Page 1

Communication Protocol

Profibus

DP/V1 Interface for Bayard-Alpert / Pirani Gauge

and High Pressure / Pirani Gauge

BPG400-SP

HPG400-SP

tira36e1-a (0310) 1

Page 2

About this Document

This document describes the functionality and programming of the Profibus interface of the BPG400-SP and HPG400-SP gauges. The interface hardware, the

firmware, and the communication protocol are practically the same for both gauges.

Information that applies to only one of the above gauge types is correspondingly

identified in this document.

For safety information on and technical data of the gauges, please refer

to their respective operating manuals (→ [1], [3] for BPG400-SP and

[4], [6] for HPG400-SP).

In information referring to the ionization vacuum measuring part of the gauge, the

short designations

"BA" (BPG400-SP, Bayard-Alpert measuring principle)

"HP" (HPG400-SP High Pressure Gauge)

are used. The short designation "BA/HP" means that the corresponding information

applies to both gauge types.

The designation "Pirani" is used in information referring to the Pirani vacuum

measuring part of the gauge.

Product Identification

In all communications with INFICON, please specify the information on the product

nameplate. For convenient reference copy that information into the space provided

below.

INFICON AG, LI-9496 Balzers

Model:

PN:

SN:

V W

Validity

2 tira36e1-a (0310) BPG/HPG400 v1.cp

This document applies to products with part numbers

BPG400-SP (with Profibus interface and switching functions)

353-505

353-506 (vacuum connection DN 40 CF-R)

HPG400-SP (with Profibus interface and switching functions)

353-525

353-526 (vacuum connection DN 40 CF-R)

The part number (PN) can be taken from the product nameplate.

(vacuum connection DN 25 ISO-KF)

(vacuum connection DN 25 ISO-KF)

Page 3

Intended Use

The BPG400-SP and HPG400-SP gauges allow vacuum measurement of non

flammable gases and gas mixtures (pressure ranges → [1], [3] for BPG400-SP

and [4], [6] for HPG400-SP).

The gauges can be operated with an INFICON controller or another instrument or

control device.

Functional Principle

Trademarks

The functions of the gauges are described in their respective operating manuals

(→ [1], [2], [3] for BPG400-SP and [4], [5], [6] for HPG400-SP).

The integrated Profibus interface allows operating the gauge in connection with

other suitable devices in a Profibus network according to the standard described in

[6], [7].

®

Semiconductor Equipment and Materials International, California

SEMI

tira36e1-a (0310) BPG/HPG400 v1.cp 3

Page 4

Contents

About this Document 2

Product Identification 2

Validity 2

Intended Use 3

Functional Principle 3

Trademarks 3

1 General Data 6

1.1 Data Rate 6

1.2 Device Address 6

1.3 Ident Number 6

1.4 Configuration Data 6

1.5 User Parameter Data 7

1.6 Types of Communication 7

2 Data Exchange Mode 8

2.1 Acyclic Data Transmission with Profibus DPV1 Functionality 8

2.2 Structure of the Cyclic Data Telegrams in Data Exchange Mode 9

2.2.1 Parameter Channel 10

2.2.1.1 PKE Parameter Signature Value 10

2.2.1.2 PWE Parameter Process Value 11

2.2.1.3 Error Code (Error Message) 11

2.3 Cyclic Message Telegrams 12

3 Block Model 13

3.1 Device Block 14

3.1.1 Information on the Individual Indices 15

3.1.1.1 Block Type ID 16 15

3.1.1.2 Device Type ID 17 15

3.1.1.3 Standard Revision Level ID 18 15

3.1.1.4 Device Manufacturer Identifier ID 19 15

3.1.1.5 Manufacturer Model Number ID 20 15

3.1.1.6 Software or Firmware Revision Level ID 21 15

3.1.1.7 Hardware Revision Level ID 22 15

3.1.1.8 Device Configuration ID 24 15

3.1.1.9 Device State ID 25 15

3.1.1.10 Exception Status ID 26 16

3.1.1.11 Exception Detail Alarm ID 27 17

3.1.1.12 Exception Detail Warning ID 28 19

3.1.1.13 Emission On Switch ID 202 (HPG400-SP Only) 20

3.1.1.14 Sensor Calibration Switch ID 203 (HPG400-SP Only) 21

3.1.1.15 Copy Common Exception Detail Alarm 0 ID 204 21

3.1.1.16 Copy Device Exception Detail Alarm 0 … 3 ID 205 21

3.1.1.17 Copy Manufacturer Exception Detail Alarm 0 ID 206 21

3.1.1.18 Copy Common Exception Detail Warning 0 ID 207 21

3.1.1.19 Copy Device Exception Detail Warning 1 … 4 ID 208 21

3.1.1.20 Copy Manufacturer Exception Detail Warning 0 ID 209 21

3.1.2 Device Block, Device Behavior 22

3.1.2.1 Device Block State Command 23

3.2 Analog Input Block 23

3.2.1 One Of N Analog Input Function Block / SLOT 1 24

3.2.1.1 AI Block Adjust Command (Adjustment at Atmospheric Pressure) 24

3.2.1.2 Block Type 24

3.2.1.3 Channel Instance Selector 24

3.2.1.4 PV Selector 24

3.2.2 Analog Sensor Input Function Block Instance 1 / SLOT 1 25

3.2.2.1 Process Value 25

3.2.2.2 Status 25

3.2.2.3 Data Type 26

3.2.2.4 Data Unit 26

3.2.2.5 Reading Valid 26

3.2.2.6 Full Scale 26

3.2.2.7 Safe State 27

3.2.2.8 Safe Value 27

3.2.2.9 Overrange 27

3.2.2.10 Underrange 27

3.2.3 Analog Sensor Input Function Block Instance 2 / SLOT 1 28

3.2.3.1 Process Value 28

4 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 5

3.2.3.2 Status 29

3.2.3.3 Data Type 29

3.2.3.4 Data Unit 29

3.2.3.5 Reading Valid 30

3.2.3.6 Full Scale 30

3.2.3.7 Safe State 30

3.2.3.8 Safe Value 30

3.2.3.9 Overrange 31

3.2.3.10 Underrange 31

3.2.4 Analog Sensor Input Function Block Instances 3 and 4 / SLOT 1 32

3.2.4.1 Process Value 32

3.2.4.2 Status 33

3.2.4.3 Data Type 33

3.2.4.4 Data Unit 33

3.2.4.5 Reading Valid 33

3.3 Transducer Block 33

3.3.1 One Of N Vacuum Gauge Transducer Block / SLOT 1 33

3.3.1.1 One Of N Status Extension 33

3.3.2 Heat Transfer Vacuum Gauge Transducer Block / SLOT 1 33

3.3.2.1 Block Type 33

3.3.2.2 Status Extension 34

3.3.2.3 Sensor Alarm 34

3.3.2.4 Sensor Warning 34

3.3.2.5 Full Scale State 34

3.3.3 Hot Cathode Ion Gauge Transducer Block / SLOT 1 35

3.3.3.1 Block Type 35

3.3.3.2 Status Extension 35

3.3.3.3 Sensor Alarm 35

3.3.3.4 Sensor Warning 35

3.3.3.5 Emission Status 36

3.3.3.6 Emission Current (BPG400-SP Only) 36

3.3.3.7 Degas Status (BPG400-SP Only) 36

3.3.3.8 Hot Cathode Block State Command (BPG400-SP Only) 36

Appendix A: Definitions 37

Appendix B: Block Type 40

Appendix C: Electrical Connections 41

Appendix D: Literature 43

For cross-references to other documents, the symbol (→ [XY]) is used.

tira36e1-a (0310) BPG/HPG400 v1.cp 5

Page 6

1 General Data

1.1 Data Rate

1.2 Device Address

1.3 Ident Number

The gauge supports all data rates defined in the EN 50170 standard (→ [8]) up

to 12 Mbaud. Automatic data rate setting is supported. Alternatively, a fixed data

rate can be selected.

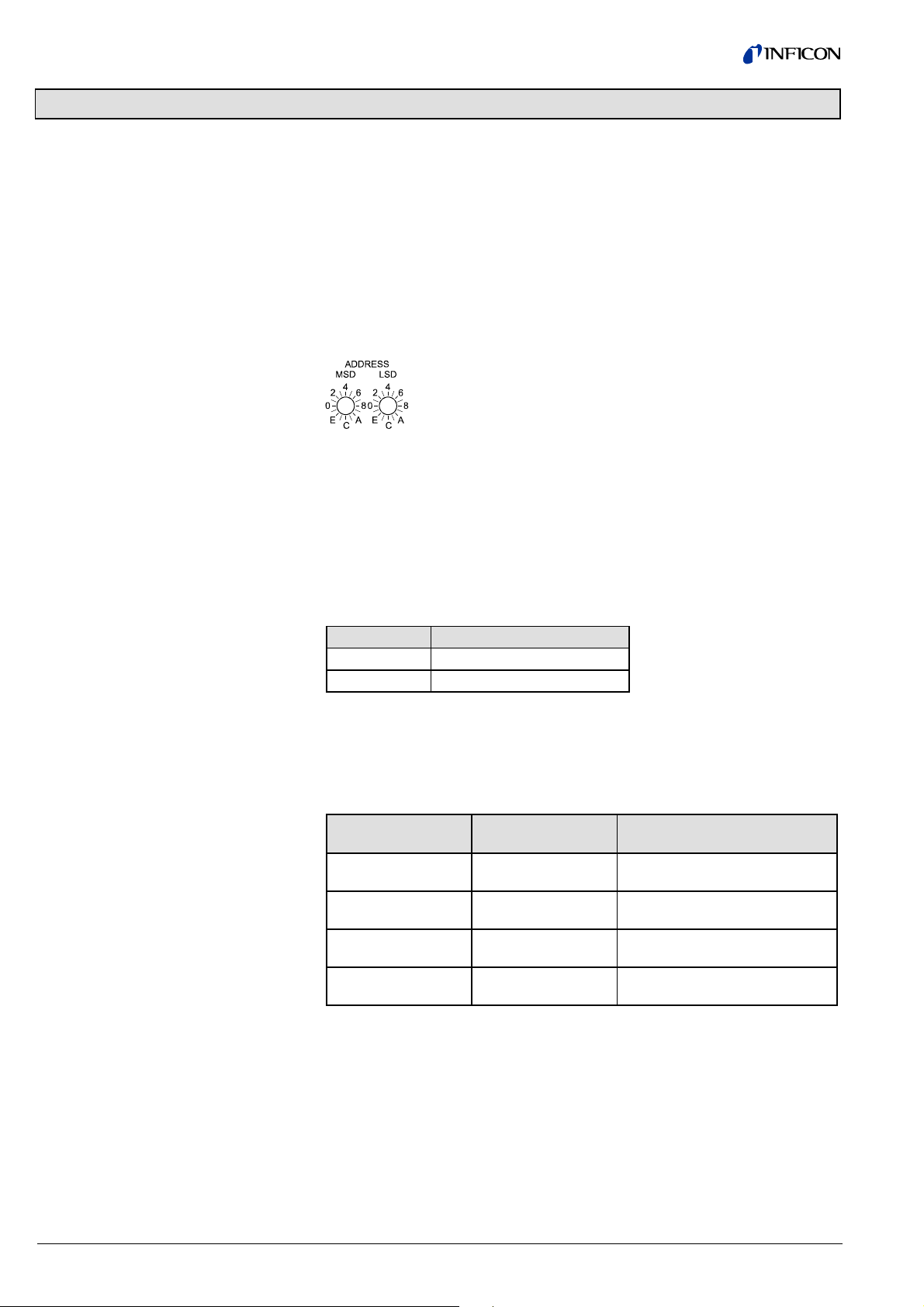

The device address ( node address) must be set via two rotary switches when the

gauge is installed.

For unambiguous identification of the gauge in a Profibus environment, a node

address is required. The node address setting is made on the gauge.

The node address (0 … 125

(00 … 7D

used for setting the high-order address nibble and the "LSD"

switch for defining the low-order address nibble.

The node address is polled by the firmware when the gauge is switched on. If the

setting deviates from the stored value, the new value is taken over into the

NVRAM. If a value >7D

stored in the device remains valid. However, the address can be set via the

Profibus master with the "Set Slave Address" service. This address setting will be

stored in the EEPROM of the gauge.

The ident numbers assigned to the gauges by the PNO (→ [7]) are:

) via the "ADDRESS" switches. The "MSD" switch is

hex

hex

(>125

) is entered, the node address setting currently

dec

) is set in hexadecimal form

dec

1.4 Configuration Data

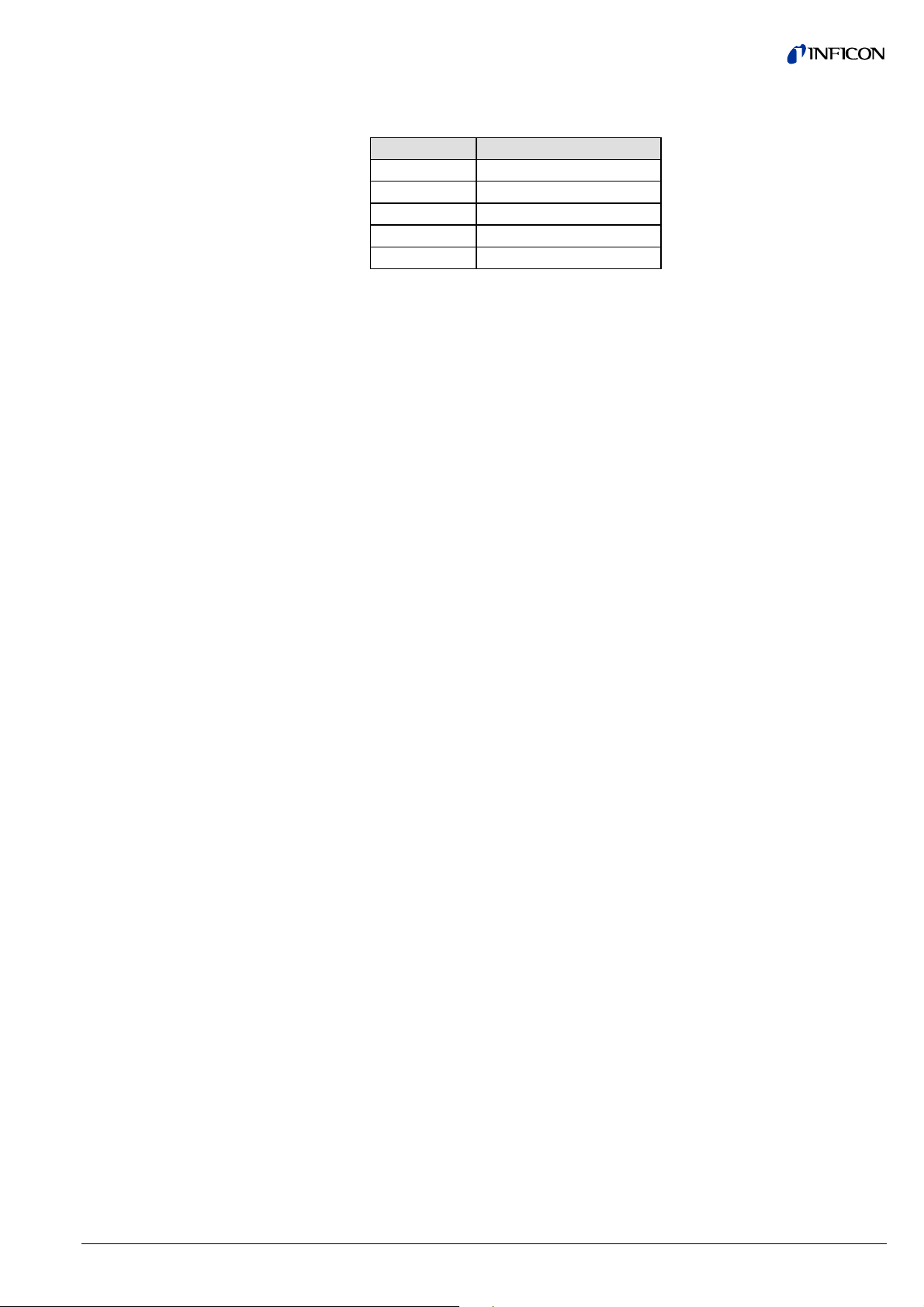

Gauge Ident number (hexadecimal)

BPG400-SP 06A9

HPG400-SP 06A8

Depending on the standard telegrams used (→ section "Cyclic Message Telegrams"), the following configuration data have to be transmitted to the gauge during

the configuration phase:

Standard telegram

Master ⇒ Slave

- 2 0x44, 0x84, 0x05, 0x05, 0x05,

- 3 0x44, 0x86, 0x05, 0x05, 0x05,

1 4 0xC6, 0x87, 0x8c, 0x0A, 0x0A,

1 5 0xC6, 0x87, 0x8E, 0x0A, 0x0A,

Standard telegram

Slave ⇒ Master

Configuration data

0x03

0x08

0x05, 0x05, 0x05, 0x03

0x05, 0x05, 0x05, x08

6 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 7

1.5 User Parameter Data

Depending on the pressure unit setting ( data unit), the following configuration

string has to be transmitted to the gauge (parameter data in hexadecimal format):

1.6 Types of

Communication

Pressure unit User parameter data string

COUNTS

1)

00 00 00 03 E9

Torr 00 00 00 05 15

Micron 00 00 00 05 16

mbar 00 00 00 05 1C

Pascal 00 00 00 05 1D

1)

If COUNTS is selected as pressure unit, a value is output, which can be converted into a corresponding pressure value by means of a formula (→ section

"Analog Sensor Input Function Block" for more information).

BPG400-SP and HPG400-SP work according to the Profibus DPV1 specification

and can be addressed in cyclic or acyclic data traffic (→ [7]).

Acyclic data traffic should be used to make device or process specific settings such

as definition of the Safe Values, Safe States etc. or for reading or writing of rarely

used attributes.

Cyclic data traffic is used for continuous exchange of the required process parameter values, i.e. pressure value and status indications. A number of standard

telegrams are available for cyclic data traffic. They can be selected according to

requirements (→ section "Cyclic Message Telegrams").

tira36e1-a (0310) BPG/HPG400 v1.cp 7

Page 8

2 Data Exchange Mode

2.1 Acyclic Data Transmission with Profibus

DPV1 Functionality

Block, slot and

index assignment

The reading and writing operations defined in the Profibus are based on a slot

index address scheme. In BPG400-SP / HPG400-SP, all device functions are

organized in the following blocks:

• A device block describing all organizational parameters of the gauge (serial

number, manufacturer, software version, …)

• An Analog Sensor Function Block describing the function of the pressure presentation

• An Analog Sensor Transducer Block describing the physical interface between

the gauge and the process (emission current, ion current, …).

The block model is described in detail in section "Block Model".

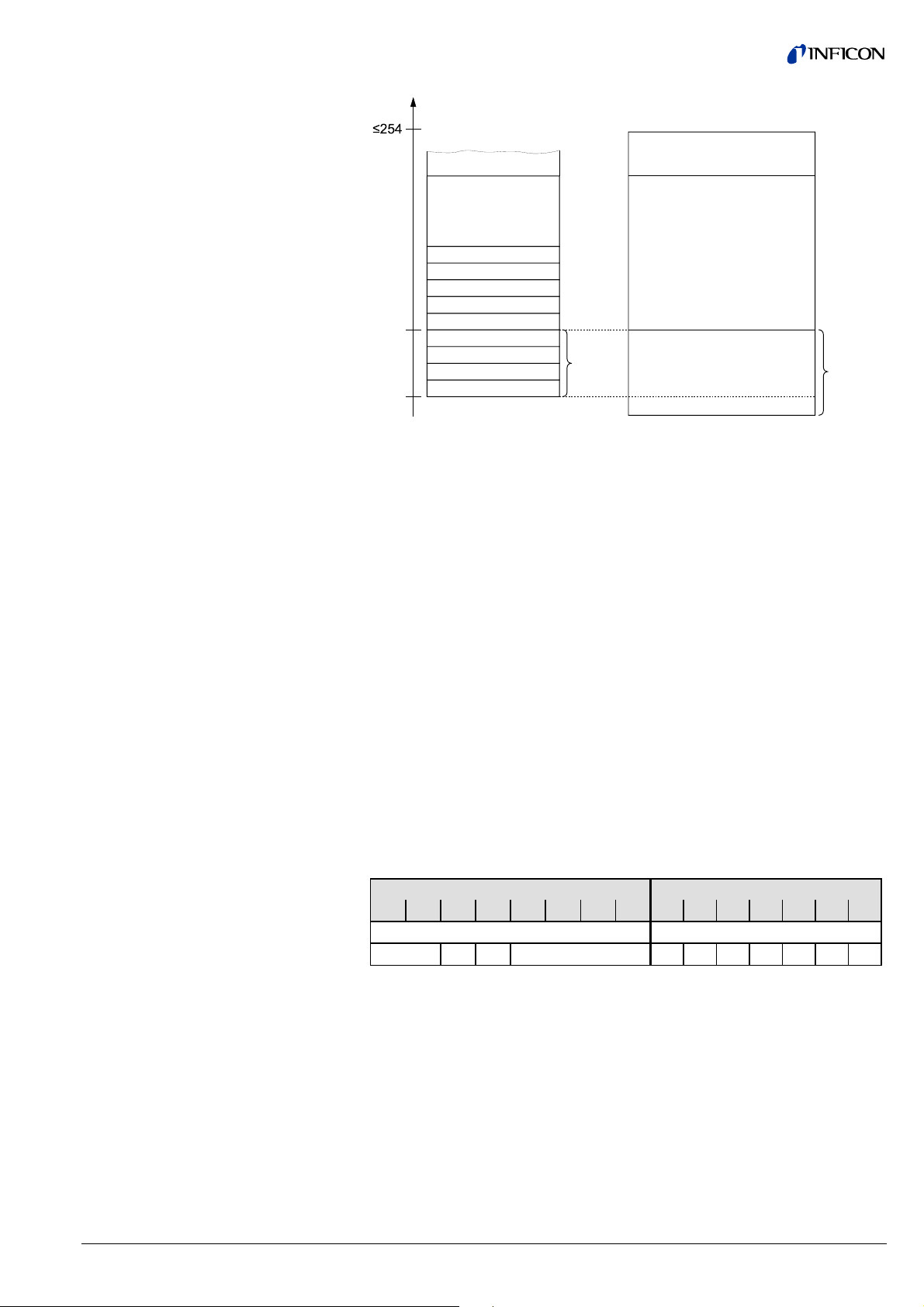

Each block is assigned to a separate slot. The exact assignment

Block ⇒ Slot ⇒ Index is described in section "Block Model". The Device Block is

assigned to Slot 0, the transducer and functional blocks to Slot 1.

Index

254

Device

Block

Block_1 Block_2 Block_3

0

There are 254 indices per slot. The indices can have a width of 255 bytes. All values that can be accessed via Profibus have to be mirrored to one of these slots/

indices.

The parameters are generally numbered in ascending order, starting with index 16.

Services such as "Degas On" or "Full scale" are numbered in descending order,

starting with index 15.

0123

8 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 9

Assignment of the block elements to the slot indices

Index

2.2 Structure of the Cyclic

Data Telegrams in Data

Exchange Mode

Parameter_n

Block_x

Parameter_2

Parameter_1

16

0

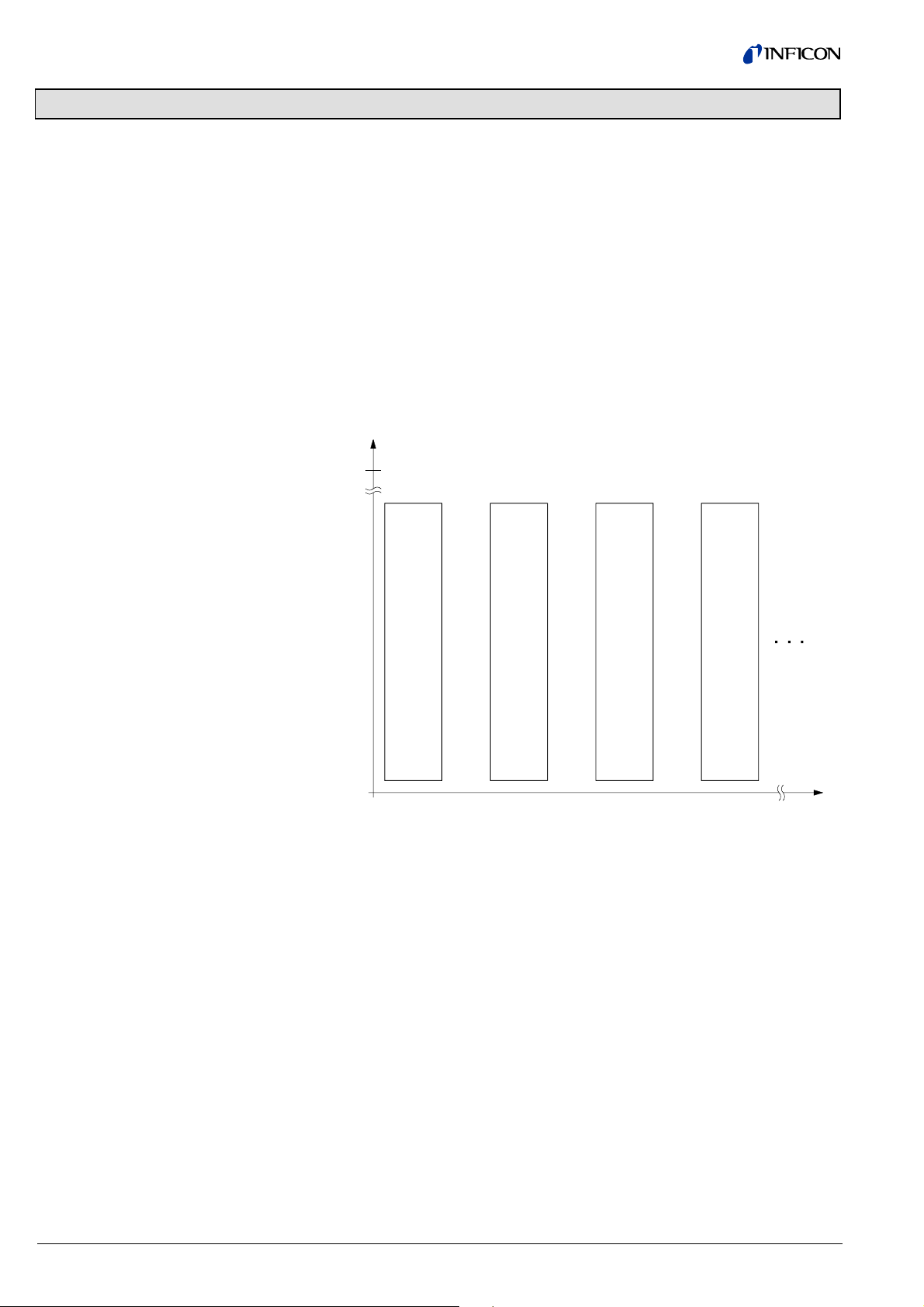

In Data Exchange mode, the DP master class 1 cyclically transmits data from and

to all slaves that are connected to the bus.

In this document, data transmitted from the slave to the master are called "input

data" and data transmitted from the master to the slave are called "output data".

The input and output data of the BPG400-SP / HPG400-SP have two logic parts:

1) the parameter channel

2) the process data channel

There is a number of standard telegrams, consisting of:

a) the parameter channel only

b) the process data channel only

c) both, the parameter and process data channel

The parameter channels allows masters without Profibus DPV1 to access device

specific parameters that are not part of the normal cyclic data telegram. For masters with Profibus DPV1, no parameter channel is required.

Parameter_0

Operation_1

Operation_2

Operation_n

optional

Block_Type_Name

Attributes

Public

Operations Public

optional

Private

Input data

tira36e1-a (0310) BPG/HPG400 v1.cp 9

The input data (transmitted by the BPG400-SP / HPG400-SP) consist of the

8 bytes of the parameter channel (if there is a parameter channel in the standard

telegram) and of 5 … 7 bytes of process data depending on the selected standard

telegram.

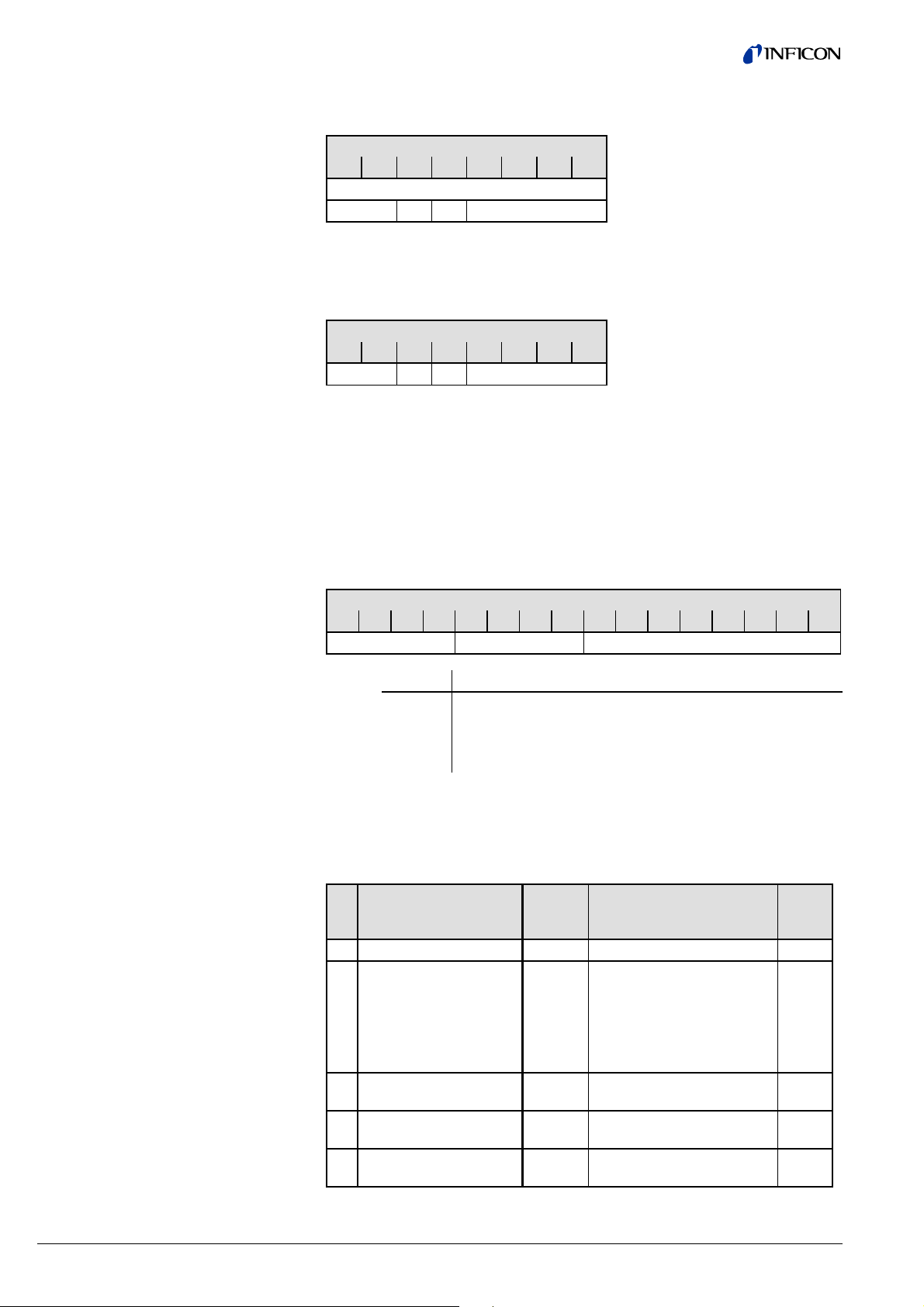

Byte Byte

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Parameter channel Process data

PKE IND res. PWE

Where: PKE = Parameter Signature Value

IND = Sub Index

res. = reserved

PWE = Process Value

Reading or writing command and definition of the slot

Index No. of the index to be

read (→ "Block Model")

Value to be read or written

Page 10

Output data

The output data (transmitted by the master) consist of 8 bytes of the parameter

channel or, if there is no parameter channel in the standard telegram, of 0 bytes.

Byte

1 2 3 4 5 6 7 8

Parameter channel

PKE IND res. PWE

2.2.1 Parameter Channel

2.2.1.1 PKE Parameter

Signature Value

The structure of the parameter channel is described in the table below.

The parameter channel (called PKW Interface hereinafter) consists of 8 bytes.

Octets

1 2 3 4 5 6 7 8

PKE IND res. PWE

The PKW Interface allows reading and writing of slave parameters with a maximum

data length of 4 bytes. Strings cannot be read.

The slave generates exactly one response per instruction transmitted by the

master. The instruction and response cannot be blocked. This means that exactly

one instruction per output telegram can be transmitted to the slave and that exactly

one response per input telegram can be transmitted to the master. 4 bytes of actual

data can thus be transmitted at a time.

The instruction and response are represented in the first two bytes (PKE) of the

parameter channel:

Bit position

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

AK res. Slot

Where: Bits Meaning

15 … 12

AK Instruction/response signature

11 … 8 Reserved

7 … 0 Define the slot from which data are read or onto which a

value is to be written

Instruction signature

In Master ⇒ Slave communication, the AK field contains the instruction signature of

the master.

In Slave ⇒ Master communication, the AK field contains the instruction signature of

the slave.

AK Function

Master ⇒ Slave

(Instruction signature)

AK

normal

Function

Slave ⇒ Master

(Response signature)

AK

error

0 No instruction 0 No response

1 Read parameter value 1

Transmit parameter value

7

1)

(word)

2

Transmit parameter value

(double word)

11

Transmit parameter value

(byte)

2 Write parameter value

1 Transmit parameter value

(data type: word)

3 Write parameter value

2 Transmit parameter value

(data type: double word)

10 Write parameter value

11 Transmit parameter value

(data type: byte)

1)

Instruction cannot be executed (error code)

(word)

(double word)

(byte)

7

7

7

1)

1)

1)

10 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 11

On the left of the table, the instruction signatures of the master are listed according

to their function. On the right of the table, the corresponding normal responses (AK

Normal) and error codes (AK Error) transmitted by the slave are listed.

Instruction – response

sequence

2.2.1.2 PWE Parameter

Process Value

2.2.1.3 Error Code

(Error Message)

1) The master transmits an instruction to the slave and repeats that instruction

until it receives a response from the slave.

2) The slave keeps transmitting the response to the instruction until the master

transmits a new instruction.

3) The master marks the end of the first instruction cycle by setting AK to zero.

Only after that, a new instruction/response cycle may be started.

The PWE represents the data element to be transmitted.

If a byte is to be transmitted, that byte has to be in position 8 of the parameter

channel.

Integers are transmitted with bytes 7 and 8. Double integer and float values are

transmitted with bytes 5 … 8.

In the event of a transmission error (AK response signature = 7), the slave transmits an error code in byte positions 7 and 8 (data type: INT16).

Error code Meaning

0 Undefined slot

1 Parameter not changeable

2 Lower or upper value range limit overflow

3 Index error

5 Data type error

17 Instruction not allowed in this state

18 Other errors

201 Already in requested state

202 Object state conflict

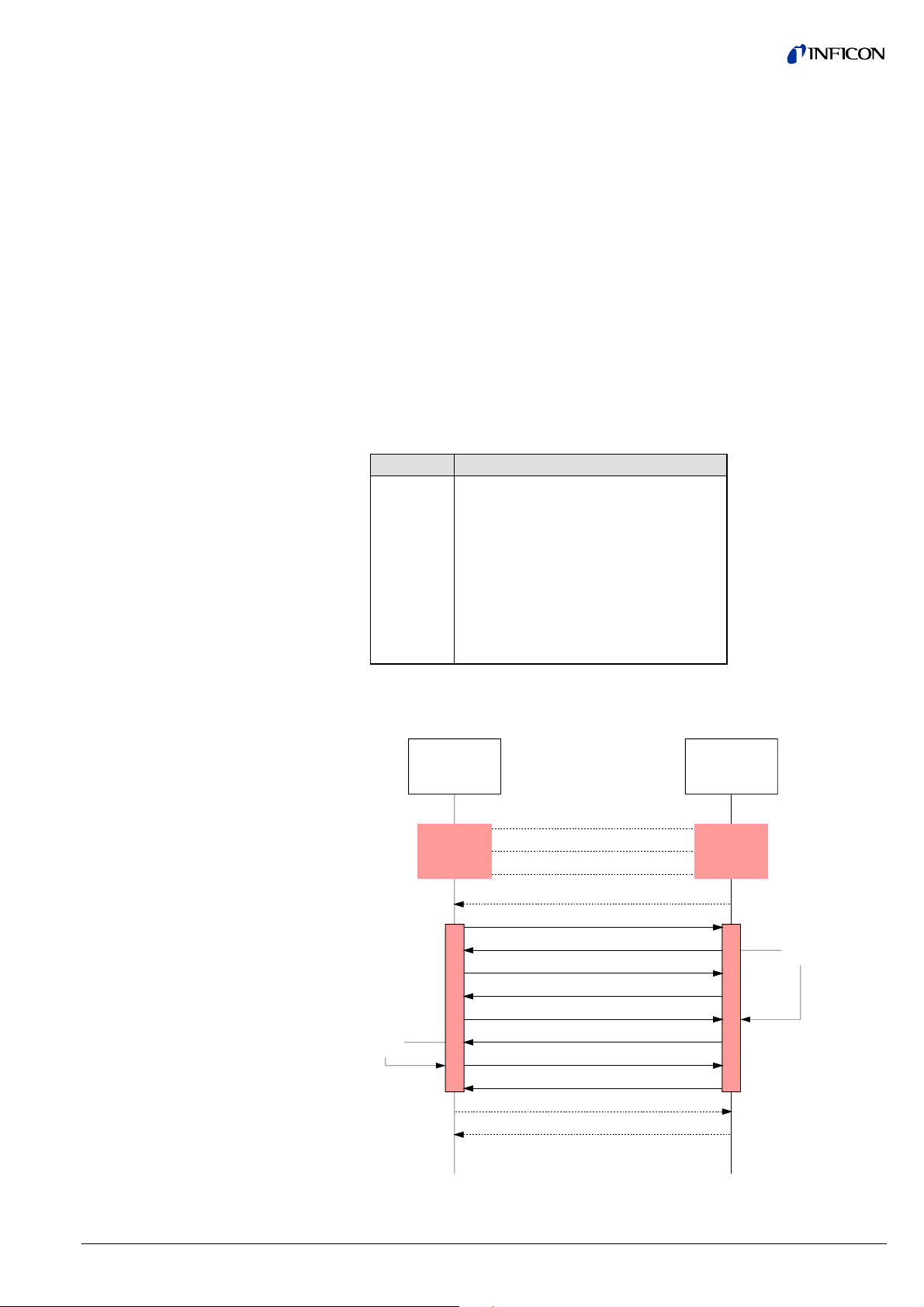

The following diagram shows an example of a data request from a master to a

BPG400-SP / HPG400-SP via parameter channel.

BPG400-SP

HPG400-SP

Parameter

Request

(Server)

Fetch

Data

Store

Data

DP-Master

Parameter

Request

(Client)

AK(IS) = 0

AK(RS) = 0

AK(IS) = 0

AK(RS) = 0

AK (IS) = 1

AK(RS) = 0

AK (IS) = 1

AK(RS) = 0

AK (IS) = 1

AK(RS) = 1

AK (IS) = 0

AK(RS) = 0

AK (IS) = 0

AK(RS) = 0

tira36e1-a (0310) BPG/HPG400 v1.cp 11

Page 12

2.3 Cyclic Message

Telegrams

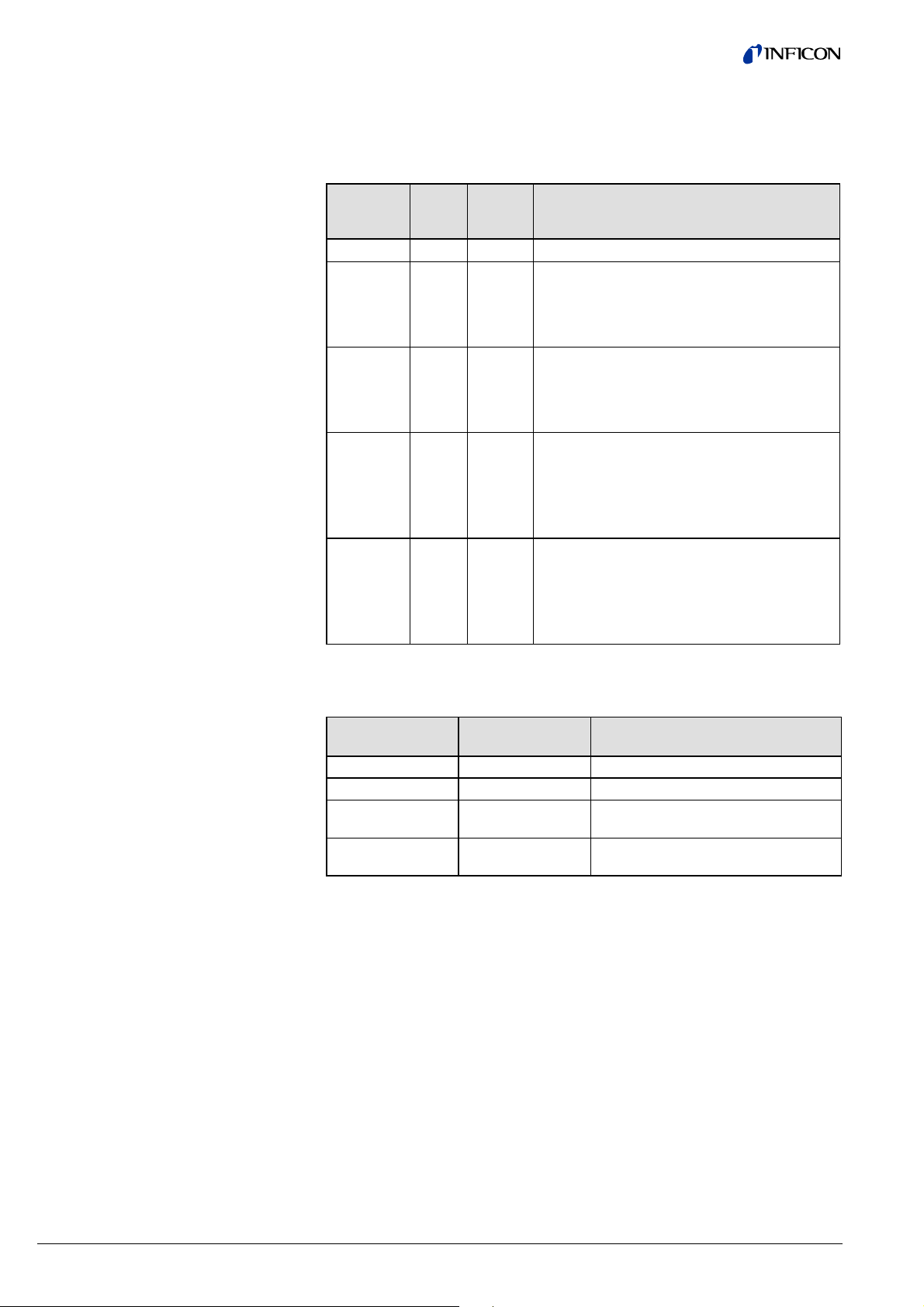

The message telegrams listed below are implemented in the gauge. They can be

selected according to requirements. When selecting a message telegram, ascertain

what output format of the measured value (integer/float) is required and whether a

parameter channel is needed or not. The gauge can also be operated in such a

way that the master does not transmit any output data to the slave.

Standard

telegram

1

2

3

4

5

Master

⇔

Slave

M ⇒ S

S ⇒ M

S ⇒ M

S ⇒ M

S ⇒ M

Byte Meaning

1 … 8 Parameter channel

1 Exception status

2 One Of N status extension

3 One Of N PV selector

4 … 5 Process value UINT16

1 Exception status

2 One Of N status extension

3 One Of N PV selector

4 … 7 Process value float

1 … 8 Parameter channel

9 Exception status

10 One Of N status extension

11 One Of N PV selector

12 … 13 Process value UINT16

1 … 8 Parameter channel

9 Exception status

10 One Of N status extension

11 One Of N PV selector

12 … 15 Process value float

Configuration data

In the following table, the possible reasonable combinations are listed with the

corresponding configuration data.

Standard telegram

Master ⇒ Slave

- 2 0x44, 0x84, 0x05, 0x05, 0x05, 0x03

- 3 0x44, 0x86, 0x05, 0x05, 0x05, 0x08

1 4 0xC6, 0x87, 0x8c, 0x0A, 0x0A, 0x05,

1 5 0xC6, 0x87, 0x8E, 0x0A, 0x0A, 0x05,

Standard telegram

Slave ⇒ Master

Configuration data

0x05, 0x05, 0x03

0x05, 0x05, x08

12 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 13

3 Block Model

Data to the BPG400-SP / HPG400-SP can be transmitted by means of a number of

communication protocols and corresponding masters. Profibus defines a master

class 1 as normal control unit of the slave (typically a PLC) and a master class 2 as

configuration and service unit. The following communication protocols are defined

according to the Profibus DPV1 standard.

MS0 Cyclic data traffic between master class 1 and slave

MS1 Acyclic data traffic between master class 1 and slave

MS2 Acyclic data traffic between master class 2 and slave

In BPG400-SP / HPG400-SP, all functions that are made available by the gauge

via Profibus are organized in blocks. Access to the individual parameters of the

blocks is possible via acyclic services or, for byte, integer and float values, also in

cyclic data traffic via the parameter channel.

Block types

The following block types are defined in the gauge.

Device Block The Device Block contains all data that are required for de-

scribing the device and handling its state (status of Device

State Machine).

Transducer Block The physical, process specific functions or interfaces between

the BPG400-SP / HPG400-SP and the process such as

current and voltage values are represented in transducer

blocks.

The following transducer blocks are implemented:

• One of N Vacuum Gauge Transducer Block

• Heat Transfer Vacuum Gauge Transducer Block (Pirani)

• Hot Cathode Ion Gauge Transducer Block (BA/HP)

Function Block Application specific values such as pressure values that result

from or can be calculated from the values of the transducer

block are represented in the function blocks.

• One Of N Analog Input Function Block

• Analog Input Function Block, Instance 1, Instance 2,

Instance 3, Instance 4

tira36e1-a (0310) BPG/HPG400 v1.cp 13

Page 14

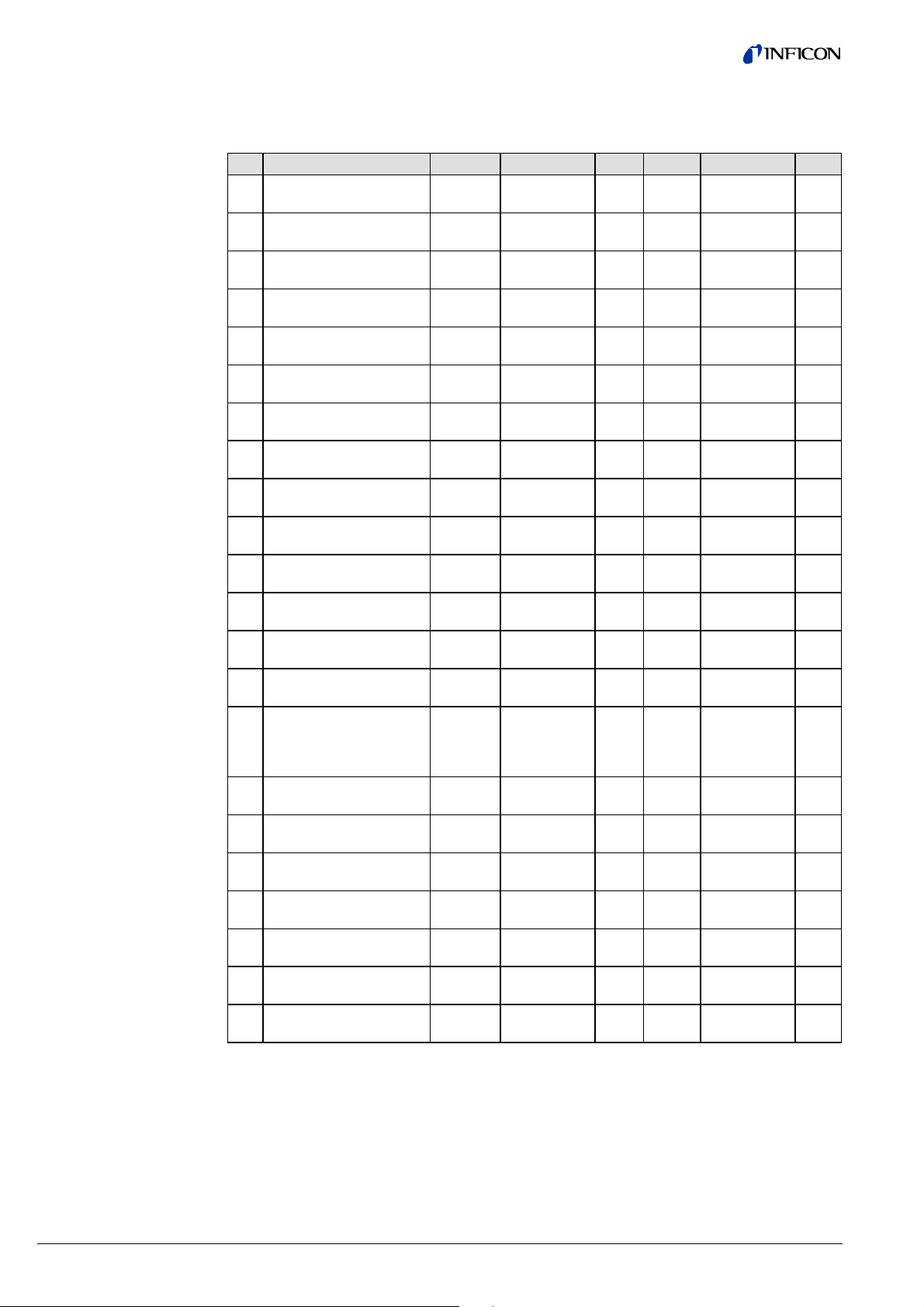

3.1 Device Block

The following table lists the services and parameters integrated in the Device Block

(→ Appendix A for abbreviations).

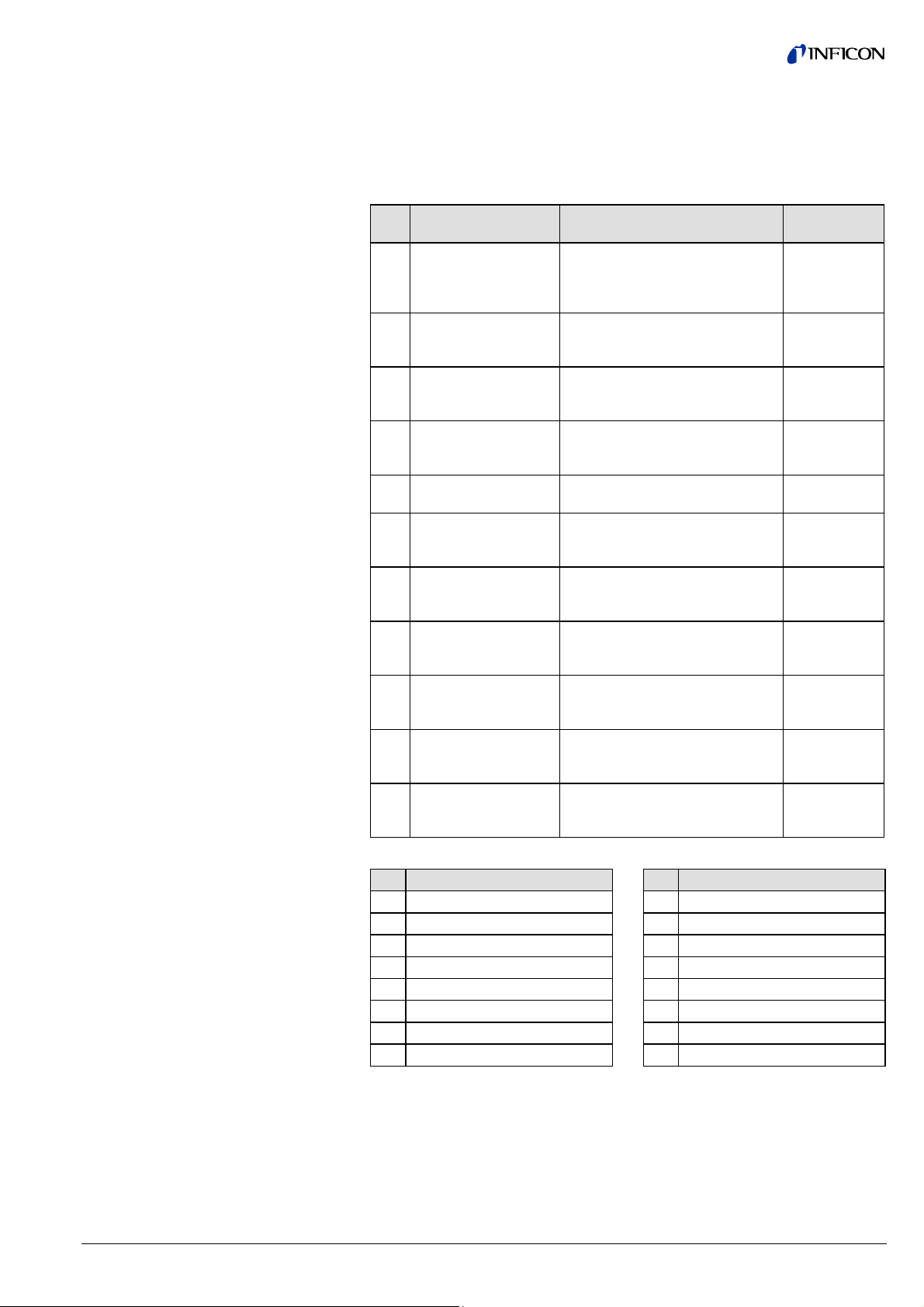

ID Name Structure Data type Bytes Access Value Store

15 Device Block State Simple Unsigned8 1 1_R/W

2_R/W

16 Block Type Simple Octet string 4 1/2_R 1 N

17 Device Type Simple Visible string 8 1/2_R CG N

18 Standard Revision Level Simple Visible string 9 1/2_R E54-0997 N

19 Device Manufacturer

Identifier

20 Manufacturer

Model Number

21 Software or Firmware

Revision Level

22 Hardware Revision Level Simple Visible string 8 1/2_R e.g. 1.0 N

23 Serial Number Simple Visible string 30 1/2_R e.g. 100 N

24 Device Configuration Simple Visible string 50 1/2_R e.g.

25 Device State Simple Unsigned8 1 1/2_R V

26 Exception Status Simple Unsigned8 1 0_XI

27 Exception Detail Alarm Record

28 Exception Detail

Warning

202 Emission On Switch Simple Analogical to

203 Sensor Calibration

Switch

204 Common Exception

Detail Alarm 0

205 Device Exception Detail

Alarm 0 … 3

206 Manufacturer Exception

Detail Alarm 0

207 Common Exception

Detail Warning 0

208 Device Exception Detail

Warning 1 … 4

209 Manufacturer Exception

Detail Warning 0

Simple Visible string 20 1/2_R INFICON AG N

Simple Visible string 20 1/2_R e.g.

353-525

Simple Visible string 8 1/2_R e.g. 1.01 N

HPG400-SP

1/2_R

→ below

Record

Simple UINT8 1 1/2_R V

Simple UINT8 1 1/2_R V

Struct Array of

Simple UINT8 1 1/2 _R V

Simple UINT8 1 1/2 _R V

Struct Array of

Simple UINT8 1 1/2_R V

→ below

data type

value (parameter 21)

4 bytes

4 bytes

- 1/2_R V

- 1/2_R V

1 1/2_R V

4 1/2_R V

4 1/2 _R V

N

N

V

14 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 15

3.1.1 Information on the

Individual Indices

3.1.1.1 Block Type ID 16

3.1.1.2 Device Type ID 17

3.1.1.3 Standard Revision Level

ID 18

3.1.1.4 Device Manufacturer

Identifier ID 19

3.1.1.5 Manufacturer Model

Number ID 20

The Block Type Parameter contains an ID which describes the block type. The

block type ID of the Device Block 1. The other defined block types are listed in

Appendix B.

The Device Type identifies the device type which is connected to the field bus via

Profibus.

The Device Type of the BPG400-SP / HPG400-SP gauges is "CG", the abbreviation of "Combination Gauge".

This parameter describes the version of the "Sensor/Actuator Network Specific

Device Model" published by the SEMI

International, California), according to which the profile of this device has been

developed.

The fixed setting of this parameter is "E54-0997".

This parameter describes the manufacturer of the device, "INFICON AG".

This parameter represents the part number of the gauge (→ section "Validity").

BPG400-SP and HPG400-SP are available with two different vacuum connection

types each, for example:

Gauge Vacuum connection Part number

HPG400-SP 25 KF 353-525

®

(Semiconductor Equipment and Materials

3.1.1.6 Software or Firmware

Revision Level ID 21

3.1.1.7 Hardware Revision Level

ID 22

3.1.1.8 Device Configuration ID 24

3.1.1.9 Device State ID 25

This parameter indicates the software version of the Profibus option in the format

"1.01".

This parameter indicates the hardware version of the gauge in the format "1.0".

This parameter indicates the device name. If the BPG400-SP is connected,

BPG400-SP is output, if the HPG400-SP is connected, HPG400-SP is output.

This parameter indicates the status of the gauge. Due to the structure of the Device

State Machine, the following statuses are possible:

Parameter value Status

0 Undefined

1 Self testing

2 Idle

3 Self test exception

4 Executing

5 Abort

6 Critical fault

The device statuses are described in detail in section "Device Block, Device

Behavior".

tira36e1-a (0310) BPG/HPG400 v1.cp 15

Page 16

3.1.1.10 Exception Status ID 26

The Exception Status describes the alarm and warning statuses of the gauge in an

"Expanded error output format".

A difference is made between warnings and errors.

Alarms and errors are divided into three groups (→ sections "Exception Detail

Alarm" and "Exception Detail Warning" for details):

• ALARM / Warning Device Common

• ALARM / Warning Device Specific

• ALARM / Warning Manufacturer

Specific

In each of the above groups, there are several error or warning conditions. The individual fields are presented in the "Exception Detail Alarm" and "Exception Detail

Warning". If an error message occurs in "Exception Detail Alarm" or "Exception

Detail Warning”, the corresponding bit is set in the Exception Status. Therefore, if

bits 0 … 6 of the Exception Status are on "0" there is no warning message pending.

If a bit is set, the actual error can be read in the corresponding group.

The Exception Status is output in cyclic data and informs on the current error status

using only one byte. If an error occurs, the current error status can be read via

acyclic services or in cyclic data exchange via the parameter channel. This ensures

that while the current error status is always available in the cyclic data, no

unnecessary data overhead is transmitted.

Bit Function Meaning

0 ALARM, device common The bit is set if an error of the Alarm

1 ALARM, device specific The bit is set if an error of the Alarm

2 ALARM, manufacturer specific The bit is set if an error of the Alarm

3

4 WARNING, device common The bit is set if an error of the Warning

5 WARNING, device specific The bit is set if an error of the Warning

6 WARNING, manufacturer

specific

7 Expanded Format Is constantly on "1" and marks the use of

--

For errors that occur independently of

the type of device used, e.g. supply

error, RAM, ROM, or EEPROM error.

For device specific errors, e.g. filament

rupture (Pirani), or cathode rupture

(BA/HP).

For errors defined by the manufacturer

that are not mentioned in the standard.

Device Common group is detected.

Device Specific group is detected.

Manufacturer Specific group is detected.

Device Common group is detected.

Device Specific group is detected.

The bit is set if an error of the Warning

Manufacturer Common group is detected.

the expanded error output format.

16 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 17

3.1.1.11 Exception Detail Alarm

ID 27

If, in the Exception Status, one of the bits 0 … 2 is set, the current error can be

read in the "Exception Detail Alarm" parameter. The "Exception Detail Alarm"

parameter consists of a total of 10 bytes that inform on the error status of the

gauge.

Due to the use of the expanded error output format, these bytes have the following

structure:

ByteNoName Description Value

0 Common Exception

Detail Size

1 Common Exception

Detail 0

2 Common Exception

Detail 1

3 Device Exception

Detail Size

4 Device Exception

Detail 0

(Pirani error data)

5 Device Exception

Detail 1

(Pirani error data)

6 Device Exception

Detail 2

(BA/HP error data)

7 Device Exception

Detail 3

(BA/HP error data)

8 Manufacturer

Exception Detail Size

9 Manufacturer

Exception Detail 0

Indicates the number of subsequent bytes that contain the

Common Exception Detail Alarm.

Contains current error messages

from the Common Exception

Detail Alarm group.

Contains current error messages

from the Common Exception

Detail Alarm group.

Indicates the number of subsequent bytes that contain the

Device Exception Detail Alarm.

This error information from the

Common Exception Detail Alarm

group refers to Pirani.

This error information from the

Common Exception Detail Alarm

group refers to Pirani.

This error information from the

Common Exception Detail Alarm

group refers to BA/HP.

This error information from the

Common Exception Detail Alarm

group refers to BA/HP.

Indicates the number of subsequent bytes that contain the

Device Exception Detail Alarm.

Contains current error messages

from the Manufacturer Exception

Detail Alarm group.

2

Depending on

error status

Depending on

error status

4

Depending on

error status

Depending on

error status

Depending on

error status

Depending on

error status

1

Depending on

error status

Common Exception

Detail Alarm

Bit Common Exception Detail 0 Bit Common Exception Detail 1

00 00

10 10

2 EPROM exception 2 0

3 EPROM exception 3 0

4 RAM exception 4 0

50 50

60 60

70 70

tira36e1-a (0310) BPG/HPG400 v1.cp 17

Page 18

Device Exception

Detail Alarm

Bit Device Exception Detail 0

Referring to Pirani

1)

Bit Device Exception Detail 1

Referring to Pirani

2)

00 00

1 0 1 Electronics/sensor error Pirani

20 20

30 30

40 40

50 50

60 60

70 70

1)

This byte is a copy of Sensor

Alarm byte 0 of the Heat Transfer

Vacuum Gauge Transducer

Block Common Exception

2)

This byte is a copy of Sensor

Alarm byte 1 of the Heat Transfer

Vacuum Gauge Transducer

Block.

Detail 0.

Manufacturer Exception

Detail Alarm 0

Bit Device Exception Detail 2

Referring to BA/HP

3)

Bit Device Exception Detail 3

Referring to BA/HP

4)

00 00

10 1

Electronics/sensor error BA/HP

20 20

30 30

40 40

50 50

60 60

70 70

3)

This byte is a copy of Sensor

Alarm byte 0 of the Hot Cathode

Ion Gauge Transducer Block.

4)

This byte is a copy of Sensor

Alarm byte 1 of the Hot Cathode

Ion Gauge Transducer Block.

If there is an internal communication error in the gauge, the byte Manufacturer

Exception Detail 0 is set to "1".

18 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 19

3.1.1.12 Exception Detail Warning

ID 28

If, in the Exception Status, one of bits 4 … 6 is set, the current warning can be read

in the parameter "Exception Detail Warning". The Exception Detail Warning

parameter consists of a total of 11 bytes that inform on the error status of the

gauge.

Due to the use of the expanded error output format, these bytes have the following

structure:

ByteNoName Description Value

0 Common Exception

Detail Size

1 Common Exception

Detail 0

2 Common Exception

Detail 1

3 Device Exception

Detail Size

4 Device Exception

Detail 0

5 Device Exception

Detail 1

(Pirani)

6 Device Exception

Detail 2

(Pirani)

7 Device Exception

Detail 3

(BA/HP)

8 Device Exception

Detail 4

(BA/HP)

9 Manufacturer

Exception Detail Size

10 Manufacturer

Exception Detail

Indicates the number of subsequent bytes that contain the

2

Common Exception Detail

Warning.

Contains current error messages

from the Common Exception

Depending on

warning status

Detail Warning group.

Contains current error messages

from the Common Exception

Depending on

warning status

Detail Warning group.

Indicates the number of subsequent bytes that contain the

5

Device Exception Detail Warning.

One Of N Status Extension. Depending on

warning status

This error information from the

Common Exception Detail

Depending on

warning status

Warning group refers to Pirani.

This error information from the

Common Exception Detail

Depending on

warning status

Warnings group refers to Pirani.

This error information from the

Common Exception Detail Alarm

Depending on

warning status

group refers to BA/HP.

This error information from the

Common Exception Detail Alarm

Depending on

warning status

group refers to BA/HP.

Indicates the number of subsequent bytes that contain the

1

Device Exception Detail Warning.

Contains current error messages

from the Manufacturer Exception

Depending on

warning status

Detail Alarm group.

Common Exception

Detail Warning

Bit Common Exception Detail 0 Bit Common Exception Detail 1

00 00

10 10

2 EPROM exception 2 0

3 EPROM exception 3 0

4 RAM exception 4 0

50 50

60 60

70 70

The warning bits are set in the same way as the error bits because here, warnings

have the same meaning as errors.

tira36e1-a (0310) BPG/HPG400 v1.cp 19

Page 20

Device Exception

Detail Warning

Bit Device Exception Detail 0

0 Bit set if

Reading Invalid

1 Bit set if

Device Overrange

2 Bit set if

Device Underrange

30

40

50

60

70

Device Exception Detail 1

Bit

Referring to Pirani

1)

Device Exception Detail 2

Bit

Referring to Pirani

2)

00 00

1 0 1 Electronics/sensor warning

Pirani

20 20

30 30

40 40

50 50

60 60

70 70

1)

This byte is a copy of Sensor

Warning byte 0 of the Heat

Transfer Vacuum Gauge

Transducer Block.

Device Exception Detail 3

Bit

Referring to BA/HP

3)

2)

This byte is a copy of Sensor

Warning byte 1 of the Heat

Transfer Vacuum Gauge

Transducer Block.

Device Exception Detail 4

Bit

Referring to BA/HP

4)

00 00

10 1

Electronics/sensor warning

BA/HP

20 20

30 30

40 40

50 50

60 60

70 70

3)

This byte is a copy of Sensor

Warning byte 0 of the Hot

Cathode Ion Gauge Transducer

Block.

4)

This byte is a copy of Sensor

Warning byte 1 of the Hot

Cathode Ion Gauge Transducer

Block.

Manufacturer Exception

Detail Warning 0

3.1.1.13 Emission On Switch

ID 202

(HPG400-SP Only)

If there is an internal communication error in the gauge, the byte "Manufacturer

Exception Detail 0" is set to "1" (according to the alarm condition).

The parameter contains the value of the switchover point from Pirani to HP

measurement (→ [4], [5], [6]).

This value can be read only and corresponds to the value that can be set with the

"LOW-HIGH" switch on the side of the gauge (→ [4], [6]). The value of the

switchover point is output in the currently selected data unit ( pressure unit).

20 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 21

If COUNTS is selected as pressure unit, the switchover pressure can be calculated

by means of the following formula (PV is the abbreviation of Process Value):

3.1.1.14 Sensor Calibration Switch

ID 203

(HPG400-SP Only)

PV

mbar

The following settings can be made with the five possible switch positions.

Switch position Switchover

0; 1 1 mbar 28 333

2; 3 5×10-1 mbar 32 632

4; 5 2×10-1 mbar 27 867

6; 7 1×10-1 mbar 27 666

8; 9 5×10-2 mbar 27 466

This parameter represents the setting of the calibration switch "CAL ADJ", which is

used for adjusting the sensitivity of the gauge (→ [4], [6]).

The value output corresponds to the marking on the switch.

The following parameters (ID 204 … ID 209) present copies of elements

of the Exception Detail Alarm (ID 27) or the Exception Detail Warning

(ID 28). These parameters are made available in order to allow masters

that do not support the Profibus DPV1 to access the elements of the

Exception Detail Alarm and Warning via the parameter channel. Since

the parameter channel has a limited actual data length (4 bytes), the

attributes ID 27 and ID 28 cannot be read via the parameter channel.

(6 × COUNTS / 4000) - 42.5

=10

pressure

COUNTS

3.1.1.15 Copy Common Exception

Detail Alarm 0 ID 204

3.1.1.16 Copy Device Exception

Detail Alarm 0 … 3 ID 205

3.1.1.17 Copy Manufacturer Exception Detail Alarm 0 ID 206

3.1.1.18 Copy Common Exception

Detail Warning 0 ID 207

3.1.1.19 Copy Device Exception

Detail Warning 1 … 4

ID 208

3.1.1.20 Copy Manufacturer Exception Detail

Warning 0 ID 209

This parameter corresponds to the Common Exception Detail Alarm of the

Exception Detail Alarm (ID 27).

This parameter corresponds to the Device Exception Detail Alarm of the Exception

Detail Alarm (ID 27).

This parameter corresponds to the Manufacturer Exception Detail Alarm of the

Exception Detail Alarm (ID 27).

This parameter corresponds to the Common Exception Detail Warning of the

Exception Detail Warning (ID 28).

This parameter corresponds to the Device Exception Detail Warning of the

Exception Detail Warning (ID 28).

This parameter corresponds to the Manufacturer Exception Detail Warning of the

Exception Detail Warning (ID 28).

tira36e1-a (0310) BPG/HPG400 v1.cp 21

Page 22

3.1.2 Device Block, Device

Behavior

The BPG400-SP / HPG400-SP behaves as described in the status diagram below.

NORMAL

(0)

INIT

(

1

3

(1

(13)

(14)

3)

)

RUNNING

SELFTESTING

)

2

(

(

SELFTEST

EXCEPTION

)

3

(

1

)

OK

IDLE

(10)

EXECUTING

(4)

(5)

(8)

ABORT

(9)

CRITICAL

FAULT

After the start, the gauge independently runs through the INIT and SELFTESTING

status and eventually changes to the IDLE status (if there is no error) or to the

SELFTEST_EXCEPTION status (if there is a gauge error).

When data traffic is taken up, a difference has to be made between cyclic and

acyclic data traffic.

Cyclic data traffic

Acyclic data traffic

As soon as cyclic data interchange is taken up, the gauge automatically changes to

the EXECUTING status.

In acyclic data traffic, a START service has to be transmitted to bring the gauge to

the EXECUTING status.

22 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 23

Device statuses

Status name Description

NORMAL The communication interface can respond to com-

mands. All defined blocks of the gauge exist.

RUNNING All block instances are initialized and the individual

parameters have their initial or default values.

SELFTESTING In this status, the gauge performs a selftest.

IDLE All blocks defined in the gauge are initialized and the

complete hardware has been tested and found free

of errors. The value defined in the Safe State is output as measured value.

SELFTESTEXCEPTION During the self test, an error has been detected. The

gauge has changed to the SELFTESTEXCEPTION

status. The cause of the error can be found in the

attributes Device Exception Detail Alarm/Warning of

the Device Block. The value defined in the Safe State

is output as measured value.

EXECUTING The gauge functions normally and outputs the

measured value.

ABORT The Device Block is in the ABORT status. The gauge

specific measurement functions are not carried out.

CRITICALFAULT A device error has occurred. The gauge specific

measurement functions are not carried out. The

value defined in the Safe State is output as

measured value.

3.1.2.1 Device Block

State Command

There are a number of special commands for bringing the gauge into a status it

does not automatically go to.

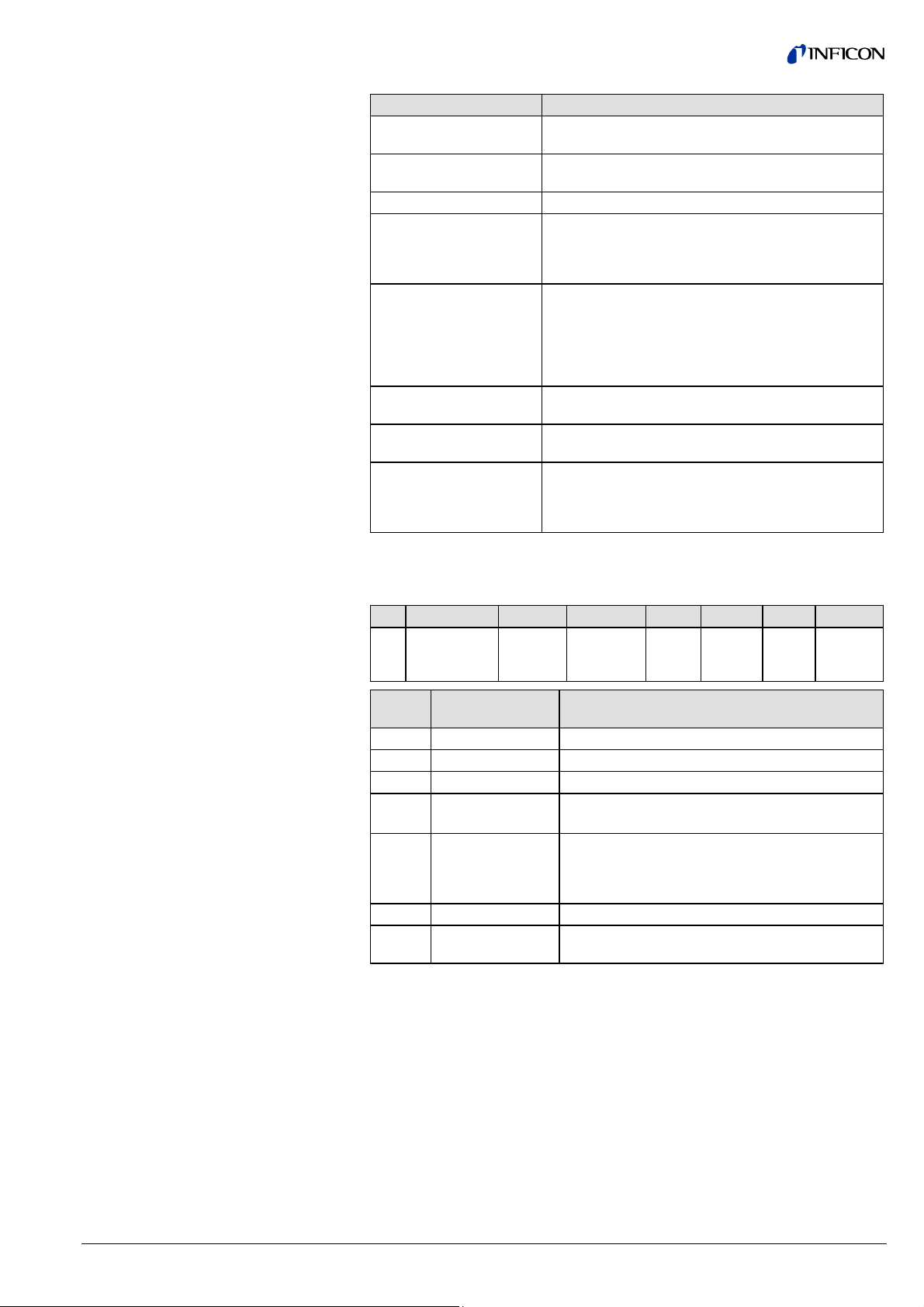

ID Name Structure Data type Bytes Access Store Range

15 Device Block

State

Command

ID

Name Description

value

0 Inactive No action.

1 Reset Used for reinitializing the device.

2 Abort Brings the device to the ABORT status.

3 Recover Used for bringing the device from the ABORT

4 Execute Brings the unit to the EXECUTING status, in which

5 Stop Brings the gauge to the IDLE status.

6 Perform

Diagnostic

Simple Unsigned8 1 1_R/W

2_R/W

status into the Recovered State IDLE.

the gauge functions normally. As soon as cyclic

data traffic is initialized, this status command is

executed automatically.

Stops the running activity and starts SELFTEST.

N

→ below

3.2 Analog Input Block

tira36e1-a (0310) BPG/HPG400 v1.cp 23

All gauge functions of the BPG400-SP / HPG400-SP are described in the Analog

Input Block.

Since the gauge includes two measuring systems, there are also two Analog Input

Block Instances representing the Pirani measuring part and the ionization measuring part (BA/HP) respectively.

Page 24

3.2.1 One Of N Analog Input

Function Block / SLOT 1

ID Name

15 AI Block Adjust

1)

Structure Data type Bytes Access Store

Simple Unsigned8 1 1/2_W -

Command

16 Block Type Simple Octet string 4 2_R N

46 Channel Instance

Simple Unsigned8 1 1/2_R/W N

Selector

47 PV Selector Simple Unsigned8 1 0_XI 1/2_R D

1)

The above parameters are described below.

3.2.1.1 AI Block Adjust Command

(Adjustment at Atmospheric Pressure)

3.2.1.2 Block Type

3.2.1.3 Channel Instance Selector

3.2.1.4 PV Selector

This service is used for adjusting the gauge at atmospheric pressure (→ [1], [3]

for BPG400-SP and [4], [6] for HPG400-SP). For this purpose, the value "1" has

to be transmitted.

The value of the Block Type ID is "3" (→ table in Appendix A).

The gauge has two instances of the Analog Input Function Block and two instances

of the Vacuum Gauge Transducer Block, or one instance of each block per

measuring systems (Pirani and BA/HP). There are two additional instances for

describing the switching functions (→ section "Analog Sensor Input Function

Block", Instances 3 and 4).

However, there is only one address range for both, querying and setting the corresponding parameters. The Parameter Channel Instance Selector is used for defining the parameters that are written into the address range.

If the Parameter Channel Instance Selector is set to "1", the attributes of Instance 1

are mapped into that address range and can be written or read by addressing

Slot ⇒ Instance ⇒ Parameter-ID.

The PV Selector is determined by the gauge and defines the Analog Input Function

Block Instance from which the measured value is copied into the cyclic output data

telegrams. Therefore, the value output in the cyclic data is always the measured

value of the active instance, i.e. the one that is currently measuring. While the

gauge is measuring in the BA/HP range, the measured value of the ionization

vacuum meter is output in the cyclic data and while the gauge is measuring in the

Pirani range, the measured value of the Pirani is output.

Measuring range

BPG-400-SP

Measuring range

HPG-400-SP

The measured values of Instances 3 and 4 (thresholds of the switching

functions) are not output in the cyclic data.

The pressure ranges, in which measurement is performed either by the Pirani

measuring part or by the BA/HP measuring part, and which are thus called "active",

are indicated below:

Pressure [mbar] PV Selector

5.5×10-3 < p ≤ Overrange

-10

5×10

< p < 5.5×10

1)

Overrange means pressure values >1000 mbar.

1)

-3

Pirani (=1)

BA (=2)

The activation value of the emission of the HPG400-SP can be defined

via a switch on the gauge (→ [4], [6]). The selected value is called

"p_active_threshold". The activation value of the emission can be read

with the parameter ID 202 "Emission Switch ON Switch" in the Device

Block.

Pressure [mbar] PV Selector

p_active_threshold < p < Overrange

Underrange ≤ p < p_active_threshold

1)

Overrange means pressure values >1000 mbar.

1)

Pirani (=1)

HP (=2)

24 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 25

3.2.2 Analog Sensor Input

Function Block

Instance 1 / SLOT 1

Instance 1 of the Analog Sensor Input Function Blocks describes the functionality

of the Pirani measuring part of the gauge.

The following attributes are supported:

ID Name Structure Data type Bytes Access Store

19 Process Value

(PV)

Simple According to

Parameter Data

Type

- 0_XI

1_R

2_R

20 Status Simple Unsigned8 1 0_XI

D

D

1/2_R

21 Data Type Simple Unsigned8 1 2_R/W N

22 Data Units Simple Unsigned16 2 2_R/W N

23 Reading Valid Simple Boolean 1 1_R

D

2_R

24 Full Scale Simple According to

- 1/2_R N

Data Type value

(Parameter 21)

39 Safe State Simple Unsigned8 1 1/2_R/W N

40 Safe Value Simple According to

- 1/2_R/W N

Data Type value

(Parameter 21)

44 Overrange Simple According to

- 1/2_R N

Data Type value

(Parameter 21)

45 Underrange Simple According to

- 1/2_R N

Data Type value

(Parameter 21)

3.2.2.1 Process Value

BPG400-SP

HPG400-SP

The Process Value contains the measured value of the Pirani Device Instance in

the currently selected data unit (ID 22) and in the selected data type (ID 21).

If the device is not in the Executing Status (ID 25, Device Block), the value defined

in the Safe State is output.

Values output in the data unit COUNTS can be converted into a pressure value by

means of the following formulas:

Calculation of the pressure (PV is the abbreviation used for Process Value):

PV

PV

PV

PV

mbar

Torr

Micron

Pa

(COUNTS / 1000) - 12.5

=10

= 0.75006168 × PV

=10-3 × PV

= 100 × PV

Torr

mbar

mbar

Calculation of the pressure (PV is the abbreviation used for Process Value):

PV

PV

mbar

Torr

(6 × COUNTS / 4000) - 42.5

=10

= 0.75006168 × PV

mbar

PV

Micron

PV

Pa

3.2.2.2 Status

tira36e1-a (0310) BPG/HPG400 v1.cp 25

This parameter remains on "0".

=10-3 × PV

= 100 × PV

Torr

mbar

Page 26

3.2.2.3 Data Type

Two data types are supported: Float and Integer16.

In cyclic data exchange, the data type cannot be modified. The data type setting

can only be modified when the gauge is in the IDLE status. By defining the

configuration data for cyclic data exchange (selection of standard telegrams), the

data type used in the selected standard telegram is taken over. All settings

previously made in acyclic data traffic are thus overwritten.

If the data type is set in one instance, that data type setting applies to all instances.

Likewise, when a standard telegram is selected, the data type used by that

standard telegram will be valid for all instances.

Coding Data type

3 Integer16

8 Float

3.2.2.4 Data Unit

3.2.2.5 Reading Valid

The gauge supports the following pressure units:

Coding Data type

1001 COUNTS

1301 Torr

1302 mTorr (Micron)

1308 mbar

1309 Pascal

For safety reasons, it is not possible to change the pressure unit while

the gauge is cyclically interchanging data with a DP/V0 master.

The data unit setting can only be modified when the gauge is in the IDLE

status.

In cyclic data traffic, the data unit must be set in the User Parameter

Data. All settings previously made in acyclic data traffic are overwritten

(→ section "User Parameter Data").

If the data unit is set in one instance, that data unit setting applies to all

instances. Likewise, the data unit setting made in the User Parameter

Data is valid for all instances.

This parameter indicates that the pressure reading is within a valid range, which

means that:

• The gauge is in the EXECUTING status.

• There is no error (ID 26, 27 or 28 of the Device Block)

• The measured value is lower than the overrange value and higher than the

underrange value.

If this value is set to zero, the pressure reading is not valid. In such a

case, either check Exception Status (ID 26, Device Block) to find out

whether there is an error or check One Of N Status Extension (ID 120,

One Of N Vacuum Gauge Transducer Block) to find out whether the

measured value is out of the specified measuring range (overrange or

underrange mode).

3.2.2.6 Full Scale

BGP400-SP

26 tira36e1-a (0310) BPG/HPG400 v1.cp

This parameter contains the valid maximum value of the pressure reading

(1000 mbar) in the currently selected data unit and data type.

Pressure unit Full scale

COUNTS 31 000

Torr 750.06168

mTorr (Micron) 750 061.68

mbar 1 000

Pascal 100 000

Page 27

HGP400-SP

Pressure unit Full scale

COUNTS 30 333

Torr 750.06168

mTorr (Micron) 750 061.68

mbar 1 000

Pascal 100 000

3.2.2.7 Safe State

3.2.2.8 Safe Value

3.2.2.9 Overrange

When the gauge is not in the EXECUTING status (ID 25, Device Block) or if there

is a device error, a value defined by Safe State is output as pressure value. You

can select among:

• "0"

• Full scale

• Last valid value

• Safe Value (user-definable in ID 40)

Safe State Coding PV behavior

Zero 0 The Process Value (measured value ID 19) is set

to 0.

Full Scale 1 The Process Value (measured value ID 19) is set

to the full scale value (ID 24).

Hold Last Value 2 The Process Value is set to the last valid value

obtained in the EXECUTING status.

Use Safe Value 3 The Process Value (measured value ID 19) is set

to the Safe Value (ID 40).

The Safe Value is the value output with the Process Value parameter (ID 19) when

an error occurs or the gauge goes to the NOT EXECUTING status. If this value is

set to zero, it will remain on zero when the data unit is changed.

Overrange is the highest valid measured value at which Reading Valid is still on

"1".

BGP400-SP

HGP400-SP

3.2.2.10 Underrange

BGP400-SP

Pressure unit Overrange

COUNTS 31 000

Torr 750.06168

mTorr (Micron) 750 061.68

mbar 1 000

Pascal 100 000

Pressure unit Overrange

COUNTS 30 333

Torr 750.06168

mTorr (Micron) 750 061.68

mbar 1 000

Pascal 100 000

Underrange is the lowest valid measured value at which Reading Valid is still on

"1".

Pressure unit Underrange

COUNTS 20 480.7254

Torr 4.12534×10

-3

mTorr (Micron) 4.12534

mbar 5.5×10

-3

Pascal 0.55

tira36e1-a (0310) BPG/HPG400 v1.cp 27

Page 28

HGP400-SP

Pressure unit Underrange

COUNTS 27 000

Torr 7.50053×10

mTorr (Micron) 7.50053

mbar 1.0×10

Pascal 1

-2

-3

3.2.3 Analog Sensor Input

Function Block

Instance 2 / SLOT 1

Instance 2 of the Analog Sensor Input Function Block describes the functionality of

the BA/HP measuring part of the gauge.

In Instance 2, the same attributes as in Instance 1 are supported:

ID Name Structure Data type Bytes Access Store

19 Process Value

(PV)

20 Status Simple Unsigned8 1 0_XI

21 Data Type Simple Unsigned8 1 2_R/W N

22 Data Units Simple Unsigned16 2 2_R/W N

23 Reading Valid Simple Boolean 1 1_R

24 Full Scale Simple According to

39 Safe State Simple Unsigned8 1 1/2_R/W N

40 Safe Value Simple According to

44 Overrange Simple According to

45

Underrange Simple According to

Simple According to

Parameter Data

Type

Data Type value

(parameter 21)

Data Type value

(parameter 21)

Data Type value

(parameter 21)

Data Type value

(parameter 21)

- 0_XI

1_R

2_R

1/2_R

2_R

- 1/2_R N

- 1/2_R/W N

- 1/2_R N

- 1/2_R N

D

D

D

3.2.3.1 Process Value

28 tira36e1-a (0310) BPG/HPG400 v1.cp

The Process Value contains the measured value of the BA/HP Device Instance in

the currently selected data unit (ID 22) and in the selected data type (ID 21).

If the device is not in the EXECUTING status (ID 25, Device Block), the value

defined in the Safe State is output.

Values output in the data unit COUNTS can be converted into a pressure value by

means of the following formulas:

Page 29

BPG400-SP

Calculation of the pressure (PV is the abbreviation used for Process Value):

PV

mbar

(COUNTS / 2000) - 12.5

=10

HPG400-SP

3.2.3.2 Status

3.2.3.3 Data Type

PV

PV

PV

Torr

Micron

Pa

= 0.75006168 × PV

=10-3 × PV

= 100 × PV

Torr

mbar

mbar

Calculation of the pressure (PV is the abbreviation used for Process Value):

PV

PV

PV

PV

mbar

Torr

Micron

Pa

(6 × COUNTS / 16000) - 9.125

=10

= 0.75006168 × PV

=10-3 × PV

= 100 × PV

Torr

mbar

mbar

This parameter is remains on "0".

Two data types are supported: Float and Integer16.

In cyclic data traffic, the data type cannot be modified. The data type setting can

only be modified when the gauge is in the IDLE status. By defining the configuration data for cyclic data traffic (selection of standard telegram), the data type used

in the selected standard telegram is taken over. All settings previously made in

acyclic data traffic are thus overwritten.

If the data type is set in one instance, that data type setting applies to all instances.

Likewise, when a standard telegram is selected, the data type used by that

standard telegram will be valid for all instances

3.2.3.4 Data Unit

Coding Data type

3 Integer16

8 Float

The gauge supports the following pressure units:

Coding Pressure unit

1001 COUNTS

1301 Torr

1302 mTorr (Micron)

1308 mbar

1309 Pascal

For safety reasons, it is not possible to change the pressure unit while

the gauge is cyclically interchanging data with a DP/V0 master.

The data unit setting can only be modified when the gauge is in the IDLE

status.

In cyclic data traffic, the data unit must be set in the User Parameter

Data. All settings previously made in acyclic data traffic are overwritten

(→ section "User Parameter Data").

If the data unit is set in one instance, that data unit setting applies to all

instances. Likewise, the data unit setting made in the User Parameter

Data is valid for all instances.

tira36e1-a (0310) BPG/HPG400 v1.cp 29

Page 30

3.2.3.5 Reading Valid

This parameter indicates that the pressure reading is within a valid range, which

means that:

• The gauge is in the EXECUTING status.

• There is no error (ID 26, 27 or 28 of the Device Block)

• The measured value is lower than the overrange value and higher than the

underrange value.

If this value is set to zero, the pressure reading is not valid. In such a

case, either check Exception Status (ID 26, Device Block) to find out

whether there is an error or check One Of N Status Extension (ID 120,

One Of N Vacuum Gauge Transducer Block) to find out whether the

measured value is out of the specified measuring range (overrange or

underrange mode).

3.2.3.6 Full Scale

BGP400-SP

HGP400-SP

3.2.3.7 Safe State

This parameter contains the valid maximum value of the pressure reading

(1000 mbar) in the currently selected data unit and data type.

Pressure unit Full scale

COUNTS 21 602.06

Torr 1.50×10

-2

mTorr (Micron) 1.5

mbar 2.0×10

-2

Pascal 2

Pressure unit Full scale

COUNTS 24 333

Torr 7.5006168×10

mTorr (Micron) 7.5006168×10

-1

2

mbar 1

Pascal 100

When the gauge is not in the EXECUTING status (ID 25, Device Block) or if there

is a device error, a value defined by Safe State is output as pressure value. You

can select among:

• "0"

• Full scale

• Last valid value

• Safe Value (user-definable in ID 40)

Safe State Coding PV behavior

Zero 0 The Process Value (measured value ID 19) is set

to 0.

Full Scale 1 The Process Value (measured value ID 19) is set

to the full scale value (ID 24).

Hold Last Value 2 The Process Value is set to the last valid value

obtained in the EXECUTING status.

Use Safe Value 3 The Process Value (measured value ID 19) is set

to the Safe Value (ID 40).

3.2.3.8 Safe Value

The Safe Value is the value output with the Process Value Parameter (ID 19) when

an error occurs or the gauge goes to the NOT EXECUTING status. If this value is

set to zero, it will remain on zero when the data unit is changed.

30 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 31

3.2.3.9 Overrange

Overrange is the highest valid measured value at which Reading Valid is still on

"1".

BGP400-SP

HGP400-SP

3.2.3.10 Underrange

BGP400-SP

Pressure unit Overrange

COUNTS 21 602.06

Torr 1.5×10

-2

mTorr (Micron) 1.5

mbar 2×10

-2

Pascal 2.0

Pressure unit Overrange

COUNTS 24 333

Torr 7.5006168×10

mTorr (Micron) 7.5006168×10

-1

2

mbar 1

Pascal 100

Underrange is the lowest valid measured value at which Reading Valid is still on

"1".

Pressure unit Underrange

COUNTS 6397.95

Torr 3.7503×10

mTorr (Micron) 3.7503×10

mbar 5.0×10

Pascal 5.0×10

-10

-7

-10

-8

HGP400-SP

Pressure unit Underrange

COUNTS 8333

Torr 7.5006168×10

mTorr (Micron) 7.5006168×10

mbar 1×10

Pascal 1×10

-6

-4

-7

-4

tira36e1-a (0310) BPG/HPG400 v1.cp 31

Page 32

3.2.4 Analog Sensor Input

Function Block

Instances 3

and 4 / SLOT 1

Instances 3 and 4 of the Analog Sensor Input Function Block describe the functionality of the two switching functions (Setpoint A / Setpoint B) of the gauge

(setting the switching functions → [2], [3] for BPG400-SP and [5], [6] for

HPG400-SP):

Instance Setpoint

3A

4B

With Process Values (ID 19), the current threshold setting (made by means of the

potentiometers) is read; with Status, the relay status (open/closed) can be read.

ID Name Structure Data type Bytes Access Store

19 Process Value

(PV)

20 Status Simple Unsigned8 1 1_R

Simple Unsigned16 - 1_R

2_R

D

D

2_R

21 Data Type Simple Unsigned8 1 2_R

N

2_W

22 Data Units Simple Unsigned16 2 2_R

N

2_W

23 Reading Valid Simple Boolean 1 1_R

D

2_R

3.2.4.1 Process Value

BPG400-SP

HPG400-SP

BPG400-SP

HPG400-SP

The Process Value contains the current setting of the threshold potentiometers for

"Setpoint A" and "Setpoint B" in the currently selected data unit and data type.

If the pressure drops below the set threshold, the relay is closed. If after that, the

pressure rises above that threshold with a hysteresis of 10%, the relay is opened

again (→ [2], [3] for BPG400-SP and [5], [6] for HPG400-SP).

The Process Value PV is output in the currently selected data unit and data type.

Values output in the pressure unit COUNTS can be converted into a pressure value

by means of the following formulas:

p

p

mbar

mbar

(COUNTS / 2000) - 12.5

=10

(COUNTS - 22 999) / 2444

=10

The threshold voltages of the Setpoint potentiometer converted into a pressure

value by means of the following formulas:

p

p

mbar

mbar

(1.23011 × U) - 9.30102999

=10

(9 × U / 10) - 6

=10

Where: U is the threshold voltage [V] of the corresponding Setpoint (A, B),

measured at the D-Sub connector (sensor cable connector) of the gauge

(→ [2], [3] for BPG400-SP and [5], [6] for HPG400-SP).

The switching functions work only at pressures <100 mbar. If a higher

threshold has been selected, the relay is only activated at pressures

lower than 100 mbar.

32 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 33

3.2.4.2 Status

If the pressure drops below the set threshold, the relay is activated (normally open

contact closed). If the pressure than rises above the set threshold with a hysteresis

of 10%, the relay is deactivated again (normally open contact open).

Bit Definition

00

1 Low Alarm Exception: 0 = cleared; 1 = set

20

3 Low Warning Exception: 0 = cleared; 1 = set

40

50

60

70

3.2.4.3 Data Type

3.2.4.4 Data Unit

3.2.4.5 Reading Valid

3.3 Transducer Block

3.3.1 One Of N Vacuum Gauge

Transducer Block /

SLOT 1

3.3.1.1 One Of N Status Extension

Description → Instance 1.

Description → Instance 1.

This parameter is always on "1".

ID Name Structure Data type Bytes Access Store

120 One Of N Status

Extension

This parameter indicates whether the overrange or underrange of the gauge is

exceeded.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

00000Underrange

If the gauge is operated in its overrange or underrange, the corresponding bit and

additionally the bit "Reading Invalid" is set.

If an error occurs, the bit "Reading Invalid" as well as the corresponding error bits

in Device Block (ID 26, 27, 28 Device Block) are set.

Simple UINT8 1 1_R

2_R

Overrange

Exceeded

Exceeded

V

Reading

Invalid

3.3.2 Heat Transfer Vacuum

Gauge Transducer

Block / SLOT 1

3.3.2.1 Block Type

tira36e1-a (0310) BPG/HPG400 v1.cp 33

ID Name Structure Data type Bytes Access Store

101 Block Type Simple Octet string 4 2_R

102 Status Extension Simple UINT8 1 1/2_R V

103 Sensor Alarm Struct Array of 2 bytes 2 1/2_R V

104 Sensor Warning Struct Array of 2 bytes 2 1/2_R V

140 Full Scale State Simple UINT8 1 1/2_R V

According to the table in Appendix A, the Block Type ID has the value "13".

Page 34

3.3.2.2 Status Extension

This parameter indicates whether the overrange or underrange of the Heat

Transfer Vacuum Gauge device instance is exceeded.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 0 0 0 0 Underrange

Exceeded

Overrange

Exceeded

Reading

Invalid

If the instance is operated in its overrange or underrange, the corresponding bit

and additionally the bit "Reading Invalid" is set.

If an error occurs, the bit "Reading Invalid" as well as the corresponding error bits

in Device Block (ID 26, 27, 28 Device Block) are set.

3.3.2.3 Sensor Alarm

3.3.2.4 Sensor Warning

3.3.2.5 Full Scale State

This parameter indicates the detectable errors occurring in connection with the

Pirani measuring part. The present implementation allows detection of one error.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Byte 0 0 0 0 0 0 0 Reserved 0

Byte 1 0 0 0 0 0 0 Electronics Failure

1)

Electronics Failure includes a sensor error.

1)

0

The Sensor Alarm bits defined here are copied into the Device Block ID 27 in the

"Device Exception Detail Alarm" range of the Pirani measuring part.

This parameter indicates the detectable warnings occurring in connection with the

Pirani measuring part. The present implementation allows detection of one warning.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Byte 0 0 0 0 0 0 0 Reserved 0

Byte 1 0 0 0 0 0 0 Electronics Warning

1)

Electronics Warning indicates that the Pirani measuring part has to be adjusted

1)

0

(→ [1], [3] for BPG400-SP and [4], [6] for HPG400-SP).

The Sensor Warning bits defined here are copied into the Device Block ID 28 in the

"Device Exception Detail Warning" range of the Pirani measuring part.

This Parameter is set to "1" while the Full Scale adjustment is carried out

(→ [1], [3] for BPG400-SP and [4], [6] for HPG400-SP).

34 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 35

3.3.3 Hot Cathode Ion Gauge

Transducer Block /

SLOT 1

ID Name Structure Data type Bytes Access Store Initial Value

14 Hot Cathode

Block State

Rec 1 1_W

2_W

FALSE

Command

101 Block Type Simple Octet

4 2_R 16

string

102 Status

Extension

103 Sensor

Alarm

104 Sensor

Warning

105 Emission

Status

106 Emission

Current

109 Degas

Status

Simple UINT8 1 1_R

2_R

Struct Array of

2 bytes

Struct Array of

2 bytes

2 1_R

2_R

2 1_R

2_R

Simple Boolean 1 1_R/W

2_R/W

Simple FLOAT 4 1_R/W

2_R/W

Simple Boolean 1 1_R

2_R

V0

V0

V0

V0

NV BPG400-SP

only

V BPG400-SP

only

3.3.3.1 Block Type

3.3.3.2 Status Extension

3.3.3.3 Sensor Alarm

According to the table in Appendix a, the Block Type ID has the value "16".

This parameter indicates that the overrange or underrange of the Hot Cathode Ion

Gauge instance is exceeded.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 0 0 0 0 Underrange

Exceeded

Overrange

Exceeded

Reading

Invalid

If the instance is operated in its overrange or underrange, the corresponding bit

and additionally the bit "Reading Invalid" is set.

If an error occurs, the bit "Reading Invalid" as well as the corresponding error bits

in Device Block (ID 26, 27, 28 Device Block) are set.

This parameter indicates the detectable errors occurring in connection with the

BA/HP measuring part. The present implementation allows detection of one error.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Byte 0 0 0 0 0 0 0 0 0

Byte 1 0 0 0 0 0 0 Electronics Failure

1)

Electronics Failure includes a sensor error.

1)

0

The Sensor Alarm bits defined here are copied into the Device Block ID 27 in the

"Device Exception Detail Alarm" range of the BA measuring part.

3.3.3.4 Sensor Warning

This parameter indicates the detectable warnings occurring in connection with the

BA/HP measuring part. The present implementation allows detection of one

warning.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Byte 0 0 0 0 0 0 0 0 0

Byte 1 0 0 0 0 0 0 Electronics Warning 0

The Sensor Warning bits defined here are copied into the Device Block ID 28 in the

"Device Exception Detail Warning" range of the BA/HP measuring part.

tira36e1-a (0310) BPG/HPG400 v1.cp 35

Page 36

3.3.3.5 Emission Status

This parameter indicates the emission status of the gauge.

BPG400-SP

HPG400-SP

3.3.3.6 Emission Current

(BPG400-SP Only)

3.3.3.7 Degas Status

(BPG400-SP Only)

Emission status Bit 1 Bit 0 Meaning

False 0 0 Emission Off

TRUE 0 1 Emission current low

TRUE 1 0 Emission current high

TRUE 1 1 Degas

Emission status Bit 0 Meaning

FALSE 0 Emission Off

TRUE 1 Emission On

This parameter indicates the value of the emission current in mA.

Emission current [mA] Bit 1 Bit 0

000

0.025 0 1

510

20 1 1

This parameter indicates whether the gauge is in Degas mode.

Degas Status Bit 0 Bit 1 Meaning

FALSE 0 0 Degas Off

TRUE 1 1 Degas On

3.3.3.8 Hot Cathode Block State

Command

(BPG400-SP Only)

This service is used for activating the Degas mode via Profibus.

Byte Name Structure Data type Bytes Access

0 State Command Simple Unsigned8 1 1/2_W

1 State Command

Data Field...

State

Command

0 Inactive No action

1 Set Degas

1)

The State Command Data Field can have the following values:

0 Degas Off

1 Degas On

1)

Name Description

Activates/deactivates the Degas mode

State

This service is used for activating/deactivating the

Degas mode (p < 7.2×10

If the Degas mode has not been deactivated with

Degas Off before, it is automatically turned off after

3 minutes.

Simple Unsigned8 1 1/2_W

-6

mbar).

36 tira36e1-a (0310) BPG/HPG400 v1.cp

Page 37

Appendix A: Definitions

Data types

Definitions

Store characteristics

Abbreviation Range Data type

INT8 -27 … (27 - 1) Integer 1 byte

INT16 -215 … (2

15

- 1) Integer 2 byte

INT32 -231 … (231 - 1) Integer 4 byte

UINT8 0 … (28 - 1) Unsigned integer 1 byte

UINT16 0 … (216 - 1) Unsigned integer 2 byte

UINT32 0 … (231 - 1) Unsigned integer 4 byte

FLOAT

±3.402 × 10

38

Floating Point, IEEE 754 Short Real Number,

4 byte

VSTRING(n) ISO 646 and ISO 2375

OSTRING(n) Octet string

Term Meaning

Byte Number of bytes used by a data structure (integer value)

Store This parameter defines whether the values are stored in non-

volatile memory (→ store characteristics)

Default Manufacturer-defined value

Abbreviation Meaning

V "Volatile": Value is not saved to the RAM or EEPROM and is lost

in the event of a power failure

N "Nonvolatile": Value is saved to the RAM or EEPROM and is not

lost in the event of a power failure

Data access

Abbreviation Meaning

1_R/W Acyclically readable and writeable by a Master Class 1

2_R/W Acyclically readable and writeable by a Master Class 2

1/2_R/W Acyclically readable and writeable by a Master Class 1 and 2

1_R Acyclically readable by a master Class 1

2_R Acyclically readable by a master Class 2

1/2_R Acyclically readable by a master Class 1 and 2

1_W Acyclically writeable by a master Class 1

2_W Acyclically writeable by a master Class 2

1/2_W Acyclically writeable by a master Class 1 and 2

0_XI Cyclic output data with master Class 1

tira36e1-a (0310) BPG/HPG400 v1.cp 37

Page 38

Definitions from the Profibus

standard

The following table explains terms used in connection with the Profibus.

Term Meaning

Alert Elements Alert Elements are used to communicate notification mes-

sages from slave to master when warnings, alarms or

events are detected.

Application A software functional unit consisting of an interconnected

aggregation of function blocks, events and objects, which

may be distributed and which may have interfaces with

other applications.

Characteristic An characteristic is a property or characteristic of an entity.

(Au) In block applications a block interface is defined by

input/output parameters. These parameters have characteristics called parameter characteristics. Examples are

access rights and identification names.

(IT) The UML defines characteristics as a feature within a

classifier that describes a range of values that instances of

the classifier may hold. It is a property of a class instance

(object).

Block

(Block Instance)

Class (IT) A class represents a template for several objects and

Configuration (of a

system/device)

Data Structure An aggregate whose elements need not be of the same

Data Type A data item with certain characteristics and permissible

Device A physical entity capable of performing one or more speci-

Direction of Data Input data are transmitted from the device to the bus.

Direction of Flow A positive set point causes a flow from P to A.

Entity A particular thing, such as a person, place, process, object,

Function (1) A specific purpose of an entity.

Function Block A named block consisting of one or more input, output and

A logical processing unit of software comprising an individual, named copy of the block and associated parameters

specified by a block type, which persists from one invocation of the block to the next. Concept similar to the class/

object approach, but well suited to the automation requirements.

describes how these objects are structured internally. Objects of the same class have the same definition both for

their operations and for their information structures.

A step in system design: selecting functional units, assigning their locations and identifiers and defining their interconnections.

data type, and each of them is uniquely referenced by an

offset identifier.

operations on that data, e.g. INT8.

fied functions in a particular context and delimited by its

interfaces.

Output data are transmitted from the bus to the device.

concept, association or event.

(2) One of a group of actions performed by an entity.

contained parameters. Function blocks represent the basic

automation functions performed by an application which is

as independent as possible from the specifics of I/O devices