Page 1

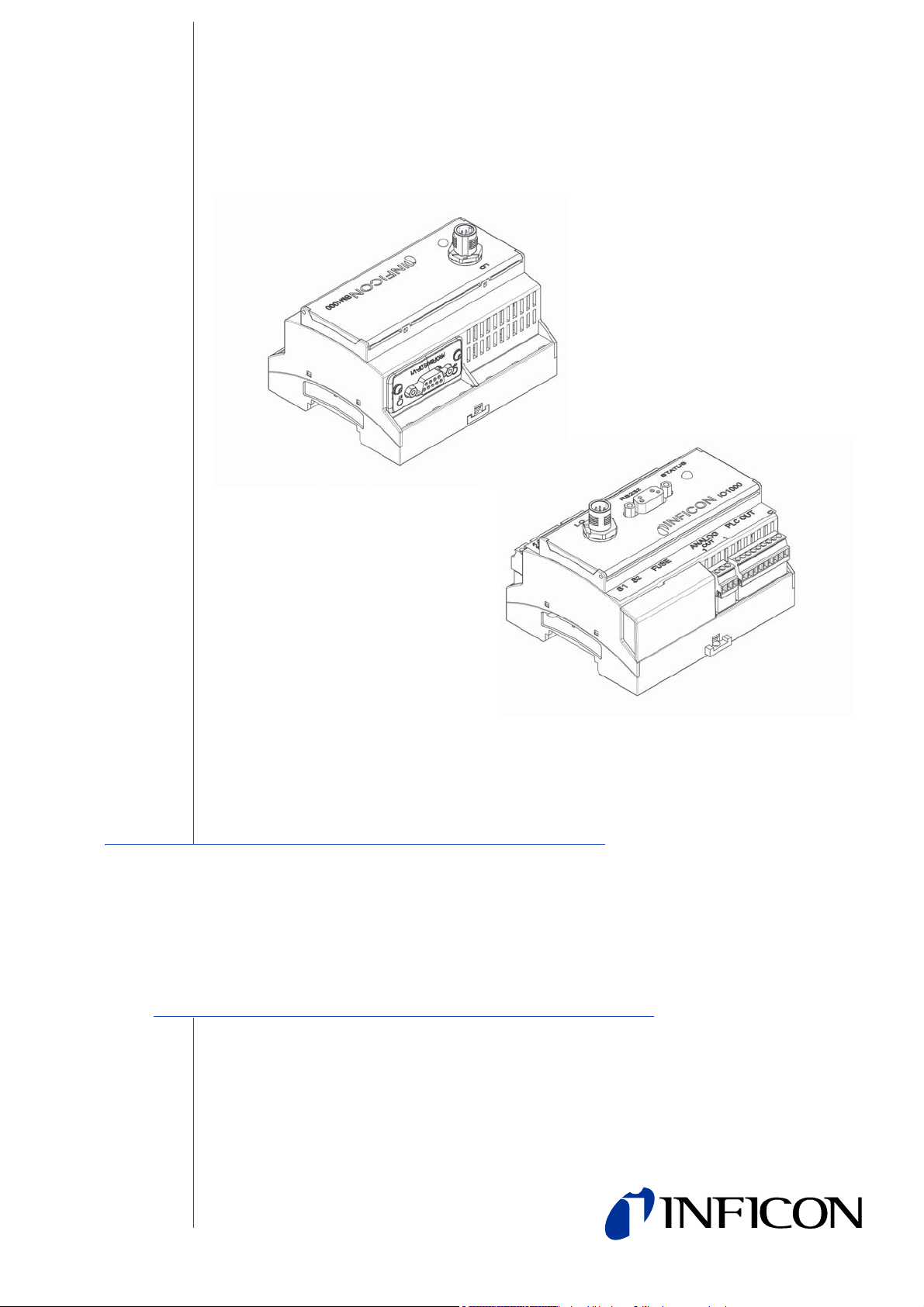

PROTOCOL DESCRIPTIONS

Type designation

LDS3000

Product description

Interface Protocols

Catalog no.

from software version

Document no.

560-310, 560-315

MS Module 1.0

jira54e1-a (1212)

Page 2

This document applies to the software version stated on the cover page. If you need

a different version, please contact our sales staff.

Reprint, translation and duplication need to be approved in writing by

INFICON GmbH.

2

Page 3

Content

1 Interface Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Serial Interface Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Field Bus Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 ASCII Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Comparison between ASCCI- and LD protocol . . . . . . . . . . . . . . . . . . 7

2.2 Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 LDS1000 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Interface Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Interface Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.1 Main functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.2 Status Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.3 Request for Measurement Data . . . . . . . . . . . . . . . . . . . . . . 20

3.2.4 Entry of Instrument Settings . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.5 Running of service functions . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Binary Interface Protocol . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 LD Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Command format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.1 Telegram structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.3 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.4 Enumerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6 Fieldbus Communication . . . . . . . . . . . . . . . . . . . . . . . 49

6.1 Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.3 Process Data Mapping for Cyclic Data Transfer . . . . . . . . . . . . . . . . . 49

6.3.1 Write Process Data (PLC-> Leak Detector) . . . . . . . . . . . . . 49

6.3.2 Read Process Data (Leak Detector PLC) . . . . . . . . . . . . . 50

Content 3

Page 4

6.4 Acyclic Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.4.1 Addressing Rules for Acyclic Access . . . . . . . . . . . . . . . . . . . 51

6.5 Hardware Configuration for Profibus . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.5.1 Assignment of the PROFIBUS Address . . . . . . . . . . . . . . . . 52

6.5.2 Diagnosis with the CU1000 Info Menu . . . . . . . . . . . . . . . . . 53

6.5.3 Serial communication via RS232 (common) . . . . . . . . . . . . . 53

6.5.4 ASCII Protocol specific . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.5.5 LD Protocol specific . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 Content

Page 5

Content 5

Page 6

1 Interface Protocols

1.1 Serial Interface Protocols

With the IO1000 module you can communicate with the LDS3000 via the following

serial interface protocols:

• ASCII Protocol (enabled by default)

• LD Protocol

If you want to replace a LDS1000 or LDS2010 with a LDS3000 you can also use

• Binary Interface Protocol

• LDS1000 Compatibility Protocol

Do not use the last two protocols for new developments. They have limited

functional range and may not be supported in future.

The serial interface protocol can be selected via DIP switch at the IO module IO1000

or via control unit CU1000. Please refere to appropriate documentation.

1.2 Field Bus Protocols

With the Bus module BM1000 you can communicate with the LDS3000 via the

following field bus protocols:

• PROFIBUS-DP Protocol

• Other fieldbus protocols (PROFINET, DeviceNet, EtherNet/IP, MODBUS RTU,

MODBUS TCP, CANopen, EtherCAT, CC-Link, ControlNet) may be available on

request. Please contact your local INFICON representative.

6 Interface Protocols

Page 7

2 ASCII Protocol

2.1 Comparison between ASCCI- and LD protocol

ASCII- and LD protocol have nearly the same functional range, but each of them

have some advantages and disadvantages :

ASCII protocol:

Advantages:

• human readable

• easy to use with simple terminal program

Disadvantages:

• No checksum, therefor lower data security

• PC/ PLC software must convert numerical values from ASCII string to binary

• Lower efficiency (for example: 8 data bytes for one float value)

LD protocol:

Advantages:

• Leak detector status always transmitted in each slave telegram

• High data security due to CRC checksum

• Binary transmission of numerical values – no conversion needed in PC/ PLC

software

• High efficiency (for example: 4 Byte data bytes for one float value)

Disadvantages:

• Not human readable

• Not useable with simple terminal program

2.2 Communication Parameters

Data format

Baudrate 19.200, 8 data bits, 1 stop bit, no parity

2.3 Command Format

In ASCII protocol any command starts with « * » (ASCII code 42dec/2Ahex) and is

finished with the end sign CR (ASCII code 13dex/0Dhex). There is no differentiation

between upper and lower case. A blank is required between the command and the

parameter, no other blanks are allowed.

There is a short and an extended form of the command. Either the short or the

extended command must be used, no other abbreviations are allowed (The short

form is here written in capitals but the SW don’t difference upper and lower cases).

Command Words have to be separated by a colon. A command can be composed

of up to three words. Parameters have to be separated by a comma.

ASCII Protocol 7

Page 8

Each command is answered with the requested data, „ok“ or „EXX“ (in case of an

error). For a list of all error messages 2.6. The transmission can be cancelled and the

receive-buffer will be cleared with ESC (ASCII code 27dec/1Bhex), ^C (ASCII code

3dec/03hex) or ^X (ASCII code 24dec/18hex).

Some commands can be used as queries, some can be used to set menu parameter

and some can be used for both. A query is marked by a „?“ (ASCII code 63dec/

3Fhex) after the command; for setting data the command has to be followed by the

new value to be set.

Parameter can be Boolean or numerical:

<b> Boolean 0 / 1 or OFF / ON

<No> Numeric representation format: integer, real (15.6) or exponential (4.5

Format: [space] [sign] [ddd] [.] [e[sign]ddd] (d:digit)

Notice Always use a point as the decimal marker. If a comma is used during

numerical data entry, the conversion of the number is cancelled at this

point and only the integer part of the number will be used.

Timing recommendations for the PC/PLC - Program:

Sample rate > 100 ms

Timeout between request to and answer from LDS3000: 1500 ms

After sending a command the answer must be waited for before sending a new

command. Otherwise the receive buffer may be overwritten.

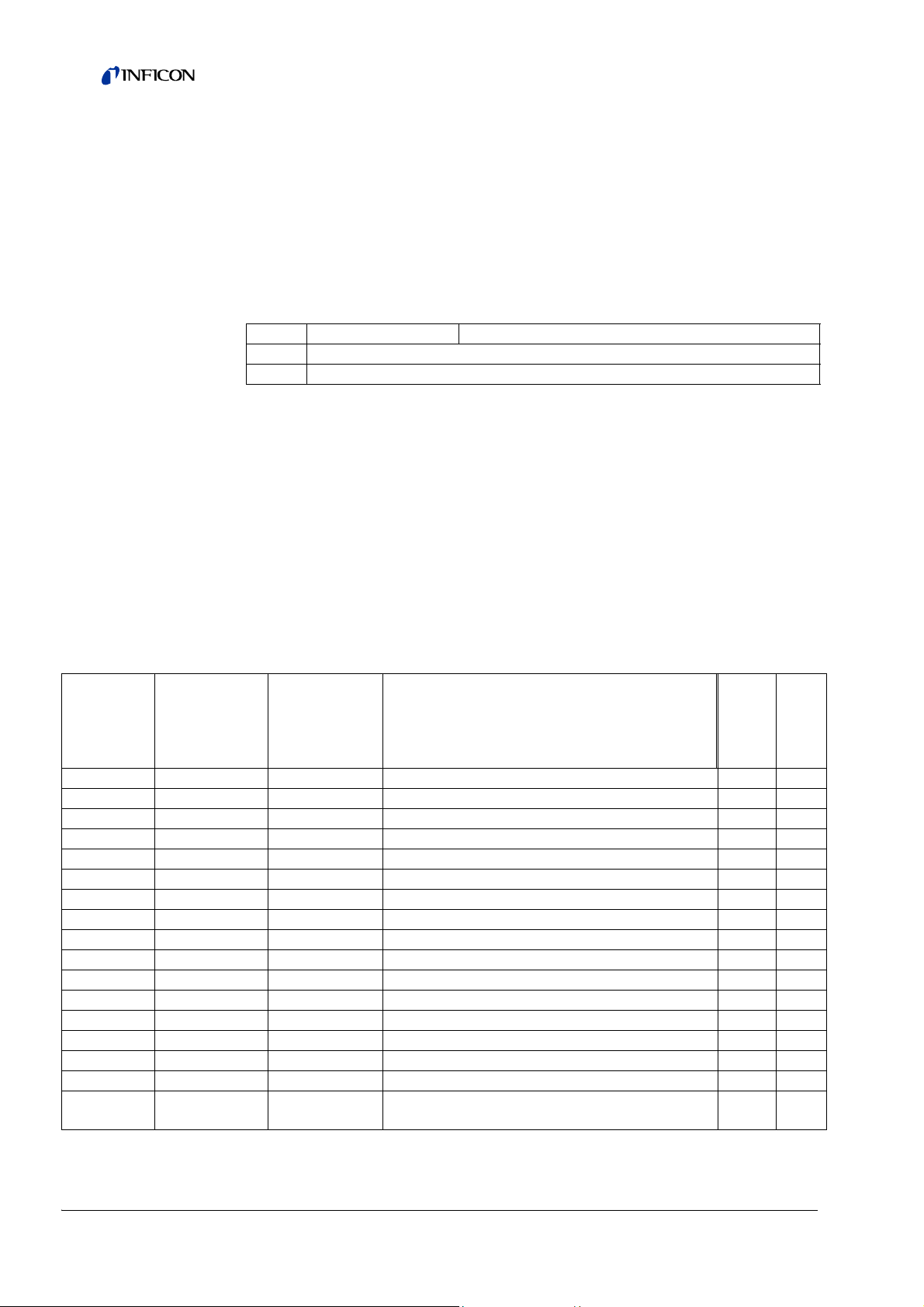

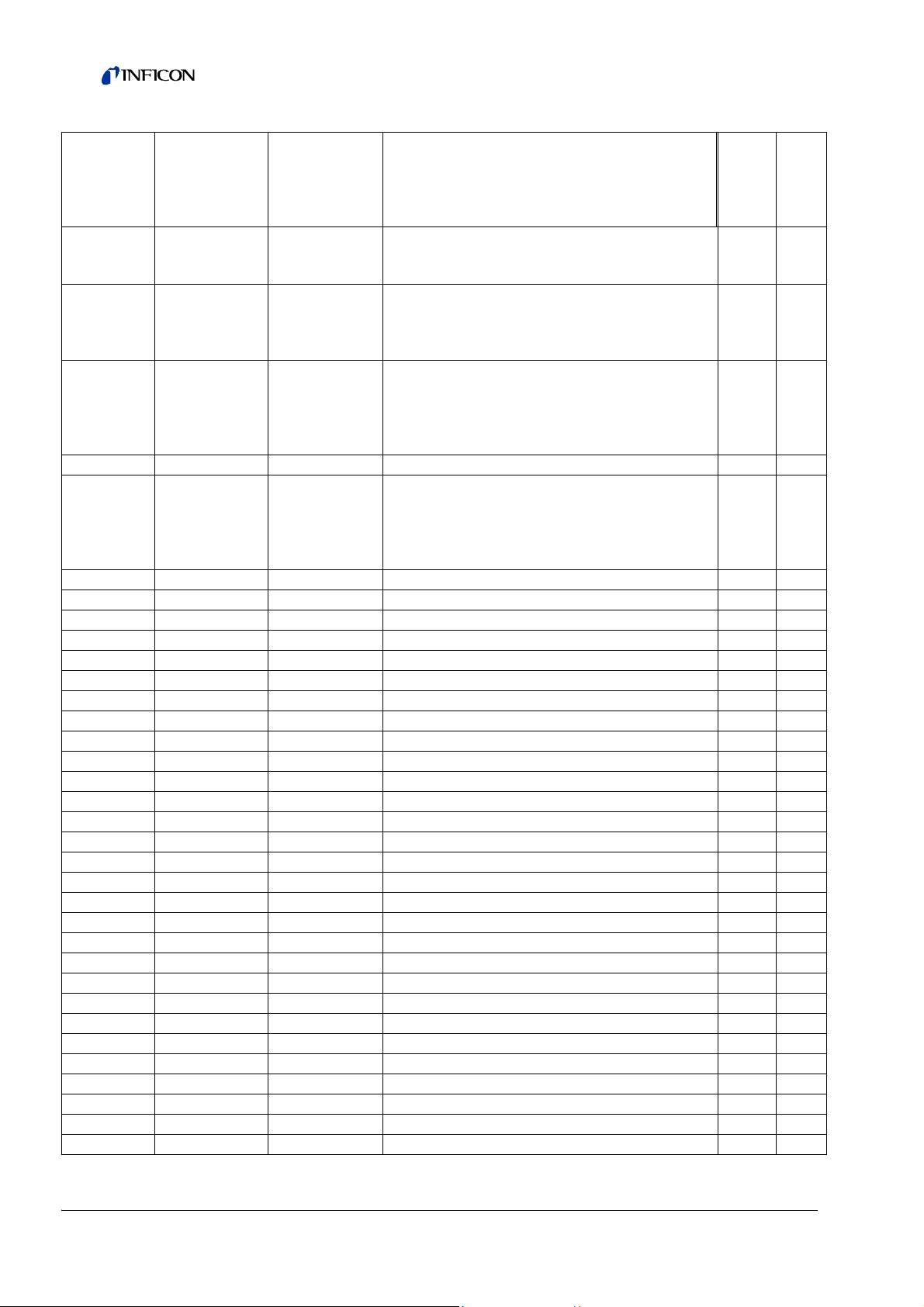

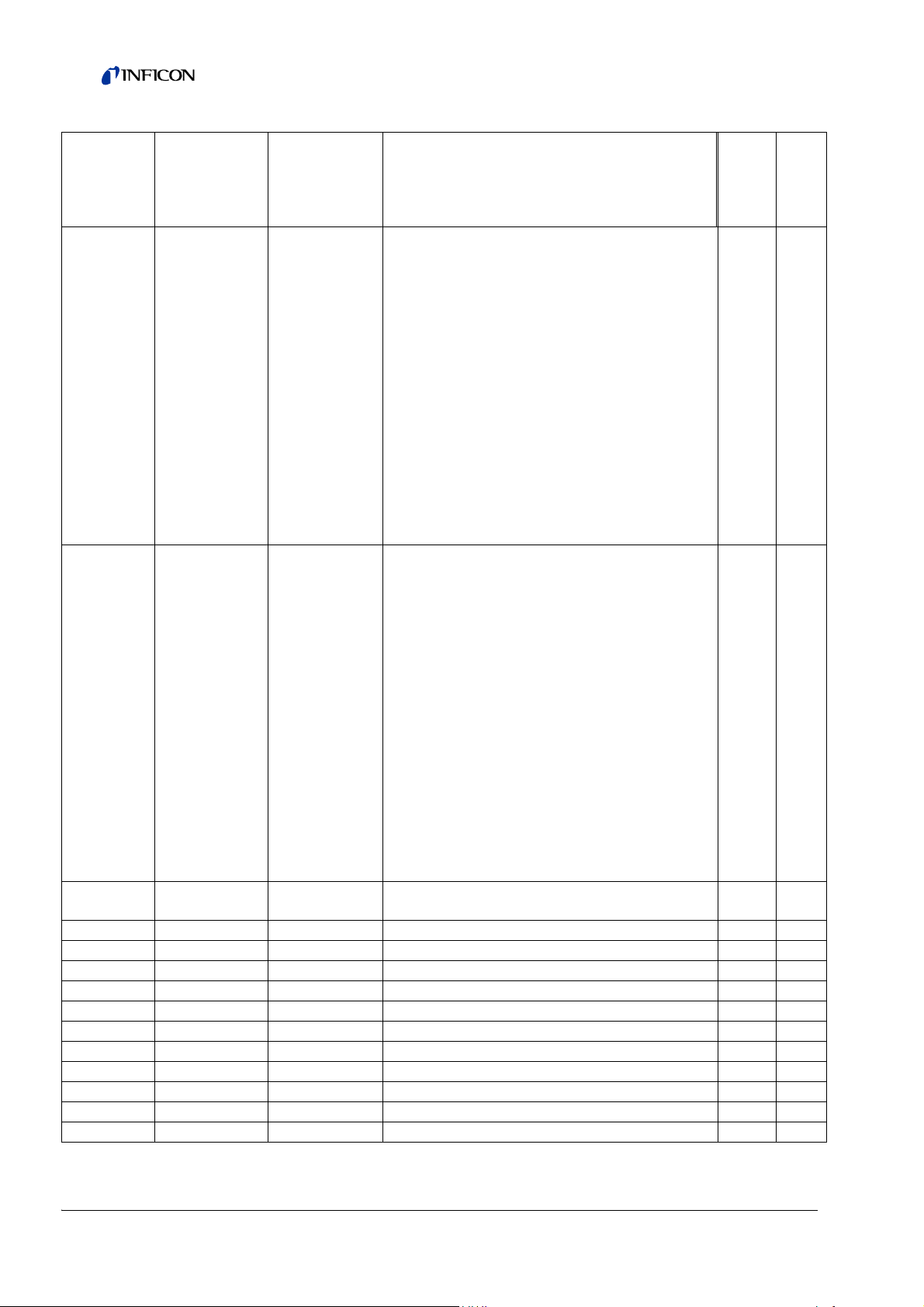

2.4 Commands

Relates to

LD cmd. no.

*CLS Clear Error 5 S

*IDN Identification

:CRC check sum 320 R

:DEVice name of instrument 301 R

:VERsion software version MSB 310 R

:SERial serial-number leak detector R

:TURBO software version TMP controller 315 R

:DIP1 MSB DipSwitch 1 (binär) 321 R

:DIP2 MSB DipSwitch 2 (binär) 321 R

:CUversion software version control unit 314 R

:IOversion software version I/O modul 313 R

:TCHARDware hardware version TMP controller 316 R

:TCNAME TMP controller name 317 R

:BMVersion software version Bus modul R

:BMSerial serial-number Bus modul R

:BMNETType Bus module network type R

*STATus

status of LDS2010 (

EMIOFF)

ACCL, STBY, MEAS, CAL, ERROR,

Status

word

-7

)

Read /

R

Set

8 ASCII Protocol

Page 9

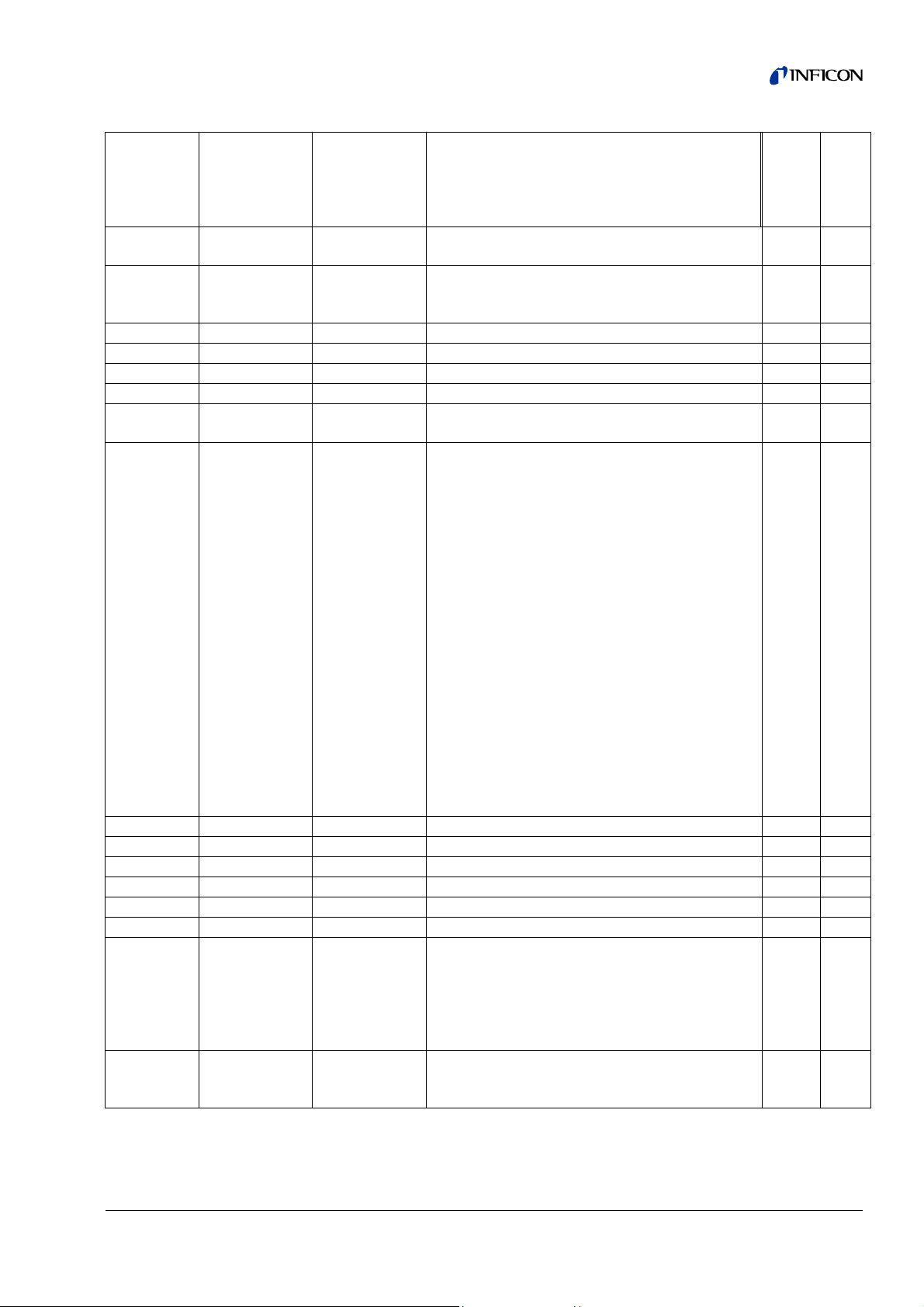

:CAL

:CALHist

:ERRor

:ERRHist

status of calibration

DYNCAL, CLOSE, FAIL)

(IDLE, INTCAL, EXTCAL,

Last error history entry

Factor, Test leak, Anode voltage, Mass, Date,

Time, Cathode, State

1 Calibration history entry 1 (newest)

2 Calibration history entry 2

…

10 error history entry 10 (oldest)

current number of error / warning („NO ERROR/

WARNING“, 3-digit failure number)

Actual error history entry

In LDS2010 compatibility mode:

dd.mm.yy hh.mm Exx

Exx is error number from LDS2010 error number

group

All other compatibility modes:

ListNo 'ERR' or 'WRN' ErrNo ErrValue(float),

year/month/day hour:min:sec 'SwOnCnt:'

SwitchOnCnt 'OnTm:' MinSinceStart

“WRNxxx vvv yy/mm/dd hh:mm:ss SwOnCnt:

zzz OnTm: ttt“

or

“ERRxxx vvv yy/mm/dd hh:mm:ss SwOnCnt: zzz

OnTm: ttt“

Relates to

LD cmd. no.

260 R

275 R

290 R

290 R

Read /

Set

xxx: Error or warning number from LDS3000

error number group

vvv: Measured value

1 error history entry 1 (newest) 290 R

2 error history entry 2 290 R

.....

16 error history entry 16 (oldest) 290 R

:MODE actual vacuum mode (VAC, SNIFF) 401 R

:ZERO Zero (ON, OFF) 6 R

status of valves

0...255 as 8-bit binary number

:VALVE

(0:off; 1:on)

Bit0: Test leak

449 R

Bit4: Sniffer valve

Bit1: Gas ballast

status of trigger

:TRIGger

S1,S2,S3,S4 with S1…S4 is “ON” or “OFF”

385 R

depending of the states of trigger1 to trigger4

ASCII Protocol 9

Page 10

Relates to

LD cmd. no.

:PREAMPRESi

stor

:CAThode

:BUSModule

:EXCEPtion Exception Code of Bus module as hex value R

:ERRORCnt

:ADDRess Field bus address R

:BAUDrate Baud rate at field bus R

*READ leak rate in current unit 128 R

:ATM*cc/s leak rate in Atm*cc/s --- R

:G/a leak rate in g/a (only in sniff) --- R

:MBAR*l/s leak rate in mbar*l/s 129 R

:PA*m3/s leak rate in Pa*m3/s --- R

:PPM leak rate in ppm (only in sniff) --- R

:TORR*l/s leak rate in Torr*l/s --- R

*STArt start 1 S

*STOp stop 2 S

*CAL :STOP abort calibration 11 S

:INT start internal calibration 4 S

:DYN start external dynamic calibration 4 S

:EXT start external calibration 4 S

:CLOSED report test leak closed (ext. cal. only) 11 S

*ZERO switch zero on 6 S

:ON switch zero on 6 S

:OFF switch zero off 6 S

*MEAS

:P or :P1 P1 pressure in current unit 130 R

:ATM P1 pressure in atm --- R

:MBAR P1 pressure in mbar 83 R

:PA P1 pressure in Pa --- R

:TORR P1 pressure in Torr --- R

:P2 P2 pressure in current unit 132 R

:ATM P2 pressure in atm --- R

:MBAR P2 pressure in mbar 133 R

:PA P2 pressure in Pa --- R

currently used resistance of pre-amplifier

(13M, 470M, 15G, 500G, 13M_FIXED,

470M_FIXED, 15G_FIXED, 500G_FIXED)

actual state of the cathode

OFF, ON1 (fix cathode 1), ON2 (fix cathode 2),

AUTO1 / AUTO2 (automatic switching; cathode

1 respectively 2 actual active)

Status Bus-Modul

“SETUP”,"NW_INIT”,

"WAIT_PROCESS","IDLE",

"PROCESS_ACTIVE","ERROR", "UNKNOWN",

"EXCEPTION"

Four error counters, format “a,b,c,d”

a: Discarded commands

b: Discarded responses

c: Serial reception errors

d: Fragmentation errors

502 R

530 R

330 R

Read /

R

Set

10 ASCII Protocol

Page 11

Relates to

LD cmd. no.

:TORR P2 pressure in Torr --- R

:P3 P3 pressure (only for service) 134 R

:P4 P4 pressure (only for service) 135 R

:UVV preamplifier voltage [V] 202 R

:MIAP anode potential [V] 167 R

:MIKP cathode potential [V] 168 R

:MISP suppressor potential [V] 169 R

:MIAKP anode-/cathode potential [V] 170 R

:U15N -15 V supply [V] 211 R

:U15P +15 V supply [V] 210 R

:U24 24 V supply [V] 200 R

:U24IO 24 V supply IO [V] 213 R

:U24IO_OUT 24V power out IO [V] 219 R

:U24PI 24 V power out pirani [V] 214 R

:U24PWR1_2 24 V power out12 [V] 215 R

:U24PWR5_6 24 V power out56 [V] 217 R

:U24RC 24V_2 power out RC [V] 212 R

:U5 +5 V supply [V] 218 R

:TEMPeratur

:Amplifier preamplifier temperature [°C] 166 R

:Electronic electronic temperature [°C] 165 R

:TCElectronic TMP electronic temperature [°C] 144

:TCPump TMP temperature bottom [°C] 143 R

:TCBearing TMP temperature bearing [°C] 145 R

:TCMotor TMP electronic temperature [°C] 146 R

:TURBO

:Frequency TMP frequency [Hz] 138 R

:Voltage TMP voltage [Hz] 150 R

:Current TMP current [A] 151 R

:Power TMP power [W] 139 R

:ANALOGOUT

1

:ANALOGOUT

2

Output voltage analog output channel 1 221 R

Output voltage analog output channel 2 221 R

Read /

Set

ASCII Protocol 11

Page 12

*CONFig

Relates to

LD cmd. no.

state of the PLC inputs as 16-bit binary number;

inactive=0, active=1

Byte 0, Bit 0: PLC In 1

Byte 0, Bit 1: PLC In 2

Byte 0, Bit 2: PLC In 3

Byte 0, Bit 3: PLC In 4

Byte 0, Bit 4: PLC In 5

Byte 0, Bit 5: PLC In 6

:DIGITALIN

:IMess Unfiltered ion current [A] 1568 R

:CALleak leak rate of test leak

:INT internal test leak in mbarl/s 394 R/S

:EXTVac

:EXTSniff external test leak in sniff mode in current sniff unit 392 R/S

:CALREQ

:CAThode

:RS232 Protocol (ASCII, LD, LDS1000) 26 R/S

:MASS mass (2,3,4) 506 R/S

:MFAE actual anode potential reference [V] 167 R

:M2 anode potential reference for mass 2 [V] 433 R/S

:M3 anode potential reference for mass 3 [V] 434 R/S

:M4 anode potential reference for mass 4 [V] 435 R/S

:MODE operating mode (VAC, SNIFF) 401 R/S

:RECorder

:LINK1

:LINK2

Byte 0, Bit 6: PLC In 7

Byte 0, Bit 7: PLC In 8

Byte 1, Bit 0: PLC In 9

Byte 1, Bit 1: PLC In 10

Byte 1, Bit 2: DIP_1

Byte 1, Bit 3: DIP_2:

Byte 1, Bit 4: DIP_3:

Byte 1, Bit 5: DIP_4

Byte 1, Bit 6: DIP_5

external test leak in vacuum mode in current vac

unit

calibration request (OFF,ON);

with read: (OFF, ON_REQUESTED,

ON_NOTREQUESTED)

target state of the cathode

OFF (not saved after power loss)

ON1 (fix cathode 1)

ON2 (fix cathode 2)

AUTO (automatic switching cathode)

with read: AUTO1 / AUTO2: Auto with cathode 1

respectively 2 actual active

Function at analog output channel 1

(OFF, P1, P2, MANT, EXP, LR_LIN, LR_LOG,

LR_LOG_H, EXTERN)

Function at analog output channel 1

(OFF, P1, P2, MANT, EXP, LR_LIN, LR_LOG,

LR_LOG_H, EXTERN)

261 R

390 R/S

419 R/S

530 R/S

222 R/S

222 R/S

Read /

Set

12 ASCII Protocol

Page 13

Relates to

LD cmd. no.

:SCALE Analog out scaling 223 R/S

:UPPEREXP Upper Exponent (in mbar*l/s) for analog out 224 R/S

:TRIGger1 trigger1 in current unit 384 R/S

:ATM*cc/s trigger1 in Atm*cc/s --- R/S

:G/a trigger1 in g/a --- R/S

:MBAR*l/s trigger1 in mbar*l/s 385 R/S

:PA*m3/s trigger1 in Pa*m3/s --- R/S

:PPM trigger1 in ppm --- R/S

:TORR*l/s trigger1 in Torr*l/s --- R/S

:TRIGger2 trigger2 in current unit 384 R/S

:ATM*cc/s trigger2 in Atm*cc/s --- R/S

:G/a trigger2 in g/a --- R/S

:MBAR*l/s trigger2 in mbar*l/s 385 R/S

:PA*m3/s trigger2 in Pa*m3/s --- R/S

:PPM trigger2 in ppm --- R/S

:TORR*l/s trigger2 in Torr*l/s --- R/S

:TRIGger3 trigger3 in current unit 384 R/S

:ATM*cc/s trigger3in Atm*cc/s --- R/S

:G/a trigger3in g/a --- R/S

:MBAR*l/s trigger3in mbar*l/s 385 R/S

:PA*m3/s trigger3in Pa*m3/s --- R/S

:PPM trigger3in ppm --- R/S

:TORR*l/s trigger3in Torr*l/s --- R/S

:TRIGger4 trigger4 in current unit 384 R/S

:ATM*cc/s trigger4 in Atm*cc/s --- R/S

:G/a trigger4 in g/a --- R/S

:MBAR*l/s trigger4 in mbar*l/s 385 R/S

:PA*m3/s trigger4 in Pa*m3/s --- R/S

:PPM trigger4 in ppm --- R/S

:TORR*l/s trigger4 in Torr*l/s --- R/S

:UNIT

:LRVac

:LRSniff

leak rate unit vac mode (ATM*cc/c, MBAR*l/s,

PA*m3/s, TORR*l/s)

leak rate unit sniff mode (ATM*cc/c, MBAR*l/s,

PA*m3/s, TORR*l/s, ppm, g/a)

431 R/S

432 R/S

:Pressure pressure unit (ATM, MBAR, PA, TORR) 430 R/S

:ZEROTime zerotime in seconds (0,5…30s) 411 R/S

:CORSTBY R/S

:ZEROSTART zero at start (OFF, ON) 409 R/S

:SPEEDTMP rotation speed of TMP in Hz 501 R/S

:BUTSniffer button of the sniffer probe (OFF, ON) 412 R/S

:LRFilter filter switch-over threshold in current leak rate 403 R/S

Read /

Set

ASCII Protocol 13

Page 14

*HOUR

*FACtor

Relates to

LD cmd. no.

assignment of PLC-outputs

"OPEN", “INV_OPEN”,

"TRIGGER_1","INV_TRIGGER_1",

"TRIGGER_2","INV_TRIGGER_2",

:1 or :1_2

:2 or :3_4

:3 or :5_6

:PLCOUTLINK

:PLCINLINK

:DECADEZero

:DATE date TT,MM,JJJJ 450 R/S

:DEVice operating hours of device 142 R

:POWer time since switching on (in minutes) 147 R

:TIME time hh,mm 450 R/S

:TURBO operating hours of TMP 140 R

:TC operating hours of converter 141 R

:FACSniff sniff factor 523 R/S

:FACMachine machine factor 522 R/S

:RESistor resistor factor 500 G / 15 G 504 R/S

:4 or :7_8

:5 or :9_10

:6 or :11_12

:7 or :13_14

:8 or :15_16

:1

:2

:3

:4

:5

:6

:7

:8

:9

:10

"TRIGGER_3","INV_TRIGGER_3",

"TRIGGER_4","INV_TRIGGER_4",

"READY","INV_READY",

"WARNING","INV_WARNING",

"ERROR",”INV_ERROR”,

“CAL_ACTIVE",“INV_CAL_ACTIVE",

"CAL_REQUEST",”INV_CAL_REQUEST”,

"RUN_UP", “INV_RUN_UP”,

"ZERO_ACTIVE", "INV_ZERO_ACTIVE",

“EMISSION_ON", “INV_EMISSION_ON”

"MEASURE", “INV_MEASURE”,

"STANDBY", “INV_STANDBY”,

"SNIFF", “INV_SNIFF”

assignment of PLC-inputs

(„NOT_USED“,

„DYN_CAL“, „INV_ DYN_CAL “,

„EXT_CAL“, „INV_ EXT_CAL “,

„INT_CAL“, „INV_ INT_CAL “,

„SNIFF“, „INV_ SNIFF“,

„START“, „INV_ START “,

„STOP“, „INV_ STOP “,

„ZERO“, „INV_ZERO“,

„ZERO_PULS”, „INV_ ZERO_PULS”

“CLEAR”, “INV_CLEAR”,

“GAS_BALLAST”, “INV_ GAS_BALLAST

”,"SEL_DYN_NORM", "INV_SEL_DYN_NORM",

"START_STOP", "INV_START_STOP",

„KEY1”, „INV_ KEY1”,

„KEY2”, „INV_ KEY2”,

„KEY3”, „INV_KEY3”,

)

zero function

„NORM“,(„1-2“, “2-3“, „19/20“, „2“, „3-4“)

263 R/S

438 R/S

410 R/S

Read /

Set

14 ASCII Protocol

Page 15

Relates to

LD cmd. no.

:CALSniff calibration factor sniff 521 R/S

:CALVac calibration factor vacuum 520 R/S

*SERVICE

:READBuffer Read service buffer

*STARTFLA

SH

*RST :FACTORY Sets all parameters to factory default 1161 S

:CALHistory Clears calibration history 1161 S

:ERRORHistory Clears error history 1161 S

Flash-Update starten 2619 S

1300 ..

1310

2.5 Examples

Command answer

*stat? (CR) MEAS (CR) mode

*status? (CR) MEAS (CR) mode

*read? (CR) 2.876E-7 (CR)

*read:pa*m3/s? (CR) 2.876E-6 (CR) leak rate in a different unit

*start (CR) OK (CR) start measurement

*conf:trig1? (CR) 1.0E-9 (CR) retrieve trigger 1

*conf:trig1 2.0E-9 (CR) OK (CR) set trigger 1

leak rate according to

programmed unit

Read /

R

Set

2.6 Error Messages

Message Meaning

OK command completed

E01 wrong command start (no „*“)

E02 illegal blank

E03 command word 1 illegal

E04 command word 2 illegal

E05 command word 3 illegal

E06 control by RS232 not enabled

E07 argument faulty

E08 no data available

E09 error buffer overflow

E10 command invalid

E11 query not allowed

E12 only query allowed

E13 not yet implemented

ASCII Protocol 15

Page 16

3 LDS1000 Protocol

3.1 Interface Parameters

So that the connected instruments (PC) may communicate with the LDS3000, it is

required to set-up the interface parameters on the connected instruments.

The settings for the LDS3000 are:

9600 baud, 8 data bits, no parity, 1 stop bit, No handshake and CR as the end sign.

3.2 Interface Commands

The list is ordered to their functions.

The interface commands are composed of the following parts:

Structure

COMMAND <cr>

COMMAND PARAMETER <cr> COMMAND PARAMETER,

PARAMETER <cr>

<cr>: Carriage return (13d)

Example

STOP <cr> G10 <cr>

U24.0 <cr>

There exist several types of command. The main functions of the leak detector are

in plain text which points to the function. For example, the command "START <cr>"

starts the measurement mode. In response to this command, the PC receives "OK

<cr>". A list of the main functions is provided in Chapter 1.4.1.1.

Besides this, conditions may be queried through commands which begin with a "S"

for "Status" and which have a parameter attached. A list of all status query

commands is given in Chapter 1.4.1.2.

Measurement quantities can be queried through the command "G" for "Get", for

example: "G1<cr>". The LDS 3000 will then respond by outputting the current leak

rate. All measurement quantities which may be queried are listed in Chapter 1.4.1.3.

If the entry of settings is required in the way normally performed through the menus

shown on the Control Unit, the command "U" for "Update" may be used to change

the corresponding parameter. The parameter itself may be output via the serial interface through the command "Q" for "Query". For example, "U 0, 1.0E-04<cr>"

changes the

level for the first trigger to 1E-4. The commands used to set and query parameters

are listed in Chapter 1.4.1.4.

Through "Q 0<cr>" the trigger level can be read.

Less frequently used functions which normally will only be run for servicing can be

invoked through the command "F" for "Function". For example: "F10<cr>" switches

the emission off. A list of these functions is given in Chapter 1.4.1.5.

During servicing the command "V" for "Valves" may be used to switch the valves. For

example: "V 1,0 <cr>" opens the internal calibrated leak.

16 LDS1000 Protocol

Page 17

Through the reset character <ESC> (27d or 1Bh) without <cr> the interface of the

LDS 1000 may be reset back to a defined state. A received string which might be

processed at that moment is erased and its processing is terminated. Receiving of

the <ESC> character is acknowledged by "OK<cr>" (In the case of the "TERMINAL"

program from Microsoft the character "O" is not displayed when the local echo is on).

Thereafter, the interface is ready to receive. Through this character its is easily

possible to check whether or not the data link has been properly installed.

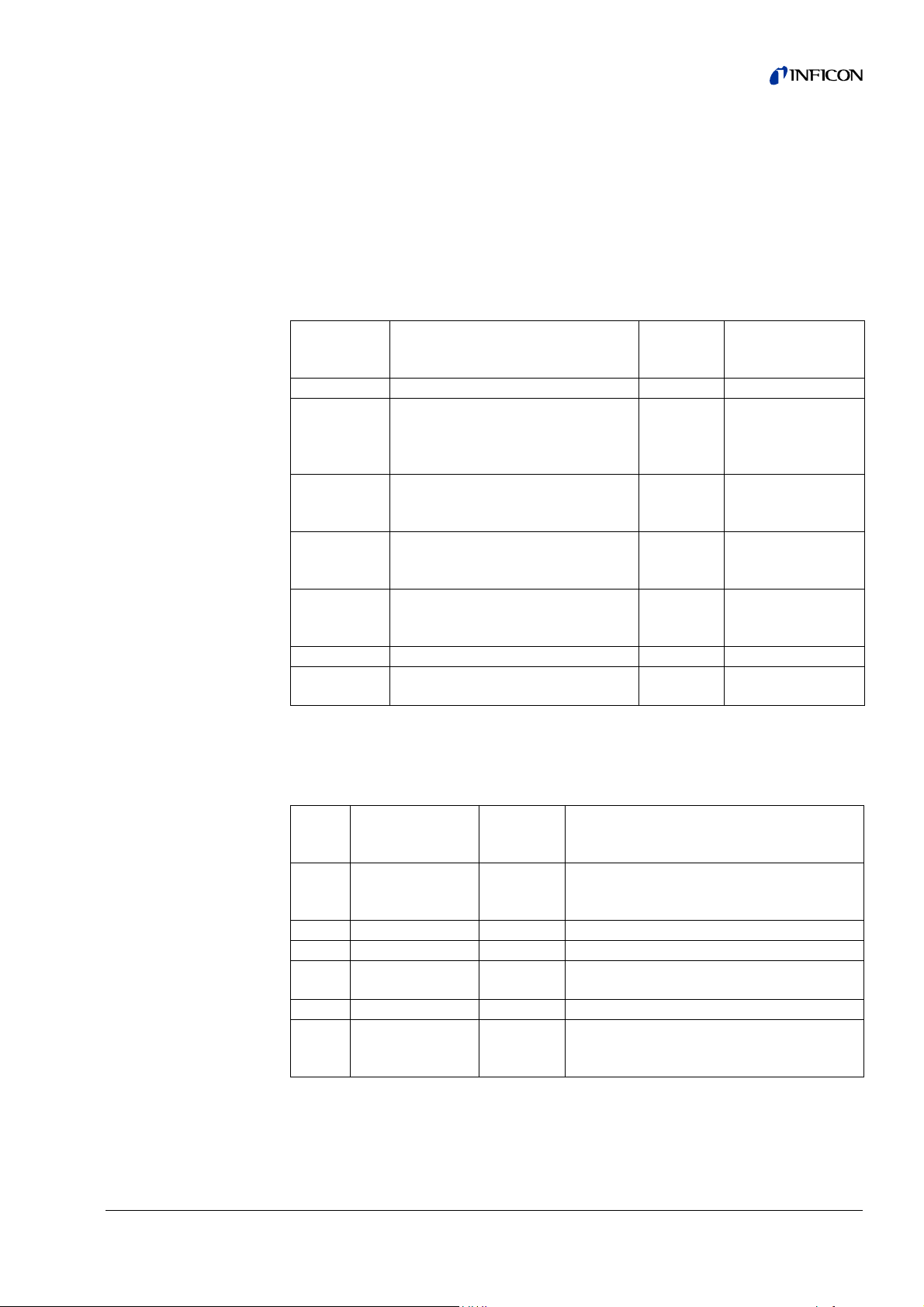

3.2.1 Main functions

Command Meaning

Reply

from the

LDS1000

Equivalent to key

or PLC input

LR Leak rate, date, time, output status

Start measurement mode,

START

suppress the background which

was measured upon operating

OK MEAS active

START

Stop the measurement mode,

STOP

display the current background

OK MEAS inactive

level

ZERO mode on, suppress the

ZERO

background which was measured

OK ZERO active

upon operating ZERO

ZERO mode off, display the

ZERO OFF

background which was measured

OK ZERO inactive

upon operating ZERO

x1)

CAL

CLEAR

X1*)

Calibration: In the STANDBY mode, the internal calibration is started.

Internal/external calibration OK CAL

Interrupt calibration/erase error

status

OK CLEAR active

In the MEASURE mode, the external calibration is started. The status of the external

calibration may be queried through S12. Sequence of commands for external calibration:

Reply

Command

from the

Meaning

LDS1000

The LDS1000 enters the measurement

1START OK

mode, the calibrated leak must be opened,

wait until the signal has stabilised.

2 CAL OK External calibration is being started.

3 S12 1 External calibration is running.

4S12 2

Calibrated leak must be closed, wait until

the signal is stable.

5 CAL OK Calibration is continued.

Calibration complete, the LDS1000 is in

6S12 0

the measurement mode, the instrument is

running in the MEASUREMENT mode.

The internal calibration process is run automatically. There after, the LDS3000 will

be in the STANDBY mode.

LDS1000 Protocol 17

Page 18

3.2.2 Status Requests

Besides the main functions, there exist a variety of request commands for outputting

the status which reflect the current state of the LDS3000.

For example: "S 2<cr>". The LDS3000 replies by: "00000110<cr>", for example. This

means that the LDS3000 is in the "Measure" mode.

Status Information:

S2

S3 Relay status xxxx xxxx (always 8 characters) (Byte 0 first)

S4 Exceeding of

S6 Key switch status

S10 Current error

S12 External CAL status

Meaning Representation

xxxx

xxxx

Byte 0

Byte 1

Instrument status

(number)

measurement range

limits (leak rate)

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

BYTE 7

Byte 0: < TRIG 1

Byte 1: < TRIG 2

Byte 2: < TRIG 3

Byte 3: < TRIG 4

Byte 4: Ready

Byte 5: always 0

Byte 6: CAL-REQUEST

Byte 7: no ERROR

Useful when leak rates are uueried through the

command G1.

0 - within the measurement range

1 - Underrange. The actual leak rate is below the

output value. This may occur in particular after

activating the Zero function or when restricting

the measurement range through "MANUAL".

2 - Overrange

0 - Key switch defective

1 - No key

2 - Key 1

3 - Key 2

4 - Key 3

0 - no errorr / warning > 0 otherwise error

number (not yet acknowledged). See TH ???

Chapter ????. If the error is no longer present,

the message may be erased through "CLEAR".

Is used to monitor the calibration process with

an external calibrated leak. See also TH ???

Chapter ???.

0 - inactive

1 - active; calibration is running at the moment.

2 - "Close" The external calibrated test leak

must be closed and acknowledged through

CAL after the signal has stabilised.

(always 8 characters) (Byte 0

right)

0 = VAC 1 = SNIFF

always 0

0 = STANDBY 1 = MEASURE

0 = CAL inactive 1 = CAL active

refers to external calibration 0 =

STANDARD 1 = DYNAMIC

-ACCELERATION

FAIL

18 LDS1000 Protocol

Page 19

Meaning Representation

"Zero"

S14 ZERO status

0 - no correction

1 - a constant leak rate is suppressed

See command Q/U 19

S18 CAL request status

0 - no request

1 - request is present (temperature difference of

5°)

Serviceinformationen, die bei Rückfragen oder im Fehlerfall zur Lösung eines

Problems beitragen können

S30 software version e.g.:1.00

S31 Serial number xxxxxxxxxxxxxxx

S32 Operating hours counter xxxxxx

xy (always 2 characters)

"1" valve open

S35 Valve position

"0" valve closed

Byte x Valve for calibrated leak

Byte y Sniffer valve

See TH ??? Chapter ???.

xxxxxxx (always 7 signs) (Byte 0 first)

Byte 0: Input 7

Byte 1: Input 6

S39

Status of the remote

contol inputs

Byte 2: Input 5

Byte 3: Input 4

S41 Preamplifier

S42 Turbo pump

Byte 4: Input 3

Byte 5: Input 2

Byte 6: Input 1

Byte 7: always 0

Amplification of the preamplifier can be changed

through F26 … F30. xy

x: Status: 0 - auto, 1 - manuell

y: Amplification: 0 - 13M; 1 - 470M; 2- 15G; 3 0,5T

xxxxx (Byte 0 first)

Byte 0: speed too low

Byte 1: speed too high

Byte 2: always 0

Byte 3: FAIL converter ("1"-Error)

Byte 4: running up/ acceleration

LDS1000 Protocol 19

Page 20

Meaning Representation

S43 Emission control

S51

S52 Calibration M4 Sniff

S70

S72

S73

Calibration factor M4

Vacuum

Output the number of the

current interface error

Output the number of the

current error message

(except interface errors)

Output the number of the

wrong parameter

xxxxx (Byte 0 first)

Byte 0: Status number

Byte 1: Nominal status

0- off, 1 - Standby, 2 -on

Byte 2: Actual status

0 - off, 1 - Standby, 2 -on

Byte 3: Cathode

1 - Cathode 1, 2 - Cathode 2

e.g.: 7.492E-13

e.g.: 7.492E-13

"ok", if no error is present.

e.g.: ER53 12.Oct. 11:50

"ok", if no error is present.

3.2.3 Request for Measurement Data

Measurement data can be queried through the command G for "GET".

Command Meaning Representation

G6

G7

G8

G9

G10 Anode potential (MIAP) in volts. e.g.: 457

G11

G12

G13

G19

Measurement data for servicing:

G6

G7 Preamplifier signal (EVS) in volts. e.g.: 01.456

Forevacuum pressure (PV) in

volts (1000 mbar: 10.0V).

Preamplifier signal (EVS) in

volts.

Electronics temperature (ELTA)

in °C

Amplifier temperature (EVSTA)

in °C

Cathode potential (MIKP) in

volts.

Suppressor potential (MISP) in

volts.

Anode-Cathode potential

(MIAKP) in volts.

Speed of the turbopump (TMP)

in Hz.

Forevacuum pressure (PV) in volts

(1000 mbar: 10.0V).

e.g.: 02.629

e.g.: 01.456

e.g.: 23.5

e.g.: 29,2

e.g.: 378

e.g.: 330

e.g.: 79

e.g.: 1048

e.g.: 02.629

20 LDS1000 Protocol

Page 21

Command Meaning Representation

G8

G9

G10 Anode potential (MIAP) in volts. e.g.: 457

G11 Cathode potential (MIKP) in volts. e.g.: 378

G12

G13

G19

Electronics temperature (ELTA) in

°C

Amplifier temperature (EVSTA) in

°C

Suppressor potential (MISP) in

volts.

Anode-Cathode potential (MIAKP)

in volts.

Speed of the turbopump (TMP) in

Hz.

3.2.4 Entry of Instrument Settings

The settings of parameters in the control modus "RS232" may be changed via the

command "U" for update when the jumper XJ1 has been set to RS232. The parameters may be output via the serial interface through the command "Q" for query.

Forexample, "U0, 1.0E-4<cr>" changes the level for the first trigger to 1.0x 10-4.

Through "Q0<cr>" the trigger level can be read.

The settings are each explained in the Technical Handbook jina50e1-a.

In order to use the commands U51 to U66 the password needs to be entered.

e.g.: 23.5

e.g.: 29,2

e.g.: 330

e.g.: 79

e.g.: 1048

Command Meaning Representation

Q/U0 Trigger 1 in current unit e.g.: 1.0E-5

Q/U1 Trigger 2 in current unit e.g.: 1.0E-5

Q/U2 Trigger 3 in current unit e.g.: 1.0E-5

Q/U3 Trigger 4 in current unit e.g.: 1.0E-5

x, y (always 2 signs)

Q4 Output the operating mode

Select operating mode This setting

U4

Q/U7

Q/U8

Q10 Always 0

Q11 Limit-Low in current unit e.g.: 1.0E-8

Q12 Limit-HIGH in current unit e.g.: 1.0E4

Q/U13 Machine factor for VAC e.g.: 1.0E0

is not saved when switching the

mains power off.

Sensitivity Threshold. Leak rate in

current unit at which the sensitivity

(averaging time) is

Zero time in seconds (period of

time for which the leak rate signal

must remain below the saved

background level until the saved

background level itself is

corrected).

switched over.

X: 0 – SPS, 1 - RS232

Y: 0 – VAC. 1 - SNIFF

0 - VAC

1 - SNIFF

e.g.: 1.0E-10

e.g.: 5

LDS1000 Protocol 21

Page 22

Command Meaning Representation

Q/U14 Correction factor for SNIFF e.g.: 1.0E0

Operating mode for ext. CAL The

Q/U16

Q/U19

Q/U20

Q/U21 Date

Q/U22 Time e.g.: 14:40:07

setting is not saved when switching

off the mains power.

Request for CAL (Enable CAL

message for a temperature

difference of 5° C).

Mass of the gas which is detected

in the mass spectrometer

Q/U24 Unit (unit of measurement for

pressure and leak rate in VAC

and SNIFF)

0 - with autotune

1- dyn. CAL without autotune

0 - off

1 - on

2 , 3, 4

e.g.: 4

e.g.: 24.Nov04

Abbreviations for the months:

Jan May Sep Feb Jun Oct Mar

Jul Nov Apr Aug Dec

0 - mbar and mbar l/s

1 - Pa and Pa m

3/s

2 - atm and atm cc/s

3 - mbar and g/a

ppm and g/a is not available for

VAC

Q/U27 Leak rate of the internal

calibrated leak (always in mbar

4 - mbar and ppm

5 - Torr and Tor l/s

e.g.: 1.0E-7

9.9E-1 for not available

l/s

Q/U28

leak rate of the external

calibrated leak

e.g.: 1.0E-5

9.9E-1 for not available

Q/U31 Number of suppressed decades 0 - 1 to 2 decades

1 - 2 to 3 decades

2 - 3 to 4 decades

3 - 2 decades

4 – complete value

5 - 19/20 of value

22 LDS1000 Protocol

Q/U32 Zero suppression when START

U45

Q/U56 Factor 500G - 15G

Q/U57

Compatibility

Mode

MSV anode potential for masse 2

in volts

0 - off

1 - on

2 – LDS2010-Mode

3 – LDS3000-Mode

e.g.: 890

Page 23

Command Meaning Representation

Q/U58

MSV anode potential for masse 3

in volts

e.g.: 590

Q/U59

Q/U66 Always 0

MSV anode potential for masse 4

in volts

3.2.5 Running of service functions

These function calls are not required for normal measurement operations. They are

thus all protected by the password (see command U5) with the exception of function

F3. The control mode must be set to RS232.

Command Meaning Representation

Parameter RESET, resetting of all

F3

F17 Switch on cathode 1

F18 Switch on cathode 2 (MEK2 = on)

parameters (except internal test

leak and LCD-contrast) to factory

defaults. Erase error memory.

Hardware RESET (same as when

switching OFF and the ON again)

e.g.: 455

LDS1000 Protocol 23

Page 24

4 Binary Interface Protocol

4.1 Communication Parameters

Data format

Baudrate 19.200, 8 data bits, no parity, 1 stop bit

float 4 Bytes, IEEE754 (± 10

1 Byte Exponent/Sign

unsigned long int [ulint]: 4 Bytes, integer without algebraic sign MSB …

LSB (0 … 4294967295)

unsigned short int [usint]: 2 Bytes, integer without algebraic sign MSB,

LSB (0 … 65535)

signed short int 2 Bytes, integer without algebraic sign MSB, LSB

(-32768 … 32767)

unsigned char [uchar]: 1 Byte, integer without algebraic sign (0 … 255)

unsigned char [uchar]: 1 Byte, character ASCII Code (0 … 255)

4.2 Commands

On every command you have to acknowlede with a cmd number. In case of error

instead of a cmd number a error byte ( 230) is transfered.

±38

), 3 Byte Mantissa,

Nr Name Description Parameter Data

2 GetPv Fore vacuum pressure

5 GetDeviceID Device type LDS2000Plus: 31dec.

8

9

36

37

40

41

50

51

54 GetCal Read calibration state 0-int.Cal; 1-ext.Cal

55 SetCal Start / Stop calibration 0-int.Cal; 1-ext.Cal

GetGasballast

SetGasballast

GetCalFac

SetCalFac

GetMass

SetMass

GetZero

SetZero

Gas ballast valve

Calibration factor

Measure mass [uchar, 2/3/4 for mass 2/3/4]

Zero (suppress background)

Byte 0: unit (0-mbar,

1-Pa, 2-atm, 3-Torr)

Byte 0: 0-Vacuum;

1-Sniff

Pv [float]

Byte 0: 0-off, 1-on,

2- main fail safe -on

Factor [float]

0-off

1-on

0-inactiv; 1-active; 2-wait for

calibrated leak close (only

at external calibrations)

0-stop; 1-start; 2-finish (

TL close; only at external

calibrations)

24 Binary Interface Protocol

Page 25

Nr Name Description Parameter Data

Byte 0: 1...4 for Trigger

1...4

56

57

GetTrigger

SetTrigger

Set / read trigger

Byte 1: Einheit: 0mbar*l/s, 1-Pa*m³/s,

2-atmcc/s, 3-Torrl/s;

In sniff mode additional

4-ppm and 5-g/a

[float]: Trigger value

58

59

60

61

62 GetErrorCode Read actual error number

63 SetClearError Quit error / cancel calibration

66

67

68

69

GetOpMode

SetOpMode

GetStBy

SetStBy

GetTL

SetTL

GetFilterSetPoint

SetFilterSetPoint

Set / read operation mode

Stand-By read / set

Value of the calibrated leak

read / set

Leak rate for switching the

averting time

Byte 0: 0-int.TL;

1-ext.TL-vac;

2-ext.TL-sniff

Byte 1: unit: 0-mbar*l/s,

1-Pa*m³/s, .2-atmcc/s,

3-Torrl/s;

In sniff mode

additionally: 4-ppm,

5-g/a

Unit: 0-mbar*l/s, 1Pa*m³/s, .2-atmcc/s,

3-Torrl/s;

In sniff mode

additionally: 4-ppm,

5-g/a

0-Vacuum;

1-Sniff

0-Stand-By;

1-measurement

Actual error number

(1 Byte)

0= no error

5 [float]: value calibrated

leak

(Int.. cal : 1E-15mbarl/s for

no internal calibrated leak in

use)

[float]: LR-limit value

70 GetSerialNumber Read serialnumber

0-Standby; 1-error; 2-Cal;

72 GetState State of the device

74 GetOpHours Read operating hours [uint; h];

76 GetSWVersionNr Read software version

78

79

GetFacMachine

SetFacMachine

Read / set machine factor [float]

Binary Interface Protocol 25

3-run up; 4-ready;

5-Emisssion off

Byte 0: Main-Version;

Byte 1: Sub-Version

Page 26

Nr Name Description Parameter Data

0=2-3 Decades;

1=1-2 Decades;

82

83

GetZeroMode

SetZeroMode

Choice zero function

2=19/20 of valuet;

3=2 Decades;

4=3-4Decades

5=complete value

84

85

92

93

99 GetLr Leak rate

GetFacSniff

SetFacSniff

GetUnit

SetUnit

Read sniff factor [float]

unit read / set

Example:

SET Trigger 2 to 1.2E-7mbarl/s

HOST LDS2010:

Unit (0-mbar*l/s,

1-Pa*m³/s, .2-atmcc/s,

3-Torrl/s;

In sniff mode

additionally 4-ppm,

5-g/a)

Byte 0: LR-vac; Byte 1:

LR-sniff; Byte 2: pressure

0-mbar / mbarl/s; 1-Pa /

Pam³/s; 2-atm / atmcc/s;

3-Torr / Torrl/s

only for LR-sniff: 4-ppm;

5-g/a

[float]

5 10 57 2 0 52 0 217 89 176

0x05 0x0A 0x39 0x02 0x00 0x34 0x00 0xD9 0x59 0xB0

Start Len Cmd Para0 Para1 Data Data Data Data Checksum

Trigger Trig. 2 mbarl/s 1.2E-7

(4-Byte float)

LDS2010 HOST

35760

0x03 0x39 0x3C

Len Cmd Checksum

GET Trigger 2 in mbarl/s

HOST LDS2010:

26 Binary Interface Protocol

Page 27

56562069

0x05 0x06 0x38 0x02 0x00 0x45

Start Len Cmd Para0 Para1 Checksum

Trigger Trig. 2 mbarl/s

LDS2010 HOST

7 57 52 0 217 89 166

0x07 0x39 0x34 0x00 0xD9 0x59 0xA6

Len Cmd Data Data Data Data Checksum

1.2E-7 (4-Byte float)

4.3 Error messages

232 RS232Invalid Temporary not allowed (example CAL during run up)

240 RS232Cmd Command existiert nicht

243 RS232Len Numbrer or length of parameters faulty

244 RS232Para Parameter out of acceptable range

252 RS232Start First character wrong (unlike 0x05)

253 RS232Checksum Transmited and calculated Checksumme unlike

254 RS232Timeout Timeout (Transmission of a command not completed after

500 msec )

255 RS232Buffer Bufferoverflow (Overflow of the Receive-Buffers)

Binary Interface Protocol 27

Page 28

5 LD Protocol

5.1 Communication Parameters

Data format

Baudrate 19.200, 8 data bits, 1 stop bit, no parity

5.2 Command format

5.2.1 Telegram structure

Master sends

ENQ LEN ADR CmdH CmdL DATA (n bytes) CRC

012 345 5+n

Slave answers

STX LEN StwH StwL CmdH CmdL DATA (n bytes) CRC

0123456 6+n

Command Meaning

ENQ 0x05 Start of master request

STX 0x02 Start of slave response

LEN

ADR Slave address

Stw H/L Status word Info from slave to master (5.3)

Cmd H/L Command

DATA

CRC Checksum

Number of

telegram bytes

Data belonging

to master

request

(Slave reply to

write command

is sent without

data)

without ENQ(STX)/LEN, however with CRC

max. 253, so the total slave telegram length is max.

255

Slave address = 1: non-addressed bus. Address byte

is ignored.

Bit 15 ... 13: Command-specifier Read/Write etc. (see

table “Cmd H/L: Command: Command-specifier”)

Bit 12: free

Bit 11 ... 0: Command (5.3)

0 <= n <= 248

If I/O module (7-byte additional header) is used, then

limit maximum data length to 241.

Calculate CRC for all bytes (except CRC byte)

Polynomial: 0x98,

Name: DOWCRC,

Maxim/Dallas, X^8+X^5+X^4+1

Info:

CRC calculation see document "CRC_calculation.c"

(C souce code)

28 LD Protocol

Page 29

Cmd H/L: Command: Command-specifier

Bit 15 ... 13 Meaning High Nibble (Hex) Comments

000 Read value 0

001 Write value 2

Min values also

010 Read lower limit value 4

defined for read

commands.

Max values also

011 Read upper limit value 6

defined for read

commands.

Def values also

100 Read default value 8

defined for read

commands.

Please refer to

101

Read command name in

plain text

A

chapter “Command

name in plain text”

below.

Please refer to table

110 Read command info C

“Command info”

below

111 not used E

Command name in plain text

• 7-Bit ASCII, only printable characters (0x20 and 0x7E)

• Always in English

• Units in square brackets

Command info

1. Byte Data type (see table “Data types”)

Number of array elements:

2. Byte

0 = no data, no array

1 = data, no array

2 ... 255 = array

Bit 0: 1 = Reading allowed, 0 = Reading not allowed

3. Byte

Bit 1: 1 = Writing allowed, 0 = Writing not allowed

Bit 2 ... 7: always 0 (not used)

LD Protocol 29

Page 30

Data types

Value Meaning Acronym Comments

1 Signed 8 bit integer SINT8

2 Signed 16 bit integer SINT16

3 Signed 32 bit integer SINT32

4 Unsigned 8 bit integer UINT8

5 Unsigned 16 bit integer UINT16

6 Unsigned 32 bit integer UINT32

7 Character CHAR ISO 8859-1; printable characters

16 Signed 64 bit integer SINT64

17 Unsigned 64 bit integer UINT64

18

20 no data NO_DATA

All data types are used in Big Endian format (Motorola format), i.e. the byte with the

highest-order bits is transferred first.

Arrays

• Read single elements: Array index in first DATA-byte

• Write single elements: Array index in first DATA byte and values in following

• Read all elements: Pseudo array index 255 in first DATA byte

Floating point/real

number

DATA bytes

FLOAT IEEE 754

For commands without data, such as

Start

• Write all elements: Pseudo array index 255 in first DATA byte and values in

following DATA bytes

• Response from slave (in case data are sent): Array index or pseudo array index

in first DATA byte and values in following DATA bytes

All elements of an array have the same Min/Def/Max value.

30 LD Protocol

Page 31

5.3 Commands

Comm

and dez

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

Status

word

0 0 NOP R NO_DATA "No operation", replies without data

1 1 Start W NO_DATA Switch from "standby" to "measure"

2 2 Stop W NO_DATA Switch from "measure" to "standby"

4 4 Start calibration W UINT8

5 5 Clear error W NO_DATA Clear Error or Warning

6 6 Zero R/W UINT8

99

Com

mand

hex

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Bit 8

Bit 9

Bit 10

Bit 11

Bit 12

Bit 13

Bit 14

Bit 15

Name R/W Data type

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Status word in

slave telegram

Emission

nominal status

R/W UINT8

Min-, Def.-, Maxvalue

Meaning

Device state Bit 0

Device state Bit 1

Device state Bit 2

Device state Bit 3

ZERO

Still warning

Sniffer Key

USER CHANGE

PLC Output Change

Trigger 1

1 = Trigger 1 exceeded

Trigger 2

1 = Trigger 2 exceeded

not used

not used

Device warning

Device error

Syntax / Command error

Start calibration:

0 = internal

1 = external

2 = dynamic

3 = machine/sniff factor

0 = Zero "Off"

1 = Zero "On" respectively update zero

value

Emission nominal status

0 = off

1 = on

LD Protocol 31

Page 32

Comm

and dez

10 A

11 B

Com

mand

hex

Name R/W Data type

TMP nominal

status

Calibration

acknowledge

R/W UINT8

WUINT8

Min-, Def.-, Maxvalue

Meaning

TMP nominal status

0 = off

1 = on

1 = Continue calibration

0 = cancel calibration

12 C

128 80

129 81

130 82

131 83

132 84

133 85

134 86

135 87

138 8A

139 8B TMP power [W] R FLOAT

140 8C

141 8D

142 8E

143 8F

144 90

Open/close int.

testleak

Leak rate [sel.

unit]

Leak rate

[mbar*l/s]

Internal

pressure 1 [sel.

unit]

Internal

pressure 1

[mbar]

Internal

Pressure 2 [sel.

unit]

Internal

Pressure 2

[mbar]

Pressure

sensor 3

Pressure

sensor 4

TMP actual

rotation speed

[Hz]

TMP operation

hours [h]

Frequency

converter

operation hours

[h]

Leak detector

operation hours

TMP

temperature

bottom [deg. C]

TMP

temperature

electronic [deg.

C]

R/W UINT8

R FLOAT Leak rate in selected unit

R FLOAT Leak rate in mbar*l/s

R FLOAT Pressure p1 in selected unit

R FLOAT Pressure p1 in mbar

R FLOAT Pressure p2 in selected unit

R FLOAT Pressure p2

RFLOAT

RFLOAT

R UINT16 TMP actual rotation speed

R UINT32 TMP operation hours

R UINT32 Frequency converter operation hours [h]

R UINT32 Leak detector operation hours

R FLOAT TMP temperatur bottom [deg. C]

R FLOAT TMP temperatur electronic [deg. C]

0 = close 1 = open

incl. Emission monitoring (less sensitive)

internal calibration will overwrite the state

Sensor (0...10 V). Config via commands

2630,2634,2638

Sensor (0...20 mA) config via commands

2632,2636,2639

TMP power in Watt as reportet by TMP

controller

32 LD Protocol

Page 33

Comm

and dez

Com

mand

hex

Name R/W Data type

Min-, Def.-, Maxvalue

Meaning

TMP

145 91

temperature

bearing [deg.

R FLOAT TMP temperatur bearing [deg. C]

C]

TMP

146 92

temperature

R FLOAT TMP temperatur motor [deg. C]

motor [deg. C]

147 93

148 94

149 95

150 96

151 97 TMP current [A] R FLOAT

157 9D

Time since

power on [min]

Cathode1

operation hours

Cathode2

operation hours

TMP voltage

[V]

Switch on

counter

R UINT32 Time since power on [min]

UINT32 Cathode1 operation hours

UINT32 Cathode2 operation hours

RFLOAT

TMP voltage as reported by TMP

controller

TMP current as reported by TMP

controller

RUINT16

Counts the switch on cycles

0, 0, 65534

Electronic

165 A5

temperature

R FLOAT MSB temperature in °C

[deg. C]

Preamplifier

166 A6

temperature

R FLOAT VV temperature in °C

[deg. C]

167 A7

168 A8

169 A9

170 AA

171 AB

Anode voltage

[V]

Cathode

voltage [V]

Suppressor

voltage [V]

Anode-cathode

voltage [V]

Emission

current [A]

R FLOAT Anode voltage in V

R FLOAT Cathode voltage in V

R FLOAT Suppressor voltage in V

R FLOAT Anode/cathode voltage in V

R FLOAT Emission current (A)

172 AC Heater input [V] R FLOAT DAC heater (V)

200 C8 24 V supply [V] R FLOAT

202 CA

206 CE

207 CF

209 D1

210 D2

Pre amplifier

voltage [V]

Heater voltage

[V]

Heater power

[W]

24 V power out

TMP [V]

+15 V supply

[V]

R FLOAT Pre amplifier voltage [V]

R FLOAT Heater voltage in V

R FLOAT Heater power in W

R FLOAT 24 V TMP, MSB Pin C30 voltage in V

R FLOAT +15 V voltage in V

24 V supply voltage for heater,

processor, preamplifier in V

211 D3 -15 V supply [V] R FLOAT -15 V voltage in V

LD Protocol 33

Page 34

Comm

and dez

212 D4

213 D5

214 D6

215 D7

216 D8

217 D9

218 DA +5 V supply [V] R FLOAT +5 V voltage in V

219 DB

220 DC

221 DD

Com

mand

hex

Name R/W Data type

24 V power out

RC [V]

24 V supply IO

[V]

24 V power out

pirani [V]

24 V power

out12 [V]

24 V power

out34 [V]

24 V power

out56 [V]

24V power out

IO [V]

Analog input IO

[V]

Analog outputs

IO [V]

RFLOAT

R/W FLOAT 24 V IO module supply voltage [V]

RFLOAT

RFLOAT

RFLOAT

RFLOAT

RFLOAT

R/W FLOAT Analog input voltage IO module in [V]

R/W FLOAT[2]

Min-, Def.-, Maxvalue

Meaning

2 4 V R C , r e m o t e c o n t r o l , M S B P i n A 3 0 ,

voltage in V

24 V Pirani, sniffer MSB Pin C31

Voltage in V

2 4 V p o w e r o u t p u t s 1 . 2 M S B P i n C 2 7

Voltage in V

2 4 V p o w e r o u t p u t s 3 . 4 M S B P i n C 2 1

Voltage in V

24 V power outputs 5.6 MSB Pin B31

Voltage in V

24 V IO modul,

MSB Pin B30

Voltage in V

Analog output voltage for IO module in

[V]

It is possible to write an arbitrary voltage

value, if the "Analog output

configuration" (command 222) of the

accordant channel is set to 8

222 DE

223 DF

224 E0

228 E4

260 104

261 105

Analog output

configuration

IO modul

Analog output

leak rate scale

(log. only)

Analog output

upper exponent

Gasballast

mode

State

calibration

PLC input state

IO modul

ANALOG-OUT 1:

R/W UINT8[2]

R/W UINT8 0, 0, 7

R/W SINT8 1E-12, 1E-5, 1E7

R/W UINT8 0, 0, 2

RUINT8

R/W UINT16

0, 3, 12

ANALOG-OUT 2:

0, 4, 12

Function of analog output

Index 0: Channel 1

Index 1: Channel 2

Functions see table "Analog output

configuration"

Leak rate scaling of analog output in

logarithmic mode

Functions see table "Analog output

configuration"

Upper limit for the analog out at the I/O

modul. Value is exponent of the mbar*l/s

value. Example: -5 = 1E-5 mbar*l/s

0=off,

1=on,

2=on (continuous on, not PLC controlled)

Status of calibration

See table "State calibration"

Get PLC input state and DIP switch state

IO modul

Bit 0..9 = PLCin 1..10

Bit 10..15 = DIP 1..6

(S1.1,S1.2,S1.3,S1.4,S2.1,S2.2)

34 LD Protocol

Page 35

Comm

and dez

262 106

Com

mand

hex

Name R/W Data type

PLC output

state IO modul

RUINT8

PLC output

263 107

configuration

R/W SINT8[8]

IO modul

264 108

274 112

Emission

actual status

Last entry in cal

history

RUINT8

UINT8

275 113 Cal history CHAR[*]

277 115

Last entry in

error history

UINT8

287 11F Error history R CHAR[*]

288 120

TMP error

history

R CHAR[*]

Min-, Def.-, Maxvalue

PLC_OUT1: -16, 2, 16

PLC_OUT2: -16, 3, 16

PLC_OUT3: -16, 4, 16

PLC_OUT4: -16, 5, 16

PLC_OUT5: -16, 6, 16

PLC_OUT6: -16, 8, 16

PLC_OUT7: -16,

0, 16

PLC_OUT8: -16,

0, 16

Meaning

Get PLC output state IO modul

Bit0..7 = PLCOut 1..8

Index 0...7 = PLC_OUT1 ... PLC_OUT_8

See table "PLC output conf."

Emission status:

STOP= 0

START= 1

WAIT= 2,

RAMP= 3,

REGULATE= 4

STABLE= 5

DOWN= 6

OFF= 7

History list index of the last (newest)

entry in the calibration history

Text of calibration in the history list.

To read send after the array index 255

the UINT8 history list index (0...9).

Without history list index you will get the

last (newest) entry.

Entry format: see enumerations table

Index of the last (newest) entry in the

error history list

Text of an error/warning in the history

list.

To read send after the array index 255

the UINT8 history list index (0...15).

Without history list index you will get the

last (newest) entry.

Entry format: see enumerations table

Text of an error/warning in the TMP

history list.

To read send after the array index 255

the UINT8 history list index (1...10).

Entry format: see enumerations table

LD Protocol 35

Page 36

Comm

and dez

289 121

290 122

291 123

294 126

296 128

297 129

300 12C

301 12D Device name R CHAR[*]

310 136

313 139

314 13A

315 13B

316 13C

317 13D

318 13E

319 13F

320 140

Com

mand

hex

Name R/W Data type

Value of actual

error

Number of

actual error

List of signal

values of active

errors

Text of error

number

List of active

errors

Present

warnings

Device

identification

SW-version

MSB

SW-version I/O

modul

SW-version

control unit

SW version

TMP controller

HW-version

TMP controller

TMP controller

name

SW version

boot loader

SW version

boot loader I/O

modul

CRC-code

MSB

RFLOAT

RUINT16

FLOAT[10

R

]

R CHAR[*]

UINT16[1

R

0]

RUINT32

R UINT8[2]

R UINT8[3]

R/W UINT8[3]

R/W UINT8[3]

R CHAR[6] Character string from turbo controller

R CHAR[6] Character string from turbo controller

R CHAR[6] Character string from turbo controller

R UINT8[3] Software version of boot loader

R/W UINT8[3] Software version of boot loader IO modul

RUINT32

Min-, Def.-, Maxvalue

Meaning

Value associated with the actual error or

warning

Error number of the actual error or

warning

Lists the signal values of the errors/

warnings since the last "clear error"

text of an error/warning number

To read send after the index the UINT16

error number

Without error number you will get the

actual error/warning

Use only with index=255!

Lists the error/warning numbers since

the last "clear error"

Each bit represents a warning see

enumerations table

Device identification, always {1,45} for

MSB

Get device name as ASCII string, 'always

"MSB"

Software version MSB

Index 0: Main version

Index 1: Sub version

Index 2: Debug version

Software version IO modul

Index 0: Main version

Index 1: Sub version

Index 2: Debug version

Software version control unit

Index 0: Main version

Index 1: Sub version

Index 2: Debug version

CRC-code interface board

abcdwxyz (hex)

abcd: caclulated value

wxyz: nominal value

36 LD Protocol

Page 37

Comm

and dez

Com

mand

hex

321 141

322 142

323 143

324 144

325 145

326 146

327 147

328 148

329 149

330 14A

331 14B

385 181

390 186

392 188

394 18A

401 191

Name R/W Data type

DIP switch

MSB

Field bus status

word

SW version bus

modul

Bus module

fieldbus type

RUINT8

RUINT16

R UINT8[3] SW version bus modul

RUINT16

Serial number

plug-in unit bus

R UINT8[4] Serial number plug-in unit bus modul

modul

Field bus

address

Field bus baud

rate

Exception code

bus modul

Error counters

bus module

Bus module

state

RUINT8

RUINT8

R UINT8 Exception code bus module

R UINT16[4]

RUINT8

Field bus

address

R/W UNIT8

nominal value

Trigger [mbar*l/

s]

R/W FLOAT[4] 1E-12, 1E-5, 1E3 Trigger in mbar*l/s

Test leak

extern vacuum

R/W FLOAT

[mbar*l/s]

Test leak

extern sniff

R/W FLOAT

[mbar*l/s]

Testleak intern

[mbar*l/s]

Operation

mode

R/W FLOAT

R/W UINT8 0, 0, 1

Min-, Def.-, Maxvalue

1E-9, 9.9E-2,

9.9E-2

1E-7, 9.9E-2,

9.9E-2

1E-7, 9.9E-2,

9.9E-2

Meaning

DIP switch setting of the MSB:

Bit7: S171, switch 4

Bit6: S171, switch 3

Bit5: S171, switch 2

Bit4: S171, switch 1

Bit3: S170, switch 4

Bit2...0: not used,always 0

Status word for Bus modul

refer to Bus module documentation

Bus module fieldbus type.

Refer to AnybusCC specification for

enumeration.

Fiedbus address

Refer to AnybusCC specification for

enumeration.

Baud rate at field bus

Refer to AnybusCC specification for

enumeration.

Error counters bus module

Index:

0: Discarded commands

1: Discarded Responses

2: Serial Reception errors

3: Fragmentation errors

State of bus module

see Enumarations

Fieldbus address nominal value. Refer to

AnybusCC specification for enumeration.

Test leak extern for vacuum mode in

mbar*l/s

Test leak extern for sniff mode in

mbar*l/s

Testleak intern in mbar*l/s

0 = VACUUM

1 = SNIFF

LD Protocol 37

Page 38

Comm

and dez

402 192 Leak rate filter R/W UINT8 0, 1 ,2

403 193

406 196

407 197

408 198

409 199 Zero with start R/W UINT8 0, 0 ,1

410 19A Zero mode R/W UINT8 0, 0, 5

Com

mand

hex

Name R/W Data type

Leak rate

threshold for

averaging time

[mbar*l/s]

Serial number

leak detector

Serial number

MSB

Serial number

IO modul

R/W FLOAT

R CHAR[11]

R CHAR[11] Serial number of the MSB

R CHAR[11] Serial number of the IO modul

Min-, Def.-, Maxvalue

1E-11, 1E-10,

9.9E3

Meaning

0 = 2-zone

1 = I•CAL

2 = Fixed

Leak rate threshold for averaging time in

mbar*l/s. Below this value the averaging

time is 10,24s. Above this value the

averaging time is 160ms.

Serial number of the complete leak

detector

Zero with Start

0 = OFF, 1 = ON

unterdrückte Dekaden:

0 = suppress all

1 = 1 -2 decades background

suppression

2 = 2 -3 decades background

suppression

3 = 2 decades background suppression

4 = 3-4 decades background

suppression

5 = 19/20 of the raw signal background

suppression

411 19B Zero time R/W UINT16 0 , 5 , 30

412 19C

419 1A3

430 1AE Pressure unit R/W UINT8 0, 0, 3

431 1AF

Zero Sniffer

Key Enable

Calibration

request enable

Leak rate unit

vacuum

R/W UINT8 0, 1, 1

R/W UINT8 0, 0, 1

R/W UINT8 0, 0, 2

Update interval for offset value if leakrate

signal is negative.

Resolution 0,1 s (50 = 5,0 s)

0 = zero key disabled

1 = zero key enabled

0 = Calibration request disabled

1 = Calibration request enabled

Pressure unit

mbar = 0

Pa = 1

atm = 2

Torr = 3

Leak rate unit vacuum

0 - mbarl/s

1 - Pam

2 - Atm ccs

3 - Torrl/s

4 - ppm

5 - g/a

3

/s

38 LD Protocol

Page 39

Comm

and dez

Com

mand

hex

432 1B0

433 1B1

434 1B2

435 1B3

436 1B4

438 1B6

439 1B7

Name R/W Data type

Leak rate unit

sniff

Anode setpoint

M2 [V]

Anode setpoint

M3 [V]

Anode setpoint

M4 [V]

R/W UINT8 0, 0, 5

R/W UINT16 785, 905, 995

R/W UINT16 510, 610, 670 Anode voltage setpoint for mass 3 in V

R/W UINT16 390, 465, 520

Emission

current setpoint

R/W FLOAT

[V]

PLC input

configuration

R/W UINT8[10]

IO module

Key switch

state

RUINT8

Min-, Def.-, Maxvalue

1E-4, 2.5E-3,

2.8E-3

PLC_IN 1: -16, 11,

16

PLC_IN 2: -16, 4,

16

PLC_IN 3: -16, -12,

16

PLC_IN 4: -16, 7,

16

PLC_IN 5: -16, 2,

16

PLC_IN 6: -16, 3,

16

PLC_IN 7: -16,

9,16

PLC_IN 8: -16, 0,

16

PLC_IN 9: -16, 0,

16

PLC_IN 10: -16, 0,

16

Meaning

Leak rate unit sniff

0 - mbarl/s

1 - Pam3/s

2 - Atm ccs

3 - Torrl/s

4 - ppm

5 - g/a

Anode voltage setpoint for mass 2

(hydrogen) in V

Anode voltage setpoint for mass 4

(helium) in V

Emission current setpoint [V]

Configuration of PLC input port of the IO

module

Index 0...9 = PLC_IN1...PLC_IN10

See table "PLC input conf."

Key switch state

0=inactive, 1=active, 2= not used

Bit0&1: KEY_1

Bit2&3: KEY_2

Bit4&5: KEY_3

Bit6&7: not used

448 1C0

Valve control

location

R/W UINT16

449 1C1 Switch valves R/W UINT16

Bit=0: Controled by leak detector

Bit=1: Controled by write command 449

see table "Valves"

For setting valve by write comman see

also command 448

LD Protocol 39

Page 40

Comm

and dez

450 1C2

Com

mand

hex

Name R/W Data type

Date+Time

[YMDhms]

R/W UINT8[6]

Min-, Def.-, Maxvalue

Meaning

Date and time

use only with array-index 255 (all bytes)

year (1..99), month, day,

hour (0..23), min, sec

452 1C4

453 1C5 Max pressure R/W FLOAT 1E-3, 18, 18

499 1F3

501 1F5

502 1F6 Amplifier range R/W UINT8 0, 3, 3

504 1F8

506 1FA Mass R/W UINT8 2, 4, 4

508 1FC

520 208

521 209

522 20A

Min pressure

sniff

Fan output

TMP controller

TMP rotation

speed

500GOhm

value

Amplifier

control location

Calibration

factors vacuum

Calibration

factors sniff

Machine

factors vacuum

R/W FLOAT 1E-3, 4E-1, 18

R/W UINT8 0, 0, 1

R/W UINT16 1000, 1500, 1500

R/W FLOAT

R/W UINT8

R/W FLOAT[3] 1E-2, 1, 5000

R/W FLOAT[3] 1E-2, 1, 100

R/W FLOAT[3] 1E-4, 1, 1E4

4.5E1, 5E11,

5.5E11Ohm

0 = controlled by

write command

502

1 = controlled

auto

Minimum pressure p1 im mbar for sniff

mode. If pressure falls below this value,

warning 540 (Flow too low) is generated.

Maximum pressure p1 in mbar for sniff

and vacuum. If pressure rises above this

value, warning 520 (Pressure too high) is

generated.

0 = always on

1 = temperature controlled

only valid after restart of leak detector

TMP rotation speed

1000, 1500Hz

Amplifier range

Amplifier control location 504

automatically set (not auto)

0 = 13 MOhm

1 = 470 MOhm

2 = 15 GOhm

3 = 500 GOhm

500GOhm value

2 = Mass 2 (H2)

3 = Mass 3

4 = Mass 4 (Helium)

Amplifier control location

Calibration factors for vacuum mode

Index 0: mass 2

Index 1: mass 3

Index 2: mass 4

Calibration factors for sniff mode

Index 0: mass 2

Index 1: mass 3

Index 2: mass 4

Machine factors for vacuum mode

Index 0: mass 2

Index 1: mass 3

Index 2: mass 4

40 LD Protocol

Page 41

Comm

and dez

Com

mand

hex

Name R/W Data type

Min-, Def.-, Maxvalue

Meaning

Machine factors for sniff mode

523 20B

Machine

factors sniff

R/W FLOAT[3] 1E-4, 1, 1E5

Index 0: mass 2

Index 1: mass 3

Index 2: mass 4

524 20C

Machine factor

in standby on/

off

R/W UINT8 0, 0, 1

machine factor in standby

0 = OFF, 1 = ON

0 = CAT1

1 = CAT2

2= Auto Cat1

3= Auto Cat2

530 212

Cathode

selection

R/W UINT8 0, 3, 4

4 = OFF

Parameter reset:

0: Load factory settings

1161 489

Parameter

reset

WUINT8

3: Clear error history

4: Clear calibration history

10:

PARA_RESET_ LDS1000_MODE

11: PARA_RESET_ LDS2010_MODE

Counter for telegrams received via

commands 1280 and 1281

Index:

0=LD protocol

1=ASCII protocol

3=Binary protocol

1282 502

IO module

telegram

receive

counters

R UINT16[5]

4=LDS1000 protocol

Counter for telegrams transmitted

Index:

0=LD protocol

1=ASCII protocol

3=Binary protocol

1283 503

IO module

telegram

transmit

counters

R UINT16[5]

4=LDS1000 protocol

1284 504 Control word R/W UINT16 Control word (used for Bus module)

1285 505

1300 514

1301 515

1302 516

1303 517

1304 518

1305 519

1306 51A

Stop service

buffer

Service buffer

ion current

Service buffer

pressure 1

Service buffer

emis current

Service buffer

anode voltage

Service buffer

cathode

voltage

Service buffer

heater power

Service buffer

leakrate

R/W UINT8

FLOAT[15

R

0]

FLOAT[15

R

0]

FLOAT[15

R

0]

FLOAT[15

R

0]

FLOAT[15

R

0]

FLOAT[15

R

0]

FLOAT[15

R

0]

0=save new information 1=no new

information

To read send after the array index 255

the UINT8 block number, each block 10

values (block 14 is newest)

see command 1300

see command 1300

see command 1300

see command 1300

see command 1300

see command 1300

LD Protocol 41

Page 42

Comm

and dez

1307 51B

1308 51C

1309 51D

1310 51E

1568 620

1569 621

1573 625

1800 708

1815 717 Reset source R UINT8 Shows the last reason of reset

Com

mand

hex

Name R/W Data type

Service buffer

TMP mode

Service buffer

TMP speed

Service buffer

emission mode

Service buffer

sensor 3

Unfiltered ion

current [A]

Amplifier 1

internal

Filtered ion

current [A]

Active protocol

IO

FLOAT[15

R

0]

FLOAT[15

R

0]

FLOAT[15

R

0]

FLOAT[15

R

0]

R FLOAT Unfiltered ion current in A

RFLOAT

R FLOAT Filtered ion current in A

RUINT8

Min-, Def.-, Maxvalue

Meaning

see command 1300

see command 1300

see command 1300

see command 1301

Active interface protocol for I/O module.

Defined by DIP switch at I/O module or

command 2593.

Values: See enumerations table

2593 A21

2594 A22

2619 A3B

2630 A46

2632 A48

2634 A4A

2636 A4C

2638 A4E P3 mode UINT8 0, 1, 1 Sensor 3 mode 0=lin, 1=log

2639 A4F P4 mode UINT8 0, 0, 1 Sensor 4 mode 0=lin, 1=log

2650 A5A

2660 A64

2661 A65

Interface

protocol IO

Compatibilty

Mode

Start flash

update

P3 min max

pressure

P4 min max

pressure

P3 min max

voltage

P4 min max

current

Set suppressor

voltage [V]

Maintenance

activ

Set

maintenance

R/W UINT8 0, 1, 4

R/W UINT8 0, 2, 2 Selected Compatibility Mode

WUINT16

FLOAT[2] 0, 5E-4, 1E4 Range sensor 3 (0..10 V)

FLOAT[2] 0, 0, 1E4 Range sensor 4 (0..20 mA)

FLOAT[2] -10, 1.9, 10 Voltage range sensor 3 (0..10 V)

FLOAT[2] -20, 4, 20 Current range sensor 4 (0..20 mA)

FLOAT Suppressorvoltage for test

R/W UINT8 0, 0, 1 0 = off, 1 = on

W UINT8 1= bearing/lubricant

Selected interface protocol for I/O

module. Only valid if DIP switch at I/O

module is set to "000"=

Writing 0x5555 to start flash update via

control unit interface

2662 A66

Maintenance

done

42 LD Protocol

R CHAR[*]

To read send after the array index 255

the UINT8 maintenance list index (0...9).

Without history list index you will get the

last (newest) entry Entry format: see

enumerations table

Page 43

5.4 Enumerations

Analog output configuration (command 222)

Value Meaning

0off

1p1

2p2

3 Leak rate mantissa

4 Leak rate exponent

5 Leak rate linear

6 Leak rate logarithmic

7 Leak rate logarithmic H.

8

9

10

11

12

Analog output leak rate scale (log. only) (command 223)

Value Meaning

0 0,5 V / decade

1 1 V / decade

2 2 V / decade

3 2,5 V / decade

4 3 V / decade

5 5 V / decade

6 10 V / decade

7 special_1

Voltage setable by command 221

Leak rate exponent invers

Leak rate mantissa hysteresis

p1 1V/decade

p2 1V/decade

State calibration (command 260)

Value Meaning

0 READY

1 START_INT

2 WAIT_TL_INT

3 PEAK_INT

4 MEAS_TL_INT

5 WAIT_ZERO_INT

6 MEAS_ZERO_INT

11 START_EXT

13 PEAK_EXT

14 MEAS_TL_EXT

15 WAIT_ZERO_EXT

16 MEAS_ZERO_EXT

21 START_DYN

25 WAIT_ZERO_DYN

26 ZERO_DYN

51 CURRENT

52 FAIL_STATUS

53 FAIL_TL_TO_SMALL

LD Protocol 43

Page 44

Value Meaning

54 FAIL_FACTOR

55 WARN_FACTOR

56 FAIL_EMIS

59 PEAKERR

PLC output configuration IO module (command 263)

Value Meaning

-16 SNIFF_N

-15 STANDBY_N

-14 MEASURE_N

-13 EMISSION_ON_N

-12 ZERO_ACTIVE_N

-11 RUN_UP_N

-10 CAL_REQUEST_N

-9 CAL_ACTIVE_N

-8 ERROR_N

-7 WARNING_N

-6 READY_N

-5 TRIG4_N

-4 TRIG3_N

-3 TRIG2_N

-2 TRIG1_N

-1 OPEN_N

0 OPEN

1 OPEN

2TRIG1

3TRIG2

4TRIG3

5TRIG4

6 READY

7 WARNING

8ERROR

9 CAL_ACTIVE

10 CAL_REQUEST

11 RUN_UP

12 ZERO_ACTIVE

13 EMISSION_ON

14 MEASURE

15 STANDBY

16 SNIFF

44 LD Protocol

Page 45

Cal history (command 275)

ListNo, 'Fac:', Calfac(float), 'Leak:', Testleak(float),

Answer

'Anod:', Anodevoltage, 'M', Mass, 'VAC' or 'SNIF',

year/month/day, hour:min:sec,

'Cat:', Cathode, 'State:', cal state

08 Fac: 0.00E+0 Leak: 0.00E+0

Example

Anod: 000 M2 VAC

2000/00/00 00:00:00

Cat: 1 State: 000

Error history (command 287)

ListNo, 'ERR' or 'WRN', ErrNo, ErrValue(float),

Answer

year/month/day, hour:min:sec,