Page 1

GB

Operator’s manual

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

ES

DE

FR

Manual de instrucciones

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und

machen Sie sich mit dem Inhalt vertraut, bevor Sie das

Gerät benutzen.

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

HUSQVARNA CONSTRUCTION PRODUCTS

PG 400

PG 280

GB ES DE FR

Page 2

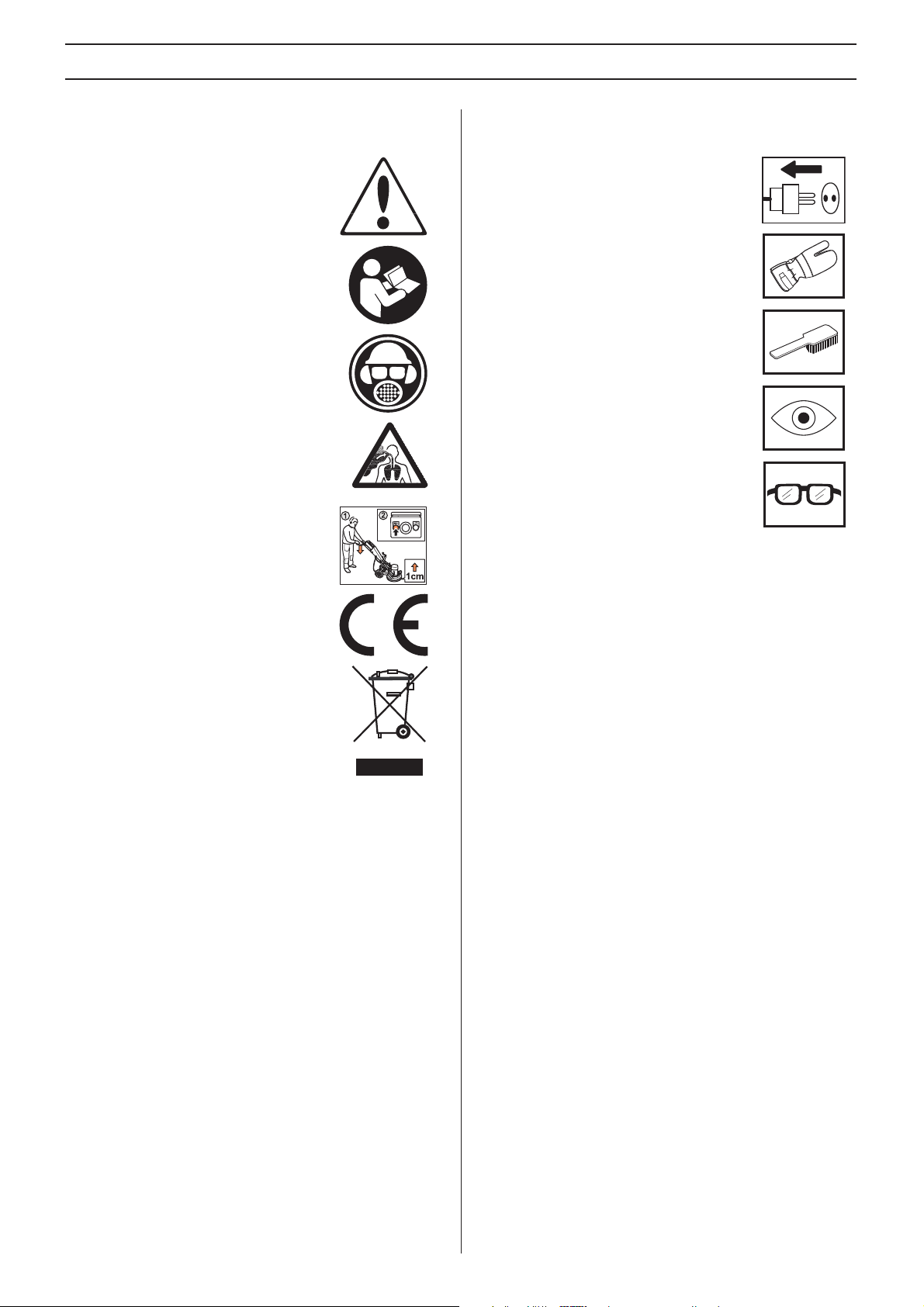

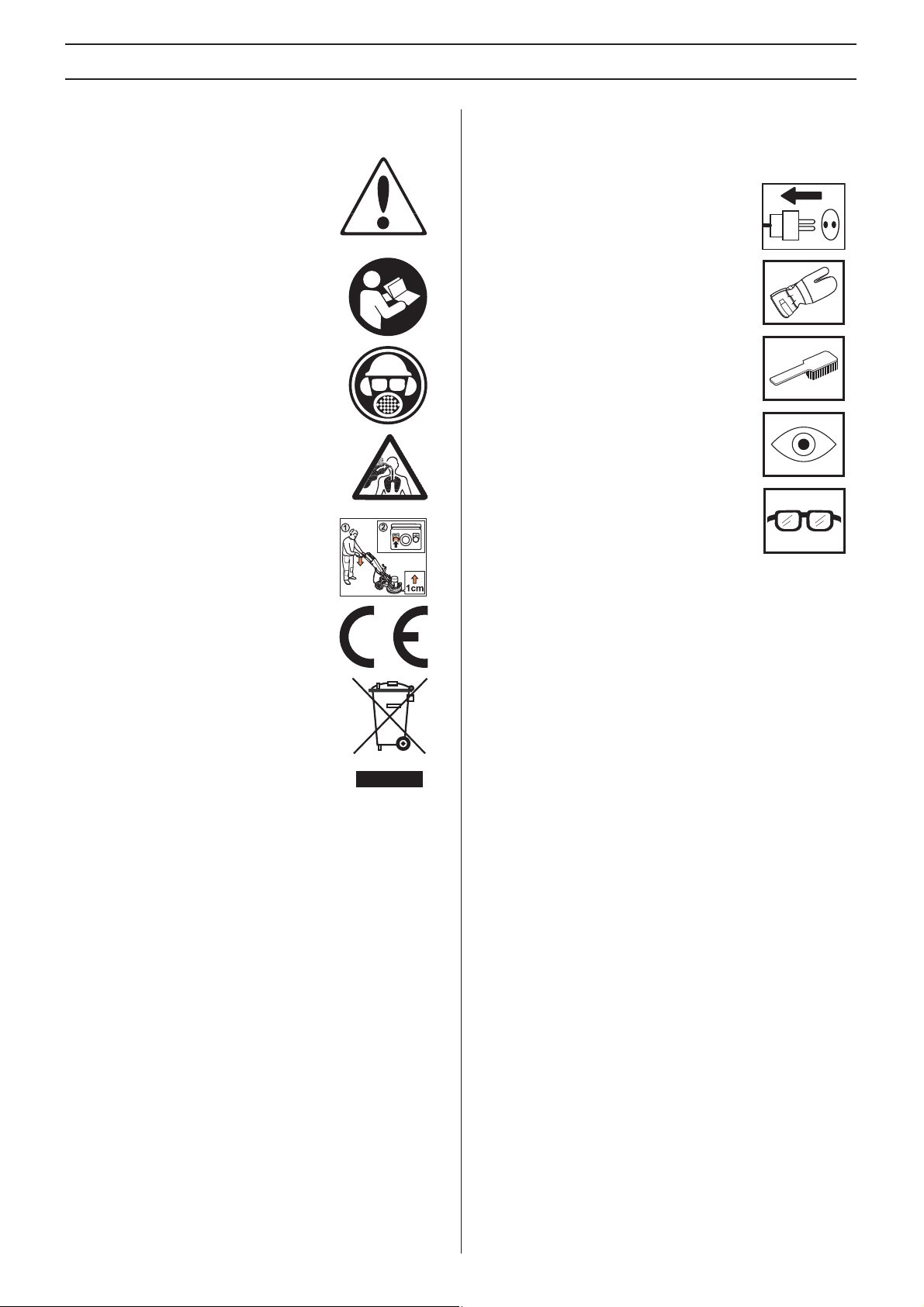

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure y

instructions before using the machine.

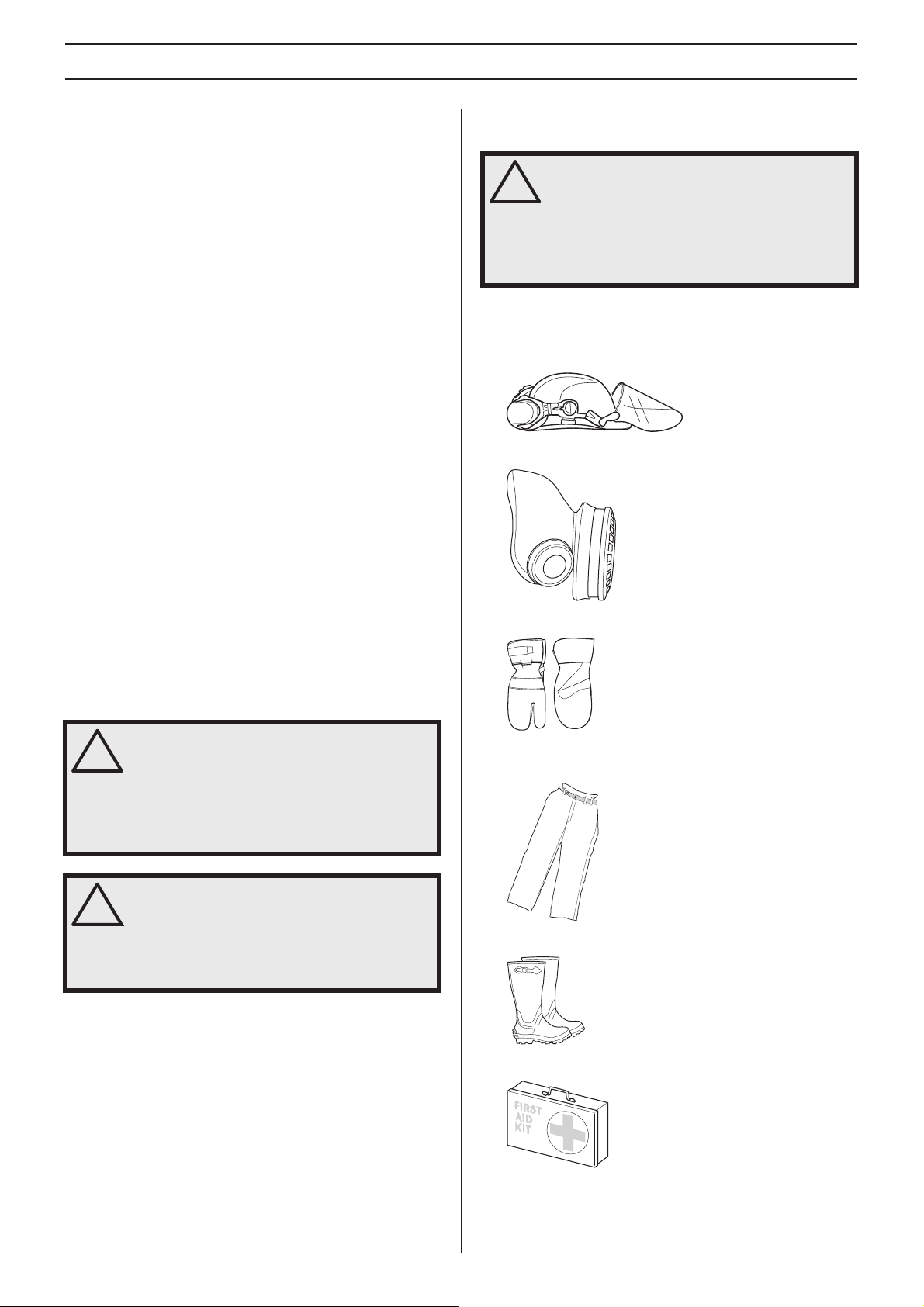

Wear personal protective equipment. See

instructions under the heading ”P

protective equipment”.

WARNING! Dust forms when grinding,

which can cause injuries if inhaled.

approved breathing mask. Always provide f or

good ventilation.

Starting: Reduce the pressure between

gr

inding disc and floor by pushing down on

the handle without raising the grinding unit

off the ground.

ou understand the

ersonal

Use an

Symbols in the operator’s manual:

Inspection and/or maintenance should be

carried out with the motor switched off and

the plug disconnected.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

This product is in accordance with

applicable EC directiv

Environmental marking. Symbols on the

product or its packaging indicate that this

product cannot be handled as domestic

waste.

By ensuring that this product is taken care of

correctly, y

potential negative impact on the environment

and people that can otherwise result through

the incorrect waste management of this product.

For more detailed information about recycling this product,

contact your m

shop from where you purchased the product.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

ou can help to counteract the

es.

unicipality , y our domestic w aste service or the

2 – English

Page 3

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ............................................. 2

Symbols in the operator’s manual: ............................... 2

CONTENTS

Contents ...................................................................... 3

WHAT IS WHAT?

What is what on the grinder? ....................................... 4

SAFETY INSTRUCTIONS

Before using a new grinder .......................................... 5

Personal protective equipment ..................................... 5

General safety precautions .......................................... 6

ASSEMBLY

Fit the handle ............................................................... 8

Changing the diamonds ............................................... 8

Connect the vacuum cleaner ....................................... 9

Transport ...................................................................... 9

GRINDING GUIDE

Diamonds ..................................................................... 10

Determining the hardness of concrete ......................... 10

Diamond selection ....................................................... 11

The motor’s direction of rotation .................................. 13

STARTING AND STOPPING

Before starting ............................................................. 14

Starting ........................................................................ 14

Stopping ....................................................................... 14

MAINTENANCE

Faults and trouble shooting .......................................... 15

Maintenance ................................................................ 15

Service ......................................................................... 15

TECHNICAL DATA

Technical data .............................................................. 16

EC-declaration of conformity ........................................ 16

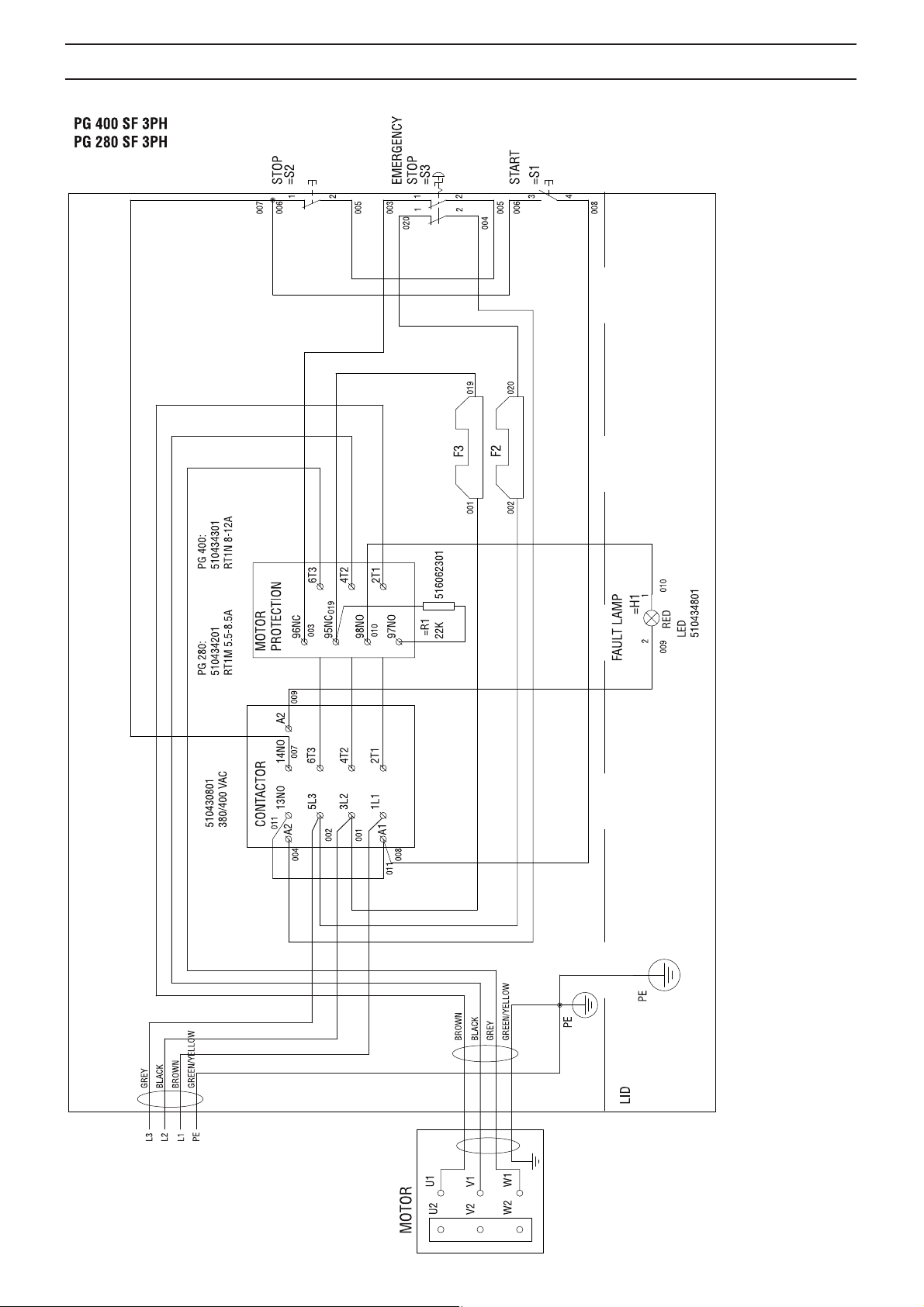

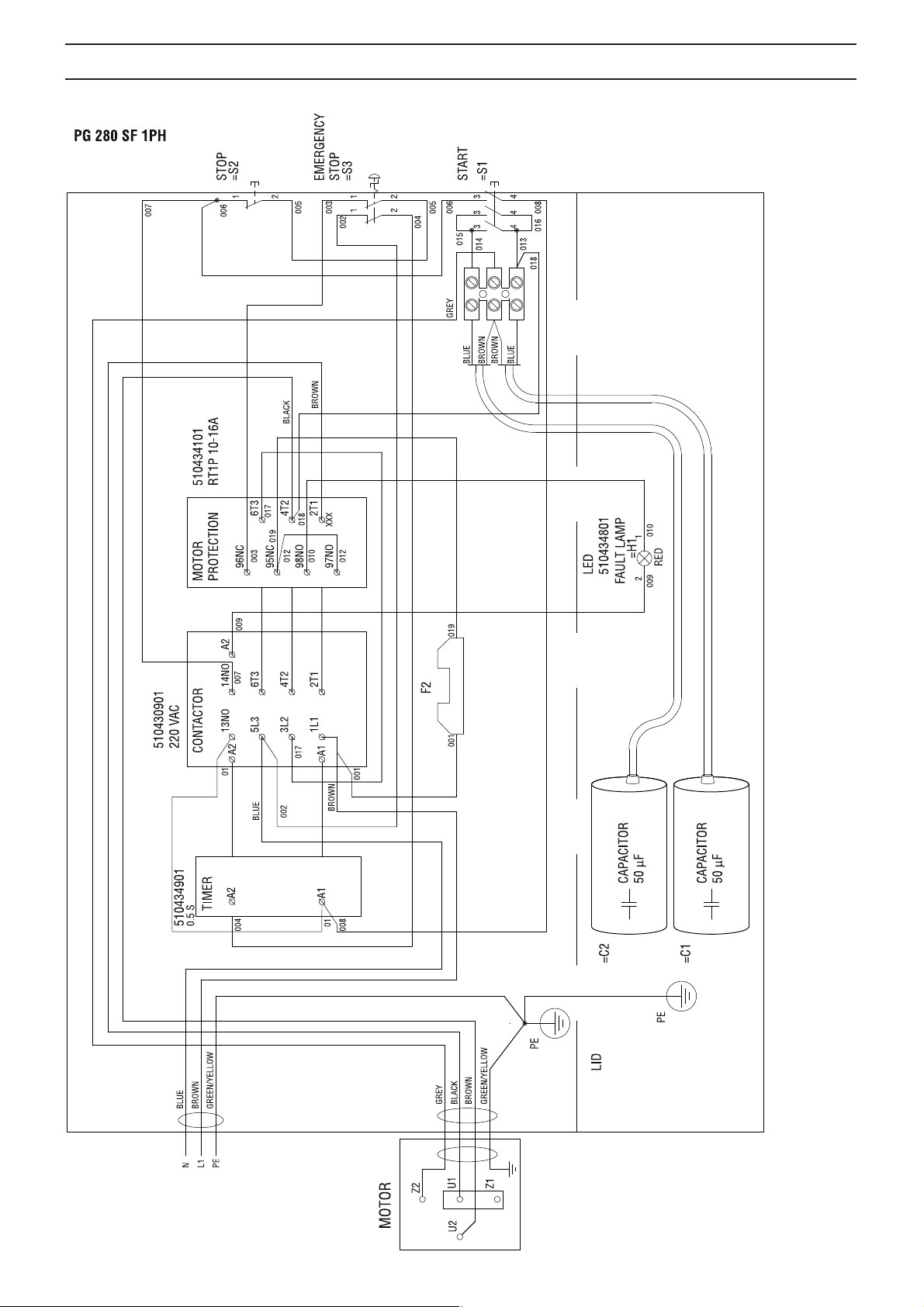

WIRING DIAGRAM

English – 3

Page 4

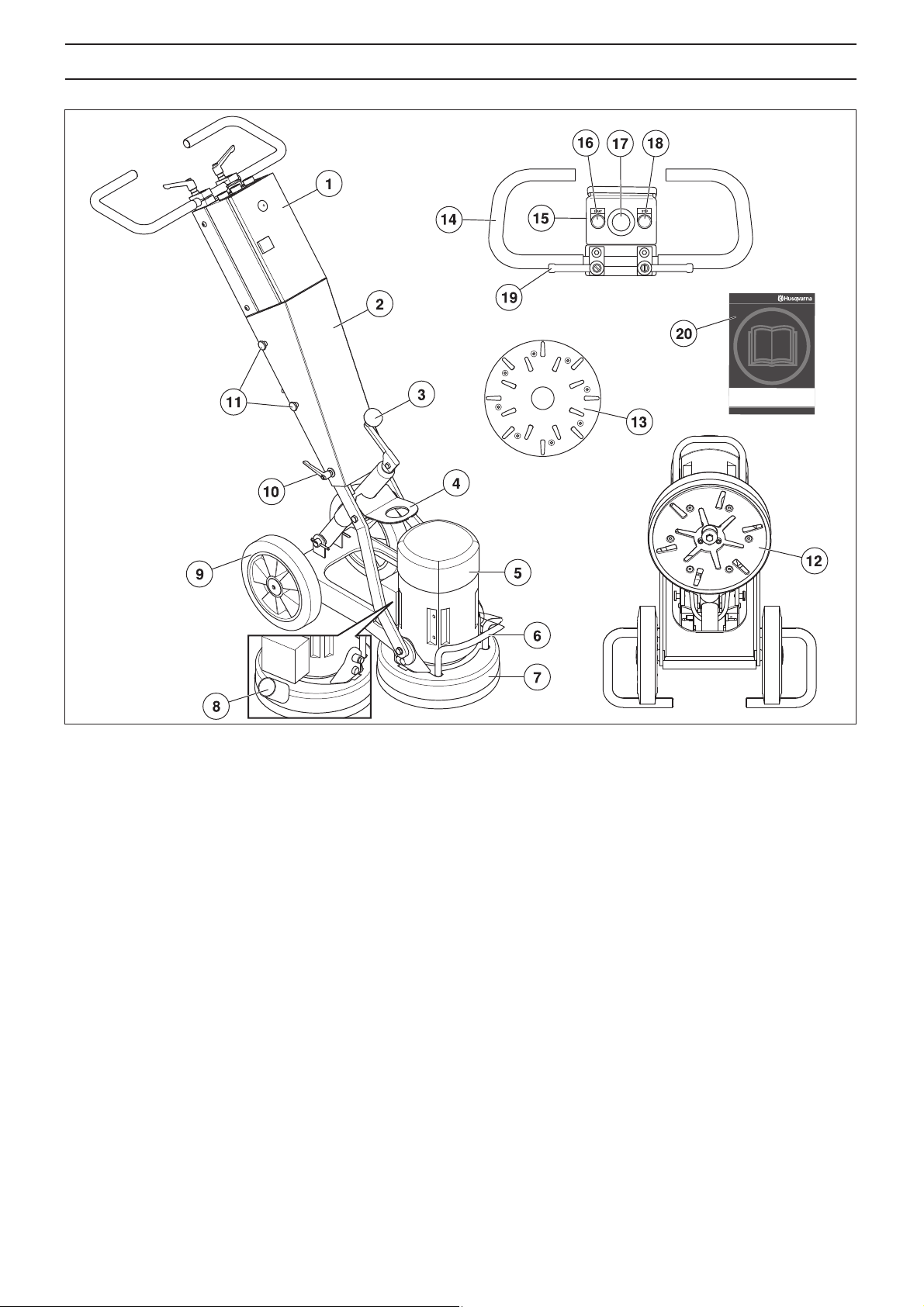

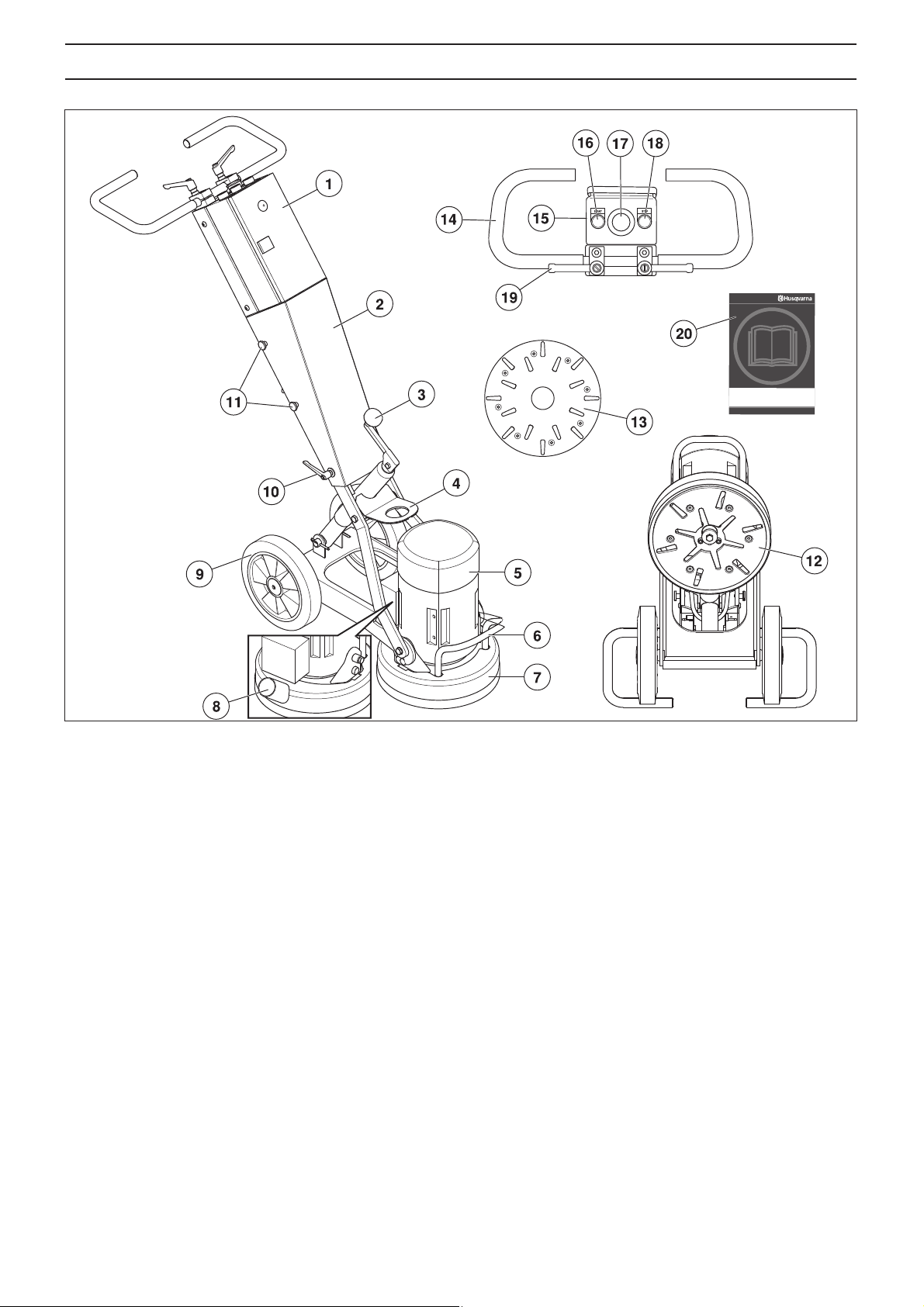

WHAT IS WHAT?

What is what on the grinder?

1 Electric box

2Cover

3 Crank for adjusing grinding pressure

4 Lifting eye

5 Electric motor

6 Lifting handle

7 Skirt

8 Connection for vacuum cleaner

9 Wheel set

10 Cover locking knob

11 Screws, cover

12 Grinding unit - PG 280 SF

13 Grinding unit - PG 400 SF

14 Handle / handlebar

15 Control Panel

16 Start button

17 Emergency stop

18 Stop button

19 Locking knob for handlebar adjustment

20 Operator

′s manual

4 – English

Page 5

SAFETY INSTRUCTIONS

Before using a new grinder

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• Grinders PG 400 SF and PG 280 SF are designed for

surface remo

like from concrete floors and grinding and flattening out

concrete floors. SF stands for single disc, fixed speed.

• The machine can cause serious personal injury. Read the

safety instr

machine.

• Only staff that have received the necessary education,

both practically and theoretically concer

should operate the machinery.

Always use common sense

It is not possible to cover e v ery conceivable situation y ou can

face. Always exercise care and use your common sense.

Avoid all situations which you consider to be beyond your

capability. If you still feel uncertain about operating

procedures after reading these instructions, you should

consult an expert before continuing.

Do not hesitate to contact your dealer if you have any more

questions about the use of the machine.

service and provide you with advice as well as help you to use

your machine both efficiently and safely.

Let your Husqvarna dealer regularly check the machine and

make essential adjustments and repairs

All information and all data in the Operator’s Manual were

applicable at the time the Oper

val of glue/adhesive residues, putty and the

uctions carefully. Learn how to use the

ning their usage

We will willingly be of

.

ator’s Manual w as sent to print.

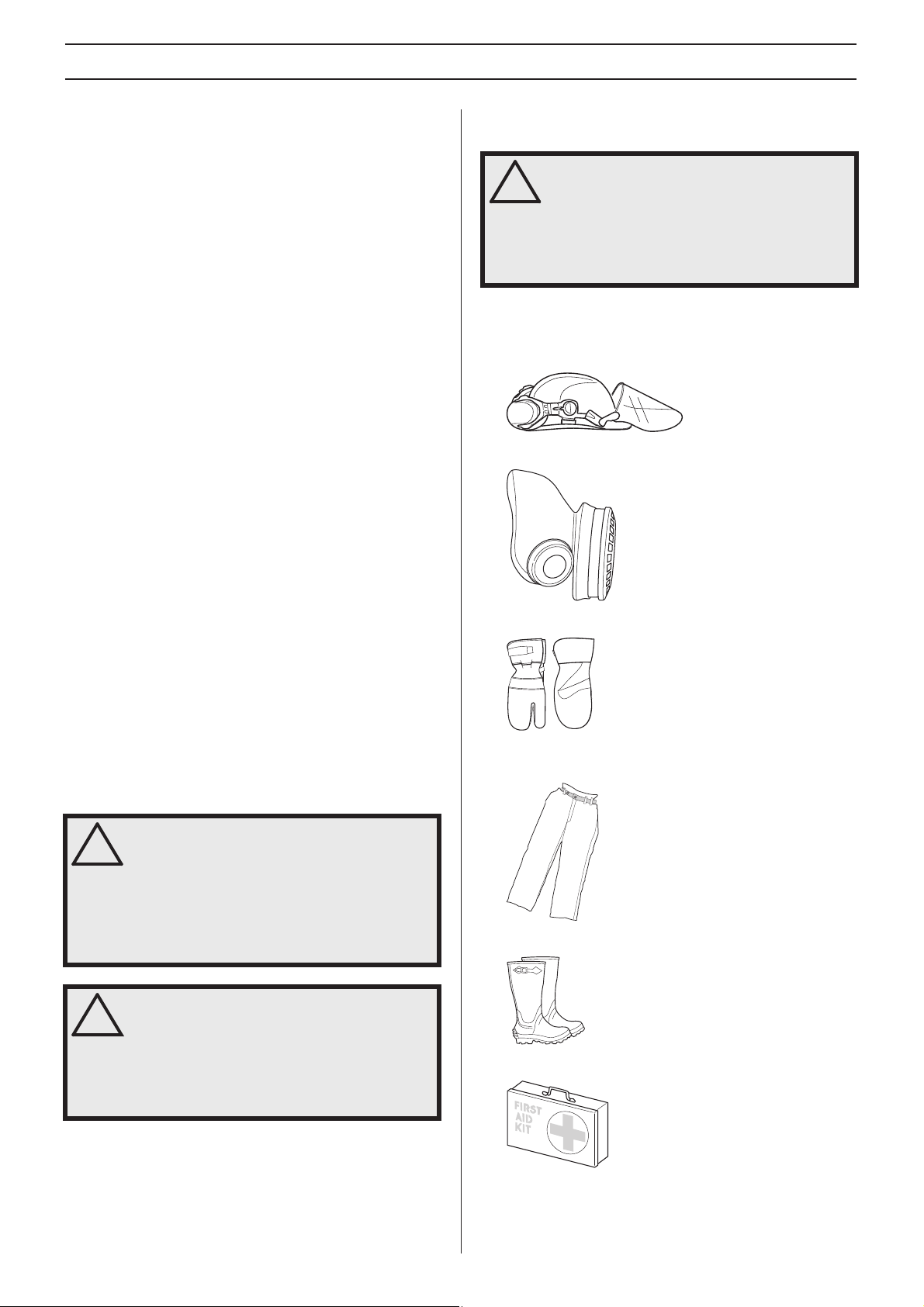

Personal protective equipment

WARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

WARNING! Under no circumstances should

you modify the original design of the

!

machine without approval from the

manufacturer. Always use original spare

parts. Unauthorized modifications and/or

accessories may lead to serious injury or

death to the user or others.

WARNING! Use of pr oducts which cut, grind,

drill, sand or shape material can generate

!

dust and vapors which may contain harmful

chemicals. Know the nature of the material

being worked on and wear appropriate dust

mask or respirator protection.

• Tight-fitting, heavy-duty and comfortable clothing that

mits full freedom of movement.

per

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

English – 5

Page 6

SAFETY INSTRUCTIONS

General safety precautions

WARNING! This section describes basic

safety directions for using the machine. This

!

information is never a substitute for

professional skills and experience. If y ou get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced user. Do not

attempt any task that you feel unsure of!

• Do not use the machine without first reading and

understanding the contents of this Operator’s Manual.

Work area safety

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc.

• Keep work area clean and well lit. Cluttered or dark areas

invite accidents

• The machine should not be used in areas where potential

for fire or e

Electrical safety

!

• Never drag the machine by means of the cord and never

pull out the plug by pulling the cord.

• Keep all cables a wa y of w ater , oil and sharp edges. Make

sure the cable is not pinched in doors

It can cause the object to become live.

• Check that the cables are intact and in good condition.

Use cable intended f

• Never use the machine if any cab le is damaged, but hand

it in to an authoriz

• The machine should be connected to an earthed outlet

et.

sock

• Check that the mains voltage corresponds with that stated

on the rating plate on the machine

• Be on your guard for electrical shocks. A v oid having body

contact with lightning-conductors/metal in the ground.

Do not use an extension cord while it is rolled up to av oid

•

erheating.

ov

• Ensure the cord is behind you when you start to use the

machine so that the cord will not be damaged.

.

xplosions exist.

WARNING! There is always a risk of shocks

from electrically powered machines. Avoid

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Alwa ys follow the instructions in the

Operator’s manual to avoid damage.

, fences or the like.

or outdoor use.

ed service workshop for repair.

.

Personal safety

WARNING! Overexposure to vibration can

lead to circulatory damage or nerve damage

!

in people who have impaired circulation.

Contact your doctor if you experience

symptoms of overexposure to vibration.

Such symptoms include numbness, loss of

feeling, tingling, pricking, pain, loss of

strength, changes in skin colour or

condition. These symptoms normally appear

in the fingers, hands or wrists. These

symptoms may be increased in cold

temperatures.

• Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could aff

your vision, your judgement or your co-ordination.

• Never allow anyone else to use the machine without first

ensuring that the

operator’s manual.

• All operators shall be trained in the use of the machine.

The owner is responsib

receive training.

• People and animals can distract you causing you to lose

control of the machine.

concentrated and focused on the task.

• Be careful as clothing, long hair, and jewellery can get

caught in moving par

• Never leave the machine unsupervised with the motor

running.

Make sure that there is always another person close at

•

hand when you use the machines

help if an accident should occur.

• Always ensure you have a safe and stable working

position.

y have understood the contents of the

le for ensuring that the operators

For this reason, always remain

ts.

, so that you can call for

ect

6 – English

Page 7

SAFETY INSTRUCTIONS

Use and care

• Only use the machine for the purpose it was intended for.

• Keep all parts in good working order and ensure that all

fixtures are properly tightened.

Never use a machine that is faulty. Carry out the checks,

•

maintenance and service instr

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Do not modify safety equipment. Check regularly that they

function as they should.

defective or disassembled safety equipment.

• Never use a machine that has been modified in any way

from its original specification.

Machinery should only be started when grinding heads

•

are resting on the ground unless carr

procedure as outlined in this manual.

• The machine should not be started without the rubber

dust skirt attached.

machine and floor be established for safety, especially

when operating in dry grinding applications.

• During grinding, the machine must be connected to a

vacuum cleaner to suc

• When changing the grinding discs ensure power supply to

the unit is OFF by engaging the Emergency Stop b

and the power-plug disconnected.

• After each grinding/polishing operation always remov e the

diamond tools.

Make sure that the rubber skirt is intact and clean and that

•

it seals tightly against the floor.

should always be replaced.

• When removing glue, asphalt, paint etc. always raise the

machine from the surface after use to pre

sticking to the floor due to the heat. Make sure the

grinding head has stopped rotating before raising the

machine.

• Diamond tools may be very hot after use. Leave machine

to cool off before remo

protective gloves.

• Always use the machine mounted lifting eye when lifting.

• Always carry the machine by the carrying handle and the

.

handle

It is essential a good seal between

king off the dust.

ving the diamond segments. Use

uctions described in this

The machine must not be run with

ying out a testing

utton

Damaged rubber skirt

vent it from

Transport and storage

• The machine should always be transported under cover

limiting the exposed to natural elements – in particular

rain and snow.

• Store the equipment in a lockable area so that it is out of

reach of children and unauthoriz

• The machine should always be stored in a dry place when

not in use.

ed persons.

English – 7

Page 8

ASSEMBLY

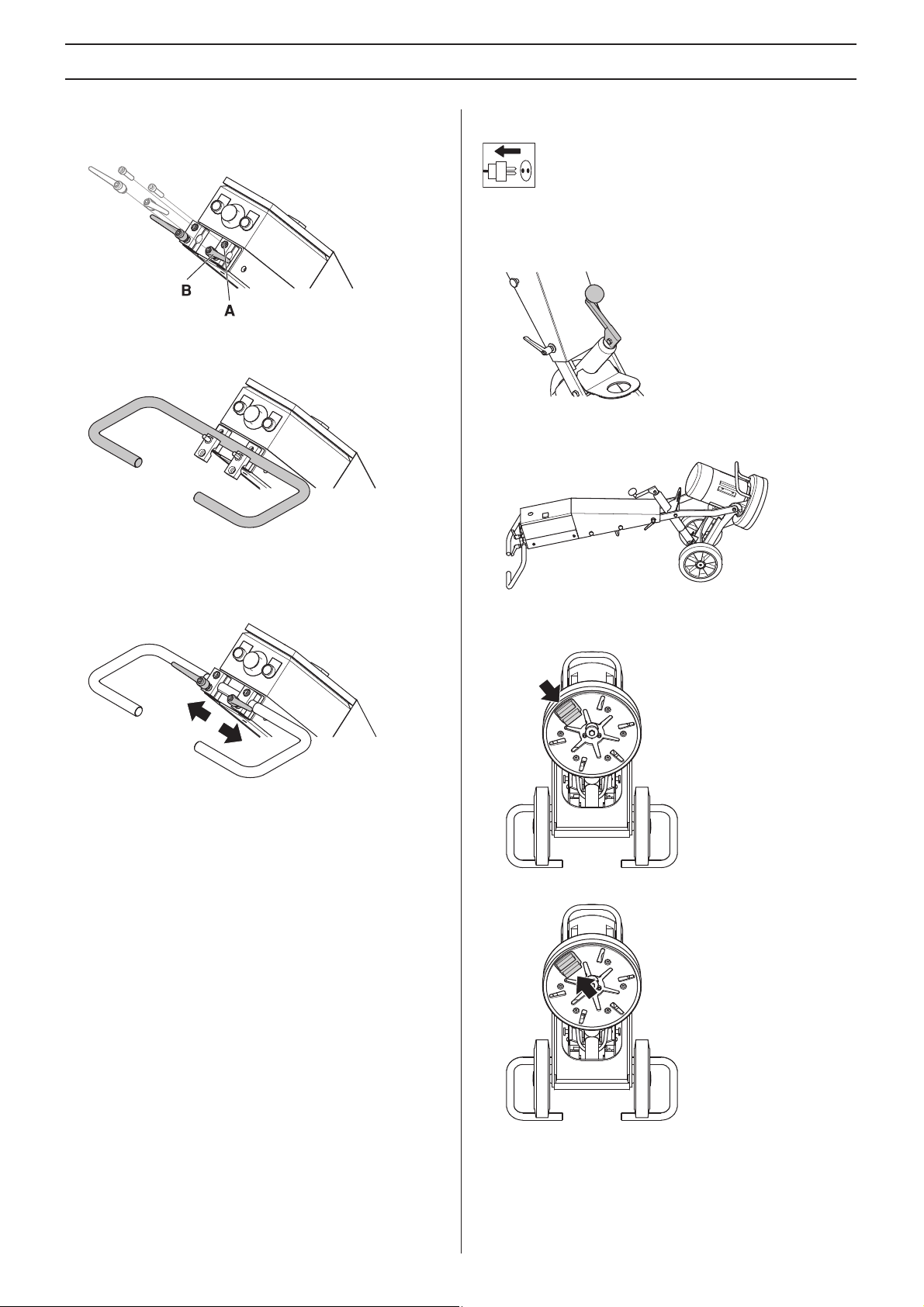

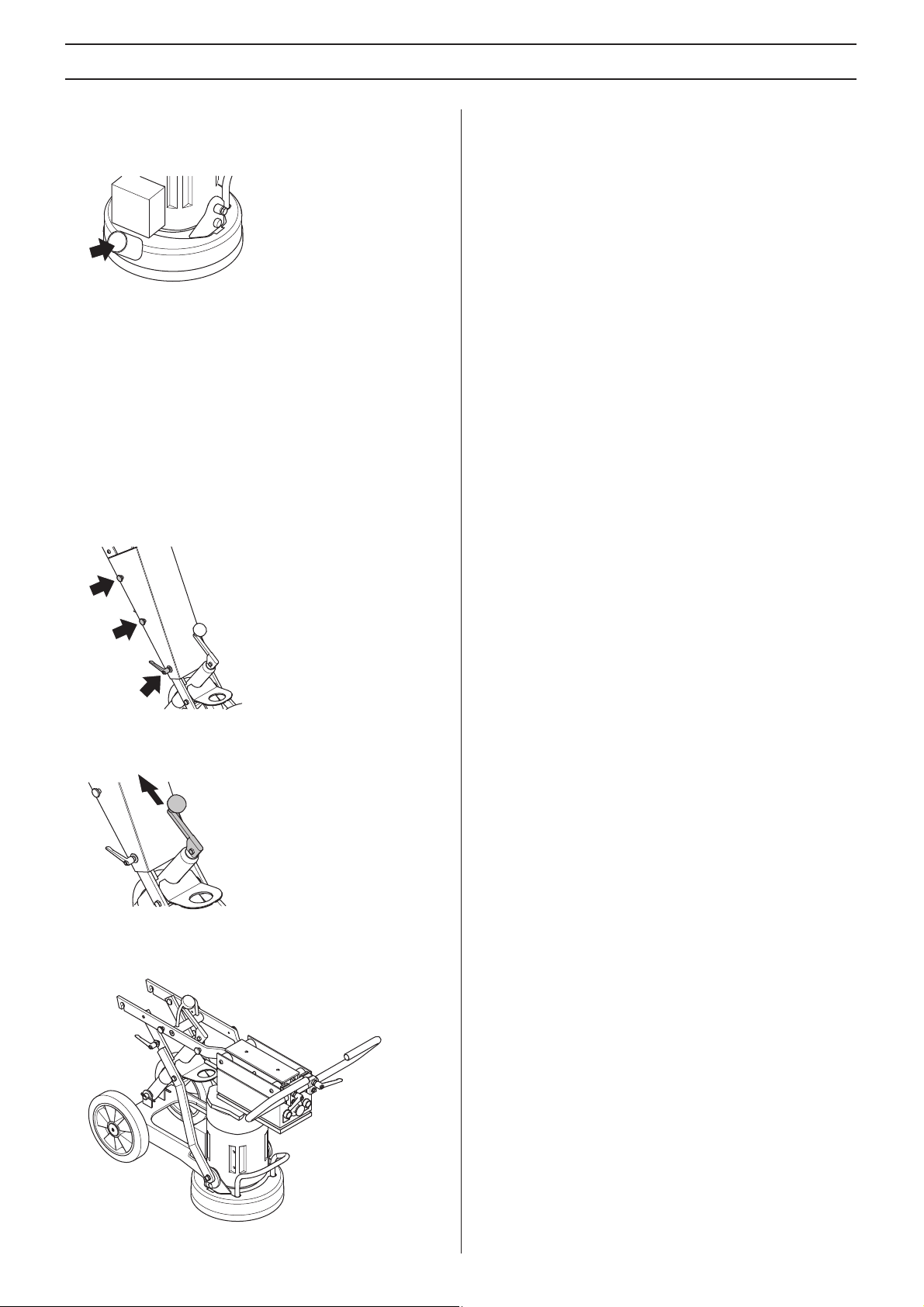

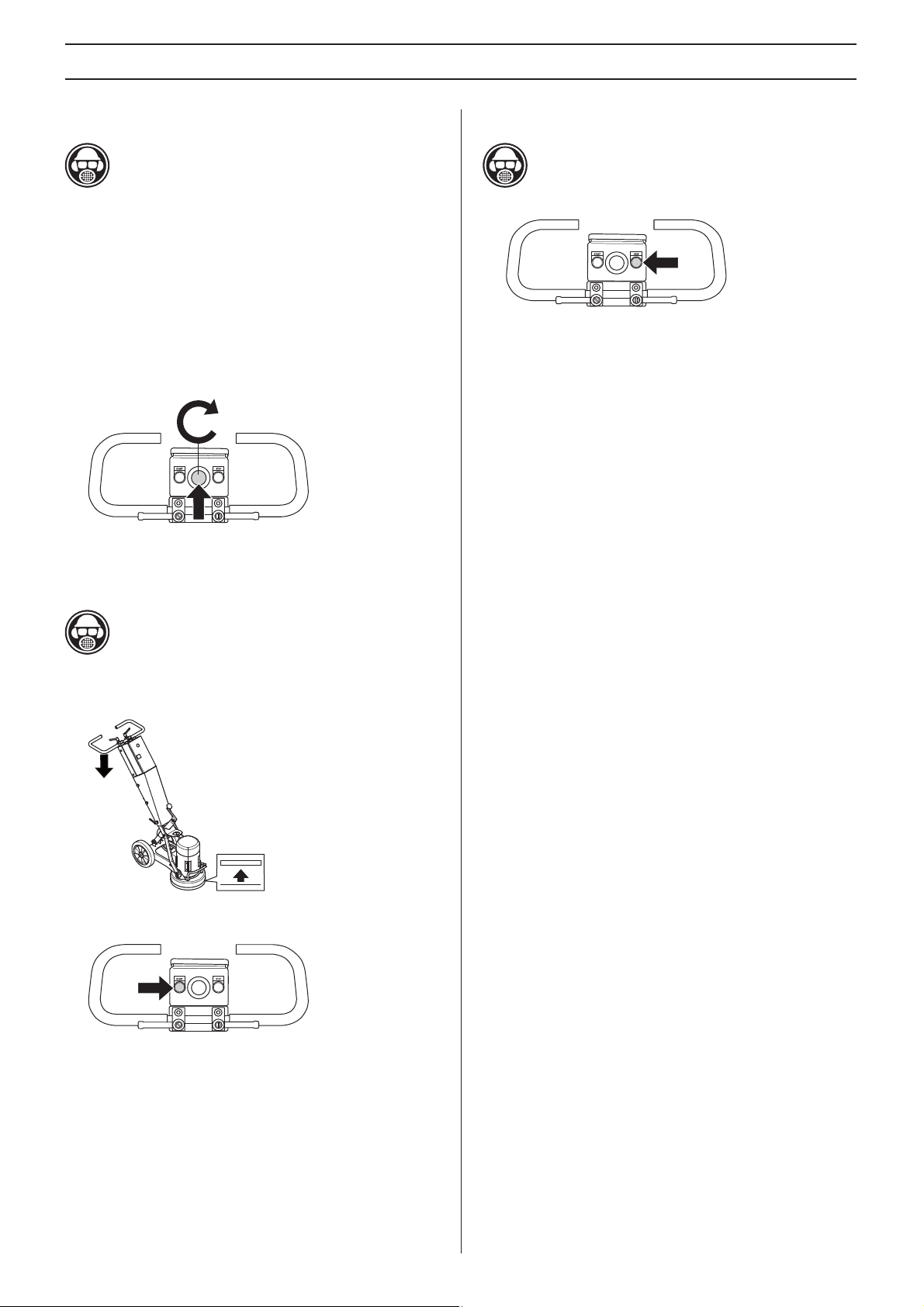

Fit the handle

• Remove the screws (A).

• Remove the locking knobs (B).

• Fit the handle in the handle stand-off on the machine.

• Refit screws (A) and locking knobs (B).

• The locking knobs should be positioned in-line with the

handlebar to reduce the risk of damaging the knobs when

ying down the machinge when changing tools.

la

Changing the diamonds

Shut down the machine and disconnect the power plug.

Have a set of glov es ready , as diamond tools can get v ery hot.

• Crank up the handlebar to the highest position.

• Pull back on handle to lift grinding head off the ground.

• Lay machine back on the ground.

• Put on gloves.

• Use a hammer to remove the diamond segments.

8 – English

• Affix new diamond segments on the grinding disc.

• Once new diamond segments have been attached,

erse procedure to lower machine to ground.

v

re

Page 9

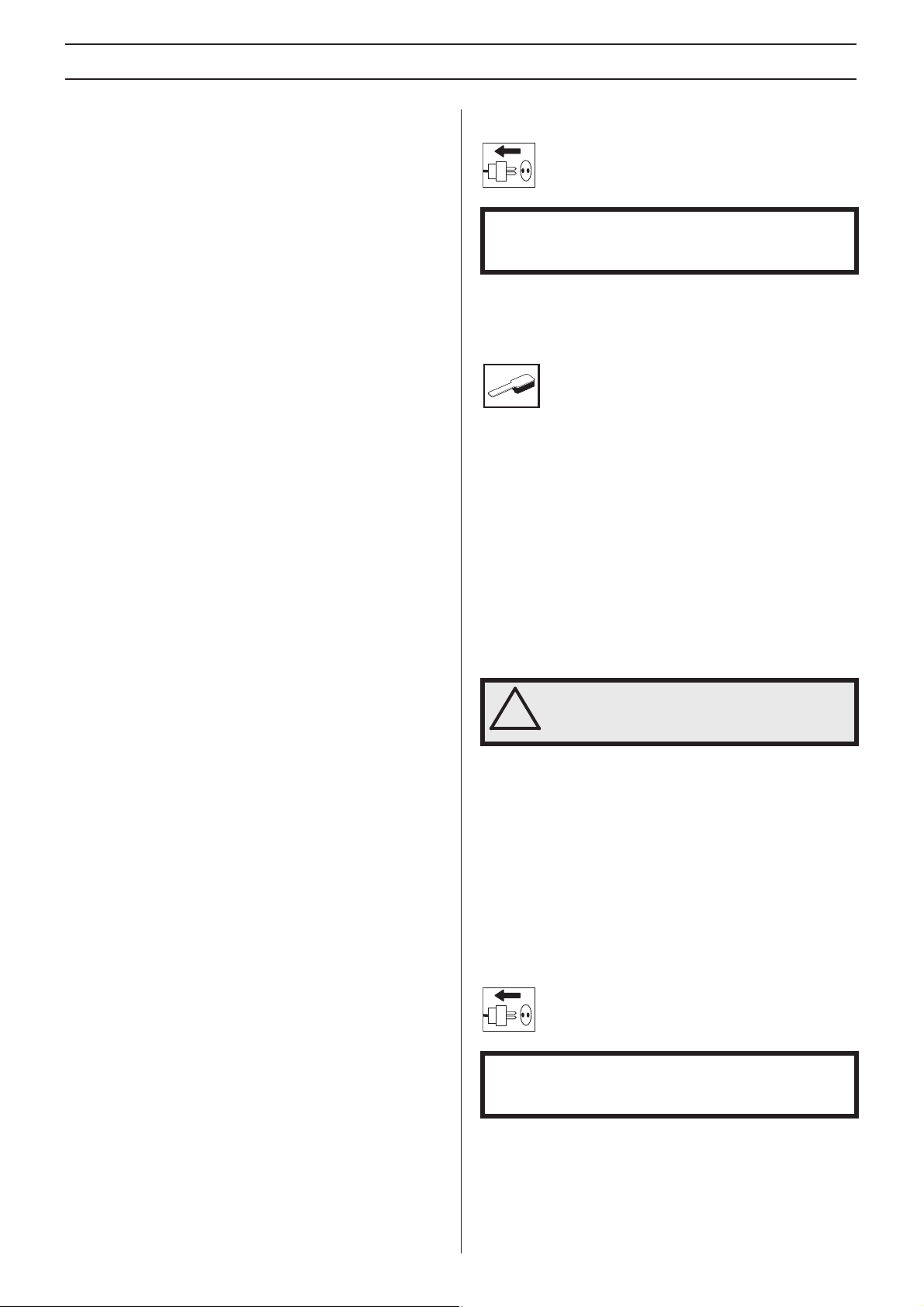

ASSEMBLY

Connect the vacuum cleaner

Connect the vacuum cleaner to the machine. Use a 50 mm

(2 inch) hose.

• It is highly recommended to use the Husqvarna DC 3300

dust extraction system for complete dust control.

• Make sure that the filters in the vacuum cleaner are intact

and clean. P

• Adjust the rubber skirt to be in contact with the floor to

ensure efficient dust collection.

Transport

The machine can be folded to minimize space needed for

transport.

• Loosen the screws and the lock handle that hold the cov er

in place.

ay attention to dust during operation.

• Remove the cover.

• Place the crank with the handle pointing straight upwards.

• Carefully fold the machine forward. Put padding between

the motor and the electric box to prevent damage to the

machine.

• The cover can be attached to the side of the machine.

English – 9

Page 10

GRINDING GUIDE

Diamonds

Background

Diamond abrasives usually consist of 2 components:

• Diamond powder (also known as diamond crystals or grit).

By changing the size of the diamond po

can change how coarse or fine the scratches will be that

are left behind from the grinding process.

• A binding agent (metal or resin). Diamond powder is

mixed and suspended in either a metal or resin binding

When suspended in a metal binding agent, the

agent.

finished product is referred to as a Metal Bond or Sintered

diamond segment. When suspended in a resin binding

agent, the finished product is referred to as a Resin Bond

diamond segment or pad. By changing the hardness of

the binding agent, we can change how fast or slow the

diamond abrasive will wear.

General Principles

The following are general rules regarding diamond segments

in grinding applications. As with all general rules there are

exceptions or cases when it is not the case.

Diamond grit size

Changing the size of the diamond grit to a smaller particle/grit

size will effect the performance of the diamond tool in the

following ways:

• Create a finer scratch pattern.

• Increase life of diamond tool.

The opposite will occur when changing to a larger particle/grit

ize.

s

Binding agent

Increasing hardness of bond will:

• Create a finer scratch pattern.

• Increase life of diamond tool.

• Decrease production rate.

The opposite will occur when making the metal or resin bond

.

softer

Number of diamond segments/pads under the

machine

Increasing the number of segments under the machine will:

• Reduce pressure on each individual diamond segment reduce wear r

• Reduce load on the machine and cause the grinder to

w less current.

dra

• Create a smoother scratch pattern (particularly on soft

floors).

The opposite will occur when decreasing the number of

segments under the machine

Summary of diamond principles

Diamond segments need to wear in order to achieve

productivity . Diamond segment wear can be influenced by the

following factors:

ate on diamond segments.

.

wder or grit, we

• Pressure.

• Hardness of bond.

• Diamond grit size.

• Number of segments under the machine.

• Adding an additional abrasive (e.g. sand, silicone carbide)

ear

on the floor will increase w

Generally , the faster a diamond segment w ears, the faster the

productivity will be.

can also be made to effect the following:

• Scratch pattern.

• Current draw of machine.

• Flatness of floor (see next section).

• Ease of operation.

By varying the above factors, changes

.

Determining the hardness of concrete

All concretes are measured by their compressive strength

and depending on which part of the world you are from,

different compressive strength indices (e.g. PSi & MPa) are

used. Generally, the higher the compressive strength rating,

the harder the concrete and therefore, the harder it will be to

grind.

However, other factors beside compressive strength ratings

determine ho

correct diamond selection. Since grinding normally only deals

with the surface of the concrete (top 5mm or 1/4 inch), often

the way the concrete floor has been finished or the condition

of the surface will have a greater bearing on what type of

diamond to select, rather than the compressive strength

rating of the concrete.

Surface factors to consider when making a diamond

selection

Generally , if a concrete surf ace is very smooth (i.e. Most likely

it has been heavily trowelled/helicoptered), the concrete will

behave as if it has a high compressive strength and theref ore,

require a soft bond segment.

Accordingly, if a concrete surface is coarse/aggressive (e.g.

rain-damaged, shot b

e.t.c.), the concrete will behave as if it has a lo w compressive

strength and therefore, require a hard bond segment.

Surface coatings/contaminants (e.g. Epoxy coatings , ceramic

tile adhesives

larger bearing on what diamond to select, than will the

compressive strength of the concrete.

As a general rule, when grinding a concrete slab for the first

time and you are unsure about its hardness

with harder bond diamonds under the machine. This will

ensure the least amount of wear on the diamond segments. If

a hard diamond segment is not suited to the application, all it

has cost is a little amount of time without wearing out the

diamonds.

If performed the other way around (i.e. a soft segment is used

to begin with) and the concrete is soft or possesses an

abrasiv

wear-out a considerable amount of diamond in very short

period of time.

w hard the floor will be, and therefore, the

lasted, scarified, exposed aggregate

, levelling compounds/screeds) will often ha ve a

, always begin

e surface or surface contaminant, it is quite possib le to

10 – English

Page 11

GRINDING GUIDE

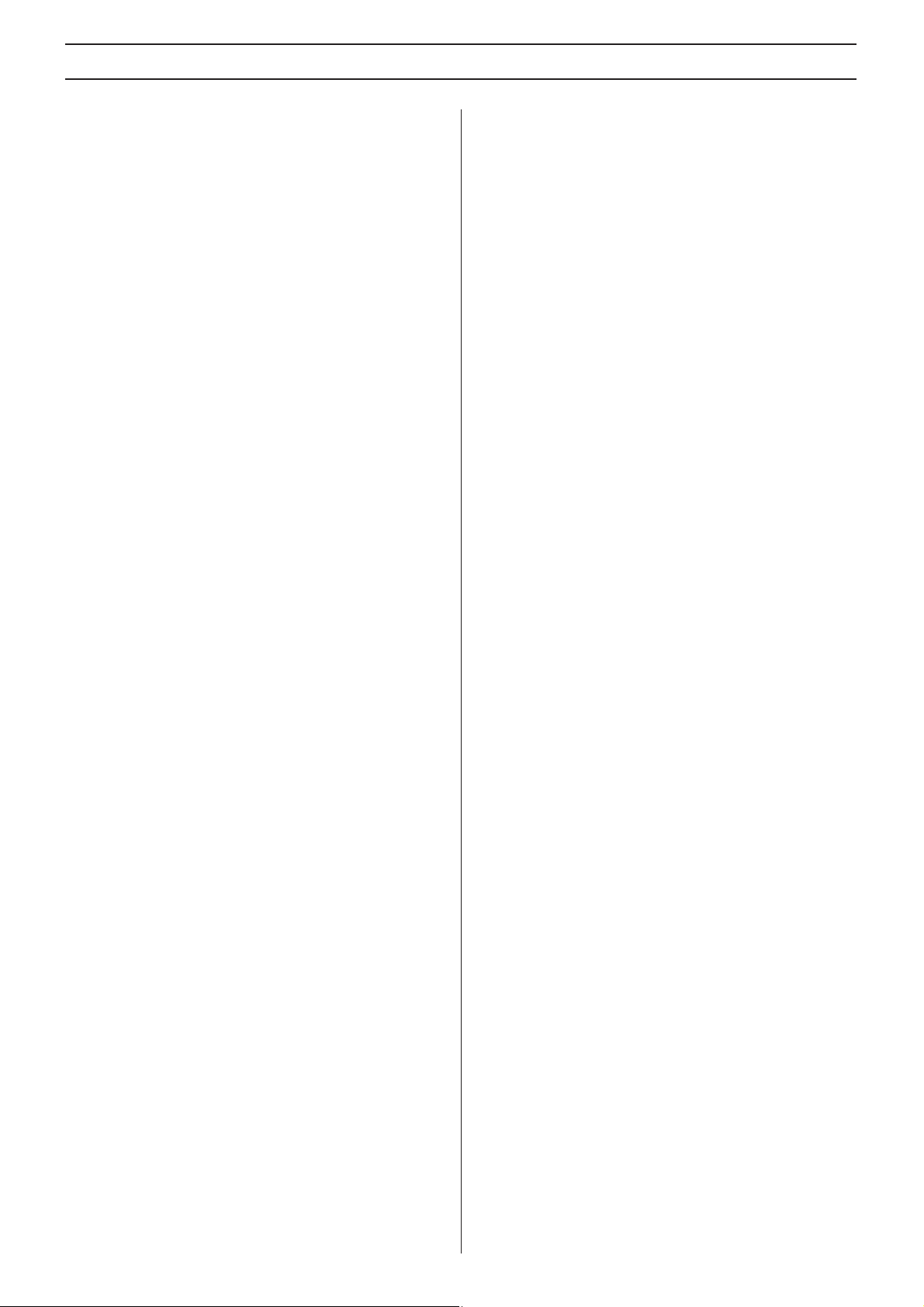

Diamond selection

They way diamond segments are set-up on the g rinding unit will greatly influence the performance of the machine, the productivity

levels and also the finished floor quality.

There are a number of different diamond configurations that can be achieved on both the PG 400 SF and PG 280 SF.

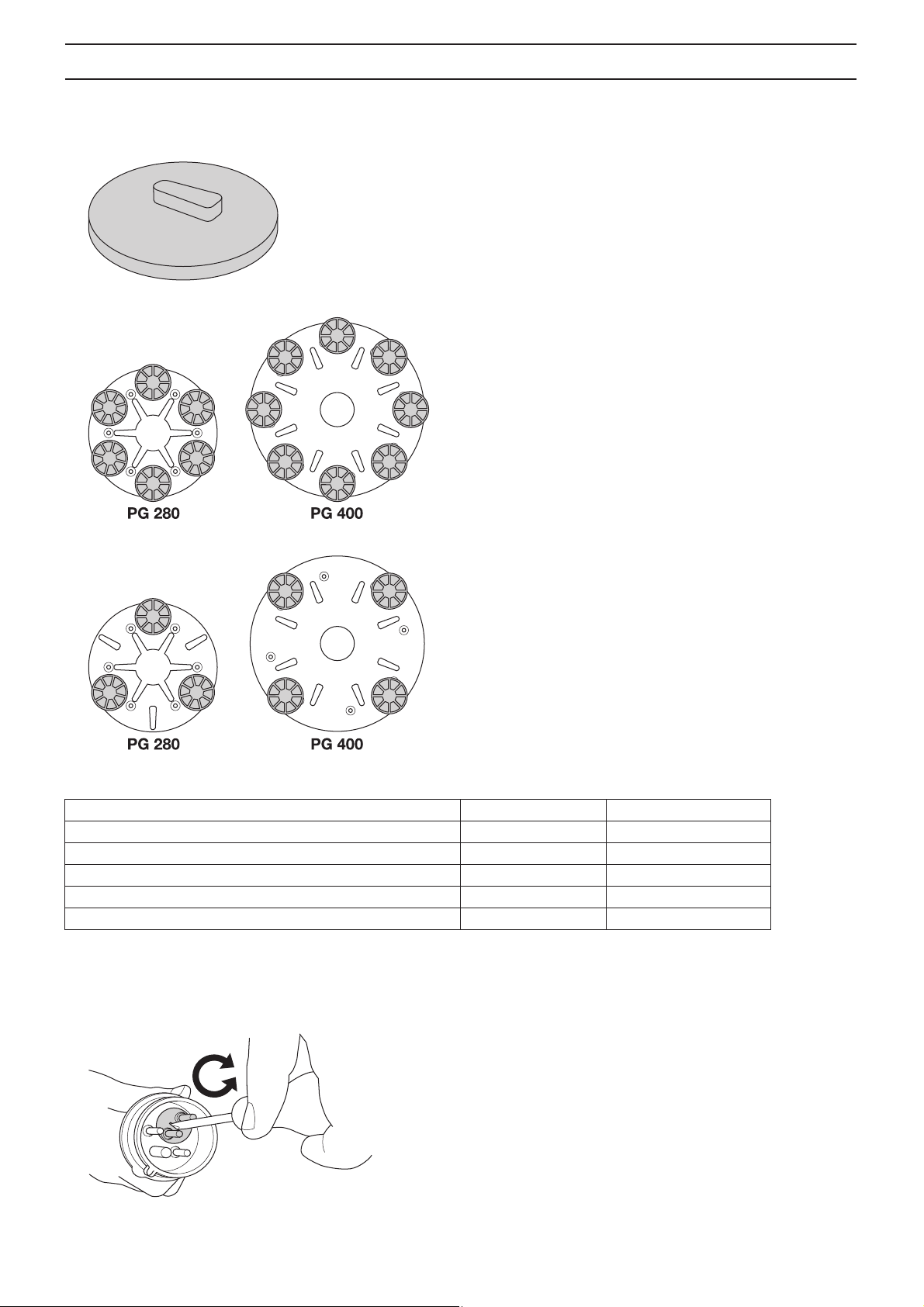

Metal bond diamonds

Full set - inner and outer row

Full set - outer row

Half set - inner and outer row

Half set - outer row

English – 11

Page 12

GRINDING GUIDE

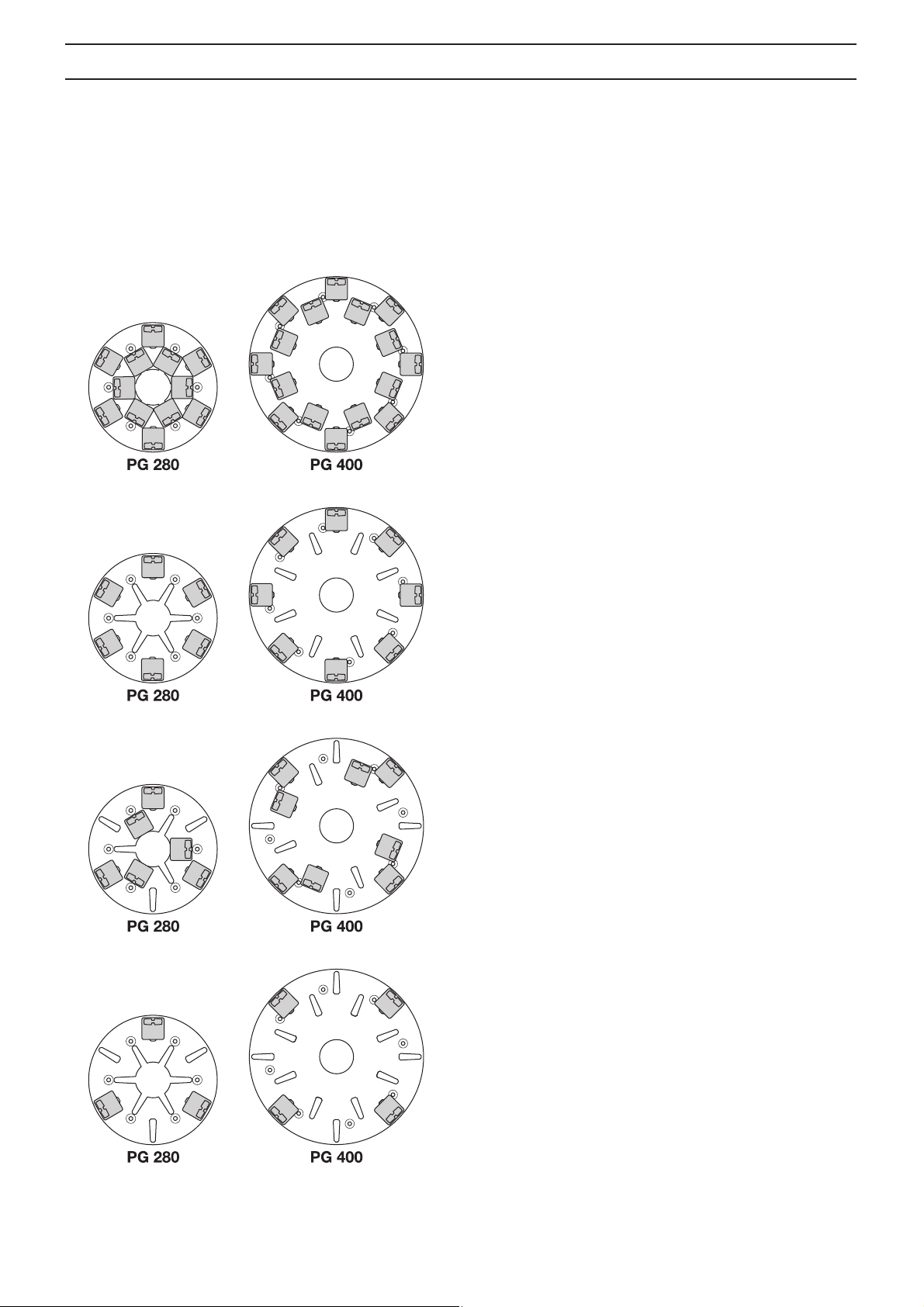

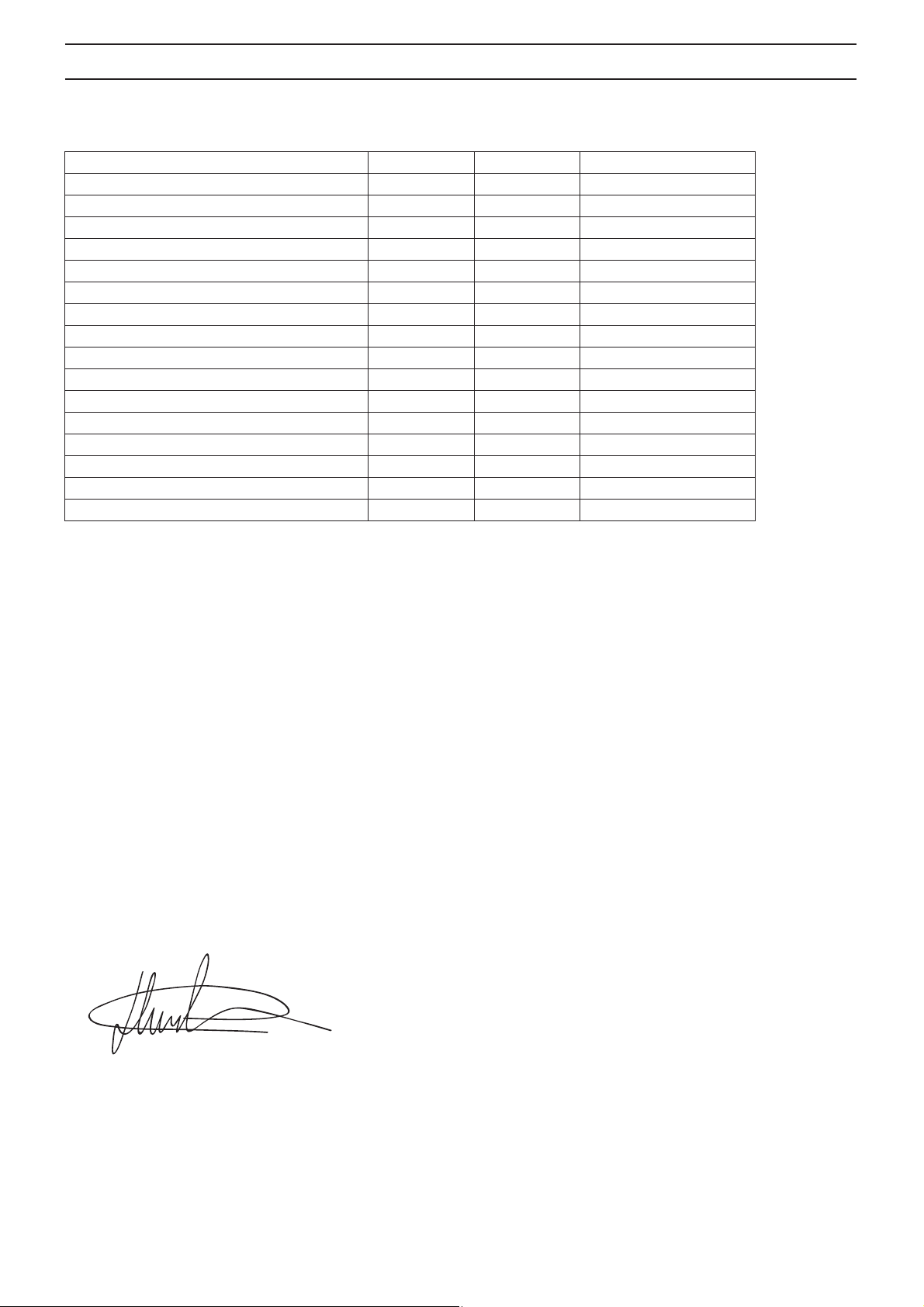

Select the correct metal bond diamonds for your application

The following suggestion cover the basic configurations for metal bonded diamond tools.

Applications

Flatten floor - Hard concrete Soft 16 or 30 X

Flatten floor - Medium concrete Medium 16 or 30 X

Flatten floor - Soft concrete Hard 16 or 30 X

Ceramic tile adhesive removal Medium

Vinyl or Carpet glue removal -

Hard concrete

Vinyl or Carpet glue removal -

Medium concrete

Vinyl or Carpet glue removal -

Soft concrete

Epoxy paint removal -

Hard concrete

Epoxy paint removal -

Medium concrete

Epoxy paint removal -

Soft concrete

Rain damaged concrete Hard 16-30 X X

Smoothen exposed aggregate Hard 16-30 X X

Lippage removal in terrazzo/stone

tiles

Surface polishing of concrete

floors - Hard concrete

Surface polishing of concrete

floors - Medium concrete

Surface polishing of concrete

floors - Soft concrete

Grinding to exposed aggregate in

concrete - Hard concrete

Grinding to exposed aggregate in

concrete - Medium concrete

Grinding to exposed aggregate in

concrete - Soft concrete

Flatten undulation in concrete

floors - Hard concrete

Flatten undulation in concrete

floors - Medium concrete

Flatten undulation in concrete

floors - Soft concrete

Metal

bond

Soft

Medium

Hard

Soft

Medium

Hard

Soft 30 or 60 X

Soft 60 X X

Medium 60 X X

Hard 60 X X

Soft 16-30 X X X

Medium 16-30 X X X

Hard 16-30 X X

Soft 16 or 30 X X X

Medium 16 or 30 X X

Hard 16 or 30 X X

Grit size

PIRANHA™ or

16-30

PIRANHA™ or

16-30

PIRANHA™ or

16-30

PIRANHA™ or

16-30

PIRANHA™ or

16-30

PIRANHA™ or

16-30

PIRANHA™ or

16-30

Full set - inner

and outer row

X

Full set outer row

X X

X

X

Half set - inner

and outer row

X X

X X

X X

Half set outer row

12 – English

Page 13

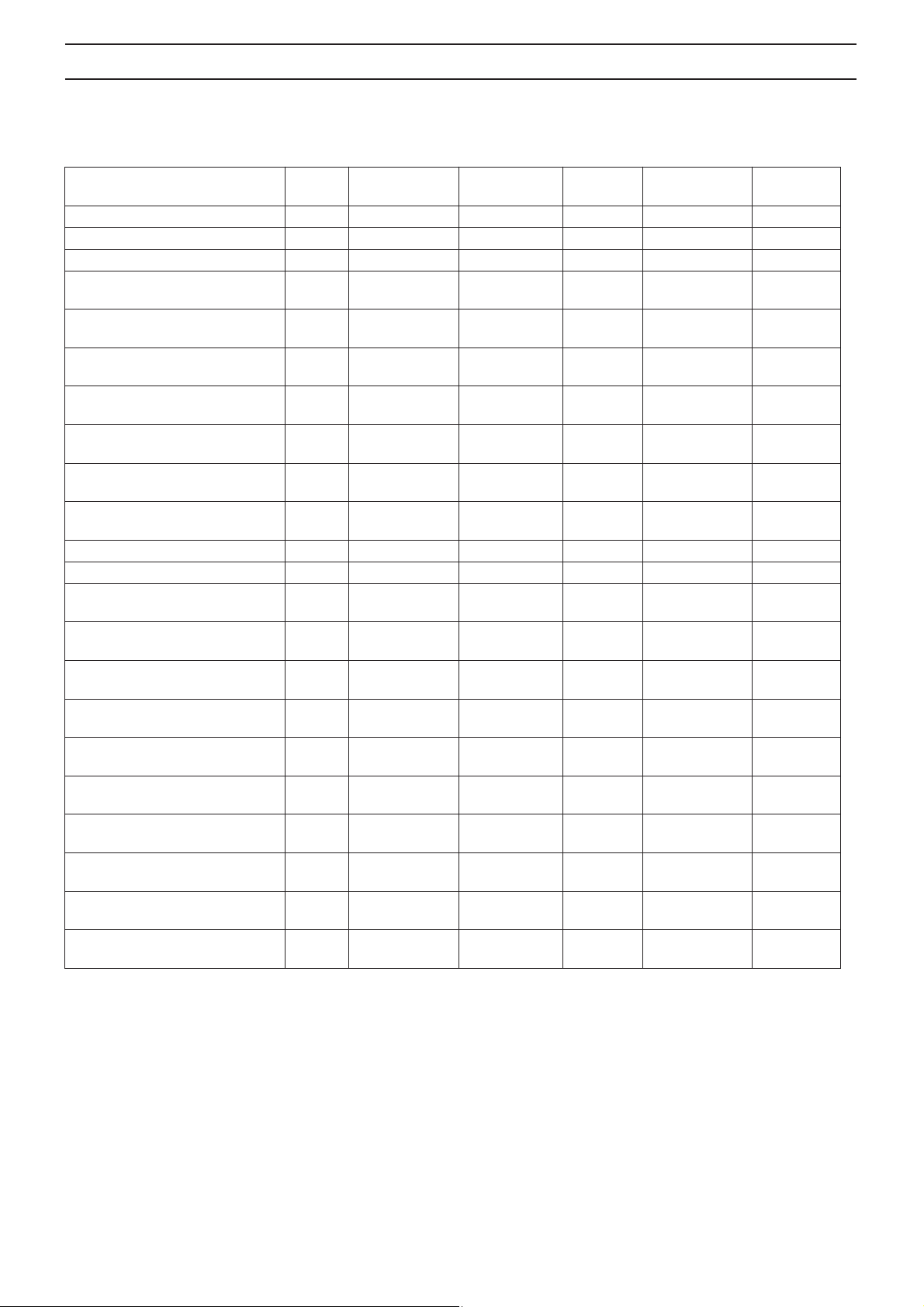

Resin bond diamonds

Redi Lock resin attachment adaptor

Full set - outer row

GRINDING GUIDE

Half set - outer row

Selecting the correct resin bond diamond configuration for your application

Applications Full set - outer row Half set - outer row

Polishing terrazzo/stone tiles X

Resurfacing terrazzo/stone tiles X

Surface polishing of concrete floors - Hard concrete X

Surface polishing of concrete floors - Medium concrete X

Surface polishing of concrete floors - Soft concrete

X

The motor’s direction of rotation (3 phase)

The motor´s direction can be changed by reversing the poles in the power plug.

NOTE! The Piranha/PCD tools are designed to run in only one direction.

English – 13

Page 14

STARTING AND STOPPING

Before starting

• Position grinder on the working area.

• Make sure there are diamonds beneath the machine and

that they are fir

• Connect the vacuum cleaner to the machine.

• Use locking knobs for handlebar adjustment to set most

or

table working height.

comf

• Plug power supply to machine.

• Check that the emergency stop button is not pressed by

ning it cloc

tur

• Check the motor’s direction of rotation

mly attached.

kwise.

Stopping

• Use the stop button to shut down the machine.

• Keep grinding segments in contact with the floor when

stopping.

stop quickly. Do not lift the grinding head off the floor

when stopping as this can create a significant amount of

dust in the air.

This will help bring the machine to a complete

Starting

• Reduce the pressure between grinding disc and floor by

pushing down on the handle without raising the grinding

unit off the ground.

• Press the start button and keep it pressed a few seconds

to start the machine

.

14 – English

Page 15

MAINTENANCE

Faults and trouble shooting

The machine will not run

• Check the power supply and the power cables and make

sure that they are not damaged.

• Check that the emergency stop button is not pressed by

turning it cloc

Machine is hard to hold onto

• Not enough diamonds under the machine (if grinding thick

glue or soft floors, too few diamonds under the machine

will greatly increase the load on grinder and operator).

Usually also accompanied by high current draw by motor.

Increase number of diamonds under machine to reduce

load on gr

Machine is jumping around

• Rubber shock absorber pads in grinding unit may be worn

out or damaged. Check and change if necessary.

• Diamonds may not be fitted correctly or have different

heights.

and are the same height.

The machine stops after just a while

• The machine is overloaded and the overload protection

has been released. Reduce load. The machine will reboot

after about a minute when the motor has cooled off.

kwise.

inder and operator.

Check to ensure all diamonds are fitted correctly

Maintenance

IMPORTANT! Inspection and/or maintenance should be

carried out with the motor switched off and the plug

disconnected.

Used correctly , the machine is an extremely low-maintenance

and reliable product.

Cleaning

Always pull out the plug from the outlet socket before

cleaning, maintenance or assembly.

Always clean all the equipment at the end of the working day.

Do not use a high pressure washer to clean the machine

In order for the machine to always be cooled sufficiently the

cooling air openings must be k

ept clear and clean.

Rubber shock absorber pads

Check the rubber shock absorbing pads every month.

Replace if necessary.

Electrical Feed

.

The machine stops during start-up

• The electric motor has been overloaded or a phase is

missing. Allow the machine one or two minues to reset

and try again. When this does not help, contact an

authorised service workshop.

WARNING! Ne ver use dama ged cables. They

can cause serious, even fatal, personal

!

injuries.

Check that the cord and extension cord are intact and in good

condition.

Never use the machine if the cord is damaged, hand it in to an

authoriz

ed service workshop for repair.

Skirt

Make sure that the rubber skirt is intact and clean and that it

seals tightly against the floor. Damaged rubber skirt should

always be replaced.

Service

IMPORT ANT! All types of repairs ma y only be carried out by

authorised repairmen. This is so that the operators are not

exposed to great risks.

English – 15

Page 16

TECHNICAL DATA

Technical data

PG 400 SF PG 280 SF PG 280 SF (Single-phase)

Motor Power, kW/hp 4/5,4 3/4 2,2/3,0

Rated current, A 16 16 12,9

Rated voltage, V 400 400 230

Weight, kg/lbs 115/254 70/154 70/154

Grinding width, mm/inch 400/16 280/11 280/11

Grinding pressure, kg/lbs 65/143 35/77 35/77

Speed, rpm 1400 2800 1400

Noise emissions (see note 1)

Sound power level, measured dB(A) 107 107 107

Sound power level, guaranteed L

Sound levels (see note 2)

Sound pressure level at the operators ear , dB(A) 89 89 89

Vibration levels (see note 3)

Handle right, m/s

Handle left, m/s

2

2

dB(A) 108 108 108

WA

3,4 3,4 3,4

3,4 3,4 3,4

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EN 61029-1.

Note 2: Noise pressure level according to EN 61029-1. Reported data for noise pressure level has a typical statistical dispersion

(standard deviation) of 1.0 dB(A).

Vibration level according to EN 61029-1. Reported data for vibration level has a typical statistical dispersion (standard

Note 3:

deviation) of 1 m/s

2

.

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that the Husqvarna PG

400 SF, Husqvarna PG 280 SF dating from 2010 serial numbers and onwards (the year is clearly stated on the rating plate,

followed by the serial number), complies with the requirements of the COUNCILíS DIRECTIVE:

• of May 17, 2006 "relating to machinery"

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment”

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55015-2/A1:2001, EN 61000-3-2:2006,

EN 61000-3-3/A1/A2:2005, EN 13862/A1:2009.

The supplied machine conforms to the example that underwent EC type examination.

Göteborg December 29, 2009

2006/42/EC

2006/95/EC.

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

16 – English

Page 17

WIRING DIAGRAM

English – 17

Page 18

WIRING DIAGRAM

18 – English

Page 19

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina:

¡ATENCIÓN! La máquina, si se utiliza de

forma errónea o descuidada, puede ser

una herramienta peligrosa que puede

causar daños graves e incluso la m uerte al

usuario y a otras personas.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

Utilice el equipo de protección personal.

las instrucciones bajo el título ”Equipo de

protección personal”.

¡A

TENCIÓN! Al amolar se genera polvo que

puede causar daños por inhalación. Utilice

una máscar

Procure que haya buena ventilación.

Arranque: Reduzca la presión entre el

disco de amolado y el suelo empujando

hacia abajo la empuñadura sin le

unidad de amolado del suelo.

a respiratoria homologada.

V ea

vantar la

Símbolos en el manual de instrucciones:

El control y/o mantenimiento de la máquina

debe hacerse con el motor parado y el

enchufe desenchufado.

Utilice siempre guantes protectores

homologados.

La máquina debe limpiarse regular

Control visual.

Debe utilizarse gafas protectoras o visor.

mente.

Este producto cumple con la directiva CE

vigente.

Etiquetado ecológico. El símbolo en el

producto o en su envase indica que no se

puede tratar este producto como desperdicio

doméstico.

Haciendo que este producto sea manipulado

adecuadamente, se a

consecuencias negativas potenciales para el

medio ambiente y las personas, lo que

puede ocurrir con la manipulación inadecuada como residuos

del producto.

Para obtener inf ormación más detallada sobre el reciclado de

este producto, contacte con la oficina m

servicio de eliminación de desperdicios domésticos o con la

tienda donde compró el producto.

Los demás símbolos/etiquetas que aparecen en la

máquina corresponden a requisitos de homologación

específicos en determinados mercados.

yuda a evitar

unicipal local, con el

Spanish – 19

Page 20

ÍNDICE

Índice

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina: ............................................. 19

Símbolos en el manual de instrucciones: .................... 19

ÍNDICE

Índice ........................................................................... 20

¿QUÉ ES QUÉ?

Elementos de la amoladora ......................................... 21

INSTRUCCIONES DE SEGURIDAD

Antes de utilizar una amoladora nueva ........................ 22

Equipo de protección personal .................................... 22

Instrucciones generales de seguridad ......................... 23

MONTAJE

Ajuste la empuñadura. ................................................. 25

Cambio de los diamantes ............................................ 25

Conexión de la aspiradora ........................................... 26

Transporte .................................................................... 26

GUÍA PARA EL AMOLADO

Diamantes .................................................................... 27

Determinación de la dureza del hormigón ................... 27

Selección de diamantes ............................................... 28

Sentido de rotación del motor ...................................... 30

ARRANQUE Y P ARADA

Antes de arrancar ........................................................ 31

Arranque ...................................................................... 31

Parada ......................................................................... 31

MANTENIMIENTO

Fallos y localización de fallos ....................................... 32

Mantenimiento ............................................................. 32

Servicio ........................................................................ 32

DA TOS TECNICOS

Datos técnicos ............................................................. 33

Declaración CE de conformidad .................................. 33

ESQUEMA DE CONEXIONES ELÉCRICAS

20 – Spanish

Page 21

¿QUÉ ES QUÉ?

Elementos de la amoladora

1 Caja eléctrica

2 Cubierta

3 Cigüeñal para ajustar la presión de amolado

4 Cáncamo de elevación

5 Motor eléctrico

6 Asa de levantar

7 Faldón

8 Conexión para la aspiradora

9 Conjunto de eje con ruedas

10 Manija de cierre de la cubierta

11 Tornillos de la cubierta

12 Unidad de amolado - PG 280 SF

13 Unidad de amolado - PG 400 SF

14 Empuñadura / manillar

15 Panel de control

16 Botón de arranque

17 Parada de emergencia

18 Botón de parada

19 Manija de cierre para el ajuste del manillar

20 Manual de instrucciones

Spanish – 21

Page 22

INSTRUCCIONES DE SEGURIDAD

Antes de utilizar una amoladora nueva

• Lea detenidamente el manual de instrucciones y

asegúrese de entender su contenido antes de utilizar la

máquina.

• Las amoladoras PG 400 SF y PG 280 SF están diseñadas

para eliminar los residuos superficiales de cola /

adhesiv

hormigón, así como para amolar y alisar suelos de

hormigón. SF significa un único disco de velocidad fija

(single disc, fixed speed).

• La máquina puede ocasionar lesiones graves. Lea

atentamente las instrucciones de segur

utilizar la máquina.

• Sólo deberá manejar la maquinaria aquel personal que

hay

teórica acerca de su uso.

Emplee siempre el sentido común

Es imposible abarcar todas las situaciones en las que puede

encontrarse. Utilice siempre el equipo con cuidado y sentido

común. Evite todas aquellas situaciones que considere que

sobrepasan sus capacidades. Si, después de leer estas

instrucciones, no está seguro del procedimiento que debe

seguir, consulte a un experto antes de utilizar el equipo.

No dude en ponerse en contacto con su distribuidor si tiene

preguntas acerca del uso de la máquina. Estaremos

encantados de poder aconsejar

máquina de manera eficaz y segura.

Diríjase a su distribuidor de Husqvarna para que revise la

máquina regularmente y par

reparaciones básicas.

Toda la información y todos los datos contenidos en este

manual de instr

impresión del manual.

o, masilla y productos semejantes en suelos de

idad. Aprenda a

a recibido la formación necesaria, tanto práctica como

le y ayudarle a utilizar la

a que realice ajustes y

ucciones son vigentes en la fecha de

Equipo de protección personal

¡ATENCIÓN! Para trabajar con la máquina

debe utilizarse un equipo de protección

!

personal homologado. El equipo de

protección personal no elimina el riesgo de

lesiones, pero reduce su efecto en caso de

accidente. Pida a su distribuidor que le

asesore en la elección del equipo.

• Casco protector

• Protectores auriculares

• Gafas protectoras o visor

• Máscara respiratoria

• Guantes resistentes de agarre seguro.

• Prendas de vestir ceñidas, resistentes y cómodas que

mitan una libertad de movimientos total.

per

!

!

22 – Spanish

¡ATENCIÓN! No está permitido modificar el

diseño original de la máquina, por ningún

motivo, sin la autorización del fabricante.

Utilice siempre accesorios originales. Las

modificaciones y/o el uso de accesorios no

autorizados comportan riesgo de daöos

personales graves y peligro de muerte para

el usuario y otras personas.

¡ATENCIÓN! El uso de productos de corte,

amolado, taladrado, lijado o formación de

materiales puede generar polvo y vapores

que pueden contener productos químicos

perniciosos. Averigüe la índole del material

de trabajo y utilice una máscara contra

polvo o respiratoria adecuada.

• Botas con puntera de acero y suela antideslizante.

• Tenga siempre a mano el equipo de primeros auxilios.

Page 23

INSTRUCCIONES DE SEGURIDAD

Instrucciones generales de seguridad

¡ATENCIÓN! Este apartado trata las normas

de seguridad básicas para trabajar con el

!

dispositivo. Esta información no sustituye

en ningún caso los conocimientos y la

experiencia de un profesional. Si se

encuentra en alguna situación que le haga

sentirse inseguro, deténgase y consulte con

un experto. Consulte a su distribuidor, al

taller de servicio técnico o a un usuario

experimentado. No emplee la máquina en

aplicaciones para las que no se considere

plenamente cualificado.

• No utilice la máquina sin haber leído y comprendido el

contenido de este manual de instrucciones.

Seguridad en el área de trabajo

• No usar en condiciones climáticas desfavorables. Por

ejemplo, niebla densa, lluvia, viento fuerte, frío intenso,

etc.

• Mantenga el área de trabajo limpia y bien iluminada. Las

zonas abarrotadas de cosas u oscur

accidentes.

• La máquina no se usará en áreas donde haya posibilidad

de incendios o explosiones

.

Seguridad eléctrica

¡ATENCIÓN! Existe siempre riesgo de

sacudidas eléctricas al usar máquinas

!

eléctricas. No usar la máquina en

condiciones climáticas desfavorables y

evitar el contacto del cuerpo con pararrayos

y objetos metálicos. Seguir siempre las

instrucciones del manual para evitar daños.

• No arrastre la máquina nunca por el cordón y no quite

nunca el enchufe tirando del cordón.

• Mantenga todos los cables apartados del agua, el aceite

y los bordes agudos.

el cable se enganche en puertas, vallas o similares. Hay

riesgo de cargar objetos con electricidad.

• Compruebe que los cables están intactos y en buen

Utilice el cable proporcionado para el uso externo .

estado.

• Si se daña un cable, no utilice la máquina. Llévela a

reparar a un taller de ser

• La máquina se debe enchufar a un enchufe con masa.

• Compruebe que la tensión de red concuerda con la que

se indica en la placa de car

•

Tenga cuidado con los choques eléctricos. Evite el

contacto corpor

• Un cable de alargue no debe usarse enrollado porque hay

riesgo de sobrecalentamiento

• Al emplear la máquina, hágalo con el cable detrás suyo

vitar dañarlo.

para e

Proceda con cuidado para evitar que

vicio oficial.

acterísticas de la máquina.

al con pararrayos o metales en el suelo.

as favorecen los

.

Seguridad personal

¡ATENCIÓN! La sobreexposición a las

vibraciones puede provocar problemas

!

circulatorios y dolencias de carácter

nervioso, especialmente en personas con

patologías circulatorias. Acuda a un médico

si nota síntomas corporales que puedan

relacionarse con la sobreexposición a las

vibraciones. Son ejemplos de tales síntomas

la pérdida de sensibilidad, el 'cosquilleo', las

'punzadas', el dolor, la pérdida o reducción

de la fuerza normal o los cambios en el color

y la superficie de la piel. Estos síntomas se

presentan normalmente en dedos, manos y

muñecas. Los síntomas pueden aumentar

en temperaturas frías.

• Utilice el equipo de protección personal. Vea las

instrucciones bajo el título ”Equipo de protección

personal”.

• Nunca utilice la máquina si está cansado, si ha ingerido

alcohol o si toma medicamentos que puedan afectar

vista, su capacidad de discernimiento o el control del

cuerpo.

• Nunca deje que terceros utilicen la máquina sin

asegurarse pr

de este manual de instrucciones.

• Todos los operadores deben ser formados en el empleo

de la máquina. El propietar

formación de los operadores.

• Las personas y los animales pueden distraer y hacer

perder el control de la máquina. P

operador debe estar siempre concentrado en su trabajo.

• Tener en cuenta que las ropas, el pelo largo y las joyas

pueden atascarse en piezas móviles.

Mantenga bajo vigilancia la máquina siempre que el

•

motor esté en marcha.

• Al trabajar con las máquinas, procure siempre que haya

alguien cerca, que pueda prestar a

accidente

• Cerciórese siempre de tener una posición de trabajo

segura y firme.

imero de que hayan entendido el contenido

io es responsable de la

or consiguiente, el

yuda en caso de

.

le la

Spanish – 23

Page 24

INSTRUCCIONES DE SEGURIDAD

Uso y cuidado

• Utilice la máquina solamente para el uso al que está

destinada.

• Mantener todas las piezas en perfecto estado y

comprobar que todos los elementos de fijación estén bien

apretados.

No utilice nunca una máquina defectuosa. Siga las

•

instrucciones de mantenimiento

manual. Algunas medidas de mantenimiento y servicio

deben ser efectuadas por especialistas formados y

cualificados. Vea las instrucciones bajo el título

Mantenimiento.

• No modificar nunca los dispositivos de seguridad.

Comprobar regularmente que funcionan como es debido

La máquina no se debe operar con dispositivos de

seguridad defectuosos o ausentes.

• No utilice nunca una máquina que haya sido modificada

de modo que ya no coincida con la configur

• La máquina sólo se deberá arrancar cuando los

cabezales desbastadores estén descansando en el

suelo, a no ser que se esté ef

de prueba tal y como se indica en este manual.

• La máquina no deberá ponerse en marcha sin el faldón de

goma para el polv

una buena hermeticidad entre la máquina y el suelo,

sobre todo cuando se trabaje en una aplicación de

desbastado en seco.

• Durante el amolado, la máquina debe estar conectada a

una aspirador

• Cuando se cambien los discos desbastadores, asegúrese

de que está desconectada la toma de corriente de la

unidad pulsando el botón de par

desenchufando el cable de alimentación.

• Después de cada operación de amolado / pulimentación,

aiga siempre los útiles de diamante.

extr

• Asegúrese de que el reborde de goma está intacto y

limpio y de que queda colocado herméticamente contr

suelo. Si el reborde de goma está dañado, reemplácelo

inmediatamente.

• Cuando elimine cola, asfalto, pintura, etc., levante

siempre la máquina y sepárela de la superficie después

de utilizarla par

al calor. Asegúrese de que el cabezal de amolado ha

dejado de rotar antes de levantar la máquina.

• Los útiles de diamante pueden estar calientes después

de utilizar la máquina. Deje que la máquina se enfríe

antes de e

guantes protectores.

• Utilice siempre la argolla de izada montada en la máquina

vantarla.

para le

• Transporte siempre la máquina usando el mango de

transpor

te y el manillar.

o. Es fundamental que se establezca

a que succione el polvo.

a que no se quede pegada al suelo debido

xtraer los segmentos de diamante. Utilice

, control y servicio de este

ación original.

ectuando un procedimiento

ada de emergencia y

a el

Transporte y almacenamiento

• La máquina se deberá transportar siempre cubierta,

limitando su exposición a los elementos naturales, en

particular a la lluvia y la nieve.

• Guarde el equipo en un lugar seguro fuera del alcance de

los niños y las personas no autorizadas

• La máquina deberá guardarse en un lugar seco, cuando

no esté en uso.

.

.

24 – Spanish

Page 25

MONTAJE

Ajuste la empuñadura.

• Quite los tornillos (A).

• Retire las manijas de cierre (B).

• Coloque la empuñadura en el soporte para la

empuñadura de la máquina.

Monte los tornillos (A) y las manijas de cierre (B).

•

• Las manijas de cierre deberán estar situadas al lado del

manillar para reducir el r

cuando la máquina esté en posición horizontal al cambiar

las herramientas.

iesgo de deterioro de las mismas

Cambio de los diamantes

Apague la máquina y desconecte el enchufe.

Póngase unos guantes protectores, ya que los útiles de

diamante pueden estar muy calientes

• Gire el manillar hasta que alcance la posición más alta.

• Tire hacia atrás de la empuñadura para levantar el

cabezal desbastador del suelo

•

Vuelva a poner la máquina en el suelo.

• Póngase los guantes.

• Utilice un martillo para retirar los segmentos de diamante.

.

.

• Fije los nuevos segmentos de diamante al disco

amolador

Una vez que se hay an fijado los nuevos diamantes, lleve

•

a cabo el procedimiento inv

suelo.

a.

erso para bajar la máquina al

Spanish – 25

Page 26

MONTAJE

Conexión de la aspiradora

Conecte la aspiradora a la máquina. Utilice una manguera de

50 mm (2 pulgadas).

• Se recomienda vivamente usar el sistema de extracción

de polvo Husqvarna DC 3300 para un control completo

del polvo.

• Asegúrese de que los filtros de la aspiradora están

intactos y limpios.

utilización de la máquina.

• Ajuste el reborde de goma para que esté en contacto con

el suelo y capte el polvo de f

Tenga cuidado con el polvo durante la

orma eficaz.

Transporte

La máquina puede plegarse para minimizar el espacio

necesario para el transporte.

• Afloje los tornillos y la manija de cierre que mantienen la

cubierta en su sitio

.

• Doble cuidadosamente la máquina hacia delante.

Coloque un relleno entre el motor y la caja eléctrica par

evitar dañar la máquina.

• La cubierta puede acoplarse a un lado de la máquina.

a

• Quite la cubierta.

• Coloque el cigüeñal con la empuñadura orientada hacia

arriba.

26 – Spanish

Page 27

GUÍA PARA EL AMOLADO

Diamantes

Antecedentes

Los abrasivos de diamantes suelen constar de dos

componentes:

• Polvo de diamante (también conocido como cristales de

diamante o arenilla). Al cambiar el g

diamante o arenilla, podemos cambiar cómo van a ser de

gruesos o finos los rasguños que se queden después del

proceso de desbastado.

• Un aglutinante (metal o resina). El polvo de diamante se

mezcla y se deja suspendido en un aglutinante de metal

o resina. Cuando se deje suspendido en un aglutinante

de metal, se llamará al producto final ligamento metálico

o segmento de diamante sinterizado. Cuando esté

suspendido en un aglutinante de resina, el producto final

se denominará segmento de diamante de ligamento de

resina o almohadilla. Al cambiar la dureza del aglutinante ,

podemos cambiar lo rápido o lento que se gastará el

abrasivo de diamante.

Principios generales

Lo que sigue son reglas generales acerca de los segmentos

de diamante en aplicaciones de desbastado. Como en todas

las reglas generales, hay e xcepciones o casos en los que no

es el caso.

Tamaño del polvo de diamante

El cambio de tamaño del polvo de diamante a una partícula/

tamaño de polvo más pequeño afectará a las prestaciones de

la herramienta de diamantes de las siguientes formas:

• Creará una pauta de rasguños más fina.

• Se aumentará la vida de la herramienta de diamantes.

Ocurrirá lo contrario si se cambia a una partícula/tamaño de

o más g

polv

Aglutinante

Al aumentar la dureza del ligamento:

• Creará una pauta de rasguños más fina.

• Se aumentará la vida de la herramienta de diamantes.

• Decrecerá la tasa de producción.

Ocurrirá lo contrario cuando se haga un ligamento metálico o

de resina más sua

Número de segmentos de diamante/almohadillas

Si se aumenta el número de segmentos debajo de la

máquina:

• Se reducirá la presión en cada segmento de diamantes

individual. – Se reducirá el r

segmentos de diamantes.

• Se reducirá la carga sobre la máquina y provocará que la

desbastadora absorba menos corr

• Creará una pauta de rasguños más suave (sobre todo en

suelos blandos).

Ocurr

segmentos debajo de la máquina.

Resumen de principios del diamante

Los segmentos de diamantes necesitan desgastarse para

lograr productividad. El desgaste del segmento de diamantes

puede depender de los siguientes factores:

rande.

e).

v

itmo de desgaste en los

irá lo contrario cuando se reduzca el número de

rano del polvo de

iente.

• Presión.

• Dureza del ligamento.

• Tamaño del polvo de diamante.

• Número de segmentos debajo de la máquina.

• Si se añade un abrasivo adicional (p.ej. arena, carb uro de

silicona) en el suelo se aumentará el desgaste

En gener

diamantes, ma

factores, también se podrán hacer cambios para infl uir sobre

lo siguiente:

• Pauta de rasguños.

• Absorción de corriente de la máquina.

• Grado de allanado del suelo (véase sección siguiente).

• Facilidad de manejo.

al, cuanto más deprisa se desgaste un segmento de

yor será la productividad. Al variar los citados

.

Determinación de la dureza del hormigón

Todo hormigón se mide por su resistencia a la compresión y,

dependiendo de qué zona del mundo sea cada uno, se

medirá por diferentes índices de resistencia a la compresión

(p.ej. PSi y MPa). En general, cuanto mayor sea el grado de

resistencia a la compresión, más duro será el hormigón y , por

lo tanto, más difícil será de desbastar.

Sin embargo, además del grado de resistencia a la

compresión hay otros f

duro un suelo y, por lo tanto, la selección correcta de

diamantes. Como el desbastado normalmente sólo se aplica

a la superficie de hormigón (parte superior 5mm o 1/4

pulgada), a menudo la manera en la que se ha acabado el

suelo de hormigón o el estado de la superficie tendrá un

mayor peso sobre qué tipo de diamante seleccionar que el

grado de resistencia a la compresión del hormigón.

Factores de la superficie a considerar al seleccionar un

diamante

En general, si una superficie de hormigón es muy suave (es

decir, probablemente se haya allanado/pulido

enormemente), el hormigón se comportará como si tuviera

una elevada resistencia a la compresión y, por tanto, necesita

un segmento de ligamento blando.

Conforme a ello, si una superficie es basta/agresiva (p.ej.

dañada por la lluvia, rota por disparos, escarifi - cada,

conglomerado expuesto, etc.), el hormigón se comportará

como si tuviera una baja resistencia a la compresión y, por

tanto, necesita un segmento de ligamento duro.

Los revestimientos/contaminantes de la superficie (p.ej.

revestimientos epoxi, adhesivos de baldosas de cerámica,

nivelación de compuestos/capas de mortero) tendrán a

menudo un mayor peso en la selección del diamante que la

resistencia a la compresión del hormigón.

Por regla general, cuando se desbaste un bloque de

hormigón por primera vez y no esté seguro de su dureza,

empiece siempre con diamantes de ligamento más duro

debajo de la máquina. Esto garantizará la menor cantidad de

desgaste de los segmentos de diamantes. Si un segmento de

diamantes duros no es adecuado para la aplicación, todo lo

que habrá supuesto habrá sido un poco de tiempo, sin

desgastar los diamantes.

Si se hace de la forma contraria (es decir, se usa un

segmento b

posee una superficie abrasiva o un contaminante de

superficie, es muy posible que desgaste una cantidad

considerable de diamante en un período muy corto de

tiempo.

lando par

actores que determinan cómo es de

a empezar) y el hormigón es blando o

Spanish – 27

Page 28

GUÍA PARA EL AMOLADO

Selección de diamantes

La forma en la que los segmentos de diamante están configurados en la unidad de amolado influirá enormemente en el

rendimiento de la máquina y los niveles de productividad, así como en la calidad del acabado del suelo.

Existen diferentes configuraciones de diamante posibles con los modelos PG 400 SF y PG 280 SF.

Discos diamantados con ligante de metal

Juego completo: fila interior y exterior

Juego completo: fila exterior

Medio juego: fila interior y exterior

Medio juego: fila exterior

28 – Spanish

Page 29

GUÍA PARA EL AMOLADO

Seleccione los discos diamantados con ligante de metal adecuados para la aplicación concreta.

A continuación, le ofrecemos algunas sugerencias para las configuraciones básicas de los discos diamantados con ligante de

metal.

uego

J

Campo de aplicación

Allanamiento suelo – Hormigón

duro

Allanamiento suelo – Hormigón

medio

Allanamiento suelo – Hormigón

lando

b

Extr

acción de adhesivo de

baldosa de cerámica

Extracción de pegamento de

moqueta o vinilo – Hor

Extr

acción de pegamento de

moqueta o vinilo – Hormigón

medio

acción de pegamento de

Extr

moqueta o vinilo – Hormigón

lando

b

Extracción de pintura epoxi –

Hormigón duro

acción de pintura epoxi –

Extr

Hormigón medio

acción de pintura epoxi –

Extr

Hormigón b

Hormigón dañado por la lluvia Duro 16-30 X X

Alisado conglomerado expuesto Duro 16-30 X X

Extracción de irregularidades en

baldosas de terr

Pulido de superficie de suelos de

hormigón – Hor

Pulido de superficie de suelos de

hormigón – Hor

Pulido de superficie de suelos de

hormigón – Hor

Desbastado de conglomerado

expuesto en hor

duro

Desbastado de conglomerado

expuesto en hor

medio

Desbastado de conglomerado

expuesto en hor

blando

Allanamiento de ondulación en

suelos de hormigón – Hor

duro

Allanamiento de ondulación en

suelos de hormigón – Hor

medio

Allanamiento de ondulación en

suelos de hormigón – Hor

blando

lando

migón duro

o / piedra

az

migón duro

migón medio

migón blando

migón – Hormigón

migón – Hormigón

migón – Hormigón

migón

migón

migón

Ligamento

metálico

Blando 16 o 30 X

Medio 16 o 30 X

Duro 16 o 30 X

Medio

Blando

Medio

Duro

Blando

Medio

Duro

Blando 30 o 60 X

Blando 60 X X

Medio 60 X X

Duro 60 X X

Blando 16-30 X X X

Medio 16-30 X X X

Duro 16-30 X X

Blando 16 o 30 X X X

Medio 16 o 30 X X

Duro 16 o 30 X X

Tamaño de

polvo

PIRANHA™ o

16-30

PIRANHA™ o

16-30

PIRANHA™ o

16-30

PIRANHA™ o

16-30

PIRANHA™ o

16-30

PIRANHA™ o

16-30

PIRANHA™ o

16-30

completo:

fila interior

y e

xterior

X

Juego

completo:

fila

exterior

X X

X

X

Medio juego:

fila interior y

exterior

X X

X X

X X

Medio

juego: fila

exterior

Spanish – 29

Page 30

GUÍA PARA EL AMOLADO

Discos diamantados con ligante de resina

Adaptador para la adherencia con resina Redi Lock

Juego completo: fila exterior

Medio juego: fila exterior

Seleccione la configuración de disco diamantado con ligante de resina adecuada para la aplicación concreta.

Campo de aplicación Juego completo: fila exterior Medio juego: fila exterior

Pulimentación de baldosas de terrazo / piedra X

Repavimentación de baldosas de terrazo / piedra X

Pulido de superficie de suelos de hormigón – Hormigón duro X

Pulido de superficie de suelos de hormigón – Hormigón

medio

Pulido de superficie de suelos de hormigón – Hormigón

lando

b

X

X

Sentido de rotación del motor (Trifásica)

Podrá modificarse el sentido de rotación del motor invirtiendo los polos del enchufe.

¡ATENCIÓN! Las herramientas Piranha / PCD están diseñadas para funcionar en una única dirección.

30 – Spanish

Page 31

ARRANQUE Y PARADA

Antes de arrancar

• Coloque la desbastadora en la zona de trabajo.

• Asegúrese de que hay diamantes en la parte inferior de la

máquina y de que están firmemente ajustados

• Conecte la aspiradora a la máquina.

• Utilice manijas de cierre para el ajuste del manillar

haciendo así más cómoda la altur

• Enchufe la toma de corriente a la máquina.

• Compruebe que el botón de parada de emergencia no

está pulsado girándolo en el sentido de las agujas del

reloj.

• Compruebe el sentido de rotación del motor.

a de tr

.

abajo.

Parada

• Utilice el botón de parada para apagar la máquina.

• Mantenga los segmentos de amolado en contacto con el

suelo al parar la máquina.

se pare completamente de forma rápida. No levante el

cabezal de amolado del suelo al parar la máquina, ya que

puede crear una cantidad considerable de polvo en el

aire.

Ello ayudará a que la máquina

Arranque

• Reduzca la presión entre el disco de amolado y el suelo

empujando hacia abajo la empuñadura sin levantar la

unidad de amolado del suelo.

• Mantenga pulsado el botón de arranque durante unos

segundos para arr

ancar la máquina.

Spanish – 31

Page 32

MANTENIMIENTO

Fallos y localización de fallos

La máquina no funciona

• Compruebe el suministro eléctrico y los cables de

alimentación para asegurarse de que no están dañados.

• Compruebe que el botón de parada de emergencia no

está pulsado girándolo en el sentido de las agujas del

reloj.

Es difícil sujetar la máquina

• No hay suficientes diamantes debajo de la máquina (si

hay una capa espesa de cola de desbastado o suelos

blandos, una cantidad insuficiente de diamantes debajo

de la máquina incrementará enormemente la carga sobre

la desbastadora y el operador). Esto suele ir acompañado

de un alto consumo de corriente por parte del motor.

Aumente el número de diamantes debajo de la máquina

para reducir la carga sobre la desbastador

La máquina está dando saltos

• Las almohadillas amortiguadoras de caucho de la unidad

de amolado pueden desgastarse o deteriorarse.

Compruebe su estado y cámbielas si es necesario.

• Los diamantes pueden estar instalados incorrectamente

o a diferentes altur

todos los diamantes están ajustados correctamente y son

de la misma altura.

as. Compruebe y asegúrese de que

a y el operador.

Mantenimiento

¡IMPORTANTE! El control y/o mantenimiento de la

máquina debe hacerse con el motor parado y el enchufe

desenchufado.

Usada correctamente, la máquina tiene un mantenimiento

extremadamente bajo y gran fiabilidad.

Limpieza

Desenchufe siempre el enchufe antes de ef ectuar trabajos de

limpieza, mantenimiento o montaje de la máquina.

Limpiar siempre todo el equipo después de cada turno de

. No utilice un equipo de limpieza a alta presión para

trabajo

limpiar la máquina.

Para que la máquina tenga siempre una buena refrigeración,

las abertur

libres y limpias.

Almohadillas amortiguadoras de caucho.

Verifique las almohadillas amortiguadoras de caucho todos

los meses. Cámbielas si es necesario.

as de paso del aire refrigerante deben mantenerse

La máquina se detiene después de funcionar brevemente

• La máquina está sobrecargada y se ha activado la

protección contra sobrecarga. Reduzca la carga. La

máquina se reactivará después de aproximadamente un

minuto cuando el motor se haya enfriado.

La máquina se detiene al arrancar

• El motor eléctrico está sobrecargado o falta una fase.

Deje que la máquina se reinicie durante uno o dos

minutos e inténtelo de nuevo. Si esto no ayuda, acuda a

un taller de servicio oficial.

Suministro eléctrico

¡ATENCIÓN! No usar nunca cables dañados,

puesto que pueden causar daños

!

personales graves e incluso mortales.

Compruebe que el cable y el cable de empalme está intacto.

Si se daña el cable, no utilice la máquina. Llévela a un taller

de servicio oficial par

a reparar.

Faldón

Asegúrese de que el reborde de goma está intacto y limpio y

de que queda colocado herméticamente contra el suelo. Si el

reborde de goma está dañado, reemplácelo inmediatamente.

Servicio

¡IMPORTANTE! Las reparaciones de todo tipo deben ser

efectuadas por técnicos autorizados, únicamente. De este

modo se evita someter a los operadores a grandes riesgos.

32 – Spanish

Page 33

DATOS TECNICOS

Datos técnicos

PG 400 SF PG 280 SF PG 280 SF (Monofásico)

Potencia del motor, kW/CV 4/5,4 3/4 2,2/3,0

Amperaje nominal, A 16 16 12,9

Tensión nominal, V 400 400 230

Peso, kg/lb 115/254 70/154 70/154

Anchura de desbastado, mm/pulgadas 400/16 280/11 280/11

Presión de desbastado, kg/lbs 65/143 35/77 35/77

Velocidad, r/min 1400 2800 1400

Emisiones de ruido (vea la nota 1)

Nivel de potencia acústica medido dB(A) 107 107 107

Nivel de potencia acústica garantizado L

Niveles acústicos (vea la nota 2)

Nivel de presión acústica en el oído del usuario, dB(A) 89 89 89

Niveles de vibraciones (vea la nota 3)

Empuñadura derecha, m/s

Empuñadura izquierda, m/s

2

2

dB(A) 108 108 108

WA

3,4 3,4 3,4

3,4 3,4 3,4

Nota 1: Emisiones sonoras en el entorno medidas como potencia sonora (LWA) según la norma EN 61029-1.

Nota 2: Nivel de presión sonora conforme a EN 61029-1. Los datos referidos del nivel de presión sonora tienen una dispersión

estadística habitual (desviación típica) de 1,0 dB (A).

Nota 3: Nivel de vibración conforme a EN 61029-1. Los datos referidos del nivel de vibración poseen una dispersión estadística

habitual (desviación típica) de 1 m/s

2

.

Declaración CE de conformidad

(Rige sólo para Europa)

Husqvarna AB, SE-433 81 Göteborg, Suecia, teléfono: +46-31-949000, declaramos que las Husqvarna PG 400 SF, Husqvarna

PG 280 SF a partir del número de serie del año 2010 en adelante (el año se indica claramente en la placa de identifi cación,

seguido del número de serie), cumplen con las siguientes disposiciones de la DIRECTIVA DEL CONSEJO:

2006/42/CE «relativa a máquinas» del 17 de mayo de 2006.

•

• 2004/108/CEE, ”referente a compatibilidad electromagnética”, del 15 de diciembre de 2004.

2006/95/CE del 12 de diciembre de 2006 relativa a equipos eléctricos.

•

Se han aplicado las siguientes normas: EN ISO 12100:2003, EN 55014-1:2006, EN 55015-2/A1:2001, EN 61000-3-2:2006, EN

61000-3-3/A1/A2:2005, EN 13862/A1:2009.

Se han aplicado las siguientes normas: EN 55014-1, EN55014-2, EN61000-3-2, EN61000-3-3.

Göteborg, 29 de diciembre de 2009

Henric Andersson

Vicepresidente, jefe de la sección de cortadoras y maquinaria para la construcción

Husqvarna AB

(Presentante autorizado de Husqvarna AB y responsable de la documentación técnica.)

Spanish – 33

Page 34

ESQUEMA DE CONEXIONES ELÉCRICAS

34 – Spanish

Page 35

ESQUEMA DE CONEXIONES ELÉCRICAS

Spanish – 35

Page 36

SYMBOLERKLÄRUNG

Symbole am Gerät:

WARNUNG! Das Gerät kann falsch oder

nachlässig angewendet gefährlich sein

und zu schweren oder gar

lebensgefährlichen Verletzungen des

Benutzers oder anderer Personen führen.

Lesen Sie die Bedienungsanweisung

sorgfältig durch und machen Sie sich mit

dem Inhalt ver

benutzen.

Tragen Sie persönliche Schutzausrüstung.

Siehe die Anweisungen unter der

Überschr

Schutzausrüstung”.

WARNUNG! Bei der Arbeit mit dem

Schleifer bildet sich Staub

Einatmen gesundheitsschädlich sein kann.

Verwenden Sie einen zugelassenen

Atemschutz. Sorgen Sie stets für gute

Belüftung.

Startvorrichtung: Den Druck zwischen der

Schleifscheibe und dem Boden durch

Herunterdrüc

dass das Schleifgerät vom Boden

angehoben wird.

traut, bevor Sie das Gerät

ift ”Persönliche

, der beim

ken des Griffs senken, ohne

Symbole in der Bedienungsanweisung:

Kontrollen und/oder Wartungsarbeiten sind

bei abgeschaltetem Motor und

abgezogenem Stecker durchzuführen.

Stets zugelassene Schutzhandschuhe

tragen.

Regelmäßige Reinigung ist notw

Visuelle Kontrolle.

Schutzbrille oder Gesichtsschutz müssen

ben

utzt w

erden.

endig.

Dieses Produkt stimmt mit den geltenden

CE-Richtlinien überein.

Umweltkennzeichnung. Das Symbol auf

dem Produkt oder der Verpackung gibt an,

dass dieses Produkt nicht im Hausmüll

entsorgt werden darf.

Durch eine korrekte Entsorgung dieses

Produkts tragen Sie dazu bei, mögliche

e Auswirkungen auf Ihre Umwelt und

negativ

Mitmenschen zu verhindern. Durch eine

unsachgemäße Entsorgung dieses Produkts können

Schäden entstehen.

Ausführliche Recyclinginformationen zu diesem Produkt

erhalten Sie von Ihrer K

für Hausmüll oder dem Geschäft, in dem Sie das Produkt

erworben haben.

Sonstige Symbole/Aufkleber am Gerät beziehen sich auf

spezielle Zertifizierungsanforderungen, die in

bestimmten Ländern gelten.

ommune, Entsorgungsunternehmen

36 – German

Page 37

INHALT

Inhalt

SYMBOLERKLÄRUNG

Symbole am Gerät: ...................................................... 36

Symbole in der Bedienungsanweisung: ....................... 36

INHALT

Inhalt ............................................................................ 37

WAS IST WAS?

Was ist was am Schleifer? ........................................... 38

SICHERHEITSVORSCHRIFTEN

Maßnahmen vor der Benutzung eines neuen Schleifers 39

Persönliche Schutzausrüstung .................................... 39

Allgemeine Sicherheitsvorschriften .............................. 40

MONTAGE

Befestigen des Griffs .................................................... 42

Auswechseln der Diamanten ....................................... 42

Anschließen des Unterdrucksaugers ........................... 43

Transport ...................................................................... 43

ANLEITUNG ZUM SCHLEIFEN

Diamanten ................................................................... 44

Bestimmung des Härtegrads von Beton ...................... 44

Auswahl der Diamanten ............................................... 44

Motordrehrichtung ........................................................ 47

STARTEN UND STOPPEN

Vor dem Start ............................................................... 48

Starten ......................................................................... 48

Stoppen ....................................................................... 48

WARTUNG

Störungsbeseitigung .................................................... 49

Wartung ....................................................................... 49

Service ......................................................................... 49

TECHNISCHE DATEN

Technische Daten ........................................................ 50

EG-Konformitätserklärung ........................................... 50

SCHALTPLAN

German – 37

Page 38

WAS IST WAS?

Was ist was am Schleifer?

1 Steuereinheit

2 Deckplatte

3 Kurbel zum Einstellen des Schleifdrucks

4 Lifting eye

5 Elektromotor

6 Hebegriff

7 Schürze

8 Unterdrucksauger-Anschluss

9 Radsatz

10 Verriegelungshebel Abdeckung

11 Schrauben Abdeckung

12 Schleifvorrichtung - PG 280 SF

13 Schleifvorrichtung - PG 400 SF

14 Griff/Führungsholm

15 Steuerkasten

16 Startknopf

17 Nothalt

18 Stopp-Taste

19 Verriegelungshebel für die Griffleisteneinstellung

20 Bedienungsanweisung

38 – German

Page 39

SICHERHEITSVORSCHRIFTEN

Maßnahmen vor der Benutzung eines neuen Schleifers

• Lesen Sie die Bedienungsanweisung sorgfältig durch und

machen Sie sich mit dem Inhalt vertraut, bevor Sie das

Gerät benutzen.

• Die Schleifer der Typen PG 400 SF und PG 280 SF

wurden zum Entfer

Klebstoffrückständen, Spachtelmasse und ähnlichen

Werkstoffrückständen von Betonböden sowie zum

Schleifen und Ebnen von Betonböden konstruiert. SF

bedeutet „Einzelscheibe, Konstantdrehzal' (single disc,

fixed speed).

• Das Gerät kann schwere Verletzungen verursachen. Die

Sicherheitsvorschr

wie das Gerät anzuwenden ist.

• Die Maschine darf nur von P ersonal bedient werden, das

theoretisch und praktisch an der Maschine unterwiesen

.

wurde

Stets mit gesundem Menschenverstand arbeiten!

Es ist unmöglich, alle denkbaren Situationen abzudecken, die

beim Gebrauch des Geräts auftreten könnten. Gehen Sie

stets mit Vorsicht und Vernunft vor. Vermeiden Sie

Situationen, für die Sie sich nicht ausreichend qualifiziert

fühlen. Falls Sie sich auch nach dem Lesen dieser

Anweisungen nicht über die richtige Vorgehensweise im

Klaren sind, sollten Sie einen Fachmann zu Rate ziehen,

bevor Sie fortfahren.

Sie können sich jederzeit an Ihren Händler wenden, wenn Sie

agen zur Verwendung der Maschine haben. Wir beraten

Fr

Sie gerne dabei, wie Sie Ihre Maschine besser und sicherer

einsetzen können.

Lassen Sie die Maschine regelmäßig von Ihrem HusqvarnaHändler überprüf

Reparaturen vornehmen.

Alle Informationen und Daten dieser Bedienungsanleitung

galten zum Zeitpunkt der Druc

nen von Haftmittel-/

iften gründlich durchlesen. Lernen Sie,

en und notwendige Einstellungen und

klegung.

Persönliche Schutzausrüstung

WARNUNG! Bei der Benutzung des Gerätes

muss die vorgeschriebene persönliche

!

Schutzausrüstung angewendet werden. Die

persönliche Schutzausrüstung beseitigt

nicht die Unfallgefahr, begrenzt aber den

Umfang der Verletzungen und Schäden. Bei

der Wahl der Schutzausrüstung einen

Fachhändler um Rat fragen.

• Schutzhelm

• Gehörschutz

• Schutzbrille oder Visier

• Atemschutzmaske

• Feste, griffsichere Handschuhe.

• Eng anliegende, kräftige und bequeme Kleidung tragen,

olle Bewegungsfreiheit gewährt.

die v

WARNUNG! Ohne Genehmigung des

Herstellers dürfen an der Maschine unter

!

keinen Umständen

Konstruktionsänderungen vorgenommen

werden. Stets Originalzubehör verwenden.

Unzulässige Änderungen und/oder

Zubehörteile können zu schweren

Verletzungen oder tödlichen Unfällen von

Anwendern oder anderen Personen führen.

WARNUNG! Beim Schneiden, Mahlen,

Bohren, Schmirgeln oder Formen können

!

Staubpartikel oder Dämpfe freigesetzt

werden, die gesundheitsschädliche Stoffe

enthalten können. Sie sollten daher das

Material, das bearbeitet werden soll, genau

kennen und die entsprechende Staub- oder

Atemschutzmaske tragen.

• Stiefel mit Stahlkappe und rutschfester Sohle.

• Ein Erste-Hilfe-Set soll immer griffbereit sein.

German – 39

Page 40

SICHERHEITSVORSCHRIFTEN

Allgemeine Sicherheitsvorschriften

WARNUNG! In diesem Abschnitt werden

grundlegende Sicherheitsregeln vorgestellt.

!

Die folgenden Informationen sind kein

Ersatz für das Wissen, das ein

professioneller Anwender durch seine

Ausbildung und praktische Erfahrung

erworben hat. Lassen Sie sich bei

Unsicherheiten von einer Fachkraft beraten.

Fragen Sie Ihren Fachhändler, Ihre