Assembly & Set-Up

Instructions

Rider 15 Pro

Rider 16 H

_Husqvarna

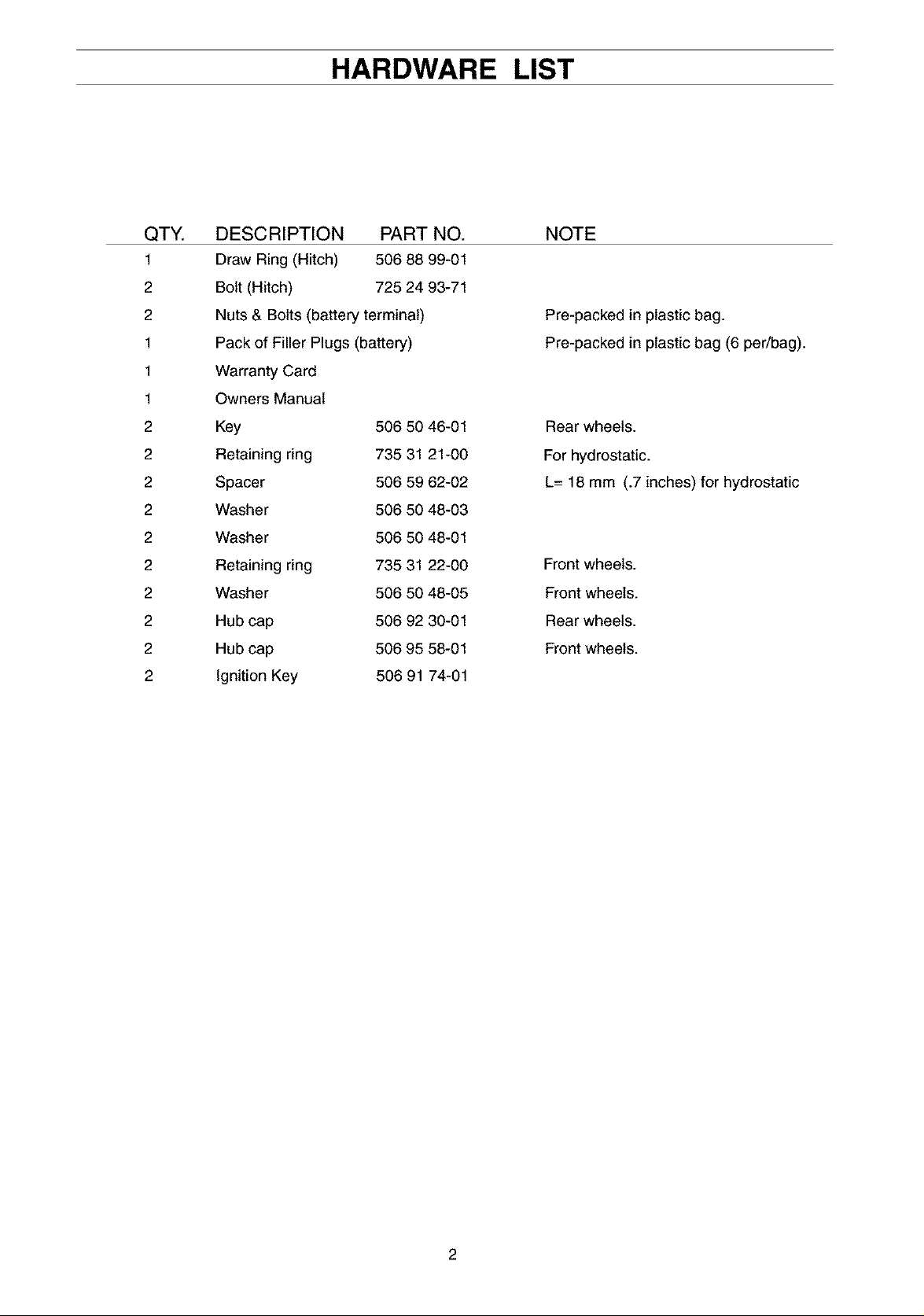

HARDWARE LIST

QTY. DESCRIPTION PART NO.

1 Draw Ring (Hitch) 506 88 99-01

2 Bolt (Hitch) 725 24 93-71

2 Nuts & Bolts (battery terminal)

1 Pack of Filler Plugs (battery)

1 Warranty Card

1 Owners Manual

2 Key 506 50 46-01

2 Retaining ring 735 31 21-00

2 Spacer 506 59 62-02

2 Washer 506 50 48-03

2 Washer 506 50 48-01

2 Retaining ring 735 31 22-00

2 Washer 506 50 48-05

2 Hub cap 506 92 30-01

2 Hub cap 506 95 58-01

2 Ignition Key 506 91 74-01

NOTE

Pre-packed in plastic bag.

Pre-packed in plastic bag (6 per/bag).

Rear wheels.

For hydrostatic.

L= 18 mm (.7 inches) for hydrostatic

Front wheels.

Front wheels.

Rear wheels.

Front wheels.

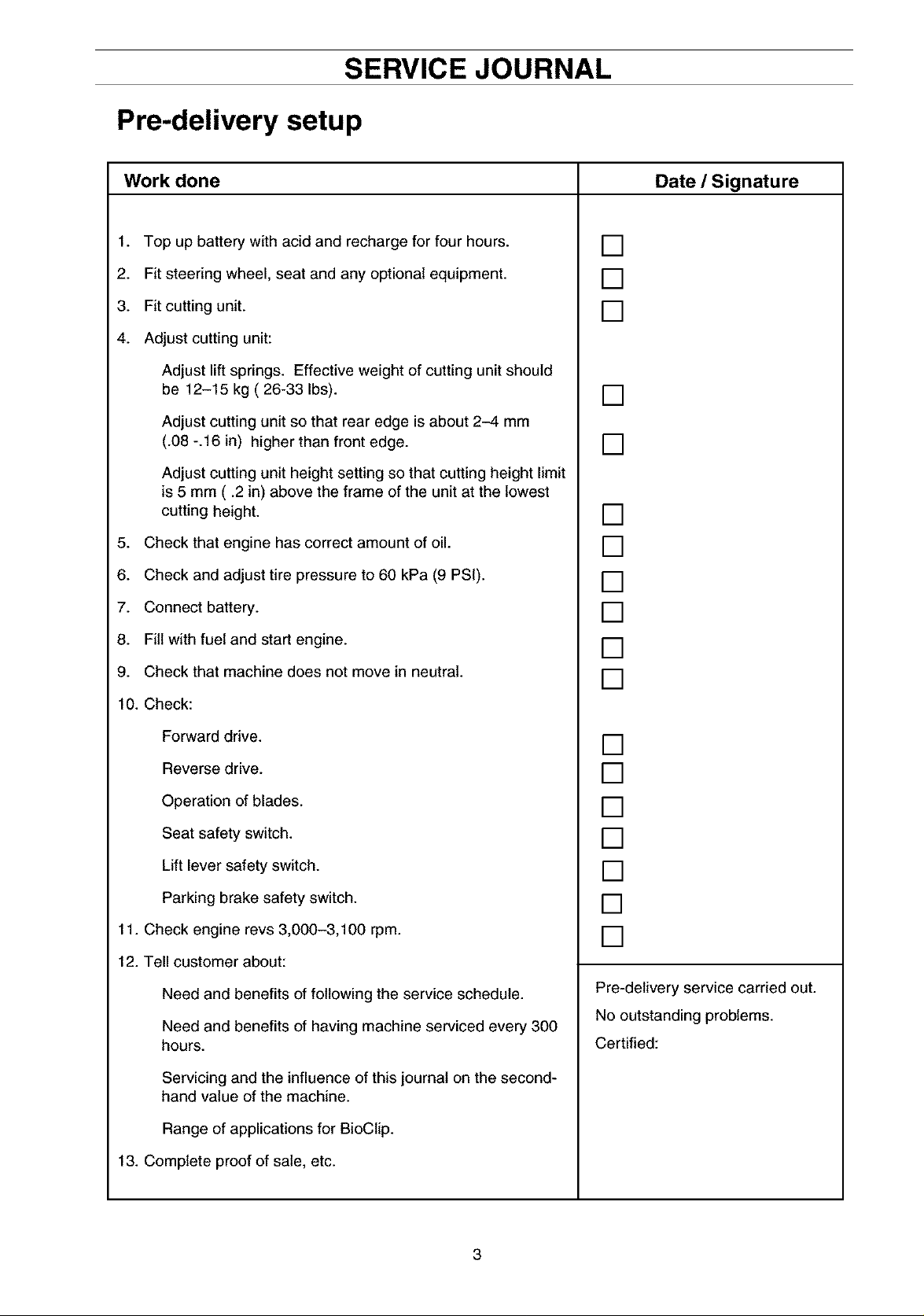

SERVICE JOURNAL

Pre-delivery setup

Work done Date / Signature

1. Top up battery with acid and recharge for four hours.

2. Fit steering wheel, seat and any optional equipment.

3. Fit cutting unit.

4. Adjust cutting unit:

Adjust lift springs. Effective weight of cutting unit should

be 12-15 kg ( 26-33 Ibs).

Adjust cutting unit so that rear edge is about 2-4 mm

(.08 -.16 in) higher than front edge.

Adjust cutting unit height setting so that cutting height limit

is 5 mm ( .2 in) above the frame of the unit at the lowest

cutting height.

5. Check that engine has correct amount of oil.

6. Check and adjust tire pressure to 60 kPa (9 PSI).

7. Connect battery.

8. Fill with fuel and start engine.

9. Check that machine does not move in neutral.

10. Check:

[]

[]

[]

[]

[]

[]

[]

[]

[]

[]

[]

Forward drive.

Reverse drive.

Operation of blades.

Seat safety switch.

Lift lever safety switch.

Parking brake safety switch.

11. Check engine revs 3,000-3,100 rpm.

12. Tell customer about:

Need and benefits of following the service schedule.

Need and benefits of having machine serviced every 300

hours.

Servicing and the influence of this journal on the second-

hand value of the machine.

Range of applications for BioClip.

13. Complete proof of sate, etc.

[]

[]

[]

[]

[]

[]

[]

Pre-detivery service carried out.

No outstanding problems.

Certified:

3

Loading...

Loading...