Page 1

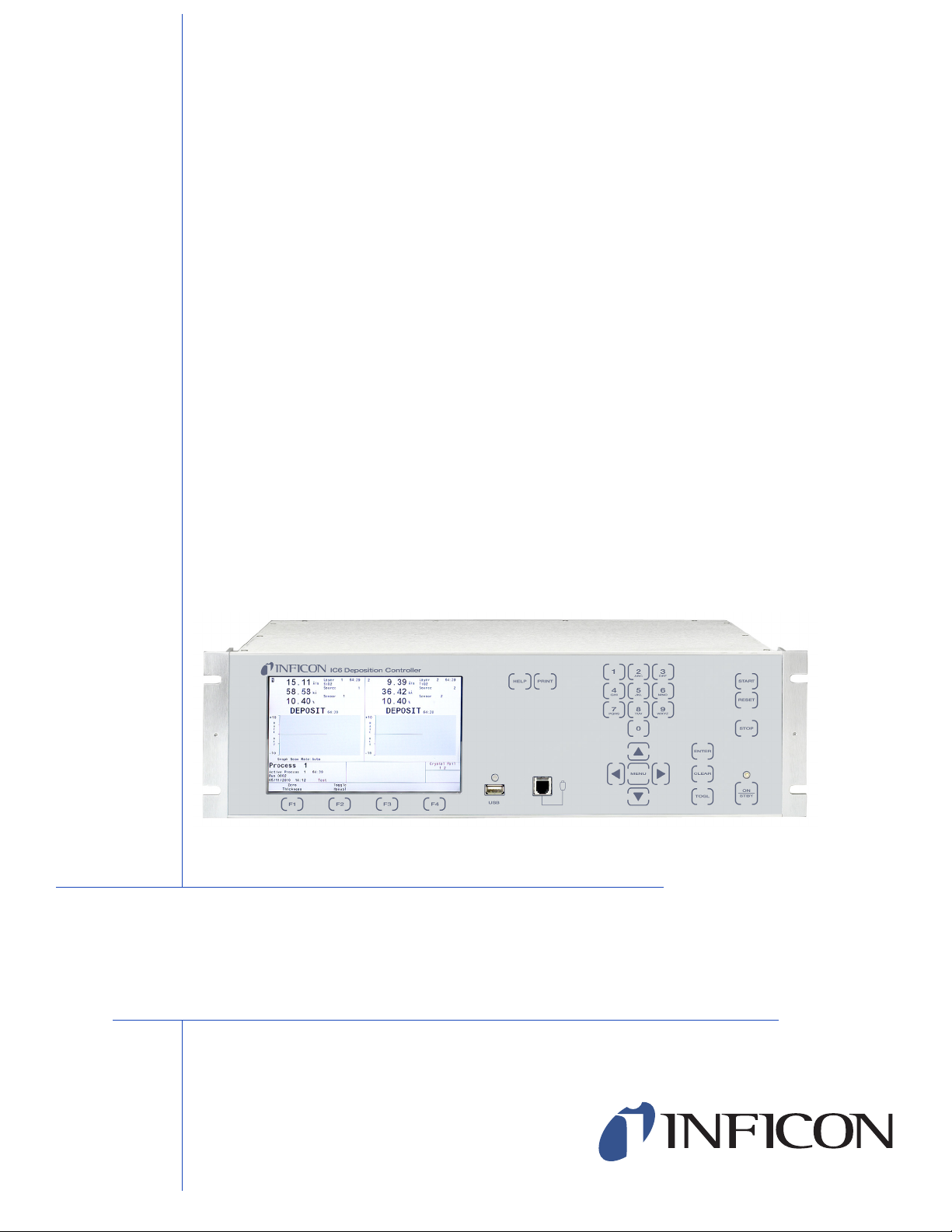

C

over Page

OPERATING MANUAL

IC6

Thin Film Deposition Controller

PN 074-505-P1F

Page 2

Page 3

Title P

age

www.inficon.com reachus@inficon.com

©2014 INFICON

®

OPERATING MANUAL

IC6

Thin Film Deposition Controller

PN 074-505-P1F

Page 4

Trademarks

The trademarks of the products mentioned in this Operating Manual are held by the companies that

produce them.

CAJON® is a registered trademark of Swagelok, Co.

RateWatcher™ is trademark of INFICON GmbH

Kingston® is a registered trademark of Kingston Technology Corporation.

Inconel® is a registered trademark of Inco Alloys International, Huntington, WV.

Lexar® is a registered trademark of Lexar Media, Inc.

Memorex® is a U.S. registered trademark of Memtek Corporation.

SanDisk® is a registered trademark of SanDisk Corporation.

Windows®, Windows 95® and Microsoft® are registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this Operating Manual is believed to be accurate and reliable. However, INFICON

assumes no responsibility for its use and shall not be liable for any special, incidental, or consequential

damages related to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2014 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Declaration Of Conformity

Page 1

Page 6

Declaration Of Conformity

Page 2

Page 7

Warranty

Standard INFICON Two Year

Page 1

Page 8

Standard INFICON Two Year Warranty

Page 2

Page 9

IC6 Operating Manual

Table Of Contents

Cover Page

Title Page

Trademarks

Disclaimer

Copyright

Declaration Of Conformity

Warranty

Chapter 1

Introduction and Specifications

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 IC6 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.2 General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.3 Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.2.4 Main Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.3.1 Returning Your IC6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.4 IC6 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.4.1 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.4.2 Screens and Hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4.3 IC6 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.4.3.1 Recipe Storage & Datalogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.4.3.2 Sensor Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

PN 074-505-P1F

1.4.3.3 Source Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.4.3.4 Material Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.4.3.5 Process Layer Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.4.3.6 General Global Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.4.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1.4.5 DAC Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.4.6 Logic Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

1.4.7 Relays / Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

1.4.8 Remote Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

1.4.9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

1.4.10 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

TOC - 1

Page 10

IC6 Operating Manual

1.4.11 Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.12 Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.13 Warm Up Period. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.14 Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4.15 Installation Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4.15.1 Connector Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4.15.2 Cooling Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4.16 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.4.17 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.6 Parts and Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.6.1 Base Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.6.2 Pre-installed Options or Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.6.3 Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1.6.4 Oscillator Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1.6.5 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1.6.6 Replacement Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

1.7 Initial Power-On Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Chapter 2

Installation and Interfaces

2.1 Location Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Sensor Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.3 IC6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 Avoiding Electrical Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1 Verifying/Establishing Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Connections to Earth Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.3 Minimizing Noise Pickup From External Cabling . . . . . . . . . . . . . . . . . . . . . 2-6

2.3 Connecting the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.1 Routing XIU Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.2 Interface Cable Fabrication and Pin-Out . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.2.1 Source Control Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.2.2 Crucible Indexer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.2.3 DAC Option Kit 781-504-G1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.2.4 I/O Expansion Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.2.5 RS-232C Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.3.2.6 Isolated +24 V (dc) Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

PN 074-505-P1F

TOC - 2

Page 11

IC6 Operating Manual

Chapter 3

Operation

3.1 Front Panel Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Rear Panel Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.3 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 Main Menu Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.2 Operate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.3.3 Sensor Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3.3.3.1 Sensor Information Rate/Xtal Display Description . . . . . . . . . . . . . . . . . . . .3-9

3.3.3.2 Crystal Life and Starting Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

3.3.3.3 Percent Life Auto-Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.3.3.3.1 Function Key Selection Choices for the

Sensor Information Rate/Xtal Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.3.3.4 Sensor Information Type/Freq Display Description . . . . . . . . . . . . . . . . . . 3-13

3.3.3.4.1 TEST XIU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.3.4 Sensor Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.3.5 Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.3.6 Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.3.6.1 Overview Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.3.6.2 Source Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.6.3 Sensor Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.6.4 Pre/Post Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.3.6.5 Deposit Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3.3.6.6 Lib A-Hf, Lib Hf-Sc, Lib Sc-Z Sub-Displays . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.3.7 Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.3.7.1 Overview Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.3.7.2 Current Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.3.7.3 1 - 10, 11 - 20 etc. Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.3.8 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

PN 074-505-P1F

3.3.8.1 Process Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.3.8.2 DACs Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.3.8.3 Comm Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.3.8.4 Message Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.3.8.5 Date/Time Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.3.8.6 Test Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.3.8.7 Lock Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.3.8.8 Audio/Visual Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3.3.9 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3.3.10 Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.3.11 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

TOC - 3

Page 12

IC6 Operating Manual

3.3.12 Counter / Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.3.13 USB Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.4 Process Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.4.1 Defining a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.4.2 Executing a Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

3.4.3 Pre-conditioning a Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.4.4 Co-deposition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.4.5 Multiple Layer Starts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.4.6 Automating a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.5 State Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3.6 Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

3.6.1 Crystal Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

3.6.1.1 XtalTwo (CrystalTwo). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

3.6.1.2 XtalSix (CrystalSix). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

3.6.1.3 Xtal12 (Crystal12). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

3.6.1.4 Generic Sensor Crystal Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

3.6.2 Source/Crucible Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

3.6.2.1 Example: Programming Turret Source Crucible Selection. . . . . . . . . . . . . 3-38

3.6.3 Auto-Z. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3.6.4 Auto Tune — Optimizing the Control Loop. . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.6.5 Rate Watcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

3.6.6 Handheld Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3.6.6.1 Determining Soak Power with the Handheld Controller . . . . . . . . . . . . . . . 3-41

3.6.7 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.6.7.1 Standard or Time Compressed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.6.7.2 Advanced Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.6.8 USB Storage Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

3.6.9 Lock and Access Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.6.10 Datalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.6.11 DAC Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

PN 074-505-P1F

Chapter 4

TOC - 4

Sensor & Source Setup

4.1 Sensor Setup Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Sensor Display Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Sensor Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Source Setup Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.1 Source Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.2 Source Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3 DAC Output Selection Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Page 13

IC6 Operating Manual

Chapter 5

Material Setup

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Material Screen Overview Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 Material Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.1.3 Material Screen Source Page Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.1.4 Material Screen Sensor Parameters Page . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

5.1.5 Pre/Post Screen Deposit Page Parameters . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.1.6 Post Deposit Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.1.7 Deposit Page Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Chapter 6

Process Setup

6.1 Process Setup Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Overview Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.3 Curr(ent) Proc(ess) Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.4 Process Layers 1 - 10 etc. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.4.1 Layer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4.1.1 Layer Parameter Editing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4.1.2 Layer Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.5 Special Layer Parameter Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.5.1 Skip Deposit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Chapter 7

General Parameters

7.1 General Setup Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 General Screen Process Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 DACs Page Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.4 COMM Page Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7.5 MESSAGE Page Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

PN 074-505-P1F

7.6 DATE / TIME Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.7 TEST Page Set Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.8 LOCK Page Code Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.9 AUDIO / VISUAL Page Set Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Chapter 8

Digital I/O

8.1 Digital I/O Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 All Input Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.3 All Output Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.4 I/O Board Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.4.1 Output Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

TOC - 5

Page 14

IC6 Operating Manual

Chapter 9

Logic Statement Setup

9.1 Logic Statement Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Editing the Logic Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.2.1 Logic Statement Groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2.2 Logic Statement Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.2.3 AND/OR and ON Logic Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.2.3.1 ON Operator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.3 IF Event Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.4 THEN Action Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

9.5 Logic Statement Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Chapter 10 Remote Communications

10.1 Remote Communication Configuration Overview . . . . . . . . . . . . . . . . . . . 10-1

10.2 Physical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2.1 RS-232C Serial Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2.2 TCP/IP Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2.2.1 Network Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.2.2.2 How to Set Up the Network Protocol on the PC. . . . . . . . . . . . . . . . . . . . . 10-3

10.3 Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.3.1 Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.3.1.1 Command Packet (Host to IC6 Message) . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.3.1.2 Response Packet (IC6 to Host Message) . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

10.3.1.3 Timeouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.3.2 Data Type Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.3.2.1 REAL_xXx and REAL_xFx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.3.2.2 TIME. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.3.2.3 ENCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.3.2.4 INTEGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.3.2.5 LOCKCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.4 Communication Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.4.1 Query and Update Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.4.2 Status Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.4.3 HELLO Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.4.4 Query Source Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.4.5 Update Source Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-13

10.4.6 Query General Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10.4.7 Update General Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-14

10.4.8 Query Input Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

10.4.9 Update Input Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-18

PN 074-505-P1F

TOC - 6

Page 15

IC6 Operating Manual

10.4.10 Query Process Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-18

10.4.11 Update Process Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-18

10.4.12 Query Logic Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

10.4.13 Update Logic Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

10.4.14 IC6 Event List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

10.4.15 IC6 Action List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.4.16 Query Material Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-26

10.4.17 Update Material Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.4.18 Query Material Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-35

10.4.19 Update Material Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-35

10.4.20 Query Output Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-35

10.4.21 Update Output Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-35

10.4.22 Query Process Layer Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-36

10.4.23 Update Process Layer Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-36

10.4.24 Query Sensor Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-37

10.4.25 Update Sensor Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-37

10.4.26 Query Output Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

10.4.27 Update Output Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-39

10.4.28 Query User Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-39

10.4.29 Update User Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-39

10.4.30 Status General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-40

10.4.31 Status Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-43

10.4.32 Status Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-45

10.4.33 Remote General Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-47

10.4.34 Remote Layer Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-50

10.4.35 IC6 Communications Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-52

10.4.35.1 General Command Packet Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-52

10.4.35.2 General Response Packet Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-52

10.4.35.3 HELLO Command, ASCII name and version . . . . . . . . . . . . . . . . . . . . . .10-52

PN 074-505-P1F

10.4.35.4 Query General Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-53

10.4.35.5 Update General Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-53

10.4.35.6 Query Material Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-53

10.4.35.7 Update Material Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-53

10.4.35.8 Query Sensor Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-53

10.4.35.9 Update Sensor Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-54

10.4.35.10 Query Source Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-54

10.4.35.11 Update Source Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-54

10.4.35.12 Query Process Layer Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-54

10.4.35.13 Update Process Layer Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-55

10.4.35.14 Query Material Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-56

TOC - 7

Page 16

IC6 Operating Manual

10.4.35.15 Update Material Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-56

10.4.35.16 Query Process Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-56

10.4.35.17 Update Process Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-56

10.4.35.18 Query Input Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-56

10.4.35.19 Update Input Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-57

10.4.35.20 Query Output Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-57

10.4.35.21 Update Output Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-57

10.4.35.22 Query Output Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-57

10.4.35.23 Update Output Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-57

10.4.35.24 Query User Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-58

10.4.35.25 Update User Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-58

10.4.35.26 Query Logic Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-58

10.4.35.27 Update Logic Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-59

10.4.35.28 Status General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-59

10.4.35.29 Status Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-60

10.4.35.30 Status Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-60

10.4.35.31 Remote General Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-60

10.4.35.32 Remote Layer Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-60

10.4.35.33 Example for Interpreting Float Responses. . . . . . . . . . . . . . . . . . . . . . . . 10-61

Chapter 11

Applications

11.1 Multiple Sensor Deposition Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.1.1 IC6 Parameters and Corrections for

Multiple Sensor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.2 Trend Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

11.2.1 IC6 Parameters Associated with the Trend Analysis Feature . . . . . . . . . . 11-5

11.3 IC6 Cygnus Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

11.4 IC6 Four & Six Layer (Cygnus Emulation) Configuration. . . . . . . . . . . . . . 11-7

11.4.1 Configure Sensors 1 to 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

11.4.2 Configure Sources 1 to 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

11.4.3 Configure six Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

11.4.4 Configure the Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.4.5 General Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.4.6 Logic Functions Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.4.7 State Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

11.4.7.1 NonDepCntl State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

11.4.7.2 Suspend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

11.4.7.3 Idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

PN 074-505-P1F

TOC - 8

Page 17

IC6 Operating Manual

Chapter 12

Maintenance and Calibration Procedures

12.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.2 Determining Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

12.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

12.4 Laboratory Determination of Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

12.5 AutoTuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

12.5.1 AutoTune Preparation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

12.5.2 AutoTune Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12.5.3 AutoTune Manual Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

12.5.4 AutoTune Tuning Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-10

12.5.5 AutoTune Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-10

12.6 Determining Cross Talk Calibration

For Co-Deposition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

12.6.1 Procedure Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

12.6.1.1 Cross Talk Calibration Procedural Notes . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

12.6.1.2 Cross Talk Calibrate Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

12.6.2 Cross Talk Calibration MANUAL display . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

12.6.2.1 Function Key Selection Choices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

12.6.3 Cross Talk Calibration CALIBRATE display. . . . . . . . . . . . . . . . . . . . . . . 12-18

12.6.4 Cross Talk Calibration SELECT display. . . . . . . . . . . . . . . . . . . . . . . . . . 12-19

12.6.4.1 Function Key Selection Choices for

Cross Talk Calibration Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-19

12.7 Source Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-20

12.7.1 Source Maintenance Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-21

12.7.1.1 Crucible Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-21

12.7.1.2 Toggle Sensor and Source Shutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21

12.7.1.3 Start/Stop Manual Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21

12.8 System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-22

PN 074-505-P1F

Chapter 13

Counters & Timers

13.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

Chapter 14

14.1 File Handling (USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.1.1 USB Storage Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.2 Directory Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.3 Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-2

14.4 Data Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

14.5 Screen Captures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-4

USB Storage

TOC - 9

Page 18

IC6 Operating Manual

Chapter 15

Troubleshooting, Status and Error Messages

15.1 Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

15.2 User Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

15.3 AutoTune and Calibration Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

15.4 STOP messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

15.5 Transient Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-9

15.6 Input Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-14

15.7 Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

15.7.1 Troubleshooting the IC6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

15.7.2 Troubleshooting Transducers/Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 15-19

15.7.3 Troubleshooting Computer Communications. . . . . . . . . . . . . . . . . . . . . . 15-23

15.8 Replacing the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-25

15.8.1 Front Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-26

15.8.2 Cool Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-27

15.8.3 Shuttered and Dual Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-28

15.8.4 Bakeable Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-28

15.8.5 Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-29

15.8.6 Crystal Snatcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-30

15.8.7 CrystalSix (XtalSix). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-30

15.9 Crystal Sensor Emulator

IPN 760-601-G1 or 760-601-G2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-31

15.9.1 Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-32

15.9.1.1 Measurement System Diagnostic Procedure. . . . . . . . . . . . . . . . . . . . . . 15-32

15.9.1.2 Feedthrough Or In-Vacuum Cable

Diagnostic Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-33

15.9.1.3 Sensor Head Or Monitor Crystal

Diagnostic Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-34

15.9.1.4 System Diagnostics Pass But

Crystal Fail Message Remains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-35

15.9.2 % XTAL Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-35

15.9.3 Sensor Cover Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-36

15.9.3.1 Compatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-36

15.9.3.2 Incompatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-36

15.9.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-37

PN 074-505-P1F

TOC - 10

Page 19

Chapter 16

16.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

16.1.1 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-2

16.1.2 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-4

16.1.3 Z-match Technique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-5

16.1.4 Active Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-6

16.1.5 ModeLock Oscillator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-7

16.1.6 Auto-Z Theory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-9

16.1.7 Control Loop Theory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-11

Appendix A

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

IC6 Operating Manual

Measurement and Control Theory

Material Table

PN 074-505-P1F

TOC - 11

Page 20

IC6 Operating Manual

This page is intentionally blank.

TOC - 12

PN 074-505-P1F

Page 21

1.1 Introduction

The IC6 is a closed loop process controller designed for use primarily in physical

vapor deposition. The IC6 monitors and/or controls the rate and thickness of the

deposition of thin films. Deposition rate and thickness are inferred from the

frequency change induced by mass added to a quartz crystal. This technique

positions sensors in the path between or to the side of the source of the vaporized

material and the target substrate. The sensor incorporates an exposed oscillating

quartz crystal whose frequency decreases as material accumulates. The change

in frequency provPN 074-505-P1Fides information to determine rate and thickness

and to continually control the evaporation power source. With user programmed

time, thickness and power limits and with desired rates and material

characteristics, the IC6 is capable of automatically controlling the process in a

precise and repeatable manner. User interaction is accomplished via the IC6 front

panel or remote communication and consists of selection or entry of parameters to

define the process.

IC6 Operating Manual

Chapter 1

Introduction and Specifications

A complete system consists of a main electronics unit also called the IC6, sensor

heads and a crystal interface unit (XIU) for each attached sensor. These items are

generally bundled at the factory and are also sold separately.

This IC6 Operating Manual provides user information for installing, programming

and operating the main electronics unit.

When reading the IC6 Operating Manual, please pay particular attention to the

Notes, Cautions, and Warnings found throughout the text. The Notes, Cautions,

and Warnings are defined in section 1.2.1 on page 1-2.

You are invited to comment on the usefulness and accuracy of this manual by

PN 074-505-P1F

visiting our website at www.inficon.com.

1.1.1 Related Manuals

Sensors are covered in separate manuals.

074-154 - Front Load Bakeable

074-155 - CrystalSix (XtalSix)

074-398 - Crystal12 (Xtal12)

074-156 - Front Load Single/Dual

074-157 - Sputtering

1 - 1

Page 22

IC6 Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.2 IC6 Safety

1.2.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the Notes, Cautions, and

Warnings found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum IC6 efficiency

when followed.

Failure to heed these messages could result in damage

to the IC6.

Failure to heed these messages could result in personal

injury.

Dangerous voltages are present which could result in

personal injury.

PN 074-505-P1F

1 - 2

Page 23

1.2.2 General Safety Information

WARNING - Risk Of Electric Shock

CAUTION

Do not open the IC6 case! There are no user-serviceable

components within the IC6 case.

Dangerous voltages may be present whenever the power

cord or external input/relay connectors are present.

Refer all maintenance to qualified personnel.

This IC6 contains delicate circuitry which is susceptible

to transient power line voltages. Disconnect the line cord

whenever making any interface connections. Refer all

maintenance to qualified personnel.

IC6 Operating Manual

PN 074-505-P1F

1 - 3

Page 24

IC6 Operating Manual

WARNING - Risk Of Electric Shock

1.2.3 Earth Ground

The IC6 is connected to earth ground through a sealed three-core

(three-conductor) power cable, which must be plugged into a socket outlet with a

protective earth terminal. Extension cables must always have three conductors

including a protective earth terminal.

Never interrupt the protective earth circuit.

Any interruption of the protective earth circuit inside or

outside the IC6, or disconnection of the protective earth

terminal is likely to make the IC6 dangerous.

This symbol indicates where the protective earth ground

is connected inside the IC6. Never unscrew or loosen this

connection.

PN 074-505-P1F

1 - 4

Page 25

1.2.4 Main Power Connection

WARNING - Risk Of Electric Shock

This IC6 has line voltage present on the primary circuits

whenever it is plugged into a main power source.

Never remove the covers from the IC6 during normal

operation.

There are no operator-serviceable items within this IC6.

Removal of the top or bottom covers must be done only

by a technically qualified person.

In order to comply with accepted safety standards, the

IC6 must be installed into a rack system which contains

a mains switch. This switch must break both sides of the

line when it is open and it must not disconnect the safety

ground.

IC6 Operating Manual

PN 074-505-P1F

1 - 5

Page 26

IC6 Operating Manual

1.3 How To Contact INFICON

Worldwide customer support information is available under Support at

www.inficon.com where you can contact:

a Technical Support Engineer with questions regarding applications for and

programming the IC6.

a Service Engineer with questions regarding troubleshooting, diagnosing or

repairing a defective IC6.

Sales and Customer Service, to find the INFICON Sales office nearest to you.

Repair Service, to find the INFICON Service Center nearest to you.

If you are experiencing a problem with your IC6, please have the following

information readily available:

the serial number and firmware version for your IC6,

a description of your problem,

an explanation of any corrective action that you may have already attempted,

and the exact wording of any error messages that you may have received.

1.3.1 Returning Your IC6

Do not return any component of your IC6 to INFICON without first speaking with a

Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your IC6.

Prior to being given an RMA number, you may be required to complete a

Declaration Of Contamination (DOC) form if your sensor has been exposed to

process materials. DOC forms must be approved by INFICON before an RMA

number is issued. INFICON may require that the sensor be sent to a designated

decontamination facility, not to the factory.

PN 074-505-P1F

1 - 6

Page 27

1.4 IC6 Specifications

1.4.1 Measurement

Measurement Frequency Range . . . 6.0 to 4.5 MHz (fixed)

Frequency Resolution . . . . . . . . . . . ± 0.0035 Hz @ 6 MHz

Thickness and Rate

Resolution/Measurement . . . . . . . . . ± 0.00433 Å @ tooling/density = 100/1

Measurement Interval. . . . . . . . . . . . 0.10 s

Thickness Accuracy . . . . . . . . . . . . . 0.5% typical, (dependent on process

Frequency Accuracy. . . . . . . . . . . . . ± 2 ppm 0 to 50°C

Measurement Frequency . . . . . . . . . 10 Hz

Measurement Technique . . . . . . . . . ModeLock with Auto-Z

IC6 Operating Manual

Fundamental frequency = 6 MHz

conditions, especially sensor location,

material stress, temperature and density)

User Interface. . . . . . . . . . . . . . . . . . LCD and limited membrane keypad. All

parameters accessible through computer

communications. Multiple message areas for

indication of states and detailed indication of

abnormal and stop conditions.

1.4.2 Screens and Hierarchy

a) Navigation . . . . . . . . . . . . . . . . . . Menu driven, four soft keys

b) Structure. . . . . . . . . . . . . . . . . . . . Separate screens dedicated to

1) Operate

2 ) Se ns or In f or ma t io n

3) Sensor Parameters

PN 074-505-P1F

4) Source Parameters

5) Material Parameters

6) Process Parameters

7) General Parameters

8) Digital I/O Display

9) Logic

10) Ma inte na nc e

11) Counter/Timer

12) USB Storage

1 - 7

Page 28

IC6 Operating Manual

1.4.3 IC6 Features

1.4.3.1 Recipe Storage & Datalogging

USB Memory Device

1.4.3.2 Sensor Parameters

Up to 8 sensors can be averaged together

(Sensor) Shutter Output . . . . . . . . . . 0 to 38

Sensor Type. . . . . . . . . . . . . . . . . . . Single, XtalTwo, XtalSix, Xtal12, Generic

(Sensor) Switch Output . . . . . . . . . . 0 to 38

Auto-Z . . . . . . . . . . . . . . . . . . . . . . . Yes/No

# of Positions (for Generic Sensor type) . . . . . . . . . 1 to 12

# of Pulses (for Generic Sensor type) . . . . . . . . . . . 1 to 10

Pulse On (Time for Generic Sensor type) . . . . . . . . 0.1 to 9.9 s

Pulse Off (Time for Generic Sensor type) . . . . . . . . 0.1 to 9.9 s

Recorder Output. . . . . . . . . . . . . . . . 0 to 12

Recorder Function . . . . . . . . . . . . . . Rate, Thickness, RateDeviation

Recorder Range. . . . . . . . . . . . . . . . 0 to 99999

1.4.3.3 Source Parameters

Up to 6 sources may be controlled at the same time

DAC Output . . . . . . . . . . . . . . . . . . . 0 to 12

(Source) Shutter Output . . . . . . . . . . 0 to 38

Crucible Selection . . . . . . . . . . . . . . Turret is indexed to selected position on a

Number of Crucibles. . . . . . . . . . 1, 4, 8, 16, 32 or 64

Crucible Output . . . . . . . . . . . . . 0 to 38

Turret Feedback. . . . . . . . . . . . . Yes / No

Turret Input. . . . . . . . . . . . . . . . . 0 to 28

Start. Turret feedback is checked whenever a

source is started. Range is from 1 to number

of crucibles.

PN 074-505-P1F

1 - 8

Turret Delay . . . . . . . . . . . . . . . . 2 to 180 s (Time-out period with feedback,

delay time without feedback)

Page 29

1.4.3.4 Material Parameters

32 materials can be specified and given unique names (15 character max.).

Density . . . . . . . . . . . . . . . . . . . . . . . 0.100 to 99.999 g/cm

Z-ratio . . . . . . . . . . . . . . . . . . . . . . . . 0.100 to 15.000

Master Tooling . . . . . . . . . . . . . . . . . 1.0 to 999.9%

Control Loop types . . . . . . . . . . . . . . Non-PID, PI, PID

Process Gain . . . . . . . . . . . . . . . . . . 0.01 to 999.99 Å/s/%Power

Time Constant . . . . . . . . . . . . . . . . . 0.010 to 9999.99 s

Dead Time . . . . . . . . . . . . . . . . . . . . 0.010 to 9999.99 s

Source . . . . . . . . . . . . . . . . . . . . . . . 1 to 6

Maximum Source Power . . . . . . . . . 0.01 to 99.99%

Minimum Source Power . . . . . . . . . . 0.00 to 99.98%

Maximum Power Option . . . . . . . . . . Continue, Post-Dep(osition), Stop Proc(ess),

IC6 Operating Manual

3

Suspend Mat(erial) — can be selected for

each Material individually

Power Ramps. . . . . . . . . . . . . . . . . . 3 per Material

Power Level . . . . . . . . . . . . . . . . 0.00 to 99.99%

Rise Time . . . . . . . . . . . . . . . . . . 00:00 to 99:59 min:s

Soak Time. . . . . . . . . . . . . . . . . . 00:00 to 99:59 min:s

Auto Soak 2 . . . . . . . . . . . . . . . . . . . Yes / No

Deposit After Pre-Deposit. . . . . . . . . Yes / No

Yes = go to Deposit

No = go to Non-Deposit Rate Control

(Control) Delay Option . . . . . . . . . . . None, Shutter, Control, Both

PN 074-505-P1F

Control Delay Time. . . . . . . . . . . . . . 00:00 to 99:59 min:s

Shutter Delay Accur(acy) . . . . . . . . . 1 to 99%

Transfer Sensor . . . . . . . . . . . . . . . . 0 to 8

Transfer Tooling . . . . . . . . . . . . . . . . 1 to 999.9%

Feed Power . . . . . . . . . . . . . . . . . . . 0.00 to 99.99%

Feed Ramp Time . . . . . . . . . . . . . . . 00:00 to 99:59 min:s

Feed Time . . . . . . . . . . . . . . . . . . . . 00:00 to 99:59 min:s

1 - 9

Page 30

IC6 Operating Manual

Idle Ramp. . . . . . . . . . . . . . . . . . . . . 1 per Source

Idle Power . . . . . . . . . . . . . . . . . 0.00 to 99.99%

Idle Ramp Time . . . . . . . . . . . . . 00:00 to 99:59 min:s

Rate . . . . . . . . . . . . . . . . . . . . . . . . . 0.000 to 999.9 Å/s

Time Limit (in Deposit) . . . . . . . . . . . 00:00 to 99:59 min:s

Rate Filter Time . . . . . . . . . . . . . . . . 0.1, 0.4, 1.0, 4.0, or 10.0, 20.0, 30.0 s

Time Power Averaging Time . . . . . . 0 to 30 minutes

Ion Assist Deposit . . . . . . . . . . . . . . Yes/No

On Final Thickness . . . . . . . . . . . . . Continue, Post-Dep(osit),

NonDep(osit)Cont(rol)

New Rate while in Deposit . . . . . . . . 2 Rate Ramps per Material

New Rate 1 or 2 . . . . . . . . . . . . . 0.000 to 999.9 Å/s

Start Ramp 1 or 2 . . . . . . . . . . . . 0.000 to 999.9 kÅ

Ramp Time 1 or 2. . . . . . . . . . . . 00:00 to 99:59 min:s

RateWatcher® . . . . . . . . . . . . . . . . Sample and Hold Feature

(RateWatcher) Option. . . . . . . . . Yes/No

(RateWatcher) Time . . . . . . . . . . 00:00 to 99:59 min:s

(RateWatcher) Accuracy . . . . . . 1 to 99%

Multipoint . . . . . . . . . . . . . . . . . . . . . Yes/No (average up to 8 sensors)

Aggregate Multiply . . . . . . . . . . . . . . Yes/No

(Sensor) Failure Action . . . . . . . . . . Unused, PostD(e)p(osit), Stop, Susp(e)nd,

TimeP(o)w(er)

(Sensor) Failure Trigger . . . . . . . . . . OnFail (when this sensor fails) or Last (when

the last sensor fails)

(Sensor) Weight . . . . . . . . . . . . . . . . 1 to 400.0%

(Sensor) Tooling (Factor) . . . . . . . . . 1.0 to 999.9%

CrystalTwo Tooling . . . . . . . . . . . . . . 1.0 to 999.9%

Cal(ibration) Thickness . . . . . . . . . . 0.000 to 999.9 kÅ (for Crosstalk correction)

CrystalSix (XtalSix) and Crystal12 (Xtal12) sensor selections to specify a subset of

available crystal positions:

PN 074-505-P1F

1 - 10

Xtal Position First . . . . . . . . . . . . 0 to 6 (XtalSix) or 12 (Xtal12)

Xtal Position Last . . . . . . . . . . . . 0 to 6 (XtalSix) or 12 (Xtal12)

Page 31

Backup Sensor . . . . . . . . . . . . . . . . . 0 to 8

Backup Tooling . . . . . . . . . . . . . . . . . 1.0 to 999.9%

(Crystal) Quality Percent . . . . . . . . . 0 to 99%

(Crystal) Quality Counts . . . . . . . . . . 0 to 99

(Crystal) Stability Single . . . . . . . . . . 0 to 9999 Hz

(Crystal) Stability Total . . . . . . . . . . . 0 to 9999 Hz

Recorder Output. . . . . . . . . . . . . . . . 0 to 12

Recorder Function . . . . . . . . . . . . . . Rate, Thick(ness), RateDev(iation), Power

Recorder Range . . . . . . . . . . . . . . . . 0 to 99999

1.4.3.5 Process Layer Parameters

50 processes can be created and given unique names (15 character max.).

Each process can contain 200 layers.

Material. . . . . . . . . . . . . . . . . . . . . . . 0 to 32

IC6 Operating Manual

Final Thick(ness) . . . . . . . . . . . . . . . 0.000 to 999.99 kÅ

Thick(ness) Limit . . . . . . . . . . . . . . . 0.000 to 999.99 kÅ

Cruc(ible) . . . . . . . . . . . . . . . . . . . . . 1 to 64

Co-Dep(osition) . . . . . . . . . . . . . . . . Yes/No

Ratio C(o)ntr(o)l . . . . . . . . . . . . . . . . 0 to 999.9% (if CoDep)

1.4.3.6 General Global Parameters

Active Process . . . . . . . . . . . . . . . . . 1 to 50

Layer To Start . . . . . . . . . . . . . . . . . 1 to 200

Run # . . . . . . . . . . . . . . . . . . . . . . . . 1 to 9999

PN 074-505-P1F

Auto Start Next (Layer) . . . . . . . . . . . Yes / No

Max Concurrent Layer . . . . . . . . . . . 1 to 6

Layers Displayed . . . . . . . . . . . . . . . Auto, 4 Layers, 6 Layers

Active Layer Output . . . . . . . . . . . . . First of eight consecutive outputs encoded to

indicate the number of the loaded layer (first

if multiple layers) that will be executed on a

Start. 00000001 indicates layer 1, 00010011

indicates layer 200.

Date Format . . . . . . . . . . . . . . . . . . . DDMMYYYY or MMDDYYYY

1 - 11

Page 32

IC6 Operating Manual

LCD Dimmer Time . . . . . . . . . . . . . . 0 for Always On or # of Minutes till Off

0 to 99 minutes

Graph Scale . . . . . . . . . . . . . . . . . . . Power, +/-10 Å/s, +/-20 Å/s

Graph Scan Rate . . . . . . . . . . . . . . . Auto, Slow, Medium, Fast

Test . . . . . . . . . . . . . . . . . . . . . . . . . On / Off

Advanced Test . . . . . . . . . . . . . . . . . On / Off

Time Compressed . . . . . . . . . . . . . . Yes / No

Audio Feedback . . . . . . . . . . . . . . . . Yes / No

RS232 Baud Rate . . . . . . . . . . . . . . 9600, 19200, 38400, 57600, 115200

RS232 Protocol . . . . . . . . . . . . . . . . Standard, D(ata)log Page, D(ata)log Comma

DataLog XTAL History . . . . . . . . . . . Yes / No

USB Datalog Format . . . . . . . . . . . . Log Off (No datalogging), Page, Comma

Thickness Eq(uation) 1 . . . . . . . . . . Up to 6 Source numbers can be specified,

each Source number can be used only once

in the equation.

Thickness Eq(uation) 2 . . . . . . . . . . Up to 6 Source numbers can be specified,

each Source number can be used only once

in the equation.

Thickness Eq(uation) 3 . . . . . . . . . . Up to 6 Source numbers can be specified,

each Source number can be used only once

in the equation.

DAC 1 to 12 Scale . . . . . . . . . . . . . . 0.1 to 10.0

DAC 1 to 12 Polarity. . . . . . . . . . . . . Positive / Negative

Source DAC Required . . . . . . . . . . . Yes/No (to allow 6 Rate and 6 Thickness

DACs option)

PN 074-505-P1F

1 - 12

Page 33

1.4.4 Display

Type/Color/Size . . . . . . . . . . . . . . . . LCD/Color/TFT/7 inch diagonal

Dimming Feature . . . . . . . . . . . . . . . Always Full on or Full on when in use.

Format . . . . . . . . . . . . . . . . . . . . . . . WVGA

Resolution . . . . . . . . . . . . . . . . . . . . 800 W x 480 H

Backlighting . . . . . . . . . . . . . . . . . . . LED

Thickness Display Range. . . . . . . . . 0.000 to +/-9999 kÅ

Thickness Display Resolution . . . . . 1 Å for 0.000 to +/-9.999 kÅ,

Rate Display Range . . . . . . . . . . . . . 0.000 to +/-999.9 Å/s

IC6 Operating Manual

Full off when no process running and no key

interaction for dimming time

10 Å for +/-10.00 to +/-99.99 kÅ

100Å for +/-100.0 to +/-999.9 kÅ

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 kÅ for +/-1000 to +/-9999 kÅ

Rate Display Resolution . . . . . . . . . . 0.001 Å/s for 0.000 to +/-9.999 Å/s if Rate

Filter Time is 10 s or greater, otherwise 0.01

Å/s for 0.00 to +/-99.99 Å/s

0.1 Å/s for +/-100.0 to +/-999.9 Å/s

Power Display Range. . . . . . . . . . . . 0.00 to 99.99%

Graphic Display Functions . . . . . . . . Rate Deviation at ±10 or ±20 Å/s or

Power at 0 to 100%

Display Data Update Rate . . . . . . . . 1 Hz

PN 074-505-P1F

1 - 13

Page 34

IC6 Operating Manual

1.4.5 DAC Outputs

Quantity and Type . . . . . . . . . . . . . . 6 with BNC, 6 optional with 15 pin miniature

Configuration . . . . . . . . . . . . . . . . . . User programmable for recorder

Function and Ranges . . . . . . . . . . . . Power, Rate, Rate Deviation, Thickness

Current rating . . . . . . . . . . . . . . . . . . 20 mA per channel

Resolution . . . . . . . . . . . . . . . . . . . . 15 bits over full range (10 V)

Update Rate . . . . . . . . . . . . . . . . . . . 10 Hz, maximum, (dependent on source

Recorder Output Functions . . . . . . . Aggregate Rate, Thickness or Rate

D-sub providing analog outputs for Rate and

Thickness.

or source control.

Full scale voltage value fully selectable up to

+ or - 10V relative to 0 V at 0 output

characteristics).

Deviation; Individual Sensor Rate, Thickness

or Rate Deviation; or Source Power.

Recorder Output Ranges

Rate . . . . . . . . . . . . . . . . . . . . . . 0 to up to 99999 Å/s programmable

Thickness . . . . . . . . . . . . . . . . . . 0 to up to 99999 Å programmable, [Function

modulo (Thickness Range, Thickness)output

is "saw-tooth" like with increasing thickness.]

Rate Deviation . . . . . . . . . . . . . . Desired rate ±50 Å/s

Accuracy . . . . . . . . . . . . . . . . . . . . . ±1% relative to Full Scale 10 V

PN 074-505-P1F

1 - 14

Page 35

1.4.6 Logic Processing

Type . . . . . . . . . . . . . . . . . . . . . . . . . If/Then statements

Logical Functions . . . . . . . . . . . . . . . And; Or; Not; Parentheses; ON

Depth . . . . . . . . . . . . . . . . . . . . . . . . 5 "If" conditions and 5 "Then" results/actions

# of Statements. . . . . . . . . . . . . . . . . 100 If/Then

Selectable events . . . . . . . . . . . . . . . Deposition monitor events, states, external

Hierarchy . . . . . . . . . . . . . . . . . . . . . Statements evaluated in numerical order at

Partitioning . . . . . . . . . . . . . . . . . . . . None

Initialization. . . . . . . . . . . . . . . . . . . . All outputs transition to their normal states as

IC6 Operating Manual

per statement

inputs, relays, timers, and counters.

10 Hz any time the IC6 is on.

early as possible during power-on

initialization sequence.

1.4.7 Relays / Inputs

Relays . . . . . . . . . . . . . . . . . . . . . . . SPST 2.5 A relays rated @ 30 V (dc) or

30 V (ac) RMS or 42 V (peak) maximum;

(8 standard, up to 16 optional with 2

additional I/O cards); D sub connector; relays

are normally open in the power off state, but

may be programmed to normally open or

normally closed during operation.

Relay Ratings . . . . . . . . . . . . . . . . . . 100 VA inductive; 2.5 A maximum.

# of TTL Compatible Outputs . . . . . . 14 with optional I/O card. Internally pulled up

to 5 V (dc). May be pulled up externally to

24 V (dc) through 2.4 k resistor.

PN 074-505-P1F

Inputs (TTL Compatible). . . . . . . . . . (14 standard, 14 additional optional)

Input Levels

maximum high . . . . . . . . . . . . . . 24 V

minimum high . . . . . . . . . . . . . . . 2.5 V

minimum high level 0.5 mA load @3.75 V

maximum low level 10 mA load @1.1 V

maximum low . . . . . . . . . . . . . . . 1.1 V

Scan/Update Rate . . . . . . . . . . . . . . 10 Hz

Input/Output Name . . . . . . . . . . . . . . Those that are Non-Hardware reserved may

be named. (15 character max.)

1 - 15

Page 36

IC6 Operating Manual

1.4.8 Remote Communications

RS232C Serial Port . . . . . . . . . . . . . Standard; INFICON binary protocol

Baud Rates . . . . . . . . . . . . . . . . . . . 115,200, 57,600, 38,400, 19,200, 9,600

Ethernet . . . . . . . . . . . . . . . . . . . . . . Optional, Programmable IP Address and

USB port. . . . . . . . . . . . . . . . . . . . . . Print screen bitmap (.bmp) files, Datalogging

1.4.9 Accessories

Connector Kit . . . . . . . . . . . . . . . . . . Connectors for inputs and relays

Operating Manual. . . . . . . . . . . . . . . 074-5000-G1 CD-ROM

1.4.10 Power

Power . . . . . . . . . . . . . . . . . . . . . . . . 100-230 V (ac) +/-15% V (ac); 50/60 Hz

Net Mask

file, Configuration file store/retrieve

+/-3Hz Maximum apparent power 150 VA

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . use 250 V 4 Amp, 5 x 20, Slow Blow

1.4.11 Operating Environment

Usage. . . . . . . . . . . . . . . . . . . . . . . . Indoor only

Temperature . . . . . . . . . . . . . . . . . . . 0 to 50°C (32-122°F)

Humidity . . . . . . . . . . . . . . . . . . . . . . Up to 85% RH, non-condensing

Altitude . . . . . . . . . . . . . . . . . . . . . . . Up to 2000 meters

Installation (Overvoltage) . . . . . . . . . Category II per IEC 60664

Pollution Degree. . . . . . . . . . . . . . . . 2 per EN 61010

1.4.12 Storage Temperature

Storage Temperature . . . . . . . . . . . . -10 to 60°C (14 to 140°F)

1.4.13 Warm Up Period

Warm Up Period. . . . . . . . . . . . . . . . None required;

PN 074-505-P1F

For maximum stability allow 5 minutes.

1 - 16

Page 37

1.4.14 Size

Height-Width-Depth, not including mounts or user connectors

133.4 x 447.7 x 330 mm (5.25 x 17.625 x 13 in.)

Height-Width-Depth including mounts, but no user connectors

133.4 x 482.6 x 330 mm (5.25 x 19 x 13 in.)

1.4.15 Installation Clearance Requirements

1.4.15.1 Connector Clearance

Front . . . . . . . . . . . . . . . . . . . . . . . . . 25 mm (1.0 in.) minimum without USB,

64 mm (2.5 in.) minimum dependent on size

of USB storage device

Rear . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm (4.0 in.) minimum

1.4.15.2 Cooling Clearance

Rear . . . . . . . . . . . . . . . . . . . . . . . . . 100 mm (4.0 in.) minimum

IC6 Operating Manual

Sides . . . . . . . . . . . . . . . . . . . . . . . . 7 mm (1/4 in.) minimum

1.4.16 Weight

With all options . . . . . . . . . . . . . . . . . 5.9 kg (13 lb.)

1.4.17 Cleaning

Use a mild, nonabrasive cleaner or detergent taking care to prevent cleaner from

entering the IC6.

PN 074-505-P1F

1 - 17

Page 38

IC6 Operating Manual

1.5 Unpacking and Inspection

1 If the IC6 has not been removed from its shipping container, do so now.

2 Carefully examine the IC6 for damage that may have occurred during shipping.

This is especially important if you notice obvious rough handling on the outside

of the container. Immediately report any damage to the carrier and to INFICON.

3 Do not discard the packing materials until you have taken inventory and have

at least performed a power on verification.

4 Take an inventory of your order by referring to your order invoice and the

information contained in section 1.6 on page 1-18.

5 To perform a power-on verification, see section 1.7 on page 1-20.

6 For additional information or technical assistance, contact INFICON, refer to

section 1.3, How To Contact INFICON, on page 1-6.

1.6 Parts and Options Overview

1.6.1 Base Configurations

IC6 Control Unit . . . . . . . . . . . . . . . . 781-500-G1 North America,

Ship Kit. . . . . . . . . . . . . . . . . . . . . . . 781-020-G1 North America,

Operating Manual on CD ROM . . . . 074-505 on 074-5000-G1 CD ROM included

I/O Relay . . . . . . . . . . . . . . . . . . . . . Contains Input/Relay Interface Connectors

1.6.2 Pre-installed Options or Spares

Additional Sensor Module . . . . . . . . 781-132-G1 (up to 3 extra)

The following contain board and interface connector

I/O Relay Card . . . . . . . . . . . . . . . . . 781-122-G1

781-500-G2 Europe

781-020-G2 Europe

in Ship Kit

(8 relay outputs, 14 TTL inputs). Included in

Ship Kit.

PN 074-505-P1F

(8 relay outputs, 14 TTL inputs)

781-122-G2

(8 relay outputs, 14 TTL outputs)

1 - 18

DAC Option Board and Kit . . . . . . . . 781-162-G1

Ethernet . . . . . . . . . . . . . . . . . . . . . . 781-102-G2

Page 39

1.6.3 Optional Accessories

Pneumatic Shutter

Actuator Control Valve . . . . . . . . . . . 750-420-G1

Sensor Emulator Kit . . . . . . . . . . . . . 760-601-G2

Handheld Controller . . . . . . . . . . . . 755-262-G1

Function . . . . . . . . . . . . . . . . . . . Power Increase/Decrease/Stop/

Adapter Cables

IC6 to IC/4 Kit . . . . . . . . . . . . . . . 600-1084-P1 (Relays and Inputs - for IC/4 or

1.6.4 Oscillator Packages

IC6 Oscillator, 15 ft. and 6 in. cable pkg. . . . . . . . . . 781-611-G15

IC6 Oscillator, 30 ft. and 6 in. cable pkg. . . . . . . . . . 781-611-G30

IC6 Oscillator, 50 ft. and 6 in. cable pkg. . . . . . . . . . 781-611-G50

IC6 Operating Manual

Switch Crystal

IC/4 PLUS)

IC6 Oscillator, 100 ft. and 6 in. cable pkg. . . . . . . . . 781-611-G100

4 Meter Oscillator, 15 ft. and 6 in. cable pkg. . . . . . .781-612-G15

4 Meter Oscillator, 30 ft. and 6 in. cable pkg. . . . . . .781-612-G30

4 Meter Oscillator, 50 ft. and 6 in. cable pkg. . . . . . .781-612-G50

4 Meter Oscillator, 100 ft. and 6 in. cable pkg. . . . . .781-612-G100

4 Meter Oscillator, 15 ft. and 20 in. cable pkg. . . . . .781-613-G15

4 Meter Oscillator, 20 ft. and 20 in. cable pkg. . . . . .781-613-G20

4 Meter Oscillator, 50 ft. and 20 in. cable pkg. . . . . .781-613-G50

4 Meter Oscillator, 100 ft. and 20 in. cable pkg. . . . .781-613-G100

PN 074-505-P1F

1.6.5 Sensors

Contact INFICON for a complete listing of sensors.

1.6.6 Replacement Cables

Oscillator to vacuum. . . . . . . . . . . . . 755-257-G6

feedthrough cable, 6 in.

IC6 Unit to Oscillator Cable 15 ft. . . 600-1261-P15

IC6 Unit to Oscillator Cable, 30 ft. . . 600-1261-P30

IC6 Unit to Oscillator Cable, 50 ft. . . 600-1261-P50

IC6 Unit to Oscillator Cable, 100 ft. . 600-1261-P100

1 - 19

Page 40

IC6 Operating Manual

WARNING - Risk Of Electric Shock

WARNING - Risk Of Electric Shock

1.7 Initial Power-On Verification

A preliminary functional check of the IC6 can be made before formal installation. It

is not necessary to have sensors, source controls, inputs or relays connected to do

this. For more complete installation information, refer to Chapter 2, Installation and

Interfaces and to Chapter 12, Maintenance and Calibration Procedures.

There are no user-serviceable components within the IC6

case.

Dangerous voltages may be present whenever the power

cord or external input/relay connectors are present.

Refer all maintenance to qualified personnel.

Never interrupt the protective earth circuit.

Any interruption of the protective earth circuit inside or

outside the IC6, or disconnection of the protective earth

terminal is likely to make the IC6 dangerous.

This symbol indicates where the protective earth ground

is connected inside the IC6. Never unscrew or loosen this

connection.

PN 074-505-P1F

1 - 20

Page 41

IC6 Operating Manual

1 Confirm that AC line voltage is supplied and proper for the IC6.

2 Confirm that the back panel (main) AC switch is in the ON position.

3 Press the ON/STBY button on the front panel. A green pilot light should be seen

next to the power switch.

4 The fan at the back of the IC6 should be exhausting air.

5 After the initial temporary boot-up screen which can be viewed in Maintenance

Sys Status, see section 12.8 on page 12-22, the LCD monitor will display an

image similar to the one shown in Figure 1-1.

Figure 1-1 Operate Screen

PN 074-505-P1F

1 - 21

Page 42

IC6 Operating Manual

This page is intentionally blank.

1 - 22

PN 074-505-P1F

Page 43

2.1 Location Guidelines

CAUTION

Before permanently installing the IC6, read this entire chapter on installation and

interfaces and follow its recommendations as closely as possible. INFICON has

taken numerous steps to ensure its equipment will operate in a variety of harsh

situations. Failure to adhere to these simple practices may adversely affect the

performance and longevity of the IC6.

2.1.1 Sensor Types

The choice of sensor type must be dictated by the Process, the deposition material

and the physical characteristics of the process chamber. General guidelines for

each sensor type produced by INFICON are outlined in the Sensor Data Sheets on

the www.inficon.com website. For specific recommendations, consult your

INFICON representative.

IC6 Operating Manual

Chapter 2

Installation and Interfaces

The performance of this IC6 depends on the careful

installation of the chosen transducer. Improper

installation will cause problems with deposition

repeatability, crystal life and rate stability.

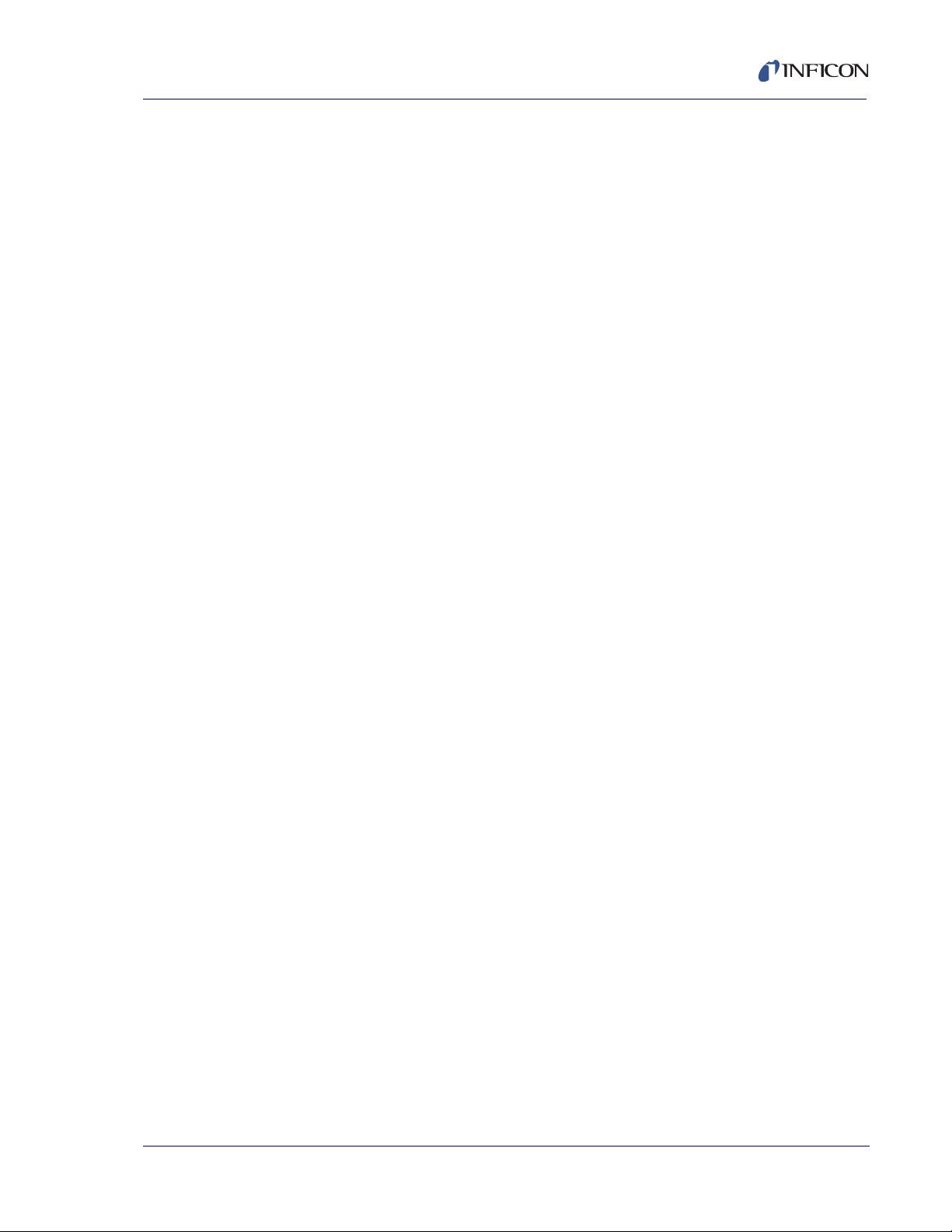

2.1.2 Sensor Installation

Figure 2-1 shows a typical installation of an INFICON water cooled crystal sensor

PN 074-505-P1F

in the vacuum process chamber. Use the illustration and the following guidelines to

install your sensors for optimum performance and convenience.

2 - 1

Page 44

IC6 Operating Manual

Mounting Bracket

Coax Cable

(Routed with

Water Tubes)

Or,

Customer Supplied

Cajon Coupling

Brazing

Adapters

Water In

Water Out

XIU (Oscillator)

Instrument Chassis

Source

Source

Shutter

Pneumatic

Actuator

To

Source Controller

Source to Sensor

10" Minimum

Sensor

Shutter

Air, 80 PSI, 110 PSI Max.

To

Sensor

Shutter

IPN 750-420-G1

Shutter

Solenoid

Assembly

Figure 2-1 Typical installation

PN 074-505-P1F

2 - 2

Page 45

IC6 Operating Manual

Correct

Incorrect

Correct

Incorrect

Incorrect