Page 1

TECHNICAL HANDBOOK

kina40e1-g (1007)

Catalog No.

510-010

510-015

510-016

510-017

510-018

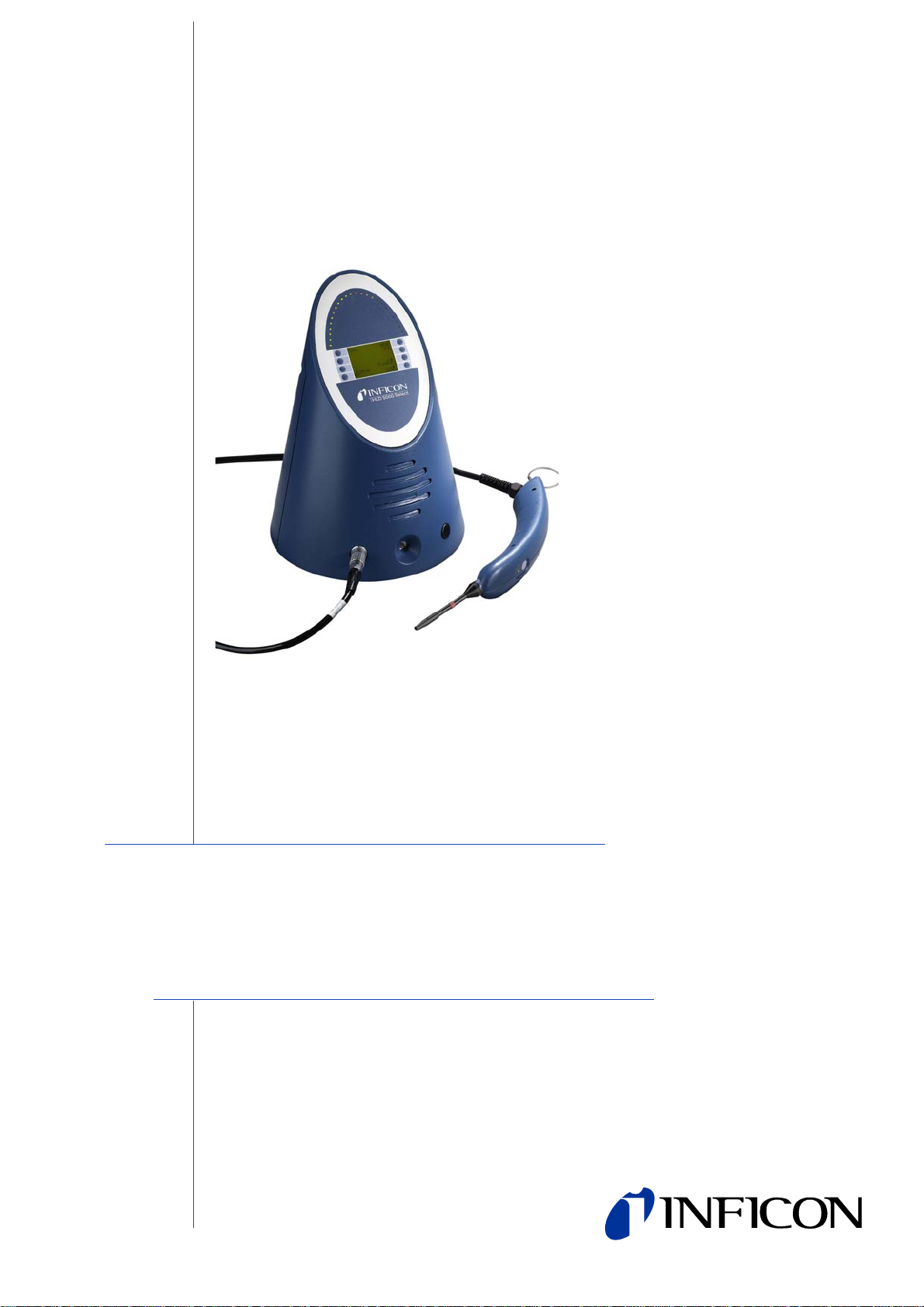

HLD5000

Refrigerant Sniffer Leak Detector

from software version V 4.1

Page 2

0-2

kina40e IVZ.fm technical handbook(1007)

Page 3

Content

1 General 1-1

1.1 Introduction 1-1

1.1.1 Purpose 1-1

1.2 Technical Data 1-2

1.2.1 Physical Data 1-2

1.2.2 Electrical Data 1-2

1.2.3 Other Data 1-2

1.2.4 Ordering Information 1-3

1.3 Supplied Equipment 1-3

1.3.1 Replacement parts / Accessories 1-4

1.4 Service 1-5

1.4.1 Service Centers 1-6

1.5 Notes on How to Read this Manual 1-8

1.5.1 Definition of Terms 1-8

1.6 Installation 1-9

1.6.1 Unpacking 1-9

1.6.2 Mechanical Connections 1-9

1.6.3 Electrical Connection 1-9

1.6.4 Wall Mounting 1-9

1.6.5 RS232 Interface 1-10

1.6.6 The Sniffer Tip 1-10

1.6.6.1 Changing the sniffer tip 1-10

1.6.6.2 Use of the flexible sniffer tip 1-11

1.6.6.3 Use of the sniffer tip extension 1-11

1.6.6.4 Use of water protection tip 1-11

2 Principle of Operation 2-1

2.1 Description 2-1

2.2 HLD5000 Overview 2-2

3 Operating the HLD5000 3-1

3.1 Start-up 3-1

3.2 Working with the HLD5000 3-2

3.3 Controls and their Function 3-3

3.3.1 Overview of the Controls and Display Components 3-3

3.3.2 Mains Switch 3-3

3.3.3 LED Display of the HLD5000 3-3

3.3.4 LC Display 3-3

3.3.5 Probe 3-5

4 HLD5000 Settings (Menu Structure) 4-1

4.1 Description of the Menu "Program” 4-1

4.1.1 TRIGGER 4-2

4.1.2 VOLUME 4-3

kina40e IVZ.fm technical handbook(1007)

4.1.3 CONTRAST 4-3

Content 0-3

Page 4

4.1.4 OPTIONS 4-4

4.1.5 CAL 4-6

4.1.6 LIST ERRORS 4-6

4.1.7 INFO 4-6

4.2 Description of the Menu Item INFO 4-8

4.3 Menu Item STANDBY 4-9

4.4 Selecting the gas type 4-9

4.5 Calibration 4-9

4.5.1 Checking the Calibration 4-10

4.5.2 Calibrating the HLD5000

with the COOL-Check 4-10

4.5.3 Calibrated leak (COOL-Check) 4-11

4.6 Shutting Down 4-11

4.7 Switching probes 4-11

5 Messages 5-1

6 Maintenance 6-1

6.1 INFICON Service 6-1

6.2 Maintenance Work 6-1

6.2.1 Replacing the Filters 6-1

6.2.1.1 Exchanging the filters in the sniffer line 6-1

6.2.2 Cleaning the Opening of the Calibrated Leak 6-3

6.2.3 Cleaning 6-3

6.2.4 Replacing Fuses 6-3

6.2.5 Replacing the Calibrated Leak

(not for SF6 / CO2 version) 6-3

Appendix A-1

kina40e IVZ.fm technical handbook(1007)

0-4 Content

Page 5

General Safety Precautions

Warning

Caution

Warning

Warning

Warning

Indicates procedures that must be strictly observed to prevent hazards to persons.

Indicates procedures that must strictly be observed to prevent damage to or

destruction of the HLD5000 leak detector.

Notice Indicates special technical requirements that the user must comply with.

The INFICON HLD5000 leak detector has been designed for safe and efficient

operation when used properly and in accord ance with this Te chnical Handbo ok. It is

the responsibility of the user to carefully read and strictly observe all safety

precautions described in this chapter and throughout this Technical Handbook. The

HLD5000 must only be operated in the proper condition and under the conditions

described in this Technical Handbook. It must be operated and maintained by trained

personal only. Consult local, state, and national agencies regarding specific

requirements and regulations. Adress any further safety, operation and / or

maintenance questions to our nearest office.

Failure to observe the following precautions could result in serious personal

injury:

The HLD5000 must not be operated while standing in water or under running or

dripping water. The same applies to all other kinds of liquids.

The HLD5000 should only be used indoors.

The HLD5000 must not be operated in explosion hazard areas.

Do not use the HLD5000 on hot surfaces.

Only mains cords having three conductors with a protective ground conductor may

be used. The HLD5000 must never be operated with a disconnected protective

kina40e IVZ.fm technical handbook(1007)

ground conductor.

General Safety Precautions 0-5

Page 6

Warning

Danger of electric shock.

Warning

Caution

Caution

Caution

Caution

Caution

• Don’t touch live parts with the sniffer tip.

• Test samples need to be disconnected from electricity before leak testing.

To replace the fuses remove the mains cord first.

Failure to observe the following precautions could result in damage to the

equipment:

Avoid contact of the HLD5000 with bases, acids or solvents and also avoid

exposure to extreme climatic conditions.

Before loosening the connecting nut, you must switch off the HLD5000 first. When

exchanging the sniffer tip make sure th at no dust or particles of dirt enter into the

opening.

The HLD5000 will only operate after having connected the sniffer line first.

Do not place the HLD5000 on hot surfaces.

During warm-up the sniffer tip must not be inserted in the test leak opening.

Otherwise, the internal calibration will be disabled and an error message will be

displayed.

0-6 General Safety Precautions

kina40e IVZ.fm technical handbook(1007)

Page 7

Caution

Under all circumstances the intake of liquids which may still be present on the

Caution

Caution

Caution

surface of the test object has to be avoided.

In the case of moist test objects (e.g. condensed water) the use of the water

protection tip is recommended (see Chapter 1.6.6).

Under all circumstances memorize the new PIN!

The PIN can only be reset by INFICON’s service organization.

Before exchanging any of the sniffer line filters please switch off the HLD5000.

When replacing filters please make sure that no particles enter into the intake

opening.

Before replacing the air filter at the bottom of the housing please disconnect the

HLD5000.

kina40e IVZ.fm technical handbook(1007)

General Safety Precautions 0-7

Page 8

0-8 General Safety Precautions

kina40e IVZ.fm technical handbook(1007)

Page 9

1 General

Warning

Caution

Warning

The refrigerant leak detector HLD5000 is delivered ready for use. Even so, we

strongly recommend that you carefully read this manual so as to ensure optimum

operating conditions right from the start.

1.1 Introduction

1.1.1 Purpose

The HLD5000 is suited for running sniffer leak tests on air conditioning and

automotive air-conditioning systems (overpressure method). Its area of application is

within the air-conditioning industry and it is used to check air-conditioners as well as

components these contain.

The HLD5000 must not be operated while standing in water or under running or

dripping water. The same applies to all other kinds of liquids.

The HLD5000 should only be used indoors.

Avoid contact of the HLD5000 with bases, acids or solvents and also avoid

exposure to extreme climatic conditions.

The HLD5000 must not be operated in explosion hazard areas.

Do not use the HLD5000 on hot surfaces.

Applied guide lines, harmonized standards and applied national standards in

languages and specifications:

EN 50081-1 electromagnetical compatibility

EN 61000-6-2 electromagnetical compatibility

EN 61010-1 electrical safety

kina40e 01.fm technical handbook(1007)

General 1-1

Page 10

1.2 Technical Data

1.2.1 Physical Data

Lowest trigger level setting

Maximum trigger level setting 50 g/a (1.76 oz/yr)

Measurement range

Detectable refrigerants

Response time 1 s

Time until ready for operation 30 s

Recovery time approx. 2 s

Gross leak recovery time approx. 8 s

For single gas probes 1.0 g/a (0.04 oz/yr)

For universal Smart probe 0.5 g/a (0.02 oz/yr)

For single gas probes 0 - 100 g/a (3.57 oz/yr)

For universal Smart probe 0 - 300 g/a (10.7 oz/yr)

Single gas probe

(depending on the instrument version)

Universal Smart probe all halogens

R134a,

R744 (CO

), SF

2

6

1.2.2 Electrical Data

Mains supply voltage 100 V ... 230 V ± 10 %

Power consumption

in standby

Protection IP 30

Overvoltage category II

Gas flow at the intake 320 sccm

1.2.3 Other Data

Dimensions (height, diameter) 365 mm; 260 mm

Weight of the main unit 4.5 kg (10 lb.)

Weight of the probe 390 g (0.9 lb.)

Permissible ambient temperatur e ra ng e

(during operation)

Max. rel. humidity of the air 80 % at +31 °C, decreasing

Length of the sniffer line 4.8 m (15.5 ft.)

50/60 Hz

< 60 VA

< 40 VA

(14.4 in.; 10.25 in.)

5 – 50 °C; 40 – 120 °F

to 50% at 40°C (104°F)

1-2 General

kina40e 01.fm technical handbook(1007)

Page 11

Visual leak rate indication LED display, 24 pcs.;

Noise level <50 dBA

Pollution degree 2

Audio alarm 100 dBA

Max. permissible height above sea level

(during operation)

1.2.4 Ordering Information

HLD5000 for R134a Cat. No. 510-010

HLD5000 for R744 (CO

HLD5000 for SF

HLD5000 with Smart Probe Cat. No. 510-017

HLD5000 for R600a/R290 Cat. No. 510-018

1.3 Supplied Equipment

0 – 200 %;

(trigger level = 100 %)

2000 m

) Cat. No. 510-015

2

6

Cat. No. 510-016

The HLD5000 is delivered ready for operation. Before installing the HLD5000 please

read Chapter 1.6. The following items have been included with the leak detector:

• Probe with line

• Sniffer tip, 100 mm long

• Flexible extension for sniffer tip with adapter

• 2 mains cords EU version, US version

• Documentation

– Operating Instructions of the HLD5000 kima40e2

– Technical Handbook HLD5000 kina40e1

– Interface Description HLD5000 kins40e1

– Spare Parts List HLD5000 kiua40e1

– Repair Instructions kipa40e1

– HEX Code

• Set of spare fuses

• Set of replacement filter holders (5 pieces)

• Set of replacement silicone filter cartridges (4 pieces)

For R744 (CO

• Adapter for CO

) version (510-015) only:

2

calibration

2

kina40e 01.fm technical handbook(1007)

General 1-3

Page 12

1.3.1 Replacement parts / Accessories

Sniffer tips

Probe tip, 100 mm long 511-021

Probe tip, 400 mm long, flexible 511-024

Extension line, 400 mm long (flexible) for the

probe tip (20 pieces)

Extension (flexible) for sniffer tip,

angled by 45° (20 pieces) 511-029

Water protection tip 511-025

Filters

Filter holders (20 pieces) 511-027

Filter cartridge (20 pcs.) 511-018

COOL-Check 511-010

Cat.-No.

511-020

Sniffer lines including

handle (for conversion to

other refrigerants)

R134a 511-030

R744 (CO

SF

6

Smart probe 511-037

R600a/R290 511-018

Sniffer line extension, 5 m 511-040

Adapter for CO

) 511-035

2

511-036

calibration 511-042

2

1-4 General

kina40e 01.fm technical handbook(1007)

Page 13

1.4 Service

INFICON GmbH

Bonner Str. 498,50968 Cologne, Germany

Tel: +49 221 3474 2222 Fax: +49 221 3474 2221

m

zisa01e1-a

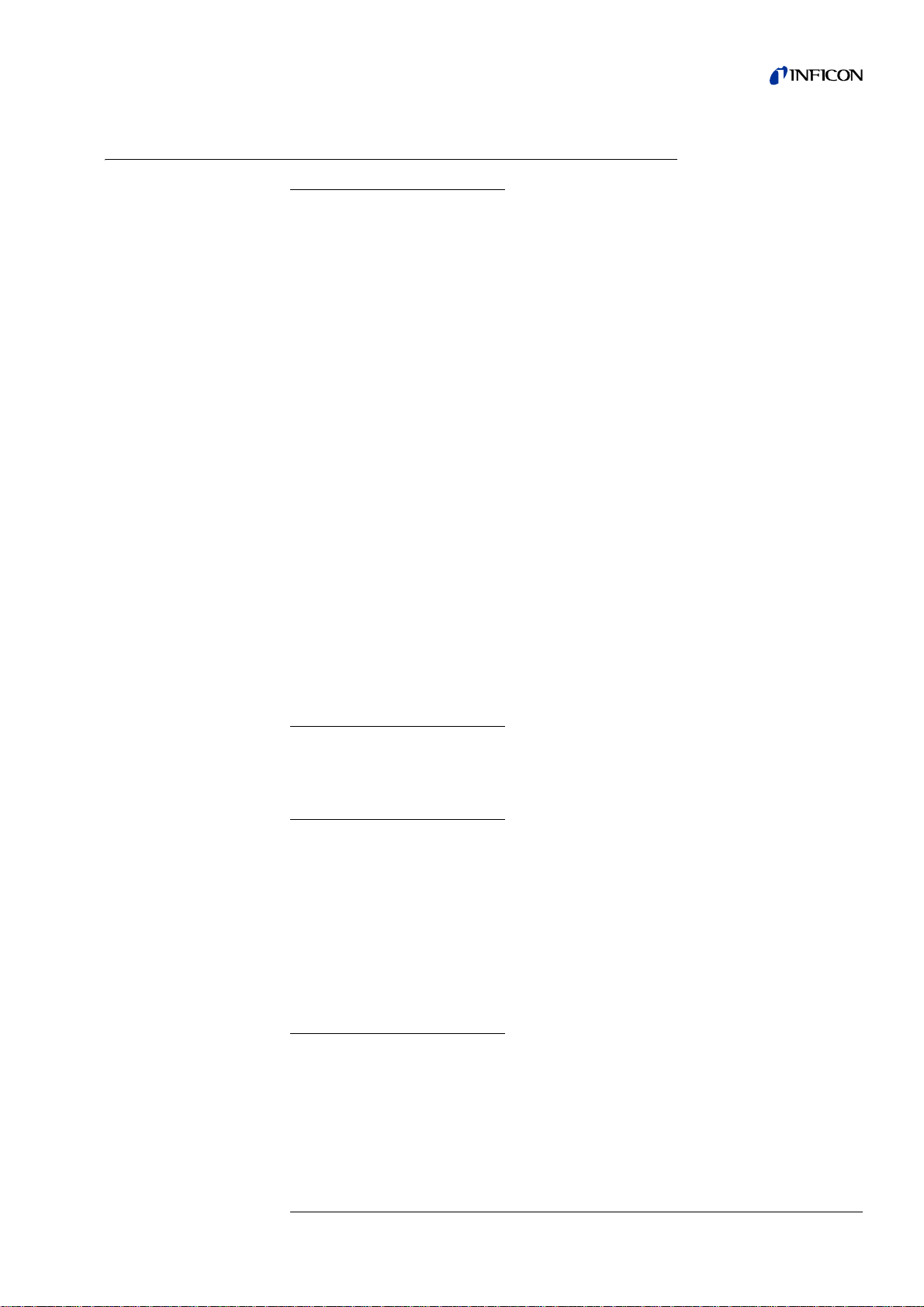

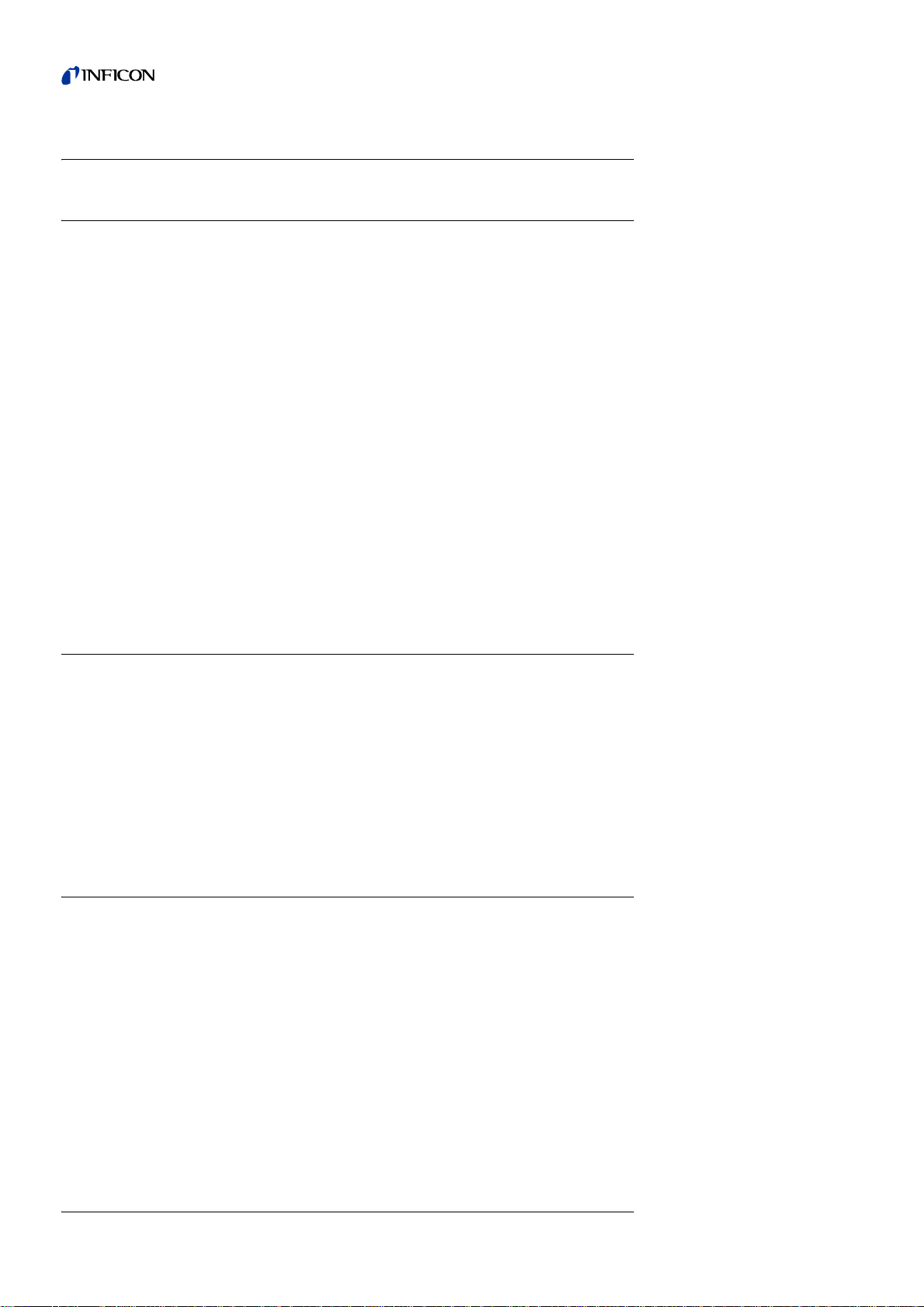

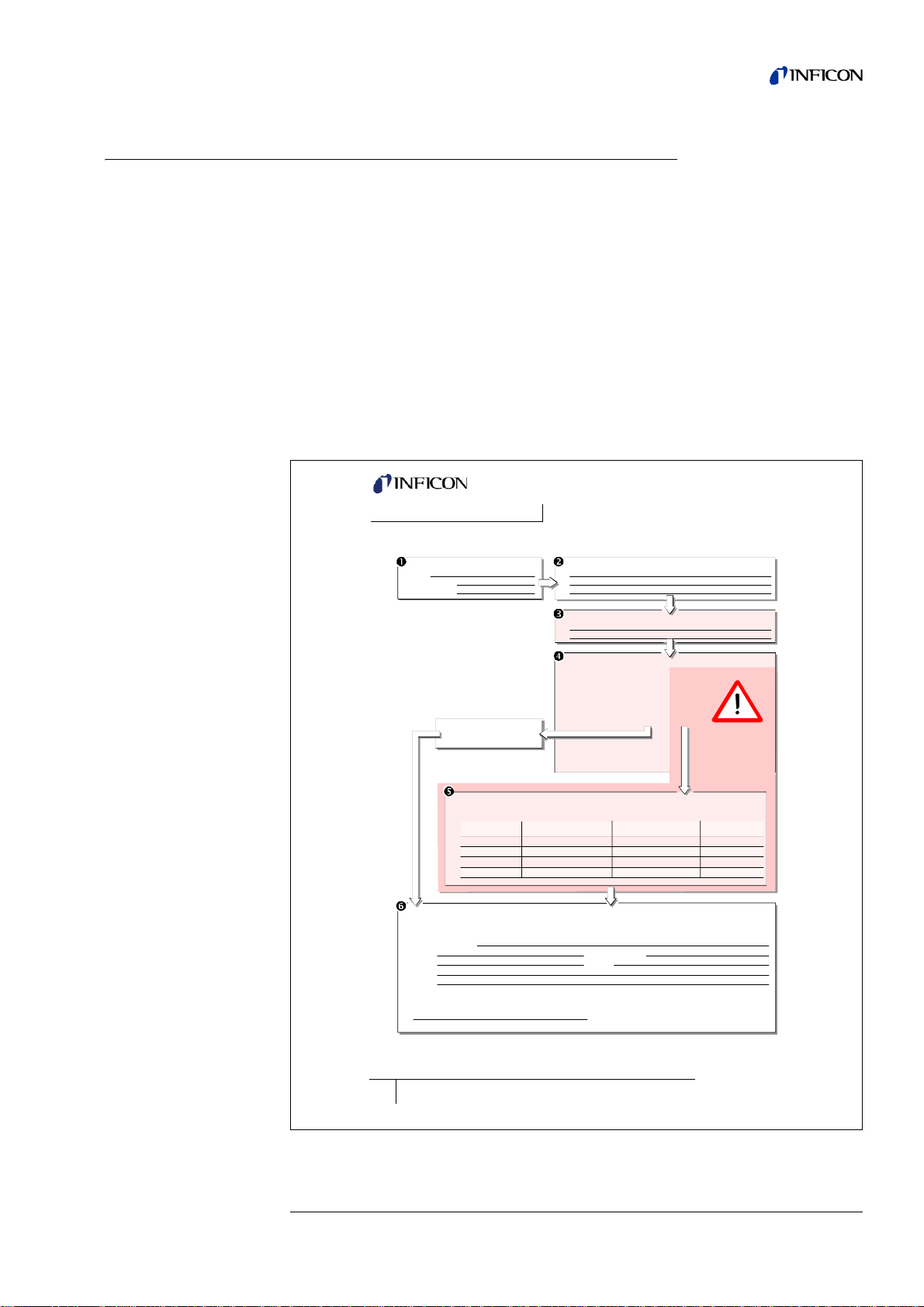

Declaration of Contamination

Legally binding declaration:

I/we hereby declare that the information on this form is complete and accurate and that I/we will assume any further costs that may

arise. The contaminated product will be dispatched in accordance with the applicable regulations.

Organization/company

Address Post code, place

Phone Fax

Email

Name

Date and legally binding signature Company stamp

1) or not containing any amount

of hazardous residues that

exceed the permissible ex posure limits

Process related contamination of product:

toxic no 1) yes

caustic no 1) yes

biological hazard no yes 2)

explosive no yes 2)

radioactive no yes 2)

other harmful substances no1) yes

The service, repair, and/or disposal of vacuum equipment and components will only be carried out if a correctly completed declaration has

been submitted. Non-completion will result in delay.

This declaration may only be completed (in block letters) and signed by authorized and qualified staff.

Copies:

Original for addressee - 1 copy for accompanying documents - 1 copy for file of sender

Harmful substances, gases and/or by-products

Please list all substances, gases, and by-products which the product may have come into contact with:

Trade/product name

Chemical name

(or symbol)

Precautions associated

with substance

Action if human contact

Description of product

Type

Article Number

Serial Number

Reason for return

Operating fluid(s) used (Must be drained before shipping.)

The product is free of any substances which are damaging to

health yes

This form can be downloaded

from our website.

2) Products thus contami nated will not be ac cepted without written

evidence of decontami nation!

If the HLD5000 is returned to INFICON, indicate whether the leak detector is free of

substances damaging to hea lth or whether it is contamin ated. If it is contaminated

also indicate the nature of the hazard. INFICON will return any leak detector without

a "Declaration of Contamination” to the sender’s address.

Before returning any equipment, please get in touch with the Service Center for the

purpose of discussing the issue (RMA number, for example).

General

We reserve the right to modify the design and the specified data. The illustrations are

not binding.

Please refer to national shipping requirements - Dangerous Goods - due to

pressurized calibrated leak.

kina40e 01.fm technical handbook(1007)

Fig. 1-1 Declaration of Contamination (original size see attachment)

www.inficon.com leakdetection.service@inficon.co

General 1-5

Page 14

1.4.1 Service Centers

Algeria jhj@agramkow.dk Finland jhj@agramkow.dk

Agramkow

Sonderborg

Belarus akhlestine@gertnergroup.de France Christophe.Zaffanella@oerlikon.com

Gertner Service

Moscow

Belgium leakdetection.service@inficon.com Germany leakdetection.service@inficon.com

INFICON GmbH

Cologne

Brazil fernandoz@prestvacuo.com.br Hungary adam.lovics@kon-trade.hu

PV Pest Vácuo Ltda.

Santa de Parnaíba

Bulgaria leakdetection.service@inficon.com India asdash@hotmail.com

INFICON GmbH

Cologne

Canada reachus@vpcinc.ca Ireland reach.unitedkingdom@inficon.com

Vacuum Products Canada Ltd.

Ontario

Central America infoqro@meisa.com Italy davide.giovanetti@inficon.com

MEISA S.a. de C.V.

Querètaro

China reach.china@inficon.com Israel urimark@mark-tec.co.il

INFICON LTD

Hong Kong

INFICON LTD

Beijing

INFICON LTD

Guangzhou

INFICON LTD

Shanghai

Czech Republic filip.lisec@inficon.com Korea reach.korea@inficon.com

INFICON GmbH

Pilsen

Denmark jhj@agramkow.dk INFICON Ltd.

Agramkow

Sonderborg

Egypt jhj@agramkow.dk Latvia leakdetection.service@inficon.com

Agramkow

Sonderborg

Estonia leakdetection.service@inficon.com Lithuania leakdetection.service@inficon.com

INFICON GmbH

Cologne

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +7 959 319 646

Fax: +7 959 319 645

Phone: +49 221 34742222

Fax: +49 221 347 42221

Phone: +55 114 154 4888

Fax: +55 114 154 4888

Phone: +49 221 34742222

Fax: +49 221 347 42221

Phone: +905.672.7704

Fax: +905.672.2249

Phone: +52 44 22 25 42 80

Fax: +52 44 22 25 41 57

Phone: +852.2862.8863

Fax: +852.2865.6883

Phone: +86.10.6590.0164

Fax: +86.10.6590.0521

Phone: +86.20.8723.6889

Fax: +86.20.8723.6003

Phone: +86.21.6209.3094

Fax: +86.21.6295.2852

Phone +420 734 331 758

Fax: +420 604 203 037

Phone: +45 744 336 36

Fax: +45 744 336 46

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 34742222

Fax: +49 221 347 42221

Agramkow

Sonderborg

OLV France

Orsay

INFICON GmbH

Cologne

Kontrade

Budaörs

Dashpute

400 064

INFICON

Blackburn

INFICON GmbH

Castelnuovo

Mark Technologies Ltd.

Kiriat Ono

Japan reach.japan@inficon.com

INFICON Co. Ltd.

Yokohama

INFICON Ltd.

Sungnam city

Suwon City

INFICON Ltd.

Cheonan City

INFICON GmbH

Cologne

INFICON GmbH

Cologne

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +33 476 351 584

Fax: +33 476 351 584

Phone: +49 221 34742222

Fax: +49 221 347 42221

Phone: +36 23 50 38 80

Fax: +36 23 50 38 96

Phone: +91 22 888 0324

Fax: +91 22 888 0324

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Phone: +39 045 6 40 25 56

Fax: +39 045 6 40 24 21

Phone: +972 35 34 68 22

Fax: +972 35 34 25 89

Phone: +81.45.471.3396

Fax: +81.45.471.3387

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +49 221 34742222

Fax: +49 221 347 42221

Phone: +49 221 34742222

Fax: +49 221 347 42221

1-6 General

kina40e 01.fm technical handbook(1007)

Page 15

Mexico infoqro@meisa.com Spain richard.cunill@leyboldoptics.com

MEISA S.a. de C.V.

Querètaro

Phone: +52 442 225 42 80

Fax: +52 442 225 41 57

Leybold Optics Ibérica

Barcelona

Phone: +34 93 66 60 778

Fax: +34 93 66 64 612

Netherlands leakdetection.service@inficon.com Sweden jhj@agramkow.dk

INFICON GmbH

Cologne

Phone: +49 221 347 42222

Fax: +49 221 347 42221

Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

Norway jhj@agramkow.dk Syria leakdetection.service@inficon.com

Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

INFICON GmbH

Cologne

Phone: +49 221 34742222

Fax: +49 221 347 42221

Poland kamola@vakpol.com Taiwan Susan.Chang@inficon.com

VAK-POL & GAZ Sp. zo.o

Pulawy

Phone: +48 60 23 15 212

Fax: +48 60 23 15 212

INFICON Company Limited

Chupei City, HsinChu Hsien

Phone: +886.3.5525.828

Fax: +886.3.5525.829

Portugal ana.correia@zickermann.pt Tunisia leakdetection.service@inficon.com

Sociedade Zickermann

S.A.R.L, Lissabon

Phone: +351 21 322 41 60

Fax: +351 21 346 91 29

INFICON GmbH

Cologne

Phone: +49 221 34742222

Fax: +49 221 347 42221

Republic of South Africa vacuquip@hotmail.com Turkey jhj@agramkow.dk

Vacuquip

Randburg

Phone: +27 73 15 78 355 Agramkow

Sonderborg

Phone: +45 741 236 36

Fax: +45 744 336 46

Russia leakdetection.service@inficon.com Ukraine leakdetection.service@inficon.com

INFICON GmbH

Cologne

Phone: +49 221 34742222

Fax: +49 221 347 42221

INFICON GmbH

Cologne

Phone: +49 221 34742222

Fax: +49 221 347 42221

Singapore reach.singapore@inficon.com United Kingdom reach.unitedkingdom@inficon.com

INFICON PTE LTD.

Singapur

Phone: +65.890.6250

Fax: +65.890.6266

INFICON

Blackburn

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Slovakia filip.lisec@inficon.com United Arab Emirates leakdetection.service@inficon.com

INFICON GmbH

Pilsen

Phone +420 734 331 758

Fax: +420 604 203 037

INFICON GmbH

Cologne

Phone: +49 221 34742222

Fax: +49 221 347 42221

Slovenia medivak@siol.net USA service.usa@inficon.com

Medivac

Ljubljani

South America except Brazil infoqro@meisa.com Inficon Inc.

MEISA S.a. de C.V.

Querètaro

Phone: +386 15 63 91 50

Fax: +386 17 22 04 51

Phone: +52 44 22 12 36 15

Fax: +52 44 22 12 19 40

Inficon Inc.

East Syracuse, NY

San Jose, CA

Inficon Inc.

Austin, TX

Phone: +1.315.434.1167

Fax: +1.315.434.2551

Phone: +1.408.361.1200

Fax: +1.408.362.1556

Phone: +1.512.448.0488

Fax: +1.512.448.0398

kina40e 01.fm technical handbook(1007)

General 1-7

Page 16

1.5 Notes on How to Read this Manual

Caution

Warning

Important remarks concerning operational safety and protection are emphazised as

follows:

Indicates procedures that must strictly be observed to prevent damage to or

destruction of the HLD5000 leak detector.

Indicates procedures that must be strictly observed to prevent haza rd s to per sons.

Notice Indicates special technical requirements that the user must comply with.

The references to diagrams, e.g. (2-2/1) consist of the Chapter No., Fig. No. and the

Item No. in that order. For example: (2-2/1) refers to item 1 in the second figure of

chapter 2, i.e. the calibration port for the calibrated leak.

1.5.1 Definition of Terms

Rejection leak rate Trigger level or leak rate limit setting at which the test sample

Default status State the HLD5000 is in when leaving the factory.

Main menu This is the first menu which is displayed after switching on the

Submenus All further menus which can be accessed from the main

Menu item A single menu line.

Standby mode Resting status of the HLD5000. The pump and valve system

PIN Personal password number so as to be able to prevent

reaches the limit between good and bad. If the reject le ak rate

is exceeded, in the measurement mode the HLD5000 will

output a visually and audibly apparent alarm.

HLD5000.

menu.

is off in this mode.

unauthorised changes to leak detector settings.

1-8 General

kina40e 01.fm technical handbook(1007)

Page 17

1.6 Installation

Warning

1.6.1 Unpacking

Unpack the HLD5000 immediately after delivery, even if it is to be installed later on.

Examine the shipping container for any external damage. Completely remove the

packaging materials.

Notice Retain the shipping container and the packaging materials in the event of

complaints about damage.

Check that the HLD5000 is complete and carefully examine the HLD5000 visually.

If any damage is discovered, report it immediately to the forwarding agent and

insurer. If the damaged part has to be replaced, please contact the orders

department.

Remove the protection foil from the display.

After switching on the HLD5000 the programmed type of gas has to appear in the

upper left corner of the display and has to match with the sticker on the probe.

1.6.2 Mechanical Connections

In order to operate the HLD5000, a sniffer line must be connected. The connection

(Fig. 2-1/2) is located on the left side on the front of the main unit. Insert the plug into

the opening until it engages. For this the red ma rk o n the p l ug must cor re spon d with

the mark on the main unit.

To disconnect the plug, retract the coupling and remove the probe’s line.

1.6.3 Electrical Connection

The HLD5000 is equipped with a wide voltage ra nge power supply unit cover ing 100

V to 230 V (± 10 %, 50/60 Hz). The mains cord is connected to the mains socket (Fig.

2-1/7) on the rear of the main unit. A fuse (Fig. 2-1/8) for each conductor of the mains

cord has been integrated in the mains socket (Fig. 2-1/7) of the main unit.

Only mains cords having three conductors with a protective ground conductor may

be used. The HLD5000 must never be operated with a disconnected protective

ground conductor.

1.6.4 Wall Mounting

kina40e 01.fm technical handbook(1007)

A fixture at the bottom of the HLD5000 (Fig. 2-2/7) allows mounting the leak detector

on walls, (for example due to space restrictions). It is recommended to place the

HLD5000 high enough (at least 2 m) so that the display points down wards.

General 1-9

Page 18

1.6.5 RS232 Interface

Caution

The HLD5000 is equipped with a RS232 in terface which is located on the rear of the

main unit under the mains connection (Fig. 1-2). This interface is of the DCE type

(Data Communications Equipment) and allows the connection of a PC for mo nitoring

and data logging. The connection is provided through a commercially available SubD plug. For further information see "Interface Description HLD5000” (kins40e1).

Fig. 1-2 RS232 Interface

Pos. Description Pos. Description

1. Mains Socket 3. RS232 Interface

2. Mains Fuses

1.6.6 The Sniffer Tip

1.6.6.1 Changing the sniffer tip

To change the complete sniffer tip (see Fig. 1-3) loosen the nut connection (Fig. 1-3 )

and pull off the sniffer tip. Insert the new sniffer tip with the guide pin (Fig. 1-3/2)

running in the groove, and firmly retighten the nut.

Ensure, that the filter cartridge (Fig. 1-3/1) is clean, and replace it as required.

Before loosening the connecting nut, you must switch off the HLD5000 first. When

exchanging the sniffer tip make sure th at no dust or particles of dirt enter into the

opening.

1-10 General

kina40e 01.fm technical handbook(1007)

Page 19

Fig. 1-3 Sniffer tip with accessories

Pos. Description Pos. Description

1 filter cartridge 5 filter holder

2 guide pin 6 extension

3 connecting nut 7 water protection tip

4 sniffer tip 8 holder for extension

1.6.6.2 Use of the flexible sniffer tip

In addition to the rigid sniffer tip included with th e HLD5000, also a 400 mm long

flexible tip (Cat. No. 511-024) may be used. By correspondingly bendin g the flexible

tip, areas which are hard to access can be reached.

1.6.6.3 Use of the sniffer tip extension

For the purpose of measuring refrigerant concentrations (e.g. in the case of already

packaged test objects in the package), for reaching points which are difficult to

access or for finding large leaks quickly a flexible extension (Cat. No. 511-020) may

be screwed onto the filter holder (see Fig. Fig. 1- 3/5). Make sure that the plastic hose

surrounds holder and filter holder. The 400 mm long extension (Fig. 1-3/6) may be

pulled out after pressing down the ring of th e h older ( Fig . 1- 3/8) ; if required , you ca n

cut the extension down to the required length. The tip facing the test object must

always be cut at an angle of approximately 45°.

1.6.6.4 Use of water protection tip

In order to avoid sucking in liquids, the water protection tip (Fig. 1- 3/7) (Cat. No. 511-

025) may be screwed onto the filter holder. The water protection tip will prevent

liquids in up to about 3 mm in he ight (the e.g. puddles of condensed water) fr om

being sucked.

kina40e 01.fm technical handbook(1007)

Fig. 1-4 Water protection tip fitted

General 1-11

Page 20

In order to prevent the entry of liquids when working on moist test objects, the handle

should not be held vertically with the sniffer tip facing up, this avoids liquids in the

water protection tip from flowing back into the sensor. If, even so, liquid has been

sucked into the sensor system, let the HLD5000 run for about 10 minutes (n ot in the

standby mode) to pump out the liquid from the sensor system via th e supply pump in

the main unit.

1-12 General

kina40e 01.fm technical handbook(1007)

Page 21

2 Principle of Operation

2.1 Description

The HLD5000 is capable of detecting, measuring and displaying quantitatively the

refrigerant, C0

analyzer.

The important subassemblies of the HLD5000 are:

• the sensor system subassembly located in the probe

• the pump system together with the electric and electronic subassemblies

accommodated in the main unit

Infrared light from a corresponding source is made to pass through a cell through

which also the gas taken in by the HLD5000 flows. This light is filtered so that only

light having a specific wavelength is allowed to pass on to an infrared light detector.

If in the presence of a leak, refrigerant, SF

cell, the infrared light is partly absorbed by the refrigerant. The intensity of the light

arriving at the detector is thus reduced.

The change in the intensity of the light is amplified electronically, converted from

analogue to digital and is displayed visually and audibly after processing by the

microprocessor in the main unit. By means of a reference measurement based on

the ambient air, the background concentration of the test gas or other interfering

gases is taken into account when processing the measured data.

or SF6 sucked in through the probe’s line by means of its infrared gas

2

or CO2 enters with the air taken into the

6

Fig. 2-1 Flow of the gas within the HLD5000

kina40e 02.fm technical handbook(1007)

Principle of Operation 2-1

Page 22

2.2 HLD5000 Overview

Fig. 2-2 Overview

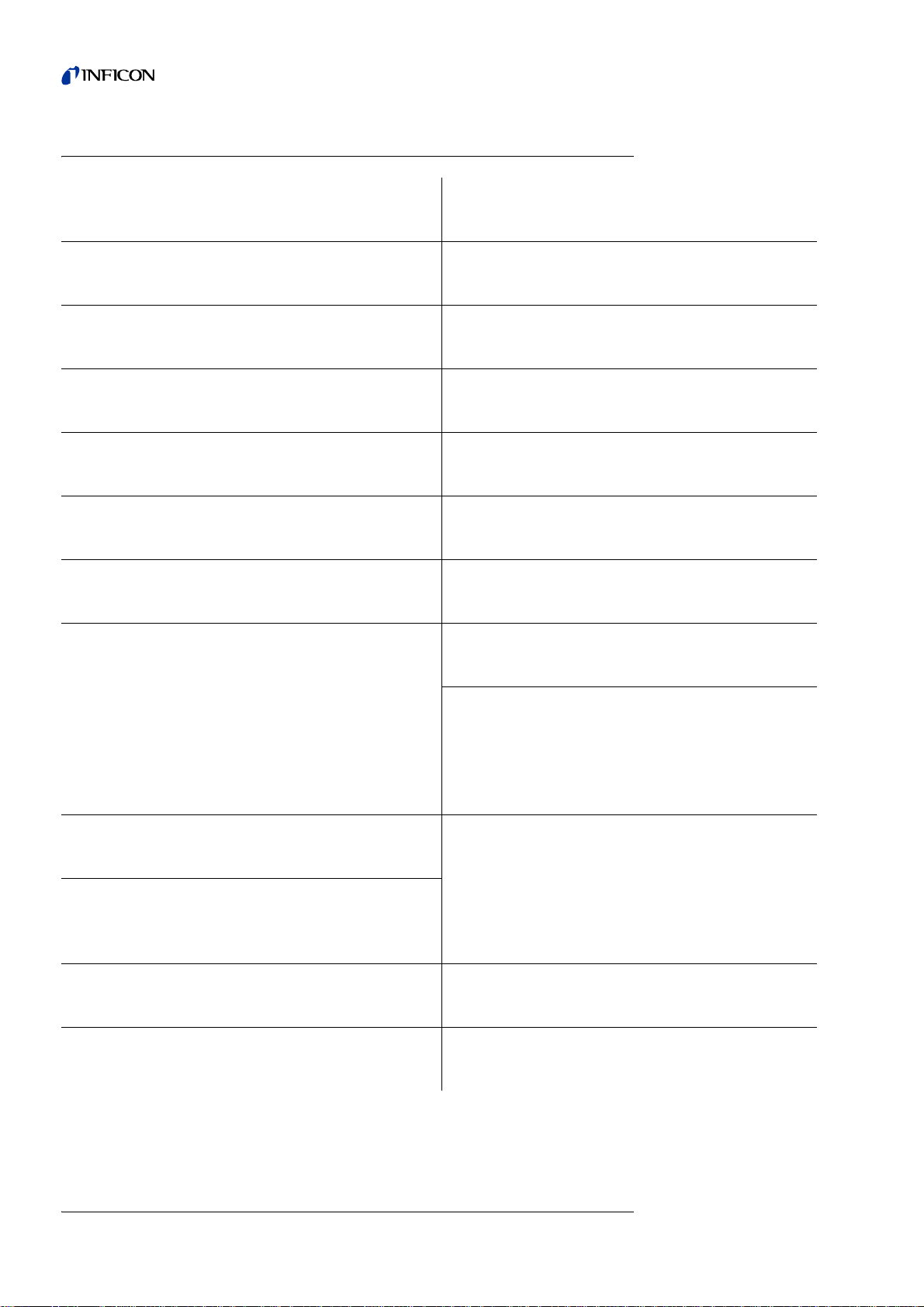

Pos. Description Pos. Description

1 Calibration port 9 RS232 Interface

2 Connection for the probe’s line 10 Mount

3 Keys for operating the menu 11 Built-in calibrated leak

4 LC display (not for SF

5 LED display 12 Air filter

6 Mains switch 13 Probe

7 Mains socket 14 Sniffer tip

8Mains fuses 15Eye

/CO2 version)

6

2-2 Principle of Operation

kina40e 02.fm technical handbook(1007)

Page 23

3 Operating the HLD5000

Caution

Caution

Caution

3.1 Start-up

Put the HLD5000 in place (see also chapter wall installation), connect the sniffer line

and the mains cord.

The HLD5000 will only operate after having connected the sniffer line first.

Do not place the HLD5000 on hot surfaces.

Notice In the default setting the serial numbers of the main unit and the probe has

to match.

Press the mains switch (Fig. 3-2/6) to switch on the HLD5000. The HLD5000 will take

about 30 seconds to warm up as indicated by the display.

During warm-up the sniffer tip must not be inserted in the test leak opening.

Otherwise, the internal calibration will be disabled and an error message will be

displayed.

In the default setting, the HLD5000 uses English menu text. To switch to another

language press the keys

the chosen language and confirm with “OK”.

After the warm-up phase of the HLD5000, an audible signal is produced and the leak

detector will be ready to make measurements. The green LED (Fig. 3-3/2) in the

probe indicates that the HLD5000 is ready to make measurements. The type of gas

to which the HLD5000 has been programmed as well as the un it of measurement for

the leak rate (factory default: g/a) is indicated on the display (Fig. 3-2/4). Moreover,

the type of probe (detectable gas) to which the HLD5000 has been set up is indicate d

on the sticker on the probe.

The main unit is usable for all refrigerants, the detectable refrigerant is determined

by the probe.

kina40e 03.fm technical handbook(1007)

PROGRAMM, OPTIONS AND LANGUAGE. Press the button for

Operating the HLD5000 3-1

Page 24

3.2 Working with the HLD5000

Warning

Caution

Provided the HLD5000 has been adapted to the specific requirements of the

application (see Chapter 4) and calibrate d accordingly, a le ak test can be per formed

as follows:

Lead the probe tip as close as possible to the locations that are to be tested. If

needed, the tip may even touch the unit under test.

Danger of electric shock.

• Do not touch live parts with the sniffer tip.

• Test samples need to be disconnected from electricity before leak testing.

Under all circumstances the intake of liquids which may still be present on the

surface of the test object has to be avoided.

In the case of moist test objects (e.g. condensed water) the use of the water

protection tip is recommended (see Chapter 1.6.6).

If a welded seam or a joint needs to be tested, the tip of the probe should be moved

no faster than 2.5 cm/s (1 inch/s) across the location which is to be tested. The

distance between probe tip and unit under test should be kept as small as possible.

In the case of probing a specific location, the tip should remain in place briefly (at

least 1 s).

The HLD5000 compares the measured leak rates with the rejection leak rates

(trigger levels) set up as described in Chapter 4.1. If the measured leak rate exceed s

the rejection leak rate, then more than half of the yellow lamps (LED) on the arcshaped display (Fig. 3-2/5) will come on and an audible alarm is released.

Due to its working principle (see Chapter 2.1) background concentrations in the

environment are suppressed and do not cause an alarm. Refrigerant clouds in front

of large leaks will also be considered a background concentration. Different from the

behavior of its predecessor HLD4000, the HLD5000 will not alarm when only

approaching leaks from a larger distance. Larger leaks will also only be detected

when close to the leak and thus, can be localized reliably.

Notice If you can not guarantee getting close enough to the leak (as described

above) larger leaks may be missed. In this case, please use the flexible

sniffer tip extension (Cat. no. 511-020) which is delivered with the

HLD5000. For this application the extension tip can be cut down to 100 mm

(4 in.) length for easier handling. (see Chapter 1.6.6.3)

Depending on the measurement mode (see Chapter 4.1) the test should be repeated

with the key of the probe pres sed to precis ely pinpoint the location of the leak or to

double check the rejection leak rate.

3-2 Operating the HLD5000

kina40e 03.fm technical handbook(1007)

Page 25

3.3 Controls and their Function

3.3.1 Overview of the Controls and Display Components

The controls and display components of the HLD5000, with the exception of the

button and the LED at the probe, are all located at the main unit (Fig. 3-2).

3.3.2 Mains Switch

The HLD5000 is switched on and off via the mains switch (Fig. 3-2/6). In addition, it

can enter a standby mode which can be activated automatically or manually.

3.3.3 LED Display of the HLD5000

The arc-shaped LED display (Fig. 3-2/5) is divided into a green half (on the left) and

a yellow half (on the right). The relative leak rates as detected are indicated here. The

center of the arc of LEDs where the LEDs change from green to yellow indica tes the

rejection leak rate which has been set up. Leak rates which remain below the

rejection leak rate are indicated by the green LEDs, higher leak rates are indicated

by the yellow LEDs. The last yellow LED corresponds to approximately 200% of the

trigger level entered.

3.3.4 LC Display

In its default setting the LC display (Fig. 3-2/4) will show the measuring screen after

switching on:

• The type of gas, for example R134a, which is detected is indicated at the top on

the left side.

• If a universal Smart probe is connected the designation “Smart” is displayed

below the gas type.

• The currently entered rejection leak rate (trigger level), for example 09.0 g/a is

indicated at the top on the right

• The actual leak rate currently detected is displayed in the center of the display.

(The lower display limit is 0.3 g/a (0.02 oz / yr) for single gas probes, and 0.2 g/a

(0.02 oz / yr) for the Smart probe.)

kina40e 03.fm technical handbook(1007)

Operating the HLD5000 3-3

Page 26

Fig. 3-1

Pos. Description Pos. Description

1 Gas type of probe 4 Info button

2 Trigger 5 Display of leak rate

3 Standby button 6 Menu button

• The left lower button opens the main menu.

• The right lower button opens the info page HLD5000 to sleep mode.

3-4 Operating the HLD5000

kina40e 03.fm technical handbook(1007)

Page 27

Fig. 3-2 Main unit

Pos. Description Pos. Description

1 Calibration port 4 LC display

2 Connection for the probe 5 LED display (leak rate display)

3 Keys to operate the menuto 4 and on

the right from 5 to 8)

(Key numbering on the left side is from

top to bottom from 1

6 mains switch

3.3.5 Probe

The probe (see Fig. 3-3) is firmly attached to the probe’s line; only the sniffer, tip

which is available in different lengths, can be exchanged.

Located on the probe are an LED (Fig. 3-3/2) and a button (Fig. 3-3/3). The LED

indicates the following operating modes:

Operating condition Description

off: HLD5000 not ready to measure

green (steady): normal operating mode / no errors

green, flashing: error / measurement not possible or

accuracy of the measurements can not be

guaranteed.

kina40e 03.fm technical handbook(1007)

Operating the HLD5000 3-5

Page 28

Operating condition Description

yellow (steady): measured leak rate >40% but below the

rejection leak rate.

yellow, flashing fast: the measured leak rate has exceeded the

rejection leak rate.

yellow / green, flashing: after a restart no link between probe and

main unit has yet been established.

Fig. 3-3 hand unit

Pos. Description Pos. Description

1 filter holder 3 button

2LED 4 eye

The button is provided to select the different testing modes, see Chapter 4 and to

calibrate the HLD5000, see Chapter 4.5.

The eye (see Fig. 3-3/4) serves the purpose of hanging the handle, for example,

when not being used.

3-6 Operating the HLD5000

kina40e 03.fm technical handbook(1007)

Page 29

4 HLD5000 Settings (Menu Structure)

Fig. 4-1 Structure of the menu

Via the menu, the HLD5000 may be adapted to the specific operating conditions or

requirements in each case.

The menu opens by pressing the

PROGRAM key.

Operating

STANDBY sets the HLD5000 into the standby mode in which the valve and

pump are switched off.

INFO contains set-up information on important parameters and settings.

The entries for the parameters are made according to th e same scheme. After having

selected the menupoint which is to be set up, for example

desired numerical value is selected. If, for example, an 8 is to be entered, press the

key next to the numbers 8 and 9, thereafter the number 8 may be selected. In order

to skip a setting or to return, the keys next to the arrows ← and → can be pressed.

In order to save changed entries into the menu, these must be acknowledged by

"OK”. Entries may be cancelled at any time by pressing "ESC”. In such a case the

new entries are not saved.

All parameters necessary to operate the HLD5000 are saved even after powering

down the HLD5000.

4.1 Description of the Menu "Program”

This menu consists of the following items:

TRIGGER

VOLUME

CONTRAST

OPTIONS

TRIGGER → LEVEL, the

CAL

LIST

ERRORS

kina40e 04.fm technical handbook(1007)

INFO

HLD5000 Settings (Menu Structure) 4-1

Page 30

4.1.1 TRIGGER

LEVEL (rejection leak rate)

Through this menu item the following settings can be entered:

LEVEL (rejection leak rate)

ALT LEVEL

GAS TYPE (with Smart probe only)

BUTTON

UNIT

These settings are described in the following:

The "

LEVEL” menu item is selected when wanting to enter the leak rate at which the

units under test shall be rejected. The level may be set 1 g/a (0.04 oz/yr) (depending

on type of gas) and 50 g/a (1.76 oz/yr). For further units please refer to the following

table:

Unit Lower display limit Upper display limit

g/a (0.5) 1.0 50.0

mbar l/s

lb/yr (1) 2 x 10

oz/yr (0.02) 0.04 1.76

Pa m

-1

3xs-1

4x10

4x10

-6

-3

-7

3.9 x 10

1.0 x 10

3.9 x 10

-4

-1

-5

(Values in parenthesis are for Smart probe only)

ALT LEVEL

Entry of the alternative rejection rate. This rejection rate is used only when the key

on the handle has been programmed to "

entered representing a percen tage of the value for

absolute terms, for example 10 g/a.

GAS TYPE (For Smart

probe only)

The HLD5000 with Smart probe offers 5 pre-programmed gases to choose from.

When opening the gas type menu a list of these five gases plus three user-definable

gases is displayed. The bottom two buttons on the left side of the display allow to

scroll the list. The currently selected gas is highlighted by inverted colors.

When switching between the pre-programmed gases the HLD50 00 does not re quire

to be recalibrated. The HLD5000 will automatically adjust for the different sensitivities

the Smart probe has for the different gases. However, the trigger value will stay the

same.

When choosing a user definable gas the HLD5000 can either be calibrated externally

or a calibration factor can be entered to enable a calibration with the built-in

calibrated leak. These factors have to be determined for each additional gas and may

be obtained from INFICON on request in most cases. When not entering a calibration

ALT” (see below). This setting may be

LEVEL, for example 50 %, or in

4-2 HLD5000 Settings (Menu Structure)

kina40e 04.fm technical handbook(1007)

Page 31

BUTTON

factor a request for external calibration will be issued after selecting this gas. If a

calibration factor is entered the HLD5000 may be calibrated with the internal

calibrated leak as for all other gases from the list.

The HLD5000 permits the entry of different configurations as to the operation of the

button in the probe so as to allow different working and test methods to be

implemented:

UNIT

"OFF" "

OFF” means that the button in the probe is disabled ( except du ring the

calibration process, see Chapter 4.5.2). The rejection leak rate (

set up under the menu item "

TRIGGER” is used, the alternative rejection

LEVEL)

leak rate does not apply here.

"ALT" "

ALT” should be selected if a unit under test is to be tested at two

different points at differing sensitivities. If the button on the probe is not

pressed the rejection leak rate set up under "

LEVEL” will apply. When

operating the button, then the alternative rejection leak rate will apply

(as set up under "

"SEARCH" With the setting "

ALT LEVEL”).

SEARCH” selected it is possible to quickly sniff the unit

under test at a high sensitivity defined by the HLD5000 with the button

on the probe not pressed. As soon as the HLD5000 has detected a

leak, the button may then be pressed to determine if the leak found

exceeds the rejection leak rate as set up under "

LEVEL”. The alternative

rejection leak rate is not available in this mode. In the main menu and

with this setting, Search (Test) will be displayed when button on at the

handle is not pressed.

Here the unit of measurement required for the measurements can be selected. One

may select from g/a; mbar x l /s; lb/yr; oz/yr and Pa x m

3

/s.

For the Smart probe only g/a, oz/yr and lb/yr are available. When switching from a

pre-programmed gas to a user-definable gas the HLD5000 will default to g/a.

4.1.2 VOLUME

Here the loudspeaker may be switched "OFF” or "ON”. When selecting "ON” the

volume may be adjusted from 1 (quiet) to 20 (loud) with the aid of the arrows ↑ and ↓.

With the Test button the selected volume can be checked.

The error sound is a two-tone sound.

4.1.3 CONTRAST

Through this function one may set up the contrast for the LC display. For this press

the keys "brighter” or "darker” as required until the desired level of brightness has

kina40e 04.fm technical handbook(1007)

been attained. The range spans from 1 to 99.

HLD5000 Settings (Menu Structure) 4-3

Page 32

4.1.4 OPTIONS

Caution

LANGUAGE

If by accident the display has been set too bright or too dark so that it can not be re ad

anymore, this may be changed as follows:

Switch off the HLD5000 and switch it on again. During the warm up phase hold the

menu key 3 or 7 pressed (see Fig. 3-2) until the display can be read properly again.

(Keys are numbered beginning at the top left side with No. 1, going down and end

with No. 8 at the button on the right side.) This value is saved permanently on ly after

having acknowledged it through the menu item "

confirmed, the former setting will apply once again after switching on the HLD5000

once more.

Under "OPTIONS” the following parameters can be set up:

Here one may select the language for the menus and messages which are displayed.

Choose between English, Spanish, French, German, Chinese and Japanese

(Katakana) language.

If by accident Chinese or Katakana language is chosen, press the buttons 2 and 6 to

get back to the english menu.

CONTRAST”. If this setting is not

CLOCK

CHANGE PIN

Here date and time may be set. The date setting format is day, month and year

(DD.MM.YY), the time format is the 24 hour format in hours and minutes (HH.MM).

Through this function it is possible to define or change the PIN (password).

The PIN (password) protects the program menu from unauthorized access.

A new PIN is defined by entering a four digit number twice in succession.

The PIN function can be disabled by entering 0000 as the PIN, using the steps

defined above. Enabling is possible at any time by proceeding as described above.

Under all circumstances memorize the new PIN!

The PIN can only be reset by INFICON’s service organization.

4-4 HLD5000 Settings (Menu Structure)

kina40e 04.fm technical handbook(1007)

Page 33

REQUEST

AUTO STANDBY

Request for

calibration

Request for calibration. The HLD5000 can be set up to remind the

operator at regular intervals to run a calibration. Through this function

the automatic request to calibrate can be sw itched on o r off wher eby

the time interval can be selected in increments of 30 minutes. The

setting is entered through the keys ↑ and ↓, and a period ranging

between 30 minutes and 24 hours may be selected. After the entered

time span has elapsed, the HLD5000 will sound an alarm and indicate

on the display a request to recalibrate.

Request for

filter

replacement

The HLD5000 can be set up to remind the operator at regular intervals

to replace the filter holder at the sniffer tip. By selecting

ON or OFF the

function can be enabled or disabled. When enabled the message

„Please replace filter holder!“ will be displayed every 40 hours of

operation. In this case please r eplace the filter holder (see Chapter

6.2.1) and acknowledge the message. The next request for filter

replacement will pop up after further 40 hours of operation. As factory

default the function is enabled.

The HLD5000 offers the possibility of automatically reverting to the standby mode

during pauses or periods during which it is not used. A time span ranging between 1

and 15 minutes may be entered. If the HLD5000 is not used for a period of time

longer than the one set up here, the leak detector will thereafter revert automatically

to the standby mode.

When lifting the probe, the HLD5000 will automatically revert to normal operation and

will be ready to make measurements within 2 seconds.

RS232

Through this menu, the settings for the RS232 interface of the HLD5000 can be

entered.

Protocol Selection of the interface protocol: "OFF”, "Normal” or "Simple”.

If the RS232 interface is not used, the "OFF” setting is recommend ed

to exclude the possibility of any interference.

For further details on the interface protocol refer to "Interface

Description HLD5000 (kins40e1)”.

Baud rate Entry of the baud rate for the RS232 interface. Available settings are

300, 600 1200, 2400, 4800 or 9600 baud. The default setting is 9600

baud.

External Calibrated Leak

Here the setting for the leak rate of the external leak can be entered.

The setting is performed as described on Chapter 4.4 and has to be confirmed with

“OK“. If for example the external leak rate is entered in g/a and cha nged into another

unit of measurement, the HLD5000 converts the leak rate g/a into the new unit of

kina40e 04.fm technical handbook(1007)

measurement.

HLD5000 Settings (Menu Structure) 4-5

Page 34

4.1.5 CAL

Through this menu item the HLD5000 may be calibrated with an external test leak.

The SF

calibrated leak. When pushing the „

the display: “Sniff external test leak“, the appointed leak rate and the type of

refrigerant of the external test leak.

The calibration is performed as follows:

• Enter the leak rate of the external test leak under the menu item “Ext. Test leak“.

• Go back to menu item “CAL“.

• Hold the sniffer tip against the gas outlet of the external leak until the LED signal

• Confirm with probe button.

• Keep the sniffer tip on the outlet until the information “calibration successful“ or a

The HLD5000 is calibrated now.

4.1.6 LIST ERRORS

Here a list containing the 12 most recent error messag es and the acknowledge ment

of error messages is displayed. The time, date and an error code is displayed, and

via the key "View” the error with time and date can be displayed in plain text.

and CO2 version of the HLD5000 can only be calibrated using an external

6

is stable.

beep is displayed.

CAL“ button the following information appears in

4.1.7 INFO

Main Unit Info

The error code consists of a letter and a two digit number.

Meaning of the letter:

• E: Error / warning was displayed

• R: Error / warning has been removed (remove)

• M: General message, for example "power up” (message)

The two digit number in the error code corresponds to th e number given in the table ,

found in the repair instruction (doc. no. kipa40e).

The INFO key provides important information to the user relating to the entered

parameters and the operating modes of the HLD5000. By scrolling forward and

backward using the arrow keys the 6 different information pages can be displayed.

Detailed in the following is the information which can be accessed:

• Internal housing temperature

• Number of operating hours of the main unit

• Software version number for the main unit

4-6 HLD5000 Settings (Menu Structure)

kina40e 04.fm technical handbook(1007)

Page 35

Probe Info 1

Probe Info 2

CAL Info

• Internal sensitivity factor S for monitoring the sensor circuitry

• Differential pressures Δp1and Δp2 to monitor the gas flows in the measurement

and reference lines

• Channel used by the AD converter

• Number of operating hours for the probe

• Software version number for the probe

• HEX Code of probe

• Contains information for service people

•CAL factor

• Phase

• Sensor factor e.g. R134a → R404A

• Factor which is multiplied with the internal test leak to get the equivalent leak rate

for the measured gas.

Test leak info

U / I-Info

• Leak rate for the calibrated leak normalized to 20 °C

• Leak rate of the calibrated leak compensated for temperature and type of gas

• + 12 Volt supply voltage (U+)

• - 12 Volt supply voltage (U-)

• Supply voltage for the infrared light source in the probe (U light)

• Current flow through the infrared light source in the probe (I light)

• Probe test voltage to monitor the voltage supply (U probe)

kina40e 04.fm technical handbook(1007)

HLD5000 Settings (Menu Structure) 4-7

Page 36

4.2 Description of the Menu Item INFO

The INFO menu item contains set-up information relating to the following

parameters. By scrolling back and forth you can switch between „Setup-Info 1“ and

„Setup-Info 2“.

Setup-Info 1: Trigger level

Alt. trigger level

Button

Volume

Setup-Info 2: Date

Time

Next calibration

TRIGGER LEVEL

Displays the selected rejection leak rate, for example 10 g/a.

ALT. TRIGGER LEVEL

Displays the selected alternative rejection leak rate. Values which were entered in %

are converted to absolute values.

BUTTON

Informs about the selected setting (

VOLUME

Indicates the volume setting for the loudspeaker.

DATE

Indicates the current date as day, month and year.

TIME

Indicates the current time as hours, minutes and seconds.

NEXT CALIBRATION

Indicates how long it will be (hours and minutes) until the reminder to calibrate will be

displayed.

OFF, ALT, TEST) for the button in the probe.

4-8 HLD5000 Settings (Menu Structure)

kina40e 04.fm technical handbook(1007)

Page 37

4.3 Menu Item STANDBY

Pressing the standby key makes the HLD5000 enter the standby mode during which

the valve in the handle is disabled and the diaphragm pump is shut down.

In this mode, no leak rate measurements can be run.

When letting the HLD5000 enter the standby mode by operating the key "Standby”

and not through the automatic shut down feature (can be configured through the

menu item "

reactivated by pressing any key.

After this time, operating any key on the HLD5000 or moving the handle will reset the

leak detector back to the measurement mode.

AUTO STANDBY”) during the first 25 seconds, the HLD5000 can only be

4.4 Selecting the gas type

For selective, single gas probes (Cat. No. 510-010 through 510-016 or sniffer line

Cat. No. 511-030 to 511-036) the detected gas type can be changed by connecting

a different, selective sniffer line.

For the Smart probe the detectable gas can be selected from a list of 5 preprogrammed gases plus three user-definable gases. (See „Gas Type“ in Chapter

4.1.1)

4.5 Calibration

The HLD5000 is equipped with a built-in calibrated leak by means of which the leak

detector may be calibrated. The service life of the calibrated leak is about 2 years.

Three months before expiration of the calibrated leak a message will be displayed

reminding the operator to replace it.

Notice The SF

calibrated leak. Calibration will only be possible using an external

calibrated leak (see „Gas Type“ in Chapter 4.1.1).

Notice When operating the Smart probe user definable gases will require to be

calibrated with an external test leak until a calibration factor is entered for

this gas type.

Notice Replacement leaks should not be purchased in advance of their need as

they have a limited lifetime. Any leaks being held in stock should be kept in

a cool place.

Notice In order to ensure accurate measurements wait for at least five minutes

after switching on before running a calibration .

and CO2 version of the HLD5000 is not equipped with its own

6

kina40e 04.fm technical handbook(1007)

HLD5000 Settings (Menu Structure) 4-9

Page 38

4.5.1 Checking the Calibration

A calibration can be checked by inserting the probe tip into the calibration port

without depressing the button on the probe. A message will be displayed indicating

whether or not the calibration is still OK (refer also to Chapter 4.1.4, manual

calibration).

On the leak rate display, two LEDs to the left and right of the 100% mark will flash. If

the measured value is outside this mark, a recalibration will be required. The

currently measured value is indicated by two moving LEDs just like during the

calibration process. Moreover, the calibration status is indicated on the display.

A recalibration can be started immediately by pressing the button, and the probe tip

does not have to be removed from the calibration port.

If a recalibration is required, this is indicated on the display and by an audible tone.

During the check, the probe must be held still and straight.

4.5.2 Calibrating the HLD5000 with the COOL-Check

To calibrate the HLD5000, press the button on the probe and insert the sniffer tip into

the calibration port at the front of the main unit. The HLD5000 will then start the

calibration process automatically. During the calibration process it is not necessary

to keep the button on the probe pressed. The individual phases of the calibration

process are indicated on the display which also informs the user about a successful

calibration.

Notice During the calibration process, the probe must be held still and straight,

otherwise no calibration will be possible.

Notice During the calibration, the opening for the calibrated leak should not be

exposed to strong air flows (from air-conditioning units, for example).

Notice When performing the calibration using the extension tip Cat. No. 511-020

the insert should be used in the opening of the calib r at ed leak so as to

ensure that the tip is properly centered in the opening.

Fig. 4-2 Opening at the calibration port

4-10 HLD5000 Settings (Menu Structure)

kina40e 04.fm technical handbook(1007)

Page 39

Fig. 4-3 Calibrated leak

4.5.3 Calibrated leak (COOL-Check)

The calibrated leak is located in the bottom of the main unit. It consists of a gas

canister with a printed circuit board attached to the bottom.

When the calibrated leak is nearly empty, the message "Leak nearly empty. Please

replace!” will be displayed.

The user will have to replace the calibrated leak within two to three months before

the calibrated leak will be completely empty.

How to replace the COOL-Check is described in Chapter 6.2.5.

Notice Replacement leaks should not be purchased in advance of their need as

they have a limited lifetime.

4.6 Shutting Down

The HLD5000 may be switched off at any time by operating the mains switch

independently of the operating mode it is in.

All parameters are saved when the HLD5000 is powered down.

4.7 Switching probes

To convert the HLD5000 to a different probe shut down the HLD5000, unplug the

current sniffer line and connect a different sniffer line with a different probe. The

probe type will be indicated in the upper left corner of the display after restarting the

HLD5000.

kina40e 04.fm technical handbook(1007)

HLD5000 Settings (Menu Structure) 4-11

Page 40

4-12 HLD5000 Settings (Menu Structure)

kina40e 04.fm technical handbook(1007)

Page 41

5 Messages

While operating in the leak detection mode, the display will provide information which

will support the operator using the HLD5000. Besides messages relating to leak

detector settings also warnings and error messages may be displayed.

The HLD5000 is equipped with comprehensive self-diagnostic means. If a fault

condition is detected by the controller board this is indicated via the display to the

operator.

Errors are events which force an interruption to the measurement sequence and

which the HLD5000 is not capable of remedying on its own. Errors are displayed in

plain text on the display. The error sound is a two-tone sound.

The error message can be erased by pressing the "OK” key.

As long as an error status exists, a warning triangle comes up in the lower line of the

display.

An overview over the error messages which may occur while the machine is in use

and possible remedies are listed below.

A list of all error messages as well a notes for troubleshooting is provided in the

Repair Instructions (kipa40e1).

Displayed message Explanation/possible cause Remedies

Leak nearly empty

Please replace!

Probe not connected! There is no data connection to the sniffer

Leak temperature is too high! Main Unit is standing on a hot surface

Leak temperature too low! Ambient temperature too low Increase temperature around the main

Housing temperature too high! Ambient temperature too high

Flow at measuring line too low! Measuring line is blocked

Leak at measuring line! Measuring line is leaking

Service life of the Cool Check is less than

3 months

Cool Check is nearly empty

Set on wrong date

probe

Sniffer Probe is not connected

If LED at Sniffer Probe is off:

processor in the Sniffer Probe does not

run

Ambient temperature too high

Fan defect or blocked

Differential sensor is broken

One of the hoses to differential sensor is

leaking

Differential sensor is broken

Replace Cool Check

Program Main Unit with new date

Check the sniffer line

Check the LEMO plug or change sniffer

line

Decrease the temperature around the

main unit

unit

Decrease temperature around the main

unit

Change the fan

Change the filters of the sniffer tip

Change the CPU-Board (Sniffer Probe)

Check the gasket of sniffer tip

Check or change the hoses to

differential sensor

Change the CPU-Board (Sniffer Probe)

Flow at reference line too low! Reference line is blocked

Filter is clogged

kina40e 05.fm technical handbook(1007)

Differential sensor is broken

Check the sniffer line, change the sniffer

tip

Change the filters of the sniffer tip

Change the CPU-Board (Sniffer Probe)

Messages 5-1

Page 42

Displayed message Explanation/possible cause Remedies

Leak at reference line! Reference line is leaking

One of the hoses to differential sensor is

leaking

Differential sensor is broken

Leak empty. Please replace! Cool Check empty

Wrong date (main unit)

Change the sniffer line

Check or change the hoses to the

differential sensor

Change the CPU-Board (Sniffer Probe)

Change the Cool Check

Adjust new date (main unit)

Change Cool Check

Sensor sensitivity too low! Optical cell is contaminated with water Depending on the quantity of water let

run the HLD5000 from 1 minute to 2

hours

Light barrier dirty Dust has accumulated in the test leak

opening and is interrupting the light

barrier.

Turn off HLD5000. Blow out the test leak

opening with compressed air. Restart

HLD5000.

Calibration with internal test leak can be

started from the main menu manually.

Calibration proof not possible

Wrong gas type in internal test leak

Calibration not possible

Wrong gas type in internal test leak

Smart probe programmed to userdefinable gas

or SF6 probe connected

CO

2

Smart probe programmed to userdefinable gas

or SF6 probe connected

CO

2

Check calibration with external test leak

Check calibration with external test leak

Warning 02: light barrier dirty Light barrier dirty Clean test port of calibrated leak

If problem persists confirm and calibrate

with external leak until light barrier is

replaced

Calibration time out limit exceeded Light barrier dirty Clean test port of calibrated leak

If problem persists shut down the

HLD5000 and restart. Calibrate with

external leak afterwards until light

barrier is replaced

5-2 Messages

kina40e 05.fm technical handbook(1007)

Page 43

6 Maintenance

6.1 INFICON Service

If an the HLD5000 is returned to INFICON, please indicate whether it is free of

substances damaging to hea lth or whether it is contamin ated. If it is contaminated

also indicate the nature of the hazard. For this you must use a form pre-prepared,

which we will send to you upon request or which you may copy from this manual.

The form is called: "Declaration of Contamination of Vacuum Equipment and

Components”.

Affix this form to the HLD5000 or enclose it with the leak detector. This Declaration

of Contamination is required by us to meet the requirements of the laws and to

protect our staff.

INFICON will return any leak detectors without a "Declaration of Contamination" to

the sender’s address.

6.2 Maintenance Work

No fixed maintenance intervals have been specified for the HLD5000. The work

described in the following will only have to be done as required.

6.2.1 Replacing the Filters

The filters serve the purpose of filtering the air taken in. In order not to obstruct the

airflow and to prevent the HLD5000 from being contaminated all filters should be

exchanged preventatively.

There are three filters in the HLD5000, two within the sniffer tip filtering the air intake

through the sniffer line and one air filter at the bottom of the housing.

6.2.1.1 Exchanging the filters in the sniffer line

We recommend to exchange the filter holder at the probe tip preventatively at least

once a week and the filter cartridg e at the bottom of the sniffer tip at least once a

month.

If the function “Request for filter replacement“ is enabled, the message „Please

replace filter holder!“ will be displayed every 40 hours of operation. After replacing

the filter holder and acknowledging the message the internal counter for this function

will be reset and the message will pop up after another 40 hours of operation. Any

dirty or clogged filter in the sniffer line will lead to the same error message as a dirty

tip filter holder. In dirty conditions the error message “flow at measuring line too low”

or “flow at reference line too low” may occur before expiration of these time limits. On

occurrence of these error messages please exchange the tip filter holder first. If this

does not fix the problem, please also exchange the filter cartridge.

kina40e 06.fm technical handbook(1007)

Maintenance 6-1

Page 44

Caution

Before exchanging any of the sniffer line filters please switch off the HLD5000.

Caution

When replacing filters please make sure that no particles enter into the intake

opening.

The fine filters at the probe tip are firmly built into the filter holder. To replace the filter

holder please:

1 Unscrew the filter holder from the probe tip

2 Screw on a new filter holder.

Replacement filter holders are available for order in sets of 20 pieces as

Cat. No. 511-027.

The fine filters at the bottom of the sniffer tip are firmly built into the filter cartridge.

To exchange the filter cartridge please:

1 Loosen the screw at the bottom of the sniffer tip and detach the sniffer tip from the

probe handle

2 Take off the filter cartridge from the bottom of the sniffer tip

3 Place a new one on the two ends of the measurement and reference line

4 Attach the sniffer tip back onto the probe handle and retighten the screw at the

bottom of the sniffer tip.

Replacement filter cartridges are available for order in sets of 20 pieces as Cat. No.

511-018.

5 Exchanging the air filter at the bottom of the housing.

The air filter at the bottom of the housing sh ould be replaced once it has turned dark

gray or deposits of dirt are clearly visible on the filter.

Before replacing the air filter at the bottom of the housing please disconnect the

HLD5000.

1 Switch off the HLD5000 off and pull the mains plug

2 Unscrew the screws in the middle of the filter

3 Remove the filter and depending on how dirty it is either replace it or clean it (for

example with compressed air or a brush)

4 Insert the filter once more

5 Tighten the screw

Replacement air filters are available for order as Cat.No. 200 000 086.

kina40e 06.fm technical handbook(1007)

6-2 Maintenance

Page 45

6.2.2 Cleaning the Opening of the Calibrated Leak

Warning

In order to prevent the light barrier in the opening of the calibrated leak from being

interrupted by dirt, the opening should be blown out with clean compressed air

regularly.

6.2.3 Cleaning

The housing of the HLD5000 is made of plastic. Therefore to clean the housing use

cleaning only agents which are recommended to clean plastic surfaces (for example

mild household cleaning agents). Do not use any solvents which attack plastic

materials.

6.2.4 Replacing Fuses

To replace the fuses remove the mains cord first.

The fuse holder (Fig. 2-2/8) of the HLD5000 is located below the ma ins socket on the

rear of the main unit. To replace the fuses proceed as follows:

1 Press down the pin in center and pull the fuse holder out.

2 Pull the fuses out and check these.

3 If required insert a new fuse. In any case two fuses of the same rating will have to be

inserted. The mains fuses required are slow-blow T 1 A (Ø 5 x 20 mm).

4 Insert the fuse holder once more and press it home until the securing pin engages.

After having replaced the fuses, reconnect the mains cord to the HLD5000 and

switch on the leak detector.

6.2.5 Replacing the Calibrated Leak (not for SF6 / CO2 version)

The calibrated leak should be rep laced two to three months at the latest after the

message " Leak nearly empty. Please replace!” has been displayed. The calibrated

leak is replaced as follows:

1 Switch off the HLD5000 off and pull the mains plug.

2 Turn the main unit on its side to expose the base.

3 Turn the yellow plastic screw back completely.

4 Carefully remove the calibrated leak. Don’t damage the cable.

5 Pull off the plug (blue) from the calibrated leak’s printed circuit board.

kina40e 06.fm technical handbook(1007)

6 Take a new calibrated leak and insert the plug into the socket.

Maintenance 6-3

Page 46

7 Insert the new calibrated leak and feed the cable with the plug through the hole.

8 Secure with the screw. Please make sure that the rubber seal is firmly in place and

that the outlet opening of the calibrated leak is positioned approximately at the

middle of the opening for the calibrated leak.

9 Switch off the HLD5000 on and run a new calibration after about 5 minutes.

A residual amount of refrigerant might be left un der pressure (more than 5 bar) in the

canister of the empty leak standard. Therefore the COOL-Check must be disposed

PROPERLY - following the local, state and national regulations - or must be sent

back to INFICON / your supplier.

6-4 Maintenance

kina40e 06.fm technical handbook(1007)

Page 47

INFICON GmbH

Bonner Str. 498,50968 Cologne, Germany

Tel: +49 221 3474 2222 Fax: +49 221 3474 2221

m

zisa01e1-a

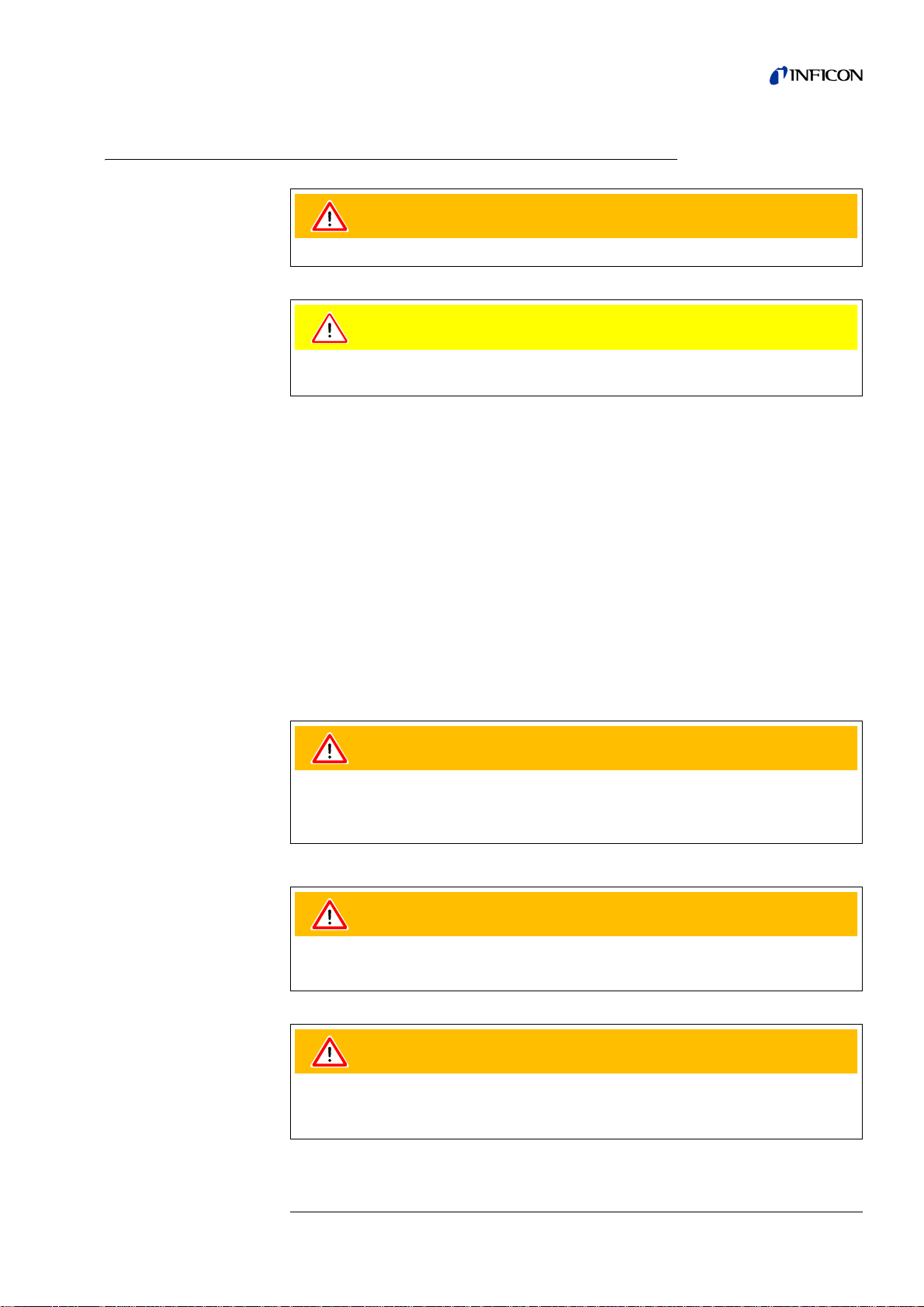

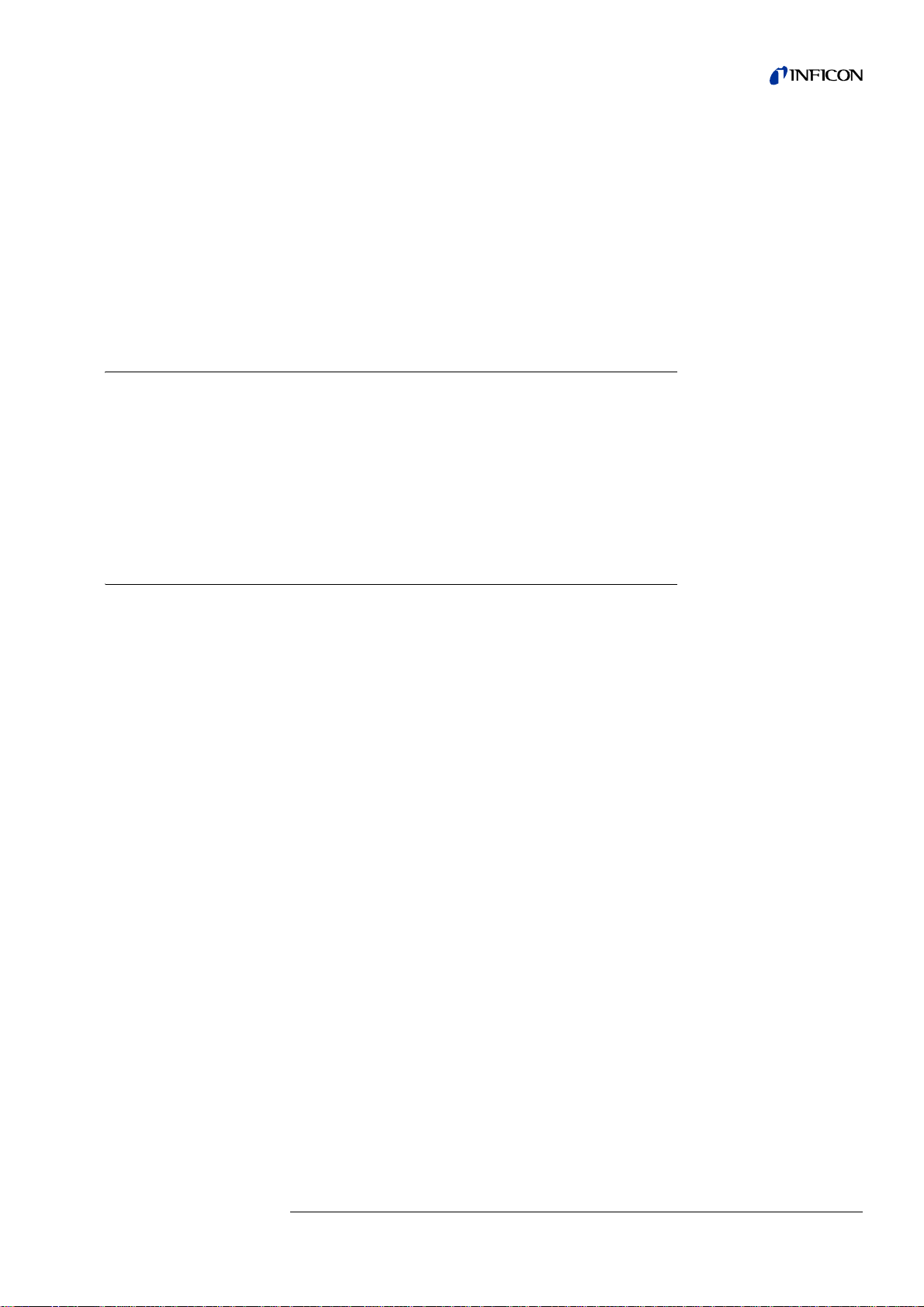

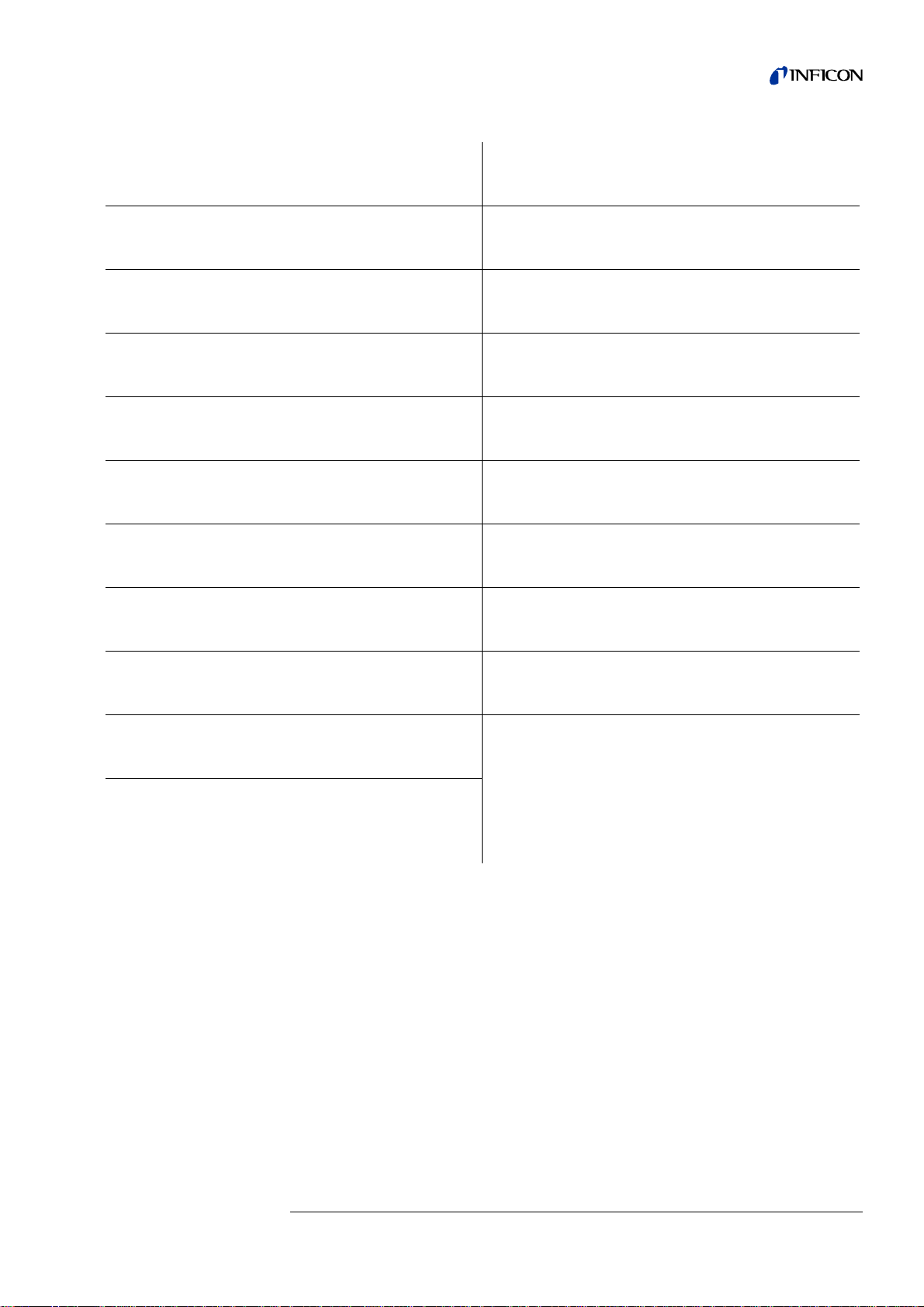

Declaration of Contamination

Legally binding declaration:

I/we hereby declare that the information on this form is complete and accurate and that I/we will assume any further costs that may

arise. The contaminated product will be dispatched in accordance with the applicable regulations.

Organization/company

Address Post code, place

Phone Fax

Email

Name

Date and legally binding signature Company stamp

1) or not containing any amount

of hazardous residues that

exceed the permissible ex posure limits

Process related contamination of product:

toxic no 1) yes

caustic no 1) yes

biological hazard no

yes 2)

explosive no

yes 2)

radioactive n o

yes 2)

other harmful substances no1) yes

The service, repair, and/or disposal of vacuum equipment and components will only be carried out if a correctly completed declaration has

been submitted. Non-completion will result in delay.

This declaration may only be completed (in block letters) and signed by authorized and qualified staff.

Copies:

Original for addressee - 1 copy for accompanying documents - 1 copy for file of sender

Harmful substances, gases and/or by-products

Please list all substances, gases, and by-products which the product may have come into contact with:

Trade/product name

Chemical name

(or symbol)

Precautions associated

with substance

Action if human contact

Description of product

Type

Article Number

Serial Number

Reason for return

Operating fluid(s) used (Must be drained before shipping.)

The product is free of any substances which are damaging to

health yes

This form can be downloaded

from our website.

2) Products thus contam i nated will not be ac cepted without written

evidence of decontam i nation!

Fig. 6-1 Declaration of contamination

kina40e 06.fm technical handbook(1007)

www.inficon.com leakdetection.service@inficon.co

Maintenance 6-5

Page 48

Fig. 6-2 Declaration of Conformity

6-6 Maintenance

kina40e 06.fm technical handbook(1007)

Page 49

Appendix

A

alarm 1-3

alarm, audible 3-2

B

baud rate 4-5

BUTTON 4-8

button 4-3

C

calibrated leak 4-11, 6-3

calibrated leak, external 4-5

calibration 4-5–4-6, 4-8–4-9

calibration factor 4-2, 4-9

checking the calibration 4-10

control component 3-3

COOL-Check 4-10

D

G

gas type 1-9

gases 2-1, 4-2, 4-9

I

installation 1-9

interface 1-10, 4-5

interface description 1-3, 1-10

L

language 4-4

leak test 3-2

LED 3-3, 3-5, 4-10

LED, green 3-1

LED, yellow 3-2

level (ALT) 4-2

loudspeaker 4-3

M

data communications equipment 1-10

data, electrical 1-2

data, other 1-2

data, physical 1-2

dimensions 1-2

display component 3-3

display limit, lower 4-2

display limit, upper 4-2

E

error 4-6

extension 1-11, 3-2

F

filter 1-3, 6-1

Filter cartridge 1-4

filter cartridge 6-1

filter holder 6-2

filter replacement 4-5

kina40eSIX.fm technical handbook(1007)

mains supply voltage 1-2

mains switch 3-3

maintenance 6-1

measured leak rate 3-2

measurement range 1-2

menu 1-8

menu structure 4-1

P

Pin, change 4-4

power supply unit 1-9

probe 3-1, 3-5

R

refrigerant 1-2

rejection leak rate 4-2

replacing fuses 6-3

request 4-5

request to calibrate 4-5

response time 1-2

Appendix A-1

Page 50

RS232 1-10, 4-5

S

sensitivity 4-3, 4-7

Settings HLD5000 4-1

shipping container 1-9

sniffer tip 0-6, 1-10, 4-6, 6-2

solvent 6-3

standby 1-2, 4-1, 4-5, 4-9

T

test leak, internal 4-10

trigger 3-3, 4-1–4-2, 4-8

trigger level setting 1-2

U

unit 3-1, 4-3, 4-5

V

volume 4-3, 4-8

W

warm-up phase 3-1

water protection tip 0-7, 3-2

Weight 1-2

A-2 Appendix

kina40eSIX.fm technical handbook(1007)

Page 51

kina40eSIX.fm technical handbook(1007)

Appendix A-3

Page 52

INFICON GmbH, Bonner Strasse 498, D-50968 Cologne, Germany

Phone: +49 (0)221 347-40 Fax: +49 (0)221 347-41429 E-mail: leakdetection@inficon.com

UNITED STATES TAIWAN JAPAN KOREA SINGAPORE GERMANY FRANCE UNITED KINGDOM HONG KONG

Visit our website for contact information and other sales offices worldwide. www.inficon.com

Dokument: kina22e1-g (1007)