Page 1

Translation of the Original

CU1000

Operating unit

Catalog No.

560-320

From software version

2.72 (LDS3000) / 2.72 (CU1000)

jina54en1-06-(1901)

Page 2

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

Page 3

INFICON Table of Contents

Table of Contents

1 About these instructions ...................................................................................................................................5

1.1 Target groups ...........................................................................................................................................5

1.2 Other associated documents ....................................................................................................................5

1.3 Warnings...................................................................................................................................................5

2 Safety ...............................................................................................................................................................6

2.1 Intended use .............................................................................................................................................6

2.2 Owner requirements .................................................................................................................................6

2.3 Operator requirements..............................................................................................................................6

3 Shipment, Transport, Storage ..........................................................................................................................7

4 Description........................................................................................................................................................8

4.1 Device setup .............................................................................................................................................8

4.2 Function ....................................................................................................................................................9

4.3 Technical data ..........................................................................................................................................9

5 Installation ......................................................................................................................................................10

5.1 Connecting the control unit .....................................................................................................................10

5.2 Installing the control unit .........................................................................................................................11

6 Operation CU1000..........................................................................................................................................12

6.1 Touchscreen elements ...........................................................................................................................12

6.1.1 Measurement display elements ..................................................................................................12

6.2 Elements of the error and warning display .............................................................................................15

6.3 Settings and functions ............................................................................................................................16

6.3.1 Touch screen settings................................................................................................................. 16

6.3.2 Operator types and authorizations.............................................................................................. 19

6.3.2.1 Logging out the operator ....................................................................................................21

6.3.3 Functions .................................................................................................................................... 21

6.3.3.1 Resetting the settings.........................................................................................................21

6.3.3.2 Recording data...................................................................................................................21

6.3.3.3 Calling up information ........................................................................................................22

6.3.4 Updating the software .................................................................................................................26

6.3.4.1 Updating the software of the control unit............................................................................26

6.3.4.2 Checking and updating the software version of the MSB box............................................26

6.3.4.3 Updating the software of the I/O module............................................................................27

CU1000-operating-instructions-jina54en1-06-(1901) iii

Page 4

Table of Contents INFICON

7 Decommissioning the measuring instrument..................................................................................................29

7.1 Disposing of the device...........................................................................................................................29

7.2 Sending in the device .............................................................................................................................29

8 Appendix.........................................................................................................................................................31

8.1 CE Declaration of Conformity .................................................................................................................31

8.2 RoHS ......................................................................................................................................................32

iv CU1000-operating-instructions-jina54en1-06-(1901)

Page 5

INFICON About these instructions | 1

1 About these instructions

1.1 Target groups

These operating instructions are intended for the owner and for technically qualified

personnel with experience in leak detection technology and integration of leak

detection devices in leak detection systems. In addition, the installation and use of the

device require knowledge of electronic interfaces.

1.2 Other associated documents

Mass spectrometer module operating

instructions

Operating instructions bus module jiqb10

Operating instructions I/O module jiqc10

Protocol Descriptions jira54

1.3 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation resulting in potential death or serious injuries

jiqa54

CAUTION

Hazardous situation resulting in minor injuries

NOTICE

Hazardous situation resulting in damage to property or the environment

CU1000-operating-instructions-jina54en1-06-(1901) 5 / 36

Page 6

2 | Safety INFICON

2 Safety

2.1 Intended use

The unit is intended for querying and configuring the data of the mass spectrometer

module LDS3000.

► Install, operate and service the unit only in compliance with these instructions.

► Maintain the application limits (refer to Chapter 4.3, page 10).

2.2 Owner requirements

Safety conscious

operation

Personnel

qualifications

Operate and install the device only in technically perfect working order and as

specified, in a safety-conscious and hazard-conscious manner and in compliance with

these instructions.

► Fulfill and ensure compliance with the following regulations:

- Intended use

Universally valid safety and accident prevention regulations

- International, national and local standards and guidelines

- Additional device-related provisions and regulations

► Use only original parts or parts approved by the manufacturer.

► Keep this manual available at the operating site.

► All work must be performed only by technically qualified specialists who have been

trained on the device.

► Allow personnel in training to work on the device only under the supervision of

technically qualified specialists.

► Make sure that the authorized personnel have read and understood these

instructions and all other applicable documents (refer to "Other associated

documents"), especially the information on safety, maintenance and repairs, before

starting work.

► Define responsibilities, authorizations and supervision of personnel.

2.3 Operator requirements

► Read, observe and follow the information in these instructions and the working

instructions created by the owner, especially the safety instructions and warnings.

6 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 7

INFICON Shipment, Transport, Storage | 3

3 Shipment, Transport, Storage

Shipment

Transport

Storage

Item Quantity

Control unit 1

Touch PIN 1

Operating instructions 1

► Please check the scope of delivery of the product for completeness after receipt.

NOTICE

Damage due to unsuitable packaging material

Transport in unsuitable packaging material can damage the device.

► ► Transport the device only in the original packaging.

► ► Keep the original packaging.

► Store the device taking into consideration the technical data, refer to Chapter 4.3,

page 10.

CU1000-operating-instructions-jina54en1-06-(1901) 7 / 36

Page 8

4 | Description INFICON

4 Description

4.1 Device setup

Fig.1:

Front view

1 Touchscreen 4 USB port

2 Status LED 5 Mounting holes

3 Rest button

Status LED

Status LED illuminated Control unit operates normally

Status LED flashing Display is set to power saving mode

Fig.2:

Rear view

1 Rating plate with control unit 3 Calibration button for calibrating

the touch screen (LCD-CAL), can

be operated with touch PIN

2 Connection for headphones 4 Connection for the cable to the

leak detector (LD)

8 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 9

INFICON Description | 4

4.2 Function

You can use the control unit to configure the mass spectrometer module LDS3000. It

also lets you output the data stored in the MSB box.

4.3 Technical data

Mechanical data

560-320

Dimensions (lxwxh) 106,2 mm x 128,4 mm x 49,2 mm

Electrical data

560-320

Memory capacity for measured data 16 MB

Ambient conditions

560-320

Max. altitude above sea level 2000 m

Max. relative humidity above 40 °C 50%

Max. relative humidity from 31 °C to 40°C80% to 50% (linear abfallend)

Max. relative humidity to 40 °C 80%

Storage temperature -20 °C - 60 °C

Pollution degree II

CU1000-operating-instructions-jina54en1-06-(1901) 9 / 36

Page 10

5 | Installation INFICON

5 Installation

5.1 Connecting the control unit

Establish connection of "LD" of the control unit and "Control Unit" of the MSB box with

the data cable.

The data cable on the control unit can also be connected or removed during operation.

► If needed, connect headphones or speakers to the headphones symbol.

DANGER

Hearing damage from loud volume setting

Loud volume setting can damage hearing.

► Do no set volume of headphones too loud.

10 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 11

INFICON Installation | 5

5.2 Installing the control unit

Fig.3:

Dimensions of the control unit in mm (inches in brackets)

• Recess for the control unit integrated in the test system.

► Push the control unit into the recess and screw it tight.

► Pull protection film from touch screen.

CU1000-operating-instructions-jina54en1-06-(1901) 11 / 36

Page 12

6 | Operation CU1000 INFICON

6 Operation CU1000

NOTICE

Damage to touch screen from incorrect operation.

The touch screen can be damaged with a hard or pointed item.

► Operate touch screen with fingers only.

6.1 Touchscreen elements

6.1.1 Measurement display elements

Fig.4:

Measurement display

12 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 13

INFICON Operation CU1000 | 6

1 Keyboard lock 2 Communication status 3 Data recording

4 Operator 5 Zero 6 Message

7 Tracer gas 8 Operation mode 9 Leak rate with peak hold function

10 Graphic representation of the leak

rate and the peak hold function

13 Button "Favorite 2" 14 Button "Favorite 1" 15 Menu

16 Value axis 17 Value axis

11 Time axis 12 Foreline pressure

1 - Keyboard lock

The control unit is locked or unlocked by pressing and holding the icon for the

keyboard lock.

2 - Icon for the communication status

• Icon connected: The device communicates with the mass spectrometer module.

• Icon disconnected: The device does not communicate with the mass spectrometer

module.

Establish communication:

1

Reset control unit.

2

Checking the status of the mass spectrometer module.

3

Check cable connection.

3 - Icon for the data recording

The measurement is recorded.

4 - Ser

The registered operator is shown abbreviated.

Display Meaning

Ope Operator

Sup Supervisor

Int Integrator

Ser Service

For more information, see Chapter 6.2.2., Page 20.

5 - Zero

Background suppression is active.

CU1000-operating-instructions-jina54en1-06-(1901) 13 / 36

Page 14

6 | Operation CU1000 INFICON

6 - Caution icon

Active warnings are stored in the unit.

The active warnings can be displayed via the menu "Info > History > Warnings".

7 - Tracer gas

Set tracer gas and tracer gas concentration percentage.

Display Meaning

He Helium (4He)

H2 Hydrogen

M3 E.g. H-D, 3He or H

3

8 - Operation mode

Configured operation mode

Display Operation mode

VA Vacuum

SNIF Sniff

LOW FLOW XL sniffer adapter in LOW FLOW

HIGH FLOW XL sniffer adapter in HIGH FLOW

Standby XL sniffer adapter in HIGH FLOW on

standby

9 - Leak rate

Current measurement for the leak rate.

10 - Graph

Graphic display of the leak rate Q(t).

11 - Leak rate

Time axis of the leak rate Q(t).

12 - Primary vacuum pressure (not with operation mode XL Sniffer

Adapter)

Backing pressure p1.

13 - Button "Favorite 2"

You can assign preferred parameters to this button (see Page 19 ). In Fig. 4 the button

"Favorite 2" is assigned the function "Start/Stop" for example.

14 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 15

INFICON Operation CU1000 | 6

Displayed

message

with details

Detailed display

further active

errors or

warnings

(if present)

To the display

further active

errors or

warnings

(if present)

WARNING

Number: 500

Pressure sensor not connected

(Value = 4.23E-2)

Further errors or warnings

To confirm

all messages

Information to

cause or remedy

to the message shown

above

501

502

14 - Button "Favorite 1"

You can assign preferred parameters to this button (see Page 19 ). In Fig. 4 the button

"Favorite 1" is assigned the function "ZERO" for example.

15 - Icon for the menu

All functions and parameters of the control unit can be accessed using the "Menu"

key .

A full display of the menu of the menu is included as a file on the USB flash drive

supplied with the LDS3000.

16 - Value axis

Value axis of the leak rate Q(t).

17 - Device of measurement

Device of measurement of the value axis.

6.2 Elements of the error and warning display

CU1000-operating-instructions-jina54en1-06-(1901) 15 / 36

You will find an overview of possible errors and warnings in the operating instructions

of the LDS3000 (mass spectrometer module), chapter "Warning and error messages".

Page 16

6 | Operation CU1000 INFICON

6.3 Settings and functions

Settings and functions of the control unit are explained in the following. You will find

the settings and functions of the mass spectrometer module LDS3000 you can set

using the control unit in the operating instructions of the mass spectrometer module.

6.3.1 Touch screen settings

The touch screen grays out the parameters if

• the user is not authorized to modify the values,

• the older version of the software run by mass spectrometer module LDS3000 does

not support this parameter.

Scaling of the Q(t)axis

Linear or logarithmic

Lin.

Log.

Control unit Display > Q(t) axis > Linear or logarithmic

Number of decades with logarithmic view

1

2

3

4

Control unit Display > Q(t) axis > Decades

Autoscale

Off (When ”Off”, you can change the appearance by pressing the intersection of the

coordinate axes, then flicking and releasing the desired axis with your finger, or by

pressing and releasing the end of the desired co-ordinate axis)

On

Control unit Display > Q(t) axis > Auto scale

Scaling of the time axis

16 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Scaling of the time axis

15 s

30 s

60 s

120 s

Control unit Display > Time axis > Time axis scale

240 s

480 s

960 s

Page 17

INFICON Operation CU1000 | 6

Display units

Measured value

display

Device of pressure

Mbar

Pa

Atm

Torr

Control unit Display > Units (display) > Pressure unit

Type of graphic display

Diagram

Bar graph

Control unit Display > Measurement view > Measurement view mode

Numeric representation of the measurements

Off

On

Control unit Display > Measurement view > Show value

Display brightness

Trigger display on the

touch screen

Assigning favorite

buttons

Display brightness

20 ... 100%

Control unit Display > Brightness > Display brightness

Selection of the trigger (leak rate threshold) displayed on the touch screen.

1

2

3

4

Control unit Settings > Trigger > Trigger sel.

The favorite buttons offer direct access to individual functions. They can be assigned

with access control "Supervisor" or higher by the user.

Favorite 1: Middle button (see Fig. 4, Page 15).

Favorite 2: Right button

Favorite 3: Button on the bottom right of the main menu.

CAL

ZERO (at AQ instead of ZERO: ZERO

AQ)

Measurement view

Start/Stop

CU1000-operating-instructions-jina54en1-06-(1901) 17 / 36

Volume

- - - (= without function)

Check CAL

Flow control

(At AQ additionally: AQ Wizard)

Page 18

6 | Operation CU1000 INFICON

View settings

Control unit Settings > Favorites > Favorite 1 (2, 3)

Display of messages

on the touch screen

Show calibration note

Show calibration

request

Warnings and error messages can be displayed on the touch screen.

Off

On

Control unit Settings > Set up > Control unit > Messages > Show

warnings

Suppress or allow the calibration note with the following content:

• Leak rate of the applied calibration leak

• No calibration should take place during the first 20 mins

OFF (suppressed)

ON (allowed)

Control unit Settings > Set up > Control unit > Messages > Show

calibration notes

The calibration request can be allowed or suppressed.

OFF (suppressed)

Display of messages

on the touch screen

Setting the audio alarm

ON (allowed)

Control unit Settings > Set up > Control unit > Messages > Show

calibration request

Warnings and error messages can be displayed on the touch screen.

Off

On

Control unit Settings > Set up > Control unit > Messages > Show

warnings

Volume of the headphones or active speaker

--- No sound

Proportional: The frequency of the audible signal is proportional to the bar graph

display or diagram height. The frequency range is 300 Hz to 3300 Hz.

Setpoint: The pitch is proportional to the leak rate. The signal sounds if the leak rate

exceeds the selected trigger value.

18 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 19

INFICON Operation CU1000 | 6

Pinpoint: The sound of the acoustic signal changes its frequency within a specific

range of leak rates. Range: A decade below the selected trigger threshold up to one

decade above. The sound keeps at a constant low and a constant high frequency

below and above this range, respectively.

Trigger: If the selected trigger threshold is exceeded, a two-pitch signal sounds.

Control unit Settings > Set up > Control unit > Audio > Audio alarm mode

Automatic switch off of

the touch screen

6.3.2 Operator types and authorizations

Behavior with warnings or error messages:

error, then a two-pitch signal sounds simultaneously.

The touch screen can be switched off automatically after a specific time without any

operation to save energy.

30 s

1 min

2 min

5 min

Control unit Settings > Set up > Control unit > Energy > Display off after

There are four different operator types that are distinguished by different

authorizations. The integrator is registered ex works.

Additional operators can be registered. The following table shows options for

individual operator types to register new operator types.

10 min

30 min

1 h ∞ (=never)

If the touch screen shows a warning or an

Operator registration

Viewer Operator Supervisor Integrator

- Operator

Viewer

For the types "Integrator", "Supervisor" and "Operator", a four-digit PIN must be

assigned during registration (0000 ... 9999). "0000" is assigned to all operators ex

works.

If an operator keeps the pin "0000", this operator will always be registered is during

the start up of the system (without PIN query).

A key-operated switch can be used in addition to a PIN if an I/O module is connected.

The key-operated switch is connected to the I/O module via three digital inputs (see

operating instructions of the LDS3000).

The following table shows the authorizations of individual operator types.

Supervisor

Operator

Viewer

Integrator

Supervisor

Operator

Viewer

CU1000-operating-instructions-jina54en1-06-(1901) 19 / 36

Page 20

6 | Operation CU1000 INFICON

Function Viewer Operator Supervisor Integrator

Load parameters

Save parameters

Changing

- x x x

parameters

Changing the

- x x x

display of error

information

Calling up

- - - x

factory settings

Entering

- - - x

maintenance

history

The menu "Service" is accessible only to INFICON service staff.

The saved/backed-up parameters of control unit CU1000 and of the mass

spectrometer module can be loaded from a USB stick.

Control unit Function > Data > Parameters > Load

The parameters of control unit CU1000 and of the mass spectrometer module can be

saved to a USB flash drive.

Display error

information

Parameter list display

and change

Control unit Function > Data > Parameters > Save

The type of error information can be set differently for each operator type. The

Integrator always receives the complete information.

Number: Message number

text: Brief description

Info: Expanded message information

• Only numbers

• Number and text

• Number, text and info

Control unit Function > Data > Parameter > Error info

Viewer (Operator, Supervisor)

Parameters can be displayed as an alphabetical list with names and current value s.

Each list entry is a button which, when pressed, will open the parameter's set-up

dialog box.

Control unit List > Parameters list

or:

Functions > Data > Parameters > List

Display list of

parameter change

authorizations

Parameters can be displayed as an alphabetical list with names and current change

authorizations. Each list entry is a button which, when pressed, will change access

control. Changes are possible in accordance with the hierarchy of the operator.

Control unit Functions > Data > Parameters >

Parameter Access

20 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 21

INFICON Operation CU1000 | 6

6.3.2.1 Logging out the operator

The operator activates access level "Viewer" to log out. "Access Ctrl > Viewer"

6.3.3 Functions

6.3.3.1 Resetting the settings

Mass spectrometer

module

Access controls

Control unit

6.3.3.2 Recording data

The settings of the mass spectrometer module can be reset to factory settings.

Control unit Functions > Data > Parameters > Reset >

MSB settings

The authorization for changing parameters can be reset to factory setting.

Control unit Functions > Data > Parameters > Reset >

Param. access control

The control unit settings can be reset to factory settings.

Control unit Functions > Data > Parameters > Reset >

Control unit settings

The data is saved as a TXT file. Each TXT file contains the following information:

• Date created

• Software version

• Serial number

Switching on/off

Record interval

• Start time

• Time stamp (measurement indicates offset in seconds in relation to start time)

• File name

• Time stamp (offset in seconds in relation to start time)

• Leak rate (expressed in selected unit)

• Pressure p1 (expressed in selected unit)

• Device status

Switching data recording on/off

• Off

• On

Control unit Functions > Data > Recorder > Settings >

Data recording

Time interval between data recordings

• 100 ms, 200 ms, 500 ms, 1 s, 2 s, 5 s

CU1000-operating-instructions-jina54en1-06-(1901) 21 / 36

Page 22

6 | Operation CU1000 INFICON

Control unit Functions > Data > Recorder > Settings >

Record interval

Memory location

Copy data

Deleting data

The data stored in the control unit can be saved to a USB stick. The memory in the

control unit is limited to the recording of a 24-hour measurement.

• USB flash drive

• Control unit

Control unit Functions > Data > Recorder > Settings >

Storage location

The data stored in the control unit can be saved to a USB stick. The memory in the

control unit is limited to the recording of a 24-hour measurement.

• USB flash drive

• Control unit

Control unit Functions > Data > Recorder > Copy >

Copy files

The data stored in the control unit can be saved to a USB stick. The memory in the

control unit is limited to the recording of a 24-hour measurement.

• USB flash drive

• Control unit

6.3.3.3 Calling up information

Measurement values

Temperature

Energy and operating

hours

History

Control unit Functions > Data > Recorder > Delete >

Delete files

Different information and states of the system can be called up with the info menu.

• Preamplifier

• Environment

• TMP

• Electronic

• TMP

• Energy values: Information on consumption values

• Operation hours: Display for operating hours

• Supply voltages: Information on internal supply voltages

• Power supply: Information on the supply voltages of the components

• Error, error history / warning history

• Calibration, calibration history

• TMP error, TMP history

• Warnings, active warnings

22 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 23

INFICON Operation CU1000 | 6

• Maintenance, maintenance history

Control unit

Mass spectrometer

module

Interfaces

• Version control unit: Information on the software version

• Memory: Information on available memory

• Settings: Control unit settings.

• Serial port wired: Information on the communication connection

• Data exchange: Information on the data exchange between mass spectrometer

module and the control unit

• MSB (1): Information on the software version

• MSB (2): Information on operating parameters

• TMP controller (1): Information on the turbo molecular pump

• TMP controller (2): Information on the turbo molecular pump, continued

• Ion source: Information on the ion source used

• Preamplifier: Information on the preamplifier

• Preamplifier test: Information on the preamplifier test.

• I/O module (1): Information on the software version, inputs and outputs

• I/O module (2): Visualized information to the digital inputs

CU1000-operating-instructions-jina54en1-06-(1901) 23 / 36

Page 24

6 | Operation CU1000 INFICON

Fig.5:

I/O module (2): Visualized information to the digital inputs

1 Input signal condition 2 Configured function (INV =

Function is inverted)

3 Status of the function (active or

inactive)

• I/O module (3): Visualized information to the digital outputs

24 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 25

INFICON Operation CU1000 | 6

Fig.6:

Visualized information to the digital outputs

1 Configured function (INV =

2 Output signal condition

Function is inverted)

3 Status of the function (active or

inactive)

• Bus module (1): Information on the bus module

• Bus module (2): Information on the bus module, continued

CU1000-operating-instructions-jina54en1-06-(1901) 25 / 36

Page 26

6 | Operation CU1000 INFICON

6.3.4 Updating the software

Software updates from INFICON are installed with the aid of a USB flash drive. The

update function of the device can be found under "Functions > Data > Update".

An update is possible,

• if one or several updates are available on the USB flash drive, but only one update

per type at most (control unit, MSB box, I/O module),

• if these parts are also connected free of disturbances and have an update

function.

The corresponding buttons in the update menu such as "Control Unit", "MSB Box",

and "I/O Module" are active and can be activated individually.

NOTICE

Aborted connection

Data loss due to an aborted connection

► Do not switch off the device and do not remove the USB flash drive while the

software is being updated!

►

Switch the device off and back on after a software update has taken place.

6.3.4.1 Updating the software of the control unit

The software is included in two files named Handset_IFC_Vx.xx.xx.exe and

Handset_IFC_Vx.xx.xx.key.

1

Copy the file into the main directory of a USB flash drive.

2

Connect the USB flash drive to the USB port on the device.

3

Select: "Functions > Data > Update > Control unit".

ð Do not switch off the device and do not remove the USB flash drive while the

software is being updated!

4

Check the version information.

5

Select the "Start" button to start the update. Do not switch off the device and do

not remove the USB flash drive while the software is being updated!

6

Follow the instructions on the touchscreen and wait until the update is complete.

6.3.4.2 Checking and updating the software version of the MSB box

The current software is available from the Inficon support.

The functions of the XL Sniffer adapter set are taken into consideration in system

software version 2.11 or higher.

26 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 27

INFICON Operation CU1000 | 6

1

Copy the file Flash_LDS3000_MSB_Vxx.xx.xxx.bin into the main directory of a

USB flash drive.

2

Connect the USB flash drive to the USB port on the device.

3

Select: "Functions > Data > Update > MSB".

ð The display shows information on the current and the new software version

as well as on the boot loader.

4

Check the version information.

ð Select the "Start" button to start the update.

ð Do not switch off the device and do not remove the USB flash drive while the

software is being updated! Do not switch off the device and do not remove

the USB flash drive while the software is being updated!

5

Follow the instructions on the touchscreen and wait until the update is complete.

6

If the system displays warning 104 or 106, confirm with "C".

6.3.4.3 Updating the software of the I/O module

The software of the I/O module can be updated from the control unit if the mass

spectrometer module has the software version "MS module 1.02" or higher.

1

Copy the file Flash_LDS3000_IO_Vxx.xx.xxx.bin into the main directory of a

USB flash drive.

2

Connect the USB flash drive to the USB port on the device.

3

Select: "Functions > Data > Update > I/O module"

ð The display shows information on the current and the new software as well as

on the current boot loader.

4

Check the version information.

5

Select the "Start" button to start the update.

ð Do not switch off the device and do not remove the USB flash drive while the

software is being updated!

6

Follow the instructions on the touchscreen and wait until the update is complete.

ð The following tips are shown after selecting the "Start" button on the

touchscreen:

• Connect and switch on the IO1000.

• Activate boot mode (switch DIP S2.3 on and off once).

• When the STATUS LED flashes green, press OK.

CU1000-operating-instructions-jina54en1-06-(1901) 27 / 36

Page 28

6 | Operation CU1000 INFICON

Fig.7:

DIP switch on the I/O module

28 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 29

INFICON Decommissioning the measuring instrument | 7

7 Decommissioning the measuring

instrument

7.1 Disposing of the device

The device can either be disposed of by the operator or be sent to the manufacturer.

The device consists of materials that can be recycled. This option should be exercised

to prevent waste and also to protect the environment.

During disposal, observe the environmental and safety regulations of your country.

7.2 Sending in the device

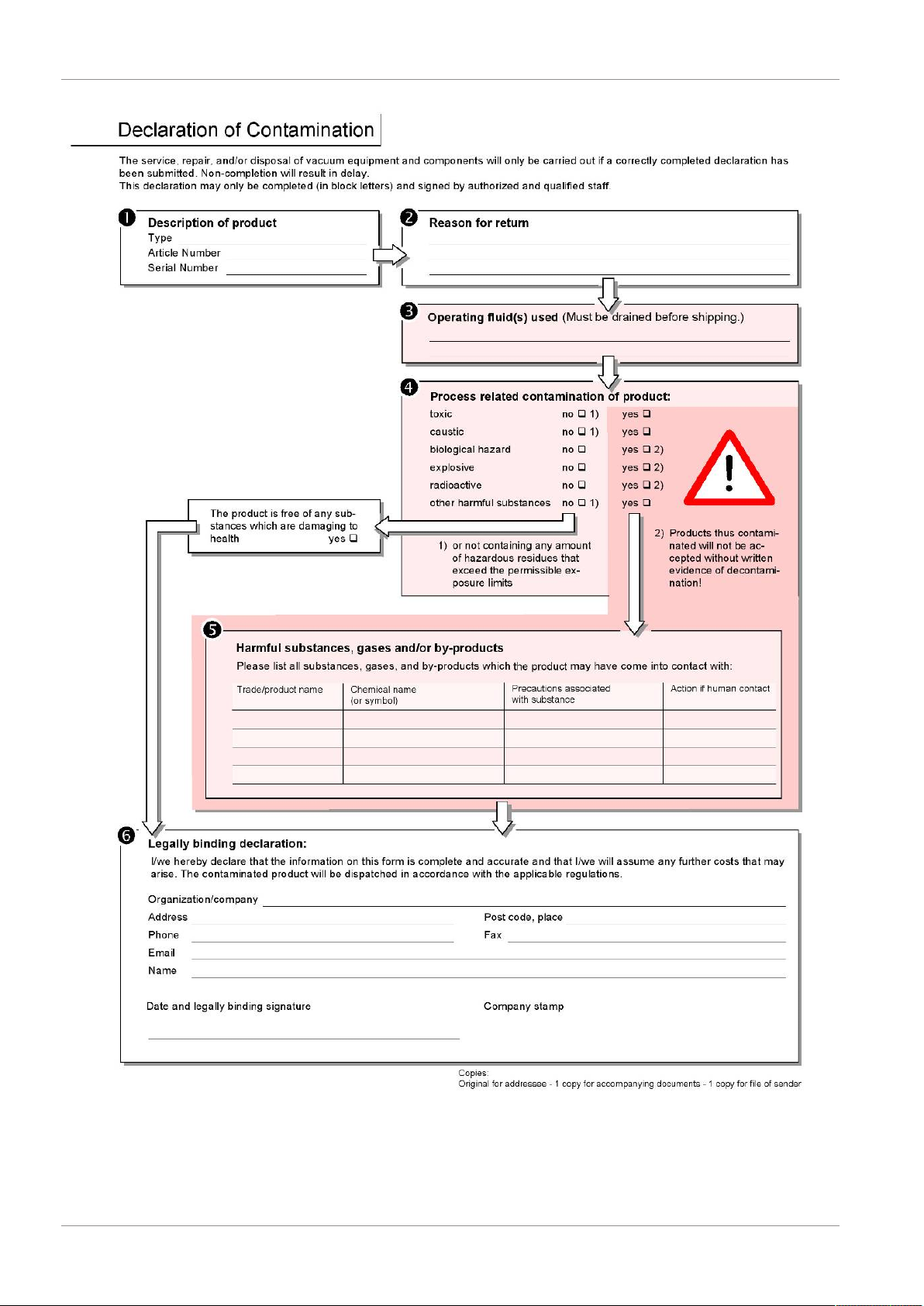

WARNING

Danger due to harmful substances

Contaminated devices could endanger the health. The contamination declaration

serves to protect all persons who come into contact with the device.

► Fill in the declaration of contamination completely.

1

Please do not hesitate to contact us and send a completed declaration of

contamination before sending anything to us.

ð You will then receive a return number from us.

2

Use the original packaging when returning.

3

Before sending the device, attach a copy of the completed contamination

declaration. See below.

CU1000-operating-instructions-jina54en1-06-(1901) 29 / 36

Page 30

7 | Decommissioning the measuring instrument INFICON

30 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 31

INFICON Appendix | 8

8 Appendix

8.1 CE Declaration of Conformity

CU1000-operating-instructions-jina54en1-06-(1901) 31 / 36

Page 32

8 | Appendix INFICON

8.2 RoHS

32 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 33

INFICON Appendix | 8

CU1000-operating-instructions-jina54en1-06-(1901) 33 / 36

Page 34

8 | Appendix INFICON

34 / 36 CU1000-operating-instructions-jina54en1-06-(1901)

Page 35

Page 36

Loading...

Loading...