Page 1

OPERATING MANUAL

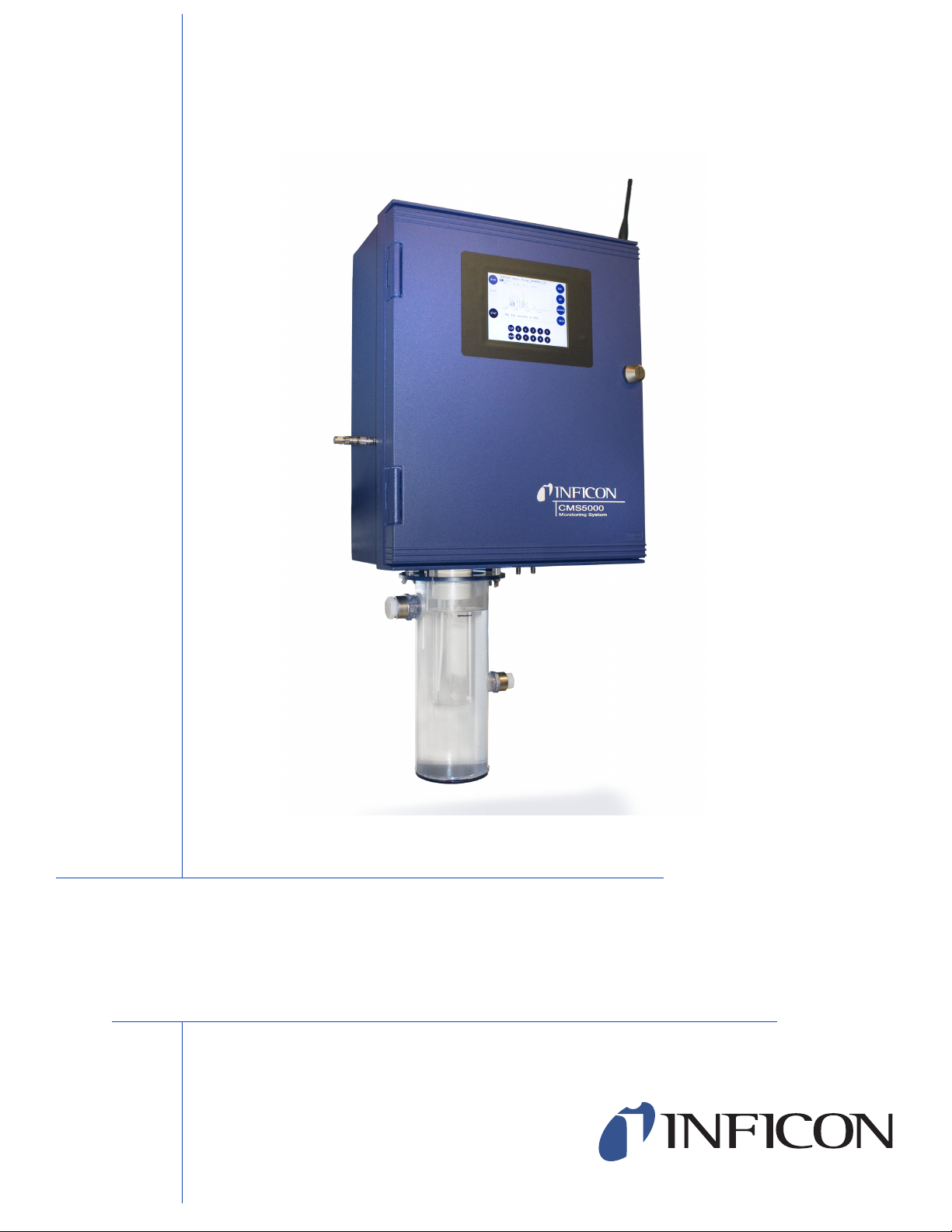

CMS5000 (shown in water sampling configuration)

CMS5000

Monitoring System

IPN 074-508-P1C

Page 2

Page 3

www.inficon.com reachus@inficon.com

Due to our continuing program of product improvements, specifications are subject to change without notice.

©2009 INFICON

TM

OPERATING MANUAL

CMS5000

Monitoring Syst

IPN 074-508-P1C

em

Page 4

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

INFICON® is a registered trademark of INFICON.

SWAGELOK® is a registered trademark of Swagelok Co.

Tygon® is a registered trademark of Saint-Gobain Performance Plastics.

Teflon® and Tedlar® are registered trademarks of Dupont.

PEEK™ is a trademark of Victrex plc.

Fischer Connectors® is a registered trademark of Fischer Connectors SA.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuous improvement program, specifications are subject to change without notice.

While photos are believed to be accurate and reliable, slight variations in equipment or software may occur.

Copyright

©2009 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

Page 5

Page 6

Page 7

Warranty

www.inficon.com reachus@inficon.com

INFICON warrants that the products sold by it are delivered free from any

defect in materials, workmanship and construction, and meet the products'

specifications set forth by INFICON.

INFICON warrants the products for one (1) year from the date of shipping

invoice of the products to the customer. The warranty excludes carrier gas,

GC columns, concentrator tubes, and all other items deemed by INFICON as

consumables. In the event the customer finds any defective products which do

not meet the aforesaid warranty, it shall give notice to that effect to INFICON.

The customer will return defective systems, accessories and parts to be

repaired to INFICON or INFICON contracted suppliers after obtaining a Return

Material Authorization (RMA) from INFICON Service Department.

INFICON liability under this warranty is limited to such products as are

returned, transportation prepaid, to INFICON plant no later than thirty (30)

days after the expiration of the warranty coverage and are found by INFICON

examination to have failed because of defective workmanship. At INFICON

election, it may either repair and return the product, or furnish a replacement

product, with transportation paid by INFICON in either case.

This warranty is made and accepted in lieu of all other warranties, express or

implied, whether of merchantability or of fitness for a particular purpose or

otherwise, as buyer's exclusive remedy for any defects in the product sold

hereunder. All other obligations and liabilities of INFICON, whether in contract

or tort (including negligence) or otherwise, are expressly excluded. In no event

shall INFICON be liable for any costs, expenses or damages, whether direct

or indirect, on any claim of defective product, in excess of the price paid by the

buyer for the products plus return transportation charges prepaid.

No warranty is made by INFICON for any INFICON product which has been

installed, used or operated contrary to INFICON written instruction manual or

which has been subject to misuse, negligence or accident, or has been

repaired or altered by anyone other than INFICON or which has been used in

a manner or for a purpose for which the product was not designed.

Page 8

Page 9

Chapter 1

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Gas Chromatograph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Micro Argon Ionization Detector (MAID). . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Radioactive Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Definition of Note, Hint, Danger, Warning

Chapter 2

2.1 Gas Chromatograph Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 MAID - Micro Argon Ionization Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.4 Physical Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.5 Analysis and Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

CMS5000 Operating Manual

Table Of Contents

Introduction

and Caution Paragraphs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Specifications

Chapter 3

System Setup

3.1 CMS5000 Feature Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.1 Analytical Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.2 Sampling Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.3 Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1.4 Ship Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.5 Laptop PC with CMS IQ Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 CMS5000 Ship Kit Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 CMS5000 Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

IPN 074-508-P1C

3.4 Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5 Water Monitoring Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.6 Attaching the Water Sampling Vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.7 Connecting the Water Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.8 Air Monitoring Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.8.1 Ambient Air Sampling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.8.2 Air Line Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.9 Connecting the Argon Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.10 Connecting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.11 Communication Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.11.1 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

3.11.2 I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

TOC - 1

Page 10

Chapter 4

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Setting Up Laptop Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Configuring the CMS5000 for Laptop Communications. . . . . . . . . . . . . . . . 4-4

Chapter 5

5.1 Software Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Calibrating the Check Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Calibrating the Water or Air Purge Methods. . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.4 FTP Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.5 System Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.6 Setting Startup Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

5.7 Input Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.8 Method Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

CMS5000 Operating Manual

Setting Up Laptop Communication

Software Setup

Chapter 6

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 SYS Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 TIME Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 NET Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.5 STAT Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.6 FIRM Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Chapter 7

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Default Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.3 System Calibration Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.4 Operating the CMS5000 using the Front Panel . . . . . . . . . . . . . . . . . . . . . . 7-1

Chapter 8

8.1 Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Status Button

Operation

IPN 074-508-P1C

Review Data

TOC - 2

Page 11

CMS5000 Operating Manual

Chapter 9

System Option

9.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.2 System Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.3 Set Date, Time and Time Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.3.1 Set Network Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.3.2 Set Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Chapter 10

Exit Option

10.1 Exit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Accessing Exit Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

10.3 Restart System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

10.4 Reboot System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

10.5 Return to Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Chapter 11

CMS IQ System Setup

11.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

11.2 System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.2.1 System Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

11.2.2 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

11.2.2.1 Generate Trend Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11.2.3 Functions Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-7

11.2.4 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

11.2.4.1 Port Settings Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-9

11.2.4.2 Display Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-10

11.2.4.3 Miscellaneous Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

11.2.5 Tools Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-18

IPN 074-508-P1C

11.2.5.1 Set Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-18

11.2.5.1.1 Changing Access Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-19

11.2.5.1.2 Setting or Changing the Access Level Password. . . . . . . . . . . . . . . . . . . 11-20

11.2.6 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-21

11.2.7 Window Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-22

11.2.8 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

11.3 System Setup Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-23

11.4 Safety DB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-26

11.5 Manage Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-30

11.6 Status Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-34

11.6.1 Status Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-35

TOC - 3

Page 12

CMS5000 Operating Manual

11.6.2 CMS5000 Time Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-36

11.6.3 CMS5000 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-40

11.6.4 Pressure Flows and Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-41

11.6.5 Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-44

11.6.6 Data Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-45

11.6.7 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-48

11.6.8 Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-49

11.7 Front Panel Display Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-54

11.8 CMS5000 Sensor Status Icon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-55

11.8.1 Update CMS5000 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-55

11.8.2 Bring Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-56

11.8.2.1 Communication Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-56

11.8.3 Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-56

Chapter 12

Data Review Screen

12.1 Introduction to Data Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.2 Accessing the Data Review Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.3 Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

12.3.1 Data Review Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

12.4 Data Review Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

12.5 Data File Information Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

12.6 Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

12.6.1 Access Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

12.6.2 Summary Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

12.6.3 Quantitative Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-7

12.7 Chromatogram Window Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

12.7.1 Manual Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

12.7.2 View All Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-12

12.7.3 View Temperature Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

12.7.4 Change Plot Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

12.7.5 Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

12.7.5.1 Search for Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

IPN 074-508-P1C

12.7.5.1.1 Add Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

12.7.5.1.2 Peak Search Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

12.7.5.1.3 Redo Peak Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

12.7.5.1.4 Report Preview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-17

12.7.5.2 Show/Update Current Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-18

12.7.5.3 Edit Base Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-18

12.7.5.4 Clear the Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-20

TOC - 4

Page 13

CMS5000 Operating Manual

12.7.5.5 Label the Peaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21

12.7.5.6 Change Search Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-21

12.7.5.7 Previous Search Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-22

12.7.6 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-24

12.7.7 Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-25

12.8 How to Access the Scan Cursor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-25

12.9 Using the Zoom Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-26

12.10 Range Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-31

12.10.1 Selecting a Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-34

Chapter 13

Run Method

13.1 Run Method Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Chapter 14

Chromatogram Overlay

14.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.2 Chromatogram Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.3 Chromatogram Subtract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

Chapter 15

Method Editor

15.1 The Method Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-1

15.2 Accessing Method Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-3

15.3 Description Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

15.4 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-5

15.4.1 CMS5000 Temperatures (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

15.4.2 Method Type Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-6

15.5 Inlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-6

IPN 074-508-P1C

15.5.1 Inlet States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

15.5.2 GC Temperature Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-11

15.5.3 Scan Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-12

15.6 Search Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-13

15.6.1 Setting Up a Quantitative Search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-14

15.7 Data Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

15.7.1 Data File Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

15.7.2 Date and Time Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-17

15.7.3 Use Default Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-19

15.7.4 Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-19

15.8 Summary Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-20

15.9 Saving a Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-21

TOC - 5

Page 14

Chapter 16

16.1 Introduction To Quantitative Analysis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

16.2 Using the Calibrate Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-2

16.3 Glossary of Terms in the Calibrate Window . . . . . . . . . . . . . . . . . . . . . . . 16-17

16.3.1 Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

16.3.2 Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-18

16.3.3 Peak Search Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

16.3.4 Calibrate Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

16.3.5 Analytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

16.3.6 View Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-20

16.3.7 Calibrate Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-21

Appendix A

A.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

A.2 CMS5000API.H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

CMS5000 Operating Manual

Creating Calibration Libraries

Ethernet Integration

TOC - 6

IPN 074-508-P1C

Page 15

1.1 Introduction

WARNING

Partition Coefficient

VOC

water

VOC

gas

------------------------=

The CMS5000 Monitoring System provides online water or air monitoring for the

detection and analysis of VOCs. The programmable sample collection system

allows for on-site, rapid analysis of current air or water conditions without the need

for pre-treatment or filtration.

CMS5000 Operating Manual

Chapter 1

Introduction

Due to U.S. Nuclear Regulatory Commission regulations,

the CMS5000 oven, which contains a sealed radioactive

source, may not be repaired by unauthorized personnel.

INFICON will provide the maintenance, repair,

replacement and disposal of the radioactive source, as

well as any part of the detector.

For water analysis, VOCs are purged from the water flowing through the water

vessel. Argon will bubble into the water, the gas bubbles will rise through the water

and collect at the top of the collection tube. As the bubbles rise, a portion of the

VOCs will pass from the water phase to the gas phase — this is known as

"partitioning". The ratio of the VOC concentration in the water phase, VOC

the concentration in the gas phase, VOC

equation [1].

IPN 074-508-P1C

Each compound will partition according to its solubility in water, its vapor pressure,

the specific water sampling matrix and the temperature. The quantity of VOCs

detected is dependent on the partition coefficient. In general, highly polar

compounds are more readily detected than less polar compounds.

A permeation tube that contains toluene is used as a check standard to ensure

proper system calibration and verify sample integrity. It will compensate for normal

fluctuations in the column, the concentrator and detector sensitivity. The lifetime of

the permeation tube is approximately 8 years.

After collection, the VOCs from the air or water samples are drawn into the

CMS5000 with the internal pump and adsorbed by the concentrator. The VOCs are

then desorbed into the column of the gas chromatograph by heating the

concentrator and reversing the carrier gas flow.

, is the partition coefficient. See

gas

water,

to

[1]

1 - 1

Page 16

CMS5000 Operating Manual

1.2 Gas Chromatograph

The gas chromatograph (GC) performs a time separation of the sample

compounds. The separation order is primarily based on increasing compound

boiling point.

Argon is used as the carrier gas to transport analytes through a 100%

dimethylpolysiloxane, 0.32 mm id, 30 M, 4.0 µm (or equivalent) column. The inside

of the column is coated with a thin layer of material known as the stationary phase.

The stationary phase selectively attracts components in a sample mixture. The

mixture of sample compounds in the argon gas, also known as the mobile phase,

interact with the chemicals of the stationary phase. The chemicals which spend the

least time partitioned in the column will elute (exit) off the column first.

The time taken by an individual compound to travel into the system until the

compound elutes from the column is referred to as the retention time (RT). If the

GC conditions remain constant, the same compound will elute from the column at

nearly the same retention time for each injection.

The performance of the column is affected by temperature, therefore, the column

is housed in a temperature controlled oven. The oven is programmed to increase

the temperature gradually (called ramping) to improve compound separation while

decreasing analysis time. As the temperature increases, the compounds with the

lowest boiling points will elute first with the standard non-polar phase coated

column installed.

A chromatogram of eluting organic gases from the gas chromatograph is plotted as

a function of time from the injection the compound mixture. The chromatogram

depicts the separation of the various compounds from each other by the action of

the gas chromatograph, as described above.

1.3 Micro Argon Ionization Detector (MAID)

The Micro Argon Ionization Detector (MAID) is sensitive to organic compounds

having an ionization potential of 11.7 eV or lower, which includes halomethanes,

haloethanes, carbon tetrachloride and 1,1,1-trichloroethane. The CMS5000 can

detect these compounds, as well as other hydrocarbons, to parts-per trillion (PPT)

levels.

The MAID uses argon as a carrier gas. When argon flows over a nickel-63 (Ni-63)

source, argon atoms are energized to an excited, metastable state, while other

argon atoms are ionized. The excitation energy of argon is approximately 11.7 eV.

Ar

Ar* (Energized to excited state)

IPN 074-508-P1C

1 - 2

Page 17

When an organic molecule (R) enters the detector, it collides with the metastable

WARNING

argon (Ar*). During this collision, energy is released to the organic molecule. Since

the ionization potential of most organic compounds is less than 11.7 eV, the

metastable argon atoms will ionize them, producing positive ions and electrons.

The reaction is illustrated as follows:

Ar* + R

Ar + R + e

High voltage applied across the detector produces a current, which is amplified and

measured to produce a chromatogram.

1.4 Radioactive Source

The MAID in the CMS5000 contains a radioactive isotope in a solid form of Ni-63,

with an activity level of up to 2.4 millicuries. The half-life of Ni-63 is approximately

96 years. The source of the radioactivity is sealed within a stainless steel cylinder

which is located within the detector cavity. Per New York State radioactive materials

license regulations, a wipe test is required for the Ni-63 source every 36 months.

The first test is completed at the factory prior to shipment.

CMS5000 Operating Manual

-

No repair of the detector cell should be performed by the

user. If the detector cell does not exhibit an electronic

signal, the isotope may require replacement. Contact

INFICON for repair or replacement of the detector cell.

The State of New York Department of Labor, Division of Safety and Health and the

United States Nuclear Regulatory Commission under either a Specific License or a

General License authorizes possession and use of the radioactive source in the

instrument. A copy of the terms and requirements of a General Licensee (section

12 NYCRR, part 38:41, table 3, item b) accompanied INFICON transfer of this

instrument. The safety requirements of the Specific License or General License are

designed to protect the user and the public from unnecessary prolonged exposure

IPN 074-508-P1C

to radiation. Following these requirements is imperative.

1 - 3

Page 18

CMS5000 Operating Manual

WARNING

WARNING - Risk Of Electric Shock

CAUTION

1.5 Definition of Note, Hint, Danger, Warning and Caution Paragraphs

NOTE: This is a note paragraph. Notes provide additional information about the

current topic.

HINT: This is a hint paragraph. Hints provide insight into product usage

This is a Warning paragraph. It warns of actions that may

cause physical injury.

This Warning paragraph warns of the presence of

electrical voltages which may cause physical injury.

This is a Caution paragraph. It cautions against actions

which may damage the instrument or lead to the loss of

data.

IPN 074-508-P1C

1 - 4

Page 19

2.1 Gas Chromatograph Specifications

Column . . . . . . . . . . . . . . . . . . . . . . . 100% dimethylpolysiloxane, 0.32 mm id,

4.0

µm df or equivalent

Valves . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel body/Teflon diaphragm

Temperature Programmable

Column Module . . . . . . . . . . . . . . . . 55-200

Carrier Gas. . . . . . . . . . . . . . . . . . . . Argon 99.9999% @ 414-689 kPa

(60-100 psi)

Variable Column Pressure Control . . Regulator pre-set to 90 psi

Sample Inlet . . . . . . . . . . . . . . . . . . . Water Vessel with purge-and-trap SituProbe

Air Sampling Tube

CMS5000 Operating Manual

Chapter 2

Specifications

°C

2.2 MAID - Micro Argon Ionization Detector

Temperature . . . . . . . . . . . . . . . . . . . Maximum 110°C

Sensitivity . . . . . . . . . . . . . . . . . . . . . 0.5 ppb Benzene in water, s/n > 200:1

0.5 ppb MTBE in water, s/n > 15:1

Detection Limit . . . . . . . . . . . . . . . . . PPB- PPT in air

Dynamic Range . . . . . . . . . . . . . . . . 3 decades

Stability . . . . . . . . . . . . . . . . . . . . . . . 5 runs of 5 ppb Benzene in air and water:

RSD calculated <15%

Radioactive Source . . . . . . . . . . . . . 2.4 mCi Ni-63

IPN 074-508-P1C

2.3 Communication

Integration . . . . . . . . . . . . . . . . . . . . TCP/IP based

USB for local diagnostics

I/O Relay Contacts

FTP. . . . . . . . . . . . . . . . . . . . . . . . . . Configurable for automated data upload

Storage/Archival . . . . . . . . . . . . . . . . 16 GB Flash Drive

System Status . . . . . . . . . . . . . . . . . Status table for system operating changes

Wireless Connectivity . . . . . . . . . . . . 802.11 B/G

Optional Touch Screen . . . . . . . . . . . 6.5" VGA color display with touch screen

2 - 1

Page 20

CMS5000 Operating Manual

2.4 Physical Operating Requirements

Size . . . . . . . . . . . . . . . . . . . . . . . . . 16.9 in x 32.7 in x 10.2 in

(43 cm x 83 cm x 26 cm)

Weight . . . . . . . . . . . . . . . . . . . . . . . 55.1 lb (25 kg)

Power . . . . . . . . . . . . . . . . . . . . . . . . 120-240 V(ac)

Temperature . . . . . . . . . . . . . . . . . . . 5

2.5 Analysis and Protocols

Integrated Performance Standard . . Toluene permeation tube for check standard

Detectable Compounds . . . . . . . . . . Volatile organic compounds

Acceptance Protocol . . . . . . . . . . . . Initial setup with BTEX standard

Data Analysis . . . . . . . . . . . . . . . . . . Automatic peak detection and area

°C to 45°C (ambient and water

temperature)

calibration

(e.g. halogenated and non-halogenated

aliphatic and aromatic hydrocarbons, etc.)

integration for known compounds

2 - 2

IPN 074-508-P1C

Page 21

3.1 CMS5000 Feature Options

3.1.1 Analytical Unit

CMS5000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .935-600-G1

3.1.2 Sampling Source

Water, No Vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .935-700-G1

Water, Standard Vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . .935-700-G3

Air, Sampling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 935-701-G1

3.1.3 Integration

CMS5000 Operating Manual

Chapter 3

System Setup

Ethernet, 802.11g, Wireless . . . . . . . . . . . . . . . . . . . . . . . . .935-710-G1

I/O Relays and 3’ cable, Ethernet, and 802.11g Wireless . . 935-711-G1

3.1.4 Ship Kits

CMS5000 120 V (USA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 935-721-G1

CMS5000 230 V (European) . . . . . . . . . . . . . . . . . . . . . . . .935-721-G2

CMS5000 230 V (UK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .935-721-G3

CMS5000 230 V (China) . . . . . . . . . . . . . . . . . . . . . . . . . . . 935-721-G4

3.1.5 Laptop PC with CMS IQ Software

IPN 074-508-P1C

CMS IQ Software, No Laptop. . . . . . . . . . . . . . . . . . . . . . . .935-030-G1

Laptop w/CMS IQ Software (USA) . . . . . . . . . . . . . . . . . . . .935-731-G1

Laptop w/CMS IQ Software (European). . . . . . . . . . . . . . . .935-731-G2

Laptop w/CMS IQ Software (UK) . . . . . . . . . . . . . . . . . . . . .935-731-G3

Laptop w/CMS IQ Software (China) . . . . . . . . . . . . . . . . . . .935-731-G4

3 - 1

Page 22

CMS5000 Operating Manual

3.2 CMS5000 Ship Kit Contents

The Ship Kit will contain the following items:

Power Supply . . . . . . . . . . . . . . . . . . 930-469-P1 (110 V USA)

Ethernet Cable . . . . . . . . . . . . . . . . . 600-1319-P2

CMS5000 Operator Manual . . . . . . . 074-508-P1

Argon Tank Regulator . . . . . . . . . . . 935-412-P1

Argon Fill Line . . . . . . . . . . . . . . . . . 935-212-G1

Quick Disconnect Stem . . . . . . . . . . 059-0329

CMS5000 Training CD . . . . . . . . . . . 074-5020-G1

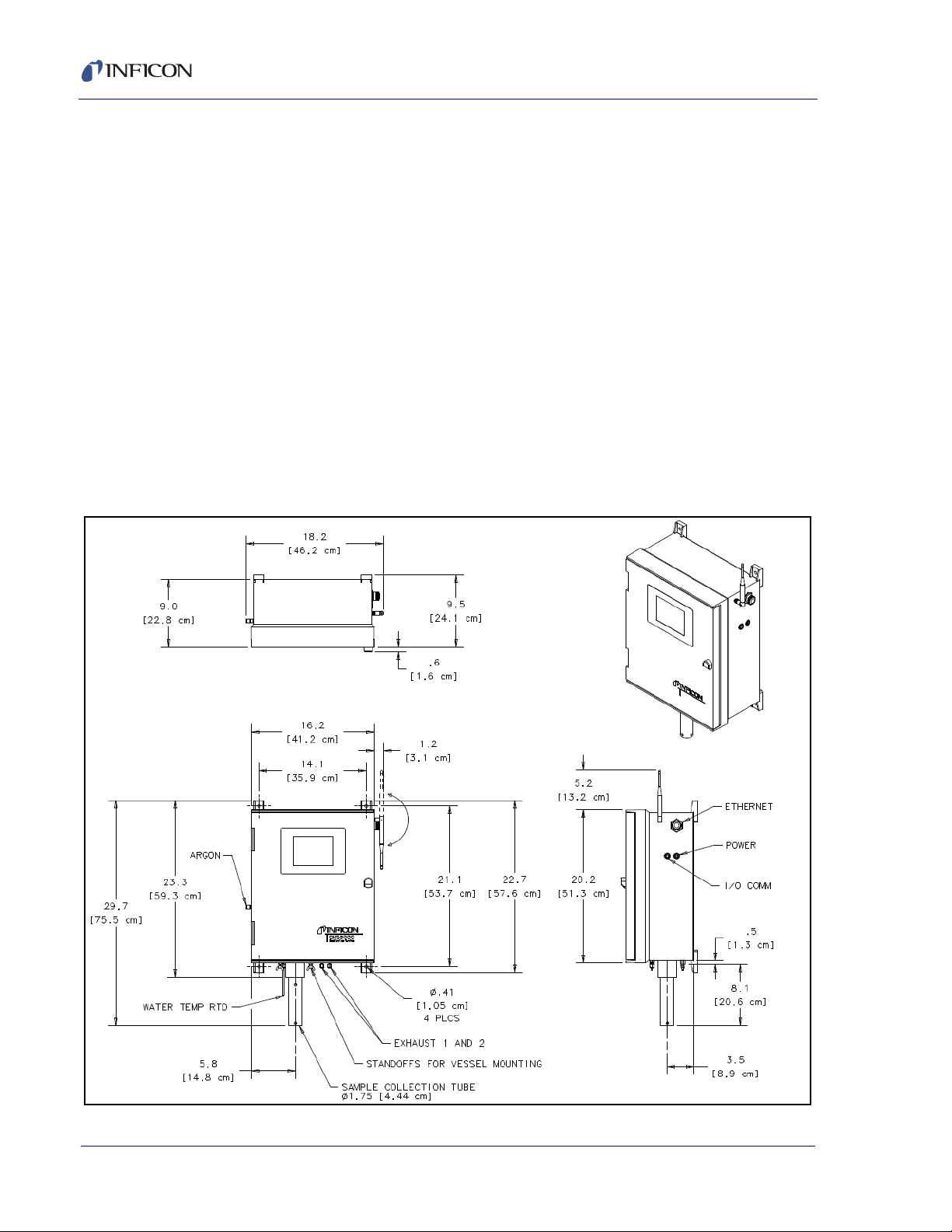

3.3 CMS5000 Diagram

930-469-G4 (230 V China)

930-469-P2 (230 V European)

930-469-G3 (230 V UK)

3 - 2

IPN 074-508-P1C

Page 23

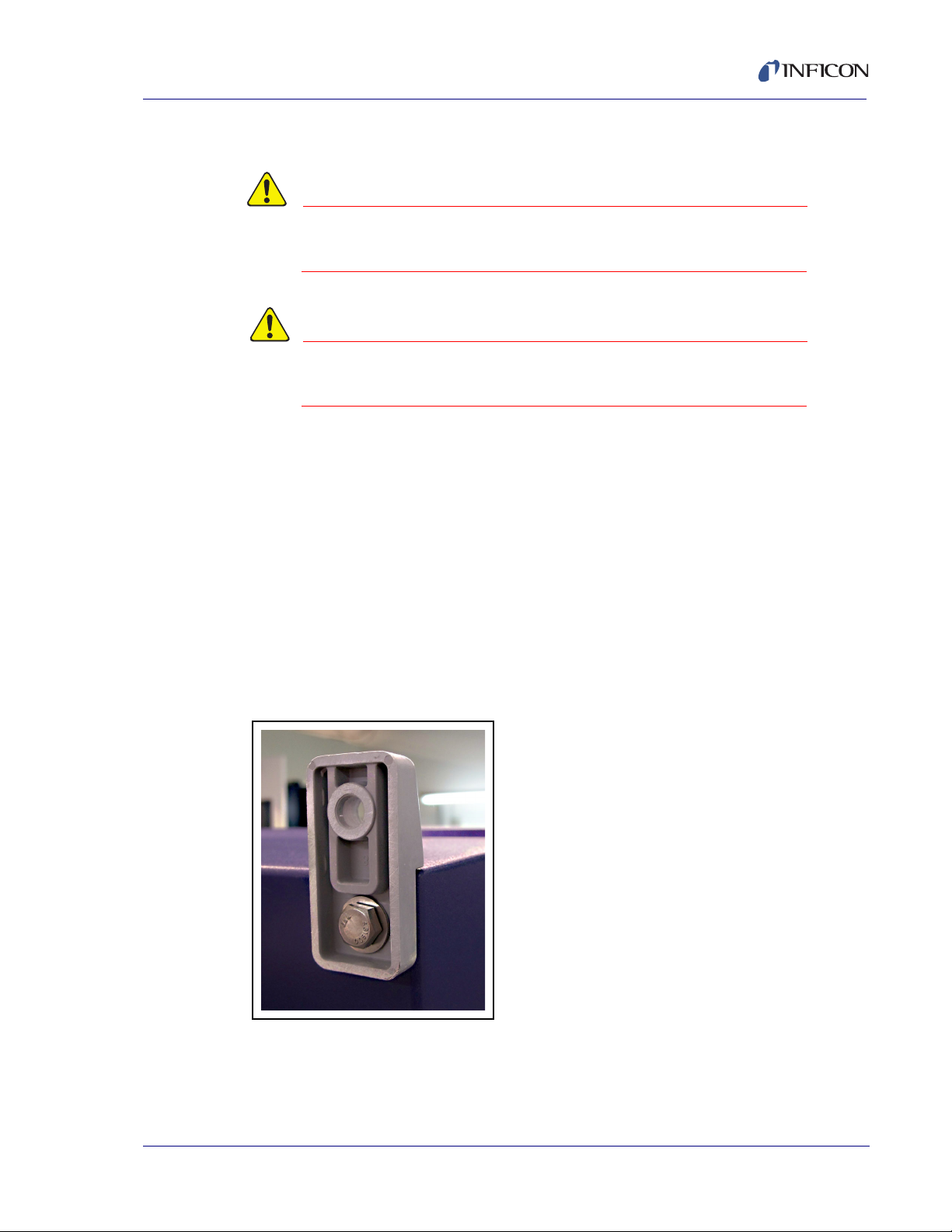

3.4 Mounting Instructions

CAUTION

WARNING

Installation of the CMS5000 must be performed by an

INFICON authorized technician.

The CMS5000 Monitoring System is heavy. Use proper

saftey procedures and PPE when mounting the unit.

NOTE: After the CMS5000 has been powered on, the system should only be

operated with the door closed to ensure stability of heated internal

components

The CMS5000 Monitoring System requires mounting as well as some minor

assembly. The four mounting brackets included in the ship kit need to be attached

to the four corners on the back of the unit. Position the bracket on the analytical

module by lining up the openings in the bracket and on the unit. Place the washer

over the lag bolt and using a socket wrench, screw in the lag bolt until tight (see

page 5 of the instructions included with the hardware). See Figure 3-1.

CMS5000 Operating Manual

NOTE: The nuts included with the lag bolts are not needed to mount the brackets

to the unit.

Figure 3-1 Attaching the Mounting Brackets

IPN 074-508-P1C

Structural mounting hardware is not included. It is the responsibility of the user to

ensure that proper mounting hardware is used to support the weight of the

CMS5000, and (if the CMS5000 is to be used for continual online water monitoring)

3 - 3

Page 24

CMS5000 Operating Manual

the filled sampling vessel. The CMS5000 weighs 55.1 lbs. (25 kg). All plumbing to

and from the sampling vessel should be supported independently of the analytical

module, as the system design will not support any additional weight.

For air monitoring, the CMS5000 should be mounted in an optimal location for

collecting air samples of interest. Care should be exercised to avoid locations

affected by air currents from heating or cooling systems, doors, windows or

structural openings.

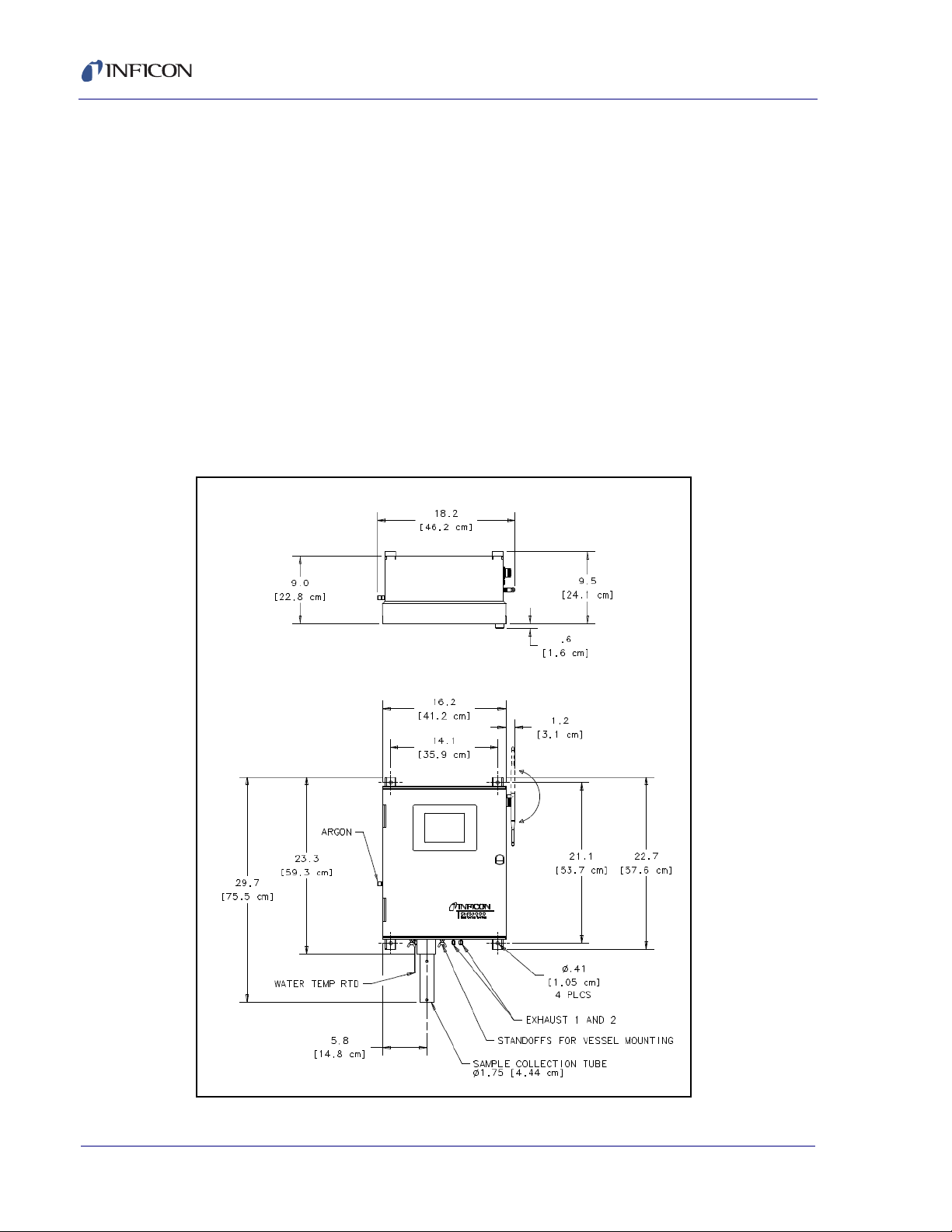

To ensure proper operation when utilizing the CMS5000 for continuous water

monitoring, it is necessary to determine optimal mounting height and unit

placement to accommodate both the water intake as well as allow for clearance for

the sample collection tube when attaching and removing the sampling vessel.

Allow a minimum of a 15” (38.1 cm) clearance below the mounted sampling vessel

for vessel removal. Verify that the CMS5000 is level when mounted and that the

slope is less than five percent. See Figure 3-2.

Figure 3-2 Dimensions for Mounting the CMS5000

3 - 4

IPN 074-508-P1C

Page 25

CMS5000 Operating Manual

3.5 Water Monitoring Assembly Instructions

If not using the CMS5000 for water monitoring, skip to section 3.8 on page 3-8.

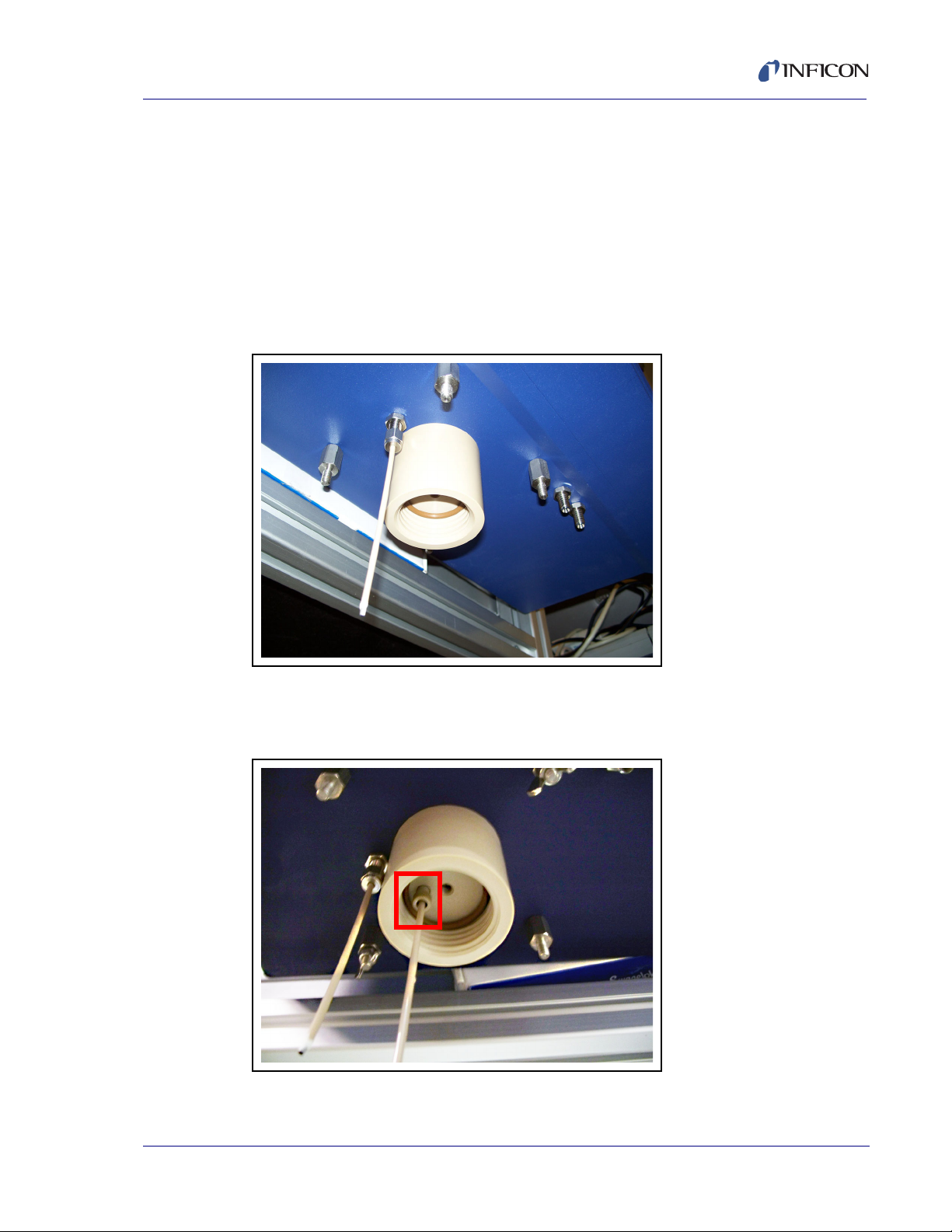

The temperature sensor, or RTD, will be unfastened and taped to the bottom of the

CMS5000 for shipment. Remove the tape, guide the excess wire back into the

CMS5000, and screw the stainless steel nut into the port nearest to the beige

sample collection tube mounting bracket located on the bottom of the CMS5000.

The Swagelok® fitting should be tightened 1/4 turn past finger tight using a 7/16”

open end wrench. See Figure 3-3.

Figure 3-3 Attaching the Temperature Sensor

The PEEK purge tube (found in the ship kit) is attached to the middle port in the

beige sample collection tube mounting bracket. See Figure 3-4.

Figure 3-4 Attaching the PEEK Purge Tube

IPN 074-508-P1C

3 - 5

Page 26

CMS5000 Operating Manual

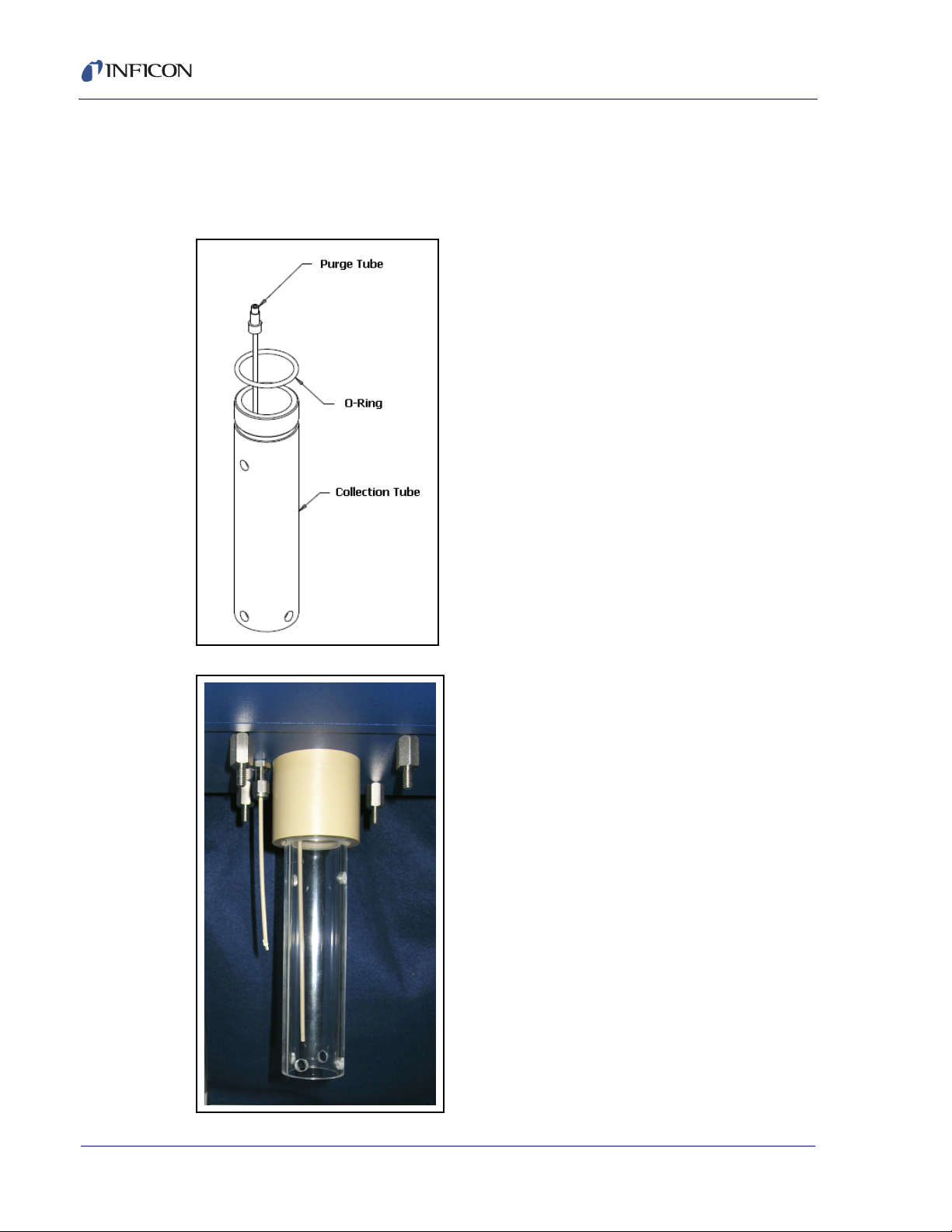

Install the collection tube o-ring into the beige sample collection tube mounting

bracket. Screw the clear acrylic sample collection tube from the ship kit into the

beige sample collection tube mounting bracket located on the bottom of the

CMS5000 until finger tight. Do not over tighten. See Figure 3-5 and Figure 3-6.

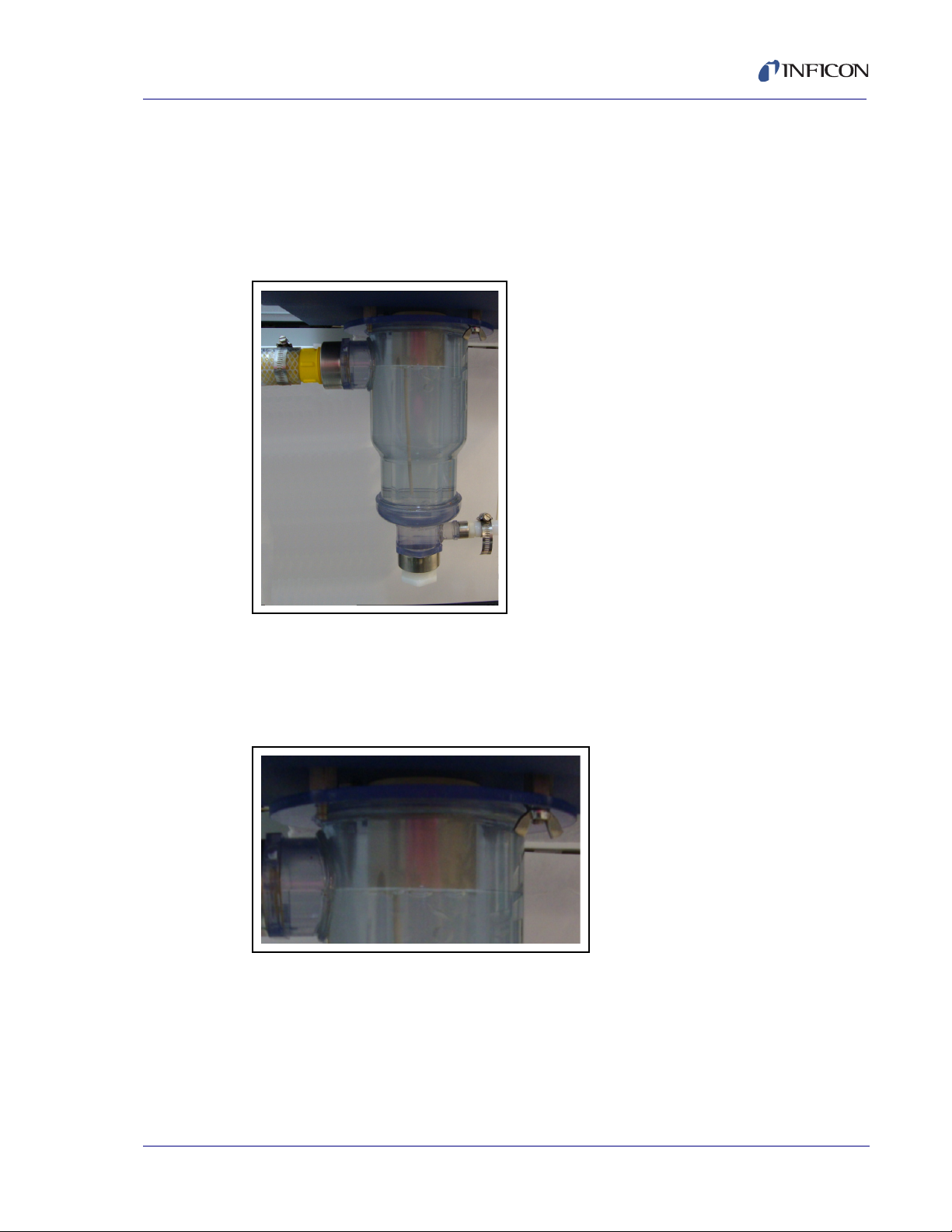

Figure 3-5 Attaching the sample collection tube

Figure 3-6 Attached Sample Tube

IPN 074-508-P1C

3 - 6

Page 27

CMS5000 Operating Manual

3.6 Attaching the Water Sampling Vessel

NOTE: If you are not using the CMS5000 for water monitoring, skip sections

section 3.6 and section 3.7.

The optional sampling vessel mounts to the bottom of the CMS5000 using the wing

nuts supplied in the sampling source kit. See Figure 3-7.

Figure 3-7 Optional Sampling Vessel

Attach the sampling vessel to the CMS5000 by aligning the screws with the four

openings on the flange of the sampling vessel. Hold the vessel against the

mounting screw standoffs and screw on the wing nuts to hold the sampling vessel

in place. See Figure 3-8.

Figure 3-8 Attaching the Sampling Vessel

IPN 074-508-P1C

The function of the standoffs is to provide spacing between the CMS5000 and the

vessel to allow water overflow to prevent water from entering the analytical module.

See Figure 3-9.

3 - 7

Page 28

CMS5000 Operating Manual

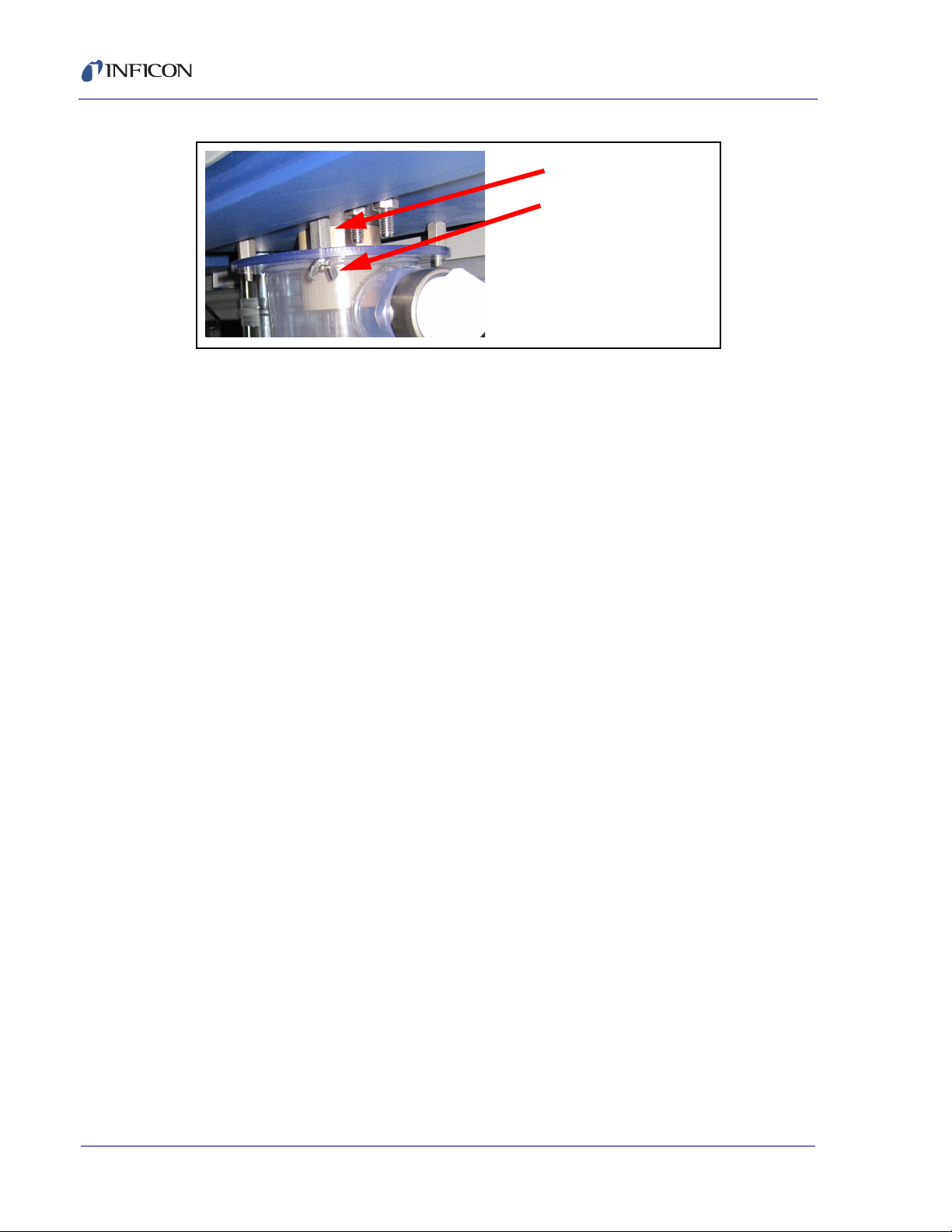

Standoffs

Wingnuts

Figure 3-9 Standoffs for Overflow

3.7 Connecting the Water Supply

If not using the CMS5000 for water monitoring, skip this section.

It is the responsibility of the integrator to configure any and all plumbing. Care

should be taken to support the weight of all plumbing hoses and hardware

independently of the CMS5000.

3.8 Air Monitoring Assembly Instructions

The CMS5000 easily converts to a continuous Air Monitoring System via two

configurations. The first configuration, designed for ambient air sampling, requires

the user to replace the water collection tube with a air collection tube with attached

filter. The filter at the opening of the collection tube prevents large particulates in

the sampling environment from entering the system.The second configuration is

designed for in-line air sampling. This configuration is more complex.

IPN 074-508-P1C

3 - 8

Page 29

3.8.1 Ambient Air Sampling

Ambient air sampling requires only the Air Sampling Tube (Figure 3-10). See

Figure 3-10.

Figure 3-10 CMS5000 Air Sampling Tube

Attach the Air Sampling Tube. See Figure 3-11.

CMS5000 Operating Manual

Figure 3-11 CMS5000 with Air Sampling Tube Attached

IPN 074-508-P1C

3 - 9

Page 30

CMS5000 Operating Manual

Center Port

Air Monitoring

Sample Inlet Line

Configuration

3.8.2 Air Line Sampling

Preparing the CMS5000 is more intensive for this type of sampling. First, attach a

sampling inlet line with a 1/8" compression fitting (with ferrule). In the example, the

purge line is removed from the center port (Figure 3-12) and moved to the right port

to become the Sample Inlet Line (Figure 3-13).

Figure 3-12 Purge Line in Position for Water Sampling

Figure 3-13 Sample Inlet Line in Postition for Air Sampling

IPN 074-508-P1C

3 - 10

Page 31

CMS5000 Operating Manual

CAUTION

Sample

Compression

Fitting

Sample Inlet

Exhaust Line

Detector

Exhaust

If switching from air line sampling to water sampling,

carefully move the purge tube back to the proper inlet.

Placing the sample inlet line in the wrong port will allow

water to be drawn into the CMS5000 and will cause

severe damage to the unit.

The pressure of the sample in the air line must be greater than exhaust of the

CMS5000 but no more than 1 atm. This will prevent any back pressure from

re-entering the sample path and collecting more sample than necessary onto the

concentrator. Sample flow is directional, and when the pressure changes the flow

also changes. The exhaust line is attached to the exhaust port via a compression

fitting (see Figure 3-14). The exhaust line should have at least the same internal

diameter as the sample inlet.

Figure 3-14 Exhaust Line Attached

IPN 074-508-P1C

An example of air line sampling setup is shown in Figure 3-15.

Figure 3-15 Example Air Line Sampling Setup

3 - 11

Page 32

CMS5000 Operating Manual

3.9 Connecting the Argon Supply

It is the responsibility of the user to provide the argon supply. An ultra high purity

source of argon (99.99999%) is required for optimal operation of the MAID. The

included regulator is preset at the factory to the required pressure (90 psi). Connect

the argon supply to the CMS5000 using the included Teflon argon supply line and

the quick connect valve. The fitting for the quick connect is located on the left side

of the mounted analytical module. See Figure 3-16.

Figure 3-16 Connecting the Argon Supply to the CMS5000

3 - 12

IPN 074-508-P1C

Page 33

3.10 Connecting the Power Supply

Power Supply

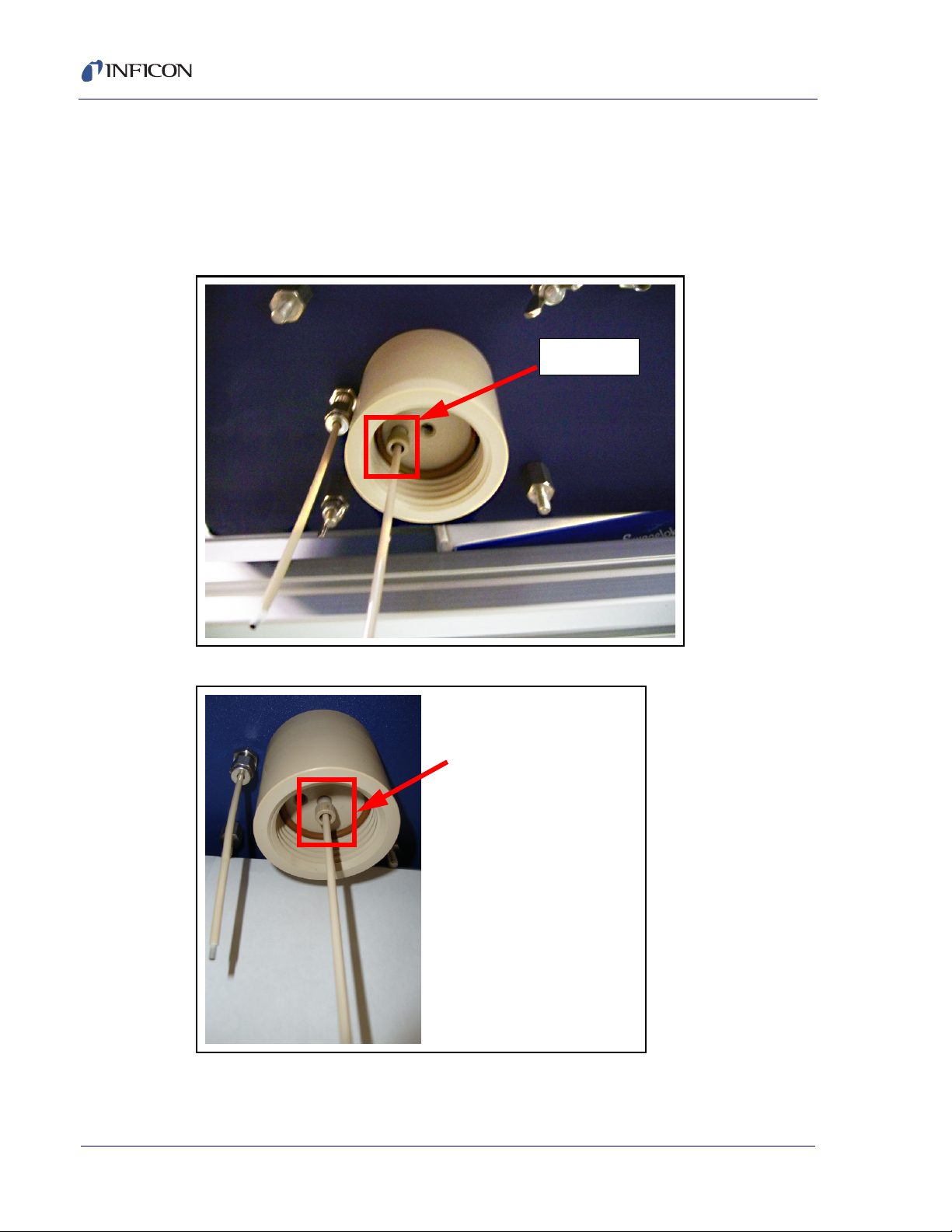

Connect the 4 pin Fischer Connector® from the power supply to the 4 pin

receptacle near the rear of the upper right side of the CMS5000. Connect the plug

end of the power supply to electrical outlet. The CMS5000 will power on

automatically. The CMS5000 does not have an “on” switch. See Figure 3-17.

Figure 3-17 Connecting the Power Supply

CMS5000 Operating Manual

NOTE: The CMS5000 contains an onboard permeation tube for internal

calibration. The permeation tube is designed to continually emit toluene at

a particular rate. During shipments, power outages, or prolonged periods

of time when the CMS5000 is powered off, the permeation tube will

continue to emit toluene, thus causing a buildup of toluene within the

CMS5000. This is normal and expected. To compensate for this buildup, it

is necessary to run the CMS5000 with an argon purge for a period of

approximately 24 hours to allow the permeation tube to equilibrate. The

permeation tube is considered to be equilibrated when a stable response

for toluene is observed from consecutive runs of the check standard

calibration method. See Chapter 5, Software Setup for information on

calibrating the check standard.

IPN 074-508-P1C

3 - 13

Page 34

CMS5000 Operating Manual

Ethernet

I/O

3.11 Communication Configuration

Select the desired communication configuration from the selections below.

3.11.1 Ethernet

The Ethernet port used to connect the CMS5000 to a PC or network is located on

the upper right side of the CMS5000, next to the wireless antenna. Plug the end of

the Ethernet cable with the water tight cap into the CMS5000 and plug the other

end into a PC or network. See Figure 3-18.

3.11.2 I/O

The multi-pin I/O cable receptacle is located on the right side of the CMS5000 next

to the power supply receptacle. Plug the multi-pin Fischer Connector from the I/O

cable into the CMS5000 and configure the other end of the cable as desired. See

Figure 3-18.

Figure 3-18 Connecting the Ethernet and I/O

3 - 14

IPN 074-508-P1C

Page 35

Setting Up Laptop Communication

4.1 Introduction

Communication must be established between the CMS5000 and the PC in order

to run analysis and review data from the laptop. It is necessary to use the laptop to

calibrate the CMS5000 methods and setup software parameters.

4.1.1 Setting Up Laptop Communications

NOTE: Setting up communication is an Advanced User function. To change the

access level, see section 11.2.5.1, Set Access Level, on page 11-18.

1 Open CMS IQ Software. From the System drop-down menu, select

Properties. See Figure 4-1.

Figure 4-1 Selecting Properties from the System Drop-down Menu

CMS5000 Operating Manual

Chapter 4

2 Click the CMS5000 List button. See Figure 4-2.

Figure 4-2 CMS5000 List Button

IPN 074-508-P1C

4 - 1

Page 36

CMS5000 Operating Manual

3 Enter the IP Address for the CMS5000 into the Enter New CMS5000 Name or

IP Address. (The IP Address can be found on the Front Panel of the CMS5000

by touching STAT Scroll down using the DOWN key to select NET.) See section

6.4, NET Option, on page 6-2. An example of an IP address is 10.210.50.116.

Click Add. See Figure 4-3.

Figure 4-3 Add CMS5000

4 The newly added CMS5000 will be displayed in the CMS5000 List.

Double-click OK.

Figure 4-4 Closing the CMS5000/TCP Window

IPN 074-508-P1C

4 - 2

Page 37

CMS5000 Operating Manual

5 Press OK on the System Properties Window.

Figure 4-5 Closing the System Properties Window

6 The newly added CMS5000 icon will now be displayed at the bottom of the

System Setup Screen. If the CMS5000 is displayed without an "X", as in Figure

4-6, communication has been established.

Figure 4-6 Newly Added CMS5000

6a If the CMS5000 is overlaid with a red "X", the CMS5000 is not properly

communicating with the Laptop. If the CMS5000 icon is overlaid with a blue "X",

communication has not been fully established. See Figure 4-8 and Figure 4-8.

Figure 4-7 CMS5000 Not Properly Communicating with the Laptop

IPN 074-508-P1C

Figure 4-8 Communication Has Not Been Established Between CMS5000 and Laptop

4 - 3

Page 38

CMS5000 Operating Manual

NOTE: If a communication error has occurred, which is indicated by an "X",

contact the system administrator or integrator. If not available, follow the

instructions in Configuring the CMS5000 for Laptop Communications, see

section 4.1.2.

4.1.2 Configuring the CMS5000 for Laptop Communications

1 Touch the STAT key on the front panel of the CMS5000 to display the STATUS

page. See Figure 4-9.

Figure 4-9 STATKey

2 Use the DOWN key to highlight NET and touch SEL. See Figure 4-10.

Figure 4-10 Accessing NET Screen

IPN 074-508-P1C

4 - 4

Page 39

CMS5000 Operating Manual

3 Each CMS5000 will have a unique IP address. An example of an IP address is

10.210.50.107. The subnet mask is also displayed on the NET page. An

example of a subnet mask is 255.252.0.0. See Figure 4-11.

Figure 4-11 NET Page

4 On the PC, click the Windows Explorer Start button. See Figure 4-12.

Figure 4-12 Start

4a Mouse over Settings and click Network Connections. See Figure 4-13.

Figure 4-13 Network Connections

IPN 074-508-P1C

4 - 5

Page 40

CMS5000 Operating Manual

5 Double-click on the desired connection. Choose Local Area Connection to

connect with an Ethernet cable. Choose Wireless Connection to connect

wirelessly.

Figure 4-14 Select Connection

6 The Connection Status window will open. Click Properties. See Figure 4-15.

Figure 4-15 Local Area Connection Status Window

4 - 6

IPN 074-508-P1C

Page 41

CMS5000 Operating Manual

7 In the General tab, scroll down and highlight Internet Protocol (TCP/IP), click

Properties. See Figure 4-16.

Figure 4-16 Selecting Internet Protocol (TCP/IP)

8 Select Use the following IP address. Enter the first number of the IP address

into the first slot. For example, if the IP address is 10.210.50.107, enter 10 into

the first slot. Refer to Step 2 on page 16-3 to find the IP address on the

CMS5000. See Figure 4-17.

Figure 4-17 Entering First Number of IP Address

IPN 074-508-P1C

4 - 7

Page 42

CMS5000 Operating Manual

9 For the second number of the IP address, enter 210 if connecting with the

cable, or 209 if connecting with the wireless radio, into the second slot. See

Figure 4-18.

Figure 4-18 Entering Second Number of IP Address

10 For the third number of the IP address, add 128 (the maximum total number is

255) to the number in the IP address. In this example, adding 128 to 50 equals

178, so 178 is entered into the third slot. See Figure 4-19.

NOTE: If the total third number is greater than 255, add 5 to the original third

number.

Figure 4-19 Entering Third Number of IP Address

IPN 074-508-P1C

4 - 8

Page 43

CMS5000 Operating Manual

11 The fourth number of the IP address is entered into the fourth slot without

modification. Therefore, in this example, 50 would be entered into the fourth

slot. See Figure 4-20.

Figure 4-20 Entering Fourth Number of IP Address

12 Press OK in the Internet Protocol Properties window to close. See Figure

4-21.

Figure 4-21 Closing the Internet Protocol Properties Window

IPN 074-508-P1C

4 - 9

Page 44

CMS5000 Operating Manual

13 Communication between the CMS5000 and the Laptop is now established as

indicated by the absence of an "X" over the CMS5000 Sensor in the System

Setup Screen. See Figure 4-22.

Figure 4-22 Active CMS5000 Sensor Icon

4 - 10

IPN 074-508-P1C

Page 45

5.1 Software Setup

Prior to running continuous analyses, CMS5000 methods require calibration. This

chapter provides instructions for calibrating the Check Standard method, the Water

Purge method, and the Air Purge method.

Various software parameters will need to be established in order to operate the

CMS5000 and retrieve data. This includes entering startup and input methods,

setting up the FTP server(s) and if desired, sequencing methods.

5.2 Calibrating the Check Standard

1 Run the check standard method, CMS5000 Ck Std. See Chapter 7, Operation

for information on running a method.

CMS5000 Operating Manual

Chapter 5

Software Setup

NOTE: The onboard toluene permeation tube is considered to be equilibrated

when a stable response for toluene is observed. Consecutive runs of

the check standard method may need to be run until the toluene

response is stable.

2 The finished run will look similar to the chromatogram shown in Figure 5-1.

Figure 5-1 Check Standard Method Run

IPN 074-508-P1C

3 When the method has finished running, open CMS IQ on the PC.

Figure 5-2 CMS IQ

5 - 1

Page 46

CMS5000 Operating Manual

4 Click on the Calibrate button on the top toolbar. See Figure 5-3.

Figure 5-3 Calibrate Button

5 Double-click to select the desired method. See Figure 5-4.

Figure 5-4 Selecting Method for Calibration

6 A screen similar to Figure 5-5 will be displayed.

Figure 5-5 Calibrate Screen

IPN 074-508-P1C

5 - 2

Page 47

CMS5000 Operating Manual

NOTE: To change the selected method, use the top Browse button in the

Method section on the left hand side of the screen. See Figure 5-6.

Figure 5-6 Browse Button

7 Click the Browse button in the Data Files section to enter a data file. See

Figure 5-7.

Figure 5-7 Data File Browse Button

IPN 074-508-P1C

5 - 3

Page 48

CMS5000 Operating Manual

8 Select the data file generated from the method run in step 1. To locate the file,

first select the data folder for the method. Then, select the individual data file.

See Figure 5-8 and Figure 5-9.

Figure 5-8 Method Data Folder

Figure 5-9 Individual Data File

IPN 074-508-P1C

5 - 4

Page 49

CMS5000 Operating Manual

9 Verify that toluene is the only component in the library. See Figure 5-10.

Figure 5-10 Is Check Std Library Box

NOTE: If the Methods Differ message is displayed, verify that the differing

parameters are acceptable and click Yes. If the parameters are not

acceptable, run a calibration sample with the exact method selected in

the Method box and use that data file. See Figure 5-11.

Figure 5-11 Methods Differ Message

IPN 074-508-P1C

inconsistent. This message is displayed because units for the data files have

yet to be selected. Click OK to continue. See Figure 5-12.

Figure 5-12 Inconsistent Data Files

5 - 5

10 A message will be displayed stating that the units between the data files are

Page 50

CMS5000 Operating Manual

11 The data file will be loaded into the Data Files list. See Figure 5-13.

NOTE: Only one file should be loaded into this list.

Figure 5-13 Data File List

12 Check the Reset Library box. Checking this box will reset the calibration curve

by deleting all points currently contained in the library. See Figure 5-14.

Figure 5-14 Reset Library

IPN 074-508-P1C

5 - 6

Page 51

CMS5000 Operating Manual

13 In the Conc/Factor column, set the concentration to 1. See Figure 5-15.

Figure 5-15 Conc/Factor Column

14 Check the Selection box to process this data file. See Figure 5-16.

Figure 5-16 Selection Box

IPN 074-508-P1C

5 - 7

Page 52

CMS5000 Operating Manual

15 Underneath Peak Search, verify that Search is selected. Click on Start to run

the calibration. See Figure 5-17.

Figure 5-17 Running Calibration

16 Click on the Analytes in File tab to view the area counts for the data file.

Ensure that an area count is displayed for the analyte. Then, save the method

by clicking Save. See Figure 5-18.

Figure 5-18 Analytes in File Tab

17 The check standard calibration is now complete.

IPN 074-508-P1C

5 - 8

Page 53

CMS5000 Operating Manual

5.3 Calibrating the Water or Air Purge Methods

1 Both CMS5000 Water Purge and Air Purge methods requires calibration at

initial startup. Susbsequent calibrations may be performed as necessary.

NOTE: In the CMS5000 Water Purge method, the actual water temperature is

recorded during calibration-the CMS IQ software uses the Beta Value

to automatically compensate for the water sample temperature

fluctuations.

2 Refer to section 16.2, Using the Calibrate Function, and follow steps 1-11 to

prepare and run standards for the calibration.

NOTE: The water temperature of the calibration standards needs to be

uniform when creating water calibration methods.

3 Verify that the retention times of the analytes in the standard with the highest

concentration correspond to the retention times in the library template

associated with the method.

3a To select a peak, follow the instructions in section 12.8, How to Access the

Scan Cursor, on page 12-25. See Figure 5-19.

Figure 5-19 Selecting a Peak

4 The actual retention times should be within +/- 0.5 seconds of the library

retention times

5 Refer to section 16.2, Using the Calibrate Function, and follow steps 22-23.

IPN 074-508-P1C

6 Refer to section 16.2, Using the Calibrate Function, and follow steps 27-37.

7 Perform an initial calibration verification of the CMS5000 Water Purge method

by running the calibration standard at a concentration within the limits of the

calibration curve. See Chapter 7, Operation, for information on running a

method.

8 Refer to section 16.3.6, View Reports, to access the report of the calibration

verification standard. Verify that the reported concentration is within 30% of the

actual concentration.

5 - 9

Page 54

CMS5000 Operating Manual

5.4 FTP Connection

Up to three FTP servers, each with its own unique IP address, user name and

password, can be configured to upload data files and can be enabled or disabled

independently. If a FTP server is enabled, the CMS5000 will maintain a queue on

which to upload data files. After each run, the CMS5000 will upload the files onto

the queues. If the CMS5000 cannot connect or login to an FTP server, the data file

will be stored in the queue until another data file is ready to be uploaded. At this

point, the CMS5000 will attempt to upload both the new and the previous data file.

If there is a loss of power, the data files will continue to be stored in the queues.

However, if a data file is deleted by a user prior to uploading, the CMS5000 will not

transfer the file to the FTP server. The CMS5000 also has an option to clear the

files in the queue if the data is no longer desired.

1 Verify that the PC will connect to the FTP server. If the PC can connect to both

the FTP server and the CMS5000, it can be configured to upload data files.

2 To verify the connection, first open Internet Explorer. See Figure 5-20.

Figure 5-20 FTP Server

5 - 10

IPN 074-508-P1C

Page 55

CMS5000 Operating Manual

3 Type in the FTP address of the server using the following format: "ftp://<ip

address>". See Figure 5-21.

Figure 5-21 FTP Server

4 Enter the Username and Password of the ftp server. Click Log On. See Figure

5-22.

Figure 5-22 Entering Username and Password

IPN 074-508-P1C

5 - 11

Page 56

CMS5000 Operating Manual

5 When the PC connects to the FTP site, the screen will look similar to the one

that is displayed in Figure 5-23. Once the connection has been verified, this

screen can be closed by clicking the "X" button.

Figure 5-23 FTP Site

6 Open CMS IQ which is located on the desktop. See Figure 5-24.

Figure 5-24 CMS IQ Icon

7 Click the Status icon. See Figure 5-25.

Figure 5-25 Status Icon

IPN 074-508-P1C

5 - 12

Page 57

CMS5000 Operating Manual

8 Click on the Data Settings tab. See Figure 5-26.

Figure 5-26 Data Settings Tab

9 Click on the Configure FTP Settings button. See Figure 5-27.

Figure 5-27 Configure FTP Settings

IPN 074-508-P1C

5 - 13

Page 58

CMS5000 Operating Manual

10 Enable the number of FTP servers to upload by checking the Enable FTP

boxes. Note that FTP1 is enabled as default. Up to three FTP servers can be

uploaded. See Figure 5-28.

Figure 5-28 FTP Config Window

5 - 14

IPN 074-508-P1C

Page 59

CMS5000 Operating Manual

11 Enter in the FTP server information including FTP Server IP address,

username, and password. Also enter the Connection Timeout (the amount of

time the CMS5000 will wait for a response from the FTP site), the Upload

Timeout (the allotted time for a single file to upload), and the # of Upload

Retries (the number of times the CMS5000 will attempt to communicate with

the FTP server if the Upload Timeout is reached).

NOTE: The State will be indicated as Standby mode . When the CMS5000 is

actively transmitting data to the FTP server, the State will indicate

Running. See Figure 5-29.

Figure 5-29 Entering FTP Server Information

IPN 074-508-P1C

5 - 15

Page 60

CMS5000 Operating Manual

12 Click on the Network Settings button. See Figure 5-30.

Figure 5-30 Network Settings

13 To locate the Network Gateway, click on the start button on the desktop. See

Figure 5-31.

Figure 5-31 Start Button

14 Select Run... from the menu. See Figure 5-32.

Figure 5-32 Run

IPN 074-508-P1C

5 - 16

Page 61

CMS5000 Operating Manual

15 The Run window will be displayed. See Figure 5-33.

Figure 5-33 Run Window

16 Type in cmd and click OK. See Figure 5-34.

Figure 5-34 CMD

17 At command prompts on the PC, enter route PRINT to verify the default

Network Gateway setting. See Figure 5-35.

Figure 5-35 route PRINT

18 The default gateway will be displayed. See Figure 5-36.

IPN 074-508-P1C

Figure 5-36 Default Gateway

5 - 17

Page 62

CMS5000 Operating Manual

19 Enter in the Network Gateway settings. See Figure 5-37 and Figure 5-38.

Figure 5-37 Network Gateway Settings

Figure 5-38 Entering Network Gateway Settings

20 The number at the bottom of the screen should match the Network Gateway

setting in CMS IQ. If not, re-enter the Network Gateway setting displayed on

the PC into CMS IQ. See Figure 5-39.

Figure 5-39 Matching Gateway Settings

5 - 18

IPN 074-508-P1C

21 Accept the Network Gateway settings by clicking OK. See Figure 5-40.

Figure 5-40 Accepting Network Gateway Settings

Page 63

CMS5000 Operating Manual

22 Accept the FTP Server settings by clicking OK. See Figure 5-41.

Figure 5-41 FTP Server Settings

23 Click OK to exit the Properties screen. See Figure 5-42.

Figure 5-42 Exiting the Properties Screen

IPN 074-508-P1C

24 FTP site is now setup and communicating.

5 - 19

Page 64

CMS5000 Operating Manual

5.5 System Integration

The current system I/O integration allows only input commands. This includes the

selection and start of a method created in the CMS IQ software. See section 5.6,

Setting Startup Methods, for details on how to input methods. For more advanced

integration details, please contact INFICON.

5.6 Setting Startup Methods

The CMS5000 can be operated automatically. In the Parameters tab, a Startup

Method, a method that will automatically run when powering on the system, can

be selected. Additionally, a method sequence can be selected as a startup method.

See section 5.8 on page 5-25 for information on creating a method sequence.

1 Double-click the Status icon, which is located on the System Setup screen of

CMS IQ. See Figure 5-43.

Figure 5-43 Status Icon

2 Click on the Parameters tab. See Figure 5-44.

Figure 5-44 Parameters Tab

IPN 074-508-P1C

5 - 20

Page 65

CMS5000 Operating Manual

3 Click on the Browse button for the startup method. See Figure 5-45.

Figure 5-45 Browse Button

4 Double-click on the desired method from the method folder or highlight the

method and click OK. See Figure 5-46.

Figure 5-46 Choosing Startup Method

IPN 074-508-P1C

5 - 21

Page 66

CMS5000 Operating Manual

5 The chosen method will be displayed. See Figure 5-47.

Figure 5-47 Startup Method

6 To clear the startup method, click on Clear Startup Method. See Figure 5-48.

Figure 5-48 Clear Startup Method

5 - 22

IPN 074-508-P1C

Page 67

5.7 Input Methods

In the Input/Output tab, up to four input methods can be selected. An input method

will begin when a relay contact, which has been integrated into the water/air control

system, triggers its start. Also, a method sequence can be selected as an input

method. See section 5.8 on page 5-25 for information on creating a method

sequence.

1 To enter input methods, click the appropriate Browse button. See Figure 5-49.

Figure 5-49 Input Browse Buttons

CMS5000 Operating Manual

2 Double-click on the desired method from the method folder. See Figure 5-50.

Figure 5-50 Choosing Input Method

IPN 074-508-P1C

5 - 23

Page 68

CMS5000 Operating Manual

3 The selected input method will appear in the Input 1 Method field. To clear the

input method, click the Browse button for the desired method.

See Figure 5-51.

Figure 5-51 Clearing Input Method

4 Click X without selecting a method. See Figure 5-52.

Figure 5-52 Clicking "X"

5 - 24

IPN 074-508-P1C

Page 69

5 The method will be cleared from the selected input method line.

See Figure 5-53.

Figure 5-53 Method Cleared

5.8 Method Sequence

CMS5000 Operating Manual

A series of methods can be selected to run at timed intervals, which includes

consecutive runs. Once the series has been started, it can run unattended and

unprompted until the sequence has finished. Follow the instructions below to

create a method sequence.

1 From the CMS IQ Setup screen, double-click the Method Editor icon.

See Figure 5-54.

Figure 5-54 Method Editor Icon

2 The Edit Method window will be displayed. Click on Method Sequence.

IPN 074-508-P1C

See Figure 5-55.

Figure 5-55 Edit Method Window

5 - 25

Page 70

CMS5000 Operating Manual

3 In the Method Name box, type in a name for the method sequence or use the

name provided. Verify that the file extension for the method name is .xmth.

See Figure 5-56.

Figure 5-56 Method Name Box

4 Click the Method Sequence (...) button. See 4.

Figure 5-57 Adding Method File

IPN 074-508-P1C

5 - 26

Page 71

CMS5000 Operating Manual

5 A list of methods will be displayed. Double-click the desired method for

sequencing. See Figure 5-58.

Figure 5-58 Selecting Method to Sequence

6 The selected method will be displayed in the method sequence list. See Figure

5-59.

Figure 5-59 Selected Method

IPN 074-508-P1C

5 - 27

Page 72

CMS5000 Operating Manual

7 In the Start Run column, choose either Run Button or Immediately for each

method. This selection determines how each method in the run is started. See

Figure 5-60.

NOTE: If the Run Button option is selected, the run button will have to be

pressed each time. If Immediately is selected, the method will

automatically commence.

Figure 5-60 Start Column Selection

8 In the End Run column, choose Sleep for or Sleep until for each method. See

Figure 5-61.

NOTE: The Sleep for option is used to enter a time period, such as one hour.

The Sleep until option is for a specific time, such as one o’clock.

Figure 5-61 Sleep Column

IPN 074-508-P1C

5 - 28

Page 73

CMS5000 Operating Manual

9 In the End Run column, enter the desired time for the next method to start or

the length of time to sleep before the next method starts. See Figure 5-62.

NOTE: Enter 0:00:00 to run the next method as soon as the previous one has

finished.

Figure 5-62 Time Column

10 Repeat steps 4-9 to add additional methods for sequencing. Alternately,

right-click anywhere in the windowand select Duplicate Row. See Figure 5-63.

Figure 5-63 Duplicate Row

IPN 074-508-P1C

11 When the desired sequence has been entered, the user can either enter a

number up to repeat the sequence a set number of times (Number of

Iterations, see Figure 5-64), or run a continuous loop of the sequence without

stopping (Run Continuously, see Figure 5-65).

5 - 29

Page 74

CMS5000 Operating Manual

NOTE: When using Run Continuously, the Number of Iterations option is

grayed out. See Figure 5-65.

Figure 5-64 Number of Iterations

Figure 5-65 Run Continuously

IPN 074-508-P1C

5 - 30

Page 75

CMS5000 Operating Manual

12 Click Save when all the desired methods have been entered. See Figure 5-66.

Figure 5-66 Saving the Method Sequence

13 Save the method sequence to the desired location. Click OK. See Figure 5-67.

Figure 5-67 Save Method Sequence

IPN 074-508-P1C

5 - 31

Page 76

CMS5000 Operating Manual

This page is intentionally blank.

5 - 32

IPN 074-508-P1C

Page 77

6.1 Introduction

The STAT button provides real time data regarding various system parameters.

These parameters include the SYS (system) option, the TIME (time) option, the

NET (network) option, the STAT (status) option and the FIRM (firmware) option.

6.2 SYS Option

The first option, SYS, provides system information including the Hostname, Serial

Num (Number), Ver sion number, Built on (build date), Free Disk space, and the

Startup method. The Hostname is used for PC communication, and the Serial

Num is the serial number of the unit that is used for identification. Version displays

the version of CMS5000 software that is loaded onto the system. The date and time

that the software was released is located in the Built on field. Free Disk is the

amount of free disk space available for data storage and the last entry is the

Startup which is the method that will automatically run when turning on the unit.

See Figure 6-1. Navigate through the SYS options by using the UP and DOWN

buttons.

CMS5000 Operating Manual

Chapter 6

Status Button

Figure 6-1 SYS Option

IPN 074-508-P1C

6 - 1

Page 78

CMS5000 Operating Manual

IP Address

Subnet Mask

6.3 TIME Option

The TIME option gives Date, Time (in a 24 hour format) and Time Zone

information. This option is used to timestamp the data files. See Figure 5-2. If the

time is incorrect, see section 9.3, Set Date, Time and Time Zone, on page 9-3 for

instructions.

Figure 6-2 TIME Option

6.4 NET Option

The NET option displays the IP Address, Subnet Mask, and the User Host. The

IP address and subnet mask can be used to set up communication between a

CMS5000 and a PC. This communication will allow for data to be transferred from

the CMS5000 to the PC for analysis and storage. The User Host is the laptop that

is communicating with CMS5000. See Figure 6-3.

Figure 6-3 NET Option

IPN 074-508-P1C

6 - 2

Page 79

6.5 STAT Option

The STAT option displays temperature information and carrier gas pressure. This

includes the current temperatures and the setpoint temperatures of the Regulator

Heater, Check Standard, Valve Oven, Column, Detector (MAID), and the Argon

Supply pressure. The state of the heaters will be shown, as well, with ctrl

indicating that the heaters are within 2 degrees of their setpoint. The temperature

of the water sample and the temperature of the card cage, which holds the boards

of the unit, are located beneath the temperatures of the heated components. The

pressure of the argon carrier gas is the last listing on the screen. See Figure 6-4.

NOTE: If the argon pressure is 380 kPa or less, a low-pressure warning will

Figure 6-4 STAT Option

CMS5000 Operating Manual

appear. When the pressure drops to 350 kPa, a low pressure error

message will be displayed.

6.6 FIRM Option

The FIRM option displays the firmware version for the gas chromatograph (GC)

and the front panel (FP). See Figure 6-5.

IPN 074-508-P1C

Figure 6-5 FIRM Option

6 - 3

Page 80

CMS5000 Operating Manual

This page is intentionally blank.

6 - 4

IPN 074-508-P1C

Page 81

7.1 Introduction

The CMS5000 can be programmed to operate uninterrupted or at timed intervals,

either through remote operation or through the front panel. Following a method run,

analysis results can be uploaded onto an FTP site allowing for data review at an

off-site location. The results are also stored directly onto the hard drive of the

CMS5000 unit.

The CMS5000 will commence sampling the air sample or the headspace above the

water sample at the beginning of the method run. The results will be shown on the

front panel during the run. If accessing data from a remote location, the results will

be available immediately following the method run.

7.2 Default Methods

Default methods are included with the CMS5000. The CMS5000 Ck Std method

verifies that the retention time and the response of the internal calibration standard

is within range. The CMS5000 Water Purge method detects specifically selected

VOCs during water monitoring. The CMS5000 Air Purge method detects

specifically selected VOCs during air monitoring.

CMS5000 Operating Manual

Chapter 7

Operation

7.3 System Calibration Standard

A toluene filled permeation tube is used to calibrate the CMS5000 system and has

a life span of approximately eight years. The software will use this calibration to

automatically compensate for normal fluctuations in detector sensitivity.

7.4 Operating the CMS5000 using the Front Panel

1 Touch ESC until the CMS5000 Main Menu is displayed. See Figure 7-1.

Figure 7-1 Main Menu

IPN 074-508-P1C

7 - 1

Page 82

CMS5000 Operating Manual

2 Run Method will be highlighted. Touch SEL. See Figure 7-2.

Figure 7-2 Selecting Run Method