Page 1

OPERATING MANUAL

®

Cygnus

Thin Film Deposition Monitor

IPN 074-379-P1K

Page 2

Page 3

OPERATING MANUAL

®

Cygnus

Thin Film Deposition Monitor

IPN 074-379-P1K

www.inficon.com reachus@inficon.com

Due to our continuing program of product improvements, specifications are subject to change without notice.

©2004 INFICON

Page 4

Trademarks

The trademarks of the products mentioned in this Operating Manual are held by the companies that

produce them.

INFICON® and Cygnus® are trademarks of INFICON Inc.

Windows®, Windows 95® and Microsoft® are registered trademarks of Microsoft Corporation.

CAJON® is a registered trademark of Swagelok, Co.

All other brand and product names are trademarks or registered trademarks of their respective companies.

The information contained in this Operating Manual is believed to be accurate and reliable. However, INFICON

assumes no responsibility for its use and shall not be liable for any special, incidental, or consequential

damages related to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

©2004 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

DECLARATION

OF

CONFORMITY

This is to certify that this equipment, designed and manufactured by:

INFICON Inc.

Two Technology Place

East Syracuse, NY 13057

USA

meets the essential safety requirements of the European Union and is placed on the

market accordingly. It has been constructed in accordance with good engineering

practice in safety matters in force in the Community and does not endanger the safety

of persons, domestic animals or property when properly installed and maintained and

used in applications for which it was made.

Equipment Description: Cygnus Thin Film Deposition Controllers, including

Oscillators and Crystal Sensors as properly installed.

Applicable Directives: 73/23/EEC as amended by 93/68/EEC

89/336/EEC as amended by 93/68/EEC

Applicable Standards: EN 61010-1:2001

EN 61326:1997 (Industrial Use)

EN 61000-3-2:1995/A14:2000

EN 61000-3-3:1995

CE Implementation Date: August 22, 2003

Authorized Representative: Gary W. Lewis

Vice President - Quality Assurance

INFICON Inc.

ANY QUESTIONS RELATIVE TO THIS DECLARATION OR TO THE SAFETY OF LEYBOLD INFICON'S PRODUCTS SHOULD BE

DIRECTED, IN WRITING, TO THE QUALITY ASSURANCE DEPARTMENT AT THE ABOVE ADDRESS.

01-22-04

Page 6

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

two (2) years from the date of shipment thereof by Seller. Seller's liability under

this warranty is limited to such of the above products or parts thereof as are

returned, transportation prepaid, to Seller's plant, not later than thirty (30) days

after the expiration of the period of warranty coverage in respect thereof and are

found by Seller's examination to have failed to function properly because of

defective workmanship or materials and not because of improper installation or

misuse and is limited to, at Seller's election, either (a) repairing and returning the

product or part thereof, or (b) furnishing a replacement product or part thereof,

transportation prepaid by Seller in either case. In the event Buyer discovers or

learns that a product does not conform to warranty, Buyer shall immediately notify

Seller in writing of such non-conformity, specifying in reasonable detail the nature

of such non-conformity. If Seller is not provided with such written notification,

Seller shall not be liable for any further damages which could have been avoided if

Seller had been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

Cygnus Operating Manual

Table Of Contents

Chapter 1

Introduction and Specifications

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Related Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Instrument Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Definition of Notes, Cautions and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.2 General Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.3 Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.2.4 Main Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3 How To Contact Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.3.1 Returning Your Cygnus to INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4 Cygnus Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.4.1 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.4.2 Screens and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4.2.1 Instrument Set Up Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.4.2.2 Set Up Parameters for Each Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.4.3 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.4.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.4.5 Source / Recorder Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1.4.6 Logic Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1.4.7 Relays / Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1.4.8 Remote Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

1.4.9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

1.4.10 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1.4.11 Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

IPN 074-379-P1K

1.4.12 Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.13 Warm Up Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

1.4.14 Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

1.4.15 Connector Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.16 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.4.17 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

1.6 Parts and Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

1.6.1 Base Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

1.6.2 Pre-Installed Options or Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1.6.3 Oscillator Packages, Optional Accessories, and Sensors . . . . . . . . . . . . . 1-18

1.7 Initial Power-On Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

TOC - 1

Page 10

Cygnus Operating Manual

Chapter 2

Operation

2.1 Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Rear Panel Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.1 ALL CHANNELS Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3.1.1 GENERAL PARAMETERS Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.1.2 General MAINTENANCE Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.1.2.1 All Channels Sensor MAINTENANCE Display. . . . . . . . . . . . . . . . . . . . . . 2-11

2.3.1.3 CHANNEL Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.3.1.3.1 Channel Parameters Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.3.1.3.1.1 HARDWARE PROCESS Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.3.1.3.2 Channel SENSOR MAINTENANCE Display . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.3.1.3.2.1 Channel SOURCE MAINTENANCE Display . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.4 Crystal Life, Starting Frequency and Activity . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.5 Defining a Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.5.1 Executing a Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.6 State Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7 Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.1 Crystal Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7.2 Rotary Sensor Crystal Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.3 Source/Crucible Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.7.3.1 Example: Programming Turret Source Crucible Selection. . . . . . . . . . . . . 2-26

2.7.4 Hand-Held Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.7.5 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.7.6 Floppy Disk (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.7.7 Lock Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2.7.8 Datalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2.7.9 Auto Soak 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

IPN 074-379-P1K

Chapter 3

TOC - 2

Channel Parameters

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Channel Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.1 Channel Parameter Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Channel Hardware Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.3.1 Channel Hardware Parameters Definition . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Page 11

Cygnus Operating Manual

Chapter 4

General Parameters

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 General Parameter Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 General Parameters Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.4 Logic Directory Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.4.1 Logic Statement Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.4.2 Editing Logic Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.4.2.1 Logic Statement Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.4.2.2 Logic Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.4.2.3 Logic Statement Event Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4.2.3.1 Event Definitions (IF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4.4.2.4 Logic Statement Action Editing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

4.4.2.4.1 Action Definitions (THEN). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

4.5 Counters Timers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4.6 I/O Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

4.7 Floppy Disk. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Chapter 5

Remote Communications

5.1 Remote Communications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Physical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.1 RS232C Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.2 IEEE488 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Message Protocols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.1 INFICON Cygnus Message Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.3.2 Basic Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.3.2.1 Command Packet (Host to Instrument Message). . . . . . . . . . . . . . . . . . . . .5-4

IPN 074-379-P1K

5.3.2.2 Response Packet (Instrument to Host Message). . . . . . . . . . . . . . . . . . . . . 5-6

5.4 Cygnus Communication Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.4.1 ECHO Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

5.4.2 HELLO Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

5.4.3 Parameter Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4.3.1 All Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.3.1.1 Query All Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5.4.3.1.2 Update All Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.3.2 Channel Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5.4.3.2.1 Query Channel Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.4.3.2.2 Update Channel Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

TOC - 3

Page 12

Cygnus Operating Manual

5.4.3.3 General Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.4.3.3.1 Query General Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.4.3.3.2 Update General Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.4.3.4 Input Name Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4.3.4.1 Query Input Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4.3.4.2 Update Input Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4.3.5 Logic Statements Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.4.3.5.1 Query Logic Statements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.4.3.5.2 Update Logic Statements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.4.3.6 Output Name Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.4.3.6.1 Query Output Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.4.3.6.2 Update Output Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.4.3.7 Type of Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.4.3.7.1 Query Output Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.4.3.7.2 Update Output Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.4.4 STATUS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

5.4.4.1 Status Channel Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.4.4.2 Status General Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.4.5 REMOTE Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

5.4.5.1 Remote Channel Action Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

5.4.5.2 Remote General Action Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

5.4.6 Negative Response Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

5.5 Sample Cygnus Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

5.5.1 Remote Communications Example — Updating a

Channel’s Rate Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37

Chapter 6

Installation and Interfaces

6.1 Location Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Sensor Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.2 Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.1.3 Control Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.2 Avoiding Electrical Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.2.1 Verifying/Establishing Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.2.2 Connections to Earth Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.2.3 Minimizing Noise Pickup From External Cabling . . . . . . . . . . . . . . . . . . . . . 6-7

6.3 Connecting the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.1 Verifying the Correct Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.3.2 Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

IPN 074-379-P1K

TOC - 4

Page 13

Cygnus Operating Manual

6.3.3 Routing XIU Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.3.4 Interface Cable Fabrication and Pin-Out . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.3.4.1 Source Control Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

6.3.4.2 Input/Relay Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

6.3.4.3 RS-232C Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.3.4.4 Isolated +24 V(dc) Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.3.4.5 Optional DAC Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Chapter 7

Calibration Procedures

7.1 Importance of Density, Tooling and Z-Ratio. . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Determining Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.3 Determining Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.4 Laboratory Determination of Z-Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.5 Determining Cross Sensitivity Correction For Co-Deposition. . . . . . . . . . . .7-4

7.5.1 Procedure Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.5.2 Procedure Assumptions and Requirements. . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.5.3 Detailed Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Chapter 8

Troubleshooting, Status and Error Messages

8.1 Status and Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

8.2.1 Major Instrument Components and Assemblies. . . . . . . . . . . . . . . . . . . . . . 8-9

8.2.2 Troubleshooting the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.2.3 Troubleshooting Transducers/Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

8.2.4 Troubleshooting Computer Communications . . . . . . . . . . . . . . . . . . . . . . .8-18

8.3 Replacing the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

8.3.1 Standard and Compact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-20

8.3.2 Shuttered and Dual Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

IPN 074-379-P1K

8.3.3 Bakeable Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-22

8.3.4 Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

8.3.5 Crystal Snatcher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-24

8.3.6 CrystalSix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

8.3.7 Crystal12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-24

8.4 Crystal Sensor Emulator IPN 760-601-G1 or 760-601-G2. . . . . . . . . . . . . 8-25

8.4.1 Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-26

8.4.1.1 Measurement System Diagnostic Procedure . . . . . . . . . . . . . . . . . . . . . . .8-26

8.4.1.2 Feed-Through Or In-Vacuum Cable Diagnostic Procedure . . . . . . . . . . . .8-27

8.4.1.3 Sensor Head Or Monitor Crystal Diagnostic Procedure. . . . . . . . . . . . . . . 8-28

8.4.1.4 System Diagnostics Pass But Crystal Fail Message Remains. . . . . . . . . . 8-29

TOC - 5

Page 14

Cygnus Operating Manual

8.4.2 % XTAL Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

8.4.3 Sensor Cover Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8.4.3.1 Compatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8.4.3.2 Incompatible Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

8.4.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

Chapter 9

Measurement and Control Theory

9.1 Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.1 Monitor Crystals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.1.2 Period Measurement Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.1.3 Z-Match Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.1.4 Active Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.1.5 ModeLock Oscillator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.1.6 Auto Z-Match Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.1.7 Control Loop Theory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Appendix A

Index

Material Table

IPN 074-379-P1K

TOC - 6

Page 15

1.1 Introduction

Cygnus is a closed loop process controller designed for use primarily in physical

vapor deposition. The unit monitors and/or controls the rate and thickness of the

deposition of thin films. Deposition rate and thickness are inferred from the

frequency change induced by mass added to a quartz crystal. This technique

positions sensors in the path between or to the side of the source of the vaporized

material and the target substrate. The sensor incorporates an exposed oscillating

quartz crystal whose frequency decreases as material accumulates. The change

in frequency provides information to determine rate and thickness and to

continually control the evaporation power source. With user supplied time,

thickness and power limits and with desired rates and material characteristics, the

unit is capable of automatically controlling the process in a precise and repeatable

manner. User interaction is accomplished via the unit's front panel and consists of

selection or entry of parameters to define the process.

Cygnus Operating Manual

Chapter 1

Introduction and Specifications

The complete system consists of a main electronics unit, the Cygnus, sensor

heads and a crystal interface unit (XIU) for each attached sensor. These items are

generally bundled at the factory and are also sold separately.

The Cygnus Manual provides user information for installing, programming,

calibrating and operating the main electronics unit.

When reading the Cygnus Manual, please pay particular attention to the NOTES,

CAUTIONS, and WARNINGS found throughout the text. The Notes, Cautions, and

Warnings are defined in section 1.2.1 on page 1-2.

You are invited to comment on the usefulness and accuracy of this manual by filling

out the registration card and returning it.

IPN 074-379-P1K

1.1.1 Related Manuals

Sensors are covered in separate manuals.

074-154 - Bakeable

074-155 - CrystalSix

074-156 - Single/Dual

074-157 - Sputtering

074-398 - Crystal12

1 - 1

Page 16

Cygnus Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.2 Instrument Safety

1.2.1 Definition of Notes, Cautions and Warnings

When using this manual, please pay attention to the NOTES, CAUTIONS and

WARNINGS found throughout. For the purposes of this manual they are defined as

follows:

NOTE: Pertinent information that is useful in achieving maximum instrument

efficiency when followed.

Failure to heed these messages could result in damage

to the instrument.

Failure to heed these messages could result in personal

injury.

Dangerous voltages are present which could result in

personal injury.

IPN 074-379-P1K

1 - 2

Page 17

1.2.2 General Safety Information

WARNING - Risk Of Electric Shock

CAUTION

Do not open the instrument case! There are no

user-serviceable components within the instrument

case.

Dangerous voltages may be present whenever the power

cord or external input/relay connectors are present.

Refer all maintenance to qualified personnel.

This instrument contains delicate circuitry which is

susceptible to transient power line voltages. Disconnect

the line cord whenever making any interface

connections. Refer all maintenance to qualified

personnel.

Cygnus Operating Manual

IPN 074-379-P1K

1 - 3

Page 18

Cygnus Operating Manual

WARNING - Risk Of Electric Shock

1.2.3 Earth Ground

Cygnus is connected to earth ground through a sealed three-core

(three-conductor) power cable, which must be plugged into a socket outlet with a

protective earth terminal. Extension cables must always have three conductors

including a protective earth terminal.

Never interrupt the protective earth circuit.

Any interruption of the protective earth circuit inside or

outside the instrument, or disconnection of the

protective earth terminal is likely to make the instrument

dangerous.

This symbol indicates where the protective earth ground

is connected inside the instrument. Never unscrew or

loosen this connection.

IPN 074-379-P1K

1 - 4

Page 19

1.2.4 Main Power Connection

WARNING - Risk Of Electric Shock

This instrument has line voltage present on the primary

circuits whenever it is plugged into a main power source.

Never remove the covers from the instrument during

normal operation.

There are no operator-serviceable items within this

instrument.

Removal of the top or bottom covers must be done only

by a technically qualified person.

In order to comply with accepted safety standards, this

instrument must be installed into a rack system which

contains a mains switch. This switch must break both

sides of the line when it is open and it must not

disconnect the safety ground.

Cygnus Operating Manual

IPN 074-379-P1K

1 - 5

Page 20

Cygnus Operating Manual

1.3 How To Contact Customer Support

Worldwide support information regarding:

Technical Support, to contact an applications engineer with questions

regarding INFICON products and applications, or

Sales and Customer Service, to contact the INFICON Sales office nearest you,

or

Repair Service, to contact the INFICON Service Center nearest you,

is available at www.inficon.com.

If you are experiencing a problem with your instrument, please have the following

information readily available:

the serial number for your instrument,

a description of your problem,

an explanation of any corrective action that you may have already attempted,

and the exact wording of any error messages that you may have received.

To contact Customer Support, see Support at www.inficon.com.

1.3.1 Returning Your Cygnus to INFICON

Do not return any component of your Cygnus to INFICON without first speaking

with a Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your

instrument.

Prior to being given an RMA number, you may be required to complete a

Declaration Of Contamination (DOC) form if your instrument has been exposed to

process materials. DOC forms must be approved by INFICON before an RMA

number is issued. INFICON may require that the instrument be sent to a

designated decontamination facility, not to the factory. Failure to follow these

procedures will delay the repair of your instrument.

IPN 074-379-P1K

1 - 6

Page 21

1.4 Cygnus Specifications

1.4.1 Measurement

Crystal Frequency . . . . . . . . . . . . . . 6.0 MHz (new crystal) to 4.5 MHz

Internal Precision . . . . . . . . . . . . . . . ± 0.004657 Hz over 100 ms sample for

Thickness & Rate Resolution . . . . . . 0.00577 Å (new crystal);

Thickness Accuracy . . . . . . . . . . . . . 0.5% typical, (dependent on process

Frequency Accuracy. . . . . . . . . . . . . ± 2 ppm 0-50 °C

Measurement Frequency . . . . . . . . . 10 Hz

Measurement Technique . . . . . . . . . ModeLock

Cygnus Operating Manual

fundamental and anharmonic frequencies

0.01016 Å (crystal @ 4.5 MHz) over

100 ms sample for material density = 1.0,

Z-ratio = 1.0

conditions, especially sensor location,

material stress, temperature and density)

User Interface. . . . . . . . . . . . . . . . . . CRT and limited membrane keypad. All

parameters accessible through computer

communications. Multiple message areas for

indication of states and detailed indication of

abnormal and stop conditions.

1.4.2 Screens and Parameters

Navigation . . . . . . . . . . . . . . . . . . . . Six soft keys

Structure. . . . . . . . . . . . . . . . . . . . . . Separate screens dedicated to

1) All Channel Data Display, 2) Individual

Channel Data, 3) Channel Parameters,

4) Channel Hardware Parameters,

IPN 074-379-P1K

# of Source / Sensor Channels . . . . 6, Sources can be started or stopped

5) General Parameters, 6) Logic,

7) Maintenance, 8) Communications.

individually or in any combination.

1 - 7

Page 22

Cygnus Operating Manual

1.4.2.1 Instrument Set Up Parameters

Test On. . . . . . . . . . . . . . . . . . . . . . . Yes / No

Time Compressed . . . . . . . . . . . . . . Yes / No

Audio Feedback . . . . . . . . . . . . . . . . Yes / No

RS232 Baud Rate . . . . . . . . . . . . . . 2400, 4800, 9600, 19200

IEEE Address. . . . . . . . . . . . . . . . . . 1-30

Data Logging Path . . . . . . . . . . . . . . 0 = No Data Logging

Data Log XTAL History. . . . . . . . . . . Yes / No

Print Screen Path . . . . . . . . . . . . . . . 2 = Floppy Disk

Print Screen Number . . . . . . . . . . . . 0 to 999

DAC Output Option . . . . . . . . . . . . . 0 = Power/Rate for 6 channels

2 = File, Page Format

3 = File, Comma Format

1 = Power/Thickness for 6 channels

2 = Power/Rate/Thickness for 4 channels

3 = Rate/Thickness for 6 channels

Thickness Equation 1. . . . . . . . . . . . Up to 6 channel numbers can be specified,

Thickness Equation 2. . . . . . . . . . . . Up to 6 channel numbers can be specified,

Thickness Equation 3. . . . . . . . . . . . Up to 6 channel numbers can be specified,

1.4.2.2 Set Up Parameters for Each Source

Source States . . . . . . . . . . . . . . . . . . Film template defines state sequence.

Power Ramps. . . . . . . . . . . . . . . . . . 2 per Source

Power Level . . . . . . . . . . . . . . . . 0.00 to 99.99%

Rise Time . . . . . . . . . . . . . . . . . . 00:00 to 99:59 min:sec

Soak Time . . . . . . . . . . . . . . . . . 00:00 to 99:59 min:sec

each channel number can be used only

once.

each channel number can be used only

once.

each channel number can be used only

once.

IPN 074-379-P1K

Flexible sequencing is a done by skipping

states or vectoring to a different state.

1 - 8

Rate Filter Time . . . . . . . . . . . . . . . . 0.1, 0.4, 1.0, 4.0, 10.0, 20.0, or 30.0 sec

Page 23

Cygnus Operating Manual

Rate & Thickness Control with

Shutter open . . . . . . . . . . . . . . . . . 0.001 to 999.9 Å/sec

Rate Control with Shutter closed . . . 0.001 to 999.9 Å/sec

Idle Ramp . . . . . . . . . . . . . . . . . . . . . 1 per Source

Idle Power. . . . . . . . . . . . . . . . . . 0.00 to 99.99%

Idle Ramp Time . . . . . . . . . . . . . 00:00 to 99:59 min:sec

Deposit After Pre-Deposit. . . . . . . . . Yes / No

Yes = go to Deposit

No = go to Non-Deposit Rate Control

Density . . . . . . . . . . . . . . . . . . . . . . . 0.100 to 99.999 gm/cc

Z-ratio . . . . . . . . . . . . . . . . . . . . . . . . 0.100 to 15.000

Control Loop types . . . . . . . . . . . . . . 0 / 1 / 2

Non-PID, PI, PID

PID Control Mode. . . . . . . . . . . . . . . Fast or Slow Source

Process Gain . . . . . . . . . . . . . . . 0.01 to 999.99 Å/sec/%Power

Primary Time Constant . . . . . . . . 0.010 to 9999.99 seconds

System Dead Time. . . . . . . . . . . 0.010 to 9999.99 seconds

Tooling Factor. . . . . . . . . . . . . . . . . . 1.0 to 999.9%

Secondary Tooling . . . . . . . . . . . . . . 1.0 to 999.9%

Sensors . . . . . . . . . . . . . . . . . . . . . . 2 standard, 4 additional w/optional hardware

Sensor Type . . . . . . . . . . . . . . . . . . . 1 / 2 / 6 / 7 / 12

(Single, CrystalTwo, CrystalSix, Rotary,

Crystal12)

CrystalSix Position Select. . . . . . Indexes to next good crystal

IPN 074-379-P1K

Sensor Switch Output. . . . . . . . . . . . 0 to 38

Sensor Shutter Output . . . . . . . . . . . 0 to 38

Sensor Shutter Output Type. . . . . . . 0 / 1

Normally Open, Normally Closed

Maximum Source Power . . . . . . . . . 0.01 to 99.99%

Minimum Source Power . . . . . . . . . . 0.00 to 99.98%

Maximum Power Option . . . . . . . . . . Stop / Idle Ramp / Continue — can be

selected for each source individually.

Averaging Time . . . . . . . . . . . . . . . . 0 to 30 minutes

Final Thickness . . . . . . . . . . . . . . . . 0.000 to 999.9 kÅ

1 - 9

Page 24

Cygnus Operating Manual

ON Final Thickness . . . . . . . . . . . . . 0 / 1 / 2

0 = Go to Non-Deposit Control

1 = Go to Idle Ramp

2 = Continue

Cross Talk Percent . . . . . . . . . . . . . . 0.00 to 99.99%, Correction for 2 sensors,

multiple instances of 2 sensor correction is

allowed (maximum of 3 instances of 2 sensor

correction).

Crucible Selection . . . . . . . . . . . . . . Turret is indexed to selected position on a

start. Turret feedback is checked whenever a

source is started. Range is from 1 to number

of crucibles.

Number of Crucibles. . . . . . . . . . 1, 4, 8, 16, 32 or 64

Crucible Output . . . . . . . . . . . . . 0 to 37

Crucible Output Type . . . . . . . . . 0 / 1

0 = Normally Open, 1 = Normally Closed.

Turret Feedback. . . . . . . . . . . . . Yes / No

Turret Input. . . . . . . . . . . . . . . . . 0 to 28

Turret Delay . . . . . . . . . . . . . . . . 1 to 60 secs.

RateWatcher® . . . . . . . . . . . . . . . . . Sample and Hold Feature

RateWatcher Option. . . . . . . . . . 0 = None, 1 = Non-deposit,

2 = Non-deposit and Deposit

RateWatcher Time . . . . . . . . . . . 00:01 to 99:59 min:sec

RateWatcher . . . . . . . . . . . . . . . Accuracy 1 to 99%

Source Voltage Range . . . . . . . . . . . 0 to 10 V, 0 to 5 V, 0 to 2.5 V, 0 to -10 V,

0 to -5 V, 0 to -2.5 V

DAC Rate Range . . . . . . . . . . . . . . . 0 = 10 Å/sec, 1 = 50 Å/sec, 2 = 100 Å/sec,

3 = 1000 Å/sec, 4 = 1 Å/sec

DAC Thickness Range. . . . . . . . . . . 0 = 100 Å, 1 = 1000 Å, 2 = 2000 Å,

3 = 3000 Å, 4 = 5000 Å

Substrate Shutter Output . . . . . . . . . 0 to 38

Substrate Shutter Output Type. . . . . 0 / 1

0 = Normally Open, 1 = Normally Closed

IPN 074-379-P1K

1 - 10

Page 25

Crystal Fail Option . . . . . . . . . . . . . . 0 / 1 / 2

Crystal Quality . . . . . . . . . . . . . . . . . 0 to 9

Crystal Stability . . . . . . . . . . . . . . . . . 0 to 9

Auto-Z. . . . . . . . . . . . . . . . . . . . . . . . Yes / No

1.4.3 User Interface

Front Panel / CRT. . . . . . . . . . . . . . . Parameters can be programmed through

Remote Communications . . . . . . . . . Parameters can be programmed through

Cygnus Operating Manual

0 = Time Power,

1 = Idle Ramp

2 = Stop

Can be selected for each source individually.

Cygnus front panel. There is a display for

each source with graphical and text / number

information. There is also a display showing

text and number information for all sources.

computer communications. Complete control

of source state sequencing available by

remote communications.

I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . Control of state sequencing, starting /

stopping each source, is available using

Inputs and Outputs.

PC Applications Software. . . . . . . . . Optional, Compatible with RS232

communications or National Instruments

PCI-GPIB Controller and NI-488.2 protocol.

Operating System. . . . . . . . . . . . Windows 2000

Function . . . . . . . . . . . . . . . . . . . Complete Cygnus programming, Monitoring

of sources.

IPN 074-379-P1K

1 - 11

Page 26

1.4.4 Display

Type / Color / Size . . . . . . . . . . . . . . CRT / Amber /

Format . . . . . . . . . . . . . . . . . . . . . . . 23 kHz Horizontal Scan Rate

Resolution . . . . . . . . . . . . . . . . . . . . 750 W x 350 H Monochrome

Vertical Scan Rate . . . . . . . . . . . . . . 50/60 Hz automatically detected

Thickness Display Range. . . . . . . . . 0.000 to 999.9 kÅ

Thickness Display Resolution . . . . . 1 Å

Rate Display Range . . . . . . . . . . . . . 0.000 to 9999 Å/sec

Rate Display Resolution. . . . . . . . . . 0.001 Å/sec for 0 to 9.999 Å/sec

Power Display Range. . . . . . . . . . . . 0.00 to 99.99%

Cygnus Operating Manual

5" H x 9" W (127 mm x 228.6 mm)

0.01 Å/sec for 10.00 to 99.99 Å/sec

0.1 Å/sec for 100.0 to 999.9 Å/sec

1 Å/sec for 1000 to 9999 Å/sec

Graphic Display Functions . . . . . . . . Rate Deviation at ±10 or ±20 Å/sec or Power

at 0 to 100%

Graphic Scan Rate. . . . . . . . . . . . . . 0 = Auto, 1 = Slow, 2 = Med, 3 = Fast

Display Data Update Rate . . . . . . . . 1 Hz

IPN 074-379-P1K

1 - 12

Page 27

1.4.5 Source / Recorder Outputs

Quantity . . . . . . . . . . . . . . . . . . . . . . 6 standard, an additional 6 are optional with

Type . . . . . . . . . . . . . . . . . . . . . . . . . 6 standard with BNC Connectors for Source

Source control voltage range

(BNC connectors). . . . . . . . . . . . 0 to 10V, 0 to 5V, 0 to 2.5V,

Recorder Voltage Range . . . . . . . . . 0 to 10V

Current rating . . . . . . . . . . . . . . . . . . 20 mA per channel

Resolution . . . . . . . . . . . . . . . . . . . . 15 bits over full range (10 V)

Update Rate . . . . . . . . . . . . . . . . . . . 10 Hz, maximum, (dependent on source

Cygnus Operating Manual

2nd DAC board.

control. 6 optional with 15 pin miniature

D-sub providing analog outputs for Rate and

Thickness.

0 to -10V, 0 to -5V, 0 to -2.5V.

characteristics).

Accuracy. . . . . . . . . . . . . . . . . . . . . . ± 3% full scale

Zero Adjust . . . . . . . . . . . . . . . . . . . . Individual potentiometer

IPN 074-379-P1K

1 - 13

Page 28

Cygnus Operating Manual

1.4.6 Logic Processing

Type . . . . . . . . . . . . . . . . . . . . . . . . . If/Then statements

Logical Functions . . . . . . . . . . . . . . . And; Or; Not; Parentheses

Depth . . . . . . . . . . . . . . . . . . . . . . . . 5 "If" conditions and 5 "Then" results/actions

# of Statements . . . . . . . . . . . . . . . . 100 If/Then

Selectable events. . . . . . . . . . . . . . . Deposition monitor events, states, external

Hierarchy . . . . . . . . . . . . . . . . . . . . . Statements evaluated in numerical order at

Partitioning . . . . . . . . . . . . . . . . . . . . None

Initialization . . . . . . . . . . . . . . . . . . . All outputs transition to their normal states as

per statement

inputs, relays, timers, and counters.

10 Hz any time the unit is on.

early as possible during power-on

initialization sequence.

1.4.7 Relays / Inputs

Relays . . . . . . . . . . . . . . . . . . . . . . . SPST 2.5 A relays rated @ 30 V(dc) or

Relay Ratings. . . . . . . . . . . . . . . . . . 100 VA inductive; 2.5A maximum.

# of TTL Compatible Outputs . . . . . . 14 with optional I/O card. Internally pulled up

Inputs (TTL Compatible). . . . . . . . . . (14 standard, 14 additional optional)

Input Levels

maximum high . . . . . . . . . . . . . . 24 V

minimum high. . . . . . . . . . . . . . . 2.5 V

30 V(ac) RMS or 42 V(peak) maximum;

(8 standard, up to 16 optional with 2

additional I/O cards); D sub connector; relays

are normally open in the power off state, but

may be programmed to normally open or

normally closed during operation.

to 5 V(dc). May be pulled up externally to

24 V(dc) through 2.4k resistor.

minimum high level 0.5mA load @3.75 V

maximum low level 10mA load @1.1 V

IPN 074-379-P1K

1 - 14

maximum low . . . . . . . . . . . . . . . 1.1 V

Scan/Update Rate . . . . . . . . . . . . . . 10 Hz

Page 29

1.4.8 Remote Communications

RS232C Serial Port . . . . . . . . . . . . . Standard

Baud Rates. . . . . . . . . . . . . . . . . . . . 19,200; 9,600; 4,800; 2,400

IEEE488 Parallel Port. . . . . . . . . . . . Optional

IEEE Service Requests . . . . . . . . . . Supported with RQS and MAV status bits

1.4.9 Accessories

Manual Power

Control Connection. . . . . . . . . . . . . . Front panel

Function . . . . . . . . . . . . . . . . . . . . . . Handheld, increase/decrease/stop

Floppy (Optional) . . . . . . . . . . . . . . . 3.5', 1.44 MByte for process and

Connector Kit . . . . . . . . . . . . . . . . . . Connectors for inputs and relays

Operating Manual. . . . . . . . . . . . . . . PDF format on CD

Cygnus Operating Manual

datalog storage

1.4.10 Power

Power . . . . . . . . . . . . . . . . . . . . . . . . 100 +10%, -15% V(ac) 50/60 Hz

120 +10%, -10% V(ac) 50/60 Hz

230 +10%, -10% V(ac) 50/60 Hz

240 +10%, -15% V(ac) 50/60 Hz

Maximum apparent power . . . . . . . . 300 VA

Fuse . . . . . . . . . . . . . . . . . . . . . . . . . 100 V(ac), 120 V(ac) use 4 Amp IEC 127

approved type T

230 V(ac), 240 V(ac) use 2 Amp IEC 127

approved type T

IPN 074-379-P1K

1 - 15

Page 30

Cygnus Operating Manual

1.4.11 Operating Environment

Usage. . . . . . . . . . . . . . . . . . . . . . . . Indoor only

Temperature. . . . . . . . . . . . . . . . . . . 0 to 50 °C (32-122 °F)

Humidity . . . . . . . . . . . . . . . . . . . . . . Up to 85%RH, non-condensing

Altitude . . . . . . . . . . . . . . . . . . . . . . . Up to 2000 meters

Installation (Overvoltage) . . . . . . . . . Category II per IEC 664

Pollution Degree. . . . . . . . . . . . . . . . 1 per IEC 664

1.4.12 Storage Temperature

Storage Temperature . . . . . . . . . . . . -10 to 60 °C (14 to 140 °F)

1.4.13 Warm Up Period

Warm Up Period. . . . . . . . . . . . . . . . None required;

For maximum stability allow 5 minutes.

1.4.14 Size

Not including mounts or user connectors

5.25" H x 17.625" W x 17.3" D

(133.4 mm H x 447.7 mm W x 435.1 mm D)

Including mounts, but no user connectors

5.25" H x 18.85" W x 17.3" D

(133.4 mm H x 478.8 mm W x 435.1 mm D)

1.4.15 Connector Clearance Requirements

Front. . . . . . . . . . . . . . . . . . . . . . . . . Minimum 1.0" (25.4 mm)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . Minimum 4.0" (101.6 mm)

1.4.16 Weight

With all options. . . . . . . . . . . . . . . . . 13.2 kg / 29 lb

1.4.17 Cleaning

IPN 074-379-P1K

1 - 16

Use a mild, nonabrasive cleaner or detergent taking care to prevent cleaner from

entering the unit.

Page 31

1.5 Unpacking and Inspection

1 If the Cygnus control unit has not been removed from its shipping container, do

so now.

2 Carefully examine the unit for damage that may have occurred during shipping.

This is especially important if you notice obvious rough handling on the outside

of the container. Immediately report any damage to the carrier and to INFICON.

3 Do not discard the packing materials until you have taken inventory and have

at least performed a power on verification.

4 Take an inventory of your order by referring to your order invoice and the

information contained in section 1.6 on page 1-17.

5 To perform a power-on verification, see section 1.7 on page 1-20.

6 For additional information or technical assistance, contact your nearest

INFICON Inc. sales office.

1.6 Parts and Options Overview

Cygnus Operating Manual

1.6.1 Base Configurations

Cygnus Control Unit . . . . . . . . . . . . . 779-700-G1 (100 V(ac) 50/60 Hz)

779-700-G2 (120 V(ac) 50/60 Hz)

779-700-G3 (230 V(ac) 50/60 Hz)

779 -700 -G4 (240 V(ac) 50/60 Hz)

Technical Manual . . . . . . . . . . . . . . . 074-379

Hand Controller . . . . . . . . . . . . . . . . 755-262-G1

I/O Relay Ship Kit . . . . . . . . . . . . . . . 760-024-G1

Power Cord . . . . . . . . . . . . . . . . . . . 068-0433

(shielded power cord - North America)

068-0434

IPN 074-379-P1K

Ship Kit . . . . . . . . . . . . . . . . . . . . . . . 779-610-G1 (100 V(ac), 120 V(ac))

(shielded power cord - European)

779-610-G2 (230 V(ac), 240 V(ac))

1 - 17

Page 32

Cygnus Operating Manual

1.6.2 Pre-Installed Options or Spares

Additional Sensor Module (std.) . . . . 760-1132-G1 (up to 2 extra)

Relay Card . . . . . . . . . . . . . . . . . . . . 760-162-G1

Relay Card . . . . . . . . . . . . . . . . . . . . 760-162-G2

I/O Relay Ship Kit. . . . . . . . . . . . . . . 760-024-G1

IEEE488 Parallel . . . . . . . . . . . . . . . 760-142-G1

Communications

Floppy disk . . . . . . . . . . . . . . . . . . . . 760-023-G1

Optional DAC Card . . . . . . . . . . . . . 760-1112-G2

(8 relay outputs, 14 TTL inputs)

(8 relay outputs, 14 TTL outputs)

(8 relay outputs, 14 TTL inputs)

760-024-G2

(8 relay outputs, 14 TTL outputs)

1.6.3 Oscillator Packages, Optional Accessories, and Sensors

IC/5 XIU (Oscillator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 760-600-G1

Oscillator to vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 755-257-G6

feedthrough cable, 6" (152.4 mm)

IC/5 Unit to Oscillator Cable 15' (4.6 m). . . . . . . . . . . . . . . . . . . 600-1039-G15

IC/5 Unit to Oscillator Cable, 30' (9.2 m) . . . . . . . . . . . . . . . . . . 600-1039-G30

IC/5 Unit to Oscillator Cable, 50' (15.3 m) . . . . . . . . . . . . . . . . . 600-1039-G50

IC/5 Unit to Oscillator Cable, 100' (30.5 m) . . . . . . . . . . . . . . . . 600-1039-6100

Pneumatic Shutter Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750-420-G1

Control Valve

Sensor Emulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 760-601-G2

Cygnus Editor Applications Software. . . . . . . . . . . . . . . . . . . . . 779-030-G1

IC/5 Oscillator, 15' and 6" cable pkg. . . . . . . . . . . . . . . . . . . . . . 760-025-G15

IC/5 Oscillator, 30' and 6" cable pkg. . . . . . . . . . . . . . . . . . . . . . 760-025-G30

IC/5 Oscillator, 50' and 6" cable pkg. . . . . . . . . . . . . . . . . . . . . . 760-025-G50

IPN 074-379-P1K

1 - 18

IC/5 Oscillator, 100' and 6" cable pkg. . . . . . . . . . . . . . . . . . . . . 760-025-G100

4 Meter Oscillator Kit . . . . . . . . . . . . . . ............................ . . . . . . . 4XI5-nnn

NOTE: For operation with 3 m to 4 m long in-vacuum cable, contact INFICON for

part the number.

Page 33

Cygnus Operating Manual

Standard Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750-211-G1

Standard Sensor with Shutter. . . . . . . . . . . . . . . . . . . . . . . . . . . 750-211-G2

Compact Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750-213-G1

Compact Sensor with Shutter. . . . . . . . . . . . . . . . . . . . . . . . . . . 750-213-G2

Sputtering Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750-618-G1

UHV Bakeable Sensor, 12" (304.8 mm) . . . . . . . . . . . . . . . . . . . 007-219

UHV Bakeable Sensor, 20" (508 mm) . . . . . . . . . . . . . . . . . . . . 007-220

UHV Bakeable Sensor, 30" (762 mm) . . . . . . . . . . . . . . . . . . . . 007-221

UHV Bakeable Sensor with Shutter, 12" (304.8 mm) . . . . . . . . . 750-012-G1

UHV Bakeable Sensor with Shutter, 20" (508 mm) . . . . . . . . . . 750-012-G2

UHV Bakeable Sensor with Shutter, 30" (762 mm) . . . . . . . . . . 750-012-G3

Dual Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750-212-G2

CrystaISix Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750-446-G1

Crystal12 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 750-667-G1

CrystalTwo Switch with two 6" (152.4 mm) BNC cables . . . . . . 779-220-G1

CrystalTwo Switch with two 20" (508 mm) BNC cables . . . . . . . 779-220-G2

NOTE: Contact INFICON for a complete listing of oscillators and sensors.

IPN 074-379-P1K

1 - 19

Page 34

Cygnus Operating Manual

WARNING - Risk Of Electric Shock

WARNING - Risk Of Electric Shock

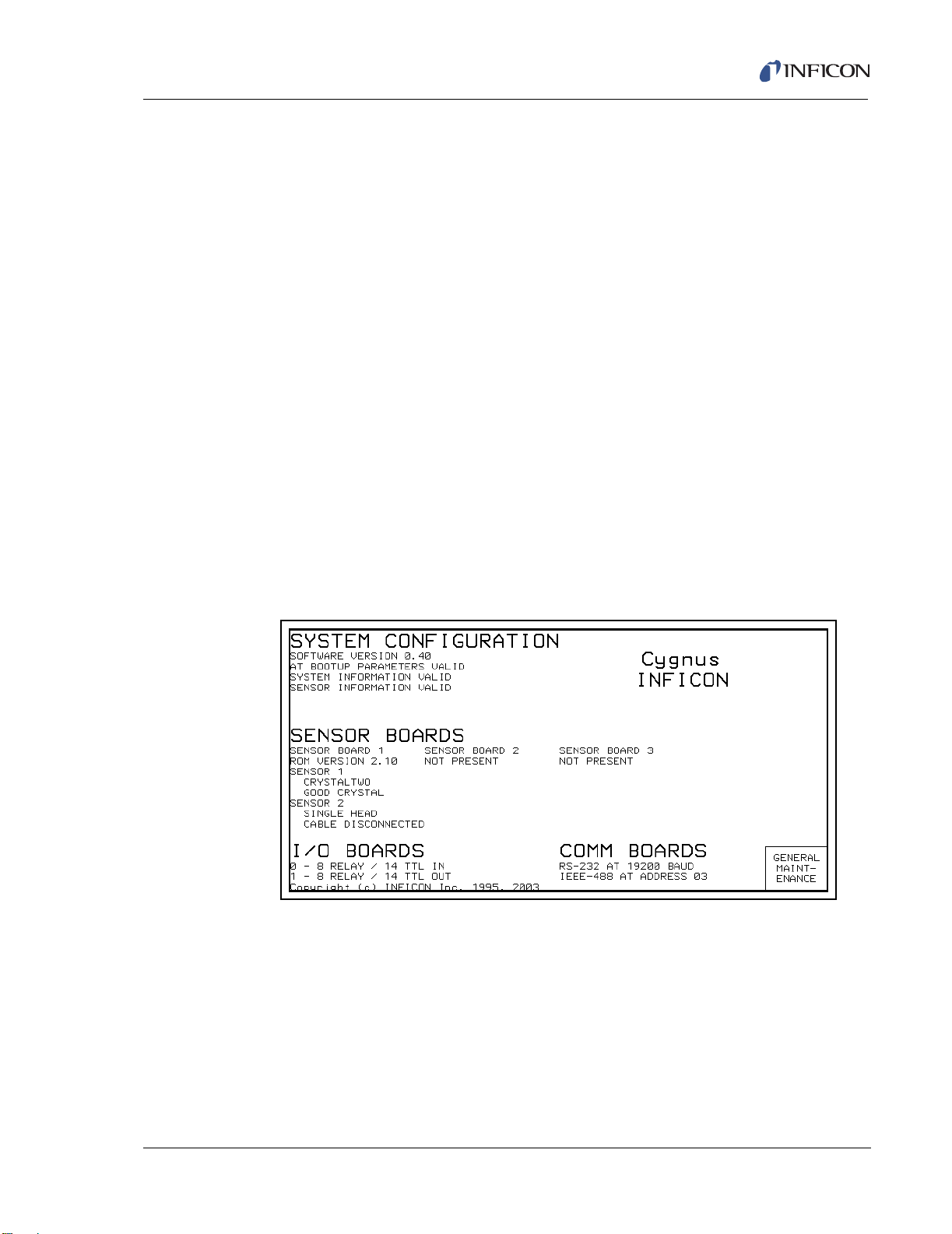

1.7 Initial Power-On Verification

A preliminary functional check of the instrument can be made before formal

installation. It is not necessary to have sensors, source controls, inputs or relays

connected to do this. For more complete installation information, see Chapter 6,

Installation and Interfaces and Chapter 7, Calibration Procedures.

There are no user-serviceable components within the

instrument case.

Dangerous voltages may be present whenever the power

cord or external input/relay connectors are present.

Refer all maintenance to qualified personnel.

Never interrupt the protective earth circuit.

Any interruption of the protective earth circuit inside or

outside the instrument, or disconnection of the

protective earth terminal is likely to make the instrument

dangerous.

This symbol indicates where the protective earth ground

is connected inside the instrument. Never unscrew or

loosen this connection.

IPN 074-379-P1K

1 - 20

Page 35

Cygnus Operating Manual

1 Confirm that AC line voltage is supplied and proper for the instrument. Line

voltage should be indicated on the instrument back label.

2 Press the power button on the front panel. A green pilot light should be seen

next to the power switch.

3 The fan at the back of the instrument should be exhausting air.

4 Video monitor will display an image similar to the one shown in Figure 1-1.

5 Compare the configuration information on the screen against the unit

configuration ordered.

6 Status of parameter information will be displayed. If information was valid prior

to this power up, it should stay valid.

7 After a delay, the instrument will enter the OPERATE display.

8 In the OPERATE display, confirm that the display is centered vertically. Lines

between the function keys (F1...F6) should align with the lines between the

panels on the right side of the display.

9 Using a non-conducting alignment tool, verify that the brightness pot is

operative. Adjust for the desired brightness. Access to the brightness pot is at

the bottom-center of the face panel, see Figure 2-1 on page 2-1.

Figure 1-1 Cygnus System Status Screen

(Display will vary depending on options present)

IPN 074-379-P1K

1 - 21

Page 36

Cygnus Operating Manual

This page is intentionally blank.

1 - 22

IPN 074-379-P1K

Page 37

2.1 Front Panel Controls

12345

7891011

6

Operational controls for Cygnus are located on the front panel of the instrument, as

depicted in Figure 2-1.

Figure 2-1 Cygnus Front Panel

Cygnus Operating Manual

Chapter 2

Operation

1 CRT Screen

Provides graphical displays, set-up menus, status and error messages.

2 Function Keys

An array of function keys are located adjacent to the screen. These keys are

labeled F1 through F6. They are used to select displays or menu items. Their

IPN 074-379-P1K

function is indicated on the display and is described in subsequent sections.

3 Data Entry Keys

A keypad array with numerics 0 through 9 and keys for Yes (Y), No (N), Enter

(E), Clear (C), Print, and Help used for selection and parameter entry. All

numeric and Yes/No entries need to be followed by Enter. Clear is used to

erase data entry errors. If an illegal value has been entered, Clear will erase the

error message and re-display the last valid data. The Print Screen key is used

to send the display information to the floppy drive. The Help key displays

parameter information and the parameter’s value range on the upper portion of

the display, replacing the screen name area.

2 - 1

Page 38

Cygnus Operating Manual

4 System Switches

An array of four keys that provide START, STOP, RESET and STOP ALL

functions, for process control.

5 3.5" Floppy Disk Access Port

Receptacle for the optional 3.5", 1.44 MB floppy disk.

6 Stop ALL Key

A key which when pressed will place all channels in a STOP state regardless

of the screen display.

7 Power

This switch controls secondary power to the instrument between ON and

STANDBY. Power is provided when the button is in its depressed position. The

instrument is initialized for approximately 5 seconds before providing an

operational screen.

8 Pilot Light

A green pilot light, adjacent to the power switch, is illuminated when power is

on.

9 Remote Control Jack

Receptacle for the wired hand-held remote controller.

10 Cursor Keys

An array of four keys that are used to move the display cursor either up, down,

left or right. The keys auto-repeat; the cursor will continue to move as long as

the key is held down or until a display field boundary is met.

11 Brightness Adjustment

An access hole for the display’s brightness adjustment potentiometer. Use a

nonconductive TV adjustment tool to increase the brightness by turning the

potentiometer clockwise.

IPN 074-379-P1K

2 - 2

Page 39

2.2 Rear Panel Interfaces

1 2345678 9 10

111213

Interfaces for Cygnus are located on the rear panel of the instrument as depicted

in Figure 2-2.

Figure 2-2 Cygnus Rear Panel

Cygnus Operating Manual

1 IEEE488 Connector (Optional)

Provides connections for IEEE-GPIB interface.

2 Digital to Analog Converter (optional)

Provides recorder output for six channels (15 pin miniature D-sub connector).

Outputs are programmable for recorder function.

3 Sensor Connectors - Channels 1 & 2 (standard)

Provides connection for the units two standard sensor channels.

4 Sensor Connectors - Channels 3 & 4 (optional)

Expansion panel to accommodate the optional addition of two more sensors,

IPN 074-379-P1K

sensors 3 & 4.

5 Sensor Connectors - Channels 5 & 6 (optional)

Expansion panel to accommodate the optional addition of two more sensors,

sensors 5 & 6.

6 8 Relay x 14 Input I/O Card (standard)

Provides pin connection for 8 Relays rated for 30 V(dc) or

30 V(ac) RMS or 42 V(peak) maximum, and 14 TTL Inputs.

7 8 Relay x 14 Input I/O Card (optional)

Provides pin connection for 8 relays rated for 30 V(dc) or

30 V(ac) RMS or 42 V(peak) maximum, and 14 TTL inputs.

2 - 3

Page 40

Cygnus Operating Manual

8 8 Relay x 14 Output I/O Card (optional)

Provides pin connection for 8 relays rated for 30 V(dc) or 30 V(ac) RMS or

42 V(peak) maximum, and 14 open collector type outputs.

9 6-Channel DAC (standard)

Provides source control voltage or recorder output for 6 channels (BNC

connectors). Outputs are programmable for Source Control or Recorder

function.

10 24-Volt Supply (standard)

Provides one 24 V(dc) supply rated at 1.75 Amps.

11 Fan Outlet

Exhaust opening for the unit’s miniature fan. A grill is attached for safety.

12 AC Power Inlet

Provides a common connector for various international plug sets. The unit is

factory set for 100 V(ac), 120 V(ac), 230 V(ac) or 240 V(ac) service.

13 RS-232C Remote Communication Connector (standard)

2.3 Displays

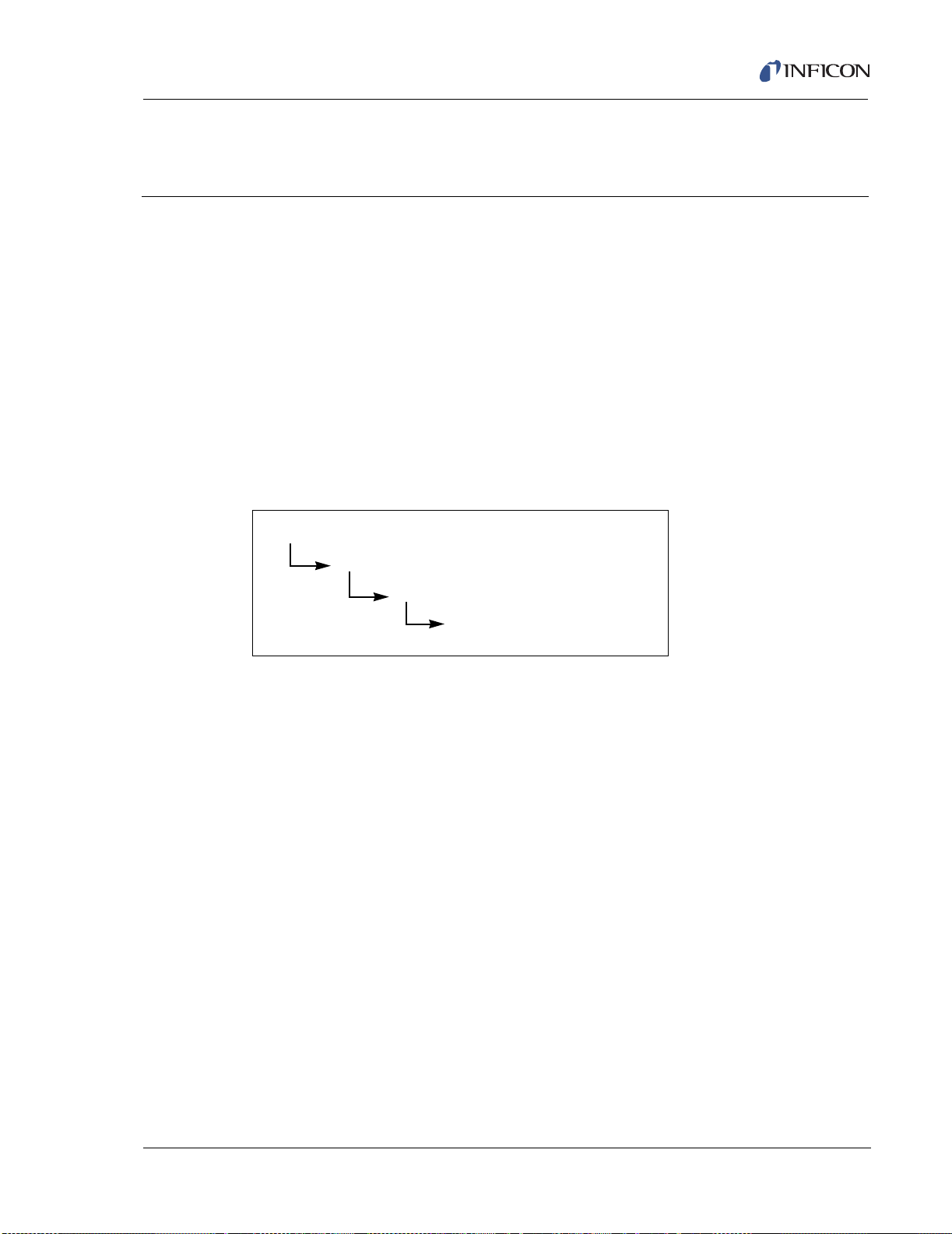

Cygnus has many display screens for monitoring and programming processes. At

the top of the hierarchy is the ALL CHANNELS display. The ALL CHANNELS

display allows the user to simultaneously monitor process information for up to six

channels. Three main types of displays, GENERAL PARMS; GENERAL

MAINTENANCE and CHANNEL are accessible from the ALL CHANNELS

DISPLAY: To move from one display to another, use the function keys to the right

of the screen. Figure 2-4 provides an overview of the Cygnus display hierarchy.

Provides a 9-pin RS-232C communications port.

IPN 074-379-P1K

2 - 4

Page 41

2.3.1 ALL CHANNELS Display

1

2

34

8

10

11

5

F1

F2

F6

F3

F4

F5

6

7

9

Figure 2-3 All Channels Display

Cygnus Operating Manual

NOTE: The four channel ALL CHANNELS display is shown when one or two

measurement boards are installed. If three measurement boards are

installed, a six channel ALL CHANNELS display is shown.

ALL CHANNELS Display Description

1 Identifies the channel number associated with the displayed information.

2 Deposition Rate of the channel

3 Accumulated Channel thickness

4 Percent power of individual channel

5 Run time

6 General message area for Test and Lock

7 Power — normal video = level is OK, inverse video = power is at max/min level

IPN 074-379-P1K

and channel is in control.

8 Cumulative thickness for the individual THICK SUM equations defined in the

GENERAL PARAMETER display

9 Rate — normal video = good crystal, inverse video = failed crystal

10 State timer

11 State of individual channel

2 - 5

Page 42

Cygnus Operating Manual

ALL CHANNELS Display Function Keys

F1 GENERAL PARMS

To view the GENERAL PARAMETERS display, press function key F1.

F2 ZERO THICKNESS

To zero the accumulated thickness for the channel indicated by the cursor,

press function key F2.

F3 MANUAL / AUTO

To toggle between the MANUAL and RATE control states for the channel

indicated by the cursor, press function key F3. When in MANUAL, the source

power is controlled by the handheld controller.

F4 CRYSTAL SWITCH

To initiate a crystal switch for the channel indicated by the cursor, press function

key F4.

F5 GENERAL MAINTENANCE

To view the GENERAL MAINTENANCE display, press function key F5.

F6 CHANNEL

To go to the CHANNEL display associated with the current cursor position,

press function key F6.

IPN 074-379-P1K

2 - 6

Page 43

Cygnus Operating Manual

GENERAL

PARMS

GENERAL

MAINTENANCE

CHANNEL

(F1)

(F2) (F6)

LOGIC

DIRECTORY

I/O

MAP

FLOPPY

DISK

COUNTERS/

TIMERS

SELECT LOGIC

STATEMENT

GENERAL

PARAMETERS

EDIT

NAME

SAVE

NAME

CANCEL

NAME

CLEAR

NAME

TOGGLE

TYPE

CHANGE

SELECT NEGATE ADD/DELETE

PARENTHESIS

DELETE

CANCEL

CHANGES

RS232

TEST

SYSTEM

STATUS

CHANGE

TIME/

DATE

CHANNEL ZERO MANUAL/

AUTO

CRYSTAL

CHANNEL

MAINT

PARMS THICKNESS

SWITCH

SWITCH TOGGLE TOGGLE

SENSOR

MANUAL

SENSOR

MAINT

CRUCIBLE SUBSTR

CLEAR

SOURCE

MAINT

QUALITY

STABILITY

ENHANCE

HARDWARE

SHUTTER SHUTTER

ALL CHANNELS

(F1) (F3)(F2)

(F4) (F5) (F6)

(F1) (F2) (F3)

(F1) (F2) (F3) (F4) (F5)

(F1) (F2) (F3) (F4) (F5)

(F1) (F2) (F3) (F4) (F5)

(F5)(F4)(F3)

(F1) (F2) (F3) (F4) (F5)

REPLACE INSERT

(F1) (F2)

ZERO

COUNTER

START

TIMER

CANCEL

TIMER

(F1) (F2) (F3)

TIMER

LOGIC

DIRECTORY

(F6)

PAG E

FORWARD

PAG E

BACK

EDIT

LOGIC

(F1) (F2) (F5)

PROGRAM

LOCK

SENSOR

MAINTENANCE

(F4) (F5)

CRYSTAL ROTATE TEST

XIU

CLEAR

SWITCH XTAL

QUALITY

(F1) (F2) (F3) (F4)

HEAD

STABILITY

GENERAL

MAINTENANCE

(F5)

CRYSTAL

SWITCH

(F1)

ROTATE

XTAL HEAD

(F2)

PARAMETERS

GENERAL

PAR AME TER S

(F6)

CHANNEL

(F6)

CHANNEL

(F6)

ALL

(F6)

CHANNELS

ALL

(F6)

CHANNELS

ALL

(F6)

CHANNELS

LOGIC

(F6)

DIRECTORY

WITH SAVE

SAVE LOAD DELETE

ALL

(F1) (F2) (F3) (F5)

GENERAL

PARAMETERS

(F6)

ALL

(F6)

CHANNELS

TO

FLOPPY

FROM

FILES

FLOPPY

LOGIC

DIRECTORY

(F6)

STATEMENT

(F6)

CHANNEL

(F1) (F6)

CLEAR

FAIL ED

CRYSTALS

Figure 2-4 Cygnus Display Hierarchy

IPN 074-379-P1K

2 - 7

Page 44

Cygnus Operating Manual

2.3.1.1 GENERAL PARAMETERS Display

Figure 2-5 GENERAL PARMATERS Display

See Chapter 4 for a detailed description for programming the General Parameters.

GENERAL PARAMETER Display Function Keys

F1 LOGIC DIRECTORY

For a display that facilitates selection of Logic Statements for editing, press

function key F1.

F2 I/O MAP

To view the I/O MAP display, press function key F2. Provides access to a

display where inputs or outputs may be assigned names and where the output

type may be designated as normally open or normally closed.

F3 FLOPPY DISK

To view the files currently stored on the floppy disk, press function key F3.

Saves or retrieves parameters to or from floppy disk.

F6 ALL CHANNELS

To return to the ALL CHANNELS display, press function key F6.

IPN 074-379-P1K

2 - 8

Page 45

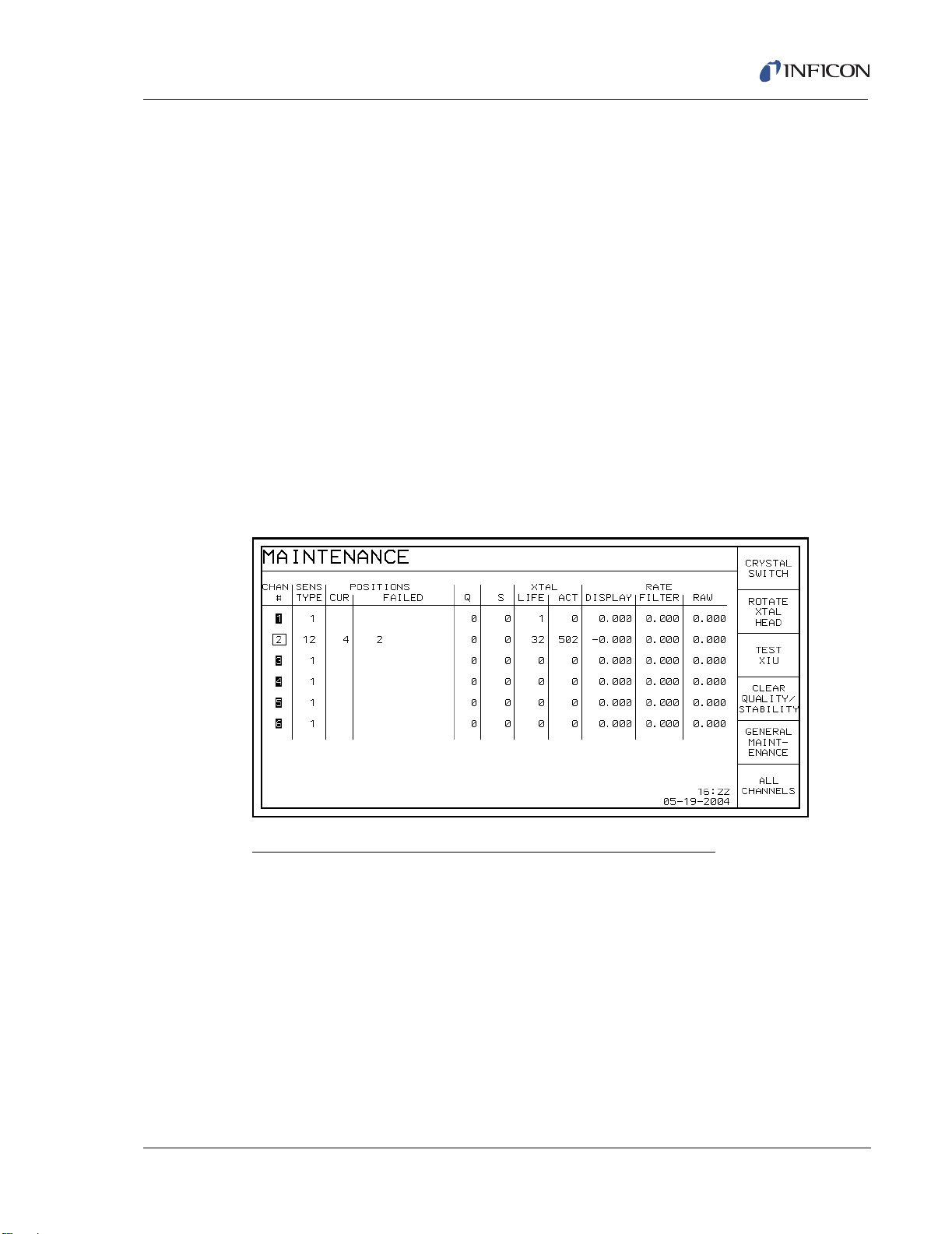

2.3.1.2 General MAINTENANCE Display

These displays provide a simple method for system maintenance and diagnostics.

To access the MAINTENANCE display, press the GENERAL MAINTENANCE

function key (F2) on the ALL CHANNELS display.

Figure 2-6 General MAINTENANCE Display

Cygnus Operating Manual

General MAINTENANCE Display Description

CHAN #

These numbers correspond to the measurement channel numbers on the

Cygnus rear panel. The cursor keys are used to position the box cursor over

the desired channel number. When either the Crystal Switch, Rotate Crystal

Head, Test XIU, or Clear Quality / Stability function key is pressed, the function

will be performed on the channel indicated by the box cursor. It is not allowed

to cursor to channel numbers that do not have the corresponding measurement

card installed. If a crystal fail has occurred for a particular channel this condition

is indicated by displaying the channel number in reverse video.

SENS TYPE

IPN 074-379-P1K

This field indicates the Sensor Type chosen for each channel number. A “1”

indicates a single crystal head, a “2” indicates a CrystalTwo head, a “6”

indicates a CrystalSix sensor head, a “7” indicates a Rotary sensor and a “12”

indicates a Crystal12.

POSITIONS

This field is subdivided into two categories; current position (CUR), and

FAILED. Information is displayed in these fields if the sensor has more than one

position. For a single sensor type, the CUR and FAILED fields have no

meaning. For a multi-position sensor type, the CUR field indicates the current

position of the sensor head. The FAILED field indicates the sensor head

positions containing failed crystals.

2 - 9

Page 46

Cygnus Operating Manual

Q (Crystal Quality value field)

This field displays the value currently accumulated in the Crystal Quality

counter when active. The Crystal Quality counter will become active five

seconds after entering DEPOSIT and if the Crystal Quality parameter is

non-zero. The function of the Crystal Quality counter is described in section

3.2.1 on page 3-2.

S (Crystal Stability value field)

This field displays the value currently accumulated in the Crystal Stability

counter. The function of the Crystal Stability counter is described in section

3.2.1 on page 3-2.

XTAL

This field is subdivided into two categories. The first category, LIFE displays the

crystal life. The second category is a measurement of the crystal activity, ACT.

For a detailed explanation of LIFE and ACT, see section 2.4 on page 2-21.

RATE

This field is subdivided into three categories. These fields are useful in

identifying if a sensor’s rate measurements are becoming erratic. 0.000 will be

displayed in these fields for channels not in use. All values are refreshed at the

display’s one second update rate.

The first category is DISPLAY. The value displayed here is the channel’s

average rate. This average is calculated based on a 1 second average.

The second field labeled FILTER is based on the average of the RAW rate

(100 msec) measurements over the Rate Filter Time selected in the Channel

Parms screen for that particular channel.

The third field is RAW representing the instantaneous 100 msec frequency

change measurement restated in Angstrom/second units.

General MAINTENANCE Display Function Keys

F1 RS232 TEST

To initiate the RS-232C COMM PORT self test, press function key F1. Upon

completion of the test, the unit will display a message indicating the test was

successful and the COMM PORT is okay; or the test failed and the COMM

PORT is bad.

NOTE: The RS-232C Loop Back connector, IPN 760-406-P1 must be installed

on the Cygnus RS-232C port for the self-test to work properly.

F2 SYSTEM STATUS

To access the SYSTEM STATUS display (refer to Figure 1-1 on page 1-21),

press function key F2.

IPN 074-379-P1K

2 - 10

Page 47

F3 CHANGE TIME/DATE

To access the display to edit the time and date for the instrument, press function

key F3.

F4 PROGRAM LOCK

To access a display for setting a program lock code, press function key F4.

F5 SENSOR MAINTENANCE

To access the All Channels Sensor MAINTENANCE display, see Figure 2-7,

press function key F5.

F6 ALL CHANNELS

To return to the ALL CHANNELS display, press function key F6.

2.3.1.2.1 All Channels Sensor MAINTENANCE Display

This display provides a simple way to view sensor information for all the sensors

as well as providing general sensor maintenance functions.

Figure 2-7 All Channels Sensor MAINTENANCE Display

Cygnus Operating Manual

IPN 074-379-P1K

All Channels Sensor Maintenance Display Function Keys

F1 CRYSTAL SWITCH

To initiate a crystal switch for the sensor indicated by the cursor position, press

function key F1.

F2 ROTATE XTAL HEAD

If the sensor number indicated by the cursor position is a CrystalSix, Crystal12,

or Rotary sensor, pressing F2 will sequentially rotate the sensor head through

all positions. This is useful to initialize a CrystalSix, Crystal12, or Rotary sensor

after replacing failed crystals.

2 - 11

Page 48

Cygnus Operating Manual

F3 TEST XIU

To initiate the XIU Self Test, press function key F3. The XIU Self Test

determines whether the Crystal Interface Unit (XIU) and Measurement Card

pair is operating properly.

NOTE: For the XIU Self Test to work properly, the XIU must have the

F4 CLEAR QUALITY / STABILITY

To clear the Quality and Stability counters, press function key F4.

F5 GENERAL MAINTENANCE

To access the General MAINTENANCE display, press function key F5.

F6 ALL CHANNELS

To access the ALL CHANNELS display, press function key F6.

2.3.1.3 CHANNEL Display

6" (152.4 mm) BNC cable (IPN 755-257-G6) attached and must be

disconnected from the sensor feedthrough.

The CHANNEL display (shown in Figure 2-8) provides information about the

specified channel. The rate, thickness, power level, state, state time, and run time

are all updated once a second. Near the bottom of the display is a graph that

provides an analog display of the rate deviation from the desired rate, while the

channel is in a Rate Control state. Alternatively, the graph can display the percent

power being output during a process. The SCALE and SCAN RATE parameters

control the meaning, scaling and speed of the graph.

On the top right of the display is a general message area. This area displays

information that is not channel specific, such as indicating that the instrument is in

TEST mode The region adjacent to the graph displays channel specific status

information,. For a complete list of error and status messages, see Chapter 8.

IPN 074-379-P1K

2 - 12

Page 49

Figure 2-8 CHANNEL Display

1

2

3

45679

10

11

12

14

F1

F2

F3

F4

F5

F6

8

Cygnus Operating Manual

CHANNEL Display Description

1 Identifies the channel number associated with the displayed information.

2 Accumulated Channel thickness

3 General instrument information message area

4 Function key definitions