Page 1

TRANSLATION OF THE ORIGINAL

OPERATING MANUAL

Type designation

CU1000

Product description

Control unit

Catalog no.

from software version

Document no.

560-320

Control unit 1.01

jina54en1-b (1301)

Page 2

This document applies to the software version stated on the cover page. If you need

a different version, please contact our sales staff.

Reprint, translation and duplication need to be approved in writing by

INFICON GmbH.

2

Page 3

Content

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Target groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Other applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Presentation of information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.1 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3.2 Text markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 User requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 User requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Shipment check, transport, storage . . . . . . . . . . . . . . . . 8

3.1 Checking shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Construction of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3.1 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3.2 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3.3 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3.4 Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Connecting the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Installing the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Elements on the monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1.1 Measurement display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Querying and setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2.1 Display settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.2.2 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.3 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.4 Access Ctrl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.5 Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Loading or saving parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Content 3

Page 4

6.4 Copying or deleting measured data . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.5 Lock all access levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.6 Software update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.6.1 Updating the software of the control unit . . . . . . . . . . . . . . . . 22

6.6.2 Updating the software of the MS module . . . . . . . . . . . . . . . . 22

6.6.3 Updating the software of the I/O module . . . . . . . . . . . . . . . . 22

7 Taking out of service . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 Disposing of the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 Returning the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Content

Page 5

1 About this manual

1.1 Target groups

This operating manual is intended for the operator and for technically qualified

personnel with experience in leak detection technology and integration of leak

detection devices in leak detection systems. In addition, the installation and use of

the unit require knowledge of electronic interfaces.

1.2 Other applicable documents

Installation manual for mass spectrometer module jiqa54

Bus module installation manual jiqb10

I/O module installation manual jiqc10

Interface protocols jira54

1.3 Presentation of information

1.3.1 Warnings

Imminent threat of danger resulting in death or severe injuries

Dangerous situation potentially resulting in death or severe injuries

Dangerous situation resulting in minor injuries

Dangerous situation resulting in damage to property or the environment

About this manual 5

Page 6

1.3.2 Text markings

Marking Meaning

►

1, 2, 3, ... Several instructions in a fixed order

S

MALL CAPS

Information

Requirement for execution of an action

Tool or aid for an action

Instruction

Result of an action

Designation of the unit or command/term from the menu

Useful tips and information

6 About this manual

Page 7

2 Safety

2.1 Intended use

The unit is intended for querying and configuring the data of the mass spectrometer

module LDS3000.

► Install, operate and service the unit only in compliance with this manual.

► Comply with the limits of application (see Chapter 4.3, page 10).

2.2 User requirements

Safety conscious operation

► Operate and install the unit only if it is in perfect working order and as intended,

in a safety-conscious manner and fully aware of dangers, in compliance with this

manual.

► Fulfill and ensure compliance with the following regulations:

– Intended use

– Generally applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional provisions and regulations that are specific to the unit

► Use only original parts or parts approved by the manufacturer.

► Keep this manual available at the operating site.

Personnel qualifications

► All work must be performed only by technical specialists who have been trained

on the unit.

► Allow personnel in training to work with the unit only under the supervision of

technical specialists.

► Make sure that the authorized personnel have read and understood this manual

and all other applicable documents (see Chapter 1.2, page 5), especially the

information on safety, maintenance and repairs, before starting work.

► Define responsibilities, authorizations and supervision of personnel.

2.3 User requirements

► Read, observe and follow the information in this manual and the working

instructions created by the owner, especially the safety instructions and warnings.

► Perform all work based on the complete manual.

Safety 7

Page 8

3 Shipment check, transport, storage

3.1 Checking shipment

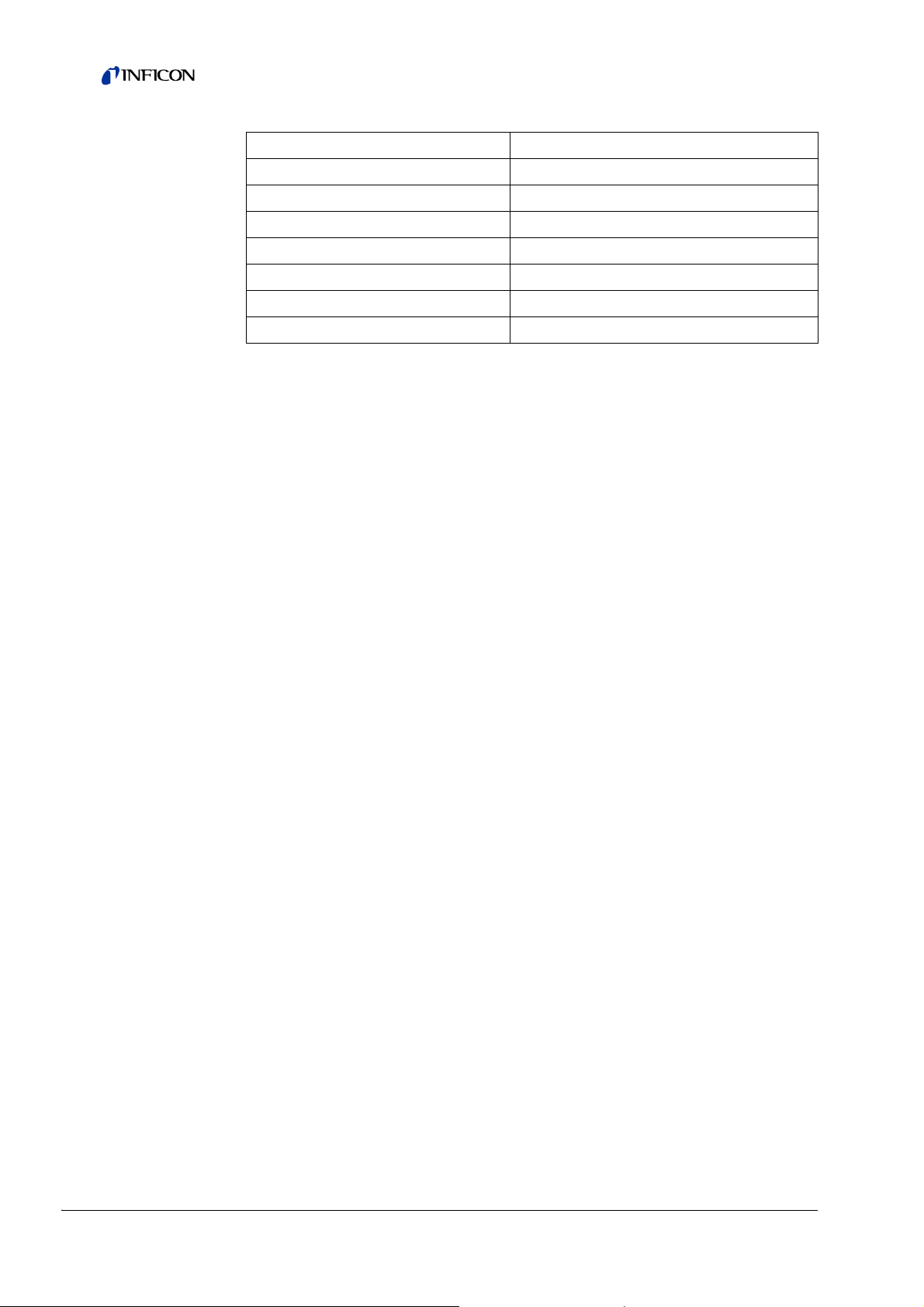

Scope of delivery

Article Quantity

Control unit 1

Touch pin 1

Operating manual 1

► Check shipment to make sure it is complete.

3.2 Transport

Damage due to unsuitable packaging material

Transport in unsuitable packaging material can damage the unit.

► Transport the unit only in the original packaging material.

► Keep original packaging material.

3.3 Storage

► Always store the unit in compliance with the technical data, see Chapter 4.3,

page 10.

8 Shipment check, transport, storage

Page 9

4 Description

4.1 Construction of the unit

Fig: 1 Front view

1 - Touch display

Display that lets you read and enter data

2 - Status LED

The Status LED indicates the status of the control unit.

Status LED illuminated Control unit operates normally

Status LED flashing Display is set to power saving mode

3 - Reset key

Key to rest the control unit (can be operated with touch pin)

Information The MS module is not reset.

4 - USB connection

Connection for USB stick (FAT formatted)

Information The connection is suitable only for USB sticks.

5 - Mounting holes

Holes for mounting the control unit

Description 9

Page 10

Fig: 2 Rear view

1 - Rating plate

Rating plate of the control unit

2 -

Connection for headphones (impedance >= 8 Ω) or active speaker

3 - LCD-CAL

Calibration key for calibrating the touch display (can be operated with touch pin)

4 - LD

Connection for the data cable to the mass spectrometer module

4.2 Function

You can use the control unit to configure the mass spectrometer module LDS3000.

It also lets you output the data stored in the MSB box.

4.3 Technical data

4.3.1 Mechanical data

Dimensions (W x H x D) 106.2 mm x 128.4 mm x 49.2 mm

Weight 500 g

4.3.2 Electrical data

Supply voltage 24 V DC

Memory capacity for measured data 16 MB

10 Description

Page 11

4.3.3 Ambient conditions

Permissible ambient temperature

(during operation)

Permissible storage temperature -20 °C ... 60 °C

Max. relative

humidity

Type of protection IP 20

Pollution degree II

Max. altitude above sea level 2000 m

4.3.4 Factory settings

The parameters of the control unit are stored in the control unit.

You can use the control unit to rest the parameters of the mass spectrometer module

and the parameters of the control unit to the factory settings, independent of each

other (see Chapter 6.2.3, page 19).

The factory settings of the mass spectrometer module are listed in the installation

manual of the mass spectrometer module.

Parameter Factory setting

Displ. upper limit exponent -1

10 °C ... 45 °C

< +31 °C 80%

+31 °C to +40 °C decreasing linearly from 80% ... 50%

> +40 °C 50%

Displ. lower limit exponent -12

Display off after 1h (= 1 hour)

Display brightness 100%

Measurement view mode Diagram

Audio alarm mode Proportional

Automatic scaling On

Data recording Off

Decades 3

Pressure unit mbar

Favorite 1 Volume level

Favorite 2 Measurement view mode

Favorite 3 CAL

Error info Operator No. and text

Error info Supervisor No., text and info

Error info Viewer Number only

Used trigger 1

Volume level 8

Leak rate unit SNIFF mbar*l/s

Leak rate unit VAC mbar*l/s

Description 11

Page 12

Parameter Factory setting

Linear or logarithmic Log.

Time axis scale 30 s

Record interval 500 ms

Memory location USB

Language English

Show warnings On

Show value On

12 Description

Page 13

5 Installation

5.1 Connecting the control unit

Data cable

Mass spectrometer module installed.

1 Connect data cable to C

2 Connect data cable to L

Information The data cable to the control unit can also be connected or

disconnected during operation.

Hearing damage from loud volume setting

Loud volume setting can damage hearing.

► Do no set volume of headphones too loud.

3 If needed, connect headphones or speakers to .

5.2 Installing the control unit

ONTROL UNIT of the MSB box.

D.

Fig: 3 Dimensions - control unit

Recess for the control unit integrated in the test system.

► Push the control unit into the recess and screw it tight.

► Remove protective foil from display.

Installation 13

Page 14

6 Operation

Damage to touch display as a result of incorrect operation

The touch display can be damaged by a hard or pointed object.

► Operate the unit only with the fingers.

6.1 Elements on the monitor

6.1.1 Measurement display

14 Operation

Fig: 4 Measurement display

1 - Keyboard lock

Press and hold to lock or unlock the control unit.

2 - Communication status

: The unit communicates with the MS module.

: The unit does not communicate with the MS module.

Establish communication:

1 Reset control unit.

2 Check status of MS module.

3 Check cable joint.

Page 15

3 -

The measurement is recorded.

4 - Ser

The logged-in user is identified by an abbreviation.

Display User

Ope Operator

Sup Supervisor

Int Integrator

Ser Service

For more information, see see Chapter 6.2.4, page 20.

5 - Zero

Background suppression is activated.

6 -

Active warnings are stored in the unit.

The active warnings can be displayed via the menu "I

7 - Test gas

NFO > HISTORY > WARNINGS".

Configured test gas.

Display Test gas

He Helium (

4

He)

H2 Hydrogen

M3 e.g. H-D,

3

He or H

8 - Operation mode

Configured operation mode.

Display Operation mode

V

AC Vacuum

S

NIF Sniffer

9 - Leak rate

Current measurement for the leakage rate.

10 - Graph

Graphic display of the leakage rate Q(t).

11 - Time axis

Time axis of the leakage rate Q(t).

3

12 - Backing pump

Backing pressure p1.

Operation 15

Page 16

13 - Key FAVORITE 2

You can assign preferred parameters to this key (see Chapter 6.2.2, page 18).

In Fig: 4 the key F

14 - Key F

AVORITE 1

AVORITE 2 is assigned the function START/STOP for example.

You can assign preferred parameters to this key (see Chapter 6.2.2, page 18).

In Fig: 4 the key F

AVORITE 1 is assigned the function ZERO for example.

15 - Menu

All functions and parameters of the control unit can be accessed using the M

ENU

key.

Refer to the supplemental sheet “LDS3000 Menu” for an overview of the menu.

16 - Value axis

Value axis of the leakage rate Q(t).

17 - Unit of measurement

Unit of measurement of the value axis.

16 Operation

Page 17

6.2 Querying and setting parameters

The following chapter describes the parameters and functions of the CU1000 control

unit. You will find the parameters and functions of the mass spectrometer module you

can set using the control unit in the installation manual of the mass spectrometer

module.

The menu tree shows the access level needed for changing the parameters (factory

settings).

The parameters explained in this chapter are displayed as follows:

Path (based on Measuring view > Menu key > Main menu)

Parameter Description

Settings Explanation of the settings (as needed)

6.2.1 Display settings

DISPLAY > Q(T) AXIS

Linear or logarithmic Linear or logarithmic Q(t) axis

Lin., Log.

Decades Number of decades of the Q(t) axis

(for logarithmic view)

1, 2, 3, 4

Automatic scaling Automatic scaling of the Q(t) axis

Off, On

DISPLAY > TIME AXIS

Time axis scale Scaling of the time axis

15 s, 30 s, 60 s, 120 s, 240 s, 480 s, 960 s

DISPLAY > DISPLAY LIMITS

Displ. upper limit

exponent

Displ. lower limit

exponent

DISPLAY > UNITS (DISPLAY)

Leak rate unit

VAC

Leak rate unit

SNIFF

Pressure unit Unit of pressure

Maximum value of the exponent of the Q(t) axis

-12 … -1

Minimum value of the exponent of the Q(t) axis

-12 … -1

Unit of the leakage rate in vacuum mode

mbar·l/s, Pa·m³/s, atm·cc/s, Torr·l/s

Unit of the leakage rate in sniff mode

mbar·l/s, Pa·m³/s, atm·cc/s, Torr·l/s, ppm, g/a

mbar, Pa, atm, Torr

Operation 17

Page 18

DISPLAY > MEAS. VIEW

6.2.2 Settings

Measurement view

mode

Type of graphic display

Diagram, bar graph

Show value Numeric representation of the measurements

Off, On

DISPLAY > BRIGHTNESS

Display brightness Brightness of the display

20 ... 100%

SETTINGS > TRIGGER > TRIGGER SEL.

Used trigger Leakage rate limit shown in the display

1...4

ETTINGS > FAVORITES

S

Favorite 1

To execute a frequently used function more quickly, you can

assign the function to the key F

The key F

AVORITE 1 is the middle key on the measurement

AVORITE 1.

display (see Fig: 4, page 14, No. 14).

CAL, Zero, Measurement view, Start/Stop, Display settings,

Volume, --- (= no function)

Favorite 2

To execute a frequently used function more quickly, you can

assign the function to the key F

The key F

AVORITE 2 is the right key on the measuring display

AVORITE 2.

(see Fig: 4, page 14, No. 13).

CAL, Zero, Measurement view, Start/Stop, Display settings,

Volume, --- (= no function)

Favorite 3

To execute a frequently used function more quickly, you can

assign the function to the key F

The key F

AVORITE 3 is the key at the bottom right of the main

AVORITE 3.

menu.

CAL, Zero, Measurement view, Start/Stop, Display settings,

Volume, --- (= no function)

Users with the access level OPERATOR, SUPERVISOR or INTEGRATOR can access the

favorites.

S

ETTINGS > SET UP > CONTROL UNIT > LANGUAGE

Language Language of the display

German, English

SETTINGS > SET UP > CONTROL UNIT > MESSAGES

Show warnings Activation of warnings on the display

Off, On

18 Operation

Page 19

SETTINGS > SET UP > CONTROL UNIT > AUDIO

Volume level Volume of the headphones or active speaker

0 ... 15

Audio alarm mode Type of audio alarm

No function -

Proportional The frequency of the audible signal is

proportional to the bar graph display or

diagram height. The frequency range is

300 Hz to 3300 Hz.

Setpoint The pitch is proportional to the leakage rate.

A signal sounds if the leakage rate exceeds

the selected trigger value.

Pinpoint The sound of the acoustic signal changes its

frequency within a specific range of leakage

rates. Range: A decade below the selected

trigger threshold up to one decade above.

The sound keeps at a constant low and a

constant high frequency below and above

this range, respectively.

Trigger If the selected trigger threshold is exceeded,

a two-pitch signal sounds.

SETTINGS > SET UP > CONTROL UNIT > ENERGY

6.2.3 Functions

Display off after Time after which the display switches off to save energy

30s, 1min, 2min, 5min, 10min, 30min, 1h, ∞ (= never)

Information If the display shows a warning or an error, then a two-pitch signal

sounds simultaneously.

FUNCTIONS > DATA > PARAMETERS > RESET

Control unit settings Resetting the control unit parameters to the factory settings

-

MSB settings Resetting the mass spectrometer module parameters to the

factory settings

-

Parameter access

level

Resetting the parameter access levels to the factory settings

-

Operation 19

Page 20

FUNCTIONS > DATA > RECORDER > SETTINGS

Data recording Activation or deactivation of data recording

Off, On

Record interval Time interval between the recording of data sets

100ms, 200ms, 500ms, 1s, 2s, 5s

Memory location Memory location of the measured data that is recorded

(USB stick, control unit)

USB The data are stored on a USB stick as a TXT

file. Each TXT file contains the following

information:

- Creation date

- Software versions

- Serial number

- Start time

- Time stamp (measurement indicates offset

in seconds in relation to start time)

- File name

- Time stamp (offset in seconds in relation to

start time)

- Leakage rate (in used unit)

- Pressure P1 (in used unit)

- Device status

internal The memory in the control unit is limited

(sufficient for recording data for a maximum

of 24 hours).

Recommendation: Record directly to USB

stick.

FUNCTIONS > DATA > PARAMETERS

6.2.4 Access Ctrl

List List of parameters that can be changed (sorted

alphabetically)

-

ACCESS CTRL > OPERATOR/SUPERVISOR/INTEGRATOR > ERROR INFO

Error info Viewer/

Operator/Supervisor

ACCESS CTRL > OPERATOR/SUPERVISOR/INTEGRATOR

Para. access List of parameter access levels

ACCESS CTRL > OPERATOR/SUPERVISOR/INTEGRATOR > PIN ASSIGN

Operator/Supervisor/

Integrator

Depth of error information

Error number, Short text, Extended information

-

PIN for the access levels

0000 ... 9999

20 Operation

Page 21

Information A key switch can be used instead of the PIN. The key switch is

connected to the I/O module via three digital inputs.

Access Ctrl

Level Designation query set

1 Viewer (V

2 Operator (O

3 Supervisor (S

4 Integrator (I

IE)NoYesNo

PE)YesYesYes

UP)Yes YesYes

NT)YesYesYes

6.2.5 Info

INFO > MEASUREMENT/TEMPERATURE/ENERGY/HISTORY/CONTROL UNIT/MS MODULE/

I

NTERFACES

Diverse parameters Information on diverse parameters, e. g. on the pre-amplifier

or the ion source

-

6.3 Loading or saving parameters

You can use a USB stick to backup and restore the control unit and mass

spectrometer module parameters.

► Load parameters as needed:

F

UNCTIONS > DATA > PARAMETER > LOAD > LOAD PARAMETER

► Save parameters as needed:

F

UNCTIONS > DATA > PARAMETER > SAVE > SAVE PARAMETER

Login with PIN

Parameter

6.4 Copying or deleting measured data

► Copy measured data from the control unit’s internal memory to a USB stick as

needed:

F

UNCTIONS > DATA > RECORDER > COPY > COPY FILES

► Delete measured data from the control unit’s internal memory as needed:

F

UNCTIONS > DATA > RECORDER > DELETE > DELETE FILES

6.5 Lock all access levels

► Lock all access levels as needed:

A

CCESS CTRL > VIEWER

Operation 21

Page 22

6.6 Software update

6.6.1 Updating the software of the control unit

1 Copy these files to the main directory of a USB stick:

– Handset_IFC_Vx.x.xx.exe

– Handset_IFC_Vx.x.xx.key

2 Plug the USB stick into the USB port on the control unit.

3 Select on measurement screen:

F

UNCTIONS > DATA > UPDATE > CONTROL UNIT

4 Press OK to confirm message.

5 Press S

TART to begin.

6.6.2 Updating the software of the MS module

1 Copy these files to the main directory of a USB stick:

– Flash_LDS3000_MSB_Vxx.xx.xxx.bin

2 Plug the USB stick into the USB port on the control unit.

3 Select on measurement screen:

F

UNCTIONS > DATA > UPDATE > MSB

4 Press O

5 Press S

K to confirm message.

TART to begin.

6.6.3 Updating the software of the I/O module

Information The software of the I/O module can be updated from the control unit if

the mass spectrometer module has the software version “MS-Modul

1.02” or higher.

1 Copy these files to the main directory of a USB stick:

– Flash_LDS3000_IO_Vxx.xx.xxx.bin

2 Switch DIP switch S2-3 of the I/O module from OFF to ON (rising flank).

22 Operation

3 Plug the USB stick into the USB port on the control unit.

4 Select on measurement screen:

F

UNCTIONS > DATA > UPDATE > I/O MODULE

5 Press OK to confirm message.

6 Press S

7 Switch DIP switch S2-3 of the I/O module to OFF.

TART to begin.

Page 23

7 Taking out of service

7.1 Disposing of the control unit

The unit can be disposed of by the user or sent to INFICON.

Information The unit is made of materials that can be reused. By recycling these

materials you reduce waste and environmental impact.

► For disposal, always comply with local and regional environmental and safety

regulations.

7.2 Returning the control unit

Danger to health

Contaminated units can damage the health of INFICON's service staff.

► Use the Declaration of Contamination.

The Declaration of Conformity is essential to ensure compliance with statutory

requirements and the protection of our employees. Units submitted without an

enclosed Declaration of Conformity will be returned to the sender by INFICON.

► Attach the form to the unit or enclose it in the unit's packaging.

Taking out of service 23

Page 24

INFICON GmbH, Bonner Strasse 498, D-50968 Cologne, Germany

UNITED STATES TAIWAN JAPAN KOREA SINGAPORE GERMANY FRANCE UNITED KINGDOM HONG KONG

Visit our website for contact information and other sales offices worldwide. www.inficon.com

Document: jina54en1-b (1301)

Loading...

Loading...