Inficon Ecotec E3000 530-001, Ecotec E3000 530-002, Ecotec E3000 530-103, Ecotec E3000 530-106, Ecotec E3000 530-104 Technical Handbook

...Page 1

TECHNICAL HANDBOOK

kina22e1-p (1206) Translation of the original instruction

Catalog No.

530-001

530-002

530-103

530-104

530-105

530-106

from software version V 2.4

Ecotec E3000

Multi-Gas Leak Detector

Page 2

0-2

kina22eIVZ.fm Technical Handbook(1206)

Page 3

Content

1 General Information 1-1

1.1 Introduction 1-1

1.1.1 Intended Use 1-1

1.2 Support by INFICON 1-2

1.2.1 Service Centers 1-5

1.3 Unpacking 1-7

1.3.1 Supplied Equipment 1-7

1.3.2 Technical Data 1-8

1.3.3 Accessories 1-9

1.4 Notes on How to Use This Handbook 1-11

1.4.1 Numbering of Figures 1-11

1.4.2 Symbols of Vacuum Technology 1-11

1.4.3 Definition of Terms 1-11

1.5 Instrument Views of the Ecotec E3000 1-13

1.6 Installation 1-13

1.6.1 Set up 1-13

1.6.2 Mechanical Connections 1-15

1.6.3 Electrical Connections 1-18

1.6.4 RS232 Interface 1-19

1.6.5 I/O Port 1-19

2 How the Instrument Works 2-1

2.1 Description of the Functions 2-1

2.2 Description of the Subassemblies 2-2

2.2.1 Backing Pump 2-2

2.2.2 Turbo Molecular Pump (TMP) 2-2

2.2.3 Mass Spectrometer 2-2

2.2.4 Quadrupole Supply 2-2

2.2.5 Control 2-2

2.3 Displays and User Interfaces 2-3

2.3.1 Main unit display 2-3

2.3.2 Sniffer line with probe display 2-4

2.3.3 Built-in ECO-Check reference leak 2-6

3 Operation of the Ecotec E3000 3-1

3.1 Start-Up 3-1

3.2 Controls on the main display unit 3-2

3.3 Controls on the probe display unit 3-5

3.4 Performing measurements 3-6

3.4.1 Standard Operation Mode 3-6

3.4.2 I•Guide Operating Mode 3-8

3.4.2.1 Starting the I•Guide Mode 3-8

3.4.2.2 Selecting an I•Guide Program 3-9

3.4.2.3 Using an I•Guide Program 3-9

kina22eIVZ.fm Technical Handbook(1206)

3.4.3 The Info Page 3-12

3.5 Calibration and Self-Test 3-14

Content 0-3

Page 4

3.5.1 Verifying a calibration (proof function) 3-15

3.5.2 Internal calibration 3-16

3.5.3 External calibration 3-17

3.6 Shutdown 3-19

4 Equipment Settings 4-1

4.1 Menu Structure 4-1

4.2 Sleep Mode 4-3

4.3 The Service Menu 4-3

4.4 Selecting gases and setting gas triggers 4-3

4.4.1 Editing gas parameters 4-4

4.4.2 Removing / adding a working gas 4-4

4.4.3 Selecting trigger values and units of measurement 4-7

4.4.4 Selecting the search level and the lower display limit 4-8

4.4.5 Enabling / disabling internal calibration 4-8

4.4.6 Selecting an alternative mass position 4-9

4.4.7 Activating the Interfering Gas Suppression (IGS) 4-10

4.4.8 Setting up a user-definable gas 4-10

4.5 Settings Sub-menu 4-12

4.5.1 Vacuum & Access Menu 4-12

4.5.2 Audio Functions 4-14

4.5.3 Display Settings 4-16

4.5.4 Setting-up / editing an I•Guide Program 4-18

4.5.5 Miscellaneous Settings 4-21

4.6 Interfaces 4-23

4.6.1 Control location 4-23

4.6.2 Recorder outputs 4-23

4.6.3 RS232 Protocol 4-26

4.6.4 Baud rate & end sign 4-27

4.6.5 Select PLC Inputs 4-27

4.6.6 Select PLC Outputs 4-28

4.6.7 ECO-Check (only available in Advanced Mode) 4-29

4.7 The Info Menu 4-30

4.8 History & Maintenance 4-34

4.9 Monitoring Sensitivity 4-39

0-4 Content

5 Ecotec E3000 Messages 6-1

5.1 Error Messages and Warnings 6-1

6 Detecting Specific Gases 5-1

6.1 R134a / Cyclopentane 5-1

6.2 R134a / R245fa 5-1

6.3 R600a / Cyclopentane / Isopentane 5-1

6.4 Helium 5-1

6.5 Hydrogen / Forming gas 5-2

6.6 Methan 5-2

kina22eIVZ.fm Technical Handbook(1206)

Page 5

7 Equipment Connections 7-1

7.1 I/O Port (Control Inputs and Outputs) 7-1

7.1.1 Ground connectors 7-2

7.1.2 24V Output 7-2

7.1.3 PLC Inputs 7-2

7.1.4 PLC Outputs 7-3

7.1.4.1 Relay outputs 7-4

7.1.4.2 Recorder Outputs 7-5

7.1.5 How to perform a calibration 7-6

7.2 RS232 interface 7-7

8 Maintenance 8-1

8.1 Maintenance schedule 8-1

8.2 Adjusting the IGS function 8-2

8.3 Exchanging the air filter 8-3

8.4 Replacing the Operation Fluid Reservoir 8-5

8.5 Exchanging the mains fuses 8-8

8.6 Replacing filters in the sniffer line 8-9

8.6.1 Replacing the felt discs of the capillary filter 8-9

8.6.2 Replacing the felt discs (with water protection tip) 8-11

8.6.3 Checking / replacing the sinter filter 8-11

8.7 Switching the capillary filter 8-12

8.7.1 Switching from metal to plastic capillary filter 8-13

8.7.2 Switching from plastic to metal capillary filter 8-14

8.8 Replacing the gas reservoir of the

ECO-Check 8-14

9 Annex 9-1

9.1 The gas library 9-1

9.2 Declaration of Conformity 9-10

kina22eIVZ.fm Technical Handbook(1206)

Content 0-5

Page 6

Important Safety Precautions

Warning

Caution

Warning

Indicates procedures that must be strictly observed to prevent hazards to persons.

Indicates procedures that must strictly be observed to prevent damage to or

destruction of the Ecotec E3000 leak detector.

Notice Indicates special requirements the user must comply with.

The INFICON Ecotec E3000 leak detector has been designed for safe and efficient

operation when used properly and in accordance with this Technical Handbook.

It is the responsibility of the user to carefully read and strictly observe all safety

precautions described in this chapter and throughout this Technical Handbook.

The Ecotec E3000 must only be operated in the proper condition and under the

conditions described in this Technical Handbook.

It must be operated and maintained by trained personal only. Consult local, state,

and national agencies regarding specific requirements and regulations.

Adress any further safety, operation and / or maintenance questions to our nearest

office.

Presumed Risk:

If it is to be assumed that safe operation is no longer possible, the device is to be

taken out of service and secured against unsupervised operation.

Notice This can e. g. be the case if:

• the unit has visible damage,

• fluid has gotten into the device,

• the device is no longer working,

• the device has been stored for an extended period of time under unfavorable

conditions or

• after significant moving or transportation stresses.

0-6 Important Safety Precautions

kina22eIVZ.fm Technical Handbook(1206)

Page 7

Failure to observe the following precautions could result in serious personal

Warning

Warning

Warning

Warning

Warning

Warning

Warning

injury:

Only 3-core mains cables having a protective ground conductor must be used.

Operation of the Ecotec E3000 with the ground conductor unconnected is not

permissible.

Do not stare into the LEDs of the sniffer line intentionally for extended times or at a

close distance as this may cause permanent damage to the eye.

Danger of electric shock.

Don’t touch voltaged parts with the sniffer tip. Test samples need to be

disconnected from electricity before leak testing.

For all contacts of the I/O Port a maximum voltage of 60 V DC or 25 V AC must not

be exceeded or reached to ground or ground equipment conductors.

According to the type of in- or outputs lower voltages had to be accepted. For this,

please refer to the information given in the responding chapters.

For all maintenance on the Ecotec E3000, the Ecotec E3000 must be disconnected

from power.

Before exchanging the air filter the Ecotec E3000 must be disconnected from

power.

Before exchanging the fuses the Ecotec E3000 must be disconnected from power.

kina22eIVZ.fm Technical Handbook(1206)

Important Safety Precautions 0-7

Page 8

Warning

Before exchanging the lubricant reservoir the Ecotec E3000 must be disconnected

Warning

Warning

Warning

Caution

Caution

from power.

Dangerous gases pollute the machine.

So you must not use the machine for detecting toxical, acidity, microbiological,

explosive, radioactive or other noxious matters.

Caution: Danger of explosion

Hydrogen forms a highly explosive gas mixture with air.

Great caution is necessary when using hydrogen! No smoking, no naked flames,

avoid sparks.

Danger of explosion!

To use the Ecotec E3000 in explosion hazard areas could cause ignition of

flammable mixtures.

The Ecotec E3000 must only be operated outside of explosion hazard areas.

Failure to observe the following precautions could result in damage to the

equipment:

The Ecotec E3000 must not be operated while standing in water or when exposed

to drip water. The same applies to all other kinds of liquids.

This Ecotec E3000 should only be used in rooms.

Avoid contact of the Ecotec E3000 with bases, acids and solvents as well as

exposure to extreme climatic conditions.

0-8 Important Safety Precautions

kina22eIVZ.fm Technical Handbook(1206)

Page 9

Caution

Ensure sufficient air cooling (see also Section 1.2)

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Before installation remove the transportation lock.

In order to ensure adequate ventilation of the Ecotec E3000, a space of at least

20 cm 8) (8 in.) must be kept unobstructed to the sides. The clearance at the rear

must be no less than 10 cm (4 in.). Moreover, the Ecotec E3000 handles for

carrying the leak detector at the sides of the main unit must not be covered at any

time as these acts as air inlet and outlet. Avoid the presence of heat sources in the

vicinity of the Ecotec E3000.

Before connecting the Ecotec E3000 to the mains you must make sure that the

mains voltage rating of the Ecotec E3000 coincides with the locally available mains

voltage.

Do not suck in any liquids.

Permissible maximum input voltage PLC 28 V.

Permissible max. voltage and current for open collector outputs are: 28 V; 50 mA.

Maximum load rating relay outputs is 60 V DC / 25 V AC and 1 A per relay.

kina22eIVZ.fm Technical Handbook(1206)

Important Safety Precautions 0-9

Page 10

Caution

The air filter should be checked for contamination at least every 6 months and

Caution

Caution

should be definitely exchanged after 2 years.

The lubricant reservoir may contain toxic substances from the pumped media.

Please dispose of lubricant reservoir as required by local regulations. A Safety Data

sheet for the lubricant is available on request.

Caution: Abrupt movements.

Abrupt movements can damage the running turbo pump.

Avoid abrupt movement and vibration of the instrument (e.g. running over cables,

door sills) during operation and up to 4 minutes after switching off since the turbo

pump can be damaged.

0-10 Important Safety Precautions

kina22eIVZ.fm Technical Handbook(1206)

Page 11

1 General Information

Caution

Caution

Caution

The Ecotec E3000 refrigerant leak detector is supplied ready for operation. However,

we recommend that you carefully read the Technical Handbook to ensure optimum

operating conditions right from the start. This handbook contains important

information on functions, installation, start-up and operation of the Ecotec E3000.

1.1 Introduction

1.1.1 Intended Use

The Ecotec E3000 is a refrigerant leak detector for sniffer applications. It may be

used to localise and quantify leaks in test samples if there is a refrigerant under an

overpressure within the test sample and when searching the test sample with a

sniffer probe from the outside (sniffer method). The use of this sniffer probe is

mandatory for proper operation and it is available as an accessory (Cat. No. 525-001

to 525-004).

The Ecotec E3000 must not be operated while standing in water or when exposed

to drip water. The same applies to all other kinds of liquids.

This Ecotec E3000 should only be used in rooms.

Avoid contact of the Ecotec E3000 with bases, acids and solvents as well as

exposure to extreme climatic conditions.

Ensure sufficient air cooling (see also Section 1.1.2)

Proper use includes:

• Conformance with the technical specifications

• Use of standard and original accessories

• Observance of the instructions and guidelines contained in this document

kina22e chapter 1.fm technical handbook(1206)

General Information 1-1

Page 12

1.2 Support by INFICON

INFICON Service

If equipment is returned to INFICON or an authorised INFICON representative

indicate whether the equipment is free of substances damaging to health or whether

it is contaminated.

If it is contaminated also indicate the nature of the hazard.

INFICON must return any equipment without a Declaration of Contamination to the

sender’s address. You will find an appropriate form at the next page.

General

We reserve the right to alter the design or any data given in this handbook.

The illustrations are not binding.

1-2 General Information

kina22e chapter 1.fm technical handbook(1206)

Page 13

kina22e chapter 1.fm technical handbook(1206)

General Information 1-3

Page 14

INFICON GmbH

Bonner Str. 498,50968 Cologne, Germany

Tel: +49 221 56788-112 Fax: +49 221 56788-9112

zisa01e1-b (1106)

Declaration of Contamination

The service, repair, and/or disposal of vacuum equipment and components will only be carried out if a correctly completed declaration has

been submitted. Non-completion will result in delay.

This declaration may only be completed (in block letters) and signed by authorized and qualified staff.

Description of product

Type

Article Number

Serial Number

The product is free of any substances which are damaging to

health yes

Harmful substances, gases and/or by-products

Please list all substances, gases, and by-products which

Trade/product name

Chemical nam e

(or symbol)

Reason for return

Operating fluid(s) used

(Must be drained before shipping.)

Process related contamination of product:

toxic no 1) yes

caustic no 1) yes

biological hazard no yes 2)

explosive no yes 2)

radi oactive no yes 2)

other harmful substances no 1) yes

1) or not containing any amount

of hazardous residues that

exceed the permissible ex posure limits

the product

Precauti ons associ ated

with substance

may have come into contact with:

2) Products thus contami nated will not be ac cepted without written

evidence of decontami nation!

Action if human contact

Legally binding declaration:

I/we hereby declare that the information on this form is complete and accurate and that I/we will assume any further costs that may

arise. The contaminated p roduct will be dispatched in accordance with the applicable regulations.

Organization/company

Address Post code, place

Phone Fax

Email

Name

Date and legally binding signature Company stamp

This form c an be downloaded

from our websit e.

www.inficon.com leakdetection.service@inficon.com

1-4 General Information

Copies:

Original for addres see - 1 copy for acco mpanying docum ents - 1 copy for file of sen der

kina22e chapter 1.fm technical handbook(1206)

Page 15

1.2.1 Service Centers

Algeria jhj@agramkow.dk Finland jhj@agramkow.dk

Agramkow

Sonderborg

Belarus leakdetection.service@inficon.com France Christophe.Zaffanella@oerlikon.com

INFICON GmbH

Cologne

Belgium leakdetection.service@inficon.com Germany leakdetection.service@inficon.com

INFICON GmbH

Cologne

Brazil fernandoz@prestvacuo.com.br Hungary adam.lovics@kon-trade.hu

PV Pest Vácuo Ltda.

Santa de Parnaíba

Bulgaria leakdetection.service@inficon.com India asdash@hotmail.com

INFICON GmbH

Cologne

Canada reachus@vpcinc.ca Ireland reach.unitedkingdom@inficon.com

Vacuum Products Canada Ltd.

Ontario

Central America infoqro@meisa.com Italy davide.giovanetti@inficon.com

MEISA S.a. de C.V.

Querètaro

China reach.china@inficon.com Israel urimark@mark-tec.co.il

INFICON LTD

Hong Kong

INFICON LTD

Beijing

INFICON LTD

Guangzhou

INFICON LTD

Shanghai

Czech Republic filip.lisec@inficon.com Korea reach.korea@inficon.com

INFICON GmbH

Pilsen

Denmark jhj@agramkow.dk INFICON Ltd.

Agramkow

Sonderborg

Egypt jhj@agramkow.dk Latvia leakdetection.service@inficon.com

Agramkow

Sonderborg

Estonia leakdetection.service@inficon.com Lithuania leakdetection.service@inficon.com

INFICON GmbH

Cologne

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +55 114 154 4888

Fax: +55 114 154 4888

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +905.672.7704

Fax: +905.672.2249

Phone: +52 44 22 25 42 80

Fax: +52 44 22 25 41 57

Phone: +852.2862.8863

Fax: +852.2865.6883

Phone: +86.10.6590.0164

Fax: +86.10.6590.0521

Phone: +86.20.8723.6889

Fax: +86.20.8723.6003

Phone: +86.21.6209.3094

Fax: +86.21.6295.2852

Phone +420 734 331 758

Fax: +420 604 203 037

Phone: +45 744 336 36

Fax: +45 744 336 46

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Agramkow

Sonderborg

OLV France

Orsay

INFICON GmbH

Cologne

Kontrade

Budaörs

Dashpute

400 064

INFICON

Blackburn

INFICON GmbH

Castelnuovo

Mark Technologies Ltd.

Kiriat Ono

Japan reach.japan@inficon.com

INFICON Co. Ltd.

Yokohama

INFICON Ltd.

Sungnam city

Suwon City

INFICON Ltd.

Cheonan City

INFICON GmbH

Cologne

INFICON GmbH

Cologne

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +33 476 351 584

Fax: +33 476 351 584

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +36 23 50 38 80

Fax: +36 23 50 38 96

Phone: +91 22 888 0324

Fax: +91 22 888 0324

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Phone: +39 045 6 40 25 56

Fax: +39 045 6 40 24 21

Phone: +972 35 34 68 22

Fax: +972 35 34 25 89

Phone: +81.45.471.3396

Fax: +81.45.471.3387

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +82 312 062 890

Fax: +82 312 063 058

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

kina22e chapter 1.fm technical handbook(1206)

General Information 1-5

Page 16

Mexico infoqro@meisa.com Spain richard.cunill@leyboldoptics.com

MEISA S.a. de C.V.

Querètaro

Netherlands leakdetection.service@inficon.com Sweden jhj@agramkow.dk

INFICON GmbH

Cologne

Norway jhj@agramkow.dk Syria leakdetection.service@inficon.com

Agramkow

Sonderborg

Poland kamola@vakpol.com Taiwan Susan.Chang@inficon.com

VAK-POL & GAZ Sp. zo.o

Pulawy

Portugal leakdetection.service@inficon.com Tunisia leakdetection.service@inficon.com

INFICON GmbH

Cologne

Republic of South Africa vacuquip@hotmail.com Turkey jhj@agramkow.dk

Vacuquip

Randburg

Russia leakdetection.service@inficon.com Ukraine leakdetection.service@inficon.com

INFICON GmbH

Cologne

Singapore reach.singapore@inficon.com United Kingdom reach.unitedkingdom@inficon.com

INFICON PTE LTD.

Singapur

Slovakia filip.lisec@inficon.com United Arab Emirates leakdetection.service@inficon.com

INFICON GmbH

Pilsen

Slovenia medivak@siol.net USA service.usa@inficon.com

Medivac

Ljubljani

South America except Brazil infoqro@meisa.com Inficon Inc.

MEISA S.a. de C.V.

Querètaro

Phone: +52 442 225 42 80

Fax: +52 442 225 41 57

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +48 60 23 15 212

Fax: +48 60 23 15 212

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +27 73 15 78 355 Agramkow

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +65.890.6250

Fax: +65.890.6266

Phone +420 734 331 758

Fax: +420 604 203 037

Phone: +386 15 63 91 50

Fax: +386 17 22 04 51

Phone: +52 44 22 12 36 15

Fax: +52 44 22 12 19 40

Leybold Optics Ibérica

Barcelona

Agramkow

Sonderborg

INFICON GmbH

Cologne

INFICON Company Limited

Chupei City, HsinChu Hsien

INFICON GmbH

Cologne

Sonderborg

INFICON GmbH

Cologne

INFICON

Blackburn

INFICON GmbH

Cologne

Inficon Inc.

East Syracuse, NY

San Jose, CA

Inficon Inc.

Austin, TX

Phone: +34 93 66 60 778

Fax: +34 93 66 64 612

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +886.3.5525.828

Fax: +886.3.5525.829

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +45 741 236 36

Fax: +45 744 336 46

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +44 1254 678 250

Fax: +44 1254 698 577

Phone: +49 221 56788-112

Fax: +49 221 56788-9112

Phone: +1.315.434.1167

Fax: +1.315.434.2551

Phone: +1.408.361.1200

Fax: +1.408.362.1556

Phone: +1.512.448.0488

Fax: +1.512.448.0398

1-6 General Information

kina22e chapter 1.fm technical handbook(1206)

Page 17

1.3 Unpacking

Unpack the Ecotec E3000 leak detector immediately after it has been received even

if it is to be put into operation at some later date. Examine the shipping container for

any external damage. Completely remove all packaging materials.

Notice: Retain the shipping container and the packaging materials in the event of

possible complaints concerning any damages.

Check if the Ecotec E3000 leak detector is complete (see Section 1.3.1) and carefully

subject it to a visual inspection. If any damage is discovered please immediately

inform the forwarding agent and the insurers. If it is required to exchange the

damaged part please contact our orders department.

1.3.1 Supplied Equipment

The Ecotec E3000 leak detector is ready for operation. Before installation please

read Section 1.5. Included with the leak detector are the following items:

• Ecotec E3000 (main unit)

• Mains cord, 3m long

• Set of fuses (3 x 10 pcs.)

• Spare air filter

• 8 mm hexagonal wrench

• 19 mm ring wrench

• Documentation

– Operating Instructions (kima22e1)

– Technical Handbook Ecotec E3000 (kina22e1)

– Spare Parts List Ecotec E3000 (kiua22d2)

– Interface Description E3000 (kins22e1)

Notice: The sniffer line is available in different configurations and needs to be

ordered separately in the desired length. The sniffer line is not part of the

Ecotec E3000 shipment. (see Section 1.3.3 Accessories)

Notice: The ECO-Check reference leak is an accessory (see Section 1.3.3

Accessories) and needs to be ordered separately

Notice: For the Ecotec E3000RC version the display unit and the connecting cable

are not part of the standard Ecotec E3000 shipment and need to be

ordered separately (see Section 1.3.3)

kina22e chapter 1.fm technical handbook(1206)

General Information 1-7

Page 18

1.3.2 Technical Data

Physical Data

Smallest detectable leak rate 0.05 g/a for refrigerants

Measurement range 6 decades

Detectable masses 2 - 200 amu

Mass spectrometer Quadrupole mass spectrometer

Ion source 2 cathodes; iridium with yttrium oxide

Time constant of the leak rate signal < 1 s

Gas flow through the capillary 160 sccm

Time until ready for operation < 2 min

Electrical Data

Mains voltages and mains frequencies 90 - 127 V, 50 / 60 Hz

(fixed) 115 - 140 V, 60 Hz

Power consumption 300 VA

Type of protection IP 20

Overvoltage category II

Mains cord 2.5 m

Noise level < 54 dBA

0.002 oz/yr for refrigerants

-6

< 1x10

mbar l/s (helium)

coating

187 - 265 V, 50 / 60 Hz

Other data

Dimensions (w x h x d) in mm 610 x 370 x 265

Weight 34 kg

Permissible ambient temperature

10 °C to 45 °C

(during operation)

Permissible storage temperature -20 °C to 60 °C

Max. rel. humidity max. 80% for temperatures up to +31°C,

decreasing linearly to 50% at +40%

Contamination level II

(according to IEC 61010 / Part 1:

“normally only non-conductive pollution

may occur. Occasionally, however, a

temporary conductivity caused by

condensation can be tolerated.”)

Max. altitude above sea level 2000m

kina22e chapter 1.fm technical handbook(1206)

1-8 General Information

Page 19

1.3.3 Accessories

Sniffer line for Ecotec E3000 Cat. No. / Ref. No.

SL3000-3, 3 m length 525-001

SL3000-5, 5 m length 525-002

SL3000-10, 10 m length 525-003

SL3000-15, 15 m length 525-004

Sniffer line for system integration (robot application) 525-015

Sniffer tips

ST 312, 120 mm long, rigid 122 13

FT 312, 120 mm long, flexible 122 14

FT 200, 200 mm long, rigid 122 18

FT 250, 250 mm long, flexible 122 66

ST 385, 385 mm long, rigid 122 15

FT 385, 385 mm long, flexible 122 16

FT 600, 600 mm long, flexible 122 09

ST 500, 500 mm long, rigid, 45° angled 122 72

Water protection tip for sniffer 122 46

Holder for SL3000 sniffer line 525-006

ECO-Check reference leak for R134a 531-001

Calibrated sniffer leaks for single refrigerants, 2 - 5 g/a

(16 g/a also available)

R134a 122 20

R600a 122 21

R404A 122 22

R502a 122 23

R22 122 25

R23 122 26

R152a 122 27

R407C 122 28

R410A 122 29

R401A 122 30

R290 122 31

R744 (CO2) 122 32

10% Hydrogen (E-5 mbarl/s) 122 33

Halon 1301 (R13B1) 122 34

HFO-1234yf 122 35

Calibrated sniffer leak for helium

S-TL 4, approx.1 x 10

S-TL 5, range 10

kina22e chapter 1.fm technical handbook(1206)

S-TL 6, range 10

-4

mbar l/s 122 37

-5

mbar l/s 122 38

-6

mbar l/s 122 39

General Information 1-9

Page 20

Calibrated leaks for forming gas (hydrogen)

10% hydrogen / 90% helium, range 10

-5

mbar l/s 122 33

(Calibrated leaks for other refrigerants on request)

External display unit for Ecotec E3000RC

for bench top use 551-100

for rack mounting 551-101

Connecting cable for external display unit

for Ecotec E3000RC, 5m 551-102

for Ecotec E3000RC, 1 m 551-103

1-10 General Information

kina22e chapter 1.fm technical handbook(1206)

Page 21

1.4 Notes on How to Use This Handbook

1.4.1 Numbering of Figures

The references to diagrams. e.g. (2-1/6) consist of the Section No., Fig. No. and the

Item No. in that order. For example (2-1/6) means: Section 2, Fig. 1and Item No. 6

(here: mains switch).

1.4.2 Symbols of Vacuum Technology

In the following some important symbols of vacuum technology as used in this

handbook are shown:

Vacuum pump in general Diaphragm pump

Turbo molecular pump Vacuum gauge

1.4.3 Definition of Terms

Main menu

This menu is shown first after operating the Menu push-button.

Sub-menus

Comprise all menus which may be accessed from the main menu. Unauthorized

changes to many of these sub-menus may be prevented by a password (see also

Section 4.5.1).

Menu item

A single menu line.

Default condition

Status of the Ecotec E3000 when supplied from the factory.

kina22e chapter 1.fm technical handbook(1206)

General Information 1-11

Page 22

Service menu

Comprises the menu lines in the “Service” sub-menu. The service menu is accessed

by scrolling in the basic menu using the navigation push-buttons (see also Section

3.2).

Autozero

Determination and compensation of the refrigerant background. With this function,

the internal ZERO level of the leak rate signal is determined in order to avoid a

readout of the internal refrigerant background and mistaking it as a properly

measured value. If subsequently negative leak rates are obtained due to this

correction, the stored offset values are changed so that ZERO will be the lowest

value which can be obtained. In this way the values adapt automatically to a

decaying background (adaptive background correction).

Internal background

The existing partial pressure in the measurement system. The level of the internal

background is measured all the time and subtracted from the measured signal.

I•Guide Mode

Unit under test

Display limit

In the I•Guide Mode different testing plans can be pre-programmed. During testing

the operator is then constantly prompted for the next action and thus guided through

the testing plan.

Test object that needs to be leak checked.

Limits the measurement data displayed depending on the unit of measurement and

the operator settings.

1-12 General Information

kina22e chapter 1.fm technical handbook(1206)

Page 23

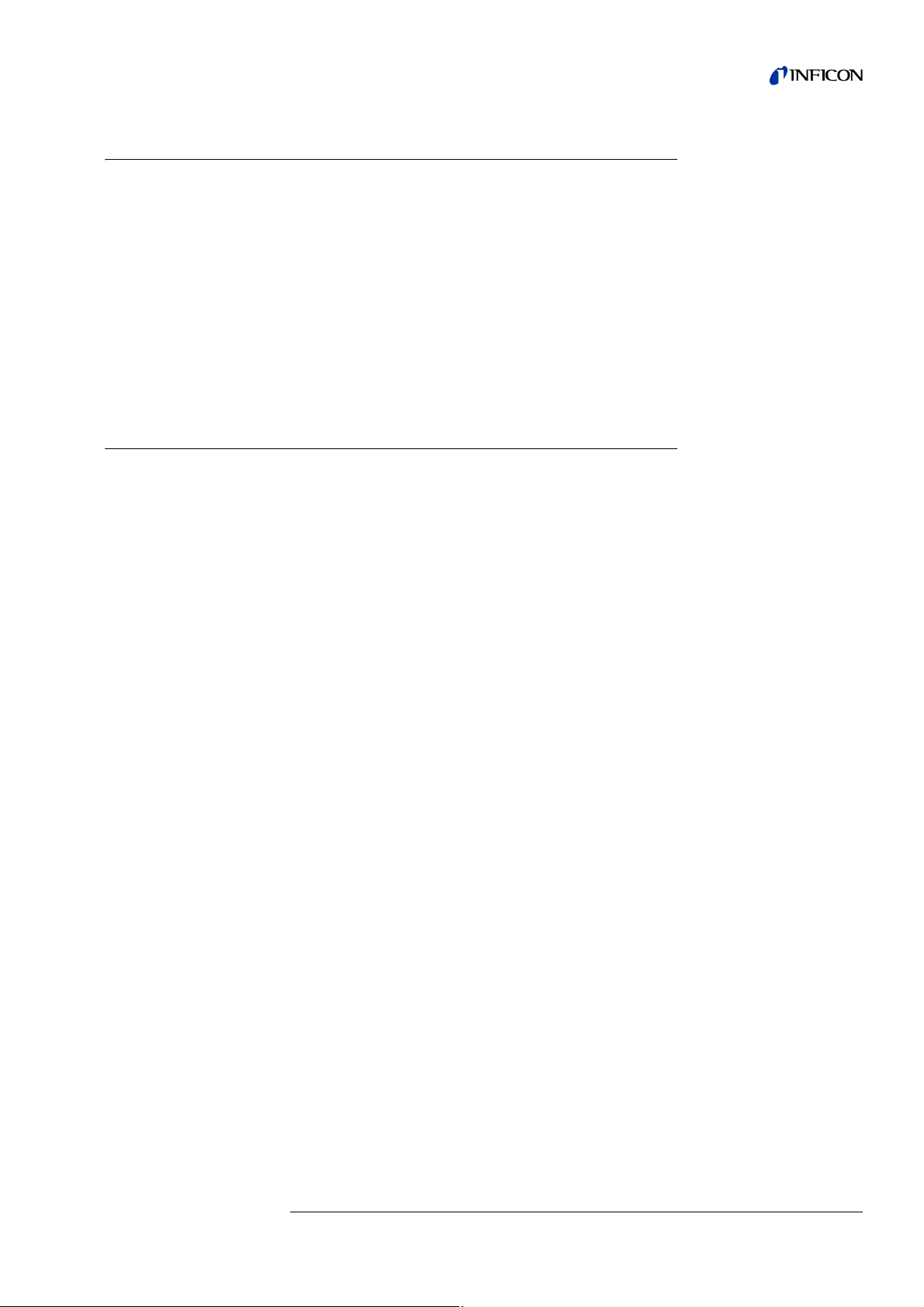

1.5 Instrument Views of the Ecotec E3000

Caution

Fig. 1-2 Instrument views of Ecotec E3000

Pos. Description Pos. Description

1 Main display 4 Lemo Connector for sniffer line

2 Handle for carrying the Ecotec E3000 5 Speaker

3 ECO-Check reference leak

1.6 Installation

1.6.1 Set up

The weight of the Ecotec E3000 exceeds 25 kg.

It therefore should not be carried by one single person.

The Ecotec E3000 may tip off its base and injure people.

Place the Ecotec E3000 on a stable base.

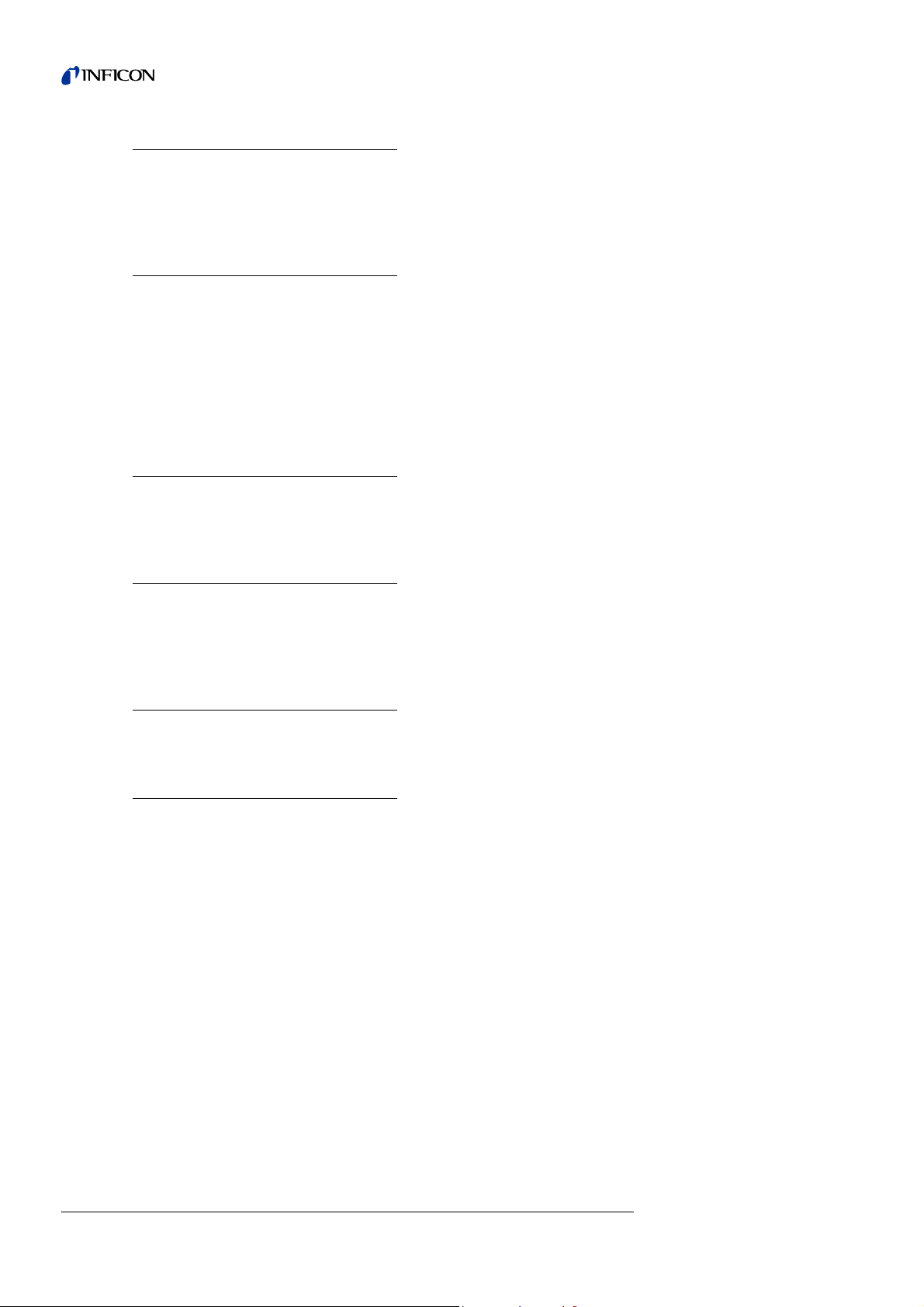

How to remove the transportation lock:

The transportation lock is located on the bottom side of the Ecotec E3000 main unit

and consists of a yellow knurled screws. Please remove this screw before startingup the Ecotec E3000. The Ecotec E3000 is supplied ready for operation. Initial startup is described in Section 3.1.

kina22e chapter 1.fm technical handbook(1206)

General Information 1-13

Page 24

Fig. 1-3 Removing the transportation lock before starting

Caution

Caution

Caution

Before installation remove the transportation lock.

In order to ensure adequate ventilation of the Ecotec E3000, a space of at least

20 cm (8 in.) must be kept unobstructed to the sides. The clearance at the rear must

be no less than 10 cm (4 in.). Moreover, the Ecotec E3000 handles for carrying the

leak detector at the sides of the main unit must not be covered at any time as these

acts as air inlet and outlet. Avoid the presence of heat sources in the vicinity of the

Ecotec E3000.

Make sure that you can always reach the mains plug.

1-14 General Information

kina22e chapter 1.fm technical handbook(1206)

Page 25

1.6.2 Mechanical Connections

ECO-Check Reference leak (optional)

Please insert the ECO-Check reference leak into the opening in the housing of the

main unit. Make sure that the Sub-D plug is properly connected with the ECO-Check

leak.

Notice: When properly inserted, the ECO-Check reference leak will still protrude by

approx. 10 mm.

On first usage of your ECO-Check you need to initialize the use of this reference leak

in the Ecotec E3000 software menu.

Please perform the following steps:

1 Insert the ECO-Check into the appropriate opening of the Ecotec E3000

2 In the software menu go to HISTORY & MAINTENANCE / REPLACE ECO-CHECK.

Notice: The Ecotec E3000 must be set to

submenu (See section 4.5.3). Go to

ADVANCED MODE for access to this

SETTINGS / DISPLAY / USER MODE)

3 On the certificate, which is delivered with the ECO-Check, you will find a serial

number and a 12-digit-code. Enter the serial number in the first line of the open

submenu and the 12-digit-code in the second line and press OK.

Notice: The ECO-Check reference leak must be installed in the Ecotec E3000

when pressing

Fig. 1-4 Initializing the ECO-Check reference leak

OK.

SL3000 Sniffer line

In order to operate the Ecotec E3000 it is essential for the sniffer line to be

connected. The connection for the sniffer line is located at the front of the Ecotec

E3000 left of the ECO-Check reference leak.

Insert the plug into the opening with the red dot on the plug and the slot in the front

cover aligned until the connector engages. To disconnect the plug, retract the

coupling and remove the probe’s line.

kina22e chapter 1.fm technical handbook(1206)

General Information 1-15

Page 26

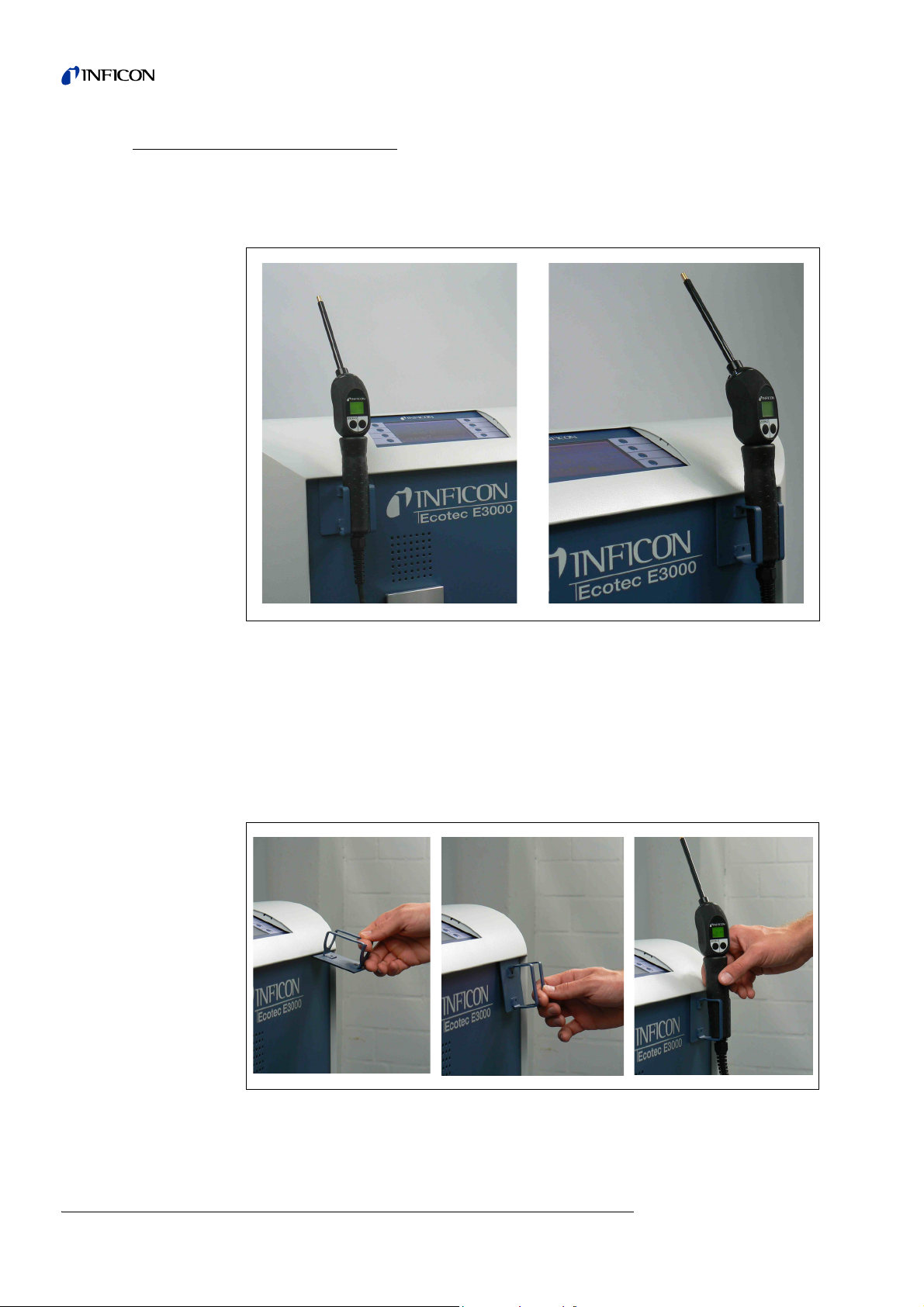

Holder for SL3000 sniffer line (optional)

An optional holder for the SL3000 sniffer line is available as cat.-no. 525-006. The

holder may be installed on the right or left side of the main unit (for right- or left

handed operators) as shown in Fig. 1-6.

Fig. 1-5 Usage of sniffer line holder

The installation is described in Fig. 1-6. There are two little slots on the front side at

the very top area of the blue square front of the main unit.

Hold the holder horizontally and then insert the two little hooks of the holder into the

two slots (either on the right or the left side).

With the hooks still inserted, let the holder flap down. It will automatically attach to

the metal front by the magnet on the backside of the holder.

Now insert the sniffer probe grip into the opening of the holder and let it sink down

until it rests in the holder.

Fig. 1-6 Installation of sniffer line holder

1-16 General Information

kina22e chapter 1.fm technical handbook(1206)

Page 27

Water protection tip (optional)

If you intend to perform leak testing on parts that are not completely dry (e.g. due to

condensation after performance testing), we strongly recommend to use a water

protection tip.

To install the water protection tip,

1 screw off the metallic capillary filter at the very end of the sniffer tip and

2 install the water protection tip instead.

Notice: Please do not forget to re-install the little rubber seal when switching to the

water protection tip.

Fig. 1-7 Installing water protection tip

ECO-Check Reference leak (optional), for helium and hydrogen only

If detecting helium or hydrogen, a ECO-Check reference leak may be used for

internal calibration. The ECO-Check reference leak has to be inserted to the Ecotec

E3000 (see section 2.3.3).

On first usage of your ECO-Check you need to initialize the use of this reference leak

in the Ecotec E3000 menu.

Please perform the following steps:

1 Insert the ECO-Check into the appropriate opening of the Ecotec E3000

2 In the software menu go to HISTORY & MAINTENANCE /REPLACE ECO-CHECK.

Notice: The Ecotec E3000 must be set to

submenu (See section 4.5.3). Go to

3 On the certificate, which is delivered with the ECO-Check, you will find a serial

number and a 12-digit-code. Enter the serial number in the first line of the open

submenu and the 12-digit-code in the second line and press OK.

USER MODE „ADVANCED“ for access to this

SETTINGS / DISPLAY / USER MODE.

kina22e chapter 1.fm technical handbook(1206)

General Information 1-17

Page 28

For Ecotec E3000RC only

Warning

1

23 456

The Ecotec E3000RC has no built-in display unit but a connectors plate is mounted

instead. Please connect the external display unit with the 5 m connecting table (Cat.no. 551-102).

Fig. 1-8 Ecotec E3000RC with external display unit for: (a) bench top use (left side),

(b) rack mounting (right side)

1.6.3 Electrical Connections

Fig. 1-9 Electrical connections

Pos. Description Pos. Description

1 Headphone port 4 Name plate

2 I/O Port 5 Power switch

3 RS232 interface 6 Power connector

Notice: The local regulations for electrical connections must always be observed

(in Germany VDE 0100). The mains voltage rating for the Ecotec E3000

can be read off from the name plate left of the power switch. The mains

voltage setting of the Ecotec E3000 is fixed and can not be changed. A

separate fuse for each of the mains conductors has been integrated into

the mains socket (Fig. 2-1/6).

Only 3-core mains cables having a protective ground conductor must be used.

Operation of the Ecotec E3000 with the ground conductor unconnected is not

permissible.

kina22e chapter 1.fm technical handbook(1206)

1-18 General Information

Page 29

The mains voltage is applied to the Ecotec E3000 via the detachable mains cable

Caution

which is supplied with the Ecotec E3000. A main power socket is available for this

purpose at the rear of the Ecotec E3000.

Before connecting the Ecotec E3000 to the mains you must make sure that the

mains voltage rating of the Ecotec E3000 coincides with the locally available mains

voltage.

1.6.4 RS232 Interface

The Ecotec E3000 is equipped with a RS232 interface which is located on the rear

right side of the main unit. This interface is of the DCE type (Data Communications

Equipment) and allows the connection of a PC for monitoring and data logging. The

connection is provided through a commercially available Sub-D plug. For further

information see “Interface Description Ecotec E3000” (kins22e1).

1.6.5 I/O Port

The I/O part allows communication with external equipment via analog data. For

details see Section 7.2.

Through this connection some functions of the Ecotec E3000 can be controlled

externally or measurement data or the Ecotec E3000 status may be communicated

to external equipment.

Through relay changeover contacts the trigger levels as well as the operating mode

(Ready) of the Ecotec E3000 may be monitored.

kina22e chapter 1.fm technical handbook(1206)

General Information 1-19

Page 30

1-20 General Information

kina22e chapter 1.fm technical handbook(1206)

Page 31

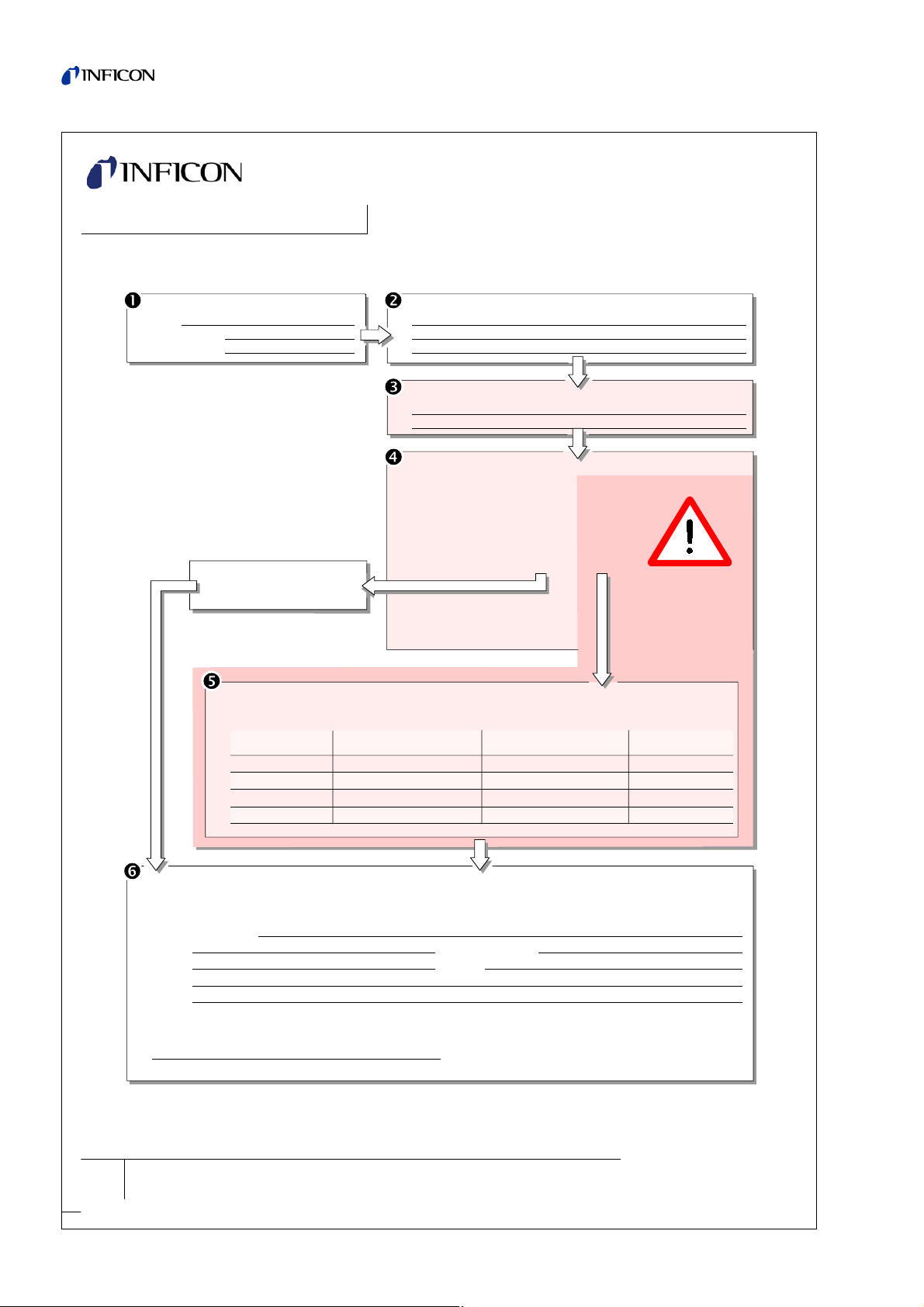

2 How the Instrument Works

ECOTEC E3000

MVP 015

Transpector

TPD 021

Sniffer probe

external

particle

filter

internal

particle

filter

flow divider 1

flow divider 2

flow meter

flow

limiter 1

flow

limiter 2

pv

1

2

2.1 Description of the Functions

The Ecotec E3000 is capable of detecting and quantifying the refrigerant sucked in

through the sniffer line by means of a selective mass spectrometer.

The Ecotec E3000 is composed of the following principal subassemblies:

• a quadrupole mass spectrometer as the detection system

• a high vacuum pump system

• an inlet system for the gas flow

• the corresponding electrical and electronic subassemblies for supplying power

and for signal conditioning.

kina22e chapter 2.fm technical handbook(1206)

Fig. 2-1 Vacuum Diagram of the Ecotec E3000

The mass spectrometer only operates under high vacuum conditions, i.e. the

pressure in the mass spectrometer must always stay below 10

-4

mbar. This vacuum

is generated by the turbo molecular pump with the support of the diaphragm pump.

The pressure pV between the two pumps is measured with a piezo resistive

measuring system and this pressure lies in the range between 4 to 10 mbar while in

the measurement mode. This pressure must not exceed a value of 10 mbar as

otherwise the turbo molecular pump will not be capable of maintaining the vacuum

in the mass spectrometer.

How the Instrument Works 2-1

Page 32

2.2 Description of the Subassemblies

2.2.1 Backing Pump

A diaphragm pump in the Ecotec E3000 serves as the backing pump. All data and

further information on this pump are given in the Operating Instructions of the pump.

The backing pump generates the fore pressure required for operation of the turbo

molecular pump and sucking in of the gas through the sniffer line.

2.2.2 Turbo Molecular Pump (TMP)

Built into the Ecotec E3000 is a turbo molecular pump with upstream compression

stage. The turbo molecular pump generates the high vacuum necessary for

operation of the mass spectrometer, whereas the compression stages permits

relatively high backing pressures without impairing the ultimate pressure in the mass

spectrometer. The TMP has a side connection. Thus a part of the taken in gas is

pumped through the TMP into the first stage of the diaphragm pump. This gas load

prevents the accumulation of water vapour in the diaphragm pump.

2.2.3 Mass Spectrometer

The TranspectorTM mass spectrometer is composed of the ion source, the separator

and the ion collector. The ion source ionizes neutral gas particles and generates an

ion beam. The positively charged ions are accelerated out of the ion source and then

enter the Quadrupole field. This field acts like a filter. Only the ions to which the

system has been adjusted are able to meet the separating conditions and arrive at

the ion collector, where their presence can be measured as a current by an

electrometer amplifier. This current is the output signal which is then used to

calculate the leak rates. Two cathodes have been integrated within the ion source. If

one cathode fails the other is selected automatically.

2.2.4 Quadrupole Supply

This subassembly generates all the voltages and currents required for operation of

the mass spectrometer. Faults in the mass spectrometer are detected and signalled

to the control assembly. The control assembly monitors the mass spectrometer

supply.

2.2.5 Control

The control assembly (microprocessor) is the central assembly of the Ecotec

E3000’s electronics. All other subassemblies are controlled and monitored by this

assembly. The microprocessor which is located here is thus continuously informed

about the status of the entire Ecotec E3000 and can respond accordingly. In order to

accept commands from the operator and to output measured values and messages,

the control subassembly is linked to the display unit.

kina22e chapter 2.fm technical handbook(1206)

2-2 How the Instrument Works

Page 33

2.3 Displays and User Interfaces

1

2

2.3.1 Main unit display

This subassembly is used to communicate with the operator. It accepts commands

from the 8 keys on both sides of the display and outputs measurement results and

messages via the display.

Fig. 2-2 Main unit display

Pos. Description Pos. Description

1 Menu buttons 1 to 4 2 Menu buttons 5 to 8

for Ecotec E3000RC only

The Ecotec E3000RC has a connectors plate for the external display unit instead of

the built-in main unit display. Two LED's left of the plug provide information about the

status of the Ecotec E3000RC, even when the external display unit is disconnected:

• The green LED will indicate that the Ecotec E3000RC is in operation (switched

on). The green LED will show continuous green light if an external display unit is

connected and will blink if no external display unit is detected.

• The red LED will be blinking in case of an error message, continuous red light

indicates a warning.

kina22e chapter 2.fm technical handbook(1206)

How the Instrument Works 2-3

Page 34

Fig. 2-3 Connector plate with LEDs

1

3

2

If no display unit is connected, error messages or warnings may be acknowledged

by pressing both buttons of the sniffer line simultaneously.

The external display unit also offers four buttons:

• The START / STOP buttons have no function (the external display unit may also

be used with other INFICON leak detectors which need these buttons)

• The MENU button will open the software menu.

• The ZERO button will set the current background reading to zero. (For details on

the ZERO function see Section 4.4.1)

2.3.2 Sniffer line with probe display

The probe handle also offers a small display for operating the Ecotec E3000 remotely

without access to the main unit during normal leak detection operation.

2-4 How the Instrument Works

Pos.

Fig. 2-4 Sniffer line with probe display

In addition to the display, the sniffer probe offers two press buttons. The left button

will function as the ZERO button in any operating mode. By pressing the left button

the current background reading is set to ZERO. The ZERO function can be disabled

by holding the ZERO button for 2 seconds. A beep will indicate that the ZERO

function has been successfully switched off. The ZERO function can be re-activated

by pressing the ZERO button once again. For details on the ZERO function see

section 4.5.1)

Description

Probe display

1

Button

2

ZERO button

3

kina22e chapter 2.fm technical handbook(1206)

Page 35

The right probe button is used for different functions depending on the current

Warning

operating mode the Ecotec E3000 is set to.

Fig. 2-5 Probe handle

The probe handle also offers some LEDs in the flange of the sniffer tip in order to

illuminate the location currently being leak tested.

Do not stare into the LEDs intentionally for extended times or at a close distance as

this may cause permanent damage to the eye.

The LEDs offer some bundled light. The intentional starring suspends the lid closing

reflex and also the eyes do not move anymore which may lead to overheating of the

retina.

When looking into the LEDs „incidentally“ the eye is protected by the lid closing

reflex. Also the permanent movement of the eyes prevents overheating and

consequent damage of the retina.

kina22e chapter 2.fm technical handbook(1206)

How the Instrument Works 2-5

Page 36

2.3.3 Built-in ECO-Check reference leak

A built-in ECO-Check reference leak is available for the Ecotec E3000. The ECOCheck reference leak can be used for verifying the correct functioning of the Ecotec

E3000 including the correct calibration and can also be used for re-calibrating the

Ecotec E3000 if necessary.

The ECO-Check reference leak is inserted in the front of the housing. Insertion of the

sniffer tip into the cone-shaped test leak opening is automatically detected via a light

barrier.

Fig. 2-6 Built-in ECO-Check reference leak

Fig. 2-7 ECO-Check reference leak detached from the main unit for remote use

2-6 How the Instrument Works

kina22e chapter 2.fm technical handbook(1206)

Page 37

In cases where the main unit is placed in a difficult or inconvenient to access area

the built-in ECO-Check reference leak can be removed from the main unit for easier

access and connected to the main unit via the Sub-D connector with a commonly

available extension cord. The ECO-Check reference leak can then be placed in an

area where it is convenient for the operator to be reached.

Fig. 2-8 Connections for remote use

Pos. Description Pos. Description

1 Connector at built-in test leak 2 Connector at

Ecotec E3000 housing

Notice: The ECO-Check reference leak is not part of the Ecotec E3000 shipment

and needs to be ordered as a separate part no. (see section 1.3.3).

Notice: If you have not purchased the ECO-Check reference leak, warning 71 (“No

communication with test leak”) will be issued on first start-up. Please go to

SETTINGS / INTERFACES /ECO-CHECK and set the ECO-Check to “DISABLED”

to prevent future warnings (see section 4.6.7)

The Ecotec E3000 must be set to

submenu (See section 4.5.3). Go to

USER MODE „ADVANCED“ for access to this

SETTINGS / DISPLAY / USER MODE.

kina22e chapter 2.fm technical handbook(1206)

How the Instrument Works 2-7

Page 38

2-8 How the Instrument Works

kina22e chapter 2.fm technical handbook(1206)

Page 39

3 Operation of the Ecotec E3000

3.1 Start-Up

Assemble the Ecotec E3000 (see Section 1.5). Connect the mains cord and the

sniffer line, and then switch on the Ecotec E3000. The mains switch is located on the

rear.

Fig. 3-1 Connection of the mains cord

Pos. Description Pos. Description

1 Power Switch 2 Power cord connection

The Ecotec E3000 will automatically start a self test and run-up procedure. This

takes about 2 minutes max. During the start-up the fore line pressure, the flow, the

rotation speed of the turbo molecular pump will be displayed.

Fig. 3-2 Start-up menu

The individual steps are indicated on the display. In the case of unfavorable

conditions, switching on of the emission may take several minutes.

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-1

Page 40

After switching on and completion of the run-up phase the Ecotec E3000 will be

ready to make measurements. There is no separate start function. The sniffer lines

are designed to maintain an inlet pressure low enough to make measurements.

Notice: The Ecotec E3000 will only operate after having connected the sniffer line.

Upon delivery, the data of the following gases are programmed in the factory for the

measurements, and these gases are indicated on the display:

R134a, R600a, R22, He

This selection of gases may be changed at any time.

A calibration in accordance with Section 3.5 is recommended 20 minutes after having

switched on the Ecotec E3000 on at the earliest (warm-up phase).

Notice: If you have not purchased the ECO-Check reference leak, warning 71 (“No

communication with test leak”) will be issued on first start-up. Please go to

Settings / Interfaces / ECO-Check and set the ECO-Check to “disabled” to

prevent future warnings (see section 4.6.7)

3.2 Controls on the main display unit

All set-up and control functions are integrated into the main display unit via the menu

structure. The functions of the 8 control keys are displayed on the LC display. During

measurements the main interface is the probe handle display giving all necessary

information for proper leak testing.

After start-up the Ecotec E3000 will automatically go into measurement mode.

Fig. 3-3 Measurement screen in standard operation mode

Pos. Description Pos. Description

1 Audio volume buttons 3 Calibration button

2 Menu button 4 Info button

3-2 Operation of the Ecotec E3000

kina22e chapter 3.fm technical handbook(1206)

Page 41

Bar graph display

Warning

The currently detected leak rates for all selected gases will be display in a bar graph

for each gas independently in logarithmic scale. On the upper left side of each bar

graph the selected gas type is indicated. The currently selected trigger level is

indicated by a black line, the currently selected search level is indicated by a dotted

line. If the search level is exceeded the shape of a bell is displayed right of the gas

name, if the trigger is exceeded the bell starts to blink (to “ring”). The pointer on the

right side of the bar graphs indicates the currently detected gas which gas is also

currently being displayed on the probe display.

Fig. 3-4 Measurement screen with leak

Pos. Description

1 Gas type

2 Indication of currently highest leak rate signal

3 Only when in

present

4 Indication that

5 ZERO enabled

6 Indication of trigger level being exceeded

7 Bar graph

8 Indication of active warning

9 Audio volume level

ADVANCED mode and operating in IGS mode: indication of interfering gas being

Ecotec E3000 has switched to filament B already

Audio Volume Buttons

The hearing can be harmed by the audio alarm.

The acoustic output can exceed a level of 85dB(A).

Do only expose to the audio alarm for a short time or use ear protection.

The two center keys on the left side of the display allow to adjust the volume of the

alarm sound at any time. When pressing any of the two buttons the currently selected

volume will be demonstrated by the loudspeaker as well as by a bar graph in the

status line. The selected value is also displayed as the first entry of the status line at

the bottom of the display and only applies to the loud speaker in the main unit. For

kina22e chapter 3.fm technical handbook(1206)

selecting different types of alarms see section 4.5.2.

Operation of the Ecotec E3000 3-3

Page 42

Menu Button

Cal Button

ZERO Button

The button on the bottom left side of the display will open the main menu at any

time. The menu mode offers the user many possibilities of entering Ecotec E3000

settings and special functions.

With the button on the upper right side of the display an external calibration of the

Ecotec E3000 can be started at any time. For details on how to perform an external

calibration see Section 3.5.3.

Info Button

Status line

When shortly pressing the

be updated. Holding the

ZERO button, the ZERO level for all selected refrigerants will

ZERO button for more than 2 seconds will disable the ZERO

function. In this case the ZERO indicator will be removed from the status line. For

details on the

When pressing the

ZERO function see Section 4.5.1.

i info button (bottom right side of the display) information on the

status of the Ecotec E3000 will be displayed. For details see section 3.4.3.

In the bottom line of the main display status information is indicated. First the

currently selected volume for the audio alarm is stated. Next, a small black triangle

with an exclamation mark may indicate an active warning. If the

ZERO function is

enabled the word “ZERO” is listed in the status line next.

If the first filament (filament A) is burned and the Ecotec E3000 automatically

switched to the second filament (filament B), an indication “Fil. B” is displayed in the

status line.

Only when operating in

ADVANCED mode and with IGS activated, the indication “IGS”

is displayed in the status line as long as interfering gas is detected.

3-4 Operation of the Ecotec E3000

kina22e chapter 3.fm technical handbook(1206)

Page 43

3.3 Controls on the probe display unit

1

3

2

On the display of the probe handle similar information as on the main display is

shown.

Pos. Description

1 Bar graph indicating the leak rate

2 Absolute leak rate

3 Gas currently detected

Fig. 3-5 Sniffer display in standard operation mode

The currently detected leak rate is indicated as a bar graph. In a second line the

numerical leak rate (in the same unit of measurement as on the main display) is

shown. In the third line the type of gas detected is stated (e.g. R134a).

The sniffer probe offers two press buttons. By pressing the left button the current

background reading is set to

ZERO button until a beep will indicate that the ZERO function has been successfully

switched off. The

again. For details on the

The right probe button allows to switch the bar graph display to the next of the up to

four chosen gases to be detected. This button is inactive if only one gas has been

selected. For details on this setting please refer to Section 4.5.3.

ZERO function can be re-activated by pressing the ZERO button once

ZERO. The ZERO function can be disabled by holding the

ZERO function please refer to 4.5.1. ZERO.

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-5

Page 44

3.4 Performing measurements

Warning

Caution

The Ecotec E3000 offers two modes of operation:

• The Standard Operation Mode (compatible to the EcotecII mode)

• The I•Guide Operating Mode

Danger of electric shock.

Do not touch voltaged parts with the sniffer tip. Test samples need to be

disconnected from electricity before leak testing.

Do not suck in any liquids.

A water-protection tip is available (Cat.-No. 12246) which will protect the Ecotec

E3000 against intake of liquids if necessary. For details on how to install the water

protection tip see 1.6.2)

3.4.1 Standard Operation Mode

Provided the Ecotec E3000 has been set-up to meet the requirements of the

particular application and it has been calibrated (see Section 3.5), a measurement is

run as follows:

First briefly operate the

Ecotec E3000 eliminates all interfering influences which may affect the

(i.e. the detection limit of 0.05 g/a).

Next hold the tip of the sniffer as close as possible to the suspected leak, if required

the tip may even touch the test object.

If a welded seam or alike needs to be tested, the tip should be moved at a velocity of

no more than 10 cm/s (4 inch per second) along the welded seam. The distance

between tip and test sample should be as small as possible.

If a leak is detected the bar will grow. The Ecotec E3000 continuously compares the

measured leak rates with the programmed trigger levels.

If the trigger is exceeded the background color of the probe display will change from

green to red. At the same time an alarm sound will be released by the speaker in the

probe handle and the probe handle will start to slightly vibrate.

As an additional indication of exceeding the trigger value the three white LEDs in the

flange of the sniffer tip will start flashing.

ZERO button on the sniffer probe. This will ensure that the

ZERO level

3-6 Operation of the Ecotec E3000

kina22e chapter 3.fm technical handbook(1206)

Page 45

Fig. 3-6 Sniffer display when detecting a leak

The display limits for the different units of measurement are summarized in the table

below.

Unit Lower display limit Upper display limit

g/a 0.05 1,000

oz/yr 0.002 1,000

ppm 0.5 100,000

mbar l/s 1x10

Pa m³/s 1x10

atm cc/s 1x10

Torr l/s 1x10

-7

-8

-7

-7

9.9x10

9.9x10

9.9x10

9.9x10

-2

-3

-2

-2

The lower display limit may be increased by the user. Please refer to Section 4.5.3

for how to edit the lower display limit.

As soon as an acoustic alarm sounds, the tip should be removed from the spot being

tested. After displaying a constant leak rate the ZERO button should be pressed

again to repeat the test. Thus, a measurement error can be prevented and the leak

can be located.

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-7

Page 46

3.4.2 I•Guide Operating Mode

The I•Guide operating mode has been introduced to support the operator in applying

proper sniffer leak detection technique.

The I•Guide operator guiding mode allows to store pre-programmed parameters for

different units under test. The number of locations that need to be tested per

specimen, the time each location needs to be tested for as well as the time required

to move to the next location may be programmed. In addition, a maximum allowable

global leak rate for the total unit under test is stored. In the I•Guide mode up to 10

pre-programmed testing procedures can be stored.

Notice: If the number of locations to be tested is set to 0, the Ecotec E3000 will

operate in a continuous mode without checking for a global leak rate but

still issue the timer signal for proper testing.

3.4.2.1 Starting the I•Guide Mode

To start the I•Guide Mode go to the main menu and choose SETUP I•GUIDE. In the

opening menu go to the top line item and change the setting to

side push button and press

enabled I•Guide program in the list. A message screen will pop-up notifying the

operator that I•Guide has been activated and therefore only one or two gases will be

measured from now on (the gas selected in the I•Guide program you choose).

For how to set-up and I•Guide program please refer to Section 4.5.4.

ON with the left hand

OK. The Ecotec E3000 will automatically choose the first

To switch back to the Standard Operation Mode select “I•G

Fig. 3-7 Switching to I•Guide Mode

UIDE OFF” and press “OK”.

3-8 Operation of the Ecotec E3000

kina22e chapter 3.fm technical handbook(1206)

Page 47

3.4.2.2 Selecting an I•Guide Program

To open the “SELECT I•GUIDE” menu press the ”PROGRAM LIST” button on the right side

of the display.

Fig. 3-8 Measuring Screen in I•Guide Mode

Pos. Description

1 program list

In the opening “

an arrow in front of the program name. Highlight the program number you intend to

use and press

Fig. 3-9 Selecting an I•Guide program

3.4.2.3 Using an I•Guide Program

In the measuring screen of the I•Guide operating mode the selected program, the

gas type stored in the program as well as the summarized global leak rate will be

displayed.

In the I•Guide message line the Ecotec E3000 will prompt the user for action. First it

will ask to move to the first testing position.

Also on the probe display the message “okay pos. 1?” will be shown. Please confirm

with the right probe button that the sniffer tip has reached the right location.

SELECT I•GUIDE” menu the currently selected program is indicated by

OK. The new program is now loaded.

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-9

Page 48

Fig. 3-10 I•Guide screens during measurement (one gas selected)

6

7

3

Pos. Description Pos. Description Pos. Description

1 Selected program 4 Elapsing measuring 6 ZERO button

2 Gas type stored in the time 7 I•Guide button

selected program 5 Summarized global

3 I•Guide message leak rate per unit

under test

Fig. 3-11 I•Guide screen during measurement (two gases selected)

Pos. Description Pos. Description

1 Selected program 4 Elapsing measuring time

2 Gas type stored in the selected program 5 Summarized global leak rate per

3 I•Guide message unit under test

After the first location has been confirmed the message “leak check point1” will be

indicated on the main unit display and the elapsing measurement time (stored in the

testing program) will be shown in the lower part of the menu page.

Please make sure to hold the sniffer tip in the right testing location during the total

measuring time. During this time a ticking sound will be issued by the main unit and

a beep will indicate that the measuring time has elapsed and the sniffer tip can be

moved again.

After the measurement time has elapsed the message “Move to point 2” will be

displayed on the main unit. The probe display will read “tip to pos. 2”.

Please move the sniffer tip to the next testing location and if the wait time indicated

in the display has elapsed, you may start the next measurement.

If the operator tries to start the next measurement before the wait time has elapsed,

3-10 Operation of the Ecotec E3000

kina22e chapter 3.fm technical handbook(1206)

Page 49

the message “please wait” will be displayed in the message line until a next

measurement is allowed.

Please confirm that the sniffer tip has been positioned properly by pressing the right

probe button so that the next measurement can be started.

Fig. 3-12 I•Guide screens requesting the next location

After checking the pre-programmed number of locations, the result of the testing for

the total unit under test will be displayed as shown in the following screen shots:

Fig. 3-13 Result of I•Guide program: unit under test passed

Pos. Description Pos. Description

1 Program name 3 Cycle counter

2 Gas type 4 Results of each location tested

The selected testing program as well as the gas type stored in the program will be

stated followed by the actual program cycle number.

The program cycle counter is increased by 1 after each completed cycle. The cycle

counter may be reset manually (in the Setup I•Guide menu, see section 4.5.4).

The cycle counter is also automatically reset on power off.

Next the summarized global leak rate is started. If the global leak rate is lower than

the global leak rate trigger the message "Global leak check okay!" will be displayed

followed by the testing results for each tested location.

If the summarized global leak rate exceeds the global trigger the message "Global

trigger exceeded!" will be displayed.

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-11

Page 50

Fig. 3-14 Result of I•Guide program: unit under test failed

The sniffer line display will switch to red background color if the global trigger is

exceeded (or at least one if two gases are selected for the program used).

The gas exceeding the global trigger is displayed in the results list. However, you can

switch between the results of the two different gases with the "A" and "B" buttons on

the right side of the display.

The display of the sniffer line will show the results for the two different gases

alternating automatically.

By pressing the right probe button the next testing cycle may be started.

3.4.3 The Info Page

By pressing the INFO button on the main display a general info page will open.

Information on the software version used, the number of operating hours, the serial

number, time & date and the currently selected alarm type will be stated. Also, the

selected gases with their mass position will be listed. Gases that are disabled will be

marked as such. For gases that are enabled also the currently selected trigger level

will be started.

Fig. 3-15 Info page without errors or warnings

If an active warning exists this will be displayed in the info page instead of the gas

info lines as shown below.

3-12 Operation of the Ecotec E3000

kina22e chapter 3.fm technical handbook(1206)

Page 51

Fig. 3-16 Info page with active warning

When operating in I•Guide Mode, the info page will state information about the

currently selected program: the selected program name, the gas used for this

program, the number of points to be checked for this program, the selected

measuring and wait time as well as the global trigger.

If two gases are selected for the I•Guide program, the gas type A/B and the global

trigger A/B will be displayed alternatively.

Fig. 3-17 Info page in I•Guide mode

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-13

Page 52

3.5 Calibration and Self-Test

The Ecotec E3000 can be calibrated internally with the built-in ECO-Check reference

leak or externally with an external calibrated leak (Cat. No. 122 20 - 122 35).

The built-in ECO-Check reference leak can be used for a self-test of the Ecotec

E3000 as well as for calibration of gases that are measured at mass positions

between 40 and 105 amu. If a gas is measured on a mass position below 40 amu or

above 105 amu it will be permitted for internal calibration in the “

A ECO-Check reference leak (cat. no. 521-001) maybe connected to the Ecotec

E3000 remotely and be used for internal calibration and verification of the calibration

(proof function) for helium and hydrogen. Internal calibration and verification may be

performed accordingly.

Notice Do not calibrate the Ecotec E3000 during the first 20 minutes after start-up.

Also a verification of the calibration may lead to wrong results in the first 20

minutes after start-up.

Only confirm and continue with the calibration or proof, if the real warm-up

time has been longer than 20 minutes (e.g. after a quick restart of the

Ecotec E3000)

Notice: When detecting hydrogen a longer warm-up time is required. For hydrogen

please calibrate the Ecotec E3000 not before 1 h after start-up.

EDIT GAS” menu.

Notice: The accuracy of an internal calibration is less than the accuracy of a

calibration with an external calibrated leak.

Notice: The ECO-Check reference leak is a temperature compensated leak. It

must only be used when electrically connected to the main unit, either

when inserted into its port or when connected to the main unit via a Sub-C

extension cord. The leak rate printed onto the body of the ECO-Check is

only valid at 20°C (68F) and will vary greatly with temperature.

To compensate for this the ECO-Check reference leak is equipped with a

temperature sensor and a compensation curve is stored in the software

which automatically compensates the test leak rate for changes in

temperature when connected to the main unit.

A calibration or verification with the ECO-Check reference leak not being

connected to the main unit will cause a wrong calibration of the Ecotec

E3000 and / or will lead to wrong testing results.

3-14 Operation of the Ecotec E3000

kina22e chapter 3.fm technical handbook(1206)

Page 53

3.5.1 Verifying a calibration (proof function)

Notice: The description of how to perform a verification applies to the use of the

ECO-Check reference leak for detecting helium or hydrogen (forming gas)

accordingly.

Notice: A verification can only be performed while the Ecotec E3000 is in

measurement mode (not when the main menu is opened or during startup).

If the sniffer tip is inserted into the opening of the ECO-Check reference leak a

verification of the calibration (proof function) will be started automatically.

While holding the sniffer tip in the test leak opening, the Ecotec E3000 will check the

reading from the ECO-Check. Afterwards the operator will be requested to remove

the sniffer tip from the leak opening.

Notice: Any time during the verification procedure an internal calibration may be

started by pressing either the right sniffer probe button or the CAL button

on the main display.

The results of the verification will be displayed in a summarizing screen.

Fig. 3-18 Results of proof function

For gases that are enabled for internal calibration either “Check ok” or “Recalibration

required” will be stated.

For gases that are disabled for internal calibration “Gas disabled” will be stated.

For gases that cannot be calibrated with the ECO-Check because of very high or

very low mass positions, “gas specific check impossible” will be listed.

For returning to the measuring mode, please press the right probe button or press

“

OK” on the main display.

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-15

Page 54

3.5.2 Internal calibration

Notice: The description of how to perform an internal calibration applies to the use

Notice: An internal calibration can only be performed while the Ecotec E3000 is in

If the sniffer tip is inserted into the opening of the ECO-Check reference leak with the

right probe button pressed while in measurement mode, a calibration will be started

automatically.

While holding the sniffer tip in the test leak opening, the Ecotec E3000 will first look

for a baseline, find the Argon peak of the air and then measure the test leak.

Afterwards the operator will be requested to remove the sniffer tip from the leak

opening.

After completion of the calibration a screen summarizing the results of the calibration

will be displayed.

For gases that are allowed for internal calibration the old and new calibration factor

and the old and new relative peak position will be stated.

of the ECO-Check reference leak for detecting helium or hydrogen (forming

gas) accordingly.

measurement mode (not when the main menu is opened or during startup).

Fig. 3-19 Results of internal calibration

If a gas cannot be calibrated internally, in the listing the message “int. calibration

impossible” will be displayed for these gases.

If a gas has been disabled for internal calibration in the “

message “Gas disabled” will be displayed.

To avoid unintended overwriting of a previous external (more accurate) calibration,

the operator needs to “confirm to save the new values”.

The saving of the new values may be password protected.

3-16 Operation of the Ecotec E3000

EDIT GAS” menu, the

kina22e chapter 3.fm technical handbook(1206)

Page 55

3.5.3 External calibration

For external calibration it is recommended to use leak rates > 2 g/a (0.07 oz/yr) when

calibrating the Ecotec E3000.

Notice: If significantly increased backgrounds are prevalent in your production

Notice: If a calibration is started during the first 20 minutes after power on, a

The external calibration is a semi-automatic process during which the user will have

to follow some instructions. The calibration process may be started via the “

button from the measuring mode at any time (except when the menu is open or the

function has been locked). A running calibration process may be cancelled by

operating the “

After pressing the CAL button the currently selected gases with their selected mass

positions will be listed. By pressing one of the four buttons on the right side of the

display, the gas to be calibrated externally will be selected. Only gases that are

currently enabled will be available for calibration.

environment, larger leak rates for the calibration leak may be required.

warning will be issued. Only confirm and continue with the calibration if the

real warm-up has been longer (e.g. after a quick restart of the Ecotec

E3000)

CAL” -

ESC” button.

Notice: If more than one gas is currently selected for measurement, a calibration

will be required for each gas separately.

Fig. 3-20 Gas selection for external calibration

Please check whether the leak rate and the gas type displayed equals the leak rate

and the gas type of the external leak you plan to use. If the leak rate is different press

“

EDIT LEAK RATE” and enter the correct leak rate value. Press “START” afterwards to

begin with the calibration process.

kina22e chapter 3.fm technical handbook(1206)

Operation of the Ecotec E3000 3-17

Page 56

Fig. 3-21 Setting-up the leak rate of the external leak

Please hold the sniffer tip to the outlet of the external calibrated leak. Hold the sniffer

tip steady and very close to the opening, however, do not clog the opening with the

sniffer tip.

Some air also needs to enter the sniffer tip in addition to the refrigerant from the

external calibrated leak. If the leak rate signal indicated by the bar graph is stable

press “

OK”.

Keep holding the sniffer tip steady in front of the opening while the Ecotec E3000

reads the leak rate of the calibrated leak. During this time the text “Please wait…” will

be displayed.

When the analysis of the calibrated leak signal is completed a message “sniff air!”

will be displayed.