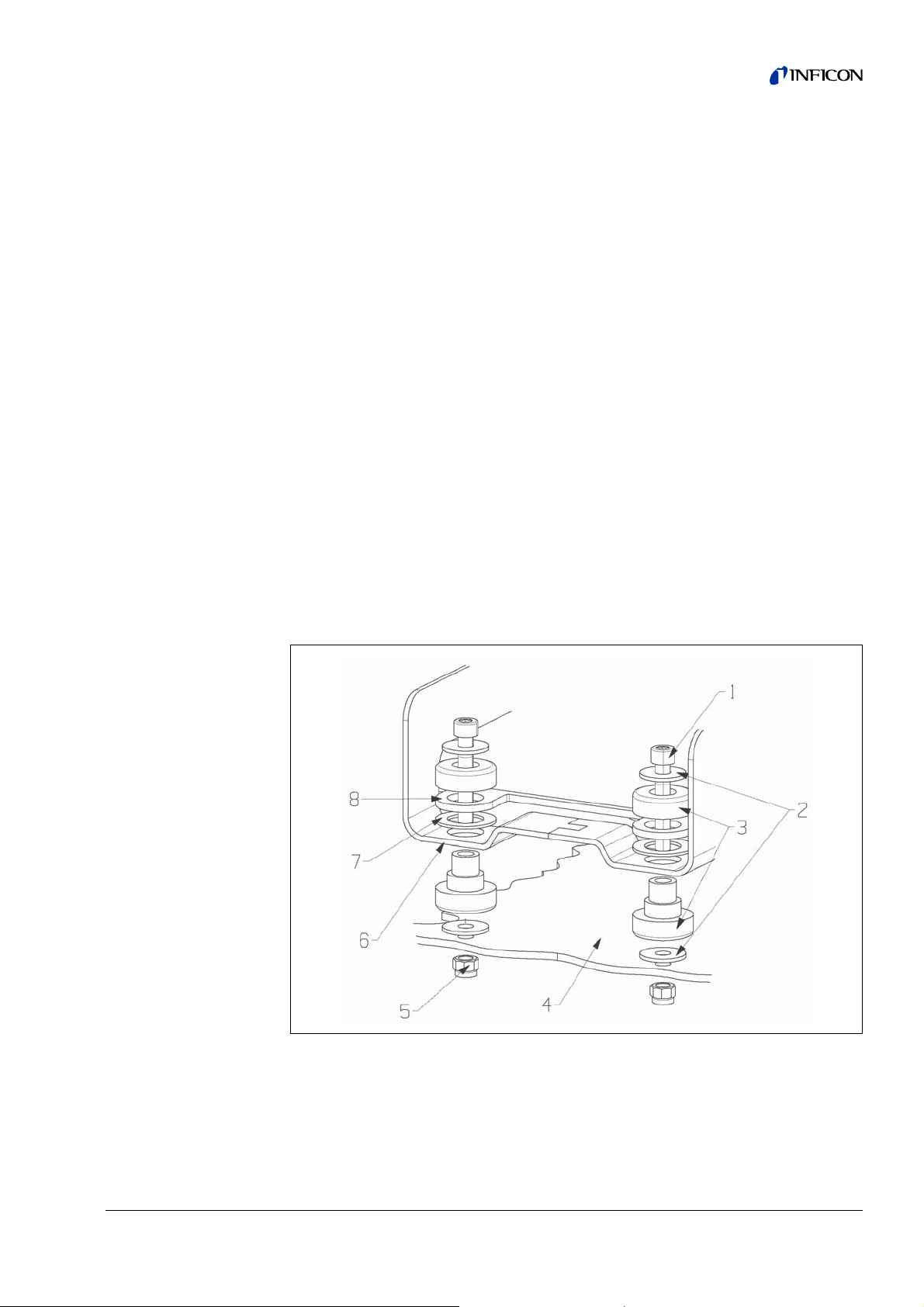

Fig: 1 Mass spectrometer module LDS3000

1 - Terminal block

Connections for test system, backing pump, PIRANI gauge, internal calibration leak

and sniffer line.

1: Connection U

Fig: 2 Connection block

LTRA, 2: Connection FINE/SNIFFER, 3: Connection GROSS/FOREPUMP

10 Description

Page 11

2- Turbo molecular pump

Turbo molecular pump with cooling unit

3 - Pre-amplifier

Pre-amplifier of the mass spectrometer module

4 - MSB box

Interfaces of the mass spectrometer module (see Chapter 4.1.1, page 11)

5 - Inverter turbo molecular pump

Electronic controller of the turbo molecular pump

6 - Rating plate

Rating plate containing mass spectrometer module specifications

7 - Fasteners

Fasteners for installing the mass spectrometer module in a test system

8 - PIRANI pressure measurement location

PIRANI gauge for measuring the pressure of the backing pump

4.1.1 MSB box

Fig: 3 MSB box connections

1 - OUTPUT

Connection for gas ballast and three valves (not used, reserve)

Connection plug arrangement

1 Valve 2 (gas ballast), 24 V, max. 1 A

2 Valve 3 (not used)

3 Valve 4 (not used)

4 Valve 6 (not used)

5GND

2 - SNIFFER

Electrical connection for the sniffer line

Description 11

Page 12

3 - GAUGES, EXT

Connection for optional external pressure measurement locations (0 ... 10 V or

0 … 20 mA) for INFICON Service

Connection plug arrangement

1 +24 V output, max. 200 mA

2 Input for P3 service gauge, 0 ... 10 V

3GND

4 Reference to input for P3 service gauge

5 20 mA input for P3 service gauge

4 - 1

Connection for PIRANI gauge, test leak and suppressor on the pre-amplifier (premounted, three-core cable)

5 - 24VDC

Connection for 24 V power supply pack used to supply mass spectrometer module,

control unit, I/O module and bus module.

6 - 2

Connection for inverter turbo molecular pump and fan turbo molecular pump (premounted, two-core cable)

7 - ION SOURCE

Connection for ion source

8 - 3

Connection for pre-amplifier

9 -

Power LED

The Power LED and Status LED indicate the status of the unit; see no. 12 - S

10 - SERVICE

RS232 connection for INFICON Service

11 - I/O / ANYBUS

Connection for I/O or bus module or control unit

Information The connections I/O / A

NYBUS and CONTROL UNIT have the same

functions. You have the choice of connecting:

– Control unit CU1000 + I/O module IO1000 or

– Control unit CU1000 + bus module BM1000 or

– I/O module IO1000 + bus module BM1000 or

– 2 control units CU1000 or

– 2 I/O modules IO1000 (configurable only together)

TATUS.

12 Description

Page 13

12 - STATUS

Status LED

The Power LED and Status LED indicate the status of the unit.

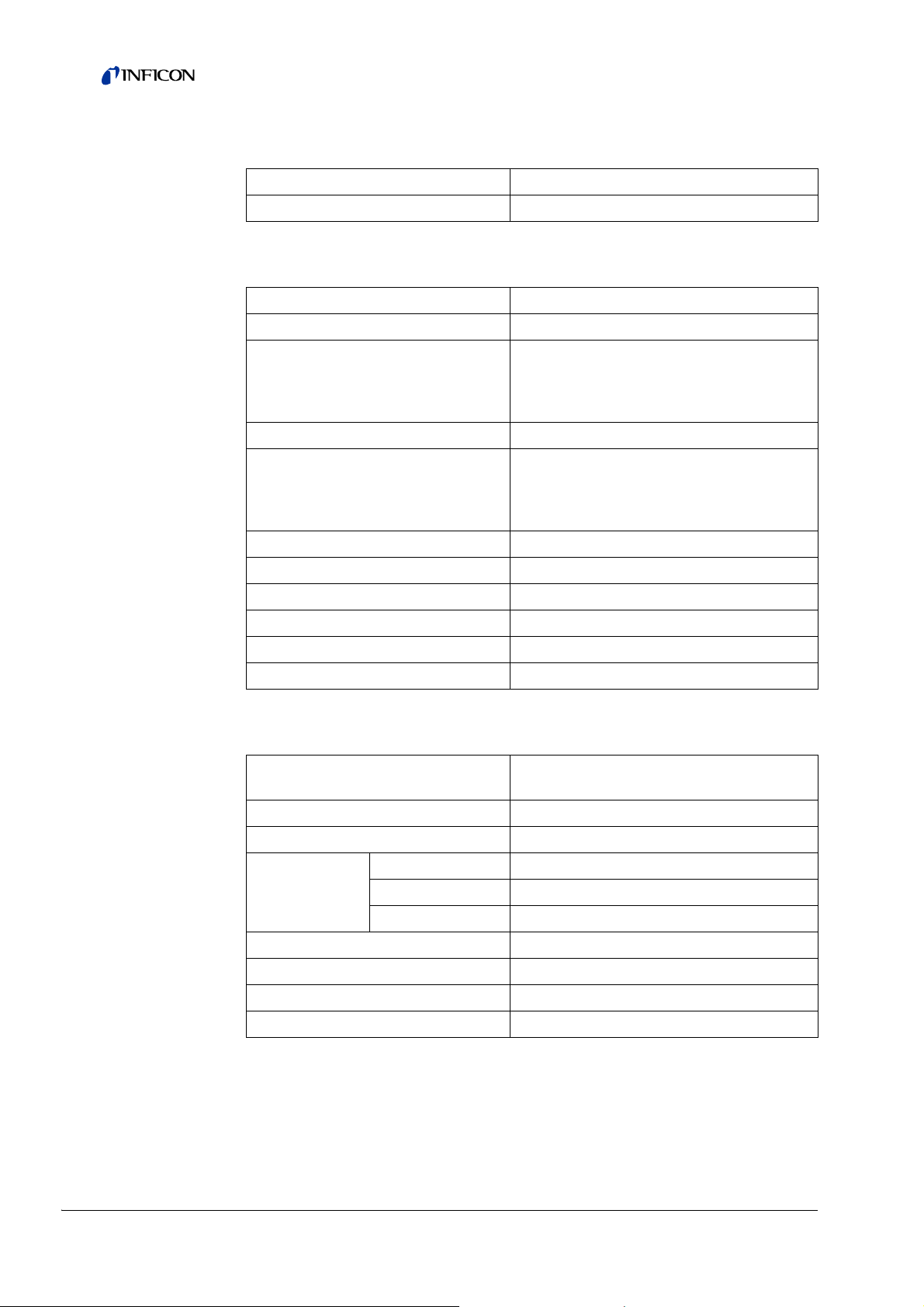

Power LED Status LED Meaning

Off Red Device not ready for operation

Green Blue Turbo molecular pump is starting

Green Orange Emission is switched on

Green Green Emission is stable

Green Violet

Green

Green, flashes slowly Supply voltage < 21.6 V

Green, flashes fast Supply voltage > 26.4 V

Green, flashes fast Off Software is being updated

Green Green, flashes fast Software is being updated

13 - CONTROL UNIT

Connection for control unit or I/O or bus module

Information The connections C

functions. You have the choice of connecting:

– Control unit CU1000 + I/O module IO1000 or

– Control unit CU1000 + bus module BM1000 or

– I/O module IO1000 + bus module BM1000 or

– 2 control units CU1000 or

– 2 I/O modules IO1000 (configurable only together)

Error codes of the

status LED

ONTROL UNIT and I/O / ANYBUS have the same

Speed of the turbo molecular pump is

not within the normal range

Different activities of the unit

4.2 Function

The mass spectrometer module is a detection device for the test gases helium and

hydrogen. Integrated in test systems, the unit is used to detect gas being emitted

from a test object in order to indicate leaks.

The unit can be used both as a vacuum leak detector and a sniffer leak detector.

The MSB box outputs data on digital interfaces to the control unit CU1000, I/O

module IO1000 or bus module BM1000.

4.3 Technical data

4.3.1 Mechanical data

Dimensions (W x H x D) 320 mm x 280 mm x 240 mm

Weight 14.3 kg

Connection G

Connection F

Connection U

ROSS/FOREPUMP 2xDN16

INE/SNIFFER 2xDN16

LTRA DN 16 and DN 25

Description 13

Page 14

4.3.2 Electrical data

Supply voltage 24 V ± 10% DC

Power input max. 10 A

4.3.3 Physical data

Noise level < 60 dB(A)

Detectable gases

Max. inlet pressure

(varying with the operation mode and

the speed of the turbo molecular

pump)

Operation in vacuum mode

Minimum detectable leak rate

(varying with the operation mode and

the speed of the turbo molecular

pump):

Time until ready for operation 150 s

Operation in Sniffer mode

4

He, H2, Mass 3 (e. g. H-D, 3He or H3)

0.2 mbar ... 18 mbar

Helium < 5 x 10

-12

mbar·l/s

Minimum detectable leak rate:

Helium < 1 x 10

Response time in Sniffer mode G

4.3.4 Ambient conditions

Permissible ambient temperature

(during operation)

Permissible storage temperature -20 °C ... 60 °C

Max. relative humidity

at temperatures:

Type of protection IP 40

Pollution degree II

Max. altitude above sea level 2000 m

Max. induction 7 mT

-7

mbar·l/s

ROSS: < 5 s, FINE/ULTRA: < 1 s

10 °C ... 45 °C

< +31 °C 80%

+31 °C to +40 °C decreasing linearly from 80% ... 50%

> +40 °C 50%

14 Description

Page 15

4.3.5 Factory settings

Parameter Factory setting

Operation mode Vacuum

Bus module address 126

Pressure capillary surveillance (min.) 0.4 mbar

Pressure capillary surveillance (max.) 2 mbar

Pressure unit mbar

Emission On

Upper limit exponent 1 x 10

Filter leak rate threshold 1 x 10

Filter zero time 5 s

Filter mode I•CAL

Gas ballast Off

I/O module protocol ASCII

Calibration request Off

Calibr. factor xxx Mx 1

-5

-10

Calibration factor VAC/SNIF Mx

1.0

(for vacuum, sniffer and all masses)

Cathode selection Auto Cat1

Compatibility mode LDS3000

Config. Analog output 1 Leak rate mantissa

Config. Analog output 2 Leak rate exponent

Config. Analog output scale 0.5 V / decade

Pin 1: Trigger 1, inverted

Pin 2: Trigger 2, inverted

Pin 3: Trigger 3, inverted

Configuration dig. outputs

Pin 4: Trigger 4, inverted

Pin 5: Ready

Pin 6: Error, inverted

Pin 7: CAL request, inverted

Pin 8: Open, inverted

Pin 1: Select dyn. / normal CAL

Pin 2: Sniff

Pin 3: Start/Stop, inverted

Pin 4: Zero

Configuration dig. Inputs

Pin 5: External CAL

Pin 6: Internal CAL

Pin 7: Clear

Pin 8: Pin 9: Pin 10: -

Leak rate unit SNIFF mbar*l/s

Leak rate unit VAC mbar*l/s

Description 15

Page 16

Parameter Factory setting

Fan mode Fan always on

Machine factor in standby Off

Machine factor / Sniff factor 1.0 (for all masses)

Mass 4

Maximum pressure VAC 18 mbar

Module at I/O connector IO1000

Nominal state TMP On

Test leak external SNIF 9.9 x 10

Test leak external VAC 9.9 x 10

Test leak internal 9.9 x 10

-2

-2

-2

Sniff factor 1.0 (for all masses)

TMP speed 1500

Trigger 1/2/3/4 level 1 x 10

-5

mbar·l/s

MOff

Zero with Start Off

Zero mode Normal

Zero key sniffer On

16 Description

Page 17

5 Installation

5.1 Rotating the MSB box

If required, you can push the MSB box into the mass spectrometer module LDS3000

on the rear side.

► Remove lock of the MSB box.

► Screw lock into the threads on the rear side of the MSB box.

► Disconnect all cables from the MSB box.

► Disconnect all cable clips from the frame.

► Pull out the MSB box.

► Push MSB box on the rear side and turned (with plug markings upside down) into

the mass spectrometer module LDS3000.

► Connect all cables to the MSB box.

► Fasten all cable clips on the frame.

► Close the lock.

The mass spectrometer module LDS3000 is ready for operation.

5.2 Installing the mass spectrometer module on the test system

Information The mass spectrometer module can be mounted in any position.

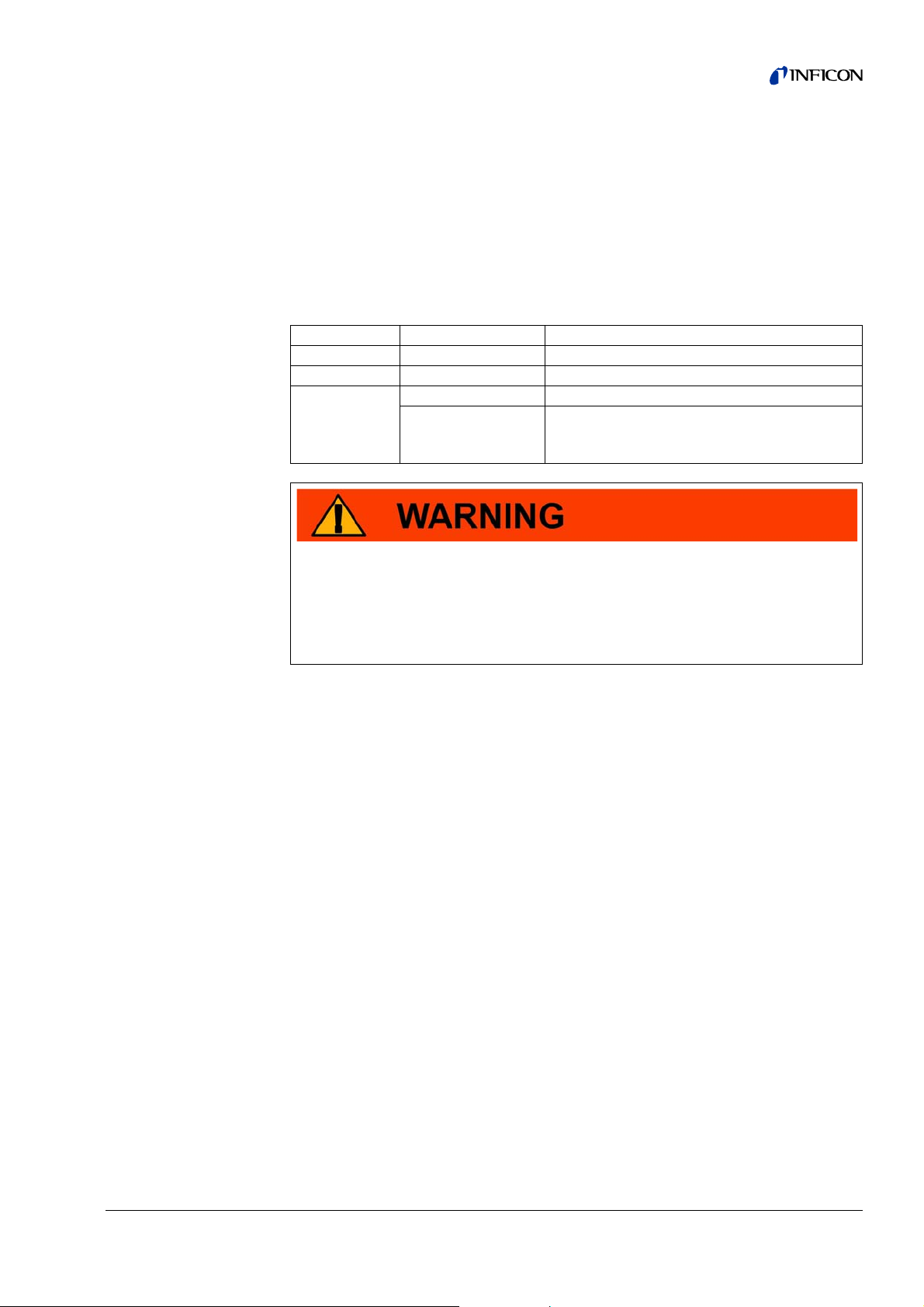

Fig: 4 Components of a fastener

1 Mounting screw M8 x 50

2Washer

3 MO bearing

4 Test system

5 Nut M8 (self-locking)

6 Base frame

7 Rubber spacer

8 MSB box guide

Installation 17

Page 18

Self-locking nuts M8

Open-end wrench, size 13

Allen wrench, size 6

Holes for installation inside the test system

The mass spectrometer module is delivered with fastening screws and transport nuts

already mounted.

1 Remove transport nuts.

2 Drill through-holes:

– X distance: 283 mm

– Y distance: 121.5 mm

– Through-hole in sheet metal: 9 mm

– Mounting screws: M8 x 50

Material damage if washers are missing

Failure to install the washers can cause the MO bearings to pull out.

► Always install washers between test system and MO bearings.

3 Use self-locking nuts (but NO transport nuts) to install the mass spectrometer

module.

Severe injuries due to mass spectrometer module breaking out

If not screwed down properly, the mass spectrometer module can be caused to

break out if the rotor of the turbo molecular pump suddenly locks up. This can result

in injuries of the most severe kind.

► Mount the mass spectrometer module so that it cannot break out.

4 Place the mass spectrometer module on top of the through-holes and screw it

down using the fasteners.

18 Installation

Page 19

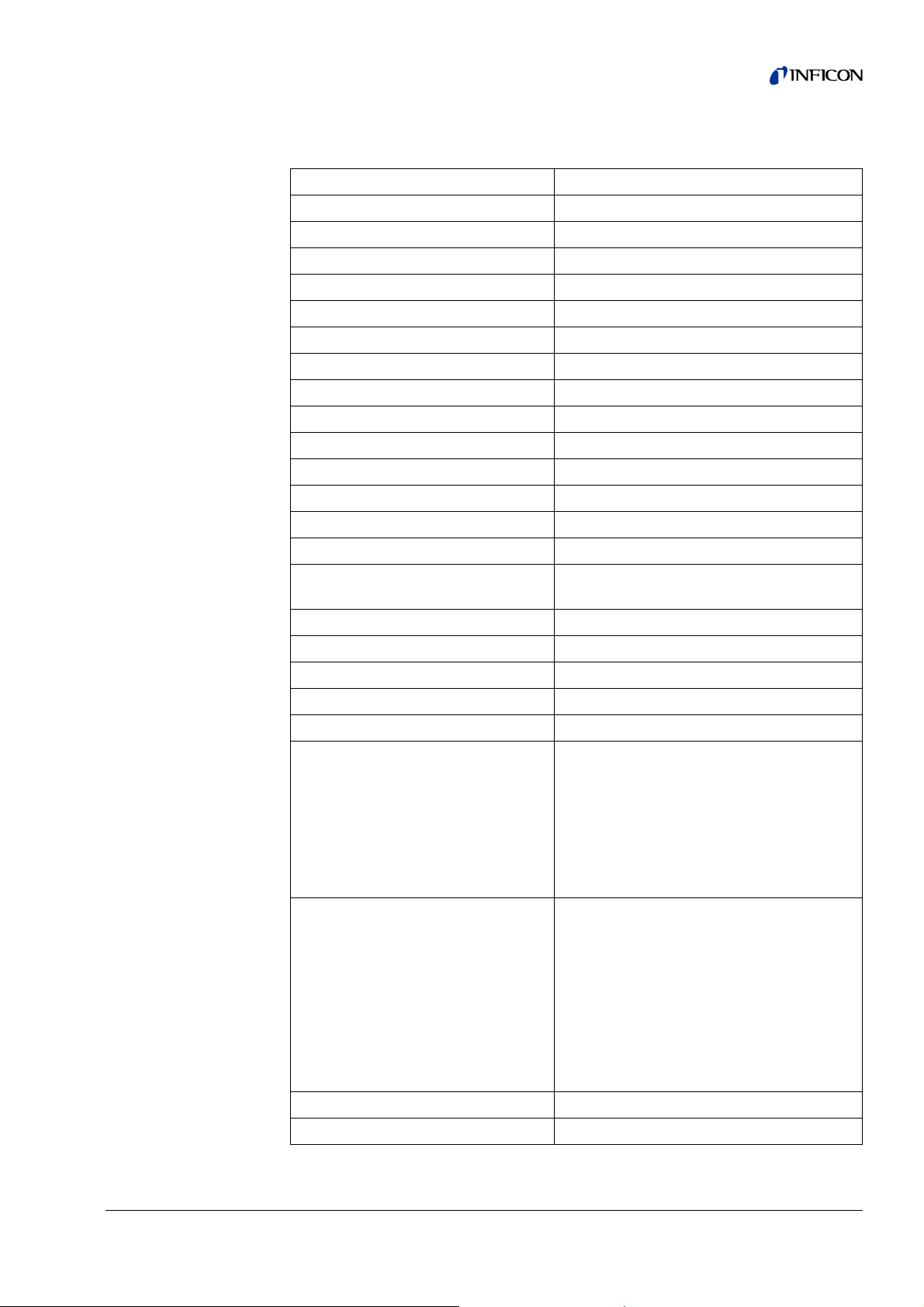

5.3 Connecting the mass spectrometer module to the test system

The operation mode of the vacuum connection and the speed of the turbo molecular

pump define:

• Minimum detectable leak rate (MDLR)

• Maximum inlet pressure (P

• Volume flow rate (S)

max

)

Connection

Speed turbo molecular pump

1000 Hz 1500 Hz

-12

mbar·l/s < 1 x 10

U

LTRA

MDLR: < 5 x 10

P

: 0.2 mbar 0.2 mbar *

max

S: 5l/s 6l/s

MDLR: < 1 x 10

INE

F

P

: 0.9 mbar 0.4 mbar *

max

-11

mbar·l/s < 5 x 10

S: 1.8 l/s 2.5 l/s

MDLR: < 1 x 10-9mbar·l/s < 2 x 10-8mbar·l/s

G

ROSS

P

: 18 mbar 15 mbar

max

S: depends on the backing pump

* constantly permissible inlet pressure

Temporary exceed (< 3 s):

Permissible inlet pressure is 0.4 mbar in U

LTRA and 0.7 mbar in FINE.

Long-term exceed (> 3 s):

Warning (TMP overheating) and possible damage to the filament.

-11

-11

mbar·l/s

mbar·l/s

Material damage due to pressure surges

Pressure surges exceeding the maximum inlet pressure will damage the mass

spectrometer module.

► Do not exceed the maximum inlet pressure.

1 Set the operation mode vacuum connection and the speed turbo molecular pump

in accordance with the physical vacuum conditions found in the test system.

2 Connect the mass spectrometer module to the U

LTRA, FINE or GROSS connections

on the vacuum system of the test system.

3 Set the speed of the turbo molecular pump.

Installation 19

Page 20

5.4 Connection of the connection block

1 Connect PIRANI gauge and backing pump to GROSS/FOREPUMP.

2 Connect the test leak to the second available flange of the vacuum connection.

For the unit to operate correctly upon opening of the sniffer valve, no additional line

can be connected between the connection block and the sniffer valve or between the

sniffer valve and the sniffer line.

3 Connect the sniffer line to F

INE.

5.5 Connecting the MSB box

Information The connections are close together. To make installation easier, first

connect the inner connections, then the outer ones.

Material damage if power supply pack has the wrong specifications or is

connected improperly

A power supply pack that has the wrong specifications or is connected improperly

can destroy the unit.

► Use a suitable power supply pack:

– Use a power supply pack that supplies an output voltage with electrically

protective separation

– Output voltage: 24 V +/-10%

– Current rating: min. 8 A

► If the short-circuit current of the power supply pack is > 10 A, connect a fuse

between power supply pack and mass spectrometer module.

► Use a power cable with a large enough cross section.

1 Connect the 24 V power cable to the included plug (connections: +24 V to 1+ and

GND to 1-).

2 Plug in the mounted plug of the 24V power supply cable in 24VDC.

3 Use the data cable to connect the control unit to C

4 Use the data cable to connect the I/O or bus module to I/O as needed.

5 Connect the PIRANI gauge and the test leak to the cable of socket 1.

6 Connect the sniffer line to S

7 Connect the gas ballast valve to O

NIFFER as needed.

UTPUT as needed.

ONTROL UNIT as needed.

20 Installation

Page 21

6 Operation

You can use the following accessories in combination with the mass spectrometer

module:

• CU1000 (control unit)

• BM1000 (bus module)

• IO1000 (I/O module)

The following applies to the functions and settings described in this chapter:

Accessories Information on Are described in

Control unit Menu Operating Manual Control Unit CU1000

Bus module Commands Interface Protocols LDS3000

I/O module

Commands Interface Protocols LDS3000

Digital input and

outputs, Analog

outputs

Danger to life and material damage due to unsuitable operating conditions

There is danger to life due to unsuitable operating conditions. The unit can become

damaged.

Installation manual I/O module IO1000

► Avoid changing the position of the unit in an abrupt manner.

► Avoid extreme external vibrations and impact.

6.1 Switching the unit on

1 Switch on the backing pump.

2 Establish the power supply to the mass spectrometer module.

System starts up automatically.

6.2 Assigning the analog outputs of the I/O module

The analog outputs of the I/O module IO1000 can be assigned different

measurement displays via the control unit CU1000 or the I/O module IO1000.

► Assign the analog outputs of the I/O module as needed:

S

ETTINGS > SET UP > INTERFACES > I/O MODULE > ANALOG OUTP. >

C

ONFIG. ANALOG OUTPUTS 1/2

Operation 21

Page 22

6.2.1 Factory layout

Analog output 1: Leak rate mantissa

Analog output 2: Leak rate exponent

6.2.2 Possible layouts

Off

The analog outputs are disabled (output voltage = 0 V).

Pressure p1 / Pressure p2

1 ... 10 V; 0.5 V / decade; 1 V = 1 x 10

Leak rate mantissa

1 ... 10 V; linear; in used unit

Information Useful only if the other analog output is assigned “Leak rate exponent”.

Leak rate exponent

1 ... 10 V; 0.5 V / decade; step function; 1 V = 1 x 10

Information Useful only if the other analog output is assigned “Leak rate mantissa”

or “Leak rate ma. hys.”.

-3

mbar

-12

; in used unit

Leak rate linear

x ... 10 V; linear; in used unit

The upper limit (= 10 V) is set via the parameter “Upper limit exponent”.

Leak rate log.

x ... 10 V; logarithmic; in used unit

The upper limit (= 10 V) and the scale (V / decades) are set via the parameters

“Upper limit exponent” and “Scale for leak rate”.

For example:

Upper limit set to 10

Scale set to 5 V / decade.

Lower limit is 10

-5

mbar·l/s (= 10 V).

-3

mbar·l/s (= 0 V).

22 Operation

Page 23

Via interface

The output voltage can be specified via the LD protocol command 221.

Leakage rate Ma. Hys.

0.7 ... 10 V; linear; in used unit

Information Useful only if the other analog output is assigned “Leak rate exponent”.

This layout prevents the exponent from constantly jumping between two decades.

0.7 V corresponds to a leakage rate of 0.7 x 10

9.9 V corresponds to a leakage rate of 9.9 x 10

Pressure p1 (1 V / dec.) / Pressure p2 (1 V / dec.)

1 ... 10 V; 1 V / decade; 2.5 V = 1 x 10

Leak rate log. H. / Leak rate exp. Inv.

This assignment ensures backward compatibility to older units.

6.2.3 Output voltages in case of error

The following voltages will be applied at the analog outputs in the event of an error:

Compatibility mode Voltage

LDS1000 0 V

LDS2010 10 V

LDS3000 10.237 V

-x

.

-x

.

-3

mbar; 8.5 V = 1000 mbar

Operation 23

Page 24

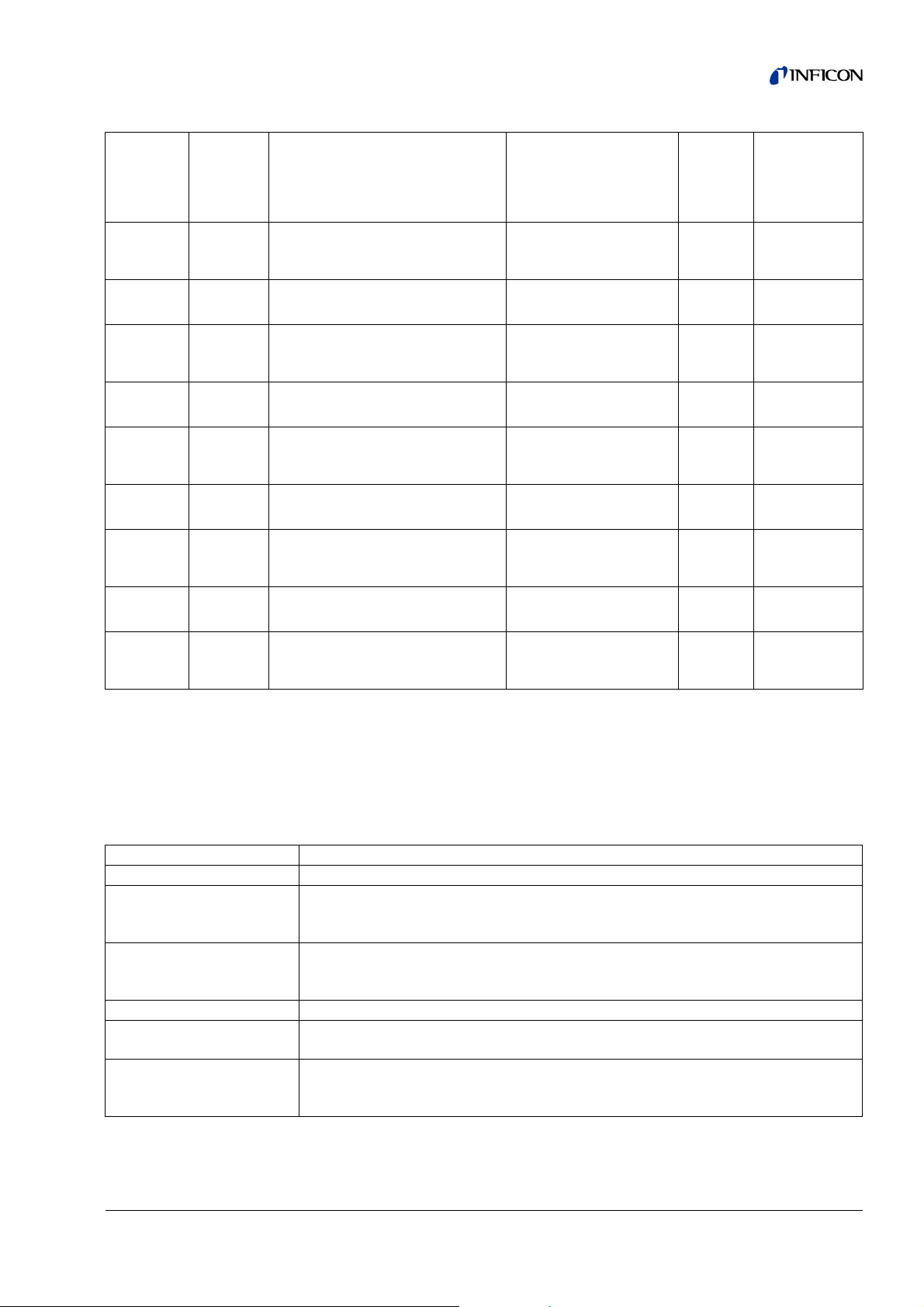

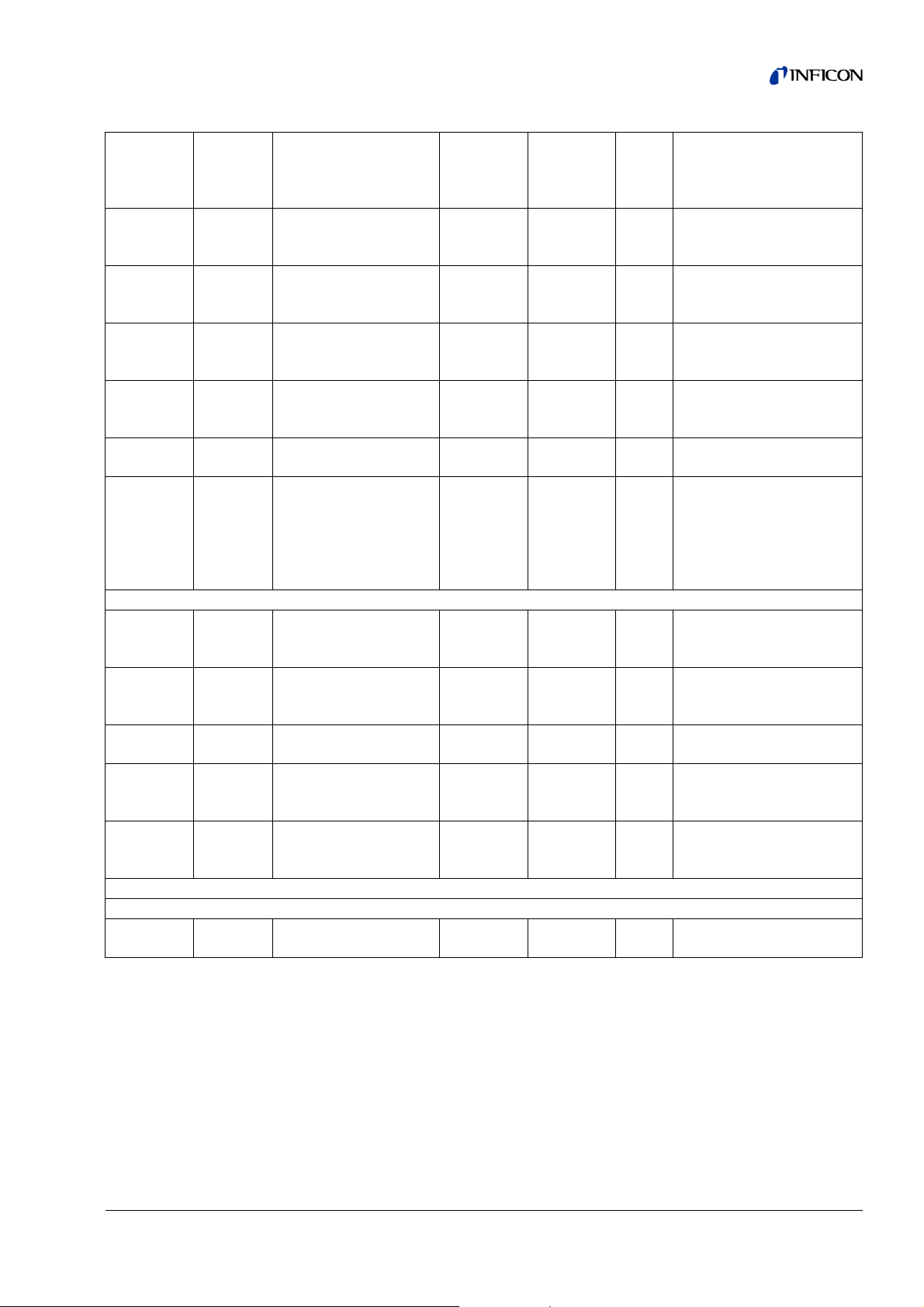

6.2.4 Configuration (LDS2010-compatible)

LDS2010

setting in

menu item

22

1 1

1 2

21

22

3 1

3 2

41

42

5 1

5 2

61

62

8 1

8 2

Analog

output

LDS2010 function LDS3000 function

Leak rate mantissa in used unit

1...10V

Leak rate exponent (step function)

in used unit

1 ... 10 V, 0.5 V/decade,

1V=1E-12

Leak rate log. in used unit

1 ... 10 V, 0.5 V/decade,

1V=1E-12

Pressure p1 log. in used unit

1 ... 10 V, 0.5 V/decade,

1V=1E-3mbar

Leak rate mantissa in mbar·l/s

1...10V

Leak rate exponent (step function)

in mbar·l/s

1 ... 10 V, -1 V/decade,

0 V = 1E0 mbar·l/s

Leak rate log.

0 ... 10 V, 1 V/decade,

0 V = 1E-10 mbar·l/s

Pressure p1 log. in mbar

1 V/decade, 2.5 ... 8.5 V,

2.5V=1E-3mbar,

5.5 V = 1E0 mbar

Leak rate mantissa in used unit

1 ... 10 V rise, 0.7 ... 10 V fall

Leak rate exponent in used unit

1 ... 10 V, 0.5 V/decade,

0V=1E-14

Leak rate log. in Pa·m³/s

0 10 V, 1 V/decade,

0 V = 1E-12 Pa·m³/s =

1E-12 mbar·l/s

Pressure p1 log. in Pa

1 V/decade, 2.5 ... 8.5 V,

2.5V=1E-3mbar

Leak rate log. in Pa·m³/s

0 ... 10 V, 1 V/decade,

0 V = 1E-12 Pa·m

1E-12 mbar·l/s

Pressure p2 log. in Pa

1 V/decade, 2.5 ... 8.5 V,

2.5V=1E-3mbar

3

/s =

Leak rate mantissa irrelevant irrelevant

Leak rate exponent irrelevant irrelevant

Leak rate log. 0.5 V/dec. 1E6 [used unit]

Pressure p1 irrelevant irrelevant

Leak rate mantissa irrelevant irrelevant

LR exponent inverted irrelevant irrelevant

Leak rate log. 1 V/dec. 1.00E+00

p1 1 V/dec. irrelevant irrelevant

LR mantissa hyst. irrelevant irrelevant

Leak rate exponent irrelevant irrelevant

Leak rate log. 1 V/dec. 1E-2 mbar·l/s

p1 1 V/dec. irrelevant irrelevant

Leak rate log. 1 V/dec. 1E-2 mbar·l/s

p2 1 V/dec. irrelevant irrelevant

Decade

scale

Upper limit

value

(10 V = ...)

24 Operation

Page 25

LDS2010

setting in

menu item

Analog

output

22

91

92

10 1

10 2

11 1

11 2

12 1

12 2

13 1

13 2

14 1

14 2

15 1

15 2

16 1

16 2

LDS2010 function LDS3000 function

Pressure p1 log. in Pa

1 V/decade, 2.5 ... 8.5 V,

p1 1 V/dec. irrelevant irrelevant

2.5 V = 1E-3 mbar

Pressure p2 log. in Pa

1 V/decade, 2.5 ... 8.5 V,

p2 1 V/dec. irrelevant irrelevant

2.5 V = 1E-3 mbar

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

Leak rate log. 2V/dec. 1E+2 mbar·l/s

0V=1E-3mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

Leak rate log. Special_1 1E+1 mbar·l/s

0V=1E-3mbar·l/s

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

Leak rate log. 2 V/dec. 1E+1 mbar·l/s

0V=1E-4mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

Leak rate log. Special_1 1E+0 mbar·l/s

0 V = 1E-4 mbar·l/s

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

Leak rate log. 2V/dec. 1E0 mbar·l/s

0V=1E-5mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

Leak rate log. Special_1 1E-1 mbar·l/s

0V=1E-5mbar·l/s

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

Leak rate log. 2 V/dec. 1E-1 mbar·l/s

0V=1E-6mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

Leak rate log. Special_1 1E-2 mbar·l/s

0V=1E-6mbar·l/s

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

Leak rate log. 2V/dec. 1E-2 mbar·l/s

0V=1E-7mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

Leak rate log. Special_1 1E-3 mbar·l/s

0V=1E-7mbar·l/s

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

Leak rate log. 2 V/dec. 1E-3 mbar·l/s

0V=1E-8mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

Leak rate log. Special_1 1E-4 mbar·l/s

0V=1E-8mbar·l/s

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

Leak rate log. 2V/dec. 1E-4 mbar·l/s

0V=1E-9mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

Leak rate log. Special_1 1E-5 mbar·l/s

0V=1E-9mbar·l/s

Decade

scale

Upper limit

value

(10 V = ...)

Operation 25

Page 26

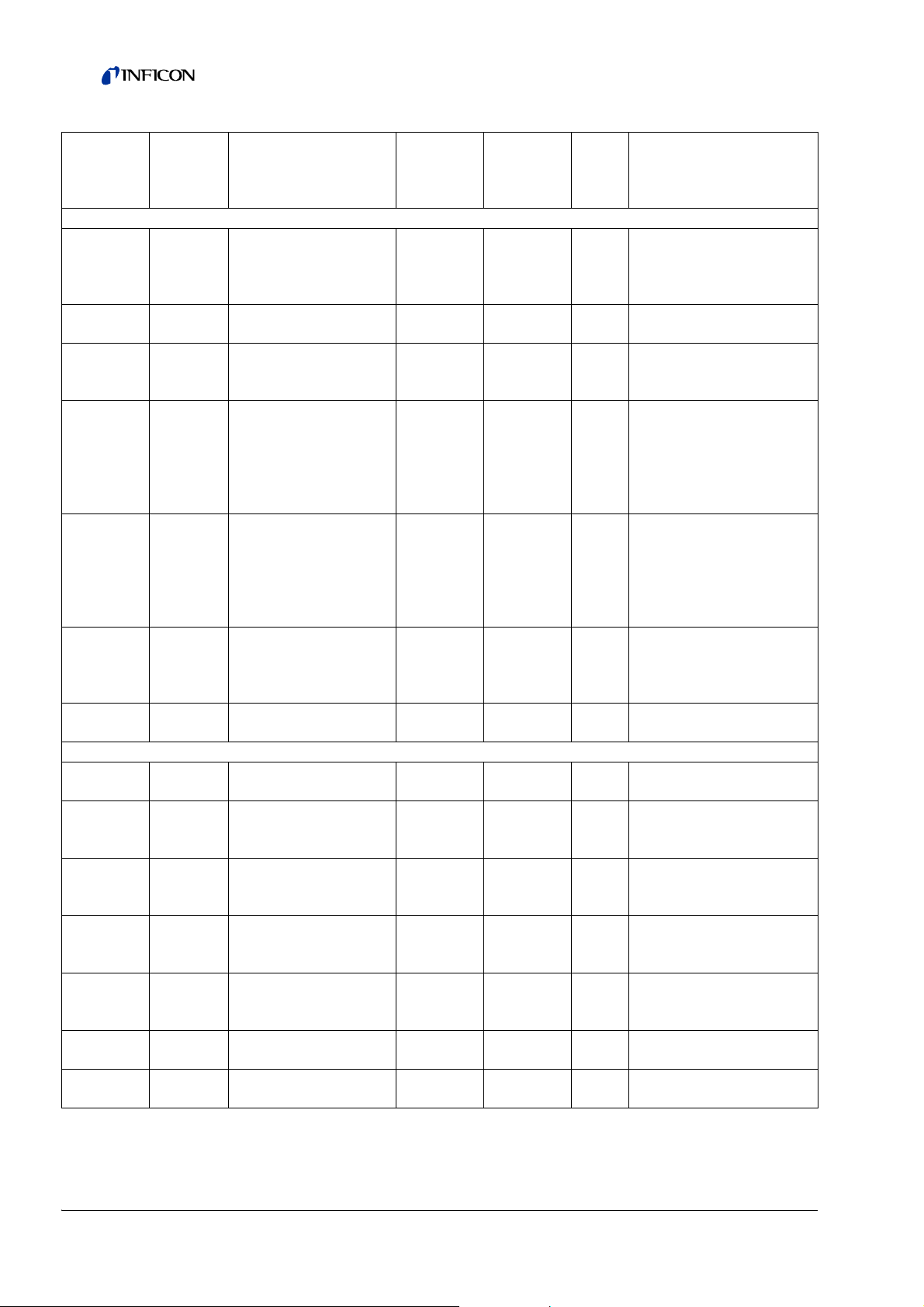

LDS2010

setting in

menu item

22

17 1

17 2

18 1

18 2

20 1

20 2

21 1

21 2

22 1

22 2

23 1

23 2

24 1

24 2

25 1

25 2

26 1

Analog

output

LDS2010 function LDS3000 function

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

0 V = 1E-10 mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

0 V = 1E-10 mbar·l/s

Leak rate log. in mbar·l/s

0...8V, 2V/decade,

0 V = 1E-11 mbar·l/s

Leak rate log. in mbar·l/s

0 ... 10 V, 3 V/decade,

0 V = 1E-11 mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0V=1E-3mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-1mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0V=1E-4mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-2mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0 V = 1E-5 mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-3mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0V=1E-6mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-4mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0V=1E-7mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-5mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0V=1E-8mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-6mbar·l/s

Leak rate log. 2 V/dec. 1E-5 mbar·l/s

Leak rate log. Special_1 1E-6 mbar·l/s

Leak rate log. 2 V/dec. 1E-6 mbar·l/s

Leak rate log. Special_1 1E-7 mbar·l/s

Leak rate linear irrelevant 1E1 mbar·l/s

Leak rate log. 1 V/dec. 1E7 mbar·l/s

Leak rate linear irrelevant 1E0 mbar·l/s

Leak rate log. 1 V/dec. 1E6 mbar·l/s

Leak rate linear irrelevant 1E-1 mbar·l/s

Leak rate log. 1 V/dec. 1E5 mbar·l/s

Leak rate linear irrelevant 1E-2 mbar·l/s

Leak rate log. 1 V/dec. 1E4 mbar·l/s

Leak rate linear irrelevant 1E-3 mbar·l/s

Leak rate log. 1 V/dec. 1E3 mbar·l/s

Leak rate linear irrelevant 1E-4 mbar·l/s

Leak rate log. 1 V/dec. 1E2 mbar·l/s

Leak rate linear irrelevant 1E-5 mbar·l/s

Decade

scale

Upper limit

value

(10 V = ...)

26 Operation

Page 27

LDS2010

setting in

menu item

22

26 2

27 1

27 2

28 1

28 2

29 1

29 2

30 1

30 2

Analog

output

LDS2010 function LDS3000 function

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0V=1E-9mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-7mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0 V = 1E-10 mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-8mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0 V = 1E-11 mbar·l/s

Leak rate lin. in mbar·l/s

0...10V, 1V=1E-9mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0 V = 1E-11 mbar·l/s

Leak rate lin. in mbar·l/s

0 ... 10 V, 1 V = 1E-10 mbar·l/s

Leak rate log. in mbar·l/s

0...4V, 1V/decade,

0 V = 1E-11 mbar·l/s

Leak rate log. 1 V/dec. 1E1 mbar·l/s

Leak rate linear irrelevant 1E-6 mbar·l/s

Leak rate log. 1V/dec. 1E0 mbar·l/s

Leak rate linear irrelevant 1E-7 mbar·l/s

Leak rate log. 1 V/dec. 1E-1 mbar·l/s

Leak rate linear irrelevant 1E-8 mbar·l/s

Leak rate log. 1V/dec. 1E-2 mbar·l/s

Leak rate linear irrelevant 1E-9 mbar·l/s

Leak rate log. 1 V/dec. 1E-3 mbar·l/s

Decade

scale

Upper limit

value

(10 V = ...)

6.3 Assigning the digital inputs of the I/O module

The available functions can be assigned in any way necessary to the digital inputs

PLC-IN 1 ... 10 of the I/O module.

Active signal: typically 24 V; inactive signal: typically 0 V.

The 24V output of the I/O module can be used as an active signal.

Function Flank/state: Description

NO_FUNCTION - no function

inactive→ active:

DYN_CAL

CAL_EXTERN

CAL_INTERN inactive→ active: Start internal calibration.

SNIFF/VAC

START

active→ inactive:

inactive→ active:

active→ inactive:

inactive→ active:

active→ inactive:

inactive→ active: Switch to Meas.

Start external dynamic calibration.

Apply value for background and finish calibration.

Start external calibration.

Apply value for background and finish calibration.

Enable sniffer mode.

Enable vacuum mode.

(Z

ERO is possible, all trigger outputs switch depending on the

leakage rate.)

Operation 27

Page 28

Function Flank/state: Description

inactive→ active:

STOP

Switch to Standby.

ERO is not possible, all trigger outputs will return "Fail".)

(Z

ZERO

inactive→ active:

active→ inactive:

Switch Z

Switch Z

ERO on.

ERO off.

ZERO_PULS inactive→ active. Switch ZERO on or off.

CLEAR

GASBALLAST

inactive→ active:

inactive→ active:

active→ inactive:

Erase warning or error message / cancel calibration.

Open gas ballast valve.

Close gas ballast valve unless always open.

External calibration mode for the "CAL" function:

inactive→ active:

External dynamic calibration

(without auto tune, allowing for the measuring times and pump

SELECT_DYN_NORMAL

active→ inactive:

cycle times set via the digital inputs)

External normal calibration

(with auto tune, not considering the system-specific measuring

times and pump cycle times)

START_STOP

inactive→ active:

active→ inactive:

Switch to Meas.

(Z

ERO is possible, all trigger outputs switch depending on the

leakage rate.)

Switch to Standby.

(Z

ERO is not possible, all trigger outputs will return "Fail".)

KEY_1 active: User "Operator"

KEY_2 active: User "Supervisor"

KEY_3 active: User "Integrator"

CAL inactive→ active:

When set to Standby, the unit will start an internal calibration.

When set to Meas, the unit will start an external calibration.

Information Every function can be inverted.

► Assign the digital inputs of the I/O module as needed:

S

ETTINGS > SET UP > INTERFACES > I/O MODULE > PLC INPUTS >

C

ONFIGURATION DIG. INPUT

6.4 Assigning the digital outputs of the I/O module

The available functions can be assigned in any way necessary to the digital outputs

PLC-OUT 1 ... 8 of the I/O module:

Function State: Description

OPEN open: always open

TRIG1

TRIG2

TRIG3

TRIG4

READY

closed:

open:

closed:

open:

closed:

open:

closed:

open:

closed:

open:

Value exceeded leak rate threshold Trigger 1

Value fell below leak rate threshold Trigger 1

Value exceeded leak rate threshold Trigger 2

Value fell below leak rate threshold Trigger 2

Value exceeded leak rate threshold Trigger 3

Value fell below leak rate threshold Trigger 3

Value exceeded leak rate threshold Trigger 4

Value fell below leak rate threshold Trigger 4

Emission switched on, calibration process inactive, no error

Emission switched off, calibration process active or error

28 Operation

Page 29

Function State: Description

WARNING

ERROR

CAL_ACTIVE

closed:

open:

closed:

open:

closed:

open:

closed:

Warning

no warning

Error

no error

Unit is calibrated.

Unit is not calibrated.

and no external calibration: Calibration request

(e. g. in case of temperature change of 5 °C)

CAL_REQUEST

closed:

and external calibration: Request "Open external calibration

leak"

RUN_UP

ZERO_ACTIVE

EMISSION_ON

MEASURE

open:

closed:

open:

closed:

open:

closed:

open:

closed:

open:

no request

Running up

no run-up

Z

ERO switched on

Z

ERO switched off

Emission switched on

Emission switched off

Meas

(Z

ERO is possible, all trigger outputs switch depending on the

leakage rate.)

Standby or Emission disabled

(Z

ERO is not possible, all trigger outputs will return "Fail".)

STANDBY

SNIFF

closed:

open:

Standby

(Z

ERO is not possible, all trigger outputs will return "Fail".)

Meas

(Z

ERO is possible, all trigger outputs switch depending on the

leakage rate.)

closed:

open:

SNIFF

VAC

Information Every function can be inverted.

► Assign the digital outputs of the I/O module as needed:

S

ETTINGS > SET UP > INTERFACES > I/O MODULE > PLC OUTPUTS >

C

ONFIGURATION DIG. OUTPUT

Operation 29

Page 30

6.5 Starting/stopping the measurement

During the measurement During standby

Z

ERO is possible. ZERO is not possible.

The trigger outputs switch depending on

the leakage rate and the trigger threshold.

Sniff is possible. Sniff is not possible.

Calibration using PLC input or output will

start an external calibration.

Starting

Device in S

► Start measurement.

TANDBY

The output at the trigger outputs is:

Leakage rate value exceeded

threshold.

Calibration using PLC input and output

will start an internal calibration.

Device switched to M

Stopping

Unit measures

► Stop measurement.

Device switches to S

EASURE state.

TANDBY state.

6.6 Loading and storing parameters

You can use a USB stick to backup and restore the control unit and mass

spectrometer module parameters.

► Load parameters as needed:

F

UNCTIONS > DATA > PARAMETER > LOAD > LOAD PARAMETER

► Save parameters as needed:

F

UNCTIONS > DATA > PARAMETER > SAVE > SAVE PARAMETER

6.7 Select operation mode

VAC = Vacuum mode

S

NIFF = Sniff mode

► Select operation mode as needed:

S

ETTINGS > SET UP > OPERATION MODES > VAC/SNIFF > OPERATION MODE

30 Operation

Page 31

6.8 Activate/deactivate ZERO

ZERO can be used to suppress undesired helium backgrounds. If ZERO is enabled,

the currently measured leakage rate value will be interpreted as a helium background

and subtracted from all subsequently measured values.

The background value suppressed by Z

background changes inside the unit.

Information If the signal filter Fixed or 2-Zone is selected, then the background value

is automatically adjusted based on the configured zero time.

► Enable or disable Z

S

ETTINGS > ZERO/FILTER > ZERO > ZERO MODE

ZERO WITH START suppresses the helium background automatically when a

measurement is started.

► Enable or disable Z

S

ETTINGS > ZERO/FILTER > ZERO > ZERO WITH START

6.9 Selecting a signal filter

Signal filter

I•CAL

Fixed The leak rates are averaged at fixed intervals of 0.2 seconds.

2-Zone

► As a rule, use signal filter I•CAL.

► If the signal filter should simulate the time behavior of older units, then use filter

Fixed or 2-Zone.

► Select desired signal filter:

S

ETTINGS > ZERO/FILTER > FILTER > FILTER MODE

The leakage rates are averaged at time intervals that are optimized

for the range of the leakage rates.

Filter compatible with LDS1000 and LDS2000

The averaging period is switched depending on the leak rate

threshold.

ERO is adjusted automatically if the

ERO as needed:

ERO WITH START as needed:

Operation 31

Page 32

6.10 Calibrating the unit

► To ensure measuring accuracy, the unit must be calibrated regularly.

Information Recalibration at the start of every shift is recommended.

Incorrect measurement results due to premature calibration

If calibrated prematurely, the unit will produce incorrect measurement results.

► Allow the unit to run for at least 20 minutes before performing the calibration.

Calibration Particularities

internal

external

external dynamic

• with internal test leak • Auto tune (mass adjustment)

• Determining the calibration

factor with the signal of the test

leak tuned

• Determining the background

Following calibration, adjust

the machine/sniff factor as

needed, see Chapter 6.10.4,

page 34

• Vacuum mode: with external

test leak installed in the test

system

• Sniffer mode: with external

sniffer leak

• Taking the test system

characteristics into account

(pressure, split flow ratio)

• with external test leak installed

in the test system

• Taking the test system

characteristics into account

(pressure, split flow ratio,

measuring time)

• Measuring time based on the

dynamic signal curve

• Auto tune (mass adjustment)

• Determining the calibration

factor after tuning the signal of

the test leak

• Determining the background

• Determining the calibration

factor before tuning the signal

of the test leak

• Determining the background

32 Operation

Page 33

6.10.1 Internal calibration

Internal test leak connected.

1 Enter leakage rate of the test leak via digital interface (control unit CU1000,

I/O module IO1000 or bus module BM1000).

2 Start calibration.

Calibration is performed automatically.

6.10.2 External calibration

Vacuum mode: External test leak installed and open in or on the test system.

Sniffer mode: Sniffer line measures sniffer leak.

1 Enter leakage rate of the external test leak via digital interface (control

unit CU1000, I/O module IO1000 or bus module BM1000).

2 Wait until leakage rate signal is tuned and stable.

3 Start calibration.

Request C

4 Vacuum mode: Close test leak inside the test system.

5 Sniffer mode: Remove sniffer line from sniffer leak.

Leakage rate signal decreases.

6 Confirm measured background value is stable.

LOSE TEST LEAK

6.10.2.1 External dynamic calibration

Vacuum mode: External test leak installed and open in or on the test system.

Sniffer mode: Sniffer line measures sniffer leak.

1 Enter leakage rate of the external test leak via digital interface (control

unit CU1000, I/O module IO1000 or bus module BM1000).

2 Wait until leakage rate signal is tuned and stable.

3 If you wish to apply non-tuned leakage rate signal: Start calibration.

This leakage rate signal will be used for the calibration.

Request C

4 To determine the helium background, close the inlet valve on the test system.

Leakage rate signal decreases.

5 Confirm significantly decreased leakage rate signal.

LOSE TEST LEAK.

Operation 33

Page 34

6.10.3 Enable/disable Calibration request

If Calibration request is enabled, the unit will prompt the user to perform a calibration

30 minutes after it has been switched on and in case of temperature changes greater

than 5 °C.

► Enable or disable Calibration request as needed:

F

UNCTIONS > CAL > SETTINGS > CAL REQUEST > CALIBRATION REQUEST

6.10.4 Setting machine and sniff factor

The internal calibration will only calibrate the measurement system of a mass

spectrometer module that is uncoupled from the test system. If the unit is operated

in parallel to an additional pump system after an internal calibration (following the

split flow principle), the unit will indicate a leakage rate that is too low based on the

split flow ratio.

With the help of a corrective machine factor (in vacuum mode) and a sniff factor (in

sniffer mode), the unit indicates the actual leakage rate.

6.10.4.1 Setting machine and sniff factor manually

Mass spectrometer module calibrated internally.

1 Measure external test leak using the test system.

The unit indicates a leakage rate that is too low based on the split flow ratio.

2 Setting machine / sniff factor:

S

ETTINGS > SET UP > OPERATION MODES > VACUUM/SNIFFER > MACHINE FACTOR >

M

ASS 2/3/4 > MACHINE/SNIFF FACTOR M2/3/4

The unit indicates the actual leakage rate.

6.10.4.2 Setting machine and sniff factor using machine calibration

Internal test leak connected.

External test leak installed in or on the test system and closed.

1 Enter leakage rate of the internal and external test leak via digital interface

(control unit CU1000, I/O module IO1000 or bus module BM1000).

2 Start machine calibration.

Internal calibration is performed automatically.

Request O

3 Open external test leak and valve (if present) between the leak detector and the

system.

4 Confirm tuned and stable leakage rate signal.

Request C

5 Close external test leak.

6 Confirm tuned and stable leakage rate signal.

Machine/sniff factor is defined.

PEN TEST LEAK (External test leak).

LOSE TEST LEAK (External test leak).

34 Operation

Page 35

6.11 Select sample gas

The mass spectrometer module is capable of measuring the following gases:

• Hydrogen (H

• Mass 3 (H-D,

• Helium (

4

He)

)

2

3

He oder H3)

► Select desired mass:

S

ETTINGS > MASS > MASS

The machine, calibration and sniff factor are dependent on the configured mass and

are saved in the mass spectrometer module.

6.12 Decontaminating backing pump from test gas

The mass spectrometer module can control an electric 24V gas ballast valve of the

backing pump via the O

UTPUT connection.

► Controlling the gas ballast valve using digital outputs.

6.13 Selecting units for leakage rate

For control unit:

► Select desired unit of the leakage rate in vacuum mode:

V

IEW SETTINGS > UNITS (DISPLAY) > LEAK RATE UNIT VAC

► Select desired unit of the leakage rate in sniff mode:

V

IEW SETTINGS > UNITS (DISPLAY) > LEAK RATE UNIT SNIFF

For I/O or bus module:

► Select desired unit of the leakage rate in vacuum mode:

S

ETTINGS > SET UP > INTERFACES > UNITS (INTERFACE) > LEAK RATE UNIT VAC

► Select desired unit of the leakage rate in sniff mode:

S

ETTINGS > SET UP > INTERFACES > UNITS (INTERFACE) > LEAK RATE UNIT SNIFF

6.14 Selecting units for pressure

For control unit:

► Select desired unit for the pressure:

V

IEW SETTINGS > UNITS (DISPLAY) > PRESSURE UNIT

For I/O or bus module:

► Select desired unit for the pressure:

S

ETTINGS > SET UP > INTERFACES > UNITS (INTERFACE) > PRESSURE UNIT

Operation 35

Page 36

6.15 Enable/disable correction of the leakage rate in Standby

Enabled = machine/sniff factor is considered in Standby.

Disable = machine/sniff factor is not considered in Standby.

► Enable or disable correction of the leakage rate in Standby as needed:

S

ETTINGS > SET UP > OPERATION MODES > LR CORRECTION > MACHINE FACTOR IN

STANDBY

6.16 Setting the leakage rate threshold value

The mass spectrometer module has four independent leakage rate threshold values.

► Set the leakage rate threshold value as needed:

S

ETTINGS > TRIGGER > TRIGGER 1/2/3/4 > TRIGGER 1/2/3/4 LEVEL

6.17 Enable/disable ZERO key (Sniffer key)

► Enable or disable ZERO key on sniffer line as needed:

S

ETTINGS > SET UP > OPERATION MODES > SNIFFER > SNIFFER KEY > ZERO KEY

SNIFFER

6.18 Setting capillary surveillance

To detect clogged sniffer lines, the backing pressure is monitored in sniffer mode.

You can adjust the pressure threshold that will result in a warning if values fall below

it.

► Setting surveillance of the backing pressure:

S

ETTINGS > SET UP > OPERATION MODES > SNIFFER > CAPILLARY >

P

RESSURE CAPILLARY BLOCKED

6.19 Compatibility with LDS1000 and LDS2010

Switching the compatibility mode will cause the unit to load the corresponding factory

settings of the LDS1000, LDS2010 or LDS3000.

6.20 Warning and malfunction messages

Error

number

ASCII

protocol*

Limit

values

Error

number

102 W

104 W

106 W

Warning/

Error

Error

Error message

LDS3000

1xx system error (RAM, ROM, EEPROM, clock, ...)

Timeout EEPROM

MSB,

(number of parameter)

One EEPROM

parameter initialized,

(number of parameter)

EEPROM parameters

initialized,

(number of parameter)

number

LDS1000

protocol

84 43

84 43

84 43

Cause

EEPROM on IF board or

MSB defective

Following software update

or EEPROM defective

Following software update

or EEPROM defective

36 Operation

Page 37

Error

Error

number

Warning/

Error

Error message

LDS3000

number

LDS1000

protocol

110 W Clock is not set 16 16

122 W

125 W

127 W

No answer from bus

module

I/O module

disconnected

Wrong bootloader

version

99 99

99 99

99 99

130 W Sniffer not connected 99 99

2xx operating voltage error

201 W

202 W

U24VHz too low

(voltage [V])

U24VHz too high,

(voltage [V])

24 120 21.6V 24V power supply pack

24 120 26.4V 24V power supply pack

Output voltage 24V

203 W

PWR12 out of range,

24 120

(voltage [V])

Output voltage 24V

204 W

PWR34 out of range,

24 120

(voltage [V])

Output voltage 24V

205 W

PWR56 out of range,

24 120

(voltage [V])

Internal voltage 24V(8)

221 W

out of range,

24 120

(voltage [V])

Internal voltage 24V(9)

222 W

out of range,

24 120

(voltage [V])

Internal voltage

223 W

24V(10) out of range,

24 120

(voltage [V])

Internal voltage

224 W

24V(11) out of range,

24 120

(voltage [V])

Voltage +15V out of

240 W

range,

24 120

(voltage [V])

Voltage -15V out of

241 W

range,

24 120

(voltage [V])

Voltage +15V or -15V

242 E

shortened,

24 120

(voltage [V])

Internal voltage 5V out

250 W

of range,

24 120

(voltage [V])

Error

number

ASCII

protocol*

Limit

values

20V

30V

20V

30V

20V

30V

20V

30V

20V

30V

20V

30V

20V

30V

4.5V

5.5V

Cause

Jumper for clock not set,

battery drained, clock

defective

Connection to BUS module

interrupted

Connection to I/O module

interrupted

Boot loader not compatible

with application

Short circuit at valve 1

(calibration leak) or valve 2

(gas ballast)

Short circuit at valve 3 or

valve 4

Short circuit at valve 5

(sniff) or valve 6

Short circuit 24V at Control

Unit output

Short circuit 24V at IO

output

Short circuit 24V of the

TMP

Short circuit 24V

Pirani (1,2,3), sniffer line

+15V too low, IF board or

MSB defective

-15V too low, short circuit

at pre-amplifier, IF board or

MSB defective

+15V or -15V too low, short

circuit at pre-amplifier, IF

board or MSB defective

+15V or 5V too low,

Short circuit at preamplifier, IF board or MSB

defective

Operation 37

Page 38

Error

number

252 E

3xx detection system (offset pre-amplifier, pre-amplifier test, emission, cathode test)

300 W

301 W

302 W

303 W

304 W

305 W

310 W

311 W

312 E

340 E

342 W

350 W

Warning/

Error

Error message

LDS3000

Voltage REF5V

shortened,

(voltage [V])

Anode voltage too low,

(anode voltage [V])

Anode voltage too high,

(anode voltage [V])

Suppressor voltage too

low,

(suppressor voltage [V])

Suppressor voltage too

high,

(suppressor voltage [V])

Anode cathode voltage

too low,

(anode - cathode

voltage)

Anode cathode voltage

too high,

(anode - cathode

voltage)

Cathode 1 broken,

(actual status)

Cathode 2 broken,

(actual status)

Cathode broken,

(actual status)

Emission error,

(emission current [A])

Cathodes not

connected

Suppressor not

connected

Error

number

LDS1000

protocol

24 120

41 132

40 131

39 130 297V

38 129 363V MSB defective

36 127 40V

35 126 140V MSB defective

45 136

46 137

47 138

44 135

47 138

39 130

Error

number

ASCII

protocol*

Limit

values

7V <

Nom.

Value

7V >

Nom.

Value

<90%

Nom.

value

>110%

Nom.

Value

Cause

+15V or REV5V too low,

short circuit at preamplifier, IF board or MSB

defective

Short circuit anode voltage,

pressure in mass

spectrometer too high, IF

board, MSB or ion source

defective

MSB defective

Short circuit suppressor, IF

board or MSB defective

Short circuit anodecathode, IF board or MSB

defective

Cathode defective, line to

cathode interrupted, IF

board or MSB defective

Cathode defective, line to

cathode interrupted, IF

board or MSB defective

Cathode defective, line to

cathode interrupted, IF

board or MSB defective

Emission was stable

previously, pressure

probably too high,

message after 15s

Both cathodes defective

during self-testing or plug

not connected

Suppressor cable during

self-testing not connected

or defective

38 Operation

Page 39

Error

number

ASCII

protocol*

Error

number

360 W

361 W

362 W

390 W

Warning/

Error

Error message

LDS3000

Preamp output too low

(preamp voltage [V])

Preamp offset too high

(Offset [V])

Preamp range error

(preamp voltage [V])

500 G out of range,

(resistor [Ω])

Error

number

LDS1000

protocol

31 123

31 123

31 123

31 123

4xx TMP error (also temperature)

400 E

402 E

403 E

404 E

Error number of TMP,

(No. from TMP)

No communication with

TMP

TMP speed too low,

(TMP speed [Hz])

TMP current too high,

(current [A])

49 15

49 15

53 142

49 2 3A

405 E No runup TMP 60 61 5 Min.

TMP temperature too

410 E

high,

49 2 61°C

(No. from TMP)

411 W

420 E

422 E

423 W

TMP temperature high,

(No. from TMP)

TMP voltage too high,

(No. from TMP)

TMP no run up,

(No. from TMP)

TMP pressure rise,

(No. from TMP)

49 2 60°C

49 2 TMP Err002 at approx. 30V

49 2 8 Min. TMP Err006

49 2 TMP Wrn168

Limit

values

<-70 mV

at

500 GΩ

>+/-50 mV

at 500 GΩ,

>+/-10 mV

at 15 GΩ,

<+/-10 mV

at 470 MΩ,

<+/-9 mV

at 13 MΩ

450 GΩ

550 GΩ

< 95%

Nom.

Value

Cause

Poor ion source or

contaminated mass

spectrometer

Pre-amplifier defective

Pre-amplifier or MSB box

defective

Pre-amplifier defective,

error at the suppressor, IF

board or MSB defective

Cable to TMP / TMP

defective, IF board or MSB

defective

Pressure too high, TMP

defective

Pressure too high, TMP

faulty

TMP Err044, Err045,

Err117, Err118, Wrn119,

Wrn143

TMP Wrn045, Wrn076,

Err117, Err118, Err119,

Err143

Operation 39

Page 40

Error

Error

number

500 W

520 W

521 W

522 W

540 W

541 E Sniffer blocked 62 146

542 W

600 W

601 W

602 W

603 W

604 W

605 W Testleak too small

610 W

Warning/

Error

Error message

LDS3000

5xx Pressure and flow errors

Pressure sensor not

connected,

(pressure p1 voltage

[V])

Pressure too high,

(pressure p1 [mbar])

Pressure rise, anode

break down,

(anode voltage [V])

Pressure rise emission

break down,

(emission current [A])

Pressure too low,

sniffer blocked,

(pressure p1 [mbar])

Sniffer broken,

(pressure p1 [mbar])

6xx Calibration errors

Calfac too low,

(calibration factor)

Calfac too high,

(calibration factor)

Calfac lower than last

calibration,

(calibration factor)

Calfac higher than last

calibration,

(calibration factor)

No int cal due to valve

control,

(valve control by user)

Machine factor too low,

(machine factor)

number

LDS1000

protocol

58 144 0.5V

73 148

73 148

73 148

63 62

64 147 Sniffer broken

81 153 0.01

81 153 5000

81 153

81 153

81 153 Test leak is not enabled

81 153

protocol*

Error

number

ASCII

Limit

values

18

mbar

< Nom.

Value 20V

< 90%

Nom.

Value

> 110%

Nom.

value

Param

eter

Sniffer

flow

warnin

g

< 50%

old

value

> 200%

old

value

1.00E-04Machine factor adjustment

Cause

Pirani P1 not connected, IF

board or MSB defective

Pressure p1 too high

Pressure p1 too high,

message after 1.4s

Emission was stable

previously, pressure p1 too

high, message after 5s

Sniffer clogged, sniffer

valve defective

Sniffer blocked, sniffer

valve defective (pressure

lower than half of the

configured warning value)

Calibration leak or machine

factor set incorrectly

Calibration leak or machine

factor set incorrectly, split

flow factor too high

Calibration leak, machine

factor or split flow factor

has changed

Calibration leak, machine

factor or split flow factor

has changed

Test leak defective or

signal too weak

inaccurate

40 Operation

Page 41

Error

Error

number

Warning/

Error

Error message

LDS3000

number

LDS1000

protocol

611 W

Machine factor too high,

(machine factor)

81 153

Machine factor lower

612 W

than last,

81 153

(machine factor)

Machine factor higher

613 W

than last,

81 153

(machine factor)

625 W

626 W

Int testleak not set,

(int. Testleak)

Ext testleak not set,

(ext. Testleak)

00

00

630 W Calibration request 0 0

7xx temperature errors (pre-amplifier, electronics)

Preamplifier temp too

700 W

low,

33 60 2°C Temperature too low

(temperature [°C])

Preamplifier temp too

702 W

high,

32 124 60°C Temperature too high

(temperature [°C])

703 E

Preamplifier not

connected

33 60

Max. MSB temperature

710 W

exceeded,

54 44 55°C Temperature too high

(temperature [°C])

MSB temperature far

711 E

too high,

54 44 65°C Temperature too high

(temperature [°C])

8xx not used

9xx Maintenance warnings (e. g. TMP)

901 W

Maintenance bearing/

lubricant

99 99 3 years

Error

number

ASCII

protocol*

Limit

values

1.00E+

04

< 50%

old

value

> 200%

old

value

Cause

Machine factor adjustment

inaccurate, split flow factor

too high

Split flow factor has

changed

Split flow factor has

changed

Leakage rate of internal

test leak is still set to

factory setting

Leakage rate of test leak is

still set to factory setting

Temperature change of

5°C, speed was changed

since last calibration, 30minute switch-on time and

still no calibration

conducted

Pre-amplifier defective,

cable not plugged in

TMP maintenance

necessary

* compatib. LDS1000/LDS2010 or binary protocol

Operation 41

Page 42

6.20.1 Error codes of the status LED

Any errors or warnings occurring in the MSB box will be indicated both as an error

code by the control unit and as a blink code by the Status LED.

The blink code is preceded by a long white signal. This is followed by an error or

warning number. An error number is indicated by means of red signals, while a

warning number is displayed using orange signals (the orange signals have a strong

green tinge, however):

• Start of blink code: long white signal

• Hundreds digit: 0 ... 9 red signals for errors / 0 ... 9 orange signals for warnings

• Break: blue signal

• Tens digit: 0 ... 9 red signals for errors / 0 ... 9 orange signals for warnings

• Break: blue signal

• Units digit: 0 ... 9 red signals for errors / 0 ... 9 orange signals for warnings

The blink code is repeated cyclically.

For example:

The pressure is too high.

-> Error code = Warning 520

-> Blink code of the Status LED: White (long), 5·orange, blue, 2·orange, blue

42 Operation

Page 43

7 Maintenance

The mass spectrometer module is a leak detector that is intended for industrial

applications. The unit is composed of parts and assemblies that are, for the most

part, low maintenance.

Servicing the mass spectrometer module merely requires that you change the

operating fluid reservoir of the turbo molecular pump and check the fan on the turbo

molecular pump.

Information We recommend that you sign a service agreement with INFICON or one

of INFICON's authorized service partners.

7.1 Maintenance and service at INFICON

Danger to health

Contaminated units can damage the health of INFICON's service staff.

► Use the Declaration of Contamination.

1 Fill out the “Declaration of Contamination”, see Chapter 9.2, page 51.

Information We will be happy to send you the form “Declaration of Contamination”

upon request. Xerox copies of the form are permissible.

The Declaration of Conformity is essential to ensure compliance with statutory

requirements and the protection of our employees. Units submitted without an

enclosed Declaration of Conformity will be returned to the sender by INFICON.

2 Attach the form to the unit or enclose it in the unit's packaging.

7.2 General maintenance information

The maintenance work that needs to be performed on the mass spectrometer

module is grouped into three service levels:

• Service level I: Customer without any technical training

• Service level II: Customer with technical and INFICON training

• Service level III: INFICON Service

Maintenance 43

Page 44

Danger to life due to electric shock

Inside the unit there are voltages of considerable magnitude. Touching parts where

electric voltage is present can result in death.

► Disconnect the unit from the power supply prior to any maintenance work.

Material damage due to unclean working conditions

Unclean working conditions can damage the unit.

► Make sure that the working environment is clean and you use clean tools

whenever performing any maintenance work.

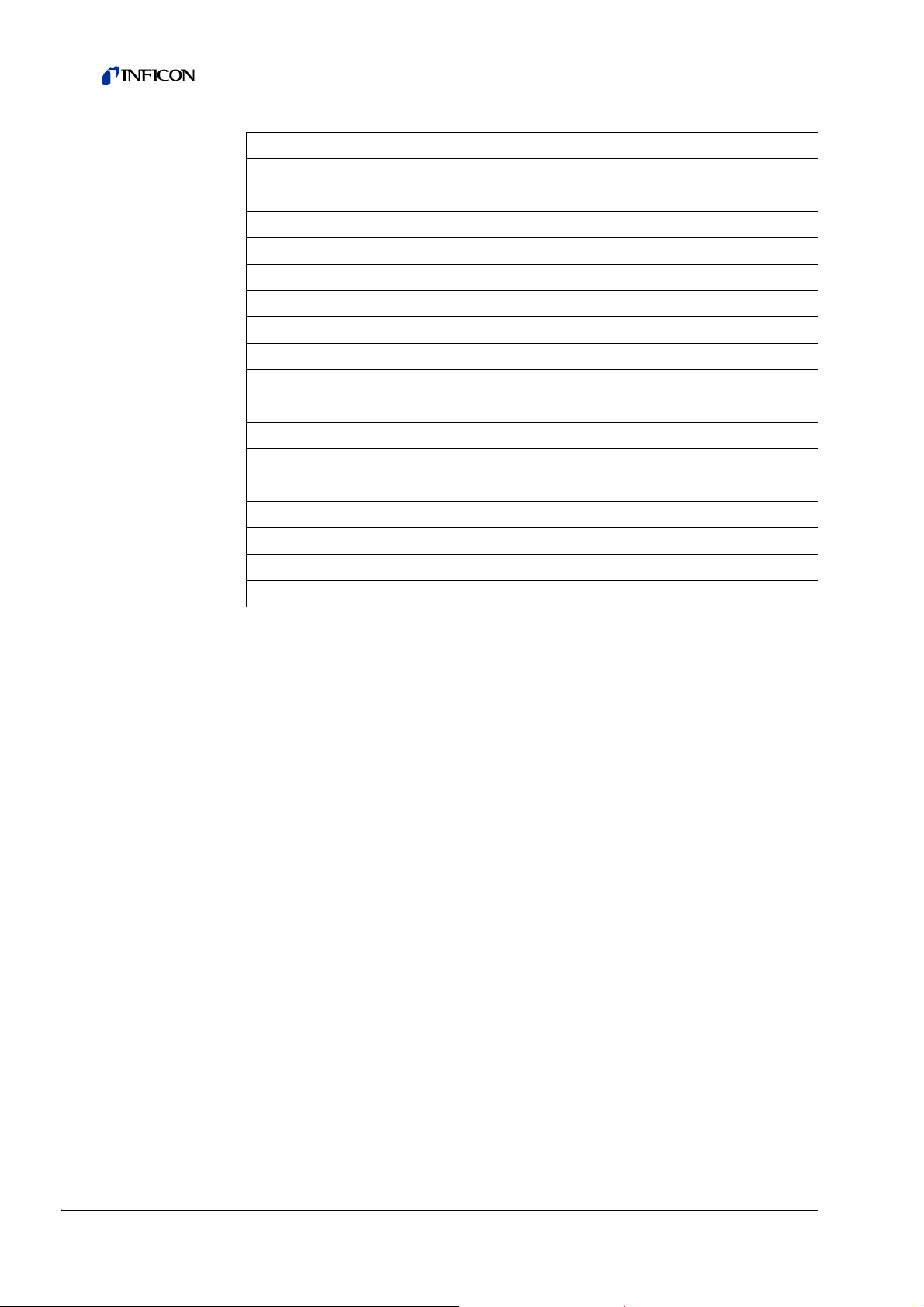

7.3 Maintenance schedule

Failure to perform the maintenance work specified in the maintenance schedule will

void the warranty granted on the mass spectrometer module LDS3000.

Maintenance

steps

Change operating

fluid reservoir

Replace bearing

Turbo molecular pump

Accessories

(recommended)

Clean fan and

check for proper

operation

Clean sniffer valve X III

Calibrate internal

test leak

Operating hours [hrs] / time period

[years]

24 2000 8000 16000 24000 36000

1/4 a 1 a 2 a 3 a

X

2

X

2

1 I and II

X

2

Service

level

Spare part

no.

II and III 200003801

III

III

Internal calibration

External calibration

Leak test MS module

44 Maintenance

Perform internal

calibration

Perform external

calibration

Perform helium leak

test on MS module

X

1

X

1

I

I

XIII

X: based on operating hours or time period

X

: based on operating hours

1

X

: based on time period

2

1: depending on environment and use

Page 45

7.4 Maintenance steps

7.4.1 Change operating fluid reservoir of turbo molecular

pump

1 Shut down mass spectrometer module, see Chapter 8, page 49.

2 Remove turbo molecular pump.

Fig: 5 Tu rbo molecular pump SplitFlow80

1 Cover

2 O-ring

Flooding mass spectrometer and turbo molecular pump

The cover of the operating fluid reservoir cannot be unscrewed unless the reservoir

has been flooded.

1 Disconnect 24 V power supply pack from MSB box.

2 Wait until turbo molecular pump is drained (at least 1 min).

3 Allow the turbo molecular pump to cool down if necessary.

4 Open the ventilation screw slowly.

Turbo molecular pump is flooded until it reaches atmospheric pressure.

3 Operating fluid reservoir

4 Ventilation screw

Maintenance 45

Page 46

Removing old operating fluid reservoir

Face pin wrench, P/N: 551-200

Two screwdrivers

Tweezers

O-ring

Operating fluid reservoir, P/N: 200 003 801

Mass spectrometer and turbo molecular pump flooded.

1 Pay attention to the expiration date of the new operating fluid reservoir.

Danger of poisoning due to harmful substances

The operating fluid reservoir and parts of the turbo molecular pump can be

contaminated with toxic substances that are contained in the pumped media.

► Take suitable safety precautions.

► Decontaminate contaminated parts prior to any maintenance work.

► Dispose of old operating fluid reservoirs in compliance with applicable

regulations.

The new operating fluid reservoir contains a sufficient level of operating fluid.

2 Do not fill in any more operating fluid.

3 Use a face pin wrench to unscrew the cover.

4 Remove old o-ring.

5 Use two screwdrivers to lift out the operating fluid reservoir.

46 Maintenance

Page 47

Fig: 6 Changing the operating fluid reservoir

1 O-ring

2 Operating fluid reservoir

3 Porex rods

4 Ventilation screw

Replacing Porex rods

1 Pull out the old Porex rods (8 pcs) using a pair of tweezers.

Material damage due to cleaning liquids

Cleaning liquids can damage the unit.

► Do not use any cleaning liquids.

► Use a clean, lint-free cloth.

2 Remove any contaminants found on the turbo molecular pump and the cover

using a clean, lint-free cloth.

3 Insert new Porex rods (8 pcs) using a pair of tweezers.

Maintenance 47

Page 48