Page 1

OPERATING MANUAL

jinb80e1-h (1011) Translation of the original manual

Catalog-No.

550-300

550-310

550-330

from software version 1.7

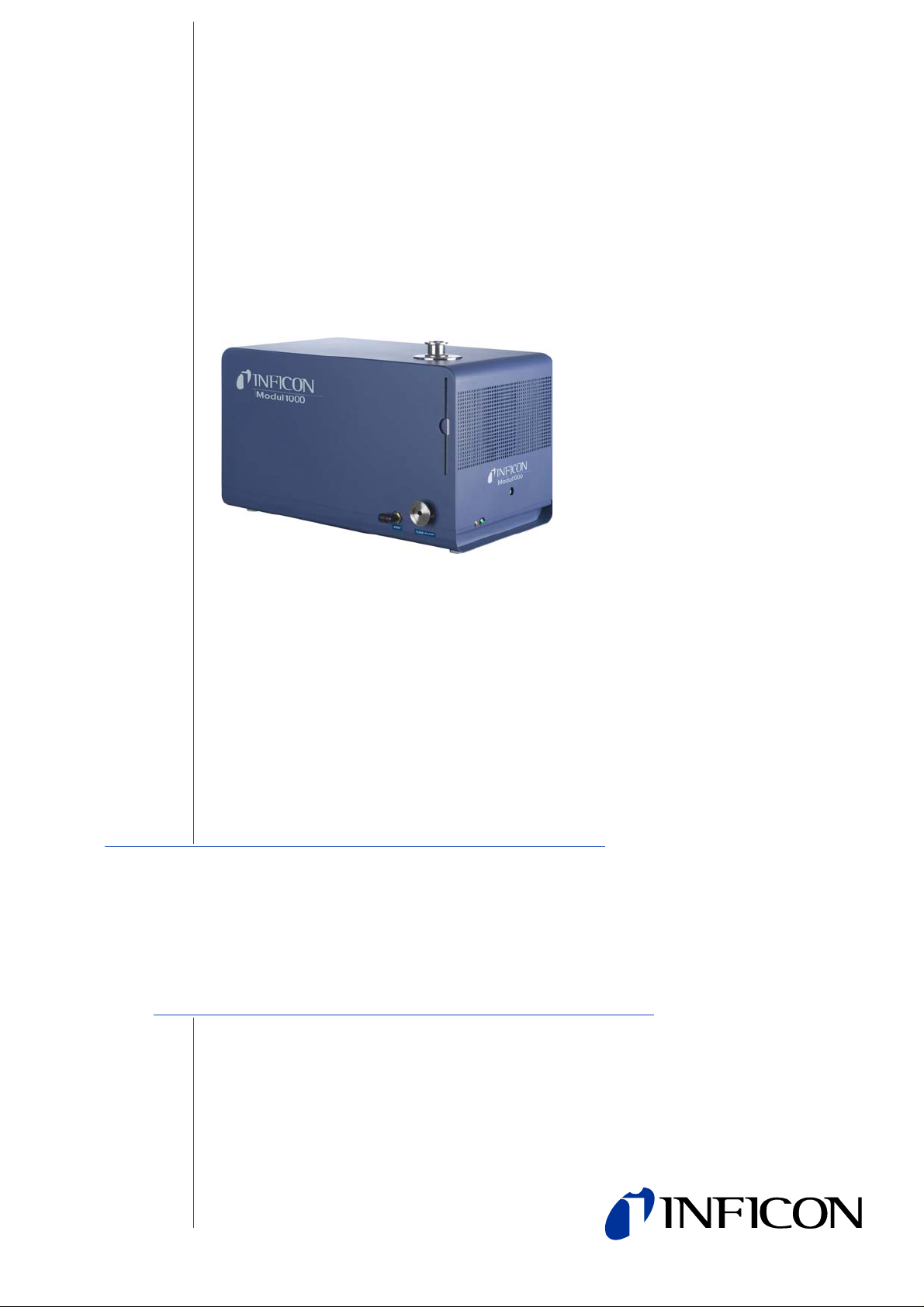

Modul1000

Modular Leak Detector

Page 2

Legal notice

INFICON GmbH

Bonner Straße 498

50968 Cologne

Germany

0-2

Copyright

©

2010 INFICON GmbH, Cologne. This document may only be reproduced

in any form with the permission of INFICON GmbH, Cologne.

jinb80e1-h Operating Manual(1011)

Page 3

Content

1 Operating instructions 1-5

1.1 How to use this manual 1-5

1.2 Warning and danger symbols 1-5

1.3 Graphic conventions 1-6

1.4 Definition of Terms 1-6

2 Important safety instructions 2-1

2.1 Intended use 2-1

2.2 User requirements 2-1

2.3 Restrictions of use 2-2

2.4 Hazards in the event of intended use 2-2

3 Description of equipment 3-1

3.1 The housing 3-1

3.2 Interfaces 3-3

3.3 Operating options 3-3

3.3.1 Desktop operation 3-4

3.3.2 Installation in switch cabinet 3-4

3.3.3 Remote control RC1000 3-5

3.4 Scope of delivery 3-6

3.5 Accessories 3-6

3.5.1 Sniffer line SL200 3-6

3.5.2 Test chamber TC1000 3-6

3.5.3 Set of male connectors for Interfaces 3-7

4 Installation 4-1

4.1 Mechanical Installation 4-1

4.2 Electrical installation 4-1

4.2.1 Mains socket 4-1

4.2.2 Electrical interfaces 4-2

4.2.3 Vacuum connections 4-6

5 Working Modes 5-1

5.1 Vacuum 5-1

5.2 Partial Flow Mode 5-2

5.3 Auto Leak Test 5-3

5.3.1 Auto Leak Test Settings 5-3

5.4 Commander mode 5-4

5.4.1 Design of a leak detector system 5-5

5.4.2 Test sequence of events 5-6

jinb80e1-h Operating Manual(1011)

5.5 Sniff mode tips 5-8

Content 1-1

Page 4

6 Operation 6-1

6.1 Switching ON 6-1

6.2 Status LED 6-1

6.3 Control 6-2

6.4 Control commands 6-3

6.5 Display 6-6

6.6 Calibration in Vacuum mode 6-9

6.7 Calibration in Sniff mode 6-10

6.8 Calibration in Auto Leak Test 6-11

6.9 Calibration in Commander mode 6-11

6.10 Machine factor 6-12

6.11 Menu structure 6-13

6.12 Explanation of Menu Items 6-15

6.12.1 Main menu

6.12.2 Main menu

6.12.3 Main menu

6.12.4 Main menu

6.12.5 Main Menu

6.12.6 Main menu

6.12.6.1 Main menu

6.12.6.2 Main menu

6.12.6.3 Main menu

6.12.6.4 Main menu

6.12.6.5 Main menu

6.12.6.6 Main menu

6.12.6.7 Main menu

6.12.7 Main menu

6.12.8 Main menu

→

Return 6-15

→

View 6-15

→

Mode 6-16

→

Trigger & Alarms 6-16

→

Calibration (CAL) Mode Vacuum 6-18

→

Settings 6-20

→

Settings→ Vacuum settings 6-20

→

Settings→ Zero & Background 6-23

→

Settings→ Mass 6-23

→

Settings→ Interfaces 6-23

→

Settings→ Miscellaneous 6-26

→

Settings→ Load/Save Parameters 6-27

→

Settings→Monitoring 6-28

→

Info 6-30

→

Access Control 6-31

7 Maintenance tasks 7-1

7.1 Maintenance and service at INFICON 7-1

7.2 General Maintenance Instructions 7-1

7.3 Maintenance schedule 7-3

7.4 Maintenance intervals 7-3

7.5 Description of the maintenance work 7-5

7.5.1 Opening of the Device 7-6

7.6 TMH 071 Replace the Lubricant Reservoir 7-7

7.7 Fuse replacement 7-10

7.7.1 Overview on Electrical Fuses 7-10

7.7.2 Replace mains fuse 7-11

7.7.3 Replace fuses on interface board 7-12

7.8 Replacing of parameter memory (I•STICK) 7-13

7.9 Replace Vent Filter 7-14

jinb80e1-h Operating Manual(1011)

1-2 Content

Page 5

8 Transport and disposal 8-1

8.1 Transporting after Contamination 8-1

8.2 Disposal 8-2

9 Technical Data 9-1

9.1 Technical data of components 9-1

9.1.1 Power supply 9-1

9.1.2 Weight / dimensions 9-1

9.1.3 Characteristics 9-1

9.1.4 Environmental Conditions 9-2

9.2 Control via the PLC inputs and outputs 9-3

9.2.1 PLC inputs 9-3

9.2.2 PLC Outputs 9-6

9.3 The digital valve outputs 9-9

9.4 Analogue Output 9-10

9.4.1 Configuration of the analogue outputs 9-10

9.5 Pin Assignments 9-13

9.5.1 PLC IN / AUDIO 9-13

9.5.2 PLC OUT 9-15

9.5.3 Pressure Gauge 9-16

9.5.4 Valves 9-19

9.5.5 Recorder 9-21

9.6 Installation diagram of the control unit for rackinstallation 9-22

9.7 Commander mode 9-23

9.8 CE-Certificate 9-24

10 Error Messages and Warnings 10-1

11 Ordering Information 11-1

11.1 Service Centres World Wide 11-3

INDEX 11-5

jinb80e1-h Operating Manual(1011)

Content 1-3

Page 6

1-4 Content

jinb80e1-h Operating Manual(1011)

Page 7

1 Operating instructions

STO P

Danger

Warning

Caution

1.1 How to use this manual

• Read this manual before using Modul1000.

• Keep the manual so that you can use it anytime.

• Enclose the operating manual if the device is ever passed on to third parties.

1.2 Warning and danger symbols

This symbol refers to an immediate hazard, which may result in fatal or serious

injuries (crippling).

This symbol refers to a possibly hazardous situation, which may result in fatal or

serious injuries.

This symbol refers to a possibly hazardous situation, which may result in slight

injuries.

This symbol is also used to alert you to the risk of material or environmental

damage.

jinb80e1-h Operating Manual(1011)

Operating instructions 1-5

Page 8

1.3 Graphic conventions

Notice: Points to very useful pieces of information.

1 Points to an operation that you have to perform.

⇒ Points to the result of an operation you accomplished.

→ Points to the button you have to press.

• Shows a listing.

1.4 Definition of Terms

Autotune / Mass alignment

The Modul1000 adjusts its tuning voltage to determine the optimal voltage for peak

efficiency.

Autoranging

The range of the pre-amplifier is selected automatically. The Autoranging feature of

the Modul1000 covers the entire range or leak rate s depending on the selected operating mode. Vacuum mode or Sniff mode Not only the leak rate signal, but also the

pressure in the test sample (inlet pressure PE) and the fore-vacuum pressure (PV)

are used for control purposes.

Auto zero

Determination and automatic adaptation of the helium background in the Vacuum

mode. Through this function, the internal zero level of the instrument is determined

which is then subtracted from the current leak rate signal. Th is functio n is run dur ing

the calibration process or when operating the start push-button, provided the

Modul1000 has been running previously for at least 20 seconds in the Standby or

Vent mode. If the helium background previously suppressed should drop, the zero

level will be adapted automatically.

Fore pressure

Fore pressure between turbo pump and fore pressure pump.

Internal helium background

The existing helium partial pressure in the measurement system. The level of the

internal helium background is measured in the Stand-by mode and subtracted from

the measured signal. (see above: Auto zero)

jinb80e1-h Operating Manual(1011)

1-6 Operating instructions

Page 9

Minimum detectable leak rate

The smallest leak rate the Modul1000 is able to detect.

-12

(5x10

mbar l/s).

Menu

The menu allows the user to program the Modul1000 accord ing to the requirements.

The menu has a tree structure.

As-delivered condition

The default settings of the Modul1000 are as delivered by the factory.

Standby

The Modul1000 is ready for operation.

MEASURE

MEASURE mode is when the Modul1000 has achieved a pressure better than the

crossover and the unit is sampling the gas load for helium leak rate.

jinb80e1-h Operating Manual(1011)

Operating instructions 1-7

Page 10

1-8 Operating instructions

jinb80e1-h Operating Manual(1011)

Page 11

2 Important safety instructions

2.1 Intended use

The Modul1000 is intended to be used for the leak test under vacuum. With the

sniffer version of Modul1000 (Catalogue-No. 550-310), it is also possible to locate

leaks in the test sample.

The Modul1000 may only be use d for leak tests with helium and hydrogen. It may

only be used in dry rooms and on dry surfaces.

Only use INFICON accessories.

The intended use includes:

• the compliance with the technical data and the ambient conditions,

• the use of standard and original accessories,

• consideration of this documentation and the observation of the included

instructions and directives.

2.2 User requirements

The Modul1000 must only be connected and operated by properly trained staff.

• Get used to the functioning of the device. Only connect and operate the device

after reading and understanding the manual.

• Consult local, State, and national agencies regarding specific requirements and

regulations.

• Address any further safety, operation and / or maintenance questions to our

nearest office.

jinb80e1-h Operating Manual(1011)

Important safety instructions 2-1

Page 12

2.3 Restrictions of use

STO P

Danger

STO P

Danger

STO P

Danger

STO P

Danger

STO P

Danger

Danger of fatal injuries due to explosion.

Switch on and operate the Modul1000 only outside of explosive areas.

Risk of dangerous gases.

The device is not suitable for caustic, toxic and explosive substances.

Only use this device for detecting harmless substances.

2.4 Hazards in the event of intended use

Before installing the Modul1000, carefully read all safety instructions and make sure

that you have properly understood them.

Danger

Danger of fatal injuries due to explosion.

When explosive gases are used as test gas, the gas container could explode.

Avoid flames and sparks, keep ignition sources far away from the device.

Danger of fatal injuries due to electric shock.

Keep the sniffer tip away from live parts.

Danger of fatal injuries due to electric shock!

Connect the Modul1000 properly with the 3-core power cable and then connect the

PE-line to earth.

2-2 Important safety instructions

jinb80e1-h Operating Manual(1011)

Page 13

STO P

Danger

Danger of fatal injuries due to electric shock!

STO P

Danger

STO P

Danger

STO P

Danger

Disconnect the Modul1000 from the power supply before the you open it.

Risk of injury and contamination caused by toxic gases.

Only use the Modul1000 for detecting harmless substances.

The device is not suitable for toxic, caustic, micro-biologic, explosive, radioactive or

other hazardous substances.

Contact the manufacturer if you plan to use the device for such substances.

Danger of fatal injuries due to implosion.

Components which are not pressure-resistant, can burst cause through implosion .

Only connect containers and pa rts to the inlet f lang e of M odu l1000 whic h are s uit-

able for vacuum.

Danger of fatal injuries due to strong permanent magnets.

Magnets can impact the functioning of pacemakers.

If you wear a pacemaker, keep away from the device as far as it is specified in the

manufacturer's instructions.

jinb80e1-h Operating Manual(1011)

Important safety instructions 2-3

Page 14

Warning

Warning

Warning

Warning

Warning

Warning

Warning

Risk of injuries through rotating parts

Before a transport leave the Modul1000 switch ed off fo r at lea st 20 min ut es .

Danger of injury through dropping devices.

Two people should carry the Modul1000 or use a lifting device.

Back injury through heavy loads.

Two people should carry the Modul1000 or use a lifting device.

Injury to health due to emissions and fumes of oil-sealed pumps.

Before it is operated in closed rooms, the oil sealed fore-pressure pump, if used,

has to be connected to an exhaust gas pipe.

Danger of fatal injuries due to electric shock!

Only operate the Modul1000 in buildings and on dry surfaces.

Risk of injury due to sucking inlet flange

If the vacuum function of the Modul1000 is activated, body parts which are close to

the inlet flange can be sucked in.

Keep your body away from the inlet flange.

2-4 Important safety instructions

jinb80e1-h Operating Manual(1011)

Page 15

Warning

Supposed risk

If it can be supposed that safe operation is not ensured any more, the device must

be switched off and must be secured against accidental switching on.

If this happens, contact the INFICON service people.

Notice: Such a problem could occur,

• when the device has visible damages,

• when liquid has penetrated into the dev ice,

• when the device does not operate any mo re ,

• after long storage time under unfavourable conditions,

• after strong transport conditions

jinb80e1-h Operating Manual(1011)

Important safety instructions 2-5

Page 16

Caution

Caution

Caution

Caution

Caution

Caution

Caution

The Modul1000 is destructed by aggressive substances.

Avoid contact to bases, acids, solvents and do not expose it to extreme climatic

conditions.

The Modul1000 may be damaged by improper transport conditions.

Only use this device for detecting helium and hydrogen.

Use a filter in the inlet of the Modul1000 to avoid dirt from getting into the vacuum

system.

The electronic system of the Modul1000 may be damaged by the wrong supply

voltage.

Check, if the local power supply voltage complies with the required supply voltag e

of the device.

The electronic system of the Modul1000 may be damaged by too high voltages.

The digital inputs are designed for maximum 30 V.

The electronic system of the Modul1000 may be damaged by too high electric

loads.

The relay outputs should be connected to maximum 60V DC or 25 V AC / 1A at

ohmic load. The semiconductor outputs should only be connected to 30V / 1A.

The electronic system of the Modul1000 can be destroyed when devices are

connected to the Modul1000 whose electronic circuitr y is not safely separated from

the mains.

Only connect devices to the Modul1000 whose connections are safely separated

from the power system.

jinb80e1-h Operating Manual(1011)

2-6 Important safety instructions

Page 17

Caution

The turbo-molecular pump may be damaged by jerky movements.

Caution

Caution

Caution

Caution

Caution

During operation, move the Modul1000 only carefully and smoothly.

Risk of damage.

The Modul1000 may be damaged by excess heat.

Pay attention to the serve messages and replace the dirty air filters.

Risk of damage.

The Modul1000 can overheat and fail when the openings are plugged.

Provide for free openings for air inlet and outlet.

The Modul1000 can be damaged when liquid gets into it.

If liquid has entered the Modul1000, do not switch it on and contact the INFICON-

Service.

The Modul1000 may be damaged by being stored in unfavourable conditions (too

damp, too hot, too cold, too high above sea level) for months or years. (refer to

Technical Data!)

If the Modul1000 has been store d und er su ch cond itions , leav e it swit ched off a nd

contact the INFICON Service Department.

Risk of damage.

The Modul1000 may be damaged by improper transport conditions.

Always transport the Modul1000 in its original pack ag ing .

jinb80e1-h Operating Manual(1011)

Important safety instructions 2-7

Page 18

2-8 Important safety instructions

jinb80e1-h Operating Manual(1011)

Page 19

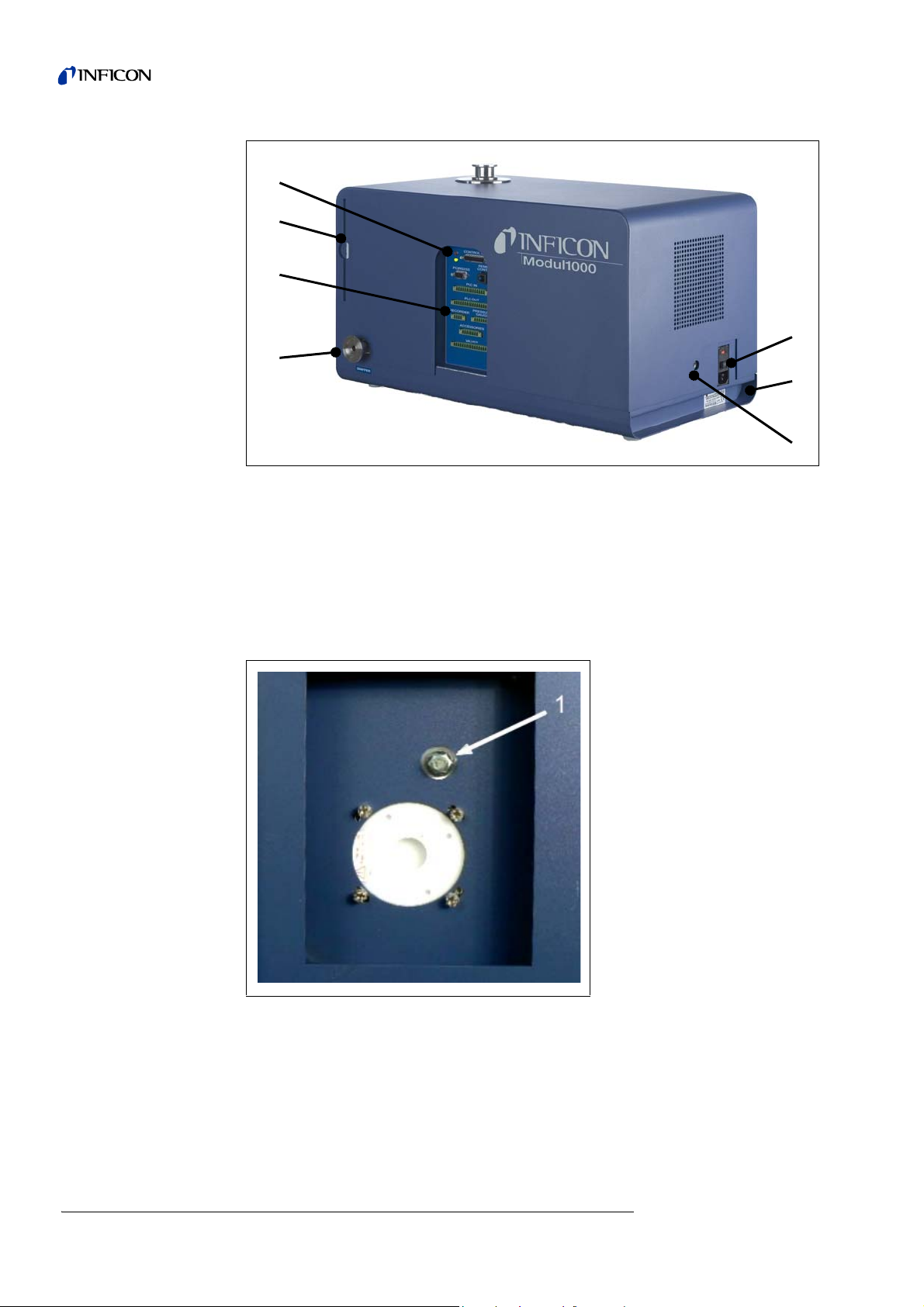

3 Description of equipment

1

2

3

4

5

6

7

8

The Modul1000 is a helium leak detector which has been designed to be insta lled in

leak test work stations or integrated machines.

The analysis system with turbo-molecularpump and a complete control unit are integrated in a compact housing. Depending on the set operating mode, the Mo dul100 0

can execute overriding control functions in a leak test system.

Multiple signal and status outputs allow the universal integration in existing or new

system versions.

The operating parameters set by the user are stored in a separate memory module

(I•STICK) which can be withdrawn easily.

All device configurations and the necessary maintenance works can be performed

without opening the device.

To generate the fore-vacuum required for the operation of the turbo-molecula r pump,

as well as for evacuation of th e conn ected test sample, a fore-vacuum pump with a

pumping speed of >2 m³/h has to be connected. It must be able to generate a final

pressure of <1x10

3.1 The housing

-2

mbar.

Fig. 3-1 Left side view and front view.

Item Description Item Description

1 Inlet flange DN25 KF 6 air filter

2 Loudspeaker / Air inlet Mains fuses

3 Openings for unlocking 7 Connection DN25 KF for

the cover Backing Pump

4 Recess handles 8 Vent connection FESTO coupling

jinb80e1-h Operating Manual(1011)

5 Status LED Hose 8 mm

Description of equipment 3-1

Page 20

Fig. 3-2 Right side view and back view

9

10

11

6

5

4

3

Item Description Item Description

3 Openings for unlocking 9 Mains socket with main switch and

the cover Mains fuses

4 Recess handles 10 Connection DN25 KF for

5 Status LED Fore-vacuum pump or sniffer line

6 air filter 11 Electrical interfaces

Fig. 3-3 Cut-out in the bottom side of Modul1000

Item Description

3-2 Description of equipment

1 Connection for the fore-vacuum pump (screwed flange)

jinb80e1-h Operating Manual(1011)

Page 21

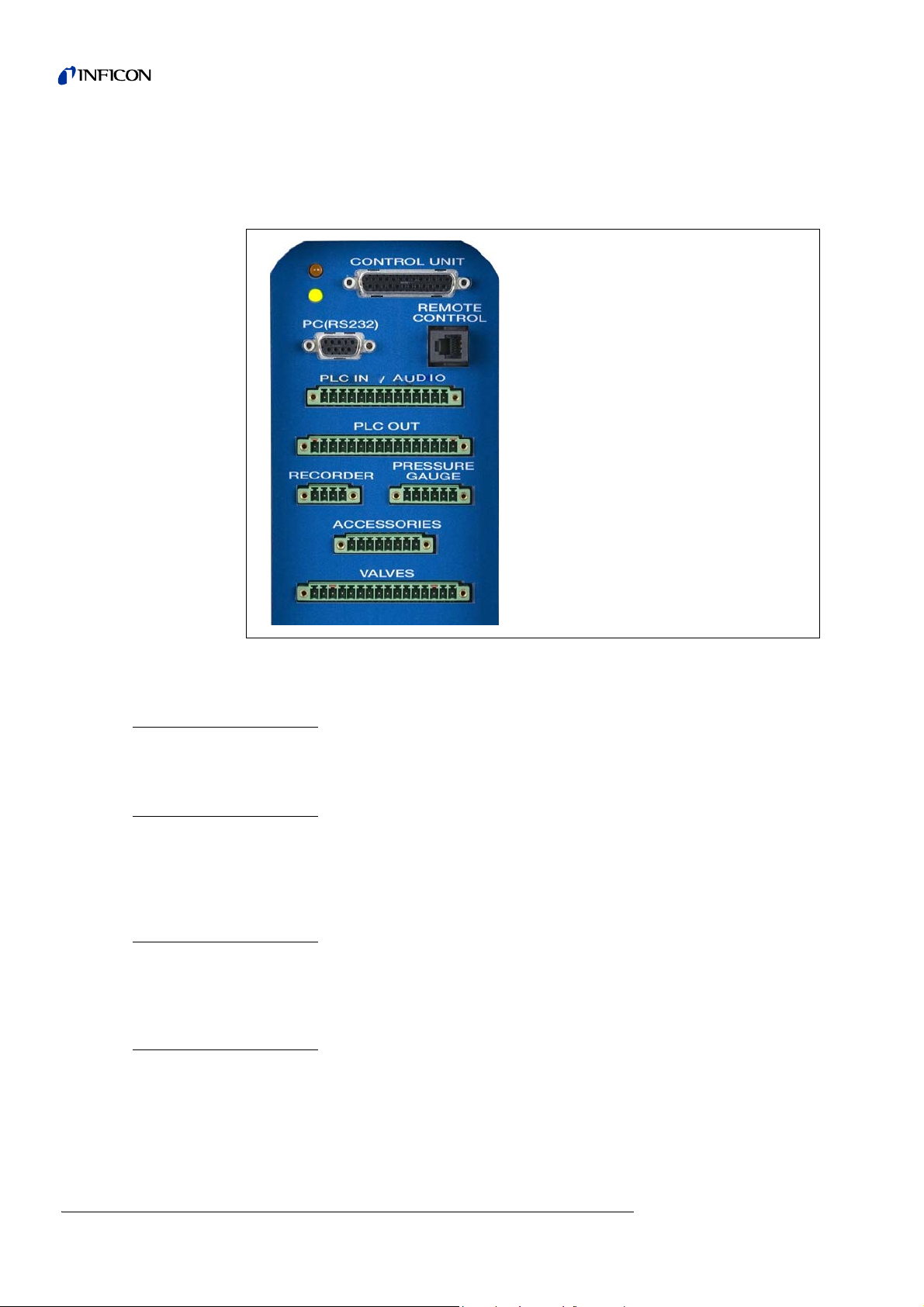

3.2 Interfaces

Connectors:

LED yellow, LED green, CONTROL UNIT

(PC) RS232, REMOTE CONTROL

PLC IN / AUDIO

PLC OUT

RECORDER, PRESSURE GAUGE

ACCESSORIES

VALVES,

Fig. 3-4

The two 16-pin plug connectors PLC OUT and VALVES are keyed so they cannot be

interchanged. For the PLC OUT, coding tongues are inserted on the pins 1 and 16,

for the VALVES connector, the tongues are on the pins 3 and 14.

3.3 Operating options

The Modul1000 can be operated via the control unit for desktop operation or the

control panel for the installation in a switch cabinet.

The Modul1000 provides an extensive software menu which serve s for operation and

configuration (refer to 6.11 Menu structure). This control unit offers access to the

menu structure.

The control unit can optionally be connected to the Modul1000 via 1 m or 5 m long

connecting cables.

The control unit is for configuring and controlling the Modul1000 individually and

parameters as well as measured values can be read out.

jinb80e1-h Operating Manual(1011)

Description of equipment 3-3

Page 22

3.3.1 Desktop operation

1

6

5

4

3

2

7

8

9

10

11

12

13

14

The control unit can be placed on even desktops and does not slip.

Fig. 3-5 Control Unit for Desktop Operation

Item Description Item Description

1 LCD display 8 Soft Key no. 5

2 Soft Key no. 1 9 Soft Key no. 6

3 Soft Key no. 2 10 Soft Key no. 7

4 Soft Key no. 3 11 Soft Key no. 8

5 Soft Key no. 4 12 Menu button

6 START button with LED 12 STOP / Vent button with LED

7 Control Unit 14 ZERO button with LED

3.3.2 Installation in switch cabinet

The control panel (Control unit as mounting version) is intended to be integrated in

the front of a 19’' rack system.

3-4 Description of equipment

Fig. 3-6 Control panel for the installation in a switch cabinet

jinb80e1-h Operating Manual(1011)

Page 23

3.3.3 Remote control RC1000

The wireless remote control RC1000 allows the operation of the Modul1000 from a

distance of maximum 100 m. The remote control can serve for controlling the functions START, STOP/VENT (STOP/Vent), ZERO (Background). It shows the measured leak rate on the display as bar graph, a s digits, or as diagram (refer to Technical

Manual of RC1000).

The measured values can be stored in the internal memory of the RC1000 for a

recorded period of maximum 24 hours. Then the data can easily be transferred to a

USB stick.

An internal trigger can be set to provide a warning if the limit leak rates are exceeded.

An optical warning is shown on the display and an acoustic warning signal is

sounded on the integrated loudspeaker or the connected headphones.

The RC1000 remote control is housed in a robust housing to ena ble ergonomic working. Magnets on the underside of the unit enab le it to be attached to horizontal or vertical metal surfaces.

With the remote control RC1000, the leak test device Modul1000 ca n also be controlled via a 28 m long cable.

Fig. 3-7 RC1000 wireless remote control

jinb80e1-h Operating Manual(1011)

Description of equipment 3-5

Page 24

3.4 Scope of delivery

• Leak test device for helium and hydrogen, Modul1000

• Power cords EU, US

• Set of spare fuses

• Folder with documents

• Tools for opening the cover 8 mm Allen-key

• Metering orifice DN25, 2 mm

3.5 Accessories

Accessories Cat. No. / Ref. No.

Sniffer line SL200 140 05

Test chamber TC1000 551-005

Set of male connectors for Interfaces 551-110

Control unit (desktop version) 551-100

Control unit (mounting version 19 inches) 551-101

Connecting cable for control unit, 1 m 551-103

Connecting cable for control unit, 5 m 551-102

Remote control 20099022

- Cable for remote control (required) 20099027

- Extension cable 14090

RC1000 remote control

- RC1000WL wireless 551-015

- RC1000WL - cable version 551-010

- Extension cable, 8 m, for RC1000C 14022

3.5.1 Sniffer line SL200

The Modul1000, in the version as vacuum or sniffer leak detector needs the sniffer

line SL200 to be able to work in sniffer mode.

3.5.2 Test chamber TC1000

The vacuum chamber TC1000 serves for integrated testing of helium-filled parts. The

test procedure can be configured individually in the software m enu of Modul1000 and

runs automatically after the chamber has bee n clos ed .

3-6 Description of equipment

jinb80e1-h Operating Manual(1011)

Page 25

3.5.3 Set of male connectors for Interfaces

The connector kit includes the following plugs:

PLC IN / AUDIO,

PLC OUT,

RECORDER,

PRESSURE GAUGE,

VALVES,

ACCESSORIES

jinb80e1-h Operating Manual(1011)

Description of equipment 3-7

Page 26

3-8 Description of equipment

jinb80e1-h Operating Manual(1011)

Page 27

4 Installation

Warning

Caution

Back injury through heavy loads.

Two people should carry the Modul1000 or use a lifting device.

4.1 Mechanical Installation

The Modul1000 can be mounted on and below desktop workplaces. The leak test

device may only be operated on horizontal surfaces. During the installation, make

sure that the Modul1000 gets enough fresh air, especially the air inlet and outlet

openings on the front and the back side have to be free. The maximum permissible

ambient temperature of the Modul1000 may not be exceeded during operation!

4.2 Electrical installation

4.2.1 Mains socket

The device is connected to the power system via th e deliv er ed po we r ca ble . Please

find the respective socket on the back of the device. (refer to Fig. 3-2/9).

Place the device in a way that you can always reach the power plug.

jinb80e1-h Operating Manual(1012)

Installation 4-1

Page 28

4.2.2 Electrical interfaces

All electrical interfaces of the Modul1000 are clearly visible arranged in a connecting

area on the right side of the device (refer to Fig. 3-2).

Connectors:

LED yellow, LED green, CONTROL UNIT

(PC) RS232, REMOTE CONTROL

PLC IN / AUDIO

PLC OUT

RECORDER, PRESSURE GAUGE

ACCESSORIES

VALVES,

Fig. 4-1 Electrical interfaces

Valves

The connection VALVES is for controlling external valves.

PLC Inputs and outputs

To connect the control inputs and outputs (PLC IN /PLC OUT) use the connector kit.

The connectors are not included in the scope of delivery, b ut are available as accessories (see 3.5, Set of male connectors for Interfaces, Part-No. 551-110)

Graphical control unit

A graphical control unit is connected to CONTROL UNIT via an appropriate connecting cable.

Hand set

The remote control is connected to REMOTE CONTROL.

4-2 Installation

jinb80e1-h Operating Manual(1012)

Page 29

Sniffer line SL200 or test chamber

STO P

Danger

TC1000 (ACCESSORIES)

The connection ACCESSORIES serves for connecting the sniffer line SL200 or the

test chamber TC1000.

External Pressure gauge

If the Modul1000 is used in Commander mode, an additional pressure gauge has to

be connected to PRESSURE GAUGE. Connect the pressure gauge as follows with

the 8-pin Phoenix-plug "PRESSURE GAUGE".

Pin Assignment

1

2GND

3 Input 1

4 GND to input 1

5 Input 2 (is not supported by the current software)

6 GND to input 2

24V fuse-protected with F3 on the interface board (0.8A, maximum output current,

on this pin together with the pin 1 on connection PLC IN)

Notice: The pressure transmitters to be connected can be supplied via the contacts

1 and 2 of the Modul1000.

If they are supplied by external power supply units, ensure th at the contacts

4 and 6 may only have a maximal potential of ±4V compared to contact 2.

Otherwise it could be damaged.

Notice: The sensor is adjusted correctly, when the zero point and the full-scale

deflection comply with the output characteristic.

Danger of fatal injuries due to electric shock!

First, disconnect the leak test device from the power supply network and then

remove the housing.

The Modul1000 can process measured current or voltage values. When delivered,

the Input 1 is configured for current measurement 4... 20 mA, Input 2 for voltage

measurement 0... 10 V.

To change the configuration of the input of the pressure gauge, the respective jumper

on the interface card in Modul1000 has to be placed onto another position. To do

that, open the device.

The jumpers are located on the interface board and are accessible a fter opening the

cover.

By changing the position of the jumper on the connector XP5, the se tting of the Input

1 can be changed. For a current signal, Pin 1 and Pin 2 of XP5 are connected, for a

voltage signal, connect Pin 2 and 3.

By changing the jumper position on the connector XP4, the setting of the Input 2 will

be changed. However, this input is not supported in the current software.

jinb80e1-h Operating Manual(1012)

Installation 4-3

Page 30

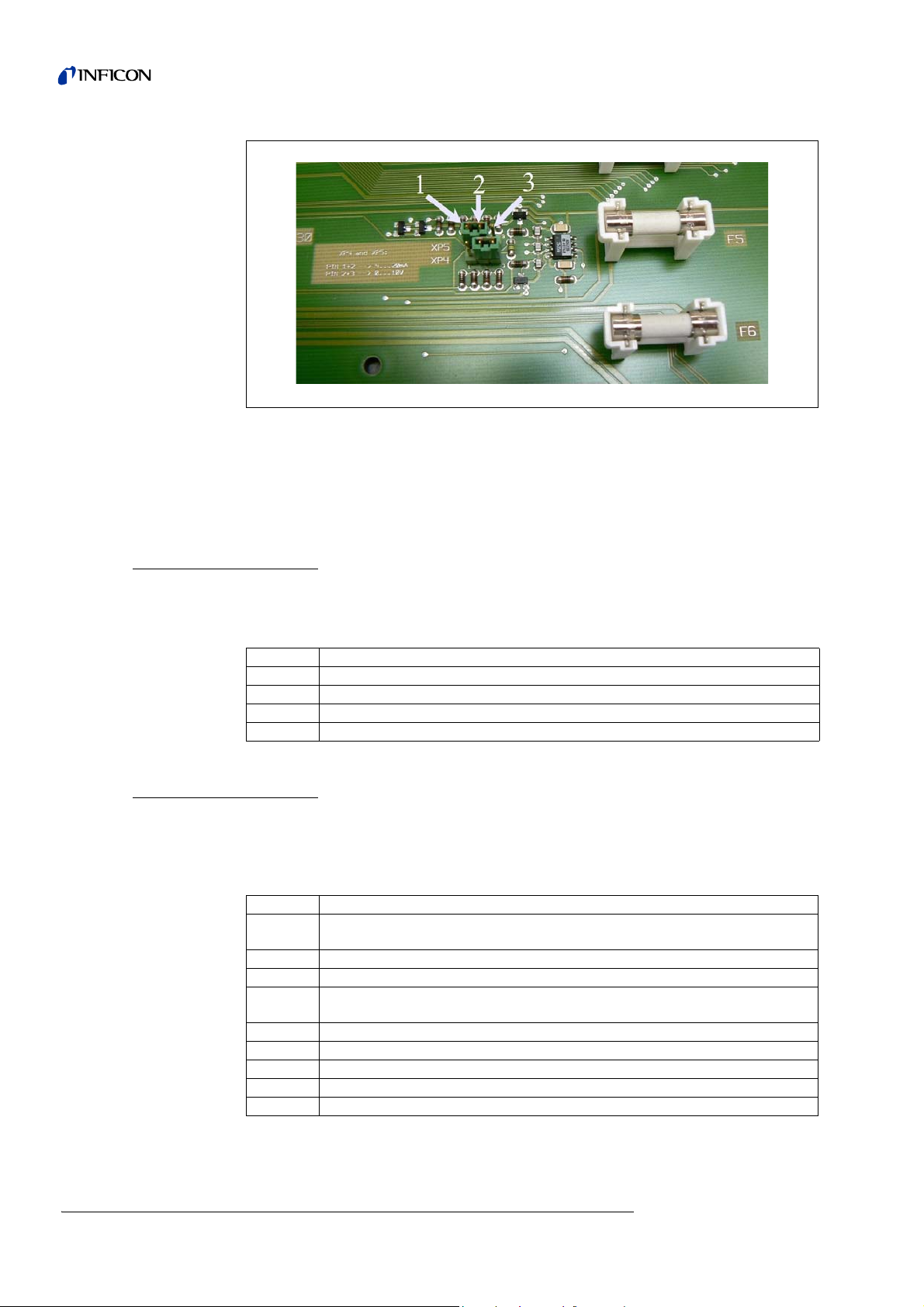

Fig. 4-2 Jumper XP5 and XP4

Item Description Item Description

1Pin 1 3Pin 3

2Pin 2

Recorder Output (analogue)

The two Recorder outputs (analogue outputs) may be used to log the leak rate, the

inlet pressure or the fore-vacuum pressure.

The output voltage is updated every 50 ms.

Pin Assignment

1

2GND

3GND

4

RS232 Interface

The RS232 interface serves for connecting a PC directly to the Modul1000.

The Modul1000 is then directly controlled by the respective instruction sets as

described in the interface description.

Recorder Output 1 (analogue output)

Recorder Output 2 (analogue output)

4-4 Installation

Pin Assignment

1

2TxD

3RxD

4

5 GND RS232

6 not used

7 not used

8 not used

9 not used

24V can tied-in via the jumper XT2, maximum current consumption 0.3 A (Pin 2

and 3 connected). As delivered, 24 V are not tied-in, Pin 1 and 2 connected.

GND 24 V can be tied-in via jumper XT1 (Pin 2 and 3 connected). On delivery,

GND 24 V is not tied-in (Pin 1 and 2 connected).

jinb80e1-h Operating Manual(1012)

Page 31

Using the jumpers XT1 or XT2, Earth or 24 V can be connected to the RS232 inter-

STO P

Danger

face by changing the positions of the jumper (Pin 2 an d 3). On deliver y: XT1 or XT2,

Pin 1 and 2 bridged ≅ "default setting (Standard) RS232“.

Danger of fatal injuries due to electric shock!

First, disconnect the leak test device from the power supply network and then

remove the housing.

The jumpers are located on the interface board and are accessible a fter opening the

cover.

Fig. 4-3 Jumper XT2 and XT1

Item Description

1Pin 1

2Pin 2

3Pin 3

jinb80e1-h Operating Manual(1012)

Installation 4-5

Page 32

4.2.3 Vacuum connections

Fore-vacuum pump

The connection for the required fore-vacuum pump is on the left front side or on the

bottom of the device. Alternatively, the pump connection of the vacuum version of the

Modul1000 can also be on the right side.

1 Unscrew the connecting flange using the jaw-wrench SW13, to modify it and remove

the sealing.

2 Unscrew the locking plug of the connection you want to use

Make sure you save the sealing.

.

3 Screw the locking plug with the sealing into the opening of the removed connection

flange.

4 Screw in the connecting flange with the sealing.

Notice: For the sniffer version of the Modul1000, only the pump connections on the

left side or on the bottom side can be used.

The used fore-vacuum pump must meet the following specifications:

• The connecting hose should have a minimal diameter of 15 mm.

• The fore-vacuum pump should provide a pumping speed of >2 m³/h

• and a possible ultimate pressure of <1x10

-2

mbar.

If the fore-vacuum pump is equipped with a solenoid gas ballast valve or purge gas

valve, it can be controlled via the valve output V22 of the Modul1000.

Test sample/Test Equipment

The test sample or the test equipment are connected using the DN25 KF inlet flange

on the top of the Modul1000.

To be able to measure with the leak test device also in case of pressures higher th an

0.4 mbar, the metering orifice, which is in the scope of delivery, can be mounted

before the inlet of the leak test device. If the metering orifice is installed in the suction

line of the leak test device, the maximum inlet pressure will be 3 mbar.

Because the pumping speed is greatly reduced when a metering orifice is inserted,

it will be reasonable to use a partial flow pump for evacuation.

To achieve short signal response times of the Modul1000, the orifice should be

mounted as close as possible to test sample, test equipment.

In Modul1000b, the metering orifice has already been in stalled and can also measure

until 3 mbar.

Notice: The maximum permissible load vertically on the flange is 400 N.

4-6 Installation

jinb80e1-h Operating Manual(1012)

Page 33

Ventilation

Sniffer line

Fig. 4-4 Installation of metering orifice

Usually the parts under test are vented with ambient air after the test has been

finished. If it is required, the parts can be vented with an different gas type (i. e. fresh

air, dry air, nitrogen, …) at a pressure of max. 1050 mbar. In these cases, the gas

supply has to be connected to flood connection (8 mm hose connection) on the left

side of the device. The gas pressure on the flood connection may not exceed

1100 mbar (absolute).

It is also possible to connect an additional external ventilating valve to the valve

output V21.

The connection for the sniffer line exists only for the sniffer version of the Modul 1000

(catalogue number 550-310). This connection is for the optional sniffer line SL200.

The SL200 is connected to the power system via the connector socket ACCESSORIES.

jinb80e1-h Operating Manual(1012)

Installation 4-7

Page 34

5 Working Modes

There are the following vacuum modes:

• Vacuum,

• Commander,

• Auto Leak Test.

In this operating mode, it is possible to use a partial flow pump.

The sniffer version of the Modul1000 also provides the operating mode:

•Sniff.

5.1 Vacuum

In standard Vacuum mode, the Modul1000 id operated as „Stand Alone“ leak detector.

The unit under test or the vacuum chamber ar e only evacuated via the inlet flang e of

the leak detector. The pumping speed on the inlet of the leak detector depends on

the used fore-vacuum pump and on the conductivity ratios of the device.

If the pressure is lower than 0.4 mbar, the device will switch over to the Measuring

mode and display the measured leak rate.

When measuring, the pumping speed at the inlet is 2.5 l/s.

The effective pumping speed at your chamber is dependent o n the integration of the

Modul1000.

5-1 Working Modes

jinb80e1-h Operating Manual(1012)

Page 35

5.2 Partial Flow Mode

To increase the effective pumping speed on the vacuum chamber or the test sample,

an external partial flow valve can be connected to the valve output V20. The

increased pumping speed accelerates the evacuation processes and the signal

response time of the Modul1000.

Depending on the settings, the partial flow pump can optionally be added via an

external partial flow valve only for evacua tio n or fo r eva cu a tio n du rin g the me as ur ement.

If the partial flow pump is also added during the measurement, the pumping speed

of the partial flow pump for helium has to be considered. In this case, adjust the

machine factor as required (refer to chapter 6.9). Furthermore, an external calib ration

is recommended (refer to chapter 6.6).

For fast venting of the device, the connection of an additional external vent valve V21

will be possible.

Fig. 5-1 Partial flow mode

Item Description Item Description

V20 Partial flow valve V21 Ventilating valve

jinb80e1-h Operating Manual(1012)

Working Modes 5-2

Page 36

5.3 Auto Leak Test

In Auto Leak Test mode, parts prefilled with helium can be tested integrated in a

vacuum chamber. In this case, the Modul1000 does all control functions completely

for the test run.

The test run is divided into the following steps:

Evacuation of the vacuum chamber,

Measurement of leak rate and

then venting of the vacuum chamber.

At the end of the test, the device displays „PASS“ on the control panel provided that

the leak rate did not exceed the set trigger value during the measuring time. If the

trigger value is exceeded, the device will display the message „FAIL“.

Optionally, the test can also be carried out in Partial Flow mode.

After pressing the START button, the whole test runs automatically. When using the

optional test chamber TC1000, the test cycle starts automatically as soon as the

chamber cover is closed.

5.3.1 Auto Leak Test Settings

Select the Auto Leak Test mode via the control panel or the RS232 interface.

The test run can be adapted to your special application of the leak detector. The

corresponding settings can be entered via the control panel or the RS232 interface

(refer to Interface Description).

Measuring time

The measuring time starts as soon as the Modul1000 switches over from the evacuation phase to the Measuring mode. The possible time settings range from 1 second

to 30 minutes.

At the end of the measuring time, the measured value is displayed.

Trigger level

If the set trigger level 1 is exceeded at the end of the measurement cycle, the

Modul1000 indicates the message „FAIL“ and hence, it signals a leaky test sample.

Part number

In the software menu, the parts counter can be enabled, which assigns a number to

the individual measurement cycles. On the menu screen "Test report", the last 12

measured results can be displayed with date and test result.

Series error message

The menu provides a setting, with which a series error message can be displayed

when a certain number of consecutive errors with the "FAIL" result occur. The set

number of consecutive measuremen ts after which the Mo dul1000 disp lays a series

error message can vary between 2 and 9. If not required, it can be disabled.

jinb80e1-h Operating Manual(1012)

5-3 Working Modes

Page 37

To ensure that such an abundance of consecutive „FAIL“- messages is not caused

by the helium background of the test equipment, a reference measurement is recommended.

Reference measurement

If the ambient helium emitted by the chamber is significant in relation to the target

leak rate, it is possible to perform a reference measurement.

In the software menu, it is possible to enable a reference measurement. If it is

enabled, it can be called via the Measurement screen.

During the reference measurement, the Modul1000 determines the internal helium

background of the test equipment and then it deducts this values from the values of

following measuring cycles.

The reduce the background of the test equipment in case of a reference measurement, the vacuum system of the device is evacuated and vented for three times.

5.4 Commander mode

If the Modul1000 is integrated in a leak detector system, in Commander mode, it can

control the whole test in the integrated chamber. All necessary valves for filling the

test sample with helium as well as the necessary pressure gauge can directly be

connected to the Modul1000. The test run can only includ e a device for helium recovery.

Optionally, the test can also be carried out in Partial Flow mode to accelerate the leak

detection.

jinb80e1-h Operating Manual(1012)

Working Modes 5-4

Page 38

5.4.1 Design of a leak detector system

Design of a leak detector system with Modul1000- - -Commander function is mainly

the same as that of the conventional integrated leak test system.

The vacuum chamber is evacuated by the Modul1000, optionally also in partial flow

mode (Fig. 5-1 Partial flow mode). The test sample in the vacuum chamber is

connected to the helium filling station through the chamber walls and is filled with

helium after the chamber has been evacuated.

Due to the difference between the helium pressure in the test sample and the

vacuum in the vacuum chamber, the helium of a leaky part flows out of the leak into

the vacuum chamber and into the leak test device whe re it can be me asured as ga s

leak.

5-5 Working Modes

Fig. 5-2 Leak detector system

Item Description Item Description

V30 Valve evacuation (test sample) 1 Vacuum chamber

V31 Flood valve (test sample) 2 Test sample

V32 Valve for helium recovery 3 Pressure gauge

V33 Filling valve (test sample) 4 Vacuum valve (test sample)

V34

Emergency valve (de-energized

open)

5 Fore-p ump (Modul1000)

jinb80e1-h Operating Manual(1012)

Page 39

Helium filling station

The helium filling station consists of a vacuum pump, the valves V30- V34, a pressure gauge and the helium supply unit.

Valves V30, V31, V32, V33, V34

The test run of the Commander software includes the control of all valve s necessary

for the helium filling procedure of the test sample. The valves are controlled via the

„VALVES“ connection.

Notice: We recommend using pressure activated valves.

Pressure gauge

The test sample is filled with helium and the gross leak test are pressure controlled

and therefore, they need a pressure gauge which has a measuring range of <

50 mbar reaching to the maximum filling pressure of the test sample. The characteristics and the measuring range of the used measuring point can be set on the

Modul1000. The pressure gauge is connected to the „PRESSURE GAUGE“ terminal

on the right side of the device.

Vacuum pump

The vacuum pump evacuates the test sample before it is filled with helium to remove

the air from the part as well as possible. We recommend using a pump with a final

pressure of < 50 mbar.

5.4.2 Test sequence of events

1 The test sample is in the vacuum chamber which is connected to the inlet of

Modul1000. The unit under test is in the vacuum chamber which is connected to the

inlet of Modul1000.

2 After the START signal, the Modul1000 starts evacuating the vacuum chamber. If a

partial flow pump is connected with Modul1000, the partial flow valve V20 (Fig. 5-1)

will be actuated and the test run is accordingly supported by the partial flow pump.

3 Before the actual helium test is executed, a gross leak test is carries out, to detect

gross leaks in the test sample or in the leak detector. When a chamber pressure of

100 mbar is reached, it will be checked, whether the pressure of the test sample has

dropped and is lower than the set pressure p_A_ for the gr oss leak test. If this is the

case, the measuring cycle will be interrupted indicating the error message 91.

4 If the system passes the gross leak test, valve V30 will be opened and the test

sample will be evacuated. If the systems passes the gross leak test, the valve V30

will open and the test sample will be evacuated. Otherwise, the measuring cycle will

be interrupted indicating the error messa g e 92 .

5 If the chamber pressure drops within the set time t_F_Readiness_for_measurement

down to the change-over pressure, the device will switch over to Measuring mode.

This change-over pressure can be set in the following menu:

Main menu --> Settings --> Monitoring --> Pressure limits for vacuum areas"

between 0.2 mbar and 0.4 mbar.

Depending on the settings in "Background suppression", an automatic background

jinb80e1-h Operating Manual(1012)

subtraction will be carried out, if necessary:

Working Modes 5-6

Page 40

• When "OFF" is set: no zeroing is carried out

• When "ON" is set: zeroing is carried out after the t_B_zeroing delay time

• When "STABLE" is set: zeroing will be carried out within the t_B_zero delay time

provided that the leak rate signal is stable enough to indicate a leak of the set

trigger level 1. If this condition is not complied with within the t_B_zero delay time,

the measuring cycle will be stopped and error message 98 will be generated.

If the chamber pressure is not low enough within the set time

t_F_Readiness_for_measurement to switch over to the measuring mode, the test

procedure will be interrupted indicating the error message 94.

6 After the evacuation of the test sample, the valve V33 is opened and the filling

process of the part with helium can start. If the pressure in the test sample reaches

the set filing pressure p_C_Filling_pressure within the set time t_C_Filling_time, the

valve V33 will be closed again and the filling process will be completed. If the filling

pressure is not reached on time, the measuring cycle will be interrupted indicating

the error message 93.

7 The actual leak test is now started. The measured leak rate is displayed when the

set time t_G_ Measuring_time has expired. If the pressure of the test sample drops

below the pressure p_E_Pressure_drop_threshold during the leak test due to a leak

in the system, the measuring cycle will be interrupted indicating the error message

99.

8 At the end of the measuring time, the valve V32 is opened.

Helium is returned from the test sample to the helium filling facility until the pressure

in the sample has reached the depressurizing pressure

p_D_Depressurizing_pressure. After that, V32 is closed again.

If this does not happen within the set time t_D_Depressurizing _time, the measuring

cycle will be interrupted indicating the error message 95.

9 To remove the residual helium from the test sample, valve V30 opens and the test

sample is evacuated by the pump 4 until the pressure p_B_ Evacuation_pressure is

reached.

This has to be done within the set time t_A_Evacuating _time, othe rwise the measuring cycle will be interrupted indicating the error message 96.

10 Valve V30 will be closed. The unit under test is vented to reach atmospheric pressure

via valve V31.

If the set filling pressure for the test sample p_A_Gross_leak_test is not reached

within the time t_E_Ventilation_time, the measuring cycle will be interrupted indicating the error message 97.

11 After that, the vacuum chamber is ventilated by the Modul1000 (and the external

flood valve V21 (Fig. 5-1), if connected) to reach the atmospheric pressure.

jinb80e1-h Operating Manual(1012)

5-7 Working Modes

Page 41

5.5 Sniff mode tips

The Modul1000 Sniffer version can be used as vacuum leak detector or as sniffer

leak detector.

To use it as sniffer leak detector, the optimized sniffer line SL200 has to be

connected to „Sniff“ on the right side of the Modul1000. In Measuring mode, the

module draws a constant gas flow through the sniffer line. The helium in the gas flow

is indicated as leak rate.

In Sniff mode, the detection limit is restricted to 1×10

pheric helium background.

The gas flow rate though the sniffer line is approximately 25 sccm.

It is electrically connected by the "ACCESSORIES“ connector.

The operating mode must be set to "Sniff mode".

In "SNIFF"-mode, the red LED on the sniffer handle indicates a bad test sample and

the green LED indicates a good test sample.

The active push-button on the sniffer handle of the sniffer line can be used for switch-

ing on the external background suppression. If the push-button is pressed for a

longer time (3 seconds), the external background suppression is switched off again.

-7

mbarl/s due to the high atmos-

jinb80e1-h Operating Manual(1012)

Working Modes 5-8

Page 42

6 Operation

6.1 Switching ON

Install the device as described in the Installation chapter. Connect the power cable.

Switch the device ON. The mains switch and the connection for the power cab le a re

at the back of the device.

After the mains switch has been actuated the devices runs up automatically.

In run-up mode (≤ 3 Min.) the following items appear on the display:

• Speed of the turbo-molecular pump

• Fore-vacuum pressure

• State of emission

• Active filament

• A bar graph which shows the run-up progress

After the run-up has been completed, the Modul1000 is in „Standby“ mode.

6.2 Status LED

The LEDs show the operating mode of the device:

Operating mode: LED, green LED, yellow

Run-up Flashes Flashes

Standby/Vent On Off

Evacuate On Flashes slowly

Measuring On On

Calibrating Flashes synchronously Flashes synchronously

Error / Warnings /

Maintenance messages

Off Flashes fast

6-1 Operation

jinb80e1-h Operating Manual(1012)

Page 43

6.3 Control

Control Panel

Hand set

The Modul1000 can be controlled via the control unit, the remote control, the PLC

inputs or via the RS232-interface. These options can be selected in the menu item

„Control location“.

(refer to: Main menu → Settings → Interfaces → Control location)

The optional control unit can be used for programming and controlling of all device

functions and information can be read out.

The functions and the menu structures of the control unit for desktop operation (refer

to chapt. 3.3.1) and the control panel for the rack installation (refer to chapt. 3.3.2)

are the same.

The optional remote control (refer to chapt. 3.3.3) includes the main functions Start,

Stop, Vent, and Zero. Additionally the volume can be controlled.

If „LOCK“ is displayed, the control of the Modul1000 via the remote control was disabled in the menu item „Control location".

RS232 Interface

The RS232 interface serves for connecting a PC directly to the Modul1000.

Then, the control commands will be sent by appropriate interface commands to the

device, as described in the interface description.

PLC Inputs and outputs

The most important control commands can also be sent to the Modul1000 via a PLC.

The functions of the inputs and outputs can be configured.

jinb80e1-h Operating Manual(1012)

Operation 6-2

Page 44

6.4 Control commands

The following control commands can optionally be sent to the Modul1000 to the

control unit / remote control via the PLC control inputs or via the RS232 interface.

START

If the control unit is connected, the LED in the START-button will flash during the

evacuation process.

During the measurement, it will light up continuously.

If the START button on the control unit is pressed during the measurement, the maximum leak rate display will be enabled (Hold function). This is the highest leak rate

which has been measured since the start.

If the START button is repeatedly pressed, this Hold function will be initialized.

The LED in the button indicates the status:

LED flashes: Evacuate

LED ON: Measuring operation:

By pressing the START button, the Modul1000 starts to evacuate the connected test

sample.

If the pressure on the inlet of the leak test device reaches < 0.4 mbar , the Modul1000

will automatically switch over to the Measuring mode.

This pressure limit can be set in the following menu:

Settings

.

→

Monitoring → Pressure limit for the vacuum area

STOP / VENT

ZERO

The STOP command stops the measurement and the leak test device switches over

to the Standby mode.

If you press the STOP button briefly, the measurements are interrupted.

If the button is pressed longer, the inlet is vented according to the conditions defined

in the menu "Vent delay".

LED ON: Inlet vented

Pressing the ZERO button activates the background suppression. To disable the

background suppression again, it will be enough to keep the ZERO push button

pressed for about 3 seconds.

The status of the ZERO-button is indicated by the LED:

LED ON: ZERO enabled

Notice: The ZERO function should be started only when the background signal is

stable. In the I-ZERO setting, the ZERO function can be used only then

when the dropping background signal beco mes constant.

jinb80e1-h Operating Manual(1012)

6-3 Operation

Page 45

Menu

Display-buttons

Fig. 6-3 Zero function (background suppression)

Item Description Item Description

1 Leak rate signal without ZERO 5 Leak 5E-10 mbarl/s with ZERO

2 ZERO is enabled 6 Floating Zero adjustment

3 Suppression of two decades 7 No Zero-adjustment

4 Leak 5E-10 mbarl/s without ZERO

Pressing the MENU button displays the selection menu.

The functions of the eight buttons on the left or on the right of the display depend on

the selected menu. Please find the description of relating functions on the display.

Numerical Entries

If you have opened a menu screen for numerical entries please proceed as follows:

• If you do not want to change any digits, press key „Cancel“ to abort.

• The digit that can be changed is displayed shaded. Use the keys No. 8 and No. 4

and go to the position to be changed.

• To change a digit to a specific number press the corresponding pair of numbers.

A sub-menu opens and the desired number can be se lect ed .

The sub-menu closes automatically and the next whole number will be displayed

with inverted colours and can be changed.

Having reached the last digit all corrections have to be confirmed by OK.

jinb80e1-h Operating Manual(1012)

Operation 6-4

Page 46

Fig. 6-4 Examples for a numeric input of Trigger Level 1

To change the trigger level from 1.0x10-9mbarl/s to 3x10-9mbarl/s please press 2/3

(button No. 3). A sub-menu is opened, in which the desired value 3 (button 4) can be

selected.

6-5 Operation

jinb80e1-h Operating Manual(1012)

Page 47

6.5 Display

Run up

Status line

The display shows measuring values, operating modes, device parameters and their

values, as well as functions of the eight buttons on the left and o n the right side of the

display.

After it has been switched on, the Modul1000 displays so me sta tu s info rm a tion .

The following details on the device are shown in the status line at the bottom of the

display after the Modul1000 has run up.

Standby

Evacuation

Display

symbols

S1, 2, 3 Trigger Level 1, 2, 3

• • Detected mass

VAC Operating Mode

ZERO ZERO Indicates if ZERO-function is active.

COR Corrected leak rate

Meaning Explanation

Sound volume Refer to chapter Volume for the audible signal

If the trigger values are exceeded these signs are

inverted. (White on black background.)

The number of dots stands for the mass number

(4 dots = helium, 2 dots = hydrogen).

Warning triangle Refer to chapter 4.4.2

VAC, SNIFF, COMMAND or AUTO LEAK TEST

stand for the selected operating mode.

It shows if the leak rate is corrected with the

machines factor.

After the run-up has been completed, the Modul10 00 a utomatica lly switches over to

Standby mode and is ready for measurement.

Pressing the START button causes the Modul1000 to evacuate the inlet.

The evacuation time depends on the volume connected the M odul1000 and the forevacuum pump or the partial flow pump.

jinb80e1-h Operating Manual(1012)

Operation 6-6

Page 48

Measuring

p

2

V2

MS

V6

V7

p

1

V1

V4

V22

Fig. 6-5 Evacuate

When the pressure on the inlet of the Modul1000 drops below the set lo wer pressure

limit, the device will change over to measuring mode.

6-7 Operation

Fig. 6-6 Measuring

jinb80e1-h Operating Manual(1012)

Page 49

Display of measured values

In Measuring mode, two ways of displaying the measured values are available.

• Numeric display with big sized numbers as bar graph.

Fig. 6-7

• Graphic display as function of the measuring time

Fig. 6-8

You can switch over between the numeric display and the graphic display using the

button No. 8. It is labelled with the symbols for numeric and graphic display.

jinb80e1-h Operating Manual(1012)

Operation 6-8

Page 50

6.6 Calibration in Vacuum mode

The Modul1000 can be calibrated in two different ways: For each calibration, calibrate the mass spectrometer to achieve maximum sensitivity (Autotune).

Depending on the applied test leak, internal or external calibration is required.

No matter, which control location is used, the calibration can be started in the following ways:

Set control location

Internal manual LOCAL, RS232 ASCII

Internal automatic LOCAL, RS232 ASCII, RS232 BINARY, PLC

External manual LOCAL, RS232 ASCII, RS232 BINARY, PLC

External automatic LOCAL, RS232 ASCII

For the internal calibration, the test leak integrated in Modul1000 is used.

For the external calibration, a separate test leak is required. External calibrations

have the advantage that they can be carried out under boundary conditions (pressure, measuring time) similar or equal to the later measurements.

If a control unit is connected to the Modul1000, the LEDs in the buttons START,

STOP / VENT and ZERO light up during the calibration.

Notice: To get an optimized calibration the machine has to warm up for at least 20

minutes before use.

Internal Calibration

If a partial flow pump is used in measuring mode, set the correct machine factor

before the 1st calibration.

The internal calibration is not done in partial flow mode, not even if it is set to „Partial

flow in measuring mode“. It will be corrected via the set machine factor.

Automatic Internal Calibration

After starting the calibration, the whole calibration procedure runs automatically.

In this case, the signal transient time of the test leak (CAL-transient time) is used

which can be set in the menu. Before, it must be adjusted to th e vo lum e at the inle t.

The CAL-transient time increases depending on the volume enclosed at the inlet.

Manual Internal Calibration

After starting the Calibration, the Modul1000 opens the internal test leak and evacuates the inlet. The signal transient time stretches depending on the connected

volume stretches.

Therefore the user has to confirm that the signal has become constant.

6-9 Operation

jinb80e1-h Operating Manual(1012)

Page 51

External Calibration

The external calibration has the advantage that it considers the application-specific

measuring conditions. The external calibration leak can b e connected to the vacuu m

chamber.

Calibration leaks with solenoid valves can be connected to the terminal VALVES at

the back of the device. Then, the Modul1000 automatically controls the valve.

Before the calibration, enter the corresponding value of the calibration leak which

shall be used for calibrating the Modul1000 in the settings of the Modul1000. This

can be done via the optional control unit or the RS232 interface.

The external calibration in the Partial Flow mode is carried out with the setting „Fore

and partial flow pump“ in the item „Measure mode". (see chapt. 6.12.6.1)

Automatic External Calibration

The automatic external calibration requires a calibration leak with solenoid valve.

It is electrically connected via the VALVES connector.

After starting the automatic external calibration, the Modul1000 runs through the

complete calibration sequence.

In this case, the signal transient time of the test leak (CAL-transient time) is used

which can be set in the menu. Before, it must be adjusted to the volume at the inlet.

The CAL-transient time increases depending on the volume enclosed at the inlet.

Manual external Calibration

In case of the manual external calibration, the test leak has to be opened and close d

manually.

Also acknowledge the steady-state test leak signal manually.

The control unit or the control panel guides the user through the calibration routine

via the display.

6.7 Calibration in Sniff mode

It only applies for devices with the catalogue No. 550-310 and 550-330.

In Sniff mode, calibration is done in the same way as it is don e for the exter nal man -

ual calibration in Vacuum mode.

With the optional sniffer line connected to the Mo dul1000, it is required to measure

a sniffer test leak and a helium background.

Acknowledge the steady-state test leak signal and the steady-state background

value manually.

jinb80e1-h Operating Manual(1012)

Operation 6-10

Page 52

6.8 Calibration in Auto Leak Test

There are four different ways of calibration:

• Internal automatic

• Internal manual

• External automatic

• External manual

For the external calibration, a separa te test leak is required , which is mounted on the

chamber.

In Partial Flow mode, always perform an external calibration.

Sequence of calibration:

1 open the test leak or it opens automatically,

2 evacuate,

3 acknowledge steady-state signal when calibrate manually,

4 autotune (Calibration to maximum sensitivity),

5 vent to atmospheric pressure,

6 evacuate, after the measuring time is over, take the signal with open test leak,

7 vent to atmospheric pressure,:

8 close the test leak, evacuate, after the measuring time take the background signal,

9 vent to atmospheric pressure.

6.9 Calibration in Commander mode

During the calibration, the test gas supply is not enabled.

There are four different ways of calibration:

• Internal automatic

• Internal manual

• External automatic

• External manual

For the external calibration, a separa te test leak is required , which is mounted on the

chamber.

The calibration procedure is the same as it is for the vacuum mode.

6-11 Operation

jinb80e1-h Operating Manual(1012)

Page 53

6.10 Machine factor

The machine factor takes into account that the Modul1000 is used in parallel with a

pumping system.(partial flow method).

Because in such a system configuration only a part of the leak gas flow reaches the

leak test device and is detected, first. the Modul1000 displays measured values on

the basis of the internal calibration which are smaller due to the partial flow ratio.

To avoid this, the machine factor can be saved in the software menu of the

Modul1000. Then, after an internal calibration, the measured leak rates are displayed

multiplied by the machine factor.

The machine factor can be estimated considering the Helium pumping speed of the

Modul1000 and of the external pump .

The measurement of an external test leak on a test sample is more accurate when it

is measured with and without an added external pump. The ratio of both results is the

machine factor.

The machine factor can also be used to correct the leak rate display referred to the

air equivalent.

The machine factor for this correction is: 3.7 x 10

When this setting is used, this status will be displayed by „COR“.

-1

.

jinb80e1-h Operating Manual(1012)

Operation 6-12

Page 54

6.11 Menu structure

Scale linear/logarithmic

Display range auto/manual

View

Mode

Trigger & Alarms

CAL Calibration

Main menu Modul1000

Settings

Time axis

Contrast

Background in standby

Lower display unit

Trigger level 1

Trigger level 2

Trigger level 3

Volume

Units

Alarm delay

Audio alarm type

Internal automatic

Internal manual

External automatic

External manual

Vacuum settings

Zero & Background

Mass

Interface

Others

Purge / Automatic gas ballast

Vent delay

Partial flow

Measuring time

Trigger level 1

Automatic Leak Test Settings

Commander functions Commander pressure threshold

Machine factor

Leak rate internal test leak

Background suppression

zero

Control location

RS232

External pressure gauge

Define PLC outputs

Define PLC inputs

Recorder Recorder output

Output gas ballast

Time/date

Language

Leak rate filter

Part Number

CAL setting time

Maintenance interval

Series Error Messages

Part Number

Reference Measurement

Commander Timing

Background suppression

Trigger level 1

Characteristics

Zero point

Full scale

Scale recorder output

Reset maintenance interval TMP

Maintenance interval TMP

Maintenance interval fan filter

Maintenance message fan filter

6-13 Operation

jinb80e1-h Operating Manual(1012)

Page 55

Settings

Main menu Modul1000

Info

Access control

Parameter load/save

Monitoring functions

View settings

View internal data

Vacuum diagram

Interface

Logged data

Calibration factors

Services

Access to CAL function

Change device PIN

Change menu PIN

Save as PARA SET 1

Save as PARA SET 2

Save as PARA SET 3

Load default

Load PARA SET 1

Load PARA SET 2

Load PARA SET 3

Calibration request

Paging function RC1000

Contamination protection

Pressure limits for vacuum

ranges

Pressure limits for sniff mode

Maximum evacuation time

View error list

Maintenance history

Calibration history

Test log

Clear test log

jinb80e1-h Operating Manual(1012)

Operation 6-14

Page 56

6.12 Explanation of Menu Items

The menu items on which the explanation refers to are written in bold letters.

Pressing the MENU button displays the selection menu. The software menu opens

the menu level which was left before.

If you press the MENU button once more, you can leave the software menu again.

With pressing the MENU button for 2 seconds the display changes to the upper menu

level, the Main Menu.

6.12.1 Main menu → Return

Returns to the previous page, does not alter any setting.

6.12.2 Main menu→ View

→

Scale linear / logarithmic

This setting is for changing the scales of the bar graph and the Y-axis (refer to the

chapter Display of Measured Values).

There is the choice of linear and logarithmic presentation. Only in the logarithmic

view, the number of shown decades can be chang ed by pressing the keys "↑" and

"↓".

→

Display range auto / manual

The upper limit of the displayed bar graph and the diagram can be set manually or

automatically.

• Manually:

If selected manually, any upper detecting limit between 10

8

mbarl/s can be set for the bar graph or the Y-axis to show the leak rate

graphically.

The lower detecting limit results from the scale setting (refer to chapter "Scale

linear/logarithmic"

• Automatically:

In the "Automatic"-setting, the bar graph and the Y-axis are automatically

adjusted when the value for graphic leak rate presentation is higher or lower.

→

Time axis

The length of the time axis in trend mode can be changed in steps from 16 to 960s.

+3

mbarl/s and 10

-

6-15 Operation

jinb80e1-h Operating Manual(1012)

Page 57

→

Contrast

The contrast of the display can be changed. The changes of the contrast are immediately visible. The recommended value under regular conditions is 50 (or close to it).

If the display setting is too light or too dark, so that the menu items cannot be read,

the contrast can be reset to the default setting as follows:

1 Shut off the Modul1000 and restart it again.

2 During the run-up phase, press the key No. 3 or 7 until the display is clearly readable.

This setting is only saved permanently after confirmation in the Contrast menu. If this

setting is not confirmed, the former setting will be used for the next start of the

Modul1000.

→

Background in Standby

In Standby mode, the internal helium background can be displayed.

→

Lower display limit

This parameter defines the lower leak rate limit in the measurement ranges. Th is is

valid for vacuum modes only. The lower display limit applies for the graphical

diagram of the leak rate and for the numeric output of the leak rate as well. The

Modul1000 does not display leak rates below the lower display limit.

The lower display limit can be selected between 1x10

-5

and 1x10

-11

mbar l/s.

6.12.3 Main menu→ Mode

The operating mode can only be changed in Standby mode.

The following operating modes can be selected:

→

Commander (refer to chapt. 5.4)

→

Sniffer (refer to chapt. 5.5)

→

Auto leak test (refer to chapt. 5.3)

→

Vacuum (refer to chapt. 5.1)

6.12.4 Main menu→ Trigger & Alarms

→

Trigger Level 1 (2 or 3)

In this menu item, you have the choice of up to thr ee leak rate trigge r thresholds. If

the measured leak rate exceeds the set trigger threshold, the Modul1000 reacts as

follows:

Display: At the bottom of the display, the symbols for the trigger 1,2, or 3 are

displayed in inverted colours.

Relay output: The trigger relay of the PLC-outputs switches over.

Alarm/Loudspeaker: If the trigger threshold 1 is exceeded, an audible alar m signal is

generated by the loudspeaker of the Modul1000.

jinb80e1-h Operating Manual(1012)

Operation 6-16

Page 58

→

Warning

Volume

The hearing may be damaged by the alarm signal.

The noise level of the Modul1000 alarm can exceed 85dB(A).

Only expose yourself to the alarm signal for a short time or use ear protection.

In the menu item "Volume", it is possible to adjust the volume of the alarm signals by

pressing the buttons "↑" and "↓" on the left and on the right of the displayed value. In

addition, the volume can also be adjusted during the measurement in the

measurement screen using the keys labelled with a loudspeaker sign.

If a minimum sound level is set in the menu item "Volume", it will not be possible to

set a lower sound level in the measurement screen or in the menu item "Loudspeaker".

Beep sound: The "Beep On" or "Beep Off" buttons serve for switching On/Off the

beep sound of the Modul1000. If the beep is switched on, the Modul1000 indicates

certain changes of status by short audio sign als.

→

Units

The units which are measured by the Modul1000 can be altered .

There is the choice of several pressure units, e.g. m bar, Pa, atm and Tor r as well as

the leak rate units, e.g. mbar l/s, Pa m3/s, Torr l/s, atm cc/m and atm cc/s.

In Sniff mode, the following additional units are selectable: ppm, g/a, oz/yr.

→

Alarm delay

To avoid a trigger alarm due to high background levels, e.g. during the evacuation

process, an alarm delay can be set. The alarm delay time will start, after the

Modul1000 has changed from the Evacuation mode to the Measurement mo de. Trigger 1 will release only then when the set alarm delay time has expired or the measured leak rate was below the set trigger value for a short time.

The alarm delay can vary between zero and ten minutes. If the set time exceeds 10

minutes, the alarm delay time is automatically set to unlimited.

→

Audio Alarm Type

There are three optional alarm types.

• Pinpoint:

The audio signal changes its frequency only within a leak rate window which

reaches from one decade below the trigger threshold 1 to one deca de above the

trigger threshold 1. Below this window, the audio signal frequency remains

constantly low and above this range it remains constantly high.

For example: The trigger limit is 4×10

from 4×10

• Leak rate prop.:

The frequency of the acoustic output is proportional to the reading on the

bargraph display. The frequency ranges from 300 Hz to 3300 Hz.

-8

mbar l/s to 4×10-6 mbar l/s.

-7

mbar l/s. With this, the window reaches

6-17 Operation

jinb80e1-h Operating Manual(1012)

Page 59

• Setpoint:

The frequency of the audio signal is proportional to the valu e of the leak rate. The

audio signal is only generated when the leak rate exceeds the Trigger 1 level.

• Trigger alarm:

If the Trigger level 1 is exceeded an audio signal will be generated.

6.12.5 Main Menu→ Calibration (CAL) Mode Vacuum

→

Internal automatic

If the internal automatic calibration method is selected, the Modul1000 will perform

the complete calibration procedure automatically.

In the automatic calibration processes, the Modul1000 runs the following sequences

automatically:

• The internal test leak is automatically opened, The inlet is evacuated.

• Measurement of test leak

• Autotune (Calibration to maximum sensitivity of the mass spectrometer)

• The internal test leak is automatically closed, the helium background is

measured.

• The newly determined calibration factor is displayed

→

Internal manual

If a manual calibration method has been selected, several entries have to be made

during the calibration procedure.

1 Only for the external manual calibration method, the test leak value has to be

entered, when the displayed leak rate does not match with the value of the used test

leak. The internal manual calibration already starts with selecting the calibration

method.

The value of the used test leak can be entered by pressing the "Change leak rate"

button (also refer to chapter "Change values").

After the test leak value has been entered, start the calibration process by pressi ng

the "Start" button.

2 After starting the calibration process, the Modul1000 evacuates the inlet area.

3 As soon as the maximum intake pressure of the Modul1000 has been reached, first,

the Modul1000 displays a varying measuring signal in the shape of a bar display.

After a certain time period, which depends on the volume connected to the inlet, the

display will stabilize.

As soon as the bar displays a constant value, it has to be acknowledg ed by pressing

"OK".

4 In the next step, the Modul1000 adjusts the mass spectrometer to maximum

sensitivity.

5 Only in case the external manual calibration is required, the Modul1000 will prompt

you to close the external test leak.

As soon as the external test leak has been closed, it has to be acknowledged by

pressing "OK".

jinb80e1-h Operating Manual(1012)

No action will be required for manual internal calibration.

Operation 6-18

Page 60

6 No entries are required during the running calibration phase.

7 In the last step, the Modul1000 saves the newly determined calibration factor.

If the newly determined calibration factor deviates from the prior ca libration facto r by

the factor 2, the new value has to be acknowledged by acceptance.

Press "Yes" and the newly determined calibration factor will be taken over.

Press "No" and the newly determined calibration factor will not be taken over. The

Modul1000 will further use the calibration factor determined in the prior calibration

procedure.

→

External automatic

This requires the connection of an external test leak with solenoid valve.

Once this procedure is started the entire procedure is performed automatically. At the

end (after about 25 s) a beep is released. Thereafte r the leak detector is rea dy for

further use.

It is possible to set the time before the test leak is opened/closed to receive a

constant measuring signal.

→

External manual

1 Make sure that the test leak is connected and opened.

2 Check the leak rate printed on the test leak and compare it with the leak rate at the

display. If the leak rates are not identical press Edit leak rate and correct the value.

If the leak rates are the same, press START.

3 The bargraph display shows a signal which must not vary much. If so, please press

OK.

4 Close the external test leak and confirm with OK.

5 The bargraph display shows a signal which must not decrease any more. There

might be a small fluctuation which is okay. There If so please press OK (Soft Key no.

8).

⇒ The Modul1000 displays the old and the newly calculated calibration factor.

6-19 Operation

jinb80e1-h Operating Manual(1012)

Page 61

6.12.6 Main menu→Settings

6.12.6.1 Main menu→Settings→ Vacuum settings

→

Purge & Gas ballast

The following functions are provided in the "Purge & Gas Balla st " menu :

• Manual purge

• Automatic purge

• Manual gas ballast

→

Vent delay

Short pressing of "Stop/Vent" causes the Mo du l1 000 to swit ch ba ck fr om th e Me asuring mode to the Standby mode. If you press the "Stop/Vent" button for a longer