Page 1

Capacitance Diaphragm Gauge

Edge CDG045D2

Edge CDG100D2

tina86e1 (2013-11) 1

Operating Manual

Incl. EC Declaration of Conformity

Page 2

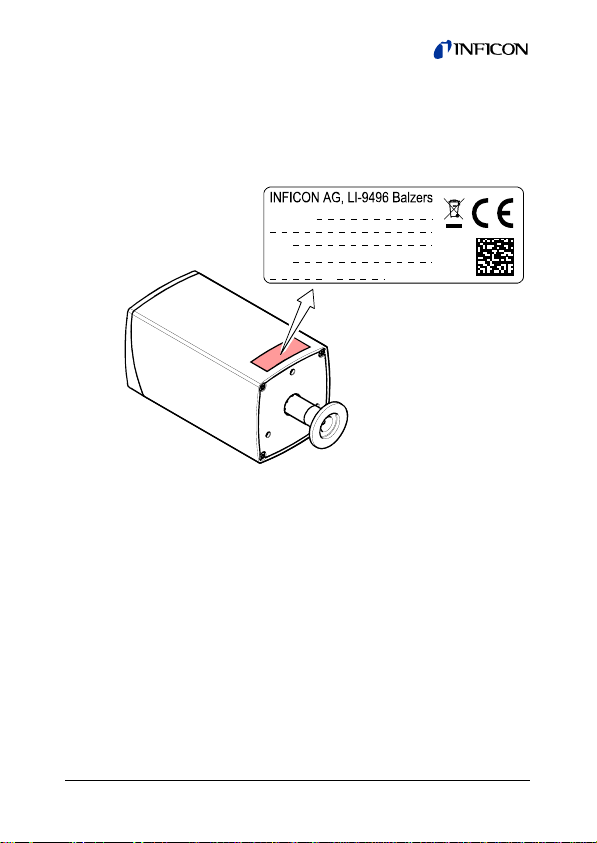

Product Identification

In all communications with INFICON, please specify the information given on the product nameplate. For convenient reference copy that information into the space provided below.

Model:

PN:

SN:

V W; LPS

2

tina86e1 (2013-11)

Page 3

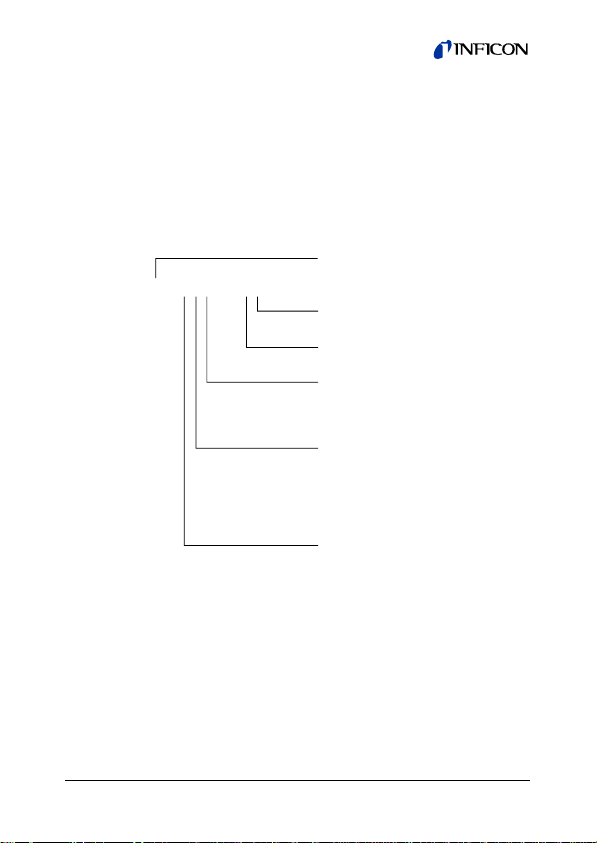

Validity

This document applies to products of the Edge CDG045D2 and

Edge CDG100D2 series.

Part numbers of standard products are indicated below. OEM

products have other part numbers and different parameter

settings (e.g. factory setting of setpoint) as defined in the

corresponding ordering information.

Sensor temperature

3Cx5-xxx-23xx

Measurement range

(F.S.)

The part number (PN) can be taken from the product nameplate.

If not indicated otherwise in the legends, the illustrations in this

document correspond to gauges with DN 16 ISO-KF vacuum

connection. They apply to the other gauges by analogy.

We reserve the right to make technical changes without prior

notice.

tina86e1 (2013-11) 3

Filter

Interface

Flange

Unit

C 45 °C

D 100 °C

0 Standard

B P control

0 None (analog)

8 EtherCAT

1 DN 16 ISO-KF

3 DN 16 CF-R

9 1/2" tube

E 8VCR female

(x 133 Pa; x 1.3 mbar)

5 Torr

(x 100 Pa)

6 mbar

6 1

7 2

8

5

10

9

A

20

B 50

C 100

D 200

E 500

F 1000 (Torr only)

G 1100 (mbar only)

Page 4

Intended Use

The temperature compensated Capacitance Diaphragm Gauges

of the CDG045D2 and CDG100D2 series are intended for

absolute pressure measurement of gases in their respective

pressure ranges (→ 3).

The gauges belong to the SKY

®

Smart Sensors family and can

be operated in connection with an INFICON Vacuum Gauge

Controller (VGC series) or another appropriate controller.

Functional Principle

A ceramic diaphragm is deflected by pressure. The deflection is

measured capacitively and converted into an analog linear output signal by the digital electronics.

The output signal is independent of the gas type.

Very accurate pressure measurement is achieved by heating the

sensor to a constant temperature of 45 °C or 100°C which

results in a compensation of changes in the ambient conditions

and a reduced deposition of process products and by-products in

process applications. An integrated baffle protects the sensor

against coating.

Trademarks

SKY® INFICON GmbH

®

VCR

Swagelok Marketing Co.

Patents

EP 1070239 B1, 1040333 B1

US Patents 6528008, 6591687, 7107855, 7140085

4

tina86e1 (2013-11)

Page 5

Scope of Delivery

1× gauge in clean room packaging

1× insulation shell (CDG100D2 only)

1× pin for adjusting settings via buttons

1× Calibration Test Report

tina86e1 (2013-11) 5

Page 6

Contents

Product Identification 2

Validity 3

Intended Use 4

Functional Principle 4

Trademarks 4

Patents 4

Scope of Delivery 5

Safety 8

1

1.1 Symbols Used 8

1.2 Personnel Qualifications 8

1.3 General Safety Instructions 9

1.4 Liability and Warranty 9

2 Technical Data 10

3 Installation 16

3.1 Vacuum Connection 16

3.2 Power Connection 20

4 Operation 22

4.1 Status Indication 23

4.2 Zeroing the Gauge 24

4.2.1 <ZERO> Adjustment 25

4.3 Switching Functions 29

4.4 Activating the Factory Setting (Factory Reset) 32

4.5 Diagnostic Port (RS232C Interface) 33

5 Deinstallation 34

5.1 Power Connection 34

5.2 Vacuum Connection 34

6 Maintenance, Repair 37

7 Returning the Product 37

8 Disposal 38

9 Accessories 39

6

tina86e1 (2013-11)

Page 7

Further Information 39

EC Declaration of Conformity 41

For cross-references within this document, the symbol (→ XY)

is used, for cross-references to further documents, listed under

"Further Information", the symbol (→ [Z]).

tina86e1 (2013-11) 7

Page 8

1 Safety

1.1 Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to

malfunctions or minor equipment damage.

Notice

<…> Labeling

1.2 Personnel Qualifications

Skilled personnel

All work described in this document may only be carried out by

persons who have suitable technical training and the necessary experience or who have been instructed by the end-user

of the product.

8

tina86e1 (2013-11)

Page 9

1.3 General Safety Instructions

• Adhere to the applicable regulations and take the necessary

precautions for the process media used.

Consider possible reactions with the product materials.

• Adhere to the applicable regulations and take the necessary

precautions for all work you are going to do and consider the

safety instructions in this document.

• Before beginning to work, find out whether any vacuum com-

ponents are contaminated. Adhere to the relevant regulations

and take the necessary precautions when handling contaminated parts.

Communicate the safety instructions to all other users.

1.4 Liability and Warranty

INFICON assumes no liability and the warranty becomes null

and void if the end-user or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of interventions (modifications, alterations etc.)

on the product

• use the product with accessories not listed in the product

documentation.

The end-user assumes the responsibility in conjunction with the

process media used.

Gauge failures due to contamination or wear and tear are not

covered by the warranty.

tina86e1 (2013-11) 9

Page 10

2 Technical Data

For further technical data for gauges with EtherCAT

interface → [5].

Measurement range

1)

Accuracy

0.2% of measured value

Temperature effect on zero 0.0025% F.S./ °C

Temperature effect on span 0.02% of reading / °C

Resolution

Gas type dependence none

Output signal analog

(measurement signal)

Measurement range 0 … +10 V

Voltage range –5 … +10.24 V

Relationship voltage-pressure linear

Output impedance

Loaded impedance

Response time

2)

Identification

Resistance R

Voltage

Ident

Remote Zero Adjust

External switching contact

→ "Validity"

0.003% F.S.

(limited to +10.24 V)

0 Ω (short-circuit proof)

>10 kΩ

30 ms

13.2 kΩ referenced to

supply common

≤5 V

digital input for zero adjustment (→ 25)

30 V (dc) / <5 mA (dc)

1)

Non-linearity, hysteresis, repeatability in the calibrated range at 25 °C

ambient operating temperature without temperature effects after

operation of 2 h.

2)

Increase 10 … 90 % F.S.R.

10

tina86e1 (2013-11)

Page 11

Switching functions SP1, SP2

Setting range 0 … 99% F.S. (0 … 9.9 V)

Hysteresis 1% F.S.

Relay contact 30 V (dc)/ ≤0.5 A (dc)

floating (NO)

closed p ≤ p

open p ≥ p

Switching time ≤50 ms

(LED lit solid)

SP

(LED off)

SP

Status relay

Relay contact 30 V (dc)/ ≤0.5 A (dc)

connected to supply com-

mon (pin 5)

closed measurement mode

warning

open no supply voltage

warming up

RS232C interface

Transmission rate

Data format

error

9600 baud

binary

8 data bits

one stop bit

no parity bit

no handshake

→ "Power Connection"

For further information on the RS232C interface → [4].

Diagnostic port Jack connector, 2.5 mm,

3-pin

tina86e1 (2013-11) 11

Page 12

Supply

DANGER

The gauge may only be connected to power supplies, instruments or control devices that conform

to the requirements of a grounded protective extralow voltage (SELV) and limited power source

(LPS), Class 2. The connection to the gauge has to

3)

be fused

Supply voltage

at the gauge

.

Class 2 / LPS

+14 … +30 V (dc) or

±15 V (±5%)

Ripple ≤1 V

Power consumption

while being heated

CDG045D2

CDG100D2

at operating temperature

CDG045D2

CDG100D2

≤15 W

≤20 W

≤10 W

≤14 W

pp

The gauge is protected against reverse polarity of the supply

voltage and overload.

Electrical connection D-Sub 15-pin, male

Sensor cable 15-pin plus shielding

Cable length

Supply voltage 15 V

≤ 4 m (0.14 mm²/conductor)

≤ 7 m (0.25 mm²/conductor)

Supply voltage 24 V ≤20 m (0.14 mm²/conductor)

≤35 m (0.25 mm²/conductor)

Supply voltage 30 V ≤40 m (0.14 mm²/conductor)

≤70 m (0.25 mm²/conductor)

For longer cables, larger conductor cross-sections are required

≤1.0 Ω).

(R

cable

3)

INFICON controllers fulfill this requirement.

12

tina86e1 (2013-11)

Page 13

Grounding concept

→ "Power Connection"

Materials exposed to vacuum ceramics (Al2O3 ≥99.5%),

stainless steel AISI 316L

3 bar

2 bar

3

Internal volume ≤4.2 cm

Admissible pressure (absolute)

200 / 500 / 1000 / 1100 F.S.

1 / 2 / 5 / 10 / 20 / 50 / 100 F.S.

Bursting pressure (absolute) 6 bar

Admissible temperatures

Storage

Operation

4)

Bakeout

Relative humidity

–40 °C … +65 °C

+10 °C … +50 °C

≤110 °C at the flange

≤80% at temperatures

≤+31 °C, decreasing to 50%

at +40°C

Use indoors only, altitude up to

2000 m NN

Degree of protection IP 40

4)

Hot surface danger warning → 16 and 22 (CDG100D2 only and at

operation temperatures >40°C).

tina86e1 (2013-11) 13

Page 14

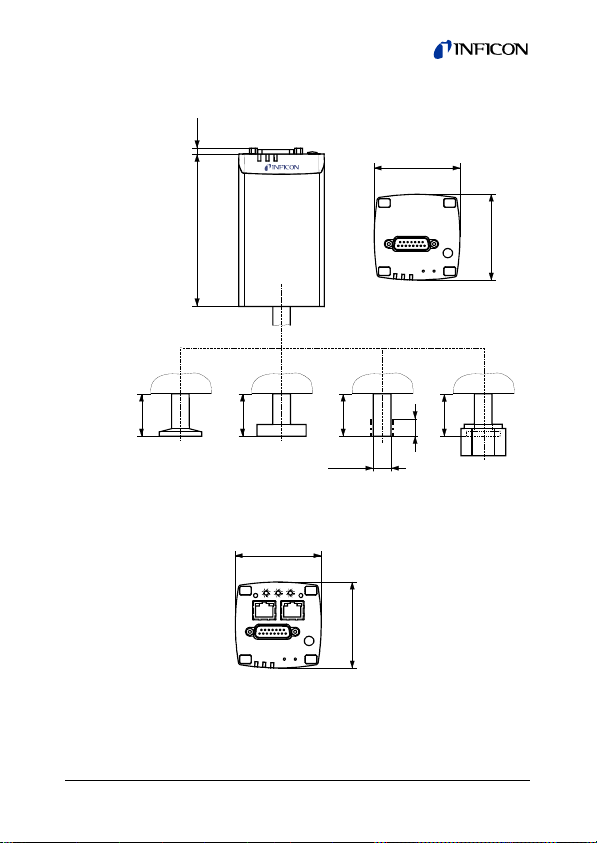

Dimensions [mm]

63

14

31.5

DN 16 ISO-KF

Weight

112.2 4.3

31.5

DN 16 CF-R

EtherCAT

63

x100 x10 x1

4

4

4

2

2

2

6

6

6

ERR RUN

80

80

A

A

A

E

E

E

IN

SP ZERO

SP1

SP2

STATUS

63

DIAG

SP ZERO

SP1

SP2

STATUS

31.5

OD½"

80

LALA

OUT

63

PWR

DIAG

31.5

13

8-VCR

female

<650 g

tina86e1 (2013-11)

Page 15

Analog Measurement Signal vs. Pressure

Pressure p

1.1×F.S.

1.0×F.S.

0.9×F.S.

0.8×F.S.

0.7×F.S.

0.6×F.S.

0.5×F.S.

0.4×F.S.

0.3×F.S.

0.2×F.S.

0.1×F.S.

0.0×F.S.

0

12 345678910

Measuring signal U

p = (U

/ 10 V) × p (F.S.)

out

Conversion Torr ↔ Pascal

Torr mbar 5) Pa

c 1.00

1013.25 / 760 =

1.3332…

[V]

out

4)

101325 / 760 =

133.3224…

Example: Gauge with 10 Torr F.S.

Measurement signal U

= 6 V

out

p = (6 V / 10 V) × 10 Torr

= 0.6 × 10 Torr = 6 Torr

5)

Source: NPL (National Physical Laboratory)

Guide to the Measurement of Pressure and Vacuum, ISBN 0904457x /

1998

tina86e1 (2013-11) 15

Page 16

3 Installation

WARNING

WARNING: fragile components

The ceramic sensor may be damaged by impacts.

Do not drop the product and prevent shocks and

3.1 Vacuum Connection

impacts.

DANGER

DANGER: hot surface (CDG100D2 only and at

operation temperatures >40°C)

Touching the hot surface (>65 °C) can cause

burns.

Protect hot parts to prevent accidental contact and

mount warning signs.

DANGER

DANGER: overpressure in the vacuum system

>1 bar

Injury caused by released parts and harm caused

by escaping process gases can result if clamps are

opened while the vacuum system is pressurized.

Do not open any clamps while the vacuum system

is pressurized. Use the type clamps which are

suited to overpressure.

16

tina86e1 (2013-11)

Page 17

DANGER: overpressure in the vacuum system

>2.5 bar

KF flange connections with elastomer seals (e.g.

O-rings) cannot withstand such pressures. Process

media can thus leak and possibly damage your

health.

Use O-rings provided with an outer centering ring.

DANGER: protective ground

Products that are not correctly connected to ground

can be extremely hazardous in the event of a fault.

Electrically connect the gauge to the grounded

vacuum chamber. This connection must conform to

the requirements of a protective connection according to EN 61010:

• CF and VCR flanges fulfill this requirement.

• For gauges with a KF flange, use a conductive

metallic clamping ring.

• For gauges with a ½" tube, take appropriate

measures to fulfill this requirement.

Caution: vacuum component

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take appro-

priate measures to ensure cleanliness and prevent

damages.

DANGER

DANGER

Caution

tina86e1 (2013-11) 17

Page 18

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use clean

tools when working in this area.

Mount the gauge so that no vibrations occur. The gauge

may be mounted in any orientation. To keep condensates and particles from getting into the measuring

chamber preferably choose a horizontal to upright position. If adjustment should be possible after the gauge

has been installed, be sure to install it so that the buttons can be accessed with a pin (→ 24).

18

tina86e1 (2013-11)

Page 19

Remove the protective lid and connect the product to the

vacuum system.

Seal with centering ring

Protective lid

Clamp

Keep the protective lid.

Mount the insulation shell (CDG100D2 only).

Insulation shell

tina86e1 (2013-11) 19

Page 20

3.2 Power Connection

Make sure the vacuum connection is properly made

(→ 16).

DANGER

The gauge may only be connected to power supplies, instruments or control devices that conform

to the requirements of a grounded protective extralow voltage (SELV) and limited power source

(LPS), Class 2. The connection to the gauge has to

6)

be fused

.

Ground loops, differences of potential, or EMC problems

may affect the measurement signal. For optimum signal

quality, please do observe the following notes:

• Use an overall metal braided shielded cable. The

connector must have a metal case.

• Connect the cable shield to ground at one side via the

connector case. Make sure the connector case has

direct contact to the cable's shield on its whole circumference. Do not connect the other side of the

shield.

• Connect the supply common with protective ground

directly at the power.

• Use differential measurement input (signal common

and supply common conducted separately).

• Potential difference between supply common and

housing ≤18 V (overvoltage protection).

6)

INFICON controllers fulfill this requirement.

20

tina86e1 (2013-11)

Page 21

If no sensor cable is available, make one according to the

following diagram (cable length and conductor cross-sections

→ 12).

TxD

RxD

1 M

3

4

1

8

9

10

13

14

2

12

7

11

5

6

15

case

Remote

Zero Adjust

14…30 V

15 V

15 V

Status

SP1

SP2

Ident

10

18 V

100nF

Pin 1,4 Relay SP1, closing contact

Pin 2 Signal output (measurement signal)

or thresholds SP1/2

9

Pin 3 Status

Pin 5 Supply common

Pin 6 Supply (-15 V)

Pin 7, 11 Supply (+14 … +30 V or +15 V)

15

Pin 8, 9 Relay SP2, closing contact

Pin 10 Gauge identification

or Remote Zero Adjust

Pin 12 Signal common

Pin 13 RS232, TxD

Pin 14 RS232, RxD

D-Sub,

15 pin

female

soldering side

Pin 15 Housing (chassis ground)

case Connector case

1

8

tina86e1 (2013-11) 21

Page 22

4 Operation

Put the gauge into operation. If you are using an INFICON controller, define the measurement range (→ [1], [2], [3]).

A warm-up time of at least 90 minutes should be allowed; for

precise pressure measurements a warm-up time of at least

3 hours is required.

If the gauge is used for fast downstream pressure con-

trol we recommend setting its signal filter to "fast".

The filter can be set via the RS232C interface or the

diagnostic port (→ [4]).

22

DANGER: hot surface (CDG100D2 only and at

operation temperatures >40°C)

Touching the hot surface (>65 °C) can cause

burns.

Don't touch the hot surface or wear protective

gloves.

DANGER

tina86e1 (2013-11)

Page 23

4.1 Status Indication

LED LED status Meaning

<STATUS> off no supply voltage

lit solid green measurement mode

blinking green

short blinks

long blinks

lit solid red error

<SP1> lit green green

blinking green waiting for setpoint 1 input

off p > setpoint 1

<SP2> lit solid green

blinking green waiting for setpoint 2 input

off p > setpoint 2

DIAG

SP ZERO

SP1

SP2

STATUS

warning, over/underrange

warming up

p

≤ setpoint 1

p

≤ setpoint 2

tina86e1 (2013-11) 23

Page 24

4.2 Zeroing the Gauge

The gauge is factory calibrated while "standing upright"

(→ "Calibration Test Report").

We recommend performing a zero adjustment, when the

gauge is operated for the first time.

Due to long time operation or contamination, a zero drift could

occur and zero adjustment may become necessary.

For adjusting the zero, operate the gauge under the same constant ambient conditions and in the same mounting orientation

as normally.

The output signal (measuring signal) is depending on the mounting orientation. The signal difference between the vertical and

horizontal mounting orientation is:

If the gauge is operated via a controller, the zero of the

whole measuring system has to be adjusted on the

controller: first, adjust the zero of the gauge and then,

the zero of the controller.

F.S. ΔU / 90°

1000 Torr/mbar ≈2 mV

100 Torr/mbar ≈10 mV

10 Torr/mbar ≈50 mV

1 Torr/mbar ≈300 mV

24

tina86e1 (2013-11)

Page 25

4.2.1 <ZERO> Adjustm ent

The zero can be adjusted via

• the <ZERO> button on the gauge,

• the diagnostic port (→ [4]),

• the digital input "Remote Zero" (briefly apply the

supply voltage to pin 10),

• the RS232C interface (→ [4]),

• an INFICON Vacuum Gauge Controller (VGC series).

While the gauge is being heated and/or under atmos-

pheric pressure, the zeroing function is locked in order

for operating errors to be prevented.

Evacuate the gauge to a pressure according to the table

below:

F.S.

1100 mbar

1000 Torr/mbar

500 Torr/mbar

200 Torr/mbar

100 Torr/mbar

50 Torr/mbar

20 Torr/mbar

10 Torr/mbar

5 Torr/mbar

2 Torr/mbar

1 Torr/mbar

If the final pressure is too high for zero adjustment (>25%

of the F.S.), the zero cannot be reached and the

<STATUS> LED blinks green. If this is the case, activate

the factory setting and adjust the zero again (→ 32).

Recommended final pressure for

zero adjustment

−

<5×10

<2.5×10

<10

<5×10

<2.5×10

<10

<5×10

<2.5×10

<10

<5×10

-2

-2

-2

-3

-3

-3

-4

-4

-4

-5

Torr

Torr

Torr

Torr

Torr

Torr

Torr

Torr

Torr

Torr

<6.65×10

<6.65×10

<3.33×10

<1.33×10

<6.65×10

<3.33×10

<1.33×10

<6.65×10

<3.33×10

<1.33×10

<6.65×10

-0

-1

-1

-1

-2

-2

-2

-3

0

0

0

Pa

Pa

Pa

Pa

Pa

Pa

Pa

Pa

Pa

Pa

Pa

<5×10

<5×10

<2.5×10

<10

<5×10

<2.5×10

<10

<5×10

<2.5×10

<10

<5×10

-2

mbar

-

2 mbar

-2

mbar

-2

mbar

-3

mbar

-3

mbar

-3

mbar

-4

mbar

-4

mbar

-4

mbar

-5

mbar

Operate the gauge for at least 90 minutes under constant

ambient conditions (until the signal is stable).

tina86e1 (2013-11) 25

Page 26

Briefly press the <ZERO> button with a pin (max.

ø1.1 mm). The zero adjustment runs automatically. The

<STATUS> LED blinks until the adjustment (duration ≤8 s)

is completed.

Press the button briefly

max. ø1.1 mm

After zero adjustment, the gauge automatically returns

to the measurement mode.

The <STATUS> LED blinks green if

• the signal output is negative (< -20 mV) when the final pressure has been attained

• the zero adjustment has failed.

4.2.2 <ZERO> Adjustment with Ramp Functi on

The ramp function allows to adjust the zero at a known reference

pressure within the measurement range of the gauge.

26

tina86e1 (2013-11)

Page 27

It also permits to adjust an offset of the characteristic curve in

order to

• compensate for the offset of the measuring system or

• obtain a slightly positive zero for a 0 … 10 V AD converter.

The offset should not exceed 2% of the F.S. (+200 mV). At a

higher positive offset, the upper limit of the measurement range

is exceeded.

Zero adjustment using the ramp function can be

performed via

• the <ZERO> button on the gauge,

• the diagnostic port (→ [4]),

• the RS232C interface (→ [4]).

Recommended procedure for adjusting the offset of a

measuring system: → Notice 24.

Operate the gauge for at least 90 minutes under constant

ambient conditions (until the signal is stable).

Push the <ZERO> button with a pin (max. ø1.1 mm) and

keep it depressed. The <STATUS> LED starts blinking.

After 5 s, the zero adjustment value, starting at the current

output value, keeps continually changing (ramp) until the

button is released or until the setting limit (max. 25% F.S.)

is reached. The corresponding output signal is delayed by

about 1 s.

tina86e1 (2013-11) 27

Page 28

Keep the button depressed

max. ø1.1 mm

Push the <ZERO> button again:

Fine adjustment

within 0...3 s:

the zero adjustment value changes

by one unit (push <ZERO> button in

intervals of 1 s)

Change of direction

within 3...5 s:

the zero adjustment changes its

direction (the blinking frequency of

the <STATUS> LED changes

briefly)

If the <ZERO> button is released for more than 5 s, the

gauge returns to the measurement mode.

The <STATUS> LED blinks green if the signal output is negative

(< -20 mV).

28

tina86e1 (2013-11)

Page 29

4.3 Switching Functions

The two switching functions can be set to any pressure within

the measurement range of the gauge (→ 15).

The current setpoint setting

• can be read/written via the diagnostic port,

• is output at the D-Sub connector instead of the measurement

signal (→ 21) and can be measured with a voltmeter after

the <SP> button is pressed, or

• can be read/written via the RS232C interface.

If the pressure is lower than the setpoint, the corresponding LED

(<SP1> or <SP2>) is lit solid and the corresponding relay

(→ 21) is energized.

Measurement signal (pressure p)

Setpoint

e

m

e

r

u

s

a

e

M

Hysteresis

(1% F.S.)

Threshold value

e

u

l

a

v

t

n

Off

On

Off

tina86e1 (2013-11) 29

Time t

Page 30

4.3.1 Adjusting the Setpoints

The setpoints can be adjusted via

• the buttons on the gauge,

• the diagnostic port (→ [4]),

• the RS232C interface (→ [4]).

DANGER

DANGER: malfunction

If processes are controlled via the signal output,

keep in mind that by pushing the <SP> button the

measurement signal is suppressed and the corresponding threshold value is output instead. This

can cause malfunctions.

Push the <SP> button only if you are sure that no

damages can arise from a malfunction.

Adjusting Setpoint <1>

Push the <SP> button with a pin (max. ø1.1 mm). The

gauge changes to the switching function mode and outputs

the current threshold value at the measurement value

output for about 10 s (LED <1> blinks).

30

tina86e1 (2013-11)

Page 31

Press the button

max. ø1.1 mm

For changing the threshold value, push the <ZERO> button

and keep it depressed. The threshold keeps changing from

the current value (ramp) until the button is released or until

the limit of the setting range is reached.

Keep the button depressed

max. ø1.1 mm

tina86e1 (2013-11) 31

Page 32

Push the <ZERO> button again:

Fine adjustment

within 0...3 s:

Change of direction

within 3...5 s:

If the <ZERO> button is released for more than 5 s, the

gauge returns the measurement mode.

The upper threshold is automatically set 1% F.S. above

the lower one (hysteresis).

the zero adjustment value changes

by one unit

the zero adjustment changes its

direction (the blinking frequency of

the <STATUS> LED changes

briefly)

Adjusting Setpoint <2>

Push the <SP> button twice (the LED <2> blinks). The

adjustment procedure is the same as for setpoint <1>.

4.4 Activating the Factory Setting (Factory Reset)

All user defined parameters (e.g. zero, filter) are restored to their

default values.

Loading of the default parameters is irreversible.

Loading the default parameters:

Put the gauge out of operation.

Keep the <ZERO> button depressed for at least 5 s while

the gauge is being put into operation (Power ON).

32

tina86e1 (2013-11)

Page 33

4.5 Diagnostic Port (RS232C Interface)

The diagnostic port <DIAG> permits to output the pressure

reading and all status information and to enter all settings at the

same time (→ [4]).

"Accessories"

→

tina86e1 (2013-11) 33

Page 34

5 Deinstallation

Preconditions:

• Vacuum system vented

• Vacuum system cooled to <50 °C

5.1 Power Connection

Put the gauge out of operation.

Unfasten the lock screws and disconnect the sensor cable.

5.2 Vacuum Connection

DANGER

DANGER: hot surface

Touching the hot surface (>65 °C) can cause

burns.

Put the product out of operation and allow it to cool

down.

WARNING

WARNING: fragile components

The ceramic sensor may be damaged by impacts.

Do not drop the product and prevent shocks and

impacts.

34

tina86e1 (2013-11)

Page 35

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution: vacuum component

Dirt and damages impair the function of the vac-

uum component.

When handling vacuum components, take appro-

priate measures to ensure cleanliness and prevent

damages.

Caution: dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use clean

tools when working in this area.

DANGER

Caution

Caution

tina86e1 (2013-11) 35

Page 36

Remove the insulation shell (CDG100D2 only).

Insulation shell

Open both sides

Remove the gauge from the vacuum system and install the

protective lid.

Seal with centering ring

36

Clamp

Protective lid

tina86e1 (2013-11)

Page 37

6 Maintenance, Repair

Under clean operating conditions, the product requires no maintenance.

Gauge failures due to contamination or wear and tear

are not covered by the warranty.

We recommend checking the zero at regular intervals

(→ 25).

INFICON assumes no liability and the warranty becomes null

and void if any repair work is carried out by the end-user or third

parties.

7 Returning the Product

WARNING

WARNING: forwarding contaminated products

Contaminated products (e.g. radioactive, toxic,

caustic or microbiological hazard) can be detrimental to health and environment.

Products returned to INFICON should preferably be

free of harmful substances. Adhere to the forwarding regulations of all involved countries and forwarding companies and enclose a duly completed

*)

Form under www.inficon.com

declaration of contamination

Products that are not clearly declared as "free of harmful substances" are decontaminated at the expense of the customer.

Products not accompanied by a duly completed declaration of

contamination are returned to the sender at his own expense.

*)

.

tina86e1 (2013-11) 37

Page 38

8 Disposal

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

Separating the components

After disassembling the product, separate its components according to the following criteria:

• Contaminated components

• Other components

when handling contaminated parts.

WARNING

WARNING: substances detrimental to the environment

Products or parts thereof (mechanical and electric

components, operating fluids etc.) can be detrimental to the environment.

Dispose of such substances in accordance with the

relevant local regulations.

Contaminated components (radioactive, toxic, caustic or biological hazard etc.) must be decontaminated in accordance

with the relevant national regulations, separated according to

their materials, and disposed of.

Such components must be separated according to their materials and recycled.

38

tina86e1 (2013-11)

Page 39

9 Accessories

Ordering number

Communication adapter (2 m) 7) 303-333

Further Information

[1] www.inficon.com

Operating Manual

Vacuum Gauge Controller VGC032

tinb02d1 (German)

tinb02e1 (English)

INFICON AG, LI–9496 Balzers, Liechtenstein

[2] www.inficon.com

Operating Manual

Single-Channel Controller VGC401

tinb01d1 (German)

tinb01e1 (English)

INFICON AG, LI–9496 Balzers, Liechtenstein

[3] www.inficon.com

Operating Manual

Two- & Three-Channel Measurement and Control Unit

VGC402, VGC403

tinb07d1 (German)

tinb07e1 (English)

INFICON AG, LI–9496 Balzers, Liechtenstein

7)

The diagnostic software (Windows NT, XP) can be downloaded from our

website.

tina86e1 (2013-11) 39

Page 40

[4] www.inficon.com

Communication Protocol

RS323C Interface

tira49d1 (German)

tira49e1 (English)

INFICON AG, LI–9496 Balzers, Liechtenstein

[5] www.inficon.com

Communication Protocol

EtherCAT CDG045D2, CDG100D2

tira68e1 (English only)

INFICON AG, LI–9496 Balzers, Liechtenstein

40

tina86e1 (2013-11)

Page 41

EC Declaration of Conformity

We, INFICON, hereby declare that the equipment mentioned

below complies with the provisions of the Directive relating to

electromagnetic compatibility 2004/108/EC and the Directive on

the restriction of the use of certain hazardous substances in

electrical and electronic equipment 2011/65/EU.

Products

Capacitance Diaphragm Gauge

Edge CDG045D2

Edge CDG100D2

Standards

Harmonized and international/national standards and specifications:

• EN 61000-6-2:2005

• EN 61000-6-3:2007

• EN 61010-1:2010

measurement, control and laboratory use)

• EN 61326:2006

measurement, control and laboratory use)

Manufacturer / Signatures

INFICON AG, Alte Landstraße 6, LI-9496 Balzers

26 November 2013 26 November 2013

(EMC: generic immunity standard)

(EMC: generic emission standard)

(Safety requirements for electrical equipment for

(EMC requirements for electrical equipment for

Dr. Urs Wälchli

Managing Director

Alex Nef

Product Manager

tina86e1 (2013-11) 41

Page 42

Notes

42

tina86e1 (2013-11)

Page 43

Notes

tina86e1 (2013-11) 43

Page 44

LI–9496 Balzers

Liechtenstein

Tel +423 / 388 3111

Fax +423 / 388 3700

Original: German tina86d1 (2013-11) reachus@inficon.com

t i na86e1

www.inficon.com

Loading...

Loading...