Page 1

Oper ator’s manual

Manuel d’utilisation

Manual de instrucciones

PG450

Please r ead the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

UUUUSSSS CCCCAAAA EEEESS

SS

Page 2

2

W

En

W

W

CA

NO

KEY T O SYMBOLS

Symbols on the mac hine:

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the

machine.

Wear personal protective equipment.

See instructions under the heading

”Personal protective equipment”.

WARNING! Dust forms when grinding,

which can cause injuries if inhaled. Use

an approved breathing mask. Always

provide for good ventilation.

vironmental marking. Symbols on

the product or its packaging indicate

that this product cannot be handled as

domestic waste.

By ensuring that this product is taken

care of correctly, you can help to

counteract the potential negative

impact on the environment and people

that can otherwise result through the

incorrect waste management of this product.

For more detailed information about recycling this

product, contact your municipality, your domestic waste

service or the shop from where you purchased the

product.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

Explanation of warning le vels

The w arnings are graded in three levels.

ARNING!

ARNING! Indicates a hazardous

situation which, if not avoided, will result

!

in death or serious injury.

CAUTION!

UTION! Indicates a hazardous

situation which, if not avoided, could

!

result in minor or moderate injury.

NOTICE!

TICE! Is used to address practices not related to

personal injury.

– English

Page 3

!

MA

ST

F

W

W

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ..................................... 2

Explanation of warning levels ............................... 2

CONTENTS

Contents ............................................................... 3

Note the following before starting: ........................ 3

PRESENT ATION

Dear customer! ..................................................... 4

Design and features ............................................. 4

PG450 .................................................................. 4

WHA T IS WHAT?

What is what on the g rinder? ................................ 5

CHINE´S SAFETY EQUIPMENT

Gener al ................................................................. 6

Stop/run switch ..................................................... 6

Emergency stop ................................................... 6

OPERA TING

Gener al safety precautions ................................... 7

Personal safety ..................................................... 8

Various machine modes ....................................... 9

Handlebar adjustment .......................................... 9

Connect the vacuum cleaner ................................ 9

Grinding guide ...................................................... 10

Determining the hardness of concrete ................. 11

The motor’s direction of rotation ........................... 11

Diamond selection ................................................ 12

Changing the diamonds ....................................... 14

Transport and storage .......................................... 14

ARTING AND STOPPING

Bef ore starting ...................................................... 16

Starting ................................................................. 16

Stopping ............................................................... 16

MAINTENANCE

aults and trouble shooting .................................. 17

Maintenance ......................................................... 17

Service ................................................................. 17

TECHNICAL D ATA

PG450 .................................................................. 18

US WARRANTY STATEMENT

ARRANTY POLICY ........................................... 19

EQUIPMENT ........................................................ 19

Note the f ollowing before starting:

ARNING! Cutting, especially when DRY

cutting, generates dust that comes from

the material being cut, which frequently

contains silica. Silica is a basic

component of sand, quartz, brick clay,

granite and numerous other minerals

and rocks. Exposure to excessive

amount of such dust can cause:

Respiratory disease (affecting your

ability to breath), including chronic

bronchitis, silicosis and pulmonary

fibrosis from exposure to silica. These

diseases may be fatal;

Skin irritation and rash.

Cancer according to NTP* and IARC* */

National Toxicology Program,

International Agency for Research on

Cancer

Take precautionary steps:

Avoid inhalation of and skin contact with

dust, mist and fumes.

Wear and ensure that all bystanders wear

appropriate respiratory protection such

as dust masks designed to filter out

microscopic particles. (See OSHA 29

CFR Part 1910.1200)

Wet cut when feasible, to minimize dust.

English

–

3

Page 4

4

′

PRESENT A TION

V

•

Dear customer!

Thank y ou for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product

and that it will be your companion for a long time. A

purchase of one of our products gives you access to

professional help with repairs and services. If the retailer

who sells your machine is not one of our authorised

dealers, ask him for the address of your nearest service

workshop.

This operator’s manual is a valuable document. Make

sure it is always at hand at the work place. By following its

content (using, service, maintenance etc.) the life span

and the second-hand value of the machine can be

extended. If you ever lend or sell this machine, make sure

that the borrower or buyer gets the operator

they will also know how to properly maintain and use it.

More than 300 y ears of innovation

Husqv arna AB is a Swedish company based on a tradition

that dates back to 1689, when the Swedish King Charles

XI ordered the construction of a factory for production of

muskets. At that time, the foundation was already laid for

the engineering skills behind the development of some of

the world's leading products in areas such as hunting

weapons, bicycles, motorcycles, domestic appliances,

sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products

for forestry, park maintenance and lawn and garden care,

as well as cutting equipment and diamond tools for the

construction and stone industries.

Owner responsibility

It is the o wner’s/employer’s responsibility that the operator

has sufficient knowledge about how to use the machine

safely. Supervisors and operators must have read and

understood the Operator’s Manual. They must be aware

of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

Local regulations could restict the use of this machine.

Find out what regulations are applicable where you work

before you start using the machine.

The man ufacturer’s reservation

Subsequent to pub lishing this manual Husqvarna may

issue additional information for safe operation of this

product. It is the owner’s obligation to keep up with the

safest methods of operation.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

For customer information and assistance, contact us at

our website: www.husqvarna.com

s manual, so

Design and f eatures

alues such as high performance, reliability, innovative

technology, advanced technical solutions and

environmental considerations distinguish Husqvarna's

products. Safe operation of this product requires the

operator to read this manual carefully. Ask your dealer or

Husqvarna should you need more information.

Some of the unique features of your product are

described below.

PG450

The machine is used for grinding and polishing

concrete floors and other hard materials.

• The machine can be folded and is collapsible for

simpler transport.

• PG450 is robust and easy to use

• The machine is equipped with a floating cover.

• Single-phase , (3 phase Japanese model only)

• 3 discs, 9 segments full set

• The machine has a planetary rotation system

• Resin holder disc - Holder for plastic-bonded diamond

tools.

– English

Page 5

1

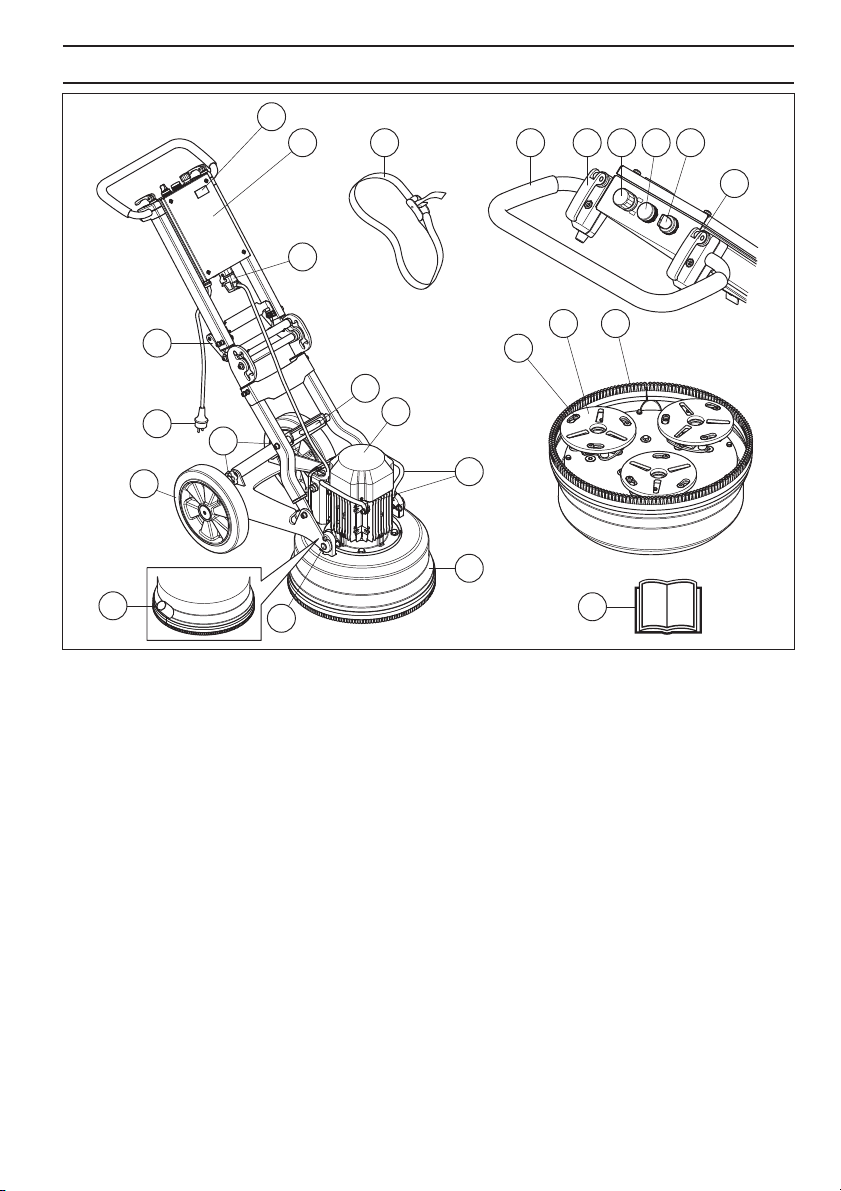

WHA T IS WHA T?

1

43

5 6 7 82

5

9

10

11

12

13

14

What is what on the grinder?

Counter

2 Electrical cabinet

3 Tensioning straps

4 Handle / handlebar

5 Locking lever for handlebar adjustment

6 Emergency stop

7 Overload lamp

8 Stop/run switch

9 Connection, quick connection for motor cable

10 Handle for angle joint

11 Plug

12 Lock knob, support foot

15

2221

20

16

17

18

19

23

13 Rubber wheels

14 Connection, vacuum hose

15 Attachment for motor/grinding head

16 Lifting eye

17 Electric motor

18 Lift handle, motor - PG450

19 Floating cover

20 Head lock-skruv

21 Satellite discs

22 Brush list

23 Operator’s manual

English – 5

Page 6

CHINE´S SAFETY EQ UIPMENT

General

ARNING! Never use a machine with

faulty safety equipment. The machine’s

!

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

This section descr ibes the machine ′ s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly.

UTION! Connect the motor cable to the electrical box

before connecting the plug.

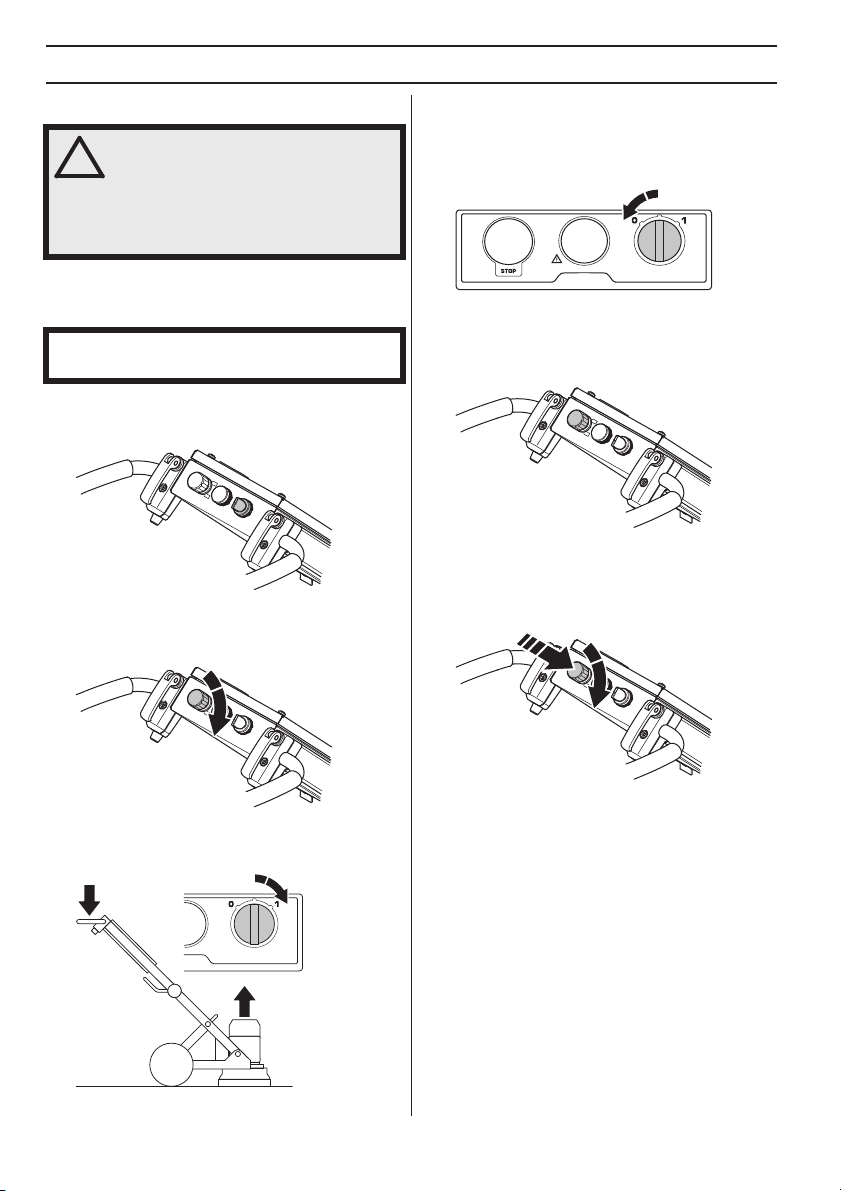

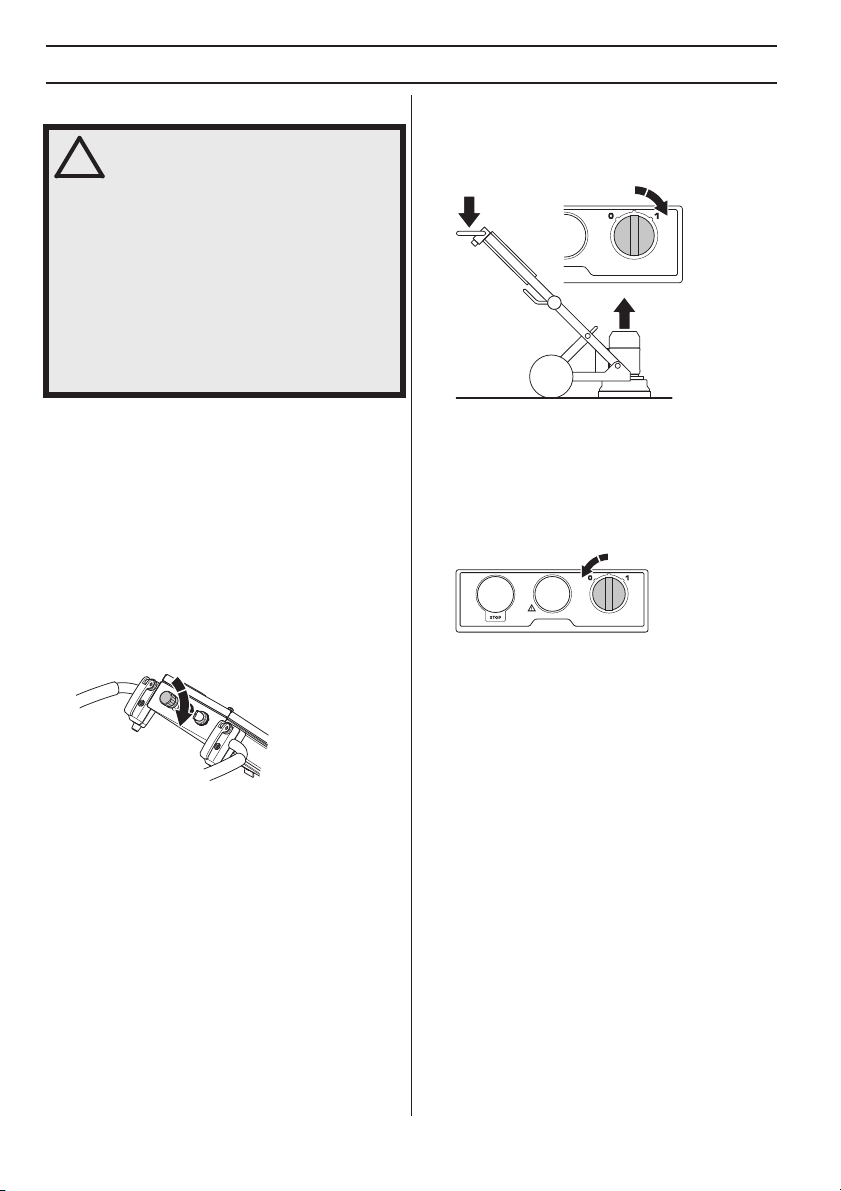

Stop/run s witch

The star t/stop knob is used to start and stop the machine.

Chec king the stop/run switch

Chec k that the emergency stop or machine stop button

are not pressed by turning them clockwise.

MA

6

T

•

W

CA

• Start the machine by turning the 0/1 knob to position

1 (drive). The machine will then start smoothly and

accelerate to the set speed within 5 seconds.

• Turn the start/stop knob to ”0” (stop) to stop the

machine.

Emer gency stop

The emergency stop is used to quic kly switch off the

engine. The emergency stop at the machine breaks the

mains power supply.

esting the emergency stop

Press the emergency stop. Check that the engine

stops.

• Disengage Emergency Stop button (twist clockwise).

1

2

• Reduce the pressure between grinding disc and floor

by pushing down the handle without lifting the grinding

unit from the floor when starting.

1

– English

2

~1 mm

Page 7

OPERA TING

!

General saf ety precautions

WARNING! This section describes basic

safety directions for using the machine.

!

This information is never a substitute for

professional skills and experience. If you

get into a situation where you feel

unsafe, stop and seek expert advice.

Contact your dealer, service agent or an

experienced user. Do not attempt any

task that you feel unsure of!

Do not use the machine without first reading and

understanding the contents of this Operator’s Manual.

Save all warnings and instructions for future

reference.

ork area safety

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• The machine should not be used in areas where

potential for fire or explosions exist.

Electrical saf ety

WARNING! There is always a risk of

shocks from electrically powered

!

machines. Avoid unfavourable weather

conditions and body contact with

lightning conductors and metal objects.

Always follow the instructions in the

Operator’s manual to avoid damage.

Never connect the machine to a outlet if

plug or cord is damaged.

Check that the mains voltage corresponds with that

stated on the rating plate on the machine.

• Inspection and/or maintenance should be carried out

with the motor switched off and the plug disconnected.

• Always shut down the machine before disconnecting

the power plug.

• Never drag the machine by means of the cord and

never pull out the plug by pulling the cord. Hold the

plug to disconnect the power cord.

• Never use the machine if any cable or plug is

damaged, but hand it in to an authorized service

workshop for repair.

• The machine must never be driven to such a depth in

water that it reaches up to the machine’s equipment.

The equipment can be damaged and the machine can

be live, resulting in personal injuries.

• Always have the power cable disconnected when

connecting and disconnecting the contact between

the motor and the electrical box.

•

ounding instructions

WARNING! Improper connection can

result in the risk of electric shock.

Contact a qualified electrician if in doubt

as to whether the appliance is properly

grounded.

Do not modify the plug. If it will not fit the

outlet have a proper outlet installed by a

qualified electrician. Make sure local

regulations and ordinances are followed.

If the grounding instructions are not fully

understood contact a qualified

electrician.

The machine is equipped with a grounded cord and

plug and should always be connected to a grounded

outlet. This reduces the risk of electric shock in the

event of malfunction.

• The use of adaptors is not allowed with the machine.

Extension cor ds and cables

• The marking on the extension cable must be the same

or higher than the value stated on the machine’s rating

plate.

• Use grounded extension cables.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

cord suitable for outdoor use reduces the risk of

electric shock. A cord marked with the letter ”W” is

suitable for outdoor use.

• Keep the connection to the extension cord dry and off

the ground.

• Keep cable away from heat, oil, charp edges or

moving parts. Damaged or entangled cable increase

the risk of electric shock.

• Check that the cables are intact and in good condition.

Never use the machine if any cable is damaged, but

hand it in to an authorized service workshop for repair.

• To avoid overheating do not use the extension cord

while it is rolled up.

• Ensure the cord is behind you when you start to use

the machine so that the cord will not be damaged.

• When using an extension cable, use only certified

extension cables with sufficient reach.

Use of a

W

•

•

Gr

•

English

–

7

Page 8

OPERATING

Personal safety

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. These

symptoms may be increased in cold

temperatures.

• Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

• Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgement or your coordination.

• Never allow anyone else to use the machine without

first ensuring that they have read and understood the

contents of the operator’s manual.

• All operators shall be trained in the use of the

machine. The owner is responsible for ensuring that

the operators receive training.

• People and animals can distract you causing you to

lose control of the machine. For this reason, always

remain concentrated and focused on the task. Never

allow children to use or be in the vicinity of the

machine.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• There is always a risk of crush injuries when working

with products containing moving parts. Keep your

distance!

• Never leave the machine unsupervised with the motor

running.

• Make sure that there is always another person close

at hand when you use the machines, so that you can

call for help if an accident should occur.

• Always ensure you have a safe and stable working

position.

Personal protective equipment

WARNING! You must use approved

personal protective equipment whenever

!

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of

injury if an accident does happen. Ask

your dealer for help in choosing the right

equipment.

• Hearing protection

• Protective goggles or a visor

• Breathing mask

8 – English

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole

• Always have a first aid kit nearby.

Use and care

• Only use the machine for the purpose it was intended

for.

• Keep all parts in good working order and ensure that

all fixtures are properly tightened.

• Never use a machine that is faulty. Carry out the safety

checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. See instructions under the

heading Maintenance.

• Do not modify safety equipment. Check regularly that

they function as they should. The machine must not be

run with defective or disassembled safety equipment.

• Never use a machine that has been modified in any

way from its original specification.

• Always use genuine accessories. Contact your dealer

for more information.

• Machinery should only be started when grinding

heads are resting on the ground unless carrying out a

testing procedure as outlined in this manual.

• The machine should not be started without the brush

list attached. It is essential a good seal between

machine and floor be established for safety, especially

when operating in dry grinding applications.

• During grinding, the machine must be connected to a

vacuum cleaner for the removal of the dust.

• Make sure the machine is without power when

changing diamond tools by pressing in the emergency

stop and disconnecting from the power outlet.

• Always dismantle the diamond tool after each grinding

operation.

• Make sure that the brush list is intact and clean and

that it seals tightly against the floor. Damaged brush

list should always be replaced.

• The tool plate continues to rotate for a while after the

motor has been switched off. Maintain grinding action

until the fan has come to a complete stop. Ensure the

tool plate has stopped rotating before lifting up the

machine.

• When grinding adhesive, asphalt, paint or the like, lift

the front of the machine slightly after use to prevent it

sticking to the floor from the heat. Ensure the tool

plate has stopped rotating before lifting up the

machine.

• Diamond tools may be very hot after use. Leave

machine to cool off before removing the diamond

segments. Use protective gloves.

• Always use the machine mounted lifting eye when

lifting.

• Always carry the machine by the carrying handle and

the handle.

Page 9

OPERATING

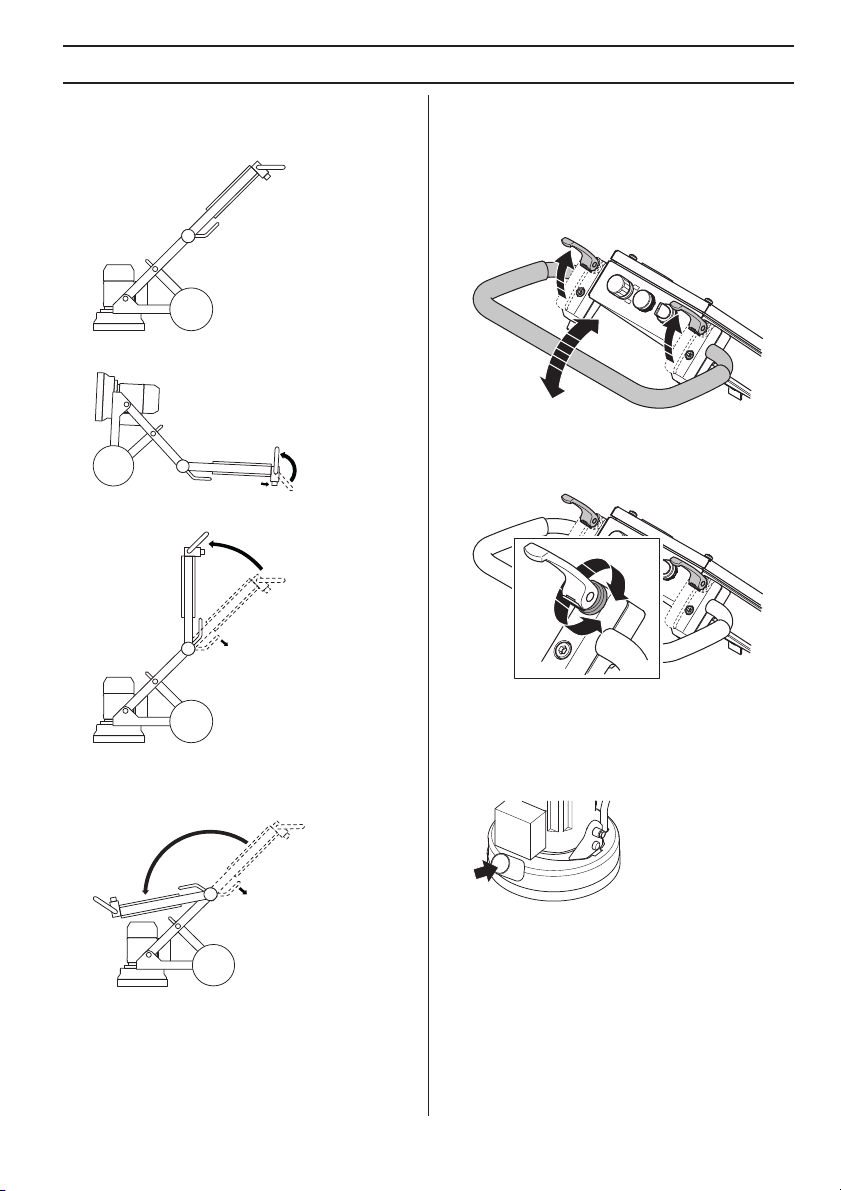

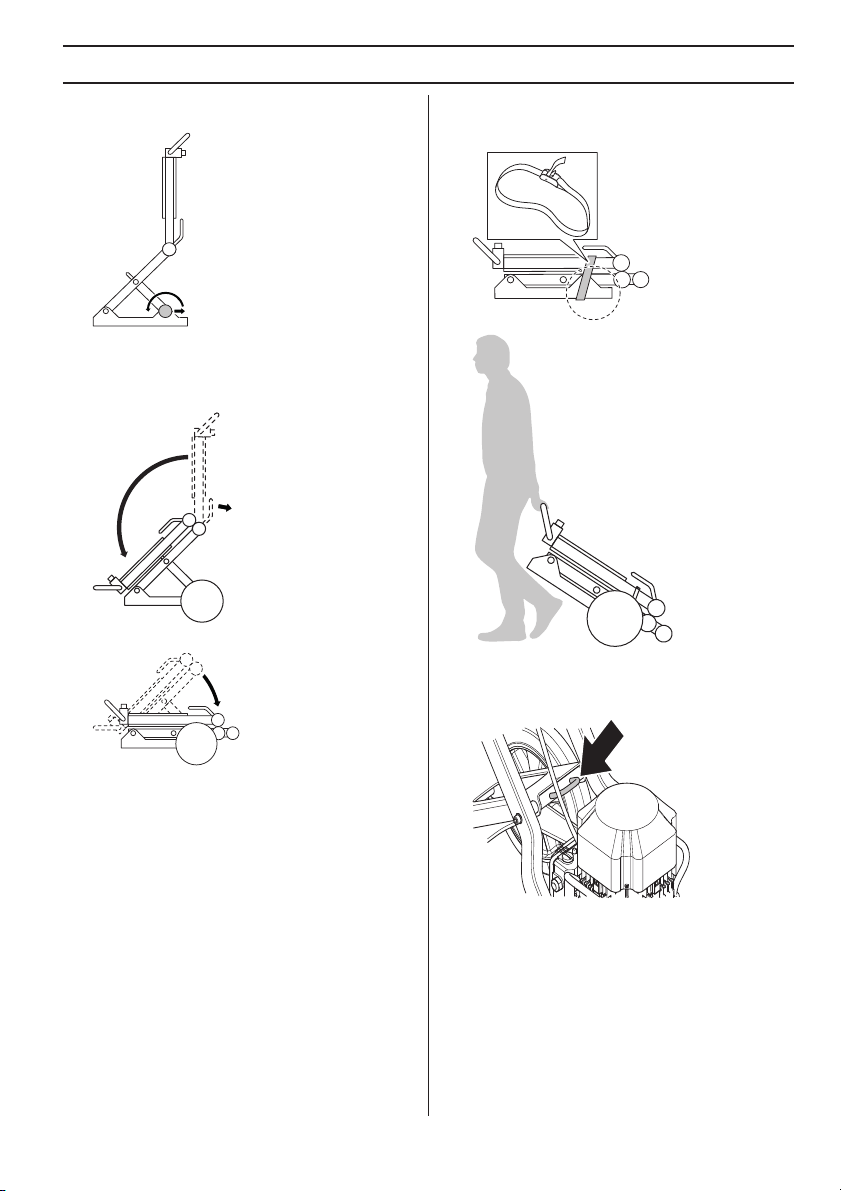

Various machine modes

Operating position

Service position

Tilting transportation position

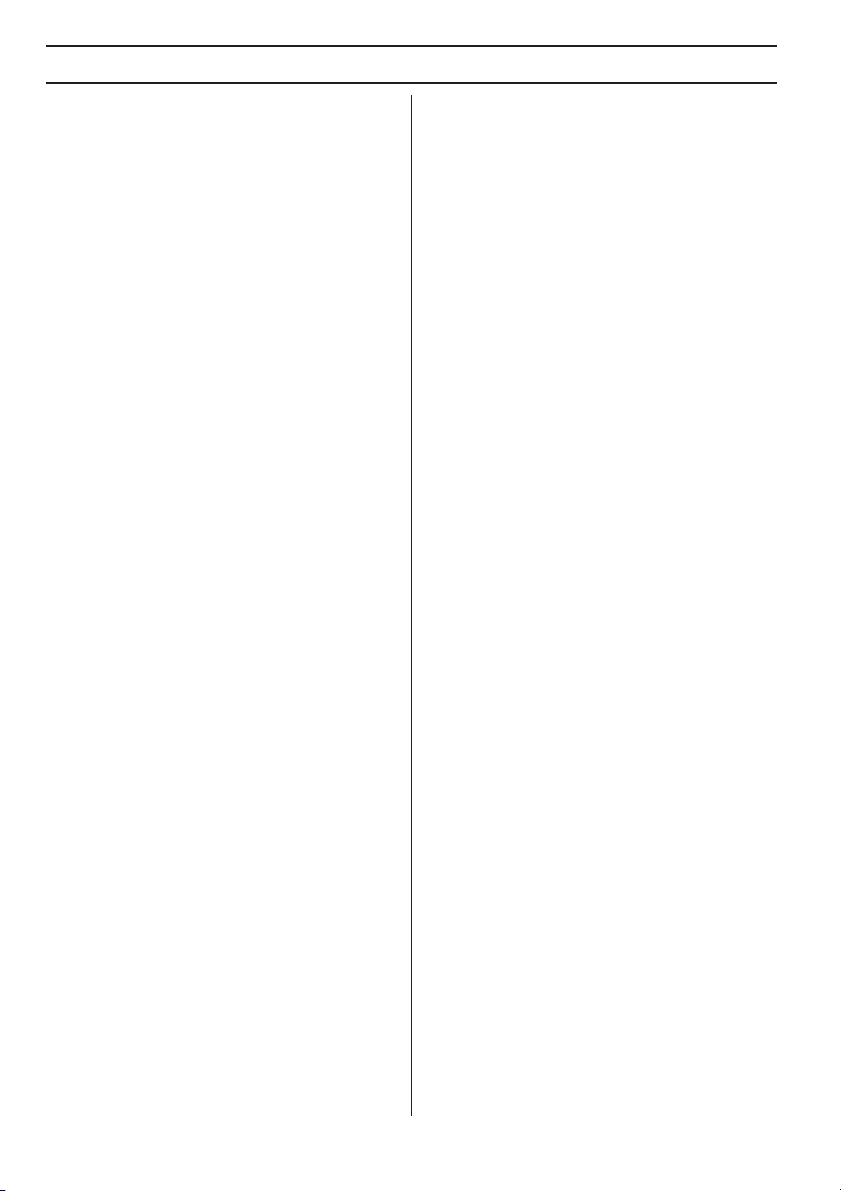

Handlebar adjustment

The handle can be infinitely adjusted. The handle lock

knob has two positions, one locked and one open

position.

• Folding up the lock knob to open position will release

the clamp holding the handle and it can be adjusted to

the desired position.

1

1

2

• Fold back the lock knob to locked position.

• How hard the lock knob clamps in locked position is

easily adjustable by turning the bushings under the

lock knob.

Lifting transportation position

Put padding between the motor and the electrical cabinet

to prevent damage to the machine.

Connect the vacuum cleaner

Use a Husqvarna dust extraction system for complete

dust control.

• Connect the vacuum cleaner to the machine. Use a

50 mm (2 inch) hose.

Make sure that the filters in the vacuum cleaner are intact

and clean. Pay attention to dust during operation.

English – 9

Page 10

OPERATING

Grinding guide Diamonds

Background

The diamond segment comprises usually of two

components:

• Diamonds (also called diamond crystals or corn).

Changing the size of the diamonds or corn will change

the coarseness or fineness of the scratches after the

grinding process.

• A bonding agent (metal or plastic). Powder is mixed

and suspended in a metal or plastic bonding agent. If

metal is used as a bonding agent, the finished product

is called metal-bonded or sintered diamond segment.

If plastic is used as a bonding agent, the finished

product is called plastic-bonded diamonds or

polishing disc. By changing the hardness of the

bonding agent, you can change how quickly or slowly

the diamond abrasive is worn down.

General Principles

General rules for using diamond tools when grinding

follow below. As with all rules, there are exceptions or

occasions when they do not apply.

Diamond grit size

Changing the size of the diamond grit to a smaller particle/

grit size will effect the performance of the diamond tool in

the following ways:

• Create a finer scratch pattern.

• Increased service life of diamond tools.

The opposite will occur when changing to a larger

particle/grit size.

Binding agent

Increasing hardness of bond will:

• Create a finer scratch pattern.

• Increased service life of diamond tools.

• Decrease production rate.

The opposite will occur when making the metal or resin

bond softer.

Number of diamond tools under the machine

An increased number of tools under the machine leads to:

• Less pressure on each individual tool – less wear on

the diamond tools.

• Reduce load on the machine and cause the grinder to

draw less current.

• Create a smoother scratch pattern (particularly on soft

floors).

The opposite will occur when decreasing the number of

segments under the machine.

Summary of diamond principles

The diamond tools must be worn in order to give a high

grinding efficiency. The wear on diamond tools can be

affected by the following factors:

• Pressure.

• Hardness of bond.

• Diamond grit size.

• Number of segments under the machine.

• Adding an additional abrasive (e.g. sand, silicone

carbide) on the floor will increase wear.

Generally, the faster a diamond tool is worn down, the

better the grinding efficiency. Changing the factors above

can also change the following results:

• Scratch pattern.

• Current draw of machine.

• Flatness of floor (see next section).

• Ease of operation.

10 – English

Page 11

OPERATING

Determining the hardness of concrete

All concretes are measured by their compressive strength

and depending on which part of the world you are from,

different compressive strength indices (e.g. PSi & MPa)

are used. Generally, the higher the compressive strength

rating, the harder the concrete and therefore, the harder it

will be to grind.

But there are also factors other than compression

strength that determine how hard a floor is and which

therefore affect the choice of diamond tool. As it is most

often only the top layer (5 mm) that we are talking about

from a grinding point of view, the surface treatment of the

concrete and the condition of the concrete surface have

many times a greater impact on the choice of diamond

segment than the compression strength.

Surface factors to consider when making a diamond

selection

Generally, if a concrete surface is very smooth (i.e. Most

likely it has been heavily trowelled/helicoptered), the

concrete will behave as if it has a high compressive

strength and therefore, require a soft bond segment.

Accordingly, if a concrete surface is coarse/aggressive

(e.g. rain-damaged, shot blasted, scarified, exposed

aggregate e.t.c.), the concrete will behave as if it has a low

compressive strength and therefore, require a hard bond

segment.

Surface coatings/contaminants (e.g. Epoxy coatings,

ceramic tile adhesives, levelling compounds/screeds) will

often have a larger bearing on what diamond to select,

than will the compressive strength of the concrete.

As a general rule, when grinding a concrete slab for the

first time and you are unsure about its hardness, always

begin with harder bond diamonds under the machine.

This will ensure the least amount of wear on the diamond

segments. If a hard diamond segment is not suited to the

application, all it has cost is a little amount of time without

wearing out the diamonds.

If performed the other way around (i.e. a soft segment is

used to begin with) and the concrete is soft or possesses

an abrasive surface or surface contaminant, it is quite

possible to wear-out a considerable amount of diamond in

very short period of time.

The motor’s direction of rotation

Single-phase

The arrow shows the direction of rotation of the motor.

3 phase

The motor´s direction can be changed by reversing the

poles in the power plug.

NOTICE! The Piranha/PCD tools are designed to run in

only one direction.

English – 11

Page 12

OPERATING

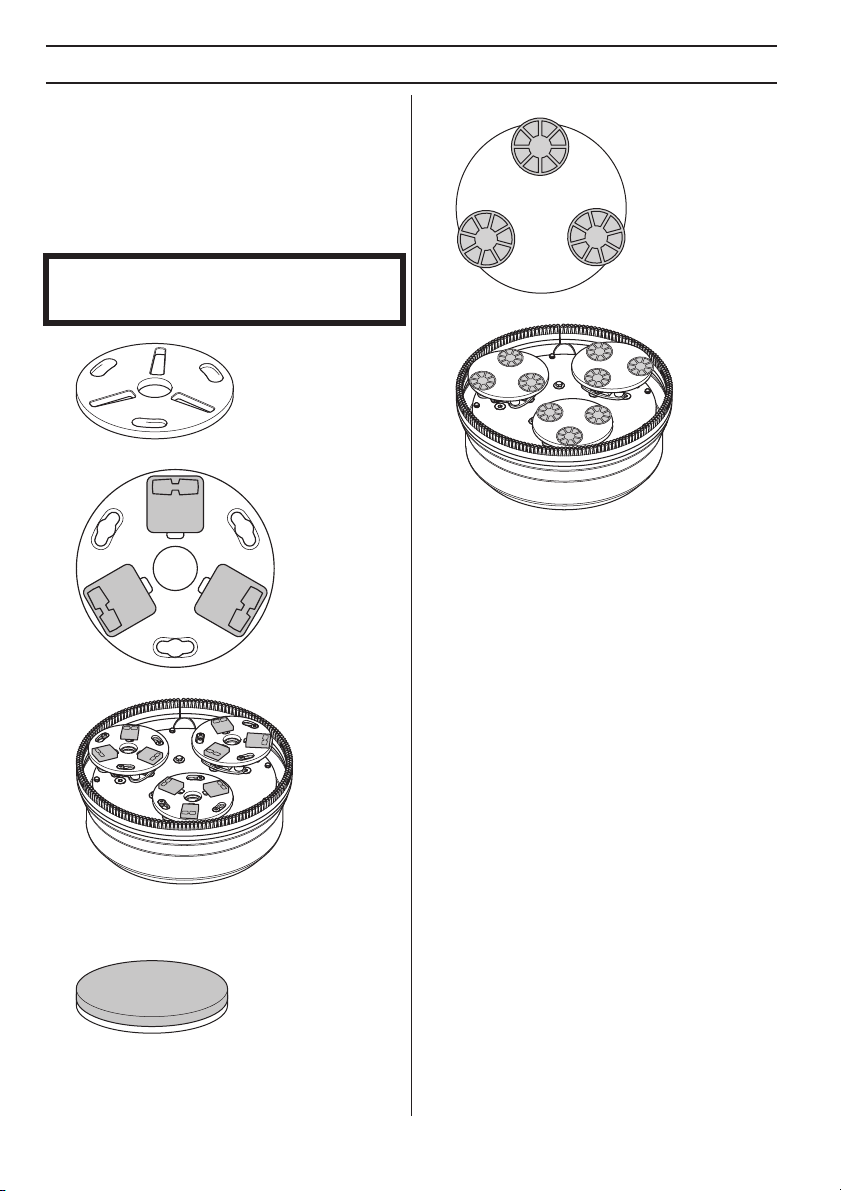

Diamond selection

They way diamond segments are set-up on the grinding

unit will greatly influence the performance of the machine,

the productivity levels and also the finished floor quality.

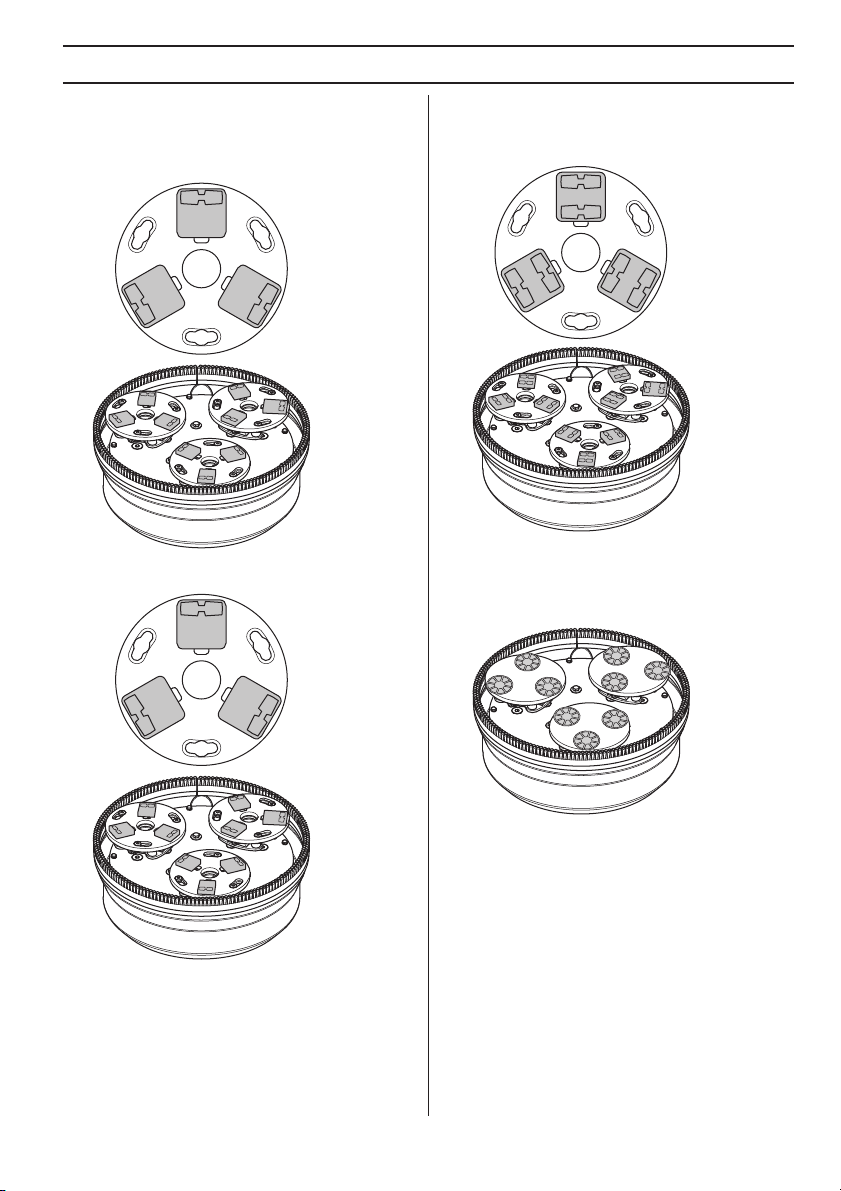

Metal bond diamonds

Redi lock holder disc - Used to fasten metal-bonded

diamond tools.

CAUTION! Husqvarna recommends three tools with

single segment on each Redi lock holder disc when

removing surfacing or normal concrete.

Complete set/satellite disc

Complete set/satellite disc

Complete set - 3 Resin holder discs, 9 tools

Complete set - 3 Redi lock holder discs, 9 tools

Resin bond diamonds

Resin holder disc - Used to fasten plastic-bonded

diamond tools.

12 – English

Page 13

OPERATING

Husqvarna’s recommendations for grinding before HiPERFLOOR

1 When grinding the first stage, use single segments on

the tool plate.

2 Change to a softer bonding agent but still use single

segments on the tool plate.

3 Change to a tool with double segments on each plate,

same hardness or softer than step two. Apply water,

GM3000 and follow the recommendations given by

Husqvarna in their HiPERFLOOR process.

4 Change to the tool holder for plastic-bonded

diamonds and use Husqvarna’s recommended tools

for the HiPERFLOOR process. Apply HiPERHARD

and allow it to cure in accordance with Husqvarna

recommendations.

English – 13

Page 14

OPERATING

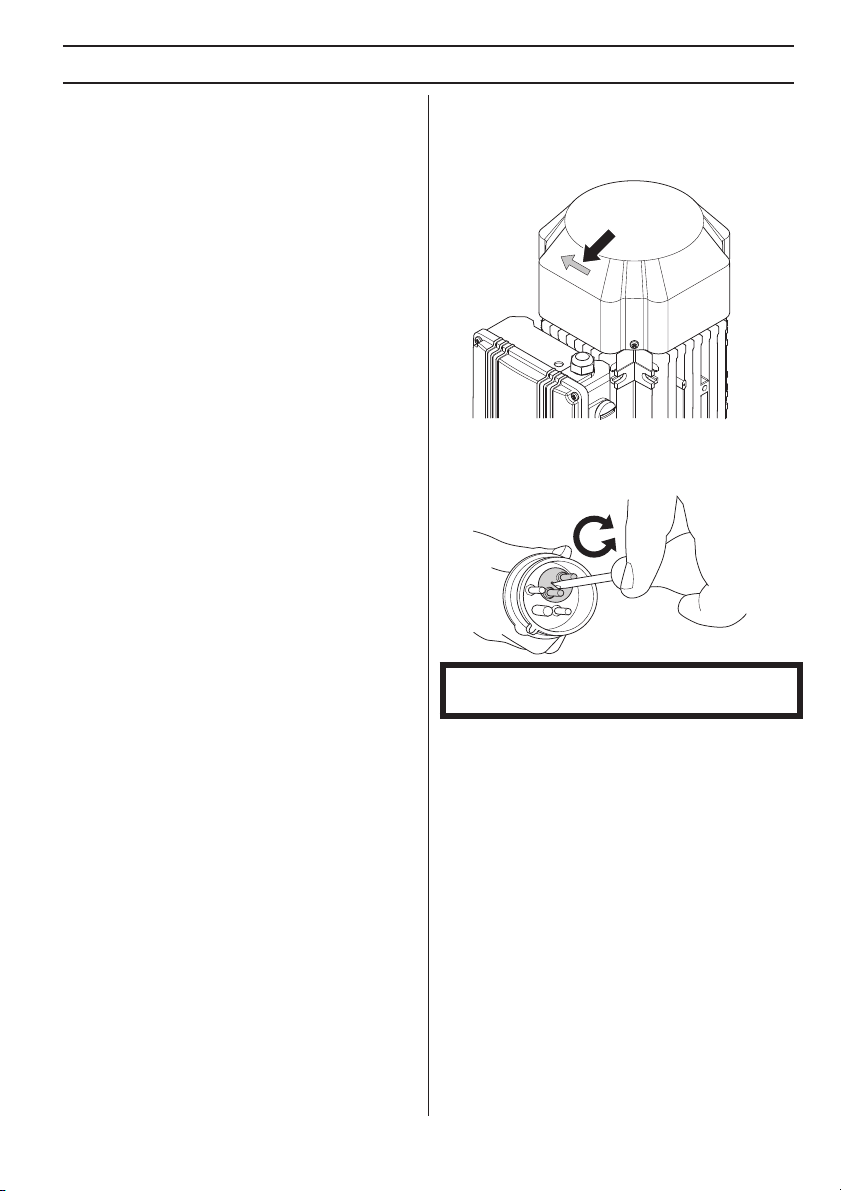

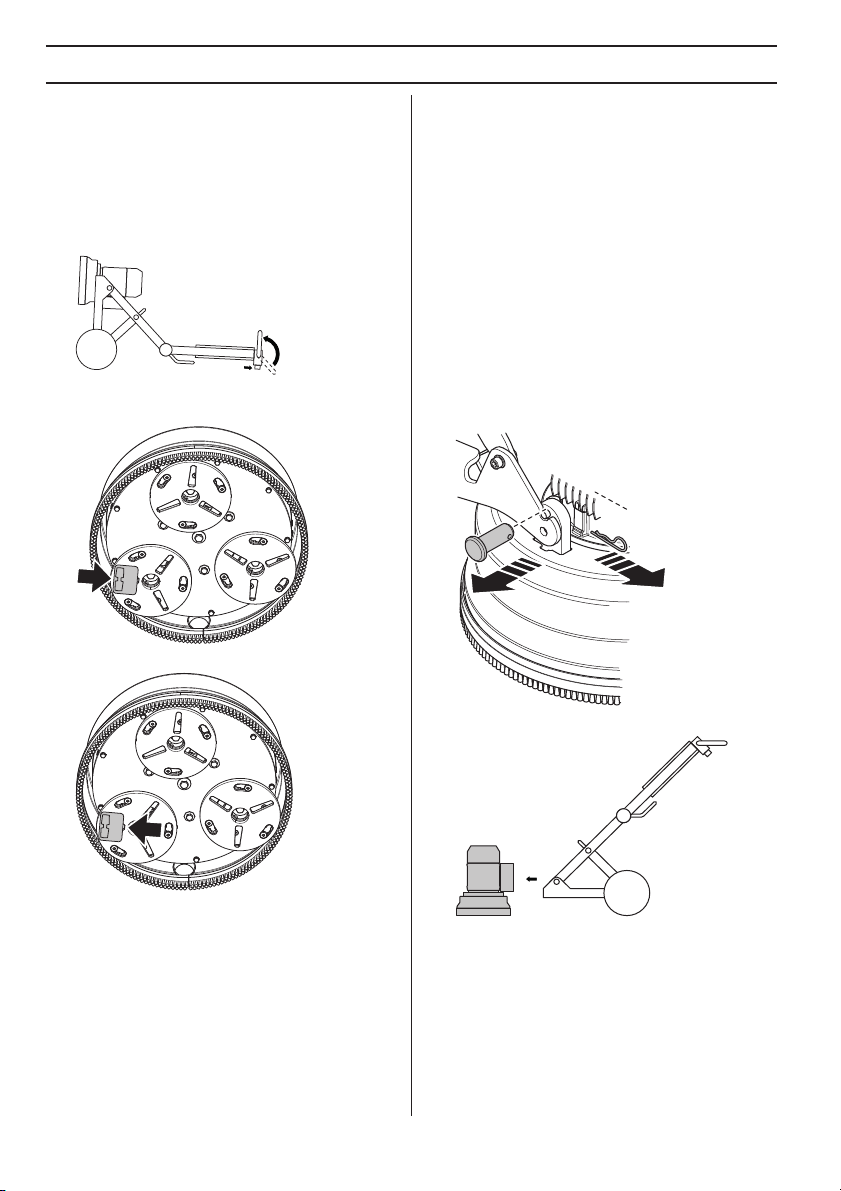

Changing the diamonds

Shut down the machine and disconnect the power plug.

Have a set of gloves ready, as diamond tools can get very

hot.

• Put the machine into service position.

• Pull back on handle to lift grinding head off the ground.

• Lay machine back on the ground.

• Put on gloves.

• Use a hammer to remove the diamond segments.

• Affix new diamond segments on the grinding disc.

Transport and storage

• Secure the equipment during transportation in order

to avoid transport damage and accidents.

• The machine should be transported under cover

where possible, limiting the exposed to natural

elements – in particular rain and snow.

• Store the equipment in a lockable area so that it is out

of reach of children and unauthorized persons.

• The machine should always be stored in a dry place

when not in use.

Transport

The machine can be taken apart and folded to give a

smaller size when transporting.

• Disconnect the motor cable from the electrical box.

• Remove the locking pins and then the bolts on each

side.

2

1

• Once new diamond segments have been attached,

reverse procedure to lower machine to ground.

14 – English

• Loosen the grinding head from the wheel chassis.

Page 15

OPERATING

• Put the machine in inclined transport position. Loosen

the locking knobs on the support foot.

• Fold back the support foot.

• Hold down the handle on the angle joint while

simultaneously angling the upper part of the frame

carefully forward.

2

1

• Carefully fold the machine forward.

• Secure the machine with an approved tensioning

strap. Make sure no machine parts are clamped or

damaged by the tensioning strap.

Lifting eye

• Always use the machine mounted lifting eye when

lifting.

English – 15

Page 16

STARTING AND STOPPING

Before starting

WARNING! Please read the operator’s

manual carefully and make sure you

!

understand the instructions before using

the machine.

Wear personal protective equipment. See

instructions under the heading ”Personal

protective equipment”.

Make sure no unauthorised persons are

in the working area, otherwise there is a

risk of serious personal injury.

Check that the machine is assembled

correctly and do not show any signs of

damage.

• Perform daily maintenance.

• Position grinder on the working area.

• Make sure there are diamonds beneath the machine

and that they are firmly attached.

• Connect the vacuum cleaner to the machine.

• Use locking knobs for handlebar adjustment to set

most comfortable working height.

• Make sure the motor cable is connected to the

electrical box before the machine is plugged into an

electric socket.

• Plug the machine into an electric socket.

• Check that the emergency stop button is not pressed

by turning it clockwise.

Starting

• Reduce the pressure between grinding disc and floor

by pushing down the handle without lifting the grinding

unit from the floor when starting.

1

2

~1 mm

• To start the machine. Start the machine by turning the

0/1 knob to position 1 (drive). The machine will then

start smoothly and accelerate to the set speed within

5 seconds.

Stopping

• Turn off the machine with the start/stop knob, turn it to

”0” (stop).

• Keep grinding segments in contact with the floor when

stopping. This will help bring the machine to a

complete stop quickly. Do not lift the grinding head off

the floor when stopping as this can create a significant

amount of dust in the air.

• Pull out the plug.

• Check the motor’s direction of rotation

16 – English

Page 17

MAINTENANCE

!

Faults and trouble shooting

The machine does not start

• Check the power supply and the power cables to

make sure they are not damaged.

• Check that the emergency stop button is not pressed

by turning it clockwise.

• Check the overload lamp. If the overload lamp is on,

allow the motor to cool down for a few minutes until the

machine is automatically reset.

Machine is hard to hold onto

• Too few diamonds under the machine or the wrong

type of tool for the application (stiff adhesive or soft

floor coverings result in high stress to the machine

and the user if there are too few diamonds under the

machine). Usually also accompanied by high current

draw by motor.

Use the number of diamonds recommended by

Husqvarna to reduce the stress on the grinder and the

user.

Machine is jumping around

• Diamonds may not be fitted correctly or have different

heights. Check to ensure all diamonds are fitted

correctly and are the same height.

The machine stops after just a while

• The machine is overloaded and the overload

protection has been released. Reduce load. The

machine will reboot after about a minute when the

engine has cooled off.

• Ensure any extension cables are not under

dimensioned.

The machine stops during start-up

• The electric motor has overloaded and the overload

lamp is on. Give the machine one or two minutes to

reset and try again. When this does not help, contact

an authorised service workshop.

• Ensure any extension cables are not under

dimensioned.

NOTICE! Good motor performance depends on proper

voltage. Extension cables that are too long and/or which

have a gage that is too small, reduce power to the motor

under load.

Maintenance

IMPORTANT! Inspection and/or maintenance should be

carried out with the motor switched off and the plug

disconnected.

Used correctly, the machine is an extremely lowmaintenance and reliable product.

Daily maintenance

• Cleaning

• Electrical Feed

• Brush list

• Satellite discs

Cleaning

Always pull out the plug from the outlet socket before

cleaning, maintenance or assembly.

Always clean all the equipment at the end of the working

day. Do not use a high pressure washer to clean the

machine.

In order for the machine to always be cooled sufficiently

the cooling air openings must be kept clear and clean.

Electrical Feed

WARNING! Never use damaged cables.

They can cause serious, even fatal,

personal injuries.

Check that the cord and extension cord are intact and in

good condition.

Never use the machine if the cord is damaged, hand it in

to an authorized service workshop for repair.

Brush list

Make sure the brush strip is whole and reaches down to

the floor.

Satellite discs

Rotate the satellite discs to make sure the internal belts

are not damaged.

Also check that the head locking screws are tight and the

rubber dampers are in good condition.

Service

IMPORTANT! All types of repairs may only be carried

out by authorised repairmen. This is so that the

operators are not exposed to great risks.

English – 17

Page 18

PG450

TECHNICAL DATA

PG450

(1-phase, 220-240V)

50 Hz 60 Hz 50 Hz 60 Hz 50 Hz 60 Hz

Motor Power, hp/kW 3,0/2,2 3,0/2,2 2,0/1,5 2,0/1,5 3,0/2,2 3,0/2,2

Rated current, A 13 13 20 19 9 9

Rated voltage, V 100-120 100-120 100-120 100-120 200 200

Cable size 3x2,5 mm23xAWG14 3x2,5 mm23xAWG10 4x2,5 mm24x2,5 mm

Weight, lbs/kg 240,3/109 240,3/109 240,3/109 240,3/109 240,3/109 240,3/109

Grinding width, inch/mm 17,7/450 17,7/450 17,7/450 17,7/450 17,7/450 17,7/450

Diameter - grinding disc, inch/mm 3x7,1/3x180 3x7,1/3x180 3x7,1/3x180 3x7,1/3x180 3x7,1/3x180 3x7,1/3x180

Grinding pressure, kg/lbs 152,1/69 152,1/69 152,1/69 152,1/69 152,1/69 152,1/69

Rotation speed - grinding disc, rpm 705 865 470 575 718 860

PG450

(1-phase, 100-120V)

PG450, (3 phase

Japanese model only)

2

18 – English

Page 19

US WARRANTY STATEMENT

WARRANTY POLICY

All warranty claims will be determined after inspection at a designated facility. A Returned Goods Authorization is

required for all warranty claims. Contact Husqvarna Customer Service Department at 800-845-1312 for an RGA. The

customer must prepay the freight and absorb any labor expense required to return or replace a product submitted for

warranty consideration. Husqvarna will pay return shipping expenses for repaired or approved replacement products.

EQUIPMENT

Equipment manufactured by Husqvarna is warranted to be free from manufacturing defects in normal service for a period

of two (2) years from date of purchase by the original consumer purchaser.

warranty periods. Call Technical Services at 800-288-5040 for complete information.

Our obilgation under this warranty is expressly limited to the replacement or repair at Husqvarna Construction Products

North America, Olathe, Kansas 66061, or at a service facility designated by us, of such part or parts as inspection shall

disclose to have been defective.

This warranty does not apply to defects caused by damage, unreasonable use, faulty repairs made by others than an

approved Husqvarna servicing dealer, or defects cacused by failure to provide reasonable maintenence, while in the

possession of the consumer. Further, the warranty is void if the product, or any of its components, are altered or modified

by the consumer purchaser, or if the product is used in an inappropriate manner or with tools not recommended by the

manufacturer.

Exceptions: Drill motors - 3 months, Wall saws - 1 year, Power cutters - 3 months, DM230 - 1 year, DM225 - 3 months,

Gyro systems - 1 year, CD40 system - 1 year, DS160 C - 1 year, Smart box - 1 year, CS2515 - 1 year, PP455 E - 1 year,

PP345 E - 1 year, HP40 - 1 year.

Wear items: Filters, spark plugs, bearings*, belts, wheels** and wear pads.

*Except IntelliSeal™ system. **Except delalmination.

Component manufacturers offer separate

English – 19

Page 20

EXPLICATION DES SYMBOLES

!

!

Symboles sur la machine:

AVERTISSEMENT! La machine utilisée

de manière imprudente ou inadéquate

peut devenir un outil dangereux,

pouvant causer des blessures graves

voire mortelles à l’utilisateur et aux

autres personnes présentes.

Lire attentivement et bien assimiler le

manuel d’utilisation avant d’utiliser la

machine.

Utiliser les équipements de protection

personnelle. Voir au chapitre

Ӄquipement de protection

personnelle”.

AVERTISSEMENT! La poussière

générée par le meulage peut

occasionner des lésions si elle est

inhalée. Il convient d'utiliser un masque

filtrant homologué. Veiller à toujours

disposer d'une bonne ventilation.

Marquage environnemental. Ce

symbole figurant sur le produit ou sur

son emballage indique que ce produit

ne peut pas être traité comme déchet

ménager.

En veillant à ce que ce produit soit

correctement éliminé, vous pouvez

contribuer à prévenir les

conséquences négatives potentielles

sur l’environnement et les hommes, qui pourraient sinon

être le résultat d’un traitement incorrect des déchets de ce

produit.

Pour des informations plus détaillées sur le recyclage de

ce produit, contactez votre commune ou le magasin où

vous avez acheté le produit.

Les autres symboles/autocollants présents sur la

machine concernent des exigences de certification

spécifiques à certains marchés.

Explication des niveaux d'avertissement

Il existe trois niveaux d'avertissement.

AVERTISSEMENT!

AVERTISSEMENT! Désigne une situation

dangereuse qui, si elle n’est pas évitée,

peut entraîner des blessures graves,

voire mortelles.

REMARQUE !

REMARQUE ! Désigne une situation

dangereuse qui, si elle n’est pas évitée,

peut entraîner des blessures mineures

ou modérées.

ATTENTION !

ATTENTION ! Sert à désigner des pratiques sans risque

de blessures corporelles.

20 – French

Page 21

SOMMAIRE

!

Sommaire Contrôler les points suivants

EXPLICATION DES SYMBOLES

Symboles sur la machine: .................................... 20

Explication des niveaux d'avertissement .............. 20

SOMMAIRE

Sommaire ............................................................. 21

Contrôler les points suivants avant la mise en

marche: .................................................................

PRÉSENTATION

Cher client, ........................................................... 22

Conception et propriétés ...................................... 22

PG450 .................................................................. 22

QUELS SONT LES COMPOSANTS?

Composants de la meule ...................................... 23

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités ........................................................... 24

Bouton stop/run .................................................... 24

Arrêt d’urgence ..................................................... 24

COMMANDE

Instructions générales de sécurité ........................ 25

Sécurité du personnel .......................................... 26

Divers modes de la machine ................................ 27

Poignée réglable ................................................... 28

Brancher l'aspirateur. ............................................ 28

Guide de meulage ................................................ 28

Déterminer la dureté du ciment ............................ 29

Sens de rotation du moteur .................................. 29

Sélection des diamants ........................................ 30

Remplacement des diamants ............................... 32

Transport et rangement ........................................ 32

DÉMARRAGE ET ARRÊT

Avant de démarrer la machine ............................. 34

Démarrage ........................................................... 34

Arrêt ...................................................................... 34

ENTRETIEN

Recherche de pannes et d’erreurs ....................... 35

Entretien ............................................................... 35

Service ................................................................. 35

CARACTÉRISTIQUES TECHNIQUES

PG450 .................................................................. 36

DECLARATION DE GARANTIE ETATS-UNIS

POLITIQUE DE GARANTIE ................................. 37

EQUIPEMENT ...................................................... 37

avant la mise en marche:

AVERTISSEMENT! La découpe,

particulièrement la découpe à SEC

soulève la poussière générée par le

matériau coupé qui contient souvent de

21

la silice. La silice est composée de sable,

de quarts d’argile, de granit et de

nombreuses autres substances

minérales et rocheuses. L’exposition à

une quantité excessive d’une telle

poussière peut causer:

Des maladies respiratoires (altérant les

facultés respiratoires), y compris

bronchites chroniques, silicose et

fibrose pulmonaire dues à une

exposition à la silice. Ces maladies

peuvent être fatales;

Irritation cutanée et démangeaisons.

Des cancers selon NTP* et IARC* */

National Toxicology Program,

International Agency for Research on

Cancer

Prendre des mesures préventives:

Éviter l’inhalation et le contact avec la

peau de la poussière, des vapeurs et des

fumées.

L’utilisateur et les personnes présentes

sur le site doivent porter des protections

respiratoires appropriées telles que des

masques spécialement prévus pour

filtrer les particules microscopiques.

(Voir OSHA 29 CFR Partie 1910.1200)

Couper si possible en utilisant le jet

d'eau afin de réduire la poussière

dispersée.

French – 21

Page 22

PRÉSENTATION

Cher client,

Nous vous remercions d'avoir choisi un produit

Husqvarna

Nous espérons que cette machine vous donnera toute

satisfaction et qu’elle vous accompagnera pendant de

longues années. L’achat de l’un des nos produits garantit

une assistance professionnelle pour l’entretien et les

réparations. Si la machine n’a pas été achetée chez l’un

de nos revendeurs autorisés, demandez l’adresse de

l’atelier d’entretien le plus proche.

Ce mode d’emploi est précieux. Veillez à ce qu'il soit

toujours à portée de main sur le lieu de travail. En suivant

les instructions qu’il contient (utilisation, révision,

entretien etc.), il est possible d’allonger considérablement

la durée de vie de la machine et d’augmenter sa valeur

sur le marché de l’occasion. En cas de vente de la

machine, ne pas oublier de remettre le manuel

d’utilisation au nouveau propriétaire.

Plus de 300 ans d'innovation

Husqvarna AB est une entreprise suédoise qui a vu le jour

en 1689 lorsque le roi Karl XI décida de construire un

arsenal pour la fabrication des mousquets. À l'époque, les

compétences en ingénierie à la base du développement

de certains des produits leaders du marché mondial dans

des domaines tels que les armes de chasse, les vélos, les

motocycles, l'électroménager, les machines à coudre et

les produits d'extérieur, étaient déjà solides.

Husqvarna est le premier fournisseur mondial de produits

motorisés pour utilisation en extérieur dans la foresterie,

l'entretien de parcs, de pelouses et de jardins, ainsi que

d'équipements de coupe et d'outils diamant destinés aux

industries de la construction et de la pierre.

Responsabilité du propriétaire

Il est de la responsabilité du propriétaire/de l’employeur

de s’assurer que l’utilisateur possède les connaissances

nécessaires pour manipuler la machine en toute sécurité.

Les responsables et les utilisateurs doivent avoir lu et

compris le Manuel d’utilisation. Ils doivent avoir

conscience :

• Des instructions de sécurité de la machine.

• Des diverses applications de la machine et de ses

• De la façon dont la machine doit être utilisée et

Les législations locales peuvent limiter l’utilisation de

cette machine. Recherchez les législations applicables

pour le lieu où vous travaillez avant d’utiliser la machine.

!

limites.

entretenue.

Droit de réserve du fabricant

Husqvarna peut éditer des informations complémentaires

concernant l’utilisation de ce produit en toute sécurité

après la publication du présent manuel. Il incombe au

propriétaire de se tenir informé des méthodes d’utilisation

les plus sûres.

Husqvarna AB travaille continuellement au

développement de ses produits et se réserve le droit d’en

modifier, entre autres, la conception et l’aspect sans

préavis.

Pour obtenir des informations et une assistance client,

contactez-nous via notre site Web

: www.husqvarna.com

Conception et propriétés

Les produits Husqvarna se distinguent par des valeurs

telles que la haute performance, la fiabilité, la technologie

innovante, les solutions techniques de pointe et les

considérations environnementales. Pour utiliser ce

produit en toute sécurité, l’utilisateur doit lire le manuel

avec attention. Contactez votre revendeur Husqvarna

pour obtenir de plus amples informations.

Certaines des caractéristiques uniques de votre produit

sont décrites ci-dessous.

PG450

• La machine est utilisée pour le meulage et le

polissage des sols en béton et d’autres matériaux

durs.

• La machine peut être repliée pour faciliter le transport.

• PG450 est robuste et facile à utiliser.

• La machine est équipée d’un couvercle flottant.

• Monophasé , (triphasé, modèle japonais uniquement)

•3 disques, 9 segments, kit complet

• La machine est équipée d’un système de rotation

planétaire

• Resin holder disc - Support pour outils diamantés à

liant plastique.

22 – French

Page 23

QUELS SONT LES COMPOSANTS?

1

43

5 6 7 82

9

5

10

16

11

17

12

13

14

Composants de la meule

1 Compteur horaire

2 Armoire électrique

3 Tendeurs

4 Poignée / guidon

5 Levier de verrouillage pour le réglage du guidon

6 Arrêt d’urgence

7 Témoin de surcharge

8 Bouton stop/run

9 Raccordement, raccordement rapide pour le câble du

moteur

10 Poignée pour joint à angle

11 Prise

15

2221

20

18

19

23

12 Levier de verrouillage, pied d’appui

13 Roues en caoutchouc

14 Raccordement, tuyau d’aspiration

15 Fixation de moteur/tête de meulage

16 Œillet de levage

17 Moteur électrique

18 Poignée de levage, moteur - PG450

19 Couvercle flottant

20 Vis HC

21 Disques satellites

22 Ensemble de brosses

23 Manuel d’utilisation

French – 23

Page 24

ÉQUIPEMENT DE SÉCURITÉ DE LA MACHINE

Généralités

AVERTISSEMENT! Ne jamais utiliser une

machine dont les équipements de

!

sécurité sont défectueux. Contrôler et

entretenir les équipements de sécurité

de la machine conformément aux

instructions données dans ce chapitre.

Si les contrôles ne donnent pas de

résultat positif, confier la machine à un

atelier spécialisé.

Ce chapitre présente les équipements de sécurité de la

machine, leur fonction, comment les utiliser et les

maintenir en bon état.

• Réduisez la pression entre le disque de meulage et le

sol en appuyant sur la poignée sans que l’unité de

meulage ne quitte le sol au démarrage.

1

2

~1 mm

REMARQUE ! Raccordez le câble du moteur au boîtier

électrique avant de brancher la prise.

Bouton stop/run

Le bouton marche/arrêt est utilisé pour démarrer et

arrêter la machine.

Vérification du bouton stop/run

Veillez à ne pas appuyer sur le bouton d’arrêt d’urgence

ou le bouton d’arrêt de la machine en les tournant dans le

sens des aiguilles d’une montre.

• Démarrez la machine en tournant le bouton 0/1 afin

qu’il soit sur la position

démarre alors sans à-coups et accélère jusqu’à

atteindre la vitesse réglée dans les 5

• Tournez le bouton marche/arrêt sur « 0 » (arrêt) pour

arrêter la machine.

1 (entraînement). La machine

secondes.

Arrêt d’urgence

L'arrêt d'urgence est utilisé pour arrêter rapidement le

moteur. L'arrêt d'urgence de la machine coupe

l'alimentation électrique principale.

Test de l'arrêt d'urgence

• Appuyez sur le bouton d’arrêt d’urgence. Vérifiez que

le moteur s'arrête.

• Libérez le bouton d’arrêt d’urgence (tournez dans le

sens des aiguilles d’une montre).

1

2

24 – French

Page 25

Instructions générales de

!

sécurité

AVERTISSEMENT! Le présent chapitre

décrit les consignes de sécurité de base

!

relatives à l'utilisation de la machine.

Aucune de ces informations ne peut

remplacer l'expérience et le savoir-faire

d'un professionnel. Si vous êtes confronté

à une situation où vous pensez ne pas être

en sécurité, arrêtez immédiatement et

consultez un spécialiste. Veillez contacter

votre revendeur, votre atelier de réparation

ou un utilisateur expérimenté. Il convient

d'éviter tous les travaux pour lesquels

vous ne vous sentez pas suffisamment

qualifié !

• Ne pas utiliser la machine sans avoir lu et compris

préalablement le présent manuel d’utilisation.

Conserver toutes ces consignes et instructions

pour toute consultation ultérieure.

Sécurité dans l’espace de travail

• Maintenir un espace de travail propre et bien

éclairé.

Les espaces encombrés ou sombres

exposent à des accidents.

• La machine ne doit pas être utilisée dans des zones à

risque d’incendie ou d’explosion.

Sécurité électrique

AVERTISSEMENT! Il existe toujours un

risque de choc avec les machines

!

électriques. Évitez de travailler par

mauvais temps ainsi que tout contact du

corps avec du métal/un parafoudre.

Suivez toujours les instructions du

manuel d’utilisation pour éviter tout

dommage.

Ne branchez jamais la machine à une

prise si la fiche ou le câble est

endommagé.

• Contrôler que la tension secteur est conforme aux

indications sur la plaque de la machine.

• Les contrôles et/ou les entretiens doivent être

effectués avec le moteur à l’arrêt et la prise électrique

débranchée.

• Éteignez toujours la machine avant de débrancher la

fiche d'alimentation.

• Ne tirez jamais la machine par le câble d’alimentation

et ne la débranchez jamais en tirant sur le câble.

Tenez la fiche pour débrancher le câble

d'alimentation.

• Ne jamais utiliser la machine si tout câble ou bouchon

est endommagé. Il convient dès lors de la confier à un

atelier d'entretien agréé.

COMMANDE

• La machine ne doit jamais être utilisée dans un niveau

tel qu’il puisse atteindre la partie supérieure de

l’équipement. Il est possible que l’équipement soit

endommagé et que la machine soit sous tension, ce

qui peut causer des blessures.

• Débranchez systématiquement le câble

d’alimentation lorsque vous mettez ou coupez le

contact entre le moteur et le boîtier électrique.

Instructions de mise à la terre

• La machine est équipée d'un câble et d'une fiche mis

à la terre et doit toujours être branchée à une prise

mise à la terre. Ceci réduit le risque de choc électrique

en cas de dysfonctionnement.

• L'utilisation d'adaptateurs n'est pas autorisée avec la

machine.

Câbles de rallonge

• Le marquage sur le câble de rallonge doit être

identique ou supérieur à la valeur indiquée sur la

plaque signalétique de la machine.

• Utilisez des câbles de rallonge mis à la terre.

• Lorsqu’une machine à usiner est utilisée à

l’extérieur, installer une rallonge adaptée à un

usage extérieur.

usage extérieur réduit le risque d’électrocution. Un

câble marqué « W » convient à un usage extérieur.

• Maintenez le branchement au câble de rallonge sec et

au-dessus du sol.

• Tenir le cordon éloigné de toute source de chaleur, de

l’huile, des bords tranchants ou des pièces mobiles.

Les cordons endommagés ou emmêlés augmentent

le risque d’électrocution.

• Contrôlez que les câbles sont intacts et en bon état.

Ne pas utiliser la machine si le câble est endommagé.

Il convient dès lors de la confier à un atelier de

réparation agréé.

• N’utilisez pas la rallonge lorsqu’elle est enroulée afin

d’éviter toute surchauffe.

• Veiller à avoir le câble derrière soi lors de l’utilisation

de la machine pour ne pas risquer de l’abîmer.

• Lorsque vous devez utiliser une rallonge, n’utilisez

que des câbles agréés d’une portée suffisante.

AVERTISSEMENT! Un mauvais

branchement risque de provoquer un

choc électrique. Contactez un électricien

diplômé si vous n'êtes pas sûr que

l'équipement soit correctement mis à la

terre.

Ne modifiez pas la fiche. Si elle n'est pas

compatible avec la prise, demandez à un

électricien diplômé d'installer une prise

qui convienne. Assurez-vous de

respecter les réglementations et

ordonnances en vigueur.

Si vous ne comprenez pas parfaitement

les instructions de mise à la terre,

contactez un électricien diplômé.

L’utilisation d’un cordon adapté à un

French – 25

Page 26

Sécurité du personnel

!

COMMANDE

Équipement de protection personnelle

AVERTISSEMENT! Une exposition

excessive aux vibrations peut entraîner

!

des troubles circulatoires ou nerveux

chez les personnes sujettes à des

troubles cardio-vasculaires. Consultez

un médecin en cas de symptômes liés à

une exposition excessive aux vibrations.

De tels symptômes peuvent être:

engourdissement, perte de sensibilité,

chatouillements, picotements, douleur,

faiblesse musculaire, décoloration ou

modification épidermique. Ces

symptômes affectent généralement les

doigts, les mains ou les poignets. Ces

symptômes peuvent être accentués par

le froid.

• Utiliser les équipements de protection personnelle.

Voir au chapitre Ӄquipement de protection

personnelle”.

• Éviter d’utiliser la machine en cas de fatigue,

d’absorption d’alcool ou de prise de médicaments

susceptibles d’affecter l’acuité visuelle, le jugement

ou la maîtrise du corps.

• Ne jamais laisser d’autres personnes utiliser la

machine sans s’être assuré au préalable que ces

personnes ont bien compris le contenu du mode

d’emploi.

• Tous les opérateurs doivent recevoir une formation

sur l’utilisation de la machine. Il incombe au

propriétaire de garantir que les opérateurs reçoivent

une formation.

• Des personnes ou des animaux peuvent détourner

l’attention de l’opérateur et l’amener à perdre le

contrôle de la machine. C’est pourquoi l’opérateur doit

toujours être attentif et concentré sur son travail. Ne

jamais laisser des enfants utiliser la machine ou se

tenir à proximité.

• Attention! Les habits, les cheveux longs et les bijoux

peuvent se coincer dans les parties en mouvement.

• Le risque de coincement est toujours présent lors de

travail avec des produits comportant des éléments

mobiles. Restez à distance !

• Ne laissez jamais la machine sans surveillance avec

le moteur en marche.

• Lors de l’utilisation des machines, prévoyez toujours

une personne à proximité afin de pouvoir obtenir de

l’aide en cas d’accident.

• Toujours adopter une position de travail sûre et stable.

AVERTISSEMENT! Un équipement de

protection personnelle homologué doit

impérativement être utilisé lors de tout

travail avec la machine. L’équipement de

protection personnelle n’élimine pas les

risques mais réduit la gravité des

blessures en cas d’accident. Demander

conseil au concessionnaire afin de

choisir un équipement adéquat.

• Protecteur d’oreilles

• Lunettes protectrices ou visière

• Masque respiratoire

• Gants solides permettant une prise sûre.

• Vêtements confortables, robustes et serrés qui

permettent une liberté totale de mouvement.

• Bottes avec coquille en acier et semelle antidérapante

• Une trousse de premiers secours doit toujours être

disponible.

Utilisation et entretien

• Utiliser la machine uniquement pour les travaux

auxquels elle est destinée.

• Assurez-vous que toutes les pièces sont en état de

fonctionnement et que tous les éléments de fixation

sont correctement serrés.

• Ne jamais utiliser une machine qui n’est pas en parfait

état de marche. Appliquer les instructions de

maintenance et d’entretien ainsi que les contrôles de

sécurité indiqués dans ce manuel d’utilisation.

Certaines mesures de maintenance et d’entretien

doivent être confiées à un spécialiste dûment formé et

qualifié. Voir les instructions à la section Maintenance.

• Ne modifiez jamais les dispositifs de sécurité.

Contrôlez régulièrement qu’ils fonctionnent

correctement. La machine ne doit pas être utilisée si

les dispositifs de sécurité sont défectueux ou ne sont

pas montés.

• Ne jamais utiliser une machine qui a été modifiée au

point de ne plus être conforme au modèle original.

• N’utiliser que des accessoires et des pièces d’origine.

Contactez votre revendeur pour de plus amples

informations.

• La machine ne doit être démarrée que lorsque les

têtes de meulage reposent sur le sol sauf pour

effectuer certains tests indiqués dans ce manuel.

• La machine ne doit pas être mise en marche sans que

l’ensemble de brosses ne soit monté. Pour des

raisons de sécurité, il est essentiel d’avoir une bonne

adhérence entre la machine et le sol, notamment

dans des applications de meulage à sec.

26 – French

Page 27

COMMANDE

• Pendant le meulage, il convient de raccorder la

machine à un aspirateur pour l'évacuation de la

poussière.

• Assurez-vous que la machine est hors tension lorsque

vous remplacez des outils diamantés en appuyant sur

le bouton d’arrêt d’urgence et en débranchant la prise

électrique.

• Démontez systématiquement l’outil diamanté après

chaque meulage.

• Assurez-vous que l’ensemble de brosses est intacte

et propre, et qu’elle est posée correctement sur le sol.

Remplacez tout ensemble de brosses endommagé.

• La plaque de l’outil continue de tourner pendant un

moment après l’arrêt du moteur. Maintenez l'action de

meulage tant que le ventilateur n'est pas

complètement arrêté. Assurez-vous que la plaque de

l’outil a cessé de tourner avant de soulever la

machine.

• Lorsque vous meulez une surface adhésive,

asphaltée, peinte ou similaire, soulevez légèrement

l’avant de la machine après utilisation pour éviter

qu’elle n’adhère au sol avec la chaleur. Assurez-vous

que la plaque de l’outil a cessé de tourner avant de

soulever la machine.

• Après utilisation, les éléments diamant peuvent être

très chauds. Laisser la machine refroidir avant d'ôter

les éléments diamant. Utiliser des gants de

protection.

• Pour soulever la machine, toujours utiliser l'œilleton

de levage dont elle est munie.

• Toujours porter la machine par les poignées.

Divers modes de la machine

Position d’utilisation

Position d’entretien

Position de transport inclinée

Position de transport relevée

Placez un rembourrage entre le moteur et l’armoire

électrique pour éviter d’endommager la machine.

French – 27

Page 28

COMMANDE

Poignée réglable

La poignée est réglable en continu. Le levier de

verrouillage de la poignée a deux positions

verrouillée et une position ouverte.

• Relever le levier de verrouillage en position ouverte

permet de desserrer le mécanisme de blocage de la

poignée, qui peut alors être réglée dans la position

souhaitée.

: une position

1

1

2

• Repliez le levier de verrouillage en position

verrouillée.

• Il est possible de régler facilement le niveau de

blocage du levier en position verrouillée en tournant

les bagues situées sous le levier de verrouillage.

Brancher l'aspirateur.

Pour une maîtrise complète des poussières, utilisez un

système d'extraction Husqvarna.

• Raccorder l'aspirateur à la machine. Utilisez une

buse de 50 mm.

Veiller à ce que les filtres de l'aspirateur soient en bon état

et propres. Faire attention à la poussière au cours de

l'opération.

Guide de meulage Diamants

Historique

Le segment en diamant est généralement composé des

deux éléments suivants

• Des diamants (également appelés cristaux ou grains

de diamant). Modifier la taille des diamants ou grains

permet de changer l’aspérité ou la finesse des rayures

après le processus de meulage.

• Un liant (métallique ou en plastique). De la poudre est

mélangée et contenue dans un liant métallique ou en

plastique. Si du métal est utilisé comme liant, le

produit fini est un segment en diamant ou à liant

métallique. Si du plastique est utilisé comme liant, le

produit fini est un diamant à liant plastique ou un

disque de polissage. En modifiant la dureté du liant,

vous pouvez modifier la vitesse à laquelle la surface

abrasive de l’outil diamanté s’use.

Principes généraux

Lorsque vous procédez à un meulage au moyen d’outils

diamantés, suivez les règles générales ci-dessous.

Comme pour toutes les règles, il existe des exceptions ou

des cas dans lesquelles elles ne s’appliquent pas.

Taille des grains de diamant

Réduire la taille des grains affecte les performances de

l’outil des manières suivantes:

• Création d’un agencement de rayures fines.

• Durée de vie accrue des outils diamantés.

Le contraire se produit si vous passez à des particules/

grains plus gros.

Agent de liage

Une augmentation de la dureté de l’alliage va:

• Création d’un agencement de rayures fines.

• Durée de vie accrue des outils diamantés.

• Réduire le taux de production.

Le contraire se produit quand l’alliage en métal ou en

résine est plus mou.

Nombre d’outils diamantés sous la machine

Une augmentation du nombre d’outils sous la machine

entraîne :

• Moins de pression sur chaque outil – moins d’usure

sur les outils diamantés.

• Réduire la charge sur la machine qui meule utilise

moins de courant.

• Créer un agencement plus régulier des rayures

(particulièrement sur les sols doux).

Le contraire se produit si vous réduisez le nombre de

segments sous la machine.

:

28 – French

Page 29

COMMANDE

Résumé des principes des diamants

Les outils diamantés doivent être usés pour permettre

une efficacité de meulage élevée. L’usure présente sur les

outils diamantés peut être affectée par les facteurs

suivants

:

• Pression.

• Dureté de l’alliage.

• Taille des grains de diamant.

• Nombre de segments sous la machine.

• L’addition d’un agent abrasif sur le sol (par ex. du

sable ou du carbure de silicone) augmentera l’usure.

En général, plus vite un outil diamanté s’use, plus grande

est l’efficacité de meulage. La modification des facteurs

ci-dessus peut également modifier les résultats suivants

• Agencement des rayures.

• Consommation de courant de la machine.

• Planéité du sol (voir la section suivante).

• Facilité d’utilisation.

Déterminer la dureté du ciment

Tous les ciments sont mesurés par leur résistance à la

compression et les unités d’évaluation de cette résistance

sont différentes en fonction de la partie du monde dans

laquelle vous vivez (ex. PSi & MPa). De manière

générale, plus la résistance à la compression est élevée,

plus le ciment est dur et plus il sera dur à meuler.

Mais il y a également d’autres facteurs que la force de

compression qui déterminent la dureté d’un sol et qui, par

conséquent, ont une incidence sur le choix des outils

diamantés. Comme il est le plus souvent question de la

couche supérieure (5

du meulage, le traitement de surface du béton et l’état de

la surface de béton ont souvent une plus grande

incidence sur le choix du segment en diamant que la force

de compression.

Facteurs de la surface à considérer lors de la

sélection du diamant

Généralement, si une surface en ciment est très lisse (c.à-d. qu’elle a probablement été finie à la truelle), le ciment

se comporte comme s’il était d’une résistance élevée à la

compression nécessitant donc un segment à alliage

doux.

Ainsi, si une surface en ciment est grossière/agressive

(c.-à-d. abîmée par la pluie, décapée au sable, scarifiée,

etc.), le ciment se comporte comme si sa résistance à la

compression était faible et il nécessite donc un segment

en alliage dur.

Les revêtements de surface (tels que les revêtements

epoxy, les colles pour dalles en céramique, les enduits de

lissage/chappes) sont souvent plus importants que la

résistance à la compression du ciment pour le choix du

diamant approprié.

mm) uniquement, du point de vue

Généralement, quand vous polissez un bloc de ciment

pour la première fois sans bien connaître son degré de

dureté, commencez toujours avec des diamants d’un

alliage dur. Ceci limite au minimum l’usure des segments

diamantés. Si un segment diamanté dur ne convient pas

à l’application, vous avez certes perdu un peu de temps

mais vous n’avez pas usé les diamants.

Si vous aviez, au contraire, commencé par utiliser un

segment doux sur un ciment doux ou recouvert d’une

surface abrasive, il est quasiment certain que vous auriez

usé une quantité considérable de diamant en très peu de

temps.

Sens de rotation du moteur

Monophasé

:

La flèche indique le sens de rotation du moteur.

3 phases

Le sens du moteur peut être modifié en inversant les

pôles de la fiche d'alimentation électrique.

ATTENTION ! Les outils Piranha/PCD sont conçus pour

ne fonctionner que dans un sens.

French – 29

Page 30

COMMANDE

Sélection des diamants

La façon dont les segments à diamant sont placés sur

l'unité de meulage influencera considérablement les

performances de la machine, les niveaux de productivité

ainsi que la qualité du sol fini.

Diamants à liant métallique

Disque support Redi lock - utilisé pour fixer des outils

diamantés à liant métallique.

REMARQUE! Husqvarna recommande l’utilisation de

trois outils à segment simple sur chaque disque support

Redi

lock pour retirer le béton normal ou meuler les

surfaces en béton.

Kit complet/disque satellite

Kit complet/disque satellite

Kit complet - 3 Resin holder disc, 9 outils

Recommandations d’Husqvarna en matière de meulage avant HiPERFLOOR

1 Lors du meulage de la première couche, utilisez des

segments simples sur la plaque de l’outil.

Kit complet - 3 disques support Redi lock, 9 outils

Diamants à liant résinoïde

Resin holder disc - utilisé pour fixer des outils diamantés

à liant plastique.

30 – French

Page 31

COMMANDE

2 Passez à un liant plus doux, mais utilisez toujours des

segments simples sur la plaque de l’outil.

3 Passez à un outil à segments doubles sur chaque

plaque, avec le même niveau de dureté ou plus

souple qu’à l’étape deux. Appliquez de l’eau

et suivez les recommandations données par

Husqvarna dans le procédé HiPERFLOOR.

GM3000

4 Changez de support d’outil et passez à des diamants

à liant plastique et utilisez les outils recommandés par

Husqvarna pour le procédé HiPERFLOOR. Appliquez

de l’HiPERHARD et laissez-le durcir, conformément

aux recommandations d’Husqvarna.

French – 31

Page 32

COMMANDE

Remplacement des diamants

Éteindre la machine et débrancher la prise d'alimentation.

Veiller à avoir une paire de gants à disposition. Les

éléments diamant peuvent en effet être très chauds.

• Mettez la machine en position d’entretien.

• Tirez la poignée pour lever la tête de surfaçage afin

qu’elle ne repose plus sur sol.

• Rabaissez la machine sur le sol.

• Mettez les gants.

• Utilisez un marteau pour retirer les segments en

diamant.

Transport et rangement

• Sécurisez l'équipement lors du transport afin d'éviter

tout dommage ou accident.

• Il convient de transporter la machine sous capot dans

la mesure du possible afin de limiter l'exposition aux

éléments naturels, en particulier à la pluie et à la

neige.

• Stockez l’équipement dans un endroit verrouillé afin

de le maintenir hors de portée des enfants et de toute

personne incompétente.

• La machine doit toujours être remisée dans un endroit

sec quand elle n’est pas utilisée.

Transport

La machine peut être démontée et repliée pour réduire

son encombrement lors du transport.

• Débranchez le câble du moteur du boîtier électrique.

• Retirez les goupilles de blocage, puis les boulons de

chaque côté.

2

1

• Fixer de nouveaux segments diamant sur le disque de

meulage.

• Une fois les nouveaux diamants en place, procédez

inversement pour abaisser la machine sur le sol.

32 – French

• Desserrez la tête de meulage du châssis de roue.

Page 33

COMMANDE

• Placez la machine en position de transport inclinée.

Desserrez les boutons de verrouillage du pied

d’appui.

• Repliez le pied d’appui.

• Appuyez sur la poignée au niveau du joint à angle,

tout en inclinant avec précaution vers l’avant la partie

supérieure du châssis.

2

1

• Sécurisez la machine avec un tendeur agréé.

Assurez-vous qu’aucune pièce de la machine n’est

pincée ou endommagée par le tendeur.

• Plier délicatement la machine vers l'avant.

Œillet de levage

• Pour soulever la machine, toujours utiliser l'œilleton

de levage dont elle est munie.

French – 33

Page 34

DÉMARRAGE ET ARRÊT

Avant de démarrer la machine

AVERTISSEMENT! Lire attentivement et

bien assimiler le manuel d’utilisation

!

avant d’utiliser la machine.

Utiliser les équipements de protection

personnelle. Voir au chapitre

”Équipement de protection personnelle”.

Veiller à ce qu’aucune personne non

autorisée ne se trouve dans la zone de

travail pour éviter le risque de blessures

graves.

Vérifiez que la machine est correctement

montée et ne présente aucun dommage.

• Effectuez un entretien quotidien.

• Positionnez la machine sur la surface de travail.

• S'assurer qu'il y a des diamants sous la machine et

qu'ils sont fixés solidement.

• Raccorder l'aspirateur à la machine.

• Utilisez les boutons de verrouillage pour régler le

guidon à une hauteur de travail plus confortable.

• Assurez-vous que le câble du moteur est raccordé au

boîtier électrique avant de brancher la machine sur

une prise électrique.

• Branchez la machine sur une prise électrique.

• Veiller à ne pas appuyer sur le bouton d'arrêt

d'urgence en le tournant dans le sens des aiguilles

d'une montre.

• Vérifier le sens de rotation du moteur.

Démarrage

• Réduisez la pression entre le disque de meulage et le

sol en appuyant sur la poignée sans que l’unité de

meulage ne quitte le sol au démarrage.

1

2

~1 mm

• Démarrer la machine. Démarrez la machine en

tournant le bouton