Page 1

OPERATING MANUAL

®

HAPSITE

Chemical Identification System

IPN 074-472-P1C

Smart Plus

Page 2

Page 3

OPERATING MANUAL

www.inficon.com reachus@inficon.com

©2008 INFICON

®

HAPSITE

Smart Plus

Chemical Identification System

IPN 074-472-P1C

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

ConFlat® is a registered trademark of Varian, Inc.

Dell™ is a trademark of Dell Inc.

INFICON® and HAPSITE® are registered trademarks of INFICON.

Loctite® is a registered trademark of Henkel Technologies.

LEMO® is a registered trademark of LEMO SA.

MicroDuster® is a registered trademark of Acctech LLC.

Microsoft®, Windows® and Excel® are either registered trademarks or trademarks of Microsoft Corporation in

the United States and/or other countries

PEEK™ is a trademarks of Victrex plc.

Swagelok® is a registered trademark of Swagelok Co.

Tedlar® and DuPont™ and Vespel® are trademarks of E. I. du Pont de Nemours and Company or its affiliate

Viton® is a registered trademark of DuPont Performance Elastomers

All other brand and product names are trademarks or registered trademarks of their respective companies.

The HAPSITE Smart Plus runs a Linux® Operating System. The source code for the Operating System is

available from INFICON by request for a nominal operating fee.

Linux® is the registered trademark of Linus Torvalds in the U.S. and other countries.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2008 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly. It has

been constructed in accordance with good engineering practice in safety matters in force in the Community and

does not endanger the safety of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

In addition, this is to certify that this equipment has also been designed and manufactured, having regard to the

state of the art, to ensure complies with the Protection Requirements of EMC directive 2004/108/EC.

A Technical Documentation File is also available for review by competent authorities and will be maintained for a

period of ten years after the date on which the equipment was last manufactured. In additional to this file technical,

safety, installation, maintenance and application related information concerning this equipment can also be found in

the Operating Manual(s) for this product or product family.

Equipment Description: HAPSITE Smart Plus Portable GC/MS with or without wireless communications,

including the HAPSITE Service Module, NEG Pump, Battery and AC to DC

HAPSITE Adapter.

Applicable Directives: 2006/95/EC (LVD)

1999/5/EC (R&TTE / EMC)

(The required compliance statement concerning this directive can be found in

Chapter 4 of this manual.)

2004/108/EC (General EMC)

2002/95/EC (RoHS)

Applicable Standards – Units with wireless communications:

Safety: EN 61010-1:2001

Emissions: ETSI EN 300 328-2 V1.4.1: 2003 (R&TTE Emissions)

(ERM for equipment operating in the 2.4 GHz ISM band)

ETSI EN 301 489-17 V1.2.1: 2002 (Flicker & Harmonics)

(ERM - Specific conditions for 2.4 GHz)

EN 61326-1:1997/A1: 1998/A2: 2001 (Radiated & Conducted Emissions)

Class A: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

Page 6

Immunity: ETSI EN 301 489-17 V1.2.1: 2002 (General EMI)

(ERM - EMC - Specific conditions for 2.4 GHz)

RoHS: Due to the classification of this product it is currently exempt from the RoHS

directive.

Wireless Restrictions:

Countries Restrictions

France Outdoor use limited to 10mW e.i.r.p. within the band

2454 to 2483.5 MHz.

Italy If used outside of own premises, general

authorization is required.

Luxembourg General authorization is required for public service.

Romania On a secondary basis. Individual license required.

Austria, Denmark, Finland,

None

Germany, Greece, Iceland,

Ireland, Liechtenstein,

Luxembourg, The Netherlands,

Norway, Portugal, Spain,

Sweden, Switzerland, The

United Kingdom

Applicable Standards – Units without wireless communications:

Safety: EN 61010-1:2001

Emissions: EN 61326-1:1997/A1: 1998/A2: 2001 (Radiated & Conducted Emissions)

Class A: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

EN 61000-3-2: 2000 (Harmonics)

EN 61000-3-3: 1995/A1: 2001 (Flicker)

Immunity: EN 61326-1:1997/A1: 1998/A2: 2001 (General EMC)

Class A: Immunity per Table A.1

(EMC – Measurement, Control & Laboratory Equipment)

RoHS: Due to the classification of this product it is currently exempt from the RoHS

directive.

CE Implementation Date: May 1, 2008

Authorized Representative: Duane H. Wright

Operations Quality Manager, ISS

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED, IN

WRITING, TO THE VICE-PRESIDENT OF OPERATIONS AT THE ABOVE ADDRESS.

Revised 11/04/08 (Rev C)

Page 7

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly. It has

been constructed in accordance with good engineering practice in safety matters in force in the Community and

does not endanger the safety of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

In addition, this is to certify that this equipment has also been designed and manufactured, having regard to the

state of the art, to ensure complies with the Protection Requirements of EMC directive 2004/108/EC.

A Technical Documentation File is also available for review by competent authorities and will be maintained for a

period of ten years after the date on which the equipment was last manufactured. In additional to this file,

technical, installation, maintenance and application information concerning this equipment can also be found in the

Operating Manual(s) for this product or product family.

Equipment Description: SituProbe

(when used with the HAPSITE Smart Portable GC/MS System)

Applicable Directives: 2006/95/EC (LVD)

2004/108/EC (General EMC)

2002/95/EC (RoHS)

Applicable Standards:

Safety: EN 61010-1:2001

Emissions: EN 61326-1:1997/A1: 1998/A2: 2001 (Radiated & Conducted Emissions)

Class A: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

Immunity: EN 61326-1:1997/A1: 1998/A2: 2001 (General EMC)

Class A: Immunity per Table A.1

(EMC – Measurement, Control & Laboratory Equipment)

RoHS: Due to the classification of this product it is currently exempt from the RoHS

directive.

Page 8

CE Implementation Date: March 31, 2006

Authorized Representative: Duane H. Wright

Operations Quality Manager, ISS

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED, IN

WRITING, TO THE VICE-PRESIDENT OF OPERATIONS AT THE ABOVE ADDRESS.

Revised 11/04/08 (Rev C)

Page 9

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly. It has

been constructed in accordance with good engineering practice in safety matters in force in the Community and

does not endanger the safety of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

In addition, this is to certify that this equipment has also been designed and manufactured, having regard to the

state of the art, to ensure complies with the Protection Requirements of EMC directive 2004/108/EC.

A Technical Documentation File is also available for review by competent authorities and will be maintained for a

period of ten years after the date on which the equipment was last manufactured. In additional to this file,

technical, installation, maintenance and application information concerning this equipment can also be found in the

Operating Manual(s) for this product or product family.

Equipment Description: Headspace

(when used with the HAPSITE Smart Portable GC/MS System)

Applicable Directives: 2006/95/EC (LVD)

2004/108/EC (General EMC)

2002/95/EC (RoHS)

Applicable Standards:

Safety: EN 61010-1:2001

Emissions: EN 61326-1:1997/A1: 1998/A2: 2001 (Radiated & Conducted Emissions)

Class A: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

Immunity: EN 61326-1:1997/A1: 1998/A2: 2001 (General EMC)

Class A: Immunity per Table A.1

(EMC – Measurement, Control & Laboratory Equipment)

RoHS: Due to the classification of this product it is currently exempt from the RoHS

directive.

Page 10

CE Implementation Date: October 2004

Authorized Representative: Duane H. Wright

Operations Quality Manager, ISS

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S PRODUCTS SHOULD BE DIRECTED, IN

WRITING, TO THE VICE-PRESIDENT OF OPERATIONS AT THE ABOVE ADDRESS.

Revised 11/04/08 (Rev B)

Page 11

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 12

Page 13

HAPSITE Smart Plus Operating Manual

DANGER

WARNING

WARNING - Risk Of Electric Shock

CAUTION

Definition of

Note, Hint, Danger, Warning and Caution Paragraphs

NOTE: This is a note paragraph. Notes provide additional information about the

current topic.

HINT: This is a hint paragraph. Hints provide insight into product usage

This is a Danger paragraph. Failure to heed these

messages has a high likelihood of resulting in serious

personal injury or even death!

This is a Warning paragraph. It warns of actions that may

cause physical injury.

This Warning paragraph warns of the presence of

electrical voltages which may cause physical injury.

IPN 074-472-P1C

This is a Caution paragraph. It cautions against actions

which may damage the instrument or lead to the loss of

data.

Page 14

HAPSITE Smart Plus Operating Manual

Operating Manual Style Conventions

The following information describes the conventions used throughout this manual.

When holding down a key and then pressing another key, this is expressed as (for

example) Press Ctrl+C

It is assumed that the hard drive used is drive c. If using another drive, substitute

the hard drive letter being used for “c:”.

Left-click means to press and release the left mouse button (LMB) and right-click

means to press and release the right mouse button (RMB).

The HAPSITE software operates in the Windows environment using the Windows®

Graphical User Interface (GUI). Actions in the HAPSITE software GUI that are

common to the Windows GUI are not explained in detail in this manual. Refer to

the Windows documentation supplied by Microsoft®.

IPN 074-472-P1C

Page 15

HAPSITE Smart Plus Operating Manual

Table Of Contents

Trademarks

Definition of Note, Hint, Danger, Warning and Caution Paragraphs

Operating Manual Style Conventions

Chapter 1

Introduction

1.1

1.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.5 Instrument Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.6 Description Of Subsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.6.1 Gas Chromatograph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.6.1.1 Membrane Isolation Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.6.2 Mass Spectrometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.6.3 Vacuum System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.6.4 Electronic Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.6.4.1 Mass Spectrometer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

The HAPSITE Smart Plus System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.6.4.2 Gas Chromatograph Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.6.4.3 Main Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.6.4.4 Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.6.5 Software Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Chapter 2

HAPSITE Components and Assemblies

2.1 Ship Kit Packing Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 930-850-G9, G12 Ship Kit Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

IPN 074-472-P1C

2.3 930-850-G10, G11 Ship Kit Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.1 Ship Kits Box 3 and 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.4 Basic Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

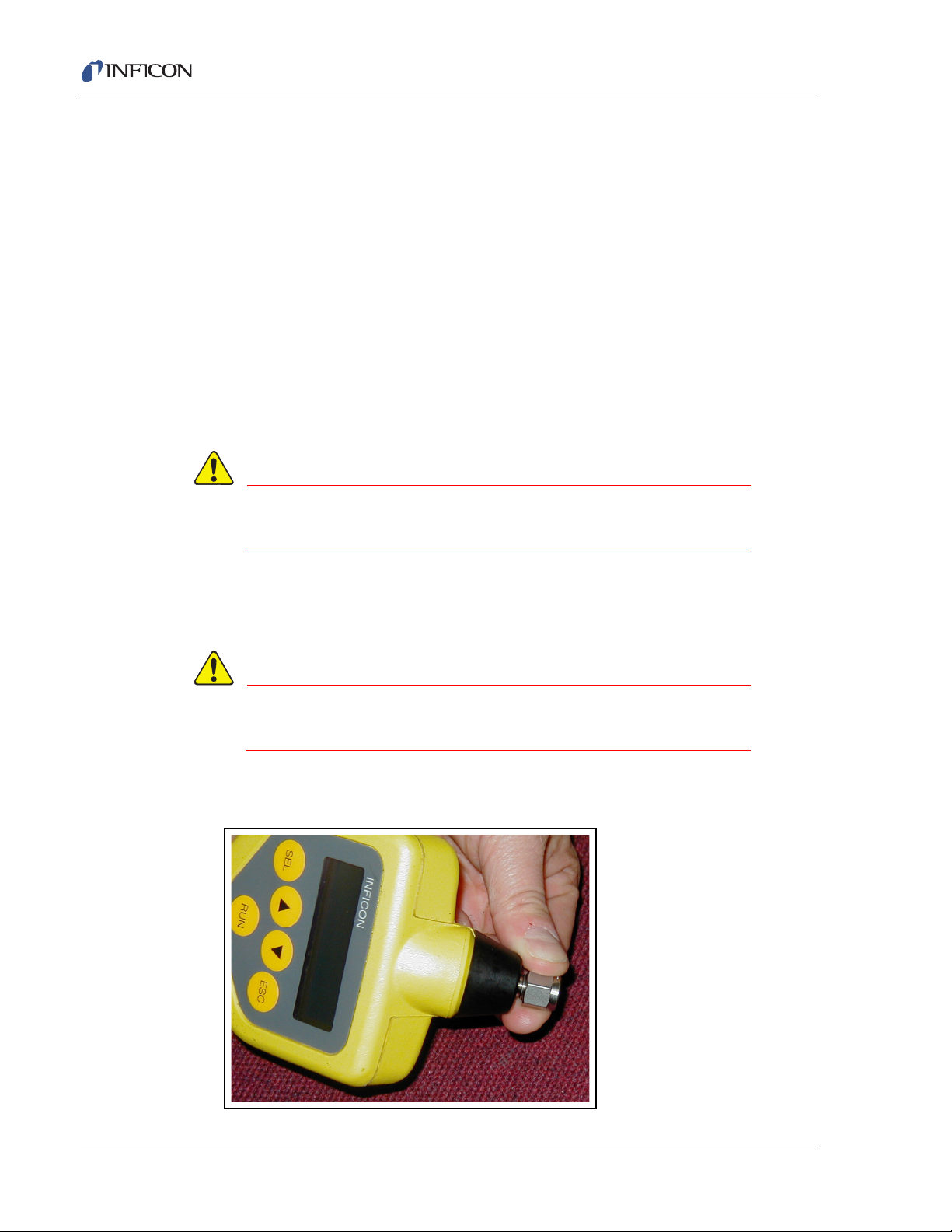

2.4.1 Attaching the Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4.2 Remove Exhaust (Vent) Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

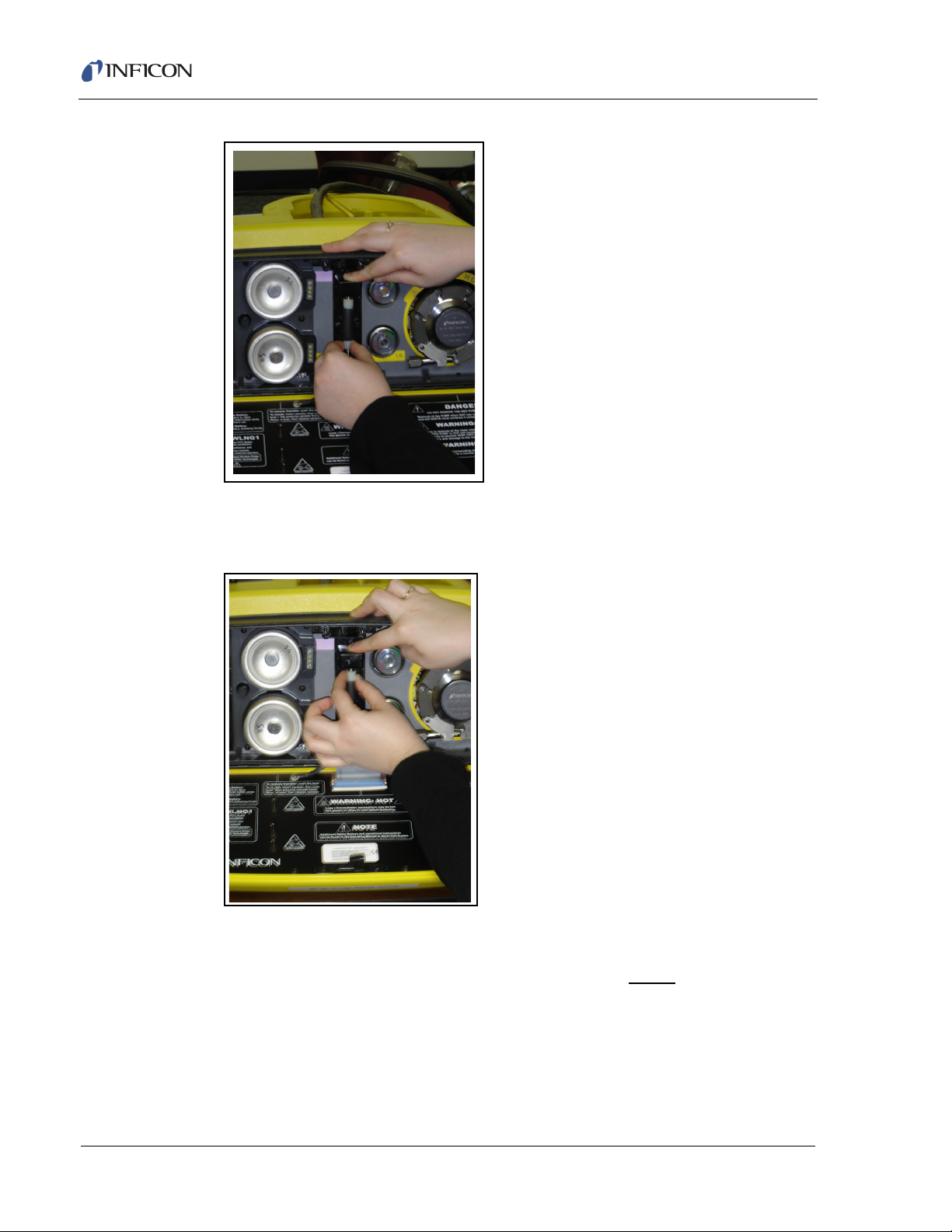

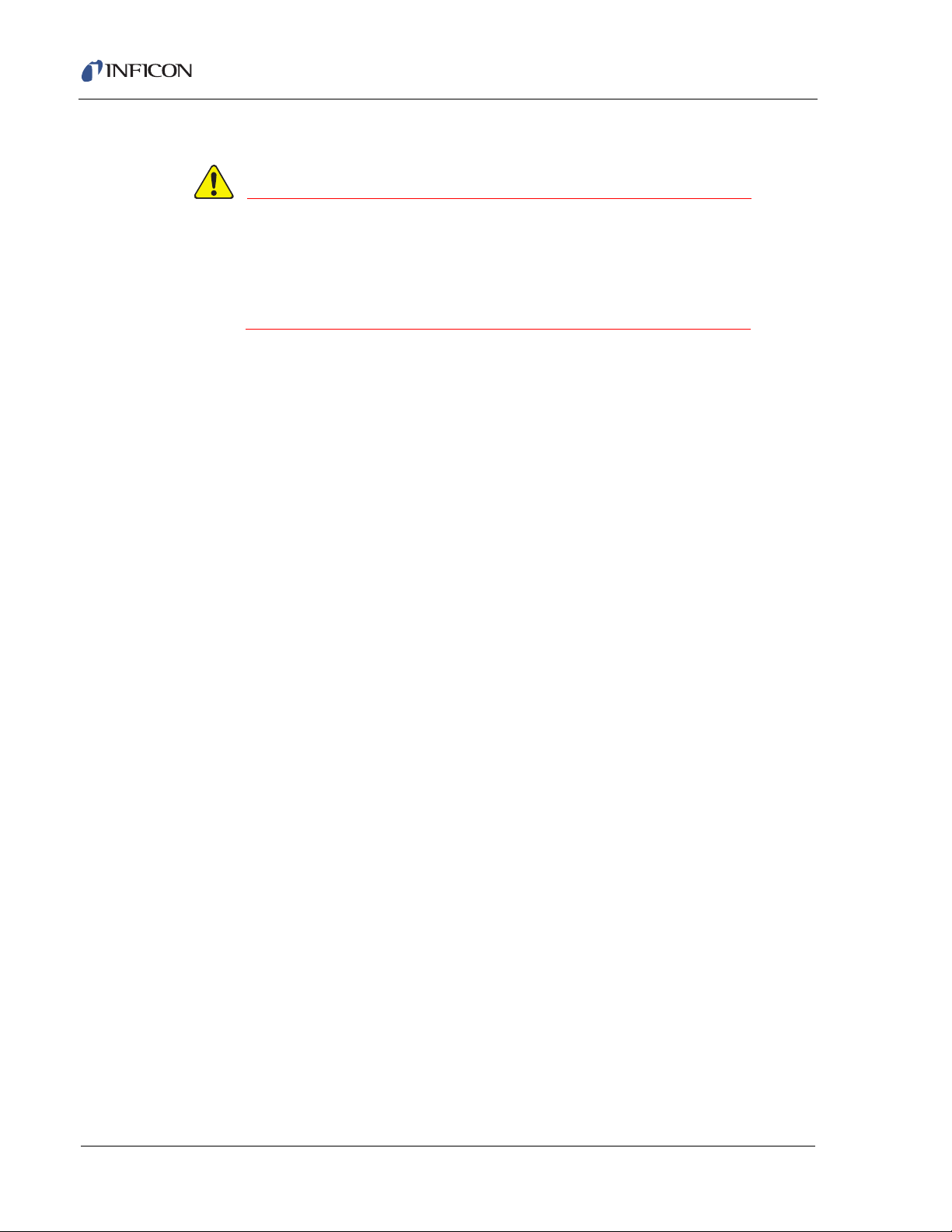

2.4.3 Installing the Gas Canisters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

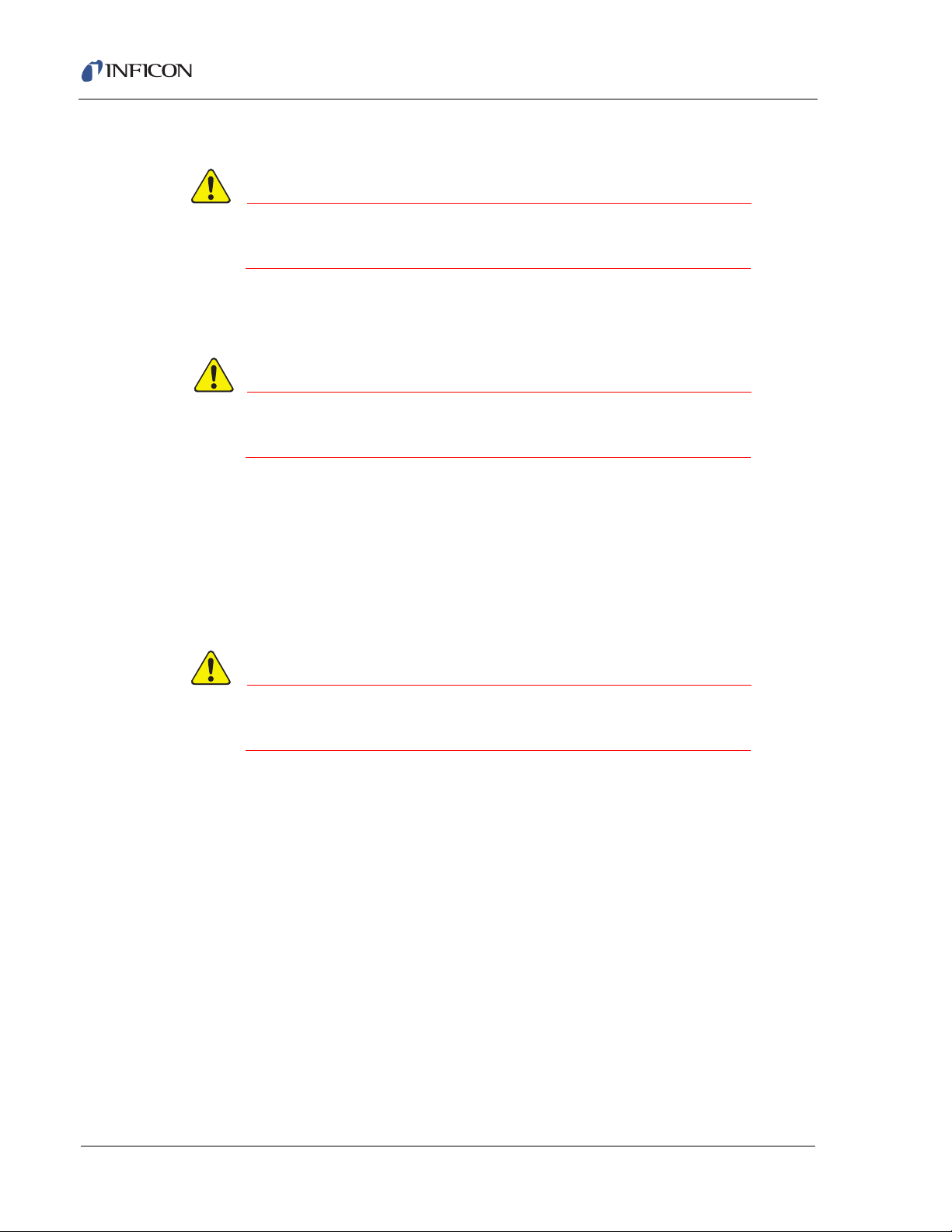

2.4.3.1 How to Change or Remove a Gas Canister . . . . . . . . . . . . . . . . . . . . . . . . .2-9

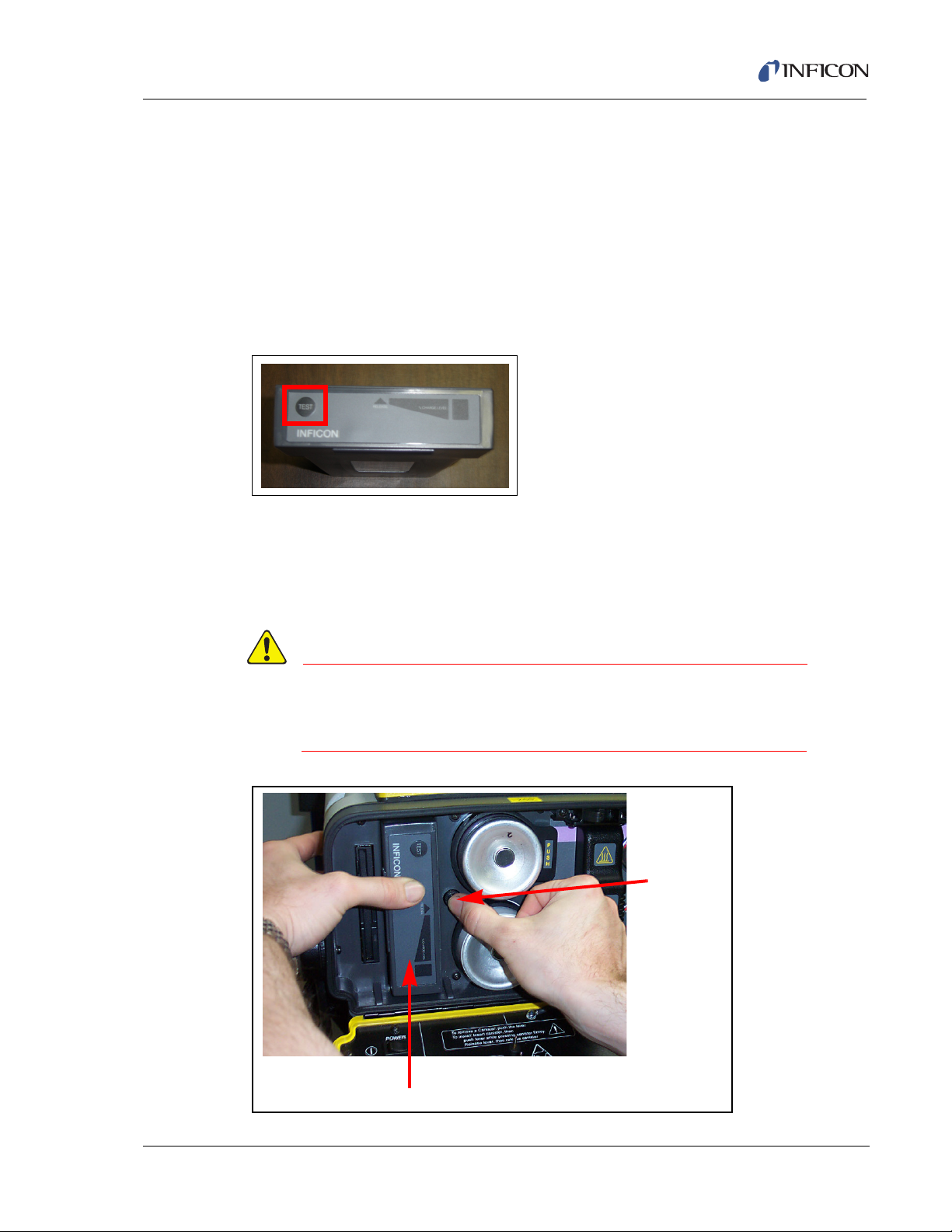

2.4.4 Install Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2.4.5 Connect the AC To DC Power Converter Power Supply . . . . . . . . . . . . . . 2-10

2.4.6 Connect Laptop (if desired) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

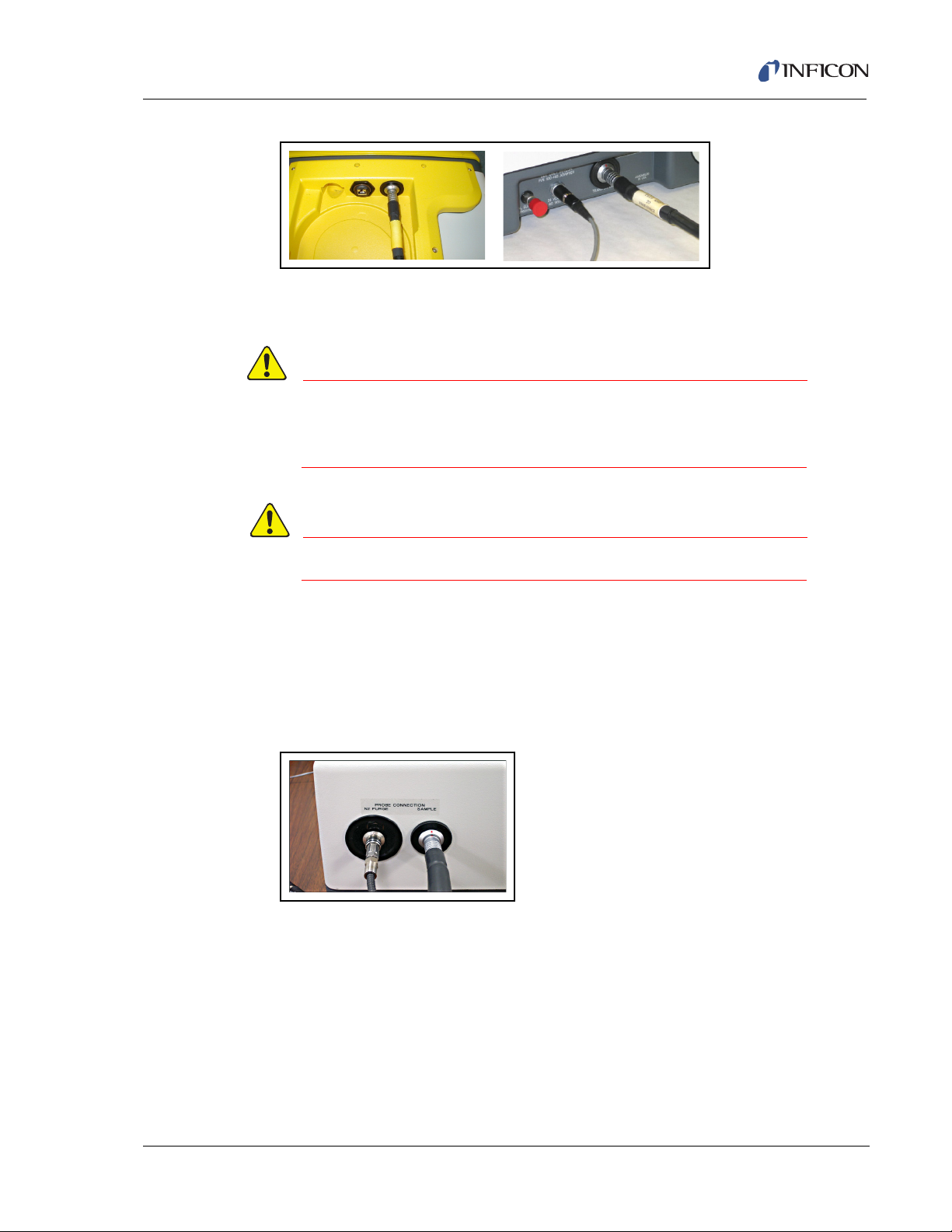

2.4.6.1 Connect Laptop with Yellow Crossover Cable . . . . . . . . . . . . . . . . . . . . . . 2-11

TOC - 1

Page 16

HAPSITE Smart Plus Operating Manual

2.4.6.2 Connect Laptop with Wireless Connection. . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5 Helpful Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.6 HAPSITE Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.7 Headspace Sampling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.7.1 Headspace Sampling System - Components Received. . . . . . . . . . . . . . . 2-13

2.7.2 Installing the Headspace Sampling System. . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.8 Service Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.8.1 Setting Up the Service Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

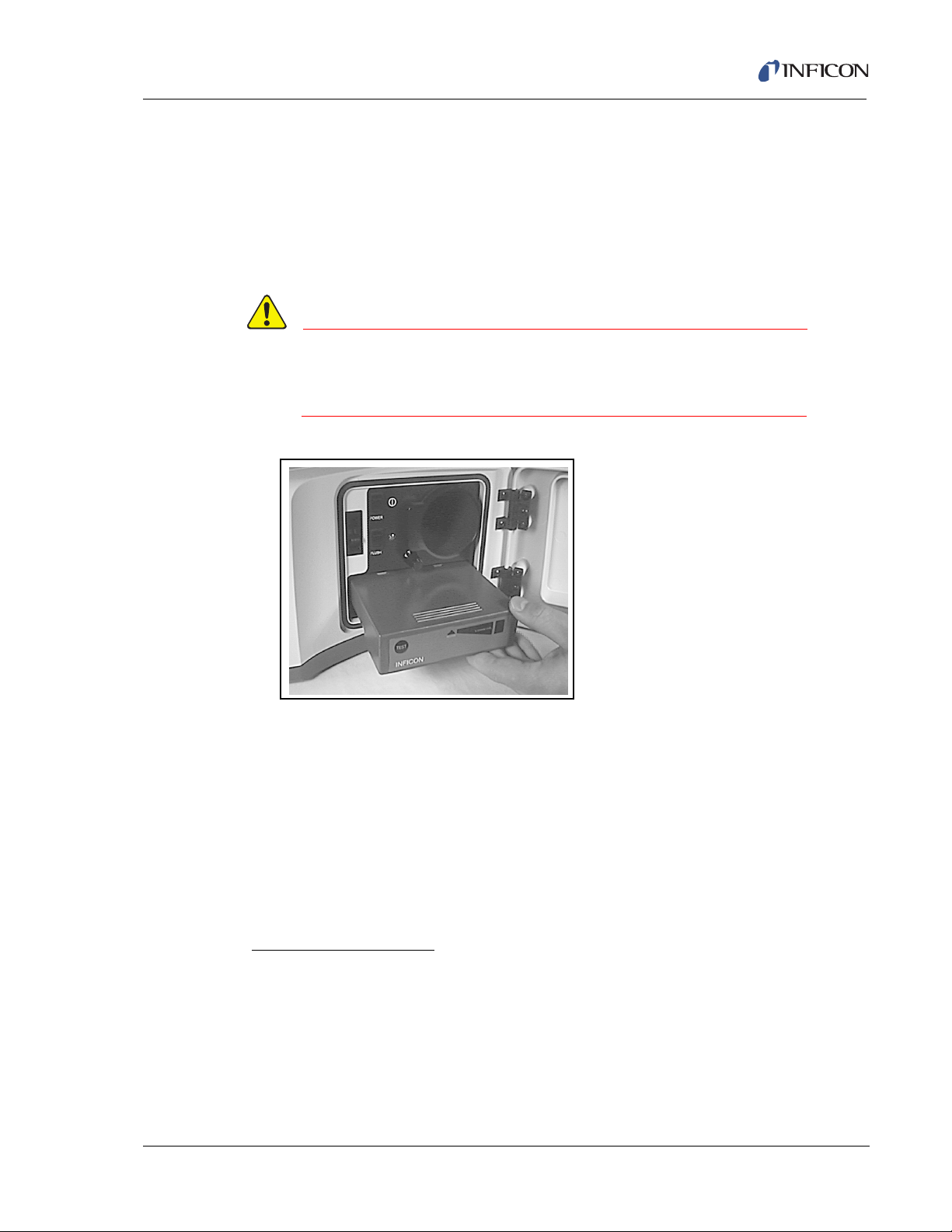

2.8.2 Placing the HAPSITE on the Service Module . . . . . . . . . . . . . . . . . . . . . . 2-24

2.8.3 Detaching the HAPSITE from the Service Module. . . . . . . . . . . . . . . . . . . 2-26

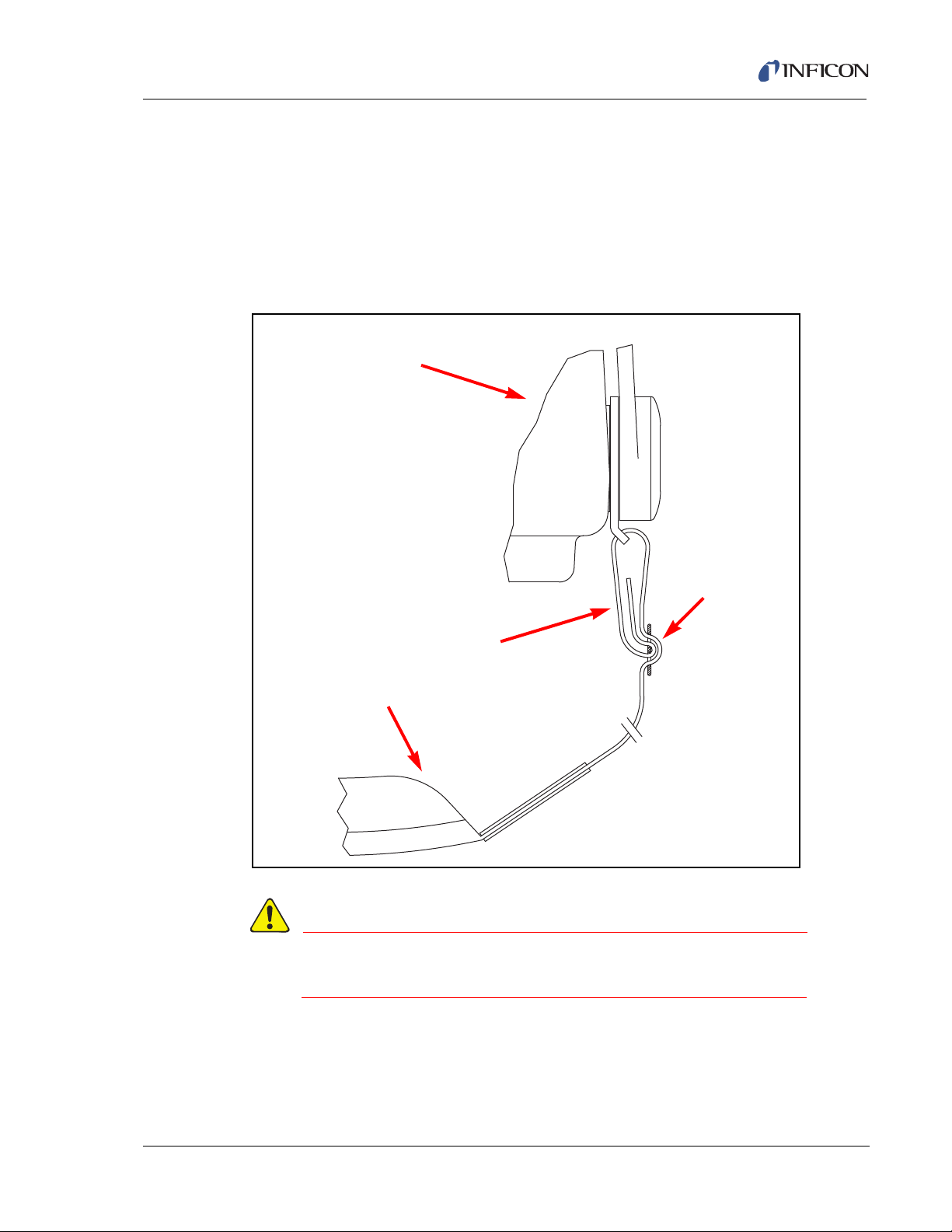

2.9 SituProbe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.10 Sample Collection Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

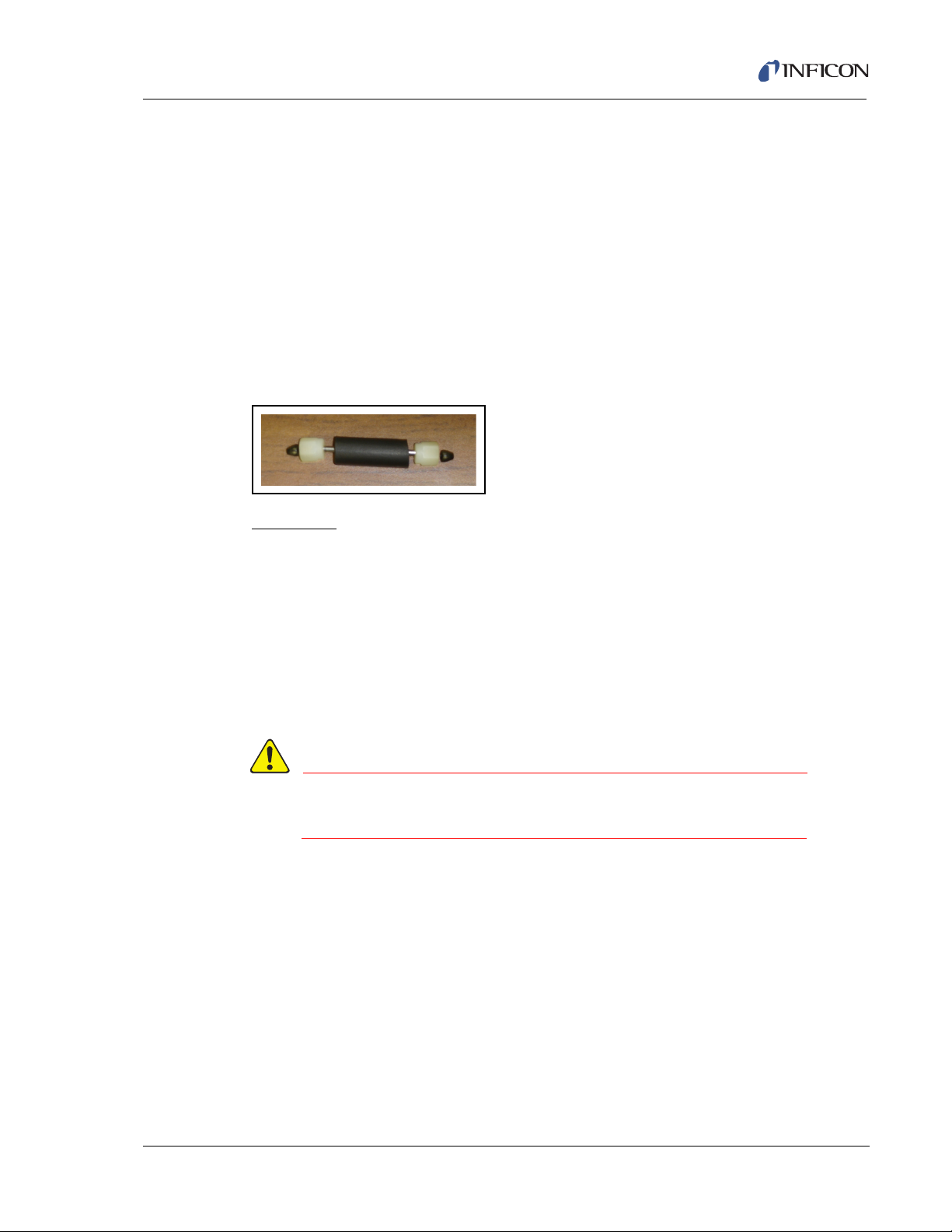

2.10.1 Installing the Sample Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2.10.2 Removing the Sample Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.10.3 Installing the Tri-Bed or Tenax Concentrator . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.10.4 Removing the Concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

2.11 Probe Sampling Options and Attachments . . . . . . . . . . . . . . . . . . . . . . . . 2-42

2.11.1 Probe Nut Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

2.11.2 Attaching a Bag Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

2.11.3 VX / R-33 Conversion Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

2.11.3.1 VX / R-33 Conversion Tube Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

2.11.3.2 VX / R-33 Conversion Tube Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

2.12 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

2.12.1 How to Remove a Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

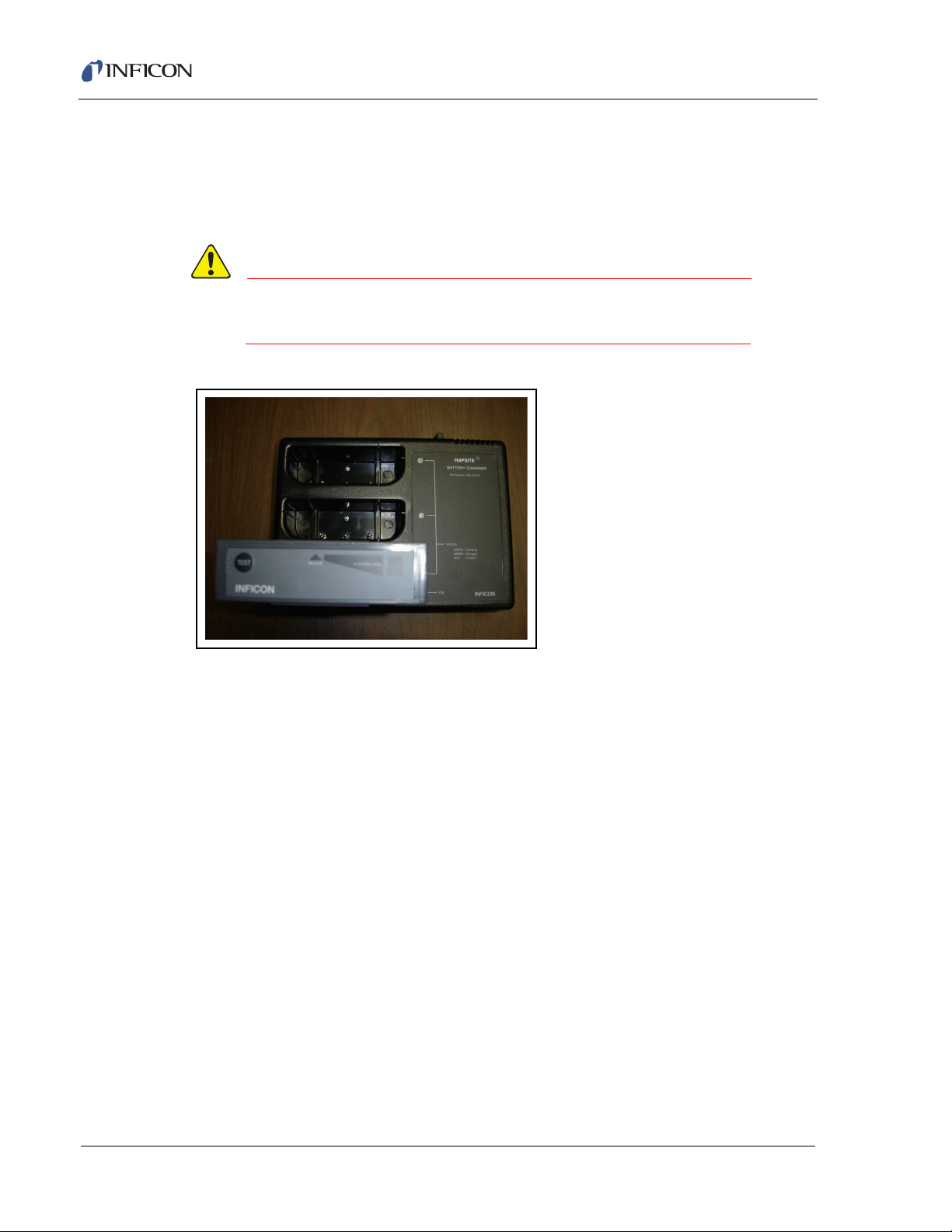

2.12.2 Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

2.12.2.1 Battery Charger Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

2.12.2.2 Battery Charger Connections and Startup . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

2.12.2.3 Loading the Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

2.12.2.4 Understanding the Battery Charger Indicators. . . . . . . . . . . . . . . . . . . . . . 2-50

2.13 Portable Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

2.13.1 HAPSITE and Headspace Sampling System Strap . . . . . . . . . . . . . . . . . . 2-51

2.13.2 HAPSITE Backpack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

2.13.2.1 Adjustment of the Backpack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

2.13.2.2 Care of the Backpack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

2.14 Hot Swap Cable (IPN 930-246-G1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

2.14.1 Connecting the Hot Swap Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

2.14.2 Storing the Hot Swap Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

2.14.3 Use as an Additional Battery Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-55

IPN 074-472-P1C

TOC - 2

Page 17

HAPSITE Smart Plus Operating Manual

Chapter 3

Operating HAPSITE in Portable Mode

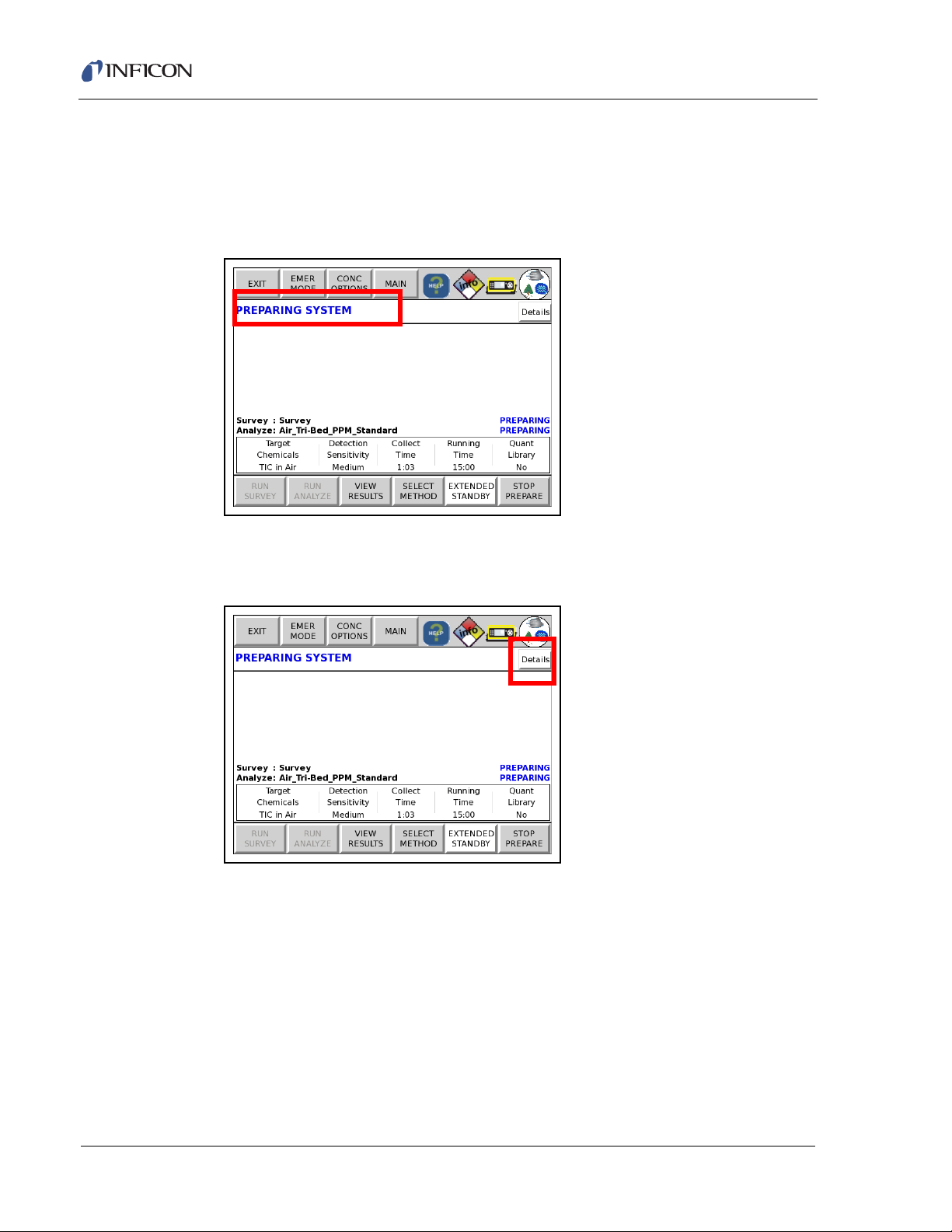

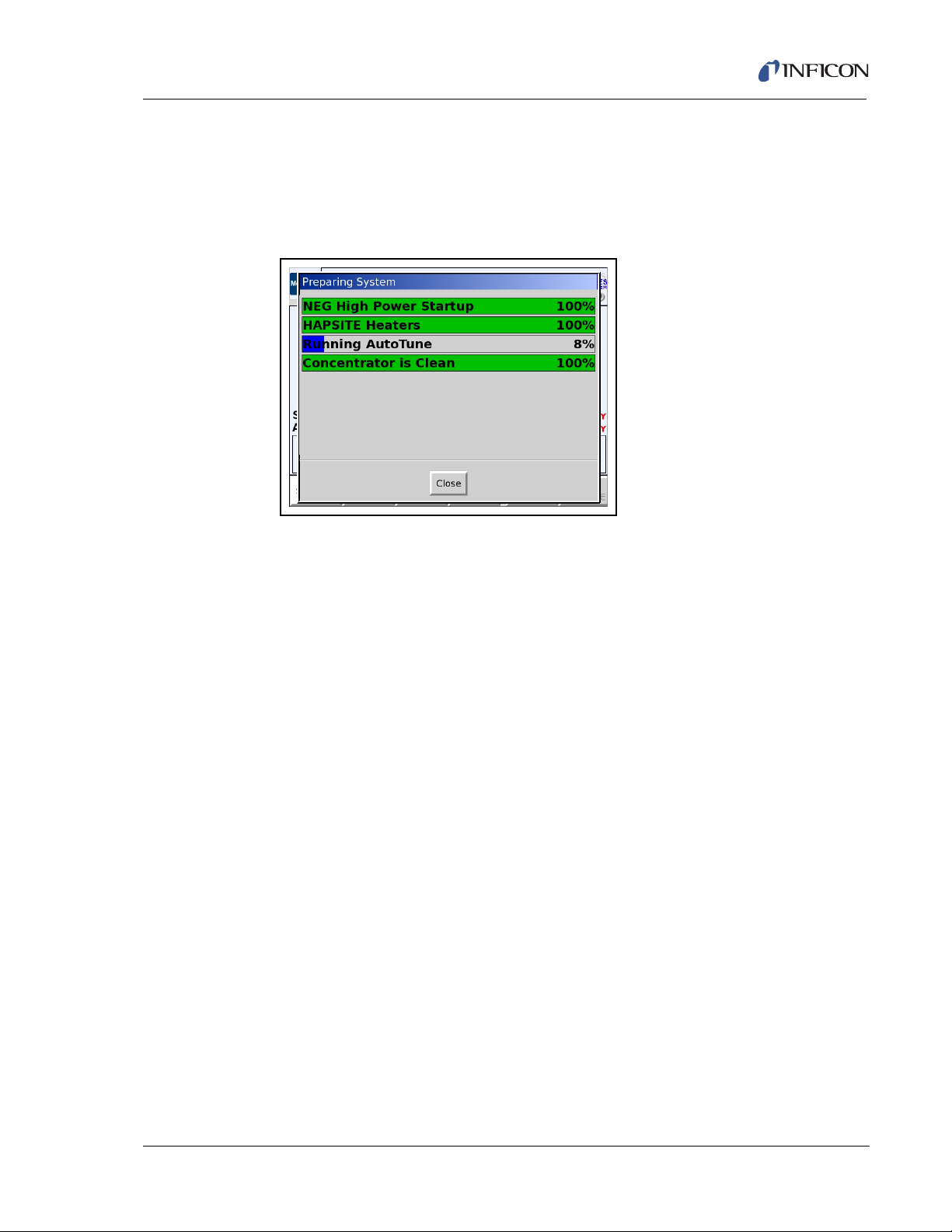

3.1 Starting the HAPSITE in Portable Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 Emergency Mode (EMER MODE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.1.2 Concentrator Options (CONC OPTIONS) . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.1.2.1 Concentrator Cleanout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.1.2.2 Skip Cleanout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3.1.3 Concentrator Cleanout Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.1.4 Quick Reference SOP — Heat-up and Tune . . . . . . . . . . . . . . . . . . . . . . .3-12

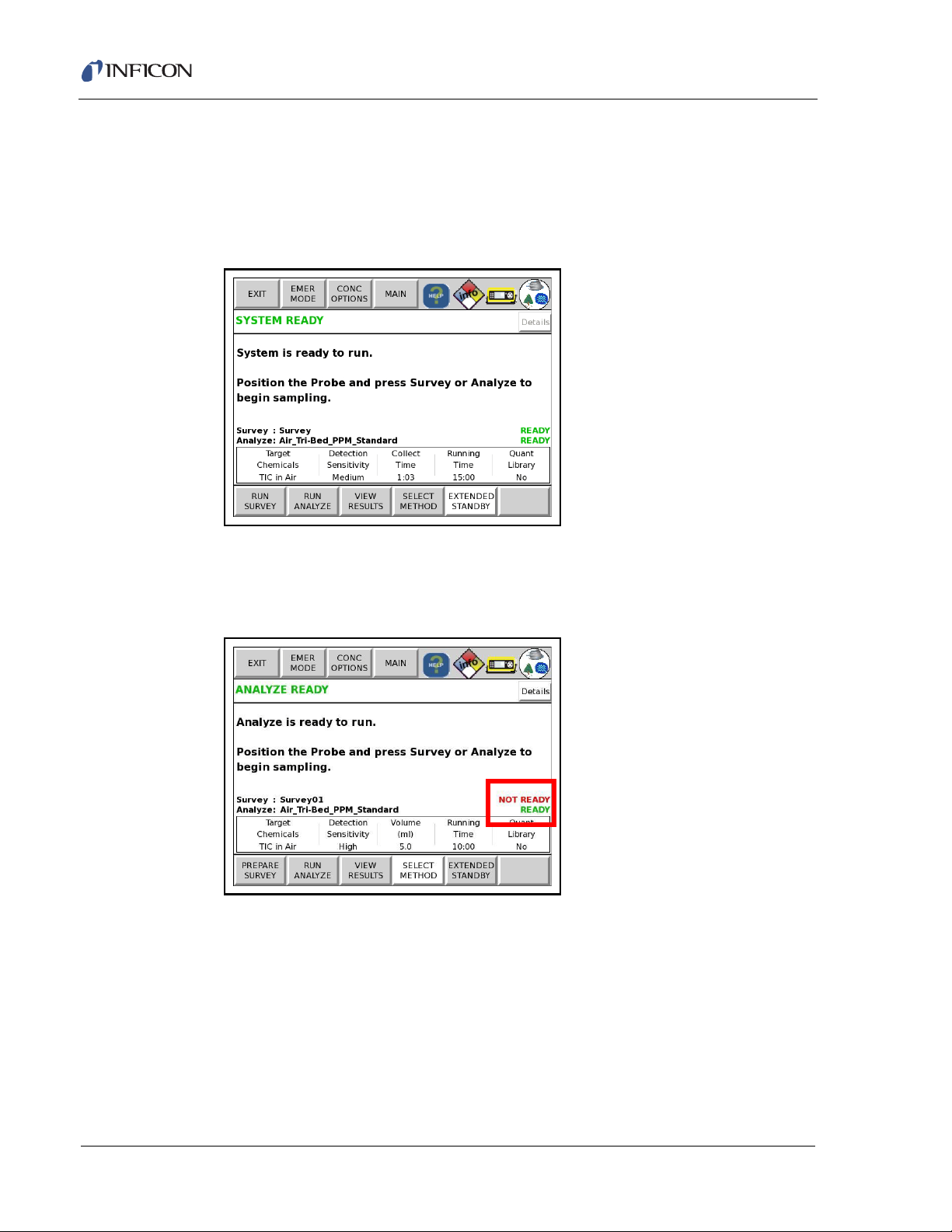

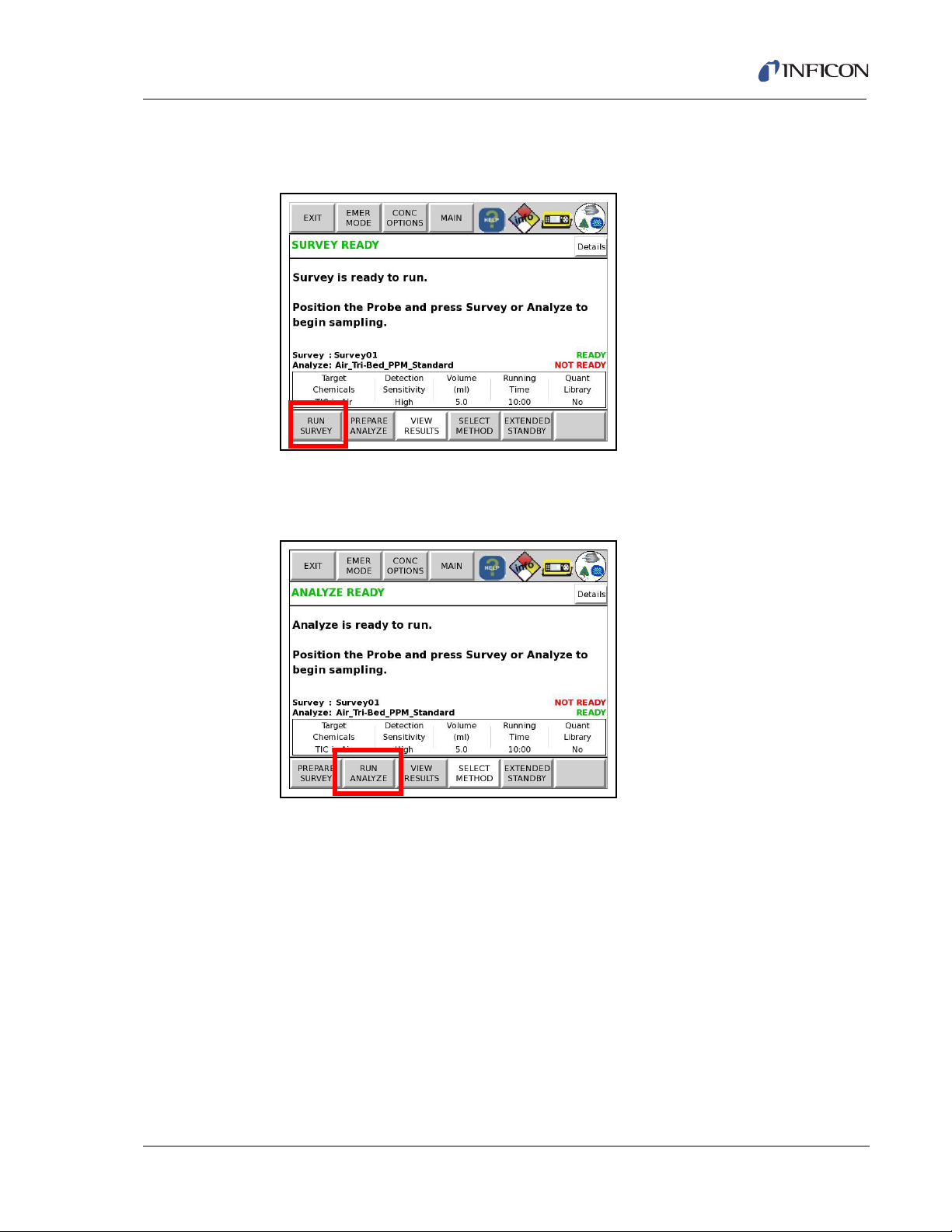

3.2 Selecting a Different Method Using the SELECT METHOD Icon. . . . . . . . 3-13

3.2.1 Changing the Default Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

3.2.2 Show All . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3.3 Survey Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.3.1 Quick Reference SOP — Survey Method . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

3.4 ANALYZE (GC/MS) Mode with the Concentrator. . . . . . . . . . . . . . . . . . . .3-25

3.4.1 The Tri- Bed Concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.4.2 The Tenax Concentrator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3.4.3 Procedure for Running Concentrator Methods. . . . . . . . . . . . . . . . . . . . . .3-25

3.4.4 Quick Reference SOP—Concentrator Methods. . . . . . . . . . . . . . . . . . . . . 3-30

3.5 Detecting Hazardous Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

3.5.1 View Results/View Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3.6 The Help Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

3.7 The Info Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-43

3.7.1 System Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

3.7.1.1 Battery Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

3.7.1.2 Carrier Gas Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51

3.7.1.3 Internal Standard Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52

3.7.1.4 HEATERS Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52

IPN 074-472-P1C

3.7.1.4.1 HEATERS Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3.7.1.4.2 NEG Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3.7.1.4.3 CONC Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-54

3.7.1.5 TUNE STATUS Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-55

3.7.1.5.1 TUNE REPORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

3.7.1.6 GPS Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-57

3.7.1.7 HAPSITE SYSTEM Icon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3.7.1.7.1 HAPS Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-58

3.7.1.7.2 FIRMWARE Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-58

3.7.1.7.3 DATE TIME Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

3.7.1.7.4 NET Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

TOC - 3

Page 18

HAPSITE Smart Plus Operating Manual

3.7.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

3.8 EXIT Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.8.1 Extended Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

3.8.1.1 End Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

3.9 Analyze (GC/MS) Mode with Headspace Sampling System

in Portable Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

3.9.1 Quick Reference SOP —

GC/MS Mode with HSS in Portable Mode . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

3.10 SituProbe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

3.10.1 Procedure for SituProbe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-73

3.10.2 Quick Reference SOP —

GC/MS Mode with SituProbe in Portable Mode . . . . . . . . . . . . . . . . . . . . . 3-77

Chapter 4

Wireless and Touch Screen Options

4.1 Wireless Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Regulatory Compliance Information for UNITED STATES Users . . . . . . . . 4-1

4.1.2.1 FCC Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.2.2 FCC RF Exposure Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.3 Regulatory Compliance Information for CANADIAN Users . . . . . . . . . . . . . 4-3

4.1.3.1 Industry Canada (IC) Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.4 Regulatory Compliance Information for EUROPEAN Users . . . . . . . . . . . . 4-3

4.1.4.1 European Usage Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.1.4.2 European EMC Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.1.4.3 European Safety Compliance Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.1.5 Wireless Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.1.6 Turning On the Radio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.1.7 Establishing Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.1.7.1 Setting the User Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.1.7.2 Setting Up Plus IQ for Communication with the HAPSITE. . . . . . . . . . . . . . 4-9

4.1.8 Wireless Module Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.1.9 Turning Off the Radio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.2 The MAIN Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.2.1 Smart Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.2.2 Adjust Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.3 Touch Screen Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.3.1 Calibrating The Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.3.2 Enabling/ Disabling the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3.2.1 Disabling the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3.2.2 Enabling the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

IPN 074-472-P1C

TOC - 4

Page 19

HAPSITE Smart Plus Operating Manual

4.4 The USB Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

4.4.1 Copying Files to the USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.4.2 Copying Files From the USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.4.3 Updating the Front Panel Software from the USB . . . . . . . . . . . . . . . . . . . 4-30

4.4.4 Retrieving Files from the USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

Chapter 5

Operating HAPSITE in Laptop Mode

5.1 Starting the HAPSITE in Laptop Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Survey Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 Quick Reference SOP — Running Survey Mode. . . . . . . . . . . . . . . . . . . . . 5-6

5.3 Selecting a New Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.4 Analyze (GC/MS) Mode with Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.4.1 Quick Reference SOP — Running Analyze (GC/MS) Loop Method . . . . . 5-14

5.5 Analyze (GC/MS) Mode with Concentrator . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.5.1 Tri- Bed Concentrator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.5.2 The Tenax Concentrator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

5.5.3 Quick Reference SOP — Tri-Bed Concentrator Method . . . . . . . . . . . . . . 5-18

5.6 Analyze (GC/MS) Mode with Headspace Sampling System . . . . . . . . . . .5-19

5.6.1 Quick Reference SOP — GC/MS Mode with HSS. . . . . . . . . . . . . . . . . . . 5-24

5.7 SituProbe Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.7.1 Procedure for SituProbe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-25

5.7.2 Quick Reference SOP — Analyze Mode with SituProbe . . . . . . . . . . . . . .5-27

Chapter 6

Methods

6.1 Introduction to Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Survey Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Building a Survey Method Library File . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

IPN 074-472-P1C

6.2.1.1 Creating Survey Methods for Target Compounds . . . . . . . . . . . . . . . . . . . . 6-3

6.2.1.2 Building a Survey Target Compound Library . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3 Analyze (GC/MS) Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.3.1 Building an Analyze (GC/MS) Method and

Target Compound Library File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Chapter 7

Tune

7.1 Introduction to AutoTune and Manual Tune . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 AutoTune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.1 Starting AutoTune from the Manual Tune Screen

on the Laptop Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.3 Viewing a Tune Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

TOC - 5

Page 20

HAPSITE Smart Plus Operating Manual

7.4 AutoTune Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.5 Manual Tune Settings and Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.5.1 Tool Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.5.2 Tune Drop Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

7.5.2.1 Tune Properties Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.5.3 Tune Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.5.3.1 Tune Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.5.4 Peak Scan Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.5.4.1 Peak Scan Window Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.5.5 Full Scan Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

7.5.6 Tune and Mass Calibration Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

7.5.7 Mass Calibration Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.5.8 Right Mouse Button (RMB) Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.5.8.1 RMB in Scan Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.5.8.2 RMB in Tune Status Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

7.5.8.3 RMB on Y Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

7.6 Performing Manual Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

7.6.1 Adjusting Base Peak Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

7.6.2 Adjusting Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.6.3 Adjusting the Ion Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Chapter 8

Plus IQ Software

8.1 The HAPSITE Software - Plus IQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Computer System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3 Installing and Updating the HAPSITE Smart Plus

and Plus IQ Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.3.1 Updating the HAPSITE Smart Plus Software. . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.4 Installing/Updating NIST and AMDIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.5 Reloading Default HAPSITE Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

8.5.1 Locating Default Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

8.5.2 Loading a Default Method to the HAPSITE . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.6 Establishing Communications between the HAPSITE and

Laptop Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.6.1 Setting Up Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

8.6.2 Configuring the HAPSITE for Communications . . . . . . . . . . . . . . . . . . . . . 8-15

8.6.3 Establishing Communication with the Service Module. . . . . . . . . . . . . . . . 8-20

8.7 Establishing Communications between the HAPSITE and

Laptop Computer Using the Wireless Connection . . . . . . . . . . . . . . . . . . . 8-22

8.8 Setting the HAPSITE Time Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

8.9 Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

IPN 074-472-P1C

TOC - 6

Page 21

HAPSITE Smart Plus Operating Manual

8.9.1 Changing Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-24

8.9.2 Setting or Changing the Access Level Password. . . . . . . . . . . . . . . . . . . .8-25

8.10 Plus IQ Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

8.10.1 System Setup Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8.10.1.1 File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-27

8.10.1.2 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

8.10.1.3 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-27

8.10.1.4 Tools Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

8.10.1.5 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-28

8.10.1.6 Window Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-28

8.10.1.7 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-28

8.11 Software Versions for the HAPSITE and Laptop . . . . . . . . . . . . . . . . . . . .8-29

8.12 HAPSITE Icons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Chapter 9

Data Review

9.1 Introduction to Data Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Accessing the Data Review Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.3 Data Review Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.4 RMB (Right Mouse Button) Menus within Data Review . . . . . . . . . . . . . . . . 9-7

9.4.1 RMB in the TIC/RIC Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.4.2 RMB in the Spectrum Display Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.5 The TIC/RIC Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.5.1 How to Access the Scan Cursor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.5.2 How to Use Background Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12

9.5.2.1 Steps Required to Perform a One Point Background Subtraction . . . . . . .9-12

9.5.2.2 Background Subtraction Using a Range of Points . . . . . . . . . . . . . . . . . . . 9-14

9.5.2.3 Additional Features of the Background Tool . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.5.3 Utilizing the Range Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

IPN 074-472-P1C

9.5.3.1 Steps Required to Range Acquisition. . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-16

9.5.3.2 Additional Features of the Range Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

9.6 Using the Zoom Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

9.6.1 Using the Zoom Function in the TIC/RIC Window . . . . . . . . . . . . . . . . . . .9-18

9.6.2 Using The Zoom Spectrum Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-19

9.7 Displaying Reconstructed Ion Chromatograms (RIC) . . . . . . . . . . . . . . . . 9-20

9.7.1 RIC Plot to Locate Specific Compounds . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

9.8 NIST Library Searches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-24

9.8.1 Searching Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

9.8.2 Analyzing Data Using AMDIS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-30

9.8.3 How To Access AMDIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-30

TOC - 7

Page 22

HAPSITE Smart Plus Operating Manual

9.8.3.1 Accessing NIST from AMDIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

9.8.4 Analyzing Data Using NIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

9.8.5 How to Grab Spectra/Utilize the Full NIST Program . . . . . . . . . . . . . . . . . 9-34

9.9 Reporting and Printing Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

9.9.1 Method Generated Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

9.10 Plus IQ Hot Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

Chapter 10

Saving and Managing Files

10.1 Saving Files on the HAPSITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1.1 Method Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1.2 Event Log Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.3 Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.1.4 Tune Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

10.1.5 Data Review. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

10.2 Saving Files to the Laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

10.2.1 Method Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.2.2 Event Log Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.2.3 Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.2.4 Tune Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.2.5 Report Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.3 Transferring Files Between the HAPSITE and Laptop. . . . . . . . . . . . . . . 10-12

Chapter 11

Method Editor

11.1 The Method Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.2 Accessing Method Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

11.3 Description Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

11.3.1 Full Scan Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

11.3.2 SIM Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-7

11.4 Startup Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

11.4.1 Headspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

11.4.2 SituProbe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

11.5 Inlet Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

11.5.1 Inlet States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

11.5.2 GC Temperature Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-22

11.5.3 Use Internal Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

11.5.4 Scan Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

11.5.5 Concentrator Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-24

11.5.6 Headspace Flow Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-24

11.5.7 SituProbe Flow Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

IPN 074-472-P1C

TOC - 8

Page 23

HAPSITE Smart Plus Operating Manual

11.6 Tune Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

11.6.1 Param Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-25

11.6.2 Report Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-25

11.7 Full Scan Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-29

11.8 SIM Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-30

11.8.1 SIM for Analyze (GC/MS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-31

11.8.2 SIM for Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-33

11.9 Search Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-35

11.9.1 Setting Up a Qualitative Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-36

11.9.2 Setting Up a Quantitative Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-41

11.10 Data Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-46

11.11 Summary Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-49

11.12 How to Create a Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-50

11.12.1 Creating a New Custom Method from an Existing Method. . . . . . . . . . . . 11-50

11.13 How to Sequence Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-53

Chapter 12

Target Compound Methods

12.1 Introduction To Quantitative Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.2 Definition of Terms in the Calibrate Window . . . . . . . . . . . . . . . . . . . . . . . 12-2

12.2.1 Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

12.2.2 Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

12.2.3 Peak Search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

12.2.4 Analytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

12.2.5 Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

12.2.6 Extracted Mass Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

12.2.7 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

12.3 Definition of Terms in the ID Unknowns Window . . . . . . . . . . . . . . . . . . . . 12-6

12.3.1 Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

IPN 074-472-P1C

12.3.2 Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

12.3.3 Peak Search. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

12.3.4 Analytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-7

12.3.5 Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

12.3.6 Extracted Mass Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

12.3.7 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-8

12.4 Display Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

12.5 Using the Calibrate Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-10

12.6 Using the ID Unknown Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-18

TOC - 9

Page 24

HAPSITE Smart Plus Operating Manual

Chapter 13

Headspace Sampling System

13.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

13.1.1 How the HSS Operates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

13.1.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

13.1.3 HSS Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-3

13.1.4 Consumables Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

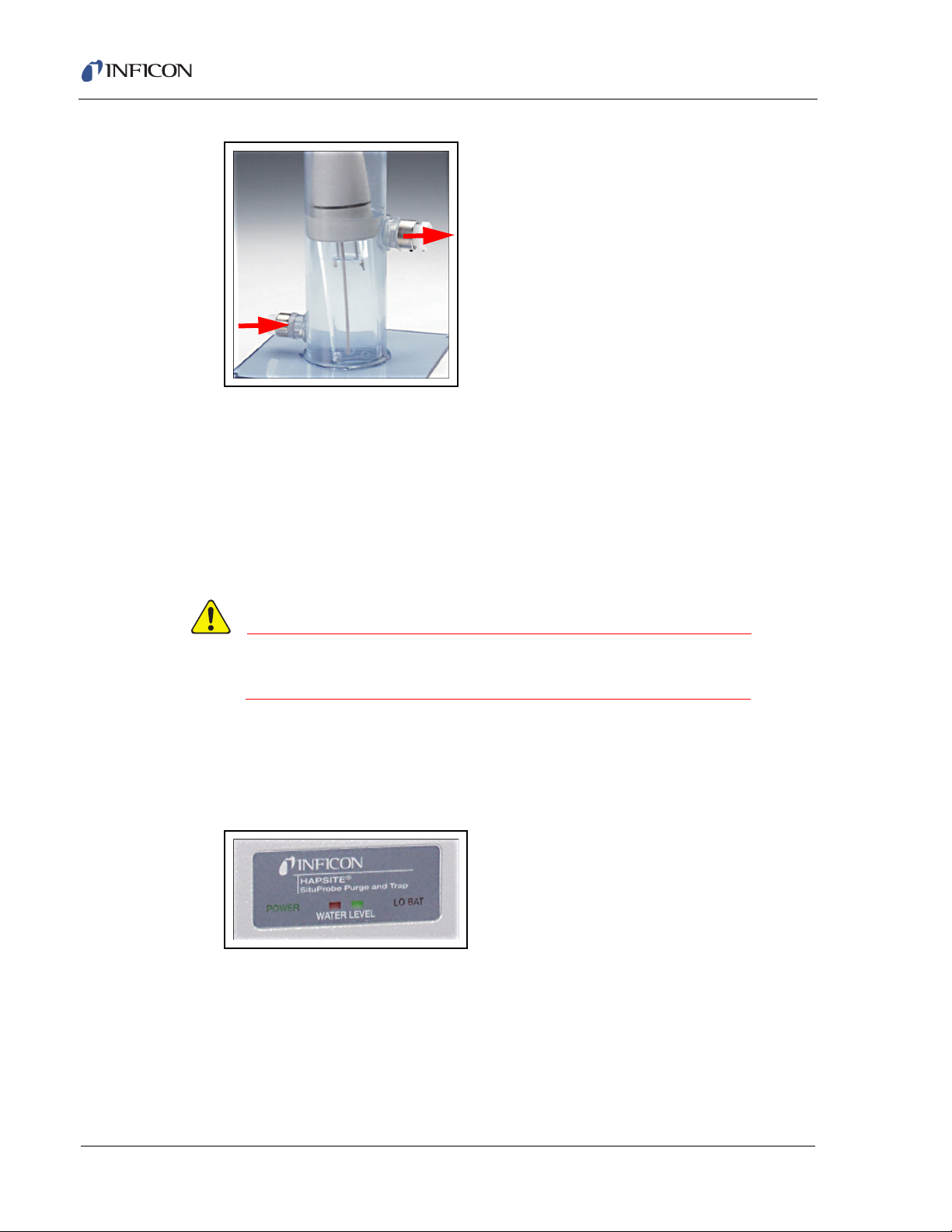

13.1.5 Connecting the HSS to the HAPSITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

13.1.6 Providing Power to the HSS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

13.1.6.1 If AC Power is Available. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

13.1.6.2 If AC Power is Not Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

13.2 Using the HAPSITE with HSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

13.2.1 Powering on the HSS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-6

13.2.2 Loading the Vials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-7

13.2.3 Loading the Wells. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-11

13.2.4 Cycling the Vials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

13.2.5 Making the Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

13.3 Maintenance of HSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-13

13.3.1 Clean Out after a High Concentration Sample. . . . . . . . . . . . . . . . . . . . . 13-14

13.3.1.1 Purge Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

13.3.2 Cleaning Up a High Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

13.3.2.1 Flush Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

13.3.3 Cleaning the HSS Wells. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-15

13.3.4 Decontaminating the HSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

13.3.5 Replacing The HSS Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-17

13.3.6 Replacing The HSS Nitrogen Canister. . . . . . . . . . . . . . . . . . . . . . . . . . . 13-18

13.4 Shipping the HSS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-18

13.5 Charging the HAPSITE Battery using the HSS . . . . . . . . . . . . . . . . . . . . 13-19

Chapter 14

14.1 SituProbe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

14.2 Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

14.3 Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

14.4 Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

14.5 Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

14.5.1 Compressed Nitrogen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

14.6 Heated Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

14.7 Valves and Sequences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

14.7.1 Headspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

TOC - 10

IPN 074-472-P1C

SituProbe

Page 25

HAPSITE Smart Plus Operating Manual

14.7.2 Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

14.7.3 Dry Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

14.8 SituProbe Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

14.8.1 Headspace Creation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-7

14.8.2 Purge Rate Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

14.8.3 Method Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-8

14.9 Background Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

14.9.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-9

14.9.2 Cleanup Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

14.9.2.1 Probe Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

14.9.2.2 HAPSITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-9

14.9.2.3 SituProbe FLUSH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

14.10 Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-10

14.10.1 Reducing Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-10

14.10.1.1 Sampling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-10

14.10.1.2 Expected Concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-10

14.10.2 Nitrogen Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-10

14.11 Calibration Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

14.11.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-11

14.11.2 Standard Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

14.11.3 Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-13

14.12 Calibration Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-13

14.13 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-14

14.13.1 Surface Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-14

Chapter 15

Service Module

15.1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-1

15.2 Service Module Input Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-2

IPN 074-472-P1C

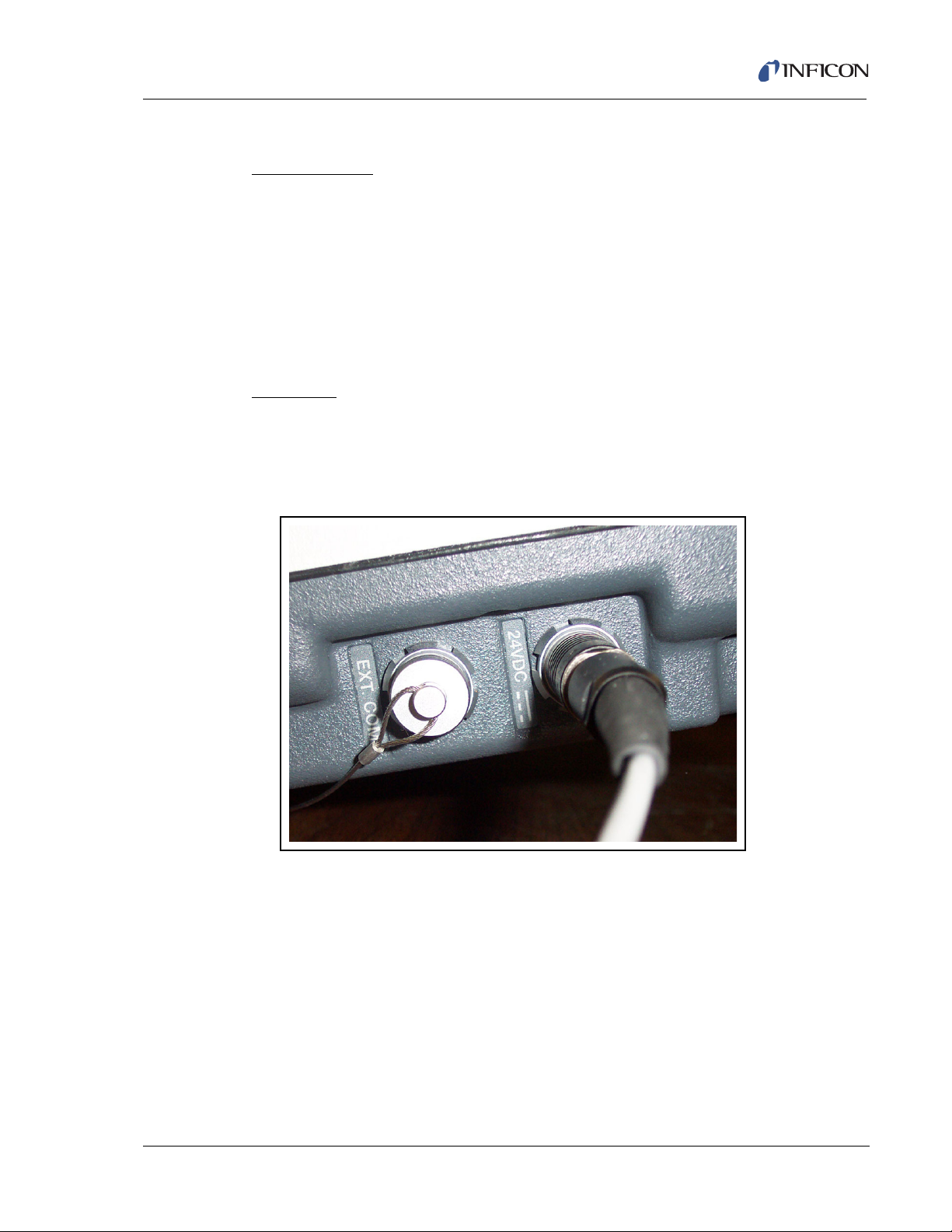

15.2.1 Service Module 110/220 V(ac) Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-2

15.2.2 Service Module 24 V(dc) Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-2

15.3 Components of the Service Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

15.3.1 Backup Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

15.3.2 MDP/Turbo Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-3

15.3.3 Manifold Vent Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-3

15.3.4 Foreline Vent Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-4

15.3.5 Roughing Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-4

15.3.6 Vacuum Interconnect Valve Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-4

15.3.7 Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-4

15.3.8 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

TOC - 11

Page 26

HAPSITE Smart Plus Operating Manual

15.3.9 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

15.4 When to Use the Service Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

15.5 Plus IQ Software for the Service Module . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

15.5.1 The Service Module Tab in Properties Window . . . . . . . . . . . . . . . . . . . . . 15-8

15.6 Starting Up HAPSITE on the Service Module . . . . . . . . . . . . . . . . . . . . . 15-11

15.7 Attaching the HAPSITE to the Service Module . . . . . . . . . . . . . . . . . . . . 15-12

15.7.1 Attaching the HAPSITE to the Service Module using the

Plus IQ Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-13

15.7.2 Attaching the HAPSITE to the Service Module using the

HAPSITE Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-15

15.8 Detaching the HAPSITE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

15.8.1 Using Plus IQ Software to Detach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-17

15.8.2 Using the Front Panel Display to Detach . . . . . . . . . . . . . . . . . . . . . . . . . 15-19

15.9 Physically Removing the HAPSITE from the Service Module . . . . . . . . . 15-19

15.10 Storing the Service Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-20

15.11 When Power to the Service Module is Lost . . . . . . . . . . . . . . . . . . . . . . . 15-23

Chapter 16

Maintenance

16.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

16.2 Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-2

16.3 HAPSITE Symptom - Cause - Remedy Chart . . . . . . . . . . . . . . . . . . . . . . 16-3

16.4 Required Environment for General Maintenance. . . . . . . . . . . . . . . . . . . . 16-7

16.5 Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-7

16.5.1 Contamination of the Mass Spectrometer . . . . . . . . . . . . . . . . . . . . . . . . . 16-8

16.5.1.1 Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-8

16.5.1.2 Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-8

16.5.2 Contamination of the Gas Chromatograph. . . . . . . . . . . . . . . . . . . . . . . . . 16-8

16.5.2.1 Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-8

16.5.2.2 Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-8

16.5.3 Contamination of the Probe and Probe Line . . . . . . . . . . . . . . . . . . . . . . . 16-9

16.5.3.1 Symptoms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-9

16.5.3.2 Decontaminate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-9

16.5.4 Decontaminating the Outside of the Analytical Module . . . . . . . . . . . . . . 16-11

16.6 NEG Pump Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-15

16.6.1 NEG Pump Bakeout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

16.6.1.1 Bakeout Using the Laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

16.6.1.2 Bakeout From Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-18

16.6.2 Reactivating the NEG Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

16.6.2.1 Reactivation Using the Laptop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

TOC - 12

IPN 074-472-P1C

Page 27

HAPSITE Smart Plus Operating Manual

16.6.2.2 Reactivation Using the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-20

16.7 NEG Pump Removal, Installation and Activation . . . . . . . . . . . . . . . . . . . 16-21

16.7.1 Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-22

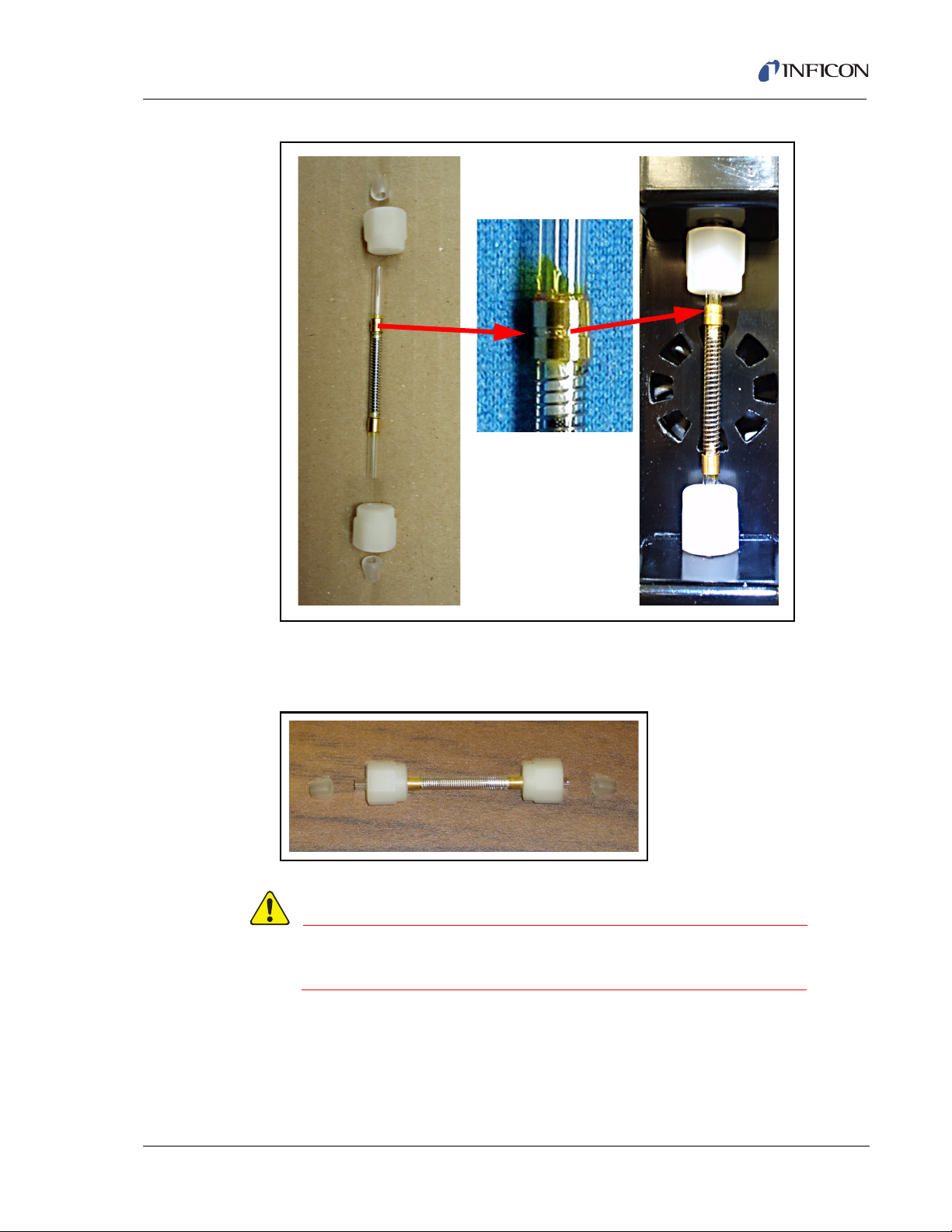

16.7.2 Part 1: NEG Pump Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-23

16.7.3 Part 2: Service Module Vacuum Interconnect (VI) Valve Cleaning . . . . . 16-26

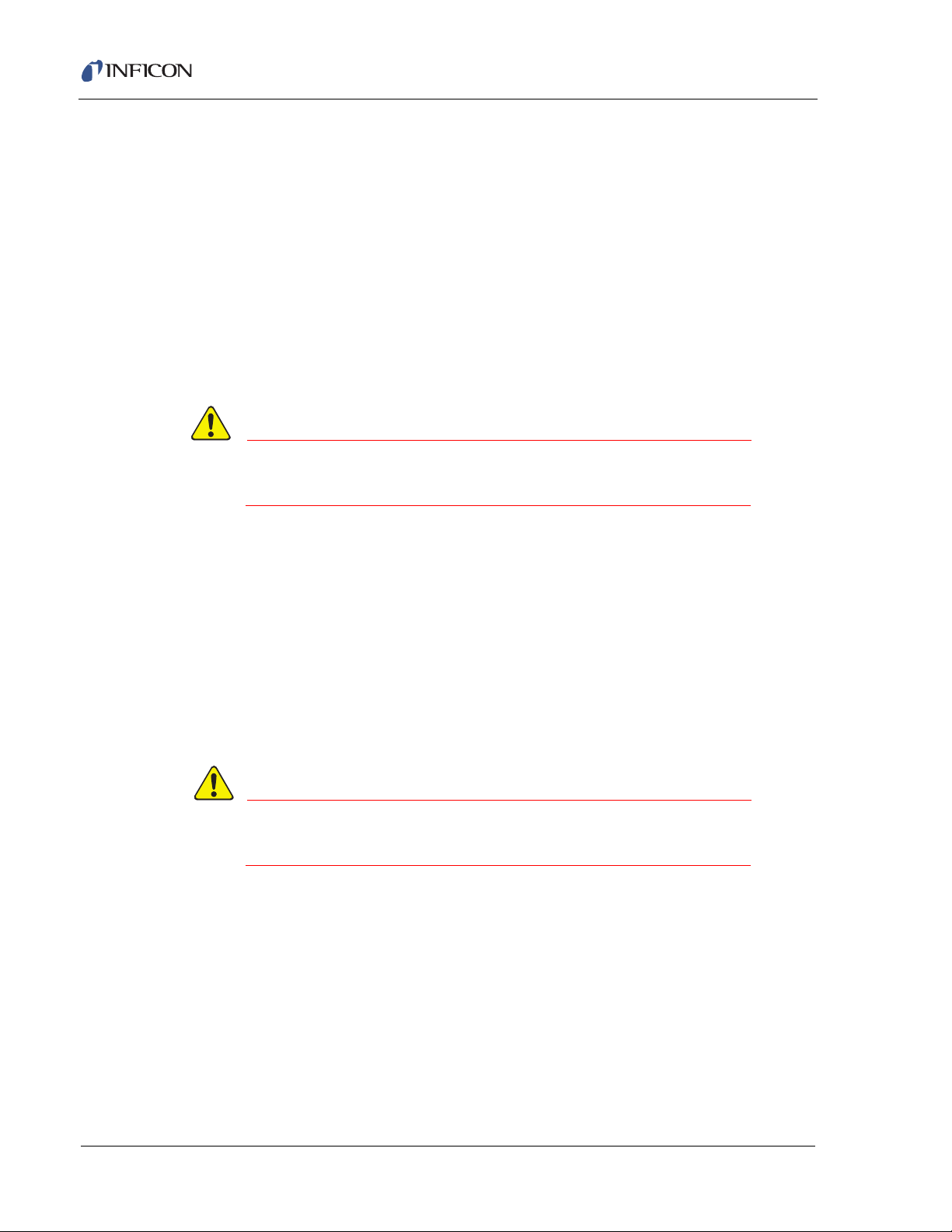

16.7.4 Part 3: Install the New NEG Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-29

16.7.5 Part 4: Leak Check of the Vacuum System . . . . . . . . . . . . . . . . . . . . . . .16-34

16.7.6 Part 5: Activation of the NEG Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-40

16.8 Replacing the Ionizer of the Mass Spectrometer . . . . . . . . . . . . . . . . . . .16-41

16.8.1 Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-41

16.9 Replacing the Headspace Sampling System Needle. . . . . . . . . . . . . . . . 16-47

16.10 Battery Charger Maintenance and Troubleshooting. . . . . . . . . . . . . . . . . 16-49

16.10.1 Cleaning The Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-49

16.10.2 Troubleshooting The Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . .16-50

16.10.2.1 If No Indicators are Illuminated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-50

16.10.2.2 If the Red Indicator is Flashing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-50

16.10.2.3 If a Battery Does Not Accept a Charge . . . . . . . . . . . . . . . . . . . . . . . . . . 16-50

Chapter 17

Glossary

17.1 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

Chapter 18

Customer Support

18.1 How To Contact Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1

18.2 Returning Your Instrument to INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . .18-1

Chapter 19

Part Numbers

19.1 HAPSITE Smart Plus System Configuration . . . . . . . . . . . . . . . . . . . . . . . 19-1

19.2 HAPSITE Smart Plus Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2

IPN 074-472-P1C

19.3 HAPSITE Smart Plus Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2

19.4 HAPSITE Smart Plus Consumables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-3

19.5 Headspace Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-4

19.6 Service Module Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-5

19.7 HAPSITE SituProbe Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-5

Appendix A

HAPSITE Target Compounds

A.1 Compounds In Order Of Elution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Appendix B

B.1

Calibrating Gas Mixtures

Acquisition, Preparation, and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

TOC - 13

Page 28

HAPSITE Smart Plus Operating Manual

B.1.1 How to Establish the Desired Concentrations . . . . . . . . . . . . . . . . . . . . . . .B-2

B.1.1.1 Using Cylinders Charged with Each Concentration . . . . . . . . . . . . . . . . . . .B-2

B.1.1.2 Diluting the Gas On SIte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

B.1.2 Correct Delivery of the Mix to the Inlet of the HAPSITE. . . . . . . . . . . . . . . .B-3

B.1.2.1 Free Flow of Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

B.1.2.2 Inert Sample Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-4

B.1.3 Gas Cylinder Safety, Contamination Checks, and Corrective Steps . . . . . .B-6

Appendix C

Shipping the HAPSITE and Consumables

C.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C.2 Shipping the Canisters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C.3 Empty Canisters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Index

TOC - 14

IPN 074-472-P1C

Page 29

HAPSITE Smart Plus Operating Manual

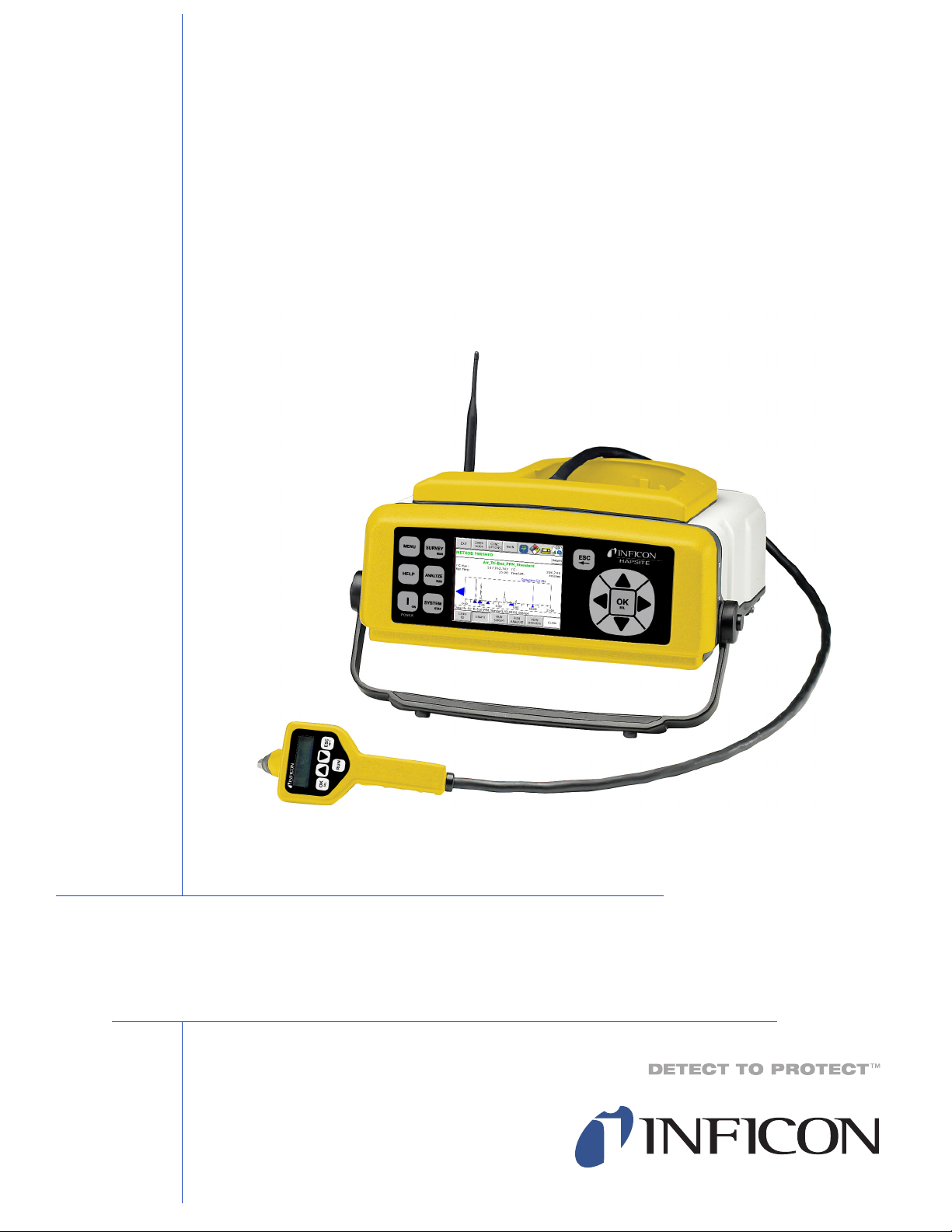

1.1 The HAPSITE Smart Plus System

The HAPSITE® Smart Plus Portable Gas Chromatograph and Mass Spectrometer

(GC/MS) is designed to measure volatile organic hazardous air pollutants at

parts-per-trillion (PPT) levels, using pre-programmed sets of instructions known as

"methods". By operating on battery power using self-contained Carrier Gas and

Internal Standard Gas supplies, the HAPSITE Smart Plus is specifically designed

to collect and analyze samples while in the field. Results can be viewed on-site, as

they are displayed on the front panel and saved on the system’s hard drive.

Through the use of a USB drive, crossover cable or wireless connection, results

can also be downloaded to a separate Laptop (PC) for analysis.

NOTE: This manual is specifically for the HAPSITE Smart Plus. The terms

"HAPSITE" and "HAPSITE Smart Plus" are used throughout this manual

to refer to the HAPSITE Smart Plus.

Chapter 1

Introduction

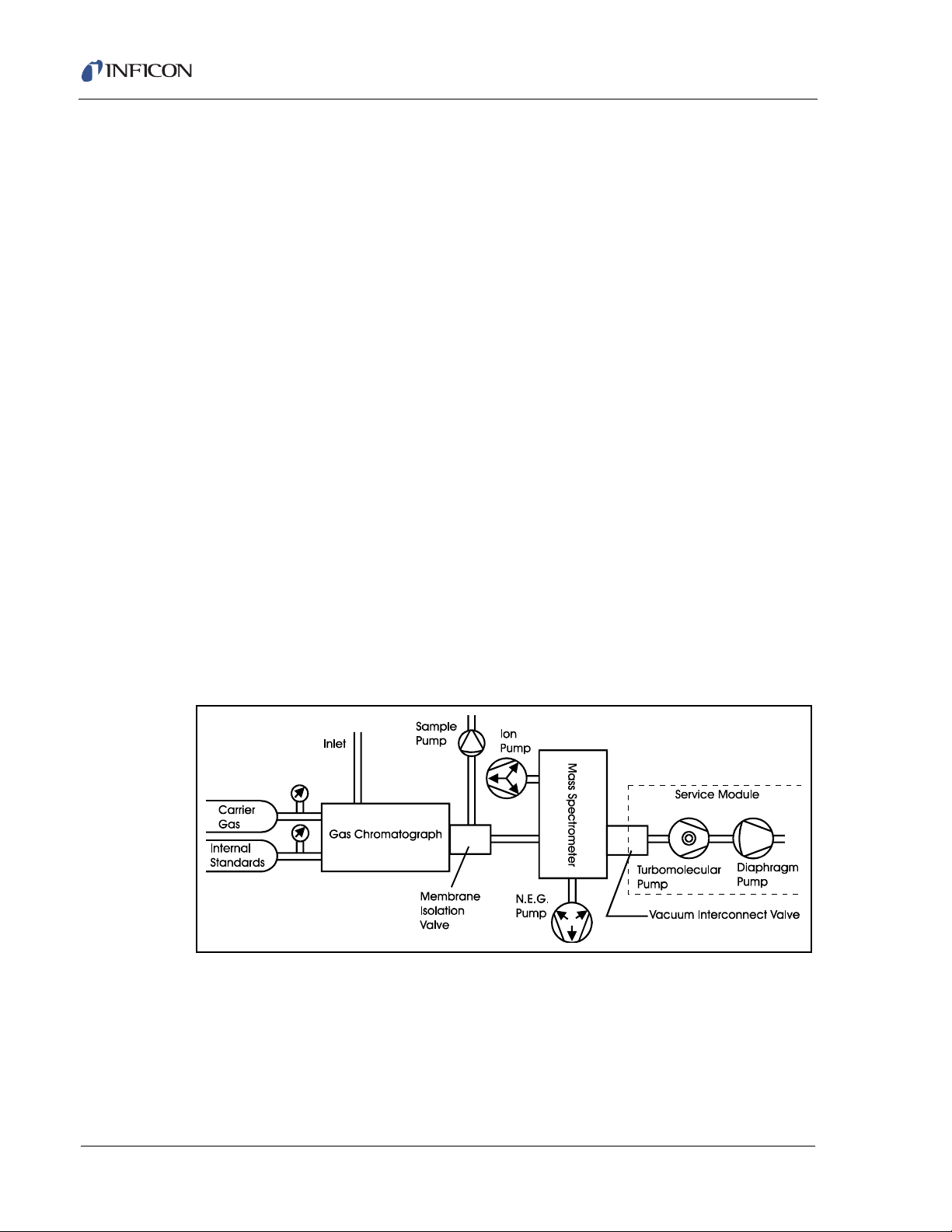

Several hardware modules comprise the HAPSITE Smart Plus system:

HAPSITE . . . . . . . . . . . . . . . . . . . . . Often referred to as the Analytical Module

(AM). The AM contains the Gas

Chromatograph, Mass Spectrometer,

cylinders of Carrier Gas and Internal

Standard Gas, High-vacuum Chemical Pump

(for portable operation), control electronics,

Battery, Keypad, Display, and a Battery

Charger.

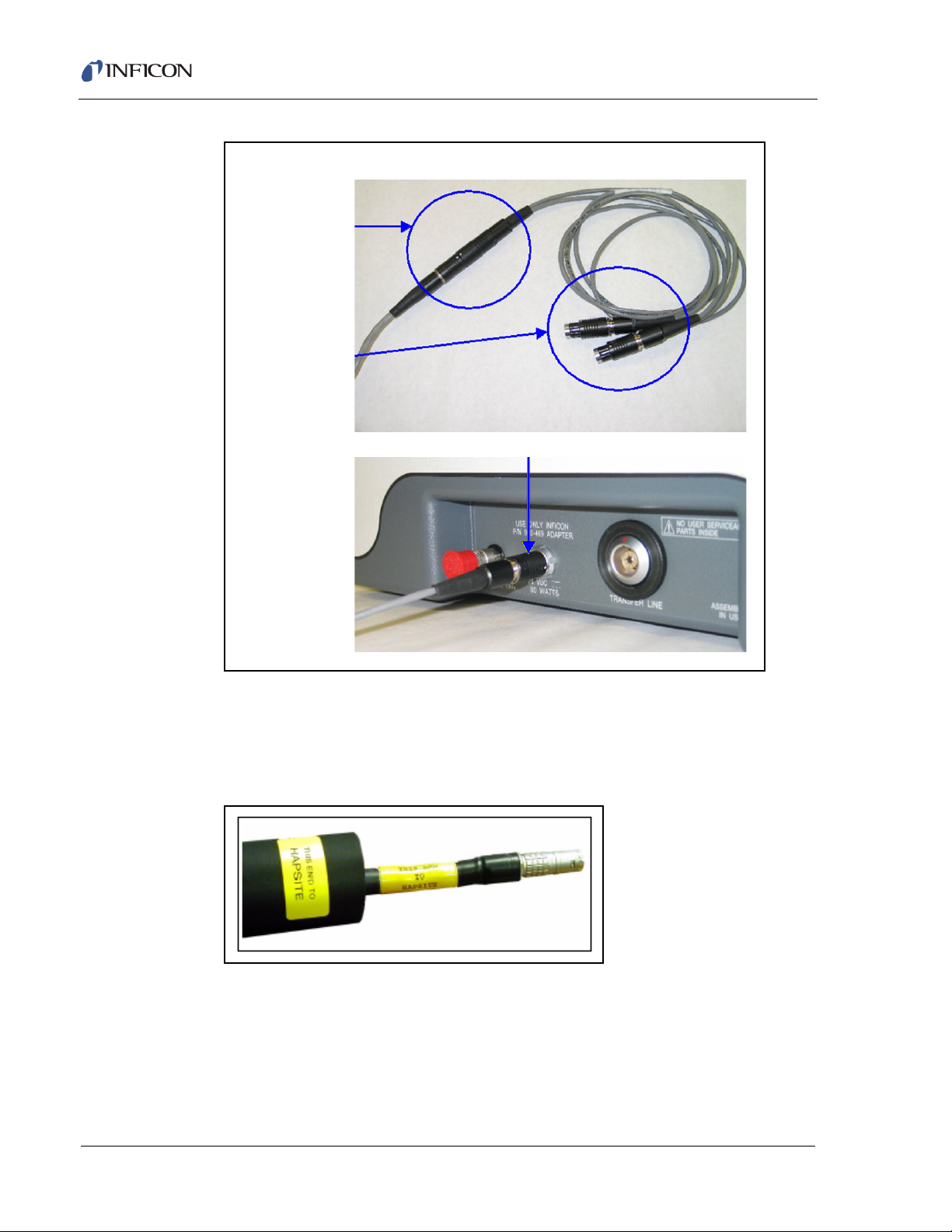

Probe . . . . . . . . . . . . . . . . . . . . . . . . Also known as the Hand Control Unit, this

consists of a hand piece and a heated inlet

IPN 074-472-P1C

Service Module . . . . . . . . . . . . . . . . Also known as the SM, the Service Module

line. The hand piece contains a small display

and buttons. The inlet line connects to the

HAPSITE and provides a flexible heated

sample flow path to the HAPSITE.

contains the turbo-molecular high-vacuum

pump, the roughing pump, the mechanism

for operating the interconnecting valve, a

battery-charger and a power supply.

1 - 1

Page 30

HAPSITE Smart Plus Operating Manual

Headspace Sampling System . . . Also known as the HSS, the HSS is an

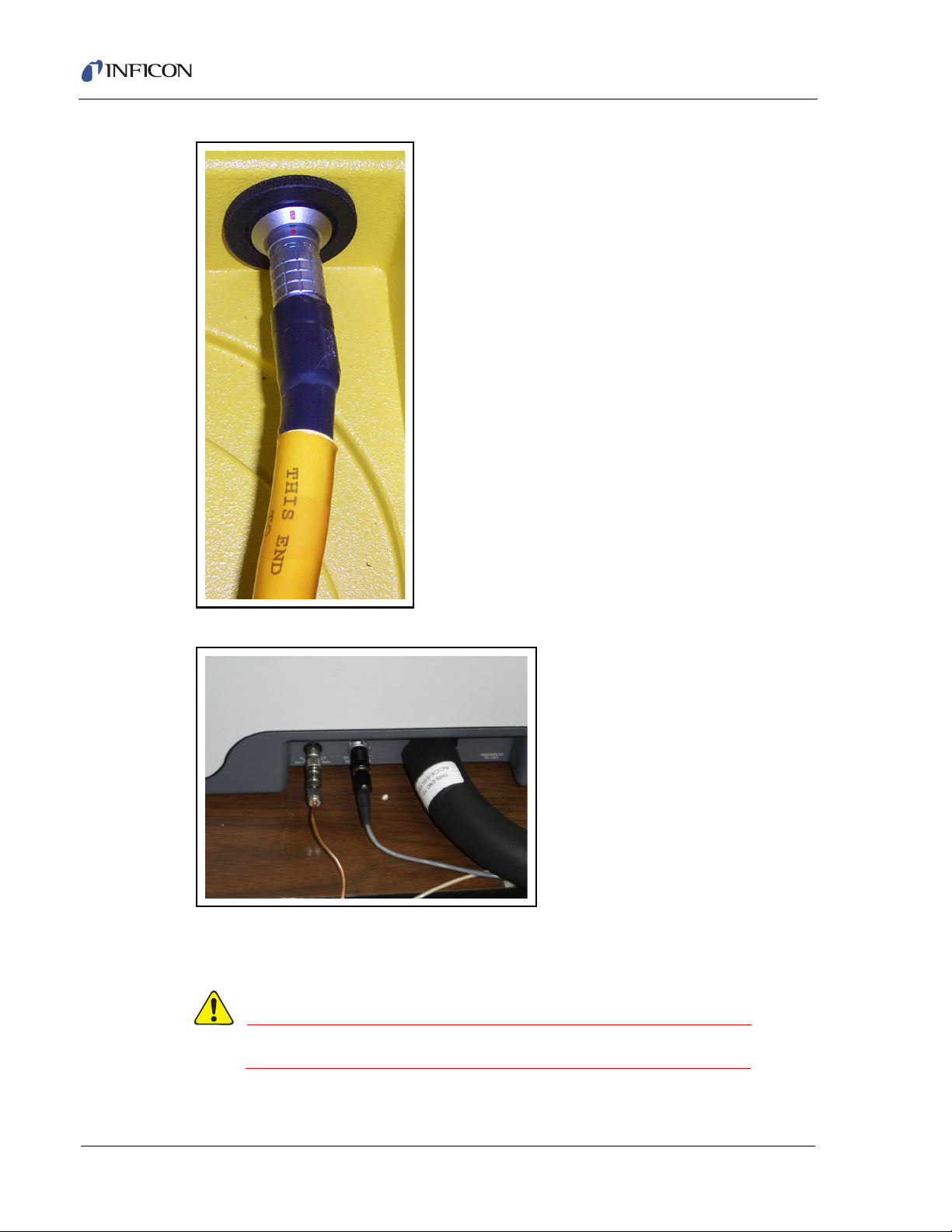

SituProbe™. . . . . . . . . . . . . . . . . . . The SituProbe accessory is a water purging

1.2 Performance Specifications

The performance specifications for the HAPSITE are shown below:

Mass range . . . . . . . . . . . . . . . . . . . . . . . 1-300 AMU

Scan Rate . . . . . . . . . . . . . . . . . . . . . . . . as much as 1000 AMU/sec @

Ionization Mode . . . . . . . . . . . . . . . . . . . . 70 eV electron impact

Vacuum System . . . . . . . . . . . . . . . . . . . . 15 l/sec NEG pump;

Operating temperature range. . . . . . . . . . 0

accessory to the HAPSITE that allows testing

for volatile compounds in solids and liquids,

including soil and water.

device that provides continuous testing of

water samples in the field.

10 points per AMU

0.2 l/sec sputter-ion pump

o

C to 45oC (32oF to 113oF)

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . .95% RH, non-condensing

Dimensions (LxWxH) . . . . . . . . . . . . . . . . 46 x 43 x 18 (cm); 18 x 17x 7 (in)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Kg (35 lb) without the battery

Internal Power Consumption . . . . . . . . . . 30 watts average, 24 V(dc)

Carrier Gas . . . . . . . . . . . . . . . . . . . . . . . Nitrogen

o

Column Temperature Range . . . . . . . . . . 60

C to 180oC

Maximum Sample Moisture Content. . . . . 8% by weight

pH Range of Sample . . . . . . . . . . . . . . . . 2 - 11

o

Boiling Point of Sample . . . . . . . . . . . . . . <250

C

Chemical Composition of Sample . . . . . . 1 - 12 Carbon atoms

GC Column . . . . . . . . . . . . . . . . . . . . . . . 100% methyl silicone phase,

30 m x 0.32 mm ID x 1.0 film

SIM Channels . . . . . . . . . . . . . . . . . . . . . 10

External Communications . . . . . . . . . . . . Ethernet Port, Wireless

Carrier Gas Use-Rate . . . . . . . . . . . . . . . 1 canister per 8 hours of operation

(This depends on the details of the

method being used.)

IPN 074-472-P1C

1 - 2

Page 31

Internal Standards Gas Use-Rate . . . . . . . 1 canister per 24 hours of operation

Battery Life . . . . . . . . . . . . . . . . . . . . . . . . Approximately 2 to 3 hours.

1.3 Serial Number Location

The serial number of the HAPSITE is located on the inside of the front panel and

on the touchscreen. Touch the HAPSITE icon, followed by the HAPSITE System

icon, and then touch HAPS to locate it.

1.4 Theory of Operation

The HAPSITE combines two analytical techniques, Gas Chromatography and

Mass Spectrometry, to separate, identify, and measure the organic components in

a gas phase sample. Using a flow of inert Nitrogen Carrier Gas, the Gas

Chromatograph (GC) performs a time separation (Retention Time) of the sample

compounds. The separation order is primarily based on increasing compound

boiling point. The Mass Spectrometer (MS) detects and identifies the eluting

compounds by breaking the molecules apart and detecting the fragments. The

resulting mass spectrum is compared to a library of mass spectra to identify the

compound.

HAPSITE Smart Plus Operating Manual

(This depends on the details of the

method being used.)

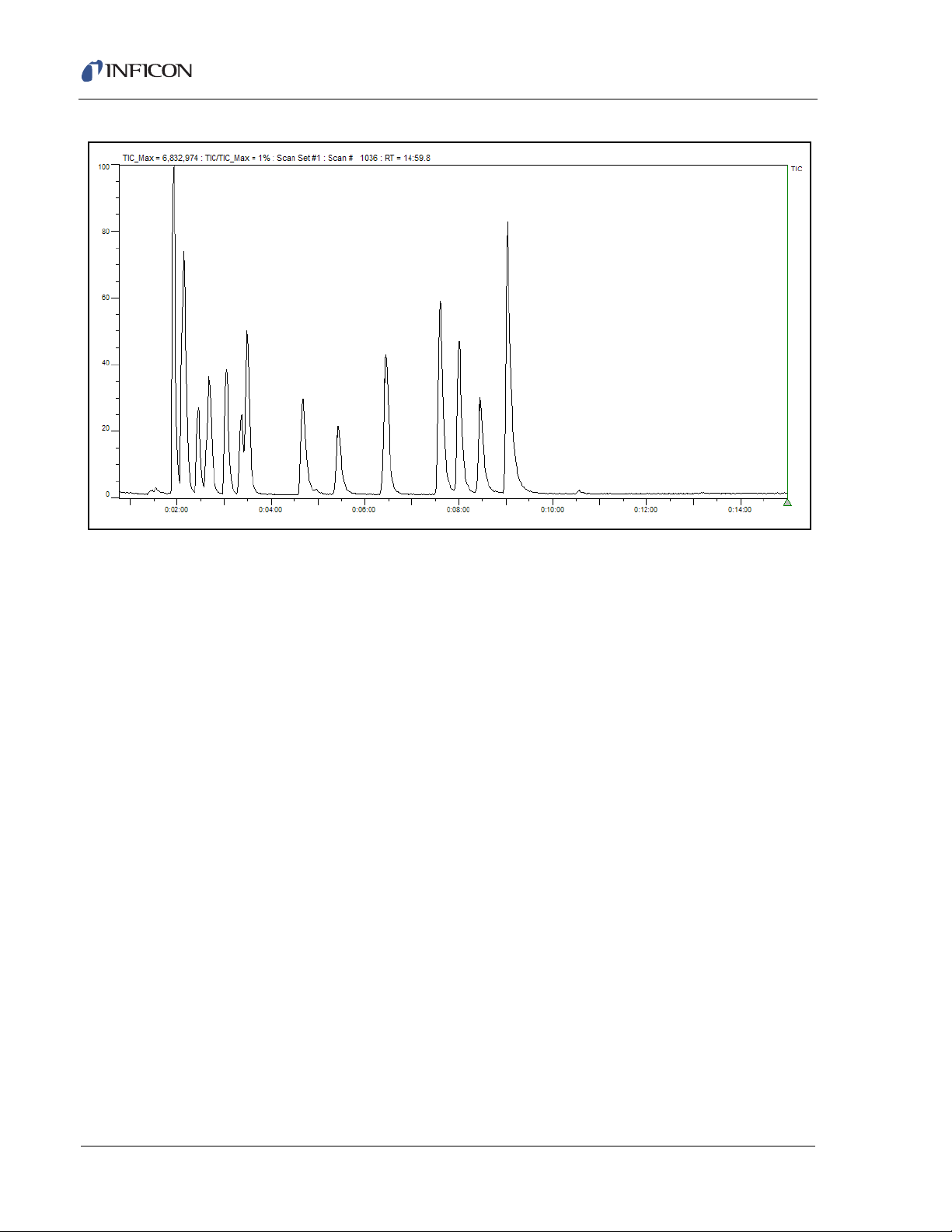

The Gas Chromatography technique cannot always separate compound mixtures

into individually eluting compounds. Some of the eluting responses or peaks may

contain two, three, or more compounds which have taken the same time to

progress (elute) through the Gas Chromatograph. GC identification of compounds

is limited to matching the retention time of the unknown compound to that of a

known standard. See section 1.6.1, Gas Chromatograph, on page 1-5 for more

information on how the GC works. In order to further identify and measure the

individual components of such mixtures, the gas stream is directed into the Mass

Spectrometer.

IPN 074-472-P1C

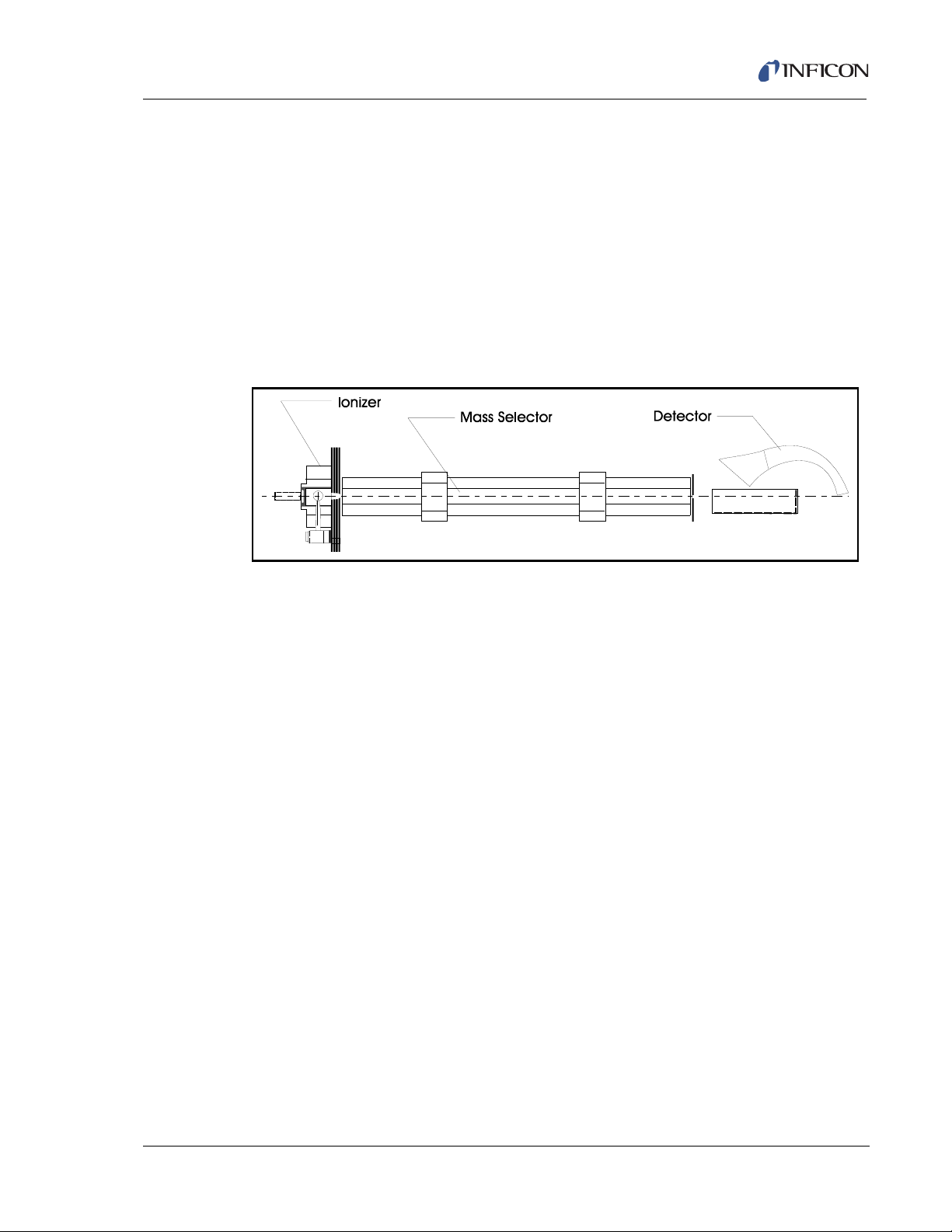

In the Mass Spectrometer, the gas stream of eluting compounds is bombarded with

electrons. The electrons fracture the molecules into a characteristic combination of

smaller molecules or mass fragments. The Mass Spectrometer (MS) measures

and plots the response of these mass fragments to display a mass spectrum. See

section 1.6.2, Mass Spectrometer, on page 1-7 for more information on how the

MS works.

The introduction of a mixture of many compounds directly to the MS would produce

a very complex and uncharacteristic mass spectrum. However, because the GC

has largely separated the gases, the MS can usually differentiate between the few

co-eluting compounds. This differentiation provides very precise identification and

measurement of the quantity of each compound. Qualitative identification can be

made by comparing the unknown compound spectrum to the NIST mass spectral

1 - 3

Page 32

HAPSITE Smart Plus Operating Manual

library (included with the Plus IQ software). See section 9.8, NIST Library

Searches, on page 9-24 for more information. Quantitative identifications can be

made by analyzing standards of known concentration and creating a target

compound library of concentration response curves. See Chapter 12, Target

Compound Methods for more information.

In summary, the GC first separates the gaseous compounds by time. Then the MS

identifies and measures the gases contained in each of the time-separated peaks.