Page 1

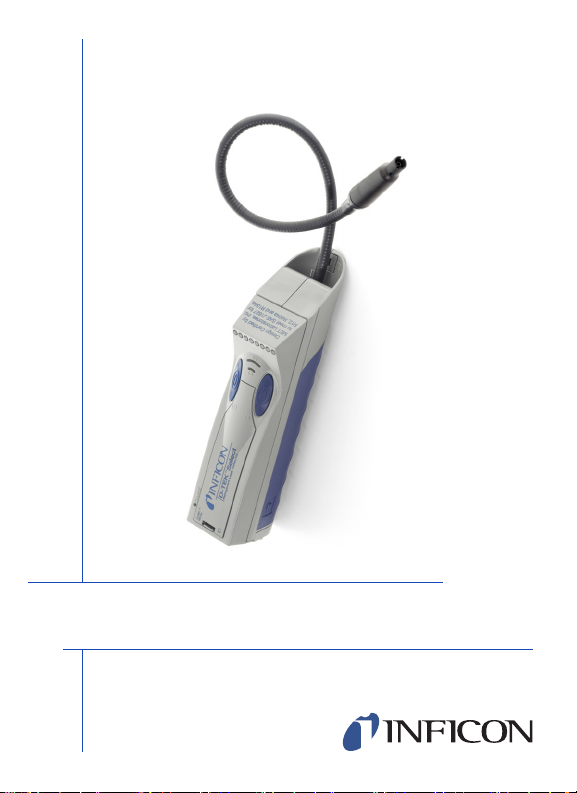

OPERATING MANUAL

D-TEK™ Select

Refrigerant Leak Detector

EN

Page 2

Declaration Of Conformity

WARNING

This is to certify that this equipment, designed and manufactured by INFICON® Inc., Two

Technology Place, East Syracuse, NY 13057 USA, meets the essential safety requirements of

the European Union and is placed on the market accordingly. It has been constructed in

accordance with good engineering practice in safety matters in force in the Community and

does not endanger the safety of persons, domestic animals or property whe n properly installed

and maintained and used in applications for which it was made.

Equipment Description . . . . . . . . . . . . . .D-TEK Select

Applicable Directives . . . . . . . . . . . . . . . 2006/95/EC (LVD)

Applicable Standards . . . . . . . . . . . . . . .EN 61010-1:2010;

CE Implementation Date. . . . . . . . . . . . .March 9, 2015

Authorized Representative . . . . . . . . . . . Brian King

Any questions relative to this declaration or to the safety of INFICON products should be

directed, in writing, to the quality assurance department at the above address.

Specification Table in Accordance with EN 14624

Minimum sensitivity to R134a, fixed (static) 1 g/yr

Maximum sensitivity to R134a, fixed (static) >50 g/yr

Minimum sensitivity to R134a, moving (dynamic) 1 g/yr

Maximum sensitivity to R134a, moving (dynamic) >50 g/yr

Minimum response/detection time <1 second

Zering time 5-7 seconds

Recovery time for 50 g/yr exposure* 1 second

Minimum sensitivity in contaminated environment 2 g/yr

Calibration frequency: Check annually with calibrated leak standard.

*Upper leak detection limit is not specified by INFICON as there is no upper limit to the size

of the leak the detector is able to detect. As no 50 g/yr leak standard was available during

testing, a 31 g/yr leak was substituted.

Refrigerant Leak Detector

2004/108/EC (EMC)

2011/65/EU (RoHS)

2006/66/EC as amended by 2013/56/EU (Battery

Directive)

EN 61326-1:2013 (Class A);

EN 62133:2013 (CB Test Cert. FI-17925)

Business Line Manager, Service Tools

INFICON Inc.

This symbol is used to alert the user to the presence of important operating

and maintenance (servicing) instructions in the literature accompanying this

instrument.

INFICON ® and D-TEK™ Select are trademarks of INFICON.

2

Page 3

Thank you for buying the INFICON D-TEK Select

Green / Yellow

LEDs

High / Low

Sensitivity Switch

Power

Switch

Power Cell

Compartment

Filter

Cartridge

Flexible

Probe

Rubberized

Grip

Tip

Power

Jack

Headphone

Jack

High / Low

Indicators

Charge

Indicator

IR Cell

Access Door

Probe

Cap

Refrigerant Leak Detector!

With normal use, your D-TEK Select from INFICON will give you years of

trouble-free service.

To get the best performance from your D-TEK Select, please read this manual

carefully before you start using the instrument. If you have any questions or need

additional assistance, please call 800-344-3304. We’ll be happy to help you.

3

Page 4

Getting Started

WARNING

The D-TEK Select is shipped with the infrared cell and power stick installed. The

nickel/metal hydride batteries in the power stick are not yet charged. To charge

them, connect the cord of the AC power adapter to the power jack at the rear of

the instrument, and plug the adapter into the appropriate mains outlet. The battery

charging light (rear left side) will flash when the detector is charging, changing to

steady illumination when the power stick is charged. Allow 10 hours for the full

charge.

NOTE: You should expect approximately 6.5 hours of operation from a fully

charged power stick. The D-TEK Select will operate off the AC power

adapter. Connecting the supplied AC power adapter will allow operation

of the detector while the power stick charges.

Using Your INFICON D-TEK Select

Do not operate this instrument in the presence of gasoline,

natural gas, propane, or in other combustive atmospheres.

Using the D-TEK Select is simple. Press the power switch once to turn the

detector ON. The green ON LED will illuminate, and the yellow LEDs will

illuminate from left to right in a scrolling fashion while the infrared cell warms up

(approximately 60 seconds). When the detector is warmed up and ready for use,

the yellow LEDs extinguish and you will hear a steady beeping.

The D-TEK Select provides similar responses to all CFC’s, HCFC’s, HFC’s and

refrigerant blends (i.e., R-404A, R407C, R-410A) as well as SF6. There is no

need to select the refrigerant you’re working with.

NOTE: The D-TEK Select does not detect R-11 due to the particular physical

properties of this refrigerant.

4

Page 5

Headphone sets may be used with the D-TEK Select. When the headphones are

WARNING

plugged into the detector, the audio signal will only be heard through the headset.

Only use headphone sets supplied by INFICON, PN 032-0430.

serious hearing damage may occur if other headphone sets are

used.

Finding Leaks

1. Place the tip of the leak-detector probe as close as possible to the site of the

suspected leak. Try to position the probe within 1/4 inch (0.5 cm) of the possible

leak source.

2. Slowly (approximately 1 - 2 inches (2.5 - 5 cm) per second) move the probe past

each possible leak point.

NOTE: It is important to move the tip of the probe past the leak to get a

correct reading. The D-TEK Select only responds to changes in

concentration of the refrigerant from the leak. Moving the probe

permits the instrument to respond properly to these changes.

3. When the instrument detects a leak source, its yellow LEDs will illuminate and

it will beep rapdily.

4. When the D-TEK Select signals a leak, pull the probe away from the leak for a

moment, then bring it back to pinpoint the location.

5. If the concentration of the refrigerant gas is high, press the sensitivity switch to

change to the LOW sensitivity setting. The LOW sensitivity setting helps find the

exact site when a leak is large.

6. Once you have isolated the leak source, return the sensitivity setting to HIGH

to continue using the D-TEK Select.

7. When you are done leak checking, press the Power switch to turn the D-TEK

Select OFF.

5

Page 6

Using the Manual Zero Mode

The D-TEK Select's automatic suppression of background contamination can be

disabled, allowing for a continuous display of a leak without "zeroing it out". When

the D-TEK Select is set in the manual zero mode, the technician may manually

reset or zero the detector.

To initialize this function, press and hold the HI/LO switch for 5 seconds. The "HI"

sensitivity indicator will flash to alert the user the detector is in manual zero mode.

Increases in concentrations of refrigerants will be displayed by the illumination of

the yellow LEDS. For best test results, allow the D-TEK Select to warm up for

5 - 10 minutes before engaging manual zero mode.

To "zero" the D-TEK Select, press the HI/LO switch once. Both the HI and LO

sensitivity indictors will flash for a few seconds while the detector measures and

sets a new background base level. Any increase in concentrations of refrigerant

above this base level will be displayed.

To turn off the manual zero mode, press and hold the HL/LO switch until the HI

sensitivity indicator becomes steady.

NOTE: When the D-TEK Select is turned on, it will always default to the

automatic zeroing mode.

6

Page 7

Recharging the Power Stick

WARNING

A fully charged power stick should provide power for approximately 6.5 hours of

continuous operation. When the battery is fully depleted, the D-TEK Select will

shut down. To show the battery is depleted, the green ON LED, the last yellow

leak LED and the amber battery charging LED will flash. Recharge the D-TEK

Select by connecting the supplied AC power adapter, or using the cigarette lighter

adapter.

NOTE: The D-TEK Select does not need to be fully charged to operate nor fully

discharged before recharging.

Do not attach any other power cords to the D-TEK select’s power

jack except the AC power adapter and DC cords designed for this

instrument.

The battery charging indicator (rear left side) will flash when the power stick is

charging, changing to steady illumination when the power stick is fully charged.

Allow 10 hours for a full charge.

The D-TEK Select will operate off the AC power adapter. Connecting the supplied

AC power adapter will allow operation of the detector while the power stick

charges.

7

Page 8

Changing the Filter Cartridge

CAUTION

The D-TEK Select utilizes a specially designed filter cartridge that fits into a

protective cap. The filter cartridge should be changed when it appears dirty or

when substances trapped in the filter cartridge seem to be affecting the sensitivity

of the D-TEK Select.

NOTE: Water or oil will not penetrate the filter material but will prevent airflow

through the filter and affect sensitivity.

Turn off the D-TEK Select and hold the probe with the filter tip

pointing down when removing the filter cap.

To change the filter cartridge, twist off the protective cap. Remove and dispose of

the used filter cartridge. Do not allow any moisture or dust to get into the probe.

Do not disassemble or attempt to clean the material inside the filter cartridge, as it

can be damaged when handled. Slide a new filter cartridge into the cap. Twist the

cap with the new filter cartridge onto the probe base until it is tight.

NOTE: It is very important that you operate the D-TEK Select with a filter

cartridge installed at all times. Failure to do so could damage the leak

detector's components.

8

Page 9

Changing the Infrared Cell

WARNING

Components may be hot. Turn off detector and disconnect power

adapter cord before removing the infrared cell door.

The D-TEK Select’s infrared cell (IR cell) is located in the body of the detector.

The IR cell is a complete assembly consisting of a metal tube, connectors and

electronic components. The IR cell is not designed to be taken apart. Doing so will

destroy the cell. This specialized IR cell will operate for about 1000 hours.

The D-TEK Select will flash all the yellow leak LEDs when the IR cell has reached

the end of its useful life. To replace the IR cell:

1. Locate on the top cover (at the rear of the detector) the latch for the IR cell door.

2. Using a small screwdriver, pull the latch forward and remove the door.

3. Grasp the IR cell according to the directions printed on its label.

Pull it straight out so both ends are released at the same time.

4. Remove the replacement IR cell from the protective package.

5. Carefully align the male leads and air tubes on the IR cell with the connectors

mounted on the circuit board. Insert the leads into the sockets and push the IR

cell straight down.

NOTE: Ensure the lead connectors on the IR cell ends are not bent and the cell

is seated tightly.

9

Page 10

Removing/Replacing the Power Stick

The D-TEK Select uses a pre-assembled power stick.

Remove the battery compartment door on the back of the D-TEK Select by

pressing on both release buttons on the grip and pulling the door straight out. The

power stick is connected to the PCB board via a miniature electrical connector.

Disengage the connector and slide the power stick out of the D-TEK Select.

Slide the new stick into the D-TEK Select and push the miniature connector on the

power stick into the mating half on the PCB board. Do not bend the PCB board’s

connector away from the board. Once the power stick is in place, close the battery

compartment by aligning the two tabs and sliding the door straight in until it

latches. Ensure the wire leads on the power stick are not pinched in the door.

Allow 10 hours to fully charge the new power stick.

NOTE: If the D-TEK Select does not power up after the power stick is replaced,

check that the key connector on the power stick is mated properly to the

connector on the circuit board. Reverse the connection if necessary and

power up again. If the Hi/Lo indicators flash in a rapid, alternating manner

when the AC adapter is connected, the power stick is installed

backwards.

10

Page 11

Replacement Parts and Accessories

Replacement parts and accessories for your D-TEK Select are available through

the same dealer from whom you bought the instrument.

Molded plastic storage case. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 712-702-G1

Headphones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 032-0430

12-volt cord with cigarette-lighter plug, 3.7 m (12 ft.). . . . . . . . . . . . . . 703-055-P1

120-volt mains adapter and cord, 1.8 m (6 ft.) . . . . . . . . . . . . . . . . . . 033-0019-G1

230-volt (Euro plug) mains adapter and cord, 1.8 m (6 ft.). . . . . . . . . 033-0020-G1

230-volt (UK plug) mains adapter and cord, 1.8 m (6 ft.). . . . . . . . . . 033-0022-G1

100-volt mains adapter and cord, 1.8 m (6 ft.) . . . . . . . . . . . . . . . . . . 033-0018-G1

230-volt (Australia) mains adapter and cord, 1.8 m (6 ft.) . . . . . . . . . 033-0035-G1

Power Stick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 712-700-G1

Replacement infrared cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 712-701-G1

Filter Cartridges, package of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 712-707-G1

Replacement Probe Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 712-705-G1

Specifications

Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Indoor or Outdoor

Minimum sensitivity to R12 and R134a . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 g/yr)

Input voltage range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 to 16 V (dc)

Input current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 mA Max.

Operating and charging temperature range* . . . . . . . . . . . . . . . . -20 °C to +50 °C

Storage temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -20 °C to +60 °C

Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95% RH NC Max.

Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 m (6500 ft.)

Pollution degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overvoltage category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Weight (with power cells) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.58 kg (1.28 lb.)

*May be operated for a limited time in lower temperature environments

( -4°F to 122 °F)

(-4°F to +140 °F)

11

Page 12

Troubleshooting Guide

Problem Cause Remedy

1) All yellow lights

flashing together.

2) Will not detect

refrigerant.

3) After warm up

sequence the green,

the last yellow and the

amber charging LEDs

flash.

4) Pump is not

working.

1a) IR sensor cell has

become unseated.

1b) IR sensor cell has

failed.

2a) Unit may not be

warmed up and

ready to use.

2d) Battery may be

dead.

2c) Filter cartridge

may be clogged,

preventing air and

refrigerant from

passing into IR cell.

2b) Pump may have

failed.

2e) User may be

working with R-11.

3a) Battery needs

recharging.

3b) Power stick has

failed.

4a) Pump has failed. 4a) See 2d.

1a) Remove sensor access

door and push both ends of

sensor down. (Do not

remove/reinsert sensor cell.)

Restart unit and examine.

1b) Replace with new sensor,

part number 712-701-G1.

2a) If yellow lights are

scrolling, wait 90 seconds to

see if the unit starts to beep

and the lights stop scrolling. If

not, contact INFICON.

2d) See #3 below.

2c) Replace used filter

cartridge with a new one.

2b) You should hear the pump

running after the warm up

sequence is completed.

VERIFY it is not a low battery

condition (see #3). If not,

contact INFICON.

2e) This refrigerant is only

detectable if the leak is quite

large.

3a) Charge battery for 10-12

hours.

3b) Replace power stick with

part #712-700-G1.

Page 13

Problem Cause Remedy

5) Unit does not

power up. Hi/Lo

indicators flash in a

rapid, alternating

manner when AC

adapter is connected.

5a) Power

stick/battery has been

connected in reverse.

5a) Reverse the battery's

connection and power unit up

again.

Warranty and Liability-Limitation

INFICON warrants your D-TEK Select Refrigerant Leak Detector to be free from

defects of materials or workmanship for two years from the date of purchase.

INFICON does not warrant items that deteriorate under normal use,

including power stick, infrared cell and filters. In addition, INFICON does not

warrant any instrument that has been subjected to misuse, negligence, or

accident, or has been repaired or altered by anyone other than INFICON.

INFICON liability is limited to instruments returned to INFICON, transportation

prepaid, not later than thirty (30) days after the warranty period expires, and which

INFICON judges to have malfunctioned because of defective materials or

workmanship. INFICON liability is limited to, at its option, repairing or replacing

the defective instrument or part.

This warranty is in lieu of all other warranties, express or implied, whether of

MERCHANTABILITY or of FITNESS FOR A PARTICULAR PURPOSE or

otherwise. All such other warranties are expressly disclaimed. INFICON shall

have no liability in excess of the price paid to INFICON for the instrument plus

return transportation charges prepaid. INFICON shall have no liability for any

incidental or consequential damages. All such liabilities are EXCLUDED.

13

Page 14

Return Materials Authorization Procedure

All instruments and parts returned to INFICON for repair or credit must be

properly packaged, insured, shipped transportation charges prepaid, and must

have a Return Material Authorization (RMA) number issued before the material is

returned. The RMA number is to be marked on all shipping labels and packing

slips. Please see your INFICON distributor for assistance. If you have any

questions contact us at 800-344-3304.

14

Page 15

15

Page 16

TWO TECHNOLOGY PLACE

EAST SYRACUSE, NY 13057-9714 USA

Phone: +1.800.344.3304

Fax: +315.437.3803

E-Mail: service.tools@inficon.com

www.inficonservicetools.com

074-392-P1L

Loading...

Loading...