Page 1

OPERATING MANUAL

CrystalSix

Sensor

IPN 074-155L

®

Page 2

Page 3

OPERATING MANUAL

CrystalSix

Sensor

IPN 074-155L

®

www.inficon.com reachus@inficon.com

©2001 INFICON

®

Page 4

Trademarks

The trademarks of the products mentioned in this Operating Manual are held by the companies that

produce them.

INFICON®, CrystalSix® and Composer® are trademarks of INFICON Inc.

ConFlat® is a registered trademark of Varian Associates.

Teflon® is a registered trademark of Dupont.

Scotch-Brite™ is a trademark of 3M.

SWAGELOK® and CAJON® are registered trademarks of Swagelok, Co.

Inconel® is a registered trademark of International Nickel Co.

Microdot® is a registered trademark of Microdot Corp.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this Operating Manual is believed to be accurate and reliable. However, INFICON

assumes no responsibility for its use and shall not be liable for any special, incidental, or consequential

damages related to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2001 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 6

Page 7

CrystalSix Sensor Operating Manual

Table Of Contents

Chapter 1

Sensor Specifications

1.1 Specifications for CrystalSix Sensor 750-446-G1 . . . . . . . . . . . . . . . . . . . .1-1

1.1.1 Installation Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1.1 Feedthrough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.1.2 Other. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.1.3 Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.3 Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.1.4 Inventory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Chapter 2

Sensor Installation

2.1 Crystals in the CrystalSix Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1.1 Handle the Crystal with Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Care of the Ceramic Retainer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2 Pre-installation Sensor Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1 IC/5 Deposition Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 XTC/2 or XTC/C Deposition Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.3 IC/4 or IC/4 PLUS Deposition Controller . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2.2.4 IC-6000 or XTC Deposition Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.3 General Guidelines for CrystalSix Sensor . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.3.1 Crystal Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4 CrystalSix Sensor Installation when

used with an IC/5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.4.1 Programming the Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

IPN 074-155K

2.4.2 Wiring the Relay Outputs with Relay I/O Boards

760-162-G1 or 760-162-G1/G2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.5 CrystalSix Sensor Installation when used

with an XTC/2 or XTC/C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.6 CrystalSix Sensor Installation when used

with an IC/4 or IC/4 PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.6.1 Programming the Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.6.2 Wiring the Relay Outputs with Relay I/O Boards

755-122-G1 or 755-122-G1/G2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.7 CrystalSix Sensor Requirement when Not Installed with an

IC/5, XTC/2, XTC/C, IC/4, or IC/4 PLUS . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

TOC - 1

Page 8

Chapter 3

3.1 Installation with 1” Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 Installation with 2 3/4” Feedthrough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Electrical and Pneumatic Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1 Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 Pneumatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Chapter 4

4.1 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Maintain the Temperature of the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Use the Optimum Crystal Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.3 Crystal Concerns when Opening the Chamber . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Crystal Holder Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Retainer Spring Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Alignment Instruction for INFICON CrystalSix Sensor

4.4.1 Alignment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.2 Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.4.3 Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.5 Troubleshooting the CrystalSix Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.6 Replacing the Bellows Assembly

4.7 How To Contact Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.8 Returning Your Instrument to INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

CrystalSix Sensor Operating Manual

Installation of the Solenoid Valve Assembly

Maintenance

(IPN 750-446). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

[lPN 750-286-P2] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Chapter 5

TOC - 2

Feedthrough Outline Drawings

IPN 074-155K

Page 9

CrystalSix Operating Manual

Sensor Specifications

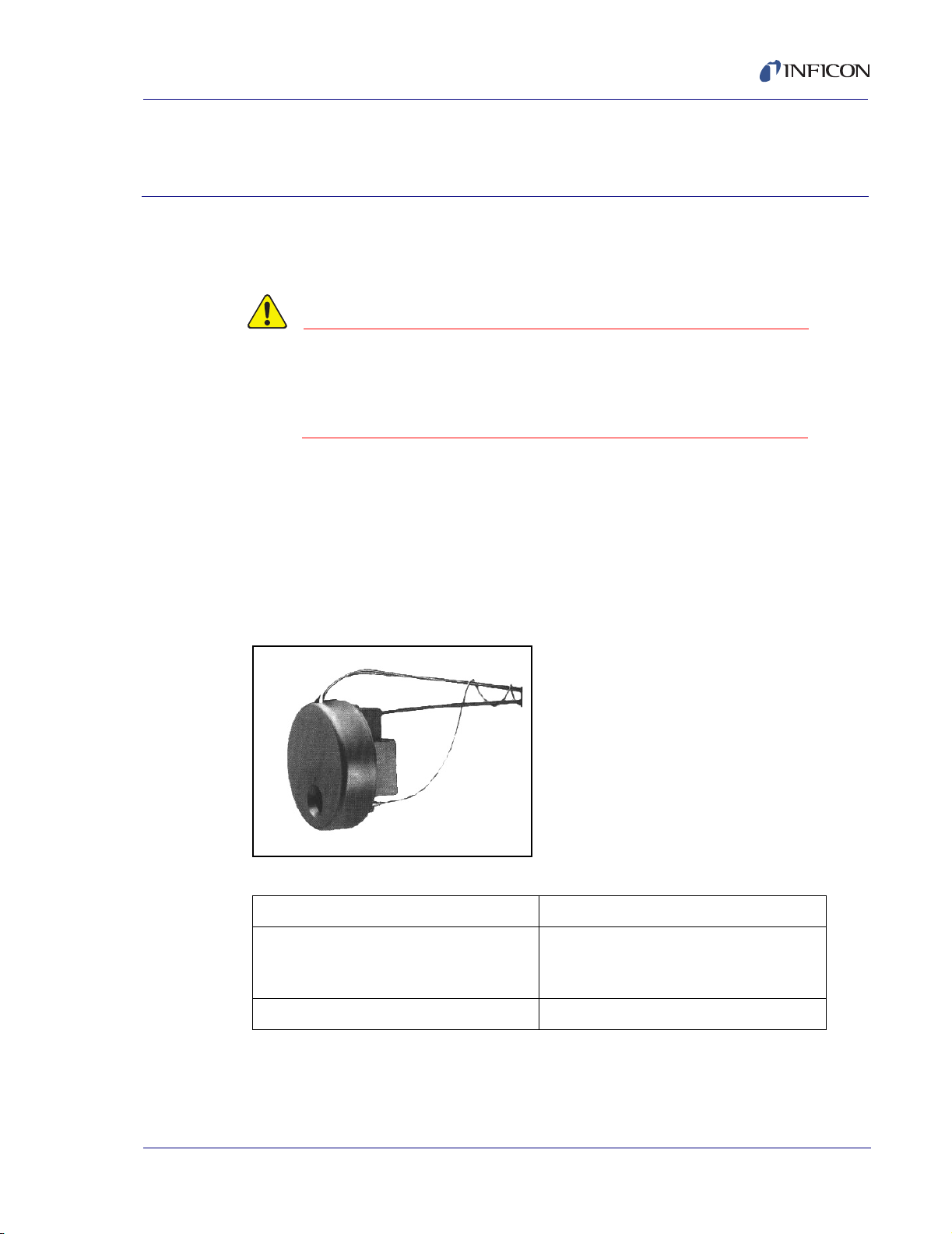

1.1 Specifications for CrystalSix Sensor 750-446-G1

CAUTION

Incorrect rotation direction with the stops disabled will

cause permanent damage rendering transducer

inoperative. See Figure 1-2 on page 1-5 for proper

direction of rotation.

The CrystalSix® sensor is a (six crystal) quartz crystal deposition monitor

transducer. When the monitor crystal being used fails a new crystal is advanced

into position, fully replacing that crystal’s function. The mechanism used for

providing this motion is pneumatically powered. The logic for automatic operation

of this transducer is conveniently provided on most current INFICON Deposition

Controllers. It is manufactured under US Patent #5,025,644, with foreign patents

pending.

Chapter 1

Figure 1-1 CrystalSix Sensor

IPN 074-155L

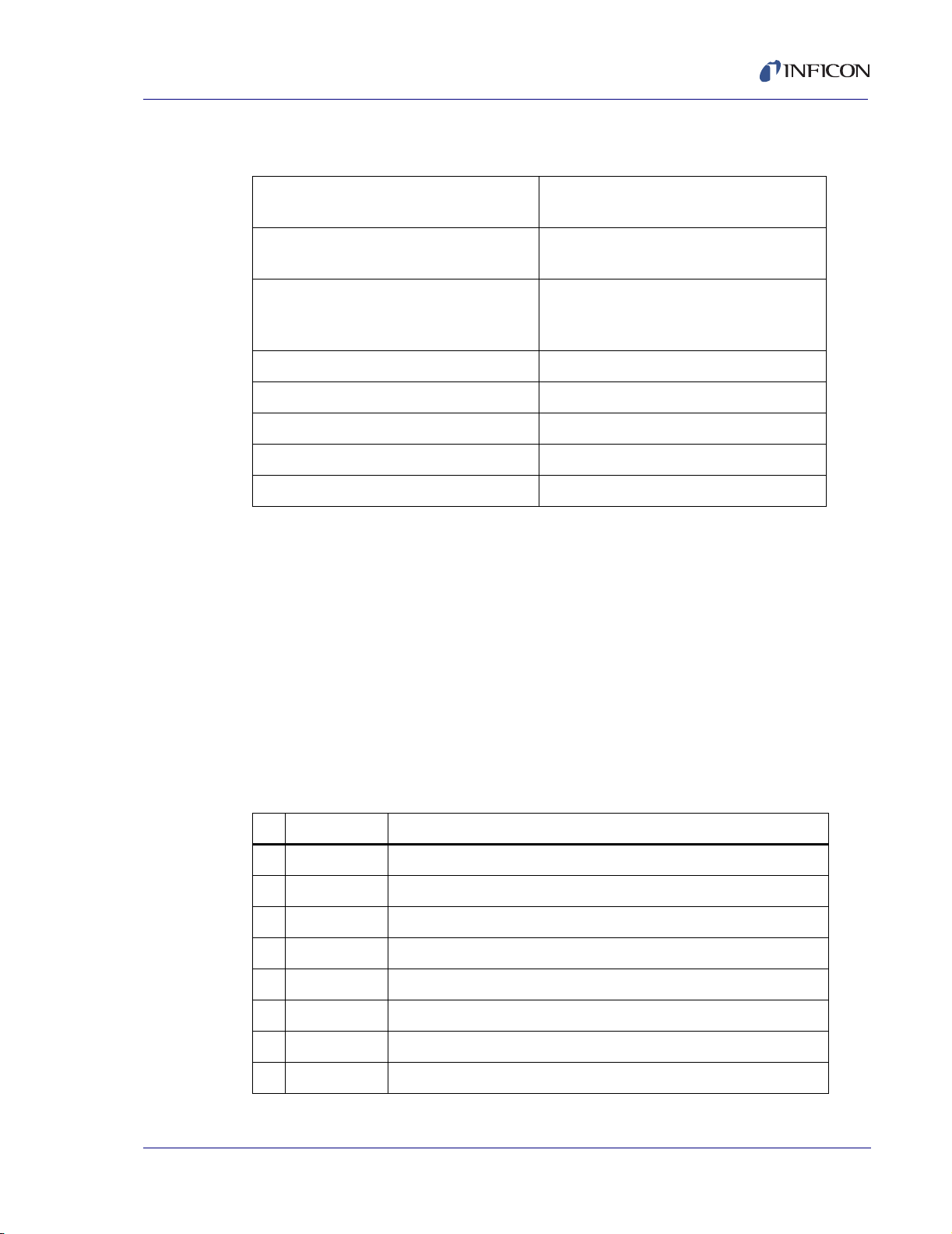

Table 1-1 Sensor specification

Maximum bakeout temp with no water 130 °C

Maximum operating isothermal

environment temperature with minimum

water flow

Size (maximum envelope) 3.8" (9.7 cm) DIA x 2.0" (5.1 cm) high

400 °C

1 - 1

Page 10

CrystalSix Operating Manual

Table 1-1 Sensor specification (continued)

Water, air and coax length Standard 30" (76 cm)

Crystal exchange Front-loading, extraction tool required

Mounting Six #4-40 tapped holes on the back of the

1.1.1 Installation Requirements

1.1.1.1 Feedthrough

Qty (1) 2-3/4" ConFlat® with two coaxial feedthroughs, two pass water, one air

IPN 002-080, See Figure 5-2 on page 5-2 or,

Qty (1) 1" bolt with one coaxial feedthrough, two pass water, one air IPN

750-030-G1, see Figure 5-1 on page 5-1.

1.1.1.2 Other

User to provide vacuum-tight braze joints or connectors for the water and air

tubes.

(supplied with unit)

sensor body

1.1.1.3 Utilities

Valve assembly for air, IPN 750-420-G1 (not provided), with a 0.022" restrictor

orifice installed by the user. (Orifice included with CrystalSix accessory kit.) See

Table 1-3 on page 1-3.

XIU or Oscillator designed to interface with the deposition controller.

Deposition controller must have been designed for this specific crystal sensor

(INFICON® XTC/2, XTC/C, IC/4, IC/4 PLUS, IC/5).

Minimum water flow 150-200 cc/min, 30 °C max (Do not allow water to freeze).

Coolant should not contain chlorides as stress corrosion cracking may occur.

Regulated air supply 80-90 PSIG (5.5 bar - 6.2 bar) [550 kPa - 620 kPa]

2 meter maximum length of 1/8" tubing between bellows assembly and the

control valve.

CAUTION

Do not allow water tubes to freeze. This may happen if the

tubes pass through a cryogenic shroud and the fluid’s

flow is interrupted.

IPN 074-155L

1 - 2

Page 11

1.1.2 Materials

Table 1-2 Materials

CrystalSix Operating Manual

Plate, Holders, Material Shield,

Mechanical Parts

Springs, Electrical Contacts Au plated Be-Cu, Au Plate Inconel®, 303

Water and air tubes S-304, 0.125" (0.32 cm) O.D. x .016" (.04

Connector (Microdot) Stainless steel

Insulators >99% A1

Cable Teflon® insulated copper

Crystal 0.550" Diameter

Body and Carousel 2024 T351 Aluminum

1.1.3 Unpacking Instructions

The CrystalSix sensor and accessories are packaged in a single cardboard carton

with rigid foam inserts.

Carefully remove the packaged accessories before removing the sensor, then

remove the red shipping plug from the sensor carousel.

304 type stainless steel

stainless steel

cm) Wall Thickness 30" Long (76 cm)

Seamless Stainless Steel Tubing

2O3

1.1.4 Inventory

In addition to the basic transducer, the complete shipping package includes an

accessory kit (IPN 750-268-G1) which consists of the following:

Table 1-3 Contents of Accessory Kit

IPN 074-155L

Qty IPN Description

X 750-268-G1 Accessory Kit, CrystalSix Sensor

1 750-254-G1 Assembly, Alignment Tool

1 750-279-P1 Crystal Puller

1 074-5000-G1 Thin Film Manuals CD

1 008-010-G10 Assembly, Sensor Crystal 6MHz

1 059-189 CC-1010-0225 Orifice 0.0225" diameter

2 070-201 #4 Split Lock Washer, Stainless Steel

2 084-032 #4-40x0.375" Long Socket Head Cap Screw, Stainless Steel

1 - 3

Page 12

CrystalSix Operating Manual

Table 1-3 Contents of Accessory Kit (continued)

Qty IPN Description

2 084-039 #4-40x0.500" Long Socket Head Cap Screw, Stainless Steel

2 084-084 #4-40x0.688" Long Socket Head Cap Screw, Stainless Steel

1 070-828 Hex Wrench 1/16" SC9-3

1 070-829 Hex Wrench 3/32" SC9-5

1 070-1175 Hex Wrench 5/64" SC9-4

1 750-037-G1 Spring Tube Bender Kit

1 008-007 Crystal Snatcher

1 750-191-G1 Molybdenum disulfide in Alcohol

1 - 4

IPN 074-155L

Page 13

5RWDWLRQ

CrystalSix Operating Manual

'LUHFWLRQ

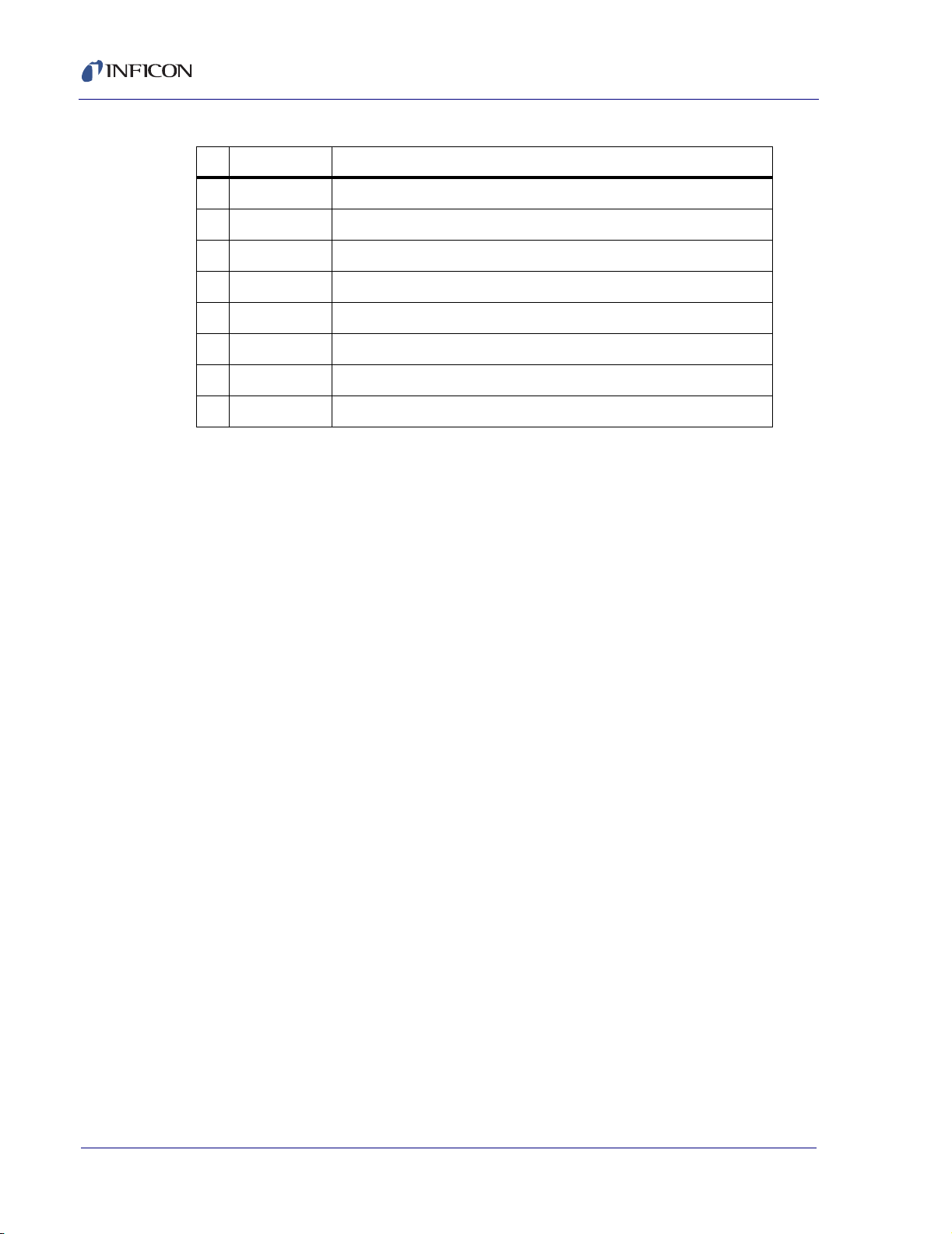

Figure 1-2 Outline Multi Crystal Sensor

IPN 074-155L

1 - 5

Page 14

CrystalSix Operating Manual

1 - 6

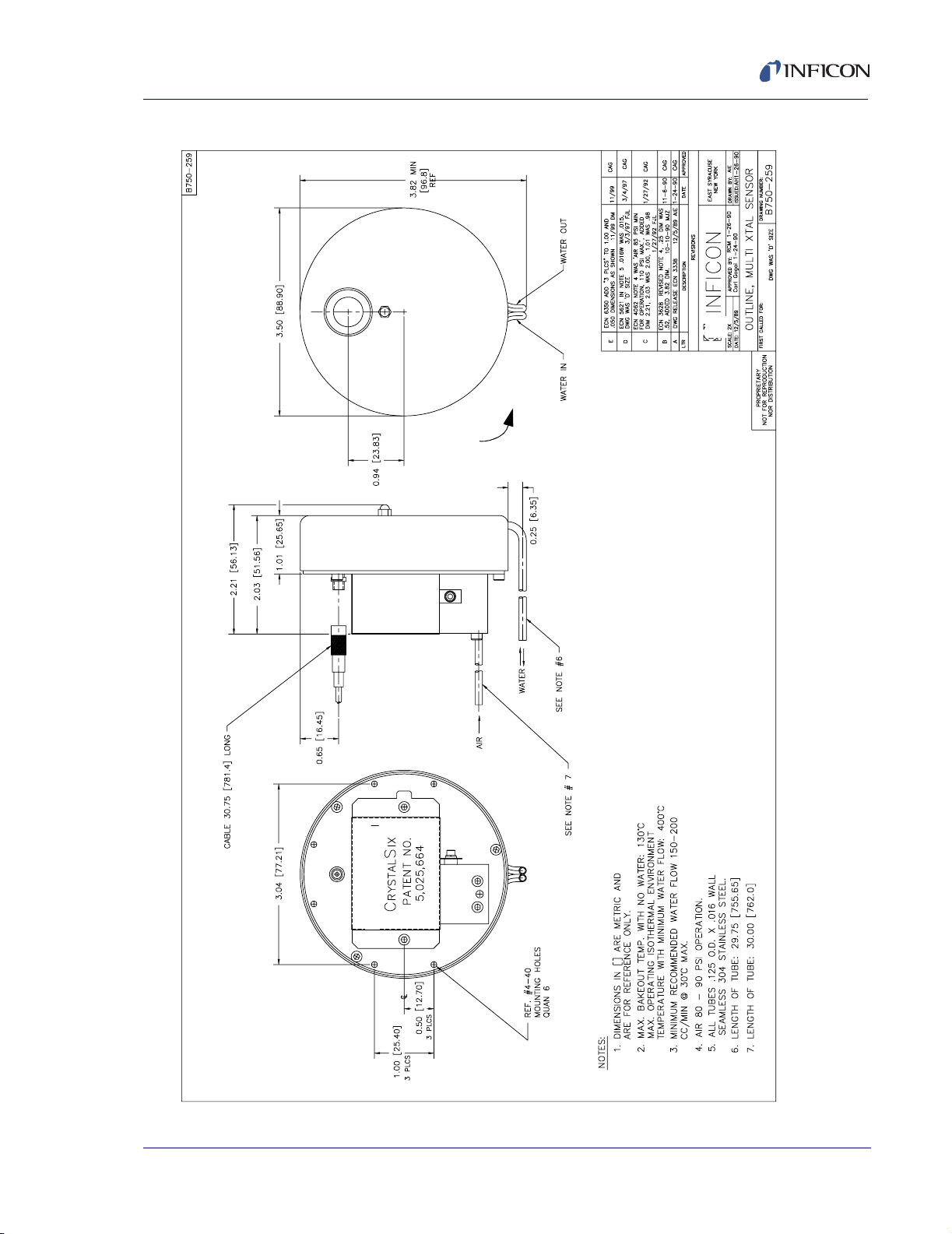

Figure 1-3 Assembly CrystalSix Sensor

IPN 074-155L

Page 15

CrystalSix Operating Manual

Chapter 2

Sensor Installation

Successful operation of any crystal sensor depends on proper placement,

compatibility of its construction with its operating environment and connection to

proper utilities.

NOTE: The sensor head, water tubes, cable, etc. should be clean and grease free

when installed in the vacuum chamber. These parts should be handled

while wearing clean nylon gloves. If parts do become contaminated, clean

them thoroughly using a suitable solvent to avoid outgassing and

excessive peeling of deposition material from the sensor’s surfaces.

CAUTION

Incorrect rotation direction will cause permanent damage

rendering transducer inoperative. Refer to Figure 1-2 on

page 1-5 for proper direction of rotation.

2.1 Crystals in the CrystalSix Sensor

2.1.1 Handle the Crystal with Care

Always use clean nylon lab gloves and clean plastic tweezers when handling the

crystal. Handle the crystals only by their edges. Anything that comes in contact with

the crystal surfaces may leave contamination, which may lead to poor film

adhesion. Poor film adhesion will result in high rate noise and premature crystal

failure.

CAUTION

IPN 074-155L

Do not use metal tweezers to handle crystals. Metal

tweezers may chip the edge of the crystal.

2 - 1

Page 16

CrystalSix Operating Manual

2.1.2 Care of the Ceramic Retainer

CAUTION

Do not use excessive force when handling the Ceramic

Retainer Assembly since breakage may occur. Always

use the crystal snatcher.

To prevent scratching the crystal electrode, do not rotate

the ceramic retainer after installation.

Always use clean nylon lab gloves and plastic tweezers

for handling the crystal. This avoids contamination which

may lead to poor adhesion of deposited material to the

electrode.

Follow the procedure below to install or replace the crystals in the CrystalSix

sensor. (Reference Figure 1-3 on page 1-6).

CAUTION

Rotating the unit in the wrong direction with the stops

disabled will cause severe damage! Do not rotate the unit

by hand to install the crystals or to check indexing.

1 Remove the heat shield (item #8) by gently pulling on the outside

circumference of the shield. The shield should snap off.

2 Since the crystal holders are packaged separately, skip the remainder of this

step for first-time installations. Using the crystal puller (IPN 750-279-P1,

provided in ship kit 750-268), remove the crystal holder by pushing the tips of

the crystal puller over the outside circumference of the crystal holder (see

Figure 2-2 on page 2-4). Gently pull the crystal holder from its receptacle. A

slight amount of pressure applied to collapse the tips of the crystal puller may

be required to extract the crystal holder.

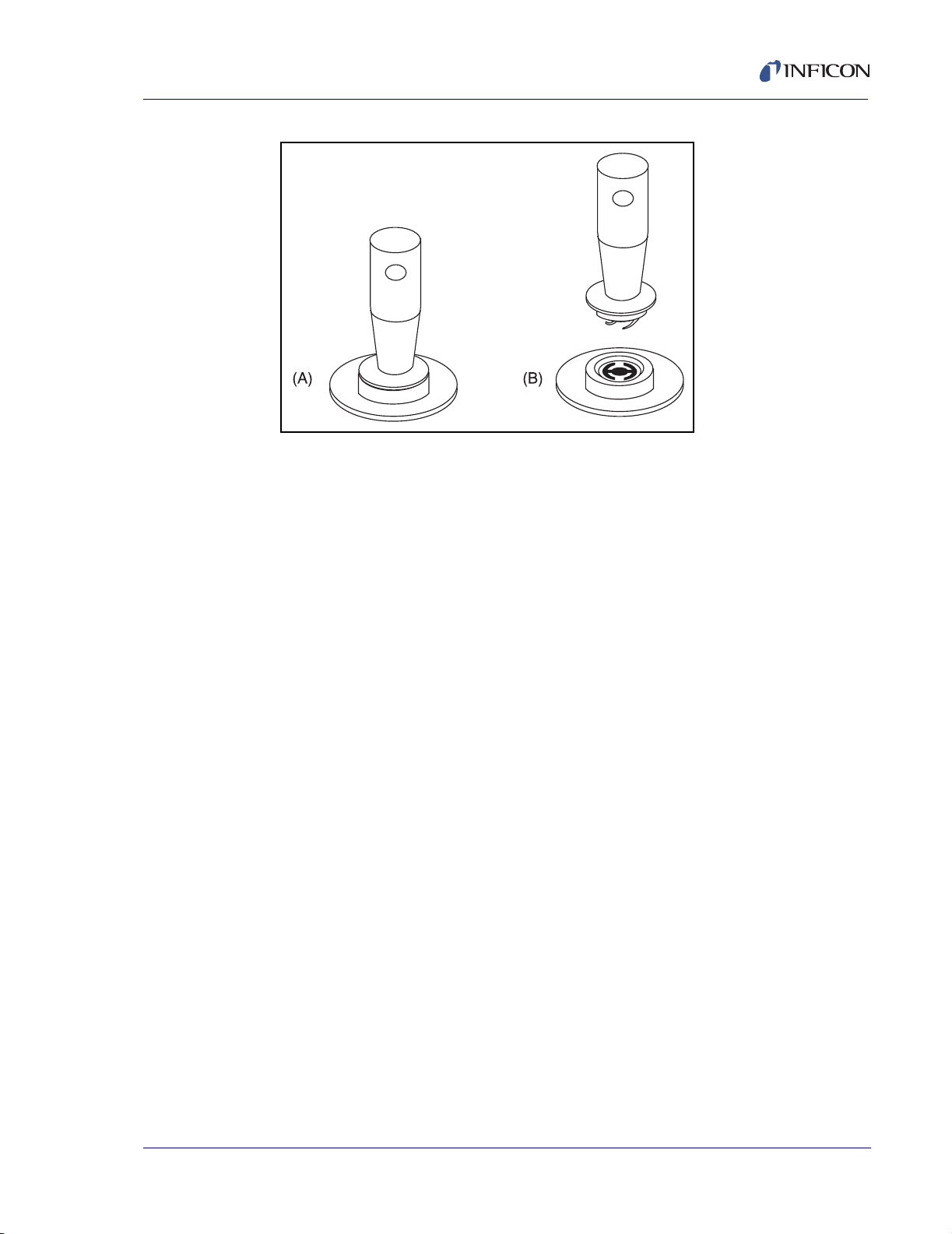

3 Insert the tapered end of the crystal snatcher (part number 008-007) into the

ceramic retainer (A) and apply a small amount of pressure. This locks the

retainer to the snatcher and allows the retainer to be pulled straight out (B). See

Figure 2-1.

IPN 074-155L

2 - 2

Page 17

CrystalSix Operating Manual

Figure 2-1 Using the Crystal Snatcher

4 Invert the crystal holder and the crystal will drop out. (Skip this step for first-time

installations.)

5 Install the new crystal per section 2.1.1 on page 2-1 and section 2.1.2 on page

2-2.

6 Using clean nylon gloves, grasp the edge of the new crystal with a clean pair of

plastic tweezers. Orient the crystal so the patterned electrode is facing up.

Gently insert the edge of the crystal beneath one of the wire segments that

protrude into the crystal cavity. Release the crystal.

7 Replace the ceramic retainer. Initially orient it at an angle to displace the spring

wire segments in the crystal holder.

8 Release the crystal snatcher with a slight side-to-side rocking motion. Using the

backside of the crystal snatcher, push on the ceramic retainer to ensure it is

completely seated.

9 Position the crystal holder between the tips of the crystal puller as illustrated in

Figure 2-2.

IPN 074-155L

10 Push the crystal holder into the receptacle of the CrystalSix sensor until

completely seated. “Snap” the crystal puller to one side to release the crystal

holder from the crystal puller. Using the non-slotted end of the crystal puller,

apply pressure to the crystal holder until it is completely seated. Verify that the

crystal fail signal on the controller display disappears. If the crystal fail signal

does not disappear, consult section 4.5 on page 4-9.

11 Press the crystal switch button on the hand held controller or the controller front

panel. The sensor will advance to the next crystal position. Repeat procedure

from Step 2 until all six new crystals have been installed.

12 Install the heat shield (item #8) by first orienting the slot in the heat shield to

accommodate the water tubes, then secure the heat shield by applying

pressure near the center of the shield. The shield should snap in place.

2 - 3

Page 18

CrystalSix Operating Manual

Figure 2-2 Using the Crystal Puller

2.2 Pre-installation Sensor Check

Prior to installing the sensor in the vacuum system, you should make certain that it

is in proper working condition by following the procedure outlined below.

2.2.1 IC/5 Deposition Controller

1 Connect the in-vacuum sensor head cable to the feedthrough or a coax adapter

(microdot/BNC).

2 Connect one end of the 6" XIU cable (IPN 755-257-G6) to the BNC connector

of the feedthrough.

3 Connect the other end of the 6" XIU cable to the connector of the XIU/5 (IPN

760-600-G1).

4 Connect one end of the XIU/5 cable (IPN 600-1039-Gxx) to the mating

connector of the XIU/5.

5 Connect the other end of the XIU/5 cable to a sensor channel at the rear of the

controller.

6 Connect power to the controller and set power switch to ON. Set density at 1.00

gm/cc, and zero thickness. The display should indicate 0/ or +/-.001 KÅ. Crystal

life should read from 0 to 5%.

7 Breathe heavily on the crystal. A thickness indication of 1.000 to 2.000 KÅ

should appear on the display. When the moisture evaporates, the thickness

indication should return to approximately zero.

If the above conditions are observed, you can assume the sensor is in proper

working order and may be installed.

IPN 074-155L

2 - 4

Page 19

2.2.2 XTC/2 or XTC/C Deposition Controller

1 Connect the in-vacuum sensor head cable to the feedthrough or a coax adapter

(microdot/BNC).

2 Connect one end of the 6" XIU cable (IPN 755-257-G6) to the BNC connector

or the feedthrough.

3 Connect the other end of the 6" XIU cable to the connector of the XIU (IPN

757-302-G1).

4 Connect one end of the XX' long XIU cable (IPN 757-303-GXX) to the mating

connector of the XIU.

5 Connect the other end of the XIU cable to a sensor channel at the rear of the

controller.

6 Connect power to the controller and set power switch to ON. Set density at 1.00

gm/cc, and zero thickness. The display should indicate 0/ or +/-.001 KÅ. Crystal

life should read from 0 to 5%.

7 Breathe heavily on the crystal. A thickness indication of 1.000 to 2.000 KÅ

should appear on the display. When the moisture evaporates, the thickness

indication should return to approximately zero.

CrystalSix Operating Manual

If the above conditions are observed, you can assume the sensor is in proper

working order and may be installed.

2.2.3 IC/4 or IC/4 PLUS Deposition Controller

1 Connect the in-vacuum sensor head cable to the feedthrough or a coax adapter

(microdot/BNC).

2 Connect one end of the 6" XIU cable (IPN 755-257-G6) to the BNC connector

or the feedthrough.

3 Connect the other end of the 6" XIU cable to the connector of the XIU (IPN

755-252-G1).

4 Connect one end of the 15' long XIU cable (IPN 755-258-G15) to the mating

IPN 074-155L

connector of the XIU.

5 Connect the other end of the XIU cable to a sensor channel at the rear of the

controller.

6 Connect power to the controller and set power switch to ON. Set density at 1.00

gm/cc, and zero thickness. The display should indicate 0/ or +/-.001 KÅ. Crystal

life should read from 0 to 5%.

7 Breathe heavily on the crystal. A thickness indication of 1.000 to 2.000 KÅ

should appear on the display. When the moisture evaporates, the thickness

indication should return to approximately zero.

If the above conditions are observed, you can assume the sensor is in proper

working order and may be installed.

2 - 5

Page 20

CrystalSix Operating Manual

2.2.4 IC-6000 or XTC Deposition Controller

NOTE: See section 2.7 on page 2-15.

1 Connect the in-vacuum sensor head cable to the feedthrough or a coax adapter

(Microdot/BNC).

2 Connect one end of the 6" OSC cable (IPN 013-070) to the receptacle on the

feedthrough.

3 Connect the other end of the 6" OSC cable to the receptacle marked XTAL on

the oscillator (IPN 013-001).

4 Connect the end of the oscillator source/sensor cable (IPN 013-067) to the

remaining BNC receptacle on the oscillator.

5 Connect the other end of the OSC source/sensor cable to the receptacle

marked OSC on the rear panel of the controller.

6 Connect power to the controller and set power switch to ON. Set density at 1.00

gm/cc, and zero the thickness. The display should indicate 0/ or +/-0.001 KÅ.

Crystal life should read from 0 to 5%.

7 Breathe heavily on the crystal. A thickness indication of 1.000 to 2.000 KÅ

should appear on the display. When the moisture evaporates, the thickness

indication should return to approximately zero.

If the above conditions are observed, you can assume the sensor is in proper

working order and may be installed.

2.3 General Guidelines for CrystalSix Sensor

Figure 2-3, Figure 2-4, and Figure 2-5 show the typical installation of an INFICON

water-cooled crystal sensor in the vacuum process chamber. Use the illustration

and the following guidelines to install your sensors for optimum performance and

convenience.

IPN 074-155L

2 - 6

Page 21

Figure 2-3 Typical CrystalSix Installation for IC/5

CrystalSix Operating Manual

G

IPN 750-420-G1

IPN 074-155L

2 - 7

Page 22

CrystalSix Operating Manual

Figure 2-4 Typical CrystalSix Installation for XTC/2 and XTC/C

G

IPN 750-420-G1

IPN 074-155L

2 - 8

Page 23

Figure 2-5 Typical CrystalSix Installation for IC/4 PLUS

CrystalSix Operating Manual

G

IPN 750-420-G1

IPN 074-155L

2 - 9

Page 24

CrystalSix Operating Manual

2.3.1 Crystal Sensor Installation

Generally, install the sensor as far as possible from the evaporation source (a

minimum of 10" or 25.4 cm) while still being in a position to accumulate thickness

at a rate proportional to accumulation on the substrate. Figure 2-6 shows proper

and improper methods of installing sensors.

Figure 2-6 Sensor Installation Guidelines

Correct

Incorrect

Obstruction

Incorrect

Incorrect

Source

Correct

To guard against spattering, use a source shutter to shield the sensor during the

initial soak periods. If the crystal is hit with even a minute particle of molten

material, it may be damaged and stop oscillating. Even in cases when it does not

completely stop oscillating, it may immediately become unstable, or shortly after

deposition begins instability may occur.

Plan the installation to insure that there are no obstructions blocking a direct path

between the sensor and the source.

Install sensors in such a manner that the center axis of the crystal is aimed directly

at the source to be monitored. Verify that the angle of the sensor location (with

reference to the source) is well within the evaporant stream.

IPN 074-155L

2 - 10

Attach the sensor with a mounting bracket anchored to the deposition chamber.

With the bracket in place, temporarily position and attach the sensor head as

outlined in the general guidelines above. Next, temporarily install the feedthrough.

You may now form, measure, and mark the sensor tubes (use the bending tool (IPN

750-036) to form tubes in the system).

Page 25

CrystalSix Operating Manual

Build the Sensor/Feedthrough Assembly. Remove the sensor and the feedthrough,

cut the water cooling tubes and air tubes to the proper length and connect them

directly to the feedthrough or use vacuum rated couplings.

CAUTION

To prevent damage to the feedthrough or sensor during

welding or brazing, insure that at least one inch of water

tube is left between the sensor and the feedthrough.

After cutting the water and air tubes, verify that they are clear of metal particles by

forcing compressed air through the tubing. Heliarc welding is recommended (torch

brazing may also be acceptable) for connecting the sensor to the feedthrough

water tube.

Vacuum rated connectors such as CAJON® are recommended for use between

the sensor and the feedthrough to speed maintenance. If brazing adapters are to

be used, attach them to the sensor water-cooling tubes prior to connection to the

feedthrough. Make connections as follows:

1 Clean the water tube and adapter surfaces with solvent if necessary.

2 Apply brazing flux to surfaces being joined.

3 Braze the connections using a flame temperature appropriate for the brazing

material being used.

CAUTION

Excessive application of brazing material, or excessive

heat due to brazing, may result in blockage of the water

tube.

IPN 074-155L

4 Verify that each joint is not blocked by blowing compressed air through the

cooling tubes.

5 Thoroughly clean the braze joint and helium leak test before installing the

sensor and feedthrough into the process chamber.

Once all water and air tube connections are fabricated, install the sensor and

feedthrough assembly into the process system and secure all retaining hardware.

Shield the coax cable from heat radiating from the evaporant source or the

substrate heater. You can do this very simply, if your process allows, by wrapping

aluminum foil around the cable and water tubes. Connect the external water tubes

from the feedthrough to your water supply system and flow controller. We

recommend using detachable couples (Swagelok® or equivalent) for external

water tube connections. Apply water pressure to verify flow and tightness.

2 - 11

Page 26

CrystalSix Operating Manual

Because of geometric factors, variations in surface temperature, and differences in

electrical potential, the crystal and substrates often do not receive the same

amount of material. If you want the thickness indication on the unit to represent the

thickness on the substrates, calibration is required to determine the tooling.

Consult your controller’s manual for the proper procedure for obtaining the tooling

factor.

CAUTION

Use of more than 80" (2 meters) of 1/8" tubing between

the valve and the bellows may cause a switcher failure

because of the time required to bleed out sufficient air

during de-pressurization. If tubing greater than 1/8" is

used, the maximum length must be reduced proportional

to the additional volume.

2.4 CrystalSix Sensor Installation when used with an IC/5

2.4.1 Programming the Relay Outputs

1 From the program menu select Source/Sensor Directory (F4).

2 Select Sensor board 1, 2, 3 or 4 (depending upon unit configuration).

3 Enter the edit mode. (F5)

4 Select Sensor type six (6) for the CrystalSix Sensor. This will enable the Crystal

Switch output (Switch Out (0, 1-38).

5 Select a CrystalSwitch output depending upon which I/O board is used.

2.4.2 Wiring the Relay Outputs with Relay I/O Boards

760-162-G1 or 760-162-G1/G2

On the relay connector, connect the leads of the solenoid valve across the one side

of a 24 volt supply (see Table 11.5 of IC/5 Operating Manual) and one side of a

relay (1-8, 1-16, or 1-24 whichever was programmed). Refer to Table 11.3 of the

IC/5 Operating Manual. Connect a jumper between the second side of the 24 volt

supply and the second side of the selected relay.

IPN 074-155L

2.5 CrystalSix Sensor Installation when used with an XTC/2 or XTC/C

Follow the instructions of Section 3.5.2 of the XTC/2 - XTC/C Operating Manual

(074-183).

2 - 12

Page 27

CrystalSix Operating Manual

2.6 CrystalSix Sensor Installation when used

with an IC/4 or IC/4 PLUS

2.6.1 Programming the Relay Outputs

1 From the program menu select Source/Sensor (F4).

2 Select Sensor board 1 or Sensor board 2.

3 Enter the edit mode. (F5)

4 Select Sensor type six (6) for the CrystalSix Sensor. This will enable the

CrystalSwitch output.

5 Select a CrystalSwitch output (Relay 1-8 or 1-16) depending upon which I/O

board is used.

6 Turn the instrument’s power “OFF”, then “ON”, to ensure that the change takes

place permanently.

2.6.2 Wiring the Relay Outputs with Relay I/O Boards

755-122-G1 or 755-122-G1/G2

1 On the relay connector, see Figure 2-7 on page 2-14, connect the leads of the

solenoid valve across the one side of a 24 volt supply (see listing) and one side

of a relay (1-16 whichever was programmed). Connect a jumper between the

second side of the 24 volt supply and the second side of the selected relay.

Refer to Figure 2-5 on page 2-9 for a typical installation utilizing relay 1 to

perform the crystal advance function for the relay I/O board.

Table 2-1 Wiring Connectors

(P4)

Top Relay Connector

Relay Pins Input Pins

1 24, 28 1 1, 20

IPN 074-155L

2 23, 27 2 2, 21

3 22, 26 3 3, 22

4 13, 19 4 4, 23

5 12, 18 5 5, 24

6 11, 17 6 6, 25

7 10, 16 7 7, 26

8 3, 7 8 8, 27

(P5)

Input Lines

2 - 13

Page 28

CrystalSix Operating Manual

Table 2-1 Wiring Connectors (continued)

(P3)

(available on G2 only)

Bottom Relay Connector

Relay Pins

9 47, 50 9 13, 32

10 14, 17 10 14, 33

11 59, 63 11 15, 34

12 53, 60 12 16, 35

13 34, 36 13 12, 31

14 28, 30 14 11, 30

15 4, 11 15 10, 29

16 1, 5 16 9, 28

Isolated 24 V(dc) source is available with a maximum of 0.4 amps total on

connector P4 at Pins 4, 9, 15 and 21 with Pins 8, 14, 20 and 25 used as returns.

2 In similar fashion, connect the Pneumatic Actuator for the source shutter if

required.

3 Connect the oscillator cable to the appropriate channel of the sensor board

programmed.

4 Connect the source one or source two cable (whichever has been

programmed) to the source controller.

Figure 2-7 Relay outputs: typical connector configuration utilizing relay #1

IPN 074-155L

2 - 14

NOTE: Contact arrangements shown are of pin mating face (plug or receptacle).

The socket mating face is a mirror image of Figure 2-7.

Page 29

CrystalSix Operating Manual

2.7 CrystalSix Sensor Requirement when Not Installed with an

IC/5, XTC/2, XTC/C, IC/4, or IC/4 PLUS

The CrystalSix can be manually operated with other Deposition Controllers. The

user must, however, be aware of the functional requirements for operation. These

include, but are not limited to:

1 The solenoid assembly must be energized and de-energized twice per crystal

position. Twelve pulses complete one revolution.

2 The electrical pulse applied to the solenoid valve must be at least one second

in duration during both the pressurization and de-pressurization phase.

3 A 24 volt AC or DC supply is required to energize the solenoid assembly.

Consult Figure 3-1 on page 3-4 for wiring assignments.

4 The user should provide some means of determining the quantity of “good”

crystals when initially loaded, and quantity of good crystals remaining at any

time.

5 Follow the guidelines shown in section 2.3 on page 2-6 for installation.

6 You will need to keep track of the total thickness as a manually generated sum

of the deposit accumulated on each crystal.

IPN 074-155L

2 - 15

Page 30

CrystalSix Operating Manual

This page is intentionally blank.

2 - 16

IPN 074-155L

Page 31

CrystalSix Operating Manual

Chapter 3

Installation of the Solenoid Valve Assembly

The solenoid valve assembly (IPN 750-420-G1) and the feedthrough should be

installed at the same time. The same valve assembly is used for both the 1" and

the (recommended) 2 3/4" feedthroughs. However, if the assembly is to be used

with the 2 3/4" feedthrough, you will need to modify the valve bracket as follows.

For the following steps, see Figure 3-2 on page 3-5. (DWG. 750-420-G1)

1 Align the score line on the valve assembly bracket (item #5) over the edge of a

table or other square edge.

2 Using pliers, grasp the part of the bracket extending over the edge and push

down. The bracket will break along the score line. Use a file to smooth any

rough edges which occur along the break.

NOTE: In order for the CrystalSix sensor to operate properly, a .022" diameter

orifice (IPN 059-189 provided in Kit 750-268) must be installed in line

between the air supply and the solenoid valve assembly. This is

accomplished by the following procedure. See Figure 3-1 on page 3-4.

1 Unthread the tube fitting attached to the normally closed (N.C.) P Supply port

of the 3-way solenoid valve (item #7).

2 Install the orifice by threading it into the normally closed (N.C.) port of the 3-way

solenoid valve.

3 Thread the tube fitting previously removed into the orifice.

NOTE: Do not install the orifice into the normally open output port. This will require

a longer time interval for depressurization of the bellows assembly and

may lead to an apparent sensor failure.

IPN 074-155L

3 - 1

Page 32

CrystalSix Operating Manual

3.1 Installation with 1” Bolts

Installation of the solenoid valve assembly for the CrystalSix sensor requires one

1" bolt feedthrough (IPN 750-030-G1, see Figure 5-1 on page 5-1).

Follow these steps:

1 Ensure that the o-ring is in placed on the bolt. Insert the 1" bolt such that the

hexagonal shaped end of the bolt is on the vacuum side of the chamber.

2 Add the Bracket.

3 Add the Washer.

4 Add the Nut.

5 Tighten the feedthrough nut.

6 Add the air fitting to the tube which has the female thread adapter installed.

7 Connect 1/8" diameter tubing from the valve output (A) to the feedthrough

fitting.

CAUTION

Use of more than 80" (2 meters) of 1/8" tubing between

the valve and the bellows may cause switcher failure

because of the time required to bleed out sufficient air

during de-pressurization. If tubing greater than 1/8" is

used, the maximum length must be reduced proportional

to the additional volume.

8 Attach the valve’s supply (normally closed (NC) port) to the 80-90 PSIG

(5.5 bar - 6.2 bar) [550 kPa - 620 kPa] source of air. Verify that the orifice (IPN

059-189) has been installed into this NC valve port. (See Figure 3-1b of Figure

3-1 on page 3-4.)

IPN 074-155L

3 - 2

Page 33

3.2 Installation with 2 3/4” Feedthrough

Installation of the solenoid valve requires a 2 3/4" feedthrough inclusive of two

coaxial feedthroughs (IPN 002-080, see Figure 5-2 on page 5-2). The second

coaxial feedthrough is not used, and should be protected from damage as a result

of process material. Follow the steps below:

1 Install the Feedthrough.

2 Add the valve bracket (modified) to the desired location as illustrated in Figure

3-3 on page 3-6.

3 Tighten the feedthrough bolts.

4 Install the air fitting to the female thread adapter.

5 Connect 1/8" diameter tubing from the valve output (A) to the feedthrough

fitting. See the CAUTION in section 3.1 above.

6 Attach the valve’s supply (P) (normally closed (NC) port) to the 80-90 PSIG

(5.5 bar - 6.2 bar) [550 kPa - 620 kPa] source of air. Verify that the orifice

(IPN 059-189) has been installed into this NC valve port. (See Figure 3-1b of

Figure 3-1 on page 3-4.)

CrystalSix Operating Manual

NOTE: Maximum temperature for the solenoid valve assembly is 105 °C for

bakeout and operation.

3.3 Electrical and Pneumatic Connections

3.3.1 Electrical

To complete installation of the assembly, make electrical connections where

indicated in Figure 3-3 on page 3-6 to either 24 V(ac) or V(dc). Current required is

approximately 70 mA.

CAUTION

IPN 074-155L

Maximum applied voltage must not exceed 26 V(ac).

3 - 3

Page 34

CrystalSix Operating Manual

3.3.2 Pneumatic

Figure 3-1 Pneumatic Solenoid Tube Connections

Figure 3-1a

Solenoid Valve

Without Orifice

(As Supplied)

P SUPPLY

(Normally Closed)

80-90 PSIG

AIR SUPPLY

TUBE FITTING

(Provided with Valve)

Figure 3-1b

Solenoid Valve

With Orifice

(Installed by User)

Figure 3-1b shows the proper installation for

all CrystalSix applications.

EXHAUST

(Normally Open)

A OUTPUT

PORT

TO AIR

FITTING OF

FEEDTHROUGH

EXHAUST

(Normally Open)

80-90 PSIG

AIR SUPPLY

3 - 4

P SUPPLY

(Normally Closed)

TUBE FITTING

(Provided with Valve)

A OUTPUT

PORT

ORIFICE (059-189)

(Provided with Accessory Kit 750-268-G1)

TO AIR

FITTING OF

FEEDTHROUGH

IPN 074-155L

Page 35

CrystalSix Operating Manual

Figure 3-2 Solenoid Valve Assembly

IPN 074-155L

3 - 5

Page 36

CrystalSix Operating Manual

3 - 6

Figure 3-3 2 3/4” Dual Coaxial Feedthrough & Valve Assembly

IPN 074-155L

Page 37

4.1 General Precautions

4.1.1 Maintain the Temperature of the Crystal

Periodically measure the water flow rate through the crystal sensor to verify that it

meets or exceeds the value specified in chapter one. Depending upon the

condition of the cooling water used, the addition of an in-line water filtering

cartridge system may be necessary to prevent flow obstructions. Many system

coaters use parallel water supply taps that provide high total flows. An obstruction

or closed valve in the pipe that supplies water to the sensor head would not result

in a noticeable reduction of total flow. The best test is to directly monitor the flow

leaving the sensor.

The crystal requires sufficient water cooling to sustain proper operational and

temperature stability. Ideally, a constant heat load is balanced by a constant flow of

water at a constant temperature. INFICON quartz crystals are designed to provide

the best possible stability under normal operating conditions. No crystal can

completely eliminate the effects of varying heat loads. Sources of heat variation

include radiated energy emanating from the evaporant source and from substrate

heaters.

CrystalSix Operating Manual

Chapter 4

Maintenance

4.1.2 Use the Optimum Crystal Type

Certain materials, especially dielectrics, may not adhere strongly to the crystal

surface and may cause erratic readings. For many dielectrics, adhesion is

improved by using crystals with silver coated electrodes. Gold is preferred for other

applications.

IPN 074-155L

4.1.3 Crystal Concerns when Opening the Chamber

Thick deposits of some materials, such as SiO, Si and Ni will normally peel off the

crystal when it is exposed to air, due to changes in film stress caused by gas

absorption. When peeling material is observed, replace the crystal.

4.2 Crystal Holder Maintenance

In dielectric coating applications, the surface where the crystal contacts the crystal

holder may require periodic cleaning. Since most dielectrics are insulators, any

buildup due to blow-by will eventually cause erratic or poor electrical contact

4 - 1

Page 38

CrystalSix Operating Manual

between the crystal and the sensor body. This buildup will also cause a reduction

in thermal transfer from the crystal to the sensor body. Both of these will result in

noisy operation and early crystal failure.

Cleaning may be accomplished by gently buffing the crystal holder to crystal

seating surface with a white Scotch-Brite™ pad followed by an ultrasonic bath in

soap solution followed by thorough rinsing in deionized water and drying or by

ultrasonic cleaning and rinsing only.

NOTE: The crystal holder seating surface is machined to a very fine finish (16

micro inches rms). This high quality finish is essential to provide good

electrical and thermal contact with the crystal. Applying excessive force

during cleaning or using overly abrasive cleaning materials may damage

this finish and reduce sensor performance.

4.3 Retainer Spring Adjustment Instructions

Occasionally you may become dissatisfied with the way the ceramic retainer is

secured in the crystal holder. To alter the magnitude of the retaining force, use the

following procedure.

Tools required:

Scribe or other pointed tool.

Needle nose pliers (two required).

1 Position the crystal holder with the crystal aperture oriented downward.

2 Insert the point of the scribe between the inside edge of the crystal holder cavity

and one of the two wire segments that protrude into the crystal cavity (Figure

4-1-a).

3 Using the scribe, gently remove the spring from its groove in the crystal holder

cavity.

4 Consult Figure 4-1-b to determine the direction in which the 'transition point'

must be relocated, to attain the desired retention forces. Moving this transition

point approximately 1/8" is generally sufficient.

5 Grasp the spring, with the pliers, just below the transition point. Using the

second set of pliers, bend the spring as illustrated by the dashed line in Figure

4-1-c to remove the existing transition point.

IPN 074-155L

4 - 2

Page 39

Figure 4-1 Location of the Transition Point

CrystalSix Operating Manual

6 Use both pliers to form a new transition point according to Figure 4-1-b, thus

returning the spring to a shape similar to the solid line delineation of Figure

4-1-c.

7 Reinstall the spring into the groove provided in the crystal cavity.

8 Determine if the retention force is acceptable and that the wire does not impede

crystal insertion. Repeat these instructions if unacceptable retention forces

persist.

4.4 Alignment Instruction for INFICON CrystalSix Sensor

(IPN 750-446)

During shipment, units may vibrate slightly out of position. This does not mean

IPN 074-155L

alignment is required. The unit will return to the centered position the first time it is

pneumatically activated.

The unit in the shipped condition has been aligned at the factory, no further

alignment is required.

NOTE: Realignment is only required if the unit has been disassembled for any

reason, such as evaporant material removal, or any electrical problem that

may occur, or if the ratchet (item #22 DWG 750-446 shown on Figure 1-3

on page 1-6) is loosened, or removed. This procedure is critical and must

be carefully undertaken.

4 - 3

Page 40

CrystalSix Operating Manual

CAUTION

Incorrect rotation direction with the stops disabled will

cause permanent damage rendering transducer

inoperative. Refer to Figure 1-2 on page 1-5 for proper

direction of rotation.

The unit, when properly aligned, will index the crystal to a position that is centered

within the aperture provided in the heat shield. The unit must be aligned if this

condition does not exist.

Reference Figure 1-3 on page 1-6.

Equipment Required:

5/64" allen wrench (Included in 750-268 Kit)

1/16" allen wrench (Included in 750-268 Kit)

3/32" allen wrench (Included in 750-268 Kit)

Alignment tool assembly 750-254-G1 (Included in 750-268 kit)

Regulated air supply 80-90 PSIG (5.5 bar - 6.2 bar) [550 kPa - 620 kPa]

NOTE: 75 PSIG (5.2 bar) [520 kPa] for alignment purposes only)

4.4.1 Alignment Instructions

With the required equipment at hand, proceed as follows:

1 Temporarily connect an air supply to the bellows assembly supply tube.

Regulate the air pressure to 75 PSIG (5.2 bar) [520 kPa].

2 Remove the actuator cover (item 15) and related hardware.

3 Insert the 0.125" diameter alignment pin (of the 750-254-G1 assembly) in the

alignment hole (if not already installed) as shown in Figure 4-2 on page 4-6.

The carousel may need to be rotated to achieve the alignment condition shown

in Figure 4-2.

4 Loosen the set screws (two set screws per item) of the ratchet (item #22) and

the stop ratchet (item #38).

5 Loosen the #2 fastener (item #42) that attaches the detent (item #41) to the

bellows assembly item #19). Do NOT remove detent.

IPN 074-155L

4 - 4

6 Actuate the bellows assembly by applying 24 volts to the leads of the solenoid

valve of the solenoid valve assembly. Consult Figure 3-1 on page 3-4 for wiring

assignments. The air pressure must be sustained.

Page 41

CrystalSix Operating Manual

7 Rotate the ratchet (item #22) counterclockwise until one tooth contacts the pin

of the pawl and actuator stem assembly (item #24). Secure the ratchet to the

0.25" diameter shaft of the carousel assembly (item #5) utilizing the #6-32 x

.125" long socket set screw (item #33).

8 Rotate the stop ratchet (item #38) CW (clockwise) until it contacts the stem of

the pawl and actuator stem assembly (item #24) as shown in Figure 4-3 on

page 4-14. Secure the stop ratchet to the 0.25” diameter shaft of the carousel

utilizing the #6-32 x .125 long socket set screws (item #33).

9 Rest the detent spacing tool on the top of the alignment pin as shown in Figure

4-4 on page 4-14. Position the detent spacing tool (of the 750-254-G1

assembly) between the detent (item #41) and ratchet (item #22) as shown in

Figure 4-4. Pull the detent against the detent spacing tool and subsequently

against the tooth of the ratchet. Tighten the #2 fastener (item #42) to secure the

detent to the bellow assembly.

10 Remove the detent spacing tool.

11 Release air pressure from the bellows assembly (item #19).

12 Remove the 0.125 diameter alignment pin of the 750-254-G1 alignment tool

assembly from the hole.

13 Prior to installation of the crystal holder assembly, check the continuity between

the center contact of the connector and the electrical contacts associated with

the carousel assembly (item #5). Install the crystal holder assembly when

electrical continuity is verified. If electrical continuity is not verified, the unit

should be disassembled (see section 4.4.2 on page 4-6). The electric contact

associated with the carousel will have to be adjusted to ensure electrical

contact when assembled.

14 Press the crystal switch button on the handheld controller or the instrument

front panel. The sensor will advance to the next crystal position. Each crystal

should be centered in the aperture. Repeat step #10 for each crystal position.

Make certain the detent drops in to engage each tooth of the ratchet (item #22)

IPN 074-155L

on each pulse.

15 Secure the actuator cover (item #15) to the top plate (item #10) using two #4-40

x 0.187" long socket head cap screws (items #16 and #17).

16 Install the heat shield (item #8) by first orienting the slot in the heat shield to

accommodate the water lines, then secure the heat shield by applying pressure

near the center of the shield. The shield should snap in place.

17 Regulate the air supply to 80-90 PSIG (5.5 bar - 6.2 bar) [550 kPa - 620 kPa]

for operation.

Unit is now ready for operation.

4 - 5

Page 42

CrystalSix Operating Manual

Figure 4-2 Alignment Pin Installation

4.4.2 Disassembly Instructions

In the following steps, reference Figure 1-3 on page 1-6 and Figure 4-2 on page

4-6.

1 Remove the two #4 fasteners that secure the actuator cover (item #15) to the

top plate (item #10).

2 Remove the actuator cover. Remove the heat shield (item #8) by gently pulling

on the outside of the shield, the shield should snap off.

3 Remove the extension spring from the pawl and actuator stem assembly (item

#24).

4 Remove the two #4 fasteners (item #20) that secure the bellows assembly

(item #19) to the top plate (item #10).

5 Carefully remove the bellows assembly. The pawl and actuator stem assembly

(item #24) and the detent (item #41) will be removed with the bellows assembly.

6 Using the 1/16" allen wrench, loosen the set screws (item #33) that secures the

ratchet (item #22) and the stop ratchet (item #38) to the carousel assembly

(item #5). Remove the ratchet (item #22) and the stop ratchet (item #38).

7 Remove the three #4 fasteners (item #14) that secure the top plate (item #10)

to the sensor body (item #11).

IPN 074-155L

4 - 6

8 Remove the top plate (item #10).

9 Remove the Teflon washer (item #39).

Page 43

CAUTION

When removing the top plate make certain the connector

terminal does not become damaged.

10 Remove the compression spring (item #28).

11 Remove the carousel assembly (item #5)

CAUTION

When removing the carousel make certain the 0.126"

diameter ball (item #27) does not become lost.

4.4.3 Assembly Instructions

In the following steps, reference Figure 1-3 on page 1-6 and Figure 4-2 on page

4-6.

CrystalSix Operating Manual

1 Place the 0.126" diameter ball (item #27) in the countersunk hole of the sensor

body (item #11).

2 Attach the corrugated springs (item #31) if not already attached to the sensor

body (item #11), as illustrated in detail "F" of Figure 1-3 on page 1-6, utilizing

the 0-80 pan head screws (item #45).

CAUTION

Be extremely careful when handling the corrugated

springs to avoid distortion. The successful operation of

this apparatus is dependent on this component's

integrity.

IPN 074-155L

3 With the free end of each corrugated spring outside the sensor body, install the

carousel assembly (item #5) so that it rests on the .126" diameter ball. Insert

the corrugated springs into the space between the carousel (item #5) and the

body (item #11). Make certain that the corrugated springs are not damaged

upon installation.

4 Rotate the carousel clockwise until the alignment hole in the carousel lines up

with the alignment hold of the body. Insert the 0.125" diameter alignment pin of

the alignment tool assembly (750-254) provided. Refer to Figure 4-2 on page

4-6.

4 - 7

Page 44

CrystalSix Operating Manual

5 Place the compression spring (item #28) in the cavity surrounding the 0.25"

diameter shaft of the carousel assembly. Install the Teflon washer (item #39)

onto the.25" diameter shaft.

6 With the connector facing outward, pass the top plate (item #10) over the 0.25"

diameter shaft of the carousel assembly (item #5) and the .125" diameter

alignment pin.

7 Secure the top plate to the sensor body utilizing the three #4-40 screws (items

#14 and 17).

8 Install the pawl and actuator stem assembly (item #24) into the bellows

assembly (item #19) by threading the actuator stem into the mating hole

located in the bore of the bellows assembly. Continue to thread the actuator

stem until the shoulder of the actuator stem is approximately .035" away from

the bellows assembly. This .035" distance specification is for reference only;

the actuator stem position may have to be adjusted to obtain the desired

condition, as illustrated in Figure 1-3 on page 1-6.

9 Fasten the bellows assembly to the top plate utilizing the two #4-40 x 1.125"

long screws (item #20). Do not tighten the screws. Position the bellows

assembly in such a fashion as to allow the actuator stem to come in contact with

the ball bearings (item #25) as illustrated in Figure 1-3 on page 1-6. Tighten the

screws. Loosen the #2 screw (item #42) which secures the detent to the bellow

assembly (item #19).

10 Slide the ratchet (item #22) and the stop ratchet (item #38) onto the 0.25"

diameter shaft of the carousel assembly (item #5) as illustrated. Do not tighten

the #6-32 set screws (item #33).

11 Attach the loop of the extension spring in the hole provided in the pawl of the

pawl and actuator stem assembly (item #24).

12 Position the ratchet (item #22) such that it engages the pin of the pawl and

actuator stem assembly (item #24).

13 Position the detent (item #41) so it engages the ratchet (item #22).

Unit is now ready to be aligned, refer to section 4.4.1 on page 4-4.

IPN 074-155L

4 - 8

Page 45

CrystalSix Operating Manual

4.5 Troubleshooting the CrystalSix Sensor

Table 4-1 Troubleshooting

Symptom Cause Remedy

1. Crystal fail signal on

front panel of unit will not

disappear even though

crystal can be seen

through heat shield

aperture.

2. Unit will not advance

when crystal switch key is

pressed.

1a. Damaged Crystal. 1a. Replace crystal.

1b. Loss of electrical

signal.

1b. Check for electrical

continuity between

feedthrough and leaf

springs that make contact

with the crystal holder in

the sensor.* If electrical

problem originates in the

sensor, consult Chapter 4

for disassembly

instructions, if necessary.

* Make certain the leaf

springs in the carousel

assembly are bent up far

enough to contact the

crystal holder when

installed.

2a. Loss of pneumatic

supply, or pressure is

insufficient for proper

2a. Establish air supply

and regulate to 80-90

PSIG for operation.

operation.

2b. Operation has been

impaired as a result of

peeling of the material

accumulated on the face

2b. Consult Chapter 4 for

disassembly instructions

to remove material or to

correct mechanical failure.

of the cover.

3. Crystal not centered in

aperture.

IPN 074-155L

3a. Improper alignment. 3a. Realign per alignment

instructions in Chapter 4.

3b. 0.0225” diameter

orifice not installed inline

to the supply side of the

3b. Install orifice where

shown on Figure 2-3 on

page 2-7.

solenoid valve assembly.

4 - 9

Page 46

CrystalSix Operating Manual

Table 4-1 Troubleshooting (continued)

Symptom Cause Remedy

4. Large jumps of

thickness reading during

deposition

5. Crystal ceases to

oscillate during deposition

before it reaches its

“normal life.

4a. Mode hopping due to

4a. Replace crystal.

damaged crystal.

4b. Crystal near the end of

4b. Replace crystal.

its life.

4c. Scratches or foreign

particles on the crystal

holder seating surface.

4c. Replace the crystal

holder (IPN 750-262-G1).

Clean, polish the crystal

seating surface of the

crystal holder.

5a. Crystal is being hit by

small droplets of molten

material from the

5a. Move the sensor

further away from the

evaporant source.

evaporation source.

5b. Damaged crystal. 5b. Change crystal.

5c. Deposition material

built-up on edge of the

5c. Clean the crystal

holder.

crystal holder and

touching the crystal.

5d. Material on crystal

5d. Clean crystal holder.

holder partially masking

full crystal area.

6. Crystal does not

oscillate or oscillates

intermittently (both in

vacuum and in air).

7. Crystal oscillates in

vacuum but stops

oscillation after open to air.

6a. Defective or damaged

crystal.

6b. Existence of electrical

short or poor electrical

contacts.

7a. Crystal was near the

end of its life; opening to

air causes film oxidation,

which increases film

stress.

7b. Excessive moisture

accumulation on the

crystal.

6a. Replace crystal.

6b. Check for electrical

continuity and short in

sensor cable, connector,

contact springs,

feedthroughs.

7a. Replace crystal

IPN 074-155L

7b. Turn off cooling water

to sensor before opening it

to air; flow hot water

through the sensor when

the chamber is open.

4 - 10

Page 47

CrystalSix Operating Manual

Table 4-1 Troubleshooting (continued)

Symptom Cause Remedy

8. Thermal instability:

large changes in thickness

reading during source

warm-up (usually causes

thickness reading to

decrease) and after the

termination of deposition

(usually causes thickness

reading to increase)

8a. Crystal not properly

seated.

8a. Check and clean

crystal seating surface of

the crystal holder.

8b. Excessive heat input

to the crystal.

8b. If heat is due to

radiation from the

evaporation source, move

sensor further away from

source and use sputtering

crystals for better thermal

stability.

8c. No cooling water. 8c. Check cooling water

flow rate. Flow rate should

be minimum of 150-200

cc/min @ 30 °C max.

8d. Poor thermal transfer

from water tube to body.

8d. Use a new water tube

whenever the clamping

assembly has been

removed from the body. If

a new water tube is not

available, use a single

layer of common

aluminum foil between the

cooling tube and the

sensor body, if your

process allows.

IPN 074-155L

4 - 11

Page 48

CrystalSix Operating Manual

Table 4-1 Troubleshooting (continued)

Symptom Cause Remedy

9. Poor thickness

reproducibility

10. Sensor jamming 10a Crystal holders come

9a. Erratic source

emission characteristics.

9b. Material does not

adhere to the crystal.

loose and jam sensor

during rotation. May be

caused by absence of

orifice in airline.

10b. Electrical contacts on

carousel may be damaged

if unit was counter rotated.

9a. Move sensor to a

different location; check

the evaporation source for

proper operating

conditions; insure

relatively constant pool

height and avoid tunneling

into the melt.

9b. Check the cleanliness

of the crystal surface;

evaporate an intermediate

layer of proper material on

the crystal to improve

adhesion.

10a. Check for orifice, see

Chapter 3.

10b. Replace contacts.

4.6 Replacing the Bellows Assembly

[lPN 750-286-P2]

Reference Figure 1-3 on page 1-6.

Equipment required:

1 /16" allen wrench

3/32" allen wrench

Alignment tool assembly 750-254-G1

Regulated air supply 80-90 PSIG (5.5 bar - 6.2 bar) [550 kPa - 620 kPa]

1 Remove the two #4-40 fasteners that secure the actuator cover (item #15) to

the top plate (item #10). Remove the heat shield (item #8) by gently pulling on

the outside circumference of the shield. The shield should snap off.

2 Advance the carousel (item #5) using the crystal switch button on the handheld

controller or on the controller front panel as many times as necessary until the

alignment holes in the sensor body (item #11), carousel assembly (item #5) and

the top plate (item #10) coincide.

IPN 074-155L

4 - 12

Page 49

CrystalSix Operating Manual

3 Insert the .125" diameter alignment pin into the alignment hole, as shown in

Figure 4-2 on page 4-6.

The bellows assembly will be removed at this time. Proceed as follows:

4 Remove the extension spring from the pawl and actuator stem assembly (item

#24).

5 Remove the two #4 fasteners (item #20) that secure the bellows assembly

(item #19) to the top plate (item #10).

6 Carefully remove the bellows assembly. The pawl and actuator stem assembly

(item #24) and the detent (item #41) will be removed with the bellows assembly.

7 Using the 1/16" allen wrench, loosen the 6-32 set screws (item #33) that

secures the ratchet (item #22) and the stop ratchet (item #38) to the carousel

assembly (item #5). Remove the stop ratchet (item #38) and the ratchet (item

#22).

8 Thread the pawl and actuator stem assembly (item #24) out of the bore of the

bellows assembly by rotating the pawl and actuator stem assembly in a

counterclockwise direction. Detach the detent (item #41) and related hardware

(items 40, 42-44) from the bellows assembly (item #19) by removing the #2

fastener (item #42).

9 Discard the bellows assembly.

10 Install the pawl and actuator stem assembly (item #24) into the new bellows

assembly by threading the actuator stem into the mating hold located in the

bore of the bellows assembly. Continue to thread the actuator stem until the

shoulder of the actuator stem is approximately .035" away from the bellows

assembly. This.035" distance specification is for reference only; the actuator

stem position may have to be adjusted to obtain the desired condition as

illustrated in Figure 1-3 on page 1-6.

11 Fasten the bellows assembly to the top plate utilizing the two #4-40 x 1.125"

long screws. Do not tighten the screws. Position the bellows assembly in such

IPN 074-155L

a fashion as to allow the actuator stem to come in contact with the ball bearings

(item #25) as illustrated. Tighten the screws.

12 Slide the ratchet (item #22) onto the 0.25" diameter shaft of the carousel

assembly (item #5). Do not tighten the #6-32 set screw (item #33). Slide the

ratchet (item #22) onto the .25" diameter of the carousel assembly. Do not

tighten the #6-32 set screws.

13 Attach the extension spring in the hole provided in the pawl of the pawl and

actuator stem assembly (item #24).

14 Position the ratchet (item #22) such that it engages the pin of the pawl and

actuator stem assembly (item #24).

4 - 13

Page 50

CrystalSix Operating Manual

15 Attach the detent and related hardware (items 40, 42-44) to the new bellows

assembly. Do not tighten. Position the detent (item #41) so that it engages the

ratchet (item #22).

Unit is now ready to be aligned. Refer to section 4.4.1 on page 4-4 for alignment

instructions.

Figure 4-3 Setting the Stop Ratchet

Figure 4-4 Setting the Detent

IPN 074-155L

4 - 14

Page 51

4.7 How To Contact Customer Support

Worldwide support information regarding:

Technical Support, to contact an applications engineer with questions

regarding INFICON products and applications, or

Sales and Customer Service, to contact the INFICON Sales office nearest you,

or

Repair Service, to contact the INFICON Service Center nearest you,

is available at www.inficon.com.

If you are experiencing a problem with your instrument, please have the following

information readily available:

the serial number for your instrument,

a description of your problem,

an explanation of any corrective action that you may have already attempted,

and the exact wording of any error messages that you may have received.

To contact Customer Support, see Support at www.inficon.com.

CrystalSix Operating Manual

4.8 Returning Your Instrument to INFICON

Do not return any component of your instrument to INFICON without first speaking

with a Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your

instrument.

Prior to being given an RMA number, you may be required to complete a

Declaration Of Contamination (DOC) form if your instrument has been exposed to

process materials. DOC forms must be approved by INFICON before an RMA

IPN 074-155L

number is issued. INFICON may require that the instrument be sent to a

designated decontamination facility, not to the factory. Failure to follow these

procedures will delay the repair of your instrument.

4 - 15

Page 52

CrystalSix Operating Manual

This page is intentionally blank.

4 - 16

IPN 074-155L

Page 53

CrystalSix Operating Manual

Chapter 5

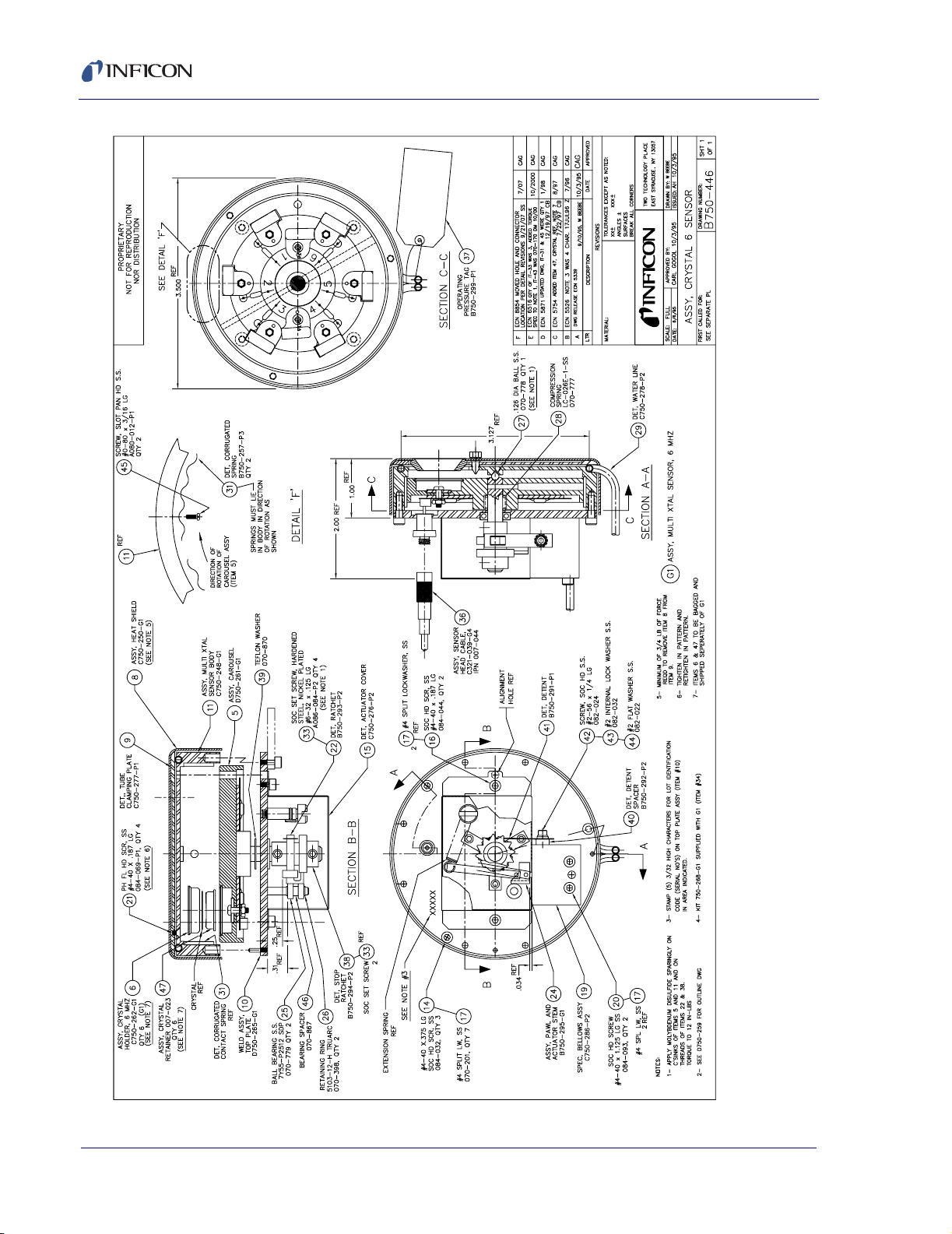

Feedthrough Outline Drawings

The following Feedthrough Outline Drawings provide dimensions and other

pertinent data necessary for planning equipment configurations.

Figure 5-1 1" Crystal feedthrough w/airtube (lPN 750-030-GI)

(contains one coaxial, two water tubes and one air tube)

IPN 074-155L

5 - 1

Page 54

CrystalSix Operating Manual

Figure 5-2 Standard 2 3/4" CONFLAT® flange (002-080)

(contains two coaxials, two water tubes and one air tube)

5 - 2

IPN 074-155L

Loading...

Loading...