Page 1

OPERATING MANUAL

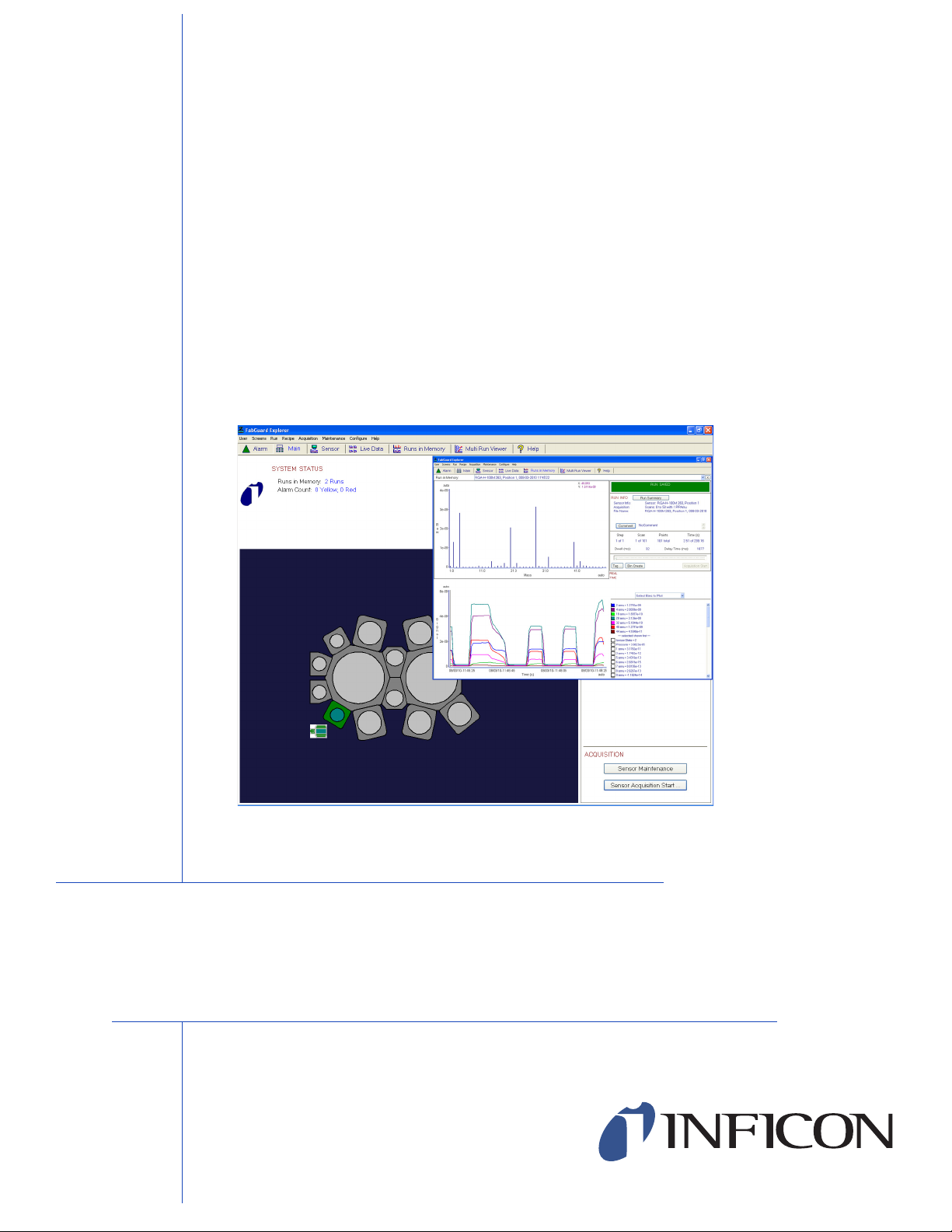

FabGuard Explorer™

Process Gas Characterization Software

IPN 074-528-P1A

Page 2

Page 3

OPERATING MANUAL

FabGuard Explorer™

Process Gas Characterization Software

IPN 074-528-P1A

www.inficon.com reachus@inficon.com

©2010 INFICON

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

FabGuard®, FabGuard Explorer™, INFICON®, Preclude™, Stiletto®, Transpector®, Transpector CPM™,

Transpector XPR™, and Quantus® are registered trademarks of INFICON GmbH.

Windows®, Windows Vista®, and Microsoft® are registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2010 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 6

Page 7

FabGuard Explorer Operating Manual

Table Of Contents

Chapter 1

Getting Started

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1.1 How to Contact Customer Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2 Operating Manual Style Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.1 Usage of the Modern Metric System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3 Inventory of Supplied Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.4 Computer System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.5 Supported Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.5.1 Transpector Models Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.5.1.1 Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.5.2 Other Supported Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.6 Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.6.1 RGA Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.6.1.1 Communications Baud Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6.1.2 Communications Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.6.1.3 USB to RS232 Standard Adapter Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6.1.3.1 Single Sensor Version (RS232) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.6.1.3.2 Multiple Sensor Version (RS485 Plus TCA485 Adapter) . . . . . . . . . . . . . . . 1-8

1.6.2 RFS100 Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.6.3 Quantus Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.6.4 Stiletto Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.7 How To Install FabGuard Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.8 How To Start FabGuard Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1.9 Where to Go From Here . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

IPN 074-528-P1A

Chapter 2

How the Software Works

2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Navigating FabGuard Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2.1 Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2 Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.2.3 Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.2.3.1 User Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3.2 Screens Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3.3 Run Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.3.4 Recipe Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

TOC - 1

Page 8

FabGuard Explorer Operating Manual

2.2.3.5 Acquisition Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.3.6 Maintenance Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.3.7 Configure Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.3.8 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.3.9 Context Sensitive Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.2.4 Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.3 FabGuard Explorer Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.3.1 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.3.2 Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.3.3 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.3.4 Live Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.5 Runs In Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.3.6 Multi Run Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.4 Basic Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.4.1 Data Acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.4.2 Leak Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.4.3 Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.4.4 Vacuum Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.5 Screen Specific Cascading Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.6 Opening Files in FabGuard Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.6.1 Importing Tware32 Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Chapter 3

Setup and Configuration

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Initial Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Communication Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Installation of Sensors Immediately After FabGuard Explorer is Opened . . 3-1

3.2.1.1 Transpector RGAs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.1.2 RFS100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.1.3 Stiletto Particle Detector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2.1.4 Quantus SPOES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.1.4.1 Automatically Assigning the Quantus an IP Address (DHCP) . . . . . . . . . . . 3-7

3.2.1.4.2 Manually Assigning the Quantus an IP Address . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.1.4.3 Setting up the Quantus in FabGuard Explorer . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2.1.5 Installation of Sensors Using I/O Connections. . . . . . . . . . . . . . . . . . . . . . . 3-9

3.2.1.5.1 Adding a Connection in the I/O Connections Menu . . . . . . . . . . . . . . . . . . 3-11

3.2.1.5.2 Edit/Test Connection Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3 Main Screen Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

IPN 074-528-P1A

TOC - 2

Page 9

FabGuard Explorer Operating Manual

3.3.1 Tool Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.3.2 Customizable Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

3.4 Sensor Configuration and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.4.1 RGA Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.4.1.1 Ionizer and Detector Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.4.1.1.1 Signal Units and References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.4.1.1.2 What State to Leave the Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3.4.1.1.3 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

3.4.1.2 RGA Configuration — Correction Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.4.1.2.1 Over-Pressure Error Recovery (Hardware) . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.4.1.2.2 Baseline Subtraction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

3.4.1.3 RGA Configuration — External I/O Tab . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.4.1.4 RGA Configuration — Calibration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

3.4.1.5 RGA Configuration — Life Time Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

3.4.1.5.1 Maintenance Life Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

3.4.1.5.2 Other Key Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

3.4.1.6 RGA Configuration — CPM Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

3.4.1.6.1 Valves and Orifices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

3.4.1.6.2 Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.4.1.6.3 Pumping Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-43

3.4.2 RFS100 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

3.4.3 Stiletto/Quantus Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-44

3.5 User Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-44

3.5.1 File Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3.5.1.1 Date Order in File Path and Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3.5.1.2 Run Save path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3.5.2 Acquisition Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

IPN 074-528-P1A

3.5.2.1 Keep Manually Acquired Runs in Memory . . . . . . . . . . . . . . . . . . . . . . . . .3-45

3.5.2.2 Maximum Monitor and Maintenance Time . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3.5.2.3 Maximum Number of Data Points Per Run . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3.5.3 Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3.5.3.1 Use Dropdown List for Sub-Screen Selection . . . . . . . . . . . . . . . . . . . . . . 3-46

3.5.3.2 Shape of Displayed Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

3.5.3.3 Real-Time Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-49

3.5.3.4 Auto-Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

3.5.3.5 Use Time of Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-50

3.5.3.6 Selection of Bins in Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-50

3.6 Access Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-51

TOC - 3

Page 10

FabGuard Explorer Operating Manual

Chapter 4

Data Acquisition

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Acquisition Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Quick Manual Acquisition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.2 Manual Acquisition from Scratch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.3 Manual Acquisition from Run in Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.4 Manual Acquisition from Recipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Manual Acquisition Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.1 Acquisition Control: Open Ion Source RGAs . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.1.1 Acquisition Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3.1.2 Scan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.3.1.3 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.3.1.4 Ionizer Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.3.1.5 Start Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.3.1.5.1 Start Mode Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.3.1.5.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.3.1.5.3 Emission and Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.1.5.4 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3.1.6 Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3.1.6.1 Stop Mode Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3.1.6.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3.1.6.3 Maximum Step Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.3.1.6.4 Emission and Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.3.1.6.5 Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.3.1.7 Stabilization Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.3.1.8 Dwell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.3.1.9 Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.3.1.10 Baseline and Peak Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.3.1.10.1 Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.3.1.10.2 Peak Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.3.2 Acquisition Control: CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4.3.2.1 Acquisition Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.3.2.2 Scan Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.3.2.3 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.3.2.4 Ionizer Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.3.2.5 Start Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

IPN 074-528-P1A

4.3.2.5.1 Start Mode Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

TOC - 4

Page 11

FabGuard Explorer Operating Manual

4.3.2.5.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.3.2.5.3 Emission and Multiplier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

4.3.2.6 Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.3.2.6.1 Stop Mode Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.3.2.6.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.3.2.6.3 Maximum Step Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.3.2.6.4 Emission and Multiplier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

4.3.2.7 Stabilization Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3.2.8 Dwell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3.2.9 Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4.3.2.10 Baseline and Peak Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.3.2.10.1 Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.3.2.10.2 Peak Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.3.2.11 Inlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.3.2.11.1 Inlet Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.3.3 Acquisition Control: RFS100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.3.3.1 Acquisition Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.3.3.2 Start Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

4.3.3.2.1 Start Mode Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.3.3.2.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.3.3.3 Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.3.3.3.1 Stop Mode Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.3.3.3.2 Data Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.3.3.3.3 Maximum Step Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.3.3.4 Sampling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4.3.3.4.1 Sampling Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4.3.3.5 Acquisition Timing (Delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

IPN 074-528-P1A

4.3.3.6 Extra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

4.3.4 Acquisition Control: Stiletto Particle Detector . . . . . . . . . . . . . . . . . . . . . . . 4-26

4.3.4.1 Acquisition Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.3.4.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.3.4.3 Start Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.3.4.4 Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

4.3.4.5 Exposure Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

4.3.4.6 Discriminator - Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

4.3.5 Acquisition Control: Quantus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

4.3.5.1 Acquisition Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4.3.5.2 Start Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

TOC - 5

Page 12

FabGuard Explorer Operating Manual

4.3.5.2.1 Start Mode Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4.3.5.2.2 Light Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4.3.5.2.3 Plasma Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

4.3.5.3 Stop Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.3.5.3.1 Stop Mode Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.3.5.3.2 Light Threshold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.3.5.3.3 Maximum Step Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.3.5.3.4 Plasma Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.3.5.4 Exposure Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.3.5.5 Acquisition Timing (Delay) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

4.3.6 Creation of Multi-Step Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

4.3.7 Bin Create . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

4.3.7.1 RGA Bin Creation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4.3.7.1.1 Existing Bins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4.3.7.1.2 Adding Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

4.3.7.2 RFS100 Bin Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

4.3.7.3 Stiletto Bin Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

4.3.7.4 Quantus Bin Creation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

4.3.8 Number of Acquisitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

4.4 Acquisition Bin/Control Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

4.4.1 Acquisition Bin Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

4.4.2 Acquisition Control Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

4.5 Data Collection Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

4.5.1 Spectrum and Trend Graph Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

4.5.1.1 Point Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

4.5.1.2 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

4.5.1.3 Tag Scan Subtract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4.5.1.4 Export Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

4.5.1.5 Graph Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

4.5.1.5.1 Logarithmic vs. Linear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

4.5.1.5.2 Zooming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4.5.1.5.3 Rescaling the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4.5.1.5.4 Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

4.5.2 Bin Legend Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

4.5.2.1 Bin Specific Right-Click Options For Actively Plotted Bins. . . . . . . . . . . . . 4-58

4.5.2.1.1 Bin: Switch to Right Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

4.5.2.1.2 Bin: Change Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

IPN 074-528-P1A

4.5.2.1.3 Bin: Un-Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

TOC - 6

Page 13

FabGuard Explorer Operating Manual

4.5.2.1.4 Bin: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

4.5.2.2 Bin Specific Right-Click Options For Inactive Bins . . . . . . . . . . . . . . . . . . . 4-58

4.5.2.2.1 Bin: Select on Left Axis with Auto Assigned Color . . . . . . . . . . . . . . . . . . . 4-58

4.5.2.2.2 Bin: Select on Left Axis with Chosen Color . . . . . . . . . . . . . . . . . . . . . . . . 4-58

4.5.2.2.3 Bin: Select on Right Axis with Auto Assigned Color. . . . . . . . . . . . . . . . . . 4-59

4.5.2.2.4 Bin: Select on Right Axis with Chosen Color . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.5.2.3 Bin Legend Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.5.2.3.1 Show All Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-59

4.5.2.3.2 Show Selected Bins First and then Non-Selected Bins . . . . . . . . . . . . . . . 4-59

4.5.2.3.3 Show Only Selected Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.5.2.4 Bin Graphing Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.5.2.4.1 Auto Select Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.5.2.4.2 Clear All Bins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.5.2.5 Enlarge Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

4.5.2.6 Display Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

4.5.2.6.1 Which Bins to Show . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

4.5.2.6.2 How to Automatically Assign Color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-60

4.5.3 Data Collection Drop Down Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

4.6 Creating Recipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-61

4.6.1 Creating Recipes From Scratch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

4.6.2 Creating Recipes From a Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-62

4.6.3 Editing a Recipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

4.7 Configuration Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

4.7.1 Configuration Monitor Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-63

4.7.1.1 Transpector RGA: Open Ion Source

(High Performance, Compact, XPR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

4.7.1.2 Transpector RGA: CPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-65

4.7.1.3 RFS100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-69

IPN 074-528-P1A

4.7.1.4 Stiletto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-70

4.7.1.5 Quantus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

Chapter 5

Visualization

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Runs in Memory Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.1 Run Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.2.2 Add/Edit Comment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.3 Spectrum Graph Selection Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.2.4 Bin Create Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

TOC - 7

Page 14

FabGuard Explorer Operating Manual

5.2.5 Run Selection Drop Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.2.6 Tag Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3 Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.1 Background Scan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3.2 Reference Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3.3 User Scan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4 Chemistry Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.1 Select Library to Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.2 Bin Create . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.5 Multi-Run Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.5.1 Result Shown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.5.2 Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.5.3 X-Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.5.3.1 X-Axis Options for Entire Run as Acquired or Specific Step . . . . . . . . . . . 5-11

5.5.3.2 X-Axis Options for Entire Run, Step Aligned

and Step Aligned and Labeled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.5.4 Frame By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5.5 Color By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.5.6 Select Bins to Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.5.7 Separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.5.8 Displayed Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.5.8.1 Emphasize Selected Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.5.8.2 Add/Remove Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.5.8.3 View Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.5.8.4 Compare Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.5.9 Multi Run Viewer Right Click Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Chapter 6

Maintenance

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Leak Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.1 Leak Check Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2.2 Leak Check Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2.3 Alarm Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3 Vacuum Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.4 Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.4.1 Tune Graph Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.4.2 Scan Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.4.3 Tune Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.4.4 Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

IPN 074-528-P1A

TOC - 8

Page 15

FabGuard Explorer Operating Manual

6.4.5 Calibration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.4.5.1 Manual Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.4.5.1.1 Adjusting Peak Resolution (Width). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.4.5.1.2 Adjusting Peak Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.4.5.2 Automatic Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6.4.6 Cancelling Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6.5 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.5.1 Calibrate Total Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

6.5.1.1 Single Point Total Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.5.2 Calibrate Electron Multiplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

6.5.2.1 EM Calibration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.5.2.2 Calibration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-19

6.5.2.3 How To Calibrate the EM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.5.3 Calibrate Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

6.5.3.1 Partial Pressure Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

6.6 Degas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.7 Reset RF Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.8 Timed Bakeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Chapter 7

Alarms

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 The Active Alarms Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2.1 Alarm Display Preferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2.2 Current Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.2.2.1 Alarm States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.2.2.2 Alarm Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.2.2.3 Right-Click Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

IPN 074-528-P1A

7.2.3 Alarm Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.2.4 Removing Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.3 Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

7.3.1 System Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.3.2 Driver Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

7.4 Typical Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.4.1 System Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.4.2 Driver Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

TOC - 9

Page 16

Chapter 8

8.1 Viewing the Status Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.1 Obtaining Version Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2.2 General Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.2.3 Transpector Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.2.4 Communications Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

FabGuard Explorer Operating Manual

When Things Go Wrong

TOC - 10

IPN 074-528-P1A

Page 17

1.1 Introduction

CAUTION

FabGuard Explorer™ is a Microsoft® Windows®-based application that both

controls and collects data from the INFICON® Transpector® family of Residual

Gas Analysis (RGA), the INFICON RFS100 RF Sensor, the INFICON Stiletto®

Scanning-Laser Particle Detector (SPD) and the INFICON Quantus® Process Gas

Sensor instruments. FabGuard Explorer is compatible with Windows XP, Windows

Vista® and Windows 7.

FabGuard Explorer provides RGA control and data collection capabilities for

monitoring production processes and diagnosing tool malfunctions. The program

makes use of a simple, intuitive user interface which clearly displays the data and

facilitates the interpretation.

FabGuard Explorer utilizes simple one-button operation for functions such as data

acquisition, leak check and tuning/calibration. This button based operation, along

with more traditional menu tabs, cascading menus and right-click options, provide

a high level of user interaction. The simplified recipe creation will also allow more

novice users to make highly functioning multi-step recipes. Data is continuously

saved whenever an acquisition is started and is tagged with a run summary which

provides the user with a full log of operation parameters.

FabGuard Explorer Operating Manual

Chapter 1

Getting Started

Currently FabGuard Explorer supports open ion source Transpector 2 instruments

(both Compact and High Performance), Transpector XPR™ instruments, the

Transpector CPM™ (Compact Process Monitor), the Preclude™ RGA, the HPR

RGA, and the CIS2. Transpector 1 RGAs and XPR1 RGAs are not supported.

NOTE: FabGuard Explorer only works with Transpector 2 Firmware version 2.13

and greater. If the sensor has an older firmware than 2.13, contact a

IPN 074-528-P1A

customer support representative to purchase a firmware upgrade.

Since FabGuard Explorer is a constantly evolving

program, the screenshots featured within this manual

may not directly match the screens of the installed

FabGuard Explorer version.

1 - 1

Page 18

FabGuard Explorer Operating Manual

CAUTION

1.1.1 How to Contact Customer Support

Worldwide support information regarding:

Technical Support, to contact an applications engineer with questions

regarding INFICON products and applications, or

Sales and Customer Service, to contact the INFICON Sales office nearest you,

or

Repair Service, to contact the INFICON Service Center nearest you,

is available at www.inficon.com.

If you are experiencing a problem with your instrument, please have the following

information readily available:

the FabGuard Explorer version number (available from the Help >> About the

Program dialog box),

the type of computer that you are using and its specifications,

your MS Windows type and version number,

a description of your problem,

an explanation of any corrective action that you may have already attempted,

what you were doing when the problem occurred,

and the exact wording of any error messages that you may have received.

Please contact your Customer Support Representative

before sending any files.

To contact Customer Support, see Support at www.inficon.com.

IPN 074-528-P1A

1 - 2

Page 19

FabGuard Explorer Operating Manual

1.2 Operating Manual Style Conventions

File names, environment variables, program names, screen prompts, command

strings, and text that you must enter on your keyboard are presented in

font. For example, Enter d:\install.

Windows dialog options, title bars, and menu options are presented in this font.

For example: select Run >> Load Run *...

When you must hold down a key then press another key, this is expressed as (for

example) Press Ctrl+C

We assume that the CD/DVD-ROM you will be using is drive D. If you are using

another drive, substitute your CD/DVD-ROM drive letter whenever you see

We also assume that your hard drive is drive C. Again, if you are using a different

drive label, substitute your drive letter whenever you see "

Often you will be required to select an option from a cascading menu. Instead of

verbose statements such as, "position the mouse pointer over the word Run, press

the left mouse button to display the cascading menu, then drag the pointer to

highlight the words Load Run *... and release the left mouse button," you will read,

"select Run >> Load Run *...."

this

"d:".

c:".

You will also be required to use buttons and tabs. For example, instead of the

statement, "position the mouse pointer over the Live Data tab, then press and

release the left mouse button to select Live Data," you will read, "click the Live

Data tab," or you may read, "select the Live Data tab."

Similarly, left-click means to press and release the left mouse button, and right-click

means to press and release the right mouse button.

FabGuard Explorer operates in the Windows environment. We make the

assumption that you know how to use the Windows Graphical User Interface (GUI).

Therefore, actions in the FabGuard Explorer GUI that are common to the Windows

GUI are not explained in detail in this manual. If you do need help with the Windows

GUI, please refer to the Windows documentation supplied by Microsoft.

IPN 074-528-P1A

1 - 3

Page 20

FabGuard Explorer Operating Manual

CAUTION

WARNING

When using this manual, please pay attention to the Notes, Cautions, and

Warnings found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum FabGuard

Explorer efficiency when followed.

Failure to heed these messages could result in the loss

of data.

Failure to heed these messages could result in personal

injury.

1.2.1 Usage of the Modern Metric System

In many places throughout this manual, American measurement units are given

along with their International System of Units equivalences. However, providing

all measurement units in all discussions becomes cumbersome to the reader.

Therefore, equivalences are not given in all cases. You may perform the

conversion as follows:

When converting from psig to bar:

psig x 0.069 = bar

When converting from psig to kPa:

psig x 6.8947 = kPa

When converting from Torr to mbar:

Torr x 1.3332 = mbar

When converting from Torr to Pascals

Torr x 133.32 = Pascals

When converting from inches (in.) to millimeter (mm)

in. x 25.4 = mm

When converting from feet (ft.) to meters (m)

ft. x 0.3048 = m

When converting from pounds (lb.) to kilograms (kg):

lb x 0.453593 = kg

IPN 074-528-P1A

1 - 4

When converting Temperature from Farenheit (T

(5/9) x (T

- 32) = T

F

C

) to Celsius (TC)

F

Page 21

FabGuard Explorer Operating Manual

1.3 Inventory of Supplied Items

One CD-ROM which contains the FabGuard Explorer program, the Operating

Manual, and the FabGuard Explorer Quick Use Guide.

1.4 Computer System Requirements

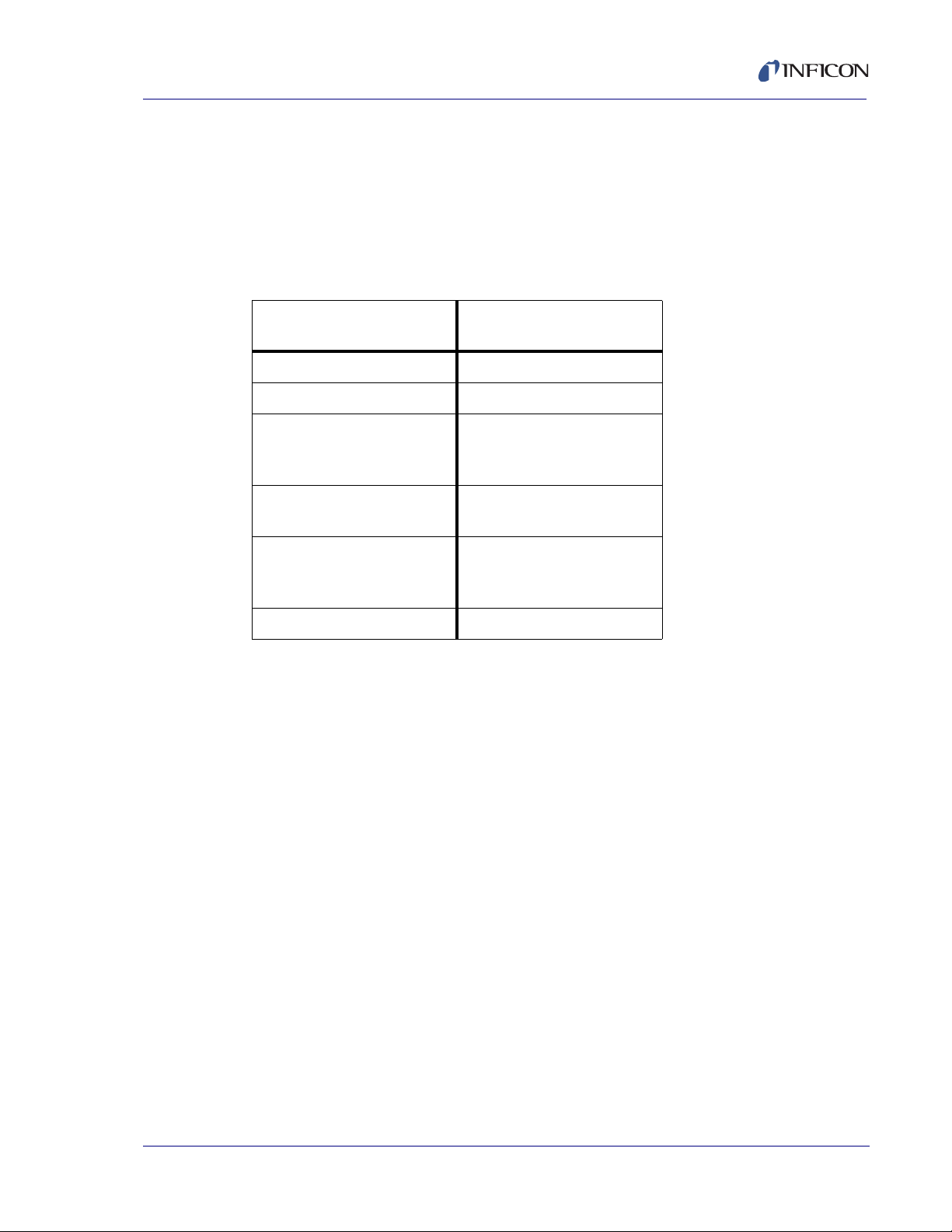

Table 1-1 Computer System Requirements

Parameters FabGuard Explorer

Requirements

Processor Pentium 4 2.0 GHz or greater

Ram 512 MB or greater

Hard Disk Space 500 MB for program,

additional space needed for

data collection

Resolution 800 x 600 16-Bit color or

greater

Serial Port One free serial port for

RS232 or TCA-485

connection

Operating System Windows XP or 7

IPN 074-528-P1A

1 - 5

Page 22

FabGuard Explorer Operating Manual

1.5 Supported Sensors

1.5.1 Transpector Models Supported

FabGuard Explorer supports Transpector 2 High Performance and Compact

sensors.

FabGuard Explorer does NOT support Transpector 1 sensors.

FabGuard Explorer also supports XPR2, XPR3, CPM, CIS2 and Preclude sensors.

1.5.1.1 Firmware

FabGuard Explorer supports Transpector 2 firmware Version 2.13 or Higher.

1.5.2 Other Supported Sensors

FabGuard Explorer also supports RFS100 sensors, Quantus sensors and Stiletto

Particle Detectors.

1.6 Communication Interface

1.6.1 RGA Communications

For RGAs, the communication interfaces supported by FabGuard Explorer are

RS-232 for a single Transpector and RS-485 via a TCA-485 (Transpector Control

Adaptor) for multiple Transpectors.

The TCA-485 (see Table 1-2) is required for RS-485 communication. One end of

the TCA-485 connects to the serial port of the computer and the other end connects

to the RS-485 bus cable. An external power supply is also required and supplied

for the TCA-485. See the instructions that come with the TCA-485 for details.

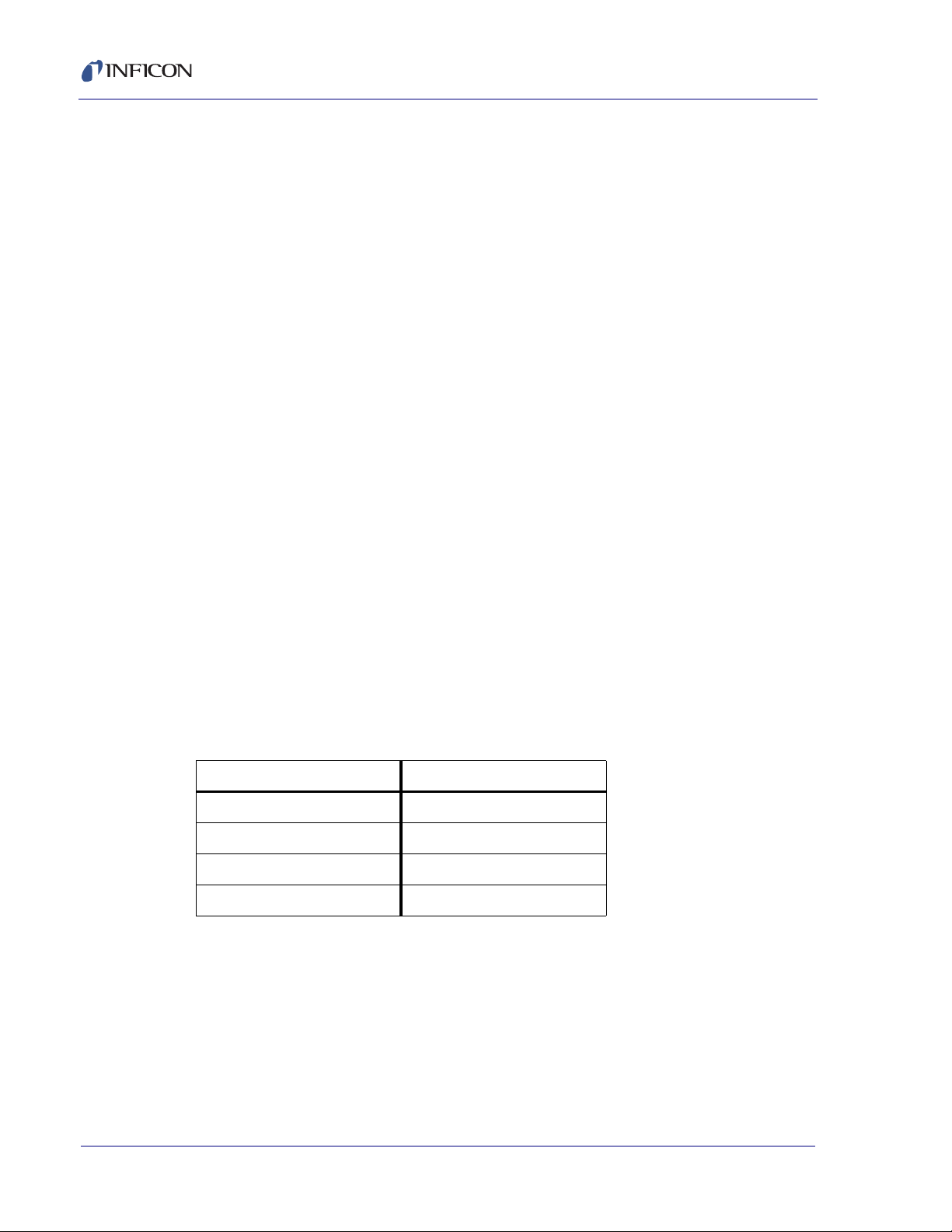

Table 1-2 Part numbers for Various Versions of TCA-485

Description INFICON Part Number

TCA-485 US Version 916-600-G2

TCA-485 German Version 916-600-G3

TCA-485 Japanese Version 916-600-G4

TCA-485 UK Version 916-600-G5

IPN 074-528-P1A

1 - 6

Page 23

1.6.1.1 Communications Baud Rate

RS-232 — selectable: 9600, 4800, 2400

RS-485 — not selectable: 57.6K (57,600)

1.6.1.2 Communications Cable

Communications cables are required to connect FabGuard Explorer to the

Transpector. Cables are different and dependant on the Communications

Interface.

If a single Transpector system was purchased, normally RS-232

Communications are used which requires a single communications cable.

Refer to the Transpector Operating Manual (IPN 074-276) section titled

"RS-232 Communications" for detailed information concerning RS-232 cabling.

If multiple Transpector sensors were purchased, RS-485 Communications

must be used, which requires two cables per Transpector. Refer to the

Transpector Operating Manual (IPN 074-276) section titled "RS-485

Communications" for detailed information regarding RS-485 cabling

FabGuard Explorer Operating Manual

Maximum Length

RS-232 — 50 feet (15 meters)

RS-485 — 1000 feet (305 meters)

1.6.1.3 USB to RS232 Standard Adapter Cable

For FabGuard Explorer computer installations requiring a USB connection rather

than a serial port connection, INFICON offers a USB to RS-232 Standard Adapter

Cable. The USB Serial Adapter, INFICON IPN 911-451-P1, provides an external

DB9 serial interface to systems that support USB. This adapter cable works with

both the Single Sensor version of FabGuard Explorer (with RS-232 cable) and the

Multiple Sensor version of FabGuard Explorer (with RS-485 cable plus TCA485

adapter). Refer to the instructions included with this cable for specific installation

directions.

IPN 074-528-P1A

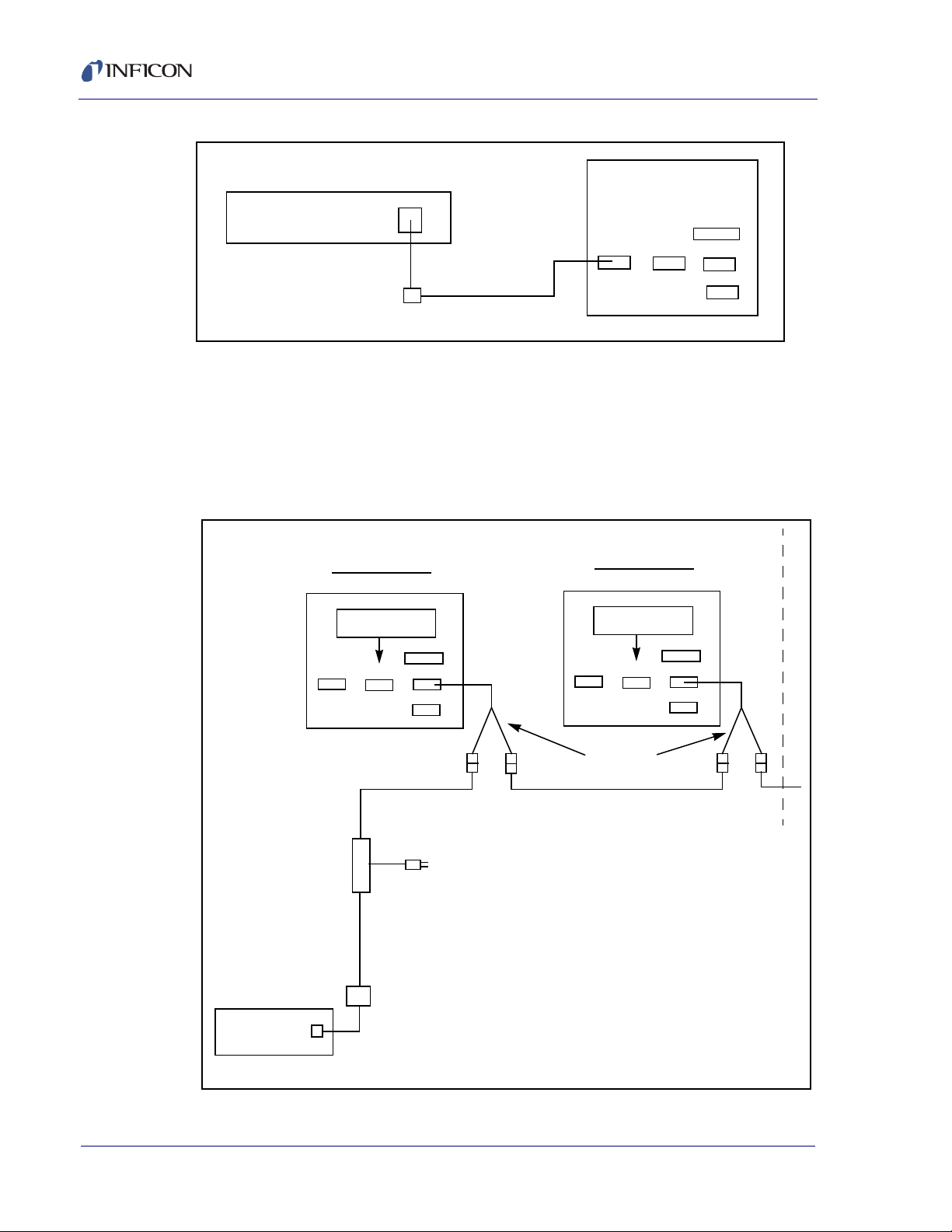

1.6.1.3.1 Single Sensor Version (RS232)

Attach the male DB9 connector on the USB to RS-232 Standard Adapter Cable to

the female DB9 connector on the Transpector RS-232 cable (IPN 600-1001-Px).

Connect the USB connector on the USB to RS-232 Standard Adapter Cable to the

computer. See Figure 1-1 on page 1-8 for the rest of the RS-232 cabling.

1 - 7

Page 24

FabGuard Explorer Operating Manual

Host Computer

911-451-P1

USB/RS-232 Adapter

RS232

Aux I/O

CNFG

RS485

Power

600-1001-P#

RS-232 Interface Cable

Transpector #1

Transpector #2

Address 1

SW 8 - Off

RS232

CNFG

Aux I/O

RS485

Power

Address 1

SW 8 - Off

RS232

CNFG

Aux I/O

RS485

Power

(Male)

(Female)

(Male)

(Female)

RS-485 "Y" Cable

911-040-G#

RS-485 Interface Cable Kit

911-040-G#

RS-485 Interface Cable Kit

AC Input

90 - 260 V(ac)

600-1118-P1

TCA Cable

911-451-P1

USB/232 Adapter

USB

Port

Host Computer

TCA

Adapter

Figure 1-1 RS-232 Connection

1.6.1.3.2 Multiple Sensor Version (RS485 Plus TCA485 Adapter)

Attach the male DB9 connector on the USB to RS-232 Standard Adapter Cable to

the female DB9 connector on the Transpector TCA485 Cable (IPN 600-1118-P1).

Connect the USB connector on the USB to RS-232 Standard Adapter Cable to the

computer. See Figure 1-2 for the rest of the RS-485 cabling.

Figure 1-2 RS-485 Installation

1 - 8

IPN 074-528-P1A

Page 25

1.6.2 RFS100 Communications

The INFICON RFS100 sensor uses RS-232 Communications with a Baud Rate of

19.2K (19,200).

For more information about RFS100 Communications, please see the RFS100

Operating Manual (IPN 074-423).

1.6.3 Quantus Communications

The INFICON Quantus sensor uses an Ethernet (TCP/IP Modbus) connection for

communication to FabGuard Explorer.

For more information about Quantus Communications, please see the Quantus

Operating Manual (IPN 074-510).

1.6.4 Stiletto Communications

The INFICON Stiletto particle detector (SPD) uses an Ethernet (TCP/IP Modbus)

connection for communication to FabGuard Explorer

FabGuard Explorer Operating Manual

For more information about Stiletto Communications, please see the Stiletto

Operating Manual (IPN 074-374).

1.7 How To Install FabGuard Explorer

Install FabGuard Explorer from within Windows as follows:

NOTE: This description assumes the CD/DVD ROM drive is drive "d". If it is not

"d", substitute the appropriate drive letter.

1 Insert the CD in the CD/DVD ROM Drive

2 Select Start >> Run... to display the Run dialog.

3 In the Open field, type d:\FabGuard_EX_Single_Installer.exe

for the Single Sensor version of FabGuard Explorer or type

IPN 074-528-P1A

d:\FabGuard_EX_Multi_Installer.exe for the Multi-Sensor

version of FabGuard Explorer.

4 Select OK.

1 - 9

Page 26

FabGuard Explorer Operating Manual

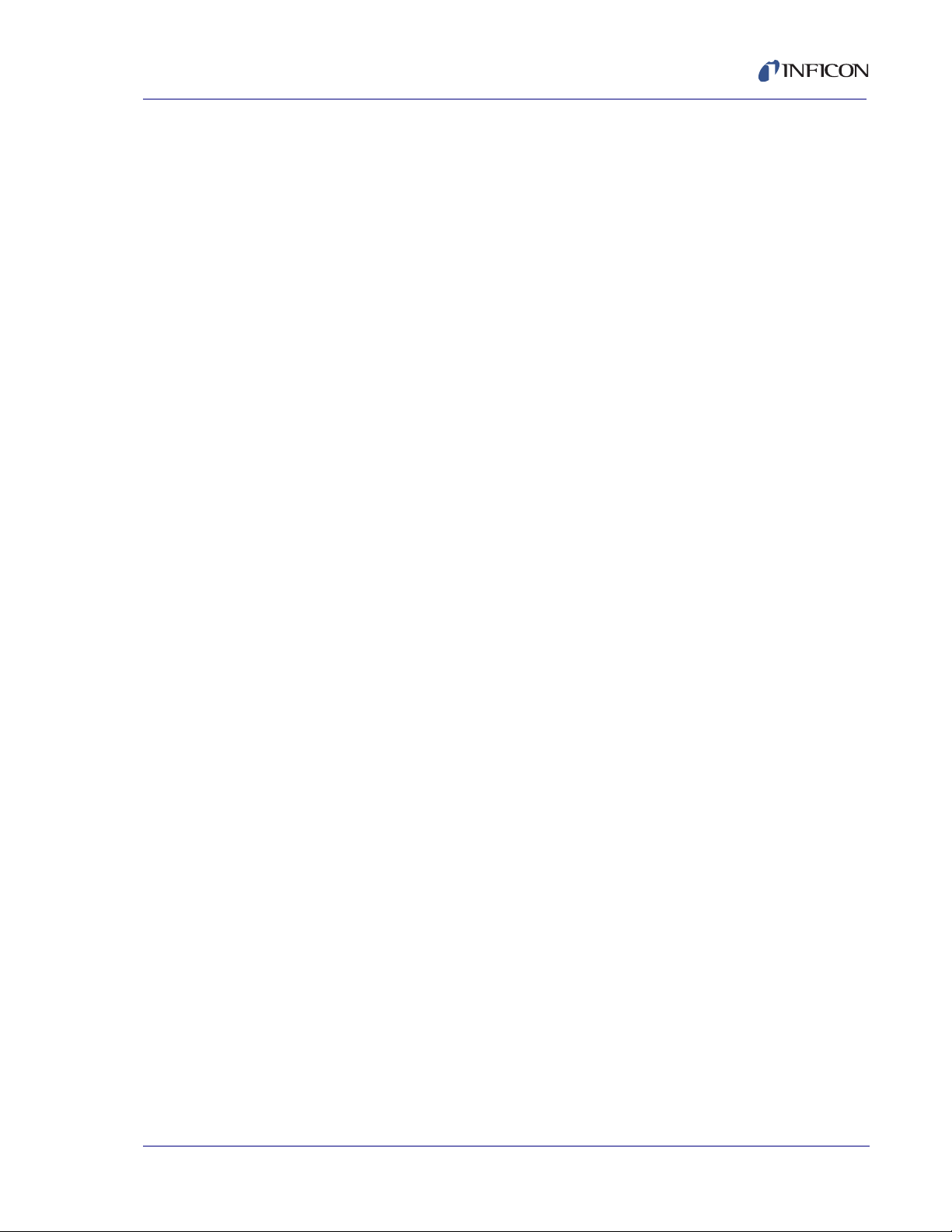

5 At the following prompt, click Next > to continue (see Figure 1-3 on page 1-10).

Figure 1-3 Initial Installation

6 Read the License Agreement and choose Yes to continue (see Figure 1-4).

Figure 1-4 License Agreement

1 - 10

IPN 074-528-P1A

Page 27

FabGuard Explorer Operating Manual

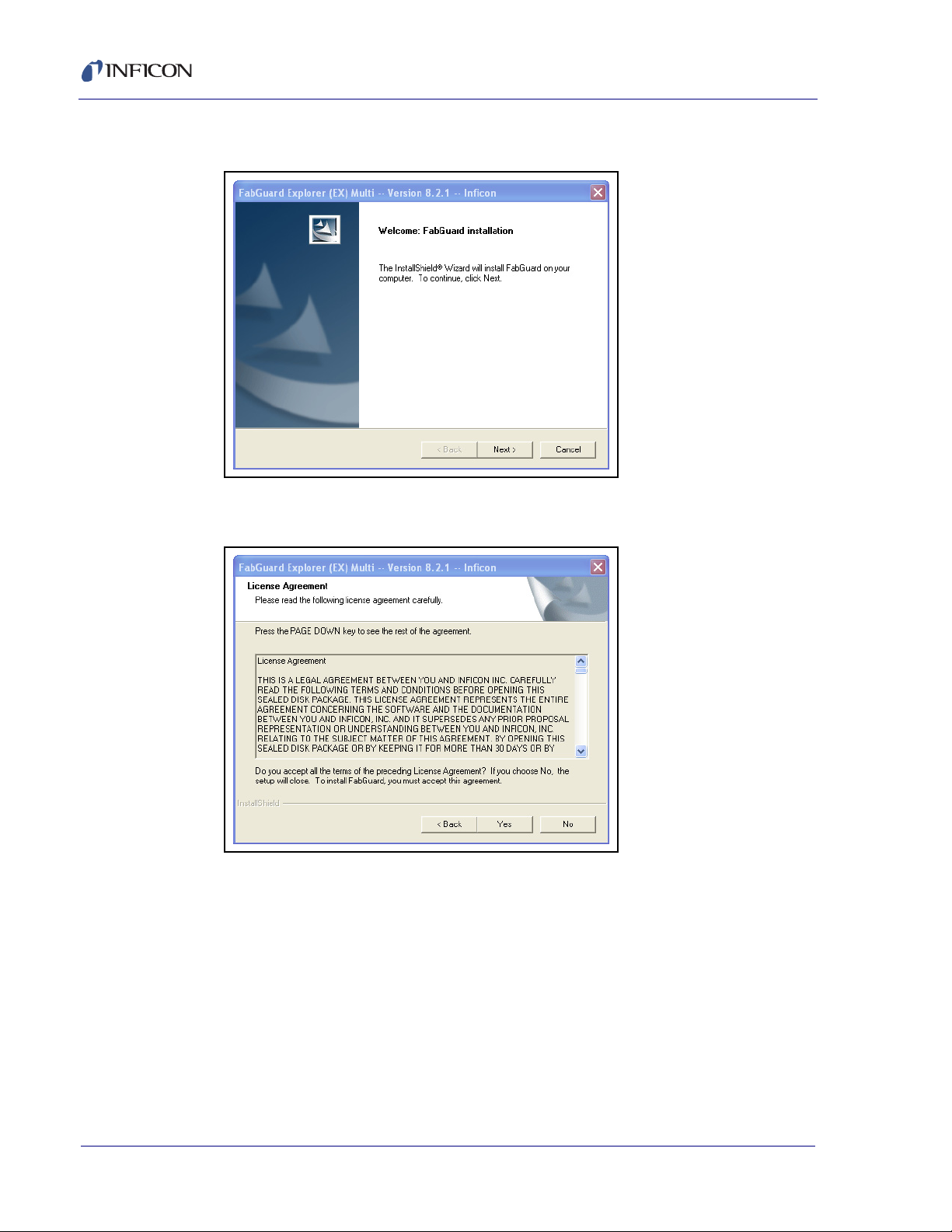

7 Choose what sensor drivers to install. Then click Next > to continue (see Figure

1-5 on page 1-11).

NOTE: ONLY install drivers for sensors that are currently installed on the

system. The additional sensor drivers are available for install through

the FabGuard installation CD at any time if a new sensor type is

installed.

Figure 1-5 Sensor Type Selection

8 Enter a user name and company. Then click Next > to continue (see Figure

1-6).

Figure 1-6 User Name and Company

IPN 074-528-P1A

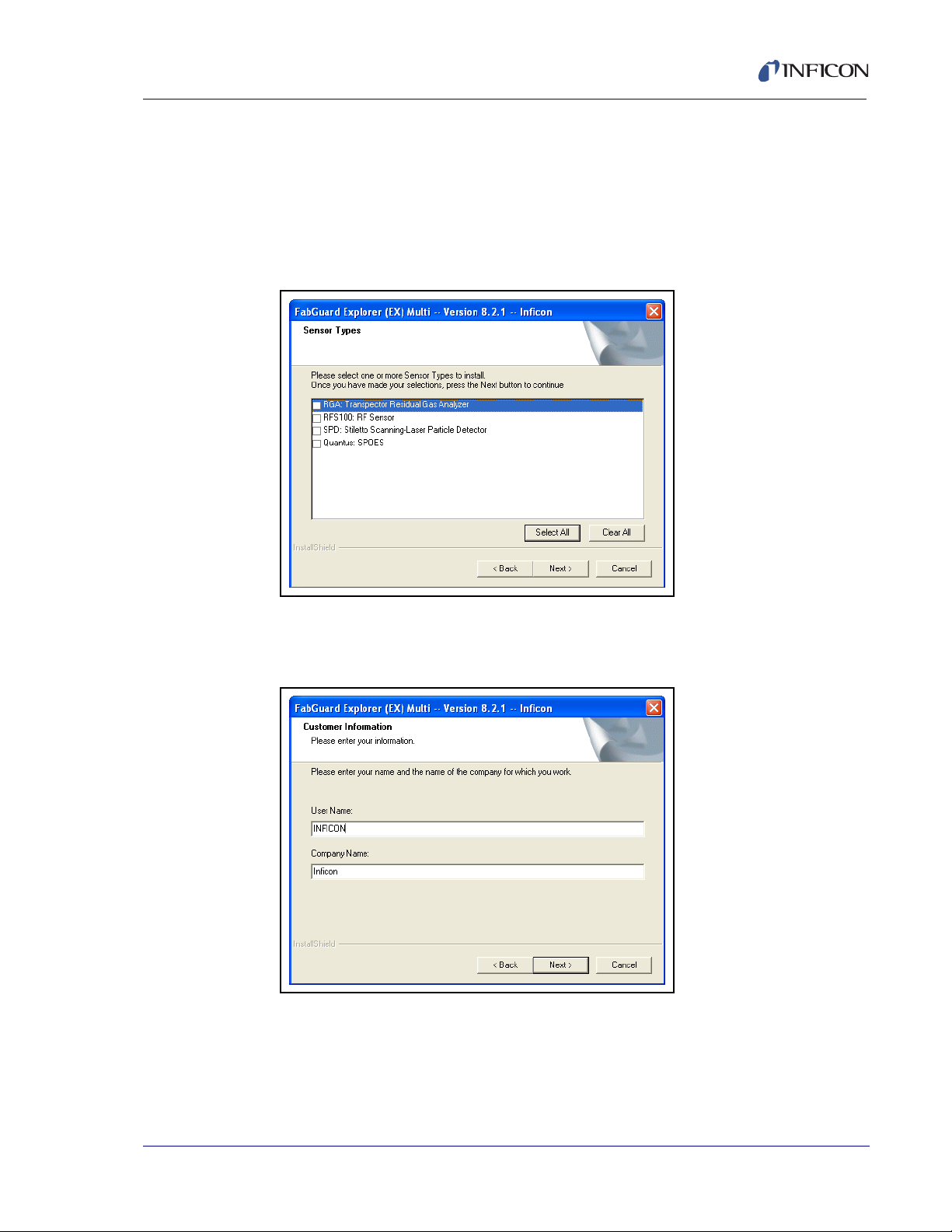

9 Select Start >> Run... to display the Run dialog.

10 In the Open field, type d:\FabGuardHelp_Installer.exe

At the following prompt, click Next > to continue (see Figure 1-7)

11

1 - 11

Page 28

FabGuard Explorer Operating Manual

Figure 1-7 FabGuard Help Installation

12 Read the License Agreement and select Yes to continue (see Figure 1-8).

Figure 1-8 Help License Agreement

1 - 12

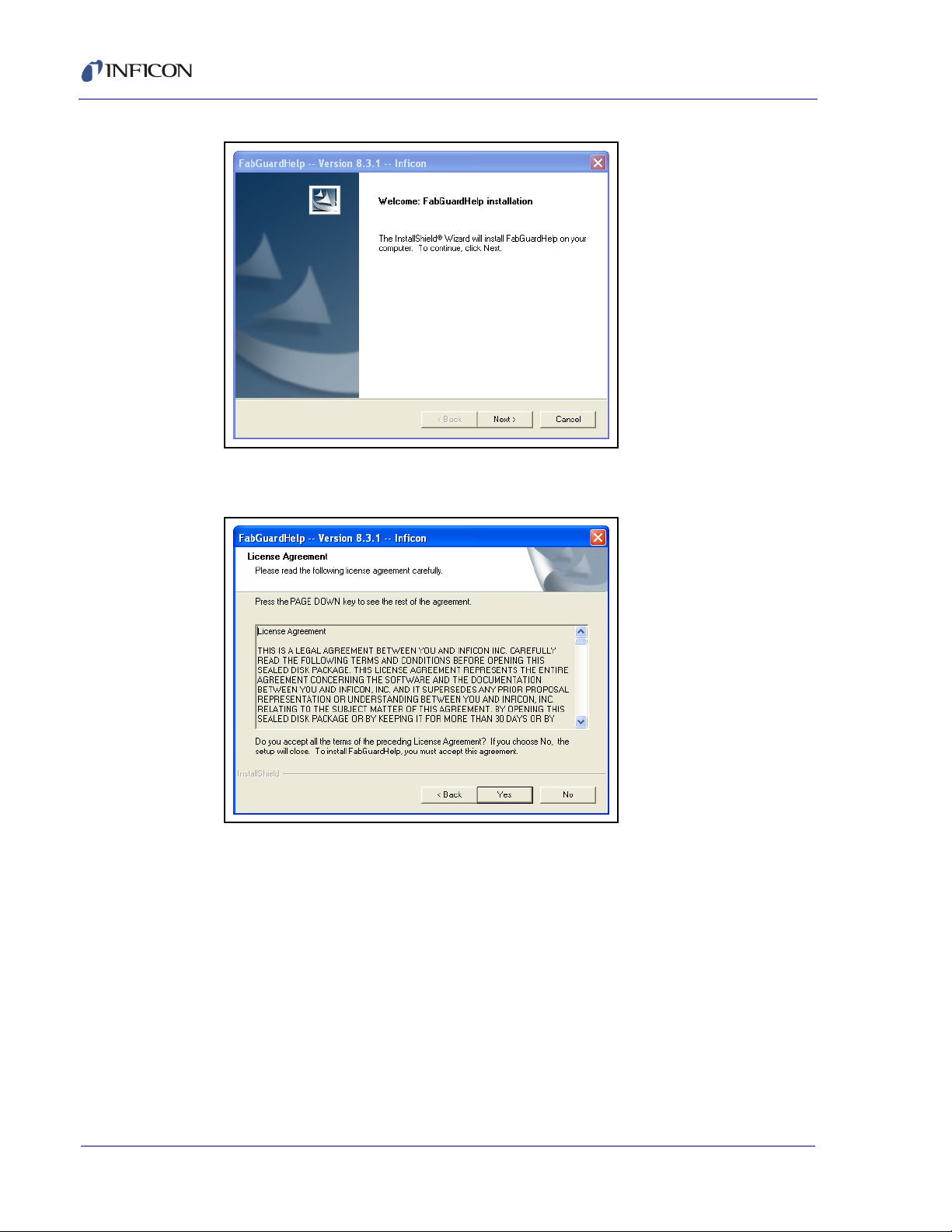

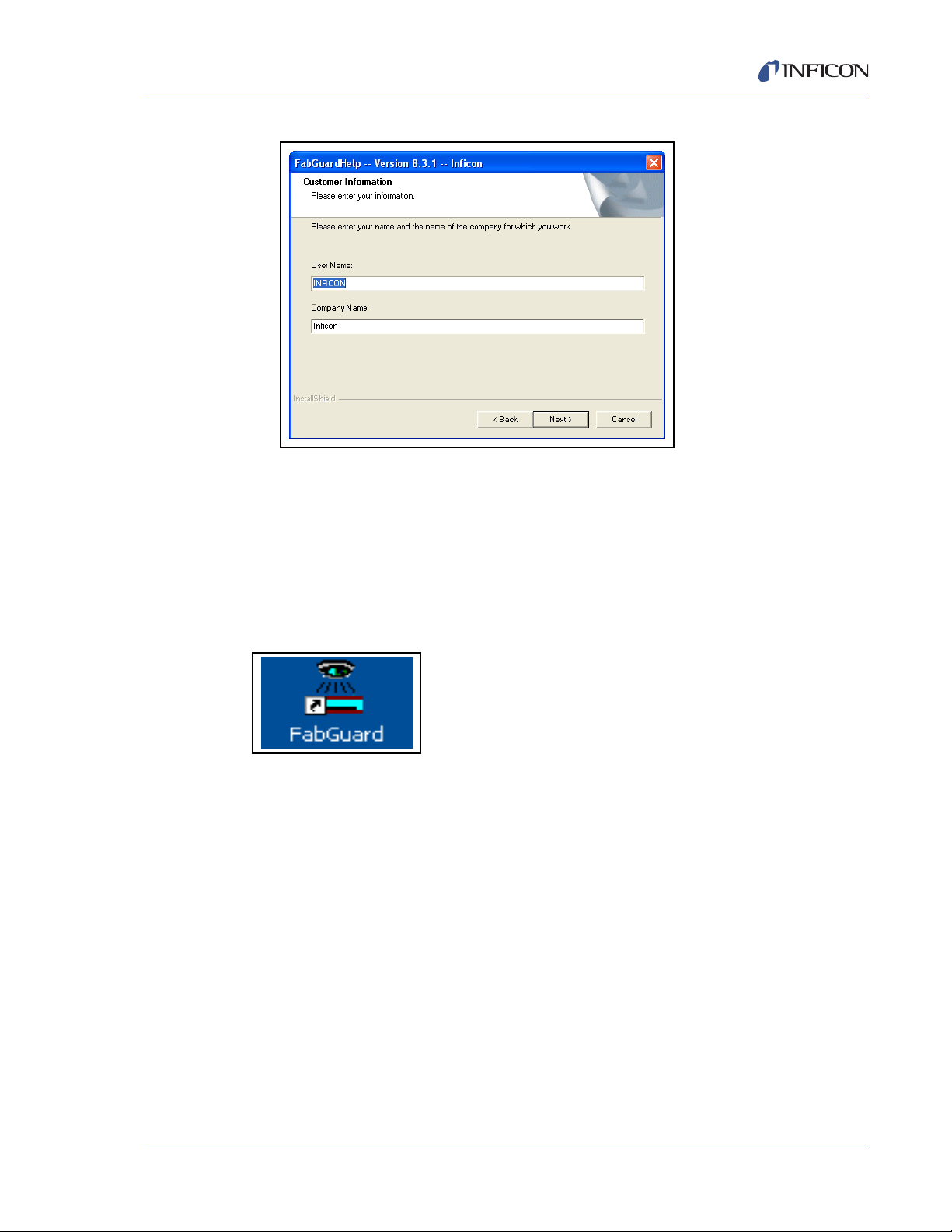

13 Enter a user name and company then click Next > to continue (see Figure 1-9

on page 1-13)

IPN 074-528-P1A

Page 29

FabGuard Explorer Operating Manual

Figure 1-9 Customer Information

14 When installation is complete, put the original CD in a safe storage area.

1.8 How To Start FabGuard Explorer

There are several different ways to start FabGuard Explorer. The easiest way is to

double-click on the icon that FabGuard Explorer installed on the desktop (see

Figure 1-10).

Figure 1-10 FabGuard Icon

The first time FabGuard Explorer is run on a computer, it will start at the main

screen with a prompt to setup connection to the installed sensors. See Chapter 3

for information on how to configure the communications interface, individual

IPN 074-528-P1A

sensors, and user preferences on the system.

1 - 13

Page 30

FabGuard Explorer Operating Manual

1.9 Where to Go From Here

This Operating Manual is intended to make the process of setting up, installing and

using FabGuard Explorer a pleasurable and trouble-free experience. Please, take

a few moments to look through it and become familiar with its contents.

The information in this manual is organized into the following chapters:

Chapter 1, Getting Started

An introduction to the FabGuard Explorer application, provides instructions on

how to install and run FabGuard Explorer and explains how to use this

Operating Manual.

Chapter 2, How the Software Works

A discussion of the underlying principles of FabGuard Explorer’s operation and

some general descriptions of the FabGuard Explorer user Interface.

Chapter 3, Setup and Configuration

A description of how to set up the software for installation and customize it to

the user’s preferences.

Chapter 4, Data Acquisition

Discusses the methods of data acquisition inside of FabGuard Explorer.

Chapter 5, Visualization

Discusses the visualization functions inside of FabGuard Explorer.

Chapter 6, Maintenance

Explains the maintenance functions inside of FabGuard Explorer. This chapter

helps keep the operating sensors in peak condition.

Chapter 7, Alarms

Introduces and explains the alarm functionality present in FabGuard Explorer.

Chapter 8, When Things Go Wrong

Includes discussions about errors in FabGuard Explorer.

IPN 074-528-P1A

1 - 14

Page 31

2.1 Overview

FabGuard Explorer is a standard 32-bit Windows application using many of the

standard user interface features with which users should be familiar from other

Windows applications. The use of cascading menus, tool bars, and context

sensitive menus common to many Windows applications makes FabGuard

Explorer easy to learn and easy to use. This chapter gives the user an introduction

to the basic layout of the FabGuard Explorer program and explains how it works.

The individual functions are described in greater detail in subsequent chapters.

2.2 Navigating FabGuard Explorer

The FabGuard Explorer screen consists of several components which are unique

to each mode, but there are some underlying features that are always present.

These features include Colors, Tabs, Menus and Buttons. Colors are always used

for informational purpose regarding the status of an instrument or function while

Tabs, Menus, and Buttons are used for navigation and functionality (see Figure 2-1

on page 2-2).

FabGuard Explorer Operating Manual

Chapter 2

How the Software Works

There are numerous ways to access the functionality of FabGuard Explorer. The

user interface was designed to put the most frequently used functions in easily

accessible places on the screen and to put less frequently used functions in less

obtrusive places. To accomplish this, most of the functionality can be accessed via

the cascading menus. The most frequently used commands are duplicated in

button form or can often be reached via right-clicking throughout the program.

IPN 074-528-P1A

2 - 1

Page 32

FabGuard Explorer Operating Manual

Buttons

Colors

Tabs

Figure 2-1 Screen Layout

2 - 2

IPN 074-528-P1A

Page 33

2.2.1 Colors

FabGuard Explorer Operating Manual

There are colors present throughout FabGuard Explorer (see Table 2-1). These

colors represent status and alarms primarily. On several screens, different colors

represent the status of the instrument or parts of the instrument (emission, electron

multiplier, etc.). On other screens represent the severity of alarms present on an

instrument. More information on alarms is present in Chapter 7.

Table 2-1 System Status Colors

Color Status

Green On or Online

Red Error, Alarm or Went Offline (from Online)

Dark Grey Off

Light Grey Not Available

Yellow Waiting, Maintenance Required, or Moderate Warning

Dark Blue Offline or Informational Alarm

2.2.2 Tabs

FabGuard Explorer utilizes modern tabular interfaces to navigate through the

software. Each screen of the software is represented by a tab which can be

accessed from any other screen, as shown in Figure 2-2.

Figure 2-2 Tabs in FabGuard Explorer

Tabs are also found inside of many of the menus in FabGuard Explorer (see Figure

2-3). These tabs help link together appropriate features without cluttering the

screen.

IPN 074-528-P1A

Figure 2-3 Tabs Inside of the Configure Function

2 - 3

Page 34

FabGuard Explorer Operating Manual

2.2.3 Menus

FabGuard Explorer utilizes the look of the traditional Windows GUI, but provides

specific menus for FabGuard Explorer. The different menus are User, Screens,

Run, Recipe, Acquisition, Configure, and Help. These cascading menus are

quick ways to reach a multitude of different functions and screens. See Figure 2-4.

Figure 2-4 FabGuard Explorer Menu Bar

2.2.3.1 User Menu

The User menu, shown in Figure 2-5, allows the user to log in for advanced access.

Figure 2-5 User Menu

2.2.3.2 Screens Menu

The Screens menu, see Figure 2-6, is a dropdown that acts as an alternative to

the Tab functions of the GUI, giving links to all five main screens.

Figure 2-6 Screens Menu

IPN 074-528-P1A

2 - 4

Page 35

2.2.3.3 Run Menu

The Run menu, see Figure 2-7, includes links to:

Figure 2-7 Run Menu

FabGuard Explorer Operating Manual

Load Run*... which allows the user to load any previously acquired Run.

IPN 074-528-P1A

Load last Run Acquired by the Sensor loads the last acquired data by the

sensor.

Shortcuts to the last five loaded Runs.

Save Run and Save Run As... both save the current Run if any changes have

been made.

Import and Export for importing/exporting data in different formats.

Clear Run, removes the current run from memory (doesn’t delete it from disk).

Clear Run and Delete it from Disk removes the current in memory run and

deletes it from the disk.

2 - 5

Page 36

FabGuard Explorer Operating Manual

Clear All Runs in Memory removes all of the runs currently loaded in the

program (doesn’t delete them from the disk).

Bin Create *... creates Bins from a loaded Run.

View Run ... opens the current run in a separate viewing window.

Run Info *... links to the Run Summary which is discussed in Chapter 4.

Print Run Info prints the Run Summary.

Run Comment *... allows the user to write a comment about the Run.

Run’s Sensor Parameters ... pulls up the sensor parameters for the Run.

Tag Scan allows the user to Tag a scan as background, normal or User for

subtraction. This is discussed in more detail in Chapter 5.

Scan Create From Bins allows the user to create a scan based on the Bins

that were collected.

Multi Run Viewer *... switches to the Multi Run Viewer which allows for

multiple scans to be compared on the same axes.

Create Recipe from Run ... allows for one click recipe creation based on the

loaded Run.

Chemistry Library enables the user to compare their Run to a Chemistry

Library. This is discussed in more detail in Chapter 5.

2.2.3.4 Recipe Menu

The Recipe menu, see Figure 2-8, has links to:

Figure 2-8 Recipe Menu

Create from Scratch ... which creates a recipe without any preset values.

Create from Run ... which generates a recipe from a successful data

collection.

Edit ... which allows the user to edit a previously created recipe.

IPN 074-528-P1A

2 - 6

Recent File which is normally populated with links to the most recently used

recipes.

Page 37

2.2.3.5 Acquisition Menu

The Acquisition menu, see Figure 2-9, has links to:

Figure 2-9 Acquisition Menu

Sensor: Configuration Monitor Start * opens the Configuration Monitor

mode for the selected sensor.

Sensor: Configuration Monitor Stop * stops the Configuration Monitor for

the selected sensor.

FabGuard Explorer Operating Manual

Sensor: Maintenance Acquisition Start allows the user to select one of five

different Maintenance Acquisition Templates which can be setup for one

click access. Hovering the cursor over this option produces the menu seen in

Figure 2-10.

Figure 2-10 Maintenance Acquisition Start Options

IPN 074-528-P1A

Sensor: Maintenance Acquisition Stop * stops any running Maintenance

Acquisitions.

Sensor: Manual Acquisition Start allows the user to start collecting data

using several different acquisition techniques. Hovering the cursor on this

option produces the menu seen in Figure 2-11. For more information on the

different acquisition methods, see Chapter 4, Data Acquisition.

Figure 2-11 Manual Acquisition Start Options

2 - 7

Page 38

FabGuard Explorer Operating Manual

Sensor: Manual Acquisition Stop * stops the manual acquisition that is

currently running.

Sensor: Acquisition Bin Defaults ... allows the user to set the default signal

bins that FabGuard Explorer uses for a Quick Manual Acquisition scan.

Sensor: Acquisition Control Defaults ... allows the user to set the default

acquisition controls that FabGuard Explorer uses for a Quick Manual

Acquisition scan.

2.2.3.6 Maintenance Menu

The Maintenance menu, see Figure 2-12, includes links to:

Figure 2-12 Maintenance Menu

2 - 8

Maintenance * which opens the Maintenance GUI.

Leak Check * which starts Leak Check mode using the selected sensor.

Leak Check (inlet open) * which starts Leak Check mode with an inlet open

(only for CPM units).

Vacuum Diagnostics * which starts Vacuum Diagnostics mode for the

selected sensor.

Maintenance (#) Start which allows the user to start one of five different

Maintenance Run Templates.

Maintenance Stop * stops the currently running Maintenance Run Template.

Configure Maintenance Run Templates ... which allows the user to configure

the Maintenance Run Templates.

More detail on all of these functions is featured in Chapter 6.

IPN 074-528-P1A

Page 39

2.2.3.7 Configure Menu

The Configure menu, see Figure 2-13, includes links to:

Figure 2-13 Configure Menu

Main Screen (Tool) ... which allows the user to configure the Main screen.

FabGuard Explorer Operating Manual

Sensor ... which allows the user to configure the selected sensor.

Sensor Bring On Line (Reset) brings an off line sensor on line.

Sensor Bring Off Line brings an on line sensor off line.

Reset All Sensors resets the connections for all installed sensors.

I/O Connections (Sensors) ... opens the I/O Connections menu.

Alarms ... opens the Alarms configuration menu.

Preferences ... opens the User Preferences menu.

Demo is only available to users with advanced access and allows Ghost

Sensors to be added.

IPN 074-528-P1A

2 - 9

Page 40

FabGuard Explorer Operating Manual

2.2.3.8 Help Menu

The Help menu, see Figure 2-14, has links to:

Figure 2-14 Help Menu

About the Program ... opens an About the Program splash screen with

FabGuard Help *... opens the electronic copy of the FabGuard Explorer

Current Status Log ... displays the current status of FabGuard Explorer in a

version information.

manual.

new internet browser window.

2 - 10

IPN 074-528-P1A

Page 41

2.2.3.9 Context Sensitive Menus

Context sensitive menus, see Figure 2-15, are pop-up menus which contain

commands most likely to be used in a specific situation. They are primarily

associated with right-click functionality. If the right mouse button is clicked, a menu

will appear near the cursor. The contents of this menu depend on what is being

displayed and where on the screen the cursor is positioned. This right-click menu

will often provide quick access to a desired function, so some experimentation is

required.

Figure 2-15 Sensor Right-Click Menu

FabGuard Explorer Operating Manual

IPN 074-528-P1A

2 - 11

Page 42

FabGuard Explorer Operating Manual

2.2.4 Buttons

Buttons represent the last feature of screen layout seen on every screen. These

buttons either have one-click functionality, wherein the user left-clicks on the button

and the function begins, see Figure 2-16, or the buttons will sometimes open a new

cascading menu where another selection must be made, see Figure 2-17.

Figure 2-16 Button Examples

Figure 2-17 Button Cascading Menu Example

IPN 074-528-P1A

2 - 12

Page 43

2.3 FabGuard Explorer Screens

Alarm Display Preferences

Current Alarms

Alarm Details

The FabGuard Explorer GUI utilizes different screens for much of the software’s

different functionality. It is very easy to navigate from screen to screen using the

tabs described in the previous section. This section will act as an introduction to the

various screens and begin the discussion of their respective functions. For further

discussion, see the various chapters that are referenced within.

2.3.1 Alarm

The Alarm screen, see Figure 2-18, shows any Informational, Moderate

Warning and Critical alarms present in the installed sensors. From the Alarm

screen, alarms can be viewed, cleared and deleted. For a more in depth discussion

of alarms, see Chapter 7.

Figure 2-18 The Alarm Screen

FabGuard Explorer Operating Manual

IPN 074-528-P1A

2 - 13

Page 44

FabGuard Explorer Operating Manual

2.3.2 Main

The Main screen, see Figure 2-19, is the first screen that is shown whenever

FabGuard Explorer is started. The Main screen includes such features as: a

customizable tool diagram; status colored representations of the installed sensors;

a synopsis of alarms and number of runs in memory; sensor information such as

name, type and serial number; the status of the emission and electron multiplier for

each installed RGA; and buttons for data acquisition and sensor maintenance. For

a more in depth discussion of the functionality, see Chapter 3 and Chapter 4.

The Main screen is important because this is where the active sensor is chosen.

In situations where there are more than one sensor installed on a system, only one

sensor can be the active sensor at any given time. The active sensor is the one

represented by the status shown on the right side of the Main screen and the

entirety of the Sensor screen. To make a sensor active, left-click once on the

sensor. The graphical representation of the sensor will change to now include a

white background around the icon. If a sensor is not made active on this screen,

clicking on the Sensor screen automatically chooses a random sensor.

Figure 2-19 The Main Screen

2 - 14

IPN 074-528-P1A

Page 45

2.3.3 Sensor

The Sensor screen, see Figure 2-20, is reliant on the type of installed sensor. In

the case where multiple sensors are installed on one system, the Sensor screen

will control the active sensor. This screen includes the ability to configure the

installed sensor via the Configure button near the bottom of the screen and the

Change button on the right side of the screen. The Configuration Monitor

function then will run a scan with the sensor using the current configuration

parameters. This allows the user to see what effect the changes in configuration

will make on the acquired data. The Sensor screen also includes access to the

Maintenance menu and the capability to Tag a Scan. For a more in depth

discussion of these functions, see Chapter 3, Setup and Configuration; Chapter 4,

Data Acquisition; Chapter 5, Visualization and Chapter 6, Maintenance.

Figure 2-20 Sensor Screen

FabGuard Explorer Operating Manual

IPN 074-528-P1A

2 - 15

Page 46

FabGuard Explorer Operating Manual

2.3.4 Live Data

The Live Data screen shows up to four live data acquisition trend graphs

concurrently. If more than four sensors are installed on the system, the drop down

menus at the top of each subscreen allow for choosing sensors other than the one