Page 1

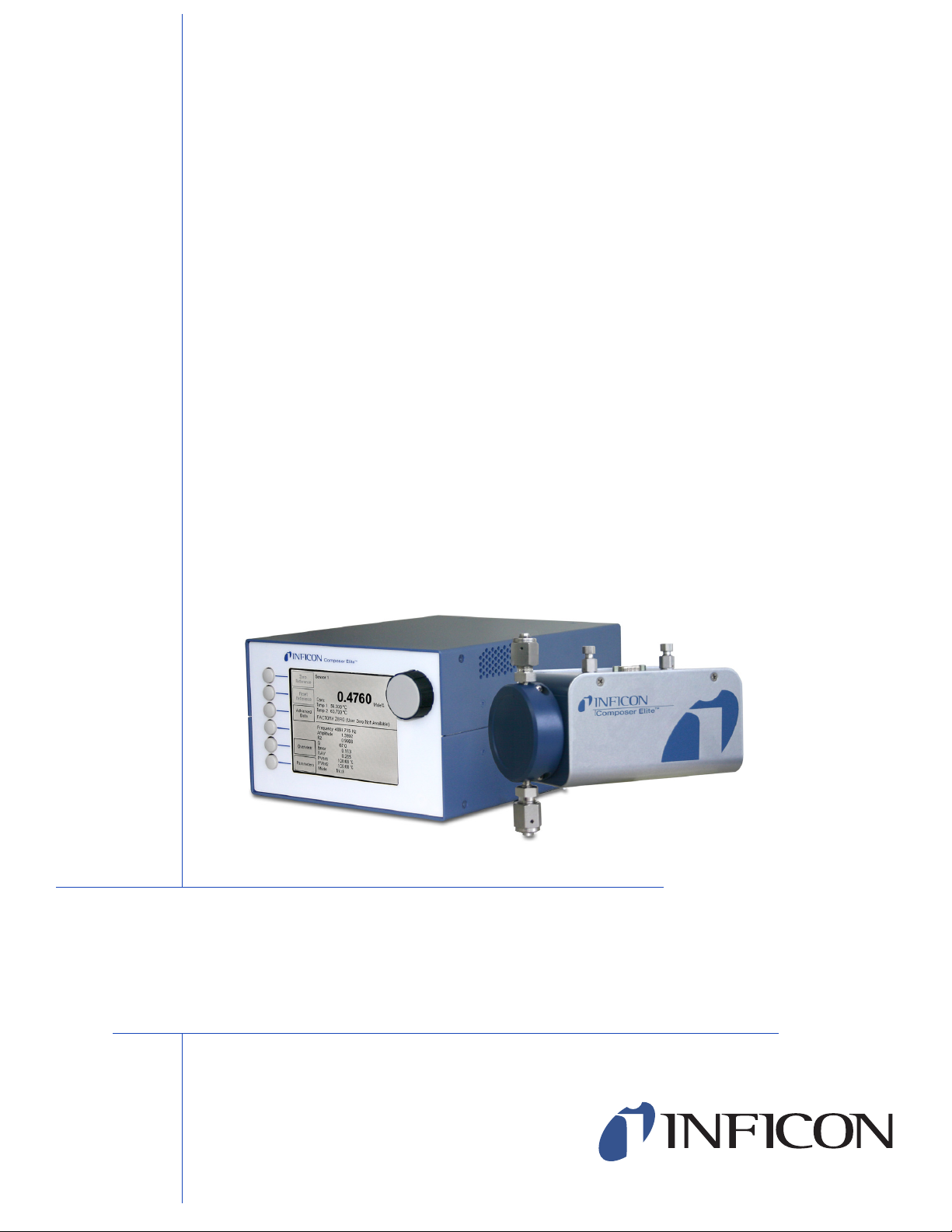

C

over Page

OPERATING MANUAL

™

Composer Elite

Gas Concentration Monitor

PN 074-566-P1B

Page 2

Page 3

www.inficon.com reachus@inficon.com

©2013 INFICON

®

Title P

age

OPERATING MANUAL

Composer Elite

Gas Concentration Monitor

™

PN 074-566-P1B

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

Beckhoff® and TwinCAT® are registered trademarks of Beckhoff Automation GmbH.

CIP™ is a registered trademark of Open DeviceNet Vendor Association, Inc.

DeviceNet™ is a registered trademark of Open DeviceNet Vendor Association, Inc.

Inconel® is a registered trademark of International Nickel Company.

INFICON® and Composer Elite™ are trademarks of INFICON GmbH

ODVA™ is a registered trademark of Open DeviceNet Vendor Association, Inc.

Viton® is registered trademark of E. I. duPont de Nemours Company.

VCR® and Swagelok® are registered trademarks of Swagelok, Company.

Windows®, Windows XP®, Window 7®, and Microsoft® are registered trademarks of Microsoft Corporation.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2013 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Page 6

Page 7

Warranty

WARRANTY AND LIABILITY - LIMITATION: Seller warrants the products

manufactured by it, or by an affiliated company and sold by it, and described on

the reverse hereof, to be, for the period of warranty coverage specified below, free

from defects of materials or workmanship under normal proper use and service.

The period of warranty coverage is specified for the respective products in the

respective Seller instruction manuals for those products but shall not be less than

one (1) year from the date of shipment thereof by Seller. Seller's liability under this

warranty is limited to such of the above products or parts thereof as are returned,

transportation prepaid, to Seller's plant, not later than thirty (30) days after the

expiration of the period of warranty coverage in respect thereof and are found by

Seller's examination to have failed to function properly because of defective

workmanship or materials and not because of improper installation or misuse and

is limited to, at Seller's election, either (a) repairing and returning the product or

part thereof, or (b) furnishing a replacement product or part thereof, transportation

prepaid by Seller in either case. In the event Buyer discovers or learns that a

product does not conform to warranty, Buyer shall immediately notify Seller in

writing of such non-conformity, specifying in reasonable detail the nature of such

non-conformity. If Seller is not provided with such written notification, Seller shall

not be liable for any further damages which could have been avoided if Seller had

been provided with immediate written notification.

THIS WARRANTY IS MADE AND ACCEPTED IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OR

OF FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE, AS BUYER'S

EXCLUSIVE REMEDY FOR ANY DEFECTS IN THE PRODUCTS TO BE SOLD

HEREUNDER. All other obligations and liabilities of Seller, whether in contract or

tort (including negligence) or otherwise, are expressly EXCLUDED. In no event

shall Seller be liable for any costs, expenses or damages, whether direct or

indirect, special, incidental, consequential, or other, on any claim of any defective

product, in excess of the price paid by Buyer for the product plus return

transportation charges prepaid.

No warranty is made by Seller of any Seller product which has been installed,

used or operated contrary to Seller's written instruction manual or which has been

subjected to misuse, negligence or accident or has been repaired or altered by

anyone other than Seller or which has been used in a manner or for a purpose for

which the Seller product was not designed nor against any defects due to plans or

instructions supplied to Seller by or for Buyer.

This manual is intended for private use by INFICON® Inc. and its customers.

Contact INFICON before reproducing its contents.

NOTE: These instructions do not provide for every contingency that may arise in

connection with the installation, operation or maintenance of this equipment.

Should you require further assistance, please contact INFICON.

www.inficon.com reachus@inficon.com

Page 8

Page 9

Composer Elite Operating Manual

Table Of Contents

Cover Page

Trademarks

Disclaimer

Copyright

Declaration Of Conformity

Warranty

Chapter 1

Introduction

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 Description of the Composer Elite System . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 Symbols and their Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.2 General Cautions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 How To Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.1 Returning Your Composer Elite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.4 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.4.1 Parts and Options Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.2 Sensor Control Unit Power-Up Verification . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.5.1 Composer Elite System Operating Specifications . . . . . . . . . . . . . . . . . . . .1-8

1.5.2 Composer Elite Sensor Control Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.5.3 Acoustic Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.5.4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.5.4.1 Rated Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

PN 074-566-P1B

1.5.4.2 Rated Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.5.4.3 Power Supply Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . .1-12

1.5.5 User Supplied Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1.5.6 Computer Requirements for Composer Elite Multi-Sensor Software . . . . . 1-13

1.5.7 DeviceNet Requirements for Composer Elite Multi-Sensor Software . . . .1-13

1.5.8 Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1.5.9 Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

1.5.10 Perimeter for Maintenance Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1.5.11 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

TOC - 1

Page 10

Composer Elite Operating Manual

Chapter 2

Installation

2.1 Composer Elite Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Pressure, Temperature, and Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1.1 Maximum Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1.2 Pressure and Tubing Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1.3 Heated Process Tubing and Acoustic Sensor Temperatures . . . . . . . . . . . 2-2

2.1.2 Grounding and Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.2.1 Power Supply Grounding Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.2.2 Earth Ground Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.2.3 Composer Elite System Grounding Requirement . . . . . . . . . . . . . . . . . . . . 2-4

2.1.2.4 Electrical Interference Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1.3 Composer Elite Location Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.3.1 Selecting The Acoustic Sensor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.3.2 Selecting The Sensor Control Unit Location . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2 Composer Elite Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.1 Installing The Sensor Control Unit in a 19 in. (48.26 cm) Rack . . . . . . . . . . 2-8

2.2.2 Installing The Acoustic Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.2.3 Installing Interconnect, Power Supply, and Communications Cables . . . . 2-11

2.2.4 Installing Composer Elite Multi-Sensor Software . . . . . . . . . . . . . . . . . . . . 2-12

Chapter 3

Operation

3.1 Initialization and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Parameter Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1.1 Composer Elite Front Panel Parameter Entry . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.1 Frequency of Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.2 Special Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.3 How to Calibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.4 How To Revert To Factory Default Settings. . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 How To Use Composer Elite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.1 How to Power Up and Power Down Composer Elite . . . . . . . . . . . . . . . . . . 3-4

3.3.2 Composer Elite Screen Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.2.1 Boot Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.2.2 Indicators Displayed On Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.2.3 Overview Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3.2.4 System Overview Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.2.5 Errors and Warnings Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

PN 074-566-P1B

TOC - 2

Page 11

Composer Elite Operating Manual

3.3.2.6 Sensor Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.3.2.7 Sensor Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.3.3 Description of Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.3.3.1 Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.3.3.2 Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.3.3.3 Ground Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.3.3.4 I/O Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.3.3.5 Control Slot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.3.3.6 Sensor 5 - I/O Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.3.3.7 Sensor Slots 1 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Chapter 4

Applications Guide

4.1 Advice and Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 What is the Required Warm Up Time?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 When and How Often to Set the Reference Zero. . . . . . . . . . . . . . . . . . . . .4-1

4.1.3 How is Performance Affected if I Use the

Factory (Reference) Zero Value? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.4 What To Do when the Specific Heat Ratio

for a Gas is Unknown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.5 What is the Ideal Operating Environment?. . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.1.6 What is the Effect of Pressure Variation?. . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.1.7 What is the Effect of Flow Variation? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.1.8 How Does This Instrumental Method Differ from

Measuring the Speed of Sound by Time of Flight? . . . . . . . . . . . . . . . . . . . 4-5

4.1.8.1 Calculation Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.1.9 What is the Long Term Stability of

this Measurement System? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.1.10 What Happens if the Reference Zero

PN 074-566-P1B

4.1.11 How to Sample Flow with a Composer Elite. . . . . . . . . . . . . . . . . . . . . . . . . 4-9

is Improperly Set?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Chapter 5

Remote Communications

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 General Type Definitions for Remote Communications . . . . . . . . . . . . . . . . 5-1

5.3 RS-232 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.4 DeviceNet Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.4.1 DeviceNet Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.4.1.1 CIP Type Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.4.1.2 Identity Objects (01h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

TOC - 3

Page 12

Composer Elite Operating Manual

5.4.1.3 Message Router (02h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4.1.4 DeviceNet Object (03h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4.1.5 Assembly Object (04h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4.1.6 Connection Object (05h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.4.1.7 Acknowledge Handler Object (2Bh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.4.1.8 I/O Data Format Object (64h). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.4.2 DeviceNet Data Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.4.2.1 Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.4.2.2 Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.4.2.2.1 Data Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.4.2.2.2 Sensor 1-5 Data Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.4.2.2.3 All 5 Sensor Card Data Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.4.2.2.4 Sensors 1,2,3 Error/Warning Data Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.4.2.2.5 Sensors 4,5 Error/Warning Data Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.4.2.2.6 5 Sensors' Concentration Data Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.4.3 DeviceNet INFICON Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.5 Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.5.1 Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.5.1.1 Command Packet (Host to Composer Elite Message). . . . . . . . . . . . . . . . 5-22

5.5.2 Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

5.5.2.1 Response Packet (Composer Elite to Host Message) . . . . . . . . . . . . . . . . 5-23

5.5.2.2 Communication Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.6 Communication Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

5.6.1 Hello Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.6.2 Query Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.6.3 Update Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

5.6.4 Status Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

5.6.5 Remote Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

5.7 Composer Elite Communications Examples . . . . . . . . . . . . . . . . . . . . . . . 5-37

5.7.1 Hello Command, ASCII Name and Version . . . . . . . . . . . . . . . . . . . . . . . . 5-37

5.7.2 Query Command, Carrier Molecular Weight . . . . . . . . . . . . . . . . . . . . . . . 5-37

5.7.3 Update Command, Carrier Molecular Weight . . . . . . . . . . . . . . . . . . . . . . 5-38

5.7.4 Update Command, Set Bit Pattern for S0 Command. . . . . . . . . . . . . . . . . 5-38

5.7.5 Status Command, Current Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

5.7.6 Remote Command, Zero Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-39

PN 074-566-P1B

TOC - 4

Page 13

Composer Elite Operating Manual

Chapter 6

Composer Elite Multi-Sensor Software

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Hardware Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2.1 Computer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2.2 RS-232 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.3 DeviceNet Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2.4 Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.1 User Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.2 Comm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.3.3 Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.3.4 Diagnostic Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

6.3.5 Sensor Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.3.6 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.3.7 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.3.7.1 Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.3.7.2 Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.3.8 Zero Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.3.9 Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.3.10 Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

6.3.11 Screen Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.3.12 Annotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6.3.13 Composer Elite Multi-Sensor Software Warnings and Errors. . . . . . . . . . . 6-16

6.3.13.1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Chapter 7

Maintenance

7.1 Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

PN 074-566-P1B

7.2 Leak Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2.1 Leak Testing the Primary (Resonant) Chamber . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2.2 Leak Testing the Secondary Containment Chambers . . . . . . . . . . . . . . . . .7-3

7.3 Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Chapter 8

Troubleshooting

8.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Errors and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.3 Failure Mode and Effects Analysis (FMEA) . . . . . . . . . . . . . . . . . . . . . . . . .8-2

TOC - 5

Page 14

Chapter 9

9.1 Speed of Sound and Gas Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Measuring the Speed of Sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.3 Composer Elite Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.4 Description of Subsystems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.4.1 Sensor Control Unit and Composer Elite Multi-Sensor Software . . . . . . . . . 9-7

9.4.2 Acoustic Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Appendix A

Appendix B

B.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Appendix C

C.1 Composer Elite Acoustic Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Composer Elite Operating Manual

Measurement and Theory

Bibliography

Material Table

Outline Drawings

TOC - 6

PN 074-566-P1B

Page 15

Composer Elite Operating Manual

1.1 Introduction

Composer Elite™ is designed to measure the precursor concentration of binary

gases. It is optimized for operation at pressures as low as 26.66 kPa

[200 Torr] and temperatures as high as 65°C. The Composer Elite System

provides unsurpassed precision and reproducibility when measuring small

concentrations of heavy molecular weight components in a lower molecular weight

carrier gas.

1.1.1 Description of the Composer Elite System

The Composer Elite System consists of:

A Sensor Control Unit which sends/receives electrical signals to/from the

Acoustic Sensor. The Sensor Control Unit provides an LCD display and

interface for user interaction (see Figure 1-1).

An Acoustic Sensor which interfaces to the process gas tubing and forms the

physical basis for the speed of sound measurement (see Figure 1-1). Two

versions of Acoustic Sensor are available:

Chapter 1

Introduction

Standard Acoustic Sensor, for use with hydrogen or helium carrier gas at

flow rates up to 2000 sccm, or for carrier gases of any molecular weight at

flow rates up to 1000 sccm.

High Flow Acoustic Sensor, for use with nitrogen carrier gas or a higher

molecular weight carrier gas, at flow rates between 1000 and 2000 sccm.

An Interconnect Cable which connects the Sensor Control Unit and

Acoustic Sensor.

An optional 24 V(dc) Power Supply which provides power to the

Sensor Control Unit.

Windows

setup through RS-232C or DeviceNet. See Chapter 6, Composer Elite

PN 074-566-P1B

Multi-Sensor Software.

Figure 1-1 Sensor control unit (left), acoustic sensor (right)

®

Composer Elite Multi-Sensor Software, for system operation and

1 - 1

Page 16

Composer Elite Operating Manual

CAUTION

WARNING

WARNING - Risk Of Electric Shock

1.2 Using this Manual

Please take a moment to read the following.

1.2.1 Symbols and their Definitions

NOTE: Notes provide additional information about the current topic.

HINT: Hints provide insight into product usage.

Failure to heed these messages could result in a

malfunction or damage to Composer Elite.

Failure to heed these messages could result in

physical injury.

Dangerous voltages are present which could result in

personal injury.

PN 074-566-P1B

1 - 2

Page 17

1.2.2 General Cautions and Warnings

WARNING - Risk Of Electric Shock

CAUTION

CAUTION

WARNING

WARNING

Dangerous voltages are present inside the 24 V power

supply whenever the power cord is connected. Do not

open the power supply casing.

Composer Elite contains circuitry susceptible to

transient mains voltages. Disconnect the power cord

whenever making any interface connections.

Composer Elite Operating Manual

Do not open the casing of any component of the

Composer Elite System. There are no user-serviceable

components inside. Refer all maintenance to qualified

INFICON personnel.

Do not install or use Composer Elite in a manner

inconsistent with the instructions in this operating

manual. Failure to do so may result in damage to the

instrument or personal injury.

PN 074-566-P1B

Many of the precursor gases that can be used with

Composer Elite are toxic. Refer to the material's Material

Safety Data Sheet for information regarding personal

safety.

1 - 3

Page 18

Composer Elite Operating Manual

1.3 How To Contact INFICON

Worldwide customer support information is available under Contact >> Support

Worldwide at www.inficon.com

Sales and Customer Service

Technical Support

Repair Service

If you are experiencing a problem with your Composer Elite or Composer Elite

Multi-Sensor software, please have the following information readily available:

The Sales Order or PO number for the Composer Elite purchase.

The version of the software if you are calling about Composer Elite

Multi-Sensor software.

A description of the problem.

An explanation of any corrective action that you may have already attempted.

The exact wording of any error messages that you may have received.

1.3.1 Returning Your Composer Elite

Do not return any component of your Composer Elite System to INFICON without

first speaking with a Customer Support Representative. You must obtain a Return

Material Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your

Composer Elite.

Prior to being given an RMA number, you will be required to complete a Declaration

Of Contamination (DoC) form if your Acoustic Sensor is being returned. DoC forms

must be approved by INFICON before an RMA number is issued. INFICON may

require that the Acoustic Sensor be sent to a designated decontamination facility,

not to the factory.

PN 074-566-P1B

1 - 4

Page 19

1.4 Unpacking and Inspection

1 If Composer Elite has not been removed from its shipping container, do so now.

Do not discard the packing materials before reading the following steps.

2 Carefully examine Composer Elite for damage that may have occurred during

shipping. This is especially important if you notice obvious rough handling on

the outside of the container. Immediately report any damage

to the carrier and to INFICON.

3 Take an inventory of your order by referring to the configuration code in your

order invoice and the information shown in section 1.4.1 and Figure 1-2.

4 Perform a power-up verification of the Sensor Control Unit. (See section 1.4.2.)

5 For additional information or technical assistance, contact INFICON

(Refer to section 1.3).

Composer Elite Operating Manual

PN 074-566-P1B

1 - 5

Page 20

Composer Elite Operating Manual

CPE–

0

1

2

3

4

5

N

0

1

2

3

4

5

0

Number of Standard

Acoustic Sensors

SEE NOTE 1

None

1

2

3

4

5

Number of High Flow

Acoustic Sensors

SEE NOTE 2

None

1

2

3

4

5

Expansion Option

Not Currently Available

None

0

1

2

0

Expansion Option

Not Currently

Available

None

Quantity of 4.6 m (15 ft.)

Acoustic Sensor Cables

None

One 4.6 m (15 ft.) cable

Two 4.6 m (15 ft.) cables

Three 4.6 m (15 ft.) cables

Four 4.6 m (15 ft.) cables

Five 4.6 m (15 ft.) cables

Optional Power Supply

None

115 V

230 V

0

1

2

3

4

5

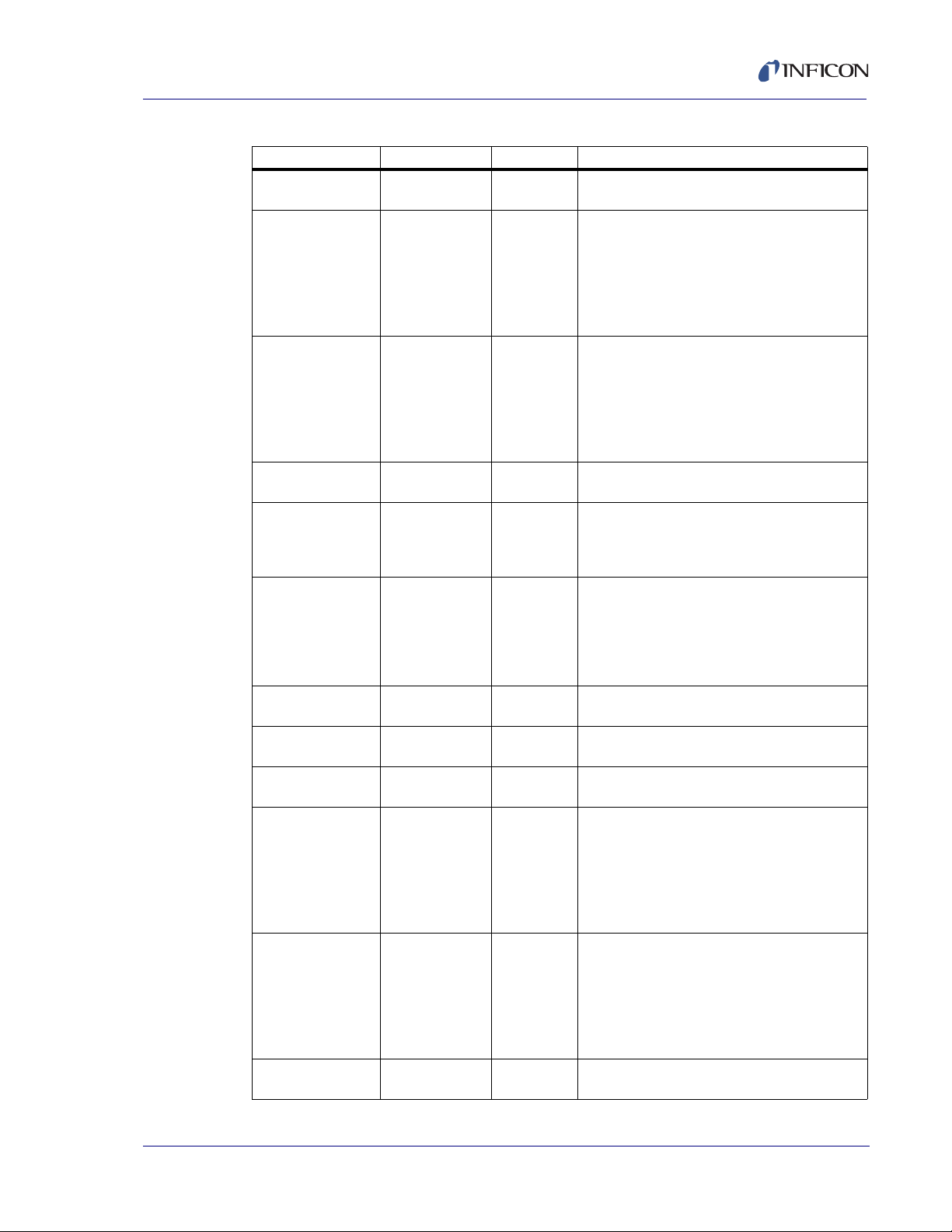

NOTE 1:

The Standard Acoustic Sensor is for use with H

2

or He carrier

gas at flow rates of 0 to 2000 sccm OR for any molecular

weight carrier gas when flow rates are 1000 sccm or less

Expansion Option

Not Currently Available

None

Note 2:

For use when the carrier gas molecular weight is 28 or

higher AND flow rates are between 1000 and 2000 sccm.

Not for use with any carrier gas molecular weight when flow

rates are below 1000 sccm.

1.4.1 Parts and Options Overview

Sensor Control Unit . . . . . . . . . . . . . . . . . . . . . . PN 761-220-G1

Acoustic Sensor

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . PN 761-219-G1

High Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . PN 761-219-G2

NOTE: The High Flow Acoustic Sensor is identified by a "G2" marking

on the inlet tube nut.

Interconnect Cable, 15 ft. (4.6 m). . . . . . . . . . . . PN 600-1447-P15

Ship Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PN 761-619-G1

Power Supply, 100-240 V(ac) (optional) . . . . . . PN 033-0056

Power Cord, 115 V (optional). . . . . . . . . . . . . . . PN 068-0433

Power Cord, 230 V (optional). . . . . . . . . . . . . . . PN 068-0434

Full Rack Extender (optional). . . . . . . . . . . . . . . PN 782-900-007

RS-232 Cable, 4.6 m (15 ft.) (optional) . . . . . . . PN 600-1001-P15

(contents: Leak Test Needle Kit;

operating manual and

Multi-Sensor software on CD)

Figure 1-2 Composer Elite part number configuration

1 - 6

PN 074-566-P1B

Page 21

Composer Elite Operating Manual

1.4.2 Sensor Control Unit Power-Up Verification

It is not necessary to have Acoustic Sensors or communications cables connected

to the Sensor Control Unit at this time.

1 Set the power switch on the rear panel of the Sensor Control Unit to the 0 (OFF)

position. (See Figure 3-8 on page 3-14.)

2 Using the INFICON (optional) 24 V power supply, or a power supply as defined

in section 1.5.4 and Table 1-1 on page 1-12, insert the output cable of the 24 V

power supply into the connector labeled 150W 24V on the rear panel of the

Sensor Control Unit (see Figure 3-8 on page 3-14). Make certain the cable is

inserted until it locks in place.

3 Connect mains power (refer to section 1.5.4.2 on page 1-12)

to the input of the 24 V power supply.

4 Power up the Sensor Control Unit from the rear panel by setting the power

switch to the 1 (ON) position. The Boot screen will appear followed by a

System Overview screen.

4a Verify that the information displayed on the Boot screen is as described by

section 3.3.2.1 on page 3-5.

4b Verify that the System Overview screen (see section 3.3.2.4 on page 3-8)

appears after the Boot screen.

5 If the information displayed on the Boot screen is not as described by section

3.3.2.1, or if the System Overview screen does not appear, contact INFICON.

6 Power down the Sensor Control Unit by setting the power switch to the

0 (OFF) position.

PN 074-566-P1B

1 - 7

Page 22

Composer Elite Operating Manual

1.5 Specifications

1.5.1 Composer Elite System Operating Specifications

Operating Pressure Range . . . . . . . 26.7 to 133.4, kPa [200-1000 Torr] absolute

Routine Overpressure Rating. . . . . . Up to 202.7 kPa [1520 Torr] absolute

Maximum Overpressure. . . . . . . . . . 826.2 kPa [6200 Torr] absolute.

Pressure over 826.2 kPa may damage

Acoustic Sensor diaphragms.

Gas Flow Range

Standard Acoustic Sensor

(for H2 and He carrier gas). . . . . 0 to 2000 sccm,

pressure drop at 2000 sccm flow is

approximately 12 Torr [1.60 kPa] at standard

temperature and pressure

High Flow Acoustic Sensor

(for N2 carrier gas or

higher molecular weight) . . . . . . 1000 to 2000 sccm,

pressure drop at 2000 sccm flow is

approximately 6 Torr [0.80 kPa] at standard

temperature and pressure.

Measurement Stability . . . . . . . . . . . 1 hour drift: +/- 0.032 Hz after 1 hour

stabilization (equivalent to +/- 2.5 ppm

Cp2Mg in N

). 8 hour drift: +/- 0.025 Hz after

2

2 hour stabilization

Determined using a N

carrier gas at

2

60°C, 800 Torr, 100 sccm flow

Measurement Rate. . . . . . . . . . . . . . 1 second

Concentration Reproducibility . . . . . <3 x 10-6 molar TMIn equivalent in H

[<2.4 x 10-5 molar TMIn equivalent in N

2

2

Sensitivity . . . . . . . . . . . . . . . . . . . . . Carrier at 60°C, 800 Torr, 100 sccm flow,

0.00011% of TMIn in H

in N

]

2

[0.0008% of TMIn

2

Time to Operation from

Room Temperature . . . . . . . . . . . . . For five Acoustic Sensors from ambient

temperature to the "at temperature" condition

is 120 minutes. Three or fewer sensors

typically require 90 minutes or less.

Reliability and Serviceability. . . . . . . Mean Time Between Failure: >8000 hours

]

PN 074-566-P1B

1 - 8

Page 23

Composer Elite Operating Manual

1.5.2 Composer Elite Sensor Control Unit

Size H x W x D . . . . . . . . . . . . . . . . . 132.8 x 213.4 x 254 mm

Measurement Channels . . . . . . . . . . Up to 5 Acoustic Sensors supported with

Required Connector Clearance . . . . 76.2 mm (3 in.) at rear panel for electrical

Rack Mount . . . . . . . . . . . . . . . . . . . Optional;

Weight . . . . . . . . . . . . . . . . . . . . . . . Approximately 3.0 kg (6.6 lb.)

Operating Temperature Range. . . . . 20 to +50°C (68 to 122°F)

Storage Temperature Range . . . . . . -10 to +70°C (14 to 158°F)

Humidity Range . . . . . . . . . . . . . . . . 0 to 80% RH non-condensing

Power Switch . . . . . . . . . . . . . . . . . . Rear panel mounted circuit breaker

(5.23 x 8.4 x 10.0 in.)

3U Half Rack

1 Sensor Control Unit

connector removal or insertion

Full Rack Extender, PN 782-900-007

rated at 7.5 A

Power Requirements . . . . . . . . . . . . 24 V(dc), 150 watts

Display . . . . . . . . . . . . . . . . . . . . . . . TFT LCD

Front Panel Keys . . . . . . . . . . . . . . . Six buttons for screen selection

Control Knob . . . . . . . . . . . . . . . . . . For parameter selection and editing

Rotate for parameter selection.

Rear Panel Connectors . . . . . . . . . . Ground stud, power connection, 15-pin

high-density D-sub connectors to sensor

cards, 9-pin D-sub connector for RS-232C

and M12x1 round connector for DeviceNet

communications

PN 074-566-P1B

Cleaning . . . . . . . . . . . . . . . . . . . . . . The casing can be safely cleaned with a mild

detergent or spray cleaner designed for that

purpose. Care should be taken to prevent

any cleaner from entering the unit

Regulatory Compliance . . . . . . . . . . Certified to CE standards, RoHS compliant,

& compliant to DeviceNet standards

Interconnect Cable . . . . . . . . . . . . . . 4.6 m (15 ft.) length, 15-pin high-density

D-sub connector on each end

1 - 9

Page 24

Composer Elite Operating Manual

1.5.3 Acoustic Sensor

Size . . . . . . . . . . . . . . . . . . . . . . . . . 124 mm (4.88 in.) between VCR-4 seal

Measurement Principle . . . . . . . . . . Precursor concentration determined by

Materials in Contact with Process Gas

Sensor Body. . . . . . . . . . . . . . . . 316L Stainless Steel

Tubing . . . . . . . . . . . . . . . . . . . . Seamless 316L SS and automatic butt weld

Isolation Diaphragms . . . . . . . . . 0.017 mm (0.00067 in.) Inconel

surfaces. Maximum outline dimensions

W x H x D (with gaskets and caps)

77.7 x 149.9 x 185.4 mm

(3.06 x 5.90 x 7.30 in.)

precision measurement of speed of sound in

a temperature controlled volume.

Measurement quality is enhanced by a

multi-chamber Helmholtz type resonator

fittings

®

X-750,

sealed with Inconel 718 gold plated c-rings

Connection to Process

®

Gas System . . . . . . . . . . . . . . . . . . . Swagelok

VCR®-4 male; inlet and outlet

inline 124 mm (4.88 in.) seal face to seal

face, near zero clearance required

Leak Test Service

Port Connection . . . . . . . . . . . . . . . . Swagelok VCR-2 female

Swept Volume . . . . . . . . . . . . . . . . . Resonant chamber: 8.9 cc

Connecting Inlet and Outlet tubes

(combined volume): 3.7 cc

Total Swept Volume . . . . . . . . . . 12.6 cc

Operating Temperature Range. . . . . 5°C minimum above ambient, range 30°C to

65°C, heat mode only

-9

Maximum Leak Rate . . . . . . . . . . . . 1x10

cm3/s helium

Electrical Connection . . . . . . . . . . . . 15-pin high-density D-sub

to Sensor Control Unit

Required Connector Clearance . . . . Required clearance 76.2 mm (3 in.) one side

for electrical connector removal or insertion

PN 074-566-P1B

1 - 10

Page 25

Mounting Requirements . . . . . . . . . . M4-0.7 (4), max. screw penetration 6.4 mm

WARNING - Risk Of Electric Shock

Weight . . . . . . . . . . . . . . . . . . . . . . . Approximately 2.3 kg (5.1 lb.)

Storage Temperature Range . . . . . . -10 to +70°C (14 to 158°F)

Humidity Range . . . . . . . . . . . . . . . . 0 to 80% RH non-condensing

1.5.4 Power Supply

The following sections detail the electrical power specifications for the optional

Power Supply. A universal input power supply converts local mains voltage to

regulated and current limited 24 V(dc) for powering the Sensor Control Unit.

Composer Elite Operating Manual

(0.25 in.) depth threaded holes provided.

Because the attachment to each system

widely varies, a mounting bracket must be

customer fabricated.

Failure to comply with the electrical power requirements

stated below may result in Composer Elite

malfunctioning or being damaged, and could result in

personal bodily injury.

1.5.4.1 Rated Output

Voltage . . . . . . . . . . . . . . . . . . . . . . . 24 V(dc) +5% / -2%

Ripple and Noise . . . . . . . . . . . . . . . 480 mV peak-to-peak max.

Current . . . . . . . . . . . . . . . . . . . . . . . 6.25 A max.

Short Circuit Protection . . . . . . . . . . Continuous, hiccup mode

24 V Connector Interface . . . . . . . . . Shielded Cable Assembly

PN 074-566-P1B

Connector . . . . . . . . . . . . . . . . . . 4-pin, Kycon KPPx-4P or equiv.

Length. . . . . . . . . . . . . . . . . . . . . 1830 mm

Wiring Size . . . . . . . . . . . . . . . . . #14 AWG

+24 V. . . . . . . . . . . . . . . . . Pins 3, 4

Gnd . . . . . . . . . . . . . . . . . . Pins 1, 2

Shield Drain. . . . . . . . . . . . Shell

Shell . . . . . . . . . . . . . . . . . Grounded

1 - 11

Page 26

Composer Elite Operating Manual

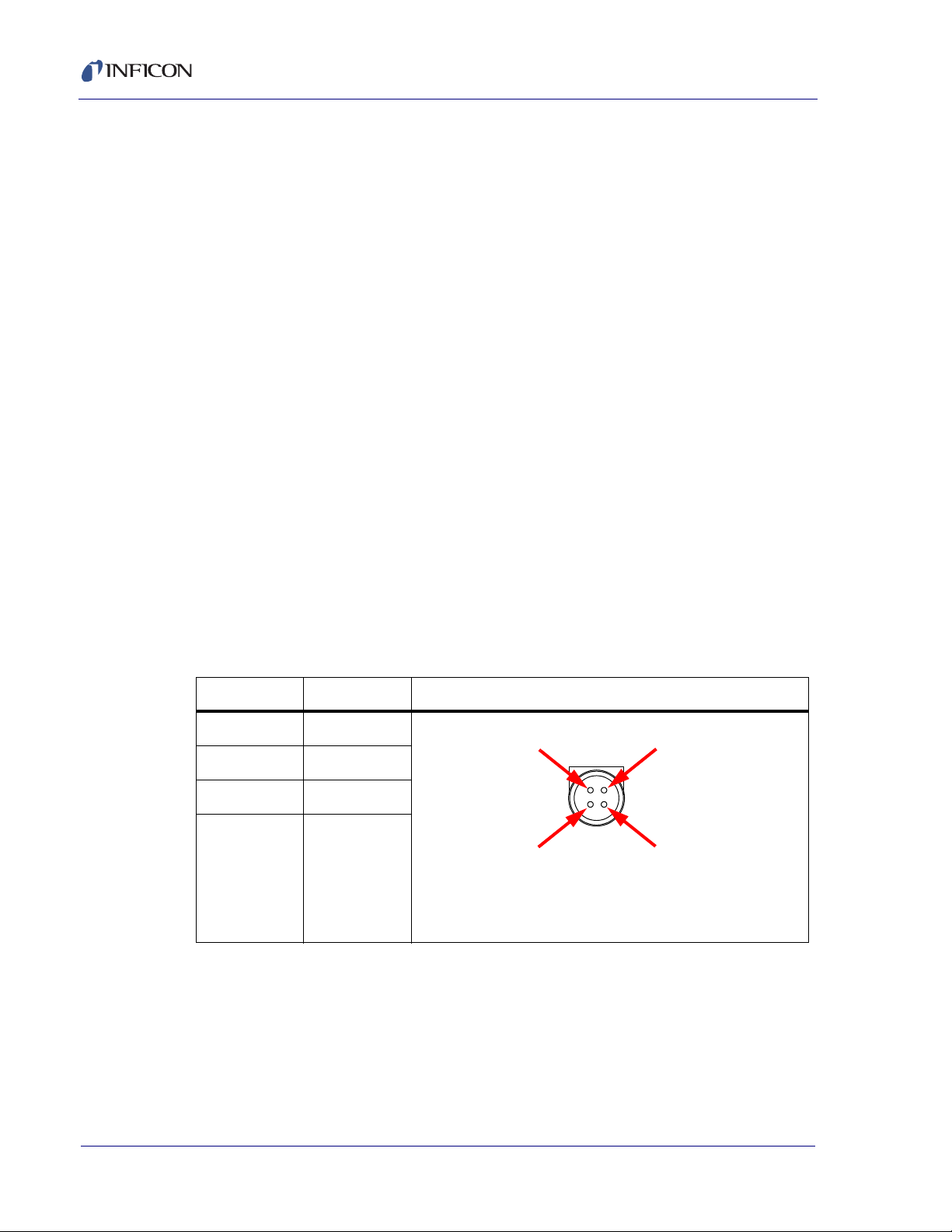

Pin 1

D.W. (GND)

Pin 2

(GND)

Pin 3

White (+V

o

)

D.W. (GND)

Pin 4

(+V

o

)

4 P POWER DIN

1.5.4.2 Rated Input

Operational Voltage Range . . . . . . . 100 to 240 V (ac) +/- 10% (ac)

Frequency Range. . . . . . . . . . . . . . . 47 to 63 Hz

In-rush Current . . . . . . . . . . . . . . . . . <60 A at 230 V(ac) input,

25°C ambient cold start

Input Current . . . . . . . . . . . . . . . . . . 2.5 A max.

Overvoltage . . . . . . . . . . . . . . . . . . . 110% - 130% of nominal

(Cycle input power to reset)

Unit Mains Connector. . . . . . . . . . . . IEC320-C14 (Accepts IEC 320-C13)

1.5.4.3 Power Supply Environmental Specifications

Operating Temperature . . . . . . . . . . 0 to +40°C

Storage Temperature . . . . . . . . . . . . -10 to +70°C

Humidity . . . . . . . . . . . . . . . . . . . . . . 20 to 90% non-condensing

1.5.5 User Supplied Power Supply

If the user provides their own power supply, it must conform to the specifications

and requirements indicated by section 1.5.4. The power supply output cable must

be wired to a 4-pin connector as shown in Table 1-1.

Table 1-1 +24 Volt power connector’s pin diagram

Pin Function Wiring Diagram for Kycon KPPx-45 Plug

1 Gnd

2 Gnd

3 +24 V

4 +24 V

PN 074-566-P1B

1 - 12

Page 27

Composer Elite Operating Manual

1.5.6 Computer Requirements for Composer Elite Multi-Sensor Software

Processor . . . . . . . . . . . . . . . . . . . . . 1 GHz

Memory . . . . . . . . . . . . . . . . . . . . . . 512 MB RAM

Display Resolution . . . . . . . . . . . . . . 1280 x 1024

Storage. . . . . . . . . . . . . . . . . . . . . . . 5 MB of Hard Drive Space

Operating System. . . . . . . . . . . . . . . Windows XP (SP3), Windows 7

Communications. . . . . . . . . . . . . . . . RS-232 Serial Port, or USB-Serial Adapter,

or DeviceNet Card

Other . . . . . . . . . . . . . . . . . . . . . . . . Microsoft

®

.Net Framework 4 Client Profile

(x86 and x64)

1.5.7 DeviceNet Requirements for Composer Elite Multi-Sensor Software

Interface Card. . . . . . . . . . . . . . . . . . Beckhoff FC5201 DeviceNet Interface Card

Connectivity . . . . . . . . . . . . . . . . . . . 1-Channel, PCI bus

Software . . . . . . . . . . . . . . . . . . . . . . Beckhoff TwinCAT I/O

Power . . . . . . . . . . . . . . . . . . . . . . . . 24 V(dc), external power supply

NOTE: These requirements do not apply when DeviceNet is used in conjunction

with other software.

1.5.8 Mounting Requirements

The Sensor Control Unit is designed for bench-top operation or mounting in a

standard 48.26 (19 in.) rack using the optional Full Rack Extender

(PN 782-900-007). The Sensor Control Unit occupies half the width of a

standard rack, so a blank-off is provided with the optional Full Rack Extender.

The Acoustic Sensor must be attached to a rigid mounting surface using the

PN 074-566-P1B

M4 threaded holes in the Acoustic Sensor cover. Maximum depth of screw

penetration into M4 mounting holes is 6.4 mm (0.25 in.).

Dimension from VCR-4 gland-to-gland is 12.4 cm (4.88 in.).

1.5.9 Ventilation Requirements

The Sensor Control Unit is adequately ventilated when operating on a bench

top or when installed in a standard 48.26 cm (19 in.) rack using the optional

Full Rack Extender (PN 782-900-007).

The Acoustic Sensor does not require ventilation.

1 - 13

Page 28

Composer Elite Operating Manual

1.5.10 Perimeter for Maintenance Access

Acoustic Sensor to be removed from the process gas tubing (Swagelok VCR-4

fittings) require side-to-side or top-to-bottom clearance of 16 cm (6 in.)

for wrench rotation.

Interconnect Cable to be removed or replaced from either Acoustic Sensor or

Sensor Control Unit requires 8 cm (3 in.) clearance.

Sensor Control Unit to be removed from rack, full 30.5 cm (12 in.)

length required.

1.5.11 Environmental Requirements

The following detail Composer Elite environmental requirements.

Operation . . . . . . . . . . . . . . . . . . . . . Composer Elite is designed for

Altitude Range . . . . . . . . . . . . . . . . . Composer Elite can be used to a maximum

indoor use only.

altitude of 2000 m (6561 ft.).

For applications above this altitude, please

contact INFICON.

Maximum Humidity. . . . . . . . . . . . . . Non-condensing relative humidity at

operating temperature.

Pollution Degree. . . . . . . . . . . . . . . . Category II (as defined by EN61010-1, only

non-conductive pollution occurs).

Operating Temperature . . . . . . . . . . Refer to section 1.5,

Specifications, on page 1-8.

PN 074-566-P1B

1 - 14

Page 29

Composer Elite Operating Manual

CAUTION

2.1 Composer Elite Installation Guidelines

The requirements and recommendations in section 2.1.1, section 2.1.2, and

section 2.1.3 must be reviewed and understood before Composer Elite is installed

as described by section 2.2, Composer Elite Installation, on page 2-8.

2.1.1 Pressure, Temperature, and Tubing

2.1.1.1 Maximum Pressure

Reliable measurement of concentration to absolute pressures as low as 26.66 kPa

(200 Torr) requires relatively thin and flexible diaphragms to be used so that

sufficient acoustic energy may be transmitted.

There is a possibility that the diaphragms may destructively rupture if an absolute

pressure greater than 826 kPa (6200 Torr) is applied. A secondary containment

chamber is built into the Acoustic Sensor to prevent process gases from escaping

the Acoustic Sensor in the event of a diaphragm rupture.

Chapter 2

Installation

Do not connect the Acoustic Sensor to process tubing

that can exceed an absolute pressure of

826 kPa (6200 Torr). Exposing the Acoustic Sensor to

excess pressure may cause catastrophic diaphragm

failure or may stretch the diaphragms, requiring on-site

reference zeroing (see section 4.1.2 on page 4-1).

A certified rupture disk should be installed upstream of

PN 074-566-P1B

the Acoustic Sensor to limit any possible over-pressure

to less than 826 kPa (6200 Torr).

2 - 1

Page 30

Composer Elite Operating Manual

2.1.1.2 Pressure and Tubing Size

The Composer Elite System is designed to operate with the gases in the Reactor's

process tubing at a pressure of 26.66 to 133.3 kPa (200 to 1000 Torr). The inner

diameter of the inlet and outlet tubes on the Standard and High Flow Acoustic

Sensors were designed to optimize performance at low pressures; however, the

Reactor’s process tubing may be of any appropriate size without degrading

Composer Elite performance.

2.1.1.3 Heated Process Tubing and Acoustic Sensor Temperatures

Operation of the Acoustic Sensor at a temperature slightly higher than the process

gas tubing will help prevent material from condensing inside the acoustic sensor.

INFICON recommends the following temperature settings:

The Temperature Setpoint 1 setting for the Acoustic Sensor's resonant

chamber temperature should be 5°C or more above ambient temperature.

See section 3.3.2.7, Sensor Parameters Screen, on page 3-12.

The Temperature Setpoint 2 setting for the Acoustic Sensor's inlet tube

temperature should be above the Temperature Setpoint 1 setting. Typically

start out with this temperature three degrees above Temperature Setpoint 1.

The inlet tube heater is designed to minimize zero point offset caused by large

flow rate changes. The optimal setting will depend on process conditions.

See section 3.3.2.7, Sensor Parameters Screen, on page 3-12.

2 - 2

PN 074-566-P1B

Page 31

2.1.2 Grounding and Shielding

WARNING - Risk Of Electric Shock

CAUTION

2.1.2.1 Power Supply Grounding Requirement

The Composer Elite 24 V Power Supply must be

connected to a grounded socket outlet using a

three-conductor power cable with ground terminal.

The Composer Elite 24 V power supply (optional) is connected to ground through

a sealed three-conductor power cable, which must be plugged into a socket outlet

with a protective ground terminal. Extension cables must always have three

conductors including a protective ground terminal.

2.1.2.2 Earth Ground Requirement

Composer Elite Operating Manual

A low impedance and reliable earth ground is required for

proper performance of Composer Elite.

If local facilities engineering cannot provide a low impedance earth ground close to

Composer Elite, the following procedure is recommended.

1 Where soil conditions allow, drive two 3 m (10 ft.) copper clad steel rods into

the ground 2 m (6 ft.) apart.

2 Pour a copper sulfate or other salt solution around the rods to improve

the soil’s conductivity.

A near zero resistance measurement between the two rods indicates that a

desirable earth ground is established. In severe cases, it may take several

soakings of solution over several days to reach this condition.

PN 074-566-P1B

NOTE: Keep connections to this grounding network as short as possible. Most

noise transients contain significant power at high frequencies. A long path

adds to the ground circuit's inductance and thereby increases its

impedance at these frequencies.

2 - 3

Page 32

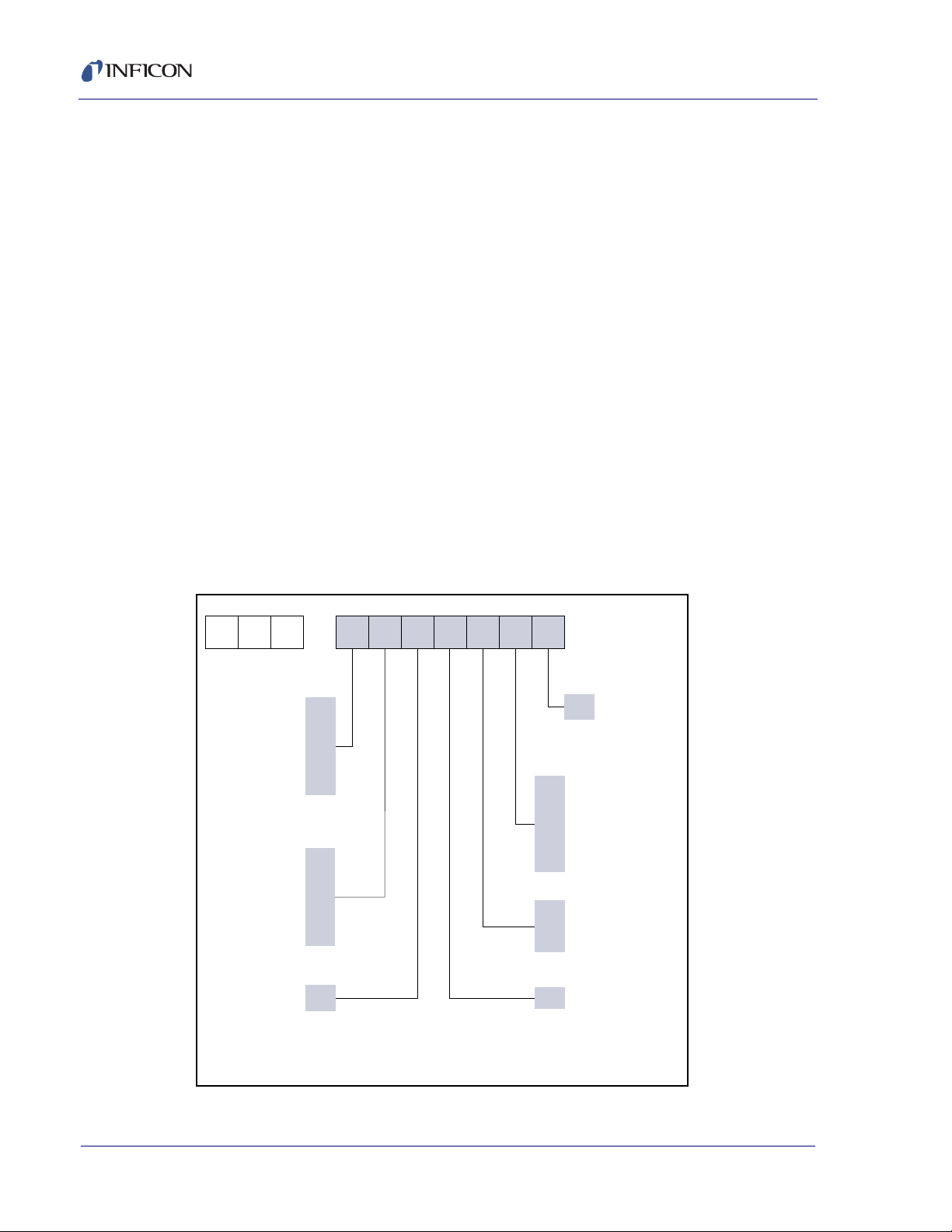

Composer Elite Operating Manual

CAUTION

Sensor Control Unit

Ground

Stud

Earth Ground

Acoustic Sensor

Reactor

Grounded

Copper Straps

Process

Tub ing

Grounded

Mounting

Surface

2.1.2.3 Composer Elite System Grounding Requirement

The Sensor Control Unit and Acoustic Sensor must be

grounded for proper performance of Composer Elite.

The following grounding method is recommended:

1 Verify that the Reactor is connected to a good, reliable earth ground (refer to

section 2.1.2.2, Earth Ground Requirement, on page 2-3). Use a solid copper

strap, at least 0.08 cm (0.030 in.) thick by 2.5 cm (1 in.) wide, and as short as

practical, for the connection between Reactor and earth ground (see

Figure 2-1).

2 Use a solid copper strap, approximately 0.08 cm (0.030 in.) thick by

2.5 cm (1 in.) wide, and as short as practical, between the Sensor Control Unit

ground stud (see Figure 2-1) and the Reactor. A ring terminal soldered to the

ground strap will allow for a good connection to the ground stud and convenient

removal or installation.

3 Connect the Acoustic Sensor to earth ground by one or both of the

3a Use the M4 mounting holes provided on the Acoustic Sensor to attach the

3b Connect the Acoustic Sensor's outlet tubing to process tubing that is connected

following methods:

Acoustic Sensor to a metal mounting surface that is connected to earth ground

(see Figure 2-1 and section 2.2.2 on page 2-9).

or

to earth ground (see Figure 2-1 and section 2.2.2 on page 2-9).

Figure 2-1 System grounding diagram

PN 074-566-P1B

2 - 4

Page 33

2.1.2.4 Electrical Interference Reduction

When Composer Elite is integrated into a deposition system, each cable

connection is a potential path for electrical noise to be conducted to the Sensor

Control Unit or Acoustic Sensor. The possibility of external electrical interference

problems can be greatly reduced by adhering to the following guidelines:

Make certain the Sensor Control Unit and Acoustic Sensor are properly

grounded. (Refer to section 2.1.2.3, Composer Elite System Grounding

Requirement, on page 2-4.)

Make certain the Sensor Control Unit covers and option panels are in place and

secured with the provided fasteners.

Use shielded cable as short as practical for remote communications.

Avoid routing the Composer Elite Interconnect cable and communications

cable near areas that have the potential to generate high levels of electrical

interference. For example, large power supplies can be a source of large and

rapidly changing electromagnetic fields. Placing cables at least 30 cm (1 ft.)

from these problem areas can result in a significant reduction

of electrical interference.

Composer Elite Operating Manual

PN 074-566-P1B

2 - 5

Page 34

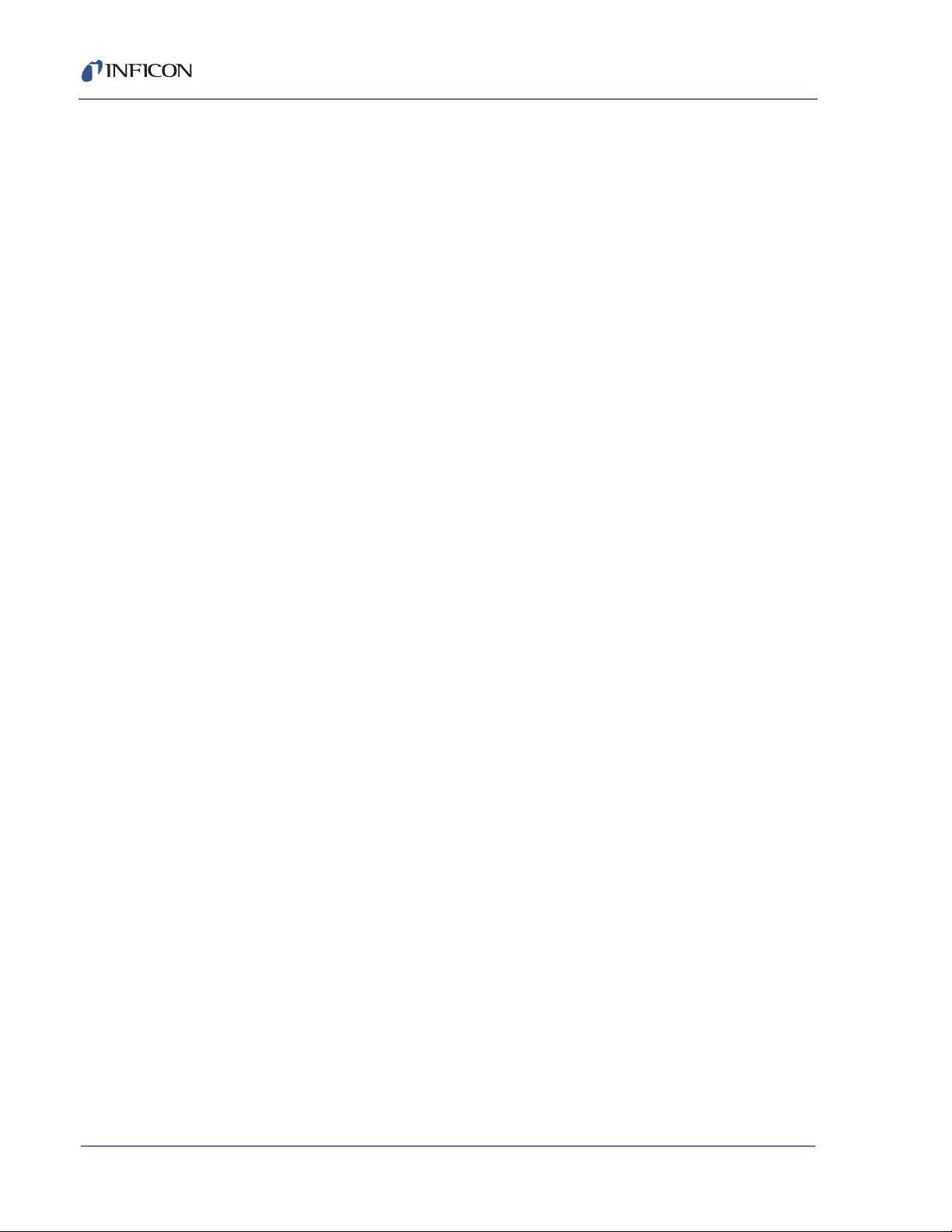

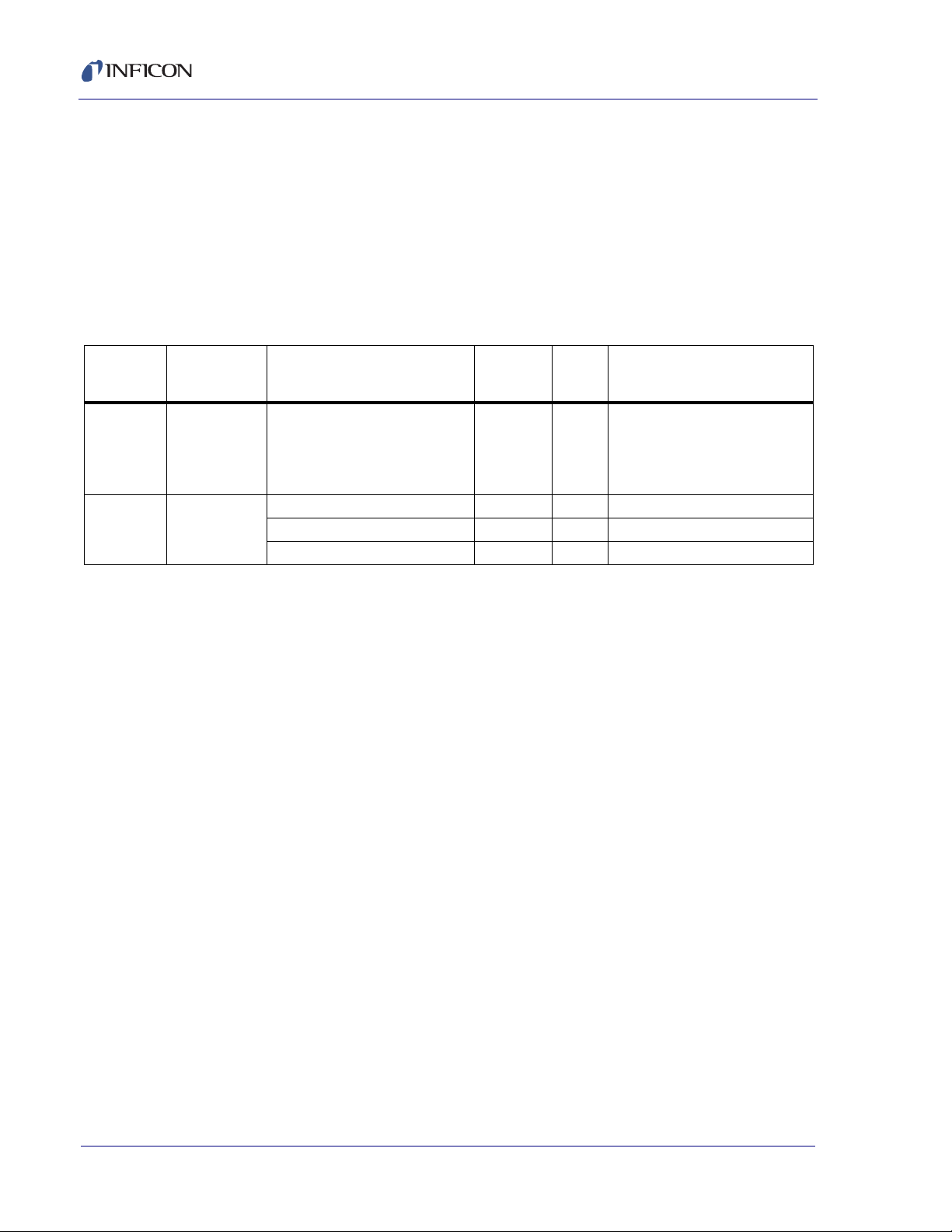

Composer Elite Operating Manual

Mains

Power

Optional

Power

Supply

24 V(dc)

RS-232

Sensor

Control

Unit

DeviceNet

Interconnect

Cable

Carrier Gas

P

MFC MFC

Bubbler

Dilution Flow

Inlet

Acoustic Sensor

Located downstream

Outlet

Back

Pressure

Controller

Reactor

MFC (Mass Flow Controller)

from Dilution Flow

2.1.3 Composer Elite Location Selection

2.1.3.1 Selecting The Acoustic Sensor Location

Locate the Acoustic Sensor at a point after the Dilution Flow gas is added and

before the Back Pressure Controller. (See Figure 2-2 on page 2-6.) This creates

the environment with the most stable pressure and flow conditions for best

Composer Elite stability. Positioning the Acoustic Sensor after the Dilution Flow

also simplifies calibration by making it easy to flow pure carrier gas through the

Acoustic Sensor to set the Reference Zero.

Figure 2-2 Basic integration with a reactor

2 - 6

The Acoustic Sensor may be installed in any orientation, however, INFICON

recommends the normal inlet and outlet tube convention (refer to Figure 2-2) be

followed. The inlet tube is substantially longer than the outlet tube to facilitate

temperature equalization. If the inlet and outlet tube connections are reversed,

there may be a small frequency or concentration offset when the total gas flow

through the sensor is varied.

Ventilation clearance is not required; however, the surface the Acoustic Sensor is

mounted to must be at least 5°C below Temperature Setpoint 1.

The dimension from inlet tube VCR-4 sealing surface to outlet tube VCR-4 sealing

surface is 124 mm (4.88 in.).

Acoustic Sensor installation or removal from process tubing requires side-to-side

or top-to-bottom clearance of 152.4 mm (6 in.) for wrench rotation.

Interconnect Cable installation or removal requires 76.2 mm (3 in.) clearance.

PN 074-566-P1B

Page 35

Composer Elite Operating Manual

WARNING

The Interconnect Cable route should be planned to minimize external electrical

interference. (Refer to section 2.1.2.4, Electrical Interference Reduction, on page

2-5.)

2.1.3.2 Selecting The Sensor Control Unit Location

The Sensor Control Unit is designed for bench top operation or mounting in a

standard 48.26 cm (19 in.) rack using the optional Full Rack Extender

(PN 782-900-007). Ventilation is adequate when operating on a bench top or when

installed in a standard rack using the optional Full Rack Extender.

If the Sensor Control Unit will not be mounted in a

standard rack, select a location where the Sensor Control

Unit is protected against falling to prevent instrument

damage and personal injury.

Sensor Control Unit removal from a standard rack requires 30.5 cm (12 in.)

clearance in front of the rack.

Clearance of 7.62 cm (3 in.) is required at the rear of the Sensor Control Unit for

installation or removal of Interconnect, Power Supply, RS-232, and DeviceNet

cables.

Sensor Control Unit location should be selected to minimize the length of the

grounding strap. (Refer to section 2.1.2.3, Composer Elite System Grounding

Requirement, on page 2-4.)

Interconnect Cable and communication cable routes should be planned to

minimize external electrical interference. (Refer to section 2.1.2.4, Electrical

Interference Reduction, on page 2-5.)

PN 074-566-P1B

2 - 7

Page 36

Composer Elite Operating Manual

CAUTION

2.2 Composer Elite Installation

2.2.1 Installing The Sensor Control Unit in a 19 in. (48.26 cm) Rack

Install the Sensor Control Unit in a standard 48.26 (19 in.) rack using the optional

Full Rack Extender (PN 782-900-007).

1 Assemble the two 7.62 x 12.7 cm (3 x 5 in.) Extender Kit side panels and the

larger front and rear panels into a box configuration using the eight 6-32

flat-head screws.

2 Thread two 10-32 shoulder screws from the inside of one of the box sides until

the threads extend fully to the outside.

3 Attach the Extender Kit to the Sensor Control Unit by threading the shoulder

screws into the matching holes in the Sensor Control Unit covers.

4 Attach the rack mounting ears with the 10-32 flat-head screws provided.

5 Carefully lift the assembly into a full width, 13.33 cm (5-1/4 in.) high rack space.

6 Attach the assembly to the rack using the necessary screws (not provided).

7 Connect the Sensor Control Unit to earth ground as described by section

2.1.2.3, Composer Elite System Grounding Requirement, on page 2-4.

Connect the Sensor Control Unit to earth ground as

described by section 2.1.2.3, Composer Elite System

Grounding Requirement, on page 2-4.

PN 074-566-P1B

2 - 8

Page 37

2.2.2 Installing The Acoustic Sensor

WARNING

CAUTION

CAUTION

CAUTION

Many gases used for film growth are toxic at very low

exposure levels.

Although the Acoustic Sensor was thoroughly leak

tested at the factory, periodic leak testing of the Acoustic

Sensor is recommended. See section 7.2, Leak Test

Procedures, on page 7-1.

1 Remove the caps from the VCR-4 fittings on the Acoustic Sensor's inlet and

outlet tubes by holding the fitting stationary with a 5/8 in. wrench while turning

the cap counterclockwise with a 3/4 in. wrench. Do not discard the caps.

Composer Elite Operating Manual

2 Remove and discard the gaskets from the VCR-4 fittings.

3 Mount the Acoustic Sensor securely to a rigid surface, using the four holes with

M4 thread, to prevent stress at the inlet and outlet tubing welds and seals. See

Figure 2-3 and Figure C-2 on page C-3.

Do not use the inlet and outlet tubing to support the

weight of the Acoustic Sensor.

PN 074-566-P1B

Figure 2-3 M4 mounting holes

Maximum allowable depth of screw penetration into the

M4 mounting holes is 6.4 mm (0.25 in.).

2 - 9

Page 38

Composer Elite Operating Manual

CAUTION

4 Install new VCR-4 gaskets (see section 7.3, Spare Parts, on page 7-5) into the

VCR fittings on the inlet and outlet tubes.

NOTE: Gaskets with retainers are directional and easily snap over the face of

the gland seal. (See Figure 2-4.)

Figure 2-4 Installation of gasket with retainer on gland

5 Connect the Acoustic Sensor to the process tubing using a 5/8 in. wrench to

tighten the VCR fittings on the inlet and outlet tubes while holding the VCR

fittings on the process tubing stationary with a wrench.

NOTE: Swagelok recommends tightening VCR type fittings 1/8 turn past

finger-tight for nickel and stainless steel gaskets.

Verify that the Acoustic Sensor is connected to earth

ground as described by section 2.1.2.3,

Composer Elite System Grounding Requirement, on

page 2-4.

PN 074-566-P1B

2 - 10

Page 39

Composer Elite Operating Manual

CAUTION

CAUTION

Power

Connector

Power

Switch

Ground

Stud

Sensor Card

Connector

DeviceNet

Connector

RS-232

Connector

2.2.3 Installing Interconnect, Power Supply, and Communications Cables

1 Set the Sensor Control Unit power switch to 0 (OFF). (See Figure 2-5.)

Composer Elite contains circuitry susceptible to

transient mains voltages. Make certain Composer Elite is

powered down whenever making any interface

connections.

Figure 2-5 Sensor control unit connections

PN 074-566-P1B

2 Connect the Interconnect Cable(s) male D-sub connector to the Sensor card(s)

connector. (Refer to Figure 2-5.) Tighten the thumb screws on the cable

connector to secure the cable to the Sensor card.

Make certain the Interconnect Cable D-sub connectors

are correctly oriented with the Sensor card / Acoustic

Sensor connectors to avoid damaging connector pins.

3 Connect the Interconnect Cable(s) female D-sub connector to the Acoustic

Sensor(s) connector. Tighten the thumb screws on the cable connector to

secure the cable to the Acoustic Sensor.

4 If applicable, connect the RS-232 cable to the Control card RS-232 connector,

or connect the DeviceNet cable to the Control card DeviceNet connector.

(Refer to Figure 2-5.)

2 - 11

Page 40

Composer Elite Operating Manual

5 Insert the 24 V Power Supply output-cable connector into the Sensor Control

Unit power connector until it locks in place. (Refer to Figure 2-5.)

6 Connect the power cord to the 24 V Power Supply inlet receptacle.

7 Connect the power cord plug to Mains power. (Refer to section 1.5.4.2, Rated

Input, on page 1-12.)

2.2.4 Installing Composer Elite Multi-Sensor Software

See section Chapter 6, Composer Elite Multi-Sensor Software, on page 6-1.

2 - 12

PN 074-566-P1B

Page 41

3.1 Initialization and Setup

1

2

3

4

5

6

7

Application-specific parameter values must be entered, or downloaded, to

Composer Elite. The parameters include the gases’ Specific Heat Ratios and

Molecular Weights.

3.1.1 Parameter Entry

Parameter values may be downloaded to Composer Elite by:

Composer Elite Multi-Sensor Software, see Chapter 6.

Remote communications using the protocol and commands in Chapter 5.

Composer Elite front panel.

Composer Elite Operating Manual

Chapter 3

Operation

3.1.1.1 Composer Elite Front Panel Parameter Entry

Composer Elite front panel parameter entry uses buttons 1 - 6 and the

Control Knob (7) shown in Figure 3-1. The function of the buttons vary, depending

on the screen displayed and parameter highlighted.

Figure 3-1 Front panel buttons

PN 074-566-P1B

When viewing editable parameters, Edit is available. Position the cursor on the

parameter to edit by rotating the control knob. Press Edit to change parameter

values. The left-most digit of the numerical parameter being edited will now be

highlighted in red. Use Next and Prev to highlight the digit to edit, then rotate the

3 - 1

Page 42

Composer Elite Operating Manual

control knob to change the value for that digit. To save the changes, press Save.

To cancel changes, press Cancel. See Figure 3-2 for an example of screen layout

while editing parameters.

Figure 3-2 Editing parameters

3.2 Calibration

Calibration obtains the exact frequency (speed of sound) for the carrier gas (or one

component of a mixture) for specific Composer Elite System operating conditions.

Calibration determines Reference Zero.

For many applications, Factory Zero is sufficient to provide the needed levels of

accuracy and reproducibility. Refer to section 4.1.3, How is Performance Affected

if I Use the Factory (Reference) Zero Value?, on page 4-2.

3.2.1 Frequency of Calibration

Applications requiring the highest degree of reproducibility should be calibrated

daily. Experience will determine if less frequent calibrations are appropriate. See:

When and How Often to Set the Reference Zero, section 4.1.2 on page 4-1

How is Performance Affected if I Use the Factory (Reference) Zero Value?,

section 4.1.3 on page 4-2

What Happens if the Reference Zero is Improperly Set?, section 4.1.10 on

page 4-8

PN 074-566-P1B

3 - 2

Page 43

3.2.2 Special Tools and Materials

Flowing a pure gas through the Acoustic Sensor at process pressure and flow rate

is required for calibration.

NOTE: For guaranteed safe operation, a calibrated high-performance mass

spectrometer leak detector should be used to check leak integrity

whenever the Acoustic Sensor has been removed and reinstalled.

3.2.3 How to Calibrate

1 In the Sensor Parameters pane, set ALLOW USER ZERO to YES.

2 Flow calibration gas, usually pure carrier gas, through the Acoustic Sensor at

normal operating pressure and flow rate.

3 Allow sufficient time for the calibration gas to cleanse any mixed gases out of

the Resonant Chamber. The carrier gas has displaced all of the formerly

contained gas mixes when the concentration stops changing.

4 STEADY and AT TEMP indicators will be displayed to indicate that the

concentration and cell temperature are stable.

Composer Elite Operating Manual

5 Set the new Reference Zero value by

On Composer Elite Multi-Sensor Software, click Zero Reference

On the Composer Elite front panel, on the Sensor window, press Zero

Reference

6 The new Reference Zero is displayed on screens as User Zero.

3.2.4 How To Revert To Factory Default Settings

Factory Zero is re-established by changing any parameter value affecting

concentration measurement, such as Acoustic Sensor Setpoint 1 Temperature,

Specific Heat Ratio or Molecular Weight or by pressing Reset Reference on the

PN 074-566-P1B

Composer Elite front panel on individual Sensor screens.

Composer Elite may be reset to the default parameters by holding 1 and 6 down

while powering up the instrument. Data Reset will be displayed on the Boot screen

if this is successful. Parameters Reset will be displayed on the Errors and

Warnings screen.

3 - 3

Page 44

Composer Elite Operating Manual

CAUTION

3.3 How To Use Composer Elite

The following sections explain how to start, stop, and power down Composer Elite.

A description and purpose of the operating modes, displays, and system I/O

connectors is also provided.

3.3.1 How to Power Up and Power Down Composer Elite

Operating Composer Elite requires a 24 V power connection. Refer to section 1.5.4

on page 1-11 for complete power specifications.

To power up Composer Elite,

1 Connect the 24 V(dc) power supply

(see section 1.5.4, Power Supply, on page 1-11).

2 Set the ON/OFF (I|O) power switch on the rear panel of the Sensor Control Unit

in the ON (I) position (see Figure 3-8 on page 3-14).

To power down Composer Elite, set the rear panel of the Sensor Control Unit in the

ON (I) position in the OFF(0) position.

When powering down Composer Elite, make sure the

precursor gases are completely purged from the

Acoustic Sensor. When power is removed from the

Sensor Control Unit, the Acoustic Sensor temperature

will cool to room temperature. If precursor gases are not

completely purged, condensation of precursor gas inside

the Acoustic Sensor may occur as the Acoustic Sensor

cools down.

PN 074-566-P1B

3 - 4

Page 45

Composer Elite Operating Manual

3.3.2 Composer Elite Screen Descriptions

Boot Screen, see section 3.3.2.1

Indicators Displayed On Screens, see section 3.3.2.2 on page 3-6

Overview Screen, see section 3.3.2.3 on page 3-6

System Overview Screen, see section 3.3.2.4 on page 3-8

Errors and Warnings Screen, see section 3.3.2.5 on page 3-9

Sensor Screen, see section 3.3.2.6 on page 3-10

Sensor Parameters Screen, see section 3.3.2.7 on page 3-12

3.3.2.1 Boot Screen

During power-up of the Sensor Control Unit, the INFICON logo is displayed. The

following information is briefly displayed before the System Overview screen is

displayed:

Version x.xx.xx HW x (Control card firmware version and hardware version)

Loading....... Please Wait (while Data, Sensor, and DeviceNet statuses are

being determined) followed by Loading....... Complete

Data Wait followed by:

Data OK (if parameter values were retained in memory)

Data Reset (if memory was cleared to factory default parameter values;

refer to section 3.2.4 on page 3-3)

Parameter Error (contact INFICON if this message appears)

Sensor Data Error (contact INFICON if this message appears)

System Data Error (contact INFICON if this message appears)

Searching followed by:

PN 074-566-P1B

DeviceNet Detected (if a DeviceNet module is installed in the Control card)

DeviceNet Not Detected (if a DeviceNet module is not installed)

DeviceNet Error (if there is a problem with the DeviceNet module)

Initializing followed by:

Sensor n Detected (for installed Sensor cards)

Sensor n Not Present (for empty Sensor card slots)

Sensor n Initialization Failed (if there is a problem with a Sensor card)

3 - 5

Page 46

Composer Elite Operating Manual

CAUTION

3.3.2.2 Indicators Displayed On Screens

AT TEMP . . . . . . . . . . . . . . . . . . . . . Indicates that the temperature is within

NEAR TEMP . . . . . . . . . . . . . . . . . . Indicates that the current temperature is near

BELOW TEMP. . . . . . . . . . . . . . . . . Indicates that the current temperature is

ABOVE TEMP . . . . . . . . . . . . . . . . . Indicates that the temperature is higher than

STEADY. . . . . . . . . . . . . . . . . . . . . . Indicates that the concentration for the last

±0.002°C of Temperature Setpoint 1 and

±0.005°C of Temperature Setpoint 2.

The text is displayed in green.

the desired temperature for Temperature

Setpoint 1. The text is displayed in blue.

below the desired temperature for

Temperature Setpoint 1. The text is

displayed in orange.

the desired temperature for Temperature

Setpoint 1. The text is displayed in red.

seven measurements have an average error

less than 0.5 Hz and the drift is less than

twice the error. The text is displayed in green.

3.3.2.3 Overview Screen

Composer Elite will attempt to measure concentration and control Acoustic Sensor

temperatures to setpoints whenever it is powered up. It will give correct readings

when the pressure is within the specified range and correct values for the gases’

Molecular Weights and Specific Heat Ratios that have been entered (see Table B-1

on page B-1) and Factory Zero is used.

If a new Reference Zero is required, section 3.2.3, How to

Calibrate, on page 3-3 must be followed for establishing

Reference Zero with the correct pure calibration gas or

incorrect concentration values will be calculated.

The Overview screen displays each of the five available sensor channels,

displaying sensor Concentration (Conc) and Temperature 1 and 2 (Temp) for all

five sensors (see Figure 3-3). Unoccupied sensor slots are displayed in grey.

Temperature value will be displayed as 99.999 for cards that are installed with no

sensor attached.

Indicators (described above in section 3.3.2.2) display when appropriate.

PN 074-566-P1B

3 - 6

Concentration is displayed in Mole%.

Page 47

Composer Elite Operating Manual

ERRORS, WARNINGS, or ERRS & WRNS may be displayed, depending on

whether errors, warnings, or both are present (see section 3.3.2.5). If no errors or

warnings are present, this area will be blank.

Figure 3-3 Overview screen

Buttons 1 through 5 represent Sensor 1 Data, Sensor 2 Data, etc. To enlarge and

view data for an individual sensor, press the button associated with that sensor

number to enter the Sensor screen. For example, press Sensor 1 Data to view

data for sensor 1.

System will display the System Overview screen.

PN 074-566-P1B

3 - 7

Page 48

Composer Elite Operating Manual

3.3.2.4 System Overview Screen

The System Overview screen displays information about the system’s hardware.

It displays remote communication port information such as the DeviceNet address

and the RS-232 Baud rate. It also displays the firmware version, hardware version,

and the version number and status for any installed sensor cards.

Figure 3-4 System Overview screen

Press Edit to edit the DeviceNet address and the DeviceNet Baud Rate.

The DeviceNet address can be adjusted to values of 0-63, appropriate to the

network topology. The default value is 63.

The DeviceNet Baud Rate can be changed to 125, 250, or 500 Kbps.

The default value is 125.

NOTE: RS-232 baud rate cannot be changed. It is always 115200 baud.

Pressing Overview will display the Overview screen.

Pressing Errors & Warnings will display the Errors and Warnings screen.

PN 074-566-P1B

3 - 8

Page 49

3.3.2.5 Errors and Warnings Screen

The Errors and Warnings screen displays current hardware errors or warnings.

The error is listed with its sensor number (if applicable) and its error code. Use the

control knob to scroll through the list of errors and/or warnings. At the bottom of the

screen is a description of the highlighted error/warning. Details on system errors

and warnings can be found in Table 5-22 on page 5-32 and Table 5-23 on page

5-34. A total of twelve errors and twelve warnings can be simultaneously displayed.

If more than twelve errors or warnings are present, a second page will display the

remaining errors.

Figure 3-5 Errors and Warnings screen

Composer Elite Operating Manual

Pressing Clear COR Errs & Wrns (when available) will clear any COR (Clear On

Read) errors or warnings present. See Table 5-22 on page 5-32 and Table 5-23 on

page 5-34 for more information about COR errors and warnings.

PN 074-566-P1B

Use Next Page and Prev Page to navigate from page to page if there are more

than twelve errors or warnings listed.

Overview will display the Overview screen.

Back will navigate back to the System Overview screen.

3 - 9