Page 1

OPERATING MANUAL

Guardian

Co-Deposition Controller

IPN 074-517-P1D

™

Page 2

Page 3

OPERATING MANUAL

www.inficon.com reachus@inficon.com

©2012 INFICON

®

Guardian

Co-Deposition Controller

IPN 074-517-P1D

™

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

ConFlat® is a registered trademark of Varian Corporation.

Guardian™ is a trademark of INFICON GmbH.

LabVIEW™ is a trademark of National Instruments

Windows®, Access®, Excel® and AxtiveX® are registered trademarks of Microsoft Corporation.

Wonderware® is a registered trademark of Invensys plc

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2012 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the market accordingly. It has

been constructed in accordance with good engineering practice in safety matters in force in the Community and

does not endanger the safety of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

In addition, this is to certify that this equipment has also been designed and manufactured, having regard to the

state of the art, to ensure complies with the Protection Requirements of EMC directive 2004/108/EC.

A Technical Documentation File is also available for review by competent authorities and will be maintained for a

period of ten years after the date on which the equipment was last manufactured. In additional to this file,

technical, installation, maintenance and application information concerning this equipment can also be found in the

Operating Manual(s) for this product or product family.

Equipment Description: EIES Guardian (including all options).

Applicable Directives: 2006/95/EC (LVD)

2004/108/EC (General EMC)

2002/95/EC (RoHS)

Applicable Standards:

Safety: EN 61010-1:2001

Emissions: EN 61326-1:1997/A1: 1998/A2: 2001 (Radiated & Conducted Emissions)

Class A: Emissions per Table 3

(EMC – Measurement, Control & Laboratory Equipment)

Immunity: EN 61326-1:1997/A1: 1998/A2: 2001 (General EMC)

Class A: Immunity per Table A1

(EMC – Measurement, Control & Laboratory Equipment)

Page 6

CE Implementation Date: May 2008 (Updated May 2010)

Authorized Representative: Steve Schill

Thin Film Business Manager

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF INFICON'S

PRODUCTS SHOULD BE DIRECTED, IN WRITING, TO THE VICE-PRESIDENT OF

OPERATIONS AT THE ABOVE ADDRESS.

Revised 5/2010

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

Chapter 1

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 EIES Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.3 EIES Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 EIES Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.5 EIES Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.6 Quartz Crystal Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.7 Analog Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.8.1 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.8.2 Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.8.3 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Guardian Co-Deposition Controller Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Introduction and Specifications

Chapter 2

Quick Start

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1.1 Sensor Covers, High Rate and Standard Rate. . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.2 Detector—Direct Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

IPN 074-517-P1D

2.2.3 Sensor to Fiber Optic Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.4 Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.5 QCM Option Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.3 EIES Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.3.1 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.3.2 EIES Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.3.3 Edit Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.3.4 Edit Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.3.5 Edit Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.3.6 Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.7 Software Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

TOC - 1

Page 10

Guardian Co-Deposition Controller Operating Manual

2.4 Initial Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.4.1 Power-up Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.4.2 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.4.3 Detector Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.4.4 Sensor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.4.5 QCM Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.4.6 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.5.1 Build a Single Layer Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.5.2 Setup Layer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.5.3 Start Deposition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.5.4 Manual Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.5.5 QCM Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.5.6 Stop Deposition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Chapter 3

EIES Software

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.1 Status Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.2 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.3 Readings Panel—Process Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.4 Readings Panel—Ratio Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.5 Readings Panel—Readings Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.5.1 Channel Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.3.5.2 Sensor Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3.5.3 QCM Readings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.4.4.1 Format of the DataLog file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

TOC - 2

3.3.6 Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4.1 File >> Open Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4.2 File >> Open and Save Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.4.3 File >> Data Log On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.4.4 File >> Data Log Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.4.5 File >> Print Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.4.6 File >> Page Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.4.7 File >> Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.5 Edit Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.6 Edit Layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

IPN 074-517-P1D

Page 11

Guardian Co-Deposition Controller Operating Manual

3.6.1 Layer Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.6.2 Rate Ramps Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3.6.3 X Chan (Cross Channel) Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3.6.4 Ratio Display Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3.6.5 Edit Layer Film Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.6.5.1 Deposit Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.6.5.2 Condition Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

3.6.6 Edit Layer Film Cal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.6.6.1 Calibration Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3.6.6.2 QCM Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3.7 Edit: Film. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3.7.1 Deposit Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.7.2 Condition Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.7.3 Film Cal(ibration) Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3.7.3.1 Calibration Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.7.3.2 QCM Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.8 Edit >> System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

3.8.1 Channel Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.8.2 Sensor Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.8.3 QCM Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3.8.4 Digital I/O Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

3.8.4.1 Relay Assign. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-33

3.8.4.2 Input Assign:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

3.8.5 Comm Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

3.8.5.1 Guardian. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

3.8.5.2 External . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

3.8.6 Display Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

3.9 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

IPN 074-517-P1D

3.9.1 Process, Ratio, Readings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.9.2 Graph Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-38

3.9.2.1 Graph Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-39

3.9.2.1.1 Show Channel — Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3.9.2.1.2 Y Axis Left/Right. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

3.9.2.1.3 X Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

TOC - 3

Page 12

Guardian Co-Deposition Controller Operating Manual

Chapter 4

Installation

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Sensor / Feedthrough Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.1 Sensor Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.2 Sensor Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.3 Rigid Sensor Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.4 Sensor Filament Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.4.1 016-600-Gxx Standard Single Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.4.2 016-601-Gxx Gas Compensating Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3 Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.3.1 Detector Cable(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.3.2 Single-Detector Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.3.3 Multiple-Detector Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.3.3.1 Fiber Optic Beam Splitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.3.2 Fiber Optic Beam Splitter Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.3.3 Optical Beam Splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.4 Optical Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.5 Computer Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.5.1 RS232 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.5.2 TCP/IP Ethernet Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.5.2.1 Network Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.5.2.2 How to Set Up the Network Protocol on the PC. . . . . . . . . . . . . . . . . . . . . 4-13

4.6 Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.6.1 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.6.2 Relay Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.6.3 Input Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.6.3.1 Emission Interlock Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.6.4 Sensor(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.6.5 Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.6.6 Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.6.7 Mains Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.7 Quartz Crystal Monitor Option (QCM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.8 Monochromator Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.8.1 Monochromator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.8.2 Monochromator Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

IPN 074-517-P1D

TOC - 4

Page 13

Guardian Co-Deposition Controller Operating Manual

Chapter 5

Maintenance & Troubleshooting

5.1 How To Contact Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Returning Your Instrument to INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 Sensor Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.3.1 Sensor Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.2 EIES Filament or Emitter Assembly Replacement . . . . . . . . . . . . . . . . . . . . 5-3

5.4 Chassis Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Chapter 6

Theory & Calibration

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Theory of EIES Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.1 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2.2 Optical Discrimination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.2.3 Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3 Theory of QCM Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.3.1 Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6.3.2 Z-Ratio or Z-Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.3 Tooling Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

6.4 EIES Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6.4.1 Detector Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

6.4.2 PMT Voltage Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.4.3 Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.4.4 Gain Calibration - Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.4.5 Gain Calibration - QCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.4.6 Cross Channel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6.5 Loop Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

IPN 074-517-P1D

Chapter 7

Communications

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 ActiveX (COM) Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2.1 Setup for ActiveX Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2.2 EIES ActiveX Comm Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2.3 EIES ActiveX Comm Program Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.2.3.1 Query Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.3.2 Update Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.2.3.3 EIES ActiveX Program Command Summary . . . . . . . . . . . . . . . . . . . . . . . . 7-3

TOC - 5

Page 14

Guardian Co-Deposition Controller Operating Manual

7.3 Guardian Controller Direct Communications . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.3.1 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.3.2 Ethernet Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.3.3 Guardian Controller Firmware Versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.3.3.1 V3.XX Controller Command/Response Format . . . . . . . . . . . . . . . . . . . . . . 7-9

7.3.3.2 V4.XX Controller Command/Response Format . . . . . . . . . . . . . . . . . . . . . . 7-9

7.3.4 Command Summary for V3.XX and V4.XX Guardian Controller . . . . . . . . 7-12

7.3.4.1 @ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.4.2 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.4.3 B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.4.4 C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.3.4.5 D. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.3.4.6 F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

7.3.4.7 G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.3.4.8 H. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.3.4.9 K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.3.4.10 M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.3.4.11 N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.3.4.12 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

7.3.4.13 T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.3.4.14 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

7.3.4.15 W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Appendix A

Material Optical Parameters

Appendix B

Material QCM Parameters

Index

IPN 074-517-P1D

TOC - 6

Page 15

1.1 Introduction

CH

4

CH

3

CH

2

CH

1

SOURCE 1

POWER SUPPLY

SOURCE 2

POWER SUPPLY

SOURCE 3

POWER SUPPLY

SOURCE 4

POWER SUPPLY

TO QUARTZ

CRYSTAL MONITOR

OPTIONAL QCM SENSOR

FOR CALIBRATION

EIES SENSOR 2

D3

D4

S2

D3

D4

S2

EIES SENSOR 1

GUARDIAN

CONTROLLER

PC

FIBER OPTIC

BEAM SPLITTER

DETECTORS

& FILTERS

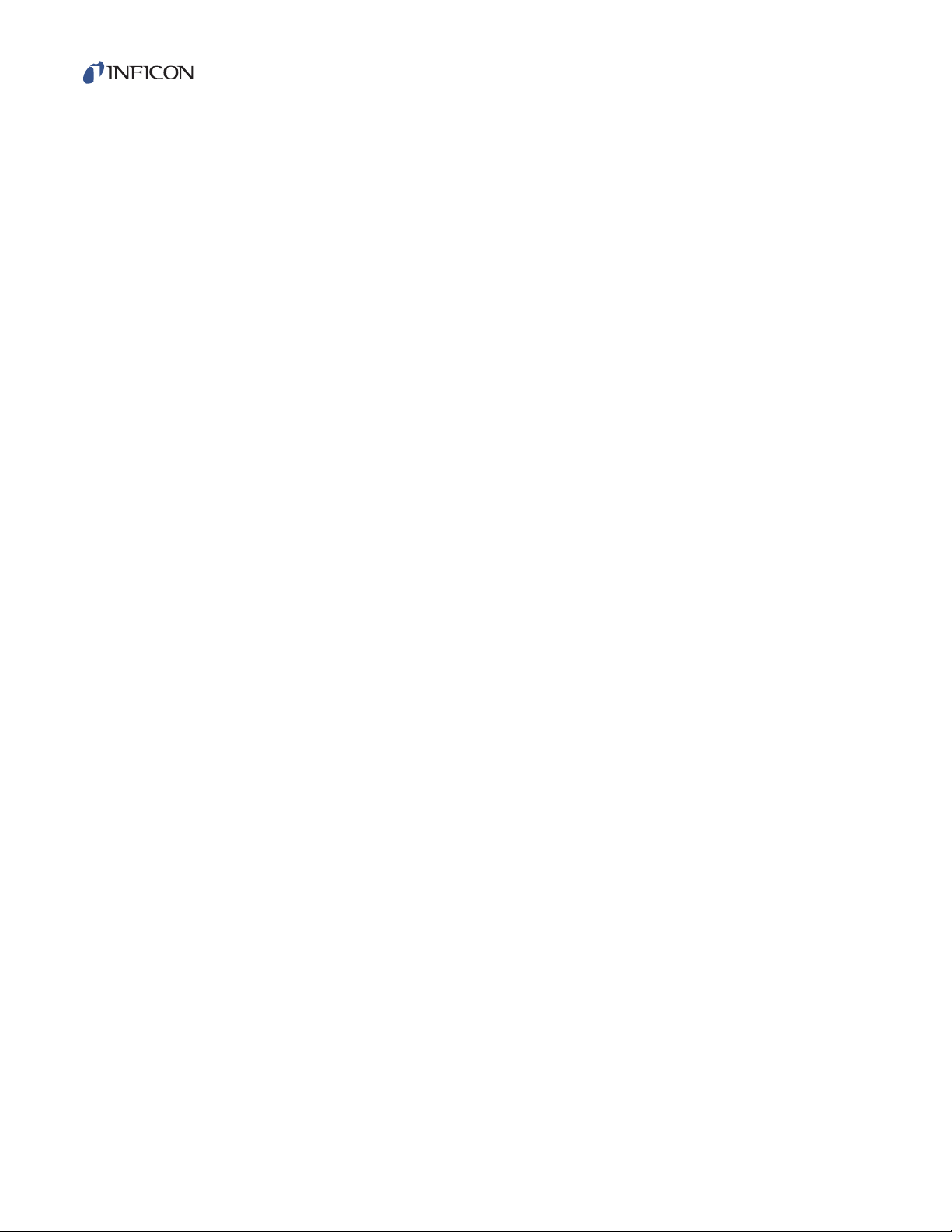

The EIES-IV Guardian uses Electron Impact Emission Spectroscopy (EIES) to

control vacuum deposition of thin films.

In EIES, the material being deposited is energized by a thermionic emitter, which

creates optical emission spectra. An optical filter passes a characteristic

wavelength of the spectra to a detector, which measures the intensity of the

emission. The measured intensity is fed to a PID control loop, which generates a

control signal for the material's evaporation power supply. By proper filter selection,

multiple detectors can control deposition of multiple materials simultaneously.

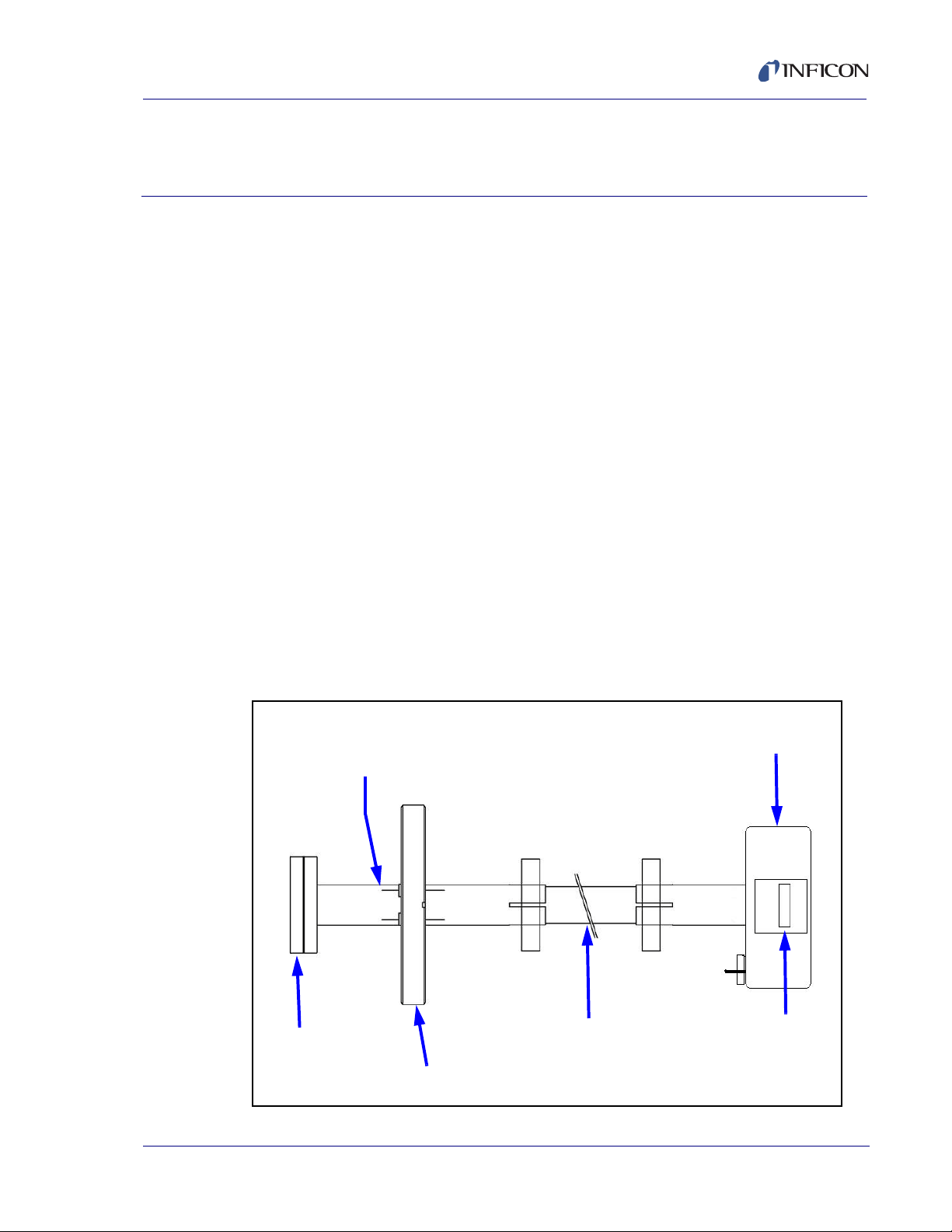

The EIES-IV Guardian consists of five basic elements: controller, sensor(s),

detector(s), software, and an optional quartz crystal monitor. A four channel, two

sensor system is shown in Figure 1-1. Actual installation must consider source to

sensor alignment requirements, see section 4.2.1, Sensor Position, on page 4-3.

Guardian Co-Deposition Controller Operating Manual

Chapter 1

Introduction and Specifications

Figure 1-1 Four Channel Two Sensor System

IPN 074-517-P1D

1 - 1

Page 16

Guardian Co-Deposition Controller Operating Manual

1.2 EIES Controller

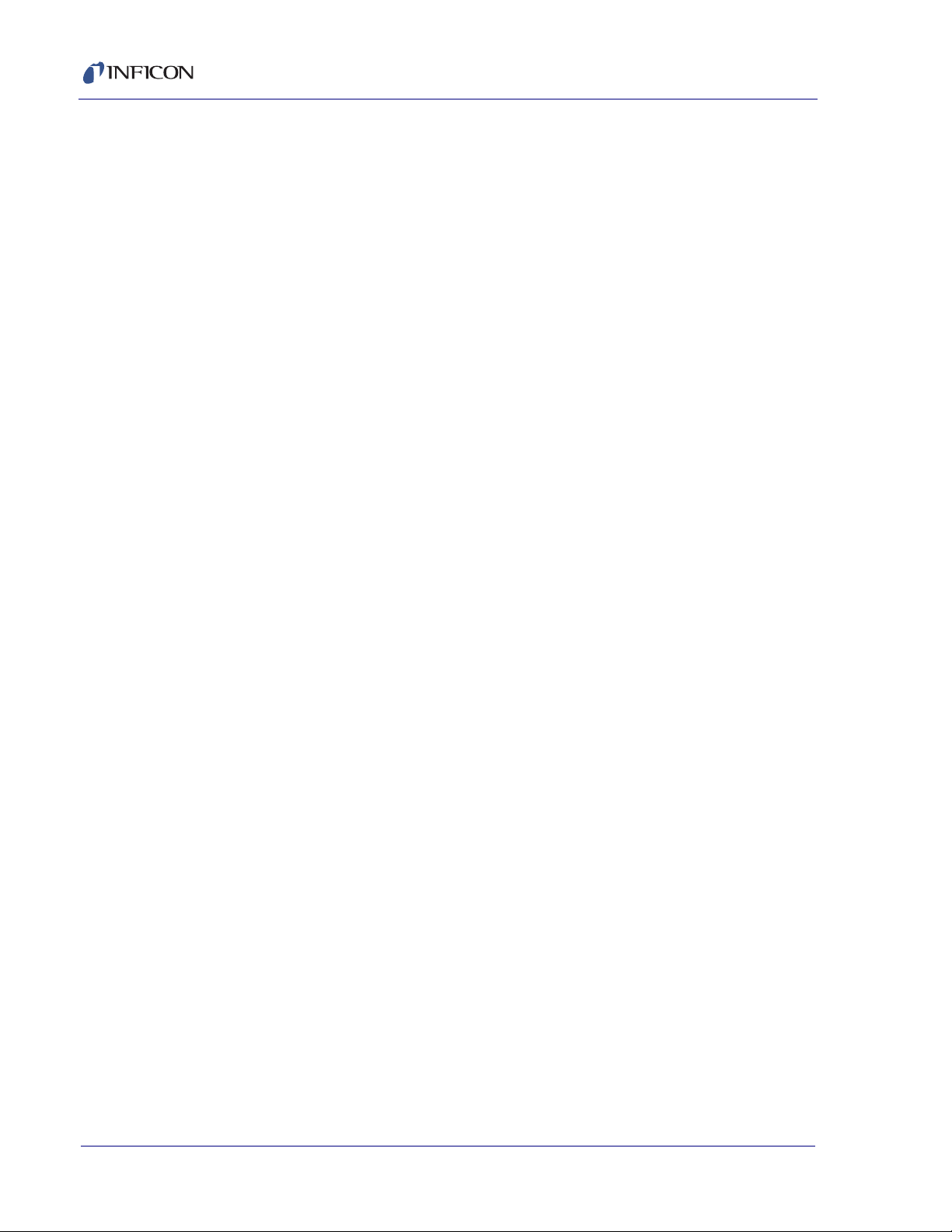

The EIES-IV Guardian Controller serves as the interface between the EIES

sensor(s) and detector(s), the evaporation power supply, and the computer running

the EIES software. See Figure 1-2.

Figure 1-2 Guardian Controller with Detector

The controller supplies power to both the filament of the sensor assembly and to

the detector modules. It communicates with each detector, passing the detector

measurements to the computer running the EIES program. Control voltages for

evaporation power supplies are also generated in the controller. Finally, relays and

digital inputs to operate shutters, etc., are included in the controller.

The controller is operated from a computer running the EIES software via RS-232

or Ethernet. Other than a power switch and a few status LEDs, there are no

operator controls on the EIES-IV Guardian Controller.

1.3 EIES Sensor

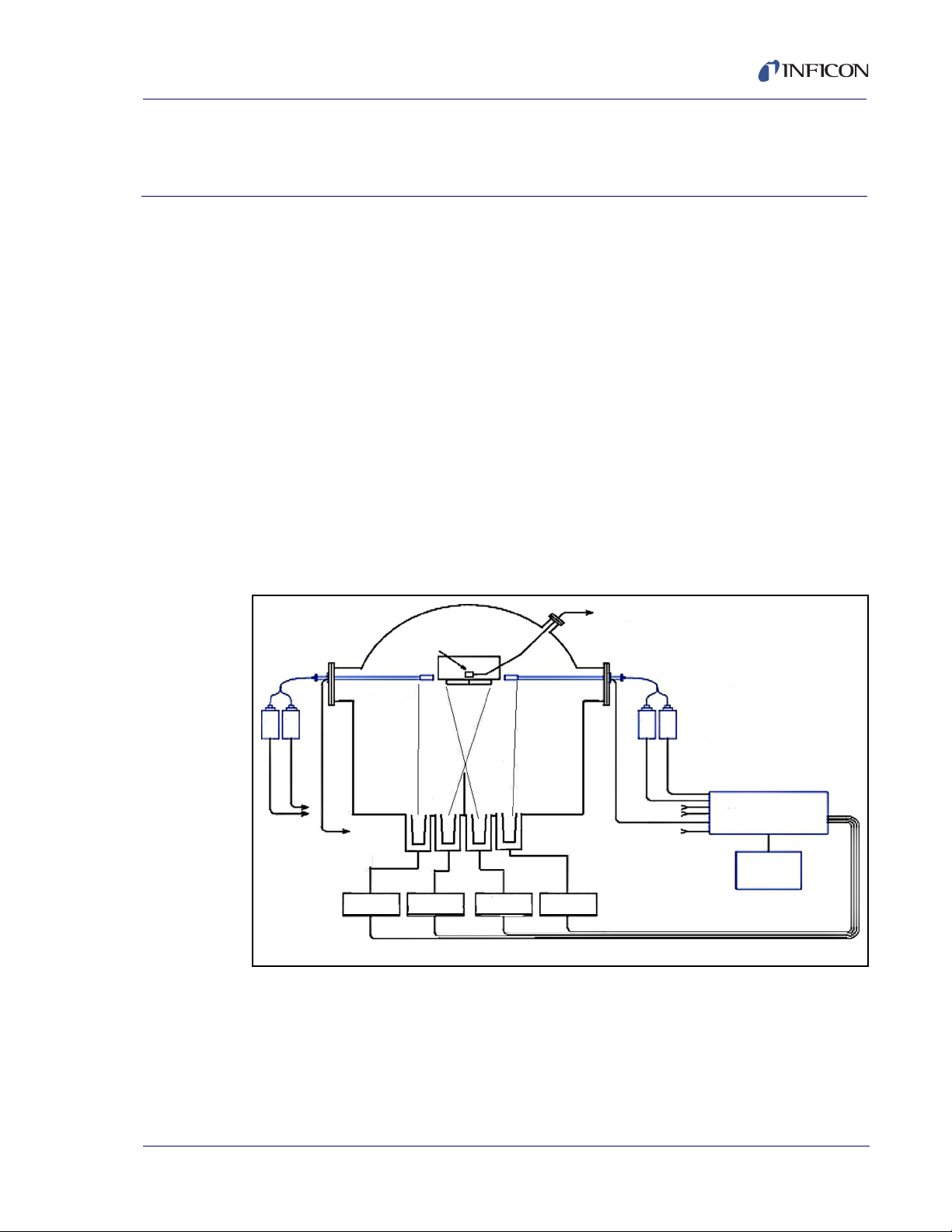

In the sensor assembly, see Figure 1-4, high-energy electrons from a hot filament

excite the valence electrons of the deposited material. These excited electrons

emit light at wavelengths that are characteristic of each material. A light tube

conducts the light to a feedthrough with a viewport, where it is measured by the

Photomultiplier Tube (PMT) of the detector module(s). A single sensor, see Figure

1-3, can be used to create emissions from multiple materials.

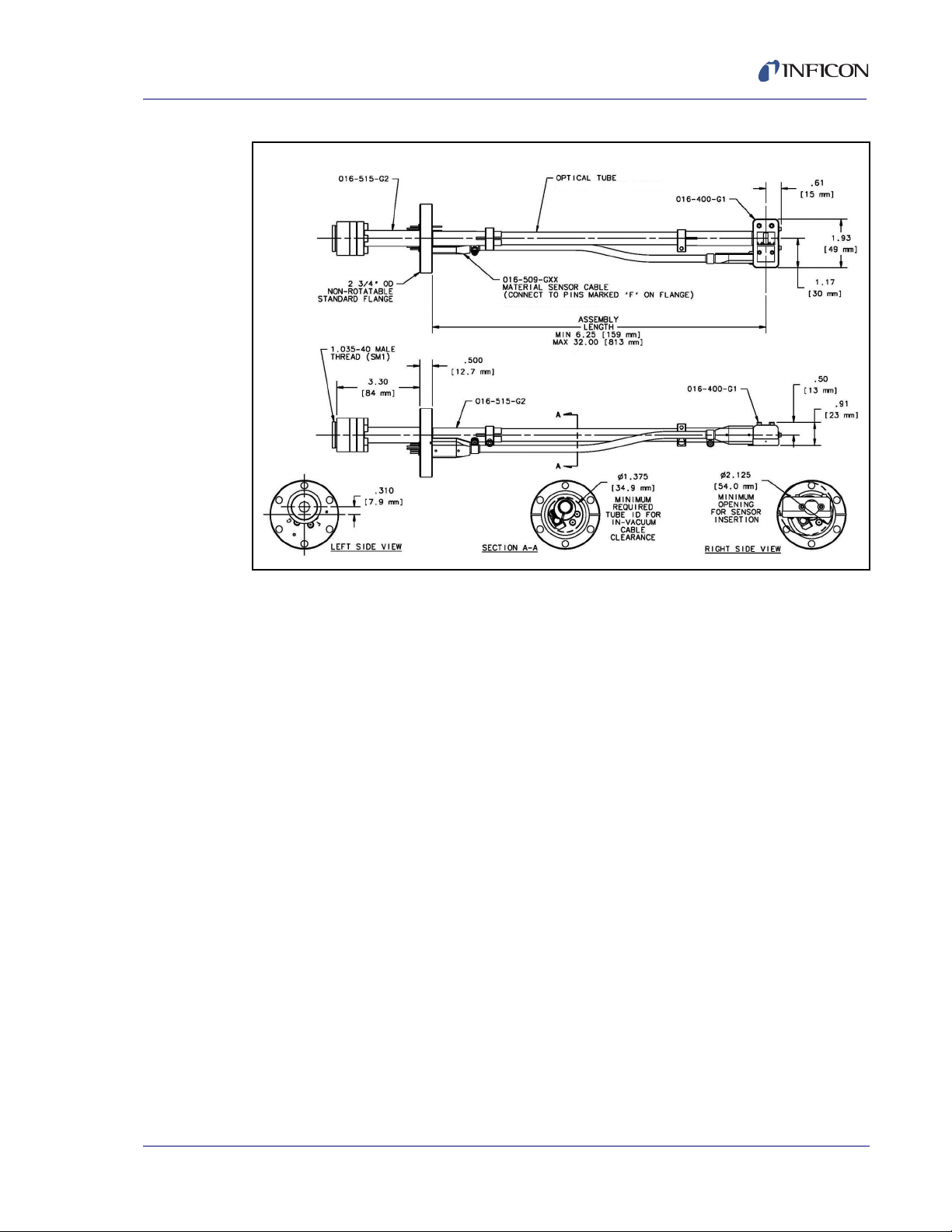

Figure 1-3 EIES Single Sensor 016-400-G1

IPN 074-517-P1D

1 - 2

Page 17

Guardian Co-Deposition Controller Operating Manual

Figure 1-4 EIES Single Sensor and Feedthrough 016-600-Gxx

The sensor assembly consists of a 1.33 in. sapphire viewport attached to a 2.75 in.

Conflat

®

flange. On the vacuum side of the flange, a telescoping light tube and two

electrical connections are attached to the thermionic emitter. The telescoping tube

can be adjusted to locate the thermionic emitter in the vapor flux.

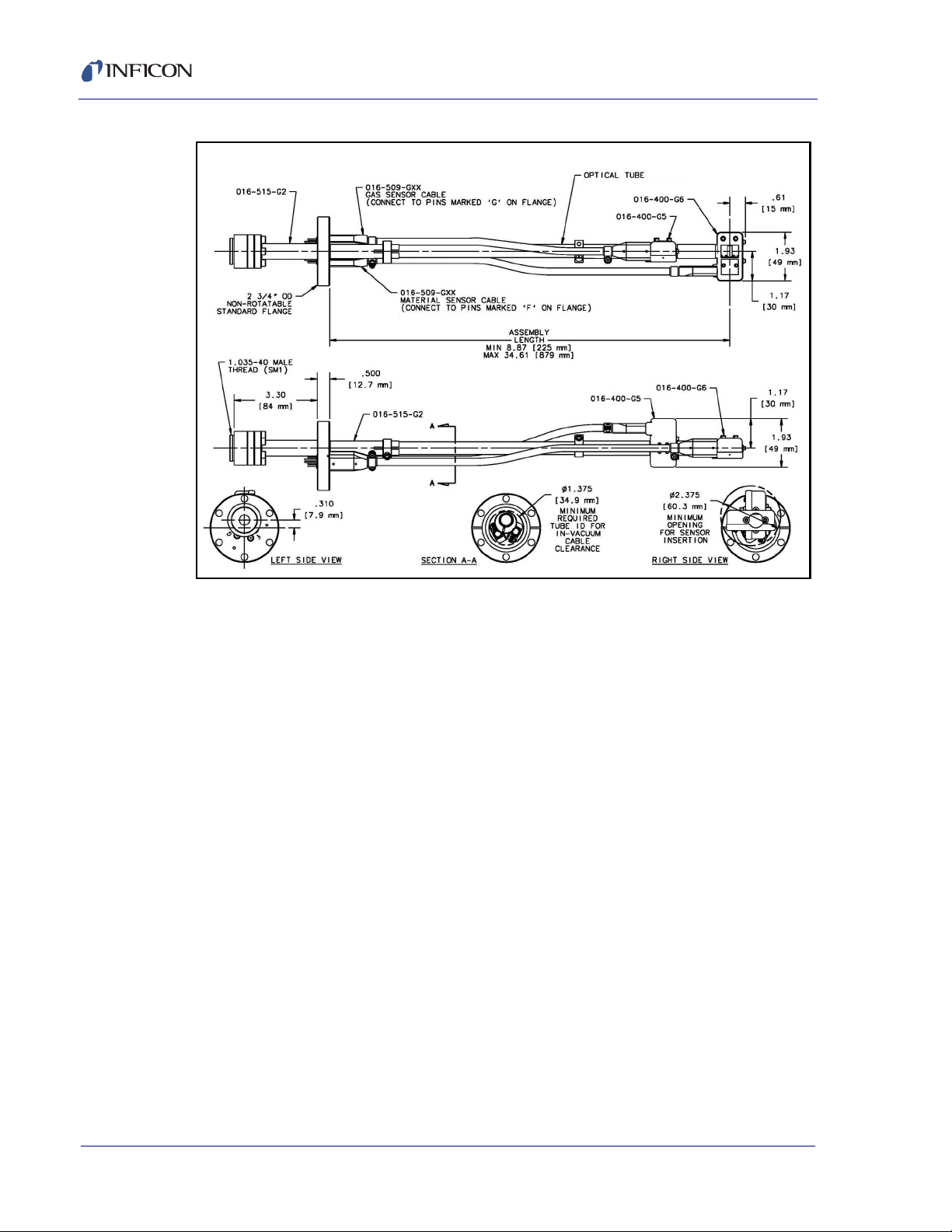

In the Gas Compensating Sensor, Figure 1-5, two sensors are stacked on the same

optical tube with the gas compensating sensor rotated 90 degrees out of the vapor

stream.

NOTE: The sensor will not pass through the 2.75 in.CF (NW35CF) port. If the

chamber is too small to allow installation from the inside, a 4.5 in. CF

(NW63CF) or larger flange adapted to the 2.75 in. CF flange is required to

IPN 074-517-P1D

allow the entire sensor to pass through.

1 - 3

Page 18

Guardian Co-Deposition Controller Operating Manual

Figure 1-5 Gas Compensating Sensor and Feedthrough 016-601-Gxx

1 - 4

IPN 074-517-P1D

Page 19

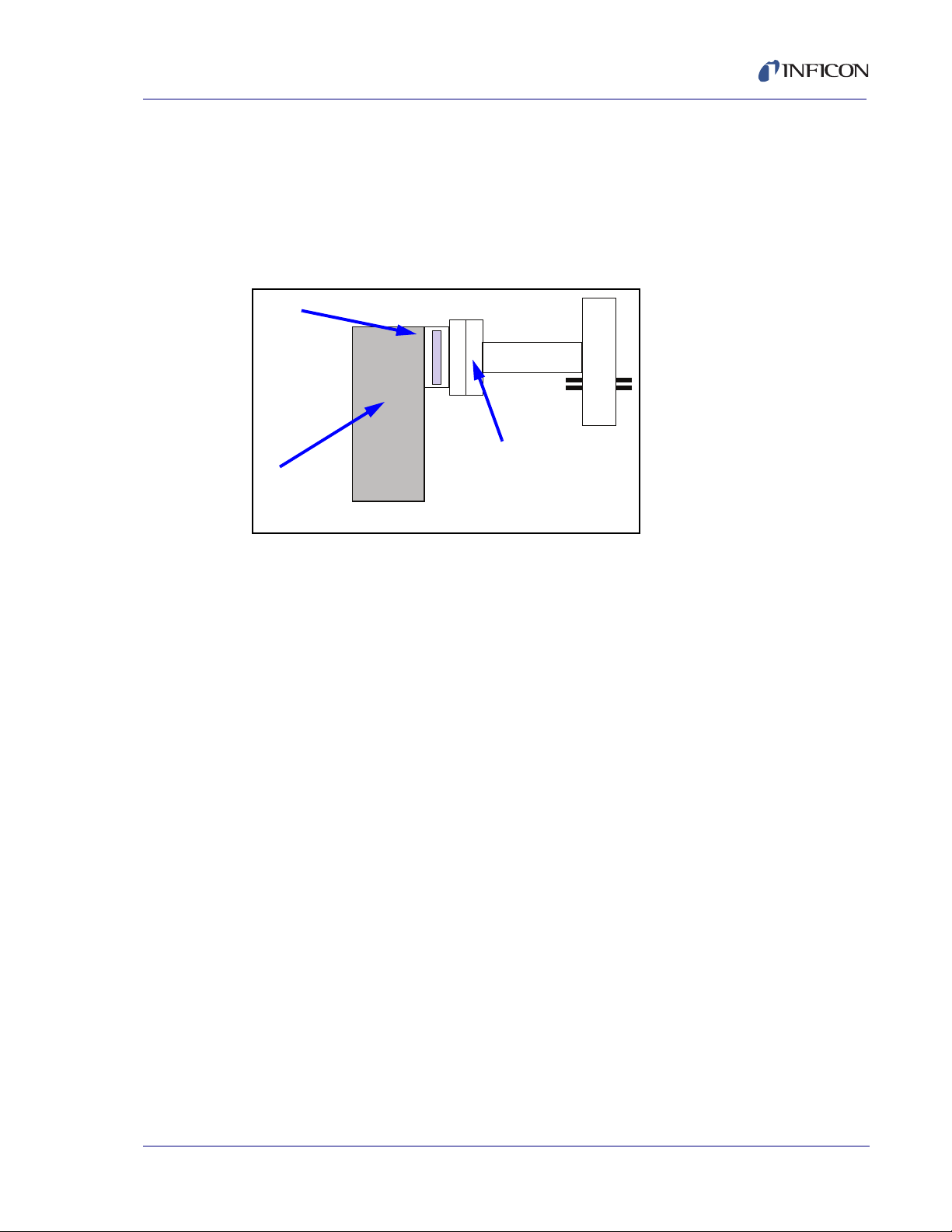

1.4 EIES Detector

Filter

Detector

Sensor

Viewport

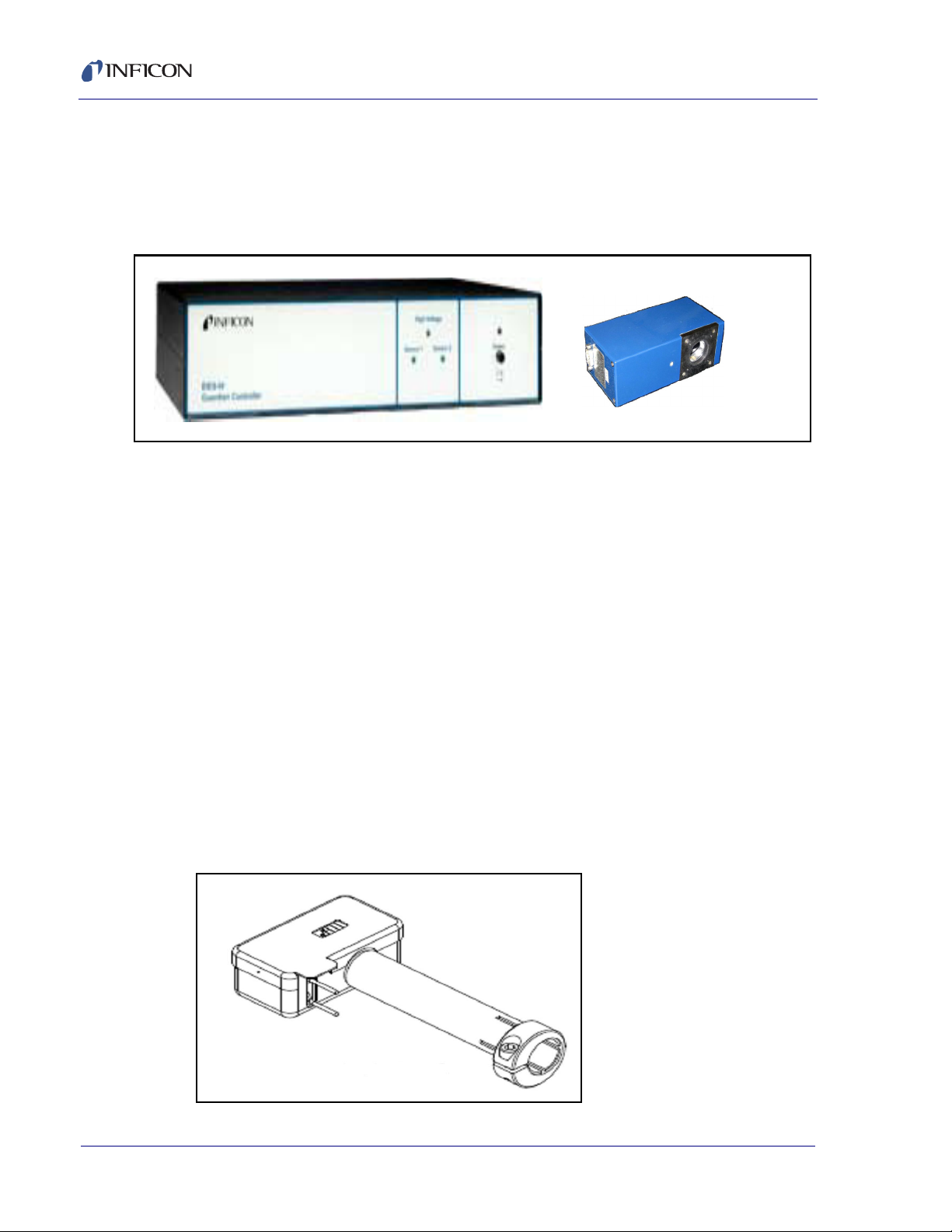

The EIES detector module's photomultiplier tube (PMT) measures the emission

intensity of a characteristic wavelength of the deposited material.

For detecting a single material, an optical filter and detector module can be

attached directly to the viewport. See Figure 1-6.

Figure 1-6 EIES Detector

Guardian Co-Deposition Controller Operating Manual

For multiple materials, a fiber optic beam splitter is attached to the viewport. The

split signal is then fed to multiple detectors. Splitting the signal reduces its intensity.

Each detector is fitted with a filter specific to the material it measures.

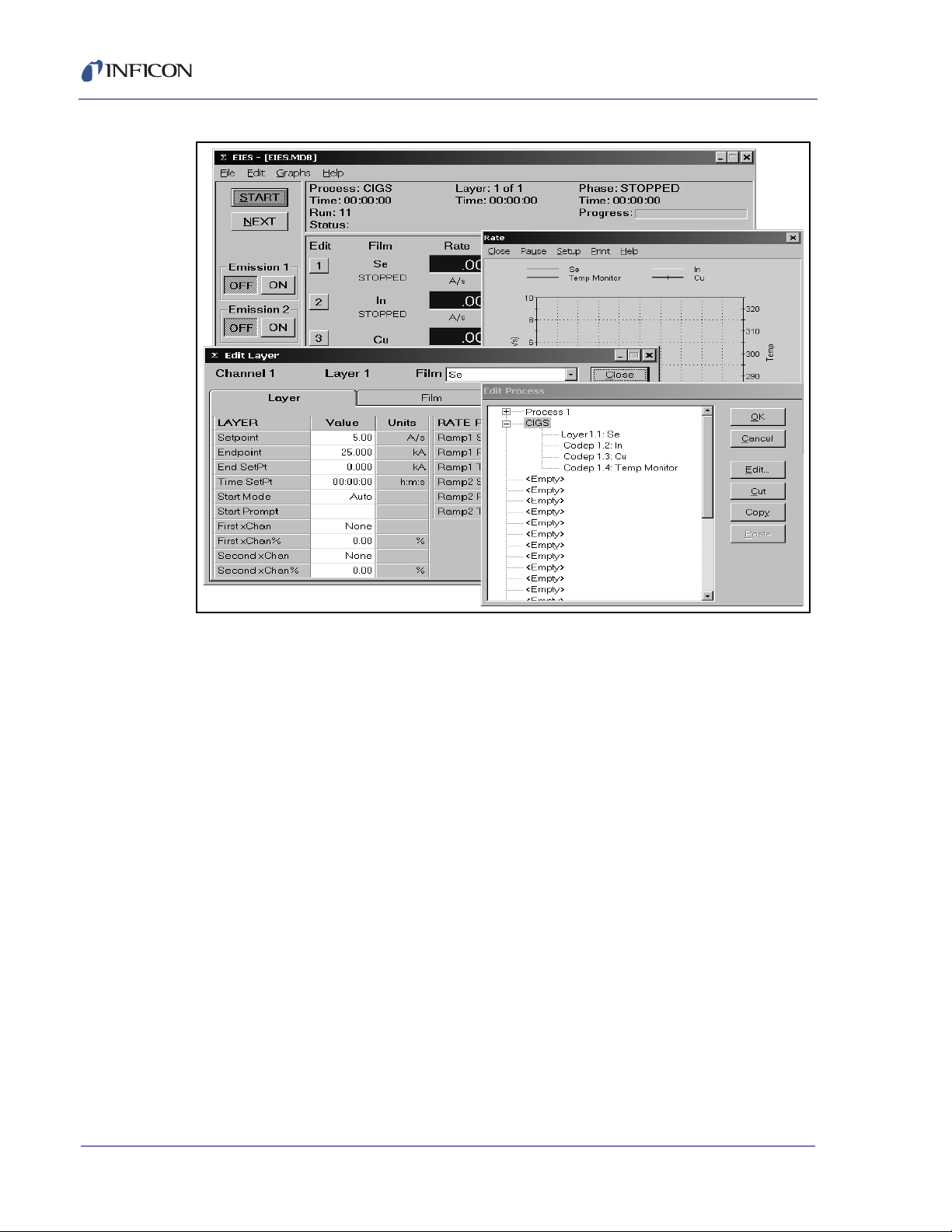

1.5 EIES Software

The EIES software provides the user interface, see Figure 1-7, for operating the

EIES-IV Guardian system. The program provides all of the functions required for

an eight sensor, eight output, multi-layer co-deposition controller. Process settings,

numeric data, and graphs can be displayed during all phases of deposition.

®

The EIES software stores process recipes in a Microsoft

database. Process data is logged to disk in comma-delimited format for easy import

IPN 074-517-P1D

into spreadsheet and graphing programs, such as Microsoft Excel

Chapter 3 details EIES software functions.

Access® compatible

®

.

1 - 5

Page 20

Guardian Co-Deposition Controller Operating Manual

Figure 1-7 EIES Software

1.6 Quartz Crystal Monitor

In the EIES system, rate is proportional to light intensity, measured as detector

current. To calibrate the detector current to actual rate, an optional quartz crystal

monitor (QCM) is available.

The EIES system uses the INFICON SQM-242

for QCM calibration of the EIES detector(s). QCM calibration can be initiated by the

user, or automatically at regular intervals during deposition. Control of a source is

also possible with a QCM input.

A separate Operating Manual covers installation of the SQM-242 or Q-pod, and

hook up of the quartz sensors.

1.7 Analog Measurements

The INFICON SAM-242™ analog input card measures four 0 to +/-10 V (dc)

signals. The SAM-242 card can be used to measure process parameters, such as

temperature and pressure, to control those process variables. The SAM-242 card

is an add-on for the SQM card and is not a stand-alone card.

The SAM-242 card is also installed in the computer running the EIES software.

Installation is covered in the SQM-242 Operating Manual.

™

PCI card or Q-pod™ Transducer

IPN 074-517-P1D

1 - 6

Page 21

1.8 Specifications

1.8.1 Sensor

Type . . . . . . . . . . . . . . . . . . . . . . . . . Single filament hot cathode or Dual filament

Sensor Materials . . . . . . . . . . . . . . . 304 SS, Inconel x-750,Tantalum, Ceramic

Filament Life (typical) . . . . . . . . . . . . ~1000 hours @ 1 x 10

Filament Material . . . . . . . . . . . . . . . Thoria coated Iridium,

Filament Current. . . . . . . . . . . . . . . . 2 to 4 amps

Emission Current . . . . . . . . . . . . . . . Yttria: 2 mA max, Thoria 4 mA max

Bias Voltage . . . . . . . . . . . . . . . . . . . 180 Volts

Operating Pressure . . . . . . . . . . . . . 5 x 10

Operating/Bakeout Temperature

for in-vacuum components . . . . . . . . 450ºC maximum

Guardian Co-Deposition Controller Operating Manual

Gas Compensating

-5

Tor r

Optional Yttria coated

-4

Torr maximum

Size . . . . . . . . . . . . . . . . . . . . . . . . . 1.94 L x 1.03 W x 0.81 H in.

(49 x 26 x 21 mm)

Mounting. . . . . . . . . . . . . . . . . . . . . . 2 ¾ in. CF (NW35CF) with sapphire viewport

Rigid SS tube from 7 in. to 16 in. (175 mm to

405 mm)

Optical Path . . . . . . . . . . . . . . . . . . . 1/2 in. (12.25 mm) dia. 304 SS rigid tube,

centerless ground (

InVac Cable . . . . . . . . . . . . . . . . . . . 16 AWG Mica insulated nickel clad Copper

Cable 016-509-Gxx

Optional ceramic bead insulated 0.050 in.

(1.3 mm) dia. Molybdenum wire Refractory

Cable 016-513-Gxx

IPN 074-517-P1D

External Wiring . . . . . . . . . . . . . . . . . 16 AWG except 18 AWG ground conductor,

40' (12 m) maximum

1 - 7

Page 22

Guardian Co-Deposition Controller Operating Manual

1.8.2 Detector

Photomultiplier Tube (PMT) . . . . . . . Hamamatsu R7518 or equivalent

Spectral Response. . . . . . . . . . . . . . 185 to 730 nm

Detection Limit . . . . . . . . . . . . . . . . . >5 fW of optical input power

PMT Gain . . . . . . . . . . . . . . . . . . . . . 10

Resolution . . . . . . . . . . . . . . . . . . . . 20 bits

Mounting . . . . . . . . . . . . . . . . . . . . . 1.035 in. x 40 threads per Compatible with

Filter Holder . . . . . . . . . . . . . . . . . . . 1 in. (25 mm) diameter x .2 in. (5 mm) thick

Size . . . . . . . . . . . . . . . . . . . . . . . . . 2 x 5½ x 2¾ in. (50 x 140 x 70 mm)

Weight . . . . . . . . . . . . . . . . . . . . . . . 1.7 lb. (0.8 kg)

Wiring . . . . . . . . . . . . . . . . . . . . . . . . DB9 Male/Female, 40 ft. (12 m) maximum

Warm Up . . . . . . . . . . . . . . . . . . . . . Allow the detector to warm up for one hour

3

to 107, programmable

Omega SM1 series

filters

for maximum stability.

1.8.3 Controller

Sensors . . . . . . . . . . . . . . . . . . . . . . 1, 2 optional

Detectors . . . . . . . . . . . . . . . . . . . . . 8

Source Control Outputs . . . . . . . . . . 8 outputs, 0 to ±10 V (dc) programmable

Digital I/O . . . . . . . . . . . . . . . . . . . . . 12 relays 30 V (dc), 3 A,

Communications . . . . . . . . . . . . . . . RS-232 or Ethernet static IP address

Power . . . . . . . . . . . . . . . . . . . . . . . . 100-240 V~ ±10% nominal, 50/60 Hz, 110 W

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . 250 V 1.6 A T

Size . . . . . . . . . . . . . . . . . . . . . . . . . 19 x 3 ½ x 12 in. (483 x 89 x 305 mm)

Weight . . . . . . . . . . . . . . . . . . . . . . . 8.5 lb. (3.9 kg)

Computer . . . . . . . . . . . . . . . . . . . . . Windows 2000/XP/Vista/7, user supplied

12 inputs 5-12 V (dc)

IPN 074-517-P1D

1 - 8

Page 23

Guardian Co-Deposition Controller Operating Manual

Operating Environment . . . . . . . . . . 0°C to 40°C

0 to 80% RH non-condensing

0 to 2,000 meters

Indoor Use Only

Class 1 Equipment (Grounded Type)

Suitable for Continuous Operation

Ordinary Protection (not protected against

harmful ingress of moisture)

Pollution Degree 2

Installation (Overvoltage) Category II for

transient overvoltages

Storage Environment . . . . . . . . . . . . -40°C to 40°C

IPN 074-517-P1D

1 - 9

Page 24

Guardian Co-Deposition Controller Operating Manual

This page is intentionally blank.

1 - 10

IPN 074-517-P1D

Page 25

2.1 Introduction

Electrical Feedthroughs

For Sensor Filament

Sapphire Window

1.33 in. CF Flange

2.75 in. CF Flange

Telescoping Tubing

For Length Adjustment

Vapor

Flux

EIES Sensor

This section covers the minimum system connections and software setup needed

to run the EIES-IV Guardian system. Consult later chapters for more detailed

installation and operating instructions.

2.2 Installation

2.2.1 Sensor Installation

Placement of the EIES sensor is the most significant factor determining EIES

system performance. The sensor must be placed so that the material vapor flux

reaches the sensor without obstruction. The sensor opening must be oriented so

that material can pass through the sensor without accumulating inside the sensor,

with the smaller sensor cutout toward the flux. See Figure 2-1. See Chapter 4 for

detailed installation instructions.

Guardian Co-Deposition Controller Operating Manual

Chapter 2

Quick Start

IPN 074-517-P1D

NOTE: The sensor will not pass through the 2.75 in.CF (NW35CF) port. If the

chamber is too small to allow installation from the inside, a 4.5 in. CF

(NW63CF) or larger flange adapted to the 2.75 in. CF flange is required to

allow the entire sensor to pass through.

Figure 2-1 Sensor Placement

2 - 1

Page 26

Guardian Co-Deposition Controller Operating Manual

016-205-P2

Standard Rate Cover

016-205-P1

High Rate Cover

To install the sensor, loosen the collar that secures the telescoping tube and

separate the 2.75” flange from the sensor assembly. Install the 2.75 in. CF

feedthrough to the vacuum chamber port, with the telescoping tube inside the

chamber.

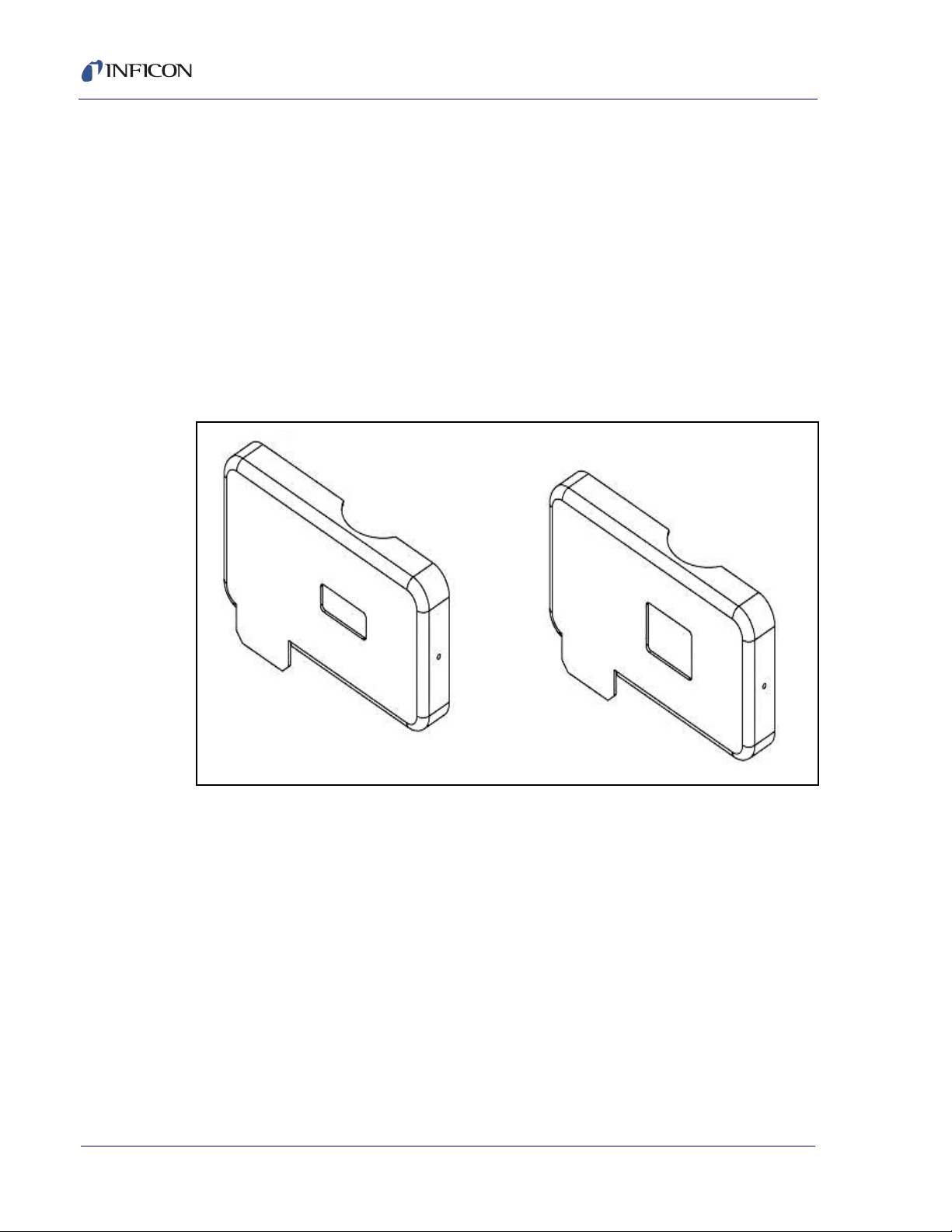

2.2.1.1 Sensor Covers, High Rate and Standard Rate

The High Rate cover 016-205-P1 is shipped installed on the flux sensor. The

Standard Rate cover 016-205-P2 is shipped separately in a poly bag. For MBE and

other applications where the sensor receives deposition rates below 10 Å/s or the

emission signal is weak, the Standard Rate cover may be preferable as it allows

more evaporant to enter the sensor. When replacing covers, be sure the cover is

securely snapped in place.

Figure 2-2 High Rate and Standard Rate Covers

2 - 2

In the vacuum chamber, slide the sensor assembly onto the telescoping light tube

and adjust the length so that the vapor flux passes through the sensor. The smaller

opening in the sensor cover points toward the evaporant. If necessary, provide

mechanical support to stabilize the sensor assembly. However, do not block the

flux path. Secure the assembly by tightening the tube collar.

Attach the cables from the feedthrough to the sensor. For a standard sensor, attach

the in-vacuum cable to the pins marked "F" (Flux). For a gas compensating sensor,

attach the cable from the outermost sensor to the pins marked "F". Attach the

in-vacuum cable from the inner sensor to the pins marked "G" (Gas). Assure there

are no potential shorting paths to the chamber. The outermost sensor’s cover must

be aligned to allow evaporant material to pass through it, entering at the smaller

rectangular opening and exiting at the large opening. The gas sensor will be

oriented at a right angle relative to the flux sensor and its cover will have several

small holes to permit residual gas to enter, but no evaporant material.

IPN 074-517-P1D

Page 27

Guardian Co-Deposition Controller Operating Manual

CAUTION

2.2.2 Detector—Direct Installation

For single detector applications, the detector may be mounted directly to the

sensor assembly viewport. Please see section 4.3.2, Single-Detector Systems, on

page 4-8 for detailed installation instructions.

2.2.3 Sensor to Fiber Optic Installation

In multi-material applications, a fiber optic beam splitter attached to the viewport

can tailor signal transmission and detector mounting to your needs. Contact

INFICON for fiber optic beam splitting requirements and capabilities. Please see

section 4.3.3, Multiple-Detector Systems, on page 4-8 for detailed installation

instructions.

Be sure power to the PMT Detector Module is turned off

whenever the PMT is exposed to room light to avoid

damage to the PMT.

IPN 074-517-P1D

2 - 3

Page 28

Guardian Co-Deposition Controller Operating Manual

CAUTION

CAUTION

WARNING

WARNING

2.2.4 Controller Installation

Mount the controller in a location that allows easy wiring access to the EIES sensor

and detector assemblies. The controller may be placed up to 25 ft. from the EIES

computer. See section 4.6, Controller Installation, on page 4-17

Properly ground the system. Connect a heavy braided

cable from the EIES controller to vacuum chamber

ground. If you are using multiple power supplies, be sure

that the outer conductor of each BNC cable is at system

ground potential.

Digital Inputs and Relays: Consult Chapter 4 for information on digital I/O wiring.

A system interlock must be present. Plug the Interlock

connector 782-505-077 (jumpers pin 1 to 10 and pin 3 to

16) supplied in the 782-703-G1 Ship Kit into the Inputs

connector. Emission cannot be turned on unless this

connector or an equivalent system interlock is present.

Power: With the power switch OFF, connect the AC mains to the controller power

input. The controller automatically accepts 100-240 V (ac), 50-60 Hz.

NOTE: Observe the power-up sequence described below to avoid power glitches

appearing at the evaporation power supply outputs during startup.

Power up in this sequence: Press the power switch on

the Guardian controller. Next, start the EIES Software.

Last, turn on the evaporation power supplies.

Verify that the power cable provided is connected to a

properly grounded mains receptacle.

IPN 074-517-P1D

2 - 4

Page 29

WARNING

Maintain adequate insulation and physical separation of

WARNING

sensor, detector, and I/O wiring from hazardous voltages.

Relay contacts are rated for 30 V (dc) maximum duty. Any

customer supplied relay contact circuit must be fused at

not more than 5A if the circuit is capable of supplying

more than 5A, including the available short circuit

current.

2.2.5 QCM Option Installation

If an SQM-242 or Q-pod will be used for calibration or control, follow its Operating

Manual to install the QCM software and sensor(s).

For accurate rate calibration, locate the QCM sensor(s) in the vacuum chamber so

that the QCM sensor(s) receives a representative sample of the materials being

deposited.

Guardian Co-Deposition Controller Operating Manual

2.3 EIES Software

Leave the Guardian Controller power OFF while you become familiar with the EIES

program. This section will introduce the concepts necessary to operate the EIES-IV

Guardian system.

2.3.1 Software Installation

Insert the INFICON Program Disk into your CD-ROM drive. The Products Menu

should appear after a few seconds, see Figure 3-2 on page 3-3. If not, open

IPN 074-517-P1D

Windows Explorer and run the UtilityDisk.exe program on the CDROM.

On the Products Menu, click EIES-IV Guardian. When EIES software installation

finishes, you may be prompted to restart your computer.

2 - 5

Page 30

Guardian Co-Deposition Controller Operating Manual

Control

Panel

Readings

Panel

Status

Panel

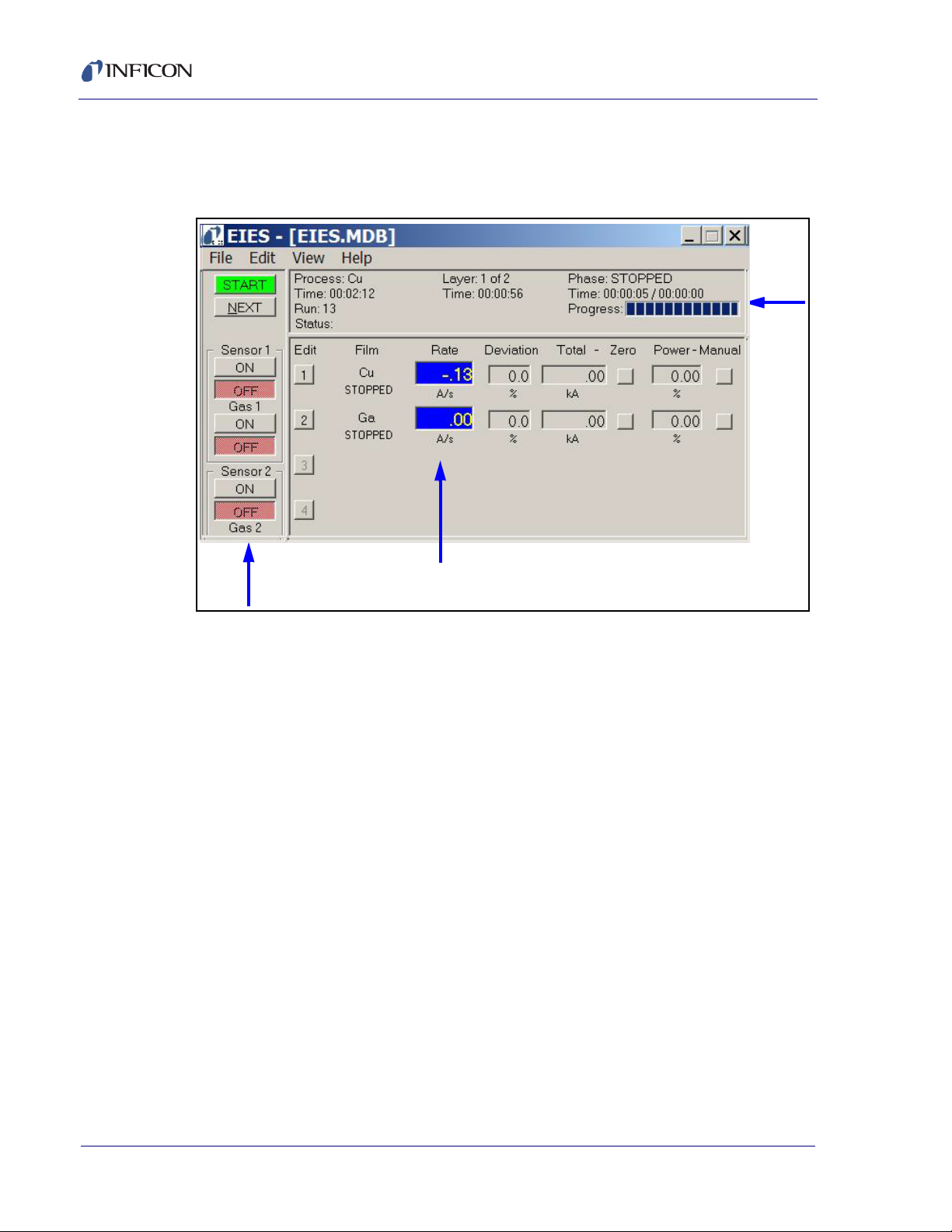

2.3.2 EIES Main Screen

Click the EIES-IV icon on your desktop (or click Start >> Programs >> INFICON

>> EIES-IV). Initially, your display may look slightly different than Figure 2-3.

Figure 2-3 Process Display

The EIES main screen shows operating controls for running your process in the left

Control Panel. Process status information is in the top Status Panel. Below the

Status Panel is the large Readings Panel where individual channel readings are

displayed.

The readings panel has three display modes: Process, Ratio and Readings. Click

View >> Process to see the Process display. The Process display shows process

related information such as films, setpoints, and manual operating controls.

The Ratio display is similar to the Process display except that the deviation

readings are replaced with the ratio of the channel’s reading to another channel.

The other channel number is shown below the ratio reading. Ratios are set up in

the Edit Layer dialog box. See Ratio Display Grid on page 3-20, for more

information on channel ratios.

Click View >> Readings to see the Readings display, Figure 2-4. This display

shows unfiltered readings from all sensors and detectors. The Readings display is

useful for equipment setup and troubleshooting.

IPN 074-517-P1D

2 - 6

Page 31

Figure 2-4 Readings Display

Guardian Co-Deposition Controller Operating Manual

Notice that, unlike the previous display, there are several references to a Gas

sensor in both the Readings Panel and the Control Panel. The EIES Guardian

controller can be configured for standard EIES sensors or Gas Compensating (GC)

sensors. When a Gas Compensating controller is detected, the extra controls and

readings are displayed automatically. Operation with GC sensors is covered later

in the manual.

IPN 074-517-P1D

2 - 7

Page 32

Guardian Co-Deposition Controller Operating Manual

2.3.3 Edit Film

Each material deposited will require unique setup parameters for proper

deposition. 25 materials can be programmed. Click the Edit >> Films to display the

Edit Film dialog box shown in Figure 2-5.

Figure 2-5 Edit Film Dialog Box

Click the film drop-down to see a list of all films. Select the first film in the list, then

click the Rename button. Change the film name to Cu, for Copper. This film will

define the basic deposition parameters for Copper. We could adjust the film

parameters, but for now we'll just rename a few more films.

Use the film drop-down to Rename the next three films In, Ga and Se. Close the

Edit Film dialog box and return to the main screen.

2.3.4 Edit Processes

Select Edit >> Processes to view a listing of the 25 processes. A process is a

sequence of layers, each consisting of one or more deposited films. We will use the

Edit Process dialog box to create a multi-layer co-deposition process.

Click the first process, then click Edit. Name the first process CIGS. We will

construct an arbitrary layer sequence using arbitrary parameters for each.

Processes are shown in an outline view, similar to Windows Explorer. Click the +

beside a process to expand the process and show the individual layers. Click - to

collapse the view of the process.

IPN 074-517-P1D

2 - 8

Page 33

Guardian Co-Deposition Controller Operating Manual

Layers are numbered sequentially starting at layer 1. After the layer number is the

EIES software channel that will display readings. Next is the EIES Guardian output

that will control the deposition power supply. And finally, the film that will be

deposited.

It is important to know which channels and outputs are being used in co-deposition,

to avoid assigning more than one film to the same measurement channel or control

output.

Now, click the first layer of process CIGS (don't worry if the material is different than

shown below). Be sure the first layer is highlighted, then click the Copy button; see

Figure 2-6.

Figure 2-6 Selecting First Layer of Process CIGS

This places a copy of the selected layer on the edit clipboard and enables the Paste

button. With the first layer still highlighted, click the CoDep option below the Paste

button, and then click the Paste button. See Figure 2-7.

IPN 074-517-P1D

2 - 9

Page 34

Guardian Co-Deposition Controller Operating Manual

Figure 2-7 CoDep Option

A co-deposition film has been added to the first layer. Click Paste again to create

a three film co-deposition layer.

Now select the Below option and click Paste to add a second layer below layer 1.

Finally, select the CoDep option and click Paste to add a CoDep film to layer 2.

See Figure 2-8.

Figure 2-8 Pasting CoDep Layer

IPN 074-517-P1D

2 - 10

The CIGS process now consists of Layer1 and Layer2. Layer1 will co-deposit three

films, and Layer2 will co-deposit two films. However, the channel, output, and films

are all duplicates. We will correct that error in the next section.

Page 35

2.3.5 Edit Layer

Highlight Layer 1: Ch:1 Out:1 Cu and click Edit to display the Edit Layer dialog

box. See Figure 2-9.

The Edit Layer dialog box shows all of the parameters needed to deposit the

selected layer. At the top of the dialog box you select the measurement channel

and output to be used, and the film to be deposited in this layer. Select Channel 1,

Output 1, and Film Se. We will set this up to be a QCM channel.

Figure 2-9 Edit Layer Dialog Box

Guardian Co-Deposition Controller Operating Manual

Select the Layer tab and set the rate Setpoint to 10 Å/s, and the thickness Endpoint

to 100 kÅ.

IPN 074-517-P1D

2 - 11

Page 36

Guardian Co-Deposition Controller Operating Manual

Click the X Chan tab to view the settings used to eliminate cross channel

interference and display the ratio of two channel’s reading. For now we will not use

these features. See Figure 2-10.

Figure 2-10 Settings Used To Eliminate Cross Channel Interference

2 - 12

IPN 074-517-P1D

Page 37

Guardian Co-Deposition Controller Operating Manual

The Film and Film Cal(ibration) tabs are for the selected film, Se. On the Film tab

set preconditioning Ramp1 Power, Ramp1 Time, and Soak1 Time as shown in

Figure 2-11.

Figure 2-11 Film Tab Settings

IPN 074-517-P1D

2 - 13

Page 38

Guardian Co-Deposition Controller Operating Manual

Now select the Film Cal(ibration) tab and verify Channel Input and Cal. QCM# are

as shown in Figure 2-12. Note that the software for the Q-pod or SQM242 QCM to

be used must be installed per the relevant instructions. Tooling must be established

as described in the QCM manual or in this manual under Tooling Factor on page

6-7.

Channel numbers correspond to inputs from up to eight EIES Detector Modules,

up to four QCM inputs or up to four SAM inputs. Any combination using up to eight

inputs for rate control is possible.

Figure 2-12 QCM Film Calibration Tab

2 - 14

Keep in mind that parameters on the Layer and X Chan tabs are unique to this

layer. Those on the Film and Film Calibrate tabs pertain to any layer using the film.

Take a few minutes to review the parameters on each tab. As you hold your mouse

pointer over each parameter, a brief explanation appears. You can also press F1

to view the help file for the selected tab.

IPN 074-517-P1D

Page 39

Guardian Co-Deposition Controller Operating Manual

When you are ready, return to the Edit Process dialog box shown in Figure 2-13

and click the indented CoDep film, immediately below Layer 1 Ch:1 Out:1 Se.

The Edit Layer dialog box will update to show the parameters for the selected layer.

In the Edit Layer dialog box, set this CoDep film to Channel 2, Output 2, and select

film In. On the Layer tab, enter a Setpoint of 5 Å/s and an Endpoint of 5 kÅ. On the

Film tab, set Ramp1 Power to 25% and set the remaining Film parameters to match

those for Se, as shown on the previous page. In the Film Cal tab, select EIES as

Input and set Cal QCM# to 2,

Figure 2-13 Edit Process

Return to the Edit Process dialog box and click the CoDep film immediately below

Codep Ch:2 Out 2 In. In the Edit Layer dialog box, set this CoDep film to Channel

3, Output 3, and film Ga. On the Layer tab, enter a Setpoint of 2 Å/s and an

Endpoint of 2 kÅ. On the Film tab, set Ramp1 Power to 15%. Edit the remaining

Film and Calibrate parameters to match those for In, as shown on the previous

IPN 074-517-P1D

page. That completes the definition of the first co-deposition layer, consisting of Se,

In, and Ga.

Edit Layer 2 so that the first entry is Layer 2 Ch:1 Out:1 Se with a rate Setpoint of

10 Å/s and thickness Endpoint of 10 kÅ. Change the codep layer for Layer 2 to

CoDep Ch:4 Out: 4 Cu with a Setpoint of 3 Å/s and Endpoint of 3 kÅ EIES Input.

When you are finished, you should have a 2-layer CIGS process as shown in

Figure 2-14.

2 - 15

Page 40

Guardian Co-Deposition Controller Operating Manual

Figure 2-14 2-Layer CIGS Process

Click OK to return to the main screen with CIGS as the active process.

2.3.6 Views

On the main screen, click the View menu and select 3. Power. You may want to

rearrange some program windows at this point. You can also resize the graph by

dragging its window border.

Figure 2-15 Power Graph

IPN 074-517-P1D

2 - 16

Graph 3.Power is normally a graph of the output power of the active channels

during deposition.

Page 41

Guardian Co-Deposition Controller Operating Manual

Click Setup on the graph menu to show the Graph Setup dialog box.

Figure 2-16 Graph Setup Dialog Box

Assign channels 1 to 4 by checking the Show Channel check boxes. Also, check

Graph On Top to keep the graph above other windows. When your Graph Setup

dialog box matches the one above, close the Graph Setup dialog box.

2.3.7 Software Summary

Spend some time with this process to become familiar with its setup. Especially, the

creation of a multi-layer and codeposition layer process. Also, review the

parameters contained in the Layer Edit screen. The Layer Edit screen will be

crucial to fine tuning your process.

IPN 074-517-P1D

2 - 17

Page 42

Guardian Co-Deposition Controller Operating Manual

2.4 Initial Setup

Connect the Guardian controller rear panel RS-232 connector to your computer

serial port using a straight through DB-9 Male-Female cable (IPN# 068-0464 in

Guardian ship kit). Connect your detector module(s) to the rear panel of the

Guardian controller with 782-505-065 (3 m) or 782-505-065-40 (10 m) cable(s).

2.4.1 Power-up Sequence

1 Press the power switch on the Guardian controller.

2 Start the EIES Software.

3 Turn on the evaporation power supplies.

2.4.2 Communications

If a Comm Error message appears on the main screen status line, click Edit >>

System, and the Comm tab. Select the Comm Port used for communications with

the Guardian controller.

Figure 2-17 Selecting Comm Port

If you are connecting to the Guardian controller by Ethernet, select Ethernet in the

Comm Port drop-down. Enter the Port (typically 2101) and address (default factory

setting is 192.168.1.200) .

IPN 074-517-P1D

2 - 18

When the proper communications parameters are entered and communication is

successfully established, the main screen Comm Error message will disappear and

the screen will show Version x.xx where x.xx is the firmware version in the

controller.

Page 43

2.4.3 Detector Calibration

The internal electronics of each EIES detector module are pre-calibrated at the

factory. To compensate for background noise once installed to a system, the

following calibration must be performed.

NOTE: Allow 1 hr warm-up for the PMT to reach optimum stability. If you replace

or exchange a detector, you must recalibrate!

To calibrate a detector, select the Channel tab of the System Edit dialog box.

Select the Channel you want to calibrate. Sensor emission should be off.

Figure 2-18 System Edit Channel Tab

Guardian Co-Deposition Controller Operating Manual

Verify that a “No Response!” error message is not shown below the Start button in

the calibration frame. If it is, check the detector to controller cable. You can also try

powering the controller off, then on. Establishing ethernet connection may take a

IPN 074-517-P1D

minute or more.

Set the detector Update rate to 10 Hz and Cal Readings to 10.

When there are no errors, click the Start calibrate button. The screen will indicate

the calibration process and end with a Calibration Complete message.

Select and calibrate any additional detector channels.

2 - 19

Page 44

Guardian Co-Deposition Controller Operating Manual

CAUTION

2.4.4 Sensor Setup

The Guardian controller can operate up to two standard or gas compensating

sensors. During operation, the controller must maintain a constant sensor emission

current. As a sensor is used and material is deposited on the sensor, an unwanted

leakage current can develop. When the leakage current becomes too large, the

Guardian controller can no longer control emission current.

The Emission current can be set as high as 10 mA but must be set at no more

than 4 mA when using 016-Series Thoria filaments and 2 mA when using

016-Series Yttria filaments. Correct emission current is stated on a label attached

to the plastic bag the sensor or replacement emitter was packaged in. Leakage

setting of 1/2 the emission current setting is recommended for most applications.

See Chapter 3 for more information on sensor setup.

Refer to the label attached to your sensor or emitter

assembly package for correct emission current settings.

Do not operate 016-xxx series sensors with Yttria

filaments at Emission current greater than 2 mA. Instant

filament failure may occur! 016-xxx series sensors with

Thoria filaments may be operated at 4 mA emission.

Figure 2-19 Edit System Sensor Tab

IPN 074-517-P1D

2 - 20

Page 45

Guardian Co-Deposition Controller Operating Manual

Guardian controllers with Gas Compensating sensors have additional Emission

and Leakage parameters for the gas sensor. A Gas Calibration factor is used to null

the gas effect from the main sensor readings. See Figure 2-20.

Figure 2-20 Gas Calibration Factor

See Sensor Tab on page 3-30 for a description of the Gas Cal parameter. For now,

uncheck Enable Gas Sensors if it is checked.

2.4.5 QCM Option

If you installed the optional SQM-242 card or Q-pod, click the QCM tab of the Edit

System dialog box.

Figure 2-21 QCM Tab

IPN 074-517-P1D

2 - 21

Page 46

Guardian Co-Deposition Controller Operating Manual

If the SQM-242 card is installed properly, Card: 2.XX, DLL: OK is displayed. If you

are using a Q-pod, its serial number appears. Verify that each sensor attached to

the QCM displays a frequency reading on the main screen.

2.4.6 Digital I/O

The I/O tab of the Edit System dialog box assigns the Guardian controller's relays

and digital inputs to program functions. See Figure 2-22. Most digital I/O is not

necessary for initial operation. Consult Chapter 3 for I/O programming, Chapter 4

for I/O wiring.

Figure 2-22 I/O Tab

2.5 Operation

This section assumes that you have worked through the example process of

section 2.2 on page 2-1 and the initial detector calibration of section 2.3 on page

2-5.

2.5.1 Build a Single Layer Process

Build a simple single-layer, single-film process in the EIES program and make it the

active process (refer to section 2.2 on page 2-1). Verify that the EIES channel you

are using has no errors, and shows a reading near zero (refer to section 2.3 on

page 2-5).

2 - 22

IPN 074-517-P1D

Page 47

2.5.2 Setup Layer Parameters

Display the Edit Layer dialog box for the channel you are using by clicking the Edit

button to the left of that channel on the main screen. Select the Layer tab of the

Edit Layer dialog box, see Figure 2-23, and verify that the Endpoint is a value high

enough to avoid prematurely halting the process during calibration.

Figure 2-23 Endpoint Value

Guardian Co-Deposition Controller Operating Manual

On the Film tab, verify that the Full Scale voltage matches the input of your power

supply. Also verify that Max. Power is consistent with the material you are

evaporating.

IPN 074-517-P1D

2 - 23

Page 48

Guardian Co-Deposition Controller Operating Manual

Figure 2-24 Film Tab Full Scale Voltage

Select the Film Cal(ibration) tab, and verify that the PMT volts setting is about 700.

Figure 2-25 PMT Voltage Setting

IPN 074-517-P1D

2 - 24

If you are using QCM calibration of the EIES measurements, select the proper

QCM Sensor# and enter the material Density and ZFactor (Z-Ratio) (see Appendix

B). For now, it is probably best to disable QCM calibration by setting Cal QCM# to

None.

Page 49

2.5.3 Start Deposition

NOTE: Pump down the vacuum chamber to below 1E-5 Torr before operating the

EIES-IV system! Allow 1 hr warm-up for the PMT to reach optimum

stability.

On the EIES main screen verify that there is no error message in the Film column

on the channel(s) being used, and verify that Rate reading is near zero.

Figure 2-26 Verifying Rate Reading is Near Zero

Guardian Co-Deposition Controller Operating Manual

On the main screen, turn Emission ON for the EIES sensor(s) you are using by

clicking ON under the sensor number on the left side of the screen. The rate

reading on each channel should still be near zero, but changing slightly.

Turn on your evaporation power supply. Click the Channel 1 Manual Power button

(on the right side of the screen). Enter a small power value and press Enter to send

the value to the power supply. Slowly increase power until the material vaporizes

IPN 074-517-P1D

and the rate reading starts to increase above zero.

If everything looks OK, increase the power to near the desired deposition rate. The

deposition rate can be determined before EIES calibration from previous

experience with the power supply output level, another measurement reference, or

from the optional QCM readings.

To optimize the detector PMT voltage, select View >> Readings to show the

detector readings. Click the channel Edit button. See Figure 2-27.

2 - 25

Page 50

Guardian Co-Deposition Controller Operating Manual

Figure 2-27 Channel Edit Button

The Edit Layer dialog box is displayed. On the Film Cal. tab of the Edit Layer dialog

box, adjust the PMT Volts until the readings for the appropriate channel are stable

and low.

HINT: Low PMT values cause low flux readings. High values increase noise and

may saturate the PMT.

Figure 2-28 Film Calibration Tab PMT Voltage

IPN 074-517-P1D

2 - 26

Page 51

2.5.4 Manual Calibration

Cal. Gain

EIES Measure Rate

Actual Rate

-----------------------------------------------=

Calibrate the main screen rate reading to match the actual rate by entering a Cal.

Gain on the Edit Layer, Film Cal. tab. The Cal. Gain parameter is calculated by

equation [1].

2.5.5 QCM Calibration

If you are not using the QCM calibration option, skip to section 2.5.6.

If you are using the QCM calibration option, select View >> Readings to display

the QCM readings grid. Verify that the QCM measured rate is as expected. The

QCM measured rate will be used to calibrate the EIES detector channel.

On the Edit Layer dialog box, Film Cal. tab, click calibrate Start. After a few

seconds the calculated Cal. Gain will appear. Verify that the main screen's rate

reading matches the QCM rate.

Guardian Co-Deposition Controller Operating Manual

[1]

2.5.6 Stop Deposition

This completes the initial operational checkout. Set Manual Power to zero on the

main screen to stop deposition. If you previously pressed Start, click Stop to halt

the process.

IPN 074-517-P1D

2 - 27

Page 52

Guardian Co-Deposition Controller Operating Manual

This page is intentionally blank.

2 - 28

IPN 074-517-P1D

Page 53

3.1 Introduction

The EIES-IV Guardian Windows program is a turnkey deposition control program

for the EIES Guardian controller. The program uses ASCII commands to

communicate with the Guardian controller. The EIES-IV Guardian software is a

powerful PC-based thin film deposition controller that can:

Measure up to eight materials simultaneously.

Operate two standard or gas compensating (GC) sensors.

Control up to eight deposition sources simultaneously.

Calibrate EIES sensors against quartz crystal sensors (SQM-242 or Q-pod

option).

Guardian Co-Deposition Controller Operating Manual

Chapter 3

EIES Software

Control analog variables such as temperature and pressure (SAM-242 option).

Store up to 25 processes and 250 layers on disk.

Graph, and log deposition data to disk, for process documentation and

analysis.

The current version 4.11 EIES-IV Guardian software is compatible only with version

4.x firmware and vice versa. Version 5.11 software only allows 2 mA operation and

is otherwise identical to version 4.11. Firmware versions prior to 4.x are compatible

with version 2.x EIES-IV Guardian software. The controller firmware is shown on

the instrument label affixed to the controller side panel. Earlier versions of the

controller may not have this label.

NOTE: If parameters are sent to the Guardian via external communications using

commands as described at section 7.3, Guardian Controller Direct

IPN 074-517-P1D

NOTE: New parameters sent to the Guardian via the ActiveX interface described

A typical deposition cycle for a thin film can be broken into three distinct phases:

pre-conditioning (ramp/soak), deposition, and post-conditioning (idle).

Communications, on page 7-8, the new parameters will not be updated on

the EIES-IV Guardian software screens.

at section 7.2, ActiveX (COM) Interface, on page 7-1, will be shown after

the relevant screen is closed and reopened.

3 - 1

Page 54

Guardian Co-Deposition Controller Operating Manual

Figure 3-1 3 Phases of Deposition Cycle

During pre-conditioning, the source material is prepared for deposition. The first

ramp/soak pre-conditioning phase is used to bring the material to a uniform molten

state. The second ramp/soak phase is typically set to a power that produces

evaporation below but near the desired deposition rate.

When pre-conditioning ends, PID rate control of deposition begins. Initially, the

substrate material may remain shuttered until the desired deposition rate is

achieved (shutter delay). Once the control loop achieves the desired rate, the

shutter opens and deposition begins. During deposition, multiple rates (rate ramps)

can be programmed.

When the desired thickness is reached, the evaporation source can be set to zero

or non-zero idle power. At this point the process may be complete, or deposition of

another layer may begin. Up to eight separate films can be co-deposited within a

single layer.

In addition to using EIES PMT detector modules for rate control, QCM inputs (from

INFICON's SQM-242 card or Q-pod) can also be used to control deposition, or to

calibrate the EIES PMT detector module. DC voltage inputs (measured by

INFICON's SAM-242 card) can also be used to control other process variables.

IPN 074-517-P1D

3 - 2

Page 55

3.2 Installation

NOTE: The EIES program may be installed and used in Simulate mode without an

To install the EIES software, insert the INFICON Program CD-ROM. If the setup

program does not start automatically, click Start, then Run, then type

<d>:UtilityDisk (where <d> is the drive you are using). The Program Disk main

menu should appear.

On the program disk menu, see Figure 3-2, click EIES Guardian Deposition

Controller, then click on EIES Guardian Software and follow the directions given

there. When installation is complete, you may be prompted to restart the computer.

Figure 3-2 Program Disk Menu

Guardian Co-Deposition Controller Operating Manual

EIES-IV Guardian controller. This is useful for learning the software, and

for off-line process development.

To start the EIES program, click the EIES desktop icon, or click Start, Programs,

IPN 074-517-P1D

INFICON, then EIES. The EIES program main screen will be displayed.

NOTE: The following description covers operation without a Guardian connected.

If a Guardian is to be connected at this time, select the communications

interface as described at section 3.8.5, Comm Tab, on page 3-35 before

proceeding. To make RS232 connections, connect a serial cable from the

Guardian serial port to the computer’s serial port. The cable required is a

DB9 female-to-male. Guardian baud rate is fixed at 115,200 and the

communications format is No Parity, 8 bits, 1 stop bit. To make ethernet

connections, connect an ethernet cable and set the IP Address as

described at section 3.8.5, Comm Tab, on page 3-35.

3 - 3

Page 56

Guardian Co-Deposition Controller Operating Manual

Figure 3-3 EIES Program Main Screen

The EIES main screen displays the last used Process, and the film(s) defined for

the first layer of the process. In Figure 3-3, three films (Se, In, and Cu) will be

deposited simultaneously in the first layer.

The main screen can show from four to eight channels of data. For most users four

channels will be adequate. To select the number of channels displayed, click the

Edit menu, then System. On the System Edit dialog box, see Figure 3-4, select

the Display tab. Select the number of channels you want to Show.

Figure 3-4 Edit System Display Tab

IPN 074-517-P1D

3 - 4

Page 57

3.3 Main Screen

The EIES main screen, see Figure 3-5, consists of three panels and a menu bar.

The Status Panel (top) displays information on the active process. The Control

Panel (left) controls operation of the EIES-IV Guardian system. The Readings

Panel displays readings from each of the channels used by the active process

layer. Finally, the menu bar provides access to process recipe and instrument

setup functions.

Figure 3-5 EIES Main Screen

Guardian Co-Deposition Controller Operating Manual

3.3.1 Status Panel

Figure 3-6 Status Panel

IPN 074-517-P1D

Process: Name of the current process. Select the active process from the menu

File, Open Process.

Process Time: The accumulated time for this run of the selected process. Resets

to zero, then starts counting when the Start button is clicked.

Process Run: The number of times this process has been run. The run count can

be zeroed on the File >> DataLog screen.

Status: Displays error conditions and other status information.

Layer: Displays the current layer and the total number of layers in the active

process. Use the Next button on the Control Panel to select layers.

3 - 5

Page 58

Guardian Co-Deposition Controller Operating Manual

Start/Stop: Click Start to run the process. The Start control is disabled

if there are no communications with the EIES controller. When the

process is running, the top control displays Stop. Click Stop to stop the