Page 1

O P E R A T I N G M A N U A L

ninp69e1-a (1410)

Type no. ILS.210.306

Sensistor ILS500 F

Leak Detection Filler

Page 2

Page 3

Content

1 General Information 8

1.1 About This Manual 8

1.2 Introduction to the ILS500 F 8

1.3 Disposal 9

2 Equipment and Storage 10

2.1 Supplied Equipment 10

2.2 Required Equipment 11

2.3 Storage 11

3 ILS500 F Description 12

3.1 Front View 12

3.2 Rear View (Electrical) 13

3.3 Configuring Ports and Interfaces (Electrical) 14

3.4 Rear View (Pneumatical) 15

3.5 Configuring Ports and Interfaces (Pneumatical) 16

3.6 Labels 16

ninp69e1-a (1410)

4 Setup 18

4.1 Placement of the ILS500 F 18

4.2 Electrical Connections 19

4.3 Pneumatic Connections 21

4.4 Connect External Leak Detector 25

4.5 Set Up Test Area 25

5 Menu System 27

5.1 ILS500 F Display 27

5.2 Passwords 29

5.3 Menu Overview 30

6 Using the ILS500 F 35

6.1 Test Sequence 35

6.2 Run a Test 36

7 Recipes 38

7.1 Recipe Overview 38

7.2 Create a Recipe 39

7.3 Test Settings 40

7.4 Optimizing the Test Cycle 46

8 Troubleshooting 50

8.1 Fault Symptoms 50

8.2 Perform Hardware Test 50

9 Maintenance Instructions 62

9.1 Maintenance Plan 62

Content 3

Page 4

9.2 Maintenance 63

9.3 Functional Verification 69

10 Service 70

11 Technical Data 71

11.1 Electrical Specifications 71

11.2 Pneumatic Specifications 72

11.3 Other Data 73

11.4 Interfaces and Connectors 74

12 Spare Parts and Accessories 84

13 Support from INFICON 85

13.1 How to Contact INFICON 85

13.2 Returning Components to INFICON 85

14 Declaration of Conformity 86

15 Declaration by the Manufacturer 87

Appendix

A: Parameter Index 88

ninp69e1-a (1410)

Content 4

Page 5

General Safety Precautions

Definitions of Warning, Caution and Notice

Warning

Indicates procedures that must be strictly observed to prevent hazards to persons.

Caution

Indicates procedures that must strictly be observed to prevent damage to or destruction

of the instrument

.

General Safety

ninp69e1-a (1410)

Notice

Failure to observe the following precautions could result in serious personal

injury:

Indicates special requirements the user must comply with.

Warning

Tracer Gases can be flammable or asphyxiating. Use only ready-made Tracer Gas

mixtures.

Warning

Since the tracer gas mix contains no oxygen, releasing large amounts of the gas in a

confined space may lead to asphyxiation.

Warning

Compressed gases contain a great deal of stored energy. Always carefully secure

gas bottles before connecting a pressure regulator. Never transport gas bottles with

a pressure regulator fitted.

5

Page 6

Warning

Pressurizing objects at too high pressures can lead to the object bursting. This in

turn can result in serious injury or even death. Never pressurize objects that have

not previously been burst-tested or have otherwise been approved for the test

pressure you intend to use.

Failure to observe the following precautions could result in damage to the

equipment:

Caution

If the tracer gas filler suffers external damage, it must be checked and repaired by a

service organization authorized by INFICON.

Caution

Always switch power off before connecting or disconnecting any cable.

Notice

Before connecting the tracer gas, confirm that the connectors or test

object is designed for operating at the test pressure to be used.

ninp69e1-a (1410)

6

Page 7

Safety ILS500 F

Warning

The ILS500 F must never be introduced to pressures higher than that approved for

the object to be tested and never beyond the ILS500 F specification.

Warning

Be sure to have a pressure relief valve in case of accidental tracer gas pressure

increase.

Warning

When dealing with high pressures, a blast protection is needed between the Test

Ports and the Test Object.

ninp69e1-a (1410)

Warning

When dealing with test objects that cannot stand high pressure increase, make sure

to mount a flow control valve on the Test Ports.

Warning

Make sure not to confound Compressed Air and Tracer Gas.

Notice

INFICON can not take any responsibility for the consequences arising from

inappropriate use of certain test pressures.

The ILS500 F has no internal emergency stop circuit. ILS500 F is

prepared for integration into an external emergency stop circuit.

Check that all relevant legislation and safety standards are complied with

before putting the ILS500 F into service. See further information under

Installation.

7

Page 8

1 General Information

Please read this Operating Manual carefully before putting your Sensistor ILS500 F

into service. When reading, please pay particular attention to the WARNINGS,

CAUTIONS and NOTICES found throughout the text.

1.1 About This Manual

The purpose of this manual is to:

• Describe the working principles of the ILS500 F and its different parts

• Show examples of different types of test stations

• Teach the reader how to set up the ILS500 F for different test purposes

1.1.1 Document History

Revision Date Remark

a 10-2014 First edition

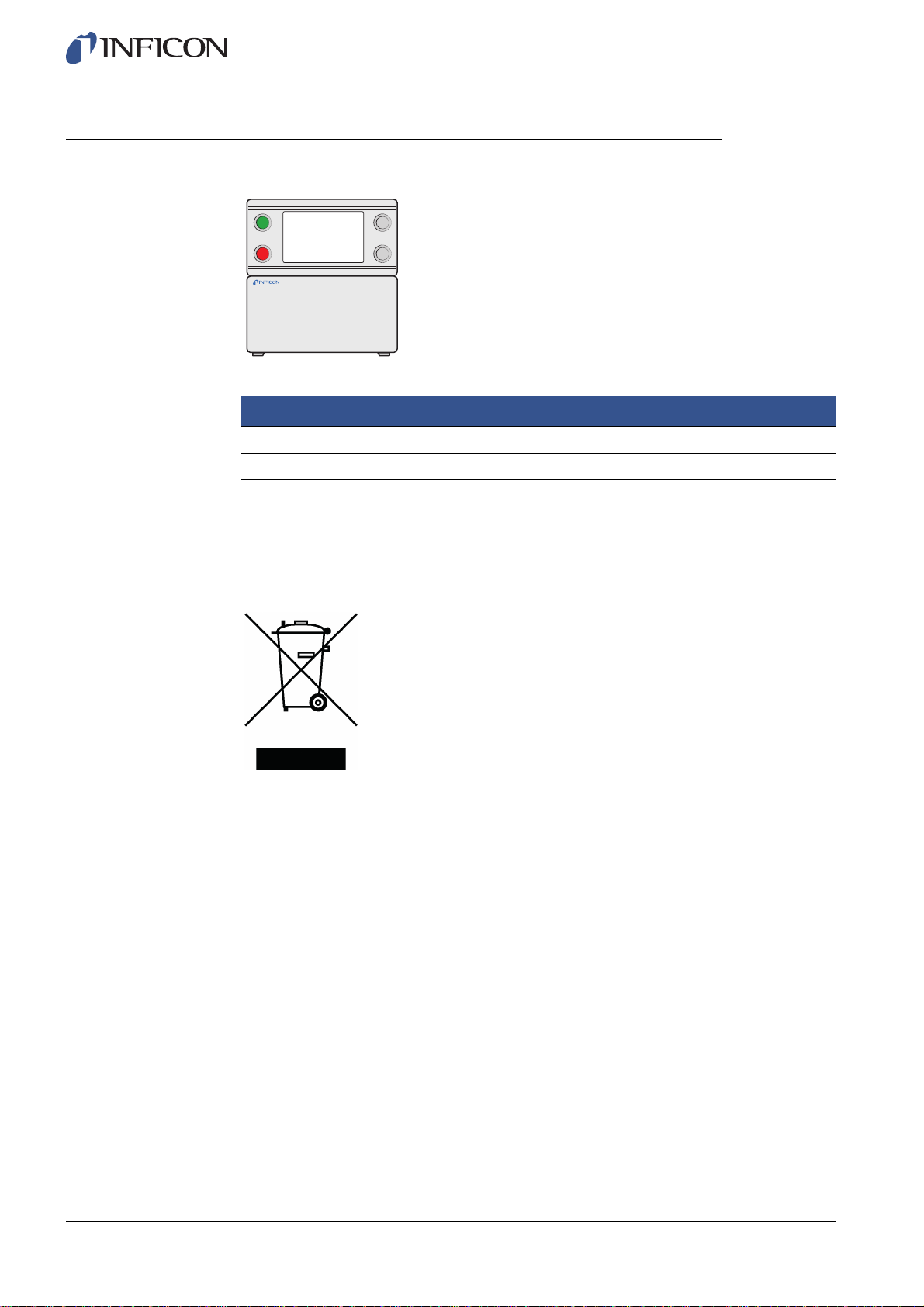

1.2 Introduction to the ILS500 F

ninp69e1-a (1410)

1.2.1 Intended Use

The Sensistor ILS500 F is a stand alone tracer gas filler with all necessary functions

integrated in one very compact housing.The purpose of the ILS500 F is to make it

possible to set up a fully automatic leak test system quickly, to a low cost.

The ILS500 F can also be combined with both hydrogen and helium INFICON leak

detectors.

If a ISH2000 Hydrogen Leak Detector is connected to the ILS500 F, via the Probe

Control Port and Leak Detector Port, the ILS500 F has the same functionality as

ILS500. For information on how to setup this configuration, please contact INFICON.

Notice

ILS500 F is designed for indoor use only.

All functions are accessible and programmable using a touch panel, a PC or via the

Internet. The test sequence is controlled by an integrated controller.

ILS500 F is not compatible with AP29, AP55, and AP57.

General Information 8

Page 9

1.2.2 Available Configurations

Sensistor ILS500 F

Sensistor ILS500 F

Standard For common tracer gas leak detection

High Pressure (HP) When a higher tracer gas pressure is needed.

The actual configuration is shown on the ILS500 F display during start-up and in the

menu when clicking Setup >> Info.

1.3 Disposal

According to EU legislation, this product must be recovered for

separation of materials and may not be disposed of as unsorted

municipal waste.

If you wish you can return this INFICON product to the manufacturer

for recovery.

The manufacturer has the right to refuse taking back products that

are inadequately packed and thereby presents safety and/or health

risks to the staff.

The manufacturer will not reimburse you for the shipping cost.

Shipping address:

INFICON AB

Westmansgatan 49

582 16 Linköping

Sweden

ninp69e1-a (1410)

9 General Information

Page 10

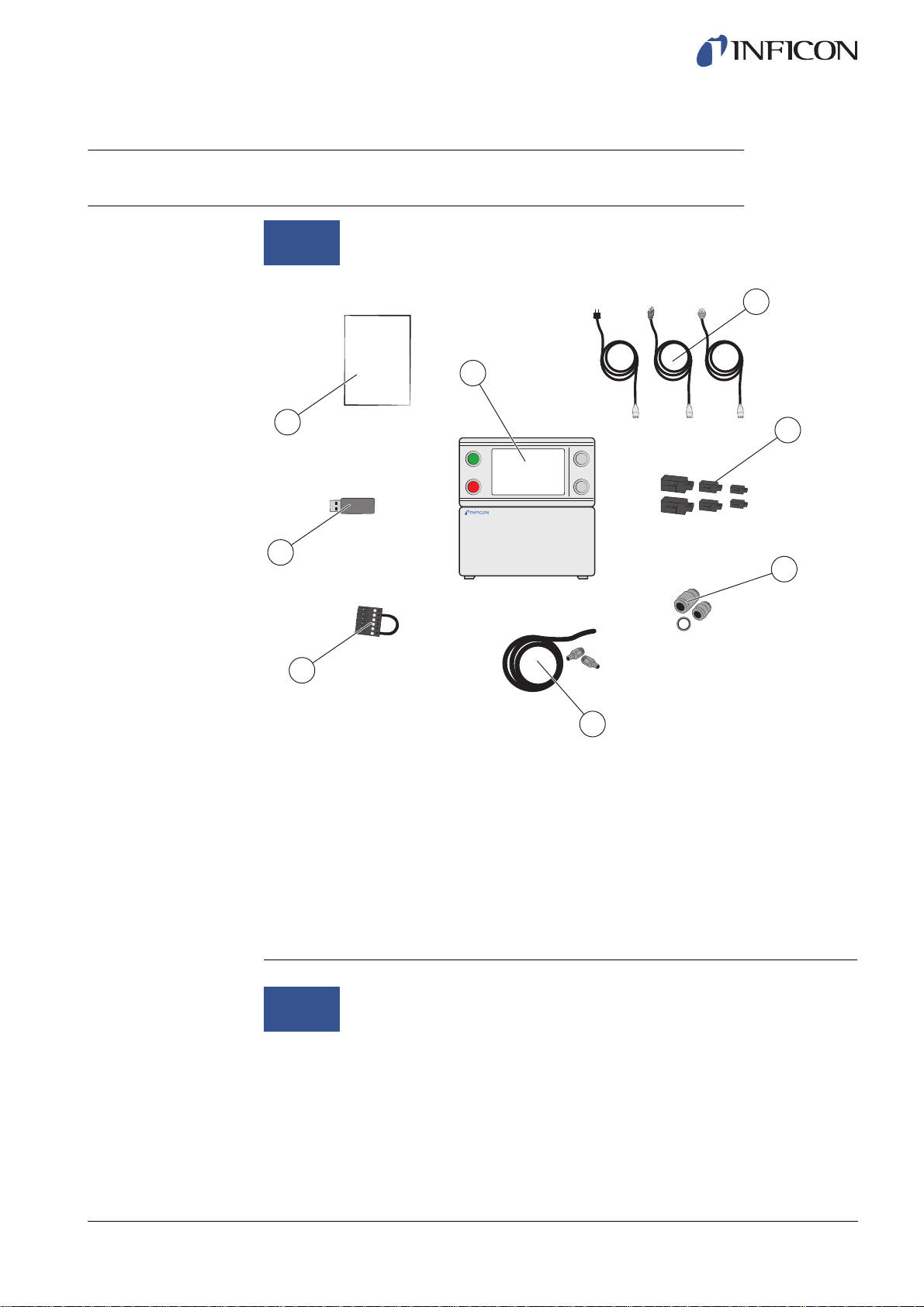

2 Equipment and Storage

2.1 Supplied Equipment

Notice

8

7

6

When receiving the equipment, check that it has not been damaged

during transport.

2

OM

ILS500 F

1

3

4

ninp69e1-a (1410)

5

Supplied Equipment

1 ILS500 F

2 Power Cables (EU, UK, US)

3 Screw Terminal Connectors for External I/O Signals

4 Thread Converter Set (ISO to NPT Conversion)

5 Hose Connection Kit

6 Safety Override Loopback

7 USB flash drive with relevant manuals

8 Operating Manual Sensistor ILS500 F (this manual)

Notice

Accessories to the ILS500 F can be found on page 84.

Some pneumatic ports are plugged upon delivery. Store the removed

plugs. They are used for future hardware testing.

Equipment and Storage 10

Page 11

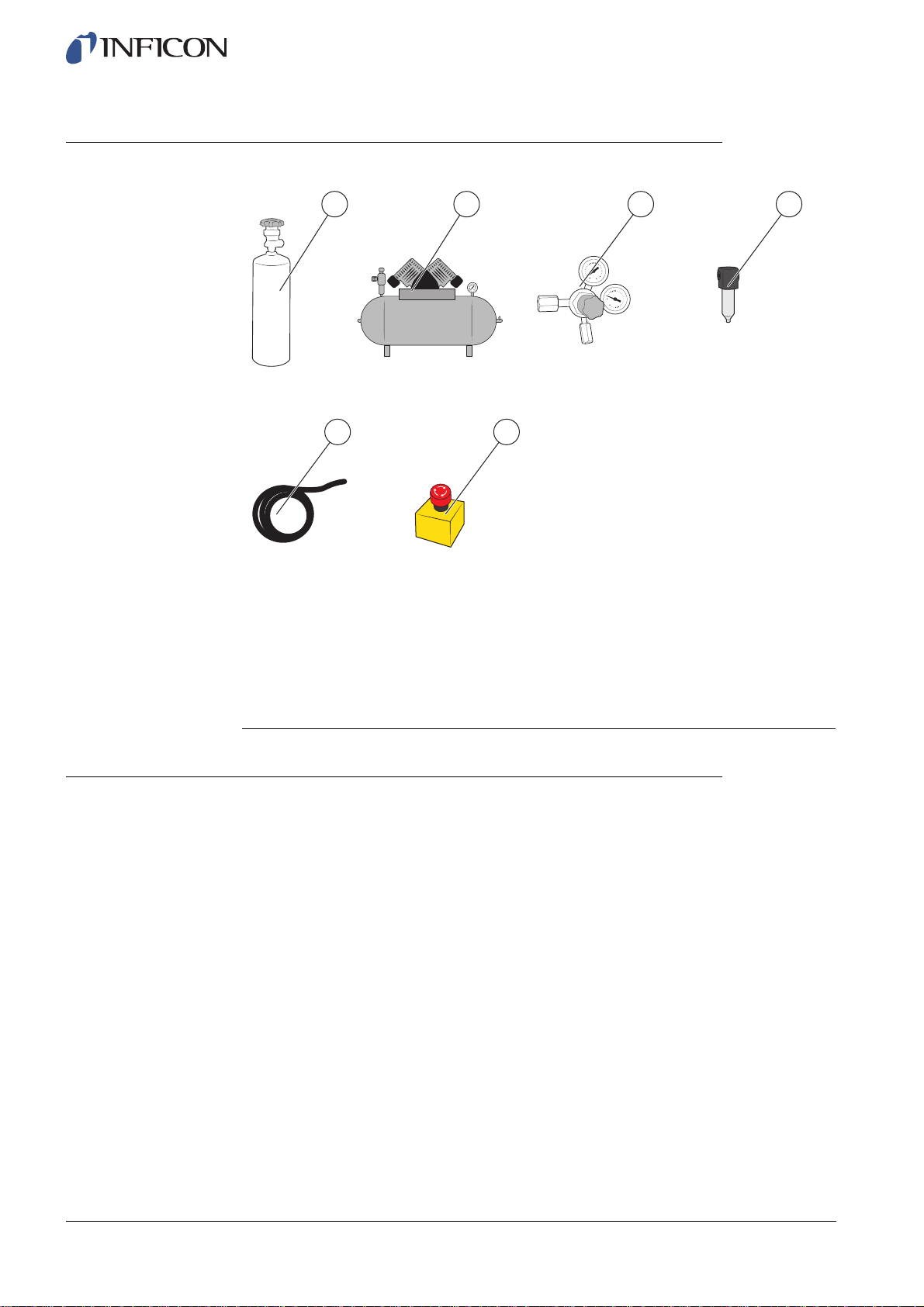

2.2 Required Equipment

1

5 6

Required Equipment

1 Tracer Gas

2 Compressed Air

3 Two-Step Gas Regulator

4 Compressed Air Filter

5 Exhaust Hose

6 Emergency Stop Circuit (recommended)

2

3

4

ninp69e1-a (1410)

2.3 Storage

For prolonged storage, factors such as temperature, humidity, saline atmosphere etc.,

may damage the detector elements.

Please contact your local representative for more information.

11 Equipment and Storage

Page 12

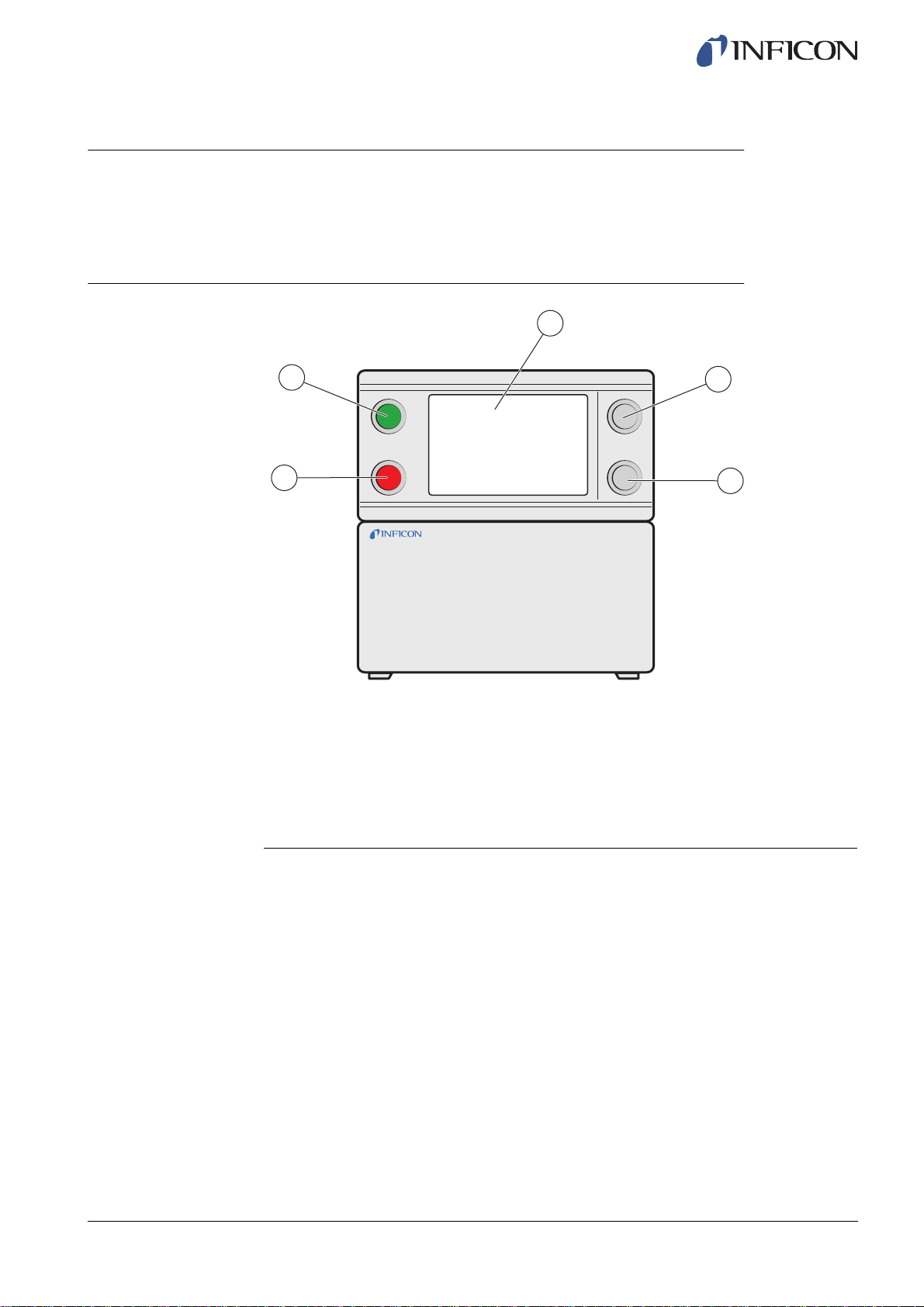

3 ILS500 F Description

ILS500 F is manually controlled using the START and STOP buttons and the menu

system of the touch panel. The screen also shows the steps of the test sequence

graphically and in plain text.

3.1 Front View

3

ninp69e1-a (1410)

2

1

ILS500 F Front View

1 Red lamp

2 Green lamp

3 ILS500 F Touch panel

4 START button

5 STOP button

4

5

ILS500 F Description 12

Page 13

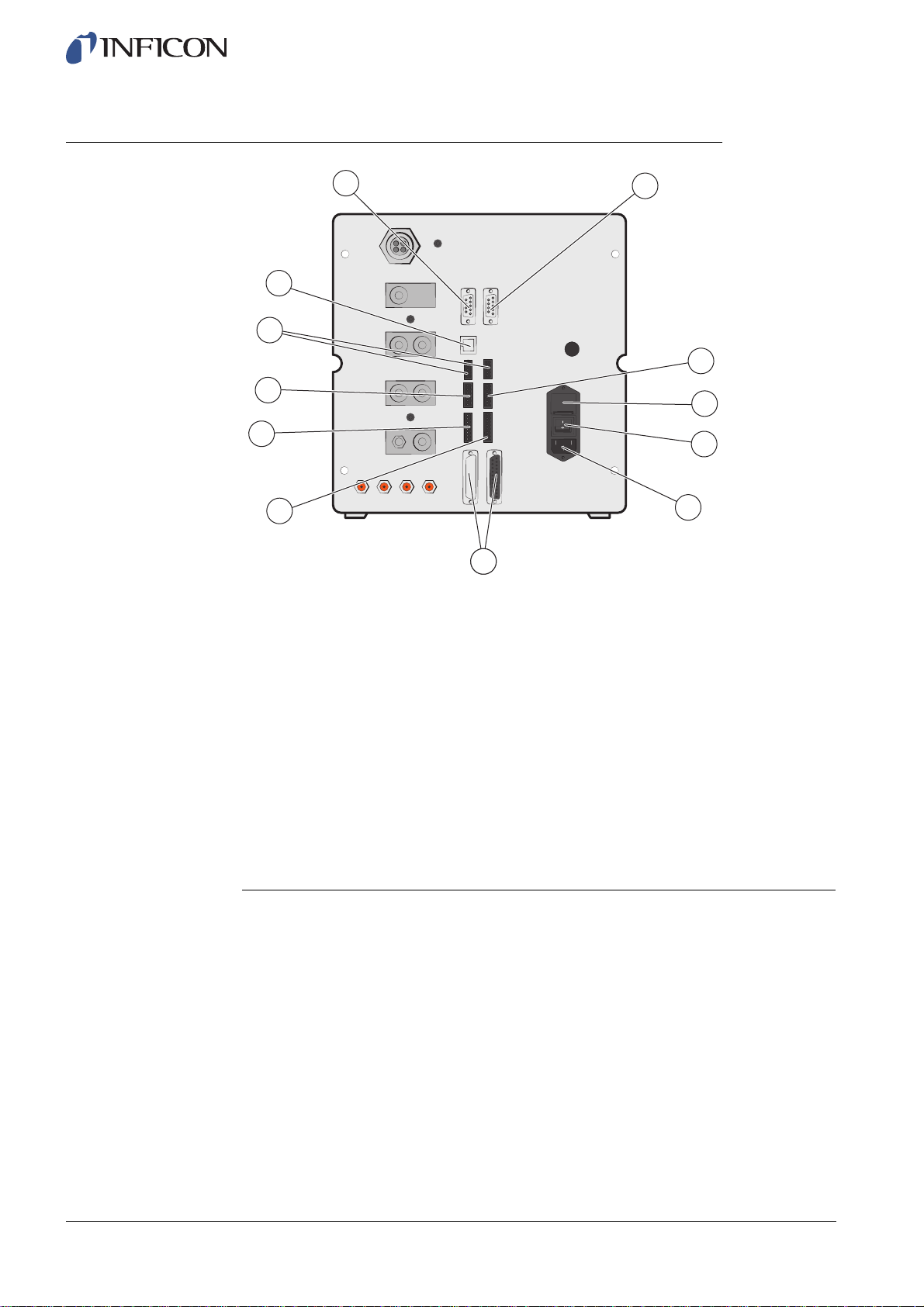

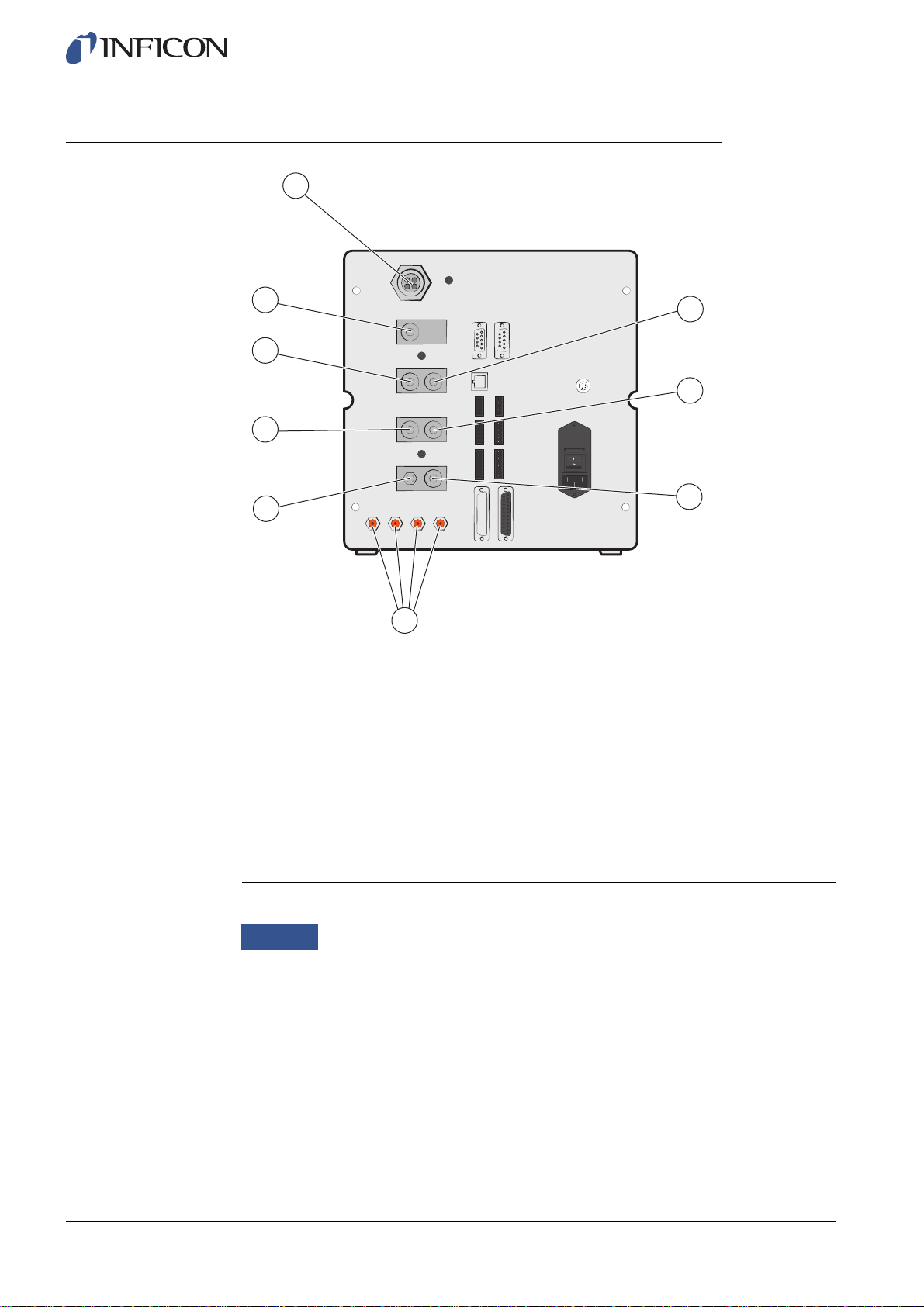

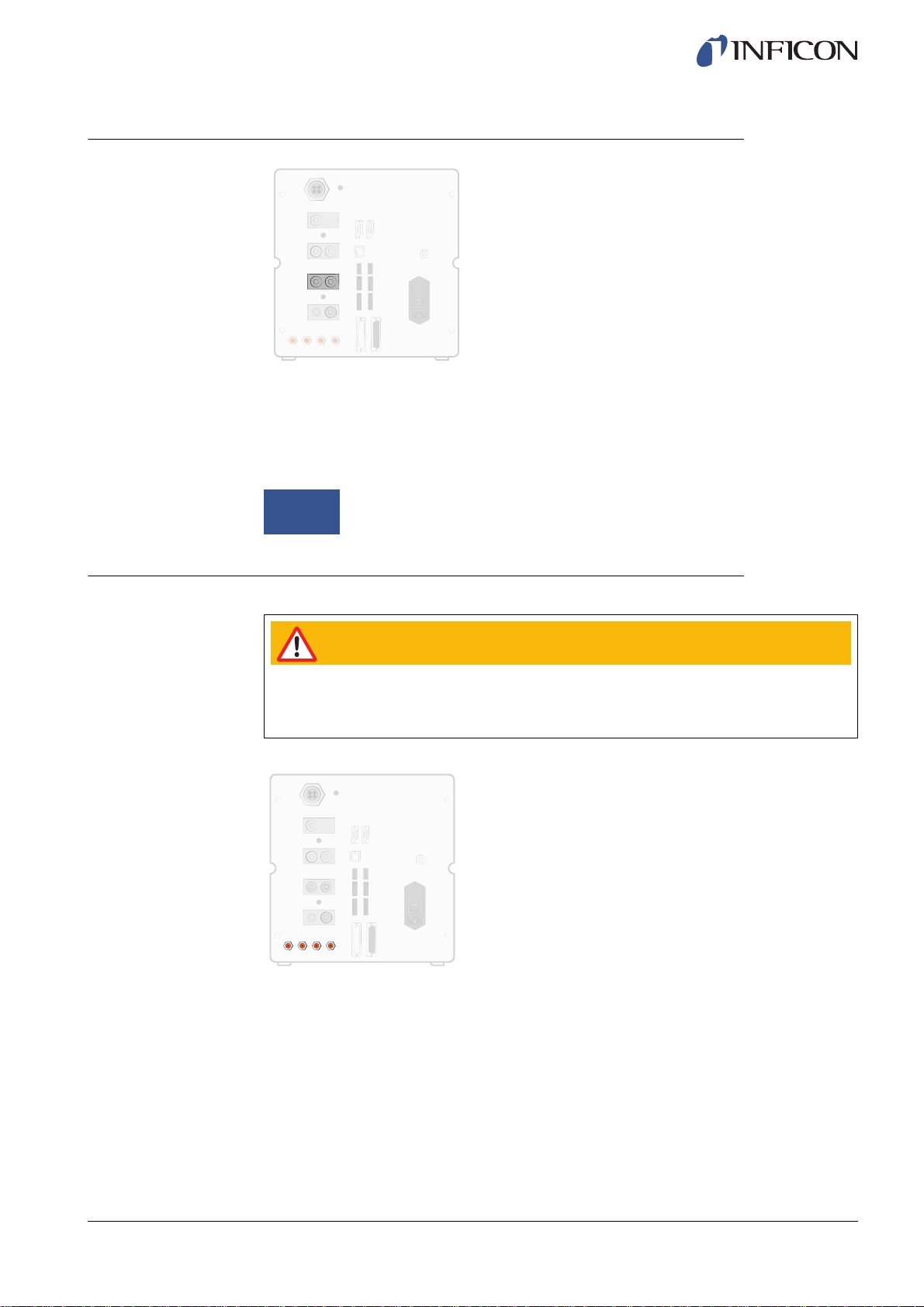

3.2 Rear View (Electrical)

12

1

11

10

9

8

7

6

Rear View (Electrical)

1 Leak Detector (for connection of ISH2000 or T-Guard)

2 Safety Interface

3 Fuses

4 Power Switch

5 Power Input

6 Probe Control Port (for connection of ISH2000)

7 Control Output

8 Tooling Interface

9 Status Output

10 Inputs 1 and 2 (optional)

11 Ethernet

12 Printer Port/RS232

2

3

4

5

ninp69e1-a (1410)

13 ILS500 F Description

For more information, see on page 71.

Page 14

3.3 Configuring Ports and Interfaces (Electrical)

Port/Interface Connect

Leak Detector ISH2000 or T-Guard.

Safety Interface Emergency Stop Circuit.

Power Input Power Cable.

Probe Control Port Pin-to-pin cable

(for external mounting of ISH2000 Leak Detector).

Control Output Optional External Valves.

Tooling Interface External sensors for tooling control.

Status Output Light Tower etc.

Input 1 (optional) Analogue Input

(not supported by std software).

Digital Input

(not supported by std software).

Input 2 Active Holder for Hand Probe

(if ISH2000 Leak Detector is connected).

ninp69e1-a (1410)

Ethernet Ethernet

(remote view and control of touch panel).

Printer Port/RS232 Serial Printer.

Logging Device

(e.g. PC).

Remote Control

(START, STOP etc.).

ILS500 F Description 14

Page 15

3.4 Rear View (Pneumatical)

9

8

7

6

5

4

Rear View (Pneumatical)

1 Optional Port

2 Test Port 2

3 Compressed Air Input

4 Tooling Valve Outputs 1-4

5 Vacuum Gauge Vent

6 Test Port 1

7 Tracer Gas Input

8 Plugged Port

9 Exhaust

1

2

3

ninp69e1-a (1410)

15 ILS500 F Description

Notice

Do not remove the plug from the plugged port in pos. 8.

Page 16

3.5 Configuring Ports and Interfaces (Pneumatical)

Port/Interface Port Thread

Exhaust Barb Fitting:

ID 25 mm (1 in.)

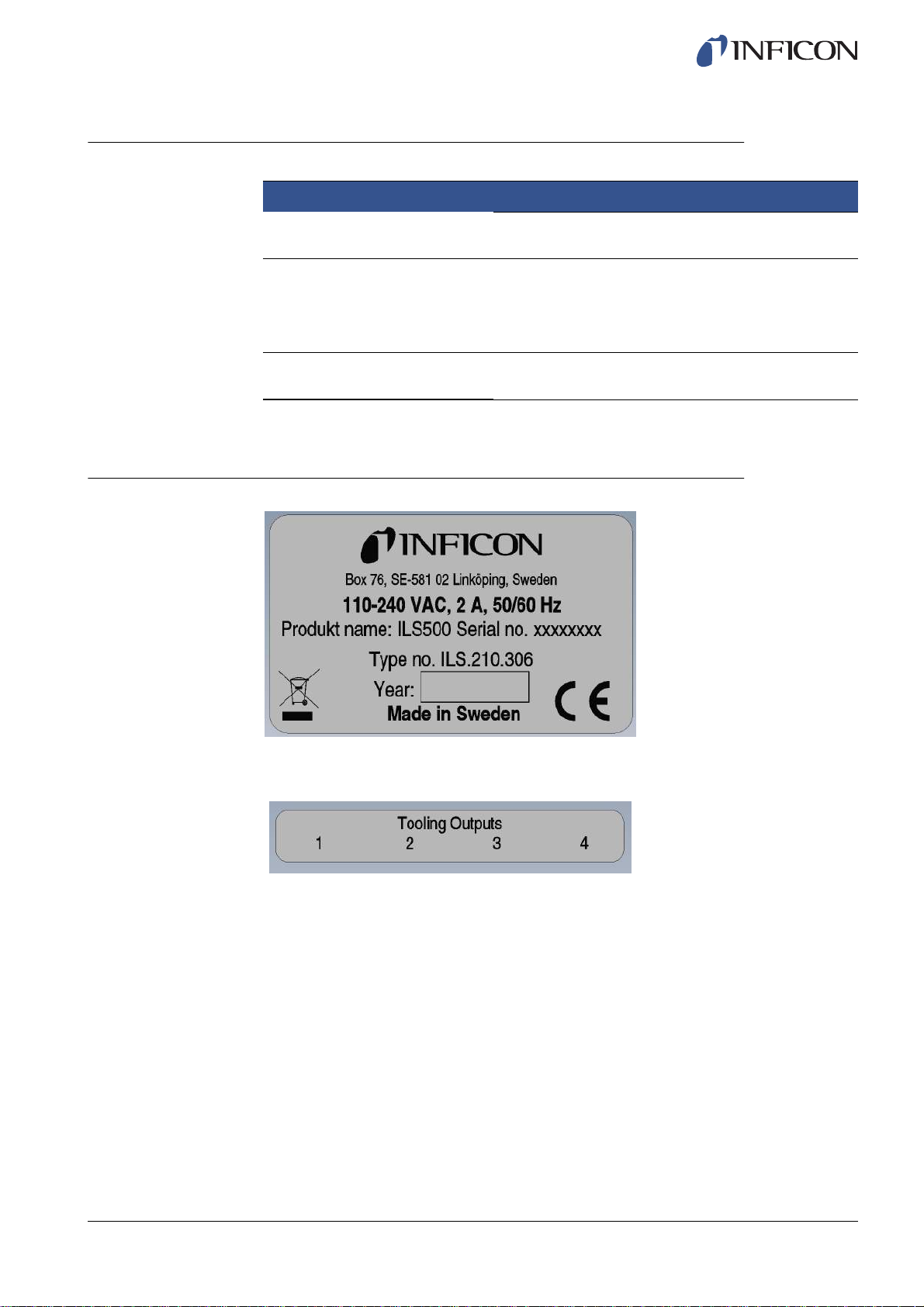

3.6 Labels

ninp69e1-a (1410)

Tracer Gas Input

Test Port 1

Test Port 2

Compressed Air Input

Tooling Valve Outputs 1-4 Hose Connectors:

BSP 3/8" (NPT 3/8" adaptor included)

BSP 3/8" (NPT 3/8" adaptor included)

BSP 3/8" (NPT 3/8" adaptor included)

BSP 3/8" (NPT 3/8" adaptor included)

OD 4 mm (0.16 in.)

Device Label

Tooling Label

ILS500 F Description 16

Page 17

Pneumatical Label Electrical Label

ninp69e1-a (1410)

17 ILS500 F Description

Page 18

4 Setup

Caution

Check that you comply with all relevant legislation and safety standards before

putting your ILS500 F into service.

Notice

Start-up time for the leak detectors can be up to 10 minutes, depending

on the condition.

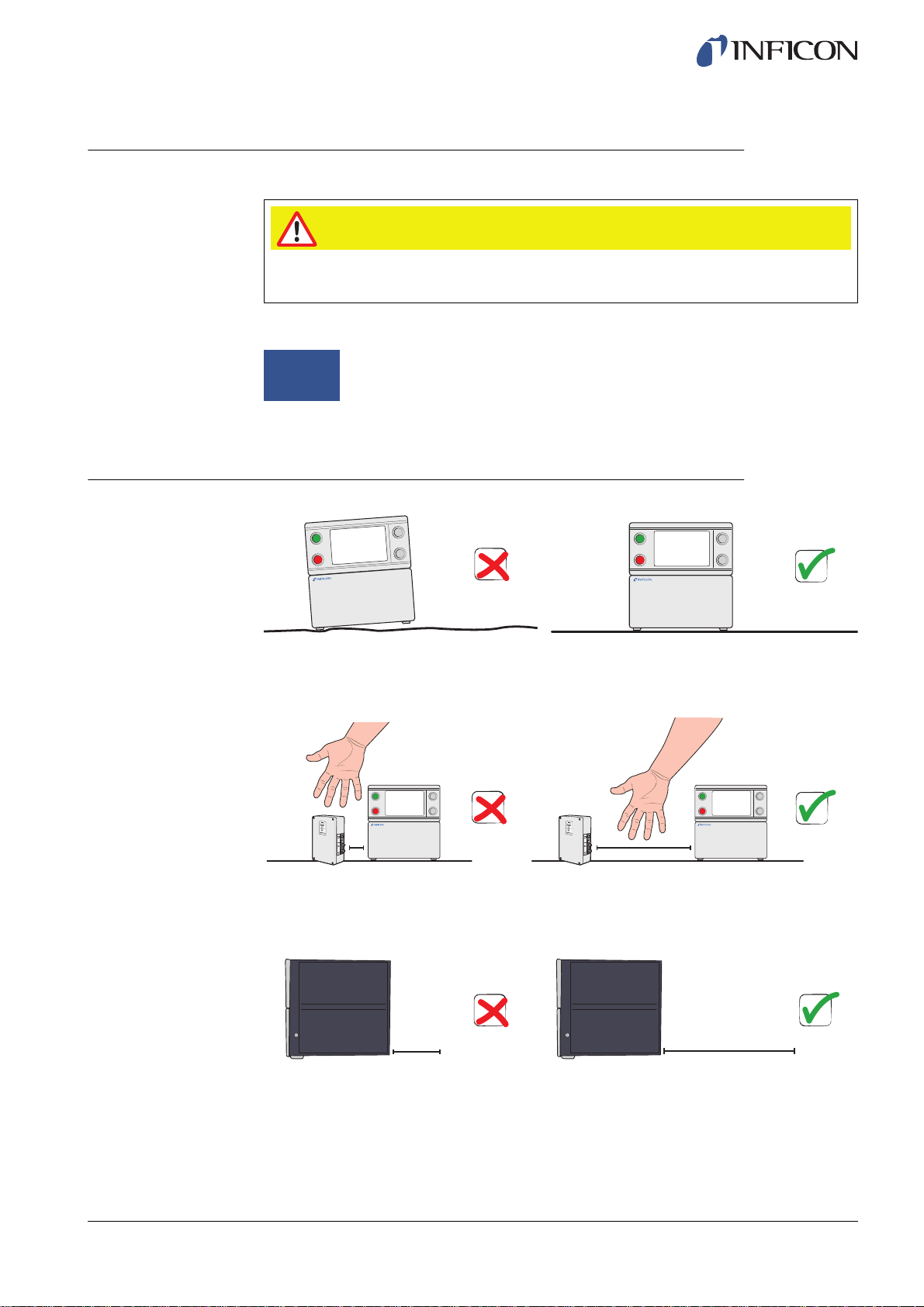

4.1 Placement of the ILS500 F

Place the ILS500 F on a flat surface, as close as possible to the test fixture and

ventilation system.

ninp69e1-a (1410)

Some free space must be provided around the ILS500 F to enable maintenance and

service access.

≥350 mm (14 in.)

Ensure that there is at least 350 mm (14 in.) of free space behind the ILS500 F to

enable removal of service hatches, connection of supplies, test fixture etc.

Setup 18

Page 19

Notice

The front feet under the ILS500 F can be flipped out to raise the front for a

better viewing angle.

4.2 Electrical Connections

4.2.1 Setting Up an Emergency Stop

Caution

To short-circuit is not recommended and should only be made for preliminary testing

before connecting compressed gases or test tooling with moving parts.

You have the following two options to prepare the ILS500 F for start:

• Connect the ILS500 F through an external emergency stop relay.

• Short circuit the SAFE SPLY terminal to “+24 V” on the Safety Connector.

Use the Safety Override Loopback delivered with the unit.

Notice

ILS500 F will not start testing unless an emergency circuit has been

installed. This is ordered separately. For more information, see on page

84.

ninp69e1-a (1410)

19 Setup

Page 20

4.2.2 Connecting to Mains

1 Plug the Power Cable into the Power Inlet of the ILS500 F and into the nearest

socket.

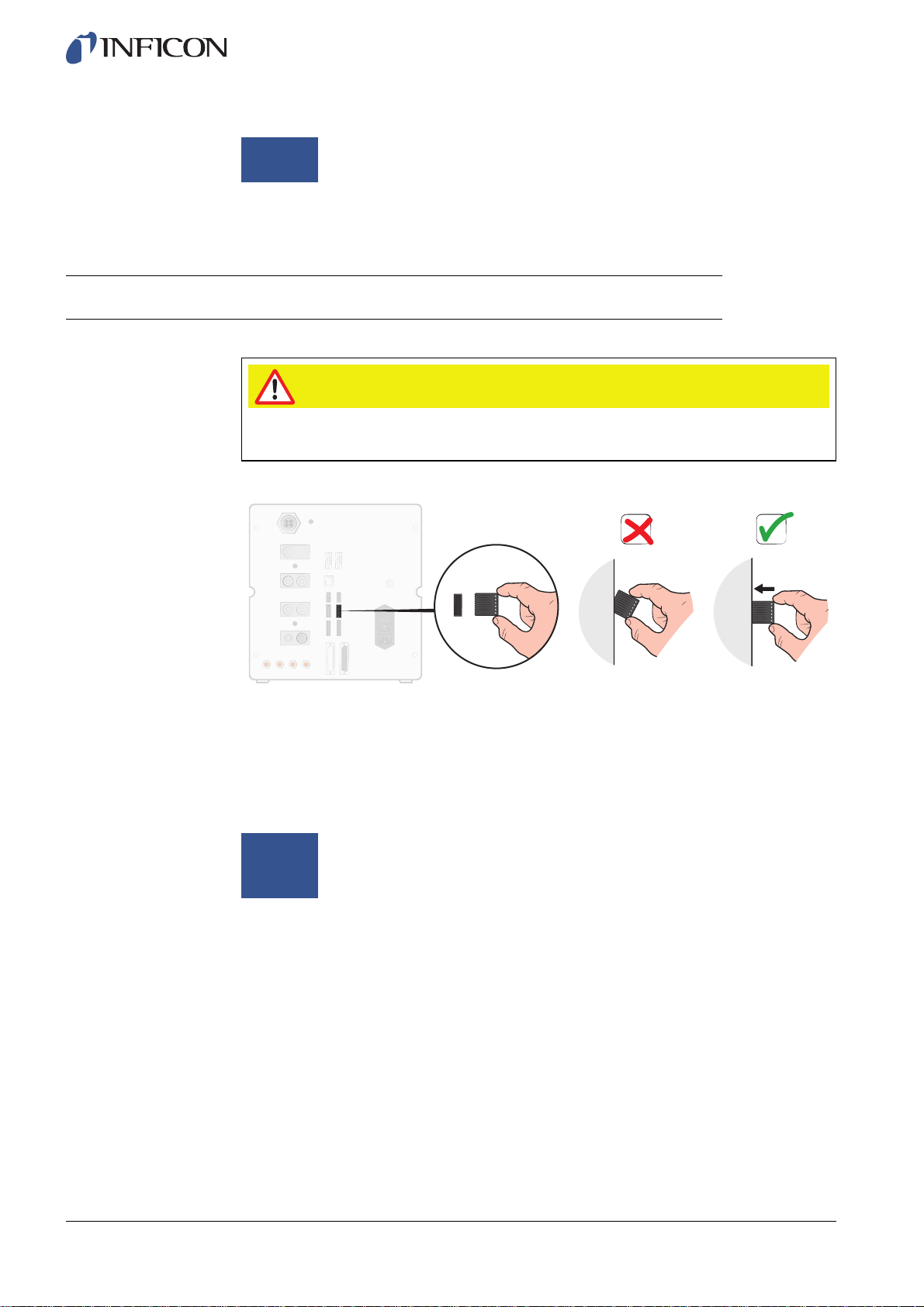

4.2.3 Connecting Extra Features

When using the ports for Options, Status, Tooling and Control, make sure to mount the

connectors as shown below.

ninp69e1-a (1410)

Top pin is number 1

For more information about the connection ports, see on page 71.

Setup 20

Page 21

4.3 Pneumatic Connections

4.3.1 Connecting Compressed Air

Caution

Make sure that compressed air is dry, well filtered and oil free. Recommended filter

grade is 5 μm or finer. Inadequate filtering will result in increased maintenance.

Caution

Make sure to use adequate pressure and flow. For more information, see on page

72.

1 Use the hose to connect the compressor and the ILS500 F.

4.3.2 Connecting Tracer Gas

Warning

Pressurizing objects at too high pressures can result in a burst object. This in turn

can result in serious injury or even death. Never pressurize objects that have not

previously been burst tested or otherwise approved for the chosen test pressure.

Warning

Tracer Gases can be flammable or asphyxiating. Use only ready-made Tracer Gas

mixtures.

ninp69e1-a (1410)

21 Setup

Page 22

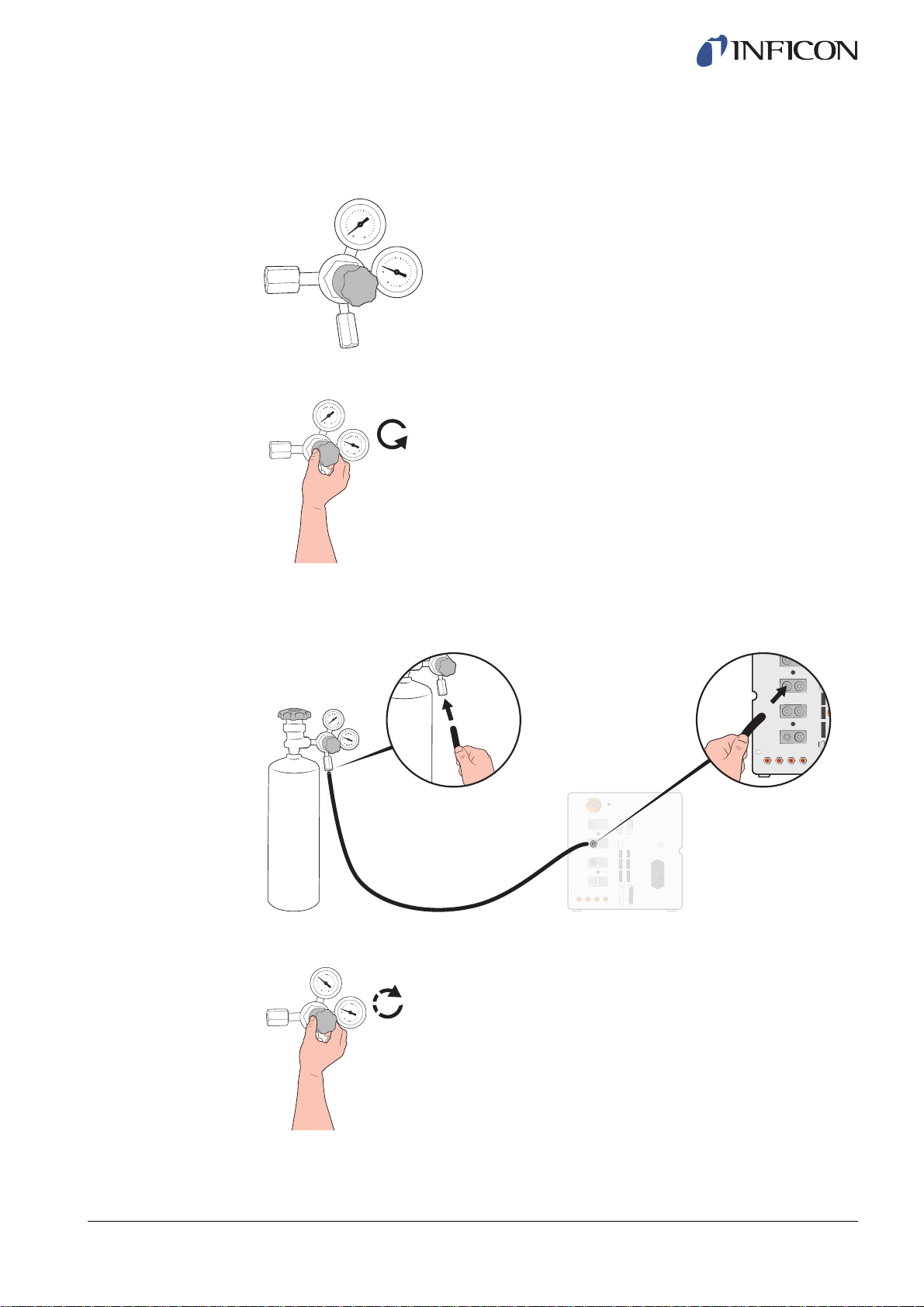

1 Secure gas cylinder safely.

2 Open the cylinder valve briefly to blow out dirt that may have collected in the outlet.

3 Install the two stage gas regulator on cylinder.

4 Turn regulator fully counterclockwise for zero output pressure.

ninp69e1-a (1410)

5 Connect a regular welding gas hose or similar between the Tracer Gas Port and

the pressure regulator. Check that the hose is certified to withstand the maximum

output pressure of the regulator.

6 Open cylinder valve and set regulator to desired pressure. See warning banner!

7 Open regulator outlet valve (if any).

Setup 22

Page 23

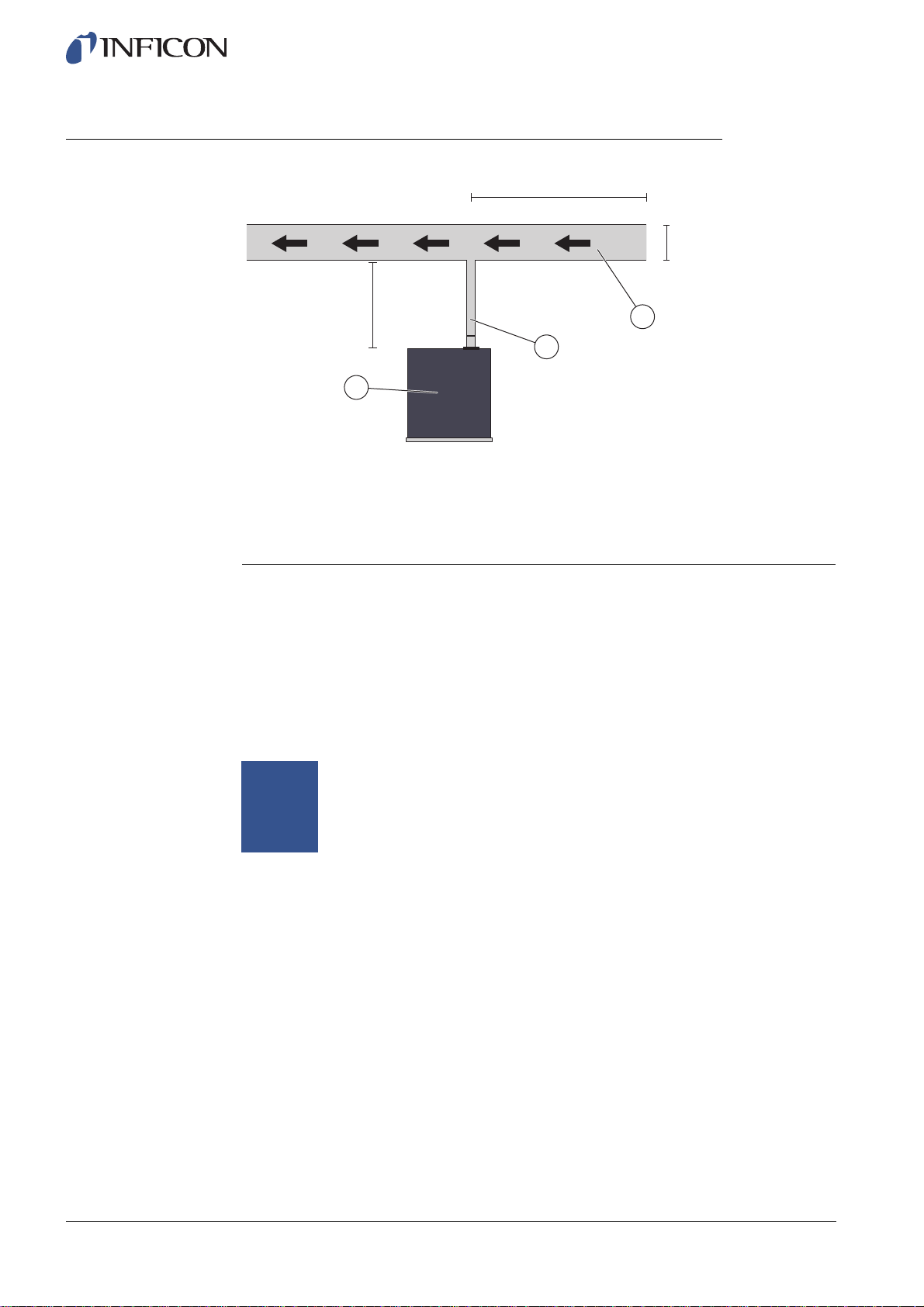

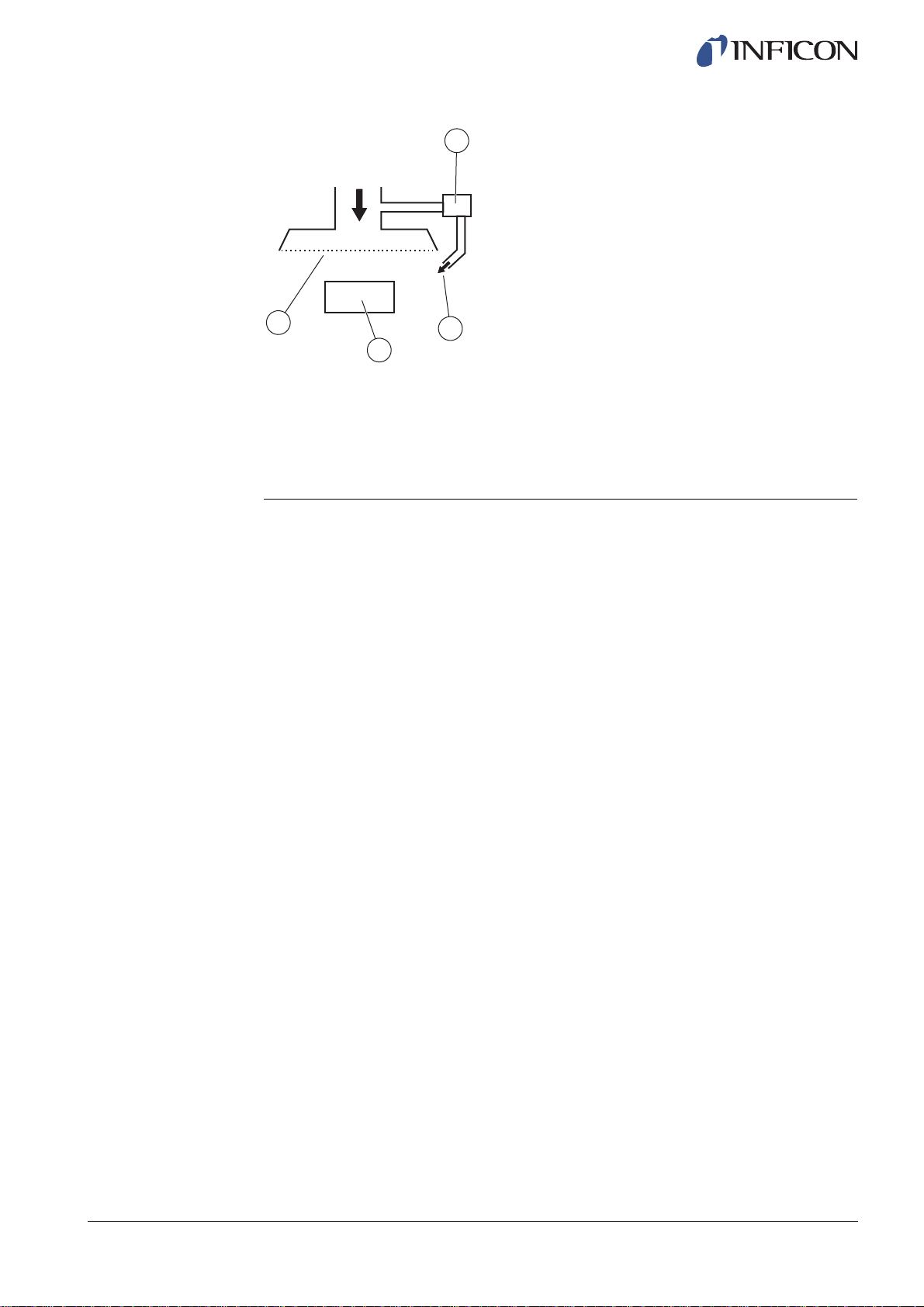

4.3.3 Connecting Exhaust to Air Vent

Min 2 m (6.5 ft.)

Ø ≥100 mm (4 in.)

Max 10 m (30 ft.)

Ø ≥25 mm (1 in.)

3

2

1

Exhaust Recommendation

1 ILS500 F

2 Exhaust Hose

3 Bleed Air

• The exhaust gas must be directed out of the building.

It is best placed on the roof of the building, far away from the fresh air intake of the

test station.

• It is recommend that a dedicated duct is installed. Install an electric duct fan and an

optional wind extractor.

• It is not recommended to use the general ventilation system to ventilate the exhaust.

If the ventilation system is equipped with energy recirculation there is a big risk that

large amounts of tracer gas will be carried back to the test room thus disturbing the

testing.

ninp69e1-a (1410)

Notice

Inadequate exhaust installation is the most common reason for problems

with tracer gas leak testing.

Too narrow or too long exhaust line will result in reduced evacuation

capacity and thereby increased cycle time.

23 Setup

Page 24

4.3.4 Connecting to Test Port 1 and 2

• Use both Test Ports if applicable.

• Hose ID ≥8 mm (0.31 in.).

• The hoses should be as short as possible.

If the test object has 2 or more ports, connect to ports on opposite sides of object.

4.3.5 Connecting Tooling

ninp69e1-a (1410)

Notice

The larger the test object, the more important to follow the

recommendations above.

Warning

Be aware that the faster the connection is made, the higher the risk for injury. Be

careful and install guards etc, according to local legislation and safety standards so

that your fixture is safe to use.

Tooling Valve Outputs 1-4 is available for connection of external Tooling.

Setup 24

Page 25

4.4 Connect External Leak Detector

Notice

Connect External ISH2000

External ISH2000 is connected to the Probe Control port and Leak Detector port. For

more information about the connections and cables, see on page 81.

Connect External T -Guard

External T-Guard is connected to the Leak Detector port. For more information about

the connection and cable, see on page 81.

4.5 Set Up Test Area

When external leak detector is connected, some settings must be

updated. These settings are made in the Hardware Setup menu.

Start-up time for the leak detectors can be up to 10 minutes, depending

on the condition.

Large distance

4

2

1

Test Area Recommendation

1 Fresh Air Fan

2 Exhaust Fan

3 Test Area

4 Test Building

• Place fresh air intake on outer wall of building.

• Place air intake far away from tracer gas exhaust, cargo bays, and other tracer gas

sources.

• Already tested objects may contain small amounts of tracer gas, which may interfere

with next measurement.

• Do not use compressed air as fresh air supply when a hydrogen mixture is used as

tracer gas. Industrial compressed air can contain varying and substantial amounts of

hydrogen.

3

ninp69e1-a (1410)

25 Setup

Page 26

1

ninp69e1-a (1410)

4

2

3

Fresh Air Curtain Recommendation

1 Fan

2 Local Air Jet

3 Test Object

4 Filter

• Try to create a laminar flow over the test area.

• Curtain should cover the entire test area (test hood or sample point) and extend at

least 0.5 m outside the area.

• Air speed in curtain should be rather low, typically 0.1 m/s.

• Additional small fan(s) can be set up within the curtain for directional purging of test

chamber etc.

Setup 26

Page 27

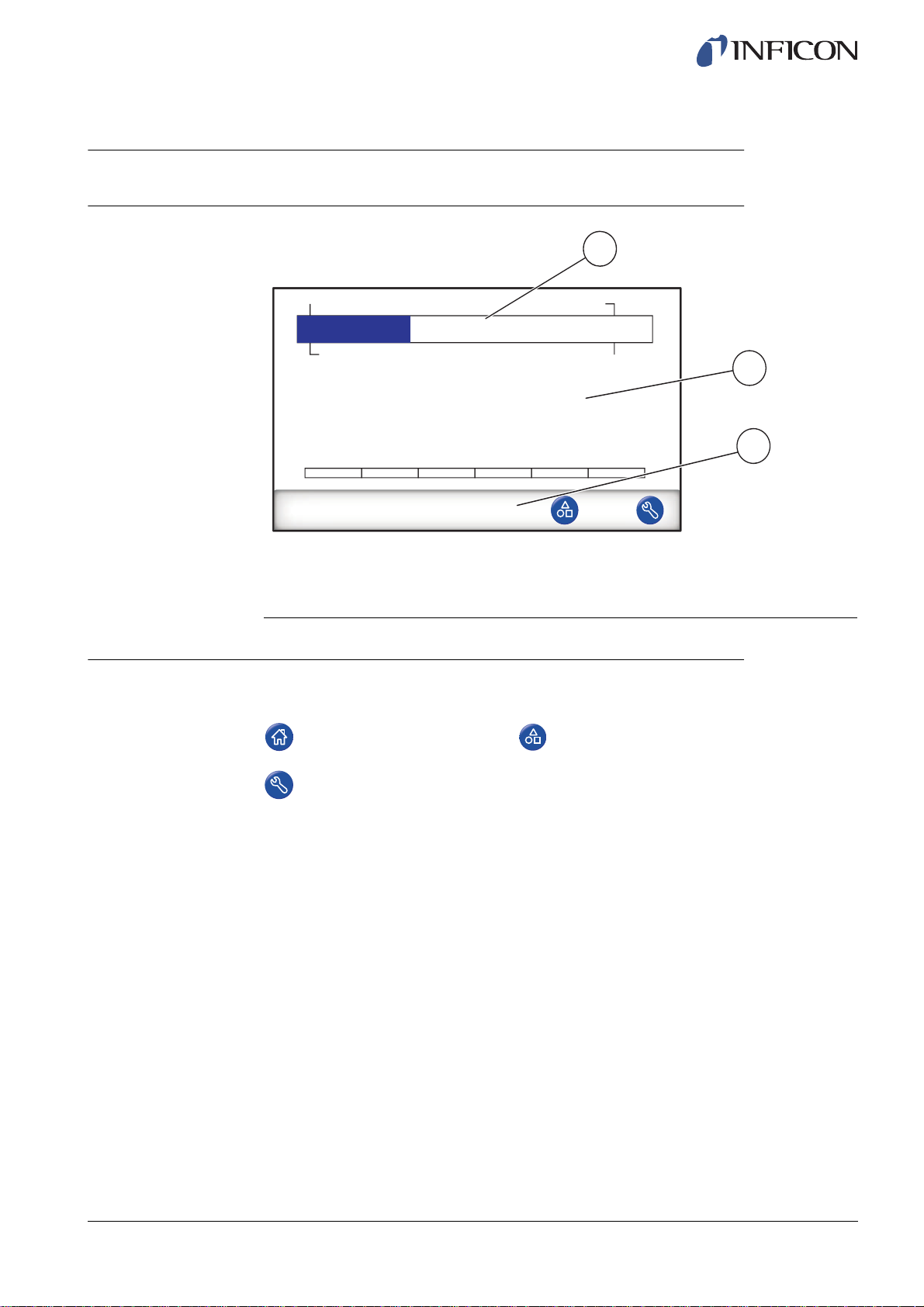

5 Menu System

5.1 ILS500 F Display

1

5.1.1 Menu Buttons

ninp69e1-a (1410)

- 0 +

-0,70

5,00

bar

Ready for Start

1 Status Bar

2 Main Display

3 Navigation Button Bar (varies depending on menu)

Use the menu buttons for quick navigation.

Home Load Recipe

2

3

Settings

Menu System 27

Page 28

5.1.2 Navigation and Other Buttons

Go Back Escape

Previous Page

(changes will be saved)

Activated Unactivated

Selected Deselected

Save

(only shown if usb is connected)

Open switch Closed switch

5.1.3 Entering Numbers and Text

To change a value:

1 Click on the value.

A numeric or alphanumeric on-screen keyboard will open.

ESC

(changes will not be saved)

Next Page

Load

2 Enter the desired digits or characters.

3 Click on the enter symbol to store the new value.

1 2

3

Esc a b c d e f Del

ghi jklmn

opqr stuv

wxy z, .?

Shift A..1

Ctrl

4

5

1 Escape

2 Delete

3 Enter

4 Control

5 Upper/Lower Case and Numbers

987

4

56

12

-0,

3

ninp69e1-a (1410)

1

Esc

2

Del

3

28 Menu System

Page 29

5.2 Passwords

To access the menus, use default password "1234" for "Service". The password can be

changed under Settings / Advance Settings / Passwords.

Passwords

Notice

5.2.1 Set Up New User

1 Click Settings >> Advance Settings >> Passwords to enter Passwords menu.

2 Click Log In and log in as Service.

3 Click Setup User.

Log In

Log Out

Setup excl. Tooling

Adv. Setup excl. Service

Setup User

Remember to change the passwords of all menus you want to protect.

Anyone using this manual can access the system if you keep the default

password.

Calibrate

Select Recipe

Service Menu

ninp69e1-a (1410)

4 Click Add.

5 Fill in user name and password for new user.

6 Click Next.

7 Select Security Group by checking the appropriate boxes.

8 Click Finish.

Menu System 29

Page 30

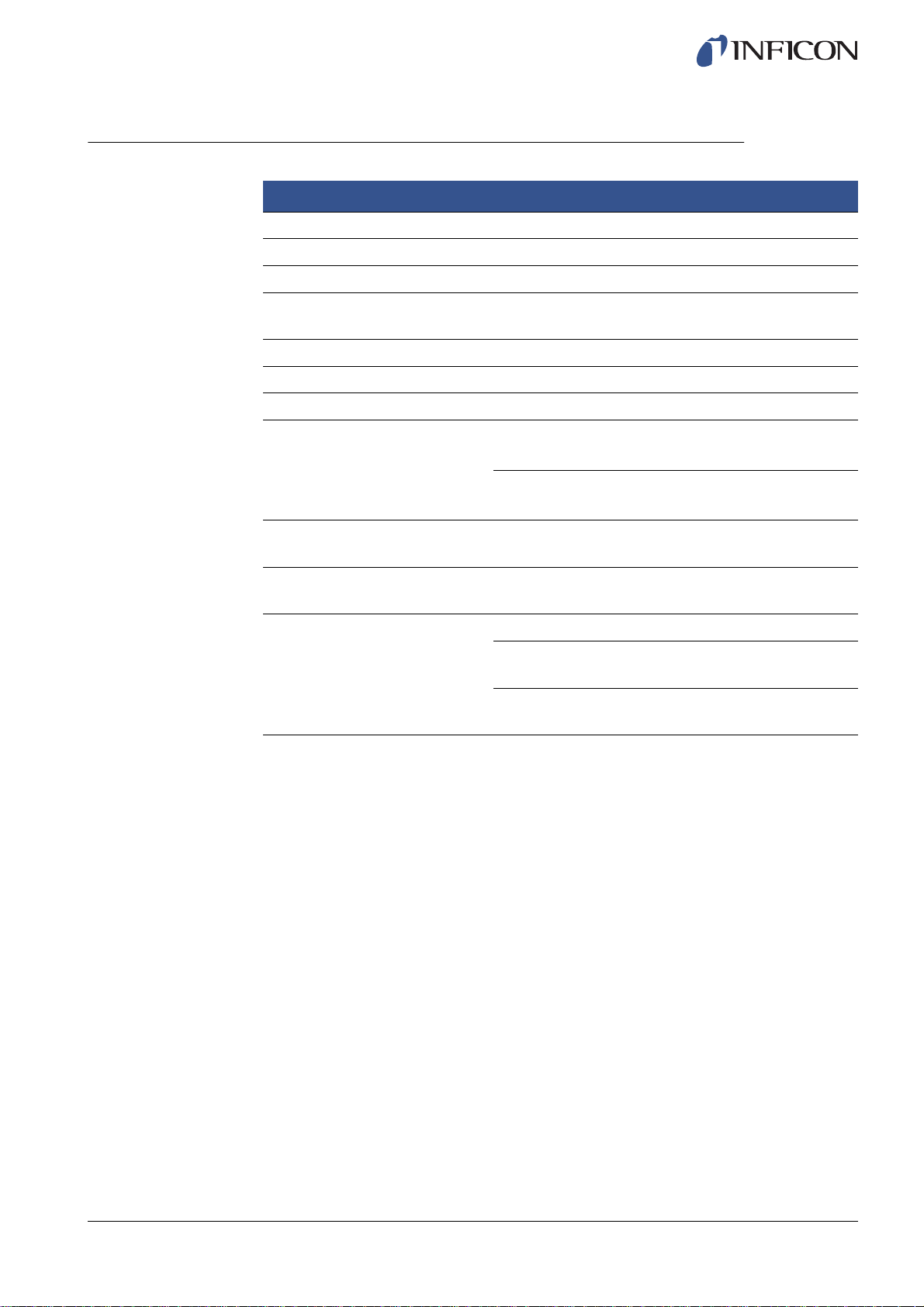

5.3 Menu Overview

For information about parameter factory default settings, see on page 88.

Notice

Load Recipe

Settings Hardware Setup

Test Settings Tooling Connection

If the instrument is equipped with a Leak Detector ISH2000, some settings

are blocked. These settings are made via the ILS500 F operator panel.

Pre Evacuation

Gross Leak Test Vacuum Decay Test

Pressure Decay Test

Tracer Gas Filling

Blockage Test

Tracer Gas Test

Gas Evacuation

Tooling

Disconnection

Advanced Settings Timers

Pressures

Options

ISH2000

Service Menu Outputs

Passwords

IP-Settings

Calibration Settings

Recipes

ninp69e1-a (1410)

Inputs

Analog Inputs

System Reset

ILS500

RS232

Service Run

Hardware Test

30 Menu System

Statistics

Region Time Zone, Region

and Daylight

Time and Date

Language

Info

Page 31

Settings

Hardware Setup

ninp69e1-a (1410)

Hardware setup.

Test Settings

For more information see chapter 7on page 38.

Menu System 31

Page 32

Advanced Settings

Advanced Settings

Timers

Pressures

Options

ISH2000

Advanced settings to fine tune the fill cycles and settings for service staff.

Service Menu

Passwords

IP-settings

Calibration settings

For more information, see chapter 10, “Service”

Recipes

For more information, see chapter 9, “Maintenance Instructions”.

ninp69e1-a (1410)

32 Menu System

Page 33

Statistics

Statistics

Total:

Accepted:

Rejected:

Evacuation:

Vacuum Decay:

Blockage:

Gas Fill:

Pressure Decay:

Gas Test:

0

0

0

0

0

0

0

0

0

Print

Reset

Press 3 sec

Information about test statistics and number cycles events during a test period.

For more information see on page 35.

Region

ninp69e1-a (1410)

Regions settings.

Language

Language

English

Japanese

German

Language settings.

Swedish

Italian

Menu System 33

Page 34

Info

Info

Type: ILS500 F

Serial number: 0

CPU software v 3.00.08

Display version: 3.00.09

Backup Battery Level (3,0 V)

Brightness display

Instrument information, software versions, battery status and display light settings.

ninp69e1-a (1410)

34 Menu System

Page 35

6 Using the ILS500 F

Warning

Ensure that the tracer gas supply pressure (feeding the ILS500 F tracer gas inlet) is

set up properly.

Caution

To abort a test sequence and reset to standby, press STOP for 3 s.

6.1 Test Sequence

ninp69e1-a (1410)

Notice

Step Comment

1 Standby ILS500 F is idle waiting for Start Signal.

2 Tooling Connection Four Air Valves and four Proximity Switch Inputs can

3 Pre Evacuation

The following description is an example for illustration only. The design of

the text fixture, the use of probe(s) and tooling functions etc. should be

adapted to suit your particular application.

be set up to control moderate test fixtures. Controller

can be expanded for more demanding fixtures.

The air is evacuated from the test object and a first

Gross Leak Test 1Evacuation Timeout

gross leak test is made simultaneously. The Gross

Leak tests are used to detect larger leaks by pressure

changes.

Evacuation is often necessary to ensure that the

Tracer Gas reaches all parts of the tested object, and

to secure that the tracer gas concentration is as high

as possible.

4 Gross Leak Test 2-

Vacuum Decay Test

Applicable for:

• very long objects (e.g. pipes or heat exchangers).

• low fill pressures (<1 atm).

Less appropriate:

• if the test object does not tolerate underpressure.

• at higher test pressures (Fill Setpoint).

Can be used to reveal leaks before filling with gas.

This minimizes spillage from gross leaks.

Using the ILS500 F 35

Page 36

Step Comment

5 Tracer Gas Filling Tracer gas filling before gas test.

6 Blockage Test

7 Gross Leak Test 3-Gas

Pressure Decay Test

• Reveals internal blockages in tested object.

• Ensures that connection lines and test fixture are

correctly connected.

The test object is filled through Test Port 1 while the

pressure is recorded in Test Port 2. Practical for

testing e.g. capillaries etc.

Performed in parallel with tracer gas test.

Can be used for integral testing in parallel with a more

sensitive gas test at selected points.

8 Leak detect pressurized

9 Gas Evacuation For a fast removal of tracer gas after test. Can also

10 Tooling Disconnection Disconnection of test fixture.

6.2 Run a Test

The ILS500 F will communicate through the lamps and messages on the display.

Lamp Status Indication

Red ON Acknowledge a leak.

test object

Notice

Perform leak detection on the test object, pressurized

with tracer gas.

include an efficient air purge.

Several of the steps are optional and can be turned off.

Chosen settings can be saved as a Recipe. For more information, see on

page 38. It is also possible to combine two recipes in one test sequence.

Contact your local supplier for more information and individual settings.

ninp69e1-a (1410)

Tested object rejected.

General error.

6.2.1 Start Up

36 Using the ILS500 F

Green ON Test sequence is over (and the tested object

accepted if Leak Detector is connected.)

Yellow

(START Button)

1 Turn the ILS500 F on.

2 Wait for Ready to Start to show on the display.

3 Click Load Recipe and choose a preset recipe, or follow the instructions in the

section on page 38.

ON The test sequence is running.

Page 37

6.2.2 Place the Test Object

1 Place the test object in the Test Chamber or connect it to one, two or more

connection ports.

2 Connect any extra equipment needed.

6.2.3 Perform Tracer Gas Filling

Caution

If ISH2000 is put into operation with ILS500 F the sensor withstands temporary

exposure to hydrogen concentration up to 100%. Avoid long exposures to high

concentrations.

T racer Gas Filling

1 Press Start on the ILS500 F.

2 Perform a tracer gas leak test.

3 Press Stop on the ILS500 F to remove the tracer gas.

ninp69e1-a (1410)

Using the ILS500 F 37

Page 38

7 Recipes

A recipe is a collection of settings suited for a particular test setup. This is used to have

different settings for different test objects.

7.1 Recipe Overview

Click Settings >> Recipes to enter the three Recipe Setup menus.

Recipe Setup

Use Recipes

Choose at startup

Recipe Setup

Connect with recipe

Load Recipe

Save Recipe Delete Recipe

0

ninp69e1-a (1410)

Use from list

Keep Tooling in Test Step

Keep Pressure in Test Step

Recipe Setup

Import from USB

Export to USB

Use Recipes Select the box to activate the recipe handling.

Choose at Startup When power is switched on, the ILS500 F prompts

Load Recipe Loads the parameters of chosen recipe.

Save Recipe Saves the current settings under chosen recipe

Factory Default

USB Memory connected

the operator to choose recipe.

A new window will open.

name.

A new window will open.

Recipes 38

Page 39

Delete Recipe Deletes the chosen recipe.

Connect with Recipe Connects two recipes to form one test cycle.

Use from list Shows all saved recipes.

Keep Tooling in Test Step Excludes the disconnection step in the first recipe

Keep Pressure in Test Step Retains gas pressure between two recipes.

Import from USB Imports recipes from connected USB memory.

Export to USB Exports all recipes to an editable file on connected

7.2 Create a Recipe

7.2.1 New Recipe

A new window will open.

Write the name of the recipe to be included, or

choose one from the list in Use from list.

By clicking the blue button the recipe displayed is

added to Connect with recipe.

when two recipes are connected as described

above.

USB memory.

1 Click Settings >> Hardware to enter the Hardware menu.

Set the correct hardware.

2 Set all ILS500 F settings for the test sequence.

For more information, see on page 40.

3 Click Settings >> Recipes to enter the three Recipe Setup menus.

4 Click Save Recipe.

5 Enter a name for the recipe.

6 Click Save.

7.2.2 Modify a Recipe

1 Click Settings >> Hardware to enter the Hardware menu.

Set the correct hardware.

2 Click Settings >> Recipes >> Load Recipe.

3 Select the recipe to modify from the list and click Load.

4 Adjust the ILS500 F settings to suit the new recipe.

For more information, see on page 40.

5 Click Settings >> Recipes >> Save Recipe.

6 Enter the name of the new recipe.

ninp69e1-a (1410)

39 Recipes

7 Click Save Recipe.

Page 40

7.3 Test Settings

1 Click Settings >> Test Settings to enter the two Test Settings menus.

Test Settings

Tooling Connection

Pre Evacuation

Gross Leak Test

Tracer Gas Filling

Test Settings

Blockage Test

Tracer Gas Test

Gas Evacuation

Tooling Disconnection

ON

ON

Setup

Setup

ninp69e1-a (1410)

7.3.1 Tooling Connection

2 Set which steps to include in the test sequence by selecting the ON boxes.

3 Click Setup to the right of each selected step to enter the Setup menus.

Notice

Connection Sequence menu shows the settings made for Tooling Connection.

Connection Sequence

Stand by

Step

Step

Step

Test

For more information about each step, see on page 35.

Tooling Outputs

2341

ON

1

ON

2

OFF

3

1 Click on the Settings symbol to edit the settings.

Notice

Up to four connection steps can be programmed.

Recipes 40

Page 41

Stand-By

STAND-BY

Go to next step with

Tooling Outputs

ON

and Tooling Inputs

1234

Start Button

Delay

1 Click on the Tooling Outputs to be activated in stand-by (between tests).

2 Choose how to move on to the next step.

- Set action in list.

- Select Tooling Inputs.

3 Set desired delay time.

0.0

Connection Step 1 — 3

Connection Step 1

ON

Tooling Outputs

Go to next step with

and Tooling Inputs

Info

1234

ON

Auto

Delay

0.0

ninp69e1-a (1410)

41 Recipes

1 Select the ON check box to activate the step.

2 Click on the Tooling Outputs to be activated.

3 Choose how to move on to the next step.

- Set action in drop-down-list.

- Select the appropriate check box(es) for the Tooling Inputs.

Then set “Open” or “Closed” status for each switch symbol.

4 Enter a text to describe the step (click the Info field to activate the on-screen

keyboard).

5 Set desired delay time.

Page 42

Test Step

Test Step

Tooling Outputs

Condition for starting test

and Tooling Inputs

123 4

ON

7.3.2 Pre Evacuation

ninp69e1-a (1410)

Info Delay

1 See Connection Step 1 - 3 above and follow the instructions.

Pre Evacuation

Pre Evacuation Setpoint

Extended Pre Evacuation

-0.70

0,0

0.0

bar

s

Pre Evacuation Setpoint A value of -0.70 bar (-0.07 MPa, -10 psi) is

adequate for most applications. This creates 70%

vacuum.

Extended Pre Evacuation To ensure a complete filling. Evacuation will

continue for the set time after Evacuation Level has

been attained.

Recipes 42

Page 43

7.3.3 Gross Leak Tests

Gross Leak Test

Evacuation Timeout

Vacuum Decay Test

- before gas test

Pressure Decay Test

- during gas test

Evacuation Timeout Object will be rejected if Pre Evacuation Setpoint is

not attained within time set.

Vacuum Decay Test If to be included in the test sequence, select the

box and click the blue button to enter Pressure

Decay Test setup menu (see below).

Pressure Decay Test If to be included in the test sequence, select the

box and click the blue button to enter Pressure

Decay Test setup menu (see below).

10.0

s

V acuum Decay Test

Vacuum Decay Test

s

Vacuum Stabilisation Time

Vacuum Decay Test Time

Vacuum Decay Limit

Vacuum Stabilisation Time Delay time before Vacuum Decay test begins.

Vacuum Decay Test Time

Vacuum Decay Limit Allowed pressure rise during test time.

Time during which pressure rise is recorded.

5.0

5.0

0.10

s

bar

ninp69e1-a (1410)

43 Recipes

Page 44

Pressure Decay Test

Gas Pressure Decay Test

Pressure Stabilisation Time

Pressure Decay Test Time

Pressure Decay Limit

Pressure Stabilisation Time Delay time before Pressure Decay test begins.

Pressure Decay Test Time Time during which pressure drop is recorded.

Pressure Decay Limit Allowed pressure drop during test time.

7.3.4 Tracer Gas Filling

Warning

The ILS500 F must never be introduced to pressures higher than that approved for

the object to be tested and never beyond the ILS500 F specification.

5.0

5.0

0.10

s

s

bar

ninp69e1-a (1410)

Notice

Tracer Gas Filling

Fill Setpoint Desired tracer gas fill pressure.

Fill Timeout Object will be rejected if Pressure Setpoint has not

Ensure that the test object has time to become filled before Fill Time Out

expires. In particular long narrow objects, as pipes, may need long filling

time.

Fill Setpoint

Fill Timeout

External Fill Regulation

Pressure Unit

bar

been attained within this time.

Cancels the fill if the test object has a major leak,

opens, or if there are loose connections.

5.00

10.0

bar

s

Recipes 44

Page 45

External Fill Regulation If selected, this is the setpoint of fill pressure alarm.

Pressure Unit Select desired unit.

7.3.5 Blockage Test

Internal pressure regulation is disengaged and

pressure will be that of the gas supply line. ILS500

F checks that fill pressure is above Pressure

Setpoint before proceeding to gas test step.

Notice

Blockage Test

Blockage Test Pressure Minimum pressure to be attained at Test Port 2

Blockage Test Time Time within which Blockage Test Pressure must be

This test can only be performed if both test ports are used and connected

on either side of the possible blockage.

Blockage Test Pressure

Blockage Test Time

0.50

bar

s

2.0

during Blockage Test time.

attained at Test Port 2.

ninp69e1-a (1410)

45 Recipes

Page 46

7.3.6 Gas Evacuation

Gas Evacuation

Gas Evacuation Setpoint

Extended Gas Evacuation Extends time for gas evacuation, after Gas

7.3.7 Tooling Disconnection

Disconnection Sequence

ninp69e1-a (1410)

Gas Evacuation Setpoint

Extended Gas Evacuation

Test

Step

Step

Step

Stand-by

1

OFF

2

OFF

3

OFF

-0,30

Set desired level of Gas Evacuation.

-30 kPa (-0.3 bar, -4.4 psi) creates 30% vacuum,

which is adequate for most applications.

Evacuation Setpoint has been reached.

Tooling Outputs

1234

0,0

bar

s

Same function as Tooling Connection but in revers order.

For information about this step, see on page 40.

7.4 Optimizing the Test Cycle

Test Cycle can be divided in six main blocks:

1 Connection of Tested Object

2 Pre Evacuation of Residual Air

3 Filling with Tracer Gas

4 Tracer Gas Leak Test

5 Removal and Venting of Tracer Gas

6 Disconnection of Tested Object

Recipes 46

Page 47

This section is a guide for optimizing step 2, 3 and 5.

0

-

7.5 Optimizing the Pre Evacuation Step

Notice

The fastest way to fill a pipe like object is to use push-through filling. That

does not require pre evacuation.

Begin to determine how deep the pre evacuation needs to be, or if it can be skipped

altogether. To do this it is important to fully understand the role of pre evacuation.

When the test object is connected it holds one atmosphere of ambient air. It is often

necessary to remove some or most of this air before filling with tracer gas.

There are two effects of not removing the air (i.e. pre evacuating):

1 the actual tracer gas concentration will be reduced

2 tracer gas does not reach all parts of the object

7.5.1 Calculate Tracer Gas Concentration

Example:

The fill pressure is 0.05 MPa (7.2 psi) above atmosphere (gauge pressure). The object

has 1 atm = 0.1 MPa of air before filling.

Leaving this air in the object means the average tracer gas concentration will be:

A = Fill Pressure

B = 1 atm

C = Tracer Gas Fill Factor

ninp69e1-a (1410)

A

--------

AB+

0.05

------------

.05 0.1+

C=

0.33=

The average tracer gas concentration in this example is only a third (33%) of what

expected.

When using a tracer gas mix of 5% the result will be:

0.33 x 5% = 1.7%

Pre evacuating down to -0.7 atm (-0.07 MPa) means there will be 0.3 atmospheres

(0.03 MPa) of residual air in the object before filling. This gives the following average

concentration:

47 Recipes

Page 48

A = Fill Pressure

B = 1 atm

C = Tracer Gas Fill Factor

D = Evacuation Pressure

AD+

--------

AB+

0.05 0.07+

---------------

0.05 0.1+

C=

0.8=

The average tracer gas concentration in this example will be 0.8 (80%). When using a

tracer gas mix of 5% the result will be:

0.8 x 5% = 4%

This is almost twice of that achieved with no pre evacuation.

7.5.2 Example - Calculate Tracer Gas Filling

The air left in the object can not always be expected to mix evenly with the injected

tracer gas. This is especially so for tube shaped objects such as pipes etc. The flow

inside a regular “tube” is predominantly laminar. This means no or very little turbulence

occurs. Air left in the “tube” will therefore be pushed in front of the injected tracer gas

and end up in the remote end of the “tube”.

ninp69e1-a (1410)

Example:

The test object is an aluminium pipe for a refrigerator with brazed copper ends. The

joints between copper and aluminium must both be tested.

Fill pressure is 0.5 MPa (72 psi). Length is 10 m (33 ft.). Skipping pre evacuation we

will have:

A = Fill Pressure

B = 1 atm

E = Air left in the object

B

--------

AB+

-----------

0.5 0.1+

0.1

E=

0.17=

of air left in the pipe. This is equivalent to 1.7 m (5.7 ft.) of the total length if no

turbulence occurs during filling. There is an evident risk that there will be only air inside

one of the joints, which means that a leak there will remain undetected.

Recipes 48

Page 49

Pre-evacuating down to -0.7 atm (-0.07 MPa) means there will be 0.3 atmospheres

(0.03 MPa) of residual air in the pipe before filling.

We will now have:

B

--------

AB+

-------------

0.5 0.03+

of air left in the pipe. This is equivalent to 0.57 m (1.9 ft.). This air volume is normally

small enough to be mixed into the tracer gas by turbulence and diffusion.

0.03

E=

0.056=

7.6 Optimizing the Tracer Gas Filling

Regulation of the tracer gas pressure can either be controlled by:

• the ILS500 F

• an external pressure regulator

Notice

The ILS500 F is set to regulate internally as default.

7.6.1 External Pressure Regulation

Notice

External regulation is recommended mainly for very small objects (<50 cc).

Tracer gas pressure is controlled by external regulator. ILS500 F opens a path

between the gas feed line and the test object. The pressure will equate and the tested

object will attain the pressure delivered by the external regulator. ILS500 F checks that

the fill pressure is above Fill Setpoint before proceeding to the next test step.

External Pressure Regulation does not support recipes with different test

pressure (i.e. Fill Setpoints).

7.6.2 Internal Pressure Regulation

Tracer gas pressure can be set to be controlled by the ILS500 F. Internally regulated

filling is generally faster than externally regulated. The reason for this is that the

feeding pressure can be set higher than Fill Setpoint which results in a higher fill flow.

ninp69e1-a (1410)

49 Recipes

Page 50

8 Troubleshooting

8.1 Fault Symptoms

Fault Symptom Fault Measures

Evacuation Failed Failed to reach vacuum

Gas Fill Failed Failed to fill to the right

Gas Refill Failed Failed to refill the object.

Gas Evac Failed Failed to reach vacuum

HW Error During Test Serious error has occurred

Test Timeout Maximum time for the test

ninp69e1-a (1410)

8.2 Perform Hardware Test

within the specified time.

Large leak on Test Object

or connections.

pressure within the

specified time.

Large leak on Test Object

or connections.

Large leak on Test Object

or connections.

within the specified time.

during test.

was exceeded.

Check the compressed air

supply.

Check the incoming gas

pressure.

Check the incoming gas

pressure.

Check external equipment,

e.g Active Probe.

Check that time is correctly

set.

Notice

Hardware Test

• For troubleshooting and testing of the system, use Service menu.

• For remote troubleshooting, use Service Run menu.

• Venturi Pump and all Gas Valves can be tested automatically.

Before performing the hardware test, carefully check that your tracer gas

and compressed air feed pressures are correct. Wrongly set pressure can

cause erroneous test results.

OUTPUTS

ILS500 F plugged

ILS500 F + Object

TEST STOP

Press “TEST”

Vacuum:

Pressure:

0.00

0.00

bar

bar

Troubleshooting 50

Page 51

The hardware test is a diagnostic tool helping you in preventive maintenance as well as

service and repair. The test takes you through a number of steps testing all units that

are subject to wear and should thereby help you to find almost any problem in the

ILS500 F system.

Notice

You can choose to test according to the limits of your specific application.

1 Setup all parameters for your test object (or load desired recipe) and connect a

leak free sample.

2 Set test selection switch to ”ILS500 F + Object” for application specific hardware

test. You can also test the ILS500 F against factory specification. In this case you

should plug both test ports using the plugs delivered with the units. Remove ISO to

NPT converters if installed and install the blind plugs. Set test selection switch to

”ILS500 F plugged” for factory specified hardware test.

3 The ”Continue” button will be displayed at the end of each test step. Press

”Continue” for next test step.

Run through the whole sequence to interpret the results correctly.

You will need the reference table at the end of this section to help you

interpret the test results correctly. Keep this manual at hand when

performing the test.

Pressure and V acuum Sensors

Hardware Test

Pressure and Vacuum Sensors

Zero Points are OK

ninp69e1-a (1410)

Vacuum:

Pressure:

CONTINUE STOP

Zero points of pressure and vacuum sensors are tested.

Possible results:

• Zero Points are OK

• Vacuum Zero Point not OK

Offset zero point can result in:

• Incorrect gas filling

• Erroneous vacuum or pressure decay results

0.00

0.00

bar

bar

51 Troubleshooting

Page 52

Evacuation V alve

Hardware Test

Evacuation Valve

No Internal Leakage

ninp69e1-a (1410)

Vacuum:

Pressure:

CONTINUE STOP

Evacuation valve is checked for internal leakage.

Possible results:

• No Internal Leakage

• Internal Leakage

Internal leakage can result in:

• False vacuum decay rejects

• Increased tracer gas consumption

-0.03

0.00

V enturi Pump

Hardware Test

Venturi Pump

Max Vacuum OK

bar

bar

Vacuum:

Pressure:

CONTINUE STOP

Checking max vacuum of Venturi pump.

Possible results:

• Max Vacuum OK

• Poor Max Vacuum

Poor max vacuum can result in:

• Failed pre-evacuation

• Slower evacuation

-0.88

0.00

bar

bar

Troubleshooting 52

Page 53

Manifold Tightness (gross)

Hardware Test

Manifold Tightness

No Leakage from Outside

Vacuum:

Pressure:

CONTINUE STOP

The overall tightness of the manifold is tested using the vacuum raise method.

Possible results:

• No Leakage from Outside

• Leakage from Outside

Leaks in the manifold can result in:

• False vacuum decay rejects

• Increased gas consumption

Minor external leakage will be found later during the

gas test step.

-0.82

0.00

bar

bar

V acuum Sensor Valve

Hardware Test

Vacuum Sensor Valve

Valve works!

Vacuum:

Pressure:

CONTINUE STOP

This checks that the valve shuts to protect vacuum sensor before filling.

Possible results:

• Valve works

• Faulty!

Malfunction can result in:

• Damage to vacuum sensor

• Failed pre-evacuation

0.00

0.00

bar

bar

ninp69e1-a (1410)

53 Troubleshooting

Page 54

T racer Gas Fill Valve

Hardware Test

Tracer Gas Fill Valve

No Internal Leakage

ninp69e1-a (1410)

Vacuum:

Pressure:

CONTINUE STOP

The step tests the gas fill valve for internal leakage by registering pressure rise behind

the valve.

Possible results:

• No Internal Leakage

• Internal Leakage

Internal leakage can result in:

• Erroneous pressure decay results

• False vacuum decay rejects increased gas consumption

0.00

0.00

bar

bar

Test Port 2 Valve

Hardware Test

Test Port 2 Valve

Valve works!

Vacuum:

Pressure:

CONTINUE STOP

Notice

This step tests Test Port 2 valve for internal leakage by registering pressure rise behind

the valve.

Possible results:

• No Internal Leakage

• Internal Leakage

Internal leakage can result in:

• False blockage test accepts

This test will fail if both test ports are connected to a test object. Proceed

and then repeat the entire hardware test sequence with both ports

plugged to perform this test step.

0.00

0.00

bar

bar

Troubleshooting 54

Page 55

T racer Gas Fill Valve

Hardware Test

Tracer Gas Fill Valve

Valve works!

bar

Vacuum:

Pressure:

CONTINUE STOP

This step tests that tracer gas fill valve opens to fill gas. Test will fail if tracer gas feed

pressure is too low. If this is the case, adjust pressure and restart hardware test from

beginning.

Possible results:

• Valve works

• Faulty!

Malfunction will result in:

0.00

0.50

bar

• Failed gas filling

External Gas Leaks

Hardware Test

Check for Leaks with Hand Probe

bar

Vacuum:

Pressure:

CONTINUE STOP

The ILS500 F is now prepared for a manual test for external leakage. Use a Leak

detector with hand probe to check for leakage.

1 Start by checking all connections between the ILS500 F and your test object.

Follow each test line carefully and check every joint.

2 Proceed to check around the gas valves and manifold inside the ILS500 F.

0.00

0.50

bar

ninp69e1-a (1410)

55 Troubleshooting

Page 56

Manifold Tightness (gross)

Hardware Test

Manifold Tightness

Internal Leakage

Vacuum:

0.00

bar

ninp69e1-a (1410)

Pressure:

CONTINUE STOP

The overall tightness of the manifold is tested using the pressure decay method. This is

a complement to the gas test, revealing leakage out, through the exhaust etc.

Possible results:

• No Internal Leakage

• Internal Leakage

Internal leakage can result in:

• False pressure and vacuum decay rejects

• Increased tracer gas consumption

0.46

bar

Evacuation V alve

Hardware Test

Evacuation Valve

Valve works!

bar

Vacuum:

Pressure:

CONTINUE STOP

This step tests that evacuation valve opens to release tracer gas to exhaust. Same test

as previously but under pressure instead of vacuum.

Possible results:

• Valve works

• Faulty!

Malfunction will result in:

• Failure to terminate test cycle

0.00

0.00

bar

Troubleshooting 56

Page 57

Indicator Lamps

Hardware Test

Lamp in Start Button

OK?

Vacuum:

0.00

bar

CONTINUE STOP

Hardware Test

Green Lamp (Top Left)

CONTINUE STOP

Hardware Test

Red Lamp (Bottom Left)

OK?

OK?

Pressure:

Vacuum:

Pressure:

Vacuum:

0.00

0.00

0.00

0.00

bar

bar

bar

bar

ninp69e1-a (1410)

Pressure:

CONTINUE STOP

This is a “manual” test. The ILS500 F lights up one lamp at the time. Simply check that

the right lamp comes on.

1 Check function of each lamp by pressing “Continue”.

0.00

bar

57 Troubleshooting

Page 58

START and STOP buttons

Hardware Test

Press Start Button (Top Right)

OK?

Vacuum:

0.00

bar

ninp69e1-a (1410)

Pressure:

STOP

Hardware Test

Press Stop Button (Bottom Right)

OK?

Vacuum:

Pressure:

STOP

This is a “manual” test. The test continues when the correct button is pressed. The test

checks the activated START and STOP buttons only. Use INPUT menu under Service

menu to check buttons that are turned off.

0.00

0.00

0.00

bar

bar

bar

Troubleshooting 58

Page 59

8.2.1 Hardware Error Messages

Error Message Reason for Error Corrective Action*

Hardware Error

Vacuum Sensor Error

Hardware Error

Pressure Sensor Error

Analog Inputs Power Off No power to AD module. Check power cable on left

* Contact your supplier if the suggested action does not clear the error.

No power to vacuum

sensor.

Sensor not connected to

AD.

Damaged vacuum sensor. Send in for repair.

No power to pressure

sensor.

Sensor not connected to

AD.

Damaged pressure sensor. Replace sensor.

Check cable to sensor.

Check connection to AD.

Check cable to sensor.

Check connection to AD.

side of AD module.

ninp69e1-a (1410)

59 Troubleshooting

Page 60

8.2.2 Interpretation of Hardware Test Results

Use the table below, to correct errors detected by the hardware test routine.

Tested Unit Tested Feature Reason for Error Action

Evacuation Valve Internal leaks Dirty or worn valve seals. Replace clean evacuation

valve.

Venturi Pump Maximum vacuum Compressed air pressure

too low or too high.

Dirt inside Venturi. Remove and clean

Dirty or broken Venturi

pilot valves.

Dirty or broken Evacuation

pilot valves.

Gas Valve Manifold Leaks from outside Leaks to outside. Check for leaks with Hand

If no gas leaks. Check internal leaks in

If no internal leaks in tracer

gas valve.

Vacuum Sensor Protection

Valve

ninp69e1-a (1410)

Function No signal to pilot valve. Check ”Sensor Protect”

Dirty or broken pilot valve. Replace valve third valve

Adjust compressed air

pressure.

Venturi.

Replace two upper valves

in pilot ramp.

Replace fourth valve from

bottom in pilot valve ramp.

Probe (later in hardware

test sequence).

tracer gas fill valve.

Replace/clean vacuum

sensor protection valve.

output.

Send in for repair.

from bottom in pilot ramp.

Vacuum sensor protection

valve broken.

Replace valve.

Troubleshooting 60

Page 61

Tested Unit Tested Feature Reason for Error Action

Tracer Gas Fill Valve Internal leaks Dirty or worn valve seals. Replace or clean tracer

gas fill valve.

Leaking pilot valve. Replace fourth valve from

bottom in pilot valve ramp.

Test Port 2 Valve Function Dirty or broken pilot valve. Replace third valve from

bottom in pilot ramp.

Test port 2 valve broken. Replace valve.

Tracer Gas Fill Valve Function Dirty or broken pilot valve. Replace fourth valve from

bottom in pilot ramp.

Tracer gas fill valve

Replace valve.

broken.

Gas Valve Manifold Leaks to outside Wrongly assembled gas

valve.

Remove leaking valve.

Clean and grease valve

seal before installing

again. See instructions.

Wrongly installed

connectors/plugs.

Remove leaking unit.

Clean and grease o-ring

Install again.

Units lacking o-ring seal

should be sealed with

Loctite 577 or similar.

Evacuation Valve Function Dirty or broken Evacuation

pilot valves.

Replace fourth valve from

bottom in pilot valve ramp.

Lamp Function Broken lamp. Replace lamp.

Send in for repair.

Tooling Valves Function Dirty or broken pilot valve. Replace first or second

valve from bottom in pilot

ramp.

Button Function Broken switch. Send in for repair.

ninp69e1-a (1410)

61 Troubleshooting

Page 62

9 Maintenance Instructions

There are three different parts that needs regular maintenance:

• Venturi Pump

Needs regular cleaning.

• Gas Valves

Needs regular cleaning and wears out.

• Pilot Valves

Maintenance free if incoming compressed air is dry and filtered to 5 μm.

Changing Venturi Pump and all Gas Valves takes less than 15 minutes.

9.1 Maintenance Plan

Part Interval Action

Venturi Pump 3 months Perform a Hardware Test.

Check Ultimate Vacuum.

Clean venturi nozzles when necessary.

ninp69e1-a (1410)

Evacuation, Fill and

Test Port 2 Valves

Vacuum Sensor Valve 12 months Perform a Hardware Test.

Pilot Valves 12 months Change valve if unexpected pressure

*Depends on the amount of particulates in the objects tested. Metal burrs and other

sharp particles will wear the valves down, requiring shorter maintenance intervals.

3-6 months* Perform a Hardware Test.

Check condition of valves.

Replace or clean valves when necessary.

Check condition of valve.

Replace or clean valve when necessary.

builds.

Maintenance Instructions 62

Page 63

9.2 Maintenance

9.2.1 Tools and Safety Equipment

When performing regular maintenance of the ILS500 F the following equipment is

needed.

Description Note

Allen Keys (Hexagonal 3 and 4 mm)

Torx Key (T25)

Screwdriver (Philip 1 or Pozidrive 1

Protective Eyewear When performing tooling output

Protective Ear Plugs When performing tooling output

9.2.2 Interior View

test.

test.

10

1 2 3

9

8

ninp69e1-a (1410)

4

5

6

7

1 Pilot Valve 6

2 Pilot Valve 1

3 Venturi Pump (Ejector)

4 Evacuation Valve

63 Maintenance Instructions

Page 64

5 Tracer Gas Fill Valve

6 Test Port Valve 2

7 Vacuum Sensor Control Valve

8 Pressure Sensor (HP model only)

9 Vacuum Sensor

10 Pressure Sensor

Pilot V alve Ramp

9.2.3 Removing the Cover

ninp69e1-a (1410)

Position

5A+6A Main Air Valve

5B+6B Venturi Pump Supply

4A Evacuation Valve

4B Tracer Gas Fill Valve

3A Test Port 2 Valve

3B Sensor Protection Valve

2A Tooling Valve 1

2B Tooling Valve 2

1A Tooling Valve 3

1B Tooling Valve 4

1 Use a T25 key to remove the two screws holding the right hand cover (next to gas

ports).

2 Slide the cover back and lift it off. Rock the rear end of the cover up and down a

few times to loosen. See below.

Valve

Maintenance Instructions 64

Page 65

9.2.4 Replacing the Venturi Pump

1 Remove the exhaust hose from the barbed hose fitting

2 Unscrew and remove the barbed hose fitting and the plastic washer.

3 Use a 4 mm Allen key to remove the four screws holding the Venturi pump.

4 Remove the o-ring under the Venturi. Remove the hose from Venturi inlet.

Push hose into connector and press orange ring down to release hose, then pull

hose out.

5 Remove the hose fitting from the Venturi.

ninp69e1-a (1410)

65 Maintenance Instructions

Page 66

6 Install new Venturi or use compressed air jet and a cotton bud, pipe cleaner or

small brush to clean the nozzles inside the Venturi.

7 Replace hose fitting on Venturi inlet.

8 Reconnect inlet hose.

9 Clean o-ring and install in groove on valve manifold.

ninp69e1-a (1410)

10 Reinstall and tighten the four screws.

11 Put plastic washer inside Venturi outlet and reinstall barbed fitting. Tighten with

spanner.

12 Reconnect the exhaust hose.

13 Run through the hardware test again to test that the Venturi delivers adequate max

vacuum.

Maintenance Instructions 66

Page 67

9.2.5 Replacing Gas Valves

1 Use a 3 mm Allen key to remove the four screws holding the valve to be changed.

2 Lift the old valve out and put the new valve in. Notice the correct orientation in the

picture below.

3 Tighten the screws 2-3 mm (0.08-0.12 in.) at a time moving the key from screw to

screw so that the valve doesn’t tilt much.

4 Tighten the screws and replace the cover.

5 Run through the hardware test again to test that the changed/removed valve(s)

perform as required.

6 Use hand probe to check that there is no external leakage (this part of Hardware

Test is routine).

ninp69e1-a (1410)

67 Maintenance Instructions

Page 68

9.2.6 Replacing Pilot Valves

1 Use small screw driver to loosen the screw holding the valve. You must back the

screw all the way out until you feel it “jumping” in the thread entrance.

2 Push down on the LEDs while pressing the screw down until you feel the locking

mechanism “snap”.

3 Lift the old valve out from the coil side. If the valve does not come off, repeat steps

3 and 4 making sure the screw is completely backed out.

ninp69e1-a (1410)

4 Push the screw in while inserting the new valve. Insert the end facing the screw

first and then push the coil side down.

5 Tighten the screw.

6 Replace the cover.

Maintenance Instructions 68

Page 69

9.2.7 Replacing Sensors

Caution

Service of the sensors may only be carried out by service organizations authorized

for this purpose by INFICON.

9.3 Functional Verification

See Perform Hardware Test on page 50.

ninp69e1-a (1410)

69 Maintenance Instructions

Page 70

10 Service

Caution

In case of a dysfunctional Sensistor ILS500 F, please send the product for service at

your most convenient service facility. Please visit www.inficon.com for addresses.

ninp69e1-a (1410)

Service 70

Page 71

11 Technical Data

294 mm (11.6 in.)

275 mm (10.8 in.)

11.1 Electrical Specifications

Electrical Supply

Mains Voltage Single Phase

Current 1.0 A at 100 VAC

Power Rating 120 W max

Inrush Current Max 40 A

ninp69e1-a (1410)

Mains Connector IEC/EN 60320-1/C14

Recommended Fuse Rating 2 A slow

I/O Port Signals

364 mm (14.3 in.)

110-240VAC 50/60 Hz

0.45 A at 230 VAC

33 W typical average

6.3 x 32 mm, 0.2 x 1.3 in. (2 needed)

Signal Specification 24 VDC logic

Output Voltage

Output Capacity Max 0.5 A

Input Voltage HI Min 16 VDC

Input Voltage LO Max 4 VDC

Input Current Consumption approximately 7 mA at 24 VDC

Communication Ports

Ethernet RJ45, 10/100 Mbit/s, TCP/IP

RS232

23 ±1 VDC

Output (max 2.5 A total)

Male, 9 pin, D-sub (x2)

Technical Data 71

Page 72

Communication Ports

Data rate 1200-115200 baud

Data bits 8

Stop bits 1

Parity None

Flow control None

11.2 Pneumatic Specifications

Compressed Air Supply

Pressure Std Model 0.35–0.7 MPa

(3.4–6.9 bar)

(50–100 psi)

Reduced vacuum capacity below:

0.5 MPa

(4.8 bar)

(70 psi)

HP model 0.5–0.7 MPa

(4.8–6.9 bar)

(70–100 psi)

Peak Consumption

at 6 bar (87 psi)

Quality Oil free and filtered to 5 μm

Dew point Max 10°C (50°F)

Tracer Gas Supply

Composition Inert non-condensing gas

Pressure Std Model 0.005–1.0 MPa

HP model 0.02–4.5 MPa

Quality Industrial grade purity (>95% purity)

240 l/min (508 SCFH)

(0.05–10.0 bar)

(0.72–145 psi)

(0.2–45.0 Bar)

(3–652 psi)

ninp69e1-a (1410)

72 Technical Data

Exhaust

Capacity in Exhaust Duct Min 30 m3/h (1000 SCFH)

Dimensions of Hose Leading to

Duct

ID 25 mm (1 in.)

Page 73

Pneumatic

Valve bore* 7 mm (0.28 in.)

*Capacity is given for 500 mm (20 in.) of ID 10 mm (0.4 in.) hose between ILS500 F

and test volume.

Evacuation

Max vacuum -85 kPa (-12.3 psi)

Capacity 0.4 s/l to -50 kPa (-7.2 psi)

1.5 s/l to -80 kPa (-11.6 psi)

Filling

Capacity at 1 MPa supply 0.1 s/l to 0.6 MPa (87 psi)

Tooling Output Valves

Valve type Normally closed, 3/2 valve

ninp69e1-a (1410)

11.3 Other Data

Q

n

C

v

Gas and Air Connection

Ports Female ISO 3/8″

Hose connector 4 of OD 10 mm (0.4 in.) connectors included

General Data

Dimensions 295 x 275 x 330 mm (12 x 11 x 13 in.)

Weight 17.6 kg (38.8 lb.)

Ambient temperature 10–40°C (50–100°F)

Ambient humidity 85% RH (non condensing)

Protection (IP30)

160 std l/min

0.16 USGPM/psi

(ISO to NPT 3/8″ adapter included)

Technical Data 73

Page 74

11.4 Interfaces and Connectors

All interfaces signals except the serial. Communication interfaces are discrete 24 VDC

logic signals.

Output signals (OUT) are sourcing transistor outputs. Input signals (IN) are transistor

inputs.

Max current of each signal is given in the tables below. Total current (sum) must,

however, be within instrument specification.

Caution

Outputs are not relay types. Do not connect external drive source such as 24 V or 100/

230 VAC.

11.4.1 Printer Port/RS232

Connector: 9 pin male D-sub

Purpose: Connection of serial printer or logging device (e.g. PC or PLC)

Cable: Standard female to female file transfer cable (null modem)

Baud Rate: 9600 default (1200 - 115200 selectable)

Pin Signal Specification

1 Not used Standard RS232C

2 RD Data rate 9600 baud

3 TD Data bits 8

4 Not used Stop bits 1

5 SG Parity none

6 Not used Flow ctrl none

7 Not used

8 Not used

9 Not used

ninp69e1-a (1410)

74 Technical Data

Page 75

Printing of results

The printer port prints the result of every test. In hand probe mode the result printed is

“ACCEPT” or “REJECT” followed by date & time and recipe name (if used) and end

Char New Line (0A, LF).<09> (Char Tab, 09) is used as a separator.

For Example: "TEST_ACCE<09>2013-09-04 13:23:03<09>Factory Default<0A>"

After an active probe test cycle the gas analysis value from the ISH2000 is printed. The

printout can be “2.4E+00A<09>2013-09-04 13:23:03<09>Factory Default<0A>".

See the ISH2000 manual. If the test cycle is rejected by any other test this will be

printed. Followed with date, time and recipe name. Hardware error prints “ERROR”.

For example: “ERROR<09>2013-09-04<09>Factory Default<0A>”.

On the ILS500 (Service/RS232), you can choose if you want to include time and date in

every result from the ILS500 or not. If it’s on the result will be: "TEST_ACCE<09>2013-

09-04 13:23:03<09>Factory Default<0A>"And if it’s off:“TEST_ACCE<0A>".

When filling is successfully completed FILL OK is printed. No information about time

and date is printed.

Results from ILS500 F

Results Explanation

TEST_ACCE Test accepted (if a leak detector is connected)

ninp69e1-a (1410)

TEST_REJE Test rejected (if a Leka detector is connected)

USER_FAIL User has pressed stop

EVAC_FAIL Evacuation failed

VDEC_FAIL Vacuum decay test failed

FILL_FAIL Tracer gas filling failed

PDEC_FAIL Pressure decay test failed

BLOC_FAIL Blockage test failed

REFI_FAIL Tracer gas refill failed

COMM_FAIL Communication with ISH2000 failed (If ISH2000 is connected)

TEST_STRT Test cycle started

TEST_DONE Test cycle finished

FILL_DONE Filling completed

CALI_STRT Calibration started (If ISH2000 is connected)

CALI_FAIL Calibration failed (If ISH2000 is connected)

CALI_DONE Calibration successful (If ISH2000 is connected)

RECH_DONE Recipe change done

RECH_FAIL Recipe change failed

ERROR Hardware error on ILS500

Technical Data 75

Page 76

Commands

The printer port can also be used to control the ILS500 F. The most commonly used

functions can be started/configured over the RS232 interface. Always use New Line

(0A,LF) as end character.

Command Action

K<0A> Starts a calibration. If the function is busy, the ILS500 prints the

time remaining for the ongoing calibration in seconds. For

example, if two seconds remains the printout is as follows:

WAIT 2 <0A>

S<0A> Statistics (see table below)

RS<0A> Reset statistics

R<09> Factory Default <0A> loads a recipe. For example

“R<09>Factory Default” loads the recipe Factory Default. When

the recipe is loaded the recipe name is echoed back. If a recipe

name isn’t in the ILS500, the answer from the ILS500 will be

“Not a recipe name!”

Statistics Printed data Explanation

REC:AP29 - recipe name. Printed if recipes is activated

TOT:00031 - total

ACC:00009 - accepted

REJ:00022 - rejected

EVA:00001 - evacuation

VDE:00000 - vacuum decay

BLO:00006 - blockage test

FIL:00001 - gas filling

PRE:00000 - pressure decay

GAS:00014 - gas detector

11.4.2 Input 1 (Optional)

ninp69e1-a (1410)

76 Technical Data

Page 77

Connector: 5 pin male Weidmüller, Omnimate BL3.5. Mating screw terminal

Purpose: Options port 1. Optional analogue or digital input (not supported by

Pin Signal Type Load Comment

1 +24 VDC SUPPLY 250 mA Option supply.

2 VIN1 IN -60 mA Voltage input:Digital 24 VDC or

3 IIN1 IN +/-30 mA Current input: 0-20 mA.

4 COM1 IN -250 mA Signal common (GND).

5 COM/SHLD GND +/-30 mA Shield.

11.4.3 Input 2 (Optional)

included.

std software).

analogue 0-10 VDC.

ninp69e1-a (1410)

Connector: 5 pin male Weidmüller, Omnimate BL3.5. Mating screw terminal

included.

Purpose: Options port 2. Used for “Active Holder for Hand Probe” (90630).

Pin Signal Type Load Comment

1 +24 VDC SUPPLY 250 mA Option supply.

2 VIN2 IN -60 mA Voltage input:Digital 24 VDC or

analogue 0-10 VDC.

3 IIN2 IN +/-30 mA Current input: 0-20 mA.

4 COM2 IN -250 mA Signal common (GND).

5 COM/SHLD GND +/-30 mA Shield.

Technical Data 77

Page 78

11.4.4 Status Output

Connector: 6 pin male Weidmüller, Omnimate BL3.5. Mating screw terminal

Purpose: Test Status Outputs. Sourcing 24 VDC transistor outputs.

Pin Signal Type Load Comment

1 RUNNING OUT 0.5 A Cycle running.

2 ACCEPT OUT 0.5 A Tested part accepted.

3 REJECT OUT 0.5 A Tested part rejected.

included.

4 ERROR OUT 0.5 A Summing error.

5 EOT/FILLED OUT 0.5 A End of test or gas filled indicator

6 COM GND -2.0 A Common GND.

Notice

11.4.5 Tooling Interface

(selectable).

Gas filling status is available on the ST A TUS connector (pin 5) on the back

of the unit. Connect to a lamp for easy notification of “End of test” status.

ninp69e1-a (1410)

78 Technical Data

Connector: 8 pin male Weidmüller, Omnimate BL3.5. Mating screw terminal

included.

Purpose: Electrical tooling interface.

Page 79

Pin Signal Type Load Comment

1 +24 VDC SUPPLY 300 mA Tooling switch supply (e.g. proximity

switch).

2 TS1 IN -7 mA Tooling switch 1.

3 TS2 IN -7 mA Tooling switch 2.

4 TS3 IN -7 mA Tooling switch 3.

5 TS4 IN -7 mA Tooling switch 4.

6 MARKER* OUT 0.5 A Marker output. Selectable mark on

REJECT or ACCEPT.

7 COM GND -1.0 A Common GND.

8 COM GND -1.0 A Common GND.

* MARKER output (Tooling Connector, pin 6) can be used to send a start pulse to

marking equipment such as an engraving machine or a valve controlling a simple

pneumatic stamp. Function and length of pulse is set by the following two

parameters:

Marker Output: Length of marker output pulse.

Output will go high at end of gas test and stay

high for the given time.

11.4.6 Control Output

ninp69e1-a (1410)

Marker Output High if Leak: Decides function of marker pulse.

To mark rejected part set to OFF.

To mark accepted part, set to ON.

Connector: 8 pin male Weidmüller, Omnimate BL3.5. Mating screw terminal

included.

Purpose: External start and stop. Control of optional external valves.

Pin Signal Type Load Comment

1 +24 VDC SUPPLY 2.0 A Start and stop switch and supply.

2 EXTSTART IN -7 mA Start button return (NO contacts) or

contact to +24 VDC.

3 EXTSTOP IN -7 mA Stop button return side (NO contact) or

contact to +24 VDC.

Technical Data 79

Page 80

Pin Signal Type Load Comment

4 EVAC1 OUT 0.5 A Venturi valve output.

5 EVAC2 OUT 0.5 A Evacuation valve output.

6 GASFILL OUT 0.5 A Fill valve output.

7 OPTOUT OUT 0.5 A

8 COM GND -1.0 A Common GND for outputs.

11.4.7 Probe Control Port

Connector: 25 pin female D-sub

Purpose: For external connection of ISH2000.

11.4.8 Power Input

Specification

AC mains voltage 110-240 V 50/60Hz.

AC mains current Typically 1 A (2 A pulse at power on).

11.4.9 Safety Interface

Risk assessment is the sole duty of the user of the ILS500 F

ninp69e1-a (1410)

Caution

80 Technical Data

Connector: 6 pin male Weidmüller, Omnimate BL3.5. Mating screw terminal

included.

Page 81

Purpose: Emergency stop interface.

Pin Signal Type Load Comment

1 +24 VDC SUPPLY 2.5 A

2 AUX1 - +/-1-5 A* Terminal 1 of safe relay contacts for

auxiliary external use.

3 AUX2 - +/-1-5 A* Terminal 2 of safe relay contacts for

auxiliary external use.

4 ESTATUS OUT 0.5 A Internal emergency circuit stopped.

Use for reset lamp or PLC

monitoring.

5 SAFESPLY** SUPPLY -2.5 A 24 VDC supply from EXTERNAL

emergency stop circuitry.

6 COM GND 1.0 A Common GND.

* 250 VAC 5 A cosj =1

30 VDC 5 A L/R = 0 ms

240 VAC 2A cosj = 0.3

11.4.10 Leak Detector

ninp69e1-a (1410)

24 VDC 1A L/R = 48 ms

** SAFESPLY feeds risk associated loads inside the ILS500 F. These include all gas

and tooling valves.

Connector: 9 pin male D-sub.

Purpose: Connection of external leak detector (ISH2000 or T-Guard)

Cable ISH2000: Pin-to-pin cable and converter.

Cable T-Guard: Nullmodem cable and converter.

Baudrate: 115200(ISH2000)/19200(T-Guard)

Pin Signal

1 Not used

2 TD

3 RD

Technical Data 81

Page 82

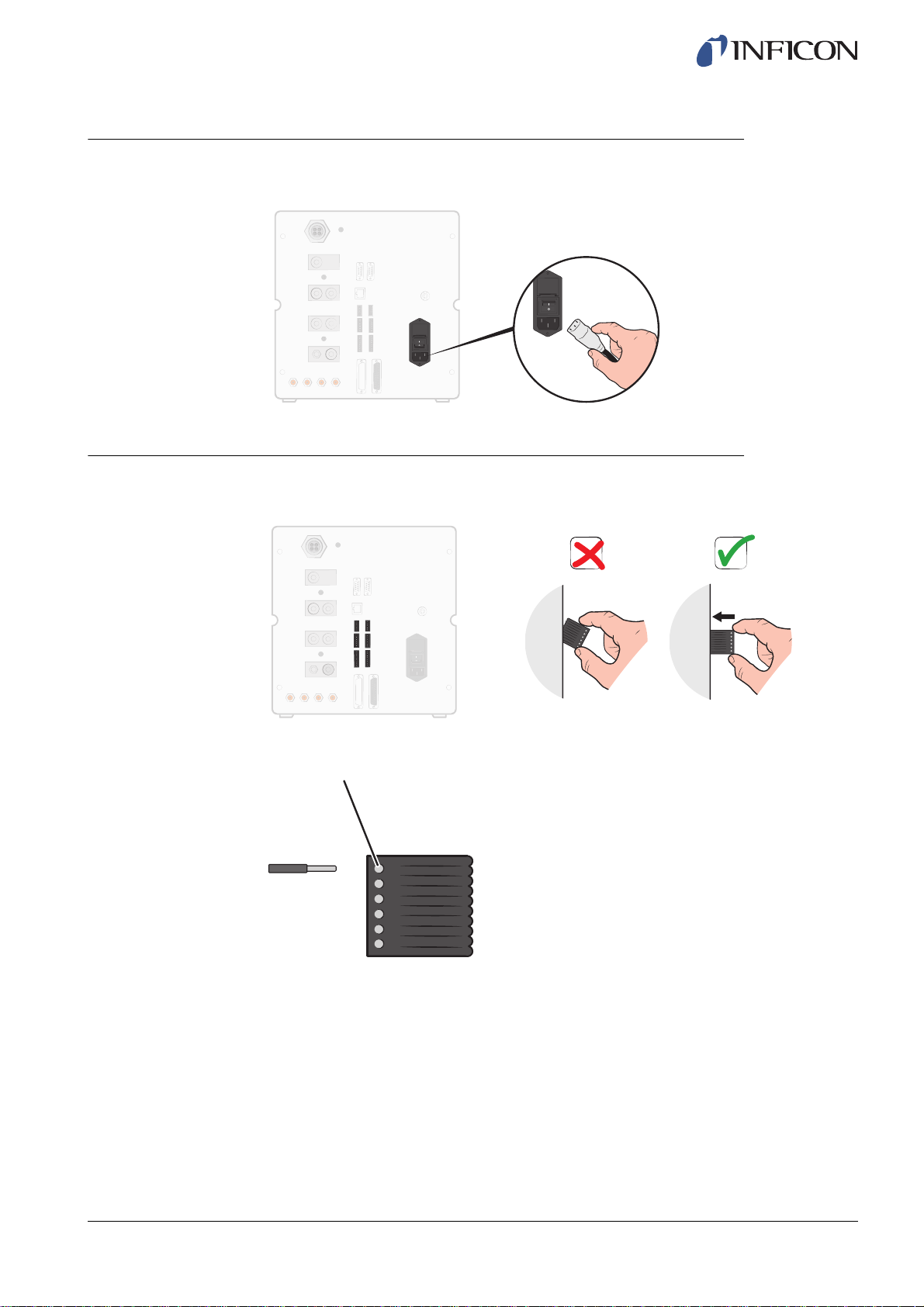

11.4.11 USB Port

Pin Signal

4 Not Used

5 GND

6 Not Used

7 Not Used

8 Not Used

9 Not Used

Connector: USB

Purpose: Used for import and export of recipes.

To access the USB port, remove the cover. See Removing the Cover on page 64.

USB is connected

USB Memory connected

Import from USB

Export to USB

An icon for USB is shown when installing the USB flash drive.

ninp69e1-a (1410)

82 Technical Data

Page 83

Import Recipe from USB

Importing database table Recipe1 from csv-file...

USB Memory connected

Import from USB

Export to USB

When importing recipes all recipes are imported from a file named Recipe1.csv.

Export Recipe from USB

Exporting database table Recipe1 to csv-file...

USB Memory connected

Import from USB

ninp69e1-a (1410)

Export to USB

When exporting recipes all recipes are exported to a file named Recipe1.csv.

Technical Data 83

Page 84

12 Spare Parts and Accessories

1 2

Pos. Part Type Description Part no.

1 Power Cables EU 591-146

UK 591-147

US 591-853

2 No-Stop Maintenance Kit Standard Model 590-680

HP Model 590-685

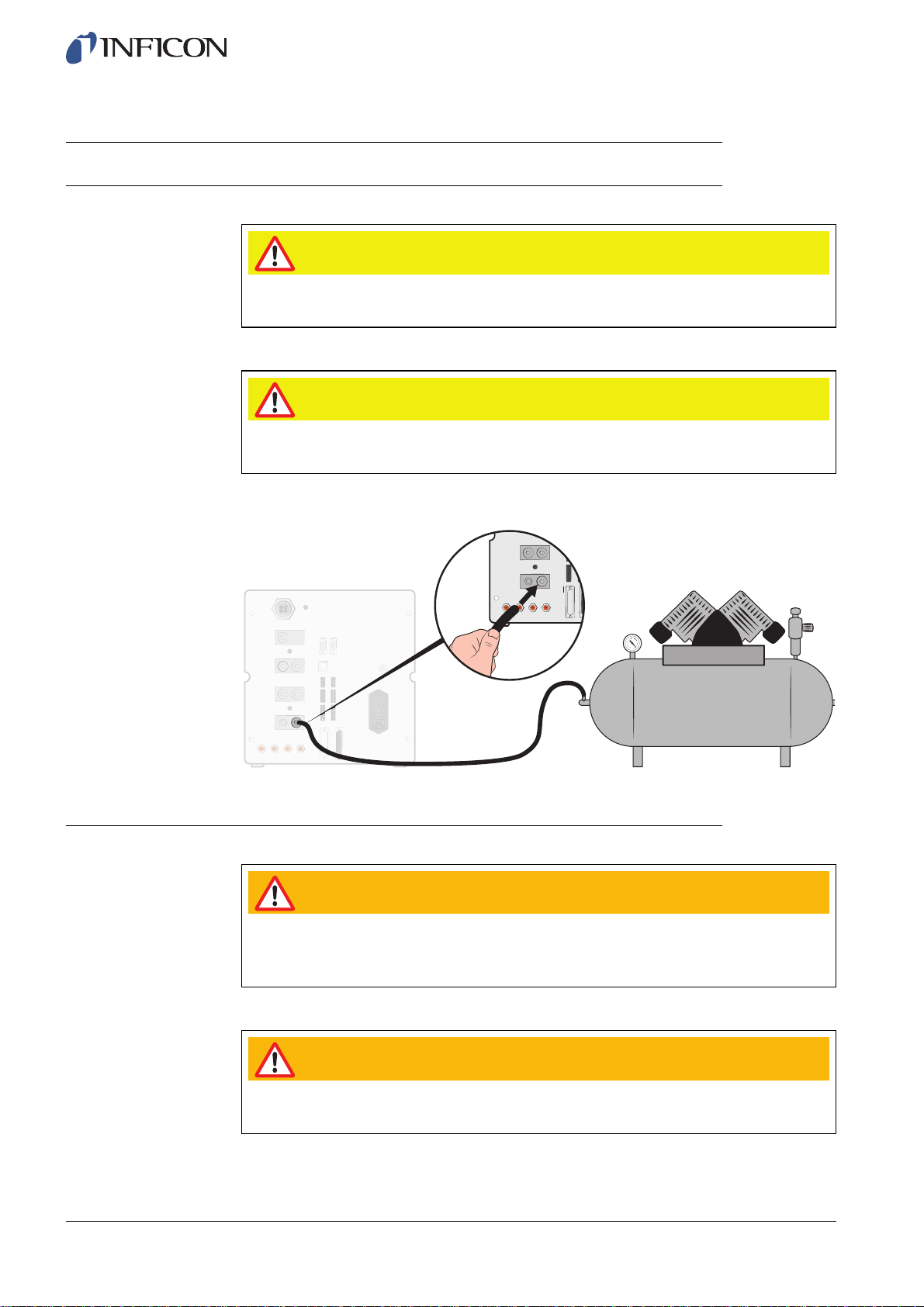

ninp69e1-a (1410)