Page 1

C

over Page

OPERATING MANUAL

TM

IQS-233

Codeposition Software

IPN 074-585-P1A

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2014 INFICON

®

Title P

age

OPERATING MANUAL

TM

IQS-233

Codeposition Software

IPN 074-585-P1A

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

LabVIEW™ is a trademark of National Instruments.

WinDriver™ is a trademark of Jungo Connectivity Ltd.

Z-Match®, IQS-233™, IQM-233™, and SQM-242™ are trademarks of INFICON GmbH.

Windows® and Microsoft® are registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2014 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 6

Page 7

IQS-233 Operating Manual

Table Of Contents

Cover Page

Title Page

Trademarks

Disclaimer

right

Copy

Warranty

Chapter 1

Introduction

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 IQS-233 Codeposition Software Features . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.2 Hardware Supported by IQS-233 Codeposition Software . . . . . . . . . . . . . . 1-2

1.1.2.1 Digital I/O Capability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.1.3 Computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.1.4 Related Operating Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.2 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3 Software Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3.2 Process Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3.3 Film Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.4 Material Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.5 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.3.6 Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

IPN 074-585-P1A

Chapter 2

IQS-233 Codeposition Software

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Installing IQS-233 Codeposition Software . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 Installing the DLL, Device Driver, and WinDriver . . . . . . . . . . . . . . . . . . . . .2-2

2.2.1.1 Troubleshooting the DLL Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2 Installing IQS-233 Codeposition Software . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.2.3 Updating IQS-233 Codeposition Software . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

TOC - 1

Page 8

IQS-233 Operating Manual

2.3 Using IQS-233 Codeposition Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.1 Starting IQS-233 Codeposition Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.1.1 Starting the Software in Windows XP or Windows 7 . . . . . . . . . . . . . . . . . . 2-7

2.3.1.2 Starting the Software in Windows 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.2 Logging On to the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.3 IQS-233 Codeposition Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.3.1 File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.3.1.1 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.3.3.1.2 Open. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.3.3.1.3 Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.3.3.1.4 Save As . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.3.3.1.5 Log Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.3.2 Print Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.3.3 User Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.3.4 Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.3.3.5 Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.3.3.5.1 Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.3.3.5.2 Process Name and Edit Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.3.3.5.3 Layer Information and Edit Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.3.3.5.4 Layer Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.3.3.5.5 Rate Ramps Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.3.3.5.6 Films. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.3.3.5.7 Edit Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.3.3.5.8 Deposit Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2.3.3.5.9 Condition Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.3.3.5.10 Source/Sensor Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.3.3.5.11 Errors Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-37

2.3.3.5.12 Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

2.3.3.6 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

2.3.3.6.1 Outputs Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

2.3.3.6.2 Sensors Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

2.3.3.6.3 Indexers Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

2.3.3.6.4 I/O Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

2.3.3.6.5 Card Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

2.3.3.6.6 Comm Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

2.3.3.6.7 Display Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

IPN 074-585-P1A

TOC - 2

Page 9

IQS-233 Operating Manual

2.3.3.7 Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

2.3.3.7.1 User Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

2.3.3.7.2 Access Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

2.3.3.7.3 Supervisor Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-65

2.3.4 View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

2.3.4.1 Film Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

2.3.4.2 Sensor Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

2.3.4.3 Rate Graph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-71

2.3.4.4 Deviation Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-71

2.3.4.5 Power Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

2.3.4.6 Sensors Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

2.3.4.7 Automatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-71

2.3.4.8 High Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

2.3.5 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

2.3.5.1 Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-73

2.3.5.2 About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-73

2.3.6 Command Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-74

2.3.7 Graph Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

2.3.7.1 Deviation Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-77

2.3.7.2 Power Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

2.3.7.3 Sensor Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-79

2.3.7.4 Rate Graph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-80

2.3.8 Process Readouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

2.4 Configuring a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-85

2.4.1 Process Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

2.4.2 Selecting a Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-86

2.4.3 Configuring a Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

IPN 074-585-P1A

2.4.4 Creating a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-87

2.4.5 Configuring the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-87

2.4.6 Starting a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-89

Chapter 3

Digital I/O

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 PLC Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Crucible Indexer I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2.2 Other Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 PLC Setup and Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.4 PLC Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

TOC - 3

Page 10

Chapter 4

4.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Determining Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Determining Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5 Tuning the Control Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.5.1 Identifying a Fast or Slow Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.2 Loop Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Appendix A

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

IQS-233 Operating Manual

Calibration Procedures

Material Table

TOC - 4

IPN 074-585-P1A

Page 11

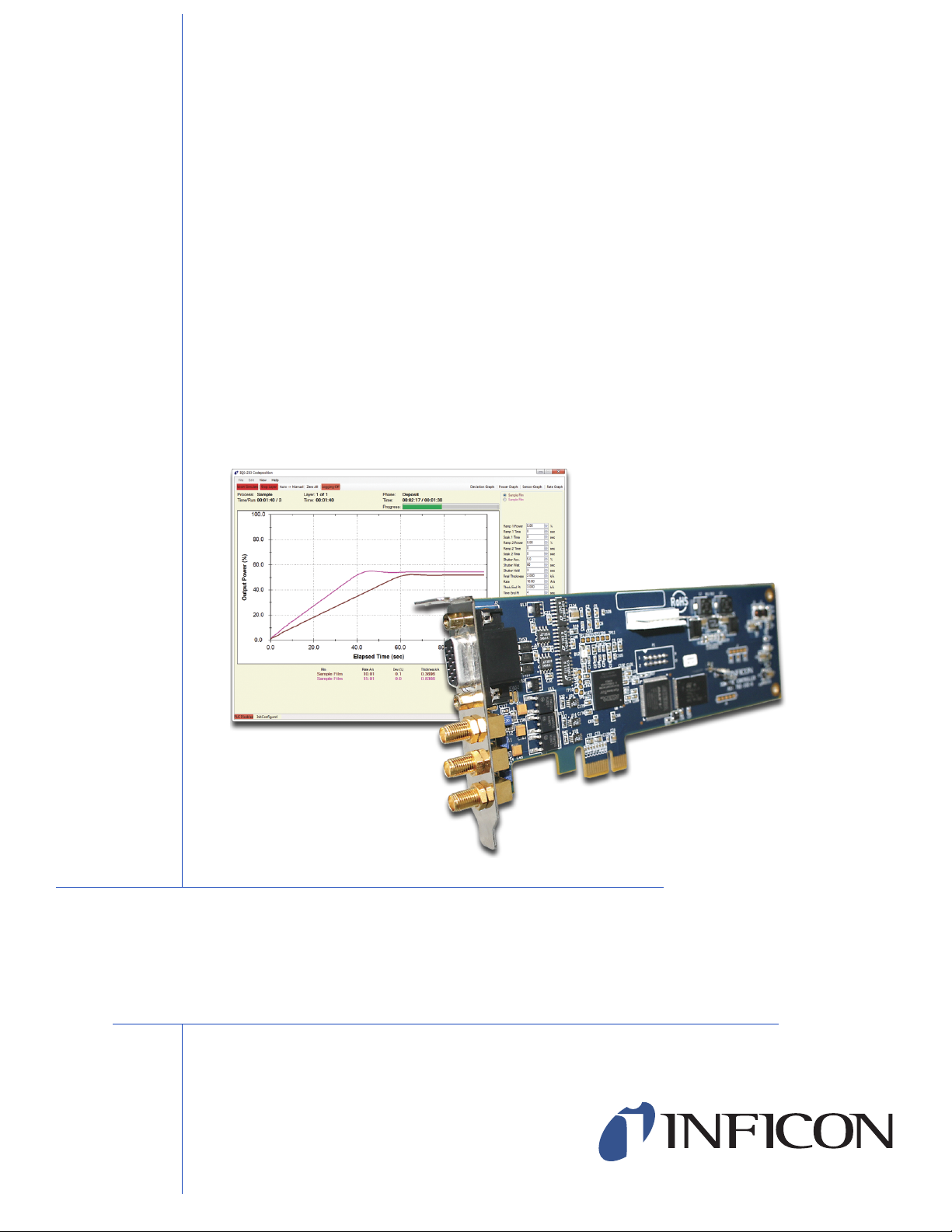

1.1 Introduction

IQS-233 Codeposition software works with INFICON IQM-233 or SQM-242 cards

to provide a powerful, Windows computer-based, thin film deposition controller.

See Figure 1-1.

Figure 1-1 IQS-233 Codeposition software display

IQS-233 Operating Manual

Chapter 1

Introduction

IPN 074-585-P1A

1 - 1

Page 12

IQS-233 Operating Manual

1.1.1 IQS-233 Codeposition Software Features

Supports up to two IQM-233 cards

Measures up to six quartz crystal sensors simultaneously

Controls up to six deposition source power supplies simultaneously for

codeposition.

Supports up to two SQM-242 cards (SAM-242 card not supported)

Measures up to eight quartz crystal sensors simultaneously

Controls up to four deposition source power supplies simultaneously for

codeposition

Allows multi-layer processes

Provides preconditioning, multiple rate ramps, and feed/idle phases

Provides graphs of deposition rate, rate deviation, or power output

Stores process, film and material parameters.

Can be controlled remotely from another computer using the RS-232 or

Ethernet command protocol

Provides flexible and reliable digital I/O using an external Programmable Logic

Controller (PLC)

Easy PLC integration for event selectable relay commands and shutter

control

NOTE: PLC is not provided by INFICON.

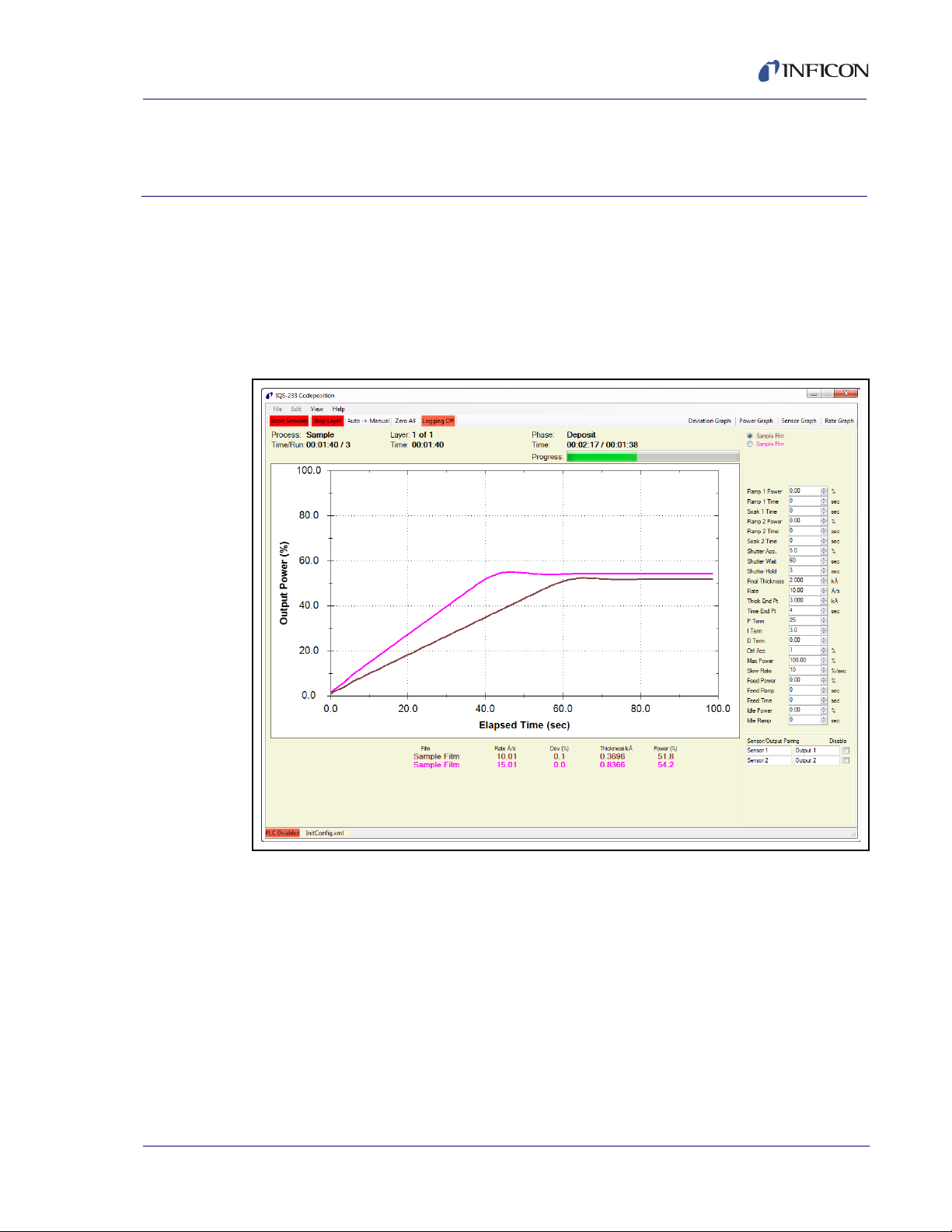

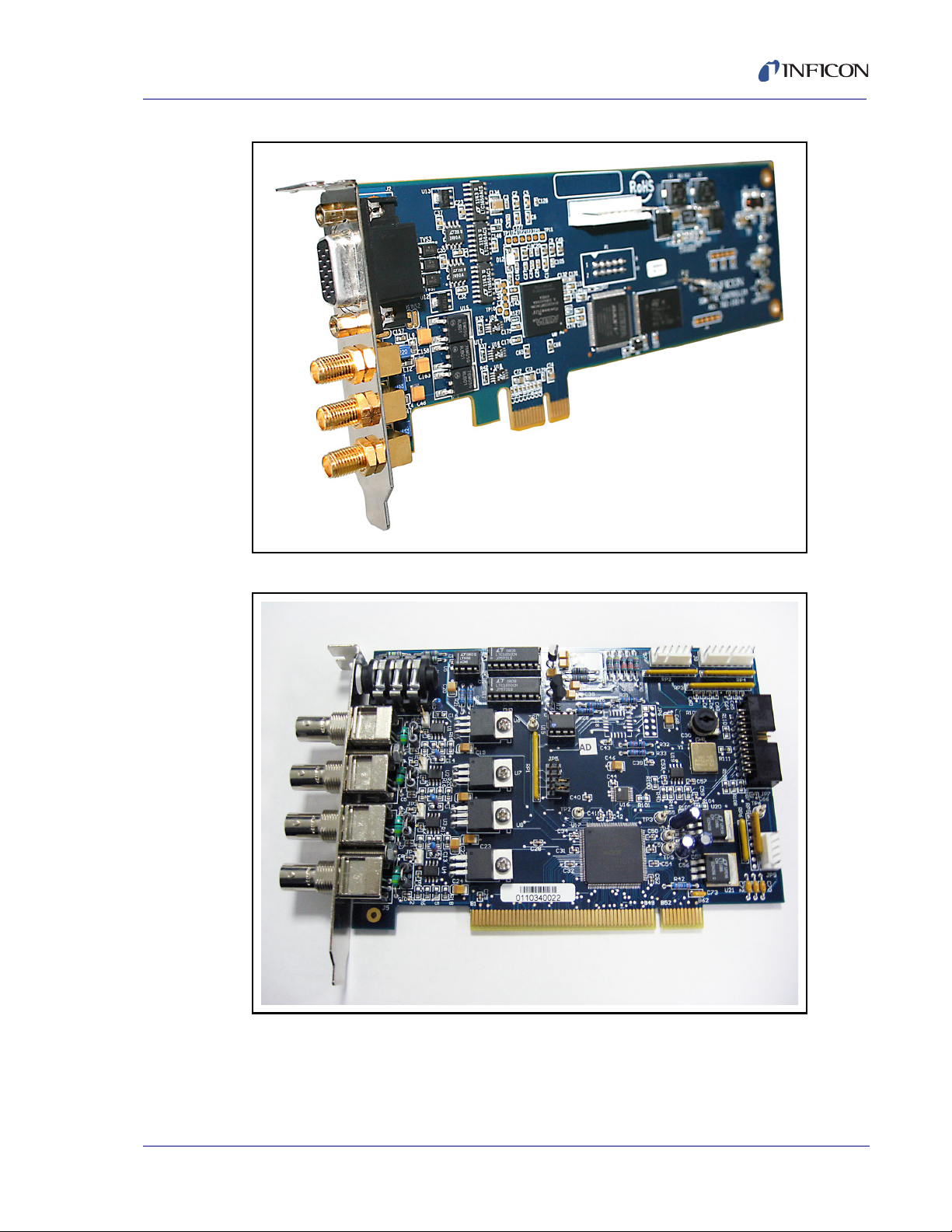

1.1.2 Hardware Supported by IQS-233 Codeposition Software

IQS-233 Codeposition software supports IQM-233 or SQM-242 cards (see

Figure 1-2 and Figure 1-3). Up to two IQM-233 or up to two SQM-242 cards can be

installed in the same computer with IQS-233 Codeposition software.

NOTE: If IQM-233 and SQM-242 cards are installed in the same computer,

IQS-233 Codeposition software will automatically select IQM-233 card(s)

and ignore SQM-242 card(s).

Refer to the IQM-233 or SQM-242 operating manuals for detailed information on

installing and using IQM-233 and SQM-242 cards.

IPN 074-585-P1A

1 - 2

Page 13

Figure 1-2 IQM-233 card

IQS-233 Operating Manual

Figure 1-3 SQM-242 card

IPN 074-585-P1A

1 - 3

Page 14

IQS-233 Operating Manual

1.1.2.1 Digital I/O Capability

IQM-233 and SQM-242 cards do not provide the digital inputs and outputs needed

to automatically control source and sensor shutters, rotate source pockets, etc.

However, digital I/O capability can be added by interfacing an external,

Programmable Logic Controller (PLC) with IQS-233 Codeposition software. The

PLC is not provided by INFICON. See Chapter 3, Digital I/O.

1.1.3 Computer Requirements

Processor . . . . . . . . . . . . . . . . . . . . . 1.5 GHz CPU minimum

RAM . . . . . . . . . . . . . . . . . . . . . . . . . 2 GB RAM minimum

Memory . . . . . . . . . . . . . . . . . . . . . . 200 MB hard disk space minimum

Operating System . . . . . . . . . . . . . . Windows XP SP3, Windows 7 32/64-bit,

Screen Resolution . . . . . . . . . . . . . . 800 x 600 minimum

Case (IQM-233 Card). . . . . . . . . . . . Standard or Small Form Factor

Windows 8 32/64-bit

Case (SQM-242 Card) . . . . . . . . . . . Standard

Bus Interface (IQM-233 Card) . . . . . PCI Express x1, x4, x8, x16

Bus Interface (SQM-242 Card) . . . . PCI

Communication Interface . . . . . . . . . RS-232C when interfacing an external PLC

RS-232C Baud Rate . . . . . . . . . . . . 4800, 9600, 19200, 38400, 57600, 115200

1.1.4 Related Operating Manuals

Operating manuals can be downloaded from www.inficon.com

074-584 . . . . . . . . . . . . . . . . . . . . . . IQM-233 Operating Manual

074-549 . . . . . . . . . . . . . . . . . . . . . . SQM-242 Operating Manual

IPN 074-585-P1A

1 - 4

Page 15

1.2 How To Contact INFICON

Worldwide customer support information is available under Contact >> Support

Worldwide at www.inficon.com:

Sales and Customer Service

Technical Support

Repair Service

If you are experiencing a problem with your IQS-233 Codeposition software,

please have the following information readily available:

The Sales Order or PO number of the software purchase.

The version of IQS-233 Codeposition software. See Figure 2-54 on page 2-72.

The version of Windows operating system.

A description of the problem.

An explanation of any corrective action that you may have already attempted.

The exact wording of any error messages that you may have received.

IQS-233 Operating Manual

1.3 Software Specifications

1.3.1 Display

Graphs . . . . . . . . . . . . . . . . . Rate, Deviation (Rate %), Power (%), Sensors

(Rate)

Readouts . . . . . . . . . . . . . . . Rate Å/s, Dev (%), Thickness kÅ, Power (%),

Frequency (MHz), Life (%), Process name, Film

name, Layer number, Phase, Process Time,

Layer Time, Phase Time

1.3.2 Process Parameters

IPN 074-585-P1A

Processes. . . . . . . . . . . . . . . Unlimited number of processes

Process Name . . . . . . . . . . . 15 characters maximum

Sensors . . . . . . . . . . . . . . . . IQM-233: 1 to 6 (1 to 3 Dual)

SQM-242: 1 to 8 (1 to 4 Dual)

Outputs. . . . . . . . . . . . . . . . . IQM-233: 1 to 6

SQM-242: 1 to 4

Layers. . . . . . . . . . . . . . . . . . Unlimited number of layers

Film. . . . . . . . . . . . . . . . . . . . Any defined film

Outputs. . . . . . . . . . . . . . . . . IQM-233: 1 to 6

SQM-242: 1 to 4

1 - 5

Page 16

IQS-233 Operating Manual

Input . . . . . . . . . . . . . . . . . . . Sensor(s), Timed Power

Setpoint Å/s . . . . . . . . . . . . . -999.90 to 999.90 Å/s

Setpoint % Pwr. . . . . . . . . . . 0.00 to 100.00% Power

Final Thickness . . . . . . . . . . 0.000 to 999.900 kÅ

Thickness Endpoint . . . . . . . 0.000 to 999.900 kÅ

Time Endpoint . . . . . . . . . . . 0.00 to 30000.00 s

Start Mode . . . . . . . . . . . . . . Manual Start, Auto Start, Skip Pre Cond

Source Indexers . . . . . . . . . . IQM-233: 6

SQM-242: 4

Index Pockets. . . . . . . . . . . . 0 to 15

Timeout . . . . . . . . . . . . . . . . 0 to 3000 s

Substrate Indexer. . . . . . . . . 1

Index Pockets. . . . . . . . . . . . 0 to 4

Timeout . . . . . . . . . . . . . . . . 0 to 3000 s

User Indexers. . . . . . . . . . . . 2

Index Pockets. . . . . . . . . . . . 0 to 15

Timeout . . . . . . . . . . . . . . . . 0 to 3000 s

Rate Ramps . . . . . . . . . . . . . Unlimited number of Rate Ramps

Start Thickness. . . . . . . . . . . 0.000 to 999.900 kÅ

Ramp Time. . . . . . . . . . . . . . 0.00 to 30000 s

Setpoint Å/s . . . . . . . . . . . . . -999.90 to 999.90 Å/s

Setpoint % Pwr. . . . . . . . . . . 0.00 to 100.00% Power

1.3.3 Film Parameters

Films. . . . . . . . . . . . . . . . . . . Unlimited number of films

Film Name . . . . . . . . . . . . . . 15 characters maximum

P Term . . . . . . . . . . . . . . . . . 0 to 9999

I Term . . . . . . . . . . . . . . . . . . 0.0 to 999.9 s

D Term . . . . . . . . . . . . . . . . . 0.00 to 99.90 s

IPN 074-585-P1A

1 - 6

Shutter Delay Accuracy . . . . 0.0 to 30.0%

Shutter Delay Wait . . . . . . . . 0.00 to 30000 s

Shutter Delay Hold . . . . . . . . 0.00 to 30000 s

Page 17

IQS-233 Operating Manual

Rate Sampling . . . . . . . . . . . Continuous, Accuracy Based, Time Based

Accuracy Based . . . . . . . . . . 0.00 to 100.00%

Time Based Sample . . . . . . . 0.00 to 100.00 s

Time Based Hold . . . . . . . . . 0.00 to 100.00 s

Ramp (1, 2) Power . . . . . . . . 0.00 to 100.00%

Ramp (1, 2) Time . . . . . . . . . 0.00 to 30000 s

Soak (1, 2) Time. . . . . . . . . . 0.00 to 30000 s

Feed Power . . . . . . . . . . . . . 0.00 to 100.0%

Feed Ramp Time . . . . . . . . . 0.00 to 100 s

Feed Time . . . . . . . . . . . . . . 0.00 to 100 s

Idle Power . . . . . . . . . . . . . . 0.00 to 100.0%

Idle Ramp Time . . . . . . . . . . 0.00 to 100 s

Material. . . . . . . . . . . . . . . . . Any defined material

Max Power . . . . . . . . . . . . . . 0.00 to 100.00%

Slew Rate . . . . . . . . . . . . . . . 0.0 to 100.0%

Sensor Tooling . . . . . . . . . . . IQM-233: 1 to 6, 0.0 to 999.0%

SQM-242: 1 to 8, 0.0 to 999.0%

On Error . . . . . . . . . . . . . . . . Ignore, Stop Layer, Timer Power

Control Error %. . . . . . . . . . . 0 to 30%

Control Error sec . . . . . . . . . 0 to 99 s

Crystal Fail Counts . . . . . . . . 0 to 99

Crystal Quality % . . . . . . . . . 0 to 50%

Crystal Quality Counts . . . . . 0 to 99

IPN 074-585-P1A

Crystal Stability Single . . . . . 25 to 9999 Hz

Crystal Stability Total . . . . . . 25 to 9999 Hz

1.3.4 Material Parameters

Name . . . . . . . . . . . . . . . . . . 24 characters maximum

Density . . . . . . . . . . . . . . . . . 0.40 to 99.99 g/cm

3

Z-Factor . . . . . . . . . . . . . . . . 0.100 to 9.999

1 - 7

Page 18

IQS-233 Operating Manual

1.3.5 System Parameters

Outputs. . . . . . . . . . . . . . . . . IQM-233: 1 to 6

Full Scale Out. . . . . . . . . . . . -10.0 to 10.0 V (dc)

Sensors . . . . . . . . . . . . . . . . IQM-233: 1 to 6 (1 to 3 Dual)

Control . . . . . . . . . . . . . . . . . Rate, Thickness

Relays (PLC required) . . . . . 16

Relay Events . . . . . . . . . . . . Source Shutter (1 to 6), Source Active (1 to 6),

Inputs (PLC required). . . . . . 12

SQM-242: 1 to 4

SQM-242: 1 to 8 (1 to 4 Dual)

Sensor Shutter (1 to 8), Process Stopped, Process

Running, Layer Stopped, Layer Running, Deposit

Phase, Pre-Cond Phase, Soak Hold Phase, Process

Active, Manual Mode, Max Power, Time Setpoint,

Thickness Setpoint, Final Thickness, All Crystals

Good, All Crystals Fail

Input Events . . . . . . . . . . . . . Start Process, Abort Process, Start Layer, Stop

Layer, Next Layer, Force Final Thickness, Zero

Thickness, Zero Time (NA), Soak 2 Hold, Soak 2

Release

Card Type. . . . . . . . . . . . . . . IQM-233, SQM-242

Period. . . . . . . . . . . . . . . . . . 0.10, 0.25, 0.50, 1.00, 2.00 s

Maximum Frequency . . . . . . 4.002000 to 6.100000 MHz

Initial Frequency. . . . . . . . . . 4.001000 to 6.099000 MHz

Minimum Frequency. . . . . . . 4.000000 to 6.098000 MHz

Computer Interface . . . . . . . RS-232, Ethernet, Windows Communication

Foundation

RS-232 Baud . . . . . . . . . . . . 4800, 9600, 19200, 38400, 57600, 115200

Filter Readings . . . . . . . . . . . 1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Last Output Displayed . . . . . 1 to 6

Units . . . . . . . . . . . . . . . . . . . Thickness, Mass

Graph X Axis Width . . . . . . . 0 to 100

IPN 074-585-P1A

1 - 8

Graph Y Axis Height. . . . . . . 0 to 10000

Page 19

1.3.6 Security

User Name . . . . . . . . . . . . . . 10 characters maximum

Password . . . . . . . . . . . . . . . 10 characters maximum

Access Levels . . . . . . . . . . . 3

IQS-233 Operating Manual

IPN 074-585-P1A

1 - 9

Page 20

IQS-233 Operating Manual

This page is intentionally blank.

1 - 10

IPN 074-585-P1A

Page 21

IQS-233 Operating Manual

CAUTION

CAUTION

IQS-233 Codeposition Software

2.1 Introduction

This chapter covers the installation and operation of IQS-233 Codeposition

software. Refer to the IQM-233 or SQM-242 operating manual for installation

instructions of an IQM-233 card or SQM-242 card.

2.2 Installing IQS-233 Codeposition Software

IQS-233 Codeposition software supports up to two IQM-233 cards or up to two

SQM-242 cards.

If IQM-233 and SQM-242 cards are installed together in

the same computer, IQS-233 Codeposition software will

communicate with up to two IQM-233 cards and ignore

the SQM-242 card(s).

Chapter 2

IQM-233 card(s) must be removed to use

IQS-233 Codeposition software with SQM-242 card(s).

The required Dynamic Link Library (DLL), device driver, and WinDriver are installed

by the IQM233 DLL or the SQM242 with IQM DLL setup file. To install the DLL,

device driver, and WinDriver, see section 2.2.1.

IPN 074-585-P1A

NOTE: IQS-233 Codeposition software and the IQM233 DLL or SQM242 with

IQM233 DLL and SQM242 with IQM DLL cannot be

installed together on the same computer.

IQM DLL may be installed before or after the installation of the IQM-233 or

SQM-242 card(s). Refer to the IQM-233 or SQM-242 operating manual for

card installation instructions.

2 - 1

Page 22

IQS-233 Operating Manual

2.2.1 Installing the DLL, Device Driver, and WinDriver

1 If the operating system is Windows 7 or 8, click Start >> Control Panel >>

System. Note the operating system size (32-bit or 64-bit) displayed under

System type.

If the operating system is Windows XP, click Start >> Settings >> Control

Panel >> System >> System Properties >> General tab. Determine the

operating system size from the operating system name displayed under

System:

Windows XP Home, Windows XP Media Center Edition, and Windows XP

Professional are 32-bit operating systems.

Windows XP Professional x64 Edition is a 64-bit operating system.

NOTE: The operating system size will generally match the performance

capabilities of the computer processor. However, it is possible to have

a 64-bit processor and a 32-bit operating system. In this case, the

64-bit installation is required.

2 Insert the IQS-233 Codeposition Operating Manual CD into the computer’s

CD drive.

3 Click Windows Explorer or File Explorer >> Computer >> (CD drive letter:)

IQS-233 >> IQM-233 Drivers.

4 If IQS-233 Codeposition software is to be used with an IQM-233 card:

For a 32-bit operating system, double-click

IQM233 DLL x86 v x.x.x.x Setup.exe

For a 64-bit operating system, double-click

IQM233 DLL x64 v x.x.x.x Setup.exe

If IQS-233 Codeposition software is to be used with an SQM-242 card:

For a 32-bit operating system, double-click

SQM242 with IQM DLL x86 v x.x.x.x Setup.exe

For a 64-bit operating system, double-click

SQM242 with IQM DLL x64 v x.x.x.x Setup.exe

IPN 074-585-P1A

2 - 2

Page 23

IQS-233 Operating Manual

CAUTION

IQM233 DLL and SQM242 DLL can be installed in the

same computer.

However, when IQM-233 and SQM-242 cards are installed

in the same computer, IQS-233 Codeposition software

will interface only with IQM-233 card(s) and ignore the

SQM-242 card(s).

IQM-233 card(s) must be removed for

IQS-233 Codeposition software to communicate with

SQM-242 card(s).

5 The InstallShield Wizard window will display.

6 Click Next.

7 Read the license agreement.

8 If it is acceptable, click I accept the terms in the license agreement.

9 Click Next.

10 Type the requested information into the User Name and Organization boxes.

11 Click Next.

12 Click Install to start the installation of the device driver and the DLL.

13 When Install Wizard Completed is displayed, click Finish to close the

InstallShield Wizard.

2.2.1.1 Troubleshooting the DLL Installation

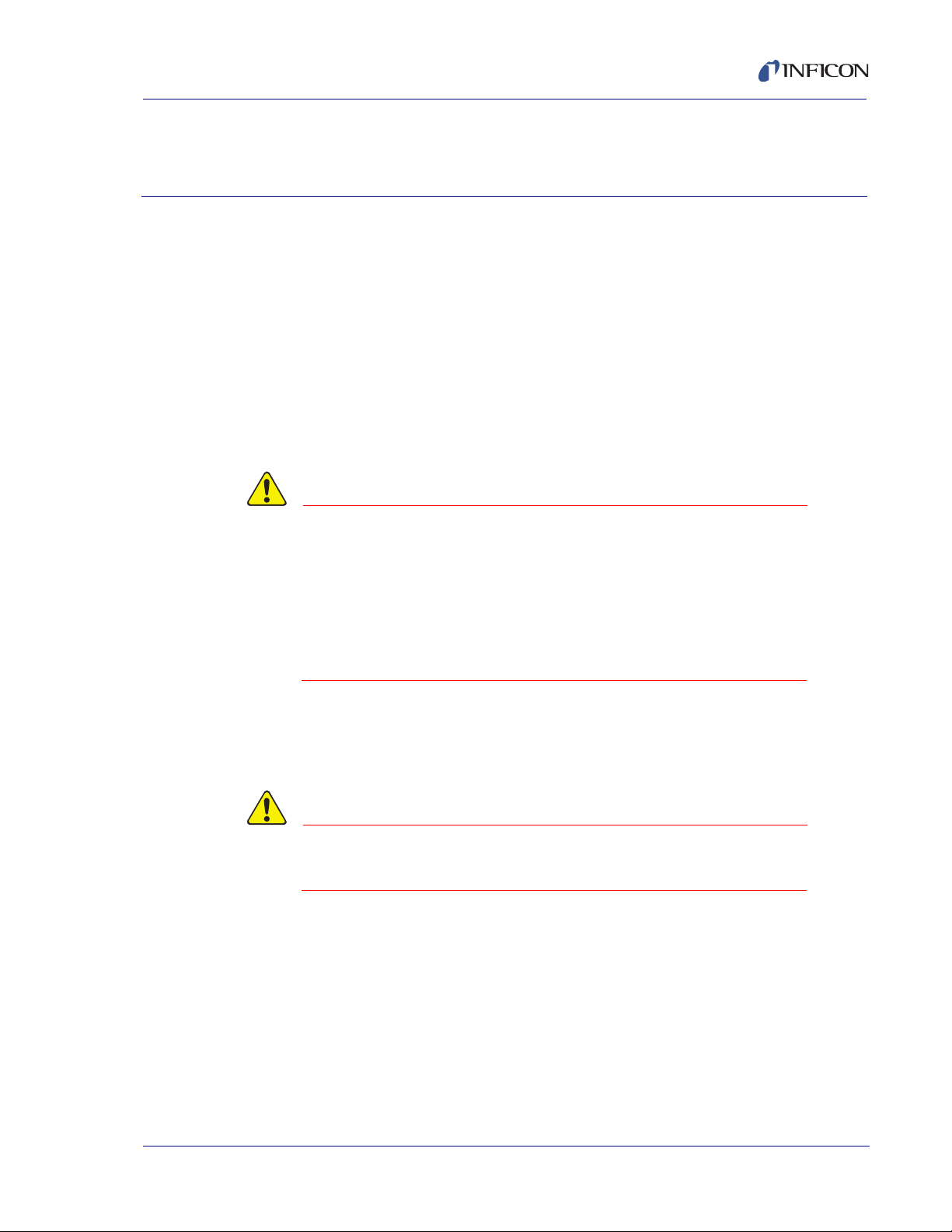

If the WDREG Error window appears (see Figure 2-1), an existing version of

IPN 074-585-P1A

WinDriver is preventing the installation of the DLL.

Figure 2-1 WDREG Error

2 - 3

Page 24

IQS-233 Operating Manual

To remove the existing WinDriver and install the required WinDriver:

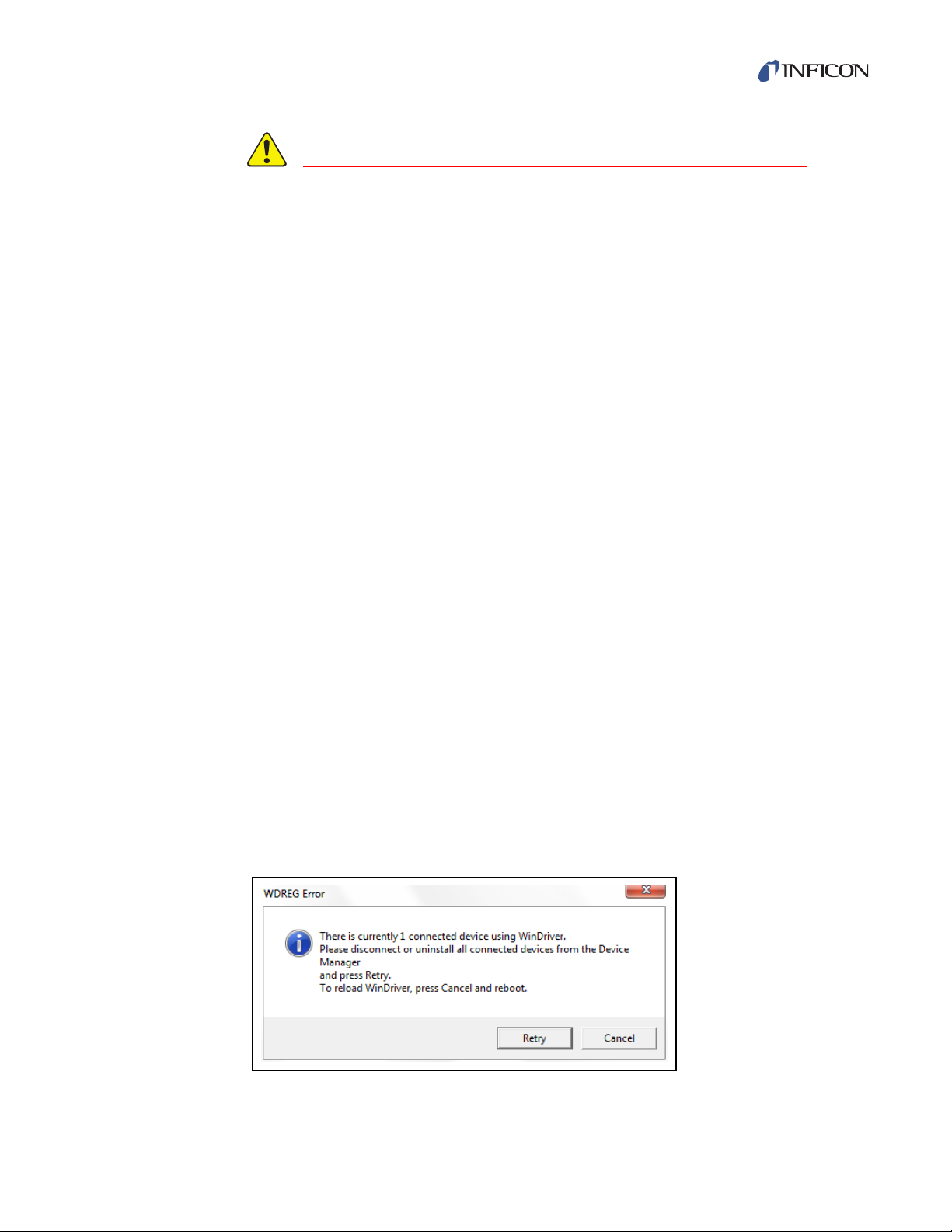

1 In Windows Device Manager, click the expansion button () next to Jungo to

display WinDriver. See Figure 2-2.

Figure 2-2 Jungo and WinDriver

2 Right-click WinDriver and click Uninstall. See Figure 2-3.

Figure 2-3 Uninstall WinDriver

3 When the Confirm Device Uninstall window appears, click OK to uninstall

WinDriver. See Figure 2-4.

Figure 2-4 Confirm Device Uninstall

4 In the WDREG Error window, click Retry to continue with the DLL installation.

Refer to Figure 2-1.

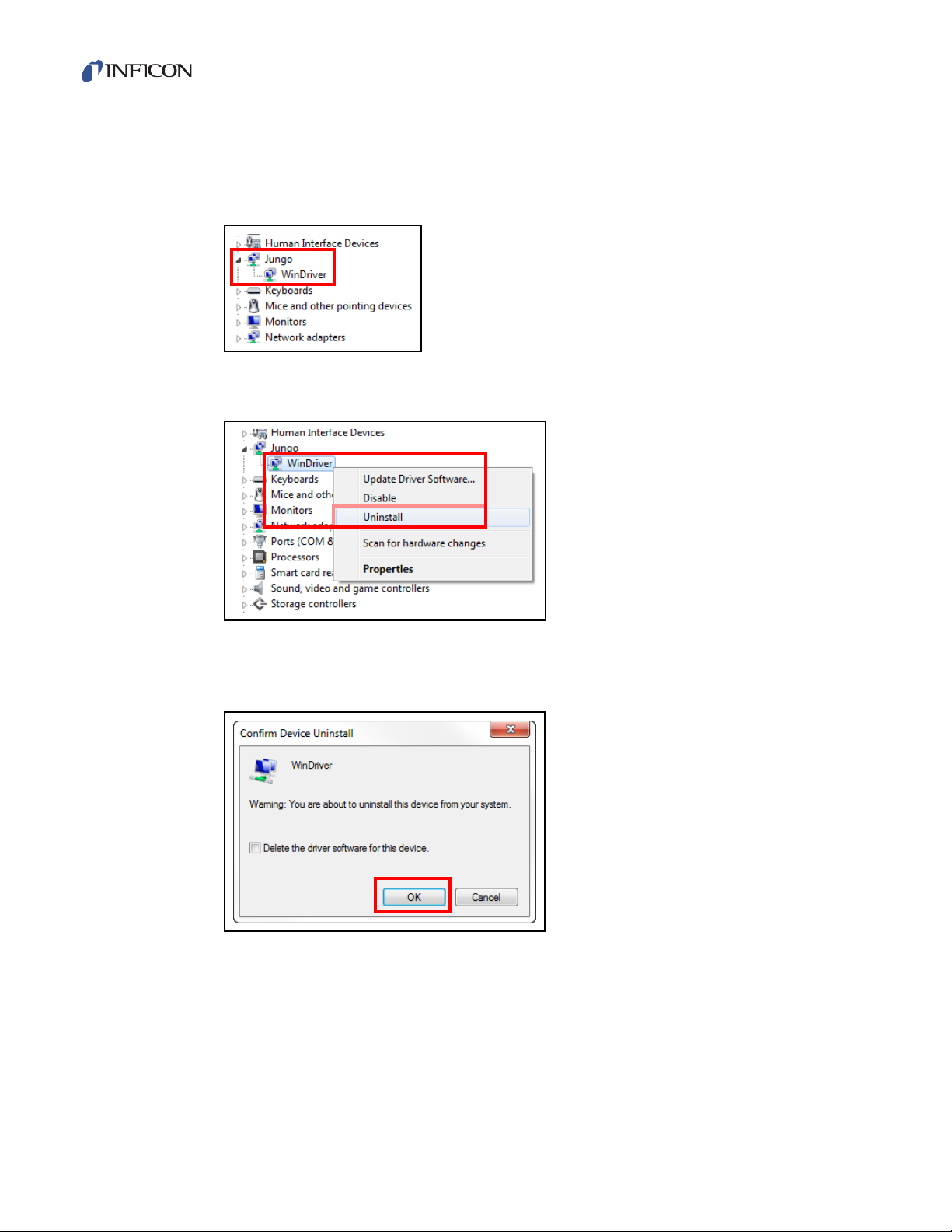

If the Windows Installer window appears (see Figure 2-5), another DLL

(IQM233 DLL or SQM242 with IQM DLL) is already installed. IQM233 DLL

and SQM242 with IQM DLL cannot be installed together on the same

computer.

IPN 074-585-P1A

2 - 4

Page 25

IQS-233 Operating Manual

Figure 2-5 Windows Installer window

4a Click OK to keep the previously installed DLL, or

4b To remove the previously installed DLL and install a different DLL:

4b1 Click OK to close the Windows Installer window.

4b2 Click Control Panel >> Programs to display a list of installed

programs.

4b3 Select the IQM233 DLL or the SQM242 with IQM DLL from the list.

4b4 Click Uninstall to remove the selected DLL.

4b5 Install the DLL again. Refer to section 2.2.1 on page 2-2.

IPN 074-585-P1A

2 - 5

Page 26

IQS-233 Operating Manual

2.2.2 Installing IQS-233 Codeposition Software

NOTE: To update an existing installation of IQS-233 Codeposition software to a

newer version, see section 2.2.3.

1 Click Windows Explorer or

File Explorer >> Computer >> (CD drive letter:) IQS-233.

2 Double-click IQS-233 SETUP.EXE.

3 The InstallShield Wizard will display.

4 Click Next.

5 Read the license agreement.

6 If it is acceptable, click I accept the terms in the license agreement.

7 Click Next.

8 Type the requested information into the User Name and Organization boxes.

9 Click Next.

10 Click Install to start the software installation.

11 When Install Wizard Completed is displayed, click Finish to close the

InstallShield Wizard window.

2.2.3 Updating IQS-233 Codeposition Software

To update an existing installation of IQS-233 Codeposition software to a newer

version:

1 Click Control Panel >> Programs.

2 If the IQS-233 Codeposition software was used with an IQM-233 card, select

IQM233 DLL x86 or IQM233 DLL x64.

If the IQS-233 Codeposition software was used with an SQM-242 card, select

SQM242 with IQM DLL x86 or SQM242 with IQM 233 DLL x64.

3 Click Uninstall to remove IQM233 DLL or SQM242 with IQM DLL.

4 In Programs, select IQS-233 Codeposition.

5 Click Uninstall to remove the previous version of IQS-233 Codeposition

software.

6 Install the latest version of IQM233 DLL or SQM242 with IQM DLL, as

appropriate. Refer to section 2.2.1 on page 2-2.

IPN 074-585-P1A

2 - 6

7 Install the latest version of IQS-233 Codeposition software. Refer to section

2.2.2.

Page 27

IQS-233 Operating Manual

2.3 Using IQS-233 Codeposition Software

2.3.1 Starting IQS-233 Codeposition Software

2.3.1.1 Starting the Software in Windows XP or Windows 7

1 Click Start >> All Programs >> INFICON >> IQS-233 Codeposition.

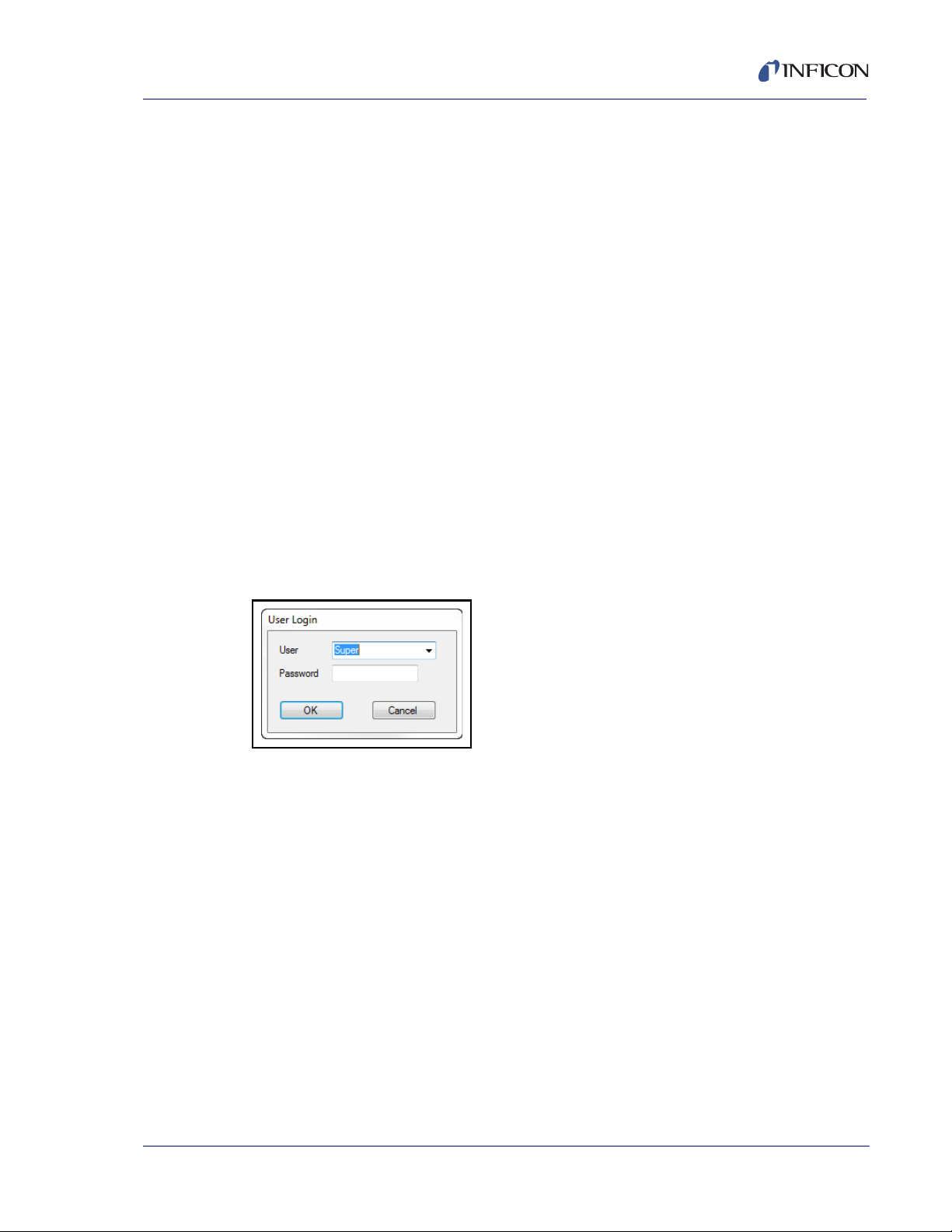

2 The User Login window will display. See Figure 2-6.

2.3.1.2 Starting the Software in Windows 8

1 In the Start window, click the IQS-233 Codeposition icon.

2 If the icon cannot be found:

2a Click Search >> Apps.

2b Type IQS-233 in the Search text box.

2c Click the IQS-233 Codeposition icon.

2.3.2 Logging On to the Software

On the initial login, the User Login window will display Super as the default User

name. See Figure 2-6.

Figure 2-6 User Login window

A Password is not required to log on to a user session with the default User name.

Click OK to close the User Login window and display the IQS-233 Codeposition

window. See Figure 2-7.

IPN 074-585-P1A

NOTE: If security settings are changed from the default values, a different User

name and Password may be required. See section 2.3.3.7 on page 2-61.

2 - 7

Page 28

IQS-233 Operating Manual

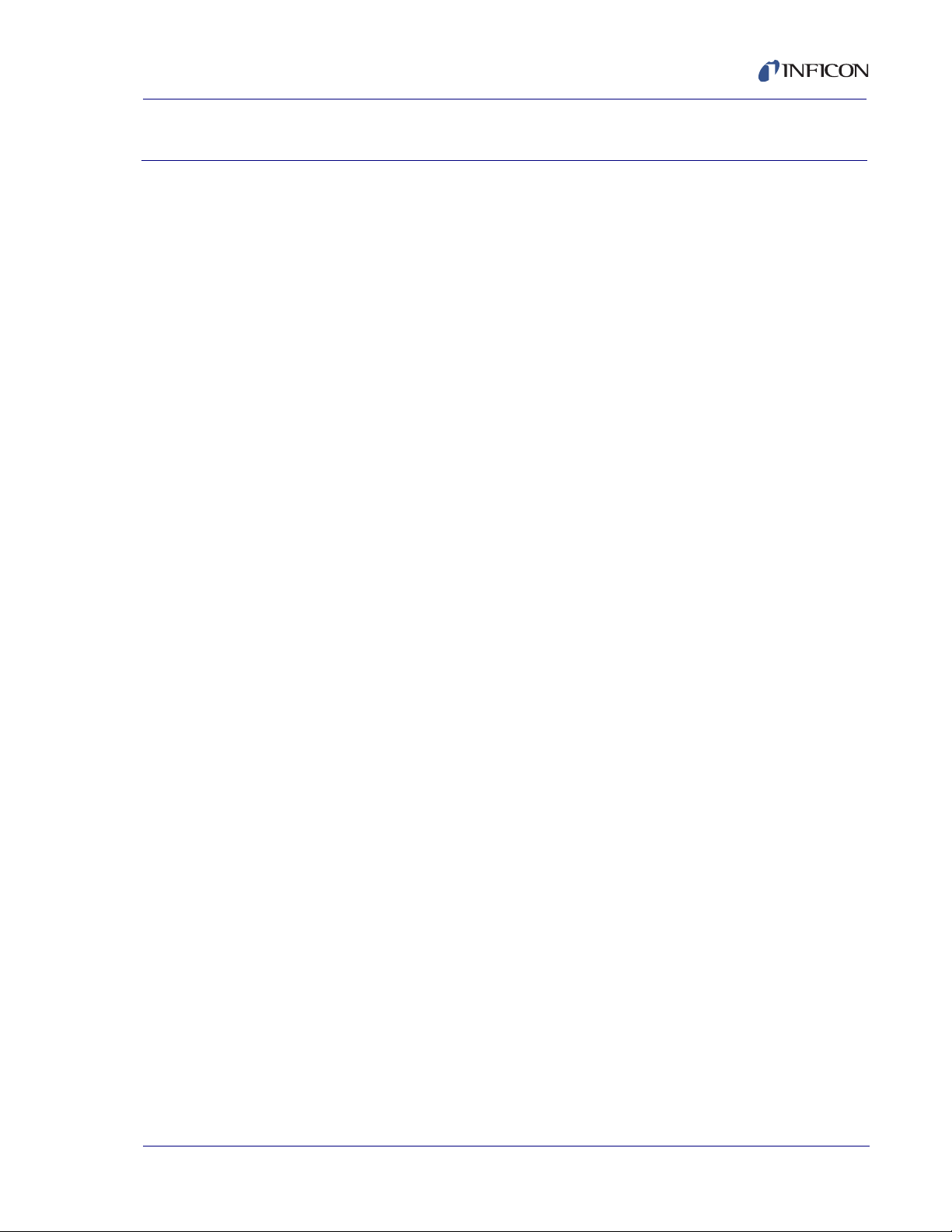

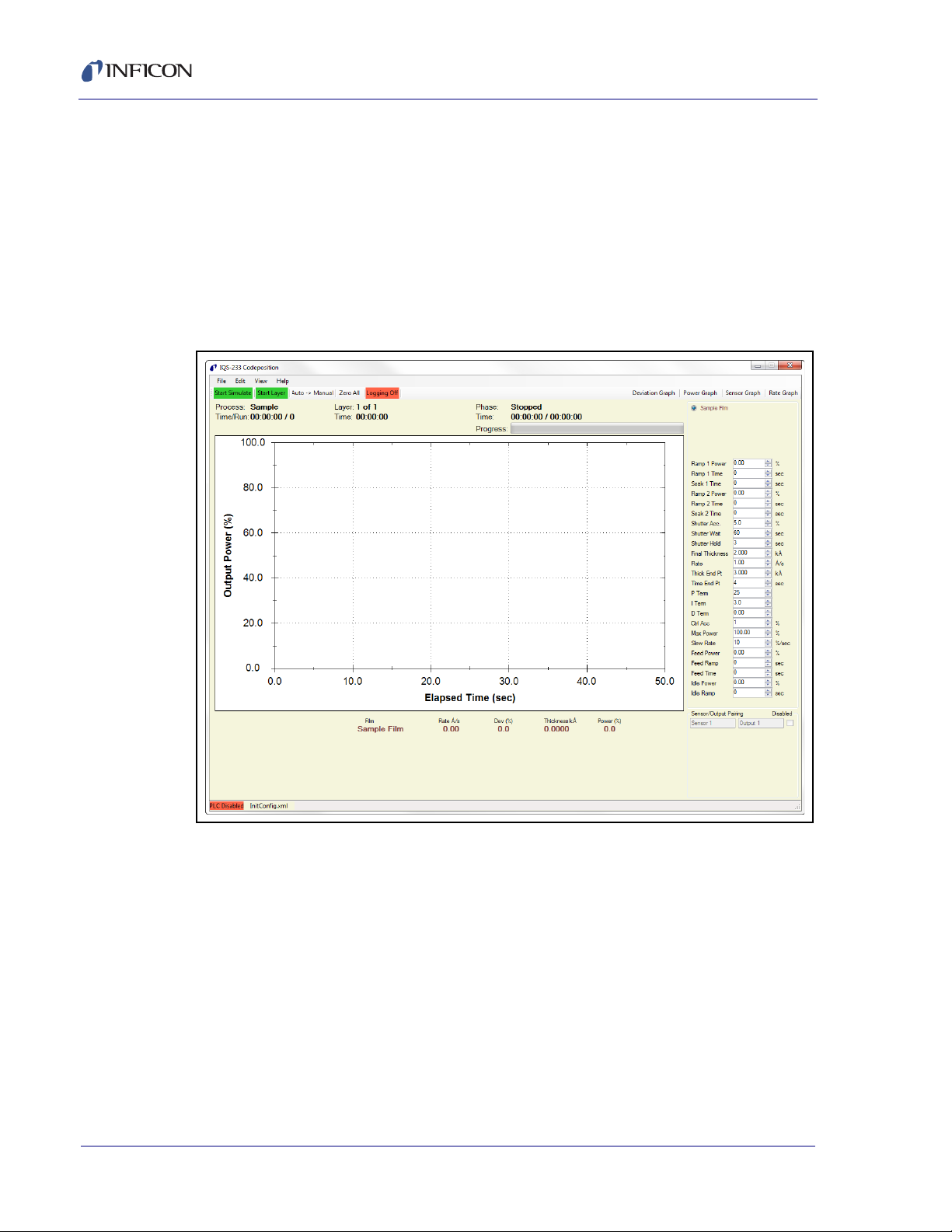

2.3.3 IQS-233 Codeposition Window

The IQS-233 Codeposition window displays readouts for Film, Rate, Deviation,

Thickness and Power simultaneously for each active output. This window also

provides Process, Layer, Phase, Run, and Time for each active output as well as

customizable process parameters, graphical information, and access to File, Edit,

View, and Help menus. See Figure 2-7.

NOTE: The Rate, Deviation, and Thickness readings displayed represent an

average of the sensors assigned to each film.

Figure 2-7 IQS-233 Codeposition window

2 - 8

NOTE: To zoom in the graph pane, click in the graph pane on the IQS-233

Codeposition window and drag to draw a box over the data needing to be

enlarged. To further zoom in, or to zoom out, rotate the wheel button up or

down, respectively, with the pointer in the graph pane.

File, see section 2.3.3.1

Edit, see section 2.3.3.5 on page 2-17

View, see section 2.3.4.1 on page 2-66

Help, see section 2.3.5.1 on page 2-73

IPN 074-585-P1A

Page 29

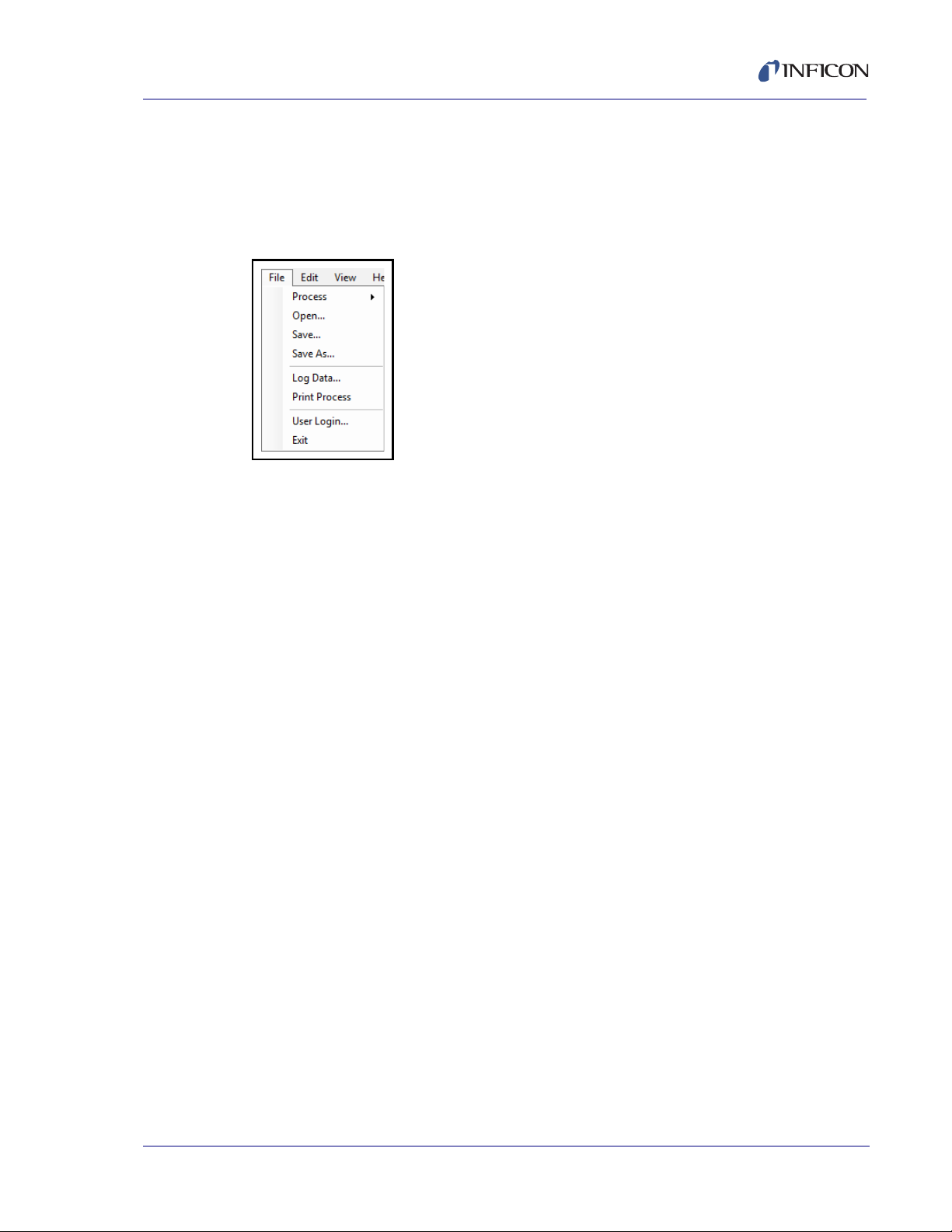

2.3.3.1 File

IQS-233 Operating Manual

Click File to display the list of File commands. See Figure 2-8.

NOTE: File commands are not available once a process is started or while a

process is running.

Figure 2-8 File commands

Process, see section 2.3.3.1.1

Open, see section 2.3.3.1.2 on page 2-11

Save, see section 2.3.3.1.3 on page 2-12

Save As, see section 2.3.3.1.4 on page 2-12

Log Data, see section 2.3.3.1.5 on page 2-14

Print Process, see section 2.3.3.2 on page 2-16

User Login, see section 2.3.3.3 on page 2-16

Exit, see section 2.3.3.4 on page 2-17

IPN 074-585-P1A

2 - 9

Page 30

IQS-233 Operating Manual

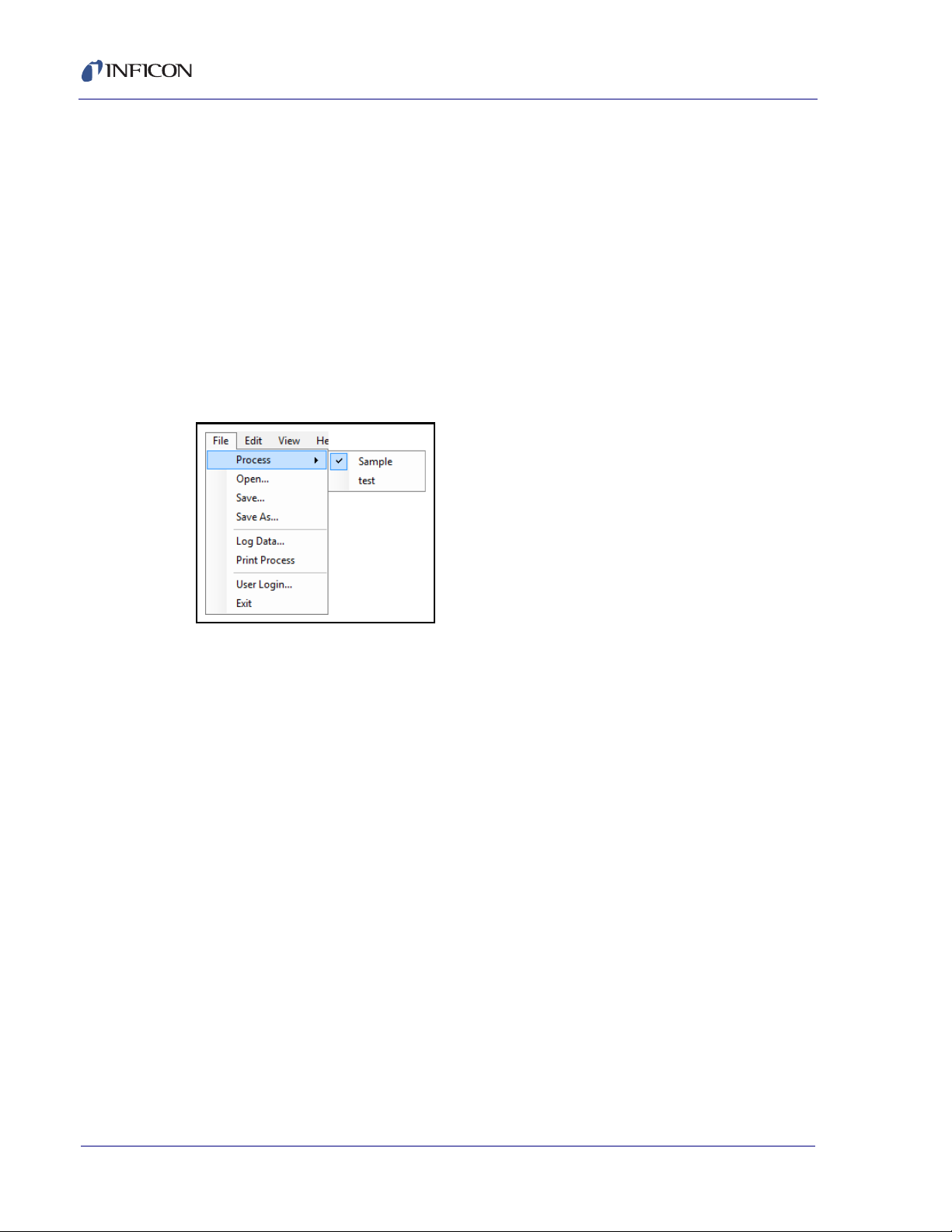

2.3.3.1.1 Process

Click File >> Process to display a list of saved process configurations (see Figure

2-9). A check mark next to the current process name indicates that the process

configuration has been loaded for that process name.

NOTE: The current process name is also displayed in the IQS-233 Codeposition

The process configuration consists of all of the parameters in the Process window

(see Figure 2-16 on page 2-18). System and security parameters are not included

in the process configuration. System parameters are contained in the .xml

configuration file. A different set of system parameters can be selected by loading

a previously saved configuration file (see section 2.3.3.1.2).

Figure 2-9 Process list

window (refer to Figure 2-7 on page 2-8).

2 - 10

IPN 074-585-P1A

Page 31

2.3.3.1.2 Open

CAUTION

IQS-233 Operating Manual

Click File >> Open to display the Load Configuration window (see Figure 2-10)

where a previously saved configuration file containing a set of parameters used for

a previous deposition can be selected and loaded.

Configuration files are in .xml format. InitConfig.xml is loaded when

IQS-233 Codeposition software is started. Once the software is running, a different

configuration file can be selected and loaded. Another process can be selected

without altering the system parameters loaded by the configuration file (refer to

section 2.3.3.1.1).

Figure 2-10 Load Configuration window

IPN 074-585-P1A

Do not delete or alter the InitConfig.xml, Materials.xml,

Setup.xml, or Users.xml files located in the

C:\ProgramData\INFICON\IQS-233 Codeposition folder.

Do not move these files to another folder.

2 - 11

Page 32

2.3.3.1.3 Save

CAUTION

Click File >> Save to save the current Process and System parameter values to

the configuration filename displayed in the message pane on the

IQS-233 Codeposition window.

If the default configuration filename, InitConfig.xml, is displayed, the default

parameters loaded when IQS-233 Codeposition software is started will be

overwritten by any changes made to the Process and System parameters.

2.3.3.1.4 Save As

Click File >> Save As to save the current Process and System configuration under

a different name. Configuration files are saved in .xml format. The default folder for

saving a configuration file is C:\ProgramData\INFICON\IQS-233 Codeposition;

however, the configuration file may be saved to another folder location if desired

(see Figure 2-11).

IQS-233 Operating Manual

Do not delete or alter the InitConfig.xml, Materials.xml,

Setup.xml, and Users.xml files located in the

C:\ProgramData\INFICON\IQS-233 Codeposition folder.

Do not move these files to another folder.

IPN 074-585-P1A

2 - 12

Page 33

Figure 2-11 Save Configuration window

IQS-233 Operating Manual

IPN 074-585-P1A

2 - 13

Page 34

IQS-233 Operating Manual

2.3.3.1.5 Log Data

Click File >> Log Data to display the DataLog window where data log preferences

can be configured and saved to a .csv format data log file (see Figure 2-12).

Figure 2-12 DataLog window

When data logging is activated, data is recorded for the following parameters:

Process Name

Run Number

Date Time

Event

Layer

Process Time

Layer Time

Deposit Time

Output Number

Film

Thickness

Rate

Rate Deviation

Power

Sensor Number

Sensor Rate

Sensor Thickness

Frequency

IPN 074-585-P1A

2 - 14

NOTE: The parameters recorded in the data log file depend on the parameter

selections in the Events to Log pane of the DataLog window.

Page 35

IQS-233 Operating Manual

Log File pane

None . . . . . . . . . . . . . . . . . . . . . . . . Data logging is unavailable.

Filename . . . . . . . . . . . . . . . . . . . . . Displays the name of the file to which

process data will be saved.

Overwrite. . . . . . . . . . . . . . . . . . . . . Each process run is saved to the file name

displayed in the Filename box.

NOTE: Subsequent process runs will

overwrite previous data in this file.

Append . . . . . . . . . . . . . . . . . . . . . . Data logged for the current process run is

added on to the end of any previously logged

data in the file displayed in the Filename box.

Run # . . . . . . . . . . . . . . . . . . . . . . . . Each process run is saved as a separate file

with the format filename_#.csv, where # is a

number that increments with each new run.

Save As . . . . . . . . . . . . . . . . . . . . . . Displays the Save As window, where process

data can be saved as a .csv format file. The

name of this file will be displayed in the

Filename box.

View . . . . . . . . . . . . . . . . . . . . . . . . . Displays the default Log folder where data

log files are stored. Click a data log file to

display a preview of the file contents or

double-click the file to open it in Microsoft®

®

Excel

IPN 074-585-P1A

.

2 - 15

Page 36

IQS-233 Operating Manual

Events to Log pane

End Deposit Phase. . . . . . . . . . . . . Data is recorded at the end of each layer’s

deposit phase.

End Each Phase . . . . . . . . . . . . . . . Data is recorded at the end of all phases.

I/O Events . . . . . . . . . . . . . . . . . . . . Data is recorded each time an external digital

input or output changes state.

Timed. . . . . . . . . . . . . . . . . . . . . . . . Data is recorded at the selected time interval.

Sensors . . . . . . . . . . . . . . . . . . . . . . Data is recorded for individual sensors in

addition to the normally recorded data.

Readings (yymmdd.log) . . . . . . . . When the Readings check box is selected,

the following data from individual sensors is

recorded and saved in a separate file: Timer,

Run Time, Sensor #, Rate, Thickness, and

Frequency. The file is saved in the format of

yymmdd.csv (for example, data saved on

January 15, 2014 will be saved to a file

named 140115.csv).

2.3.3.2 Print Process

Click File >> Print Process to print the configuration parameters for the current

Process to the default printer.

2.3.3.3 User Login

Click File >> User Login to display the User Login window (see Figure 2-13)

allowing a different user to log on to IQS-233 Codepostion software. When a

different User name and its associated Password are entered, the current session

is ended and the security access levels change to that of the new user. See

section 2.3.3.7 on page 2-61 for more information.

Figure 2-13 User Login window

IPN 074-585-P1A

2 - 16

Page 37

2.3.3.4 Exit

2.3.3.5 Edit

IQS-233 Operating Manual

Click File >> Exit to display the Exit window (see Figure 2-14). When exiting the

software, changes made to the current Process, Film, and System parameters can

be saved to the configuration filename displayed in the Exit window by selecting

the Save any changes to (name).xml check box and clicking Yes. Refer to

section 2.3.3.1.4 on page 2-12 to save parameter changes to a different

configuration filename.

Figure 2-14 Exit window

Click Edit to display the list of Edit commands. See Figure 2-15.

NOTE: The Edit commands are not available once a process is started or while a

process is running.

Figure 2-15 Edit items list

Process, see section 2.3.3.5.1

IPN 074-585-P1A

Films, see section 2.3.3.5.6 on page 2-28

Materials, see section 2.3.3.5.12 on page 2-42

System, see section 2.3.3.6 on page 2-44

Security, see section 2.3.3.7 on page 2-61

2 - 17

Page 38

2.3.3.5.1 Process

Click Edit >> Process to display the Process window. The Process window

provides the commands needed to develop a thin film deposition process

consisting of one or more Layers. See Figure 2-16.

Figure 2-16 Process window

IQS-233 Operating Manual

2 - 18

Process name and edit commands, see section 2.3.3.5.2

Layer tab, see section 2.3.3.5.4 on page 2-23

Rate Ramps tab, see section 2.3.3.5.5 on page 2-26

IPN 074-585-P1A

Page 39

2.3.3.5.2 Process Name and Edit Commands

Process Name

Process name box . . . . . . . Select a name from a list of previously saved

Process names to load the configuration for that

Process. See Figure 2-17.

Figure 2-17 Process window - Process name and edit commands

IQS-233 Operating Manual

IPN 074-585-P1A

Rename . . . . . . . . . . . . . . . Displays the Rename Process Name window where

the name of the current Process can be changed.

The original Process name is replaced. See

Figure 2-18.

Figure 2-18 Rename Process Name window

2 - 19

Page 40

IQS-233 Operating Manual

CAUTION

New . . . . . . . . . . . . . . . . . . . Displays the New Process Name window where the

name for a new Process configuration can be

entered. When the New Process Name window is

closed (by clicking OK), the name for the new

Process is displayed in the Process name box and

the default Process configuration is displayed. The

original Process name is not deleted. See

Figure 2-19.

Figure 2-19 New Process Name window

Delete . . . . . . . . . . . . . . . . . Deletes the current Process configuration from the

database of Process configurations.

Delete cannot be undone.

Copy . . . . . . . . . . . . . . . . . . Displays the Copy Selected Process to New Process

Name window where a duplicate of the current

Process configuration can be named and saved.

See Figure 2-20.

Figure 2-20 Copy Selected Process to New Process Name window

IPN 074-585-P1A

2 - 20

Page 41

2.3.3.5.3 Layer Information and Edit Commands

A Process consists of the Layer(s) displayed in the Layer information pane (see

Figure 2-21). A Layer consists of the parameters configured in the Layer tab (see

Figure 2-22 on page 2-23) and Rate Ramps tab (see Figure 2-23 on page 2-26).

Figure 2-21 Process window - Layer information and edit commands

IQS-233 Operating Manual

Layer . . . . . . . . . . . . . . . . . . Click the number of the desired Layer to display the

parameters in the Layer and Rate Ramps tabs

pertaining to that Layer.

NOTE: All related Codeposition Layers have the

IPN 074-585-P1A

same Layer number, but each Codeposition

Layer must use a different Output.

Out . . . . . . . . . . . . . . . . . . . The name of the source Output mapped to a

physical source output connection on the IQM-233

or SQM-242 card. Refer to the IQM-233 or SQM-242

operating manual for information about the source

output connection. The Output name is selected in

the Layer tab (see Figure 2-22 on page 2-23). The

relationship between the Output name and the

physical output connection on the IQM-233 or

SQM-242 card is configured in the Outputs tab of the

System Setup window (see Figure 2-37 on page

2-45).

2 - 21

Page 42

IQS-233 Operating Manual

Film . . . . . . . . . . . . . . . . . . . The Film name selected in the Layer tab.

Setpoint . . . . . . . . . . . . . . . The Setpoint value selected in the Layer tab.

Final Thickness . . . . . . . . . The Final Thickness value selected in the Layer tab.

Time Endpoint . . . . . . . . . . The Time Endpoint value selected in the Layer tab.

Cut Layer . . . . . . . . . . . . . . Deletes the selected Layer from the Layer

information pane and moves that Layer to the

Clipboard.

Copy Layer . . . . . . . . . . . . . Copies the selected Layer to the Clipboard.

Paste Layer . . . . . . . . . . . . Inserts a Layer from the Clipboard directly below the

selected Layer. The Layer number increments for

each new Layer. Any Layers below the selected

Layer are shifted downward and their Layer numbers

are incremented accordingly. Click Paste repeatedly

to insert multiple Layers. The parameters for the new

Layer(s) in the Layer and Rate Ramps tabs can then

be changed as needed.

Paste CoDep . . . . . . . . . . . Pastes a Layer from the Clipboard directly below a

selected Layer. The selected Layer and pasted

Layer will become Codeposition Layers with the

same Layer number. Any Layers below the pasted

Layer will be shifted downward and their Layer

numbers incremented accordingly.

To create Codeposition Layers

1 Click an existing Layer and click Copy Layer.

2 Change the Output in the Layer tab (see Figure 2-22) of the existing layer.

3 Click Paste CoDep to paste the cut Layer directly below the selected Layer.

The Codeposition Layers will have the same Layer number.

NOTE: Each Codeposition Layer must use a different Output.

IPN 074-585-P1A

2 - 22

Page 43

2.3.3.5.4 Layer Tab

The Layer tab (see Figure 2-22), used to configure a Layer, consists of the

following parameters:

Figure 2-22 Process window - Layer tab

IQS-233 Operating Manual

Film . . . . . . . . . . . . . . . . . . . Select the Film name to be used for the selected

Layer. A Film consists of the parameters configured

in the Film Edit window (see Figure 2-24 on page

2-28).

Output . . . . . . . . . . . . . . . . . Select the name of the source Output to be used for

IPN 074-585-P1A

the selected Layer. The relationship between the

Output name and the physical output connection on

the IQM-233 or SQM-242 card is configured in the

Outputs tab of the System Setup window (see Figure

2-36 on page 2-44). Refer to the IQM-233 or

SQM-242 operating manual for information about

the physical source output connection.

Input. . . . . . . . . . . . . . . . . . . Sensor(s), Timed Power

The Input selection determines the control method

used during the deposition phase.

2 - 23

Page 44

IQS-233 Operating Manual

Sensor(s):

Setpoint Å/s . . . . . . . . . . . . -999.90 to 999.90 Å/s

When Sensor(s) is selected, the Setpoint (Å/s) box is

displayed where a value for the deposition rate (or

the initial deposition rate if rate ramps are used) is

selected.

Timed Power

:

Setpoint % Pwr . . . . . . . . . . 0.00 to 100.00%

When Timed Power is selected, the Setpoint % Pwr

box is displayed where a value equal to a percentage

of the full scale source Output voltage is selected.

The source Output Power will remain at this constant

level during the deposition phase. The deposition

phase ends when the Final Thickness value is

reached, or the Time Endpoint value is reached,

whichever occurs first.

Final Thickness (kÅ) . . . . . 0.000 to 999.900 kÅ

When this value is reached, deposition ends and the

postcondition phases start. The postcondition

phases are configured in the Condition tab of the

Film Edit window (see Figure 2-30 on page 2-34).

Thickness Endpoint (kÅ) . . 0.000 to 999.900 kÅ

When this value is reached, the Thickness Setpoint

relay will be activated if selected in the I/O tab of the

System Setup window. See Figure 2-40 on page

2-52.

2 - 24

NOTE: The IQM-232 and SQM-242 cards do not

contain relays. A PLC is required to provide

the relays. See Chapter 3, Digital I/O.

Time Endpoint (s). . . . . . . . 0.00 to 30000.00 s

When this value is reached, the Time Setpoint relay

will be activated if selected in the I/O tab of the

System Setup window.

NOTE: IQM-232 and SQM-242 cards do not contain

relays. A PLC is required to provide the

relays. See Chapter 3, Digital I/O.

Start Mode. . . . . . . . . . . . . . Manual Start, Auto Start, Skip Pre Cond, Continuous

IPN 074-585-P1A

Page 45

IQS-233 Operating Manual

Manual Start . . . . . . . . . . . . The previous layer ends at its idle power. In the

IQS-233 Codeposition window, click Start Layer to

start the next Layer.

Auto Start . . . . . . . . . . . . . . Starts the next Layer automatically upon completion

of the previous Layer.

Skip Pre Cond . . . . . . . . . . Skips the precondition phases.

NOTE: The Start Mode selection must be the same

for all related Codeposition Layers.

Indexers pane

NOTE: A Programmable Logic Controller (PLC) is required to provide the relays

needed for control of an Indexer. See Chapter 3, Digital I/O.

Source Index. . . . . . . . . . . . None, 0 to 15

The Source Indexer pocket used by the selected

Layer. This value is sent to the PLC at the start of the

Layer.

Substrate Index . . . . . . . . . None, 0 to 4

The Substrate Indexer pocket used by the selected

Layer. This value is sent to the PLC at the start of the

Layer.

User 1 Index . . . . . . . . . . . . None, 0 to 15

The index value used by the selected Layer. This

value is sent to the PLC at the start of the Layer for

use as needed. A common application is to select

external equipment configurations.

User 2 Index . . . . . . . . . . . . None, 0 to 15

The index value used by the selected Layer. This

value is sent to the PLC at the start of the Layer for

IPN 074-585-P1A

use as needed. A common application is to select

external equipment configurations.

NOTE: To change the name of the User 1 and User 2 Index as it appears in

IQS-233 Codeposition software, open the InitConfig.xml file located at

C:\ProgramData\INFICON\IQS-233, and change the name of the indexer

in quotation marks located on lines 23 and 24 of the document. Save the

document.

<LayerIdx Name="User 1" Timeout="30" Done="False" End="15" Start="0">2</LayerIdx>

<LayerIdx Name="User 2" Timeout="30" Done="false" End="15" Start="0">3</LayerIdx>

Do not change any other portion of the document. Doing so may cause

IQS-233 Codeposition software not to operate properly.

2 - 25

Page 46

IQS-233 Operating Manual

2.3.3.5.5 Rate Ramps Tab

Click the Rate Ramps tab to display the Rate Ramp parameters (see Figure 2-23).

Rate Ramps allow for more than one deposition rate during the deposition phase.

Each Layer of a Process can have an unlimited number of Rate Ramps. Each Rate

Ramp consists of a Start Thickness value that initiates ramping to the Setpoint

value of a new rate, and a Ramp Time value for the time required to ramp to the

new rate Setpoint value.

Figure 2-23 Process window - Rate Ramps tab

2 - 26

Start Thickness (kÅ) . . . . . 0.000 to 999.900 kÅ

The value that, when reached, initiates a timed ramp

to a new rate. The Start Thickness value should be

greater for each subsequent ramp and less than the

Final Thickness of the Layer; otherwise, the Rate

Ramp is ignored.

Ramp Time (sec). . . . . . . . . 0.00 to 30000 s

The time in seconds required to achieve the new rate

Setpoint value.

Setpoint (Å/s) . . . . . . . . . . . -999.90 to 999.90 Å/s

Setpoint (Å/s) is displayed instead of Setpoint % Pwr

when Sensor(s) is selected in the Input box on the

Layer tab. Setpoint (Å/s) is the value of a new rate.

IPN 074-585-P1A

Page 47

IQS-233 Operating Manual

Setpoint % Pwr . . . . . . . . . . 0.00 to 100.00%

Setpoint % Pwr is displayed instead of Setpoint (Å/s)

when Timed Power is selected in the Input box of the

Layer tab. Setpoint % Pwr is the value of constant

Output Power used until the next Rate Ramp is

initiated or Final Thickness is reached. This value is

equal to a percentage of the full scale source Output

voltage.

Insert Ramp . . . . . . . . . . . . Inserts a new rate ramp configuration for the

selected Layer, at the selected position in the rate

ramps list. Existing rate ramps are shifted downward.

Delete Ramp . . . . . . . . . . . . Deletes the selected rate ramp.

Move Up . . . . . . . . . . . . . . . Shifts the selected rate ramp up one position.

Move Down . . . . . . . . . . . . Shifts the selected rate ramp down one position.

IPN 074-585-P1A

2 - 27

Page 48

2.3.3.5.6 Films

IQS-233 Operating Manual

Click Edit >> Films to display the Film Edit window where the configuration for a

new Film can be created and an existing Film can be renamed, copied, or deleted.

See Figure 2-24.

Figure 2-24 Film Edit window

Edit commands, see section 2.3.3.5.7

Deposit tab, see section 2.3.3.5.8 on page 2-31

Condition tab, see section 2.3.3.5.9 on page 2-34

Source/Sensor tab, see section 2.3.3.5.10 on page 2-36

Errors tab, see section 2.3.3.5.11 on page 2-37

IPN 074-585-P1A

2 - 28

Page 49

2.3.3.5.7 Edit Commands

Figure 2-25 Film Edit window - edit commands

NOTE: Edits to a Film will affect any Process with Layers using that Film.

IQS-233 Operating Manual

Film box . . . . . . . . . . . . . . . Displays a list of previously saved Film names.

Select a name from the list to display the parameters

for that Film in the Deposit, Condition,

Source/Sensor, and Errors tabs.

Rename . . . . . . . . . . . . . . . Displays the Rename Film Name window where a

new name for the current Film name can be entered

(see Figure 2-26). The original Film name is

replaced.

Figure 2-26 Rename Film Name window

IPN 074-585-P1A

2 - 29

Page 50

IQS-233 Operating Manual

CAUTION

New . . . . . . . . . . . . . . . . . . . Displays the New Film Name window where a name

for a new set of Film parameters can be entered.

When a new name is entered and the New Film

Name window is closed by clicking OK, the new

name is displayed in the Film box and the default

Process configuration is displayed in the Deposit,

Condition, Source/Sensor, and Errors tabs. These

Film parameters can then be changed as needed

and saved under the new name. The original Film

name is not deleted from the list of Film names. See

Figure 2-27.

Figure 2-27 New Film Name window

Delete . . . . . . . . . . . . . . . . . Deletes the currently displayed Film name from the

list of Film names.

NOTE: If the Film to be deleted is used in a Process,

a message will display the name of any

Process where the Film is used. The Film

must be deleted from any Process where

the Film is used before the Film can be

deleted from the list of Film names.

Delete cannot be undone.

Copy . . . . . . . . . . . . . . . . . . Displays the Copy Selected Film to New Film

Name window where a duplicate of the currently

displayed Film parameters can be named and

saved. See Figure 2-28.

Figure 2-28 Copy Selected Film to New Film Name window

IPN 074-585-P1A

2 - 30

Page 51

2.3.3.5.8 Deposit Tab

PID loop control, Shutter Delay, and Rate Sampling are configured in the Deposit

tab. See Figure 2-29.

Figure 2-29 Film Edit window - Deposit tab

IQS-233 Operating Manual

Loop pane

P Term . . . . . . . . . . . . . . . . . 0 to 9999

P is the proportional term that sets the gain of the

control loop. A value of 0 makes this command

unavailable. Enter a higher gain for a faster

responding (but potentially unstable) control loop,

and a lower gain for a slower responding control

loop. Enter a value of 25, and then gradually

increase or decrease the value to respond as

desired to rate step changes.

IPN 074-585-P1A

I Term (sec) . . . . . . . . . . . . . 0.0 to 999.9 s

I is the integral term that controls the time constant

of the loop. A value of 0 makes this command

unavailable. Enter a small I Term, such as 0.5 to 1

second, to smooth the response and minimize

overshoot to rate step changes.

2 - 31

Page 52

IQS-233 Operating Manual

D Term (sec) . . . . . . . . . . . . 0.00 to 99.90 s

D is the derivative term that determines how quickly

the control loop responds to changes. A value of 0

makes this command unavailable. Enter 0 or a very

small value to avoid rate oscillations, especially with

fast sources, such as electron beam guns. Slow

sources, such as resistively heated sources, may

require a large D value.

NOTE: For detailed information about determining the PID values, see section 4.5,

Tuning the Control Loop, on page 4-5.

Shutter Delay pane

Shutter Delay allows a stable rate to be achieved before the source shutter opens

exposing the substrate to the deposition source.

Enabled . . . . . . . . . . . . . . . . Select the check box to active Shutter Delay.

Accuracy (%) . . . . . . . . . . . 0.0 to 30.0 %

A percentage of the desired deposition rate that

must be reached within a specified time period (Wait)

and not exceeded for a specified time period (Hold).

If the Accuracy (%) value is not achieved within the

Wait time, or is exceeded before the Hold time

elapses, the layer is halted and the message Failed

to reach and hold n% control during shutter delay

time on (name) film is displayed.

Wait (sec) . . . . . . . . . . . . . . 0.00 to 30000.00 s

Maximum time allowed to achieve the Accuracy (%)

value.

Hold (sec) . . . . . . . . . . . . . . 0.00 to 30000.00 s

Time period that must elapse without the percentage

of desired rate being exceeded.

Rate Sampling pane

Rate sampling can extend the life of crystals. With rate sampling, the deposition

rate is sampled by a sensor during the Sample time and the average Output Power

required to maintain the rate during the Sample time is determined. The sensor

shutter is then closed and the Output Power is held at a constant value during the

Hold time. When the Hold time elapses, the sensor shutter is opened and the

deposition rate is sampled again. This sample and hold cycle continues until the

desired Final Thickness value is reached.

Continuous . . . . . . . . . . . . . Rate Sampling is unavailable and the sensor shutter

remains open during deposition.

IPN 074-585-P1A

2 - 32

Page 53

IQS-233 Operating Manual

Accuracy Based . . . . . . . . . Used in conjunction with the Time Based parameter.

If the Rate does not exceed the % value when the

Time Based Sample value elapses, the shutter will

be closed for the Time Based Hold time, with Output

Power held at a constant level during that time;

otherwise, the shutter will remain open until the rate

is equal to or less than the % value. The % value is

a ± percentage of the desired deposition rate (± sign

is not entered before the value).

% . . . . . . . . . . . . . . . . . . . . . 00.0 to 100.00 %

Time Based . . . . . . . . . . . . . When deposition starts, the sensor shutter will be

opened for the Sample (sec) time, and then the

shutter will be closed for the Hold (sec) time, with

source power held at a constant level during that

time.

Sample (sec) . . . . . . . . . . . . 00.0 to 100.00 s

Hold (sec) . . . . . . . . . . . . . . 00.0 to 100.00 s

IPN 074-585-P1A

2 - 33

Page 54

IQS-233 Operating Manual

2.3.3.5.9 Condition Tab

Preconditioning and postconditioning phases are configured in the Condition tab.

See Figure 2-30.

Figure 2-30 Film Edit window - Condition tab

Pre Condition pane

Before the deposition phase starts, it is often necessary to precondition the source

material, especially when using a thermal source. At the end of the precondition

phase, the power level should be at or near the power required for deposition.

Ramp 1 Power (%) . . . . . . . 0.00 to 100.00%

The output Power at the end of the Ramp 1 Time

phase. This value is a percentage of the full scale

output (Full Scale Out) selected in the Outputs tab of

the System Setup window.

Ramp 1 Time (sec) . . . . . . . 0.00 to 30000 s

The length of time to change the output power from

the initial power level to the Ramp 1 Power level.

Soak 1 Time (sec). . . . . . . . 0.00 to 30000 s

The length of time the output Power remains at the

Ramp Power level.

Ramp 2 Power (%) . . . . . . . 0.00 to 100.00%

Same command as Ramp 1 Power. Typically, the

Ramp 2 Power value is set to approximately the

power level required to achieve the desired initial

deposition rate.

IPN 074-585-P1A

2 - 34

Page 55

IQS-233 Operating Manual

Ramp 2 Time (sec) . . . . . . . 0.00 to 30000 s

Same command as Ramp 1 Time.

Soak 2 Time (sec) . . . . . . . . 0.00 to 30000 s

Same command as Soak 1 Time.

Auto Soak 2 . . . . . . . . . . . . When the check box is selected, a power value

based on the power level used during the deposition

phase is used for the Ramp 2 Power value during the

next run of the selected Layer.

Post Condition pane

Feed parameters are used with systems that provide wire-fed material to the

source. The Feed phase starts immediately after the deposition phase ends. If the

Feed parameters are at 0, the Feed phase is skipped and the Idle phase starts.

Feed Power (%). . . . . . . . . . 0.00 to 100.0%

The Power level reached at the end of the Ramp

Time. This value is a percentage of the full scale

output (Full Scale Out) selected in the Outputs tab on

the System Setup window.

Ramp Time (sec). . . . . . . . . 0.00 to 30000 s

The amount of time required to reach the Feed

Power level after the deposition phase ends.

Feed Time (sec) . . . . . . . . . 0.00 to 30000 s

The time that Output Power stays at the Feed Power

value before the Idle phase starts.

The Idle phase follows the Feed phase. If the Feed

parameters are at 0, the Feed phase is skipped and

the Idle phase starts immediately after the deposition

phase ends.

IPN 074-585-P1A

Idle Power (%). . . . . . . . . . . 0.00 to 100.0%

The Power level reached at the end of the Ramp

Time. This value is a percentage of the full scale

output (Full Scale Out) selected in the Outputs tab of

the System Setup window.

Ramp Time (sec). . . . . . . . . 0.00 to 30000 s

The time required to reach the Idle Power level after

the Feed phase ends (or the Deposition phase ends,

if Feed parameters are at 0).

2 - 35

Page 56

IQS-233 Operating Manual

2.3.3.5.10 Source/Sensor Tab

Max Power, Slew Rate, and Sensor Tooling are configured in the Source/Sensor

tab, and the material to be deposited is selected in this tab. See Figure 2-31.

Figure 2-31 Film Edit window - Source/Sensor tab

Source pane

Material . . . . . . . . . . . . . . . . Select the material to be deposited from a list of

material names. The Density and Z-Ratio values for

that material are displayed in the Materials window

(see Figure 2-33 on page 2-42) where these values

can be edited if desired.

Max Power (%) . . . . . . . . . . 0.00 to 100.00%

The maximum Output Power allowed, as a

percentage of the Full Scale Out value in the Outputs

tab on the System Setup window (see Figure 2-37 on

page 2-45). For example, if the Full Scale Out value

is -10 and the Max Power value is 75, the Output

Power will not exceed 75%, and therefore the output

voltage to the source will not exceed –7.5 V.

Slew Rate (%) . . . . . . . . . . . 0.0 to 100.0%

The maximum allowed change per second of Output

Power, for an Output using PID loop control, as a

percentage of the Full Scale Out value in the Outputs

tab on the System Setup window.

IPN 074-585-P1A

2 - 36

Page 57

Sensor Tooling (%) pane

Compensates for differences due to sensor and substrate geometry of the

Thickness measured by the sensor and the actual Thickness of material deposited

on the substrate (see section 4.3 on page 4-2). A value of 0.0 makes a sensor

unavailable.

Sensor 1 to 6 (IQM-233) . . . 0.0 to 999.0%

Sensor 1 to 8 (SQM-242) . . 0.0 to 999.0%

2.3.3.5.11 Errors Tab

Error detection and the action to occur upon the error are configured in the Errors

tab. See Figure 2-32.

Figure 2-32 Film Edit window - Errors tab

IQS-233 Operating Manual

HINT: Until the stability and repeatability of the Process has been established, the

Enabled check boxes for Control Error, Crystal Quality, and Crystal

IPN 074-585-P1A

Stability should be cleared, and the check box for Crystal Fail be selected.

On Error pane

The selected action is initiated if an error condition occurs as determined by the

Control Error pane selections. The possible actions are:

Ignore . . . . . . . . . . . . . . . . . All error conditions are ignored. The PID loop

attempts to control the rate until the deposition

phase is completed.

2 - 37

Page 58

IQS-233 Operating Manual

Stop Layer . . . . . . . . . . . . . Stops the deposition phase and sets source output

power to zero. This allows the cause of the error to

be corrected before continuing the deposition phase,

or allows the deposition phase to be completed

using manual control.

Timer Power . . . . . . . . . . . . A constant power level, based on the last "good" rate

measurements before the error occurs, is used to

complete the deposition phase.

NOTE: A good rate is defined as a rate not exceeding the Control Error % value

(if Control Error is selected), or not exceeding ±10% rate deviation (if

Control Error is cleared).

Control Error pane

If the PID control loop cannot achieve a deposition rate within a specified

percentage of the desired rate for a specified time period, the action selected in the

On Error pane is initiated.

HINT: Shutter Delay can ensure adequate rate control before the deposition

phase starts. Refer to section 2.3.3.5.8 on page 2-31.

Enabled . . . . . . . . . . . . . . . Select the check box to activate the Control Error

command

(%) . . . . . . . . . . . . . . . . . . . . 0 to 30%

The ± percentage (the sign is not entered before the

value) of deviation from the desired rate that when

exceeded for a specified time (sec) initiates the On

Error selection.

(sec). . . . . . . . . . . . . . . . . . . 0 to 99 s

The period of time the rate must exceed the (%)

value before the On Error selection is initiated.

IPN 074-585-P1A

2 - 38

Page 59

IQS-233 Operating Manual

CAUTION

CAUTION

Crystal Fail pane

A Crystal Fail error occurs if the crystal frequency of any Sensor used by the Film

is invalid for a specified number of measurements.

Enabled . . . . . . . . . . . . . . . Select the check box to activate the Crystal Fail

command.

Counts . . . . . . . . . . . . . . . . . 0 to 99

The quantity of invalid crystal frequency measurements. If this value is exceeded

the On Error action is initiated and the message Xtal Fail: Sensor x Freq is

displayed. An invalid frequency measurement is defined as no frequency, or a

frequency above the Max. Freq value or below the Min. Freq value in the Card tab

of the System Setup window.

If Ignore is selected as the On Error action and a Crystal

Fail occurs, Output Power can increase to maximum.

Selecting the Crystal Fail Enabled check box in

conjunction with selecting Stop Layer or Timed Power as

the On Error action is recommended.

When using a dual sensor, the Crystal Fail Enabled check

box must be selected for the Dual sensor shutter to open

if a Crystal Fail error occurs.

IPN 074-585-P1A

2 - 39

Page 60

IQS-233 Operating Manual

Crystal Quality pane

A Crystal Quality error occurs if the deposition rate exceeds a percentage of the

desired rate for a specified number of measurements.

Enabled . . . . . . . . . . . . . . . Select the check box to activate the Crystal Quality

command.

(%) . . . . . . . . . . . . . . . . . . . . 0 to 50%

The ± percentage (sign is not entered before the

value) of deviation from the desired rate that when

exceeded increments a counter or when not

exceeded decrements the counter. The % parameter

is used in conjunction with the (counts) parameter.

(counts) . . . . . . . . . . . . . . . . 0 to 99

During the deposition phase, each rate

measurement exceeding the (%) value increments a

counter. Each rate measurement not exceeding the

(%) value decrements the counter to a minimum

count of 0. If the quantity of measurement counts

exceeds the (counts) value, the On Error action is

initiated and the message Xtal Fail: Sensor x Qual is

displayed.

2 - 40

IPN 074-585-P1A

Page 61

IQS-233 Operating Manual

Crystal Stability pane

When material is being deposited, crystal frequency normally decreases. However,

near the end of crystal life, the crystal frequency may briefly "mode hop" to higher

frequencies. Other causes of a frequency increase include thermal effects, material

stress, and e-beam arcing. A Crystal Stability error will occur if the specified

magnitude of positive frequency increase is exceeded or the specified sum of

positive frequency increases is exceeded.

Enabled . . . . . . . . . . . . . . . Select the check box to activate the Crystal Stability