Page 1

GB

ES

Operator’s manual

Please read the operator’s manual carefully and make sure you

understand the instructions before using the machine.

Manual de

instrucciones

Lea detenidamente el manual de instrucciones y asegúrese de

entender su contenido antes de utilizar la máquina.

PG 680

DE

FR

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen

Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation avant

d’utiliser la machine.

HUSQVARNA CONSTRUCTION PRODUCTS

PG 820

GB ES DE FR

Page 2

Contents

2 - English

Page 3

Contents

English

Contents

Key to symbols 4

Safety Instructions 6

Introduction 7

Transport 7

Storage 7

What is what 8

Setting up/Operation 10

Changing the diamonds 12

Variable speed drives/

frequency converters 13

Faults and trouble shooting 16

Diamonds 18

Diamond selection 19

Maintenance 23

Maintenance schedule 27

Technical data 28

English - 3

Page 4

Key to symbols

4 - English

Page 5

Key to symbols

Key to symbols

The symbols below are used on the machine and in

this Operator’s Manual. It is important that the user

understands the signifi cance of these in order to work

with the machine safely.

Please read the operator’s manual

carefully and make sure you understand the instructions before using the

machine.

WARNING! Dust forms when grinding

which can cause injuries if inhaled. Use

an approved breathing mask. Always

provide for good ventilation.

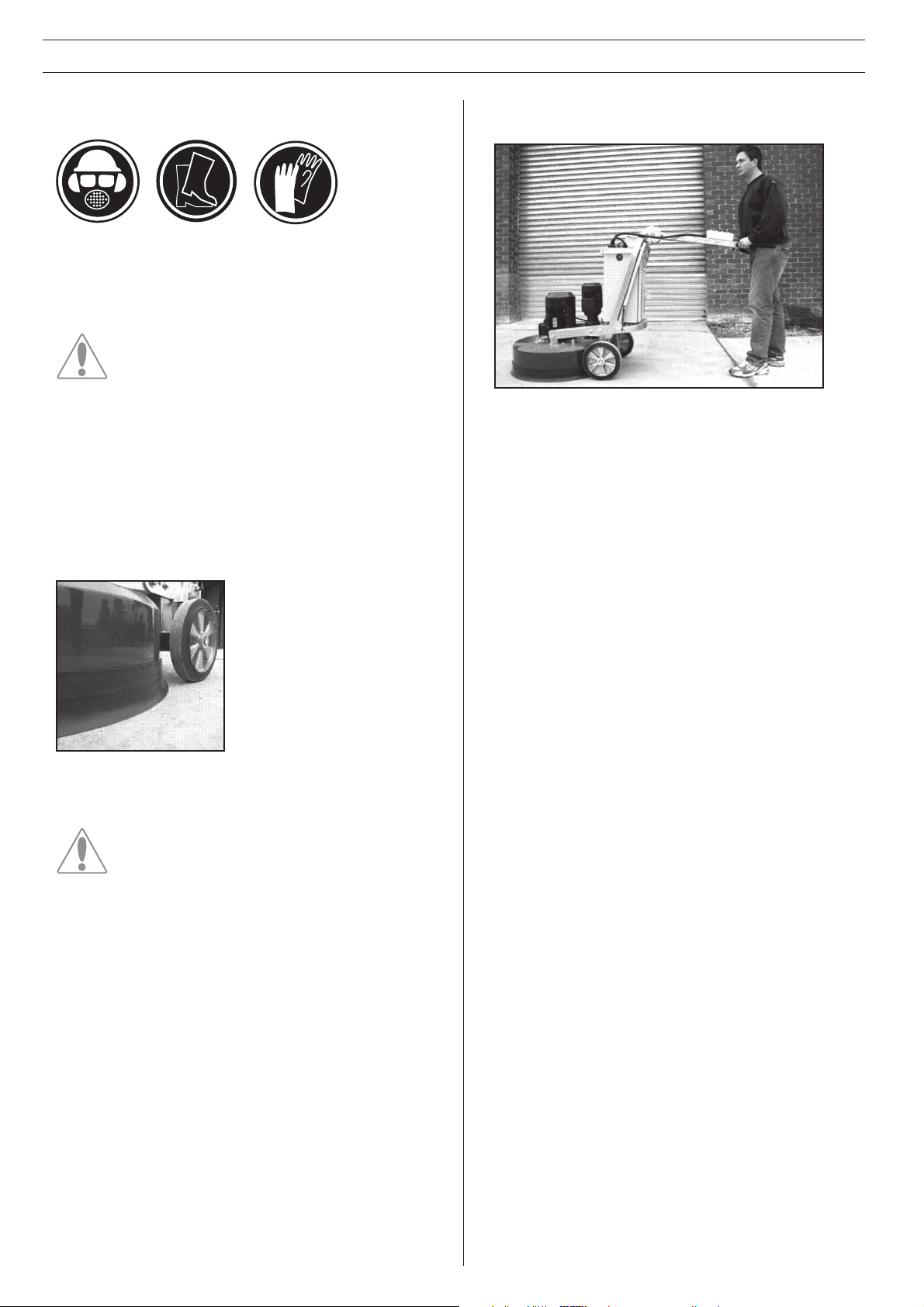

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor.

• Dust forms when grinding, which can

cause injuries if inhaled. Use dust

mask.

Always wear sturdy non-slip boots with

steel toe-caps.

Inspection and/or maintenance should

be carried out with the motor switched

off and the plug disconnected.

Visual check.

Regular cleaning is required.

This product is in accordance with applicable EC directives.

Always wear approved protective

gloves.

English - 5

Page 6

Safety Instructions

Safety Instructions

WARNING

Under no circumstances may the machine be

started without observing the safety instructions. Should the user fail to comply with

these, Husqvarna Construction Products

Sweden AB or its representatives are free

from all liability both directly and indirectly.

Read through these operating instructions

and make sure that you understand the

contents before starting to use the machine.

Should you, after reading these safety instructions, still feel uncertain about the safety

risks involved you must not use the machine,

please contact your dealer for more information.

• Please read the operator’s manual carefully.

• Only qualifi ed staff should be allowed to operate

machinery.

• Never use a machine that is faulty. Carry out the

checks, maintenance and service instructions described in this manual. All repairs not covered in this

manual must be performed by a repairer nominated

by either the manufacturer or distributor.

• Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgement or your coordination.

• Never use a machine that has been modifi ed in any

way from its original specifi cation.

• Be on your guard for electrical shocks. Avoid having

body contact with lightning-conductors/metal in the

ground.

• Never drag the machine by means of the cord and

never pull out the plug by pulling the cord. Keep all

cords and extension cords away from water, oil and

sharp edges.

• Make sure the cord is not pinched in doors, fences

or the like.

• Check that the cord and extension cord are intact

and in good condition. Never use the machine if the

cord is damaged, hand it in to an authorized service

workshop for repair.

• Do not use a rolled up extension cord

• The machine should be connected to an earthed

outlet socket.

• Check that the mains voltage corresponds with that

stated on the rating plate on the machine.

• Always wear personal safety equipment such as

sturdy non-slip boots, ear protection, dust mask and

approved eye protection.

• The machine should not be used in areas where

potential for fi re or explosions exist.

• Machinery should only be started when grinding

heads are resting on the ground unless carrying out

a testing procedure as outlined in this manual.

• The machine should not be started without the

rubber dust skirt attached. It is essential a good

seal between machine and fl oor be established for

safety, especially when operating in dry grinding

applications.

• When changing the grinding discs ensure power

supply to the unit is OFF by engaging the Emergency Stop button and the power-plug disconnected.

• The machine should not be lifted by handles, motor, chassis or other parts. Transportation of the

machine is best done on a pallet / skid to which the

machine must be fi rmly secured.

• Ensure the cord is behind you when you start to use

the machine so that the cord will not be damaged.

At no time should lifting of machinery be attempted

without mechanical means such as a hoist or fork

lift.

WARNING!

Overexposure to vibration can lead to circulatory damage or nerve damage in people

who have impaired circulation. Contact your

doctor if you experience symptoms of overexposure to vibration. These symptoms include

numbness, loss of feeling, tingling, pricking,

pain, loss of strength, changes in skin colour

or condition. These symptoms normally appear in the fi ngers, hands or wrists.

• Extreme caution must be used when moving

machinery by hand on an inclined plane. Even the

slightest slope can cause forces/momentum making

the machinery impossible to brake manually.

6 - English

Page 7

Introduction

Introduction

The Husqvarna PG 680/820 fl oor surfacing machines

are designed for wet or dry grinding of marble, terrazzo, granite and concrete. Their applications range from

rough grinding through to a polished fi nish.

This manual covers the Husqvarna PG 680/820 series

of fl oor grinders equipped with twin motor drive here

after referred to as Dual Drive Technology™.

It is extremely important all users be familiar with the

contents of this manual before

commencing operation of either machine. Failure to

do so may result in damage to machinery or expose

operator to unnecessary dangers.

IMPORTANT!

The machine should not be lifted by handle,

motor, chassis or other parts. Transportation

of the machine is best done on a pallet/skid

to which the machine must be fi rmly secured.

Do not attempt to slide the tines/forks from

a fork lift under grinding heads unless on a

pallet/skid. Failure to do so can cause irreparable damage to grinding heads of machine

and internal parts.

It is recommended that machinery be transported with

a set of diamonds attached at all times to ensure protection of locking mechanism for diamond plates.

IMPORTANT!

Only staff that have received the necessary

education, both practically and theoretically

concerning their usage should operate the

machinery.

Transportation

The machine comes equipped with inbuilt advanced

electronic systems called variable speed drives or

frequency converters. These drives enable the variable

speed and direction component of each of the motors.

The drives are located in the steel cabinet mounted on

the machine chassis.

As with all electronic equipment, the drives are sensitive to excessive vibration, rough treatment and high

levels of dust. Much care and attention has been given

by the manufacturer to ensure maximal protection is

given to the drives. Note the shock absorbing mounting system used to mount the steel cabinet on the

machine chassis/frame.

Storage

The machine should always be stored in a dry place

when not in use.

When transporting, it is important to ensure the machinery is properly secured at all times to eliminate

“bouncing” of the variable speed drives. Ensure the

chassis or frame section of the machine is secured

down at all times when in transit.

The machine should always be transported under

cover limiting the exposed to natural elements – in

particular rain and snow.

English - 7

Page 8

What is what

1.

3.

2.

4.

5.

11.

10.

9.

6.

7.

What is what

1. Hour counter

2. Electrical cabinet

3. Planetary head motor 1.5kW/1Hp

4. Grinding/Satellite heads motor 11kW/15Hp

5. Lifting lugs

6. Cover/Shroud

7. Skirt

8.

8. Chassis/Frame

9. Handle bars

10. Control Panel

11. Handle bar adjuster

8 - English

Page 9

What is what

The machine can be divided into two main parts. These

can be identifi ed as follows:

1. Chassis/Frame section – comprising handle bars,

electrical cabinet, steel frame and wheels.

2. Head – comprising of motors, cover, grinding/satel-

lite/

planetary heads and internal components.

The machine has been manufactured to allow movement between the chassis and head via the connection

point at the lifting lugs and chassis pins. This movement is important during the grinding process as it

creates a “fl oating” effect for the head.

The fl oating gives the head a self-leveling effect, negat-

ing the need to adjust the height of the head as the

machine passes over fl oor areas with different slopes

or undulations.

Control panel

The control panel consists of a number of switches and

dials giving 8 separate controls (see picture).

IMPORTANT!

Planetary head and grinding heads are set

to both turn in the same direction (i.e. both in

clockwise rotation or both in counter-clockwise rotation).

Clockwise rotation of speed control will increase speed of planetary head and grinding

heads.

Grinding satellite/ heads

Planetary head

Power - This button, when depressed, will turn on

power supply to the unit when the EMERGENCY

STOP button has been released.

Emergency Stop - When pushed will immediately

shut down machine by totally stopping power supply to

drives/ frequency converters in electrical cabinet.

Head Speed - Direction control for planetary head rotation.

Fwd/Rev (Yellow) - Direction control for planetary head

rotation.

Disc Speed - Speed control for grinding heads.

Fwd/Rev (Red) - Direction control for grinding heads.

Reset - Will clear fault function/error message on

drive/frequency converter (located in electrical cabinet)

in case of fault occurring.

Stop/Run - To start or stop machine during normal

operation.

IMPORTANT!

Dust extraction port

It is important to use the STOP/RUN switch

to control the running of the machine, not

the EMERGENCY STOP button. Each time

the EMERGENCY STOP button is pressed

it shuts down the drive/frequency converter.

Frequently powering up and down of the

drive/frequency converter will reduce the life

span of the drive/ frequency converter.

Control panel

English - 9

Page 10

Setting up/Operation

Setting up/Operation

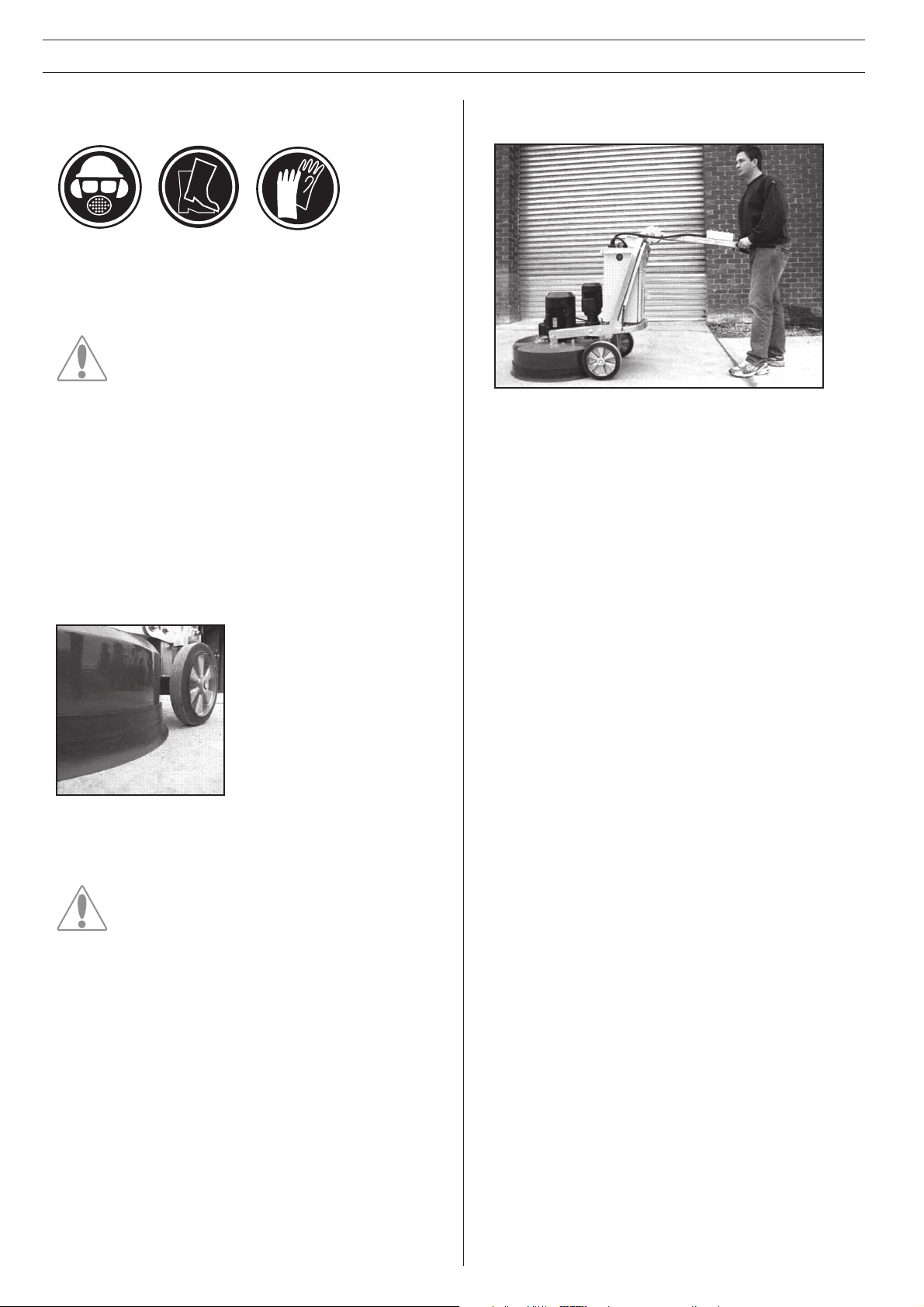

Position grinder on the working area. Make sure there

are diamonds underneath machine and that the head

locks/shear pins are tight.

IMPORTANT!

When using the machine, each grinding head

must always have the same diamond type

and number of diamonds as the other grinding heads. Each grinding head must have

diamonds the same height as the other grinding heads.

Adjust rubber skirt so that a good seal is established

between the fl oor and head of machine (see picture

below). Ensure join in skirt is at the front of the machine. Setting of the skirt is essential to obtain good

dust extraction and eliminate the possibility of airborne

dust when dry grinding.

Powering up machine

i. Ensure the STOP/RUN switch is set on Stop

(rotate counter clockwise).

ii. Plug power supply to machine. Only turn power on

at

switch once fully connected.

Set handle to most comfortable working height using

adjustment lever.

IMPORTANT!

It is recommended that this height be set as

close as possible to the height of the operator’s hip bone. When the machine is running,

there will be a grinding force/pull to one side

that can be felt through the handlebars. Use

the hip to resist this force instead of trying to

control this through the arms (such positioning will be much easier for the operator using

the machine over prolonged periods of tim.

iii. Disengage Emergency Stop button (twist clockwise).

iv. Depress Power button. On doing so, a soft “clunk”

should be heard to come from within the electrical cabinet. This indicates the line contactors have engaged,

supplying power to the drives/frequency converters.

Setting Speed and direction

On the control panel there is a FORWARD/REVERSE

and Speed dial knob. Generally, when starting the

machine for the fi rst time on any given application, it is

advised the speed setting should not exceed 7, initially.

When the operator is comfortable with the application,

speed may be increased.

10 - English

Page 11

Setting up/Operation

Speed and direction setting is often a matter of personal choice. Operators are encouraged to experiment

to fi nd which settings best suit the given applications.

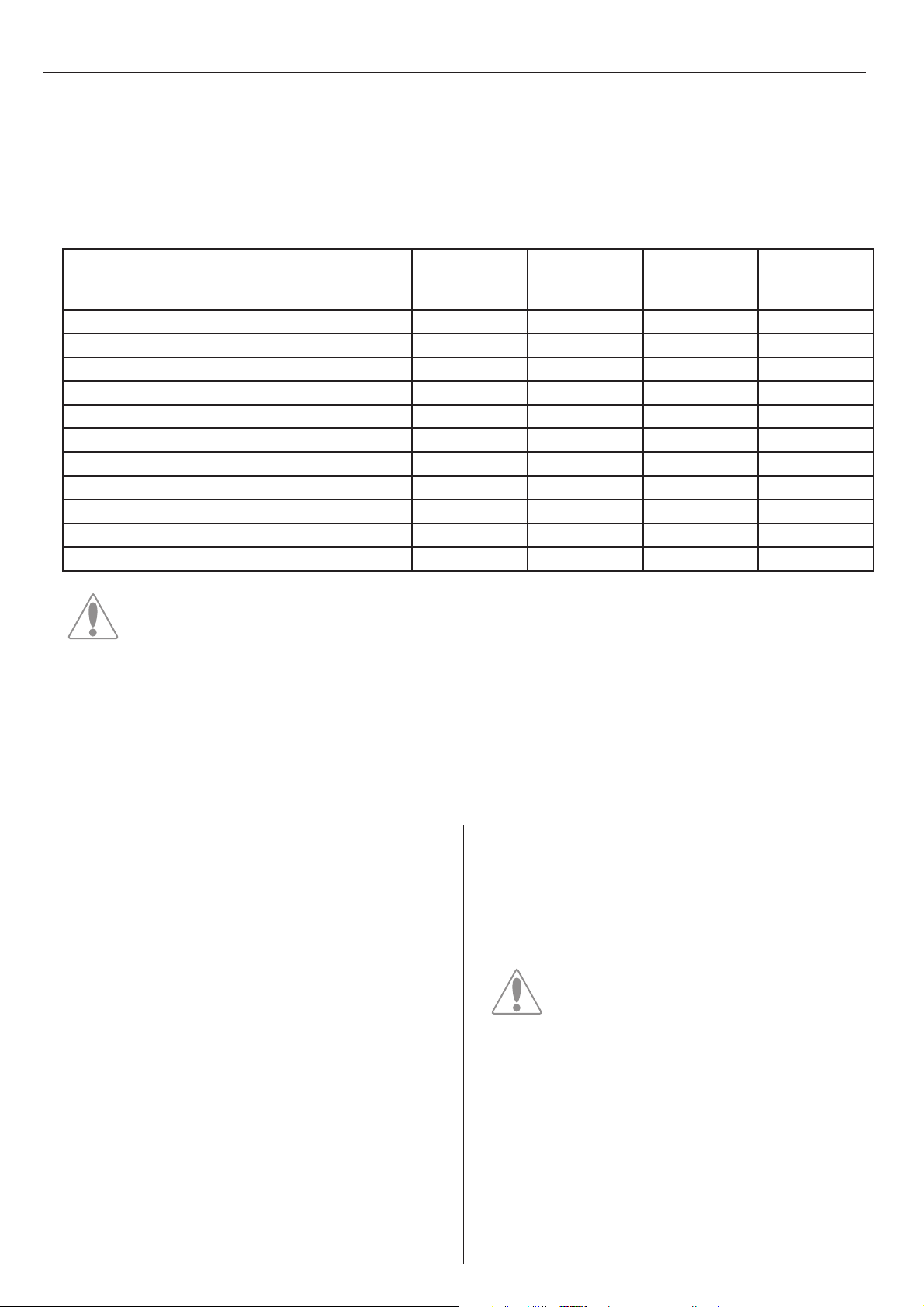

The following table lists some suggested set-ups for

different applications.

Application Planetary

head

direction

Ceramic tile adhesive removal FWD 6-7 FWD 8-10

Carpet glue removal FWD 5-7 FWD 8-10

Epoxy paint removal FWD 5-10 FWD 8-10

Rain damaged concrete FWD 7-10 FWD 8-10

Smoothen exposed aggregate FWD 7-8 FWD 8-10

Lippage removal in terrazzo/stone tiles FWD 5-7 FWD 8-10

Concrete polishing with resin bond pads FWD 10 FWD 8-10

PIRANHA™ scraper tool REV 3-5 REV 3-5

FLEXOR™ fl exible heads FWD 5-7 FWD 5-7

Bushhammer/Scarrifi er tools FWD 5 FWD 5-7

Re-grouting procedure during HiPERFLOOR™

process

IMPORTANT!

In the above table, FWD & FWD are listed

together to indicate direction settings in the

same direction (i.e. It can also be REV/REV).

The only application where direction settings must be in the same directions and also

direction specifi c is when using the PIRA-

NHA™ scraper tools. In this particular application the setting must be in the REV/REV

direction.

Direction of rotation

The correlation between FWD/REV & Clockwise/Counter clockwise rotation can be said as follows if looking

at the grinding discs from underneath the machine:

1. REV—Clockwise.

2. FWD—Reverse.

FWD 8-10 FWD 3-5

Direction is also a matter of personal preference. It

should be noted, however, that when both grinding

discs and planetary heads are running in the same

direction, a more powerful grinding force is created between the diamond abrasives and fl oor being ground.

The end result is higher productivity than when the

discs are set to run in opposite directions. It is here

that you will also experience the beneift of Dual Drive

Technology™.

Production tip - To improve the cutting effi ciency of

diamonds, change directions on a regular basis. This

will work both sides of the diamond crystals, keeping

the abrasives as sharp as possible by creating maximal exposure of the diamond crystal.

Once both a speed and direction have been

nominated, switch on dust extraction or vacuum device.

Planetary

head

speed

Grinding disc

direction

Grinding disc

speed

As mentioned, when the machine is in operation it will

“pull” to one side. The direction of pull is determined by

the planetary head direction of rotation. The head of

the machine will pull to the right (and therefore, will be

felt on the right hip of the operator) when the planetary

head is set in the REVERSE direction.

This sideways pull can be very useful when grinding,

particularly along a wall. Set the machine so that it

pulls towards the wall, and then control the machine so

it can just touch the wall. This will ensure a grind close

to the wall or object.

IMPORTANT!

It is highly recommended to use the Husqvarna DC 5500 dust extraction system

for complete dust control.

Standing behind machine with handlebars set as

described earlier, apply a small amount of downward

pressure on the handle. Switch the machine to run

mode using the STOP/RUN switch on the control

panel. The machine should start smoothly and accelerate to the selected speed over a period of 5 seconds

English - 11

Page 12

Changing the diamonds

Changing the diamonds

As different applications require different selections of

diamond tools, there will be many occasions when the

grinding discs need to be changed.

Following is a guide for this procedure.

Preparation

1. Ensure STOP/RUN switch is in STOP position as

unintentional starting of machine while changing

discs

can result in serious injury.

2. Have a set of gloves ready, as diamonds can get

very

hot during dry grinding applications.

Changing

1. Set handle in upright position (illustrated right).

2. Pull back on handle to lift grinding head off the

ground.

4. Lay machine back on the ground.

5. Put on gloves.

6. Remove grinding disc by slightly rotating disc and

then

pull off (direction that the discs will need to be rotated

will depend on the direction the machine was last

running).

7. Check to ensure all head locks/shear pins are tight.

8. Once new diamonds have been attached, reverse

procedure to lower machine to ground.

9. As new diamonds may be a different height to set

being previously used, re-adjust skirt to ensure

good seal is established with the fl oor.

12 - English

Page 13

Variable speed drives/frequency converters

Variable speed drives/

frequency converters

Each Husqvarna PG 680 & 820 is equipped with 2

variable speed drive or frequency converter. This

unit is incorporated into the machine for the following

reasons:

1. Functional

• Manipulate incoming power to enable increase/

decrease in speed & direction change.

• Regulate current and voltage supply to the motors

to ensure motors run at optimum levels (e.g.

torque boost).

2. Protection/Diagnostic

Protection

• Monitors incoming power to ensure suitability for

machine and application being performed.

• Controls current being drawn by motors to ensure

motors are running within safe operational limits (to

prevent damage to motor).

• Monitors load on machine to ensure the grinder is

not being overloaded thus offering protection for

belt, bearings and other internal components.

2.

1.

8.

7.

• Protects motors from faulty power supply (e.g. running on 2 phases).

Diagnostic

• Identifi es electrical faults with the machine and

registers fault code.

• Has monitoring menus that help isolate cause of

potential electrical faults.

• Monitoring menus also enable operator to gauge

how hard machine is working. Whilst it is not essential for an operator to intimately know every feature

of the variable speed drives or frequency converters, it is useful to be familiar with both the fault

codes as well as some of the monitoring menus.

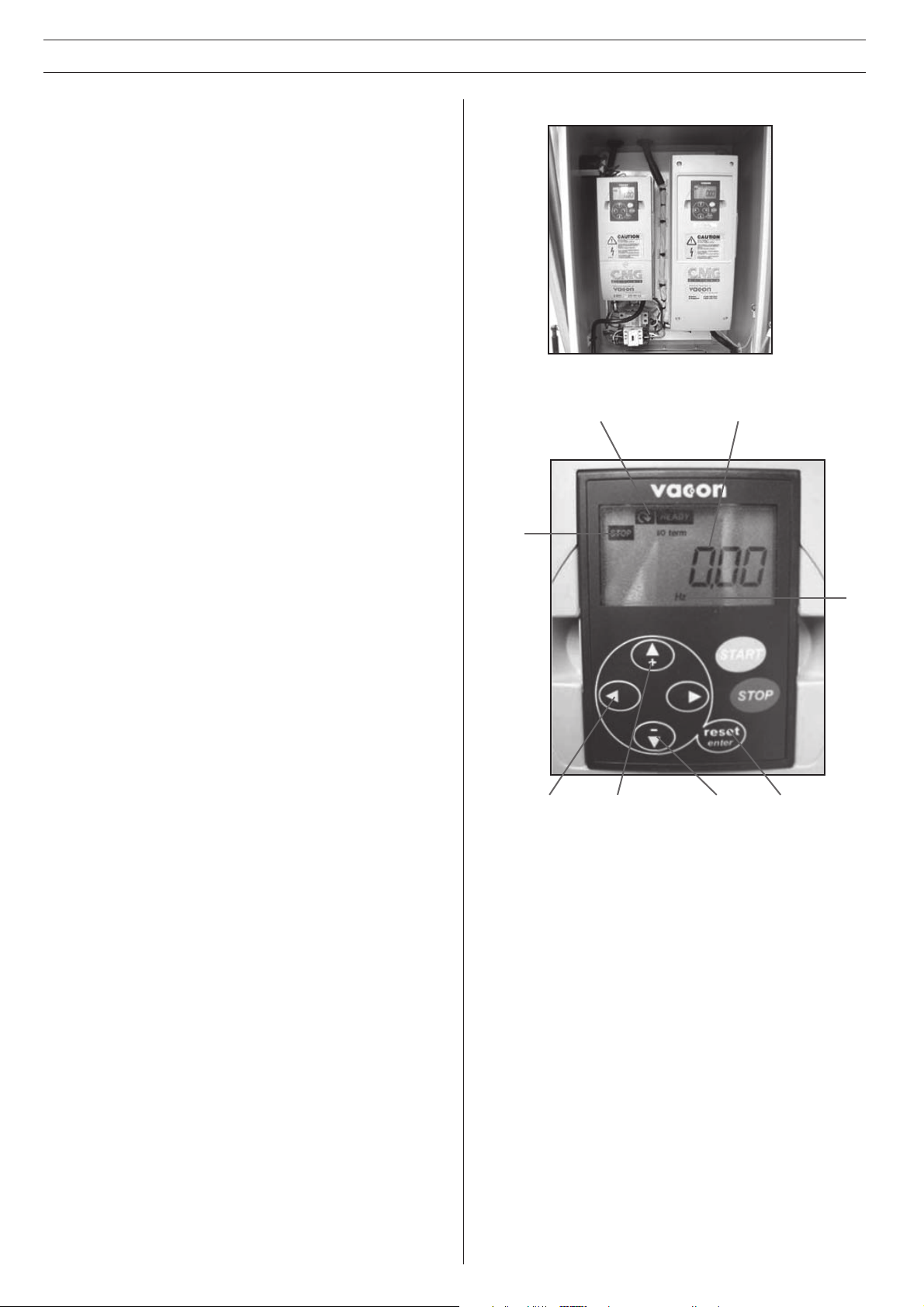

Keypad/Display

Each variable speed drive or frequency converter has

a keypad which will appear as illustrated on the right

when the machine has power connected to it.

4. 3.

1. Run direction (fwd or rev)

2. Indicates if unit is either stopped or running

3. Up key

4. Left key

5. Down key

6. Reset button

7. Output mode (Hertz in this example)

8. Output value

5.

Keypad display

6.

English - 13

Page 14

Variable speed drives/frequency converters

Monitor screen Information provided

OUTPUT FREQUENCY Frequency motor is running at when machine is running.

REF. FREQUENCY Frequency speed control dial is set to.

MOTOR SPEED Speed of motor when machine is running.

MOTOR CURRENT Current draw of motor when machine is running.

MOTOR TORQUE Percentage of motor torque when machine is running.

MOTOR POWER Percentage of motor power when machine is running.

MOTOR VOLTAGE Percentage of motor voltage when machine is running.

DC LINK VOLTAGE Indicates quality of power supply.

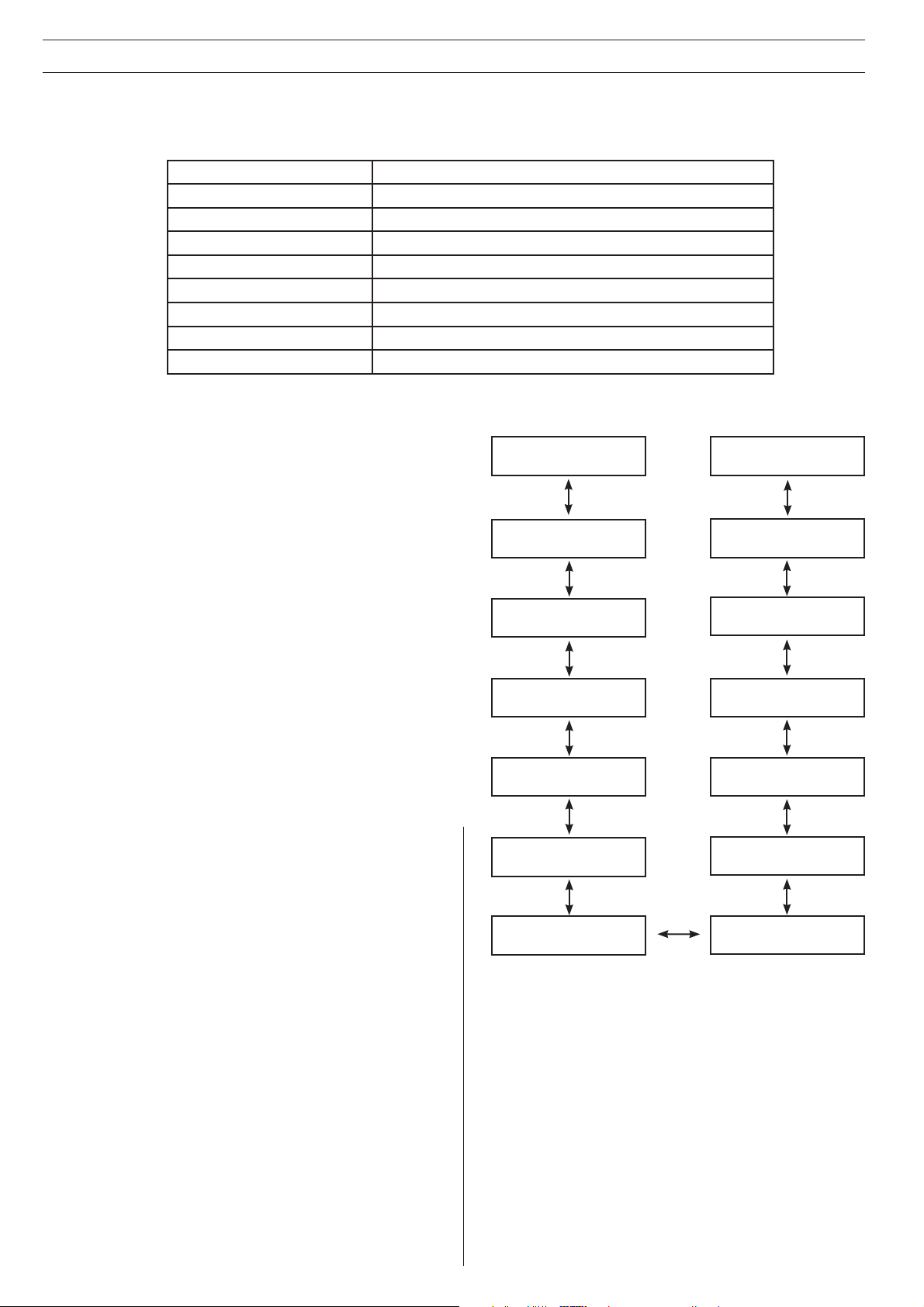

The menu tree illustrated on this page outlines the

important menu options that provide useful information

for monitoring and diagnostic purposes when using the

machine.

As can be seen on the menu tree to the right, when

the machine is turned on, the variable speed drives or

frequency converters are set to display the Output Frequency to the motor (a zero value will register when the

machine is in stand-by mode).

The Output Frequency page also falls under the Monitor

Menu.

It can be seen from the left hand column, the two primary

menus important to the operator are the Monitor Menu

and Fault History menu.

Navigation through the menu tree is achieved by using the up, down, left and right keys on the keypad (see

previous page).

Parameter Menu

Keypad

Control Menu

Active Faults Menu

Faults History Menu

System Menu

Expanded Boards

Menu

DC Link Voltage

Motor Voltage

Motor Power

Motor Torque

Motor Current

Motor Speed

14 - English

Monitor Menu

Output Frequency

Page 15

Variable speed drives/frequency converters

Menus and information they provide

The following menu items/screens on the variable

speed drive/frequency converters provide the following

useful information to the operator.

OUTPUT FREQUENCY (Monitor Menu)

This screen tells the operator the frequency the motor

is running at when the machine is in operation. The

value for output frequency should be constant when

the machine is running. If there is a fl uctuation in

output frequency when the machine is running, generally this indicates the motor is running at or near the

limit of its programmed current limit. The current limits

(predetermined and set by Husqvarna Constructions

Products) are as follows:

1. Large motor (which information is found on the large

variable speed drive/frequency converter) - 25

amps.

FAULT HISTORY

The fault history menu stores the last series of faults

experienced by the variable speed drive/frequency

converter. If there is a recurring fault pattern experienced by the machine, the information can be obtained

from the fault history menu. For more on faults, see

trouble shooting faults

2. Small motor (which information is found on the small

variable speed drive/frequency converter) - 5 amps.

If there is a fl uctuation in output frequency when the

machine is in operation, it is advisable to check the

motor current as well. This can be found by pressing

the UP arrow on the keypad 3 times. For trouble free

operation concerning current issues, it is best to keep

output current at or around 21 amps (for the large motor). The current draw of the motor can be reduced by

reducing the speed of the motor using the speed dial

on the control panel near the handle bars.

Generally speaking, most over-current problems will

be associated with the large motor (and therefore,

monitored on the large variable speed drive/frequency

converter). Keep the current draw on the small motor

under 3.5amps for consistent operation.

MOTOR CURRENT (Monitor Menu)

This screen displays the current draw of the corresponding motor (i.e. large variable speed drive/frequency converter monitors function of large motor,

small variable speed drive/frequency converter monitors function of small motor) when the motor is running.

See comments already covered under OUTPUT FREQUENCY relating to motor current.

DC LINK VOLTAGE (Monitor Menu)

This screen displays the quality of the power supply to

the machine. It will read higher values when the machine in standby and lower values when the machine

is in operation.

English - 15

Page 16

Faults and trouble shooting

Faults and trouble shooting

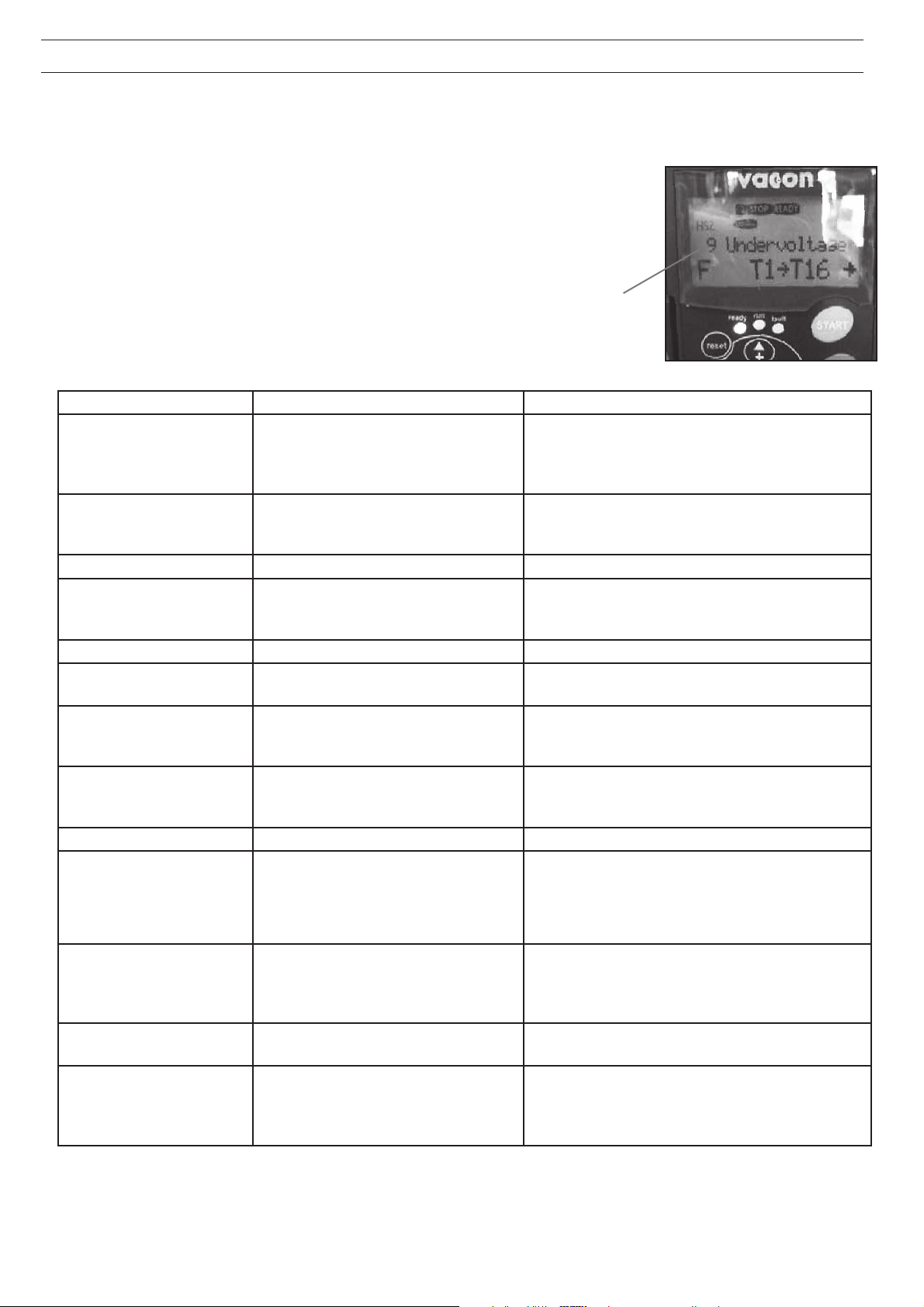

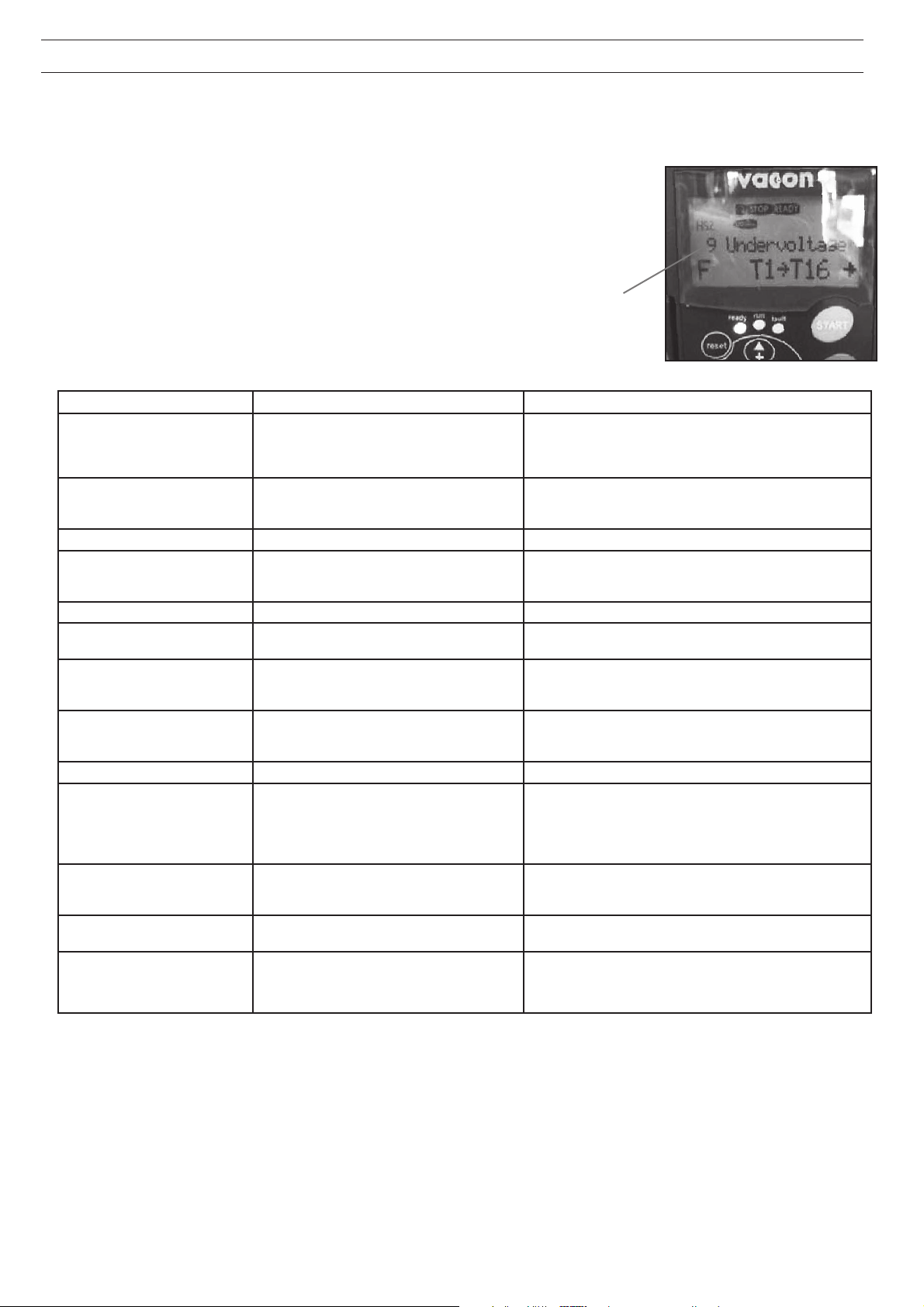

When either one of the variable speed drives or frequency converters in the machine experience a fault and “trip”

out, they will cease to run and an error message will appear fl ashing on the keypad display (see picture below).

The following list are the most commonly experienced

faults and possible action steps.

Fault Code Possible Cause Action

1—OVERCURRENT Motor being worked too hard and

drawing extra current.

Short circuit on output side of variable speed drives or frequency converters.

Motor failure (very rare) Have motor tested and replace if required.

3—EARTH FAULT Short circuit on output side of vari-

able speed drives or frequency converters.

Motor failure (very rare) Have motor tested and replace if required.

9—UNDERVOLTAGE Insuffi cient voltage supply to ma-

chine.

Power supply to variable speed

drives or frequency converters has

been turned off.

11—OUTPUT PHASE

SUPERVISION

14—UNIT OVER TEMPERATURE

Short circuit on output side of variable speed drives or frequency converters.

Motor failure (very rare) Have motor tested and replace if required.

Variable speed drives or frequency

converter over temperature due to

high temperature working environment or faulty temperature sensor.

Check current being drawn when machine is

running. Reduce speed setting and current draw

back into acceptable limits as described on

previous page.

Check wiring in plugs connected to motor cables

or inside connection boxes on motors.

Check wiring in plugs connected to motor cables

or inside connection boxes on motors.

Check power supply and ensure correct voltage.

Re-connect power to grinder.

Check wiring in plugs connected to motor cables

or inside connection boxes on motors.

Open door on electrical cabinet to increase ventilation.Have variable speed drives or frequency

converter tested by service agent.

Fault code

15—MOTOR STALLED Motor being worked too hard and

drawing extra current.

Mechanical jam preventing motor

from turning.

16 - MOTOR OVERTEMPERATURE

16 - English

Motor being worked too hard and

drawing extra current.

Check current being drawn when machine is

running. Reduce speed setting and current draw

back into acceptable limits as described on

previous page.

Try rotating grinding discs and planetary head by

hand to see if jam exists

Check current being drawn when machine is

running. Reduce speed setting and current draw

back into acceptable limits as described on

previous page.

Page 17

Faults and trouble shooting

Further problems that may be experienced when using the grinder and potential solutions are as follows:

Problem Possible Cause Potential Solution

GRINDER IS HARD TO HOLD

ONTO

GRINDER SOUNDS LIKE IT IS

OVERREVVING

GRINDER IS JUMPING AROUND Grinding heads may be worn-out or

Not enough diamonds under the

machine (if grinding thick glue or

soft fl oors, too few diamonds under

the machine will greatly increase

the load on grinder and operator).

Usually also accompanied by high

current draw by large motor.

Large motor not working (this can

be caused by fault with motor, fault

with wiring to motor, or fault with

large variable speed drive or frequency converter).

Drive belt is slipping. Remove belt tensioner cover plate on bottom of

Drive belt is broken (this can be

confi rmed by turning one of the

grinding heads by hand. If all grinding heads rotate together, belt is not

broken. If only one grinding head

turns, belt is broken).

Small planetary drive motor not

plugged in.

Small motor not working (this can

be caused by fault with motor, fault

with wiring to the motor, or fault

with large variable speed drive or

frequency converter).

damaged.

Diamonds may not be fi tted cor-

rectly or different height diamonds

may be on the grinding heads.

Increase number of diamonds under machine to

reduce load on grinder and operator.

Check large motor is plugged in. Check there

are no faults on larger variable speed drive or

frequency converter. Check that large variable

speed drive or frequency converter is on. Check

that large variable speed drive or frequency

converter is func tioning properly (unplug both motors, set display on keypad to Output Frequency,

switch machine to RUN, see if numbers on screen

change from zero and begin counting up. If numbers stay on zero, large variable speed drive or

frequency converter is not receiving run command

from switch on control panel. Machine needs to

be checked by an electrician or by Husqvarna

Construction Products

machine and check there is no water or dust on

the inside of the machine that may be causing the

belt to slip on the drive pulleys.

Replace internal drive belt.

Check small planetary drive motor is plugged in.

Check small motor is plugged in. Check there are

no faults on small variable speed drive or frequency converter. Check that small variable speed

drive and frequency converter is on. Check that

small variable speed drive or frequency converter

is functioning properly (unplug both motors, set

display on keypad to Output Frequency, switch

machine to RUN, see if numbers on screen

change from zero and begin counting up. If numbers stay on zero, small variable speed drive or

frequency converter is not receiving run command

from witch on control panel. Machine needs to be

checked by an electrician or Husqvarna Construction Products.

Check grinding heads for broken parts or excess

movement.

Check to ensure all diamonds are fi tted correctly

and are the same height.

Head locks may be loose or missing.

Check to ensure all head locks are present and

tight.

English - 17

Page 18

Diamonds

Diamonds

Background

Diamond abrasives usually consist of 2 components:

1. Diamond powder (also known as diamond crystals

or grit). By changing the size of the diamond powder

or grit, we can change how coarse or fi ne the

scratches will be that are left behind from the

grinding process.

2. A binding agent (metal or resin). Diamond powder

is mixed and suspended in either a metal or resin

binding agent. When suspended in a metal binding

agent, the fi nished product is referred to as a Metal

Bond or Sintered diamond segment. When suspended

in a resin binding agent, the fi nished product is

referred to as a Resin Bond diamond segment or

pad. By changing the hardness of the binding agent,

we can change how fast or slow the diamond abrasive

will wear.

General Principles

The following are general rules regarding diamond segments in grinding applications. As with all general rules

there are exceptions or cases when it is not the case.

DIAMOND GRIT SIZE

Changing the size of the diamond grit to a smaller particle/grit size will effect the performance of the diamond

tool in the following ways:

• Create a fi ner scratch pattern.

• Increase the life of the diamond tool.

NUMBER OF DIAMOND SEGMENTS/PADS UNDER

THE MACHINE

Increasing the number of segments under the machine

will:

• Reduce pressure on each individual diamond segment.- Reduce wear rate on diamond segments.

• Reduce load on the machine and cause the grinder

to draw less current.

• Create a smoother scratch pattern (particularly on

soft fl oors).

The opposite will occur when decreasing the number

of segments under the machine.

WET AND DRY GRINDING

When using diamond segments wet, the following

principles apply:

• Production rates will be higher than dry grinding.

• Diamond segments will wear faster (due to presence of slurry) and therefore, harder bonds can be

used (when comparing with dry grinding).

• Scratches from diamond grit will be deeper.

When using diamond segments dry, the following principles apply:

• Production rates will be slower on harder materials

than if wet grinding.

• Softer bond segments will be required in order to

encourage segment wear (as there will be not slurry

to help diamond segments to wear).

The opposite will occur when changing to a larger

particle/grit size.

BINDING AGENT—METAL BOND OR RESIN BOND

Increasing hardness of bond will:

• Increase life of diamond tool.

• Decrease production rate.

• Cause diamond tool to leave fi ner scratches in dry

- grinding applications (when compared to a softer

bond diamond tool with the same diamond grit size).

The opposite will occur when making the metal or resin

bond softer.

• Scratches from diamond grit will not be as deep

compared to if it were also used for wet grinding.

• There will be more heat generated by the diamond

segment.

Summary of diamond principles

Diamond segments need to wear in order to achieve

productivity. Diamond segment wear can be infl uenced

by the following factors:

• Pressure.

• Hardness of bond.

• Diamond grit size.

• Presence of water.

• Number of segments under the machine.

• Adding an additional abrasive (e.g. sand, silicone

carbide) on the fl oor will increase wear.

18 - English

Page 19

Diamond selection

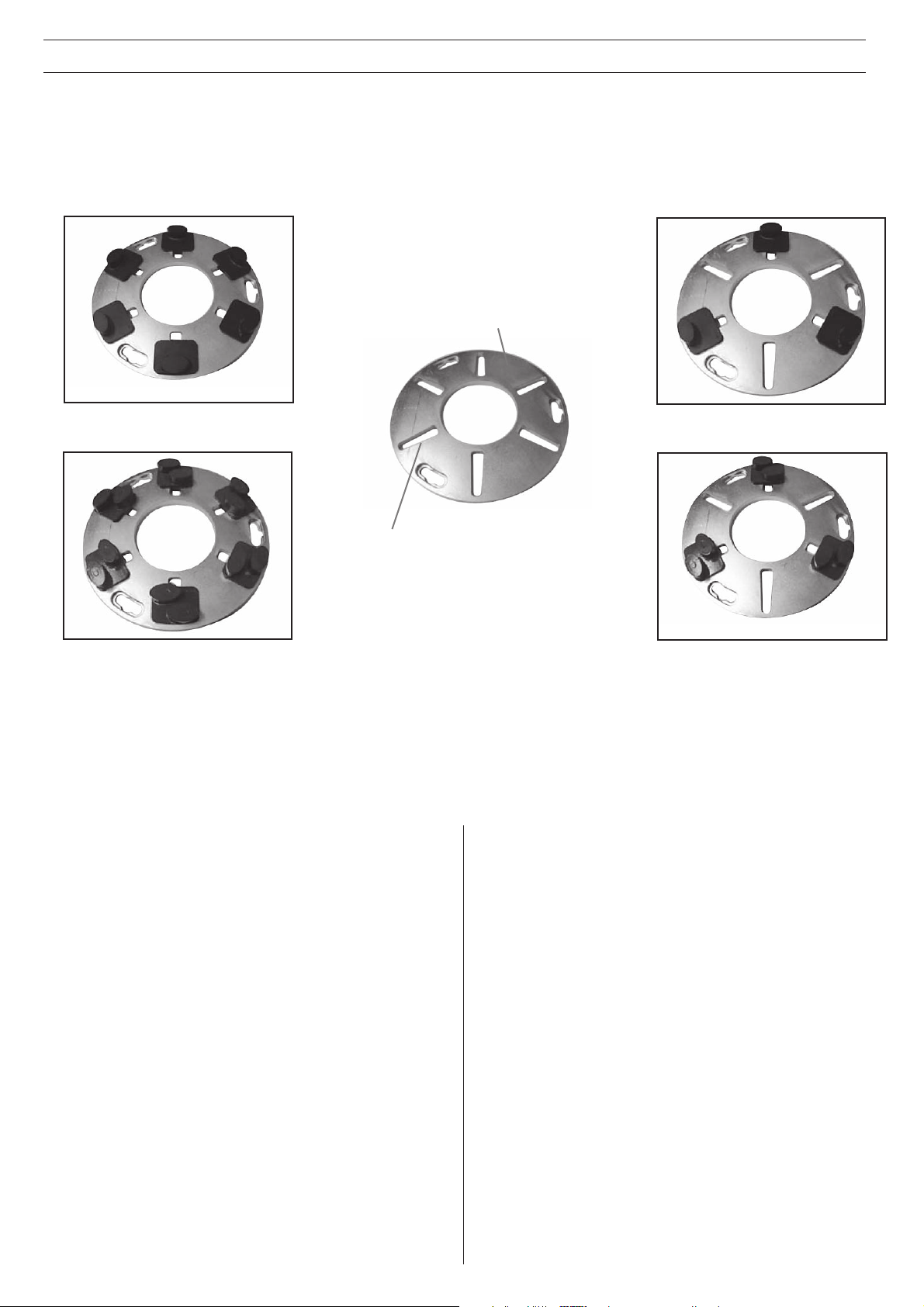

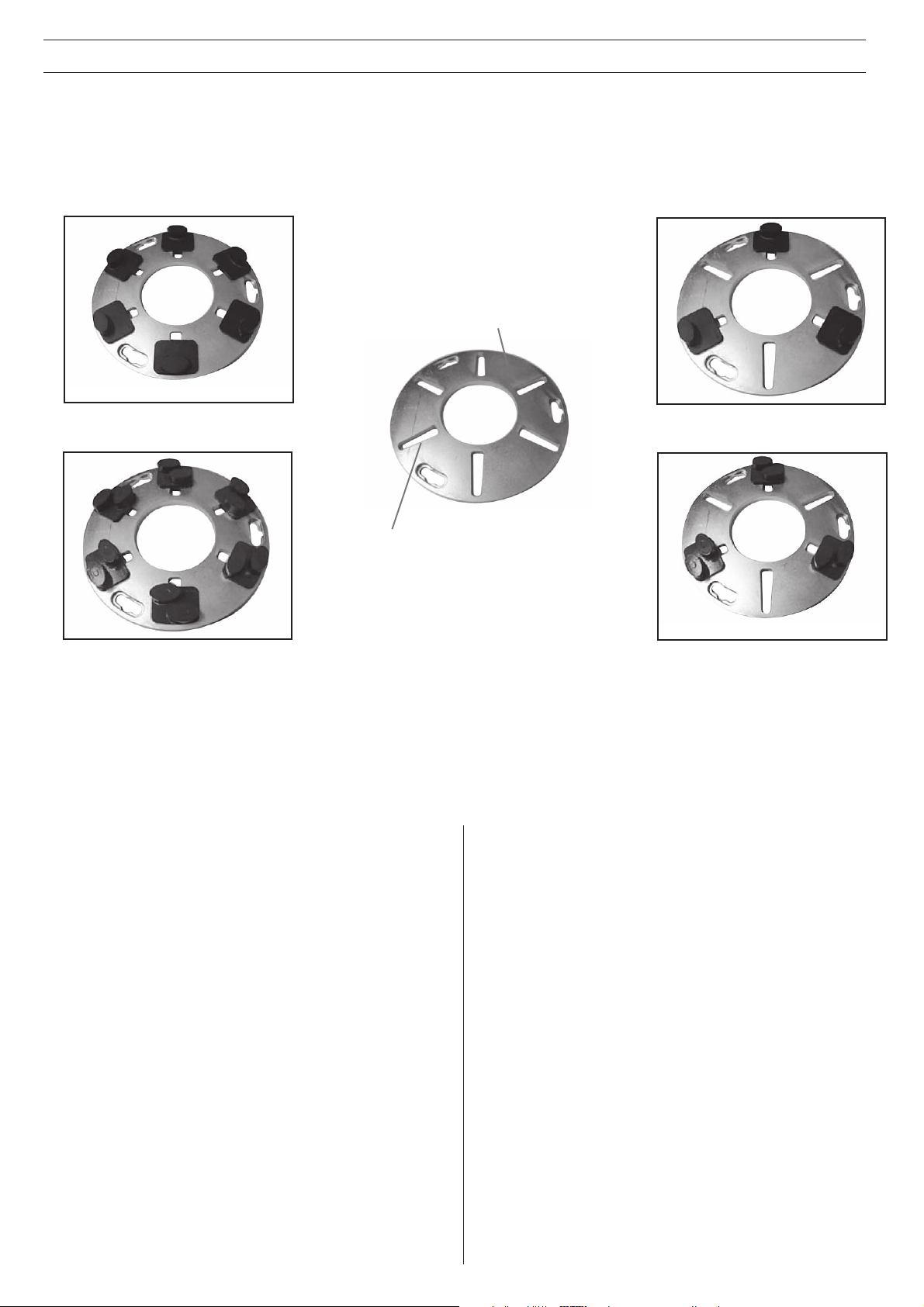

Diamond Holder Disc

Full set of single segments

Position for Diamond segment

Full set of twin segments

Generally speaking, the faster a diamond segment

wears, the faster the productivity will be. By varying the

above factors, changes can also be made to effect the

following:

• Scratch pattern.

• Current draw of machine.

• Flatness of fl oor (see next section).

Half set of single segments

Half set of twin segments

Diamond selection

The following section covers important factors to

consider when selecting the diamond segment you are

going to use for a given application.

Grinding disc set-up

The way diamond segments are set-up on the grinding

heads of the machine will also greatly infl uence the

performance of the machine, the productivity levels

and also the fi nished fl oor quality.

• Ease of operation.

There are basically two types of diamond confi gura-

tions that can be used when using the grinder:

1. Full set of diamonds – when there are diamonds

placed

at each of the six positions on the diamond holder

discs

(see pictures above).

2. Half set of diamonds – when there are diamonds

placed

at three alternating positions on the diamond holder

discs (see pictures above).

English - 19

Page 20

Diamond selection

Full and half sets of diamonds

By changing the way the diamonds are set-up on the

diamond holder discs, an operator can signifi cantly ef-

fect the performance of the machine and therefore, the

fi nished product.

HALF-SET OF DIAMONDS

When the diamonds are set-up as a half-set, they tend

to follow the surface of the fl oor. Similar to a tripod for a

camera, which can be placed on an uneven surface and

yet still fi nd a stable footing.

The half-set diamond confi guration should only be used

when a fl at fl oor fi nish is not required.

FULL-SET OF DIAMONDS

When the diamonds are set-up as a full-set, they tend

not to follow the surface of the fl oor. If the fl oor has undu-

lations, the machine will grind the high areas yet miss

the low spots (unless the high areas are ground down

fi rst).

The full-set diamond confi guration should be used when

a fl at fl oor fi nish is desired.

The below table gives some examples of possible applications for the two arrangements:

Application Full set is best Half set is best

Ceramic tile adhesive removal X

Carpet glue removal X

Epoxy paint removal X

Vinyl adhesive removal X

Rain damaged concrete X

Smoothen exposed aggregate X

Lippage removal in terrazzo/stone tiles X

Surface polishing of concrete fl oors X

Grinding to expose aggregate in concrete polishing application X

Remove lippage from terrazzo/natural stone tiles X

Flatten undulations in concrete fl oors X

Re-polish fl oors that have been ground before X

20 - English

Page 21

Diamond selection

Selecting the correct diamonds for your application

The following suggestions cover the basic principles for

diamond selection for different applications.

Application Metal

bond

Flatten fl oor - Hard concrete SOFT 16 or 30 X S

Flatten fl oor - Medium concrete MEDIUM 16 or 30 X S

Flatten fl oor - Soft concrete HARD 16 or 30 X T

Ceramic tile adhesive removal HARD 6, 16 or 30 X S/T

Vinyl or Carpet glue removal - Hard concrete SOFT 16 or 30 X S/T

Vinyl or Carpet glue removal - Medium concrete MEDIUM 6 or 16 X T

Vinyl or Carpet glue removal - Soft concrete HARD 6 or 16 X T

Epoxy paint removal - Hard concrete SOFT 6, 16 or 30 X X S

Epoxy paint removal - Medium concrete MEDIUM 6, 16 or 30 X S

Epoxy paint removal - Soft concrete HARD 6, 16 or 30 X S/T

Rain damaged concrete HARD 16 or 30 X S/T

Smoothen exposed aggregate HARD 16 or 30 X S/T

Lippage removal in terrazzo - stone tiles SOFT 30 or 60 X S

Surface polishing of concrete fl oors - Hard concrete SOFT 60 X S/T

Surface polishing of concrete fl oors - Medium concrete MEDIUM 60 X S/T

Surface polishing of concrete fl oors - Soft concrete HARD 60 X T

Grinding to exposed aggregate in concrete - Hard concrete SOFT 16 or 30 X S

Grinding to exposed aggregate in concrete - Medium con-

crete

Grinding to exposed aggregate in concrete - Soft concrete HARD 16 or 30 X T

Flatten undulation in concrete fl oors - Hard concrete SOFT 16 or 30 X S

Flatten undulation in concrete fl oors - Medium concrete MEDIUM 16 or 30 X S

Flatten undulation in concrete fl oors - Soft concrete HARD 16 or 30 X T

MEDIUM 16 or 30 X S

Grit size Full-

set

Half

set

Singles /

Twins

English - 21

Page 22

Diamond selection

Determining the hardness of concrete

All concrete may feel hard (particularly if you fall over

on it), so what do we mean when we talk about hard,

medium and soft concrete?

All concretes are measured by their compressive

strength and depending on which part of the world you

are from, different compressive strength indices (e.g.

PSi & MPa). Generally speaking, the higher the compressive strength rating, the harder the concrete and

therefore, the harder it will be to grind.

However, other factors beside compressive strength

ratings determine how hard the fl oor will be, and

therefore, the correct diamond selection. Since grinding normally only deals with the surface of the concrete

(top 5mm or 1/4 inch), often the way the concrete fl oor

has been fi nished or the condition of the surface will

have a greater bearing on what type of diamond to

select, rather than the compressive strength rating of

the concrete.

SURFACE FACTORS TO CONSIDER WHEN MAKING A DIAMOND SELECTION

Generally speaking, if a concrete surface is very

smooth (i.e. Most likely it has been heavily trowelled/

helicoptered), the concrete will behave as if it has a

high compressive strength and therefore, require a soft

bond segment.

Accordingly, if a concrete surface is coarse/aggressive

(e.g. rain-damaged, shot blasted, scarifi ed, exposed

aggregate e.t.c.), the concrete will behave as if it has a

low compressive strength and therefore, require a hard

bond segment.

Surface coatings/contaminants (e.g. Epoxy coatings,

ceramic tile adhesives, levelling compounds/screeds)

will often have a larger bearing on what diamond to select, than will the compressive strength of the concrete.

As a general rule, when grinding a concrete slab for

the fi rst time and you are unsure about its hardness,

always begin with harder bond diamonds under the

machine. This will ensure the least amount of wear on

the diamond segments. If a hard diamond segment

is not suited to the application, all it has cost is a little

amount of time without wearing out the diamonds.

If performed the other way around (i.e. a soft segment

is used to begin with) and the concrete is soft or possesses an abrasive surface or surface contaminant, it

is quite possible to wear-out a considerable amount of

diamond in very short period of time.

22 - English

Page 23

Maintenance

Maintenance

Used correctly, the machine is an extremely low-maintenance and reliable.

This section covers the general maintenance items

that need attention on a periodic basis.

There are three main mechanical items to check:

1. Grinding Heads.

2. Planetary drive system.

3. Planetary seal.

Grinding heads

There are 2 different grinding head options:

11. Conventional / Demolition heads—designed for

heavy duty preparation grinding where an extremely

robust system is required.

2. Spring steel head system—designed more for fi nish-

ing or lighter grinding applications.

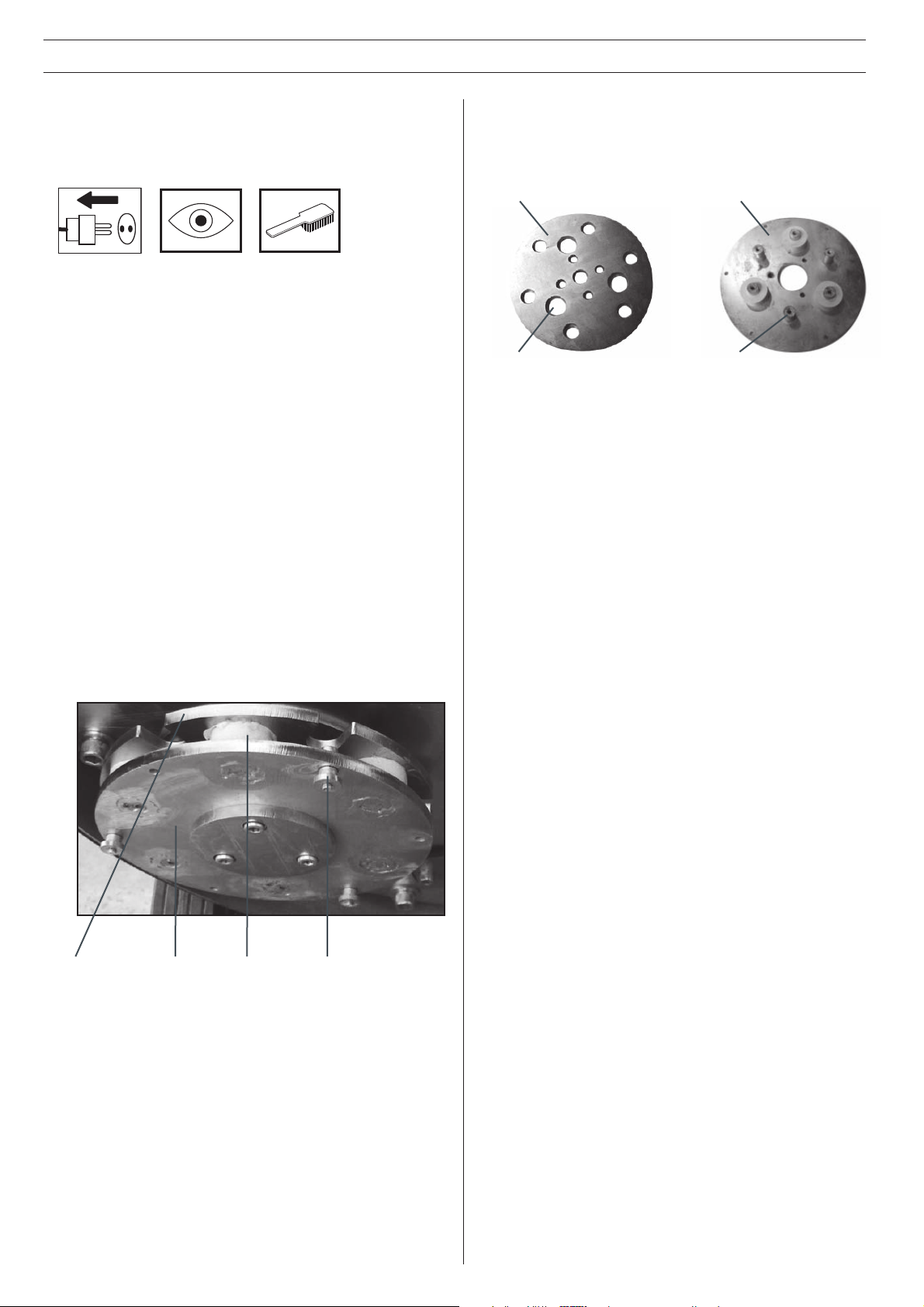

CONVENTIONAL/DEMOLITION HEADS

The below diagram illustrates the main parts compris-

ing this type of grinding head.

The head pins are fi xed to the head plate giving rigid-

ity and stability. The head mate is situated above the

head plate and is held in place by a series of holes

– head pin holes.

1.

2.

1. Head mate 1. Head plate

2. Head pin hole 2. Head pins

Between the head plate and head mate are 3 white

silicone springs which give shock absorption and fl ex-

ibility in the system.

The head pins are able to move within the head pin

holes, creating a shock absorber type system similar to

that in most motor vehicles.

Over an extended period of time, the head pin holes

wear open. Along with this, the head pins wear and

reduce in diameter. This combined wearing of the two

creates excessive movement or “slop” within the grinding heads. This “slop” will eventually cause vibration

whilst the machine is operating.

1.

2.

2.1. 4. 3.

1. Head mate

2. Head plate

3. Head lock

4. Head spring

The interrelation between the above four components

enables a dynamic system which is both robust and

fl exible.

Routine checks for slop in the grinding heads are

recommended. Life expectancy for grinding heads can

vary between 6 and 12 months depending on amount

of usage.

Replacement heads are available and simply bolt into

place when the old ones are removed

English - 23

Page 24

Maintenance

Spring Steel Heads

The below diagrams illustrate the main parts comprising

this type of grinding head.

Diagram 1

1. Spring steel spring

2. Head plate

3. Cushion ring

4. Head mate

Diagram 1. Spring Steel Head

1.

4.

3.

Between the head plate and head mate are a series of

white silicone springs, spacers and the spring steel spring

which give shock absorption and fl exibility in the system.

Unlike with the conventional/demolition heads, the spring

steel heads are able to move in a fl exible manner without

any moving parts due to the presence of the spring steel

spring.

Over an extended period of time the spring steel spring

fatigues and the spring steel “fi ngers” begin to break

off. This creates irregular movement within the grinding

heads and will cause vibration when the machine is in

operation.

Routine checks for broken “fi ngers” in the spring steel

grinding heads are recommended. Life expectancy

for grinding heads can vary between 6 and 12 months

depending on the amount of usage.

Replacement spring steel springs are available and can

be replaced without throwing the grinding head away.

The spring steel heads can also be made less fl exible

by the addition of a second spring steel spring.

2.

Diagram 2

1. Spring steel springs

2. Bolts

3. Silicone spring

4. Head mate

5. Cushion ring

6. Head buddy

7. Spacers

8. Head plate

Diagram 2

1.

7. 8.

24 - English

3. 4. 5.6.

2.

Page 25

Maintenance

Grinding Heads Drive System

The grinder comes equipped with Dual Drive Technology™. As the grinding discs are driven by the large motor via an internal belt, and because the belt is sealed

inside the machine, there is no maintenance regarding

this drive system until a major service (belt and bearing

replacement) is due. This is typically following 12-36

months of operation.

Planetary Drive System

The second component to the Dual Drive Technology™ system is the planetary head drive system which

is powered by the secondary or small motor and

gearbox arrangement. This system is on the outside

of the machine and will require routine maintenance.

The planetary drive system can be seen as illustrated

diagram 1.

Diagram 1

1. Grinding heads motor

2. Motor terminal box

3. Machine cover

4. Gearbox mounting bracket

5. Gearbox fl ange bracket

6. Gearbox

7. Motor terminal box

8. Planetary drive motor

IMOPRTANT!

Lubrication of this system will cause dust to

build up in chain ring and drastically shorten

the life of both the chain ring and planetary

drive sprocket.

Diagram 2 Diagram 3

1. 2. 1. 2.

1. Planetary drive sprocket

2. Gearbox fl ange bracket

Diagram 3

1. Machine cover

2. Chain ring

1.

8.

7.

6.

3.

2.

Diagram 1. Planetary Drive System

Beneath the gearbox and concealed by the mounting

brackets and machine cover, there is a planetary drive

sprocket situated on the output shaft of the gearbox.

This planetary sprocket engages with the chain ring

(also located beneath the machine cover) and

together form the main drive mechanism for the planetary drive system. This system is a dry system (i.e. it

is not required for there to be lubrication between the

planetary drive sprocket and chain ring), to allow any

dust that may come into contact with the chain ring to

fall back out again.

4. 5.

Diagram 4

1. Planetary seal

As the chain ring and planetary drive sprocket are

located beneath the cover of the machine, yet on the

outside of the machine, there lies the potential that

they can be exposed to dust and other debris created

during the grinding process.

To prevent this as much as possible, a planetary seal

has been installed to stop dust and other particles from

coming into contact with the planetary drive mechanism.

Diagram 4

1.

Planetary seal - closeup

English - 25

Page 26

Maintenance

The effectiveness of the planetary seal can be monitored by the simple removal of the planetary motor

/ gearbox system by removing the four bolts shown

below.

Remove 2 bolts either

side.

Remove 2 bolts either

side.

Remove this bolt.

Inspect for dust build

up here

If the planetary seal is working effectively, there should

be a very minimal amount of dust observed under

the cover of the machine. If there is a build-up of 56mm (1/4 inch), then it is more than likely it is time to

remove the machine cover and check the condition of

the planetary seal.

Remove this bolt.

Remove cover off motor

terminal box.

Remove these bolts.

26 - English

Lift off machine cover to reveal chain ring and planetary

seal.

If planetary seal is worn or needs replacement, contact

your Husqvarna Construction Products distributor for a

new planetary seal replacement kit.

Page 27

Maintenance schedule

Maintenance schedule

Item Action Frequency

Check that head locks

are tight.

Inspect heads for slop/

broken “fi ngers” if using

spring steel heads.

Check effectiveness of

planetary seal.

Check condition of

chain ring.

Tighten head locks and re-set in thread-locking compound if required (Suggested thread-locking compound

Loctite 680)

Examine machine heads while machine tipped back.

Disconnect Planetary Drive motor (small motor) and run

discs at lowest speed. Check to see how concentric/true

grinding heads are running.

Remove planetary head motor/gearbox system and

check for presence of dust under machine cover .

Remove planetary head motor/gearbox system and inspect chain links in chain ring. Ensure links are clean and

free from build-up.

Daily

Daily

Weekly

Weekly with Planetary Seal

Check condition of

Drive Sprocket.

Inspect internal components of machine.

Clean contents of electrical cabinet.

IMOPRTANT!

Prior to removing belt tensioner cover plate,

ensure cover plate and area surrounding cover

plate are totally clean. Avoid debris from entering into inside of machine.

Remove planetary head motor/gearbox system and

inspect condition of planetary drive sprocket.

Remove belt tensioner cover plate and check inside

machine for dust, moisture or belt fragments. Ensure to

re-seal cover plate with silicone sealant.

Blow out inside of electrical cabinet and variable speed

drives or frequency converters with DRY compressed air.

Weekly with Planetary Seal

6 monthly

Every 2 months

English - 27

Page 28

Technical Data

Technical Data PG 820 PG 680

Grinding width 820mm (32") 680mm (27")

Grinding disc 3x270mm (10.5") 3x240mm (9.5")

Weight 440kg (970lbs) 385kg (850lbs)

Grinding pressure total 335kg (737lbs) 300kg (660lbs)

Grinding pressure per disc 112kg (246lbs) 100kg (220lbs)

Motor Power 3-Phase 380-480V

3-Phase 380-480V

12.5kW(17.0hp)

12.5kW(17.0hp)

Power per grinding disc 4.15kW (5.7hp) 4.15kW(5.7hp)

Grinding disc speed 250 - 1100rpm 600 - 1200rpm

Planetary head speed 5 - 65rpm 5 - 70rpm

Direction of rotation Independent FWD/REV direction control

on both grinding discs and planetary head.

Power supply 3 phase 3 phase

Noise emissions (see note 1)

Sound power level, measured dB(A) 105

Sound power level, guaranteed L

dB(A) 106

WA

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 88

Vibration levels, a

Handle right, m/s

Handle left, m/s

(see note 3)

hv

2

2

2,7

4,8

Note 1: Noise emissions in the environment measured as sound power (L

) in conformity with EN 61029-1.

WA

Note 2: Noise pressure level according to EN 61029-1. Reported data for noise pressure level has a typical statistical

dispersion (standard deviation) of 1.0 dB(A).

Note 3: Vibration level according to EN 61029-1. Reported data for vibration level has a typical statistical dispersion

(standard deviation) of 1 m/s

2

.

28 - English

Page 29

Technical Data

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that the Husq-

varna PG 680, PG 820, from 2010´s serial numbers and onwards (the year is clearly stated in plain text on the rating

plate with subsequent serial number), conforms with the requirements of the COUNCIL’S DIRECTIVE:

• of May 17, 2006 “relating to machinery” 2006/42/EC

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-

3-2:2006, EN 61000-3-3/A1/A2:2005, EN 13862/A1:2009.

Göteborg December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

English - 29

Page 30

Índice

30 - Spanish

Page 31

Índice

Español

Índice

Signifi cado de los símbolos 32

Instrucciones de seguridad 34

Introducción 35

Transporte 35

Almacenamiento 35

Componentes de la máquina 36

Puesta en marcha / Manejo 38

Cambio de los diamantes 40

Discos de velocidad variable/

convertidores de frecuencia 41

Fallos y localización de fallos 44

Diamantes 46

Selección de diamantes 47

Mantenimiento 51

Programa de mantenimiento 55

Datos técnicos 56

Spanish - 31

Page 32

Signifi cado de los símbolos

32 - Spanish

Page 33

Signifi cado de los símbolos

Signifi cado de los símbolos

Los siguientes símbolos se usan en la máquina y en

este manual de instrucciones. Es importante que el

usuario entienda el signifi cado de los mismos para

trabajar con la máquina de forma segura.

Antes de utilizar la máquina, lea atentamente el manual de instrucciones y

asegúrese de haber comprendido las

instrucciones.

¡ADVERTENCIA! El polvo se forma

cuando se desbasta, lo que puede

provocar lesiones si se inhala. Use una

máscara respiratoria autorizada. Mantenga siempre una buena ventilación.

Utilice siempre:

• Casco protector aprobado

• Protección auditiva aprobada

• Gafas protectoras o un visor.

• El polvo se forma cuando se desbasta, lo que puede provocar

lesiones si se inhala. Use una máscara para el polvo.

La inspección y/o el mantenimiento se

deberá llevar a cabo con el motor apagado y el enchufe desconectado.

Comprobación visual.

Se requiere una limpieza regular.

Este producto cumple las disposiciones

de las Directivas CE aplicables.

Lleve siempre botas robustas antideslizantes con puntera de acero.

Utilice siempre guantes protectores

aprobados.

Spanish - 33

Page 34

Instrucciones de seguridad

Instrucciones de seguridad

ADVERTENCIA

La máquina no se podrá poner en marcha

bajo ninguna circunstancia si no se observan

las instrucciones de seguridad. Si el usuario

no cumpliera este requisito, Husqvarna

Construction Products Sweden AB o sus

representantes no tendrán ningún tipo de

responsabilidad, ya sea directa o indirecta.

Léase detenidamente estas instrucciones

de manejo y asegúrese de que entiende su

contenido antes de empezar a usar la máquina. Si después de leer estas instrucciones

de seguridad siguiera sin estar seguro de

los riesgos que implica para la seguridad, no

deberá usar la máquina; por favor, póngase

en contacto con su distribuidor para más

información.

• Por favor, lea con sumo cuidado el manual de

instrucciones.

• Sólo se le permitirá manejar la maquinaria a personal cualifi cado.

• No use nunca una máquina que esté defectuosa.

Lleve a cabo las comprobaciones, instrucciones

de mantenimiento y asistencia descritas en este

manual. Todas las reparaciones que no cubra este

manual las deberá llevar a cabo un reparador designado ya sea por el fabricante o por el distribuidor.

• Lleve siempre equipamiento de seguridad personal

como botas robustas antideslizantes, protección

auditiva, máscara para el polvo y protección ocular

aprobada.

• Extreme la precaución cuando mueva la máquina a

mano o en un plano inclinado. Incluso la pendiente

más suave puede provocar fuerzas/impulsos que

hagan que sea imposible frenar manualmente la

máquina.

• No use nunca la máquina si está cansado, si ha bebido alcohol, o si ha tomado alguna medicación que

pudiera afectar a su visión, su capacidad mental o

su coordinación.

• No use nunca una máquina que se haya modifcado

en algún sentido de su especifi cación original.

• Esté atento ante posibles descargas eléctricas. Evite

tener contacto corporal con pararrayos/metal en el

suelo.

• No arrastre la máquina nunca por el cordón y no

quite nunca el enchufe tirando del cordón. Mantenga todos los cordones y cordones de extensión

lejos del agua, aceite y bordes afi lados.

• Asegúrese de que el cordón no se quede atrapado

en puertas, vallas u objetos similares.

• Compruebe que el cordón y el cordón de extensión

están intactos y en buen estado. No use nunca

la máquina si el cordón está dañado, llévelo a un

taller de asistencia autorizado para su reparación.

• No use un cordón de extensión enrollado

• La máquina deberá conectarse a una toma de corriente de salida con toma de tierra.

• Compruebe que el voltaje principal se corresponde

con el que se indica en la placa de características

de la máquina.

• La máquina no se usará en áreas donde haya posibilidad de incendios o explosiones.

• La máquina sólo se deberá arrancar cuando los

cabezales desbastadores estén descansando en el

suelo, a no ser que se esté efectuando un procedimiento de prueba tal y como se indica en este

manual.

• La máquina no deberá ponerse en marcha sin el

faldón de goma para el polvo. Es fundamental que

se establezca una buena hermeticidad entre la

máquina y el suelo, sobre todo cuando se trabaje

en una aplicación de desbastado en seco.

• Cuando se cambien los discos desbastadores,

asegúrese de que está desconectada la toma de

corriente de la unidad pulsando el botón de parada

de emergencia y desenchufando el cable de alimentación.

• La máquina no se deberá levantar por las empuñaduras, el motor, el chasis y otras piezas. La mejor

manera de transportar la máquina será en una

paleta/patín al que se haya fi jado fi rmemente la

máquina.

• Asegúrese de que el cordón está detrás de Ud.

cuando empiece a usar la máquina, de modo que

no se pueda dañar el cordón.

No se deberá intentar levantar la maquina en

ningún momento sin medios mecánicos como un

cabrestante o un elevador de horquilla.

¡ADVERTENCIA!

La sobreexposición a la vibración puede

provocar lesiones circulatorias o del sistema

nervioso en personas que tengan mala circulación. Póngase en contacto con su médico

si tiene síntomas de sobreexposición a la

vibración. Estos síntomas incluyen entumecimiento, pérdida de sensación, cosquilleo,

ardor, dolor, pérdida de fuerza, cambios en

el color o el estado de la piel. Estos síntomas

aparecen normalmente en los dedos, manos

o muñecas.

34 - Spanish

Page 35

Introducción

Introducción

Las máquinas para preparar superfi cies Husqvarna

PG 680/820 se han diseñado para el desbastado

en seco o en mojado de mármol, terrazo, granito y

cemento. Sus aplicaciones abarcan desde un desbastado basto hasta un acabado completamente pulido.

Este manual se refi ere a la serie Husqvarna PG

680/820 de desbastadoras de suelo equipadas con un

disco de motor doble que se denominará en adelante

Dual Drive Technology™.

Es extremadamente importante que todos los usuarios

estén familiarizados con el contenido de este manual

antes de empezar a manejar una de las máquinas. Si

no fuera así, esto podría provocar daños en la maquinaria o la exposición del operador a peligros innecesarios.

¡IMPORTANTE!

Sólo deberá manejar la maquinaria aquel

personal que haya recibido la formación necesaria, tanto práctica como teórica acerca de

su uso.

¡IMPORTANTE!

La máquina no se deberá levantar por la empuñadura, el motor, el chasis y otras piezas.

La mejor manera de transportar la máquina

será en una paleta/patín al que se haya

fi jado fi rmemente la máquina. No intente

deslizar los dientes/horquillas de un elevador

de horquilla debajo de los cabezales desbastadores, a no ser que esté sobre una paleta/

patín. Si no lo hace, podrá provocar daños

irreparables en los cabezales desbastadores

de la máquina y en las piezas internas.

Se recomienda que la máquina se transporte con un

juego de diamantes sujeto en todo momento para

garantizar una protección del sistema de bloqueo de

las placas de diamantes.

Almacenamiento

La máquina deberá guardarse en un lugar seco,

cuando no esté en uso.

Transporte

La máquina viene equipada con sistemas electrónicos

avanzados incorporados llamados discos de velocidad

variable o convertidores de frecuencia. Estos discos

habilitan el componente de velocidad y dirección variable de cada uno de los motores. Los discos se encuentran situados en la caja de acero montada sobre

el chasis de la máquina.

Como con todo el equipamiento electrónico, los discos

son sensibles a una excesiva vibración, al maltrato y

elevados niveles de polvo. El fabricante ha dedicado

mucho cuidado y atención para garantizar la máximo

protección de los discos. Tenga en cuenta el sistema

de montaje de absorción de choques usado para

montar la caja de acero en el chasis/bastidor de la

máquina.

Cuando la transporte, es importante asegurarse de

que la máquina se ha fi jado correctamente en todo

momento para impedir que los discos de velocidad

variable vayan dando botes. Asegúrese de que la sección del chasis o el bastidor de la máquina está bien

fi jado en todo momento cuando se esté transportando.

La máquina se deberá transportar siempre cubierta,

limitando su exposición a los elementos naturales, en

particular a la lluvia y la nieve.

Spanish - 35

Page 36

Componentes de la máquina

1.

3.

2.

4.

5.

11.

10.

9.

6.

7.

Componentes de la máquina

1. Cuentahoras

2. Armario eléctrico

3. Motor del cabezal planetario 1,5kW/1CV

4. Motor de cabezales desbastadores/satélites 11kW/

15CV

5. Argollas de elevación

6. Cubierta/Protector

7. Faldón

8.

8. Chasis/Bastidor

9. Barras de la empuñadura

10. Panel de control

11. Ajustador de la barra de la empuñadura

36 - Spanish

Page 37

Componentes de la máquina

Esta máquina se puede dividir en dos partes principales. Éstas se pueden identifi car de la siguiente

forma:

1. Sección chasis/bastidor – comprende las barras de

la empuñadura, el armario eléctrico, el bastidor de

acero y las ruedas.

2. Cabezal – comprende los motores, la cubierta, los

cabezales desbastadores/satélites/planetarios y los

componentes internos.

La máquina se ha fabricado para permitir movimiento

entre el chasis y el cabezal a través del punto de conexión en las argollas de elevación y pernos del chasis.

Este movimiento es importante durante el proceso de

desbastado, ya que crea un efecto “fl otante” para el

cabezal.

Esto le proporciona al cabezal un efecto de autonivelado, eliminando la necesidad de ajustar la altura de

los cabezales cuando la máquina pasa por áreas del

suelo con diferentes inclinaciones u ondulaciones.

Panel de control

El panel de control comprende una serie de interruptores y cuadrantes que proporcionan 8 controles

diferentes (véase fi gura).

¡IMPORTANTE!

El cabezal planetario y los cabezales desbastadores se han fi jado para que giren en la

misma dirección (ya sea todos a la derecha

o todos a la izquierda).

El giro a la derecha del control de velocidad

aumentará la velocidad del cabezal planetario y los cabezales desbastadores.

Cabezales desbastadores/

satélites

Cabezal planetario

Power – Este botón, cuando está pulsado, encenderá

la unidad cuando el botón de PARADA DE EMERGENCIA se haya soltado.

Parada de emergencia – Cuando se pulse se apagará inmediatamente la máquina al detener por

completo la alimentación a los discos/convertidores de

frecuencia del armario eléctrico.

Head Speed – Control de dirección del giro del cabezal planetario.

Fwd/Rev (amarillo) – Control de dirección del giro del

cabezal planetario.

Disc Speed – Control de velocidad de los cabezales

desbastadores.

Fwd/Rev (rojo) – Control de dirección de los cabezales desbastadores.

Reset – Eliminará un funcionamiento erróneo/mensaje

de error del disco/convertidor de frecuencia (ubicado

en el armario eléctrico) en caso de que ocurra un fallo.

Stop/Run – Para arrancar o detener la máquina durante el funcionamiento normal.

Puerto de extracción de polvo

¡IMPORTANTE!

Es importante usar el interruptor STOP/RUN

para controlar el funcionamiento de la máquina, no el botón de PARADA DE EMERGENCIA. Cada vez que se pulse el botón

de PARADA DE EMERGENCIA, apagará el

disco/convertidor de frecuencia. Si se apaga

y enciende con frecuencia el disco/convertidor de frecuencia se reducirá la vida útil de

éste.

Panel de control

Spanish - 37

Page 38

Puesta en marcha / Manejo

Puesta en marcha / Manejo

Coloque la desbastadora en la zona de trabajo. Asegúrese de que hay diamantes en la parte inferior de la

máquina y de que los cierres del cabezal/clavijas de

corte están apretadas.

¡IMPORTANTE!

Cuando use la máquina, cada cabezal desbastador deberá tener siempre el mismo tipo

de diamante y el mismo número de diamantes que los otros cabezales desbastadores.

Cada cabezal desbastador deberá tener

diamantes de la misma altura que los otros

cabezales desbastadores.

Ajuste el faldón de goma de tal manera que se establezca una buena hermeticidad entre el suelo y el

cabezal de la máquina (véase la siguiente fi gura).

Asegúrese de que la unión del faldón está situada en

la parte delantera de la máquina. El ajuste del faldón

es fundamental para lograr una buena extracción del

polvo y eliminar la posibilidad de que el polvo sea

transportado por el aire cuando se desbaste en seco.

Puesta en marcha de la máquina

i. Asegúrese de que el interruptor STOP/RUN se

encuentra en Stop (gire a la izquierda).

ii. Enchufe la toma de corriente a la máquina. Encien-

da la máquina con el interruptor correspondiente

sólo cuando esté completamente conectada.

iii. Desacople el botón de parada de emergencia (gire

a la derecha).

iv. Pulse el botón de Power (encendido). Al hacerlo, se

deberá escuchar un ligero golpeteo que proviene

de dentro del armario eléctrico. Esto indica que los

contactores de línea se han acoplado, suministrando electricidad a los discos/convertidores de

frecuencia.

Coloque la empuñadura en la altura más cómoda para

trabajar usando la palanca de ajuste.

¡IMPORTANTE!

Se recomienda que esta altura se ajuste lo

más posible a la altura del hueso de la cadera del operador. Cuando la máquina esté

funcionando, habrá una fuerza de desbastado hacia un lado que se sentirá a través de

las barras de la empuñadura. Use la cadera

para aguantar esta fuerza en vez de intentarla controlar con los brazos (esa posición será

mucho más fácil para el operador cuando

use la máquina durante períodos largos de

tiempo).

Ajuste de velocidad y dirección

En el panel de control hay un cuadrante de FORWARD/REVERSE (adelante/atrás) y de Speed (velocidad). En general, cuando se arranque la máquina por

primera vez en cualquier aplicación dada, se aconseja

que el ajuste de velocidad no sobrepase 7 inicialmente.

Cuando el operador esté cómodo con la aplicación, se

podrá aumentar la velocidad.

38 - Spanish

Page 39

Puesta en marcha / Manejo

El ajuste de la velocidad y la dirección suele ser una

cuestión personal. Se anima a los operadores a que

experimenten para encontrar qué ajustes se adaptan

mejor a las aplicaciones dadas. La siguiente tabla indica sugerencias de ajustes para distintas aplicaciones.

Aplicación Dirección

del cabezal

planetario

Extracción de adhesivo de baldosa de cerámica FWD 6-7 FWD 8-10

Extracción de pegamento de moqueta FWD 5-7 FWD 8-10

Extracción de pintura epoxi FWD 5-10 FWD 8-10

Hormigón dañado por la lluvia FWD 7-10 FWD 8-10

Alisado conglomerado expuesto FWD 7-8 FWD 8-10

Extracción de irregularidades en baldosas de ter-

razo / piedra

Pulido de hormigón con almohadillas de ligamen-

to de resina

Rascador™ PIRANHA™ REV 3-5 REV 3-5

Cabezales fl exibles™ FLEXOR FWD 5-7 FWD 5-7

Martillo de cojinete / herramientas de escarifi cación FWD 5 FWD 5-7

Procedimiento de reenfoscado durante proceso™

HiPERFLOOR

¡IMPORTANTE!

En la tabla de arriba, FWD y FWD se encuentran juntos para indicar ajustes de dirección en la misma dirección (es decir, también

puede ser REV / REV). La única aplicación

en la que los ajustes de dirección deben ir

en las mismas direcciones y también en una

dirección específi ca es cuando se usan los

rascadores PIRANHA™. En esta aplicación

concreta, el ajuste deberá ser en la dirección

REV / REV.

Dirección de giro

La correlación entre FWD/REV y giro a la derecha/

izquierda se puede indicar de la siguiente manera si

se mira a los discos desbastadores desde debajo de la

máquina:

1. REV—A la derecha.

2. FWD—A la izquierda.

Como se ha indicado, cuando la máquina esté en fun-

cionamiento, “arrastrará” hacia un lado. La dirección de

arrastre estará determinada por la dirección de giro del

cabezal planetario. El cabezal de la máquina tirará hacia la derecha (y, por lo tanto, se sentirá en la cadera

derecha del operador) cuando el cabezal planetario se

ponga en dirección REVERSE (izquierda).

Este arrastre lateral podrá ser muy útil cuando se desbaste, en especial junto a una pared. Coloque la máquina de tal manera que tire hacia la pared y entonces

controle la máquina de manera que pueda tocar justo

la pared. Esto garantizará un desbastado pegado a la

pared o el objeto.

FWD 5-7 FWD 8-10

FWD 10 FWD 8-10

FWD 8-10 FWD 3-5

La dirección también es una cuestión personal. Sin

embargo, hay que tener en cuenta que cuando los

discos desbastadores y los cabezales planetarios

están funcionando en la misma dirección, se crea una

fuerza de desbastado mucho más poderosa entre los

abrasivos de los diamantes y el suelo. El resultado fi -

nal es una mayor productividad que cuando los discos

se han confi gurado en direcciones opuestas. Es aquí

donde también podrá disfrutar de las ventajas de la

Dual Drive Technology™.

Consejo de producción – Para mejorar la efi cacia

cortadora de los diamantes, cambie de dirección regularmente. Esto hará que trabajen los dos lados de los

cristales de los diamantes, manteniendo los abrasivos

lo más afi lados posible al crear una exposición máxi-

ma del cristal del diamante.

Una vez que se haya marcado la velocidad y la dirección, encienda el dispositivo de extracción o aspiración

de polvo.

Estando detrás de la máquina con las barras de la

empuñadura colocadas como se ha descrito antes,

aplique una ligera presión hacia abajo en la empuñadura. Conmute la máquina al modo de funcionamiento

usando el interruptor STOP/RUN del panel de control.

La máquina deberá arrancar suavemente y acelerar a

la velocidad seleccionada después de un período de 5

segundos

Velocidad

del cabezal

planetario

¡IMPORTANTE!

Se recomienda vivamente usar el sistema

de extracción de polvo Husqvarna DC 5500

para un control completo del polvo.

Dirección del

disco des-

bastador

Velocidad del

disco des-

bastador

Spanish - 39

Page 40

Cambio de los diamantes

Cambio de los diamantes

Como diferentes aplicaciones requieren diferentes

selecciones de herramientas de diamantes, habrá

muchas ocasiones en las que haga falta cambiar los

discos desbastadores.

A continuación le ofrecemos una guía para este procedimiento.

Preparación

1. Asegúrese de que el interruptor STOP/RUN esté en

posición STOP, ya que un arranque involuntario de

la máquina cuando se están cambiando los discos

podría provocar lesiones graves.

2. Tenga a mano un par de guantes, ya que los diamantes se pueden poner muy calientes durante las

aplicaciones de desbastado en seco.

Cambio

1. Coloque la empuñadura en posición derecha (fi gura

a la derecha)

2. Tire hacia atrás de la empuñadura para levantar el

cabezal desbastador del suelo.

4. Vuelva a poner la máquina en el suelo.

5. Póngase los guantes.

6. Quite el disco desbastador girando ligeramente

el disco y luego sacándolo (la dirección en la que

podrán girar los discos dependerá de la dirección en

la que estaba funcionando la máquina).

7. Compruebe que todos los bloqueos del cabezal/

clavijas de corte están apretados.

8. Una vez que se hayan fi jado los nuevos diamantes,

lleve a cabo el procedimiento inverso para bajar la

máquina al suelo.

9. Como los nuevos diamantes pueden tener una altura diferente a los usados previamente, reajuste el

faldón para garantizar una buena hermeticidad con

el suelo.

40 - Spanish

Page 41

Discos de velocidad variable/convertidores de frecuencia

Discos de velocidad variable/convertidores de frecuencia

Cada Husqvarna PG 680 & 820 está equipada con 2

discos de velocidad variable o convertidores de frecuencia. Esta unidad está incorporada en la máquina

por las siguientes razones:

1. Funcionalidad

• Manipula la corriente de entrada para permitir

aumentar/reducir la velocidad y el cambio de dirección.

• Regula la alimentación de corriente y voltaje a los

motores para garantizar que éstos funcionen a los

niveles óptimos (p.ej. impulso del par).

2. Protección/Diagnóstico

Protección