Page 1

INSTALLATION MANUAL

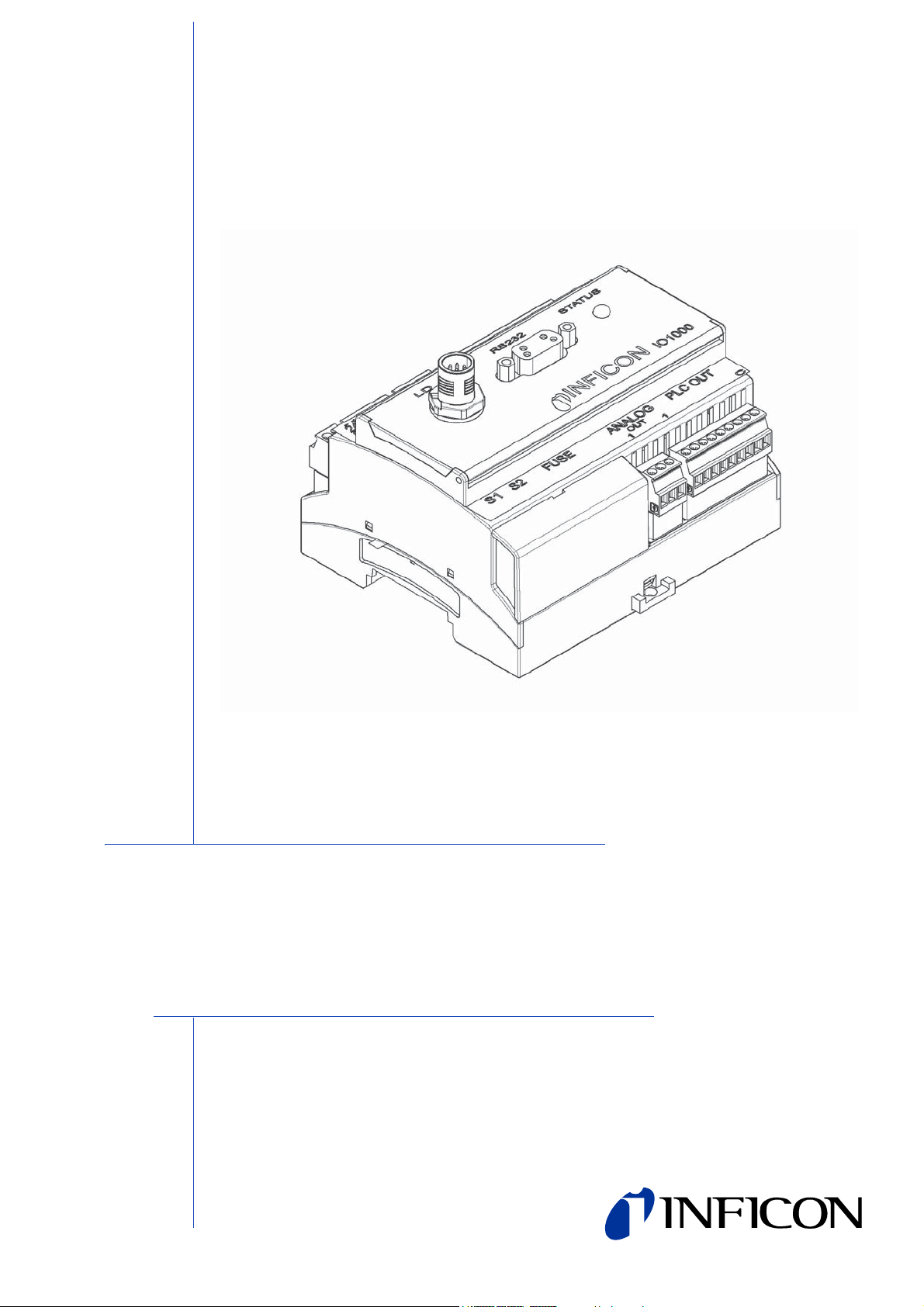

Type designation

IO1000

Product description

I/O module

Catalog no.

from software version

Document no.

560-310

I/O module 1.0

jiqc10en1-b (1301)

Page 2

This document applies to the software version stated on the cover page. If you need

a different version, please contact our sales staff.

Reprint, translation and duplication need to be approved in writing by

INFICON GmbH.

2

Page 3

Content

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Target groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Other applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Presentation of information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 Text markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 User requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 User requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Shipment check, transport, storage . . . . . . . . . . . . . . . . 7

3.1 Checking shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Construction of the I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.1 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3.3 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Installation and removal . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Mounting of I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Establish connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Removing the I/O module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 7

Content 3

Page 4

1 About this manual

1.1 Target groups

This installation manual is intended for the operator and for technically qualified

personnel with experience in leak detection technology and integration of leak

detection devices in leak detection systems. In addition, the installation and use of

the unit require knowledge of electronic interfaces.

1.2 Other applicable documents

Installation manual for mass spectrometer module jiqa54

Interface protocols jira54

1.3 Presentation of information

1.3.1 Warnings

Imminent threat of danger resulting in deat h or se ve re in jurie s

Dangerous situation potentially resulting in death or severe injuries

Dangerous situation resulting in minor injuries

Dangerous situation resulting in damage to property or the environment

4 About this manual

Page 5

1.3.2 Text markings

Marking Meaning

►

1, 2, 3, ... Several instructions in a fixed order

S

MALL CAPS

Information

Requirement for execution of an action

Tool or aid for an action

Instruction

Result of an action

Designation of the unit or command/term from the menu

Useful tips and information

About this manual 5

Page 6

2Safety

2.1 Intended use

The I/O module is a device interface between the MSB box of the mass spectrometer

module LDS3000 and an external controller, for example.

► Install, operate and service the unit only in compliance with this manual.

► Comply with the limits of application (see Chapter 4.3, page 14).

2.2 User requirements

Safety conscious operation

► Operate and install the unit only if it is in perfect working order and as intended,

in a safety-conscious manner and fully aware of dangers, in compliance with this

manual.

► Fulfill and ensure compliance with the following regulations:

– Intended use

– Generally applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional provisions and regulations that are specific to the unit

► Use only original parts or parts approved by the manufacturer.

► Keep this manual available at the operating site.

Personnel qualifications

► All work must be performed only by technical specialists who have been trained

on the unit.

► Allow personnel in training to work with the unit only under the supervision of

technical specialists.

► Make sure that the authorized personnel have read and understood this manual

and all other applicable documents (see Chapter 1.2, page 4), especially the

information on safety, maintenance and repairs, before starting work.

► Define responsibilities, authorizations and supervision of personnel.

2.3 User requirements

► Read, observe and follow the information in this manual and the working

instructions created by the owner, especially the safety instructions and warnings.

► Perform all work based on the complete manual.

6 Safety

Page 7

3 Shipment check, transport, storage

3.1 Checking shipment

Scope of delivery

Article Quantity

I/O module 1

Installation manual 1

► Check shipment to make sure it is complete.

3.2 Transport

Damage due to unsuitable packaging material

Transport in unsuitable packaging material can damage the unit.

► Transport the unit only in the original packaging material.

► Keep original packaging material.

3.3 Storage

► Always store the unit in compliance with the technical data, see Chapter 4.3,

page 14.

Shipment check, transport, storage 7

Page 8

4 Description

PLC-IN PLC-IN

1 Dyn CAL / Normal Cal

1 Dyn CAL / Normal Cal

2 SNIFF / VAC

2 SNIFF / VAC

3 STOP

4 ZERO

5 EXT.CAL

6 INT.CAL

7 CLEAR

8

9

10

11 PLC-IN-GND

3 STOP

4 ZERO

5 EXT.CAL

6 INT.CAL

7 CLEAR

8

9

10

11 PLC-IN-GND

24V-OUT

+

_

0 V

24 V

0 - 24V

PLC/SPS

PLC/SPS

4.1 Construction of the I/O module

Fig: 1 Front view

1 - PLC IN

Digital inputs

Fig: 2 Digital inputs

Electrical insulation (max. 60 V DC, 25 V AC against GND)

Max. permissible input voltage: U = 35 V

Active signal: U = 13 ... 35 V (typically 24 V), I = approx. 7 mA

Inactive signal: U < 7 V (typically 0 V), I = 0 mA

8 Description

Page 9

Connection plug arrangement

The digital inputs can be freely configured.

Pin Name Factory setting mass spectrometer module

1 PLC-IN 1 Dyn CAL / Normal Cal

2 PLC-IN 2 SNIFF/VAC

3PLC-IN 3 STOP

4PLC-IN 4 ZERO

5 PLC-IN 5 EXT.CAL

6 PLC-IN 6 INT.CAL

7 PLC-IN 7 CLEAR

8PLC-IN 8 -

9PLC-IN 9 10 PLC-IN 10 11 PLC-IN-COM COM

► For other layouts, see installation manual for mass spectrometer module

LDS3000.

Key-operated switch

An external key switch with up to three switching outputs can be connected via three

PLC inputs. The key switch can be used to select the access level of the user of the

control unit.

Key 1 - Operator

Key 2 - Supervisor

Key 3 - Integrator

Example for a suitable key switch: Hop + Schuler, No. 444-05

2- RS232

Connection for RS-232

Electrical insulation (max. 60 V DC, 25 V AC against GND)

Connection plug arrangement

Pin Name

2TxD

3RxD

5GND

A normal RS-232 cable must be used for the connection (1:1 connection, RxD and

TxD not crossed, no zero-modem cable).

► Deactivate RS-232 hardware handshake in RS-232 control program.

Description 9

Page 10

If the hardware handshake cannot be deactivated, then the RS-232 cable can be

used as follows:

Fig: 3 Connection with RS-232 cable (in case hardware handshake cannot be

deactivated)

3 - STATUS

Status LED

Color Status Meaning

Red illuminates Unit not functional or defective

Red flashes

Cyan illuminates

Not ready for operation, communication to mass

spectrometer module is not available

Ready for operation; communication to mass

spectrometer module available

Green Flashes quickly Boot loader active, ready for software update

Green Flashes slowly Data reception on RS232

Yellow Flashes slowly Data reception on RS485

4 - ANALOG OUT

Analog outputs (for logging leakage rate and backing pressure)

Electrical insulation (max. 60 V DC, 25 V AC against GND)

Voltage range 0...10V

Precision

±15 mV offset, additional ±1% from measurement (current

output voltage) as linearity error (at 25 °C)

Resolution typ. 2.5 mV

Load >10kΩ

Connection plug arrangement

The analog outputs can be freely configured.

Pin Name Factory setting mass spectrometer module

1 ANALOG-OUT 1

Leak rate mantissa

1 ... 10 V; linear; in used unit

Leak rate exponent

2 ANALOG-OUT 2

1 ... 10 V; 0.5 V / decade; step function;

1 V = 1 x 10

-12

; in used unit

3 ANALOG-OUT-GND -

► For other layouts, see installation manual for mass spectrometer module

LDS3000.

10 Description

Page 11

5 - PLC OUT

PLC_OUT_8

PLC_OUT_7

PLC_OUT_6

PLC_OUT_5

PLC_OUT_4

PLC_OUT_3

PLC_OUT_2

PLC_OUT_1

PLC_OUT_COM

FOA75

FOA75

8

7

6

5

4

3

2

1

0

Digital outputs

Fig: 4 Digital outputs

Electrical insulation (max. 60 V DC, 25 V AC against GND)

Max. permissible load per output: U = 30 V, I = 0.75 A

Fuses for digital outputs 1 ... 4 and 5 ... 8: 2 x 0.75 A

Connection plug arrangement

The digital outputs can be freely configured.

Pin Name Factory setting mass spectrometer module

1 PLC-OUT 1 TRIGGER1 INVERTED

2 PLC-OUT 2 TRIGGER2 INVERTED

3 PLC-OUT 3 TRIGGER3 INVERTED

4 PLC-OUT 4 TRIGGER4 INVERTED

5 PLC-OUT 5 READY

6 PLC-OUT 6 ERROR INVERTED

7 PLC-OUT 7 CAL-REQUEST INVERTED

8 PLC-OUT 8 OPEN

9 PLC-OUT-COM -

► For other layouts, see installation manual for mass spectrometer module

LDS3000.

Description 11

Page 12

6 - FUSE and DIP switch S1, S2

Fuses for digital outputs and DIP switches (under the cover)

Fuses for digital outputs 1 ... 4 and 5 ... 8:

2 x 0.75 A (Schurter: 7010.9800.xx)

DIP switch S1 4321

Factory setting

(default value of the interface protocol by MS module/control unit)

ASCII protocol -010

LD protocol -011

Binary protocol -101

LDS1000 protocol -110

1 = ON, 0 = OFF, – = not used

DIP switch S2 4321

Activate boot mode for software update x+––

Disable bus terminator 120 Ω for RS-485 1x––

1 = ON, + = switching OFF -> ON in operation, – = not used, x = no meaning

7 - LD

Connection for the data cable to the mass spectrometer module

8 - ANALOG IN

Analog input (input voltage range 0 V to 10.8 V)

-000

Connection plug arrangement

1 24V supply (output)

2 GND to 24V supply

3 Analog input (0 V to 10.8 V)

4 GND to analog input

12 Description

Page 13

9 - RS485

Connection for RS-485

D+

D-

RS485

A: aktiv

1

2

3

4

5

I/O-Modul

+5 V

562 Ω

DIP S2-4

120 Ω

562 Ω

0 V

D+

D-

RS485

B: ohne

1

2

3

4

5

+5 V

0 V

I/O-Modul

562 Ω

DIP S2-4

120 Ω

562 Ω

D+

D-

RS485

C: Passiv

1

2

3

4

5

I/O-Modul

+5 V

562 Ω

DIP S2-4

120 Ω

562 Ω

0 V

Fig: 5 RS-485 bus terminator

A: Active bus terminator

B: No bus terminator

C: Passive bus terminator

Electrical insulation (max. 60 V DC, 25 V AC against GND)

Connection plug arrangement

Pin Name

1 Connect pull-up resistor (562 Ω against +5 V) with D+ if necessary

2D+

3D4 Connect pull-down (562 Ω against GND) with D- if necessary

5COM

Information The bus terminator integrated in the I/O module (120 Ω) between D+

and D can be disabled via DIP switches S2-4.

The BUS address is 1.

BUS operation with more than two subscribers is not possible.

10 - 24V OUT

24V output

Connection plug arrangement

Pin Name

++24V

-GND

Information The I/O module is supplied with voltage by the MS module and requires

no separate power supply. The 24V output is not used for voltage

supply to the I/O module.

The 24V output of the I/O module can be used as an active signal for the PLC inputs

and outputs.

Description 13

Page 14

4.2 Function

The I/O module is a device interface between the MSB box of the mass spectrometer

module LDS3000 and an external controller, for example. The I/O module is

equipped with

• one RS-232 connection

• one RS-485 connection

• one analog input

• two analog outputs

• ten digital inputs

• eight digital outputs

4.3 Technical data

4.3.1 Mechanical data

Dimensions (W x H x D) 107.6 mm x 89.7 mm x 76.6 mm

Weight 300 g

4.3.2 Electrical data

Supply voltage 24 V DC

4.3.3 Ambient conditions

Permissible ambient temperature

(during operation)

Permissible storage temperature -20 °C ... 60 °C

Max. relative

humidity

Type of protection IP 20

Pollution degree II

Max. altitude above sea level 2000 m

10 °C ... 45 °C

< +31 °C 80%

+31 °C to +40 °C decreasing linearly from 80% ... 50%

> +40 °C 50%

14 Description

Page 15

5 Installation and removal

5.1 Mounting of I/O module

Fig: 6 Mount bus module on DIN-TS35 top hat rail

DIN-TS35 top hat rail

1 Hook unit on top hat rail at bottom.

2 Press unit onto top hat rail at top.

5.1.1 Establish connections

Connecting I/O module with MSB box

The I/O module communicates via data cable with the mass spectrometer module

and is supplied with voltage by the data cable.

Data cables from INFICON

1 Connect I/O module (connection L

OA

NYBUS).

2 Connect I/O module via desired interfaces with external controller:

– RS232 (RS-232 interface)

– RS485 (RS-485 interface)

–A

NALOG IN (analog input)

–A

NALOG OUT (analog outputs)

–P

LC IN (digital inputs)

D) via data cable with MSB box (connection I/

–P

LC OUT (digital outputs)

Installation and removal 15

Page 16

5.2 Removing the I/O module

Fig: 7 Removal of the bus module

Flat-tip screwdriver

1 Use the flat-tip screwdriver to pull out the locking device.

2 Remove the I/O module from the top hat rail.

16 Installation and removal

Page 17

6 Disposal

The unit can be disposed of by the user.

Information The unit is made of materials that can be reused. By recycling these

materials you reduce waste and environmental impact.

► For disposal, always comply with local and regional environmental and safety

regulations.

Disposal 17

Page 18

INFICON GmbH, Bonner Strasse 498, D-50968 Cologne, Germany

UNITED STATES TAIWAN JAPAN KOREA SINGAPORE GERMANY FRANCE UNITED KINGDOM HONG KONG

Visit our website for contact information and other sales offices worldwide. www.inficon.com

Document: jiqc10en1-b (1301)

Loading...

Loading...